Patents

Literature

80results about How to "Dissipate heat quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

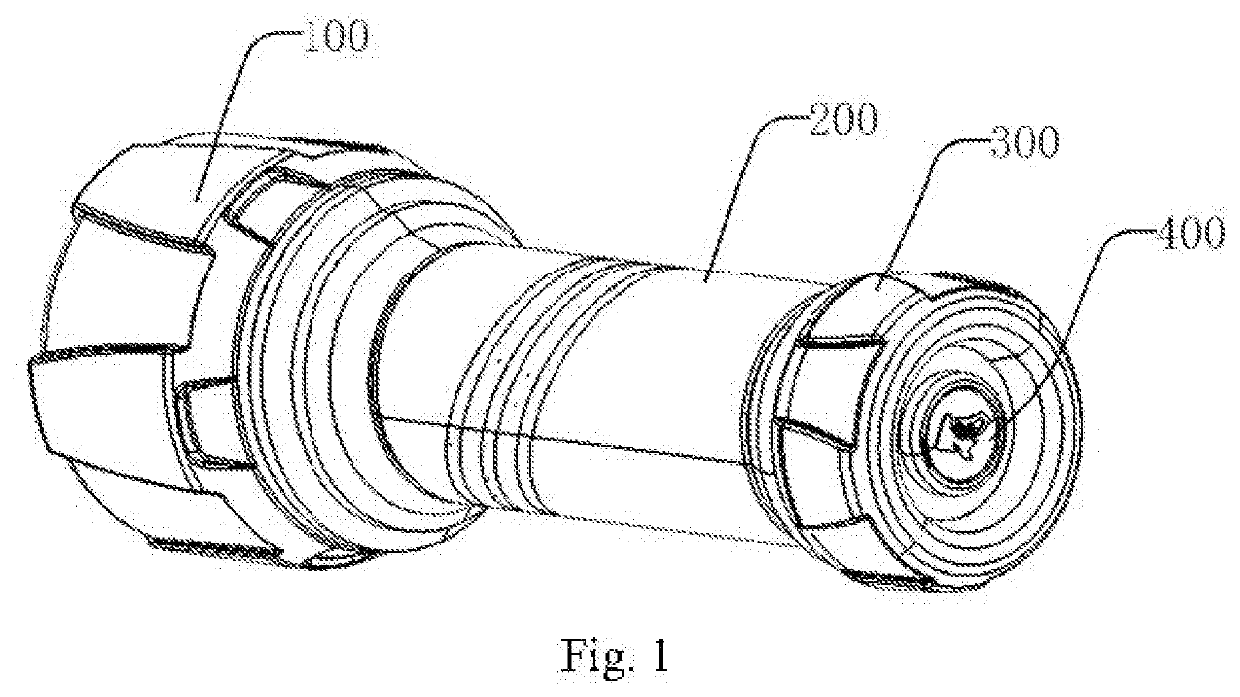

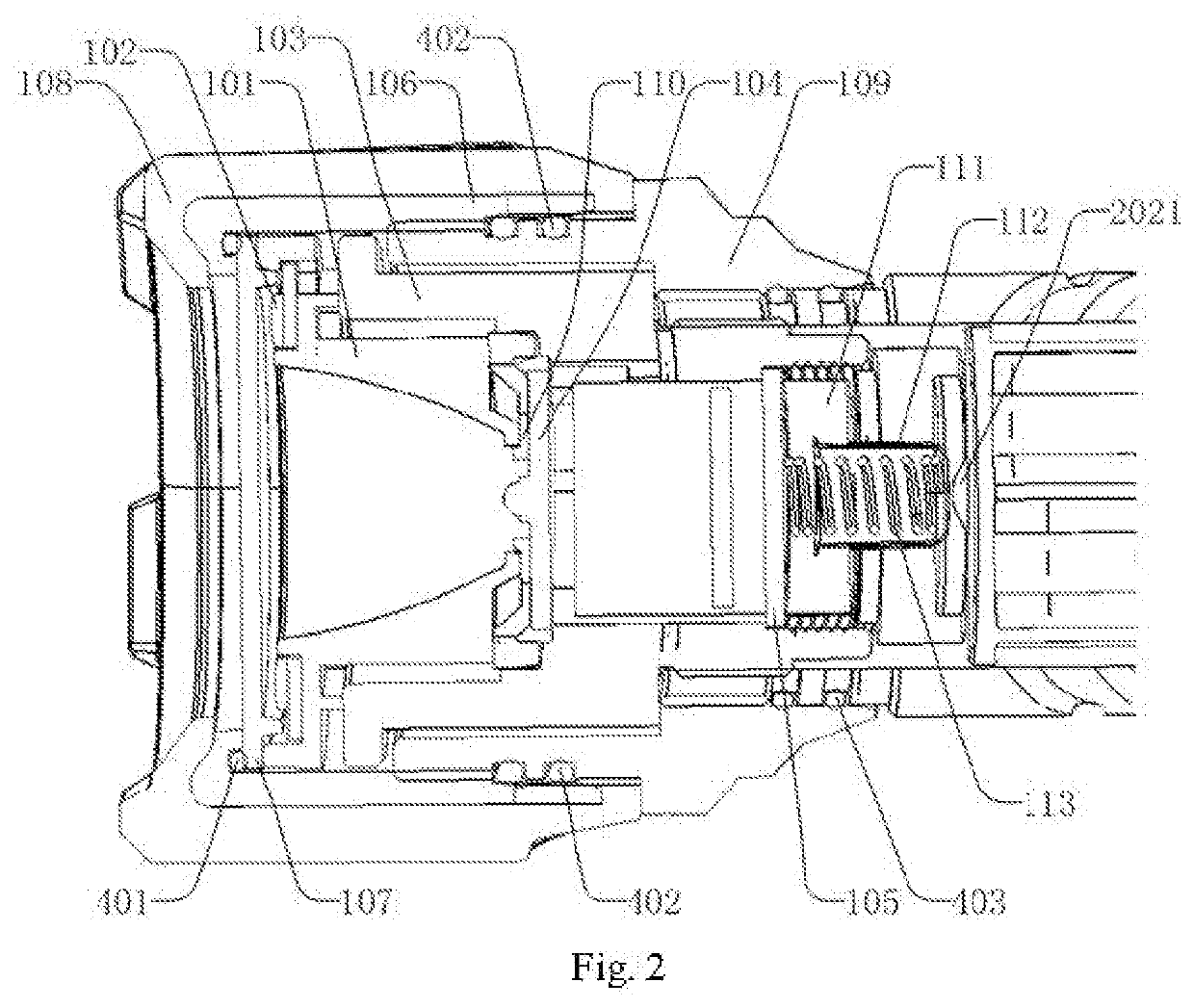

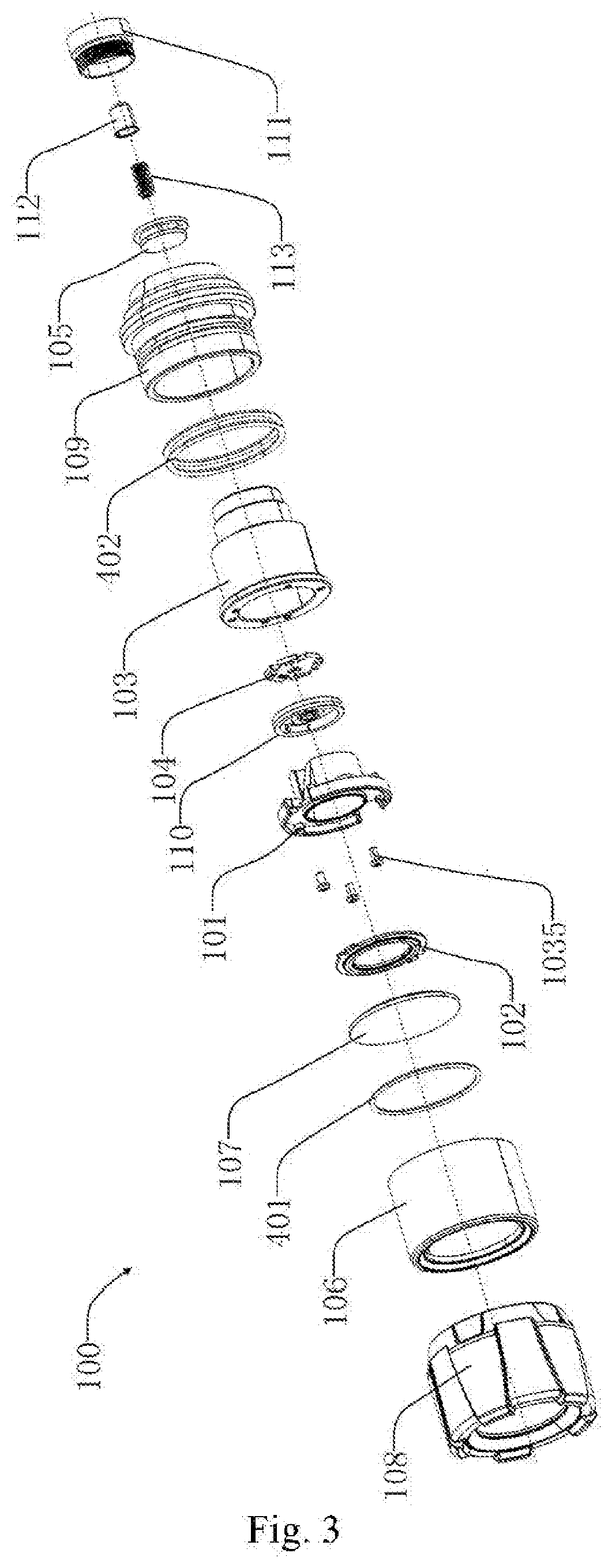

Heat dissipation device

ActiveUS20170343297A1Improve heat transfer efficiencyDissipate heat quicklyIndirect heat exchangersElectrical and Electronics engineeringEngineering

A heat dissipation device includes a first and a second housing, at least one pipe, and a working fluid. The first and the second housing internally respectively defines a first and a second chamber, in which a first and a second wick structure is respectively formed, and has at least one first and second opening communicated with the first and the second chamber respectively. The pipe has a pipe body, and a first and second extended portion, which respectively has a first and a second open end, and a first and a second through opening, and is inserted into and connected to the first and the second chamber via the first and the second opening respectively. The pipe internally defines a pipe chamber, in which a pipe wick structure is formed. The working fluid is provided in the first and the second, and the pipe chamber.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

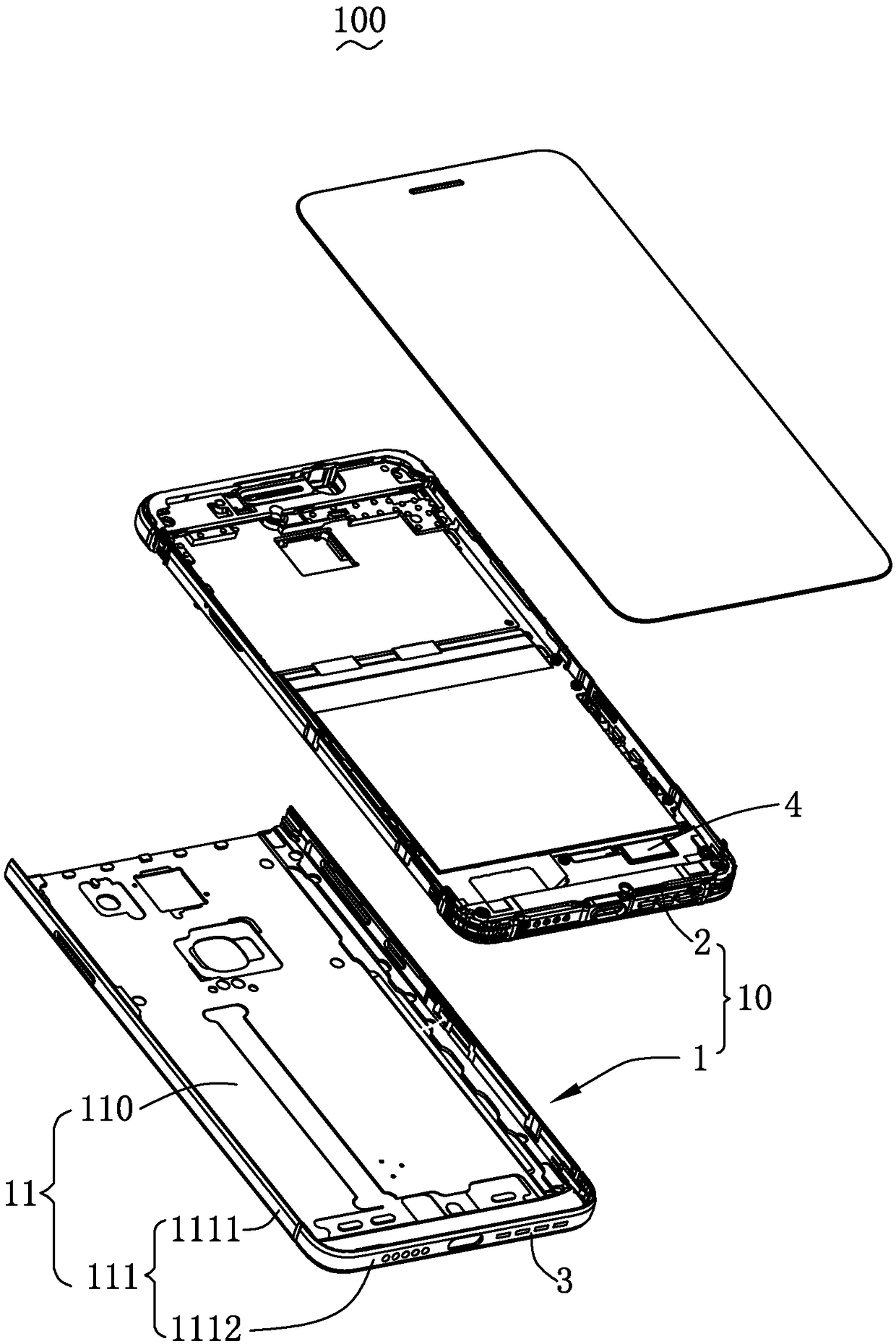

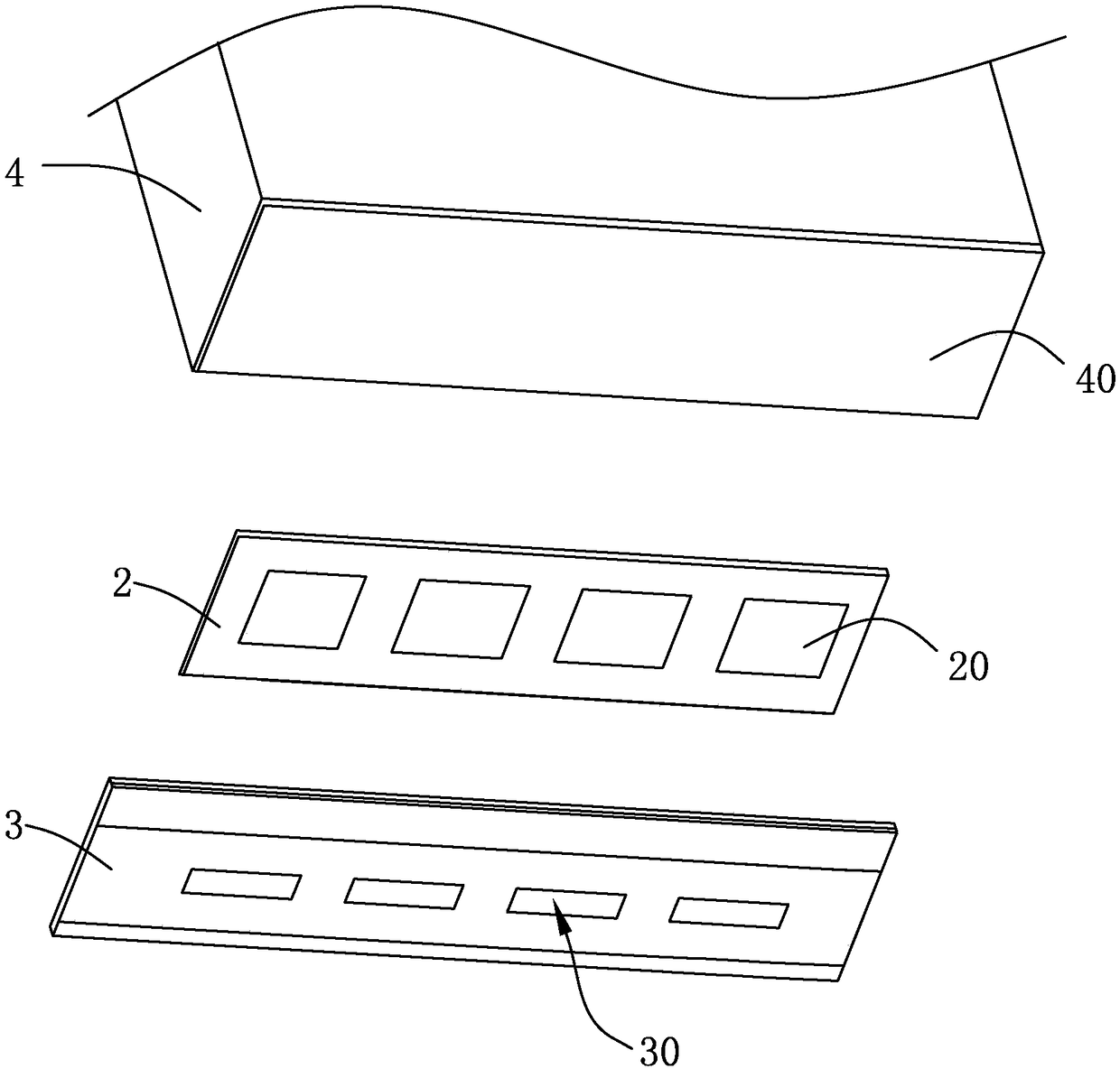

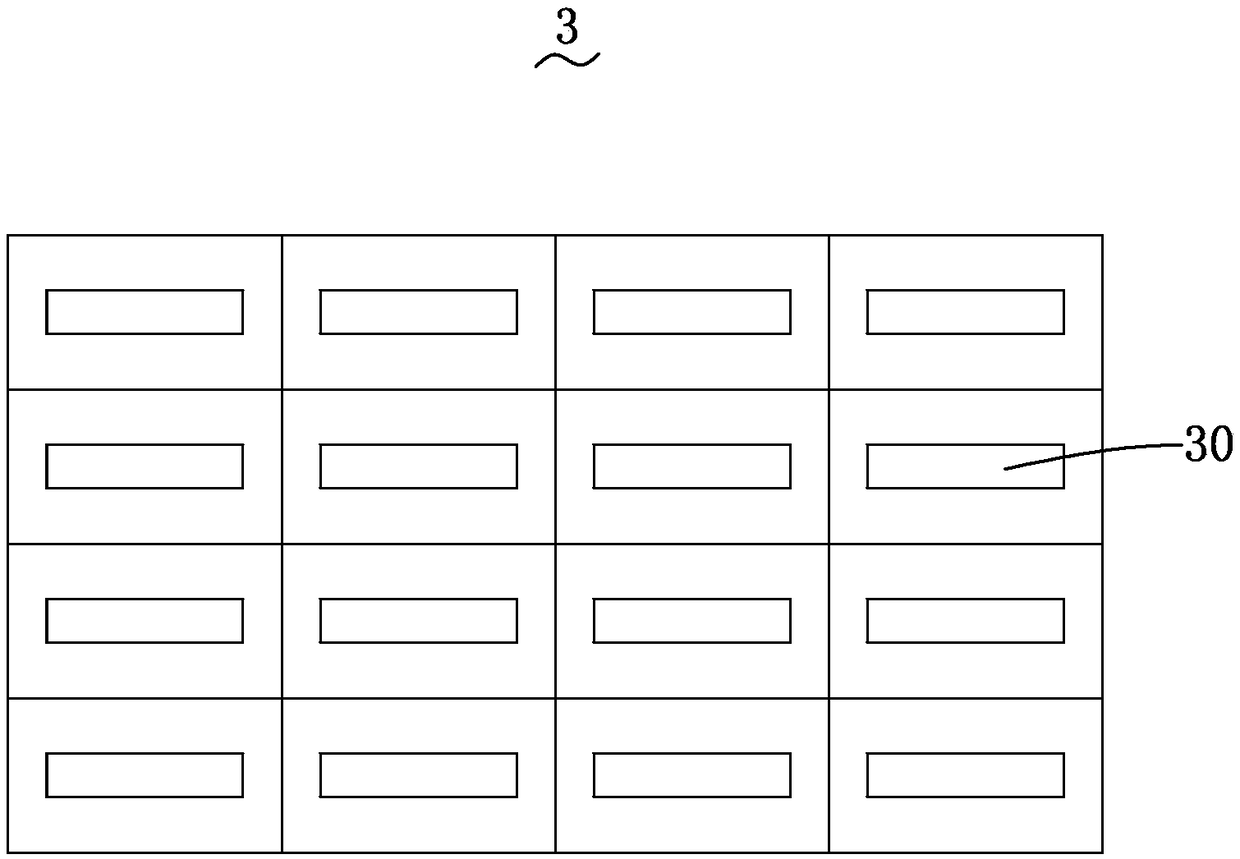

Antenna assembly and mobile terminal

InactiveCN108494925AImprove aestheticsDissipate heat quicklyAntenna supports/mountingsIndividually energised antenna arraysRadio frequency signalAntenna gain

The invention provides an antenna assembly, which comprises a shell, at least one group of antennas arranged in the shell and a phase shifter in connection with each group of antennas, wherein a wave-transmitting structure used for transmitting a radio-frequency signal is arranged at a position, corresponding to each group of antennas, of the shell; and the wave-transmitting structure comprises aplurality of antenna gaps which are arranged in an array mode. Compared with the related art, according to the antenna assembly provided by the invention, the shell is provided with a wave-transmitting structure comprising an array of multiple antenna gaps, and the wave-transmitting structure can be used for making a sound port and also can be used for transmitting a radio frequency signal, so that the antenna can be scanned in a relatively wide space range, and the antenna assembly is good in attractiveness, good in radiation performance and good in antenna gain and space coverage rate.

Owner:AAC TECH NANJING

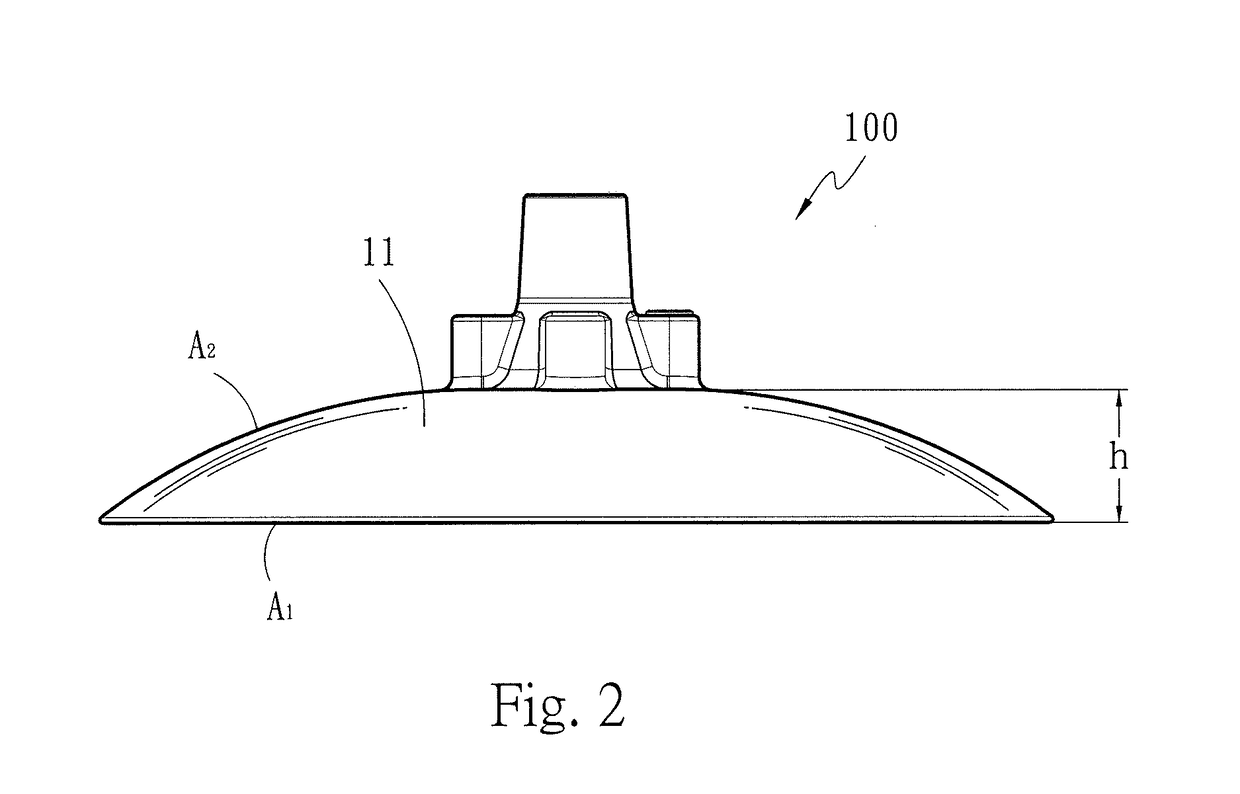

Anti-explosion LED lamp housing

InactiveUS20170146225A1Enhanced structureHard to accumulate dirt and dustLighting heating/cooling arrangementsProtective devices for lightingEngineeringLED lamp

An anti-explosion LED lamp housing is used to separate an illumination module from an external environment and comprises a housing body and a housing cover. The housing body includes a shell having a spherical segment-like shape, an accommodation basin connected with the concave portion of the shell, and a wiring hole penetrating the housing body and the accommodation basin. The accommodation basin includes a first platform encircling the wiring hole and receiving the illumination module; a second platform encircling the first platform and having a level difference to the first platform; and an annular wall encircling the second platform. The housing cover includes a light-permeable plate disposed on the second platform; an annular pressing element forcing the light-permeable plate to press against the second platform and engaged with the annular wall tightly. The diameter of the circular base face of the shell is 4-15 times the height of the shell.

Owner:LI HONG SCI & TECH

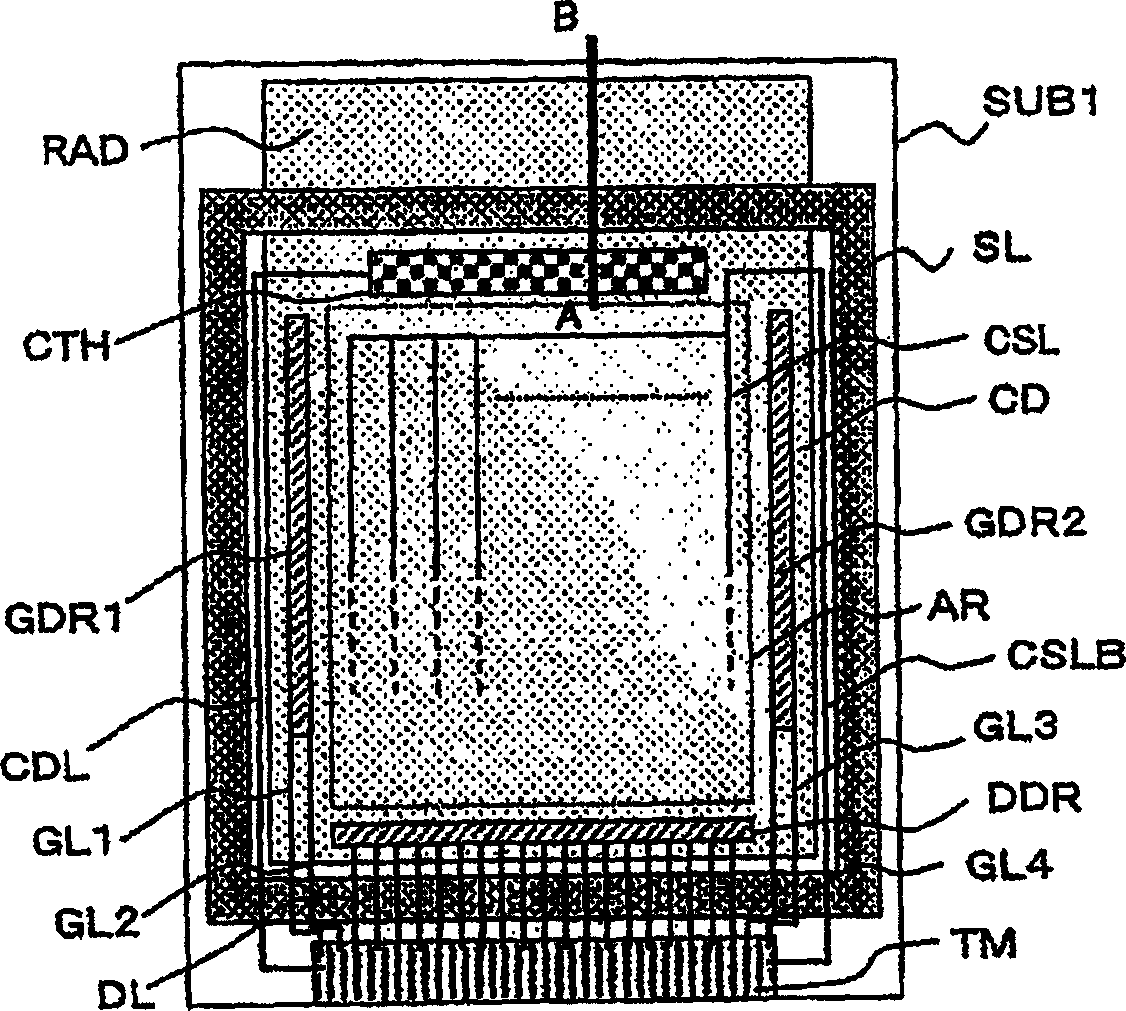

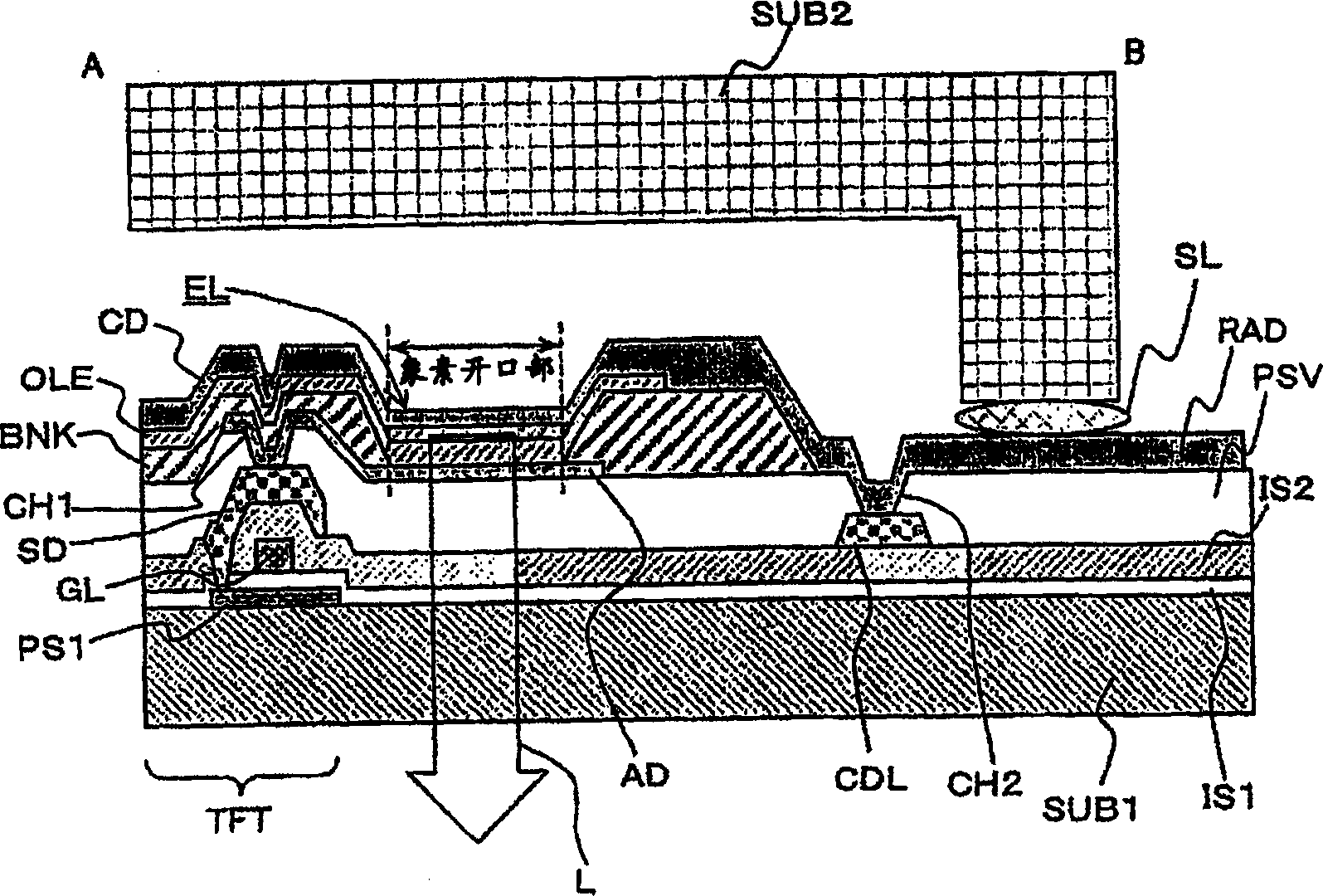

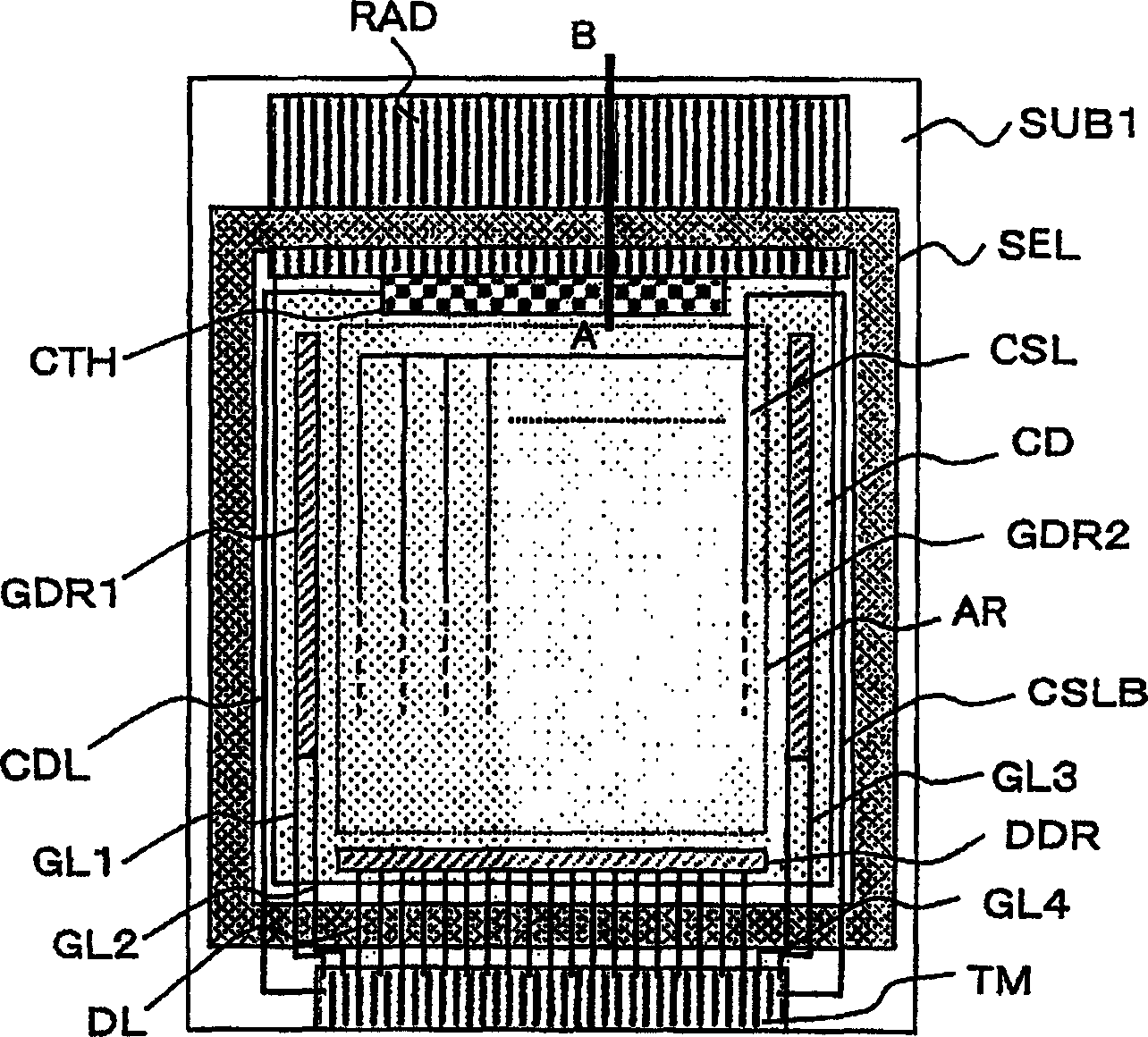

Organic light emitting display

InactiveCN1901221AExtend your lifeDissipate heat quicklySemiconductor/solid-state device detailsElectroluminescent light sourcesLight emissionRadiation

An organic light emitting display provided according to the invention maintains light emission efficiency and elongates its lifetime by radiating heat generated from organic light emitting elements to the outside of an encapsulated area. In the organic light emitting display, a part of a cathode is extended to the outside of the encapsulated area of a main substrate to form a radiation section integrally with the cathode. Heat generated from organic light emitting elements is diffused and radiated from the radiation section so that the heat can be discharged therefrom.

