Patents

Literature

310results about "Seed preservation by heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

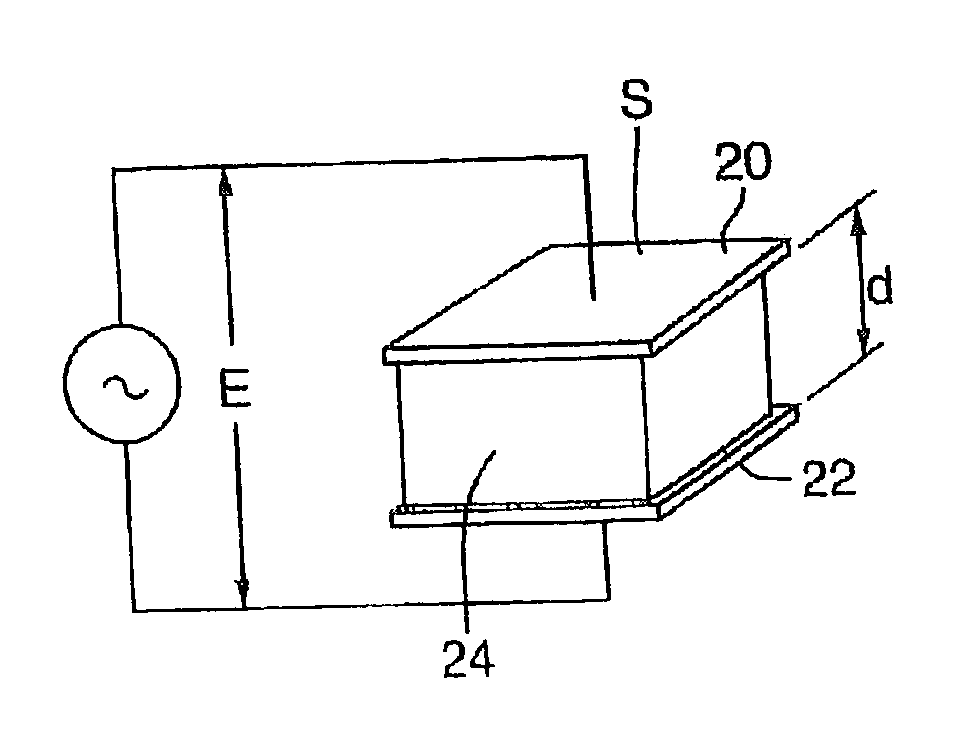

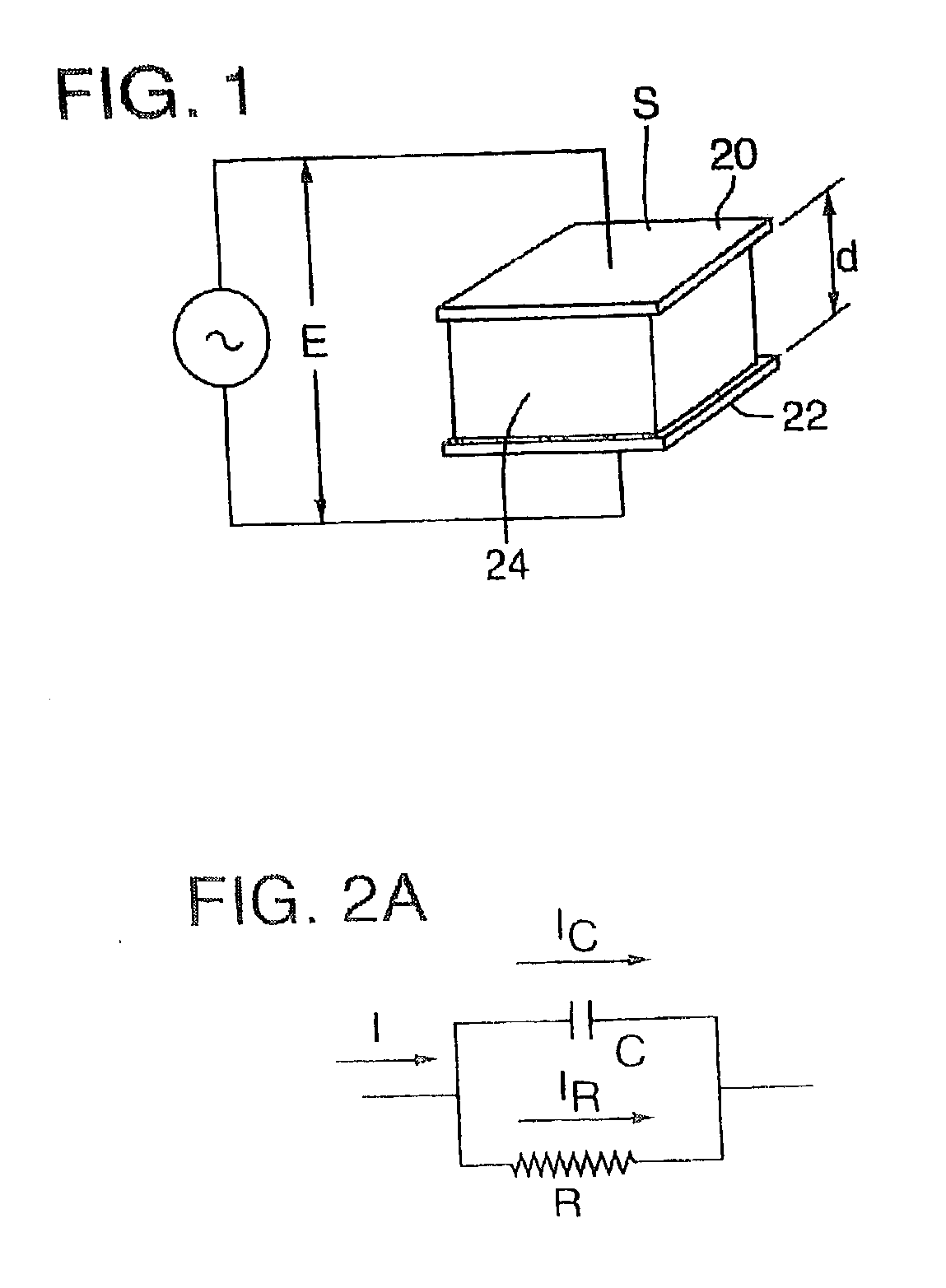

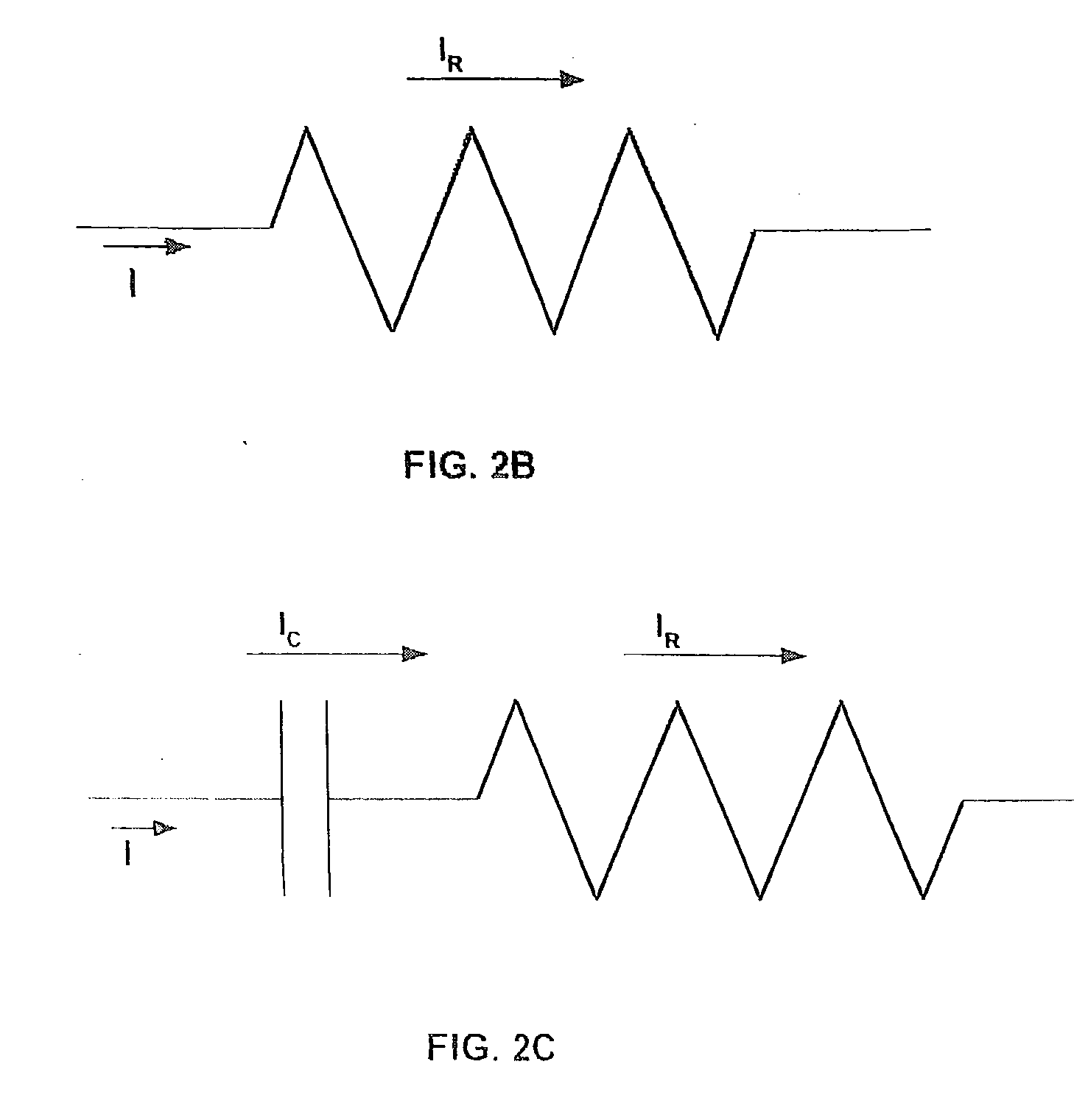

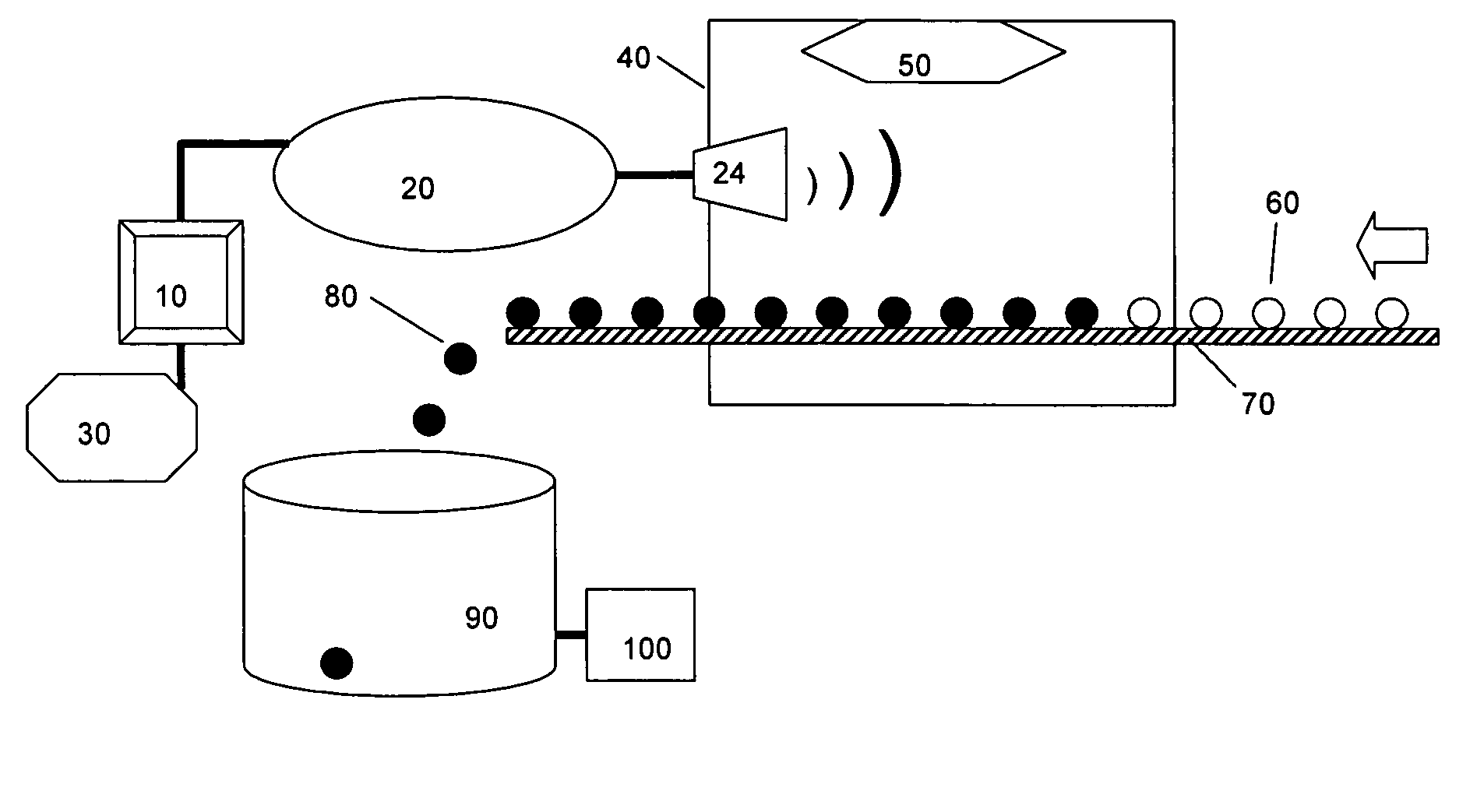

Variable frequency automated capacitive radio frequency (RF) dielectric heating system

InactiveUS20030205571A1Near independence of thermal conductivityEasy to adaptMeat/fish preservation by heatingDielectric heating circuitsEngineeringImpedance matching

A food product is heated by maintaining the food product in an AC electrical field generated by an RF signal. As the heating takes place, maximum energy is delivered to the food product using automatic impedance matching to adjust the rate of the process.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV +1

