Patents

Literature

1575results about How to "Improve winding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

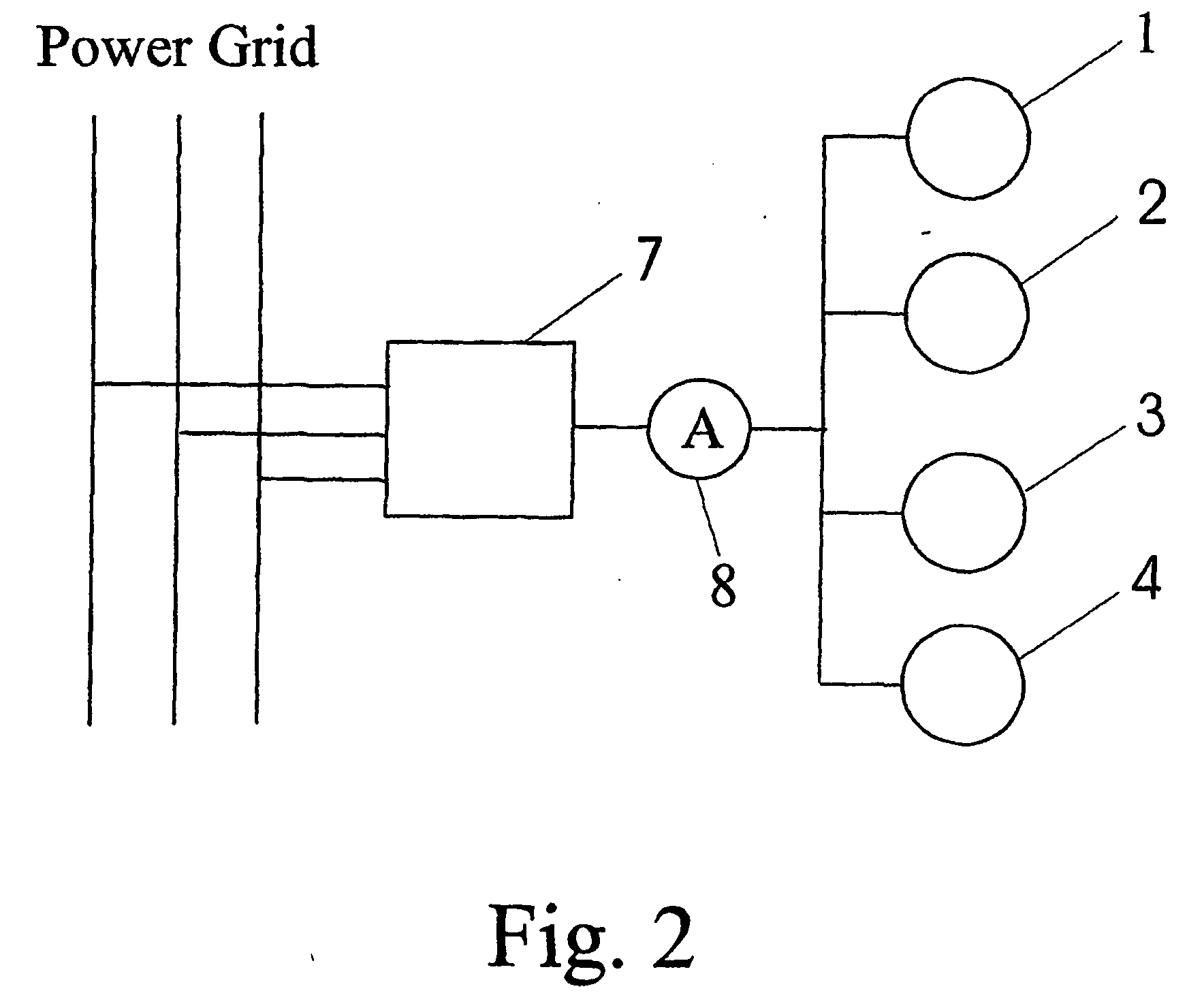

Wind farm and method for operating same

ActiveUS7372173B2Effective controlEasy to controlOptimise machine performanceWind motor controlPower gridTurbine

Owner:GE INFRASTRUCTURE TECH INT LLC

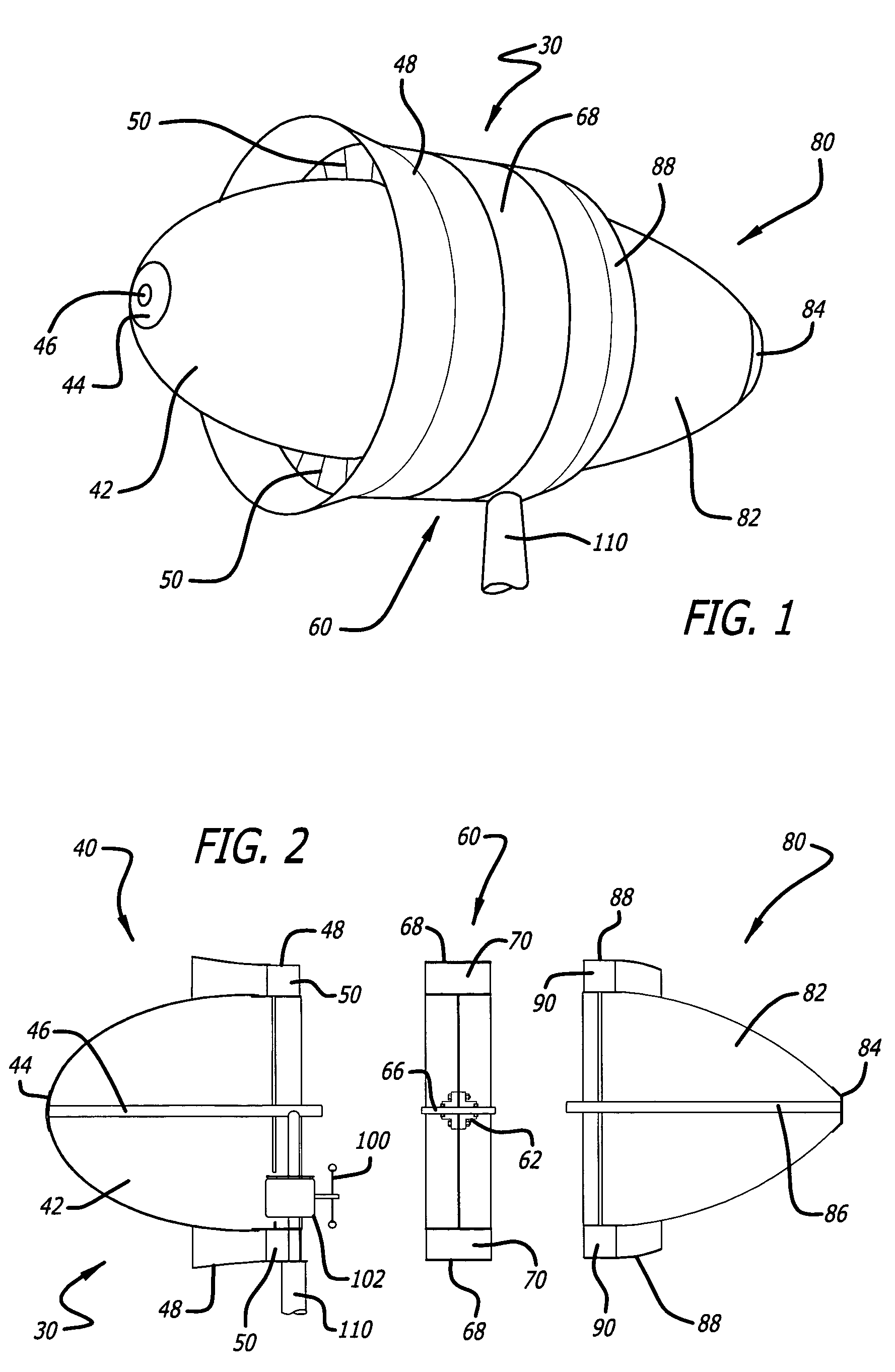

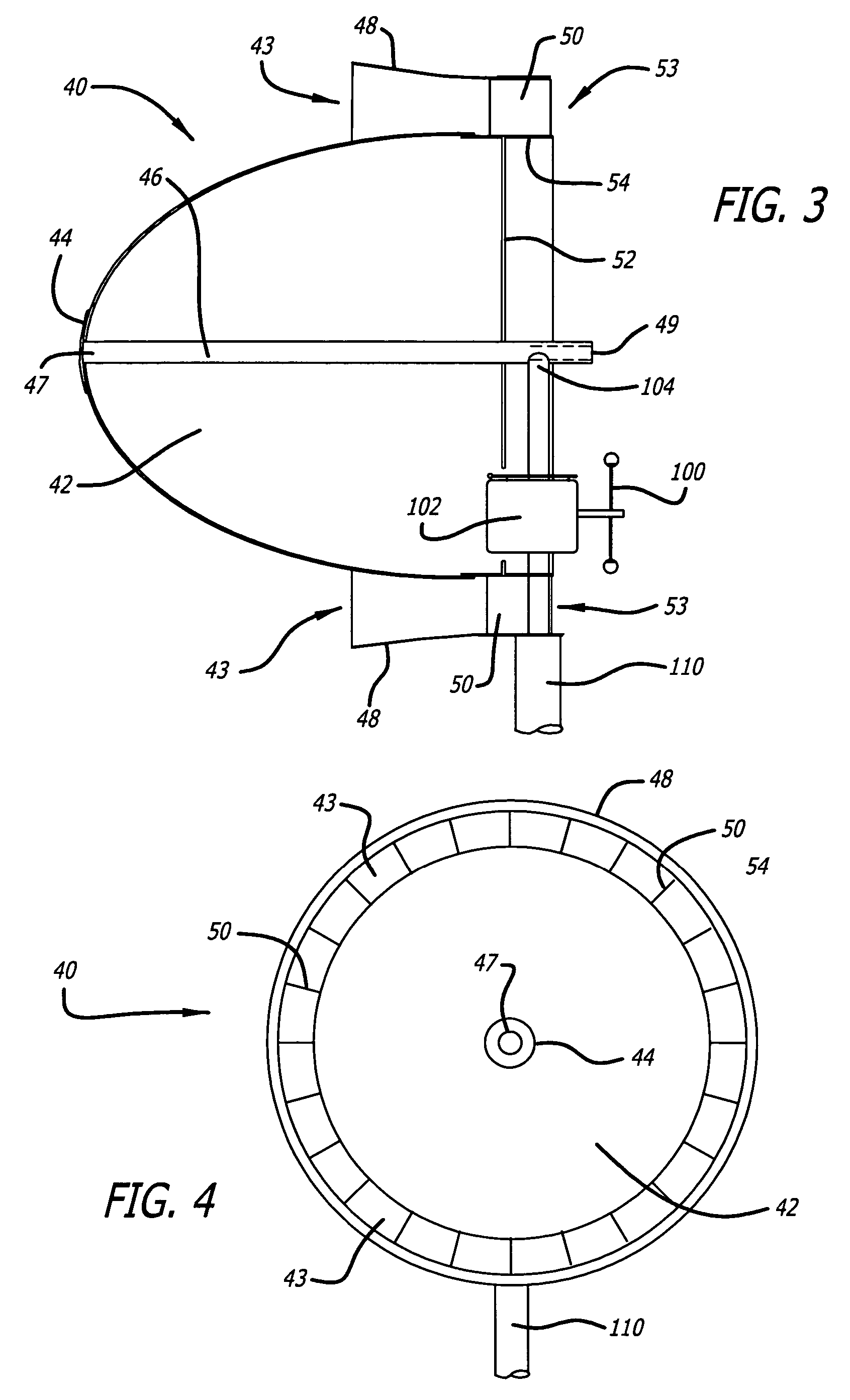

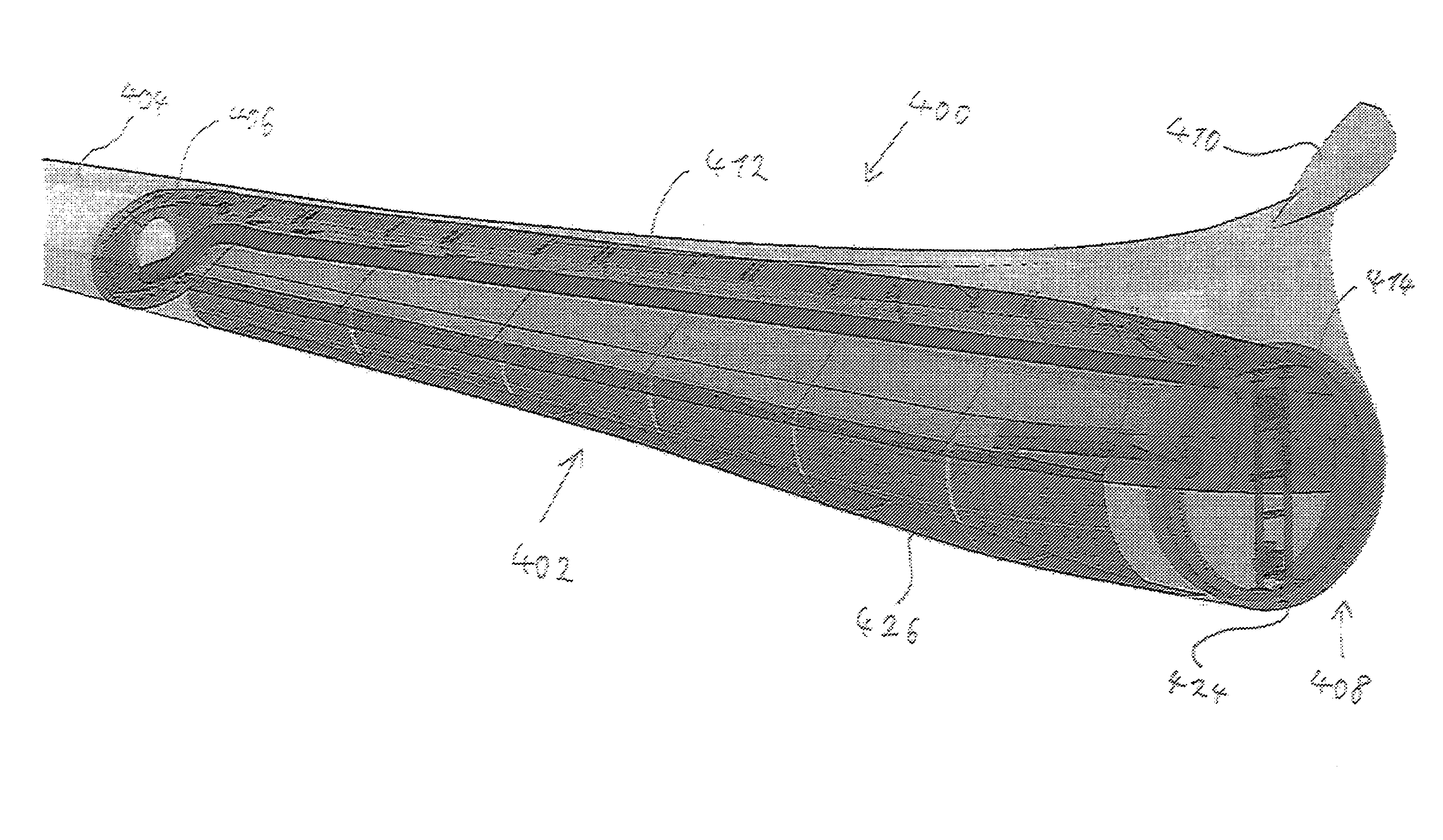

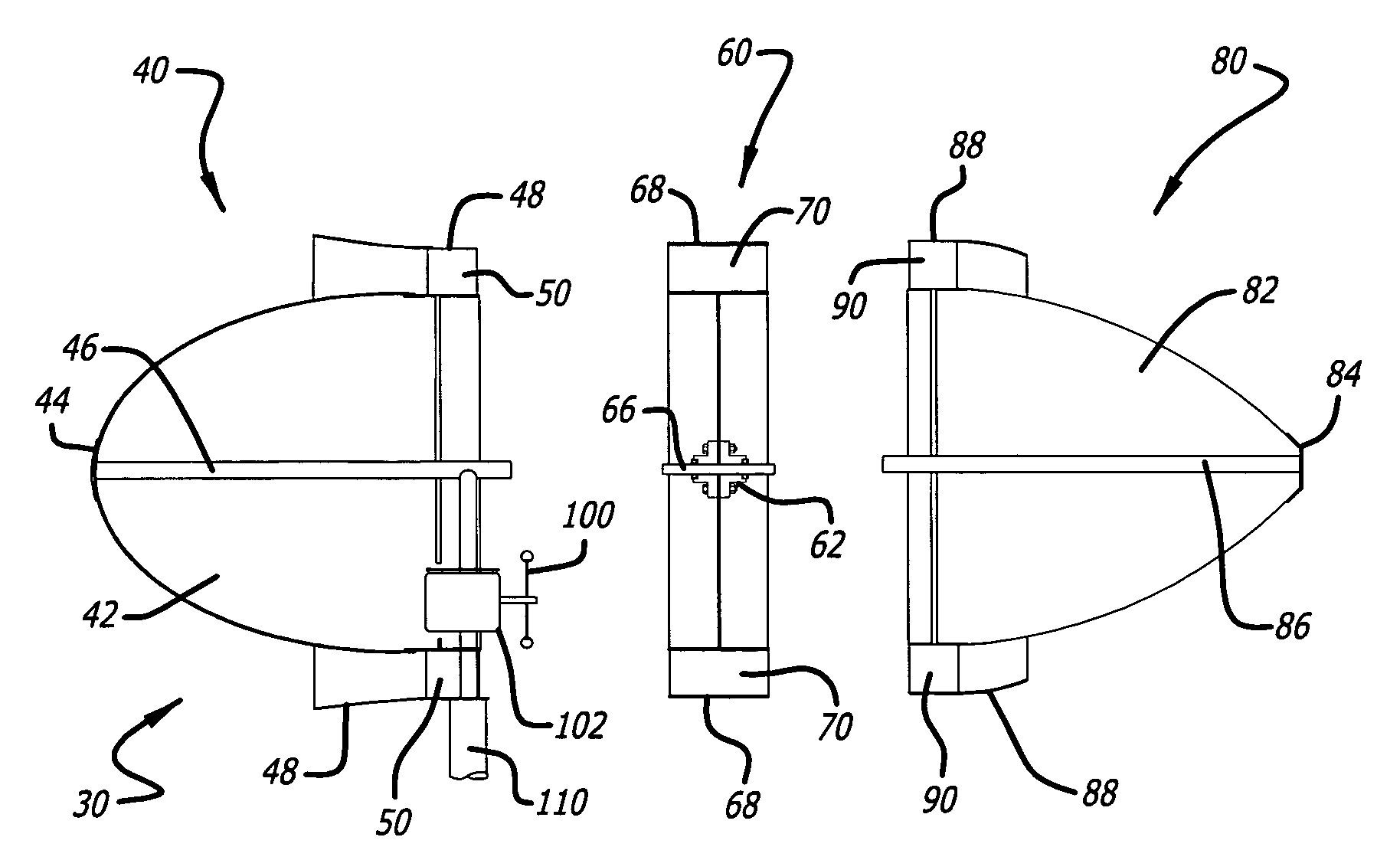

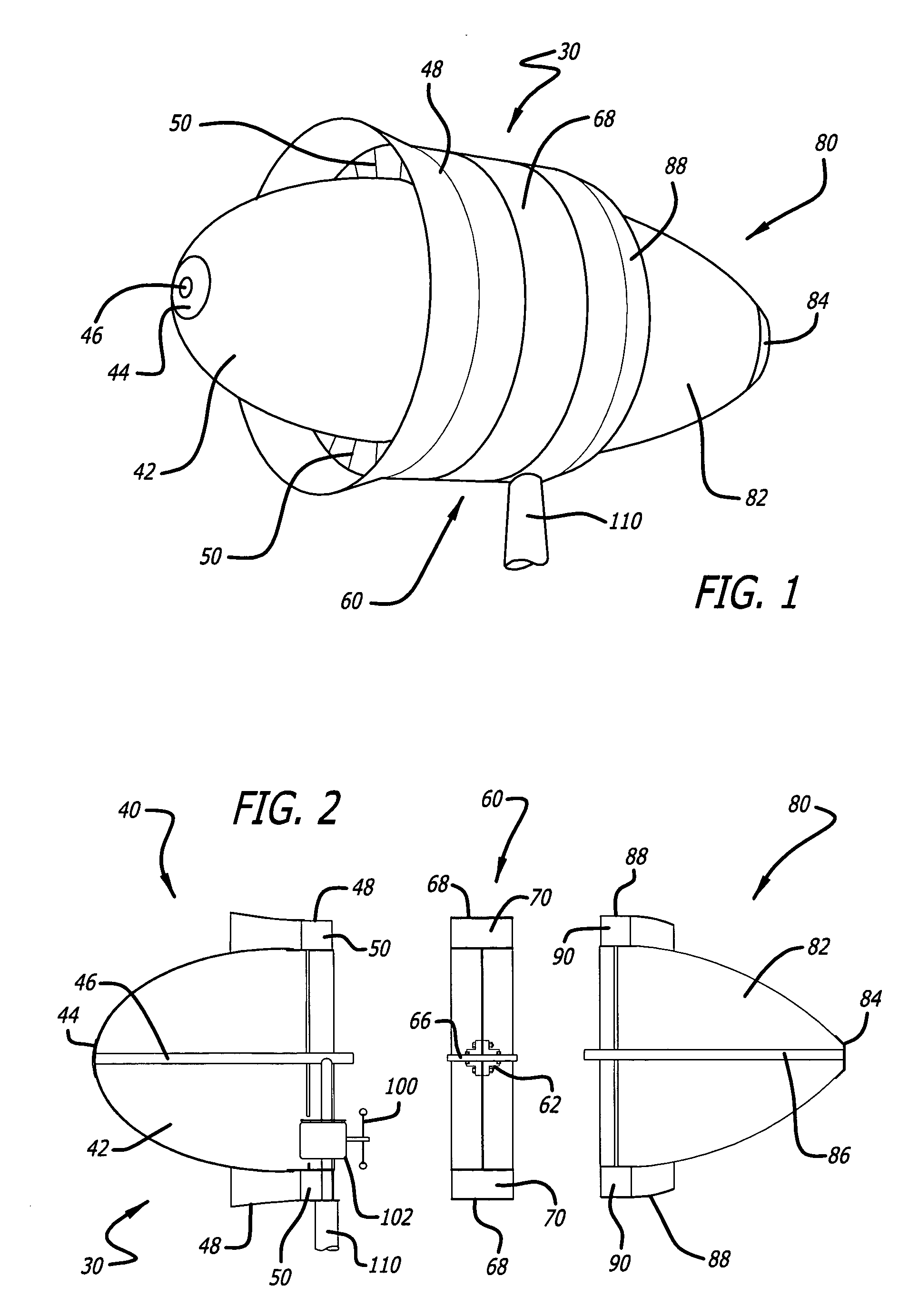

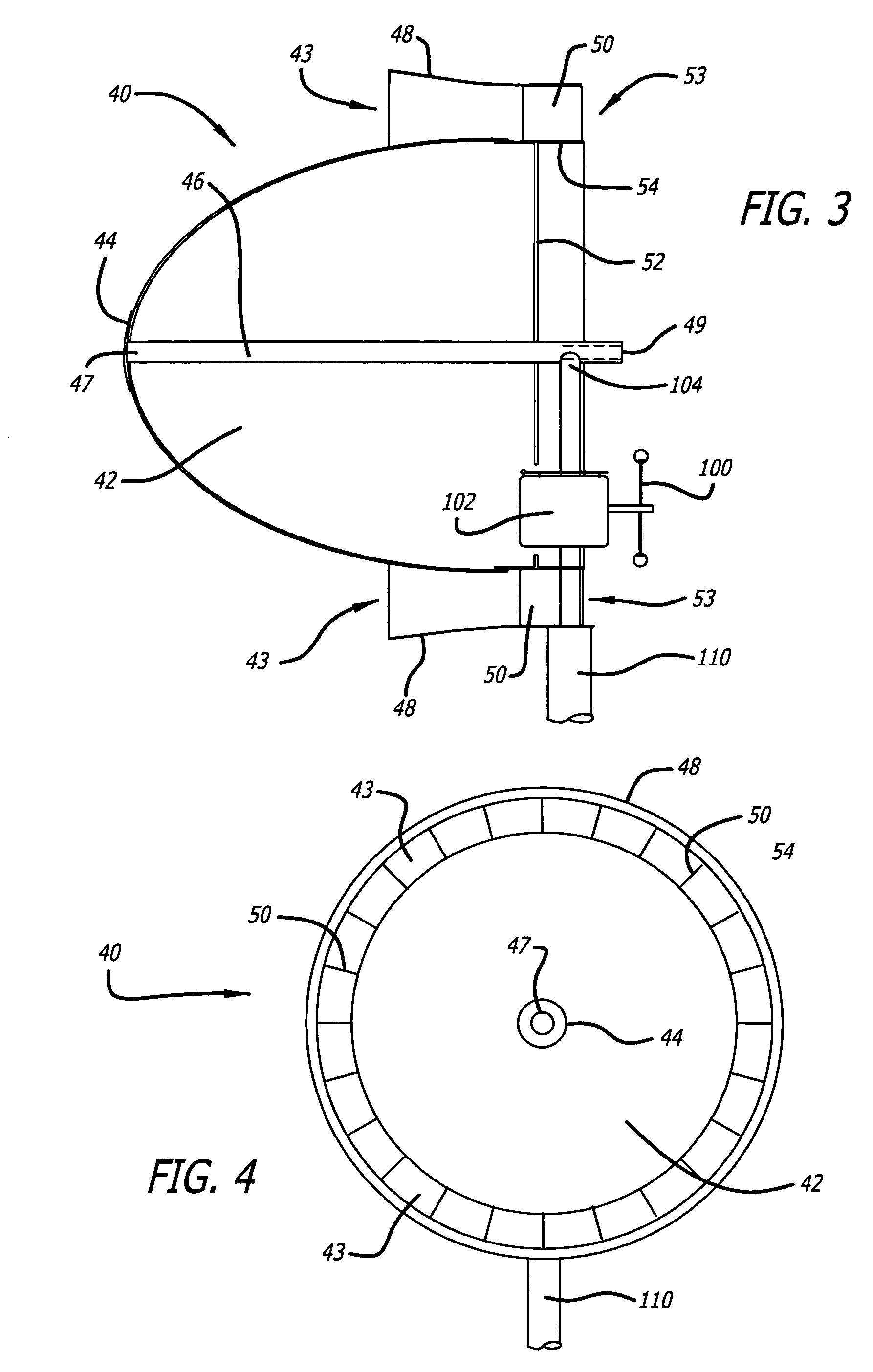

Laminar air turbine

InactiveUS7214029B2Low costMaximize rotational forcePump componentsWind motor controlWind drivenTurbine wheel