Owner:HITACHI DISPLAYS

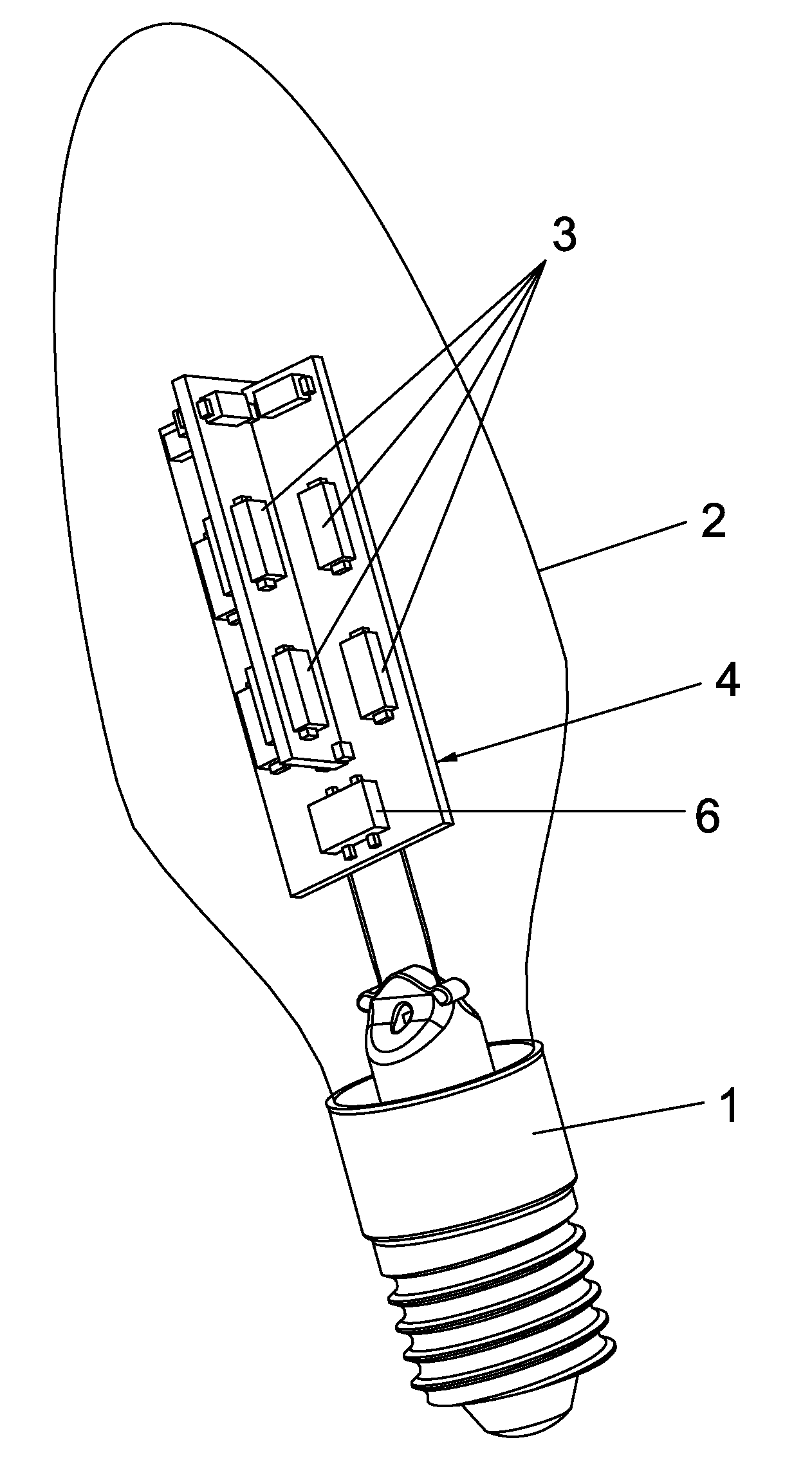

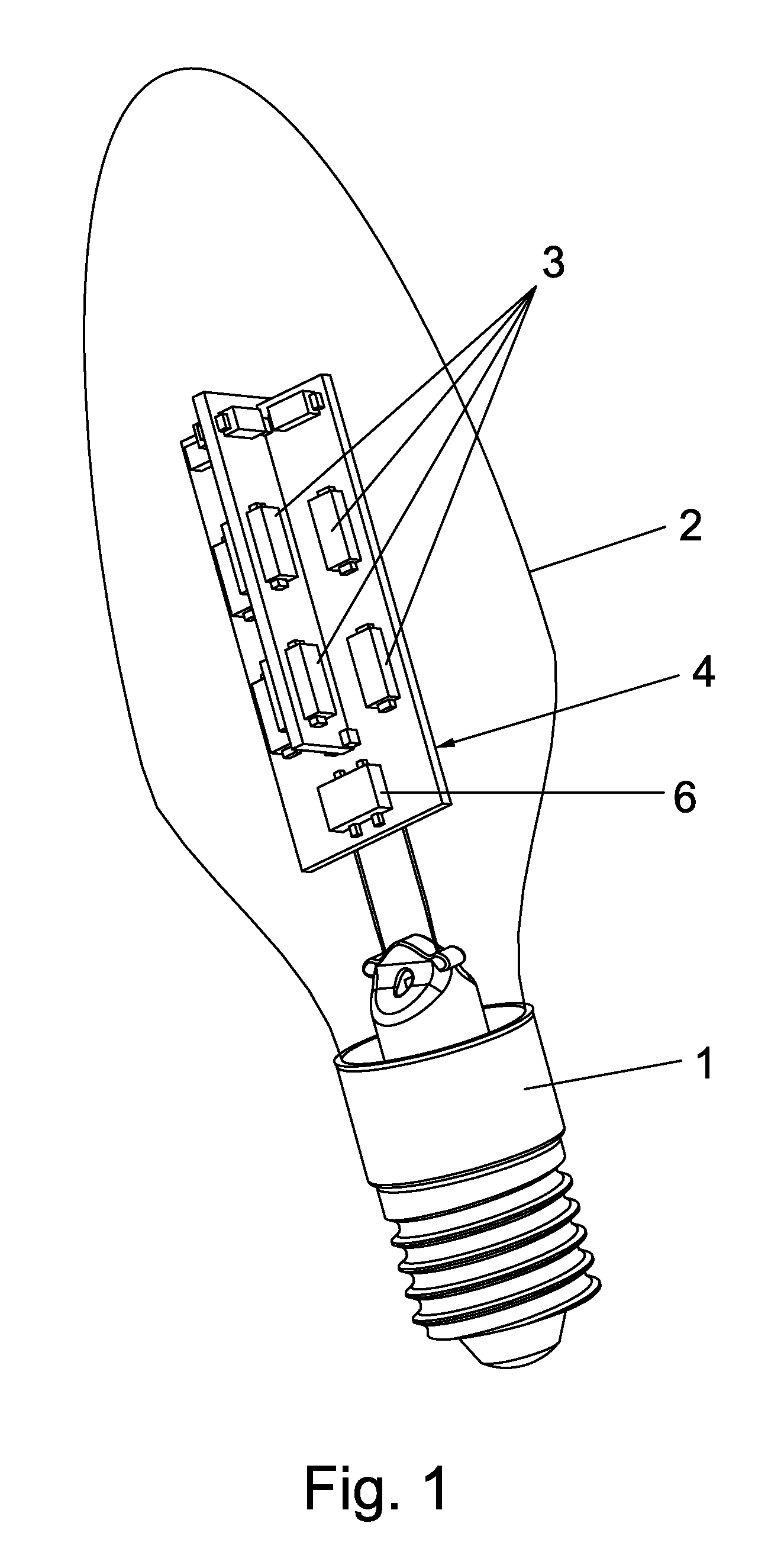

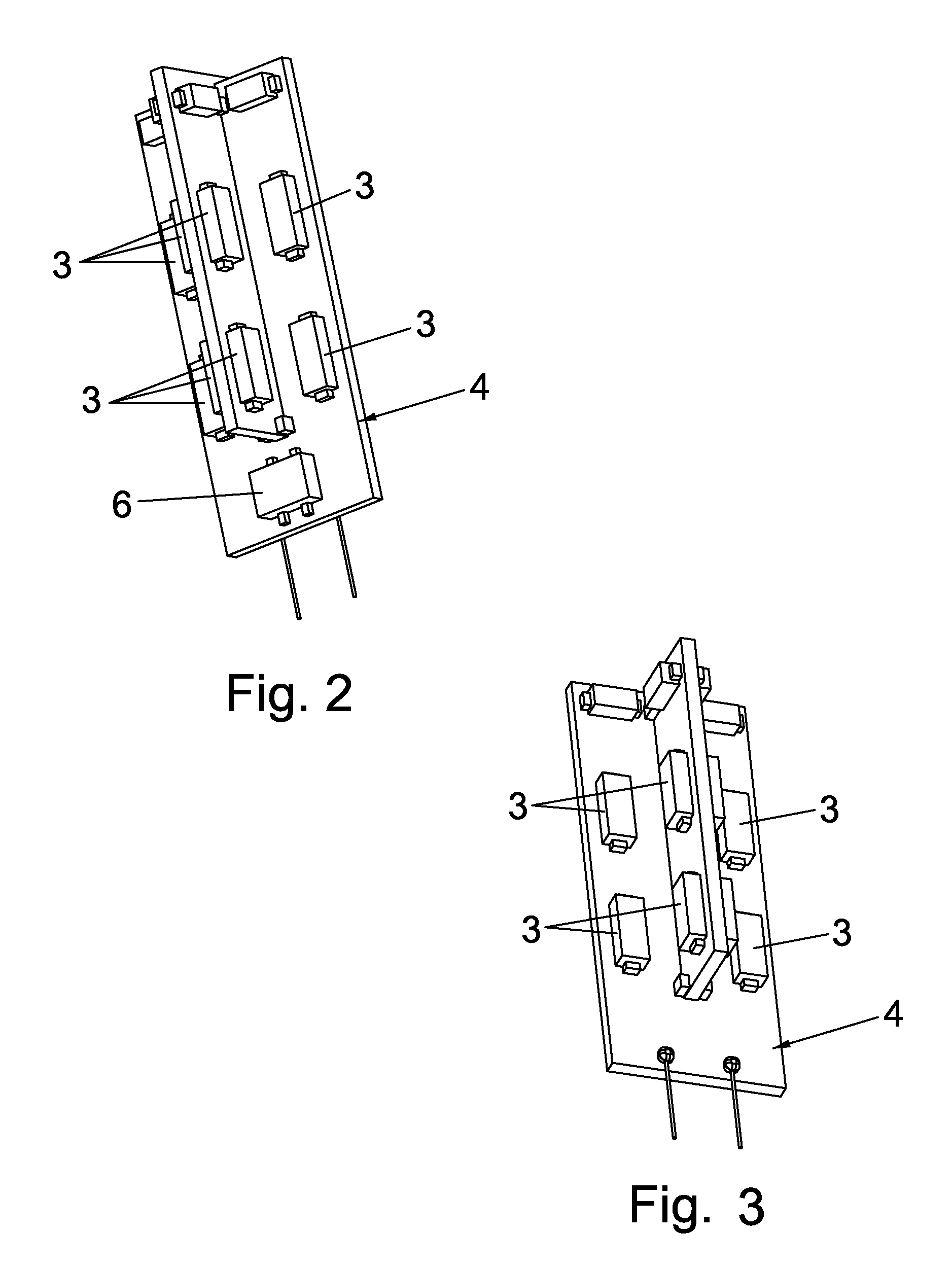

LED bulb

InactiveUS8536807B2Reduce weightLow production costPoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention relates to the technical field of illumination lamps, in particular to an LED bulb. The invention comprises a lamp cap, a lampshade, LEDS and a circuit board, wherein the bottom end of the lampshade is mounted and fixed at the top end of the lamp cap; the circuit board is mounted and fixed in the lampshade and also electrically connected with the lamp cap; and the lampshade is filled with a mixed gas which transfers heat produced by the LEDS outside the bulb. The invention transfers heat produced by the LEDS by a mixed gas; the LED bulb has such advantages to as small weight, small volume and low production cost; besides, by using the mixed gas as heat transfer medium, the invention can radiate heat produced by the LEDS outside the bulb rapidly so as to effectively solve the heat radiation issue of the LEDS and prolong the service life of the LEDS.

Owner:DONGGUAN KAIYU PHOTOELECTRIC TECH

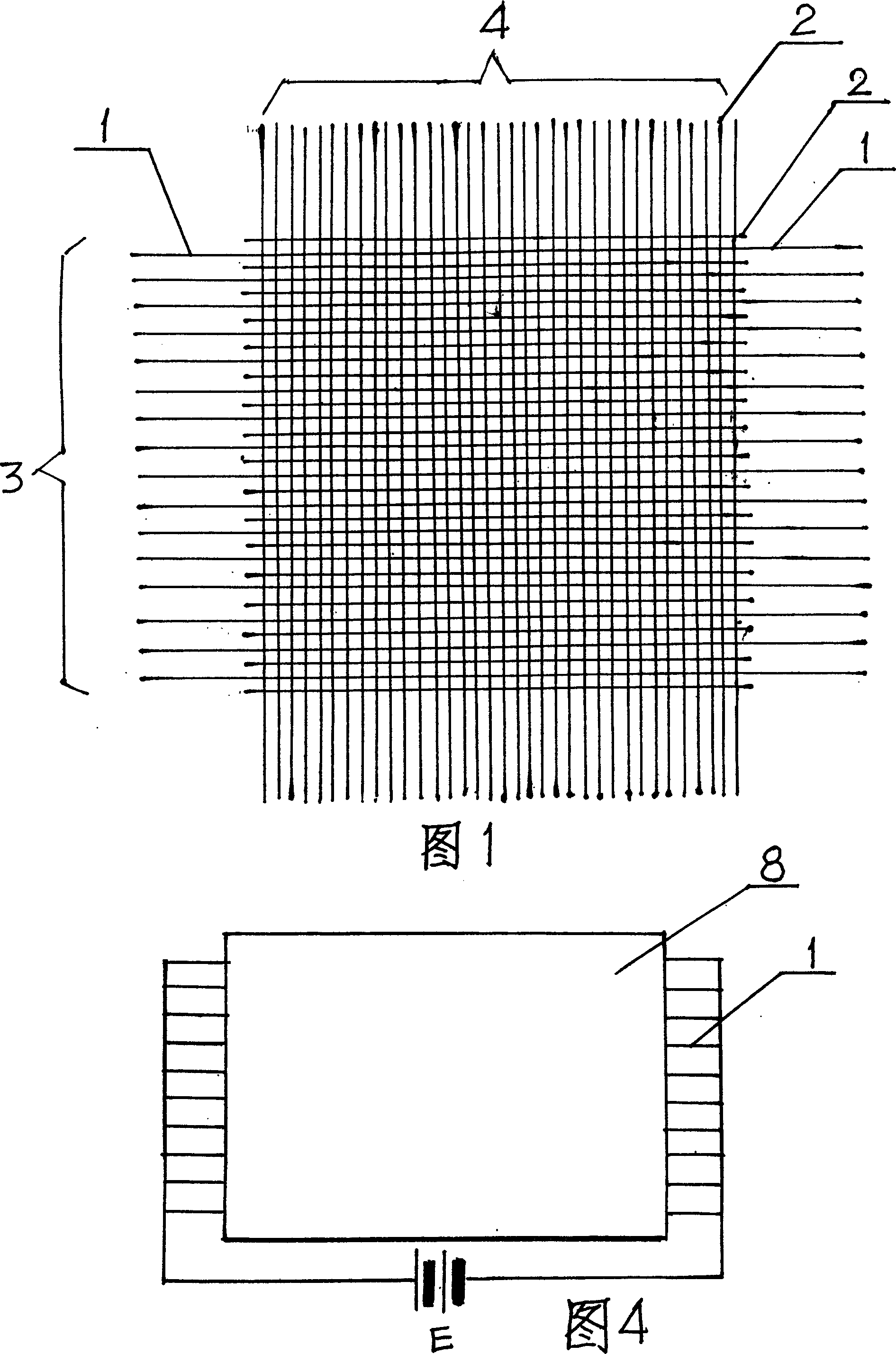

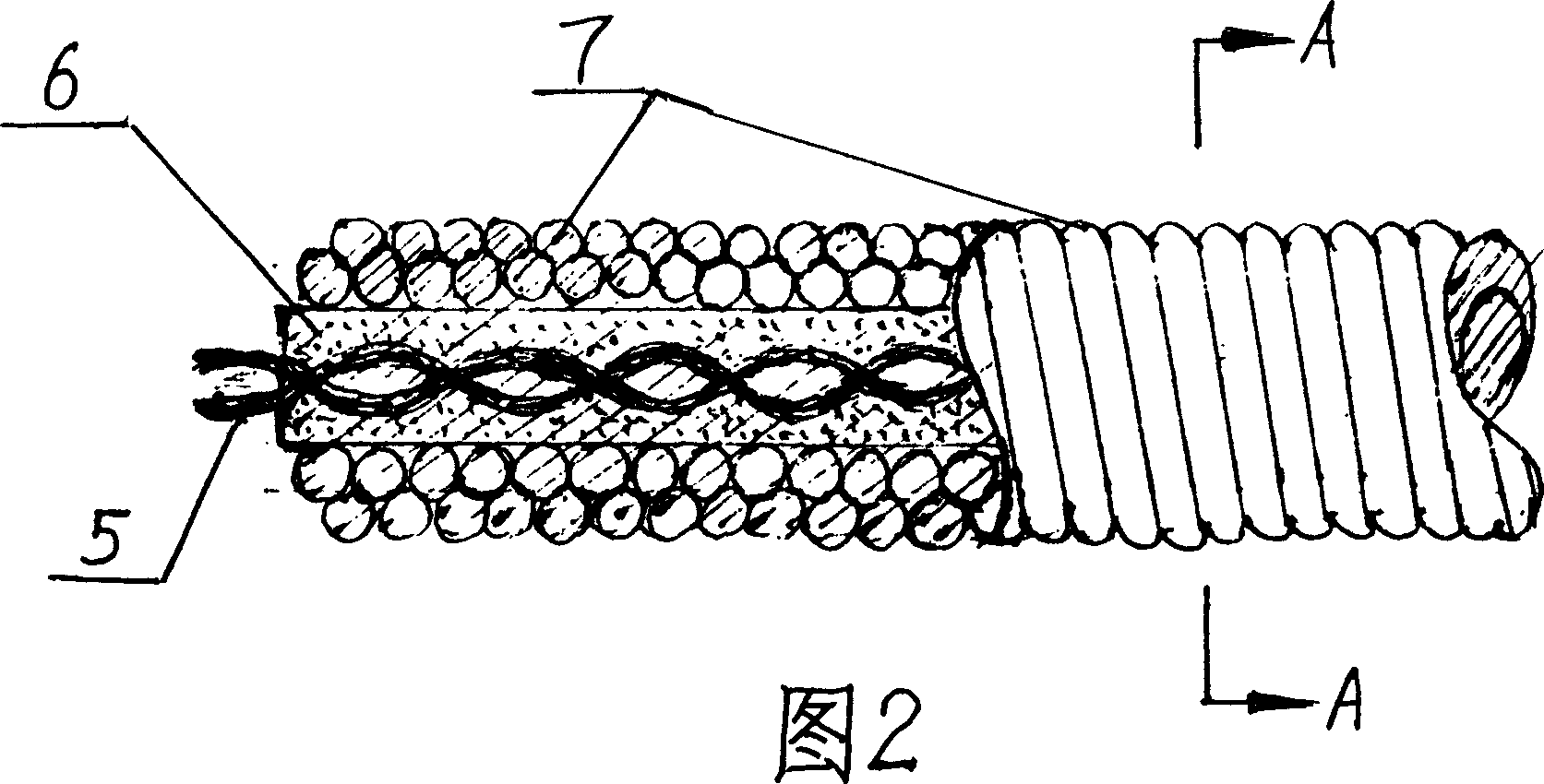

Woven heat-energy fabric

The woven heat-energy fabric is woven with both heating yarn and common yarn, and has warp yarn including common yarn and heating yarn distributed equidistantly among common yarn and weft yarn of common yarn. The woven heat-energy fabric is light, thin, soft, moisture absorbent and permeable; and may be printed, cut, sewn and washed conveniently. It can heat fast and homogeneously and has wide application.

Owner:王能生 +1

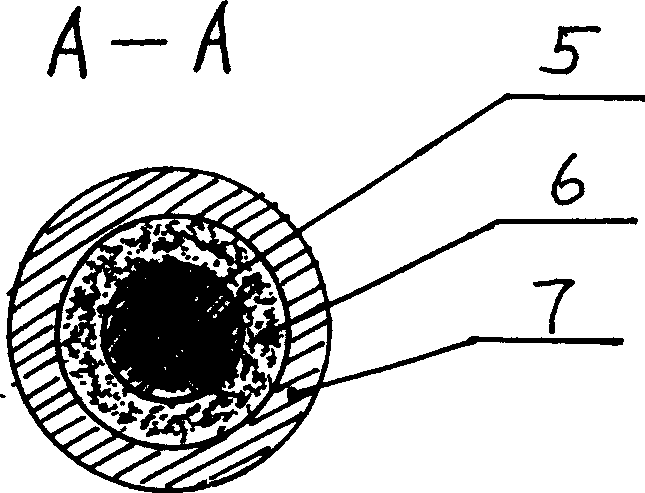

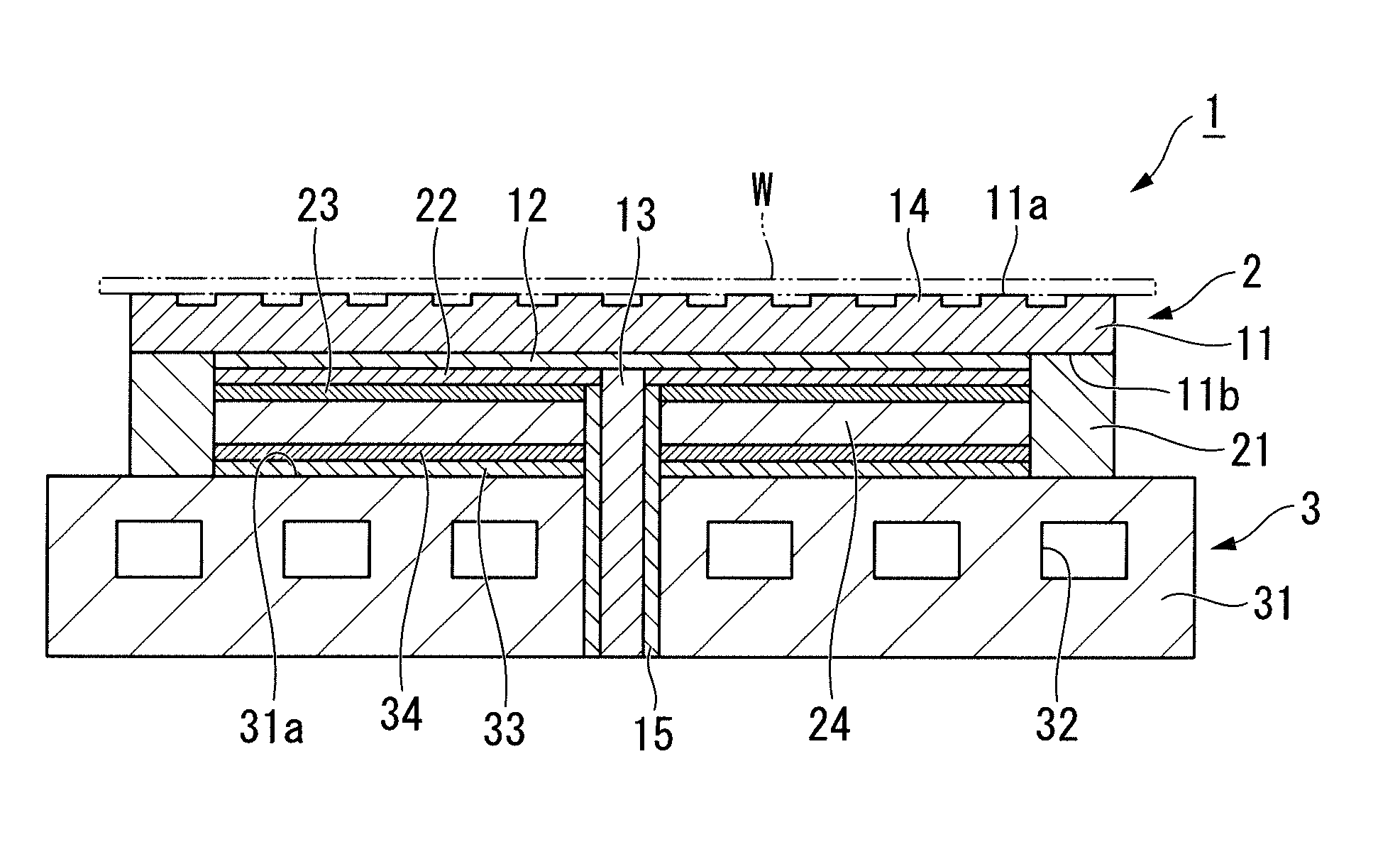

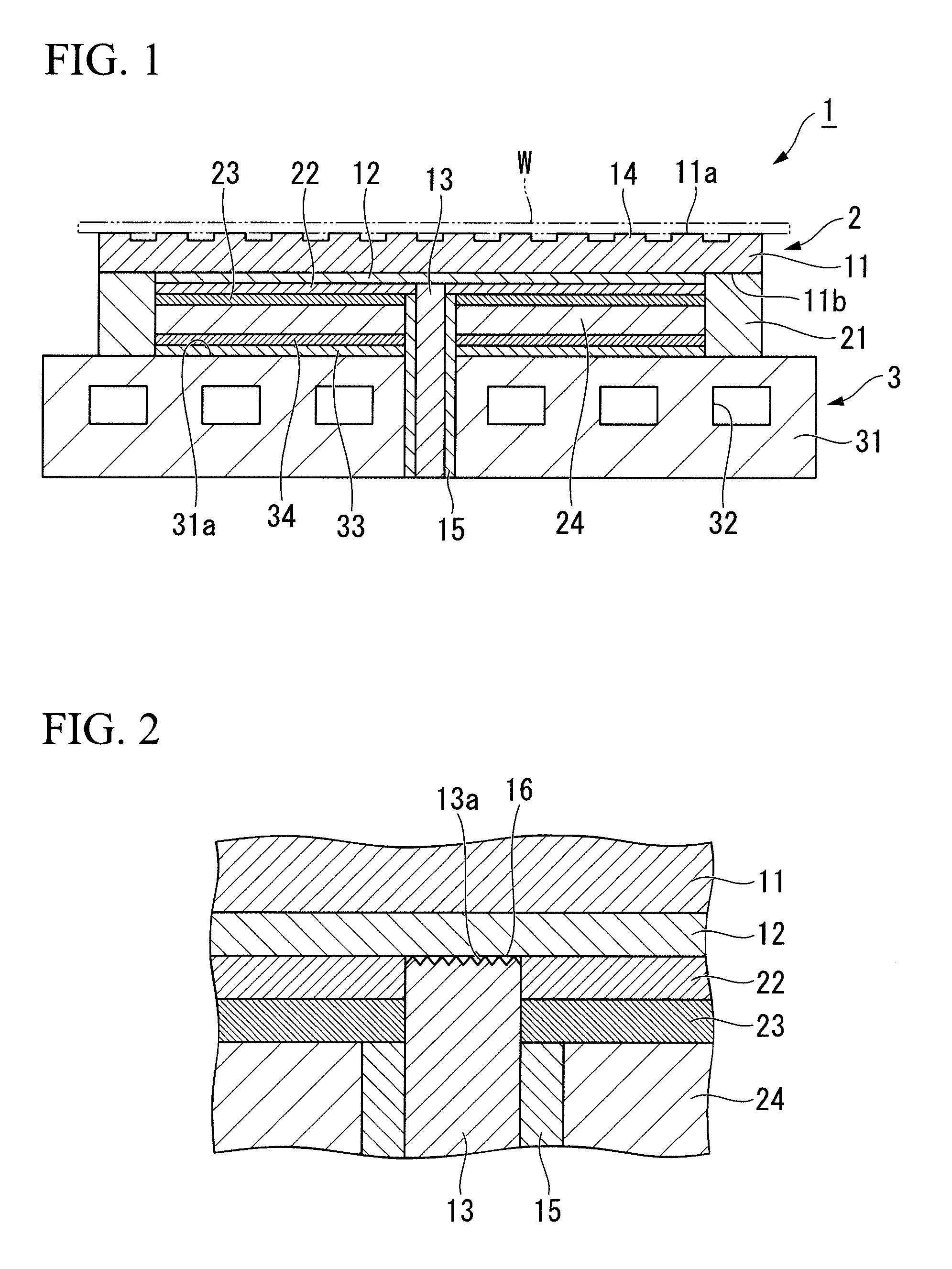

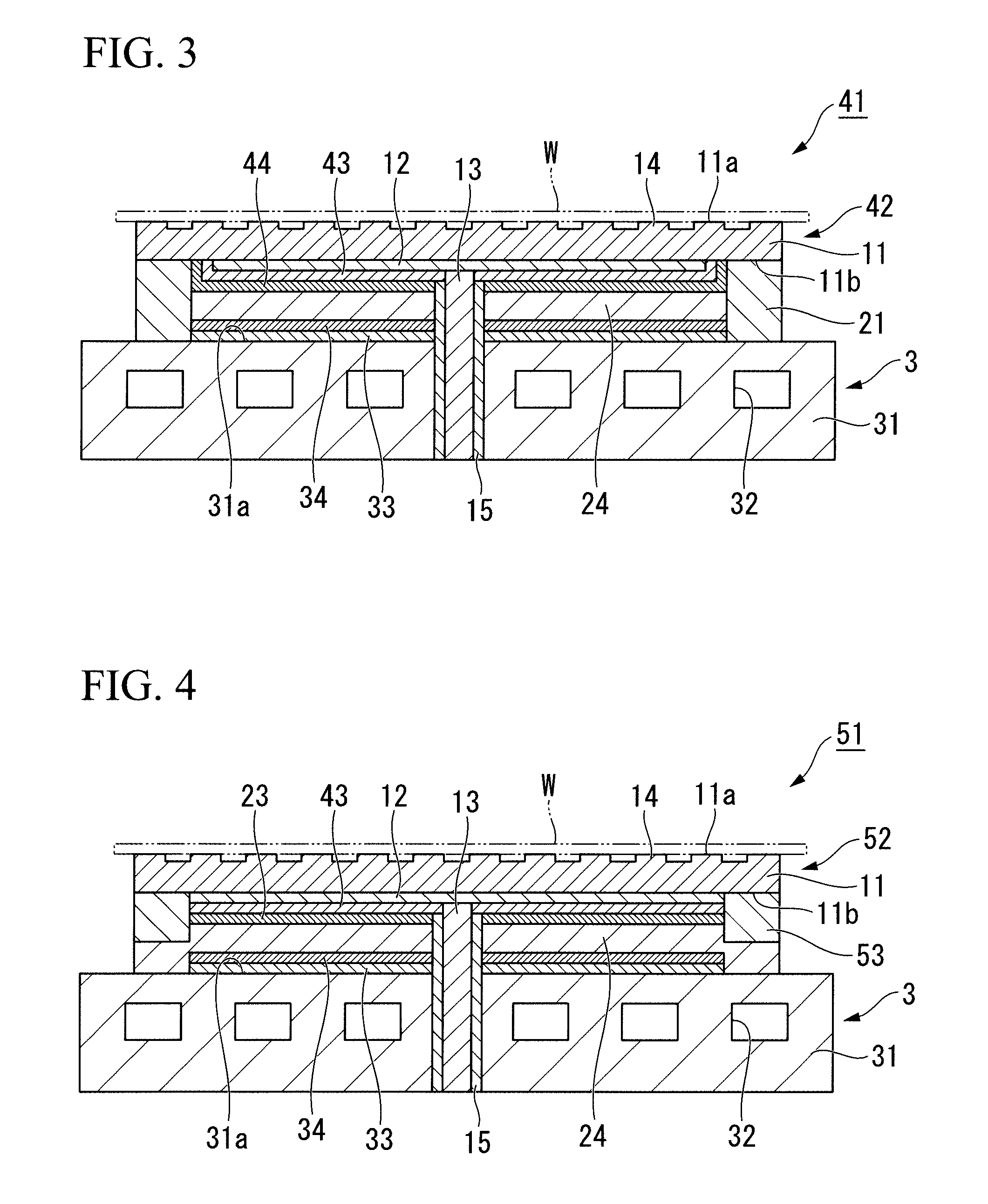

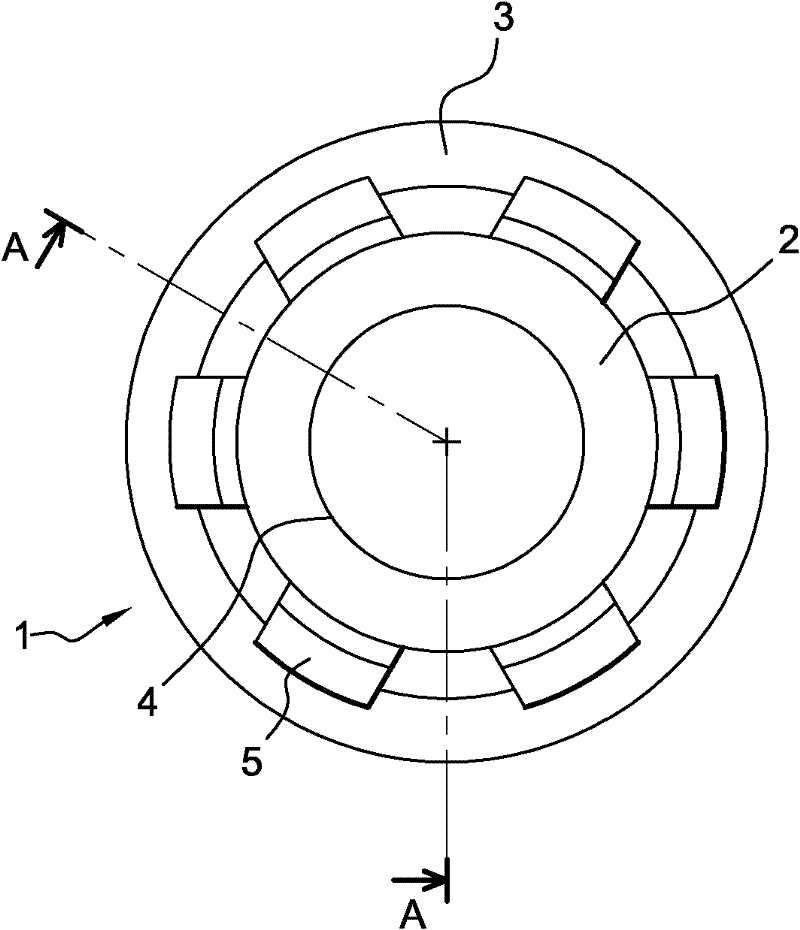

Electrostatic chucking device

ActiveUS9287156B2Move quicklyPrevent occurrence of cracking and fractureSemiconductor/solid-state device manufacturingEngineeringCeramic

The electrostatic chucking device 1 of the invention includes an electrostatic chucking portion 2 which includes a plate-like body 11, a top surface 11a of which is used as a mounting surface that mounts a plate-like specimen W, an electrostatic adsorption electrode 12 provided in the plate-like body 11 and a power-feeding terminal 13 that applies a direct-current voltage to the electrostatic adsorption electrode 12; and a base portion 31 that supports the electrostatic chucking portion 2, in which the plate-like body 11 is a corrosion-resistant ceramic, a circular insulation member 21 is provided in a circumferential edge portion between the electrostatic chucking portion 2 and the base portion 31, and a heat radiation plate 34 is provided on the top surface 31a of the base portion 31.

