Patents

Literature

235results about How to "Guarantee the quality of winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

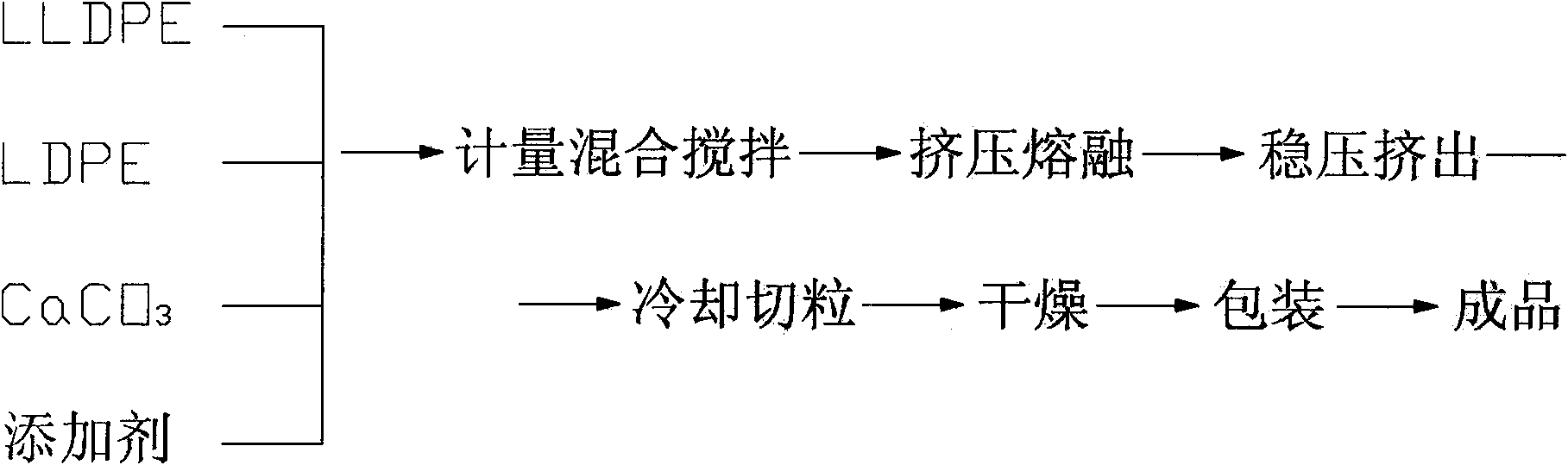

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

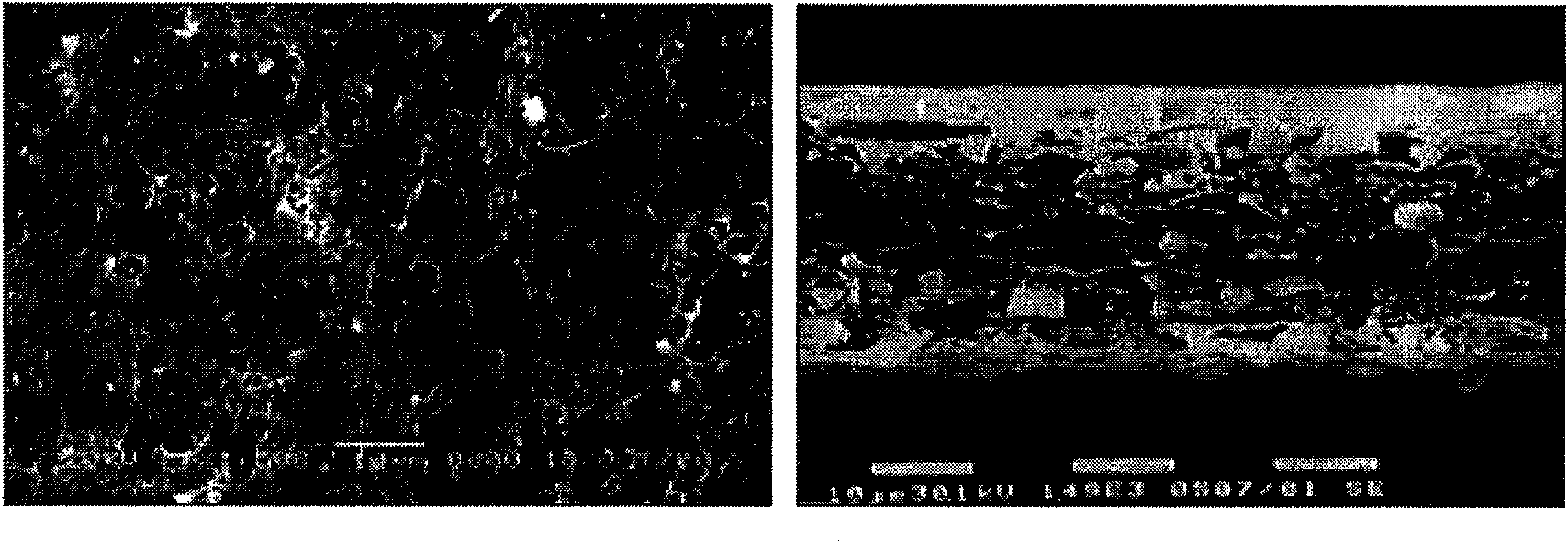

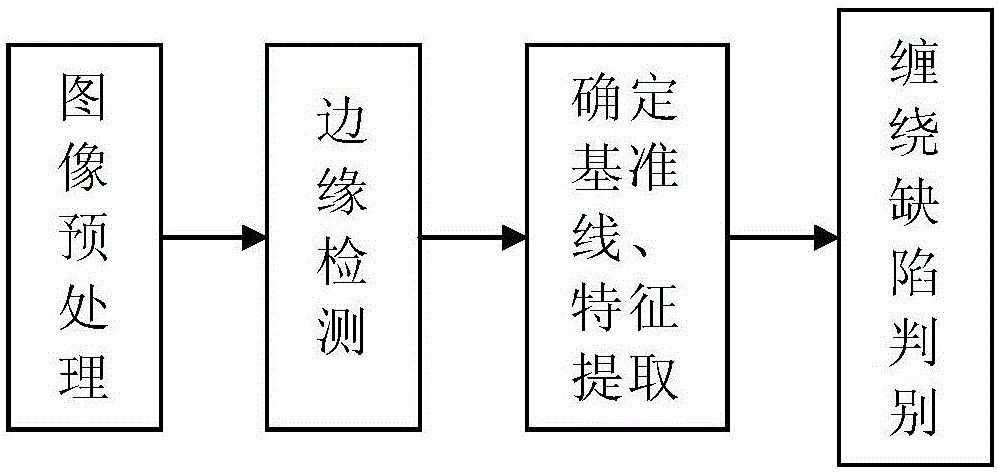

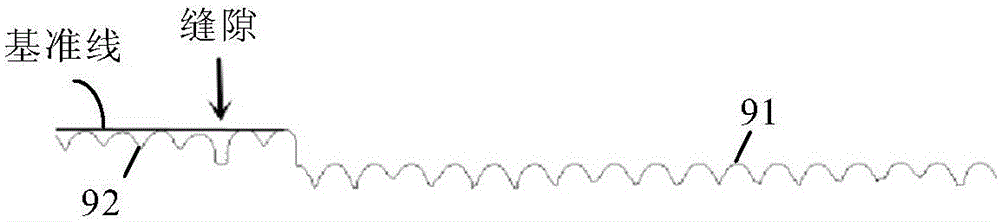

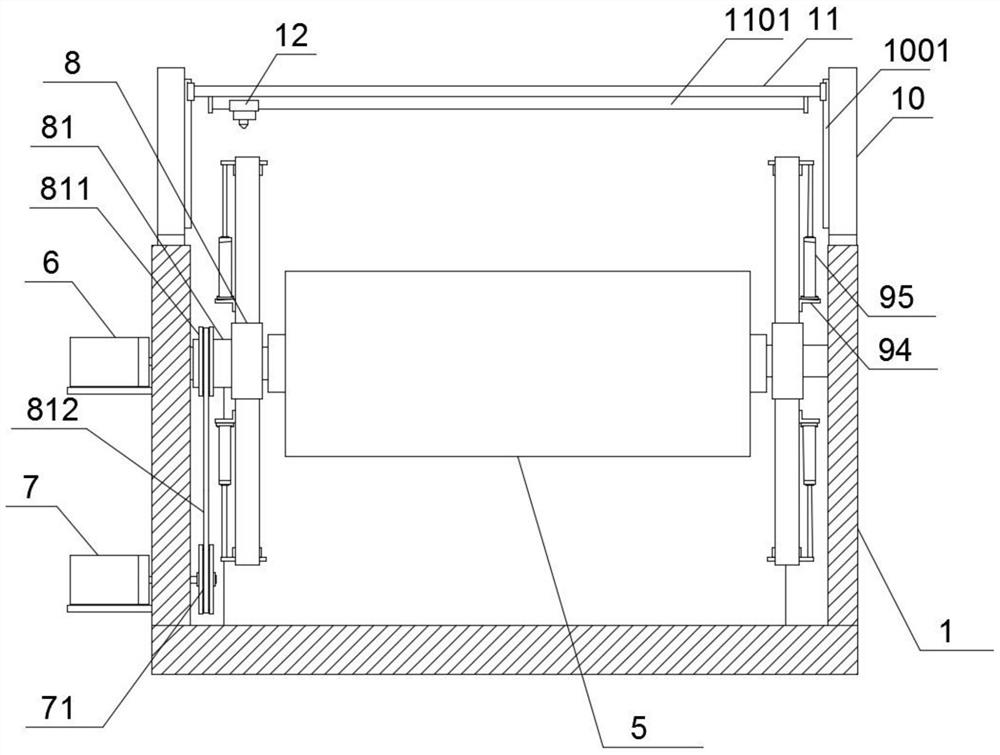

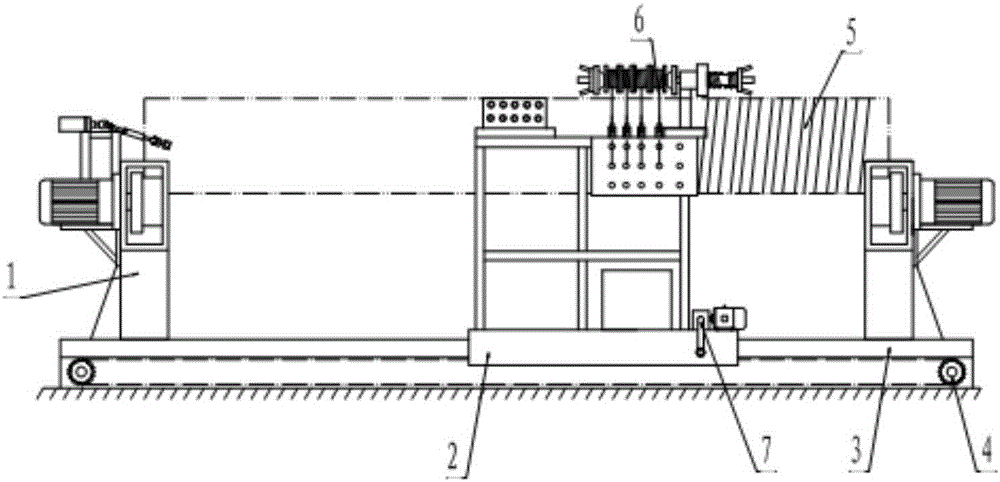

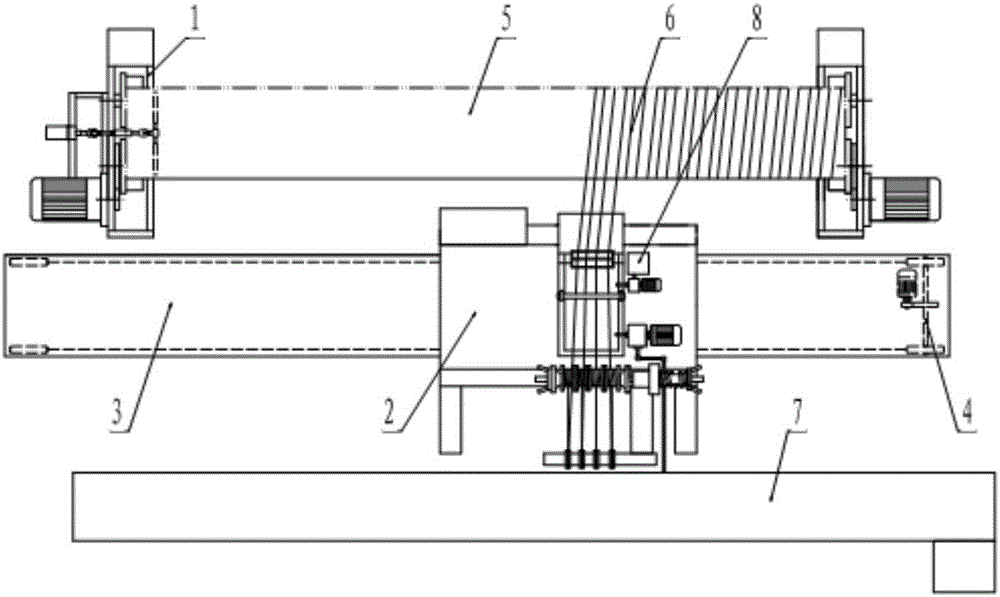

Full-automatic optical fiber winding defect detection system and method and optical fiber winding method

InactiveCN105115981ARealize real-time automatic detection functionGuarantee the quality of windingMaterial analysis by optical meansWinding machineEngineering

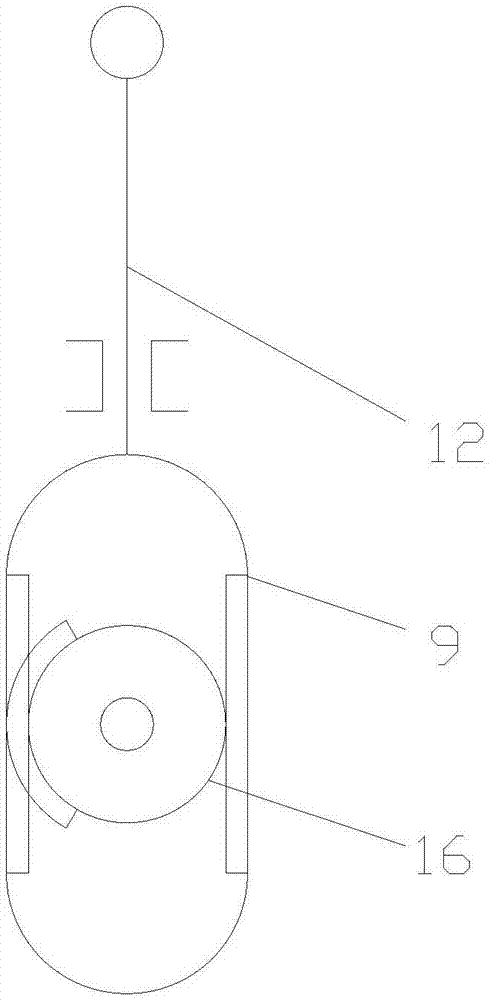

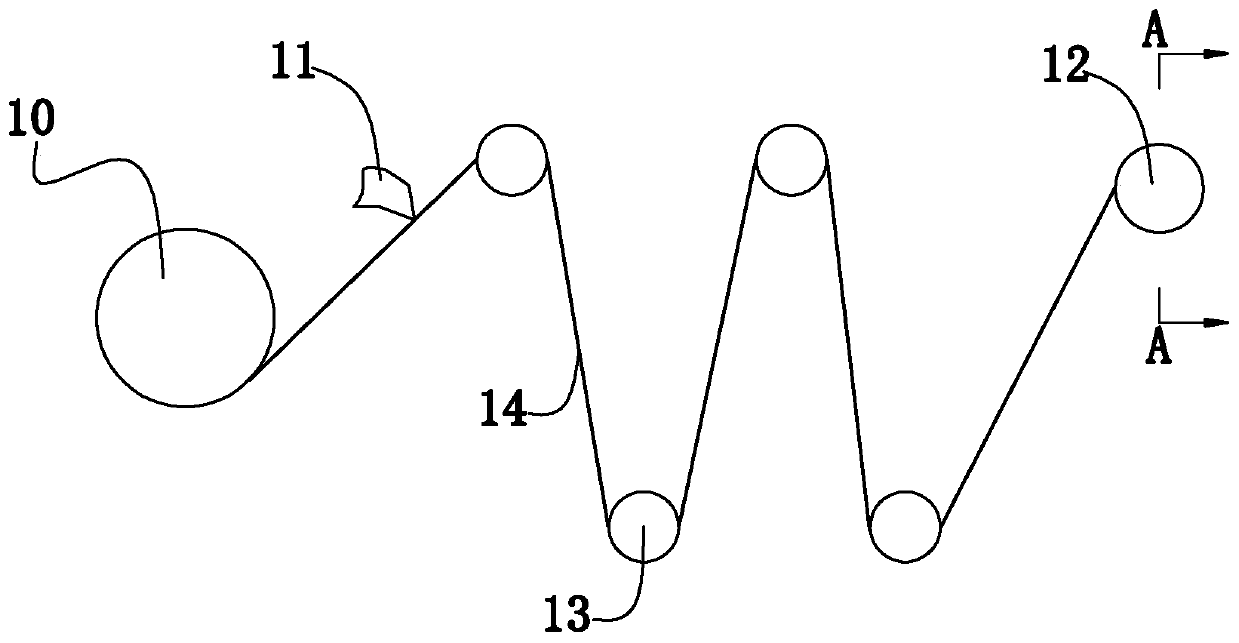

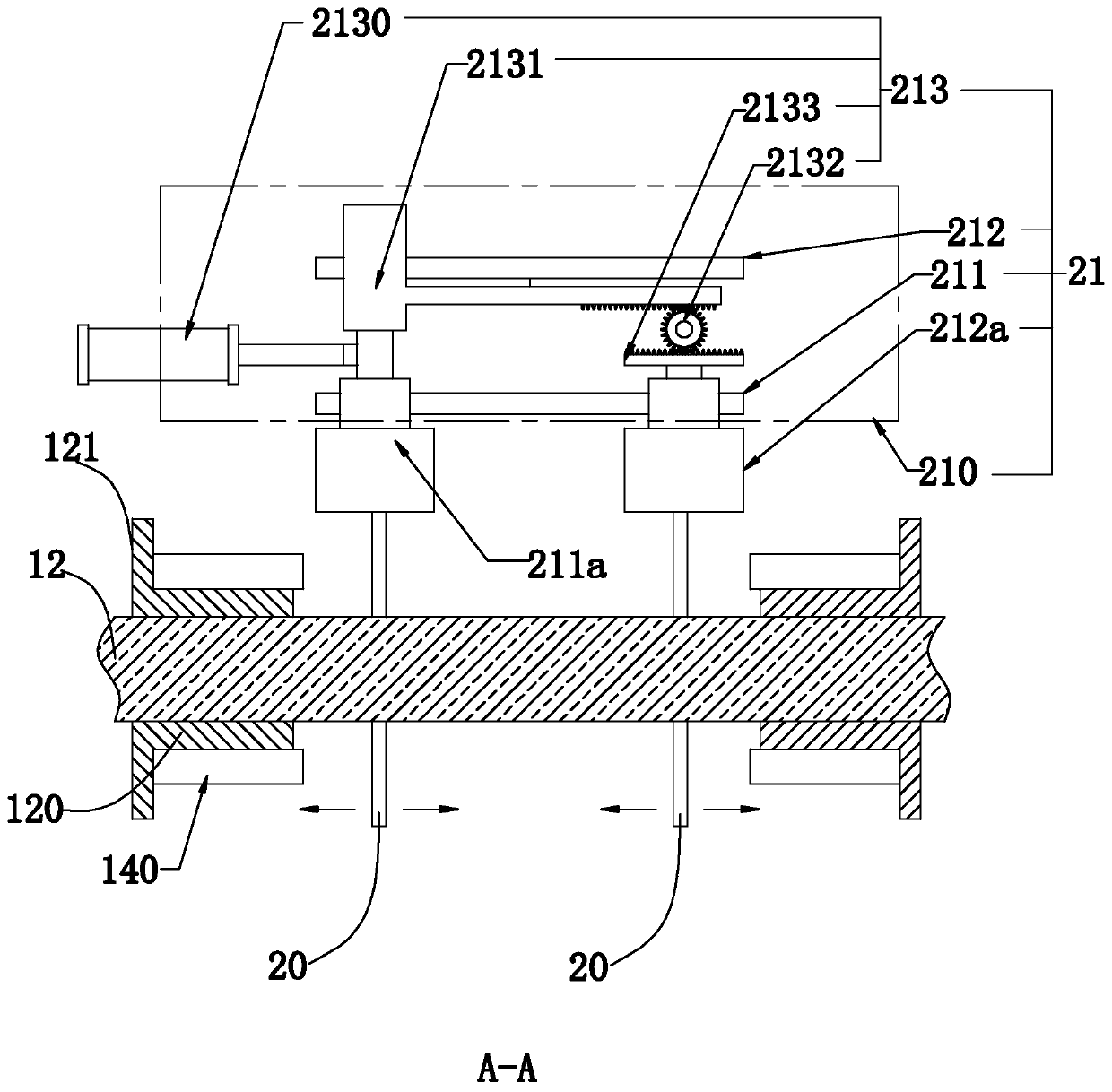

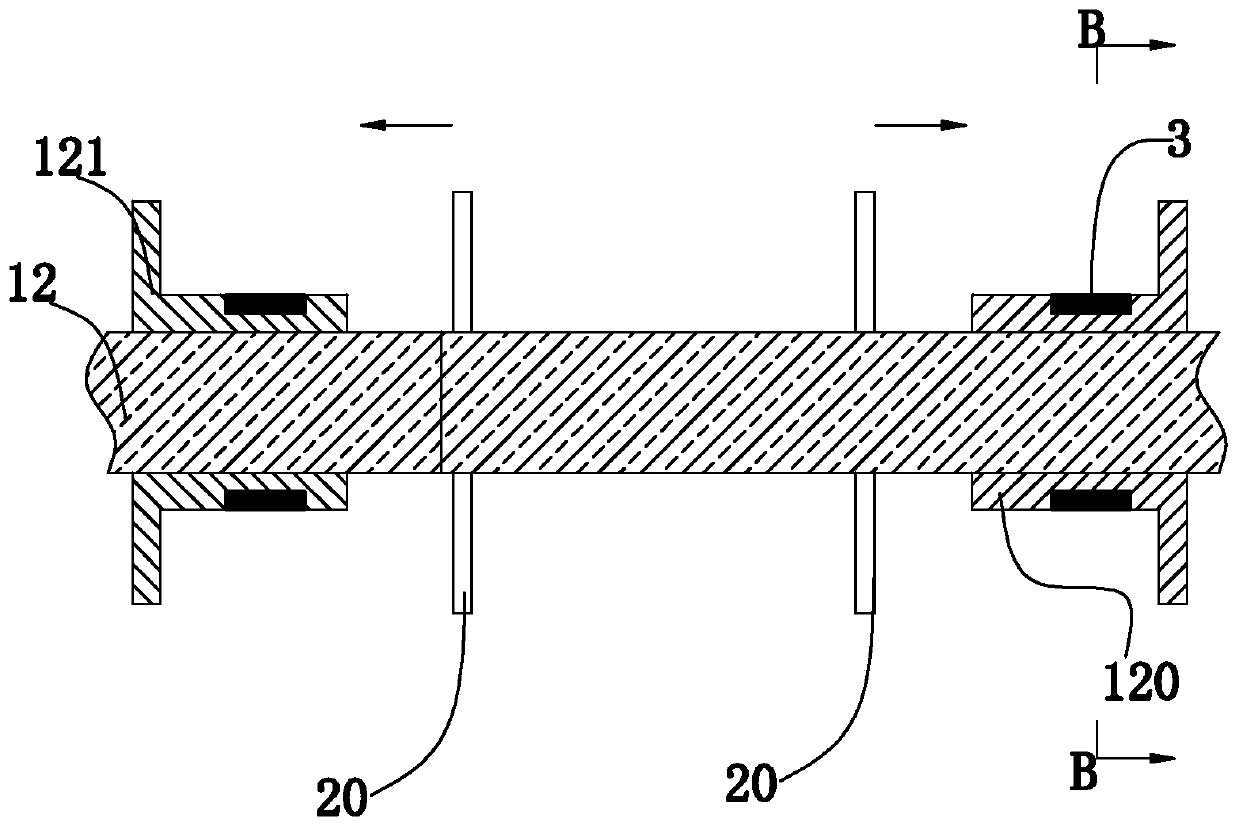

The invention discloses a full-automatic optical fiber winding defect detection system and method and an optical fiber winding method. The full-automatic optical fiber winding defect detection system comprises an industrial camera provided with an industrial lens, a light source, a moving platform, a platform moving controller and a computer, the industrial camera and the light source are arranged on two sides of a rotating shaft wound by an optical fiber respectively, rotating of the rotating shaft is controlled by an optical fiber winding machine, the industrial camera is mounted on the moving platform which is connected with the platform moving controller, and the platform moving controller, the industrial camera and the optical fiber winding machine are all connected with the computer. The full-automatic optical fiber winding defect detection system and method realizes a function of realtime and automatic detection of defects in the process of winding the optical fiber. The optical fiber winding method coordinates and cooperates with the optical fiber winding machine, full automation in winding the optical fiber can be realized, and production efficiency is high.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

