Patents

Literature

497results about How to "Fast winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

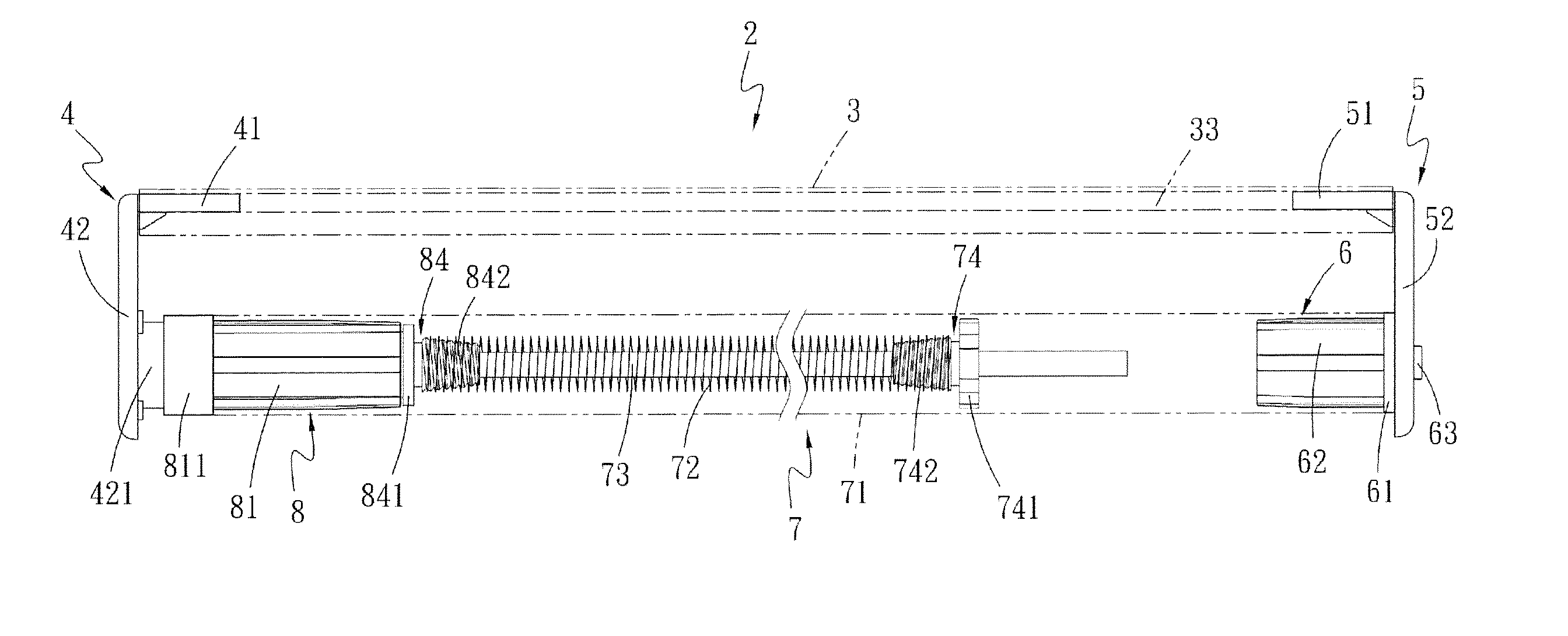

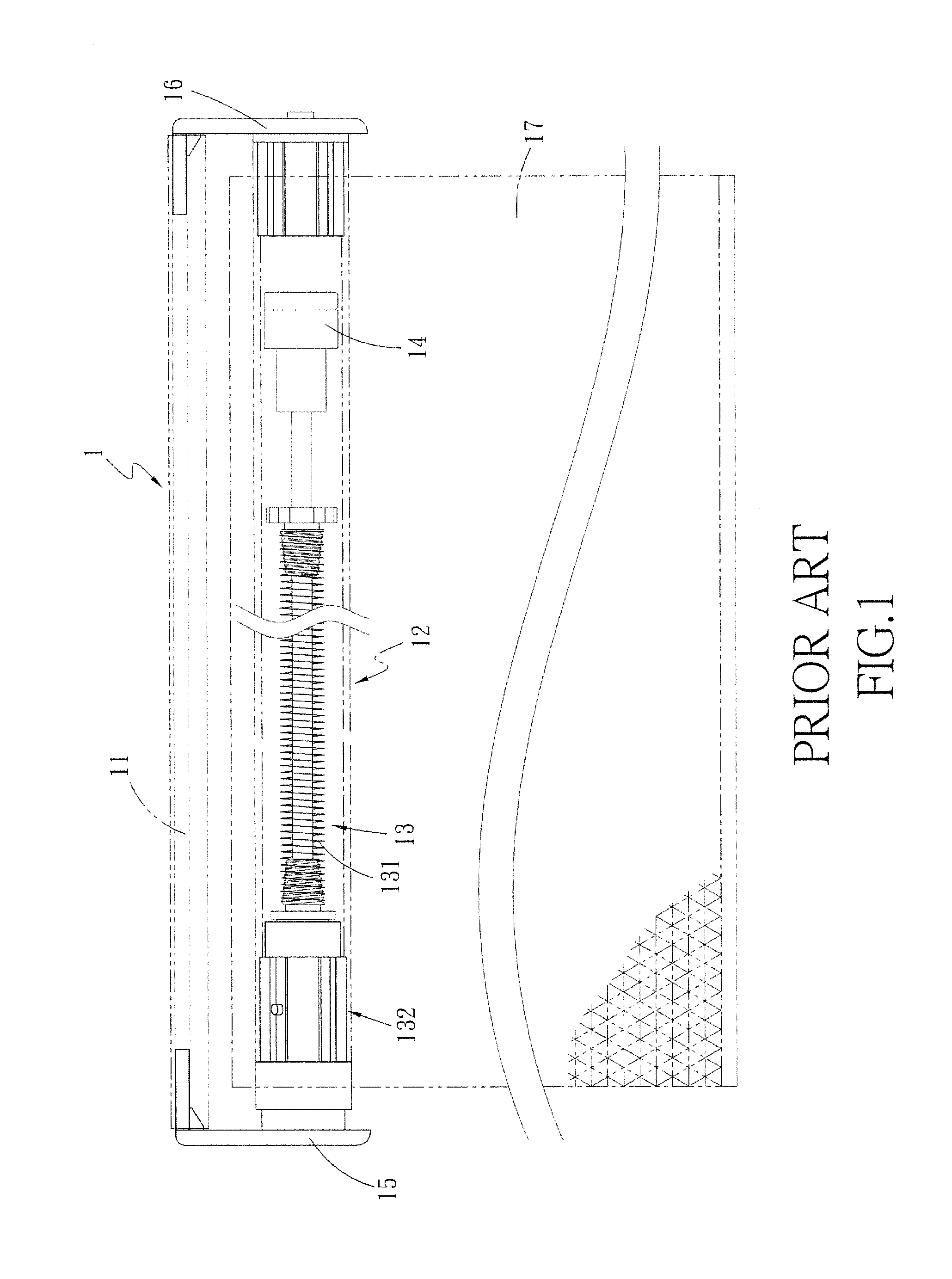

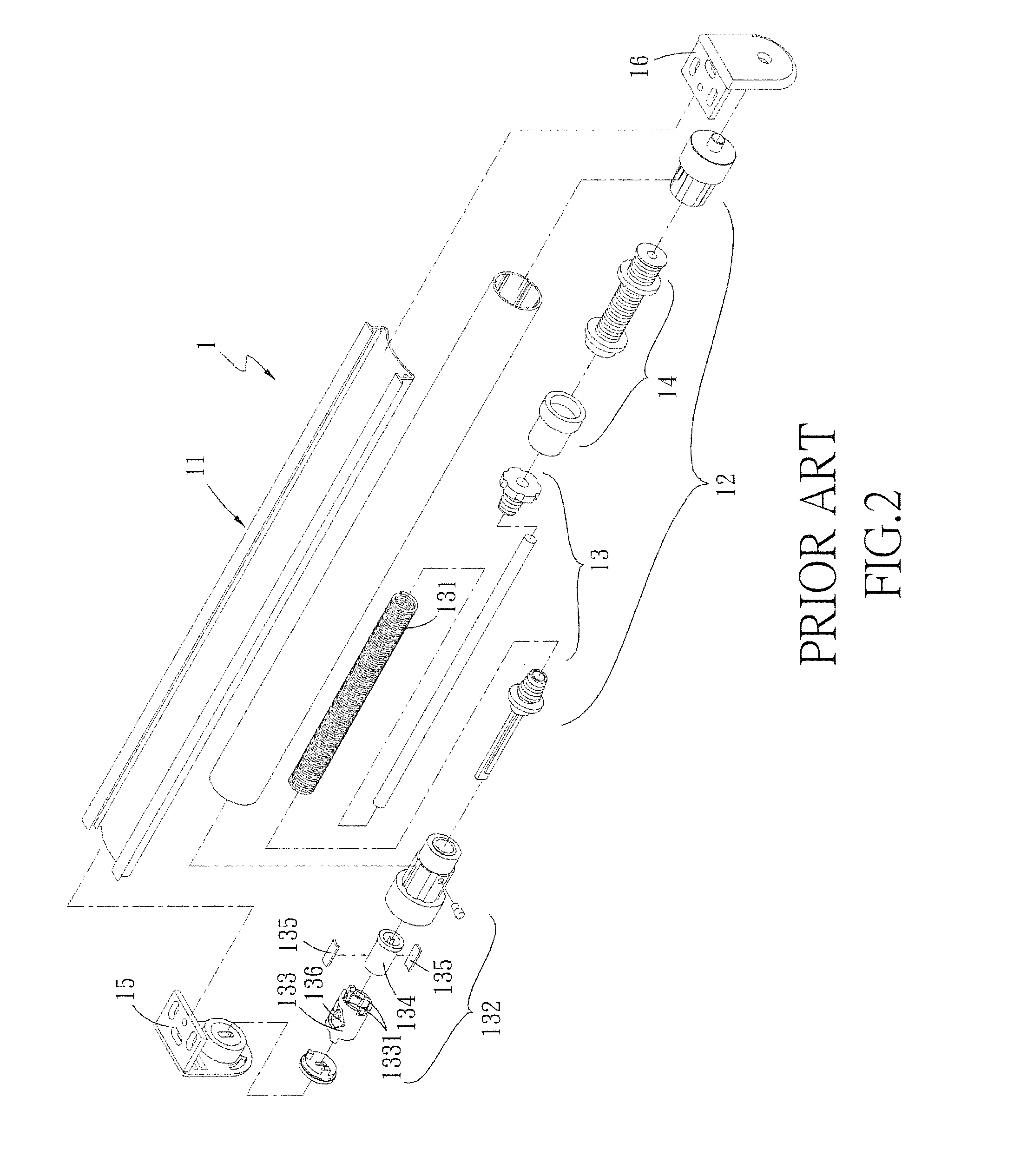

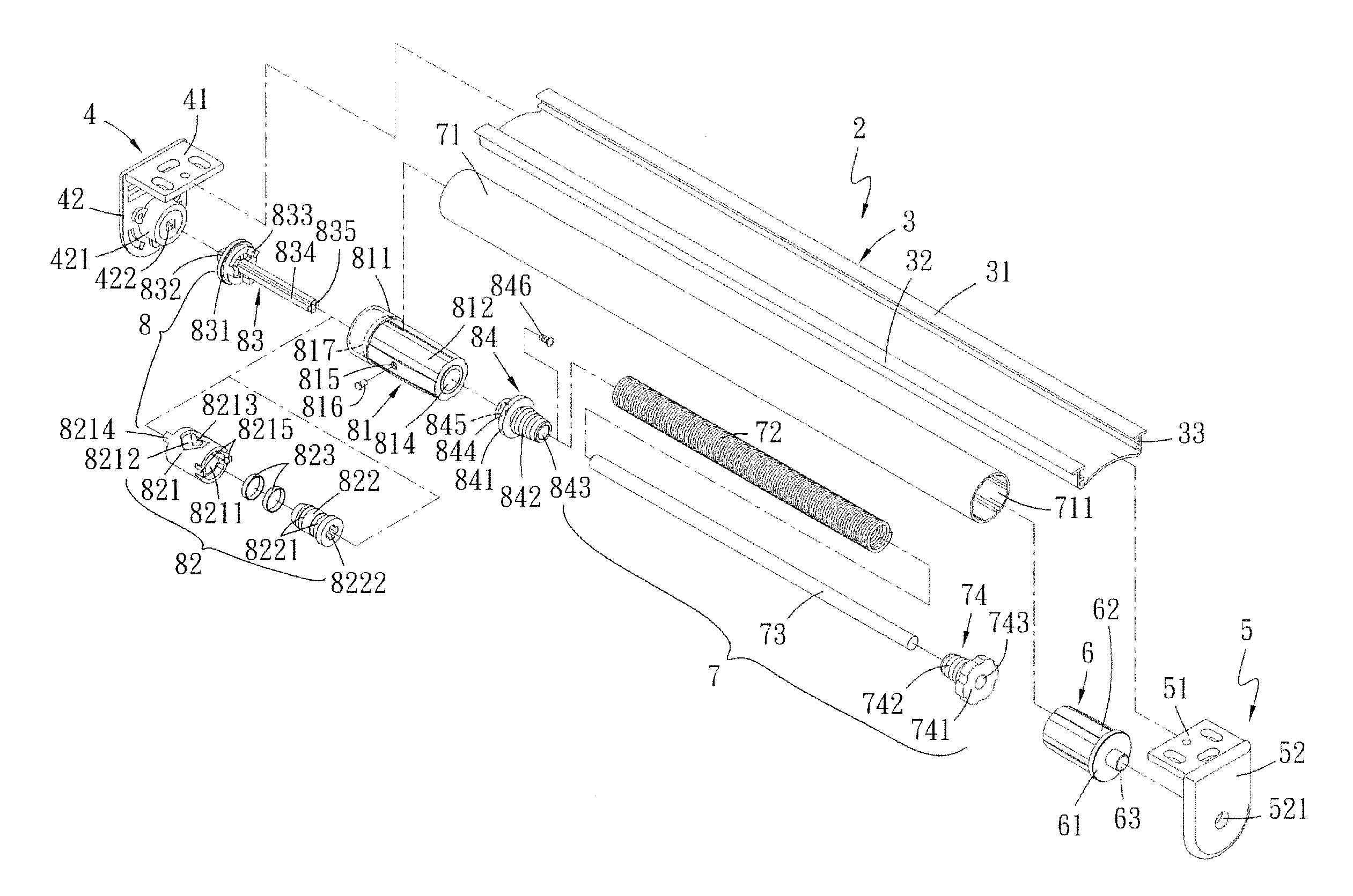

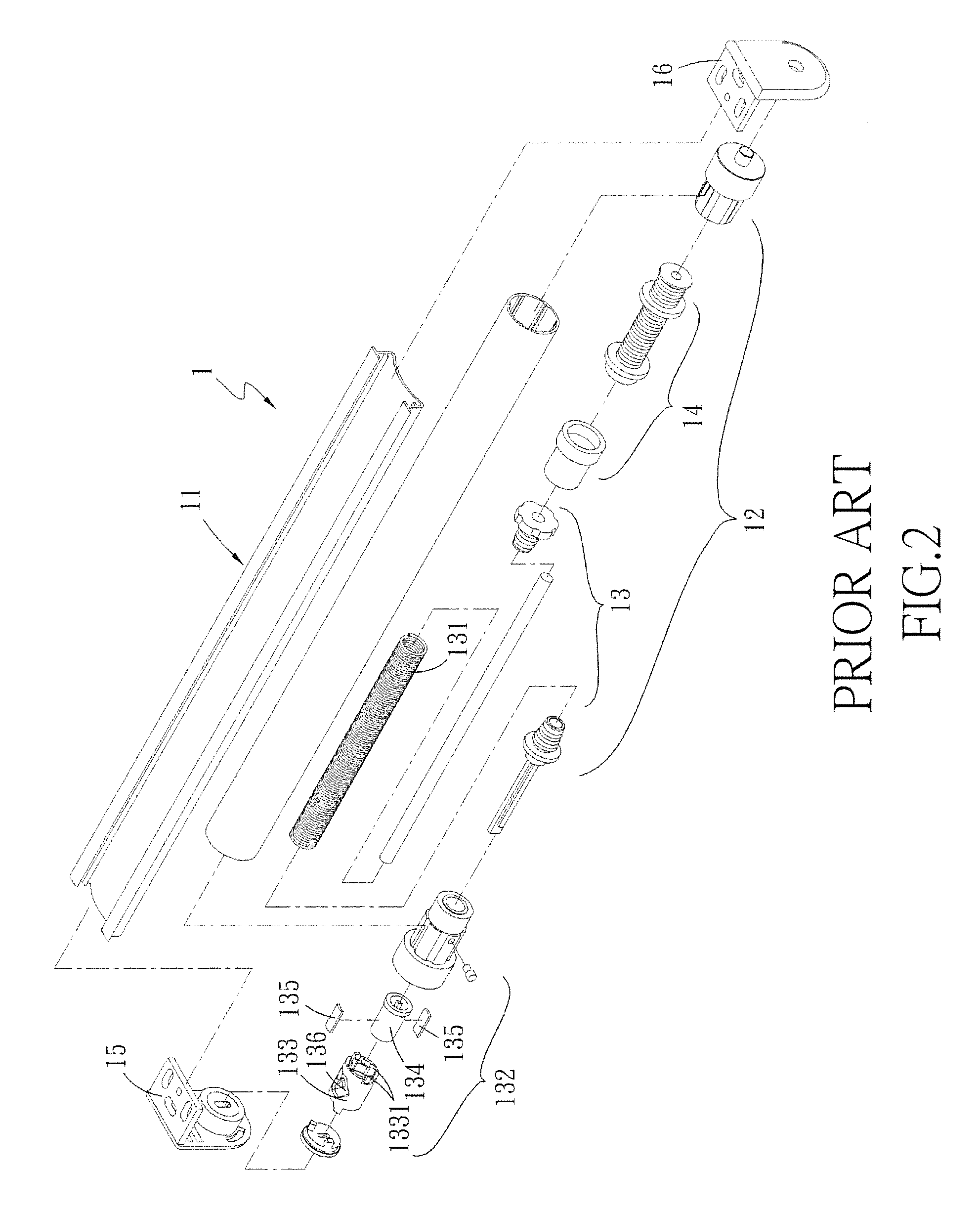

Coilable shade

A coilable shade includes a main frame to which left and right fixed seats are mounted. A drum is rotatably coupled to the right fixed seat and receives a spring receiving a shaft extending through a positioning seat. An end of the coiling spring is fixed to the positioning seat. The other end of the coiling spring is fixed to a connection seat mounted to the left fixed seat. A rotating unit is mounted in a jacket and rotatably coupled to a positioning rod fixed to the left fixed seat. A fastener is slideable along a track in a rotating member of the rotating unit to control unfolding, coiling, and positioning of a shade. The rotating unit further includes a sleeve received in the rotating member. A soft ring buffer is received in an annular groove of the sleeve and contacts an inner periphery of the rotating member.