Owner:SUMITOMO OSAKA CEMENT CO LTD

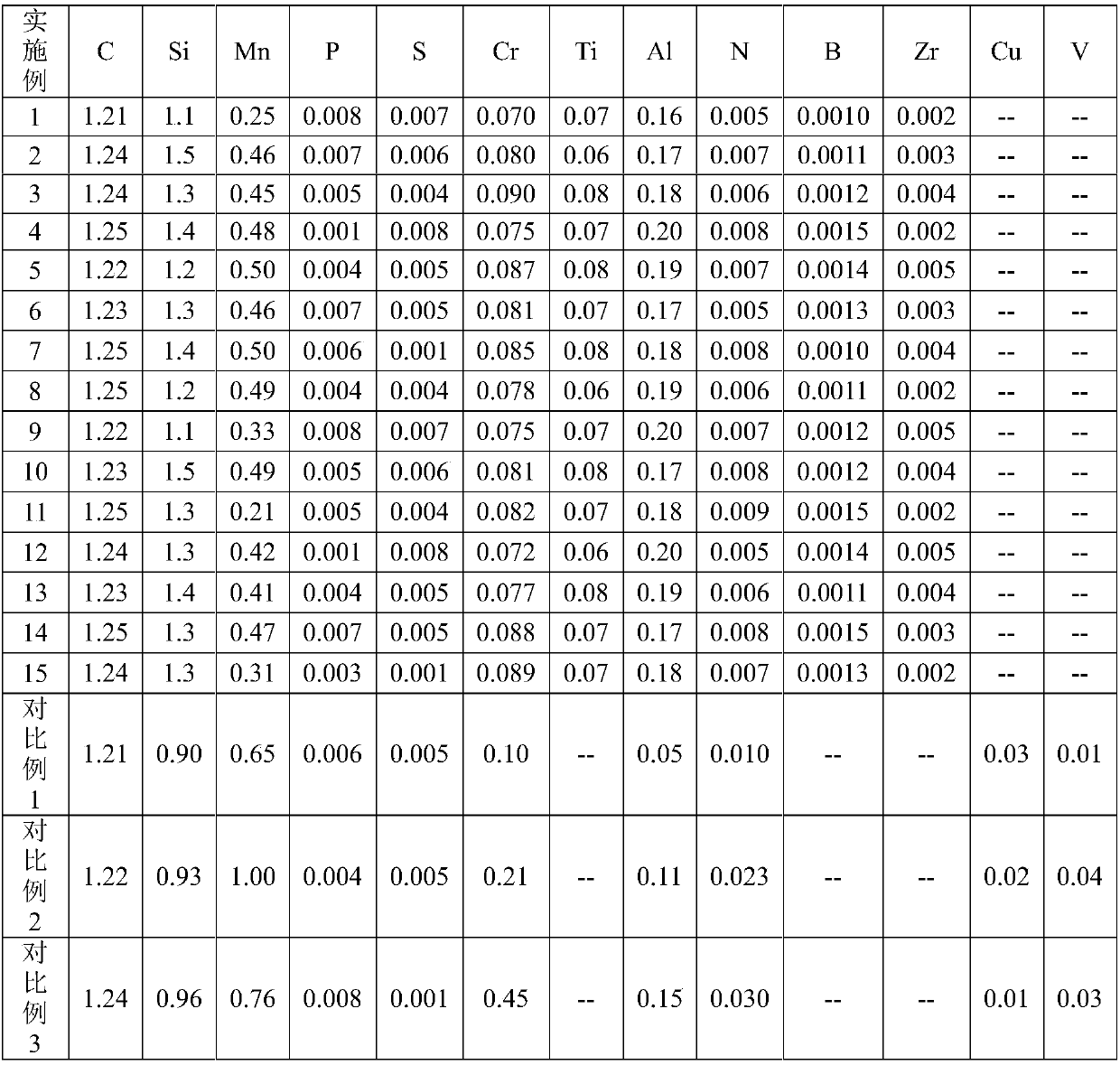

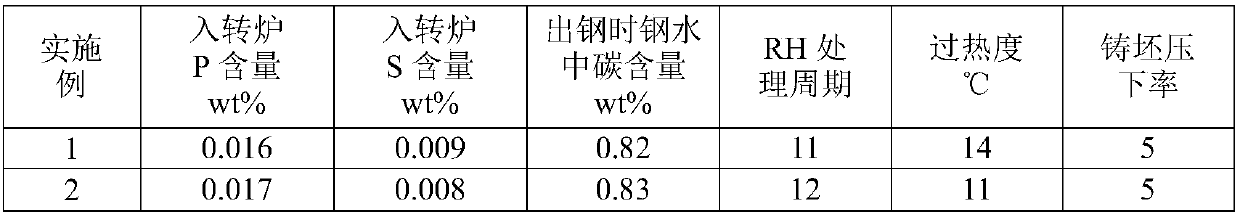

Bridge cable steel with tensile strength being greater than or equal to 2500 MPa and production method

The invention provides bridge cable steel with the tensile strength being greater than or equal to 2500 MPa. The bridge cable steel comprises chemical components of, by weight, 1.21-1.25% of C, 1.1-1.5 % of Si, 0.2-0.5 % of Mn, no more than 0.01% of P, no more than 0.01% of S, 0.07-0.09 % of Cr, 0.06-0.08% of Ti, 0.16-0.20% of Al, 0.005-0.009 % of N, 0.001-0.0015 % of B and 0.002-0.005 % of Zr. Aproduction method comprises the steps that hot metal pretreatment is conducted; converter smelting is conducted; RH vacuum treatment is conducted; continuous casting is conducted to form a billet; thecasing billet is cut through flame in the longitudinal direction after indoor stacking slow cooling is conducted; the casting billet is heated; the casting billet is initially rolled to small squarebillets; the square billets are heated after stacking slow cooling is conducted; high-speed rolling is conducted; laying is conducted; and the square billets are cooled through air to the room temperature. According to the bridge cable steel with the tensile strength being greater than or equal to 2500 MPa and the production method, the strength reaches more than 2500 MPa after the square billetsare subjected to drawing, galvanizing and stabilizing treatment, the condition that the number of torsions is not less than 12 times is simultaneously met, and the bridge cable steel can meet the construction demand of a large bridge with the bridge span being greater than 1100 meters.

Owner:武汉钢铁有限公司

Lighting equipment

ActiveUS20200173629A1Easy to operateEasy to useElongate light sourcesElectric circuit arrangementsLight equipmentEngineering

The present invention provides a lighting equipment, which successively includes a lamp head portion, a connecting portion and a tail portion; the lighting equipment further includes a short distance light source, a long distance light source, a power supply and a control switch. The short distance light source and the long distance light source are arranged inside the lamp head portion, and the light emitting direction of the short distance light source is consistent with that of the long distance light source. The power supply is provided inside the connecting portion, a positive electrode and a negative electrode of which are electrically connected to two ends of the short distance light source and two ends of the long distance light source respectively. The control switch is used for controlling a light and shade state of the short distance light source and the long distance light source.

Owner:HANGZHOU GREAT STAR IND CO LTD +1

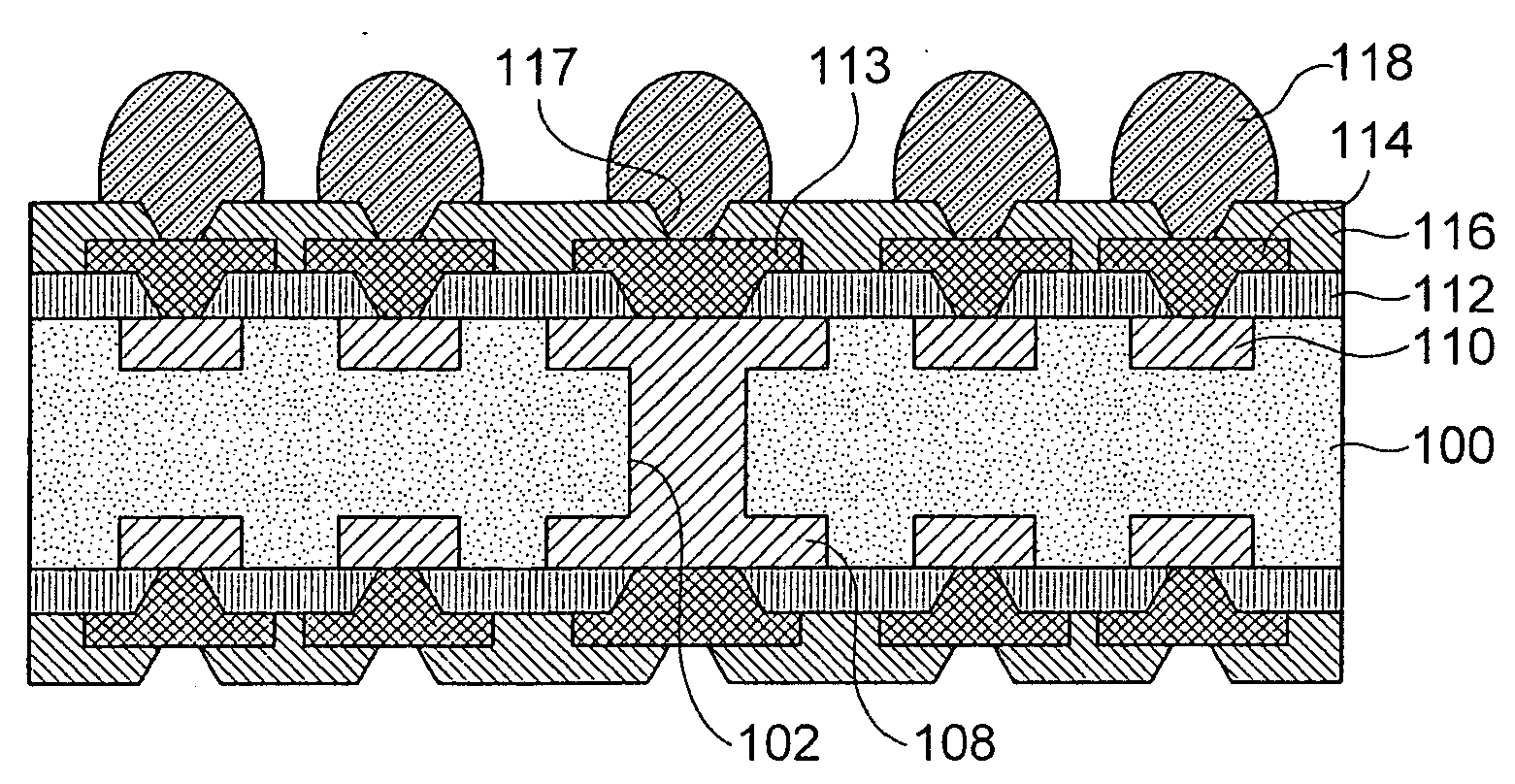

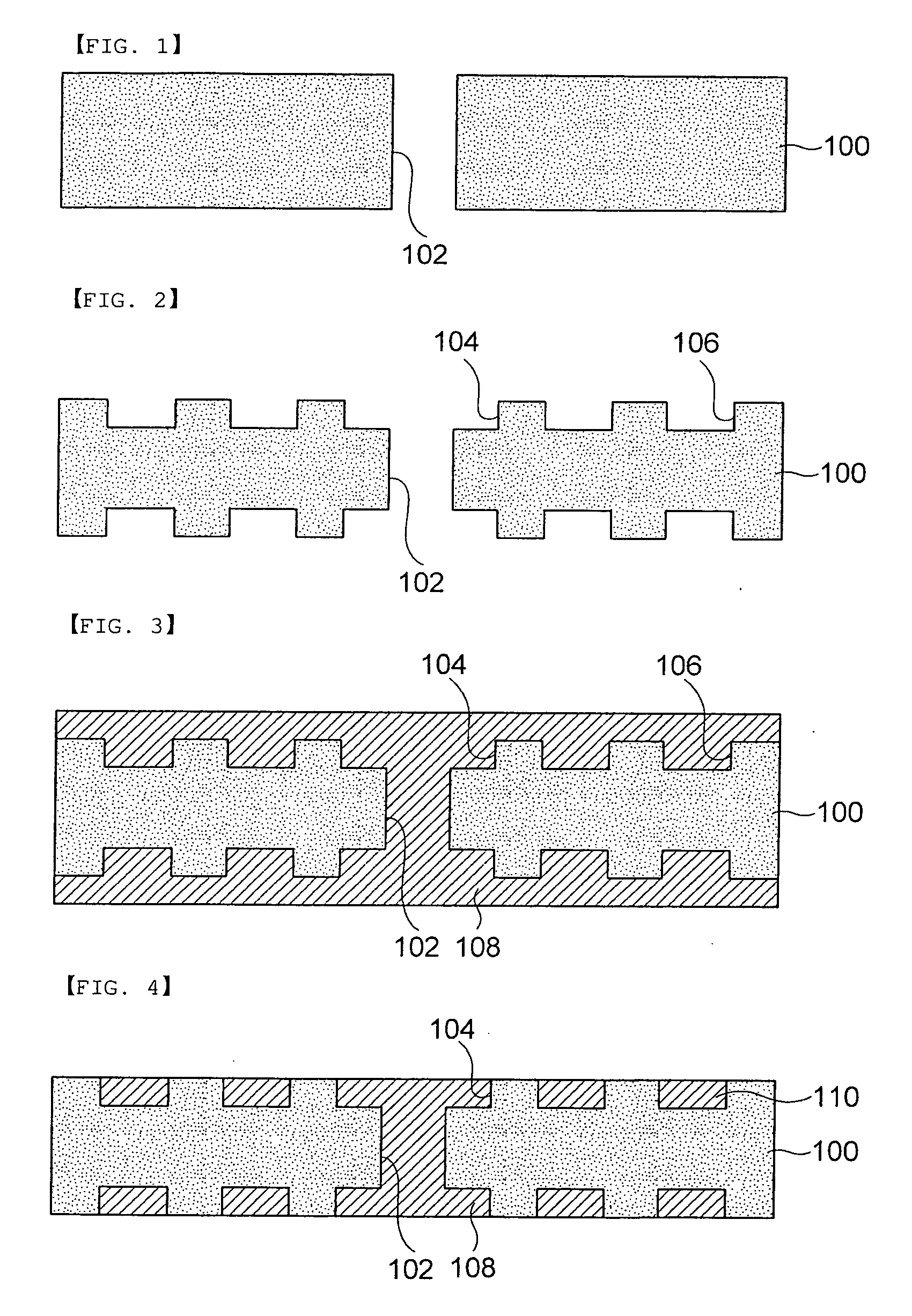

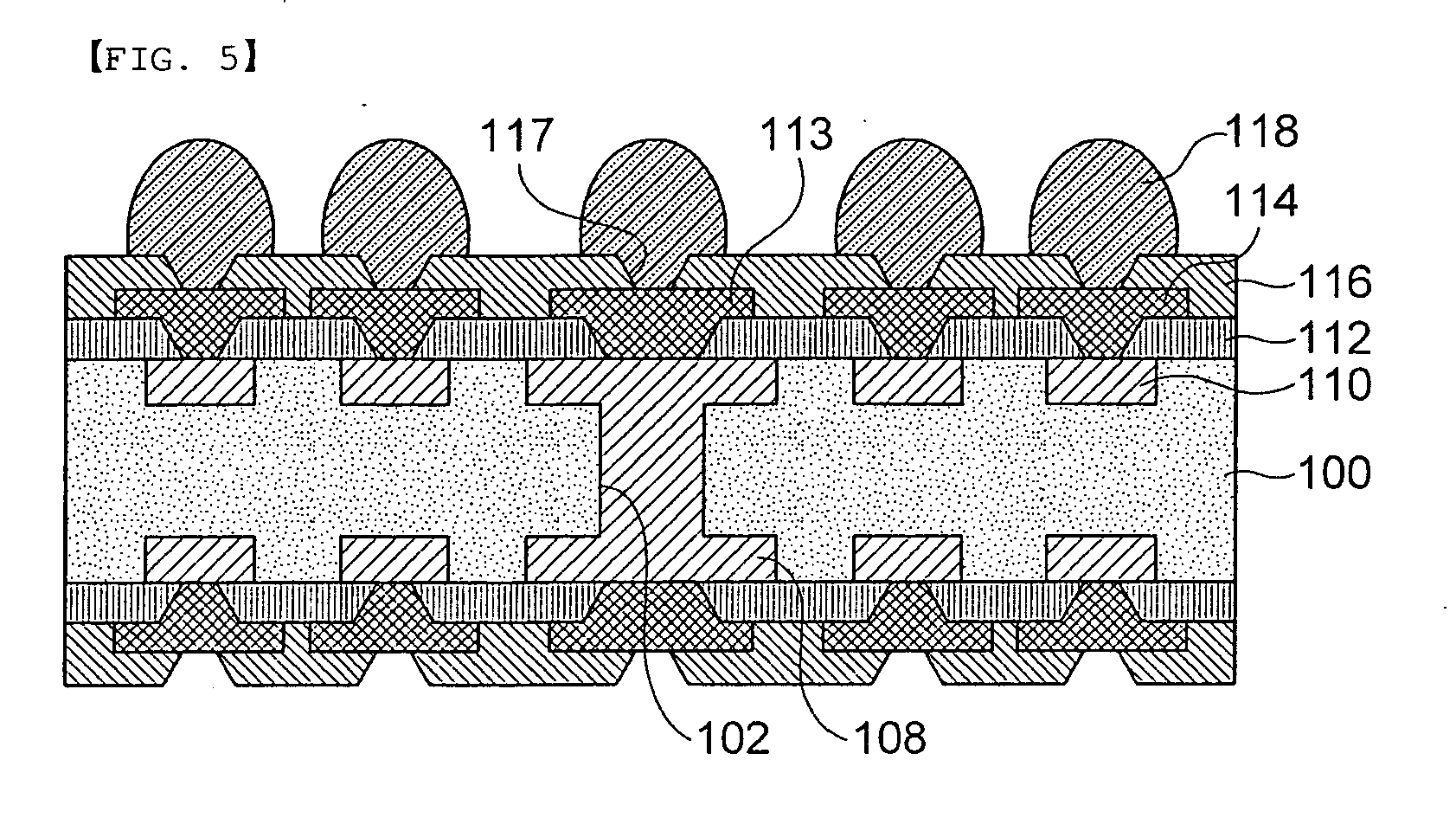

Printed circuit board and method for manufacturing the same

InactiveUS20120118618A1Good heat dissipationDissipate heat quicklySemiconductor/solid-state device detailsSolid-state devicesConductive materialsPrinted circuit board

Disclosed herein are a printed circuit board and a method for manufacturing the same. The method for manufacturing a printed circuit board includes: (a) forming at least one plate through hole penetrating through an insulating layer; (b) forming pattern grooves for implementing inner layer circuits on both surfaces of the insulating layer; and (c) filling the plate through hole and the pattern grooves with a conductive material. The method for manufacturing a printed circuit board may provide the printed circuit board having excellent heat radiating characteristics and reduce process cost.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

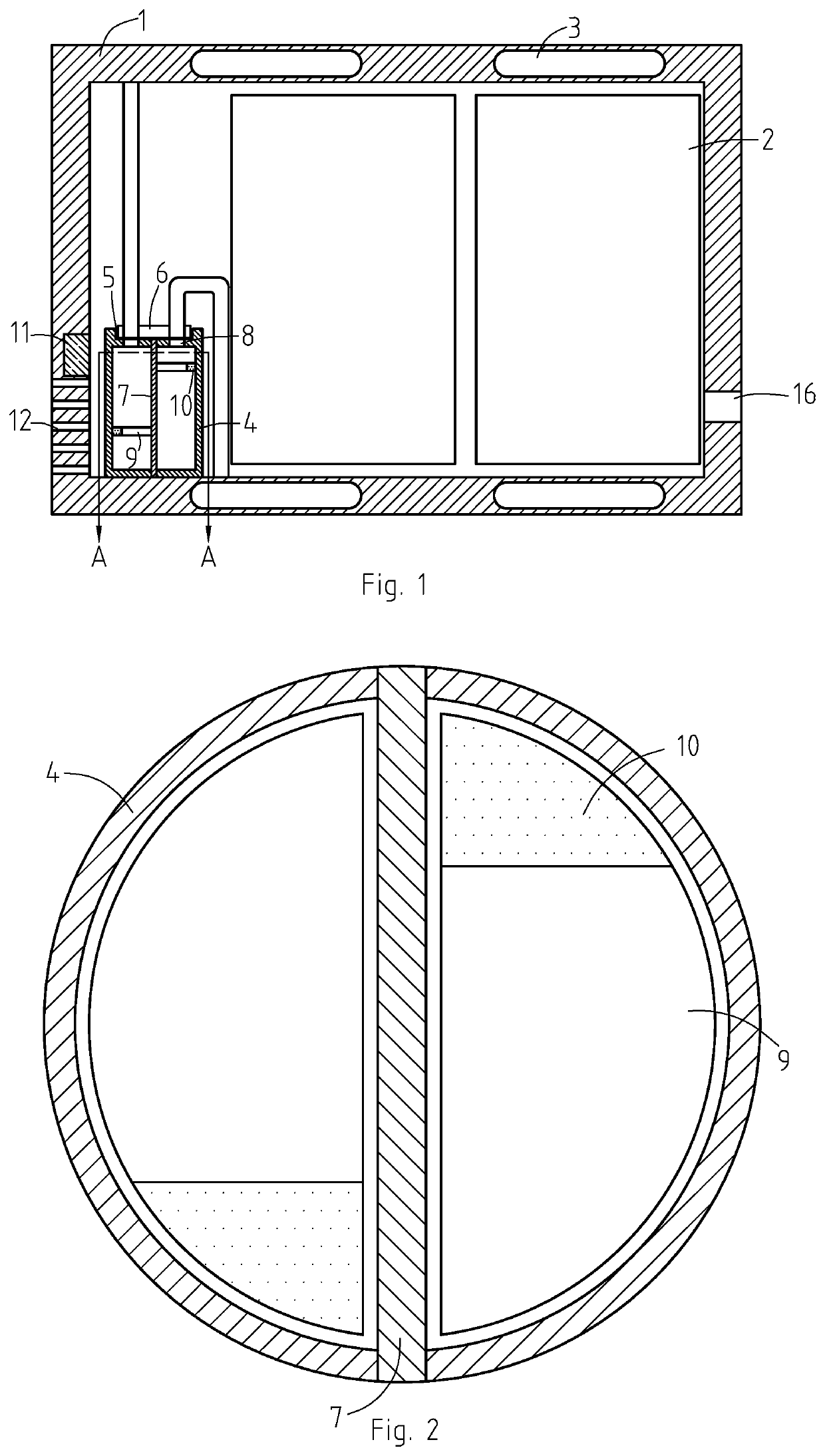

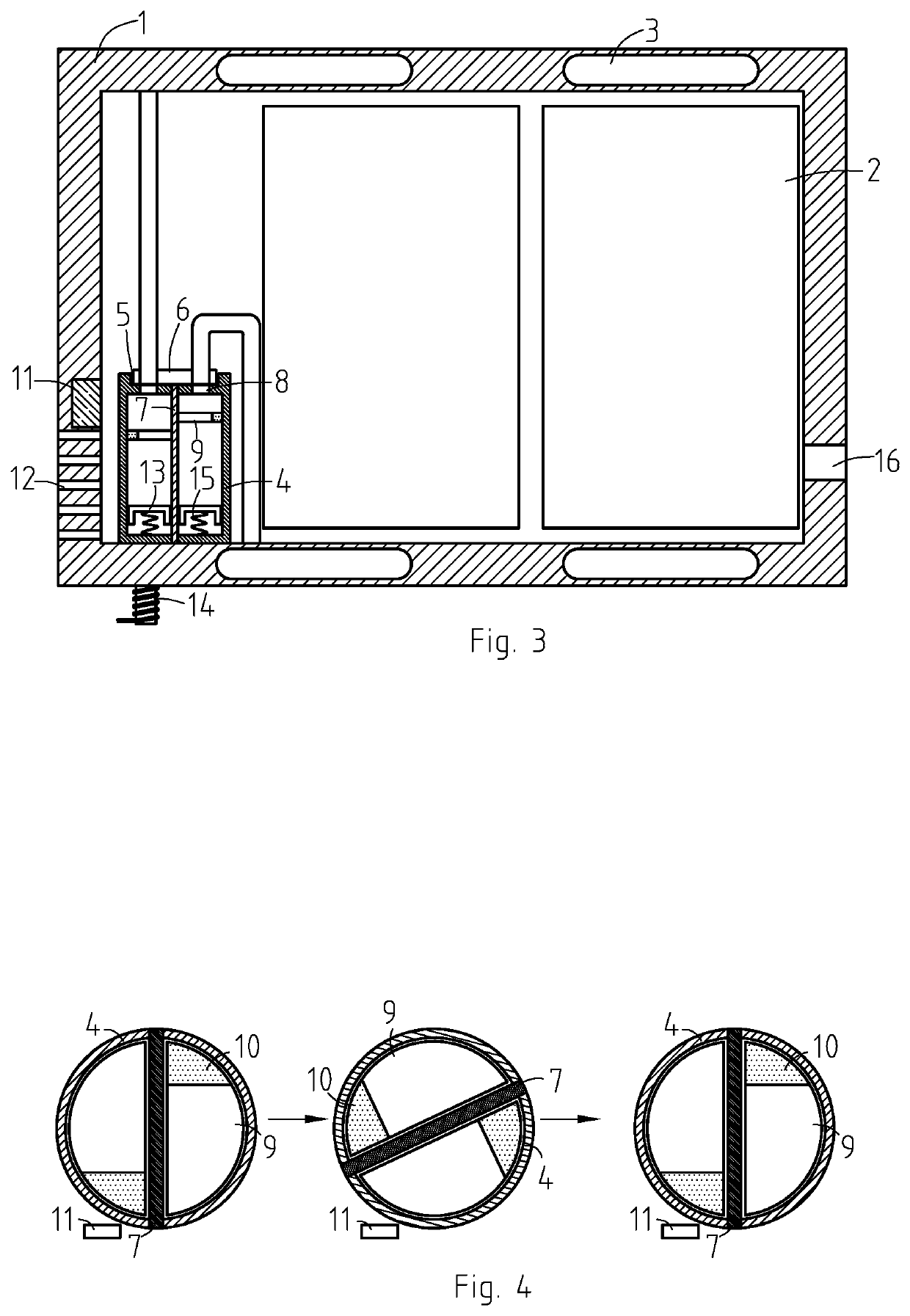

Battery cooling system for new energy vehicle

ActiveUS20210104791A1Heat dissipation fastSpeed up heat dissipationElectric devicesBattery isolationNew energyEngineering

A device has a shield boxes with a plurality of batteries installed, an inner wall of the shield box has a condenser pipe filled with coolant, a cylinder rotatably connects with an inner bottom of the shield box, an upper end of the cylinder has a circular groove arranged coaxially with the cylinder, the circular groove is sealed and rotated to connect with a circular block, a water inlet end and a water outlet end of the condenser pipe are both sealed and penetrated through the circular block, a heat insulation plate is arranged in the cylinder, the heat insulation plate divides the cylinder into two insulation chambers of the same size, an upper end of the cylinder is provided with two through holes communicating with the circular groove, a driving device for driving the cylinder to rotate is installed in the cylinder.

Owner:ZHU GONG

Peanut freshness preservation processing method

InactiveCN104432276APrevent aroma lossFast heat dissipationSeed preservation by heatingFood preparationArachis hypogaeaNitrogen

The invention provides a peanut freshness preservation processing method. The method includes the steps that peanuts are cleaned and immersed in water, soil and sand are cleaned away, the peanuts are placed in a salt solution, immersed at the indoor temperature and then taken out, and water on the surfaces of the peanuts is drained off; the peanuts are placed in a high-temperature retort pouch or an aluminum foil bag, the retort pouch or the aluminum foil bag is vacuumized, inflated with nitrogen and sealed for high-temperature high-pressure sterilization, the peanuts can be delivered out of a pot and naturally cooled, and therefore the peanuts processed by freshness preservation can be obtained. Compared with the traditional technology, the steps of heating conducted multiple times are simplified, the peanuts can be cooked and freshness of the peanuts can be preserved after high-temperature high-pressure operation is conducted once, and a chemical reagent and an antiseptic do not need to be added in the whole process. The processed peanuts taste glutinous, soft, fragrant and mellow and are delicious and rich in nutrition. The quality of the processed peanuts can be guaranteed at the normal temperature for more than one year, the surfaces of the peanuts are free of obvious water, and glutinous liquid and mildew can not be generated.

