Bridge cable steel with tensile strength being greater than or equal to 2500 MPa and production method

A technology of tensile strength and bridge cables, which is applied in the field of wire materials and production of bridge cables with tensile strength ≥ 2500MPa, can solve the problems of torsion value fluctuations, increased brittleness of steel, poor stability, etc., to improve segregation, slow down segregation, Reduce the effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] It should be noted that the following examples are used to illustrate the present invention, but the present invention is not limited to the following examples.

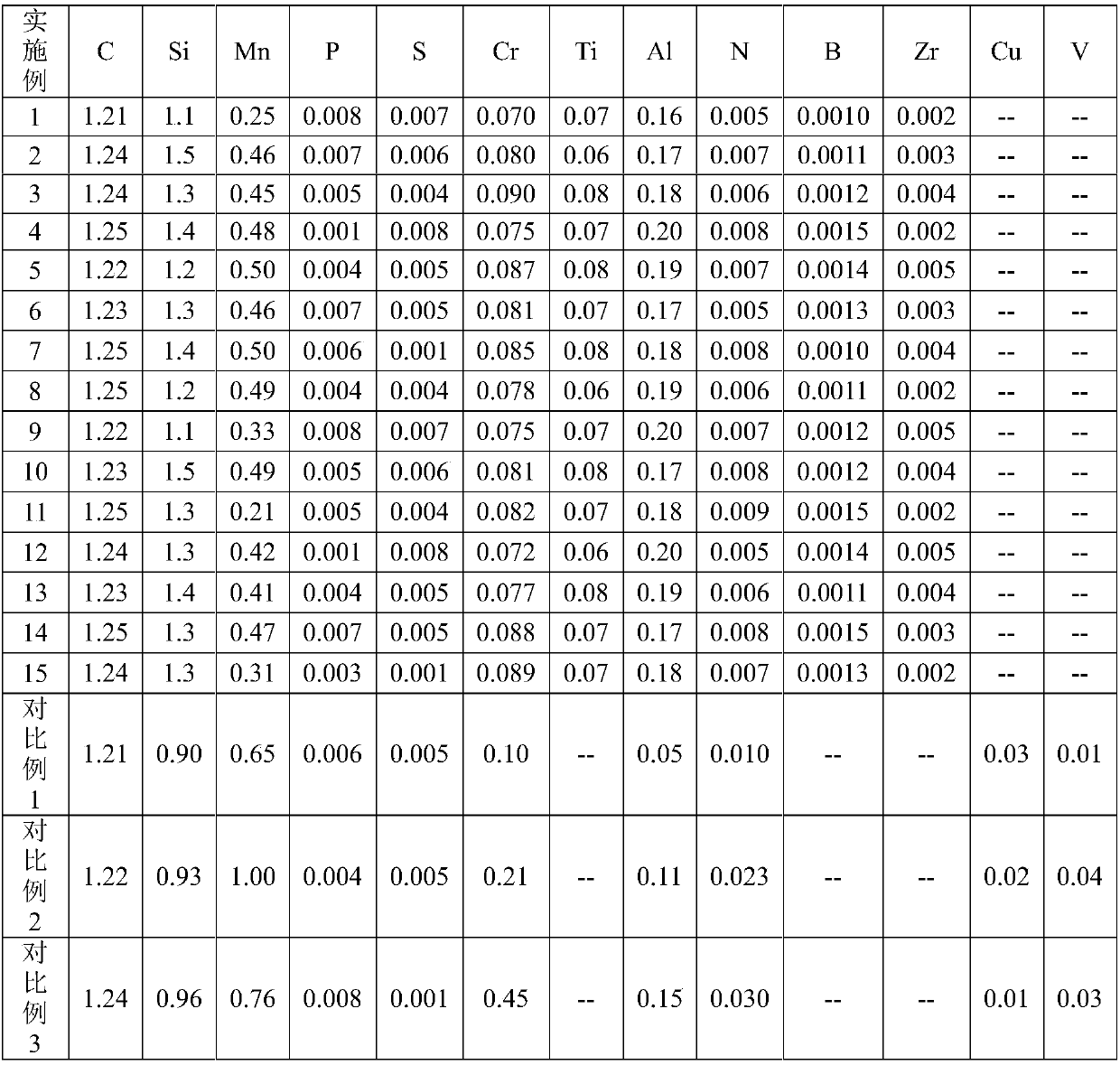

[0065] Table 1 is the value of the chemical composition of each embodiment of the present invention and comparative examples;