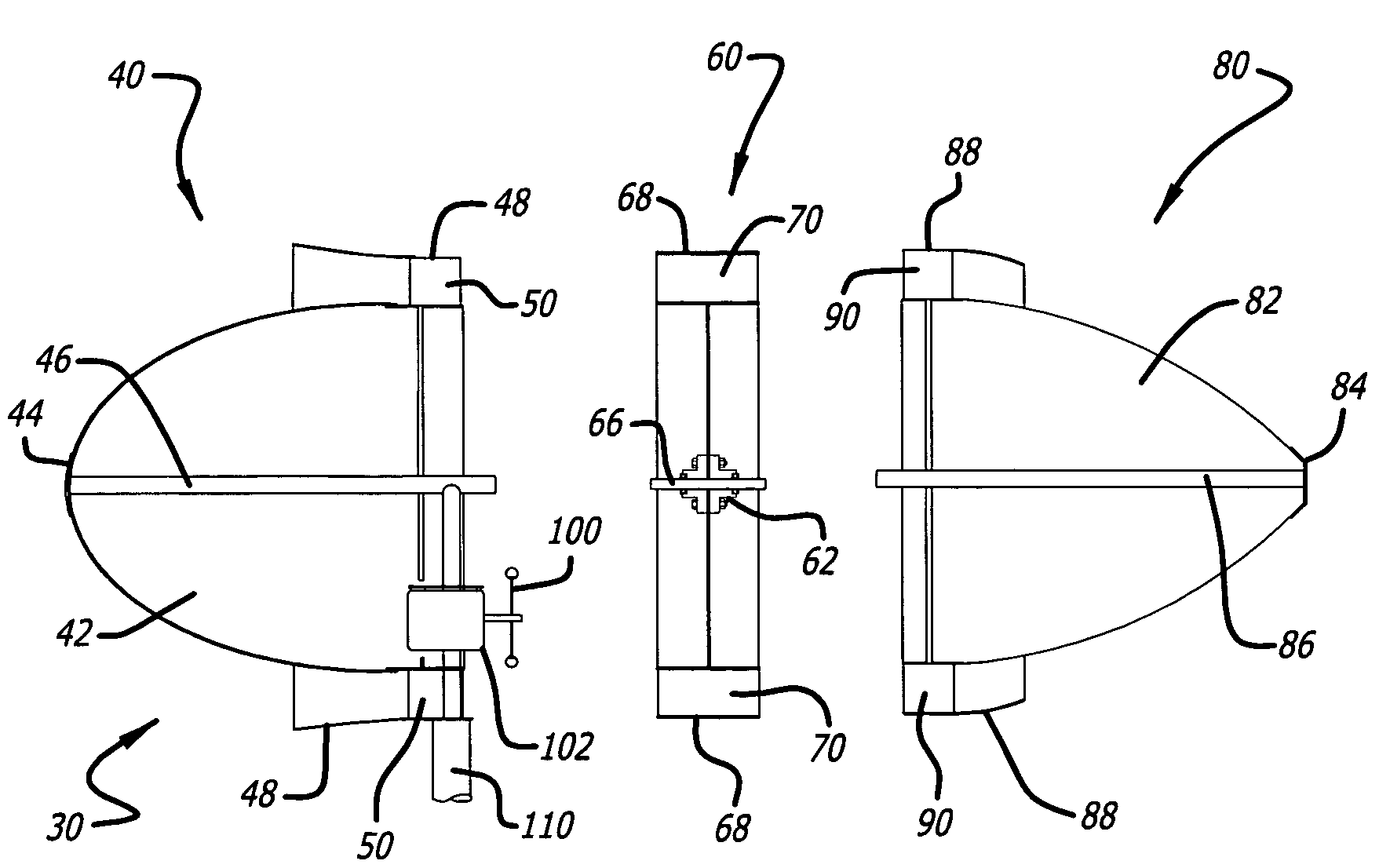

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

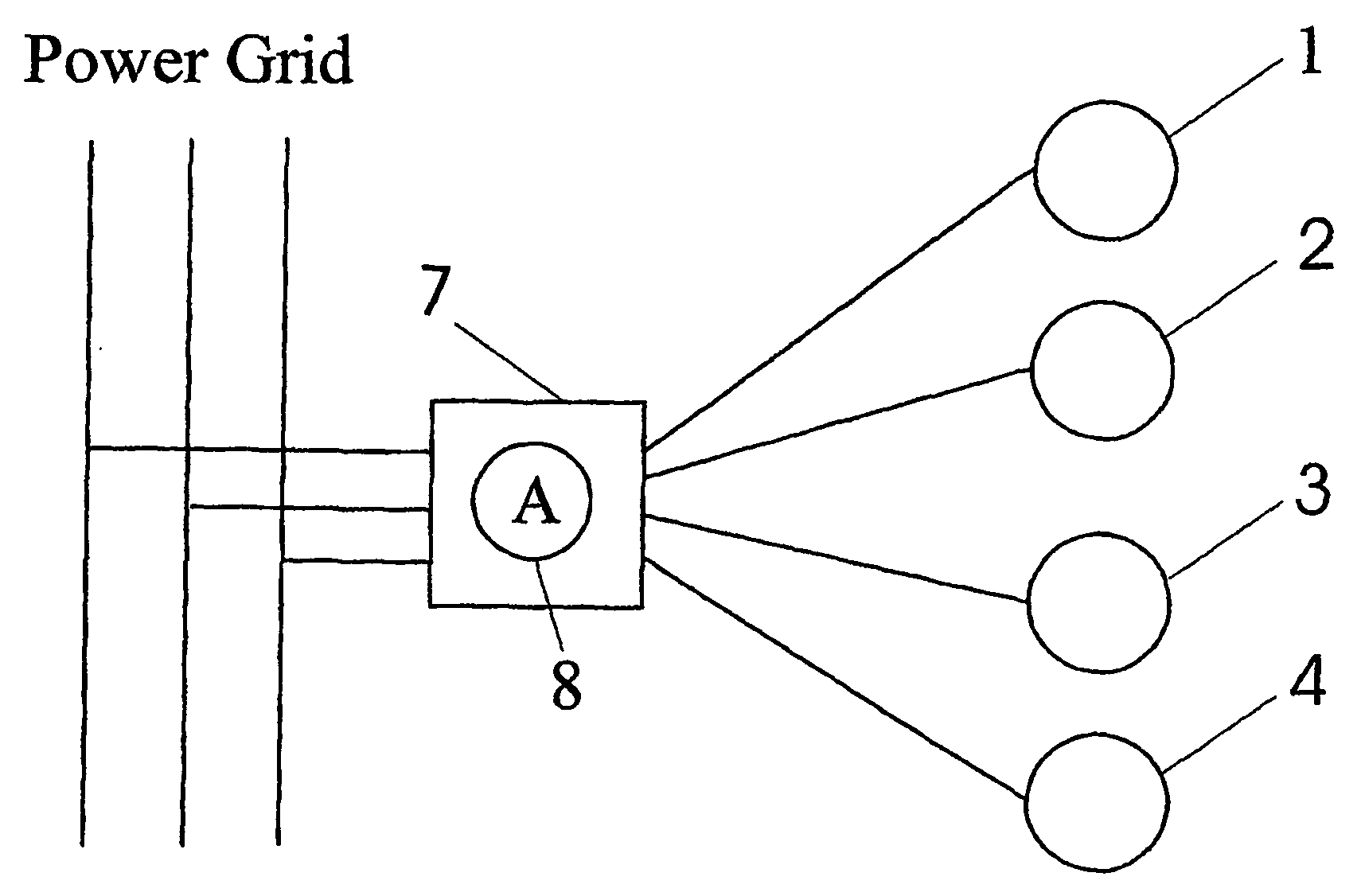

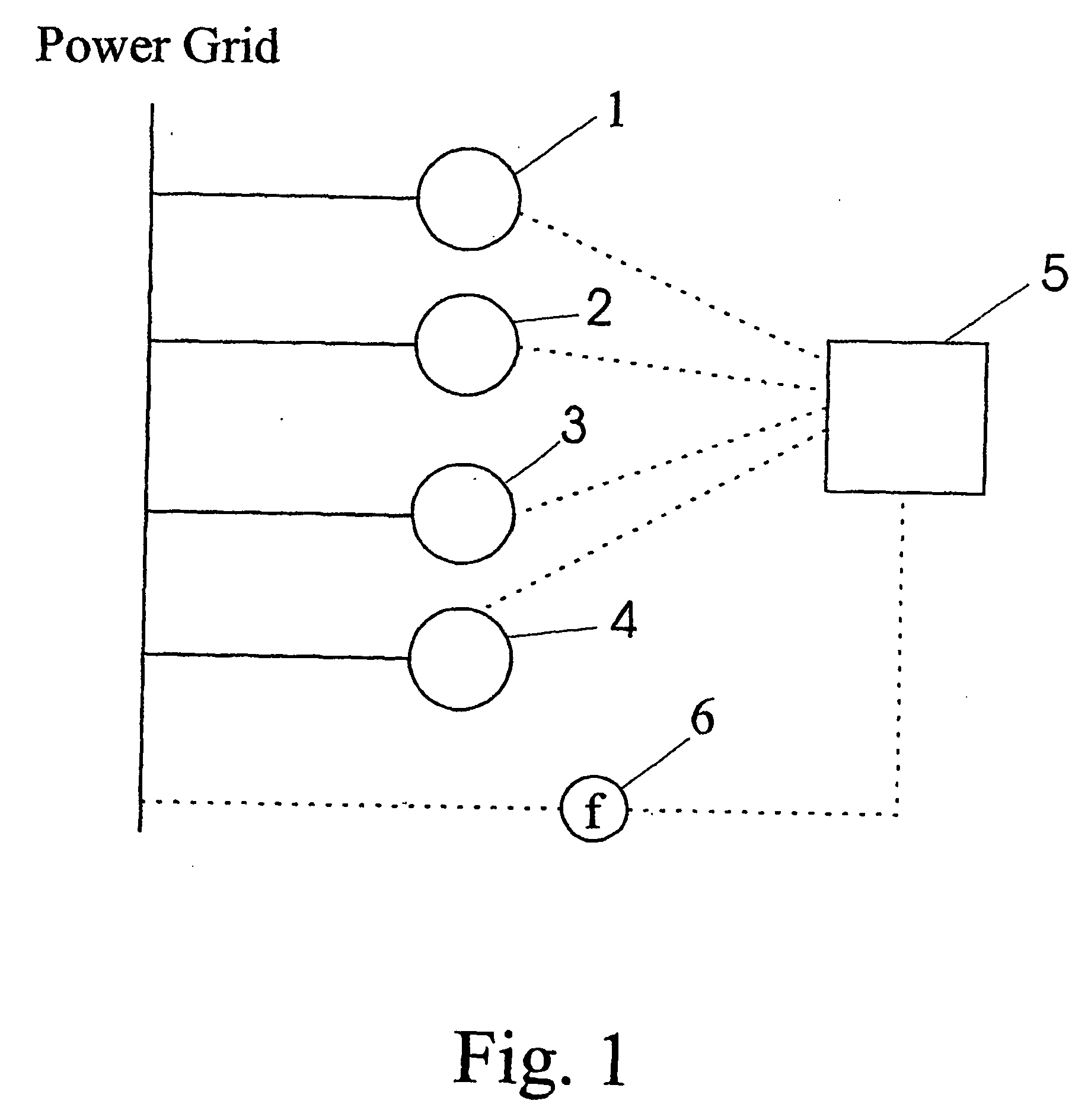

Wind farm and method for operating same

ActiveUS20070047163A1Effective controlEasy to controlOptimise machine performanceWind motor controlPower gridTurbine

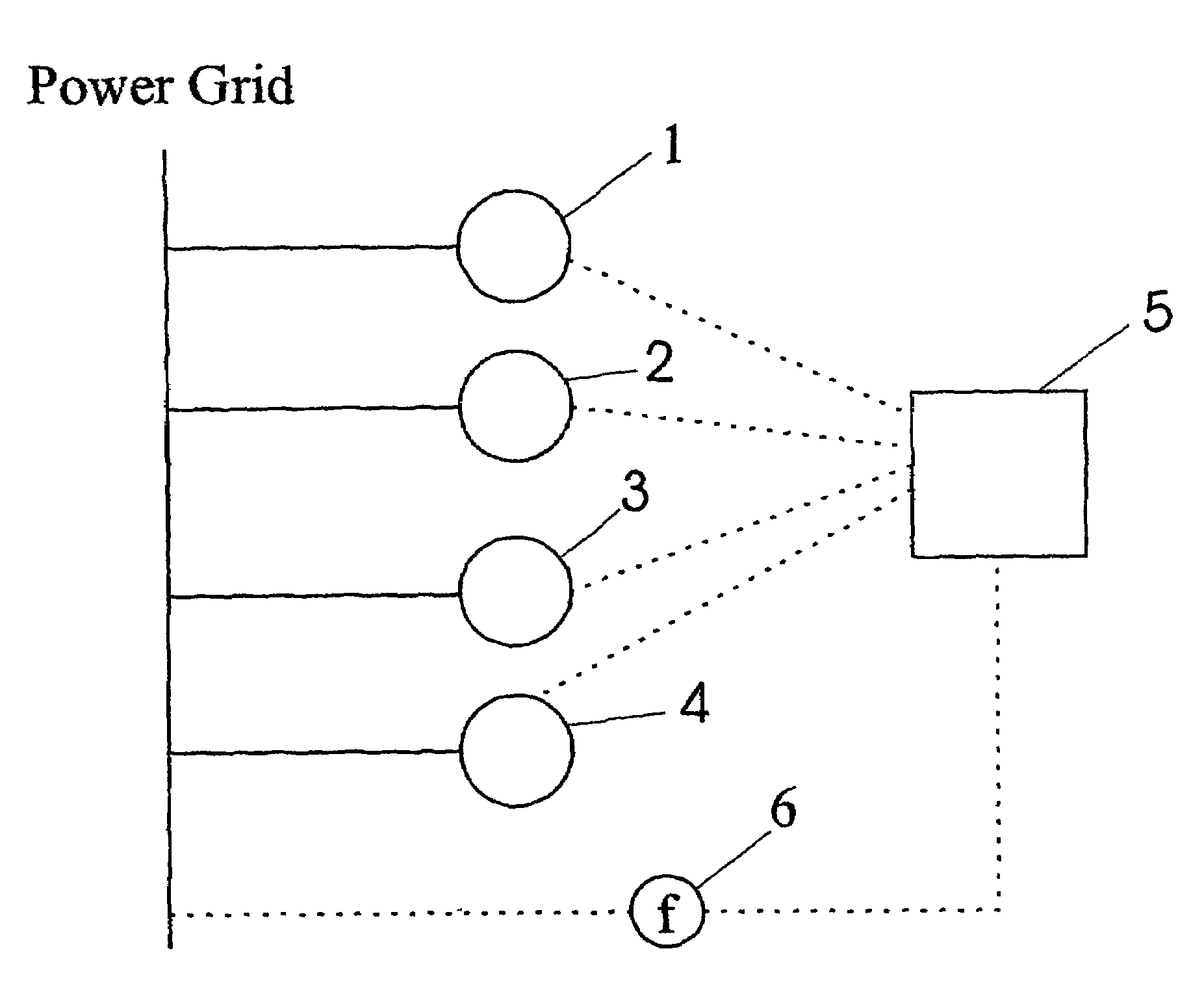

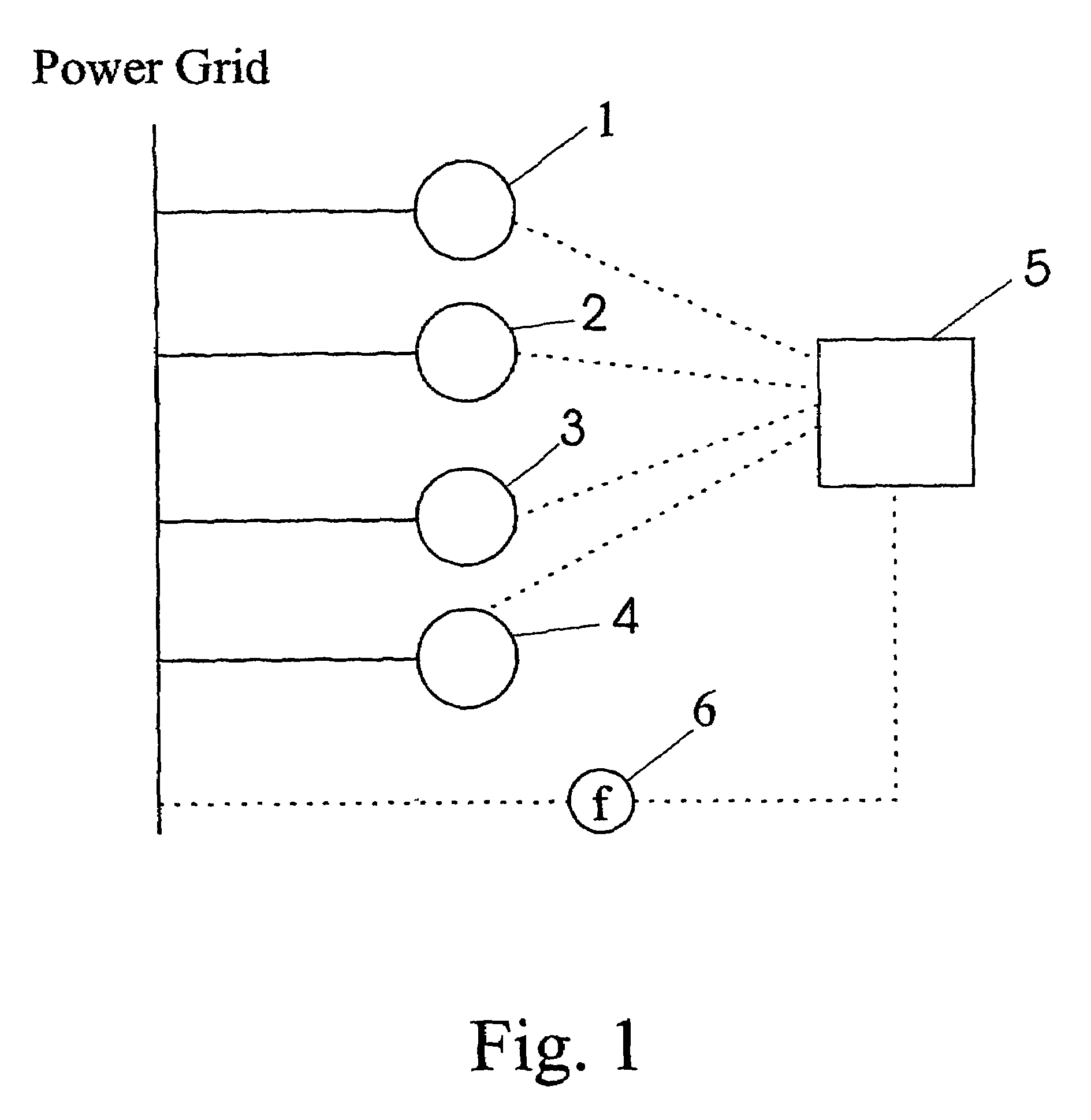

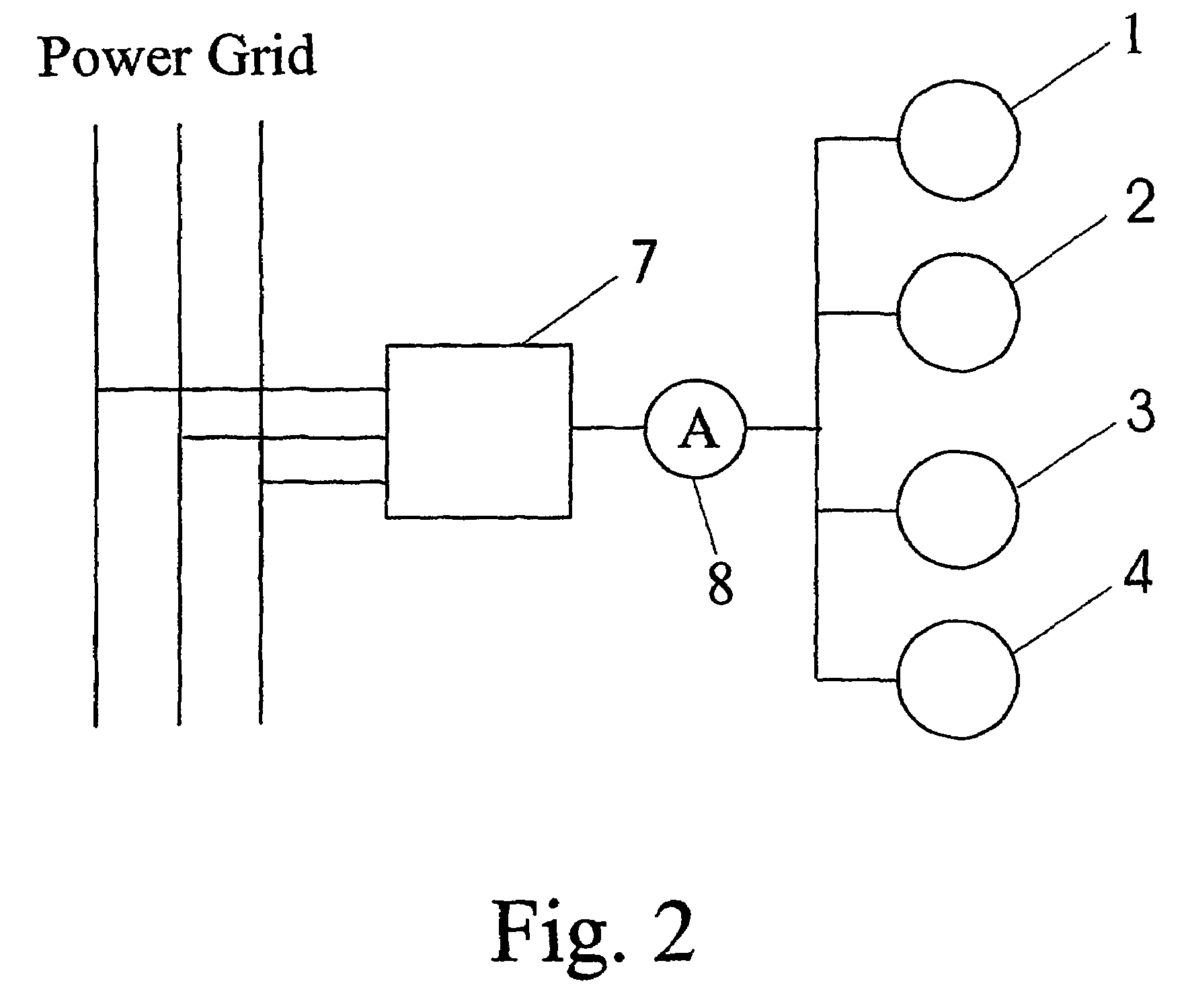

A wind farm with at least two wind turbines (1, 2, 3, 4) connected to a power grid is provided, said wind farm further comprising a control unit (5) connected to said at least two wind turbines (1, 2, 3, 4), and a sensor unit (6) connected to said power grid and said control unit (5), wherein said sensor unit (6) is adapted to measure the grid frequency of said power grid and to transmit said measured grid frequency to said control unit (5), and wherein said control unit (5) is adapted to control the output of real power of said wind farm according to said measured grid frequency. Furthermore, a method for operating a wind farm is proposed, said method comprising the steps of measuring the grid frequency with a sensor unit, transmitting said measured grid frequency to a centralized control unit, determining whether the measured grid frequency lies outside a predetermined range, and, if the measured grid frequency lies outside said predetermined range, selecting at least one out of the at least two wind turbines comprised in said wind farm by said centralized control unit and regulating the power output of said selected at least one wind turbine.

Owner:GENERAL ELECTRIC CO

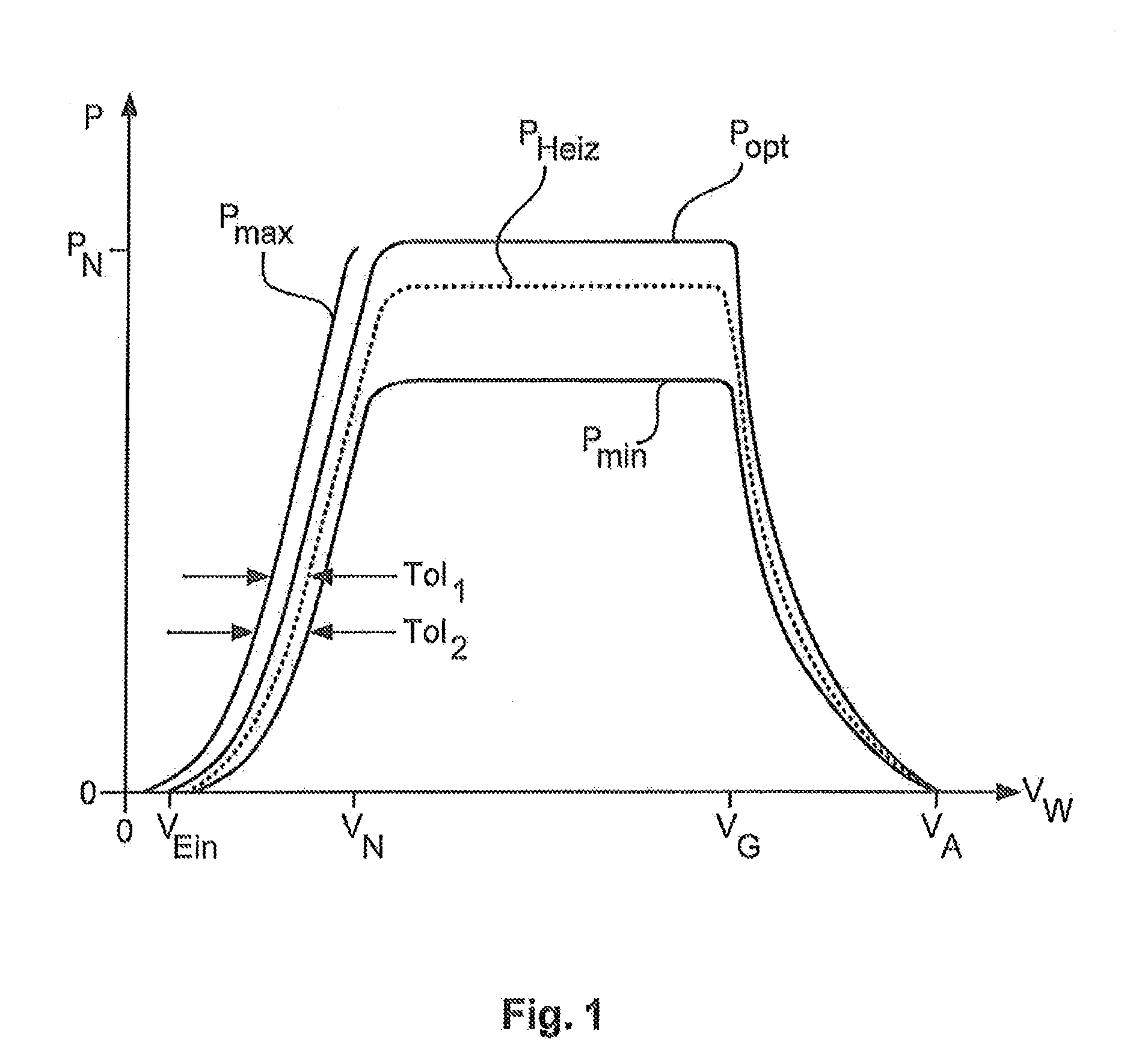

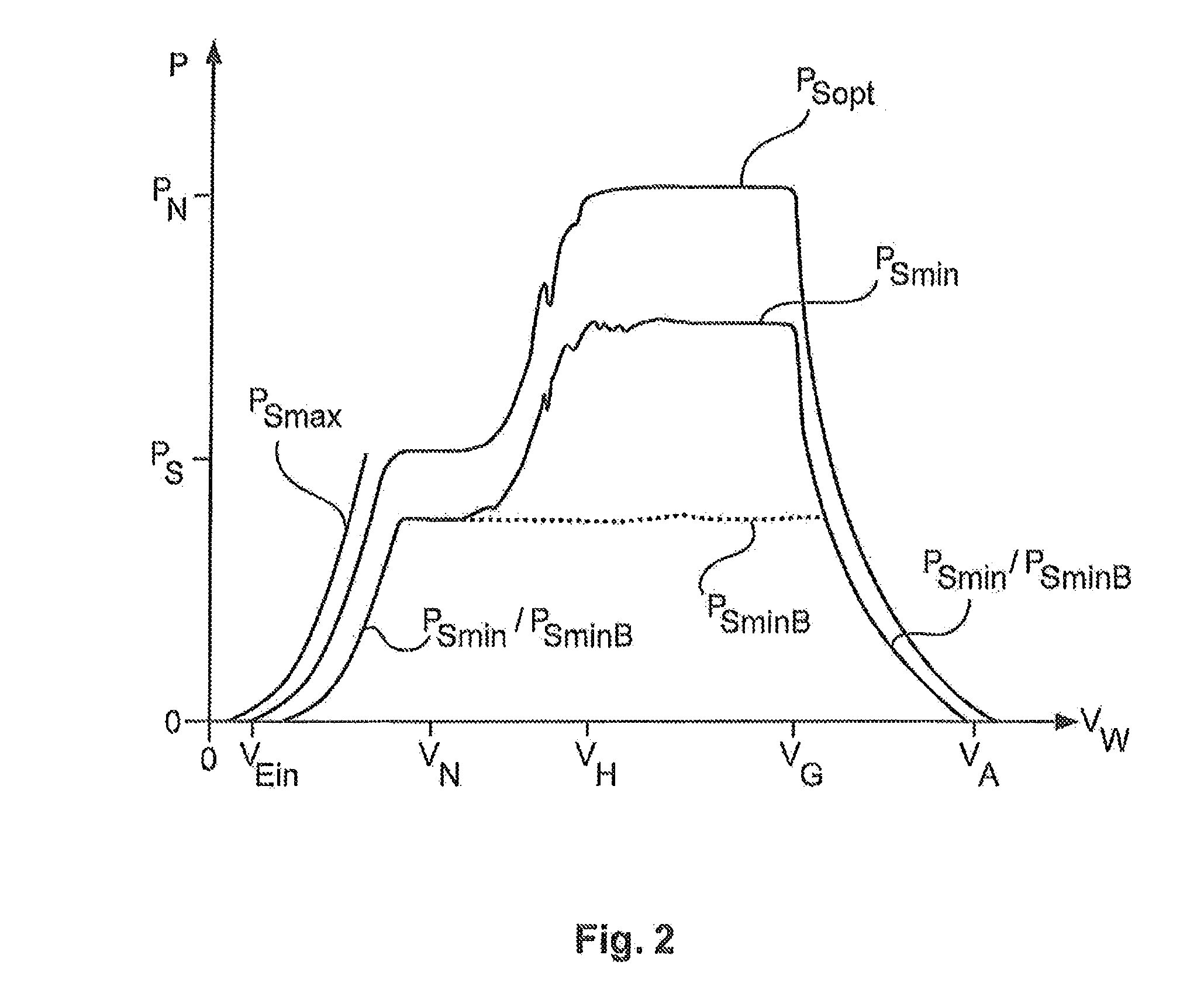

Method for the operation of a wind turbine

ActiveUS20130106108A1Improve winding efficiencyEasy to operateWind motor controlEngine fuctionsOperating pointTurbine

The invention relates to a method for operating a wind turbine comprising an aerodynamic rotor that has at least one rotor blade. Said method comprises the steps of operating the wind turbine at an operating point that depends on the wind speed, detecting an operating parameter of the operating point, comparing the detected operating parameter with a predetermined reference quantity, and heating the at least one rotor blade when the detected operating parameter exceeds a predetermined variation from the reference quantity, the operation of the wind turbine being continued.

