Patents

Literature

58 results about "Egg noodles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

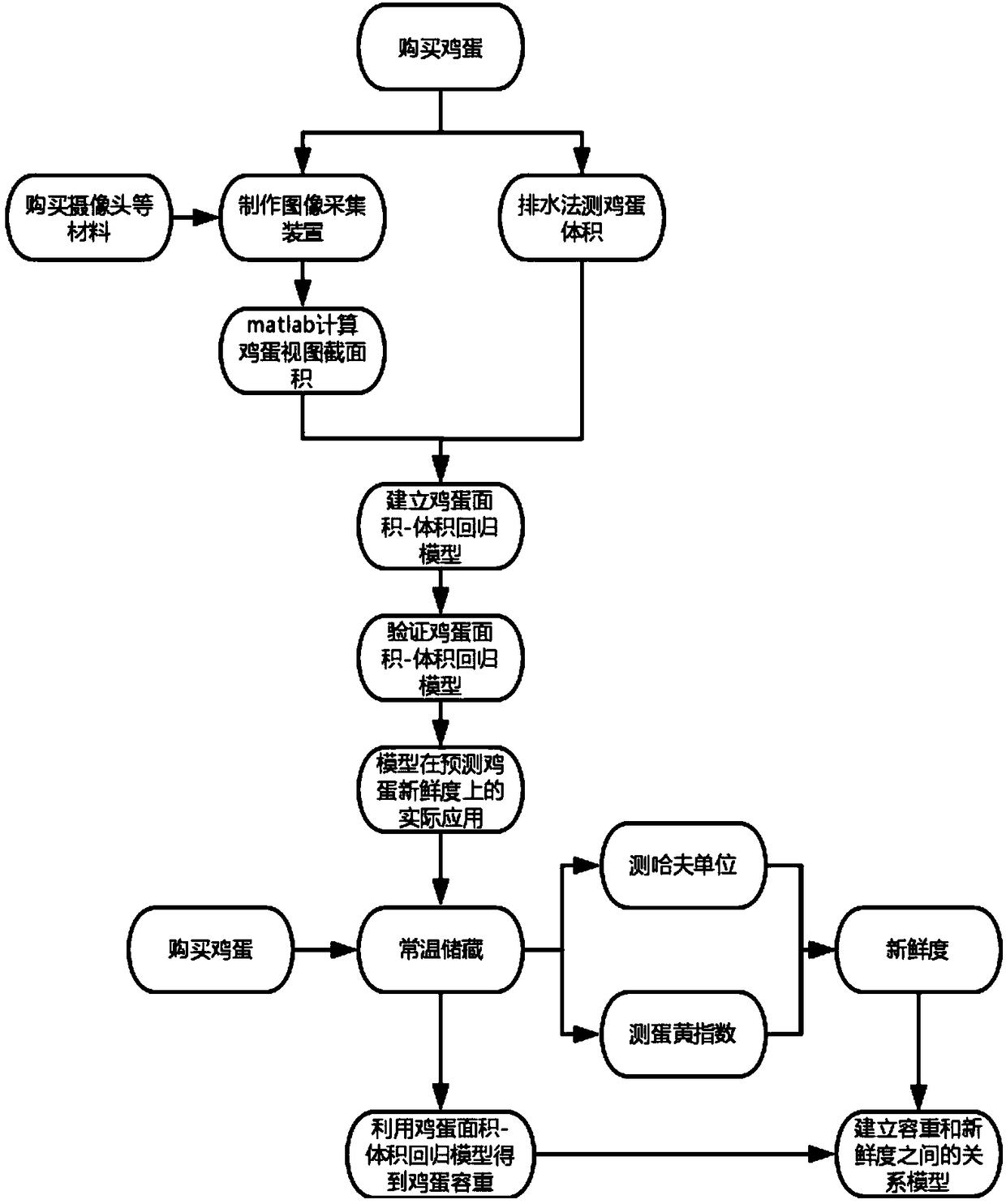

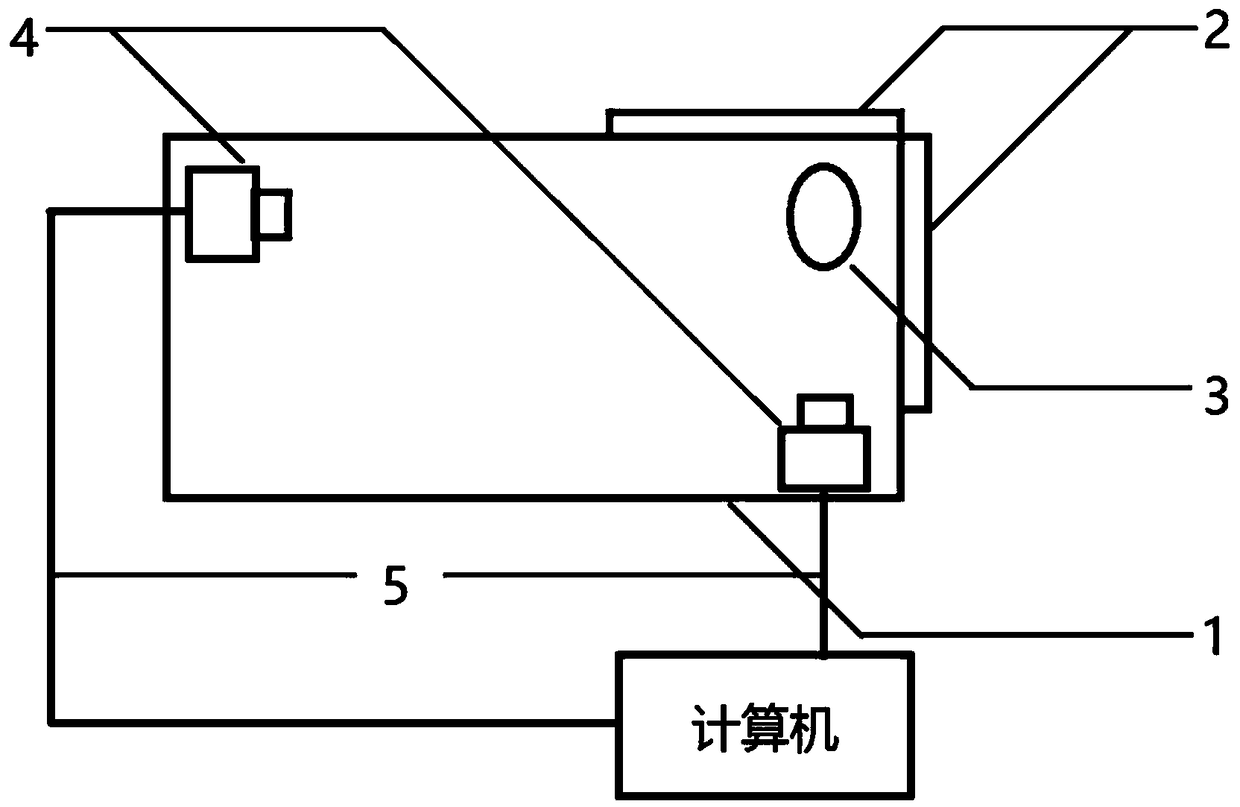

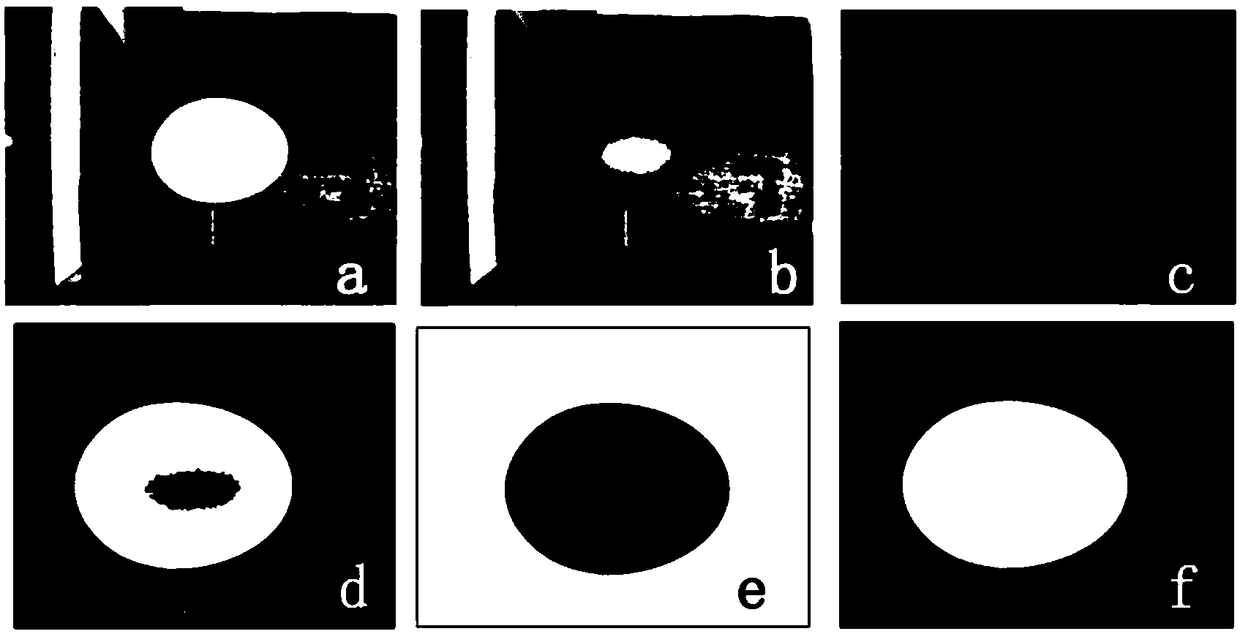

Egg quality nondestructive detection method based on unit weight of egg

InactiveCN108663367AFreshness predictionFind out the freshnessTesting eggsMaterial analysis by optical meansLinear relationshipComputer science

The invention discloses an egg quality nondestructive detection method based on the unit weight of an egg, and belongs to the technical field of nondestructive detection of the quality of agriculturalproducts. The method comprises the following steps: rapidly connecting and processing the image of every egg, establishing a linear relationship between the area and the volume of the very egg, conveniently and rapidly calculating the unit weight of every egg, and establishing a linear relationship between the unit weight of the egg and the Haugh unit, a common index for the freshness, of the egg to predicate the freshness of the egg. Eggs with the unit weight rho being equal to or more than 1.067 have a high freshness, and are suitable for consumers to eat; eggs with the unit weight rho being 1.046-1.067 can be eaten by the consumers; eggs with the unit weight rho being 0.996-1.046 have a poor freshness, and are not suitable for consumers to eat as shell eggs; and eggs with the unit weight rho being equal to or less than 0.996 cannot be eaten. The freshness of an egg can be rapidly and simply known and the egg is graded only through inputting the image of the egg into a system.

Owner:CHINA AGRI UNIV

Saccharides and saccharide compositions and mixtures

ActiveUS9364015B2Improve health benefitsGood for healthOrganic active ingredientsCosmetic preparationsReady to eatFlavored water

