Patents

Literature

96results about "Liquid/gas/vapor removal by vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

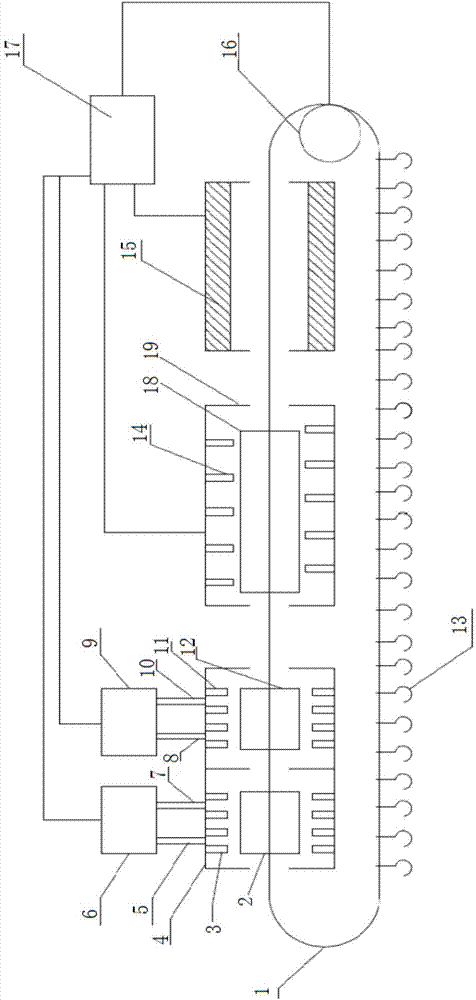

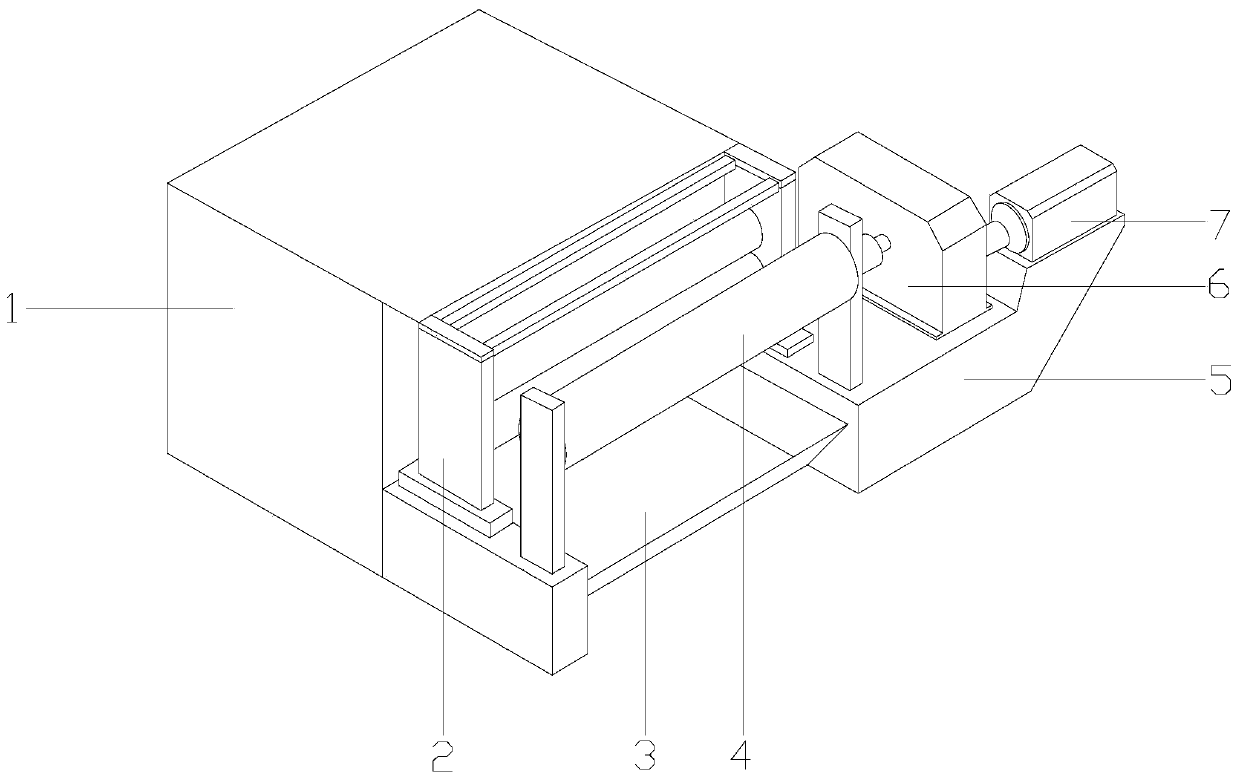

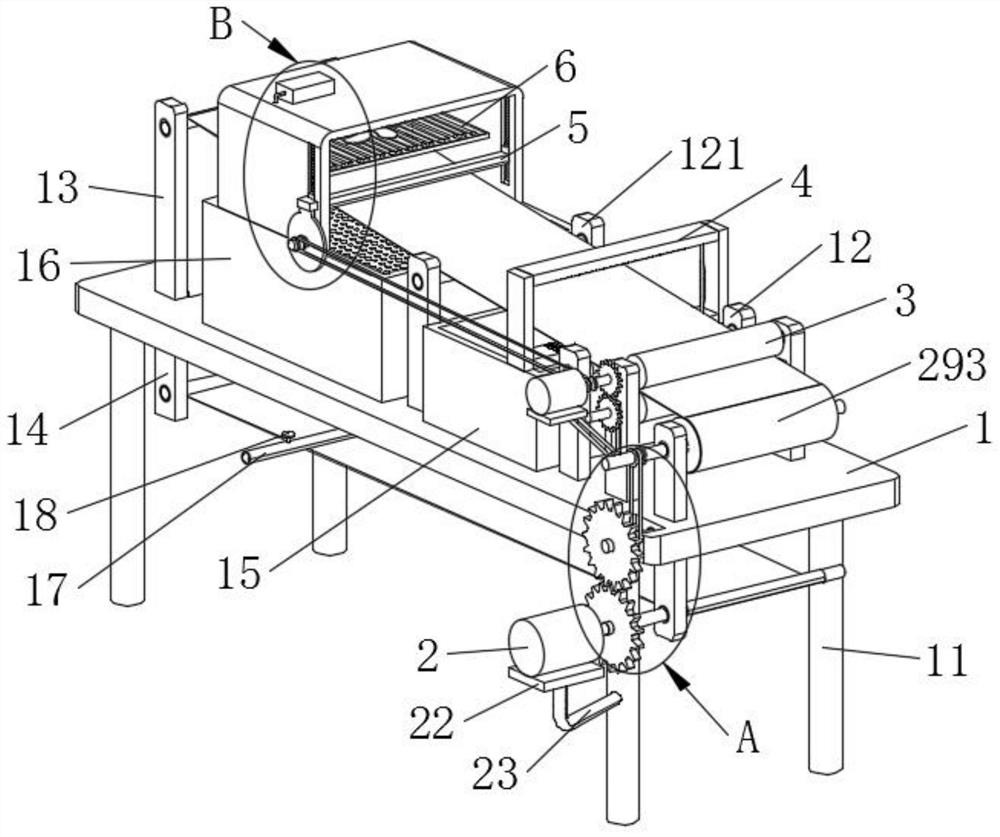

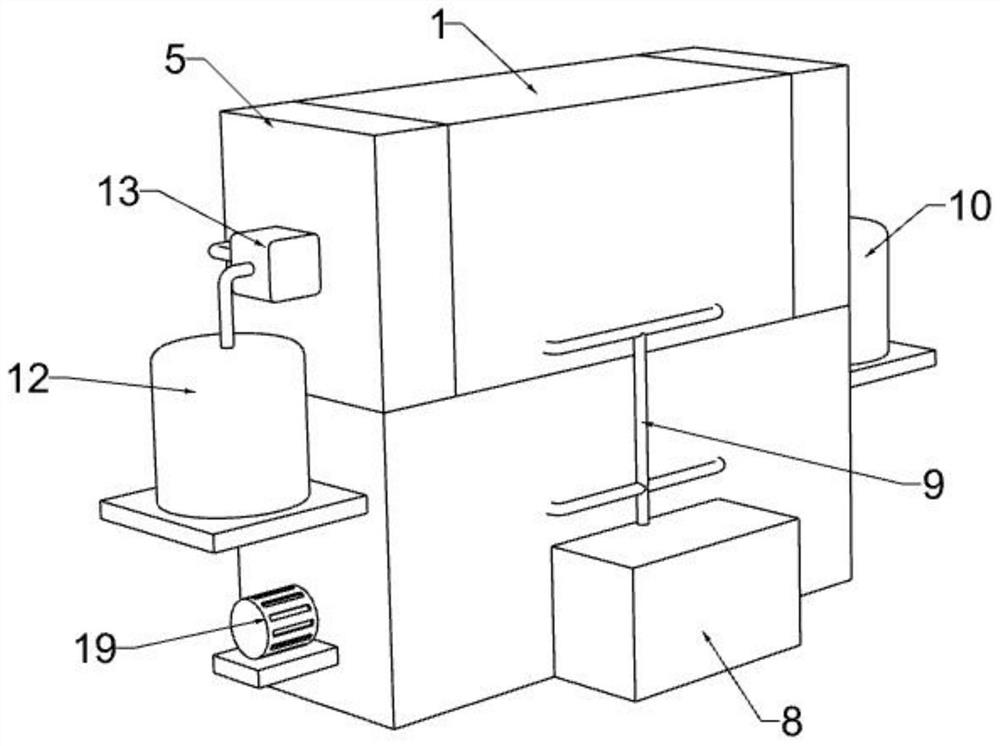

Textile fabric cleaning and drying integrated device

ActiveCN107354638AShorten the timeReduce investmentTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationAir blowerIntegrated devices

