Patents

Literature

205results about How to "Achieve displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

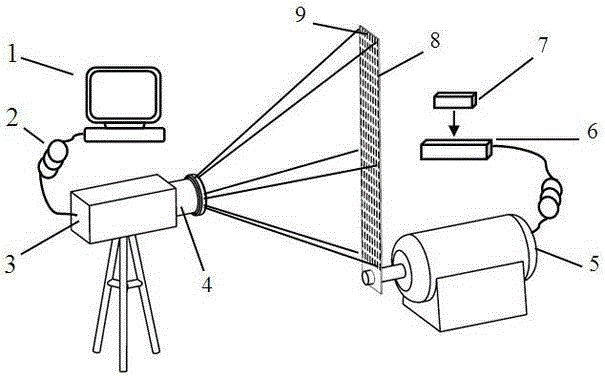

Visual experiment device and method for simulating fracture-vug type carbonatite oil reservoir gas injection

ActiveCN105221122AObservable flow stateObservable distributionConstructionsFluid removalGas phaseProduct gas

The invention provides a visual experiment device and method for simulating fracture-vug type carbonatite oil reservoir gas injection. The visual experiment device for simulating fracture-vug type carbonatite oil reservoir gas injection comprises a computer, a camera, a visual core clamping device, a planar light source, a simulation formation water piston container, a stratigraphic simulation oil piston container, a gas piston container, a constant-flux pump, a six-way valve, a pressure meter, a pressure stabilizing tank, a back-pressure valve, an oil, gas and water metering device and a pressure-resistant gas flow meter. The visual experiment device is adopted in the experiment method. By means of the device and method, fracture-vug type carbonatite oil reservoir gas injection can be simulated, production performance of the recovery efficiency is improved, and flow states and distribution conditions of a crude oil phase, a gas phase and a water phase in the gas injection huff and puff process can be observed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

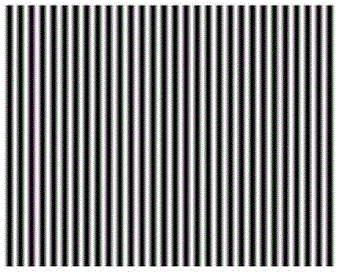

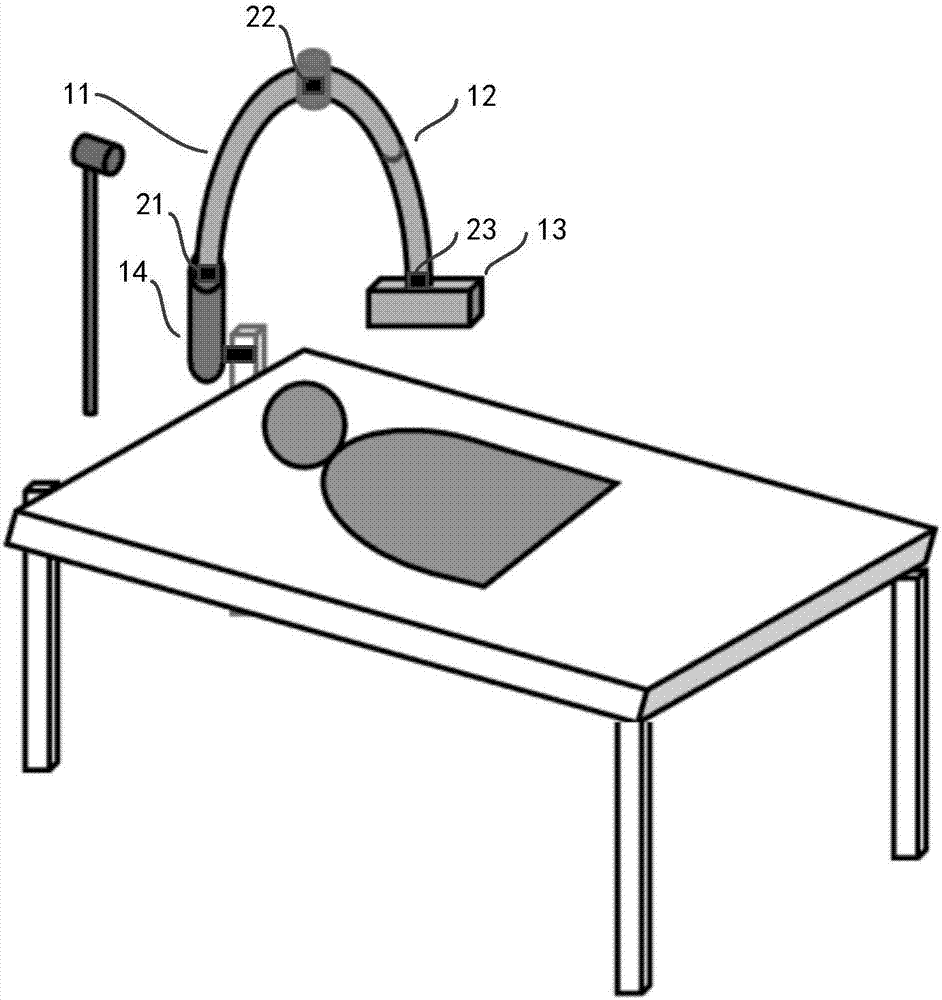

High speed multi-dimensional vibration measuring device and method based on stripe target

ActiveCN104614064AQuick measurementWith displacementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement deviceFourier transform on finite groups

The invention relates to a high speed multi-dimensional vibration measuring device and method based on a stripe target. The device comprises a stripe target, an imaging module, a signal control and processing module and a display module. The method includes the following steps: arranging the stripe target on a vibration structure to be measured; adopting an image module to conduct continuous imaging and recording on the stripe target; utilizing the imaging module to transmit the image of the stripe target to the signal control and processing module; utilizing the signal control and processing module to conduct Fourier transform on the stripes at the same position of the same stripe target in each frame of the image, adopting a certain peak value frequency correction method to accurate correct the peak value frequency, and then utilizing the imaging mathematical relation and the corrected peak value frequency to obtain a time domain curve with stripe target structure vibration, namely acquiring structure vibration signals through reduction; displaying an image processing result through a display module or conducting further data processing through vibration signals. By means of the device and method, vibration measurement of points, lines and faces in certain range is achieved, the measurement speed is high, and the accuracy is high.

Owner:FUZHOU UNIV

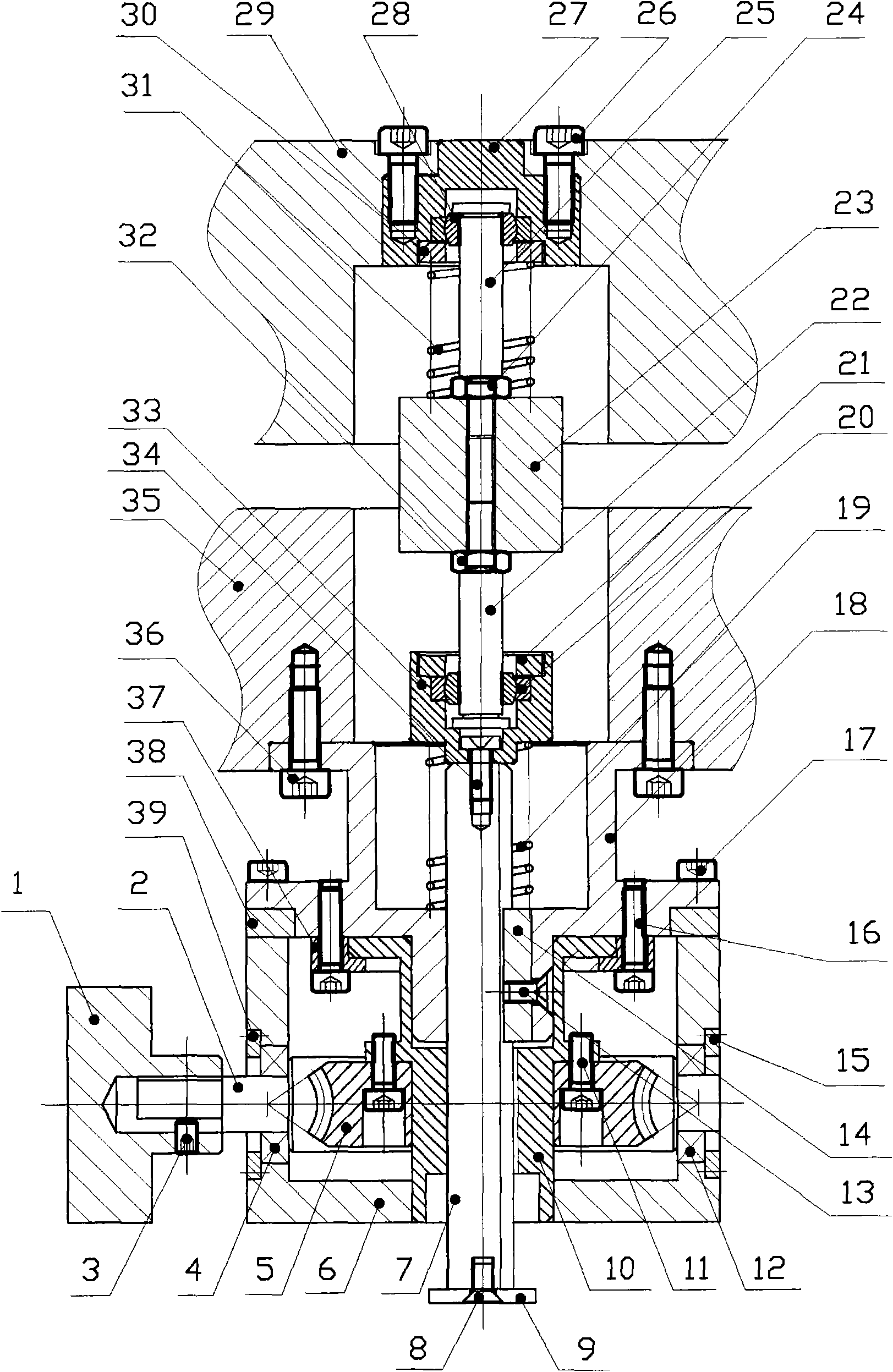

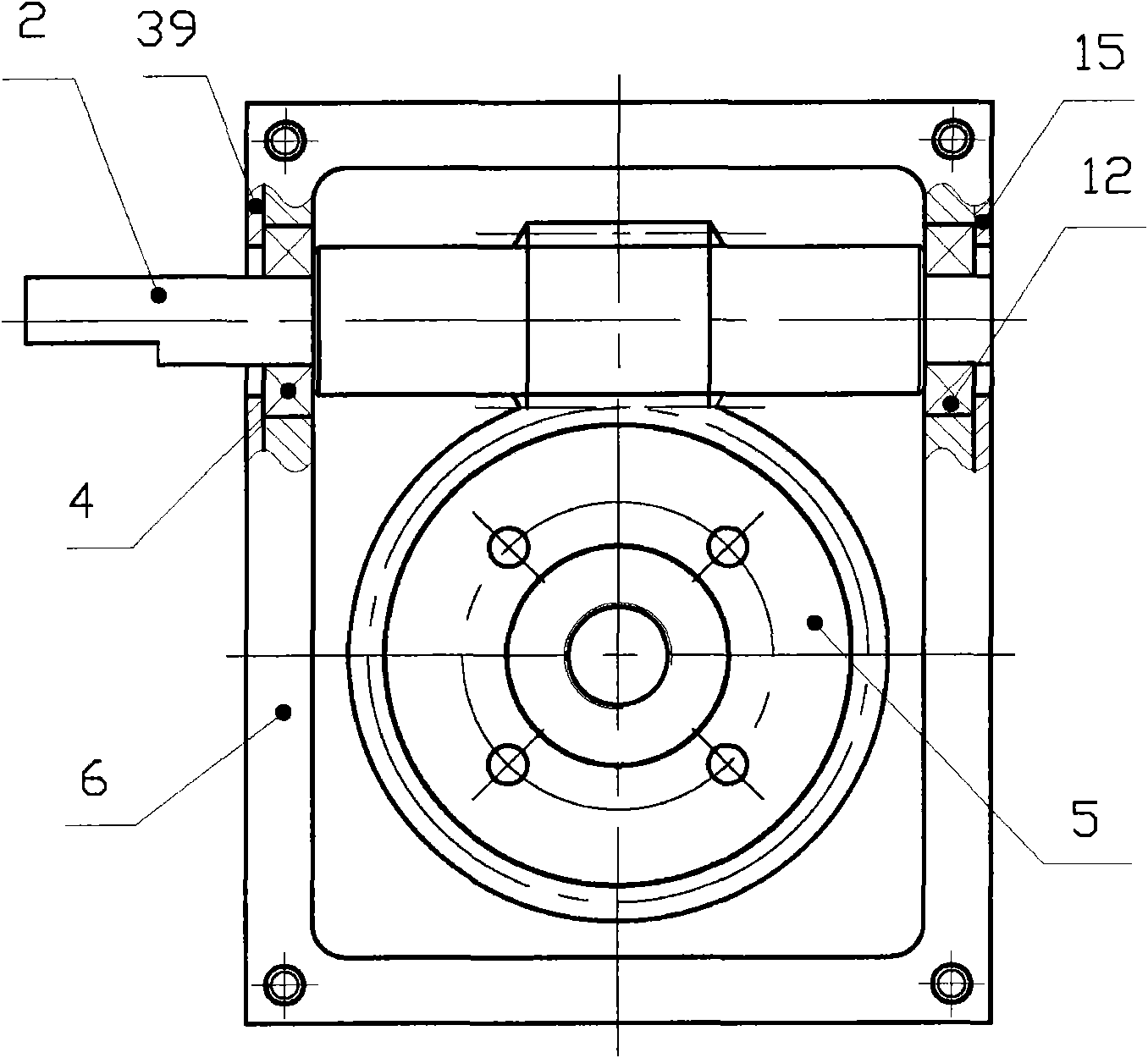

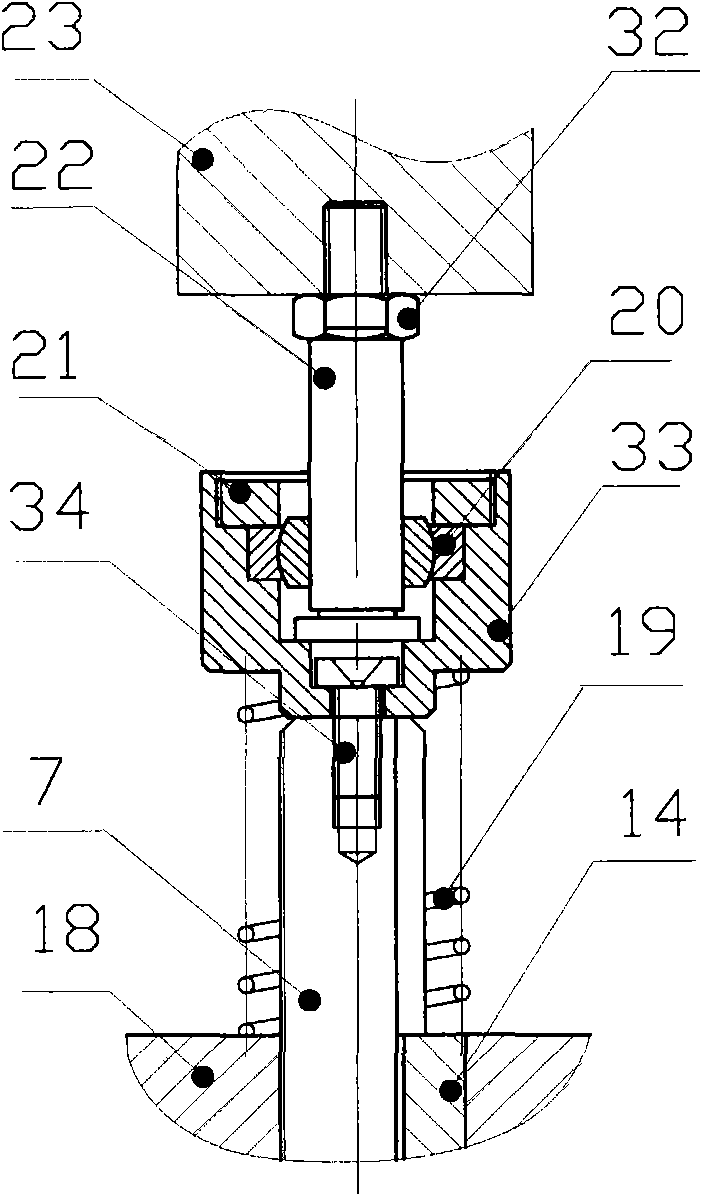

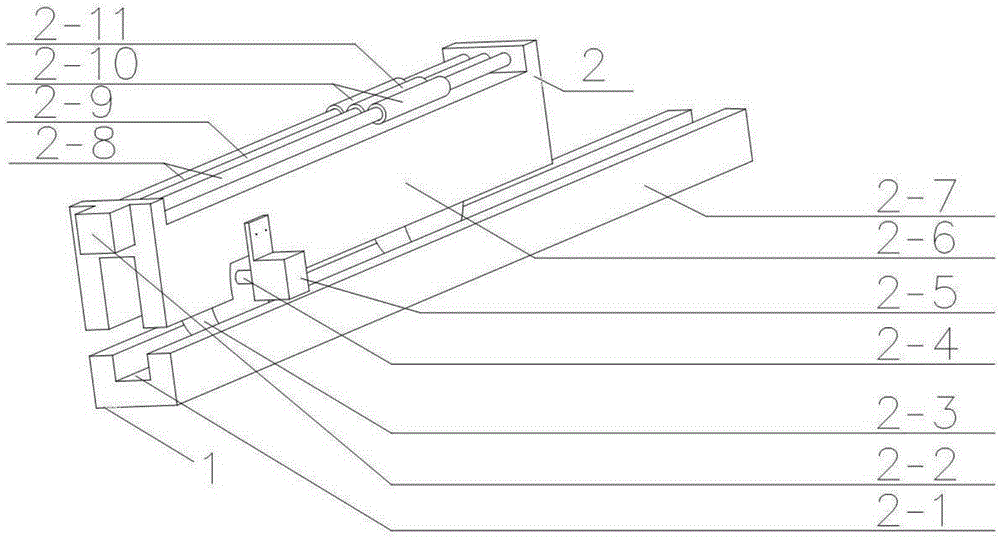

Combined type transmission variable-angle micrometric displacement regulation device

InactiveCN101673118ARealize two-stage transmissionMeet different anglesControlling membersManual control with multiple controlled membersCouplingControl system

The invention relates to a micrometric displacement regulation device, in particular to a combined type transmission variable-angle micrometric displacement regulation device comprising a fixed base,a worm gear, a worm, a screw rod, a push rod, joint bearings and a regulation and fastening part. By regulating a handle at one end of the worm, the worm and the worm gear are engaged to realize primary transmission. The center of the worm gear provides a thread hole, and secondary transmission is realized by a thread pair and the screw rod. The rotary motion of the screw rod is restricted by a flat key, and the push rod only can be pushed along a linear direction. Both ends of the push rod are respectively arranged with the joint bearing, and the push rod pushes a working platform to realizeangle rotation or linear displacement motion. The invention also can adopt a motor for control. A worm shaft is connected with a motor shaft by a shaft coupling, and the motor is connected with a computer by a driving control system to realize control. A displacement sensor can be arranged on the screw rod and used for measuring the displacement quantity of the screw rod at real time. The entire control system can adopt an open-loop or closed-loop system. The invention has compact layout and simple kinematic chain and ensures the regulation accuracy. The invention can be used by combining a single set or a plurality of sets so as to meet the regulation requirement of different angles or displacements of the working platform. The invention is especially suitable for an occasion for regulating the displacement or angle with moderate accuracy in a micron magnitude or an arc second magnitude.