Owner:KUNMING CITY YILIANG DIANWANG FOOD

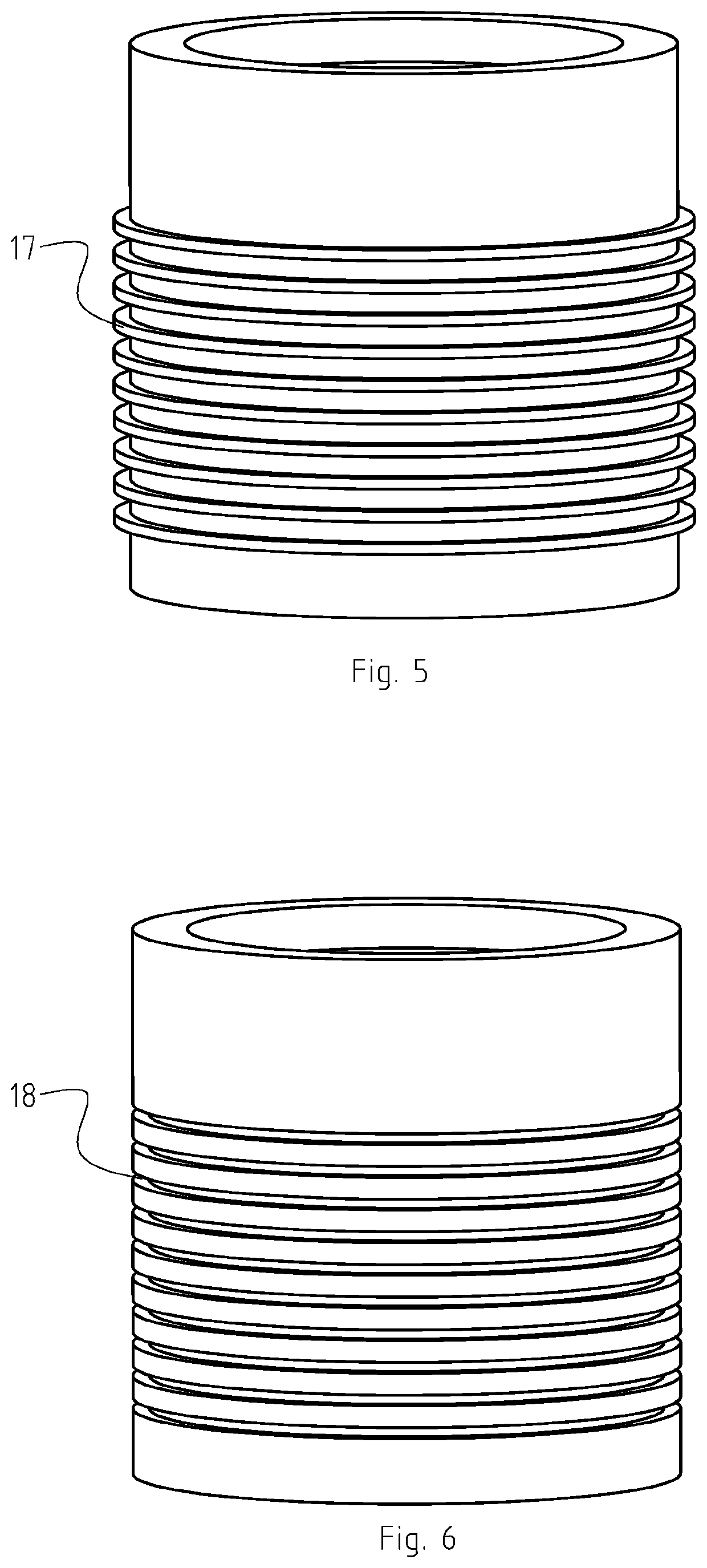

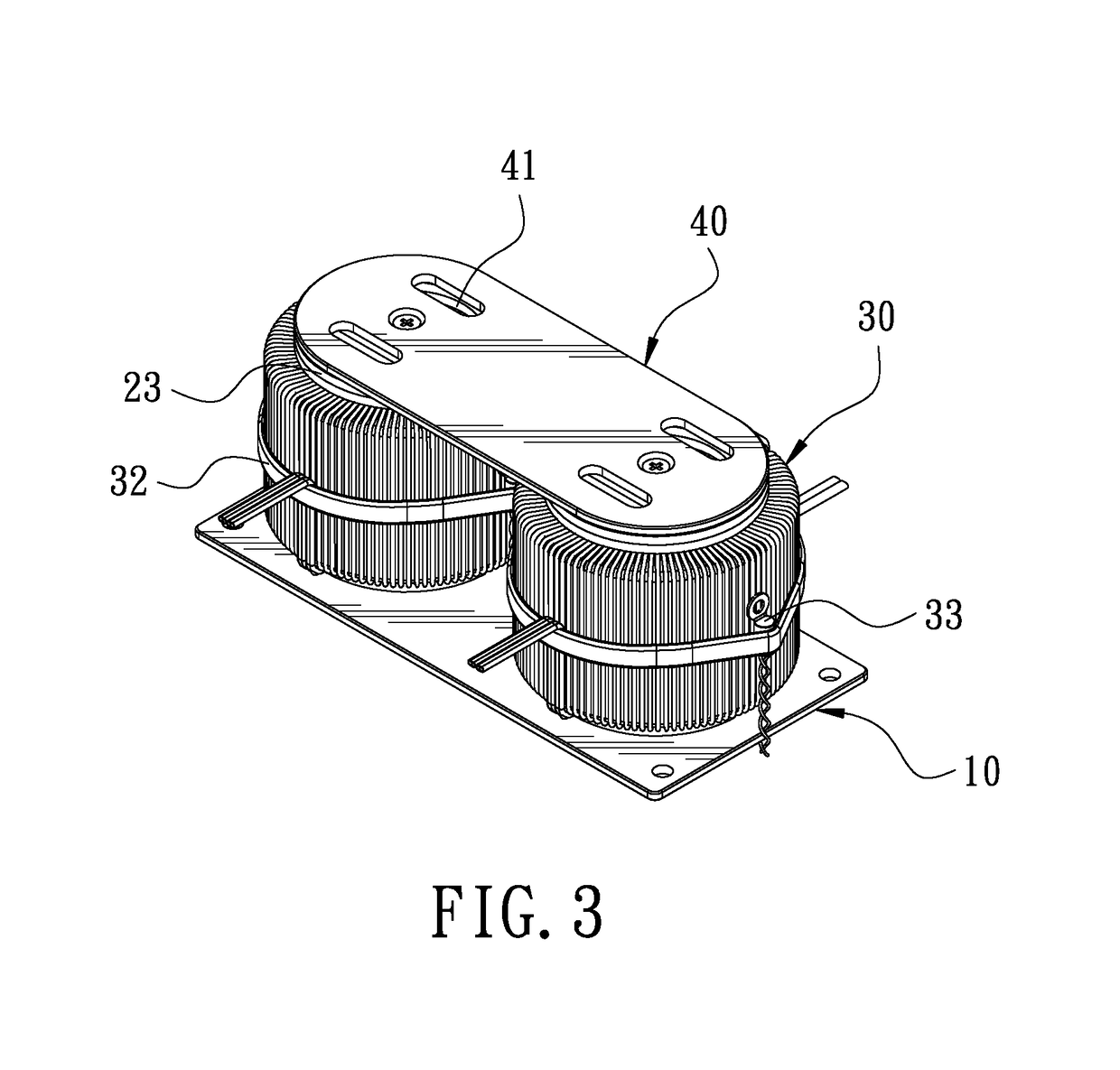

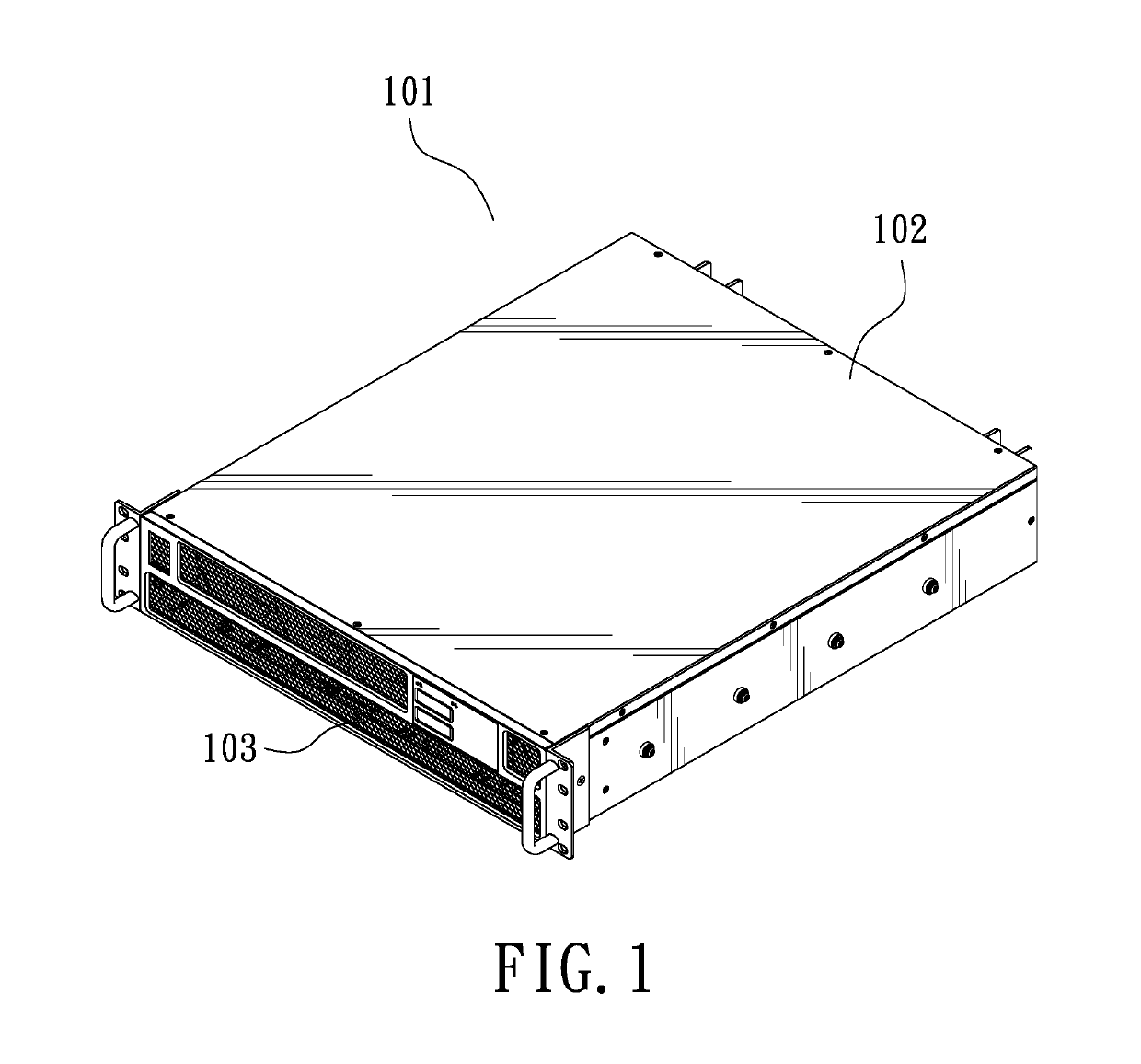

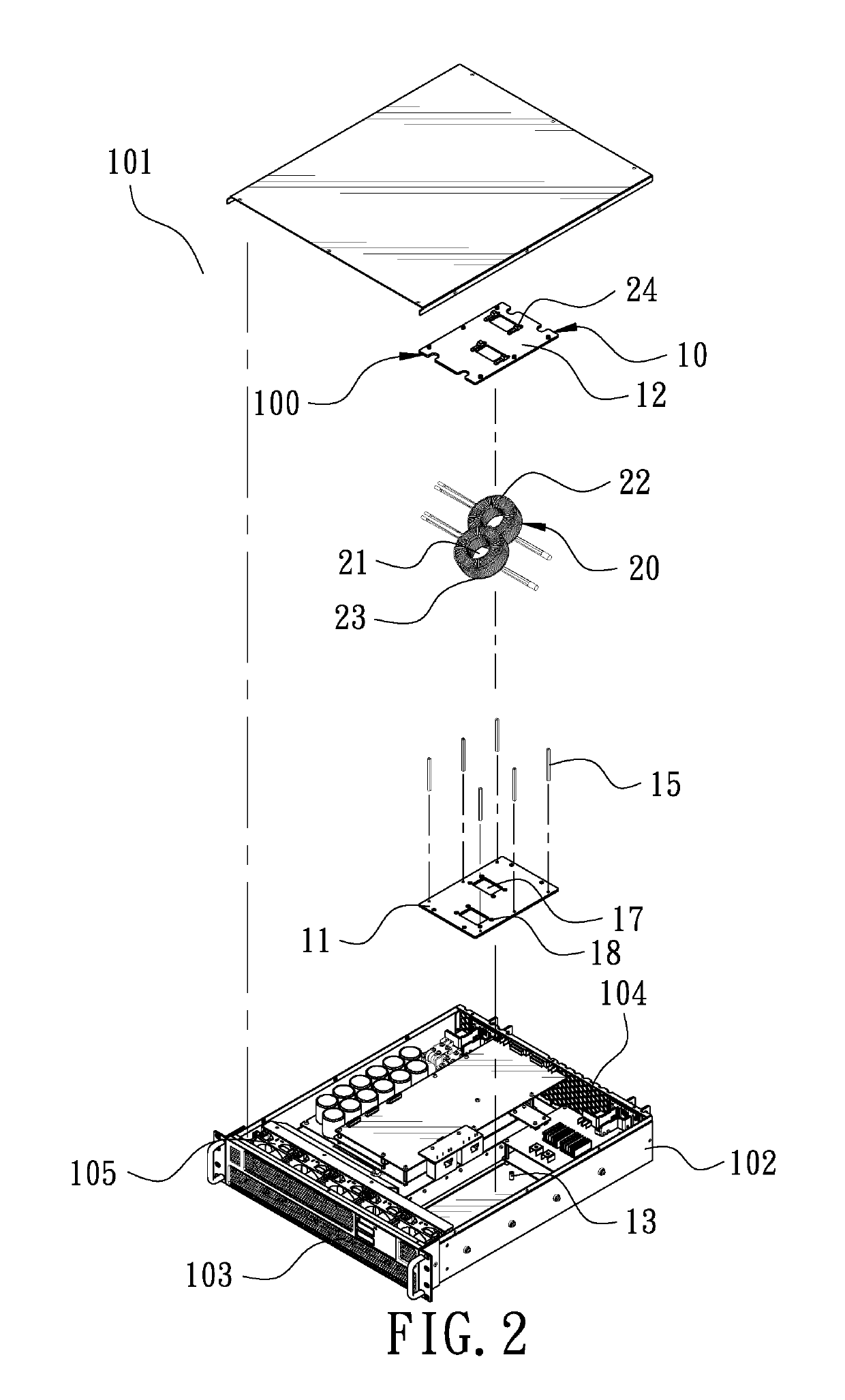

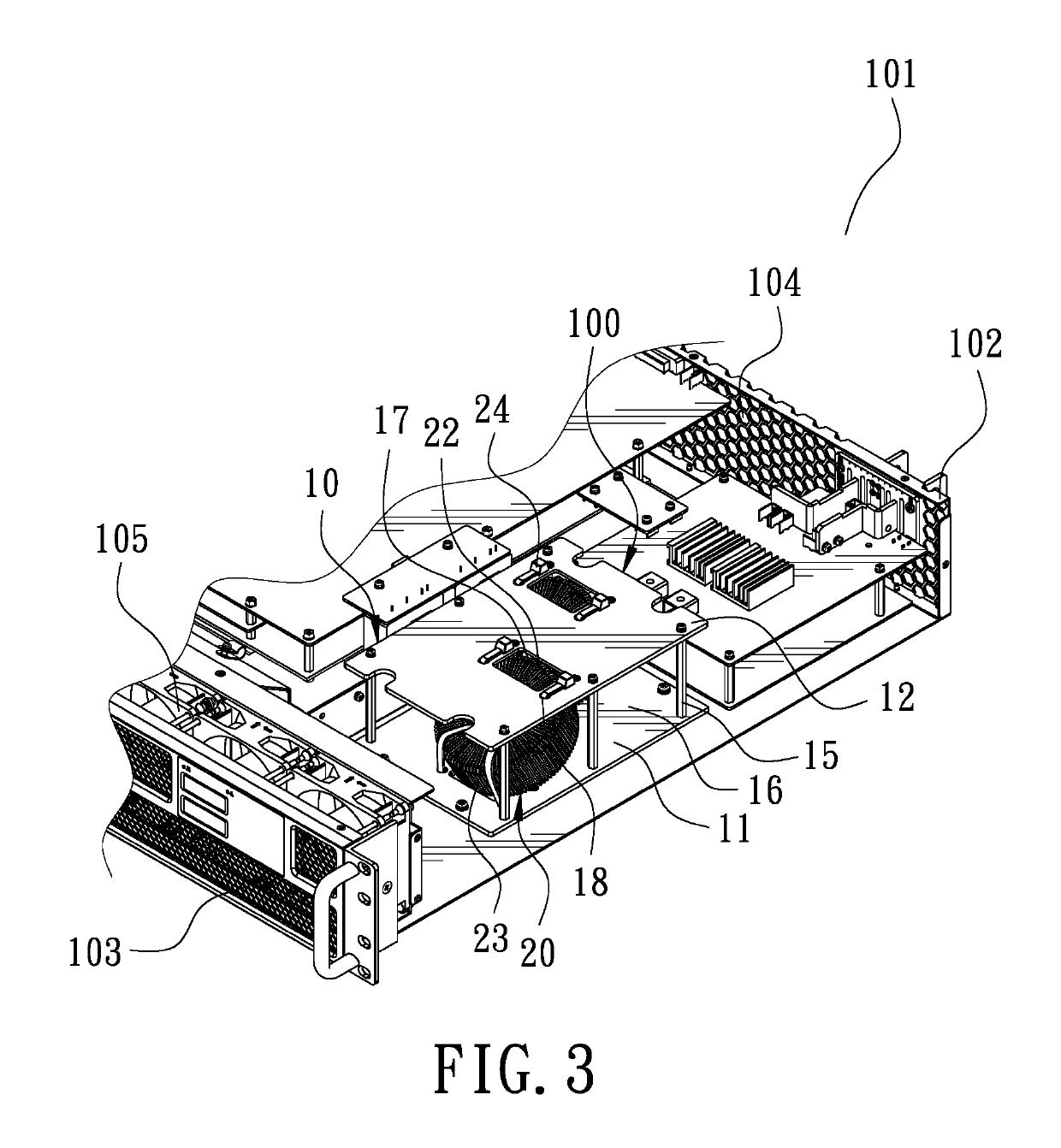

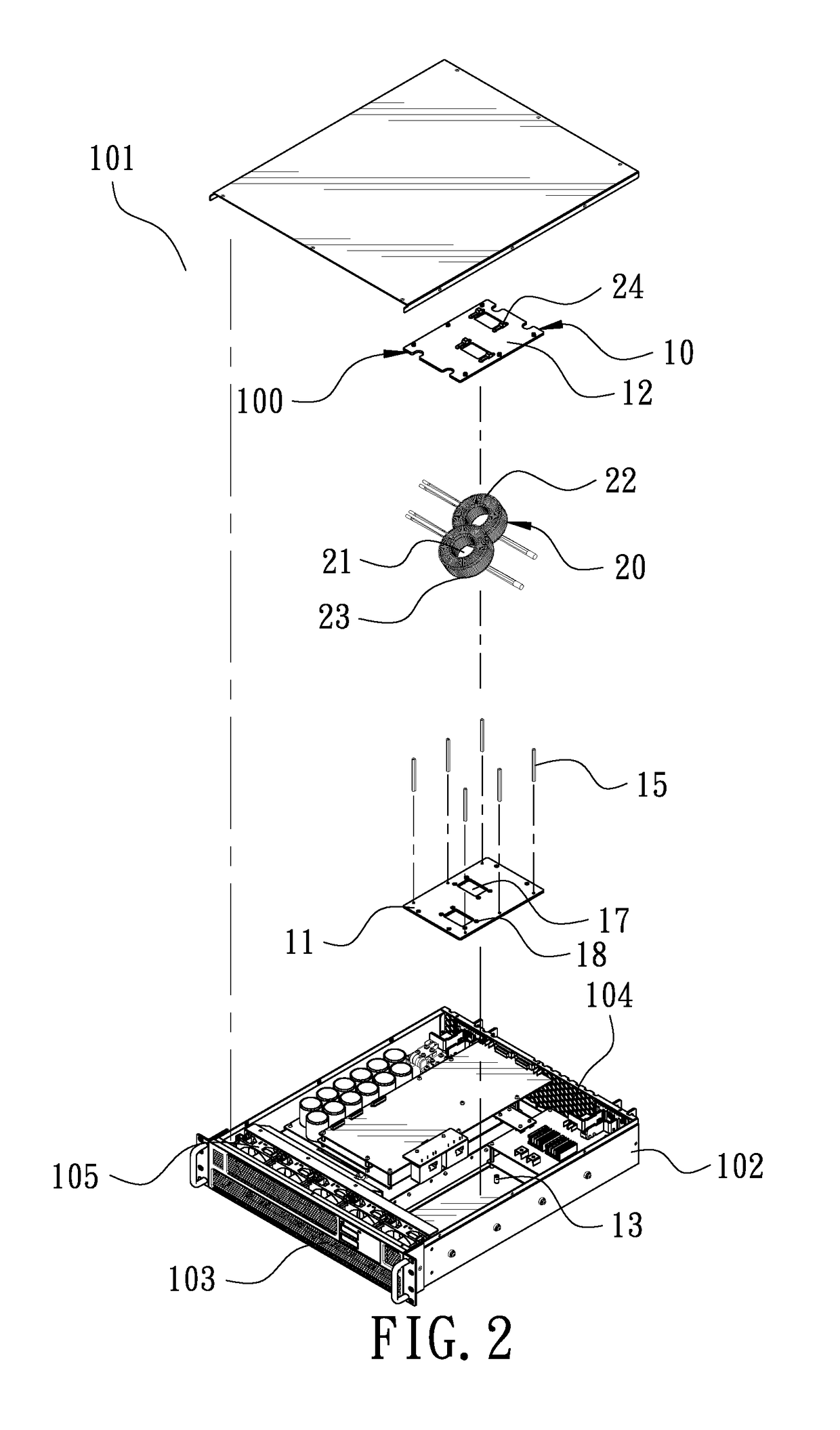

Choke coil module of high power density DC-AC power inverter

ActiveUS10062491B1Improve cooling effectImprove power densityTransformers/reacts mounting/support/suspensionTransformers/inductances coolingEngineeringAC power

A choke coil module of a high power density DC-AC power inverter includes a bottom plate and a top plate. Two upright posts are secured between the bottom plate and the top plate. The upright posts are sleeved with choke coils, respectively. The choke coils and heat radiating holes of the bottom plate and the top plate are communicated with one another to form an air guide passage. When the power converter is actuated, the choke coils generate heat. Through a fan unit, the outside air is guided into a casing via air inlets of the casing, and the heat generated by the choke coils is expelled to the outside via the air guide passage and air outlets of the casing. The choke coil module mounted in the high power density casing is able to achieve an excellent heat radiation effect.

Owner:CHYNG HONG ELECTRONICS

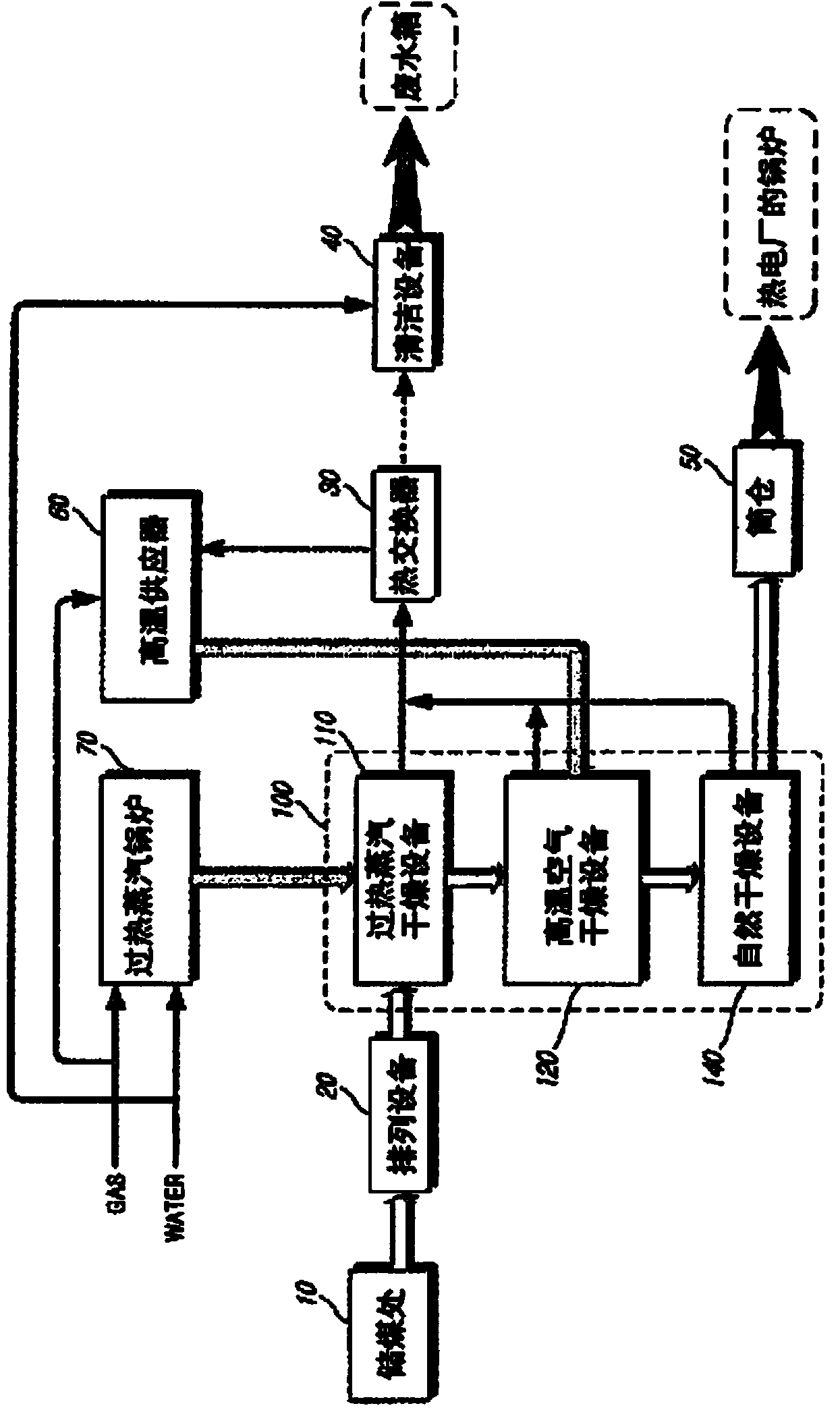

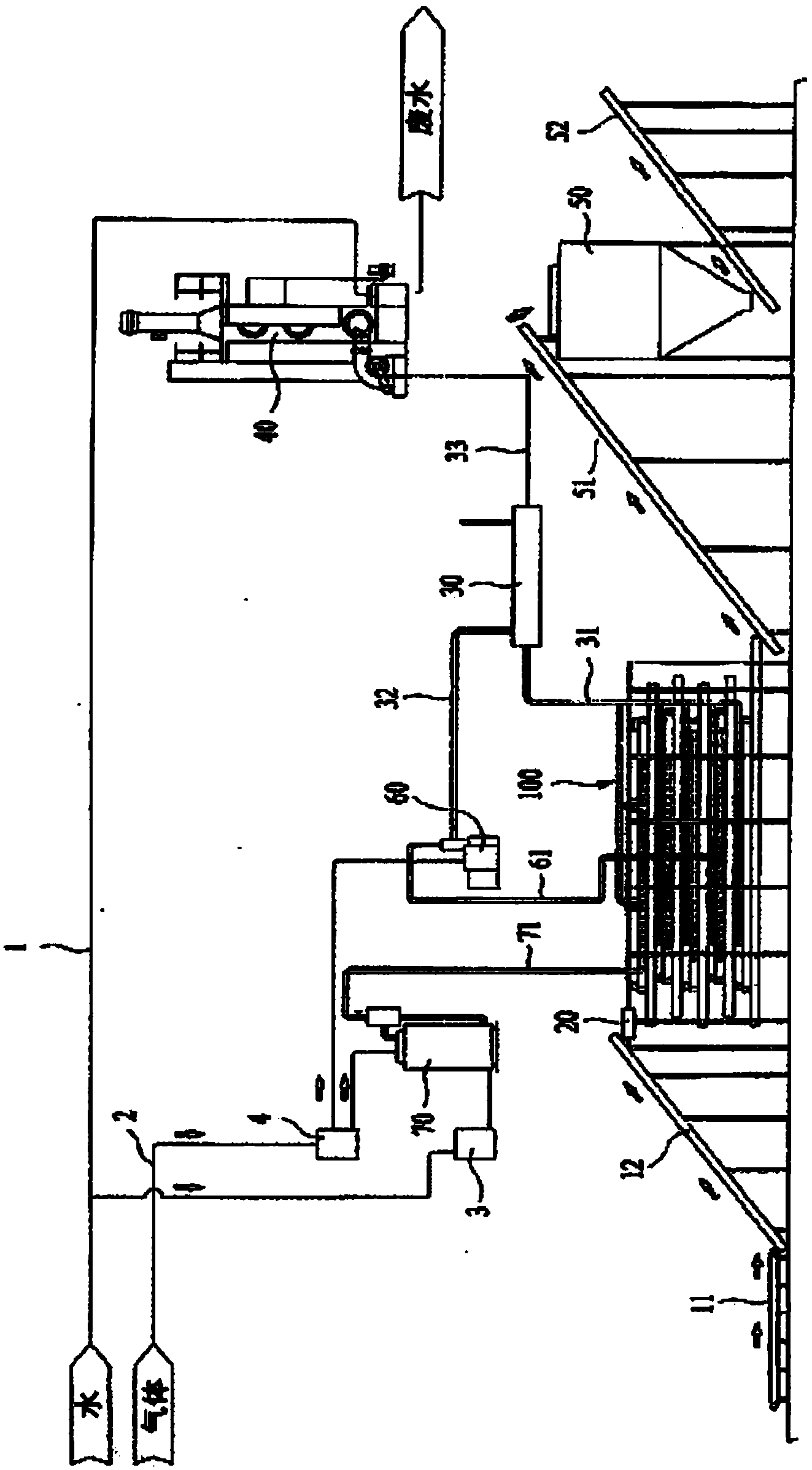

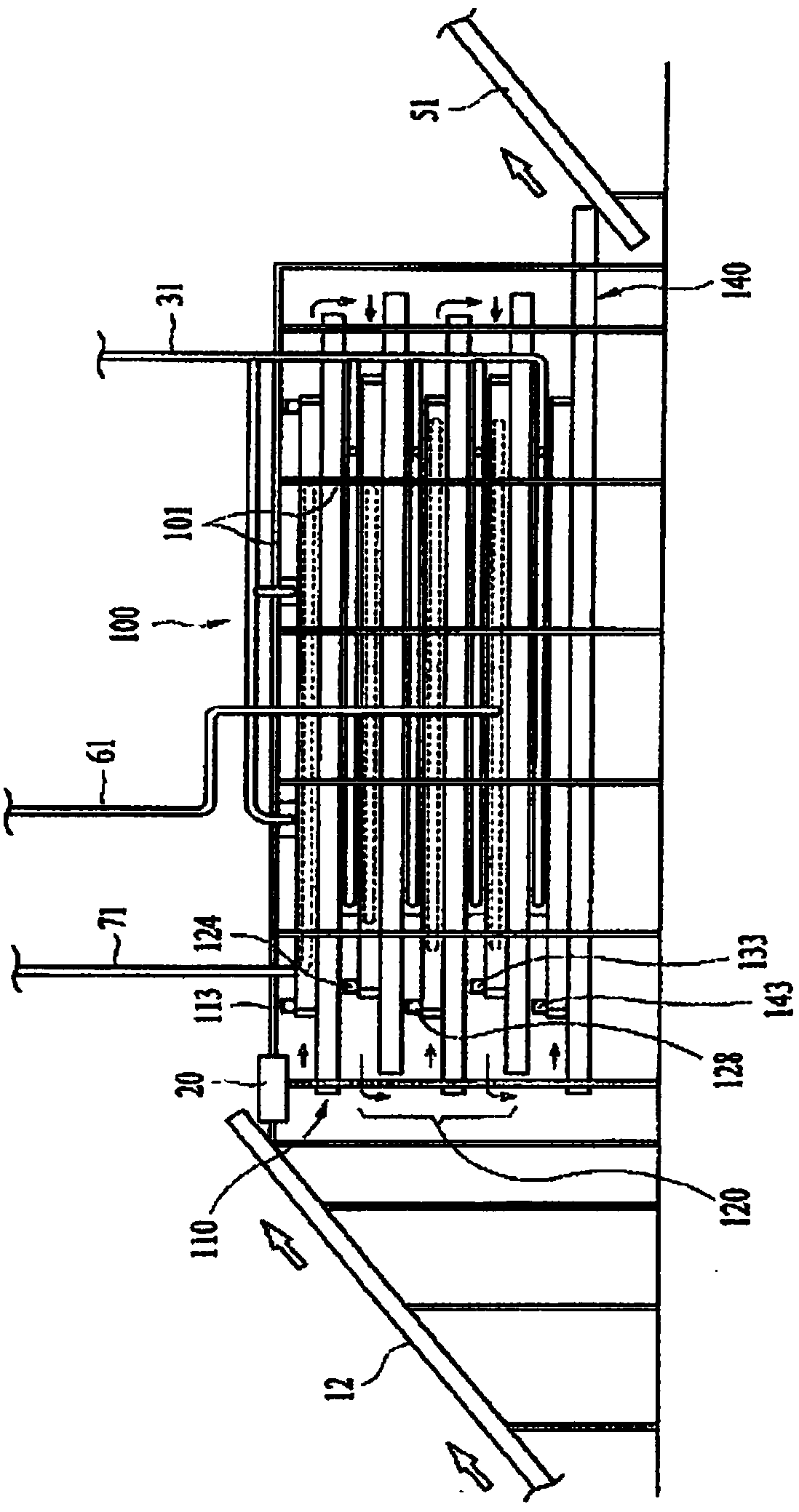

System for drying coal by using superheated steam

InactiveCN104081143AEasy to useAvoid incomplete combustionSteam generation heating methodsDrying solid materials with heatCombustionProcess engineering

The present disclosure relates to a coal drying system for removing water contained in coal used as a fuel of a thermoelectric power plant with superheated steam. The system prevents the incomplete combustion of the coal by removing water existing inside and outside the coal fuel of the thermoelectric power plane, thereby improving a heating value of coal and minimizing the discharge of pollutants, prevents the corrosion of the system and improves the durability, and increases the use of low-quality coal of which the demand is low, thereby improving the stable supply of the coal.

Owner:HANKOOK TECH

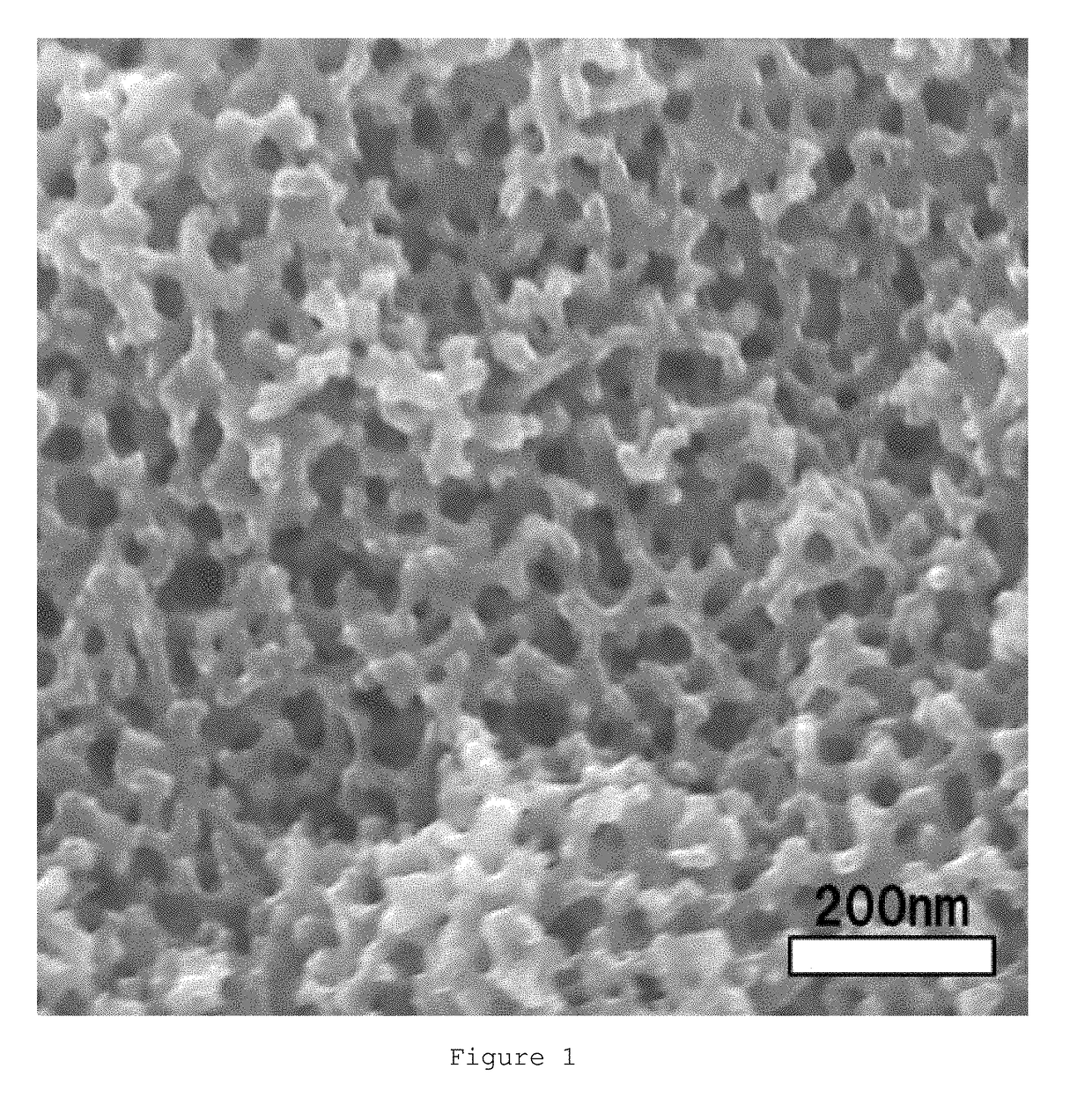

Electrode material for metal-air battery

ActiveUS20170194650A1Efficient executionSolve large capacityFuel and secondary cellsCell electrodesPorous carbonX-ray

The present invention provides an electrode material for metal-air batteries which has a homogeneous co-continuous structure due to a carbon skeleton and voids and is excellent in terms of permeability to and diffusibility of ions, oxygen, electrolytes, and electrolytic solutions and which, due to the formation of the carbon network, can rapidly diffuse the heat generated by battery reactions and has satisfactory electrical conductivity. The electrode material for metal-air batteries includes a porous carbon material having a co-continuous structure portion in which a skeleton constituted of carbon and voids form a co-continuous structure and which has a structural period, as calculated by X-ray scattering method or X-ray CT method, of 0.002-10 μm.