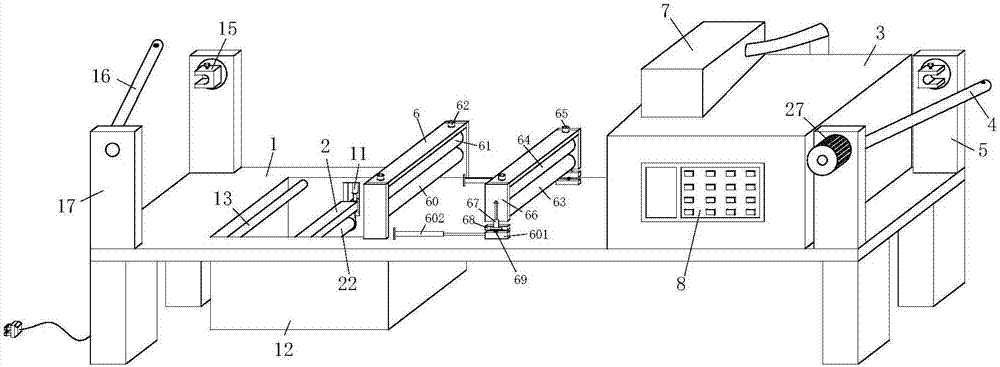

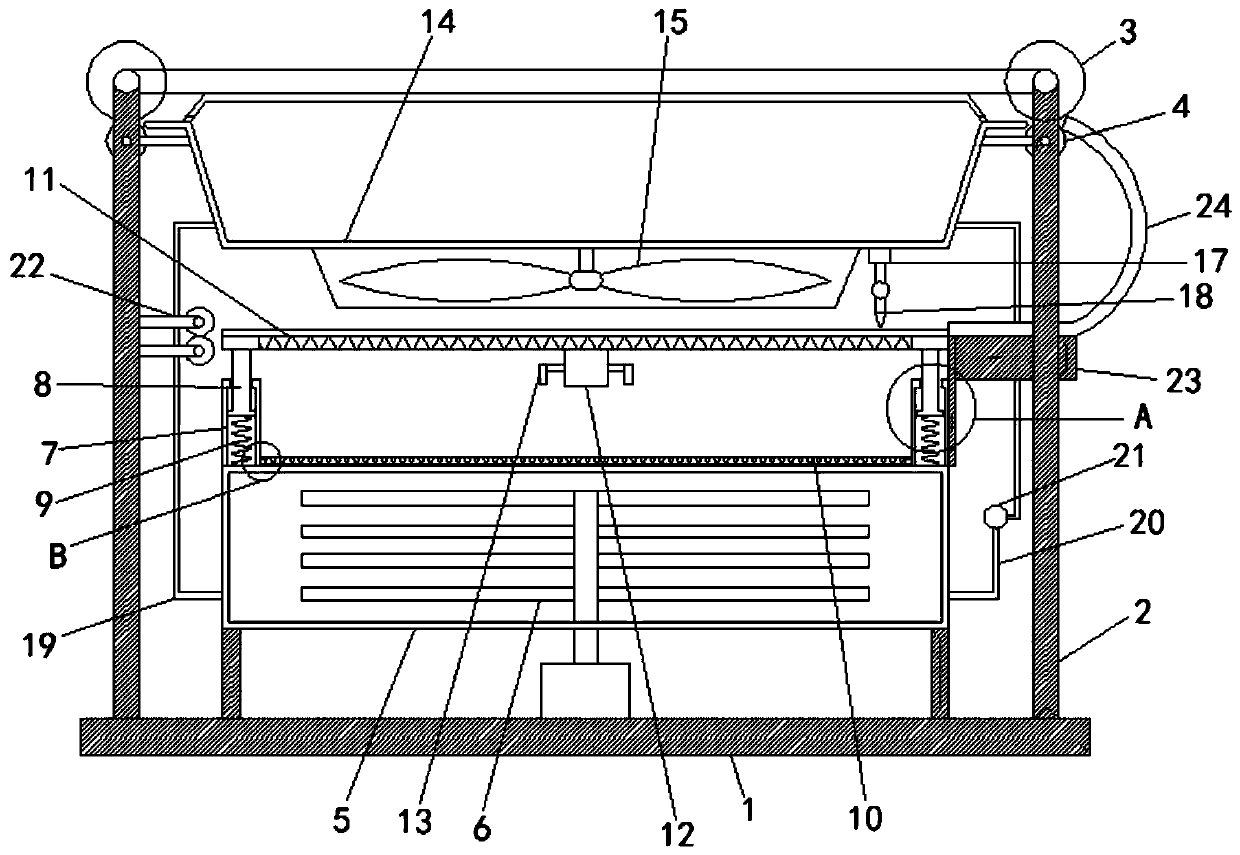

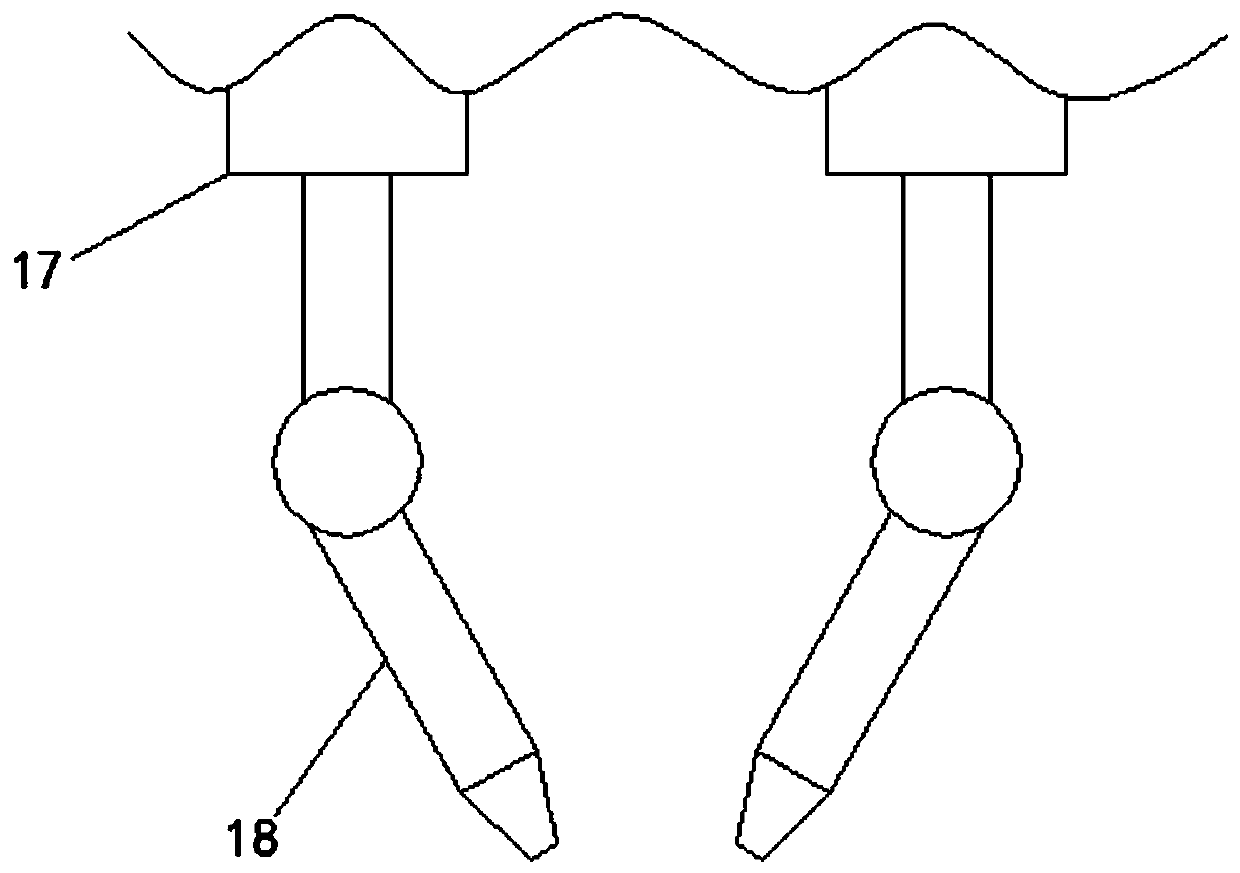

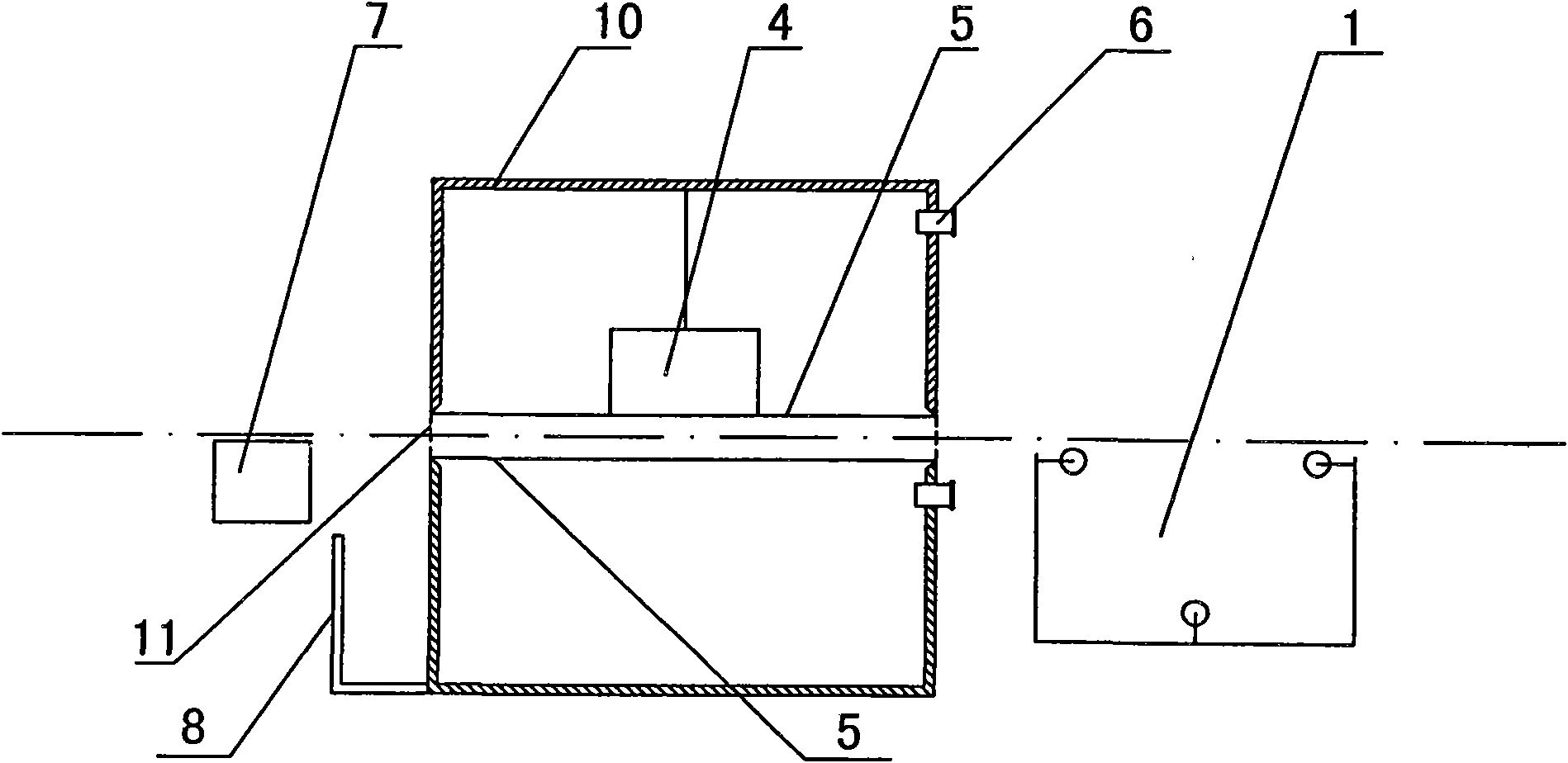

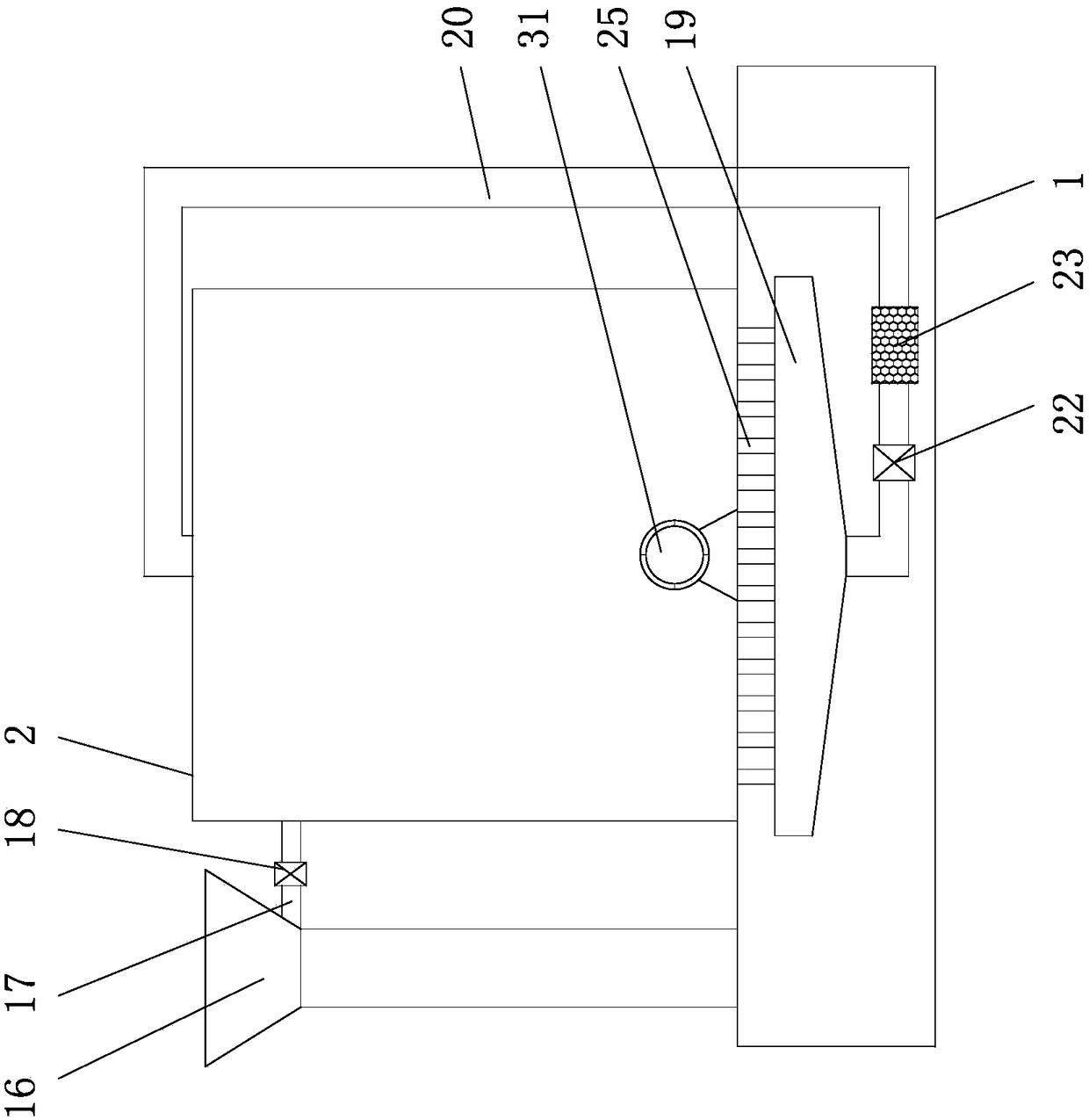

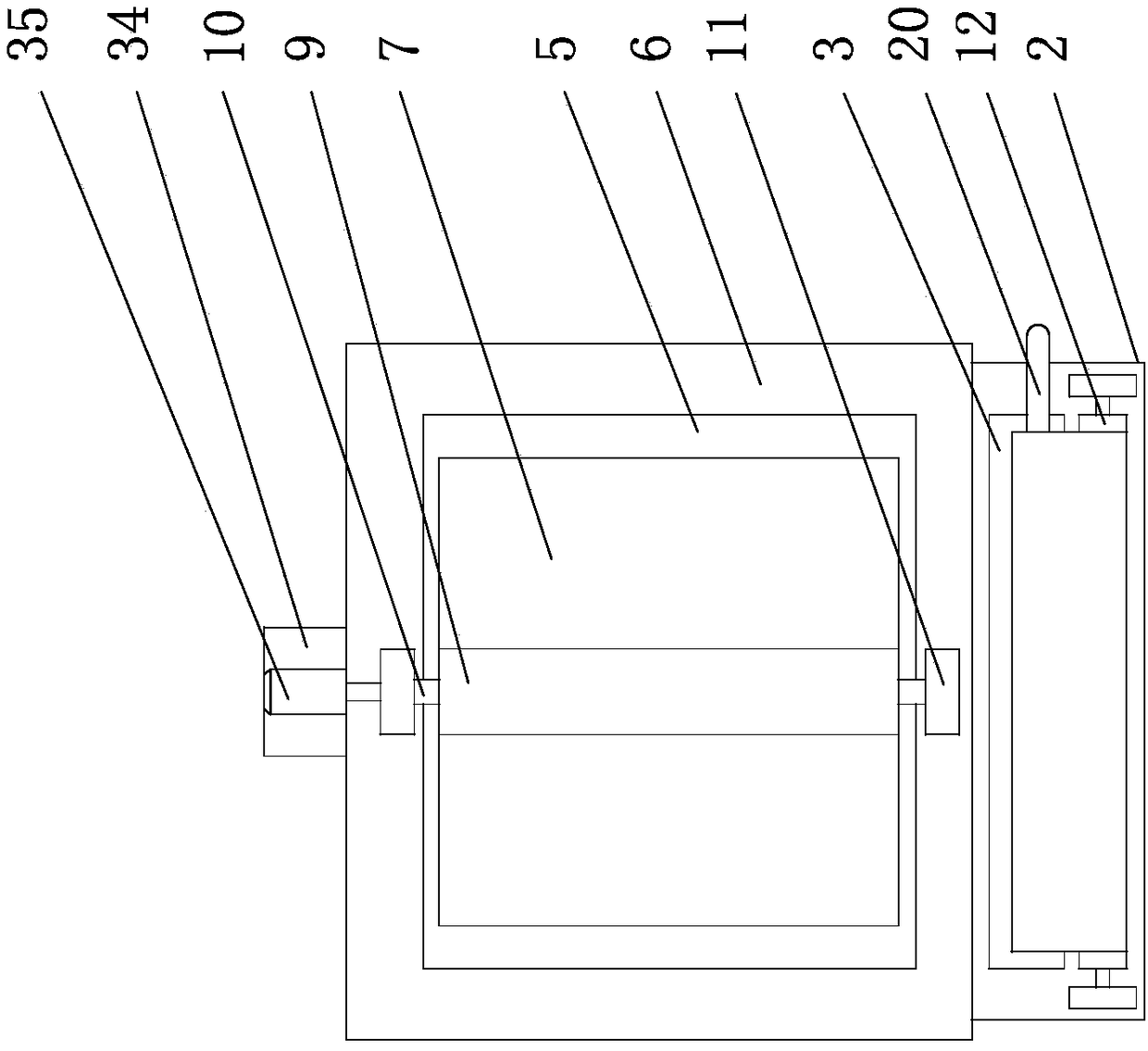

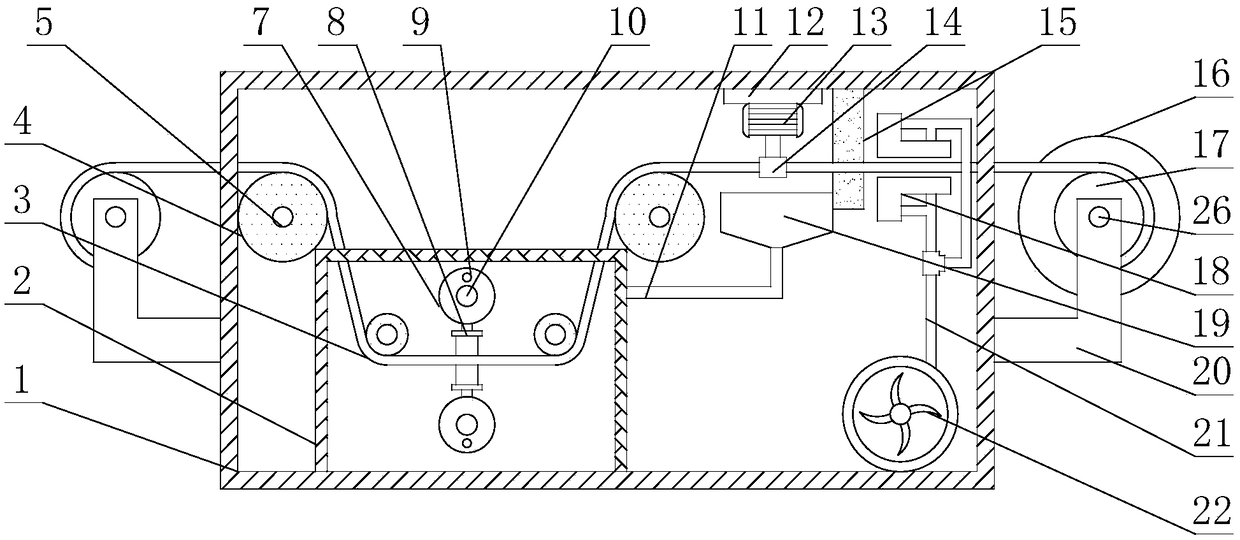

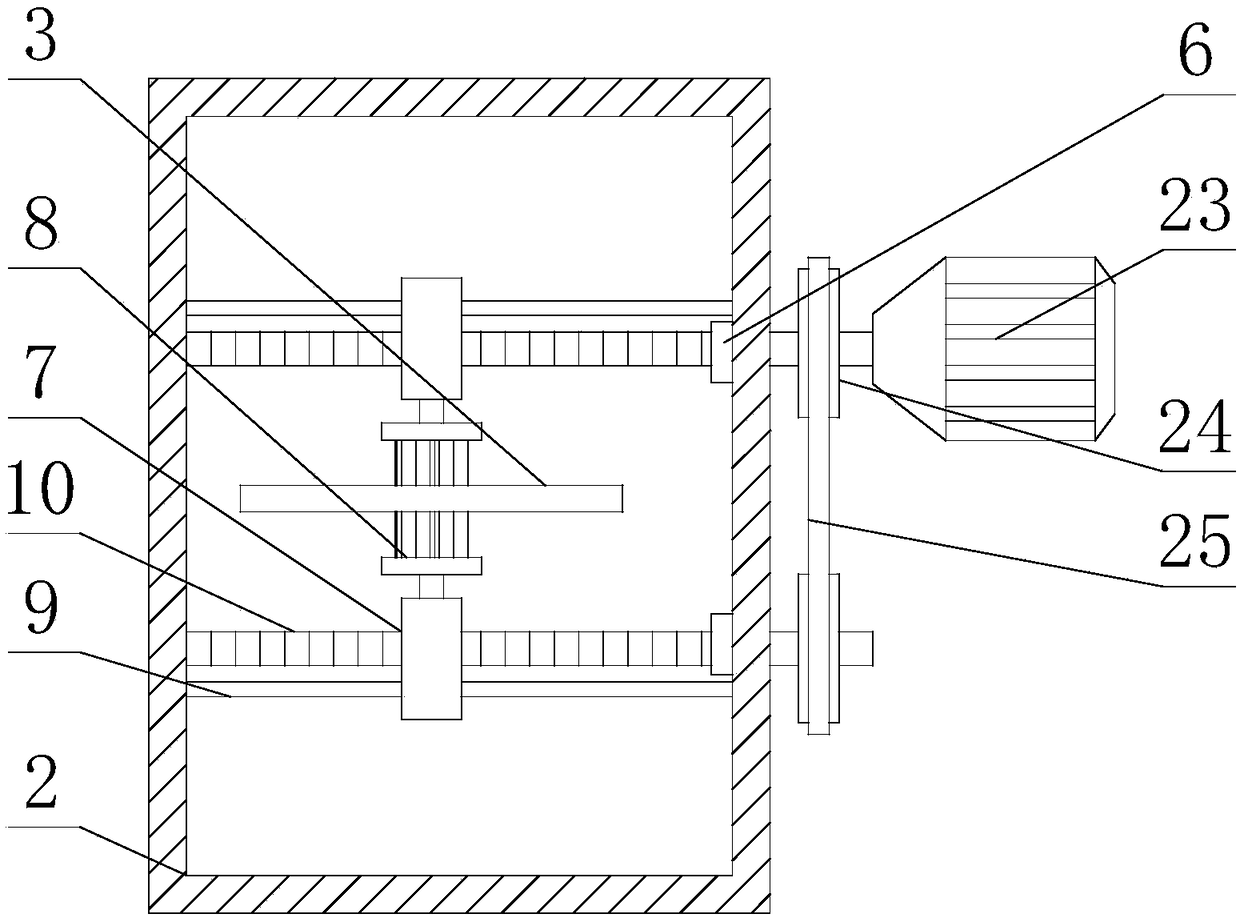

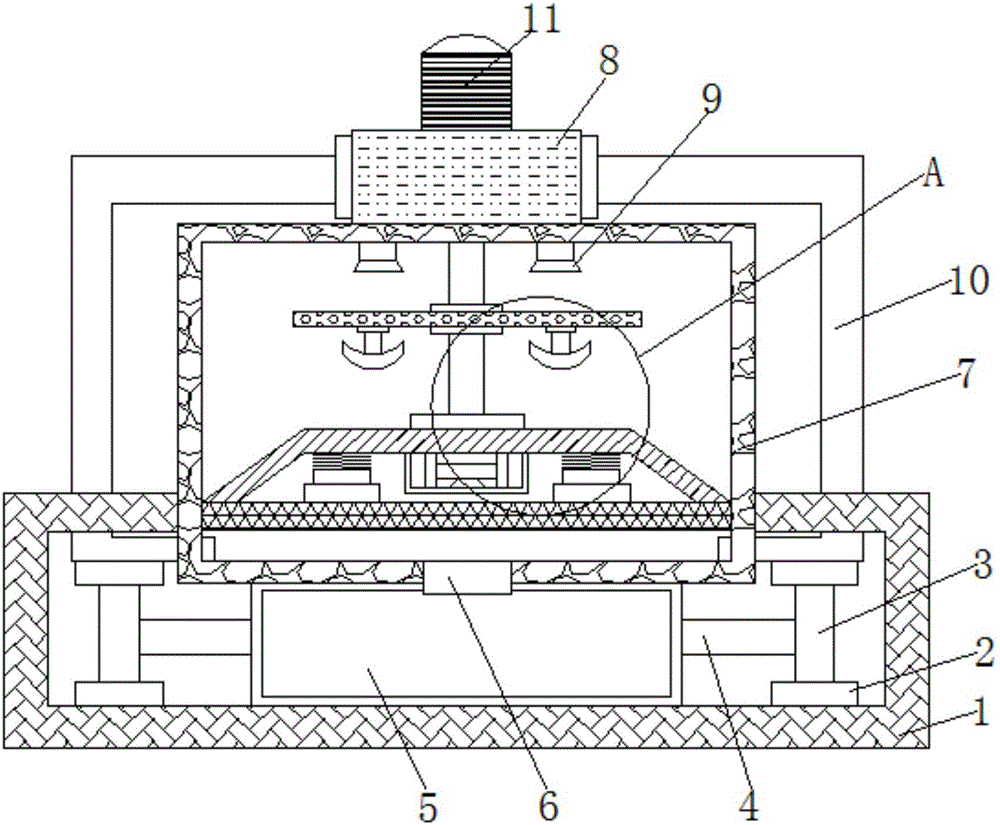

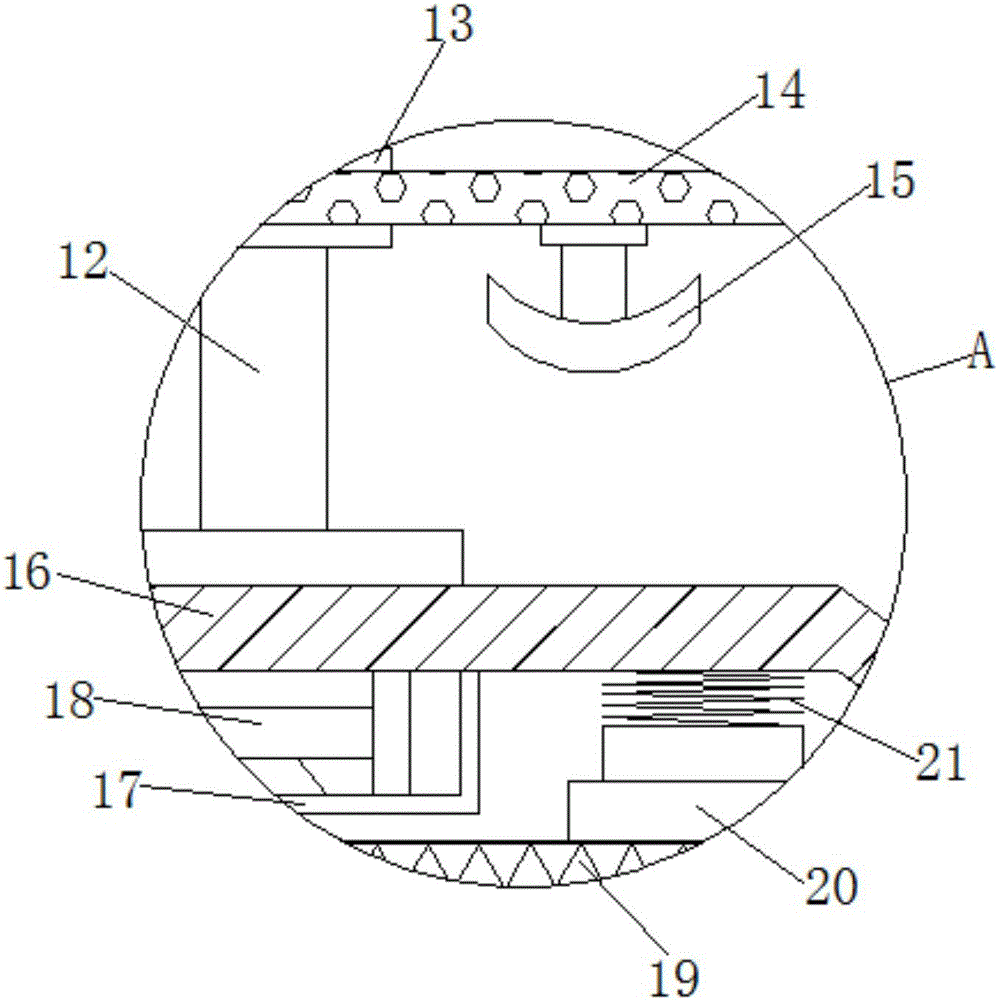

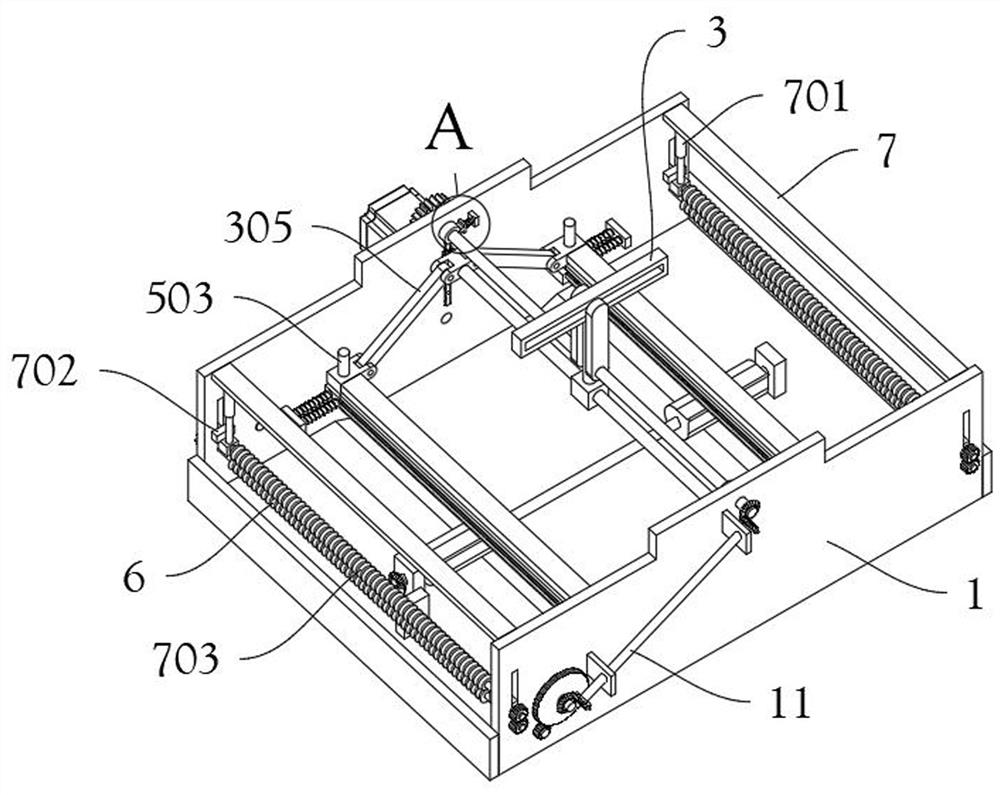

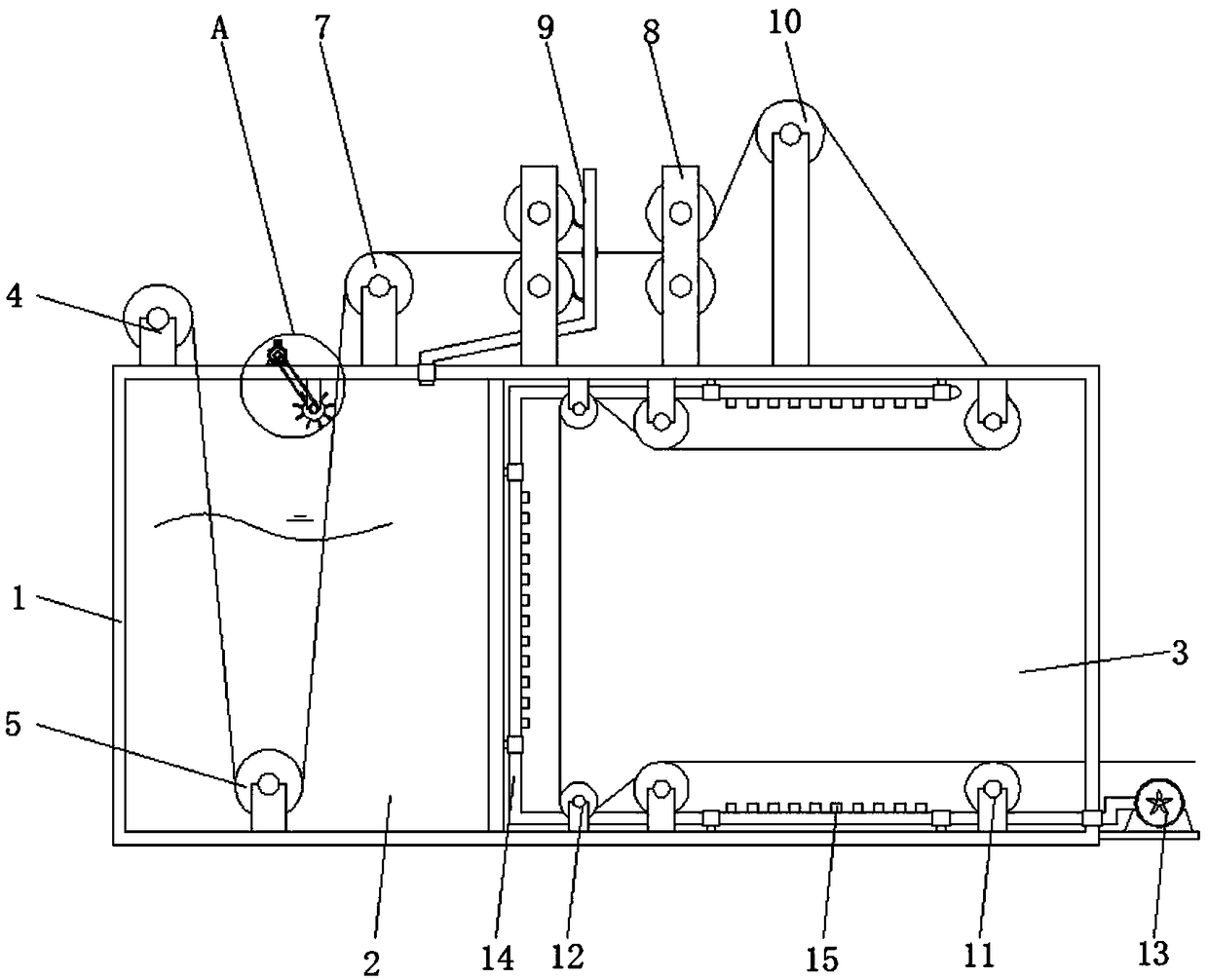

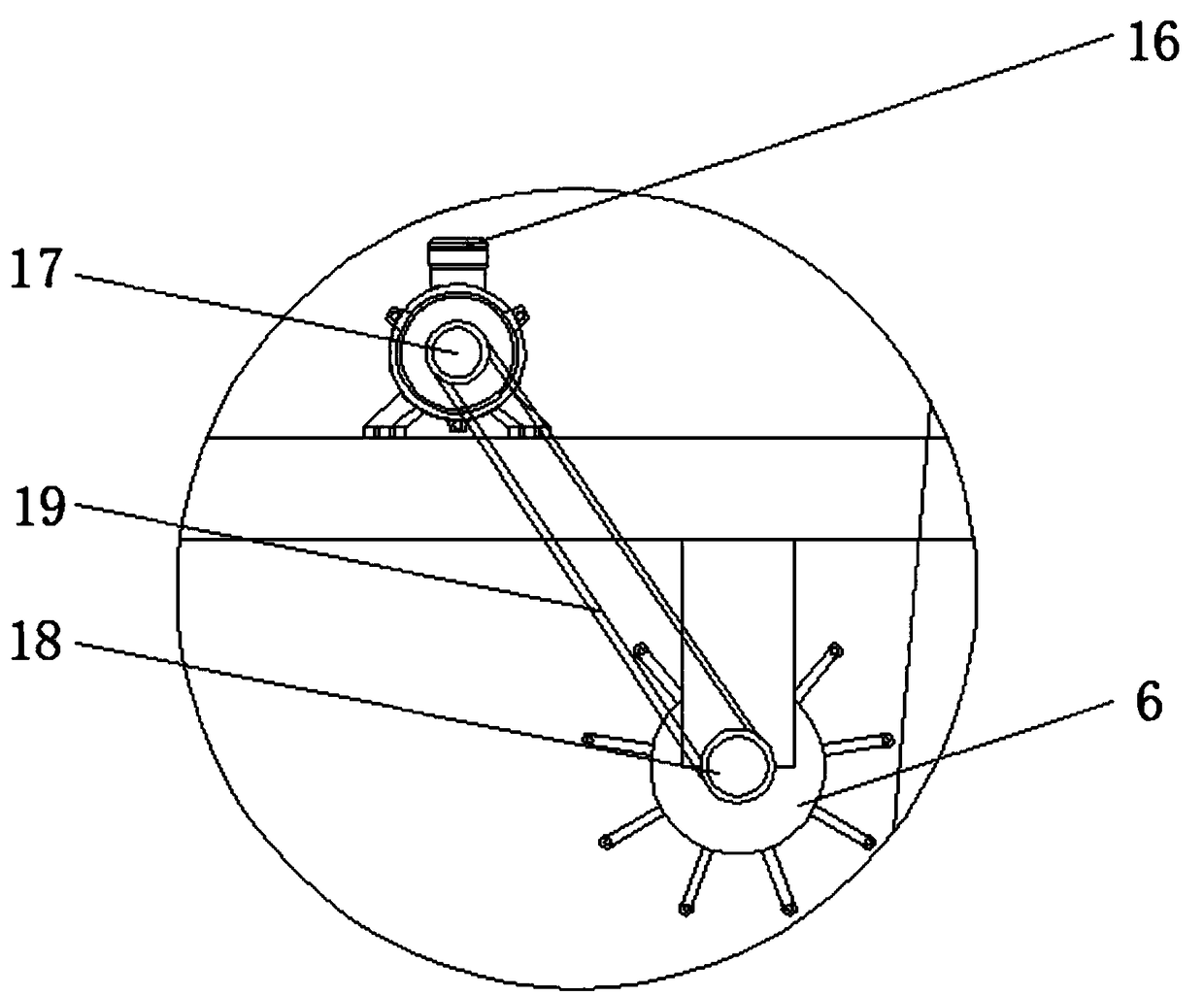

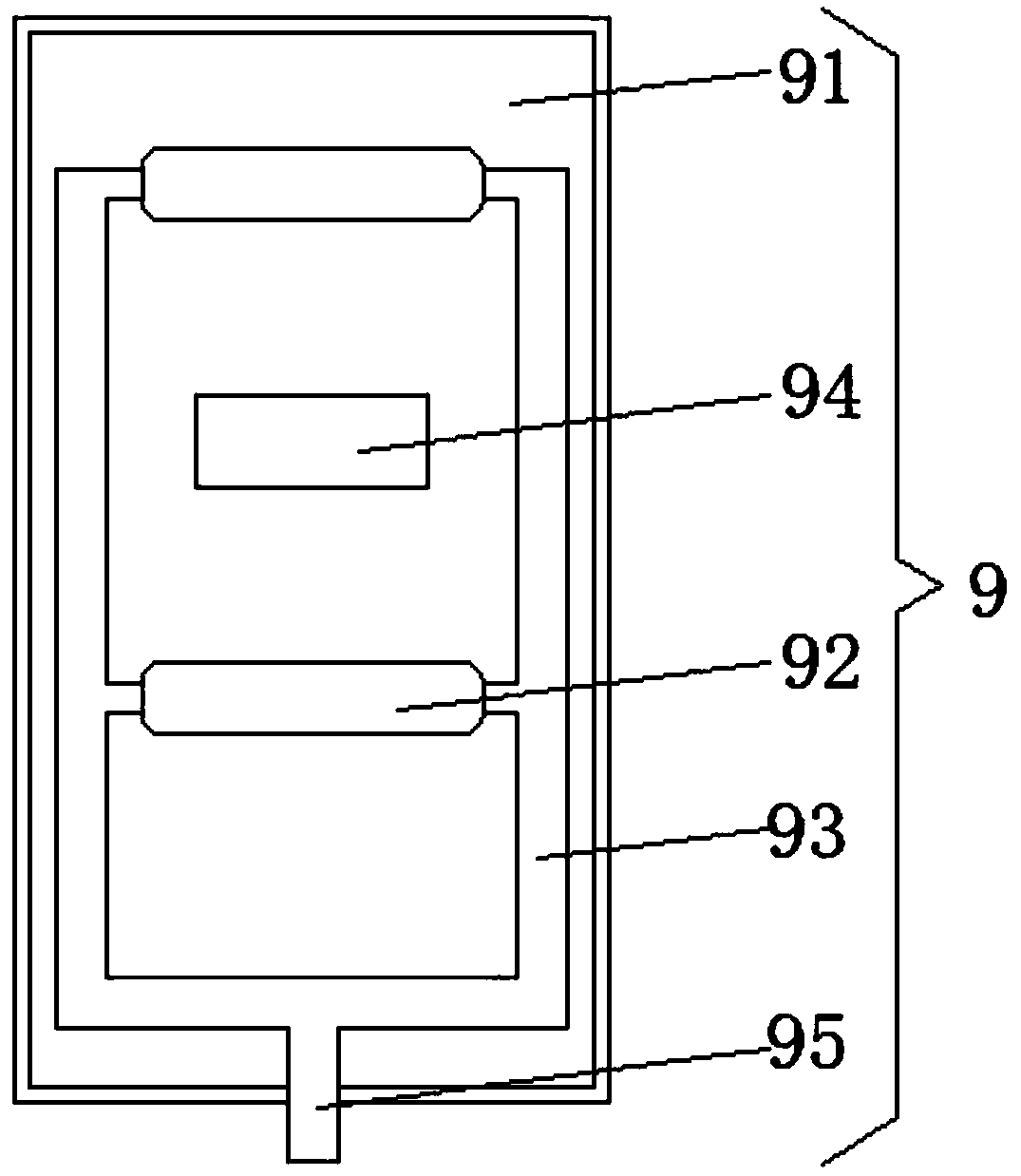

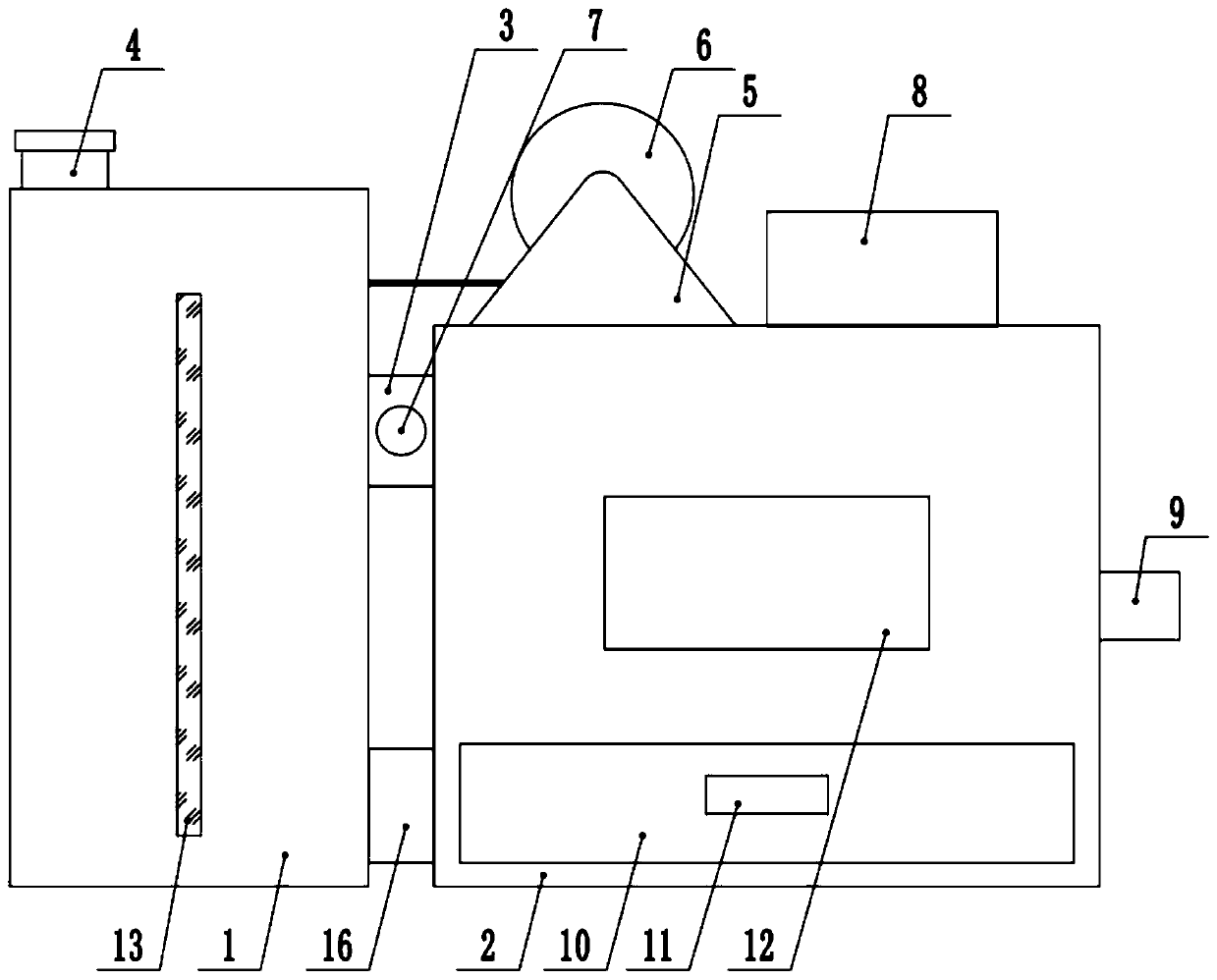

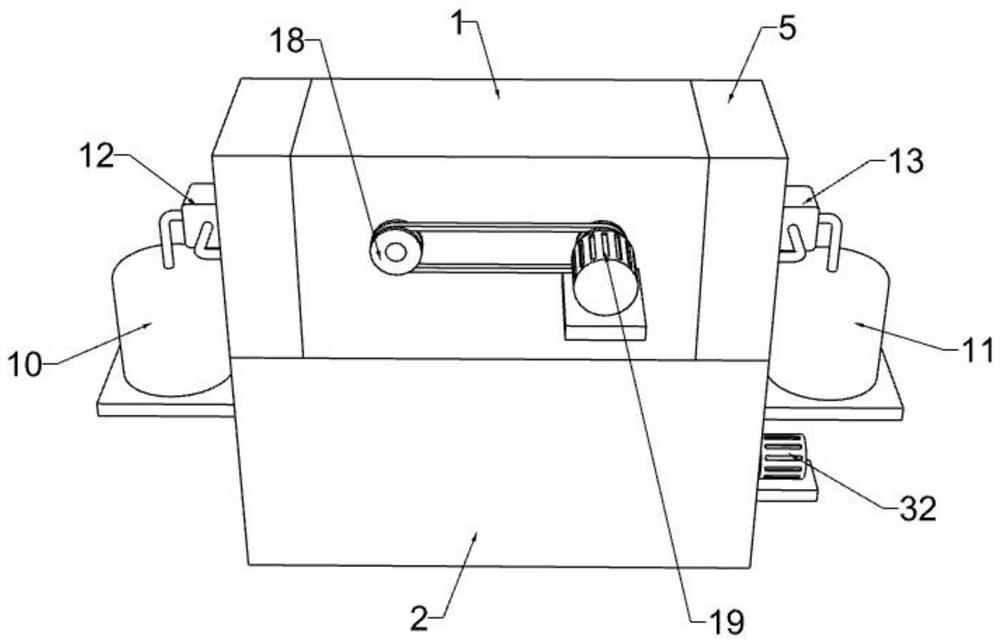

The invention relates to the technical field of spinning, in particular to a textile fabric cleaning and drying integrated device. A fabric taking-up roller and a fabric paying-off roller are installed at the front end and the rear end of a worktable, a water tank, a shaking unit and a drying box are sequentially arranged in the middle of the worktable from front to back, the shaking unit can shake off a cleaning fluid on a textile fabric, a hot-air blower in the drying box blows out hot air to dry the textile fabric, a flapping unit is installed in the drying box to flap the flap, and the cleaning fluid on the textile fabric can be rapidly separated from the textile fabric. The cleaning and drying of the textile fabric are organically combined together, the cleaned textile fabric can be dried during textile fabric cleaning, the time required for independent cleaning and independent drying is effectively shortened, meanwhile the input of the device is decreased, and the production cost is reduced.