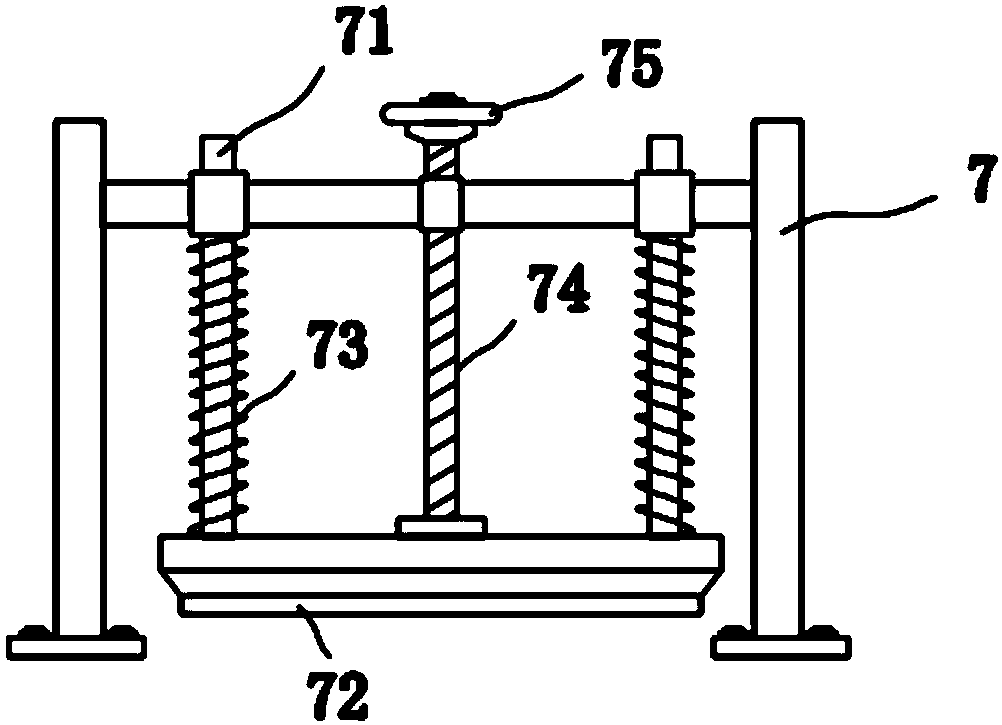

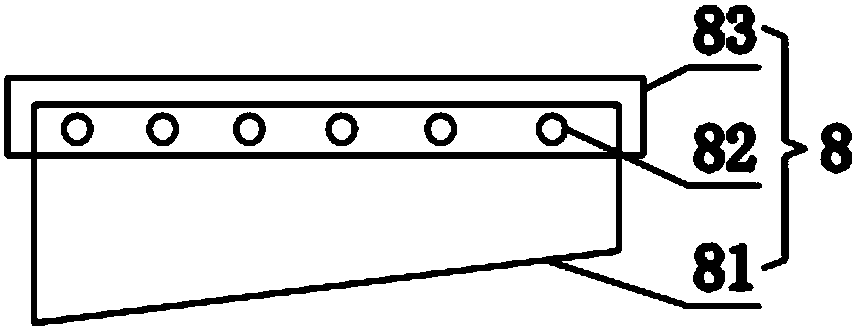

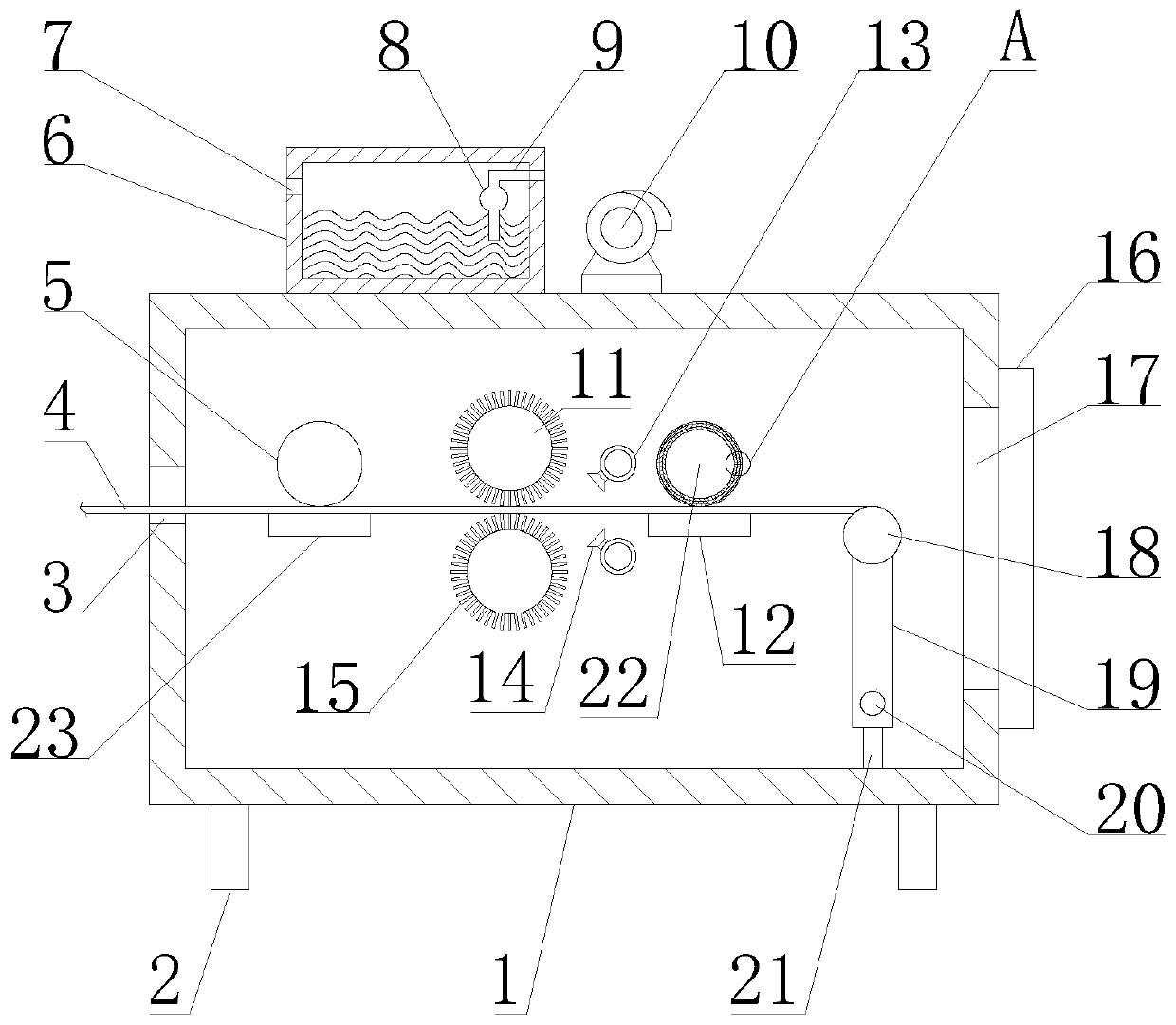

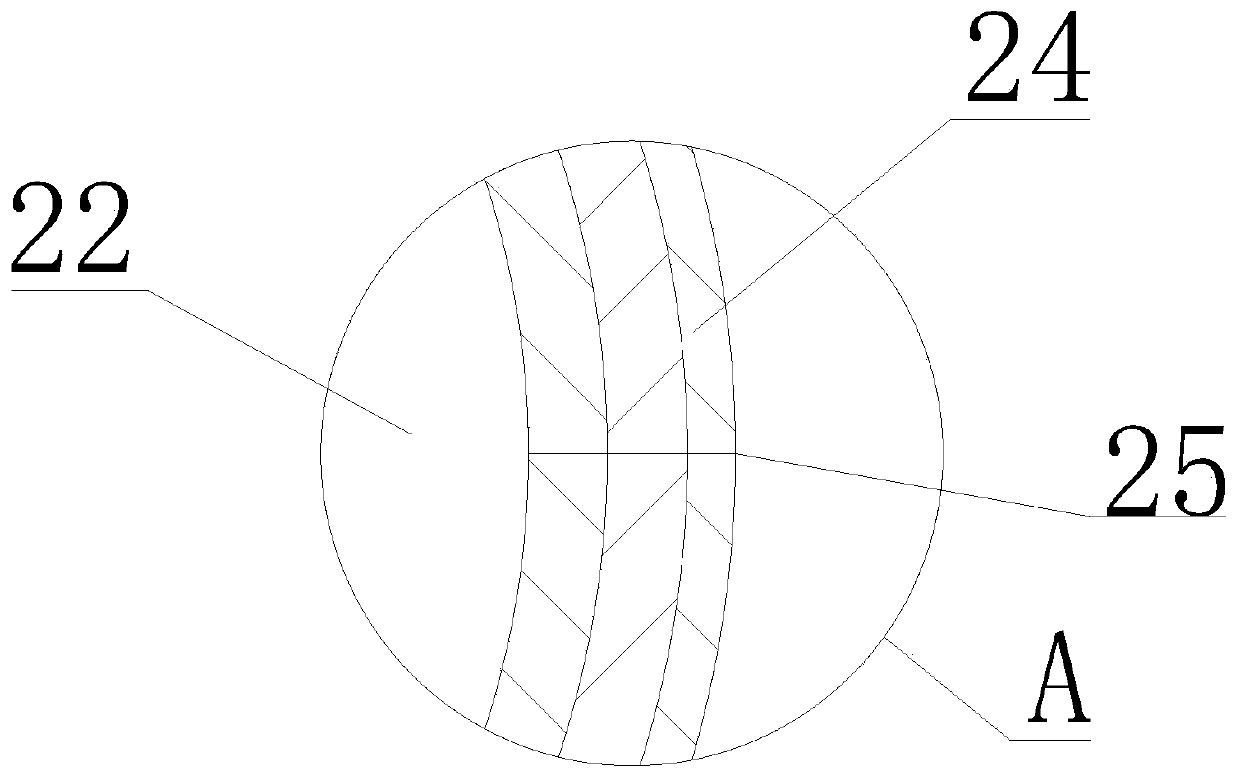

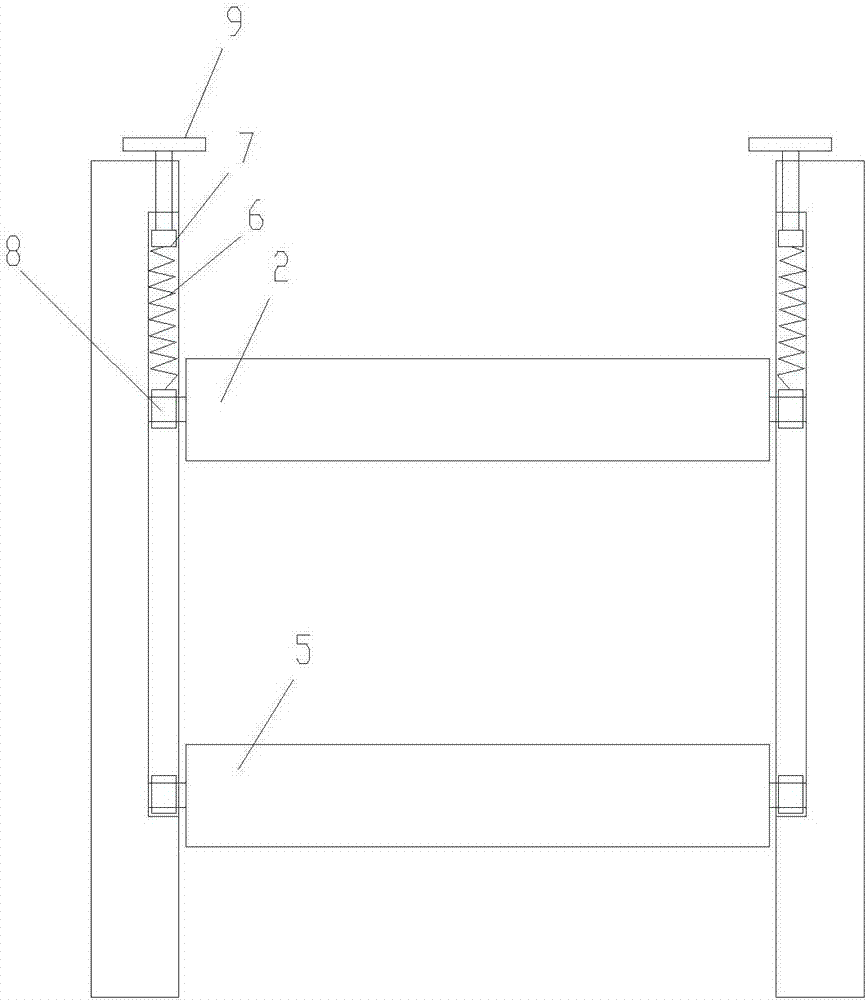

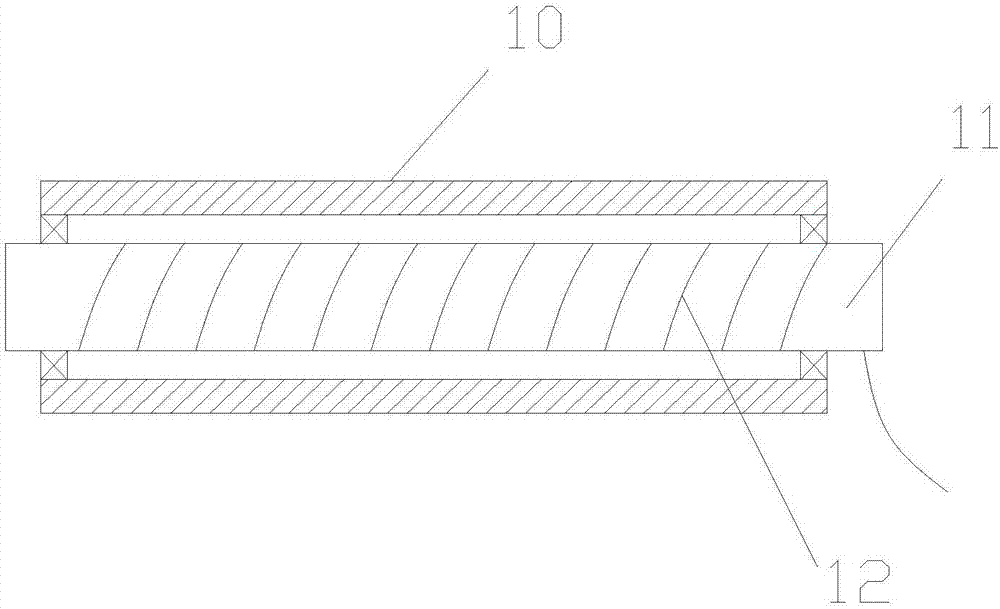

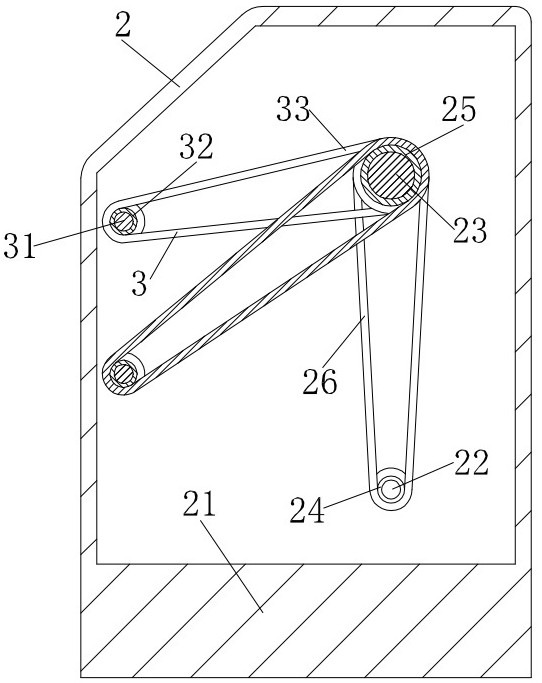

Tension-adjustable textile fabric winder based on Hooke law principle

The invention relates to the technical field of textile fabrics, and discloses a tension-adjustable textile fabric winder based on a Hooke law principle. The tension-adjustable textile fabric winder based on the Hooke law principle comprises a support frame, wherein a cloth guiding plate is fixedly connected to the inner part of the support frame; an unfolding frame is movably connected to the toppart of the cloth guiding plate; an unfolding shaft is movably connected to the inner part of the unfolding frame; an unfolding wheel is fixedly connected to the outer part of the unfolding shaft; afirst bevel gear is fixedly connected to the outer part of the unfolding shaft; a second bevel gear is connected to the outer part of the first bevel gear in a meshing way; a rotary shaft is fixedly connected to the inner part of the second bevel gear; a main gear is fixedly connected to the outer part of the rotary shaft; and a fixed cloth guiding roller is movably connected to the inner part ofthe support frame. Through the cooperative use of the cloth guiding plate and the unfolding wheel, a fabric is fully ensured to be unfolded and spread on the surface of the cloth guiding plate in therotation process of the unfolding wheel, the fabric is effectively prevented from being wrinkled and imprinted, and the fabric is fully ensured to be wound flatly.

Owner:陕西秦塬纺织有限公司

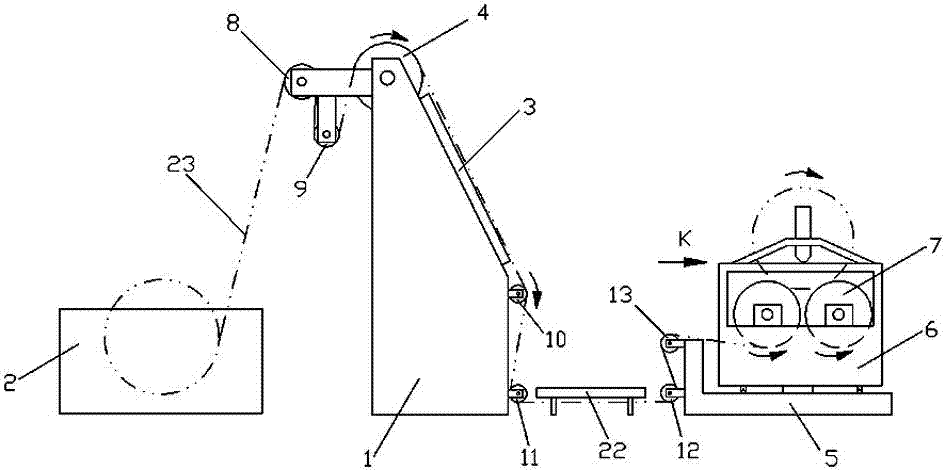

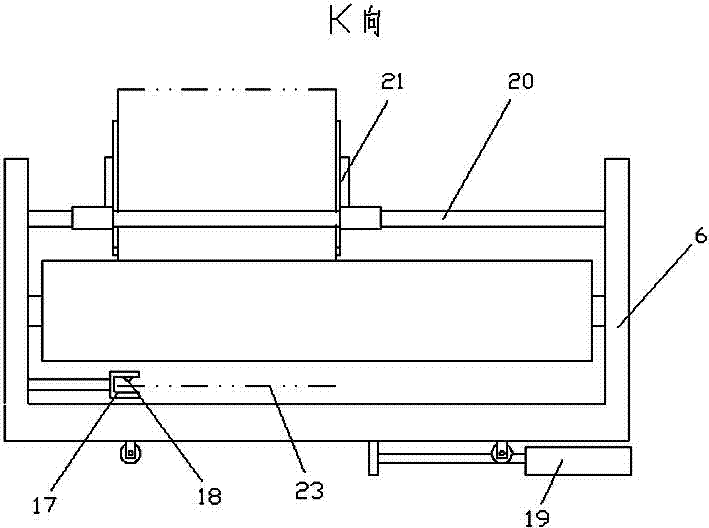

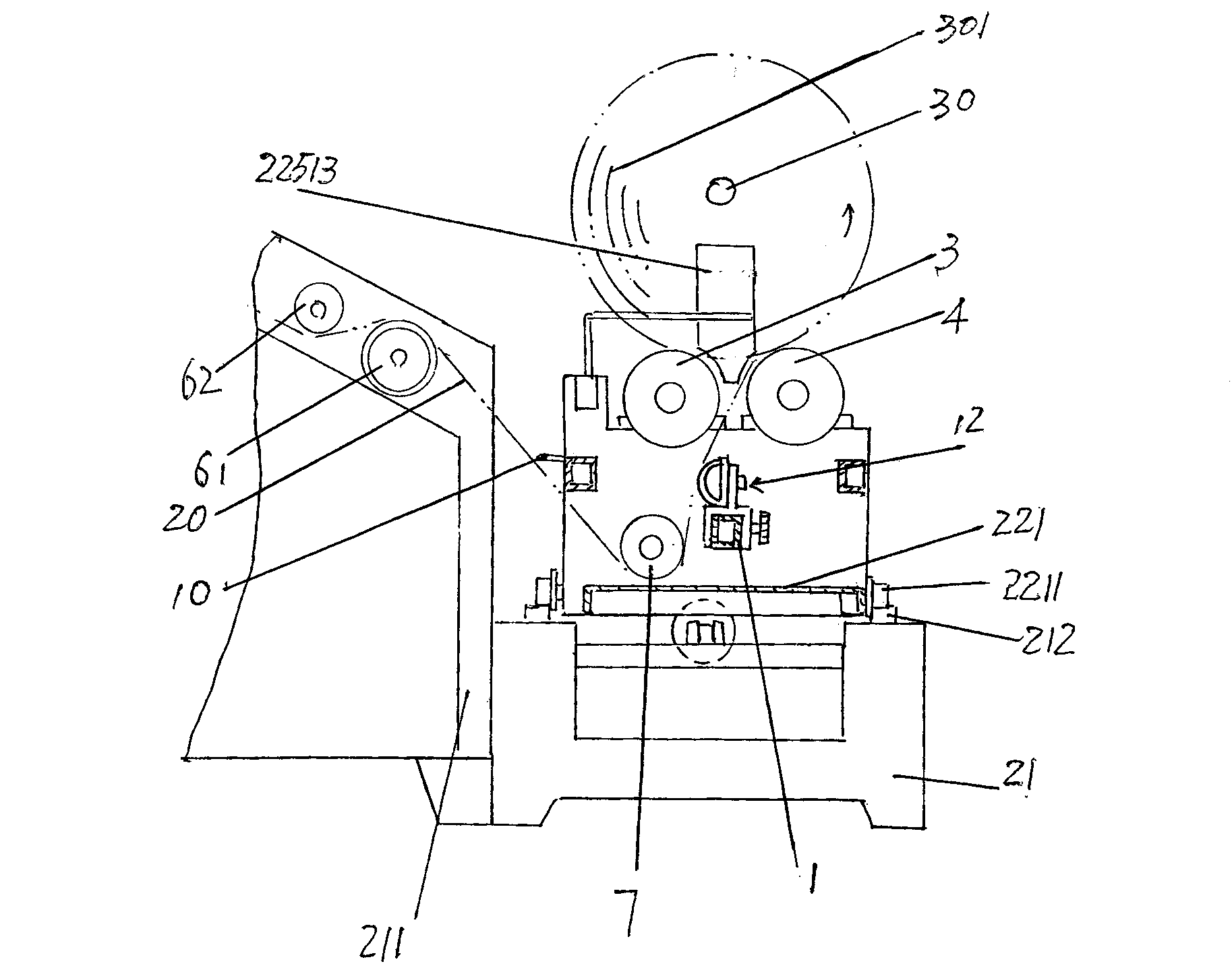

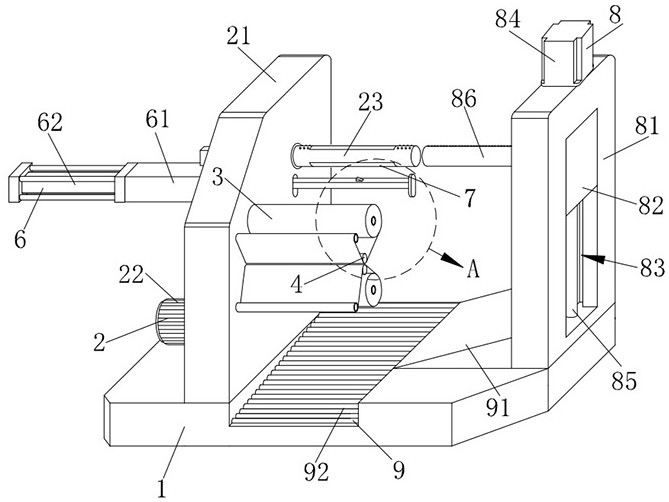

Cloth inspecting machine

The invention relates to a cloth inspecting machine. The cloth inspecting machine comprises a machine stand, a trough which is arranged behind the machine stand and a batching device arranged in front of the machine stand. An inclined lamp panel is arranged on the front side of the machine stand. The position, above the lamp panel, of the machine stand is provided with a cloth feeding roller. The batching device comprises a base. The base is provided with a seat frame which can slide leftward and rightward relative to the base. The seat frame is provided with a pair of batching rollers, wherein the batching rollers rotate synchronously, and the rotary direction is same. The batching rollers are used for carrying a polyester fabric rolling barrel which is finished in inspection. The cloth inspecting machine has the advantages that the design layout is reasonable, the utilization is convenient, the automation degree is high, the labor intensity of workers is effectively lowered, and the accuracy of an inspection result and the winding quality are guaranteed.

Owner:王少杰

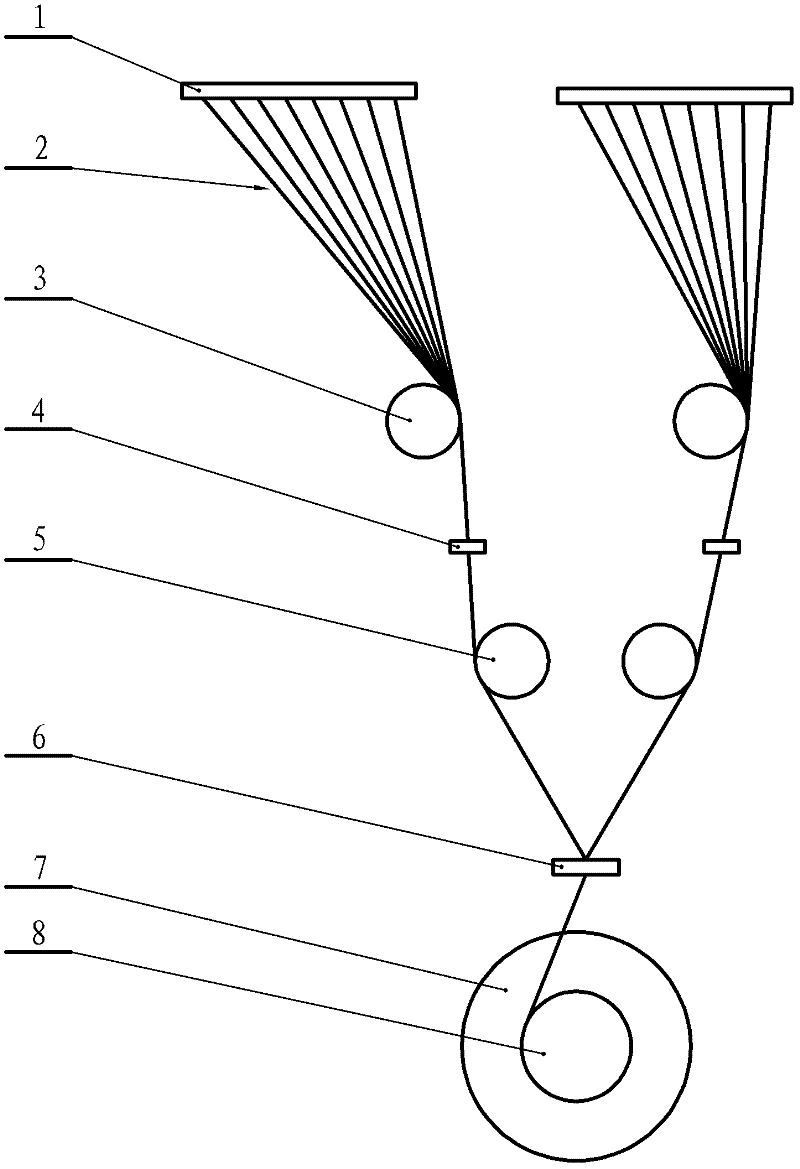

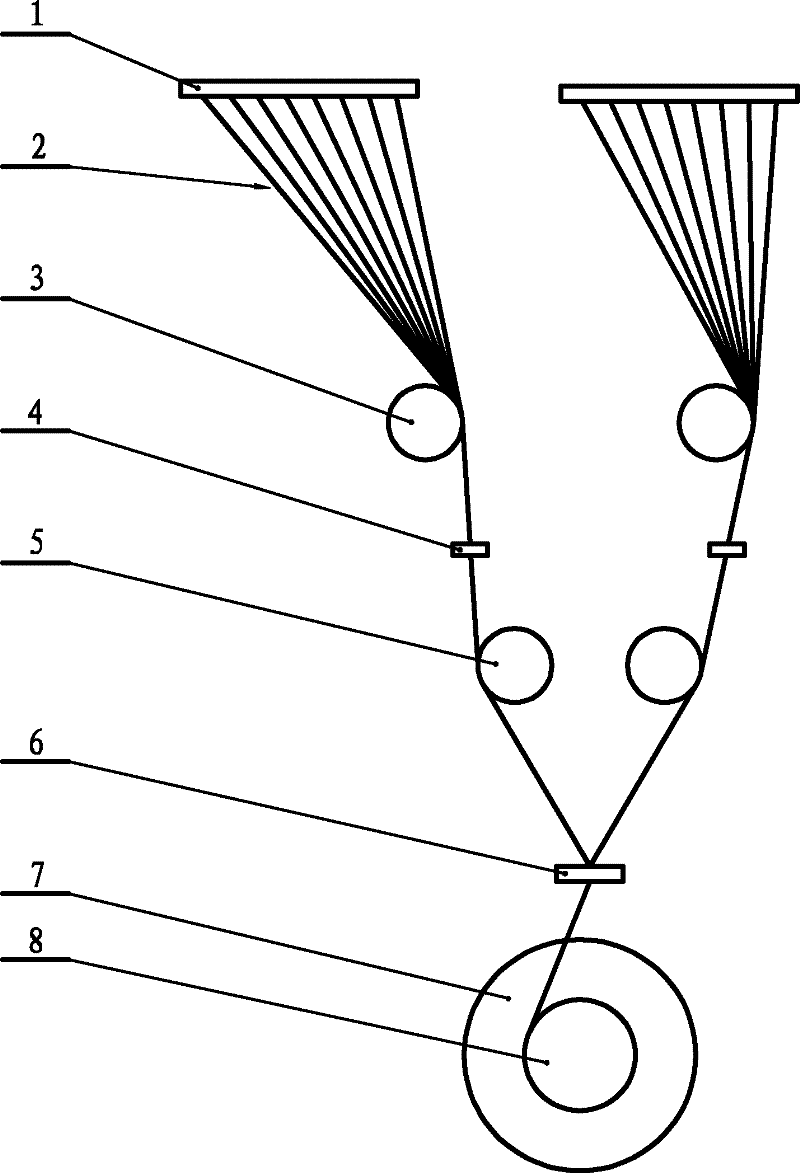

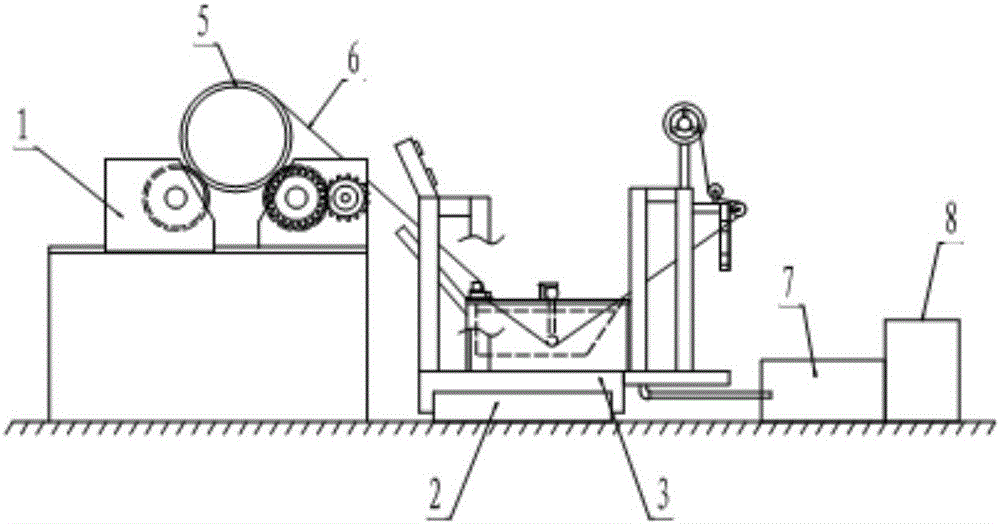

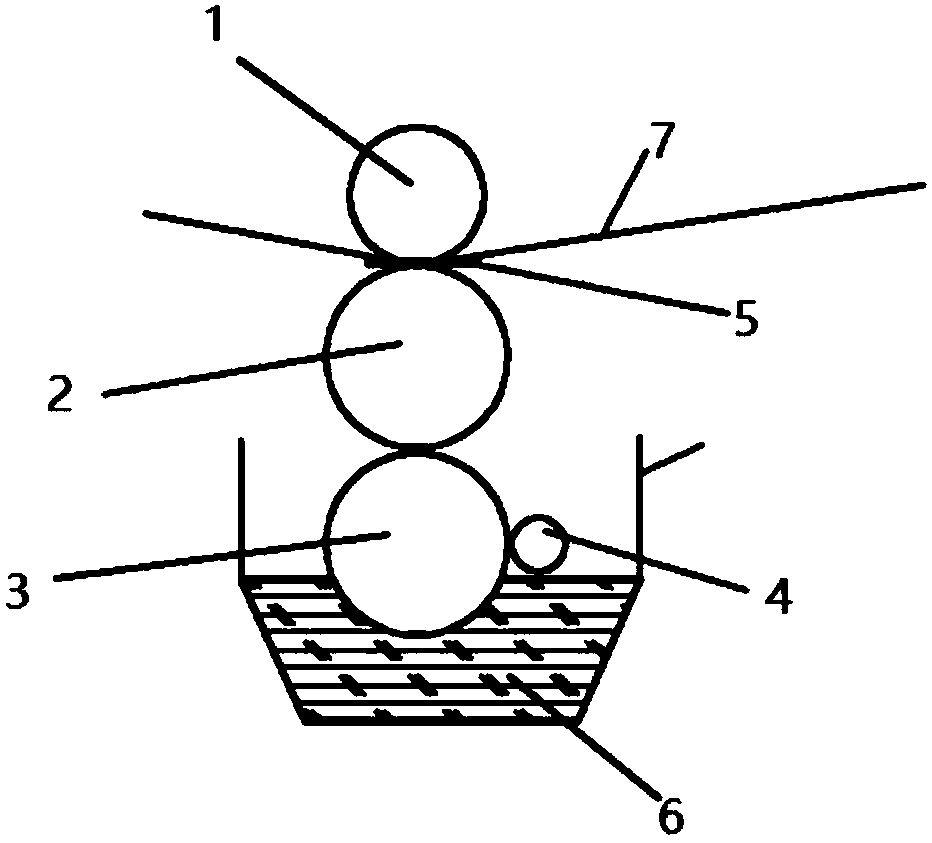

Multi-bushing plate merging wiredrawing technology and multi-bushing plate wiredrawing device employing it

