Numerical control coil winder for voltage transformer

A digitally controlled winding machine and voltage transformer technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, and coils, can solve problems such as low winding efficiency, unbalanced winding tension, and troublesome winding operations, and achieve Improve winding efficiency, high winding precision, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

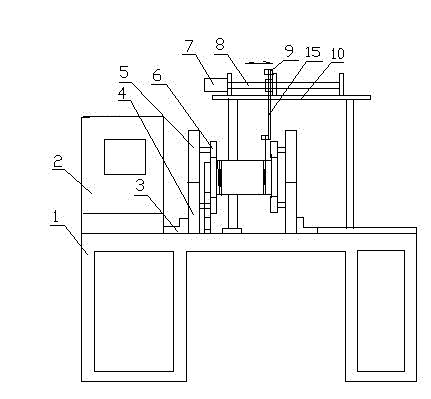

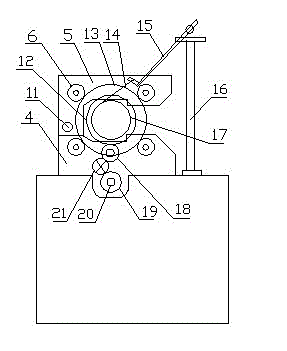

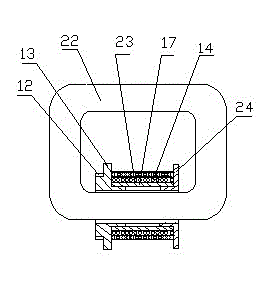

[0011] exist figure 1 , figure 2 and image 3 Among them, the voltage transformer numerical control winding machine includes a control box 2, two lower support plates 4 relatively fixed on the workbench 1 through the back plate 3 and an upper support plate 5 arranged on the lower support plate and movable placement The winding roller on the lower support plate, the winding roller includes a roller 13 and a wire sleeve 24 that can be movably combined as a whole, and a ring gear 12 is arranged on the roller, and the upper support plate can be wound around the lower support plate through the pin shaft 11 One end is rotated to open and close to lock. The upper support plate and the lower support plate are respectively provided with four guide wheels 6 that can be tangent to the rollers 13 on the winding roller. The relative positions of the guide wheels can be adjusted. In order to be suitable for winding coils of different specifications, the lower support plate is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com