Owner:XUZHOU ZHENFANG TEXTILE CO LTD

Decorative cloth cleaning and winding device

PendingCN108411518AImprove finished product qualityGuarantee the quality of windingLiquid/gas/vapor removal by vibrationTextile treatment by spraying/projectingMechanical engineeringTextile

Owner:浙江开盛新材料有限公司

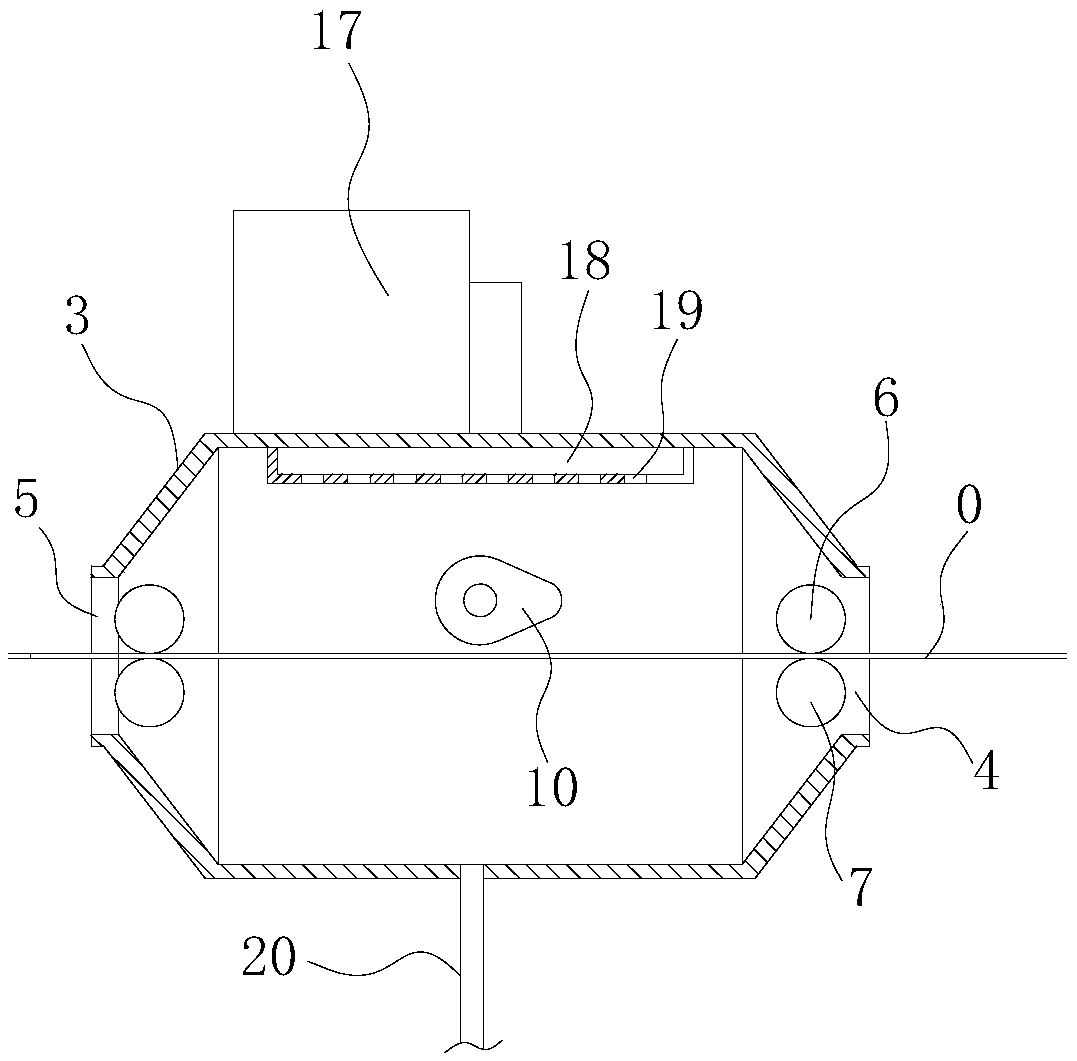

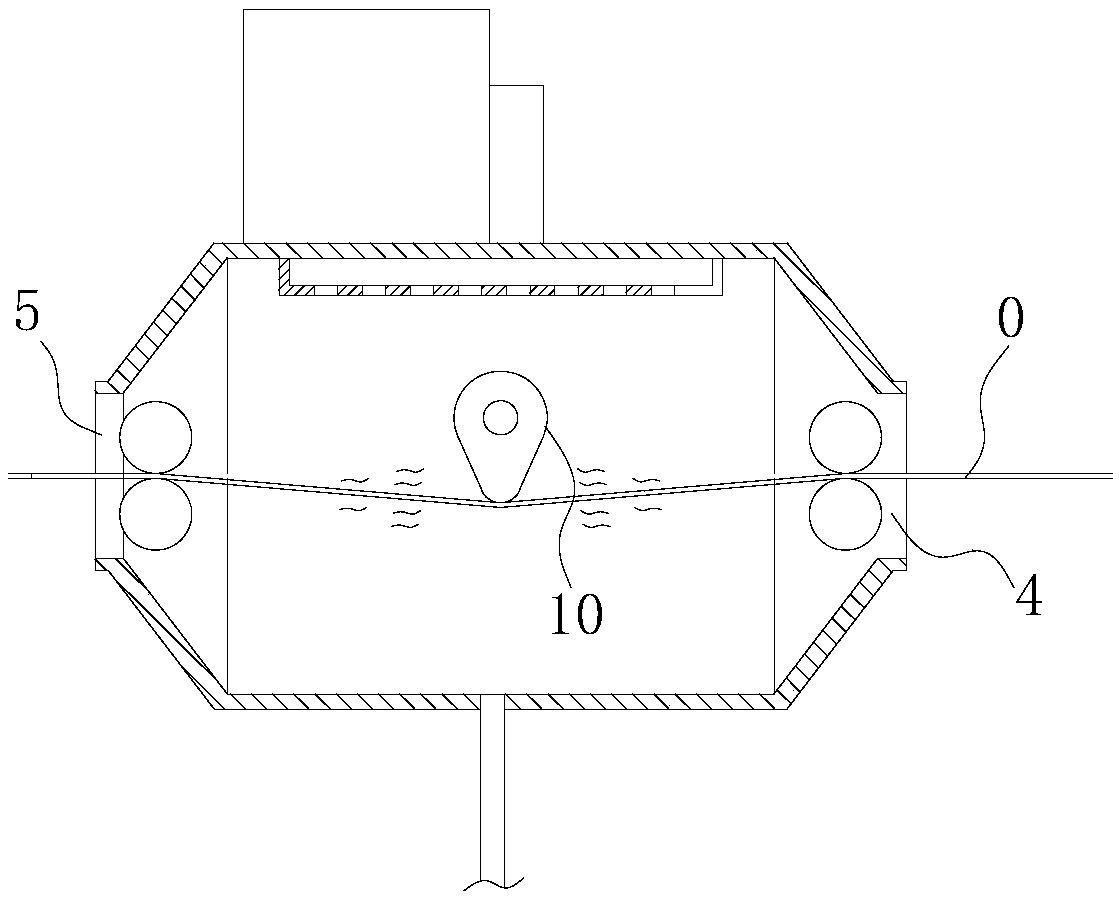

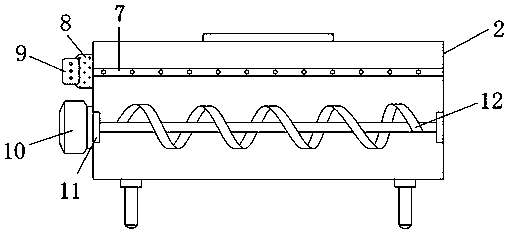

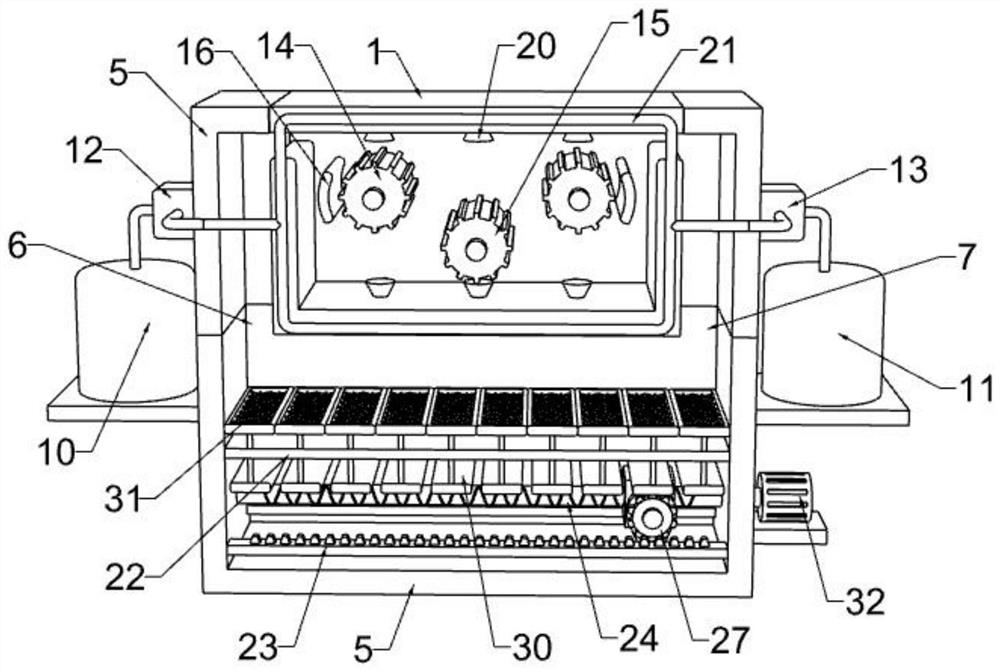

Beating type redundant sizing material cleaning machine

The invention provides a beating type redundant sizing material cleaning machine, which is used for the production of fiber and cloth. The beating type redundant sizing material cleaning machine comprises a first floating roller and a second floating roller which are in parallel arrangement and are positioned above a sizing material tank, a multi-angular flower roller which is parallel to the first floating roller and the second floating roller and is arranged in the sizing material tank is also arranged between the first floating roller and the second floating roller, the cross section of the multi-angular flower roller is of a regular polygon shape, the fiber of the cloth is transmitted to the second floating roller through the first floating roller and the multi-angular flower roller, a beating shaft and a beating rod which are parallel to the multi-angular flower roller are arranged under the lower side between the multi-angular flower roller and the second floating roller, the beating rod is fixedly connected to the beating shaft through supporting rods which are arranged at two ends of the beating rod, the beating rod is positioned under the fiber or the cloth, one end of the beating shaft is vertically and fixedly connected to a limit slanting rod, one end of the limit slanting rod is in contact with the surface of the multi-angular flower roller, and the other end of the limit slanting rod is fastened by a spring. According to the beating type redundant sizing material cleaning machine provided by the invention, redundant sizing material on the fiber or the cloth can be uniformly cleaned, and the fiber or the cloth cannot be damaged.

Owner:吉林市吉研高科技纤维有限责任公司

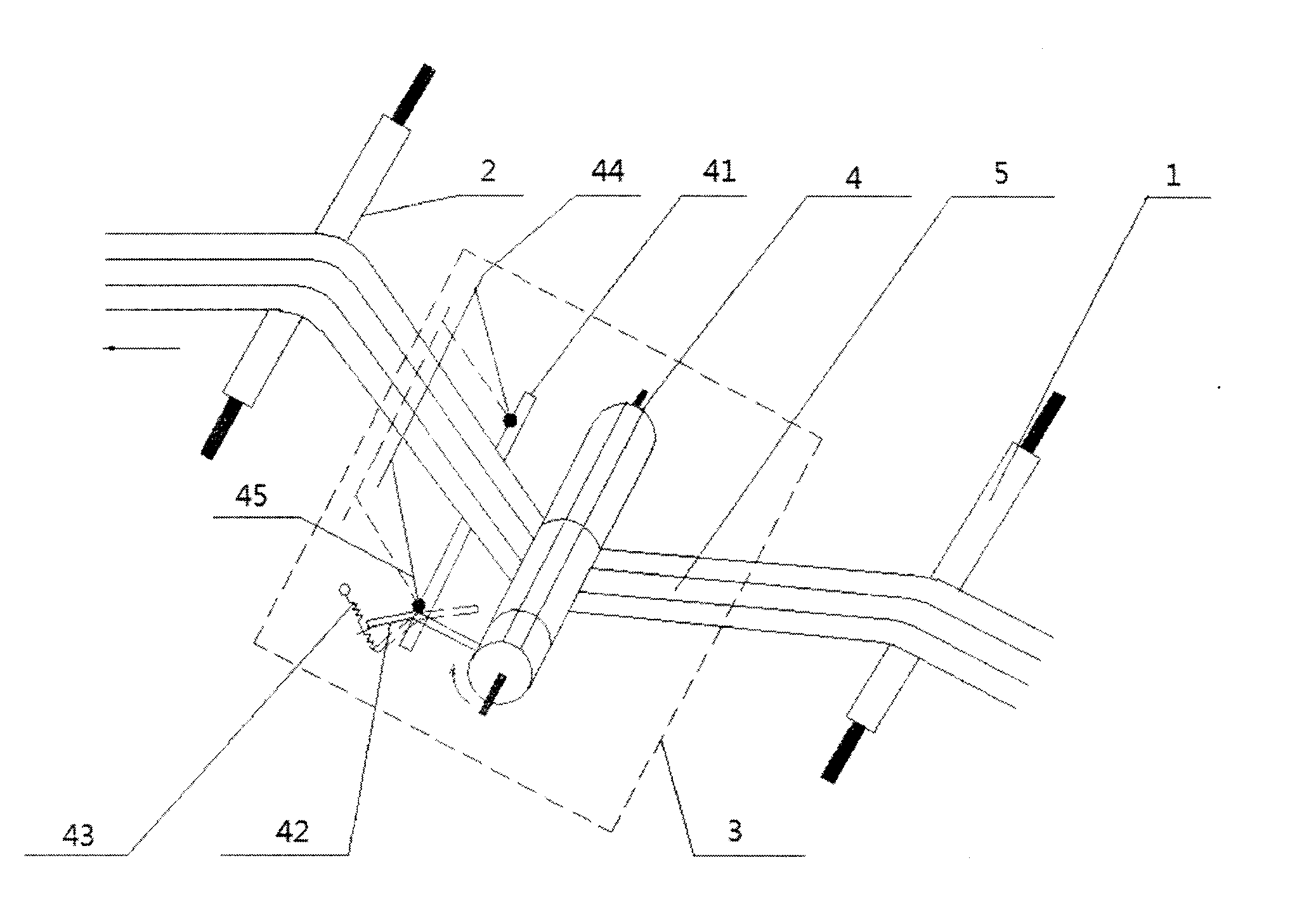

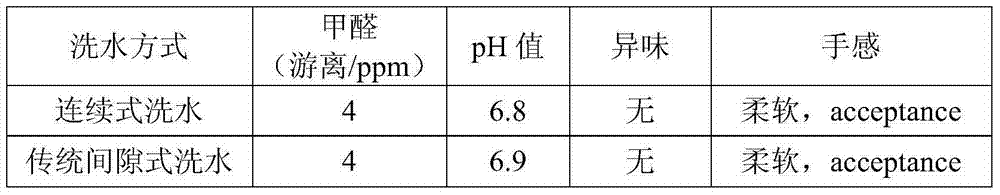

Method and equipment for water washing of clothes

ActiveCN104775247AReduce labor intensityReduce the number of employeesTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringPollution

The invention provides a method and equipment for water washing of clothes. The method comprises the following steps of pre-spraying, spraying material treatment, water removal, and suspension and drying, so as to complete the water washing process; in the pre-spraying process, a washing liquid is uniformly sprayed to the clothes by a spraying method; in the spraying material treatment process, a spraying material treatment liquid is uniformly applied to the clothes by the spraying method; preferably, in the pre-spraying and material spraying treatment process, the clothes are suspended. The invention also provides the water washing equipment using the method. By adopting the technical scheme, the method has the beneficial effects that the water washing procedures of the clothes are continuously performed, the residual liquid in the water washing procedure is recycled, the labor is saved, the water usage amount is reduced, the pollution is reduced, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Dyeing machine with uniform dyeing function and dyeing liquid recovery function

InactiveCN111155255AUniform dyeingAchieve the effect of recyclable dye liquorTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationPolymer scienceEngineering

The invention relates to the technical field of dyeing machines, and discloses a dyeing machine with a uniform dyeing function and a dyeing liquid recovery function. The dyeing machine comprises a base, wherein a vertical rod is fixedly arranged at each of the left side and the right side above the base; a dyeing liquid box is fixedly arranged above the base and is positioned at the inner sides ofthe vertical rods; a slide tube is fixedly arranged at each of the left side and the right side above the dyeing liquid box; a slide rod is arranged at the upper part of each slide tube; a first filter screen is arranged above the dyeing liquid box and are positioned at the inner sides of the slide tubes; a dip dyeing box is fixedly connected between the vertical rods; slide grooves are formed inthe lower wall of the dip dyeing box and are positioned in front and behind of a fan; slide block is arranged on each slide groove; and an air spraying pipe is arranged under each slide block. The dyeing machine with the uniform dyeing function and the dyeing liquid recovery function has the advantages that recovered dyeing liquid is filtered through the first filter screen and a second filter screen; the air spraying pipe is used for flattening cloth; and the dip dyeing box is used for dip-dyeing the cloth in a matched way, so that the effects that the dyeing is uniform, the dyeing liquid can be recovered, and the cloth can be flattened are achieved.

Owner:张发义

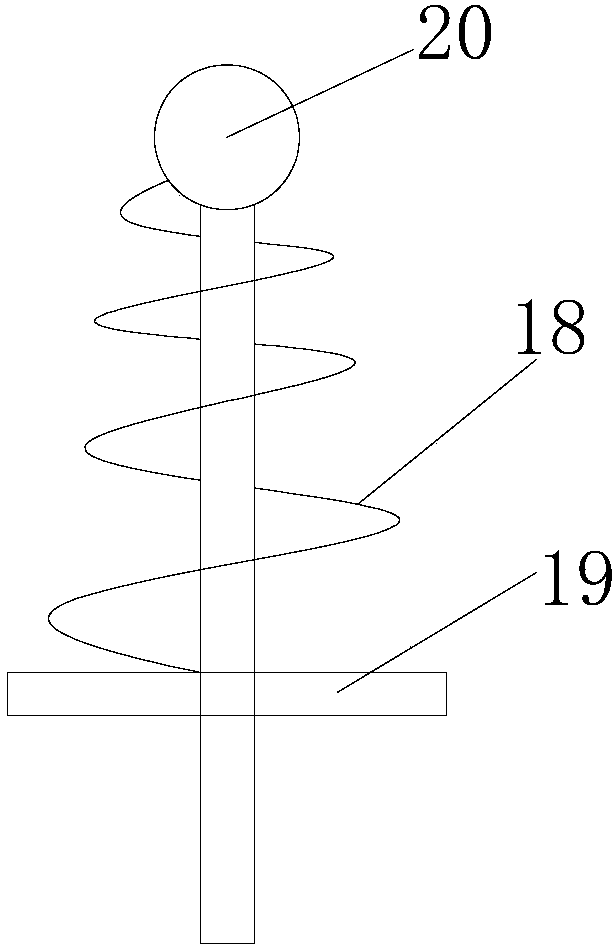

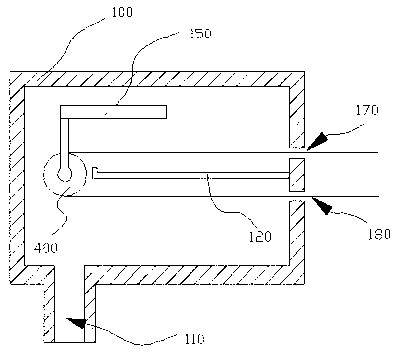

Ultrasonic wave desizing device

InactiveCN101629368AReduce dosageLittle consumptionTextile treatment containersLiquid/gas/vapor removal by suctionWater savingTransducer

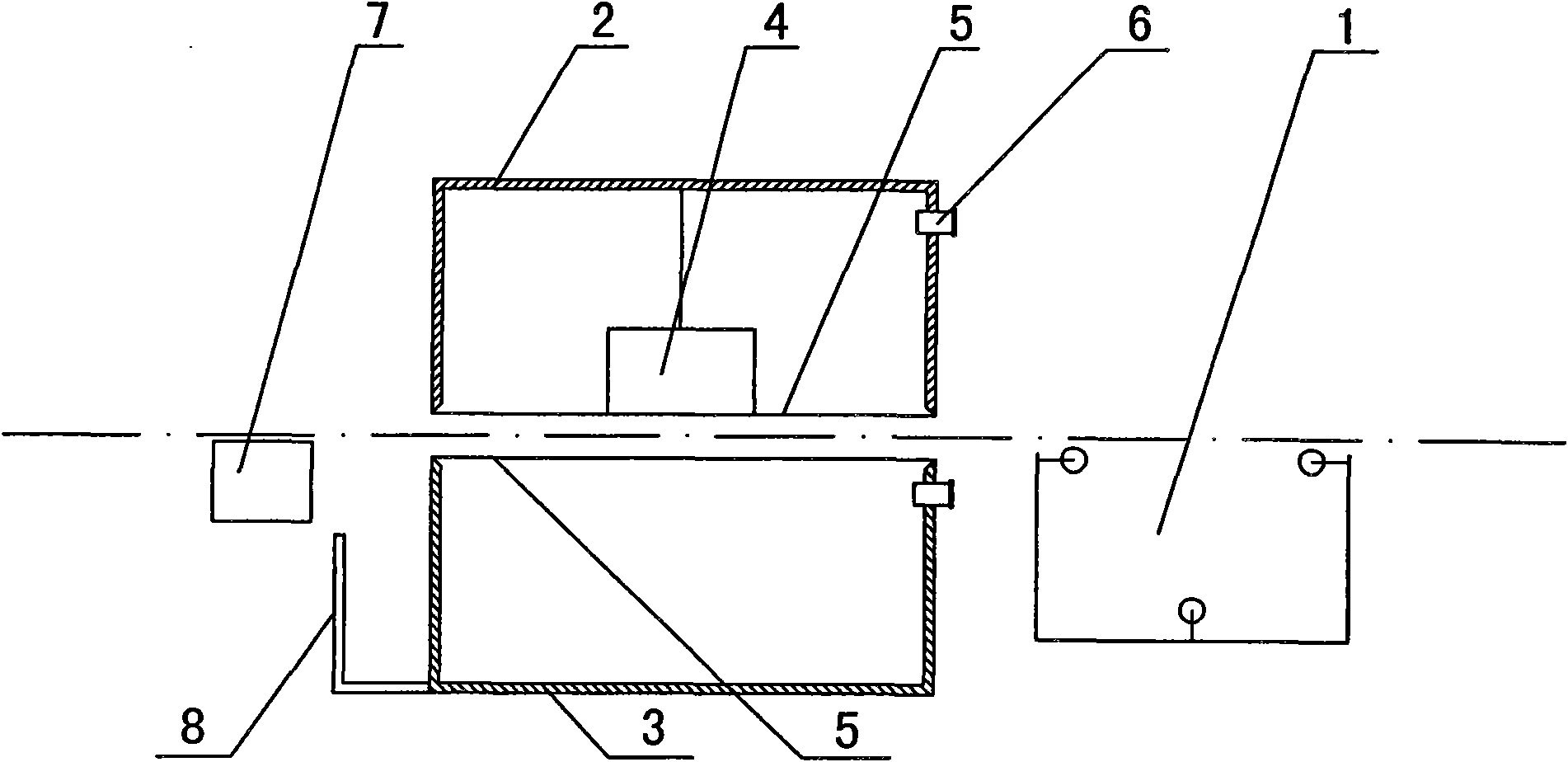

The invention discloses an ultrasonic wave desizing device, comprising a water tank unit; the water tank unit consists of two semi-enclosed water tanks, namely a water tank A and a water tank B; one unenclosed side of the water tank A is enclosed by at least one layer of film, so is one unenclosed side of the water tank B; the two outmost layers of films of the two water tanks are parallel, and a gap with the distance of less than 3mm is left between the two outmost layers of films; at least one ultrasonic wave transducer is mounted in the water tank A or the water tank B and is fixed on the inner wall of the water tank; water inlets are mounted on both the water tank A and the water tank B. The invention can completely remove sizing agent attached to the textile products in the desizing technique, and the sizing agent and water can be recycled and reused, thus greatly reducing water usage and lowering processing cost with small power consumption. The invention also features energy saving, water saving, no pollution and the like.