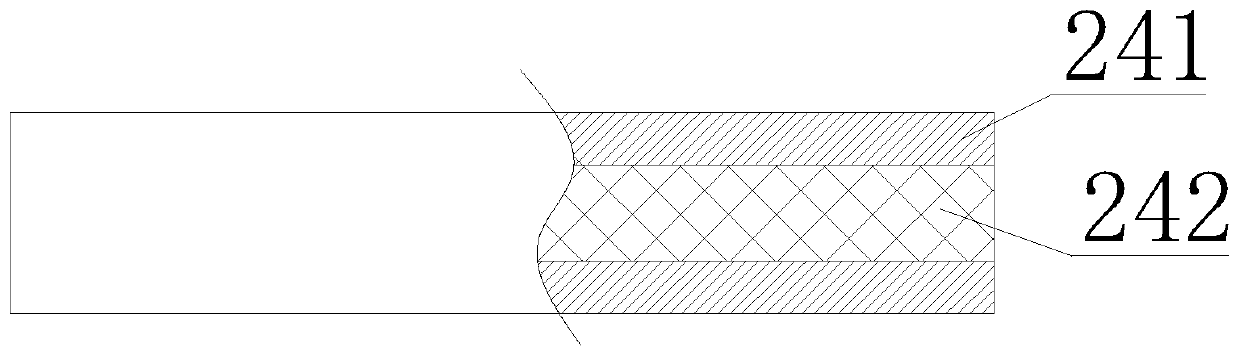

ActiveCN102515504ASimplify temperature controlReduce manufacturing costGlass making apparatusGlass fiberEngineering

The invention provides a multi-bushing plate merging wiredrawing technology. Specifically, 2 or more bushing plates are employed, and each bushing plate is provided with a plurality of leaks. Molten glass flows through each leak of each bushing plate and is cooled, and then a plurality of glass fibers can be obtained through wiredrawing molding respectively. Pulled by a wiredrawing machine driven wire cylinder, the glass fibers respectively pass through multiple upper bunchers and are neatened and gathered into glass fiber bundles, which are then neatened and gathered by a gathering buncher into a complete glass fiber bundle that is then wound on the wire cylinder into a finished glass fiber bundle. A multi-bushing plate wiredrawing device is provided with 2 or more bushing plates, each of which is equipped with a plurality of leaks. An upper buncher is installed behind each bushing plate respectively, a gathering buncher is arranged behind each upper buncher, the wiredrawing machine is disposed behind the gathering buncher, the wire cylinder is positioned on the gathering buncher, and the wire cylinder and the wiredrawing machine are in driving rotary connection. With the technology and device provided in the invention, the manufacturing cost of a bushing plate for a glass fiber bundle with a great weight of per unit length can be reduced, the band forming property of the glass fiber bundle can be improved, and the effect can be obvious.