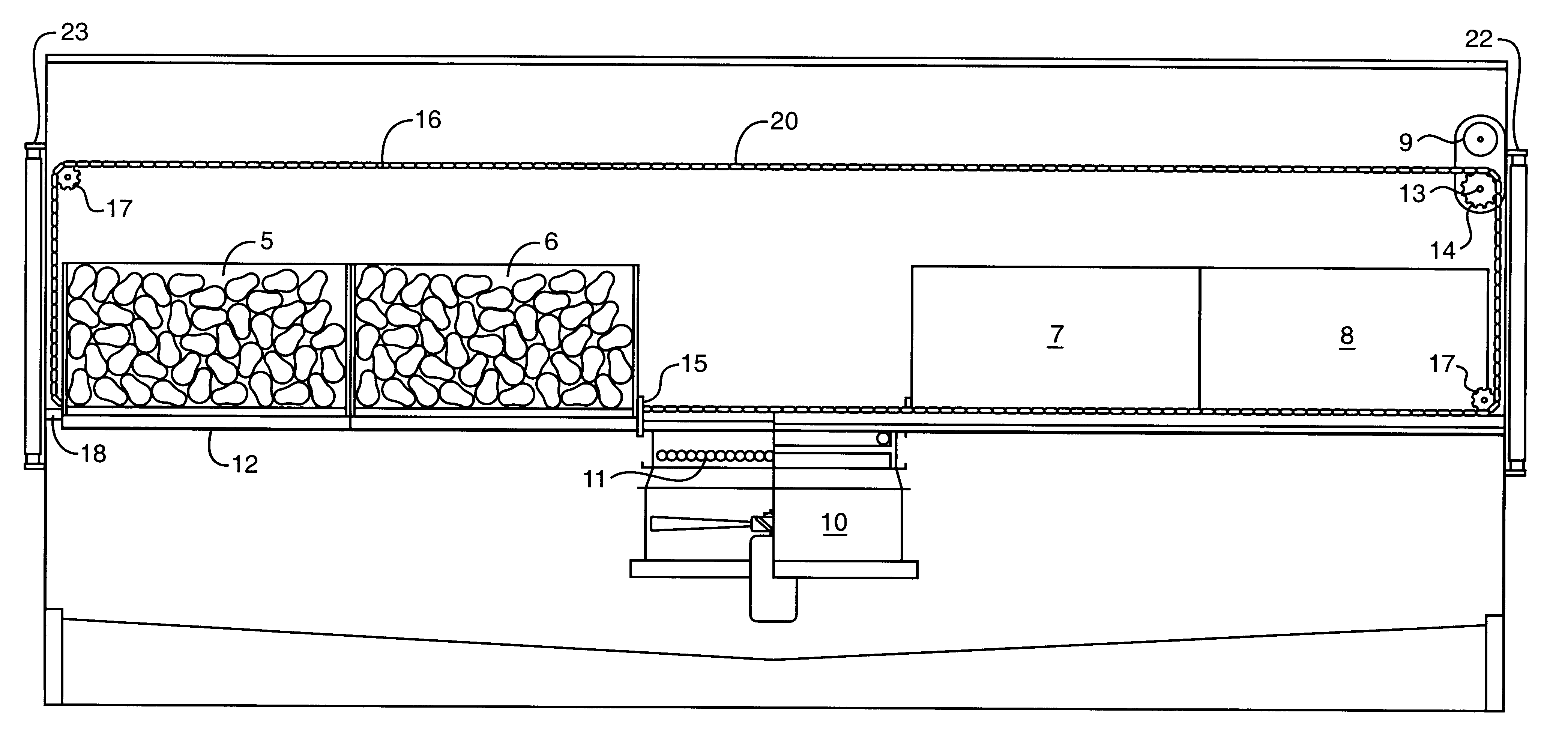

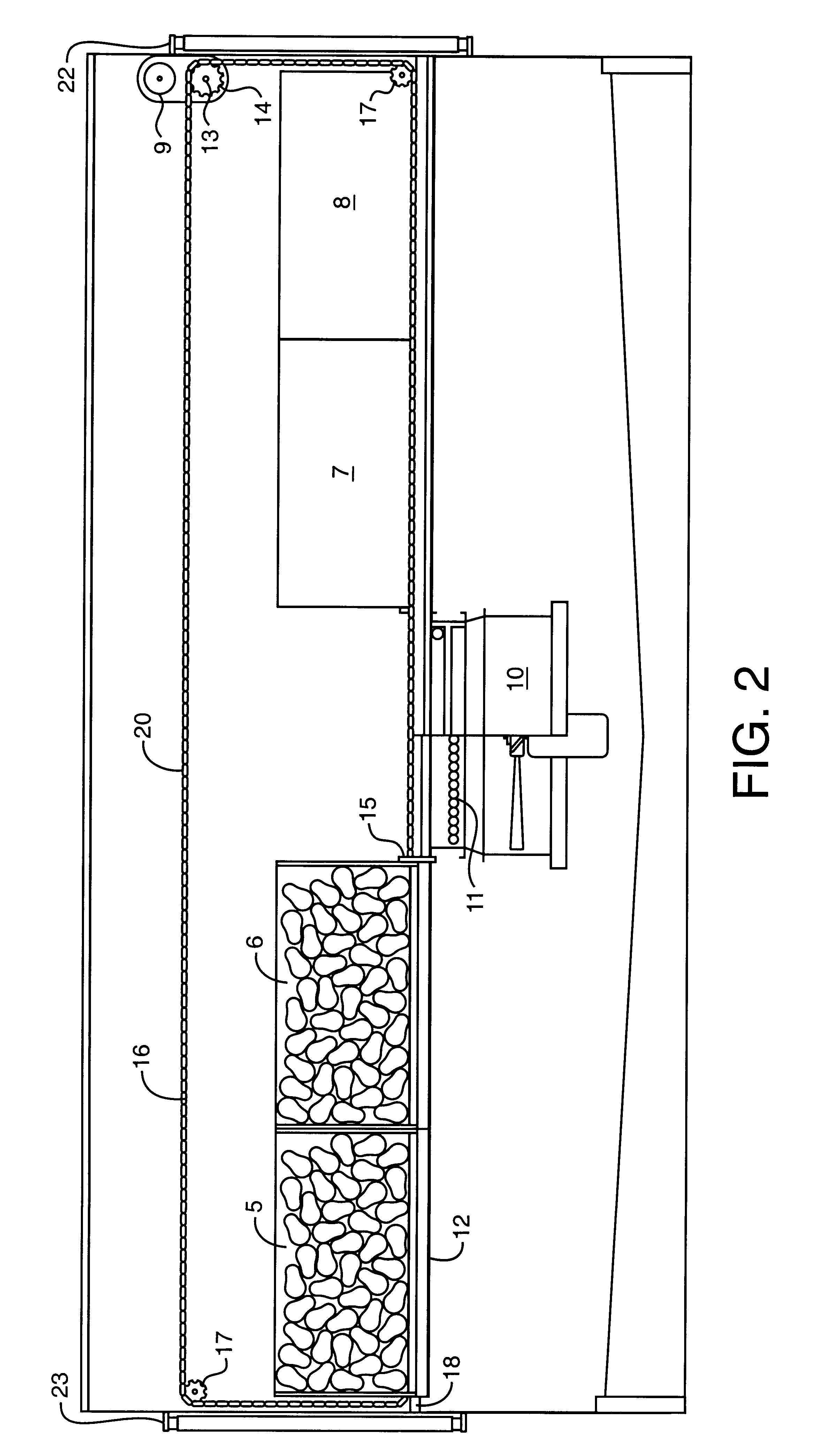

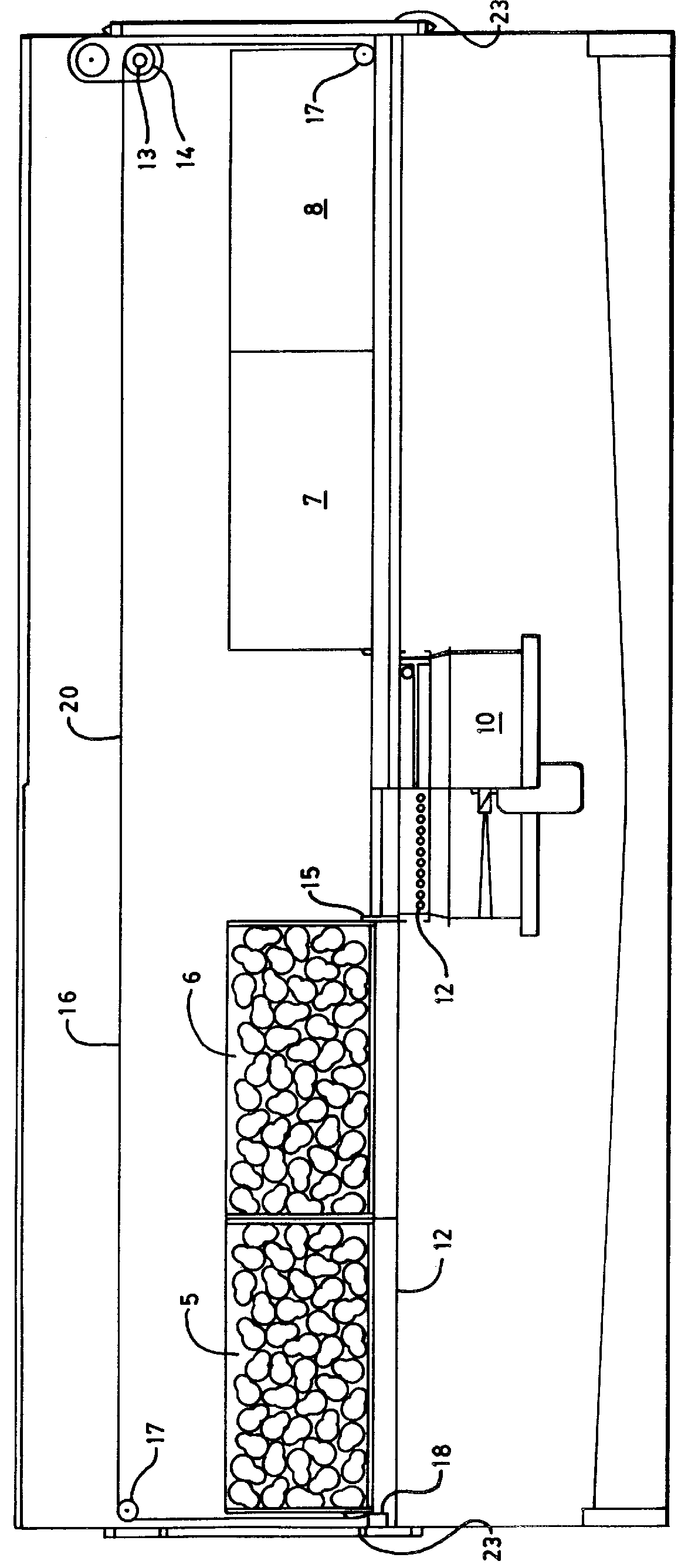

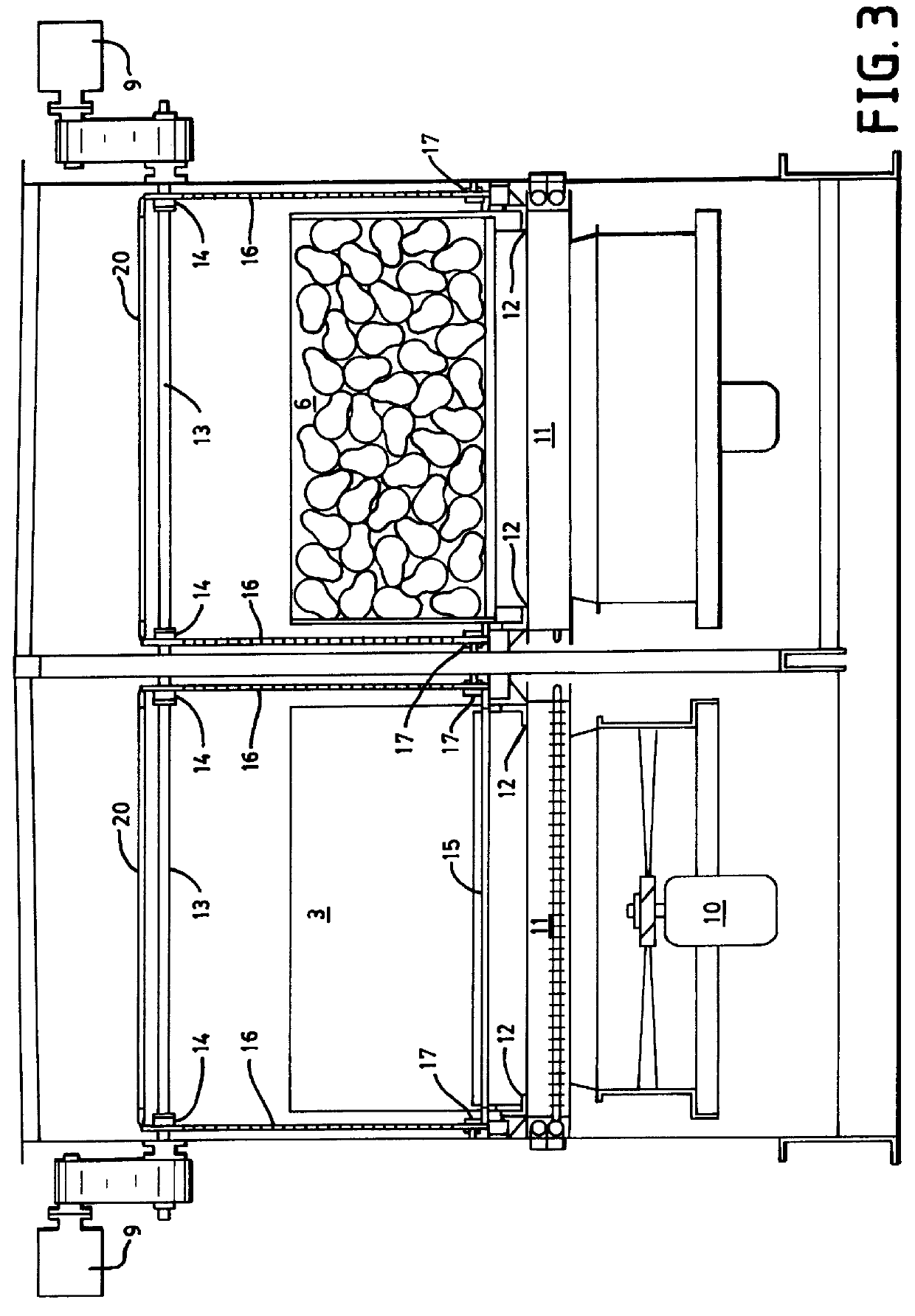

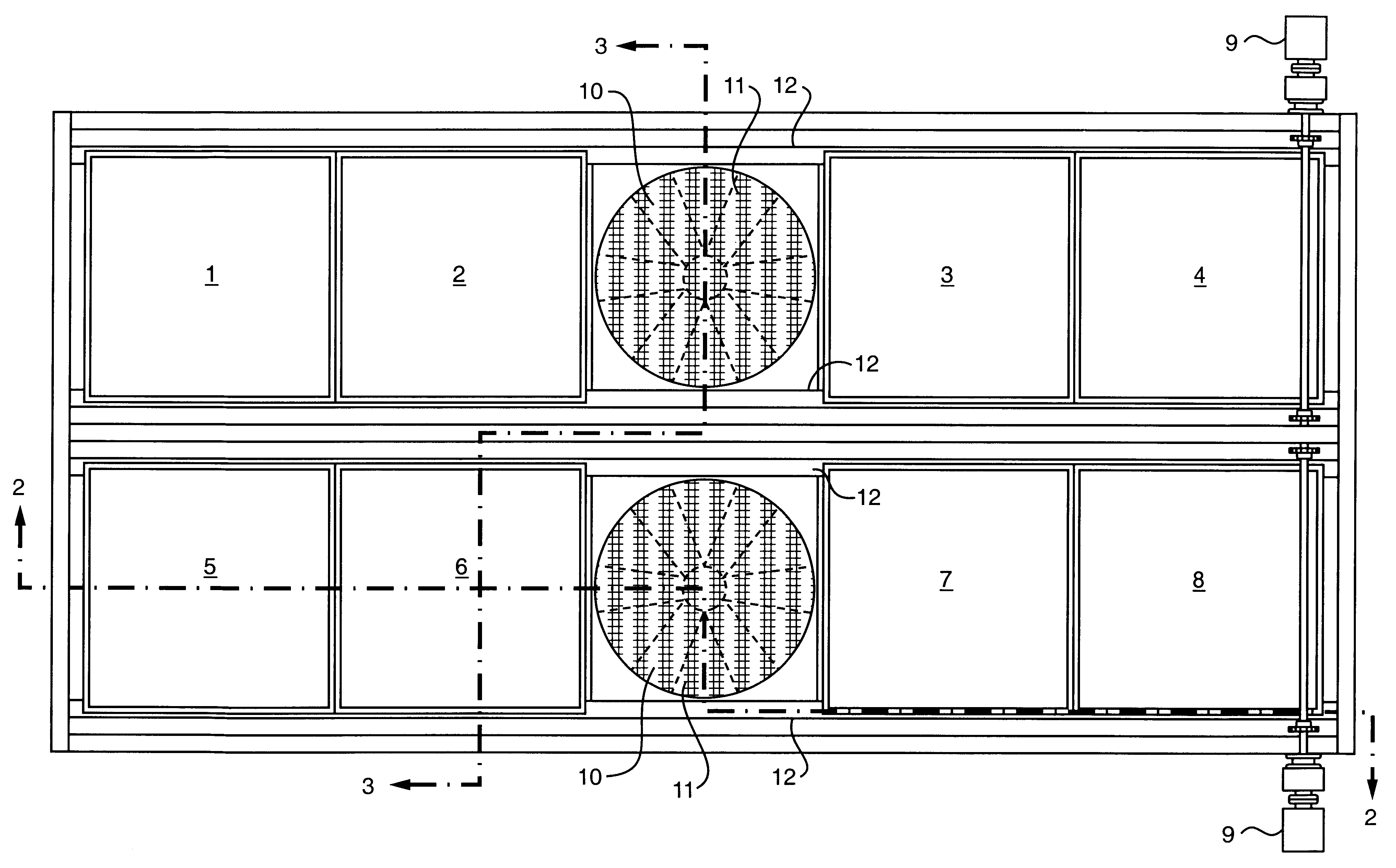

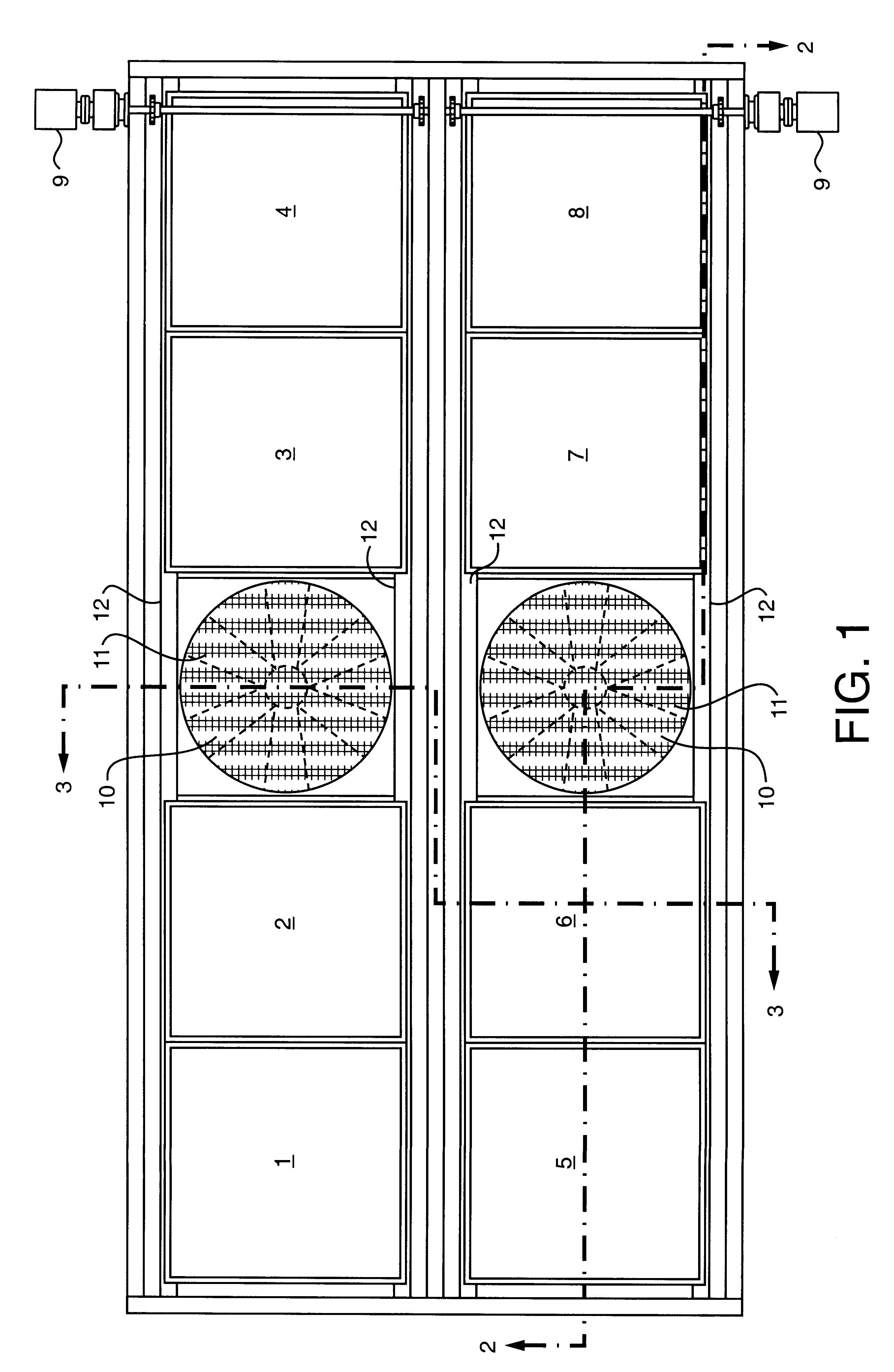

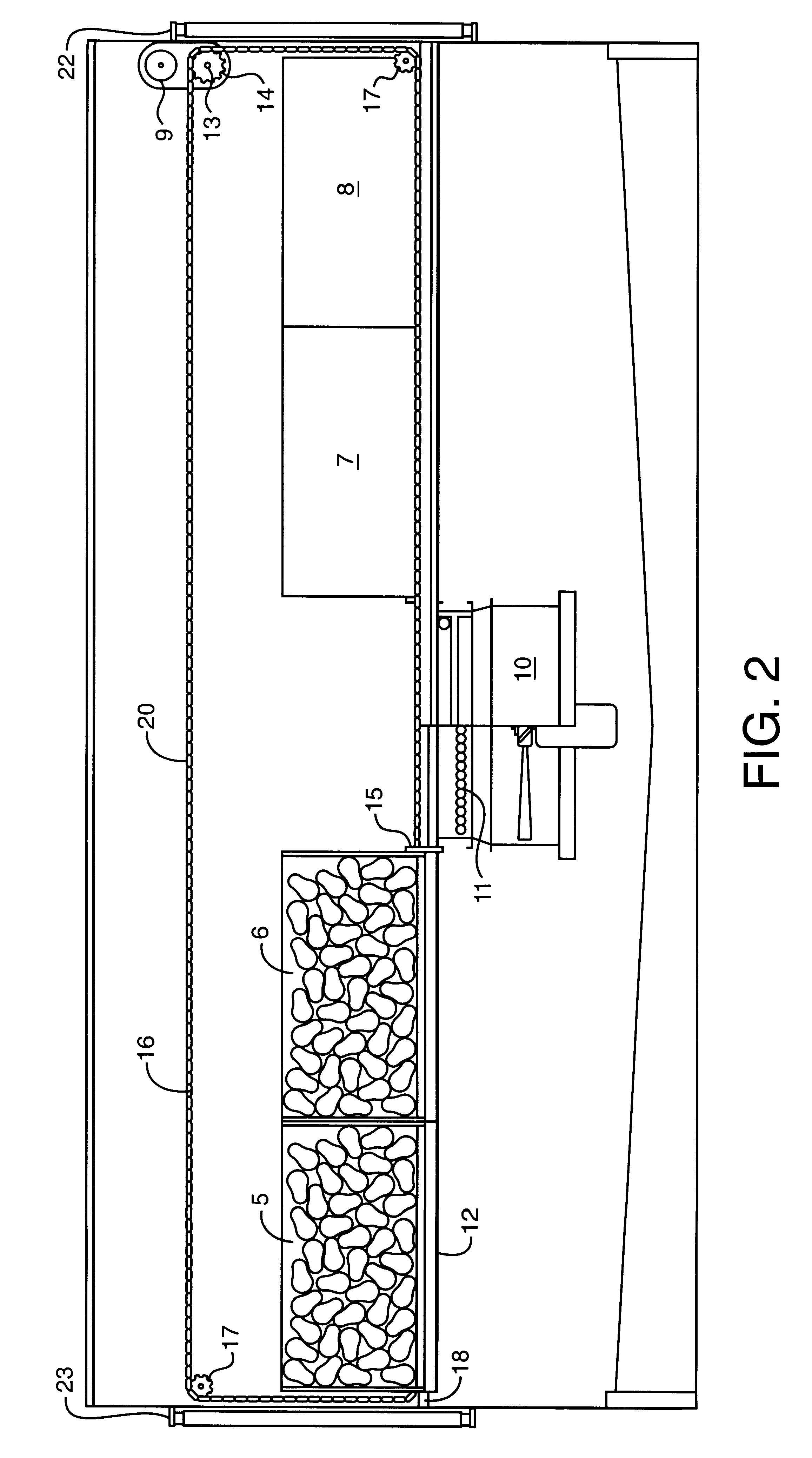

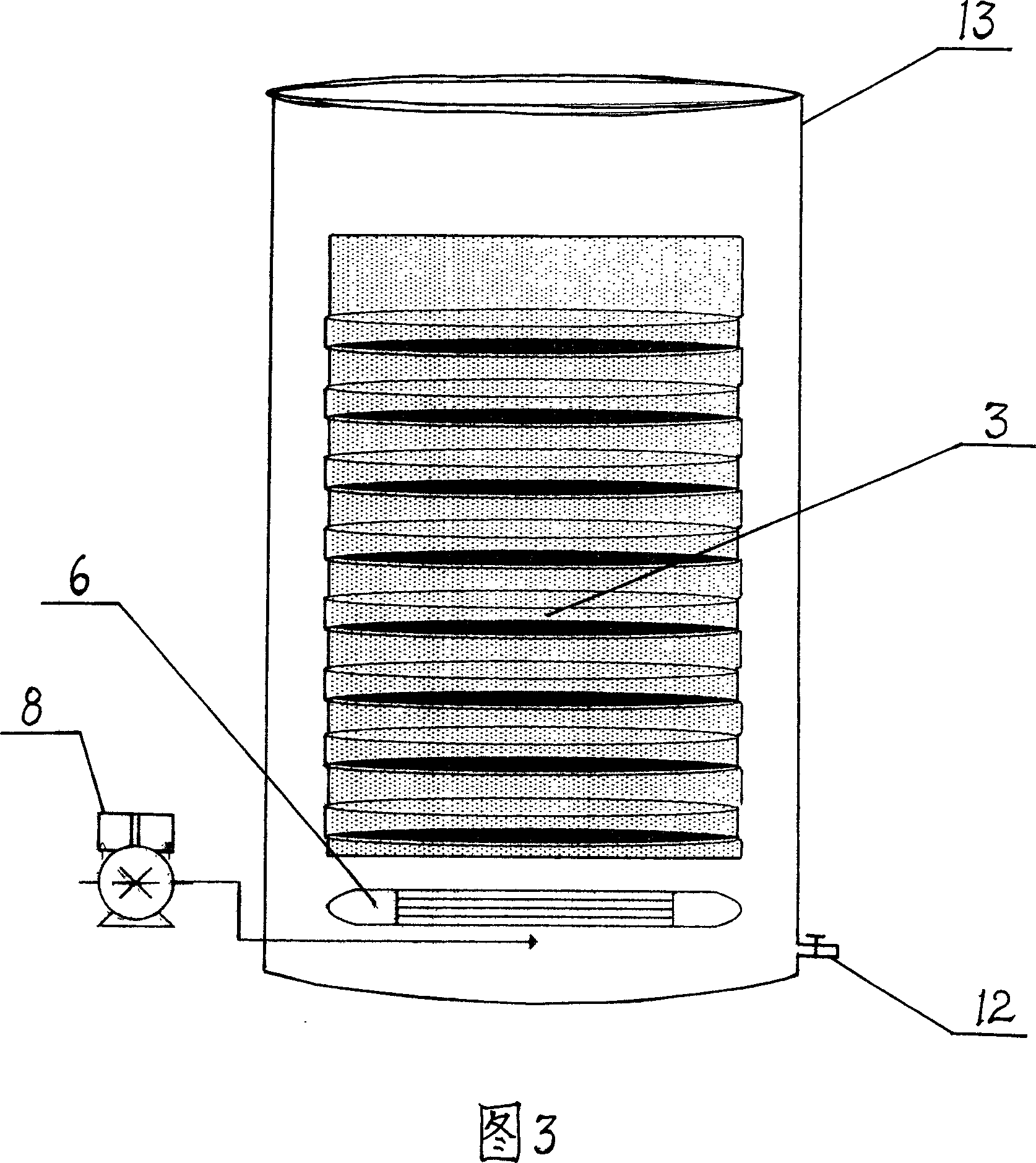

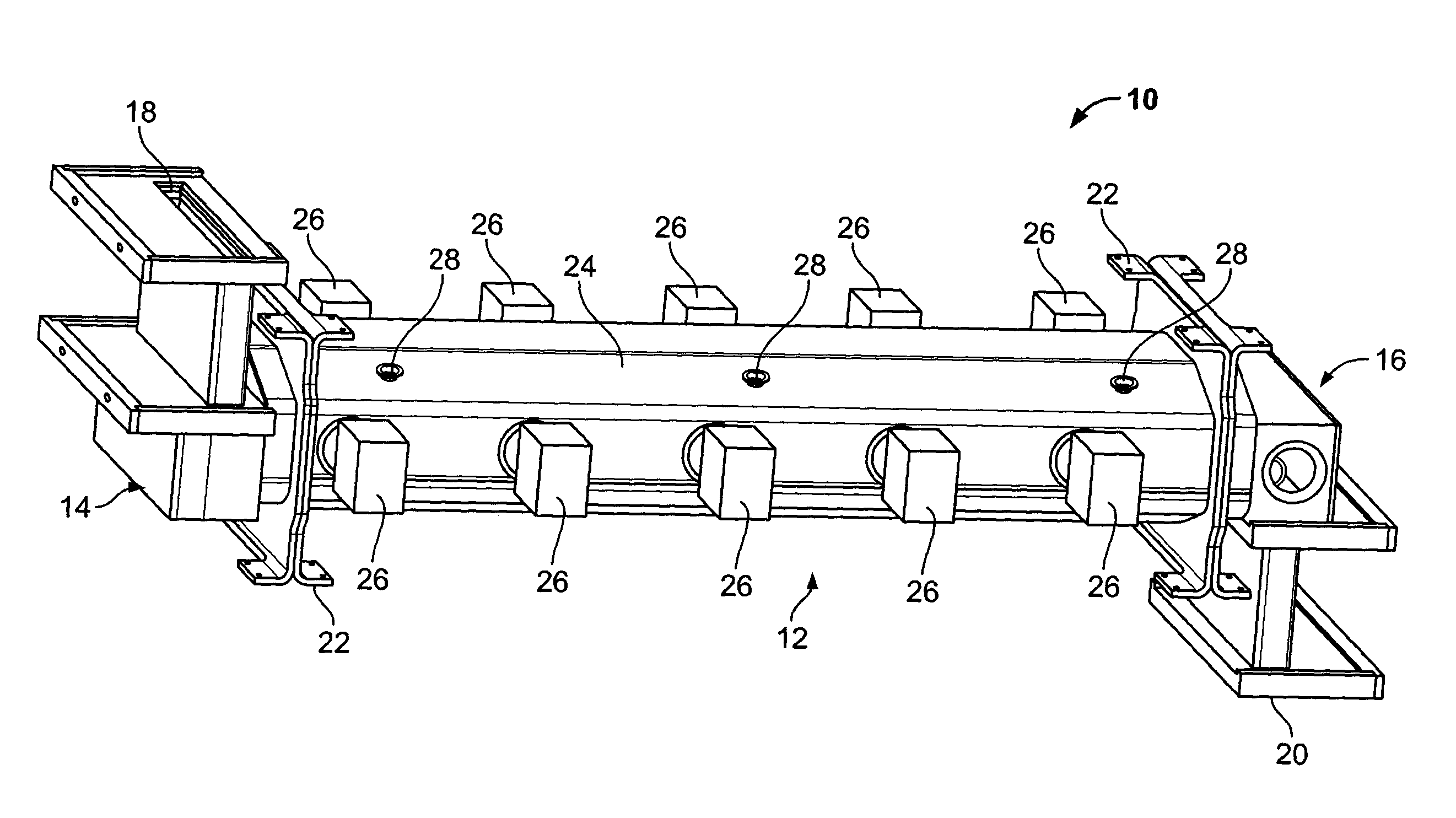

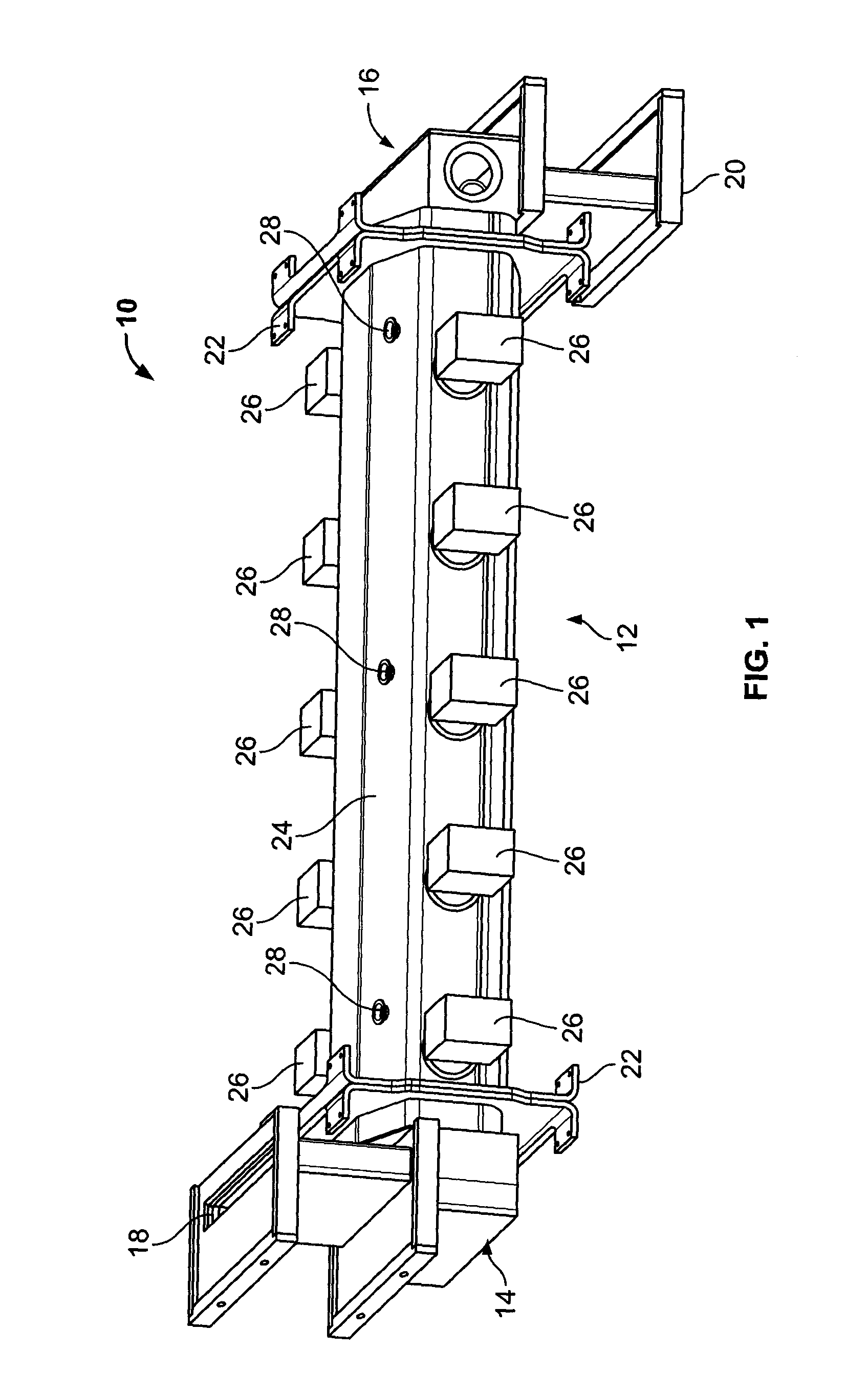

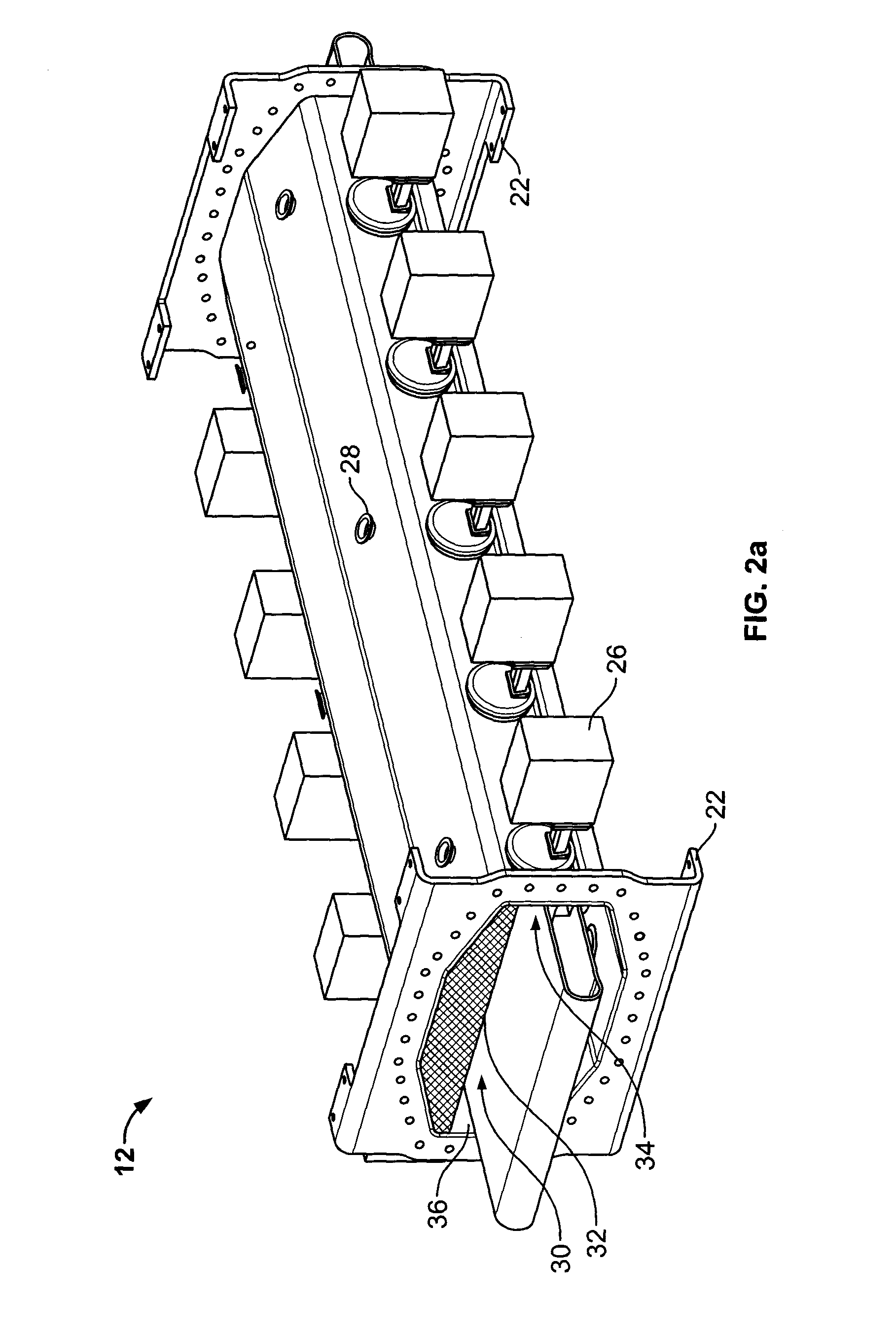

Mechanically loaded direct air circulation commodity disinfestation chamber

InactiveUS6171561B1Eliminate heat lossEliminates airflow inefficiencyFruits/vegetable preservation by heatingSeed preservation by heatingAir cycleAfter treatment

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is heated inside of the chamber in hot air having a relative humidity of 30-85% until the temperature of the commodity exceeds the thermal death point temperature of the target pest but is not so high as to adversely affect the quality of the commodity. The temperature of the commodity is held at this temperature until the pest is killed. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber. After treatment of the commodities, the bins are unloaded using the low friction conveyor track system out of the opposite end of the treatment chamber. The chamber includes a fan / heat exchanger located inside the treatment chamber and positioned under the commodity bins. The space directly above the fan / heat exchanger is left unobstructed during treatment to enhance the airflow through the commodity bins.

Owner:WILLIAMSON MICHAEL R PH D

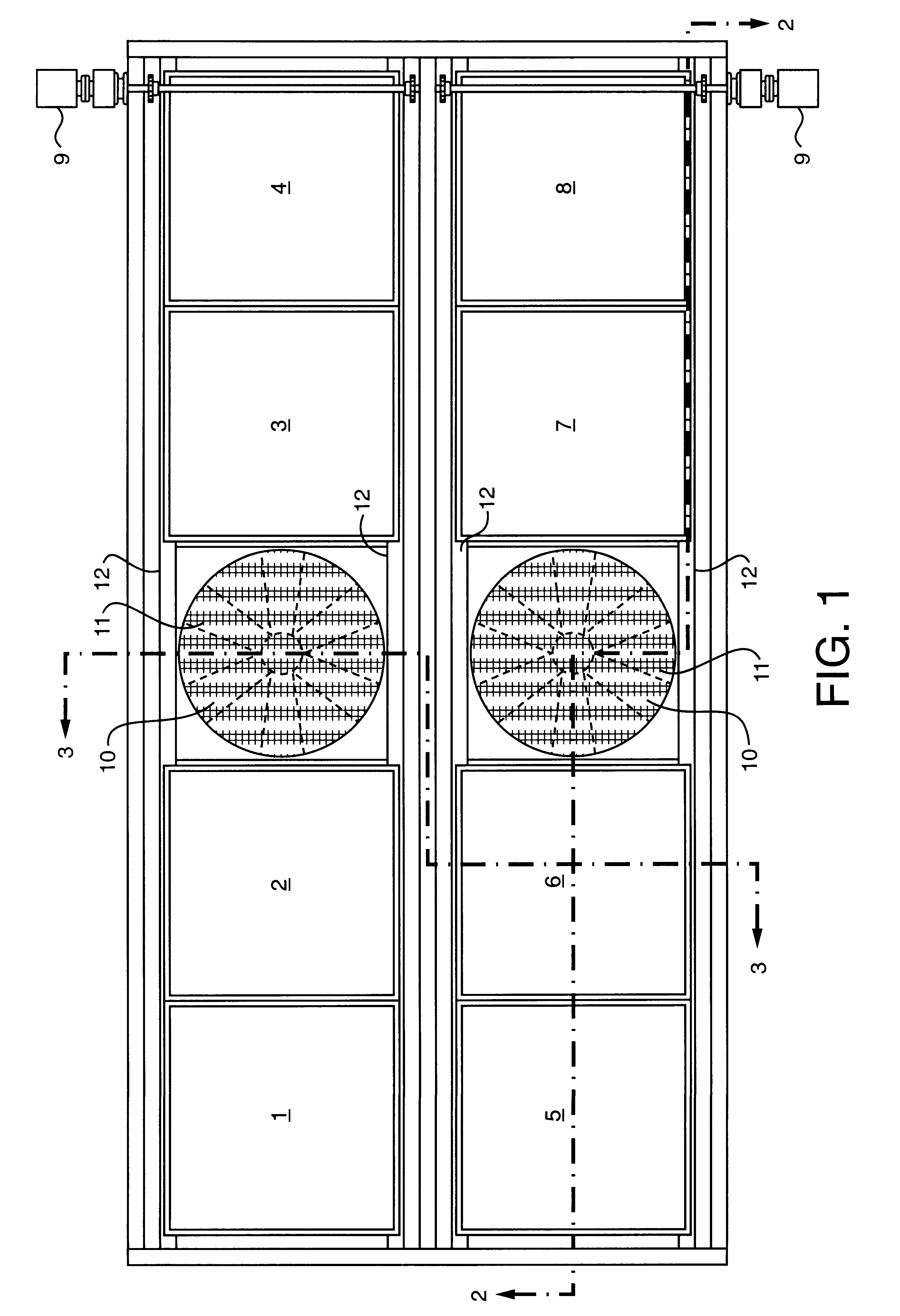

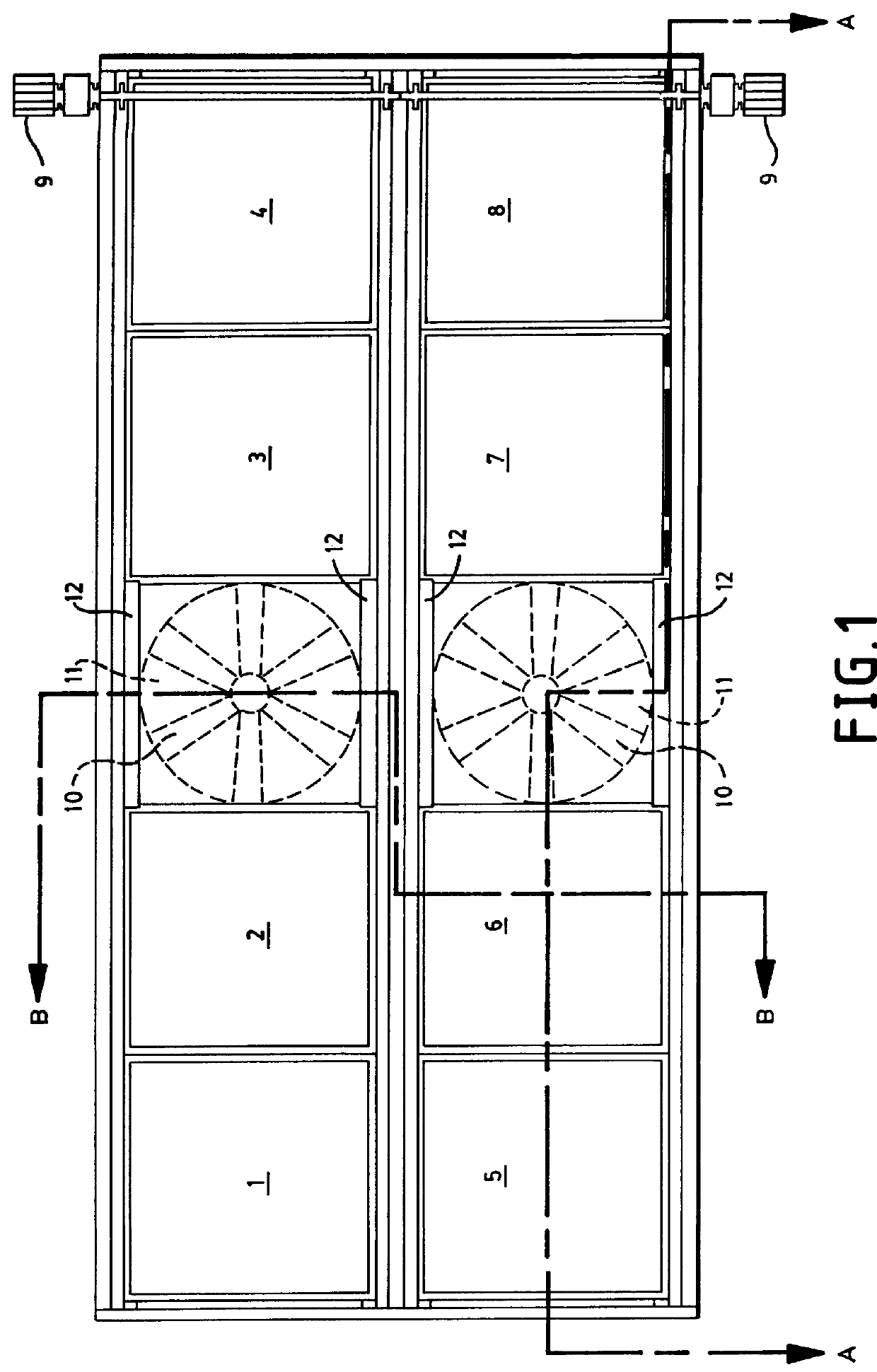

Wide body disinfestation chamber

InactiveUS6146600APrevent air leakageImprove distributionFruits/vegetable preservation by heatingSeed preservation by heatingEngineeringInfestation

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber.

