Patents

Literature

7809results about "Textile treatment machine arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

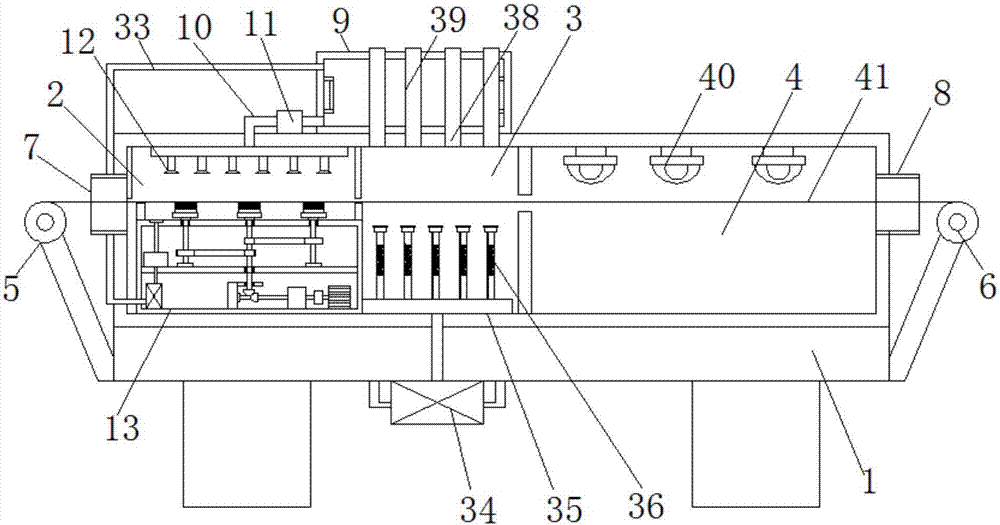

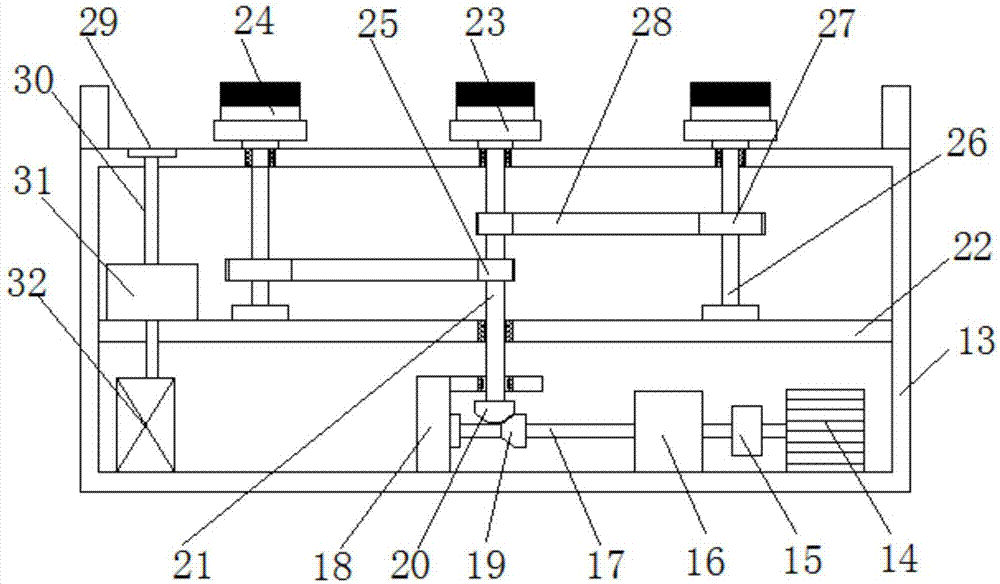

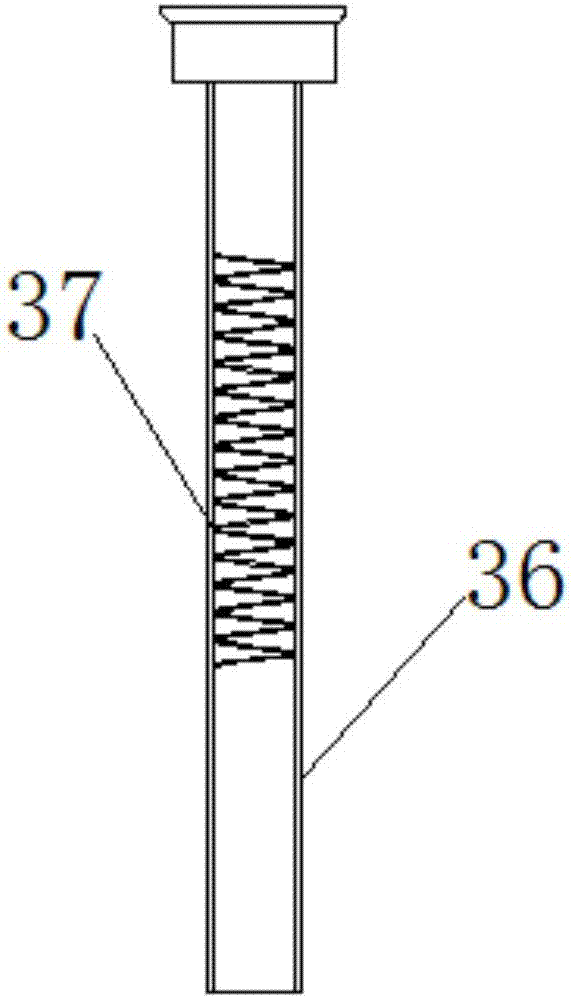

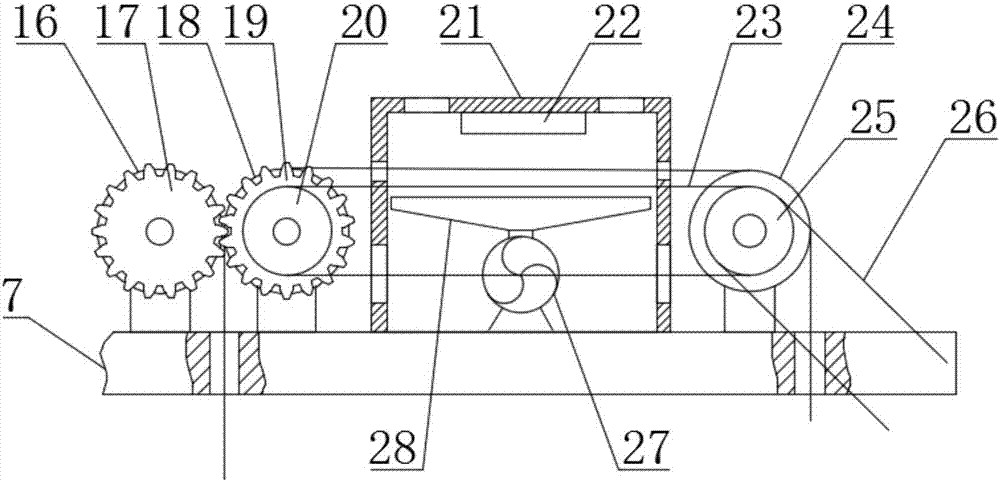

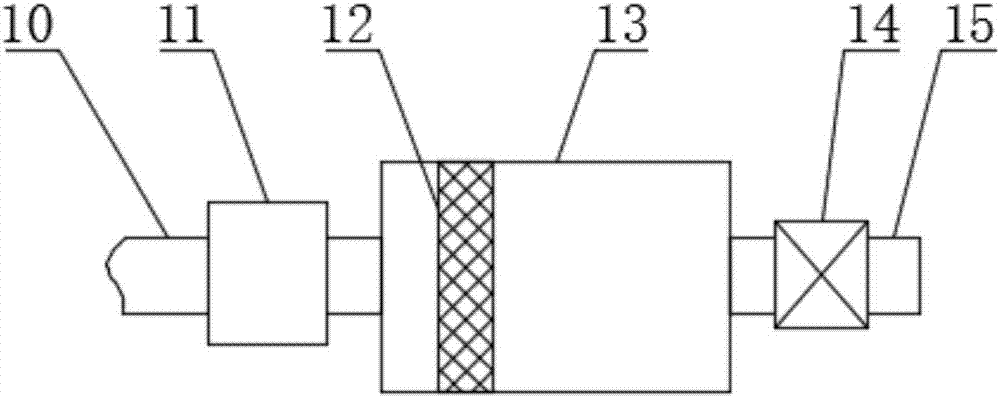

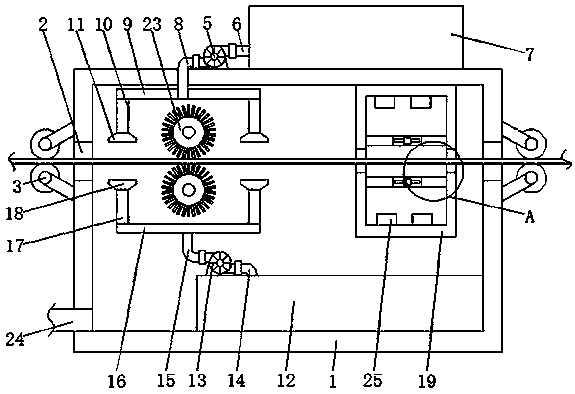

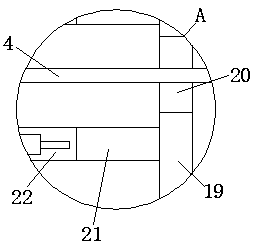

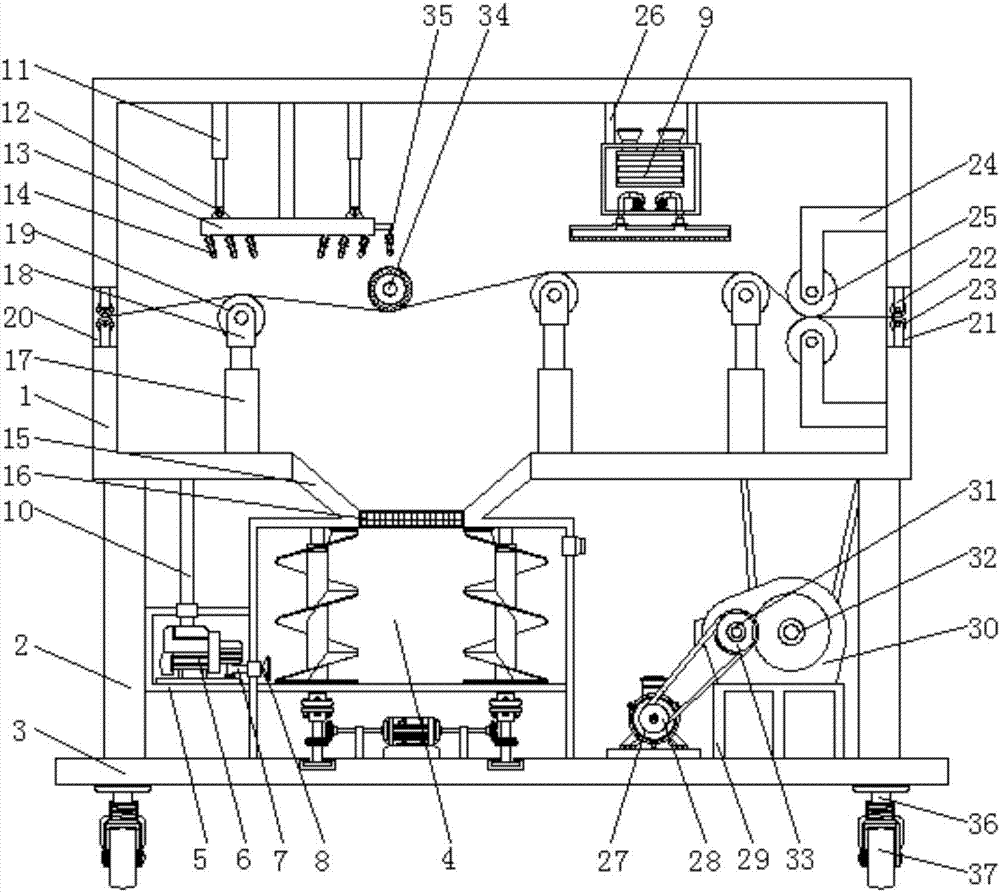

Cloth cleaning, drying and finishing integrated machine

InactiveCN107090680AImprove processing efficiencyEasy to cleanLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater filterPulp and paper industry

The invention discloses an integrated machine for cleaning, drying and finishing cloth, which comprises a base, a cleaning box is arranged on the base, two second guide rollers are rotatably connected to the front and rear side walls of the cleaning box, and a brush roller; the bottom of the cleaning box is provided with a filter box; the top of the cleaning box is provided with a top plate, and the right side of the top plate is provided with a drying box; A first gear is fixedly connected to the front end of a squeeze roller, and a second gear is fixedly connected to the front end of the second squeeze roller; a slide rail is also arranged on the base, and a fabric receiving basket is slidably connected to the slide rail through a slider , the right end of the fabric receiving basket is hinged with a connecting rod, and the other end of the connecting rod is rotationally connected with the front end of the motor. The invention integrates cloth cleaning, drying and sorting into one, which greatly improves the cloth processing efficiency; the washed water is filtered by a filter screen and then reused, which saves water resources.

Owner:王兴民

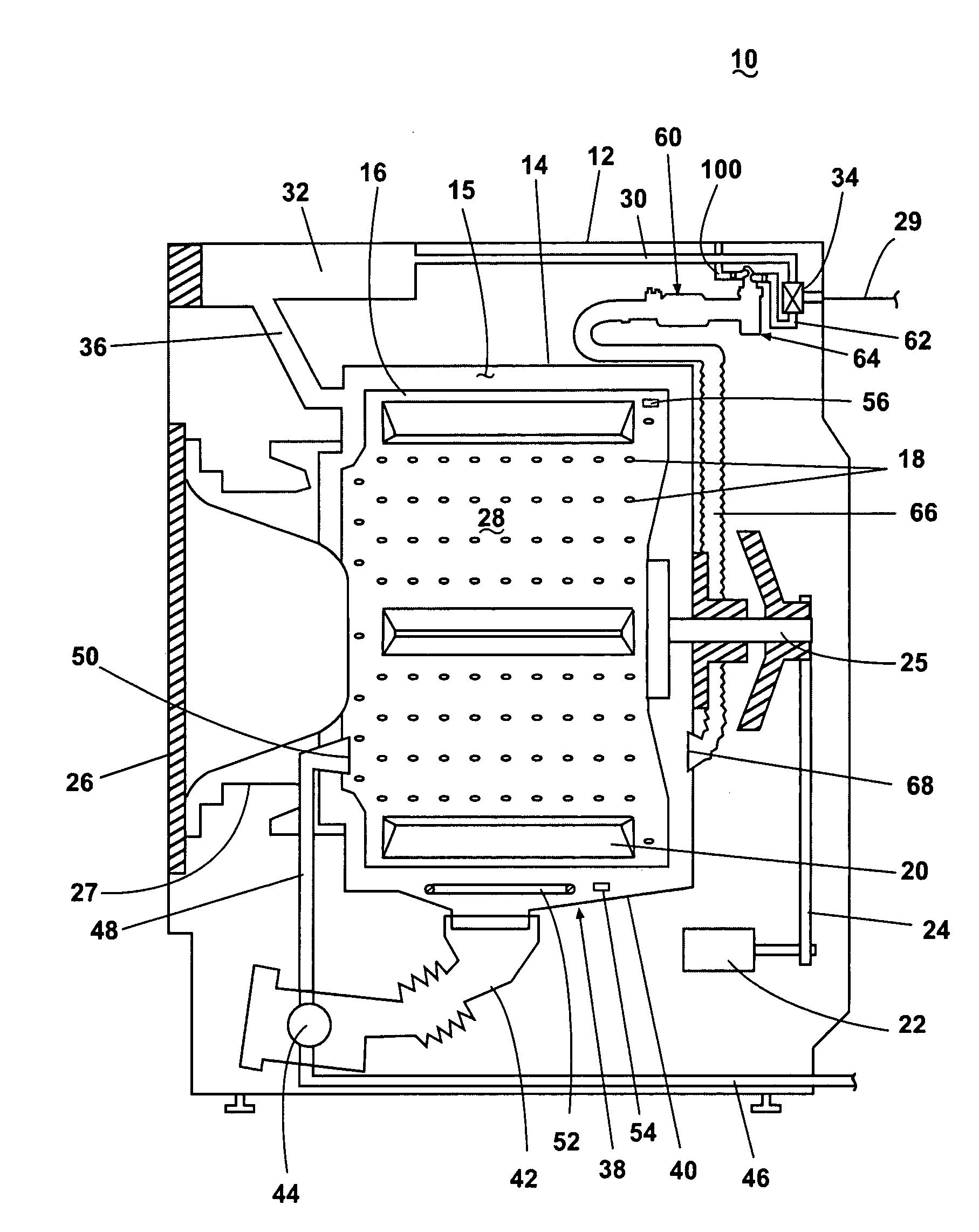

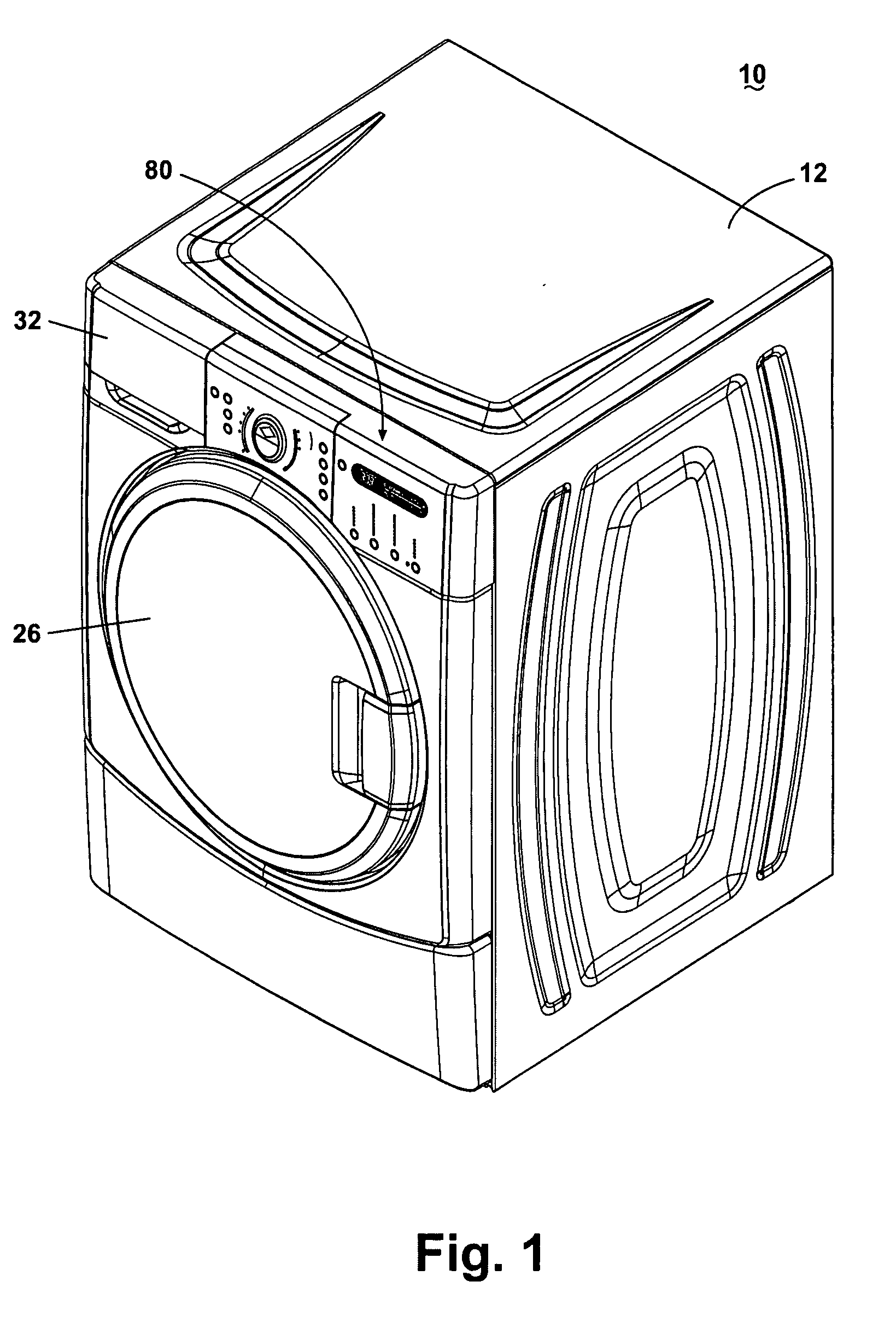

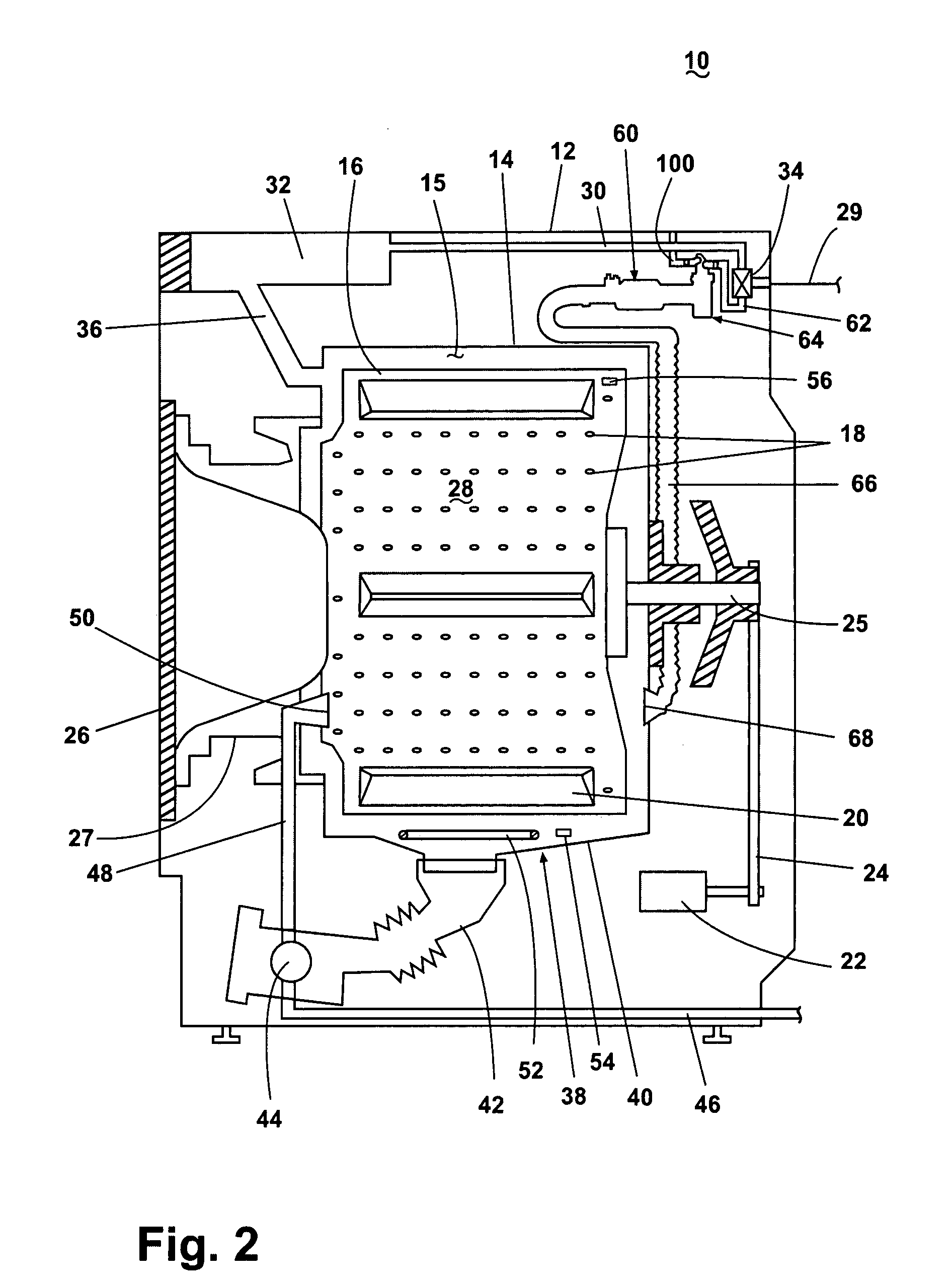

Method for Detecting Abnormality in a Fabric Treatment Appliance Having a Steam Generator

InactiveUS20090056036A1Other washing machinesTextile treatment machine arrangementsEngineeringRate control