Owner:WOBBEN PROPERTIES GMBH

Laminar air turbine

InactiveUS20060002786A1Low costMaximize rotational forceWind motor controlPump componentsWind drivenTurbine wheel

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

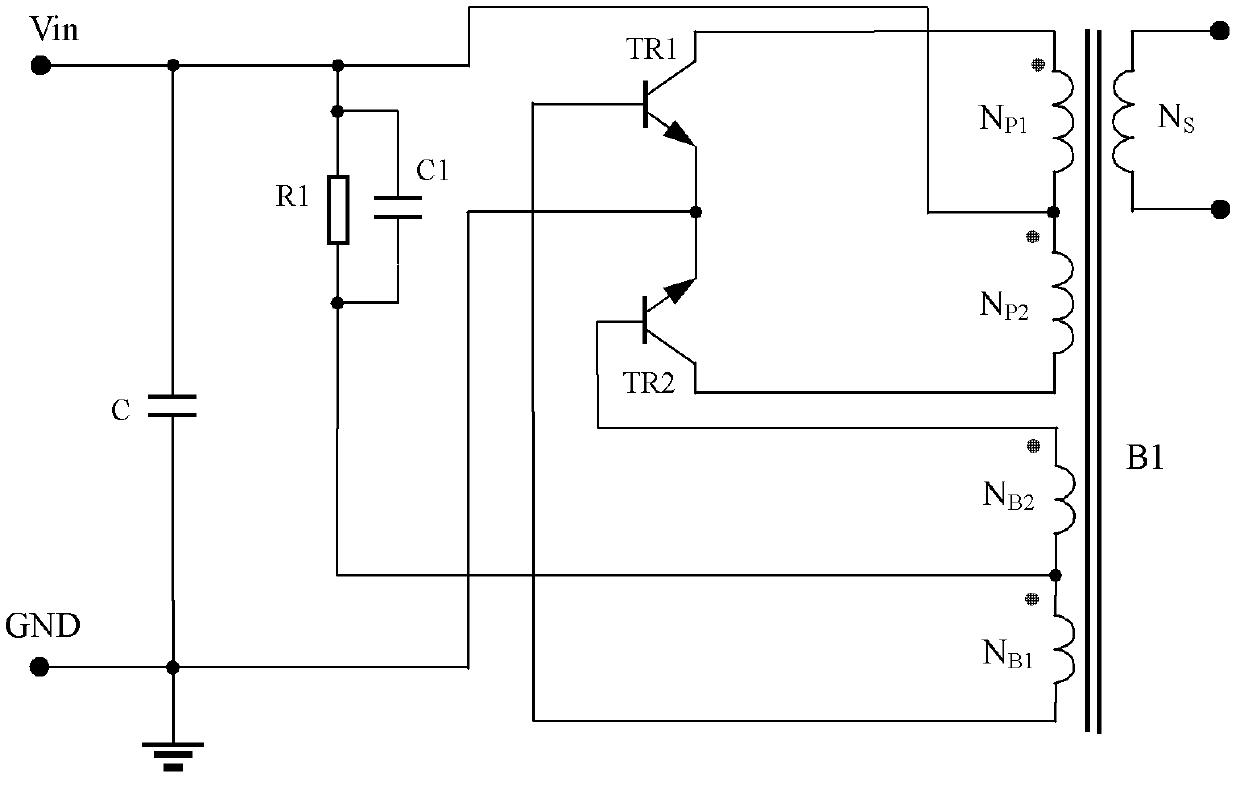

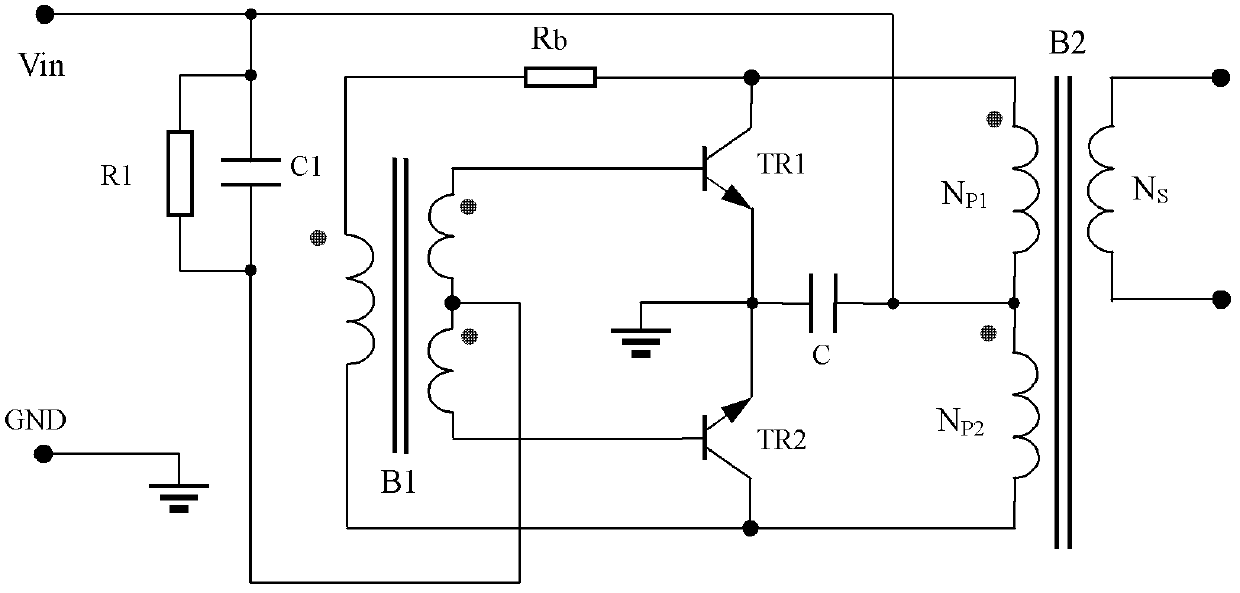

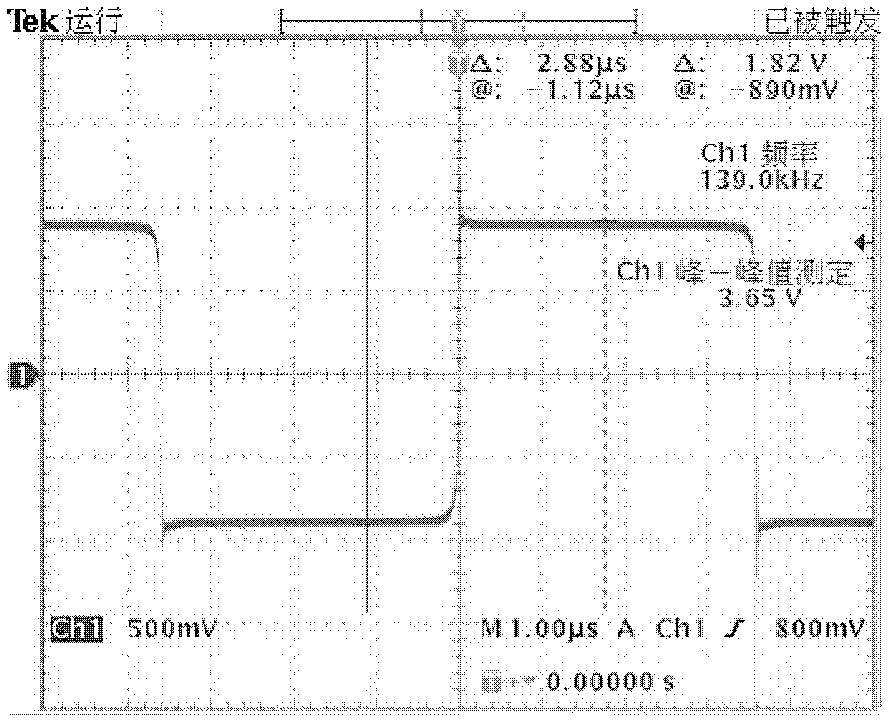

Self-excitation push-pull type converter

ActiveCN102437767AImprove efficiencyReduce power consumptionTransformers/inductances coils/windings/connectionsAc-dc conversionTransformerPush pull

The invention discloses a self-excitation push-pull type converter, comprising a transformer. A closed magnetic core or iron core of the transformer is formed by a main part and a local part, wherein the local part achieves magnetic saturation earlier than the main part under excitation of the same increasing magnetic field. The converter disclosed by the invention can overcome the defects of the traditional self-excitation push-pull type converter, thus efficiency of the self-excitation push-pull type converter is obviously improved when the self-excitation push-pull type converter is in a light load state; when the self-excitation push-pull type converter is in a rated load state, the efficiency is further improved; number of windings of coils on a magnetic saturation transformer in the self-excitation push-pull type converter is reduced; working frequency of the self-excitation push-pull type converter is improved while loss is maintained to be lower; and probability that current peak is produced when the self-excitation push-pull type converter is conducted and closed is reduced, and the efficiency is further improved while output ripple is reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