Owner:CHONGQING POLYCOMP INT

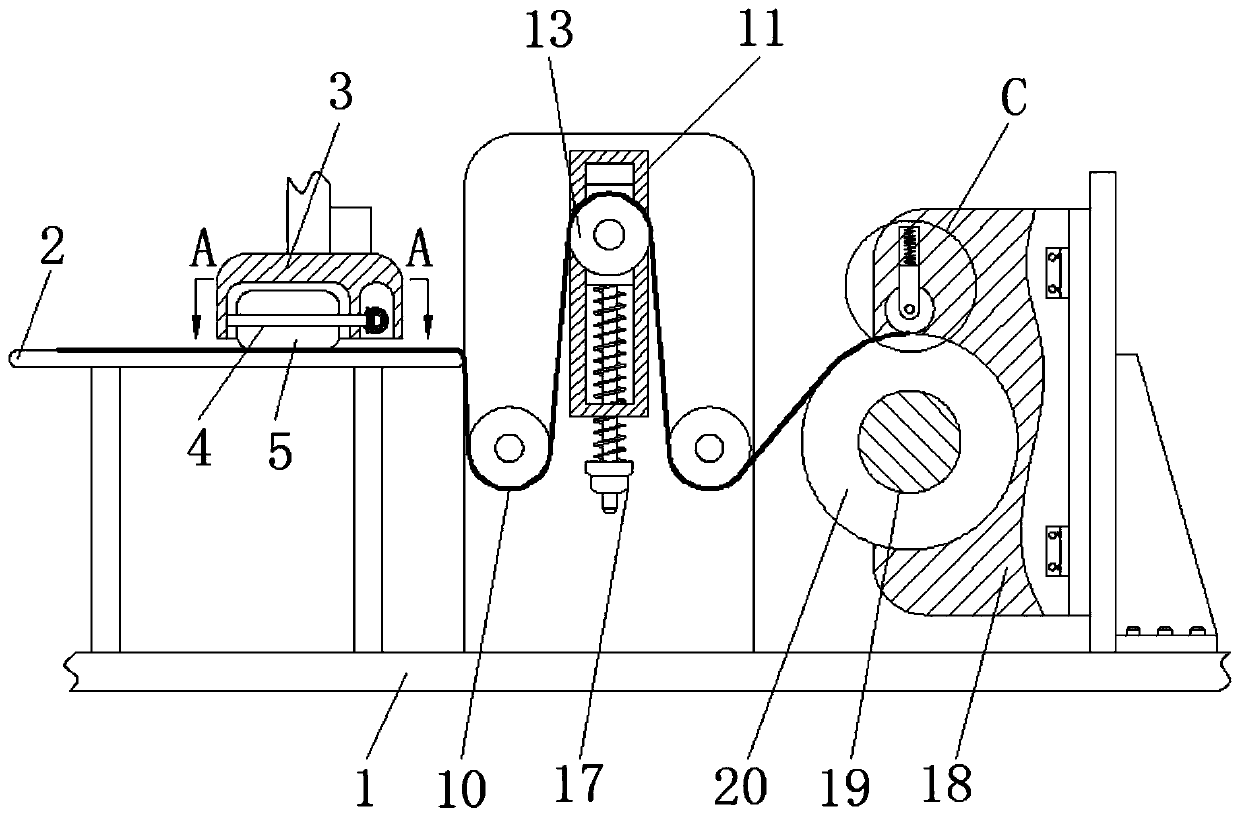

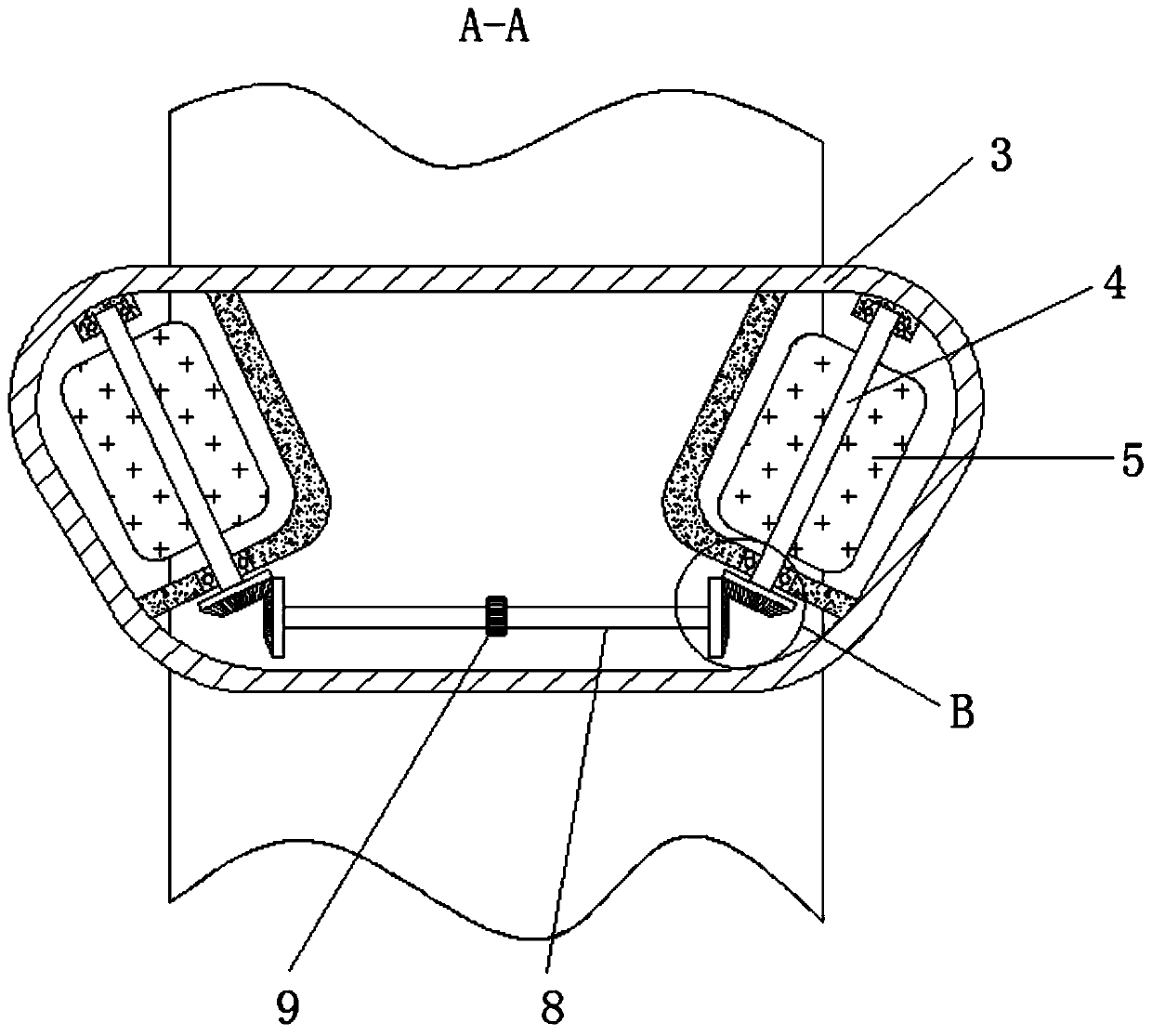

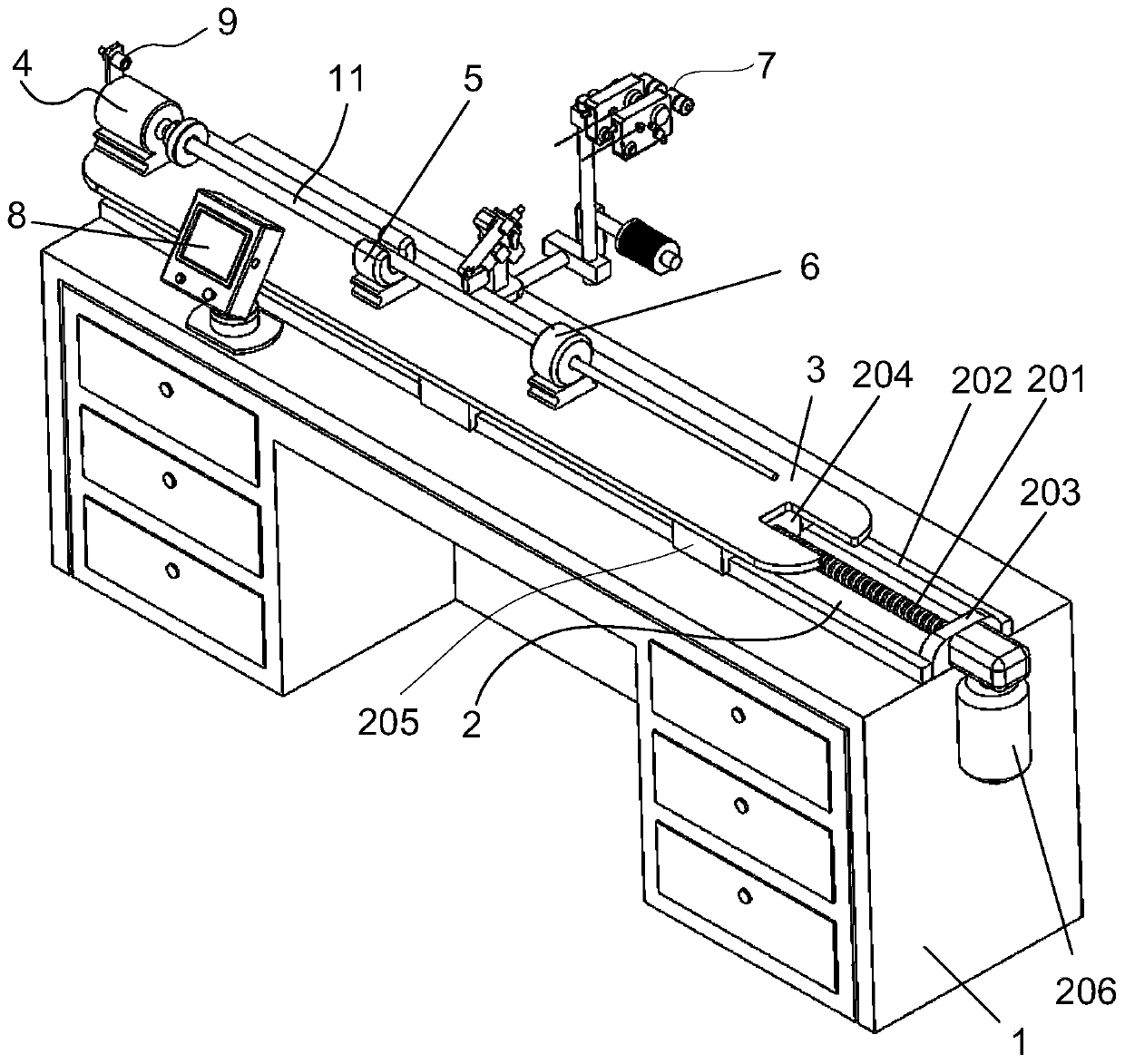

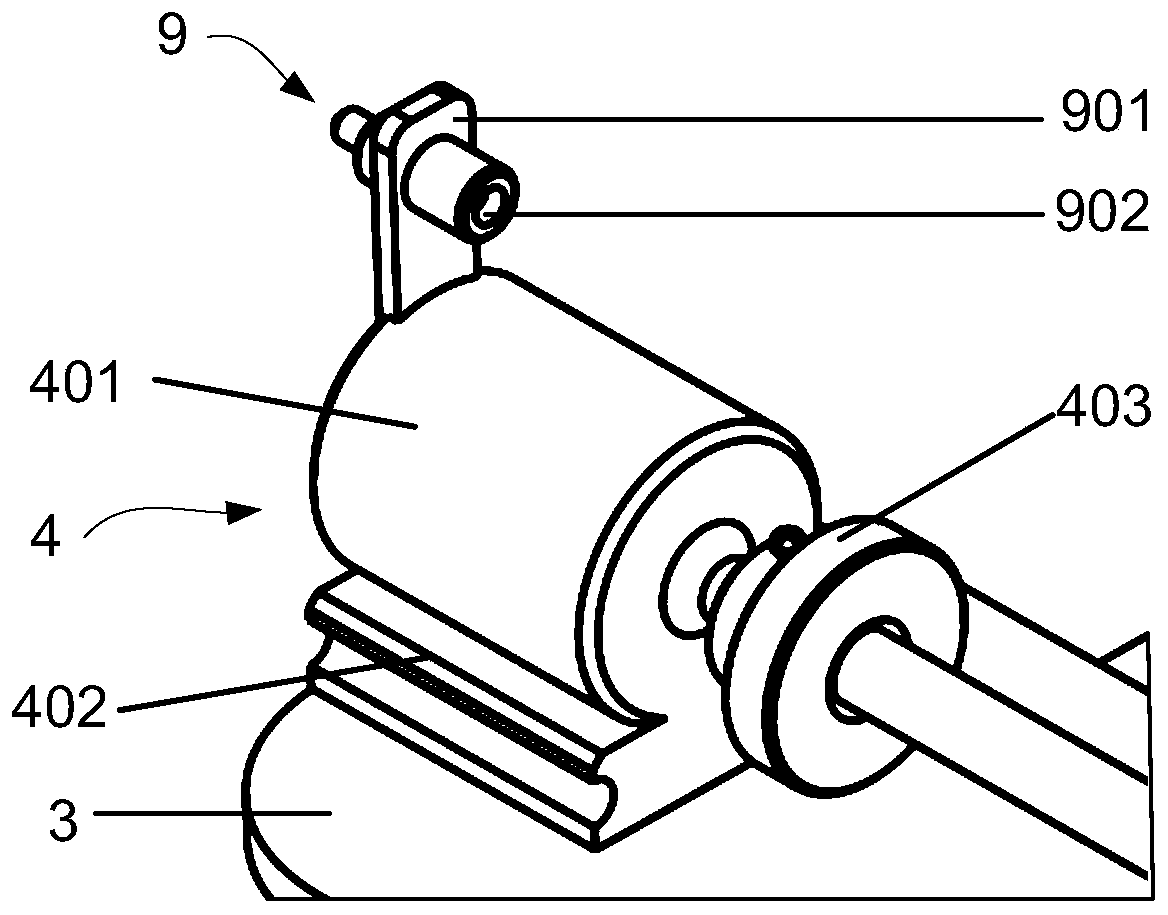

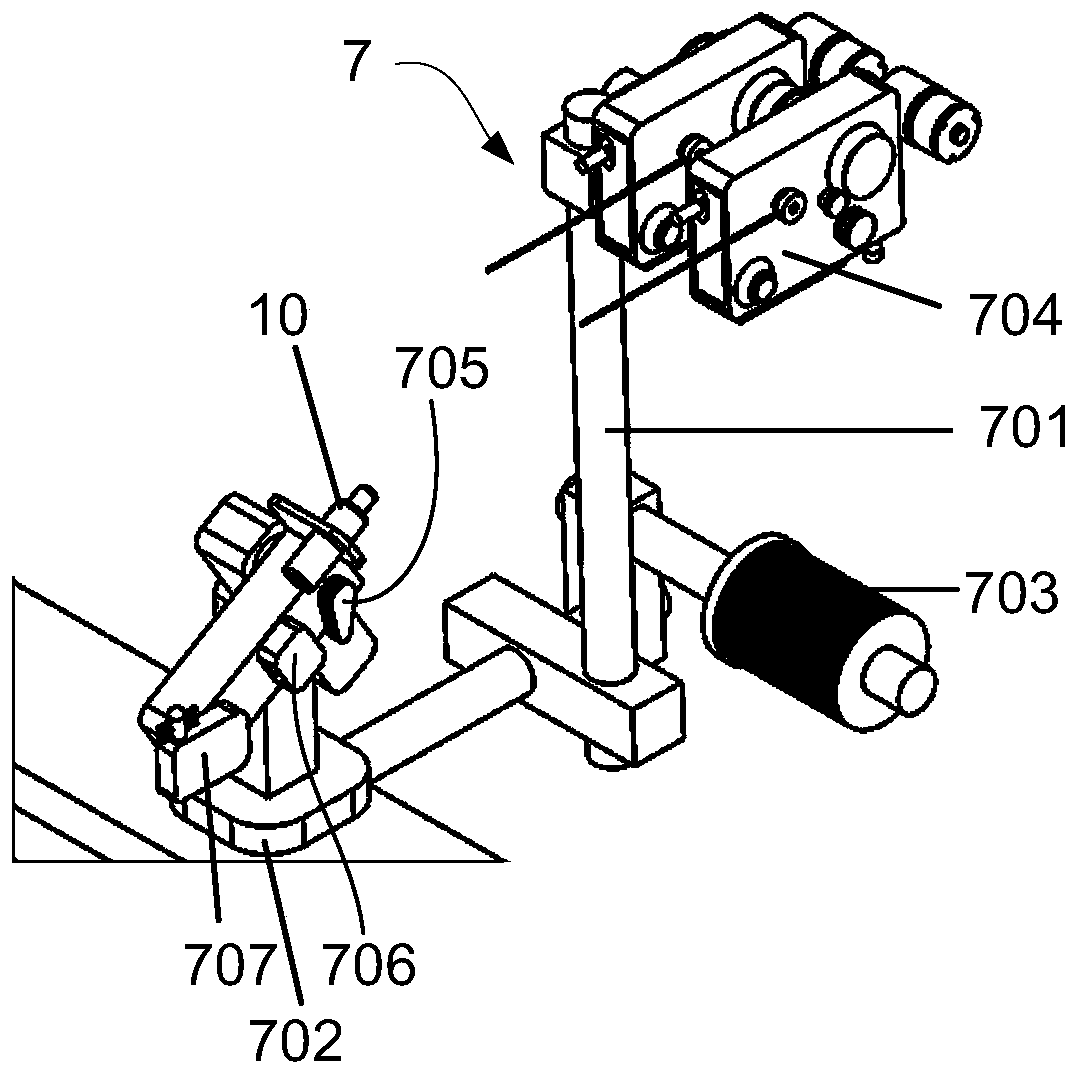

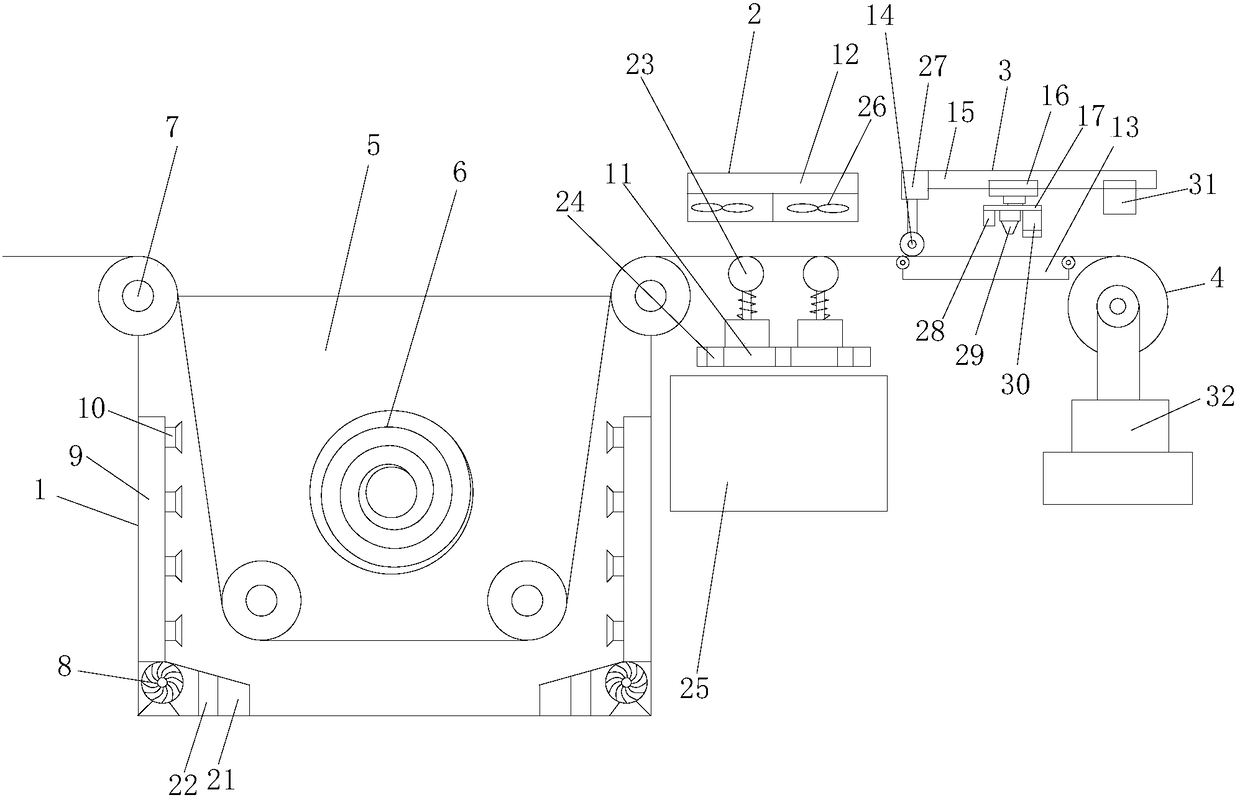

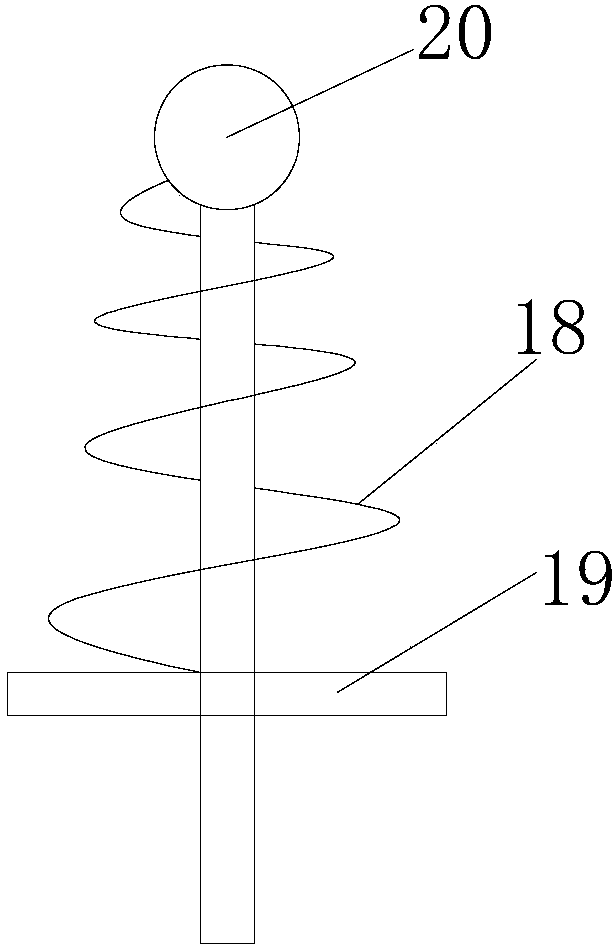

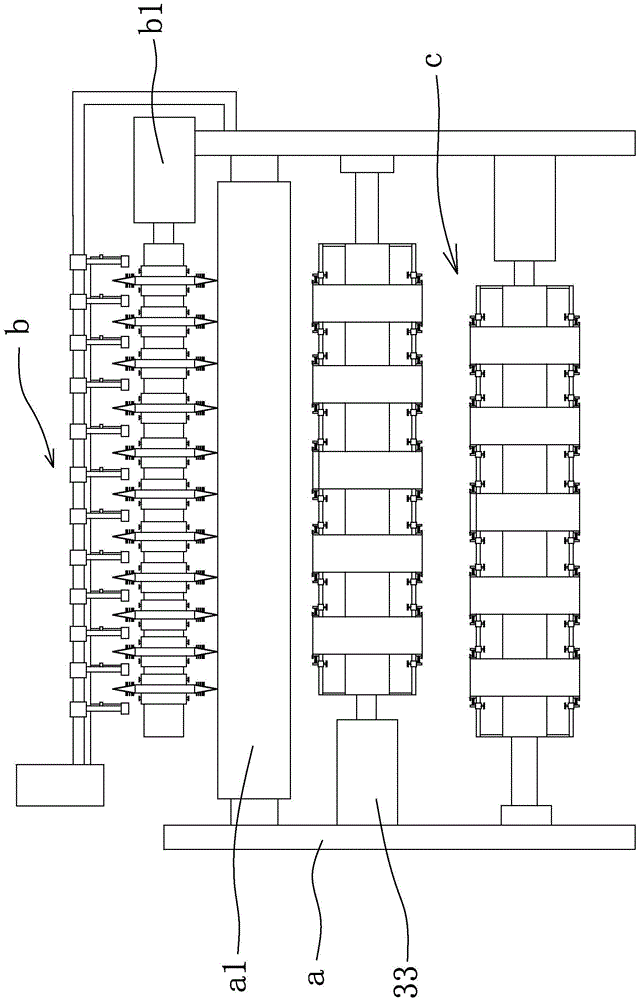

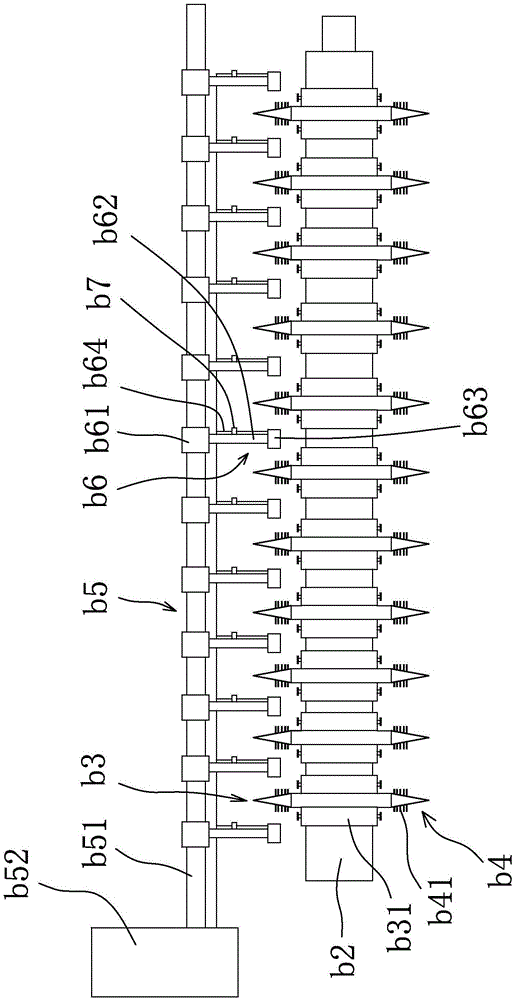

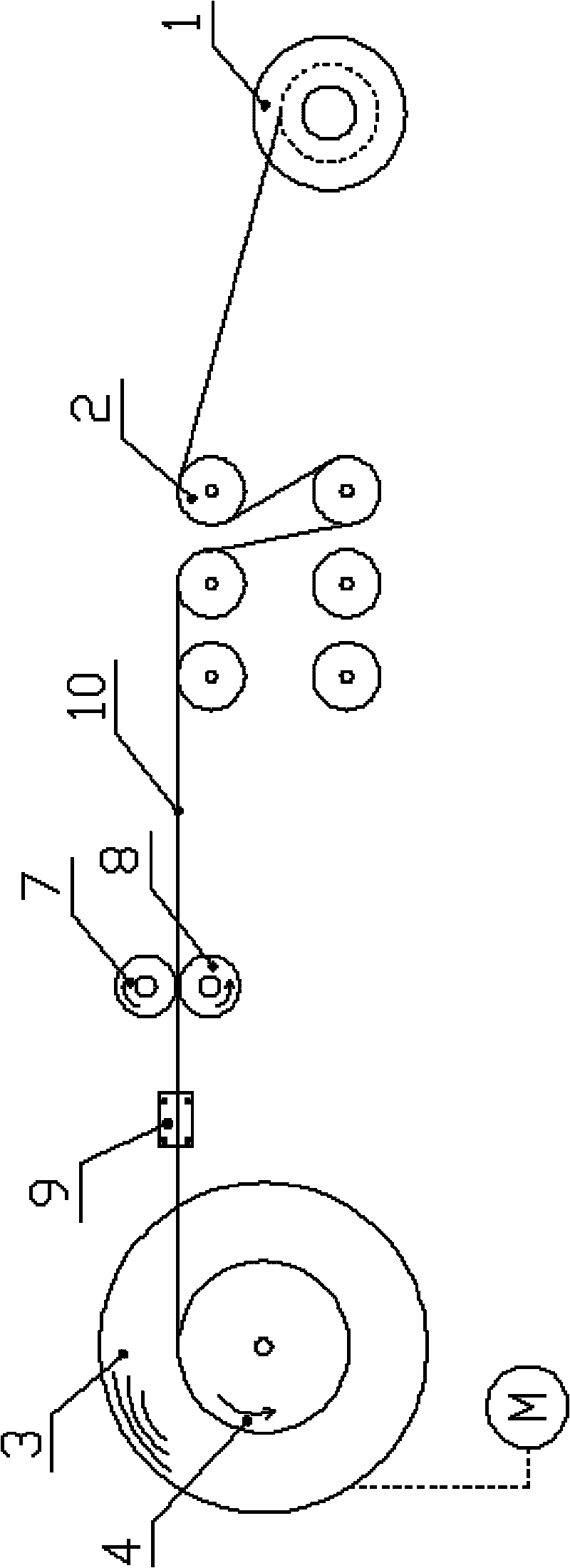

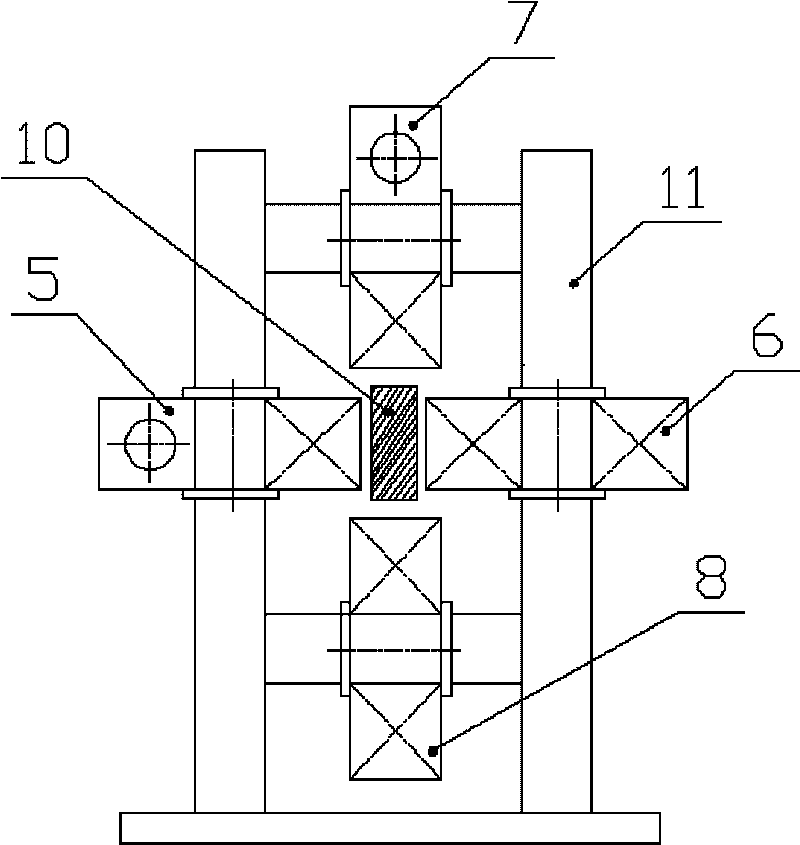

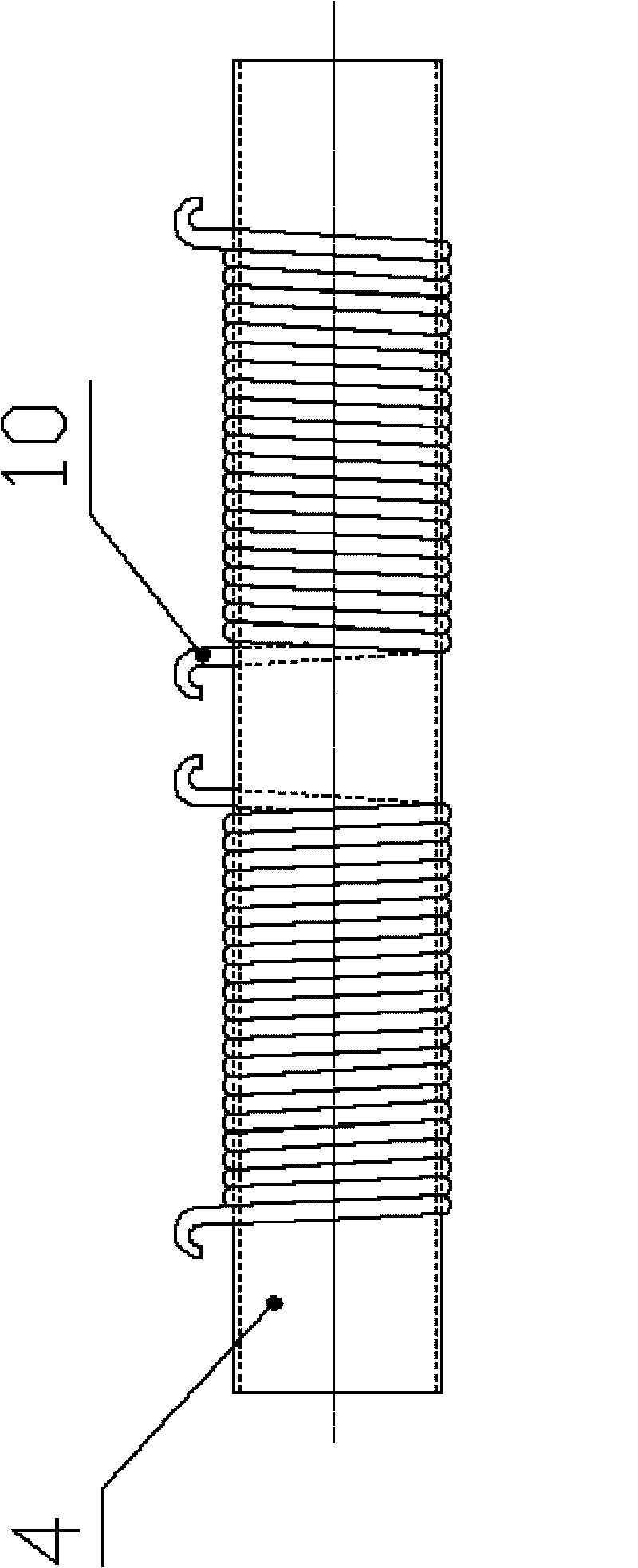

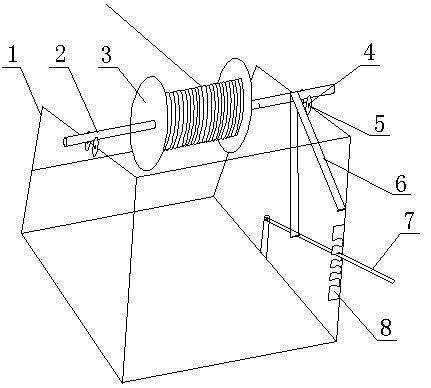

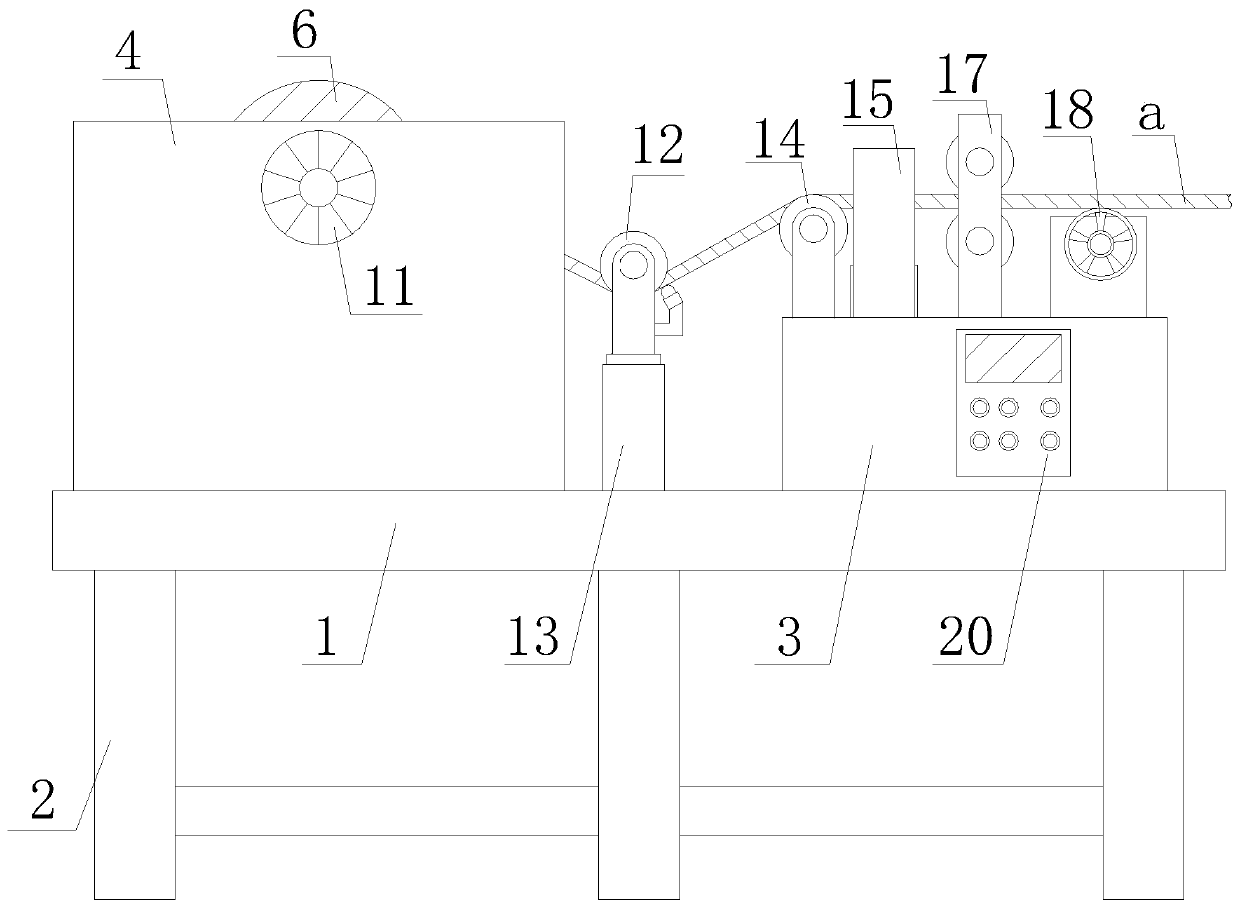

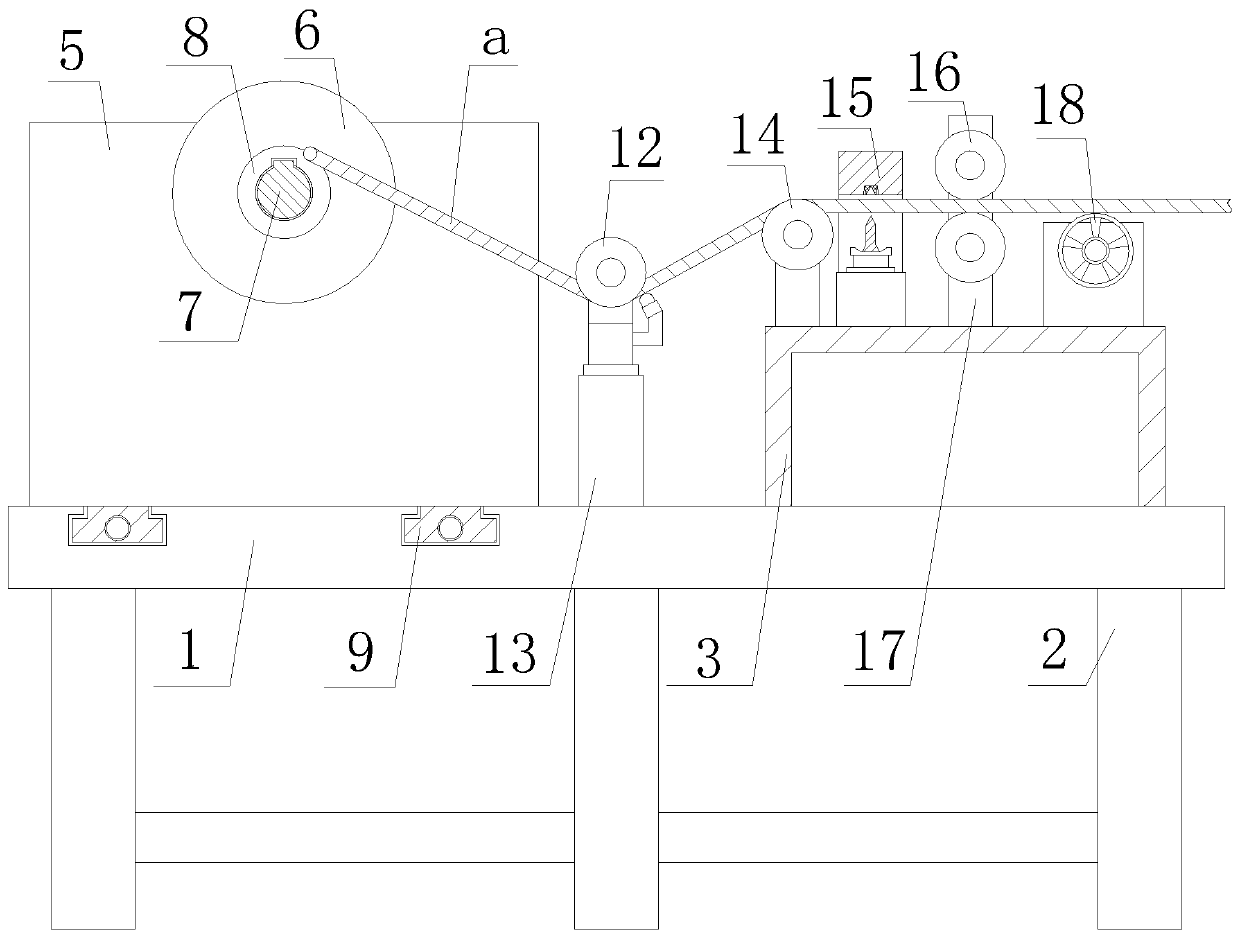

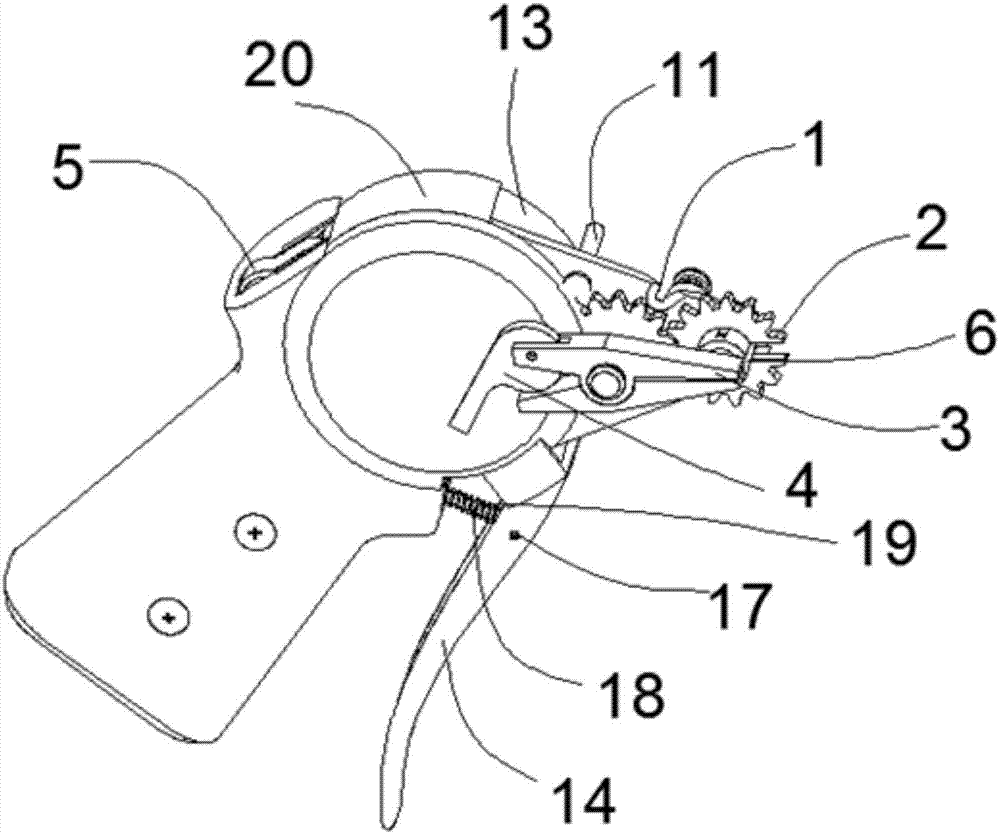

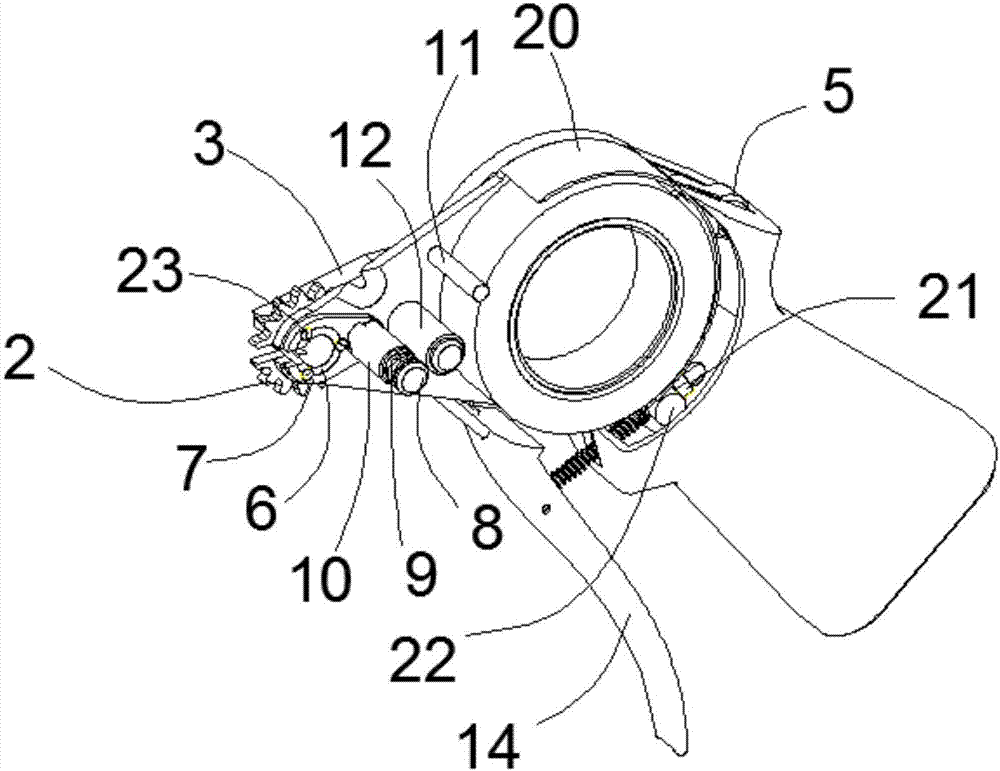

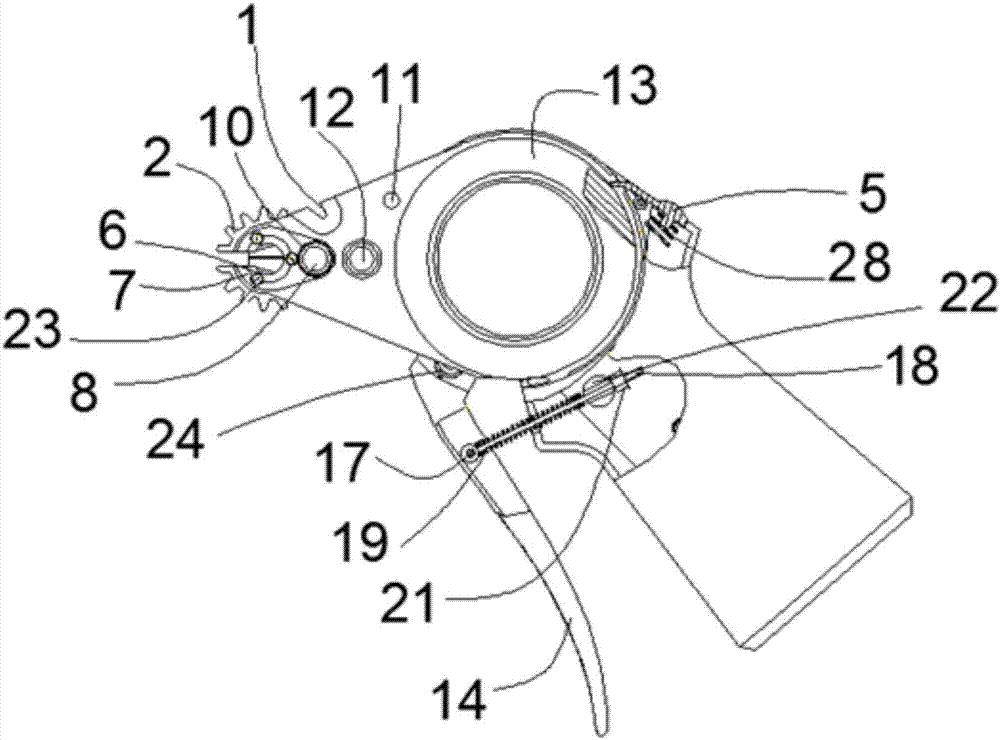

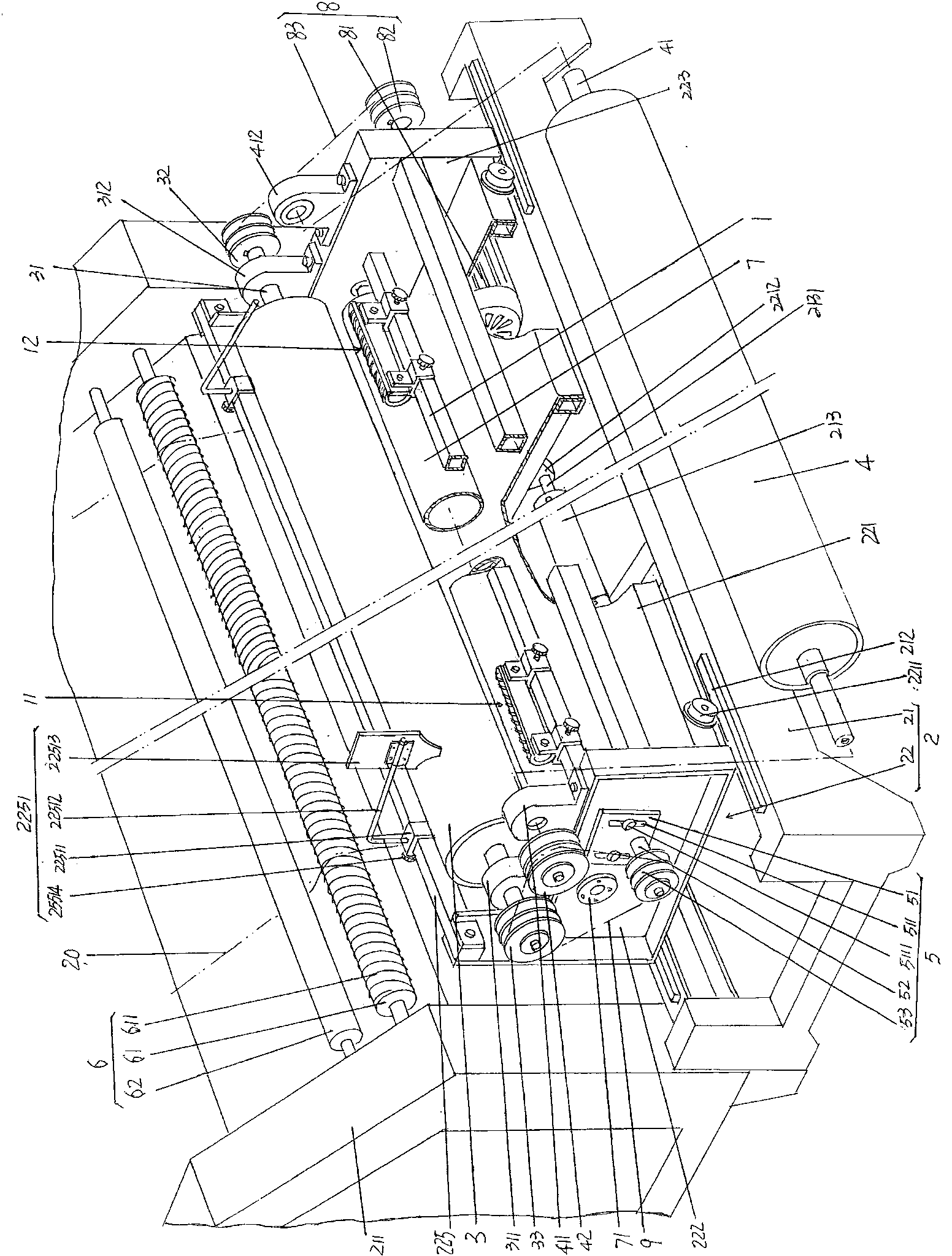

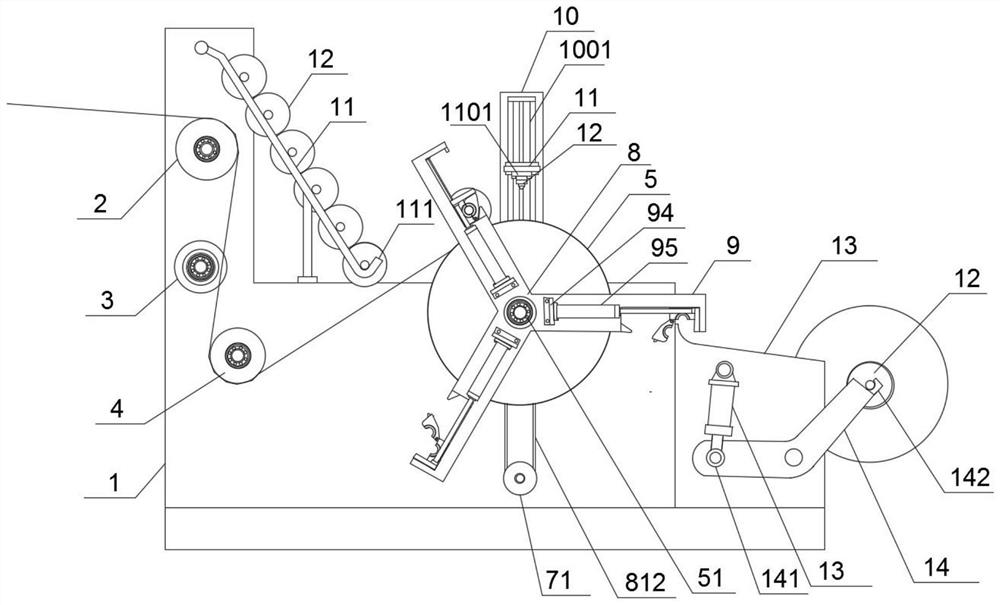

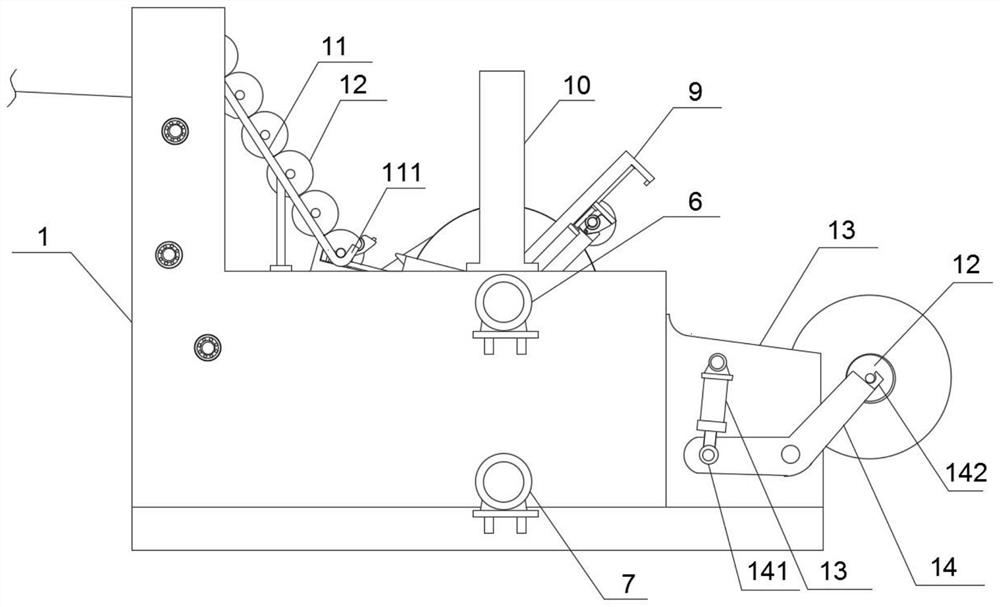

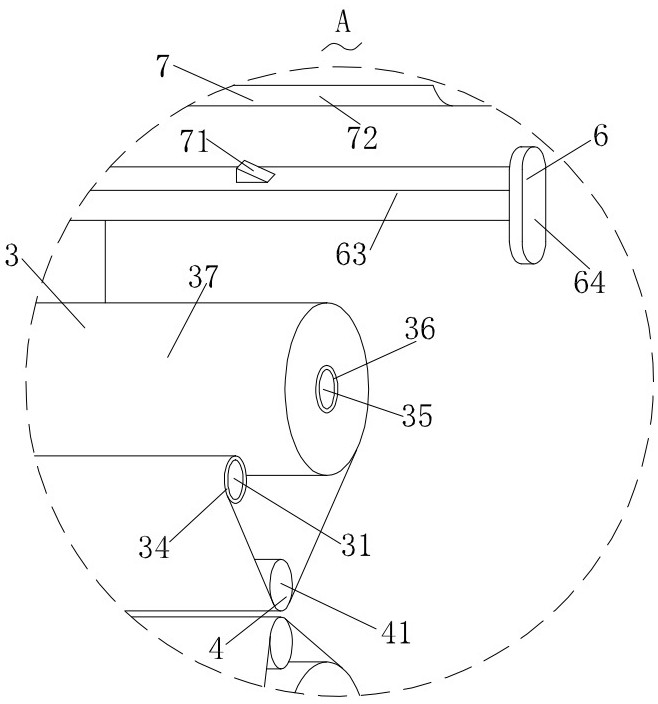

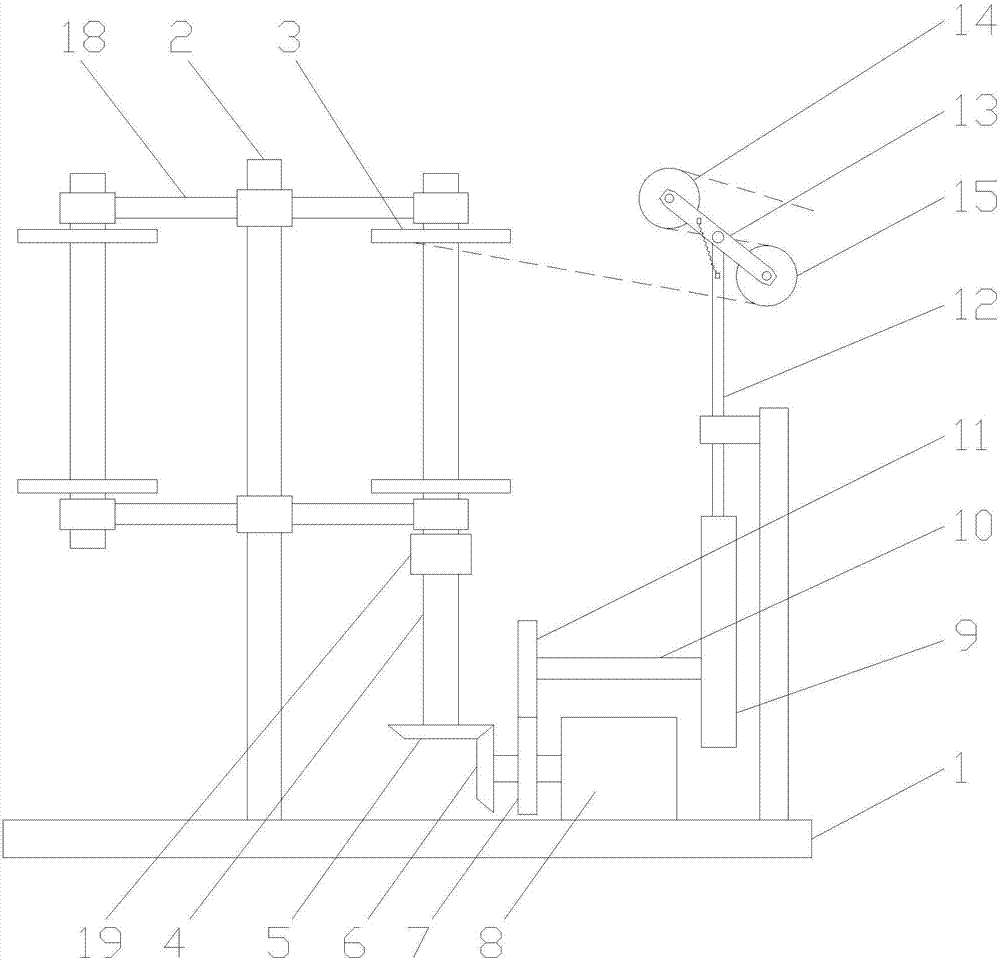

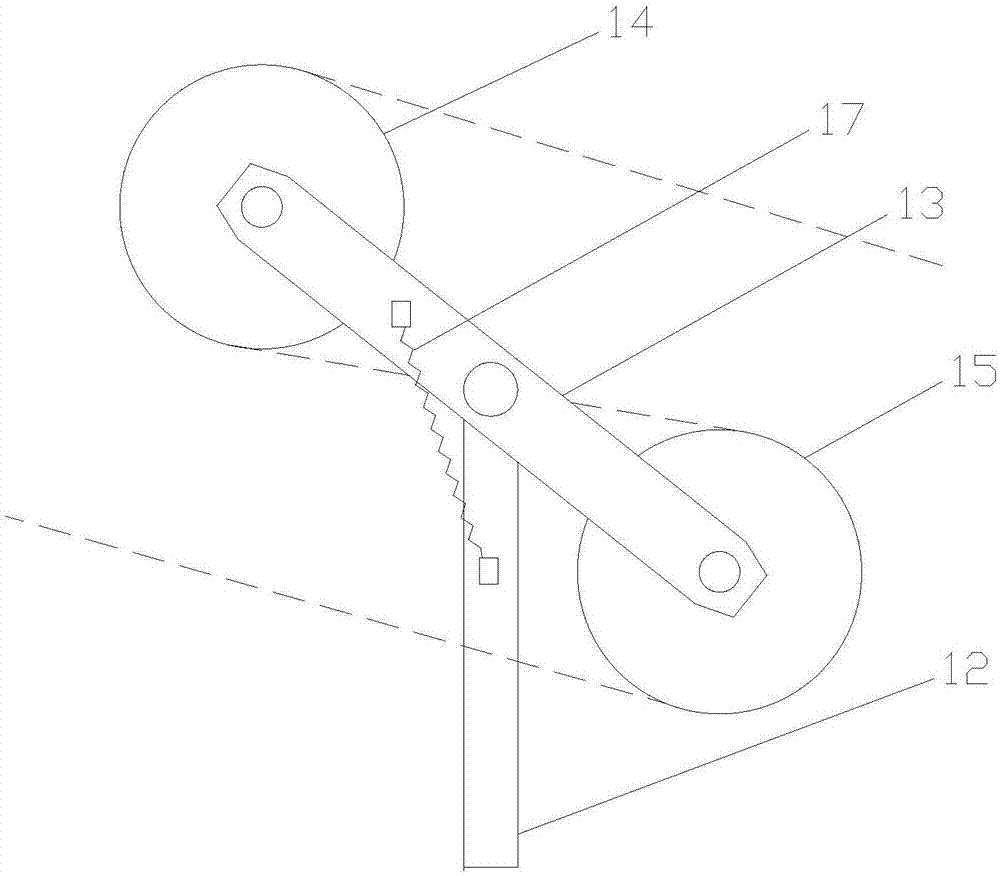

Automation equipment used for line winding procedure during fishing pole production

The invention relates to automation equipment used for a line winding procedure during fishing pole production. The technical problems of inaccurate line winding positions, low product quality, low automation degree, low efficiency and severe dependence on skilled workers, which result from the existing manual operation of workers on a line winding procedure during fishing pole production with simple tools are solved. The automation equipment comprises a base, a control panel, a translation mechanism, a sliding table, a rotating driving mechanism, a support base, a line conveying mechanism and a radial laser locating device, wherein the translation mechanism is connected with the base, the sliding table is connected with the translation mechanism, the rotating driving mechanism is connected with the sliding table, the support base is connected with the sliding table, the line conveying mechanism is connected with the base, and the radial laser locating device is connected with the line conveying mechanism. The automation equipment can be used for the line winding link in the production process of fishing poles.

Owner:SICHUAN ZHONGWU TECH

Decorative cloth cleaning and winding device

PendingCN108411518AImprove finished product qualityGuarantee the quality of windingLiquid/gas/vapor removal by vibrationTextile treatment by spraying/projectingMechanical engineeringTextile

Owner:浙江开盛新材料有限公司

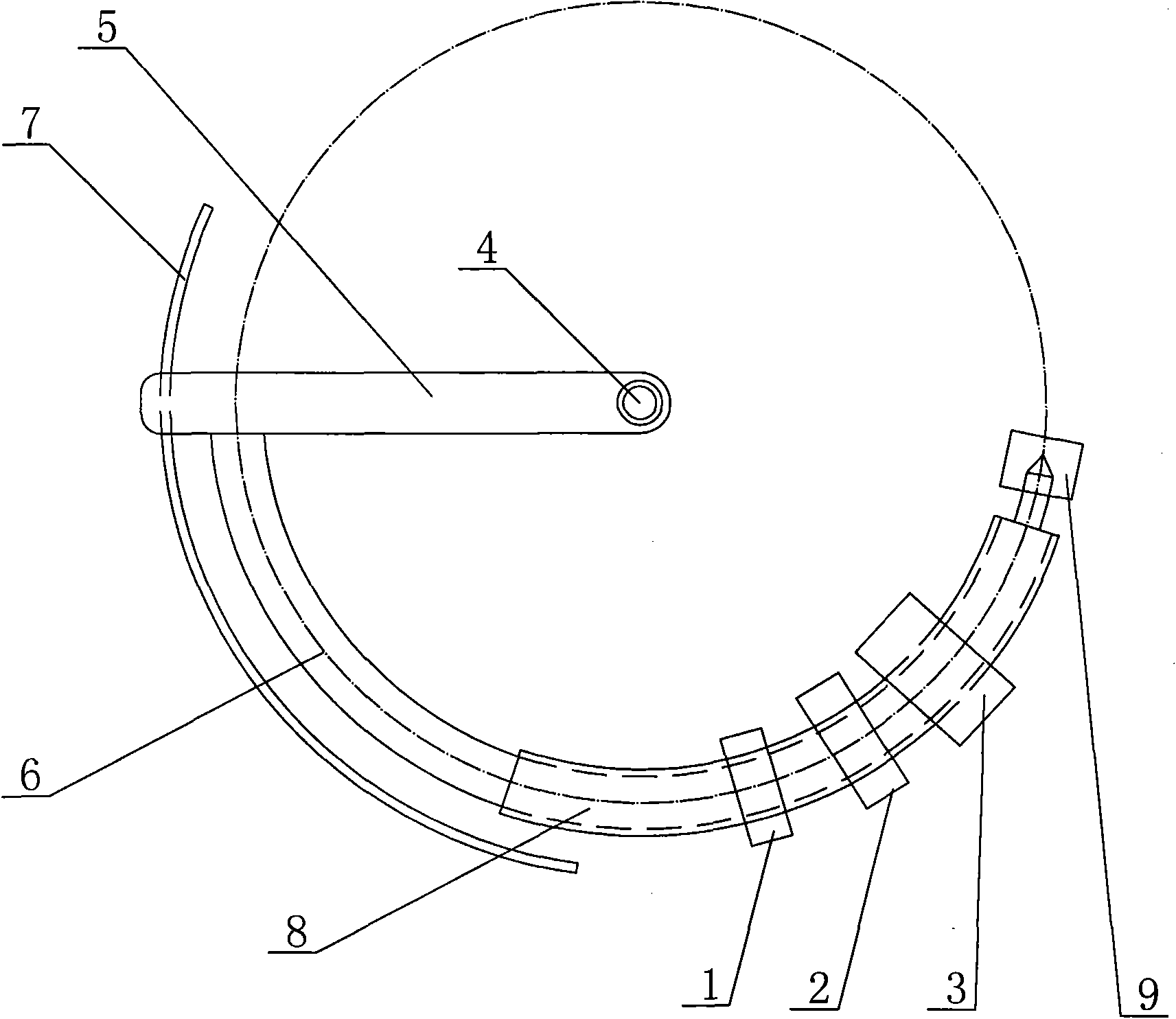

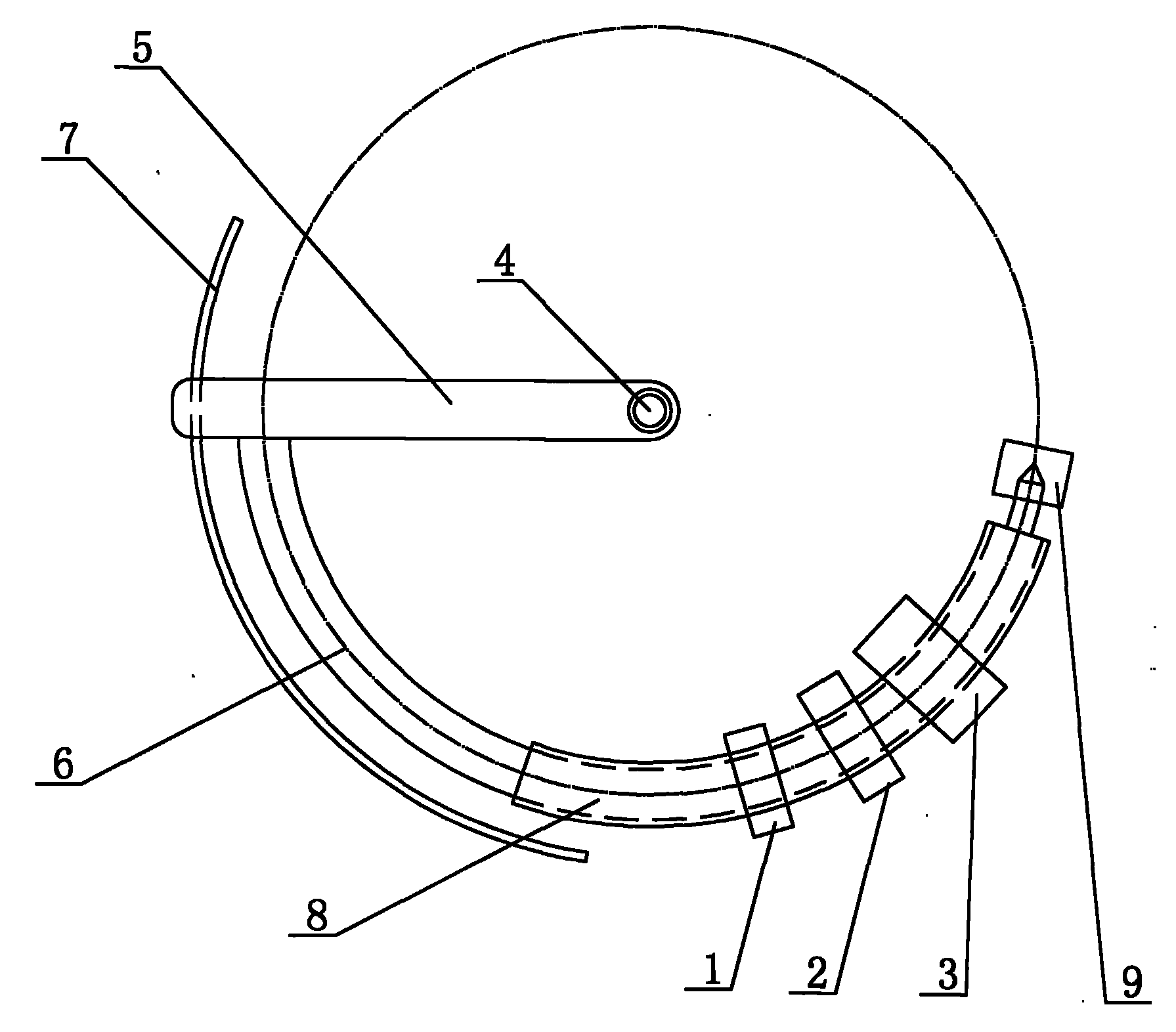

Antiseptic operation system of hot bending bent pipe and operation method thereof

InactiveCN101846230AImprove anti-corrosion performanceExtended service lifeCorrosion preventionPipe protection against corrosion/incrustationMedium frequencyEngineering

The invention discloses an antiseptic operation system of a hot bending bent pipe and an operation method thereof. The antiseptic operation system of the hot bending bent pipe comprises a rotary cantilever which comprises a rotary beam and an arc-shaped cantilever, wherein the rotary beam rotates along a revolving axle, and the arc-shaped cantilever is arranged on the rotary beam; one end of the rotary beam is installed on the revolving axle, and the other end of the rotary beam is supported on an arc-shaped rail; the hot bending bent pipe is fixedly arranged on the arc-shaped cantilever; a medium-frequency heating device, a powder spraying device, a winding device and a cooling device are arranged along the movement locus of the arc-shaped cantilever; and the hot bending bent pipe is successively matched with the medium-frequency heating device, the powder spraying device, the winding device and the cooling device. The invention can simplify the antiseptic drive lines of three layers of PE of the hot bending bent pipe, can quickly improve the operation time of the antiseptic production of the three layers of the PE of the hot bending bent pipe, improves the efficiency of mechanical antiseptic production of the three layers of the PE of the hot bending bent pipe and realizes the mechanical high-efficiency antiseptic production of the three layers of the PE of the hot bending bent pipe.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Efficient thin film slitting machine

InactiveCN105600565AQuality improvementGuaranteed stabilityArticle deliveryWebs handlingEngineeringLocking mechanism

The invention provides an efficient thin film slitting machine. The efficient thin film slitting machine comprises a rack, wherein a feeding roller is arranged on the rack; a slitting blade mechanism for slitting a thin film wound on the feeding roller is arranged above the feeding roller; the thin film, which is slit by the slitting blade mechanism, is wound on a winding mechanism; the winding mechanism comprises at least two rollers which are connected with a first driving mechanism; the two rollers are provided with tensioning mechanisms which are arranged in sequence in a staggered manner; each tensioning mechanism comprises at least one tensioning assembly; each tensioning assembly is connected with a tensioning part which sleeves a winding barrel; an elastic sealing assembly is arranged between each tensioning part and the corresponding roller; each tensioning part is provided with fastening devices which are located at the two sides of the corresponding winding barrel and can be used for tightly clamping the winding barrel; the position between the two fastening devices can be adjusted; locking mechanisms are arranged on the fastening devices. The efficient thin film slitting machine has the advantage of good slitting effect.