Owner:WHIRLPOOL CORP

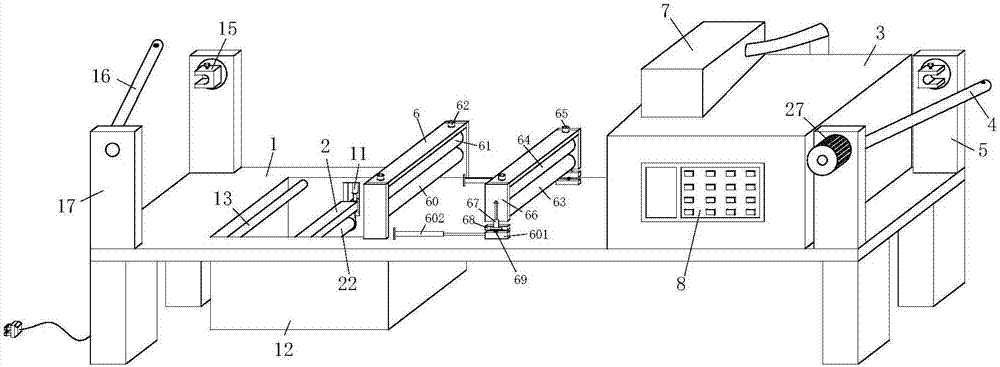

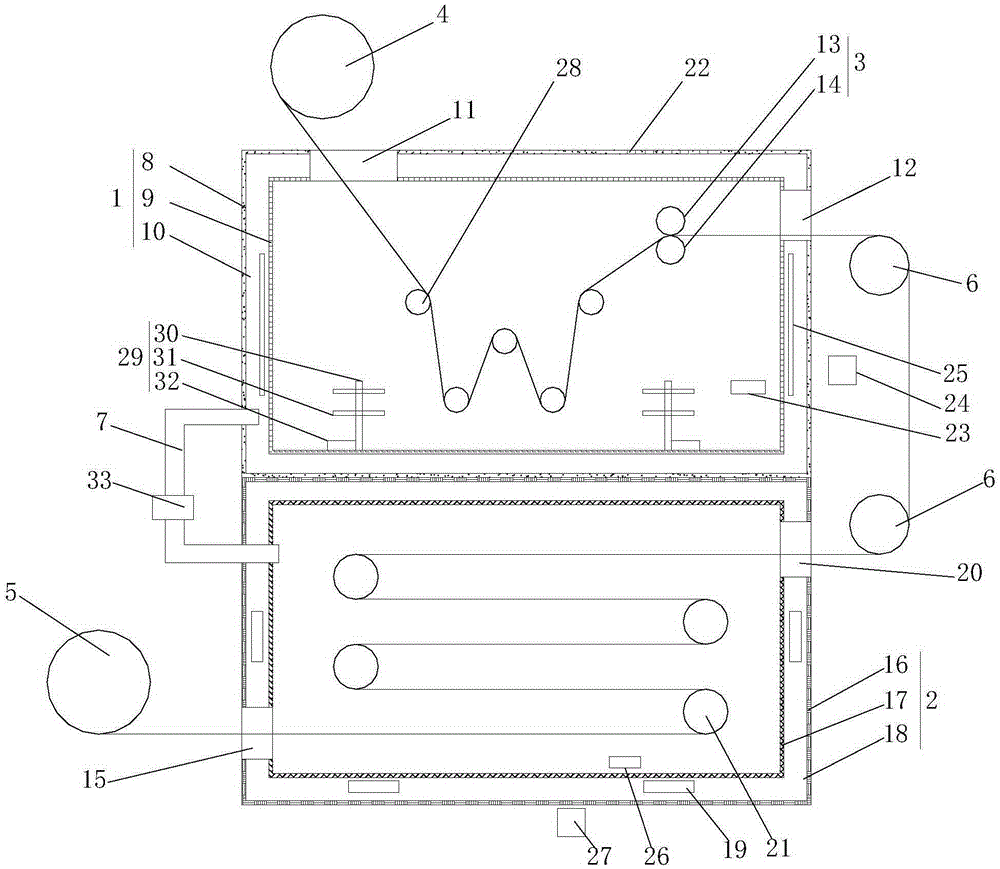

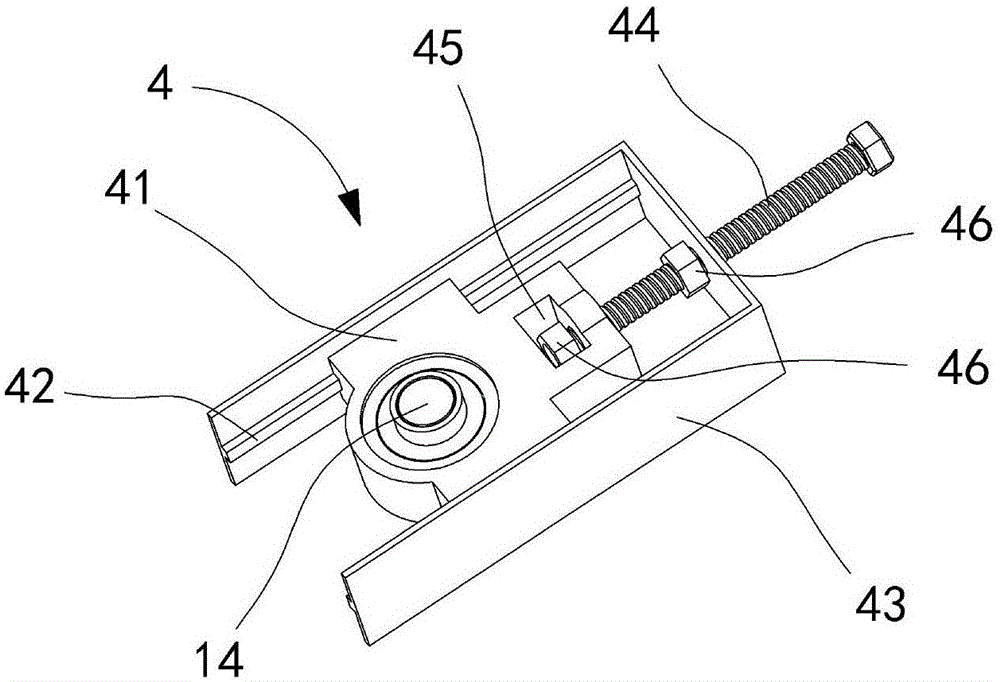

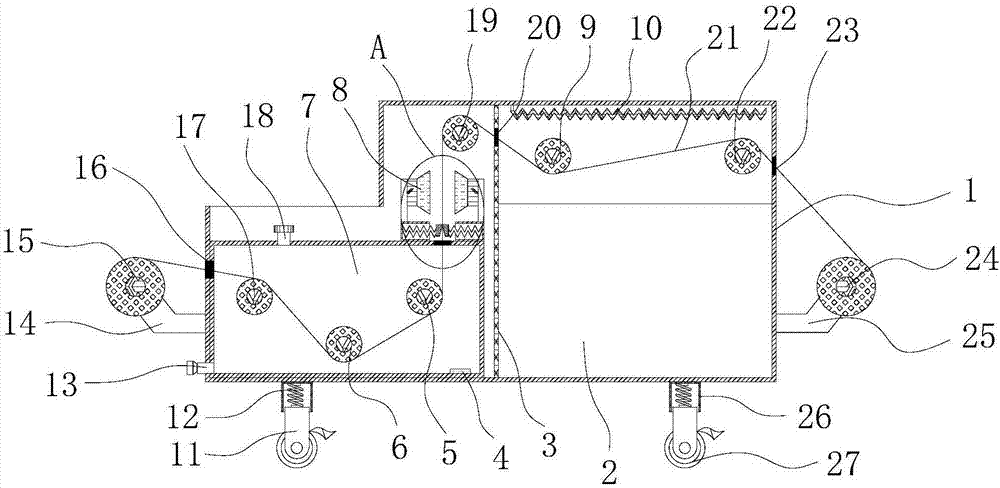

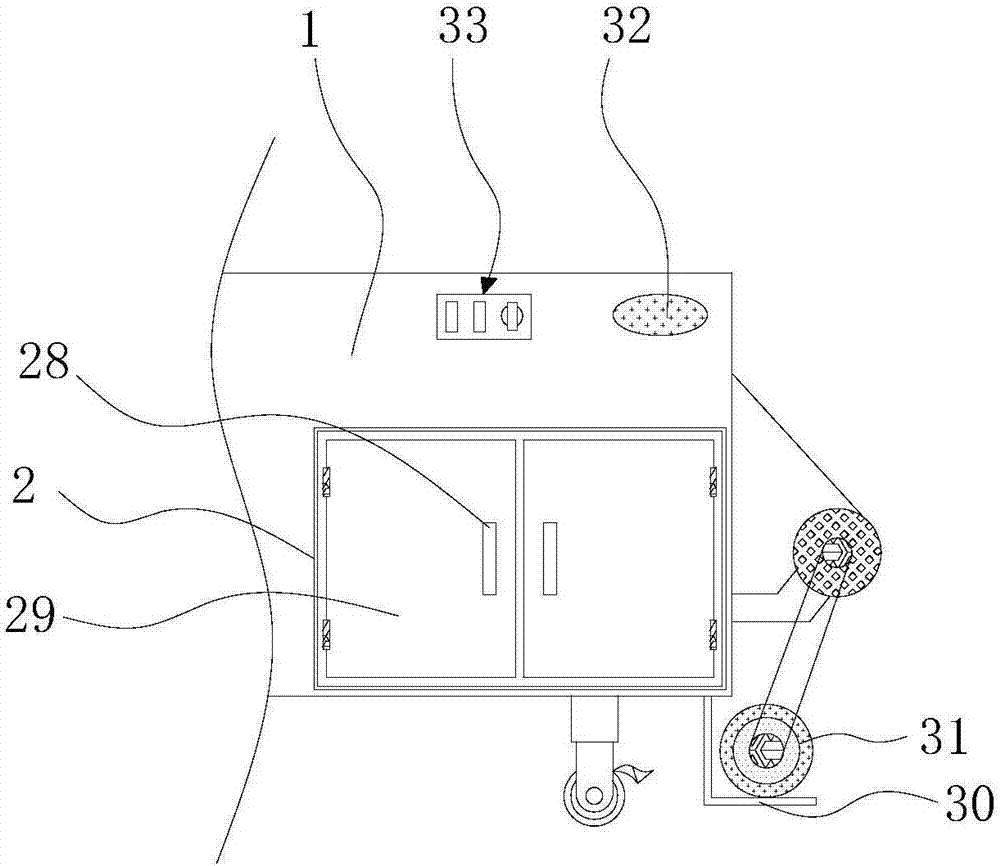

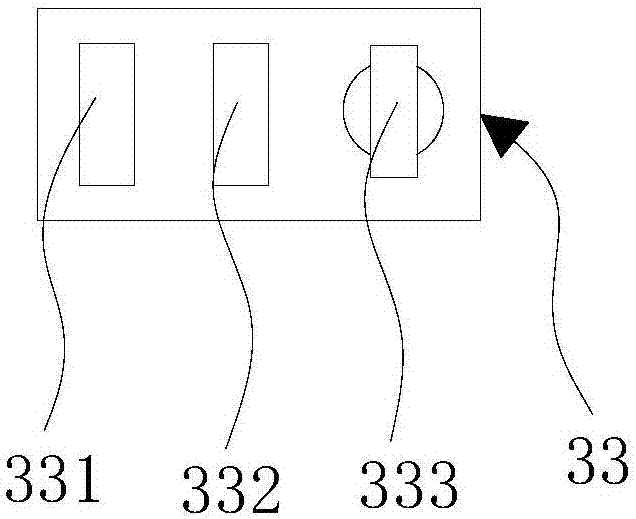

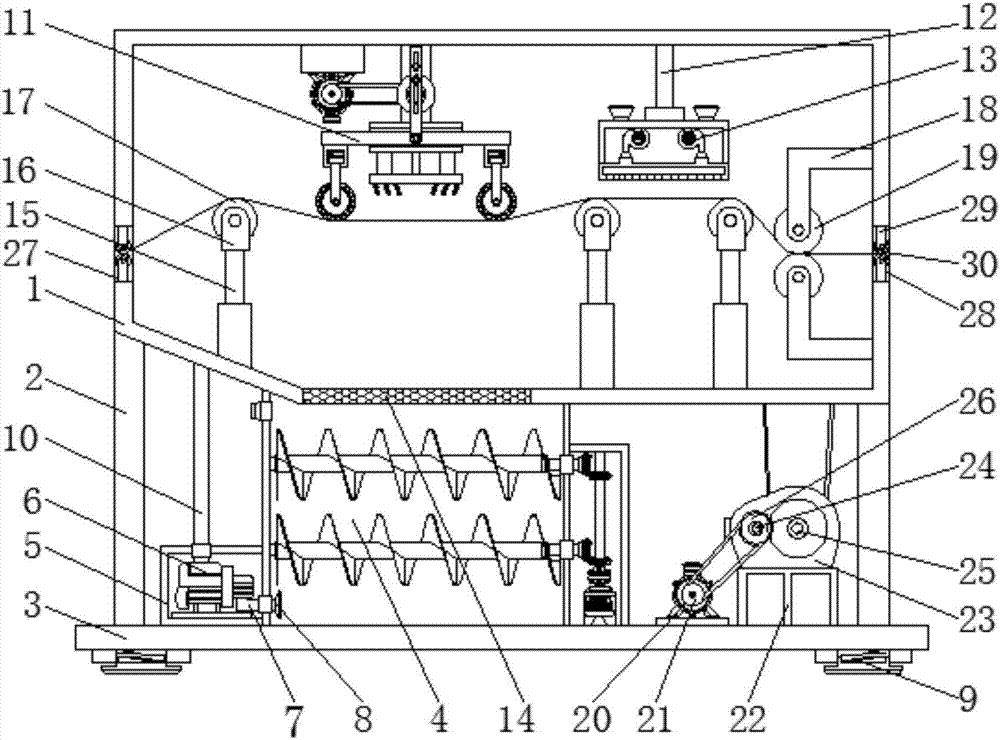

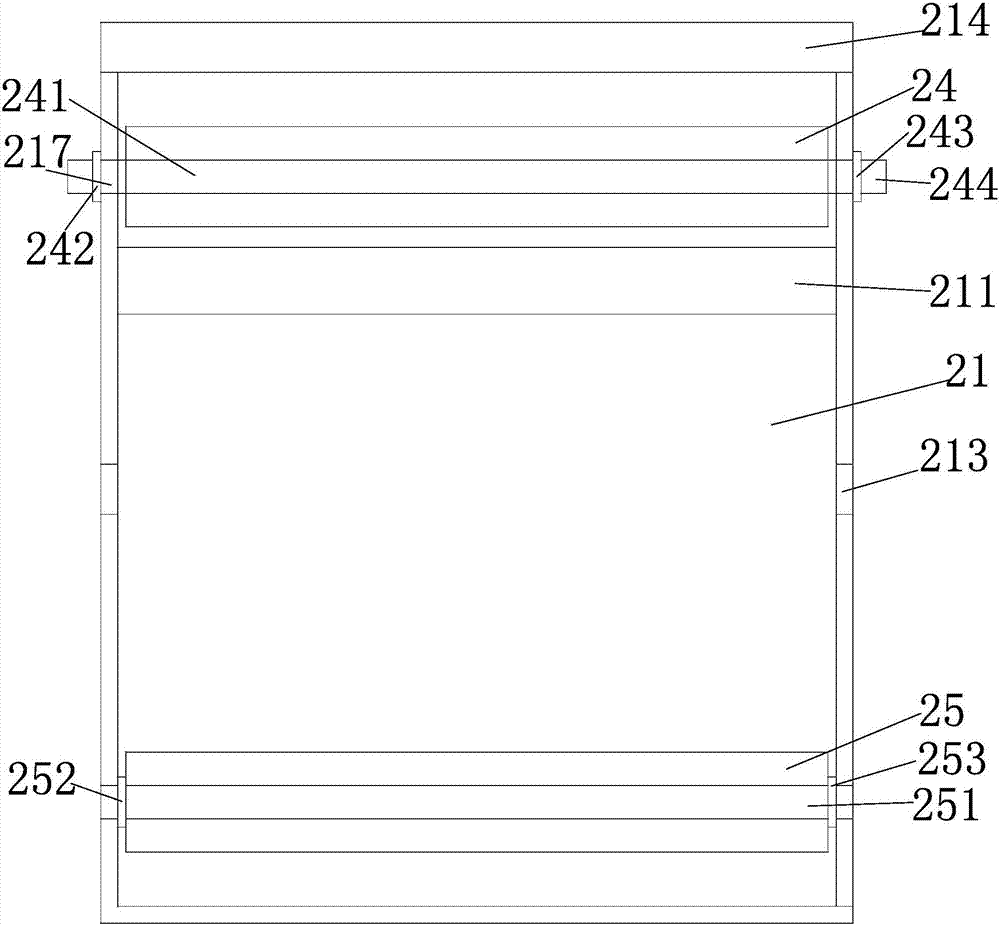

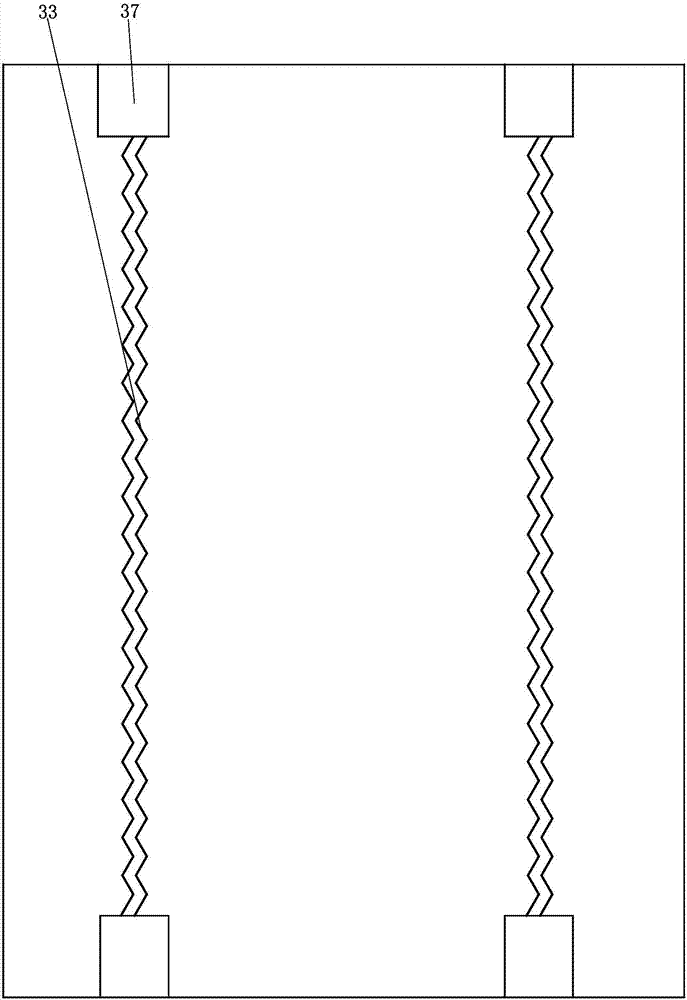

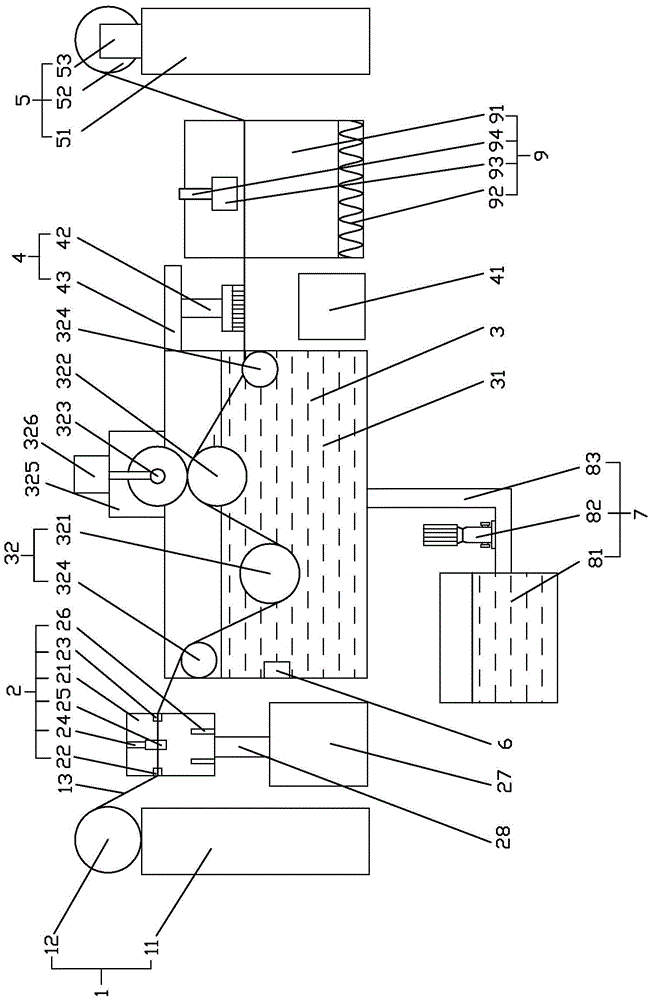

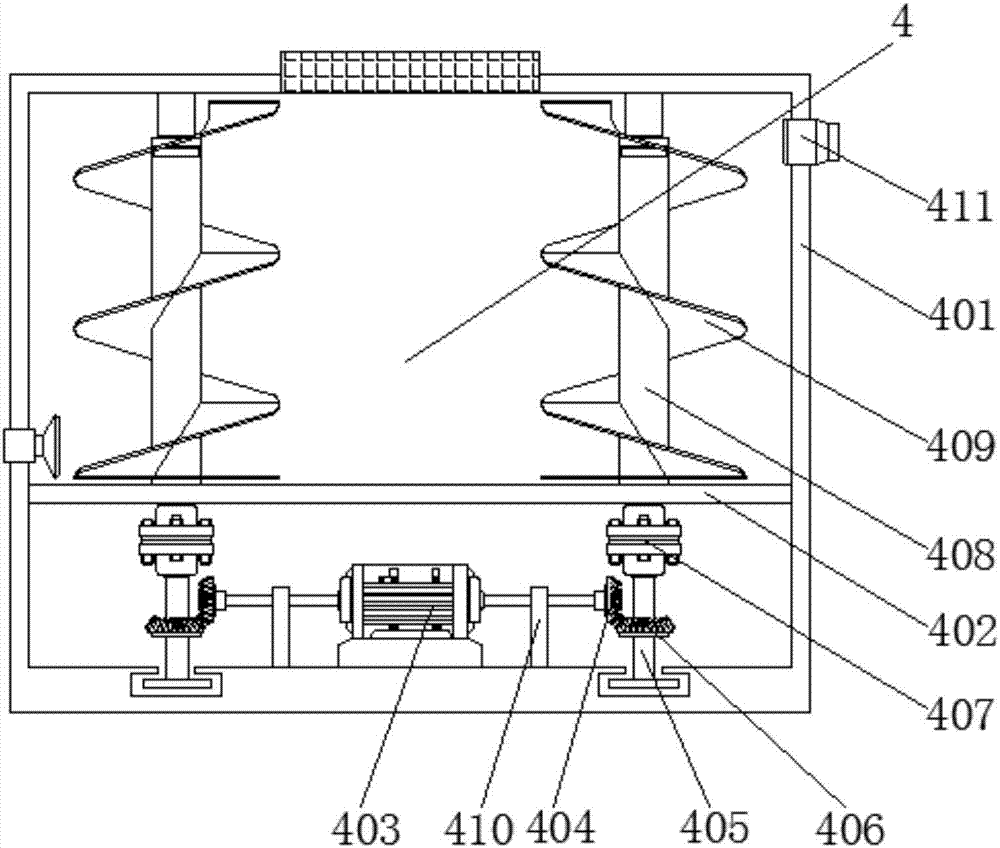

Textile fabric cleaning and drying integrated device

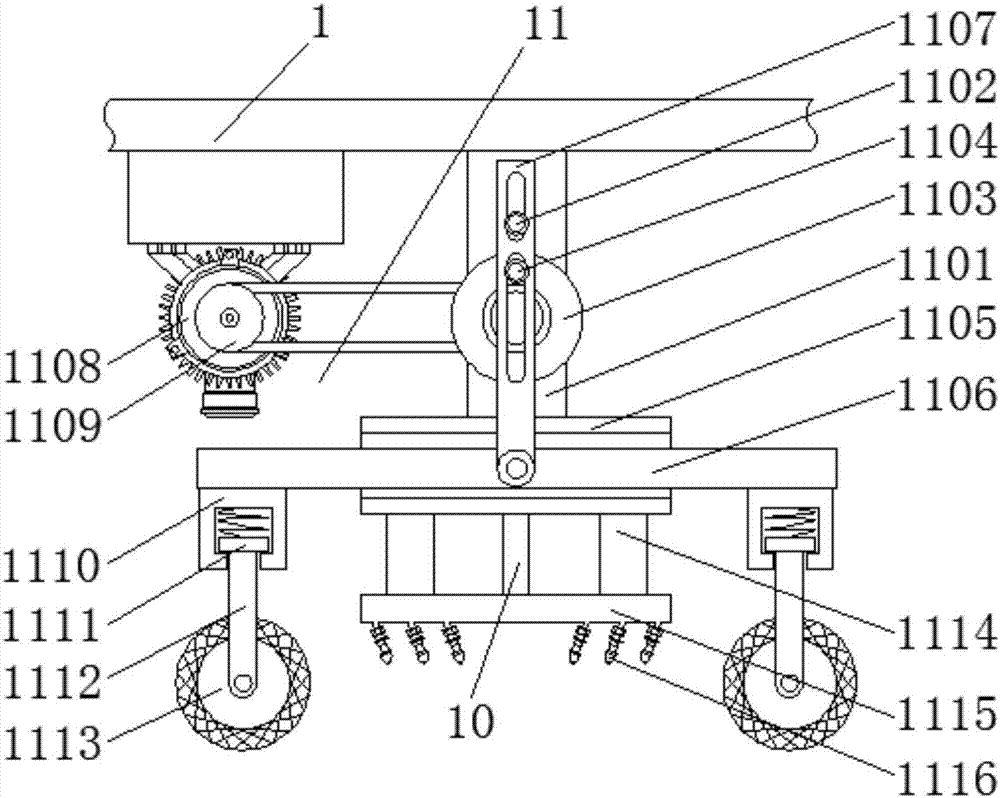

ActiveCN107354638AShorten the timeReduce investmentTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationAir blowerIntegrated devices

The invention relates to the technical field of spinning, in particular to a textile fabric cleaning and drying integrated device. A fabric taking-up roller and a fabric paying-off roller are installed at the front end and the rear end of a worktable, a water tank, a shaking unit and a drying box are sequentially arranged in the middle of the worktable from front to back, the shaking unit can shake off a cleaning fluid on a textile fabric, a hot-air blower in the drying box blows out hot air to dry the textile fabric, a flapping unit is installed in the drying box to flap the flap, and the cleaning fluid on the textile fabric can be rapidly separated from the textile fabric. The cleaning and drying of the textile fabric are organically combined together, the cleaned textile fabric can be dried during textile fabric cleaning, the time required for independent cleaning and independent drying is effectively shortened, meanwhile the input of the device is decreased, and the production cost is reduced.

Owner:XUZHOU ZHENFANG TEXTILE CO LTD

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

Cleaning equipment for spinning

InactiveCN107938211AWash thoroughlyEffective flushingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringAirflow

The invention relates to the technical field of cleaning equipment for spinning and discloses cleaning equipment for spinning. The cleaning equipment comprises an equipment body; two sides of the equipment body are symmetrically provided with first openings; two symmetrical rollers are fixedly installed on upper ends of the two sides of the equipment body; spinning fabric is stitched between the two rollers. By means of the cleaning equipment for spinning, under the effect of a first water pump and a second water pump, fabric can be effectively washed; a first nozzle and a second nozzle at theleft end can be used for washing before brushing to clean dust on the fabric; a first nozzle and a second nozzle at the right end can be used for effectively washing off the dust after the cleaning of electric rollers so as to guarantee that the fabric can be cleaned thoroughly; by means of two fans at up and down, hot air flow in a drying box can be blown to the fabric so that two sides of the fabric can be uniformly heated to accelerate drying and guarantee the drying efficiency.

Owner:胡和萍

Micro-elastic memory face fabric and production process thereof

InactiveCN101338470APromote formationSuitable for mass productionWeft knittingLoomsEngineeringCompanion animal

The invention discloses micro-stretch memory fabric and a process thereof. The process comprises the selection of weaving equipment, warp and weft, weaving gray fabric, and dyeing and finishing. The invention is characterized in that the weaving equipment is a hydraulic loom or a jet loom; the warp is PTT memory filament or PET / 144F fine denier filament; the weft is PPT / PET compound blended fabric or PBT stretch yarn; and the quality ratio of the warp and the weft is 60 to 70 / 40 to 30. The gray fabric weaving adopts X55, CM800, T400 or the PBT stretch yarn of whole original weft supplier. Warp twisting is 6 to 8 twist / cm. Twisting speed is 8500 revolutions per minute. The temperature of setting twist is 75 DEG C and heat preservation lasts for an hour or scaling treatment lasts for 24 to 48 hours. The flow of the dyeing and finishing is as follows: open-width de-sizing, preshrinking, previous form definition, dying and subsequent form definition. The process of the micro-stretch improves the quality of a product, and reduces cost. In addition, the fabric has good elasticity and good size stability, and is comfortable to be wore and easy to be handled.