Owner:KO HOU SHENG

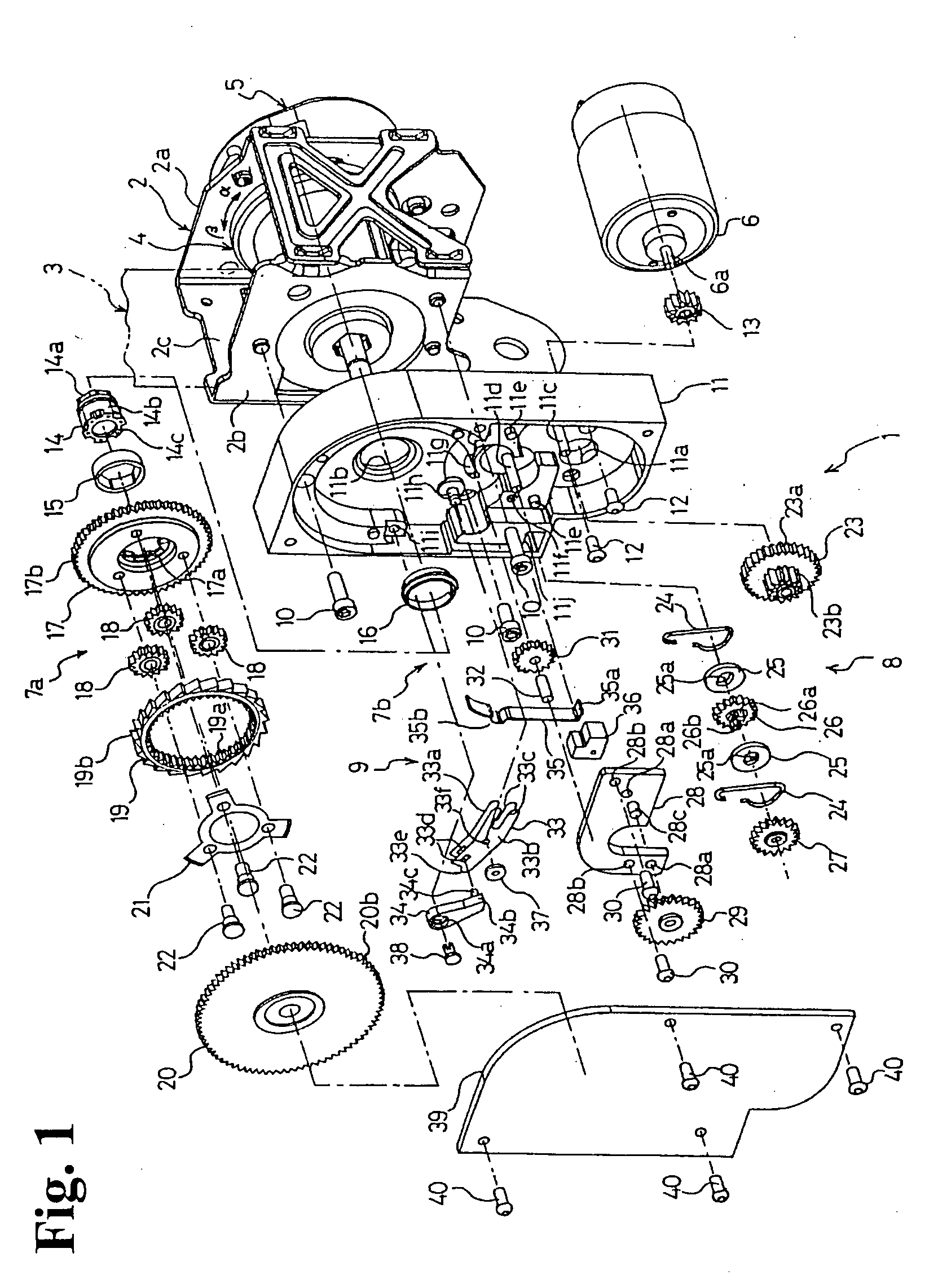

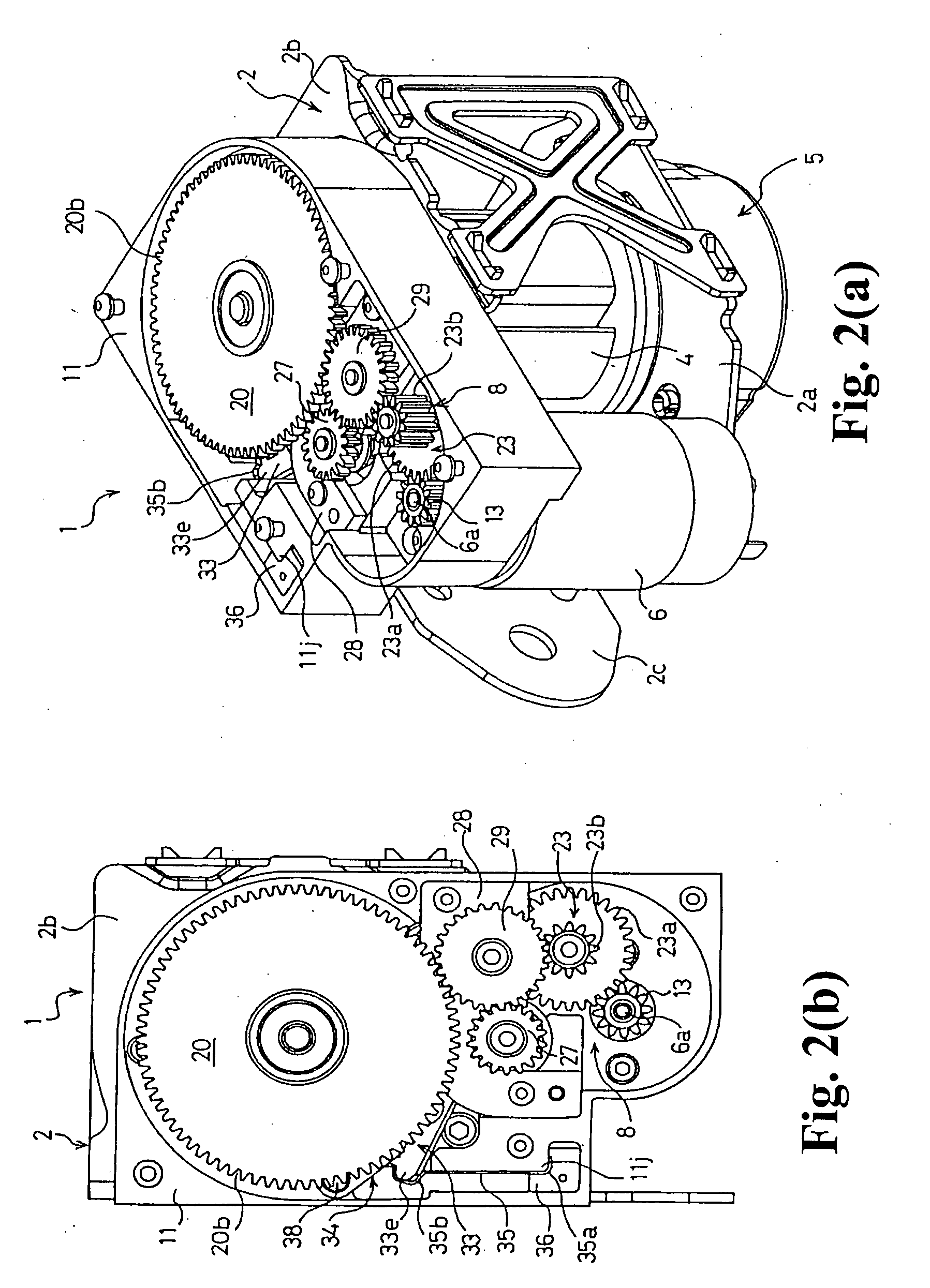

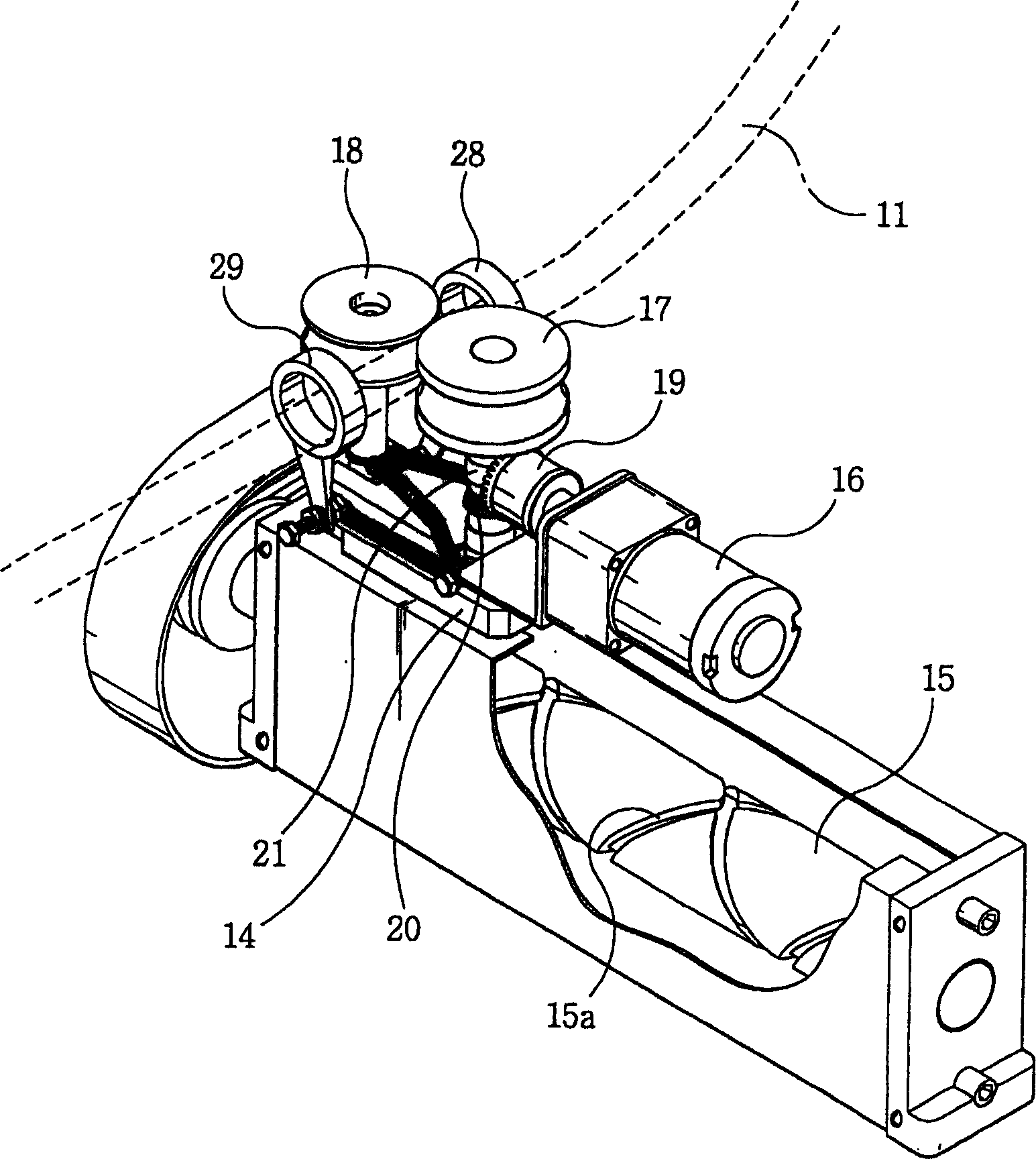

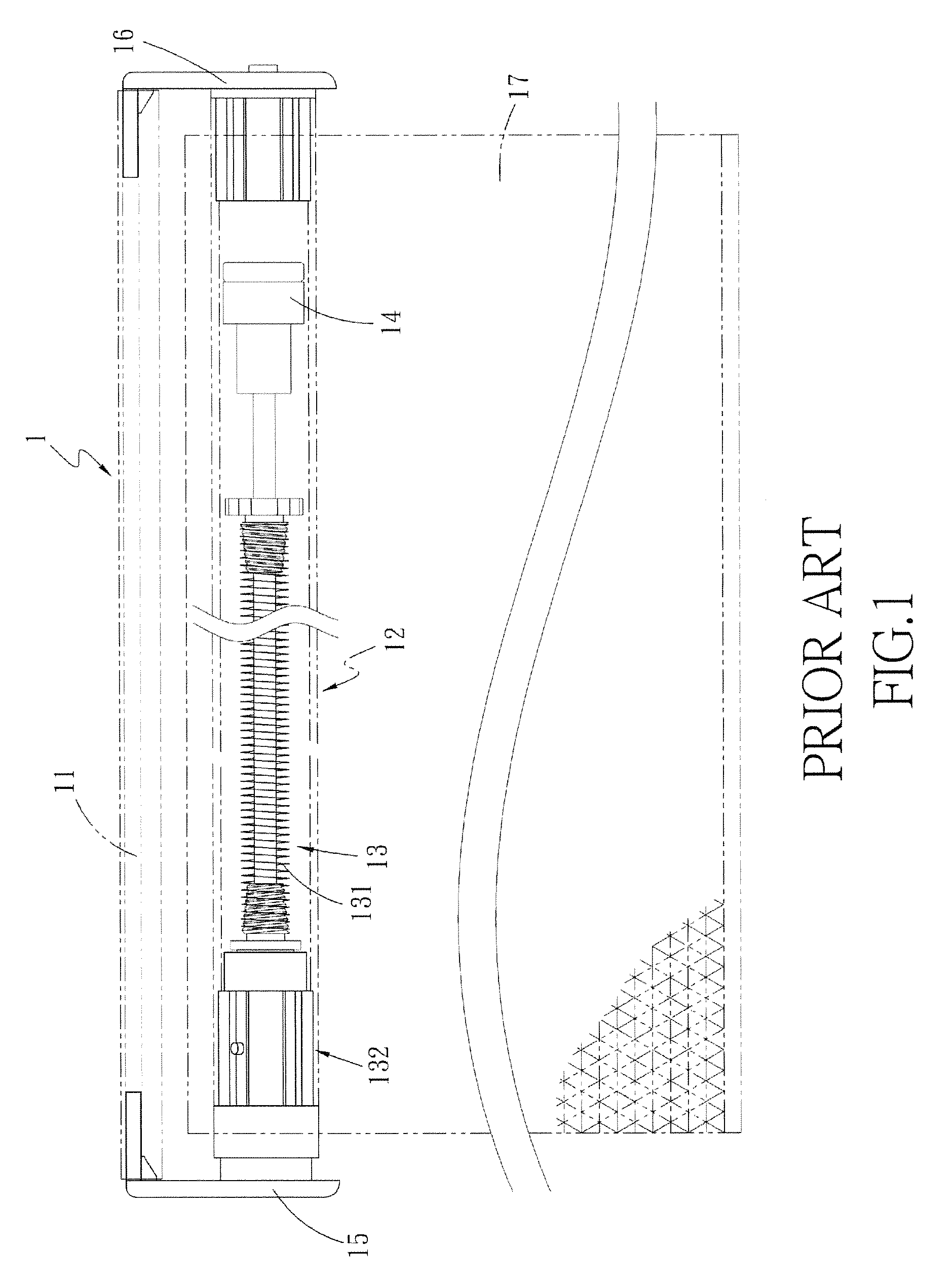

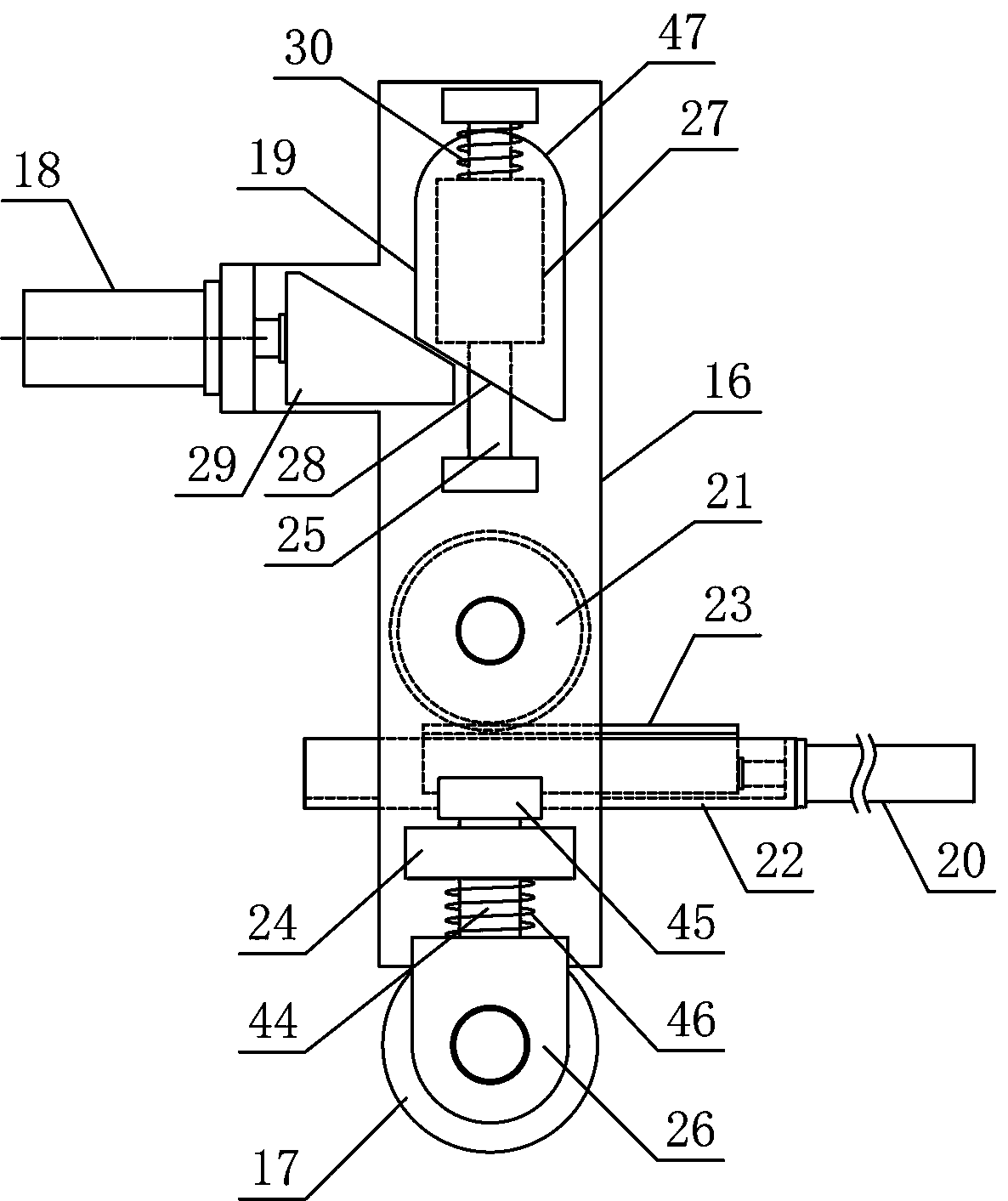

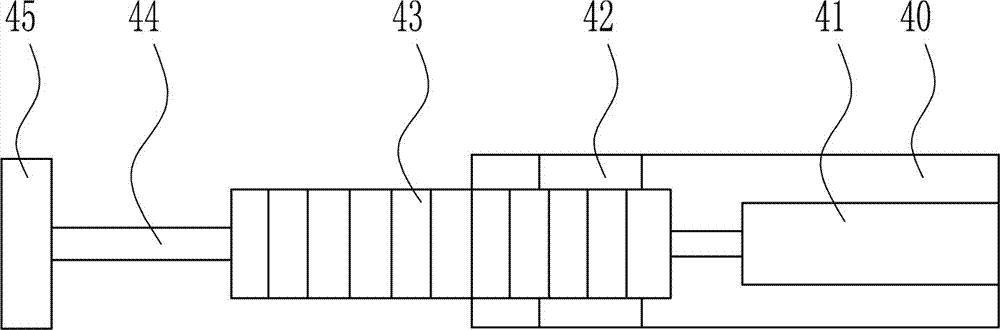

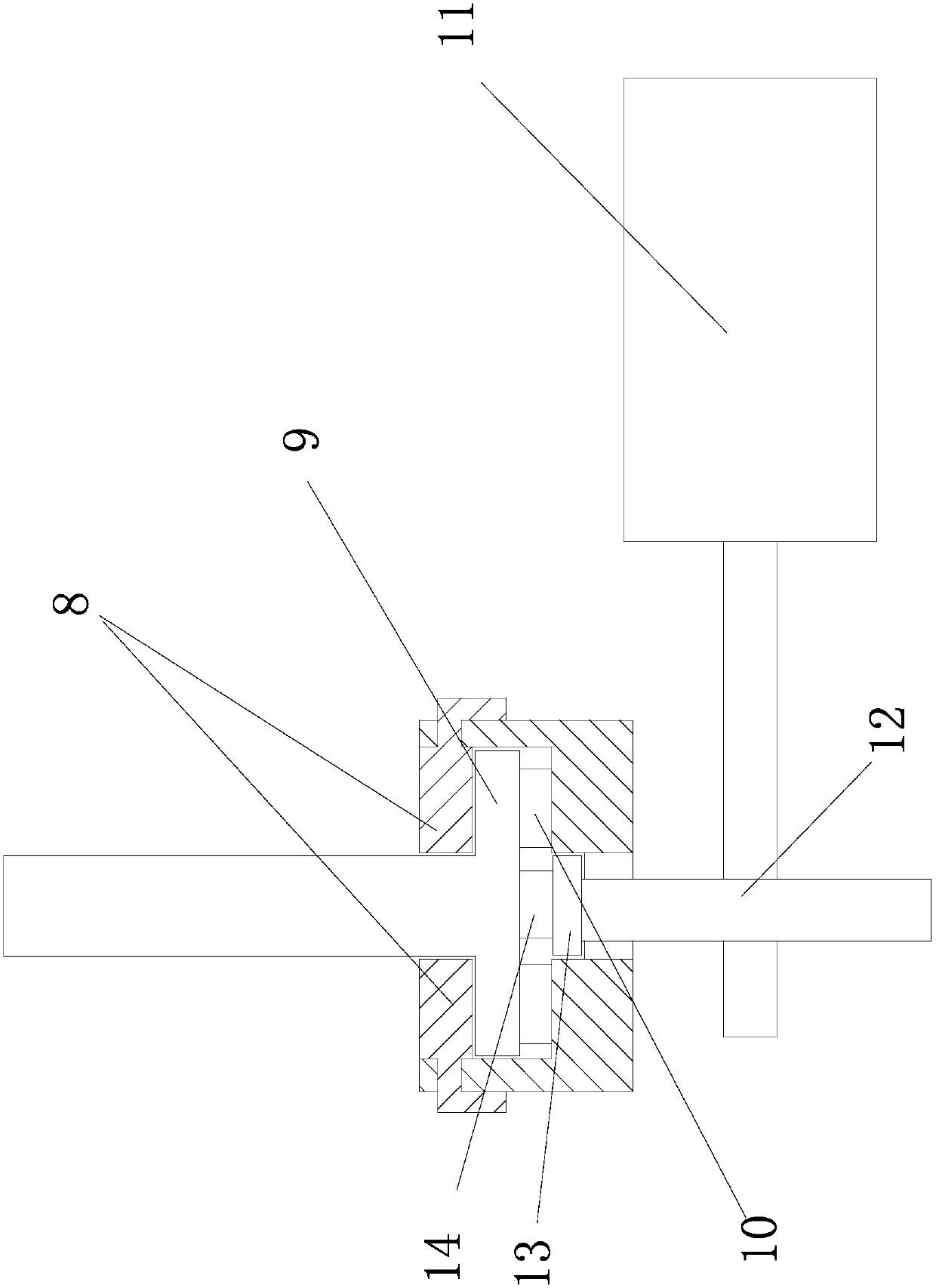

Seat belt retractor and seat belt device

InactiveUS20050011983A1High torqueReduce rotation torqueBelt retractorsBelt control systemsElectric machinerySeat belt

A seat belt retractor includes a spool for winding up a seat belt; a motor for generating rotational torque to rotate the spool; and a power transmission mechanism for transmitting the rotational torque of the motor to the spool. The seat belt retractor winds the seat belt on the spool with the rotational torque of the motor. The power transmission mechanism has a low reduction ratio transmission mode in which the rotational torque of the motor is transmitted to the spool through a low reduction ratio mechanism, and a high reduction ratio transmission mode in which the rotational torque of the motor is transmitted to the spool through a high reduction ratio mechanism. The seat belt retractor further includes a power transmission mode switching mechanism for selecting between the low reduction ratio transmission mode and the high reduction ratio transmission mode.

Owner:TAKATA CORPORATION

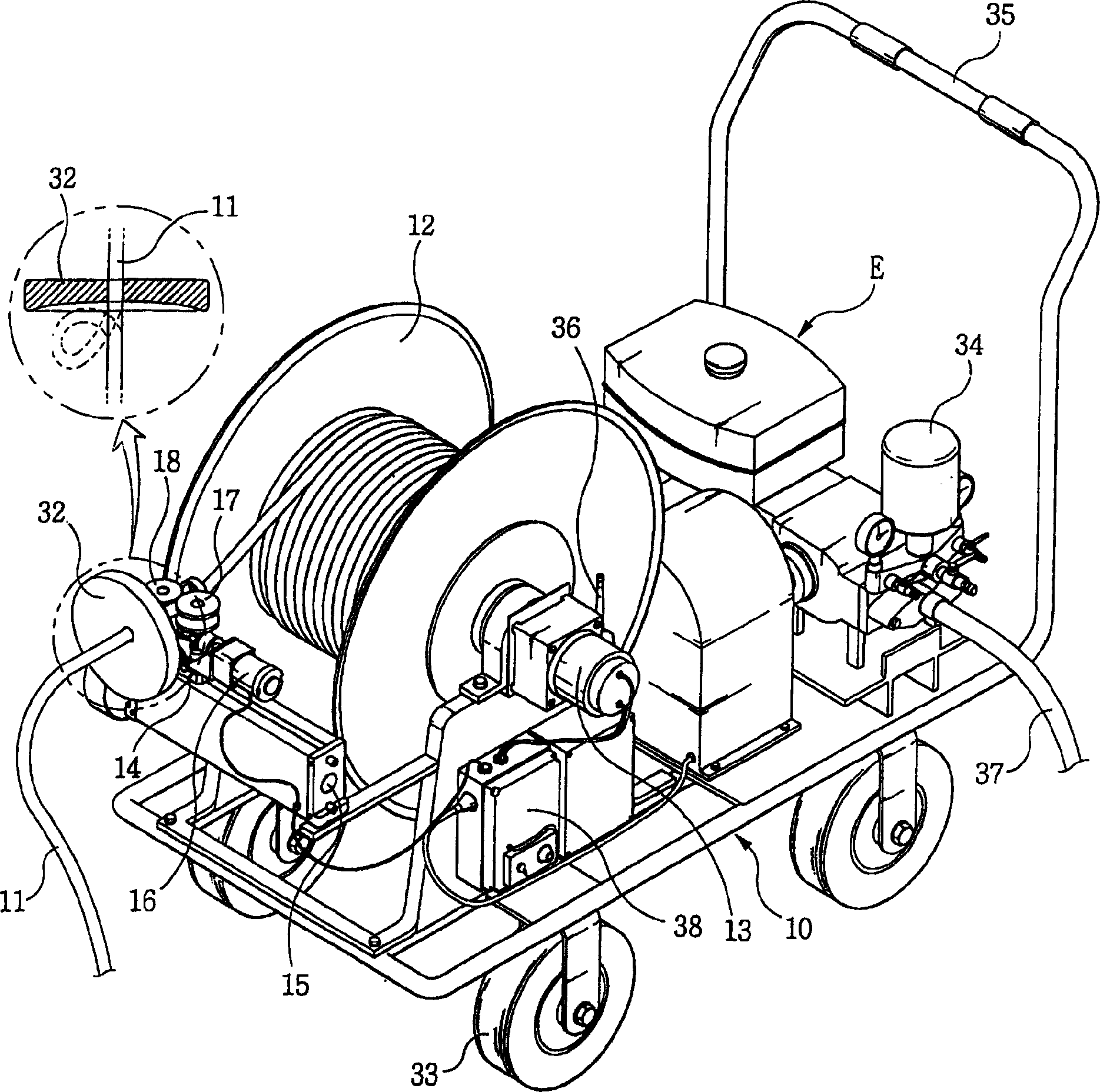

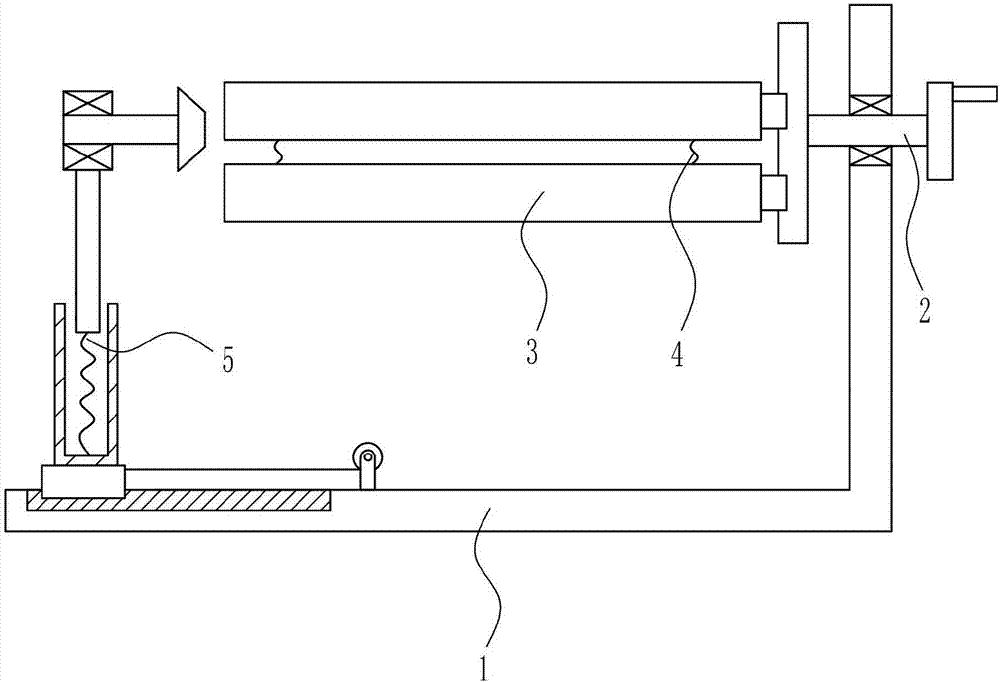

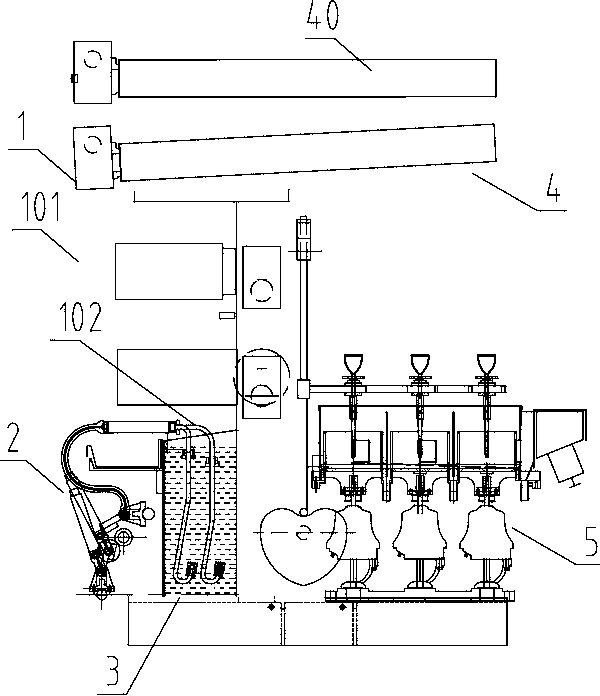

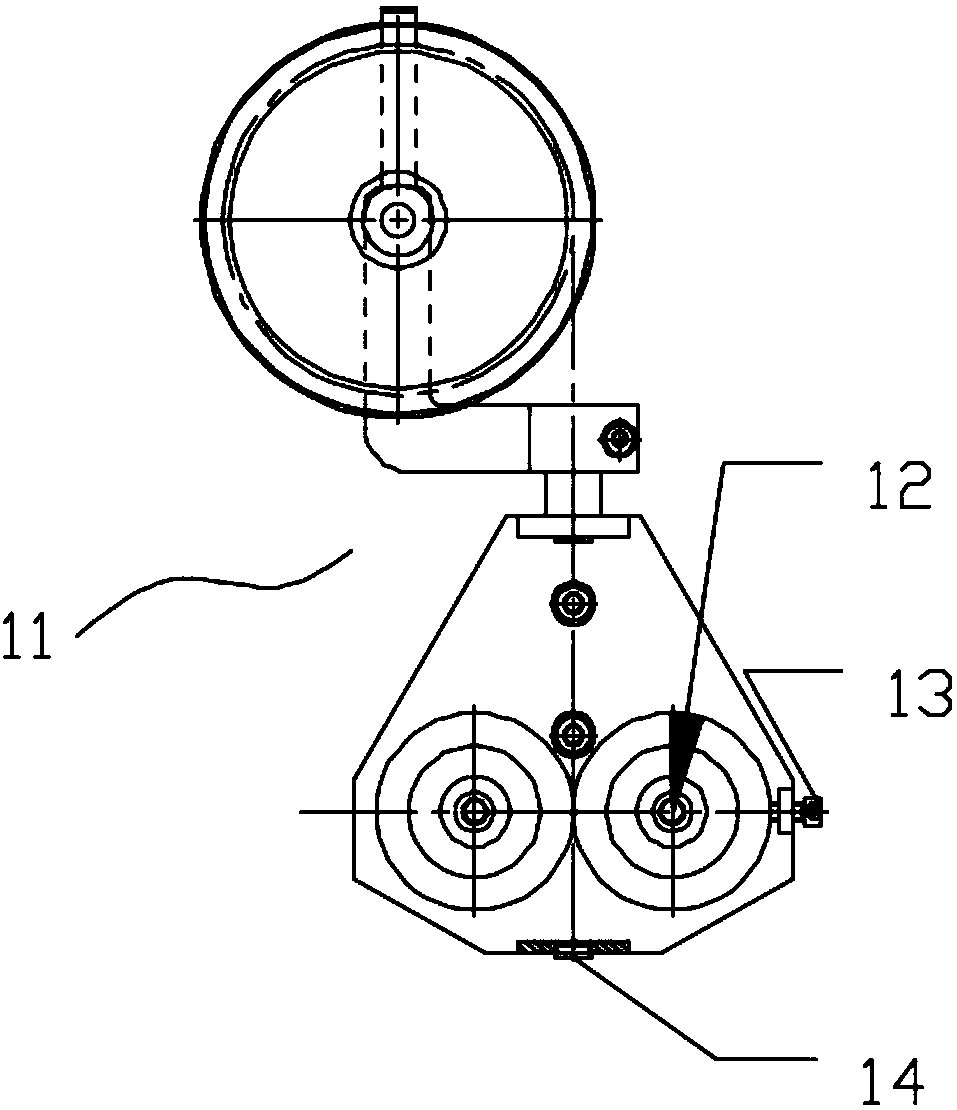

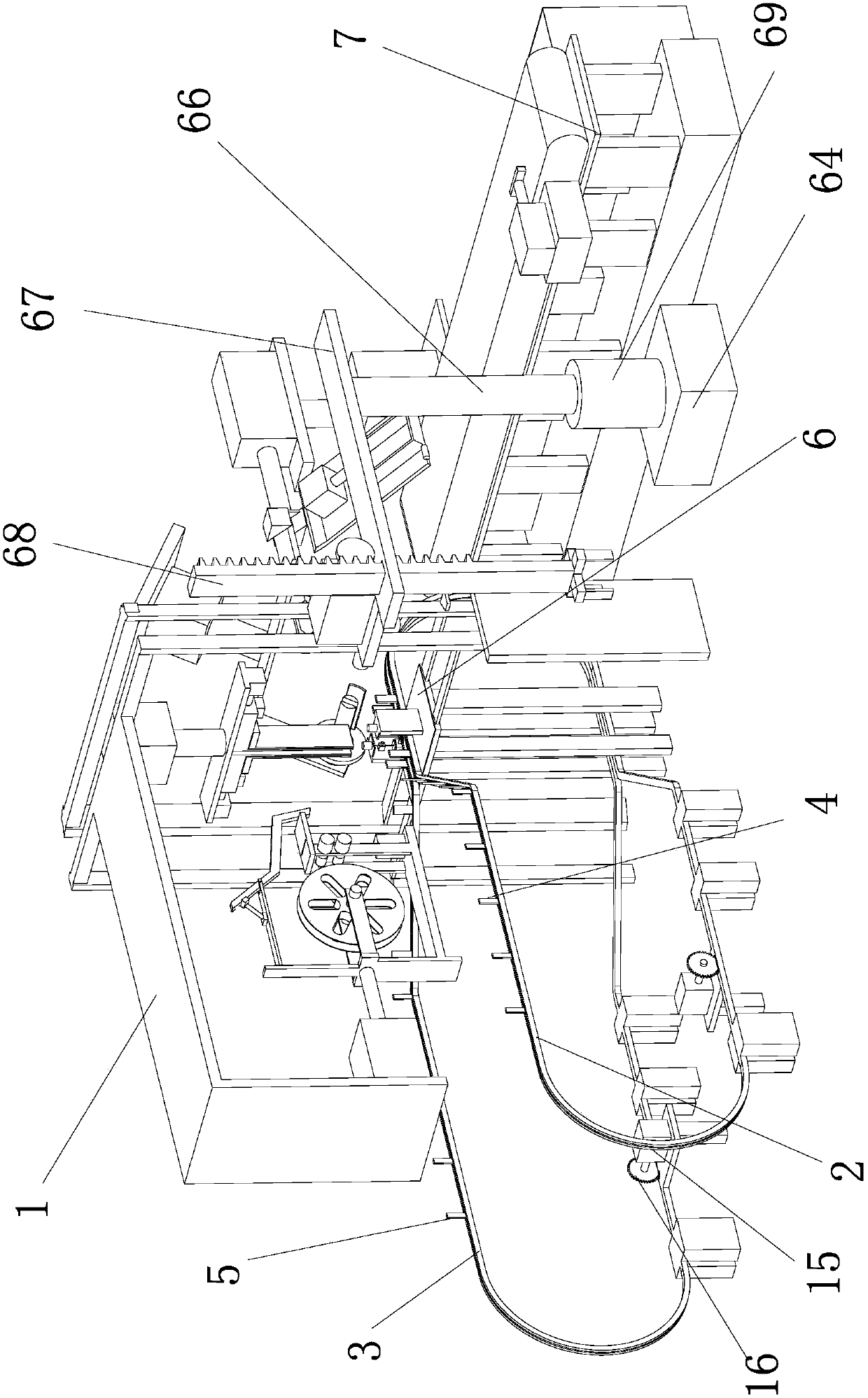

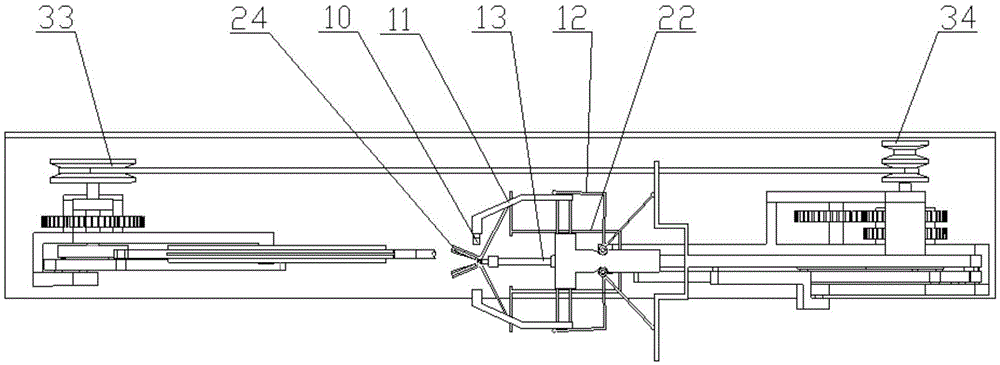

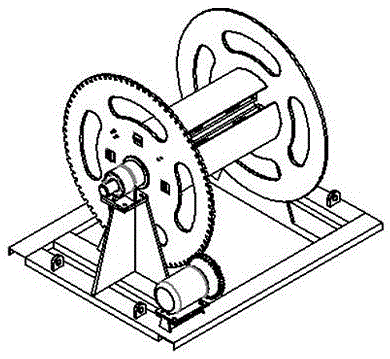

Labor alleviating type pesticide spray system with automatic hose winding and unwinding device

InactiveCN1606911ALabor savingFast windingFilament handlingInsect catchers and killersSprayerRemote control

The present invention relates to a labor-reducing pesticide spraying system with an automatic hose winding and unwinding device. The pesticide spraying system comprises: a frame, wherein a sprayer with a motor connected to an engine is arranged; a reel rotatably arranged in the frame, wherein a hose is wound on the reel; A first driving motor driven in two directions of normal direction and reverse rotation; a rotating shaft that is rotated by a driving force from a rotating shaft of a reel, and the rotating shaft reciprocates a movable member that is relatively The reel is engaged with the upper side in the left-right direction; the second drive motor, which is arranged on the movable member in cooperation with the first drive motor, is driven in the normal direction and the reverse direction according to the remote control signal; and a pair of rollers, The roller is disposed in the movable member and is rotatably connected to the second drive motor and tensions the outer surface of the hose and unwinds the hose from the reel.