Owner:TONGJI UNIV

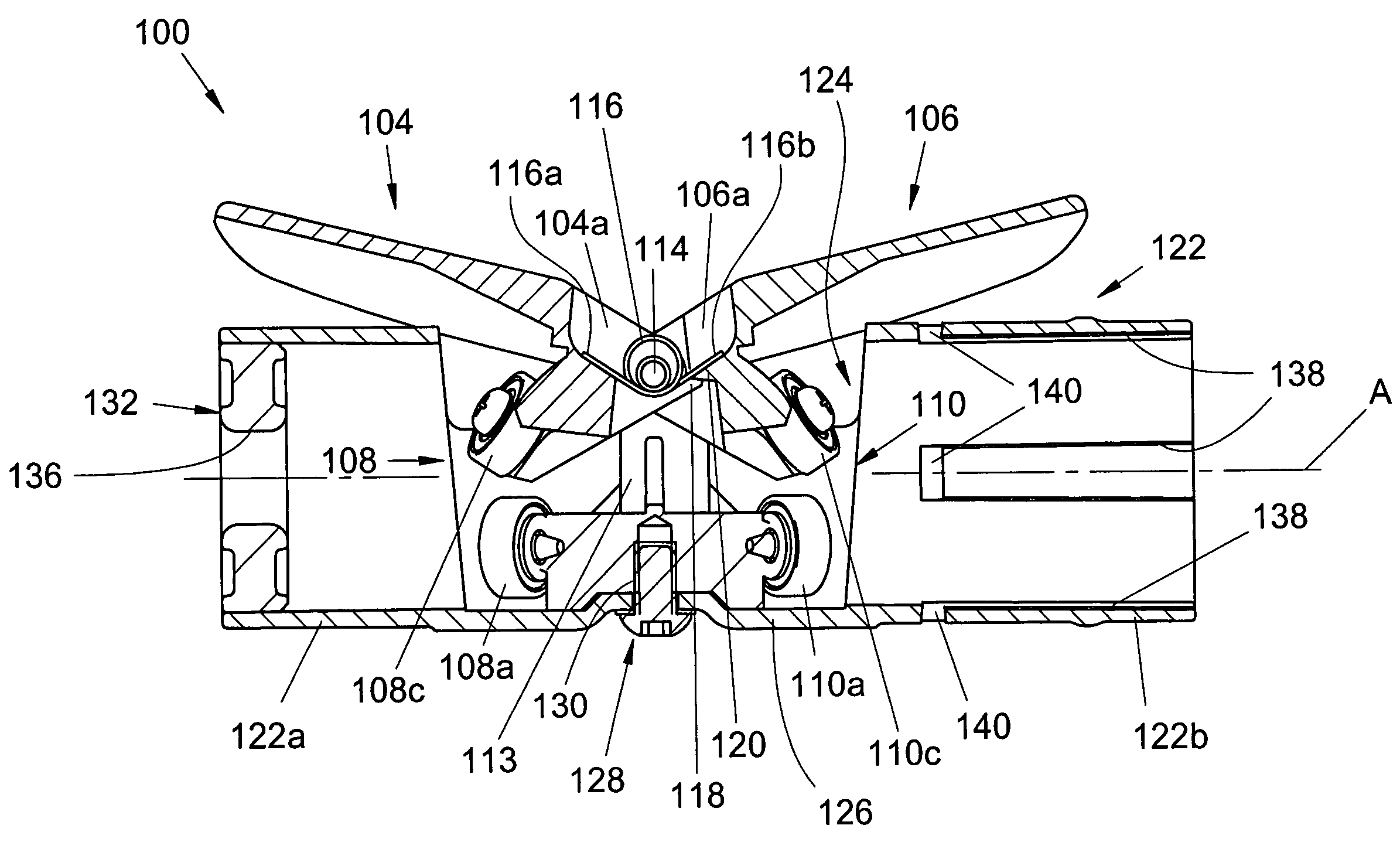

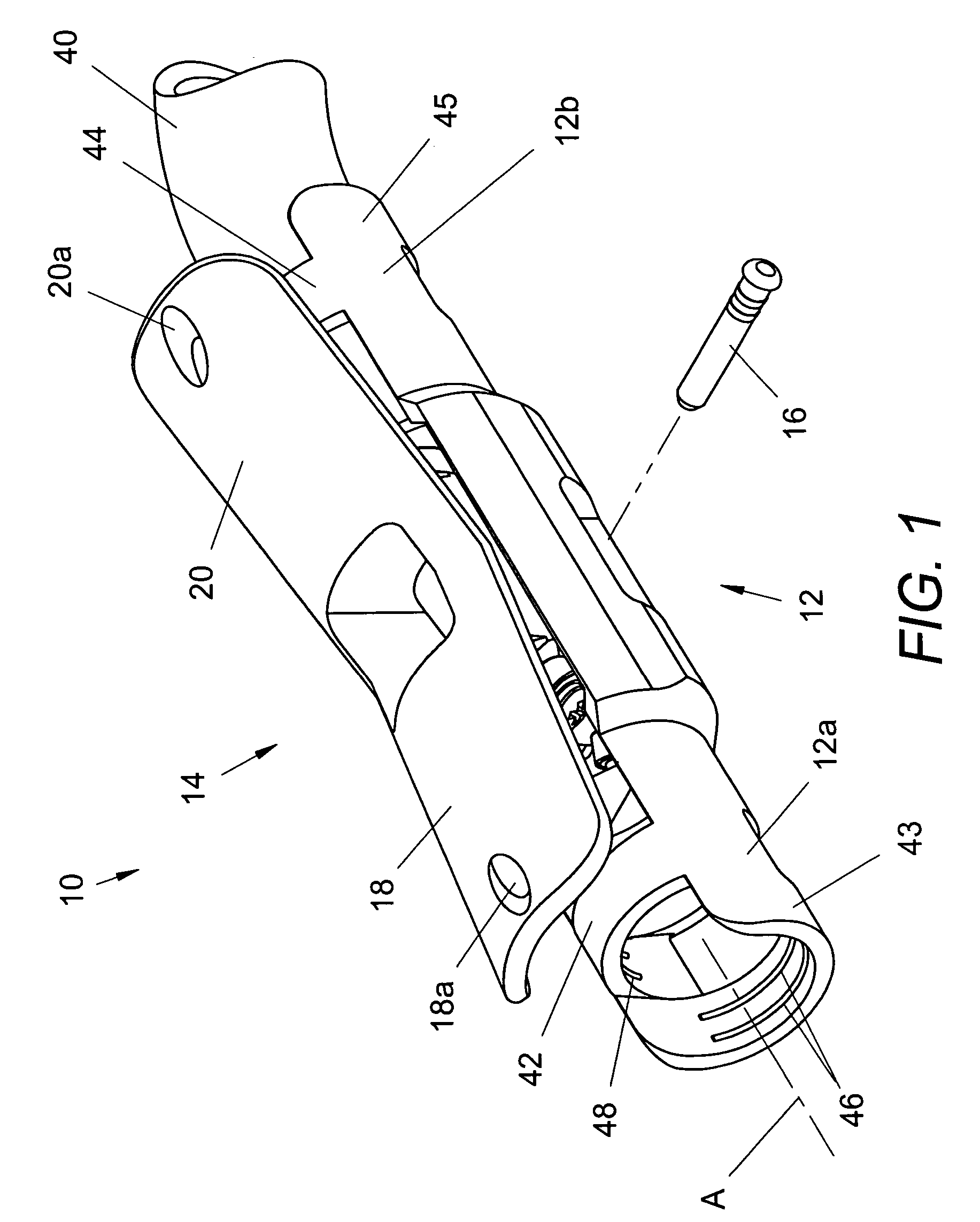

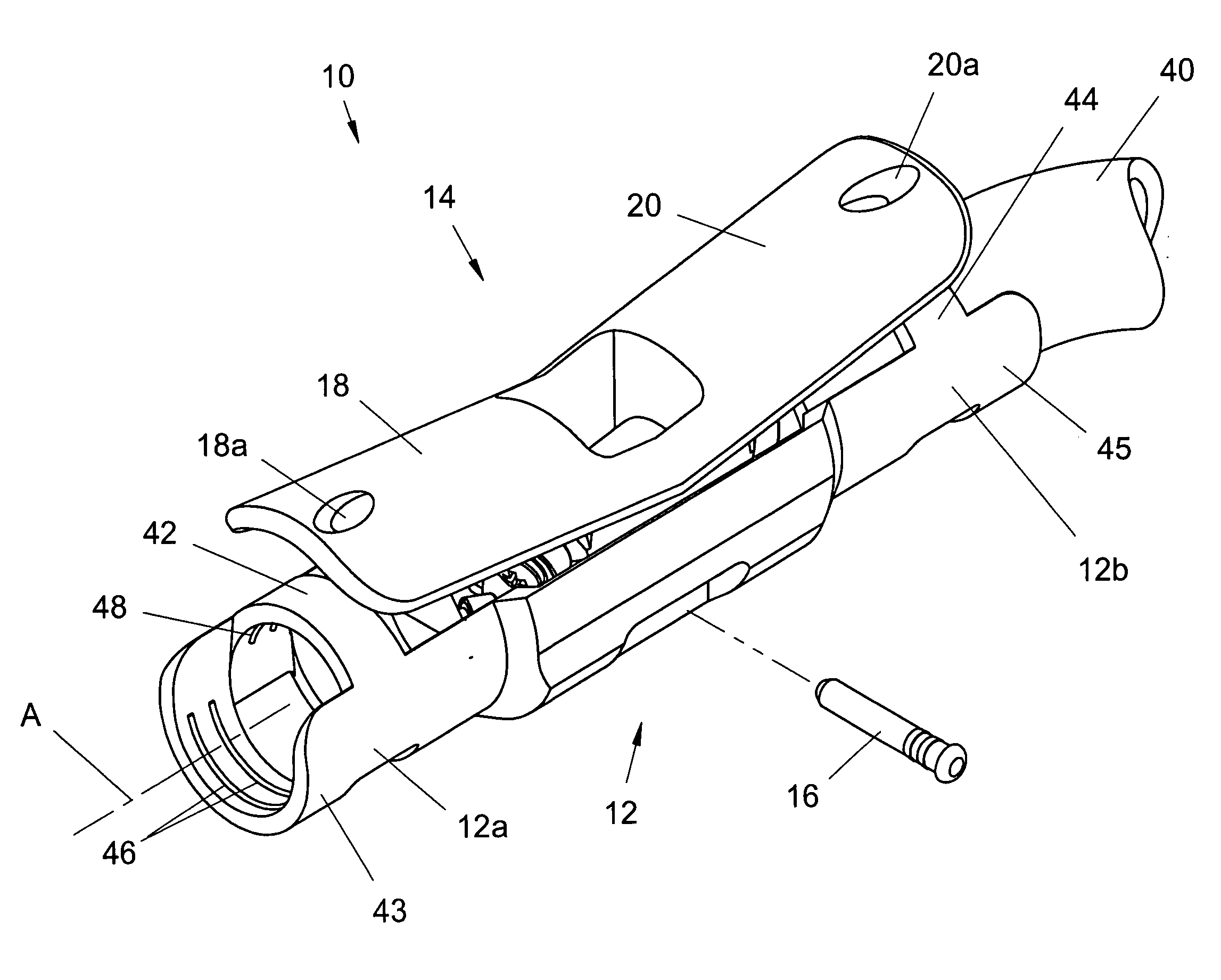

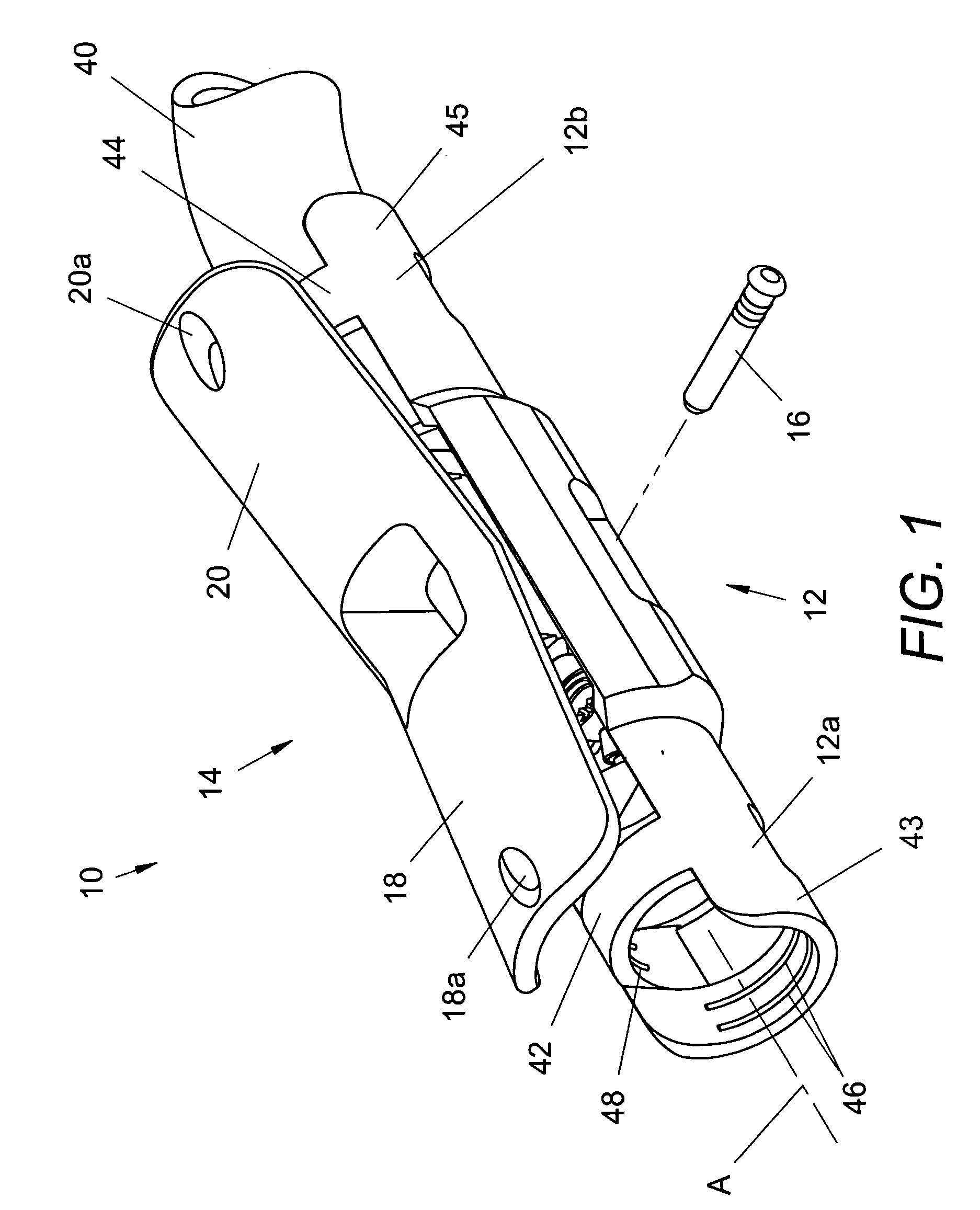

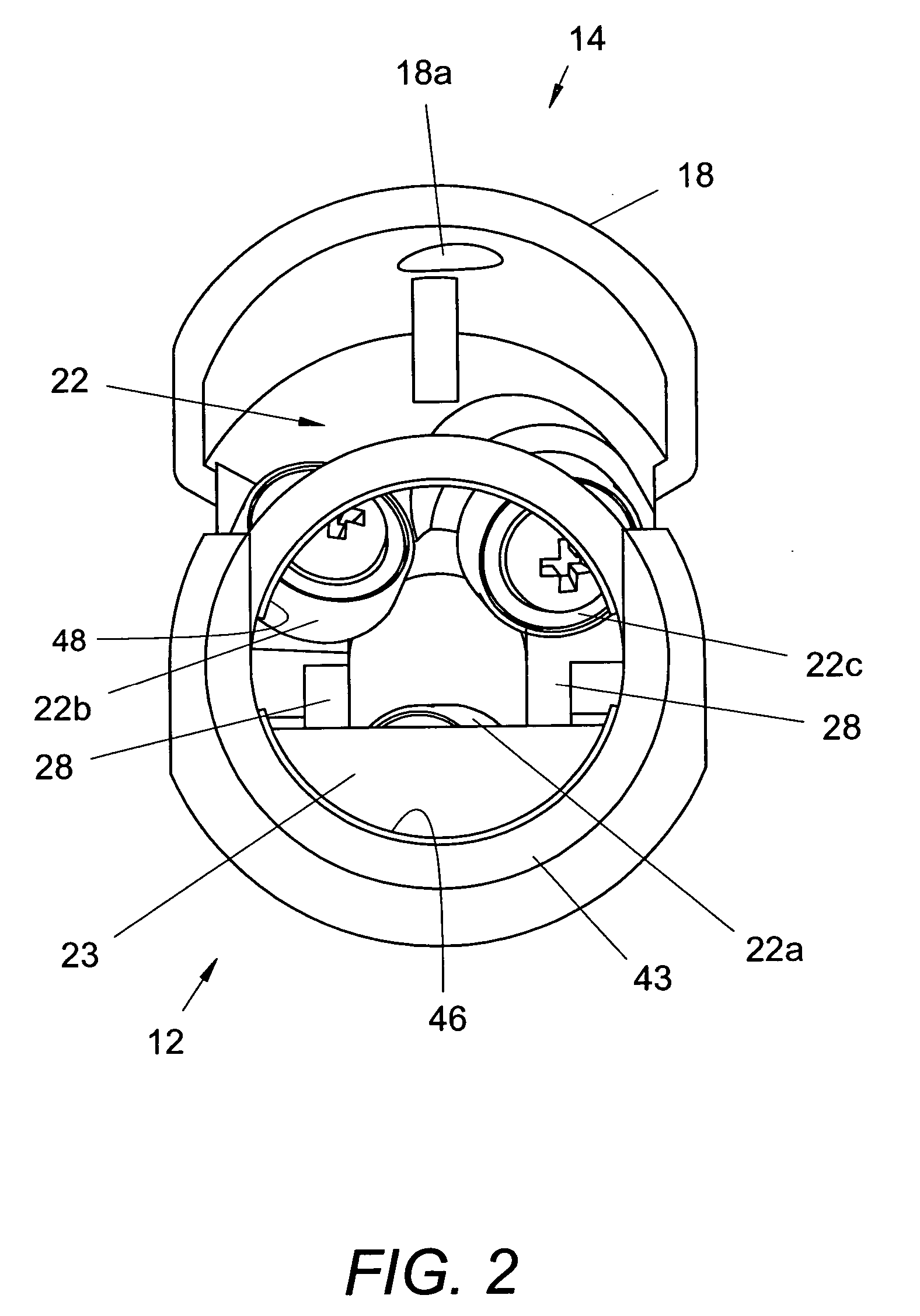

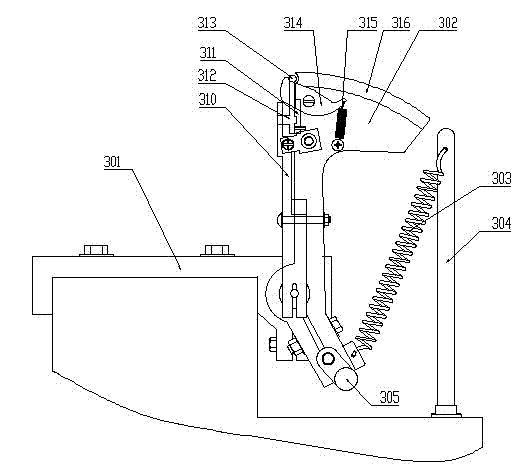

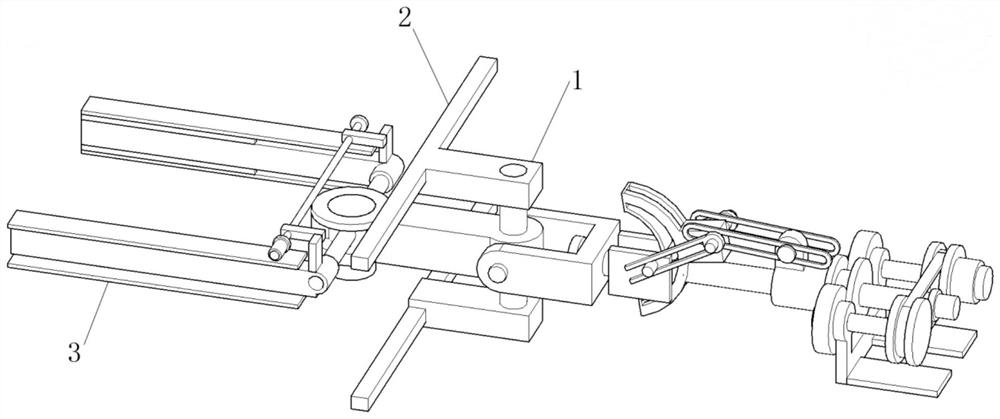

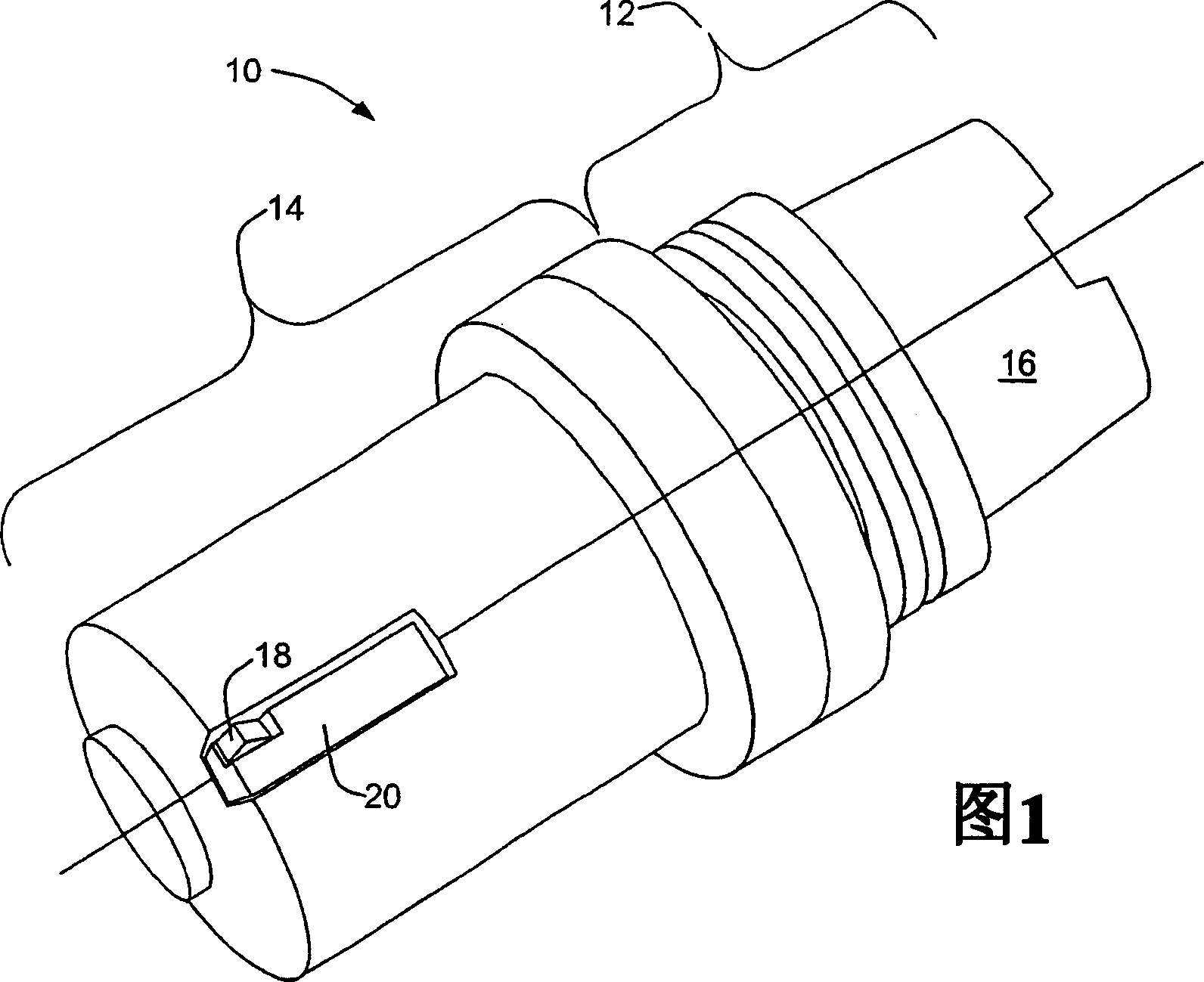

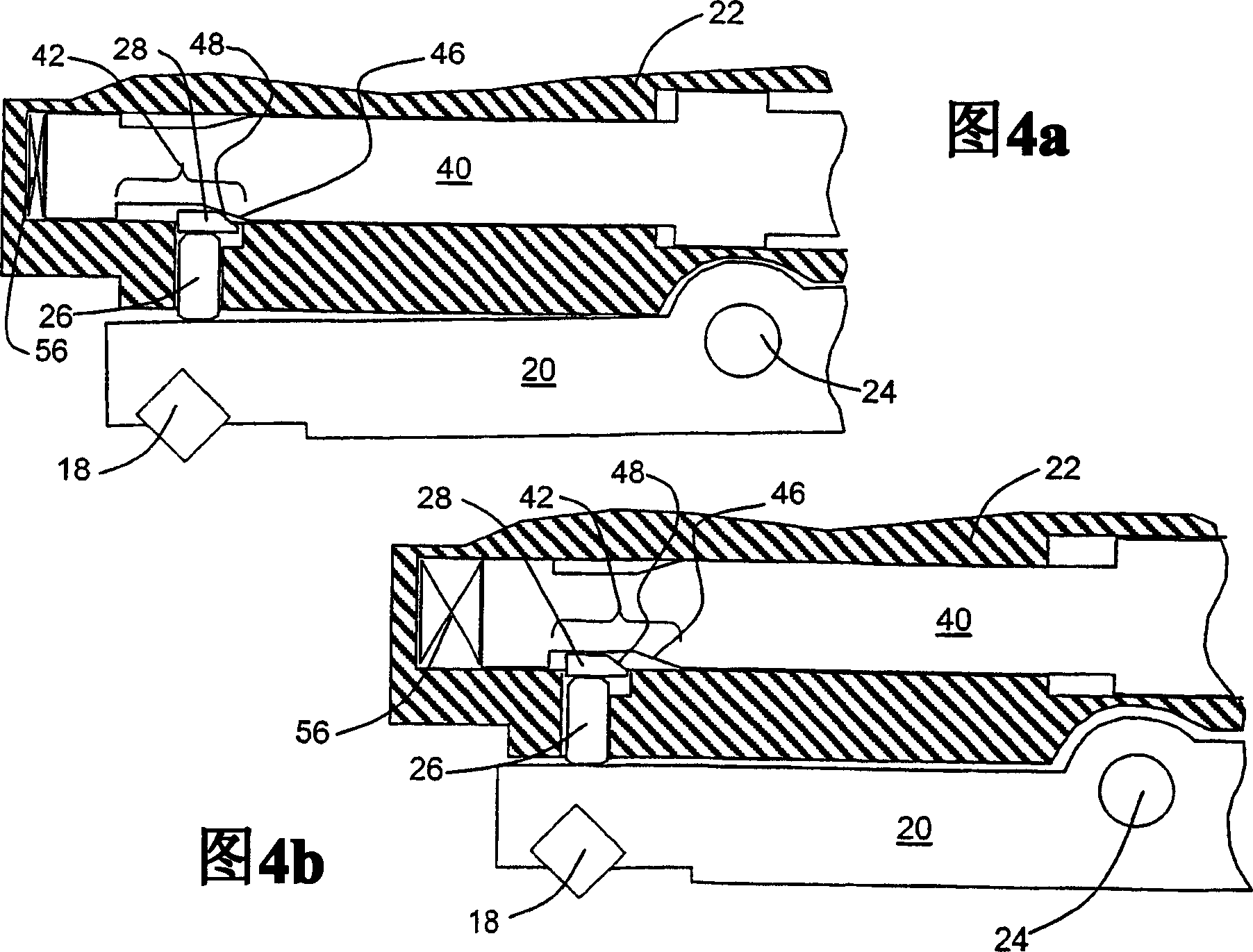

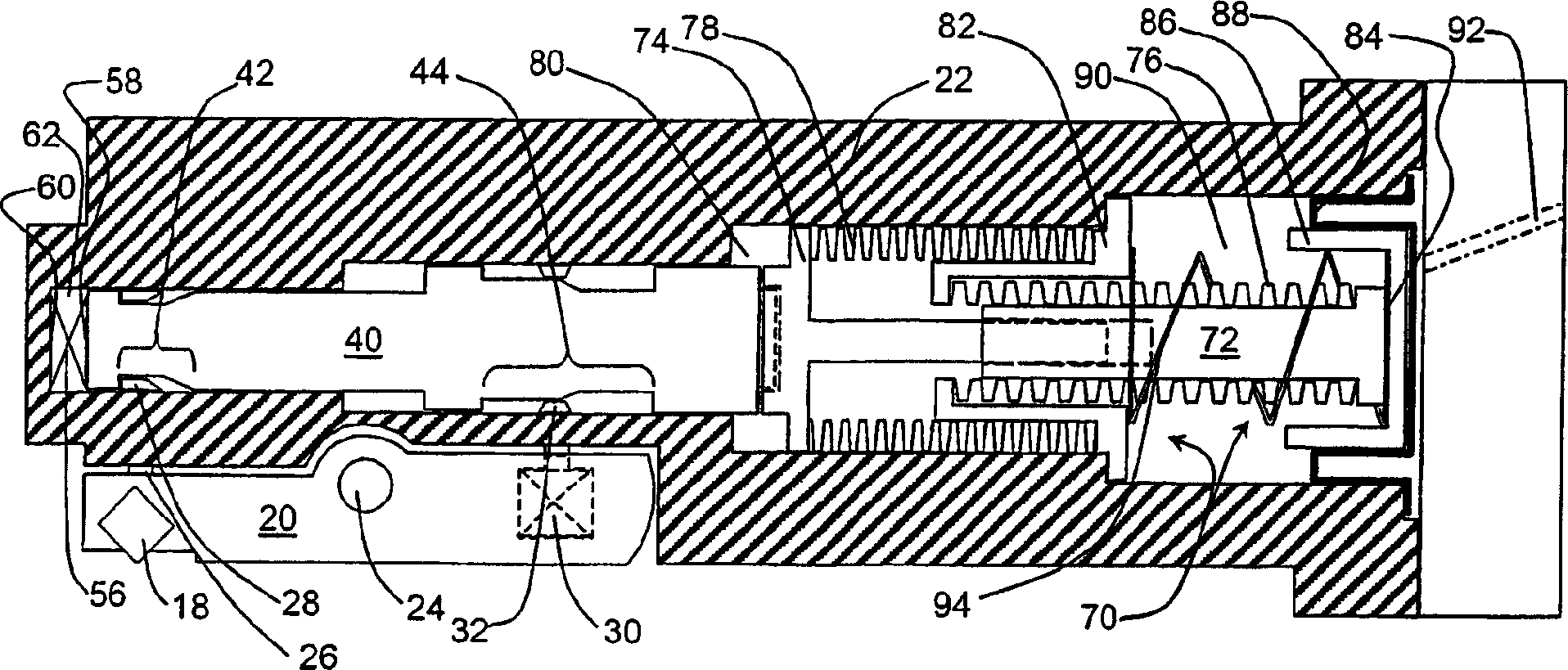

Feed control device for plumbing tools

ActiveUS7685669B2Easy to operateAchieve displacementSewer cleaningHollow article cleaningActuatorControl theory

A snake feeding device comprises a base having opposite ends, an actuator pivotally mounted on the base, and first and second sets of drive rolls spaced apart in the direction between ends of the base. Each set includes a roll on the base and two rolls on the actuator for engaging a snake therebetween and displacing the snake relative to the base in the direction between the ends thereof in response to rotation of the snake. The actuator selectively displaces the rolls of each set relative to one another.

Owner:EMERSON ELECTRIC CO

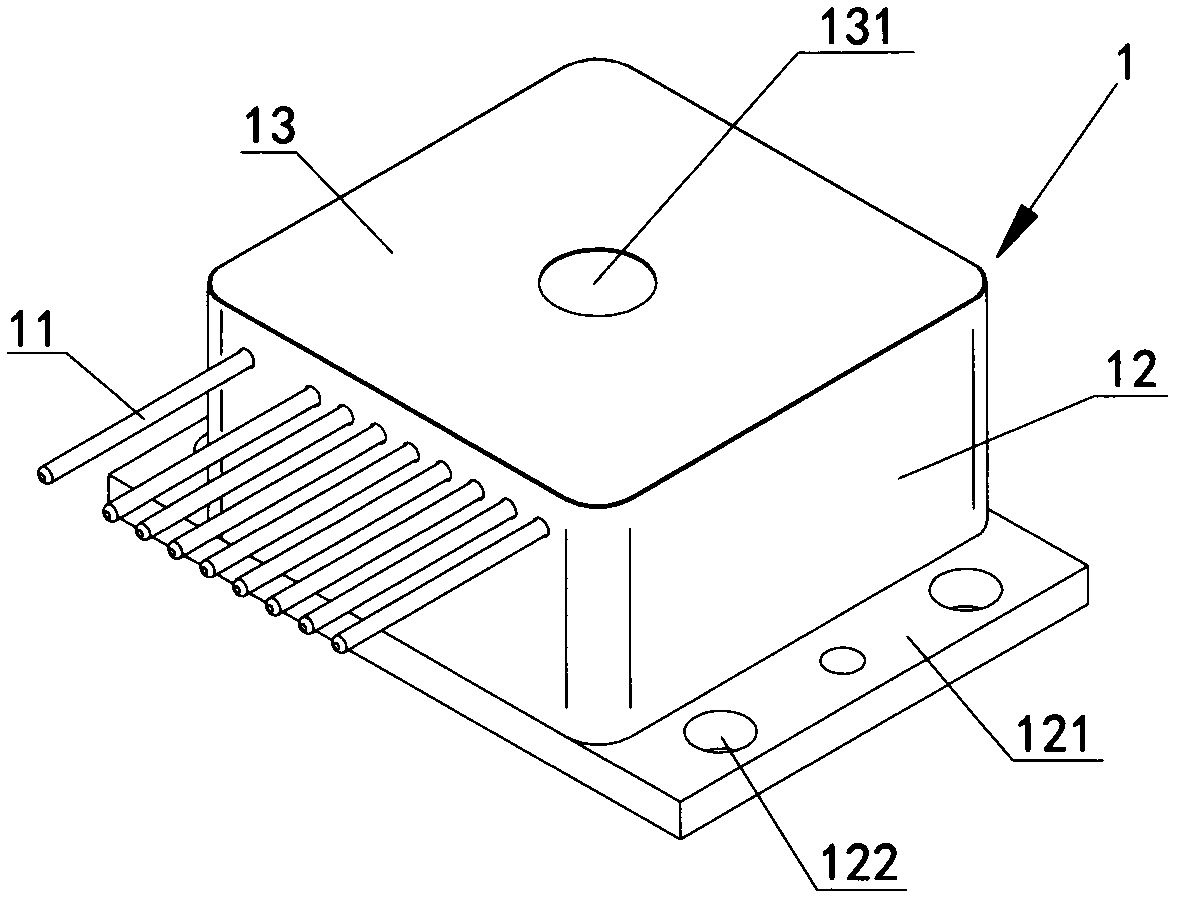

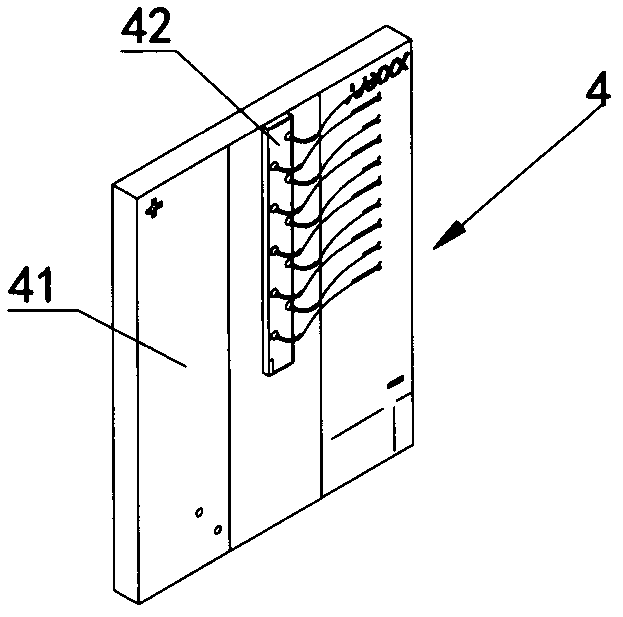

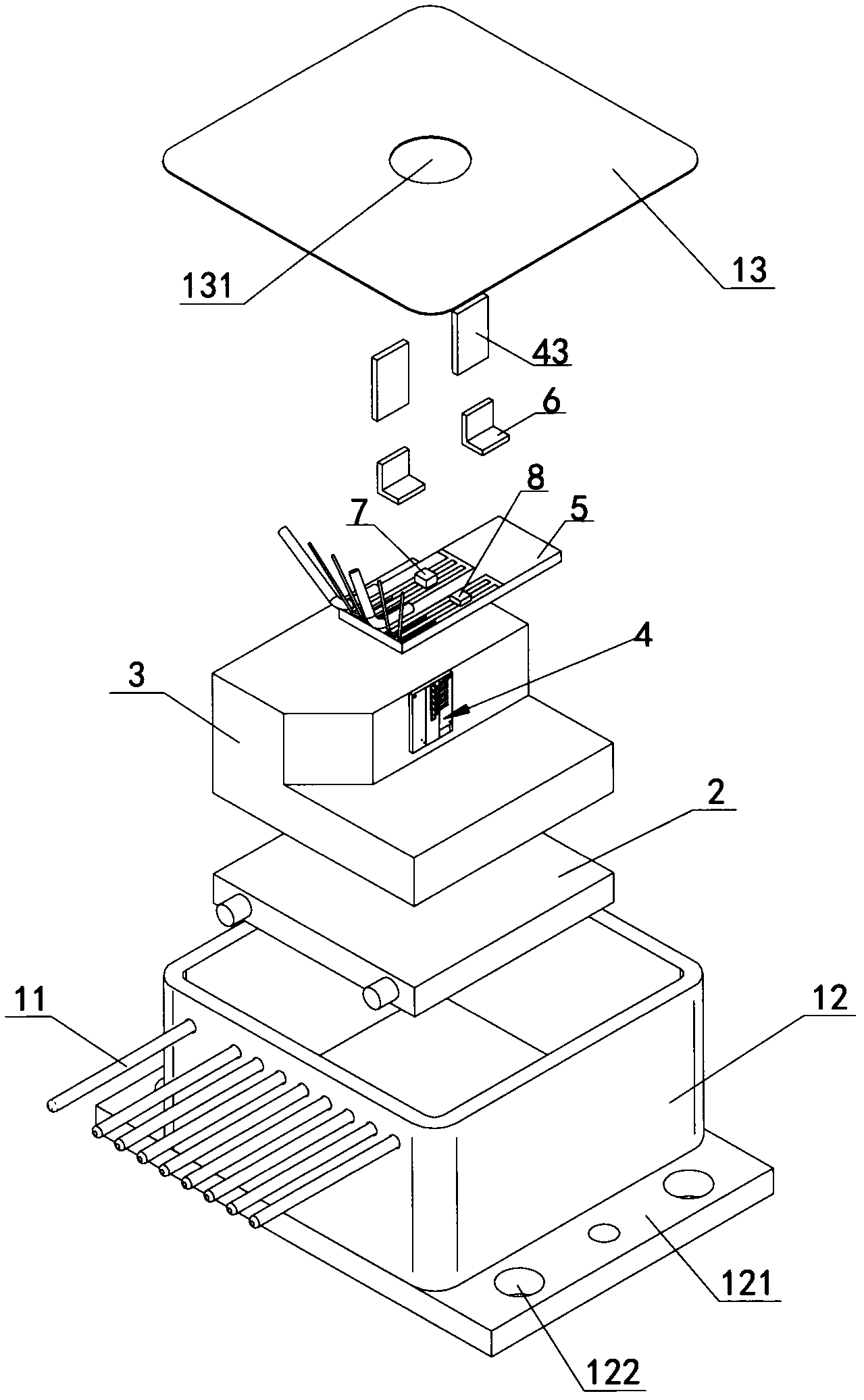

High thermal load large power semiconductor laser

InactiveCN102570293AAchieve preparationManufacturing will notLaser detailsSemiconductor lasersHigh power lasersSemiconductor chip

The invention relates to a high thermal load large power semiconductor laser which comprises a housing, a TEC refrigerator, a heat sink, a semiconductor laser chip assembly, and a circuit board. The semiconductor laser chip assembly is a chip assembly based on COS packaging and comprises a heat radiation substrate and a laser chip which is pasted on the heat radiation substrate. The heat radiation substrate is pasted on the heat sink. The circuit board is a circuit board whose metal surface is coated with ceramic, and the circuit board and the semiconductor laser chip assembly are electrically connected through a connecting copper sheet. The semiconductor laser has a good heat radiation effect, and manufacture of a large power laser can be realized. Simultaneously, the semiconductor laser chip is fixed with the heat sink by employing a pasting mode without deformation or displacement, influence on a product brought by change of machinery, temperature and the like can be overcome, and the reliability of the product is ensured.

