High speed multi-dimensional vibration measuring device and method based on stripe target

A vibration measurement, multi-dimensional technology, applied in the direction of measuring device, vibration test, machine/structural component test, etc., to achieve the effect of expanding the range of detection amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

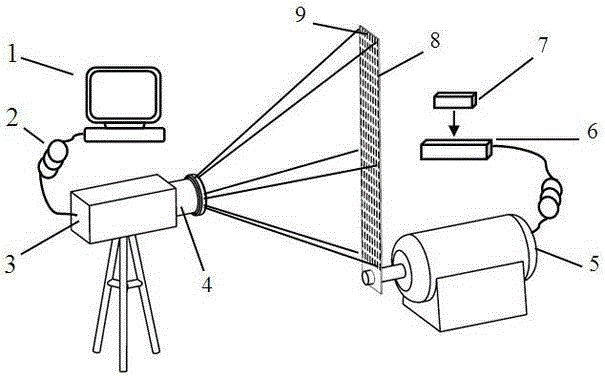

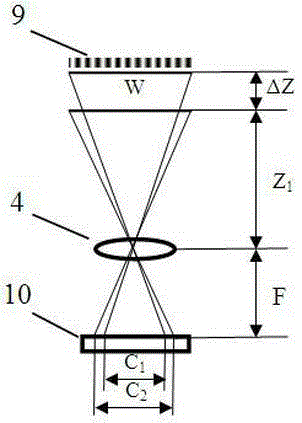

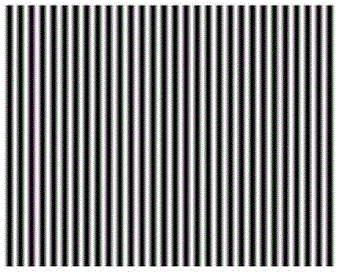

[0046] figure 1 It is a schematic diagram of the device structure of the embodiment of the present invention. Such as figure 1 As shown, the high-speed multi-dimensional vibration measurement device based on the stripe target of the present invention includes a stripe target 9, an imaging module 3, a signal control and processing module, and a display module. The stripe target 9 is arranged on the surface of the vibrating structure 8 to be tested, and is used for encoding the spatial position of the vibrating structure 8 to be tested. The imaging module 3 is used for continuous imaging and recording of the fringe target 9 on the vibrating structure 8 to be tested, and transmits the collected fringe target image to the signal control and processing module through the data transmission line 2 . The signal control and processing module is used to control the imaging module 3 and the display module, and is also used to perform data communication with the imaging module 3 and per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com