Owner:HYUPWOO TRADING

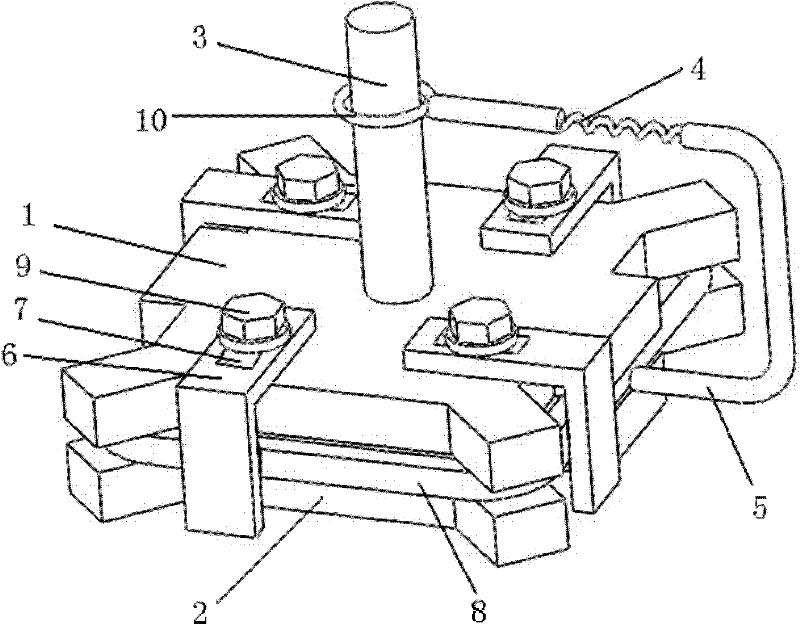

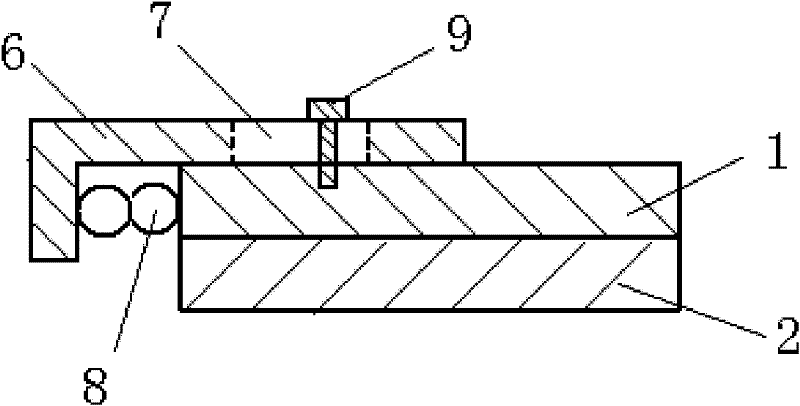

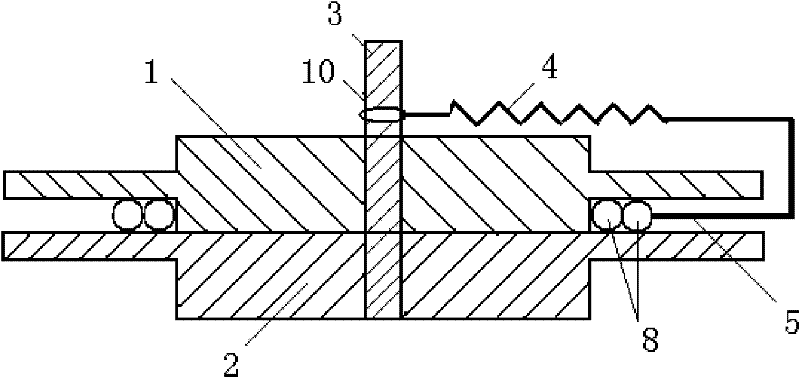

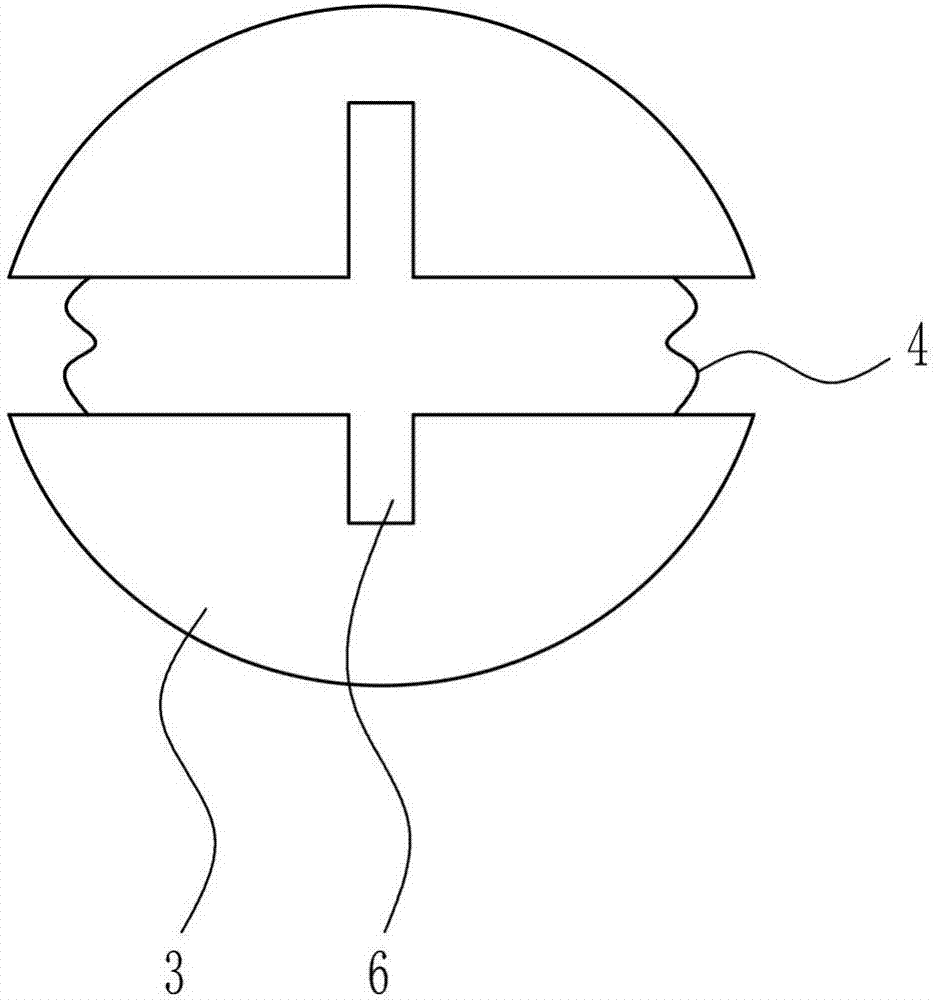

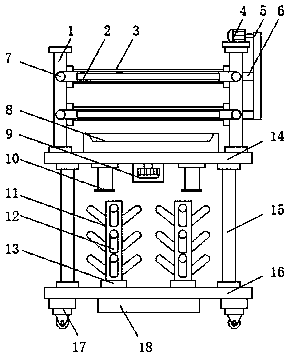

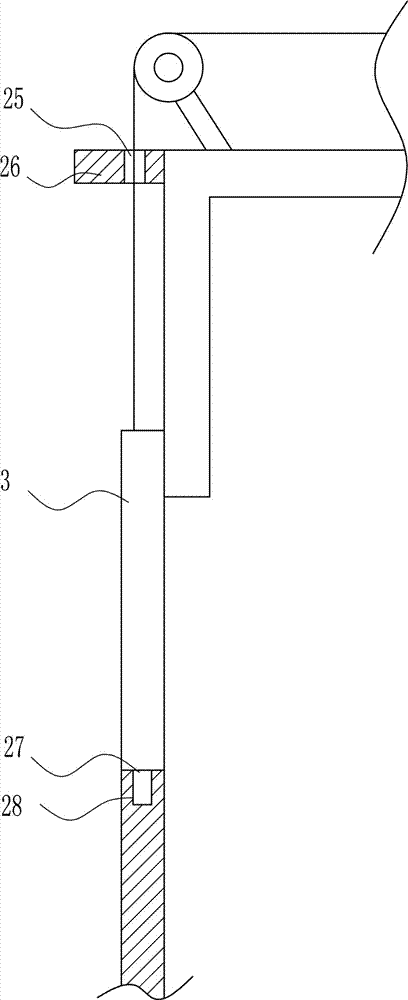

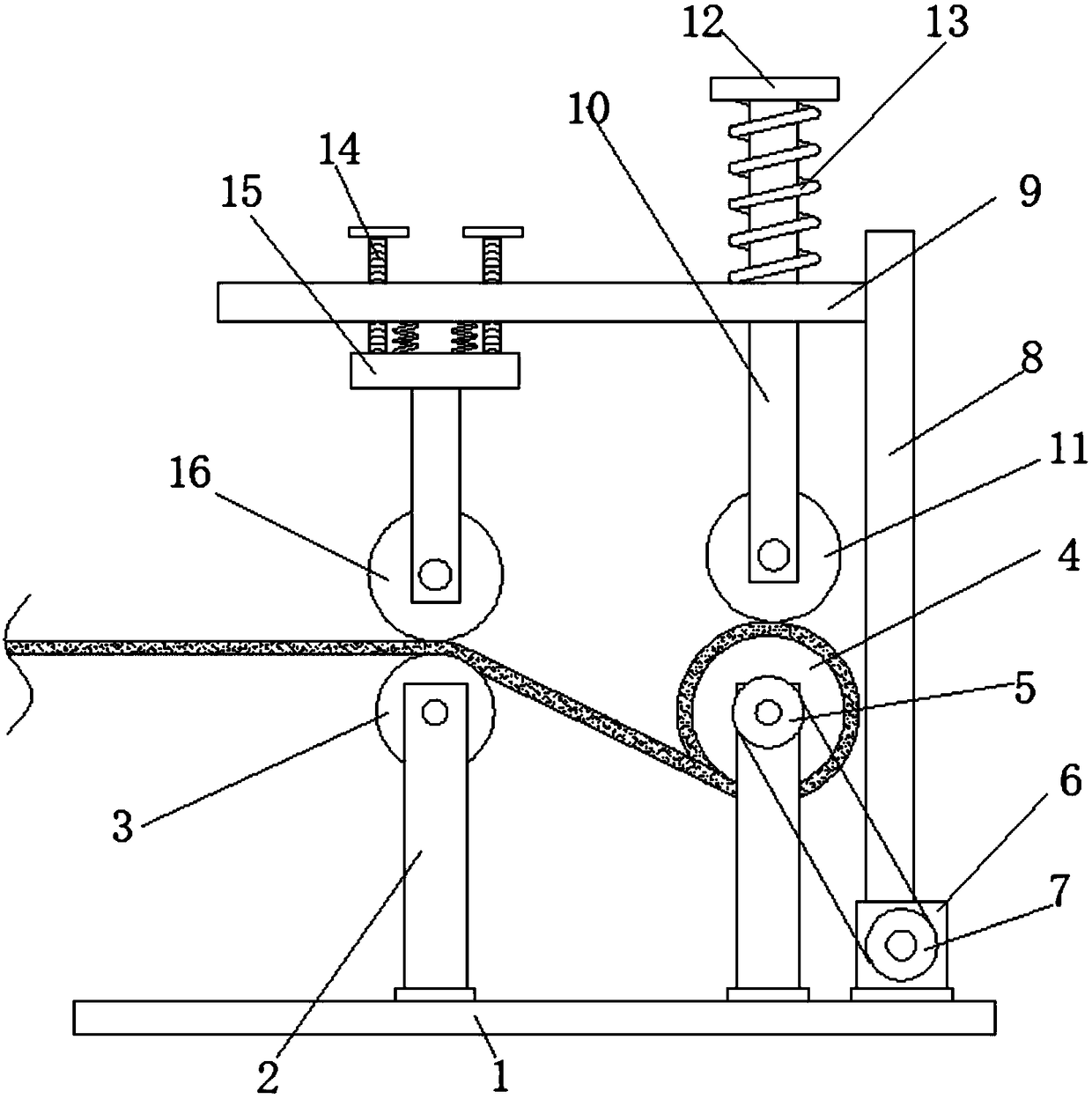

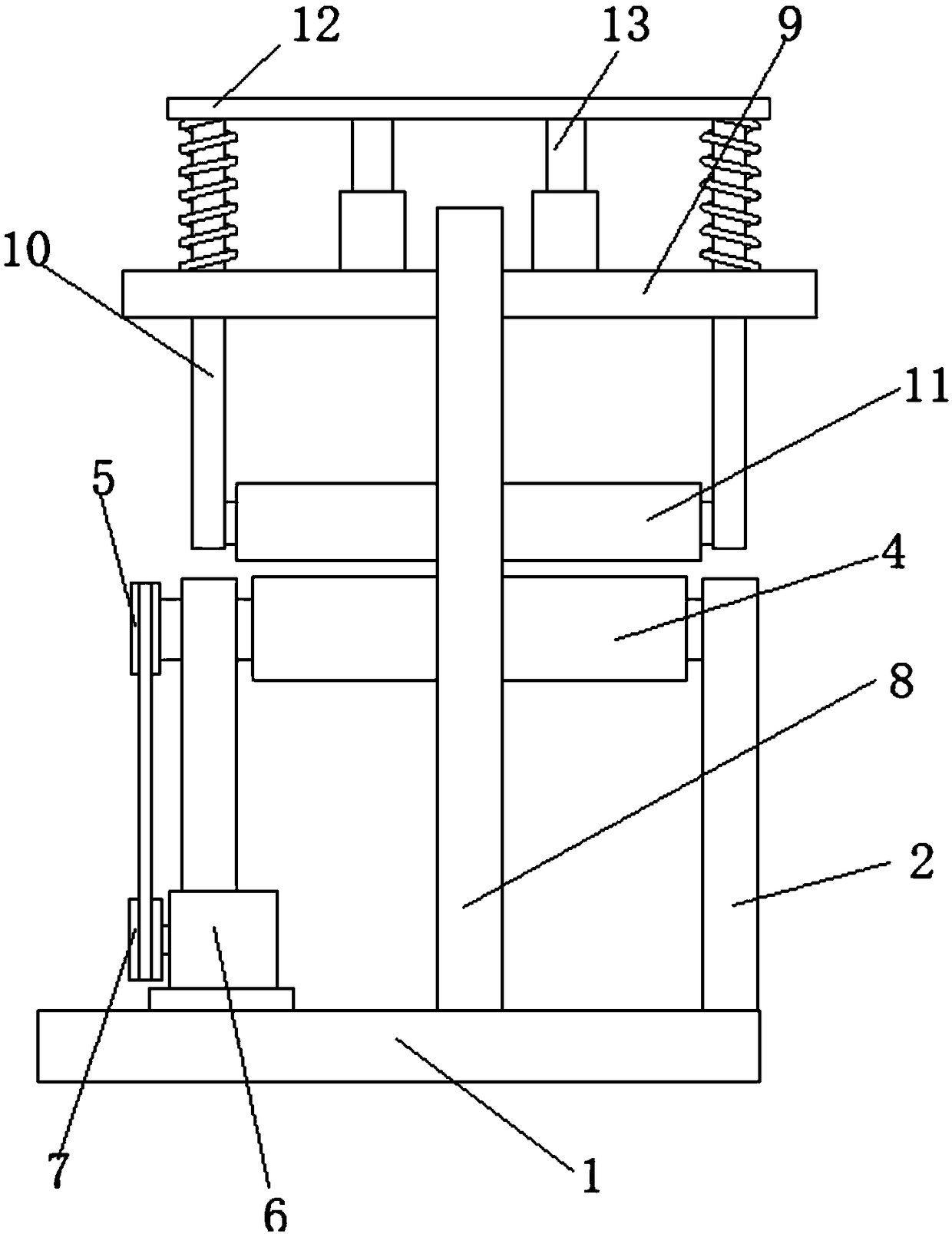

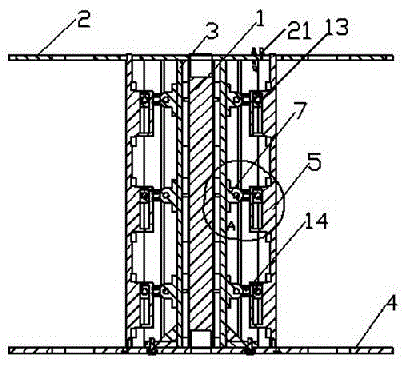

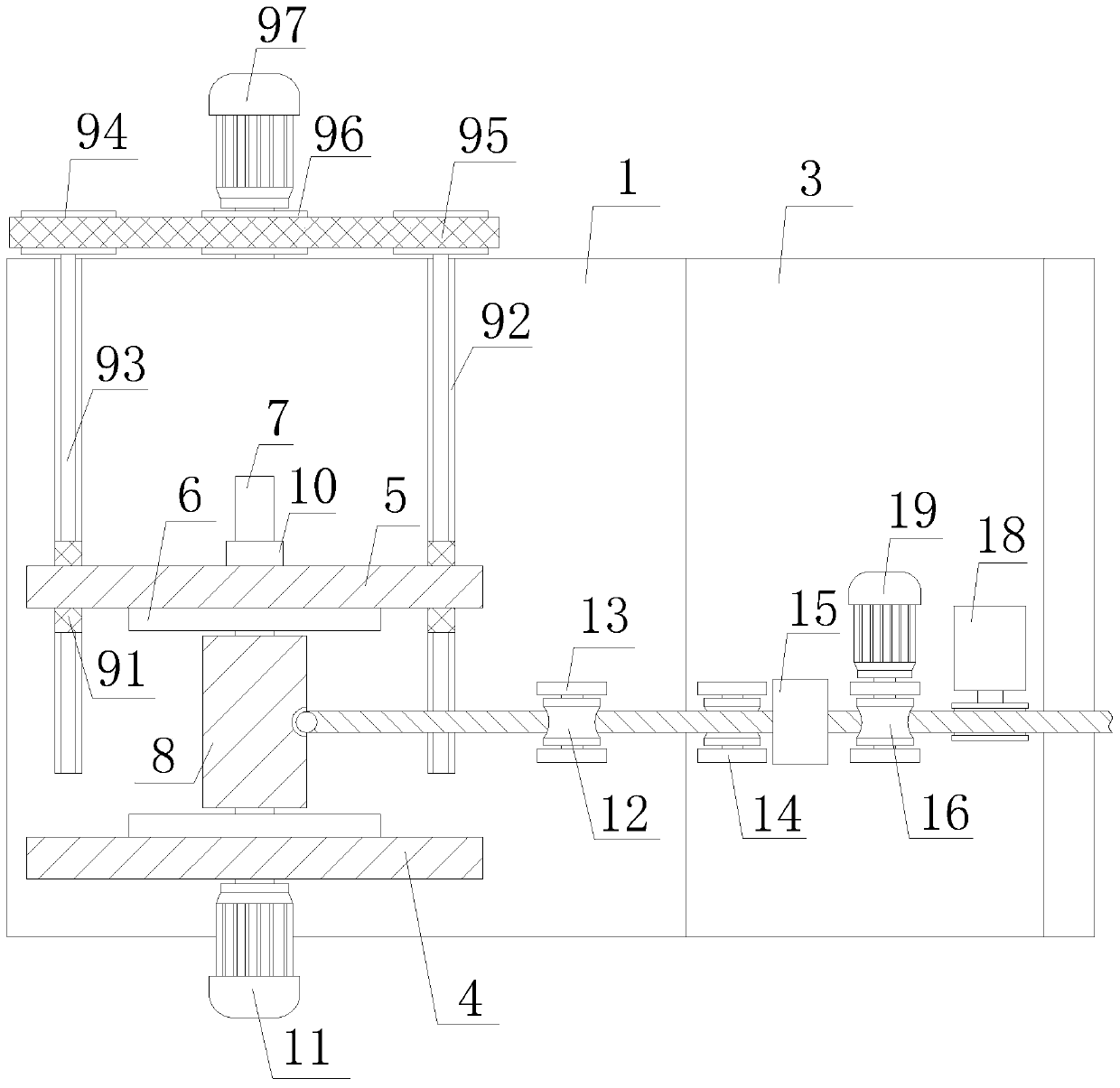

Winding device and winding method for a shim superconducting coil

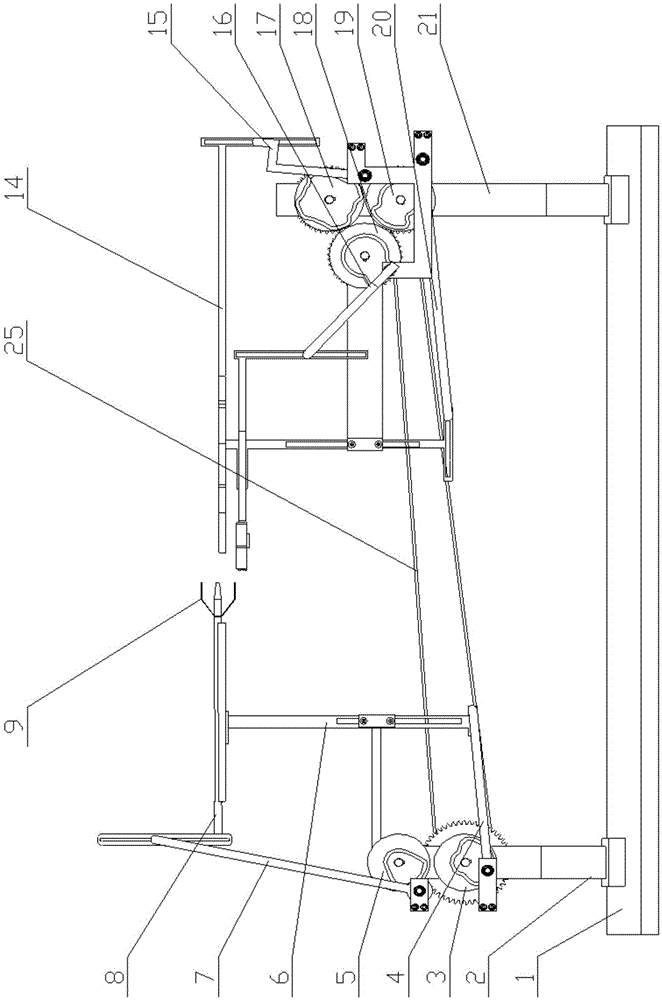

ActiveCN102290188ASimple installationThe method is simpleSuperconducting magnets/coilsCoils manufactureSuperconducting CoilsEngineering

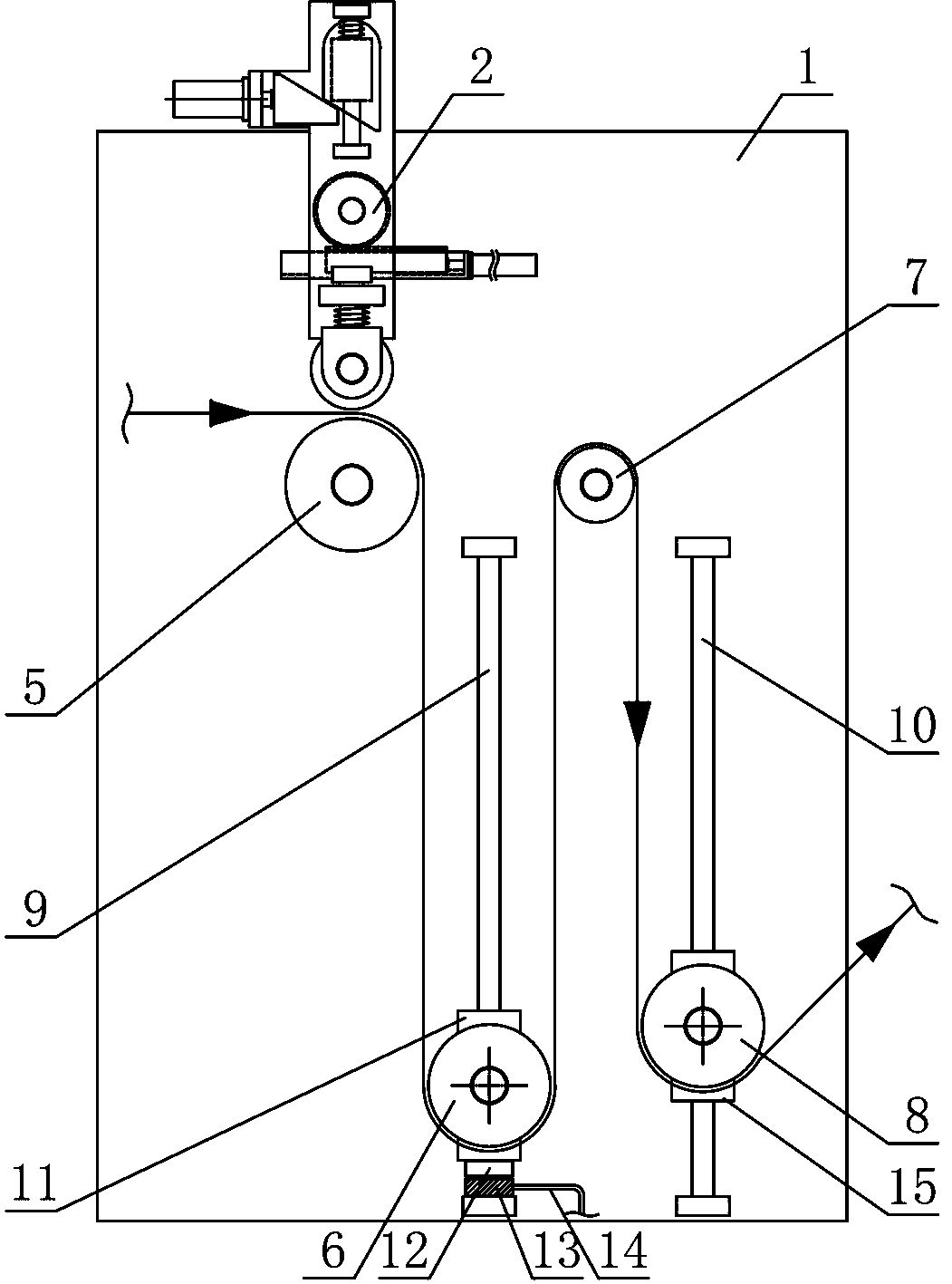

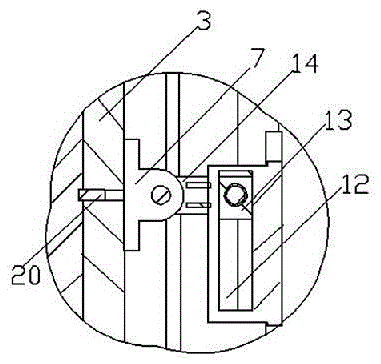

The invention relates to a winding device for a shimming superconducting coil, which comprises an upper cover plate (1), a lower cover plate (2), a central column (3), a spring (4), a pressure needle (5), a fixing clamp (6), a superconducting wire (8), a screw (9) and a ring (10). The upper cover plate (1) and the lower cover plate (2) are connected through the central column (3), and a clearancewith the size identical to the diameter of the wire is left between rectangular teeth of the upper cover plate (1) and the lower cover plate (2). The superconducting wire (8) pressed by the top end of the pressure needle (5) with the spring mechanism (4) slides along the circumference on a horizontal plane to be wound the superconducting coil.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Fabric winding equipment