Owner:YANGZHOU JIYUAN TEXTILE +1

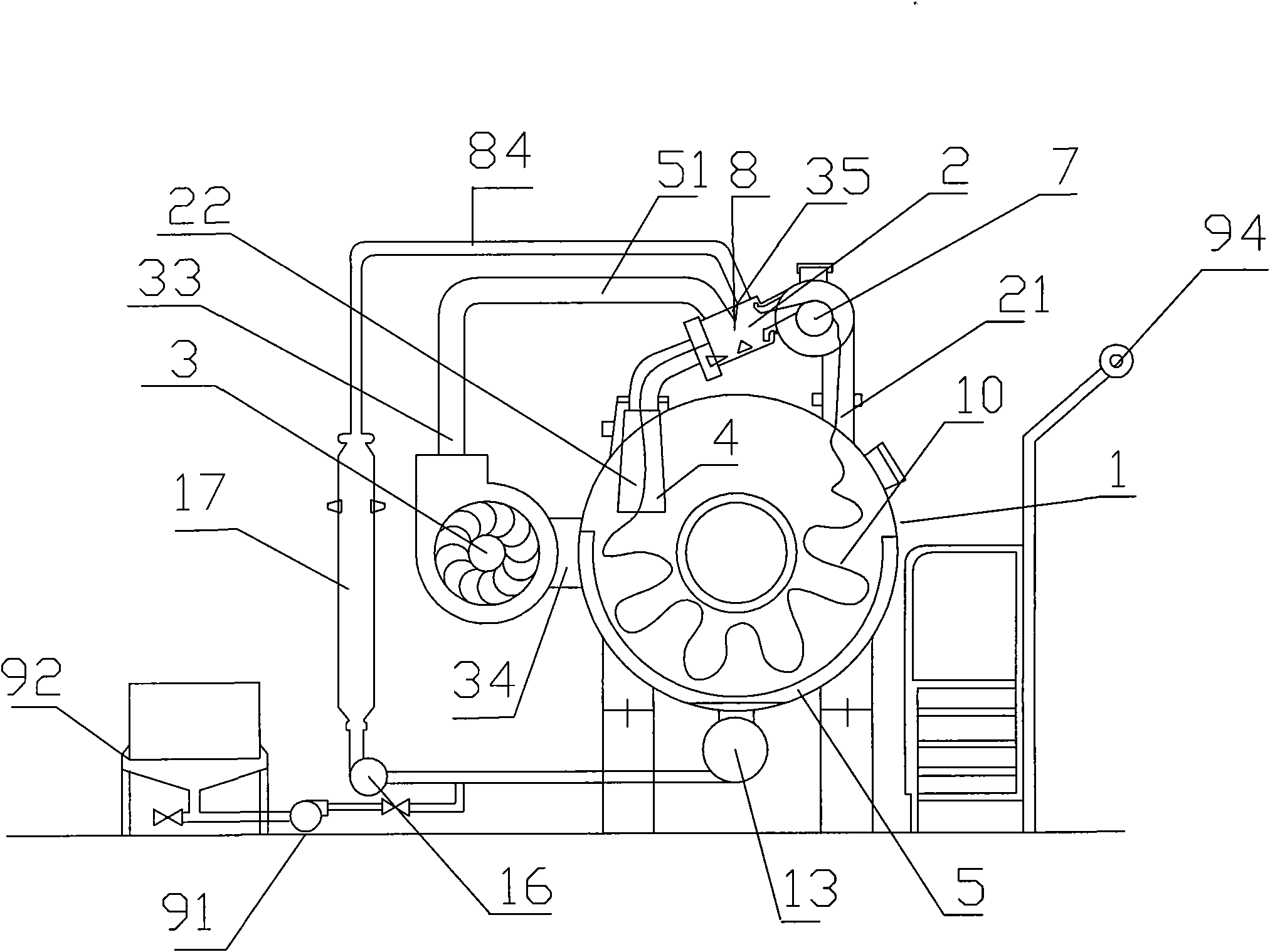

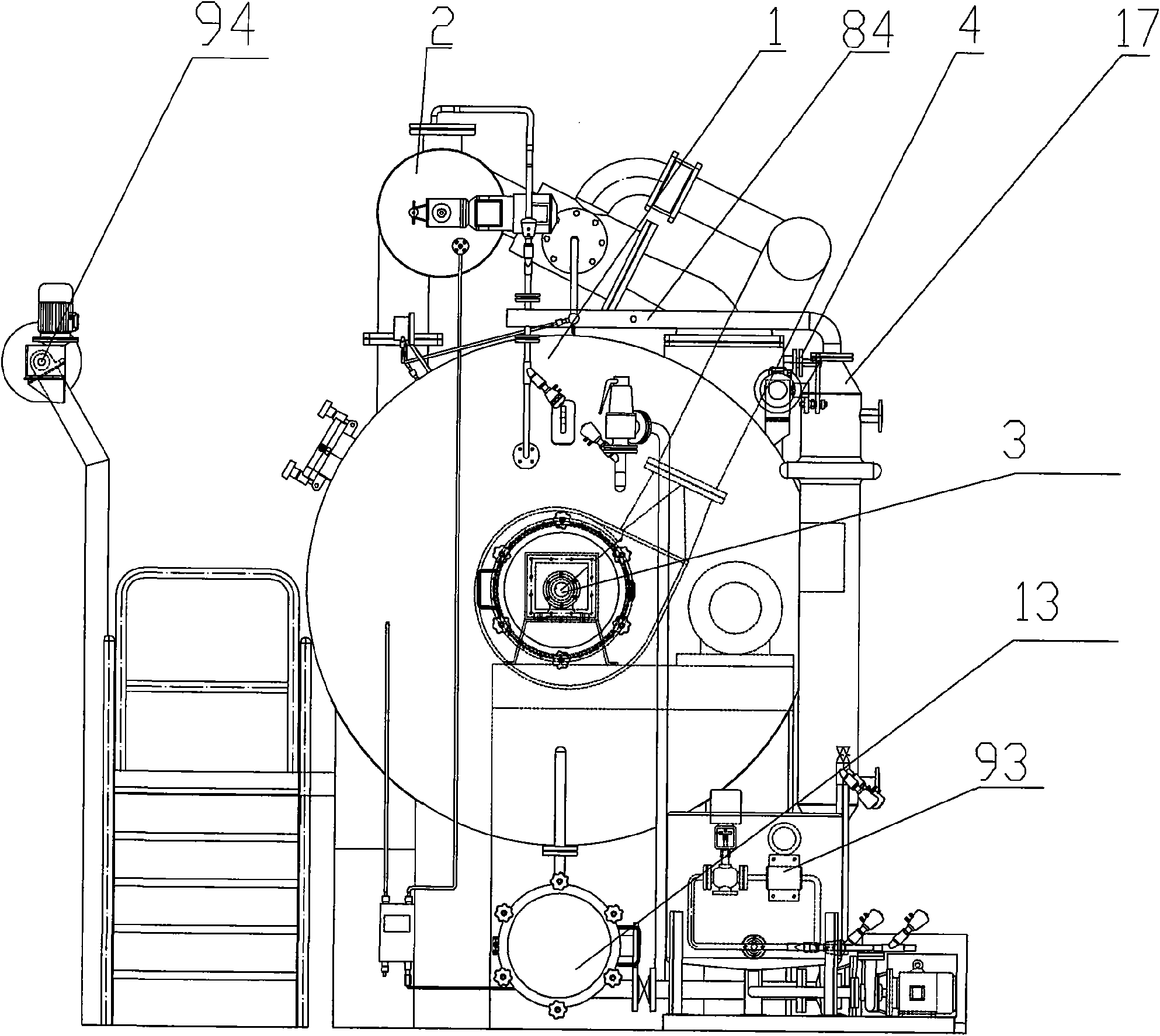

Novel gas-fog dyeing machine

InactiveCN101591845ALower liquor ratioSave energyTextile treatment machine arrangementsTextile treatment by spraying/projectingAir filterPulp and paper industry

The invention provides a novel gas-fog dyeing machine, which comprises a main cylinder body, a high pressure blower and a nozzle atomization system; an outlet at one end of the high pressure blower is communicated with a high pressure air inlet of the nozzle atomization system; two ends of the nozzle atomization system are a textile inlet and a textile outlet which are respectively communicated with the main cylinder body; a dye solution cutting nozzle, an energy converting nozzle and a cloth lifting roller are arranged in the nozzle atomization system; the dye solution cutting nozzle has an annular narrow slit shape; the axial section of the energy converting nozzle consists of three sections, namely a straight pipe section, a taper section and a gradual expansion section; and an inlet at the other end of the high pressure blower is communicated with an air filter screen in the main cylinder body. The special nozzle atomization system of the invention can well atomize the dye solution; and the dyeing machine adopts gas-fog flow for dyeing, cancels circulating dye solution dragging of textile and uses airflow to drag the textile to operate, thereby greatly reducing the bath ratio, saving the energy, reducing the pollution, and promoting the environmental protection.