Owner:WILLIAMSON MICHAEL R PH D

High pressure process and system for the production of fresh whole corn masa, nixtamalized whole corn flour, and derived products

InactiveUS6387437B1Increase pressureShort processing timeDough treatmentSeed preservation by heatingChemistryForeign matter

A high pressure process and system for the production of fresh whole corn masa, nixtamalized whole corn flour, and derivates wherein dry corn grains are transported by means of an elevator to a series of cleaning screens to separate impurities and foreign material before they are subjected to a cooking step. The corn grains as well as lime and water are fed continuously to a cooking device, which is subjected under a combination of pressure and temperature, to reduce the time of cooking of the whole corn grains. So, nixtamalized corn grains are obtained for the preparation of fresh whole corn masa and nixtamalized whole corn flour for tortillas, tortilla chips or the like.

Owner:INST POLITECNICO NACIONAL MEXICAN INSTION OF HIGHER EDUCATION

Mechanically loaded direct air circulation commodity disinfestation chamber

InactiveUS6447737B1Improve distributionAvoid lots of heatFruits/vegetable preservation by heatingSeed preservation by heatingAir cycleAgricultural science

A disinfestation treatment chamber for treating fruit, flower and vegetable commodities subject to infestation by quarantine pests. The commodities are disinfested so as to meet quarantine restrictions without adversely affecting the quality of the commodity. The commodity is heated inside of the chamber in hot air having a relative humidity of 30-85% until the temperature of the commodity exceeds the thermal death point temperature of the target pest but is not so high as to adversely affect the quality of the commodity. The temperature of the commodity is held at this temperature until the pest is killed. The commodity is loaded into the treatment chamber in bins onto a low friction conveyor track system which transports the bins from one end of the chamber to the other. The commodities are treated while they are inside of the treatment chamber. After treatment of the commodities, the bins are unloaded using the low friction conveyor track system out of the opposite end of the treatment chamber. The chamber includes a fan / heat exchanger located inside the treatment chamber and positioned under the commodity bins. The space directly above the fan / heat exchanger is left unobstructed during treatment to enhance the airflow through the commodity bins.

Owner:WILLIAMSON MICHAEL R PH D

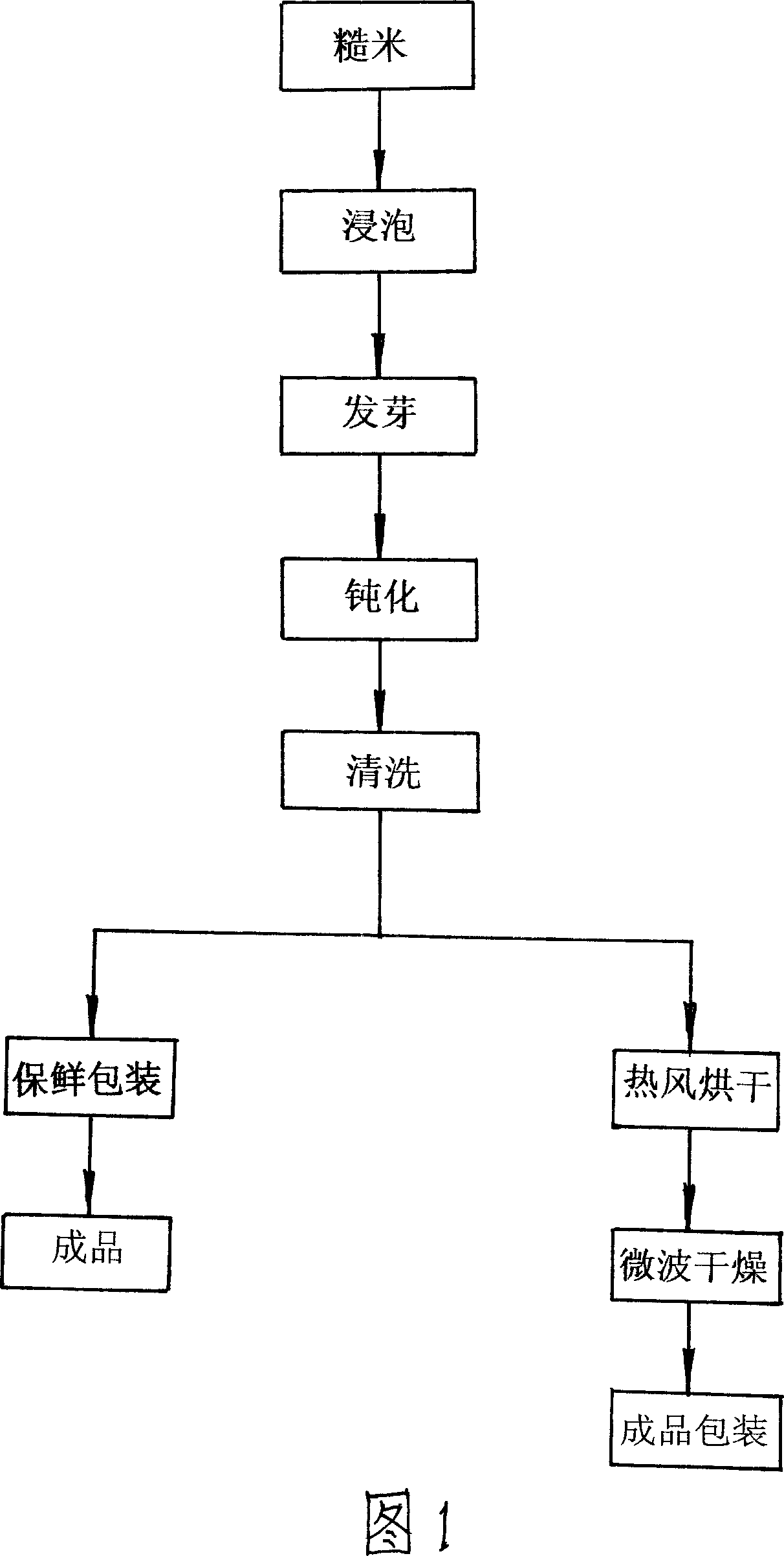

Method and equipment for producing sprouting half-polished rice

ActiveCN100998389AImprove whole bud rateHigh whole germination rateSeed preservation by heatingSeed preservation by dryingMicrowaveThin layer

A method for preparing the germinated embryo rice from non-glutinous rice includes such steps as spreading said rice to become thin layer, immersing in water, germinating, passivating in the water at 70-100 deg.C, washing, and antistaling packing or drying including hot air baking and microwave drying. Its apparatus is composed of container with openable cover or door, and rice spreading unit.

