Insulated frame for motor of block stator

An insulating frame and stator insulation technology, applied to the shape/style/structure of the winding insulation, can solve the problems that the production efficiency of the stator assembly cannot be improved, and the winding and wiring of the segmented stator are difficult, so as to achieve ingenious design and good performance , The effect of improving the winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

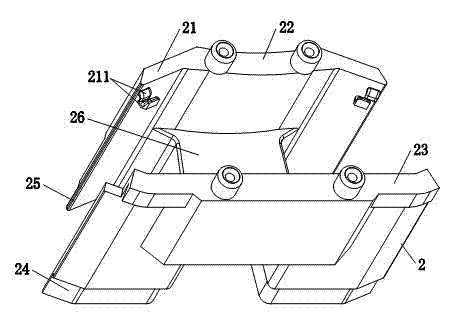

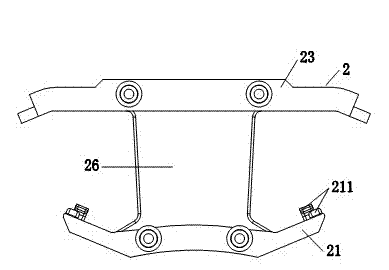

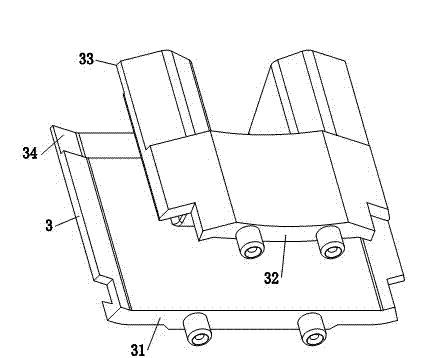

[0020] Such as Figures 1 to 7 As shown, it is an insulating frame of a motor with a segmented stator. The present invention is characterized in that it includes more than two stator insulating upper frames 2 that can be hung with wires, more than two stator insulating lower frames 3 that are not hung with wires, and two The above stator core 1; the stator insulation upper frame 2 includes an upper inner arc wall 22, an upper outer arc wall 23 and an upper connecting position 26 connecting the upper inner arc wall 22 and the upper outer arc wall 23, on the upper inner arc wall 22 The two sides of one end of one end are respectively provided with a line passing slope 21 with a distance H from the iron core pole shoe, and a wire hanging frame 4 is provided on the line passing slope 21; the stator insulation lower frame 3 includes a lower inner arc wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com