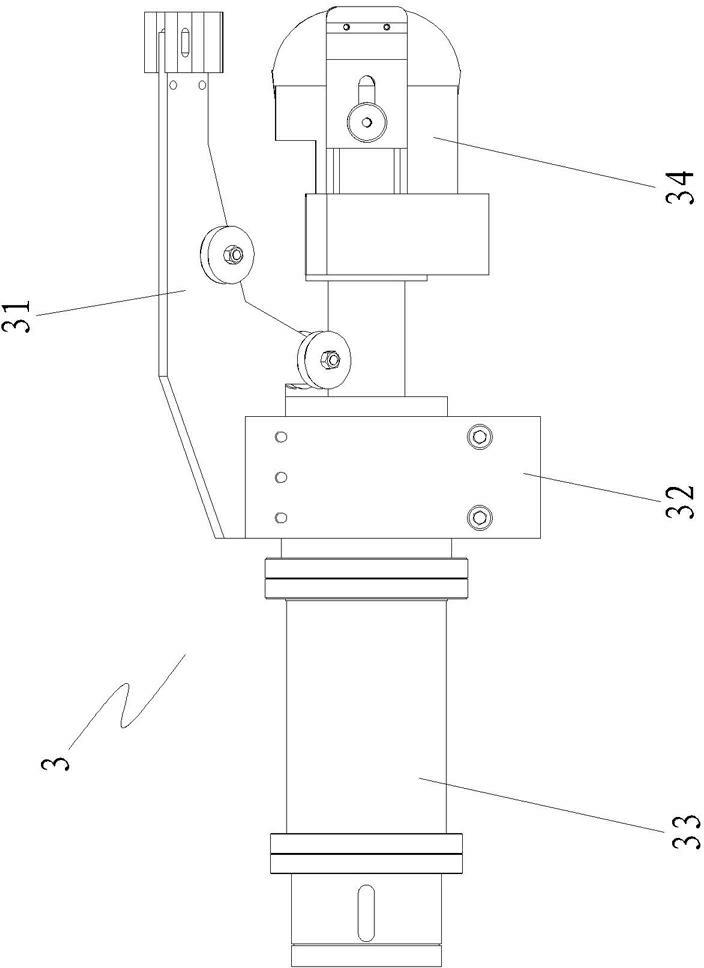

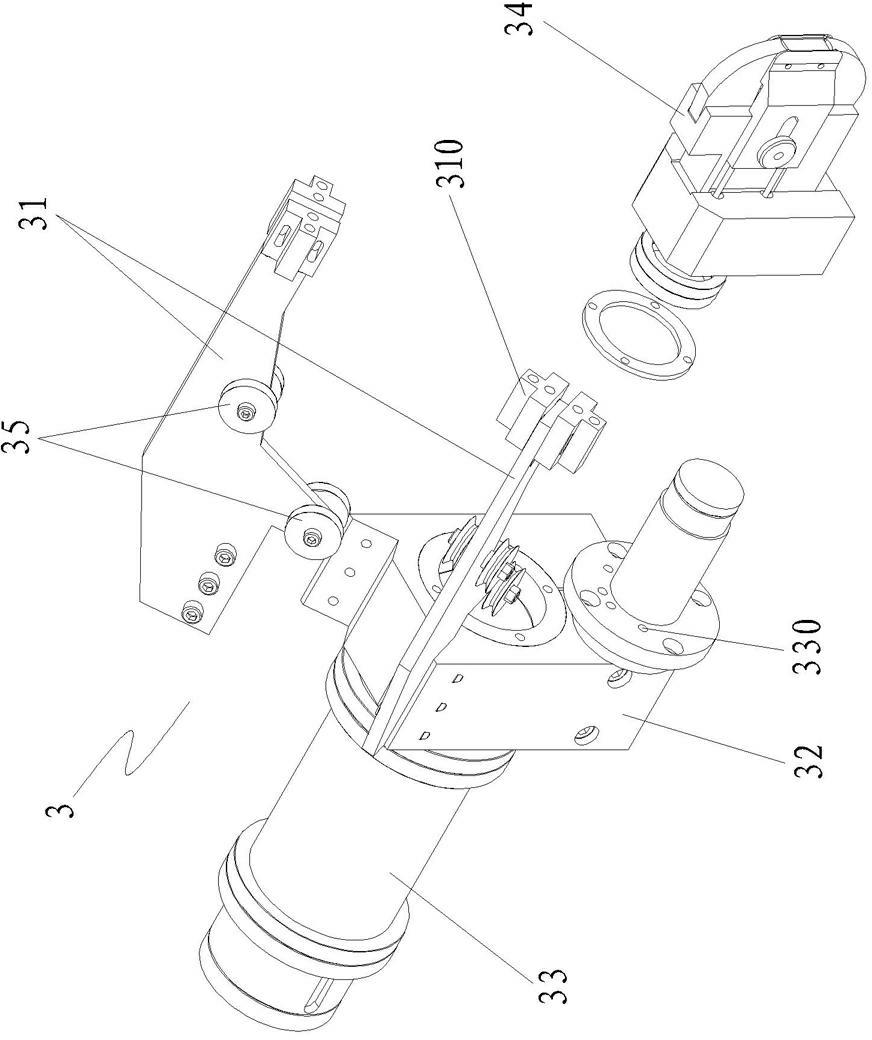

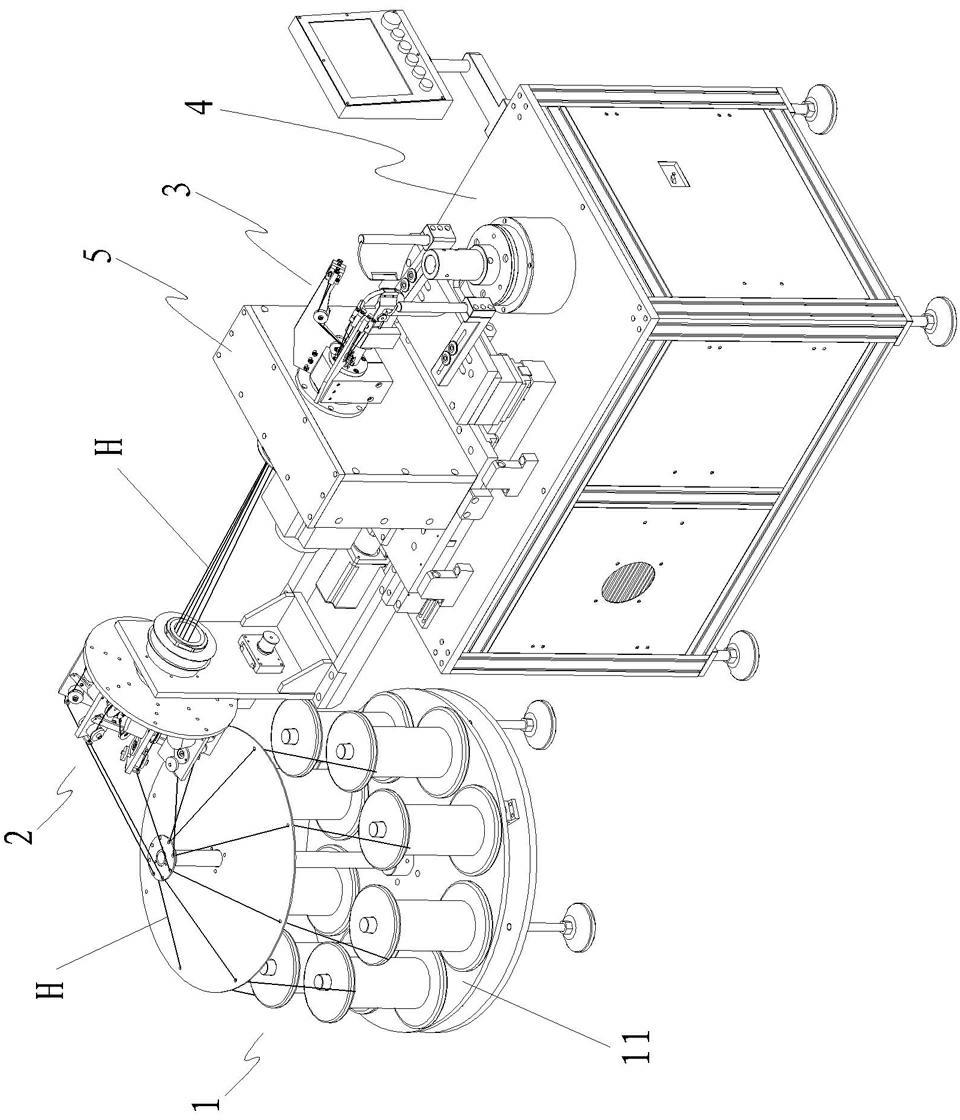

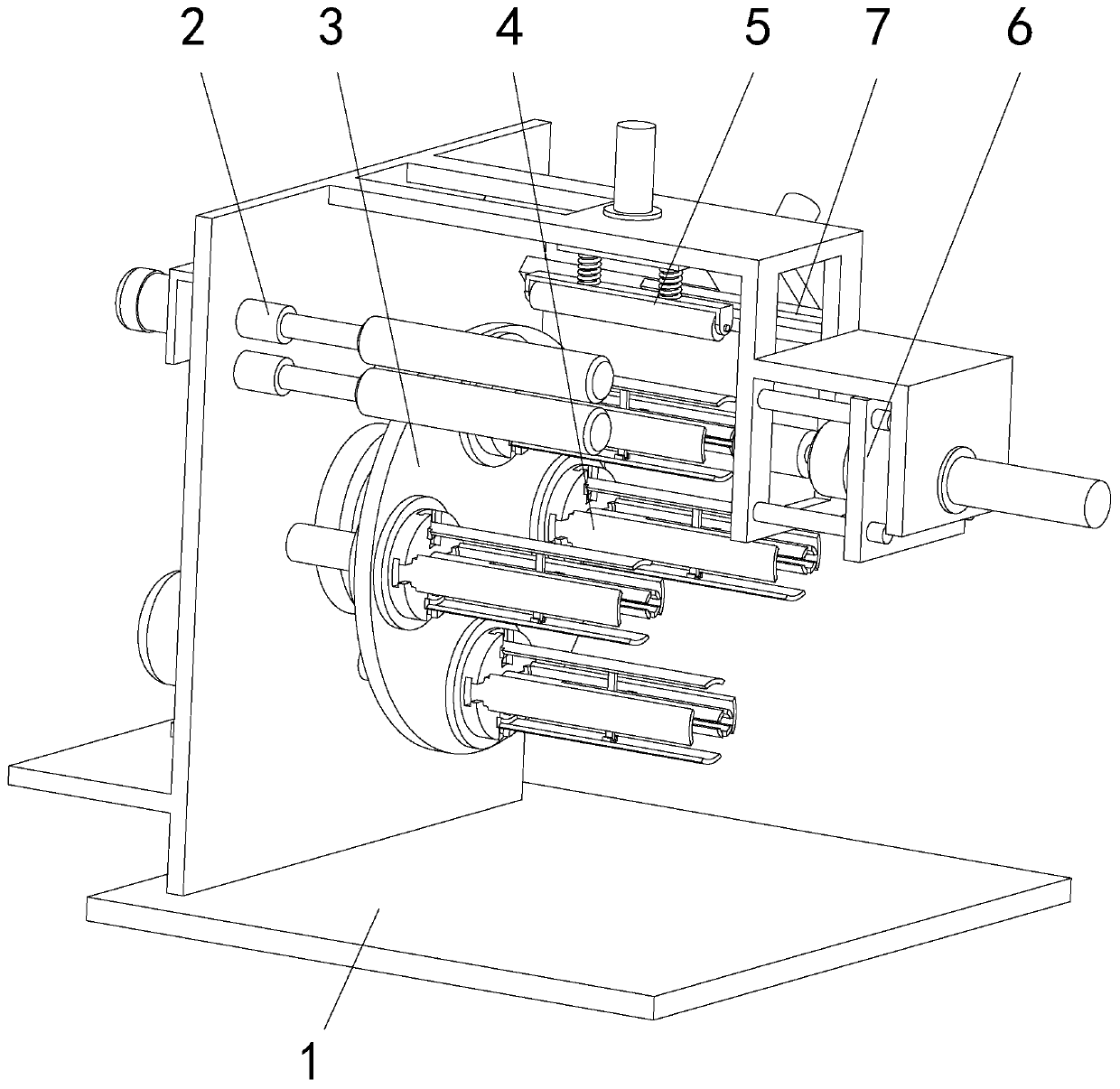

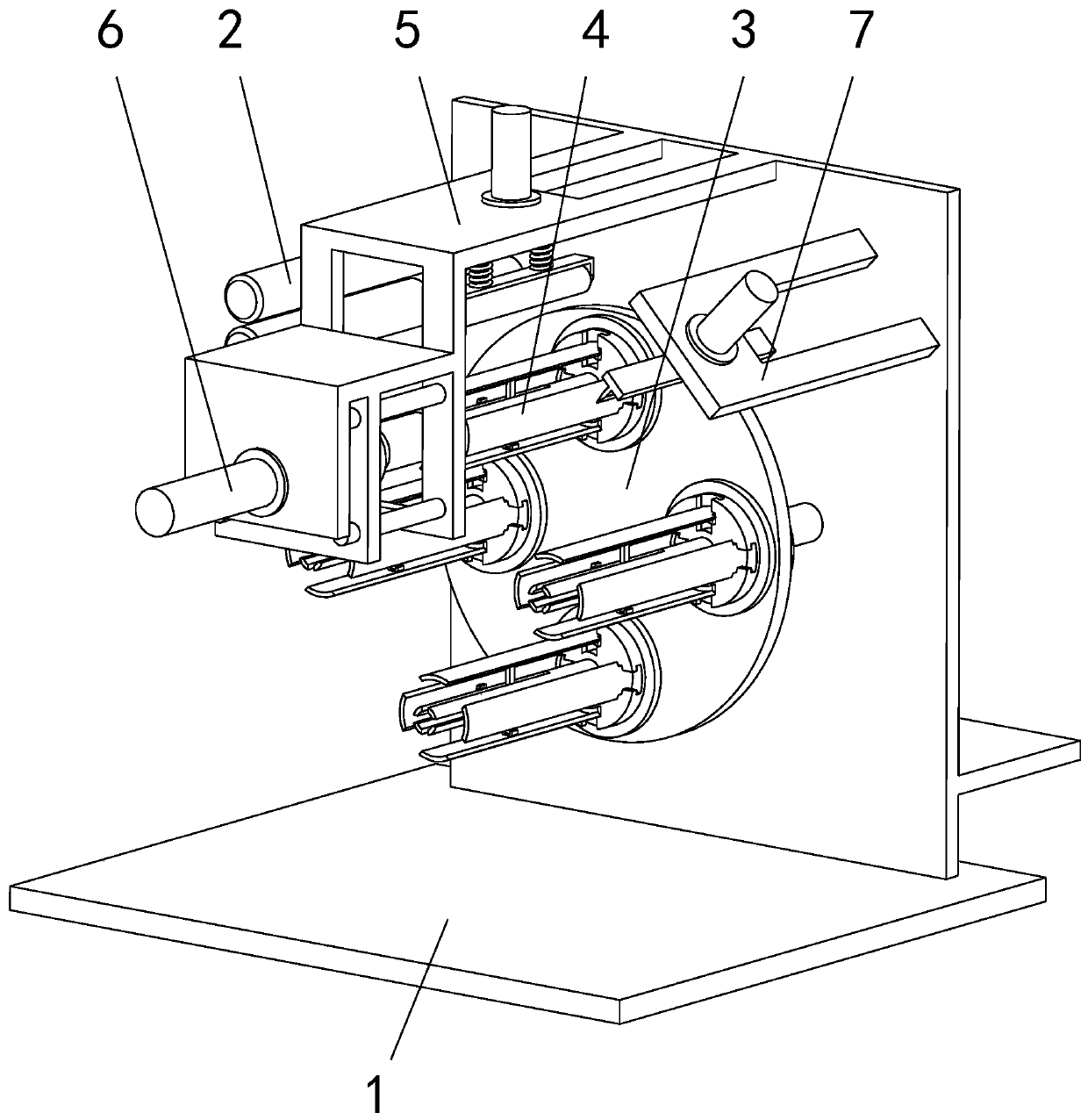

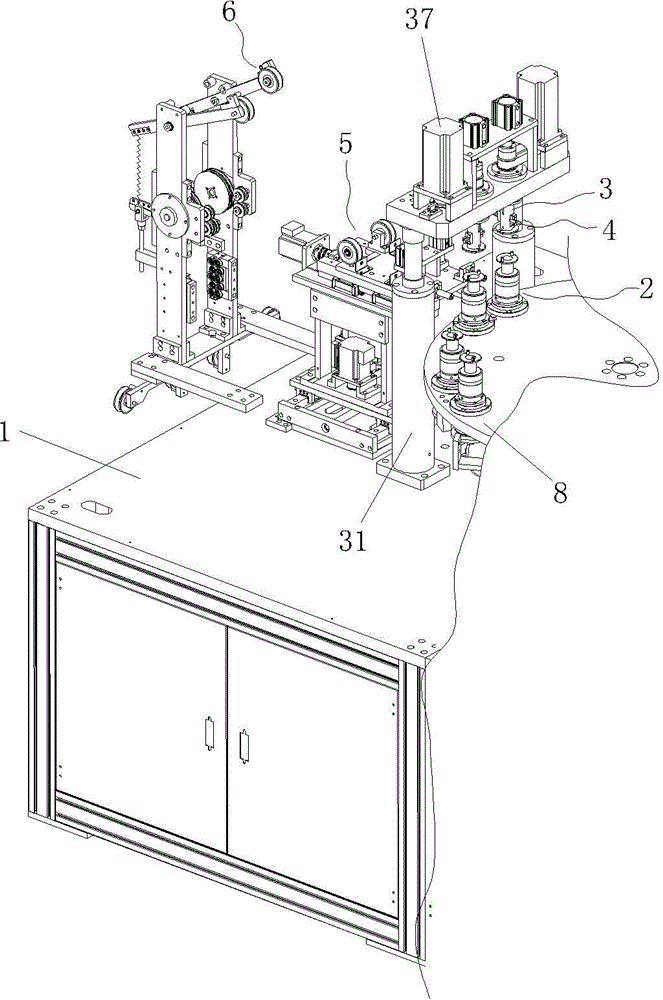

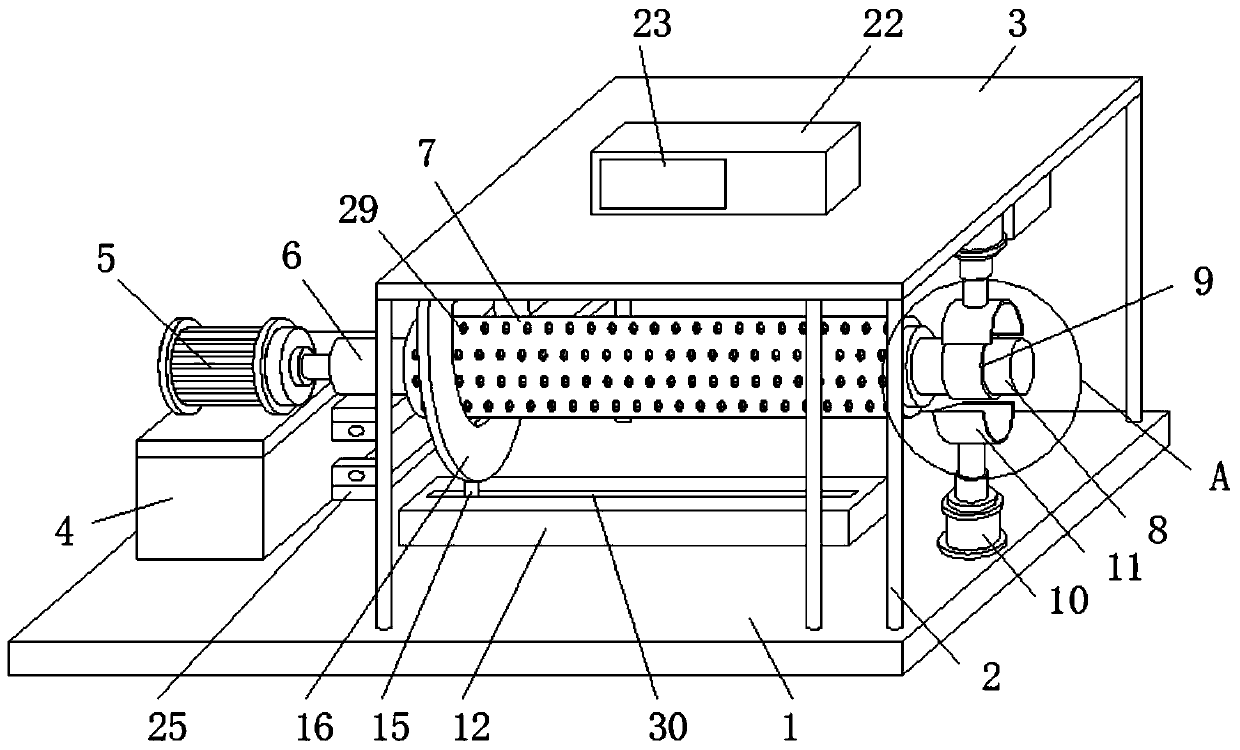

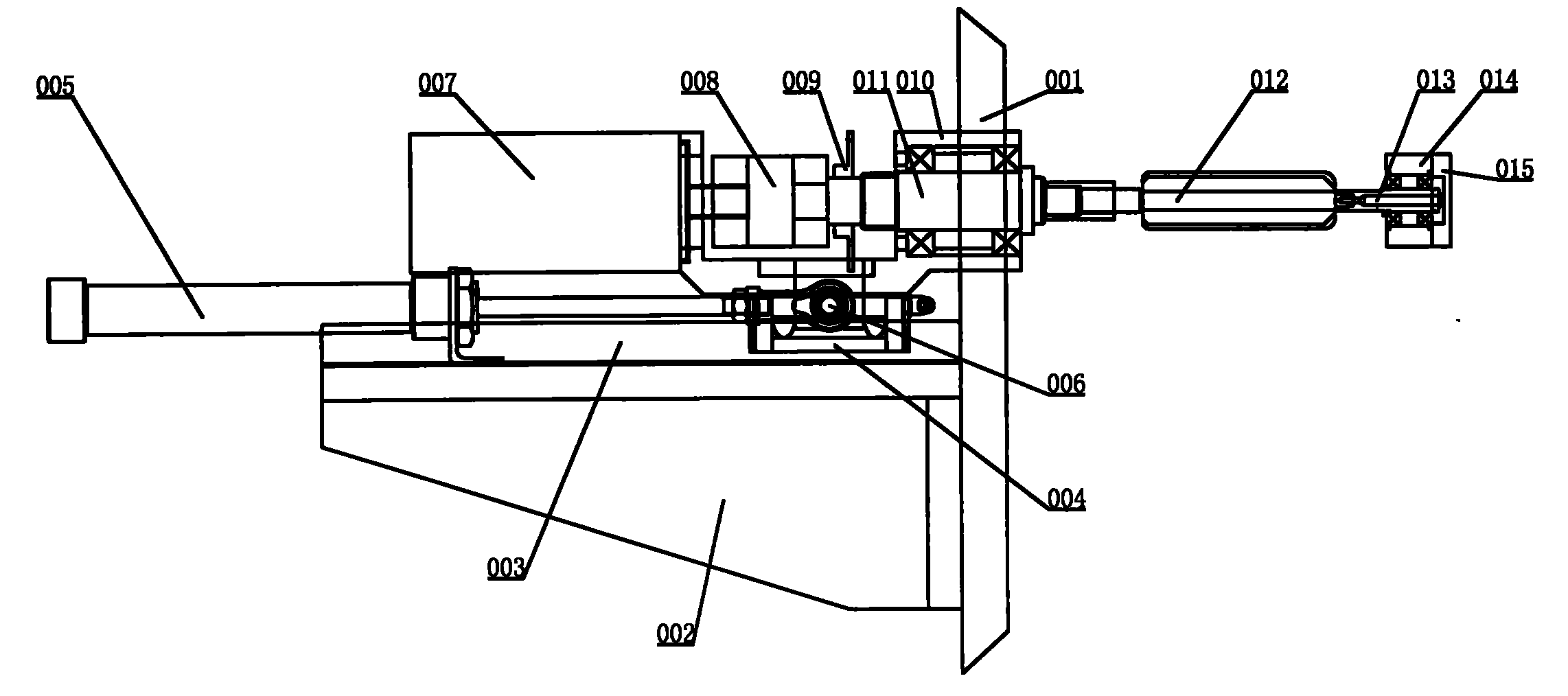

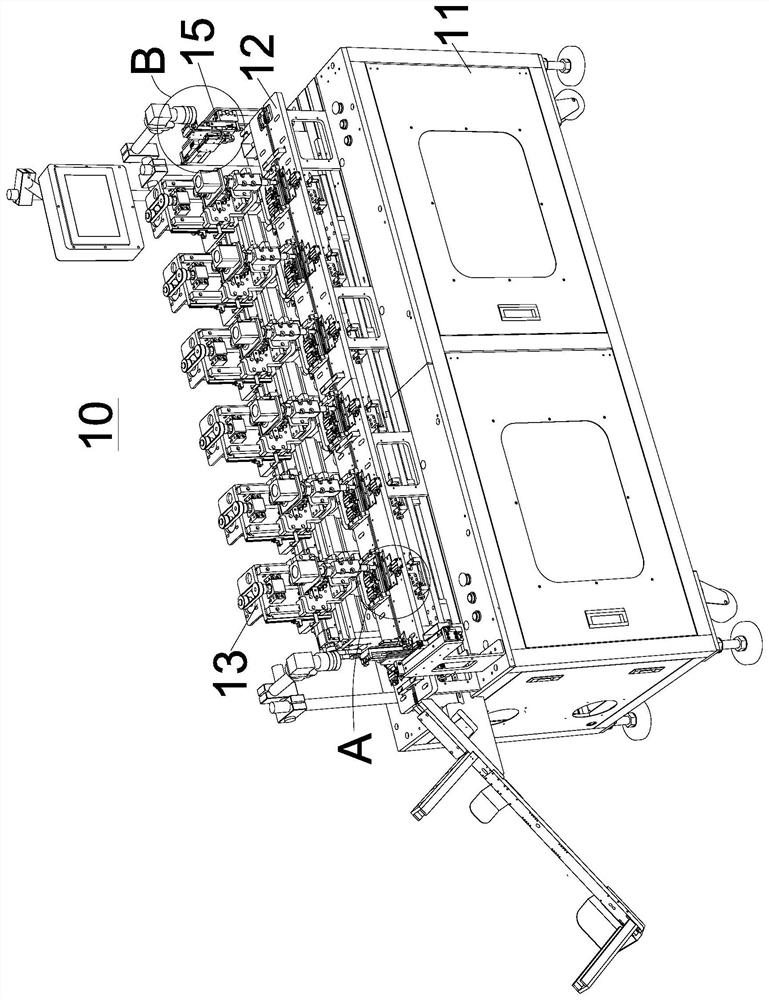

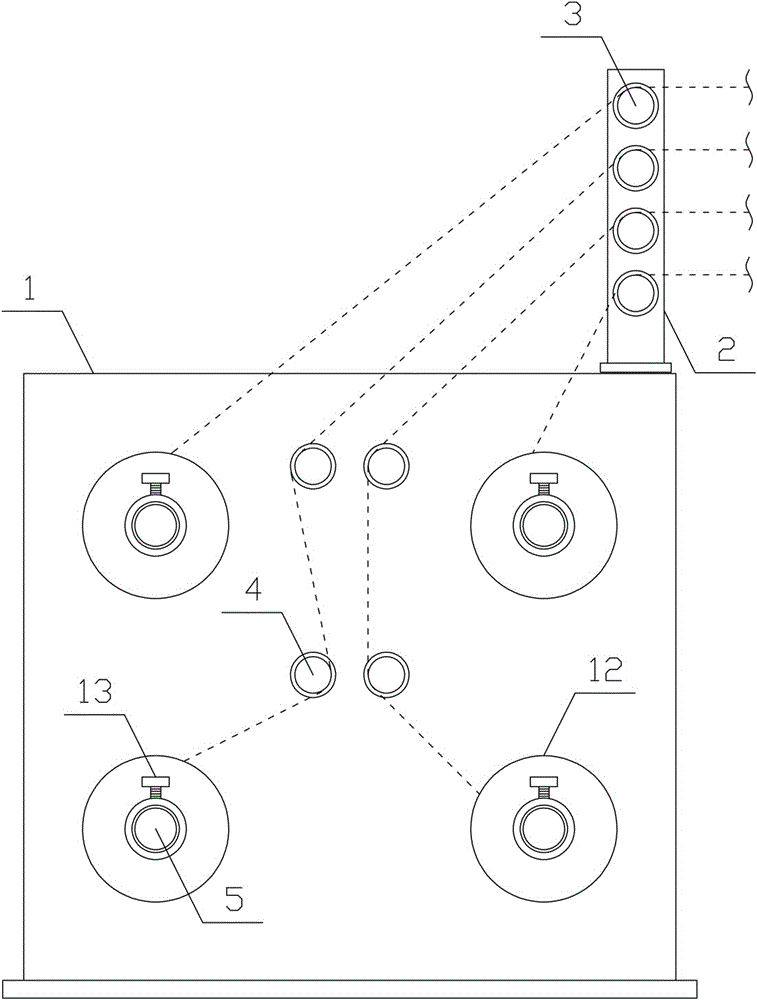

Coil winding machine with parallel winding of multiple coils

ActiveCN102497067AAvoid fluencyAvoid problems such as easy damage to the surface of the wireManufacturing dynamo-electric machinesWinding machineConductor Coil

The invention discloses a coil winding machine with parallel winding of multiple coils. The coil winding machine comprises a rotation coil transmission holder, a rotation tension force apparatus and a flying fork mechanism, wherein, the rotation coil transmission holder is a holder for providing a plurality of coils, the rotation tension force apparatus comprises tension force mechanisms with corresponding quantity and is used for adjusting a tightness degree of each coil in a coiling process, the flying fork mechanism has one or more nozzles for traversing a plurality of coils, and each coilis wound into a stator notch in order. Rotation direction and speed of the rotation coil transmission holder and the rotation tension force apparatus are synchronous with the flying fork so as to avoid that coils are possibly intertwined together in the coiling process. The coil winding machine has the advantages of reasonable structure, smooth coil entry, high coiling efficiency and the like.

Owner:厦门义胜自动化设备有限公司

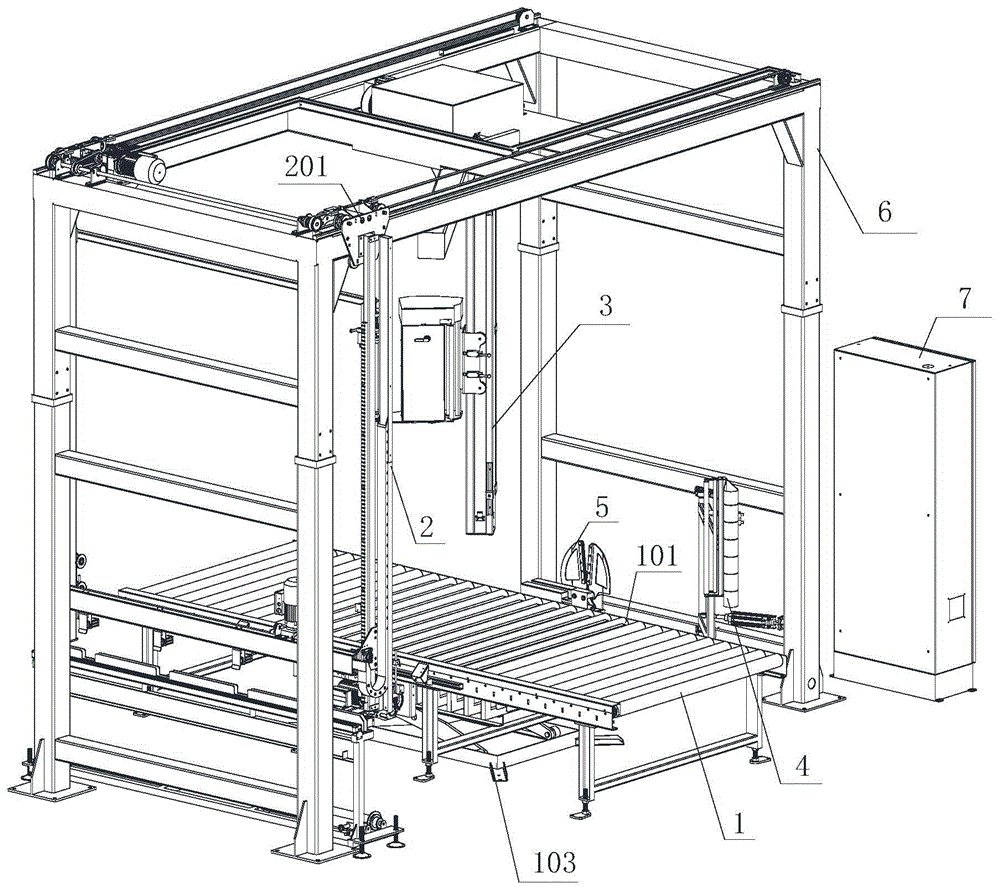

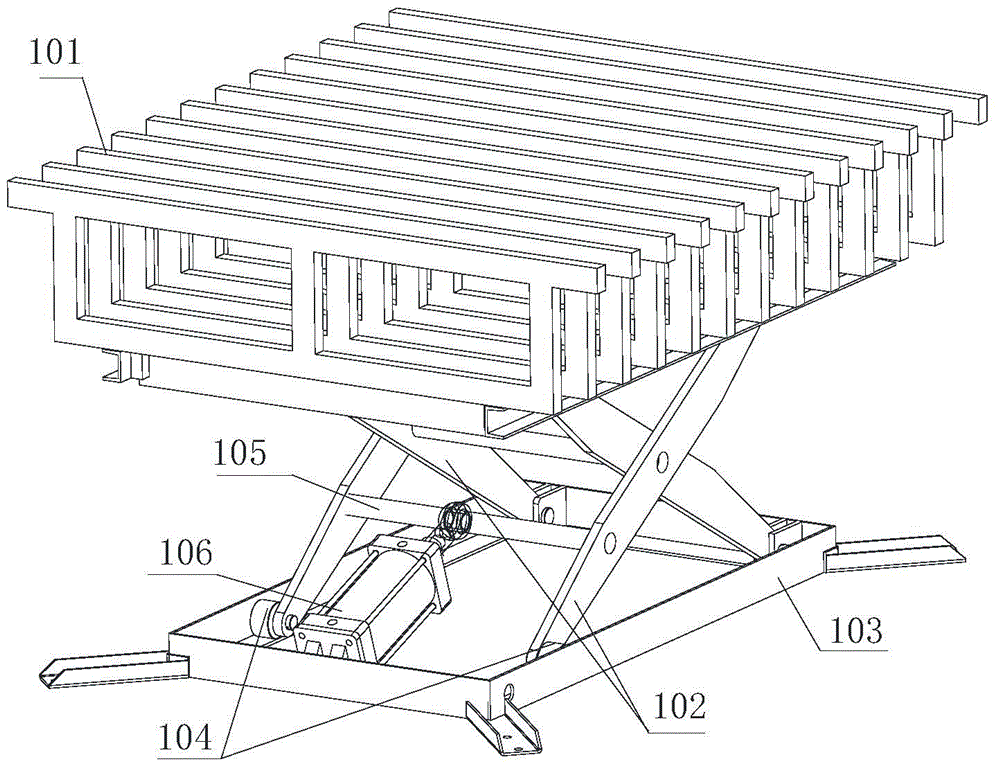

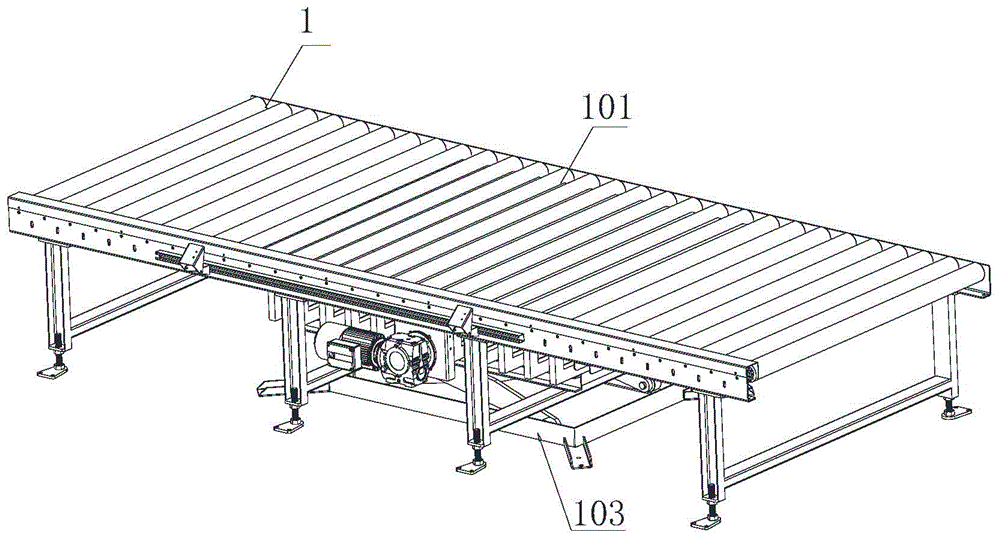

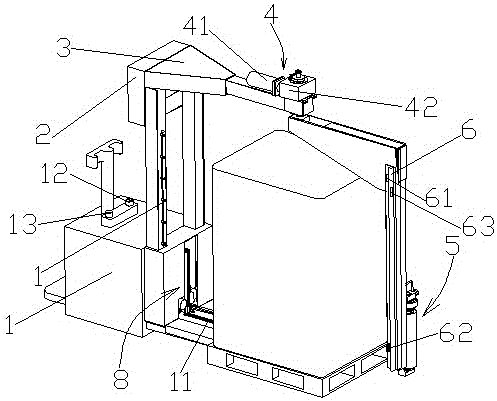

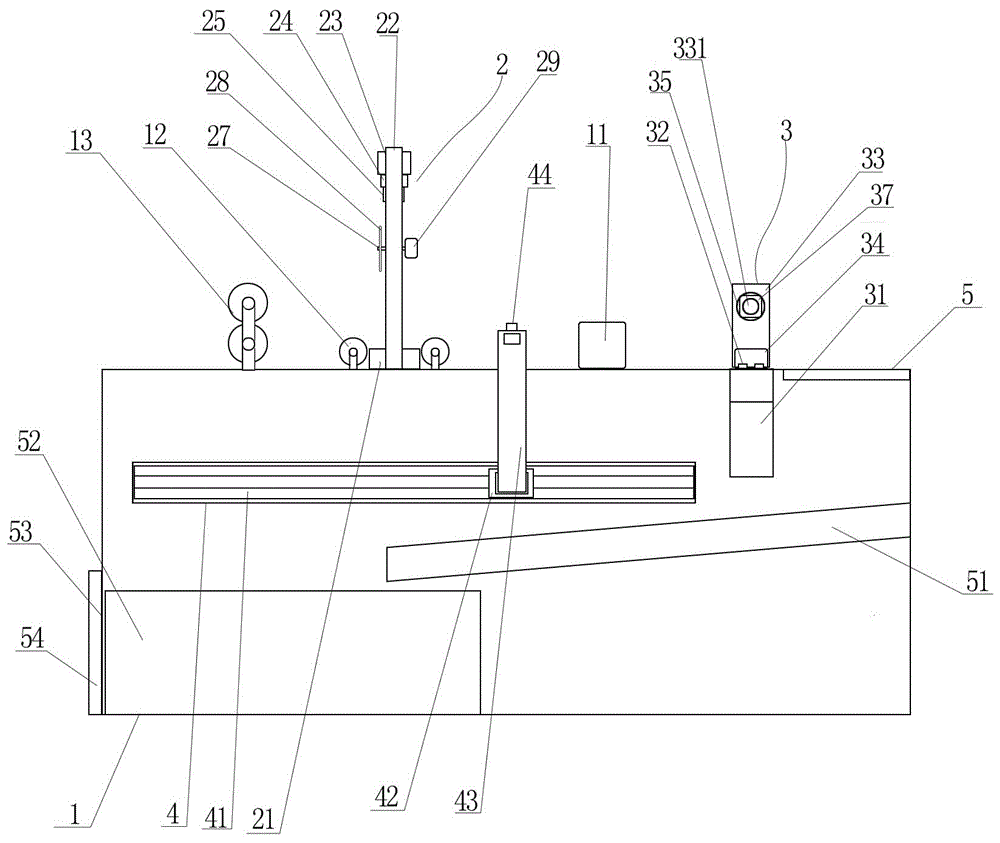

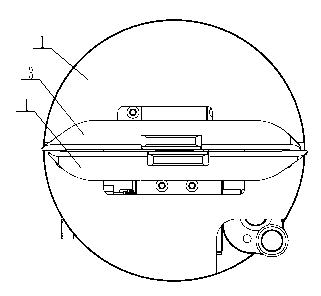

Gantry wrapping machine with jacking platform

InactiveCN104828269AEasy to operateImprove performanceWeb rotation wrappingPackaging machinesEngineeringMechanical engineering

The invention relates to a gantry wrapping machine with a jacking platform, and belongs to the field of product packaging equipment. The gantry wrapping machine comprises a goods conveying line, a gantry frame, a top coating device, and a slewing and winding device. A jacking platform is arranged on the goods conveying line. The jacking platform comprises a grid platform and an adjustable-angle X-shaped bracket. One side of the bottom end of the X-shaped bracket is connected with a base through a rotary connector, and the other side is connected with a sliding wheel sliding in a horizontal track of the base and is connected with a transverse rod which is connected with a telescopic rod of a jacking cylinder fixed to the base. Therefore, the gantry wrapping machine of the invention has the following advantages: (1) the height of goods to be packed can be adjusted as needed, and automatic positioning can be performed according to different heights of products; and (2) film feeding, cutting and hot gluing operations can be completed automatically, and the efficiency of winding and the stability of winding quality are improved.

