Patents

Literature

40 results about "Tortilla chips" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tortilla chip is a snack food made from corn tortillas, which are cut into wedges and then fried—or baked (alternatively they may be discs pressed out of corn masa then fried or baked). Corn tortillas are made of corn, vegetable oil, salt and water. Although first mass-produced commercially in the U.S. in Los Angeles in the late 1940s, tortilla chips grew out of Mexican cuisine, where similar items were well known, such as totopos and tostadas. Though usually made of yellow corn, they can also be made of white, blue, or red corn. Some manufacturers include many other ingredients including wheat, sugar, food colouring, and monosodium glutamate.

Method for making a masa based dough for use in a single mold form fryer

InactiveUS20050260314A1Large particle sizeImprove uniformityDough treatmentPre-baking dough treatmentMoisture distributionTortilla chips

A method of making a masa-based dough for use in a single mold form fryer. The invention is an improved process of making a buoyant, low density, low moisture content dough that is easily sheetable and results in a fried tortilla chip-like product with a similar texture of traditional tortilla chips. Starch is added to corn masa dough to help control moisture release during frying. The high shear mixing of the dough entrains air through nuclei formation making the dough more buoyant, and results in a smaller particle size of the dough increasing the uniformity of moisture distribution. The uniformity of moisture distribution provides more uniform buoyancy of the masa-based dough as it travels through a single mold form fryer.

Owner:FRITO LAY NORTH AMERICA INC

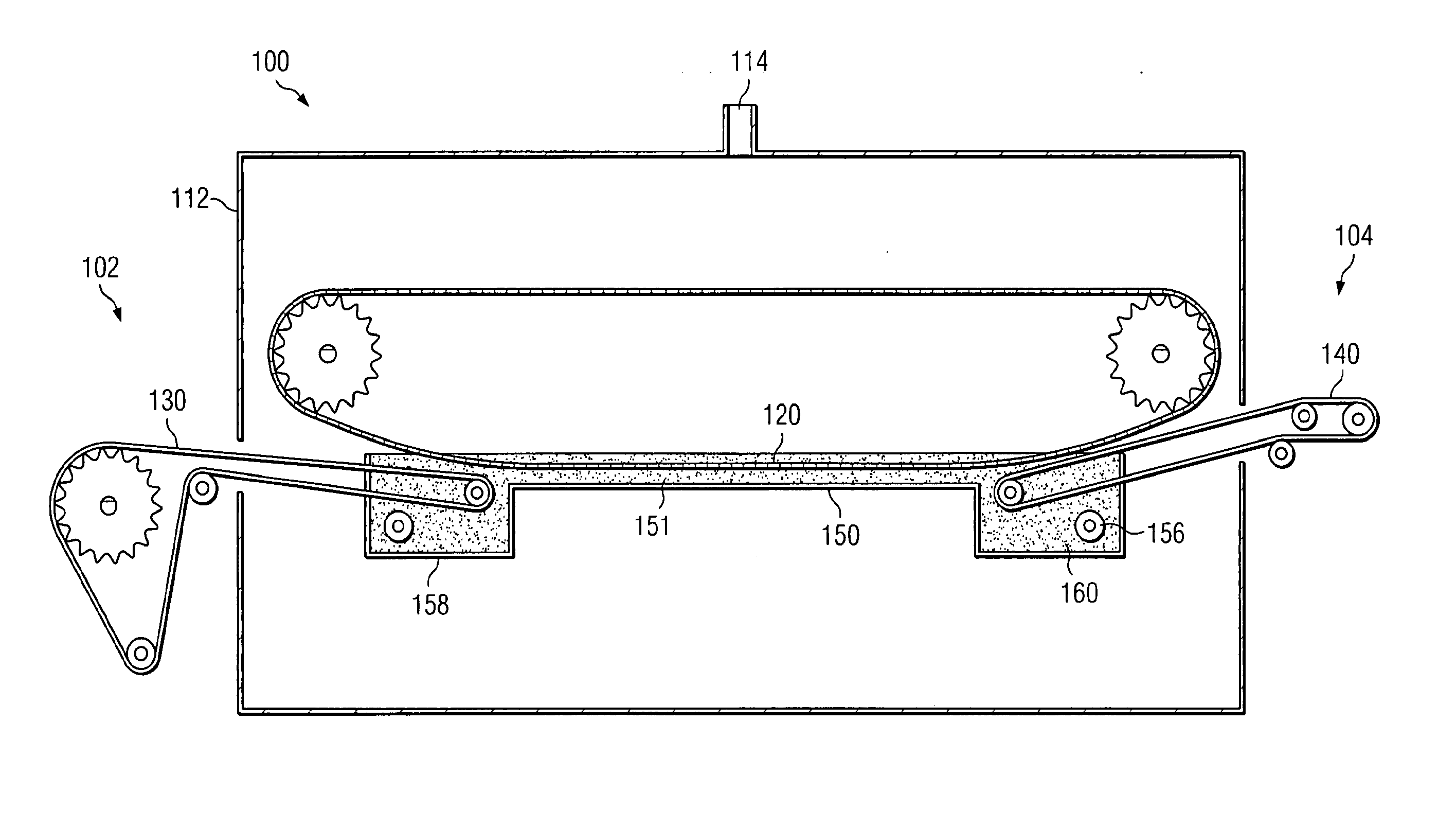

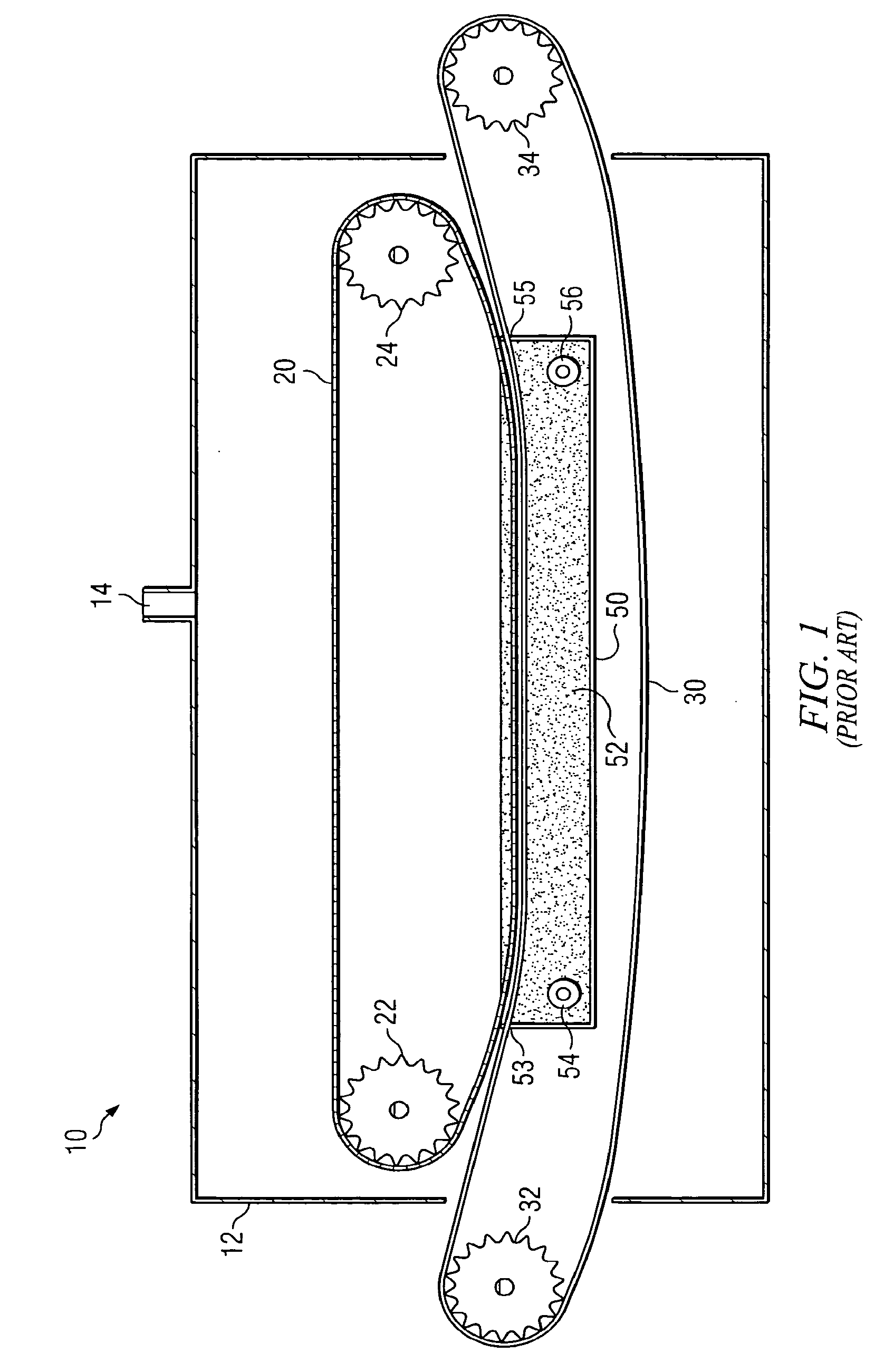

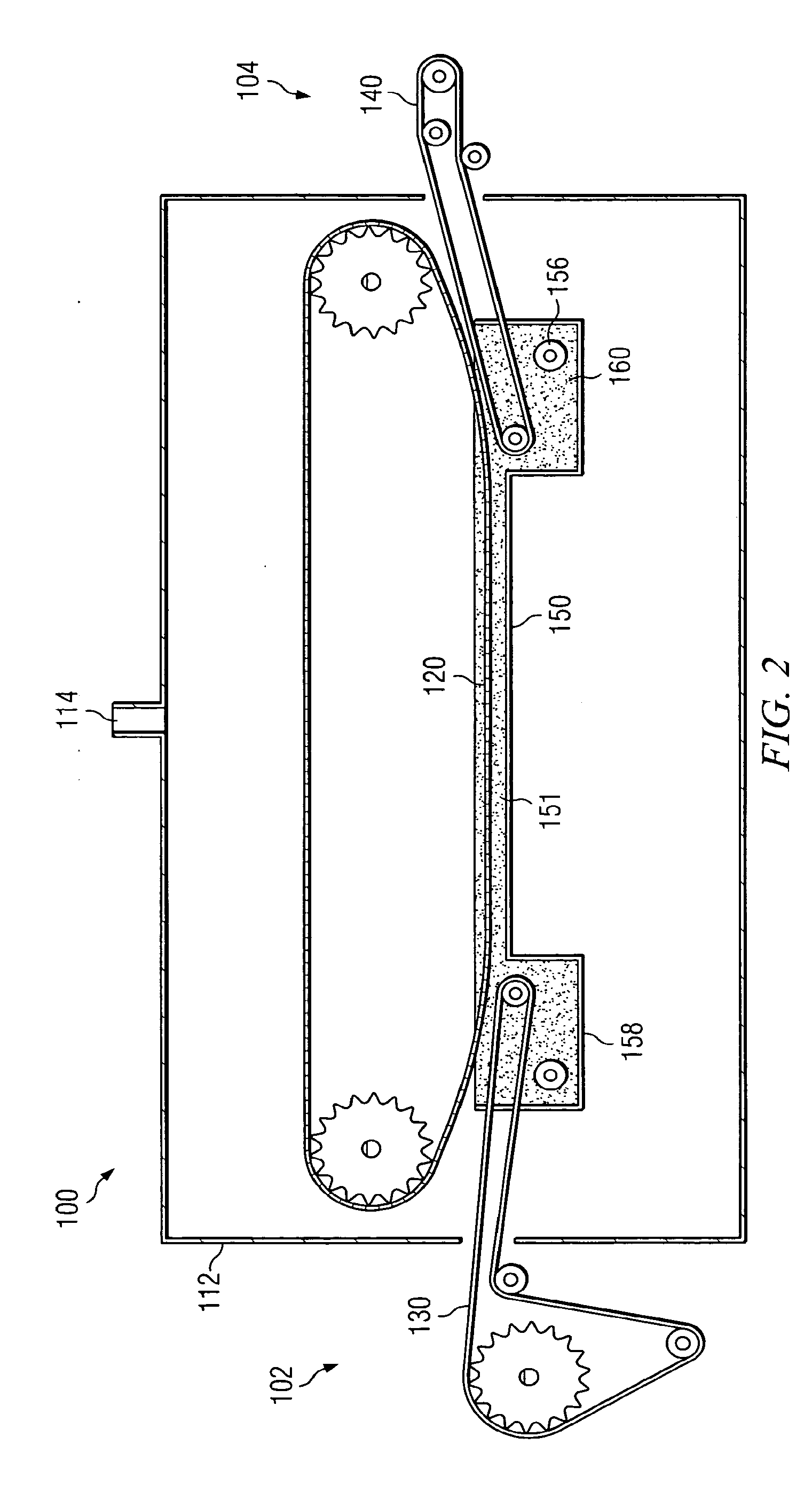

Production of whole grain shredded products

InactiveUS20060246195A1Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsSnack food