Owner:ZHEJIANG OUTE ELECTRONICS TECH CO LTD

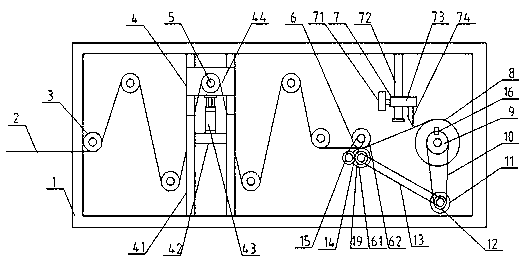

Thermal shrinkage film automatic winding mechanism

The invention provides a thermal shrinkage film automatic winding mechanism, and belongs to the field of winding mechanisms. The thermal shrinkage film automatic winding mechanism comprises a fixed frame, thermal shrinkage films, fixed guide rollers and a winding drum; multiple fixed guide rollers are arranged on the fixed frame; tension adjusting mechanisms are arranged between the fixed guide rollers; movable guide rollers are mounted on the tension adjusting mechanisms; the thermal shrinkage films are bypassed through the fixed guide rollers and the movable guide rollers to pass through anunfolding mechanism, and are wound on the winding drum for winding; a motor is connected with the winding drum through a chain; and a film cutting mechanism is arranged at the front part of the winding drum. The thermal shrinkage film automatic winding mechanism is reasonable in structure and stable in operation; the thermal shrinkage films are tidily wound on the winding drum; the unfolding mechanism has a feeding function, and is matched with the winding drum for rotation to achieve high winding speed and high production efficiency; the stretching tension of the thermal shrinkage films can be automatically adjusted, so that the product damage is prevented, the winding quality is guaranteed, and the thermal shrinkage films are tightly wound without loosening; and the film cutting mechanism is provided for automatically cutting off the thermal shrinkage films.

Owner:SHANDONG ZHONGSU TAIFU TECH

PLM clothing processing and designing tailoring device

InactiveCN108049157AGuarantee the quality of windingEasy to operateSevering textilesEngineeringConductor Coil

The invention discloses a PLM clothing processing and designing tailoring device and belongs to the technical field of clothing processing equipment. The PLM clothing processing and designing tailoring device comprises a rack and a mounting bracket which is fixed at the top of the rack; a supporting roller is rotatably connected to the bottom end of a supporting rod through a pin shaft; the top ofthe supporting rod is connected with a transverse rod at the top of the mounting bracket; a fabric on the supporting roller is connected with a supporting wheel which is fixedly mounted at the top ofthe rack; a guide wheel is further arranged between a winding roller and the supporting wheel; a driving air cylinder is mounted at the top of the mounting bracket; a bottom output end of the drivingair cylinder is connected with a retractable rod. According to the PLM clothing processing and designing tailoring device disclosed by the invention, when the fabric needs to be tailored, the fabricis tightly pressed by utilizing a pressing device, and the fabric is fixed; a tailoring cutter assembly is used for tailoring the pressed fabric, and a tailored cutting opening is uniform, so that thewinding quality of the fabric can be ensured in a winding process; the PLM clothing processing and designing tailoring device is simple and reliable to operate, reasonable and novel in structure andeasy to popularize and apply.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

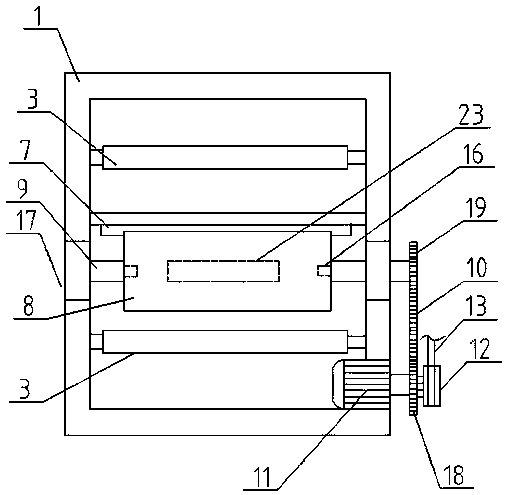

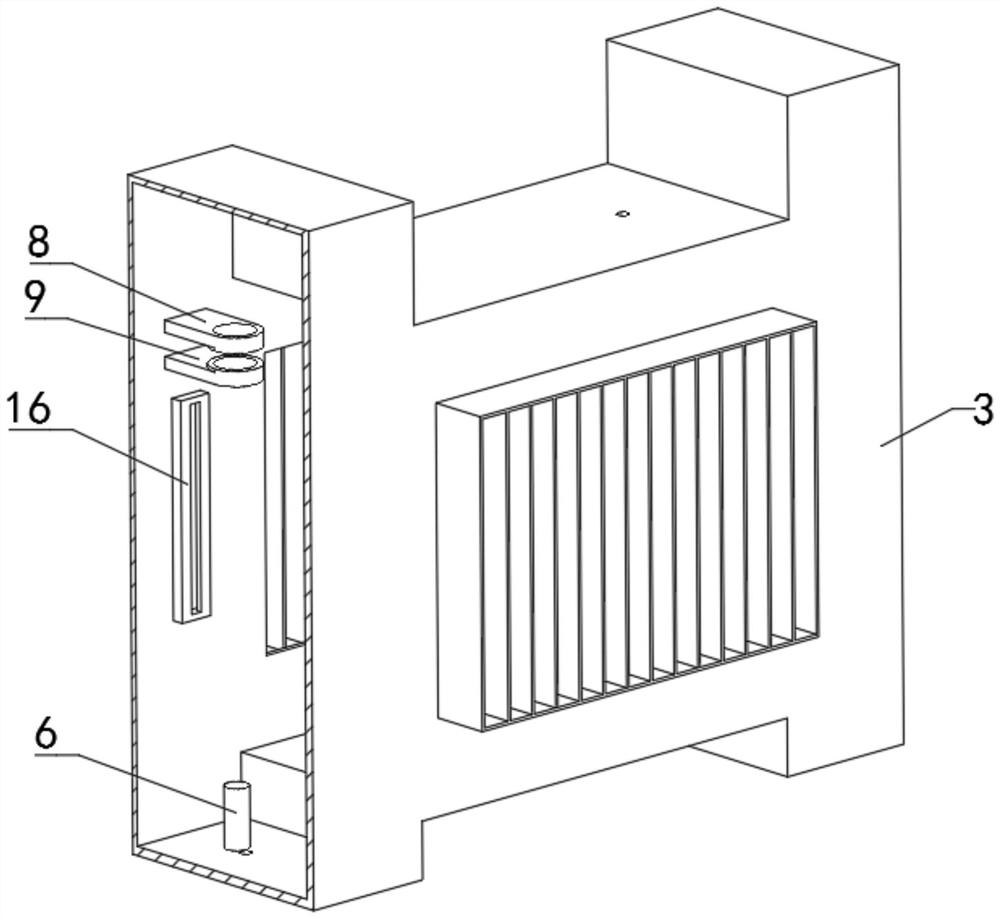

Dust removal equipment for processing of anti-static cotton cloth

ActiveCN110359263AGuarantee the quality of windingImprove the efficiency of winding and dust removalMechanical cleaningPressure cleaningWaste management

The invention belongs to the field of cotton cloth processing auxiliary devices and particularly discloses dust removal equipment for processing of anti-static cotton cloth. Aiming at the problem of influences on product quality due to residual dust on the surface of existing cotton cloth in rolling up, the scheme is put forward and includes that the dust removal equipment comprises a chamber, a dust box, a first air pipe, an air suction device, a first guide component, a sweeping component, a second guide component, a rolling-up component, a second air pipe, air suction covers and an airtightdoor. The chamber is provided with a feeding hole and a discharging port and internally provided with the first guide component, the sweeping component, the second guide component and the rolling-upcomponent sequentially in a direction from the feeding hole to the discharging hole. The second air pipe is arranged between the sweeping component and the second guide component, the air suction covers are arranged at equal intervals on the second air pipe, and the second air pipe is communicated with the dust box through the air suction device. The dust box is provided with an exhaust hole and internally filled with water, and the first air pipe is connected with an air inlet hole to extend into water. The dust removal equipment is simple in operation, convenient to use and effective in removal of dust on rolled-up cotton cloth.