Owner:杨春华

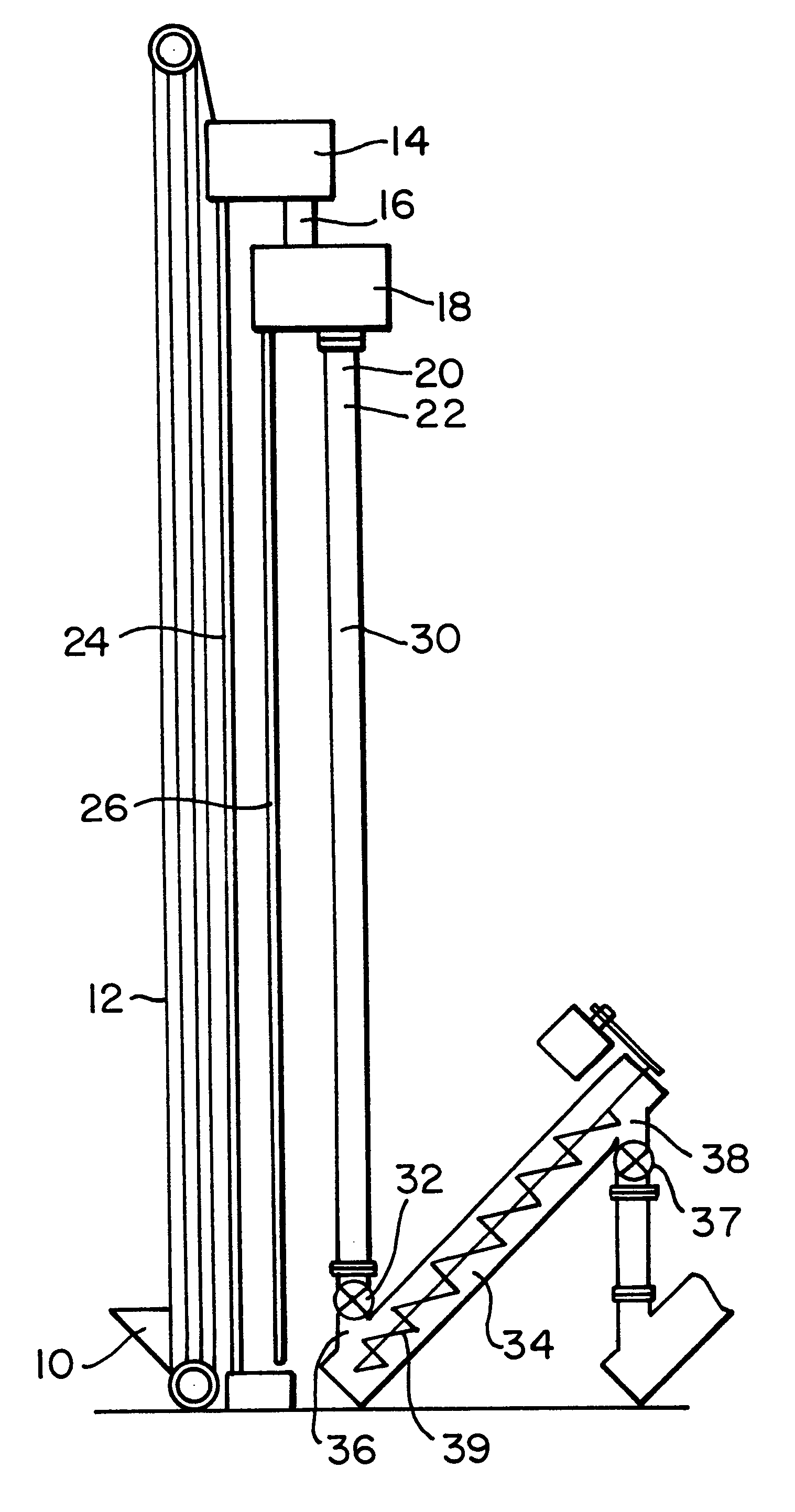

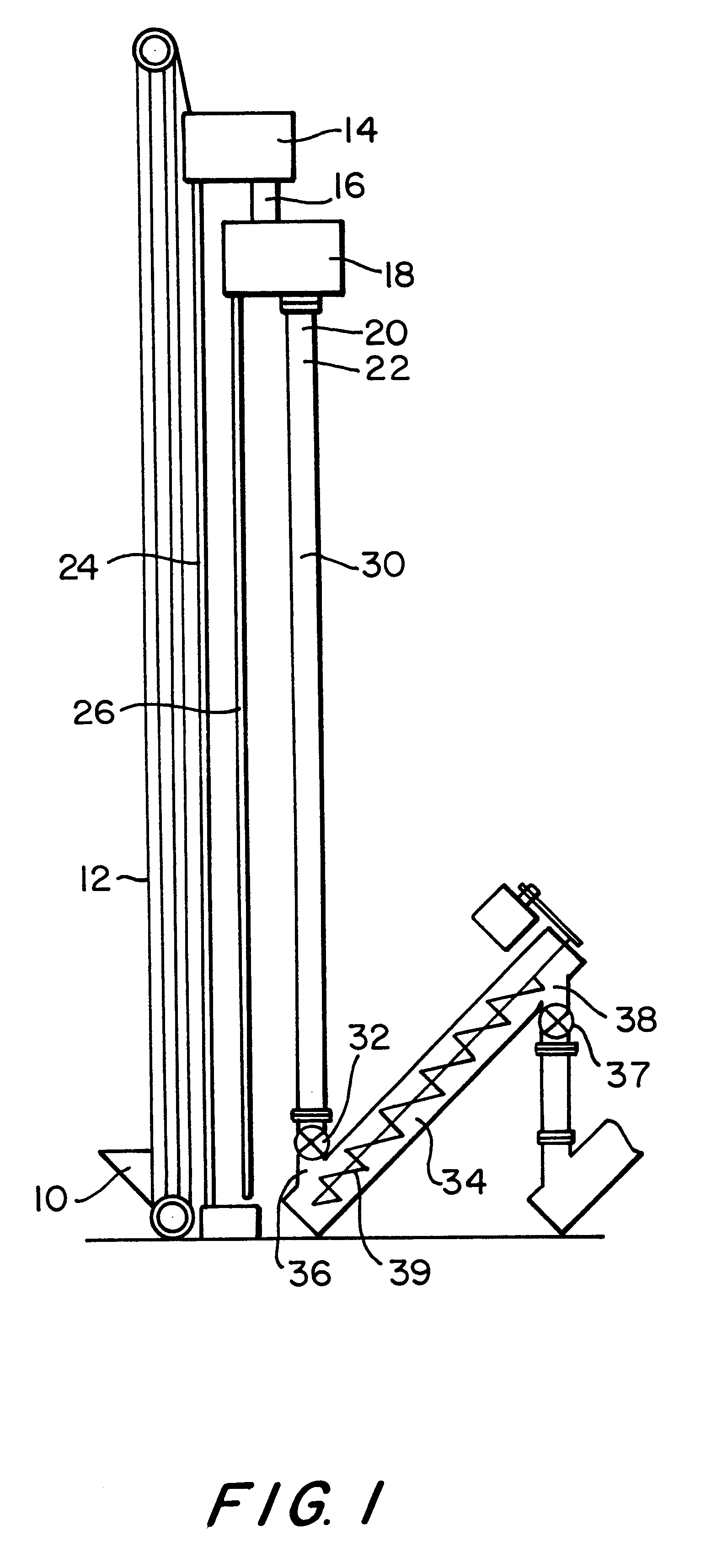

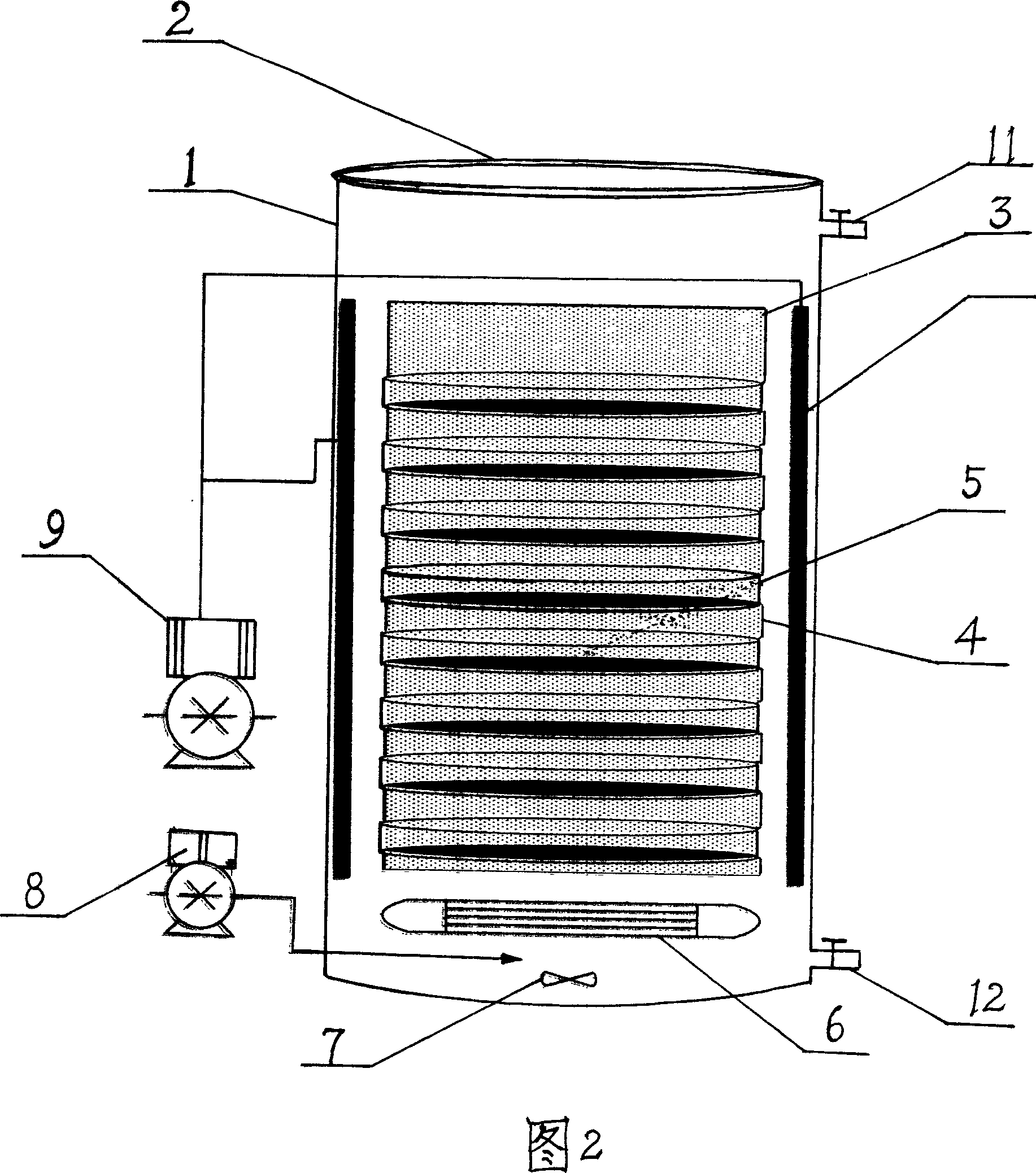

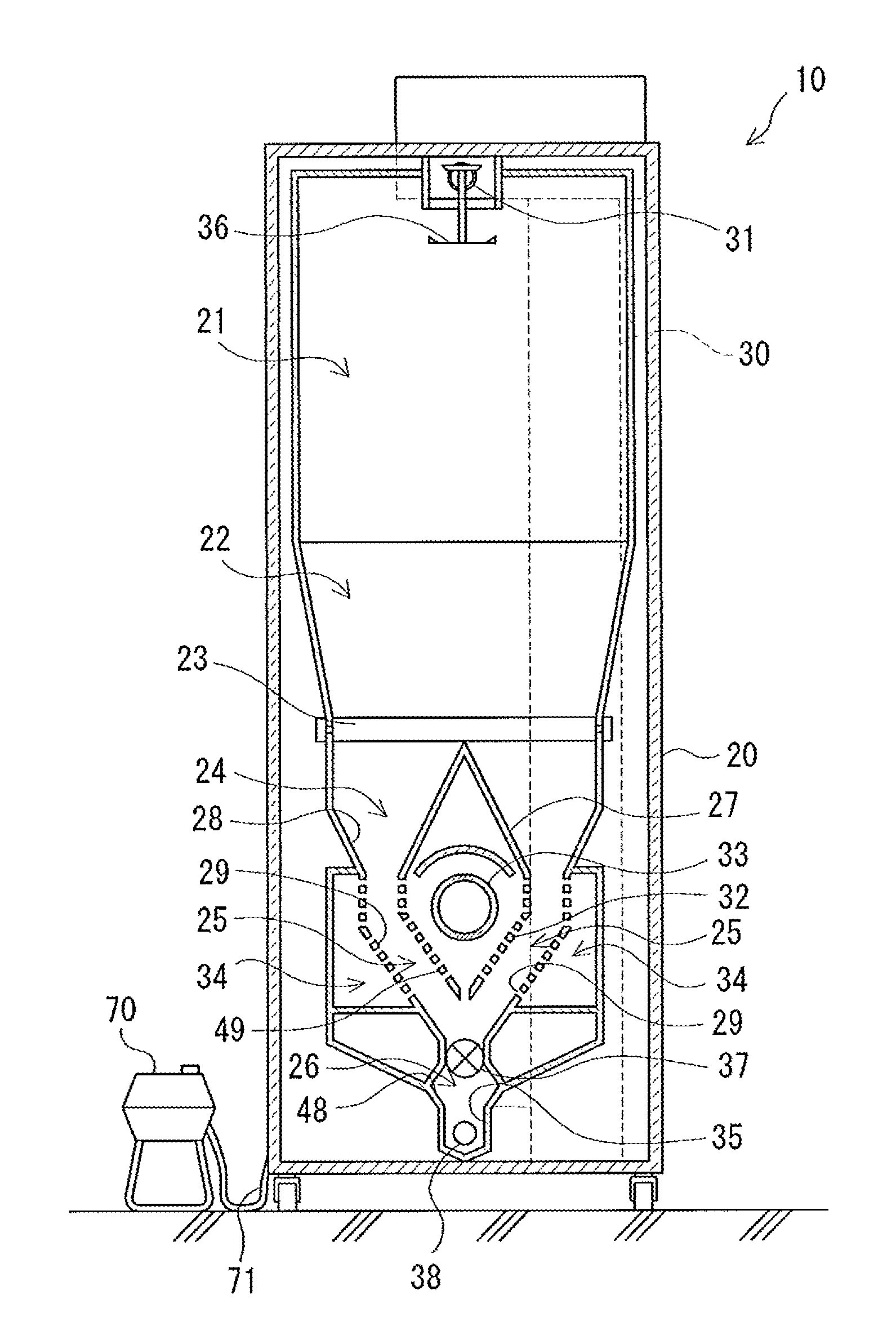

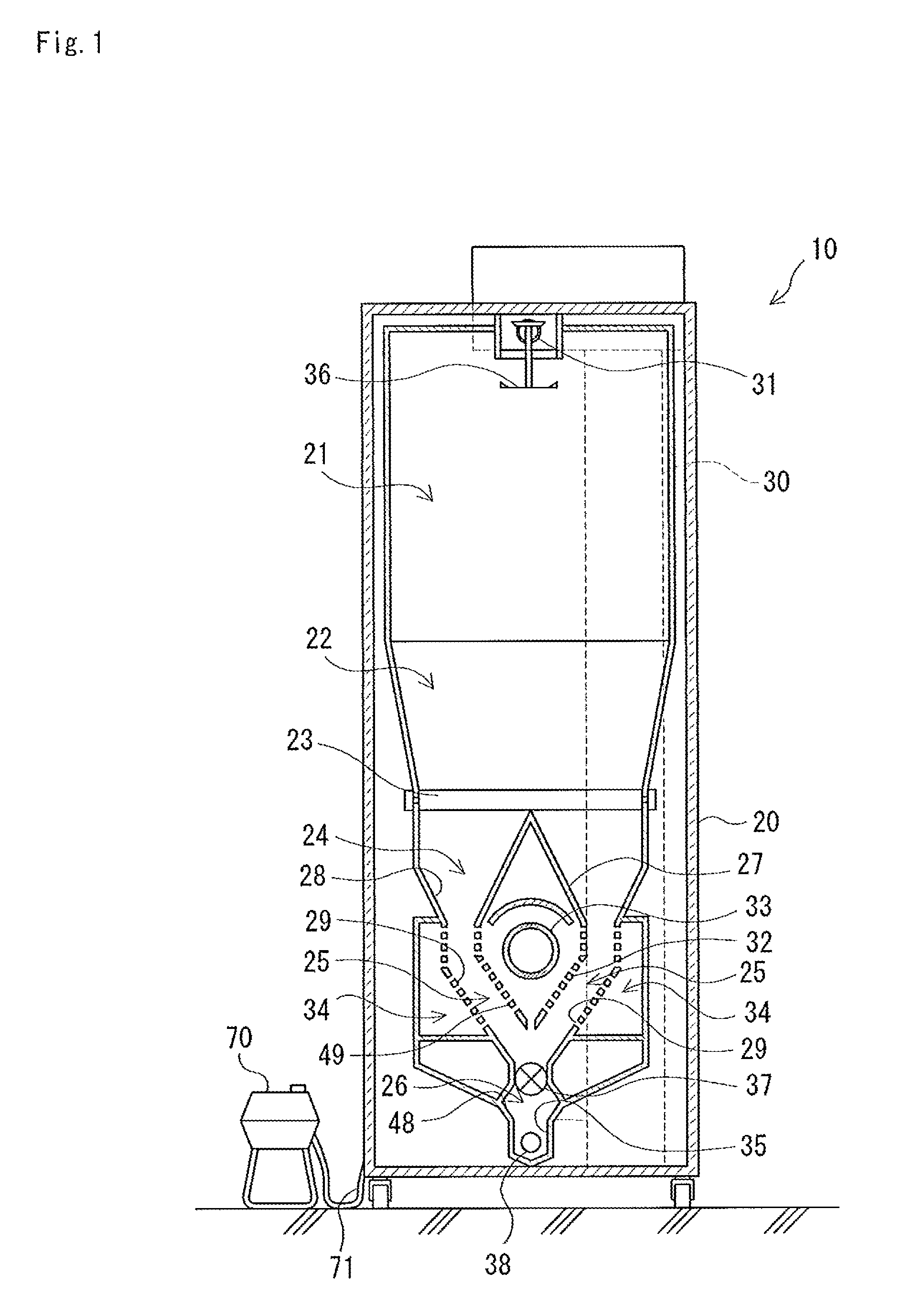

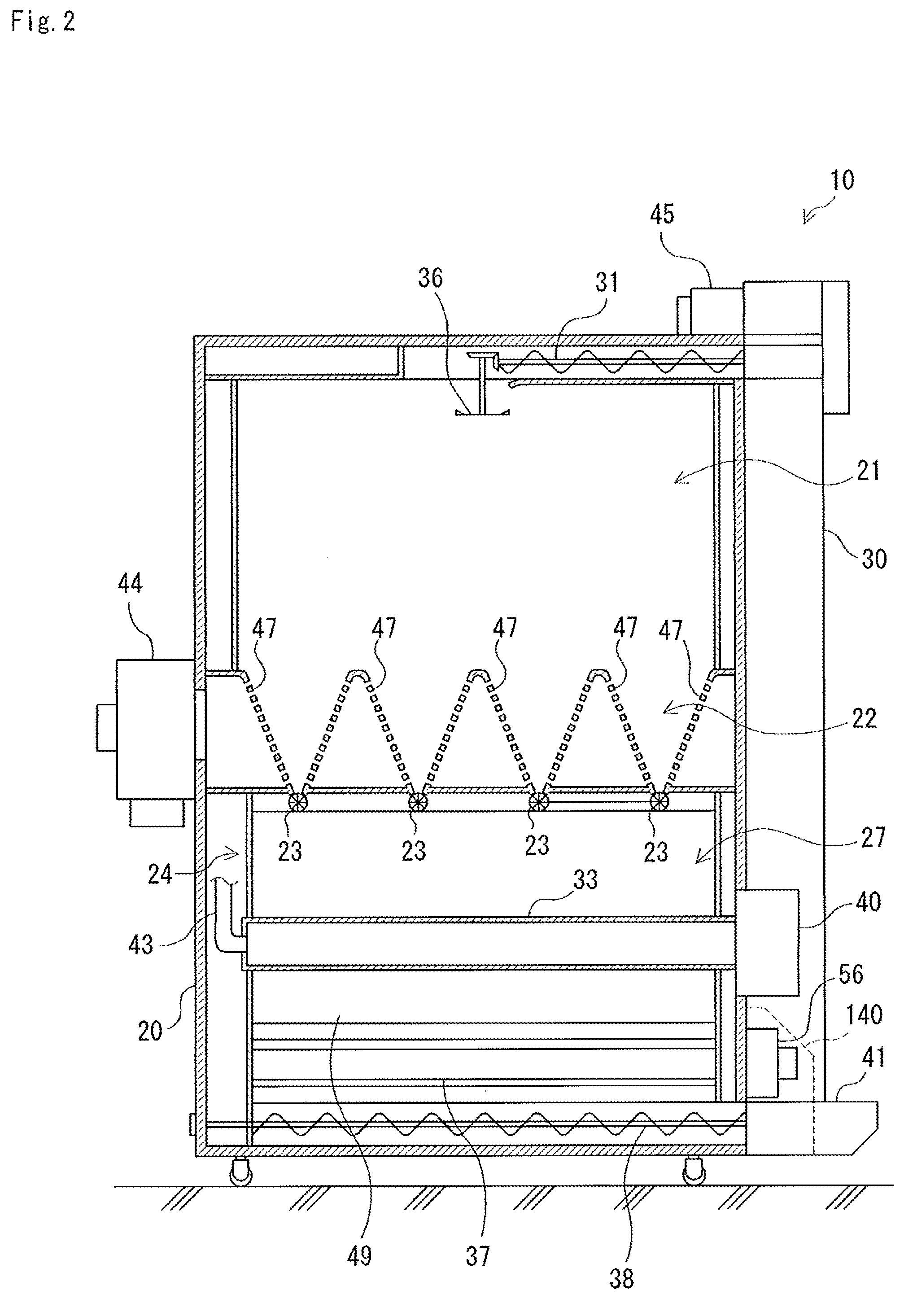

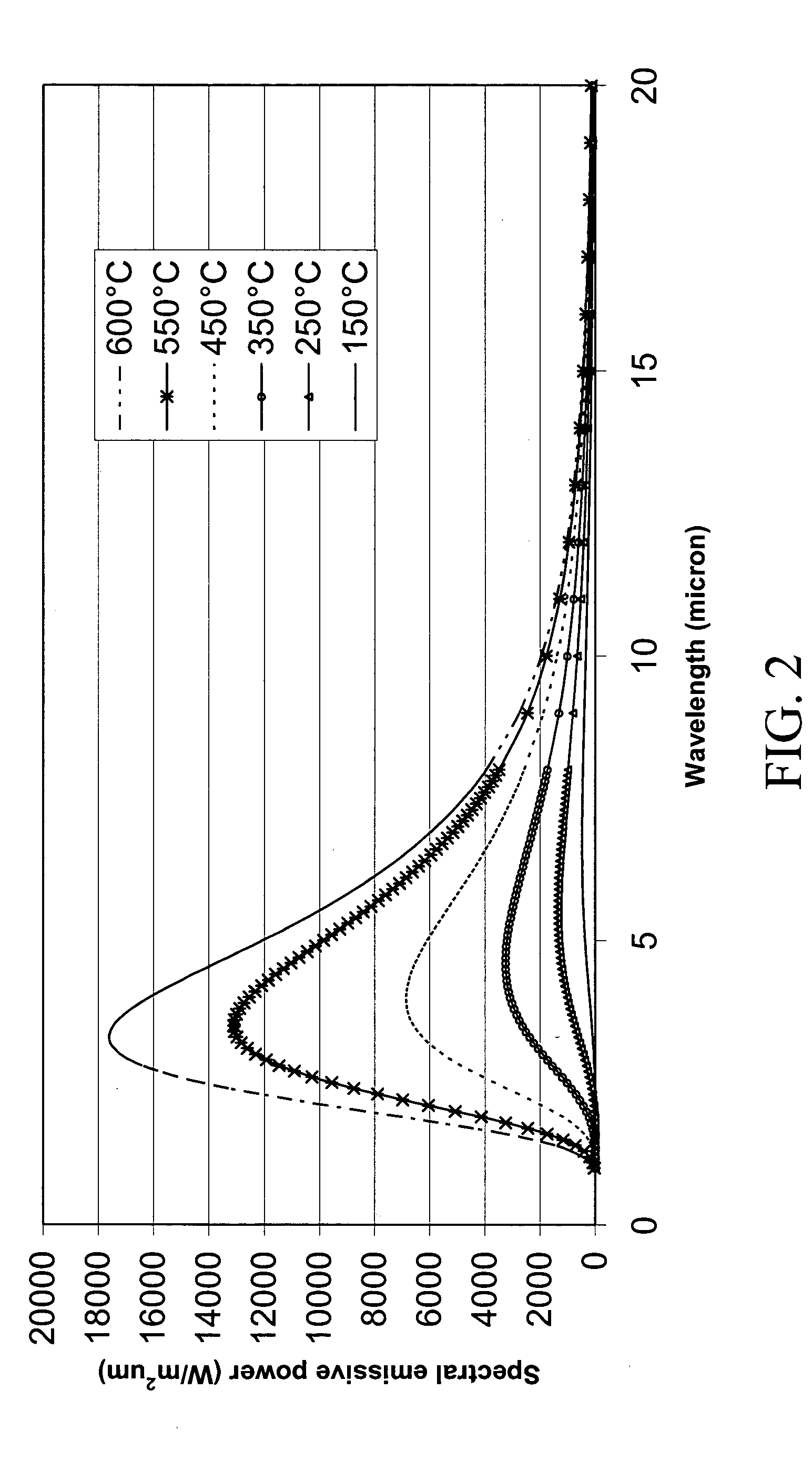

Nutrition-enriched gain manufacturing apparatus and gain drying facility including the same

InactiveUS20120066924A1Enrich a content of gamma aminobutyric acid in grain easily and efficientlyMilk preservationDrying solid materials with heatCombustorRotary valve

A nutrition-enriched grain manufacturing apparatus includes a heating processing portion including a far infrared ray radiator which emits far infrared rays to a flow-down path along which grain flows down, an upper rotary valve device and a lower rotary valve device which adjust a flow rate of the grain, an accumulation portion which accumulates the grain, a lower screw conveyer and a bucket conveyer which transport the grain which has flown down from the heating processing portion to the discharge portion to the accumulation portion, a moisture meter which measures a moisture content of the grain, a grain temperature sensor which measures a grain temperature, a main controller which controls output from a burner and operations of the upper rotary valve device and the lower rotary valve device such that the grain temperature is a predetermined grain temperature.

Owner:ANDO TOSHIHARU +1

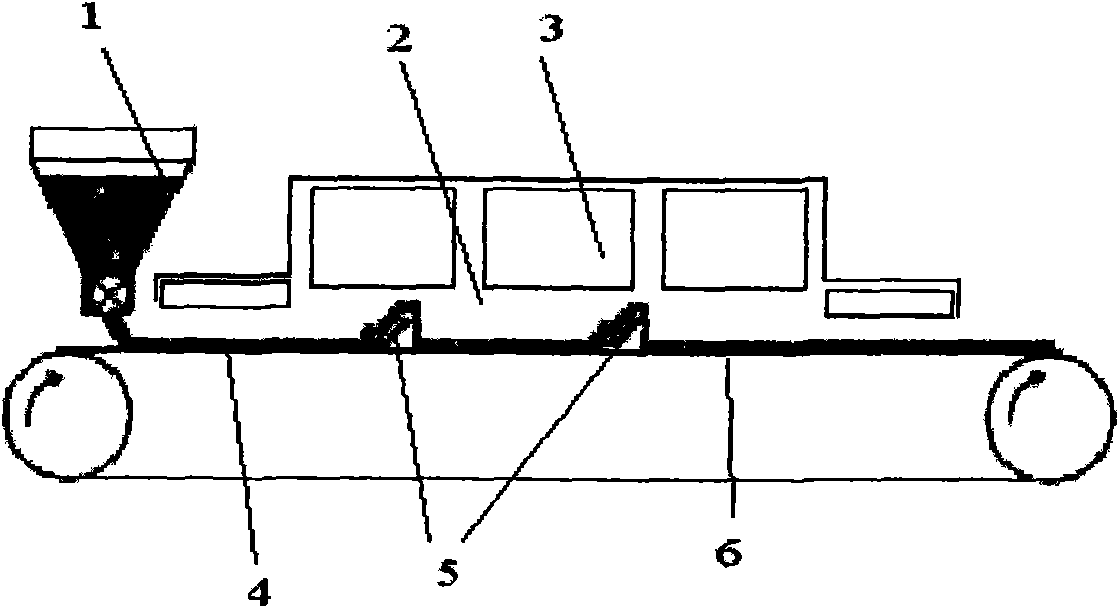

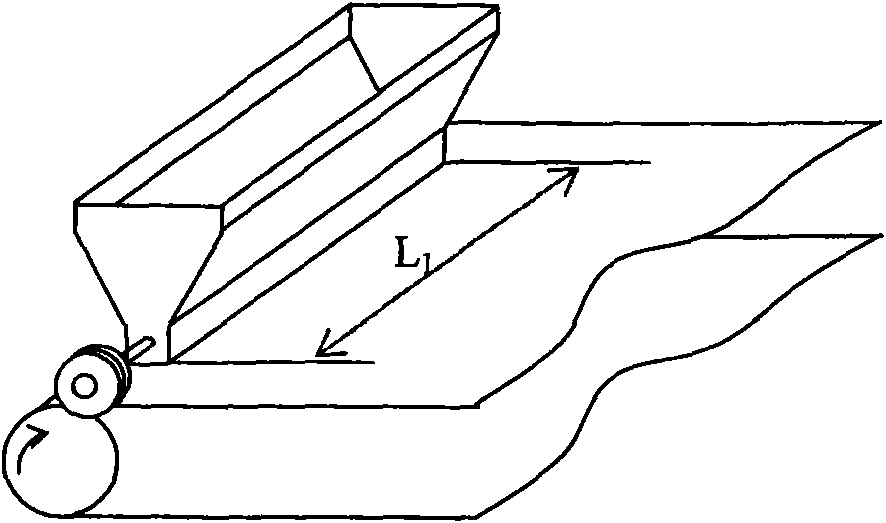

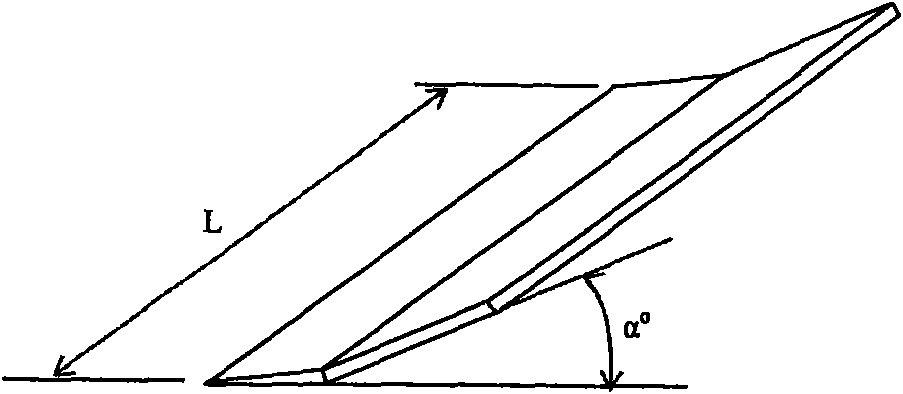

Continuous synchronous microwave enzyme inactivation and drying device and method for grain germ

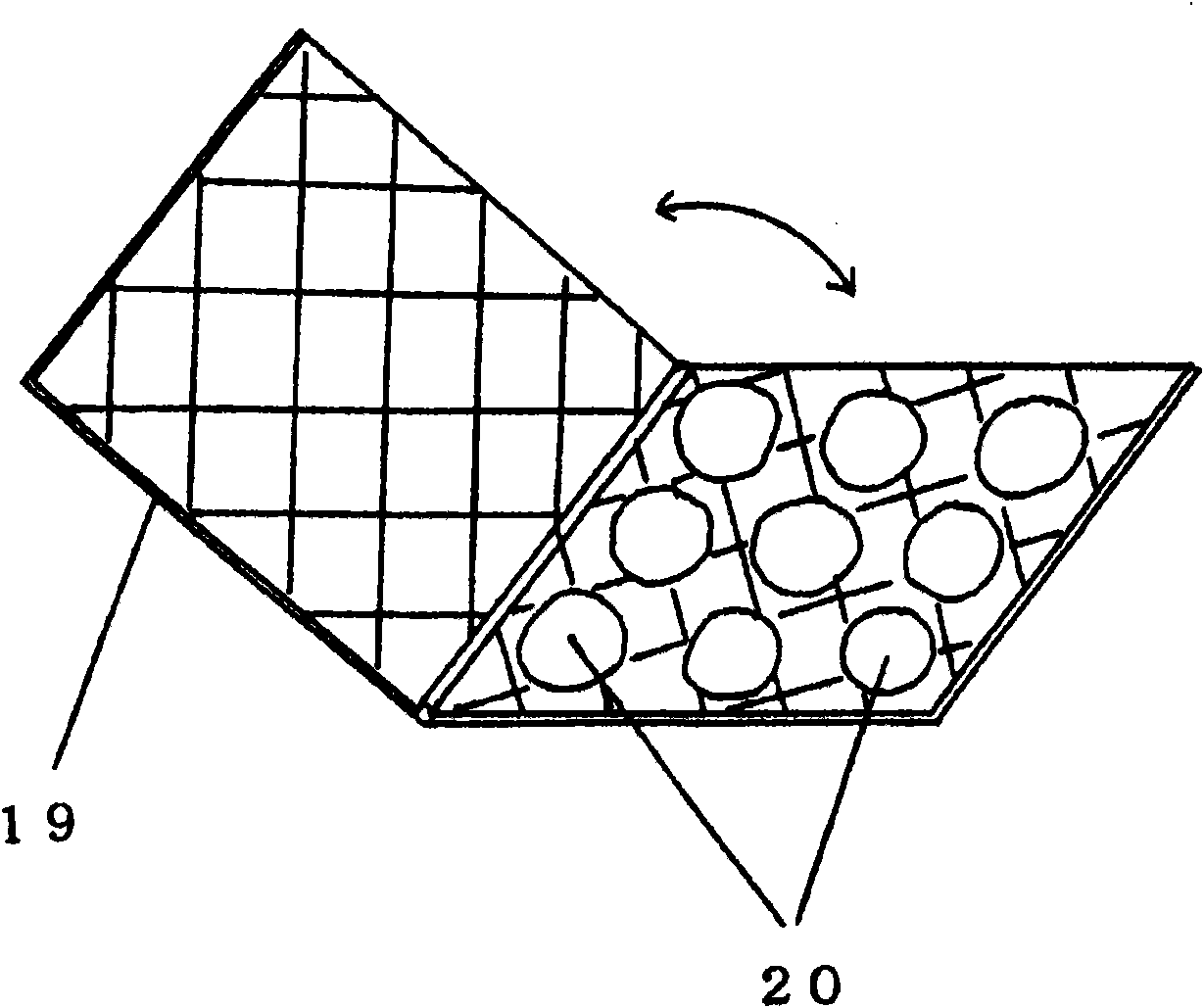

InactiveCN101658205ALarge amount of processingReduce energy consumptionSeed preservation by heatingSeed preservation by dryingWheat germMicrowave

The invention provides a continuous synchronous microwave enzyme inactivation and drying device and method for grain germ, relating to the agricultural product drying field. The device comprises a microwave tunnel (2), a microwave generator (3) and a conveyer belt (6) and also comprises a feeder (1) and a germ overturning device (5); wherein the microwave generator (3) is arranged at the top of the microwave tunnel (2), the feeder (1) is arranged at the initial end of the conveyer belt (6), and the revolution of the feeder is adjustable; the conveyer belt (6) is connected with the feeder (1) and the microwave tunnel (2) to convey materials through the microwave tunnel (2), and conveying speed is adjustable; and the germ overturning device (5) is arranged on the conveyer belt (6). The watercontent of the grain germ through microwave enzyme inactivation and drying of the invention can be reduced to 1.9-4.4%; microwave treatment is carried out on different grain germs, the grain germs can be preserved for 6-8 months at normal temperature in winter and for 3-5 months at normal temperature in summer, quality requirement of follow-up processing can still be met, and the invention is widely applicable to enzyme inactivation and drying of grain germs such as wheat germ, corn germ, rice germ (rice bran) and the like.

Owner:JIANGSU UNIV

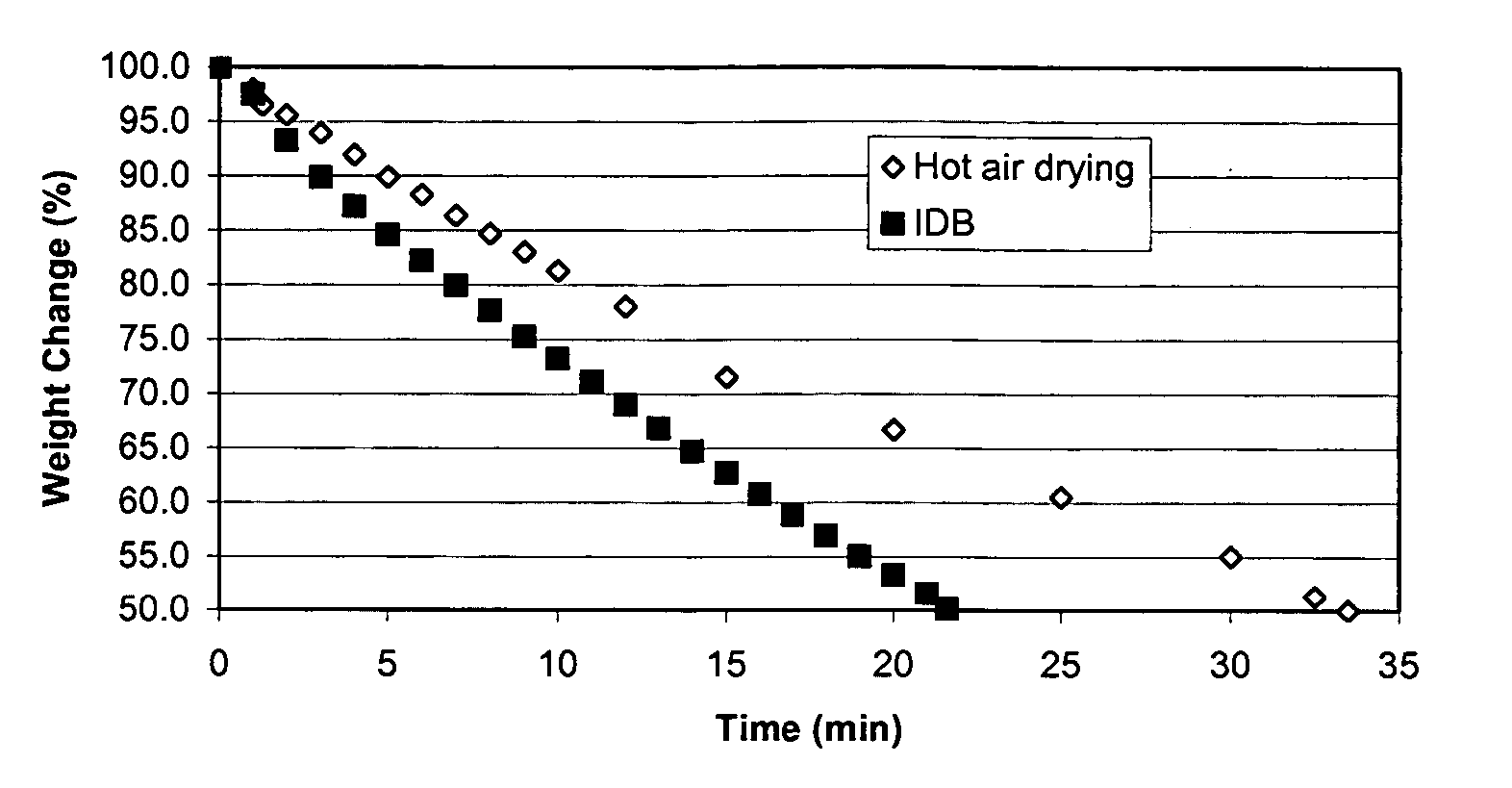

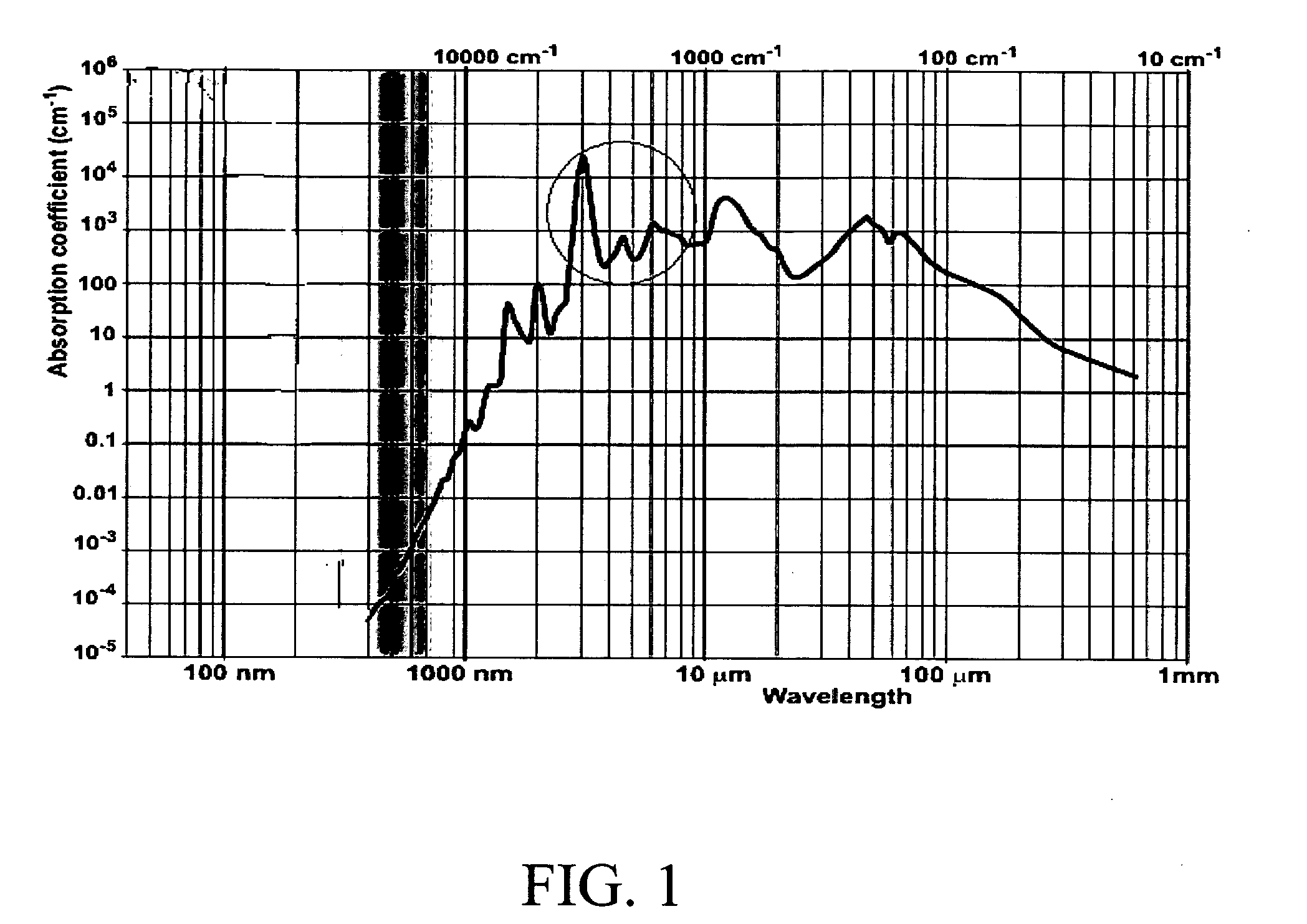

Novel infrared dry blanching (IDB), infrared blanching, and infrared drying technologies for food processing

InactiveUS20060034981A1Simple processShorten the timeMilk preservationDough treatmentSide effectVolumetric Mass Density

This invention relates to food processing and, in particular, blanching and dehydration of foods. Conventional blanching and dehydration requires use of steam and forced hot air. This invention is the first to effectively use infrared radiation energy to perform simultaneous blanching and dehydration of fruits and vegetables. Since this technology does not involve the addition of steam or water in the process of blanching, it has been named “infrared dry-blanching” (IDB) technology. IDB is intended to be a replacement for current steam, water and / or microwave blanching methods. It can be used to produce many kinds of value-added dried, refrigerated, frozen and dehydrofrozen foods such as fruit and vegetable products. In general, the advantages of IDB include (1) uniform heating which enhances energy efficiency and limits damage from over-heating, (2) capability of zone heating to address differential density, (3) ability to treat large or small lots with the same piece of equipment, (4) portability, since equipment can be built on wheels, and (5) a safe, non-toxic process with no harmful side-effects to humans or the environment.

Owner:UNITED STATES OF AMERICA +1

Method for processing germinating rice

InactiveCN101278716AShorten germination timeReduce pollutionSeed preservation by heatingSeed preservation by dryingNutrientBiology

The invention discloses a processing method for germinating rice, which comprises the steps of selecting the raw material of fresh unpolished rice, cleaning, ultrasonic pregermination, soaking, germinating, drying by combining hot air with microwave, cooling, packing, etc. Compared with the prior art, the invention increases the processing step of the ultrasonic pregermination, which shortens the germinating time of the unpolished rice by 5 to 10 hours; the drying method of combining the hot air with the microwave is adopted, which shortens the drying time by 1.5 to 3 hours; the processing method has the advantages of improving the production efficiency, reducing the loss of nutriment, utilizing the sterilization function of the microwave effectively, reducing the microorganism pollution, controlling the quality of a product well and improving the safety of the product.