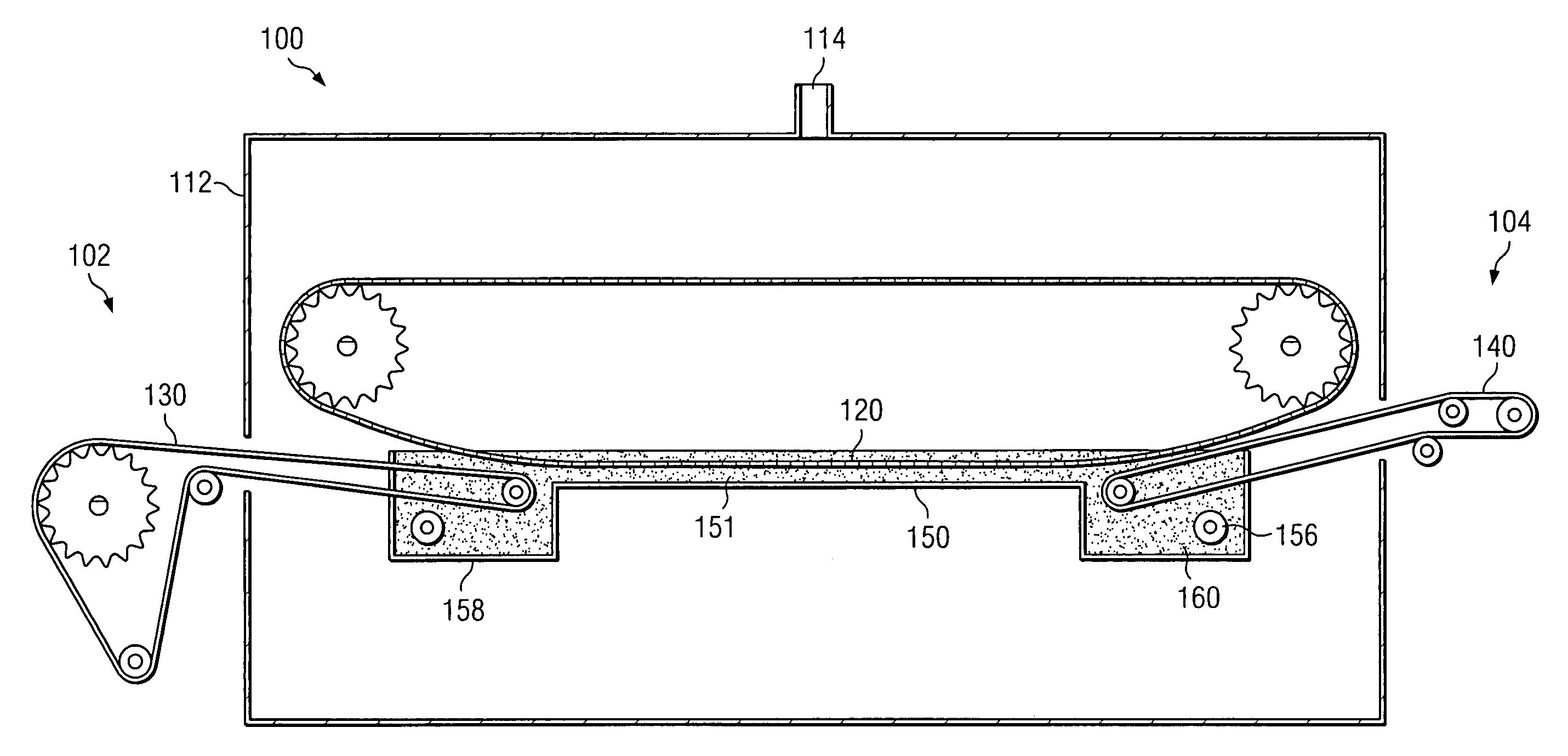

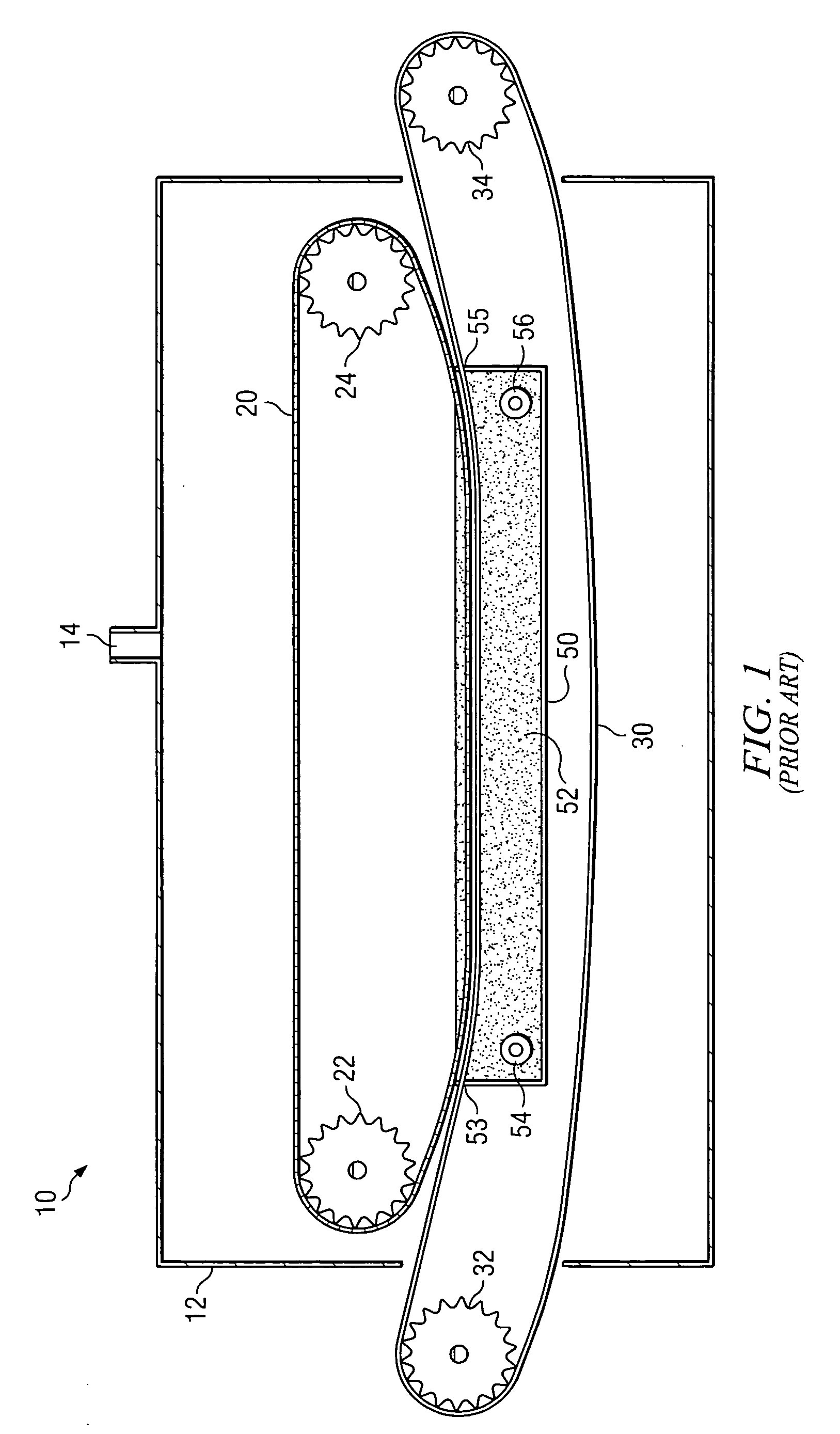

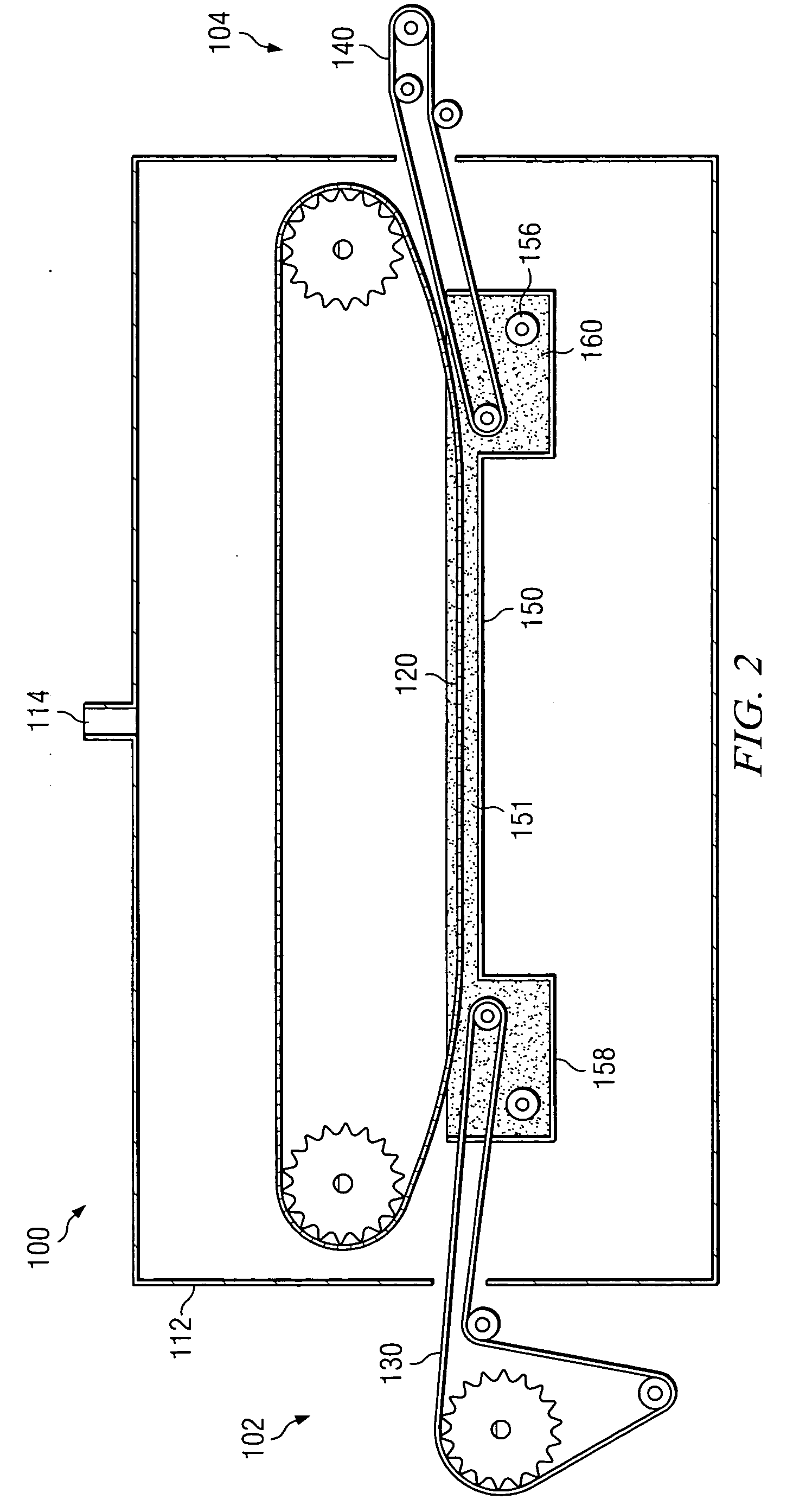

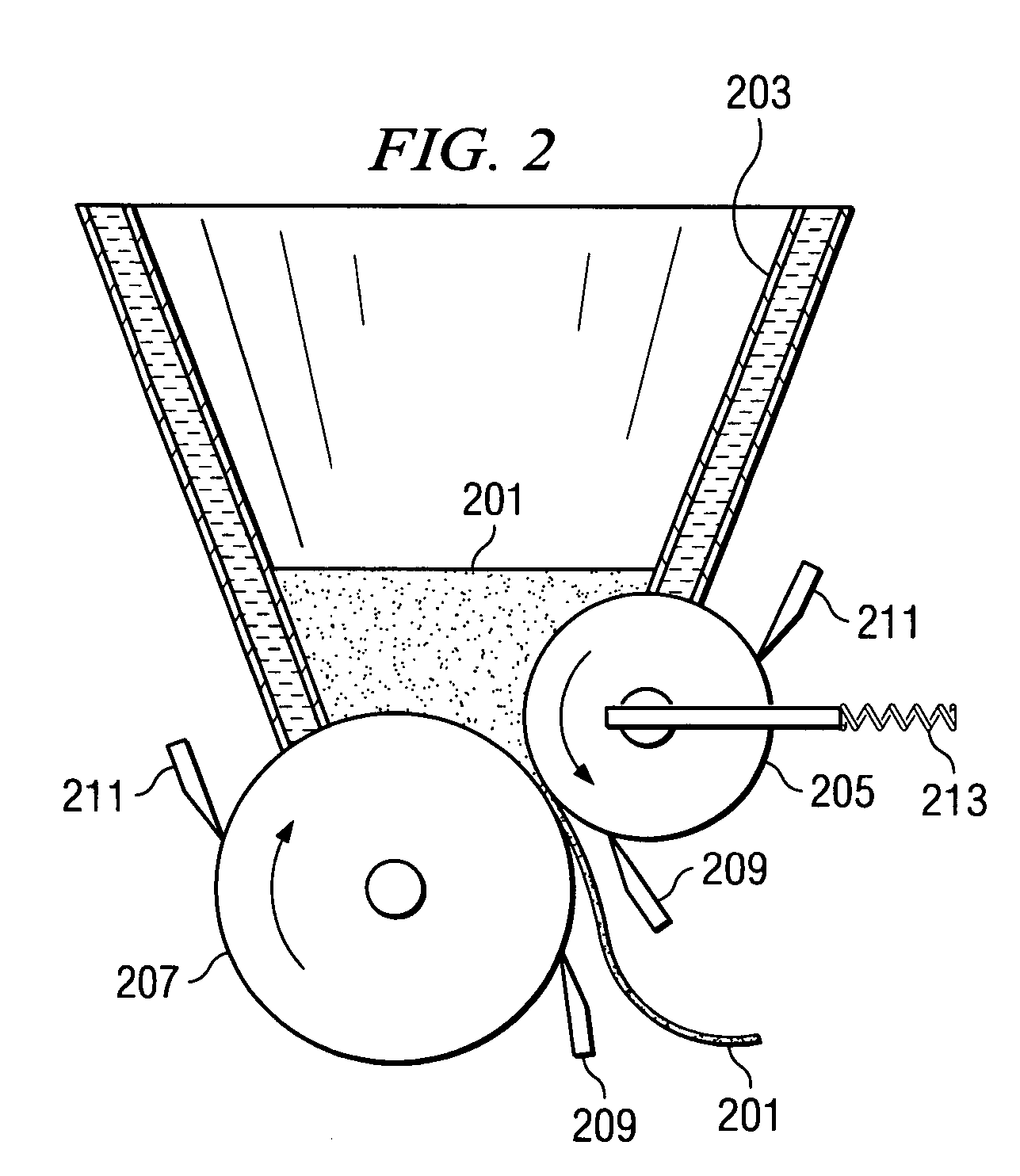

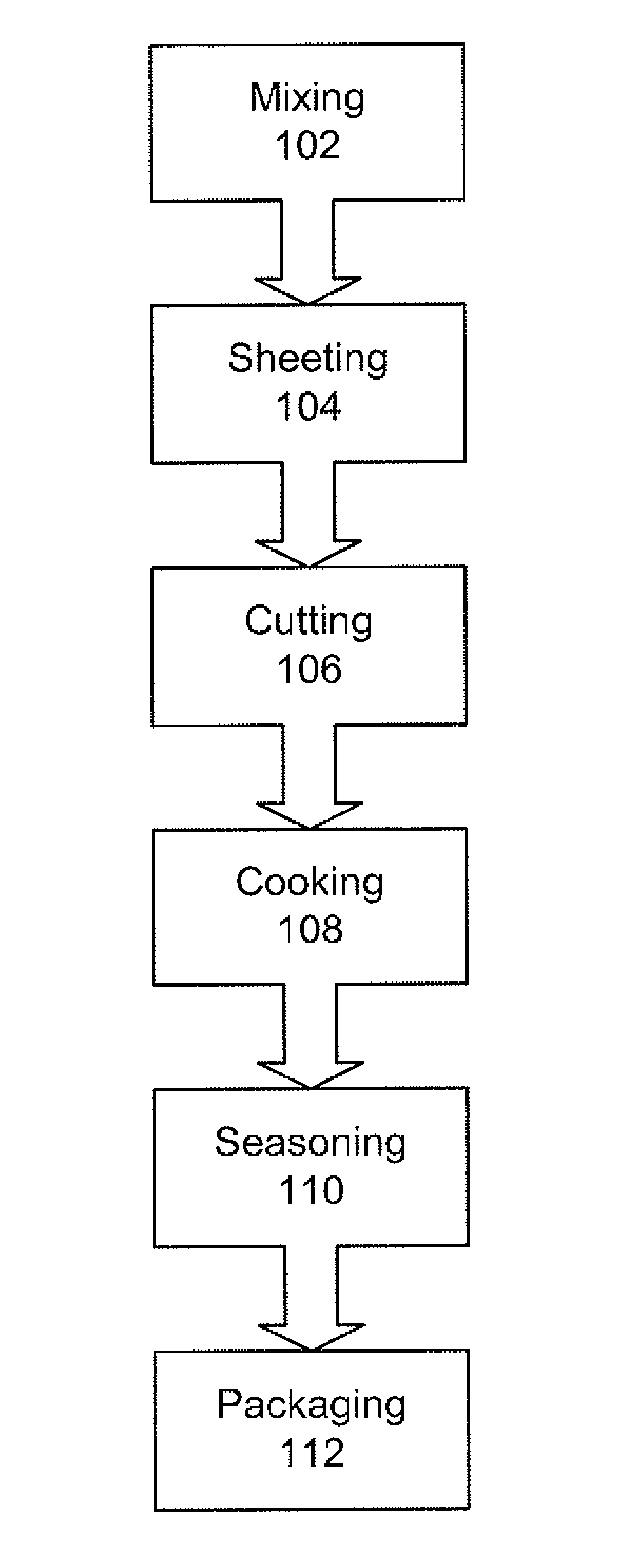

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 135° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS

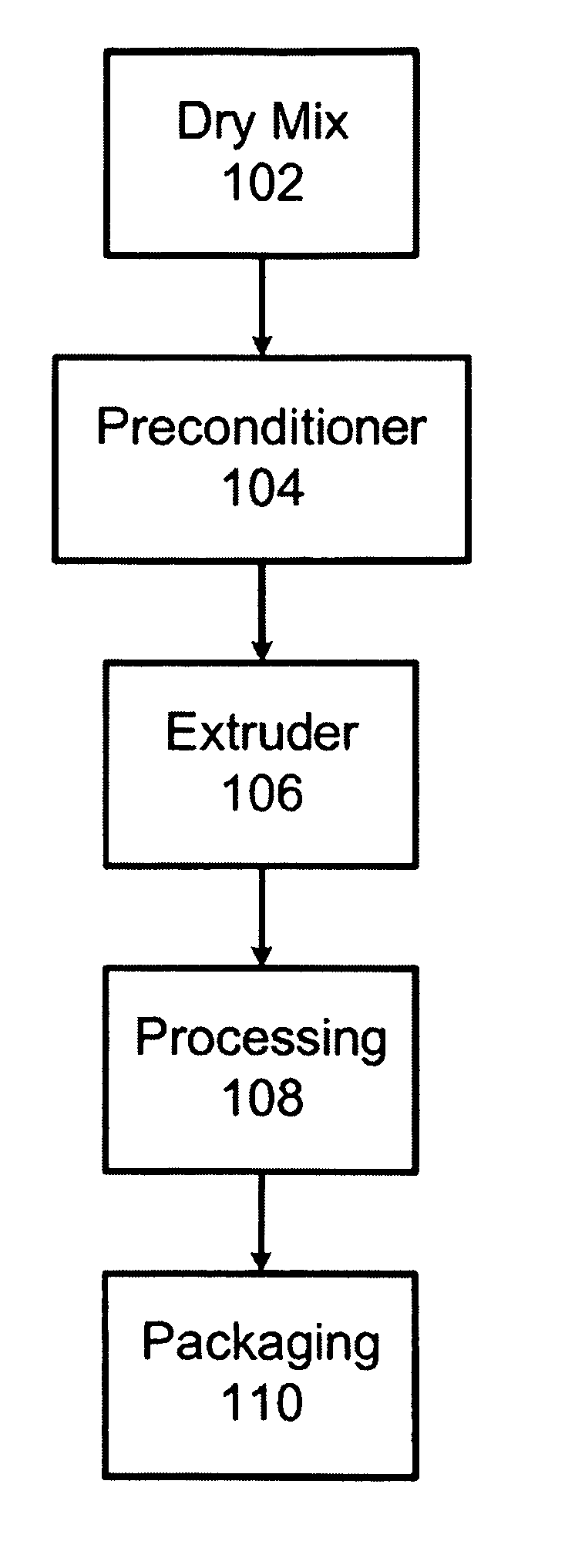

Process for producing instant breakfast samp

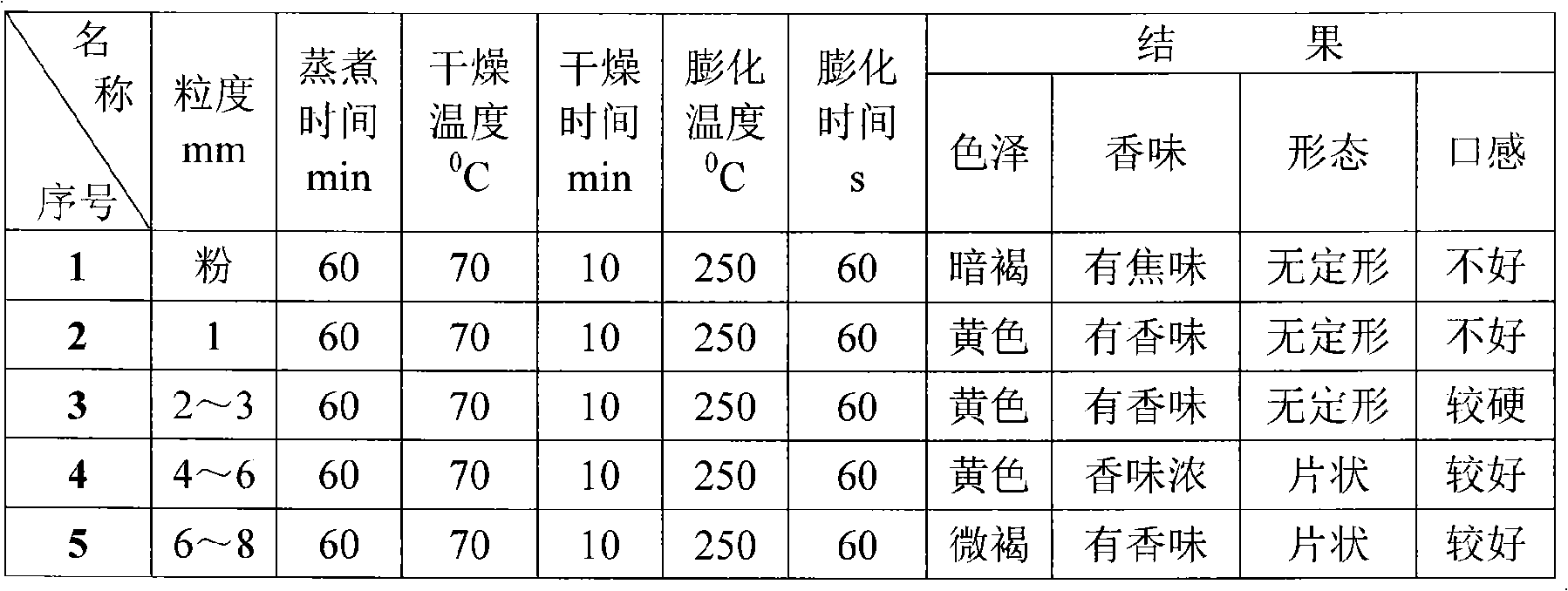

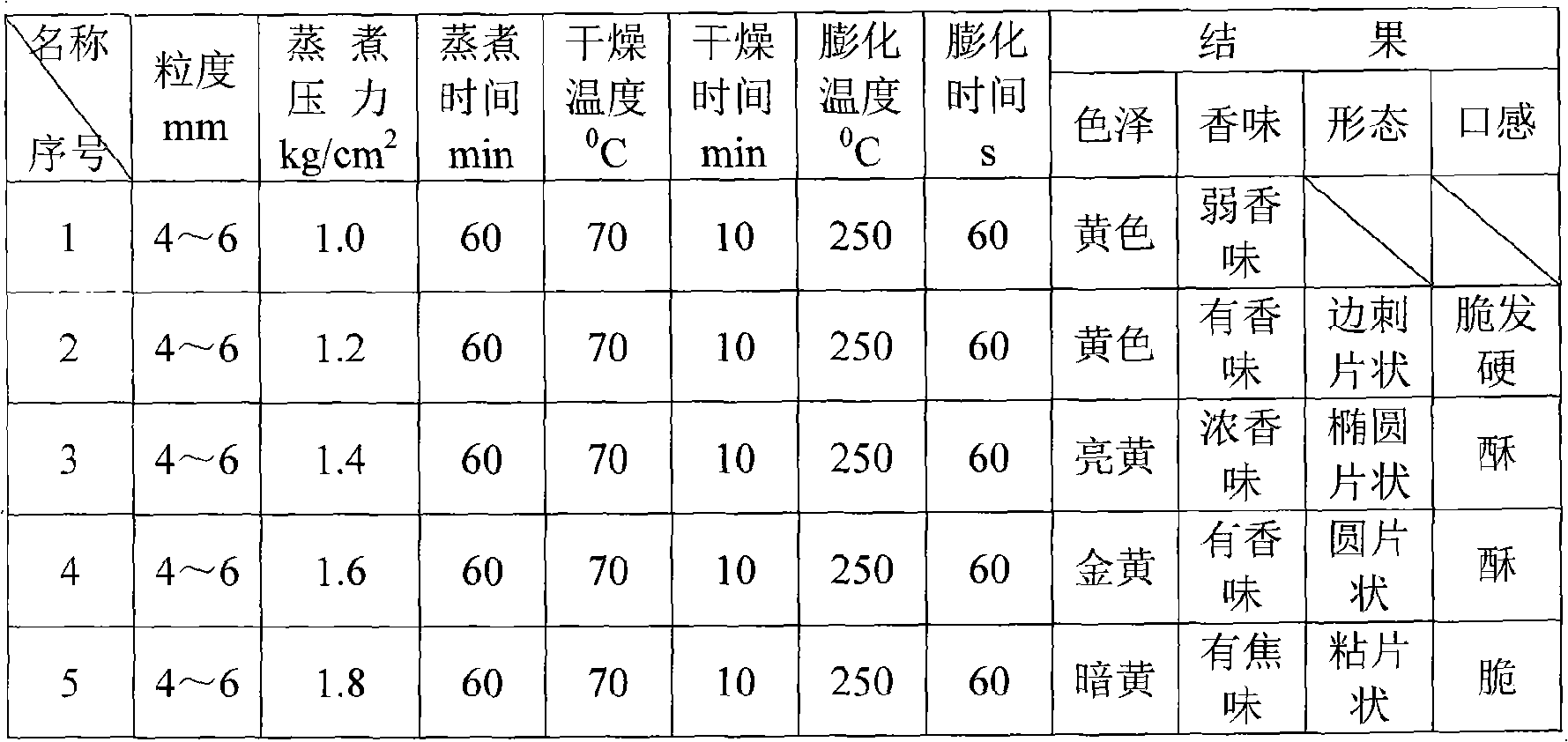

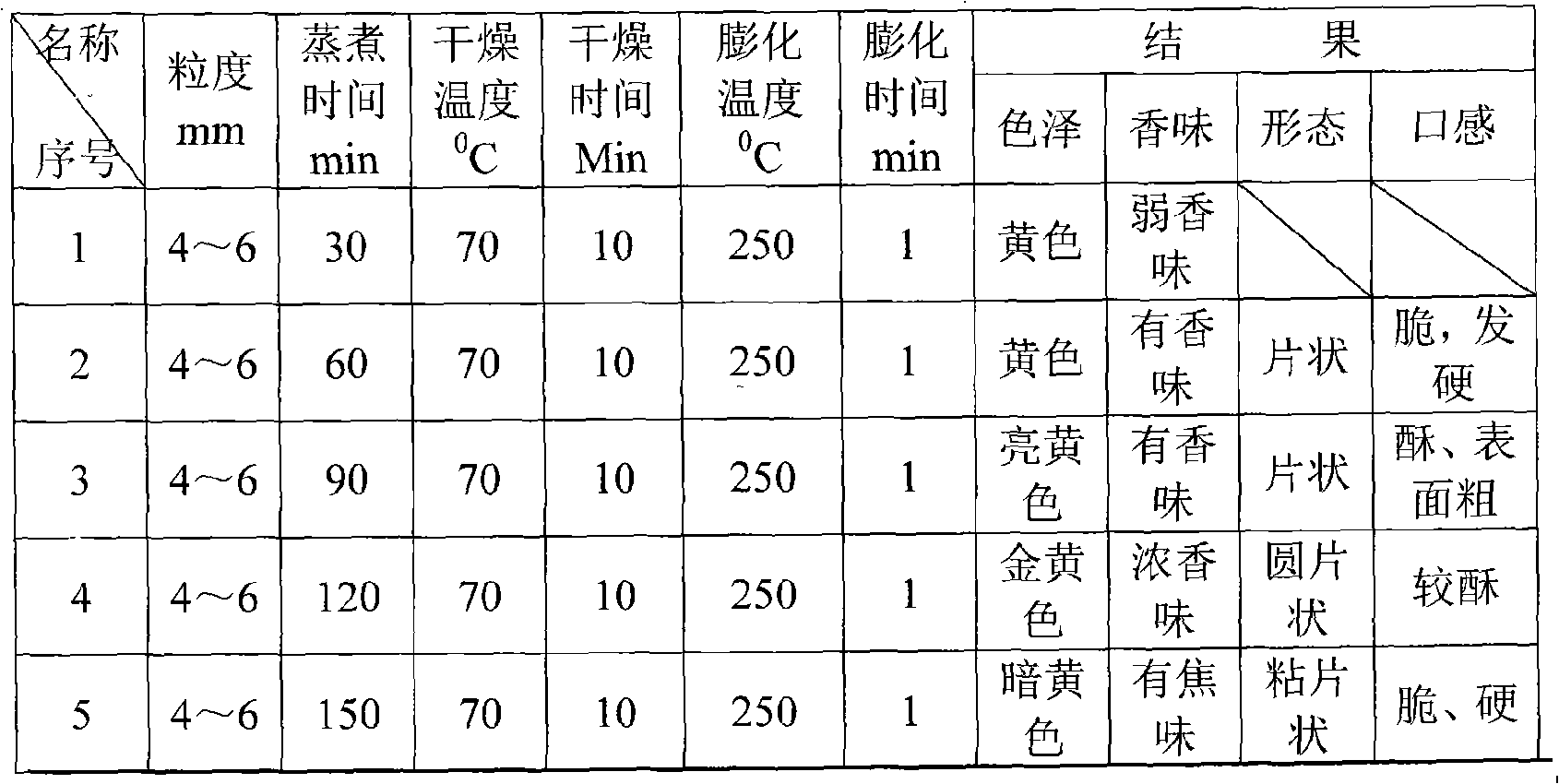

The invention relates to a process for producing an instant breakfast samp, which comprises the technological processes of core selection, cleaning, conditioning treatment, peeling and degermination, classification, corn ballast, soaking, steam boiling, loosening, quenching and tempering, continuous tabletting, drying, microbulking, cooling and packaging. The novel process for producing the instant breakfast samp solves the technical problems of anti-sticking, continuous tabletting, continuous microbulking and the like corn ballast tablet so that the instant breakfast samp cannot be produced industrially for a long time. Through the novel process, the industrial production of the instant breakfast samp appears for the first time domestically, the product quality reaches the advanced level of like products in other countries, and the produced instant breakfast samp has the advantages of low cost, crisp mouthfeel and original pure natural mouthfeel of corn.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Production of whole grain shredded products

InactiveUS20060246193A1Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 120° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