Owner:ZHEJIANG ZHUOXIN MACHINERY

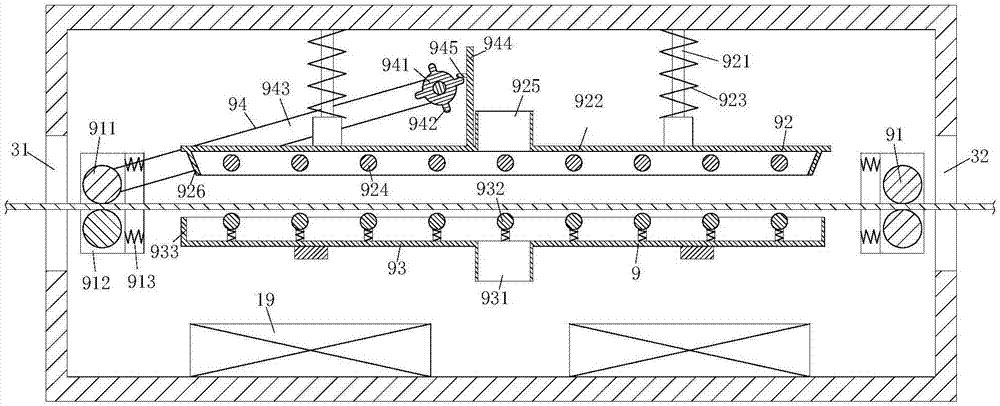

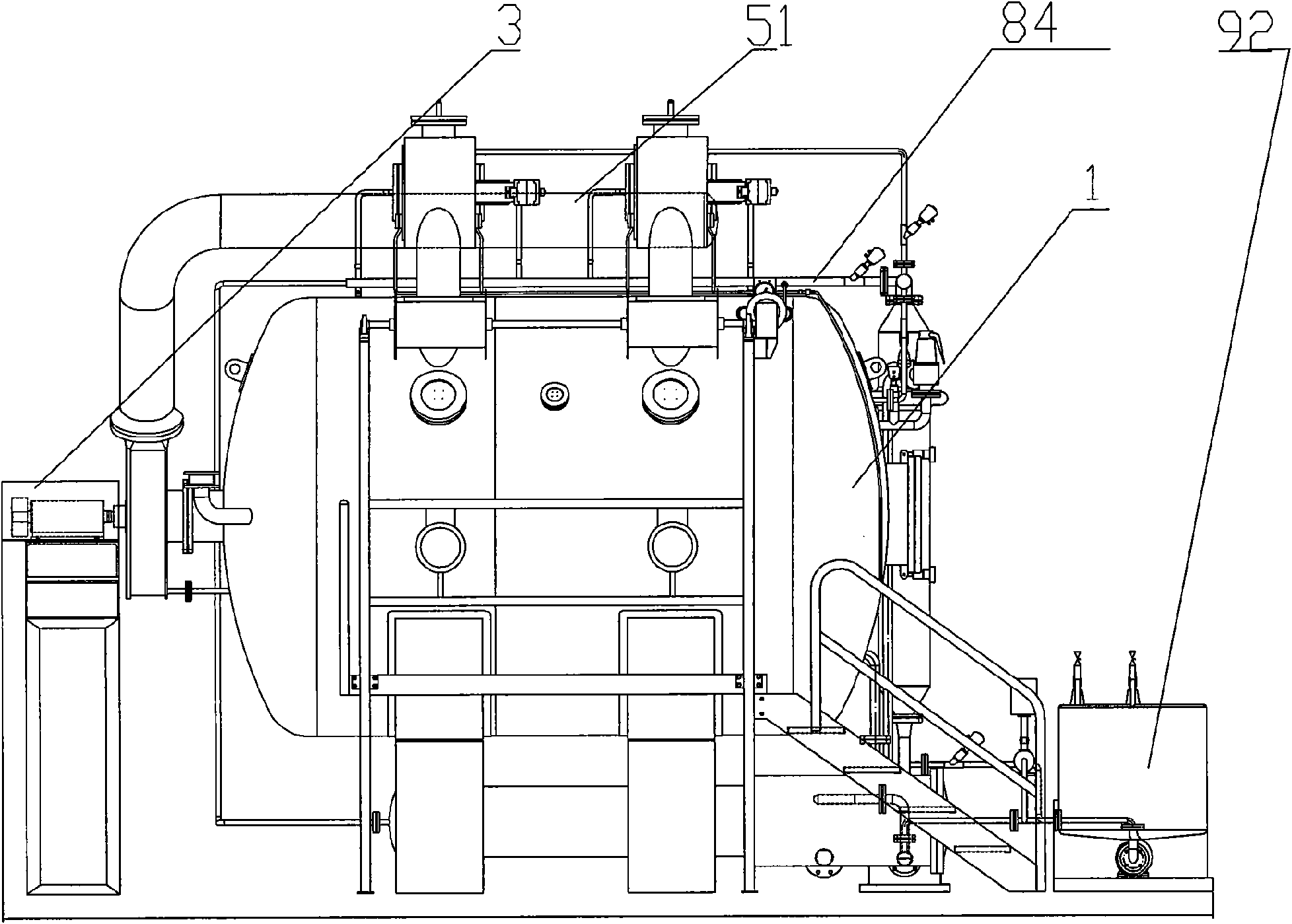

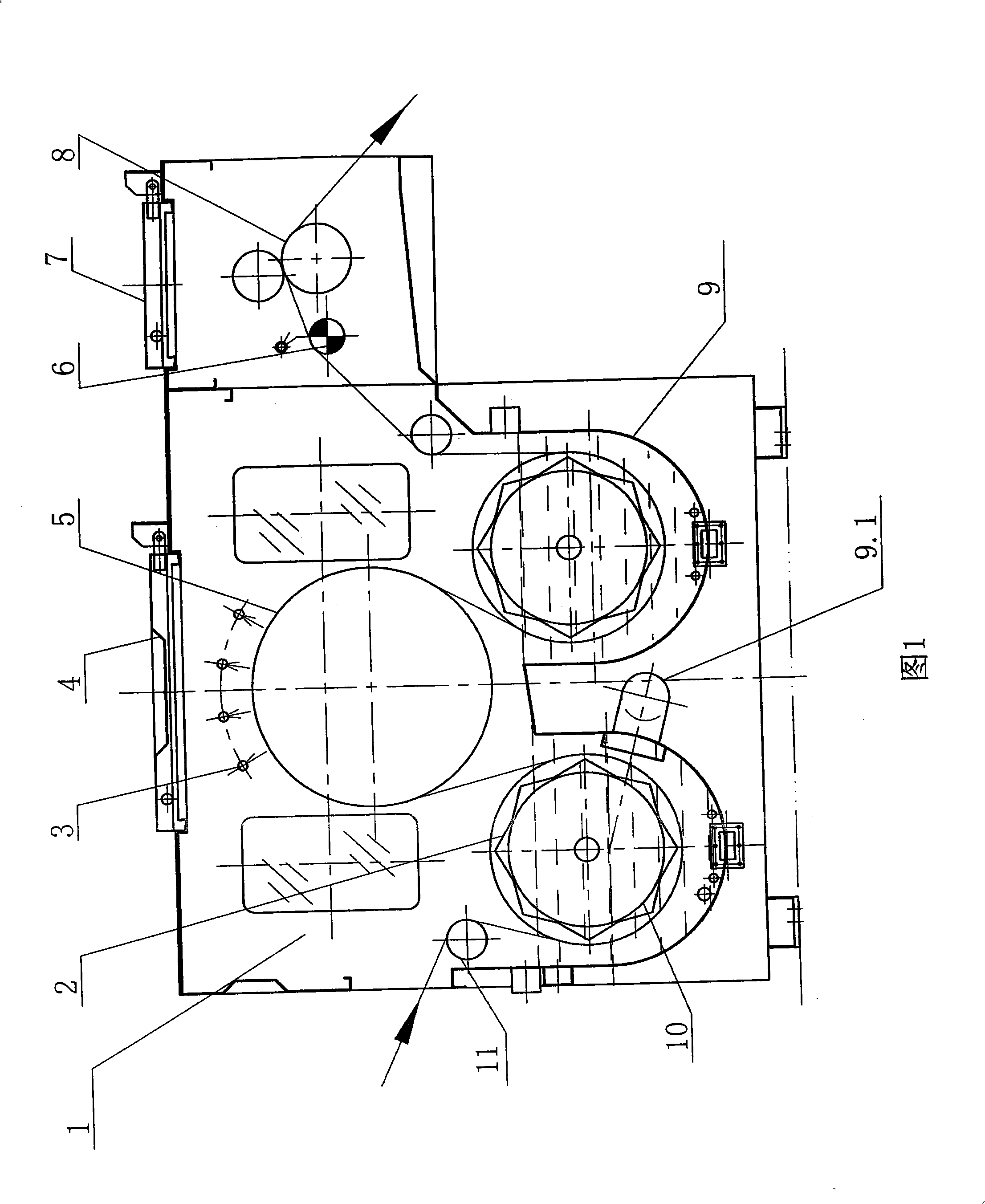

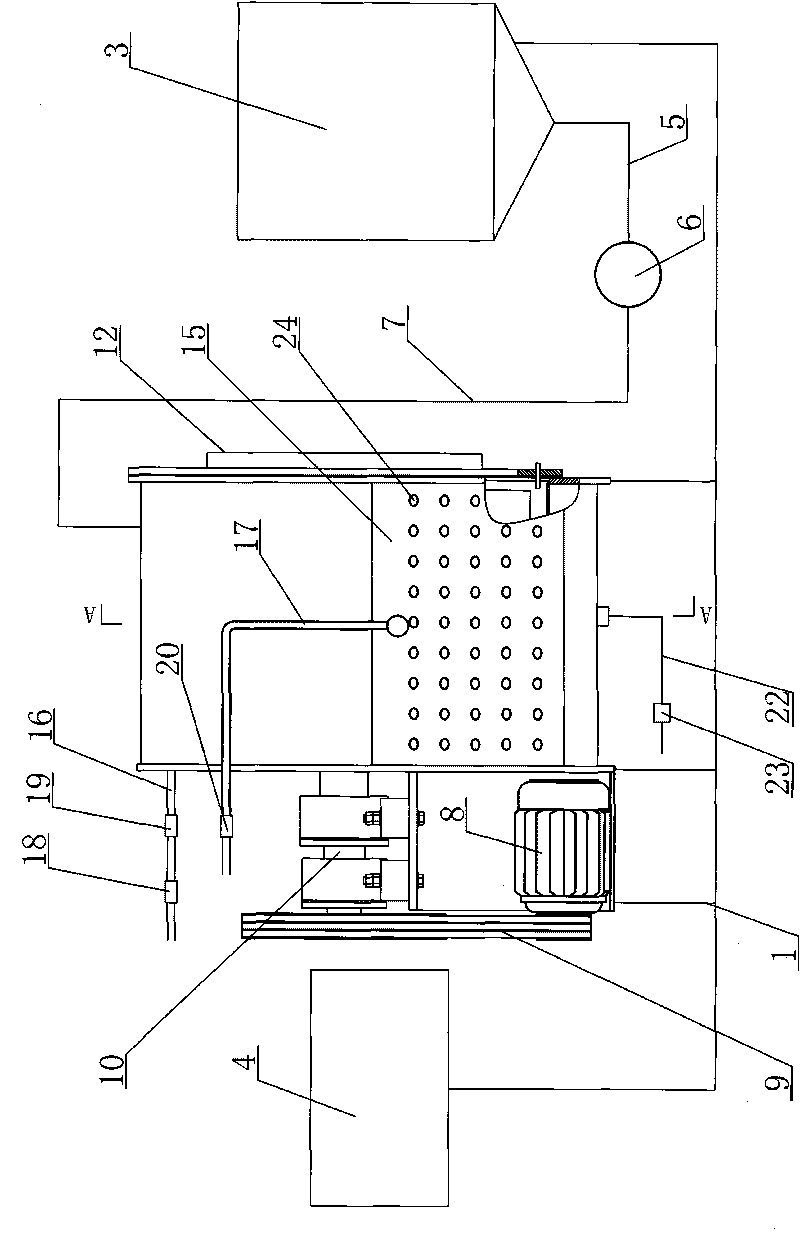

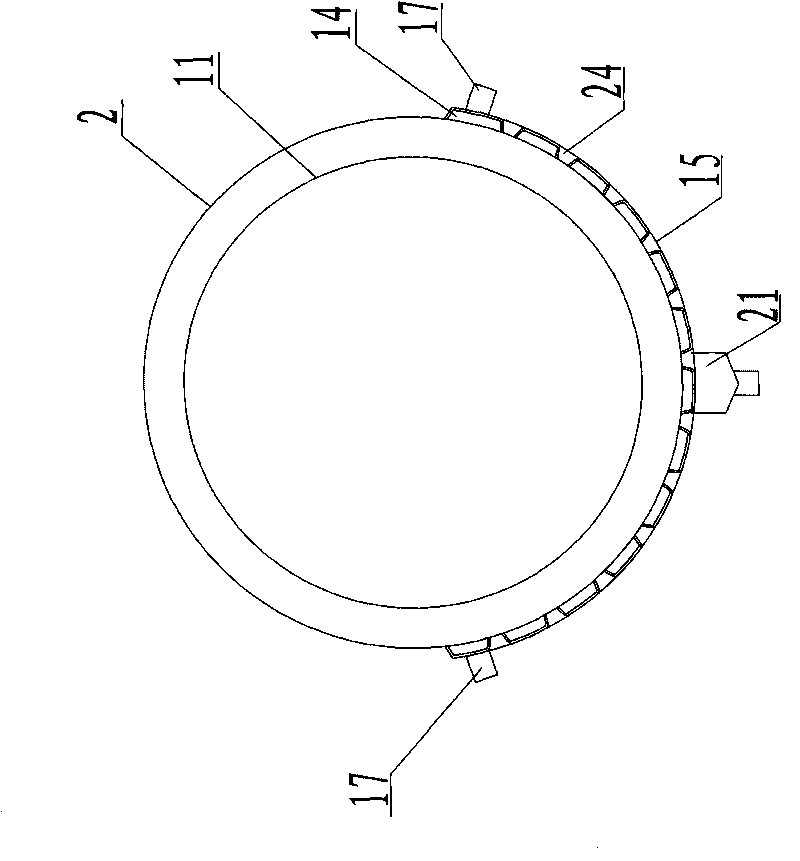

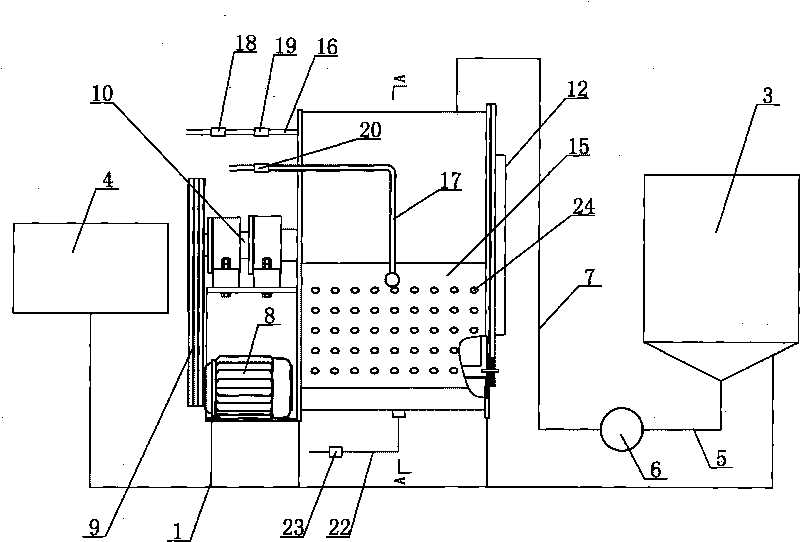

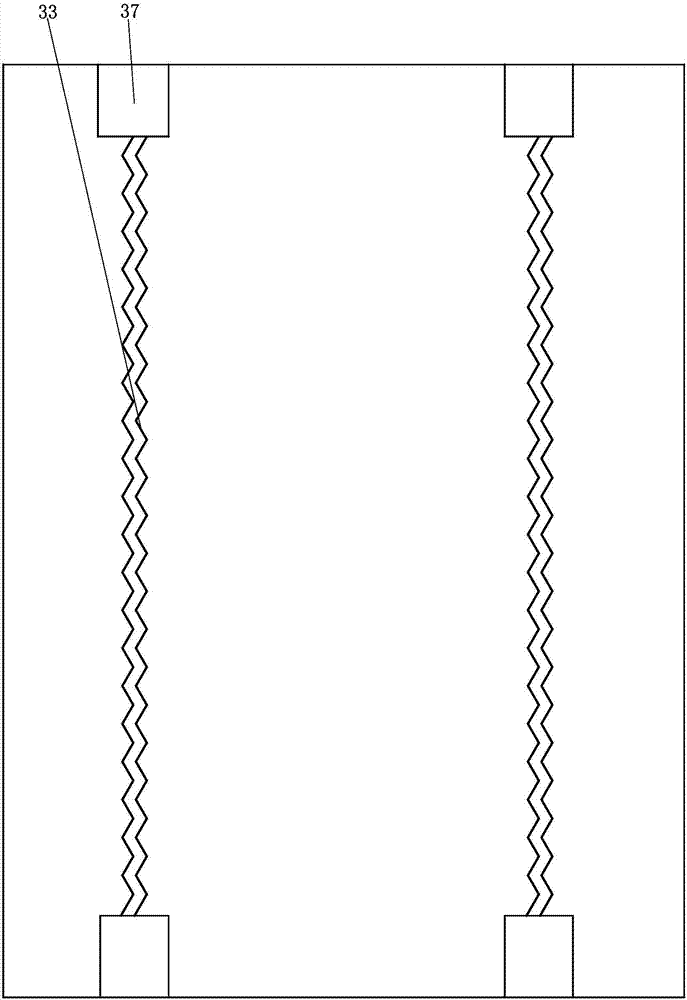

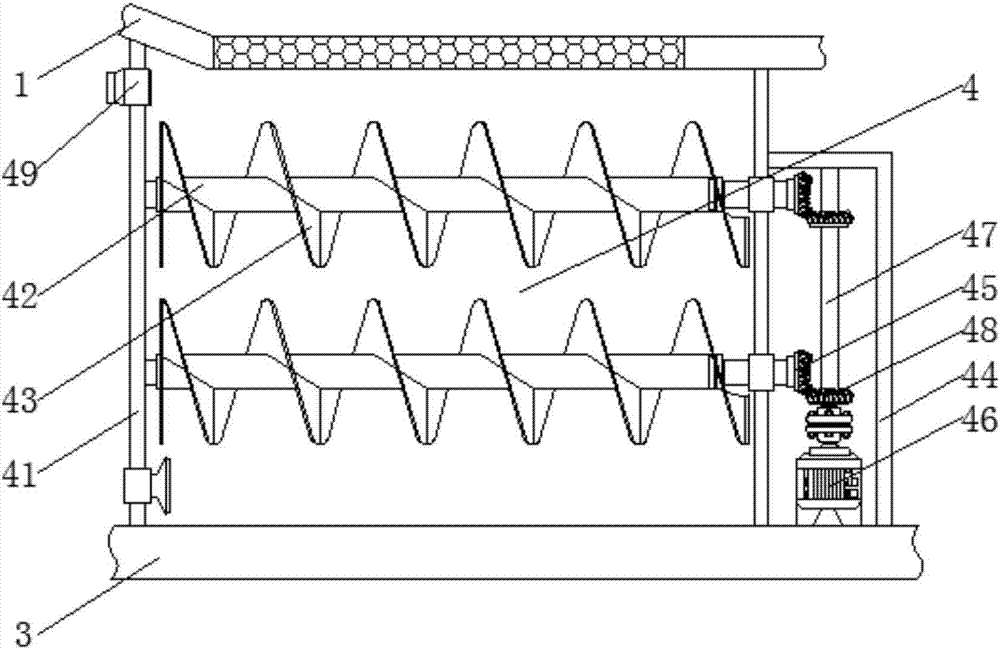

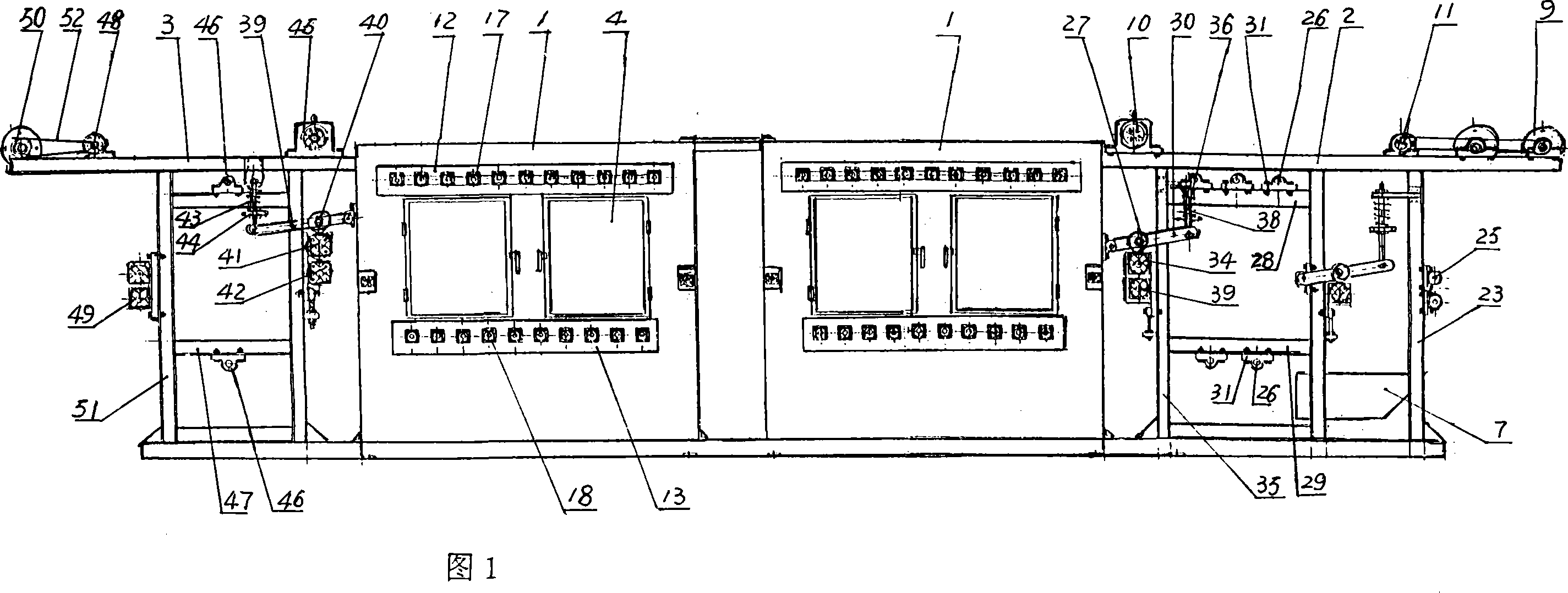

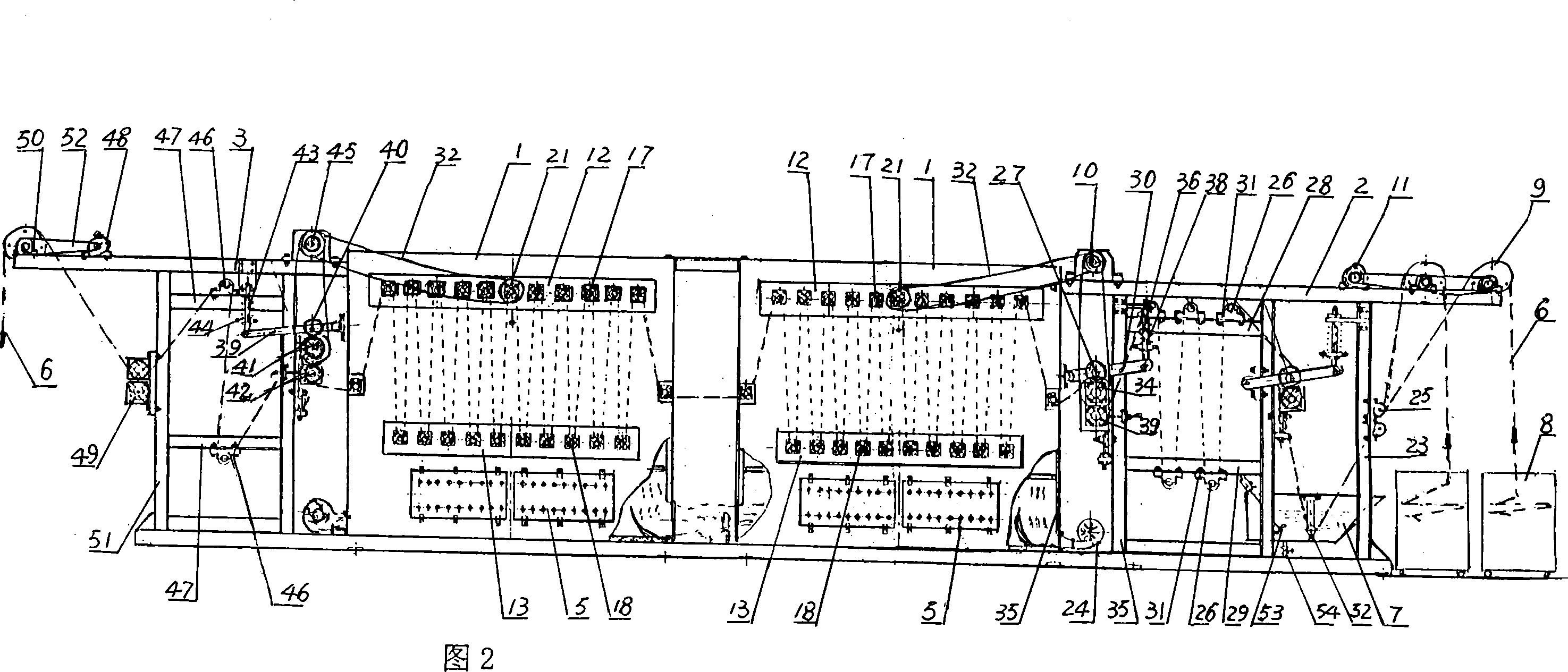

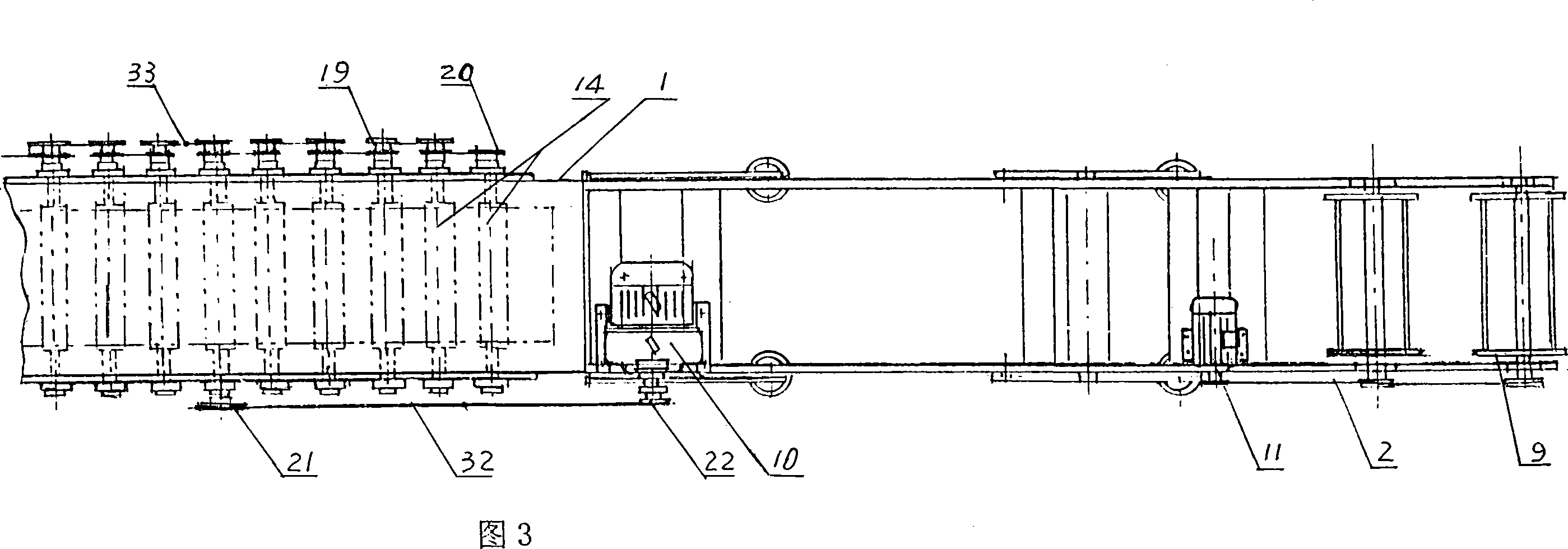

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

High-modulus flame-retardant antistatic safe protection belt and preparation method thereof

InactiveCN105064024AEasy to adjustAdjustable thicknessFibre typesTextile treatment machine arrangementsCross-linkAntistatic agent

The invention provides a high-modulus flame-retardant antistatic safe protection belt and a preparation method thereof, and solves the problems that when the conventional protection belt is used in a complex environment, the personnel safety of a user cannot be protected effectively as the conventional protection belt is not flame-retardant and antistatic, the safety is poor and no preparation methods is available. The high-modulus flame-retardant antistatic safe protection belt comprises a base cloth layer, wherein reinforcing layers are fixed on both sides of the base cloth layer; the reinforcing layers comprise the following ingredients by weight: 40 to 60 parts of polyvinyl chloride, 20 to 30 parts of polycarbonate, 6 to 10 parts of a solvent, 3 to 6 parts of magnesium oxide, 3 to 6 parts of zinc oxide, 5 to 10 parts of calcium carbonate, 2 to 4 parts of a cross-linking agent, 3 to 8 parts of a plasticizing agent, 5 to 8 parts of an antistatic agent, and 0.1 to 0.3 part of an anti-oxidant. The high-modulus flame-retardant antistatic safe protection belt and the preparation method have the advantages that the safety is high; the production is fast.