Owner:李建华

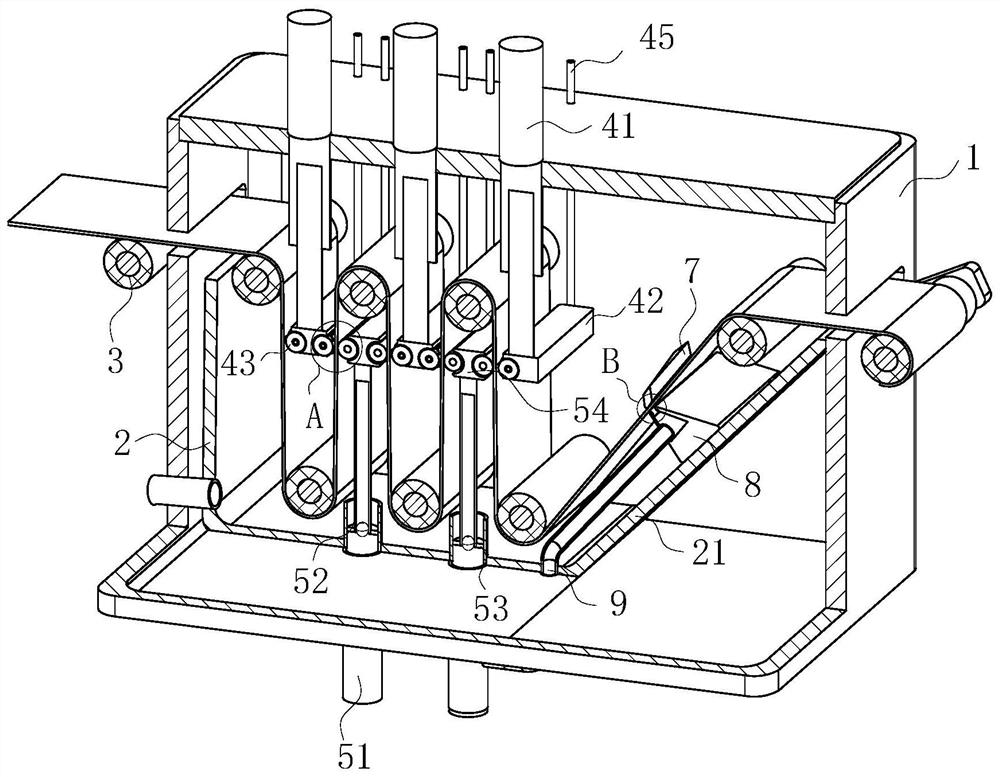

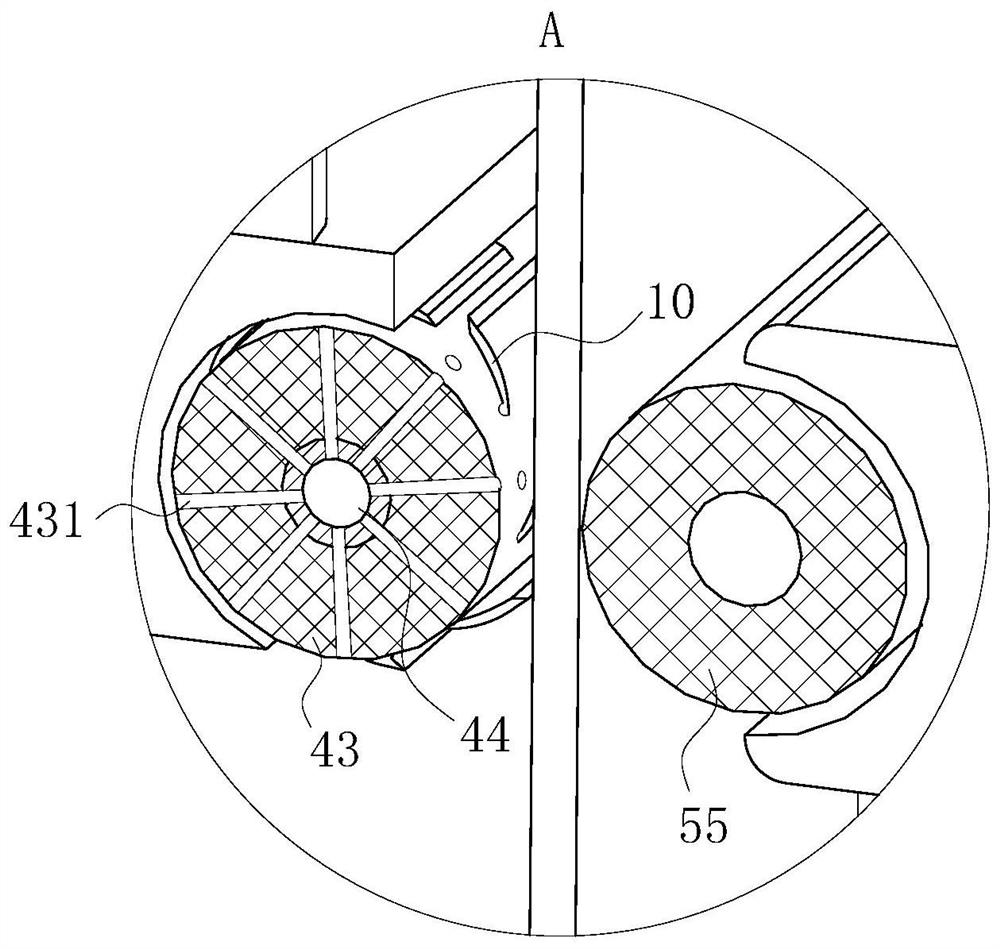

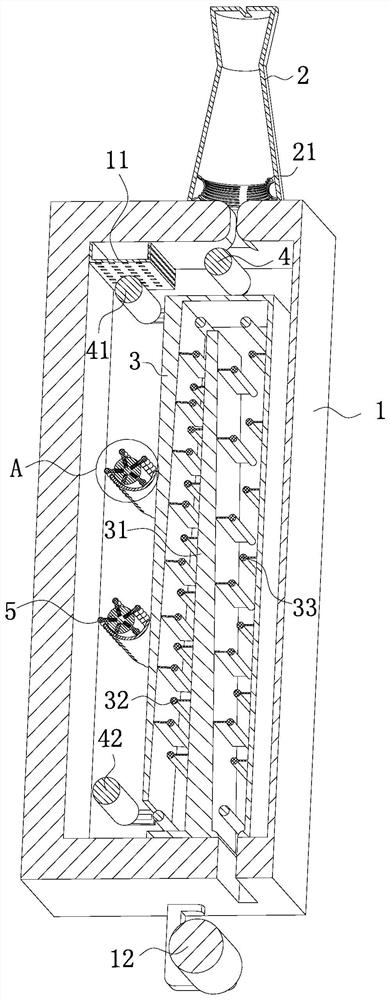

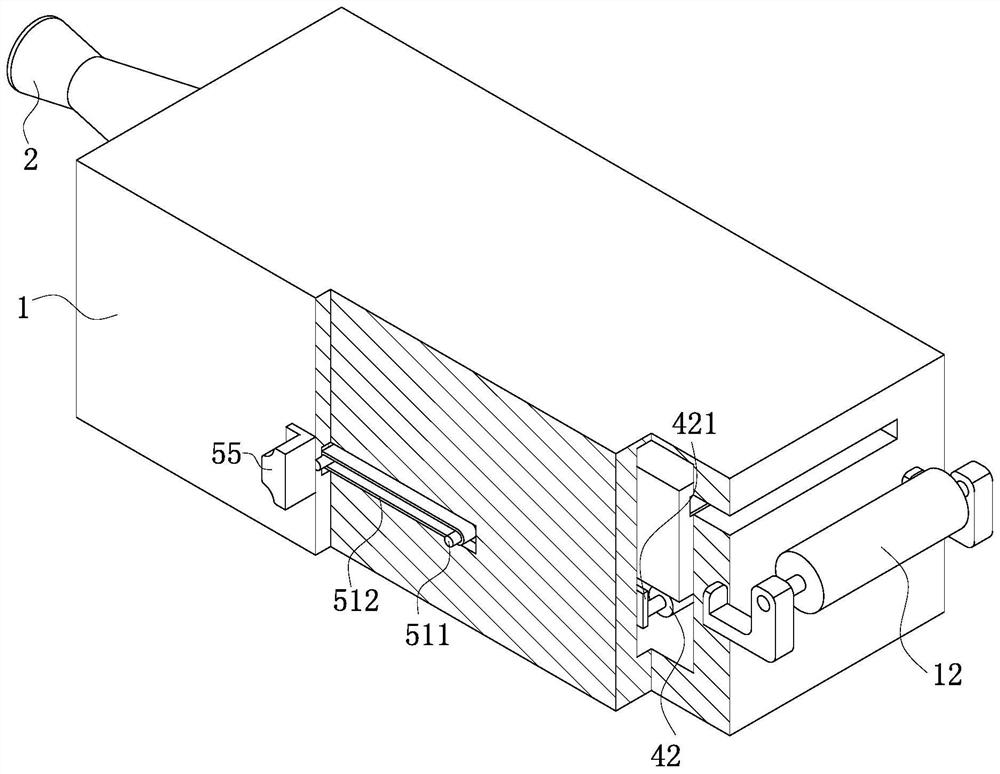

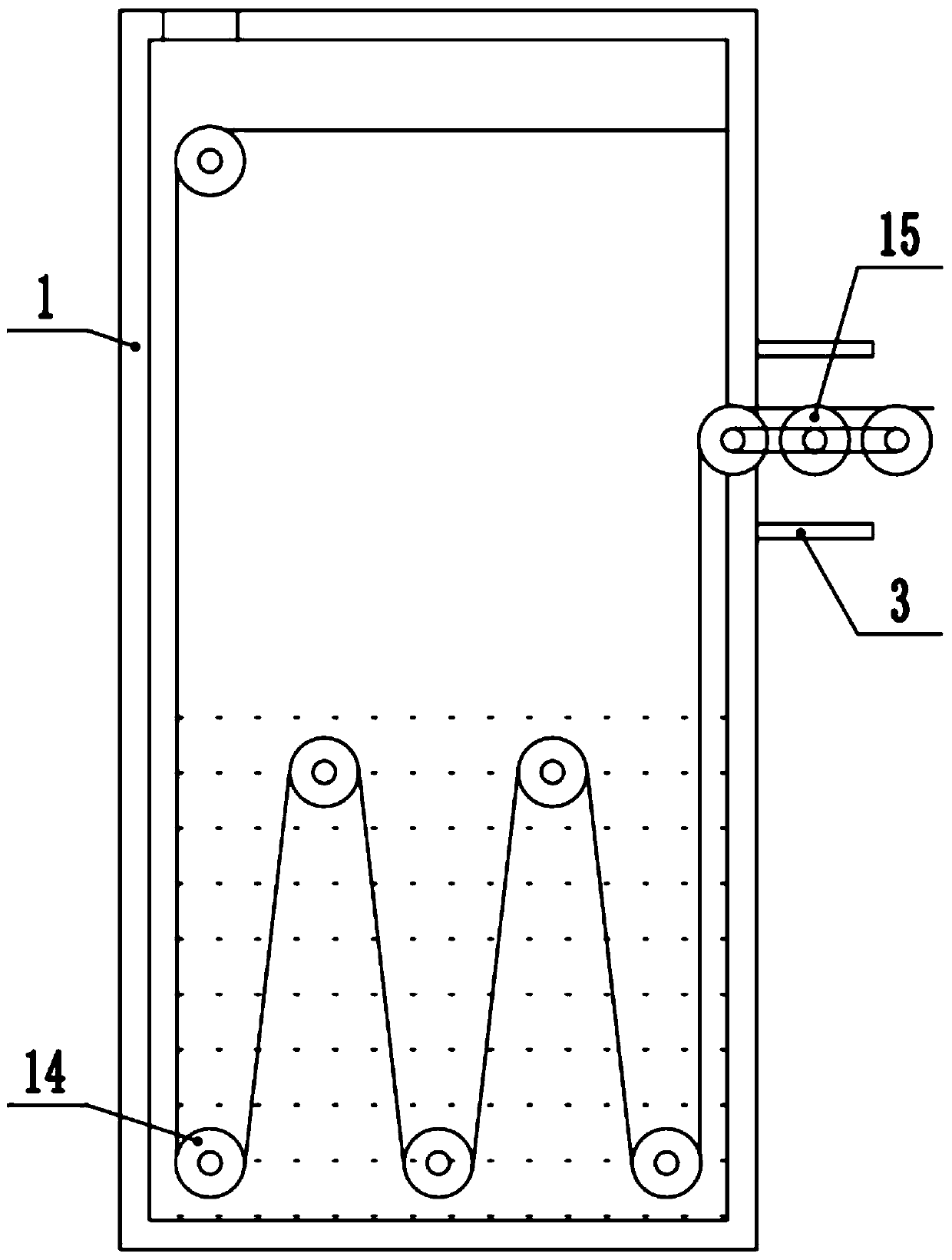

Textile fabric dewatering device

InactiveCN112981812AImprove the opening effectEasy to cleanMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

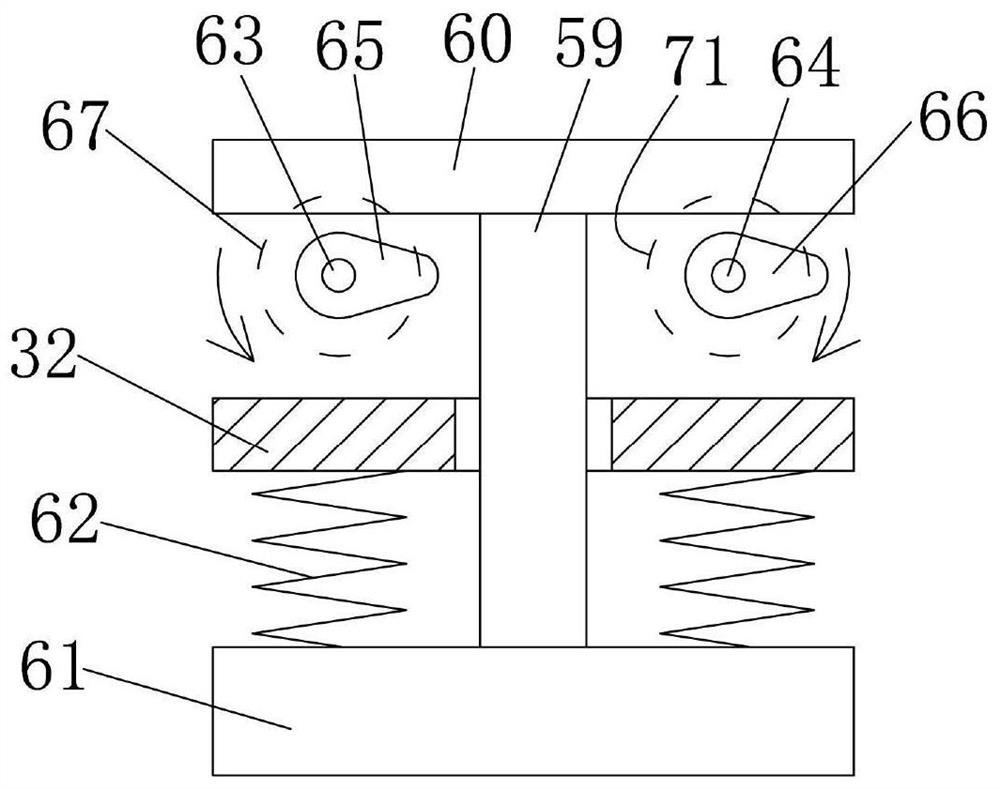

The invention discloses a textile fabric dewatering device and belongs to the technical field of textile equipment. The textile fabric dewatering device comprises a box body, a first conveying roller, a first tensioning roller, a second conveying roller, a third conveying roller, a second tensioning roller, a fourth conveying roller and a fifth conveying roller are arranged in the box body, a supporting plate is arranged between the second conveying roller and the third conveying roller, a moving rod is arranged at the center of the supporting plate in a penetrating mode, one end of the moving rod is connected with a moving plate, the other end of the moving rod is connected with a beating plate, the bottom end of the supporting plate is connected with a spring, the other end of the spring is connected with the top end of the beating plate, a first rotating shaft and a second rotating shaft are arranged between the moving plate and the supporting plate, a first cam is installed on the first rotating shaft, and a second cam is installed on the second rotating shaft. Through mutual cooperation of the first cam, the second cam, the moving plate, the moving rod, the supporting plate, the spring and the beating plate, the surface of fabric can be beaten, beating dewatering treatment is conducted on the fabric, and the beating plate can beat the fabric once every time the fabric is rotated by 180 degrees.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

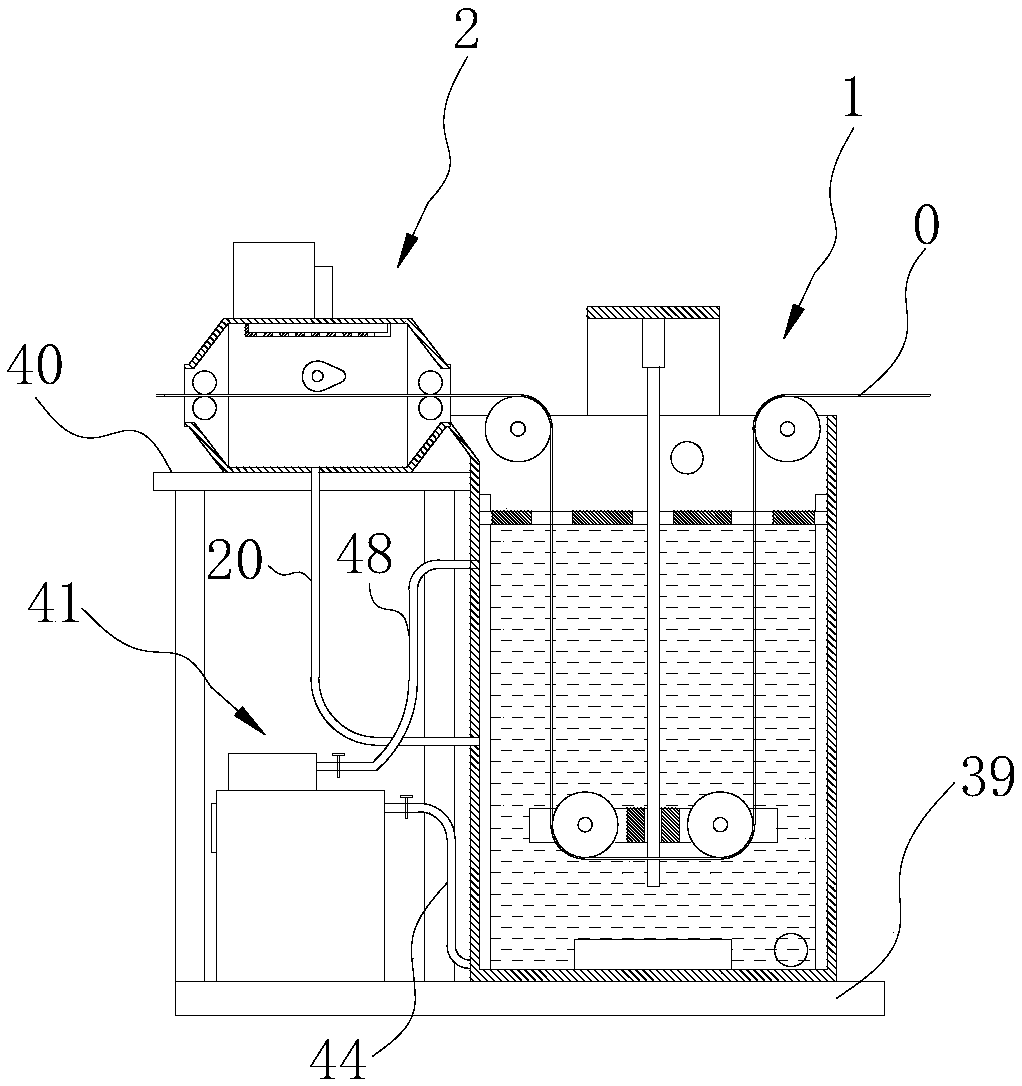

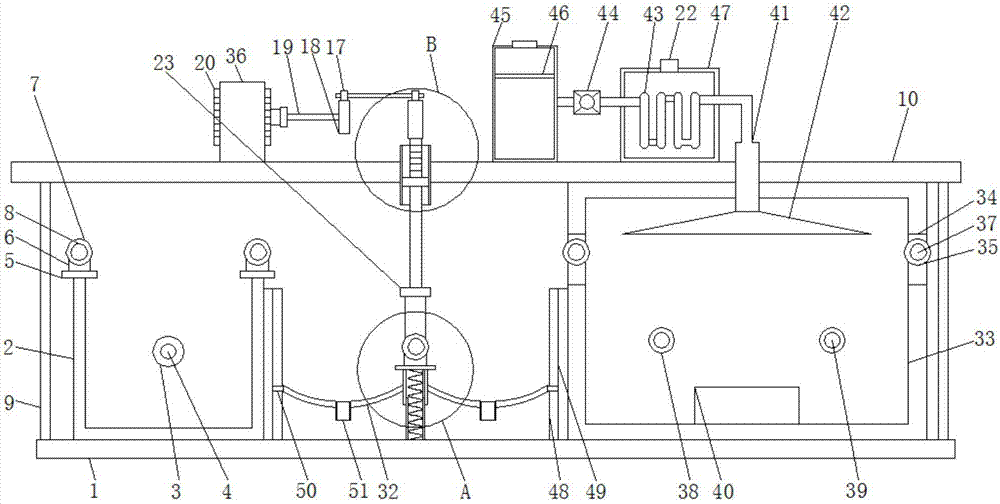

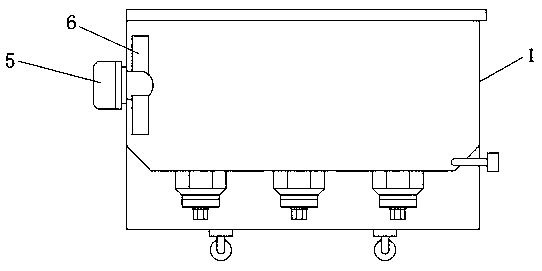

Novel yarn dip-dyeing oiling machine

ActiveCN109576928AEfficient removalQuality assuranceTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationFiberYarn

The invention relates to the technical field of spinning yarn processing, and aims at providing a novel yarn dip-dyeing oiling machine capable of achieving oil filtering. According to the technical scheme, the novel yarn dip-dyeing oiling machine comprises a bottom plate, a dip-dyeing oiling device is arranged on one side of the top face of the bottom plate, a side frame is arranged on the other side of the top face of the bottom plate, and a springing-type oil removing device is arranged on the side frame; an oil filtering device is arranged on the bottom plate below the side frame, and comprises a filtering box and a circulating pump arranged on the top face of the filtering box, a sump oil pipe is arranged at the upper portion of one side of the filtering box, and a sump-oil cleaning door is arranged at the upper portion of the other side of the filtering box; the filtering box is communicated with the lower portion of an oil containing container of the dip-dyeing oiling device through the sump oil pipe. By means of the novel yarn dip-dyeing oiling machine, oil in the dip-dyeing oiling device can be filtered, fiber impurities contained in the oil are removed, and the yarn quality is guaranteed.

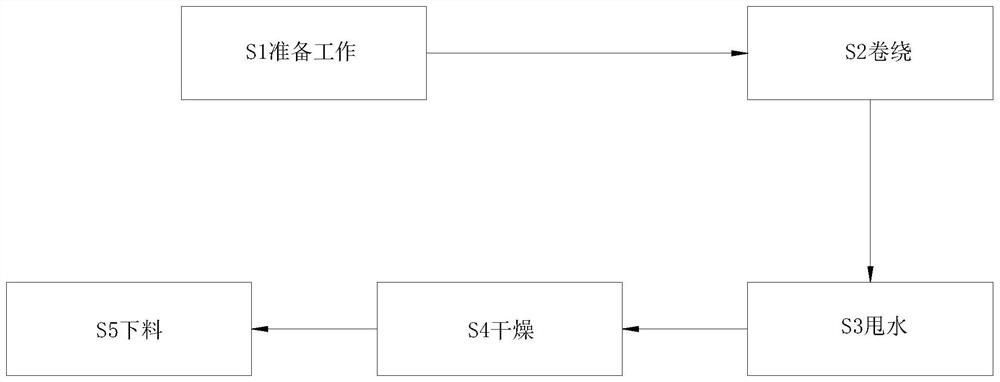

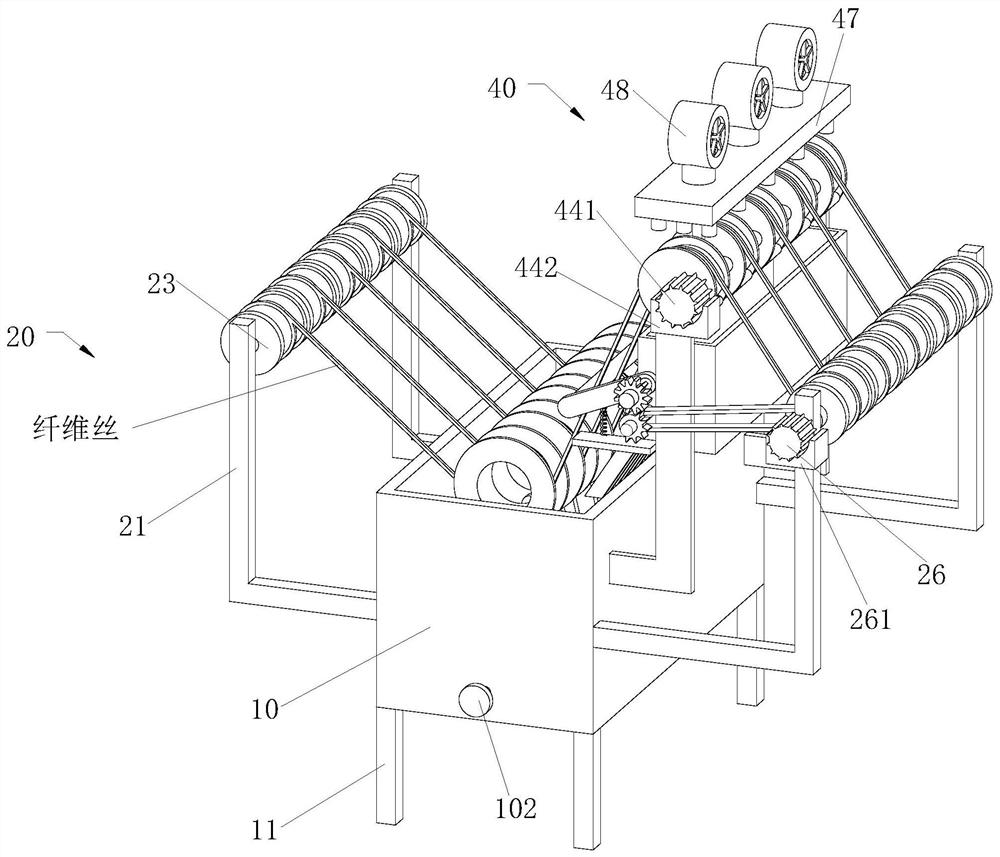

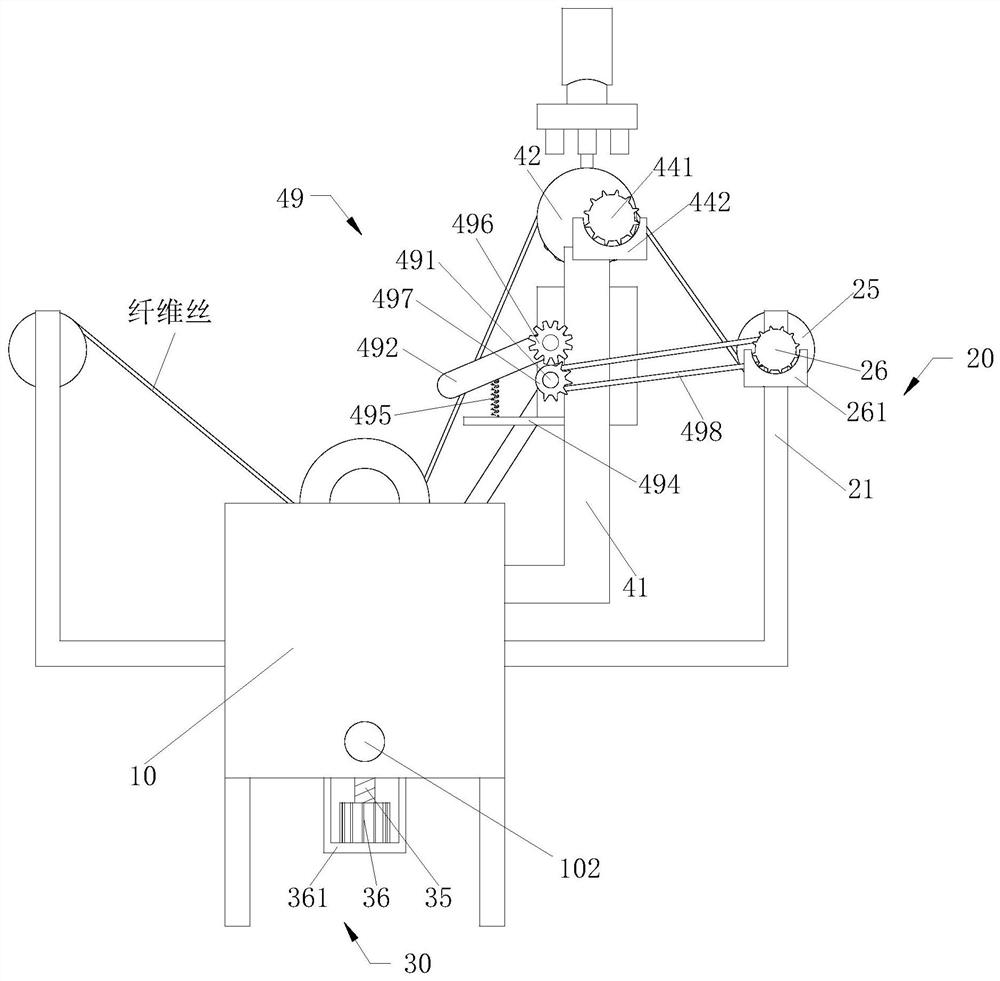

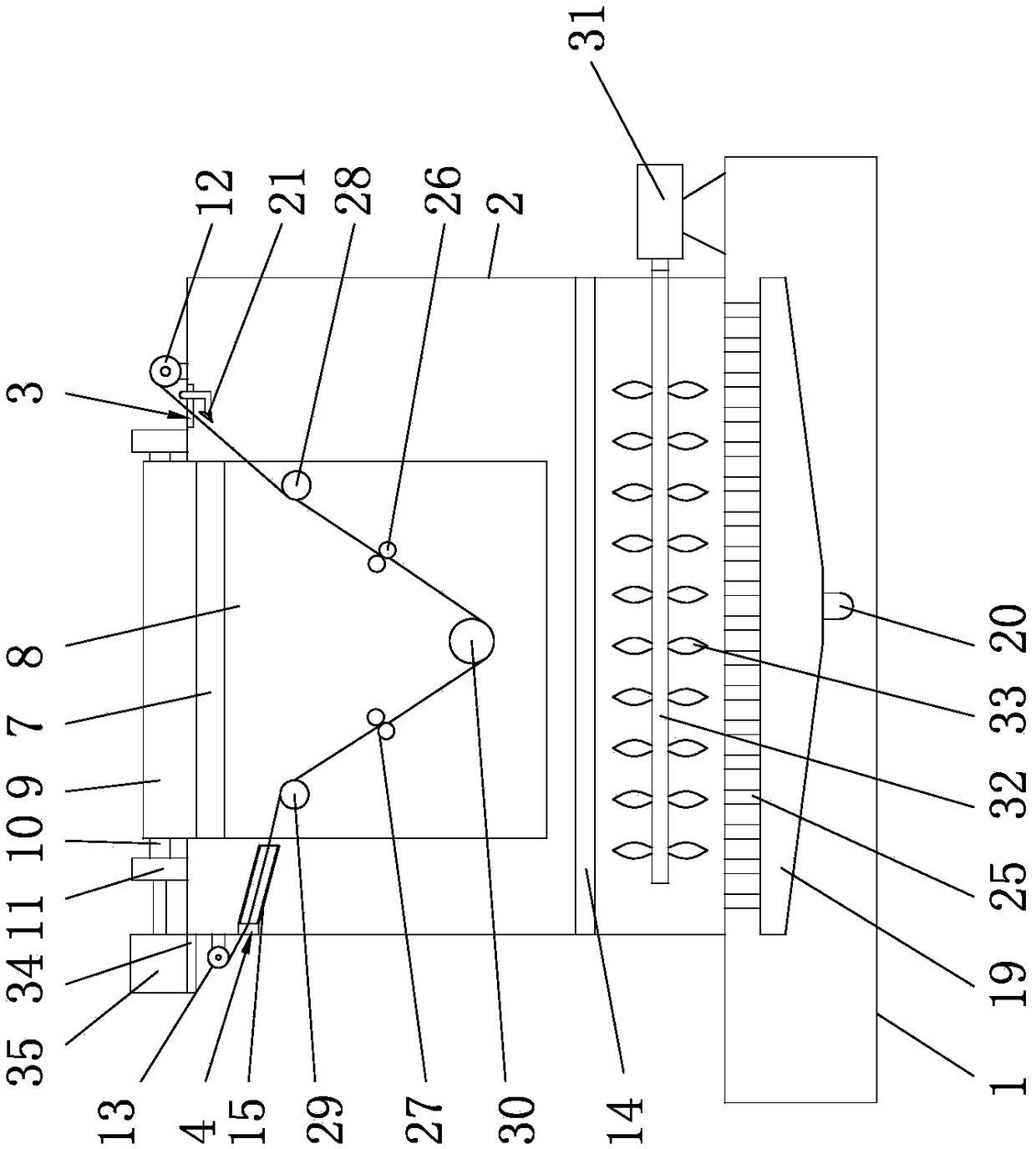

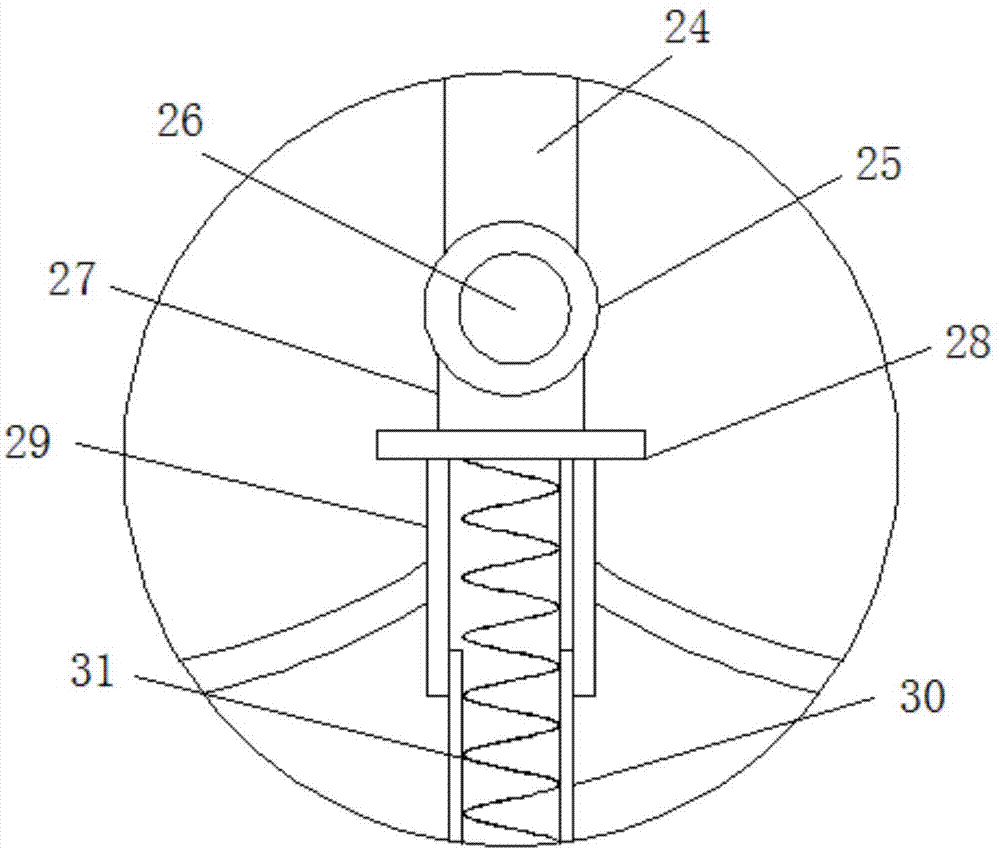

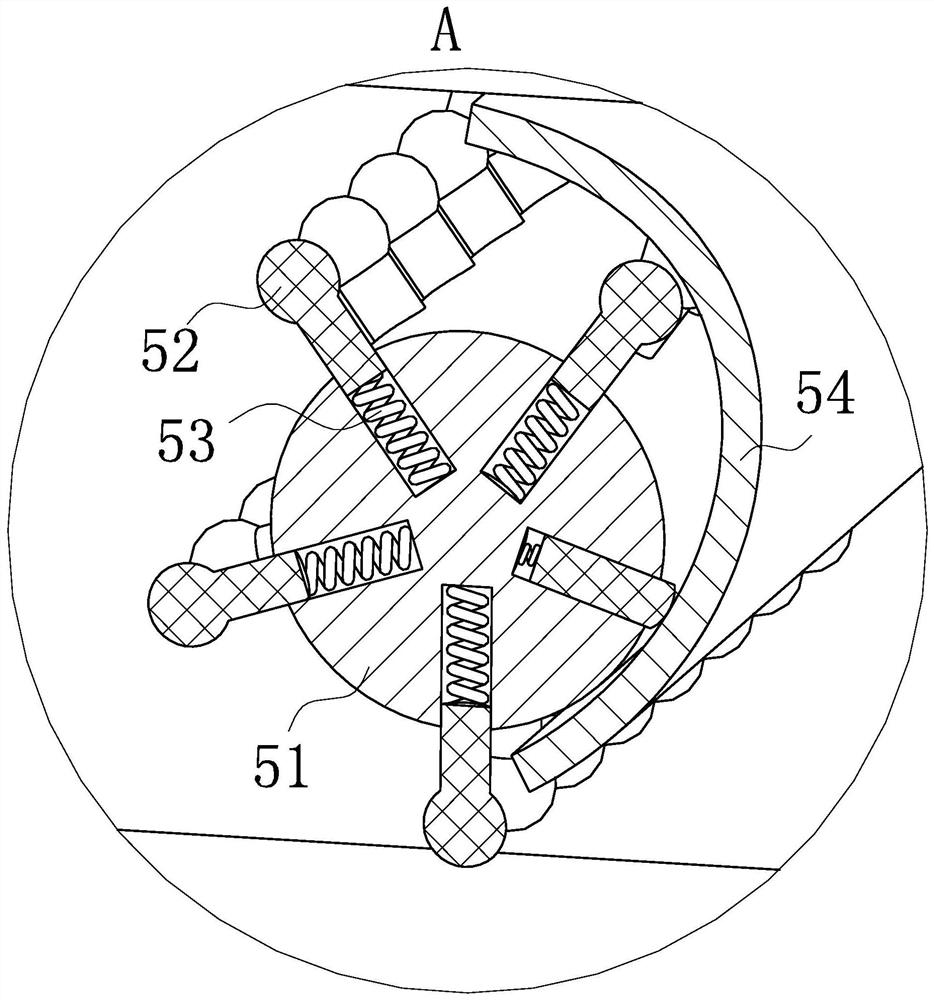

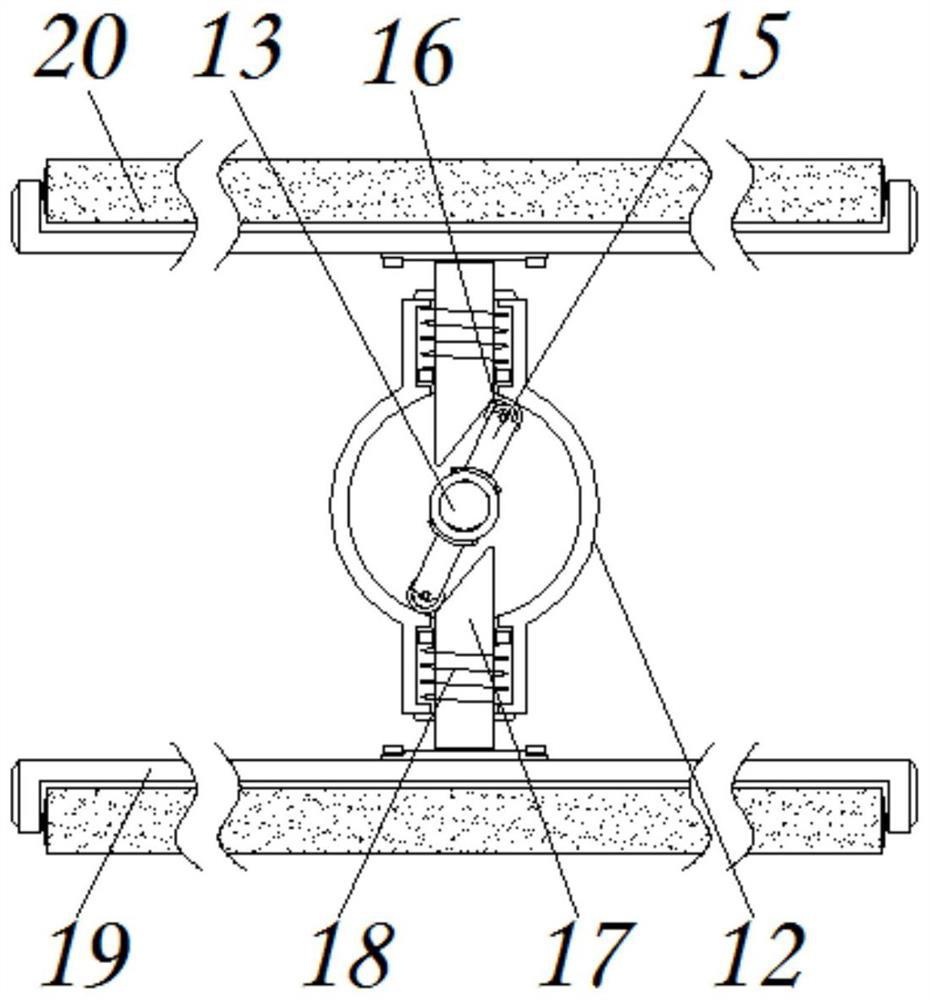

Carbon fiber yarn production process

InactiveCN112877947AAdjustable tensionVibrating screenLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersYarnFiber

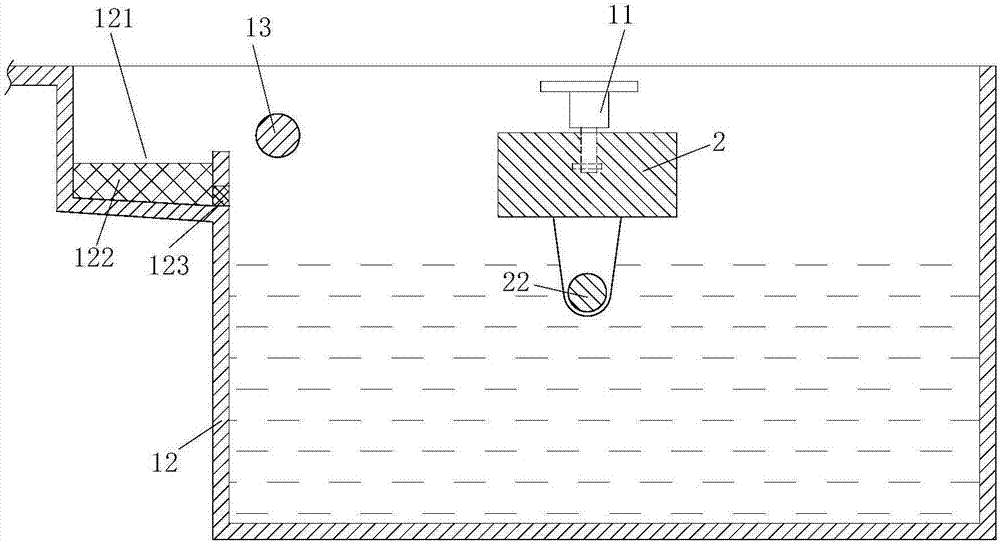

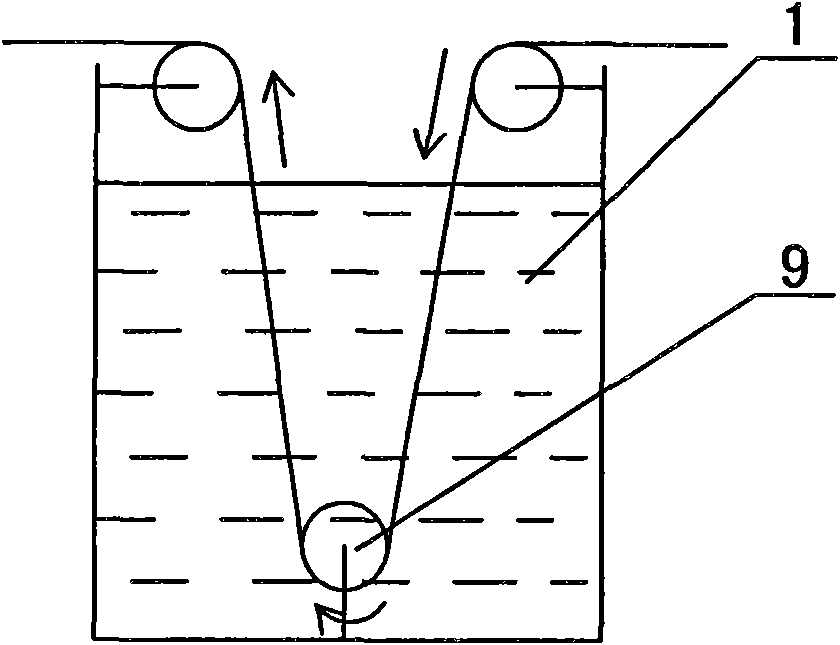

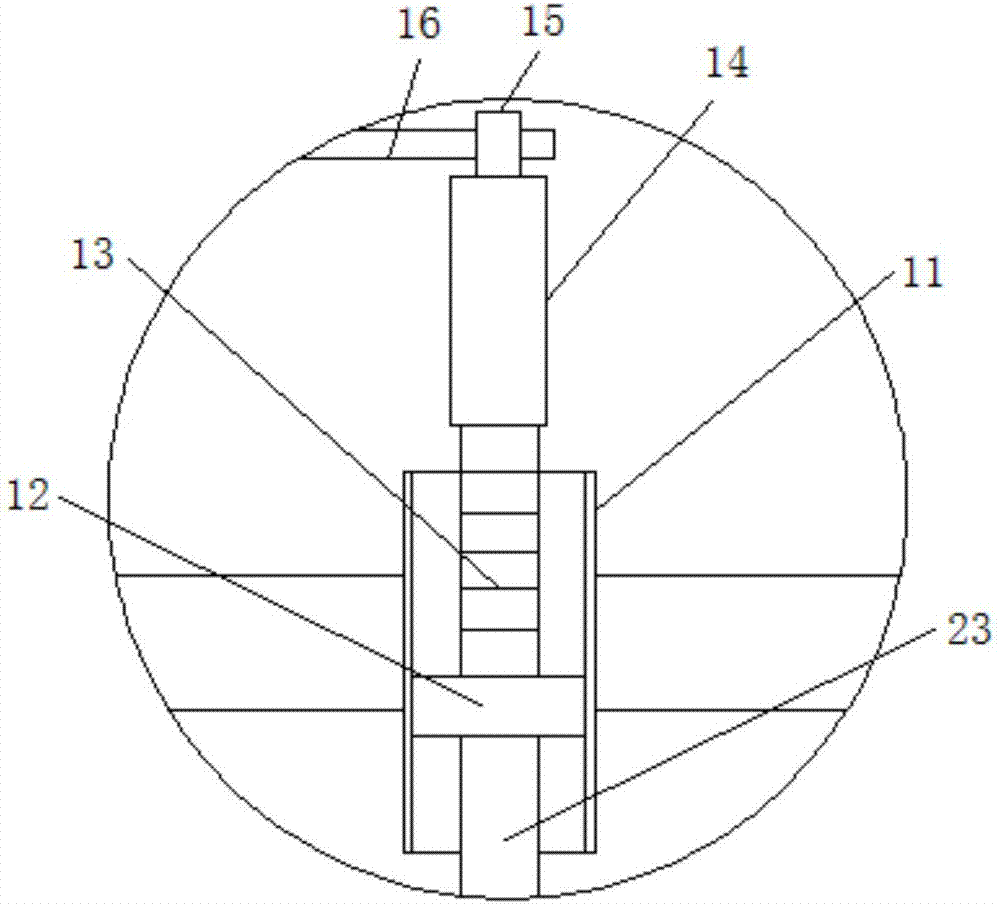

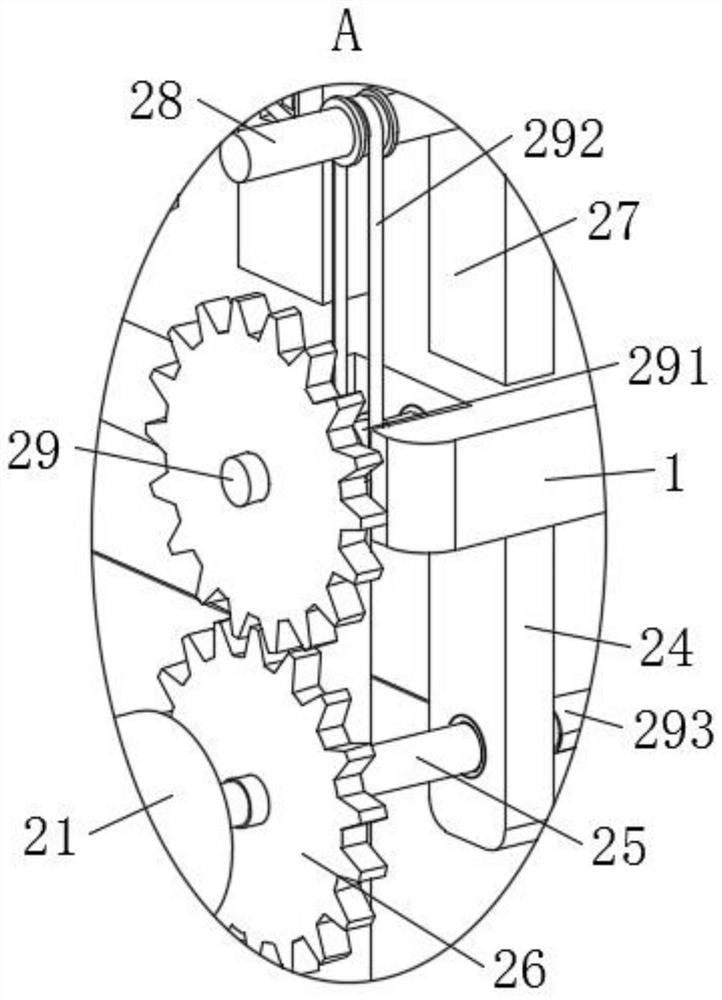

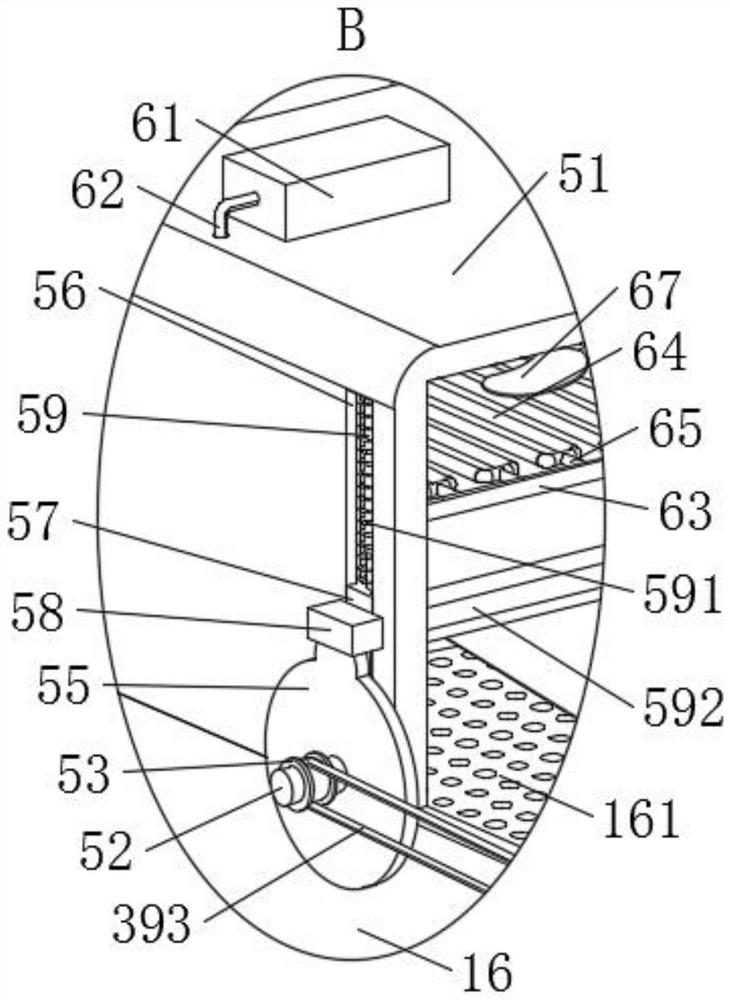

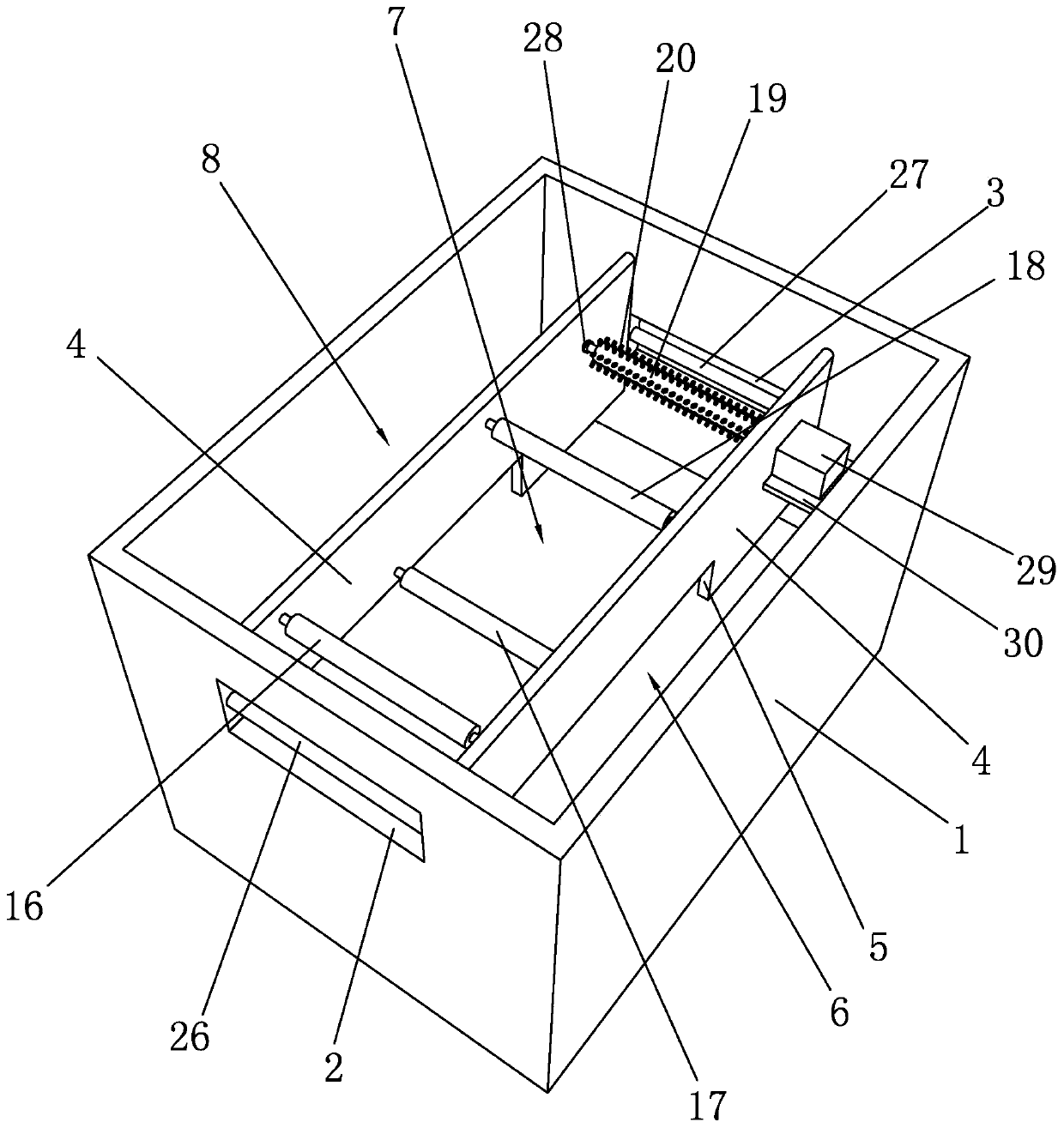

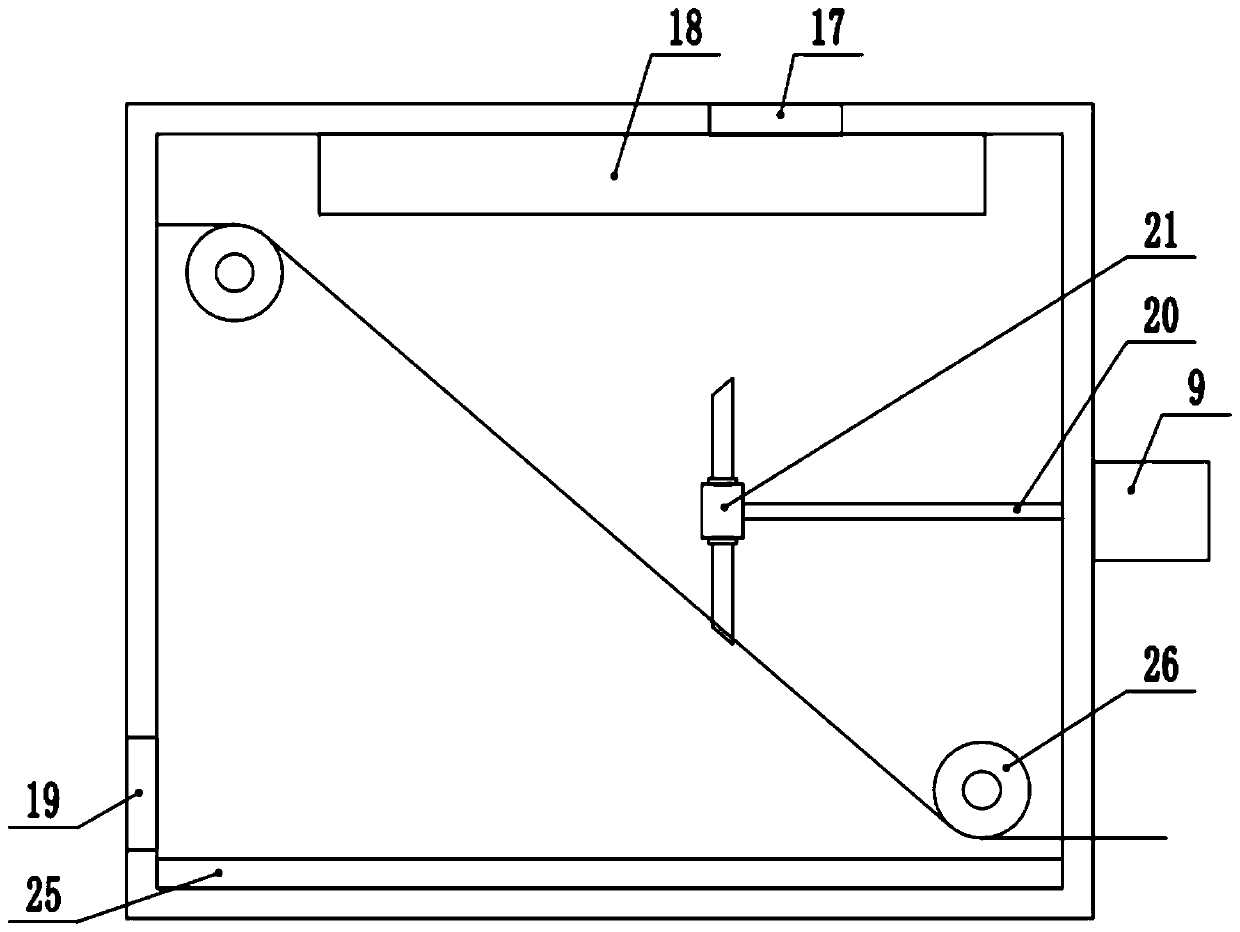

The invention relates to a carbon fiber yarn production process. The carbon fiber yarn production process uses carbon fiber yarn processing and manufacturing equipment, wherein the equipment comprises a water tank and a tensioning device arranged in the water tank, and a drying device is arranged on the outer side of the water tank. Through cooperation of a gear, an incomplete gear, a rotating plate, a flapping column and a telescopic spring, the incomplete gear can drive the gear to rotate intermittently, the gear drives the rotating plate to swing, the rotating plate can return to the original position under the action of the elastic force of the telescopic spring, and therefore water-washed carbon fibers are flapped; vibration is generated on the surfaces of the washed carbon fibers, so that moisture on the surfaces of the washed carbon fibers can be vibrated and sieved, and the surfaces of the washed carbon fibers can be conveniently dried in the later period; and through cooperation of a first transmission belt, cotton cloth and extrusion rollers, the first transmission belt can drive the cotton cloth to rotate together, and therefore secondary water removal can be carried out on the carbon fiber yarns obtained after vibration screening.

Owner:合肥曹秀化工科技有限公司

Grass cloth as Chinese painting and calligraphy carrier

ActiveCN104018270AGood ink wettingStrong water absorptionHeating/cooling textile fabricsWoven fabricsFiberEngineering

The invention discloses grass cloth which can be used as a Chinese painting and calligraphy carrier. The grass cloth is knitted and processed by ramee single yarns, the mass percentage of a gel content is 0.5%-0.6%, and the number of dents is 95-128. The grass cloth which is used as the Chinese painting and calligraphy carrier, disclosed by the invention, has the advantages of good ink moistening property, good water absorption, good ink remaining property, closer fibers, level, soft and smooth cloth covers, high tear strength, breakage resistance, no ink leakage, no stroke breakage, unique fiber defects and unique color and luster; painting and calligraphy works created on the painting and calligraphy grass cloth look quaint and elegant, and the grass cloth has stereoscopic impression and an anti-counterfeit function.

Owner:SICHUAN FUSI SURFACE TECH

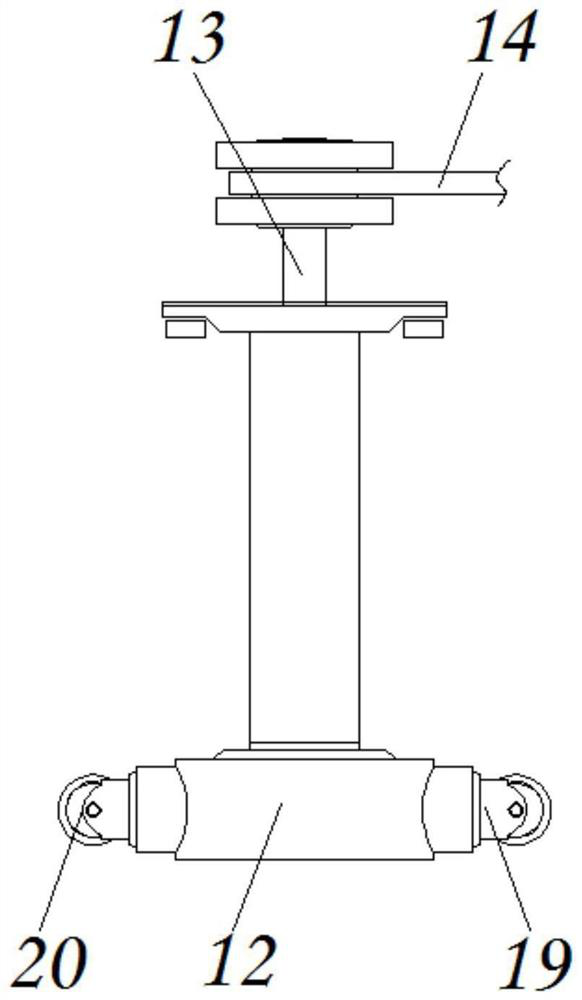

Dyeing machine for low-gram weight high-strength polyester fiber fabric

InactiveCN109183317ALow dyeabilityImprove uniformityTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationFiberPolyester

The invention provides a dyeing machine for the low-gram weight high-strength polyester fiber fabric and belongs to the technical field of weaving. The dyeing machine is characterized by comprising abase and a dyeing case, wherein the dyeing case is arranged on the base, the dyeing case has a fabric inlet and a fabric outlet, an upper end of the dyeing case is provided with a through port, the edge of the through port is provided with a supporting framework, the supporting framework is provided with a fabric swinging device, the fabric swinging device comprises a swinging plate and two parallelly-arranged connection plates, the two connection plates are fixedly connected with two sides of the swinging plate, a clamping assembly and a guide assembly are arranged between the two connectionplates, the swinging plate is provided with a connection block, two ends of the connection block respectively have a connection shaft, two ends of the supporting framework are respectively provided with a supporting seat, the connection shafts are rotatably mounted on the supporting seats through bearings, the supporting framework is further provided with a driving member used for driving the swinging plate to swing, and the fabric outlet is further provided with a liquid oscillator tube. The dyeing machine is advantaged in that through the fabric swinging device, the surface of the fabric cannot be precipitated, and the dyeing quality of the fabric is improved.

Owner:海宁市华成纺织有限公司

Device for conveniently cleaning chemical fiber fabrics

InactiveCN109023769AAvoid intertwiningSimple structureLiquid/gas/vapor removal by vibrationLiquid/gas/vapor textile treatmentFiberEngineering

The invention discloses a device for conveniently cleaning chemical fiber fabrics. The device comprises a box body, a cleaning box, fiber fabrics, a rotating drum, a rotating rod, a sealing ring, a sliding block, a hairbrush, a sliding rod, a threaded rod, a water conduit, a rubber block, a vibration motor, a connecting frame, a sponge block, a first motor, a cloth collecting wheel, an air exhausting hood, a water receiving funnel, an installation plate, an air guiding duct, a hot air blower, a second motor, a chain wheel, a chain and a shaft rod. In the device for conveniently cleaning chemical fiber fabrics, the hairbrush, the threaded rod, the rotating drum, a toothed wheel and a chain are arranged and cooperate with each other; the fiber fabrics can be well cleaned and can be preventedfrom being tangled with each other during cleaning processes; work efficiency can be greatly improved; vibration motors, the air exhausting hood, the sponge block and the air guiding duct are arranged and cooperate with each other, the fiber fabrics can be well dried after being cleaned, fiber fabric drying speed can be greatly increased, and drying efficiency and practicality can be improved.