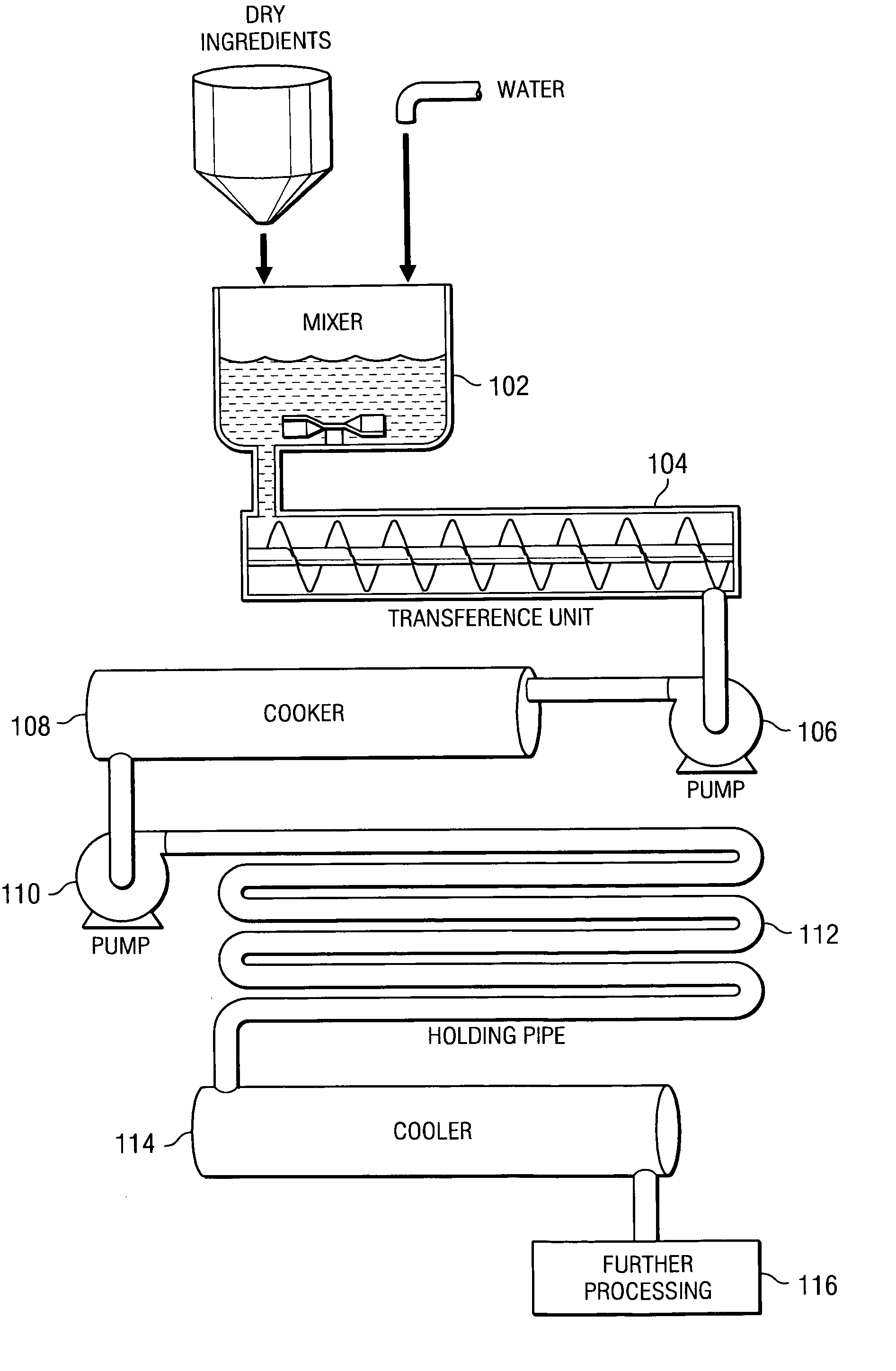

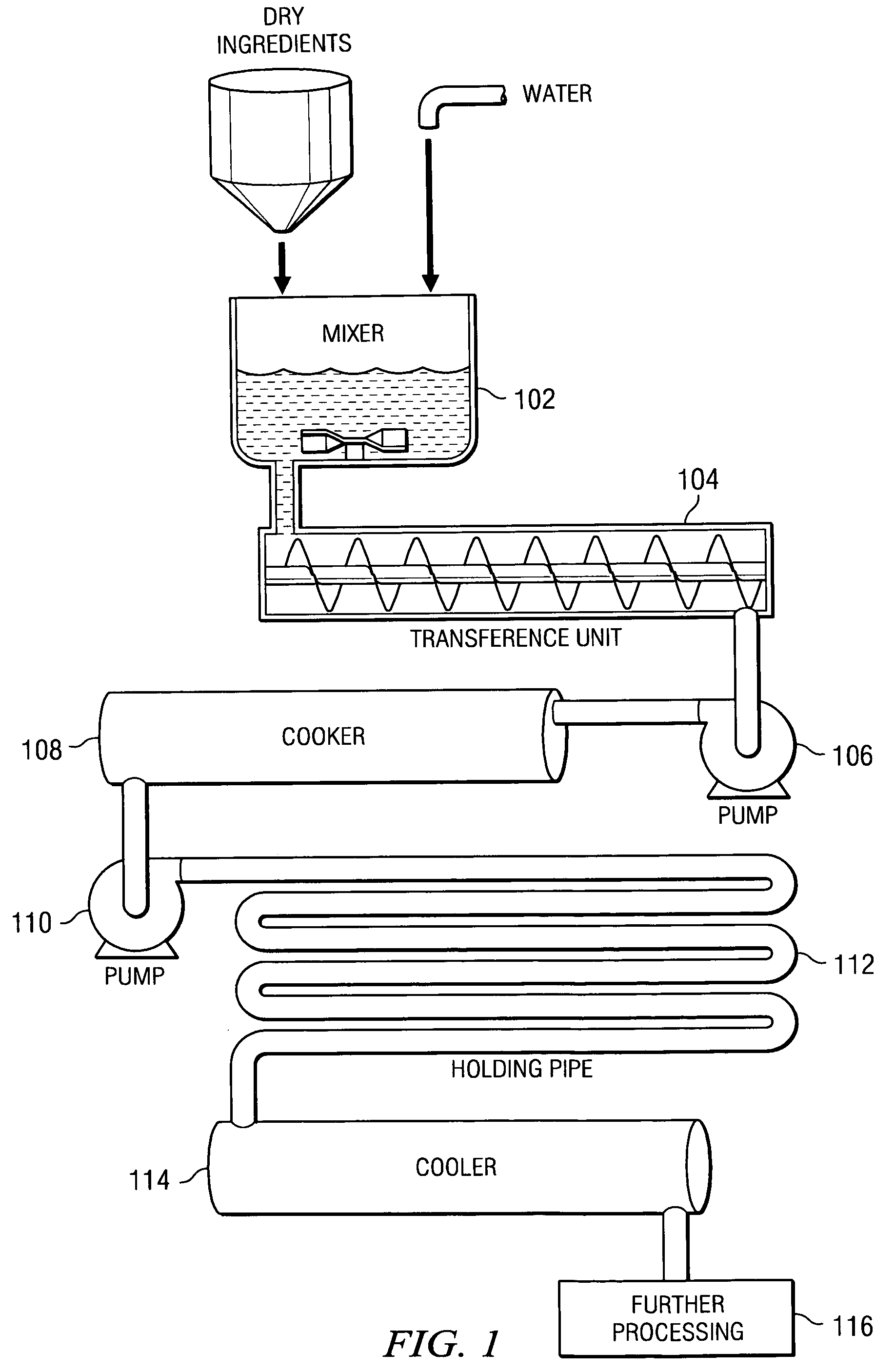

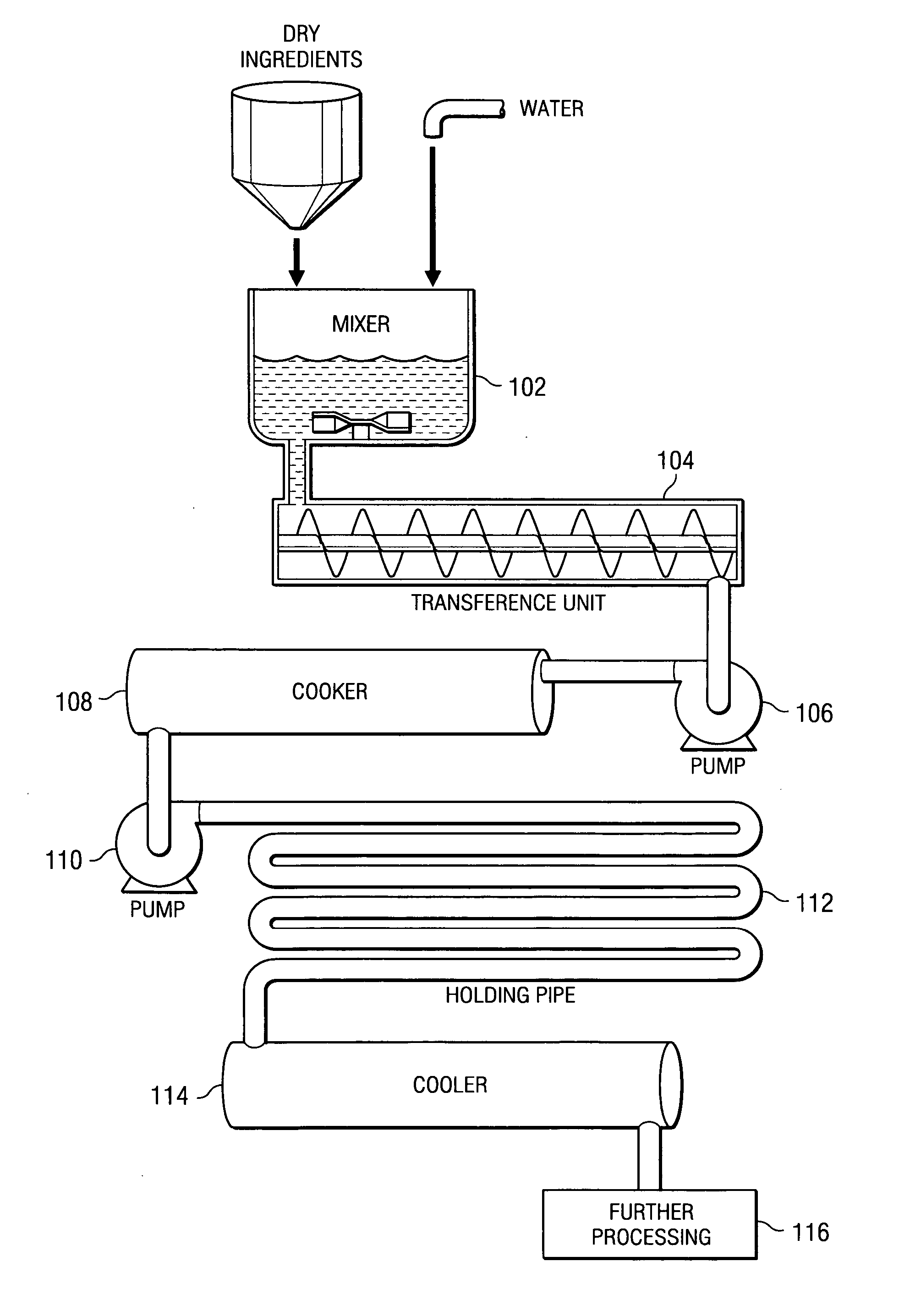

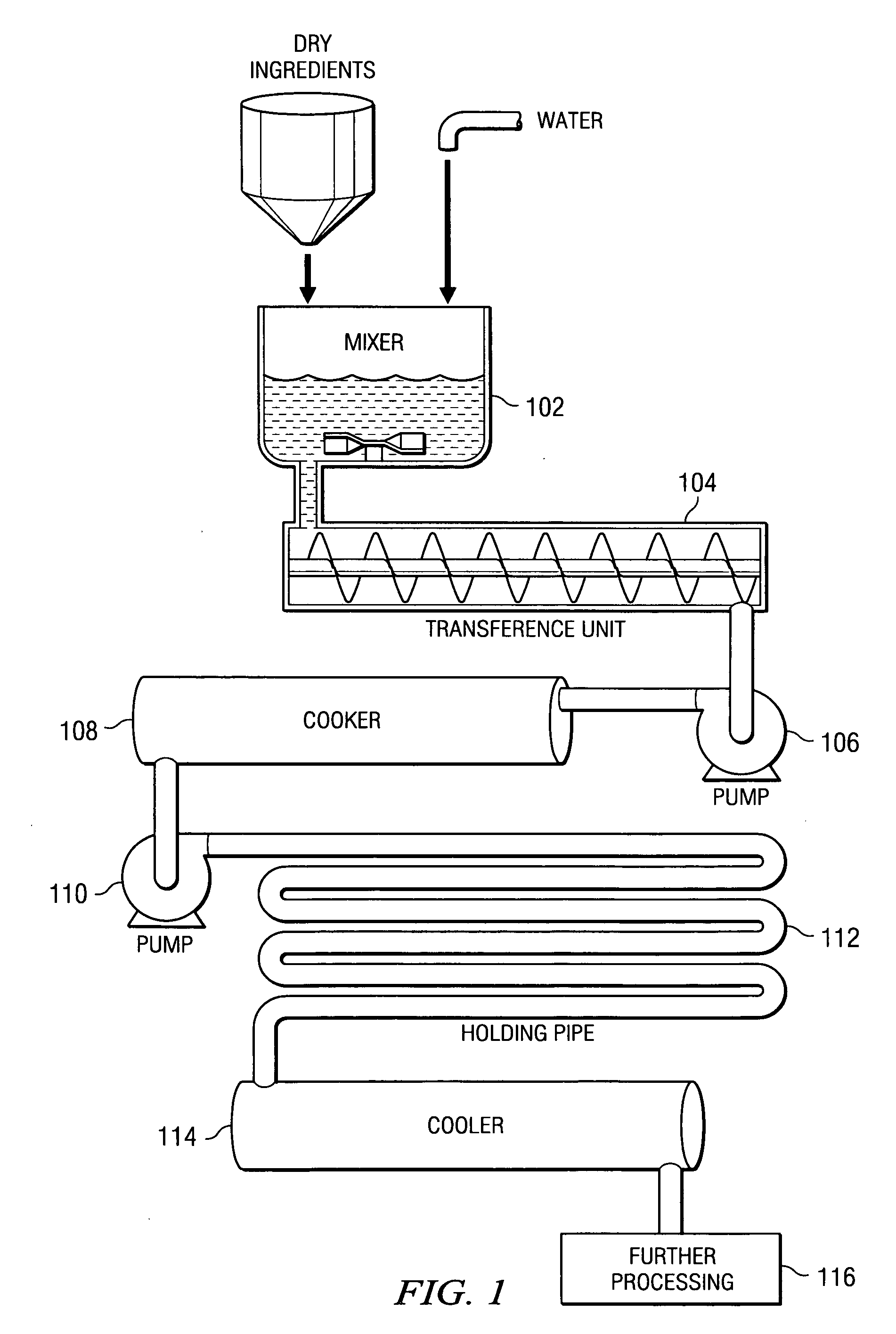

Instant masa

ActiveUS20060177557A1Easy to controlShorten the production cycleDough treatmentBaking mixturesTortilla chipsCorn flour

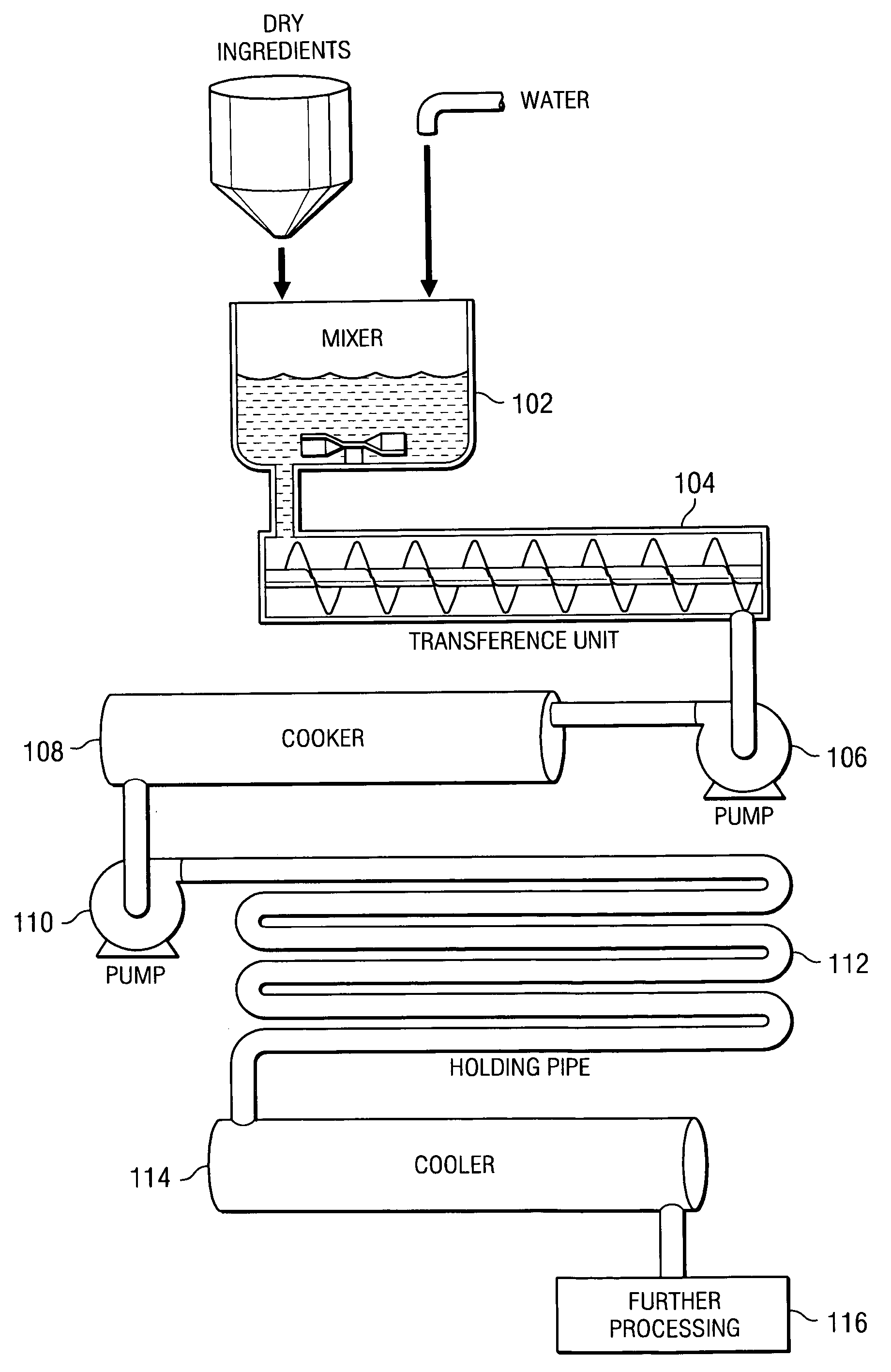

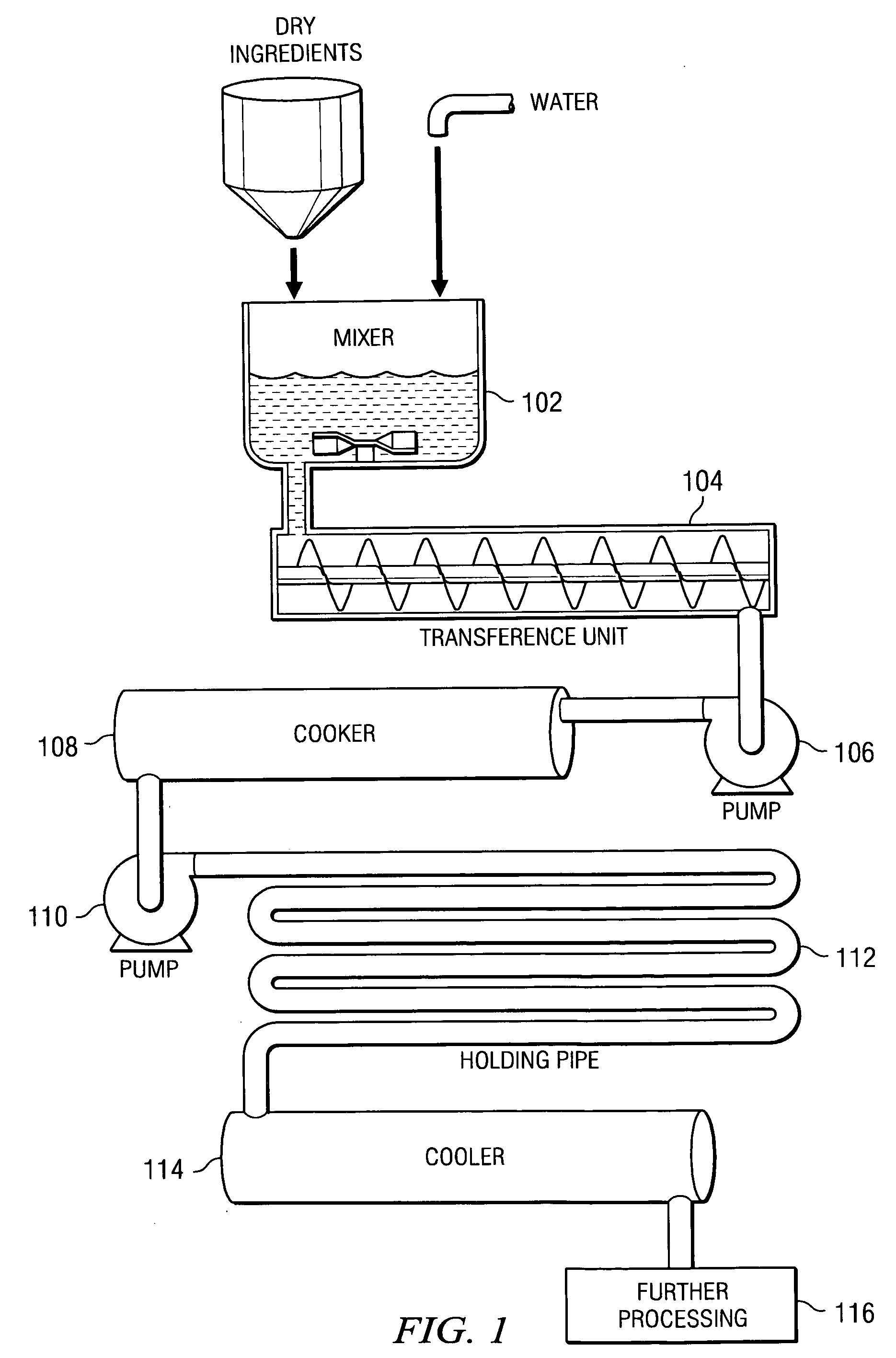

A process for the production of fresh masa, nixtamalized flour and derived products. The invention is a new process for production of corn masa (dough) to be used in the production of tortillas, fried or baked tortilla chips, tostadas, or corn chips. The new process produces masa directly from raw materials without the traditional cooking and steeping steps. It utilizes a series of processing steps including milling, blending, hydration, cooking and continuous cooling to stop gelatinization. The new process uses very little water and emits no waste water.