Owner:XYLECO INC

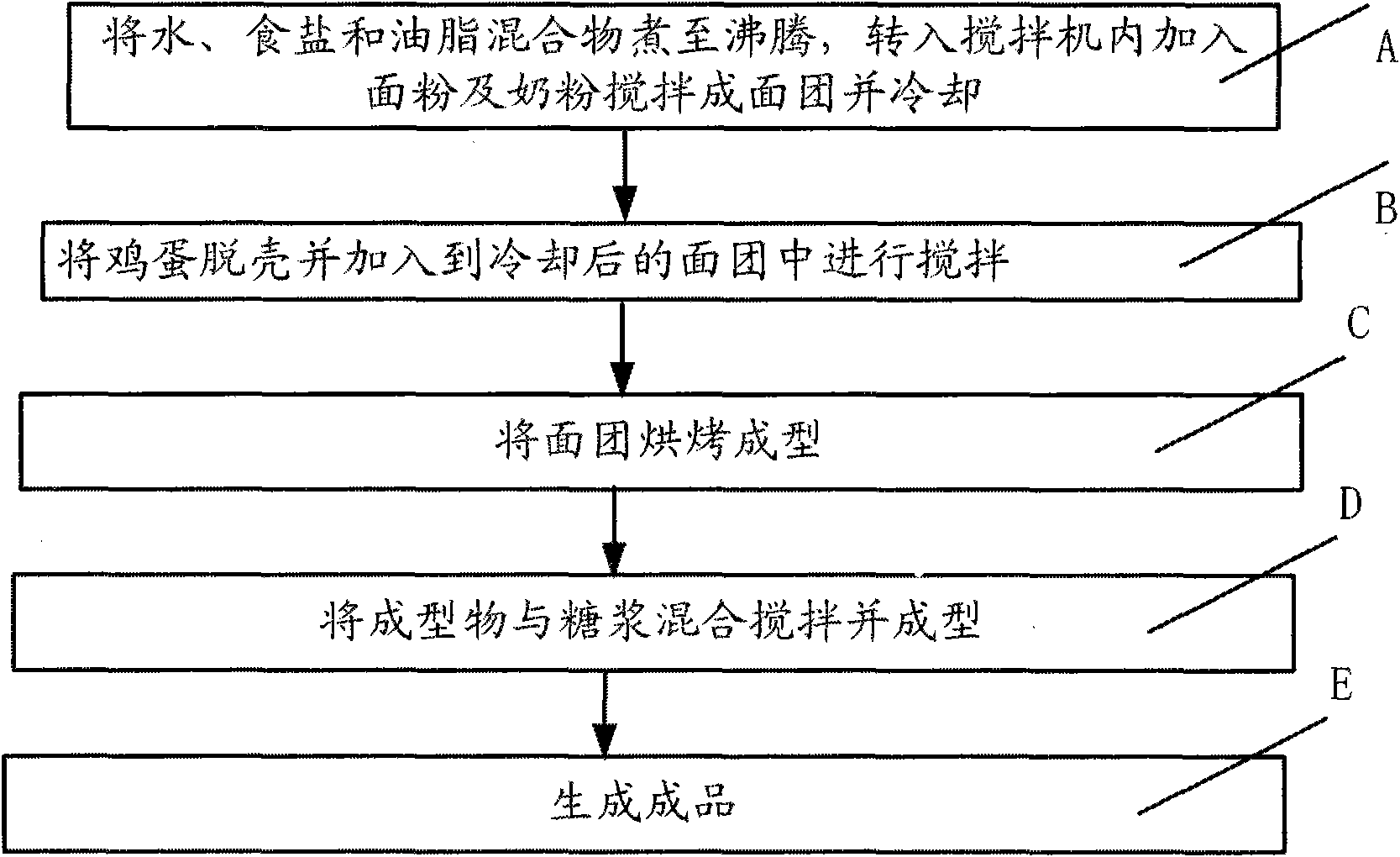

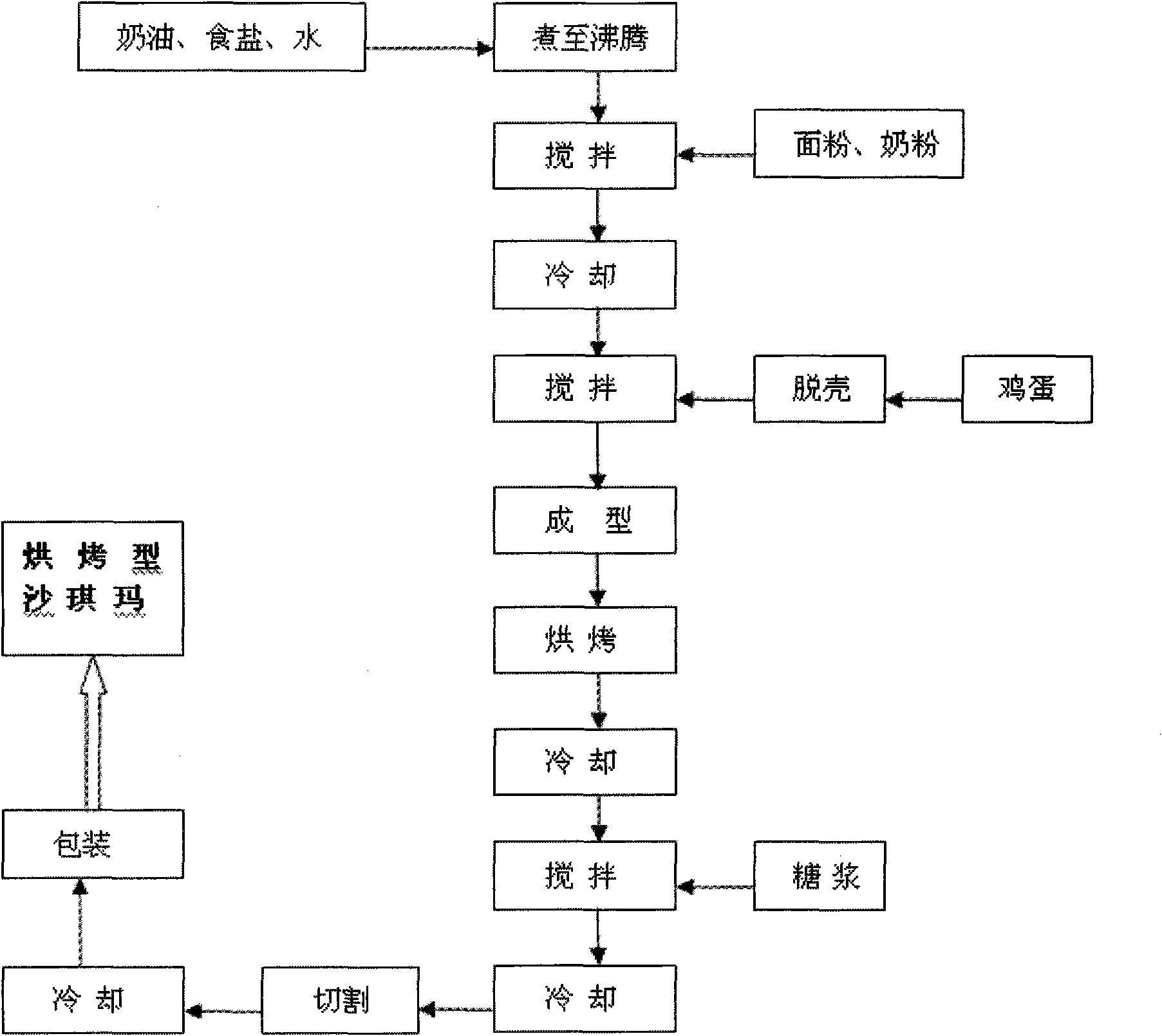

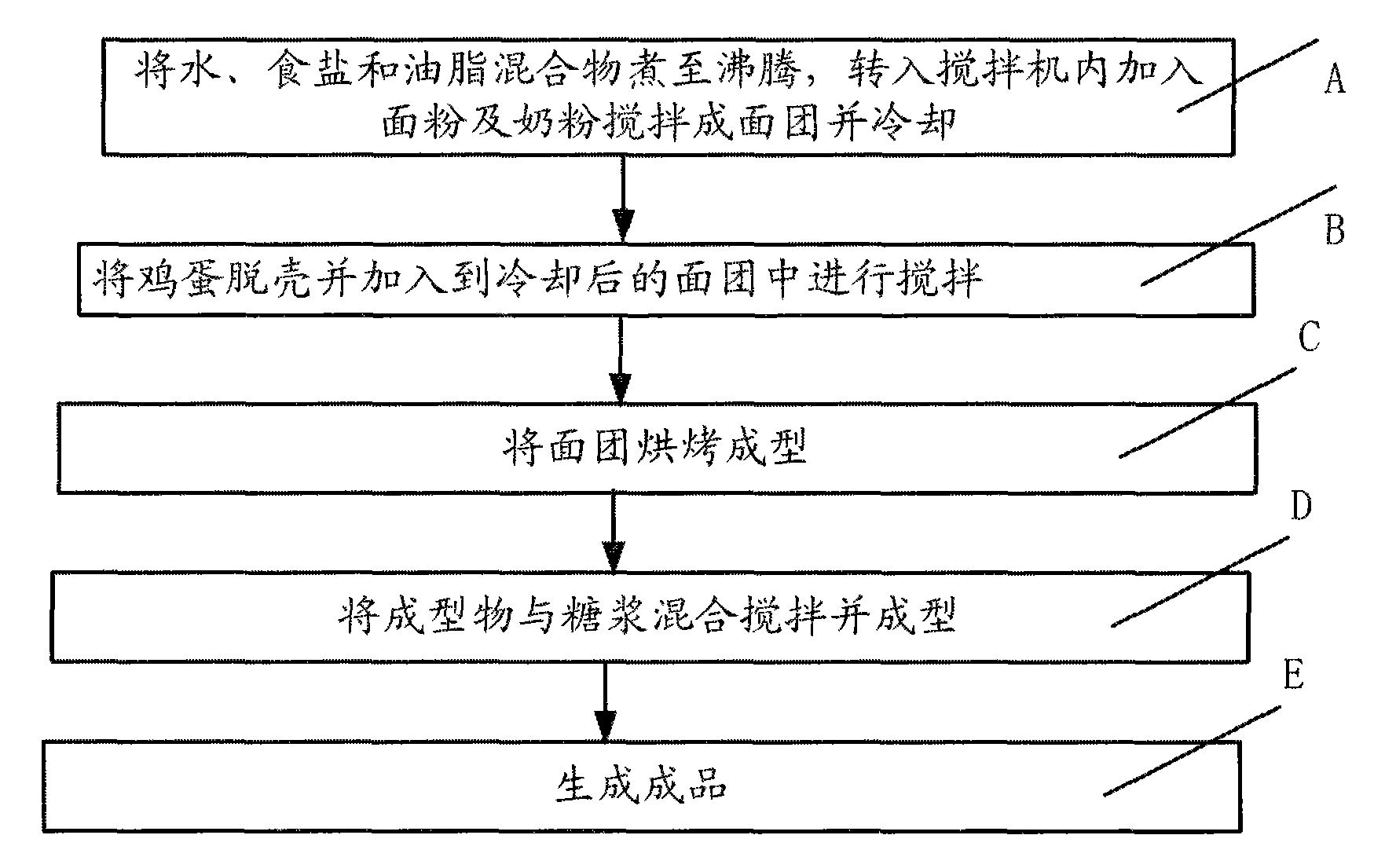

Baking-type Sachima and production method thereof

InactiveCN101919480AMaintain propertiesHigh nutritional valueConfectionerySweetmeatsFood additivePreservative

The invention relates to the food-processing industry, in particular to a baking-type Sachima prepared from the following components in percentage by weight: 30-40 percent of eggs, 18-25 percent of flour, 15-20 percent of grease, 30-35 percent of malt syrup, 3-5 percent of milk powder and 0.05-0.1 percent of salt. The invention also provides a production method of the baking-type Sachima. The invention has the advantages that natural and excellent raw materials are selected to make the Sachima in the emphasized aspects of nature, nutrition and health, no food additive or preservative is added; the Sachima has strong and natural fragrance and crispy and moisten tastes because of the high-quality grease; and a traditional frying mode in process is discarded, and a process of stripping through braking is adopted to ensure the original characteristics of the raw materials and endow the product with higher nutrition values.

Owner:杨晓勇

Saccharides and saccharide compositions and mixtures

ActiveUS20160081381A1Increase good healthIncrease nutritional well-beingBiocideOrganic active ingredientsReady to eatFlavored water

Described herein are products comprising a xylose (e.g., D-xylose or L-xylose and another sweetener such as glucose). Exemplary products include the following: ice cream, ice milk, sorbet, sherbet, gelatin candies, baby food, animal food, e.g., dog, cat, canine, or equine food, seasonings, sauces, cosmetics, dietary supplements, lip stick, lip gloss, face and body preparations, pharmaceuticals, such as flu and cold preparations, nutraceuticals, surgical preparations, procedure preparations, imaging preparations, e.g., CT scan imaging preparations, pain relievers, nasal spray, cheese, vegetables, mayonnaise, mustard, salad dressings, nuts and nut mixes, cookies, pastries, fruit flavored snacks, pancakes, waffles, hot cocoa mix, caramel, shampoo, dental floss, donuts, egg noodles, lollypops, frozen pops, soda pop, chips, potato chips, tortilla chips, corn chips, sports drinks, rice cakes, oatmeals, teas, cereals, rice mixtures, flavored water, alcohol, alcohol mixers, soaps, energy drinks, coffee, coffee flavored drinks, coffee products, cake mixes, chili, chip dip, chip sauces, fibers, such as cellulosic and lignocellulosic fibers and fiber supplements, meats, e.g., deli meats, drink mixes, pasta, meals ready to eat, coconut water, candies, e.g., hard and soft candies, chocolate, candy bars, sports bars and energy bars. In embodiments, the xylose containing product is made using a method described herein. For example, the xylose is produced from a biomass described herein.

Owner:XYLECO INC

Duck egg noodles