Owner:SOUTH CHINA AGRI UNIV

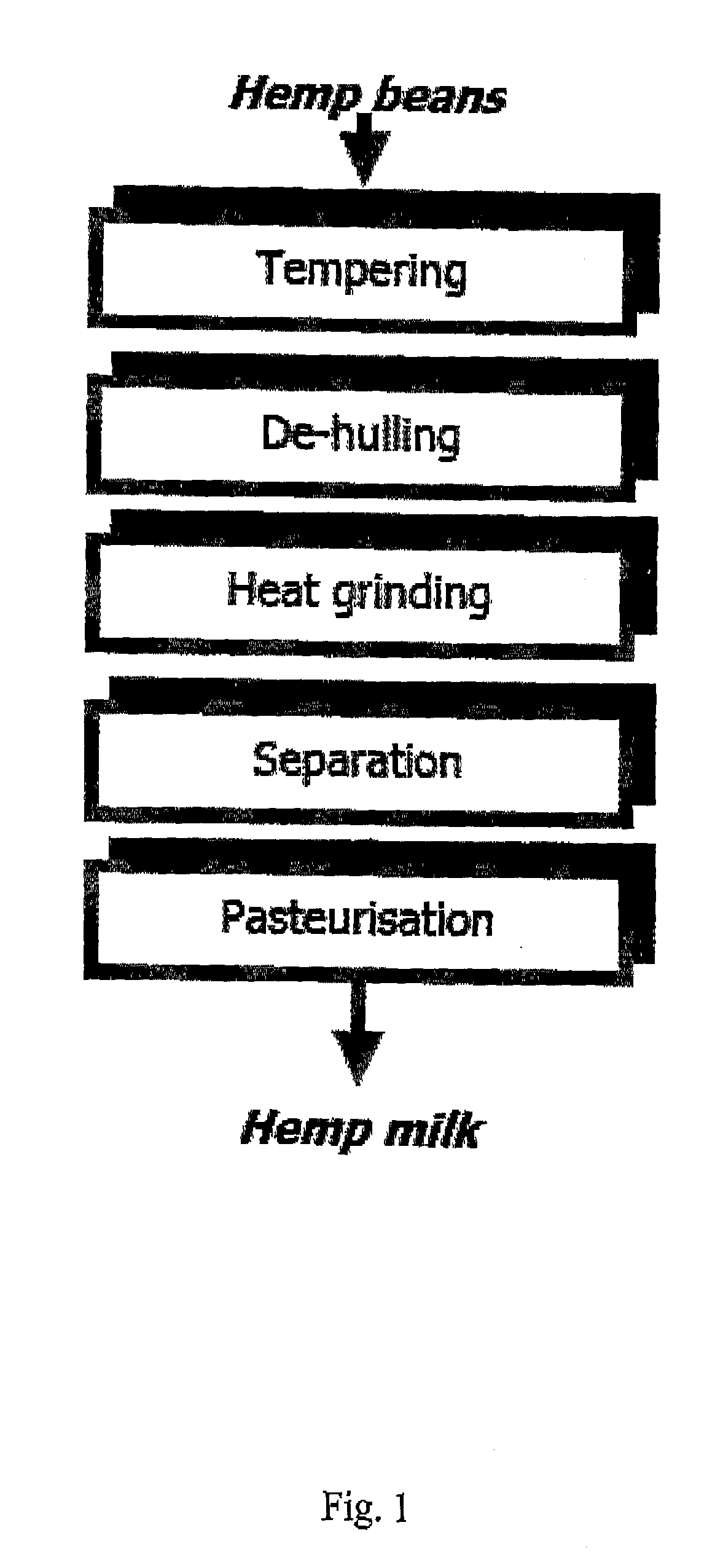

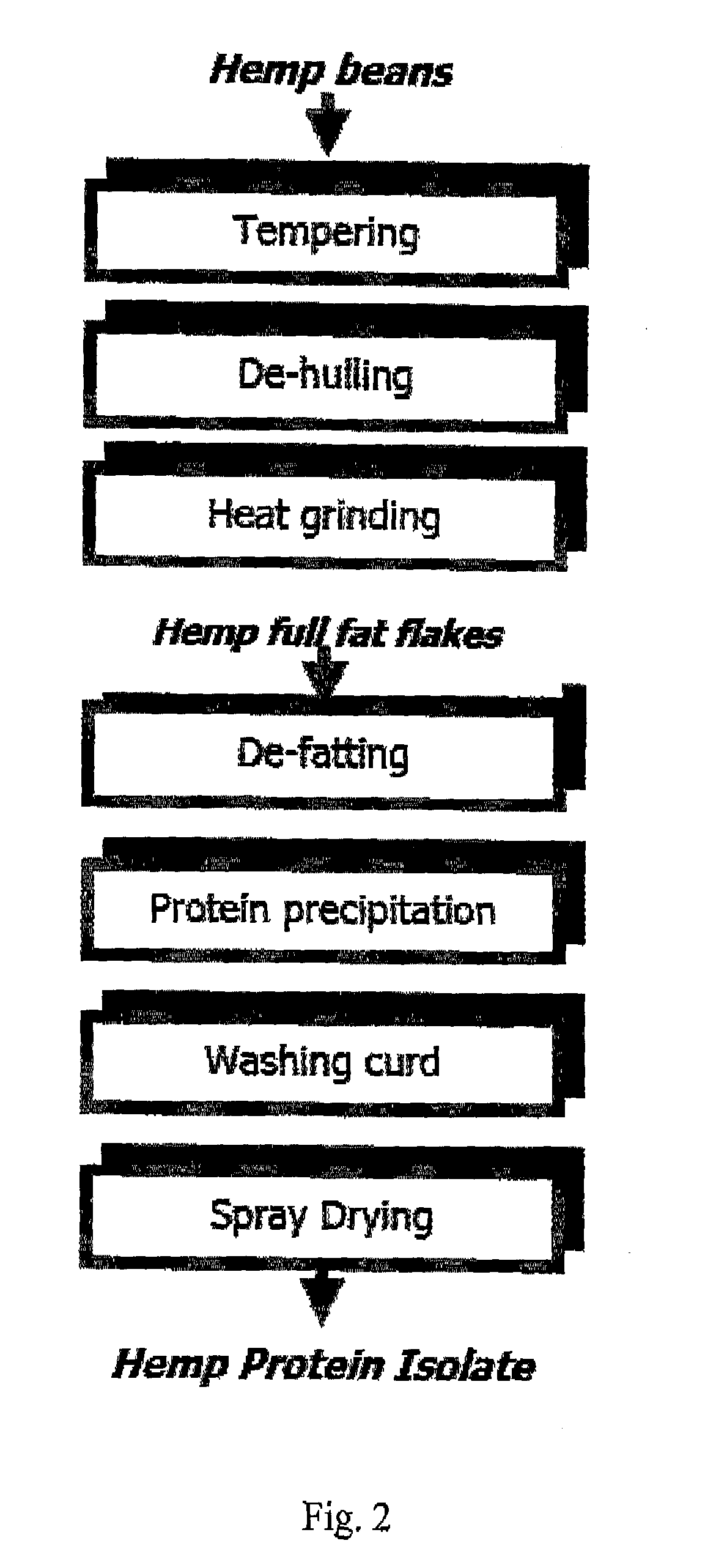

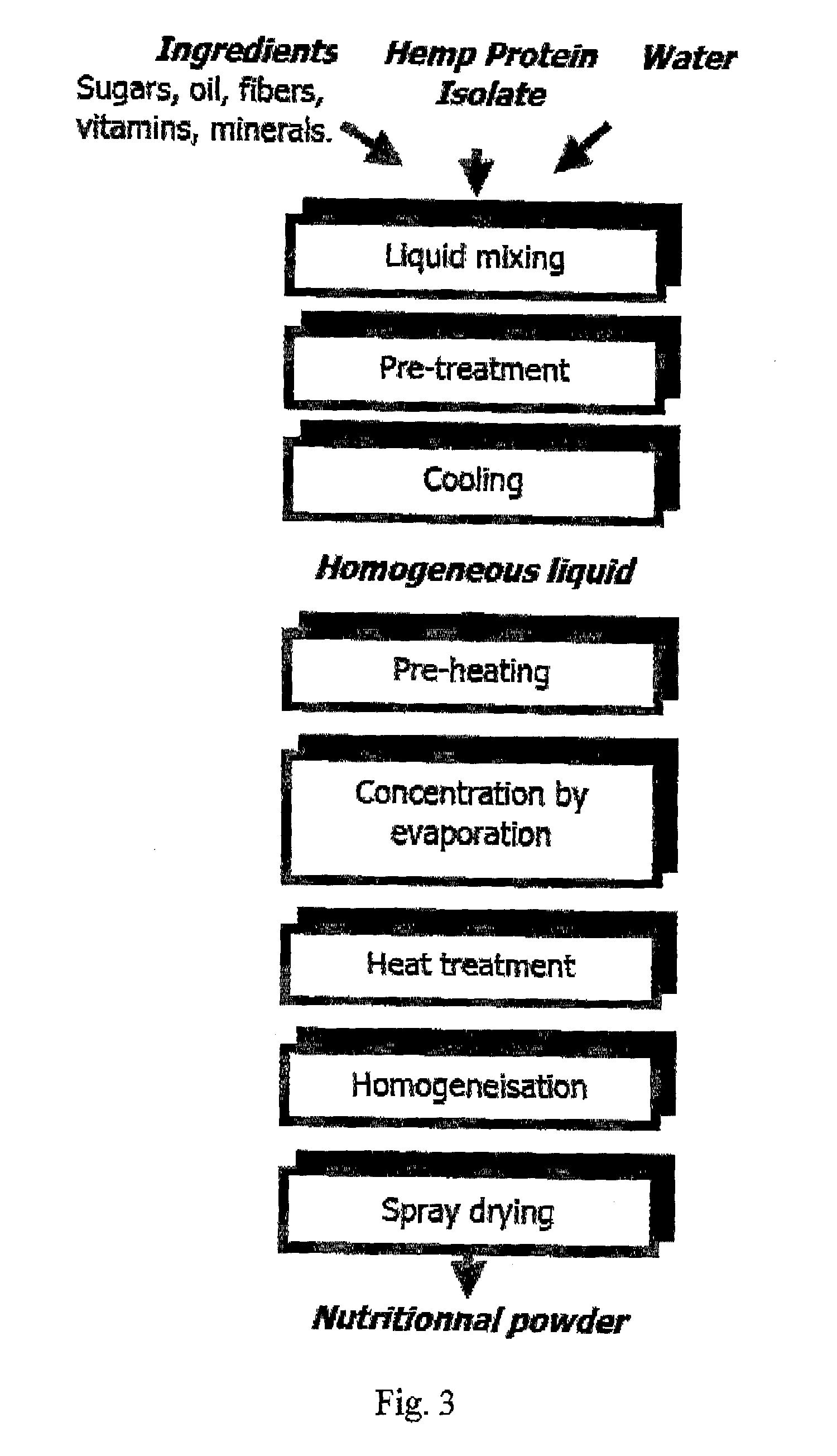

Hemp-Based Infant Formula and Methods of Making Same

InactiveUS20150079235A1Promote absorptionPromote digestionMilk preparationSolvent extractionCannabisAdditive ingredient

The present invention pertains to the field of nutrition and in particular a food product formulation based on protein and other nutrients extracted from oil seeds, such as hemp, for a plurality of uses, including, but not limited to an infant or toddler formula, a beverage, baked goods or a protein supplement. Suitable oil seeds include, but are not limited to hemp, flax, chia, pea and spirulina. Accordingly, the present invention provides a food product formulation for human consumption that can provide a complete source of dietary protein and other nutrients through oil seed protein. The formulation may be prepared in a variety of product forms, including but not limited to, a ready-to-serve liquid form, or a powder form that can be reconstituted prior to human consumption into liquid form, or a powder form that can be added to oilier ingredients to produce a baked product for human consumption, or a protein supplement.

Owner:WRIGHT JENNIFER +1

Apparatus and method for dehydration using microwave radiation

ActiveUS20150313273A1Drying solid materials with heatMeat/fish preservation by heatingElectromagnetic radiationWaveguide

An apparatus for extracting a vaporizable substance, from a material containing such substance, comprises an irradiation chamber for irradiating the material with electromagnetic radiation to vaporize the substance. The substance may comprise water and the material is dehydrated. The electromagnetic radiation comprises microwaves. The irradiation is conducted in the near-field range of the electromagnetic radiation. In one aspect, the electromagnetic radiation within the waveguide evanescently couples with the material.

Owner:NUWAVE RES

Novel approach to the controlled decontamination and or detoxification of nuts, grains, fruits and vegetables

InactiveUS20090311392A1Eliminates its formationDissipate slowlyMilk preparationDough treatmentNatural productModularity

A method and apparatus are described with which a wide range of foodstuffs can be effectively, simultaneously or consecutively, decontaminated and / or detoxified using a combined treatment of water, a heating source and defined wavelength Ultraviolet light within or without the use of a modified atmosphere. The modular system allows easy, quick and low cost adaptation to suit the decontamination and / or detoxification of almost any solid foodstuff.Unlike existing technologies, the effective control of heat on or over the product prevents denaturation, thus allowing organic and natural product to retain its viability and status.

Owner:NEWMAN PAUL BERNARD

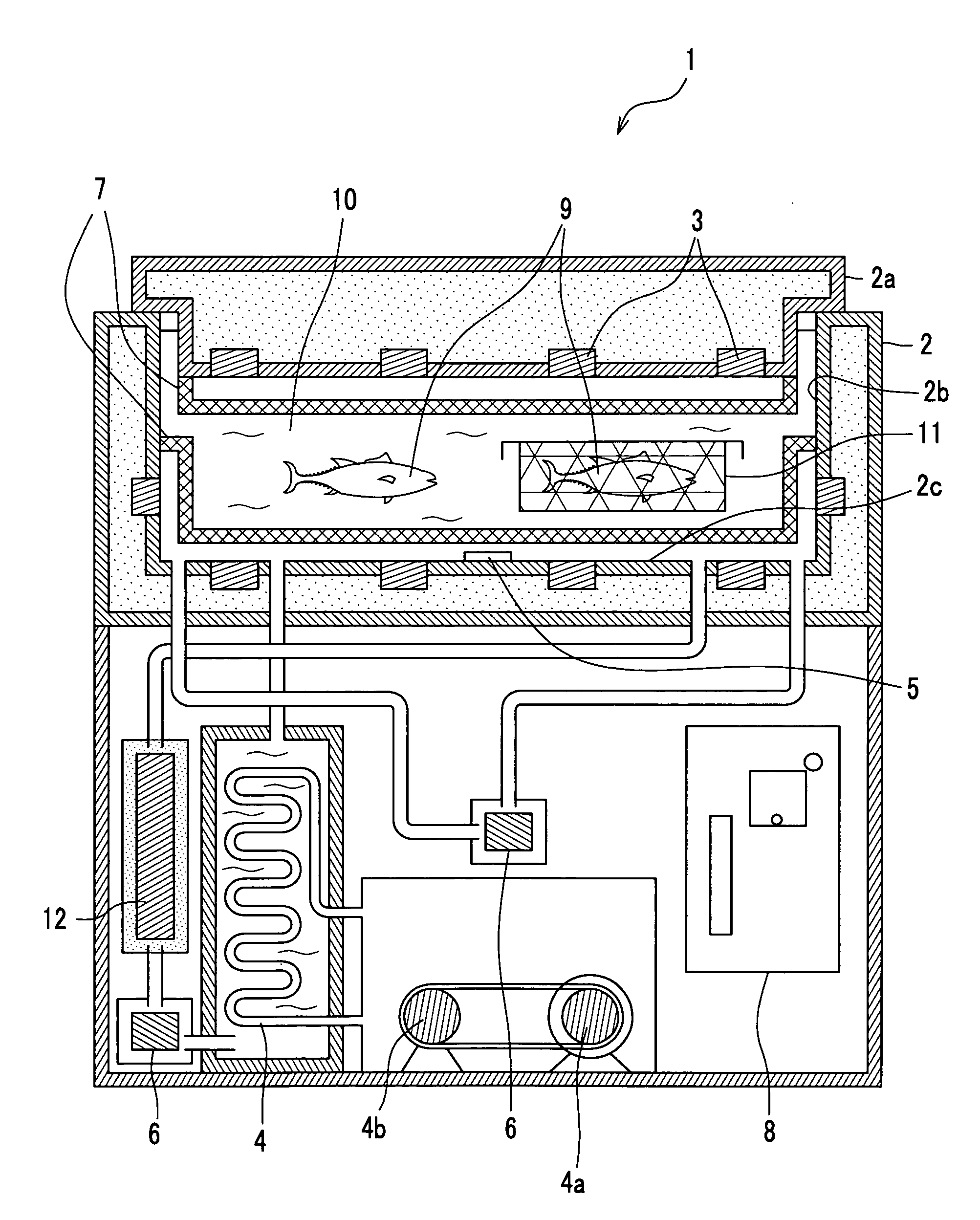

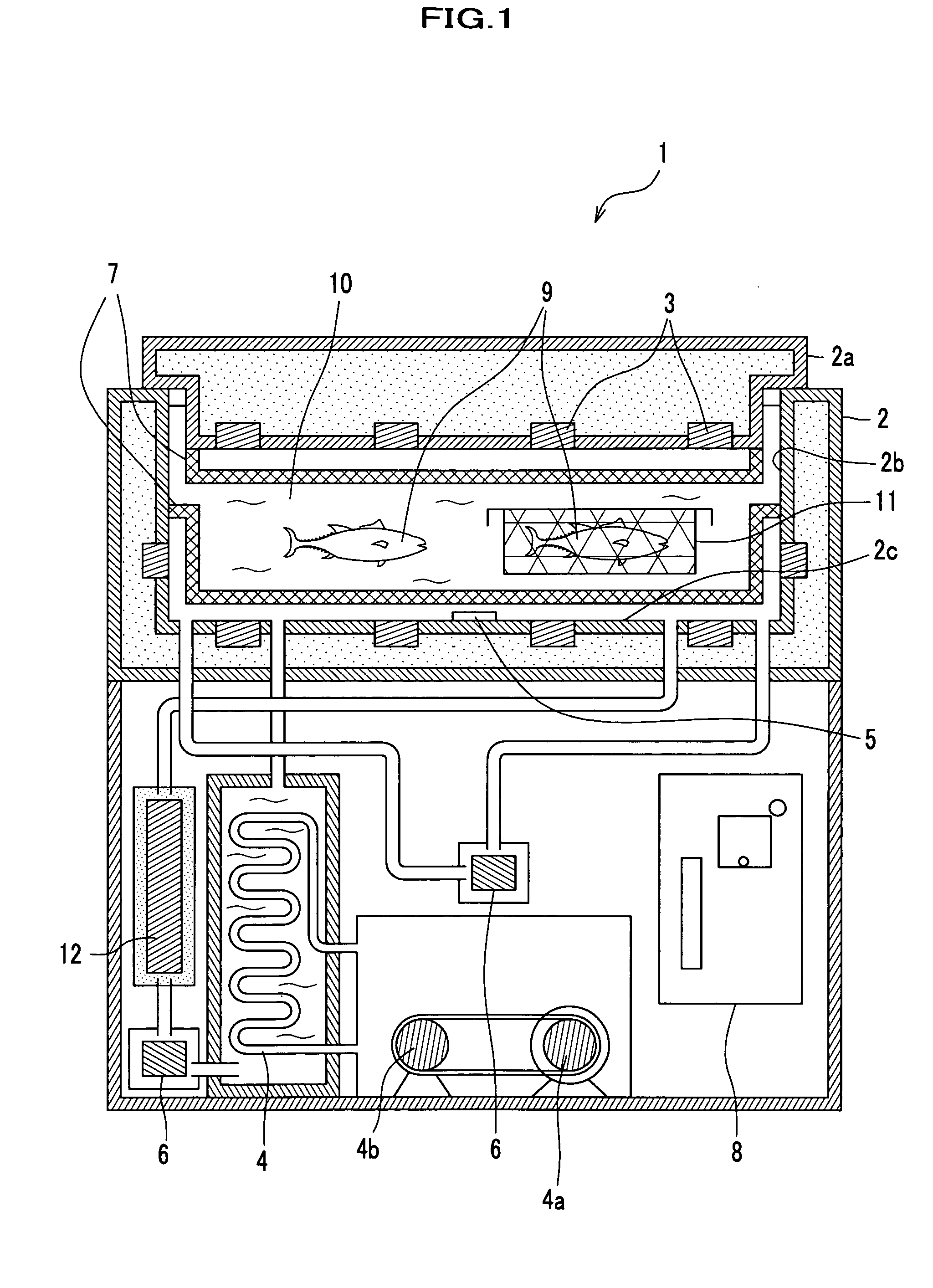

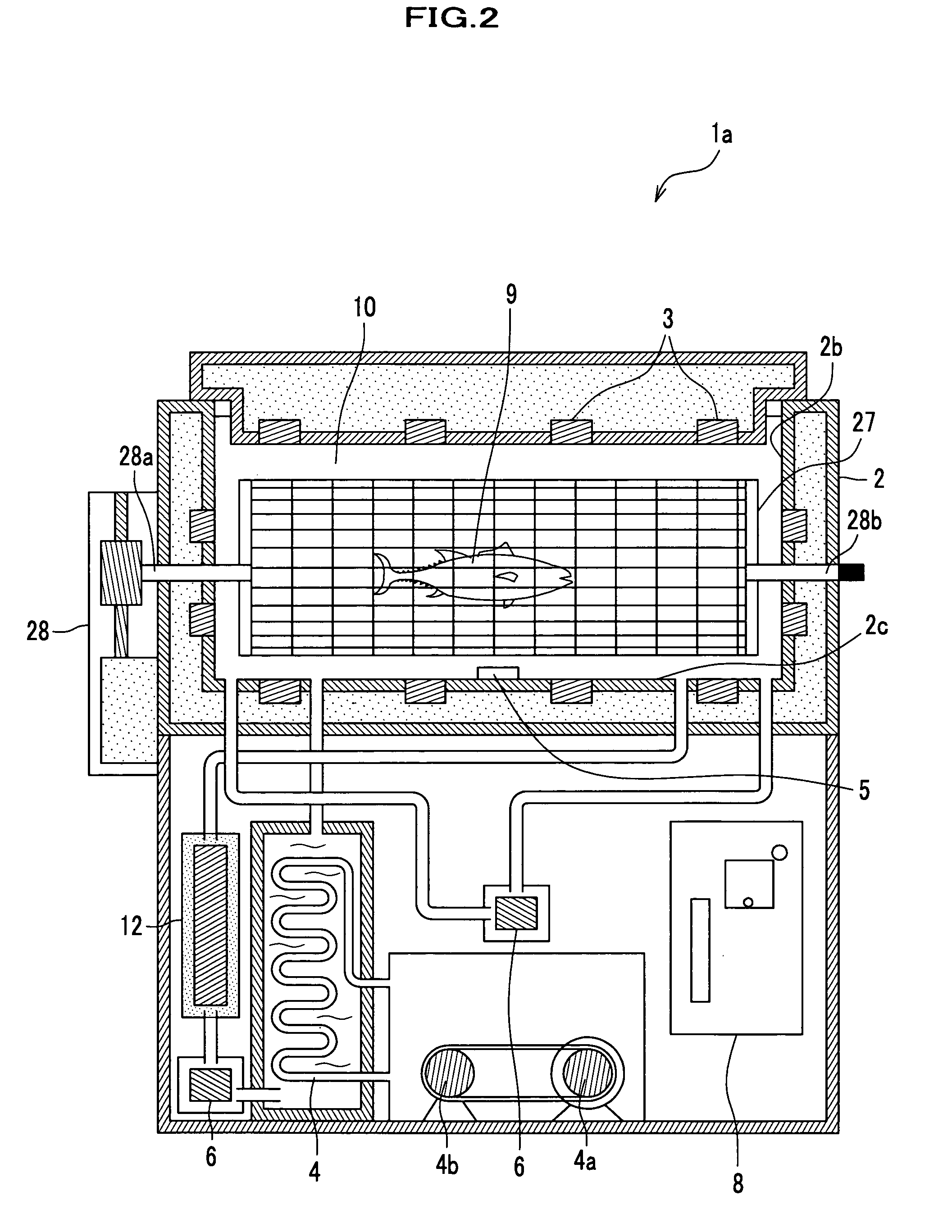

Apparatus for cooling food under water and maintaining water temperature therefor

InactiveUS20090007586A1Maintain food qualityMaintain freshnessShaking/oscillating/vibrating mixersMeat/fish preservation by heatingEnvironmental engineeringTreated water

An underwater-cooling water-temperature maintaining apparatus of a food includes: a water tank where a cooled stuff and cooling treated water of which a freezing point is not more than zero Celsius degree; a treated water cooler configured to cool the cooling treated water; a water temperature detection sensor configured to detect a water temperature of the cooling treated water; an agitator pump configured to equalize the water temperature of the cooling treated water in the water tank; ultrasonic vibrators configured to oscillate ultrasound toward an inside of the water tank in order to prevent the cooled stuff from being frozen; and a controller configured to control the ultrasonic vibrators, the water temperature detection sensor, the treated water cooler, and the agitator pump so as to maintain the water temperature of the cooling treated water at a temperature at which the cooled stuff is not frozen.

Owner:SHINYOU SANGYO

Microwave on-line disinsection method for rice or paddy

InactiveCN1528154AFast killProve the insecticidal effectSeed preservation by heatingMicrowave ovenFree cooling

The present invention discloses a microwave on-line insecticidal method for rice or paddy. It is characterized by that after the polishing process of production line for making paddy into rice or in the course of feeding paddy into bin two procedures of microwave treatment and cooling are added, the described microwave oven can adopt market continuous microwave oven, the temp. of rice or paddy outgoing from microwave oven is 54-68 deg.C, i.e. the microwave energy for controlling unit mass of rice is 0.014-0.030 Kw.h / kg, and the described cooling procedure is naturally-cooling the rice in the buffer bin after the rice is discharged from microwave oven, and the temp. can be cooled to 40 deg.C, and its cooling speed is 20-40 deg.C / h. Said method can completely kill injurious insects in the rice or paddy and all the ova of insects.

Owner:GAEA GEM RICE

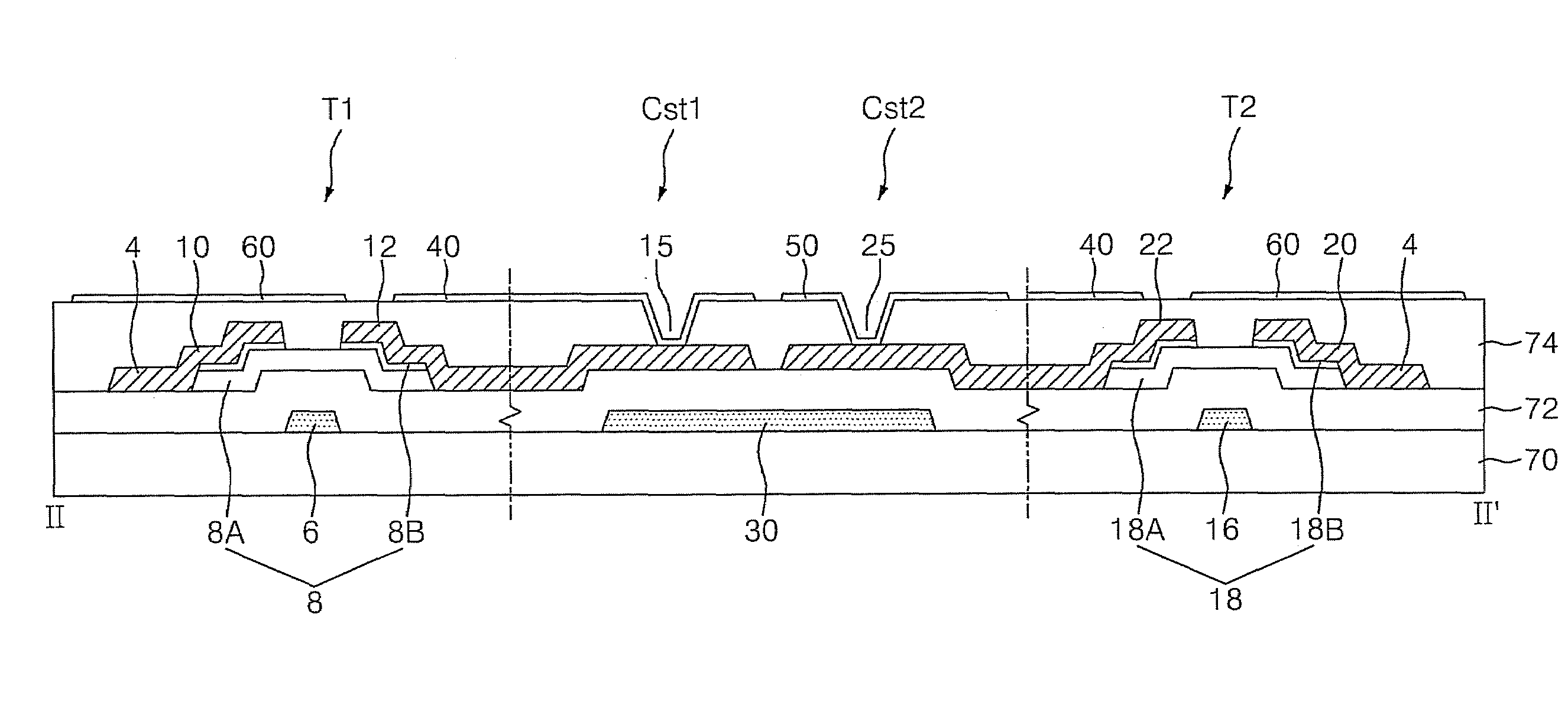

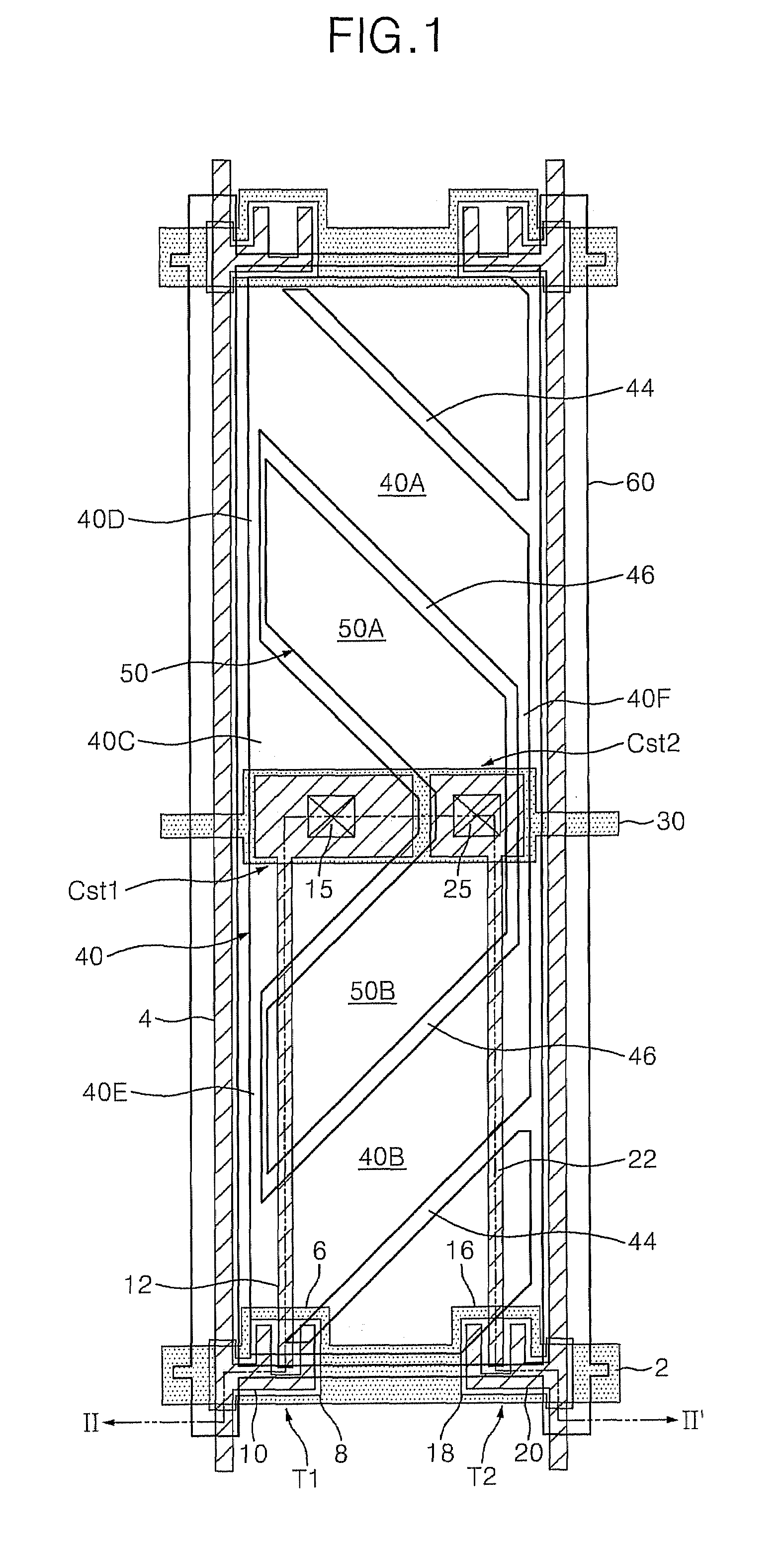

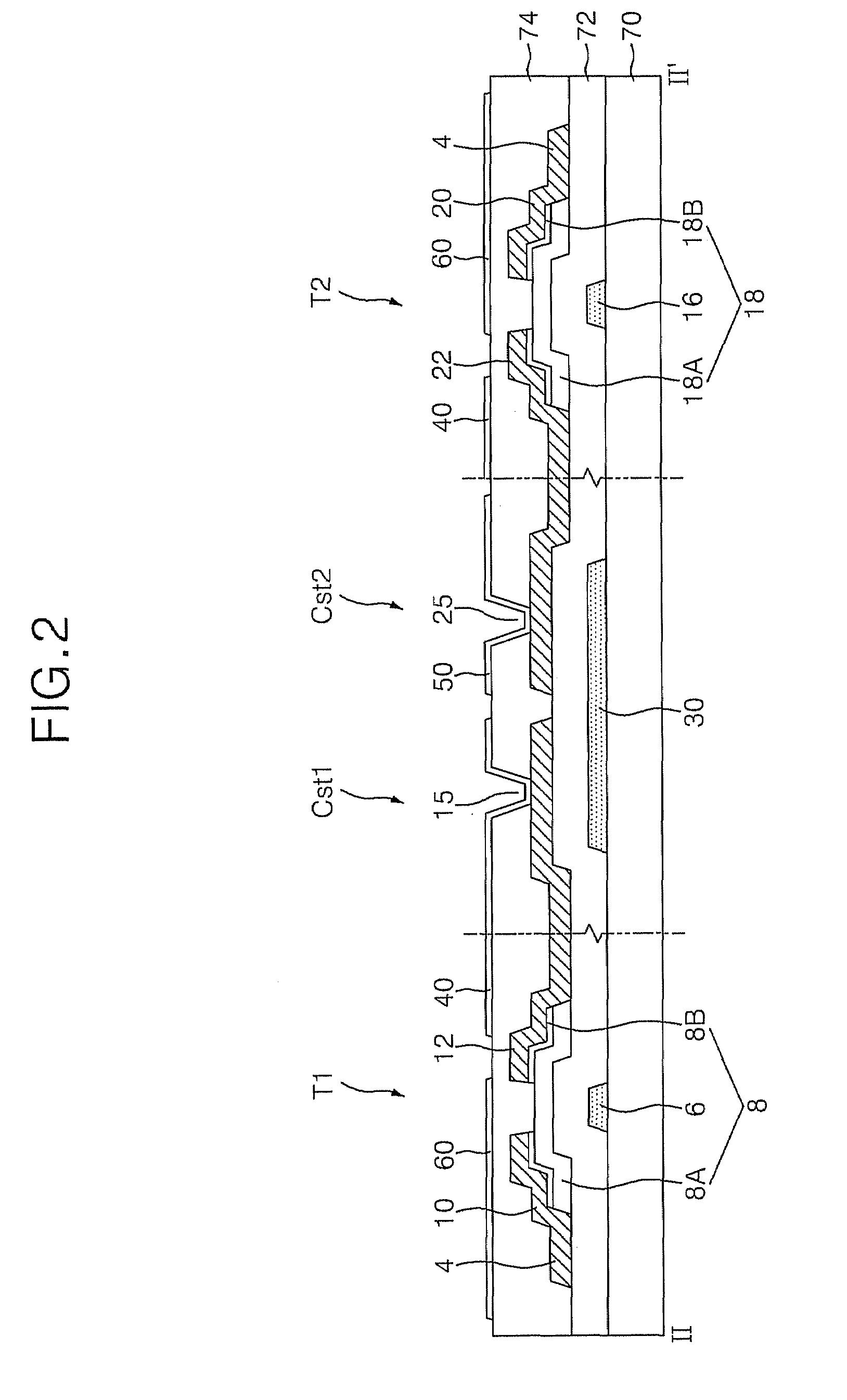

Liquid crystal display device and manufacturing method thereof

ActiveUS20070182902A1Preventing vertical crosstalkReduce the differenceConstruction materialFruits/vegetable preservation by heatingLiquid-crystal displayParasitic capacitance