Owner:SABRITAS

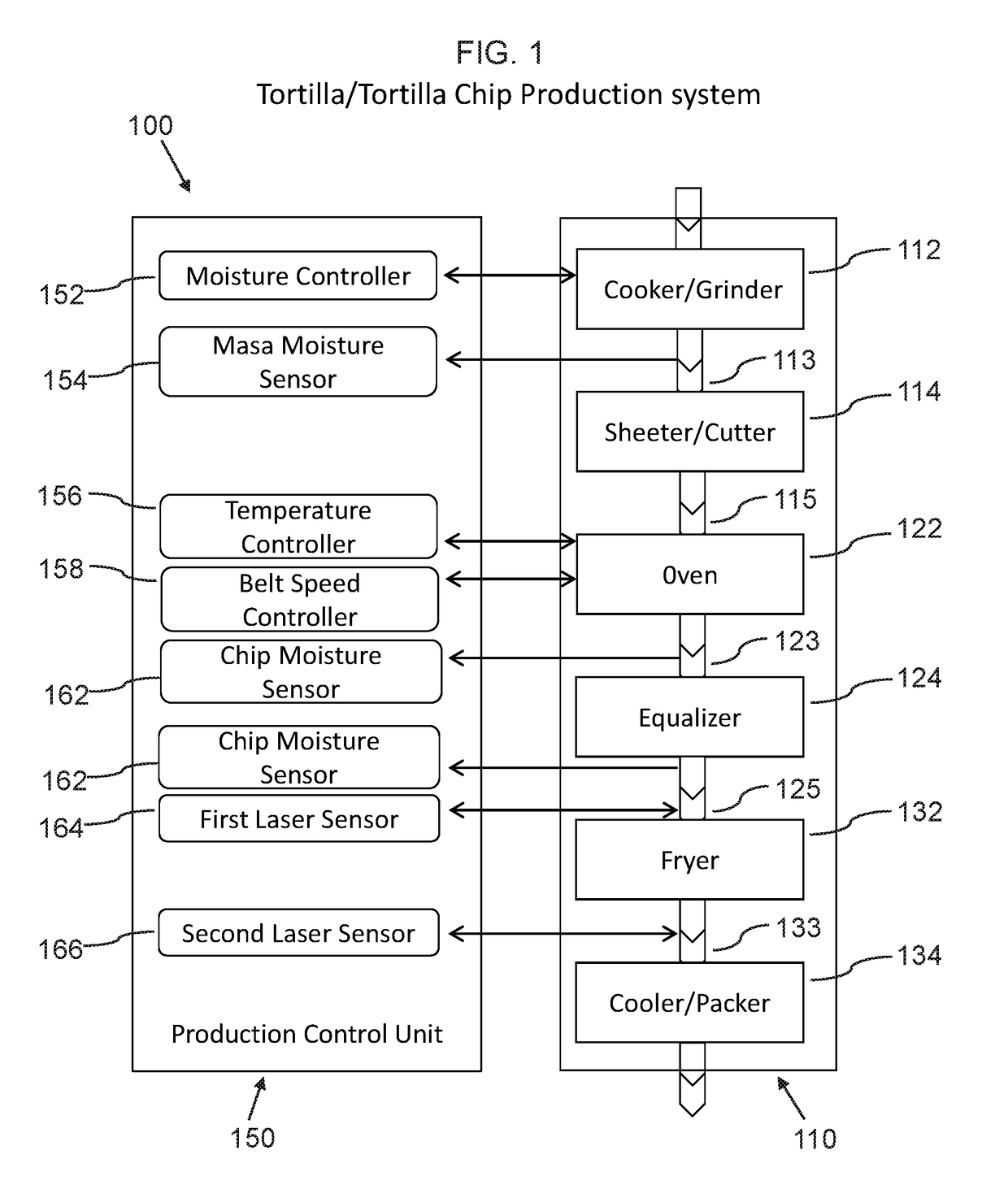

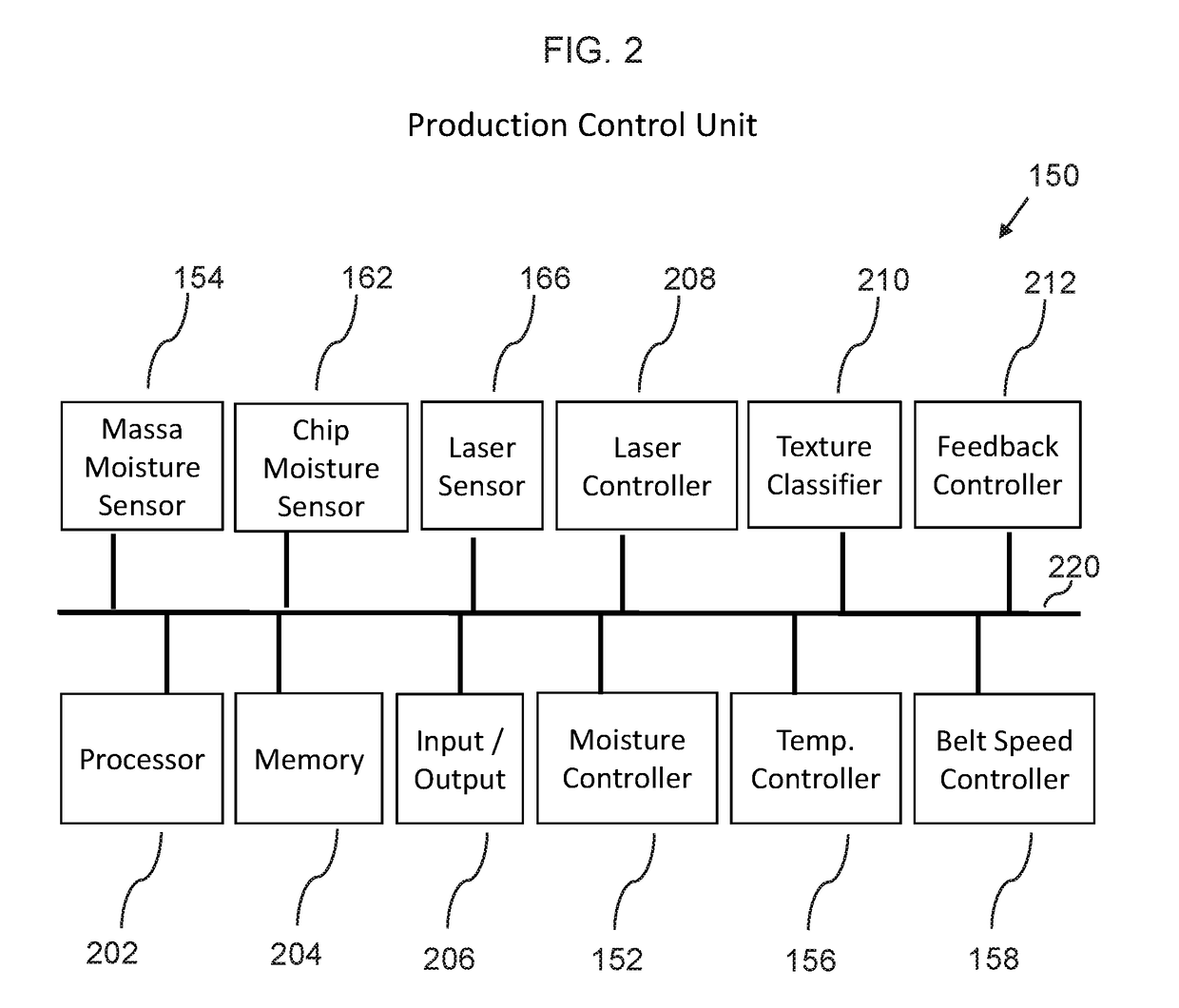

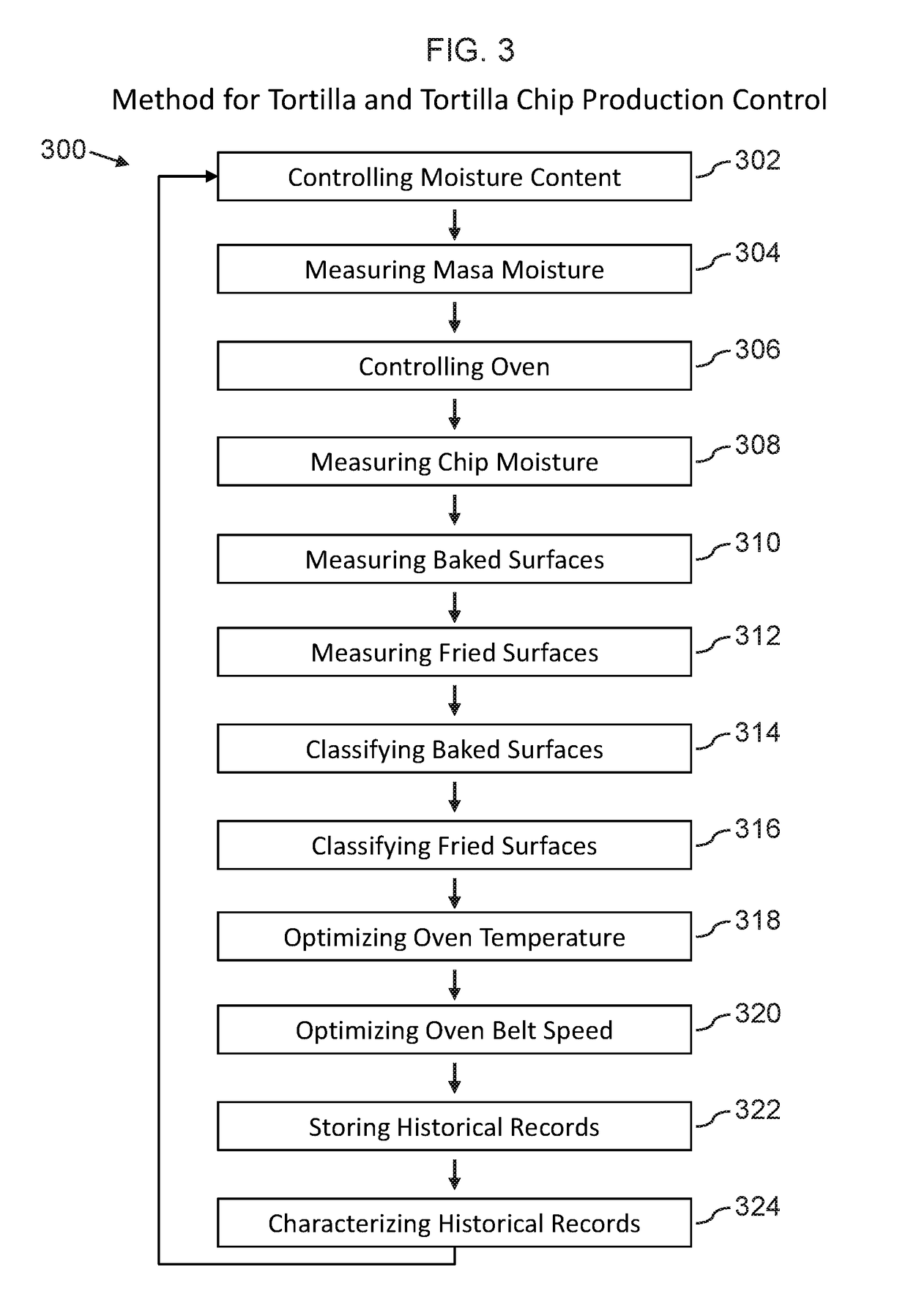

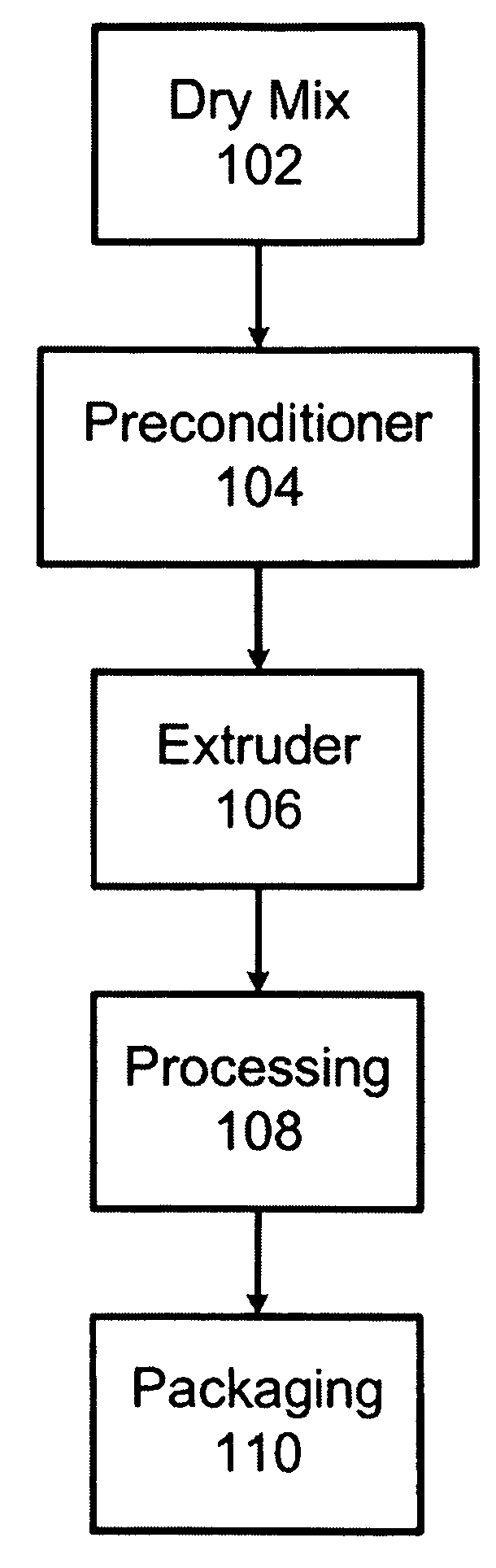

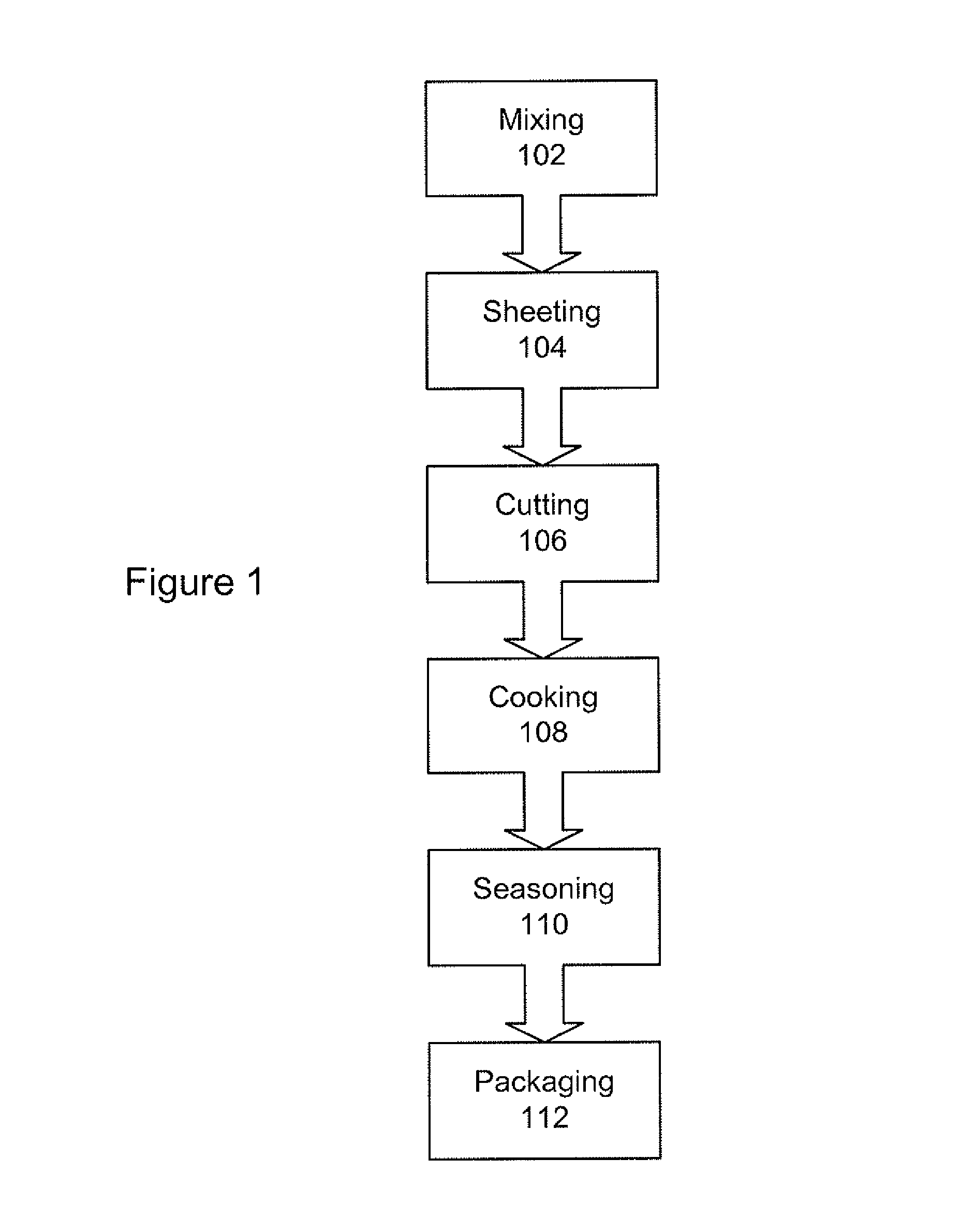

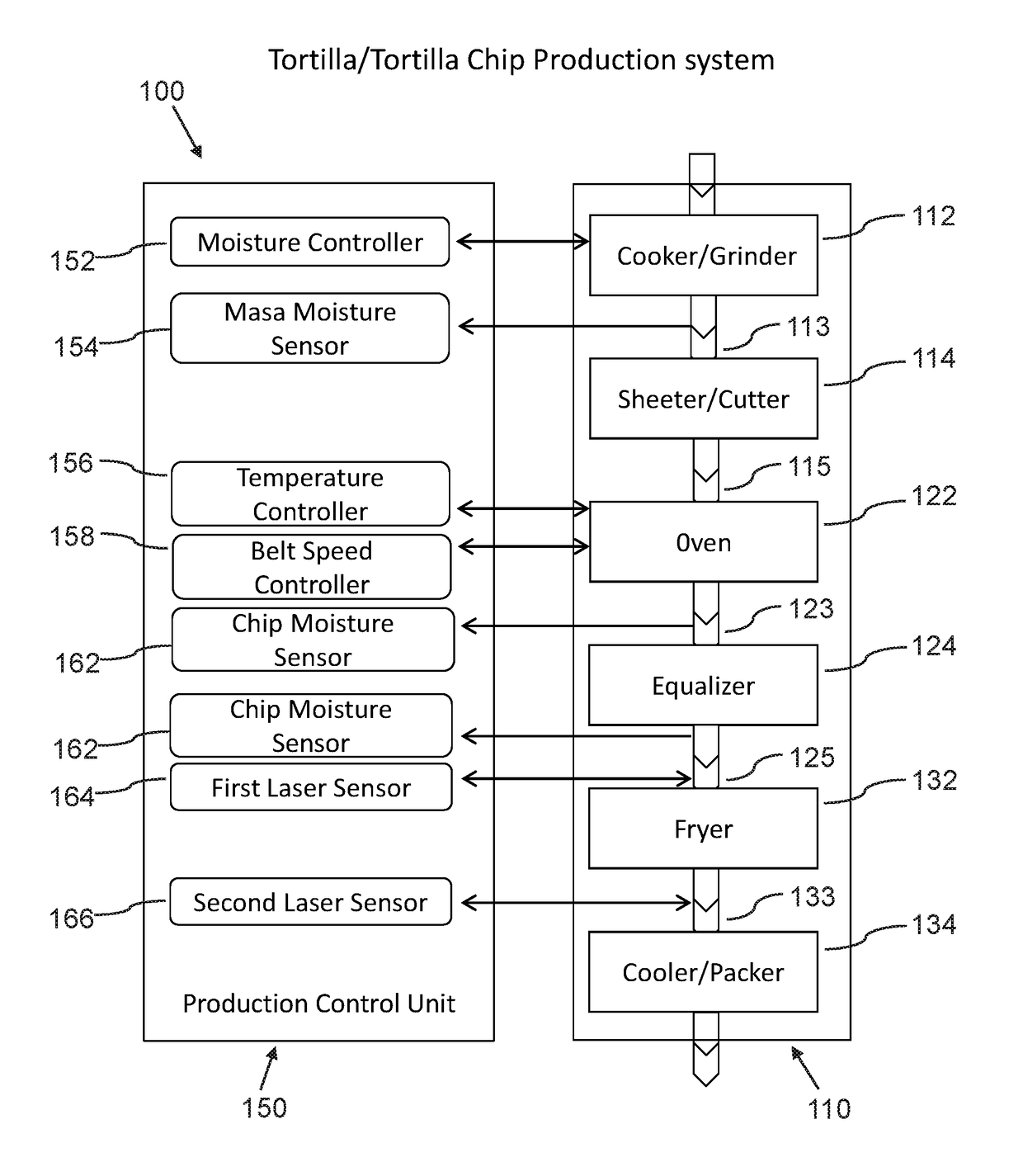

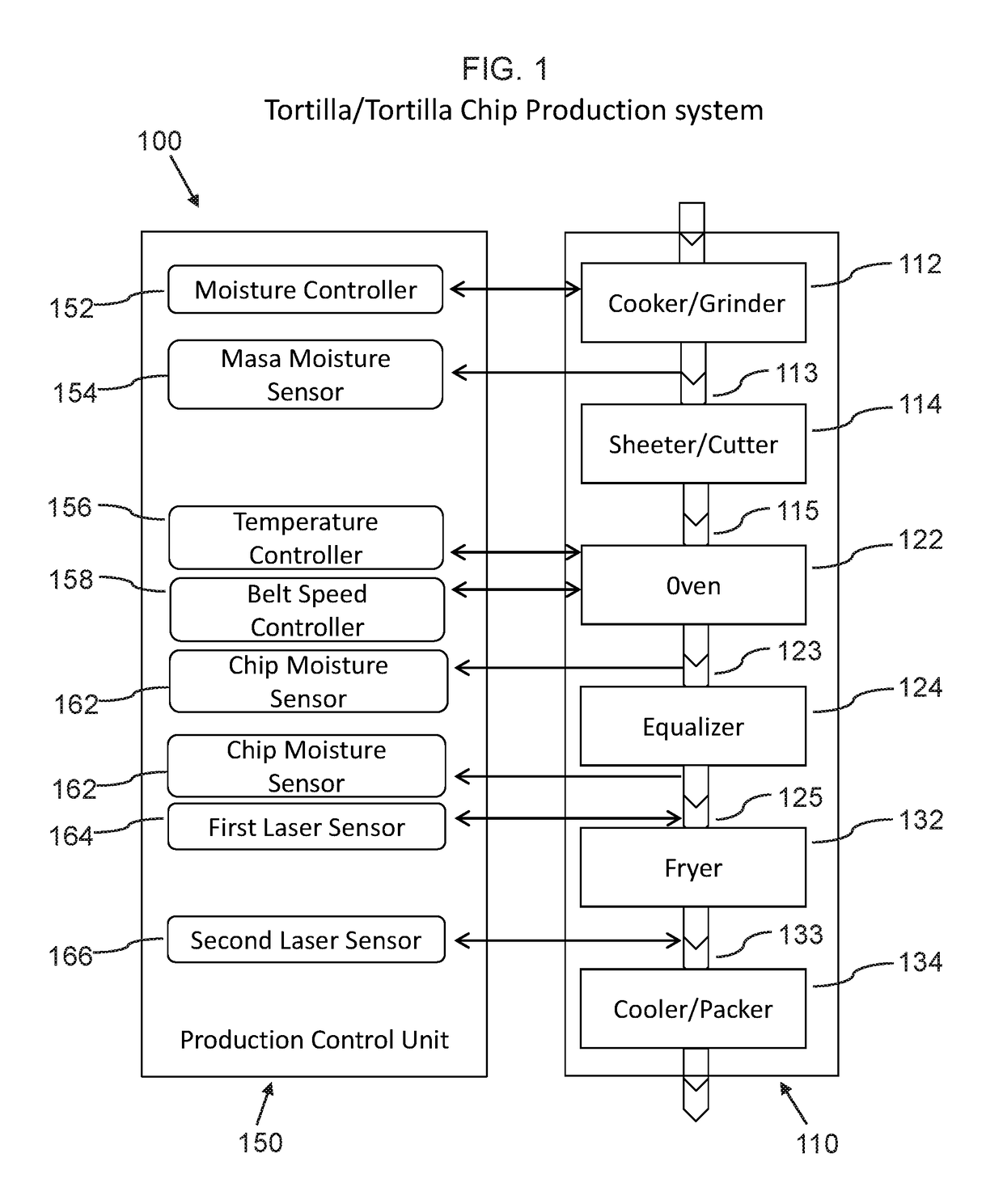

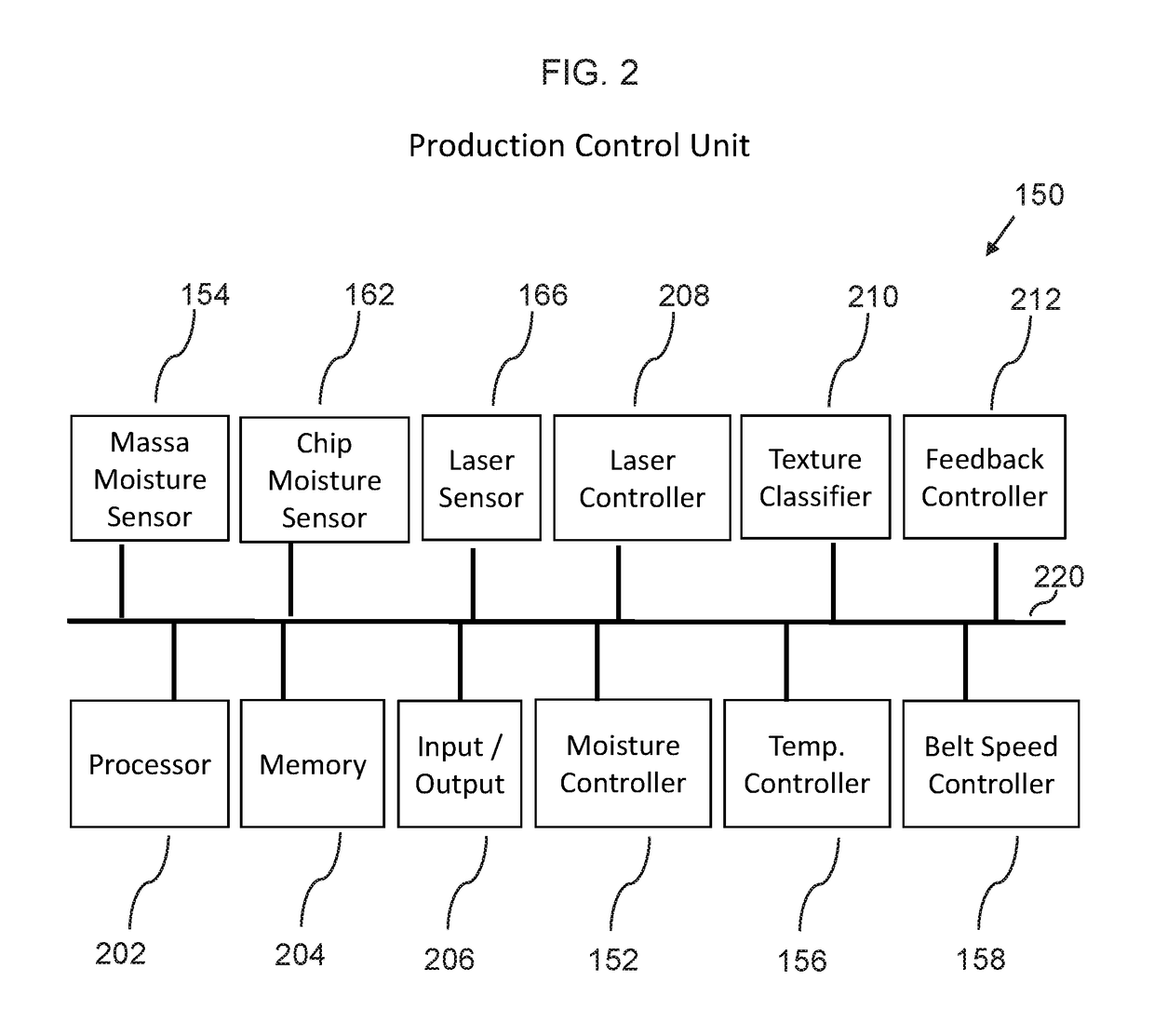

System, device, and method for moisture and texture detection and control in tortilla chip production

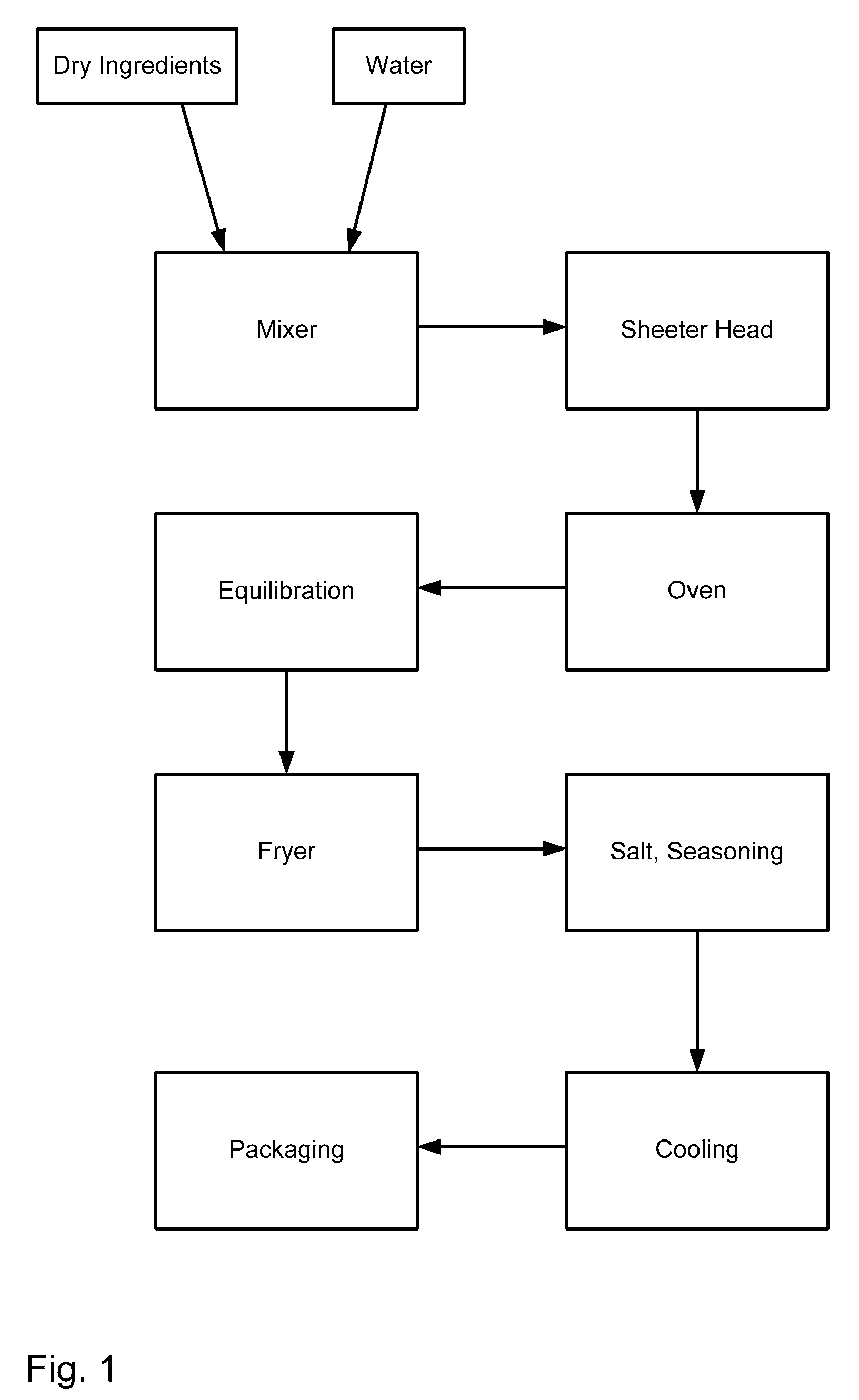

ActiveUS20170251679A1Increase temperatureDough-sheeters/rolling-machines/rolling-pinsBaking processesTortilla chipsBelt speed

A production system for moisture and texture detection and control in tortilla and tortilla chip production includes a production line, including a cooker / grinder, a sheeter / cutter, an oven, an equalizer, a fryer, and a cooler / packaging machine; and a production control unit, including a processor, non-transitory memory, an input / output component, a moisture controller, a temperature controller, a belt speed controller, a masa moisture sensor, a chip moisture sensor, laser sensors for measuring surface texture of baked and fried chips, a laser controller, a texture classifier, a feedback controller. Also disclosed is a method for production control, including controlling moisture content, measuring masa moisture, controlling oven, measuring baked surfaces, measuring fried surfaces, classifying baked surfaces, classifying fried surfaces, optimizing oven temperature, optimizing oven belt speed, storing and characterizing historical records.