Owner:HAINING JINGDA FABRIC

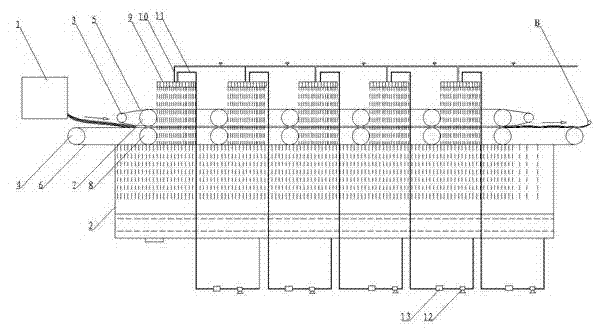

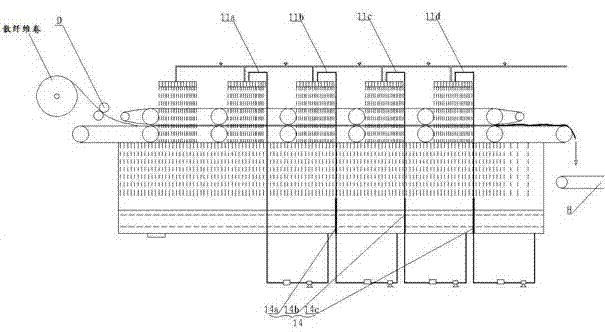

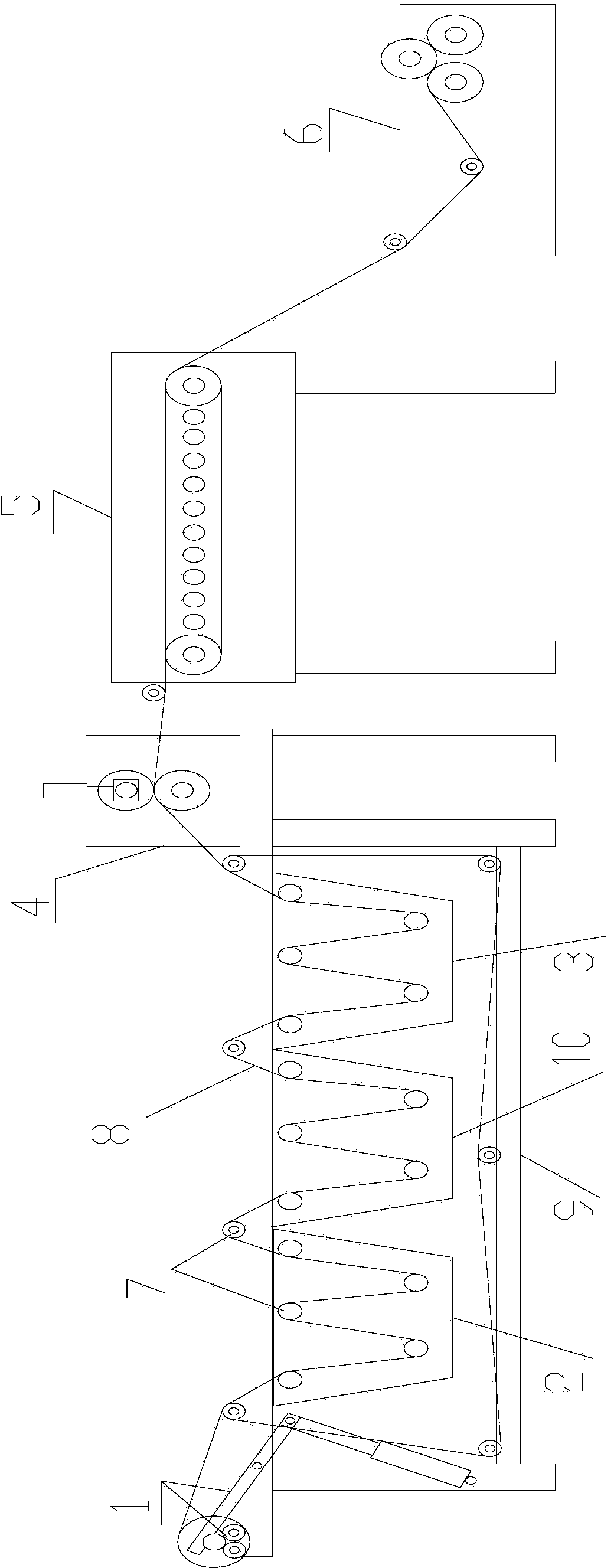

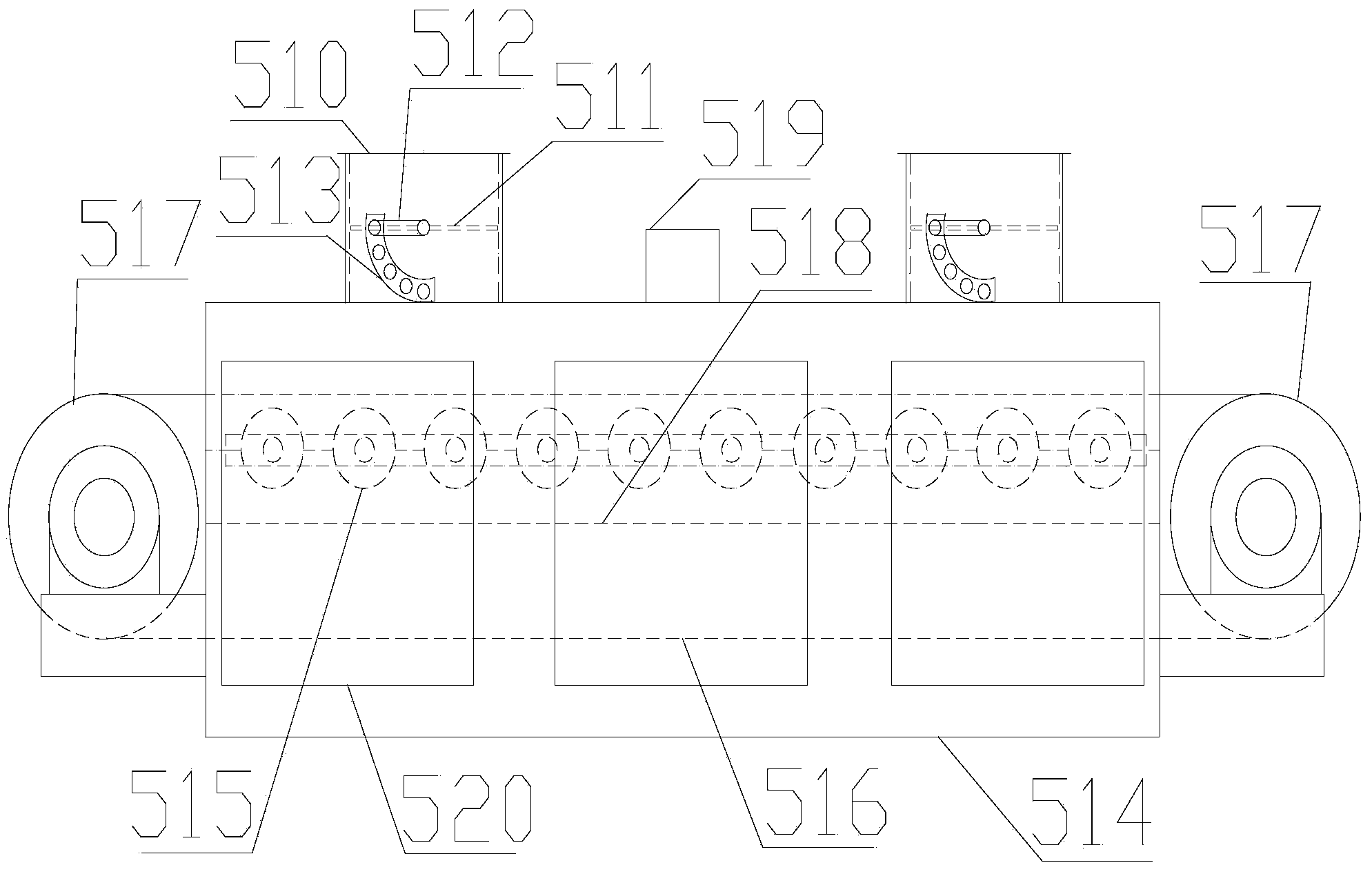

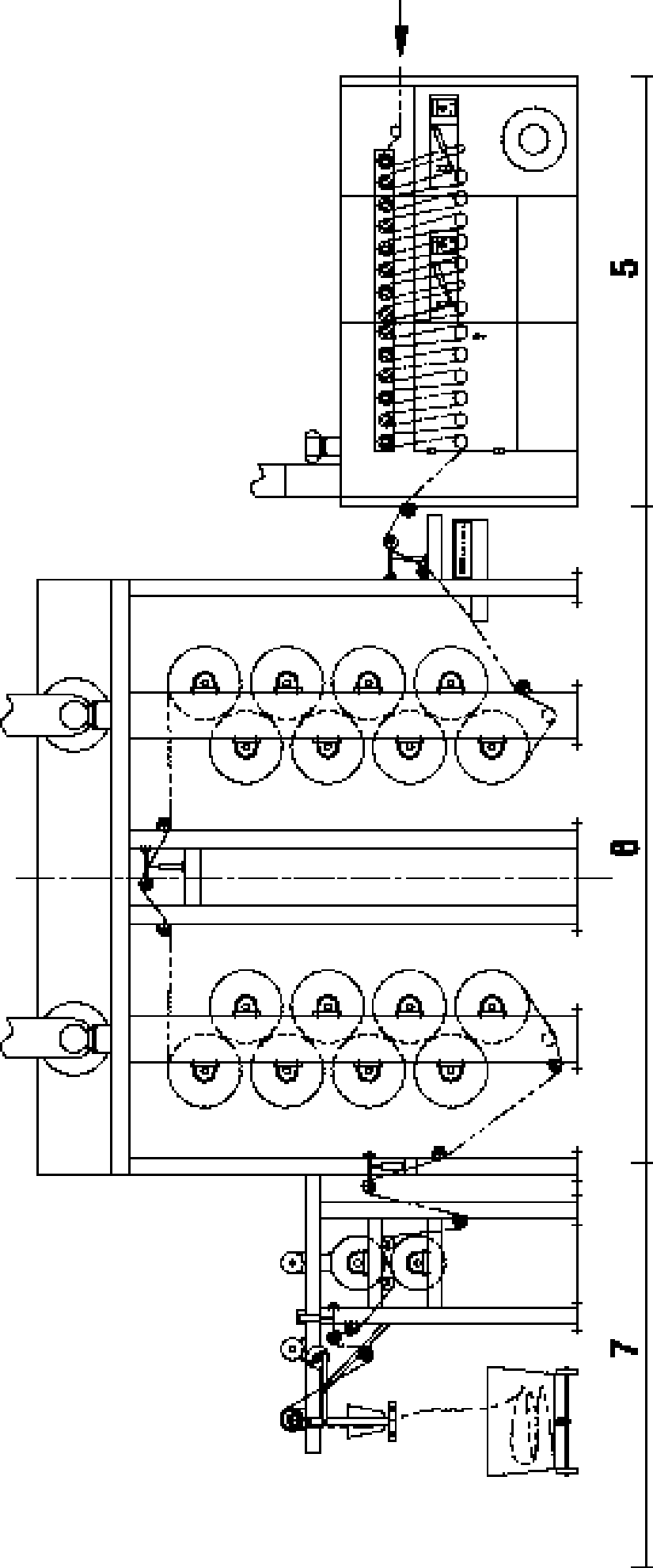

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

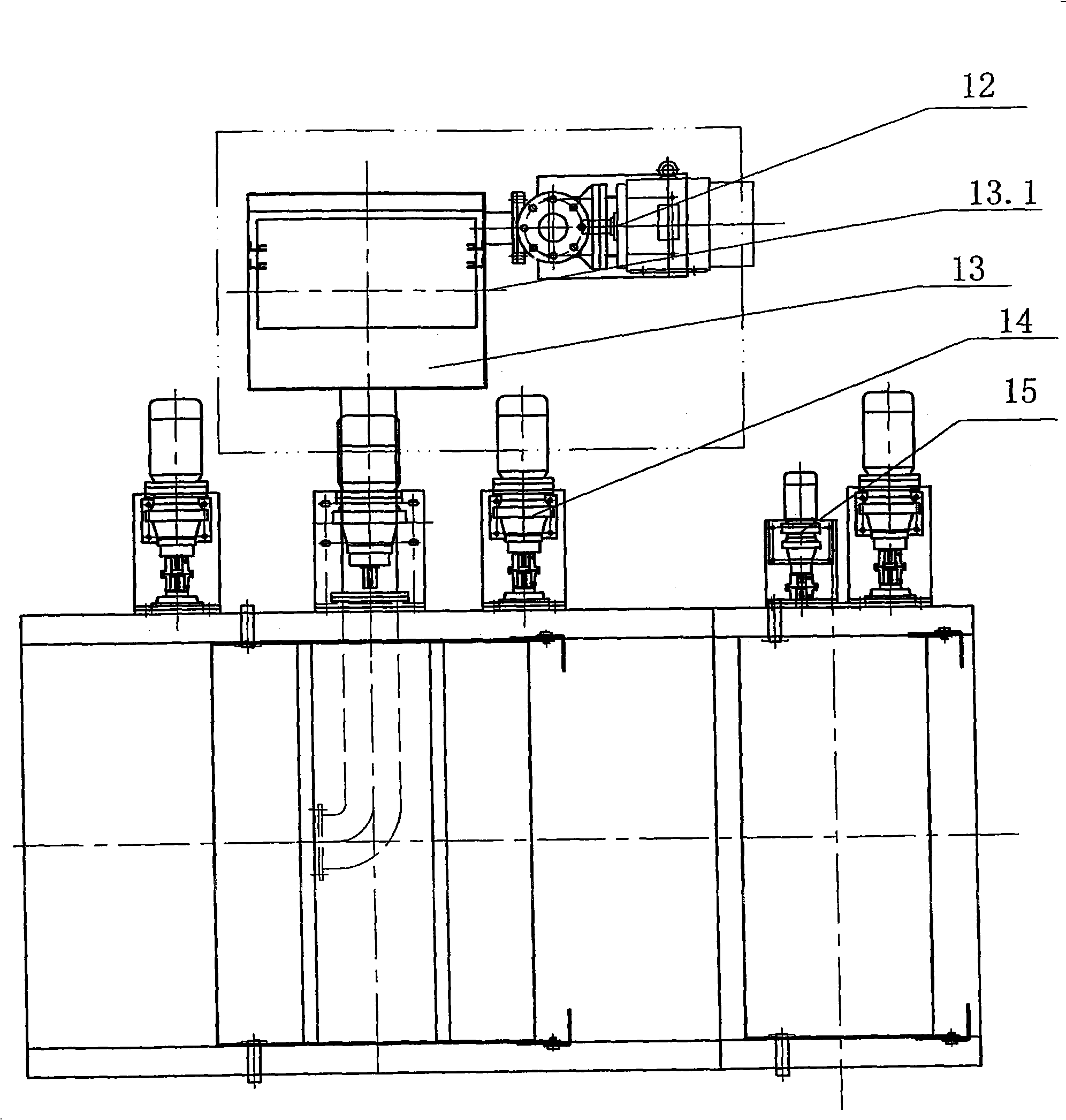

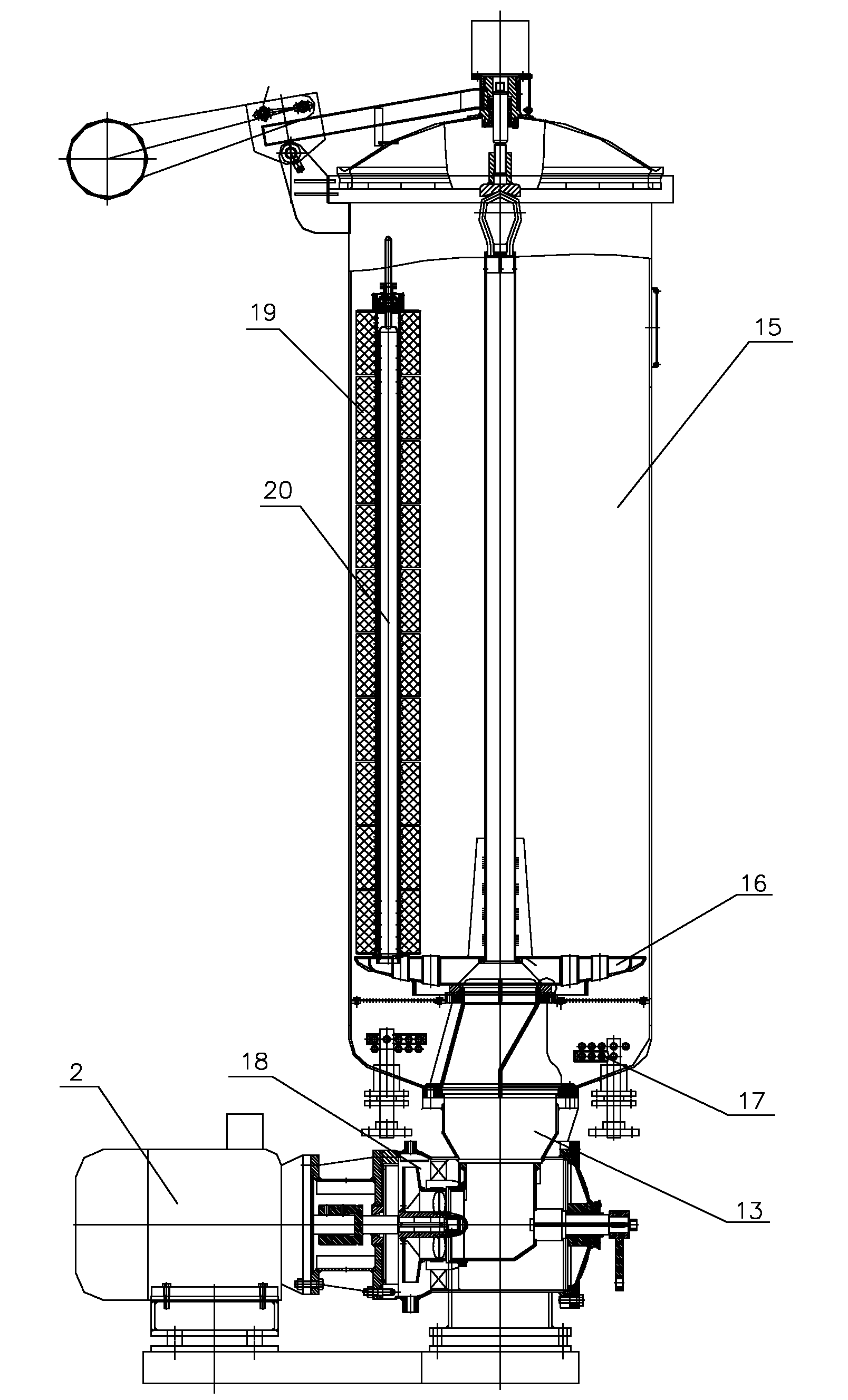

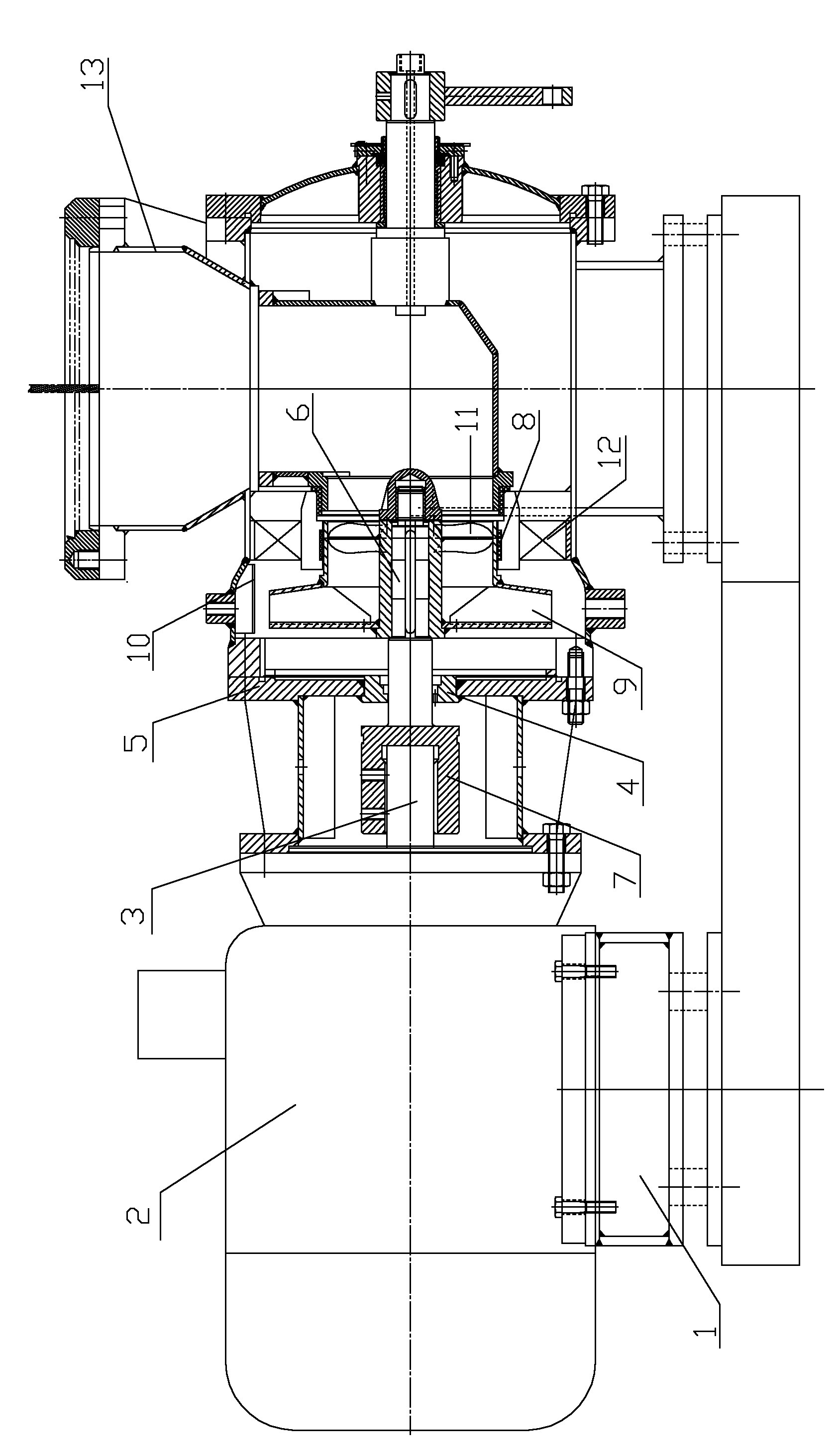

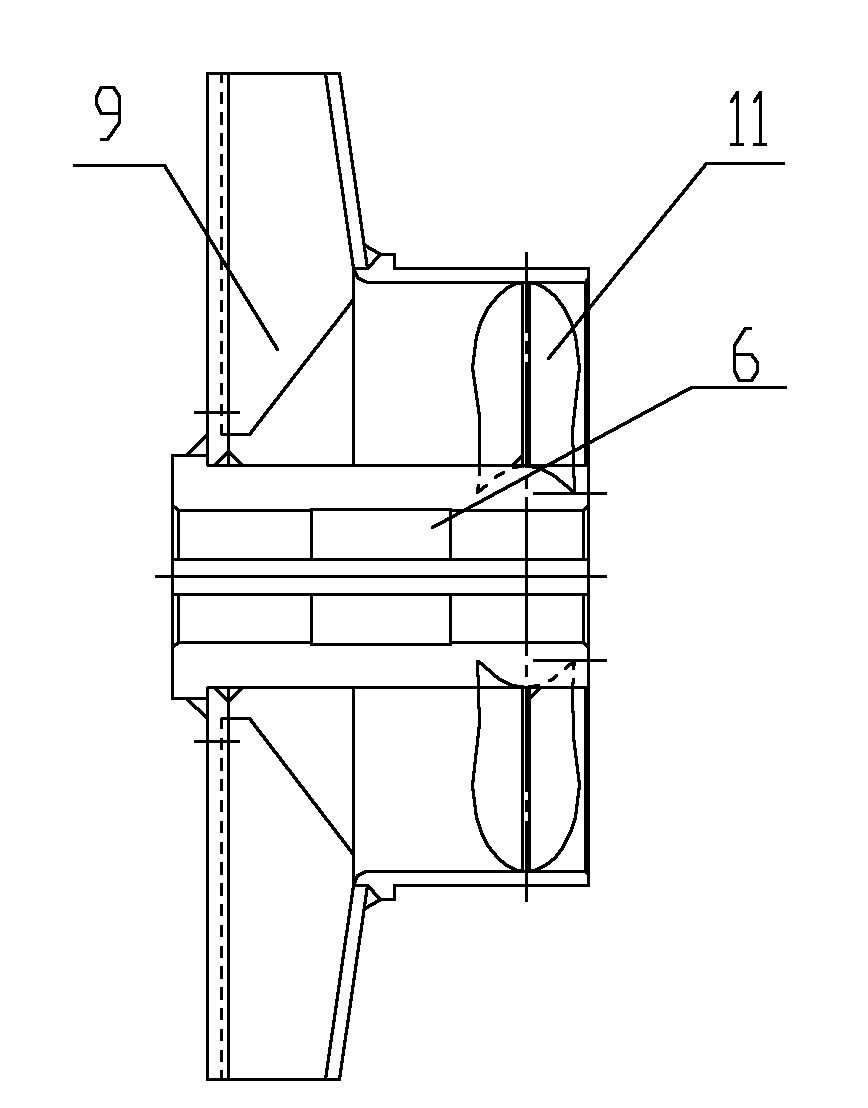

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

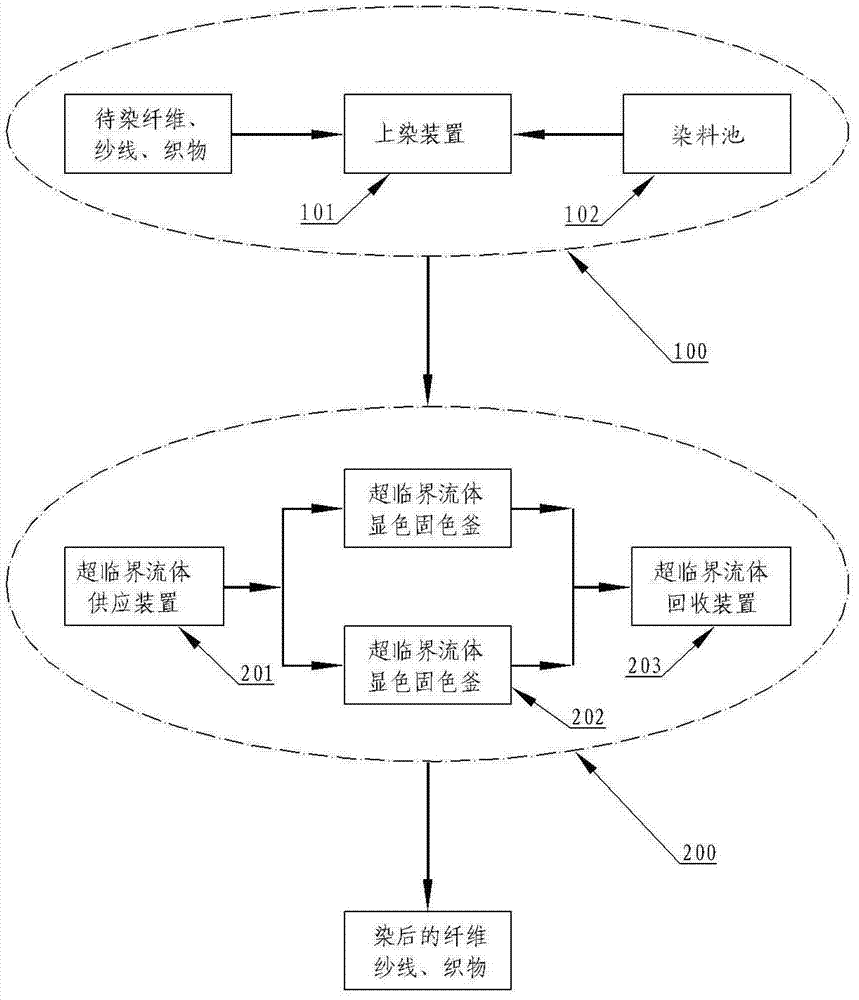

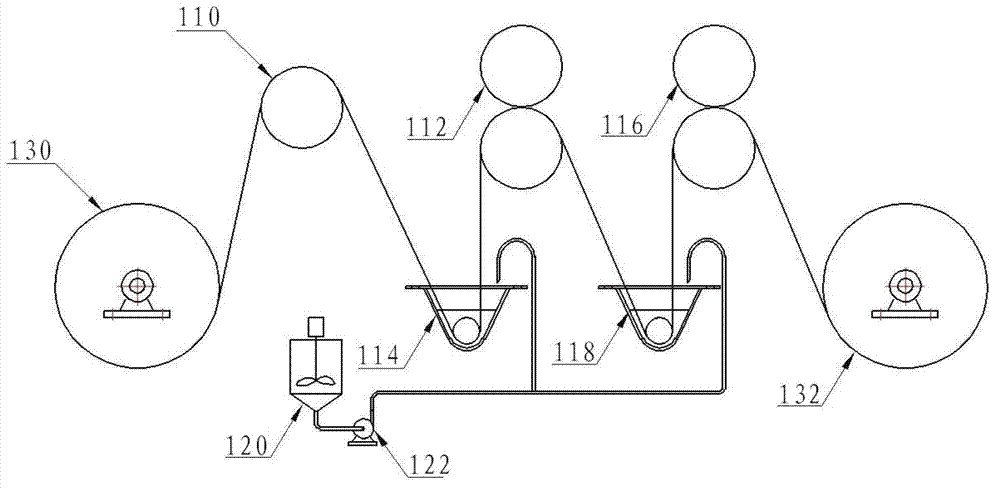

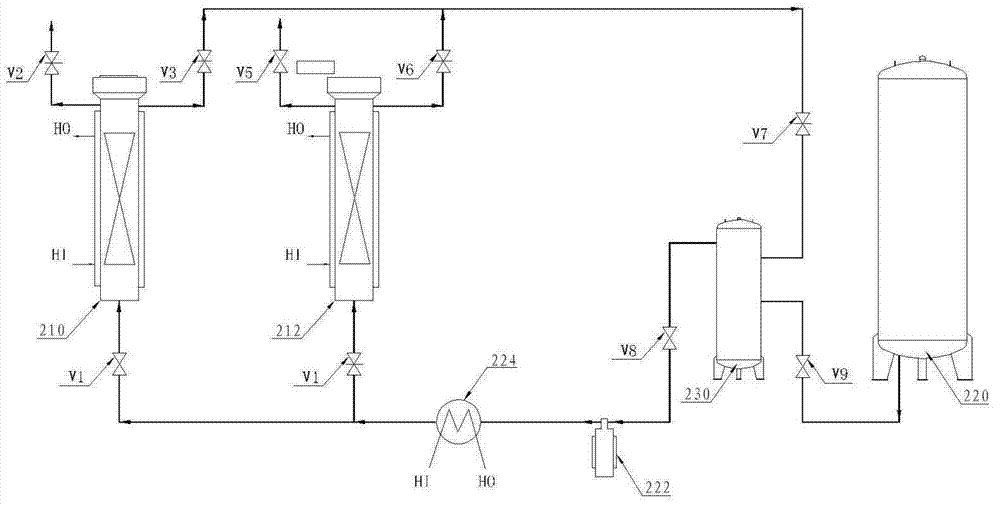

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194AMigration does not occurSolve uncontrollable difficultiesTextile treatment containersChemical fixing of textilesSystem pressureStationary state

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

Fully automatic garment dyeing machine

ActiveCN101748574AHigh degree of automationEasy to controlTextile treatment containersTextile treatment machine arrangementsPulp and paper industryFully automatic

The invention discloses a fully automatic garment dyeing machine which comprises a frame, a dyeing cylinder arranged on the frame, a dye feed cylinder and a computer controller. An electromotor is arranged at the lower end of the dyeing cylinder and connected with one end of a rotating shaft through a transmission belt; the other end of the rotating shaft is connected with a rotating cage arranged inside the dyeing cylinder; a machine door is arranged on one side of the dyeing cylinder; a temperature sensor is arranged in the dyeing cylinder; and a heating cavity is formed on the outer side at the lower end of the dyeing cylinder. The fully automatic garment dyeing machine with the structure has the advantages of high automation and convenient control; and steam can not be directly sprayed to the dyeing cylinder when the dyeing cylinder is heated, so that the water bathing ratio in the dyeing cylinder is not influenced, and the dyeing effect is improved.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

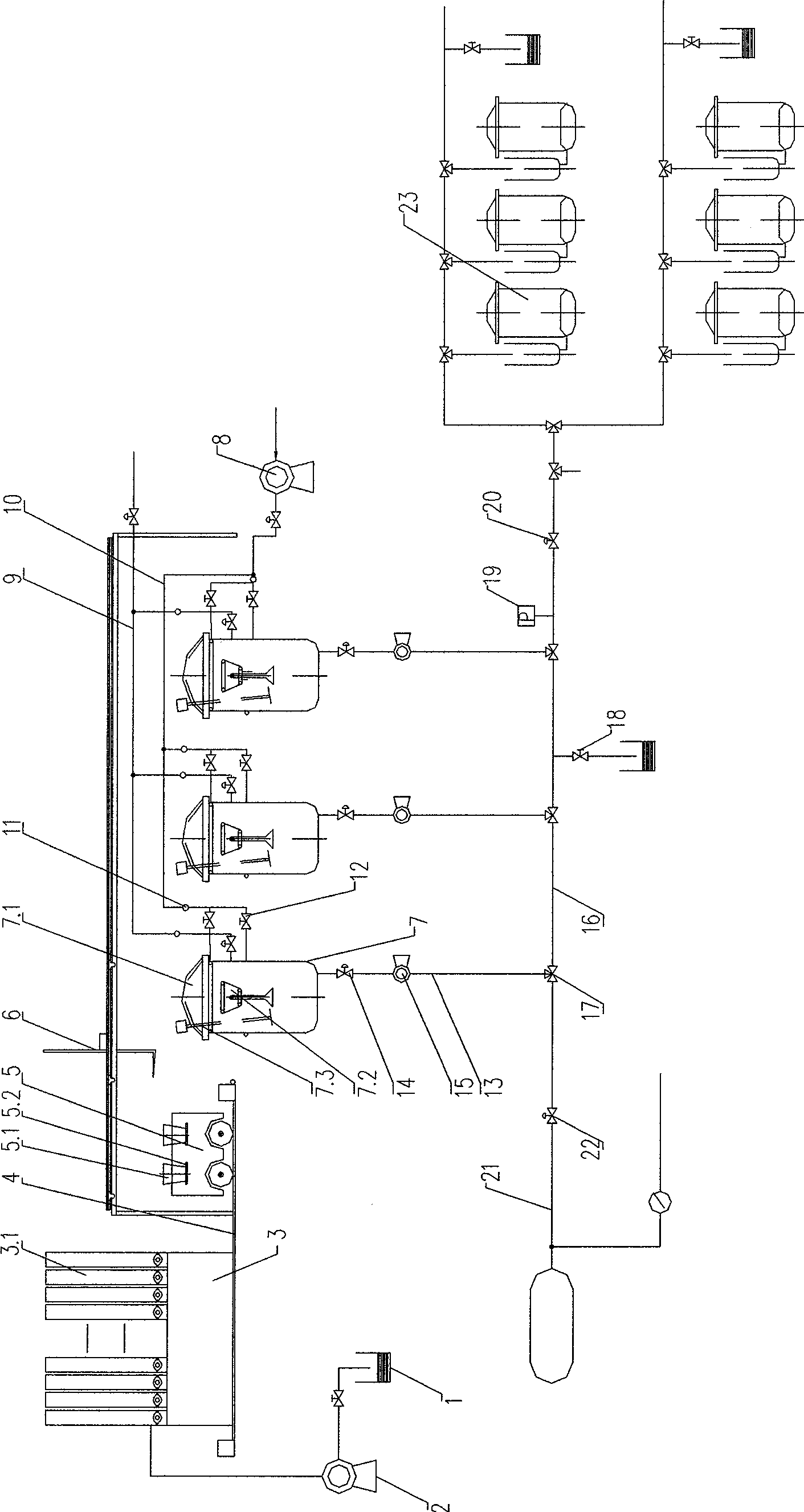

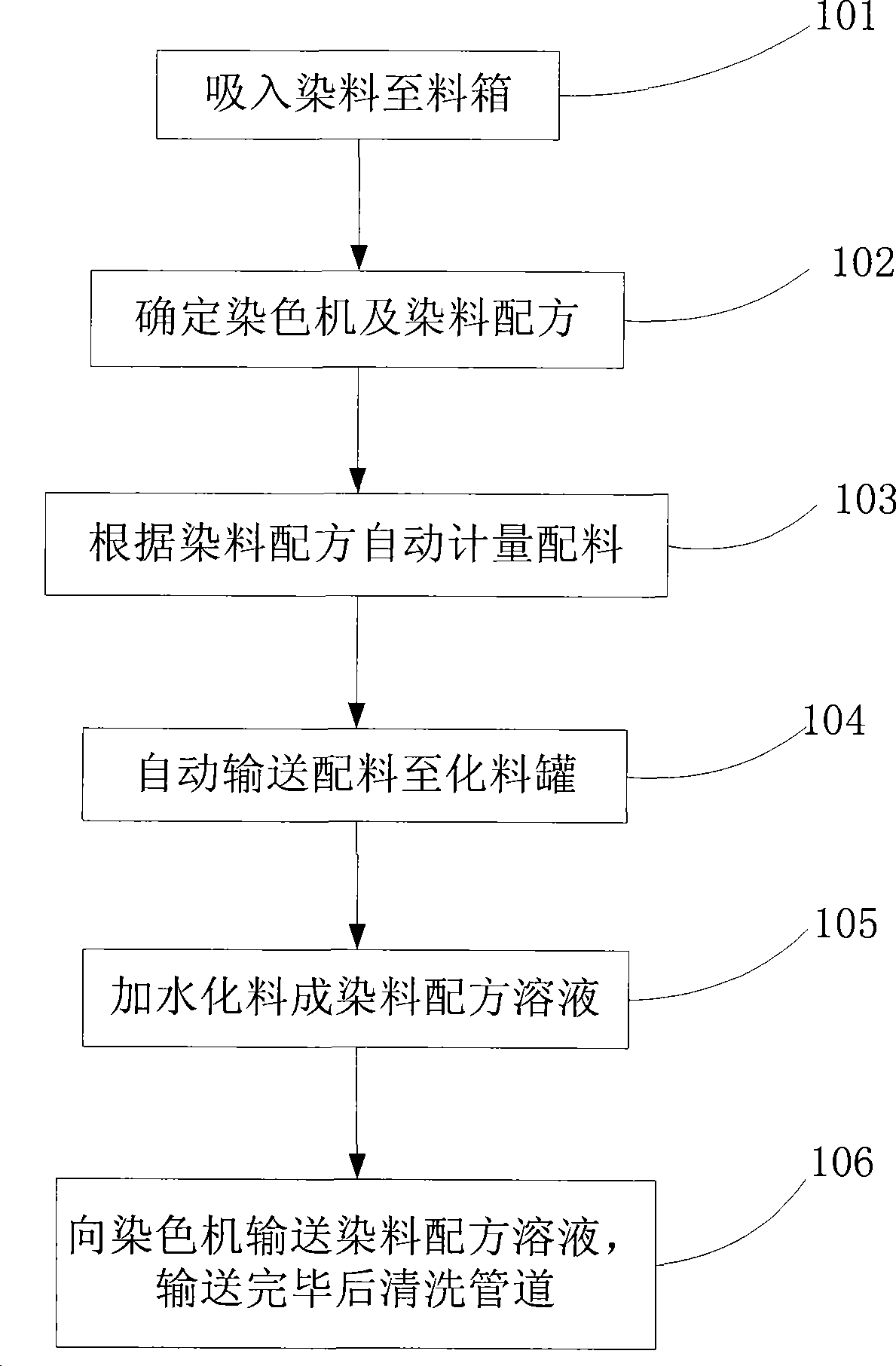

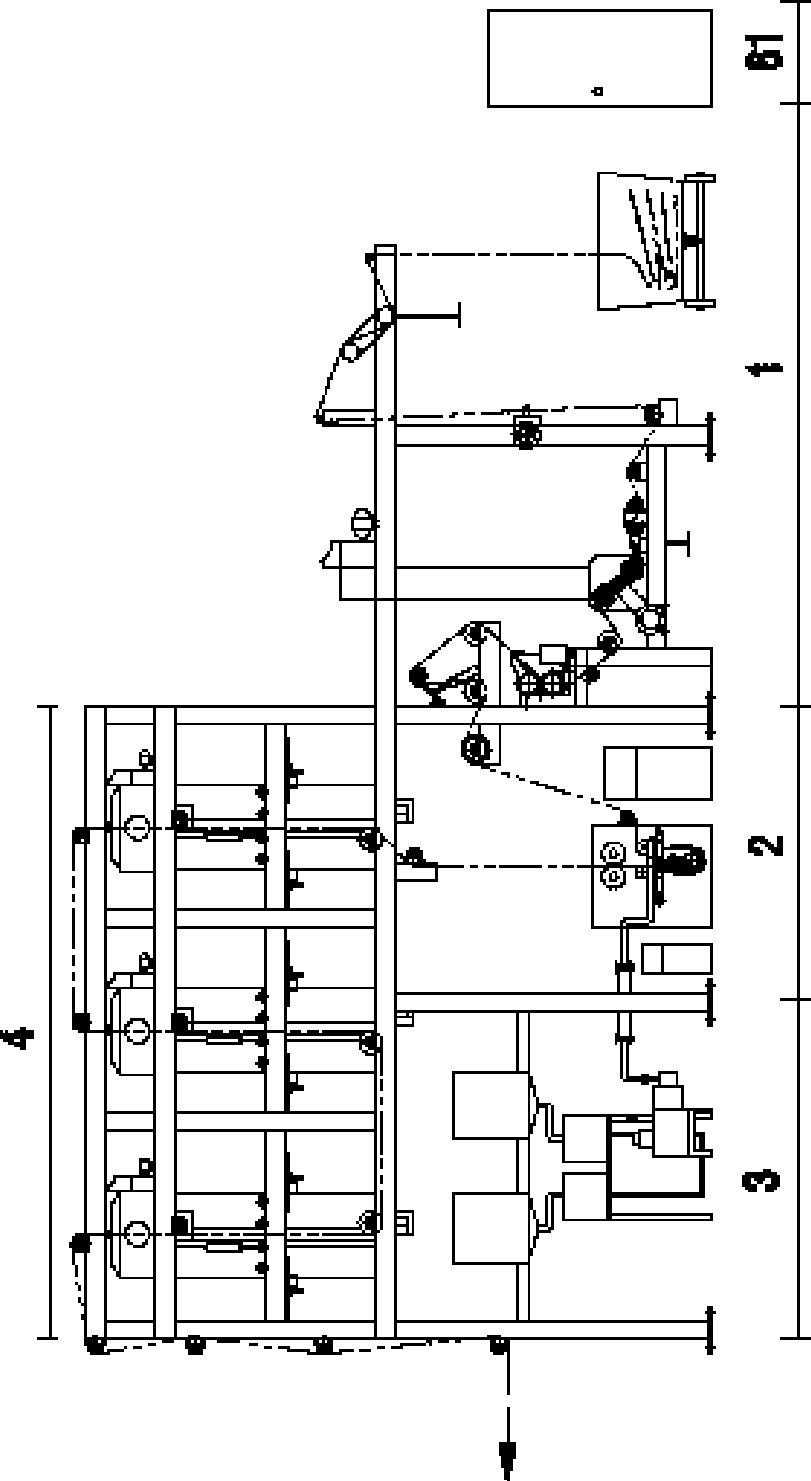

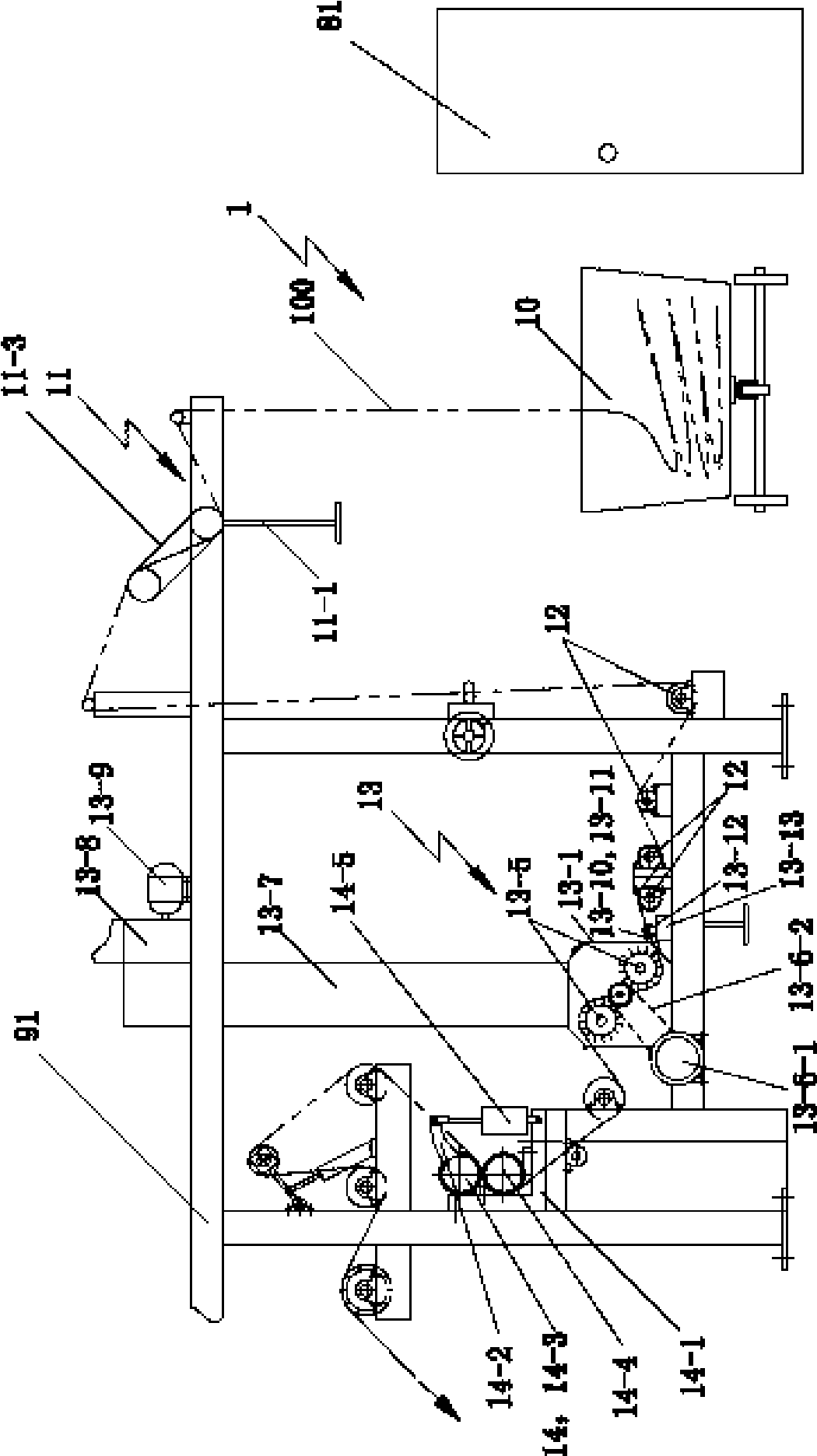

Automatic delivery method for cone yarn dyeing powdery dye and special equipment therefor

ActiveCN101476222AAvoid miscastingAvoid overshootingControlling ratio of multiple fluid flowsTextile treatment machine arrangementsWater pipeDyeing

The invention discloses a powder form dye automatic distribution and delivery method used in cheese dyeing and special-purpose equipment thereof. The method comprises the following steps: absorbing dye to dye tank; determining dyeing machine and dye formula; metering dyes automatically according to the dye formula; conveying the dyes to dye dissolving tank; adding water to dissolving the dyes into formula solution; and conveying dyes formula solution to dyeing machine. In the equipment of the invention, the raw material barrel is connected with dye tank; an proportioning track is disposed between the automatic dyes proportioning machine and the dye dissolving tank, and a metering dolly runs thereon; a robot runs between the proportioning track and the dye dissolving tank; the dye dissolving tank is connected to a water pump through a cold water pipe and a warm water pipe respectively; the dye dissolving tank is connected with the main pipe through a branch pipe; and one end of the main pipe is connected with compressed air pumping station, the other end is connected with the dyeing machine. The invention increases one time sample conforming rate, reduces the direct / indirect energy and manpower cost, realizes in time production and one time accurate production, and achieves the safe reliable clean production with less pollution.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