Owner:武汉市美奇斯机械设备有限公司

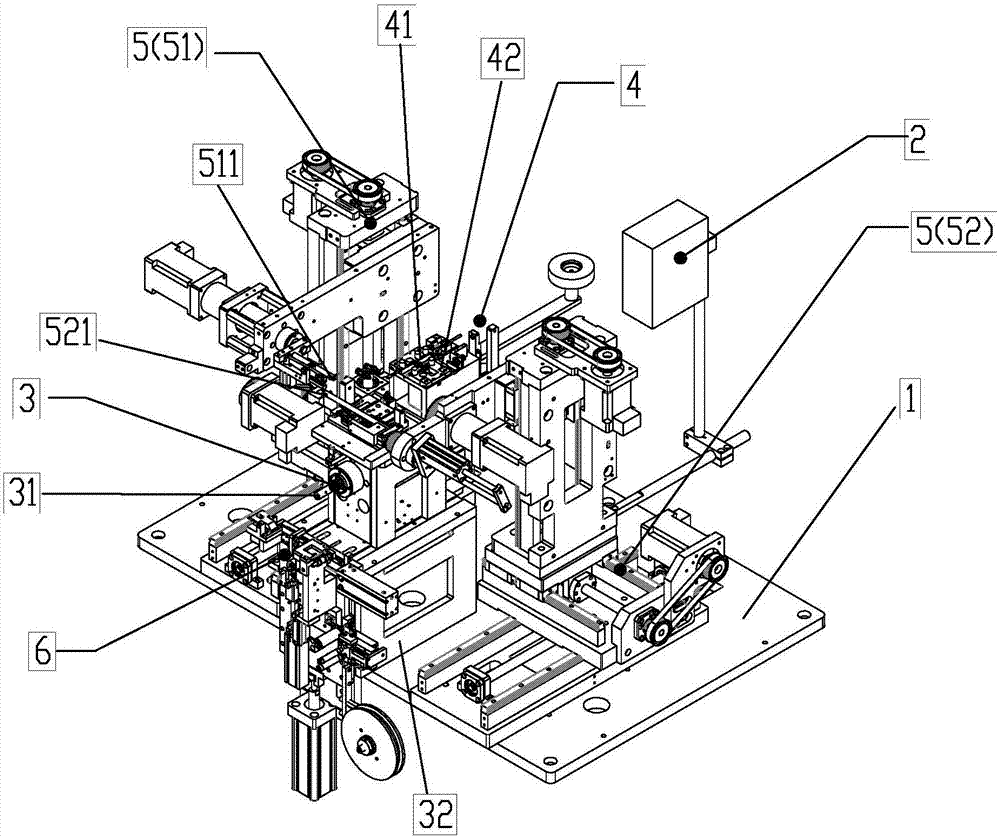

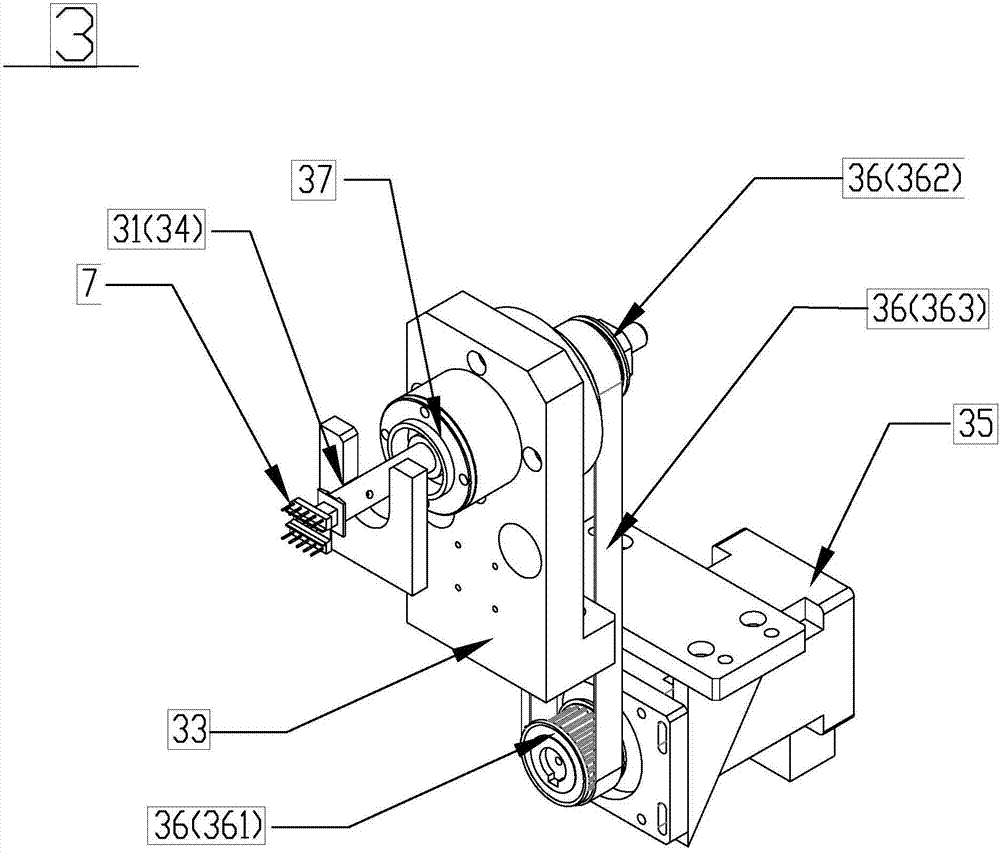

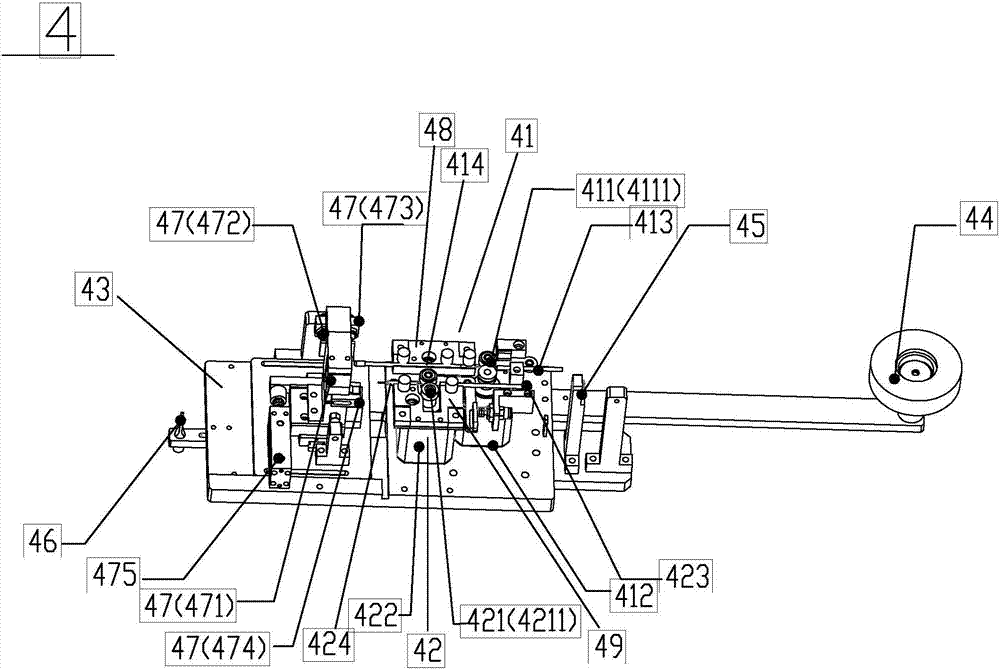

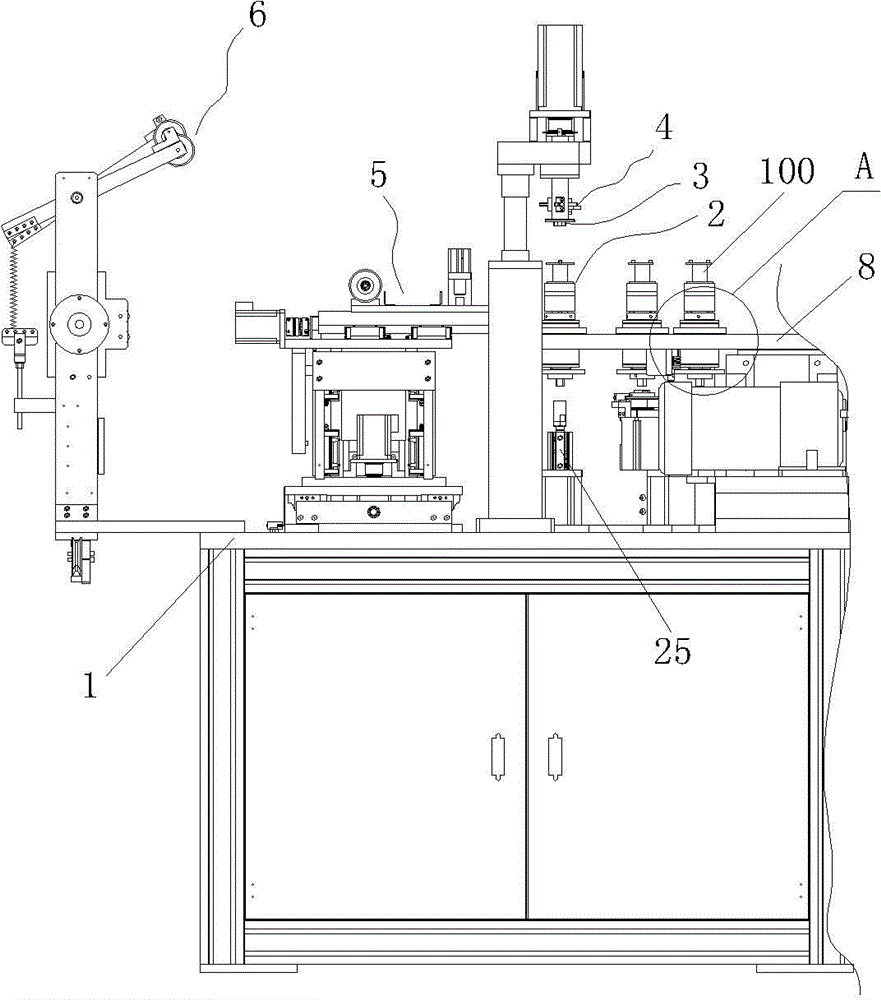

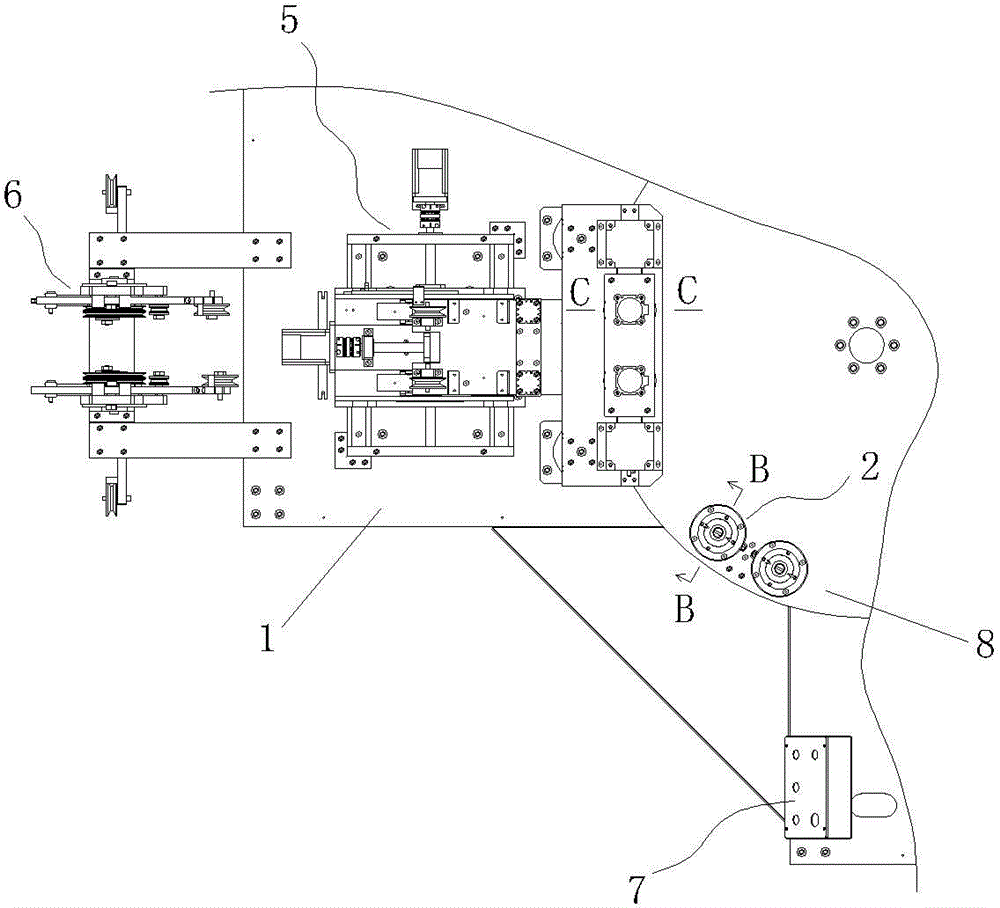

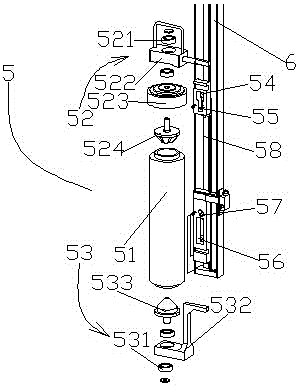

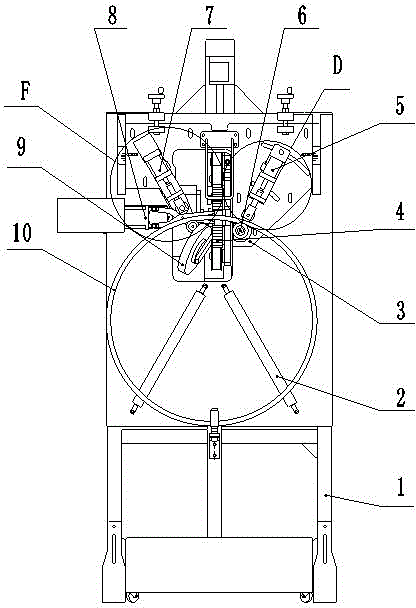

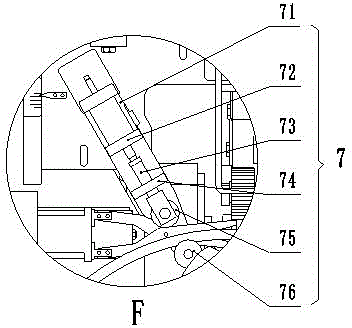

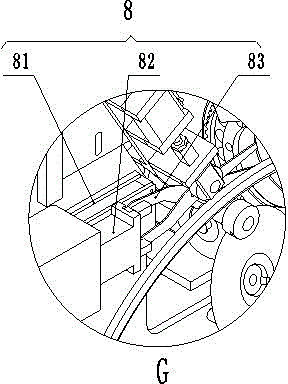

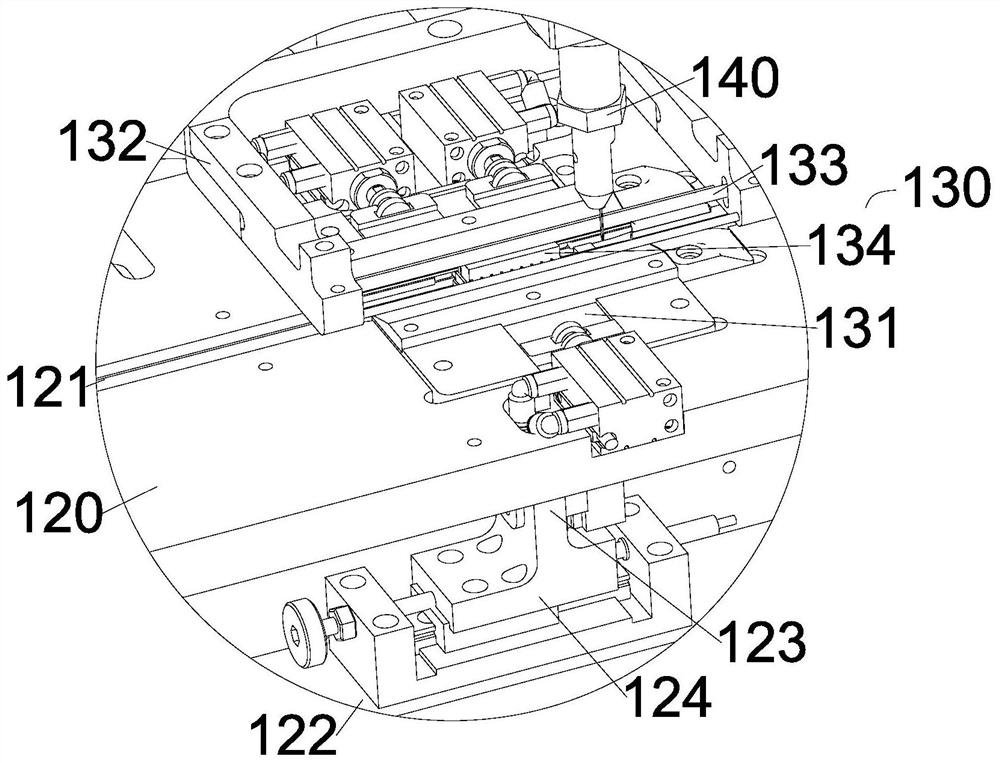

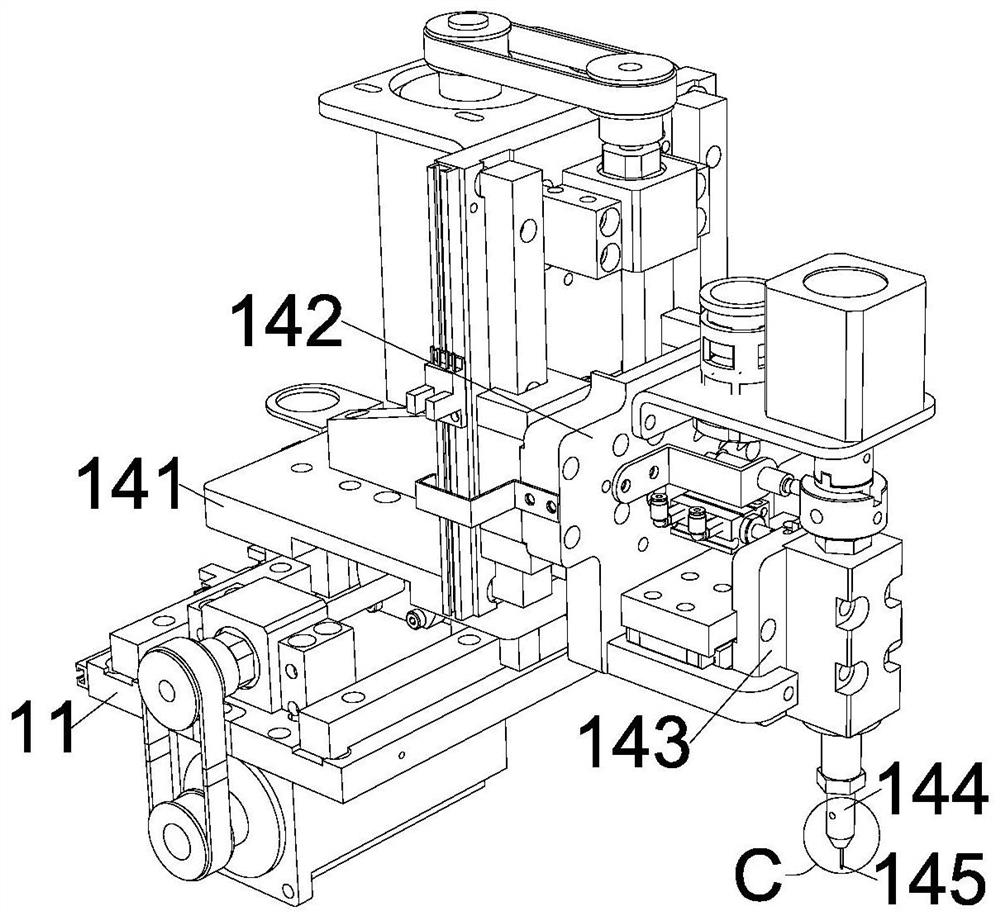

Full-automatic sleeve threading winding machine of electronic transformer

The invention discloses a full-automatic sleeve threading winding machine of an electronic transformer. The full-automatic sleeve threading winding machine comprises an installation platform, a tension mechanism, a main shaft mechanism, a sleeve threading winding mechanism, a winding device and an encapsulation mechanism, wherein the tension mechanism, the main shaft mechanism, the sleeve threading winding mechanism, the winding device and the encapsulation mechanism are arranged on the installation platform, a rotation product fixture is arranged at an end part of the main shaft mechanism, the sleeve threading mechanism comprises a sleeve feeding assembly and a line feeding assembly, the winding device comprises an initial winding mechanism and an end winding mechanism, an initial winding guide needle is movably arranged on the initial winding mechanism and extends to a side edge of the sleeve feeding assembly, and an end winding guide needle is movably arranged on the end winding mechanism and extends to a part above the sleeve threading mechanism. By the full-automatic sleeve threading winding machine, processes such as sleeve threading, sleeve assembled into a groove, twisting, pulling, winding, trimming and encapsulation are integrated on full-automatic equipment, the full-automatic operation process is achieved, action accuracy and precision are high, manual intervention is not needed any longer, and the production efficiency, the product yield and the product consistency are substantially improved.

Owner:SHENZHEN SUNLORD ELECTRONICS +1

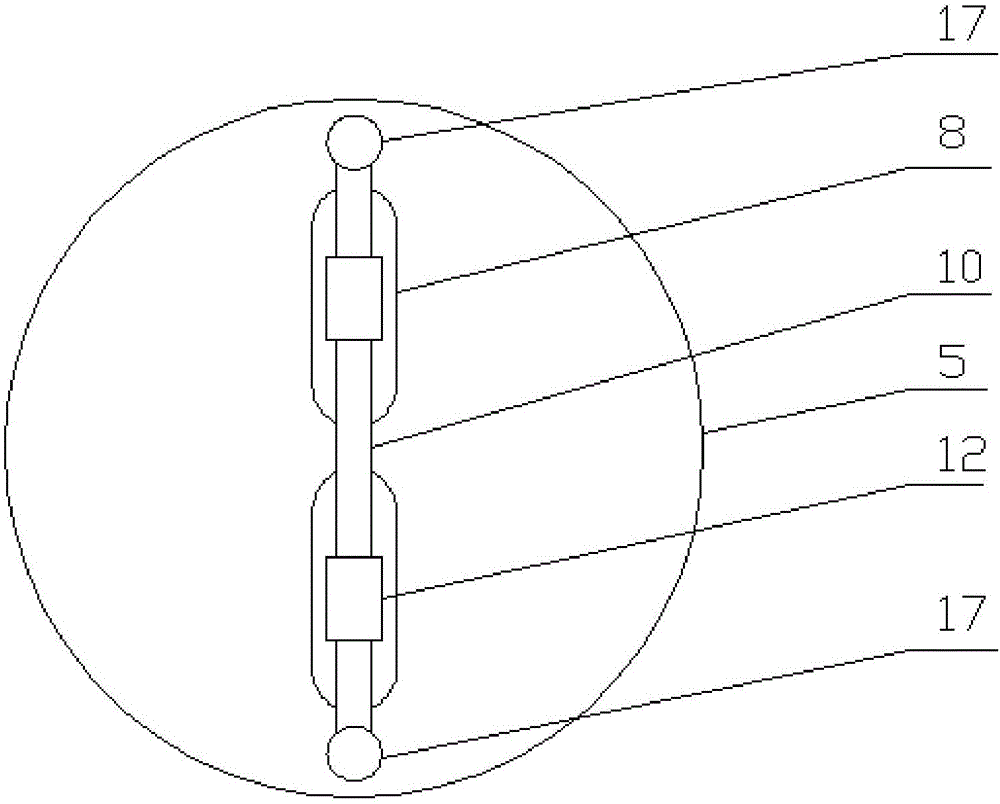

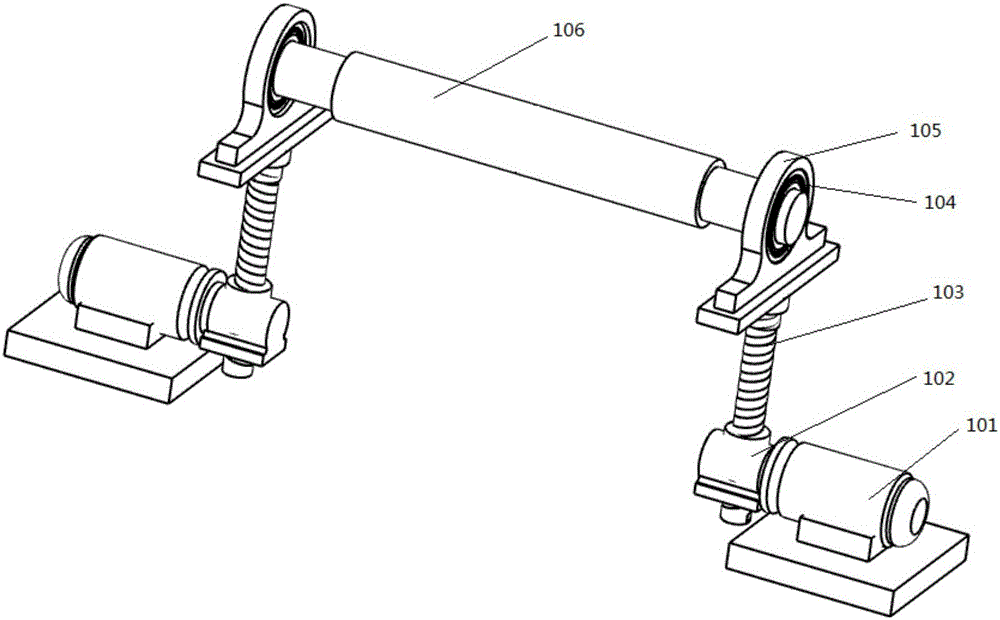

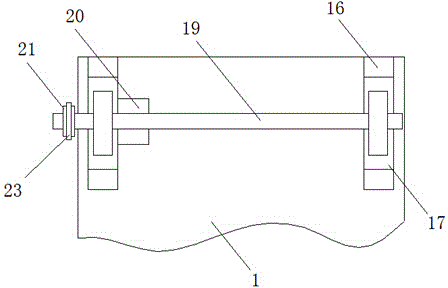

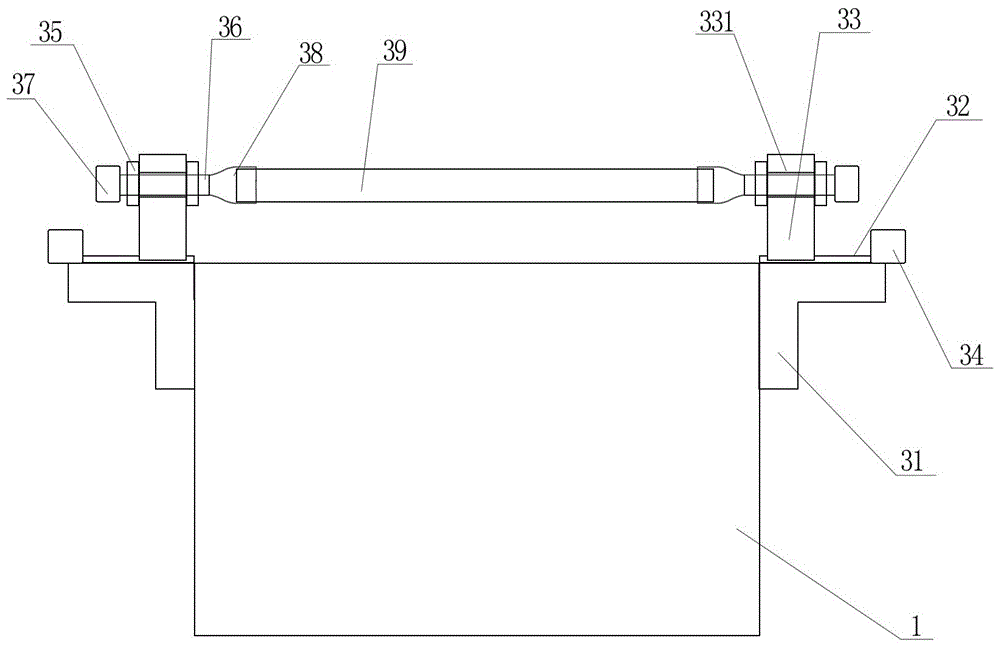

Electric wire and cable winding and unwinding device

ActiveCN105883484AEasy to wrapImprove winding efficiencyFilament handlingElectric machineryConductor Coil

The invention discloses an electric wire and cable winding and unwinding device which comprises a left bottom plate and a right bottom plate, wherein mounting bases are arranged on both of the left bottom plate and the right bottom plate; servo motors are mounted on both of the mounting bases; further, two servo motors are the same in heights but opposite in directions; screw rods are transversely arranged; the electric wire and cable winding and unwinding device also comprises a cable winding and unwinding rack used and matched with side servo motors on a left and a right; the cable winding and unwinding rack comprises a left side plate, a right side plate, and frames which are mounted on an outer side of the left side plate and an outer side of the right side plate. In the electric wire and cable winding and unwinding device, two spools are adopted to hold and wind an electric wire and a cable; the cable is wound on the spools, so that the cable can be held and wound; a certain space exists between the two spools; moreover, two ends of each of the two spools are mounted on loop bars through sleeves; the space between the two spools can be regulated through regulating the positions of the sleeves; after the space is increased, the length of the cable wound on the spools can be increased after the spools are rotated for one revolution each time; the winding efficiency of the cable is improved.