Owner:STARWAY LASER

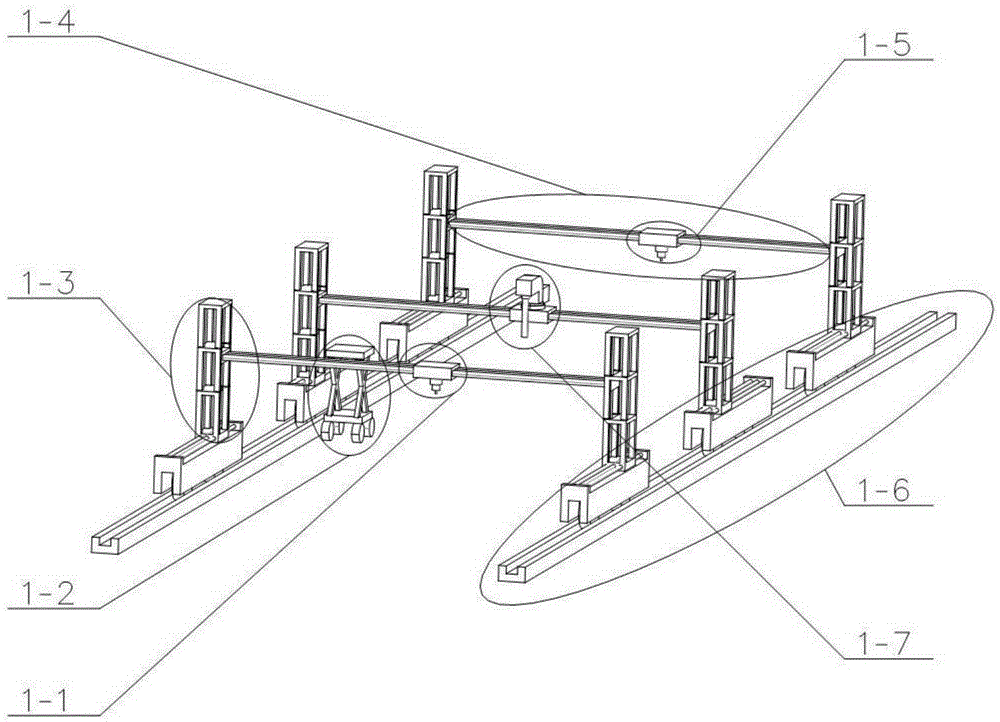

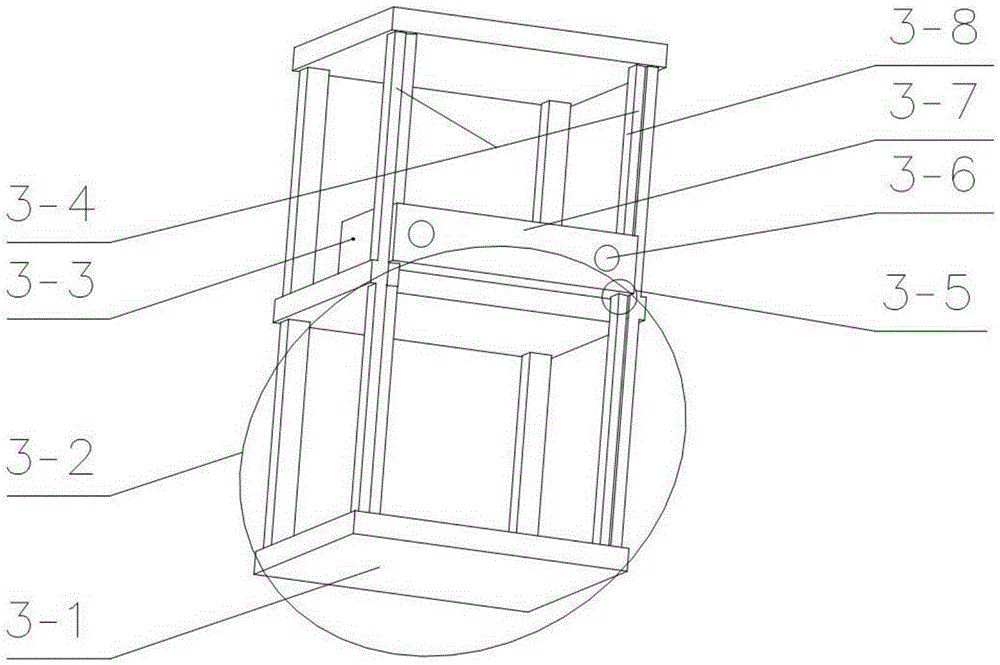

Modularized 3D building printer

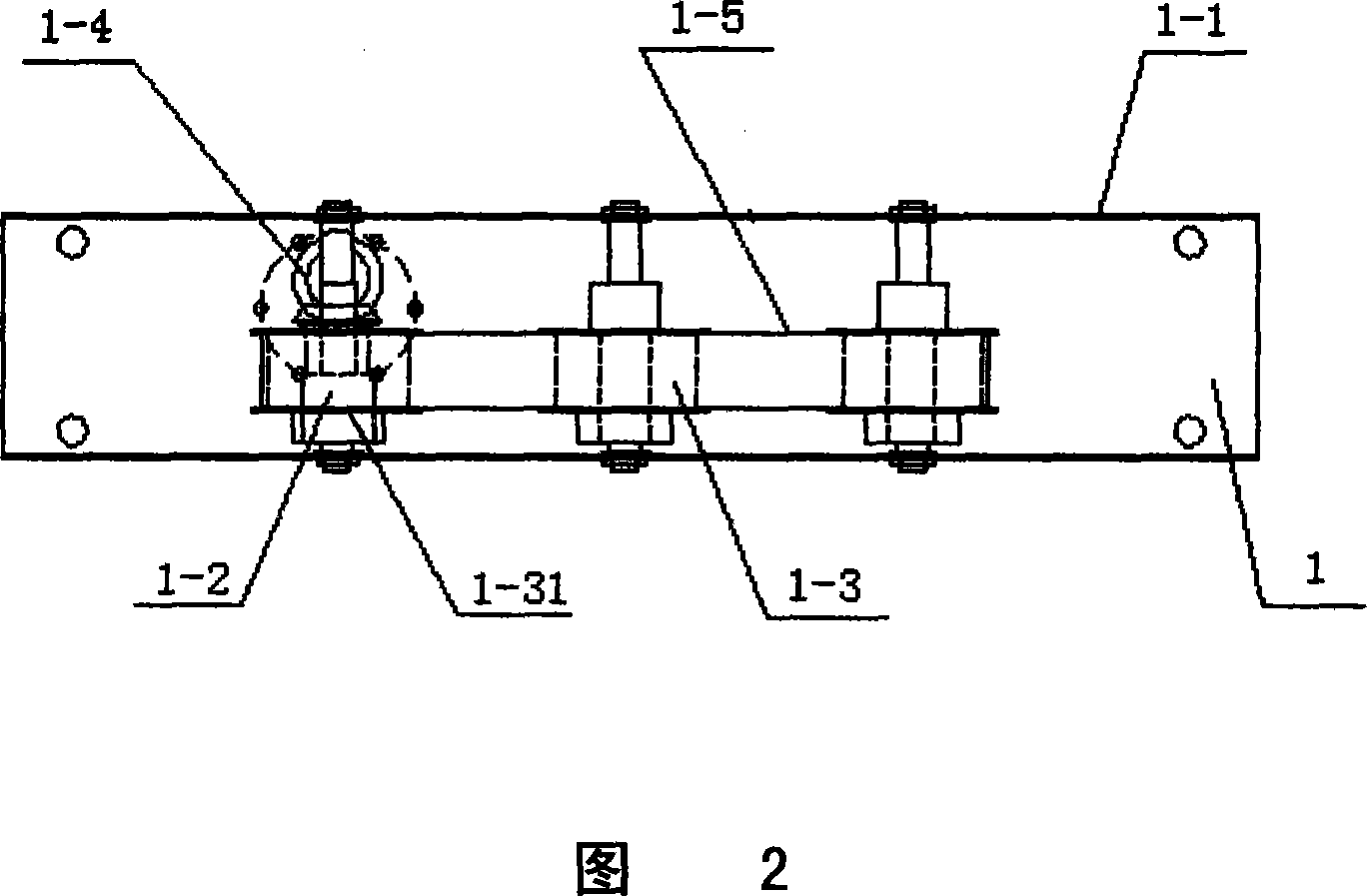

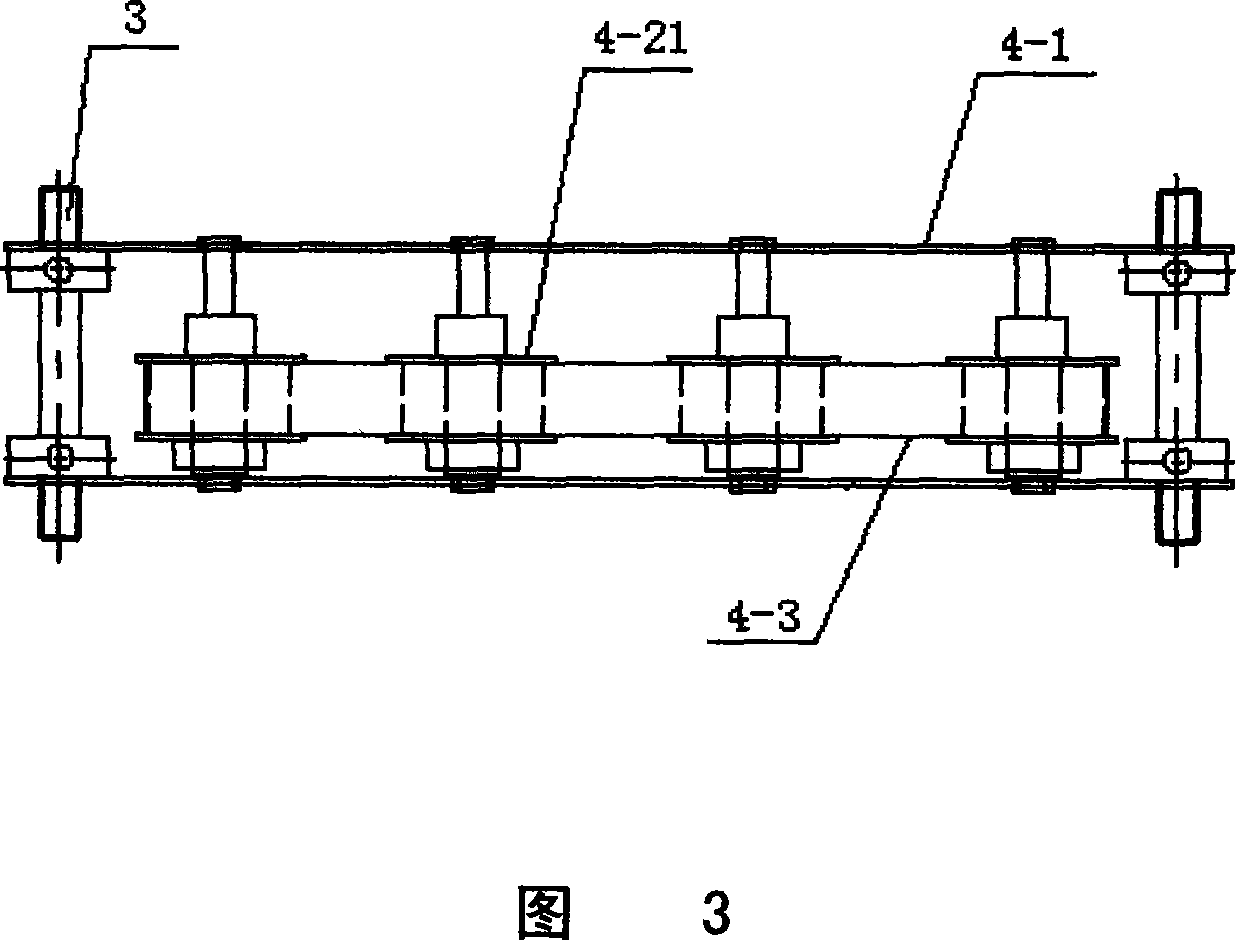

The invention discloses a modularized 3D building printer which includes spliced and lengthened double-layer walking mechanisms (1-6) positioned on two sides of the bottom and spliced and elevated vertical lifting mechanisms (1-3); three spliced and elevated vertical lifting mechanisms (1-3) are arranged on each side of each spliced and lengthened double-layer walking mechanism (1-6); six spliced and elevated vertical lifting mechanisms (1-3) form three groups, and a modularized longitudinal feed mechanism (1-4) is mounted on each group of the spliced and elevated vertical lifting mechanisms (1-3); a material delivery nozzle (1-1), a component-installation manipulator (1-7) and a material filling device (1-5) are mounted on the three modularized longitudinal feed mechanisms (1-4). The modularized 3D building printer can, based on different sizes of real buildings, be spliced reasonably to meet needs, and has the advantages of high efficiency, more free and convenient printing and automatically installed components.

Owner:CHINA UNIV OF MINING & TECH

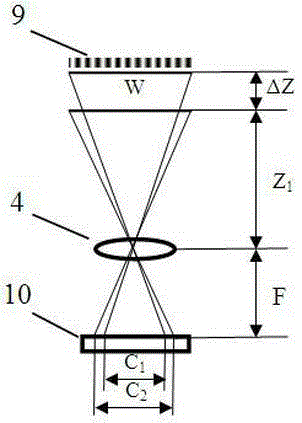

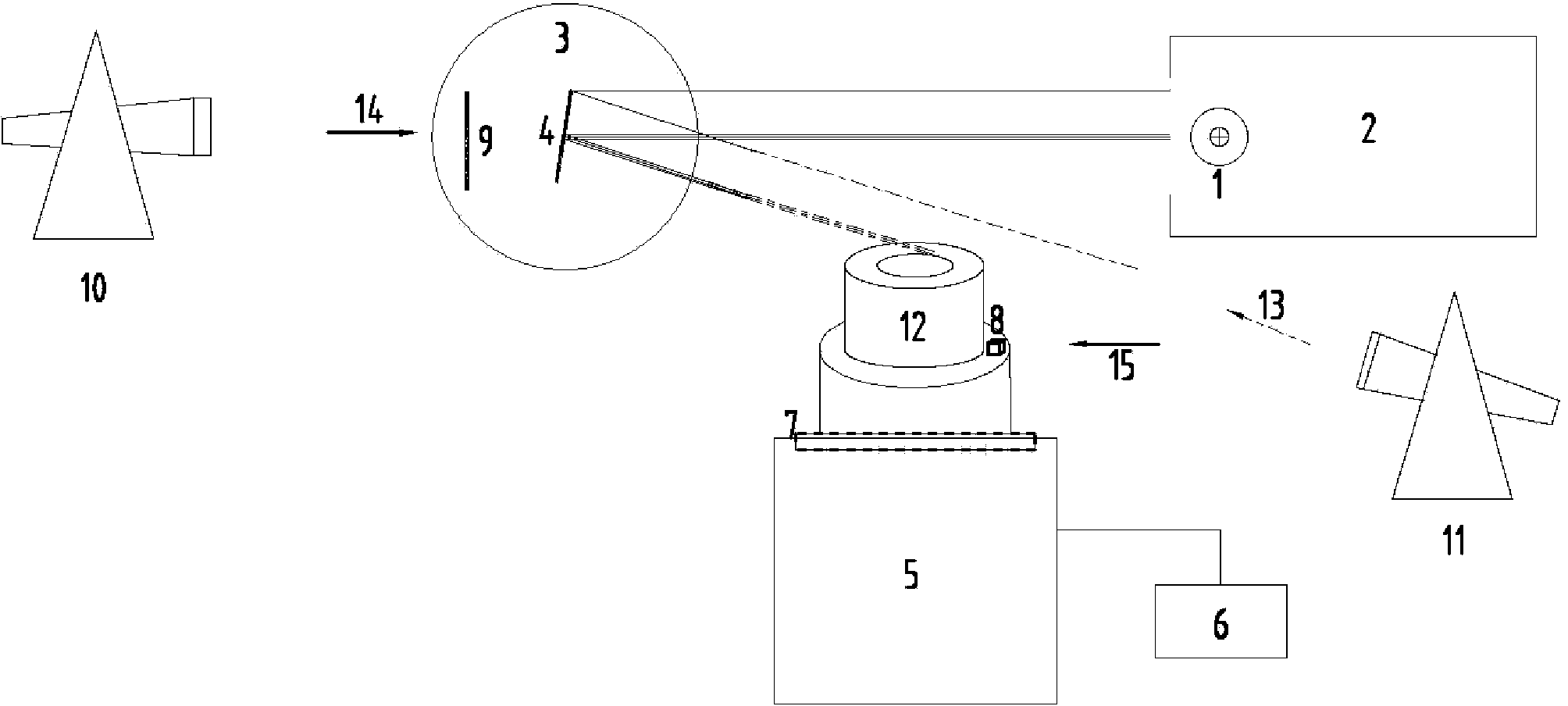

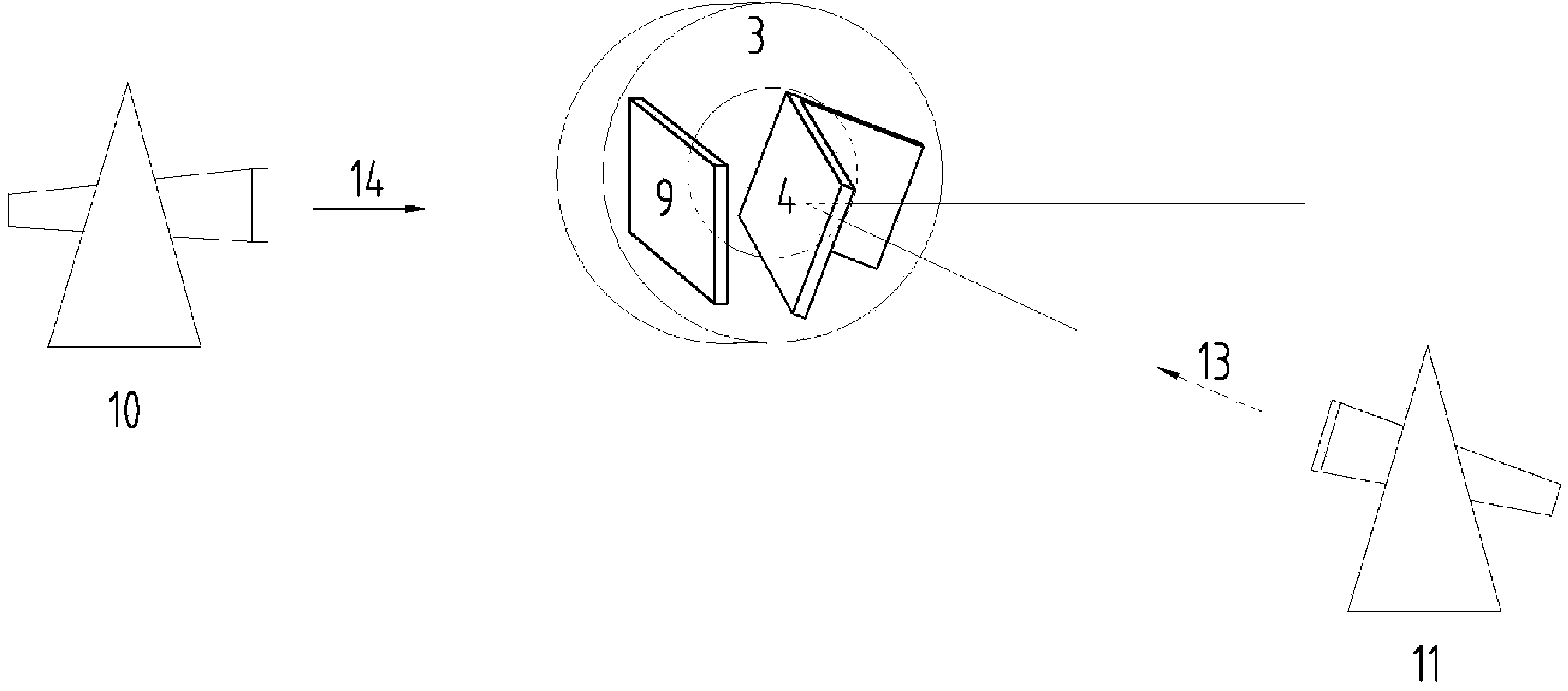

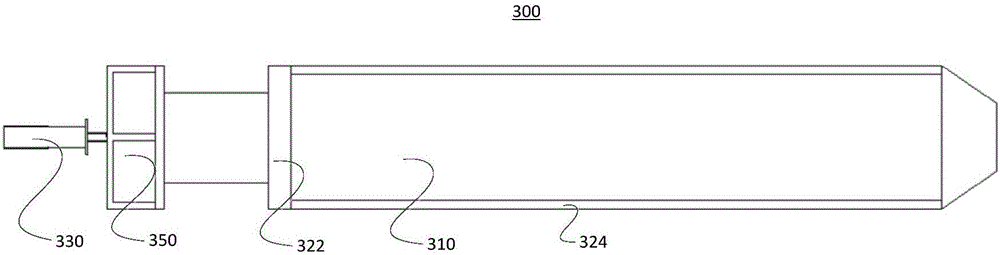

Geometric calibration device for ultraviolet imager with extra large field-of-view

InactiveCN103968858AImprove accuracyGood repeatabilitySpectrometry/spectrophotometry/monochromatorsTheodoliteLight pipe

The invention relates to a geometric calibration device for an ultraviolet imager with extra large viewing field. The geometric calibration device comprises a parallel light pipe system, a six-dimensional rotary table system and an angle monitoring system. According to the invention, the parallel light pipe system is utilized to generate ultraviolet parallel light beams along the radius vector direction of a image surface, so as to simulate an infinite target; the six-dimensional rotary table system is utilized to divide an instrument to be calibrated, with a large viewing field in a radius vector direction of a vertical image surface, so that the in the geometric calibration for the ultraviolet imager with the extra large viewing field, the requirements for stereoscopic spaces and consequent requirements for cost are finely reduced; meanwhile, the high precision and automatic level functionality of a theodolite system, as well as the digital electronic control and adequate small step length equivalent of the six-dimensional rotary table system enable the geometric calibration to have quite high accuracy and repeatability; the displacement of CCD pixel and the repeatability of sub pixel level can be achieved; the whole set of the geometric calibration device is not for a special use, so that the repeated utilization of the geometric calibration device is high; ultraviolet band signals are strong; the geometric calibration device can be utilized as soon as an installation is completed. The geometric calibration device has particularly remarkable effects on the geometric calibration of ultraviolet imager with an extra large viewing field.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Feed control device for plumbing tools

ActiveUS20050246846A1Easy to operateAchieve displacementSewer cleaningHollow article cleaningActuatorControl theory

A snake feeding device comprises a base having opposite ends, an actuator pivotally mounted on the base, and first and second sets of drive rolls spaced apart in the direction between ends of the base. Each set includes a roll on the base and two rolls on the actuator for engaging a snake therebetween and displacing the snake relative to the base in the direction between the ends thereof in response to rotation of the snake. The actuator selectively displaces the rolls of each set relative to one another.

Owner:EMERSON ELECTRIC CO

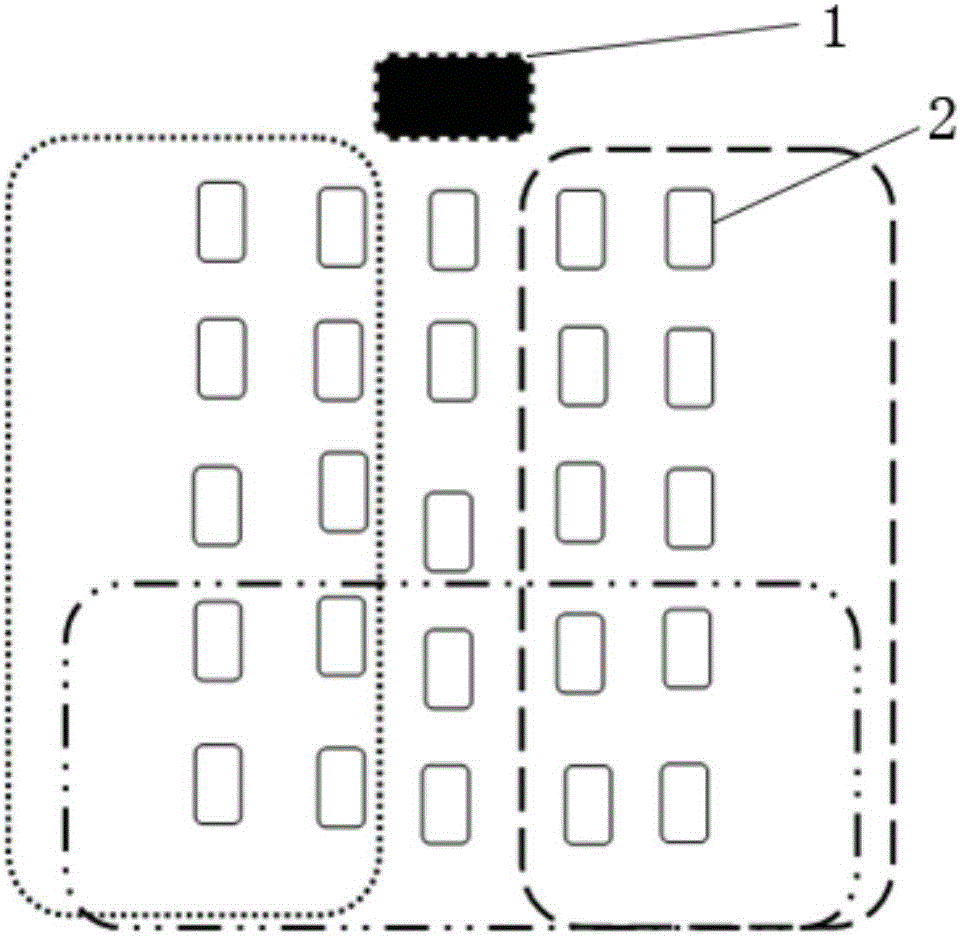

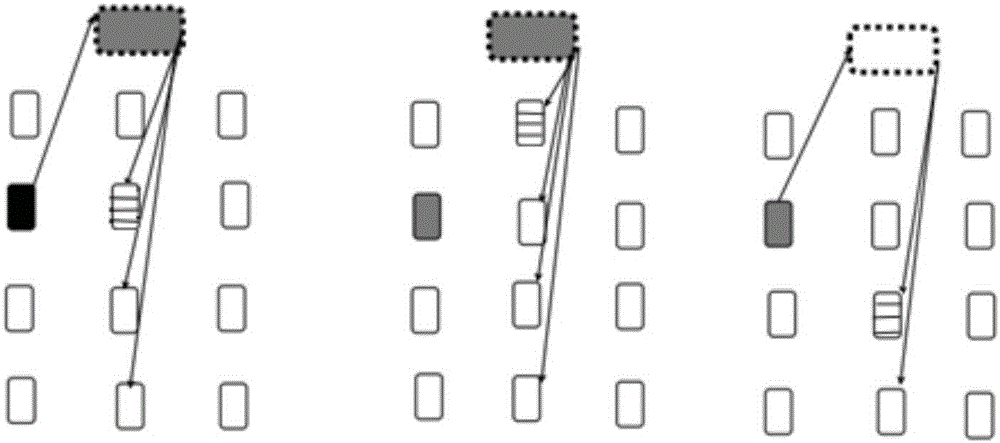

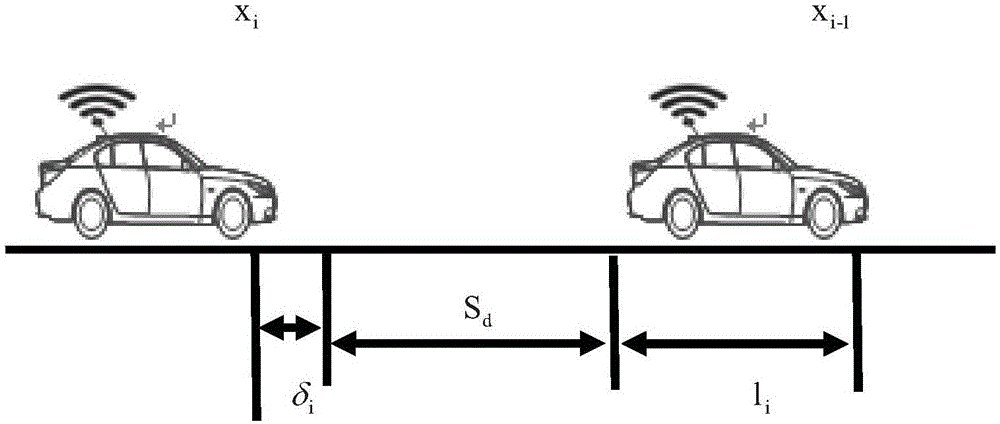

Method to control automobile to drive in cluster type formation

InactiveCN106338998ALower latencyAchieve control speedPosition/course control in two dimensionsCar drivingHorizontal and vertical

The invention discloses a method to control automobile to drive in a cluster type formation. Automobile driving is controlled by using a basic driving unit-cluster, and a speed control model is provided on the basis of horizontal and vertical formation models. The method can be used to control the speed, acceleration and displacement via horizontal and vertical control, delay of time signals can be reduced, and is significant.