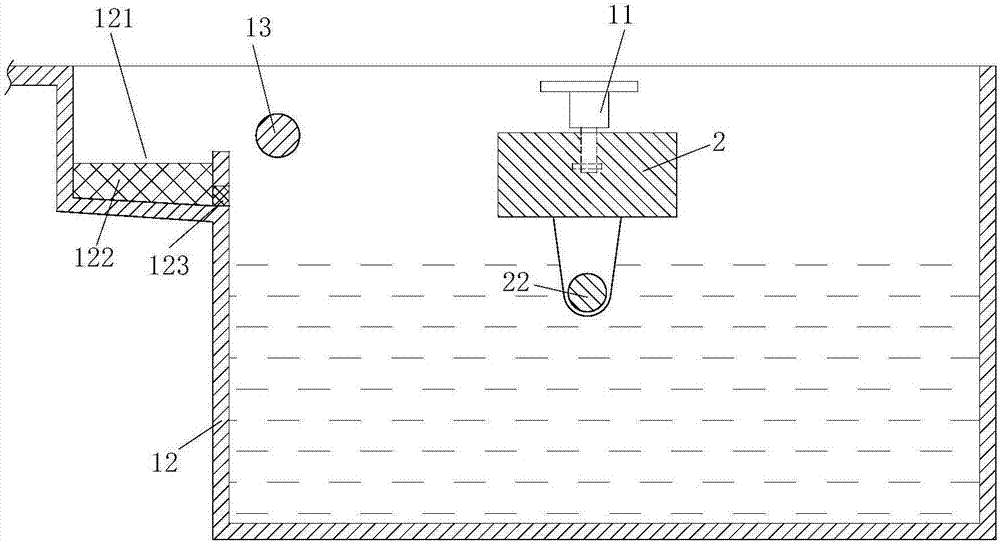

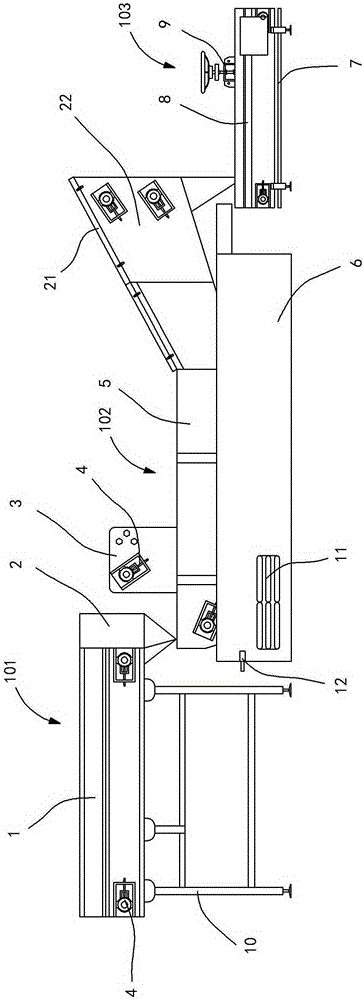

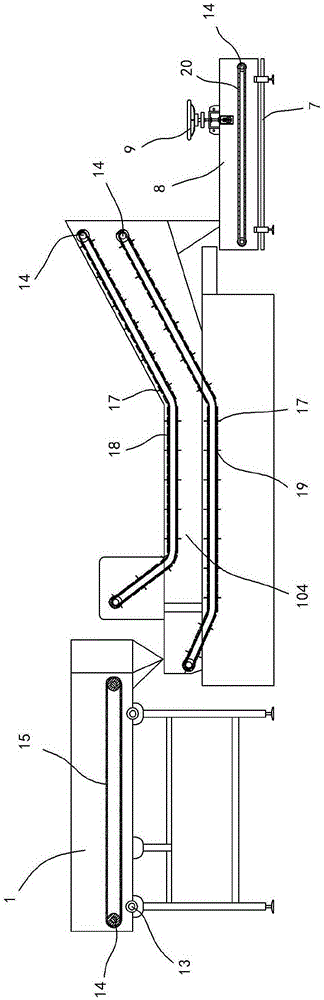

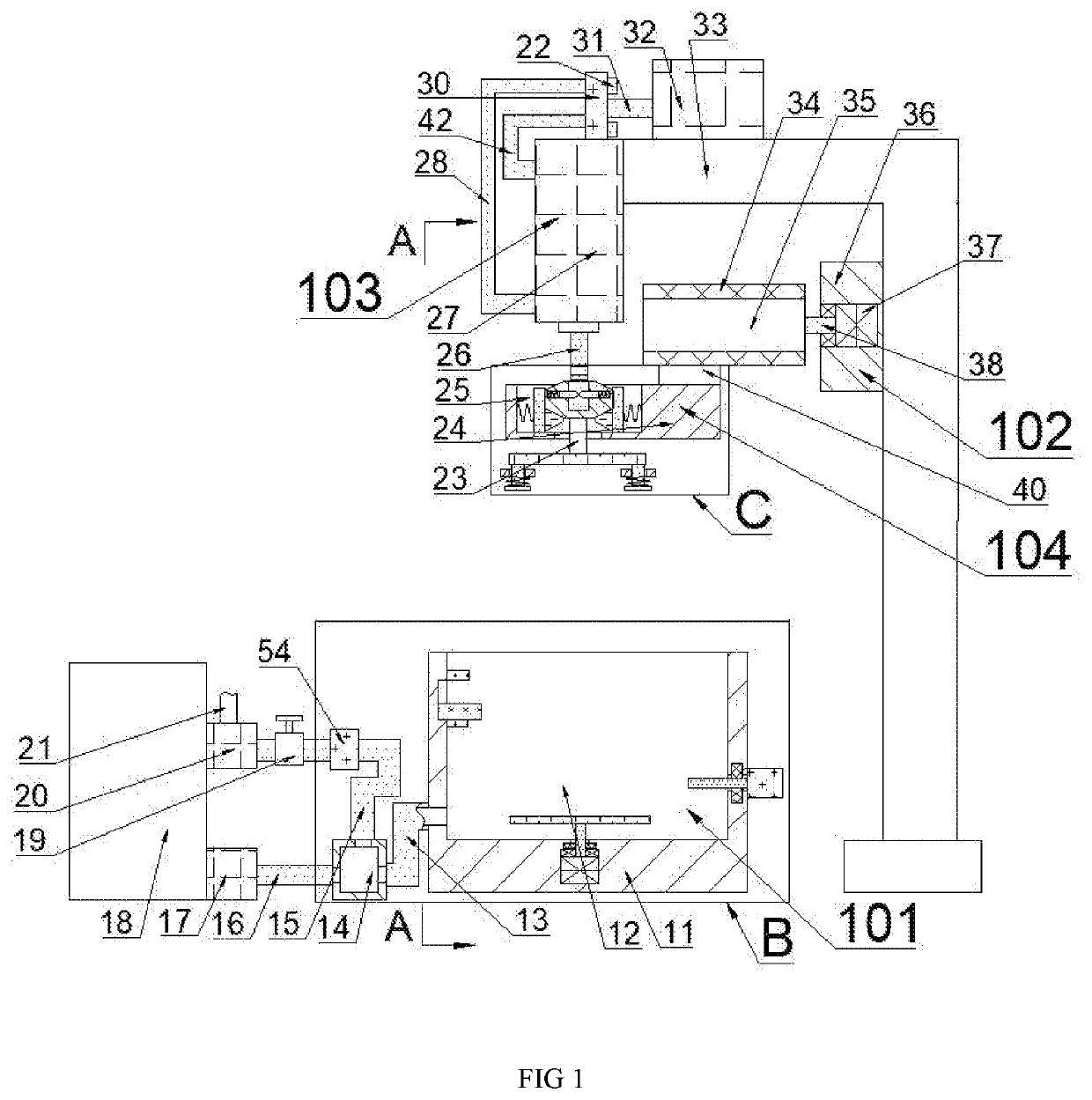

Fiber after-treatment equipment

ActiveCN105113160AIncrease productivityImprove qualityLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberAfter treatment

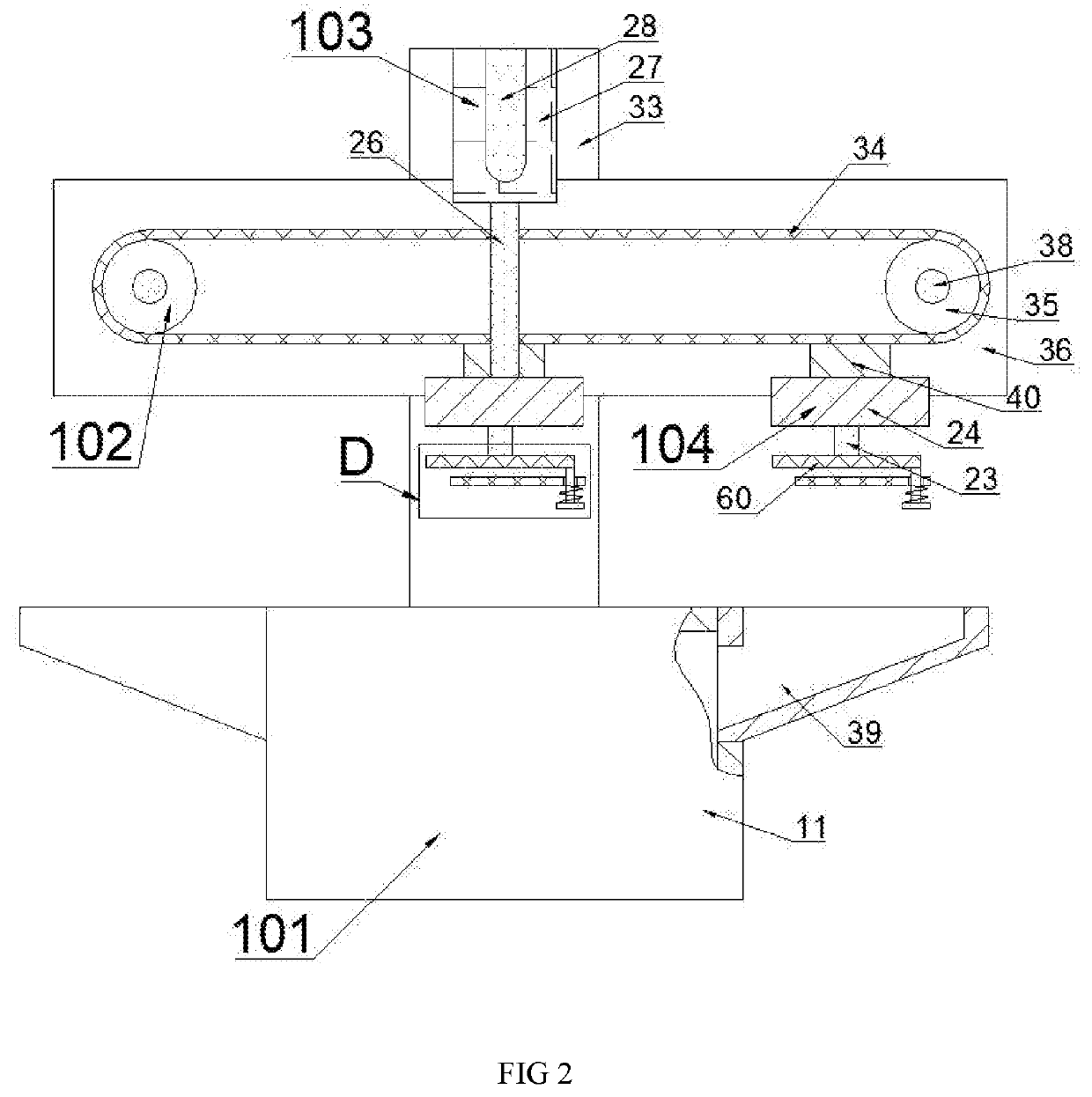

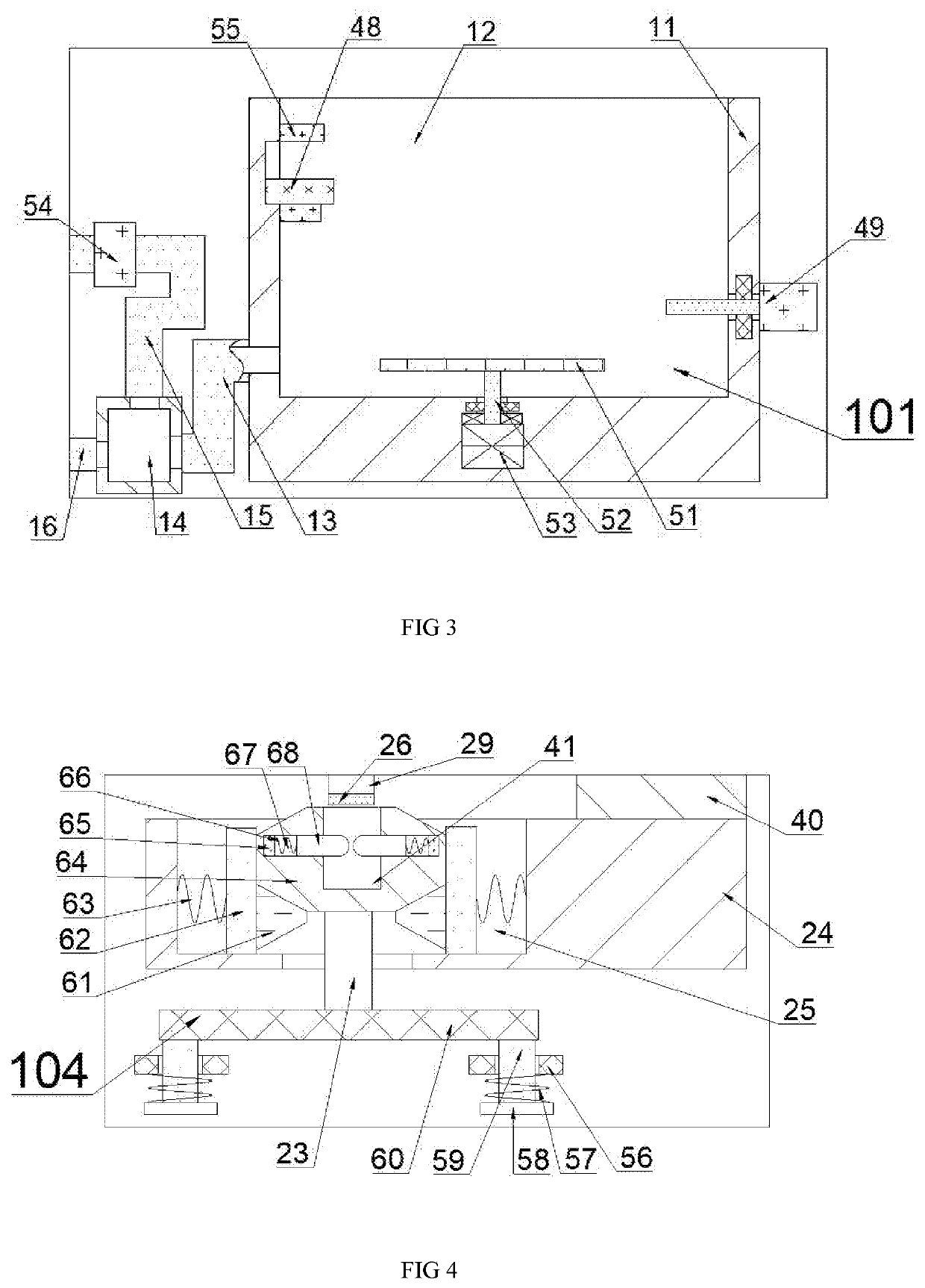

The invention discloses fiber after-treatment equipment which comprises a fiber input mechanism (101), a fiber soaking mechanism (102) and a fiber output mechanism (103). An outlet of the fiber input mechanism (101) is formed in an inlet of the fiber soaking mechanism (102). An outlet of the fiber soaking mechanism (102) is formed in an inlet of the fiber output mechanism (103). The fiber after-treatment equipment improves the production efficiency, greatly improves the quality of products, and reduces the product reject ratio in the production process.

Owner:JIANGSU XILUN NANO BIOTECH CO LTD

Textile dyeing device

InactiveCN106968069AExtended drying timeGuarantee normal dyeing workTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringDrying time

The invention discloses a textile dyeing device, comprising a box body, a dye box is fixedly installed at the left end of the bottom of the inner cavity of the box, and a first drive roller is movably installed at the upper left end of the inner cavity of the dye box. The lower end of the cavity is movably installed with a second transmission roller, the upper right end of the inner cavity of the dye box is movably installed with a third transmission roller, the right end of the upper surface of the dye box is provided with a second through hole, and the right end of the bottom of the inner cavity of the dye box is provided with a second through hole. A pressure sensor is fixedly installed. In the invention, the scraper is movably connected to the inner cavity of the second sleeve through the second spring, which can scrape off the dye adhering to the surface of the dyed fabric after dyeing. The fabric is air-dried, which solves the problem that a large amount of dye will adhere to the surface of the fabric during the dyeing process of the existing fabric dyeing machine, which not only prolongs the drying time of the fabric after dyeing, but also causes the waste of dye.