The invention discloses duck egg noodles. The invention is characterized in that duck egg noodles are prepared from the following raw materials in parts by weight: 20-40 parts of oat, 4-10 parts of wheat, 8-16 parts of buckwheat, 4-8 parts of duck egg, 1-2 parts of salt and 0.5-1 part of noodle alkali. In the invention, duck eggs are adopted to substitute chicken eggs to prepare duck egg noodles,thus noodles full of nutrients are provided for cholecystitis patient and people suffering from excessive internal heat and a new noodle product is provided for people. Since ducks is mainly fed on aquatic animals and plants, duck eggs have fishy smell and are not as delicious as chicken eggs when being eaten, and duck eggs are usually prepared into preserved duck eggs and salted duck eggs. The inventor does experiment on the proportion of the duck egg noodles to summarize a formula of duck egg noodles which can avoid the fishy smell of duck eggs and have good taste.

Owner:平塘县玉水腾龙禽蛋制品有限责任公司

Method for processing egg noodles

The invention discloses a method for processing egg noodles. The method comprises the following steps of kneading dough, standing the dough, extending and pressing, partitioning and drying, wherein the step of kneading dough comprises the specific steps of uniformly mixing eggs, tea seed oil, linseed oil and maize germ oil, thereby forming egg liquid; and then adding mixed flour and water, and performing stirring. The mixed flour is prepared from high gluten flour, wheat starch, vital gluten, sodium alginate and table salt. The method has the advantages that after being decocted, the obtained egg noodles are not broken, are delicious in taste, tough and chewy, and can not be pasted or diluted and still remain in original shape and chewiness after being stood for a period of time.

Owner:楚雄富民金鹿食品有限公司

Egg fine dried noodles and preparation method thereof

InactiveCN102783603ARich in nutrientsRefreshing and smooth tasteFood preparationBiotechnologyAnimal science

Owner:徐州京味福食品有限公司

Preparation process of egg noodles

The invention discloses a preparation process of egg noodles, relates to an improvement on noodle-type instant foods, and particularly relates to an improvement on egg-noodle foods. The preparation process comprises the following steps: mixing all materials according to certain proportion, stirring uniformly, using a wooden stick to stir flour and liquid into lumps, then putting the flour stirred uniformly into an automatic dough kneading machine for kneading, properly spreading a little of flour onto a dough during kneading to prevent the dough from being excessively wet, then putting the kneaded dough into a dough pressing machine to press into a dough piece, then folding the dough piece from the middle, putting into the dough pressing machine for pressing, repeating for 7-9 times, putting the pressed dough piece into a noodle making machine to make into noodles, then adding the prepared egg noodles into a drying machine for drying, arranging the dried egg noodles to remove scraps, preparing into fine dried noodles, finally weighing fine dried egg noodles and bagging. After adoption of the technical scheme, the preparation process has the beneficial effects that by large-scale and industrialized production and packaging, the egg noodles can be eaten after being put into boiling water and cooked.