Owner:JILIN UNIV

Line climbing robot

InactiveCN101049898AAchieve displacementExpand the use of spaceLifting devicesHoisting equipmentsDrive wheelDrive motor

A robot able to crawl along wire features that it has a primary drive mechanism composed of drive motor, drive wheels and the belt for drive wheels, a secondary one composed of drive wheels and the belt for drive wheels, and a combined clamp for linking the primary drive mechanism with the secondary one. Said drive wheels of primary and secondary drive mechanisms are staggered on the wire to make their belts to closely clamp the wire.

Owner:SHANGHAI UNIV OF ENG SCI

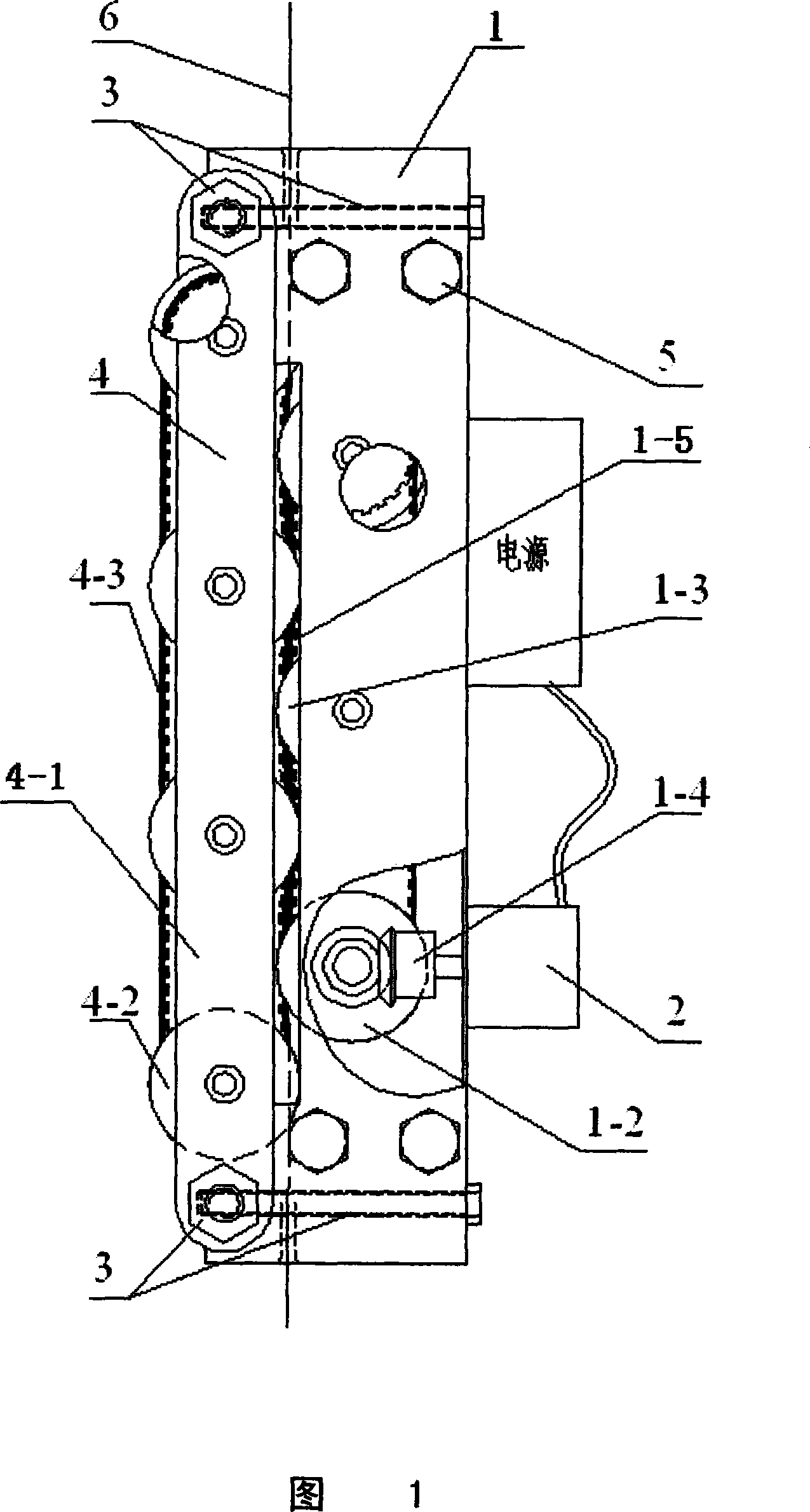

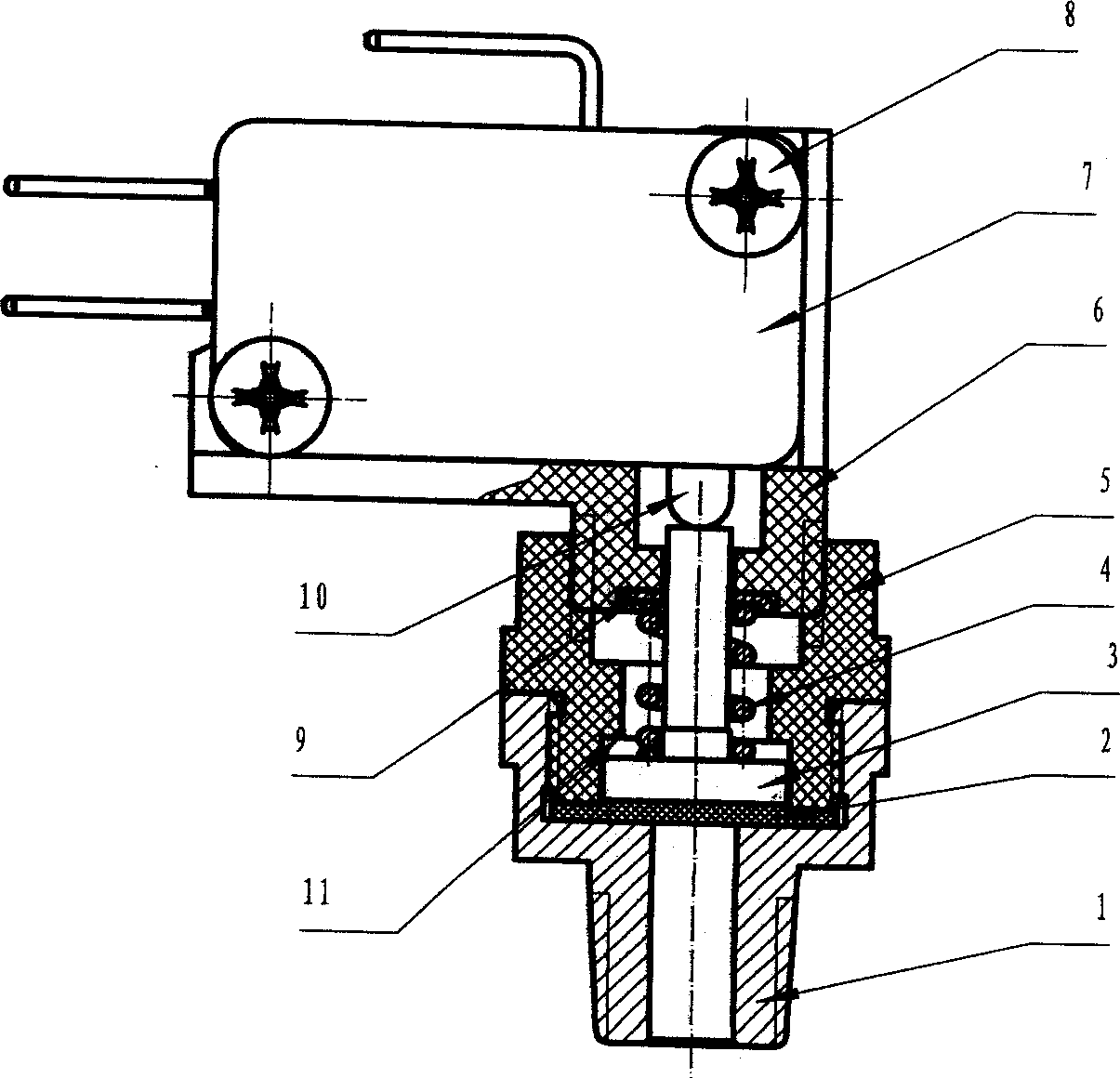

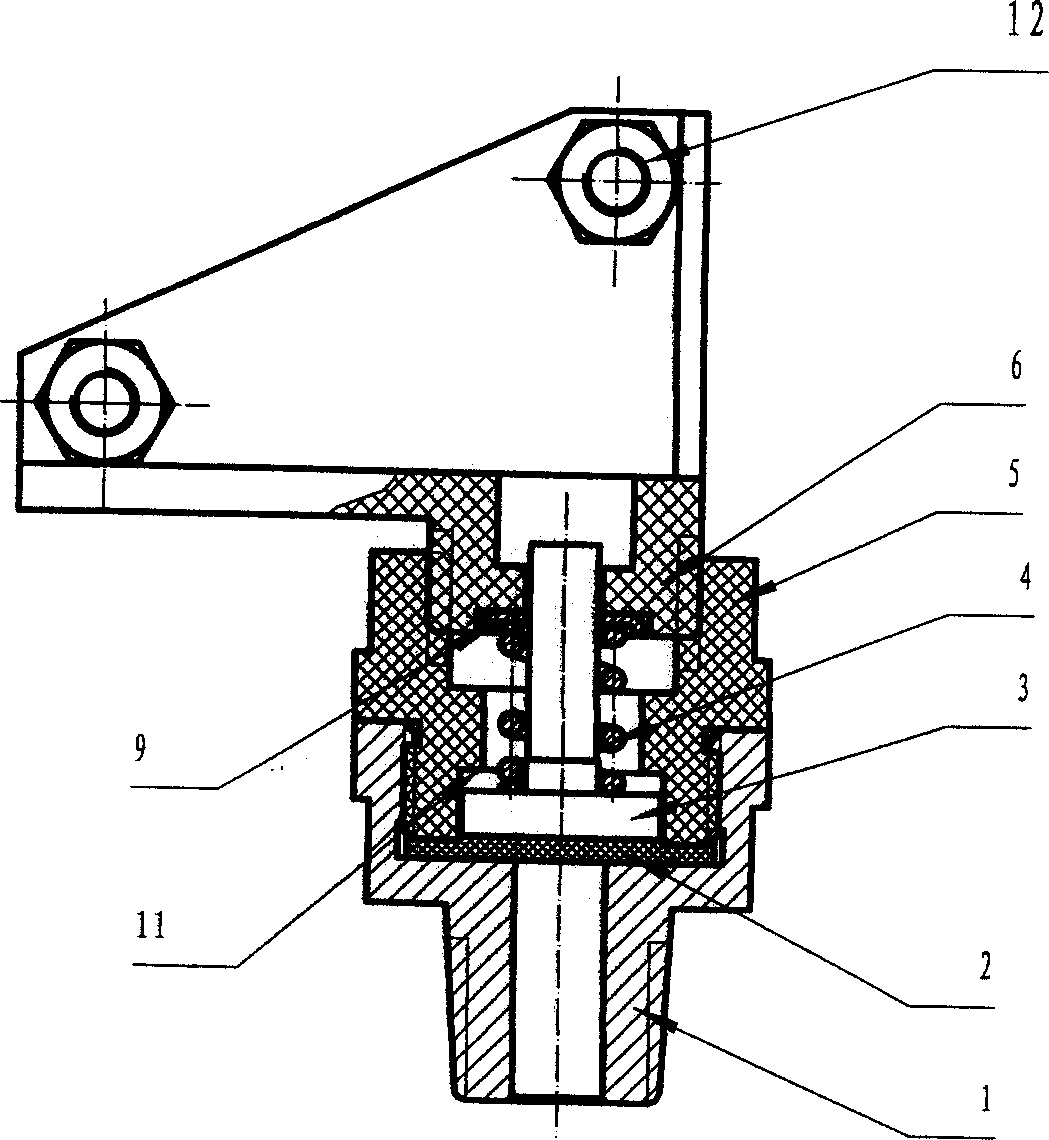

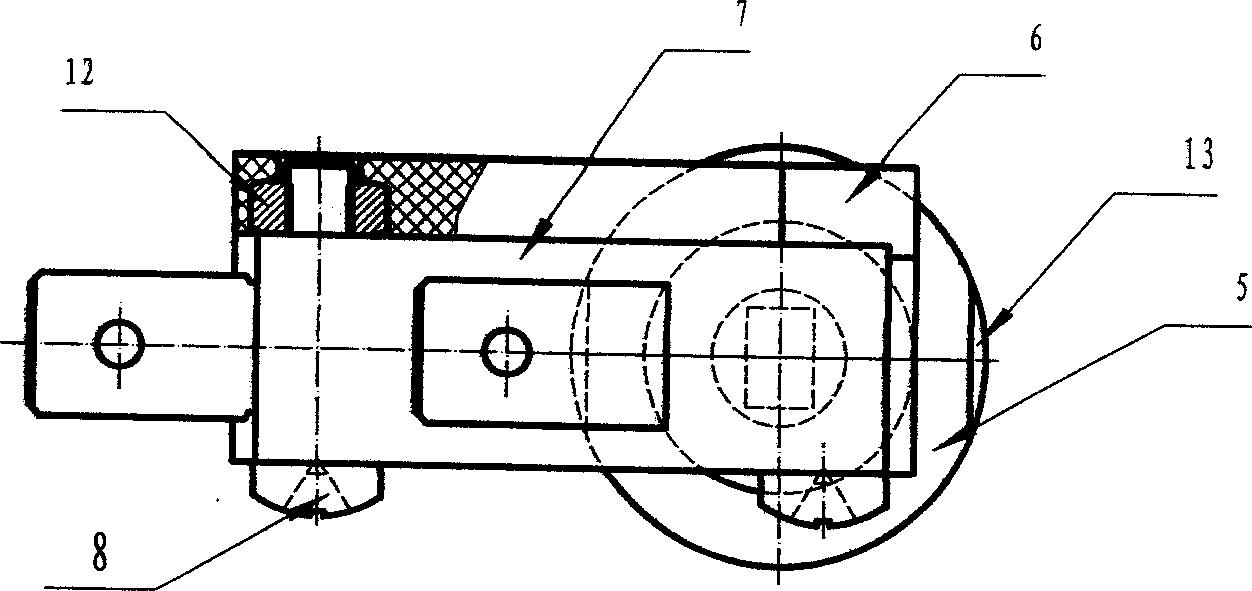

Pressure switch

The invention relates to a pressure switch used in over-pressure protection of family micro boiler steam generator, wherein it is formed by connector 1, sealing membrane 2, top rod 3, spring 4, frame 5, switch base 6, and micro switch 7; as picture 1, the connector 1 connects the pressure switch and the steam generator, as well as the mounting base of sealing membrane 2; the frame 5 mounts the membrane 2 and the top rod 3 inside the connector 1; the frame 5 mounts the switch base 6 after mounting the spring 4 and the pad 9, to form pressure sensor; the pressure volume is converted into the displacement of top rod 3, to push the trigger 10 of micro switch 7 mounted on the switch base 6; via adjusting the screw dept of switch base 6 in the frame 5, setting the operation point of pressure switch; then adhering the switch base 6 and the frame 5 with sealing rubber. Said invention uses rubber sealing membrane to replace the metal membrane, to realize lower cost and micro volume.

Owner:宁波市塞纳电热电器有限公司

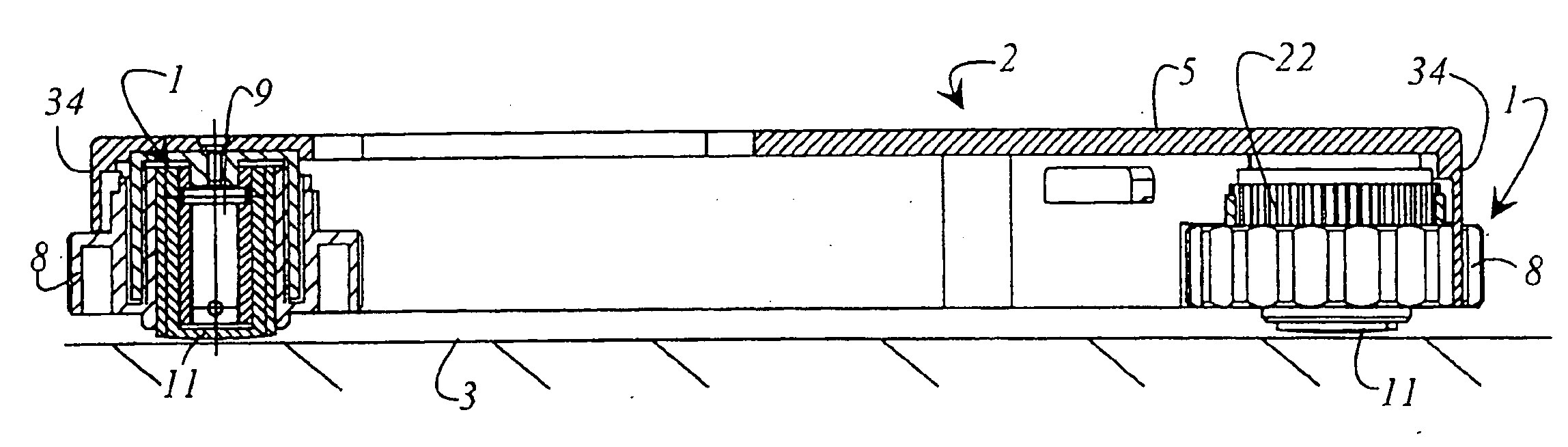

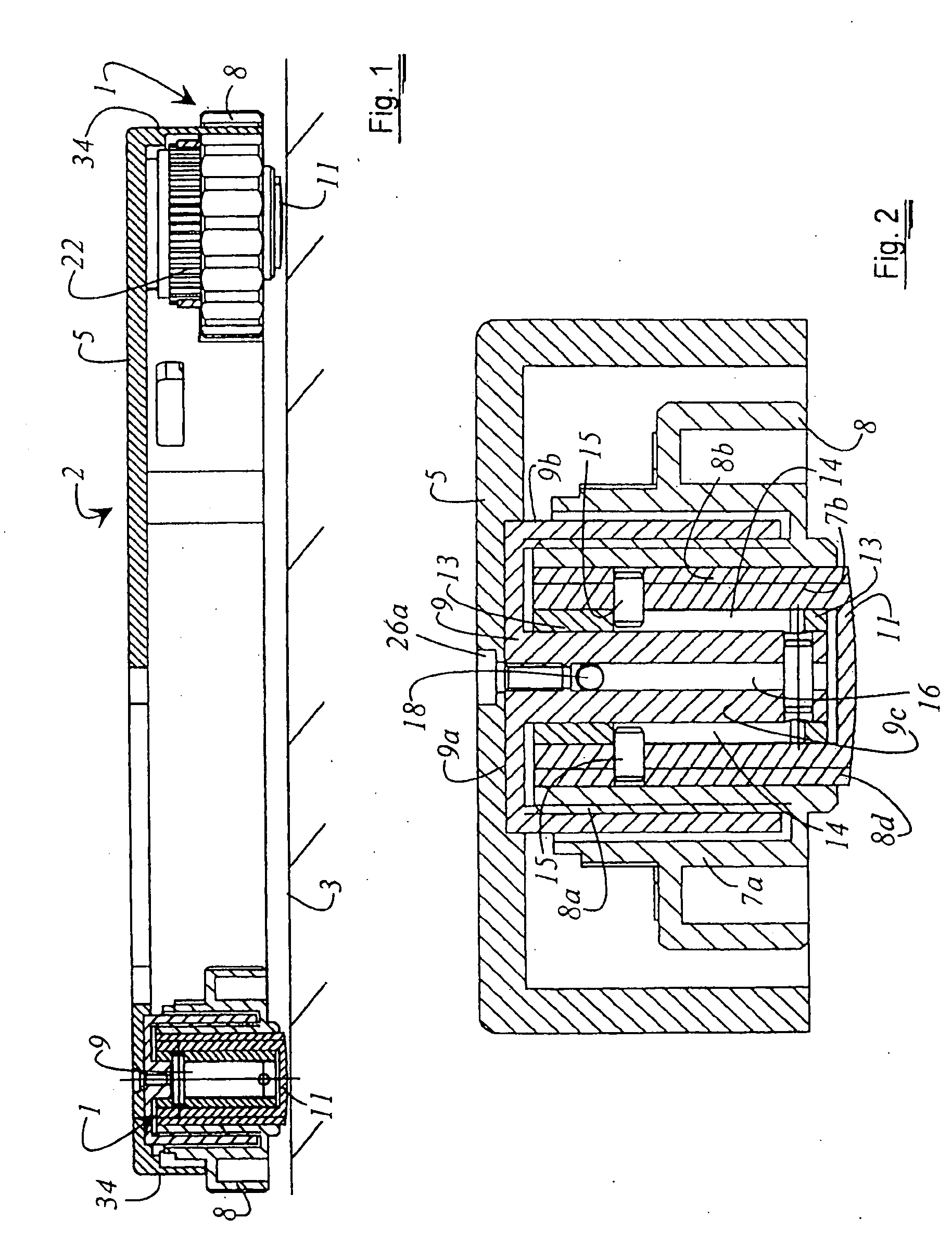

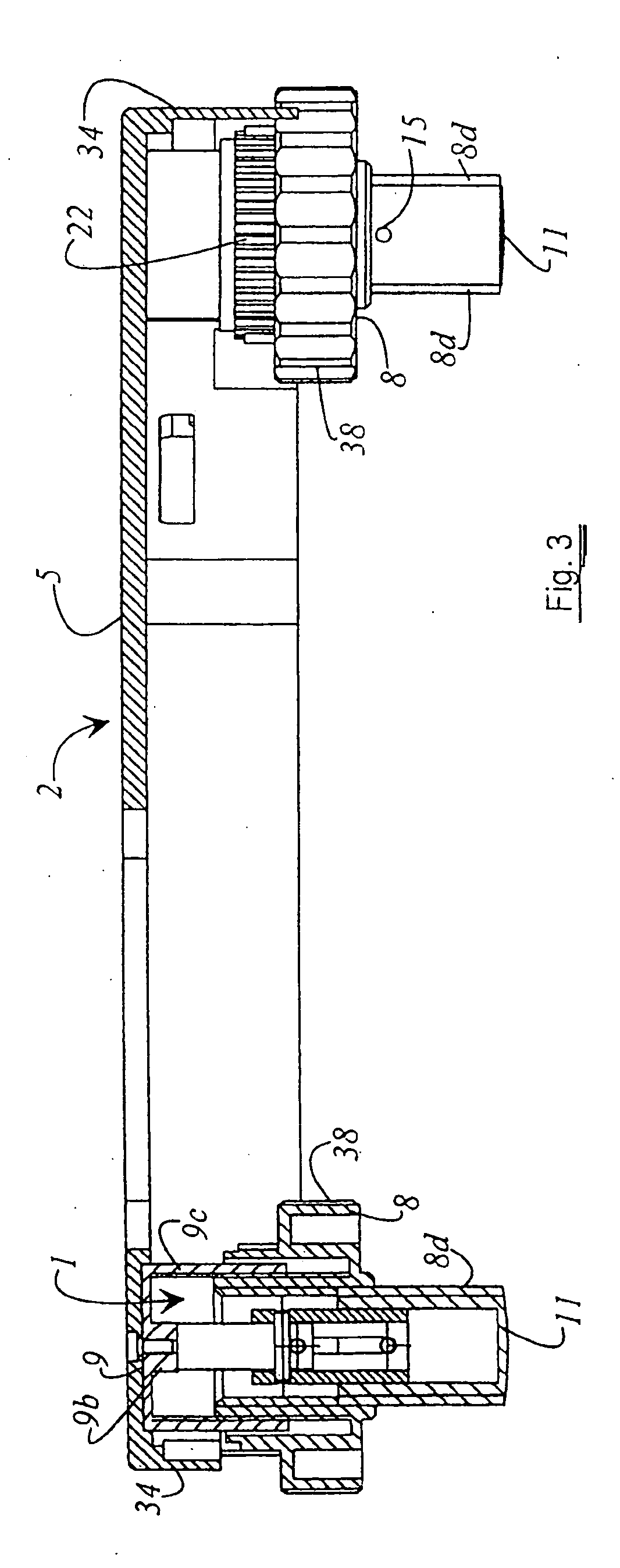

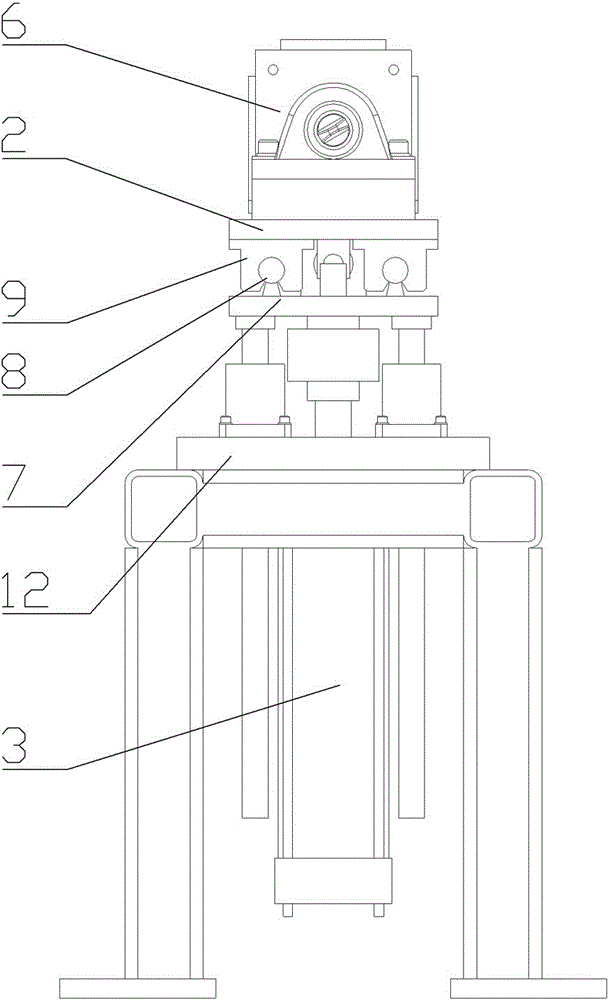

Height-adjusting device and support for optical systems, which comprises height-adjusting devices

ActiveUS20060186287A1Improved force transmissionAchieve displacementMachine framesStands/trestlesEngineeringHinge angle

A device for adjusting the height of an arrangement 2 relative to a mounting surface 3 is disclosed. Height-adjusting device 1 is designed so that during height adjustment no friction takes place as a result of rotation of the contact sites of the height-adjusting devices 1 with the mounting surface 3. Height-adjusting device 1 consists of a rotary wheel 8, a socket 9 and a foot 11. The height adjustment of rotary wheel 8 and foot 11 relative to the stationary socket 9 occurs in telescopic manner. Height-adjusting device 1 is designed so that the foot 11 undergoes a displacement twice as large as does rotary wheel 8. A support (30) for an optical system is provided with several height-adjusting devices 1 connected with the bottom 5 of a base 31 of the support 30. On the support 30 there are provided a left and a right hand rest 31a and 31b which are fastened to the base 31 of the support 30 by means of a hinge 32 so that independently of the height adjustment of the support 30, the edges 32a of the left or right hand rest located opposite the hinge always rest on the mounting surface 3.