Owner:江苏五誉兴华之瑜新材料科技有限公司

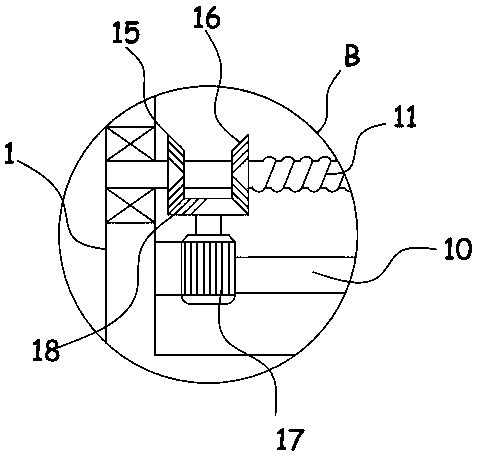

Device for winding coil by rectangular conducting wire

InactiveCN101702373AAxially arranged tightly and neatlyReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses a device for winding a coil by a rectangular conducting wire, which can enhance the winding quality of the rectangular conducting wire. The device for winding the coil by the rectangular conducting wire comprises a wire coil disk, a wire pressing device and a horizontal type wire winding machine which are sequentially arranged, wherein a coil framework is arranged on the horizontal type wire winding machine, and a positioning device which can penetrate and sleeve the rectangular conducting wire and enable the narrow side of the section of the rectangular conducting wire to be in a horizontal state is arranged between the wire pressing device and the horizontal type wire winding machine. The device has simple structure, very low cost and very convenient turning, lightens the labor strength of operators, reduces the number of the operators, lowers the winding difficulty, also shortens the winding time, ensures the tight and tidy axial arrangement and the tight radial winding of the coil after the winding is completed, ensures the winding quality and is especially suitable for popularization and use on a winding device which needs to wind the narrow side of the section of a conducting wire onto a coil framework; in addition, the rectangular conducting wire only needs to penetrate through the positioning device.

Owner:攀枝花钢城集团瑞泰电器有限公司

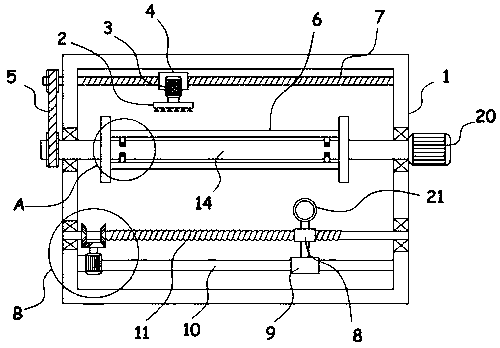

Power cable winding device

The invention discloses a power cable winding device, and relates to the technical field of cable winding. The power cable winding device comprises a fixing frame, wherein elastic tightening pieces for tightening a cable is arranged on a winding shaft, a threaded rod parallel to the winding shaft is rotationally installed in the fixing frame, an adjusting assembly used for adjusting the winding position of the cable relative to the winding shaft is arranged on the threaded rod, a reversing mechanism used for adjusting forward and reverse rotation of the threaded rod is arranged on the fixing frame, and a cleaning mechanism for cleaning the cable is fixed in the fixing frame. According to the power cable winding device, the winding effect on the cable is achieved through rotation of the winding shaft, the elastic tightening pieces are arranged to carry out elastic support on the cable, so that the cable is guaranteed to be firmly wound around an arc supporting plate, the adjusting assembly is arranged to achieve horizontal movement under the driving of the reversing mechanism so that the cable can be automatically adjusted relative to the winding position of the winding shaft, the cable can be uniformly wound around the arc supporting plate, and the cable winding quality is effectively guaranteed.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

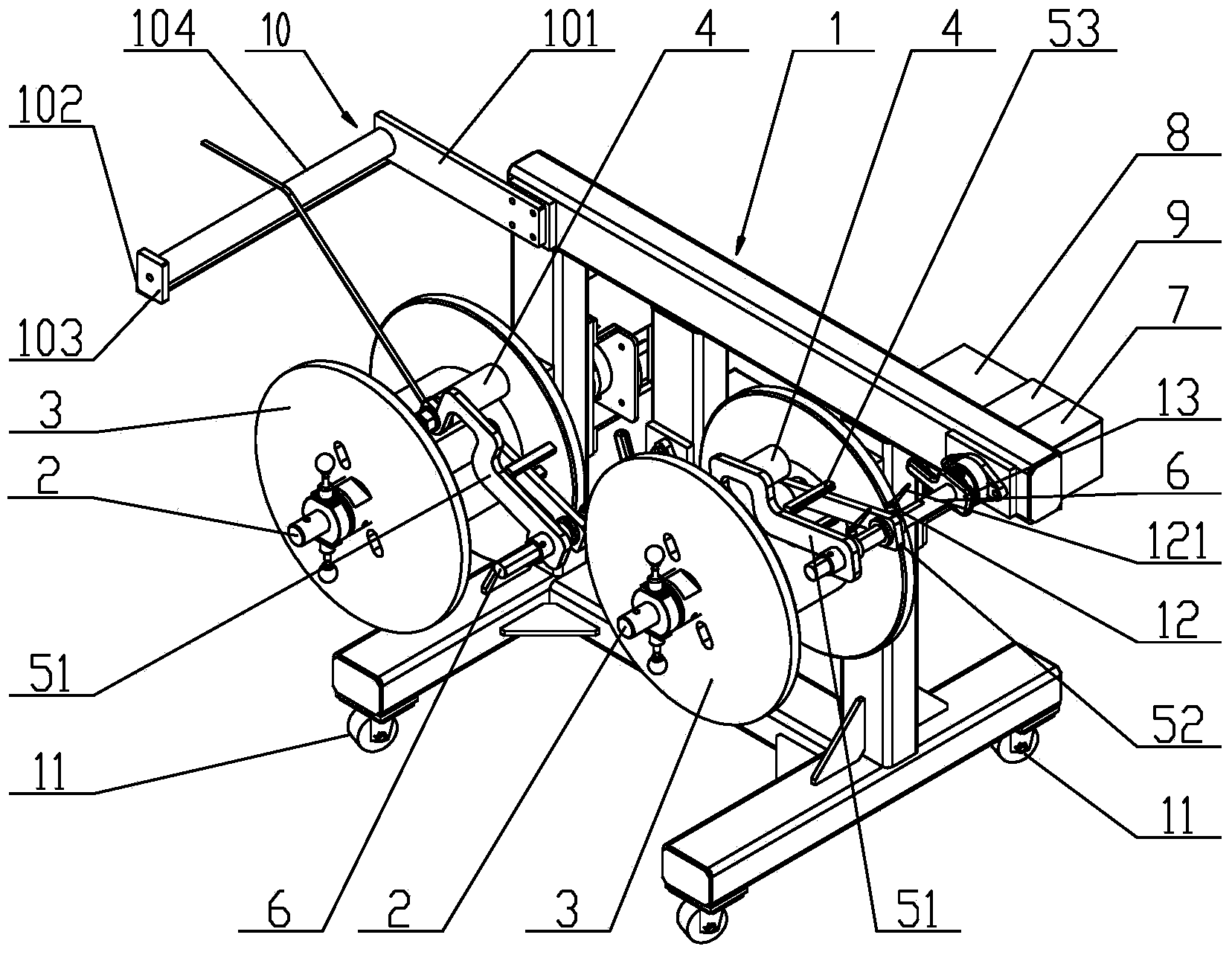

Wire wheel unwinding frame

The invention discloses a wire wheel unwinding frame. The frame comprises a bracket and a rotating shaft which penetrates through a wire wheel, wherein a support limit mechanism is arranged on the top of the bracket; a tensioning braking device is arranged on the lower part of the bracket; the support limit mechanism comprises support rollers which are connected with the bracket through mandrels; the tensioning braking device comprises a positioning support plate, an operating rod and a flexible friction belt; the positioning support plate is fixedly connected with the bracket and provided with a positioning clamping groove; one end of the operating rod is hinged with the bracket, and the other end of the operating rod is matched with the positioning clamping groove; and one end of the flexible friction belt is fixedly connected with the bracket, and the other end of the flexible friction belt moves around the rotating shaft and is connected with the operating rod. By the wire wheel unwinding frame, winding quality can be reliably ensured, and production efficiency is improved by more than two times; meanwhile, the occupancy rate of personnel can be reduced, labor intensity is reduced, and labor cost is saved; and the wire wheel unwinding frame has a simple structure, is convenient to operate, is simple, convenient and practical, and is reliable in performance.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

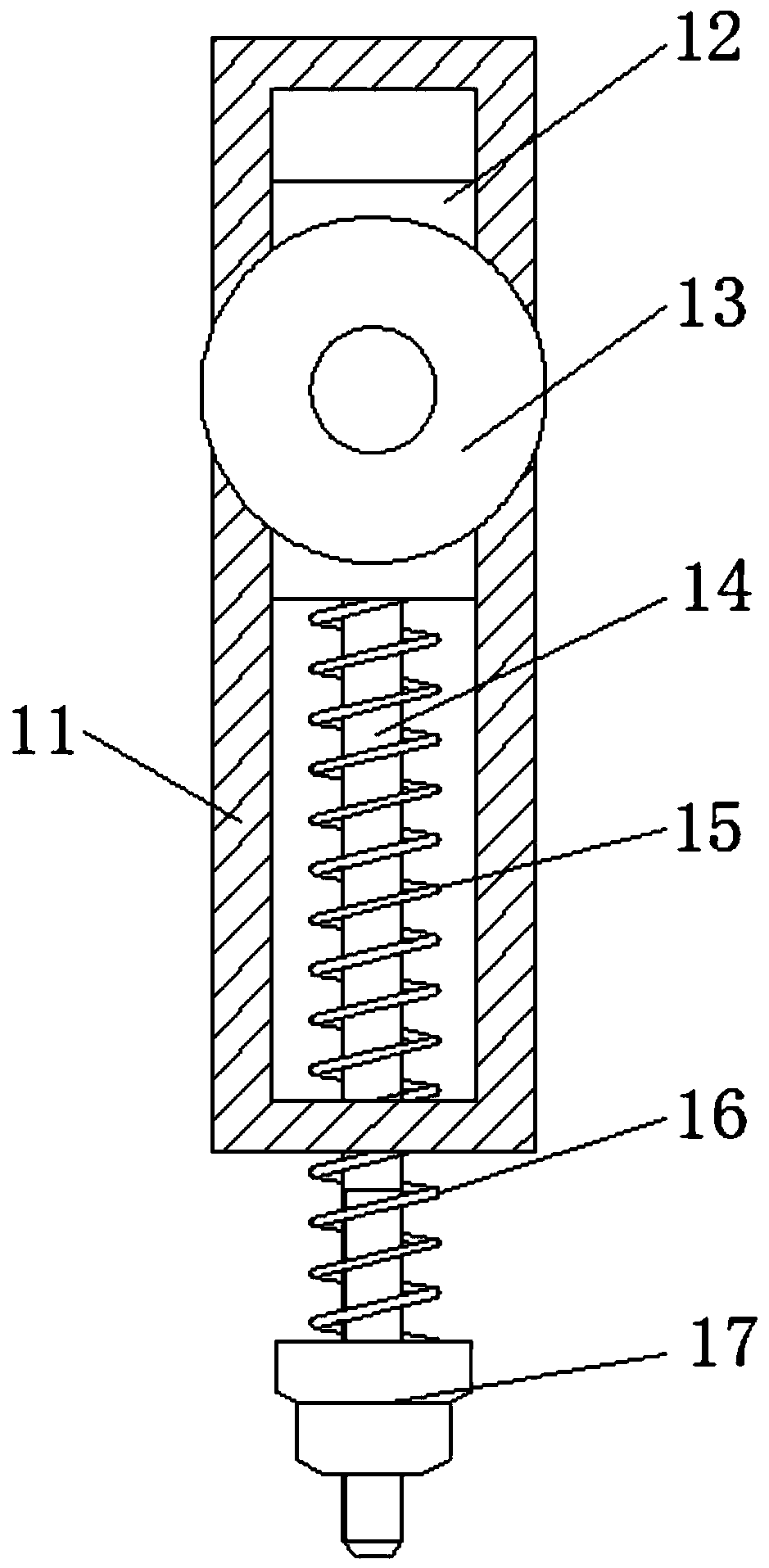

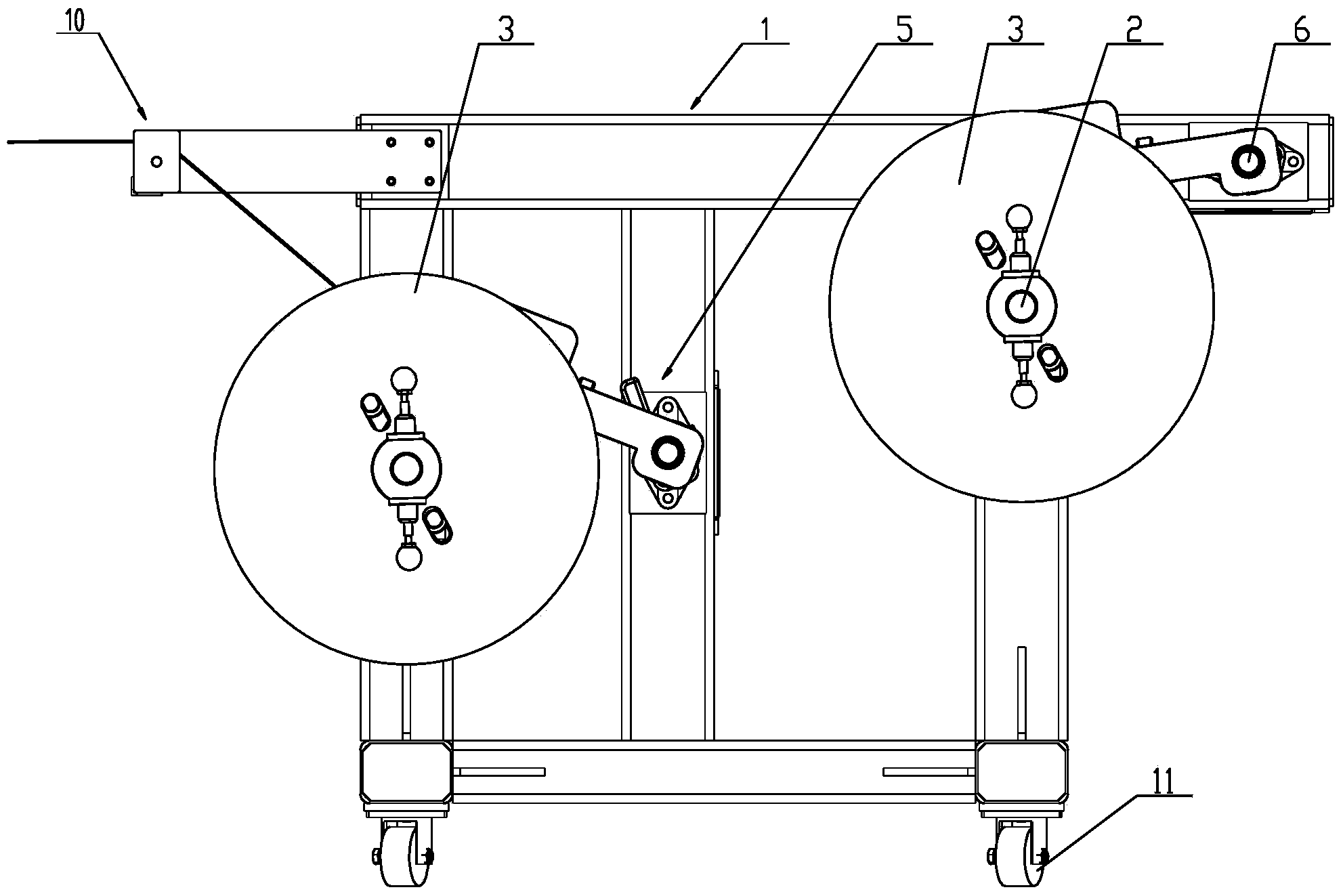

Constant-tension pay-off rack

ActiveCN103708288ASatisfy pay-off tension requirementsIncrease braking powerFilament handlingPulp and paper industry

The invention discloses a constant-tension pay-off rack, and relates to the field of cable production equipment. The constant-tension pay-off rack comprises a machine frame, a winding shaft, a winding reel pressing roller, a pressing roller arm set, a pressing roller shaft, an angle sensor, a brake and a controller, wherein the winding shaft is installed on the machine frame and is provided with the brake, a winding reel is fixedly connected with the winding shaft, the pressing roller shaft is installed on the machine frame, the pressing roller shaft is provided with the angle sensor, one end of the pressing roller arm set is connected with the pressing roller shaft, the other end of the pressing roller arm set is connected with the pressing roller, the pressing roller is pressed above a wire winding portion on the winding reel, the signal output end of the angle sensor is connected with the signal input end of the controller, and the signal output end of the controller is connected with the signal input end of the brake. The constant-tension pay-off rack is simple in structure, low in manufacturing cost, needless of a motor, environmentally friendly, convenient to operate, and capable of controlling pay-off tension constancy.

Owner:北京新特电气有限公司

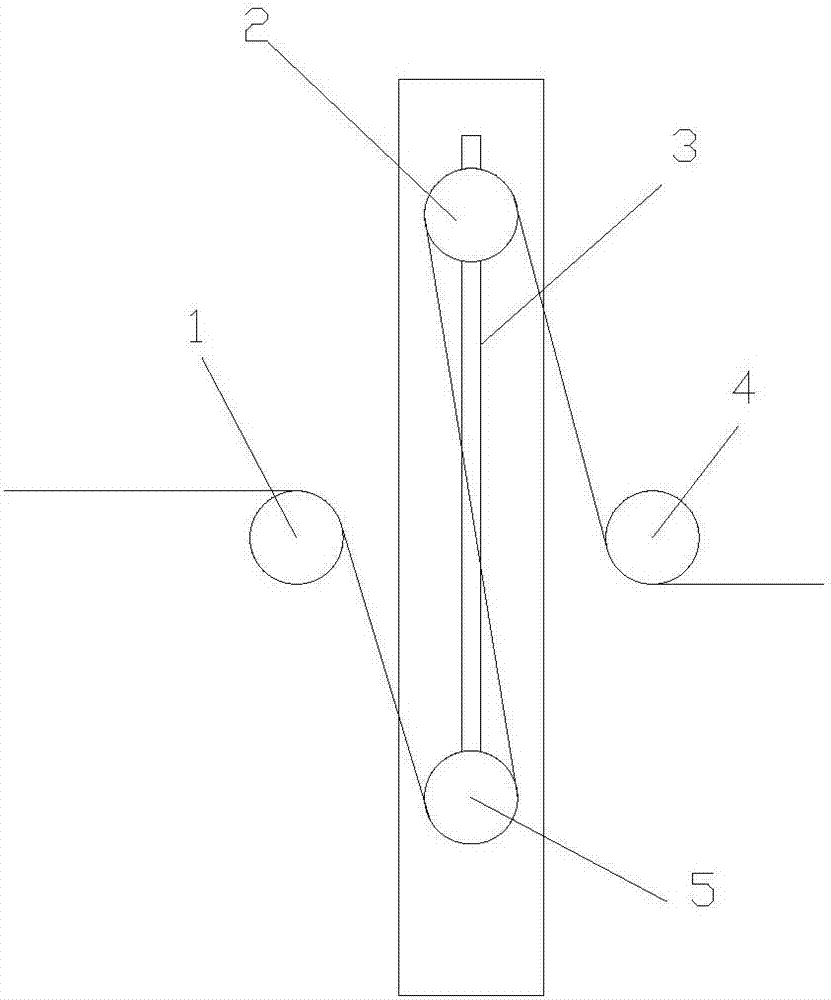

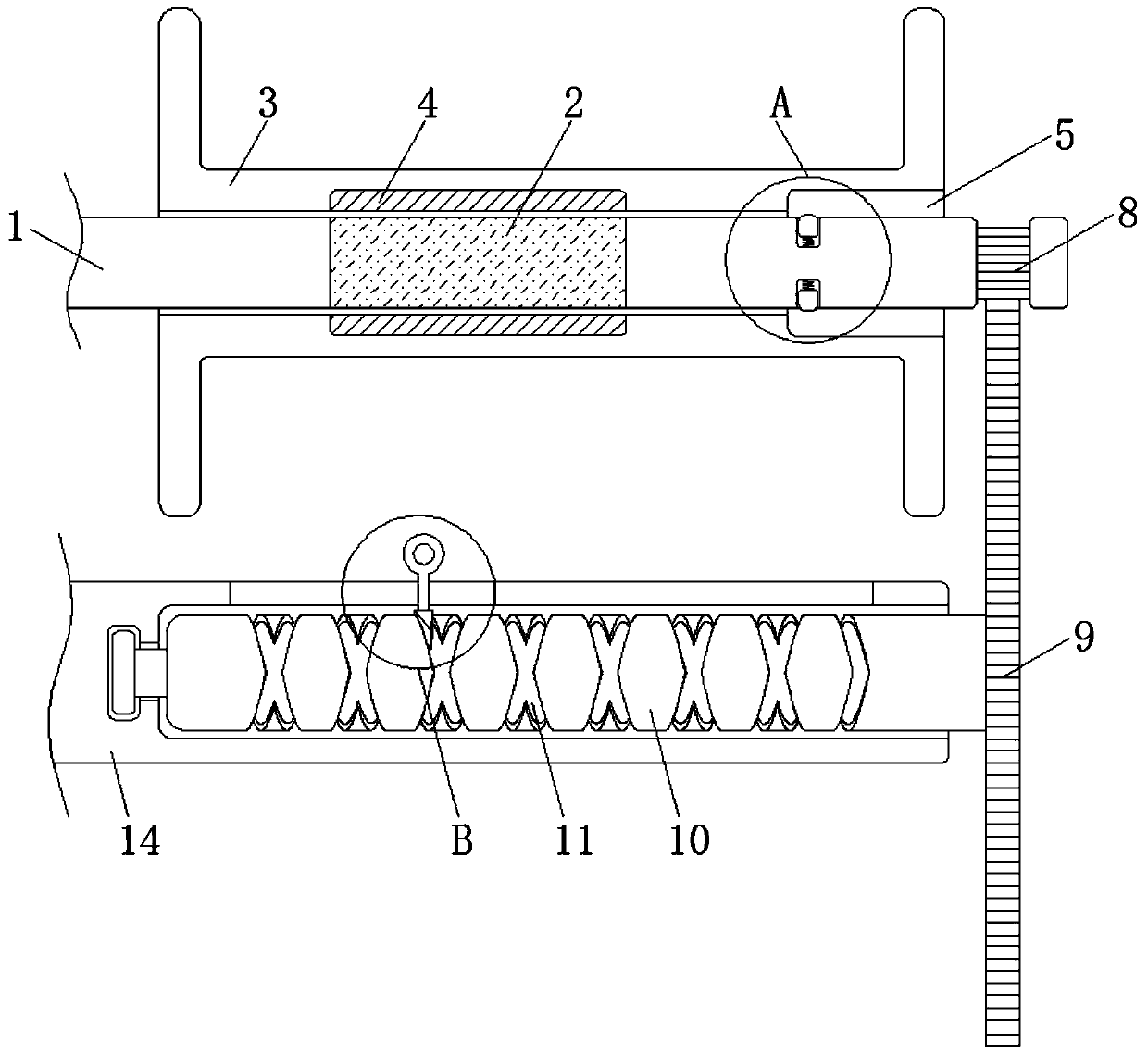

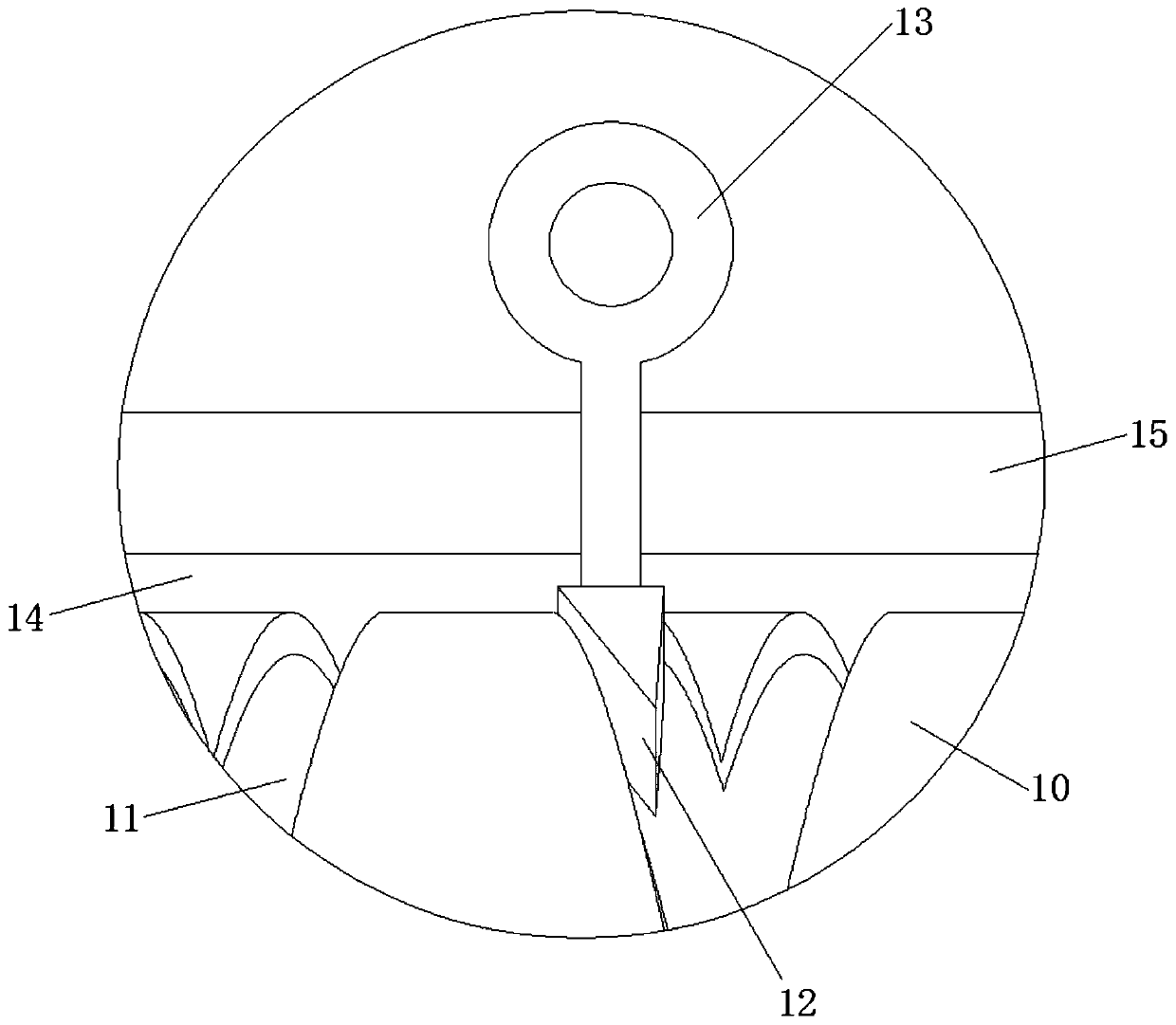

Cloth guide and dehumidification device capable of automatically adjusting tension

ActiveCN106892291AImprove flatnessGuarantee the quality of windingWebs handlingEngineeringCircular surface

The invention discloses a cloth guide and dehumidification device capable of automatically adjusting tension. The cloth guide and dehumidification device comprises a front guide roller and a rear guide roller, wherein a tensioning mechanism for tensioning cloth is arranged between the front guide roller and the rear guide roller; the tensioning mechanism comprises a rack, a fixed roller fixed on the rack, and a movable roller which is parallel to the fixed roller and is in sliding fit with the rack in a sliding manner along the vertical direction; a spring for enabling the movable roller and the fixed roller to get away from each other is connected between the movable roller and the rack; the fixed roller comprises a roller shaft and a roller sleeve sleeved outside the roller shaft in a rotatable manner; and an electrothermal wire for heating the roller sleeve is arranged on the outer circular surface of the roller shaft. The cloth guide and dehumidification device can enable anti-wear decorative cloth to be in a tensioned state all the time in a process of conveying the cloth to a material collection roller, and can also heat and dry the cloth before the cloth is wound, so that the wound cloth cannot get mildewed.