A liquid crystal display (LCD) device and a manufacturing method thereof, capable of preventing vertical crosstalk caused by a deviation of a parasitic capacitance, includes a first pixel electrode formed in a first gray scale region of each subpixel region divided into first and second gray scale regions, and a second pixel electrode formed in the second gray scale region separated from the first pixel electrode and encompassed by the first pixel electrode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

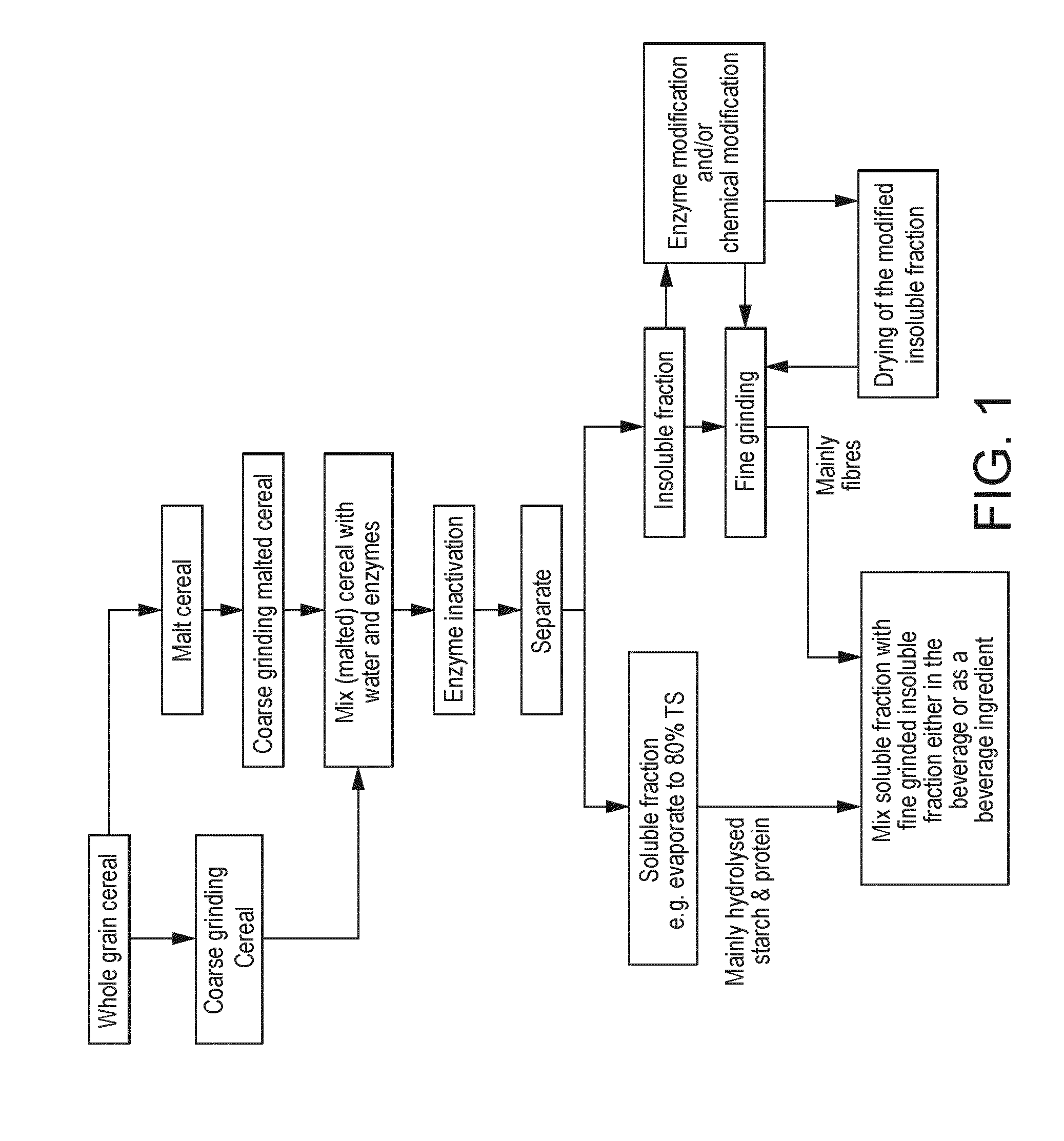

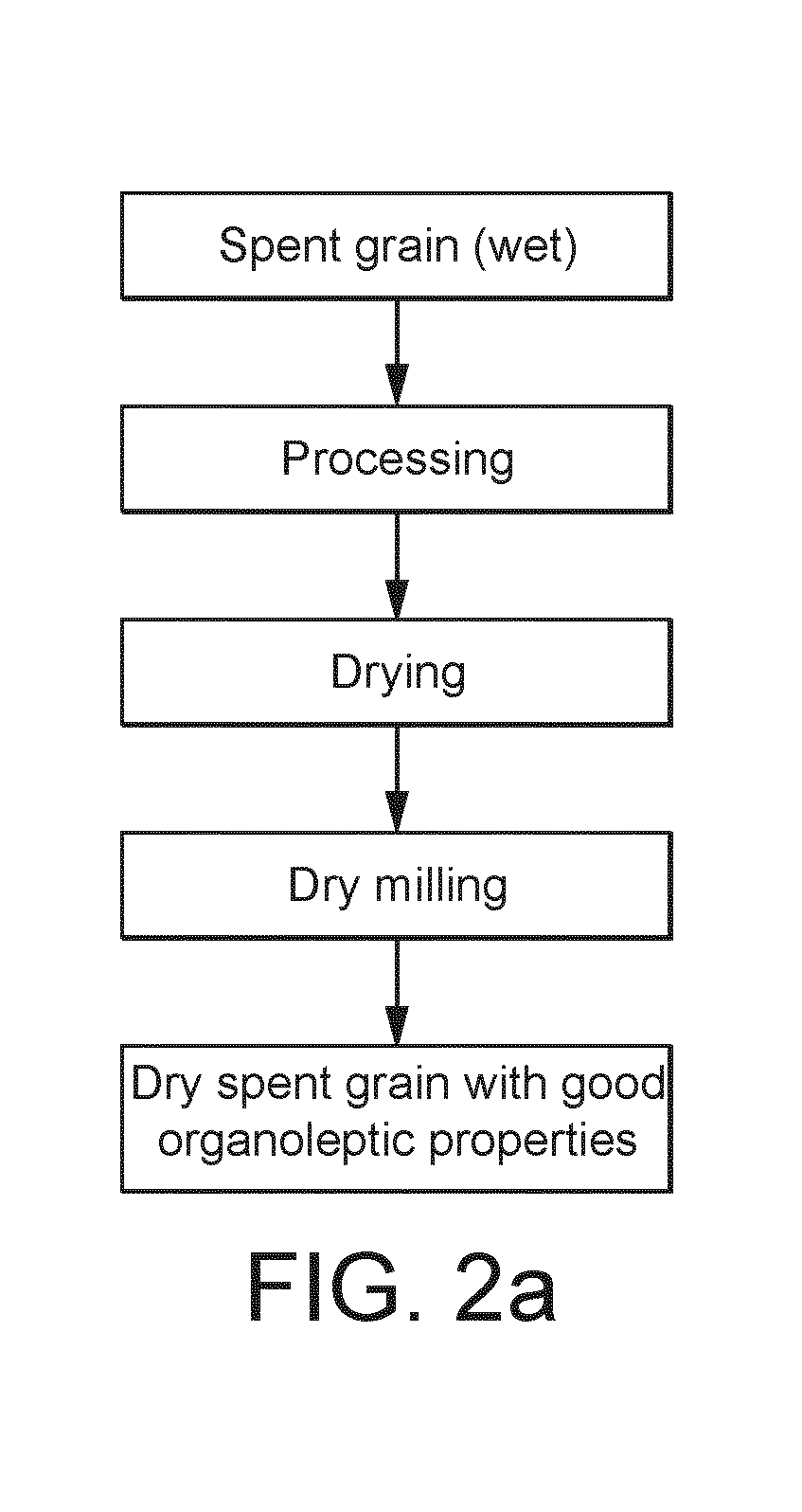

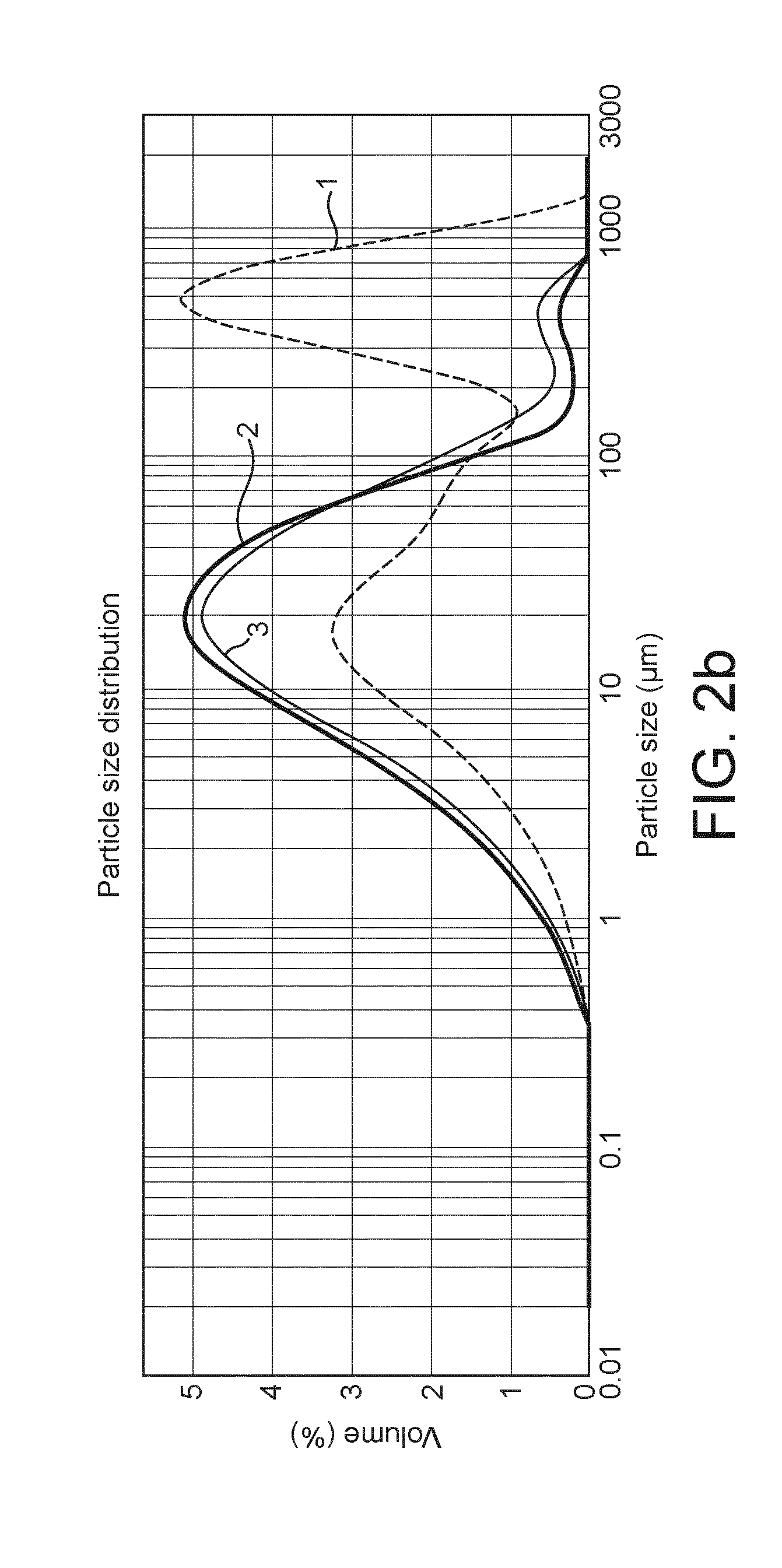

Method for providing a whole grain cereal based extract

The present invention relates to a process for preparing a whole grain cereal based extract having improved suspension properties. The process comprises the steps of: (i) providing a whole grain cereal; (ii) subjecting the whole grain cereal to a first grinding; (iii) subjecting the ground whole grain cereal to an hydrolysis of the macromolecular elements providing a modified whole grain cereal; (iv) separating a soluble fraction of the modified whole grain cereal from an insoluble fraction of the modified whole grain cereal; and (v) subjecting the insoluble fraction of the modified whole grain cereal to a second grinding and / or enzymatic modification obtaining a cereal based fraction having improved suspension properties, and comprising particles having a particle size of at the most 100 μm, such as at the most 50 μm, e.g. at the most 30 μm; and (vi) reincorporating at least part of the cereal based fraction obtained from step (v) into at least part of the soluble fraction obtained from step (iv) obtaining the whole grain cereal based extract.

Owner:NESTEC SA

Sea cucumber oil product and method for preparing same

ActiveCN101530127ASeed preservation by heatingFood preparationCarbon numberBranched chain fatty acids

The invention relates to a sea cucumber oil product and a method for preparing the same. The sea cucumber oil is prepared by using sea cucumbers (in particular stichopus japonicus and internal organs thereof as well as cucumaria frondosa and the internal organs thereof) as raw materials through the processes of cleaning, freeze drying, pulverization and carbon dioxide supercritical extraction. The fatty acid component of the prepared finished product contains high-proportion branched-chain fatty acid, odd carbon number of fatty acid, as well as omega-3 fatty acid, wherein the branched-chain fatty acid accounts for 10 to 60 percent of the total fatty acids, and the content of 12-methyl-tetradecanoic-acid accounts for 2.5 to 30 percent of the total fatty acids. The sea cucumber oil is liquid state oil with colors from orange yellow to red and has stable property and sea fishy smell. The saponification value of the sea cucumber oil is between 150 and 190 mgKOH / g, and the iodine value thereof is between 70 and 100 g / 100 g.

Owner:DALIAN HAIYANTANG BIOLOGY

Method for producing cooked refreshing food using raw fresh material by microwave energy

InactiveCN101224029AThere will be no burst bag phenomenonReduce lossesMeat/fish preservation by heatingFruits/vegetable preservation by heatingMicrowave cavityFresh food

The invention relates to a method which uses microwave energy to produce matured fresh foods with fresh raw materials. The method is characterized in that: the fresh raw materials are preprocessed and vacuum packed in bags after weighing; the vacuum packed fresh raw materials are placed in a tunnel microwave for sterilizing and maturing to produce matured foods; finally, the sterilized and matured foods are cooled to normal temperature for obtaining matured fresh foods which can be preserved at normal temperature. The method has the advantages that: as the microwave is adopted for maturing, the interior of the microwave cavity is in a low temperature state, and the vacuum bags do not blow up in the maturing process, therefore the maturing needs not to be carried out under high pressure environment; owning to the low temperature and short time of the sterilization and maturing inside the fresh raw materials, the loss of nutrient elements in the fresh raw materials is reduced during processing; due to the adoption of the tunnel microwave, industrialization production can be realized.

Owner:文舜

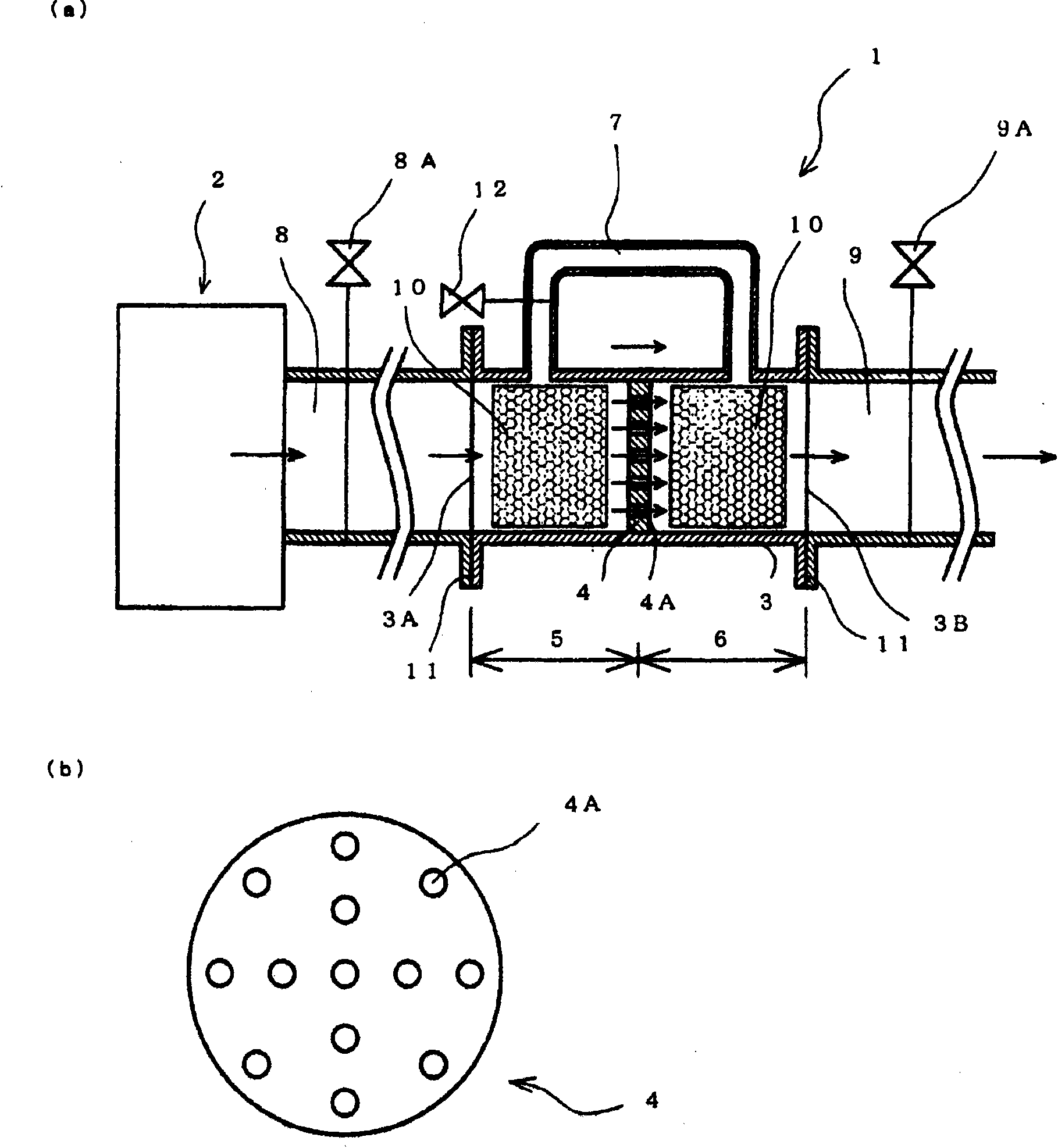

Overheated compressed hot air stream producing method and device, object processed by overheated compressed hot air stream, processing method, and processing apparatus

InactiveCN101910748ADry evenlyEven drying effectLiquid fuel feeder/distributionDrying solid materials with heatWater qualityEngineering

A method and device for producing a minus-ion air similar to a heated compressed hot air stream, electromagnetic waves in the far-infrared and submilimeter region (hereinafter referred to as ''terahertz wave'') by regulating the discharge pressure and the discharge temperature. The device is excellent in versatility, small in size, and low in cost. An object processed by using the method and device, a processing method, and a processing apparatus are also provided. Air is sent from a blower or an air compressor (2) through an air pipe (8) to a heated compressed air regulator (vessel (3)). The air sealed in the heated compressed airregulator (1) regulated under a predetermined discharge pressure (for example, 30 kPa to 150 kPa) and at a temperature (40 DEG C to 250 DEG C) is passed through a through hole (4A) of a circular plate (4) to produce a heated compressed air. In the produced hot air stream, a resonance electromagnetic wave resonating with the natural frequency of the water molecule is generated by a terahertz wave and a generated thermal shock wave, thereby the hydrogen bond of the water molecules in the air is cut, and electrons are released from hydrogen atoms, thus also producing a minus-ion air stream. A processed object, a processing method, and a processing apparatus are so constituted that the produced hot air stream is used for drying, production of a functional water by exposing water to the hot air stream, production of an aqueous fuel, beauty / health appliances, air / water quality improvement devices, combustion efficiency enhancement devices for internal combustion engines, and so forth.