Owner:LEICA MICROSYSTEMS CMS GMBH

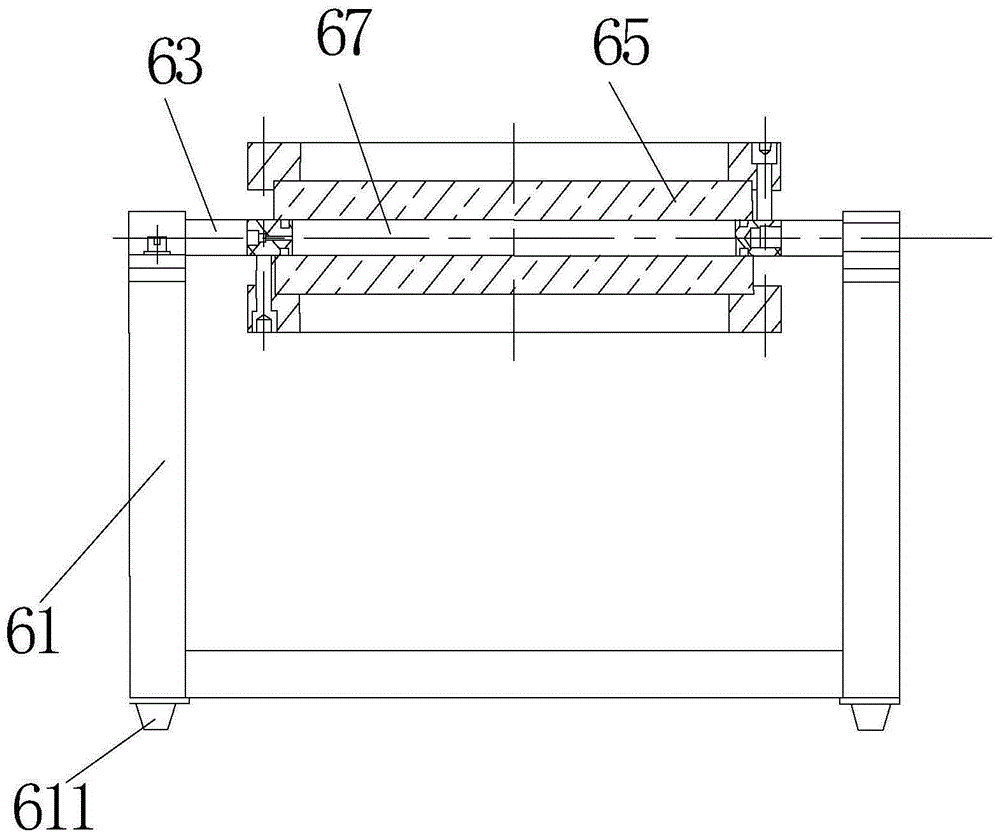

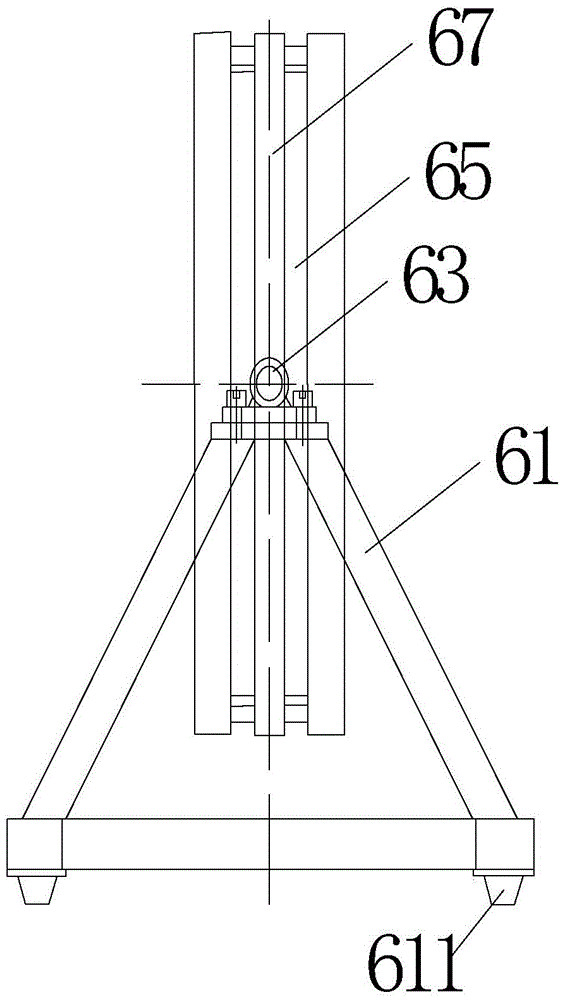

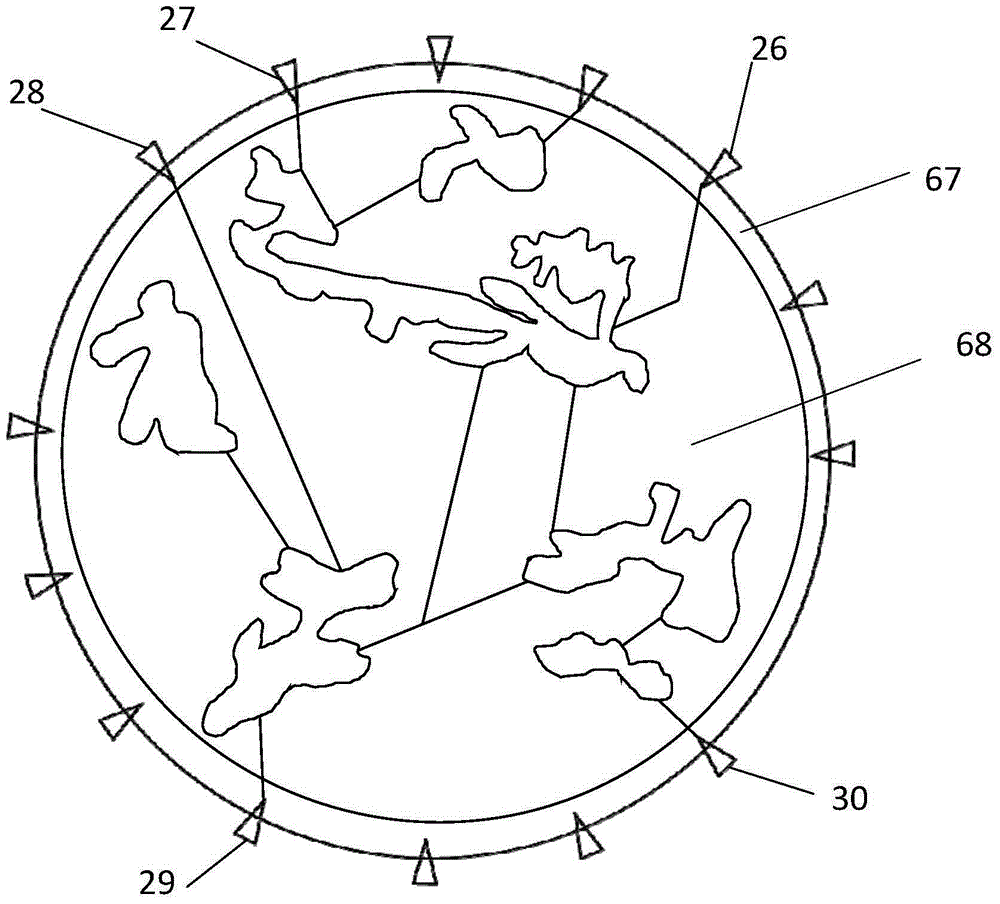

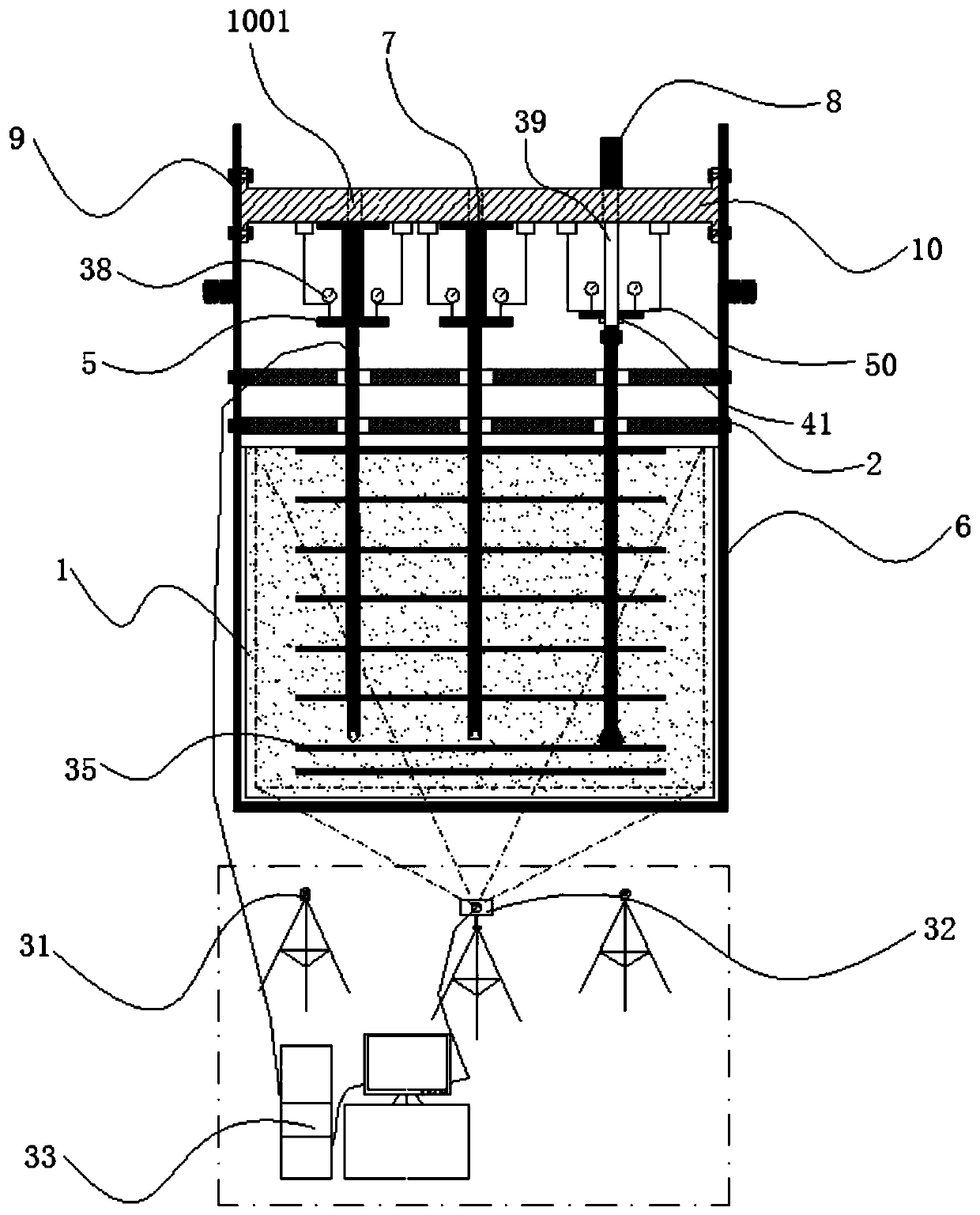

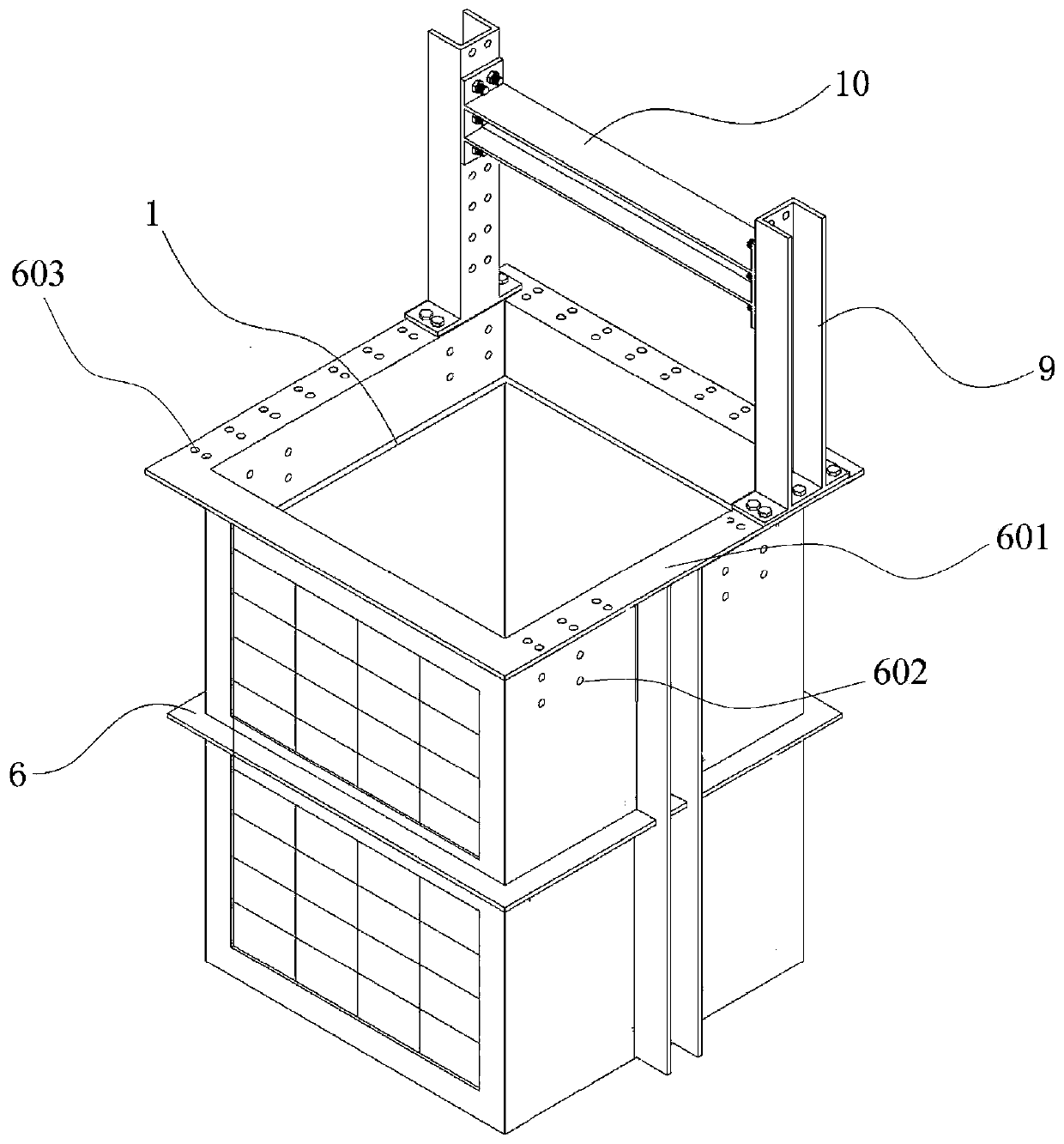

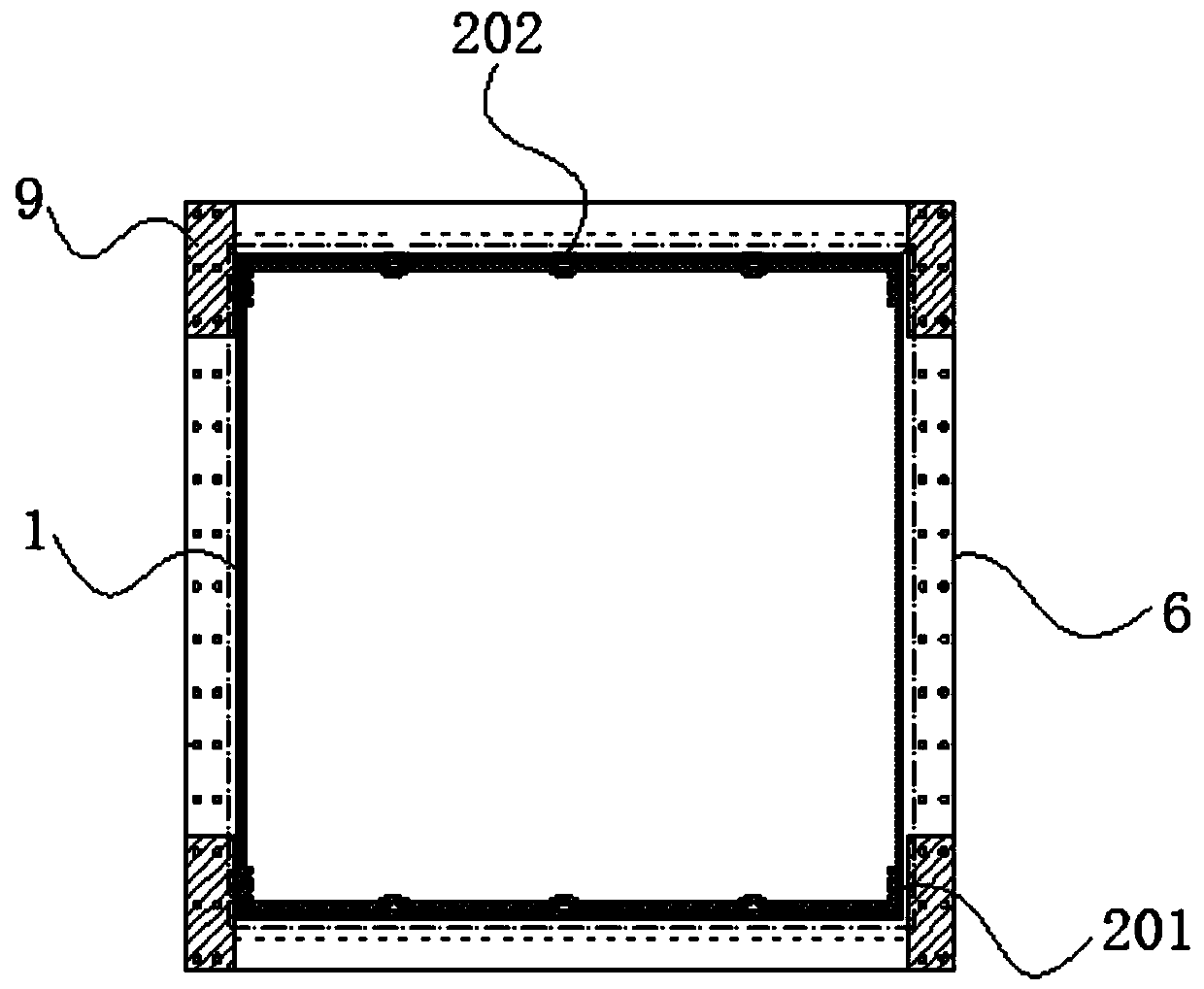

Pile and soil interaction visual testing device and method

ActiveCN109868849AGuaranteed to be verticalGuaranteed to be close to the box wallFoundation testingPorosityMeasurement device

The invention provides a pile and soil interaction visual testing device and method. The testing box device comprises a testing box, pile body limiters, model piles, a visual system and a pile body loading and measuring device; and an organic glass box body is embedded in an inner cavity of a box body supporting steel frame, and the detachable pile body limiters are located on the upper part of the testing box so as to ensure that pile bodies are vertically and tightly attached to the inner wall of the box. A matched pile and soil interaction study in soil particle layers for dyeing of the various model semi-piles is developed; the arranged visual system and a modern image processing and analysis technology are combined, and thus soil body interior detail information such as the dynamic stress, deformation, displacement, the soil body porosity and soil particle crushing in the whole process of pile and soil interaction is revealed; and according to the device, the pile-soil layer effect in the experimental study macroscopic level and the pile-soil particle effect in the finely microcosmic level are combined, various experimental study working conditions can be simulated, and the device is low in weight, good in part disassembly, and clear in acting force of structures and parts.

Owner:CHONGQING UNIV

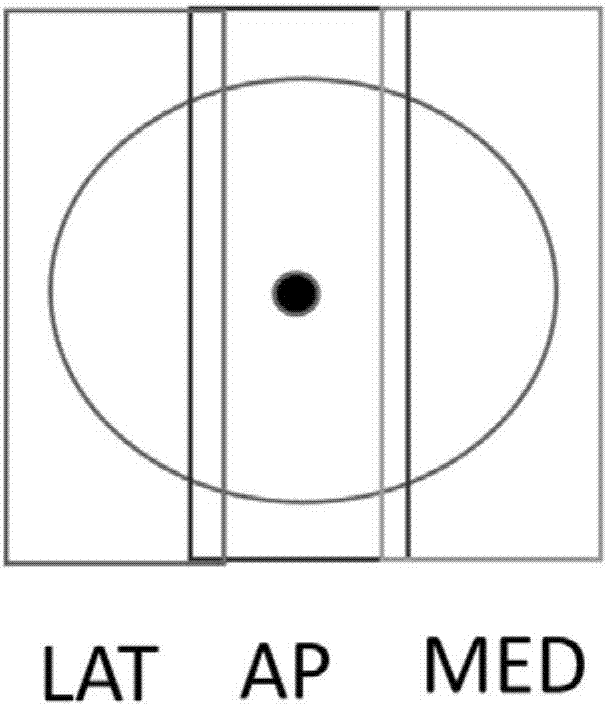

Computer breast scanning automatic machine positioning system

ActiveCN107981888AImprove accuracyAchieve rotationOrgan movement/changes detectionInfrasonic diagnosticsManipulatorComputer science

The invention discloses a computer breast scanning automatic machine positioning system, wherein a self-rotation angle encoder is installed between every two neighboring mechanical arms, and is used for measuring a relative rotation angle in a space between two mechanical arms, and sending to a processor. A mechanical arm probe is connected with one of the end parts of multiple mechanical arms, and is used for scanning the breasts in the different space positions, and transmitting a scanned image to the processor. The processor is used for recording manual calibration left / right AP positions and a nipple image initial position, and according to the space relative rotation angle of each mechanical arm corresponding to the mechanical arm probe in each different space position, determining the image positions obtained by scanning in the different space positions and the displacement of the nipple in the image. The computer breast scanning automatic machine positioning system is capable ofaccurately, efficiently and automatically determining the image position in the scanning image obtained in a moving scanning process of the ultrasonic scanning probe and the nipple image displacementinformation, and the structure is simple, and the manufacturing cost is low.

Owner:ZHEJIANG SHENBO MEDICAL TECH CO LTD

Experiment device and method for monitoring rest oil distribution in rock core in carbon dioxide displacement rock core process

ActiveCN106770377AAchieve displacementMonitor spatial distribution statusMaterial analysis using wave/particle radiationOther gas emission reduction technologiesCt scannersStorage tank

The invention relates to an experiment device and method for monitoring rest oil distribution in a rock core in a carbon dioxide displacement rock core process. The invention mainly aims at providing the experiment device capable of being used for obtaining microscopic rest oil space distribution state in the rock core in the liquid-stage or super-critical state carbon dioxide oil displacement process, and an obtaining method. The device is characterized by consisting of a first storage tank, a second storage tank, a first pressurizing pump, a second pressurizing pump, a heater, a first cooler, a rock core clamper with a sealing packer, a CT (computed tomography) scanner, a solid filter, a liquid filter, a second cooler, a first control valve, a second control valve, a first pressure meter, a second pressure meter, a first temperature indicator, a second temperature indictor and other connecting pipe fittings. By using the method and the device, the rock core CT scanning can be realized in the displacement process; through the division processing on the CT scanning image, the microscopic rest oil distribution state of the rock core in the rock core during different-state carbon dioxide displacement is monitored.

Owner:巴州广和气体资源有限公司

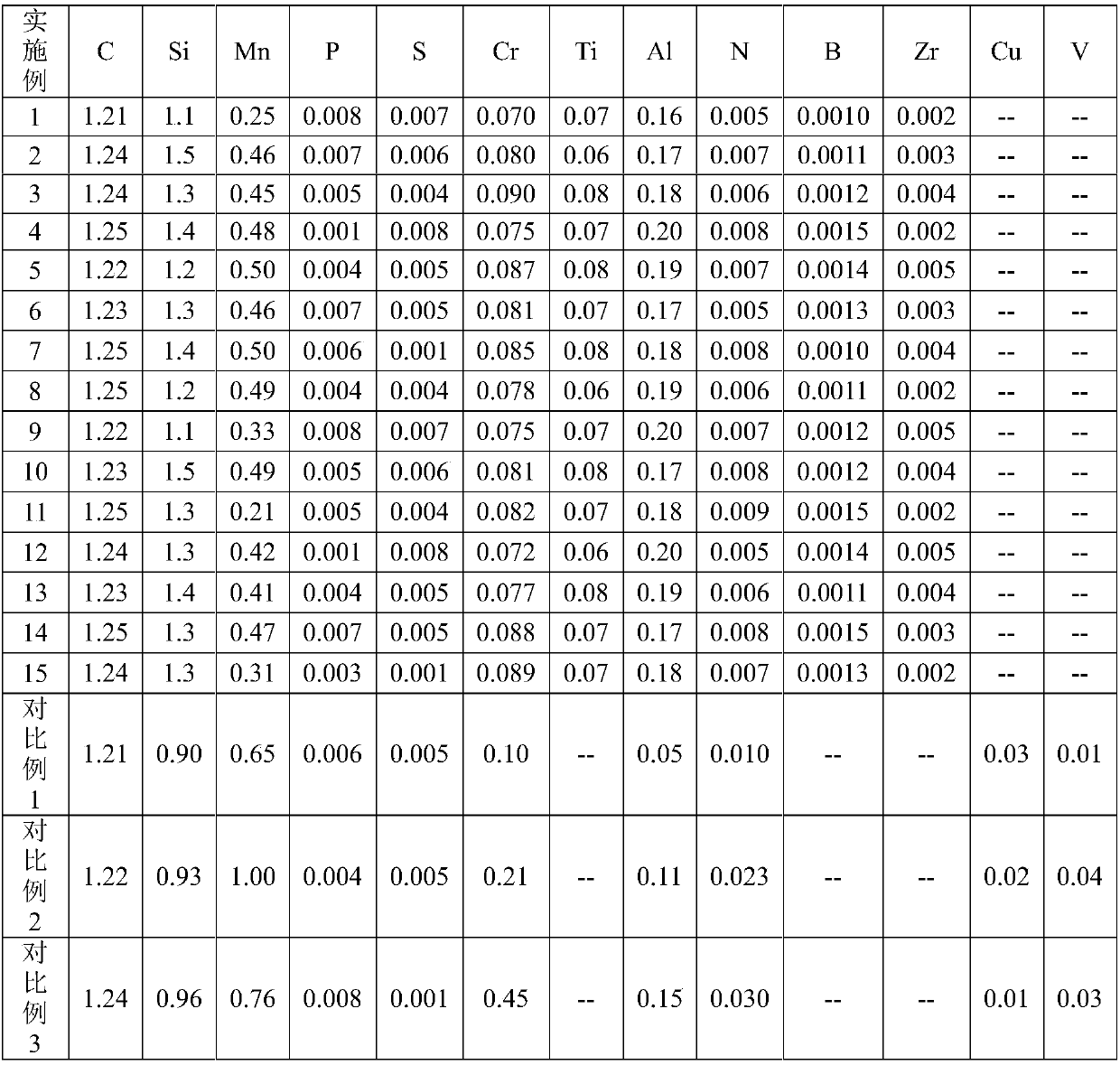

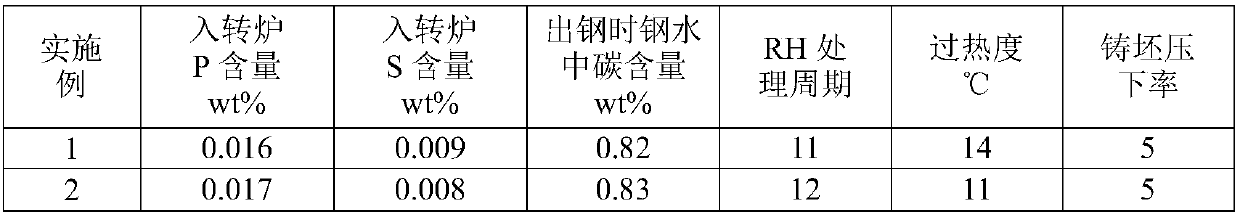

Bridge cable steel with tensile strength being greater than or equal to 2500 MPa and production method

The invention provides bridge cable steel with the tensile strength being greater than or equal to 2500 MPa. The bridge cable steel comprises chemical components of, by weight, 1.21-1.25% of C, 1.1-1.5 % of Si, 0.2-0.5 % of Mn, no more than 0.01% of P, no more than 0.01% of S, 0.07-0.09 % of Cr, 0.06-0.08% of Ti, 0.16-0.20% of Al, 0.005-0.009 % of N, 0.001-0.0015 % of B and 0.002-0.005 % of Zr. Aproduction method comprises the steps that hot metal pretreatment is conducted; converter smelting is conducted; RH vacuum treatment is conducted; continuous casting is conducted to form a billet; thecasing billet is cut through flame in the longitudinal direction after indoor stacking slow cooling is conducted; the casting billet is heated; the casting billet is initially rolled to small squarebillets; the square billets are heated after stacking slow cooling is conducted; high-speed rolling is conducted; laying is conducted; and the square billets are cooled through air to the room temperature. According to the bridge cable steel with the tensile strength being greater than or equal to 2500 MPa and the production method, the strength reaches more than 2500 MPa after the square billetsare subjected to drawing, galvanizing and stabilizing treatment, the condition that the number of torsions is not less than 12 times is simultaneously met, and the bridge cable steel can meet the construction demand of a large bridge with the bridge span being greater than 1100 meters.