Owner:扬州市源联纤维有限公司

Dyeing and finishing post-treatment process of flannel fabric

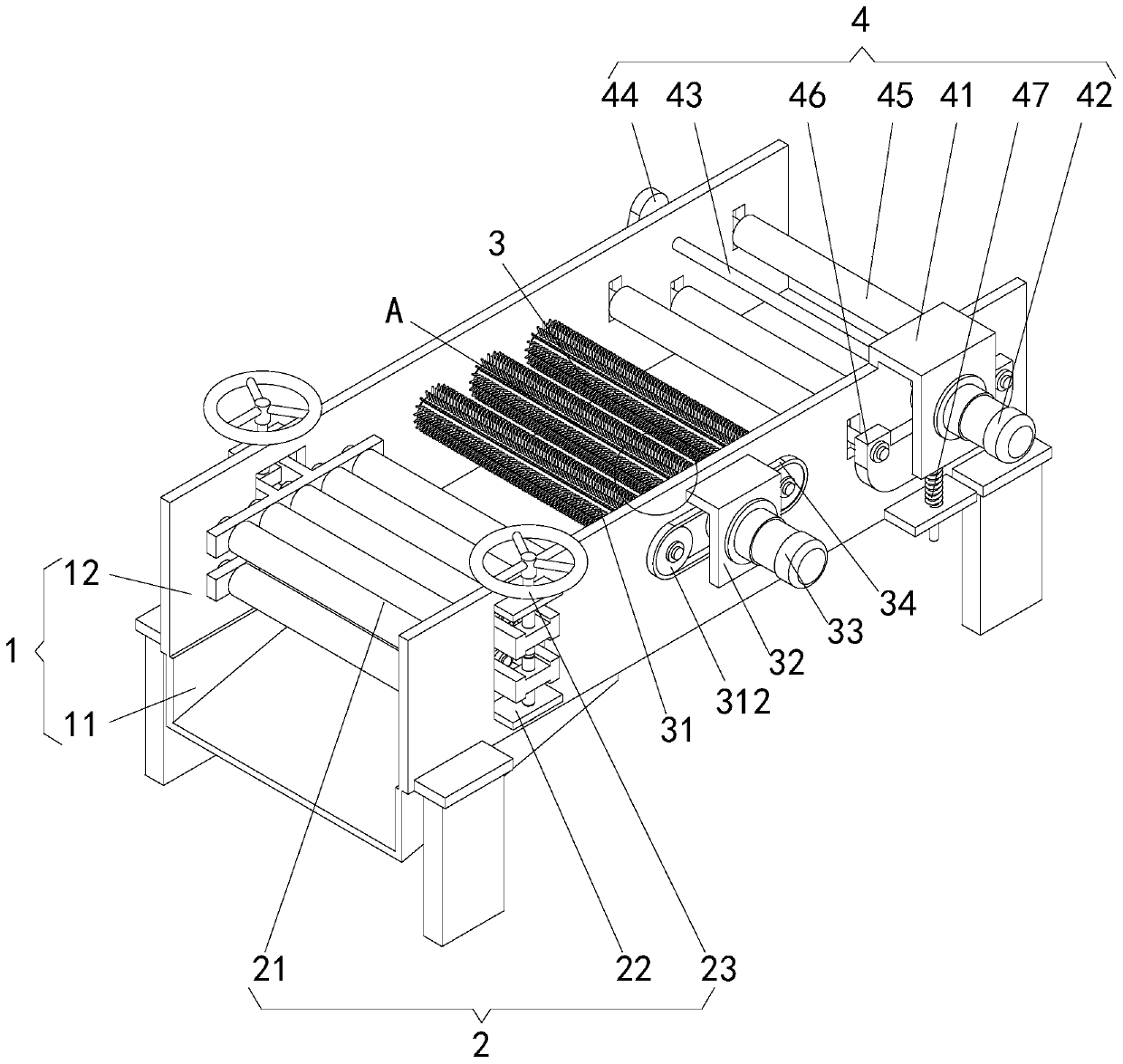

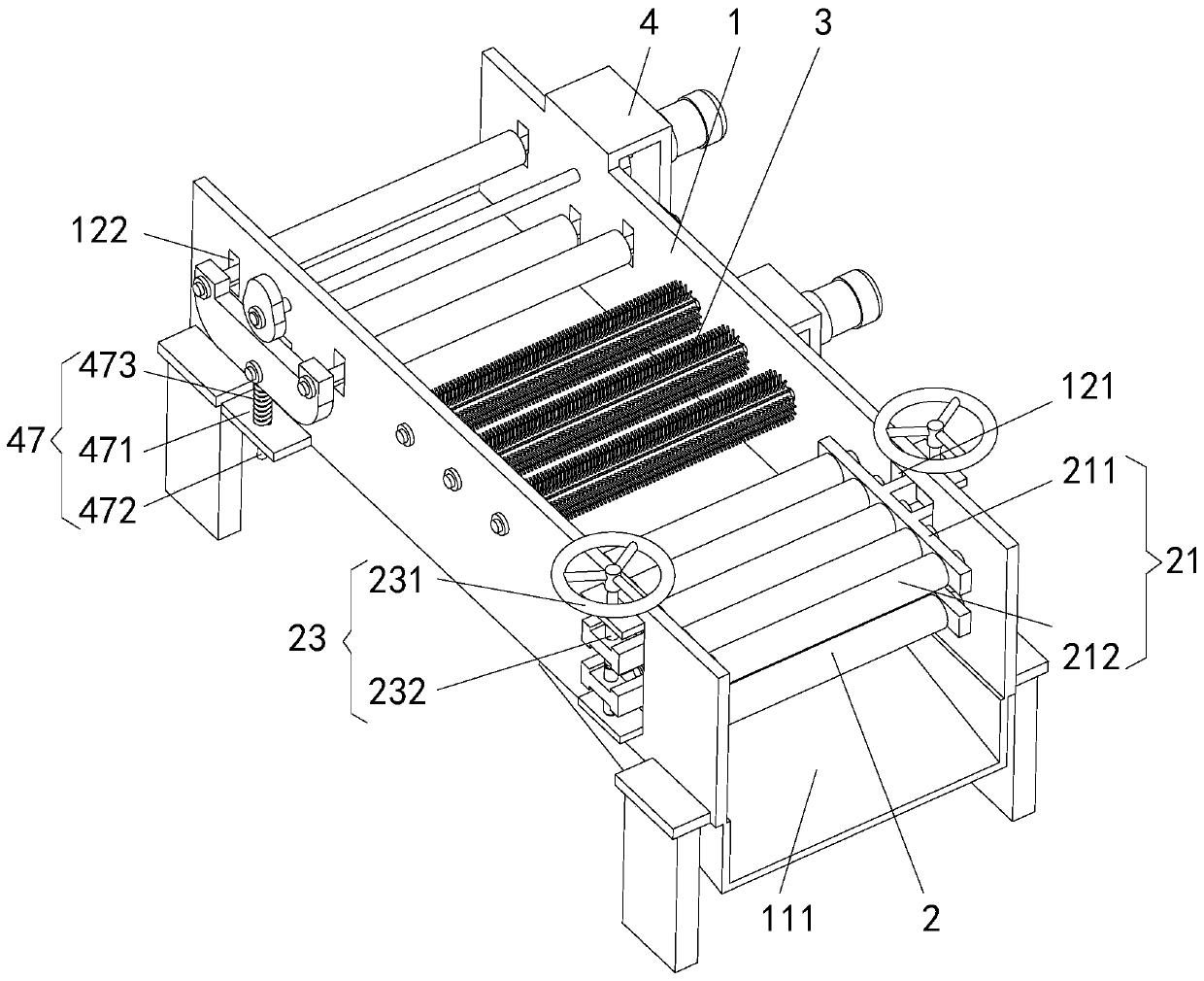

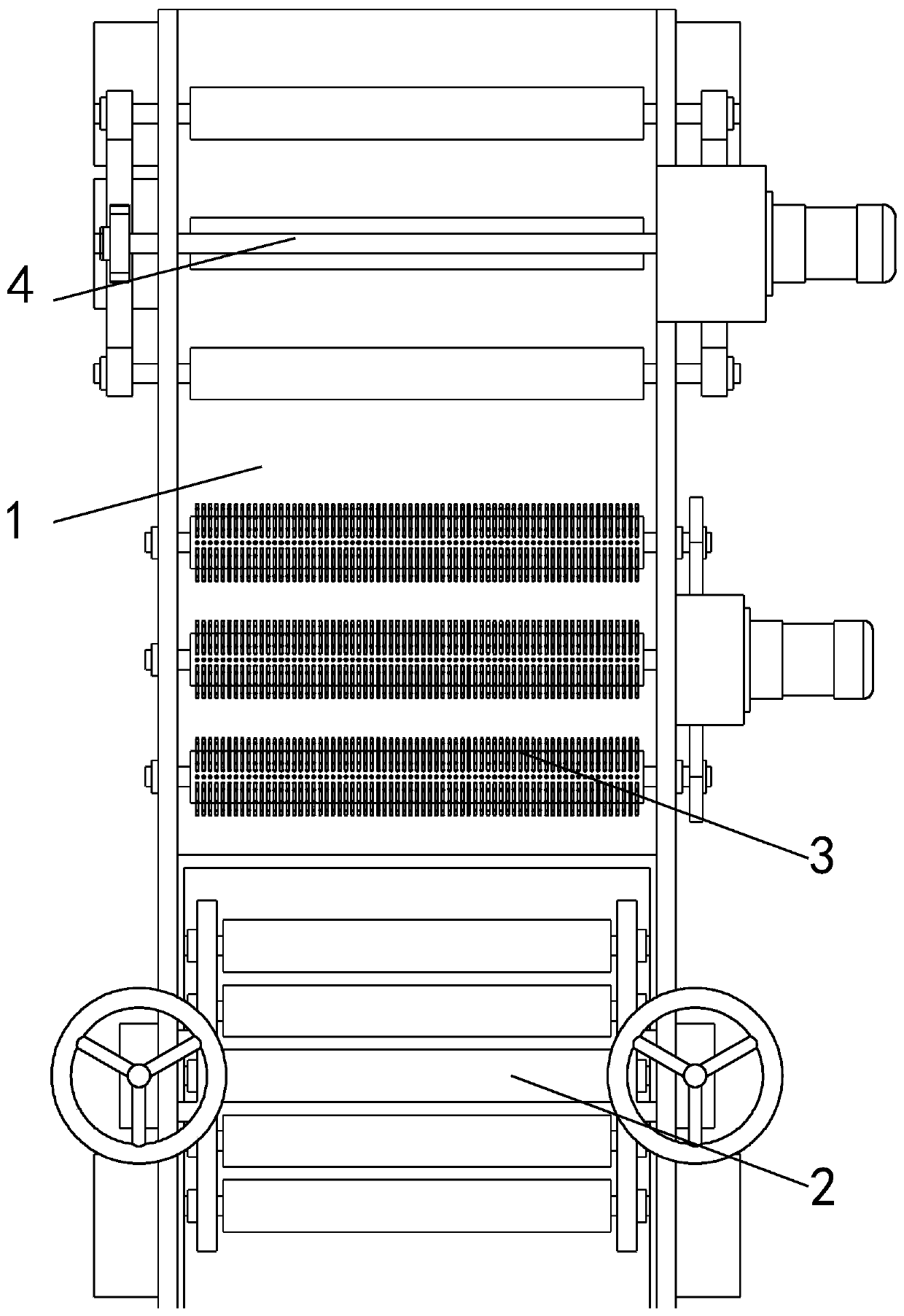

InactiveCN110952246AEffective crowding outSqueeze out fastLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by vibrationCardingProcess engineering

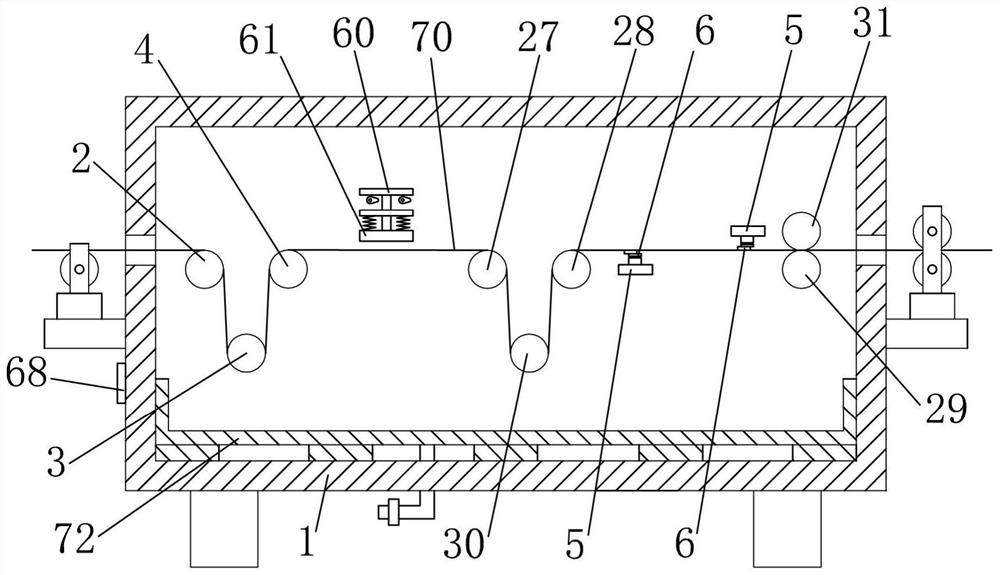

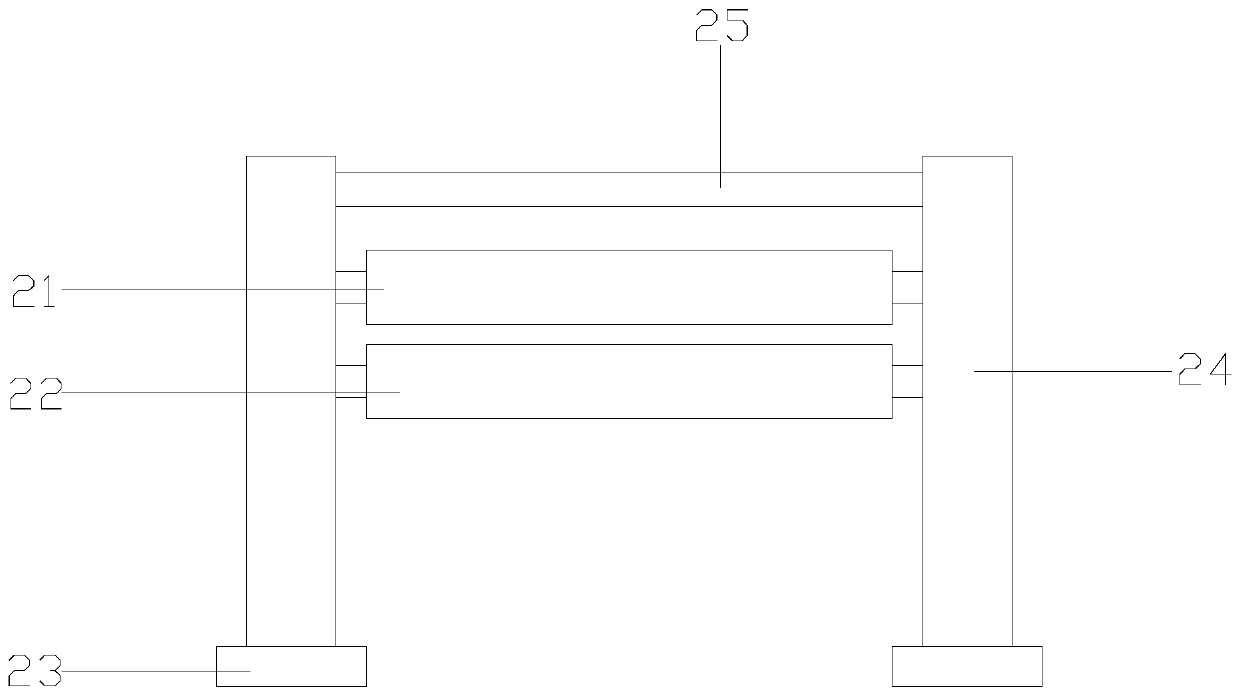

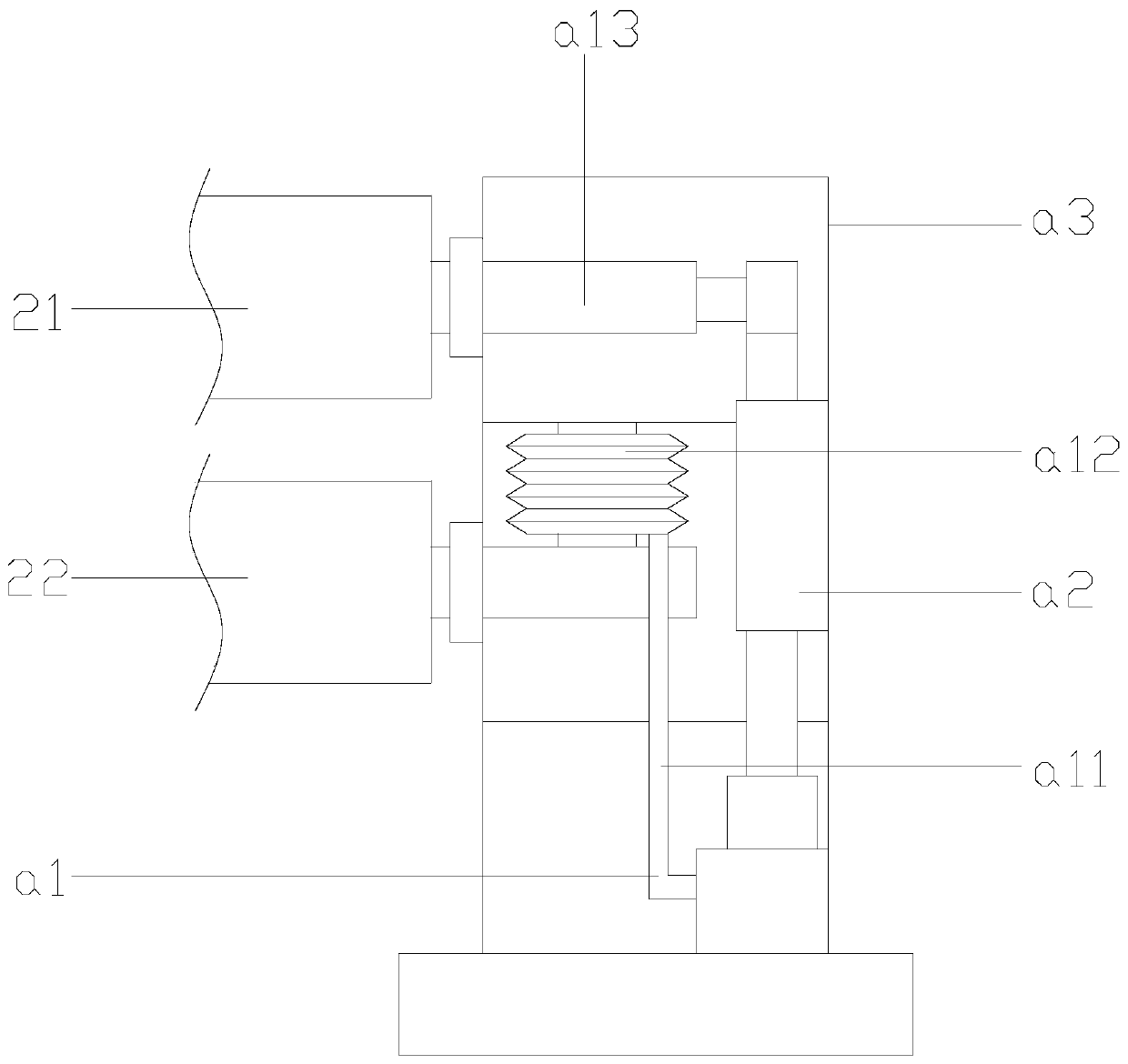

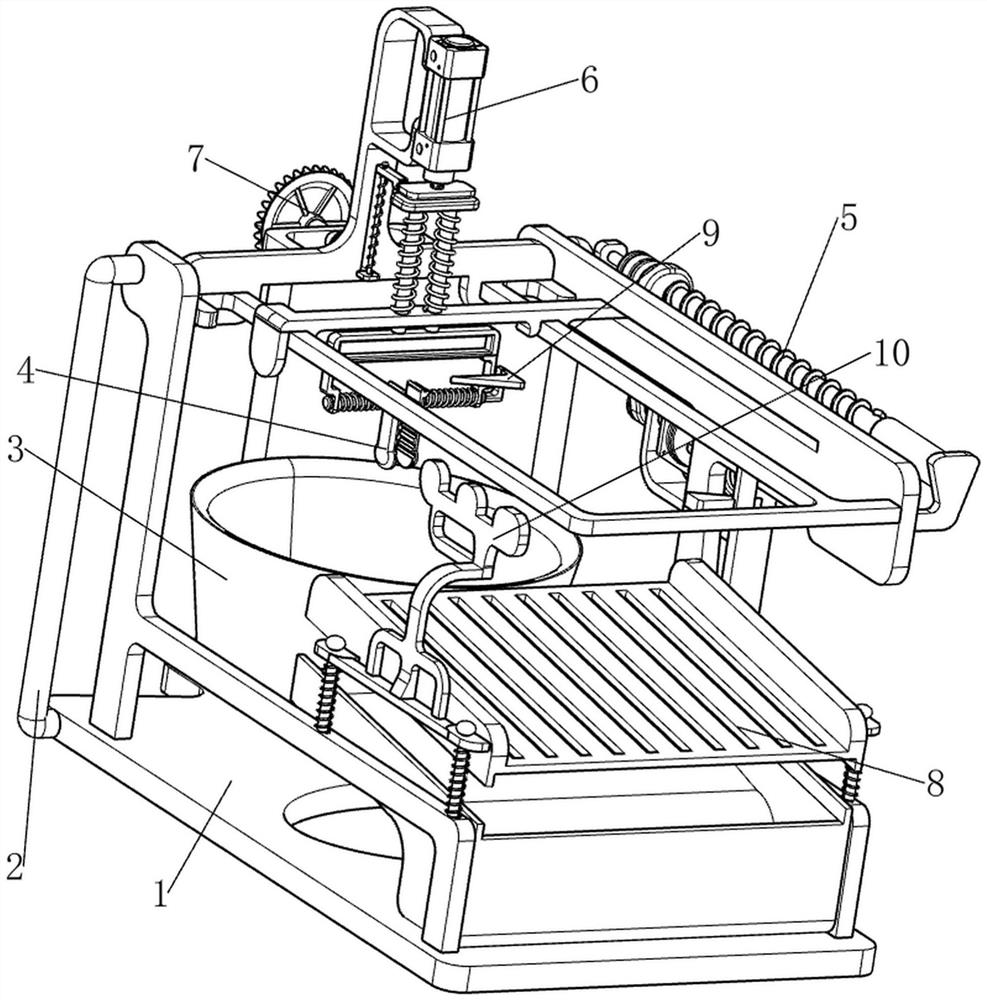

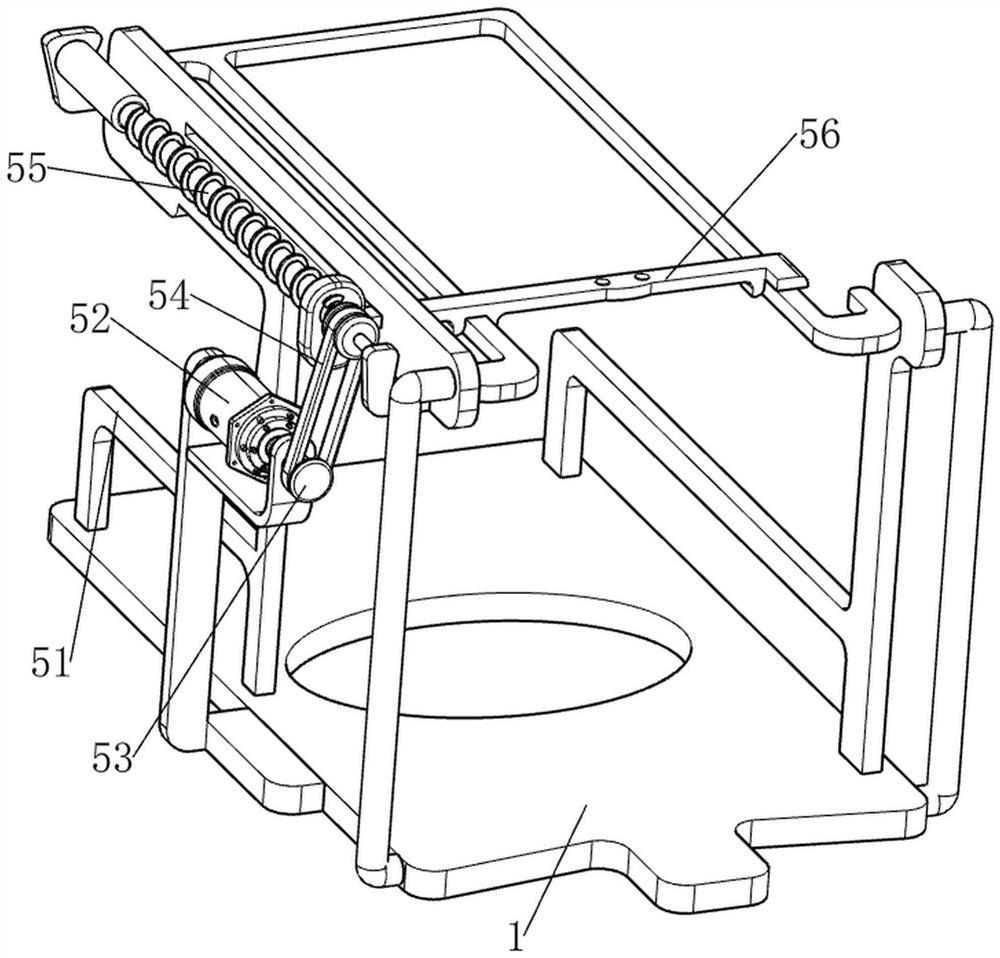

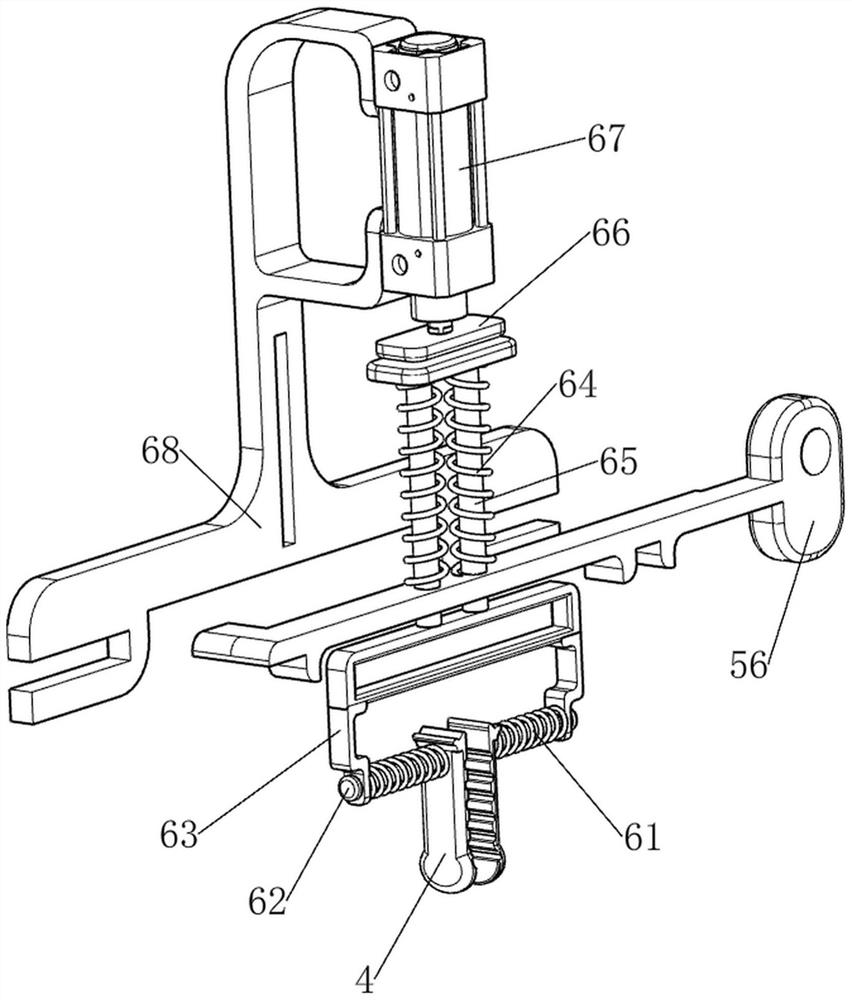

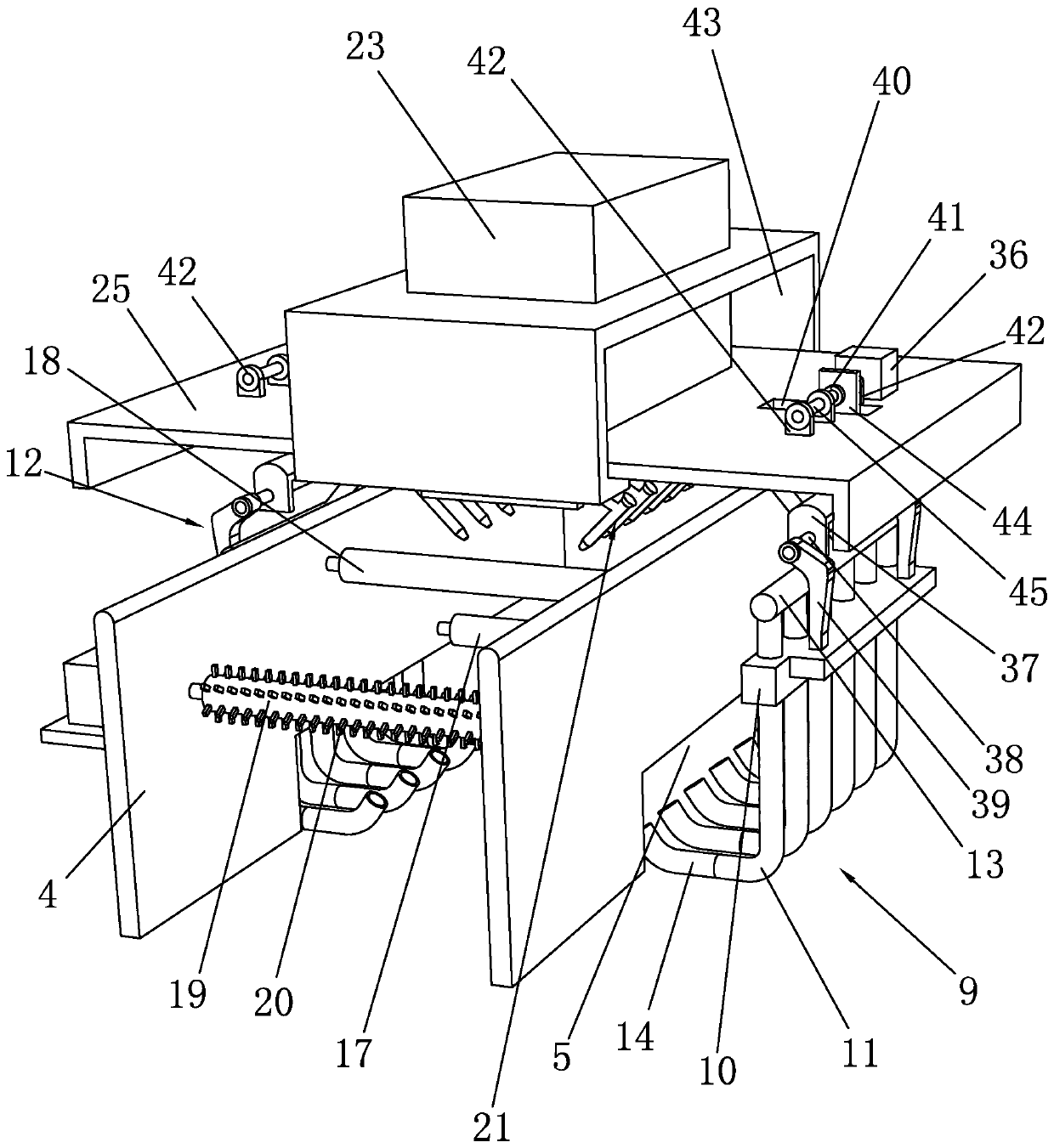

The invention relates to a dyeing and finishing post-treatment process of a flannel fabric, in particular to a dyeing and finishing post-treatment device of the flannel fabric. The dyeing and finishing post-treatment device comprises a flow operation table, an adjustable dye liquid squeezing-out mechanism, a fluff carding mechanism and a shaking mechanism, wherein the flow operation table comprises a base and two installation side plates; the two installation side plates are in parallel arrangement and are fixedly arranged on the upper end of the base; the adjustable dye liquid squeezing-out mechanism, the fluff carding mechanism and the shaking mechanism are sequentially distributed and arranged on the two installation side plates; in the process of treating the flannel fabric by using the dyeing and finishing post-treatment process, when the flannel fabric is subjected to drying treatment after being subjected to a series of treatment of dye liquid squeezing-out, fluff carding and vertical shaking through the dyeing and finishing post-treatment device, the drying speed can be greatly accelerated; the goal of fast drying is achieved; in addition, the dried and rolled flannel fabric can maintain a good state, so that the production efficiency of the whole production flow process is improved; and the effects of yield increase and efficiency improvement can be achieved.