Owner:安徽优乐亿乳业有限公司

Pork loin noodles and preparation method thereof

InactiveCN102258173ANutritional diversityNutritional balanceFood preparationMonosodium glutamateSesame Oils

The invention provides a pig loin boiled noodle, which comprises pork loin and noodles. The pork loin is fresh pork loin, which is cleaned to remove internal loin smell, and cut into kidney flowers, wherein the pork loin accounts for 25-30%, and the noodles are prepared by adding eggs, Salt, water and form a dough to wake up for a while; noodles account for 55-60%, accessories: onion, ginger, coriander, broccoli, eggs, a total of 10%, seasoning: salt, monosodium glutamate, soy sauce, cooking wine, black pepper, Sesame oil, accounts for 5% altogether. The invention also provides a preparation method of the noodles. Since the pork loin noodles provided by the invention have comprehensive nutrition, good taste, and easy-to-obtain preparation raw materials, the pork loin noodles of the present invention are convenient, quick, nutritionally balanced, and good-tasting noodles.

Owner:张志芳

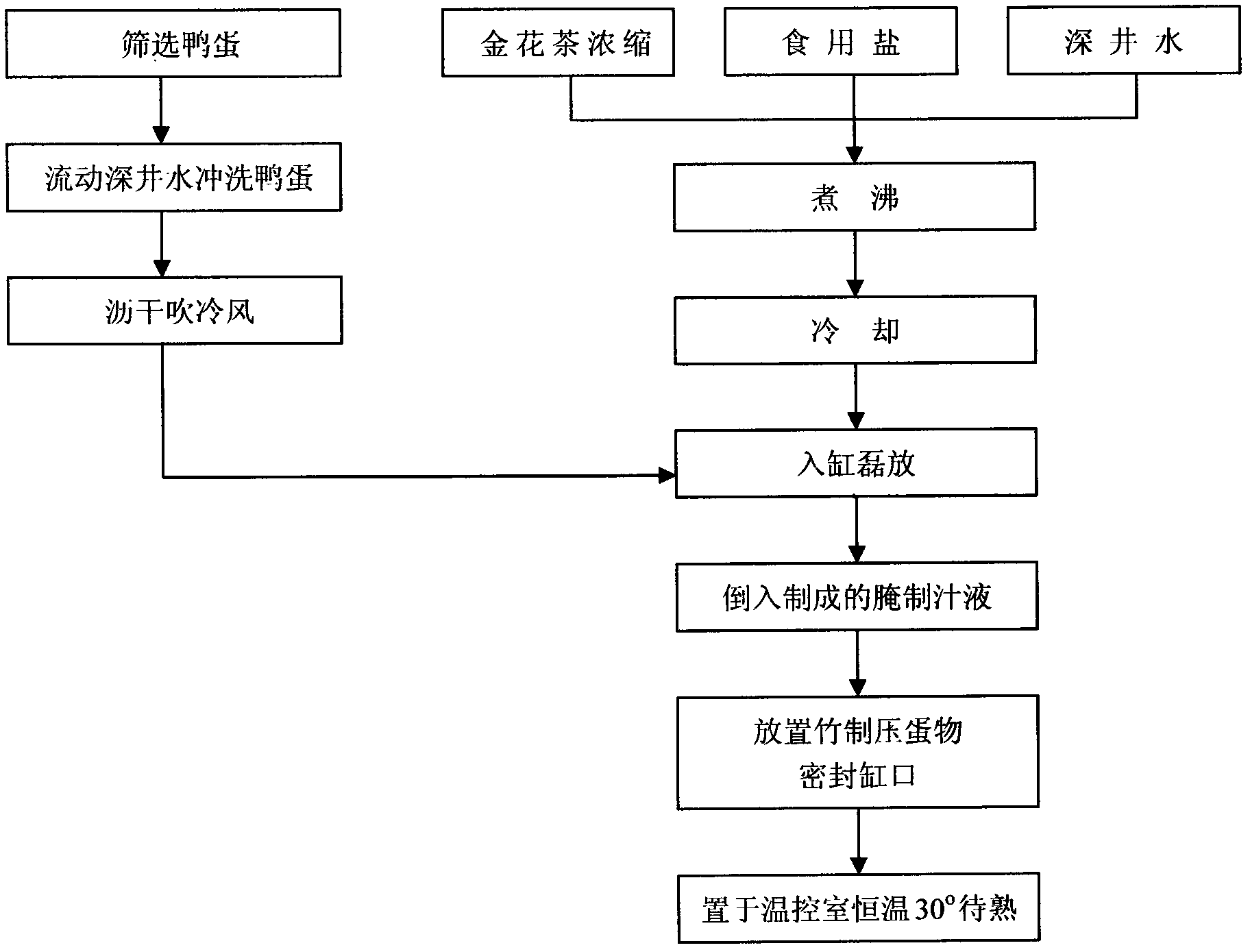

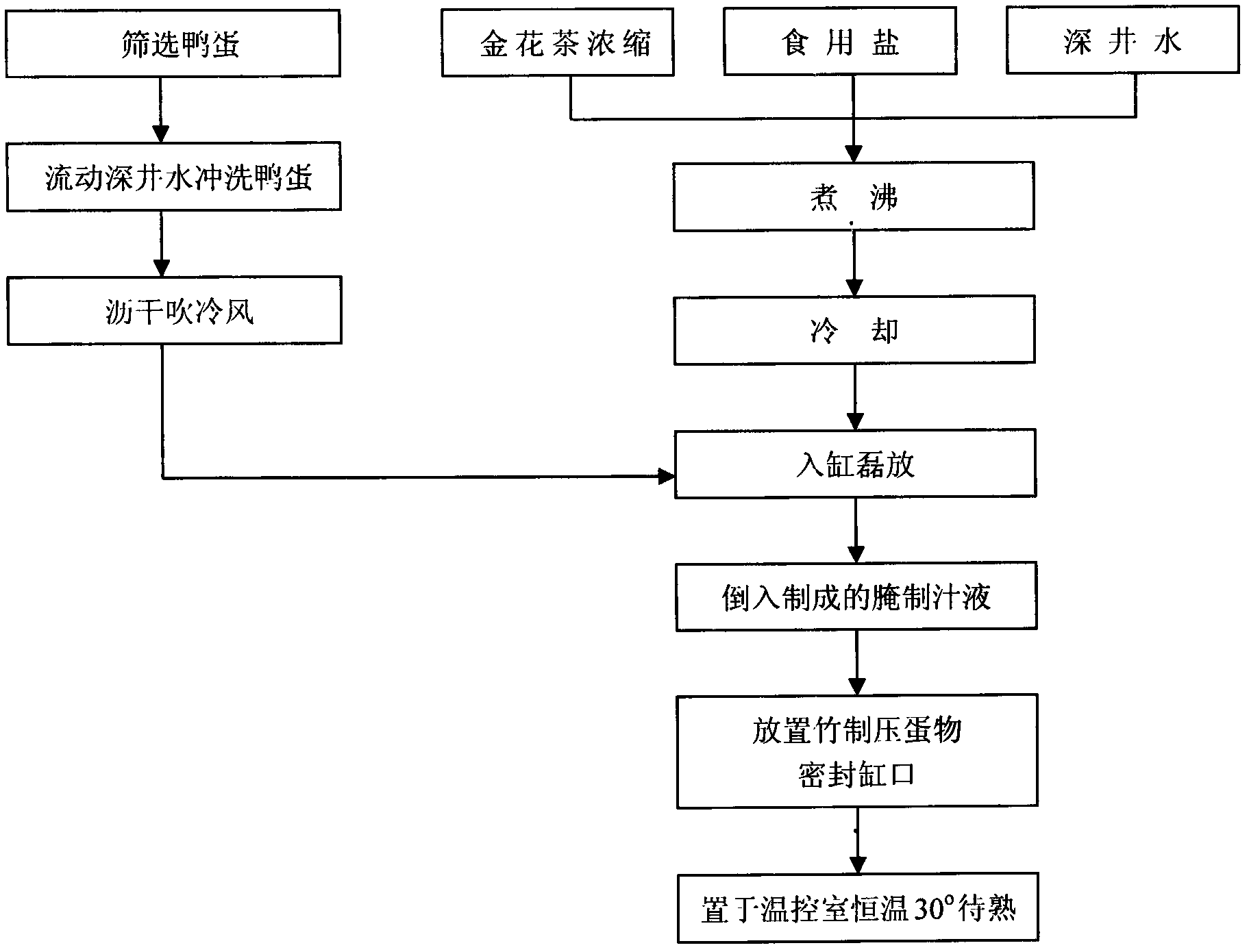

Method for pickling shelf-stable salted eggs in batches

The invention relates to a batch pickling method for storage-resistant salted eggs. The fresh leaves of Camellia chrysalis are used to make the concentrated juice in an ordinary high-pressure container for later use. Strictly select the fresh duck eggs, and then rinse the fresh duck eggs one by one with running deep well water. While draining the water, put them in the air conditioner and blow them until they are completely dry. According to the average proportion per 100 catties of fresh duck eggs, 40 catties of golden camellia concentrated juice, 22 catties of high-quality edible salt, and 68 catties of deep well water are used. Stir the above formula evenly and boil to completely dissolve