Owner:JURONG FUDA ELECTRIC TECH

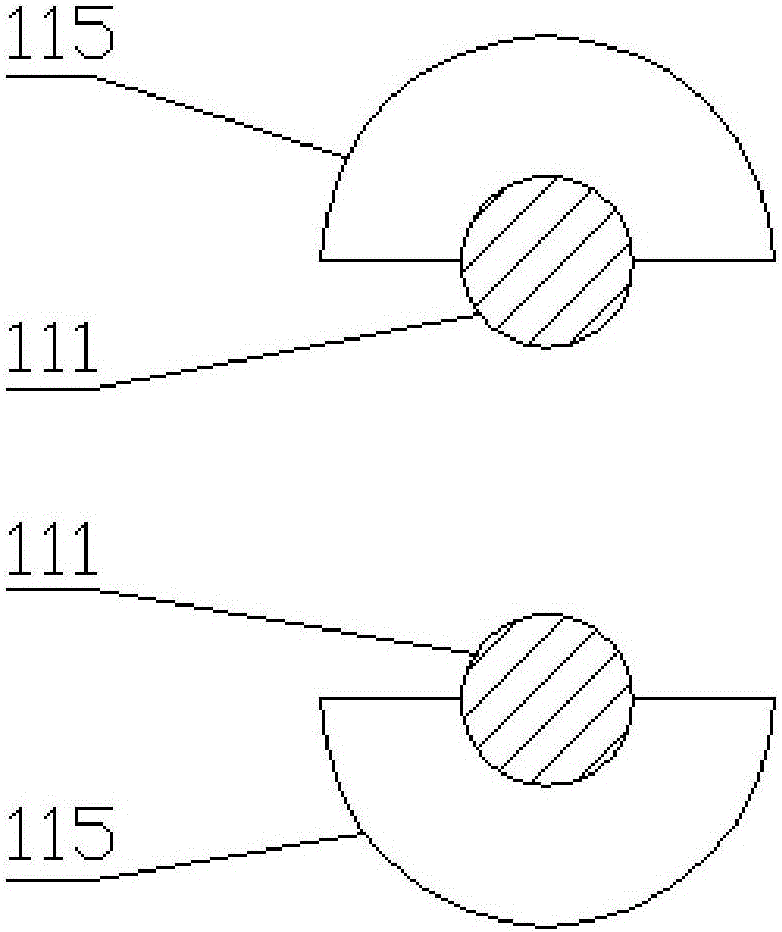

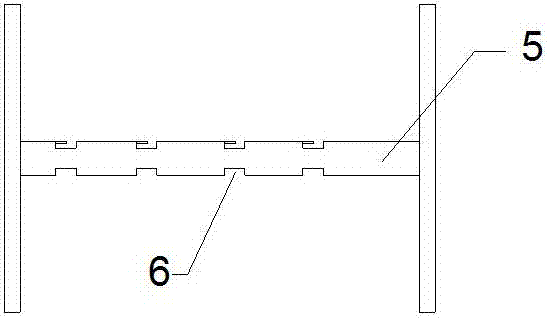

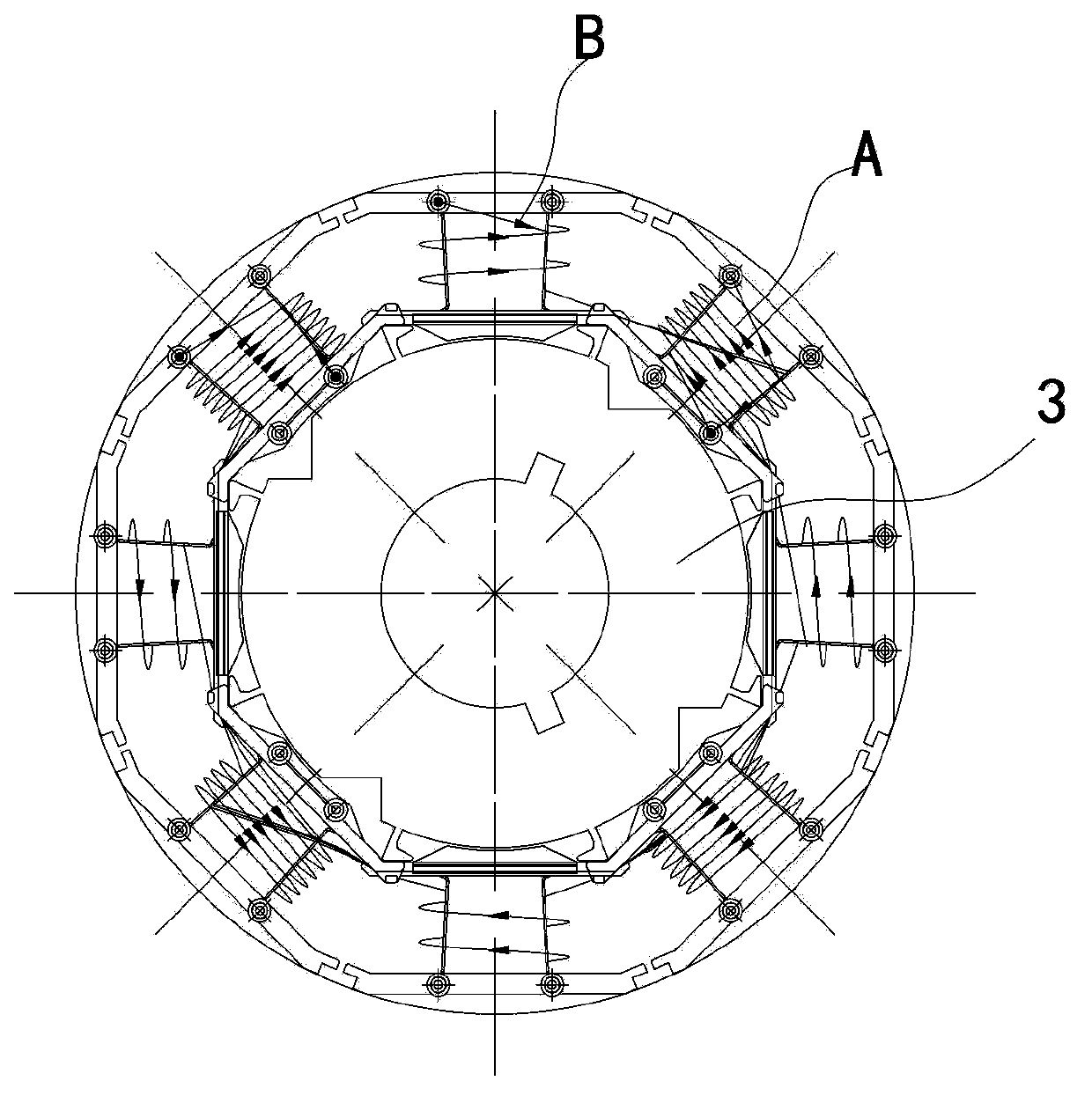

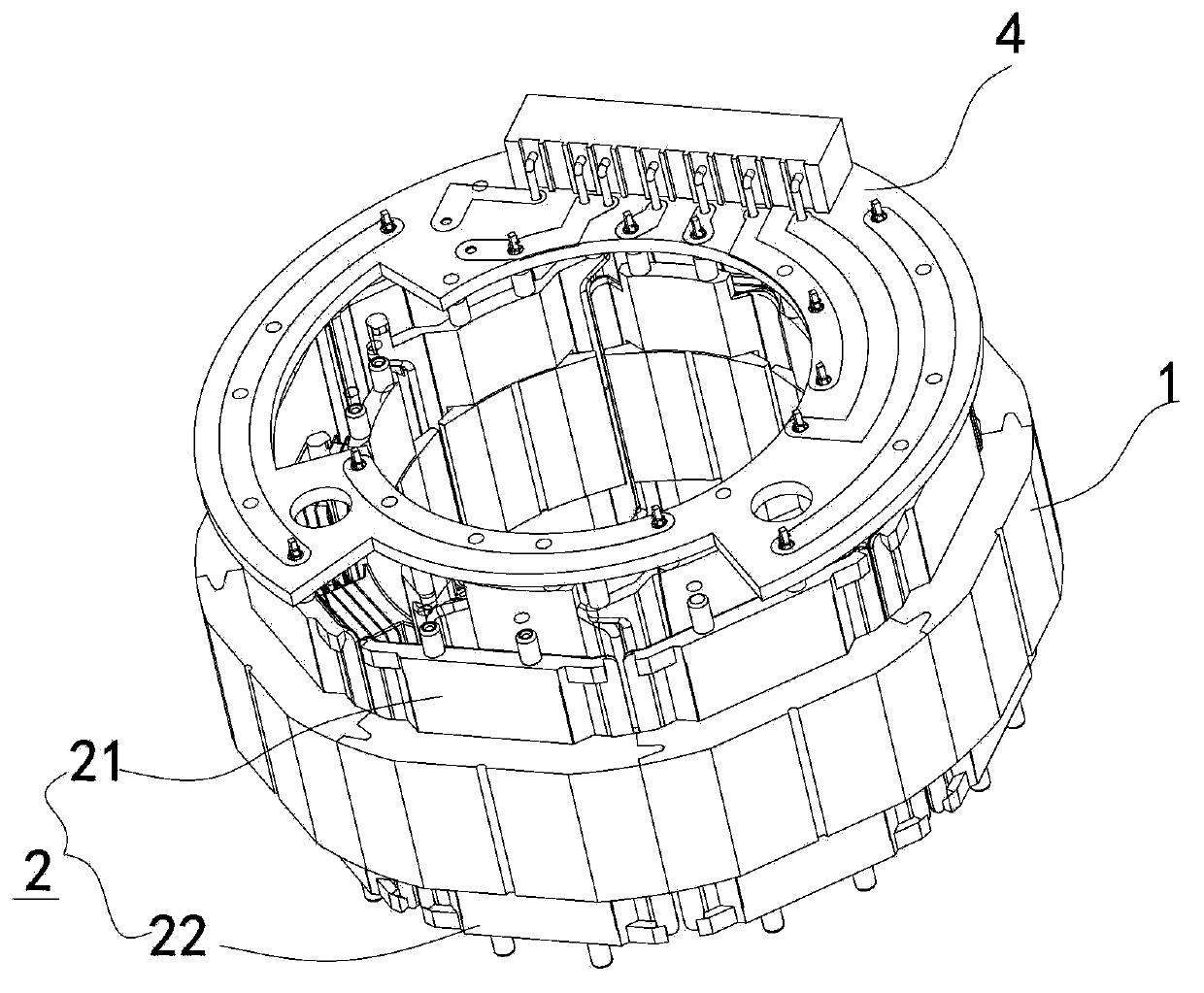

Insulated frame for motor of block stator

ActiveCN102738939AReduce in quantityImprove winding efficiencyWindings insulation shape/form/constructionEngineeringElectrical and Electronics engineering

The invention relates to an insulated frame for a motor of a block stator. The insulated frame is characterized by comprising more than two upper stator insulated frames capable of hanging lines, more than two lower stator insulated frames incapable of hanging the lines, and more than two stator cores, wherein each upper stator insulated frame comprises an upper inner arc wall, an upper outer arc wall, and an upper connecting position connected with the upper inner arc wall and the upper outer arc wall; the two sides of one end of the upper inner arc wall are respectively provided with a threading slope at away from a core pole shoe by a distance H; a line hanging rack is arranged on each threading slope; each lower stator insulated frame comprises an lower inner arc wall, an lower outer arc wall, and a connecting position connected with the lower inner arc wall and the lower outer arc wall; the other ends of the upper inner arc wall and the upper outer arc wall are respectively plugged with the other ends of the lower inner arc wall and the lower outer arc wall in a matching manner; the stator core is sleeved in the place where the upper outer arc wall and the lower outer arc wall are plugged; and the two stator cores adjacent to each other are plugged in a matching manner. With the adoption of insulated frame for the motor of the block stator, the coiling efficiency can be improved by more than three times, the joint amount is reduced, and the production efficiency is improved. The insulated frame for the motor of the block stator has the advantages of smart design, good use performance and use convenience.

Owner:MIDEA GRP CO LTD

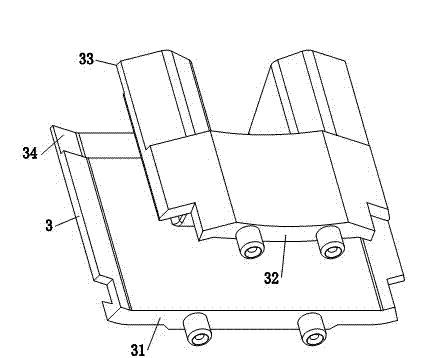

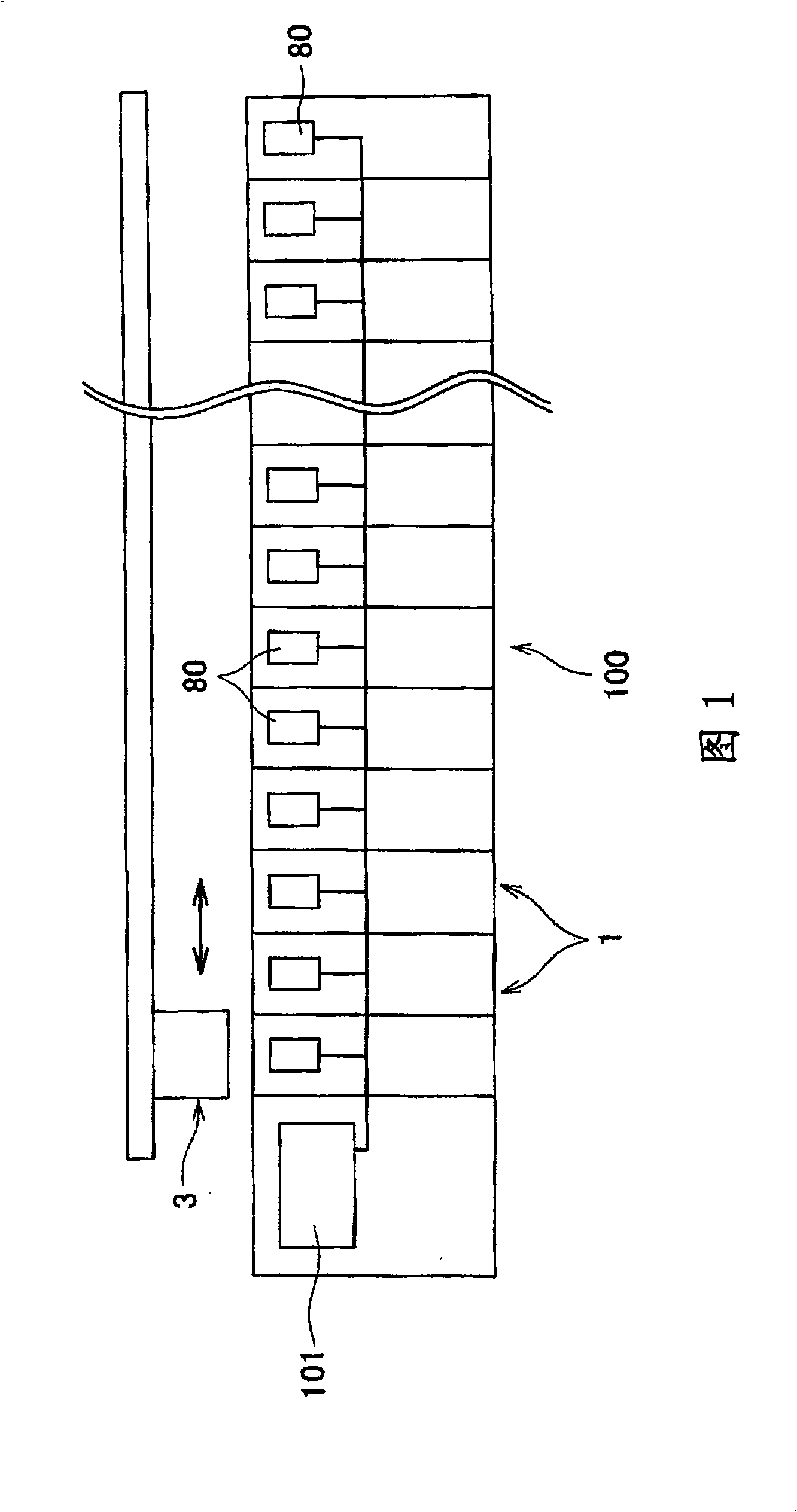

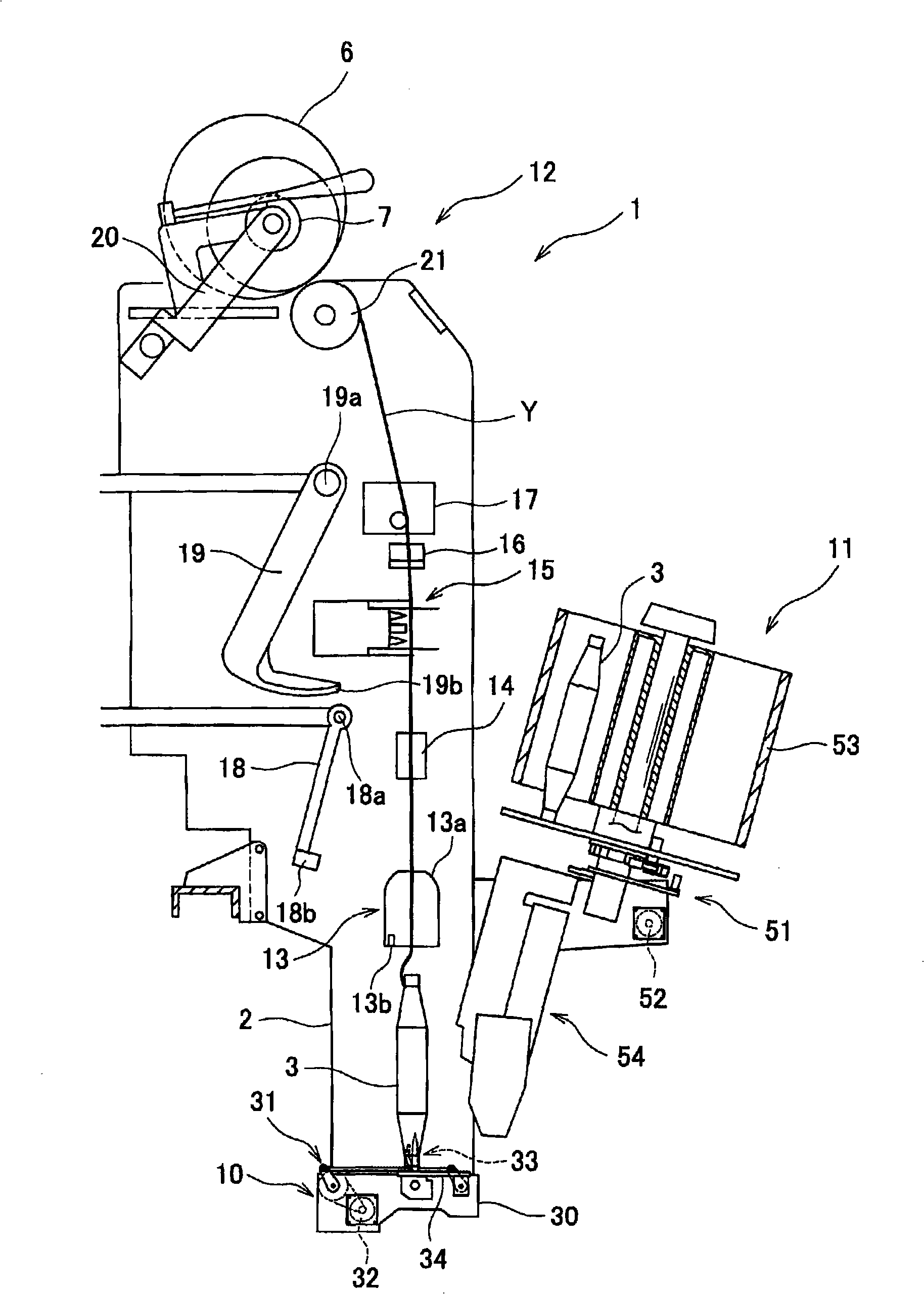

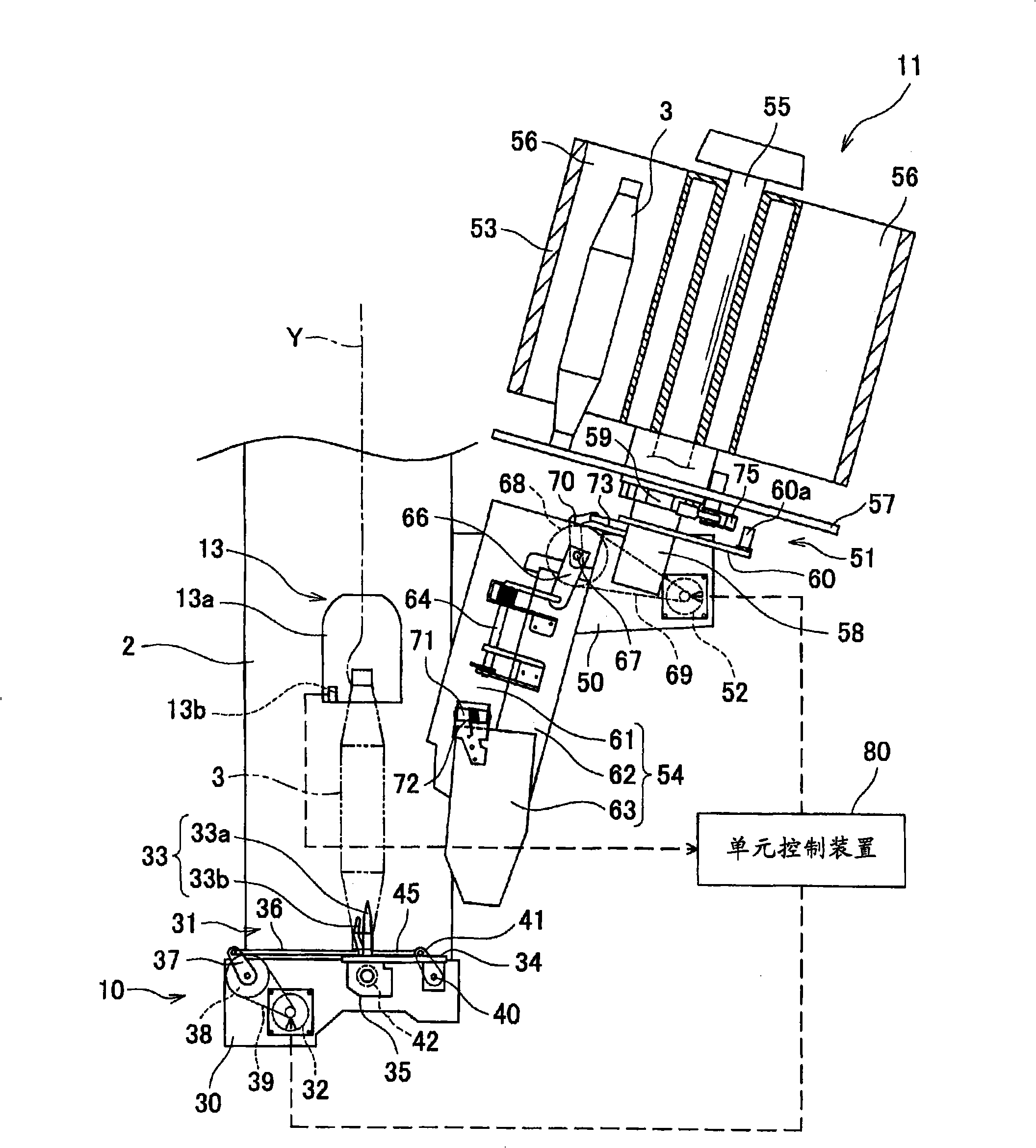

Yarn winding device and textile machine

The present relates to a yarn winding devcie and a fibre machanism. A winding unit 1 includes a yarn supplying portion 10 having a bobbin holding and discharging mechanism 31 holding a bobbin 3 from which a yarn Y is unwound and discharging the unwanted bobbin 3 and a first driving motor driving the bobbin holding and discharging mechanism 31, a bobbin supplying portion 11 having a supply mechanism 51 including a magazine 53 that accommodates a plurality of the bobbins 3 and supplying one of the plurality of bobbins 3 accommodated in the magazine 53 to the yarn supplying portion 10 and a second driving motor 52 driving the supply mechanism 51, a winding portion winding the yarn Y unwound from the bobbin 3 held by the bobbin holding and discharging mechanism 31, around a winding tube, and a unit control device 80 independently controlling the first driving motor 32 and the second driving motor 52.

Owner:MURATA MASCH LTD

Power cable winding device

InactiveCN108275512AAvoid slackGuaranteed cleanlinessFilament handlingCleaning using toolsBristlePower cable

The invention discloses a power cable winding device. A worm is meshed with a worm wheel, the worm wheel is fixedly connected with a take-up roller, and the worm wheel and the take-up roller are connected with a device body in a rotating mode; a wire inlet is formed in the left side of the device body, extrusion wheels are arranged on the upper portion and the lower portion of the right side of the wire inlet, the lower ends of the extrusion wheels are rotationally connected with a transverse plate, the transverse plate is fixedly connected with the device body, the upper ends of the extrusionwheels are connected with the lower end of a screw rod in a rotating mode, the left side of the screw rod is connected with a sliding groove in a sliding mode, the sliding groove is fixedly connectedwith the side wall of the device body, and the upper end of the screw rod is in threaded connection with a sleeve. The device drives the worm wheel and the take-up roller to rotate through rotation of the worm, and the left and right movable piston plates spray water in a water spraying cavity out of a spray head to clean a cable, and meanwhile, a rotating cleaning barrel drives bristles inside the cleaning barrel to further clean and dry the cleaned cable. The device is reasonable in structural design, and high in automation, and greatly improves the winding efficiency of the cable, achievesthe cleaning function, guarantees the cable cleaning, and reuses the cable.

Owner:山东博发智能科技有限公司

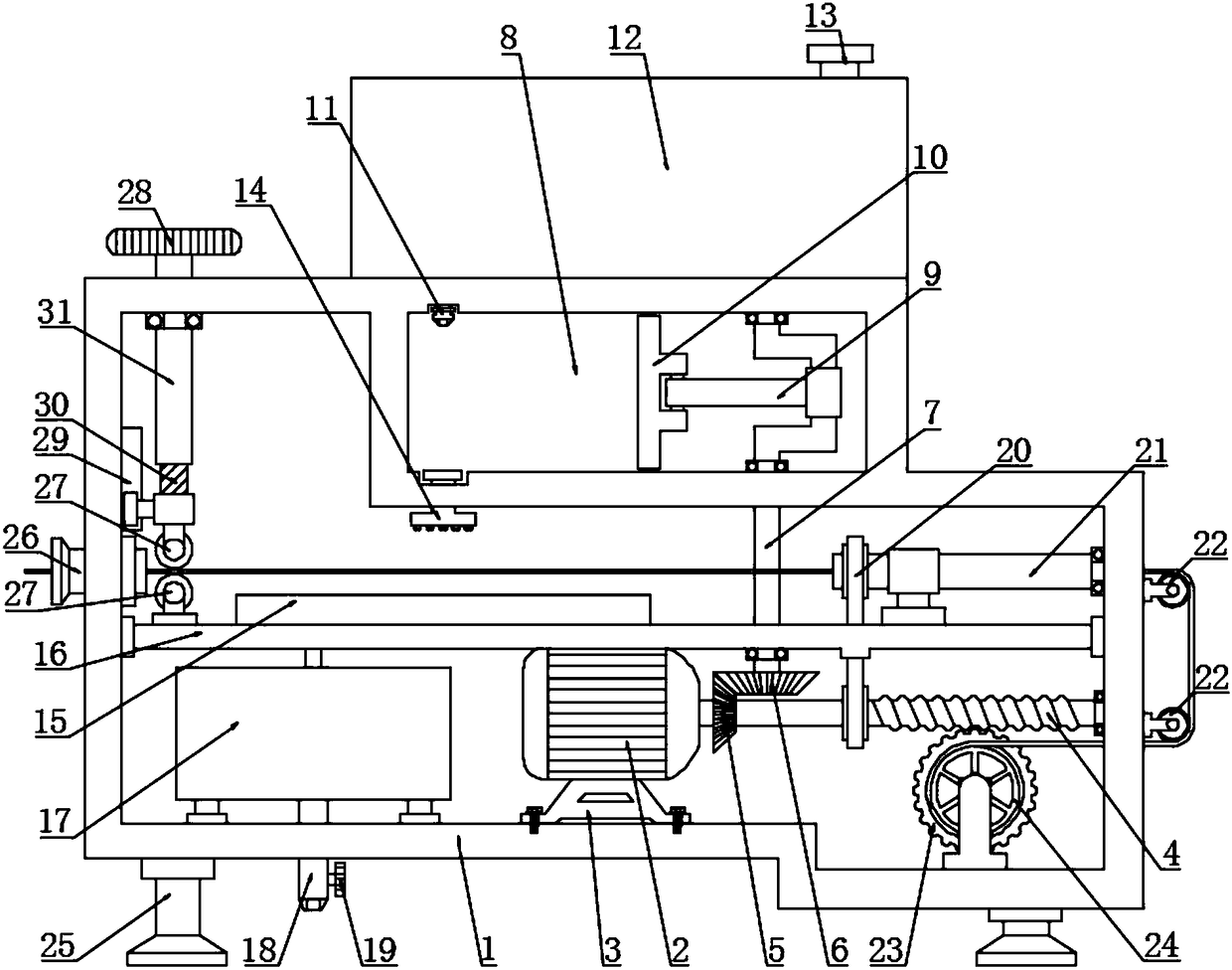

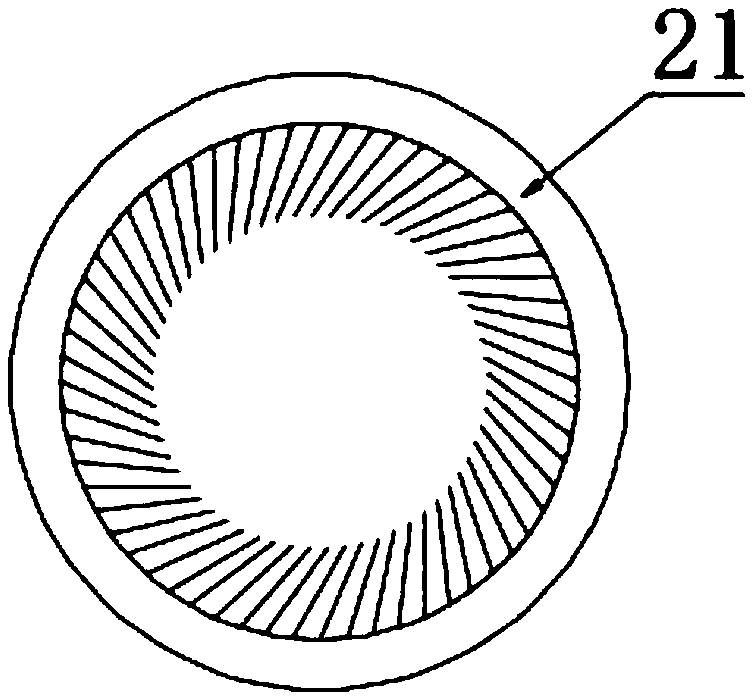

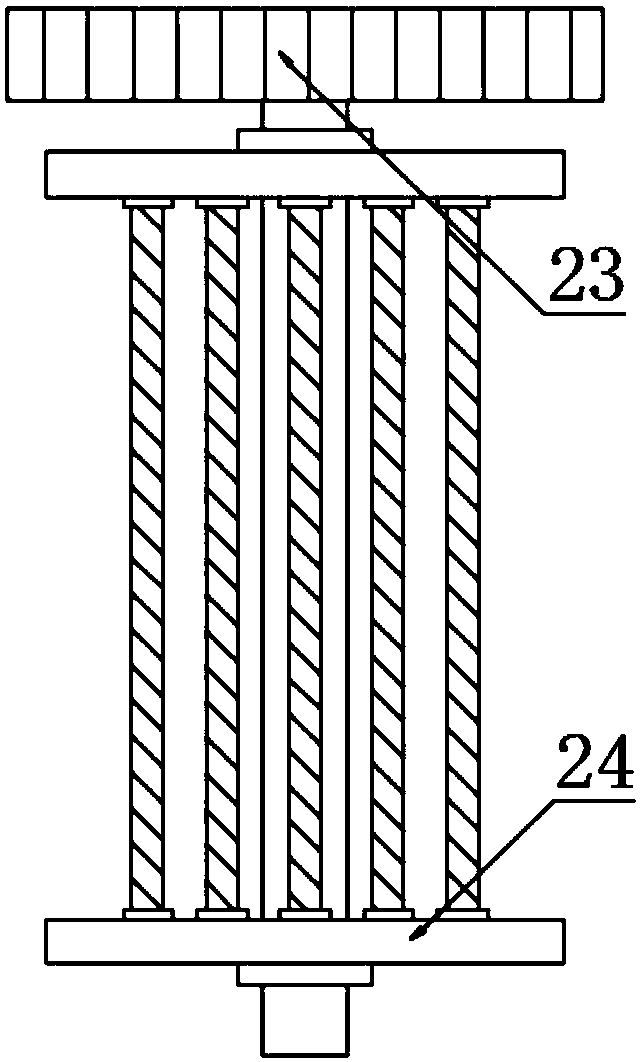

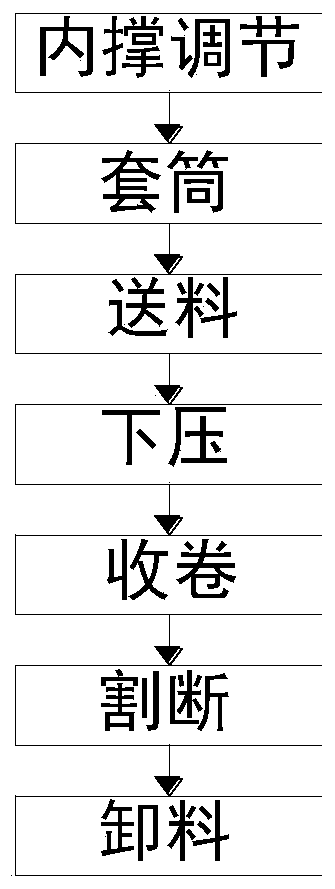

Plastic thin film preparing and coiling method

The invention relates to a plastic thin film preparing and coiling method, in particular to a plastic thin film preparing and coiling device. The device comprises a base, a feeding mechanism for conveying a plastic thin film, an intermittent rotation mechanism, four internal supporting mechanisms for internally supporting and clamping a paper tube, a press rolling mechanism for pressing the plastic thin film down, a coiling driving mechanism for driving the paper tube ro rotate to coil the thin film, and a film cutting mechanism used for cutting a plastic thin film belt off. The device involved in the method can be suitable for coiling the plastic thin film on the paper tubes with different internal diameters, continuous coiling operation can be completed at a batch, unnecessary repetitiveoperation is avoided, and the plastic thin film coiling efficiency is improved.