Owner:武汉钢铁有限公司

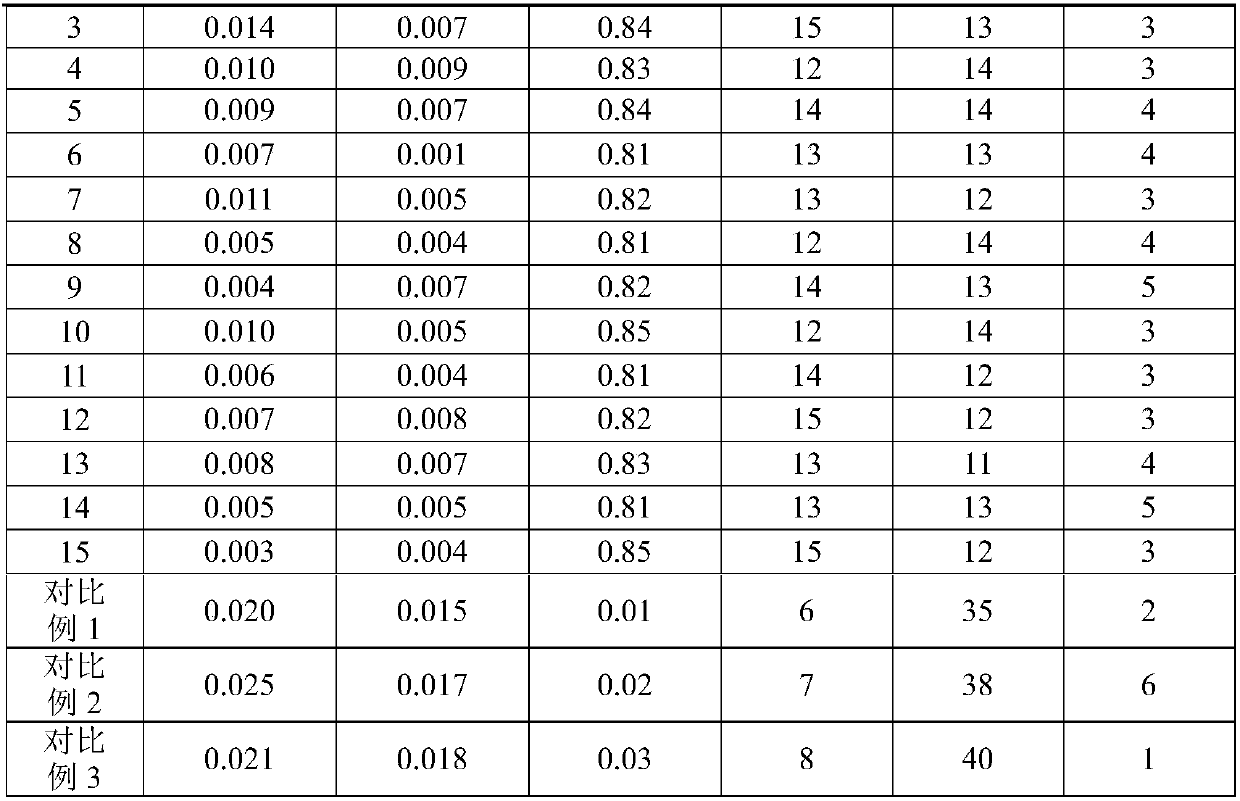

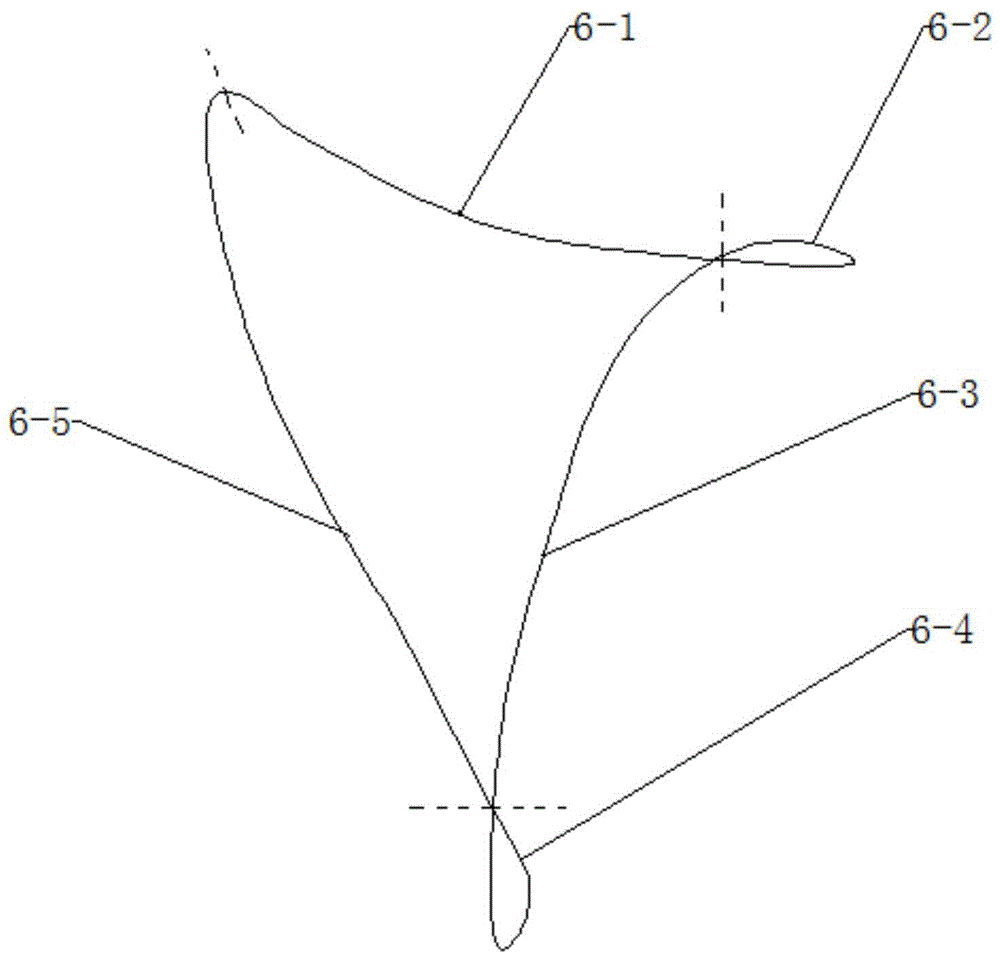

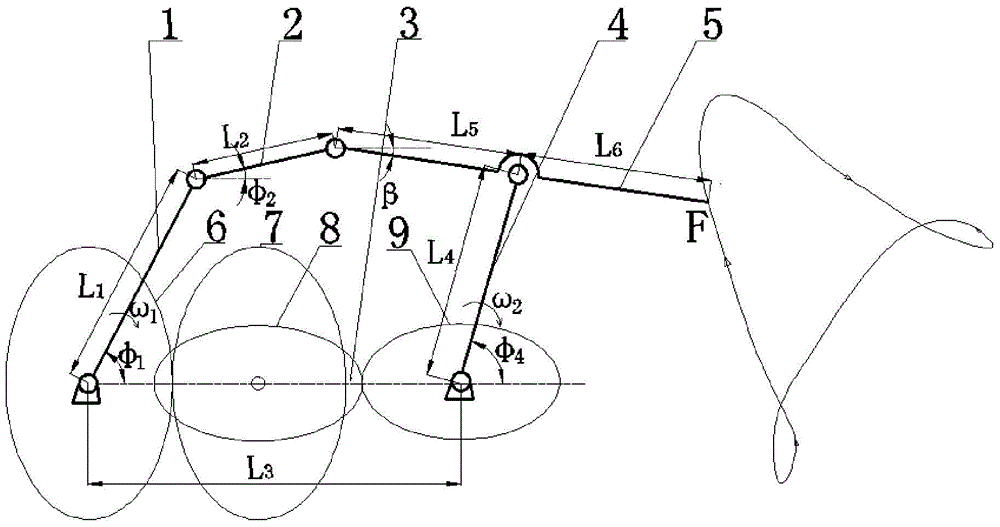

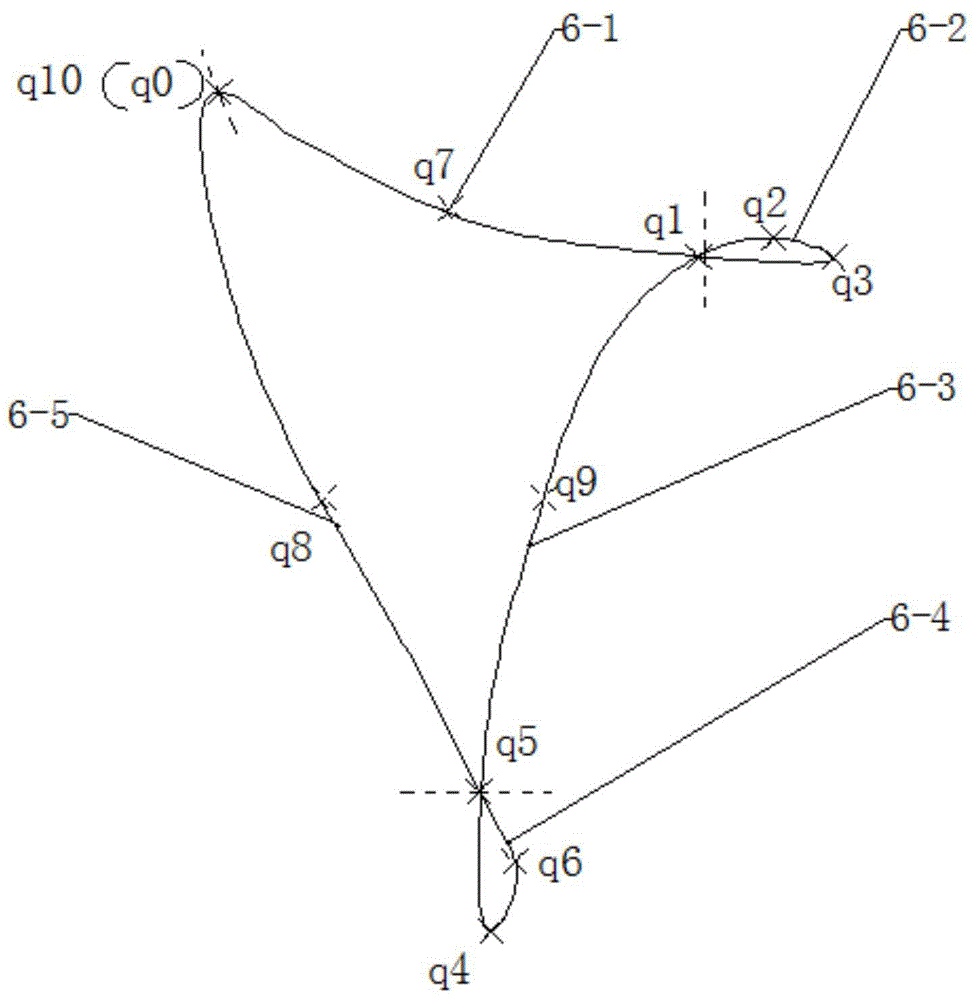

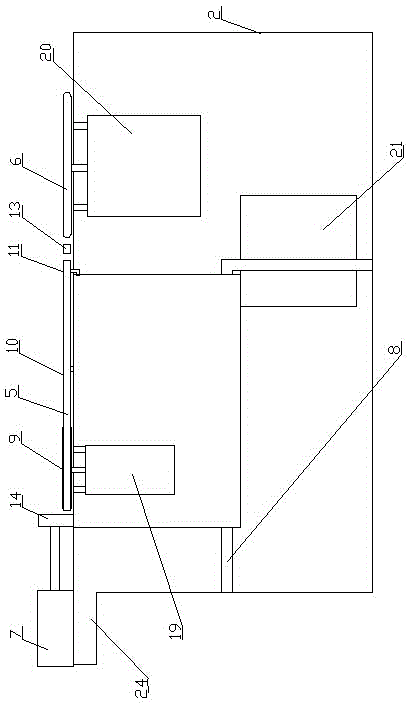

Design method for forming transplanting track by using five-rod driving mechanism with two degrees of freedom

InactiveCN104641771ARealize automatic transplantingImprove flexibilityTransplantingEngineeringControl circuit

The invention discloses a design method for forming a transplanting track by using a five-rod driving mechanism with two degrees of freedom. The existing transplanting mechanism track is not suitable for transplanting flowers. According to the design method, the angular speed w1 of a first crank is set through a normal-speed motor, and a speed-adjustable motor is adjusted through a control circuit, so that the angular speed of a second crank is shown in the specification, wherein w1 is a constant value selected from 50r / min to 70r / min, and theta is a constant value selected from pi / 4 to pi / 2; the direction of the angular speed w2 meets the following change rule under the condition that the period T=2pi, namely that the direction of the angular speed w2 is kept consistent with the direction of the angular speed w1 when the time t is from 0 to T / 3 and is opposite to the direction of the angular speed w1 when the time t is from T / 3 to T, so that a double-buckle transplanting track is formed at the sharp point of the free end of a second connecting rod. The double-buckle transplanting track is achieved by using the five-rod driving mechanism with two degrees of freedom, so that not only can the transplanting tracks of flowers be achieved, but also the fully-automatic transplanting of various crops such as melons, fruits and vegetables can be realized.

Owner:ZHEJIANG SCI-TECH UNIV

Integrated test device for stress and displacement of rock mass based on fiber bragg grating and system

PendingCN106643918AAchieve displacementForce measurement by measuring optical property variationUsing optical meansGratingFiber Bragg grating

The invention relates to the technical field of test and specifically relates to an integrated test device for stress and displacement of rock mass based on fiber bragg grating and a system. The integrated test device for stress and displacement of rock mass based on fiber bragg grating is equipped with a displacement test device and a stress test device, wherein the displacement test device is equipped with a conical component, an elastic sheet, a thimble, a protecting chamber, a connecting block, a first spring, a force transferring rod and a protecting tube; an optical grating is arranged on an upper surface and / or a lower surface of the elastic sheet; the stress test device is equipped with a fiber bragg grating hollow inclusion stress meter; the displacement test device and the stress test device are connected through a steel frame and a connector, so that the integrated test for the stress and displacement of rock mass can be realized.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

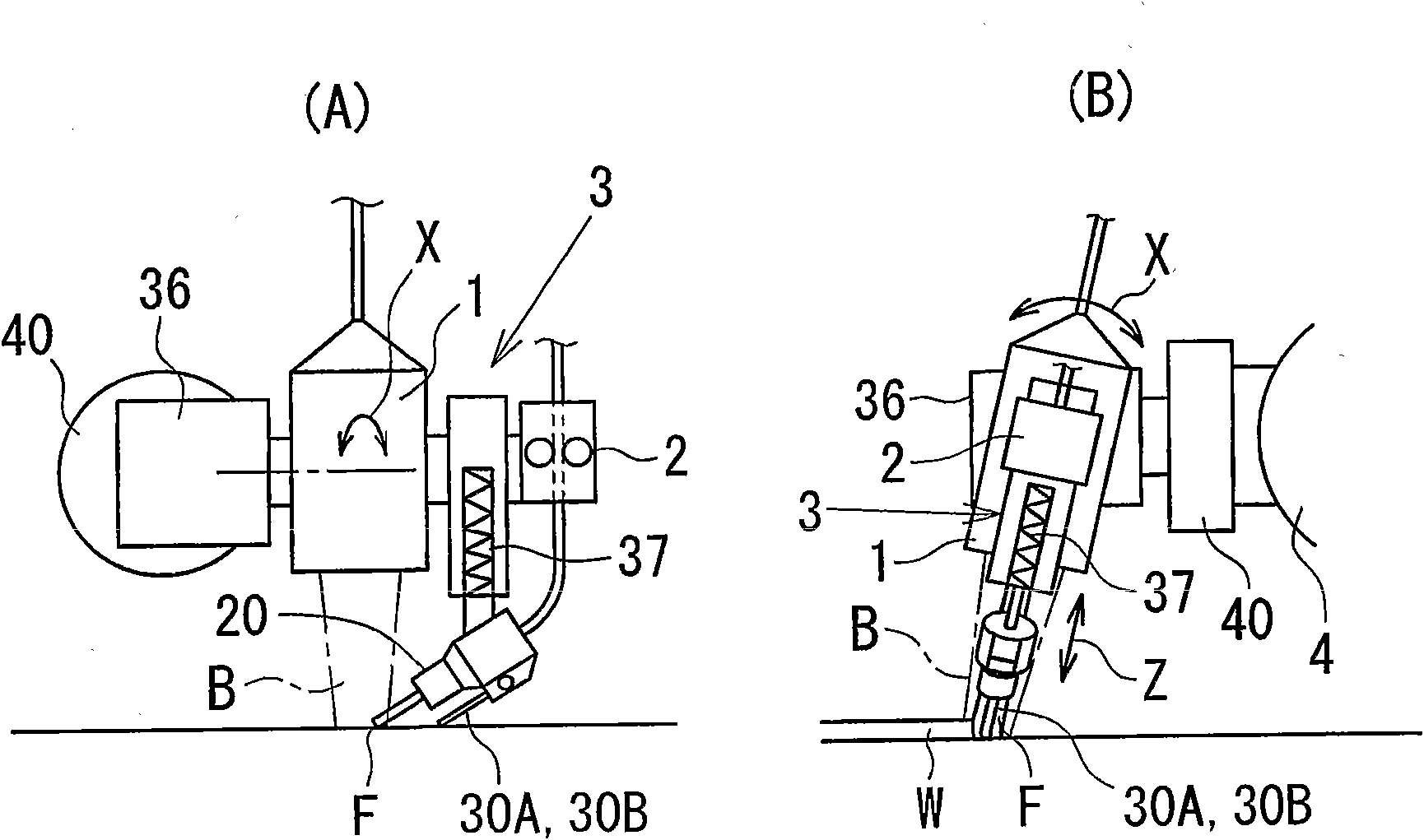

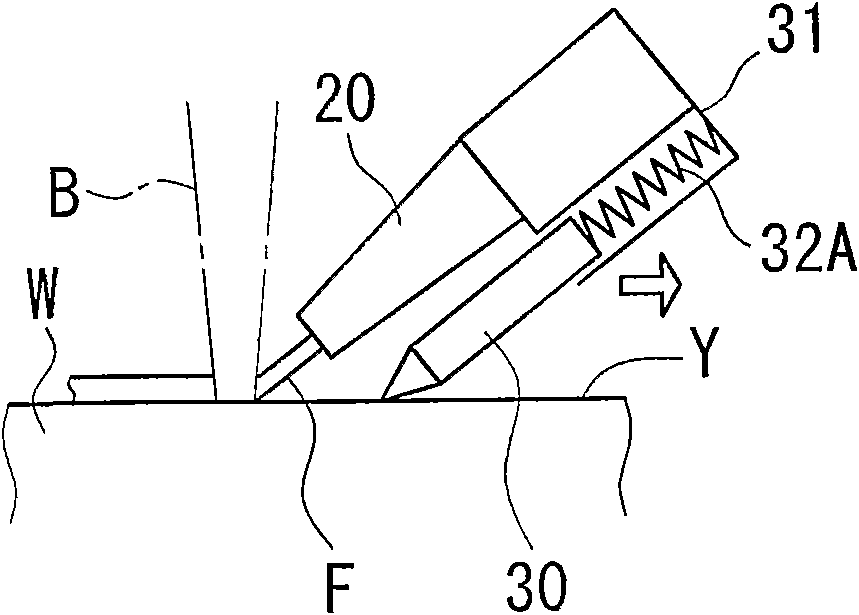

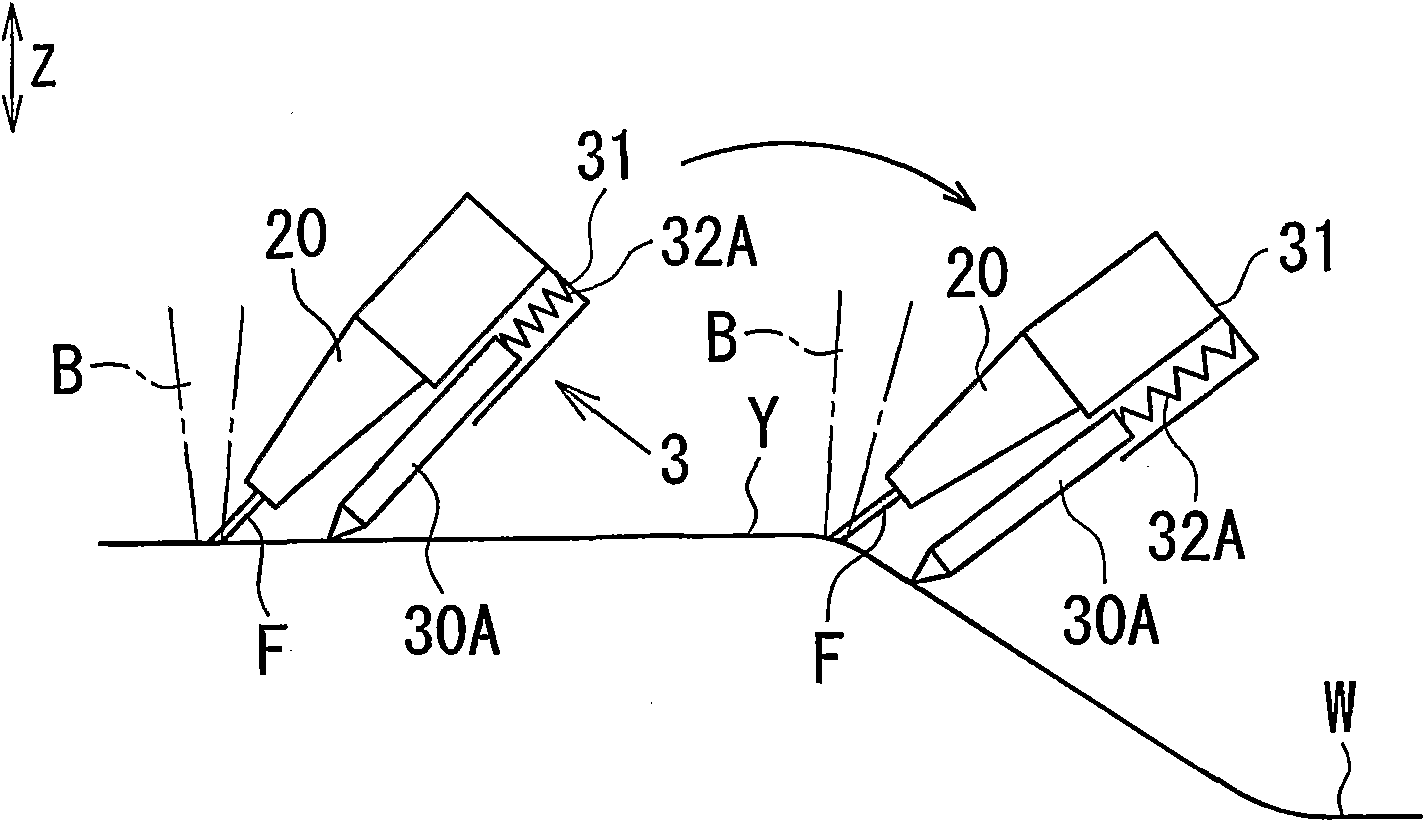

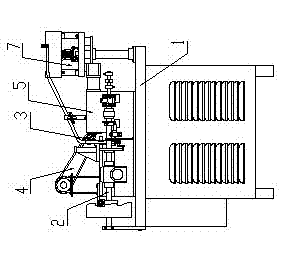

Welding equipment and welding method

InactiveCN101687282AMobile stable and reliableFit properlyArc welding apparatusElectron beam welding apparatusTorchWeld line

Welding equipment includes a torch for irradiating a laser beam (B), wire feeding means (2) for feeding a filler wire (F), and a tracking means (3) for controlling the moving tracks of the torch (1) and the wire feeding means (2) to make a welding line (Y) copy them. The tracking means (3) has a contactor (30A) provided to freely advance / retract for making contact with a joint object (W) resiliently. The joint objects (W) are jointed mutually by touching the contactor (30A) of the tracking means (3) resiliently to the joint object (W) while feeding the filler wire (F) to a welding portion andirradiating that portion with a laser beam (B), thereby moving the torch and the wire feeding means (2) to copy the welding line (Y).

Owner:TOYOTA JIDOSHA KK

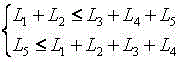

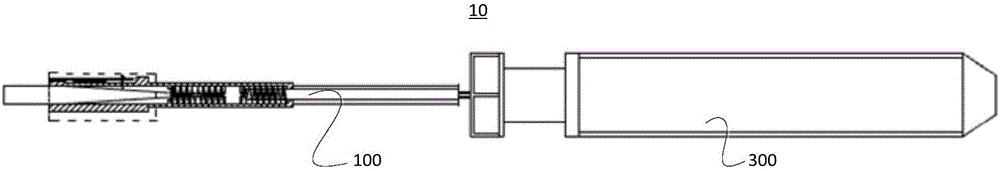

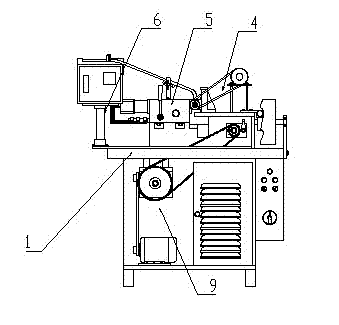

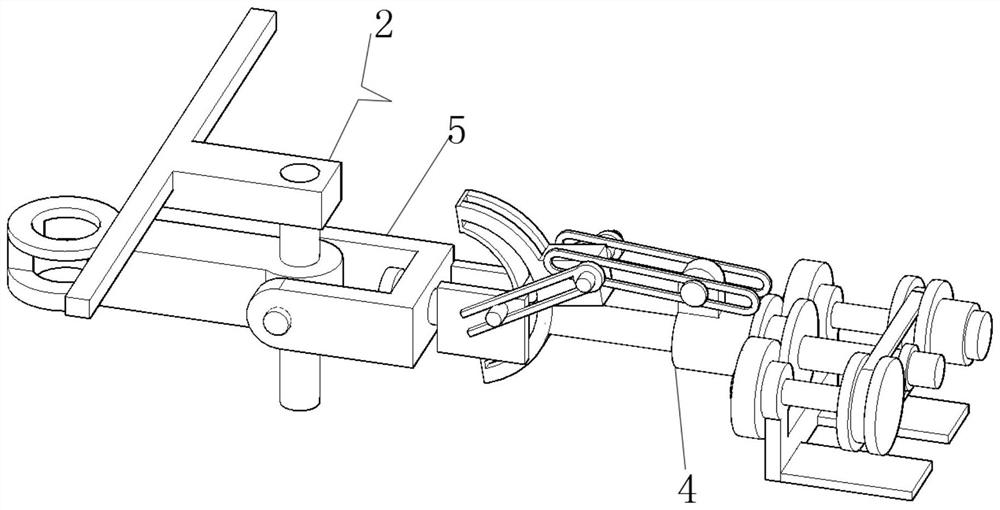

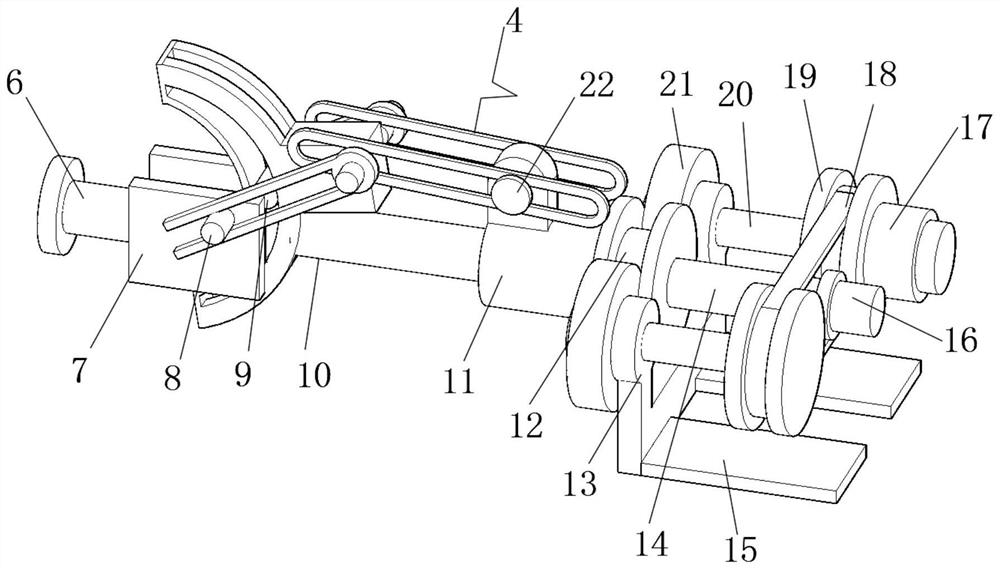

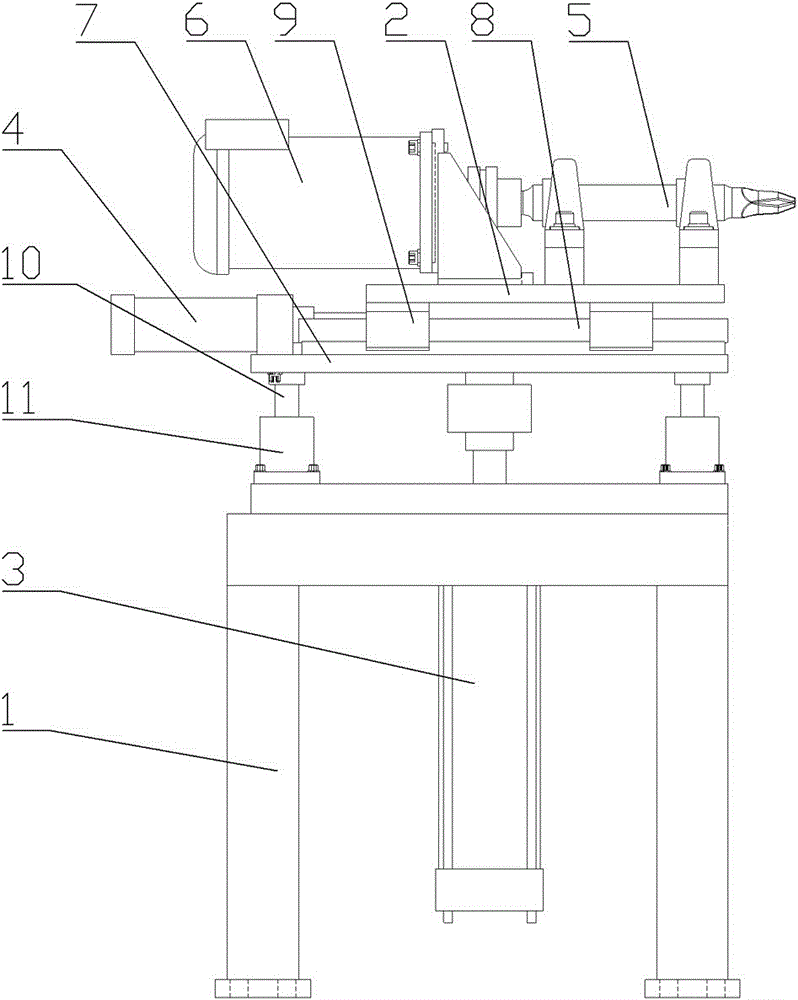

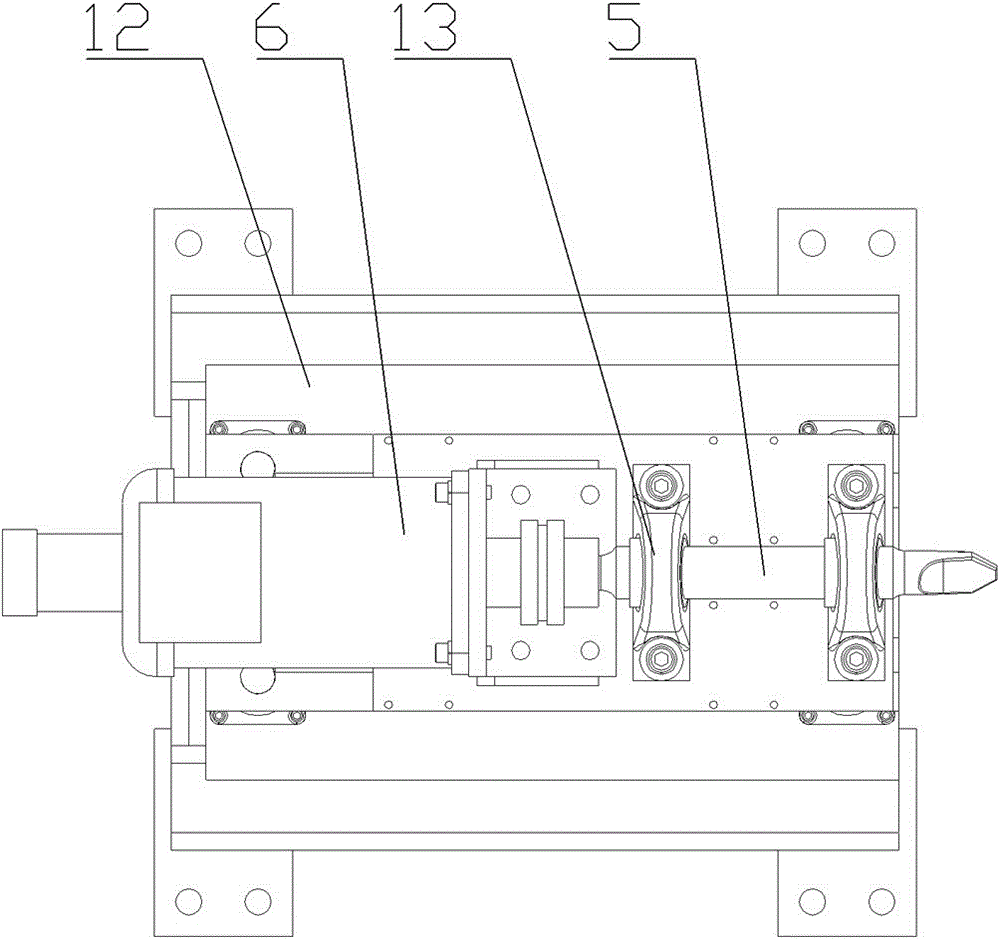

Numerical control slot milling machine for processing copper tailstock of optical fiber connector

InactiveCN102632286AReduce vibrationImprove efficiencyLarge fixed membersMilling equipment detailsNumerical controlEngineering

The invention relates to a numerical control slot milling machine for processing a copper tailstock. The slot milling machine comprises a rack, a main shaft, a feed mechanism, a mechanical arm mechanism, a clamp mechanism, a cutter mechanism, a power mechanism, a transmission mechanism and a numerical control sense mechanism, wherein the feed mechanism, the mechanical arm mechanism, the clamp mechanism, the cutter mechanism, the power mechanism, the transmission mechanism and the numerical control sense mechanism are installed on the rack; the power mechanism is connected with the transmission mechanism; the numerical control sense mechanism is connected with main shaft; and the cutter mechanism is connected with the main shaft. The numerical control slot milling machine for processing the copper tailstock is characterized in that the mechanical arm mechanism comprises a mechanical arm base, an oscillating bar, a chuck, a chuck spring, a bend board, a connecting rod, a shaft base, a push rod device, a cam device, a cullis, a scraping wing, a fixed rod, an oscillating bar spring, a connecting sliding column and an oscillating bar. The numerical control slot milling machine for processing the copper tailstock is high in automation degree, high in work efficiency, high in slot milling precision and high in slot milling speed.