the edible salt to make marinated juice for later use. After completely cooling down, put the duck eggs into the container one by one and pour in the pre-prepared pickling juice until the egg surface is covered. Place a piece of bamboo braid on the egg surface to ensure that all the marinated duck eggs are soaked in the juice and then cover and seal. , and then placed in a control room to maintain a constant temperature of 30° to mature in 83 days. Through the above formula and processing technology, the product has special flavor, rich nutrition and special storage resistance, and also ensures the uniformity of product quality.

Owner:肖景月

Egg noodles and preparation method thereof

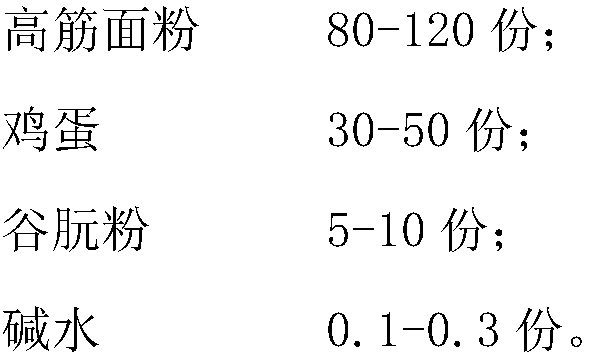

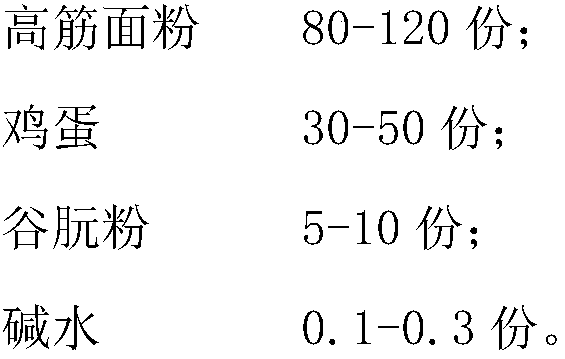

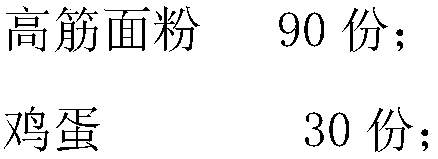

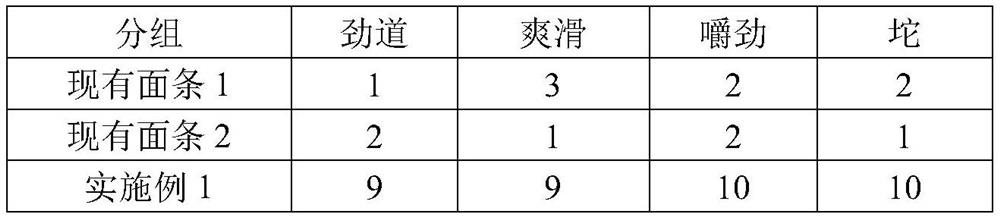

InactiveCN107594336AEasy to pack and sellGreat tasteDough shaping and cutting apparatusAlkaline waterAdditive ingredient

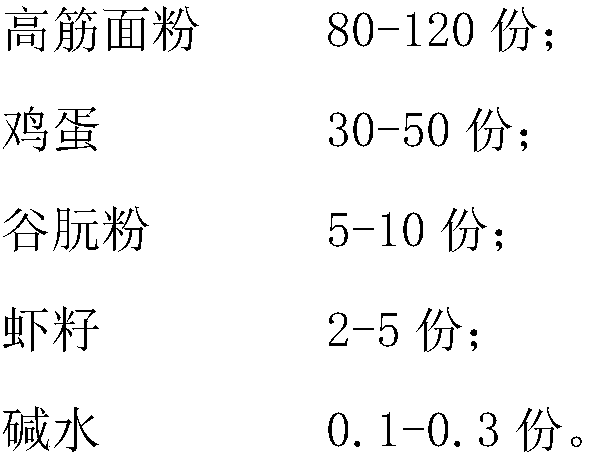

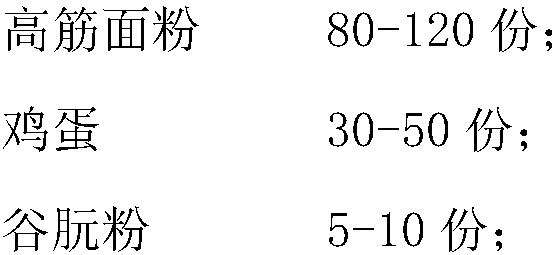

The invention discloses egg noodles which are prepared from the following raw materials in parts by weight: 80-120 parts of high gluten flour, 30-50 parts of eggs, 5-10 parts of wheat gluten and 0.1-0.3 part of alkaline water. The egg noodles disclosed by the invention take nutrient-rich high gluten flour, eggs and wheat gluten as main raw materials, and the prepared egg noodles contain rich nutritional components such as protein, vitamins and amino acids, have good taste and are not sticky to teeth; water is not added in a preparation process, the egg noodles are whole egg noodles, and the prepared egg noodles are fragrant; a preparation method is simple and easy to realize industrialization; and the prepared egg noodles are not burnt after being cooked for a long time, are fragrant and have good taste, nutrition and fragrance.