Owner:刘芳

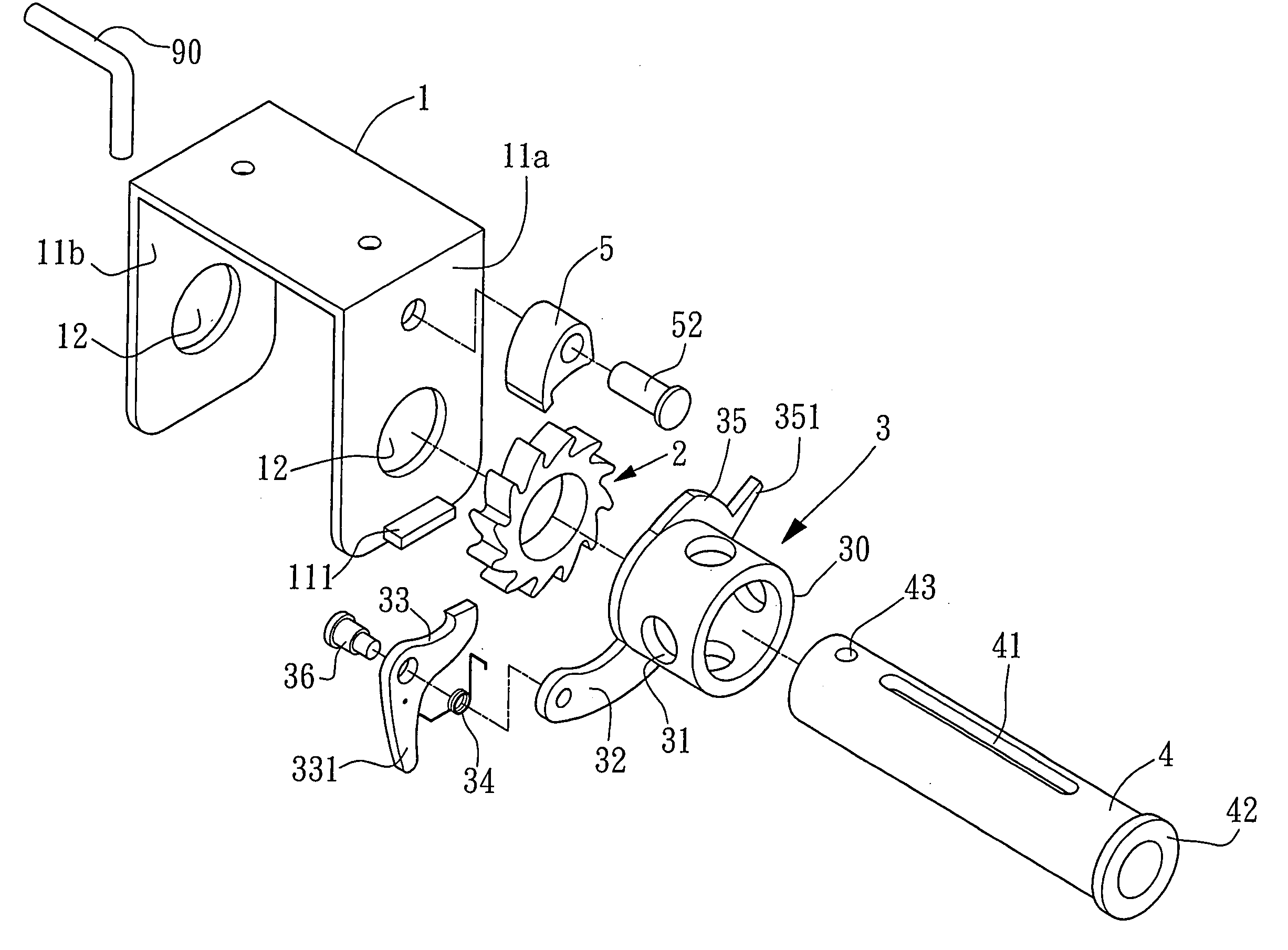

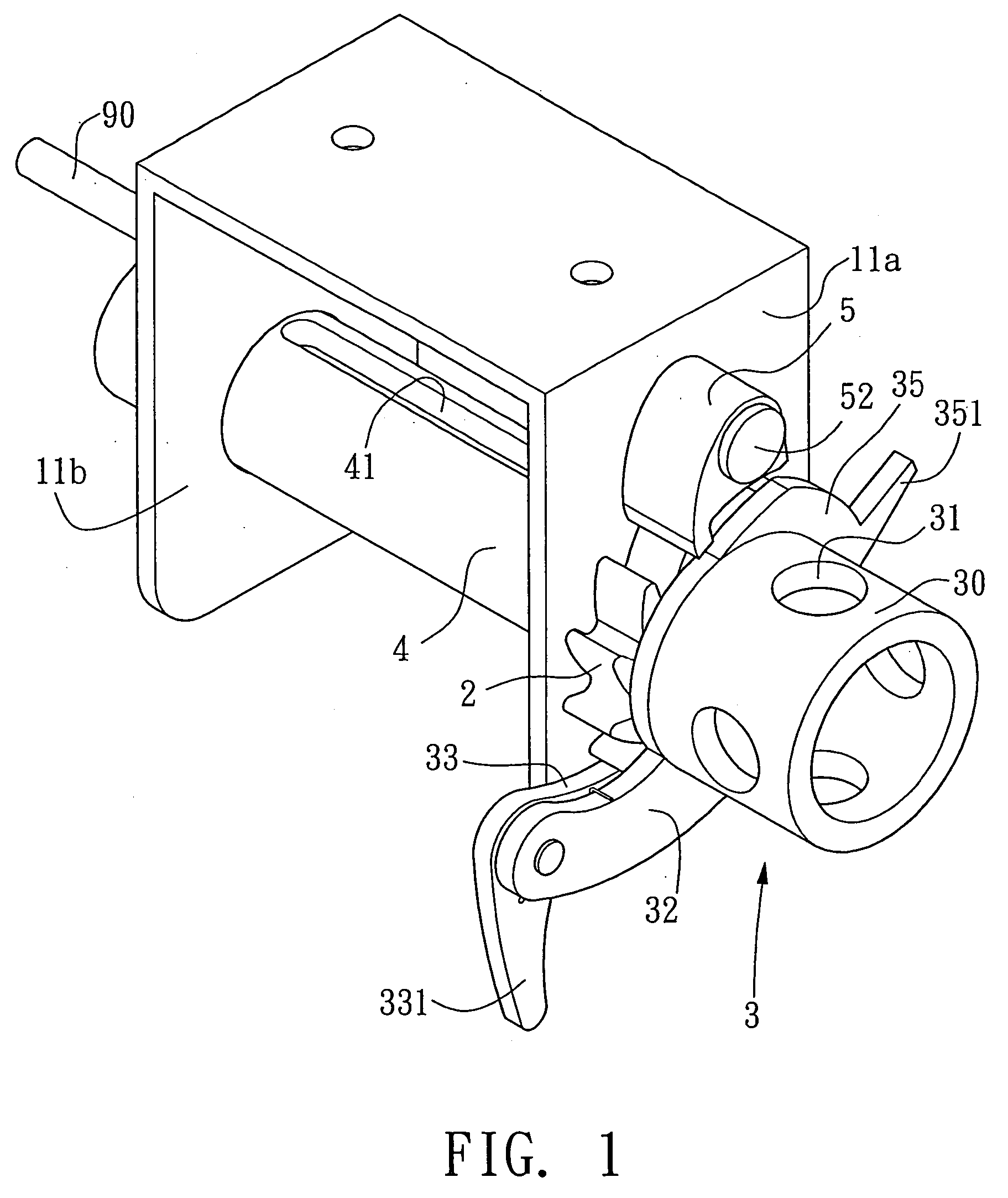

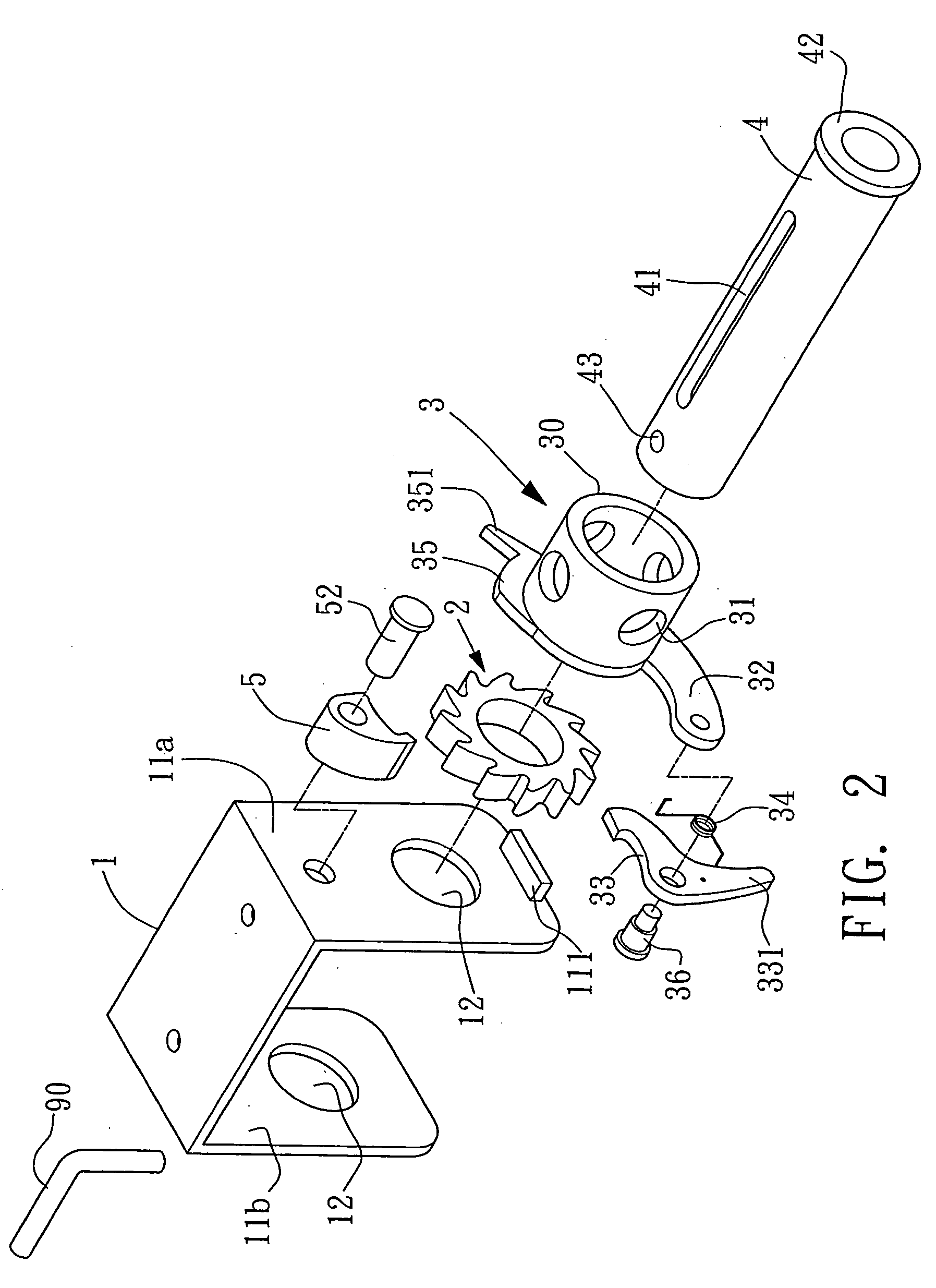

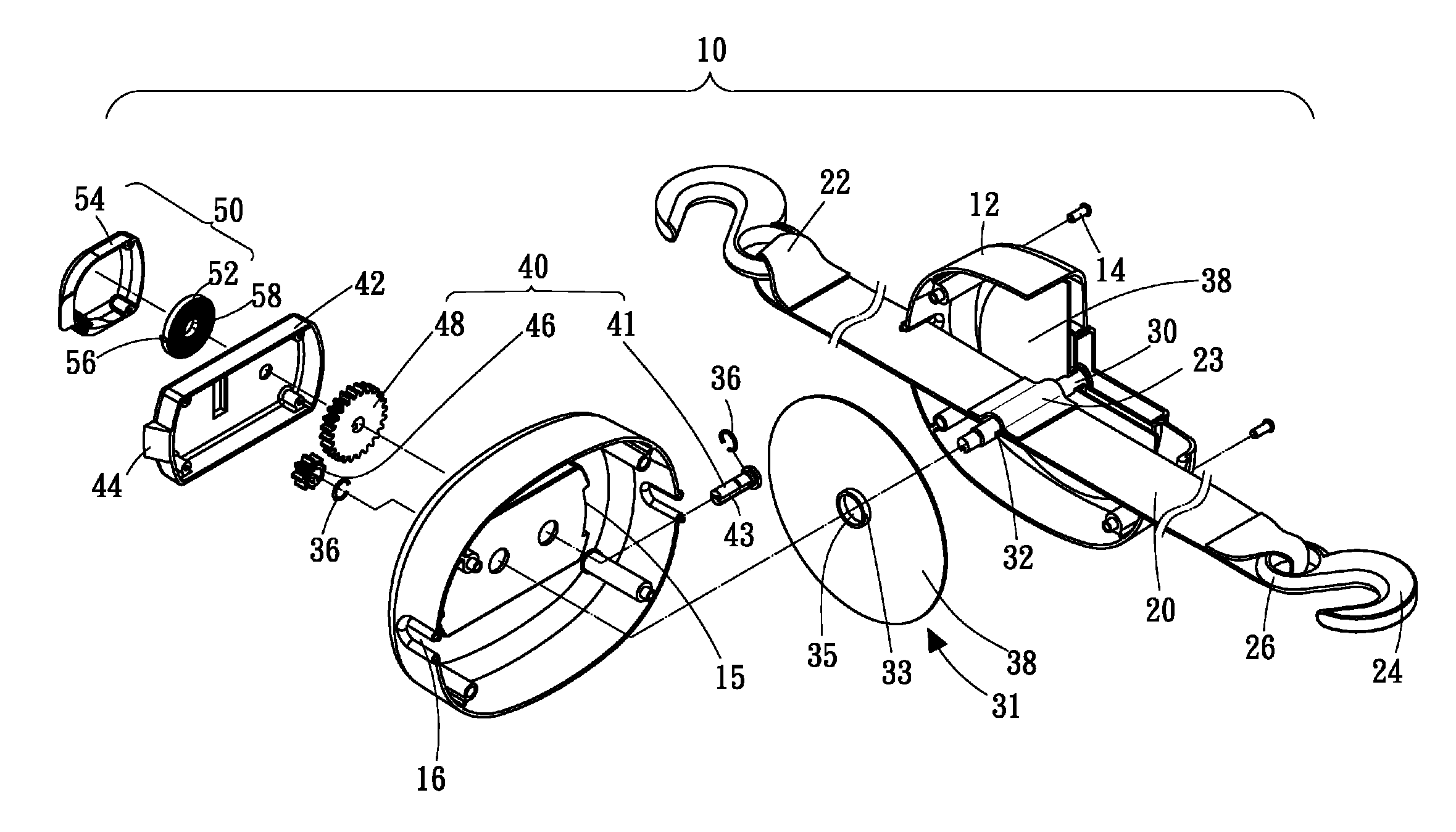

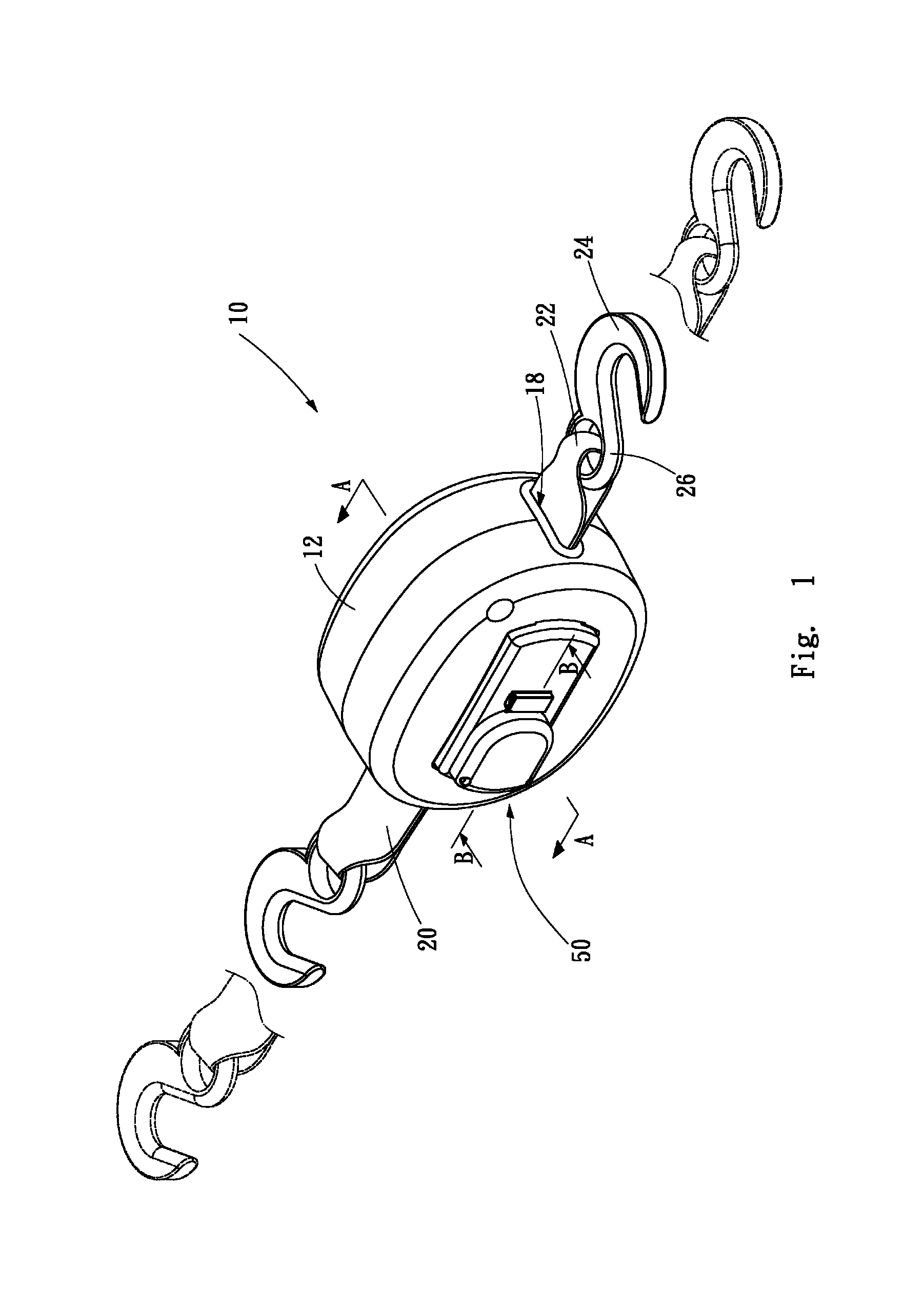

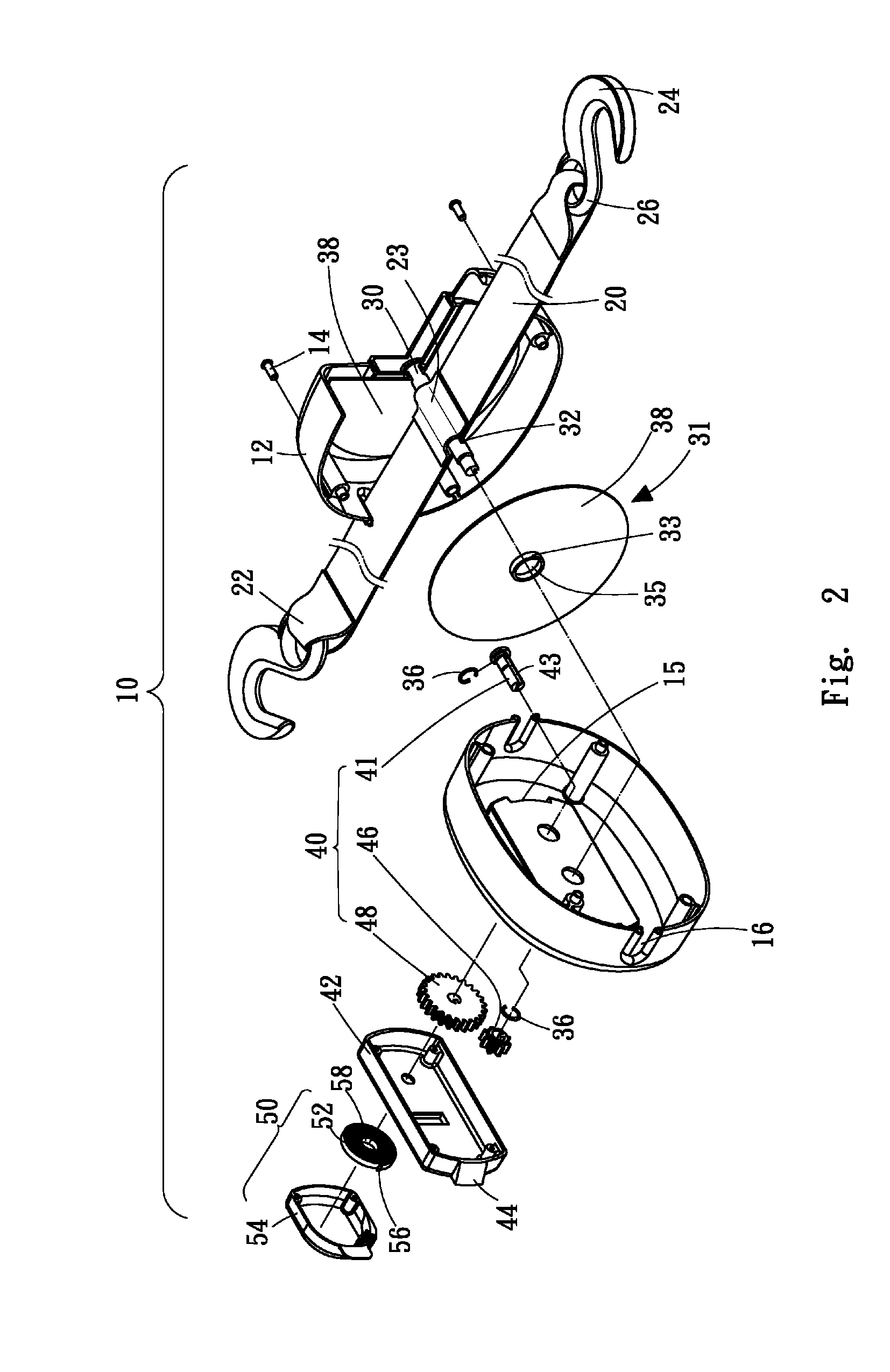

Tying device

A tying device including a seat body, a ratchet wheel, a driving member, a shaft and a detent member. A shaft is passed through the seat body and connected with the ratchet wheel. The driving member is pivotally connected with the shaft. The driving member can be wrenched to engage the detent member with different ratchets of the ratchet wheel so as to wind or release a tying belt connected with the shaft.

Owner:RACHET

Coilable shade

Owner:KO HOU SHENG

Spinning technology of two-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409824AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningMachine

The invention relates to a spinning technology of a two-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of semicontinuous spinning machines. The spinning technology comprises the steps of glue supplying, thread-line forming, spinning and winding, wherein the spinning is carried out through a spinning device. The spinning device comprises two spinning rollers which are transversely arranged relative to an operating surface of a spun surface, thread lines surround the spinning rollers, and drafting, solidifying and deacidification in the spinning steps are achieved when the spinning rollers rotate. The spinning technology solves the problems that thread lines of a semicontinuous spinning machine in the prior art are insufficient in reaction, the spinning process cannot be accelerated, and production efficiency and the product quality cannot be taken into consideration. The arrangement direction of the spinning rollers is changed so that the thread lines can walk for a longer distance while the spinning process of the spinning machine is accelerated and the structures of other components of original equipment are not changed, the thread lines can be reacted with acid bath more fully, and both production efficiency and product quality are taken into consideration.

Owner:YIBIN HIEST FIBER +2

Cloth winding drum device for textile machinery

InactiveCN107472951ARealize automatic windingConvenient coilingWebs handlingAgricultural engineeringDrive motor

The invention discloses a cloth reel device for textile machinery, comprising a base, a support column is fixedly connected to one side of the upper end of the base, and a top plate is fixedly connected to the top end of the support column, and a driving motor is arranged on the upper end of the top plate. And the lower end of the driving motor is provided with a rotating shaft, and the outward extension end of the rotating shaft passing through the inner wall of the top plate is provided with a limiting groove, and a first protrusion is inserted in the limiting groove, and the lower end of the first protrusion is fixedly connected with a The first fixed plate, the bottom end of the first fixed plate is evenly surrounded by several reels, the lower end of the second fixed plate is fixedly connected with the first fixed block through the disc, the lower end of the first fixed block A second protruding block is inserted through the groove, and the second protruding block is fixedly connected with a circular clamping block through the telescopic rod. The invention has the advantages of simple structure, easy installation and disassembly, more convenient cloth coiling, no manual winding, reduced labor force, improved production efficiency, and is suitable for wide popularization.

Owner:湖州胎福工艺品有限公司

Yarn variable speed winding mechanism

The invention discloses a yarn variable speed winding mechanism, and belongs to the field of textile machining mechanical equipment. A yarn guide mechanism and a rolling mechanism are sequentially arranged on a conveying support in the horizontal direction, yarn is sequentially connected to a yarn inlet rotating roller, a yarn storage rotating roller, a yarn guide rotating roller and a lifting rotating roller in a wound manner, a yarn compressing mechanism is vertically arranged on at the position, on the upper side of the yarn inlet rotating roller, of the conveying support, a rolling motor is in transmission connection with an output gear, a rotating crank is arranged on one side of a rolling gear in the radial direction of the rolling gear, a crank sliding block of the outer end of therotating crank is in rotatable connection to the end of one side of the rotating crank, a rolling rotating shaft is horizontally and rotatably connected to the upper side of a rolling support, a rotating rocker arm is fixedly arranged on one side of the rolling rotating shaft in the radial direction of the rolling rotating shaft, and the crank sliding block is arranged in a rolling guide groove inthe rotating rocker arm in a sliding manner. The yarn variable speed winding mechanism is reasonable in structural design, yarn can be continuously rolled efficiently and compactly, the yarn conveying and rolling automation degree is improved, and the production use needs are met.

Owner:浙江云飞扬羊绒有限公司

Tow strap apparatus

Owner:HUANG HAN CHING

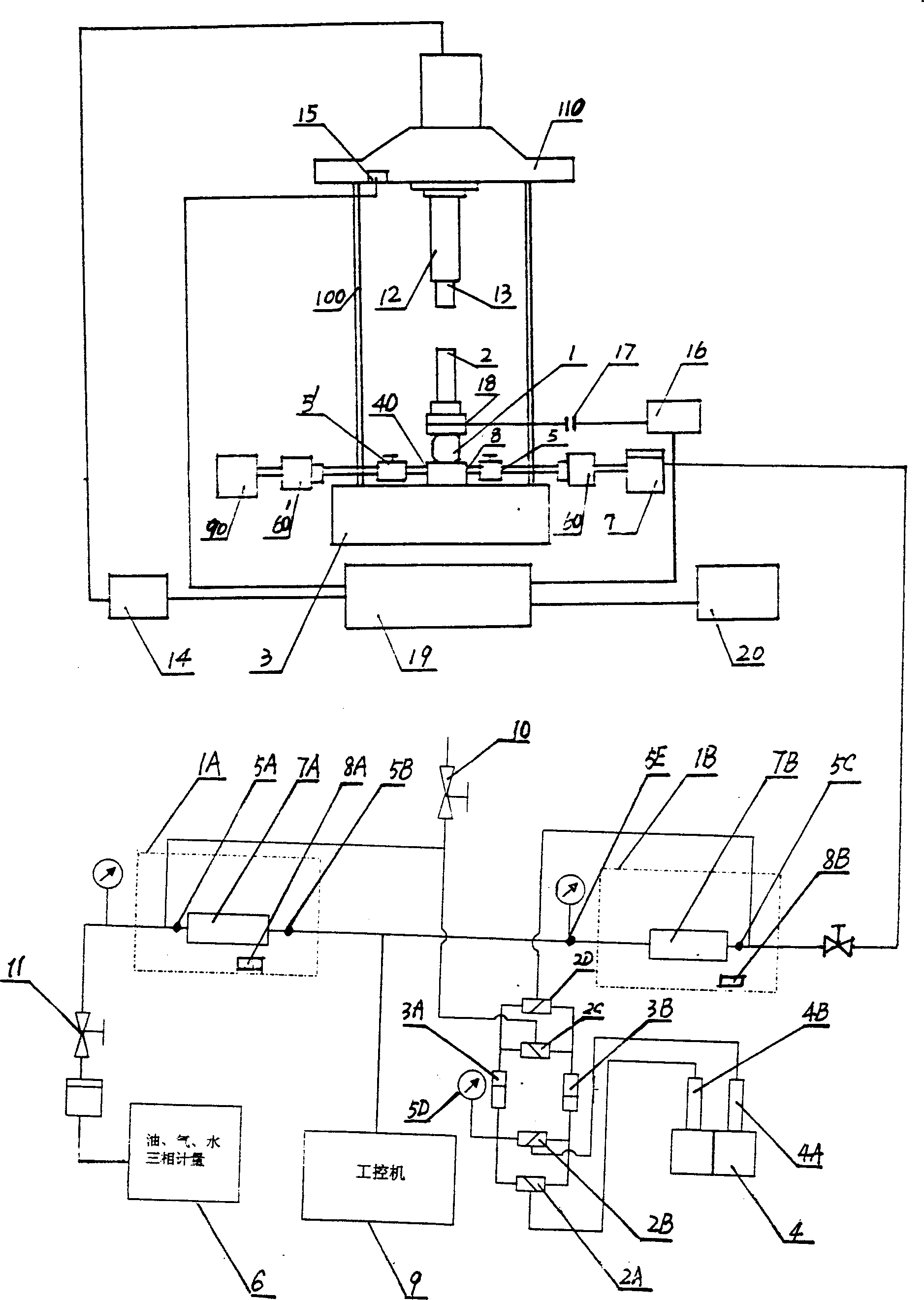

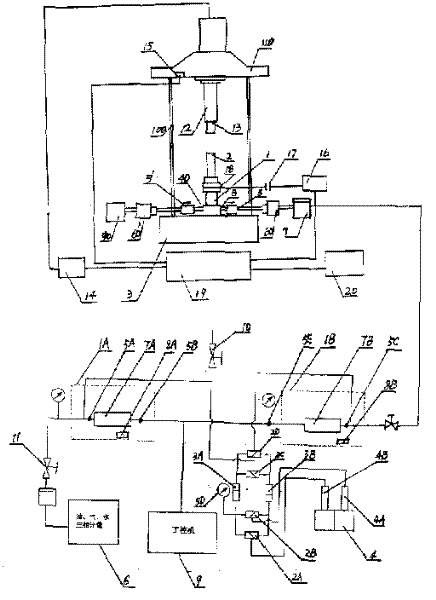

Oil gas formation, migration and accumulation analogue experiment installation

The simulating experimental facility relates to the area of the petroleum geology. The invented experimental facility includes the experimental device for simulating the creation of oil and gas and the experimental device for simulating the migration and congeries of oil and gas. The characteristics are that the back-pressure regulator of the experimental device for simulating the creation of oiland gas is connected to the constant temperature cabinet of the experimental device for simulating the migration and congeries of oil and gas. The experimental facility possesses the features of highdegree of automation, easy of maintenance, high temperature and high pressure. The invented device can realize the circulation flow so as to simulate the open system and the closed system.