Owner:SUZUYAELECTRIC SERVICE

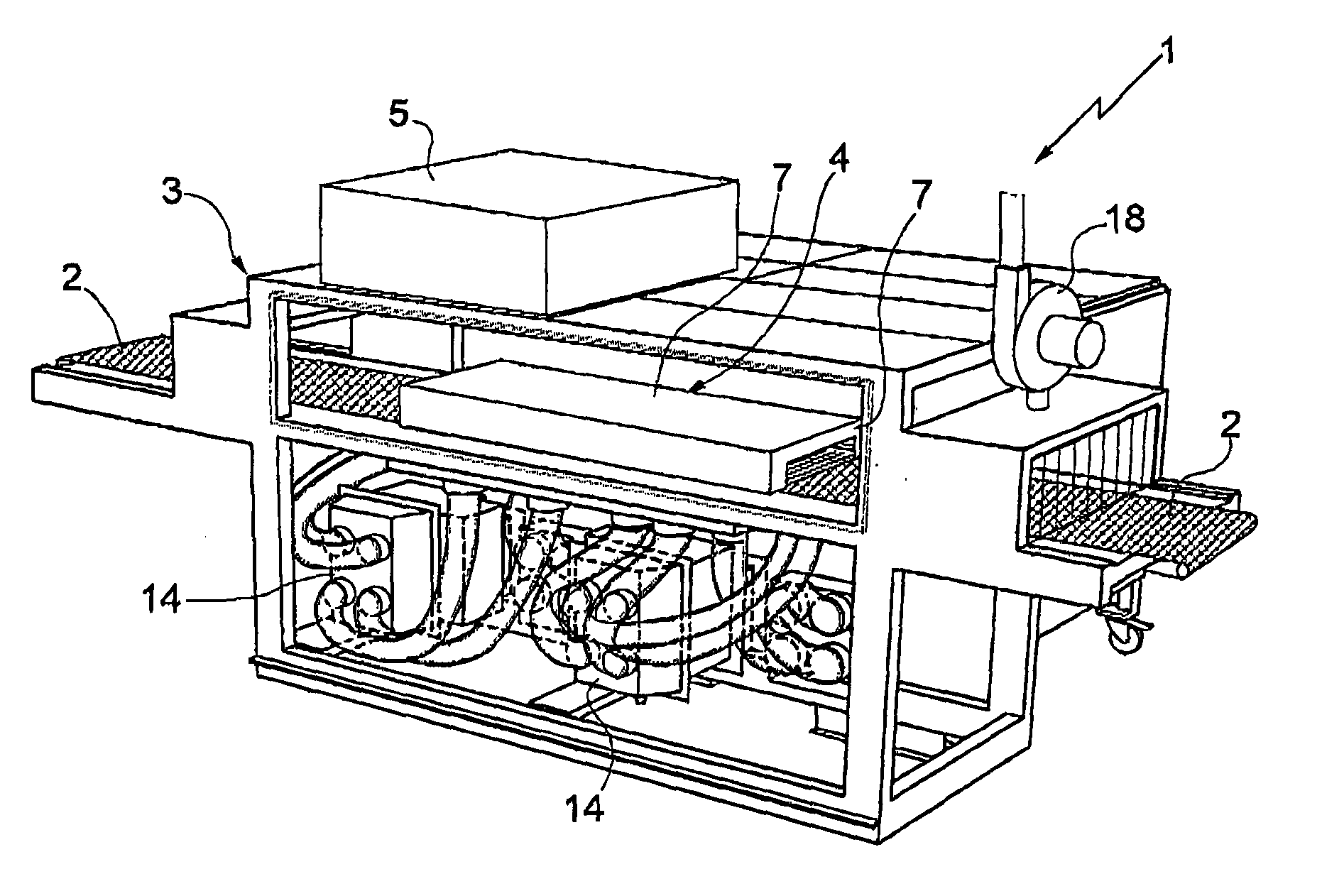

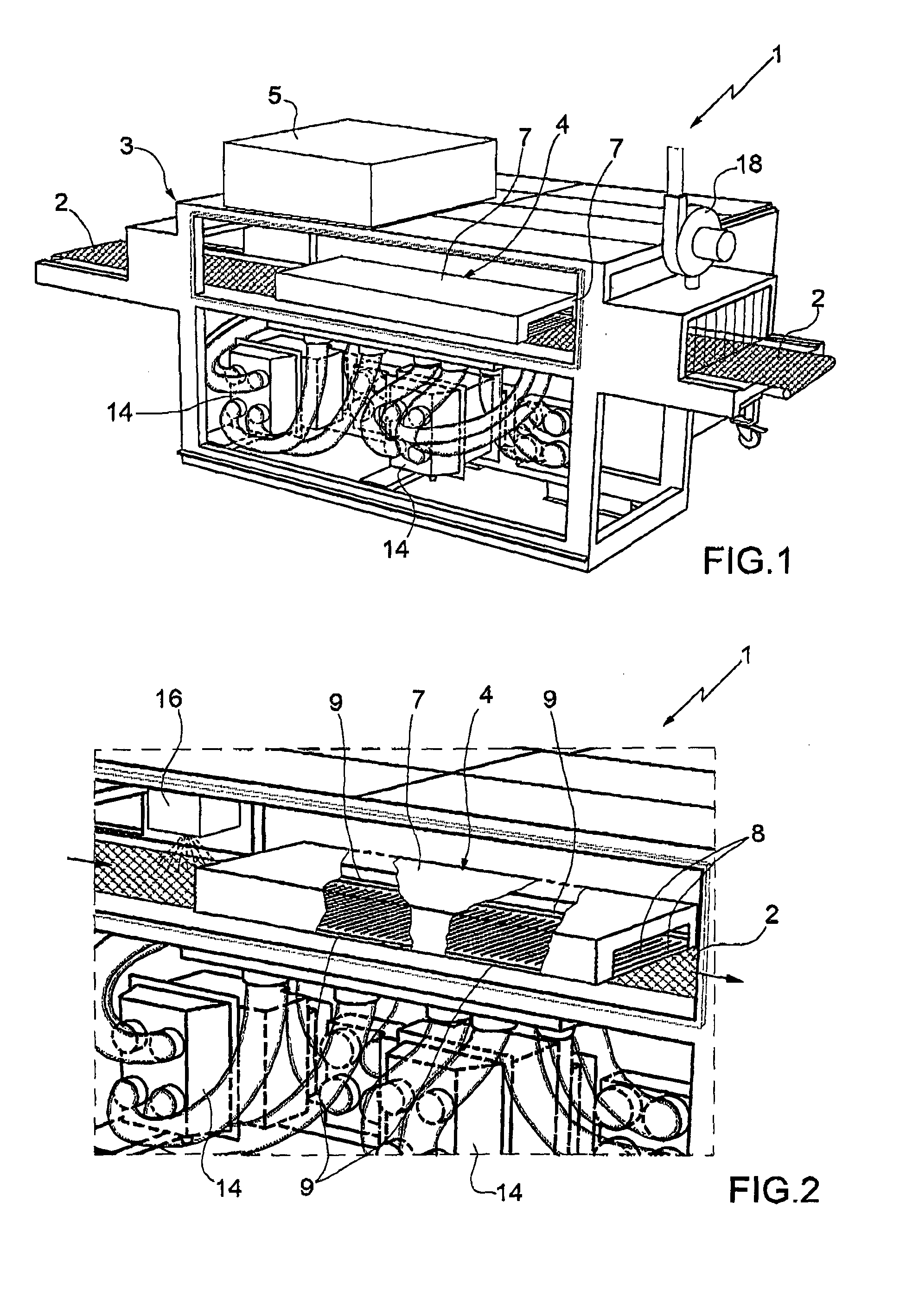

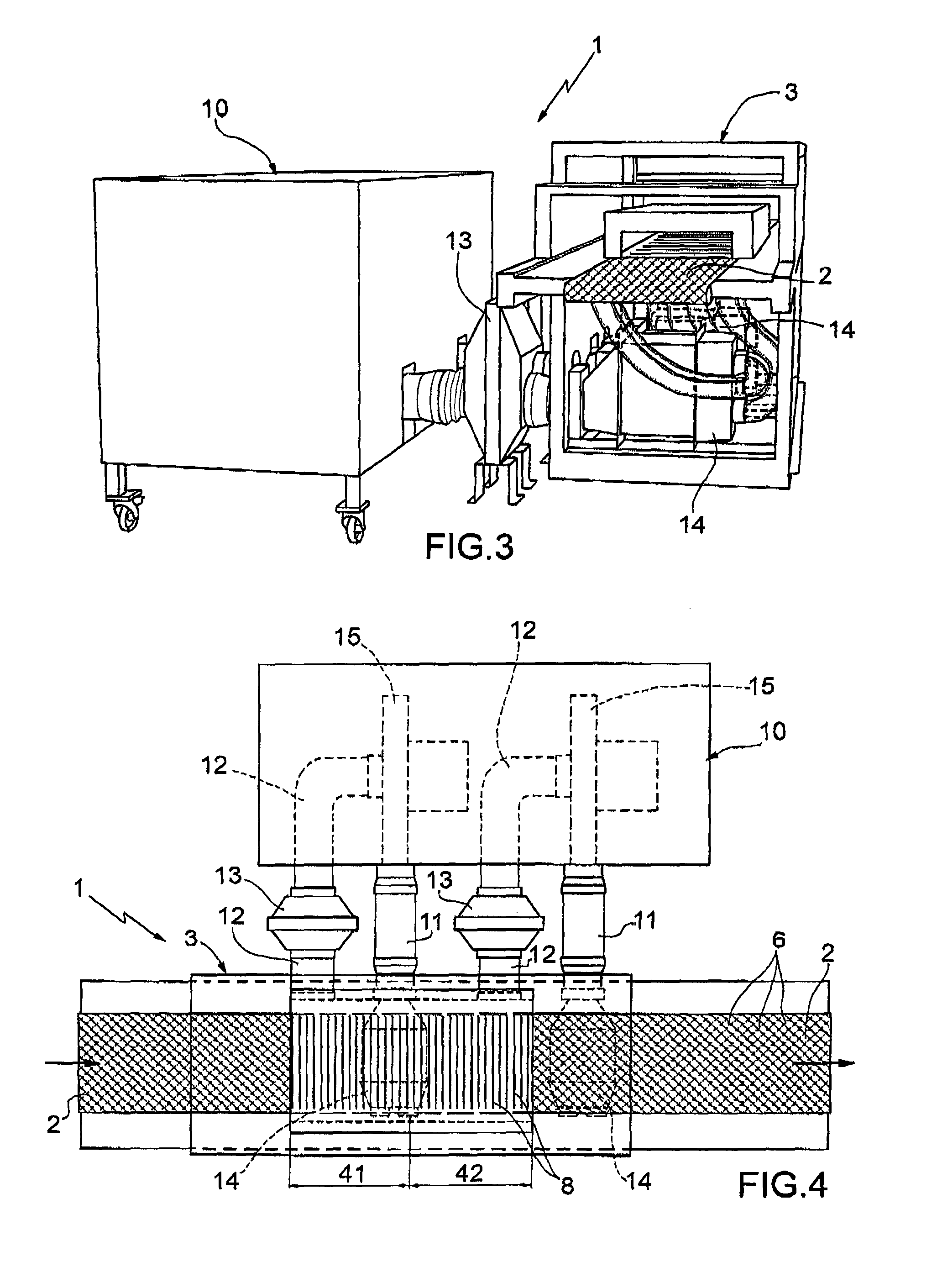

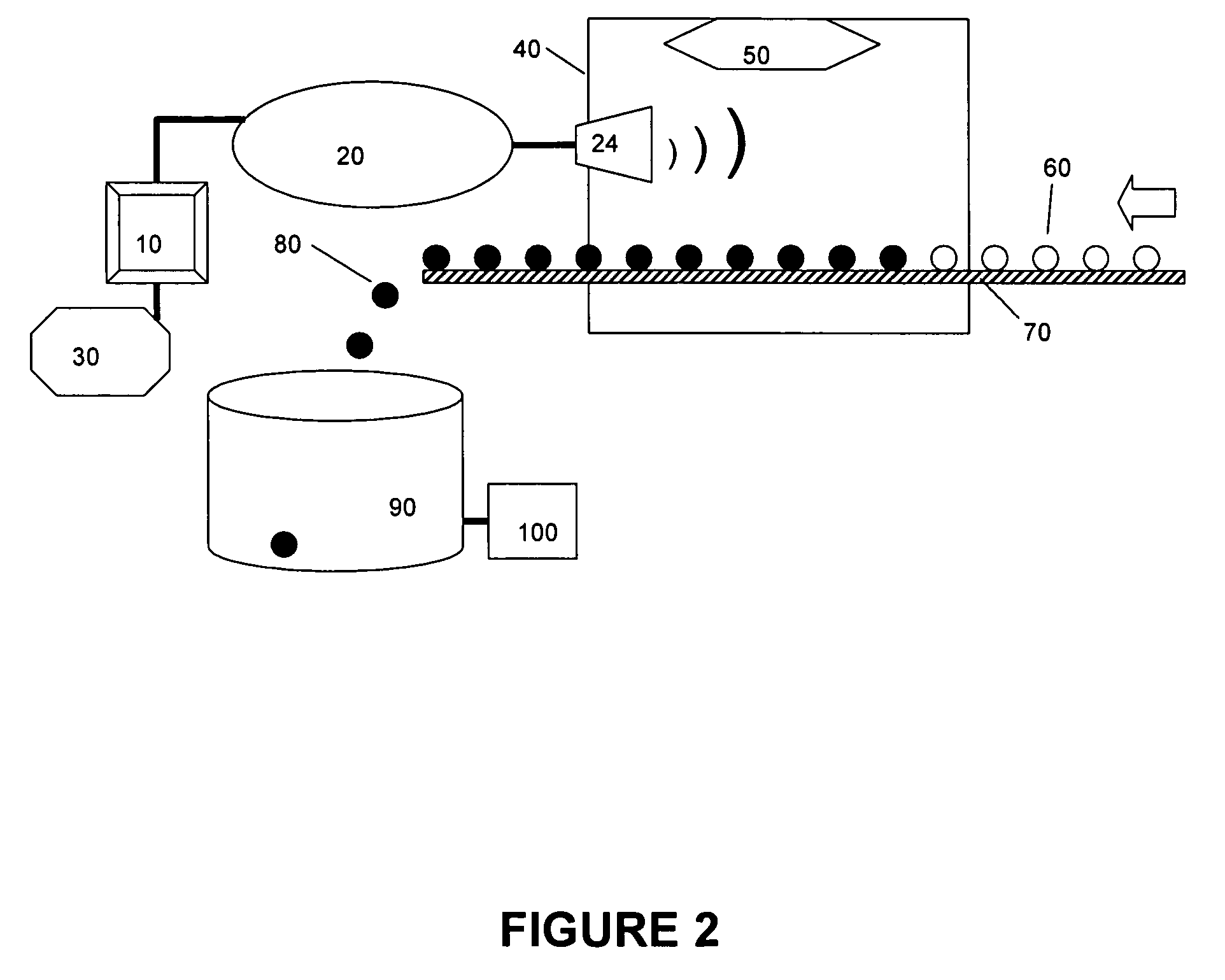

Apparatus and Method for Drying and/or Treating Loose Food Products

InactiveUS20160235109A1Way fastFruits/vegetable preservation by heatingSeed preservation by heatingMicrowaveRadiofrequency electromagnetic radiation

An apparatus and a method of drying and / or treating loose products such as food products, for example corn, flour, seeds in general, spices, tea and coffee, dried pulses, dried or shelled fruit, like hazelnuts, dry food products in general, such as dried mushrooms, etcetera, the treatment which the aforementioned loose products can be subjected to being of the type such as disinfestation, sanitization, pasteurisation, sterilisation, etcetera, wherein the aforementioned apparatus comprises a conveyor for the loose products, a treatment unit defining a treatment chamber, means for generating radio frequency electromagnetic radiation, means for applying radio frequency electromagnetic radiation and / or microwaves which act in the treatment chamber or area and designed to affect the loose products transported through the treatment chamber or area, mixing means for the loose products to be treated arranged in the treatment chamber.

Owner:STALAM

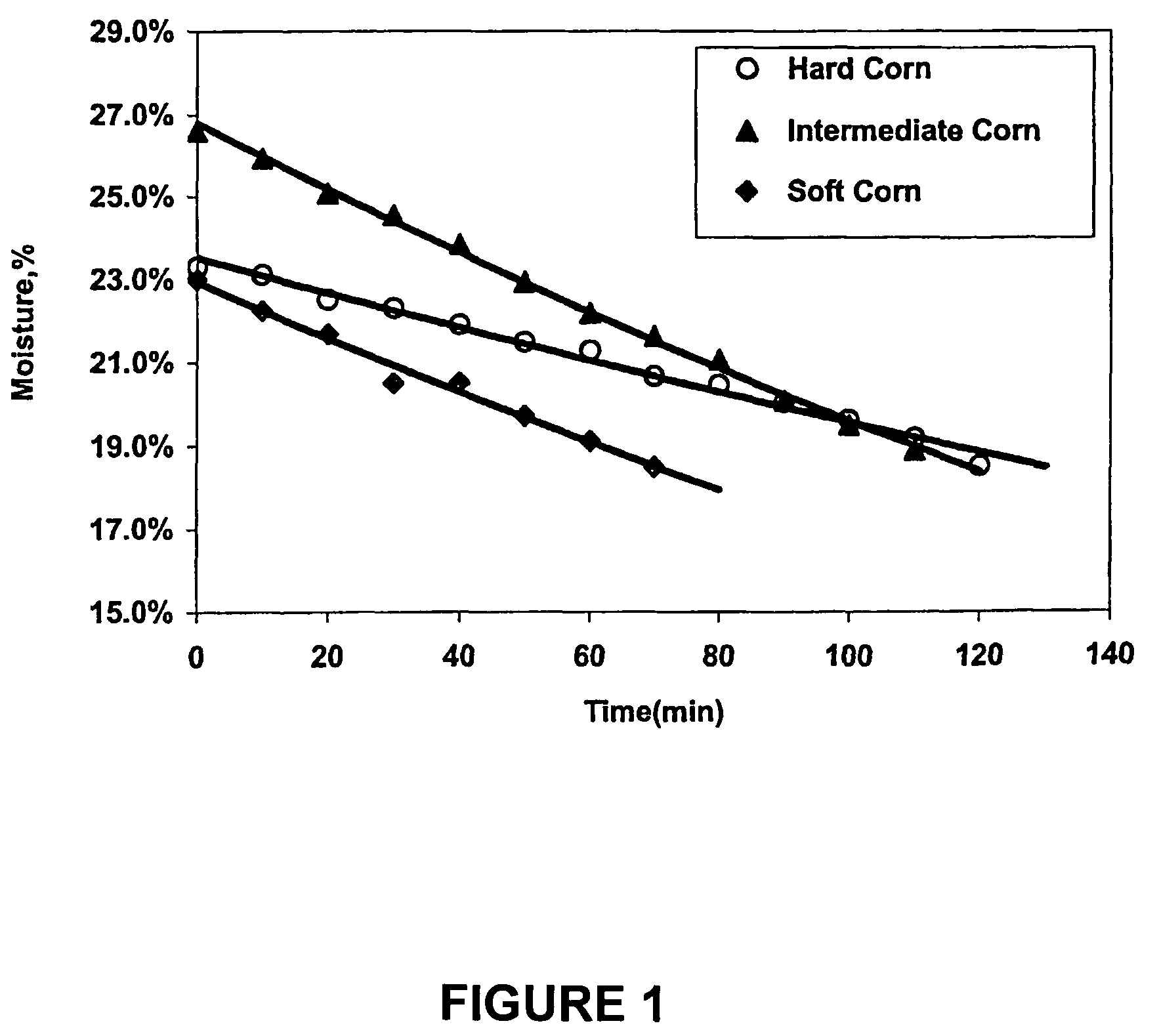

Methods and apparatus for treating plant products using electromagnetic fields

InactiveUS8039031B2Easy to optimizeMaximize absorptionMilk preparationDough treatmentHigh energyEngineering

The disclosure relates to the use of electromagnetic field energy in methods and apparatus for treatment of plant products. The energy can be in the form of pulsed EMF or continuous EMF waves. The methods and apparatus are applicable, for example, in a variety of plant products including the treating of corn, soybeans, peas, wheat, wheat flour, and durum pasta and in a variety of industrial processes including wet and dry milling and refining operations. The methods and apparatus in particular embodiments relate to the drying of corn with potential for high energy efficiency while achieving advantageous, high quality dried corn, with a low to very low level of cracks.

Owner:BAIANU ION C +1

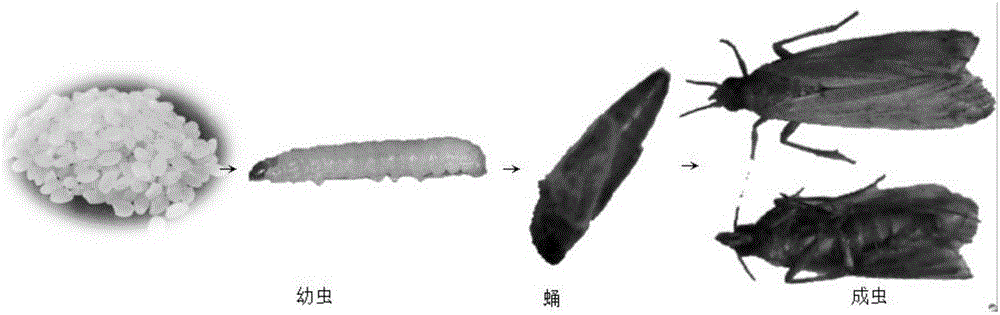

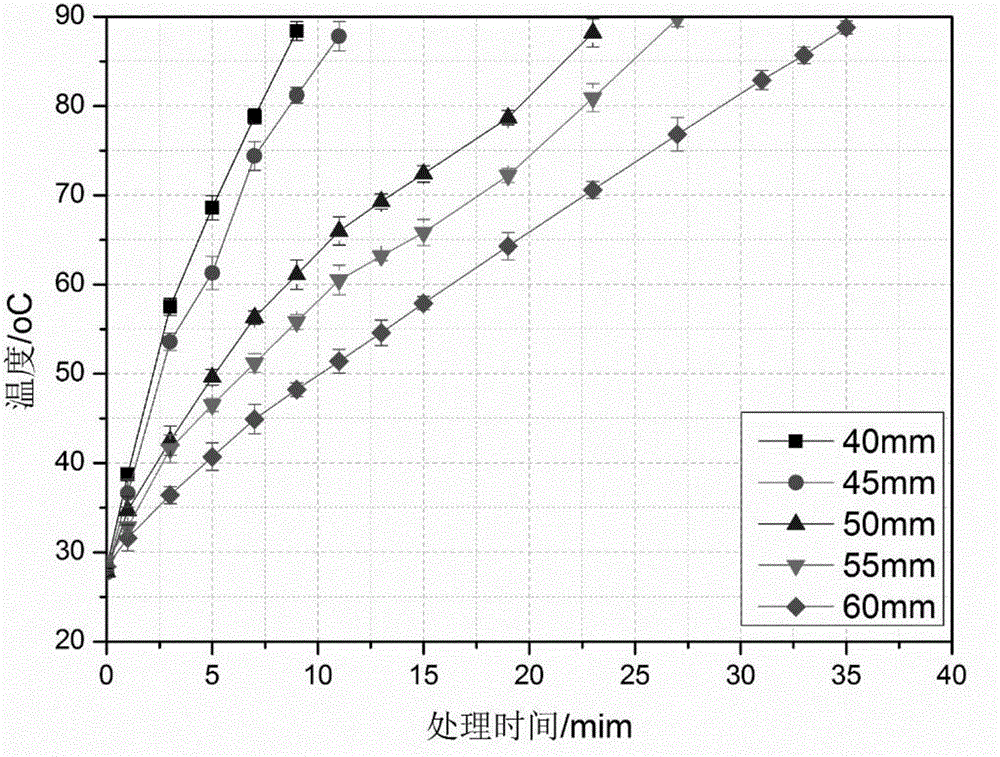

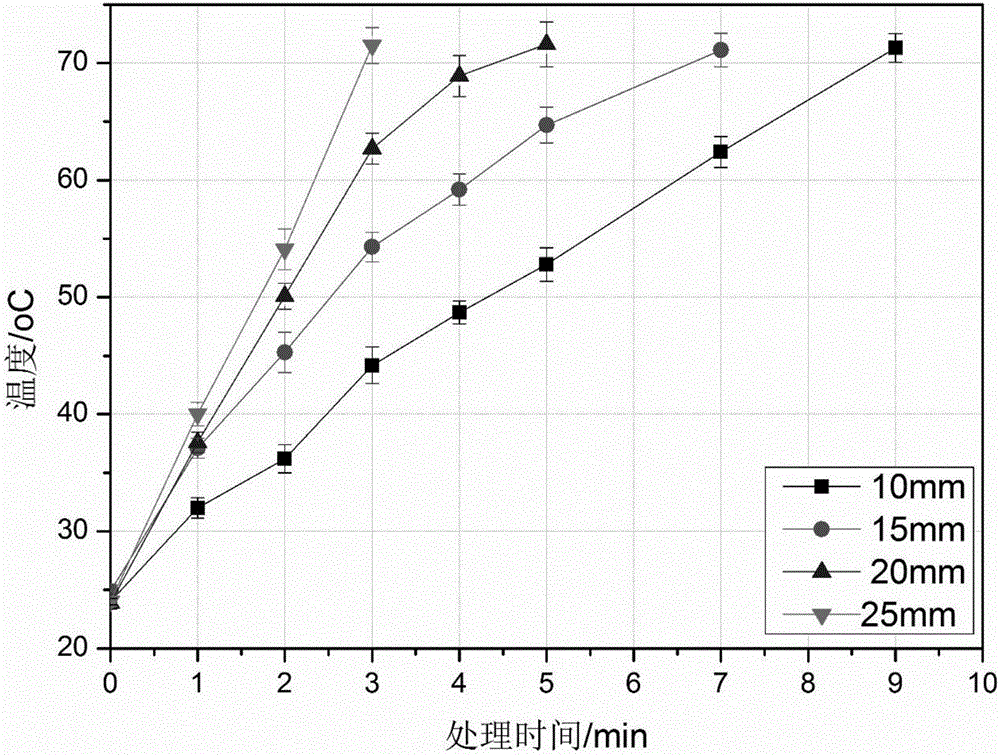

Insect disinfestation method performing radio frequency treatment on grain

InactiveCN106720284ANo effect on nutritional qualityProcessing quality is not affectedSeed preservation by heatingRoom temperatureGrain storage

The invention discloses an insect disinfestation method performing radio frequency treatment on grain and belongs to the technical field of grain storage. The insect disinfestation method includes: using a radio frequency insect disinfestation and sterilizing continuous treatment device disclosed in patent application CN104782758A to performe radio frequency treatment on the grain after the grain is harvested or before the grain is stored, discharging samples out of a radio frequency cavity after the radio frequency treatment, and performing natural or forced air cooling under room temperature, wherein the radio frequency treatment can kill insect eggs, adult insets and larvae in a large amount of grain. The insect disinfestation method has the advantages that the method is low in energy consumption, high in automation level, evident in insect disinfestation effect, safe, nontoxic and free of odor, the original color, fragrance, smell, nutritional component and germination rate of the samples are hardly changed, and the storage period of the grain is prolonged greatly.

Owner:JIANGNAN UNIV

Manufacturing process of quick-freezing corn

InactiveCN103734306AKeep fresh and plumpStop lossSeed preservation by heatingSeed preservation by freezing/coolingQuick FreezeMicroorganism

The invention discloses a manufacturing process of quick-freezing corn. A preparation method comprises the following steps: peeling and inspecting; soaking and cleaning; blanching; cooling, and draining; shaping; quickly freezing; inspecting and packaging; storing. The manufacturing process has the characteristics that the freshness and fullness of the corn are maintained after the corn is stored for 12 months; by adopting the blanching technique, the loss of nutrition components of corn is well prevented, and the microorganisms and ova attached on the corn are killed, so that the edible safety is ensured; the air in the corn is removed, the pressure formed by the ice crystals during freezing is reduced, the oxidizing degree of the raw material is correspondingly decreased, and the color and nutrition of the corn are favorably maintained; the corn is convenient to carry, and the fresh corn can be eaten at any time and any place.

Owner:周光英

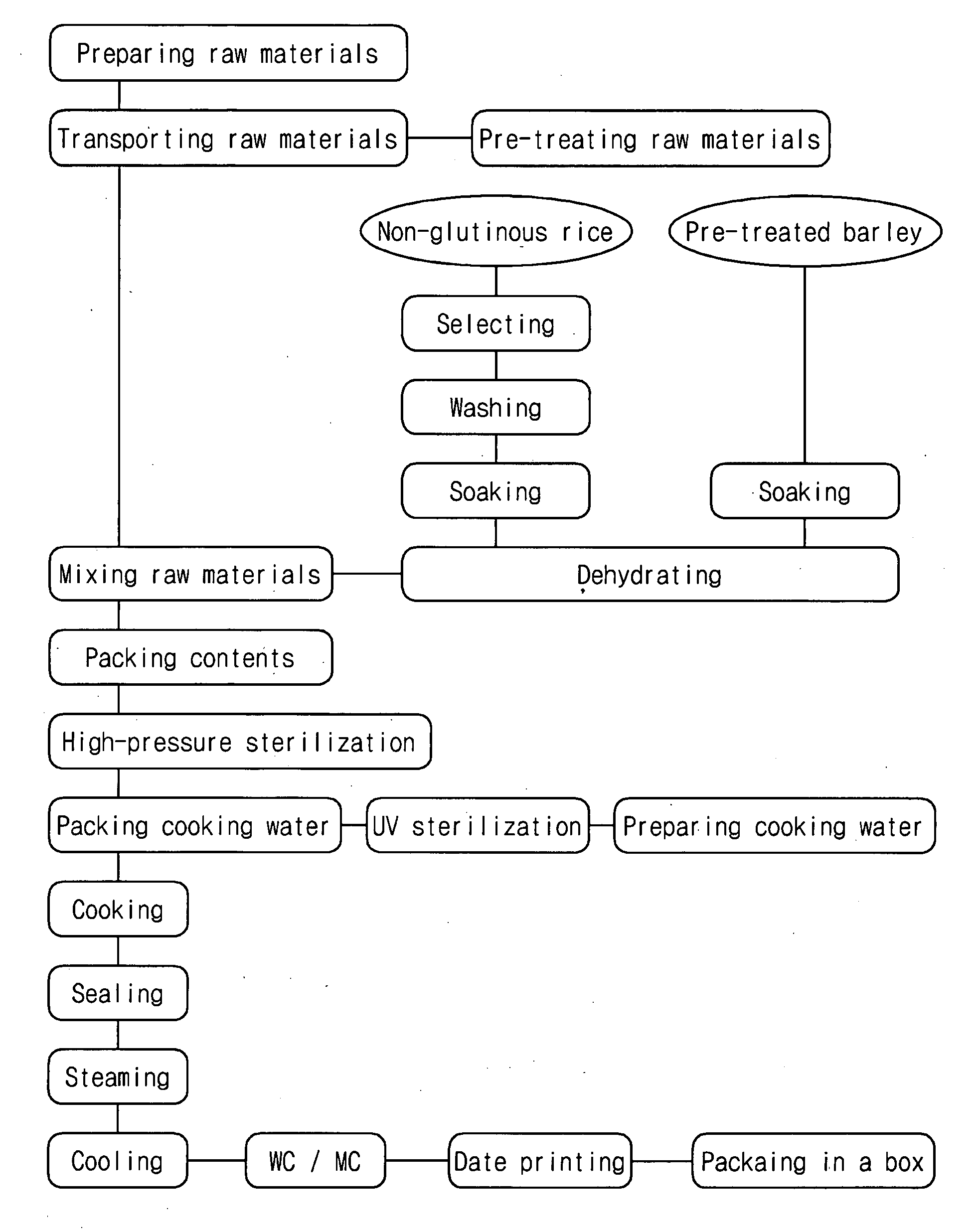

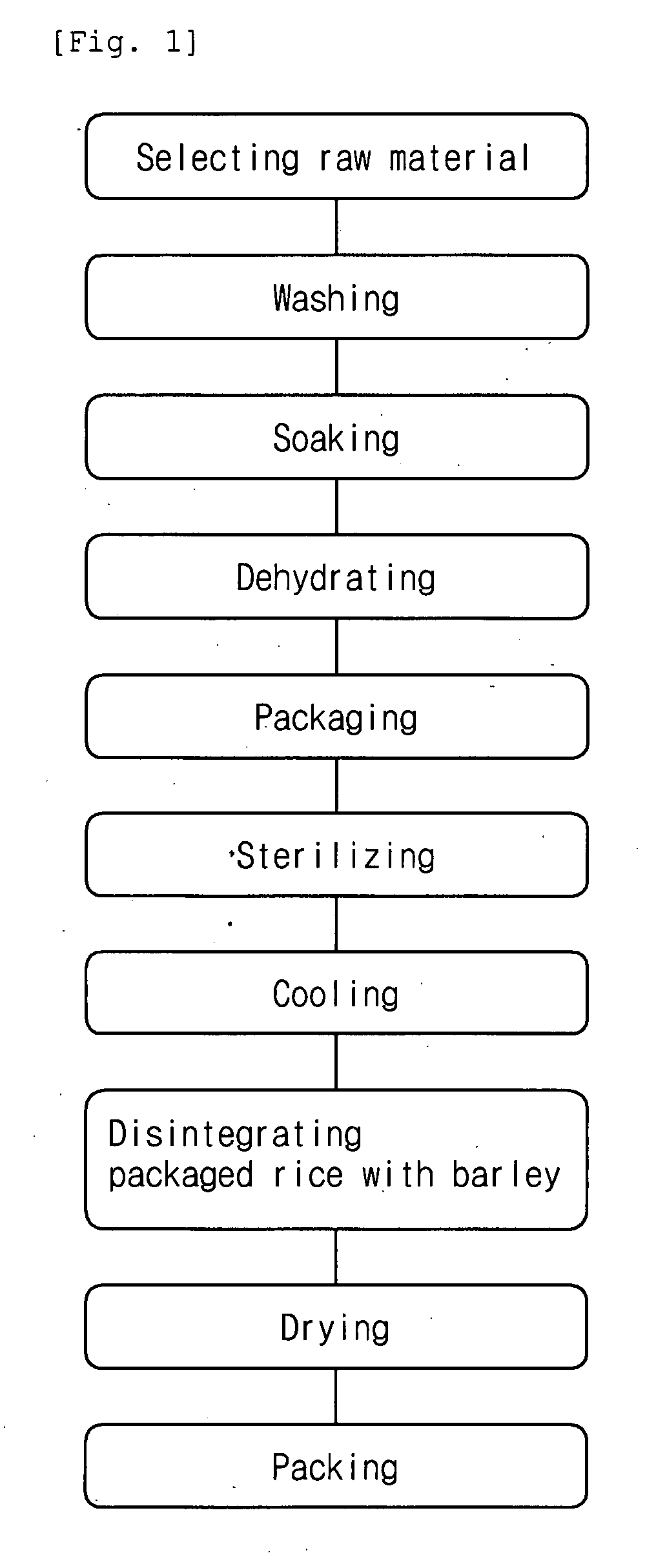

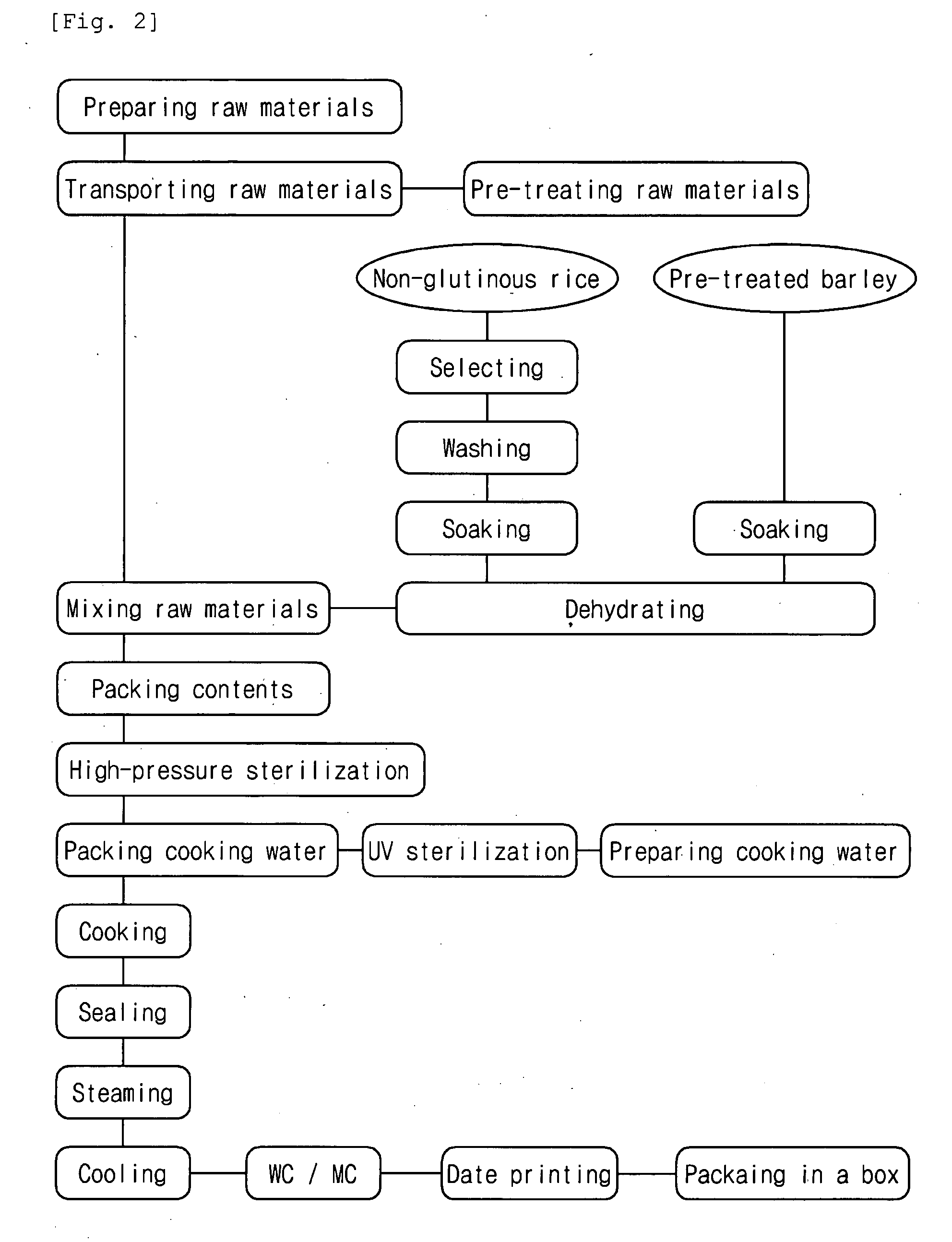

Preparation method of cooked rice with barley in aseptic packing system

ActiveUS20090004361A1Great tasteAdd flavorFruits/vegetable preservation by heatingSeed preservation by heatingMicroorganismRice dishes

The present invention relates to a method for preparing cooked rice with barley in an aseptic packing process, comprising mixing barley, which had been sterilization-treated and then dried, with non-glutinous rice. The method for preparing cooked rice with barley in an aseptic packing system according to the present invention is characterized in that by using barley that has been first gelatinized and then retrogradated, the cooked rice with barley has a reduced initial level of microorganisms in the barley, leading to excellent stability against microorganisms, a long storage life, of 6 months or longer at ambient temperature, excellent appearance, pleasant flavor, and soft, flexible, and sticky texture.