Owner:湖州梦源环保科技有限公司

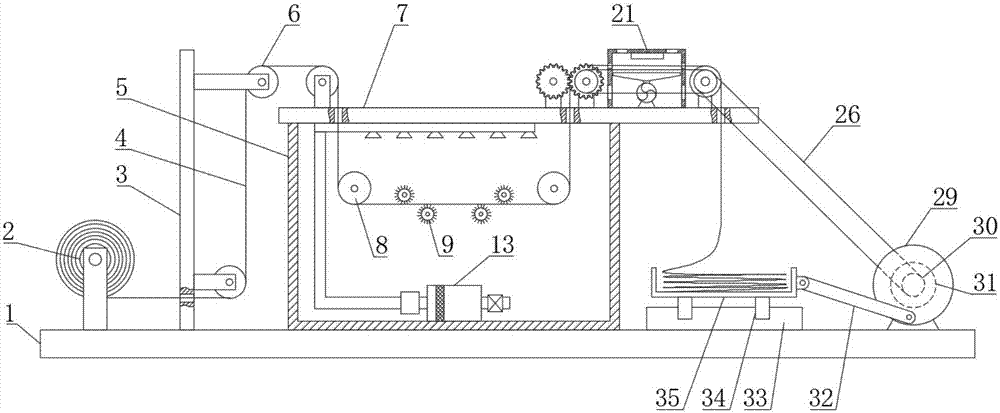

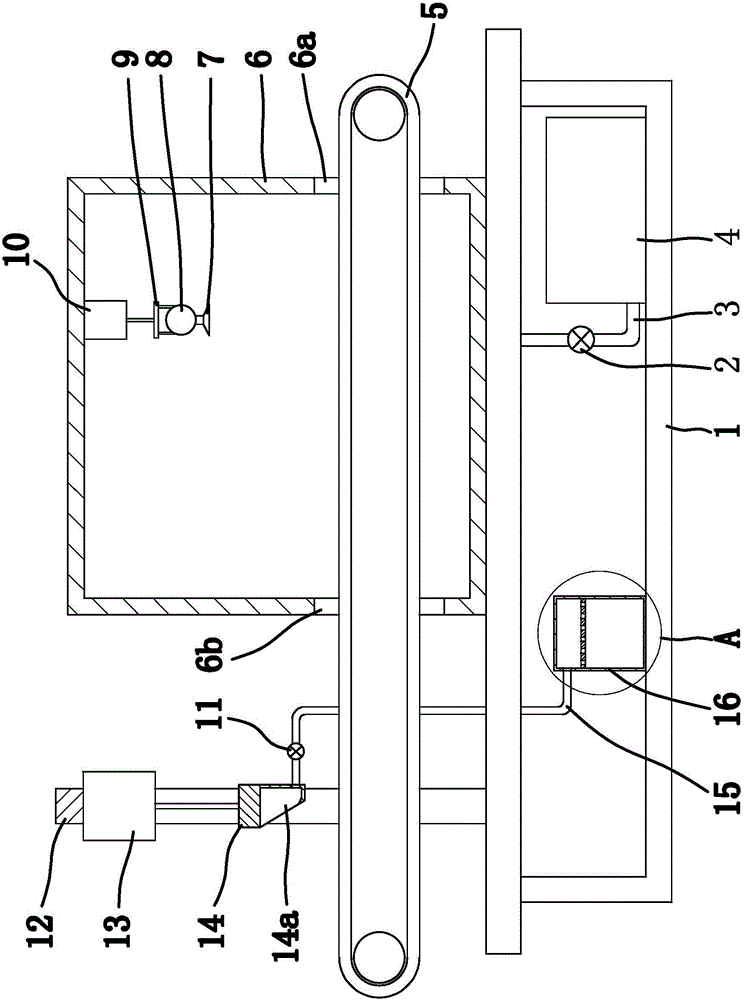

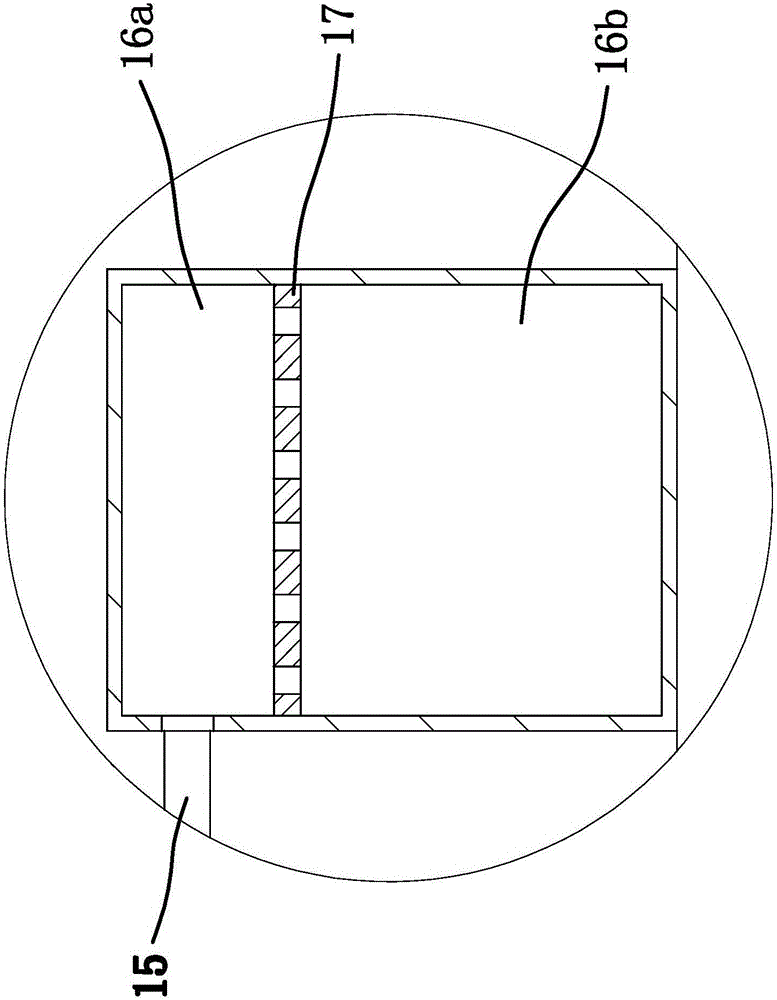

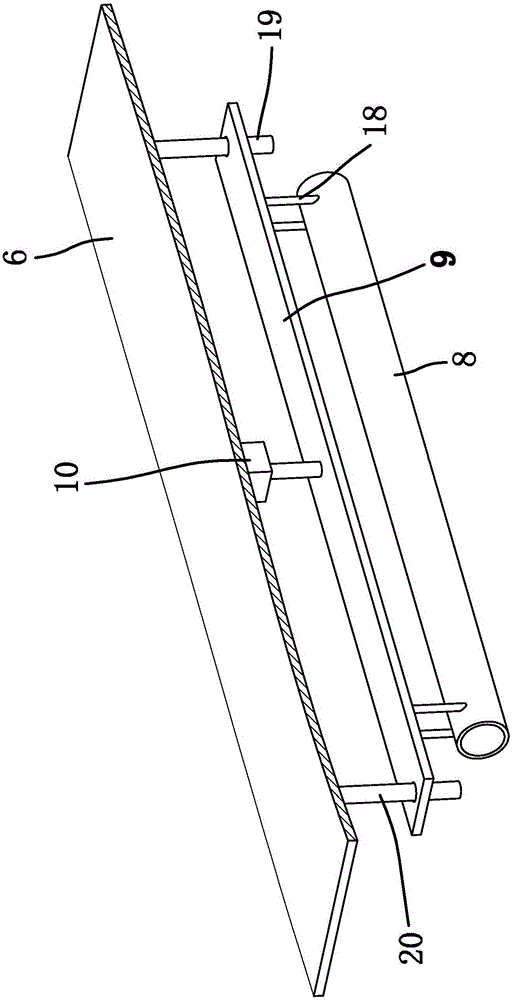

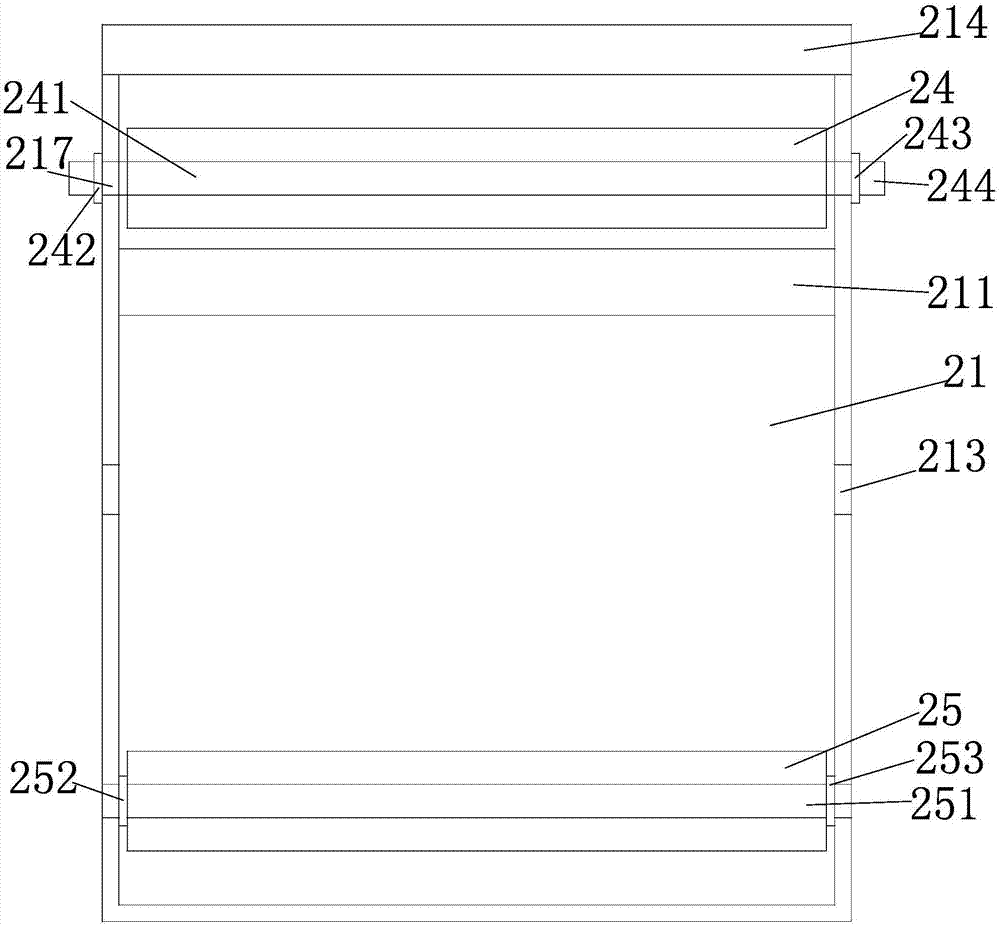

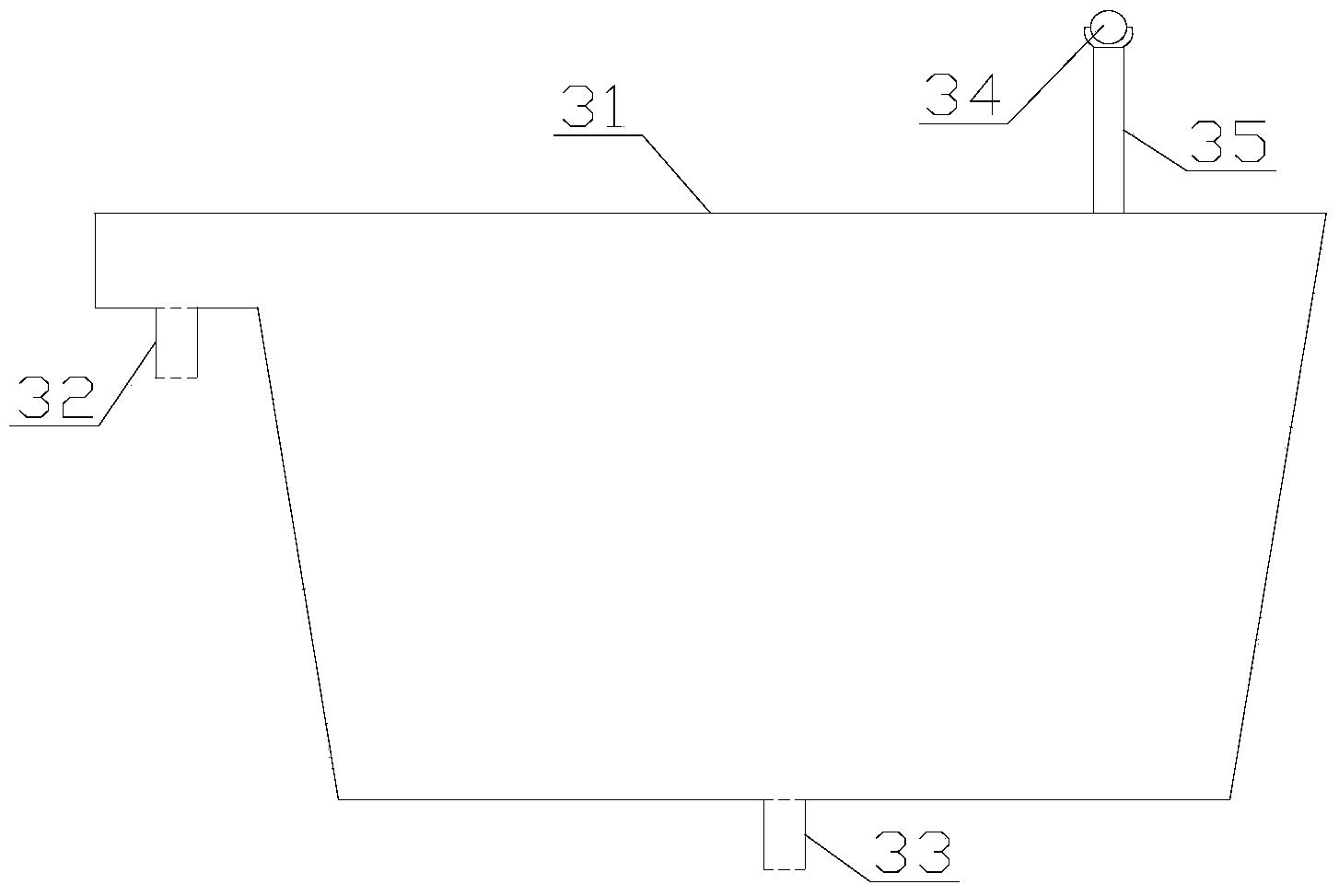

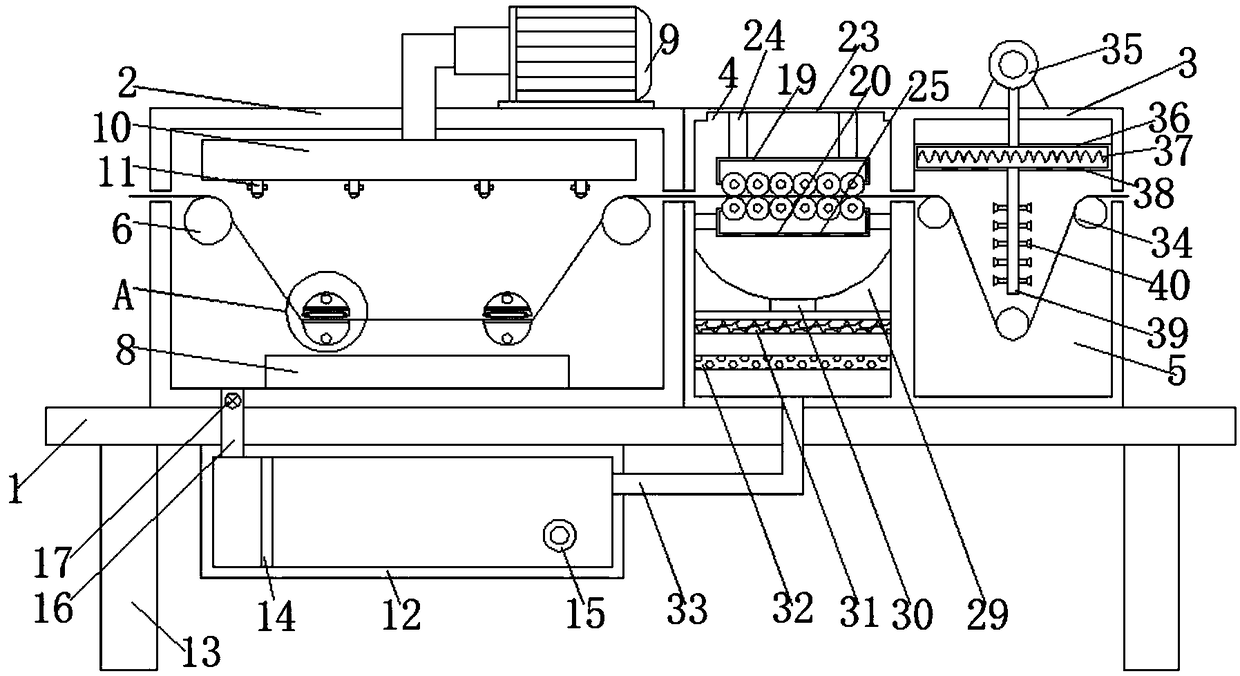

Washing and drying integrated machine for high-end fabric

InactiveCN107090682AWashing to achieveNo wasteSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersTextile technologyWater storage tank

The invention provides a washing and drying integrated machine for high-end fabric, belongs to the technical field of textile and solves the technical problem that the washing and drying effect of an existing washing and drying integrated machine for high-end fabric is not high. The washing and drying integrated machine for the high-end fabric comprises a rack, wherein a washing device for washing the fabric, a drying device for drying the washed fabric, a fabric collecting device for collecting the dried fabric and a wastewater recycling device for recycling wastewater produced during fabric washing are arranged on the rack, the washing device, the drying device and the fabric collecting device are sequentially arranged along the rack, the washing device comprises a washing tank, a water storage tank and a water pump I, multiple upper drums and multiple lower drums are horizontally arranged in the washing tank, multiple overflow ports are formed in the middle of the washing tank, the upper drums are located above the overflow ports, the lower drums are located below the overflow ports, and a nozzle is arranged at the top of the washing tank. The washing and drying effect of the machine is good, and the water resource is saved.

Owner:HAINING MEILI KNITTING CO LTD

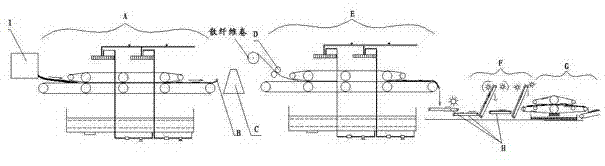

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Environment-friendly spray printing and dyeing device for textile fabric

InactiveCN107447389AStir fully and evenlyImprove utilization efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringUltimate tensile strength

The invention discloses an environment-friendly spray printing and dyeing device for a textile fabric, and relates to the technical field of textile machinery equipment. The environment-friendly spray printing and dyeing device comprises a box, two sides of the bottom of the box are fixedly connected with mutually symmetric supporting vertical plates, the bottoms of the two supporting vertical plates are fixedly connected with bottom supporting plates, two sides of the bottoms of the bottom supporting plates are fixedly connected with mutually symmetric damping anti-slip mats, the centers of the tops of the bottom supporting plates are fixedly connected with dye stirring devices, through holes are formed in the bottom of the inner wall of the box and positioned above the dye stirring devices, and an impurity filter screen is arranged on the inner walls of the through holes. The environment-friendly spray printing and dyeing device for the textile fabric solves the problems of high dyeing cost, environmental pollution, low use ratio and poor fabric dyeing effect of existing textile fabric dyeing equipment. The use efficiency of dyes is effectively improved, the device is safe and environmentally friendly, environmental pollution is reduced, manual operation of workers is omitted, the labor intensity of staff is reduced, and production efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

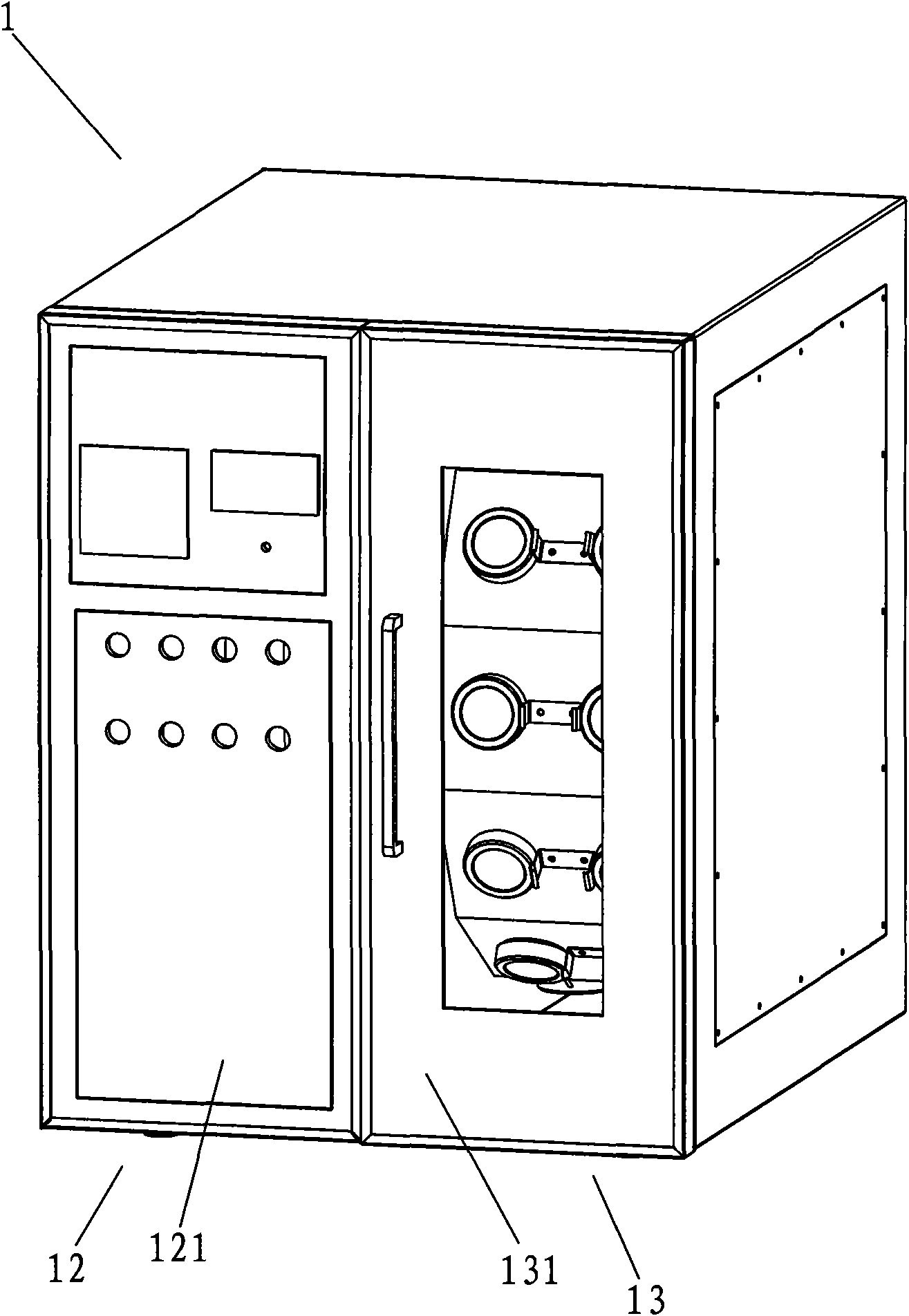

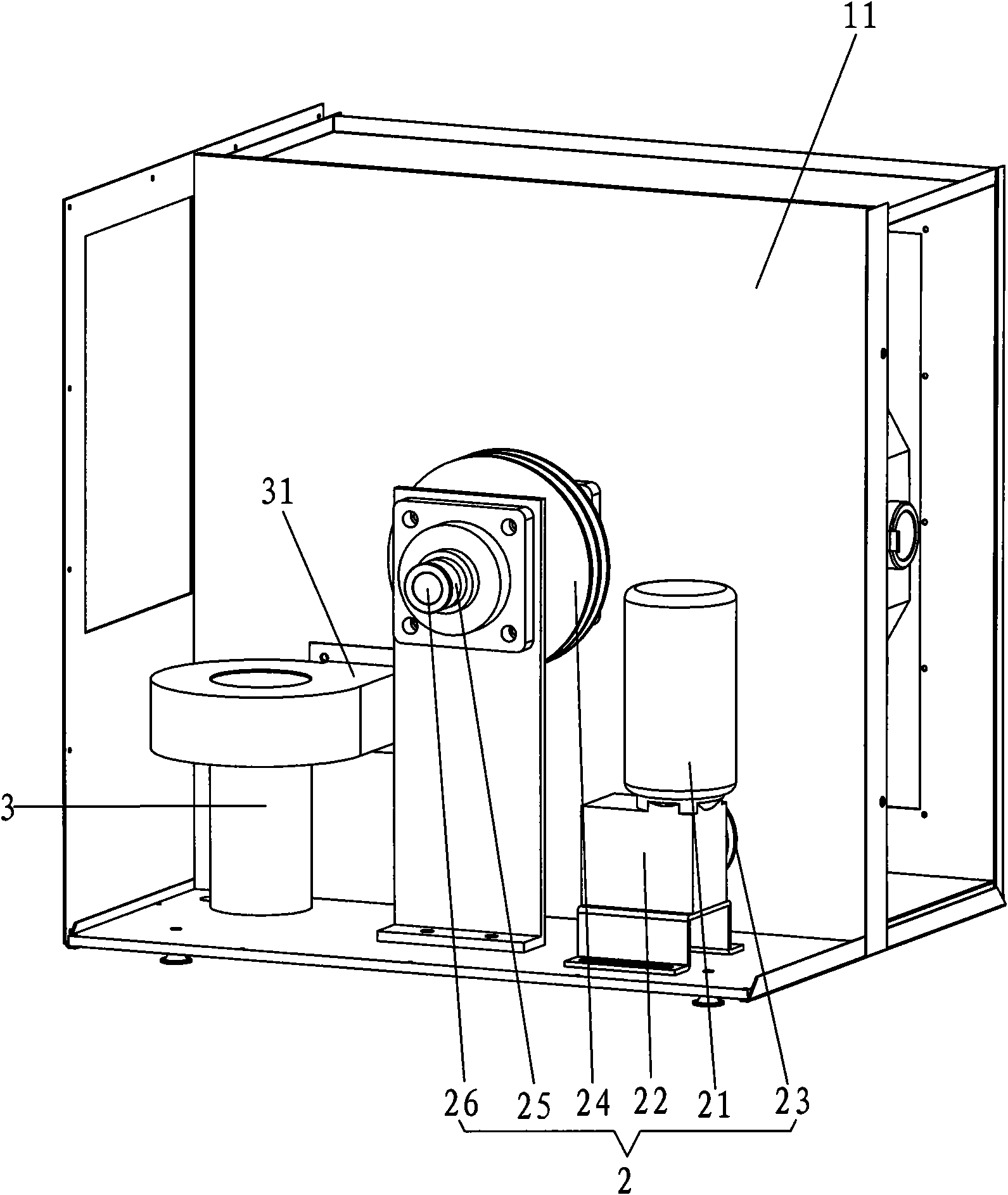

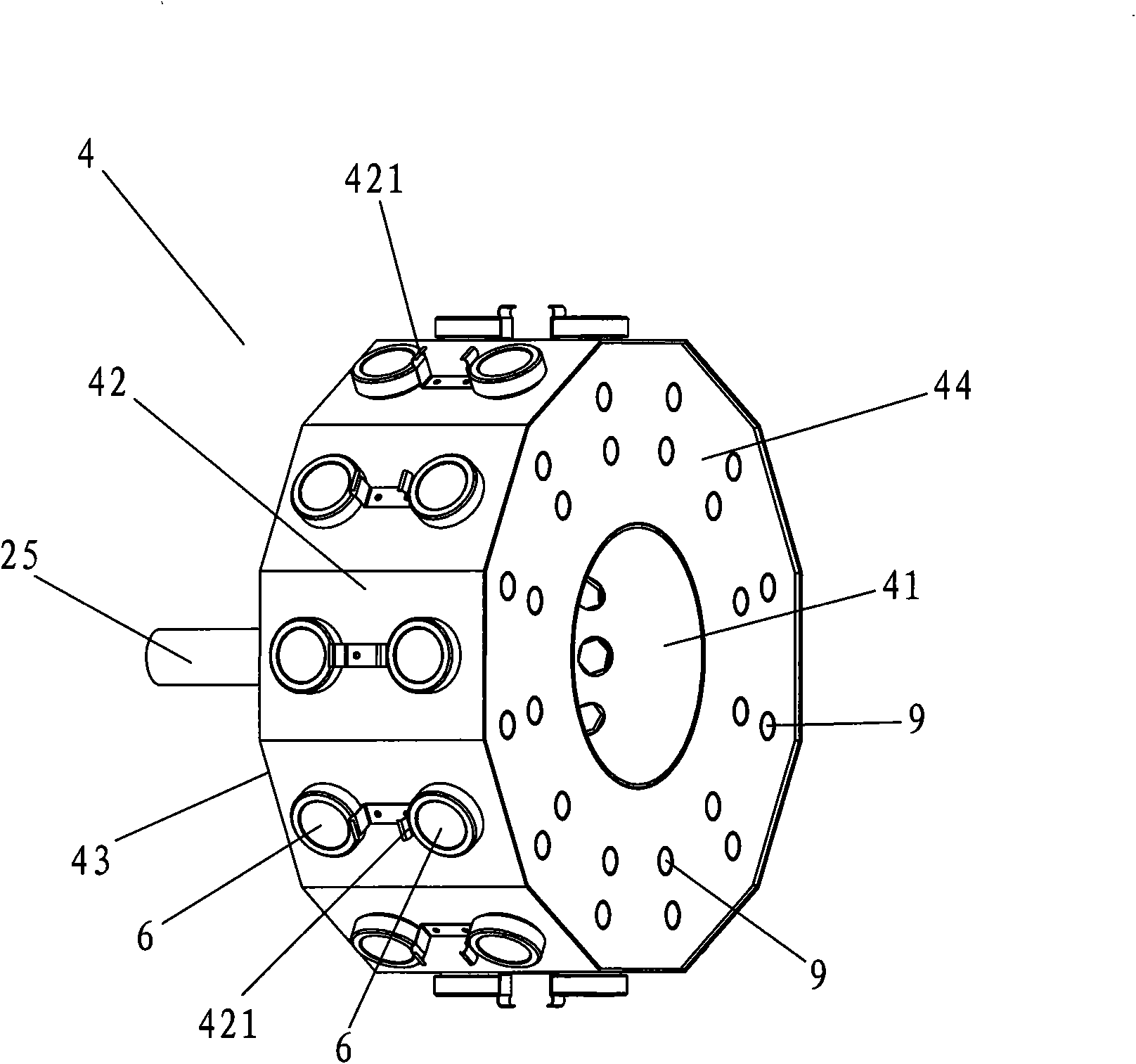

Novel sample dyeing machine

InactiveCN101603260AReduce installationImprove the operating environmentTextile treatment dyeing devicesTextile treatment machine arrangementsState of artThermal energy

The invention discloses a novel sample dyeing machine. The machine comprises a rotary frame arranged in a cylinder, a plurality of sample cups and a plurality of sample cup sleeves, wherein the rotary frame is closed and filled with a solid heat-conducting medium in which a heating device is arranged; the sample cup sleeves are fixed on the rotary frame and buried in the solid heat-conducting medium, and openings of the sample cup sleeves are exposed out of the rotary frame; and the sample cups are fixed in the sample cup sleeves respectively in a mode of being movably taken out. In the machine, the solid heat-conducting medium is used for heat conduction, and the sample cups are not contacted with a heat carrier directly, so that the pollution caused by taking glycerin as the heat carrier does not occur, and the glycerin is not consumed; compared with the prior art, the machine has the advantages of keeping the original operating habits, improving the proofing operation environment, and saving energy, along with environmental protection; the machine adopts the solid heat-conducting medium for heat conduction, and no pressure is generated in the rotary frame; moreover, the wind cooling way is adopted for cooling, so that the assembly of pipes is saved, and the machine can be used after connecting to a power supply.

Owner:SHISHI TAIRUI PRECISION MACHINERY

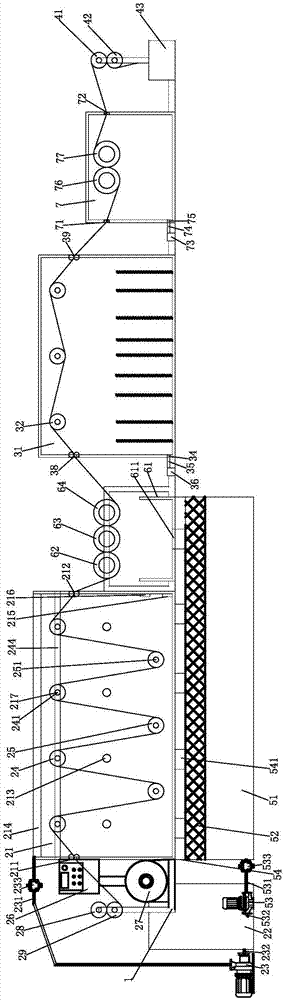

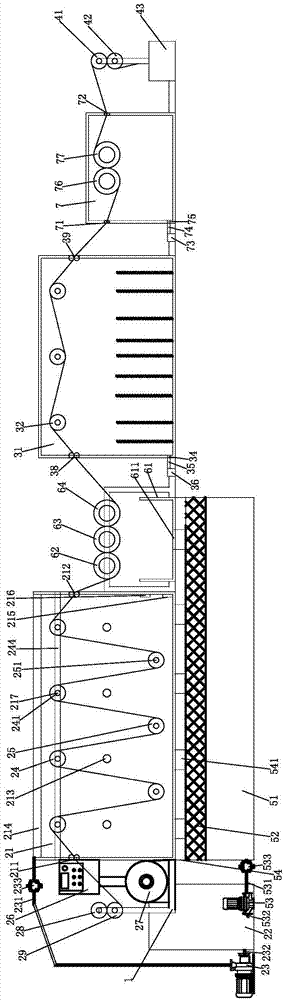

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

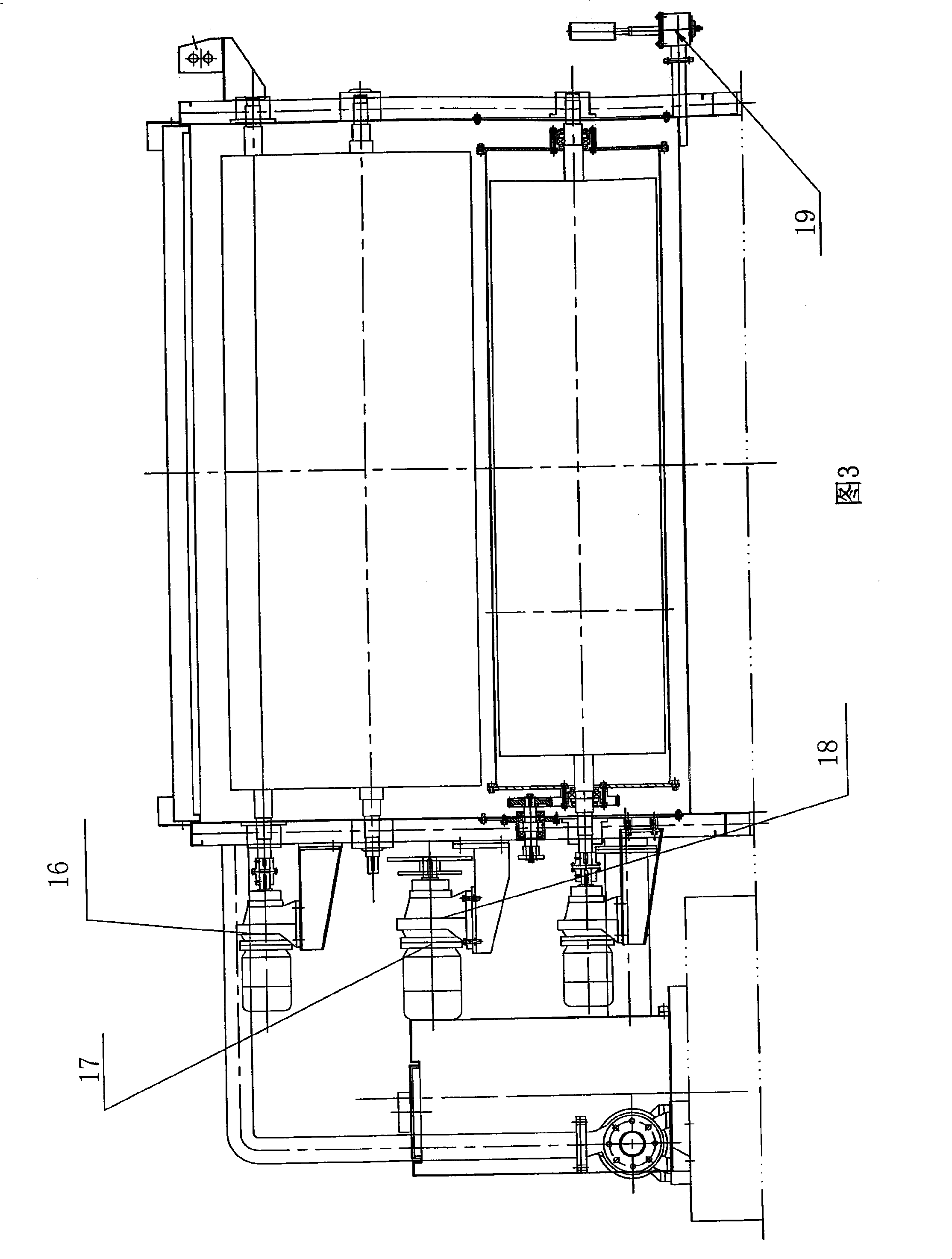

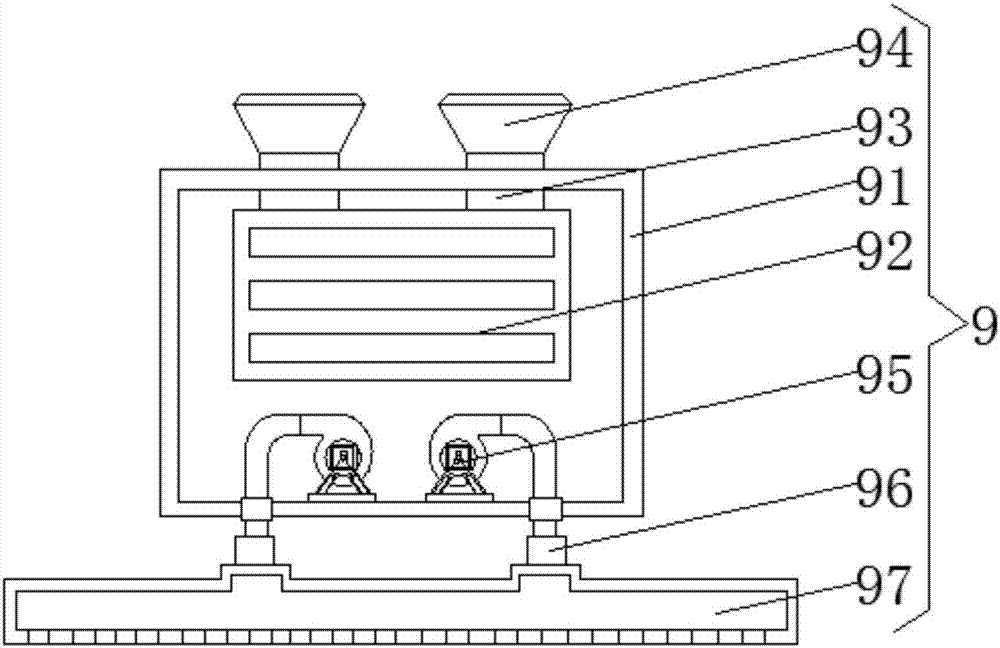

High-grade fabric washing and drying integrated machine with waste water recovery device

InactiveCN107326580ASave waterWashing to achieveMechanical cleaningPressure cleaningTextile technologyWater resources

The invention provides a high-grade fabric washing and drying integrated machine with a waste water recovery device and belongs to the technical field of textiles. The problem that an existing high-grade fabric washing and drying integrated machine cannot fully utilize waste water is solved. The high-grade fabric washing and drying integrated machine with the waste water recovery device comprises a rack, wherein a washing device for washing fabrics, an extrude-drying device for extruding washed fabrics dry, a waste water recovery device for recovering waste water produced during fabric washing, a drying device for drying the washed fabrics and a fabric collecting device for collecting dried fabrics are arranged on the rack, the washing device, the extrude-drying device, the drying device and the fabric collecting device are sequentially arranged along the rack, the waste water recovery device is located below the washing device and the extrude-drying device. The high-grade fabric washing and drying integrated machine achieves the advantages of recycling waste water and improving the utilization rate of water resources.