Owner:石油大学(北京)盆地与油藏研究中心 +1

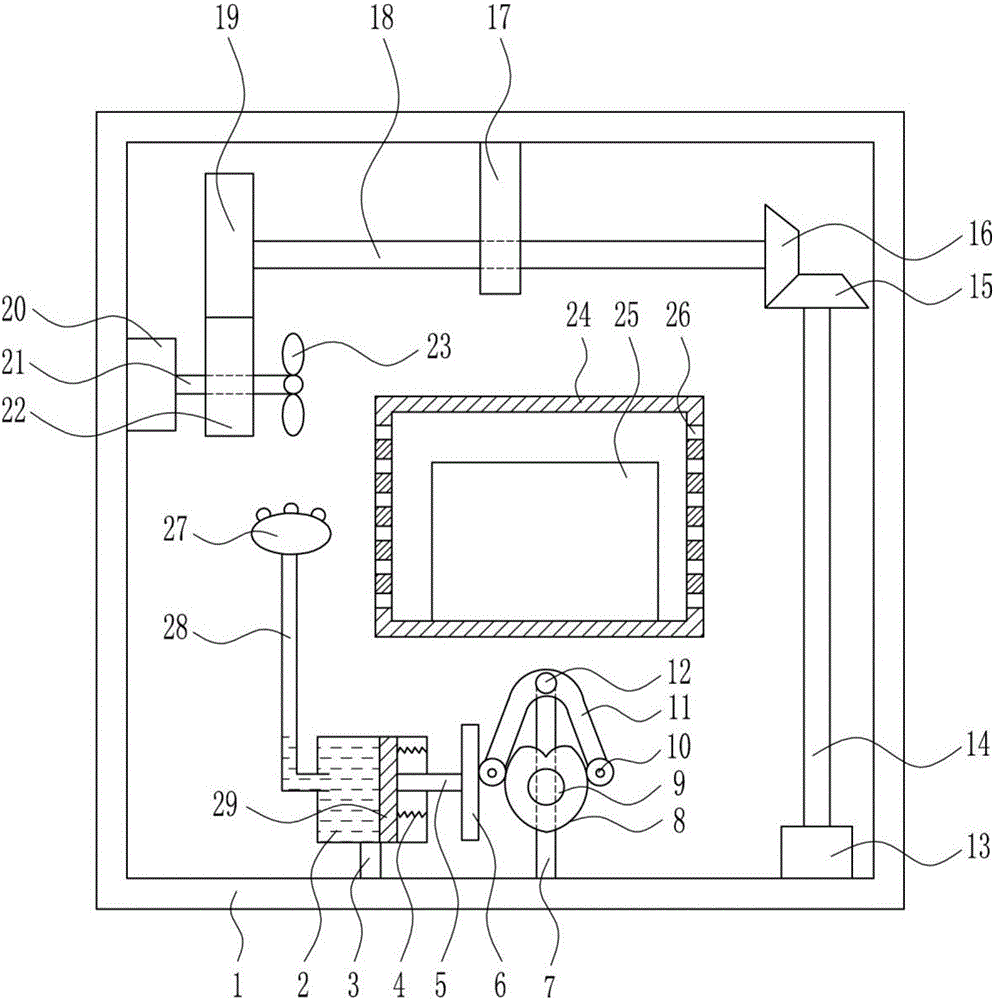

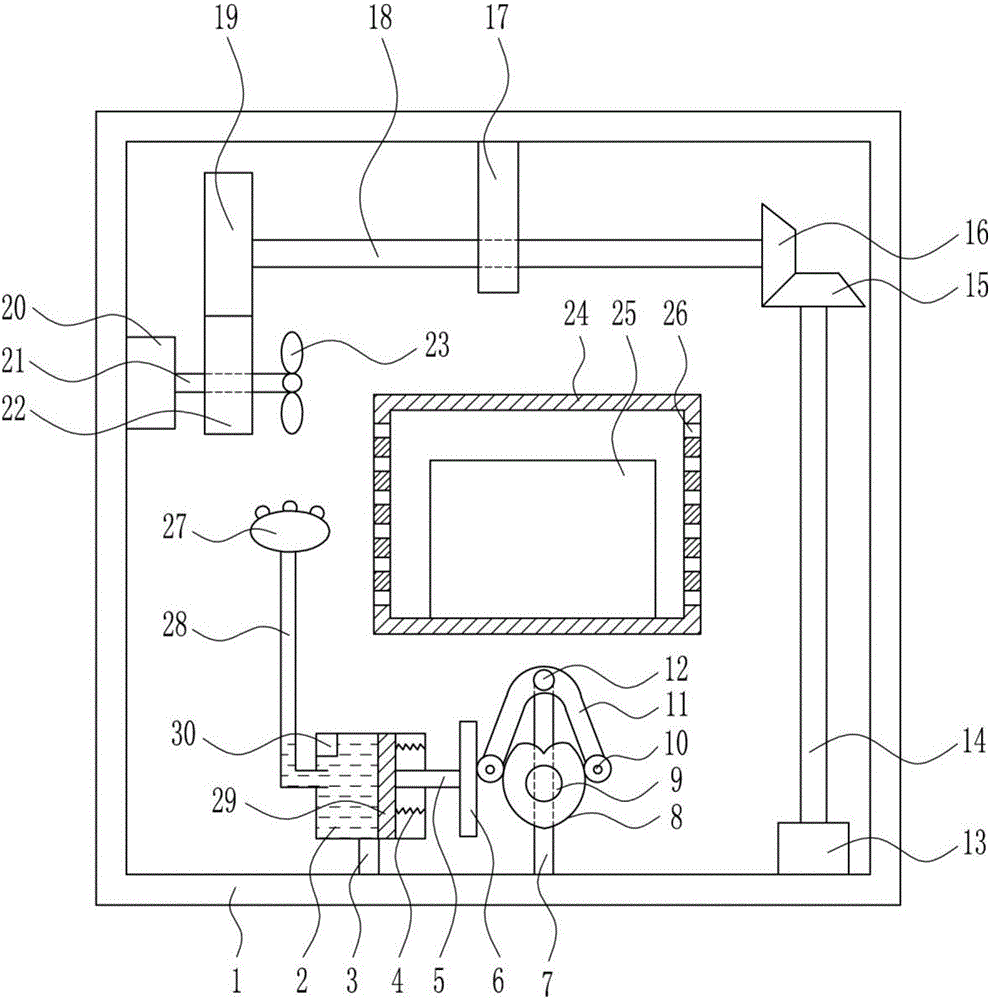

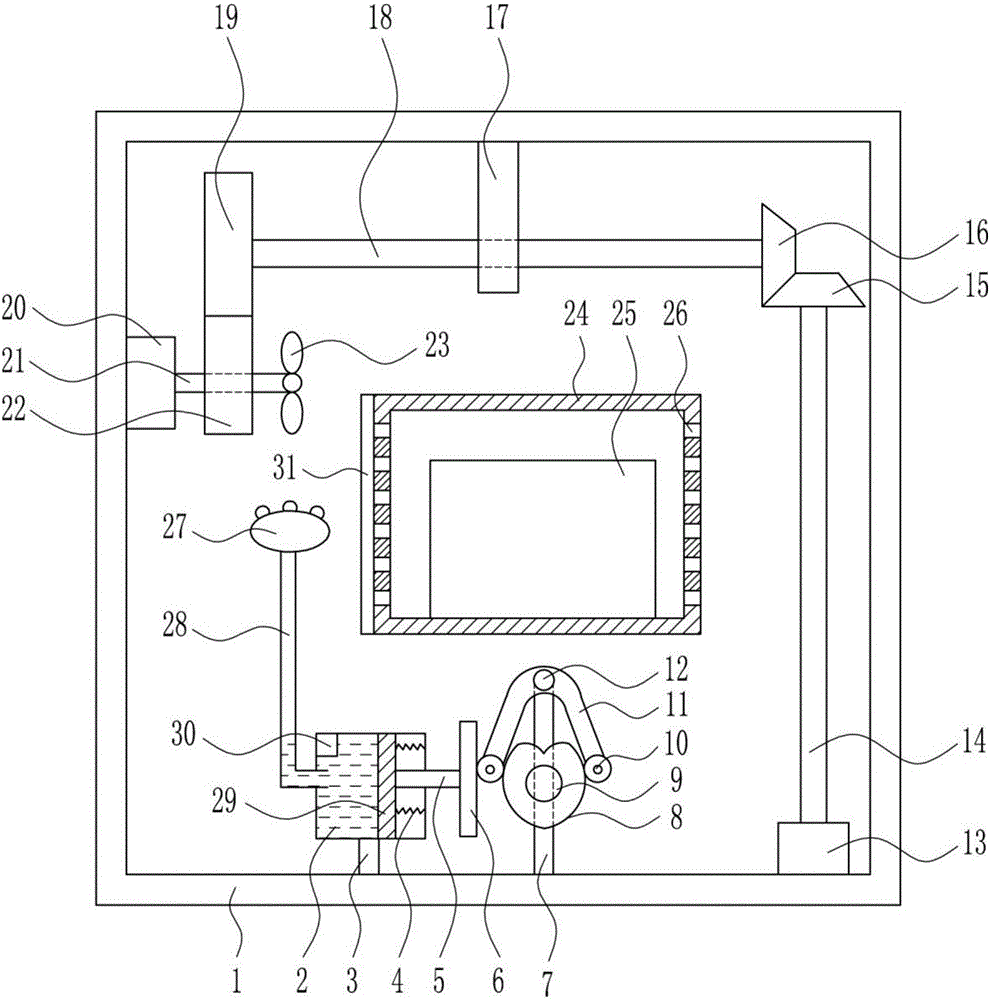

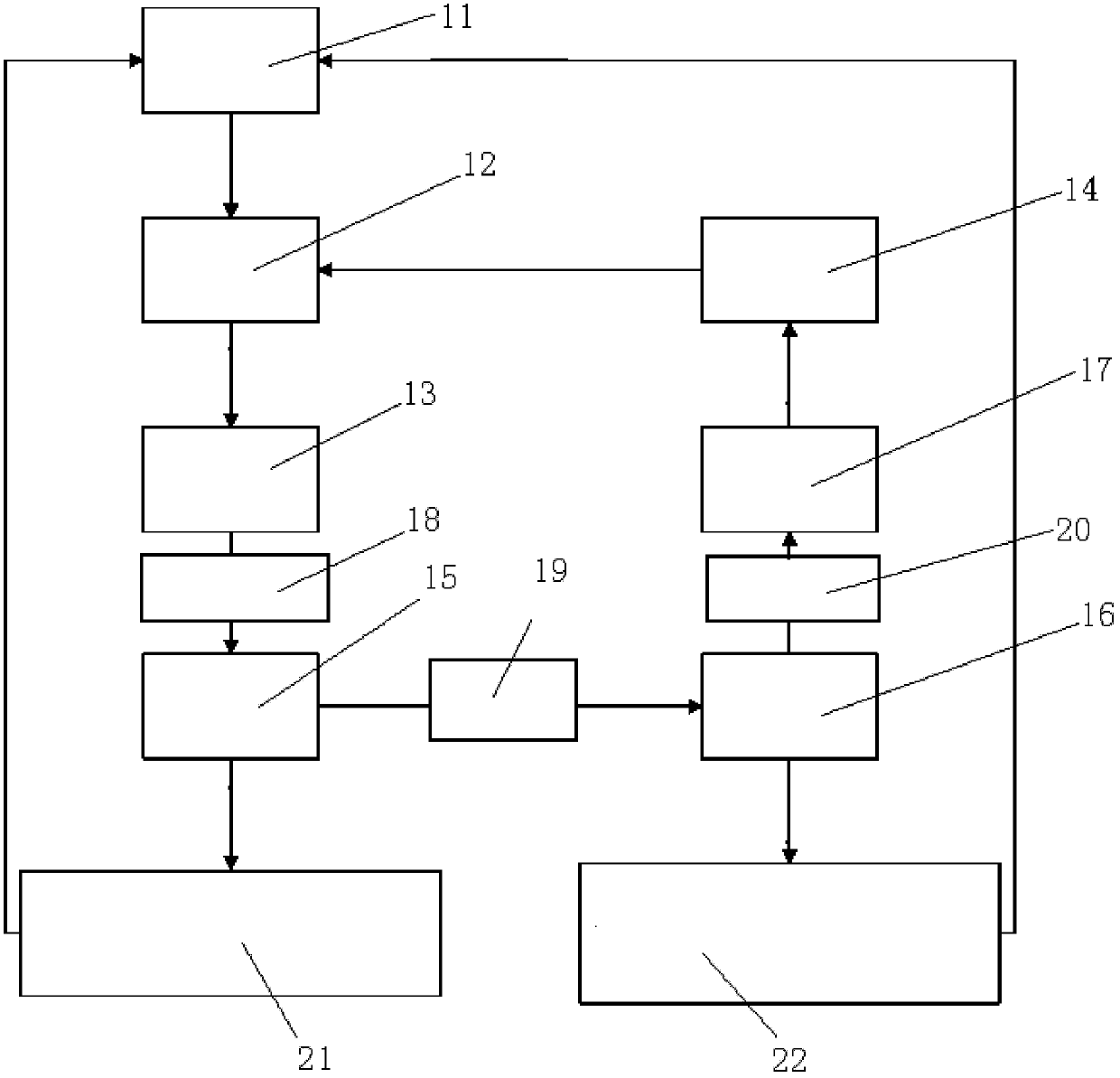

Quick air-cooled heat radiation type controller

ActiveCN106385786AEfficient cooling and heat dissipationExtended service lifeCooling/ventilation/heating modificationsCooling effectEngineering

The invention relates to a controller, and particularly to a quick air-cooled heat radiation type controller. The invention aims to settle a technical problem of supplying the quick air-cooled heat radiation type cooler with advantages of high cooling effect, high air speed and low resource consumption amount. For settling the technical problem, the quick air-cooled heat radiation type cooler provided by the invention comprises a placement box, a water tank, a first supporting rod, a spring, a connecting rod, a push plate, a second supporting rod, an equal-radius cam, a first motor, a contact roller, a curved rod, a first rotating shaft, a first bevel gear, a second bevel gear, an upper bearing seat, a third rotating shaft, a large gear, etc. The bottom in the placement box is provided with the first supporting rod, the second supporting rod and the first motor which are successively arranged from left to right. The top of the first supporting rod is provided with the water tank. The quick air-cooled heat radiation type controller has advantages of high cooling effect, high air speed and low energy consumption amount. Quick and effective heat radiation can be performed on the controller, thereby prolonging service life of the controller.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

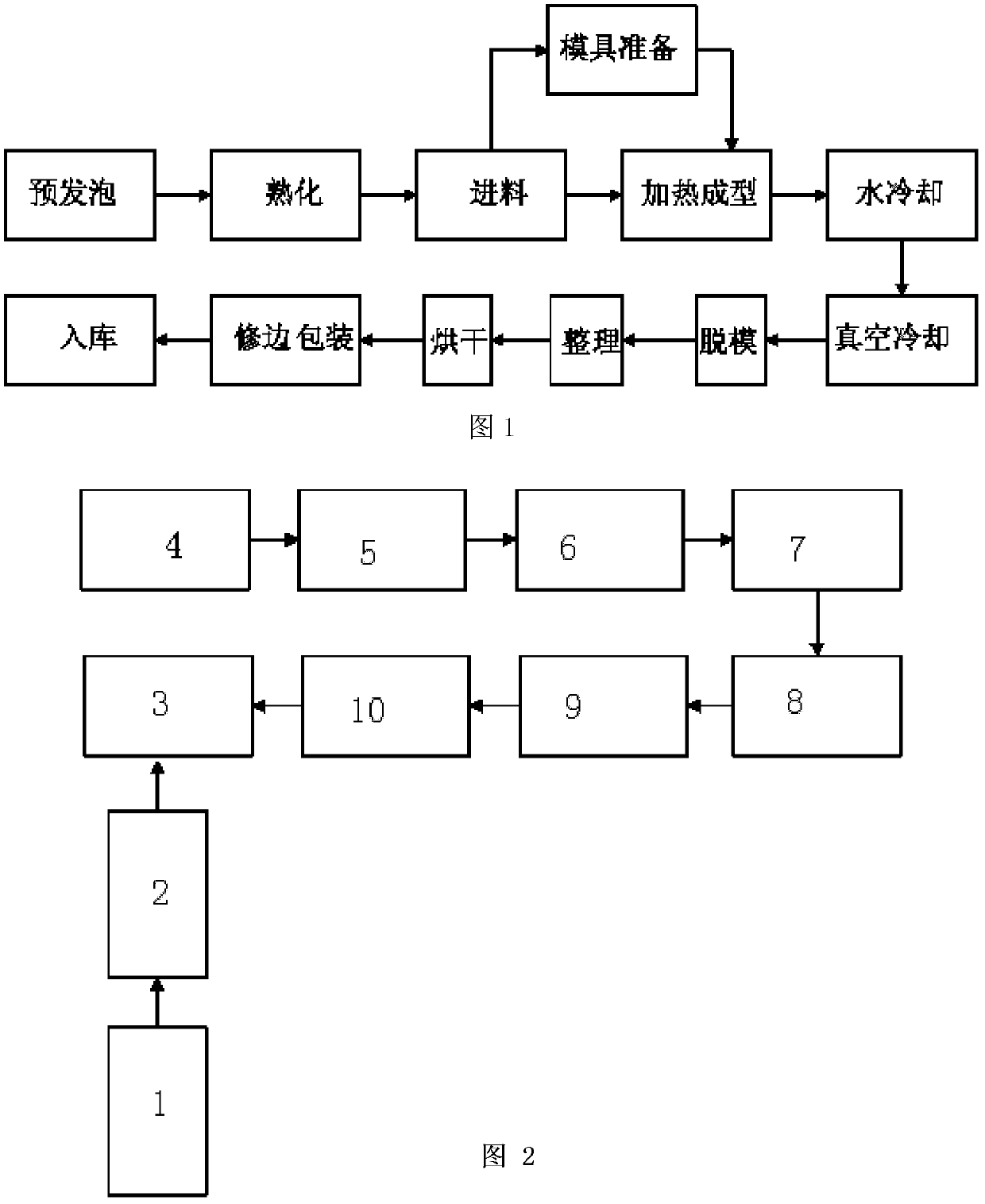

Production technique of EPS (expandable polystyrene) foam articles

The invention discloses a production technique of EPS (expandable polystyrene) foam articles. The production technique is characterized by comprising the following steps: pre-foaming, curing, feeding, preparing mould, heating and forming, water cooling, vacuum cooling, demoulding, trimming, drying, trimming, packaging and storing in warehouse, and the production technique improves the compressed air, water circular cooling and drying process. The technique disclosed by the invention has simple and reasonable technique procedures and utilizes two paths of compressed air supply systems, so that the pipeline pressure is very stable, an electromagnetic valve acts flexibly, a cylinder switching valve quickly and reliably acts, and a cooling water circulating system can quickly cool to improve the cooling efficiency, save the electric energy and vapor and reasonably utilize the energy sources; besides, a mixed mode of high and low temperature air is used, so that the articles are not deformed or expanded irrespective to the foaming density, the drying time is shortened and the resources are reasonably utilized.

Owner:安徽艾柯泡塑股份有限公司

Textile fabric and yarn quick winding, coiling and uncoiling device

The invention discloses a textile fabric and yarn quick winding, coiling and uncoiling device. The textile fabric and yarn quick winding, coiling and uncoiling device comprises a first support plate,wherein first support columns are arranged at both ends of the surface of the first support plate; a vertical column is arranged between the two first support columns; a guide rod is arranged on the vertical column; a second support plate is arranged on the first support plate; a first motor is arranged in the middle part of the bottom surface of the second support plate; rotary sleeves are arranged at both sides of the first motor; a rotary rod is arranged in each rotary sleeve; coiling rolls are arranged between the second support columns; one side of each coiling roll penetrates through thesecond support columns and is connected with a coiling shaft; a second motor is arranged at the upper end of the second support column near the coiling shafts; a cleaning frame is arranged between frame rods; the interior of the cleaning frame is provided with an opening. The textile fabric and yarn quick winding, coiling and uncoiling device has the advantages that the structure is simple, and the convenience in use is realized; the fabrics and yarns can be quickly wound into coils, and the yarn columns can be conveniently stored; the working efficiency is improved, and the labor intensity is reduced.

Owner:湖州泰鑫无纺布有限公司

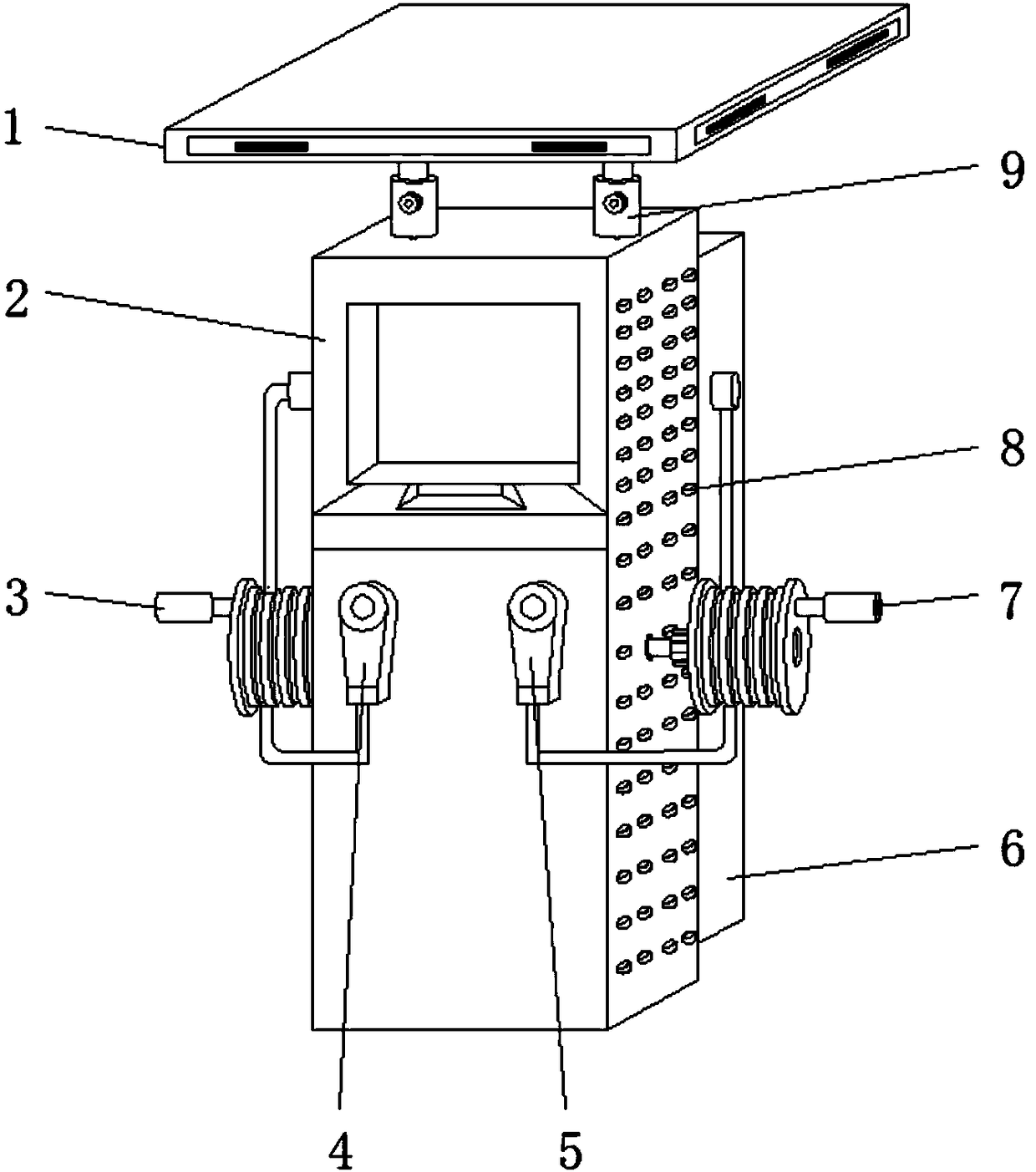

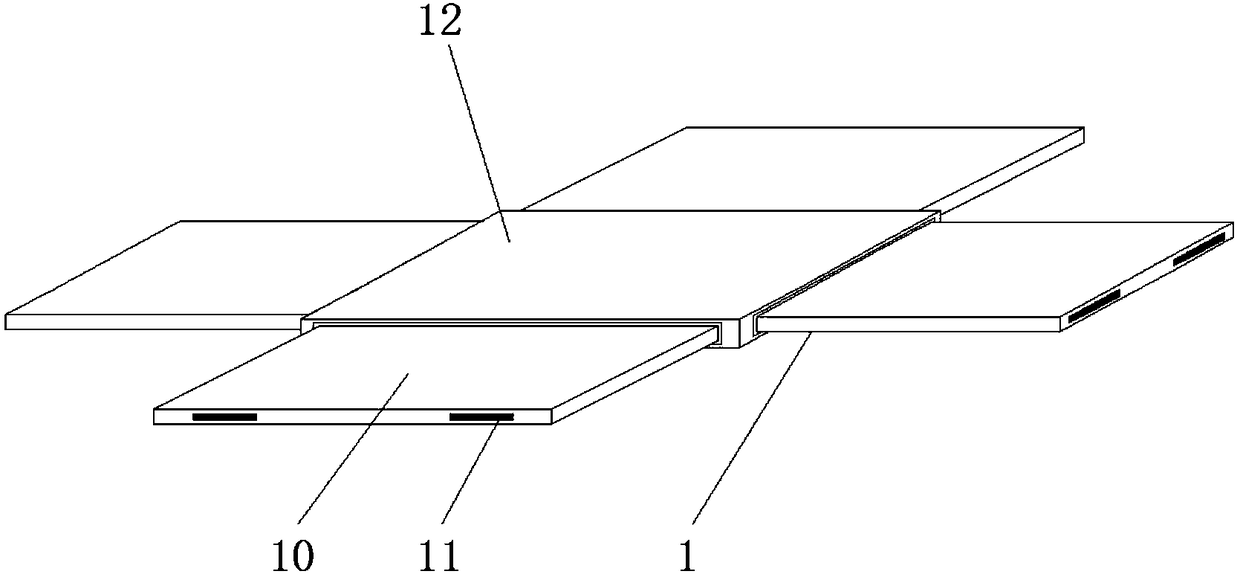

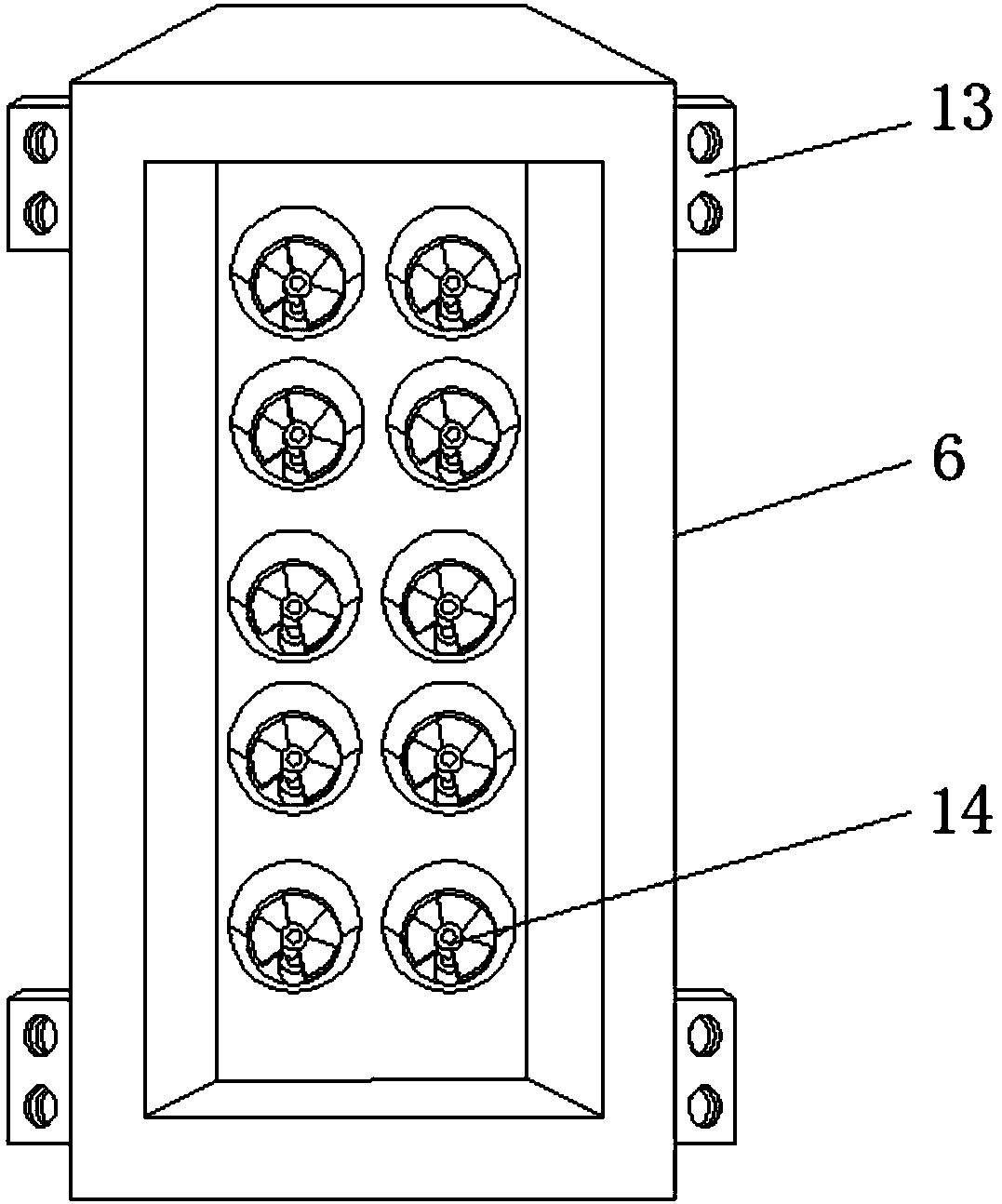

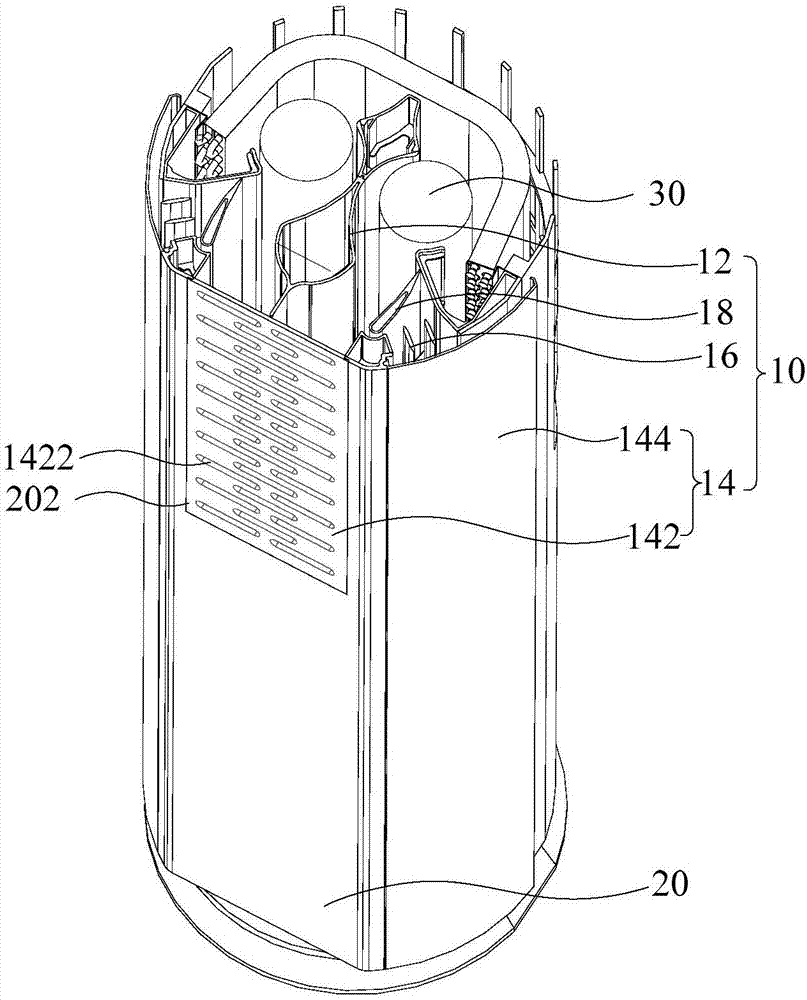

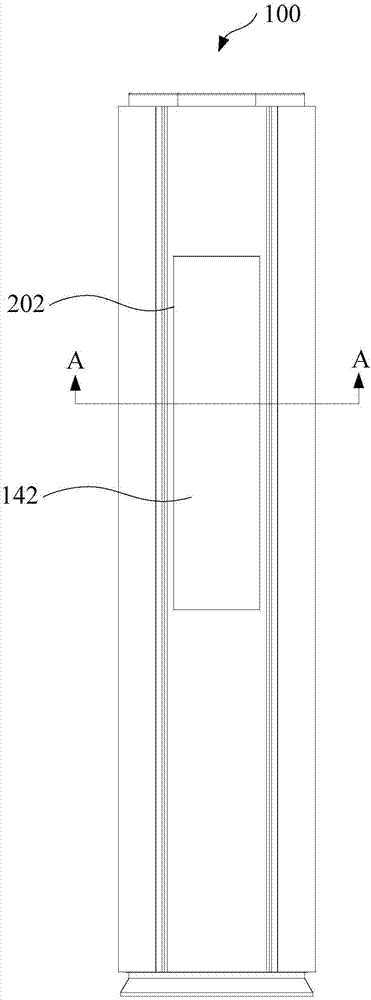

Rain-proof easy-coiling direct current charging pile

InactiveCN108422894AEasy to operateEffective protectionModifications for power electronicsPropulsion by batteries/cellsEngineeringDirect current

The invention discloses a rain-proof easy-coiling direct current charging pile which comprises a protection main body and a pile body, wherein support columns are symmetrically and fixedly mounted atthe upper end of the pile body, the protection main body is fixedly mount at the upper ends of the support columns, cooling holes are uniformly formed in the two sides of the pile body, a first charging plug and a second charging plug are symmetrically mounted on the outside of the pile body, a first coiling device and a second coiling device are rotationally mounted on one sides of the first charging plug and the second charging plug, a cooling device is fixedly mounted on the rear side of the pile body, a main shielding plate is fixedly mounted in the middle of the protection main body, telescopic shielding plates are in staggering and sliding insertion into the main shielding plate, drawing and pulling handles are symmetrically and fixedly mounted on one sides, deviated from the main shielding plate, of the telescopic shielding plates, cooling fans are symmetrically and fixedly mounted in the cooling device, and fixed plates are fixedly welded to the four corners of the cooling device. According to the rain-proof easy-coiling direct current charging pile, rain water invasion can be effectively avoided, the service lift is long, and the use is convenient.