Owner:CJ CHEILJEDANG CORP

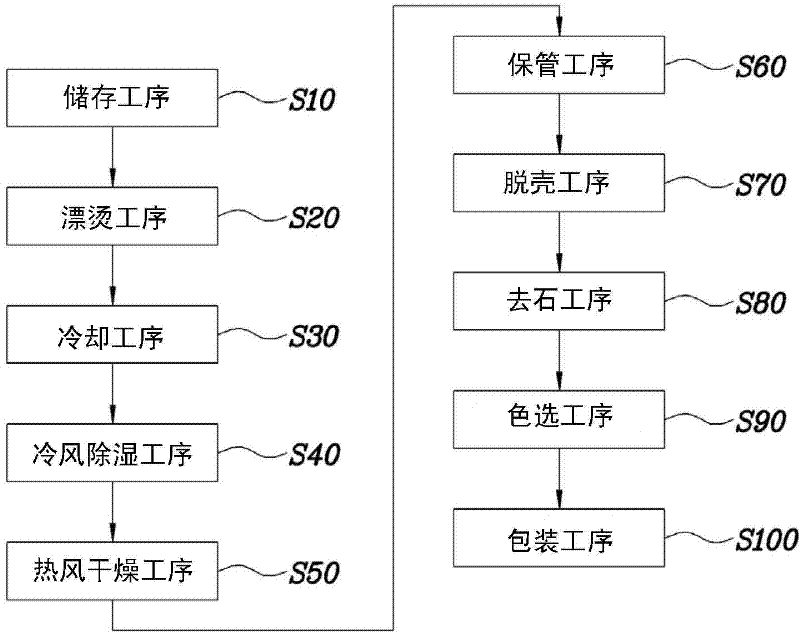

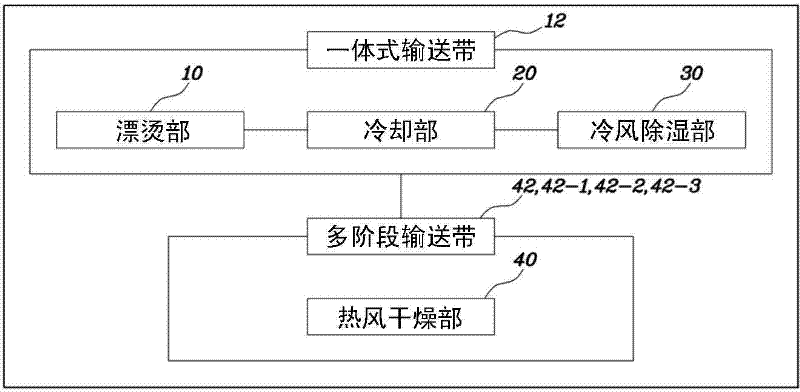

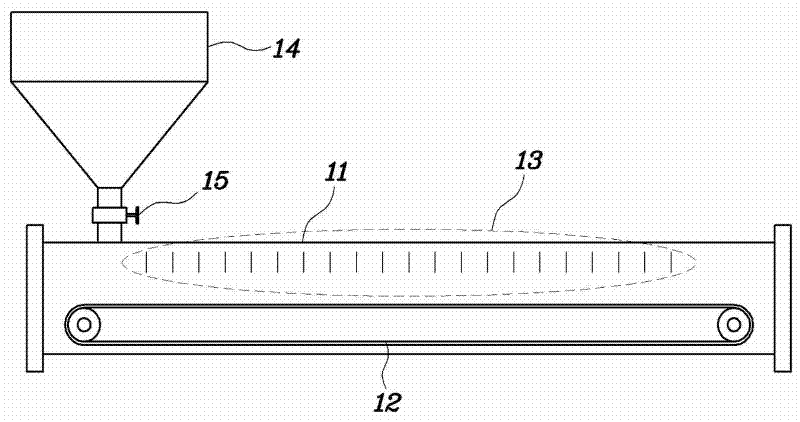

Method of processing and mass-producing green whole grains

Owner:THE IND & ACADEMIC COOP IN CHUNGNAM NAT UNIV (IAC)

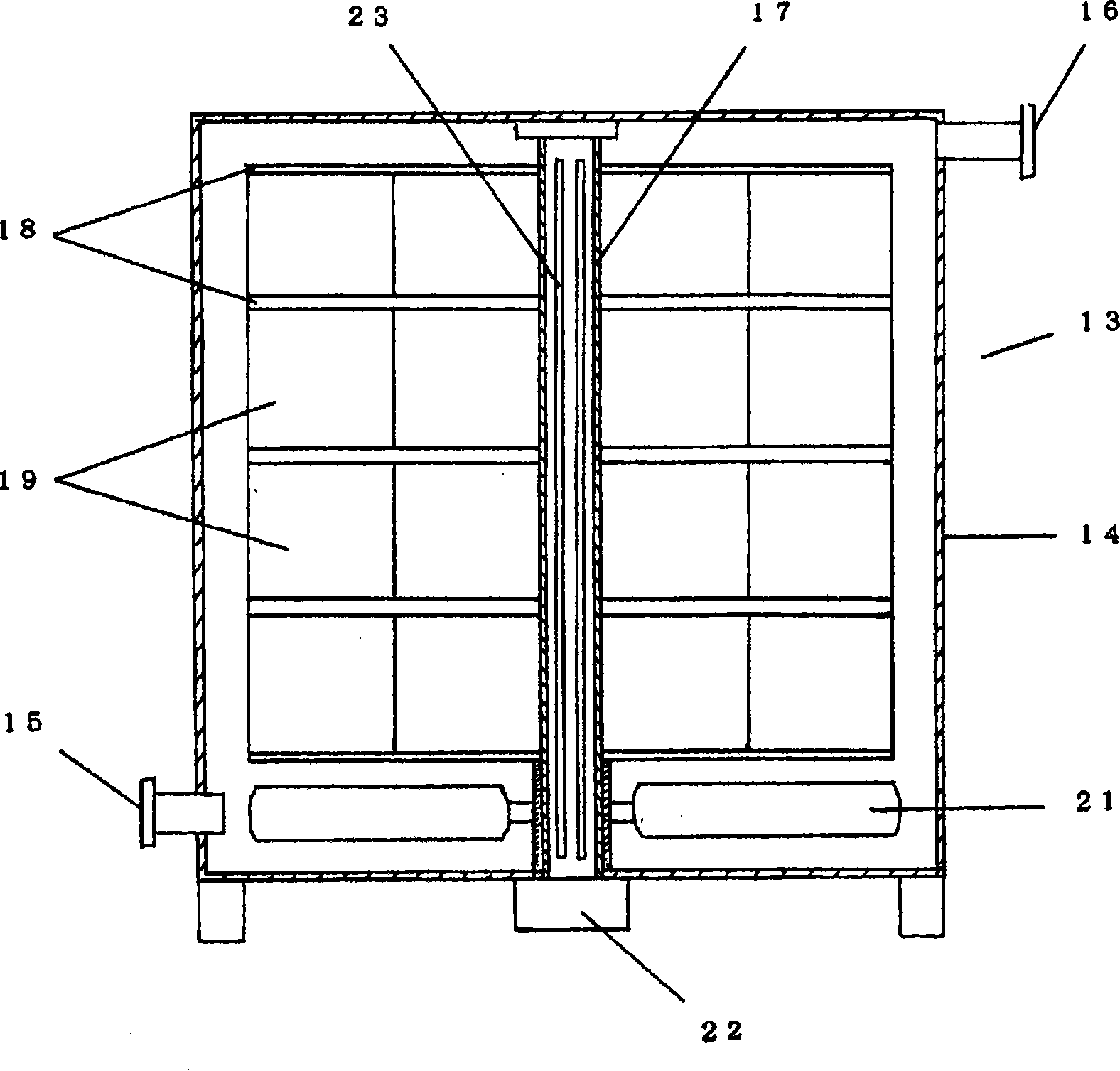

Method for drying grain and grain drier

ActiveCN101676661AIncreased efficiency of ventilation and dryingDrying solid materials with heatDrying gas arrangementsEngineeringMechanical engineering

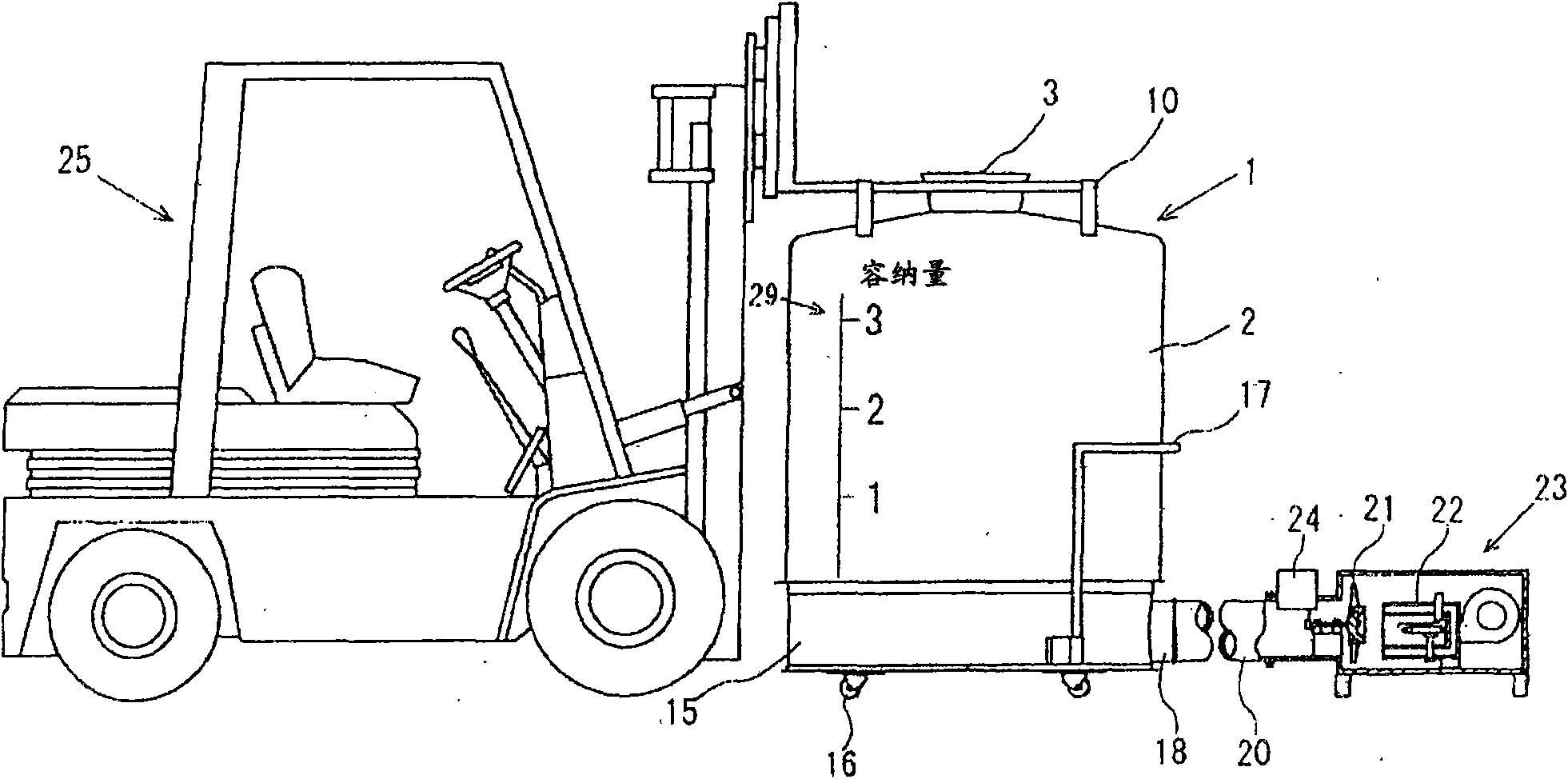

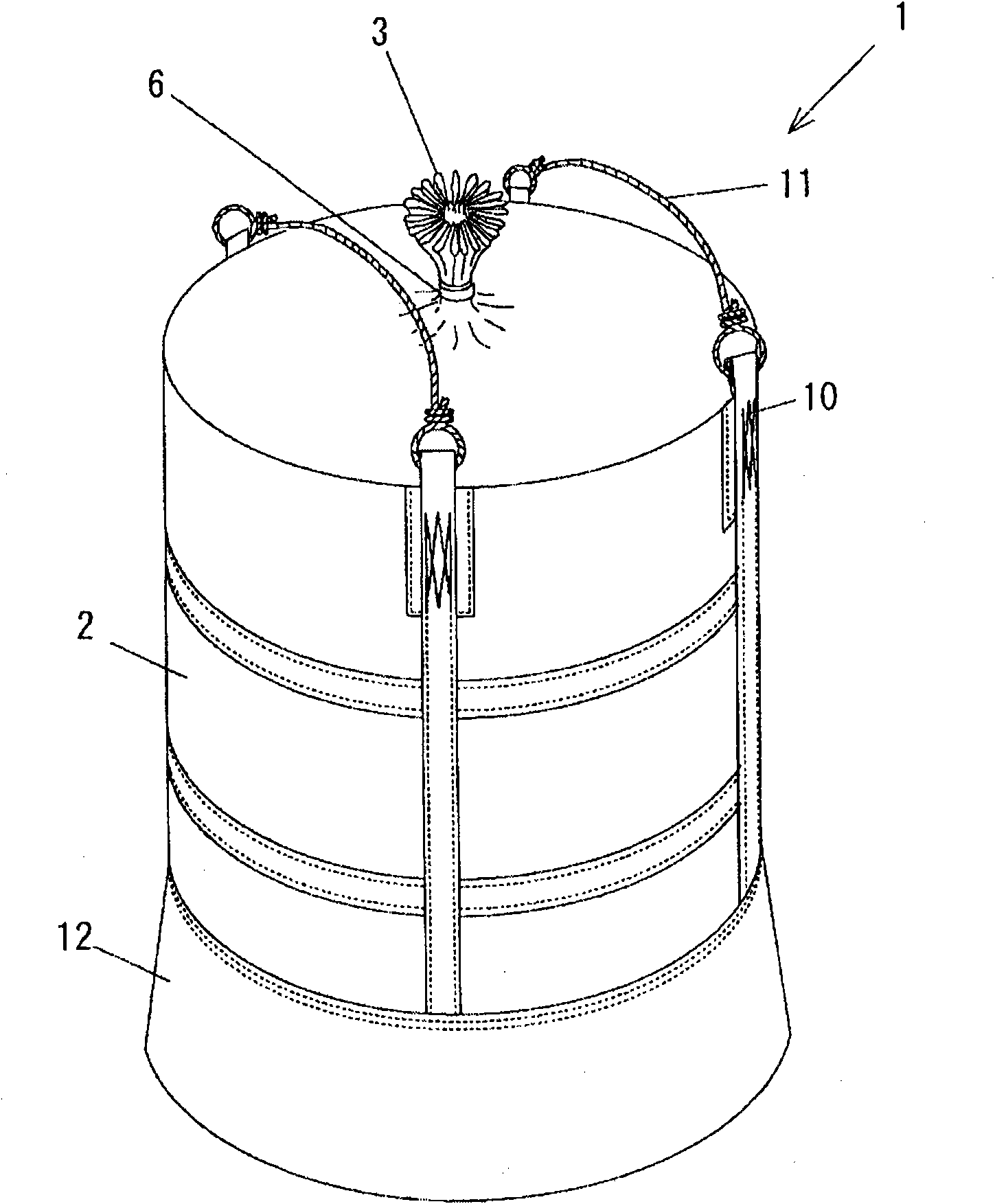

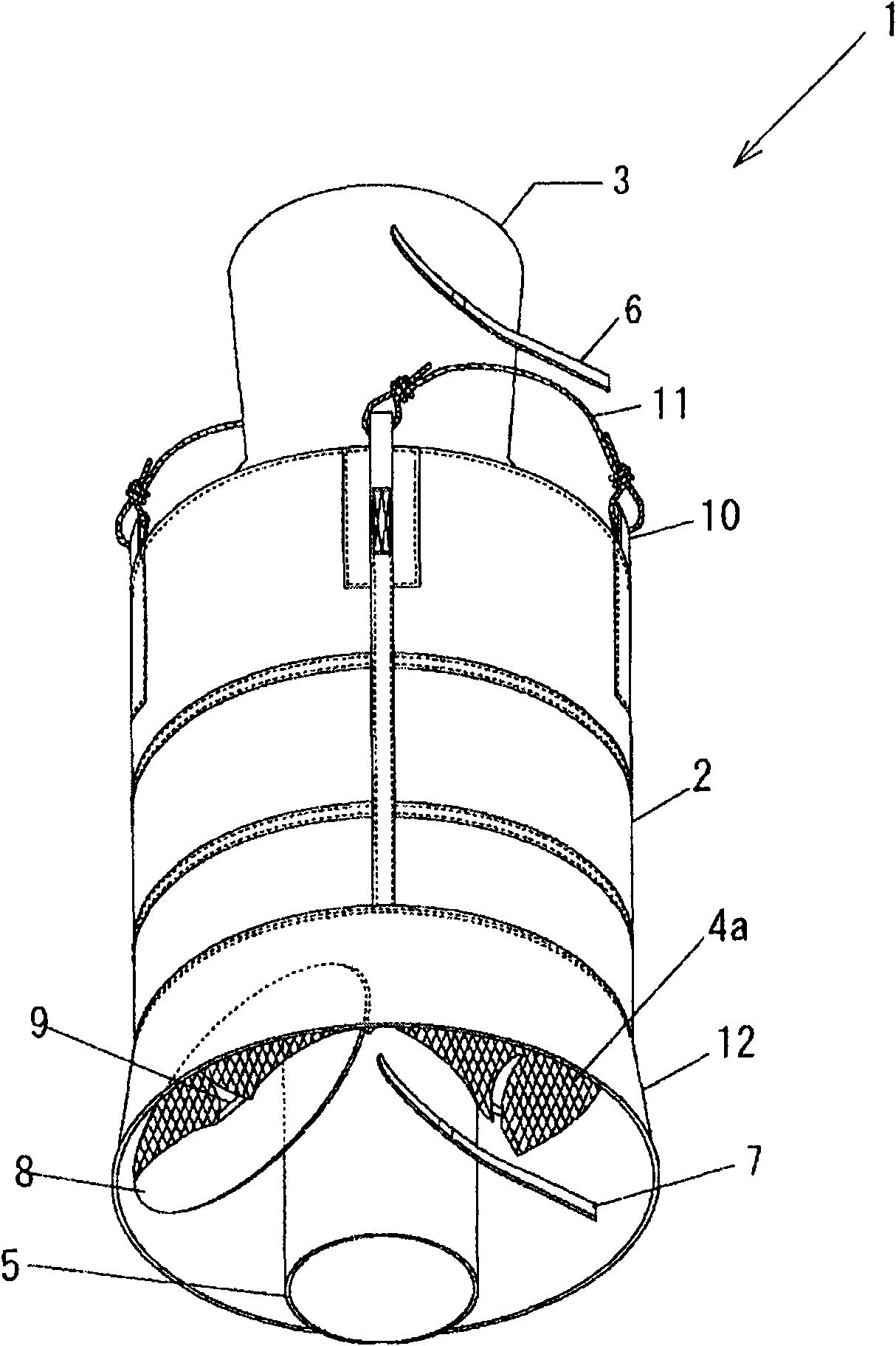

The present invention provides a method for drying grain and a grain drier, capable of drying about 1000kg of grain simultaneously without heavy work and fussy operations of processing grain and supplying wind for drying without lose. The grain drier is composed of a flexible container (1) and an air dryer. The flexible container (1) is provided with an input port (3) on the top, the bottom face of the flexible container (1) is formed by an air permeability net (4a), and the lower part circumference face of the flexible container is provided with a skirt part (12). The air drier is provided with a drying casing (15) contacted with and enclosing the bottom face or bottom of the flexible container (1), and a floor through which hot wind may pass to dry the contained grain. The flexible container (1) is arranged on the air drier, such that the lower circumference of the skirt part (12) is clinged to the external face of the drying casing (15).

Owner:SATAKE CORP +1

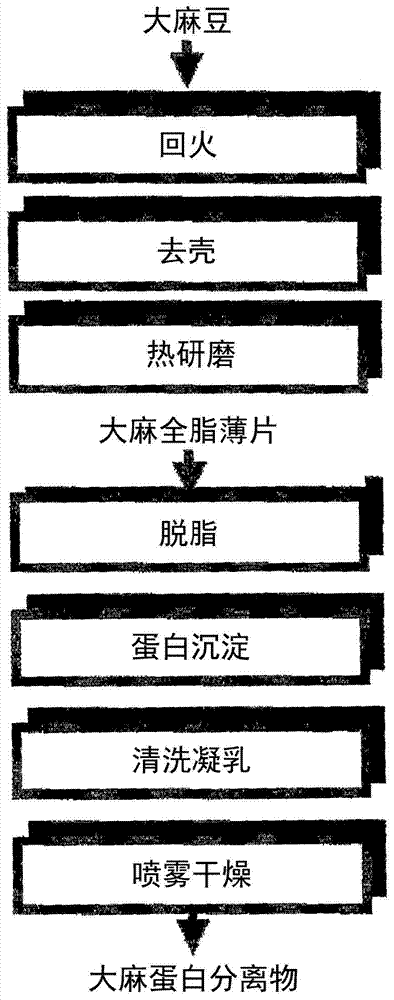

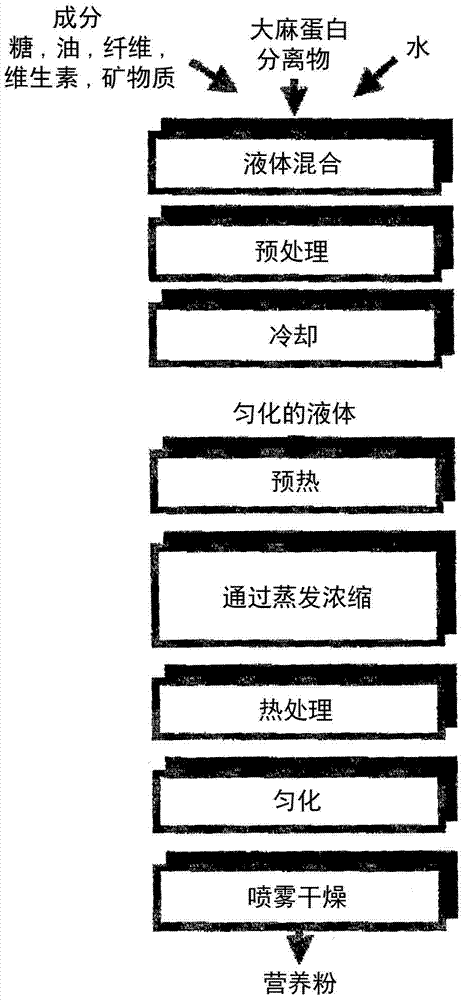

Hemp-based infant formula and methods of making same

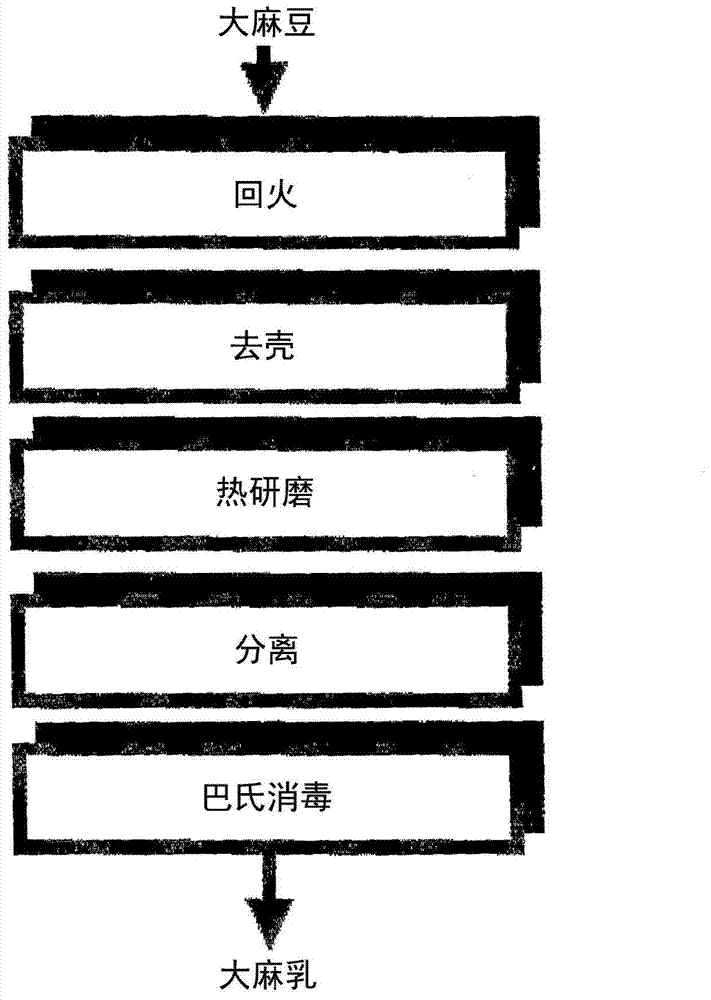

InactiveCN104302193ASolvent extractionProtein composition from vegetable seedsBiotechnologyNutrition

The present invention pertains to the field of nutrition and in particular a food product formulation based on protein and other nutrients extracted from oil seeds, such as hemp, for a plurality of uses, including, but not limited to an infant or toddler formula, a beverage, baked goods or a protein supplement. Suitable oil seeds include, but are not limited to hemp, flax, chia, pea and spirulina. Accordingly, the present invention provides a food product formulation for human consumption that can provide a complete source of dietary protein and other nutrients through oil seed protein. The formulation may be prepared in a variety of product forms, including but not limited to, a ready-to-serve liquid form, or a powder form that can be reconstituted prior to human consumption into liquid form, or a powder form that can be added to oilier ingredients to produce a baked product for human consumption, or a protein supplement.

Owner:詹尼弗·赖特 +1

Chinese chestnut brown stain preventing processing technology

ActiveCN102084894AIncrease the degree of glycationImprove the flavor of the valleySeed preservation using chemicalsSeed preservation by heatingAlcoholSweetness

The invention discloses a Chinese chestnut brown stain preventing processing method which comprises the following steps of: 1, screening Chinese chestnuts; 2, processing at low temperature; 3, processing with CO2: putting the Chinese chestnuts in an environment with the CO2 concentration of 5-30 percent (volume) and temperature of 10-20 DEG C and relative humidity of 85-95 percent for 2-20 days; 4, carrying out gas stifling treatment on the Chinese chestnuts by adopting ethylene or alcohol; 5, removing hulls and red skins; 6, inactivating enzyme: putting Chinese chestnut kernels in food-grade acidic liquid with the temperature of 80-100 DEG C or food-grade acidic stream with the temperature of 100-110 DEG C, and controlling the pH value of the liquid or stream to be 1-6 and the processing time to be 5-20min; 7, curing: putting the Chinese chestnut kernels into food-grade alkali liquid with pH value of 7-12 at a temperature of 90-100 DEG C, and processing for 5-20min; 8, bagging and sealing; 9, sterilizing with back pressure at high temperature and high pressure; and 10, cooling to normal temperature for storing. The Chinese chestnuts processed by using the technology maintain the special grain flavor and the sweetness while keeping the natural yellow color, and is best in color, favor and taste.

Owner:TIANJIN UNIV OF SCI & TECH +3

Method for restraining oat lipase liveness with microwave heating

InactiveCN101218938AImprove inactivation efficiencyExtended shelf lifeSeed preservation by heatingSeed preservation by dryingMicrowaveLiveness

The invention discloses a method for heating by microwave to restrain the activity of oat lipase which regulates the water content of oat grains to 10 to 35 percent, then carries out vacuum or sealing packaging on the treated oat grains within 0 to 24 hours, then uses the microwave to heat and fetches out the grains to dry with hot air, thus obtaining the oat grains with the lipase activities restrained or inactivated. The method of the invention has high lipase activity inactivation efficiency and can prolong the storage period or shelf life of the oat. The method of the invention has the advantages of simple and easy operation, energy saving, low cost, good working environment and sanitation environment as well as no pollution.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com