Owner:TORAY IND INC

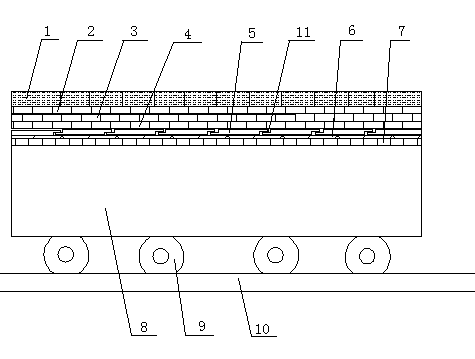

Bogie hearth for bogie hearth type resistance furnace

The invention provides a bogie hearth for a bogie hearth type resistance furnace. The bogie hearth for the bogie hearth type resistance furnace is formed by cast iron which is used for bearing workpieces, a fire-proof layer, a first thermal insulation layer, a second thermal insulation layer, a base plate layer, a heating element, a thermal preservation brick and a bogie hearth body which are arranged from top to bottom sequentially; the base plate layer is formed by a plurality of strip-shaped furnace bottom plates in a splicing mode; the furnace bottom plates are made of heat resisting steel; splicing positions of the adjacent furnace bottom plates are in hasp modes; splicing positions of the furnace bottom plates are provided with thermal expanded and cold contracted gaps; the heating element is bent to be in a wave band shape through belts; the heating element is fixed on the thermal preservation brick. The bogie hearth for the bogie hearth type resistance furnace has the advantages of guaranteeing the furnace bottom temperature; improving the surficial area of the heating element, reducing the surface load of the heating element and prolonging the service life of the heating element due to the fact that the heating element is arranged on bogie hearth; meanwhile avoiding short circuit due to the fact that oxidized iron sheets fall on the heating element and improving the production safety due to the furnace bottom plates.

Owner:徐州东创重工机械有限公司

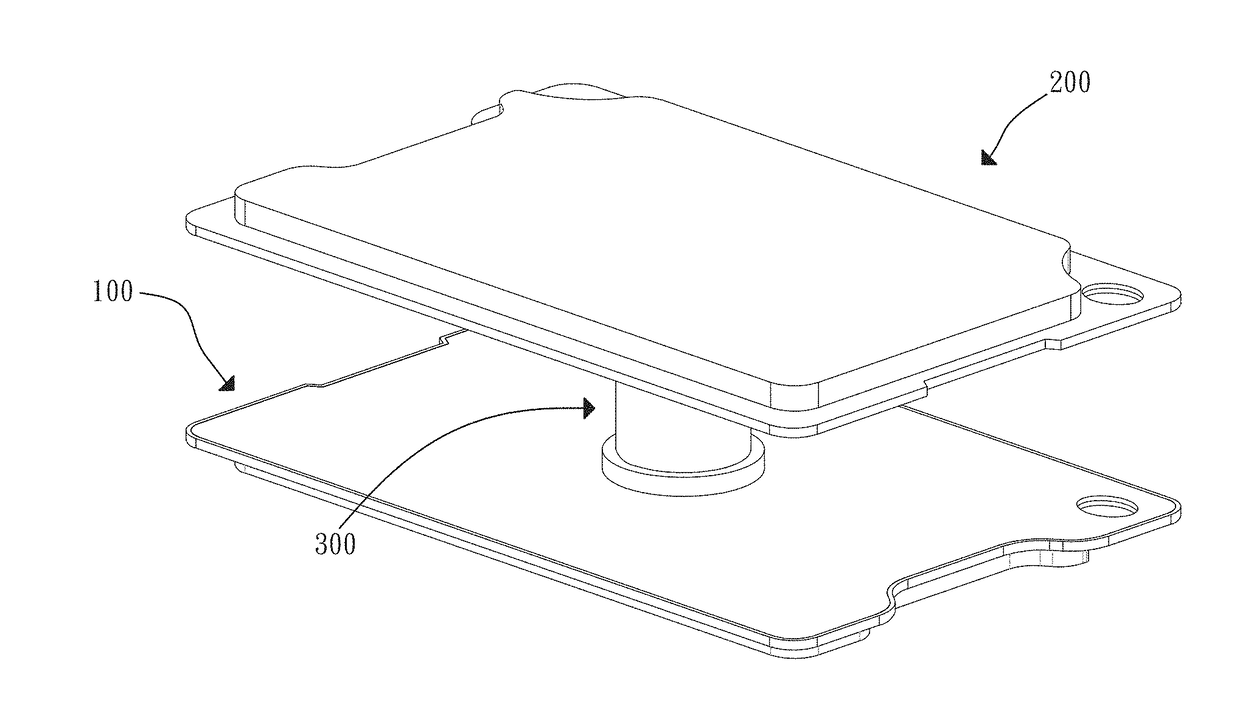

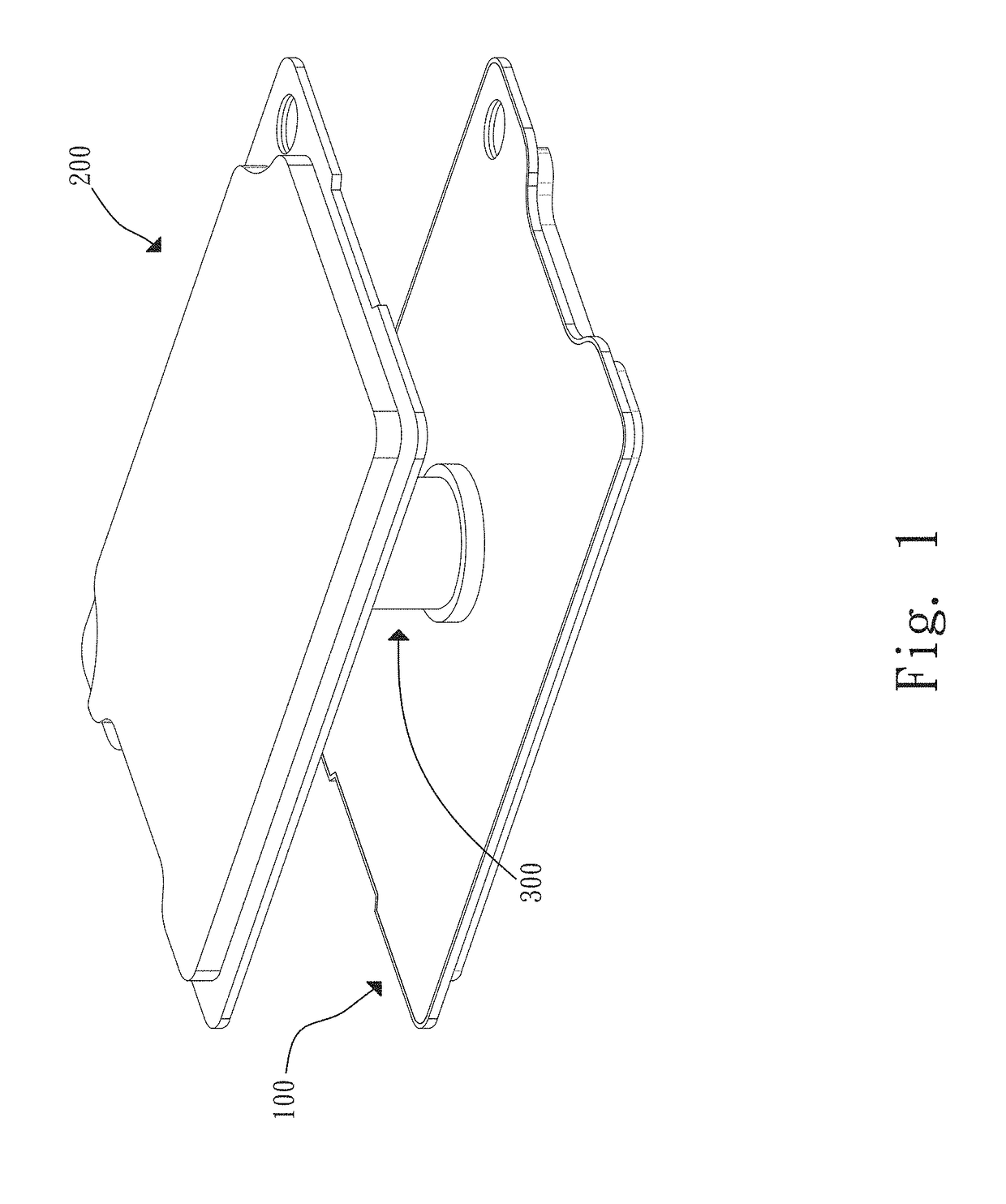

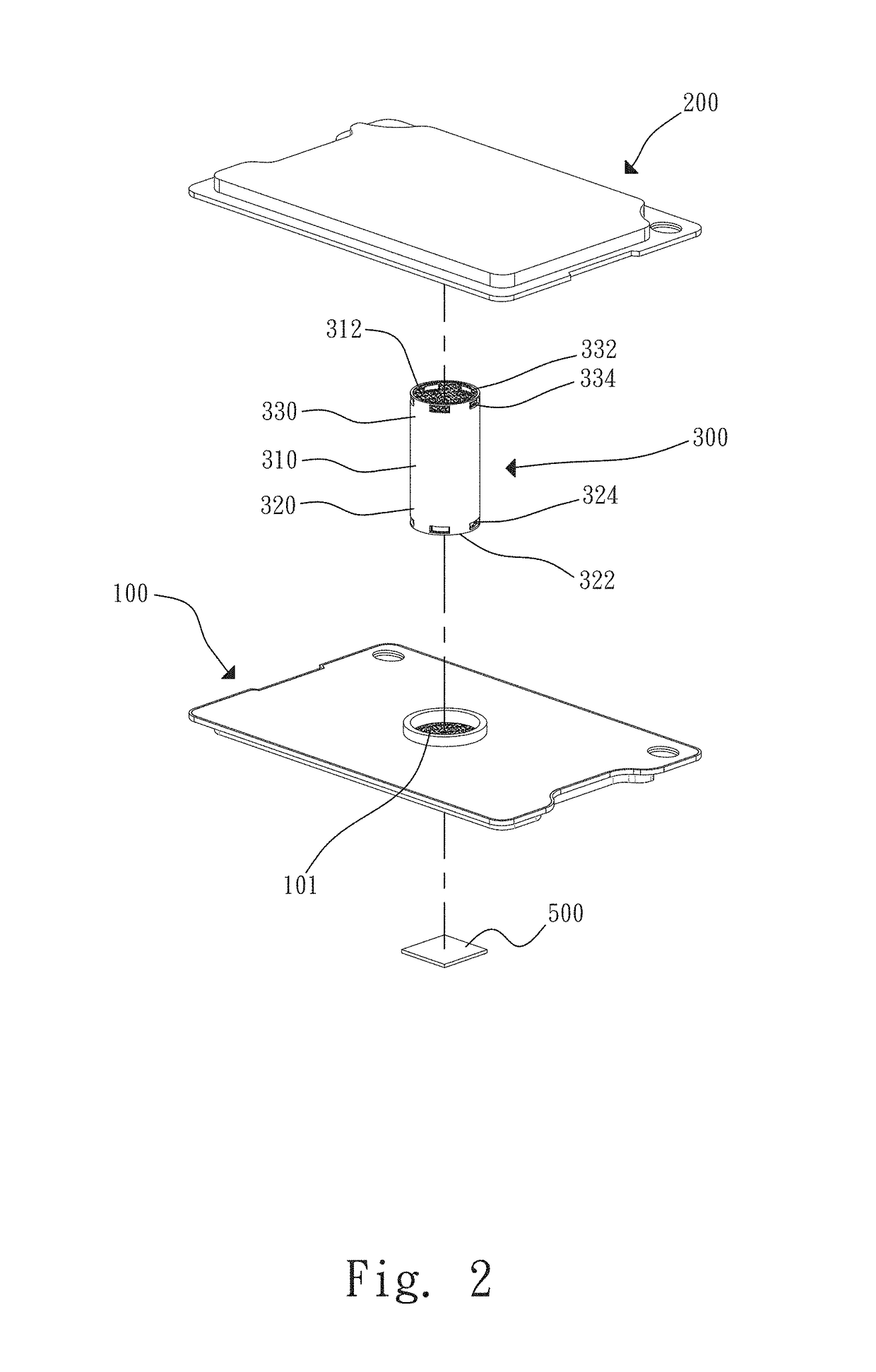

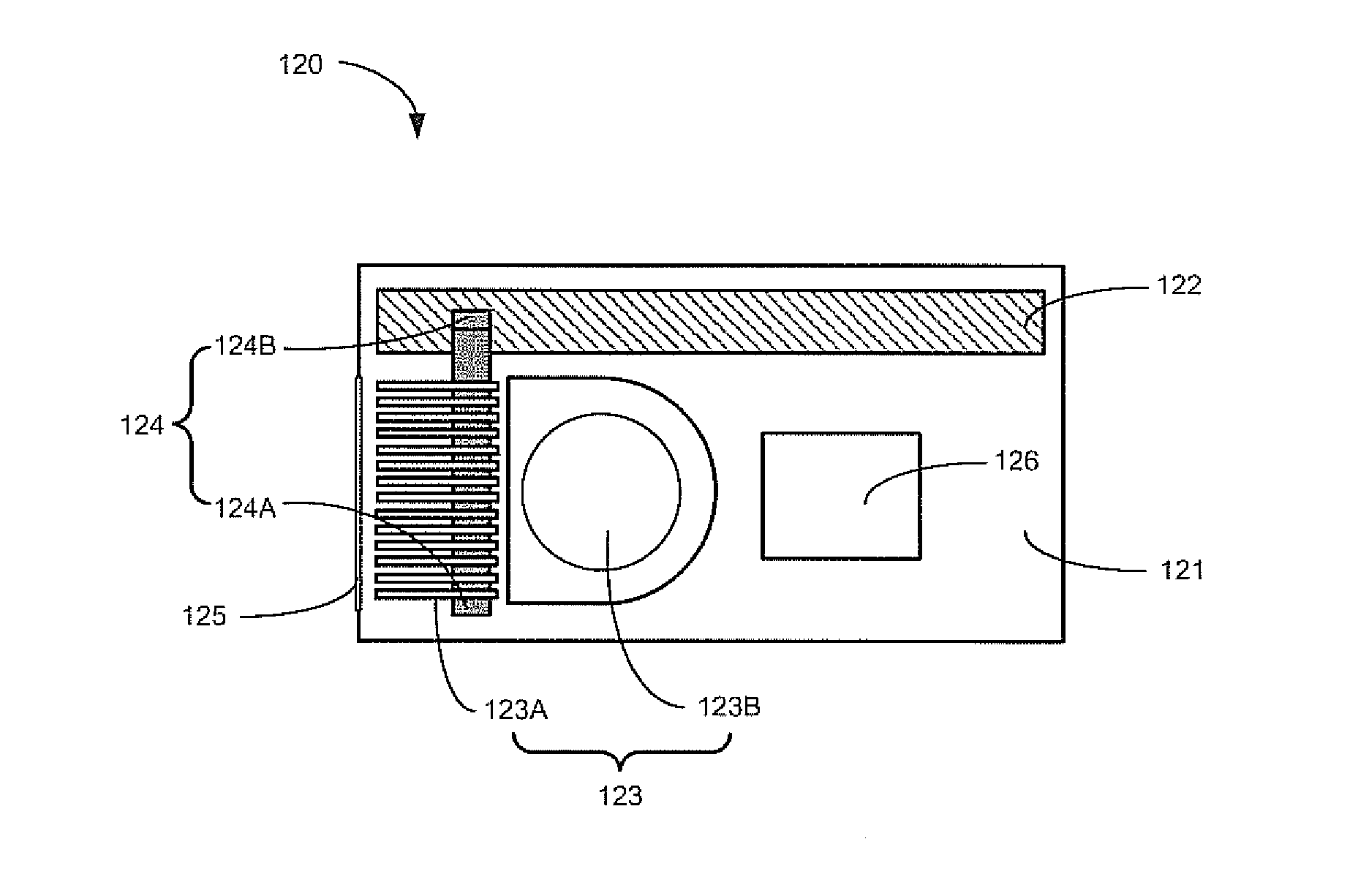

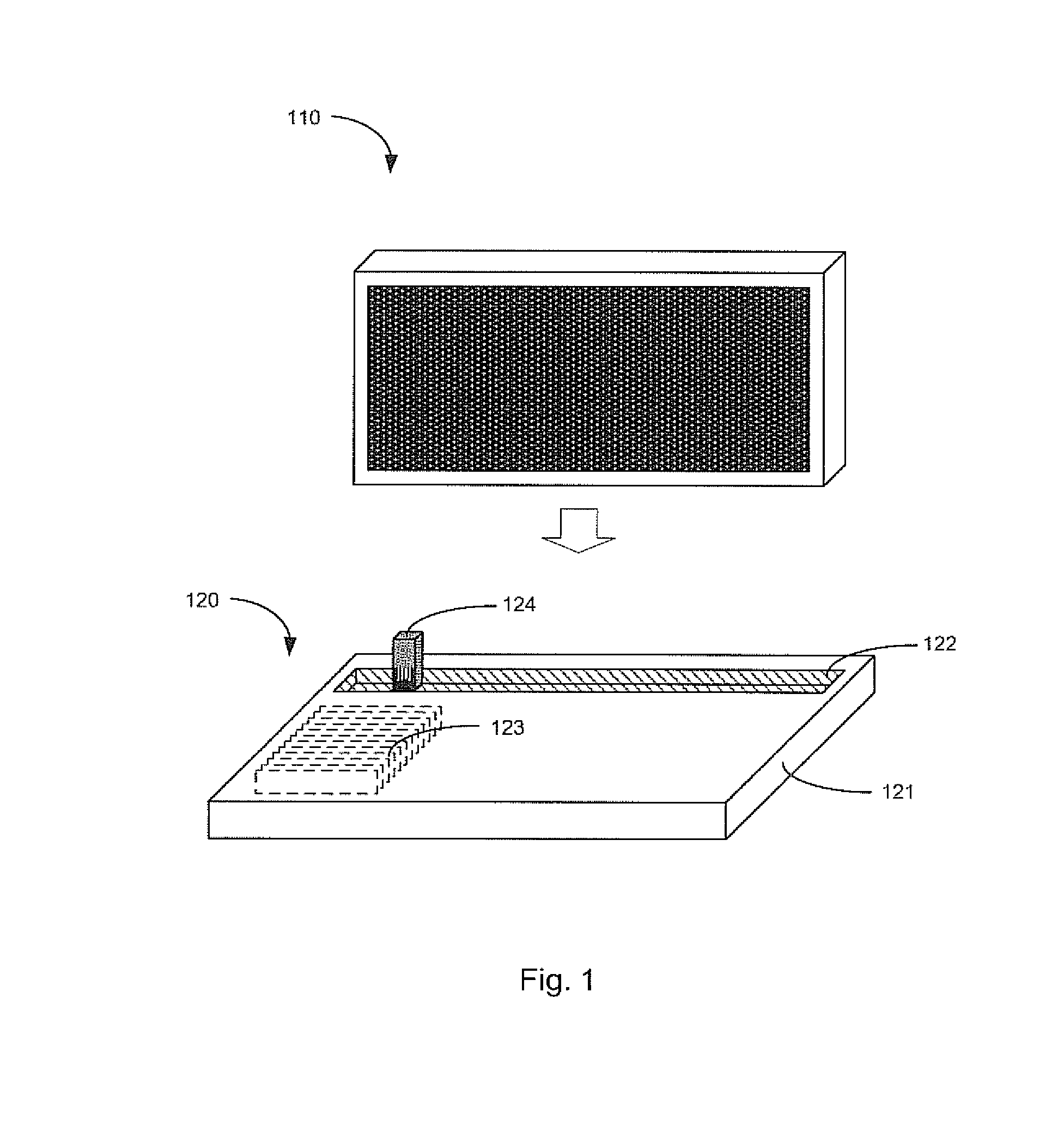

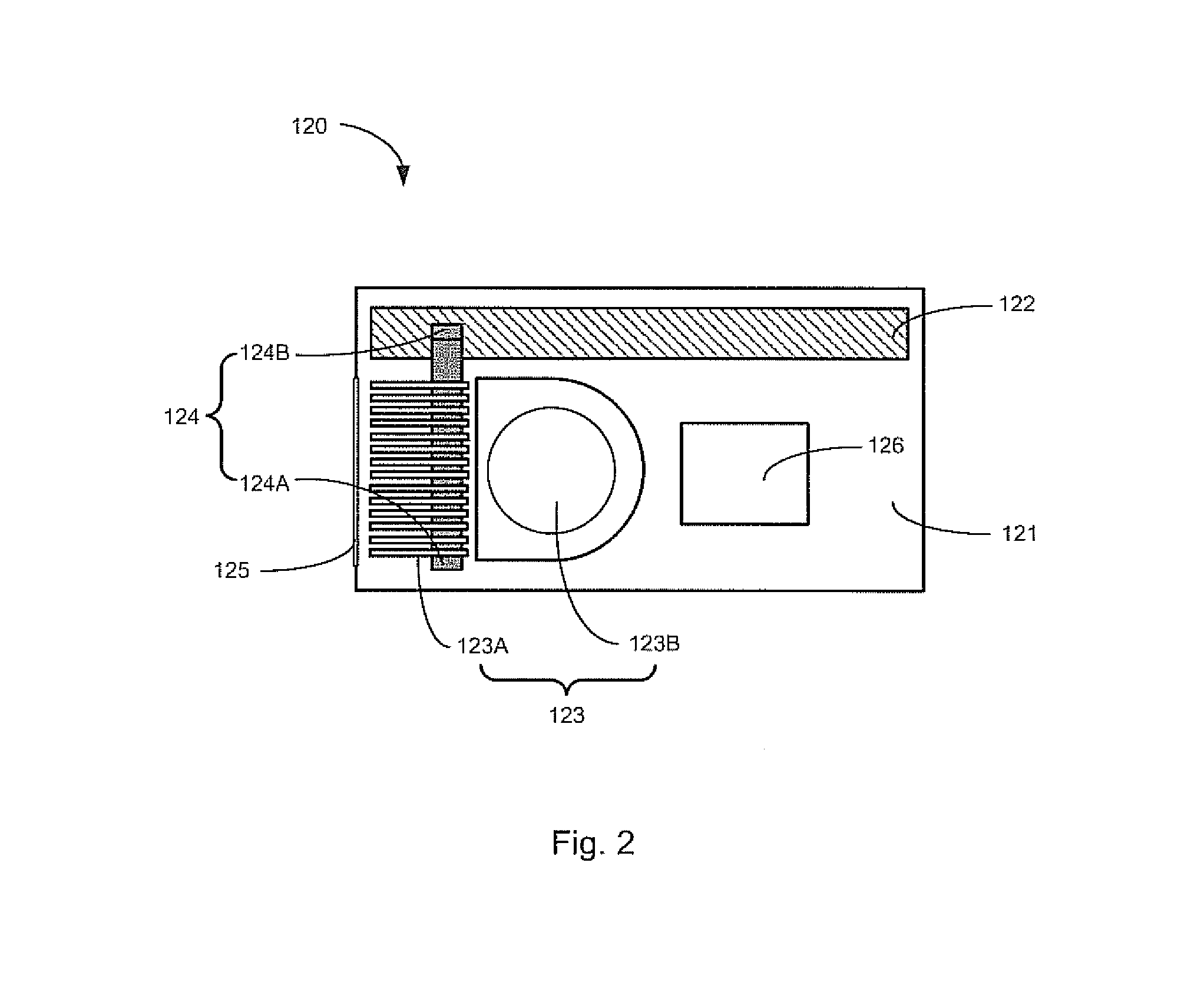

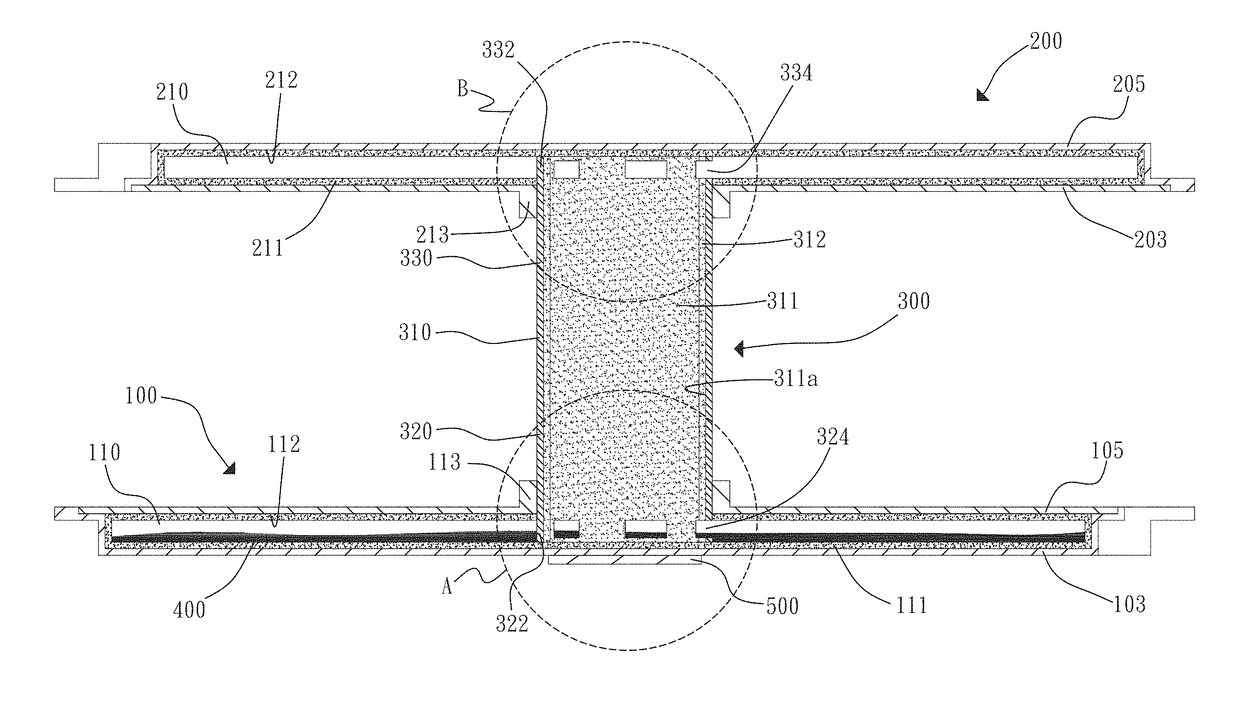

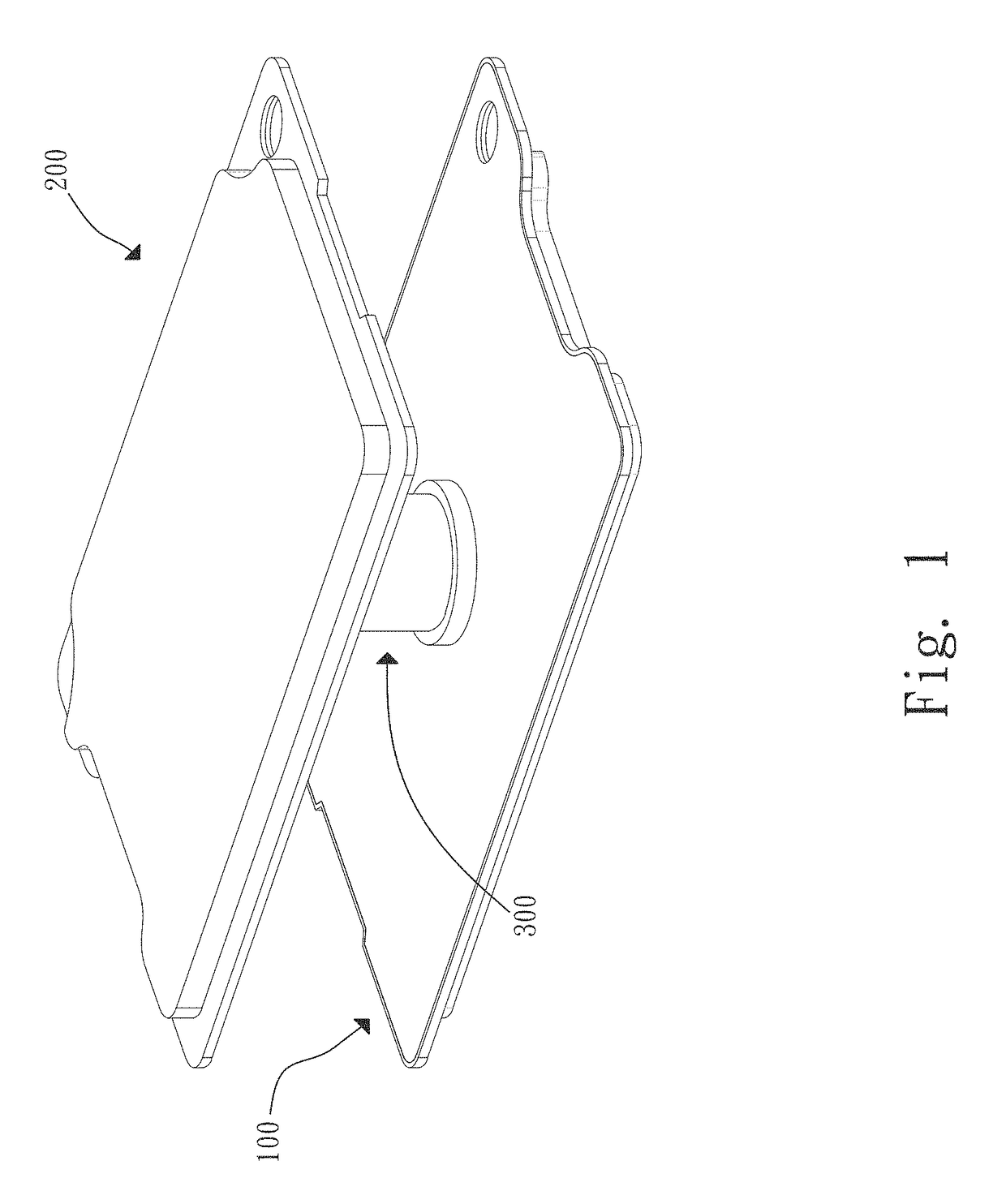

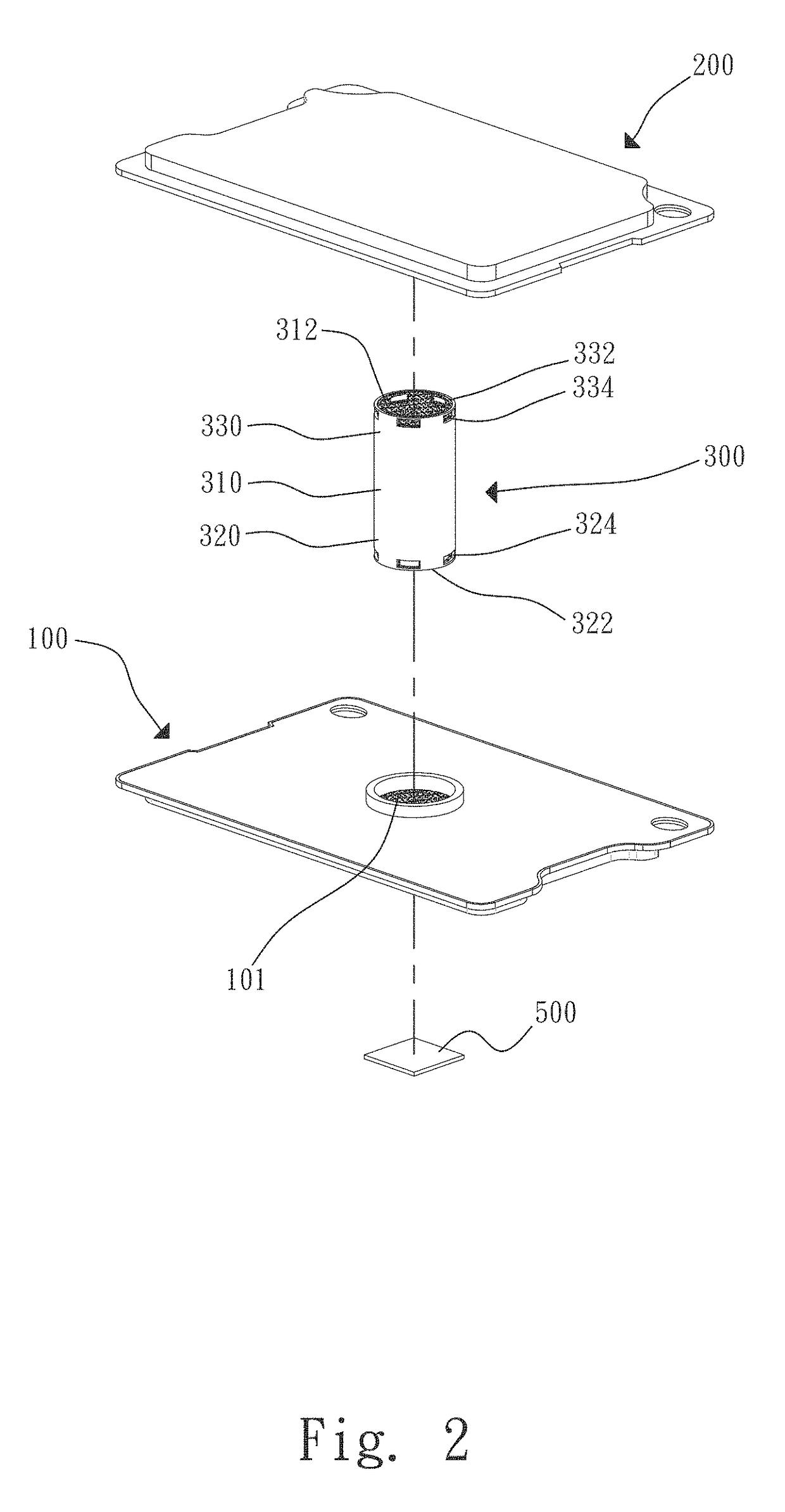

Flat panel electronic device, auxiliary heat-dissipating means thereof and assembly of both

ActiveUS20140126148A1Dissipate heat quicklyPrevent significant heat from accumulating in the flat panel electronic deviceDigital data processing detailsModifications by conduction heat transferEngineeringFlat panel

An apparatus for dissipating heat is presented. The apparatus comprises a base provided with a recess on a top thereof for containing a portion of a flat panel electronic device. It also comprises a base heat sink disposed in the base. Finally, it comprises a heat-conducting plug with a first end thereof thermally contacting with the base heat sink, and a second end thereof extending upward from a bottom of the recess for plugging into a heat-conducting socket of the flat panel electronic device when the flat panel electronic device is placed on the base.