Owner:BARTLETT BRIAN E

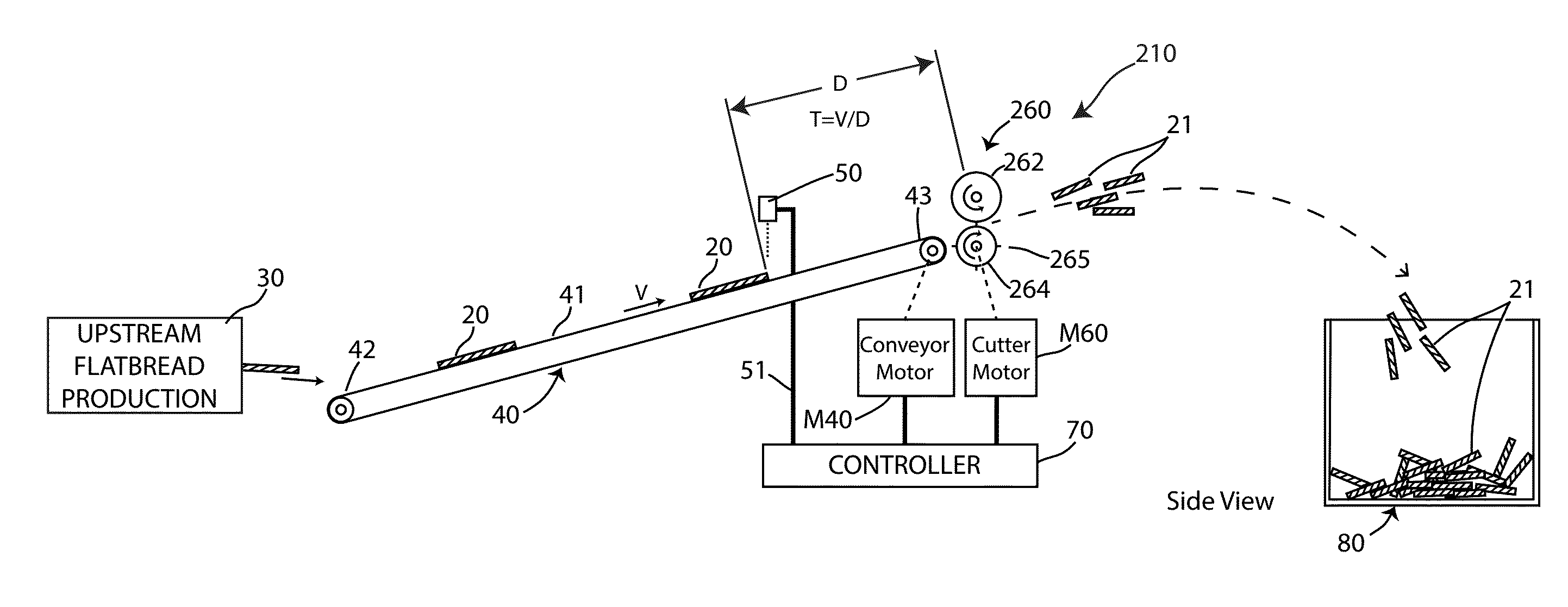

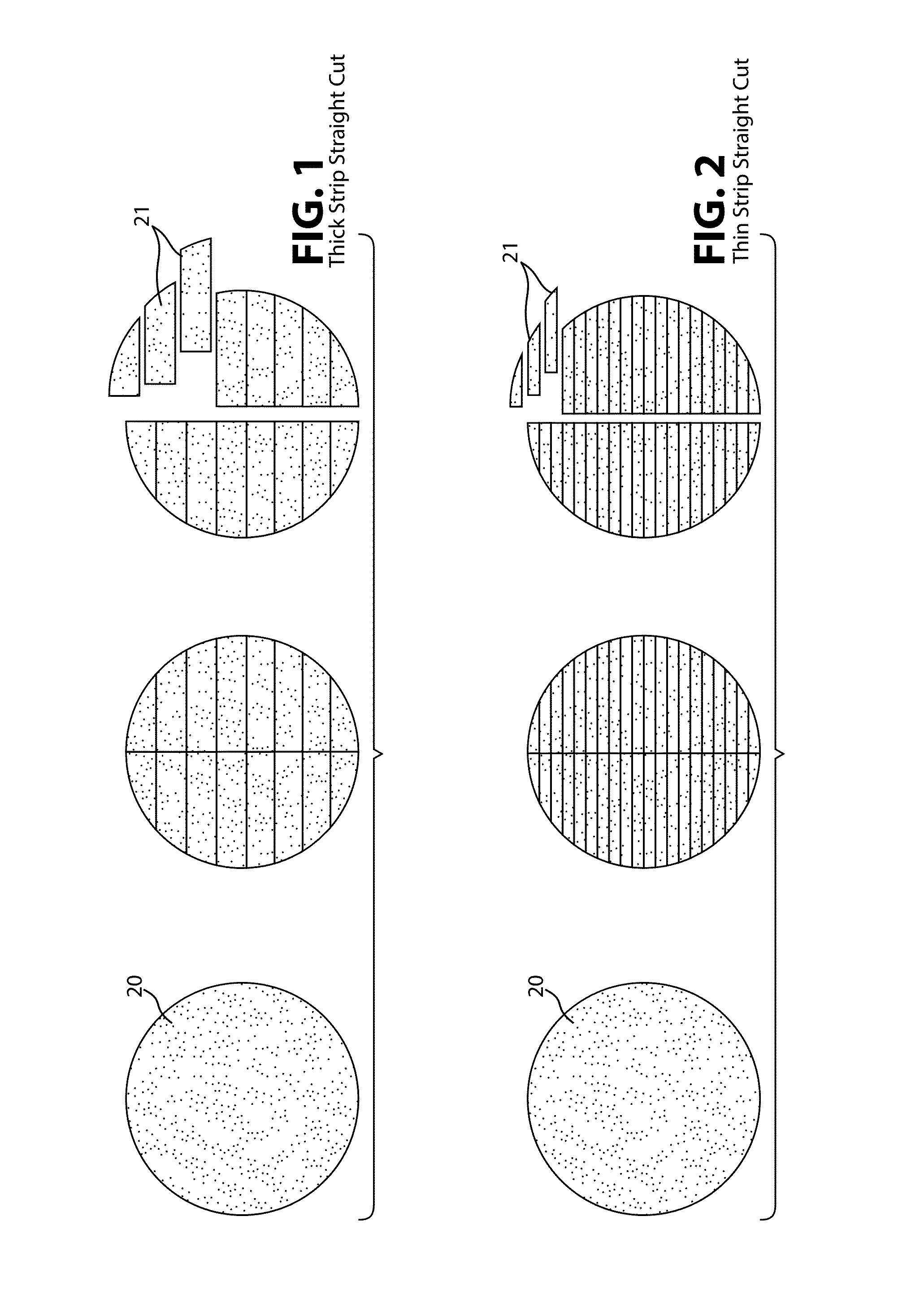

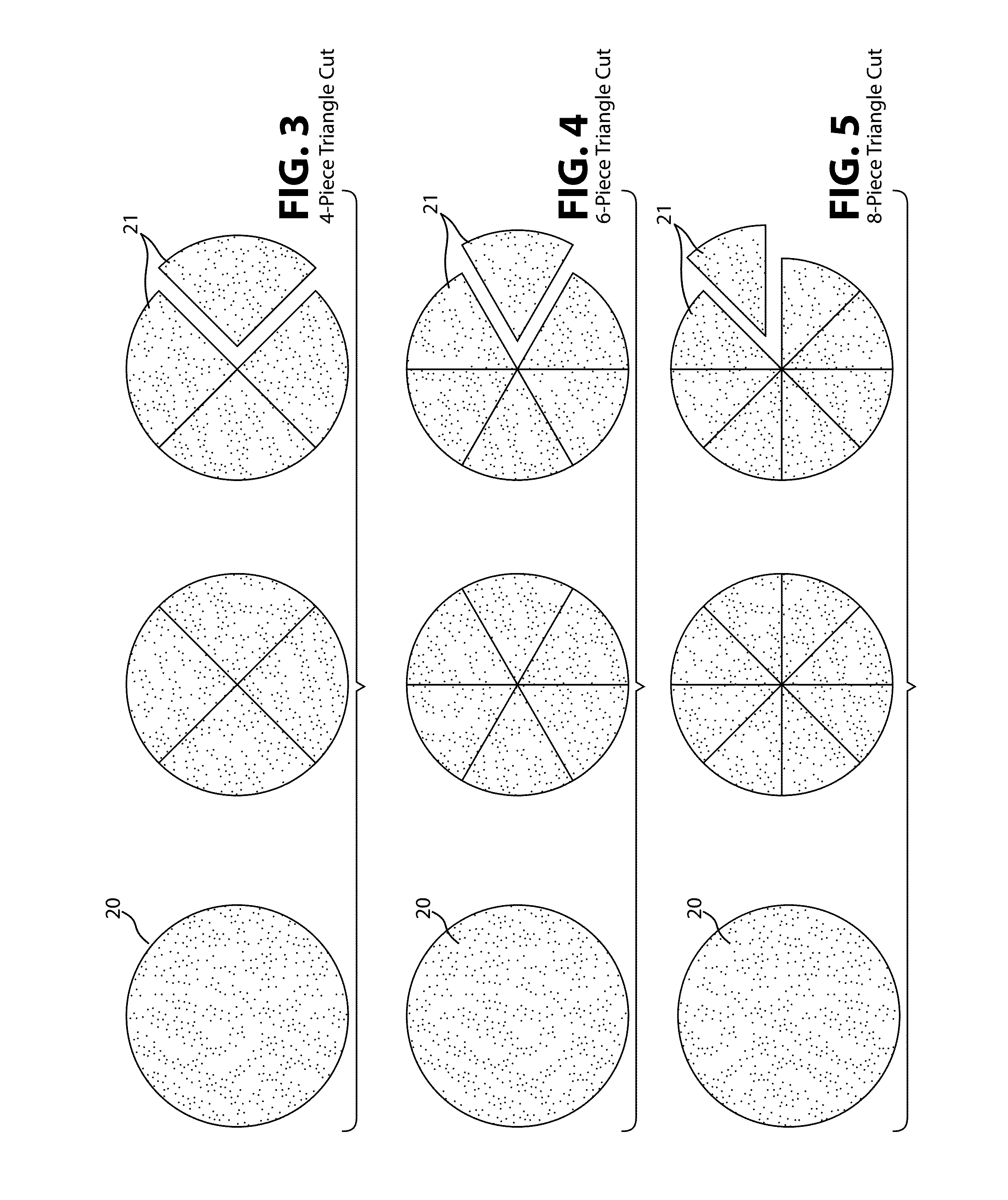

Continuous Tortilla Chip Cutter

InactiveUS20150135921A1PressureEffortMetal working apparatusFood preparationTortilla chipsProgrammable logic controller

A continuous tortilla chip cutting system where tortilla carried on a conveyor are continuously divided by a cutting mechanism into pre-cuts for frying into chips. A programmable controller drives a servo motor that moves an upper surface of the conveyor at a known velocity V, and a detector located above the conveyor at a known distance D from the cutting mechanism alerts the controller to the imminent arrival of the tortilla. The controller also controls a servo motor that actuates the cutting mechanism in a stop / start fashion. Based on the detection of the tortilla, the controller drives the servo motor associated with the cutting mechanism at just the right time and at just the right speed so that the cutter mechanism cuts each arriving tortilla into predictable sub-units called “pre-cuts” based on the velocity V of the conveyor belt, the detection of the flat bread unit carried by the conveyor, and the known distance between the moving flat bread unit and the cutter assembly.

Owner:CASA HERRARA

Method for making instant masa

ActiveUS7220443B2No waterSuitable for productionDough treatmentBaking mixturesTortilla chipsCorn flour

A process for the production of fresh masa, nixtamalized flour and derived products. The invention is a new process for production of corn masa (dough) to be used in the production of tortillas, fried or baked tortilla chips, tostadas, or corn chips. The new process produces masa directly from raw materials without the traditional cooking and steeping steps. It utilizes a series of processing steps including milling, blending, hydration, cooking and continuous cooling to stop gelatinization. The new process uses very little water and emits no waste water.

Owner:SABRITAS

Saccharides and saccharide compositions and mixtures

ActiveUS9364015B2Improve health benefitsGood for healthOrganic active ingredientsCosmetic preparationsReady to eatFlavored water

Owner:XYLECO INC

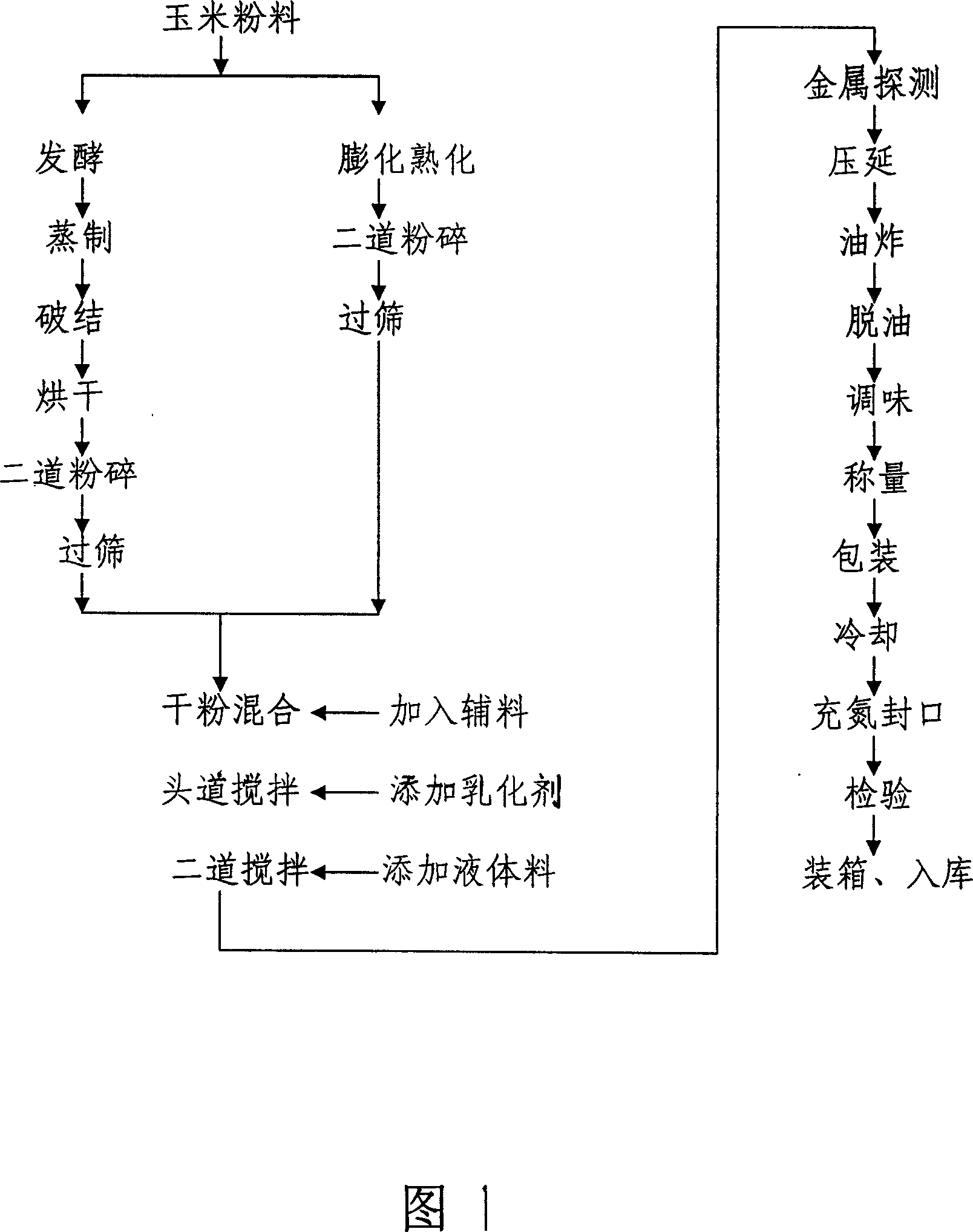

Compound corn chip

The present invention relates to a kind of composite corn chips, belonging to the field of food processing technology. It is made up by using cooked corn flour, corn fermented flour, potato powder, snow flour, modified starch, wheat starch, corn starch, soybean starch, dextrin, lecithin and milk powder through a certain preparation process. Said preparation process includes the following steps: mixing them according to a certain mixing ratio, stirring them, adding emulsifying agent, secondary stirring, adding liquid material, metal detection, rolling, forming, deep-frying, deoiling, flavouring and cooling so as to obtain the invented product.

Owner:正源控股股份有限公司

Instant masa

ActiveUS20060177554A1Minimizes crucial stepNo waterMilk preservationDough treatmentTortilla chipsCorn meal

A process for the production of fresh masa, nixtamalized flour and derived products. The invention is a new process for production of corn masa (dough) to be used in the production of tortillas, fried or baked tortilla chips, tostadas, or corn chips. The new process produces masa directly from raw materials without the traditional cooking and steeping steps. It utilizes a series of processing steps including milling, blending, hydration, cooking and continuous cooling using cooling rollers to stop gelatinization. The new process uses very little water and emits no waste water.

Owner:SABRITAS

Saccharides and saccharide compositions and mixtures

ActiveUS20160081381A1Increase good healthIncrease nutritional well-beingBiocideOrganic active ingredientsReady to eatFlavored water

Described herein are products comprising a xylose (e.g., D-xylose or L-xylose and another sweetener such as glucose). Exemplary products include the following: ice cream, ice milk, sorbet, sherbet, gelatin candies, baby food, animal food, e.g., dog, cat, canine, or equine food, seasonings, sauces, cosmetics, dietary supplements, lip stick, lip gloss, face and body preparations, pharmaceuticals, such as flu and cold preparations, nutraceuticals, surgical preparations, procedure preparations, imaging preparations, e.g., CT scan imaging preparations, pain relievers, nasal spray, cheese, vegetables, mayonnaise, mustard, salad dressings, nuts and nut mixes, cookies, pastries, fruit flavored snacks, pancakes, waffles, hot cocoa mix, caramel, shampoo, dental floss, donuts, egg noodles, lollypops, frozen pops, soda pop, chips, potato chips, tortilla chips, corn chips, sports drinks, rice cakes, oatmeals, teas, cereals, rice mixtures, flavored water, alcohol, alcohol mixers, soaps, energy drinks, coffee, coffee flavored drinks, coffee products, cake mixes, chili, chip dip, chip sauces, fibers, such as cellulosic and lignocellulosic fibers and fiber supplements, meats, e.g., deli meats, drink mixes, pasta, meals ready to eat, coconut water, candies, e.g., hard and soft candies, chocolate, candy bars, sports bars and energy bars. In embodiments, the xylose containing product is made using a method described herein. For example, the xylose is produced from a biomass described herein.

Owner:XYLECO INC

Production of whole grain shredded products

InactiveUS7939122B2Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 135° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method for Making a Masa Based Dough for Use in a Single Mold Form Fryer

InactiveUS20080044534A1Large particle sizeImprove uniformityDough treatmentPre-baking dough treatmentTortilla chipsMoisture distribution

A method of making a masa-based dough for use in a single mold form fryer. The invention is an improved process of making a buoyant, low density, low moisture content dough that is easily sheetable and results in a fried tortilla chip-like product with a similar texture of traditional tortilla chips. Starch is added to corn masa dough to help control moisture release during frying. The high shear mixing of the dough entrains air through nuclei formation making the dough more buoyant, and results in a smaller particle size of the dough increasing the uniformity of moisture distribution. The uniformity of moisture distribution provides more uniform buoyancy of the masa-based dough as it travels through a single mold form fryer.

Owner:BAKER SHERI LYNN +4

Quick Corn Nixtamalization Process

ActiveUS20090291186A1Improve production yieldReduced corn solid lossDough treatmentBaking mixturesTortilla chipsCorn meal

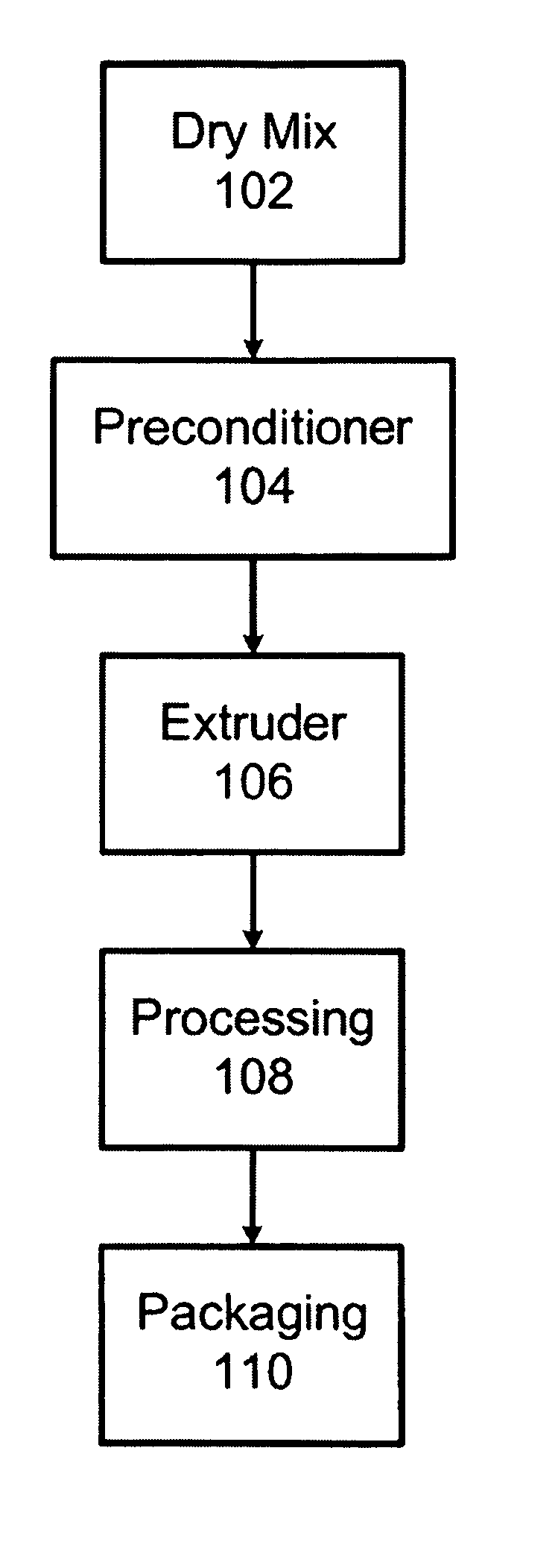

A process for the production of fresh masa, nixtamalized flour and derived products. The invention is a new process for production of corn masa (dough) to be used in the production of tortillas, fried or baked tortilla chips, tostadas, or corn chips. The new process produces masa directly from raw materials without the traditional cooking and steeping steps. It utilizes a series of processing steps including dry blending, hydrating, and working dough in an extruder having a unique screw configuration. The new process uses very little water and emits no waste water.