Owner:浙江斯泰堡纺织有限公司

Textile silk yarn winding device

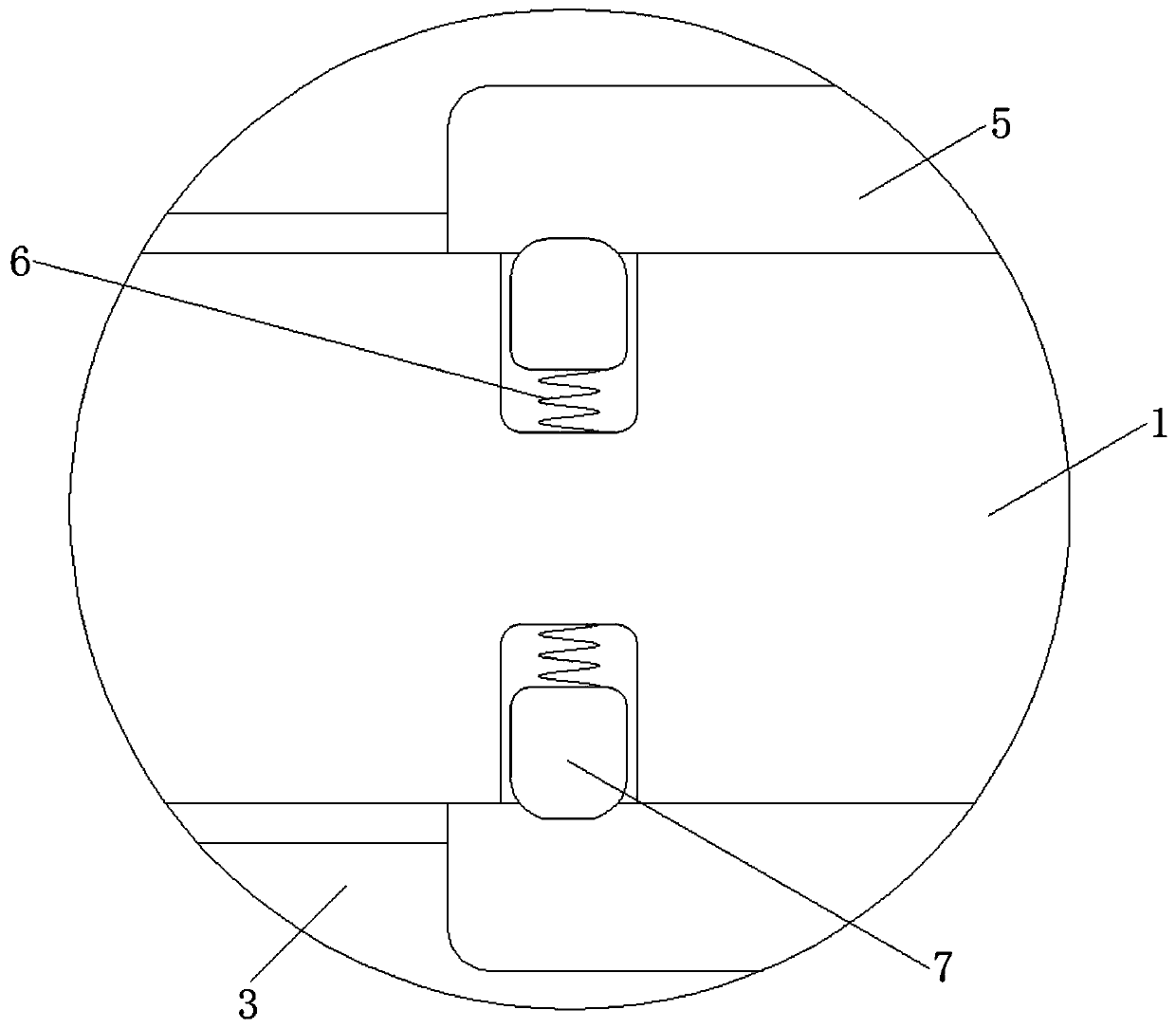

The invention discloses a textile silk yarn winding device and relates to the technical field of textile. The textile silk yarn winding device comprises a rotating shaft; a friction ring is fixedly connected to the outer side of the rotating shaft; a yarn winder is inserted connected with the outer side of the rotating shaft in an inserting mode; the inner wall of the yarn winder is fixedly connected with grinding sand; the middle of the yarn winder is provided with a stepped groove; the inner wall of the rotating shaft is fixedly connected with first springs which are evenly distributed; theouter sides of the first springs are fixedly connected with a movable block which is movably connected with the inner wall of the rotating shaft; and the right side of the rotating shaft is provided with a tooth groove. According to the textile silk yarn winding device, through coordinate application of the movable block and the friction ring, when silk yarns need to be wound, the yarn winder is arranged on the outer side of the rotating shaft in a sleeving mode, after sleeving, the friction ring and makes contact with the grinding sand, friction force of the yarn winder drum and the rotatingshaft are increased, meanwhile, when the rotating shaft drives the yarn winder to rotate, the movable block will throw the rotating shaft away under the action of centrifugal force, the movable blockis clamped with the stepped groove, the yarn winder is fixed on the rotating shaft, thus, the effect of fixing the yarn winder is achieved, the yarn winder is effectively prevent from rotating and swaying, and the silk yarn winding quality is ensured.

Owner:嘉兴市恒悦纺织股份有限公司

Traction coiling device for cable processing

The invention relates to the cable processing device technology field, and provides a traction coiling device for cable processing. The traction coiling device for the cable processing aims at solvingthe problems that 1) the standard coiled length of a cable cannot be accurately controlled; 2) in the coiling process of the cable, processing personnel need to pay attention to coiling progress at any moment, and a labor load is huge; and 3) after cable coiling is completed, the cable is inconvenient to fetch from the device, and coiling efficiency of the cable is influenced in a traditional electric coiling device. The traction coiling device for the cable processing comprises a processing platform and a plurality of support feet installed at the lower end of the processing platform, and further comprises a cable bundling cylinder, a tensioning assembly and a length counter, wherein a coiling shaft is inserted into the middle of the cable bundling cylinder, the front end of the coilingshaft runs through the side wall of a fixed plate and is installed at an output end of a first drive motor, the rear end of the coiling shaft is inserted into the side wall of a moving plate, and a cable dismounting mechanism is installed at the lower end of the moving plate. The traction coiling device for the cable processing is particularly suitable for semi-automatic coiling in the coil processing, and has high social use value and wide application prospects.

Owner:ANHUI CABLE

Electric wire connector

ActiveCN107317205AGuaranteed contact effectWind evenlyLine/current collector detailsStructural engineeringWire fixation

The invention discloses an electric wire connector that can reduce the labor intensity and has relatively good wiring quality. The electric wire connector comprises a wire connector main body, a wiring mechanism, a driving mechanism and an electric wire fixing device; the wiring mechanism comprises a wiring shaft rotatably arranged on the wire connector main body, and the driving mechanism is arranged on the wire connector main body and is in transmission connection with the wiring shaft; and the electric wire fixing device is arranged on the wire connector main body, and a clamping and fixing position of the electric wire fixing device corresponds to one end of the wiring shaft. The electric wire connector is used for connecting power lines, the thread residues are uniformly twined, the compactness is proper, and the lapping parts are sufficient, thereby being conducive to guaranteeing the contact performance of electric wires, meanwhile, the labor intensity is reduced, the wiring efficiency is improved, and moreover, the quality and efficiency of twining insulating tapes are improved.

Owner:PANZHIHUA UNIV

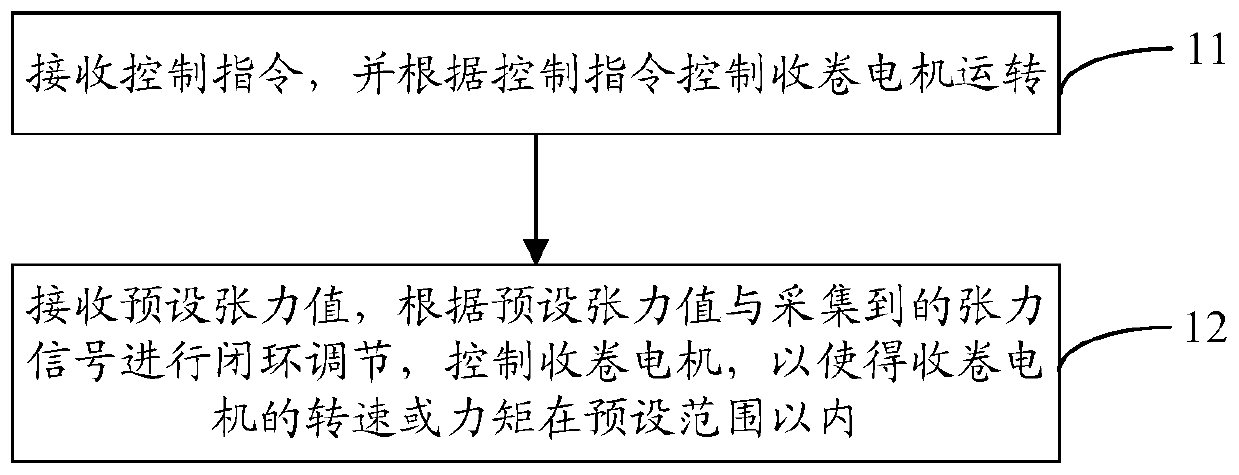

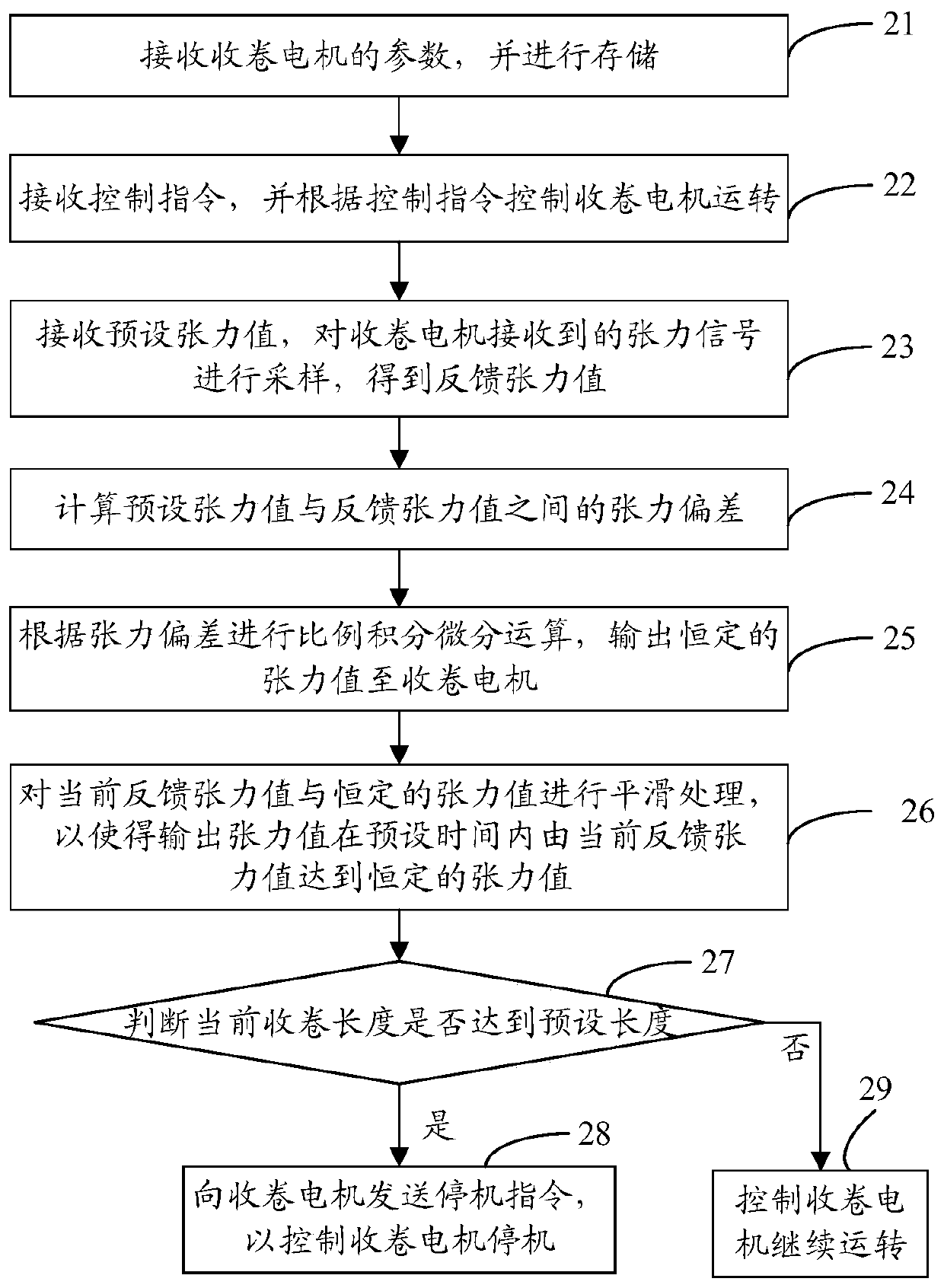

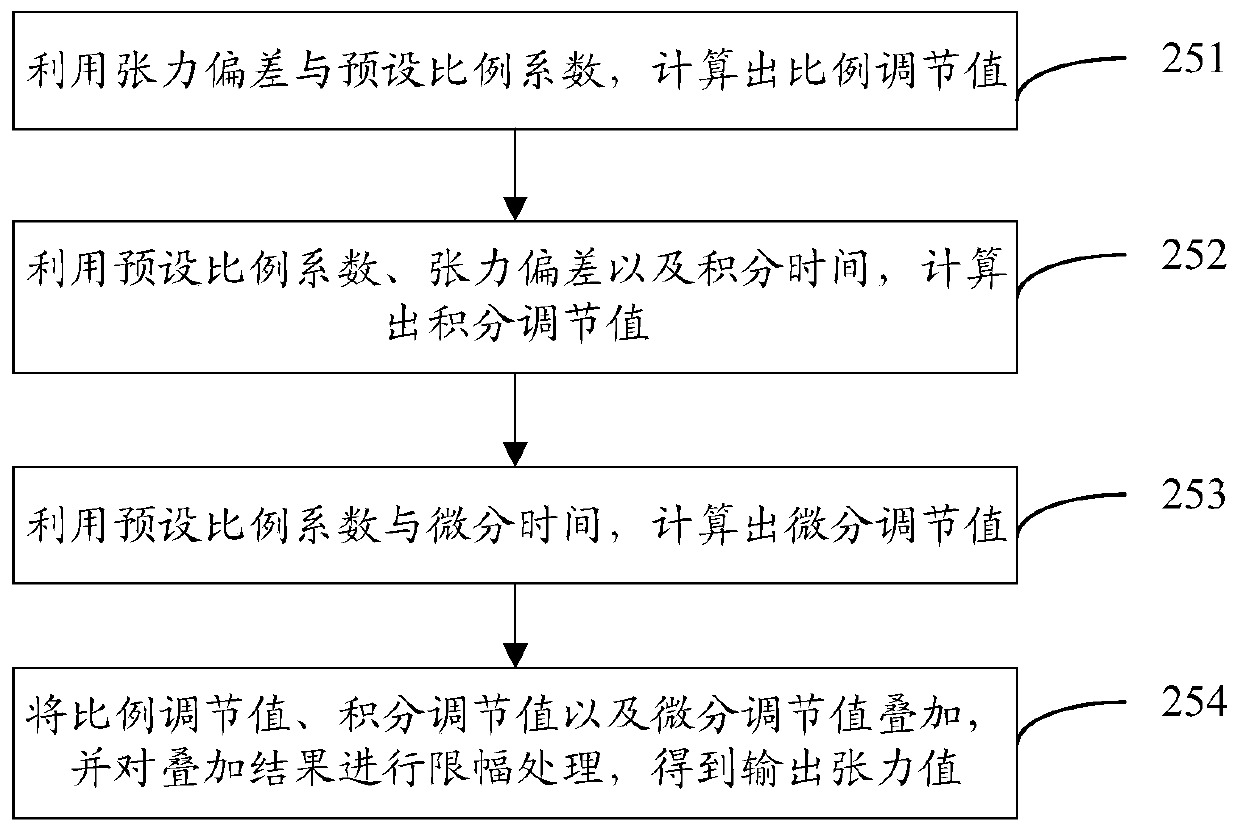

Winding control method, device and system and computer storage medium

The invention discloses a winding control method, device and system and a computer storage medium. The winding control method is applied to the winding system, and the winding system involves a winding motor; and the method comprises the following steps of receiving a control instruction and controlling the winding motor to operate according to the control instruction; and receiving a preset tension value, carrying out closed-loop adjustment according to the collected tension signal and the preset tension value, and controlling the winding motor, so that the rotating speed or moment of the winding motor is within a preset range. According to the winding control method, device and system, the tension control precision can be improved, and the winding quality is guaranteed.

Owner:苏州安驰控制系统有限公司

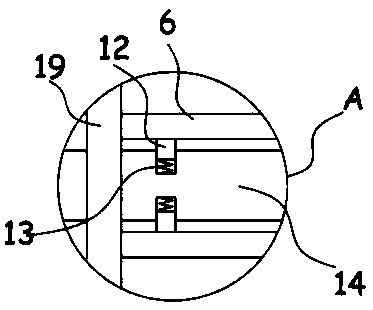

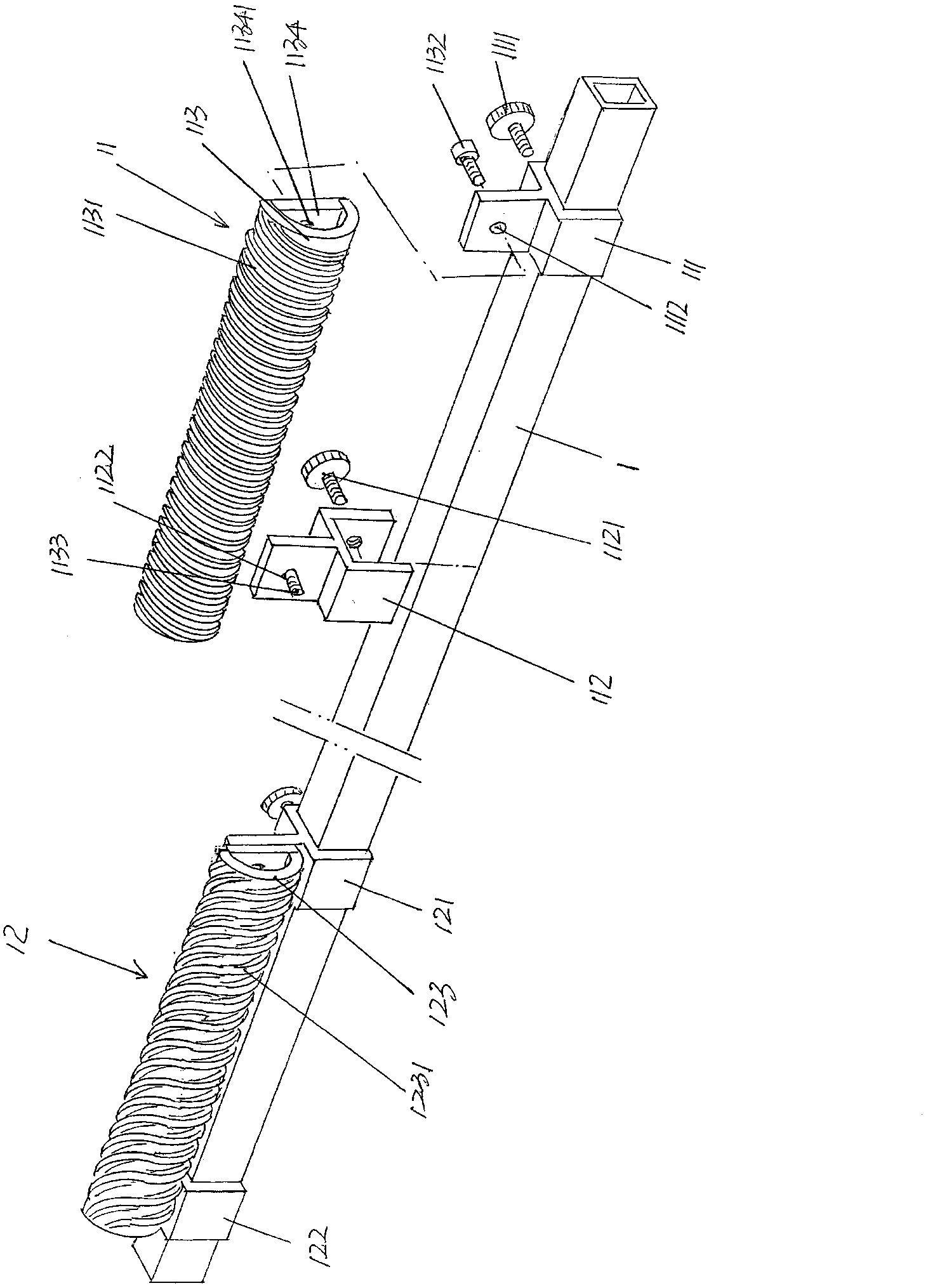

Edge peeling mechanism for knitwear rolling and inspecting machine

InactiveCN103318680AGuarantee the quality of windingImprove efficiencyWebs handlingEngineeringScrew thread

The invention belongs to the field of knitting machinery and discloses an edge peeling mechanism for a knitwear rolling and inspecting machine. The edge peeling mechanism comprises a fixed rod with a first edge peeling mechanism arranged on one end and a second edge peeling mechanism arranged on the other end, the first edge peeling mechanism comprises a first adjusting seat, a second adjusting seat and a first edge-peeling semicircular roller, the first adjusting seat and the second adjusting seat are fixed at one end of the fixed rod, one end of the first edge-peeling semicircular roller is fixed with the first adjusting seat while the other end of the same is fixed with the second adjusting seat, a first edge-peeling thread is formed on one side of the first edge-peeling semicircular roller, the second edge peeling mechanism comprises a third adjusting seat, a fourth adjusting seat and a second edge-peeling semicircular roller, the third adjusting seat and the fourth adjusting seat are fixed at the other end of the fixed rod, one end of the second edge-peeling semicircular roller is fixed with the third adjusting seat while the other end of the same is fixed with the fourth adjusting seat, a second edge-peeling thread is formed on one side of the second edge-peeling semicircular roller, and the first edge-peeling thread and the second edge-peeling thread are opposite in spiral direction. The edge peeling mechanism for the knitwear rolling and inspecting machine can guarantee the end face of a cloth roll to be flush and guarantee rolling quality of knitwear by the knitwear rolling and inspecting machine.

Owner:常熟市龙略机电有限公司

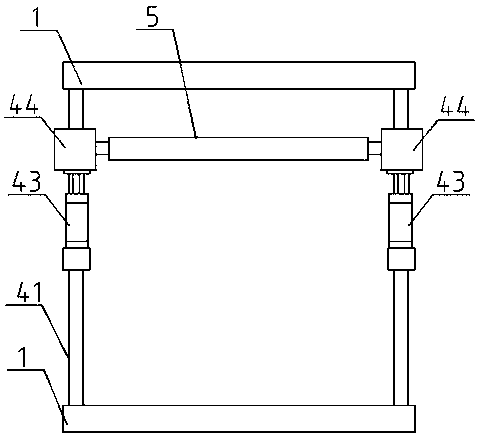

Winding equipment special for melt-blowing production

InactiveCN111874704AStable structureImprove work efficiencyArticle deliveryWebs handlingLaser cuttingStructural engineering

The invention relates to winding equipment special for melt-blowing production. The equipment comprises a rack, a guide roller, a slitting knife, a conveying roller and a power roller are sequentiallyarranged on the rack, feeding frames are arranged on the two sides of the upper end of the rack, limiting ends are arranged at the lower ends of the feeding frames, a plurality of rollers are placedon the feeding frames, and the two shaft ends of each roller are limited through the limiting ends. The two shaft ends of the power roller are rotationally arranged on the rack, and feeding mechanismsare arranged at the two shaft ends of the power roller and sequentially feed the rollers on the feeding frames. A laser cutting mechanism is arranged at the top end of the middle part of the rack andis used for transversely cutting melt-blown cloth on the power roller. The two sides of one end of the rack are connected with discharging plates, the distance between the two discharging plates is smaller than the distance of the rack, the upper ends of the discharging plates are obliquely arranged downwards, discharging mechanisms are arranged on the discharging plates, and the discharging mechanisms discharge wound rollers to a transfer trolley. The winding equipment is stable in structure and high in working efficiency, automatic feeding and discharging are achieved, and manpower consumption is reduced.

Owner:崔建中

Winding equipment for electrolytic copper foil production

ActiveCN113247663AImprove cleaningGuaranteed winding qualityCleaning using toolsWebs handlingCopper foilEngineering

The invention relates to the technical field of electrolytic copper foil production and processing, in particular to winding equipment for electrolytic copper foil production. The winding equipment comprises a base, a winding structure is mounted on the base, a cleaning structure is mounted on the winding structure, an abutting structure is mounted on the winding structure, and a limiting structure is further mounted on the winding structure. A pushing structure is arranged on the winding structure, a fixing structure is arranged on the winding structure, an unloading structure is installed on the base, and a pouring structure is arranged on the unloading structure; and when the winding structure conducts winding work, the cleaning structure can be synchronously driven to work, through work of the cleaning structure, the two faces of an electrolytic copper foil can be finely wiped in the manner that wiped cloth is wound, the problem of repeated wiping does not exist, the cleaning work on the surface of the electrolytic copper foil is increased, and the winding quality of the electrolytic copper foil is ensured.

