Winding device of battery electric core

A winding device and cell roll technology, which is applied in the manufacture of non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of the space limitation of the station conversion structure and the inconvenient manufacture of square lithium batteries, etc., to achieve Elimination of aspect ratio restrictions, simple structural design, and high winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

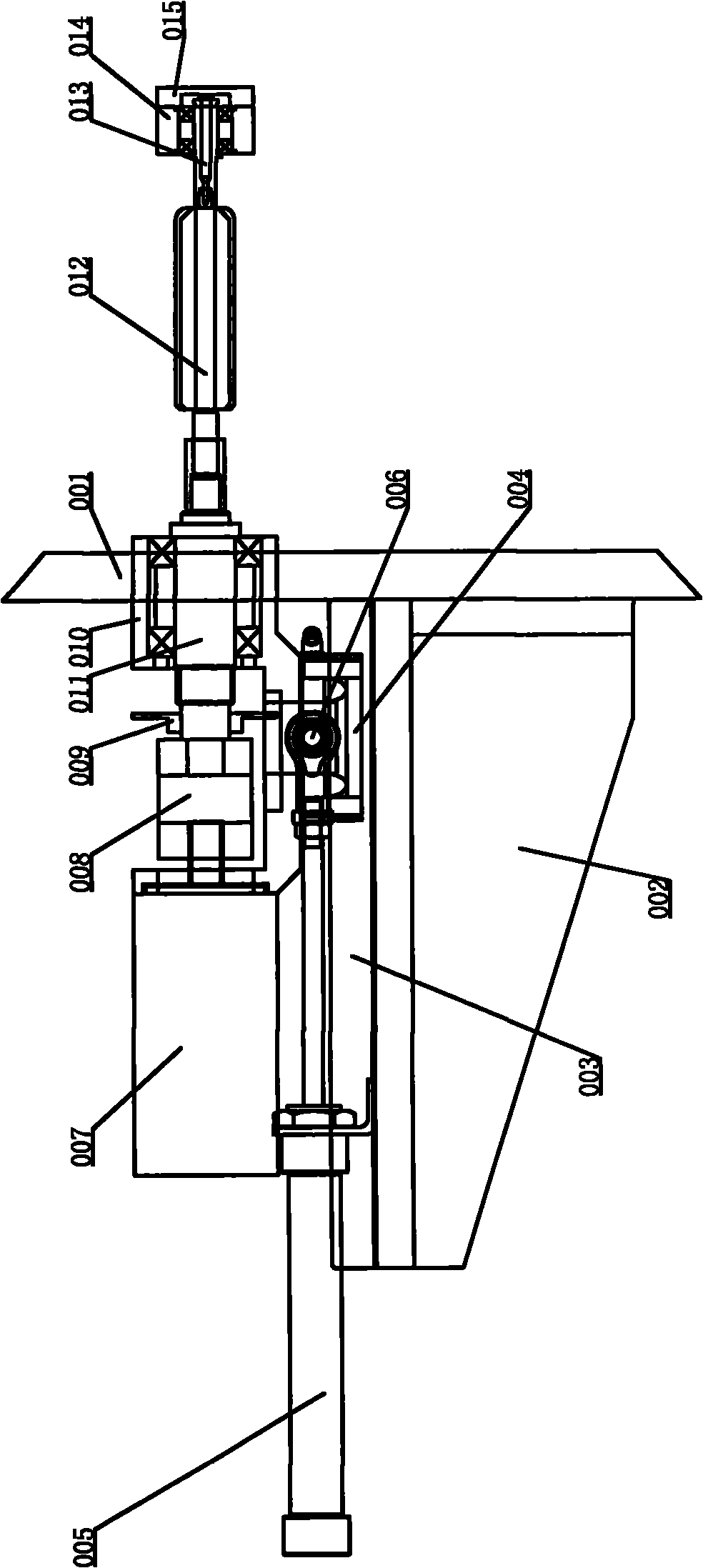

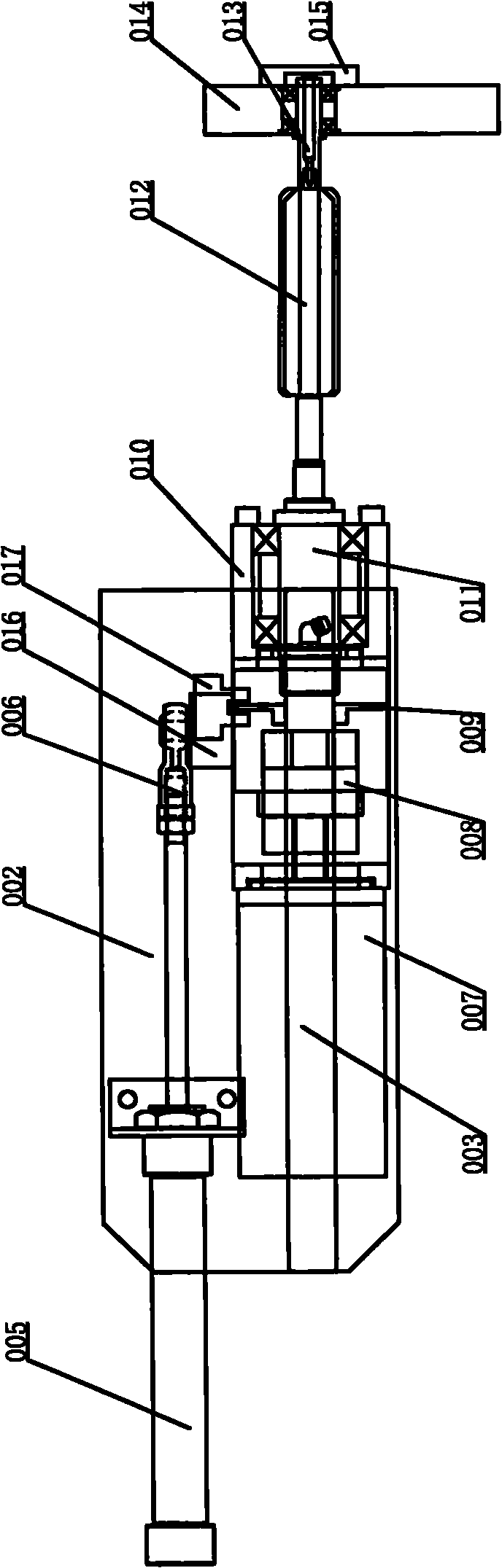

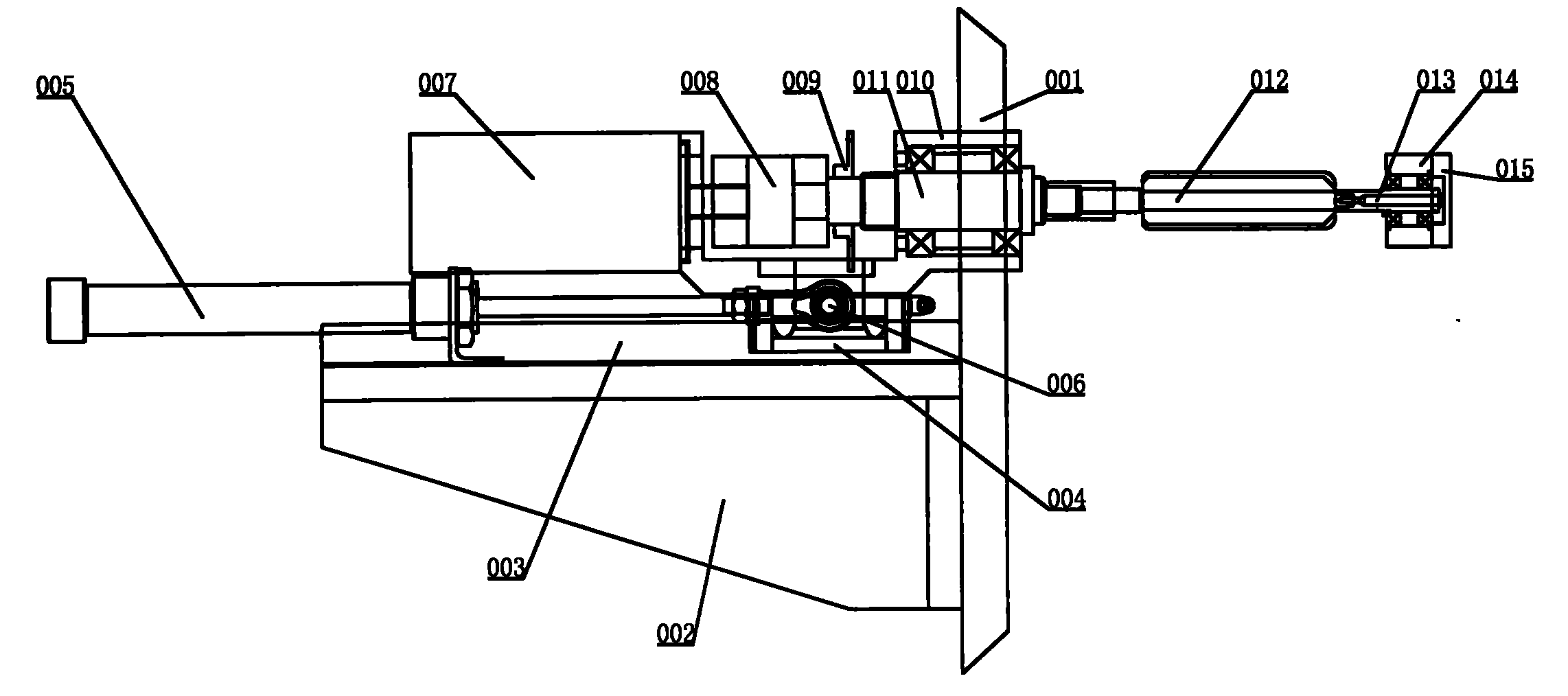

[0016] See figure 1 and figure 2 , the winding device of the present invention is a single-station semi-automatic winding machine. In one embodiment, the winding device includes a winding module, a station conversion module and a mounting plate 001 . The winding module includes a first driving mechanism, a winding needle 012 and a needle limit mechanism, and the station conversion module includes a second driving mechanism, wherein the first driving mechanism is coupled to one end of the winding needle 012 to drive the winding needle 012 to rotate, and the winding The other end of the needle 012 is radially limited by the needle winding limit mechanism during winding, and the second driving mechanism is coupled to the first driving mechanism to drive the first driving mechanism to move the winding needle 012 in the axial direction.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com