Owner:SABRITAS

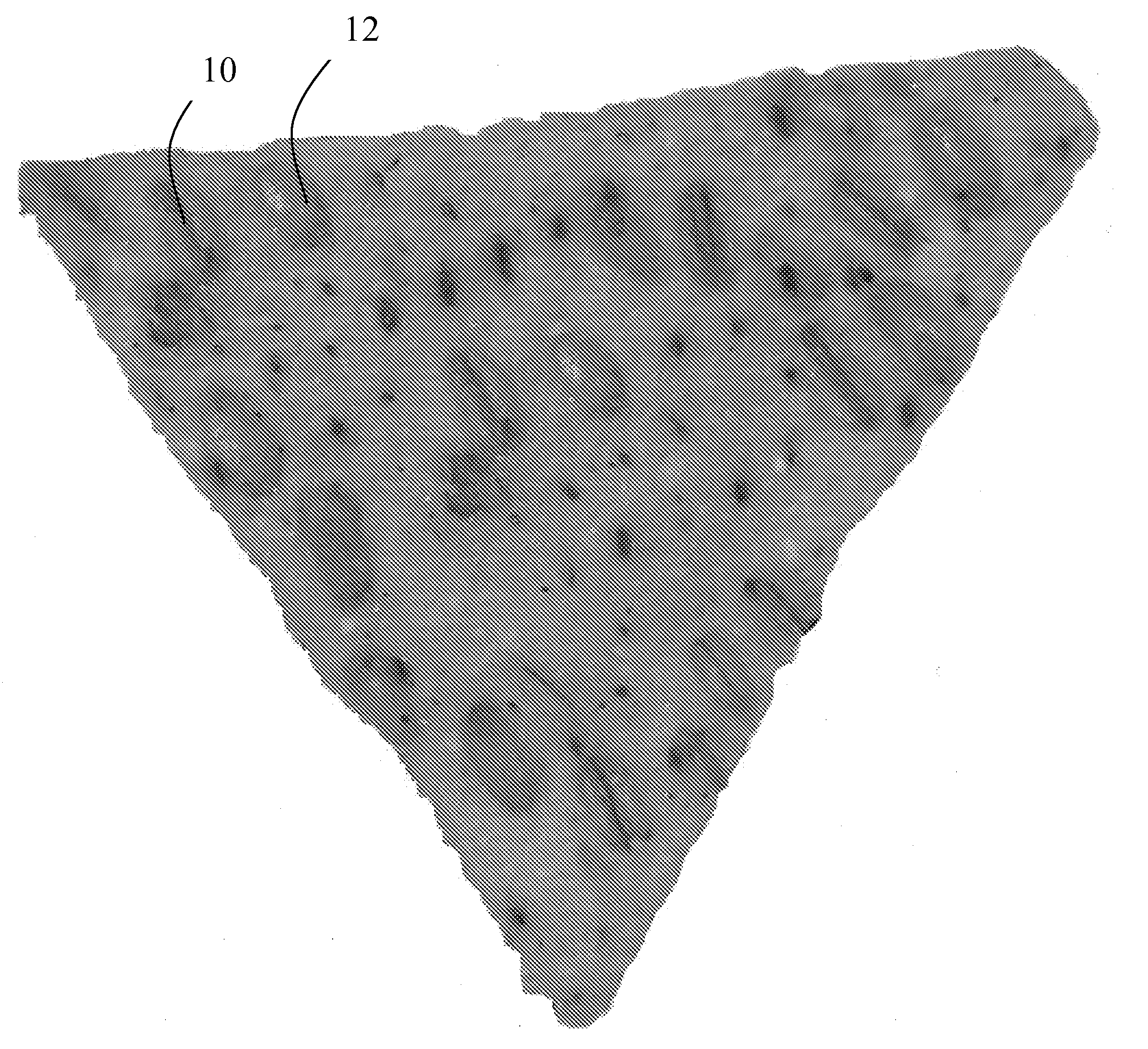

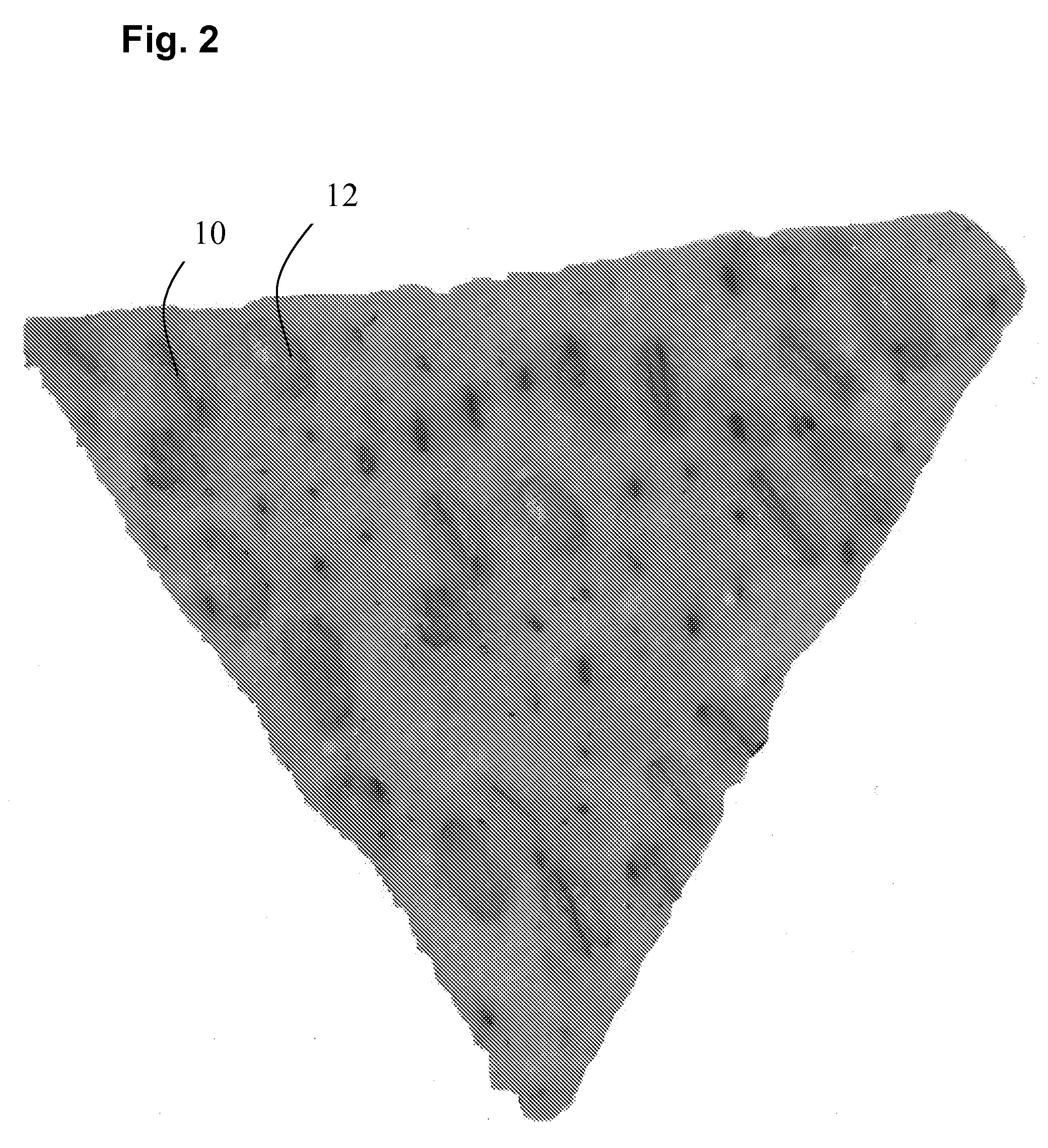

Snack chip containing buckwheat hulls

ActiveUS7897191B2Without creating excessive build-upReduce moisture contentDough treatmentBaking mixturesPolygonum fagopyrumTortilla chips

A multi-grain chip having buckwheat hull inclusion of a specific particle size. The buckwheat hull component of the chip provides a visual indication of the multi-grain characteristics of the chip. The particle size of the buckwheat hulls is specified in order to compliment production of the chip on existing corn chip lines and to enhance product visual attributes.

Owner:FRITO LAY NORTH AMERICA INC

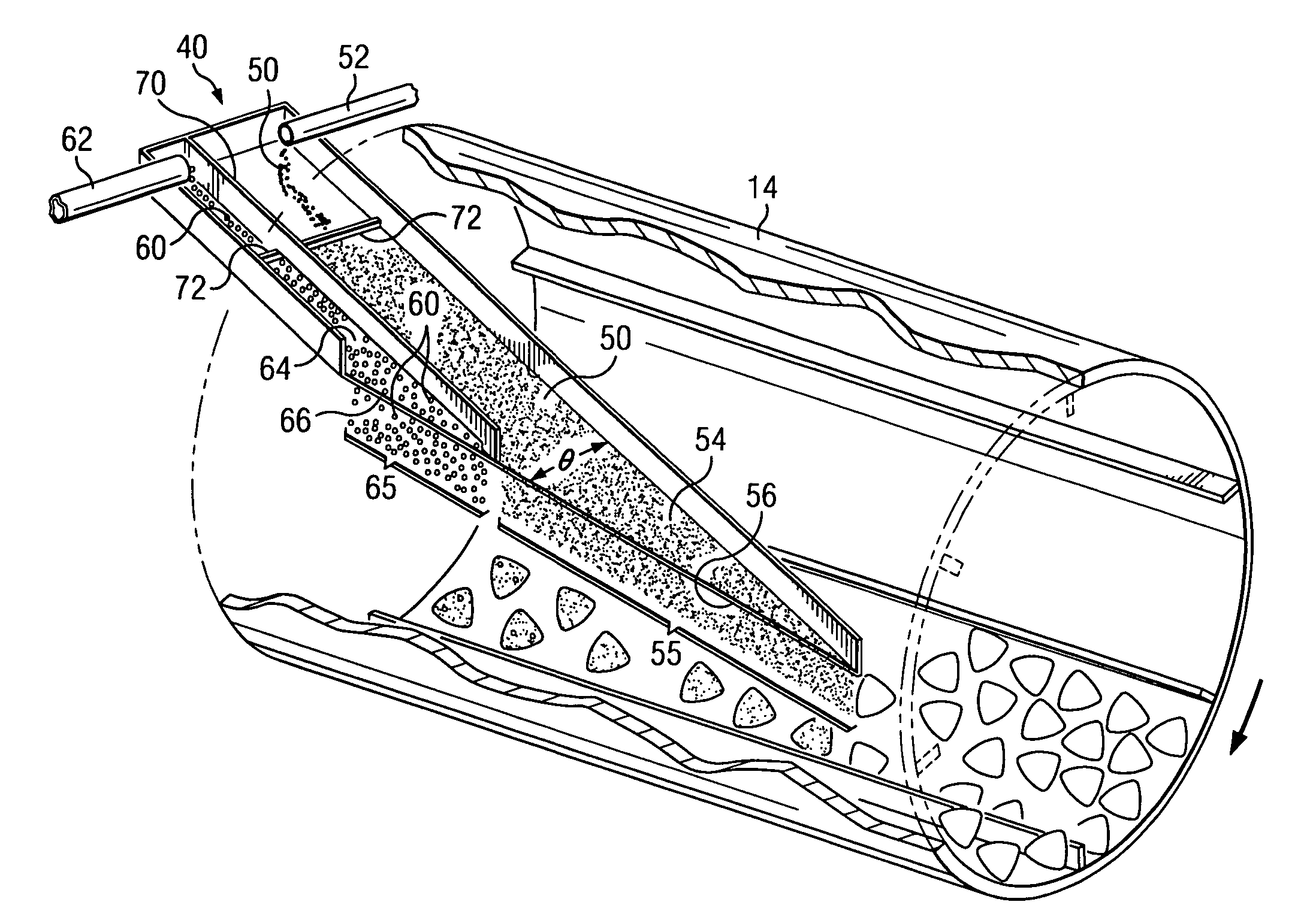

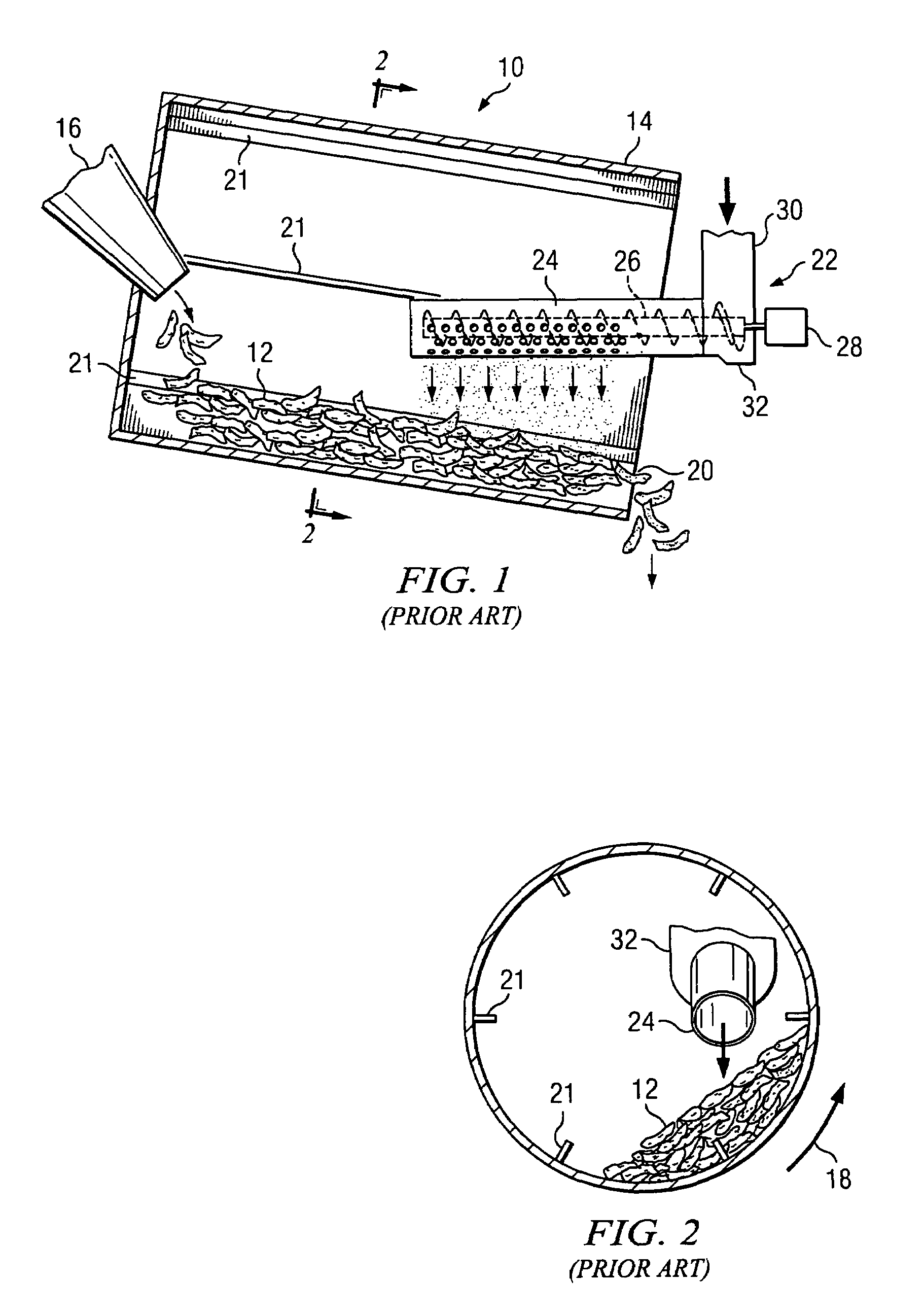

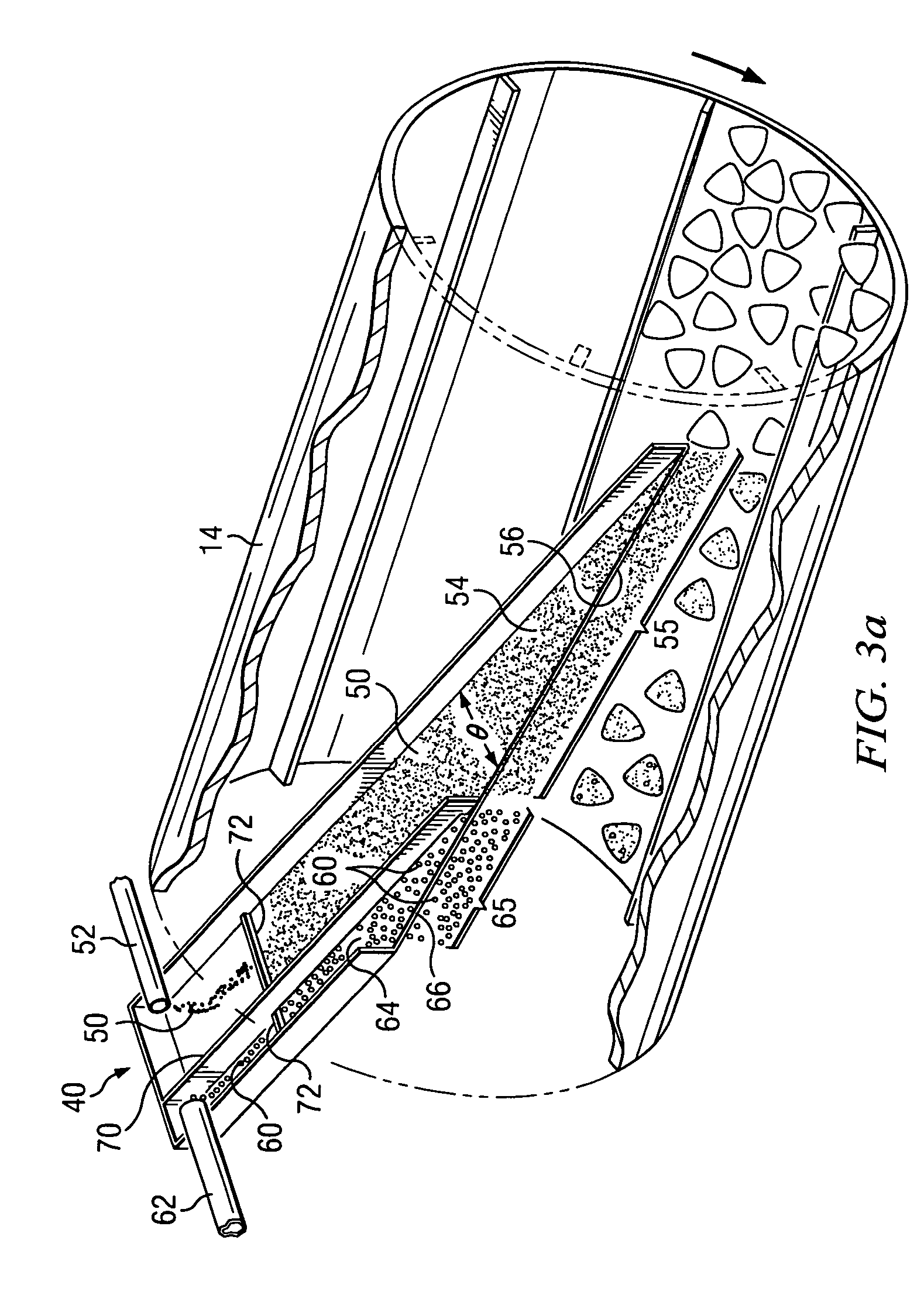

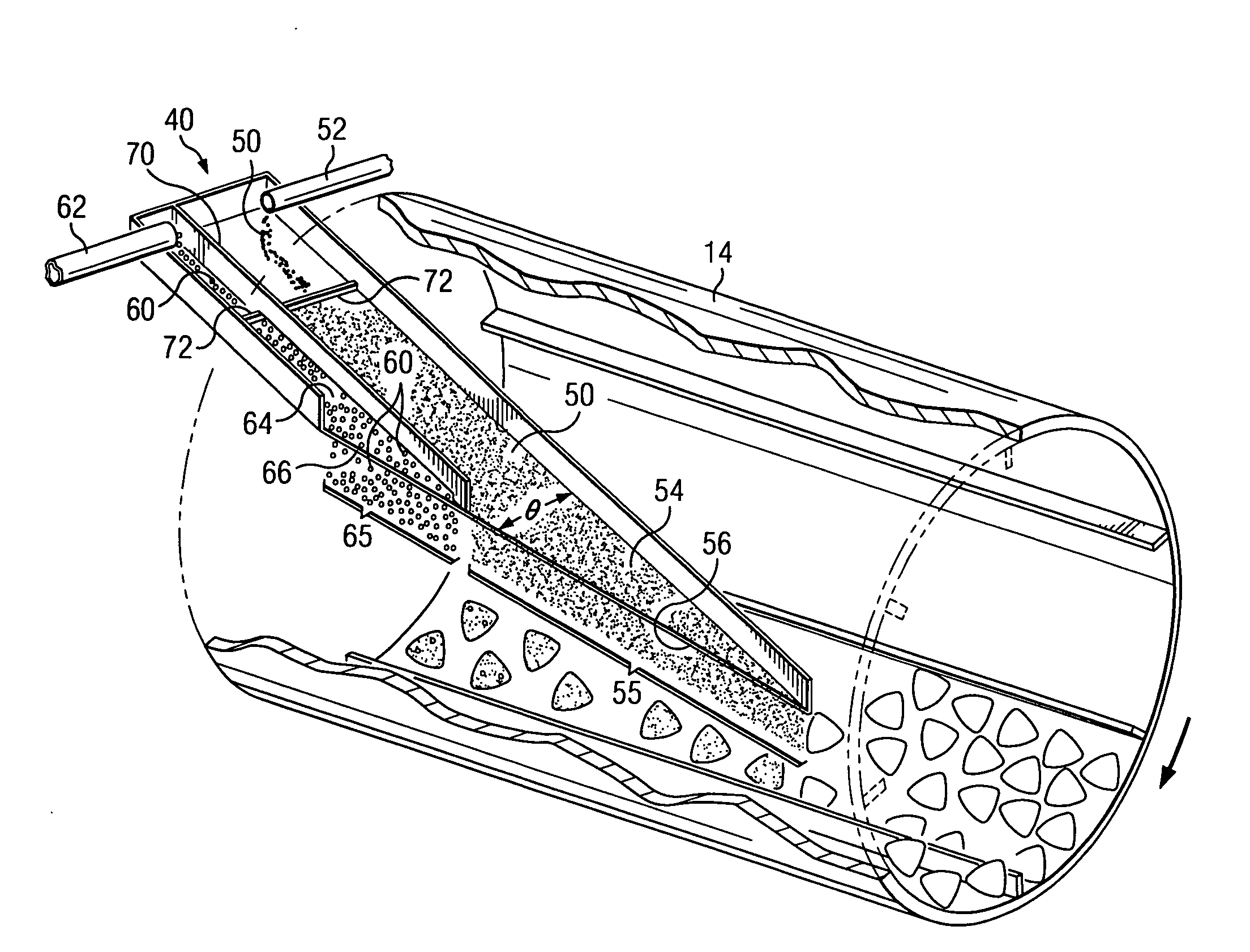

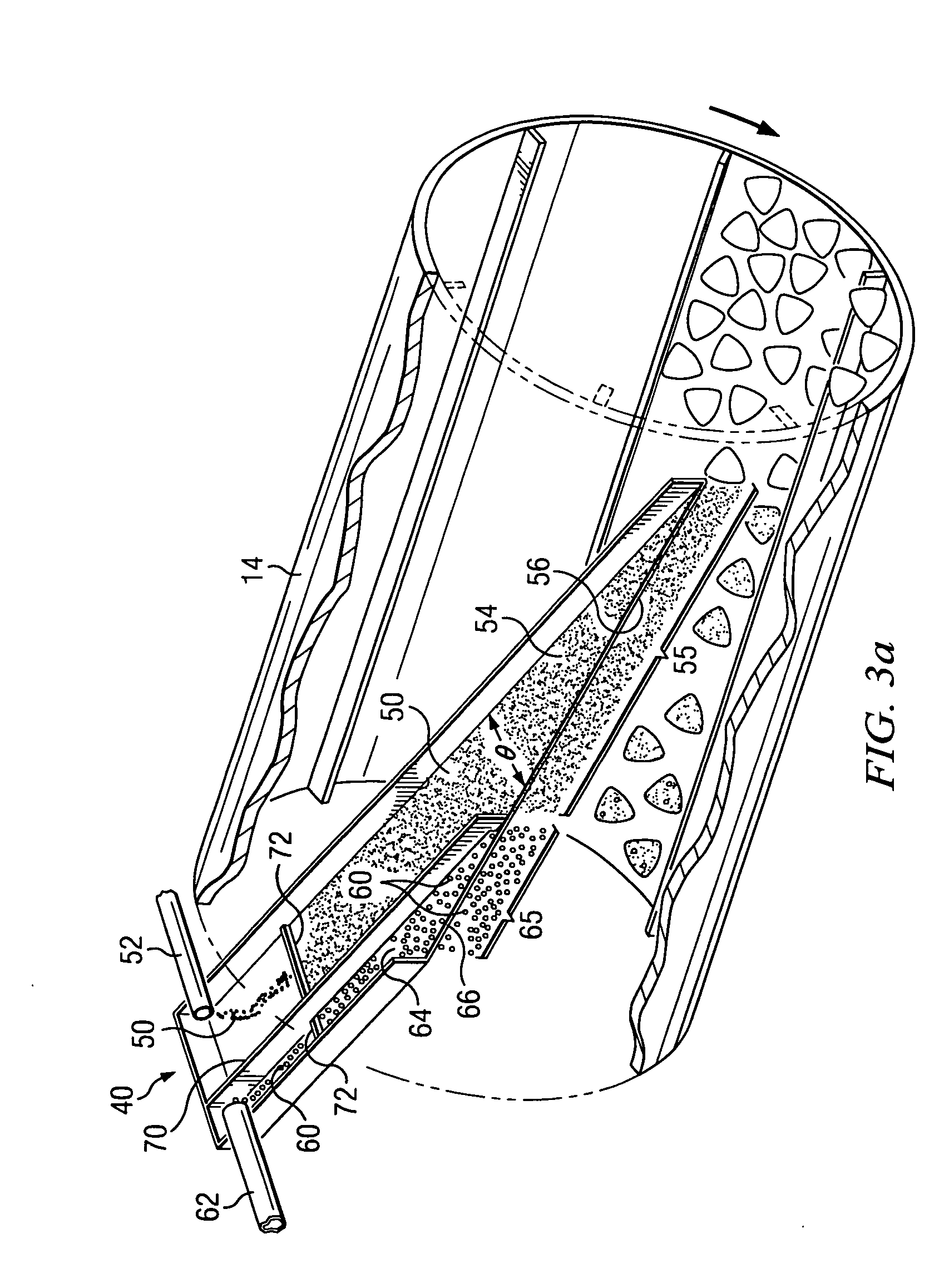

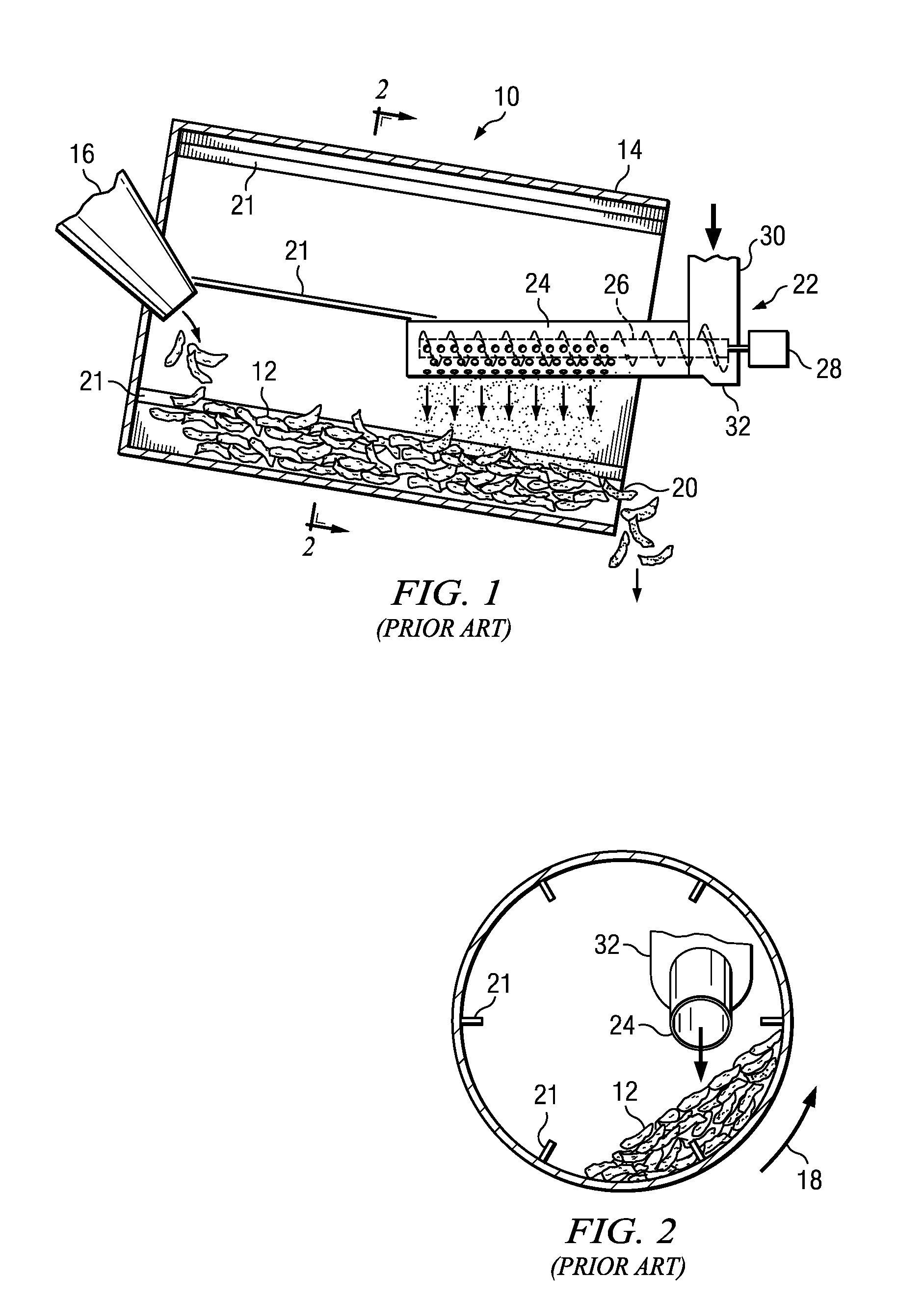

Method and apparatus for layering seasoning

An apparatus and method for providing a layered seasoning to snack food products such as potato chips or tortilla chips using a vibratory scarf plate that is divided into two or more sections by one or more walls. A different seasoning is placed in each section. The scarf plate is placed into a rotating drum having snack food product. A seasoning from each section falls off the scarf plate to form a curtain. Each curtain provides a layer of seasoning on the snack food product.

