Bogie framework for high-speed rail wagon

A technology for high-speed railways and bogies, which is applied in the direction of bogies, railway car body parts, devices for lateral relative movement between underframes and bogies, etc. Can not use the second-series air spring load-bearing mode, large difference between empty and heavy vehicles, etc., to achieve good commercial application value and economic and technical value, reasonable force, and the effect of preventing vertical relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

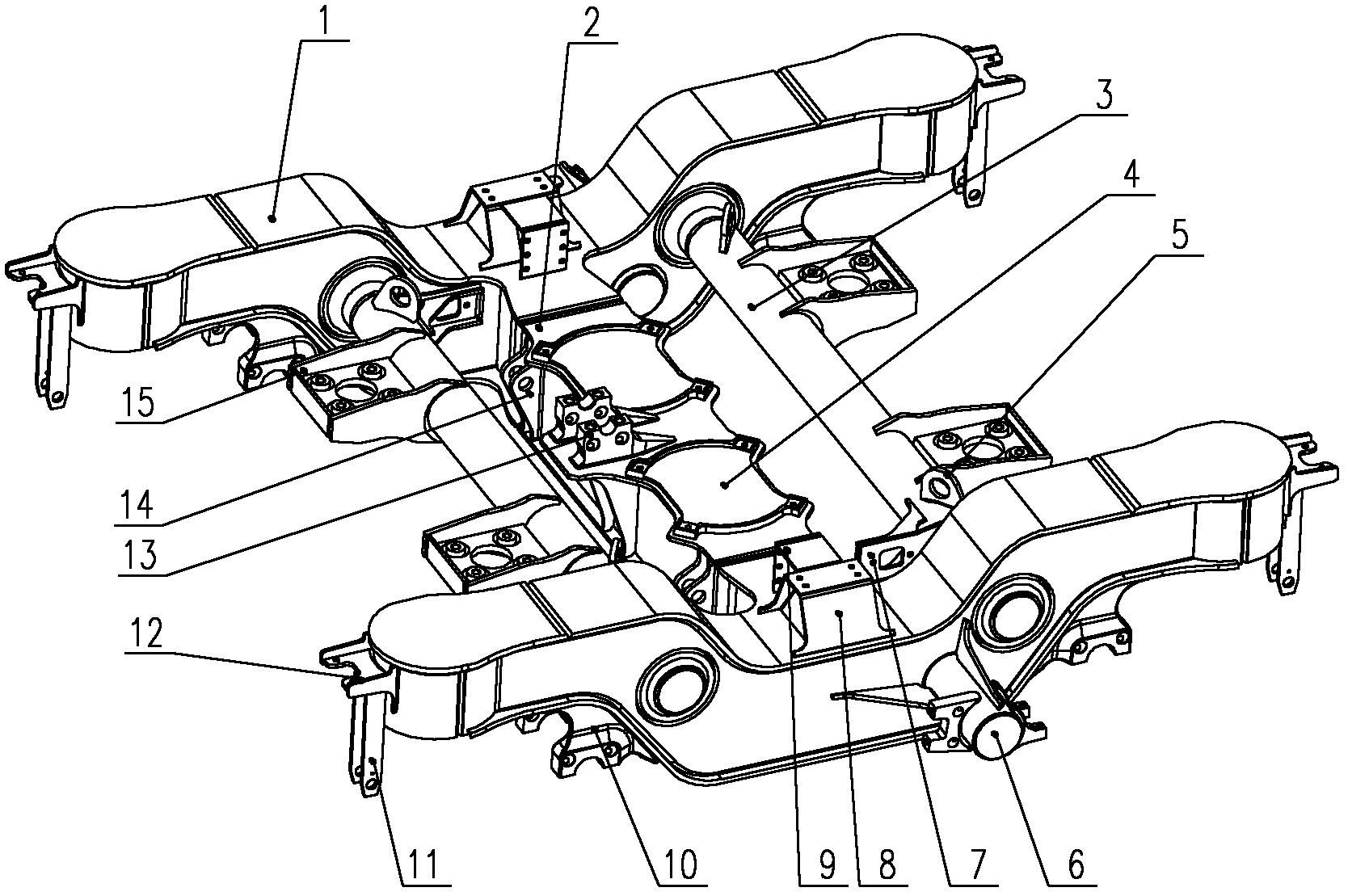

[0031] Such as figure 1 As shown, the 200km / h high-speed truck bogie frame of the present invention adopts a U-shaped structure, including two side beams 1, a large beam 2, two small