Owner:拓楚(江苏)电子科技有限公司

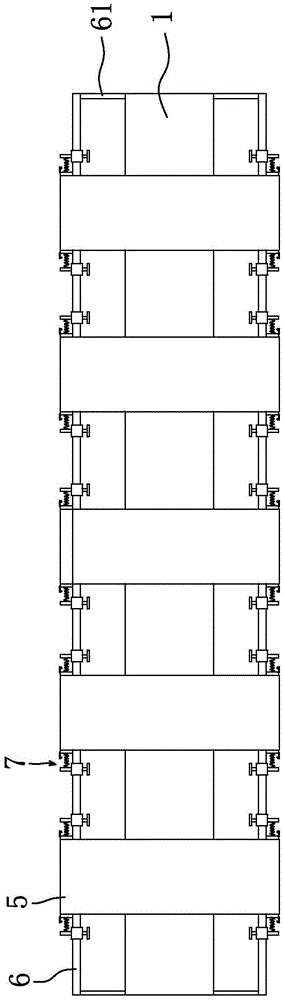

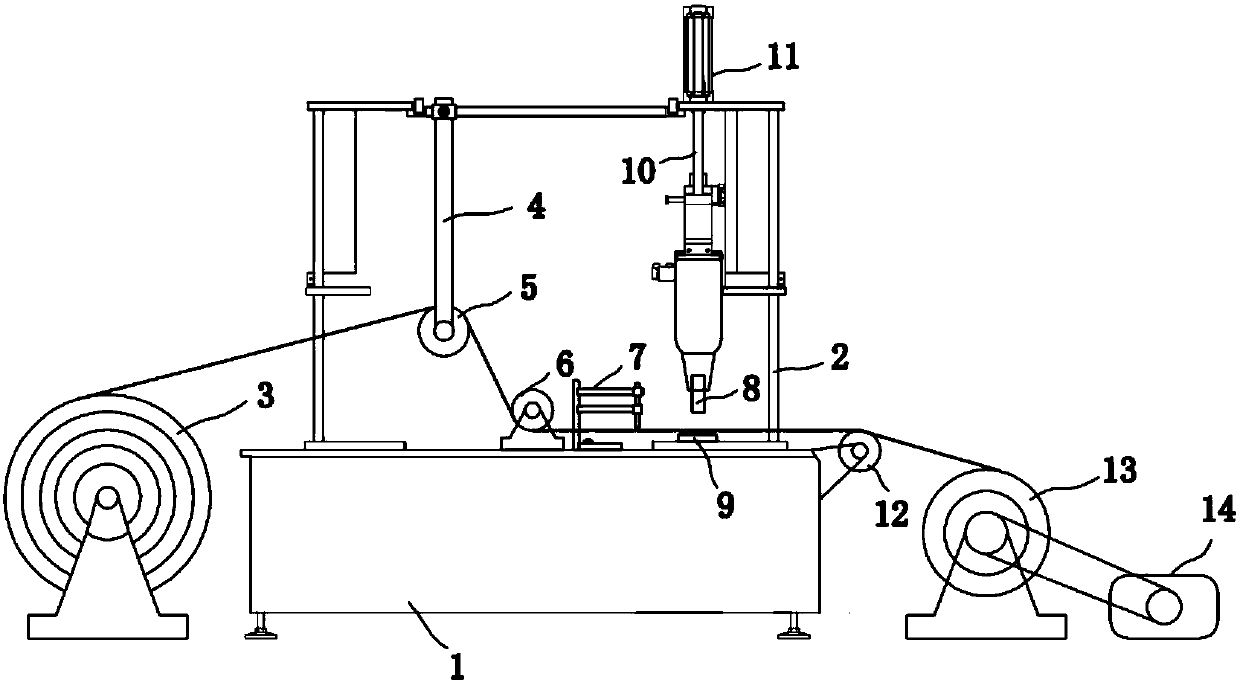

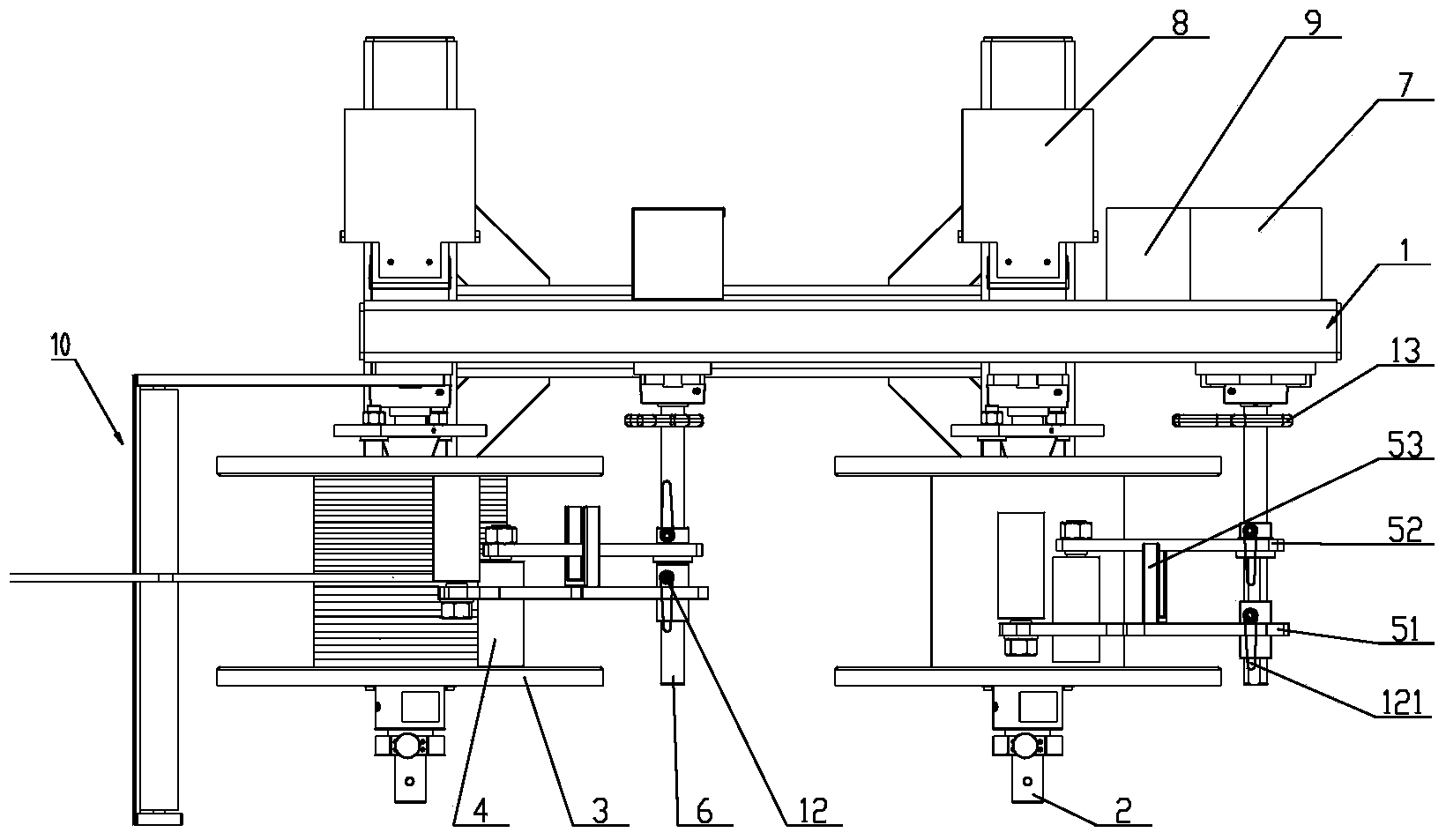

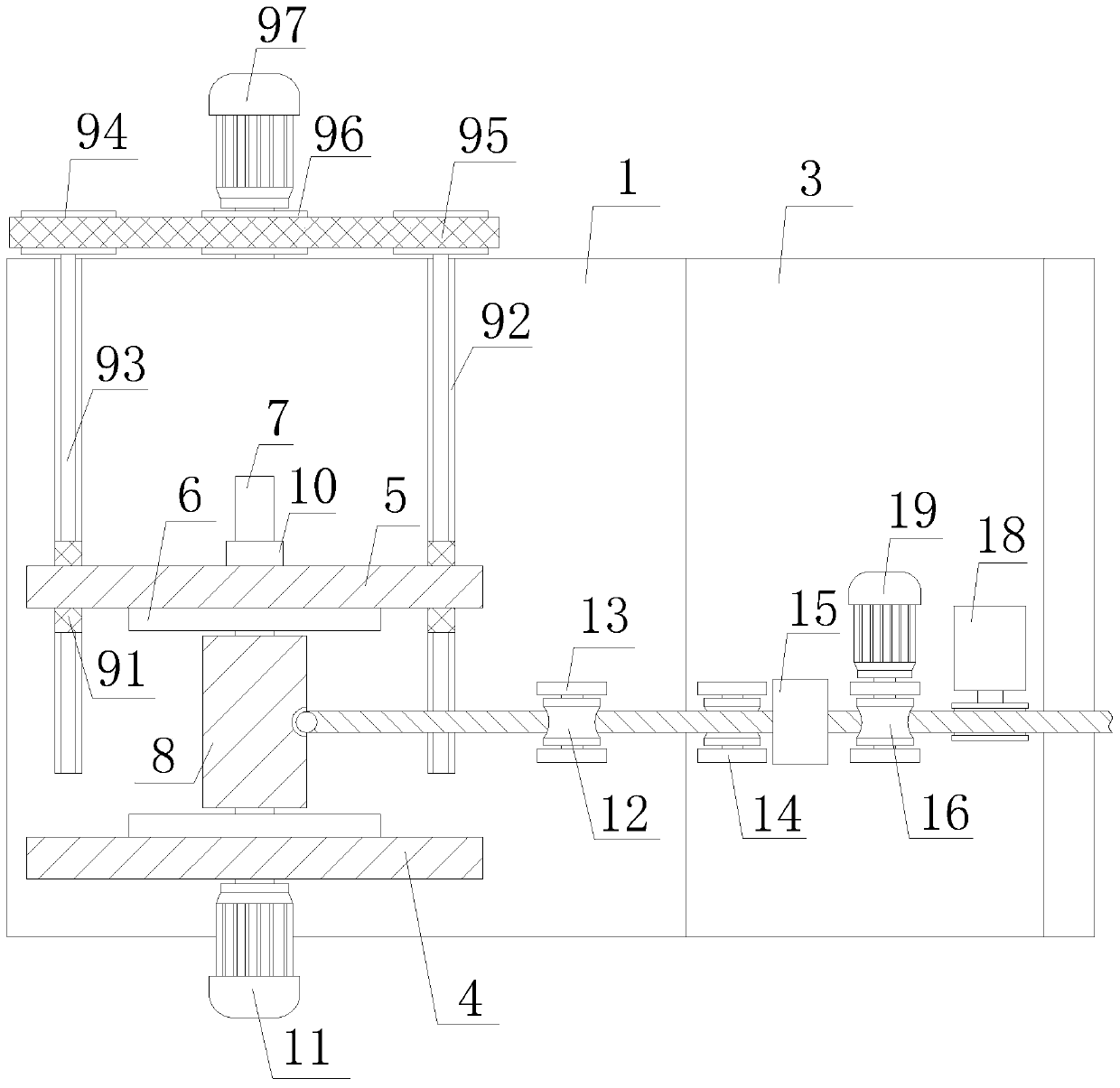

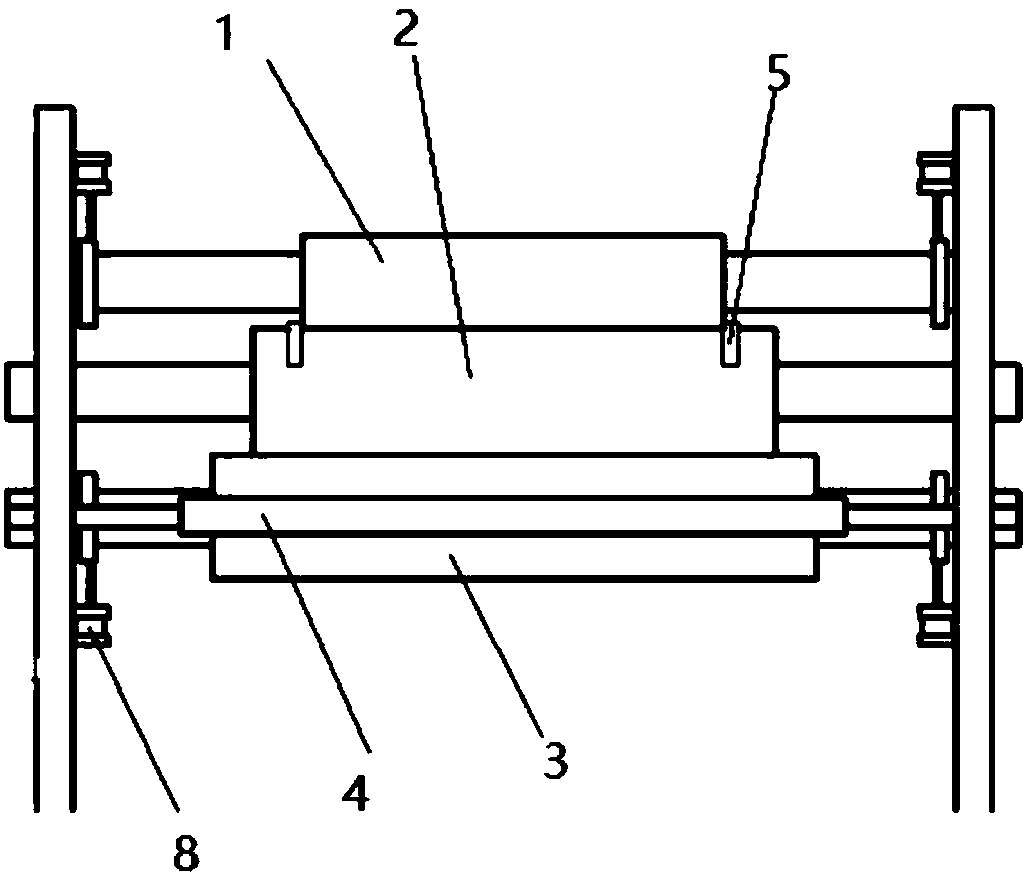

Forming equipment and process for glass steel wire outer protection anticorrosion pipe

InactiveCN106273383ARealize automatic feeding operationSolve the problem of corrosionTubular articlesGear transmissionSteel tube

The invention discloses forming equipment and a process for a glass steel wire outer protection anticorrosion pipe, and belongs to the technical field of manufacturing mechanical products. The forming equipment for the glass steel wire outer protection anticorrosion pipe comprises a workpiece supporting base, a wire winding trolley, a trolley moving guide rail and a trolley driving mechanism; the workpiece supporting base is composed of two parts arranged left and right, and each part is provided with a base, a workpiece rotating motor, a gear transmission mechanism and roller wheels, wherein the roller wheels include driving roller wheels and follow-up supporting roller wheels, and the workpiece rotating motor drives the driving roller wheels to rotate through a gear transmission mechanism to drive a steel pipe workpiece placed on the driving roller wheels and the follow-up supporting roller wheels to rotate; the trolley moving guide rail is fixed to one side of the workpiece supporting base in parallel, and the wire winding trolley and the trolley driving mechanism are assembled on the trolley moving guide rail. The working efficiency of winding glass steel wires is improved, and the winding quality of the glass steel wires is ensured.

Owner:TANGSHAN XINGBANG PIPE CONSTR EQUIP

Textile winder

The invention discloses a textile winder which comprises a bottom plate. A stand column is mounted on the bottom plate, a support is rotatably mounted on the stand column, a waiting station and a working station are symmetrically arranged at the two ends of the support, and winding shafts are rotatably mounted at the waiting station and the working station correspondingly. A first transmission shaft is arranged under the working station, and the upper end of the first transmission shaft is connected to the lower end of the winding shaft at the working station. A motor is mounted on the bottom plate, the lower end of the first transmission shaft is connected to a shaft of the motor, an up-down-reciprocating mechanism is further mounted on the bottom plate, and a tensioning mechanism is mounted at the top of the up-down-reciprocating mechanism. Through the design of the two stations, winding work efficiency is greatly improved, the yield is increased, and cost is saved; winding uniformity and the winding effect are guaranteed, labor output is lowered, and winding quality is guaranteed. The textile winder is simple in structure and good in implementation.

Owner:朱新超

Slitting system for papermaking and papermaking slitting method thereof

ActiveCN111532867AGuaranteed synchronicityGuarantee the quality of windingCleaning using gasesArticle deliveryPaper sheetPapermaking

The invention relates to a slitting system for papermaking and a papermaking slitting method thereof. The slitting system for papermaking comprises a supply roller used for installing paper rolls, a cutter used for cutting paper and a rewinding roller used for rewinding the paper and provided with at least two rewinding parts; the slitting system for papermaking is characterized by comprising at least two tidying parts and a driving device, wherein the tidying parts are movably arranged on the rewinding roller and are used for tidying the ends of the paper rolls on the rewinding parts, and thedriving device is used for driving the tidying parts to move. The slitting system for papermaking and the papermaking slitting method thereof have the beneficial effects that the tidying parts can bedriven by the driving device to move on the rewinding rollers, and one ends of the paper rolls on the rewinding parts are tidied, so that the winding effect of the paper rolls is better.

Owner:VINDA PAPER ZHEJIANG

Cloth winding barrel for spinning

The invention relates to a cloth winding barrel for spinning. The cloth winding barrel comprises a rotating shaft and a hollow winding barrel body capable of rotating along with the rotating shaft. The cloth winding barrel is characterized by further comprising a cloth clamp contained in the winding drum body, the cloth clamp comprises a central rod parallel to the axis of the winding drum body, and two clamping pieces sleeving on the central rod and capable of opening and closing around the central rod, the winding drum body axially comprises an open end and a closed end, a narrow notch allowing cloth to penetrate is arranged on the side wall of the winding drum body, one end of the notch is open at the open end, a clamping groove with an inward opening is arranged on the closed end of the winding drum body, and the corresponding end of the central rod is clamped in the clamping groove. The winding drum body is arranged to be of a hollow structure and matched with the special cloth clamp for use, so that firmness in fixing of the cloth is greatly improved; the cloth winding barrel is convenient to use and small in difficulty in operating; due to high stability in fixing of the cloth, probability of deviation of the cloth in the process of winding is greatly lowered, and winding quality is guaranteed.

Owner:WUJIANG JIUMEI MICROFIBER WEAVING

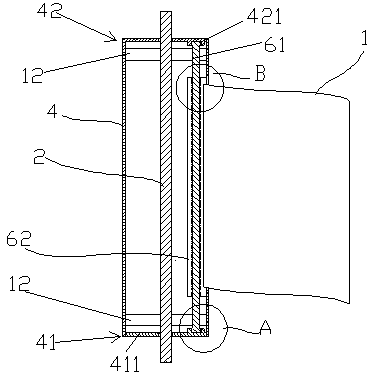

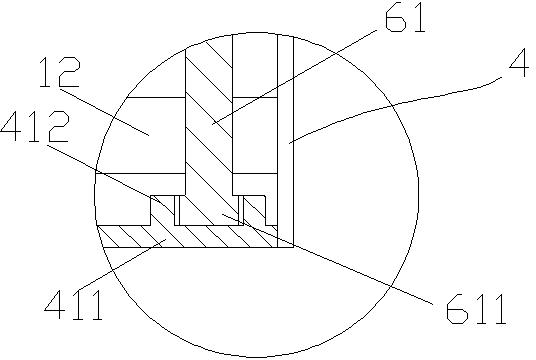

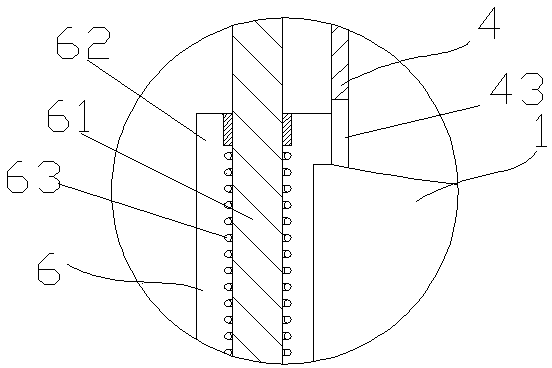

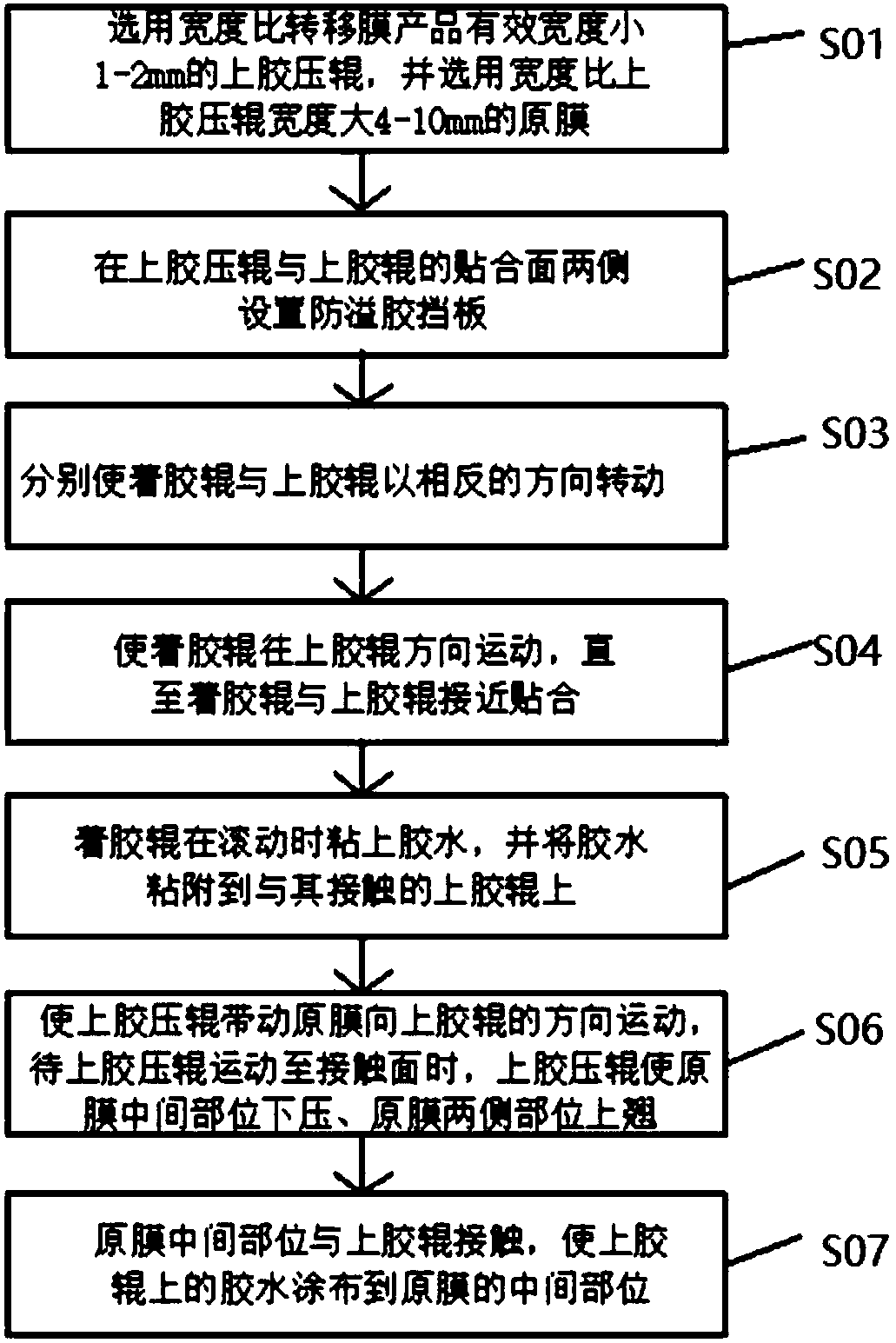

Transfer film gluing method

ActiveCN108144817AGuarantee the quality of windingLiquid surface applicatorsCoatingsPulp and paper industryBinding process

The invention discloses a transfer film gluing method. The method comprises the steps that a gluing pressing roller with the width being 1-2 mm smaller than the effective width of a transfer film product is selected, and an original film with the width being 4-10 mm larger than that of the gluing pressing roller is selected; the two sides of the binding face of the gluing pressing roller and a gluing roller are provided with glue overflowing preventing baffles; a glue adsorption roller and the gluing roller are made to rotate in the reverse directions correspondingly; the glue adsorption roller is made to move in the direction of the gluing roller till the glue adsorption roller and the gluing roller are close to binding; glue is adsorbed to the glue adsorption roller when the glue adsorption roller rolls and is pasted to the gluing roller in contact with the glue adsorption roller; the gluing pressing roller is made to drive the original film to move in the direction of the gluing roller, and when the gluing pressing roller moves to the contact face, the gluing pressing roller makes the middle of the original film be downwards pressed and the two sides of the original film be upwards warped; and the middle of the original film is in contact with the gluing roller, and the glue on the gluing roller is smeared to the middle of the original film. According to the gluing method provided by the invention, through the gluing pressing roller of certain specifications and the glue overflowing preventing baffles, the problems that the glue overflows from the edges in the binding process of the paper film to form glue blocks, and pressure points are formed on composite paper are effectively solved.

Owner:常德市德源招商投资有限公司

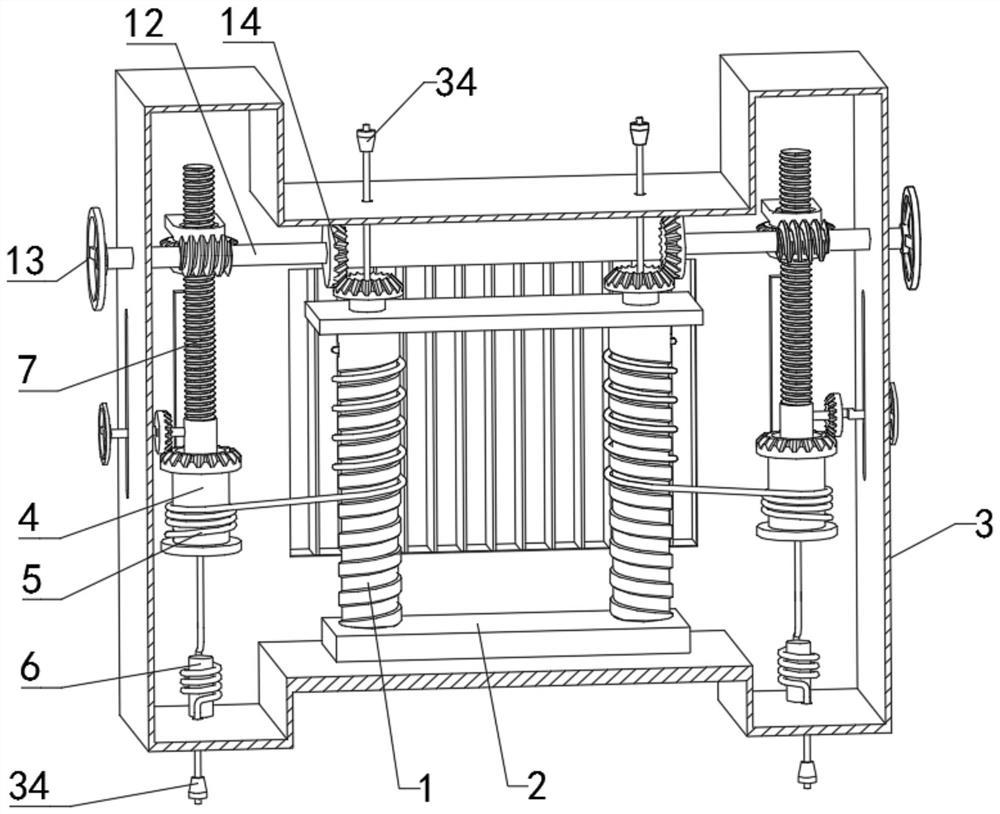

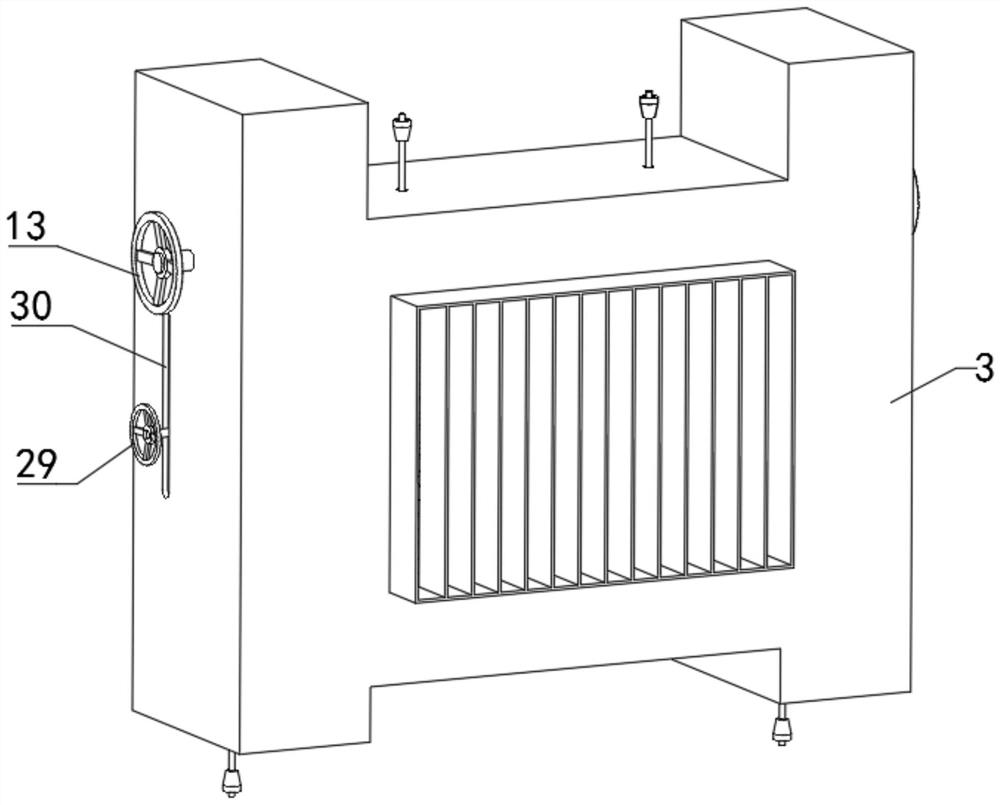

Transformer with adjustable turns

ActiveCN112712979AAdjustable densityConsistent tightnessTransformers/inductances coils/windings/connectionsVariable inductancesTransformerControl theory

The invention discloses a transformer with the adjustable number of turns. The transformer comprises a shell, an iron core, a standby spool, a lifting rotating unit and a take-up and pay-off unit, wherein the lifting speed of the standby spool and the autorotation speed of the iron core are in a preset proportion, and wound coils are spiral, consistent in tightness and adjustable in density. According to the transformer, the number of turns of the coil in the transformer can be adjusted without opening the transformer shell, and then voltage transformation operation can be completed conveniently and rapidly.

Owner:重庆重变电器有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com