Owner:NVIDIA CORP

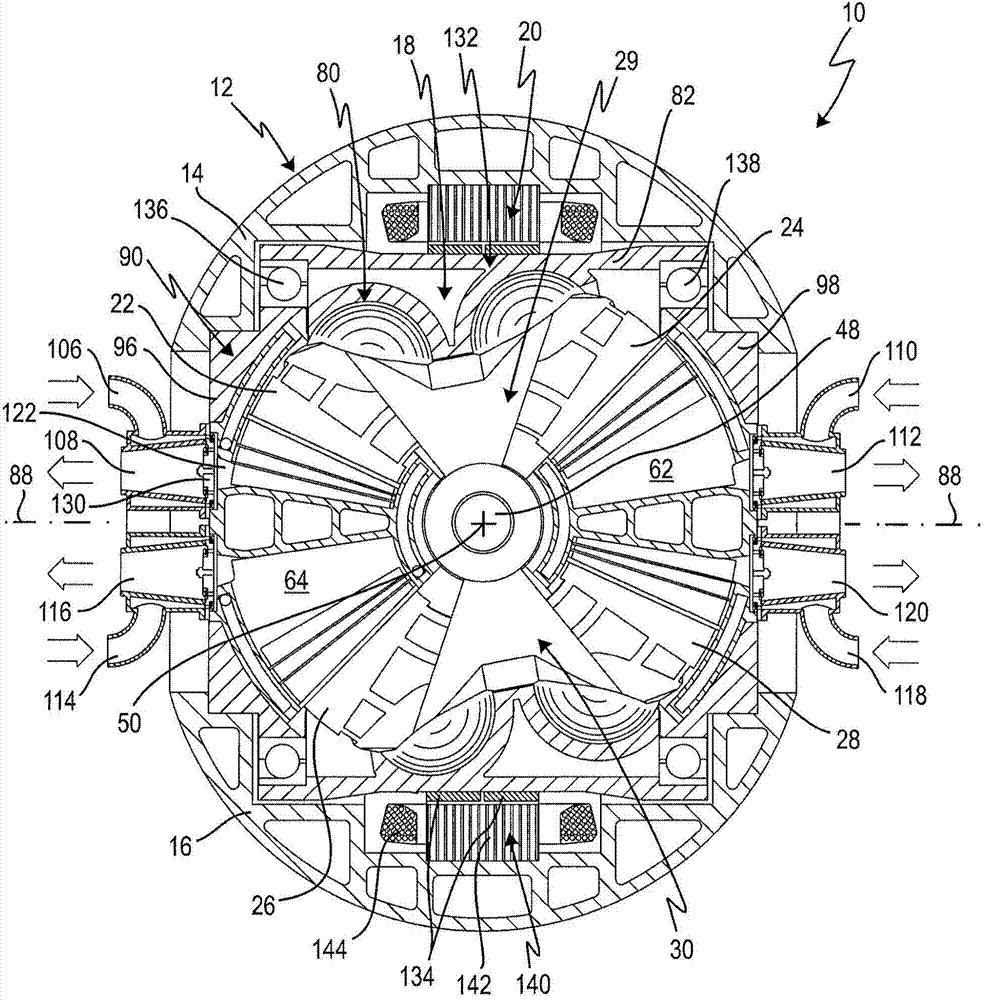

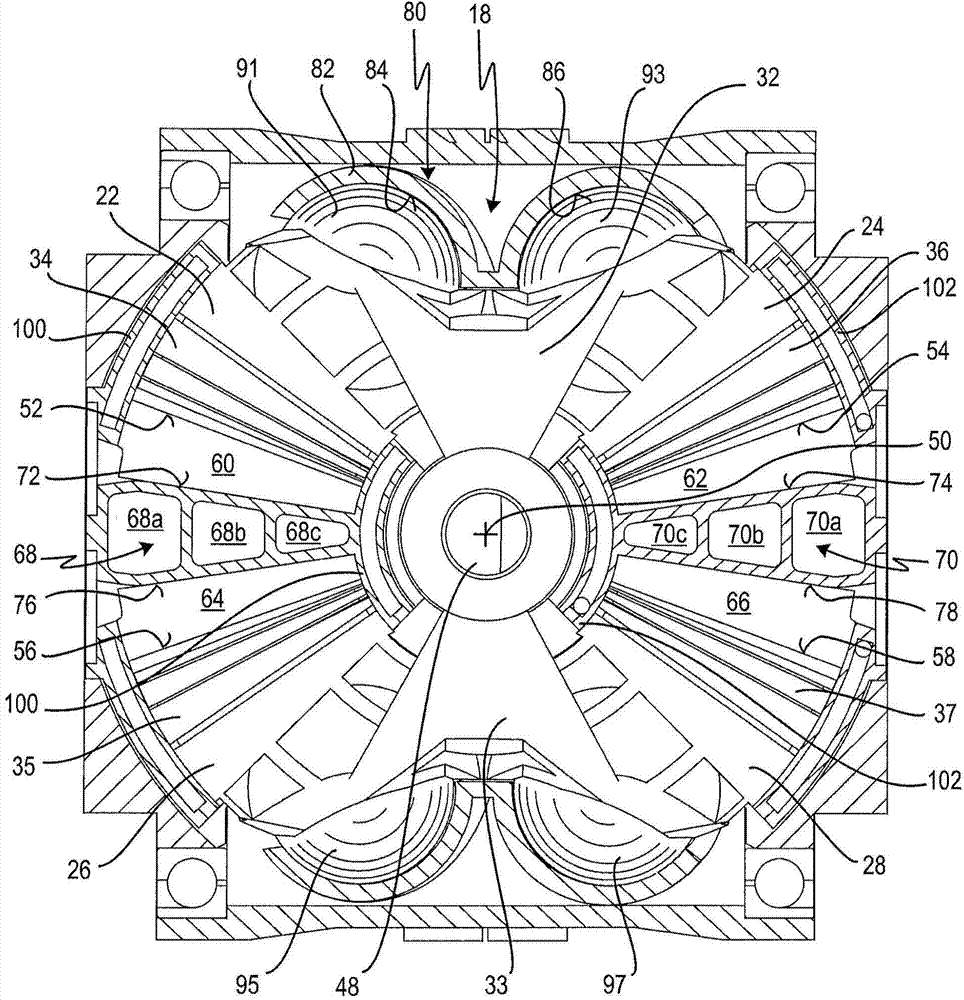

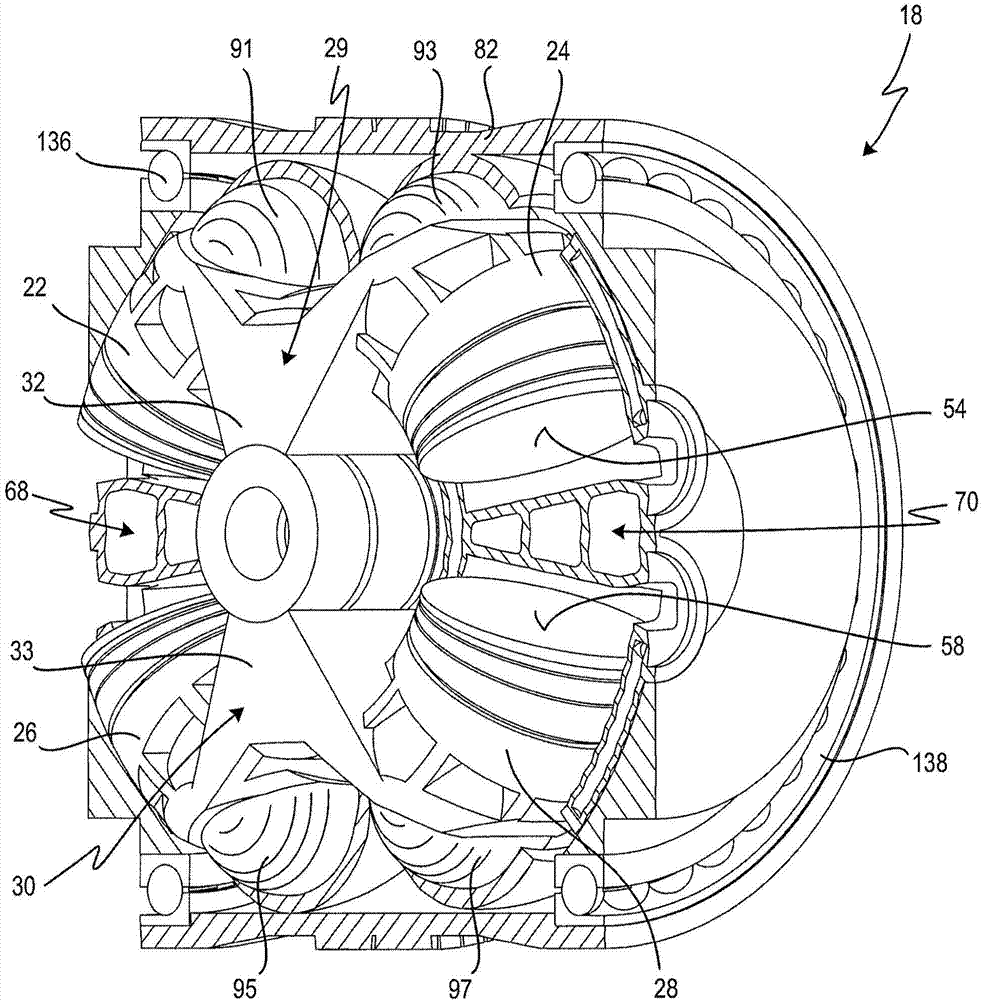

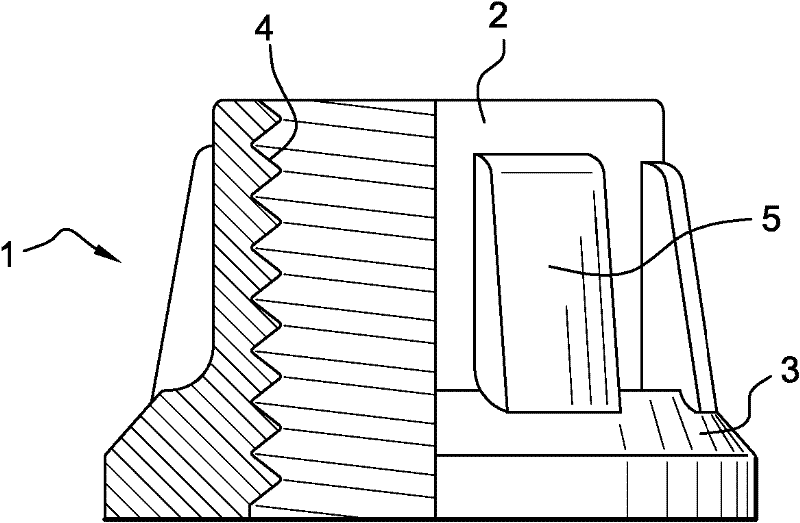

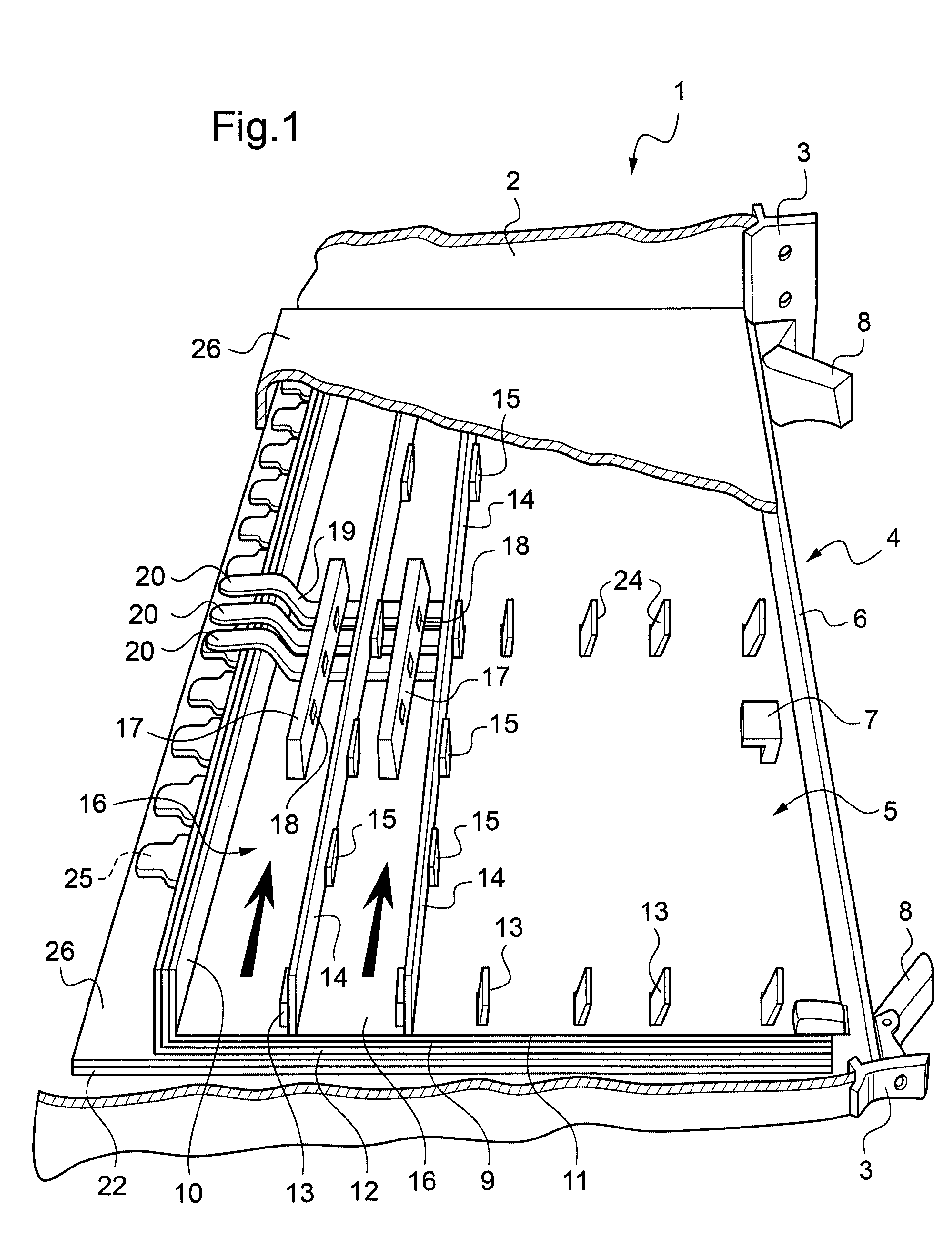

Assembly, in particular internal combustion engine or compressor

ActiveCN104854309AProduction economyReduce in quantityEngines with oscillating pistonsEngine componentsPistonCam

An assembly, in particular compressor or internal combustion engine, has a housing (12) in which there are arranged four pistons (22, 24, 26, 28) of which a first piston (22) has a first end surface (52), a second piston (24) has a second end surface (54), a third piston (26) has a third end surface (56) facing toward the first end surface (52), and a fourth piston (28) has a fourth end surface (58) facing toward the second end surface (54), wherein the pistons (22, 24, 26, 28) are pivotable in reciprocating fashion with limited stroke about a pivot axis (50); a piston cage (90) which is arranged in the housing (12) and in which the four pistons (22, 24, 26, 28) are arranged; a control mechanism (80) in the housing (12), which control mechanism has a cam element (82) on which the pistons (22, 24, 26, 28) are guided in order to generate the pivoting movements thereof, wherein the pistons are rotatable, together with the piston cage or the cam element (82), in the housing (12) about an axis of rotation (88) which is perpendicular to the pivot axis (50), wherein the cam element (82) is arranged radially outside the pistons (22, 24, 26, 28) and annularly around the axis of rotation (88); and working chambers (60; 62; 64; 66) in the housing (12) for in each case one working medium, said working chambers being formed between the end surfaces (52, 56 and 54, 58), which face toward one another, of the pistons (22, 24, 26, 28). Here, a first and a second working chamber (60, 62) are formed between the first end surface (52) of the first piston (22) and the third end surface (56) of the third piston (26), said first and second working chambers being sealingly separated from one another by a first partition (68), and a third and a fourth working chamber (64, 66) are formed between the second end surface (54) of the second piston (24) and the fourth end surface (58) of the fourth piston (28), said third and fourth working chambers being sealingly separated from one another by a second partition (70).

Owner:赫伯特·许特林

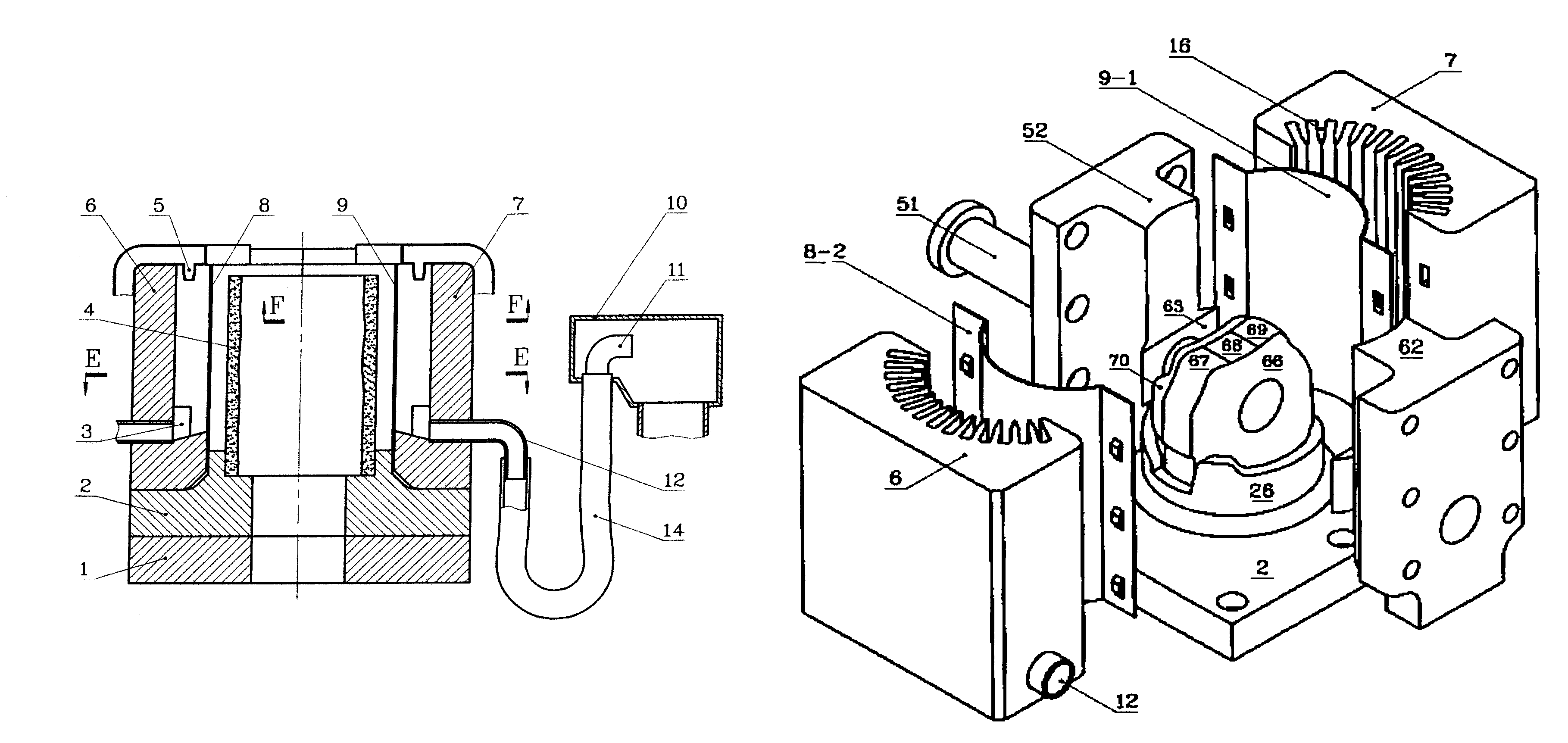

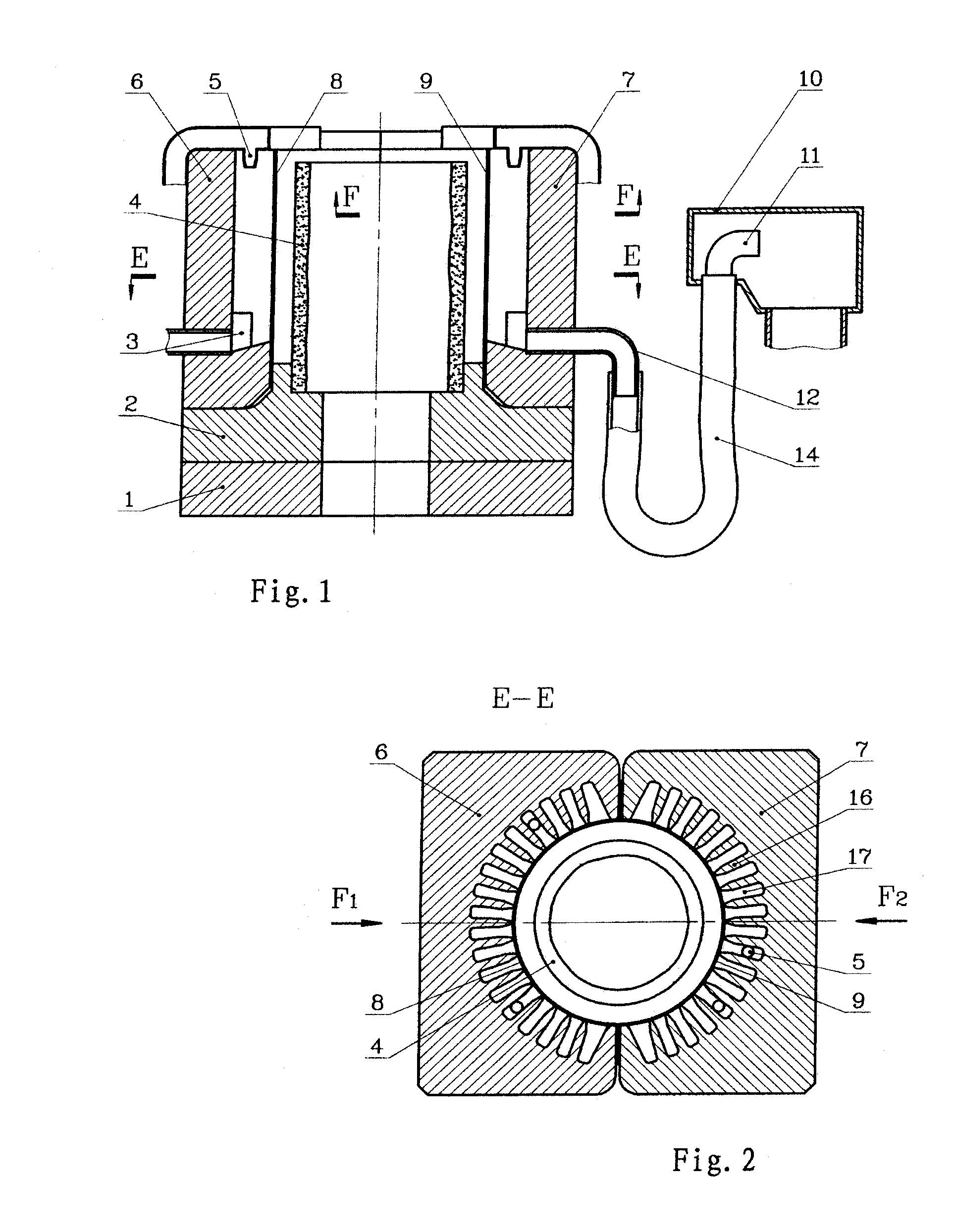

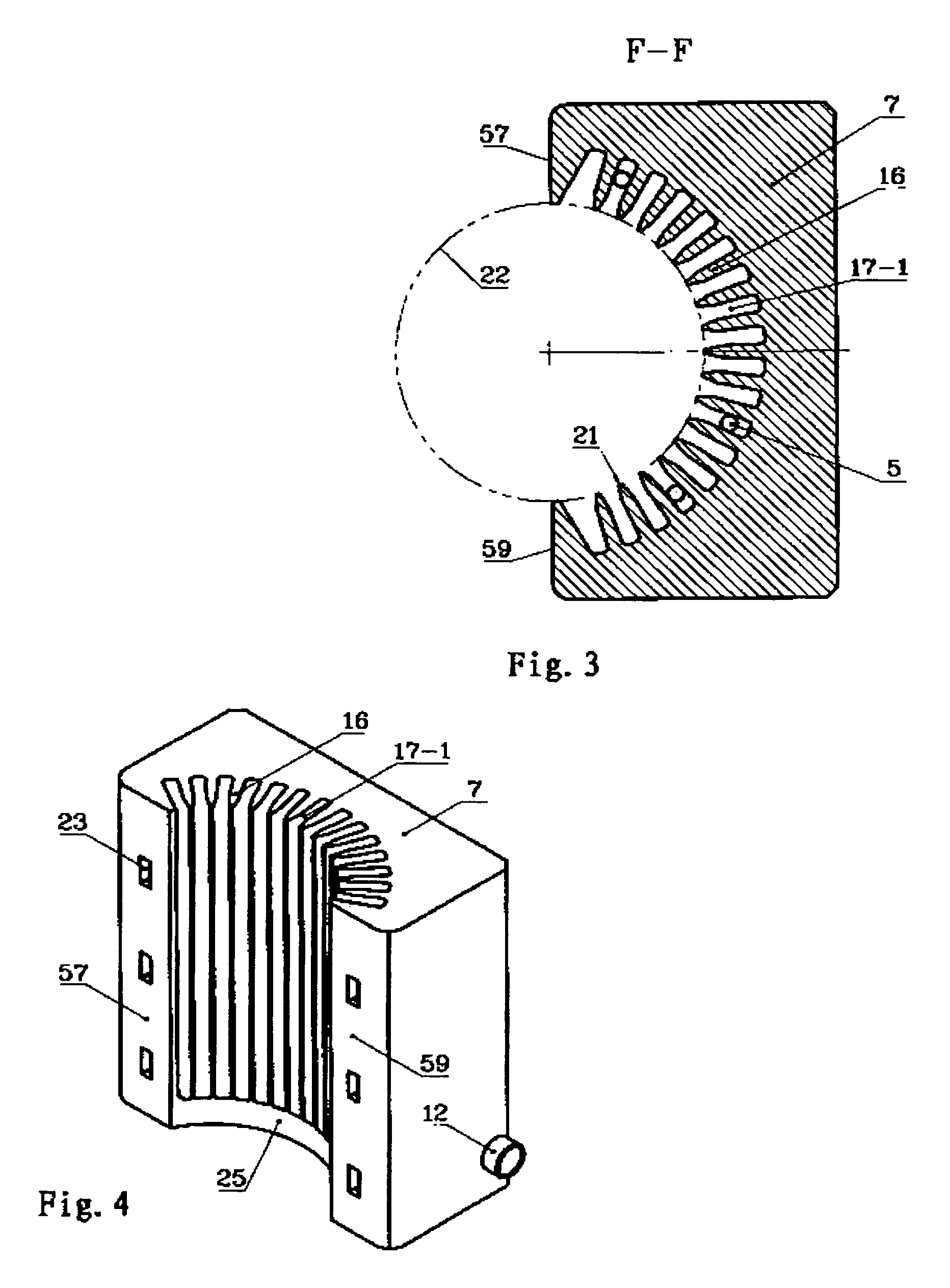

Film metal mould crystallizer and method for casting using the same

InactiveUS7549459B2Rapid and sequential thermal diffusionImprove internal qualityMelt-holding vesselsFoundry mouldsMetalComposite material

A crystallizer and method for casting using the crystallizer. The crystallizer mainly includes a plurality of-position-limiting parts (16) on the inner side of the mould seat (6, 7). The inner side of the position-limiting parts (16) is in correspondence with the external periphery of the mould wall (8-1, 9-1) of the film mould (8, 9). A medium channel (17) with a medium-supplying port (5) at its upper end is formed between the adjacent position-limiting parts (16).

Owner:BEIJING TAIHE TECH

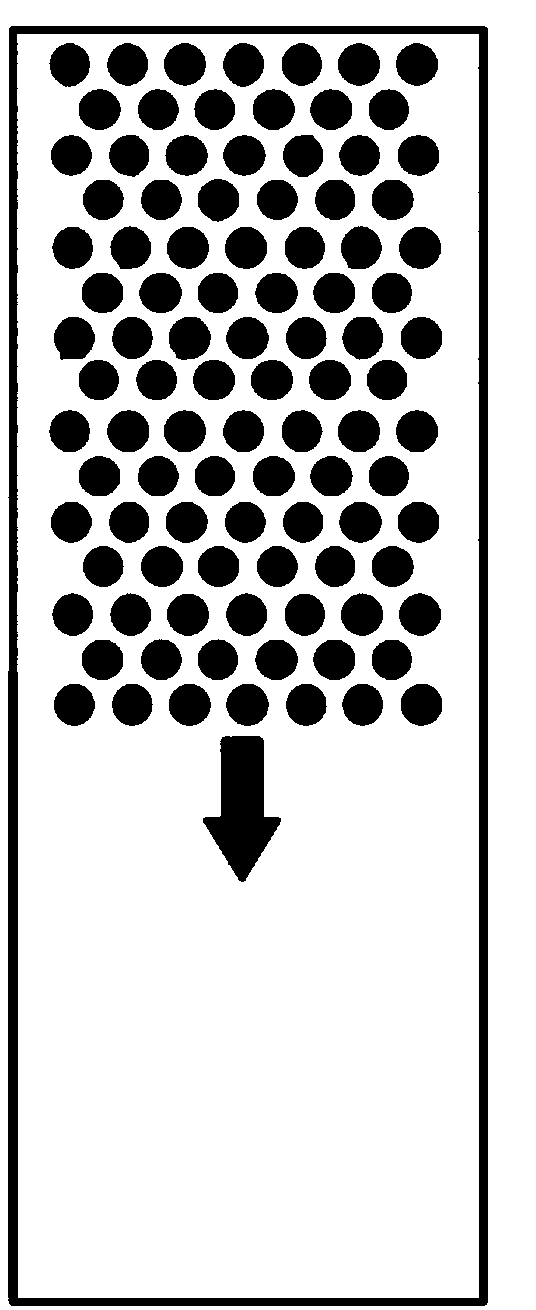

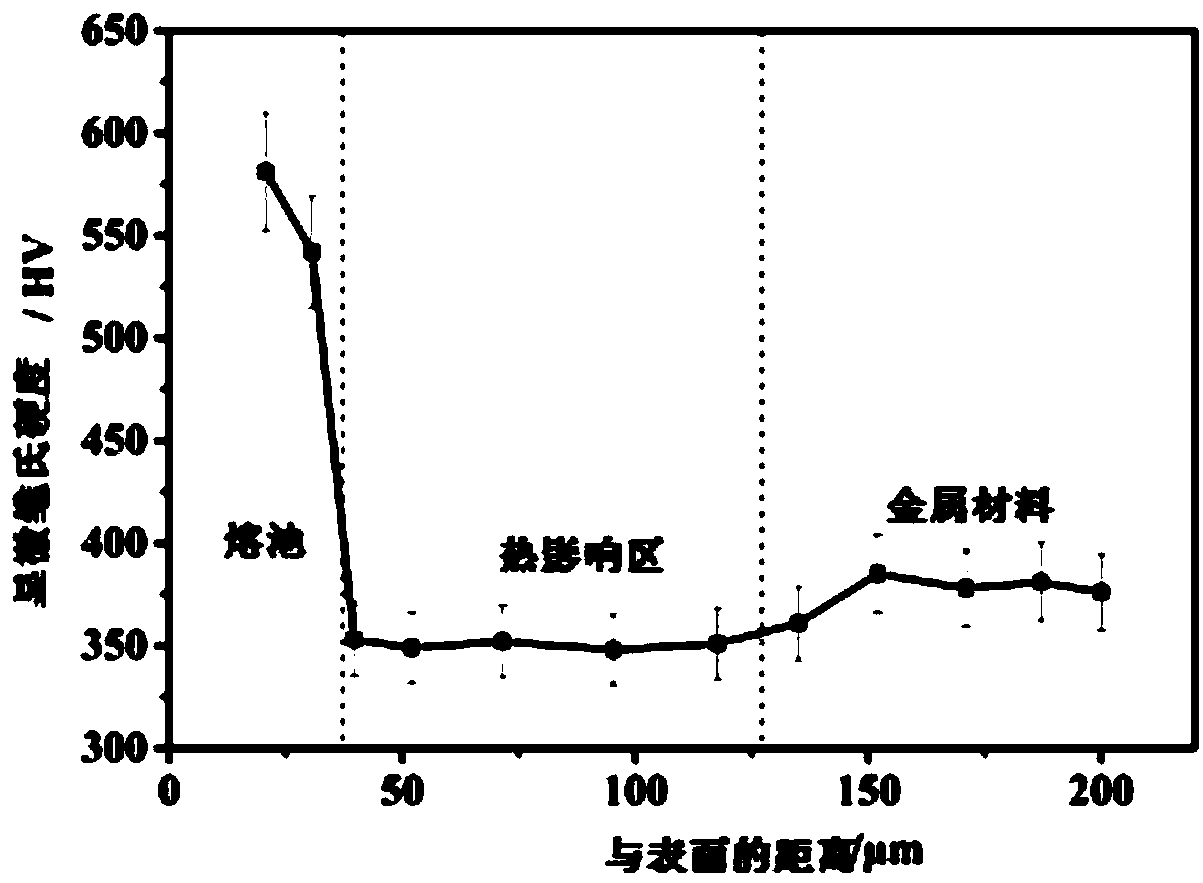

Laser surface alloying method

InactiveCN108914115AImprove wear resistanceHigh degree of automationMetallic material coating processesHeat-affected zoneVolumetric Mass Density

The invention relates to a laser surface alloying method for metal materials. The laser surface alloying method comprises the following steps: prefabricating nanocarbon powder on a metal surface; dividing the metal surface with the prefabricated nanocarbon powder into one or more working areas; dividing each working area into a number of square spot sites, wherein the size of each spot site is (1.5-5.5)*(1.5-5.5) mm; in an argon-protected low-oxygen environment, allowing low-power laser to randomly act on the discrete spot sites until all the spot sites form point-shaped shallow pools; and carrying out cooling so as to complete alloying. According to the invention, shallow alloying is realized by using a low-power high-power-density short-time laser action mode; laser action points in eachregion are randomly distributed to form discrete points, and the purposes of fast heat dissipation, small thermal stress, low workpiece deformation, high surface quality and small processing allowance are achieved; and after alloying, a cross-section coating has high hardness, and the hardness of heat-affected areas is slightly lower than a matrix, so wear resistance is further improved through compounding of hardness and softness.

Owner:北京煜鼎增材制造研究院股份有限公司

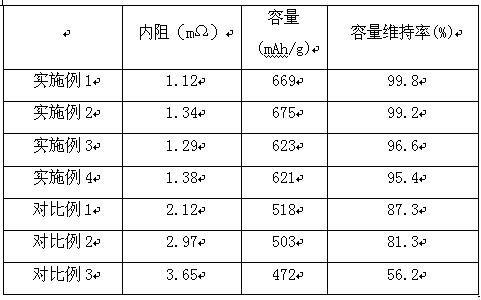

Silicon nanotube composite negative electrode material used for lithium battery and preparation method

ActiveCN107863517AGood effectSmall volume changeMaterial nanotechnologyCell electrodesCarbon layerGram

The invention relates to the technical field of a lithium battery, and particularly relates to a silicon nanotube composite negative electrode material used for a lithium battery and a preparation method. The silicon nanotube composite negative electrode material used for the lithium battery consists of a substrate and composite nanotubes vertically arranged on the substrate; and the composite nanotubes consist of silicon nanotubes, a titanium dioxide thin film and an amorphous form carbon layer from inside to outside in sequence. According to the silicon nanotube composite negative electrodematerial used for the lithium battery provided by the invention, in a charging-discharging process, the lateral volume effect in the Li de-intercalation process is relatively low, Li de-intercalationcan be quicker and more complete, the reversible specific capacity can be higher, a more stable SEI film can be formed, and the material coulombic efficiency can be improved; by virtue of a titanium oxide coating layer, volume change can be further suppressed, the service life and safety of the material can be prolonged and improved; and by virtue of C coating layer, the gram volume and electricalconductivity of the material can be improved.