beams 3, two secondary rubber spring mounting seats 4, four Bogie lifting seat 5, two anti-snake shock absorber mounting seats 6, two secondary series transverse oil pressure shock absorber mounting seats 7, two secondary series vertical stop mounting seats 8, two secondary series lateral stoppers Block mounting base 9, eight rotating arm elastic rubber node mounting bases 10, four wheel set lifting bases 11, four primary vertical oil pressure shock absorber mounting bases 12, one longitudinal traction rod mounting base 13, four elastic Safety chain mount 14, four brake suspenders 15 form.

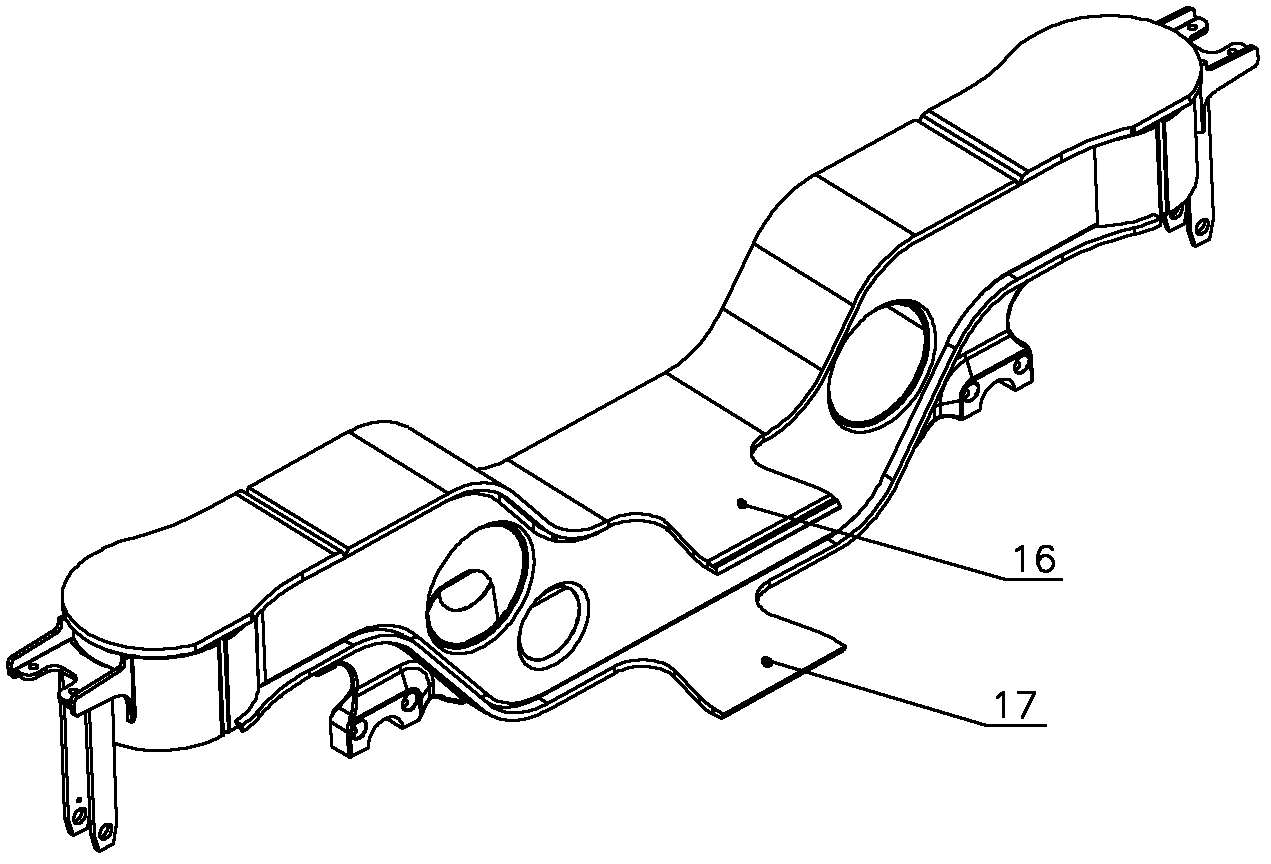

[0032] The side beam 1 is a box structure, such as figure 2 As shown, its shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com