Owner:HANGZHOU GUANHE MACHINERY MFG

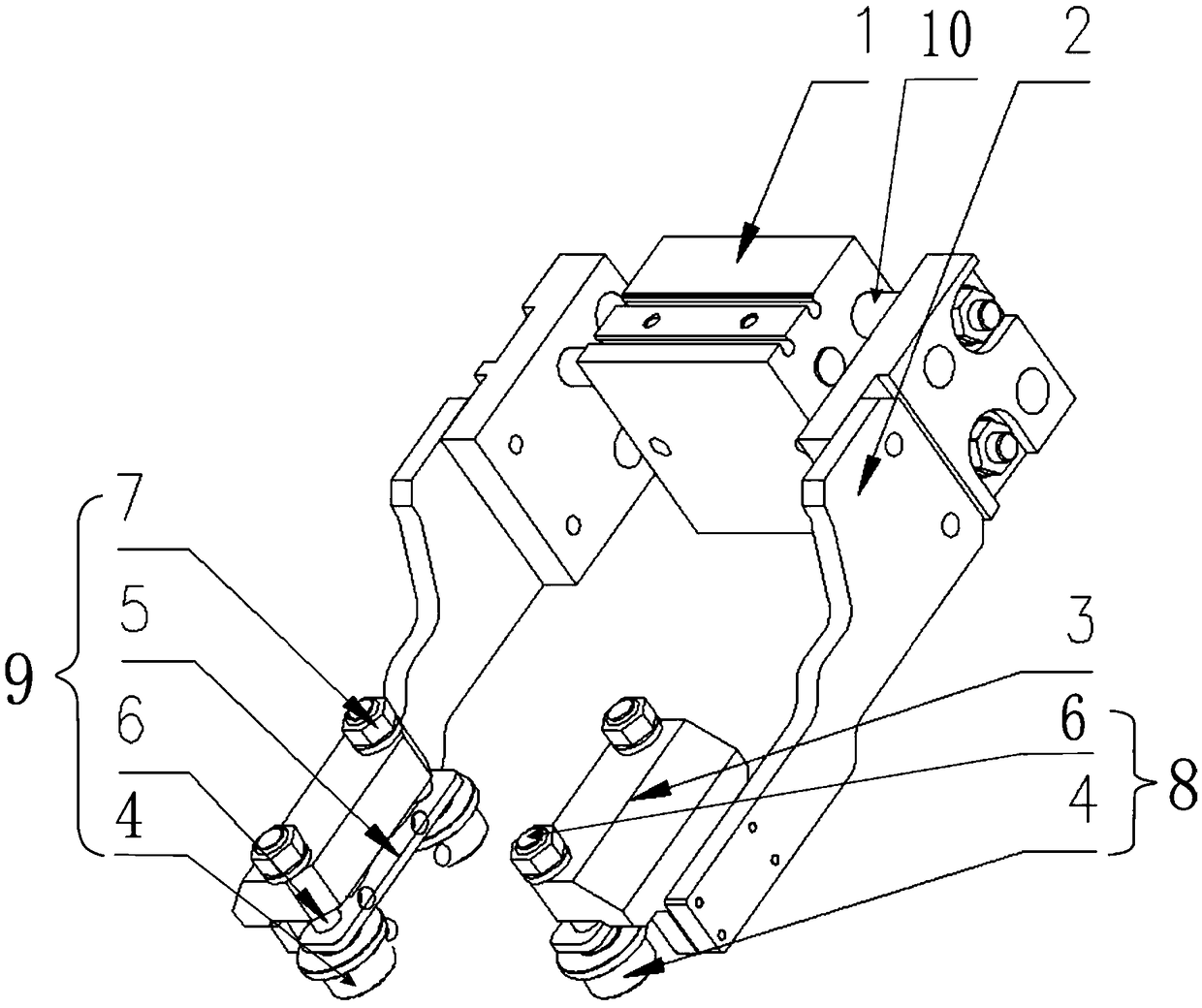

Mechanical arm end executor

The invention relates to a mechanical arm end executor, and belongs to the technical field of industrial automation. The problems are solved that existing end executors cannot accurately grasp and position circular workpieces or simultaneously rotate the circular workpieces. The mechanical arm end executor comprises a gas claw and gas claw connecting plates arranged at the two sides of the gas claw; the end portions of the gas claw connecting plates are provided with rolling wheel structures, and the rolling wheel structures are symmetrically arranged about the gas claw; each rolling wheel structure comprises a rolling wheel bracket and two rolling wheel assemblies, and the rolling wheel assemblies are arranged on each rolling wheel bracket in parallel, and used for clamping the circular workpieces and conducting centering positioning on the circular workpieces. Each rolling wheel assembly comprises a rolling wheel and a connecting rod, each rolling wheel is fixedly connected to the end portion of the corresponding connecting rod, and the connecting rods can rotate in bracket through holes and move up and down. The mechanical arm end executor is low in cost and can accurately graspthe circular workpieces and cooperate with other equipment to make the circular workpieces rotate.

Owner:BEIJING MECHANICAL EQUIP INST

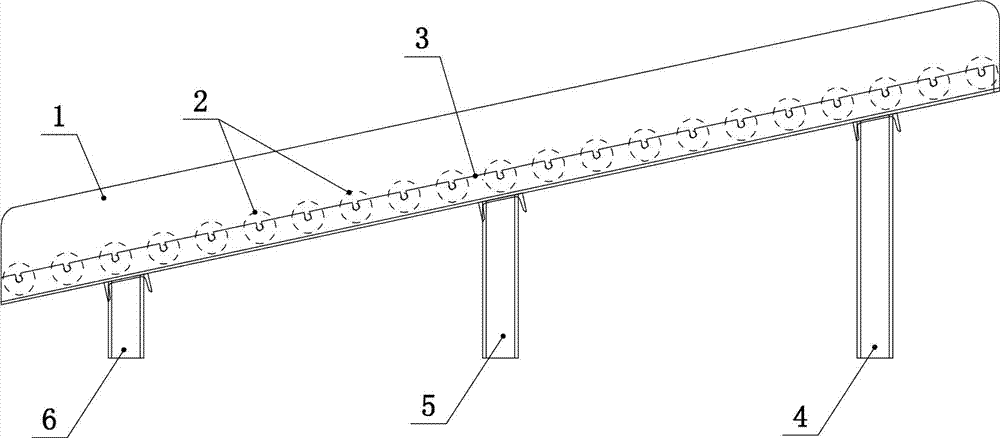

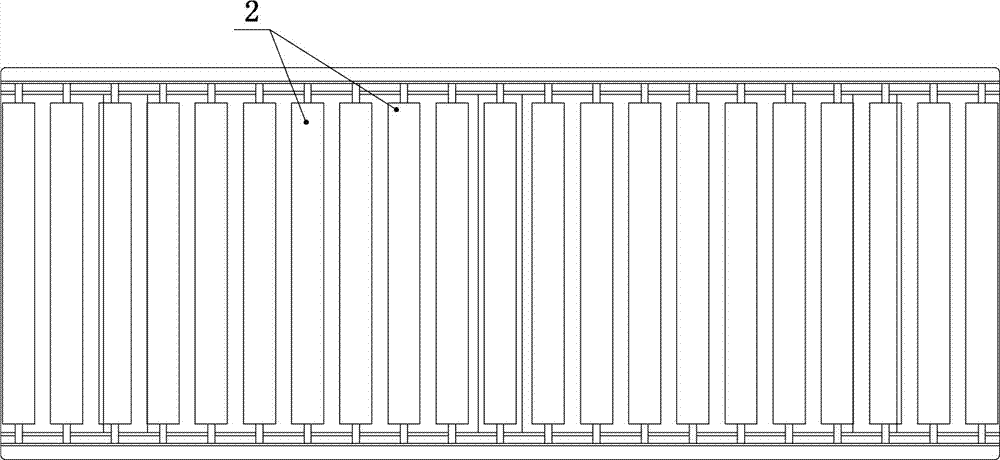

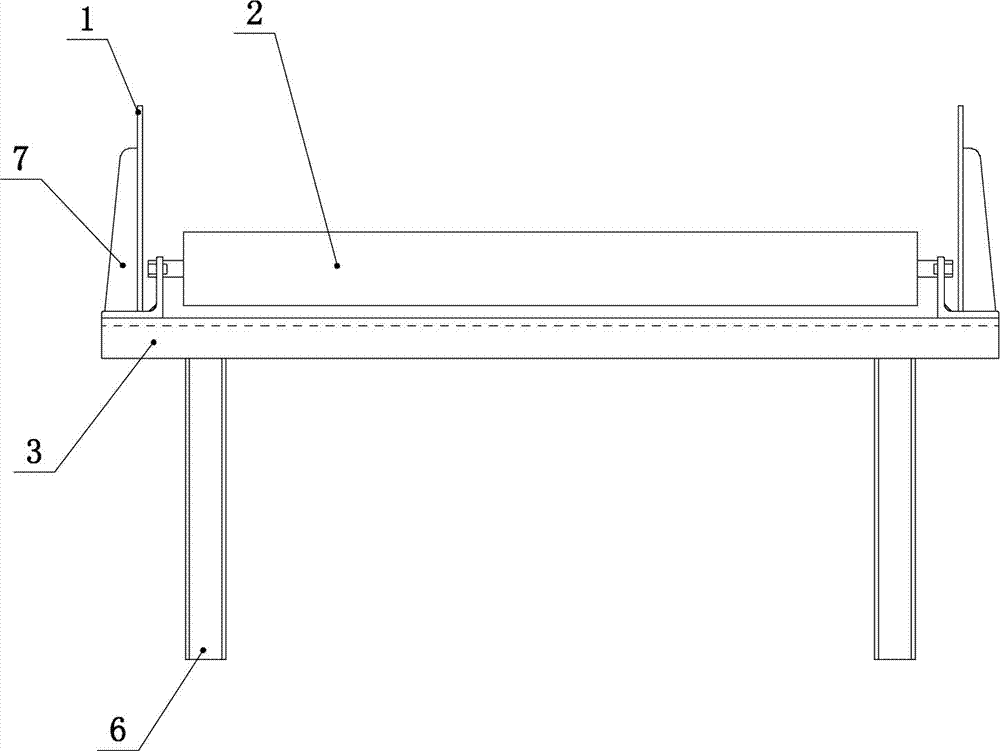

Carrier-roller gravitational material conveyer

A carrier-roller gravitational material conveyer comprises front support legs and rear support legs. A frame is fixedly connected to the upper ends of the front and rear support legs. The frame which is inclined is connected with a plurality of mutually parallel carrier rollers in a relative rotation manner. The carrier rollers are disposed from top to bottom along a slope of the frame. Retaining boards are fixedly connected to the frame outside the ends of the carrier rollers and perpendicular to the carrier rollers. Reinforcing support boards are fixedly connected outside the retaining boards and mutually perpendicular to the retaining boards. The lower edges of the reinforcing support plates are fixedly connected to the frame. Auxiliary support legs are fixedly connected below the middle of the frame. The carrier-roller gravitational material conveyer is designed according to practical field conditions according to the principle that the carrier rollers are driven to rotate to move the material on the conveyer by drive force produced by material gravity and slope level difference; the problems that field short-distance conveying of iron wires is high in labor intensity and has potential safety hazards are solved.

Owner:枣庄矿业(集团)有限责任公司柴里煤矿

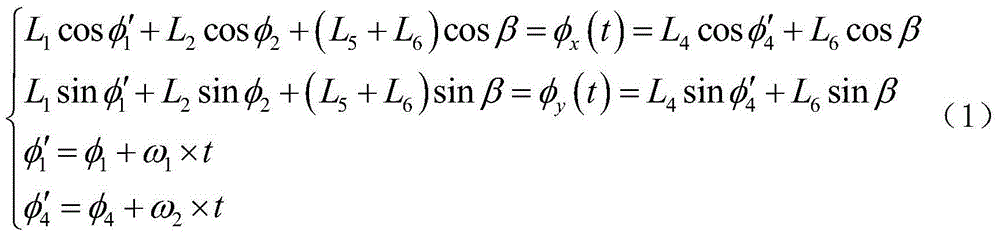

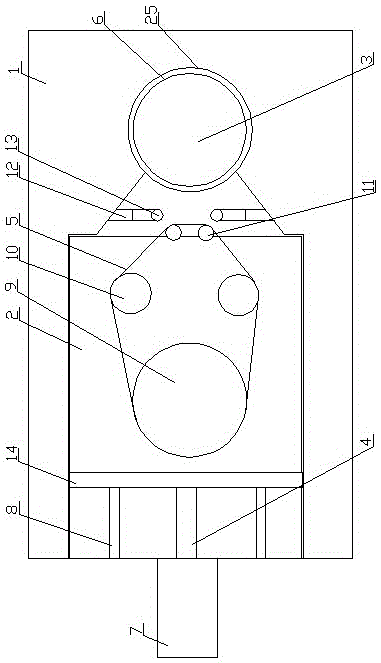

Design method for forming flower transplanting track by two-stage non-circular gear five-bar driving mechanism

ActiveCN104657546ARealize automatic transplantingImprove flexibilityTransplantingSpecial data processing applicationsMathematical modelAngular velocity

The invention discloses a design method for forming a flower transplanting track by a two-stage non-circular gear five-bar driving mechanism. An existing transplanting mechanism track is not suitable for flower transplantation. The design method specifically comprises the following steps: firstly, constructing a two-stage non-circular gear five-bar driving mechanism, and establishing a free end point of a second connecting rod, so as to form a mathematical model of a double-buckle track; then reversely determining angular velocity change rules of a first crank and a second crank through the established mathematical model, designing a two-stage non-circular gear, and verifying whether the two-stage non-circular gear five-bar driving mechanism satisfies existence conditions of the double cranks. According to the design method, the angular velocity ratio of the first crank to the second crank is changed by adopting the two-stage non-circular gear five-bar driving mechanism, the double-buckle track is realized, so as to realize seedling taking and planting motions, the flower transplanting track can be realized, and full automatic transplantation of various crops such as fruits and vegetables can be realized.

Owner:安徽翰邦科技咨询有限公司

Bent pipe outer polishing device

ActiveCN105108614AImprove polishing qualityAchieve the purpose of polishingBelt grinding machinesMachine toolAutomation

The invention discloses a bent pipe outer polishing device. The bent pipe outer polishing device comprises a machine tool body which is provided with a grinding mechanism and a reverse rotating mechanism. The grinding mechanism comprises a grinding driving mechanism and a polishing strap arranged on the grinding driving mechanism. The reverse rotating mechanism comprises a reverse driving mechanism and a rotating plate arranged on the reverse driving mechanism. The polishing strap is matched with the rotating plate. The grinding mechanism and the reverse rotating mechanism are connected with a controller. The bent pipe outer polishing device can automatically polish the outer surfaces of a bent pipe and a straight pipe. A supporting and moving mechanism of the bent pipe is omitted due to the fact that the grinding mechanism is horizontally arranged, the complexity of a traditional outer polishing device is greatly simplified, the automation degree for outer polishing is improved, and all-face dead-angle-free polishing is performed on the surface of the bent pipe.

Owner:HENAN YONGFUDE SCI & TECH CO LTD

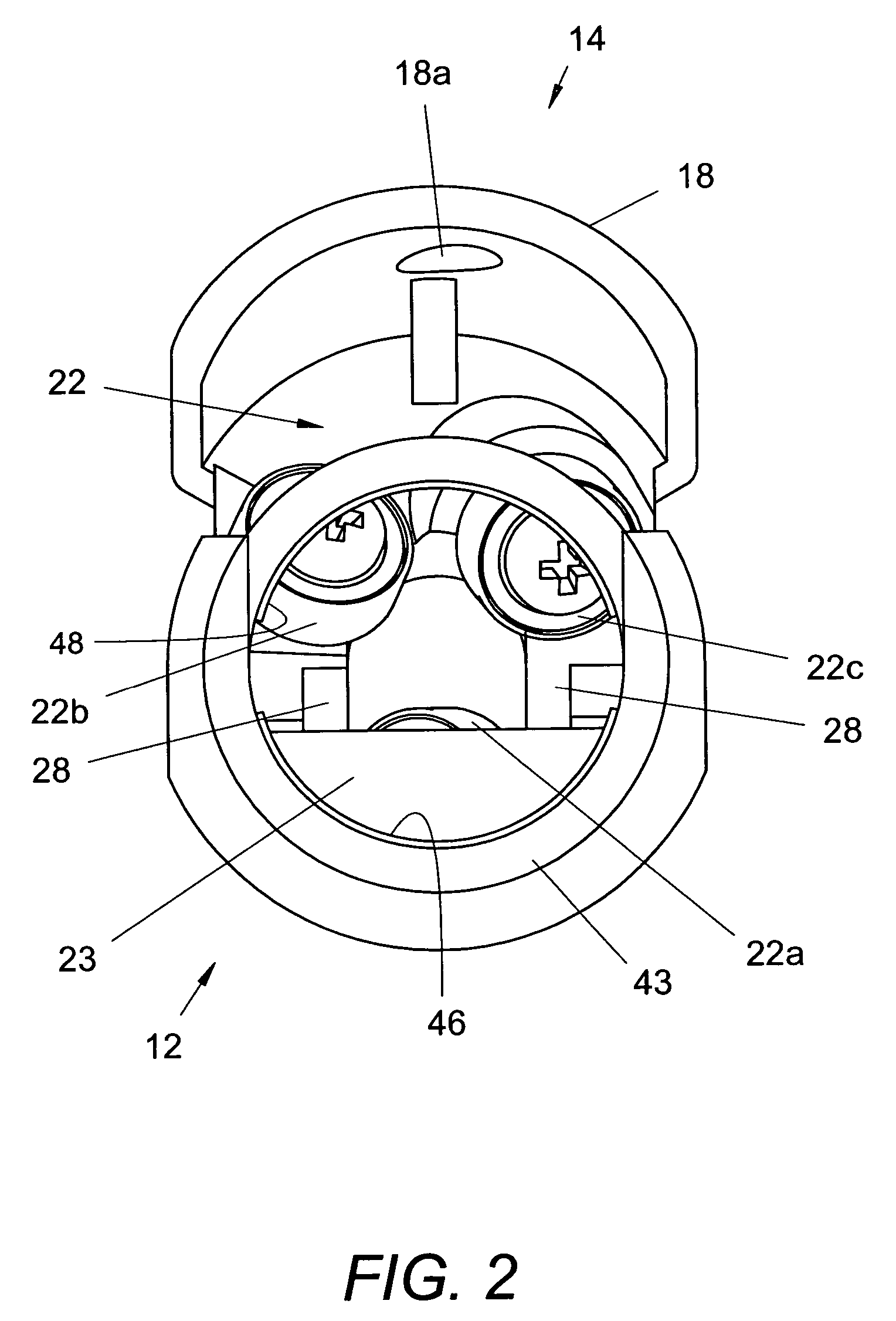

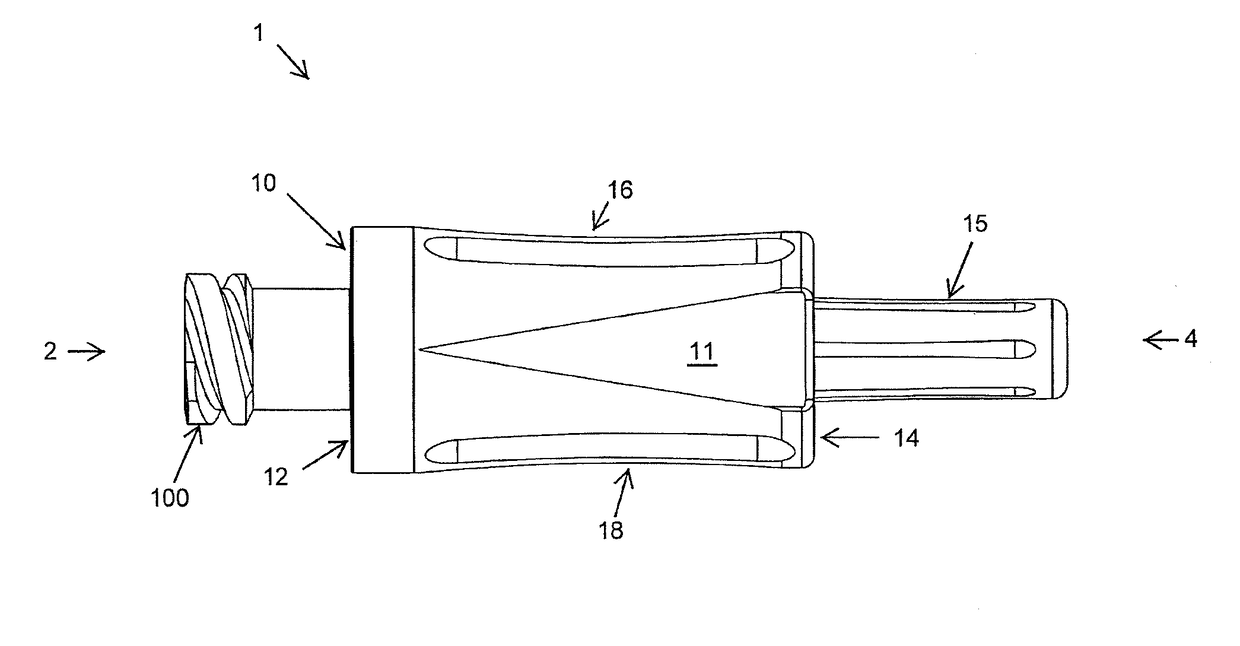

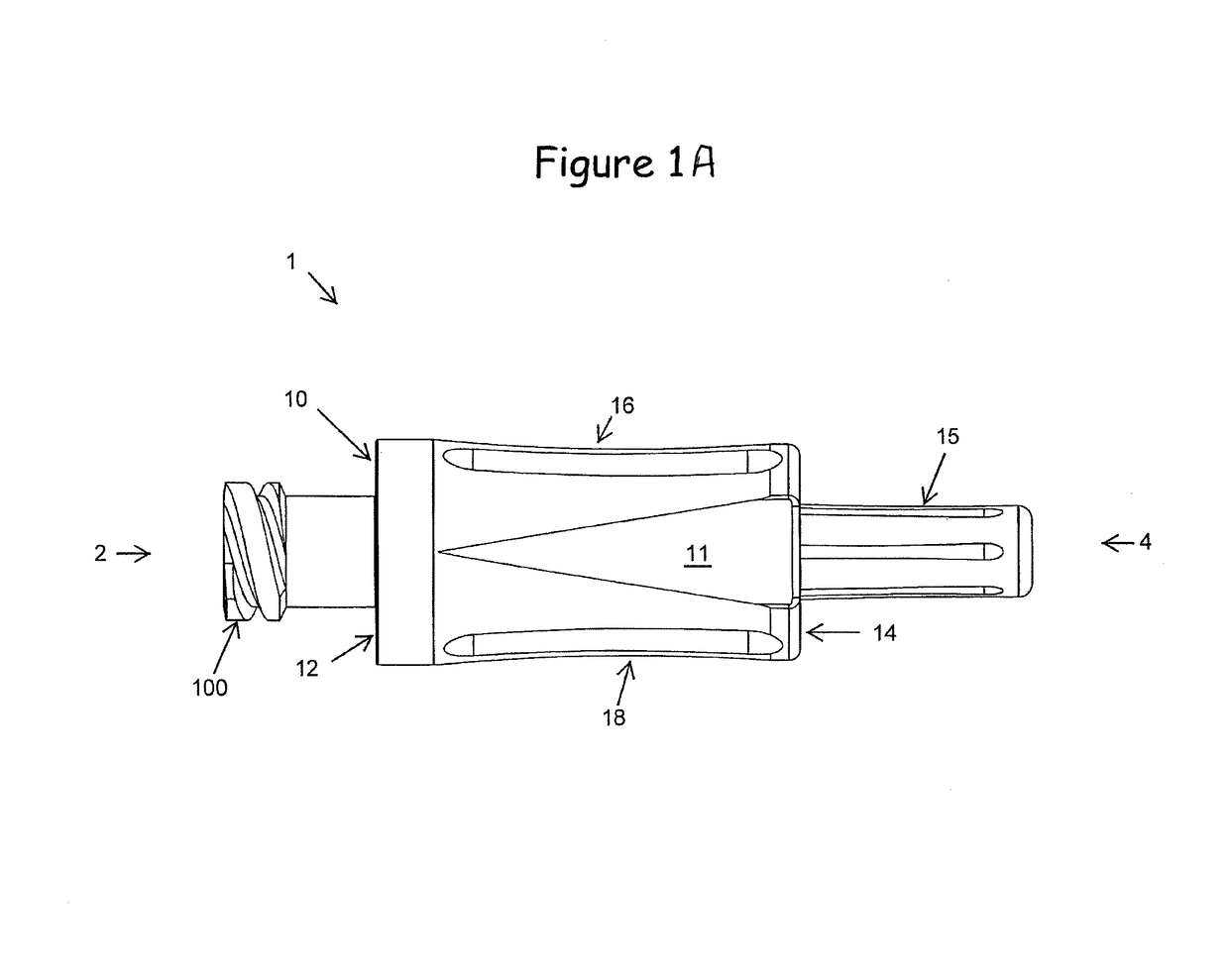

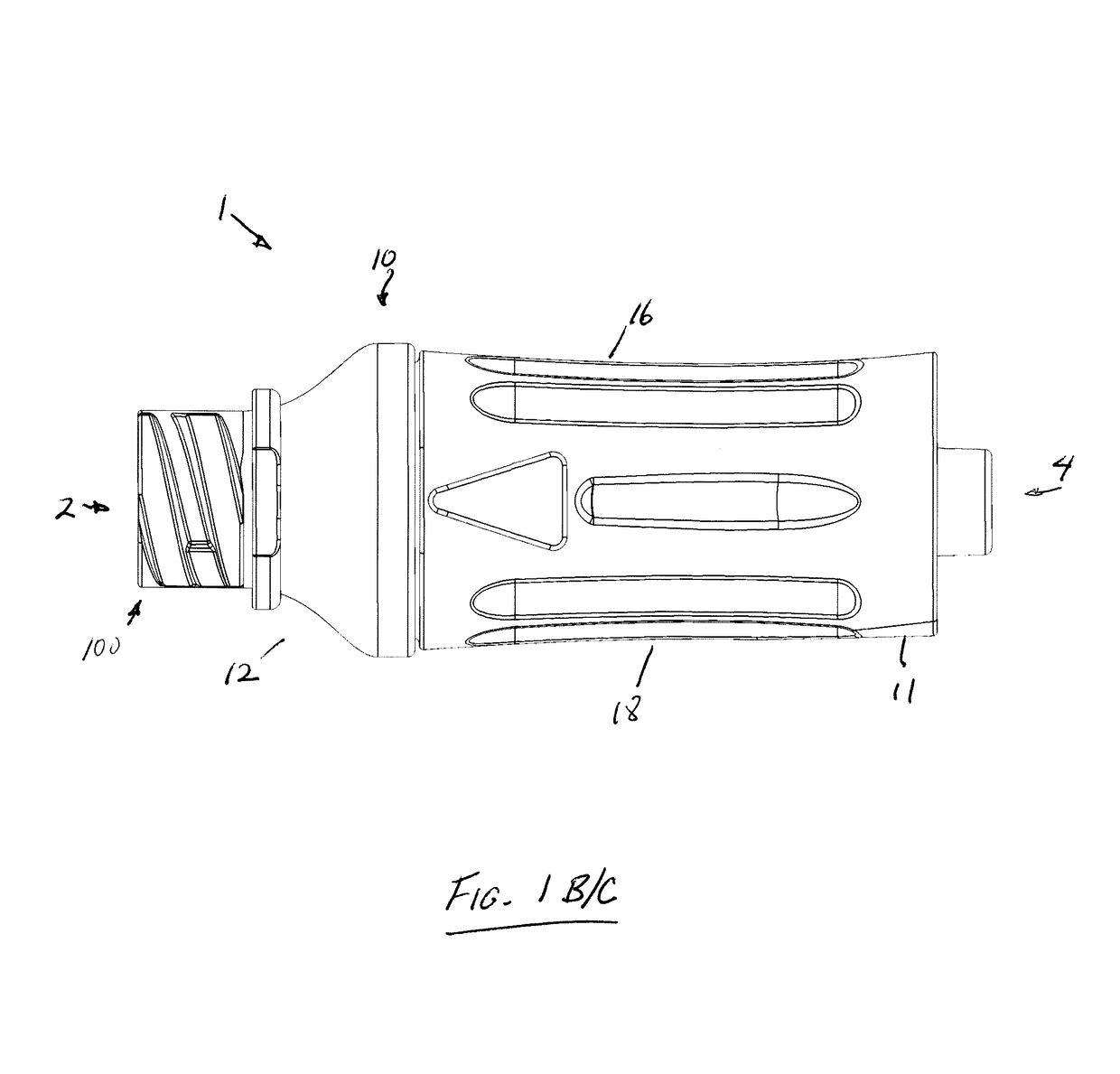

Medical luer connector

PendingUS20170106181A1Reduce the possibilityAchieve displacementMedical devicesTube connectorsEngineering

A Luer medical connector having a male Luer body for connection with a female Luer assembly which includes a female Luer body, a fluid channel insert within the female Luer body, an elastomeric seal between the female Luer body and the male Luer body, and an elastomeric stopper at a proximal end of the female Luer body.

