Winding and unwinding tension automatic correcting method of wire drawing machine

An automatic correction, winding and unwinding technology, applied in the field of control, can solve the problems of difficulty in controlling the tension of the winding material, deformation of the winding roller, etc., and achieve the effect of keeping the winding efficiency constant, the tension constant, and the force reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

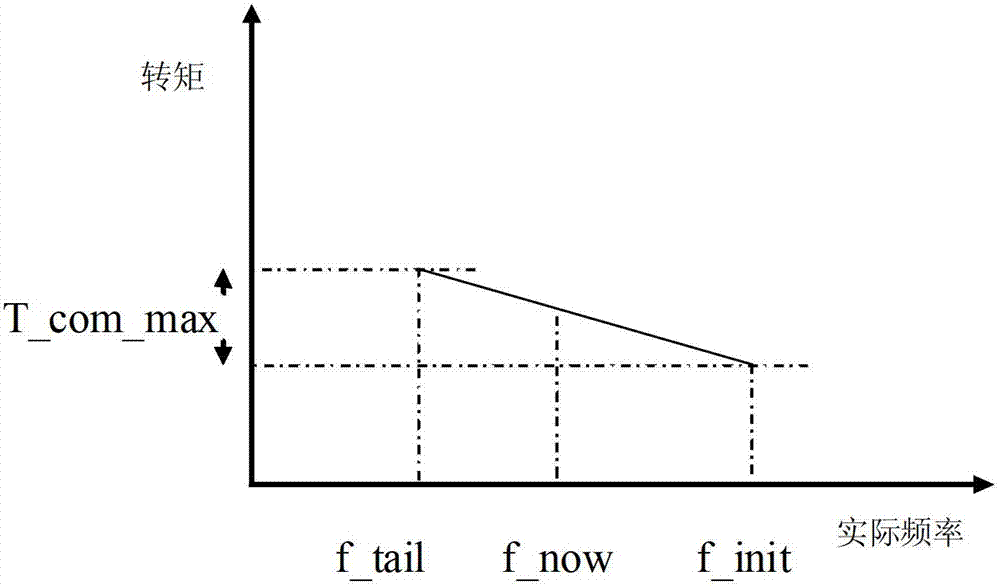

[0022] According to the well-known physical principles, the linear velocity of any point on a rigid body rotating around a fixed axis is equal to the product of the angular velocity and the distance from the point to the axis of rotation, while the power is directly proportional to the torque and inversely proportional to the rotational speed. Therefore, in the winding process controlled by constant torque, in order to maintain a constant winding line speed at the winding diameter of the winding material on the winding roller, the output frequency of the inverter driving the winding roller motor needs to change with the change of the winding diameter. According to the relationship between the output frequency of the frequency converter and the linear velocity at the coil diameter of the material, as well as the relationship between the output power of the frequency converter and the torque of the motor, it can be concluded that adjusting the output torque of the frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com