Owner:扬州晟至宝新材料科技有限公司

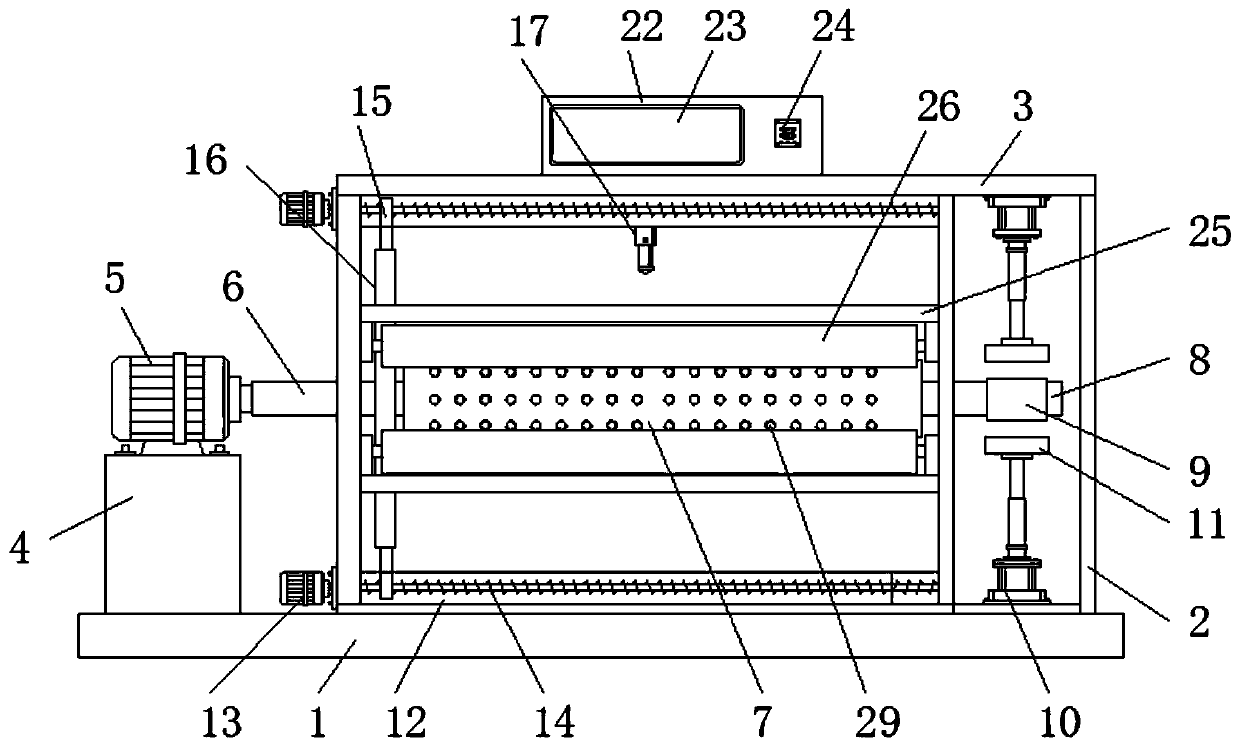

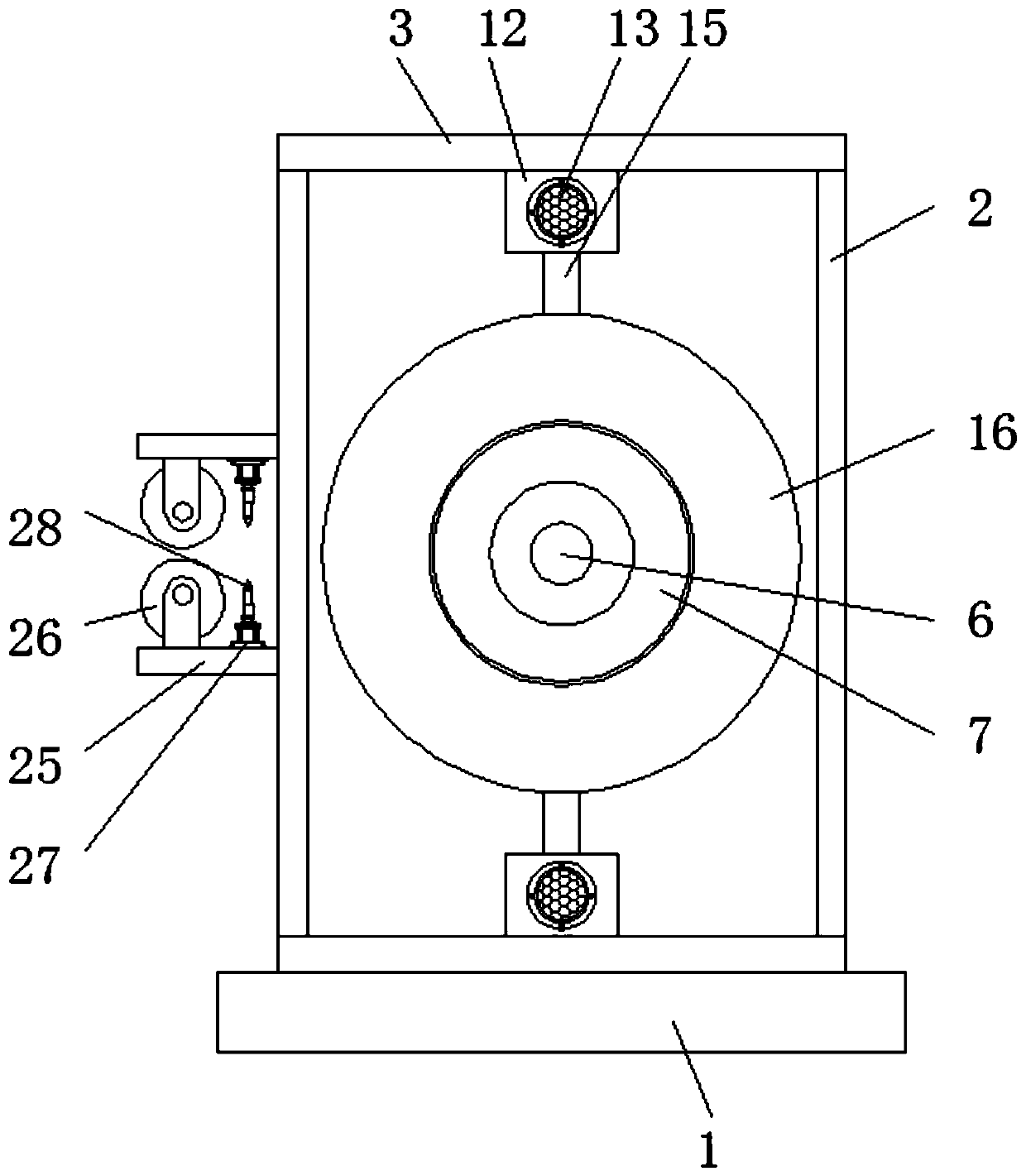

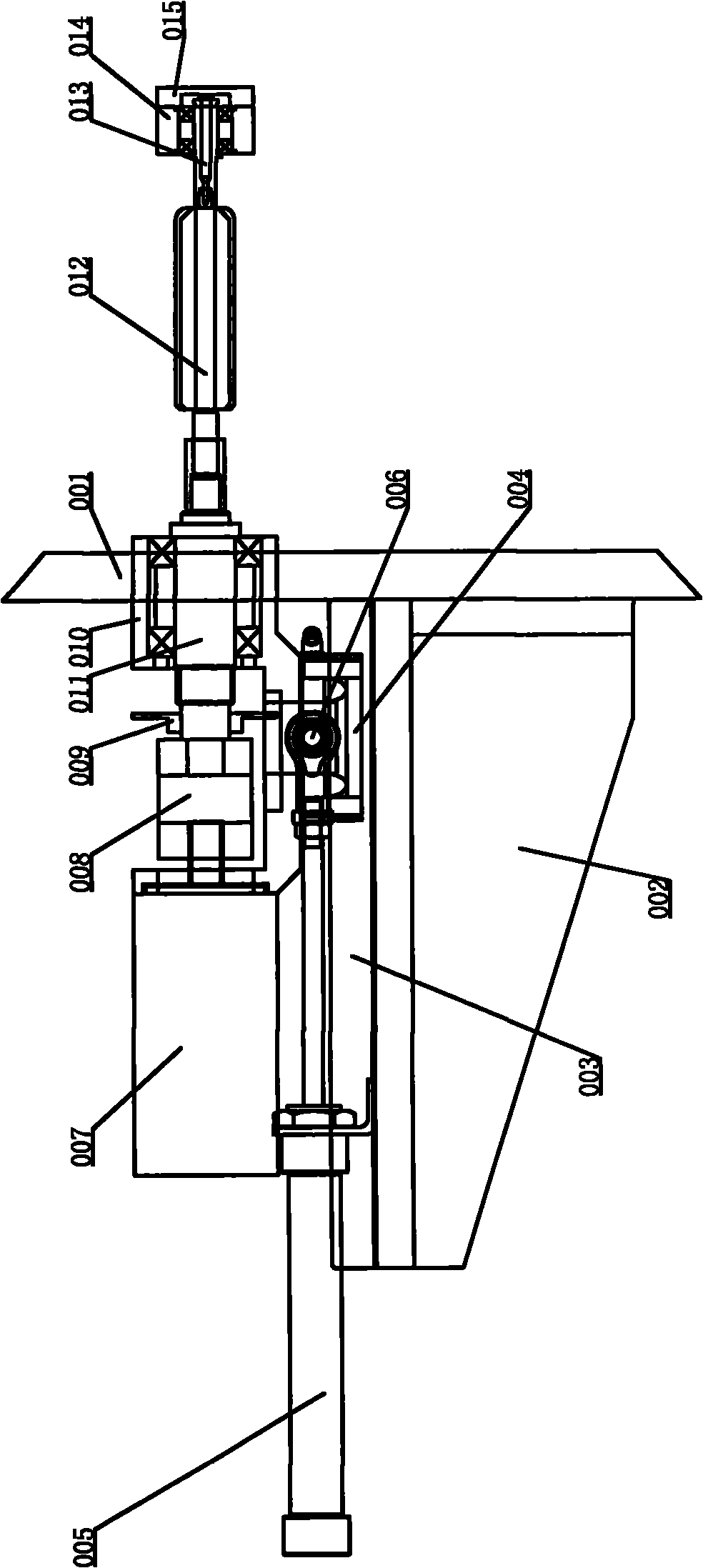

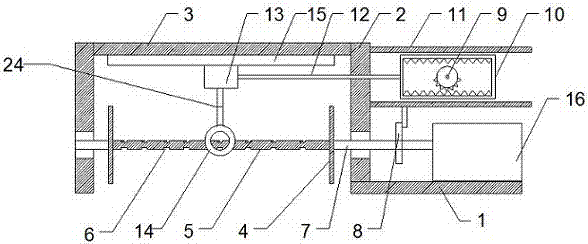

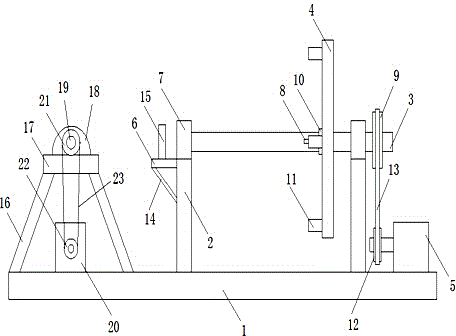

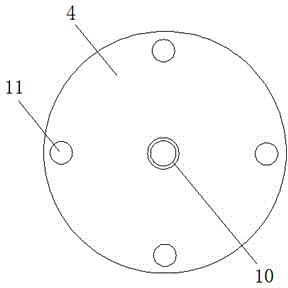

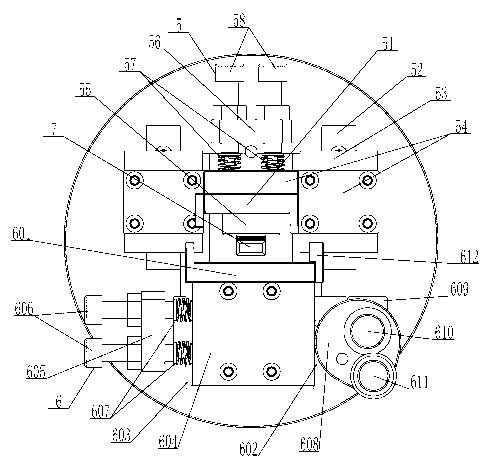

Vertical electromagnetic coil winding device

ActiveCN102982998AReduce waiting timeImprove winding efficiencyCoils manufactureDrive shaftElectric control

The invention discloses a vertical electromagnetic coil winding device. The device comprises a machine base, wherein a clamp mechanism of a coil framework, a driving mechanism for the rotation of the coil framework, a clamping and cutting mechanism of an enamelled wire, a three-coordinate moving mechanism, a tension mechanism and an electric control system are sequentially arranged on the machine base; the clamp mechanism comprises a rotating shaft which is vertically arranged; a positioning base of the coil framework is arranged on the upper end of the rotating shaft; the driving mechanism comprises a driving shaft which is vertically arranged and can be connected with the clamp mechanism to drive the coil framework to rotate; the clamping and cutting mechanism comprises a fixed clamping plate, a moveable clamping plate, a fixed cutter and a moveable cutter; the three-coordinate moving mechanism comprises a moveable base which can freely move along the horizontal direction, the longitudinal direction and the vertical direction; a wire guide pipe is arranged on the moveable base; and the clamp mechanism can be arranged on a rotating disc which can intermittently rotate. The device is high in winding efficiency, does not generate excessive wire heads in a continuous coiling process and is particularly suitable for winding an electromagnetic coil with a larger size.

Owner:XIAMEN METEOR WINDING TECH

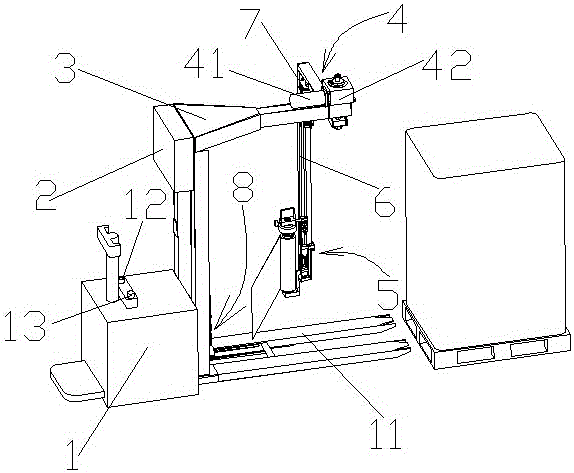

Mobile film winding machine

PendingCN105775196AControllable tensionIncrease profitWrapping material feeding apparatusWeb rotation wrappingWinding machineMotor drive

The invention discloses a mobile film winding machine which comprises a forklift body, an electric cabinet, a fixed support frame, a rotating mechanism, a film tension control mechanism, a film up-and-down moving frame, a film up-and-down moving motor and a film cutting and pressing mechanism, wherein the rotating mechanism is arranged at the tail end of the fixed support frame; the film up-and-down moving frame is movably arranged on the fixed support frame; the film tension control mechanism is arranged on the film up-and-down moving frame; the film up-and-down moving motor drives the film up-and-down moving frame to rise and fall; and the film cutting and pressing mechanism is arranged on the fixed support frame. According to the mobile film winding machine, a mobile forklift is adopted, a film is rotated upwards and wound around cargo through the rotating mechanism and a lifting mechanism, the winding efficiency is high, and the use of the mobile film winding machine is not limited and is convenient; manual operation is not needed, so that the labor intensity of workers is low, and the labor cost is saved; the film tension is controllable, the packing effect is better, and the cargo cannot become loose easily; the cargo does not need to be rotated, so that a great amount of electric energy is saved; and meanwhile, the height of the cargo is detected through photoelectricity, the utilization ratio of the film is high, and the use cost of the film is low.

Owner:北京小棉医药有限公司

Controllable-take-up-diameter take-up device facilitating automatic unloading

The invention discloses a controllable-take-up-diameter take-up device facilitating automatic unloading. The take-up device comprises a base. Six supporting rods are symmetrically arranged on the topof the base, a top plate is arranged at the top ends of the six supporting rods, a supporting seat is arranged at the position, close to one sides of the six supporting rods, of the outer wall of oneside of the base, and the top of the supporting seat is fixedly connected with a drive motor through a bolt. According to the controllable-take-up-diameter take-up device facilitating automatic unloading, supporting during take-up and opening during unloading can be achieved through lifting type arc-shaped plates, blocking of materials during unloading is effectively avoided while it is guaranteedthat rotation of a take-up roller is stable and balanced, the materials can be pushed out of the take-up roller in the horizontal direction through a horizontally-moving unloading ring, thus, automatic unloading is achieved, the trouble of manual repeated disassembly unloading is avoided, the machining continuity of the take-up device is guaranteed, and the take-up efficiency is improved.

Owner:马鞍山致青工业设计有限公司

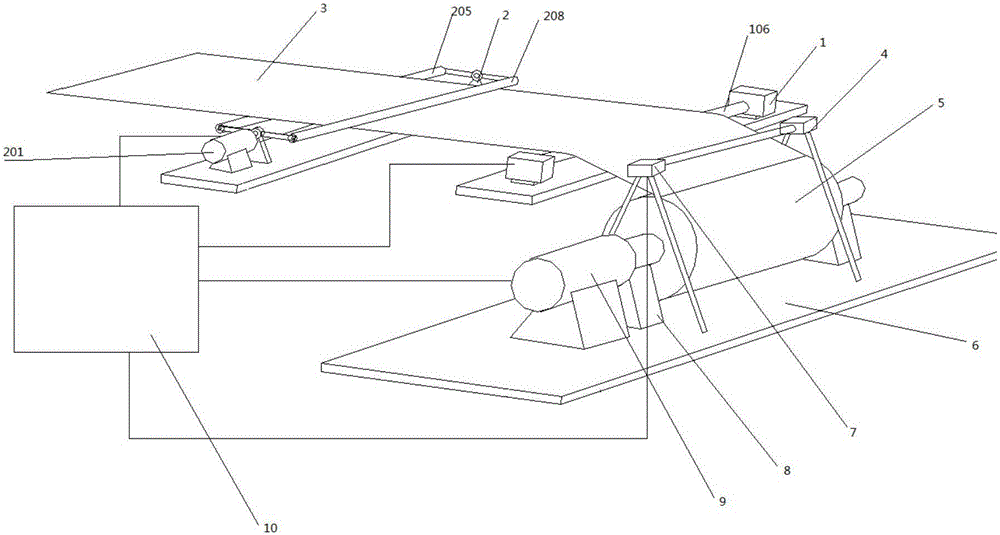

Remedying and rectifying system for belt coiling deviation and control method thereof

ActiveCN105819259AEnsure neatnessImprove winding efficiencyFunction indicatorsWebs handlingEngineeringMechanical engineering

The invention discloses a remedying and rectifying system for belt coiling deviation and a control method thereof. The system comprises a coiling device, a monitoring device, a rectifying device, a precoiling device and a control module; an image acquirer of the monitoring device acquires images in just coiling areas on two side edges of a coiling roller in real time, and transmits the images to the control module; the control module judges if coiled belts is deviated according to the received images, if so, the control module controls a coiling motor to stop rotating, and controls the precoiling device and the rectifying device to operate to finish the rectifying process; and finally, the control module controls the precoiling device and the rectifying device to return to a normal coiling position. The system can remedy and rectify the deviated coiled belts to guarantee tidy and consistent belt coiling, so that coiled belts with larger diameters can be obtained through one time of coiling, the defect of frequently replacing the coiling roller is overcome, and therefore the coiling efficiency and the coiling quality can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

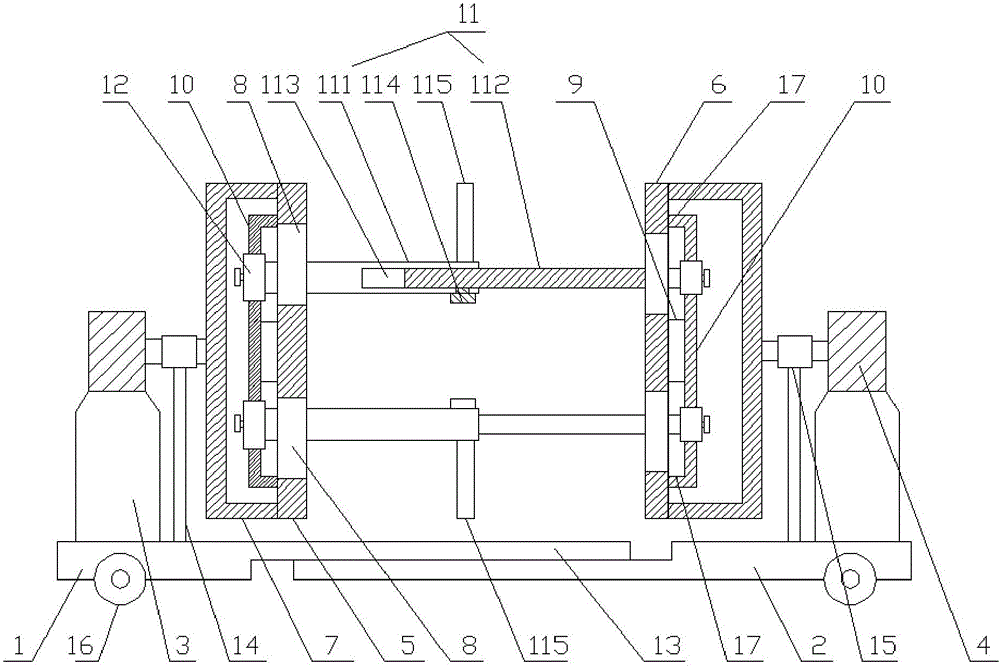

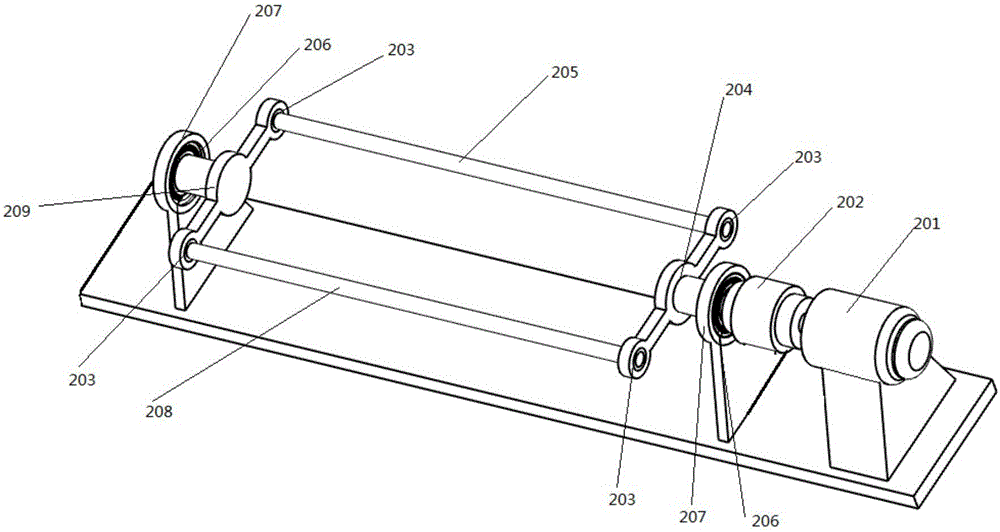

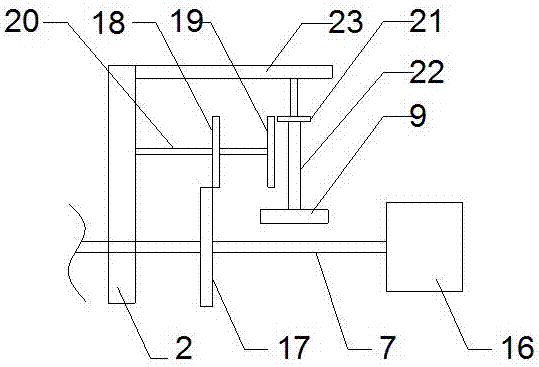

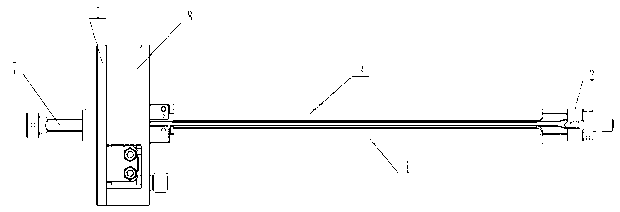

Winding device of battery electric core

ActiveCN101834314AImprove winding efficiencyEliminate the defect of aspect ratio limitationFinal product manufactureNon-aqueous electrolyte cellsEngineeringConductor Coil

The invention discloses a winding device of a battery electric core, comprising a winding module and a station conversion module, wherein the winding module comprises a first driving mechanism, a winding needle and a winding needle limiting mechanism; the station conversion module comprises a second driving mechanism; the first driving mechanism is coupled with one end of the winding needle to drive the winding needle to rotate; the other end of the winding needle is radially limited by the winding needle limiting mechanism during winding; and the second driving mechanism is coupled with the first driving mechanism to drive the first driving mechanism to move along an axial direction by carrying with the winding needle. The invention has simple structure and high winding efficiency and is beneficial to manufacturing a square lithium battery with a relatively-larger pole lug forming part dimension.

Owner:SHENZHEN YINGHE TECH

Uniform winding device for chemical fiber filament

InactiveCN107500027AWrap tightly and evenlyPrevent slidingFilament handlingFiberReciprocating motion

The invention discloses a uniform winding device for chemical fiber filaments, which comprises a bottom plate, a vertical plate and a horizontal plate; a bobbin is arranged under the horizontal plate, and a wire clamping groove is arranged in the center of the bobbin around the shaft; the bobbin is fixed A drive shaft is connected, and the drive shaft extends to the right side of the vertical plate and is connected with a winding motor; a guide ring is provided on the outside of the winding drum, and the guide ring is connected to a slider through a connecting rod, and the slider is slidably connected to a slide rail, and the slide rail It is fixedly connected with the horizontal plate; the slider is fixedly connected with the rack frame through the cross bar, and the rack frame is slidably connected with a sliding groove; the rack of the rack frame is engaged with a semi-circular gear, and the semi-circular gear is connected with the drive shaft through the linkage mechanism connect. The present invention is equipped with a reciprocating guide ring, so that the filaments are tightly and evenly wound on the rabbet, which improves the winding efficiency and winding volume; the present invention is provided with an intermediate winding shaft with a wire holding groove to avoid long The yarn slips and falls off, improving the efficiency of winding.

Owner:盐城千之诺机械有限公司

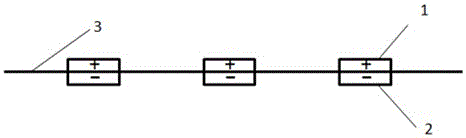

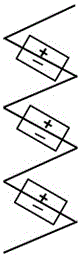

Method for producing laminated battery

InactiveCN106025374AEasy to optimizeHigh winding efficiencyFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention relates to a method for producing a laminated battery. The method comprises the following steps: taking a positive plate, a negative plate (material) and a belt-shaped diaphragm for standby use; applying a glue liquid on one side of the positive plate as well as that of the negative plate, and carrying out baking and rolling for standby use; cutting the obtained positive plate and the obtained negative plate into a plurality of standard-sized positive uniwafers and a plurality of standard-sized negative uniwafers; arranging the positive uniwafers uniformly on one side of the belt-shaped diaphragm, while arranging the negative uniwafers on the other side of the belt-shaped diaphragm in such a manner that the negative uniwafers and the positive uniwafers are opposite to each other; fixing the positive uniwafers and the negative uniwafers on two sides of the belt-shaped diaphragm according to a thermal compounding method; folding the complex of the positive uniwafers, the diaphragm and the negative uniwafers in a Z-shaped manner to form a battery roll core, and then carrying out assembling, liquid injection, formation and capacity grading to obtain the laminated battery. The method provided by the invention has the advantages that the battery production efficiency is improved; the problem that electrode uniwafers in a spirally wound laminated battery are not in close contact is solved; the safety performance of the laminated battery is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Cable processing and winding machine and operating method thereof

The invention discloses a cable processing and winding machine and an operating method thereof. The cable processing and winding machine comprises a winding device and a recovery device, and the winding device and the recovery device are arranged on the bottom plate. The cable processing and winding machine is characterized in that the winding device comprises a first support, a winding shaft, a rotary plate, a first motor and a fixing plate, and the recovery device comprises a second support, a cushion, a second bearing, a rotary shaft and a second motor. A plurality of cable fixing blocks are arranged on the rotary plate, so that cables can be wound conveniently, application range of the cable processing and winding machine is broadened, cost is reduced, the cables can thread into wire guide holes and can be conveyed in the hollow winding shaft, wear of the cables by the processing and winding machine is reduced, and quality of the cables after winding is improved; the first motor and the second motor control the winding device and the recovery device respectively, and operation efficiency is improved.