Owner:卫平山

Textile fabric desizing device

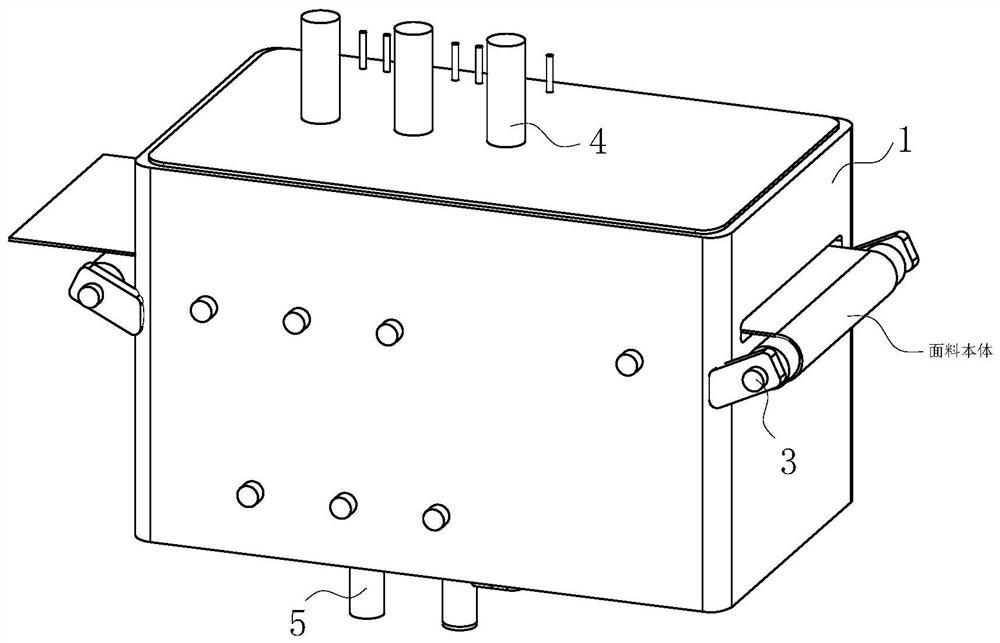

InactiveCN111962230AFast and efficient uniform desizing effectApply evenlyTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationEngineeringMechanical engineering

The invention belongs to the technical field of fabric desizing equipment, and particularly relates to a textile fabric desizing device. The textile fabric desizing device comprises a desizing pond. Asoaking trough is arranged in the desizing pond. Multiple guide rollers are rotationally arranged on the desizing pond, and the guide rollers are used for carrying out guiding and conveying on a fabric body. Multiple electric telescopic rods are fixed to a sealing plate movably arranged on the upper portion of the desizing pond, and a fixed guide strip is fixed to the telescopic end of each electric telescopic rod. The multiple fixed guide strips are located between the adjacent guide rollers, and rotating cavities are formed in the two sides of each fixed guide strip. Rotating brush rollersare rotationally arranged in the rotating cavities through cavity columns, and multiple liquid spray holes are evenly formed in the outer wall of each rotating brush roller. The end of each cavity column communicates with multiple liquid guide hose through multiple rotating sleeves. The side walls of the cavity columns communicate with the liquid spray holes through guide holes. The outer walls ofthe rotating brush rollers are in rotating contact with the outer wall of the fabric body. The rapid, efficient and even desizing effect of desizing liquid to the fabric body is improved.

Owner:宿州市悦然纺织有限公司

Dyeing and drying system for textile fabric

InactiveCN107354646AAvoid runningNo flow problemsTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsActivated carbonMechanical engineering

The invention discloses a dyeing and drying system for textile fabrics, which comprises a fixed seat, a first cloth guide roller connected between two first bearings, and a second cloth guide roller connected between two second bearings. The inner side of the first installation ring is plugged with a rotating rod, the lower side of the inner wall of the first sleeve is movably connected with a second sleeve, the fourth cloth guide roller is connected between the two fourth bearings, and the two fifth bearings A fifth cloth guide roller is connected between them, a heater is connected to the bottom of the inner cavity of the drying box, a cooling water tank is arranged outside the spiral tube, and an activated carbon layer is connected to the upper side of the top of the purification box. The invention has the advantages of conveniently collecting the dyes when dyeing the cloth and being able to treat the pungent smell produced by drying the dyed cloth, and solves the problem that the pungent smell produced by the dye flowing everywhere and without treatment will reduce the dyeing and drying of the cloth system usability issues.

Owner:梅明会

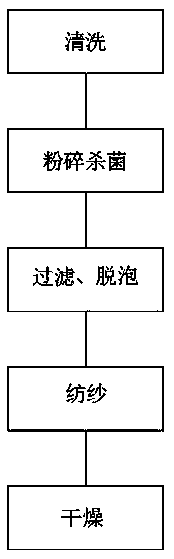

Preparation method and equipment of regenerated fiber

PendingCN110409084AGood flexibilityReflect the characteristics of environmental protectionPlastic recyclingTextile treatment machine arrangementsFiberOzone generator

The invention discloses a preparation method and equipment of regenerated fiber. The method comprises the following steps that 1, waste fiber and linters are collected; 2, cleaning is performed, wherein the waste fiber is placed in an ultrasonic cleaner for cleaning and decontamination; 3, a crushing and sterilization device is adopted, wherein the cleaned waste fiber and the linters are placed inthe crushing and sterilization device for crushing, sterilization and acidification, and an acidification agent is adopted during acidification. The waste fiber is adopted as a main material of the regenerated fiber, a small quantity of linters are added to improve the softness of the regenerated fiber, and the characteristic of environmental protection is embodied well. By arranging a stirring paddle, an ozone generator and an exhaust fan, the cleaning efficiency of the waste fiber is effectively improved, the waste fiber is sterilized through the ozone generator, the regenerated fiber is dried effectively through the arrangement of a conveying roll and a microwave generator, the regenerated fiber is effectively dried, the drying time is saved, the drying efficiency is improved, and themethod and equipment are suitable for application and wide popularization.

Owner:丹阳市三江纤维材料有限公司

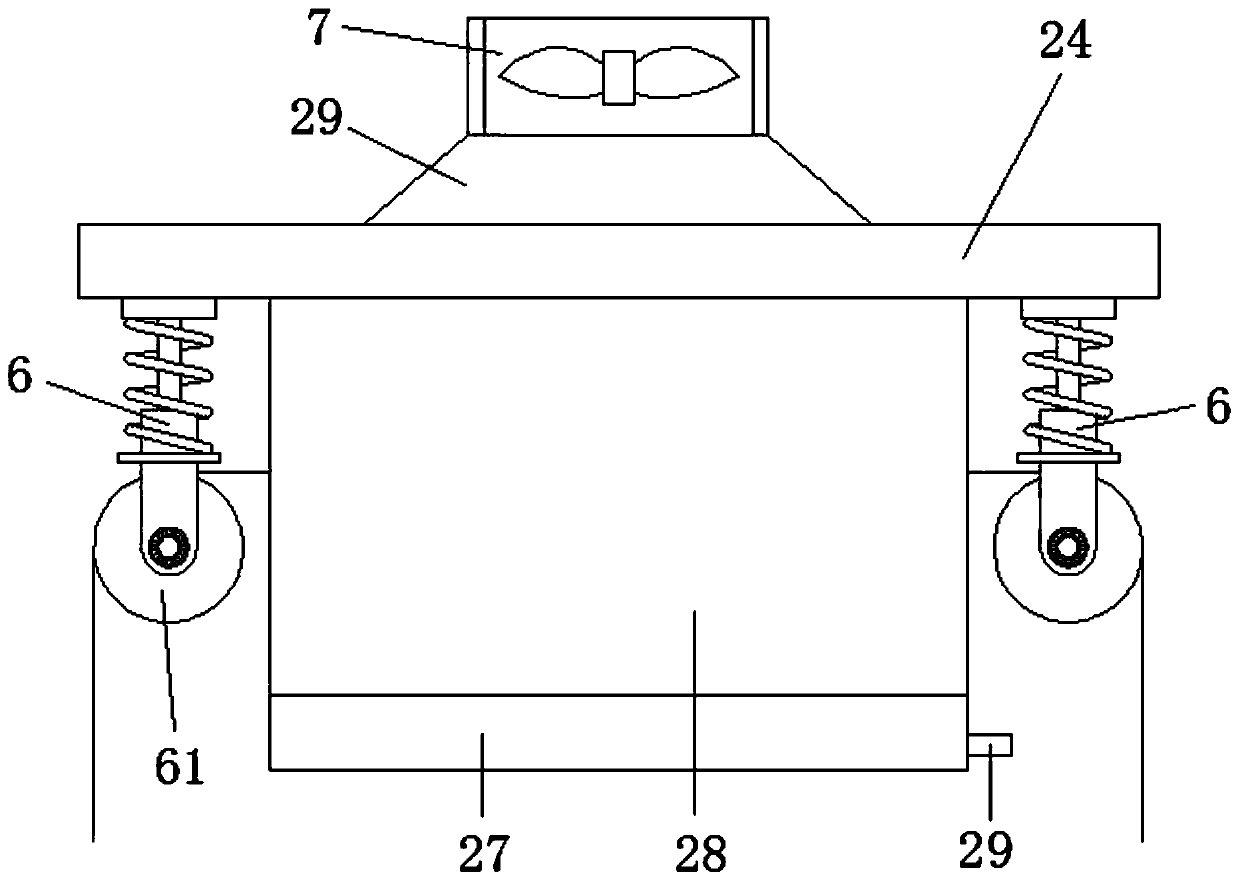

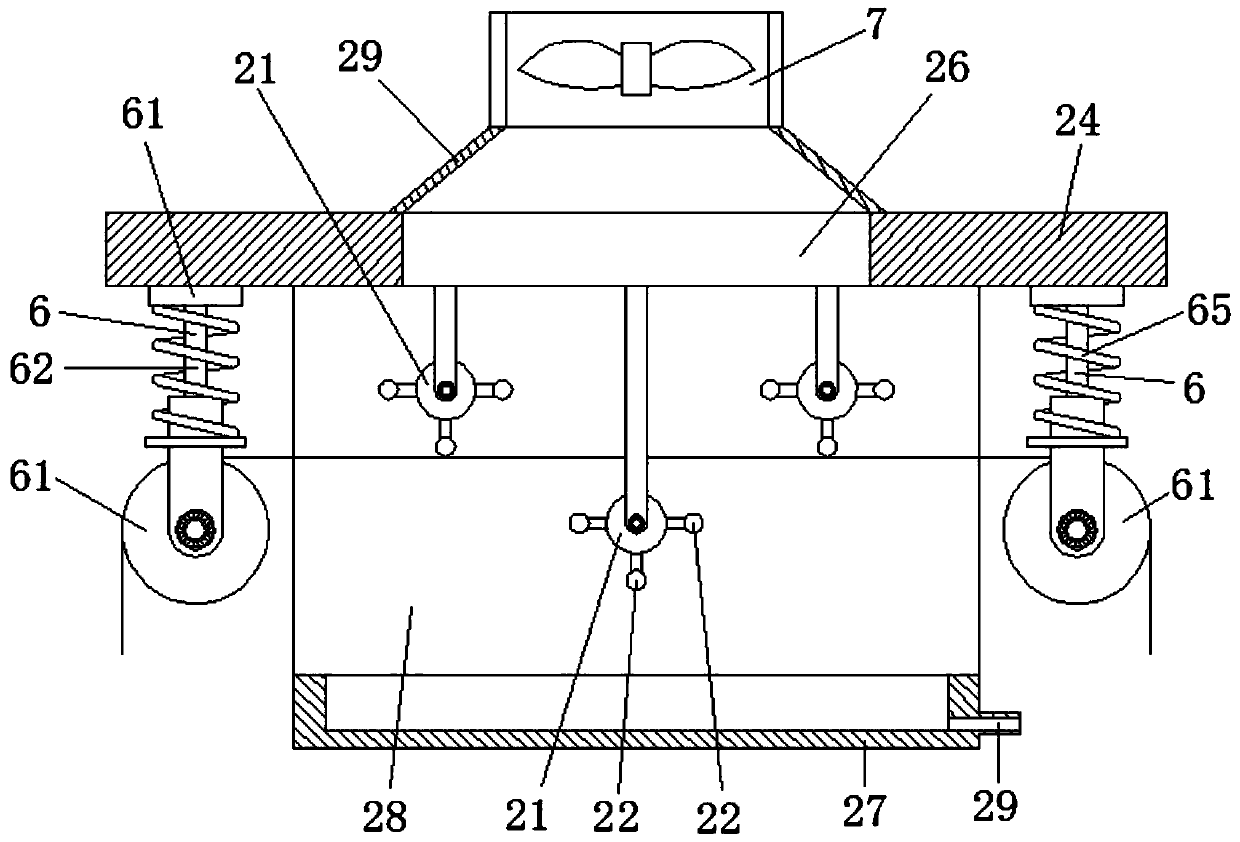

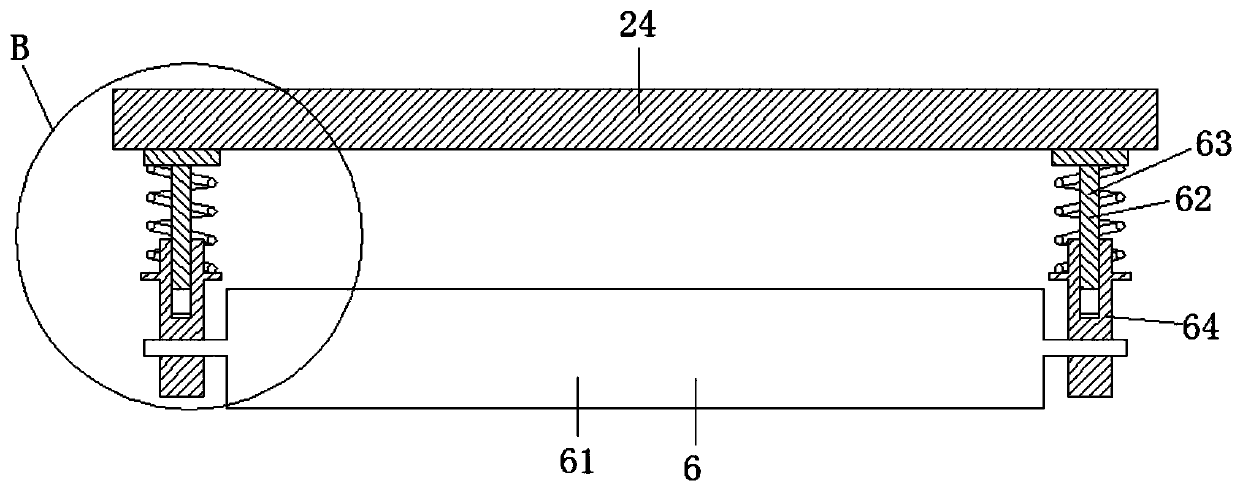

Flat dehydration device

InactiveCN111519374ALess prone to wrinklesAvoid deformationLiquid/gas/vapor removal by gas jetsLiquid/gas/vapor removal by vibrationStructural engineeringMechanical engineering

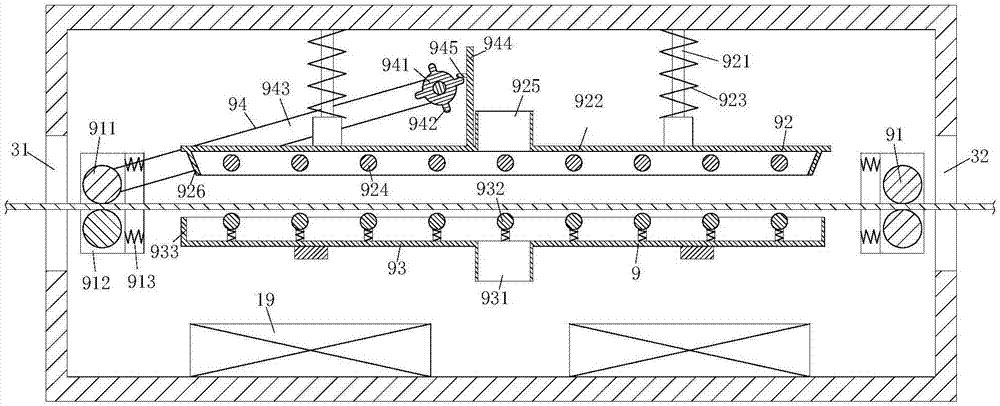

The invention discloses a flat dehydration device. The flat dehydration device comprises a roof plate, a fan arranged on the roof plate and slapping rollers arranged under the roof plate. The slappingrollers are arranged at up-down intervals along a fabric passing path, when fabric passes, the slapping rollers rotate to enable slapping strips to slap and dehydrate the upper side and the lower side of the passing fabric, the fabric is not prone to wrinkles, at the same time, top-down airflow produced by the fan can accelerate the collection of water droplets into a water collecting pan, and the air flow can further play a certain drying role; and elastic conveyor frames enable guide rollers to buffer and move up and down according to the stress size when the fabric is slapped and stressedto prevent the fabric from being slapped and deformed.

Owner:浙江嘉业印染有限公司

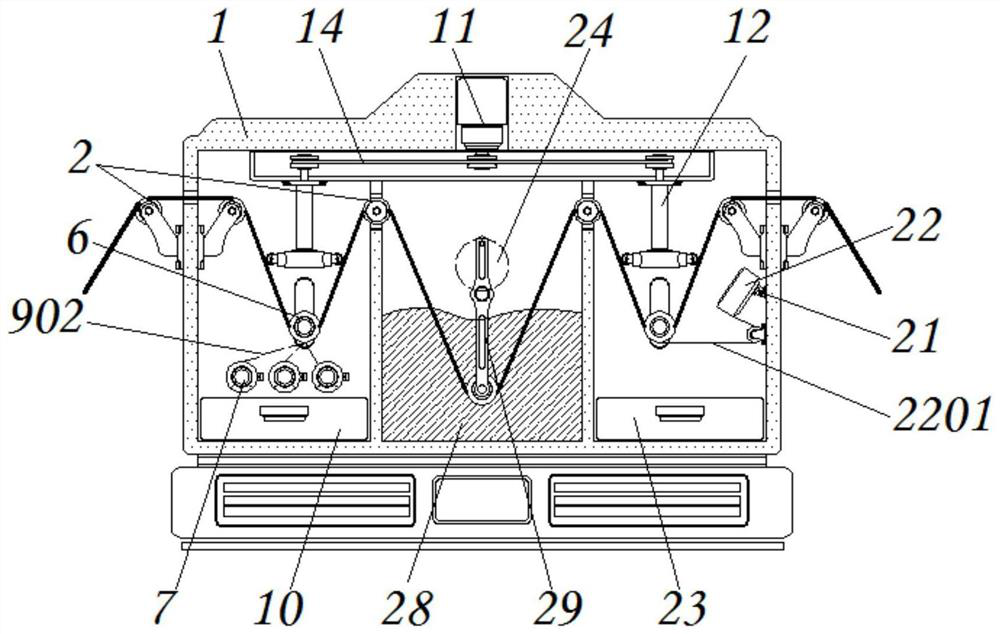

Textile printing and dyeing dewatering device adopting gravity self-deviation correcting

InactiveCN109881414AAvoid chromatic aberrationThoroughly dehydratedLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by vibrationTextile printerDrive motor

The invention discloses a textile printing and dyeing dewatering device adopting gravity self-deviation correcting. The device comprises a printing and dyeing machine main body, an extrusion dewatering structure, a waste liquid collecting tank, a traction wheel, a driving device fixing seat, a gearbox and a driving motor, the textile printing and dyeing dewatering device is provided with a self-deviation correcting frame, and when pressure rollers are offset, the self-deviation correcting frame automatically conducts adjusting to keep the two pressure rollers parallel so as to avoid uneven dewatering of textile cloth caused by the circumstance that there is no parallel extrusion of the pressure rollers, thereby causing the circumstance that the partial textile fabric has excessive residualprinting and dyeing liquid, which causes chromatic aberration; the upper dewatering pressure rollers can exert a hammering effect on the surface of the textile fabric when used, so that the textile fabric is more thoroughly dewatered and the processing quality of the textile fabric is improved.

Owner:南安市博铭工业设计有限公司

Environment-friendly washing machine for wool cashmere products

InactiveCN106637758AEnergy efficientSolve cleaningTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationPulp and paper industryWool

The invention relates to the technical field of woolen sweater processing equipment and discloses an environment-friendly washing machine for wool cashmere products. The washing machine comprises a base, wherein a cleaning device is arranged in the middle of an inner chamber of the base; a water tank is arranged at the top of the cleaning device; water sprayers are fixedly connected with the two sides of the bottom of the water tank; the bottoms of the water sprayers are penetrated through the top of the cleaning device and extend into the inner chamber of the cleaning device; backflow pipes are fixedly connected with the two sides of the water tank; one end of each backflow pipe is penetrated through the base and extends into the inner chamber of the base; a rotating motor is fixedly connected with the top of the water tank; a rotating shaft is fixedly connected with the bottom of the rotating motor; the bottom of the rotating shaft is fixedly connected with the top of a support frame; a support net plate is sleeved on the middle part of the outer surface of the rotating shaft; pothooks are fixedly connected with the two sides of the bottom of the support net plate. According to the environment-friendly washing machine for wool cashmere products, the rotating shaft is driven to rotate by the rotating motor, so that the support net plate and the pothooks are driven to rotate and the effect of cleaning the woolen sweater is effectively increased.

Owner:浙江于雁服饰有限公司

Soft antibacterial non-woven fabric and preparing method thereof

InactiveCN111705423AIncrease softnessHigh speedFabric breaking/softeningTextile treatment machine arrangementsPolymer scienceCotton fibre

The invention belongs to the technical field of non-woven fabric preparing, and particularly relates to soft antibacterial non-woven fabric and a preparing method thereof. The soft antibacterial non-woven fabric is formed through mixing of cotton fibers and polypropylene staple fibers, the proportion of the cotton fibers in the soft antibacterial non-woven fabric is 75 to 80wt%, and the balance isthe polypropylene staple fibers; the polypropylene staple fibers are fine denier fibers, and contain a silver-loaded chitosan antibacterial agent, the adding amount of the silver-loaded chitosan antibacterial agent in the polypropylene staple fibers is 5 to 10wt%, the prepared non-woven fabric has the good antibacterial property, meanwhile, through soft arranging in the physical manner, softnessis good, treatment without a softening agent is achieved, and no softening agent remains.

Owner:张小艳

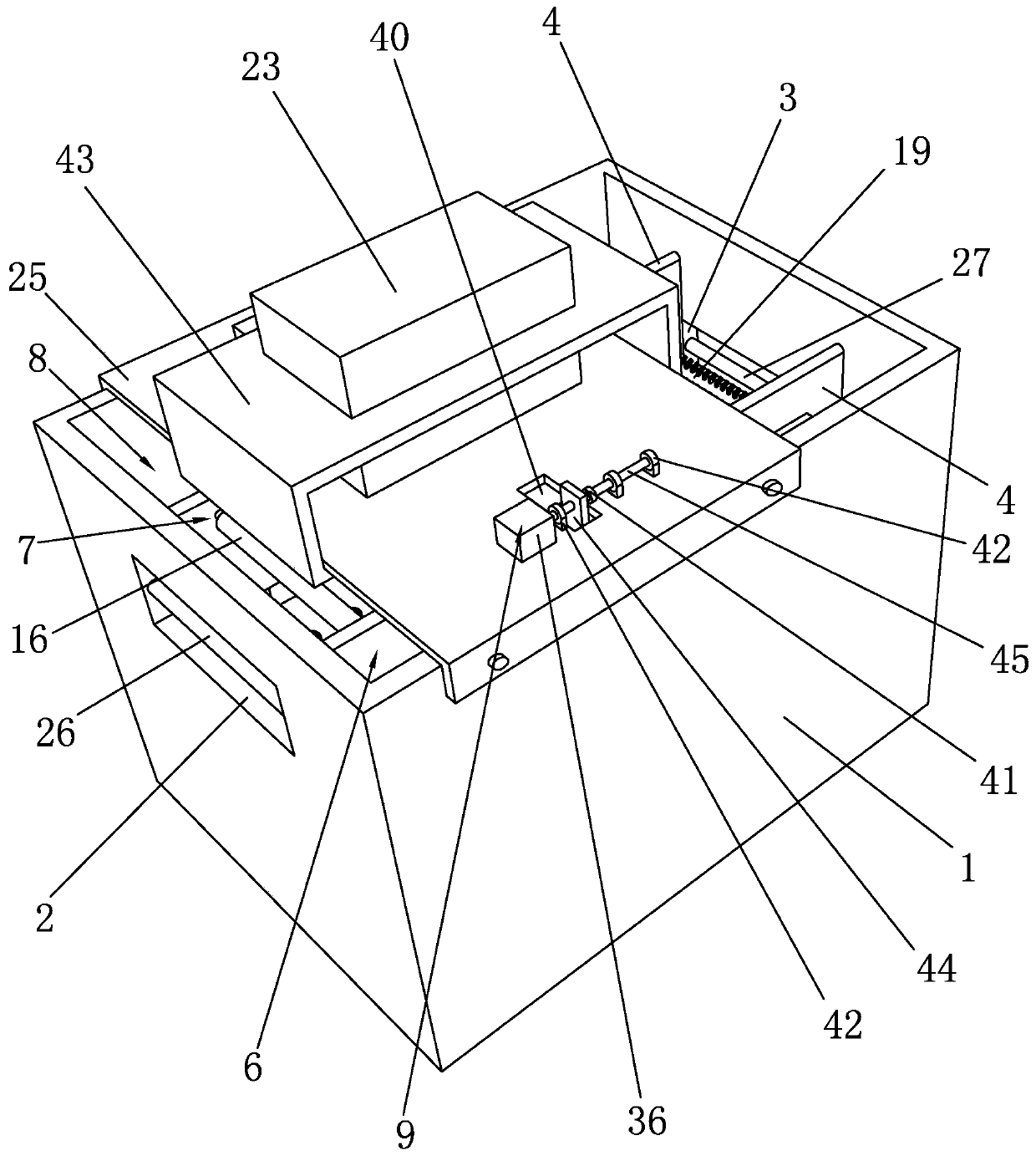

All-cotton anti-pilling super-soft sanded fabric preparation method and device

PendingCN113417084AImprove convenienceEasy to completeMechanical cleaningPressure cleaningFiberGear drive

The invention discloses an all-cotton anti-pilling super-soft sanded fabric preparation method and device. The all-cotton anti-pilling super-soft sanded fabric preparation device comprises a preparation table, a first traction device, a second traction device and a third traction device are fixedly installed on the upper surface of the preparation table correspondingly, and a fourth traction device is fixedly installed on the lower surface of the preparation table. Compared with an existing technology, a second motor is started, a driving shaft of the second motor drives a third rotating rod to rotate and drives a second transmission wheel to rotate, the third rotating rod drives the other set of second gears to synchronously and reversely rotate through one set of second gears, the other set of second gears drive a second rotating rod to rotate, the third rotating rod and the second rotating rod synchronously and reversely rotate, the third rotating rod and the second rotating rod drive a hair collecting roller to rotate, the hair collecting roller adsorbs hair fibers and other impurities on the upper and lower surfaces of a fabric body, so that the hair fibers and other impurities on the surface of the fabric body are conveniently cleaned, and the subsequent dyeing effect of the fabric body is effectively improved.

Owner:南通欧惠纺织科技有限公司

Residual coating cleaner

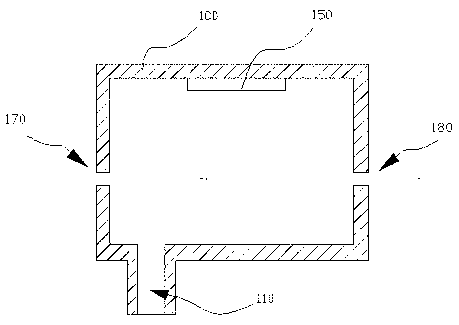

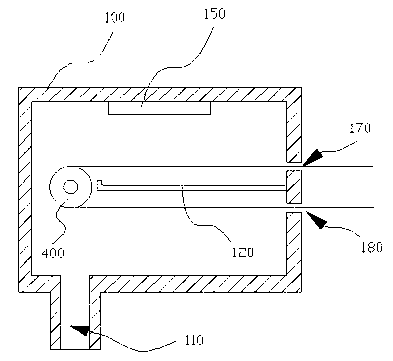

The invention discloses a residual coating cleaner. The residual coating cleaner comprises a coating cleaning chamber, wherein the coating cleaning chamber comprises a cloth inlet and a cloth outlet; at least one loudspeaker is arranged in the coating cleaning chamber; a waterproof coating covers a vibrating diaphragm of the loudspeaker; the loudspeaker is electrically connected with a power amplifier circuit; a guide path is formed in the coating cleaning chamber; and the guide path reaches to a coating pond. The residual coating cleaner can be used for cleaning the residual coating on the cloth by enabling the cloth to not contact any appliance, so that the cloth has a high yield.

Owner:SUZHOU DANFANG TEXTILE R & D

Improved nanofiber oil absorption material dyeing device and processing method thereof

ActiveCN112962247AEfficient dryingEasy to recycleMechanical cleaningPressure cleaningFiberPolymer science

The invention discloses an improved nanofiber oil absorption material dyeing device and a processing method thereof. The improved nanofiber oil absorption material dyeing device comprises a rack, a movable guide roller, an electrostatic adsorption block, a push roller and a printing and dyeing roller, wherein a fixed guide roller is fixedly installed in the rack through bolts; the inner side of the right end of the rack is in shaft connection with a fan through a shaft rod; a liquid collecting box is arranged below the fan; a rotating disc is connected to the inner side of the rack through a shaft; a shifting column is fixed to the surface of the rotating disc; a dyeing pool is arranged on the inner side of the rack; and the printing and dyeing roller is connected to the inner side of the lower end of a second roller frame through a shaft. According to the improved nanofiber oil absorption material dyeing device and the processing method thereof, in the using process, an improved nanofiber oil absorption material can be conveniently and effectively shaken before and after dyeing, so that impurities and dust are effectively removed, and redundant dye is recycled; and meanwhile, the material can be swung and the dye can be stirred in the dyeing process, so that the dyeing effect of the device is effectively improved.

Owner:MINJIANG UNIV

Dyeing device for jeans production

ActiveCN113026267AImprove dyeing efficiencyLiquid/gas/vapor article treatmentTextile treatment machine arrangementsMechanical engineeringIndustrial engineering

The invention relates to a dyeing device, in particular to a dyeing device for jeans production. According to the dyeing device for jeans production, jeans can be rapidly dyed, and meanwhile, the jeans can be dyed while being rotated, so that the jeans dyeing efficiency is effectively improved; and dye on the dyed jeans can be separated in a shaking mode, so that the labor intensity of workers can be relieved. The dyeing device for jeans production comprises a bottom frame, first supporting rods arranged on the two sides of the bottom frame, a rotating frame rotationally arranged on the bottom frame, a feeding mechanism connected between the two first supporting rods and the bottom frame, a pressing mechanism arranged on the feeding mechanism in a sliding manner, and clamping blocks arranged on the two sides of the lower portion of the pressing mechanism. According to the invention, the feeding mechanism is arranged and matched with the pressing mechanism, so that undyed jeans and dyed jeans can be conveyed in sequence.