Owner:FRITO LAY NORTH AMERICA INC

Method and apparatus for layering seasoning

An apparatus and method for providing a layered seasoning to snack food products such as potato chips or tortilla chips using a vibratory scarf plate that is divided into two or more sections by one or more walls. A different seasoning is placed in each section. The scarf plate is placed into a rotating drum having snack food product. A seasoning from each section falls off the scarf plate to form a curtain. Each curtain provides a layer of seasoning on the snack food product.

Owner:FRITO LAY NORTH AMERICA INC

Quick corn nixtamalization process

ActiveUS8110239B2Minimizes crucial stepNo waterDough treatmentBaking mixturesTortilla chipsCorn meal

Owner:SABRITAS

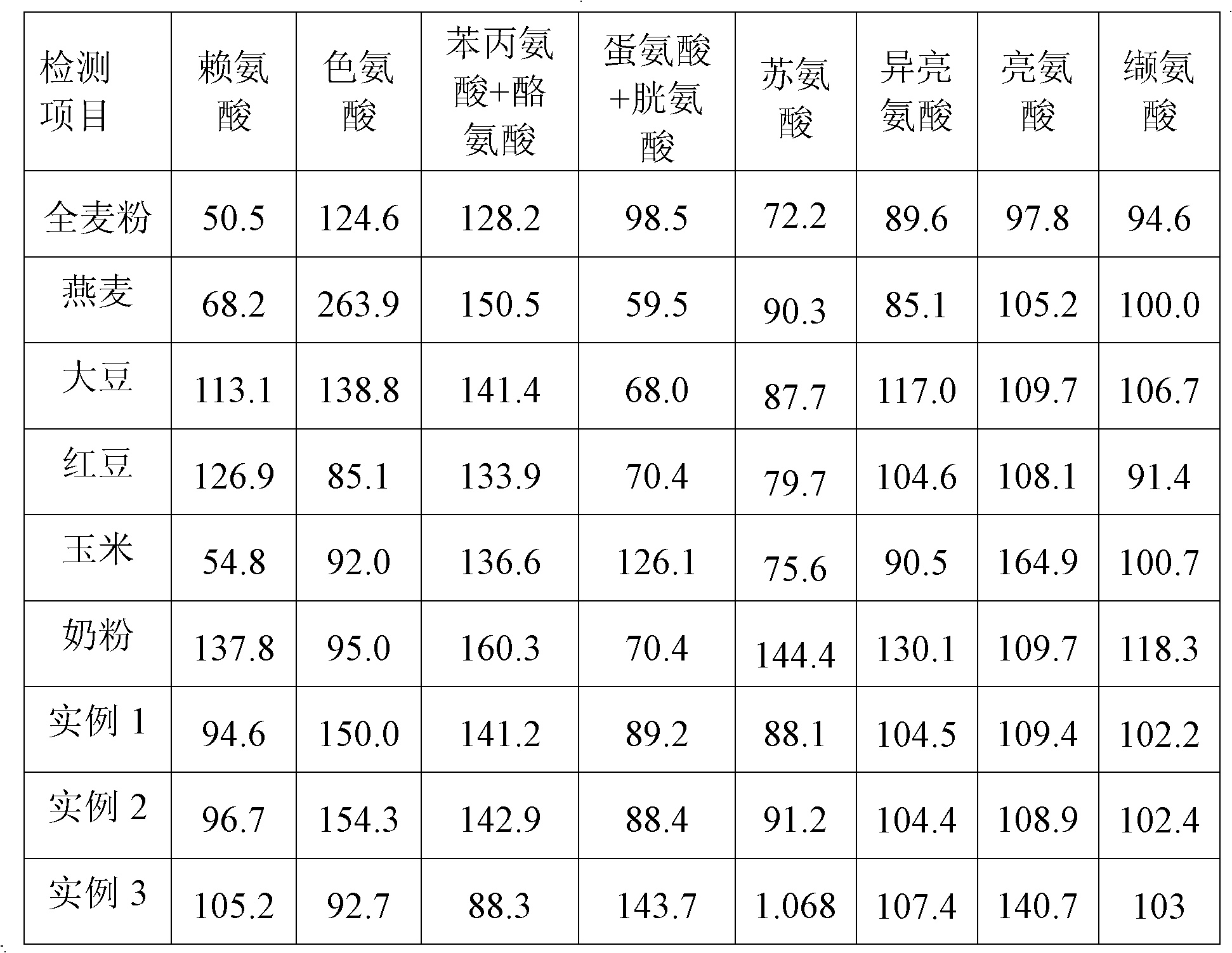

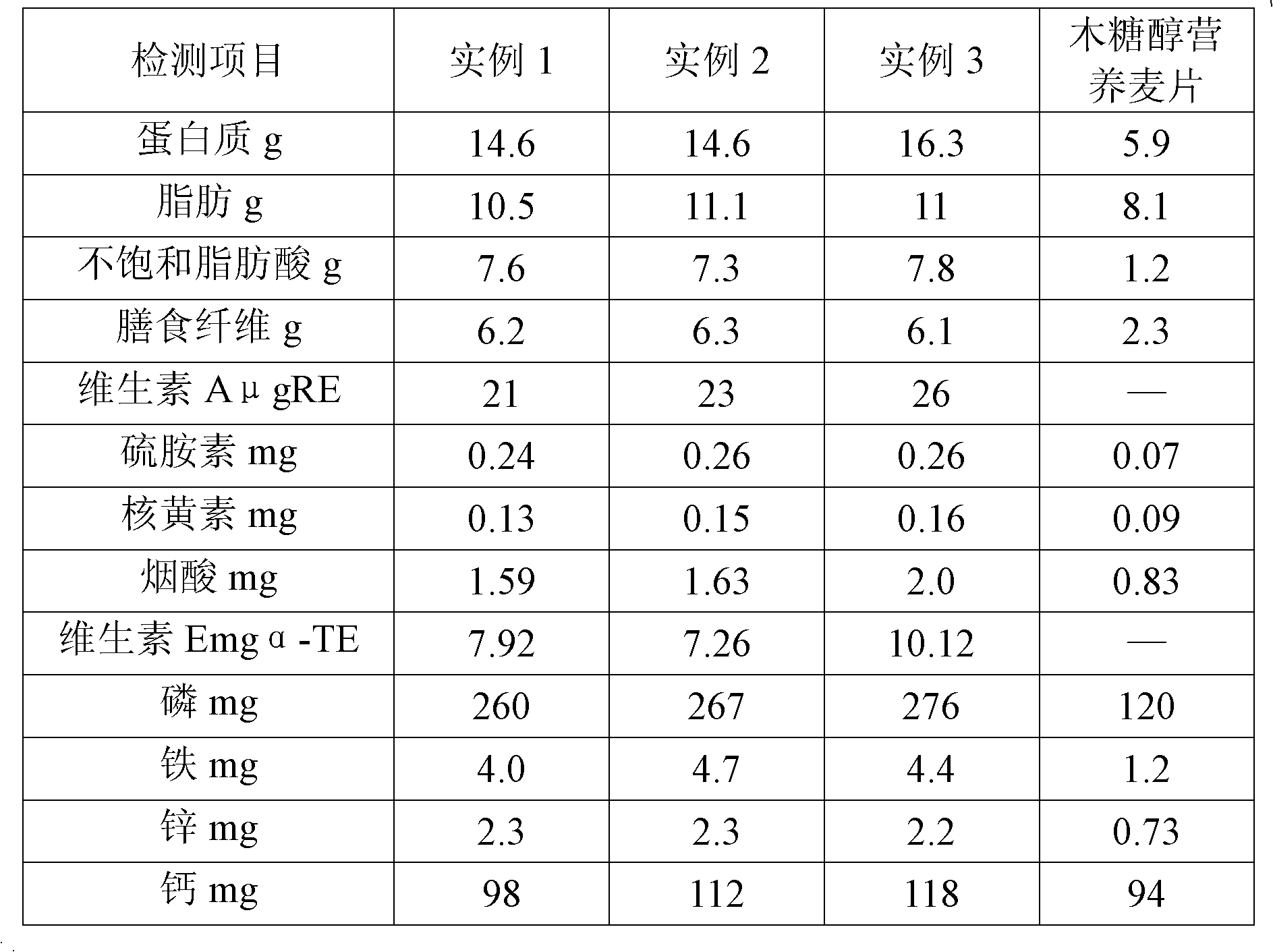

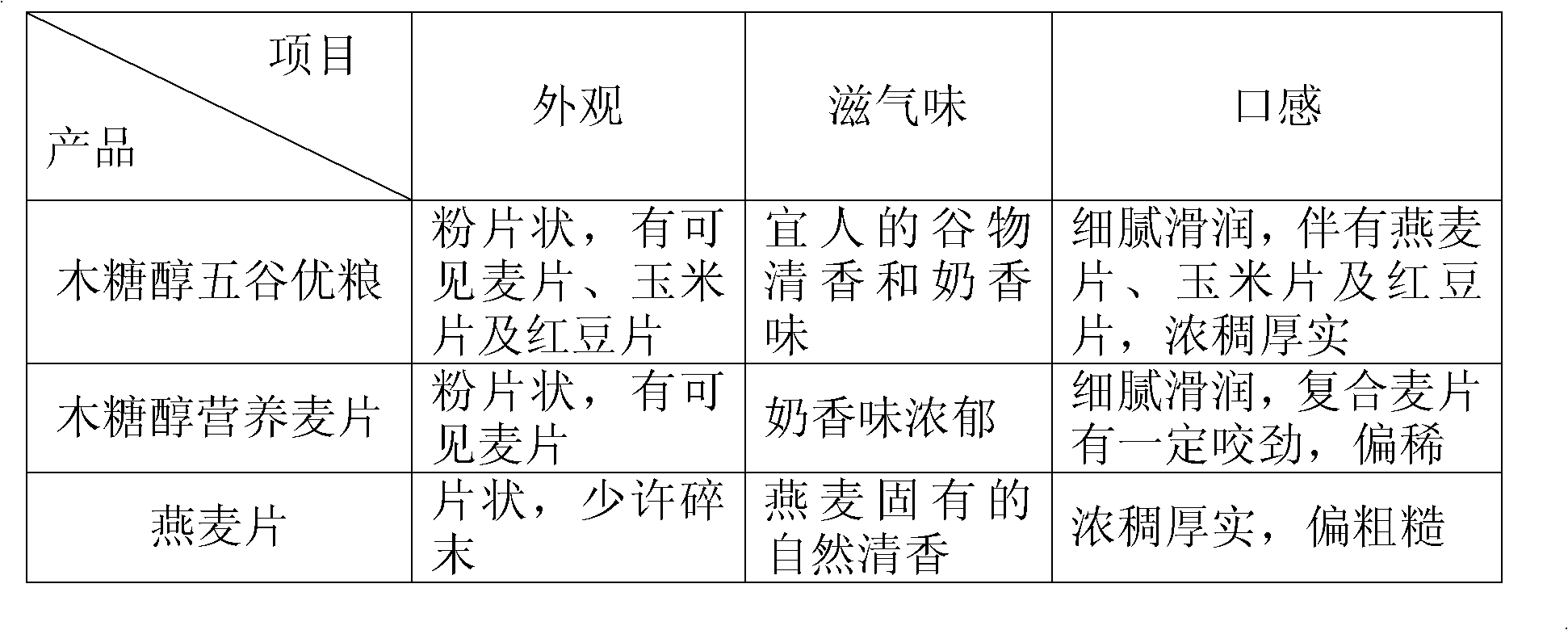

Convenient food prepared from xylitol and cereals and processing method thereof

InactiveCN102524641AFit for consumptionKeep natural fragranceFood preparationTortilla chipsCorn meal

The invention provides a convenient food prepared from xylitol and cereals and relates to a convenient food. The convenient food is prepared from the following raw materials by weight percent: 15-25% of whole wheat powder, 15-25% of rolled oats, 15-21% of soybean powder, 9-12.5% of non-diary creamer, 6-10% of red bean flakes, 3-4% of corn powder, 3-4% of core flakes, 5-8% of milk powder, 4.5-8% of xylitol, 2.6-3% of malt extract, 0.38-0.49% of edible salt, 0.31-0.37% of edible flavor, 0.14-0.18% of aspartame and 0.04-0.06% of ethyl maltol. The invention also provides a processing method of the convenient food. The convenient food belongs to the healthy and low-sugar diet, can be eaten instantly through aging treatment, is convenient and fast, is superior to the common convenient food in nutrition collocation, has more exquisite and palatable taste than the common coarse grain food and is suitable for patients with diabetes.

Owner:GUANGDONG HUANGMAI SHIJIA FOOD

Snack chip containing buckwheat hulls

ActiveUS20080138485A1Without creating excessive build-upReduce moisture contentDough treatmentBaking mixturesPolygonum fagopyrumTortilla chips

A multi-grain chip having buckwheat hull inclusion of a specific particle size. The buckwheat hull component of the chip provides a visual indication of the multi-grain characteristics of the chip. The particle size of the buckwheat hulls is specified in order to compliment production of the chip on existing corn chip lines and to enhance product visual attributes.

Owner:FRITO LAY NORTH AMERICA INC

Visually apparent oat-containing chips providing health advantages

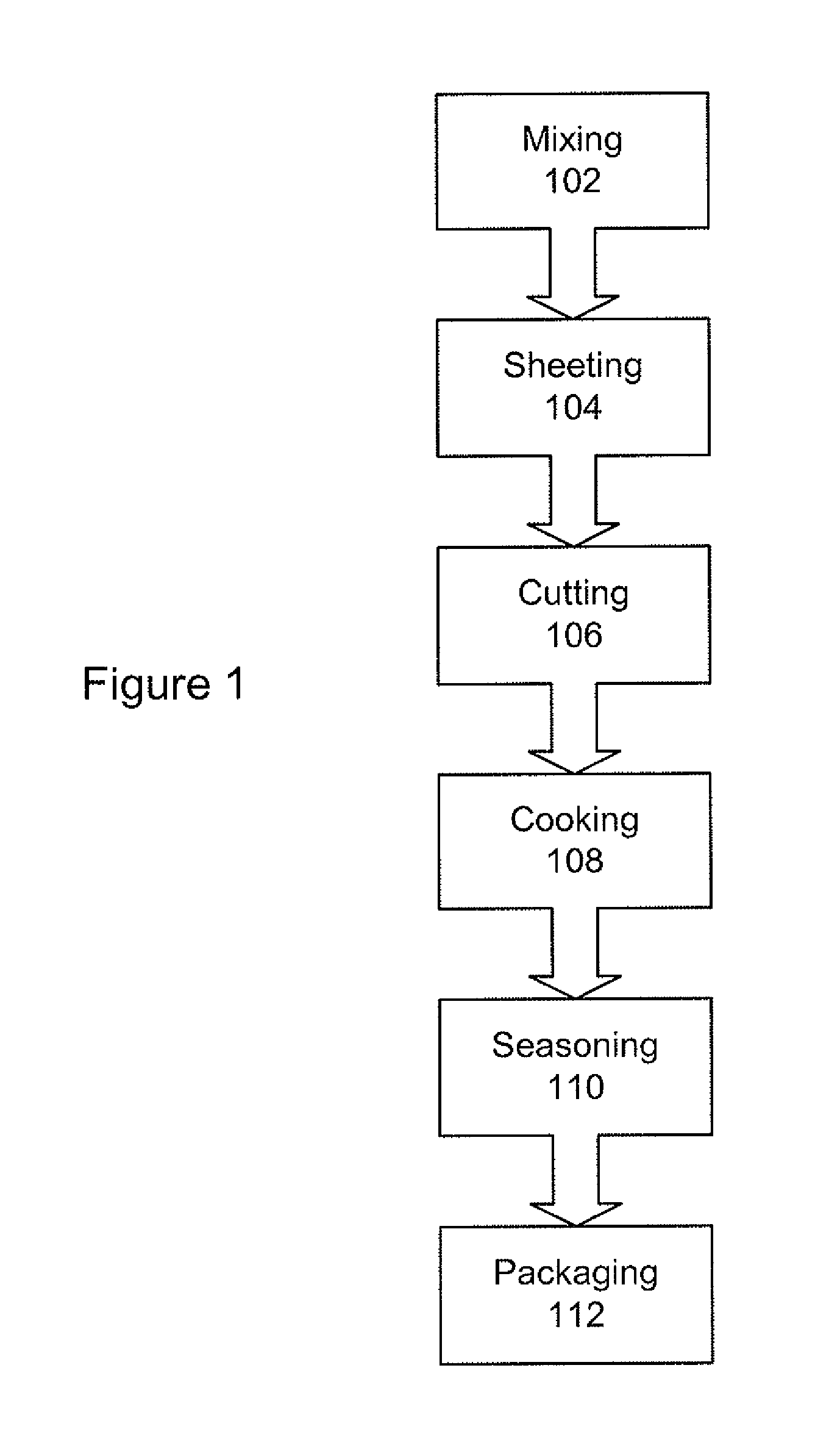

InactiveUS20070071863A1Reduce cholesterolBaking mixturesBakery productsDietary regimenTortilla chips

Masa products, processes for preparing them and dietary regimens employing them are described. A masa product, preferably a tortilla chip, comprises a cooked, sheeted dough comprising visually apparent oat groats. The oats are preferably visually identifiable on the surface of the chips and cover at least about 10% of the total exterior surface of the chip. The process for preparing the chips comprises the steps of: forming a dough from water, masa and oat groats; forming the dough into sheeted preforms; baking the sheeted preforms; holding the preforms following baking for a period of time sufficient to permit the moisture within the preforms to equilibrate; and frying the preforms following equilibration. In one preferred form, the packaged product of the invention will comprise: an air-tight package; and tortilla chips prepared from a dough comprised of masa and oats, the chip having clearly identifiable pieces of oat covering at least 10% of the total exterior surface of the chip. A regimen is also provided by the for reducing serum cholesterol, and comprises: at least 3 days out of 7, consuming a serving of tortilla chips comprising: a baked, fried sheeted hydrated mixture comprising masa and oats, and oil containing cholesterol-lowering phytosterols.