Owner:芜湖市科特电线电缆有限公司

Radial tire steel wire ring cloth wrapping winding machine and realization method thereof

The invention discloses a radial tire steel wire ring cloth wrapping winding machine and a realization method thereof. The radial tire steel wire ring cloth wrapping winding machine comprises a light-weight main framework, a side face positioning device, a height adjusting device, a protection cloth roll rotation device, a right pressing device, a steel wire ring rotation device, a left pressing device, an automatic shearing device, a protection cloth roll and a steel wire ring. The realization method is as follows: the steel wire ring is put on the steel wire ring rotation device and the left pressing device, and the protection cloth roll is mounted on the steel wire ring rotation device to finish manual feeding; a switch is pulled to an automatic gear to realize automatic winding; the left pressing device and the right pressing device are used for tightly pressing the steel wire ring; a protection cloth roll rotary motor and a steel wire ring rotary motor move at the same time to drive an opening synchronous pulley to wind the steel wire ring through the protection cloth roll; the automatic shearing device finishes shearing and then the steel wire ring is taken off; and the device is applicable to automatic cloth wrapping of the radial tire steel wire ring, and has the advantages that the cloth wrapping quality is good, the production efficiency is high, the noises are small, the automation degree is high, the structure is light and handy, the maintenance is convenient and the like.

Owner:DINGHAN TECH XIAMEN

Woven-cloth winding and storing mechanism

InactiveCN105936435AConvenient for temporary storageEasy to rewindWebs handlingConductor CoilMechanical engineering

Owner:WUJIANG HUAYUN TEXTILE

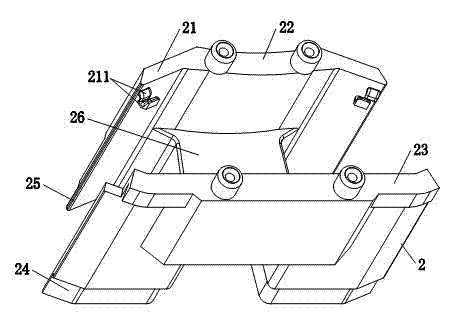

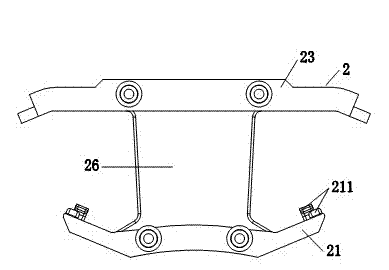

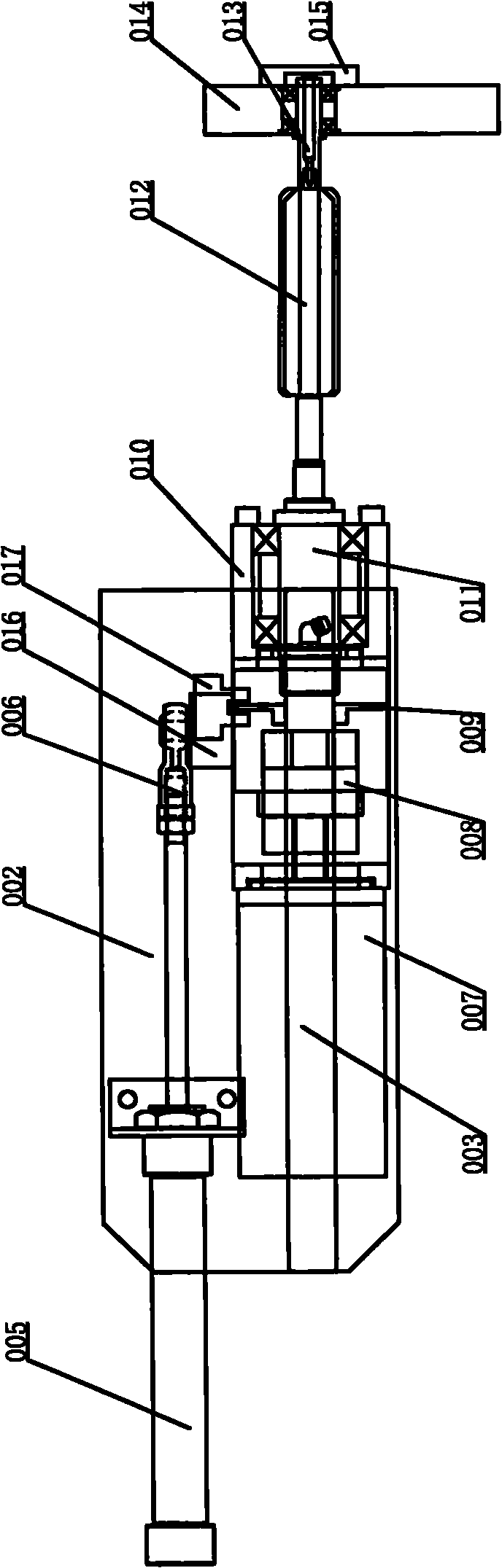

Battery winding needle structure

ActiveCN103326071AEasy to open and closeImprove winding efficiencyFinal product manufactureSecondary cellsEngineeringPole piece

The invention discloses a battery winding needle structure which comprises a first needle body and a second needle body and also comprises a vertical adjusting component and a transverse adjusting component, wherein the vertical adjusting component controls the opening and closing of the first needle body and the second needle body in the vertical direction; the transverse adjusting component controls the displacement movement of the first needle body and the second needle body in the transverse direction. According to the winding needle structure, positive and negative pole pieces and a diaphragm can simultaneously enter a winding needle, thus improving the cell winding efficiency and quality.

Owner:SHENZHEN YINGHE TECH

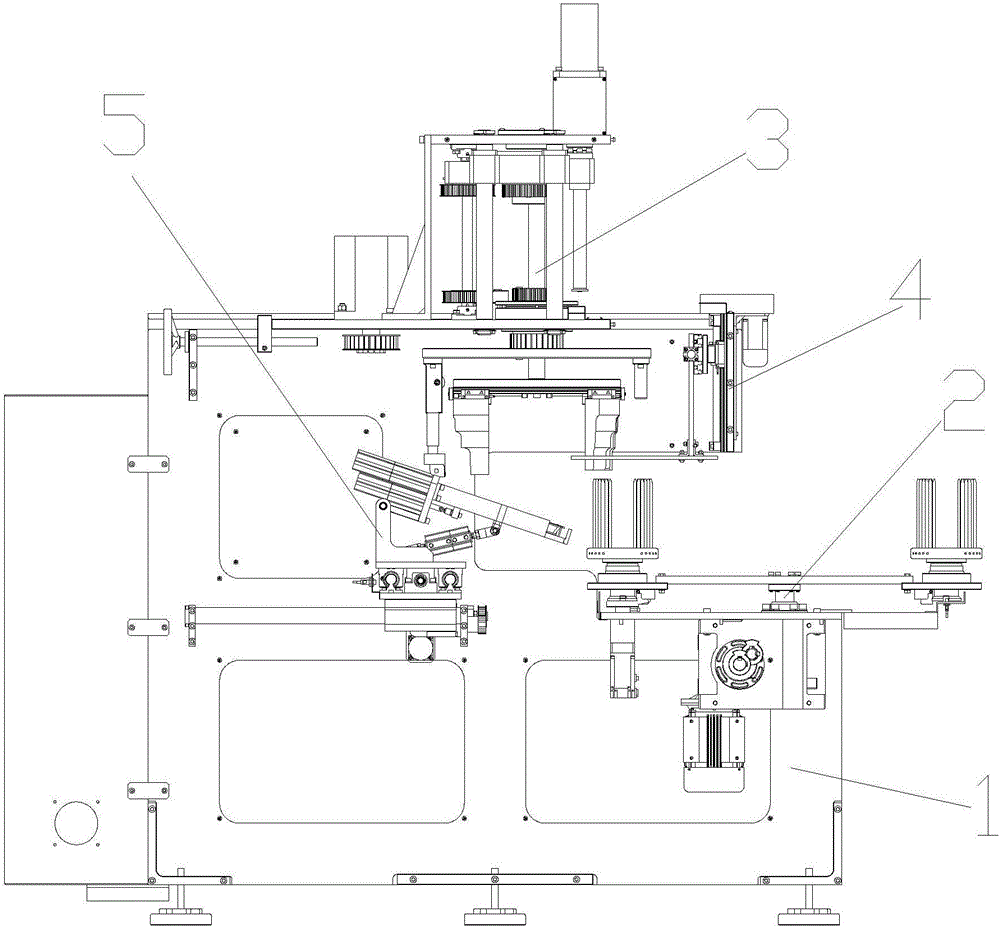

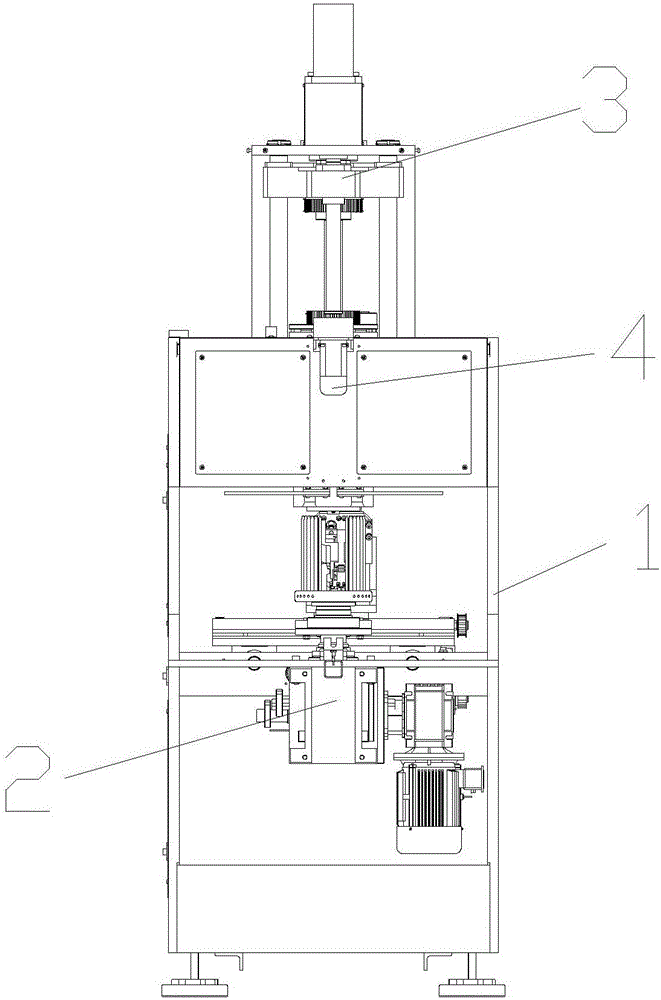

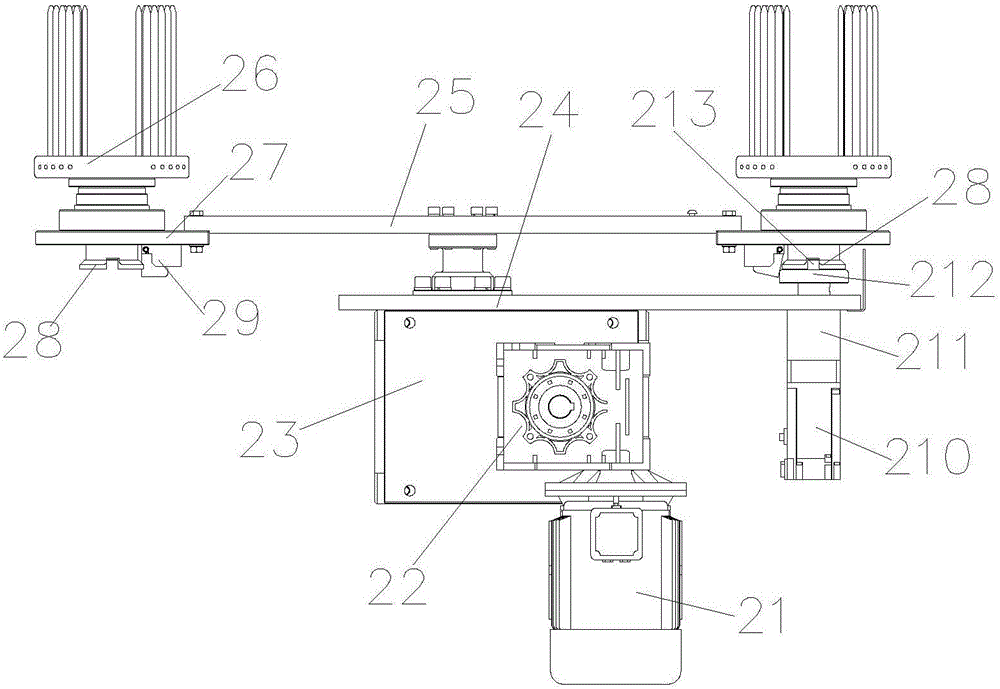

Vertical winding machine

The invention discloses a vertical winding machine. The vertical winding machine comprises a rack, a rotating plate transposition mechanism, a winding mechanism, a wire pressing mechanism and a wire shearing assembly. The rotating plate transposition mechanism is fixed below the rack. The winding mechanism is fixed above the rack and corresponds to the rotating plate transposition mechanism. The wire pressing mechanism corresponds to the winding mechanism and is located over the rotating plate transposition mechanism. The wire shearing assembly is fixed between the rotating plate transposition mechanism and the winding mechanism. Due to the mode, double-station winding can be achieved, and winding efficiency is high.

Owner:圣玛特智能设备制造(浙江)有限公司

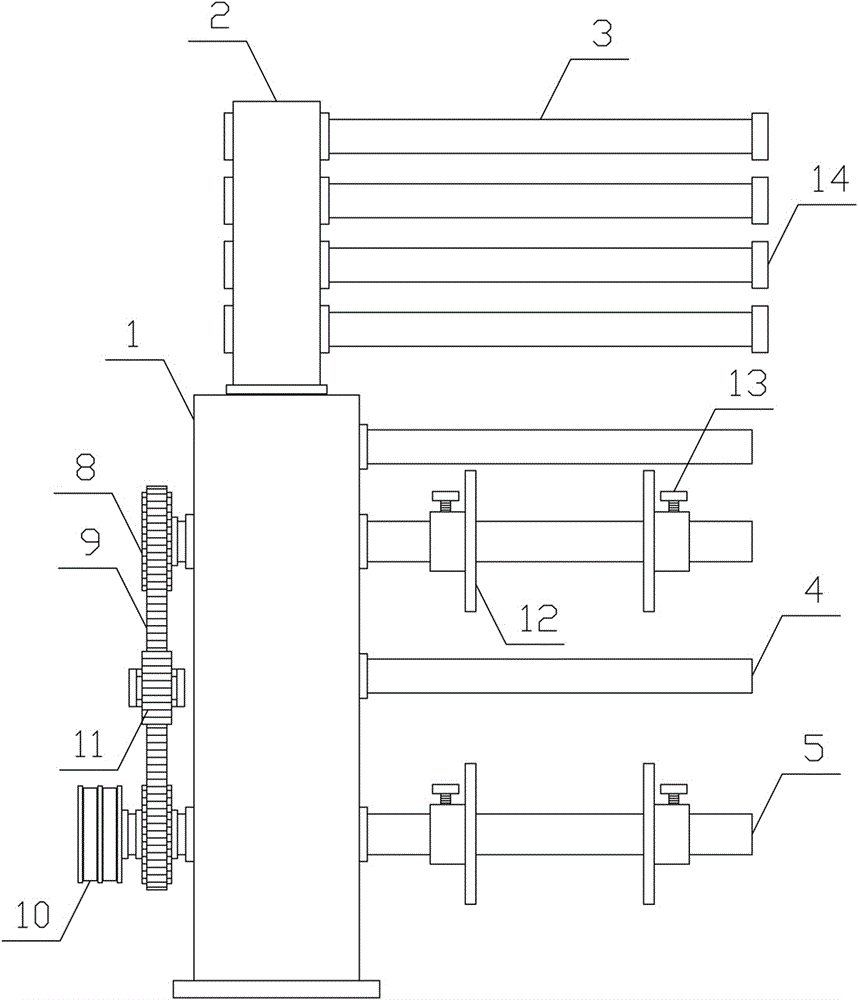

Automatic winding apparatus and winding method for network transformer production

PendingCN113658796AReduced activityShorten positioning timeCoils manufactureWinding machineTransformer

The invention relates to an automatic winding apparatus and winding method for network transformer production, and belongs to the technical field of network transformers. The automatic winding apparatus comprises a rack, a feeding mechanism and at least two sets of winding mechanisms, the feeding mechanism and the winding mechanisms are arranged on the rack, a feeding sliding way is arranged on the rack, the feeding mechanism is configured to drive electronic elements in the feeding sliding way to advance in a stepping mode, the winding mechanisms are sequentially arranged in the direction of the feeding sliding way at intervals, and the at least two sets of winding mechanisms are configured to wind different pins of electronic components. According to the automatic winding apparatus and the winding method for network transformer production, the multiple winding mechanisms are adopted to work at the multiple winding point positions at the same time, winding operation can be conducted on the multiple electronic components at a time; according to the electronic components, only parts of pins are wound at the single winding point positions; and an assembly line mode is adopted, the movement of the winding mechanisms in the winding process is reduced, the positioning time is saved, and the winding efficiency is effectively improved.

Owner:绵阳讯恒自动化设备有限公司

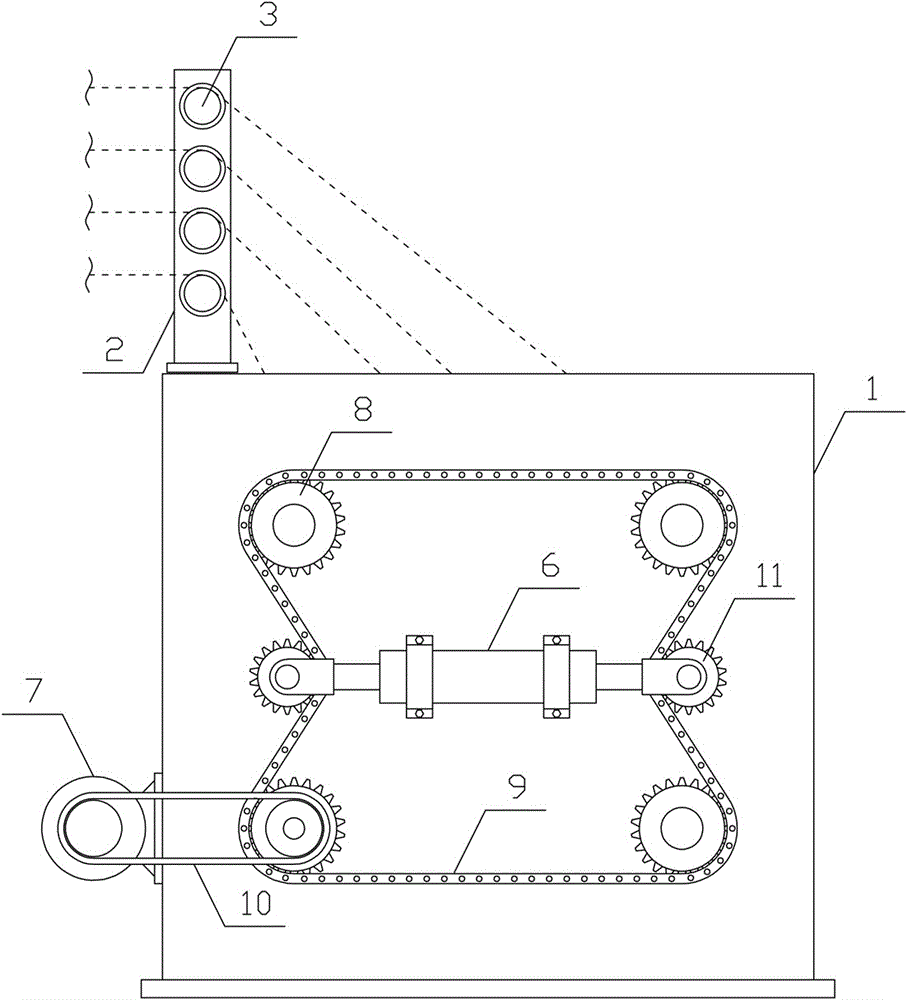

Thin film strip conveying and winding device

InactiveCN106081687ARotation synchronization is efficient and smoothThere are multiple film feeding rollers connected by rotation, and the winding is synchronously efficient and stableWebs handlingHydraulic cylinderSprocket

The invention discloses a thin film strip conveying and winding device and belongs to the field of packaging and machining mechanical equipment. The thin film strip conveying and winding device comprises a winding support, a film feeding support, film feeding rollers, film guiding rollers, winding rollers, a tensioning hydraulic cylinder and a winding motor; one side of the film feeding support is sequentially, horizontally, evenly and rotationally connected with the multiple film feeding rollers from top to bottom; the multiple winding rollers are horizontally, evenly and rotationally connected to the outer side of the winding support; the two sides of the middle portion of the winding support are sequentially, horizontally and rotationally connected with the film guiding rollers from top to bottom; one ends of the multiple winding rollers are each vertically provided with a winding chain wheel; a winding chain is connected to the winding chain wheels in an engaged manner; the winding motor and one winding chain wheel are in transmission connection through a conveying belt; the two ends of the tensioning hydraulic cylinder are vertically and rotationally connected with tensioning chain wheels correspondingly; and the winding chain is connected with the inner sides of the tensioning chain wheels in an engaged manner. The thin film strip conveying and winding device is reasonable in structural design and capable of fast and efficiently conveying and winding a plurality of thin film strips synchronously and steadily and meeting the production and use requirement.

Owner:浙江耀阳新材料科技有限公司

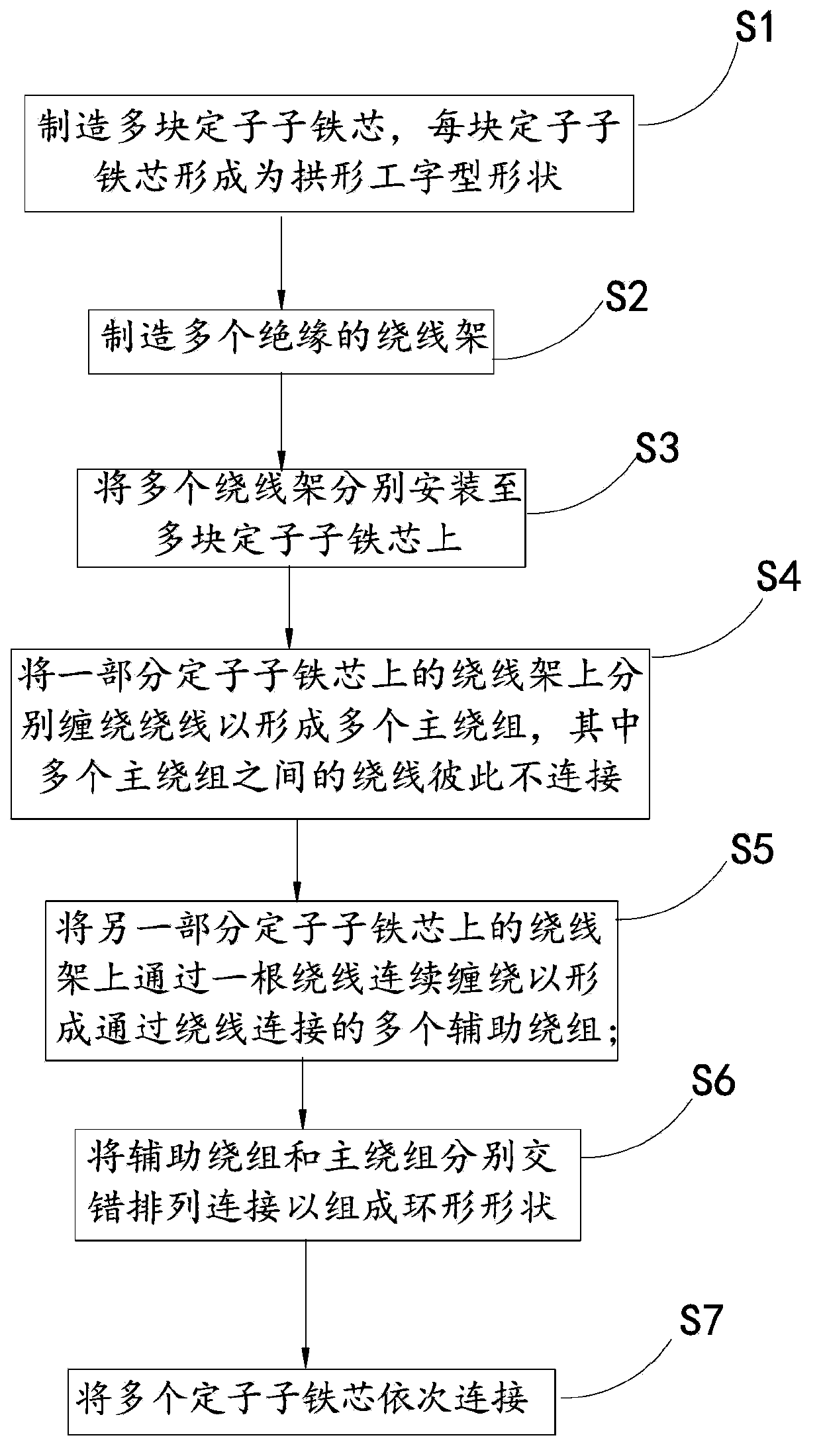

Block stator, manufacturing method of block stator, motor with block stator and household appliance

InactiveCN103973057ACombination operation is convenientEasy windingWindingsMagnetic circuit stationary partsElectric machineEngineering

A segment stator and manufacturing method thereof, an electric machine and a household electrical appliance with same. The manufacturing method comprises the following steps: manufacturing a plurality of stator segment cores (1); manufacturing a plurality of insulated winding frames (2); installing the plurality of winding frames (2) onto the plurality of stator segment cores (1), respectively; winding main coils (5a) around the winding frames (2) on some of the stator segment cores (1) to form a plurality of main windings (A), wherein the main coils (5a) of the plurality of main windings (A) are not connected to each other; winding continuously a secondary coil (5b) around the winding frames (2) on the other stator segment cores (1) to form a plurality of secondary windings (B) connected by the secondary coil; arranging and connecting the secondary windings (B) and the main windings (A) alternately to form a ring shape; and connecting the plurality of stator segment cores (1) in turn. The manufacturing method has a high winding speed.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

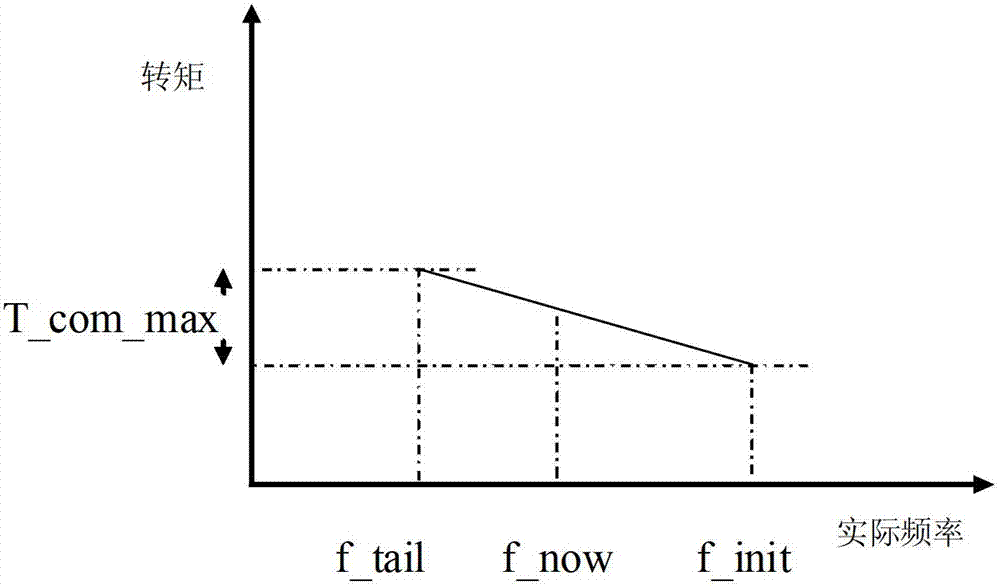

Winding and unwinding tension automatic correcting method of wire drawing machine

The invention provides a winding and unwinding tension automatic correcting method of a wire drawing machine. The method comprises the following steps: setting a radius of an winding roll in an empty state for a frequency converter; setting a frequency converter output frequency when the winding roll is empty; setting a radius of the winding roll in a fully-wound state for the frequency converter; setting a frequency converter output frequency when the winding roll is fully wound; and in the winding process, adjusting an output torque of the frequency converter according to the rolling diameter radius of a wound material, so as to change the torque of a winding roll motor, so that the tension of the wound material is constant. According to the invention, the tension in the winding and unwinding process can be constantly controlled.

Owner:EURA DRIVES ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com