Owner:盐城市新亚自控设备股份有限公司 +1

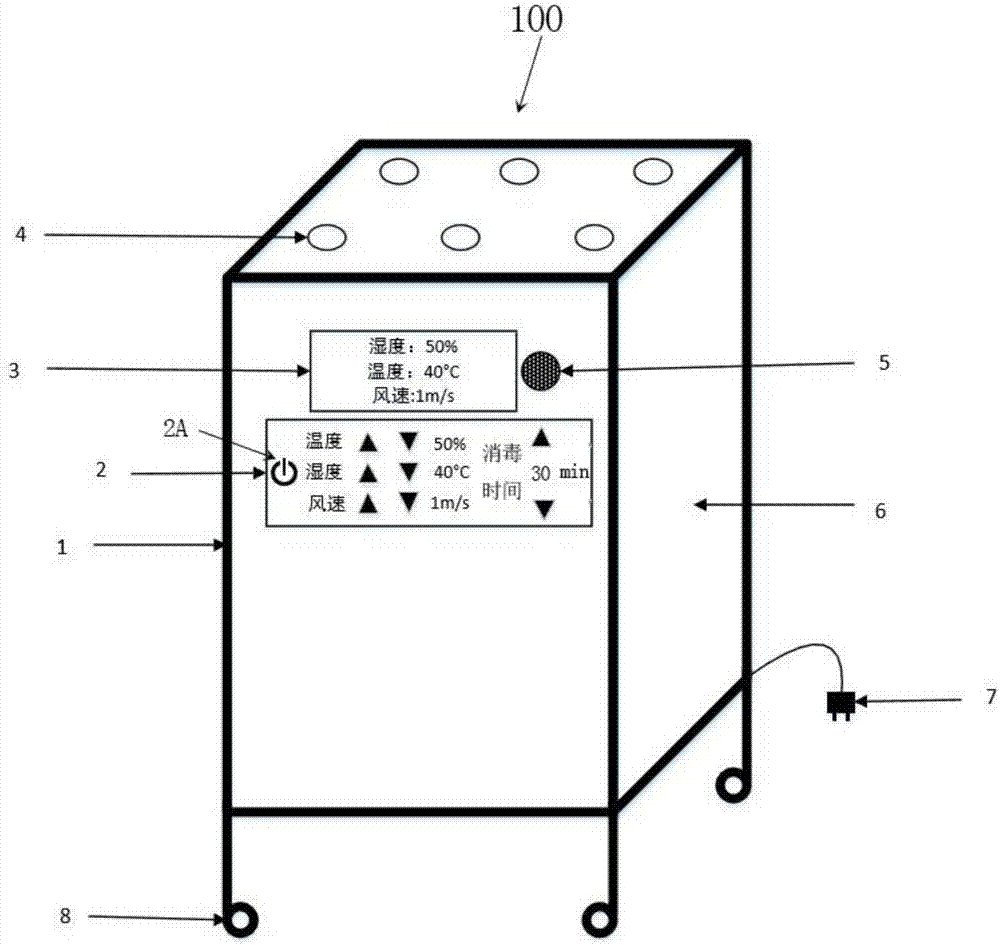

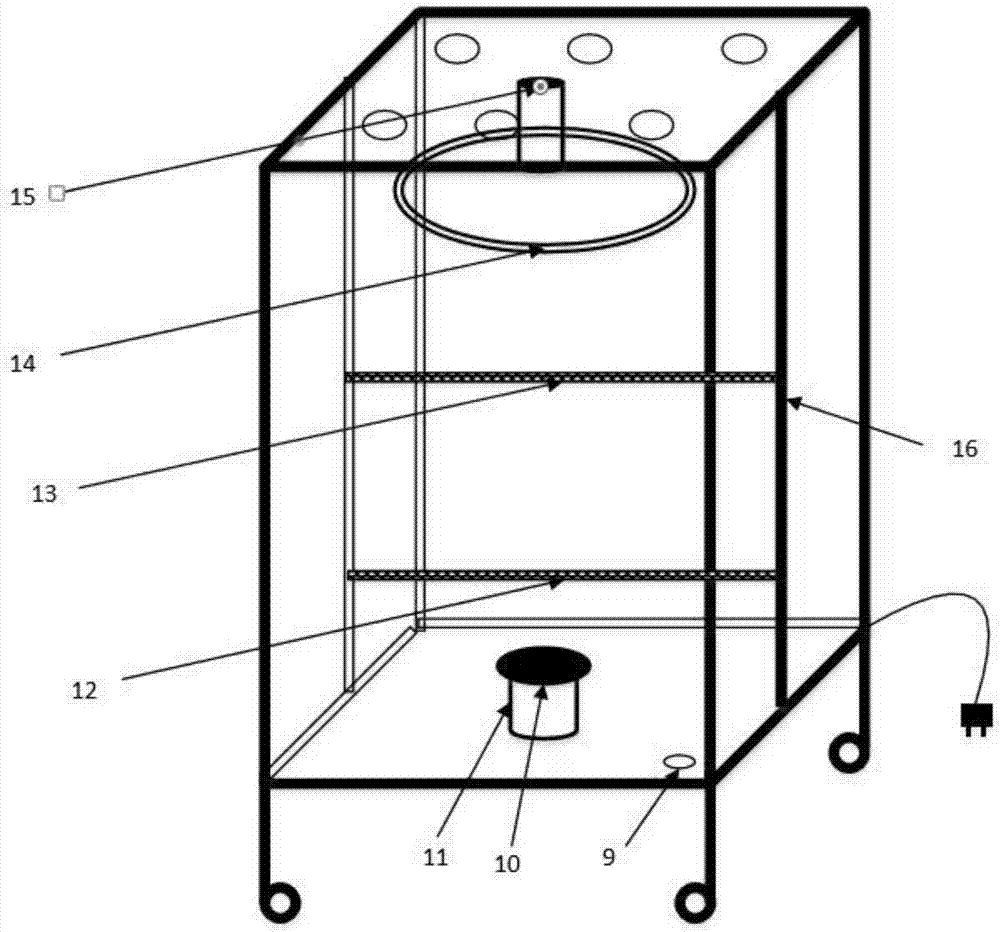

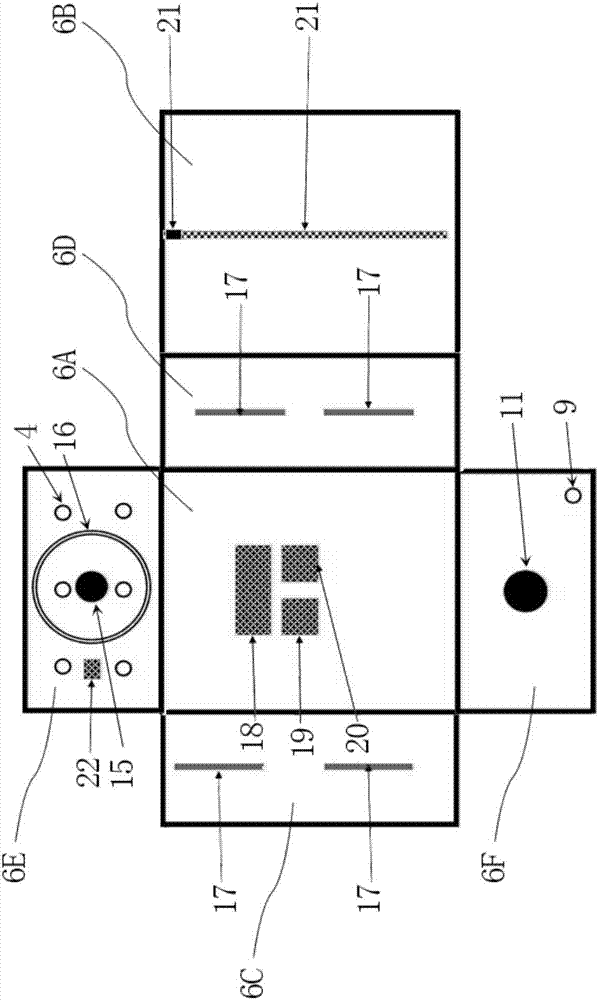

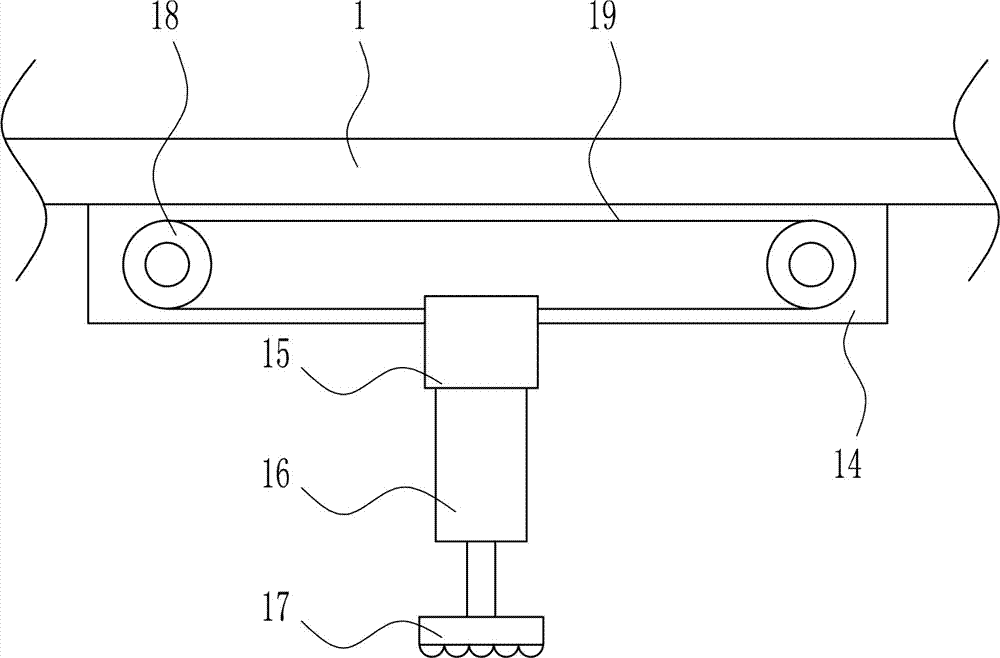

Intelligent clothes drying cabinet

ActiveCN106930077AAvoid excessive heatAvoid accidentsTextiles and paperLaundry driersEngineeringWind speed

The invention provides an intelligent clothes drying cabinet which is used for drying washed clothes. The intelligent clothes drying cabinet is characterized by comprising a cabinet body, at least one clothes hanging rod, a humidity sensor, a temperature sensor, an air speed sensor, at least one vent hole, a fan heater, a display input part and a control part, wherein the display input part is used for displaying a humidity signal, a temperature signal and an air speed signal and used for inputting a preset humidity, a preset temperature and a preset air speed by a user; the control part is used for controlling operation of the fan heater on the basis of the preset humidity, the preset temperature and the preset air speed input by the user; the fan heater comprises a heating part and an air outlet part; when the temperature inside the cabinet body is higher than the preset temperature, the heating part is controlled by the control part to reduce operation power or to be stopped; when the air speed inside the cabinet body is higher than the preset air speed, the air outlet part is controlled by the control part to reduce the air outlet speed; and when the humidity inside the cabinet body is lower than the preset humidity, the heating part is controlled by the control part to stop operation, and the air outlet part is controlled to be operated at a preset air outlet speed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Safety electric power cable storing and taking device capable of achieving reeling

ActiveCN106927302AFully wipeSmooth motionFilament handlingMechanical energy handlingMotor driveElectric power

The invention relates to a storing and taking device, in particular to a safety electric power cable storing and taking device capable of achieving reeling. According to the technical aims, the safety electric power cable storing and taking device capable of achieving reeling is multifunctional and higher in safety performance. In order to achieve the above technical aims, the safety electric power cable storing and taking device capable of achieving reeling is provided and comprises a storage box, a first support rod, a baffle, a push device, a lifting device, a second bearing block, a rotating rod, a roller, a cable, a motor, a first connecting rod and the like; the first support rod is arranged on the left side of the bottom of the interior of the storage box, a first sliding rail is arranged at the top end of the first support rod, a first sliding block is connected to the first sliding rail in a sliding manner, and the first connecting rod is arranged at the top of the first sliding block. By means of the safety electric power cable storing and taking device capable of achieving reeling, the effects of being multifunctional and high in safety performance are achieved; and according to the safety electric power cable storing and taking device, the push device is matched with the lifting device, and therefore the cable can be effectively stored and taken, and the motor drives the roller to rotate.

Owner:江苏捷成电缆有限公司

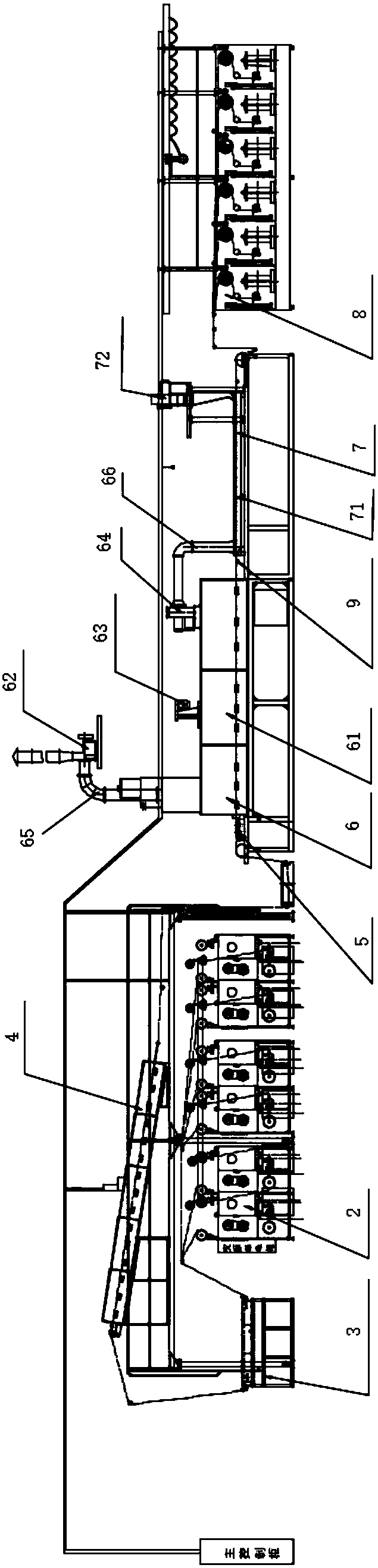

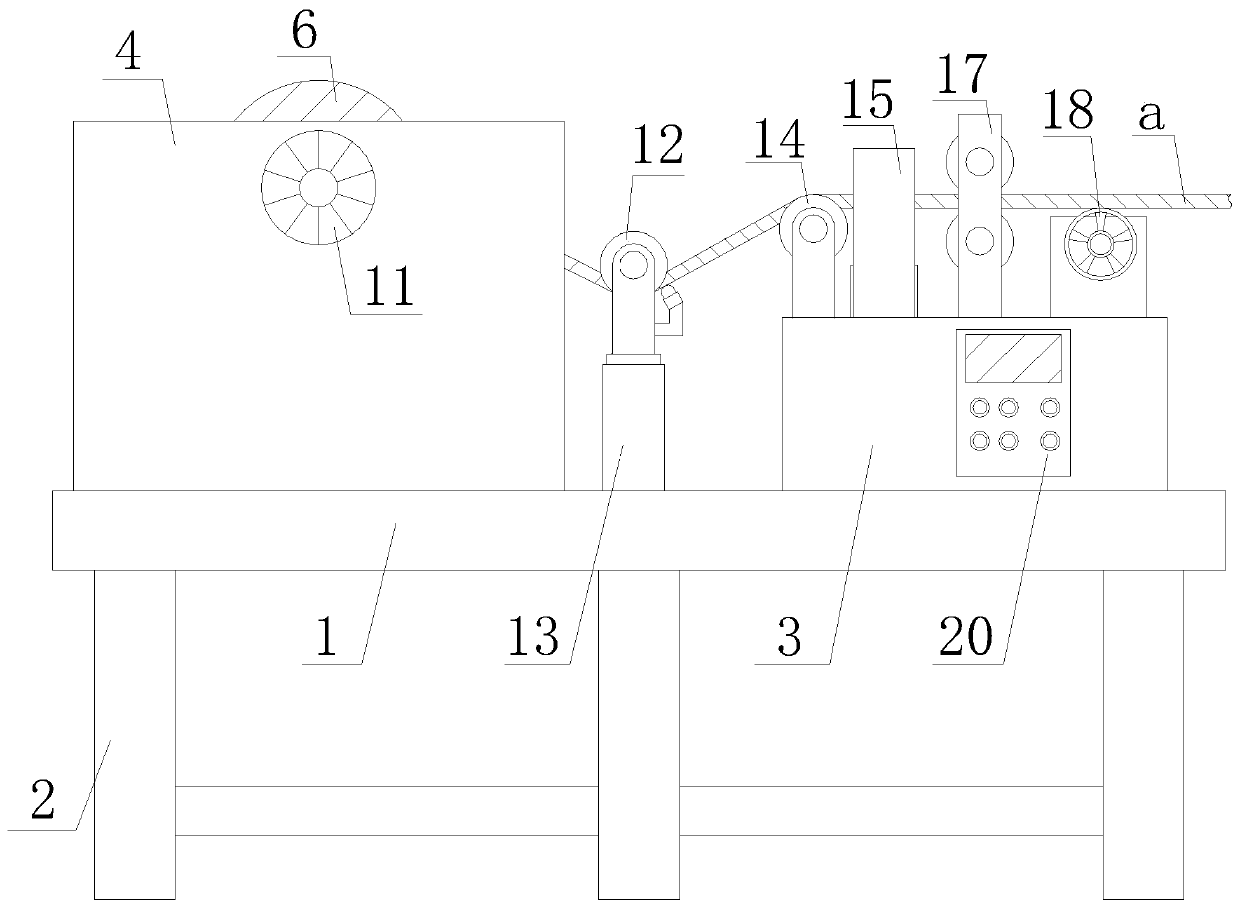

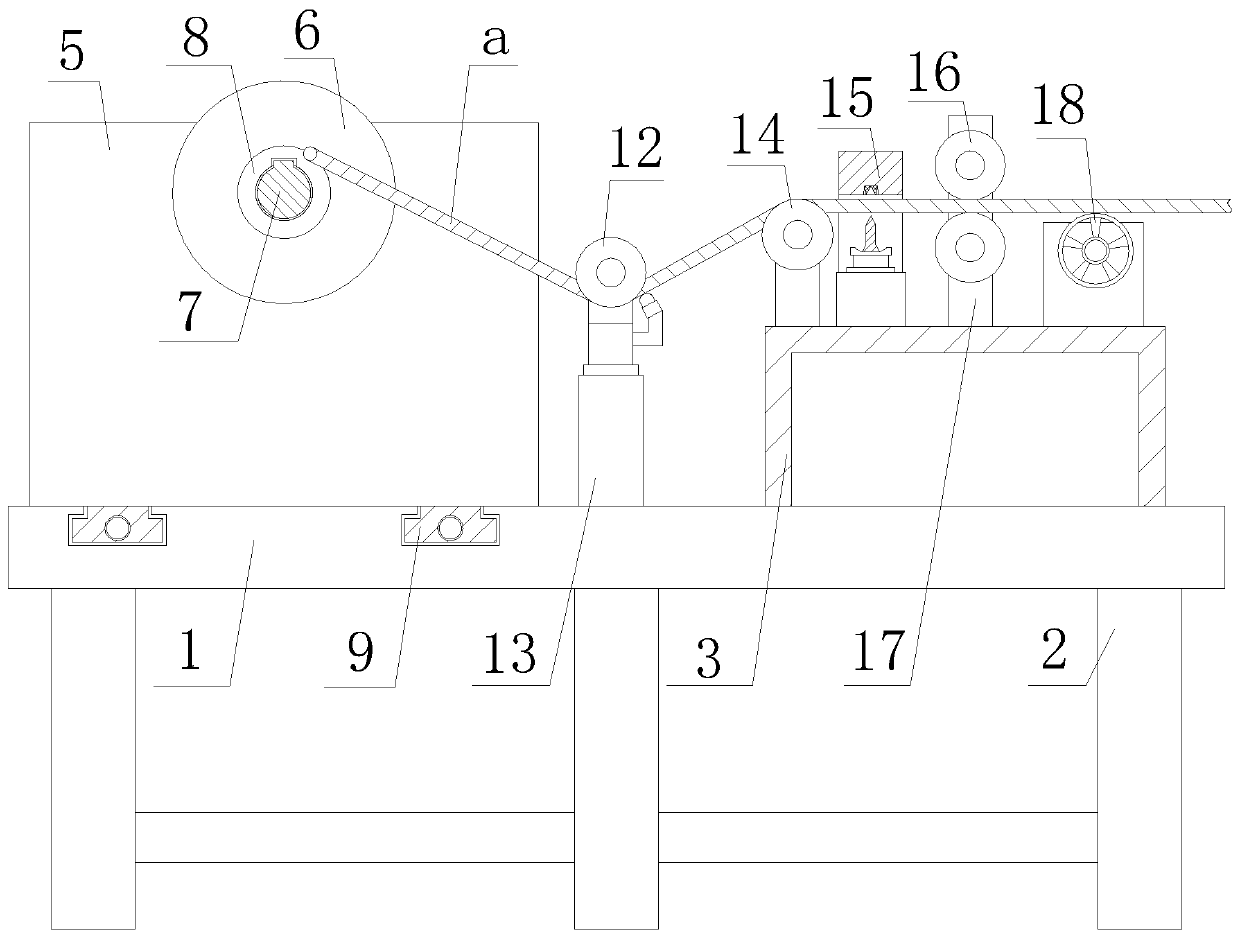

Multifunctional horizontal type aluminum wire enamelling machine

ActiveCN106205860AAvoid cloggingReduce frictionApparatus for feeding conductors/cablesInsulating conductors/cablesComing outAir volume

The invention discloses a multifunctional horizontal type aluminum wire enamelling machine. The multifunctional horizontal type aluminum wire enamelling machine comprises a pay-off apparatus, a wiredrawing apparatus, a cleaning apparatus, an annealing furnace, a painting apparatus, a baking furnace, a cooling apparatus and a take-up apparatus. The multifunctional horizontal type aluminum wire enamelling machine provided by the invention is applicable to painting and processing of metal wires of various different core materials, particularly the aluminum wire; online wiredrawing is realized, so that aluminum wire wiredrawing and enamelling can be carried out at the same time; the pay-off apparatus tightly compresses and brakes the wire through soft wheels, so that a bare wire is in a tensioned state; after the aluminum wire is subjected to online wiredrawing, the aluminum wire is cleaned by an ultrasonic cleaning machine first to remove aluminum powder and lubricating grease on the surface; a wire supporting roller is arranged between the baking furnace and the cooling apparatus, so that friction between the aluminum wire and the pipe wall can be prevented; the cooling apparatus is used for forcedly cooling a high-temperature wire coming out of the baking furnace; the air flow direction in an air channel is opposite to the marching direction of the wire; the air is large in air volume and high in air speed, so that a sufficient cooling effect can be ensured; in addition, the take-up apparatus is provided with a constant-speed apparatus; a constant-speed wheel is equipped with a wire pressing wheel, so that the take-up speed is stable.

Owner:佛山市顺德区盛永机械有限公司

Sock packer

ActiveCN107776944AAvoid violent collisionsSave productivityLabelling deformable materialsSortingSOCKSBiochemical engineering

The invention provides a sock packer, belongs to the technical field of machinery and solves the technical problems of low efficiency and the like in prior sock packing. The sock packer comprises a rack and is characterized in that a first rail and a second rail which are in closed circulation are fixed on the rack, a first gap is formed between one end of the first rail and one end of the secondrail, a second gap is formed between the other end of the first rail and the other end of the second rail, and the second gap is smaller than the first gap; a first guide groove is formed in the firstrail, a first through hole communicated with the first guide groove is formed in the lower part of the first rail, a second guide groove is formed in the second rail, and a second through hole communicated with the second guide groove is formed in the lower part of the second rail. The sock packer has the advantage that socks are packed automatically and efficiently.

Owner:全椒县瑞祥工艺品有限公司

Winding device for fabric processing

The invention discloses a winding device for fabric processing. The winding device comprises a bottom plate. Two sets of mounting supports are arranged above the bottom plate. A guide roller is arranged on one set of mounting support, and a winding roller is arranged on the other set of mounting support. One end of the winding roller is connected with a rotating disc. A motor is fixed to the bottom plate through screws, and an output shaft of the motor is connected with a drive disc through a coupling. A stand column is vertically arranged on the side, away from the guide roller, of the winding roller. One side of the stand column is horizontally connected with a top plate. Two sets of lifting rods are arranged on the top plate. The bottoms of the lifting rods are connected with a first press roller. The first press roller is arranged over the winding roller. The tops of the two sets of lifting rods are connected with a limiting plate. Telescopic air cylinders are connected between thelimiting plate and the top plate. The winding device is simple in structure and reasonable in design, fabric can be fast wound and can be effectively rolled to be flat, the fabric is wound more tightly, and fabric winding loosening is effectively avoided.

Owner:马道道

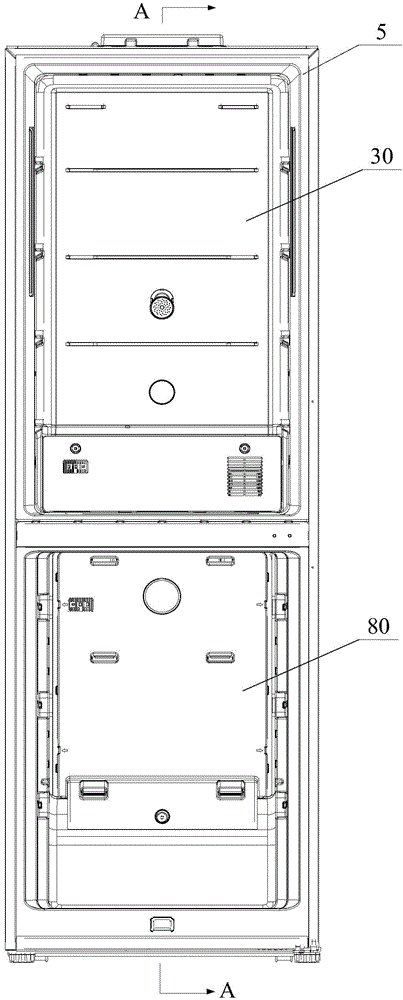

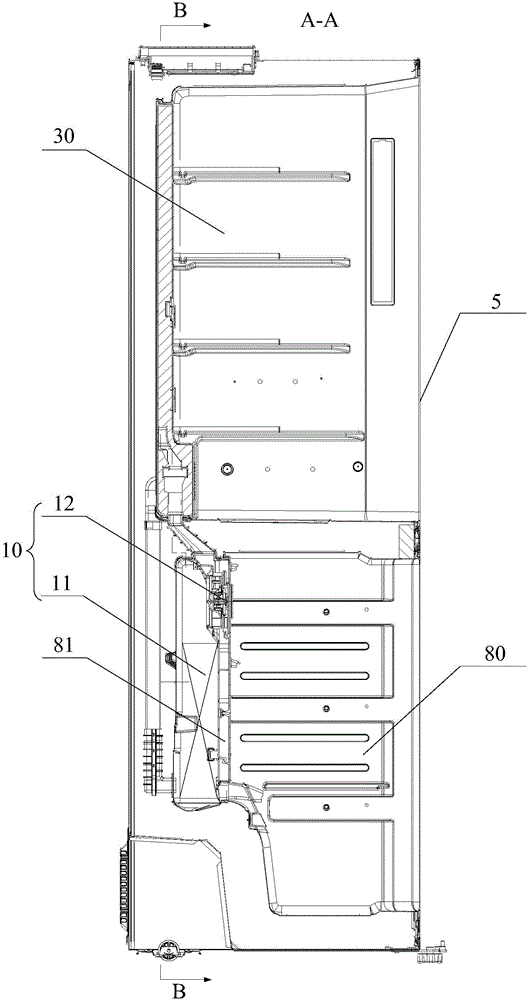

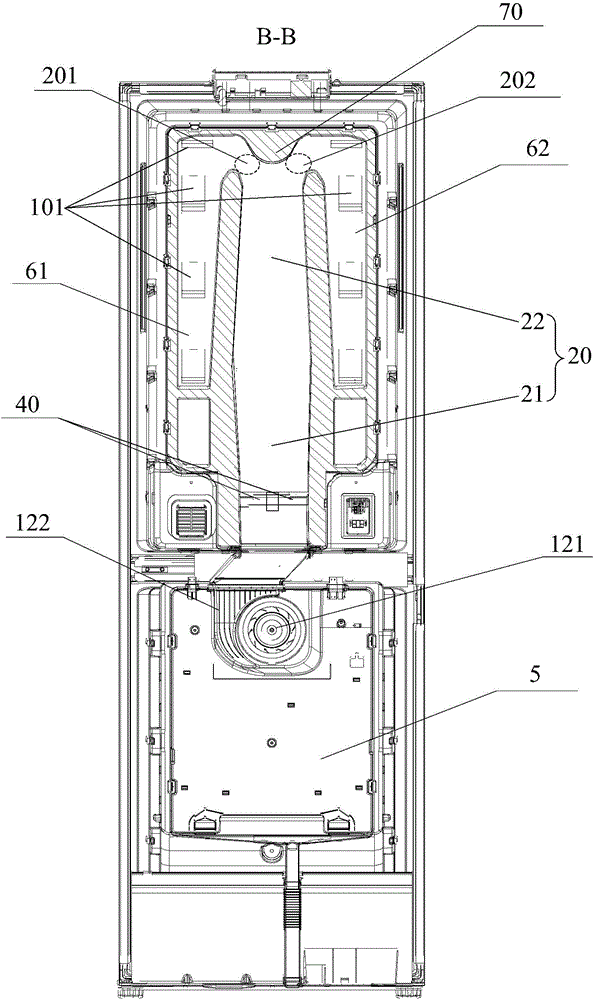

Air-cooled refrigerator

ActiveCN105318628ARapid coolingQuick freeze functionLighting and heating apparatusCooling fluid circulationCold storeRefrigeration

The invention discloses an air-cooled refrigerator. The air-cooled refrigerator comprises a refrigerator body. A refrigeration assembly, a main air channel and a refrigerating chamber are arranged in the refrigerator body. An air inlet of the main air channel is communicated with an air outlet of the refrigeration assembly. An air outlet of the main air channel is communicated with the refrigerating chamber. The main air channel comprises an air inlet section and an air outlet section. The sectional area of the air inlet section is increased progressively in the direction of the air inlet of the main air channel to the air outlet of the main air channel. The sectional area of the air outlet section is decreased progressively in the direction of the air inlet of the main air channel to the air outlet. According to the air-cooled refrigerator, the function of rapid cooling and rapid refrigeration of the air-cooled refrigerator is achieved, and the refrigerating efficiency can be improved.