Owner:CORAZONAS FOODS

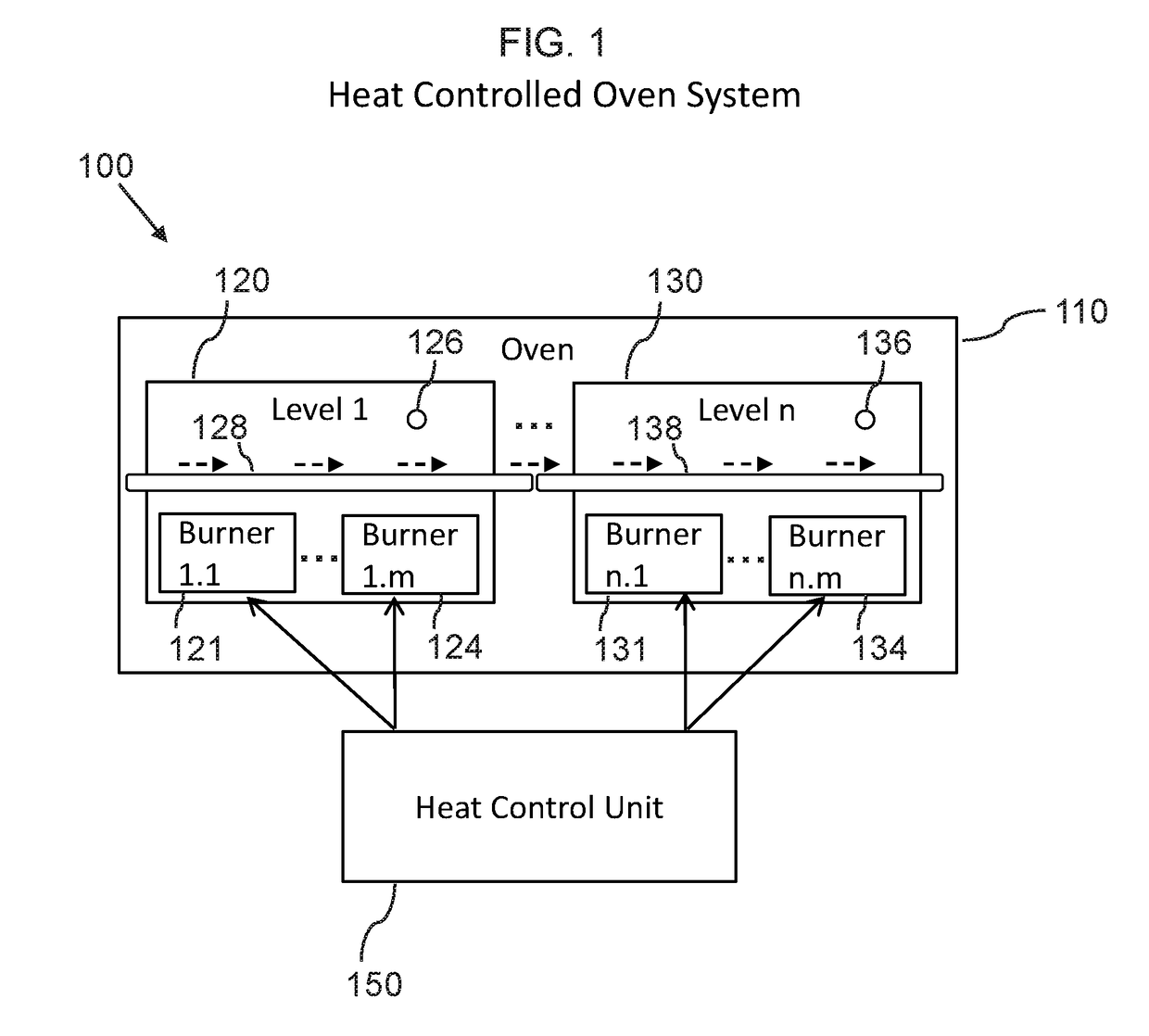

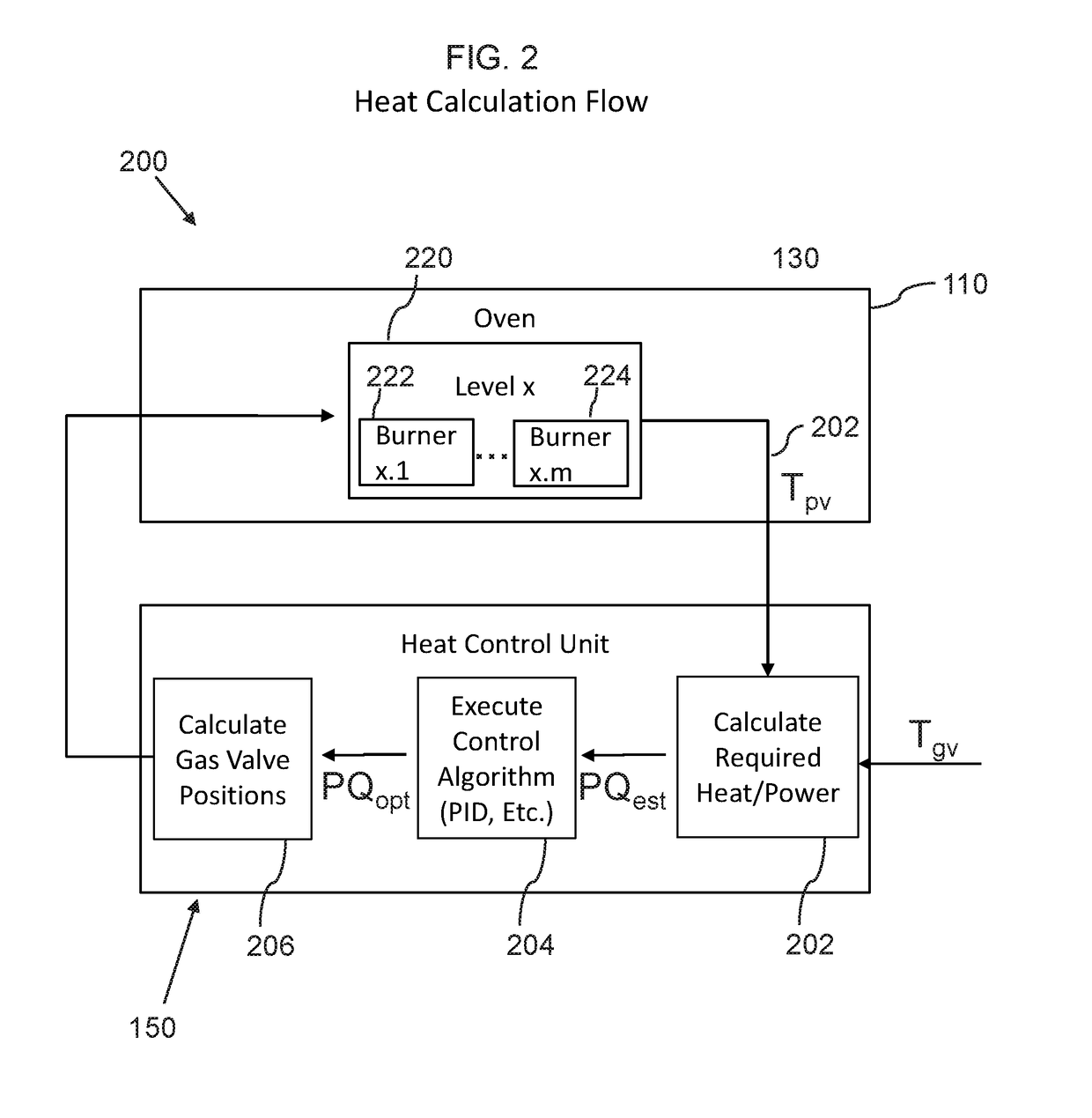

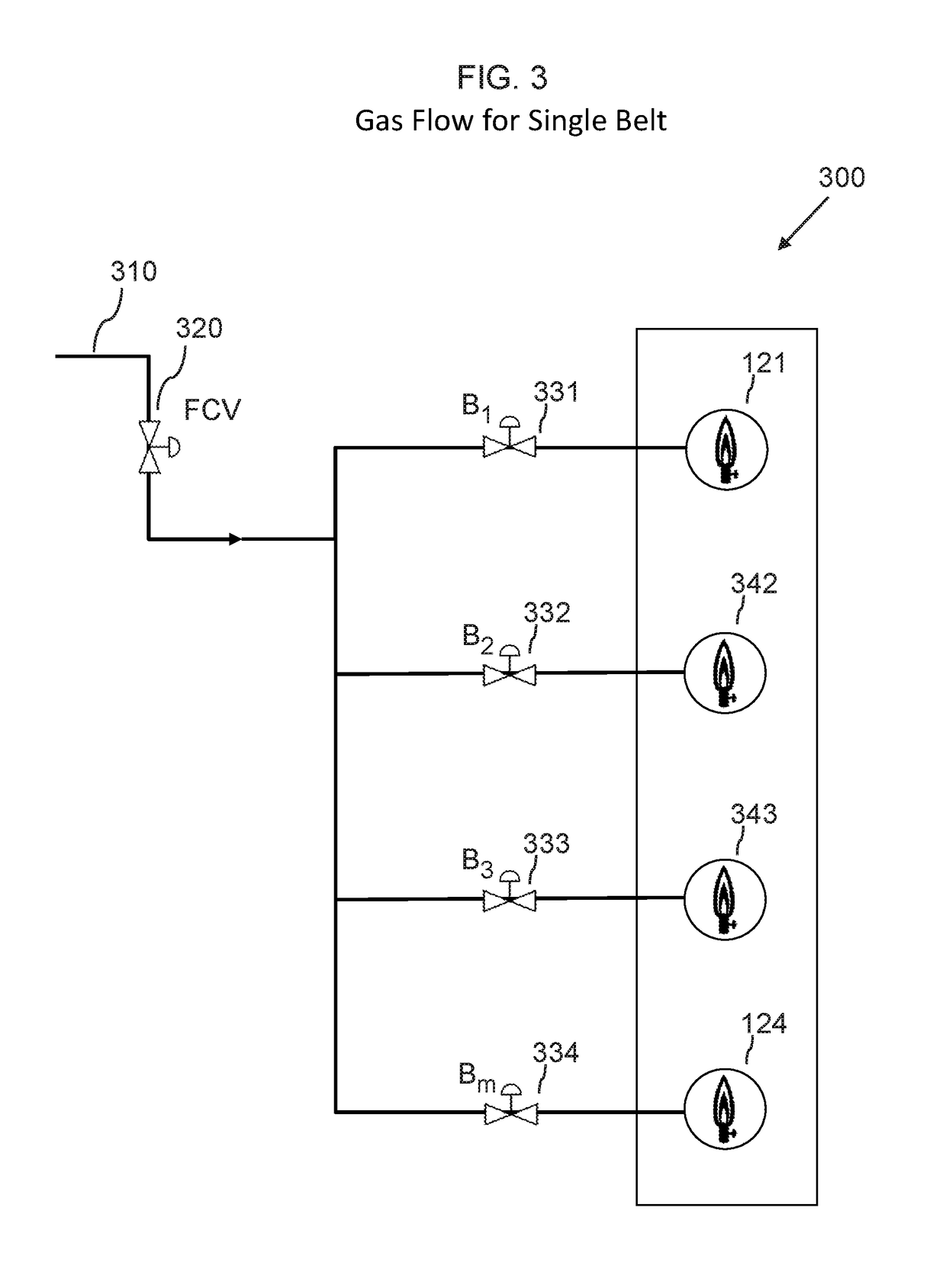

System, device, and method for oven temperature control in tortilla and tortilla chip production

A heat controlled oven system includes a plurality of oven levels, including an oven belt and gas burners; a gas flow network, including a gas supply line, a variable flow control valve, and on / off flow control valves; and a heat control unit, including a processor, a non-transitory memory, and input / output component, a heat modeler, a heat manager, a feedback controller, and a valve controller, such that the heat control unit is configured to calculate an estimated heat demand to adjust to a temperature set point, based on a heat model of the at least one oven level, and further calculates an optimized heat demand using a control loop feedback algorithm. Also disclosed is a method of heat calculation for an oven, including defining a heat model, calculating and optimizing the estimated heat demand, calculating and setting a variable valve position for the gas burners.

Owner:PREMIER INNOVATIONS LLC

Method for producing pumpkin-flavored instant cornflakes

The present invention relates to a method for producing pumpkin-flavored instant cornflakes, and belongs to the technical field of food processing. The producing method comprises the following steps: selecting materials, soaking, cooking, forming, frying, drying, and sorting and packaging. Through the method for producing pumpkin-flavored instant cornflakes, fresh corns are made into the cornflakes, so that original taste and nutrition of the corns are fundamentally maintained.

Owner:苏州科谷米业有限公司

Chocolate corn flake and method for preparing same

InactiveCN102940203AIncrease foam resistancePrevent moisture absorptionFood preparationCocoa PowdersTortilla chips

The invention provides a chocolate corn flake which can be prepared through steps of mixing, by weight, 55 parts to 65 parts of waxy corn powder, 20 parts to 30 parts of sweet corn powder, 2 parts and 4 parts of cocoa powder and 15 parts to 25 parts of water evenly, feeding the mixture into a double screw extruding machine to be extruded and molded, subjecting the mixture to granulation and sheeting to manufacture corn flakes with thickness in a range of 0.2mm to 0.4mm, roasting the corn flakes at a temperature of 150 DEG C+ / - 5 DEG C for 8 minutes to 10 minutes, cooling the roasted corn flakes to 55 DEG C + / - 2 DEG C, spraying 5 parts to 8 parts of molten bee-wax on surfaces of the corn flakes evenly and cooling the corn flakes to a room temperature to obtain the chocolate corn flake. As bee-wax is sprayed in a preparing process, soaking resistance of the corn flake in liquid foods is better than that of tradition corn flakes, and moisture absorption in a storage process of the chocolate corn flake can be effectively prevented simultaneously. Nutrition of the chocolate corn is added as the cocoa powder is added and the bee-wax is sprayed, so that varieties of the chocolate corn flakes are enriched.

Owner:HARBIN PATERNA BIOTECH DEV

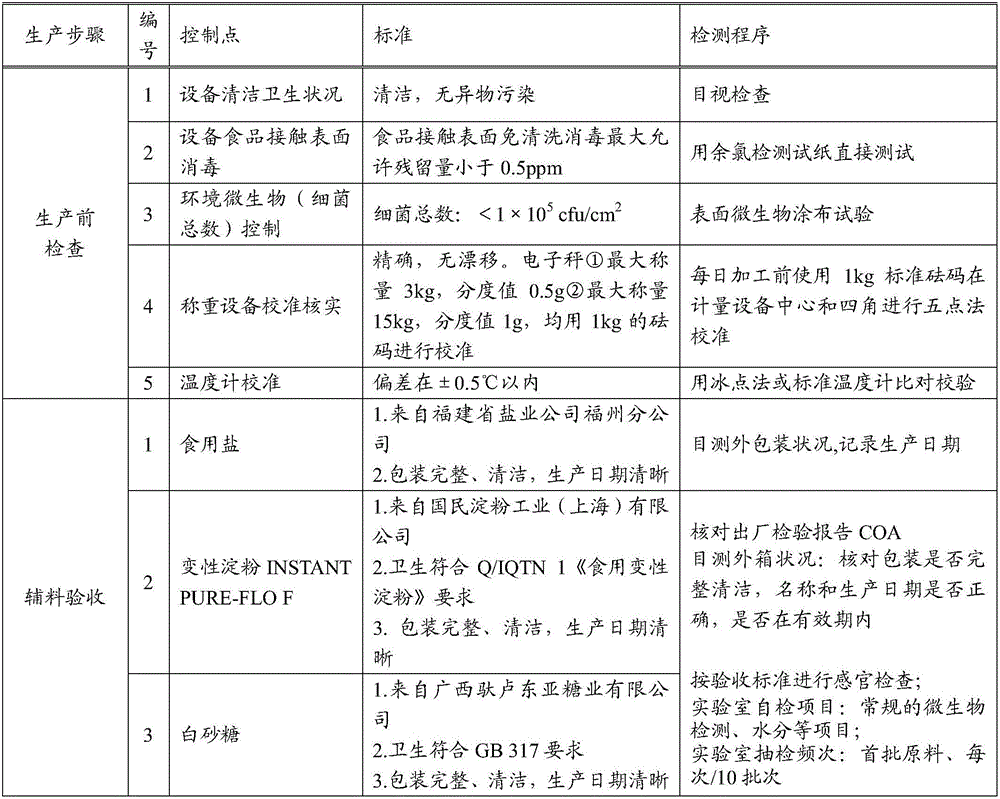

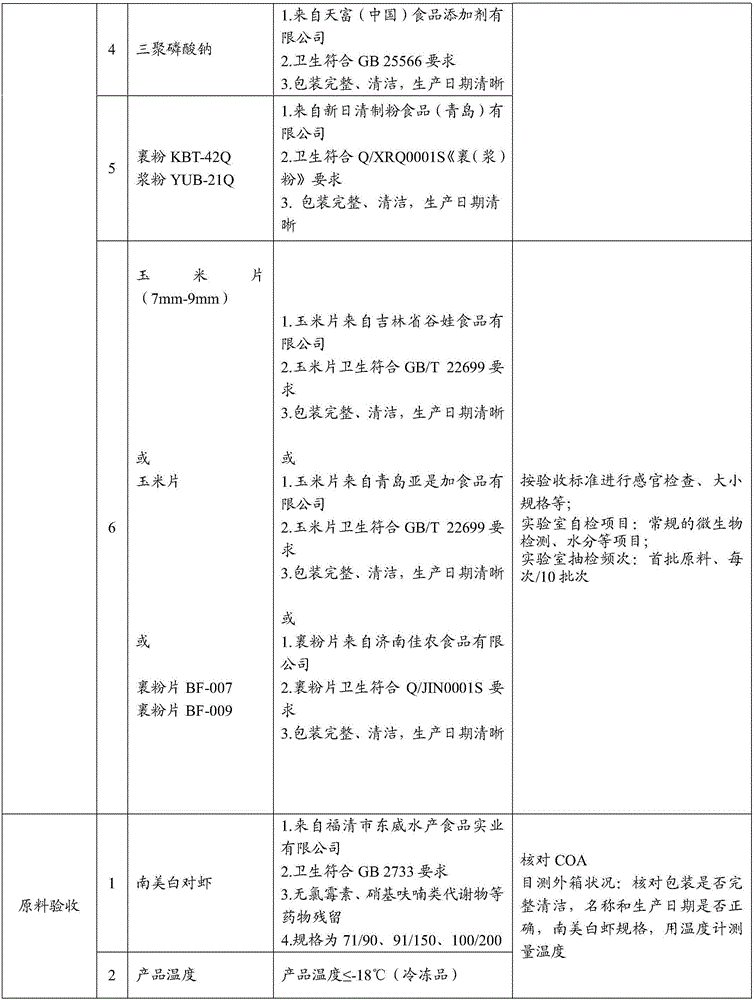

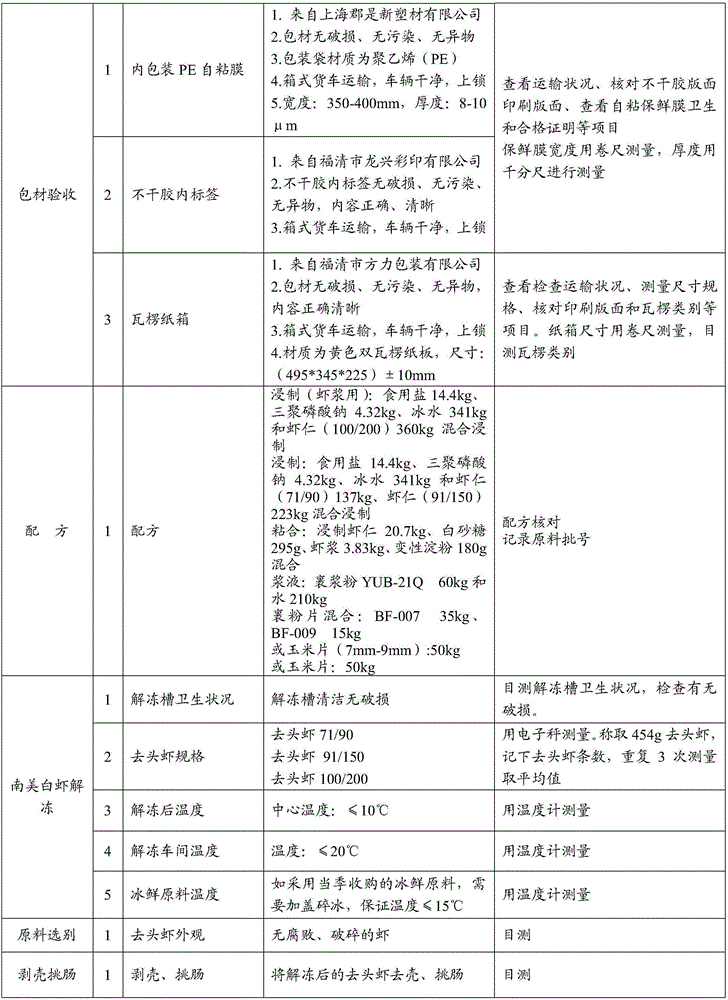

Production method of corn flake-containing shrimp cutlet

InactiveCN105918938AGet marriedNon-deterministicFood freezingFood ingredientsWeight gainingTortilla chips

The invention provides a production method of a corn flake-containing shrimp cutlet fully coated with paste and uniformly coated with corn flakes. The production method comprises mixing table salt, water, sodium tripolyphosphate and shelled shrimps, immersing the shelled shrimps until weight gain is 12-14%, taking out the shelled shrimps, carrying out drainage, immersing the shelled shrimps, smashing a part of the shelled shrimps to obtain shrimp paste, mixing the immersed shelled shrimps, white granulated sugar, shrimp paste and modified starch to obtain a mixture, quick-freezing the mixture, carrying out unfreezing to obtain a blank, coating the blank with pre-coating powder, coating the blank with paste and coating the blank with corn flakes to obtain a corn flake-containing shrimp cutlet finished product. The shelled shrimps are immersed and then are pulped and the immersed shelled shrimps are coated with the shrimp pulp, then are subjected to quick-freezing and unfreezing and then are coated with powder, pulp and corn flakes so that the coated pulp is uniform and the corn flakes do not fall off.

Owner:福建东威食品有限公司

Wet preparation method of instant corn nutrition snowflake tablets

The invention provides a wet preparation method of instant corn nutrition snowflake tablets. The method takes dry corn grits as a raw material, and comprises the following steps that (1) the raw material is pretreated; (2) the dry corn grits are soaked in drinking water with the temperature of 30-60 DEG C; (3) the dry corn grits are grinded into pulp; (4) the pulp obtained by grinding is subjectedto roller pregelatinization and pre-drying to obtain corn paste; (5) the corn paste is subjected to roller drying to obtain the corn tablets of which the water content is not higher than 8%; (6) thecorn tablets are crushed and sieved; (7) the corn snowflake tablets are subjected to microwave sterilization; (8) inner packaging, metal detection and outer packaging are carried out. The wet preparation method of the instant corn nutrition snowflake tablets can improve the nutritional value of the corn snowflake tablets, improve the brewing performance and taste of the corn snowflake tablets, andreduce the energy consumption.

Owner:SICHUAN UNIV +1

System, device, and method for moisture and texture detection and control in tortilla chip production

ActiveUS10028513B2Dough-sheeters/rolling-machines/rolling-pinsBaking processesTortilla chipsBelt speed

A production system for moisture and texture detection and control in tortilla and tortilla chip production includes a production line, including a cooker / grinder, a sheeter / cutter, an oven, an equalizer, a fryer, and a cooler / packaging machine; and a production control unit, including a processor, non-transitory memory, an input / output component, a moisture controller, a temperature controller, a belt speed controller, a masa moisture sensor, a chip moisture sensor, laser sensors for measuring surface texture of baked and fried chips, a laser controller, a texture classifier, a feedback controller. Also disclosed is a method for production control, including controlling moisture content, measuring masa moisture, controlling oven, measuring baked surfaces, measuring fried surfaces, classifying baked surfaces, classifying fried surfaces, optimizing oven temperature, optimizing oven belt speed, storing and characterizing historical records.

Owner:BARTLETT BRIAN E

Method for producing spinach-flavored instant cornflakes

The present invention relates to a method for producing spinach-flavored instant cornflakes, and belongs to the technical field of food processing. The producing method comprises the following steps: selecting materials, soaking, cooking, forming, frying, drying, and sorting and packaging. Through the method for producing spinach-flavored instant cornflakes, fresh corns are made into the cornflakes, so that original taste and nutrition of the corns are fundamentally maintained.

Owner:苏州科谷米业有限公司

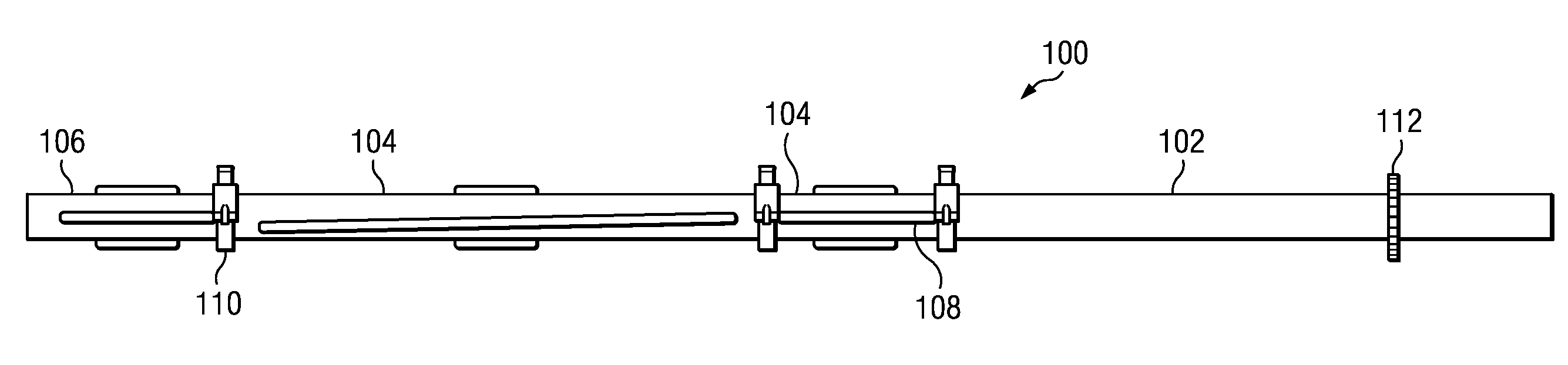

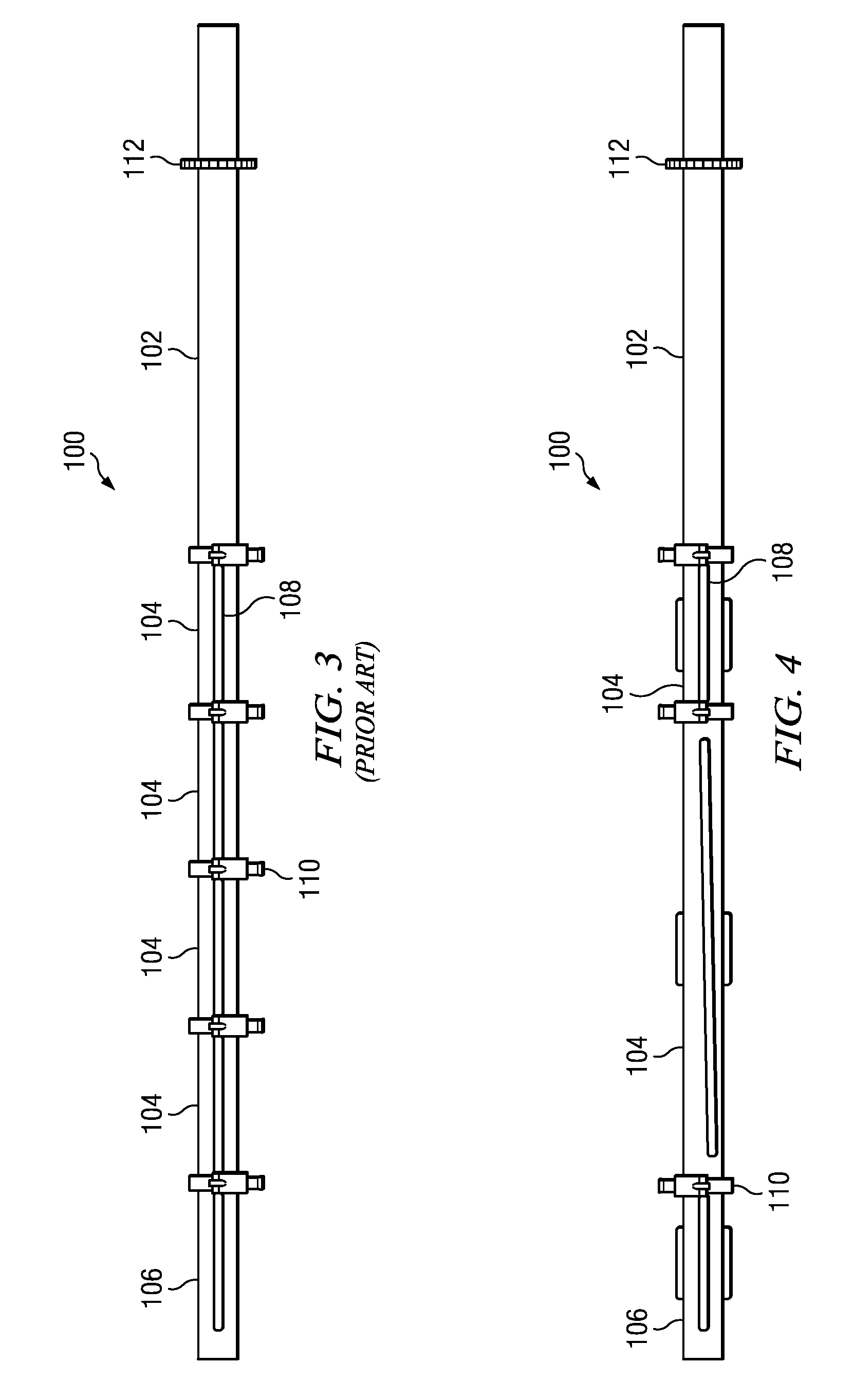

Adjustable Seasoning Distribution Tube

InactiveUS20120196012A1Reduce lossesUniform coverageConfectionerySweetmeatsChipped potatoesProduction line

An apparatus and method for providing a controlled, uniform distribution of seasoning onto snack food products such as potato chips or tortilla chips using an adjustable, segmented seasoning distribution tube adaptable to an existing product line. The tube comprises a base member attached at one end to the delivery device of the seasoning distribution system and at least two segments attached in succession to the base member. Each segment has an opening along the length of the segment, which may be adjusted above or below the longitudinal axis of the tube.

Owner:FRITO LAY NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com