Traction coiling device for cable processing

A winding device and cable technology, applied in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the inability to accurately control the standard length of cable winding, affect the efficiency of cable winding, and unfavorable standardized production, etc. problems, to improve efficiency, reduce labor intensity, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

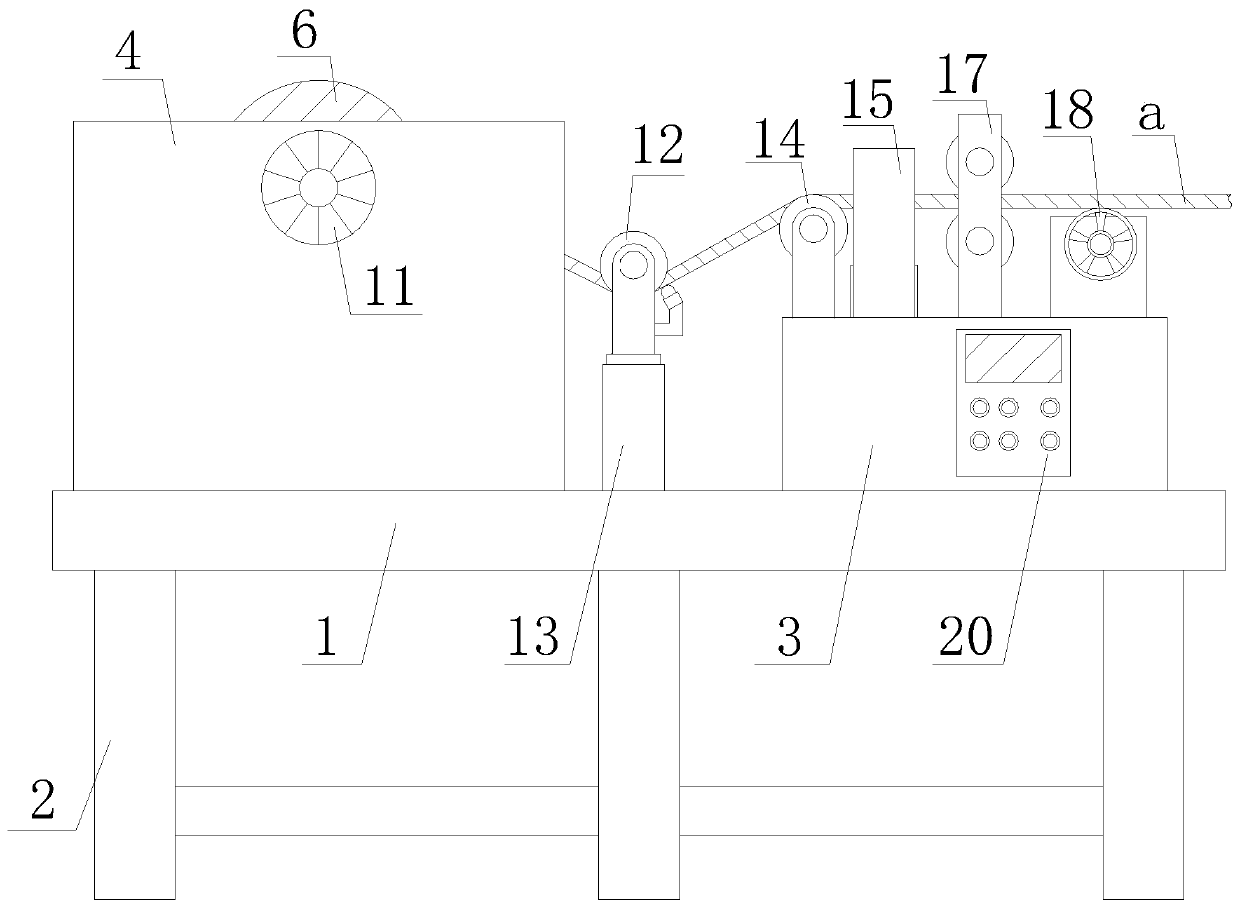

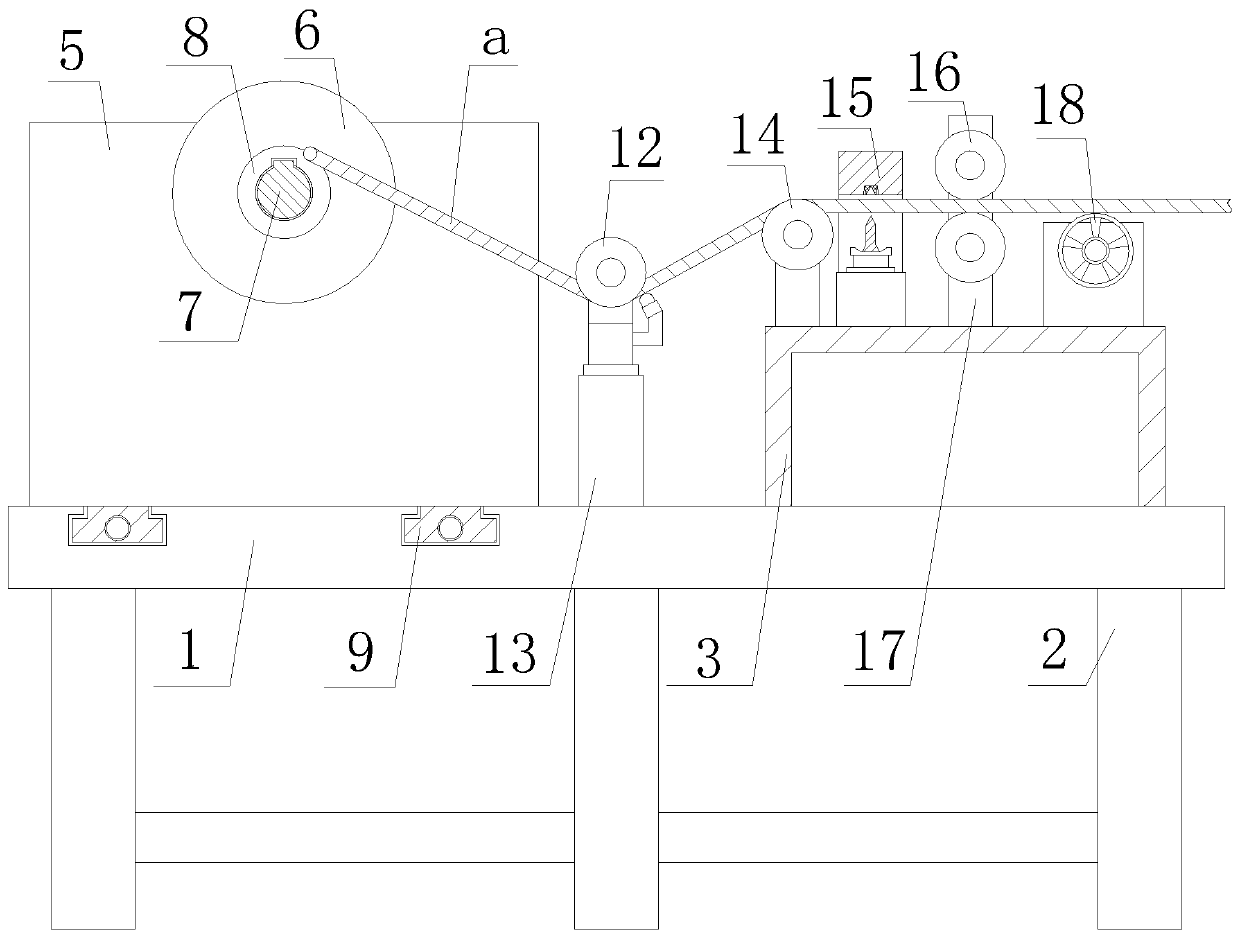

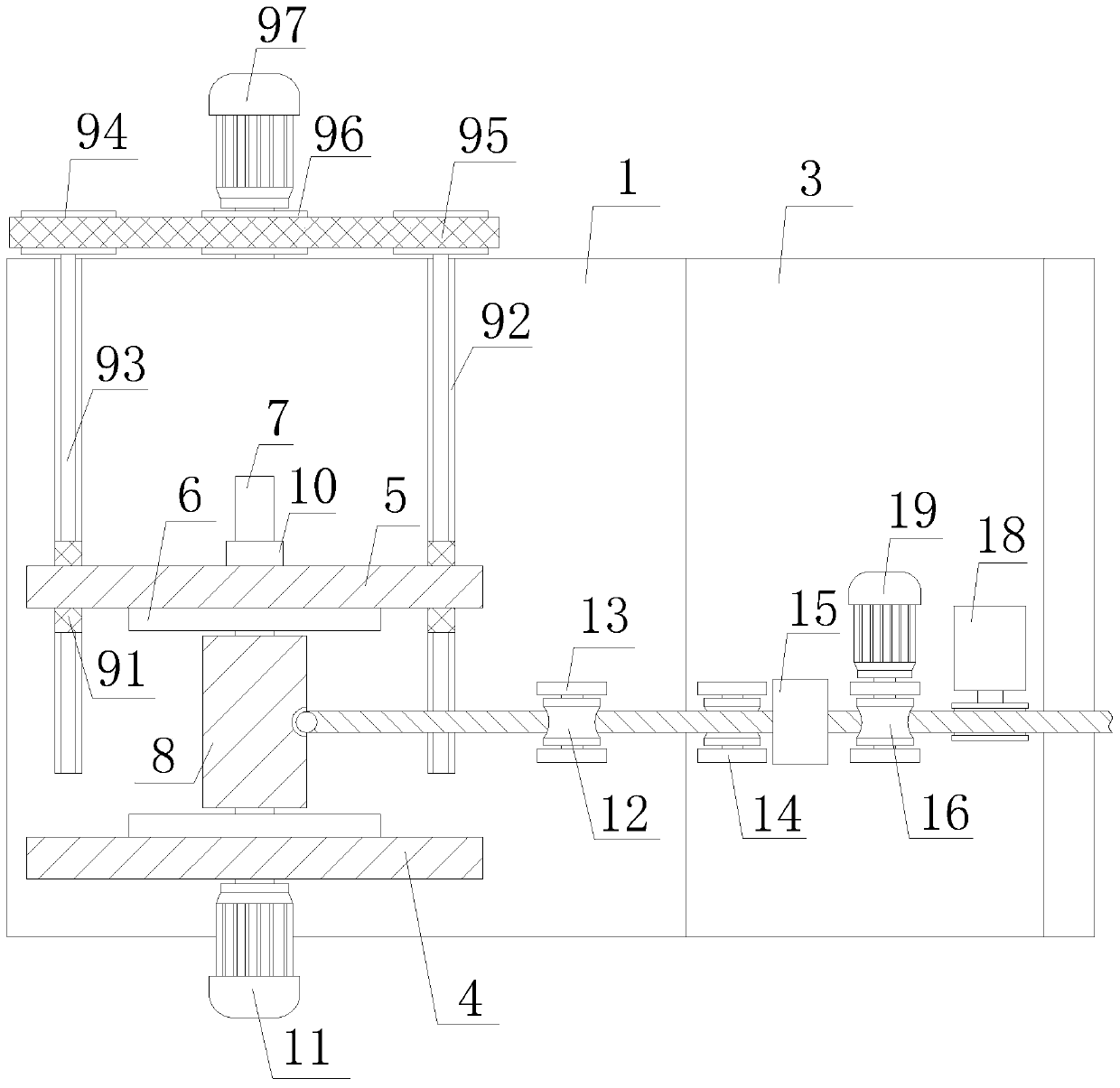

[0036] Attached below Figure 1-4 The present invention is further described with embodiment:

[0037] A traction and winding device for cable processing, including a processing platform 1, a plurality of support feet 2 installed at the lower end of the processing platform 1, and cable retracting tubes 8 distributed sequentially from upstream to downstream along the moving direction of the cable a, tensioning Components and a meter counter 18, the meter counter 18 is installed on the upper end of the installation step 3, and the meter counter 18 is used to calculate the length of the cable a that is wound around the cable bundle tube 8. In this embodiment, the meter counter 18 The meter meter 18 is a roller-type meter counter. The roller of the roller-type meter counter rolls against the cable a, and the winding length of the cable a is calculated according to the number of turns of the roller wheel, and the installation step 3 is arranged on the upper end of the processing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com