Owner:TCL INTELLIGENT TECH HEFEI

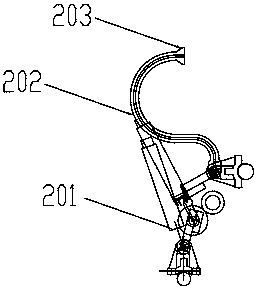

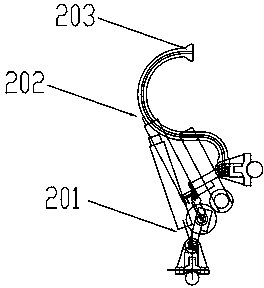

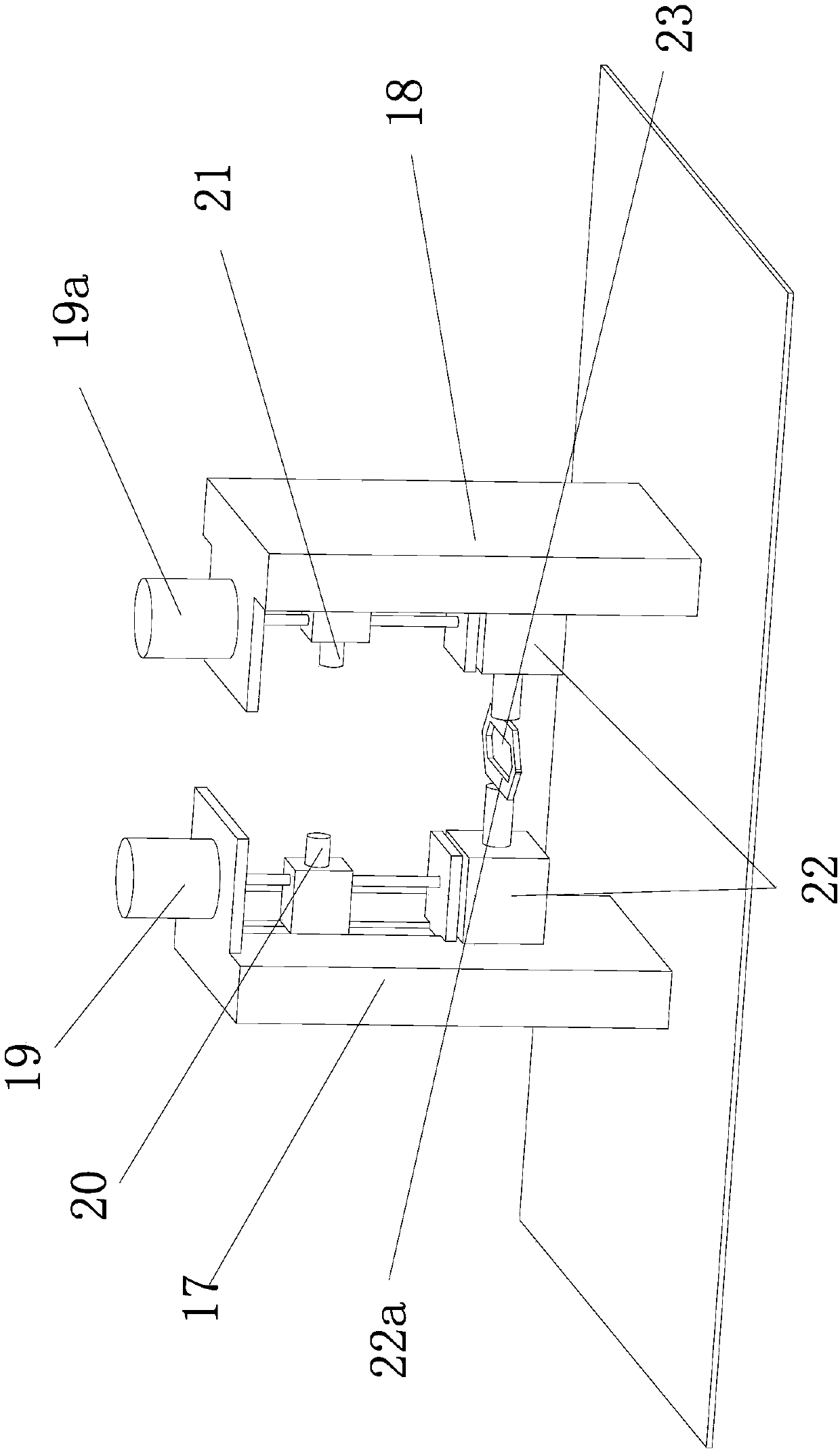

Auxiliary rope reversing mechanism used for packaging, hairy crab rope binding device and use method thereof

ActiveCN105599960AImprove simplicityFast windingBinding material applicationBundling machine detailsEngineeringBinding effect

The invention discloses an auxiliary rope reversing mechanism used for packaging, a hairy crab rope binding device and a use method thereof. The hairy crab rope binding device comprises a needle-threading plug, an auxiliary rope reversing mechanism used for reversing a hemp rope, a rope breaking mechanism used for cutting and fastening the hemp rope and a power source used for uniformly realizing the power transmission. The device can be conveniently controlled. According to the invention, the auxiliary rope reversing mechanism is arranged for meeting the requirement of binding a hairy crab rope along a single direction and the rope binding effect can be achieved without circularly winding; the rope binding device capable of synchronously moving left and right is adopted for quickly and effectively binding the hemp rope on the hairy crab; the binding for hairy crab can be finished by binding the rope twice; different from traditional manual single-rope crossing binding method, the method is more convenient and quick in unbinding the rope.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

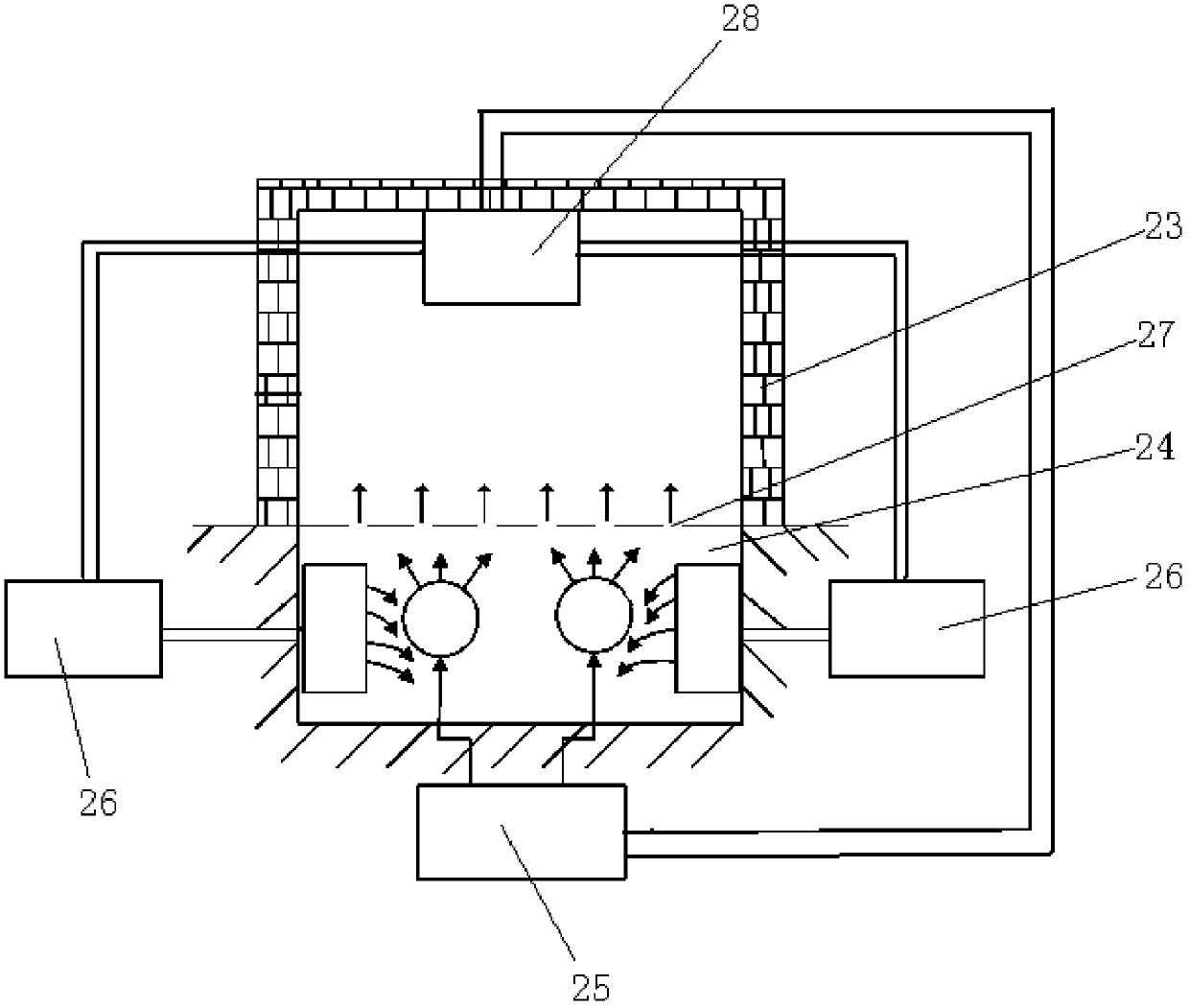

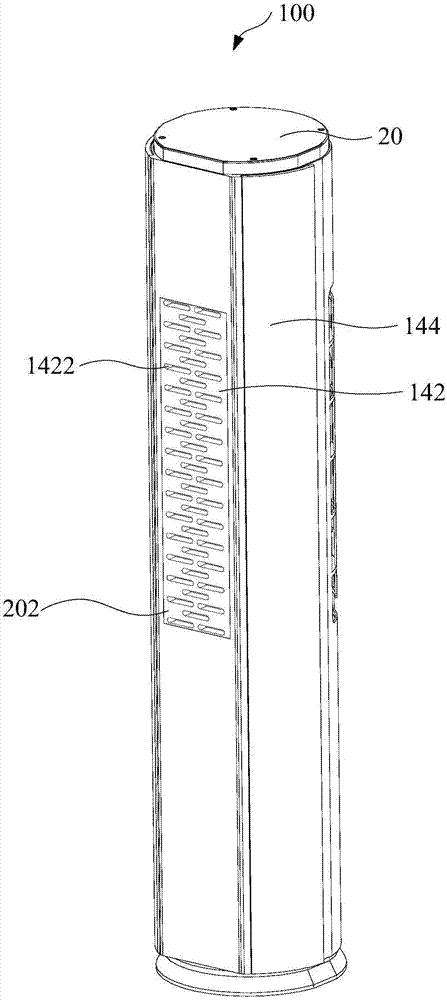

Wind guide device, wind guide control method and air conditioner

PendingCN106979555AWay of satisfactionMeet needsMechanical apparatusSpace heating and ventilation safety systemsEngineering

The invention provides a wind guide device, a wind guide control method and an air conditioner. The wind guide device comprises a wind duct assembly and a wind door assembly, wherein the wind duct assembly is arranged in a shell, two wind wheels are mounted in the wind duct assembly, and the wind door assembly is mounted on the shell and comprises at least one sense-of-windless wind outlet plate for covering a wind outlet in the middle and at least one sliding door located at wind outlets in two sides, and at least one sense-of-windless wind outlet plate is provided with multiple through holes. According to the wind guide device, wind generated when the wind wheels operate is blown to users through the through holes in the sense-of-windless wind outlet plates, so that the output wind is gentle; it is avoided that the wind is directly blown to the users through the wind outlets and consequently the users feel uncomfortable, the use comfort of the users is improved, meanwhile the sense-of-windless wind outlet plates and the sliding doors are in cooperation and slide to different positions to open or close the wind outlet in the middle and / or the wind outlets in all the side faces, quick cooling or heating is achieved and the use comfort of the users is guaranteed while sense-of-windless wind output and conventional wind output can be achieved, and the use experience of the users is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

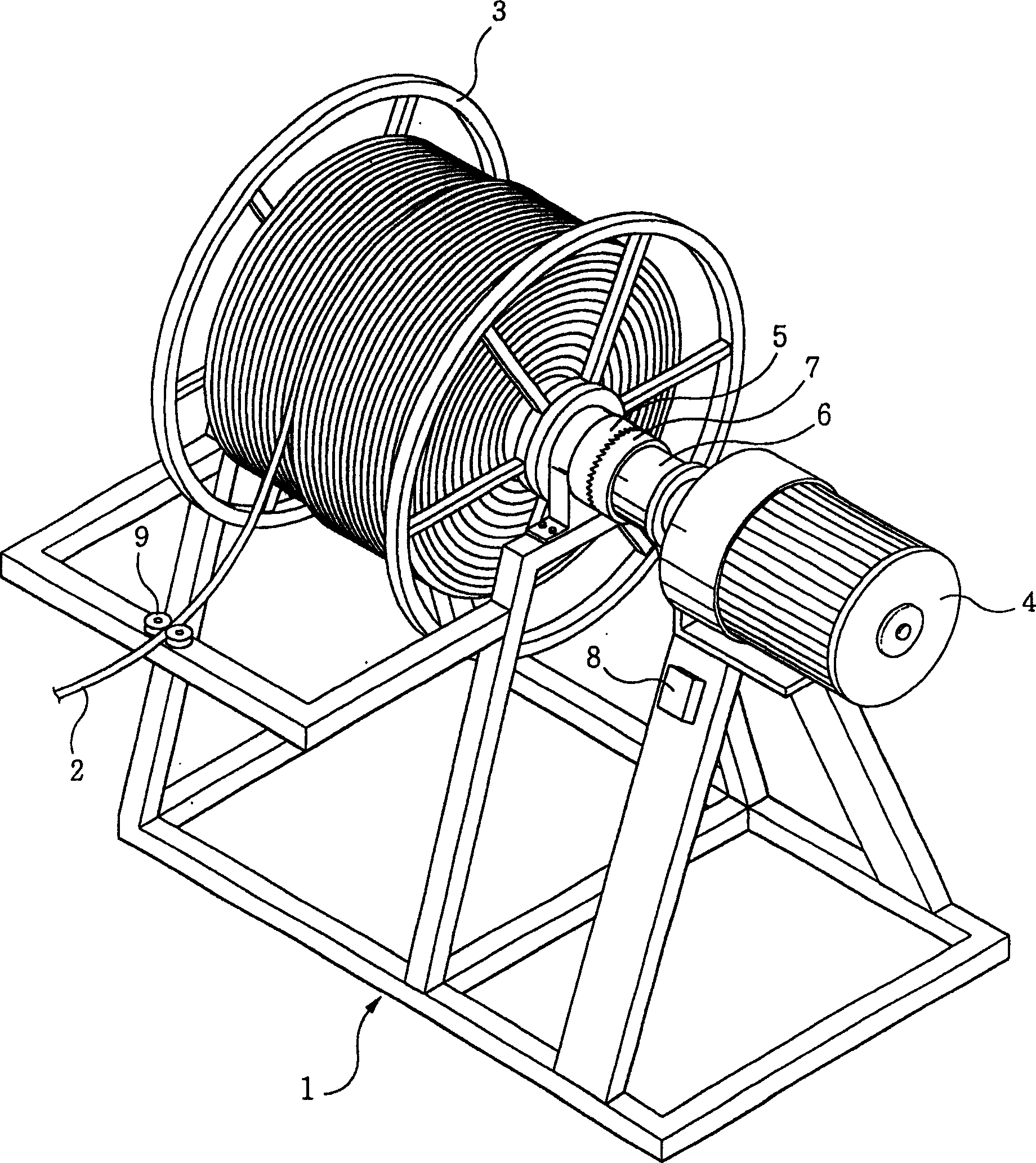

Steel wire rope winding device

ActiveCN105460817AEasy to rewindConvenient waste disposalWinding mechanismsGear wheelElectric machinery

The invention relates to a steel wire rope winding device. The steel wire rope winding device comprises a spool device, spool fixing devices, a bracket and a driving device, wherein the spool device comprises a spindle, a gear of which the side center of a circle is fixedly perpendicular to one end of the spindle, four rectangular connecting plates which are circumferentially distributed along the spindle at equal intervals, a side plate which is connected to the other end of the spindle and four fan-shaped plates; the spool fixing devices are fixed to both opposite sides of the bracket, the spool fixing devices are formed by sliding shafts, shaft sleeves and locking pins which are used for the sliding shafts to be axially positioned in the shaft sleeves, and the sliding shafts are assembled in blind holes in both ends of the spindle, so that the spool device is positioned; the driving device is fixed to the bracket and is driven to be engaged with the gear by a motor, so as to drive the gear to rotate, so that a steel wire rope is wound. According to the steel wire rope winding device, the expansion and contraction of the fan-shaped plates in the radial direction of the gear are realized by utilizing the displacement of the fan-shaped plates in the radial direction of the gear, the winding and waste discharge of the steel wire rope are realized by utilizing the removable side plate, and the winding and waste discharge of steel wire ropes of various sizes can be conveniently and quickly completed, so that the labor intensity is reduced, and additionally, the working efficiency is improved.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

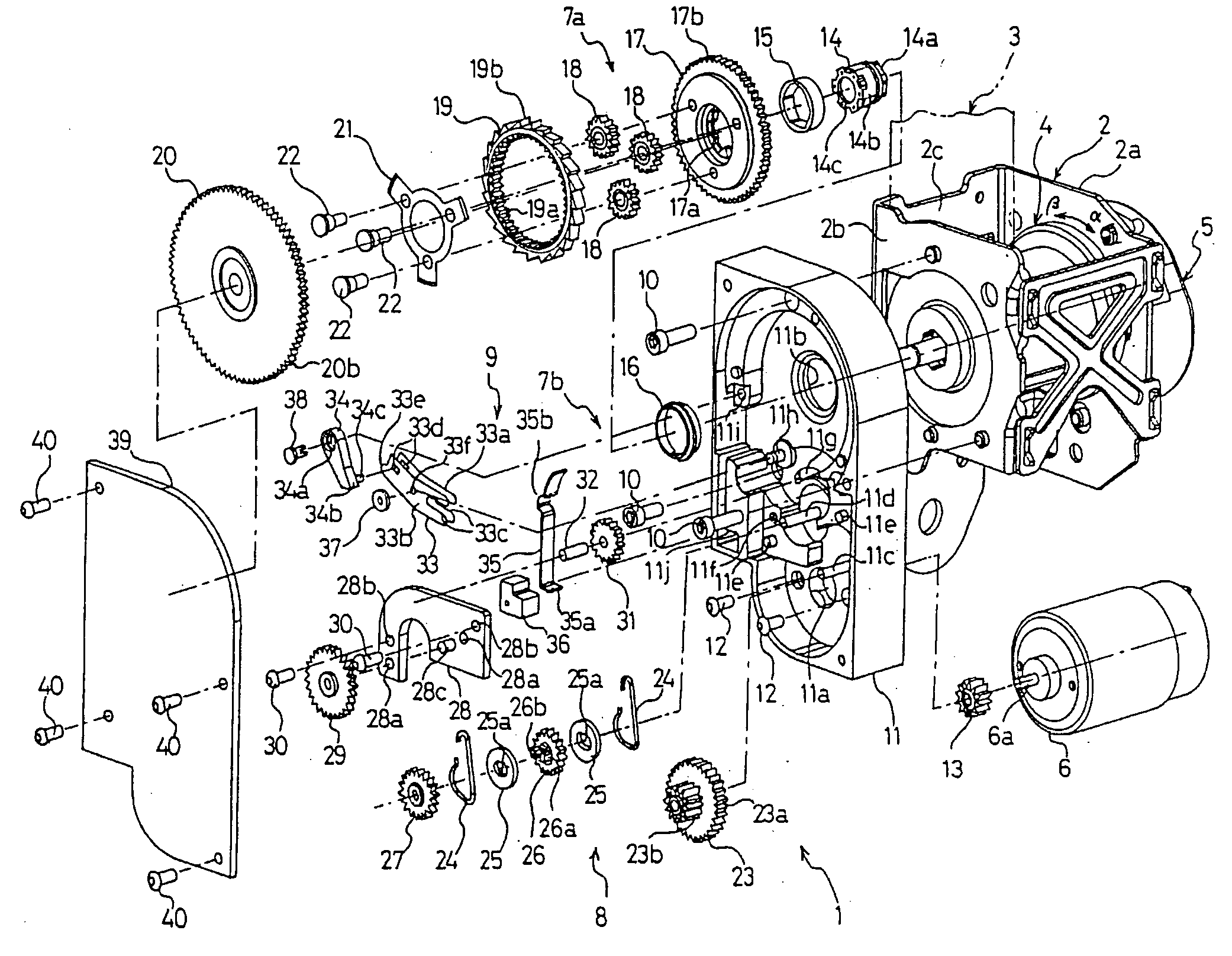

Seat belt retractor and seat belt device

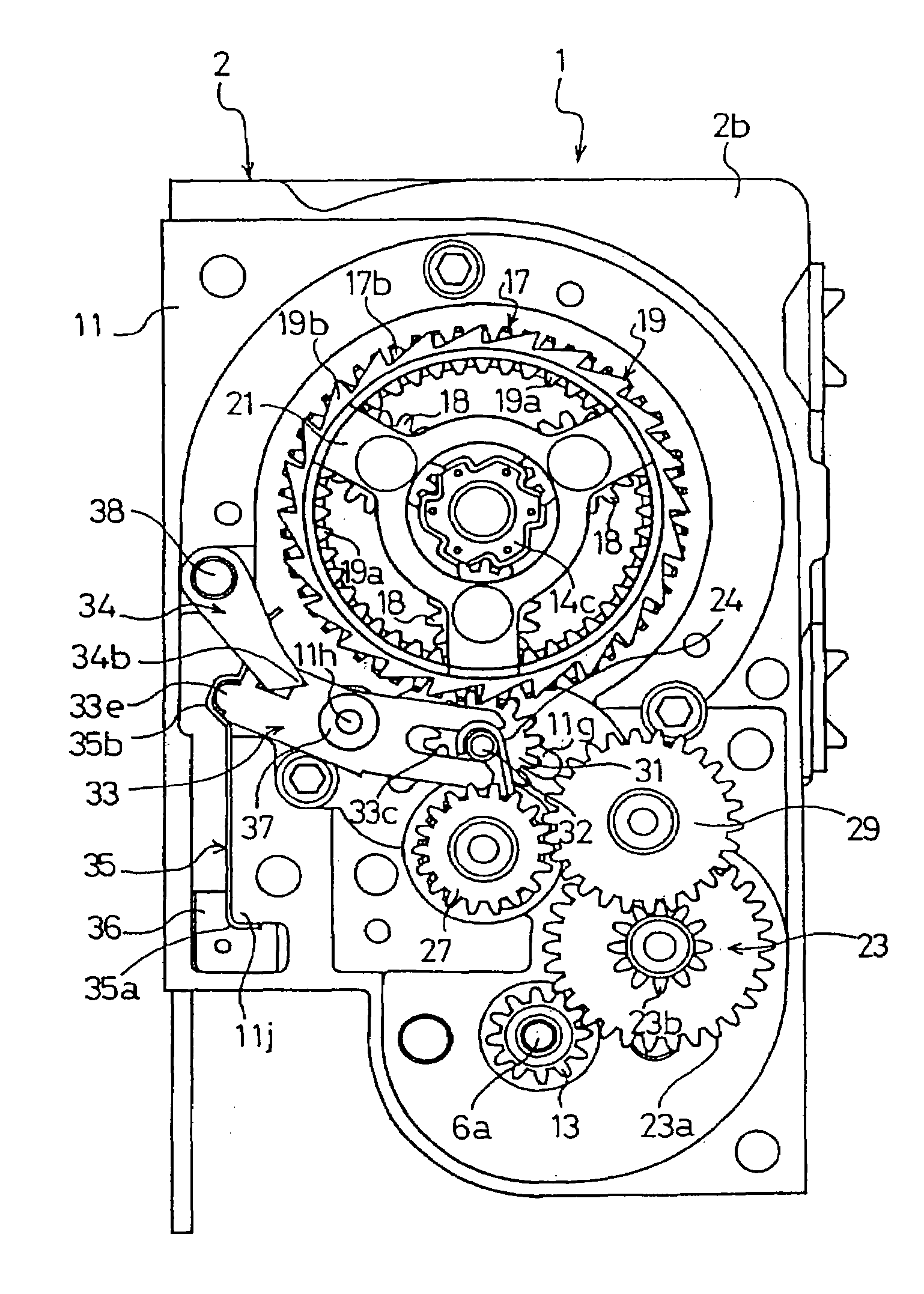

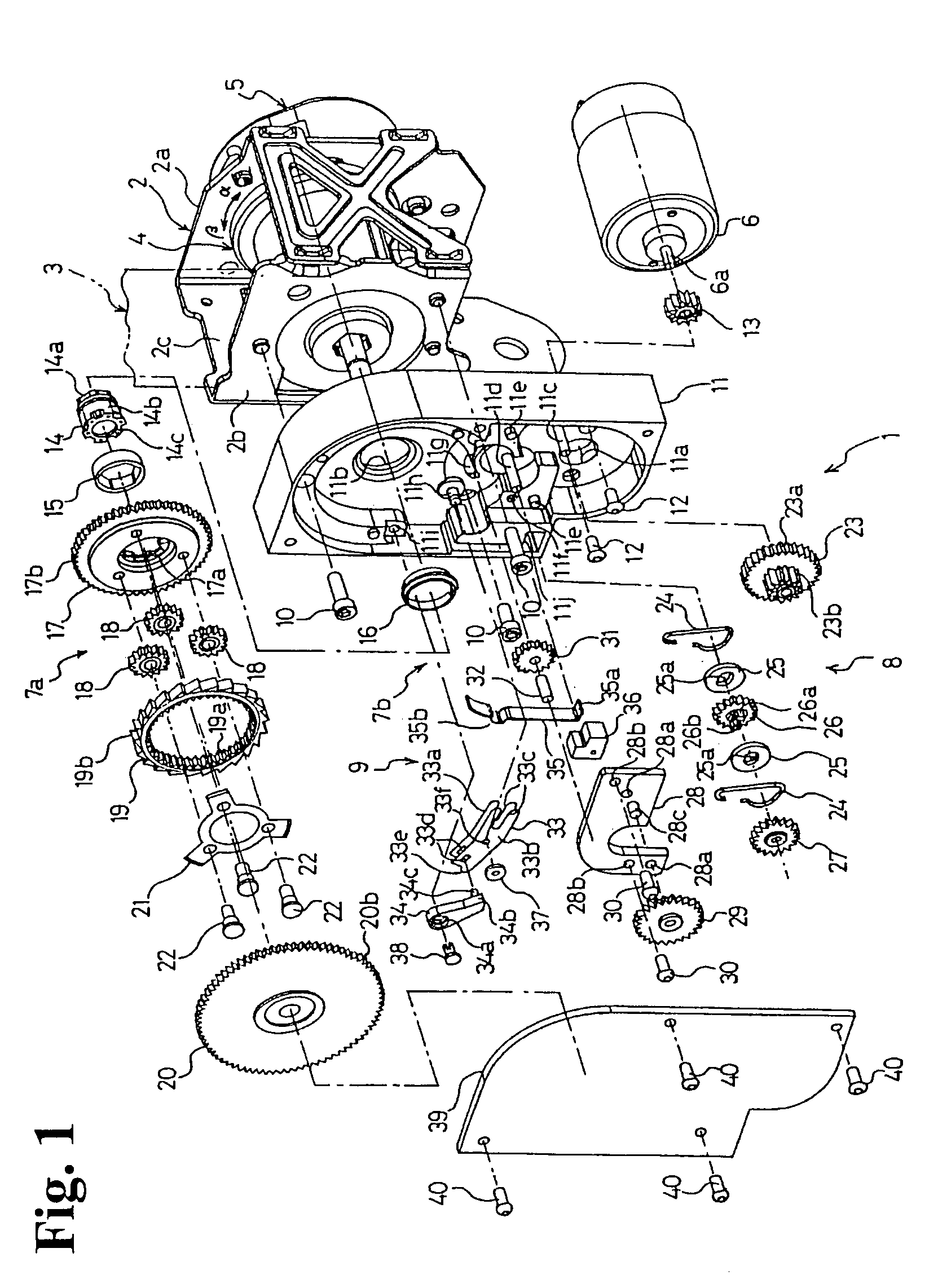

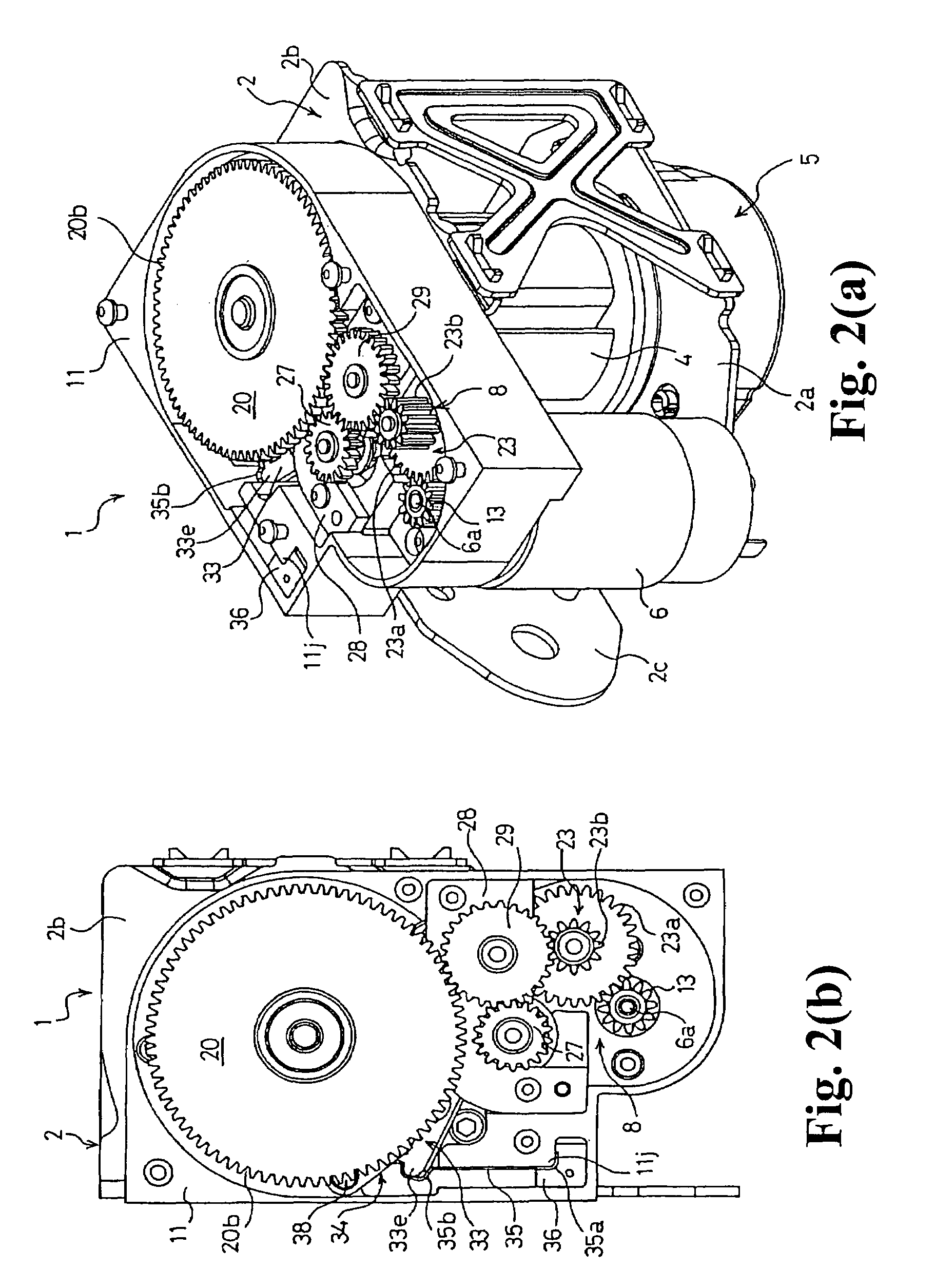

InactiveUS7278600B2Low reduction ratio transmission modeFast windingBelt retractorsBelt control systemsSeat beltElectric machinery

A seat belt retractor includes a spool for winding up a seat belt; a motor for generating rotational torque to rotate the spool; and a power transmission mechanism for transmitting the rotational torque of the motor to the spool. The seat belt retractor winds the seat belt on the spool with the rotational torque of the motor. The power transmission mechanism has a low reduction ratio transmission mode in which the rotational torque of the motor is transmitted to the spool through a low reduction ratio mechanism, and a high reduction ratio transmission mode in which the rotational torque of the motor is transmitted to the spool through a high reduction ratio mechanism. The seat belt retractor further includes a power transmission mode switching mechanism for selecting between the low reduction ratio transmission mode and the high reduction ratio transmission mode.