Owner:HAINING MEILI KNITTING CO LTD

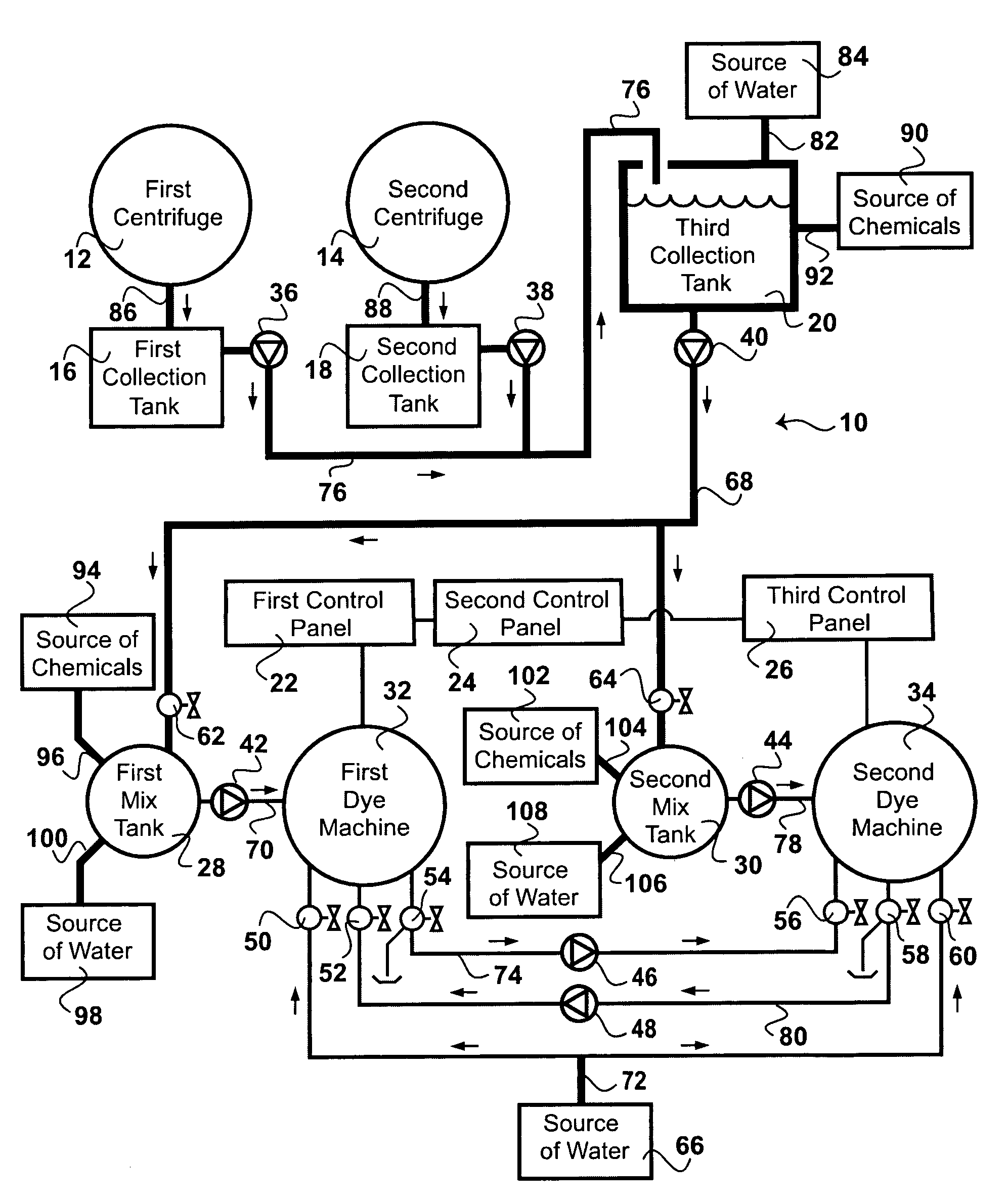

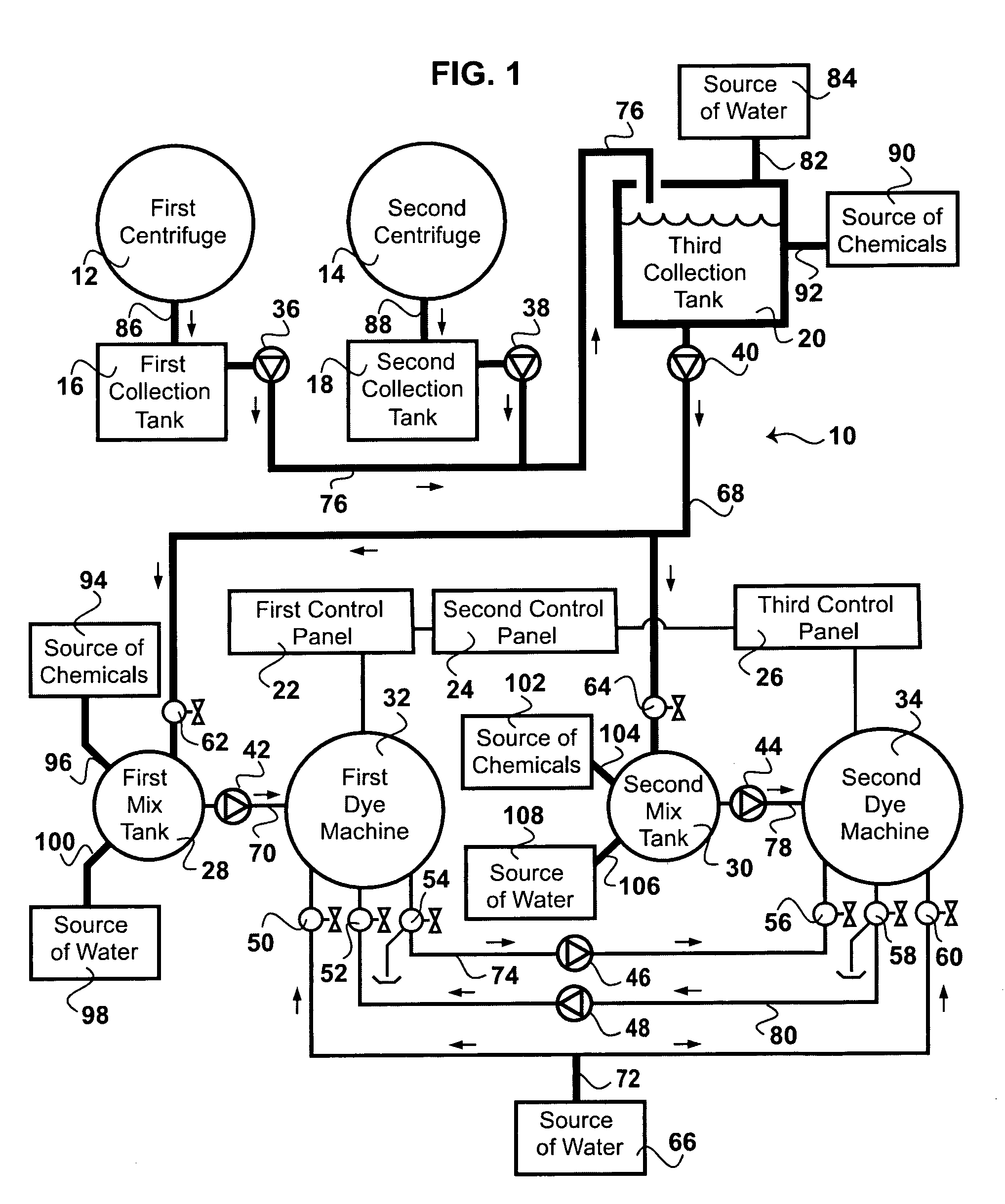

Methods, systems and compositions for fire retarding substrates

ActiveUS7211293B2Cost-effective and durableEffective treatmentLayered productsPretreated surfacesFiberCentrifugation

A closed-loop system and process is used for applying fire retardant chemicals to fibers. Fibers are preferably positioned in a vessel such as a dye machine which circulates the fire retardant chemicals. After absorption of the fire retardant composition, non-absorbed fire retardant chemicals are recovered and re-used on subsequent batches of fibers. Recovery can be achieved by directing the non-absorbed fire retardant composition into a second dye machine containing additional fibers, or by extracting the fire retardant composition by centrifugation or other means, or by a combination of the two processes. The process is environmentally friendly, and allows for higher throughput on impregnating fibers with fire retardant chemicals.

Owner:TINTORIA PIANA US

Sizing machine

InactiveCN105624951AThe sizing effect is not idealControl tensionTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnFixed frame

The invention mainly discloses a sizing machine. According to the technical scheme, the sizing machine comprises a yarn releasing device, a pre-cleaning device, a sizing mechanism, a sizing agent recovering device and a yarn withdrawing device, wherein the pre-cleaning device comprises a dust collector, the dust collector comprises a yarn inlet, a yarn outlet, dust collecting heads and an impurity box, and a yarn guiding ring is arranged inside the dust collector; the sizing mechanism comprises a sizing agent tank and sizing equipment, the sizing equipment comprises an immersing roller, a sizing roller and squeezing rollers, supports are arranged on two sides of the sizing agent tank, the squeezing rollers are movably connected onto the supports, and air cylinders are arranged on the supports and connected with the squeezing rollers; the sizing agent recovering device comprises a fixed frame, a sizing agent brush and a recovering tank; a water level sensor is arranged in the sizing agent tank, a replenishing device is arranged on one side of the sizing agent tank, and the sizing agent water level sensor is electrically connected with the replenishing device. The sizing machine is uniform in sizing and little in waste, yarn before sizing can be cleaned so as to avoid pollution of the sizing agent tank, and the sizing agent in the sizing agent tank is replenished timely.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

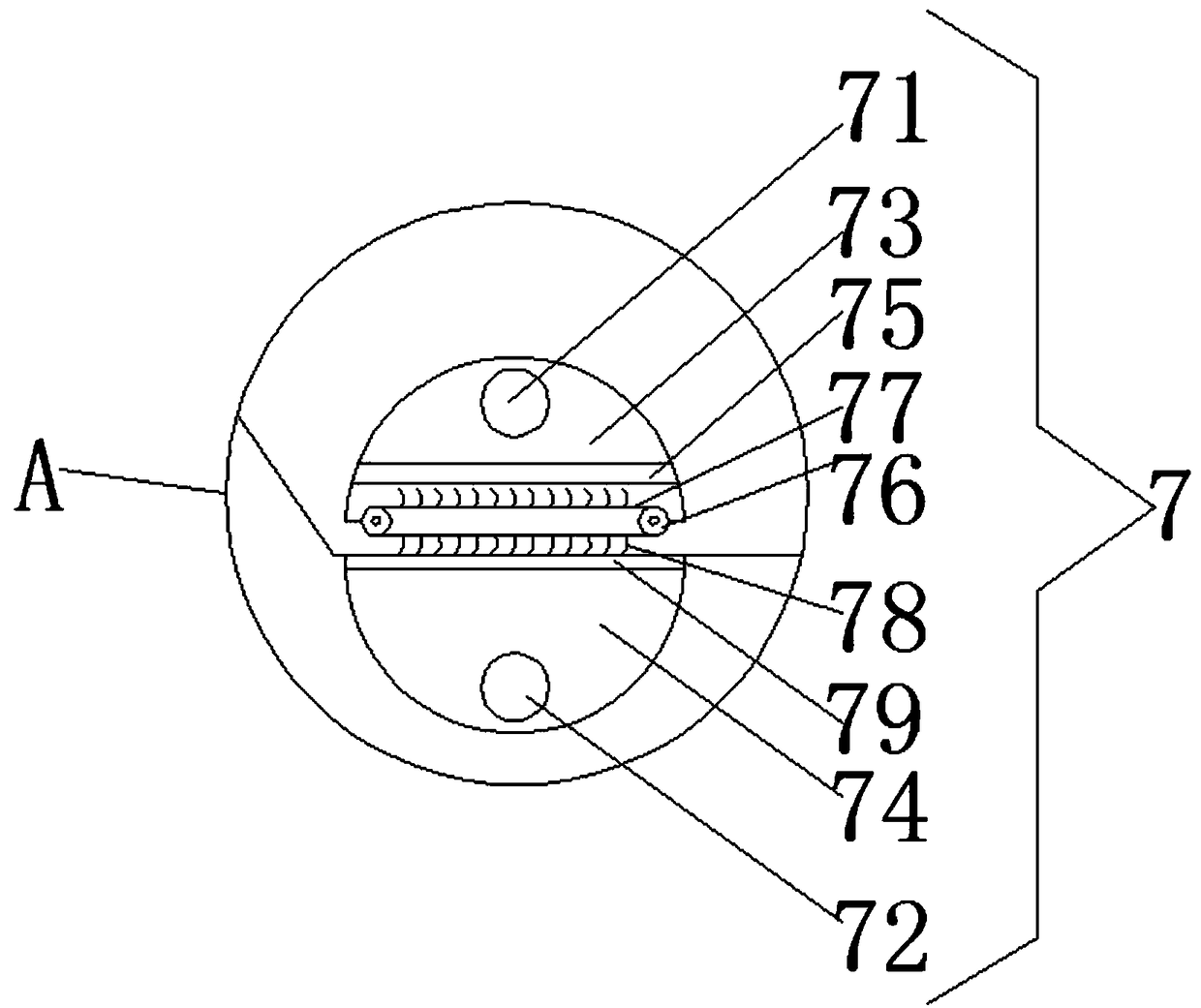

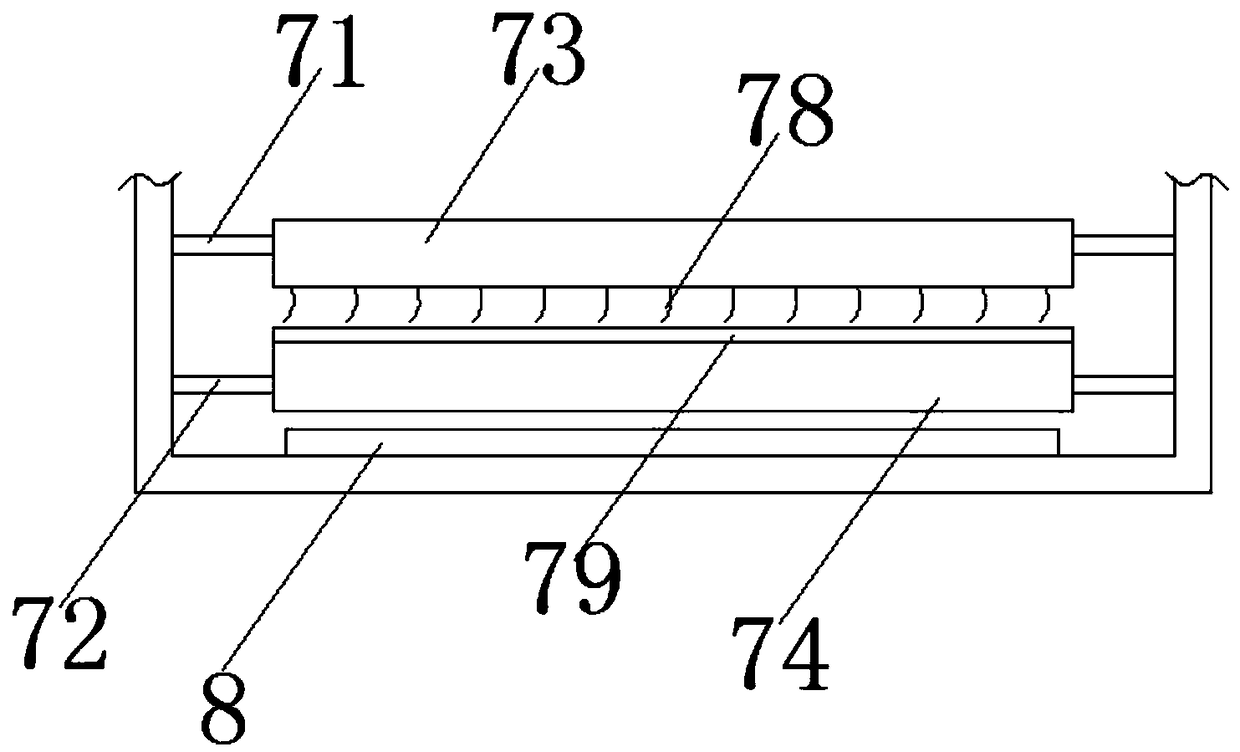

Cleaning drying device used for gauze production

ActiveCN108930110AImprove product qualityAvoid secondary adsorptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryImpurity

The invention provides a cleaning drying device used for gauze production, and relates to the technical field of gauze production and manufacturing equipment. The cleaning drying device used for gauzeproduction comprises a base. The top of the base is fixedly provided with a cleaning box and a drying box. The drying box is divided into a dehydration chamber and a drying chamber. The cleaning boxis internally provided with a first cloth guide roller and a cleaning device. The cleaning device comprises an upper supporting rod and a lower supporting rod. Using the leaning drying device used forgauze production, through cooperation of an upper supporting rod, a lower supporting rod, an upper cleaning roll, a lower cleaning roll, a scraper blade, a rotating disk, and a banister brush, gauzedrives a driving belt to drive on the rotating disk, and the banister brush on the driving belt cleans the surface of the gauze. Under operation of the driving belt, the banister brush drives impurities into the upper cleaning roll, and the impurities on the banister brush are removed through the scraper blade. Impurities pass through the scraper blade and enter into the upper cleaning roll, and the impurities on the surface of the gauze are removed in cleaning, so that product quality of the gauze is improved.

Owner:陈剑璋

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

Blue calico printing and dyeing equipment imitating traditional process

InactiveUS20200181821A1Quality improvementIncrease productivityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProcess engineeringMechanical engineering

The invention discloses a blue printing cloth printing and dyeing device which imitates the traditional process, and includes a dye box. A dyeing device is provided on the right side of the dye box, and an L-shaped support post is provided on the right side of the dye box. A conveying device for conveying cloth is provided on the column, and a lifting device on the upper side of the conveying device is provided on the support column. The lifting device provides lifting movement for the dyeing cloth. As for the holding device for holding the cloth, the cloth dyeing cylinder of the present invention can indirectly detect the concentration of the dye solution through the PH value detection, and the liquid level detection mechanism and the PH value detector can be used to control the liquid pump supply to achieve automatic control of the dye solution concentration and The liquid level height improves the printing and dyeing quality. The conveying mechanism drives the two groups of clamping mechanisms to move to the upper side of the cloth dyeing cylinder and the air-drying place. The lifting mechanism can drive the clamping mechanism to lower into the cloth dyeing cylinder for dyeing. Therefore, the present invention can replace manual Printing and dyeing with traditional techniques can improve production efficiency.

Owner:WANG MING

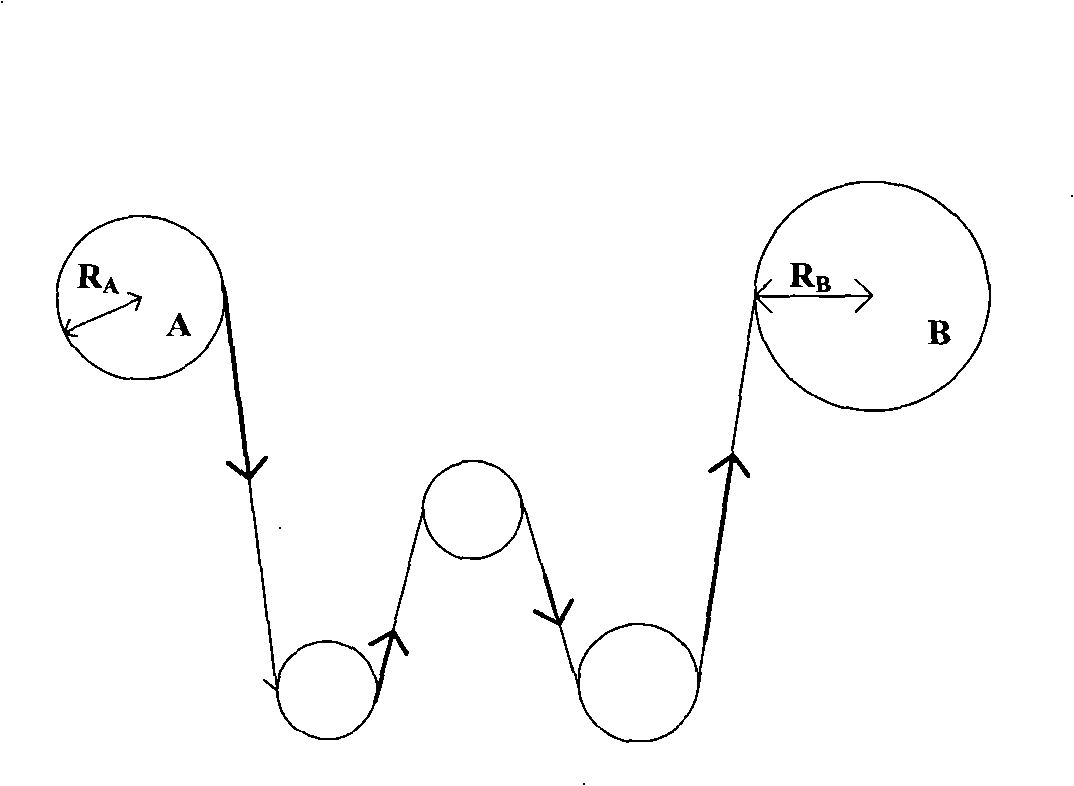

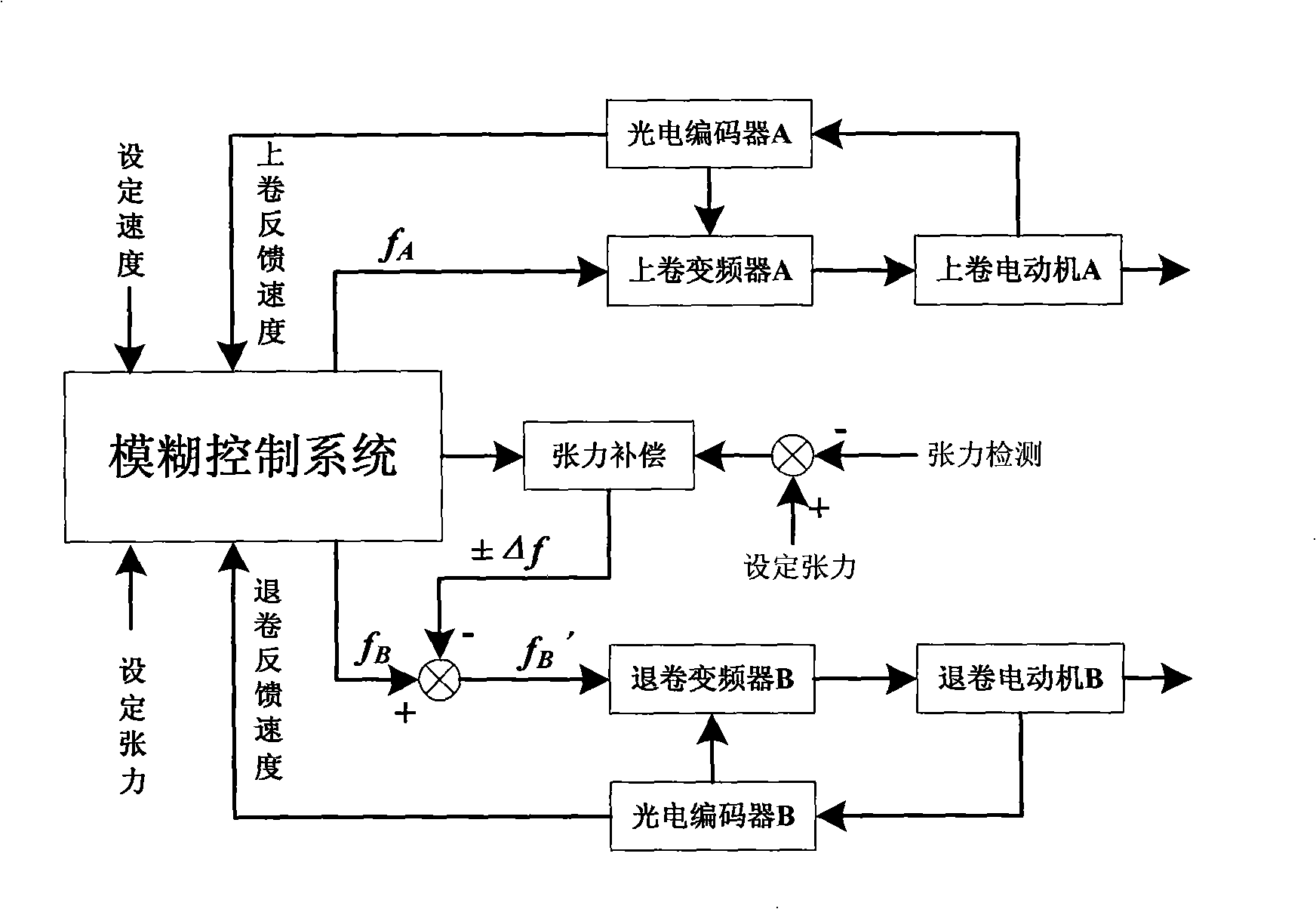

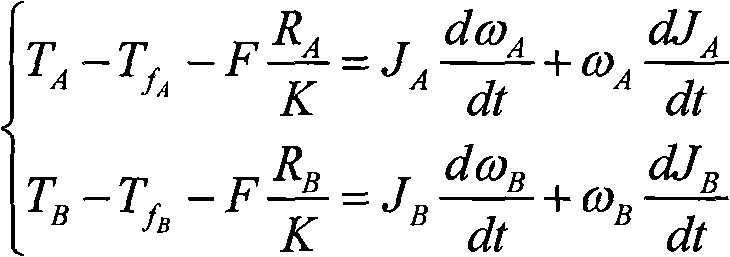

Beam dyeing machine cloth velocity-tension coordinating control method

InactiveCN101308363AImprove dyeing qualitySolve the coupling problemLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsWire speedVelocity constant

The invention discloses a speed-tension coordination control method for jigger fabrics; the method mainly uses a fuzzy control system to compare the sampling speed of a photoelectric coder with the set speed, and compare the tension-detection value of a tension detection device with the set tension, so as to timely adjust the control rules according to the dynamic changes of the errors to subsectionally and alternately control the speed and the tension to respectively obtain a coiling frequency fA and an unwinding frequency fB needed in maintaining the equal linear velocity constant tension of dyeing fabrics; a coiling electromotor and an unwinding electromotor are respectively controlled by a coiling transducer working in speed mode and an unwinding transducer working in torque conversion mode. The method solves the coupling problem between the speed and the tension of the jigger fabrics and makes more accurate speed-tension coordination control of the double-input / double-output, coupled and time-varying non-linear system of jiggers, so as to reduce dyeing color difference caused by instable speed and tension and improve the dyeing quality of fabrics.

Owner:ZHEJIANG UNIV

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

Popular searches

Cleaning using tools Radiation Liquid/gas/vapor textile treatment Textile treatment carriers Heating/cooling textile fabrics Woven fabrics Liquid/gas/vapor treatment of indefinite length materials Liquid/gas/vapor fibres/slivers/rovings treatment Textile/flexible product manufacture Liquid/gas/vapor treatment of definite length materials

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com