Owner:江门市江海区金昇咨询有限公司

Highly nutritious mixed egg noodles

The present invention discloses highly nutritious mixed egg noodles. The highly nutritious mixed egg noodles are prepared from the following raw materials in parts by weight: 100-120 parts of wheat flour, 10-12 parts of quail egg juice, 8-12 parts of eggs in first nests, 15-20 parts of sea duck eggs, 0.5-1 part of pteridium aquilinum var.latiusculum root powder, 3-8 parts of canna edulis starch, 0.8-1.2 parts of edible salt, 1-3 parts of phytic acid, 1-1.5 parts of guar gum and 15-30 parts of Beier village tea tree stem and leaf juice. A formula of the product is a "three-egg" formula using the raw materials of the quail egg juice, eggs in the first nests and sea duck eggs, so that the noodles are rich in trace elements of amino acids, phosphorus, ferrum, calcium, zinc, iodine, etc. At the same time, the pteridium aquilinum var.latiusculum root powder and canna edulis starch are added and crude proteins, crude fat and crude fibers in the noodles are increased. A long-term consumption of the noodles has a positive function for human body to comprehensively intake a large number of nutrients.

Owner:林增慈

Vitamin noodles made by efficiently utilizing quail eggs and making method

InactiveCN105942194AOvercome the disadvantage of fishy smellNo fishy smellFood scienceYolkPre treatment

The invention discloses vitamin noodles made by efficiently utilizing quail eggs and a making method. The vitamin noodles are made from, by mass, 900-1,100 g of flour, 6-10 g of salt, 2-6 g of washing and food stuff soda, 90-110 g of vegetables, 8-12 g of yellow ginger, 130-150 g of drinking water and 40-60 g of egg white of the quail eggs or 40-60 g of yolk of the quail eggs or 90-110 g of the quail eggs. The making method sequentially comprises the following steps of raw material preprocessing, powder mixing, curing, calendaring, shredding and cutting, airing and finished noodle obtaining. According to the vitamin noodles and the making method, due to the fact that the yellow ginger is added, the defect that original quail egg noodles or pigeon egg noodles have a fishy smell is overcome; the noodles produced through the method are free of the fishy smell, capable of not generating paste soup and good in chewiness. The vitamin noodles are added with the vegetables such as carrots, the quail eggs or pigeon eggs and the like and are rich in vitamins and rich protein, lecithin and mineral substances and suitable for being eaten by the crowds who has high mental and physical requirements.

Owner:重庆伯德农业发展有限公司

Preparation method of tomato egg noodles

The invention belongs to the technical field of food processing methods and in particular relates to a preparation method of tomato egg noodles, which mainly solves the problems that the traditional noodle gravy is prepared for a long time and the requirement of office workers cannot be met. The technical scheme is as follows: the preparation method of tomato egg noodles comprises the following steps: firstly, cooking soup, namely, boiling big bones, chicken, water and spices in an interlayered pot for 4-6h for later use; secondly, preparing gravy, namely adding edible oil in the pot with the conventional method, adding spices in the edible oil, frying until fragrance is emitted, fishing out all spices, adding chopped green onions, garlic granules and ginger granules, adding eggs and frying into granules, then adding tomato granules and garlic granules, frying, adding soup, pasty tomato sauce, cooking wine and salt, adding starch with weight of one-tenth of weight of soup, and boiling for 0.5-1h to prepare fresh tomato egg gravy; and thirdly, bagging. The preparation method has the advantages of simplicity, nutrition, deliciousness and rapidness.

Owner:SHANXI BAIHEYUAN FOOD

Egg noodles and preparation method thereof

InactiveCN112385770AOvercoming the lack of smooth tasteOvercome bad energyLipidic food ingredientsFood ingredient functionsBiotechnologyAnimal science

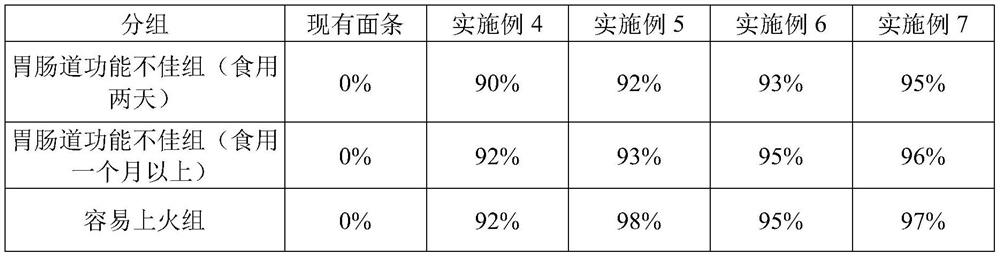

The invention provides egg noodles and a preparation method thereof, and relates to the technical field of wheaten foods. The egg noodles are mainly prepared from the following raw materials in partsby weight: 22-28 parts of flour, 0.8-1.2 parts of eggs, 0.8-1.2 parts of vegetable oil, 0.08-0.10 part of dietary alkali and 7-10 parts of water. The egg noodles have the advantages that the egg noodles provided by the invention are prepared by adopting a specific proportion and the preparation method, are rich and comprehensive in nutrition, and can overcome the defects that the existing noodlesare not smooth enough in mouth feel, not chewy enough and easy to lump due to chewiness insufficiency. Different materials are added, so that the problems of excessive internal heat and poor intestines and stomachs due to excessive eating of spicy materials and easy sour regurgitation can be effectively solved, and in addition, certain slimming and bodybuilding effects can be achieved. Meanwhile,the process does not involve too complicated processes and rare raw materials, and is low in production cost and easy to popularize.

Owner:刘秀英

Selenium-enriched egg noodles

The present application relates to selenium-enriched egg noodles. The noodles are prepared from selenium-enriched stone-milled flour, selenium-enriched eggs and selenium-enriched water. The raw material ratios are as follows in parts by weight: 100 parts of the selenium-enriched stone-milled flour, 8-10 parts of the selenium-enriched eggs, 10-16 parts of the selenium-enriched water and 0.2-0.6 part of edible salt. The selenium-enriched stone milled flour is prepared using selenium-enriched wheat and selenium-enriched malt flour at a mass ratio of 7:2.

Owner:广州优里贸易有限公司

Noodles with eggs and shrimp eggs and preparation method for noodles

The invention discloses noodles with eggs and shrimp eggs as well as a machine and a manual making method for preparing the noodles. The noodles with eggs and shrimp eggs are prepared from the following raw materials in parts by weight: 80-120 parts of high gluten flour, 30-50 parts of eggs, 5-10 parts of vital gluten, 2-5 parts of shrimp eggs and 0.1-0.3 part of alkaline water. The noodles with eggs and shrimp eggs take high gluten flour, eggs, vital gluten and shrimp eggs which are rich in nutrient as main raw materials, so that the prepared noodles with eggs and shrimp eggs have rich nutritional ingredients such as proteins, vitamins and amino acid, are fresh and sweet in mouthfeel, and are not sticky; in a preparation process, water is not added, so that the noodles are full-egg noodles, and have sweet smell; the preparation method is simple, the machine can be adopted to prepare, and manual making also can be adopted; the noodles with eggs and shrimp eggs are tough and chewy, donot paste after being cooked for a long time, have sweet smell, and are noodles with good mouthfeel, nutrition and smell.