Owner:湖北冠毓新材料科技有限公司

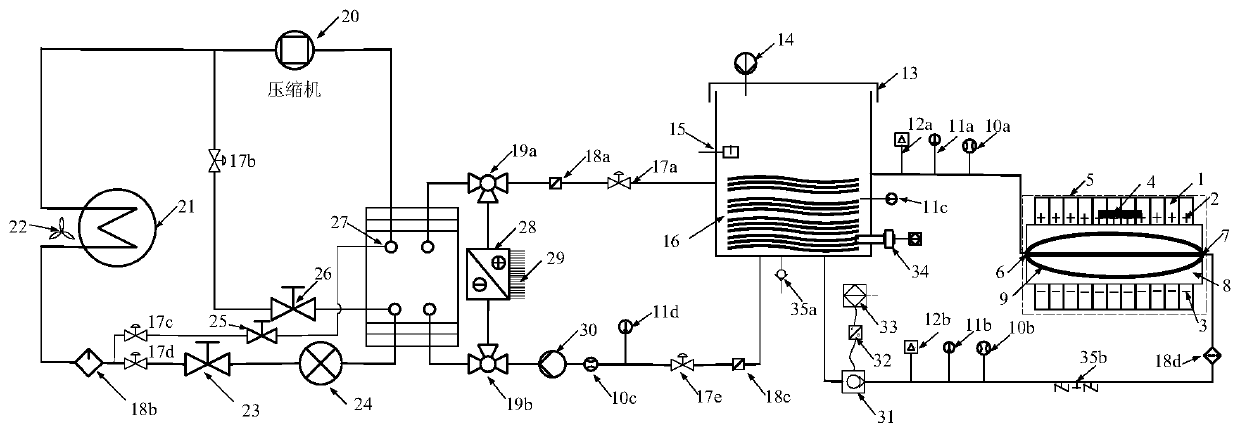

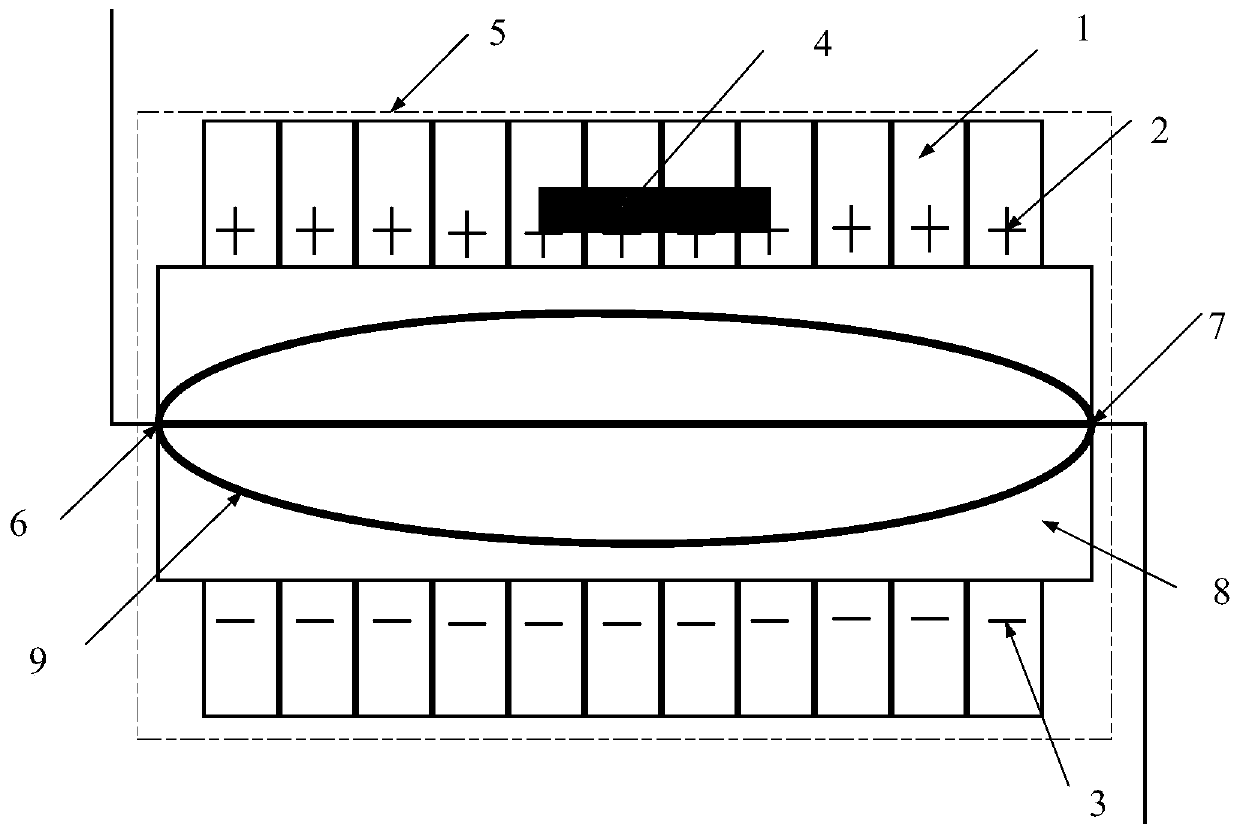

Power battery thermal management system based on tab liquid cooling mode

ActiveCN111403848AUniform current distributionReduce temperature differenceSecondary cellsPower batteryPlate heat exchanger

The invention aims to provide a power battery thermal management system based on a tab liquid cooling mode. The system comprises a battery module, a tab liquid cooling plate, a liquid storage tank, aheater, an internal circulation water pump, an external circulation water pump, a compressor, a condenser, an expansion valve, an evaporator and a plate heat exchanger, and a battery tab liquid cooling unit, a compressor unit main refrigeration unit, a plate heat exchanger auxiliary cooling unit, a liquid cooling internal circulation unit and a liquid cooling external circulation unit are formed.According to the power battery thermal management system based on the tab liquid cooling mode, circulating refrigerants are dispersed and preheated at the tabs of the battery, so that the heat exchange thermal resistance can be greatly reduced, quicker heat exchange of the battery is facilitated, the thermal management efficiency is improved, and the system integration degree is high.

Owner:HARBIN ENG UNIV

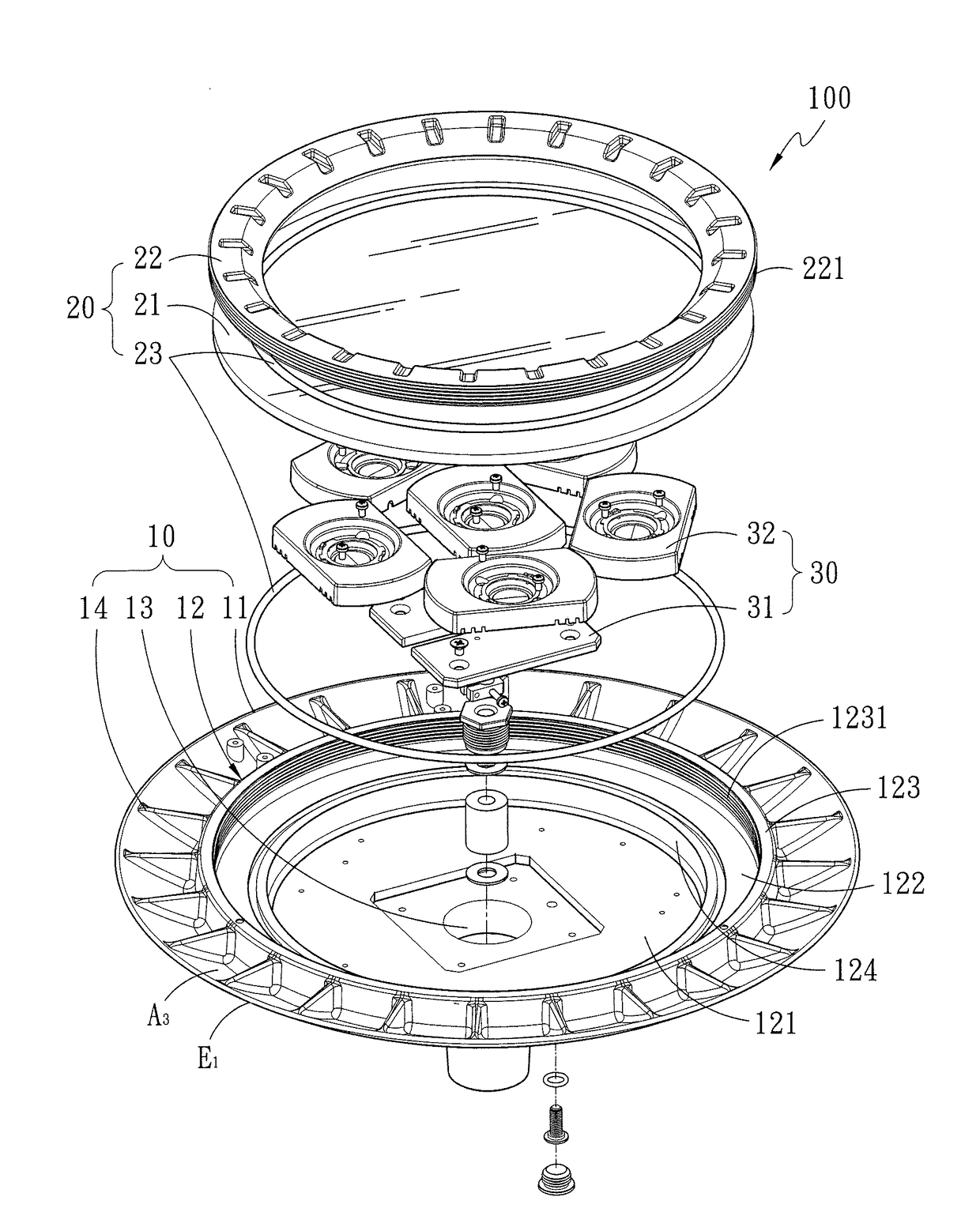

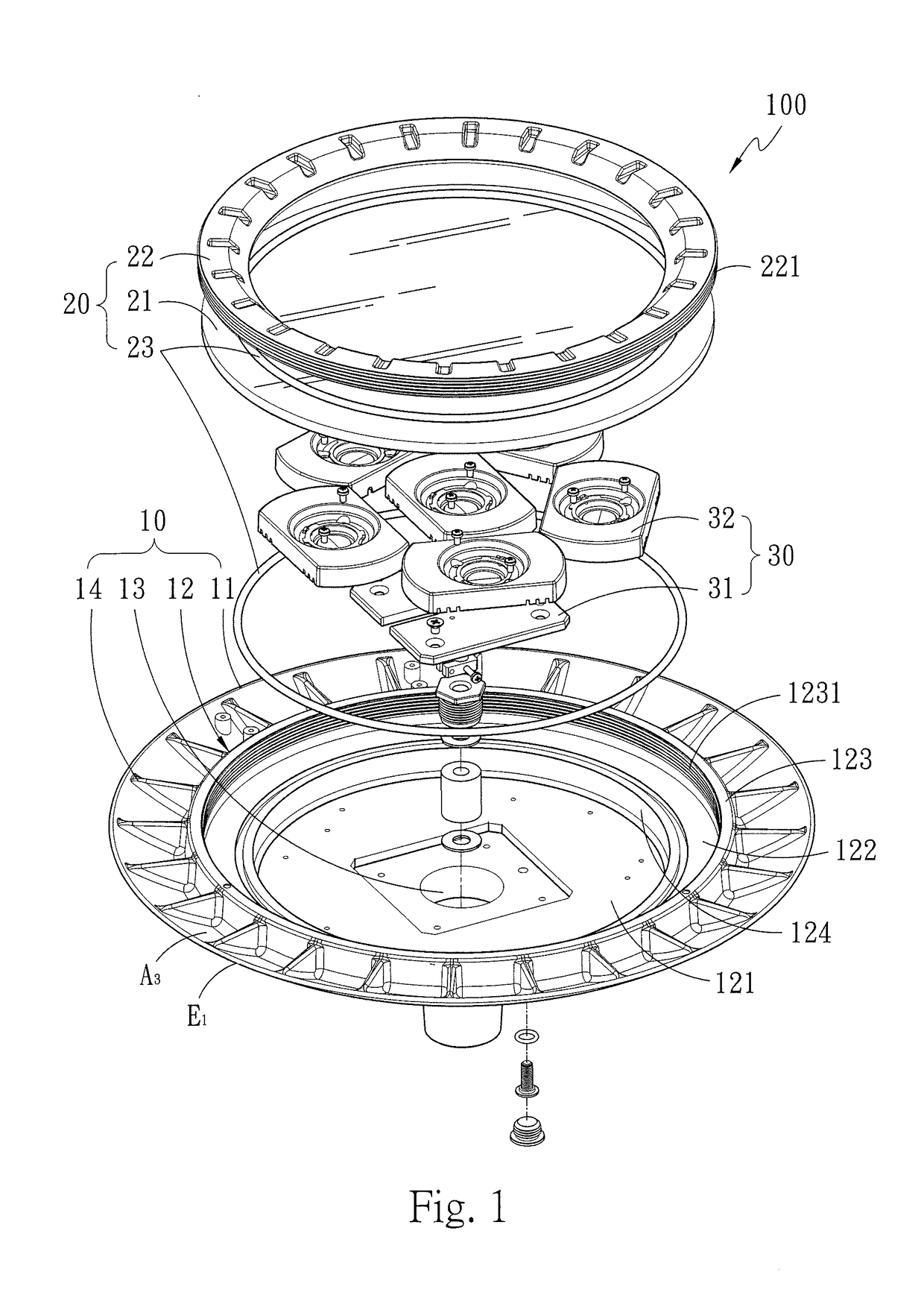

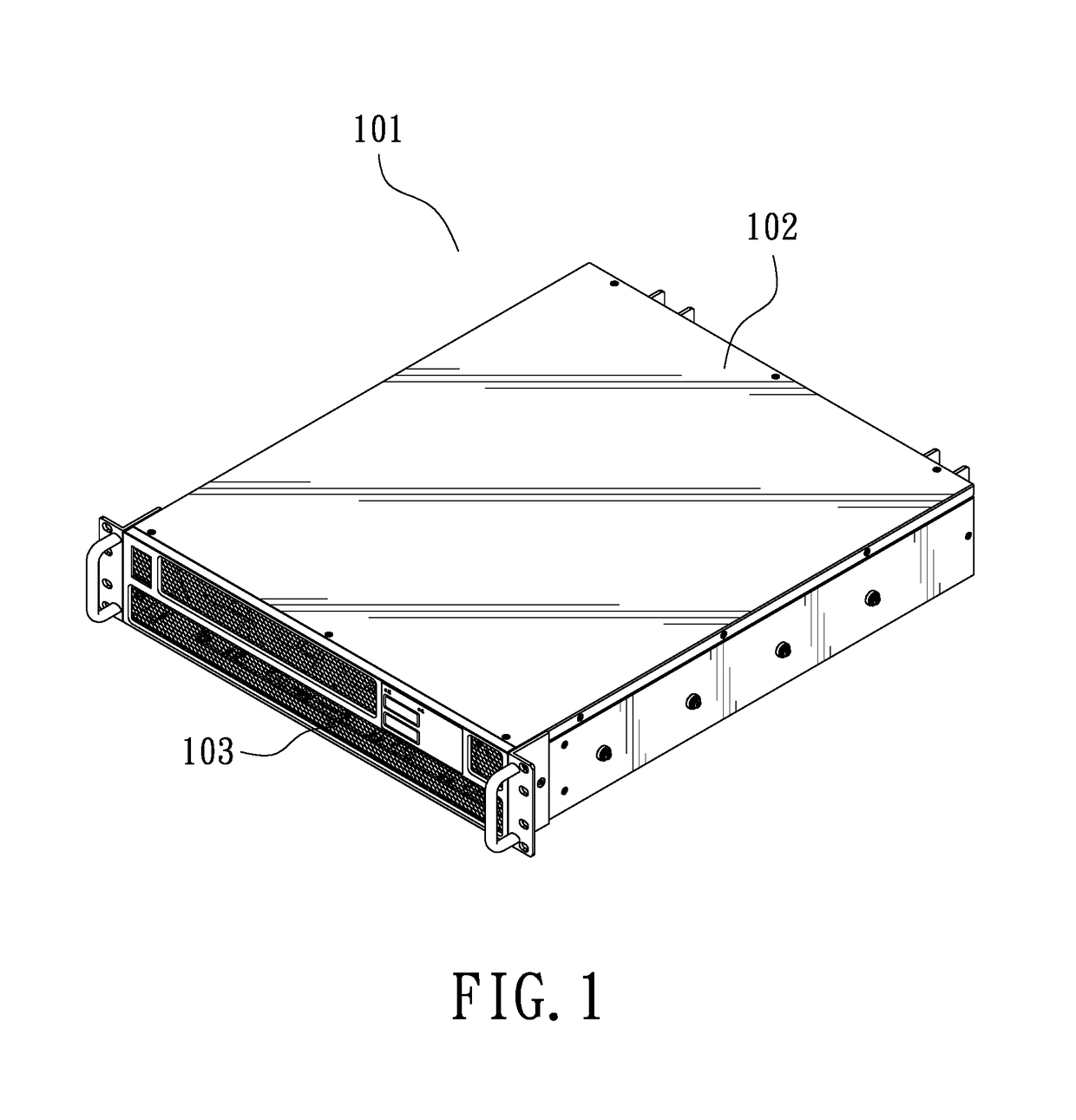

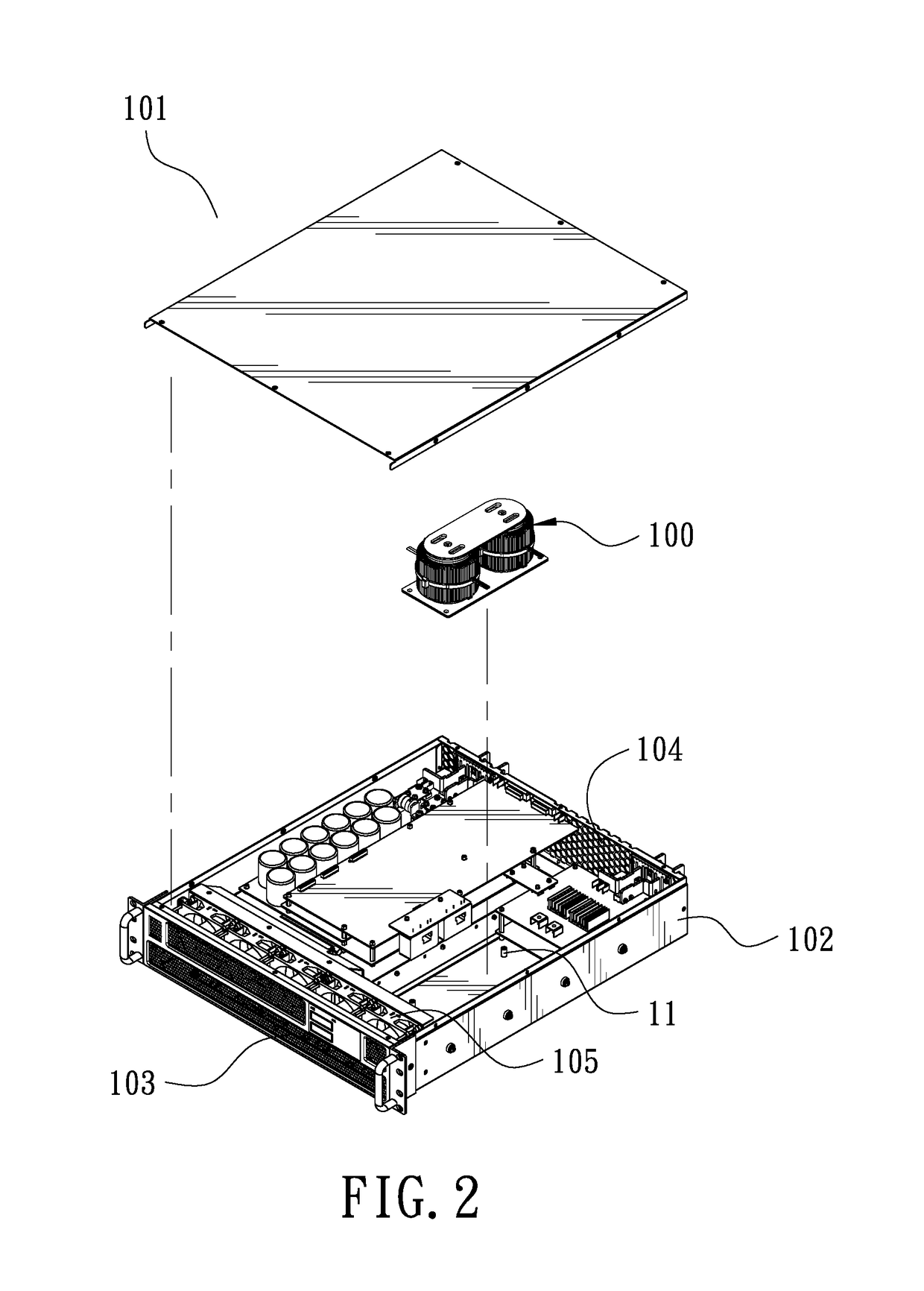

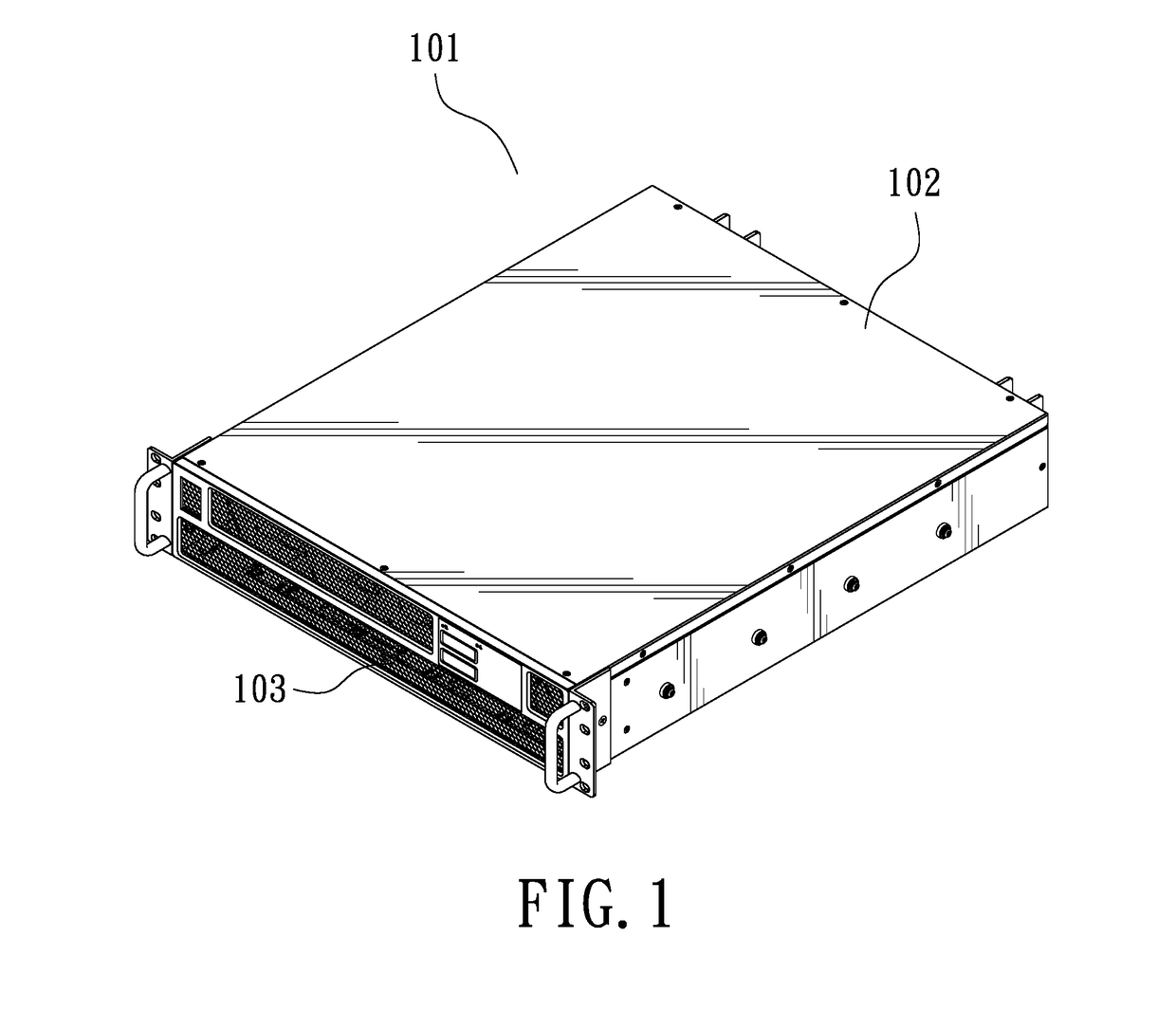

Choke coil module of high power density DC-AC power inverter

InactiveUS10276291B2Improve power densityImprove cooling effectTransformers/reacts mounting/support/suspensionServersEngineeringHigh power density

A choke coil module of a high power density DC-AC power inverter includes a retainer. The retainer includes a lower plate and an upper plate. The upper and lower plates are spaced from each other and have two slots, respectively. An accommodation space of the retainer is provided with two choke coils which are disposed obliquely in a stagger manner. Top portions and bottom portions of the choke coils protrude out of and lean against the slots of the upper plate and the lower plate, respectively. The outside air is guided by a fan unit to enter a casing through air inlets, and the heat generated by the choke coils is expelled to the outside through air outlets. The choke coil module can be mounted in a smaller casing, such as a casing with a height of 2 U, to achieve excellent heat dissipation.

Owner:CHYNG HONG ELECTRONICS

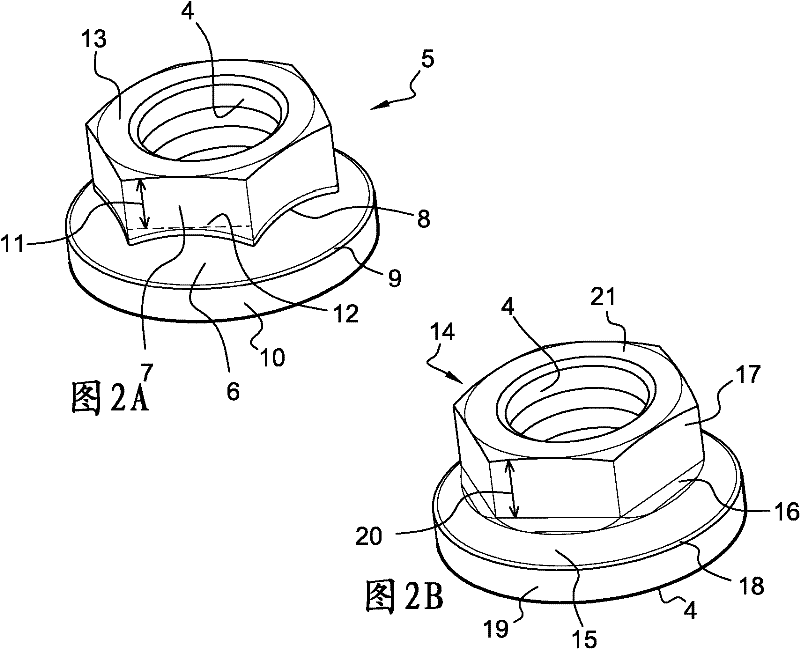

Polygonal driving means with inbuilt collar

It has become apparent that the dimensions of inbuilt-collar driving means of the same nominal size can vary according to the manufacturing process. The dimensions of the collar have to be adapted to suit the method of manufacture accordingly, at the expense of strength or mass. In addition, the torque that can be transmitted for tightening and loosening varies according to a useful height on which a wrench can gain a purchase. The idea underlying the invention, in order to have a useful height identical to the height of shank (7) is for the frustoconical collar (152) of a driving means (151) to be pushed in towards its centre in the continuation of the faces of the shank. The driving means with inbuilt collar proposed by the invention is suited to all methods of manufacture, and can be manufactured without adversely affecting the dimensions of the driving means or how it is fitted.

Owner:LISI AEROSPACE

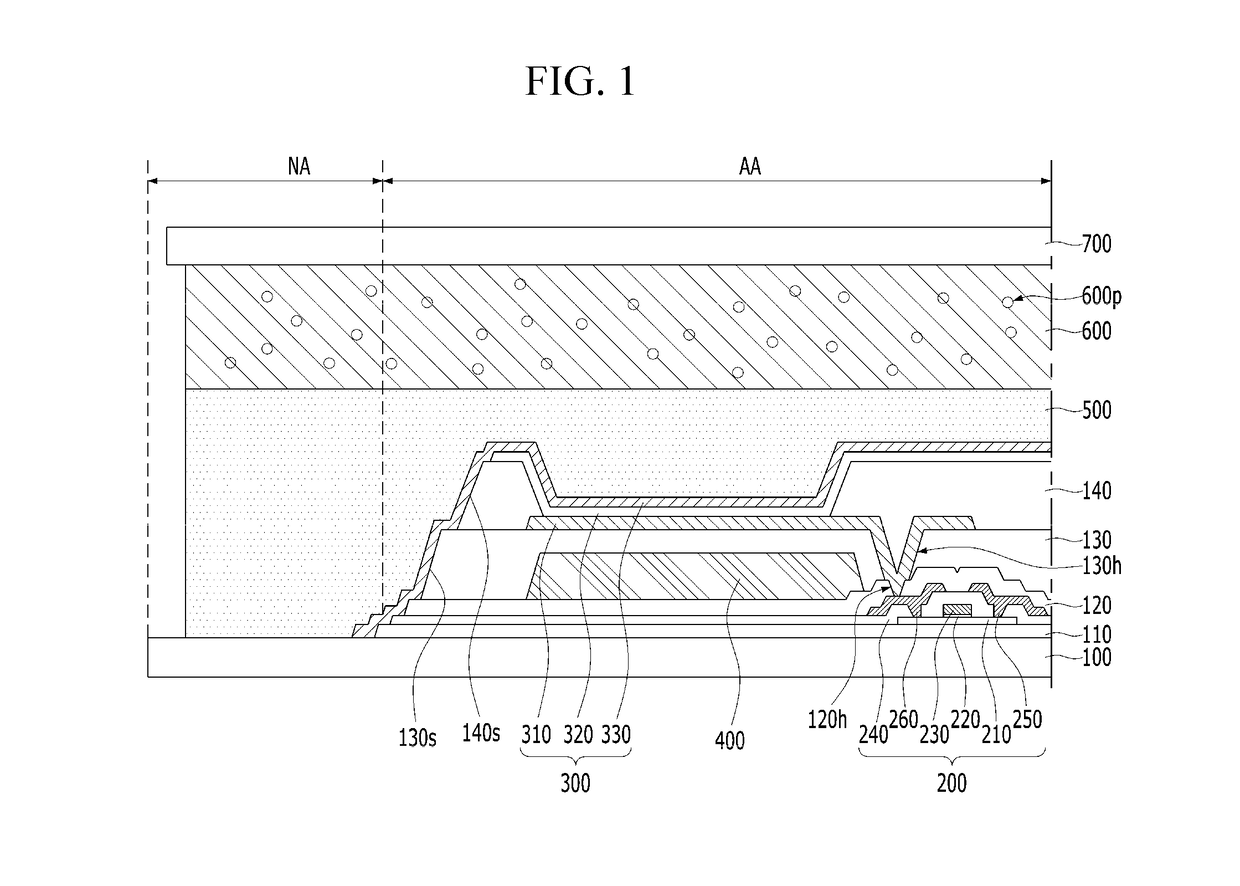

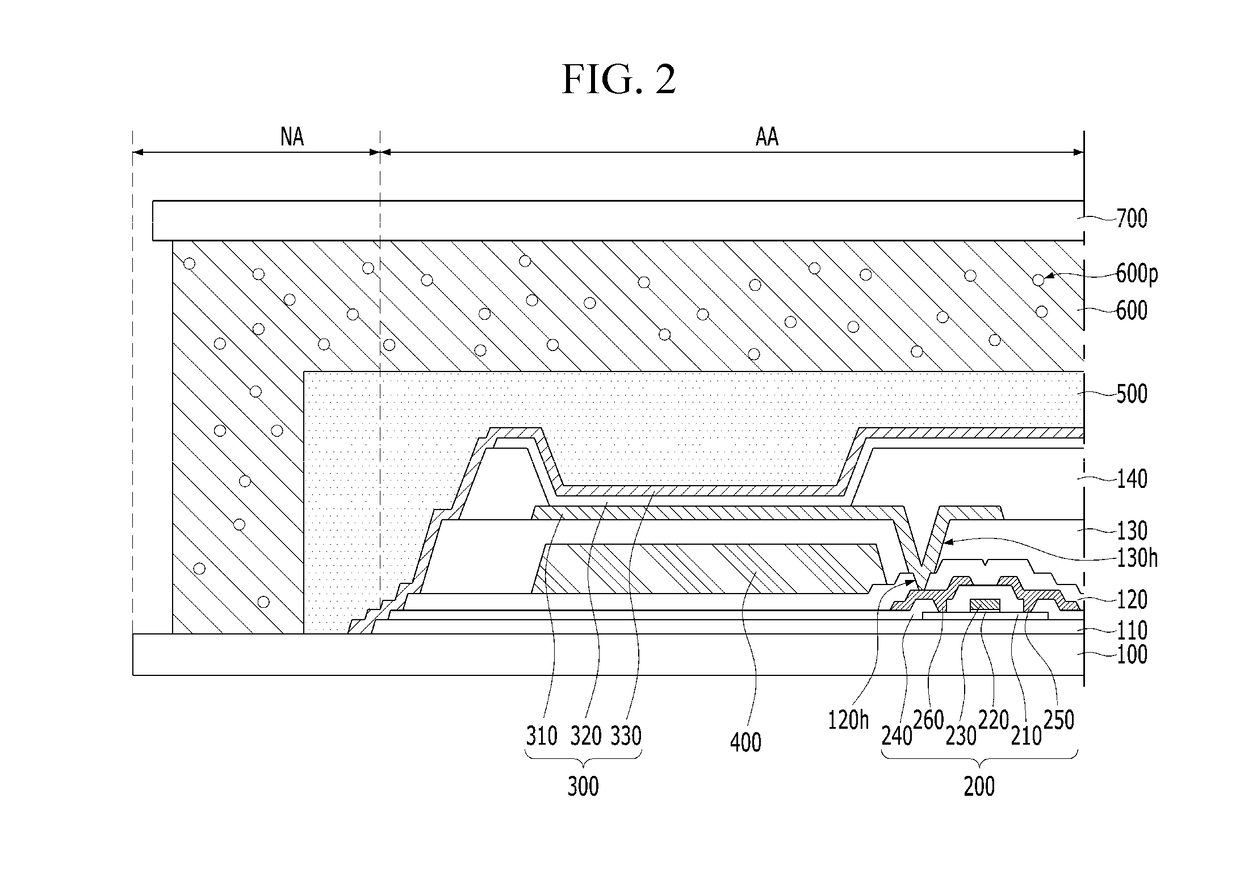

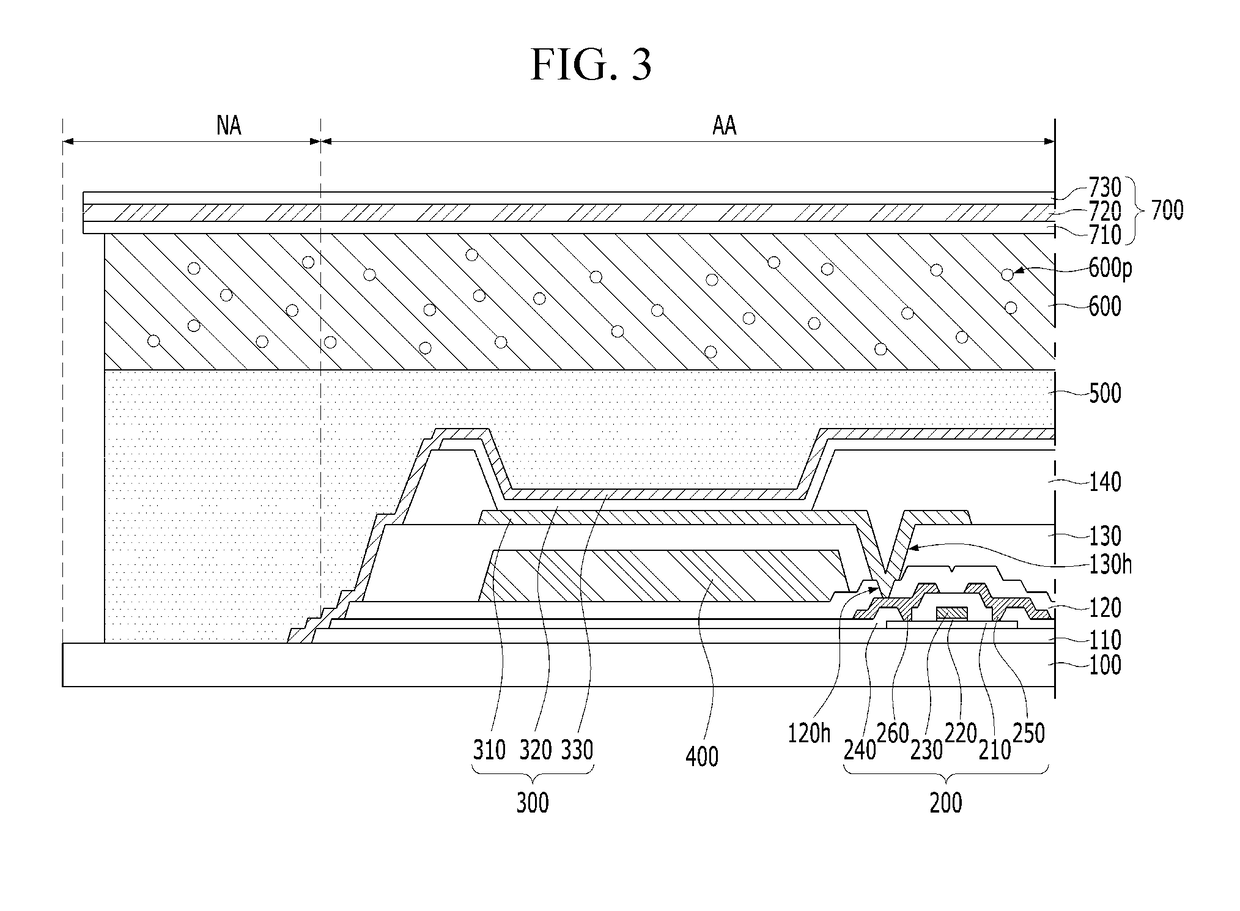

Organic light-emitting display device having an encapsulating layer

ActiveUS20190067641A1Dissipate heat quicklyInhibit deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An organic light-emitting display device including an encapsulating layer for coupling an encapsulating substrate to a device substrate in which a light-emitting structure is formed, is provided. The encapsulating layer can include a lower encapsulating layer and an upper encapsulating layer which are sequentially disposed on the light-emitting structure. The lower encapsulating layer can be in direct contact with the light-emitting structure. The upper encapsulating layer can include a moisture-absorbing material. Thus, in the organic light-emitting display device, the permeation of external moisture can be prevented, and the heat dissipation can be improved.