Owner:赣州辉之源制衣有限公司

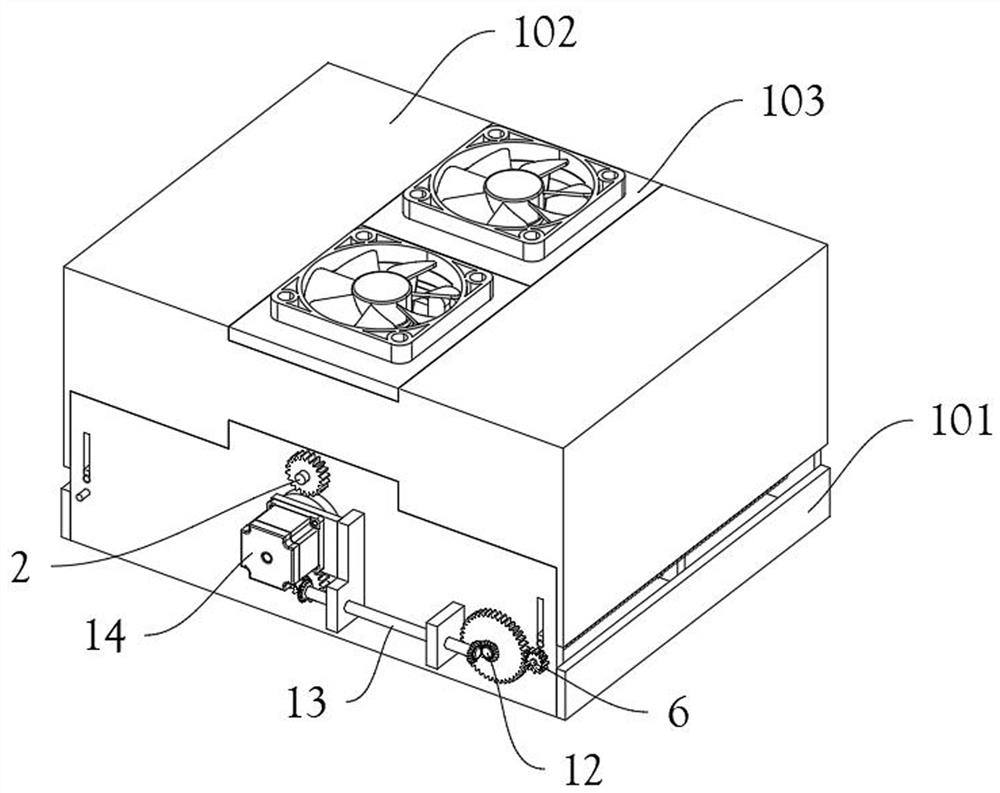

Fabric humidifier for spinning machinery

ActiveCN109706660AReduce mechanical noiseEasy to installTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationEngineeringLower face

The invention discloses a fabric humidifier for spinning machinery. The fabric humidifier comprises a box, two space plates are symmetrically and horizontally arranged in the box, and the interior ofthe box is divided into a front cavity, a middle cavity and a rear cavity through the two space plates; bottom spray rod assemblies are arranged in the front cavity and the rear cavity, the middle cavity corresponds to a fabric inlet groove and a fabric outlet groove, and a first fabric guide roller, a tension roller, a second fabric guide roller and a vibration roller are arranged in the middle cavity from left to right in sequence; a top spray rod assembly is arranged over the tension roller. According to the fabric humidifier for spinning machinery, through the top spray rod assembly and the bottom spray rod assemblies, the upper and lower faces of the fabric are humidified at the same time, compared with humidification only on one face of the fabric in the prior art, the whole fabric is more evenly humidified, more convenience is provided for following ironing operation on the fabric, based on the actual conveying angle and speed of the fabric, the angle is adjusted through the bottom spray rod assemblies, the humidification condition of the bottom face of the fabric is guaranteed, and the processing quality of the fabric in the later period is improved.

Owner:朱泽鹏

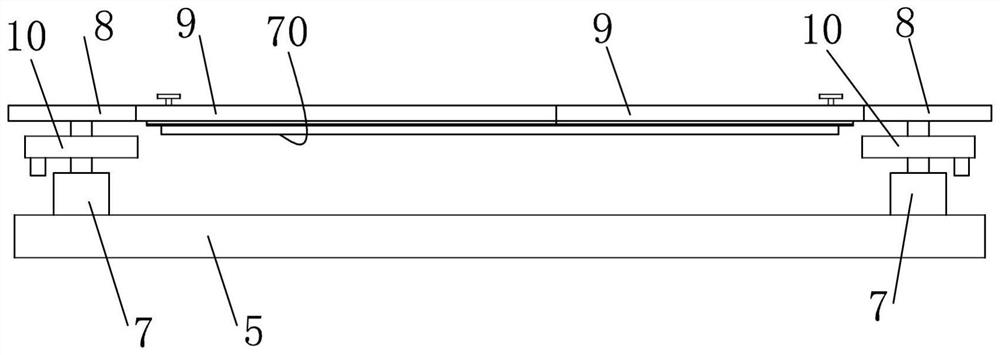

Textile fabric conveying device based on intermittent tensioning and vibration drainage drying structure

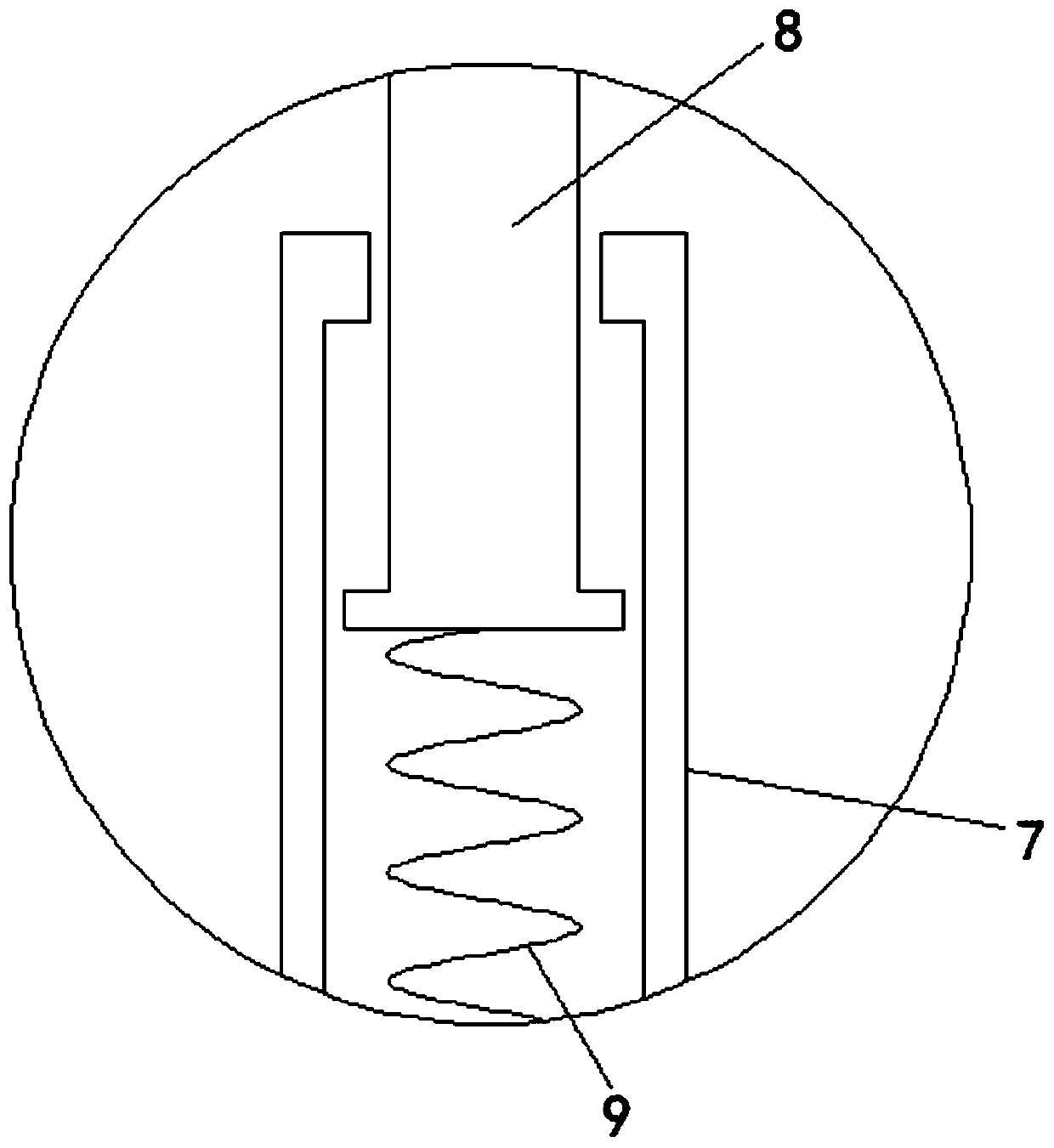

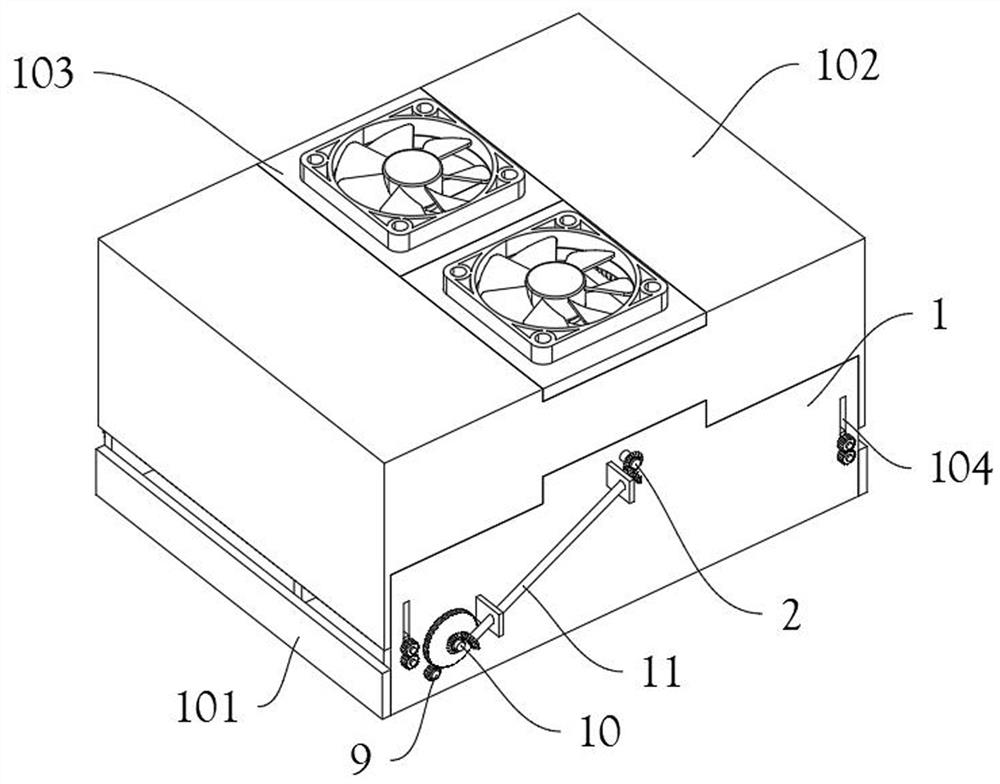

ActiveCN113249908AImprove dehydration effectPrevent deviationLiquid/gas/vapor removal by vibrationTextile treatment carriersStructural engineeringMechanical engineering

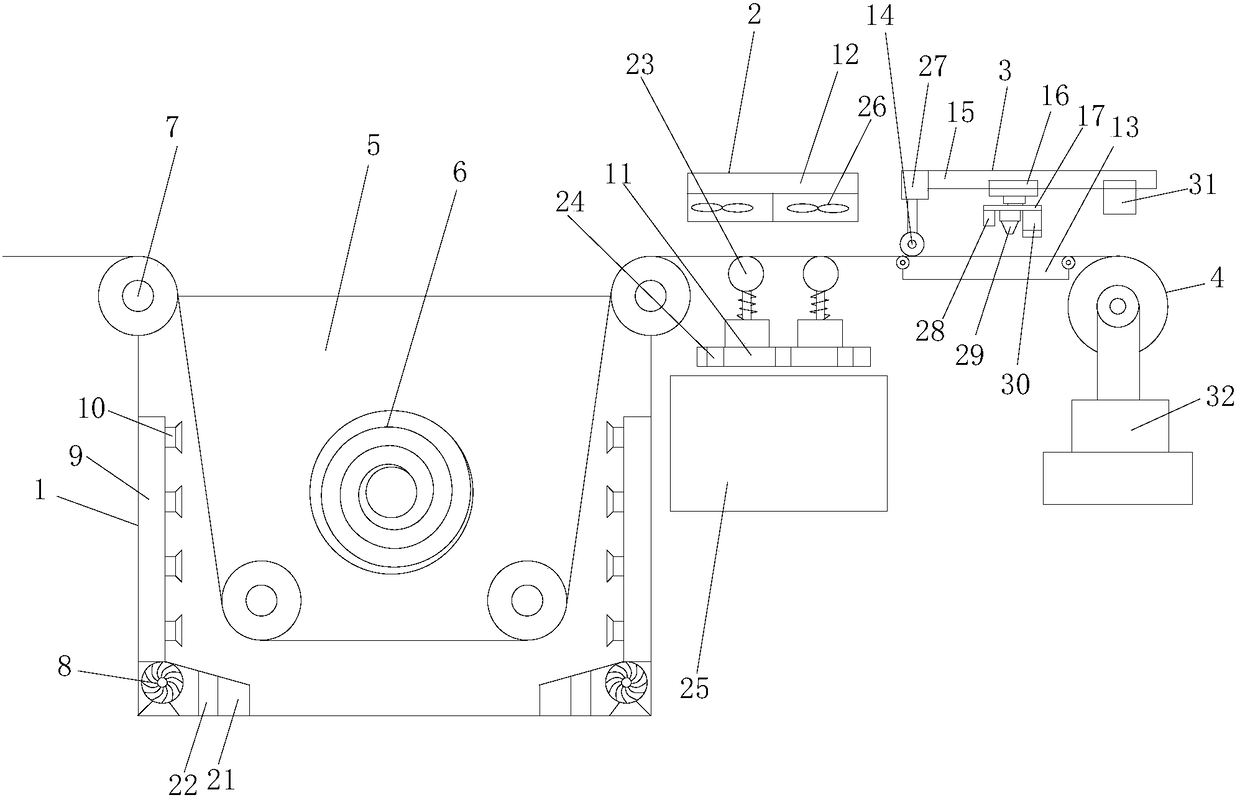

The invention discloses a textile fabric conveying device based on an intermittent tensioning and vibration drainage drying structure, and relates to the technical field of textile processing. The problem that a currently used conveying device is not provided with an automatic intermittent tensioning mechanism and a corresponding tensioning and dewatering assembly and cannot rapidly dewater fabric is solved. The textile fabric conveying device based on the intermittent tensioning and vibration drainage drying structure comprises two sets of main shell plates, two sets of lower assembly plates which are fixedly connected are arranged on the front sides and the rear sides of the bottoms of the two sets of main shell plates, and the adjacent positions of the bottoms of the lower set plates are arranged to be of a slope structure; an upper housing is fixedly arranged at the top of each main shell plate, and two sets of dryers are arranged at the top of each upper housing; and strip-shaped holes are formed in the two sides of the lower assembly plates. A dryer, a crankshaft, a strip-shaped frame and a fixing plate are arranged, an automatic intermittent tensioning mechanism and a corresponding tensioning and dewatering assembly are provided for the conveying device, and the automatic rapid dewatering function can be achieved.

Owner:江苏盈彩纺织科技有限公司

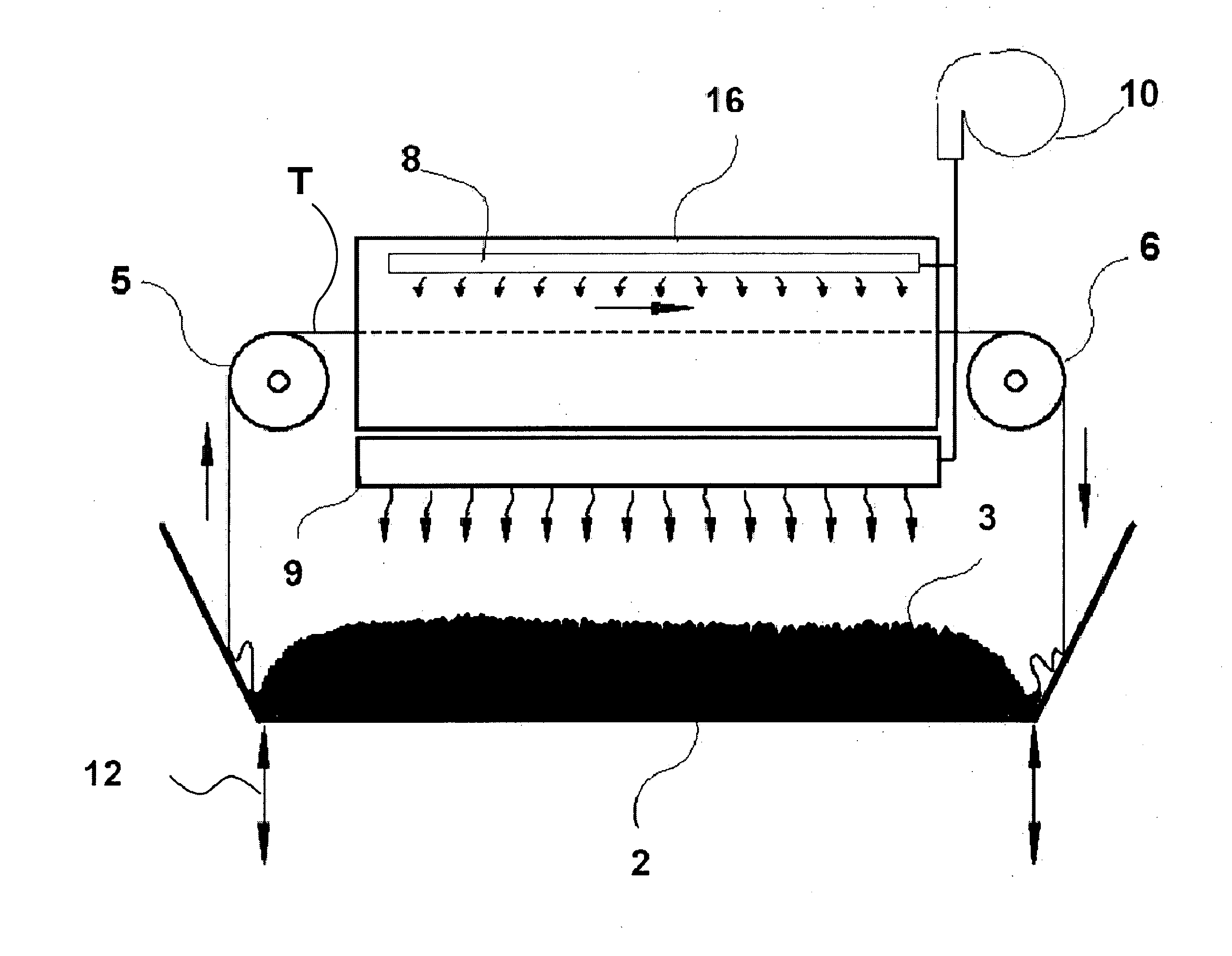

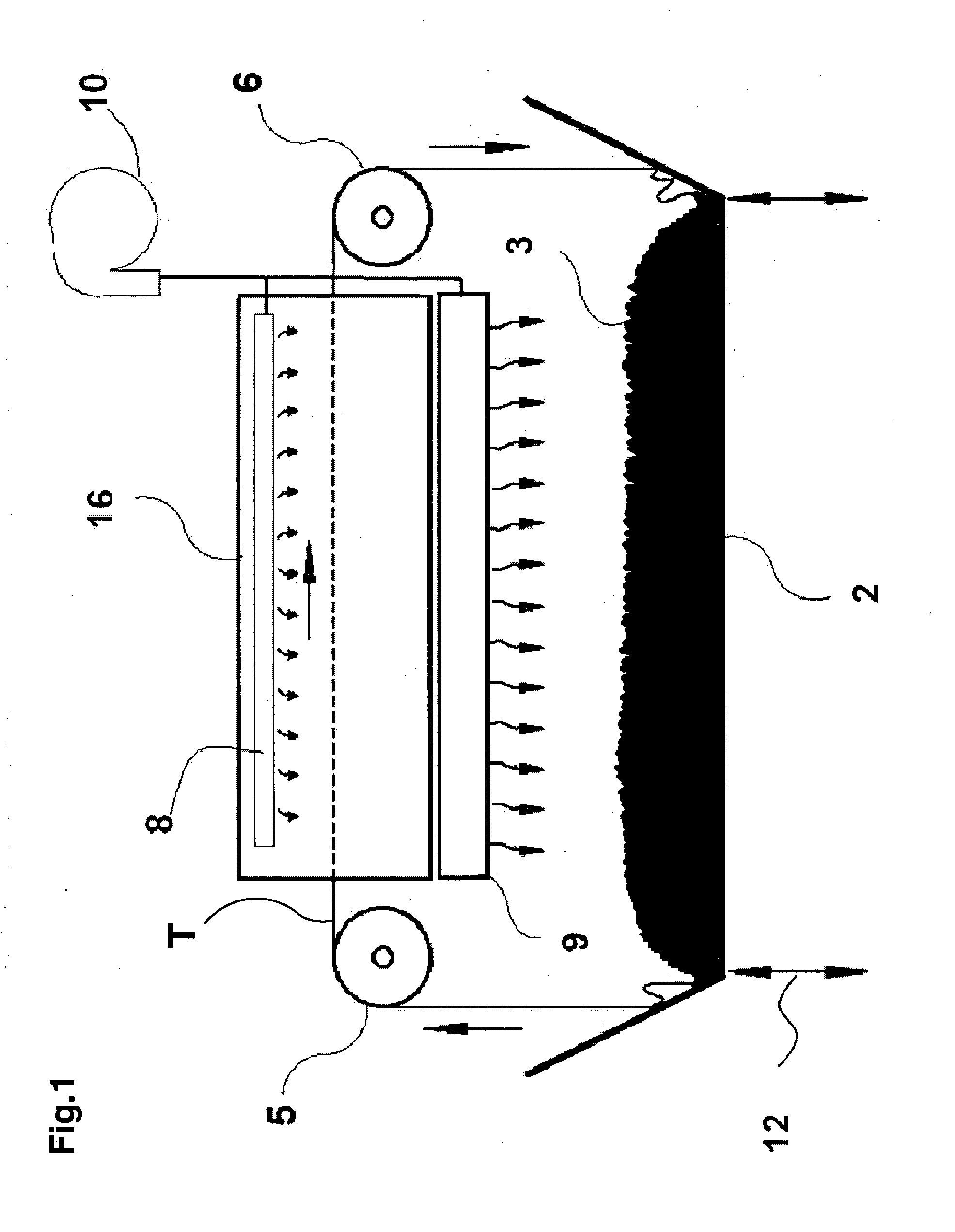

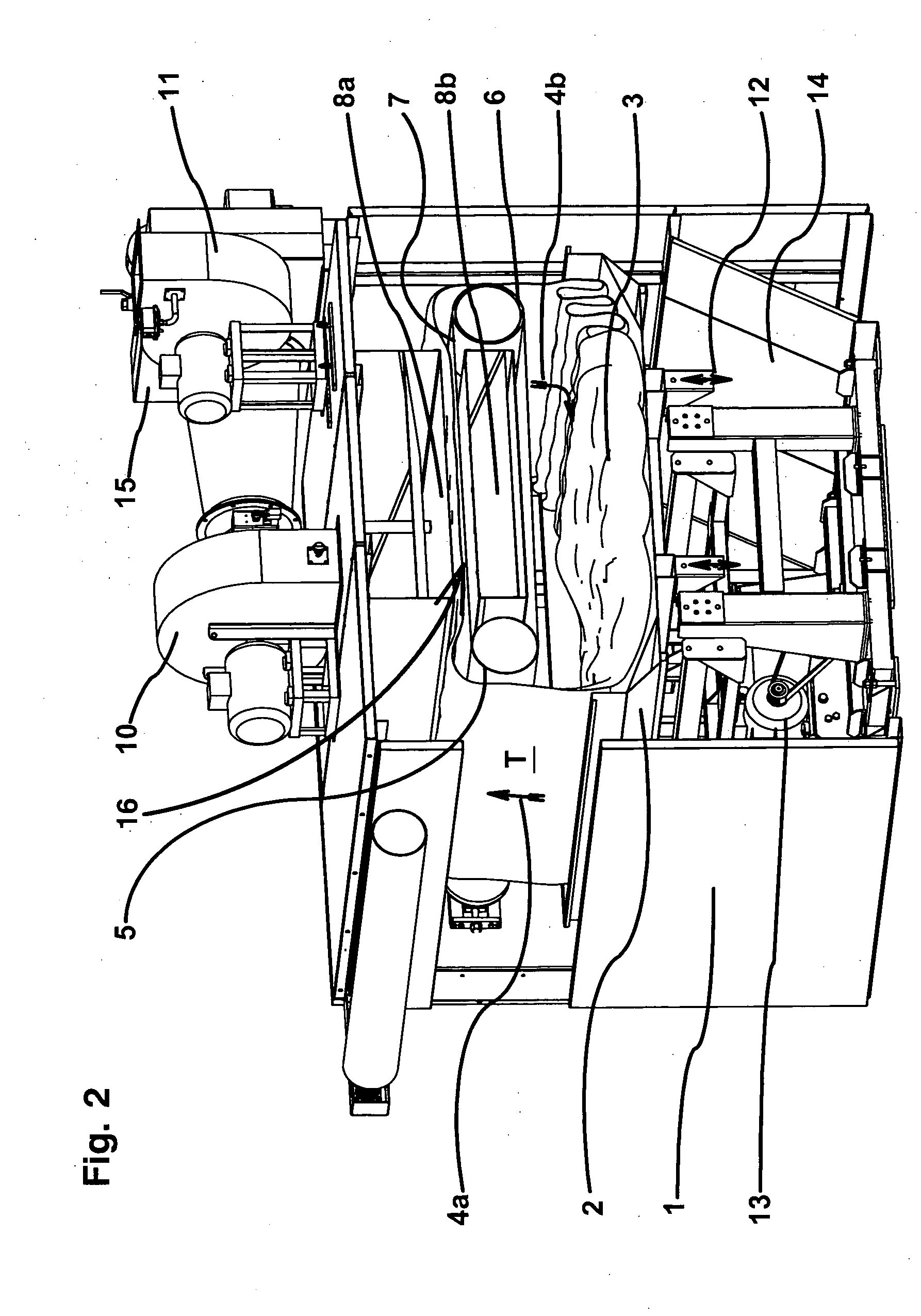

Machine and method for the combined mechanical and heat treatment of fabrics, especially knitted fabrics

ActiveUS20110232053A1Improves hand feelGood dimensional stabilityFabric breaking/softeningHeating/cooling textile fabricsVertical vibrationEngineering

Owner:BIANCALANI SRL

High-quality dip-dyeing drying device for textile fabric

InactiveCN109402915AQuality improvementReduce wasteSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryEvening

The invention discloses a high-quality dip-dyeing drying device for a textile fabric and relates to the technical field of textile. The device comprises a processing shell, a dip-dyeing groove is formed in the left side in the processing shell, and a drying chamber is formed in the right side in the processing shell; a rolling roller wheel is rotatably connected to the left side of the top of theprocessing shell, a dip-dyeing conveying wheel is rotatably connected to the middle of the bottom in the processing shell, and a beating roller wheel is rotatably connected to the middle of the top inthe processing shell; a first conveying roller wheel is rotatably connected to the portion, located at the right end of the dip-dyeing groove, of the top of the processing shell, evening mechanisms are symmetrically and fixedly connected to the portion, close to the left side of the drying chamber, of the top of the processing shell, and a scraping mechanism is arranged at the right end of the evening mechanism of the leftmost side of the top of the drying chamber. The high-quality dip-dyeing drying device for the textile fabric has the advantages that it is guaranteed that dip-dyeing for thetextile fabric is even, the high dip-dyeing quality is guaranteed, dye waste is reduced, the drying efficiency of the drying chamber is improved, the drying stroke is increased in a limited space, and the area occupied by drying is reduced.

Owner:杭州大弘科技有限公司

Textile line dyeing device for textile industry

InactiveCN111118775AGuaranteed uniformityLiquid/gas/vapor removal by vibrationTextile treatment carriersMechanical engineeringIndustrial engineering

The invention discloses a textile line dyeing device for textile industry and relates to the technical field of textile line dyeing. The textile line dyeing device comprises a dye box and a drying box, wherein a connection cover is fixedly connected between the dye box and the drying box; a line dyeing mechanism is arranged in the dye box; a line flicking device and a drying mechanism are arrangedin the drying box; the top end of the drying box is fixedly connected with a top seat; the top seat is rotationally connected with a pay-off wheel; a textile line winds the pay-off wheel; the textileline enters the inside of the connection cover after passing through the dye box, then enters the inside of the drying box and is finally output; and one top end of the dye box is fixedly connected with a feeding hole. According to the textile line dyeing device for the textile industry, the textile line released from the pay-off wheel can be dyed through arranging a line dyeing mechanism in thedye box, and the dyed textile line can be continuously stirred through arranging the line flicking device, so that excess dye on the textile line is flicked off, the dyeing uniformity is ensured, andthe dyed textile line can be dried through arranging a drying mechanism in the drying box.

Owner:唐红英

Environment-friendly dyeing device for garment production and dyeing method thereof

PendingCN113463300AProtect personal safetySaving dyeTextile treatment containersTextile treatment machine arrangementsProcess engineeringHuman health

The invention discloses an environment-friendly dyeing device for garment production and a dyeing method thereof, relates to the technical field of garment production and processing, and aims to solve the problems that in the garment production and processing process, a conventional dyeing mode is tedious in operation and relatively low in efficiency, and harmful chemical components possibly existing in dye are likely to be inhaled by a human body and harm human health. According to the scheme, the environment-friendly dyeing device comprises a dyeing box, a storage box, a spray dyeing mechanism and a shaking and draining mechanism; a feeding port and a discharging port are formed in the two opposite side walls of the dyeing box respectively; side shells are fixedly connected to the two side walls, provided with the feeding port and the discharging port, of the dyeing box; and the spray dyeing mechanism is arranged between the dyeing box and the side shells. The device is novel in structure, solves the problems that in the garment production and processing process, the conventional dyeing mode is tedious in operation and relatively low in efficiency, harmful chemical components possibly existing in dye are likely to be inhaled by the human body, and human health is harmed, and is suitable for popularization.

Owner:安徽工美服装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com