Owner:TAKATA CORPORATION

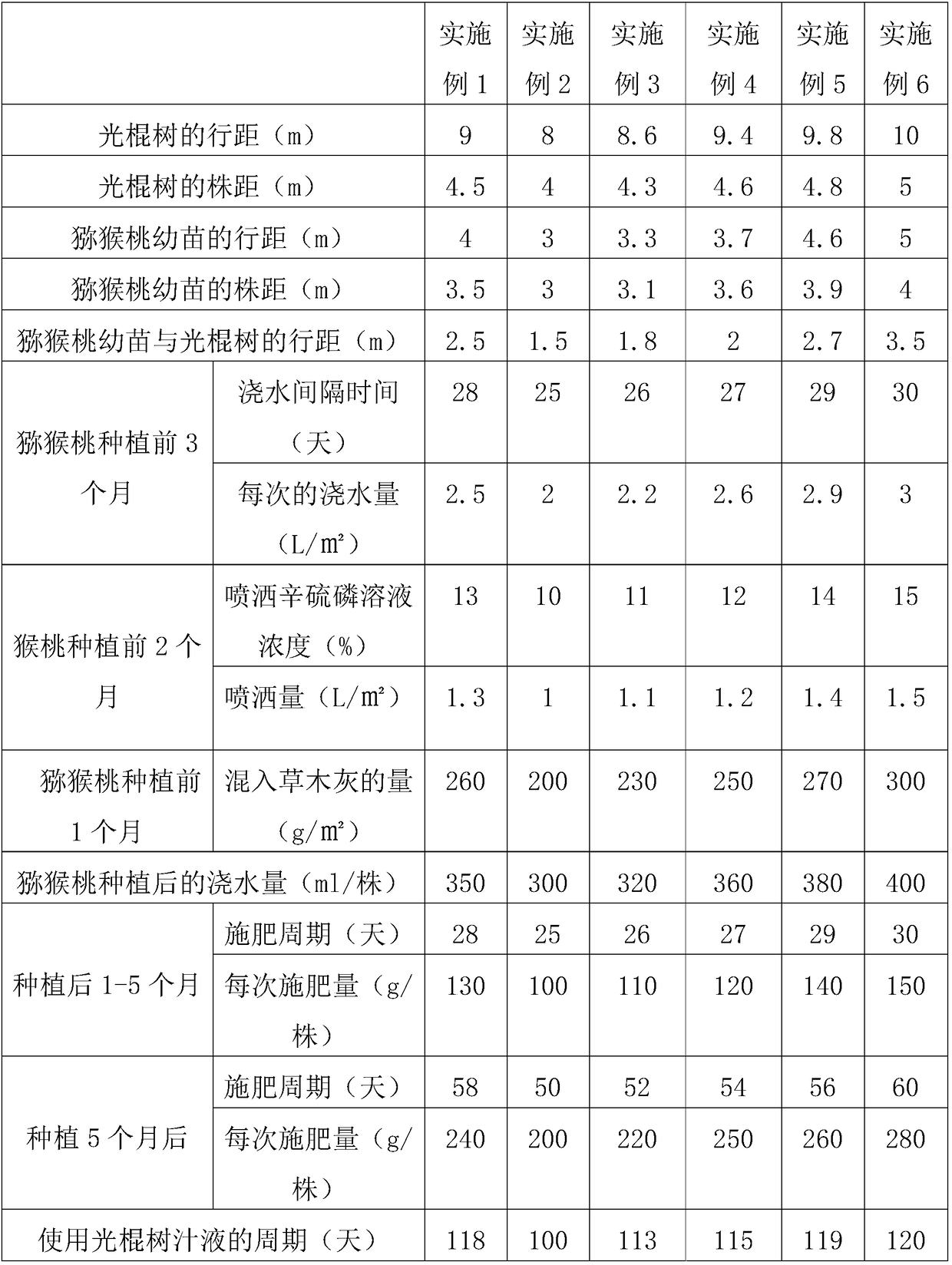

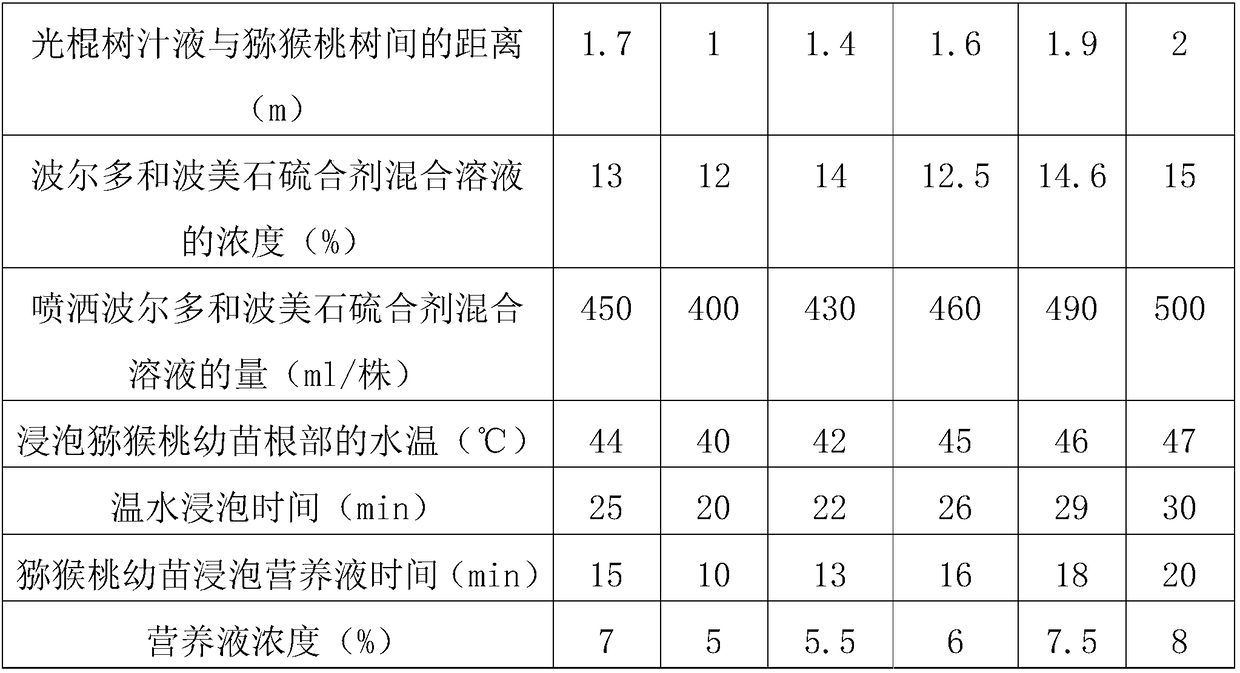

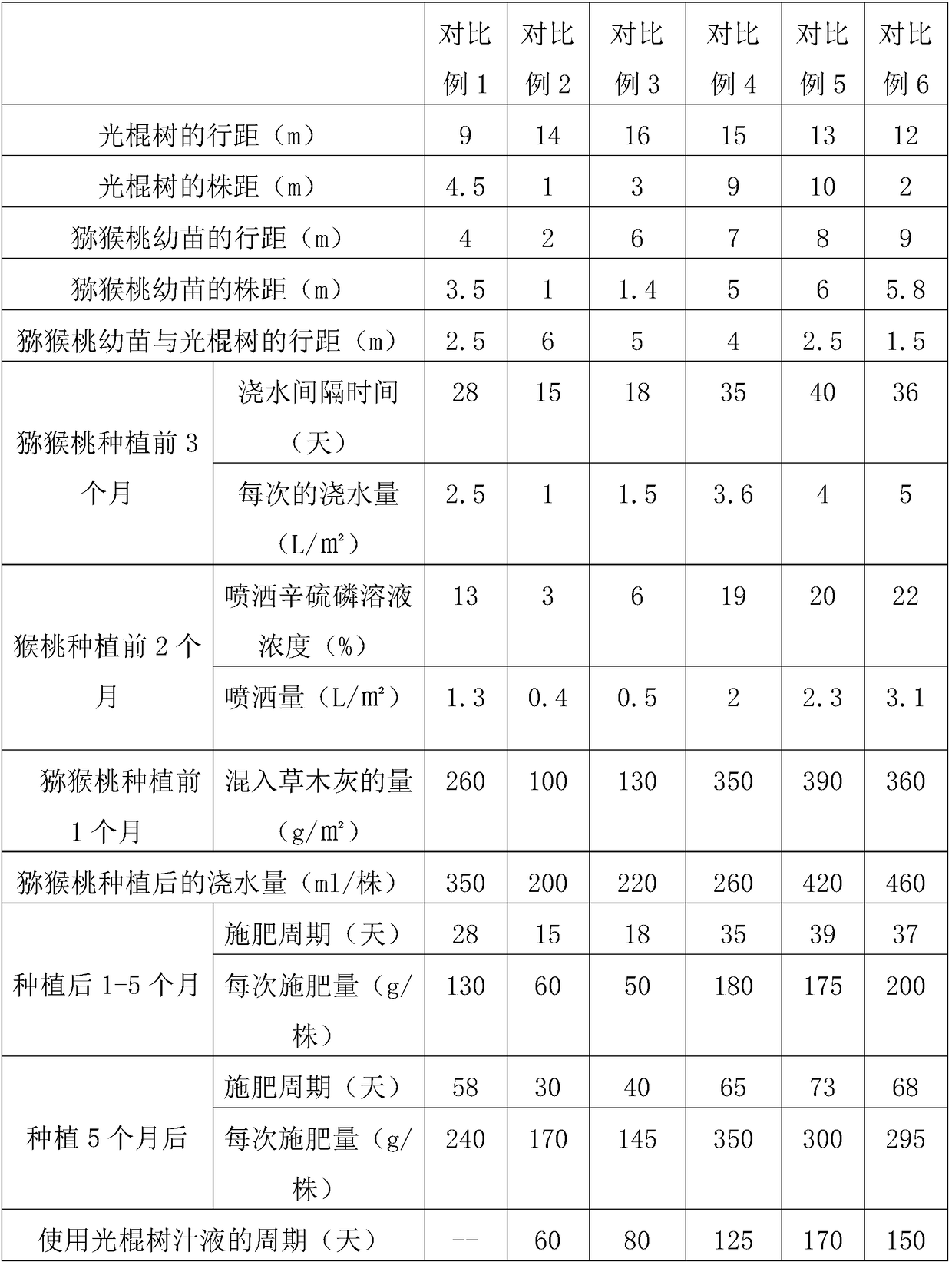

Kiwifruit planting method

ActiveCN108243830AFew leavesPrevent fallingAlkali orthophosphate fertiliserWatering devicesFruit treeActinidia

The invention belongs to the technical field of cultivation of vegetables, flowers, rice, fruit trees, grapes, hops or edible seaweeds, and discloses a kiwifruit planting method. The method includes the steps of soil preparation, interplanting, seedling, scaffolding, shaping, fertilization, disease and pest prevention, pollination and the like, and by interplating euphorbia tirucalli linn, not only can the ground grip effect of kiwifruits be increased, but also disease and pest prevention effects are achieved. The method solves the problem in the prior art that fruits easily fall in windy dayswhen the kiwifruits have the fruits.

Owner:彭章义

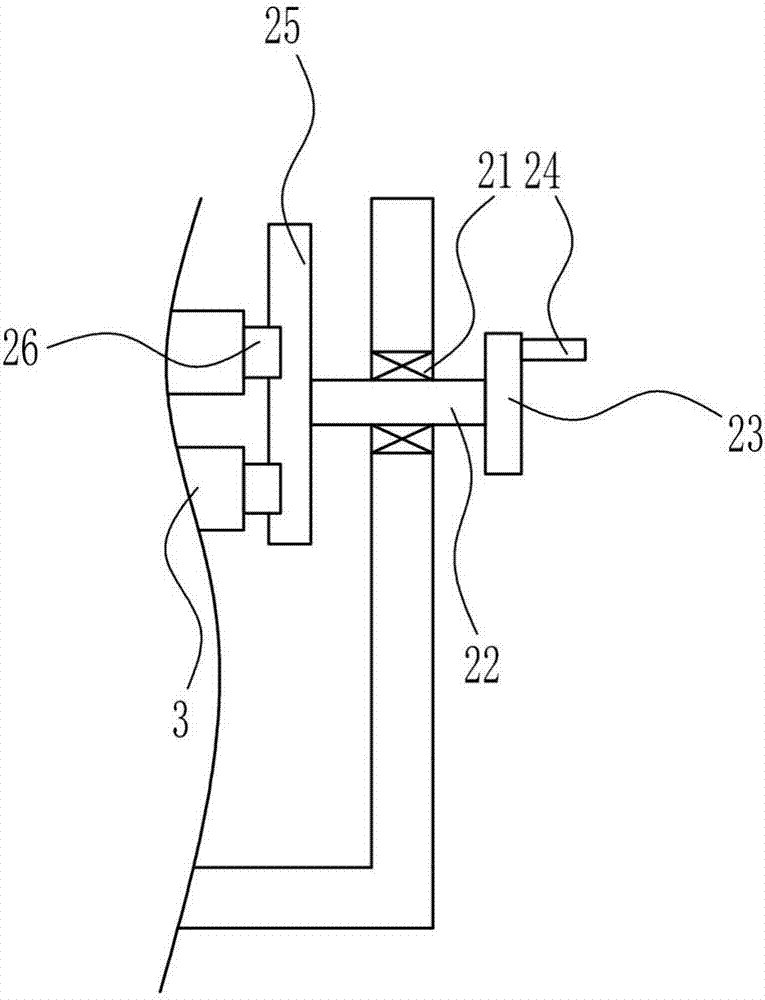

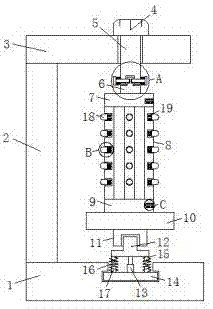

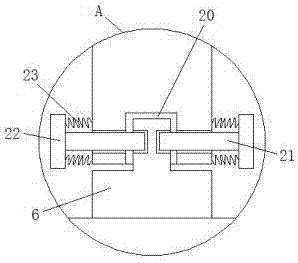

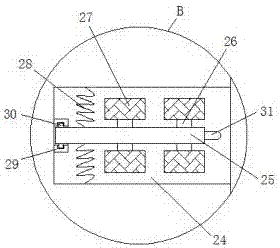

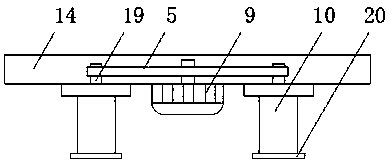

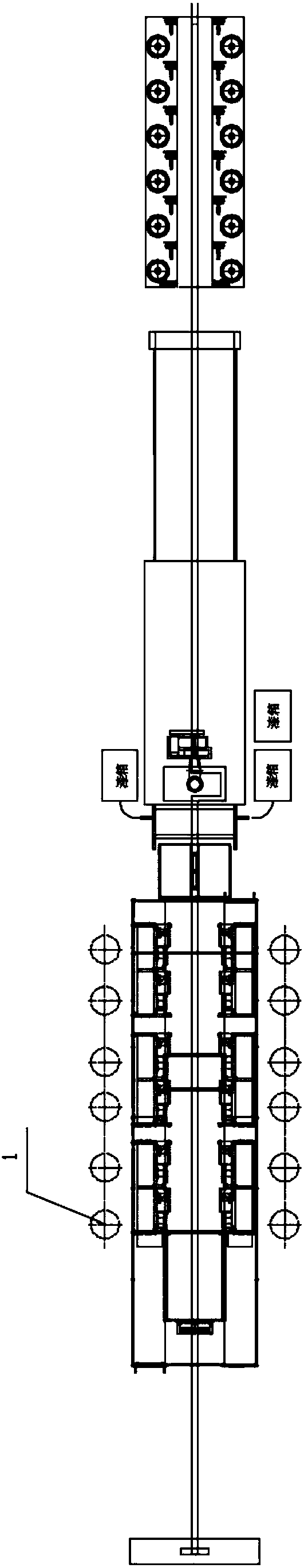

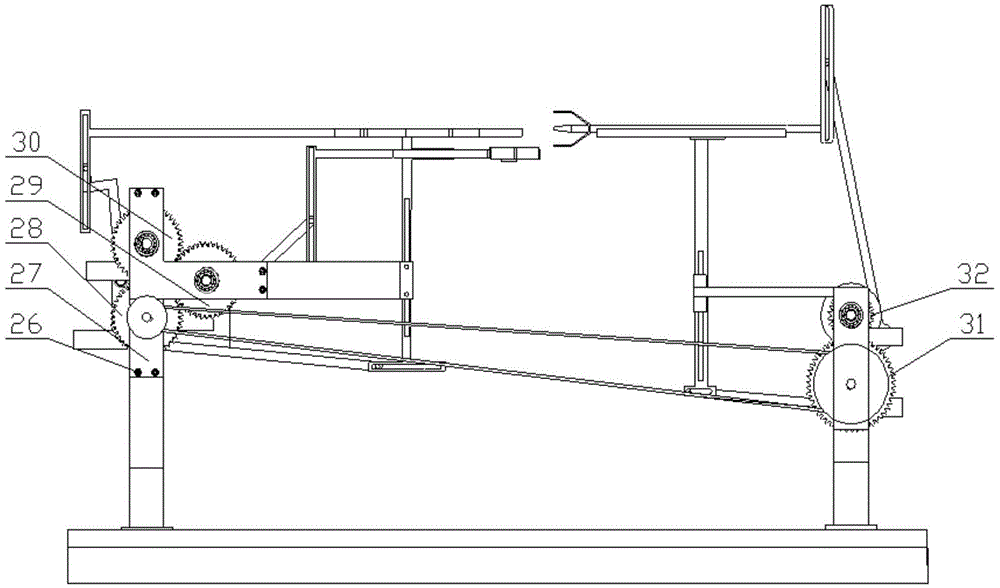

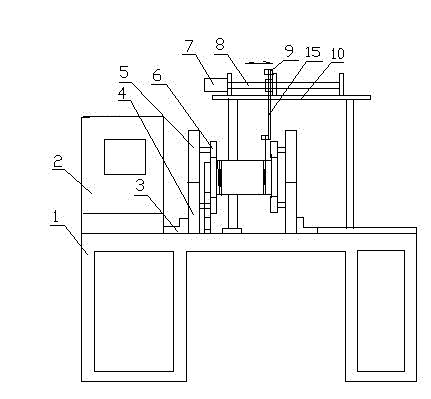

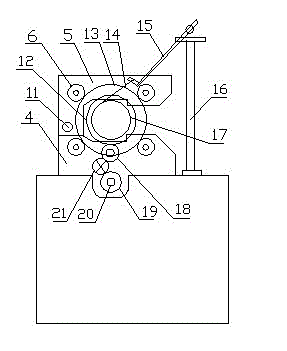

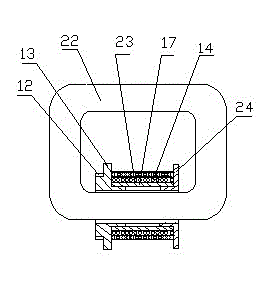

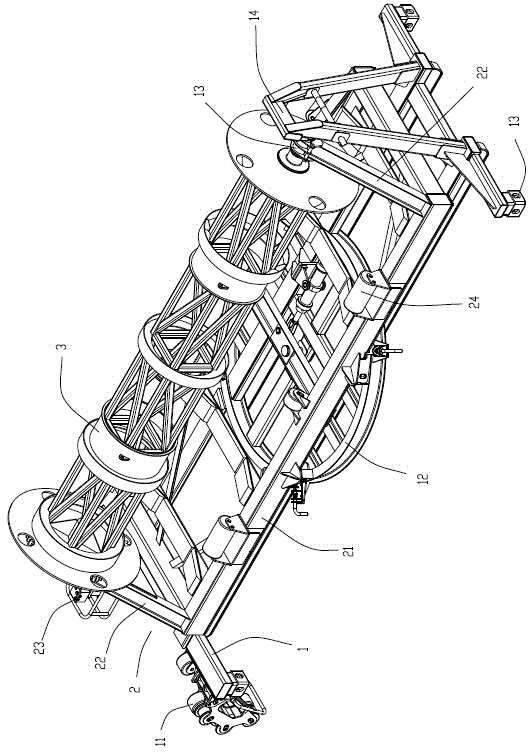

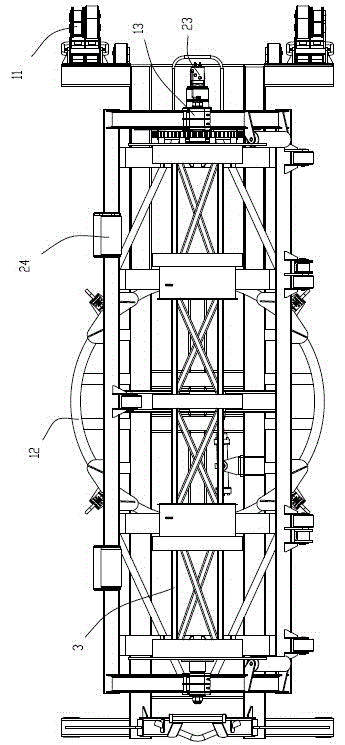

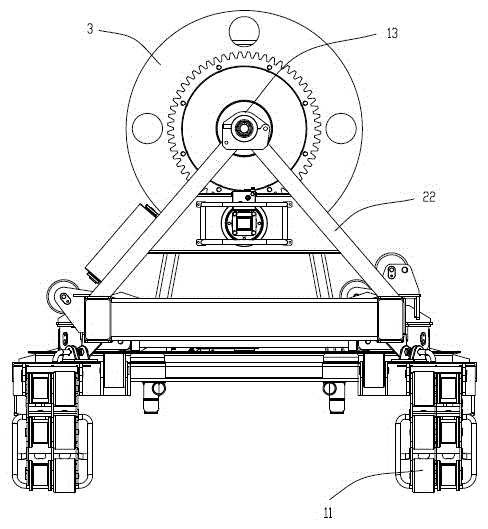

Numerical control coil winder for voltage transformer

ActiveCN103151164AFast windingImprove winding efficiencyFilament handlingCoils manufactureNumerical controlTransformer

The invention discloses a numerical control coil winder for a voltage transformer, which comprises two lower supporting boards (4) oppositely arranged on a work platform (1) and upper supporting boards (5). The upper supporting boards are arranged on the lower supporting boards and can rotate around one end of each lower supporting board, guide wheels (6) are arranged on the upper supporting boards and the lower supporting boards, drive gears (18) which can be matched with a gear ring (9) on a coil winding roller are arranged on the lower supporting boards, the coil winding roller comprises a rolling wheel (13) and a wire jacket (24) which can be movably combined into a whole, an epoxy barrel (17) is arranged between the rolling wheel and the wire jacket, a coil arrangement device is arranged on a work table board in the corresponding position between the upper supporting board and the lower supporting board and comprises stand columns (16) fixed on the work table board, a table board (10) arranged on the stand columns and a screw (8) arranged on the table board. The numerical control coil winder numerically controls gears to drive the combined coil winding roller to arrange and wind coils, so that not only can fast coil winding be achieved, coil winding efficiencies are improved, but also the coil winding accuracy is high, the applicability is wide, and the operation is convenient.

Owner:江西省一互电气有限公司

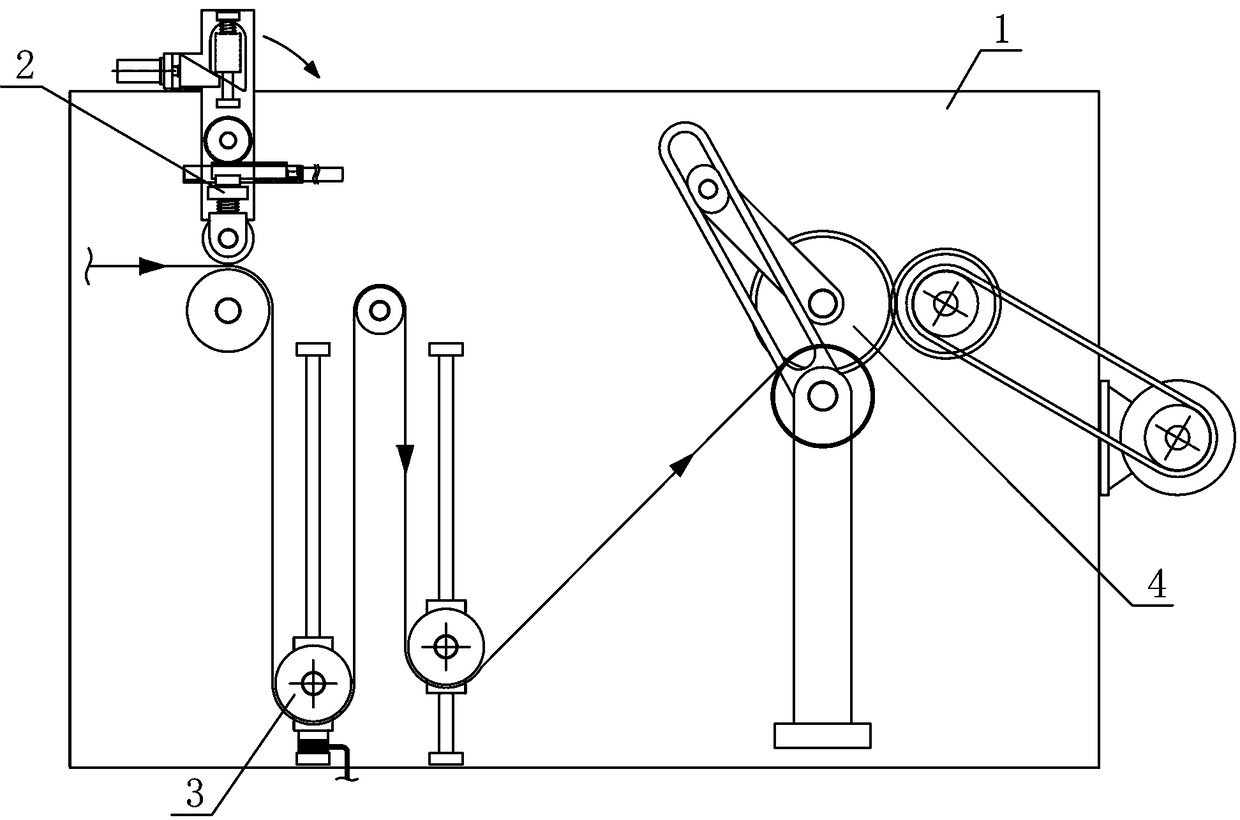

Traction coiling device for cable processing

The invention relates to the cable processing device technology field, and provides a traction coiling device for cable processing. The traction coiling device for the cable processing aims at solvingthe problems that 1) the standard coiled length of a cable cannot be accurately controlled; 2) in the coiling process of the cable, processing personnel need to pay attention to coiling progress at any moment, and a labor load is huge; and 3) after cable coiling is completed, the cable is inconvenient to fetch from the device, and coiling efficiency of the cable is influenced in a traditional electric coiling device. The traction coiling device for the cable processing comprises a processing platform and a plurality of support feet installed at the lower end of the processing platform, and further comprises a cable bundling cylinder, a tensioning assembly and a length counter, wherein a coiling shaft is inserted into the middle of the cable bundling cylinder, the front end of the coilingshaft runs through the side wall of a fixed plate and is installed at an output end of a first drive motor, the rear end of the coiling shaft is inserted into the side wall of a moving plate, and a cable dismounting mechanism is installed at the lower end of the moving plate. The traction coiling device for the cable processing is particularly suitable for semi-automatic coiling in the coil processing, and has high social use value and wide application prospects.

Owner:ANHUI CABLE

Convenient pavement rolling and spreading mechanization apparatus

InactiveCN105113374AEasy to operateReasonable mechanical structureRoads maintainenceCarrying capacityLocking plate

The invention discloses a convenient pavement rolling and spreading mechanization apparatus. The convenient pavement rolling and spreading mechanization apparatus comprises a rolling and spreading bracket undercarriage, a rolling and tying framework installed on the spreading and rolling bracket undercarriage and rolling shafts installed on the rolling and tying framework; the rolling and spreading bracket undercarriage comprises a rolling and spreading roller group which is arranged at one end and can guide a paving locking plate to the ground, a chassis for carrying the rolling and tying framework is arranged at the middle part of the rolling and spreading bracket undercarriage, and the rolling and tying framework can rotate for 90 degrees by taking the center of the chassis as the axis; the rolling and tying framework comprises a rectangular undercarriage, two ends of the undercarriage are provided with the rolling shafts by virtue of a supporting frame, one end of the undercarriage is provided with a driving device driving the rolling shafts to rotate, and the undercarriage is provided with a plurality of rollers. The convenient pavement rolling and spreading mechanization apparatus is independent and is separated from a carrier and can be loaded by utilizing a pulling arm hook of the carrier, also can be loaded by virtue of the hoisting of a crane and also can be loaded by virtue of a forklift, thereby being flexible and convenient to operate and applicable to various different environments; the convenient pavement rolling and spreading mechanization apparatus can be used for rapidly and conveniently spreading and rolling a metal material pavement, the metal material pavement can be used for a vehicle with the carrying capacity of 70 tons to pass through and is more durable, and the difficulty that an existing product only can be operated on a soft pavement can be solved.

Owner:叶建宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com