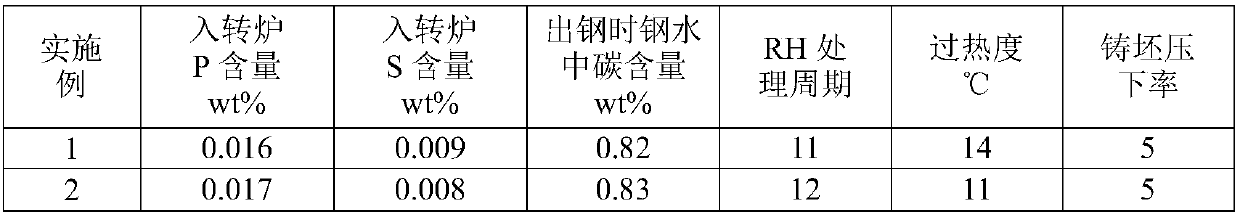

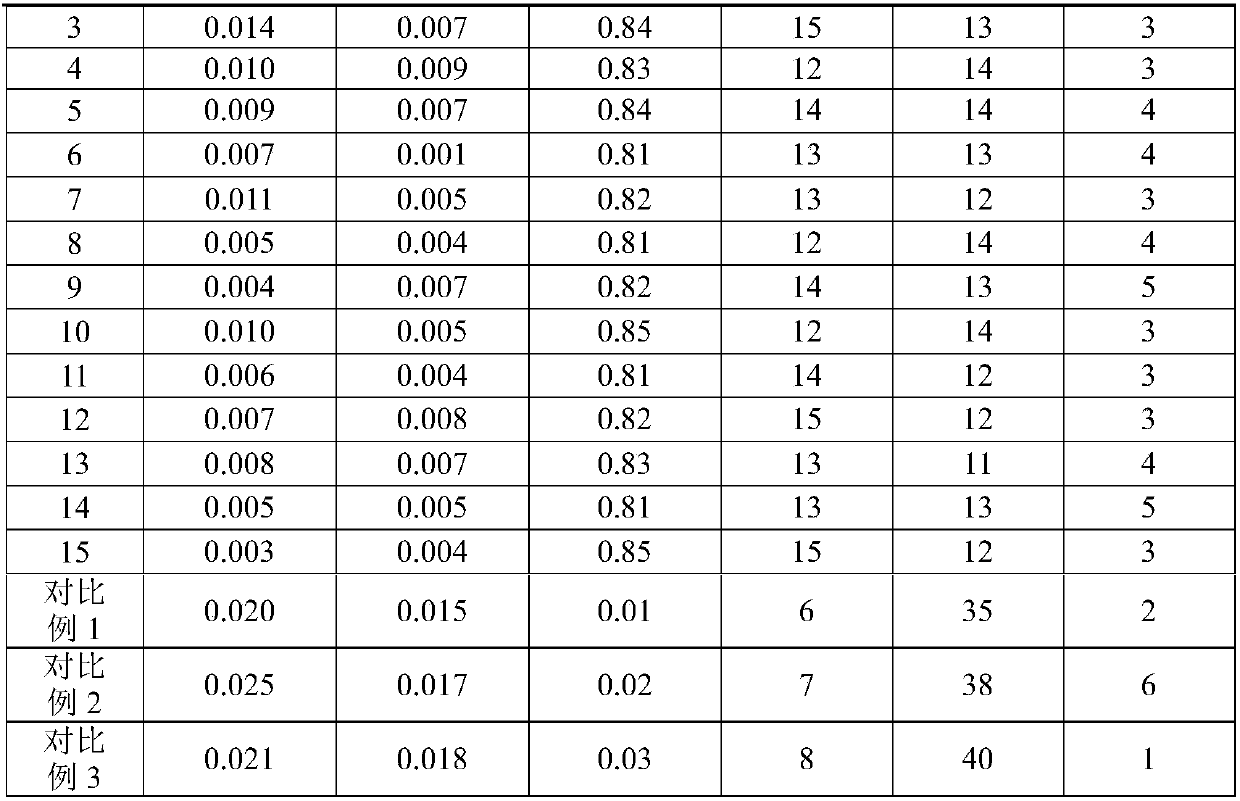

[0066] Table 2 is each embodiment of the present invention and comparative example smelting process technological parameter;

[0067] Table 3 is each embodiment of the present invention and comparative example rolling process technological parameter;

[0068] Table 4 is the experimental results of various embodiments of the present invention and comparative examples.

[0069] Each embodiment of the present invention is produced according to the following steps:

[0070] 1) Perform pretreatment of molten iron, and control the contents of P and S in the molten iron before entering the converter to be respectively: P<0.012wt%, S<0.01wt%;

[0071] 2) Carry out converter smelting, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com