Owner:HALKEY ROBERTS CORP

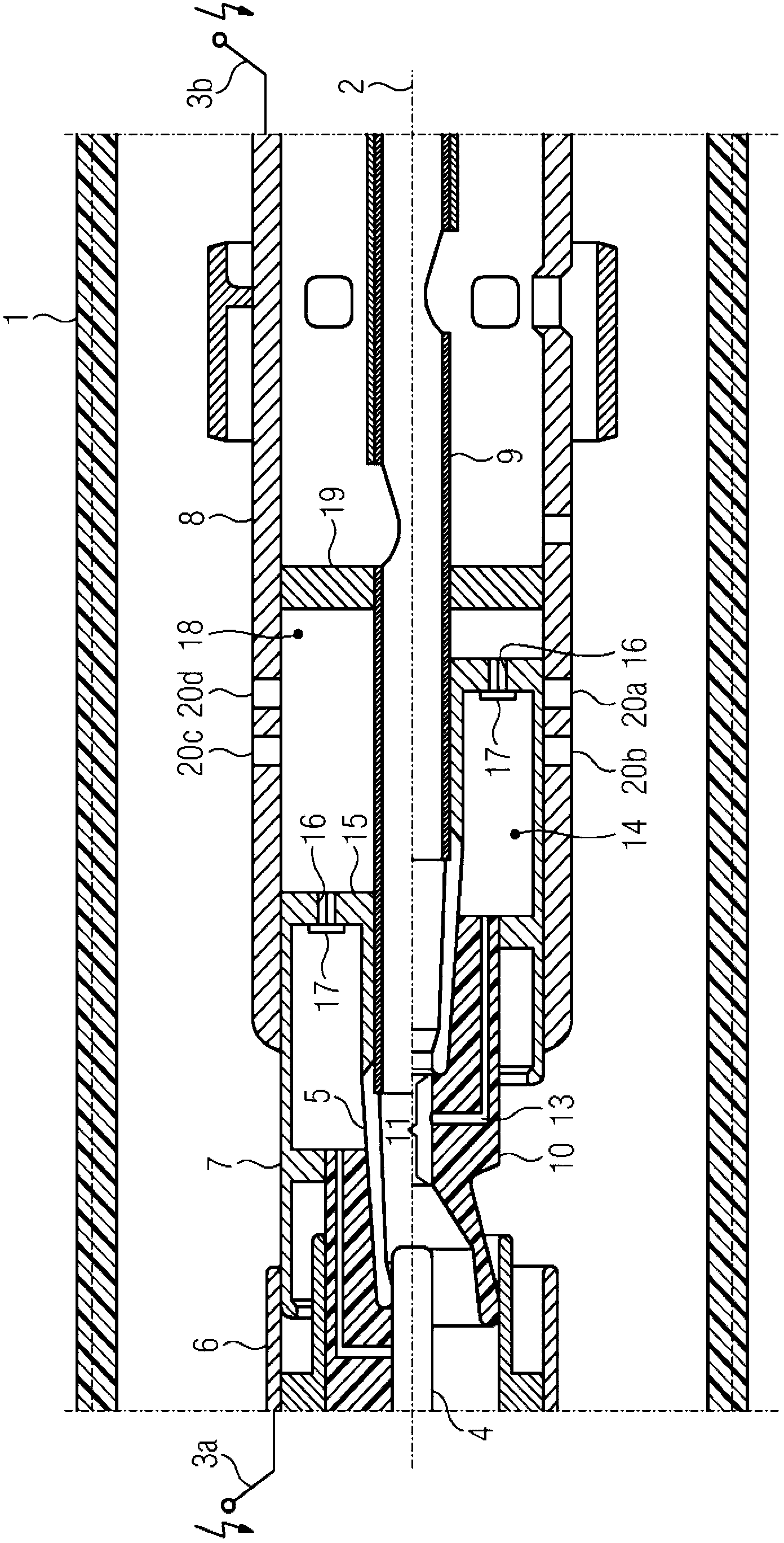

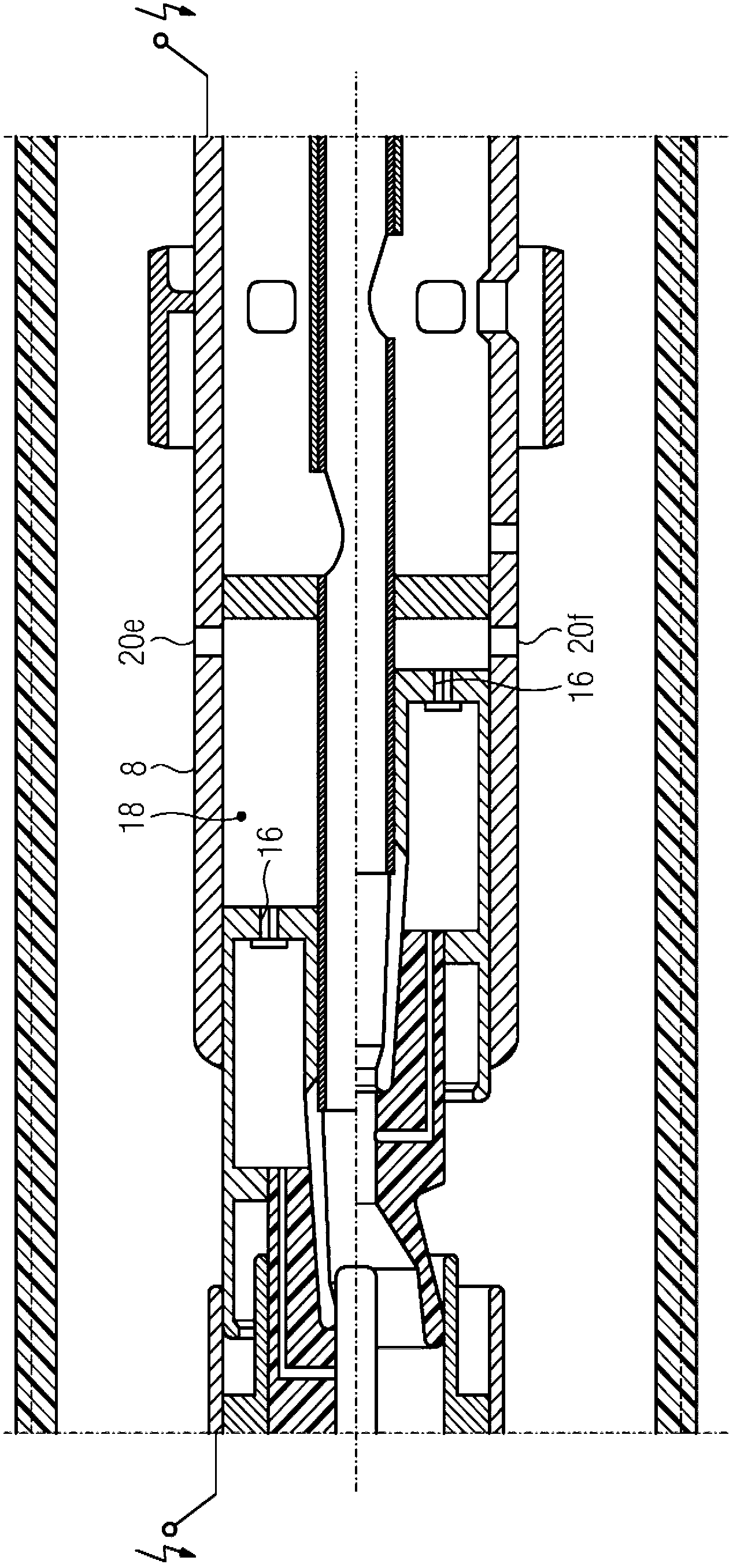

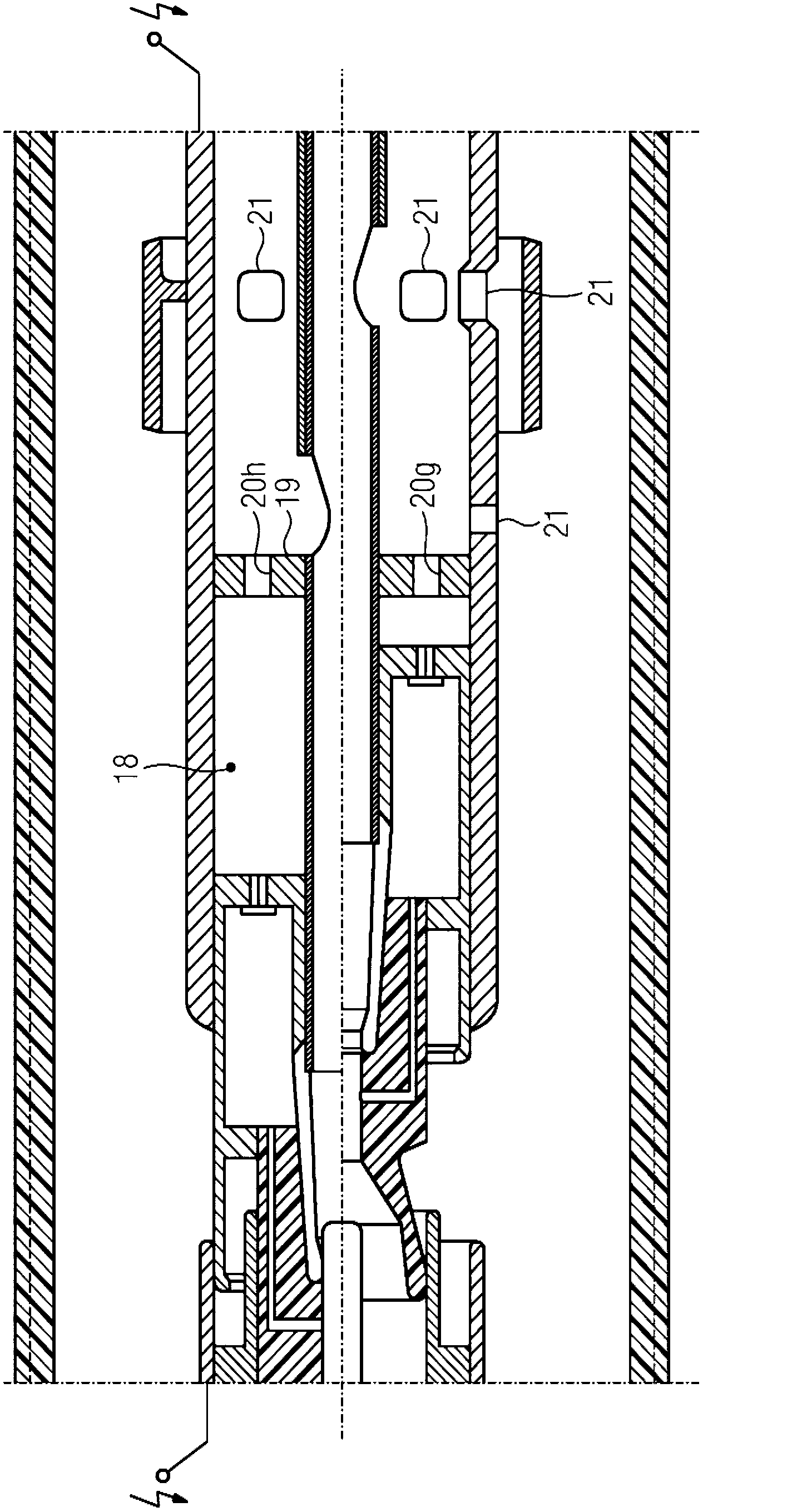

Gas blast circuit breaker

InactiveCN102985990AGuaranteed Overvoltage ProtectionAchieve displacementHigh-tension/heavy-dress switchesAir-break switchesReservoir volumeEngineering

The invention relates to a circuit breaker comprising a first contact (4) and a second contact (5). An electric arc zone is disposed between the contacts (4, 5). A feed channel (13) opens into the electric arc zone, connecting the electric arc zone to a hot gas reservoir volume (14). The hot gas reservoir volume (14), in turn, is connected to a compression volume (18). An outflow opening (20a, 20b, 20c, 20d, 20e, 20f, 20g, 20h) is disposed in a wall (8) of the compression volume (18). The outflow opening (20a, 20b, 20c, 20d, 20e, 20f, 20g, 20h) is permanently open at least in the contacting state of the contacts (4, 5).

Owner:SIEMENS AG

Self-adjustable mechanical cleaning scraping plate device

PendingCN111957621ARealize adjustment workRealize the purpose of adjustmentCleaning using toolsEngineeringRotating disc

The invention discloses a self-adjustable mechanical cleaning scraping plate device. The device comprises a scraping plate device body. A cleaning device is arranged on one side of the inner end of the scraping plate device body, an adjusting device is rotationally connected to the side end of the cleaning device, and the adjusting device comprises an adjusting piece and a linkage piece. The adjusting piece is arranged on one side of the inner end of the adjusting device, and the linkage piece is rotationally connected to the side end of the adjusting piece. The adjusting piece comprises a penetrating frame, a limiting plate, a first shaft frame, a second shaft frame, a center frame, a rotating frame, a rotating disc, a threaded frame rod, a first driving shaft, a supporting plate, a firstmotor, a second motor, a conveying belt, a guide wheel, a second driving shaft, a matching disc and a third shaft frame, and the second motor is installed on one side of the inner end of the adjusting piece. According to the self-adjustable mechanical cleaning scraping plate device, the purpose of adjusting the inner end is achieved by arranging the adjusting device.

Owner:苗袁春

Rapid chamfering device

InactiveCN106553066AQuality assuranceFlexible displacementFeeding apparatusLarge fixed membersEngineeringMachining

The invention provides a rapid chamfering device. The rapid chamfering device can enable a machining cutter to rapidly and flexibly move, the efficiency and the precision are high, and therefore the quality of chamfering of a machined part is ensured. The rapid chamfering device comprises a rack, and a travel mechanism is arranged on the rack. The rapid chamfering device is characterized in that the travel mechanism comprises a movable base, a lifting platform is arranged below the movable base, the bottom of the lifting platform is connected with a lifting air cylinder, a transverse air cylinder is arranged on the side portion of the lifting platform and connected with the movable base, sliding rails are arranged at the upper end of the lifting platform, sliding blocks are arranged at the lower end of the movable base, the movable base is connected to the sliding rails through the sliding blocks, the sliding blocks are in sliding fit with the sliding rails, the movable base is further provided with a rotating shaft, one end of the rotating shaft is connected with a motor, and the other end of the rotating shaft is connected with the machining cutter.

Owner:WUXI MINGZHU STEEL BALL

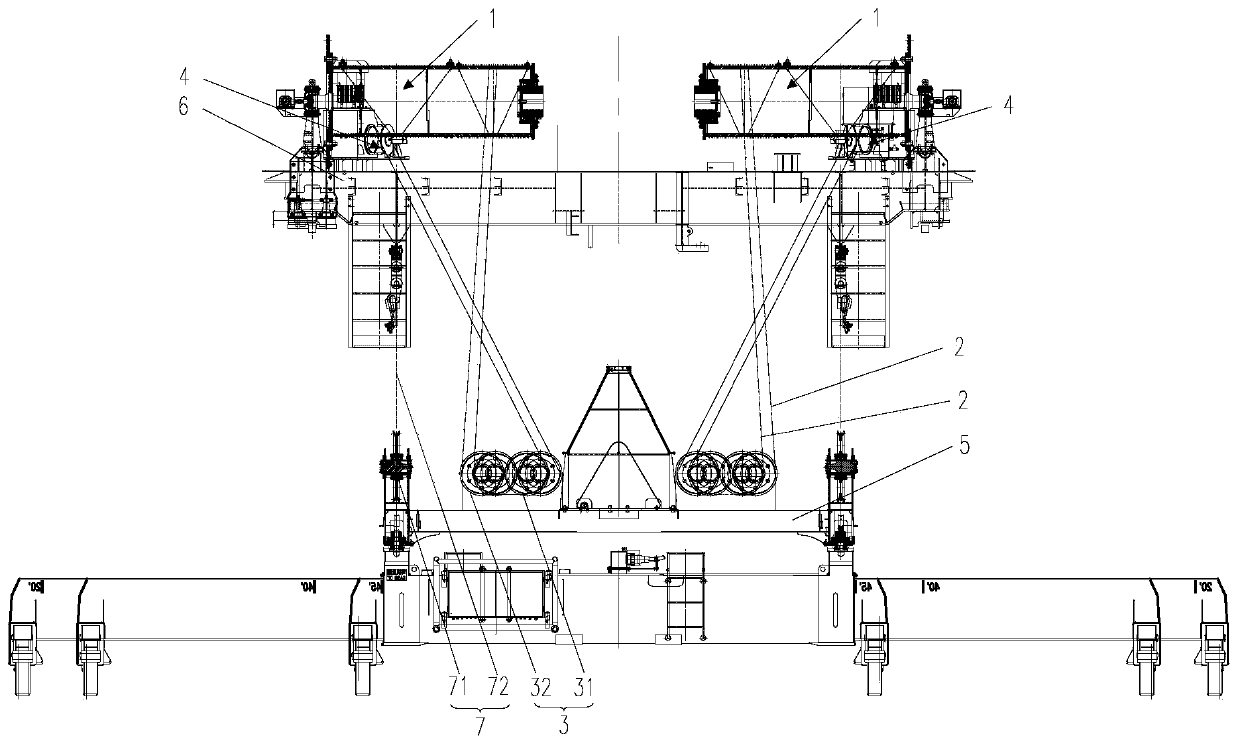

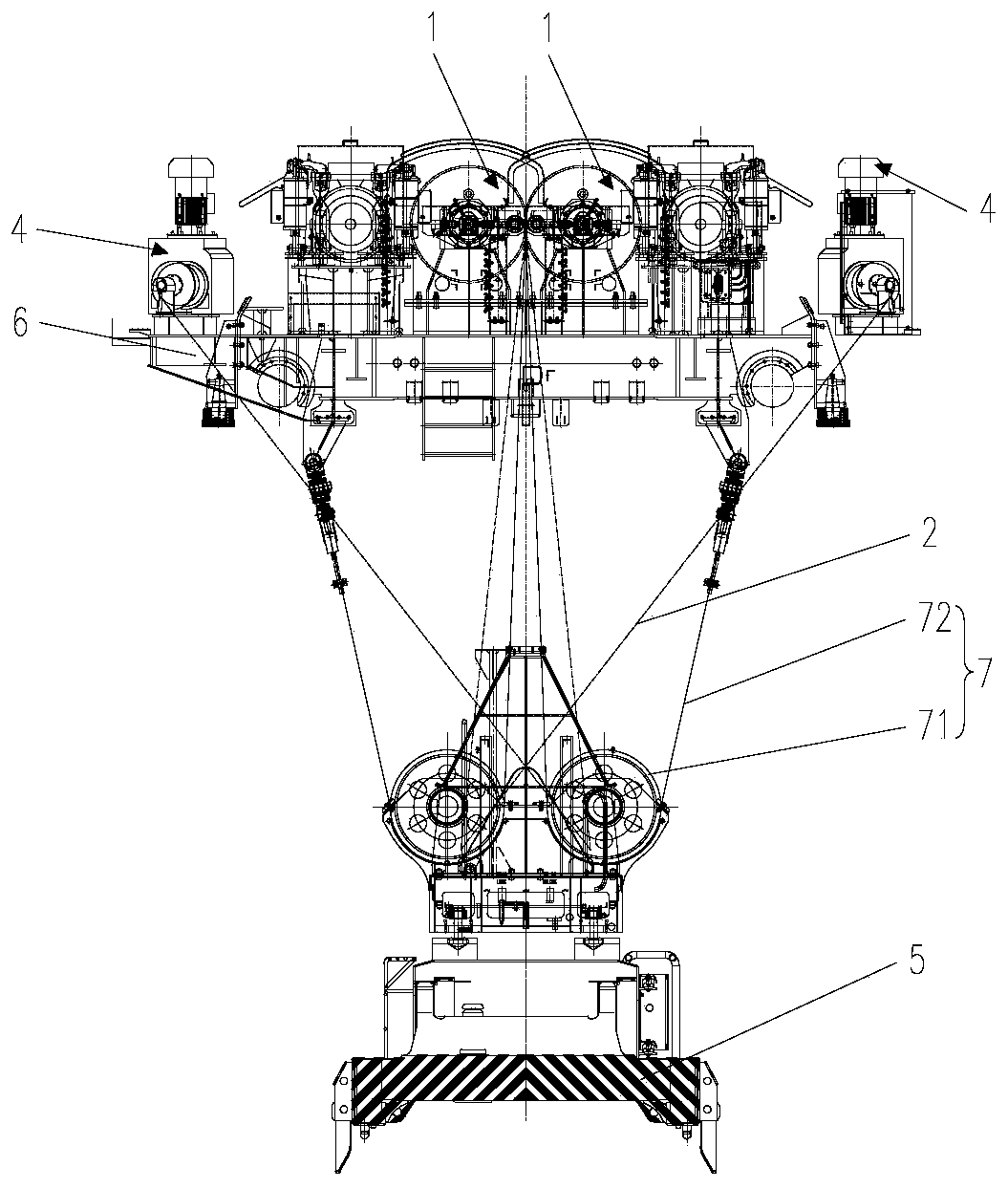

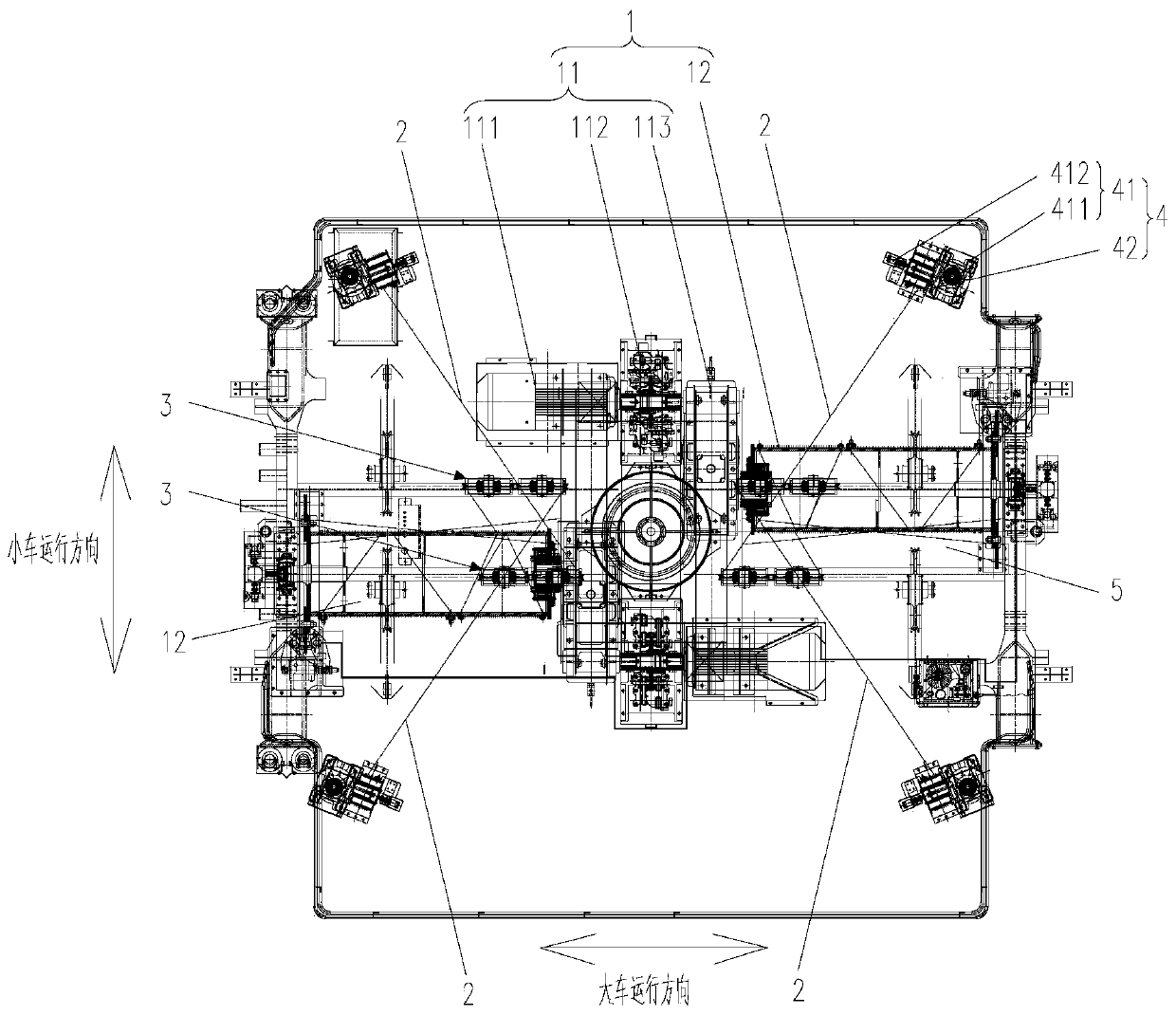

Anti-rolling winding device and tire type container gantry crane

The invention provides an anti-rolling winding device and a tire type container gantry crane, and relates to the technical field of crane rolling prevention. The anti-rolling winding device comprisesa first unwinding mechanism and a plurality of anti-rolling units, wherein each anti-rolling unit comprises a first rope body, a pulley assembly used for being installed on a lifting appliance and a second unwinding mechanism used for being installed on a trolley; one end of each first rope body is connected with the first unwinding mechanism, and the other end of each first rope body penetrates through the corresponding pulley assembly to be connected with the corresponding second unwinding mechanism; and in the moving direction of the trolley and the moving direction of a cart, an inverted triangular structure is defined by the extending path of each first rope body and the trolley. According to the anti-rolling winding device, the abrasion of the first rope bodies is relieved, the lifting structure is more stable, and the anti-rolling effect is better.

Owner:SANY MARINE HEAVY IND

Rotatable cutting tool

InactiveCN1675364AAchieve displacementMicrobiological testing/measurementBoring barsEngineeringControl force

Owner:瓦莱尼特股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com