Owner:LG DISPLAY CO LTD

Heat dissipation device

ActiveUS10077945B2Improve heat transfer efficiencyDissipate heat quicklyIndirect heat exchangersWorking fluidEngineering

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

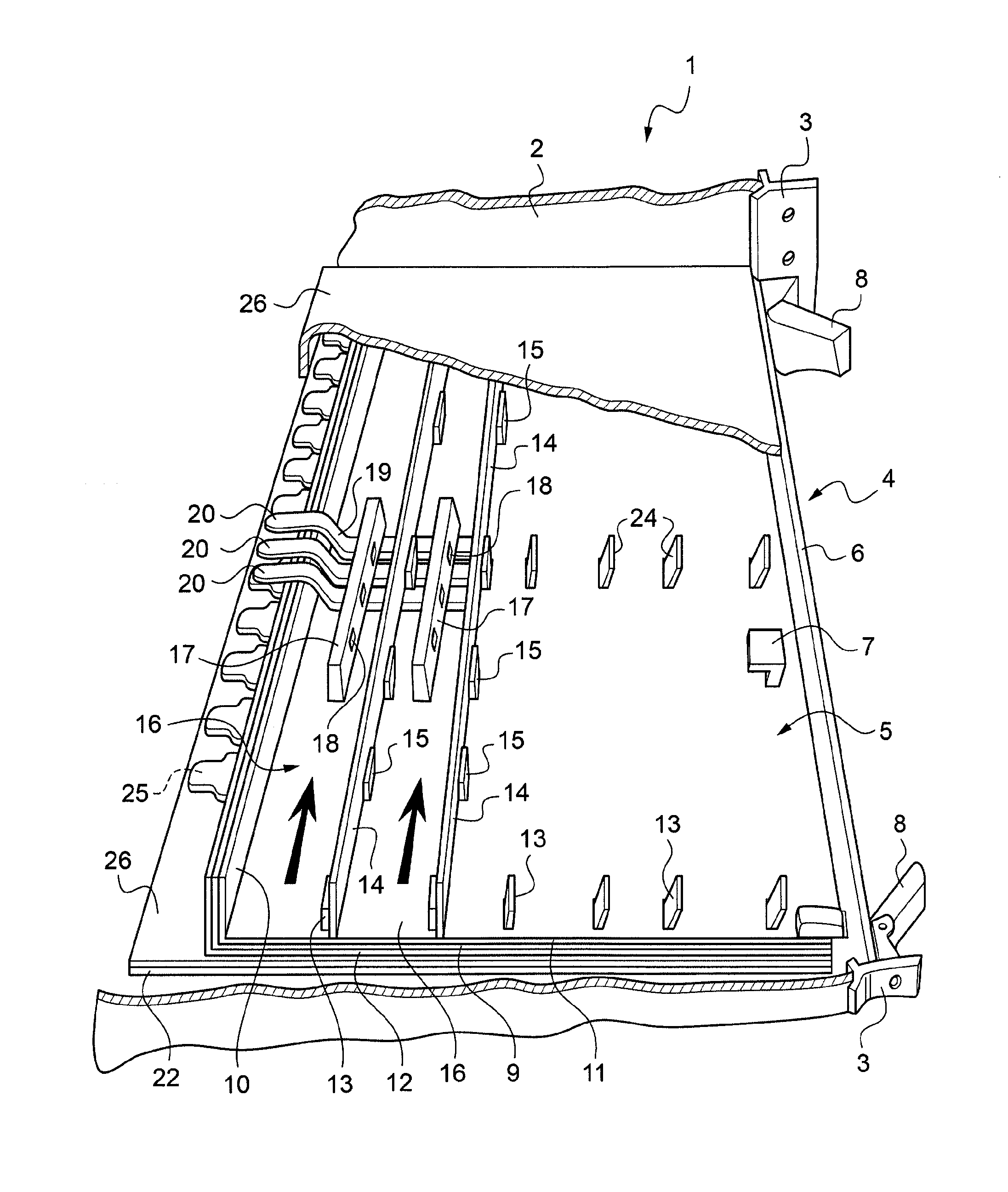

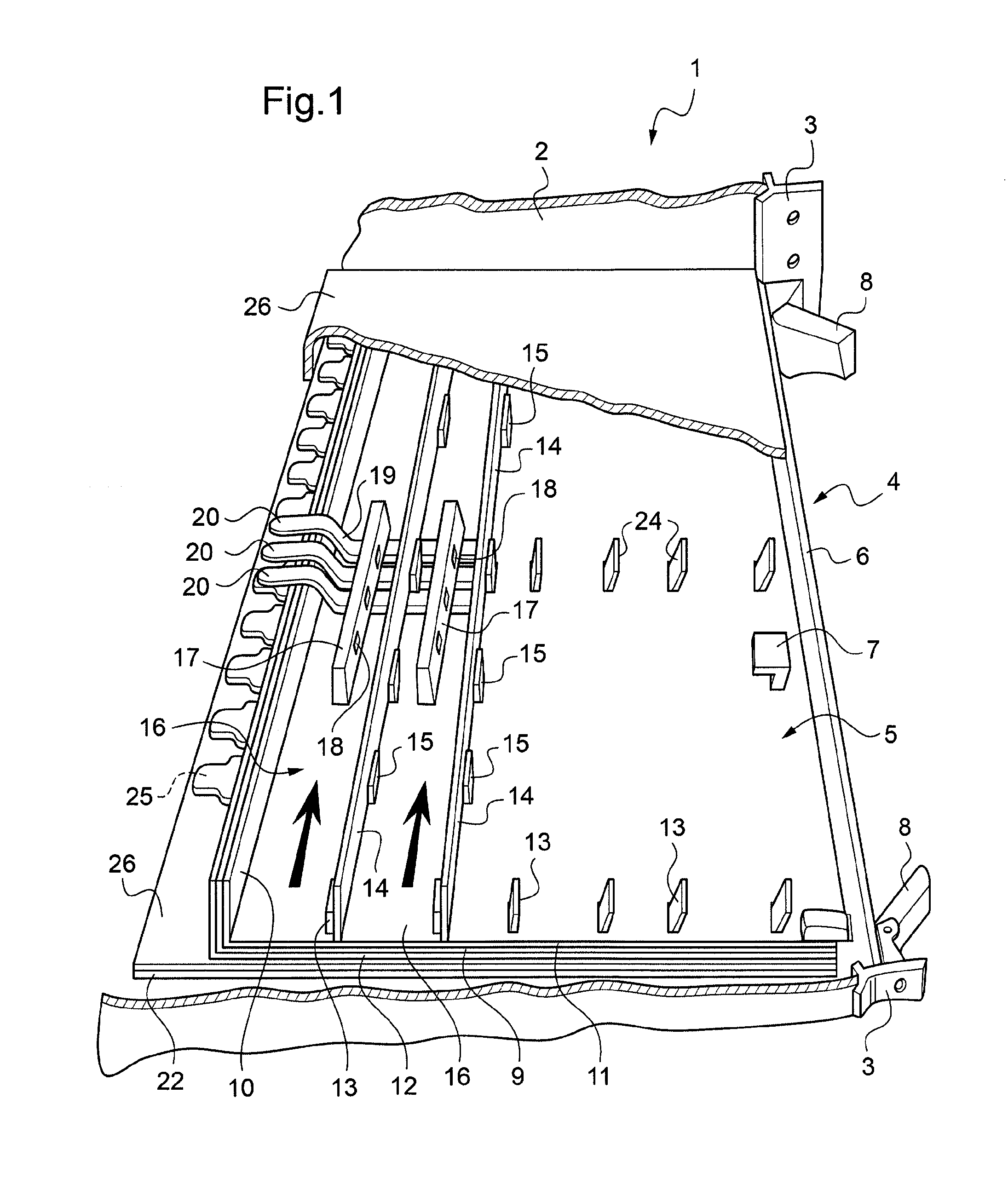

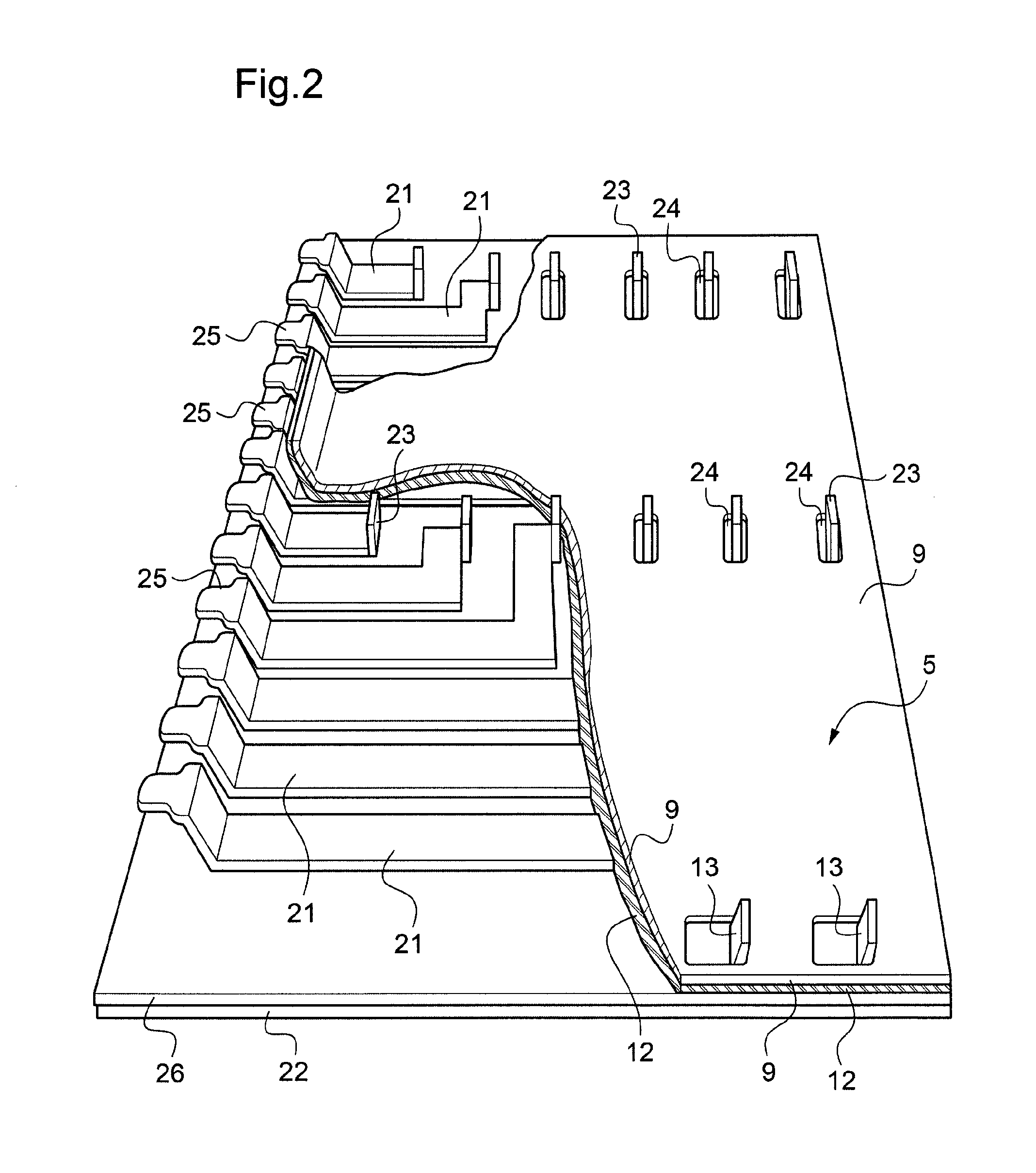

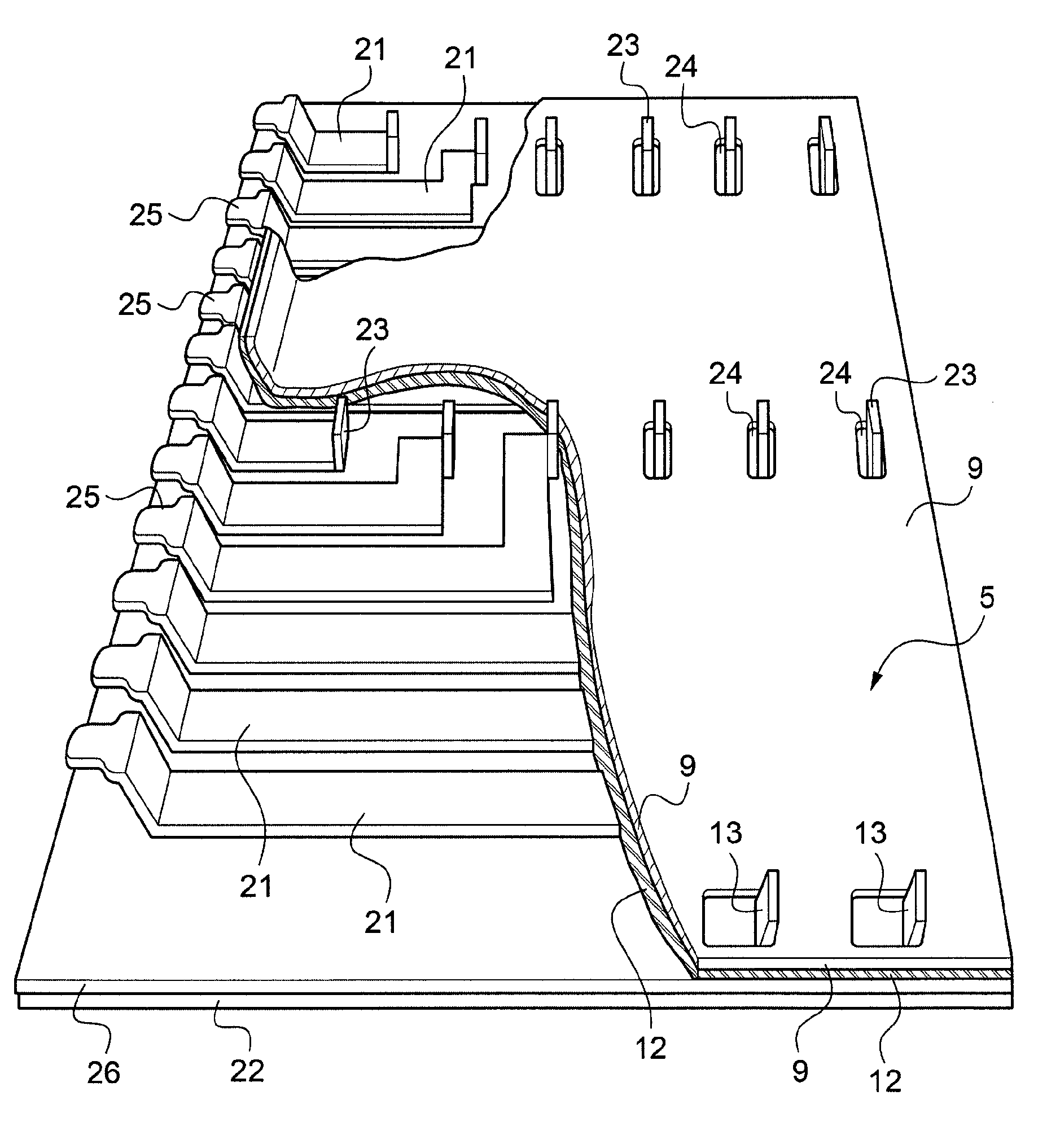

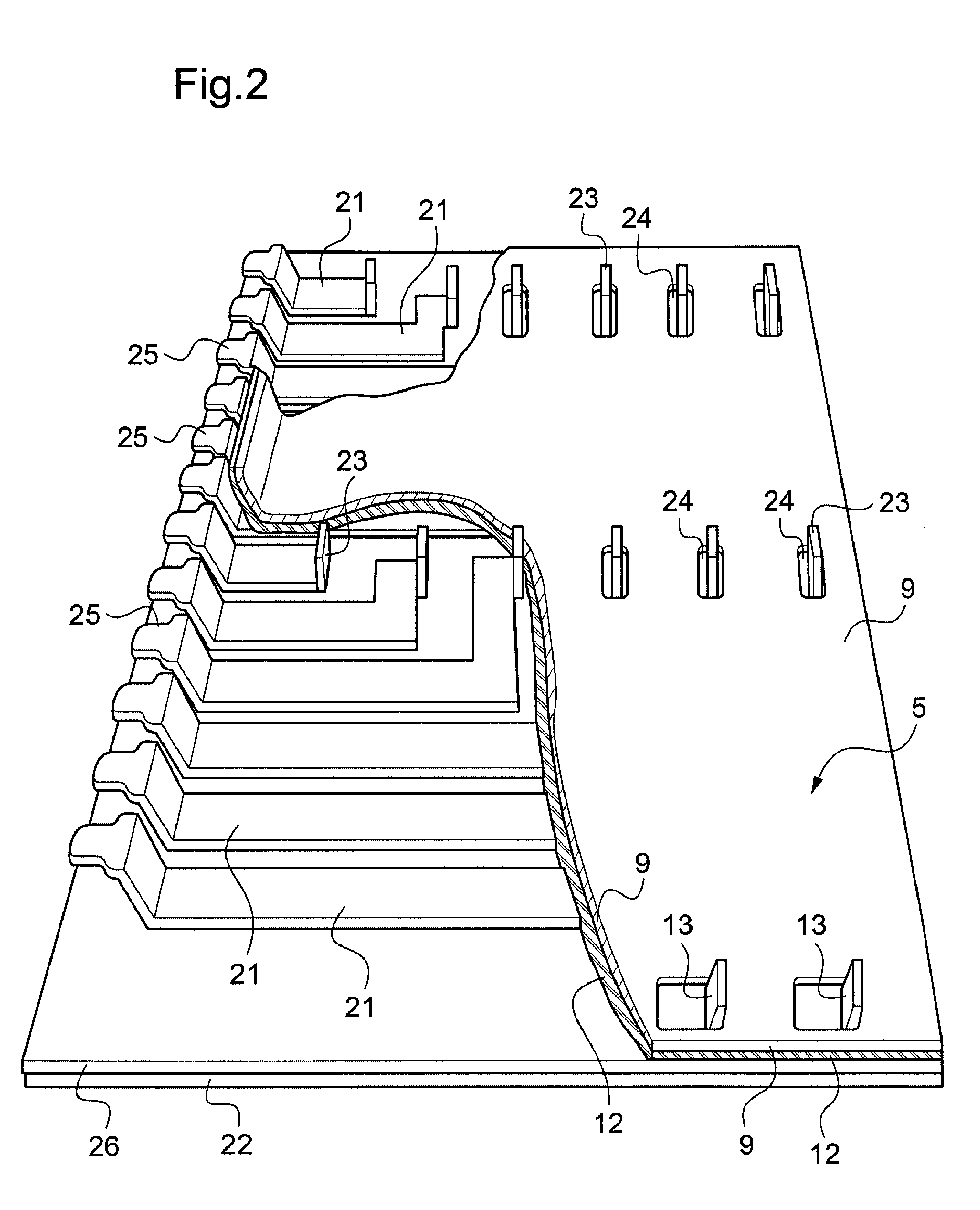

Modular electrical card for power components

ActiveUS8837117B2Easy maintenanceDissipate heat quicklyDigital data processing detailsElectrical connection printed elementsElectricityModularity

Owner:SAFRAN ELECTRONICS & DEFENSE

Modular electrical card for power components

ActiveUS20110317374A1Easy maintenanceDissipate heat quicklySlidable card holdersCard stiffenersElectricityModularity

The electrical card has power modules constituted by power components and by control components that are carried by strips fastened on a support plate comprising an electrical ground plate. The power components are connected firstly to control buses, and secondly to power buses carried by the support plate and extending in a layer adjacent to the electrical ground plate.

Owner:SAFRAN ELECTRONICS & DEFENSE

Choke coil module of high power density dc-ac power inverter

InactiveUS20180294086A1Improve cooling effectImprove power densityTransformers/reacts mounting/support/suspensionServersHigh power densityAC power

A choke coil module of a high power density DC-AC power inverter includes a retainer. The retainer includes a lower plate and an upper plate. The upper and lower plates are spaced from each other and have two slots, respectively. An accommodation space of the retainer is provided with two choke coils which are disposed obliquely in a stagger manner. Top portions and bottom portions of the choke coils protrude out of and lean against the slots of the upper plate and the lower plate, respectively. The outside air is guided by a fan unit to enter a casing through air inlets, and the heat generated by the choke coils is expelled to the outside through air outlets. The choke coil module can be mounted in a smaller casing, such as a casing with a height of 2 U, to achieve excellent heat dissipation.

Owner:CHYNG HONG ELECTRONICS

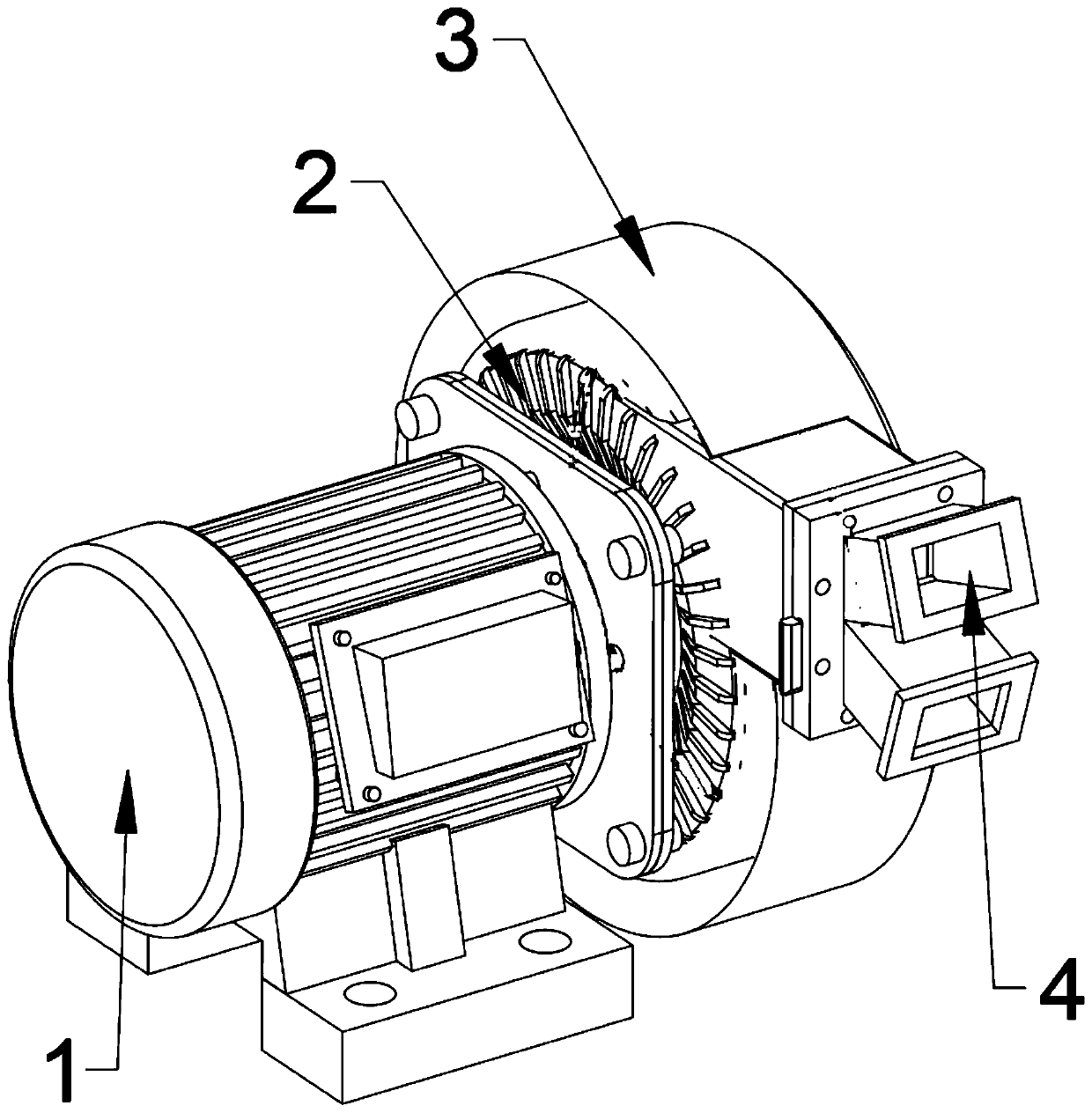

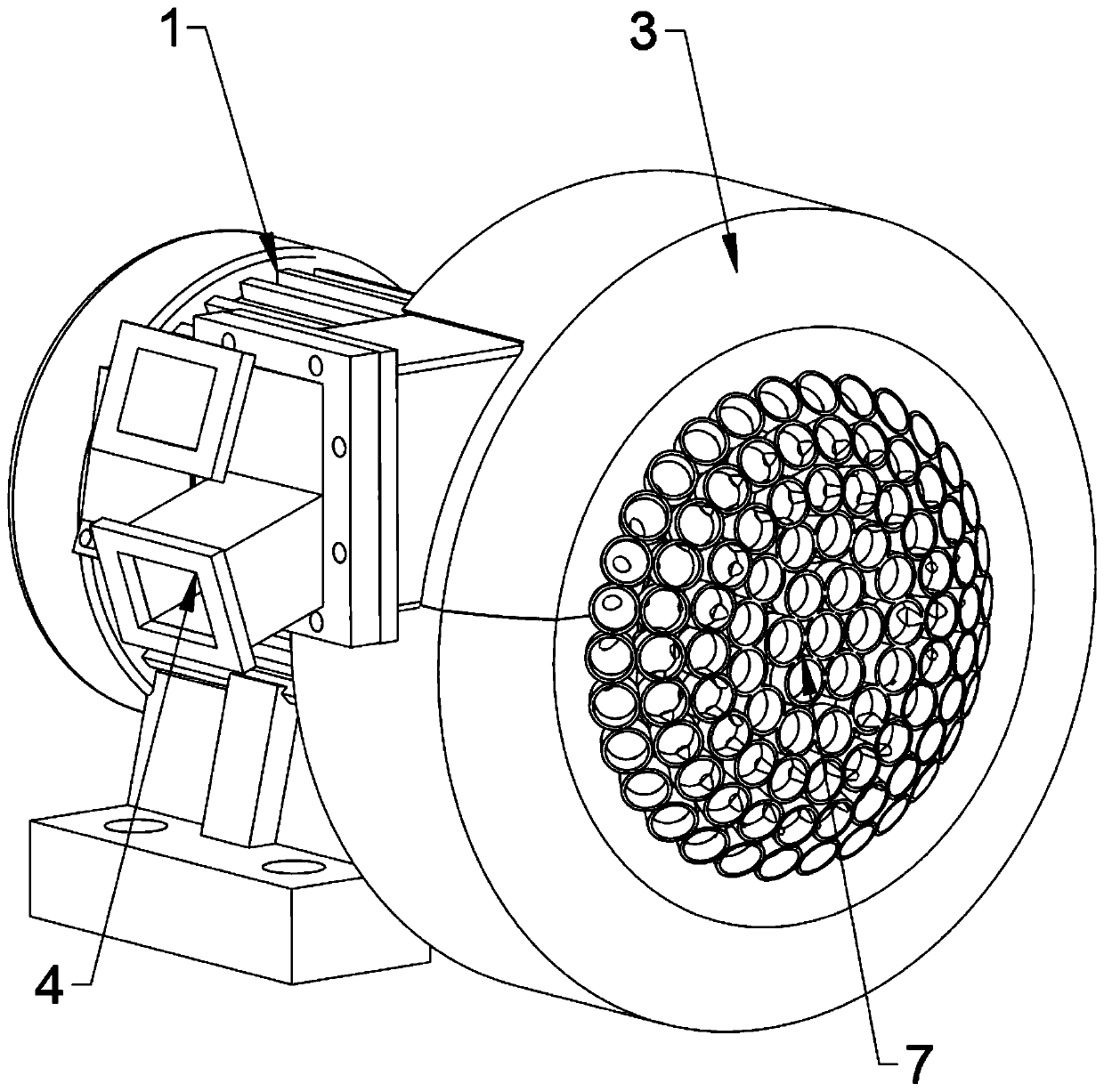

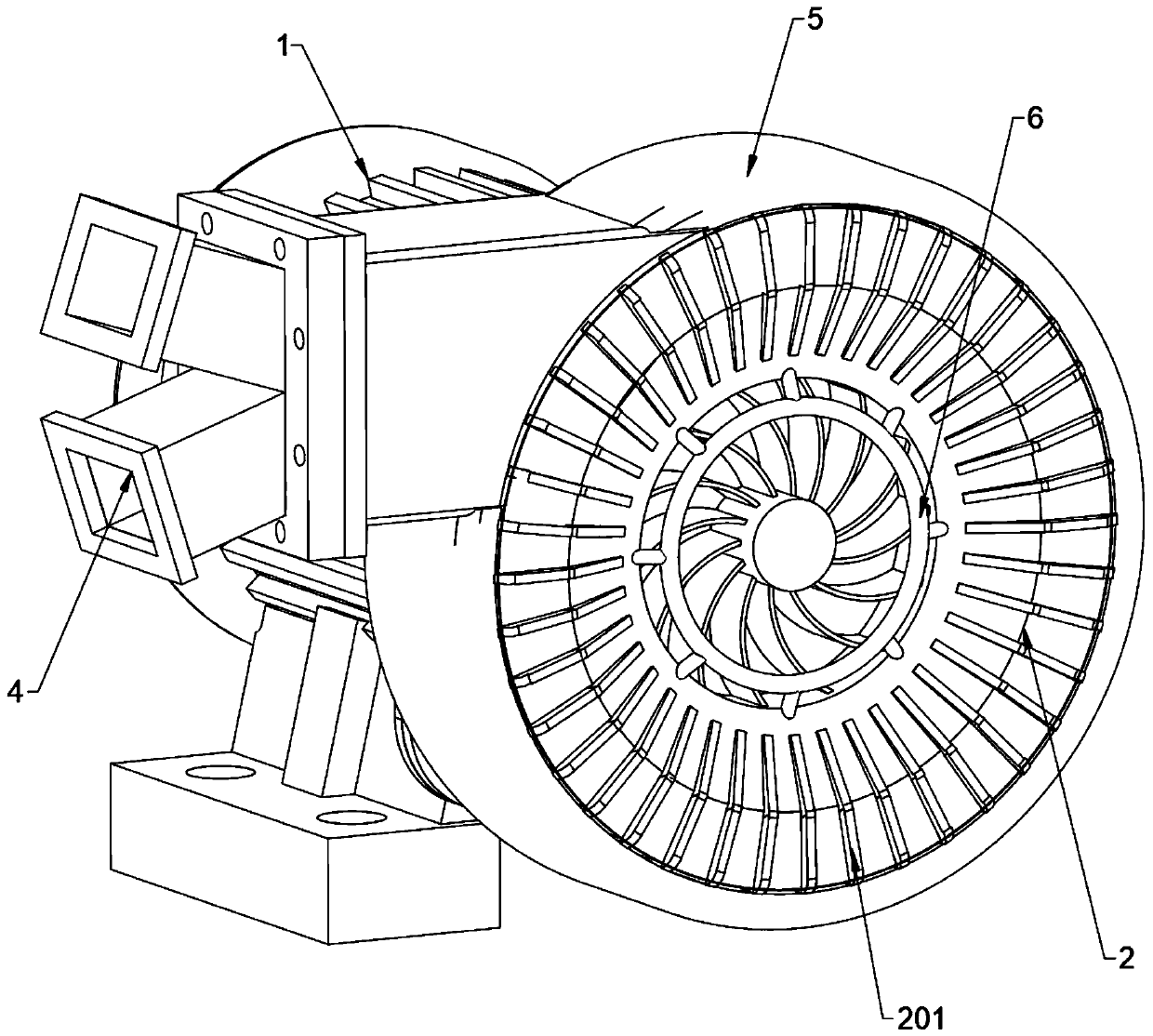

Blower capable of conducting self-physical cooling

ActiveCN110319062AHeat dissipation fastImprove cooling effectPump componentsPump installationsEngineeringHeat sink

The invention provides a blower capable of conducting self-physical cooling. The blower comprises a motor, a blowing device, cooling fins, a drainage cover, a flow guide air flue, a flow guide plate,a cooling device, a fixing frame, an air cooling device and a conical groove, wherein the blowing device is fixed on one side of the motor through bolts, the motor is connected with the blowing devicein a transmission mode, and the cooling fins are arranged on the outer wall of the blowing device; and the cooling device is arranged on the outer sides of the cooling fins, and the air cooling device is installed on the conical inner wall of the drainage cover. The blower capable of conducting the self-physical cooling covers the outer wall of the blowing device in an annular structure, an innerring of the drainage cover is fixed on the fixing frame at the air inlet of the blowing device, the design of the drainage cover is beneficial to drainage of part of air so that the air quickly passes through the surface of the cooling device, then the cooling device can quickly dissipate heat, and the air blowing device can be better cooled.

Owner:ANHUI RUIBANG BIOLOGICAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com