Owner:江门市江海区金昇咨询有限公司

Carrot and egg noodle, and its preparation method

InactiveCN102366051AMeet iron needsPrevent Iron Deficiency AnemiaFood preparationTaurineFerrous Gluconate

The invention provides a carrot and egg noodle, and a preparation method thereof. The carrot and egg noodle comprises the following raw materials by weight part: 1-10 parts of carrot powder, 0.15-0.2 parts of egg white powder, 0.048-0.06 parts of ferrous gluconate, 0.02-0.05 parts of zinc gluconate, 90-100 parts of common flour; 0.0003-0.0009parts of vitamin A; 0.03-0.05 parts of taurine, 0.1-0.2 parts of L-lysine hydrochloride, 1-5 parts of salmon powder and 20-30 parts of water. The method comprises the following steps: mixing flour, cooking, rolling, cutting into strips, drying, cutting off to obtain the carrot and egg noodle. The carrot and egg noodle has the advantages of convenient making and balanced nutrition, especially satisfies the requirements of vitamin A and taurine by children, and can be an auxiliary food for children.

Owner:宜垦(天津)农业制品有限公司

Making process of high-nutrition egg rolls

PendingCN110859199AIncrease nutritionIncrease stickinessDough treatmentModified nutritive productsBiotechnologyRapeseed

The invention provides a making process of high-nutrition egg rolls, which relates to the technical field of egg roll making, the high-nutrition egg rolls comprise the following raw materials: eggs, flour, honey, water, edible salt, black sesame seeds, chopped green onions, edible oil, walnut kernels, cashew kernels and pine nuts, and the edible oil is rapeseed oil. In the present invention, honeywater is used for replacing water for stirring between eggs and flour, so that the viscosity of the egg roll is improved, the hardness of the egg roll is reduced, so that the egg roll is suitable formore people; the overall taste of the egg roll is adjusted by adjusting the ratio of the honey water to the edible salt; the problem that the egg roll is single in taste is solved, walnut kernel, cashew kernel and pine nut powder scattered on the surface of the egg roll are used for improving the single taste of the egg roll and increasing the nutrition of the egg roll, and black sesame and chopped green onion are used for further improving the single taste of the egg roll and increasing the nutrition of the egg roll.

Owner:重庆渝海食品有限公司

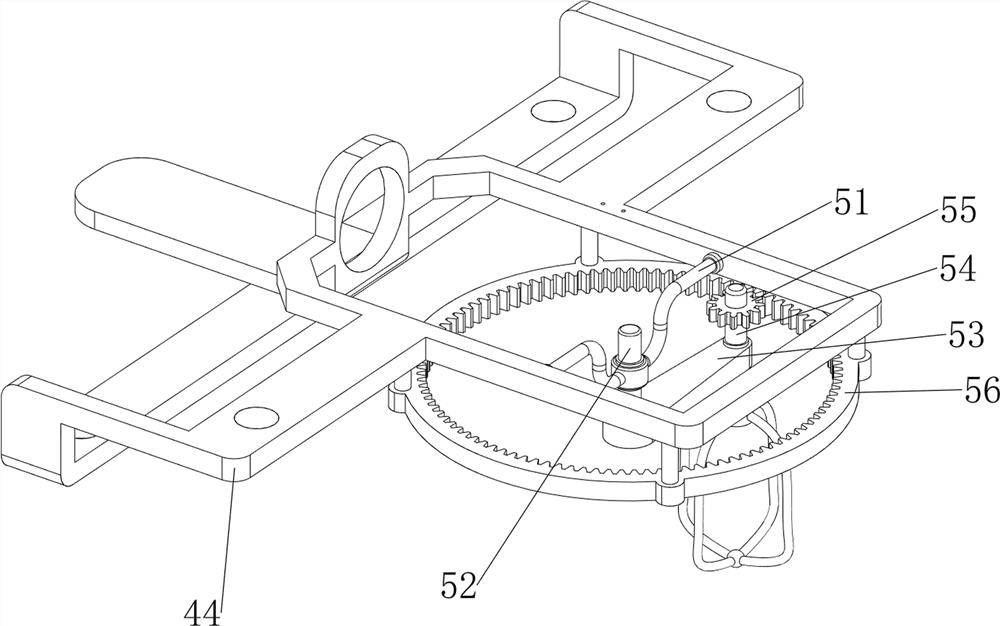

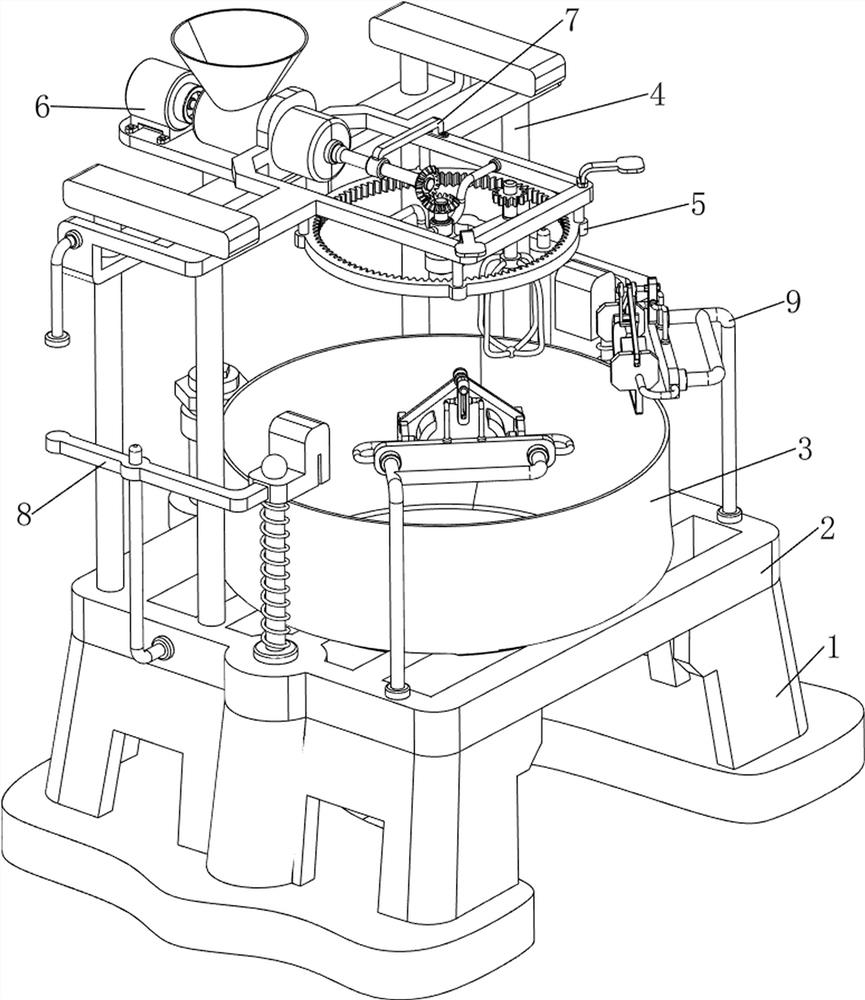

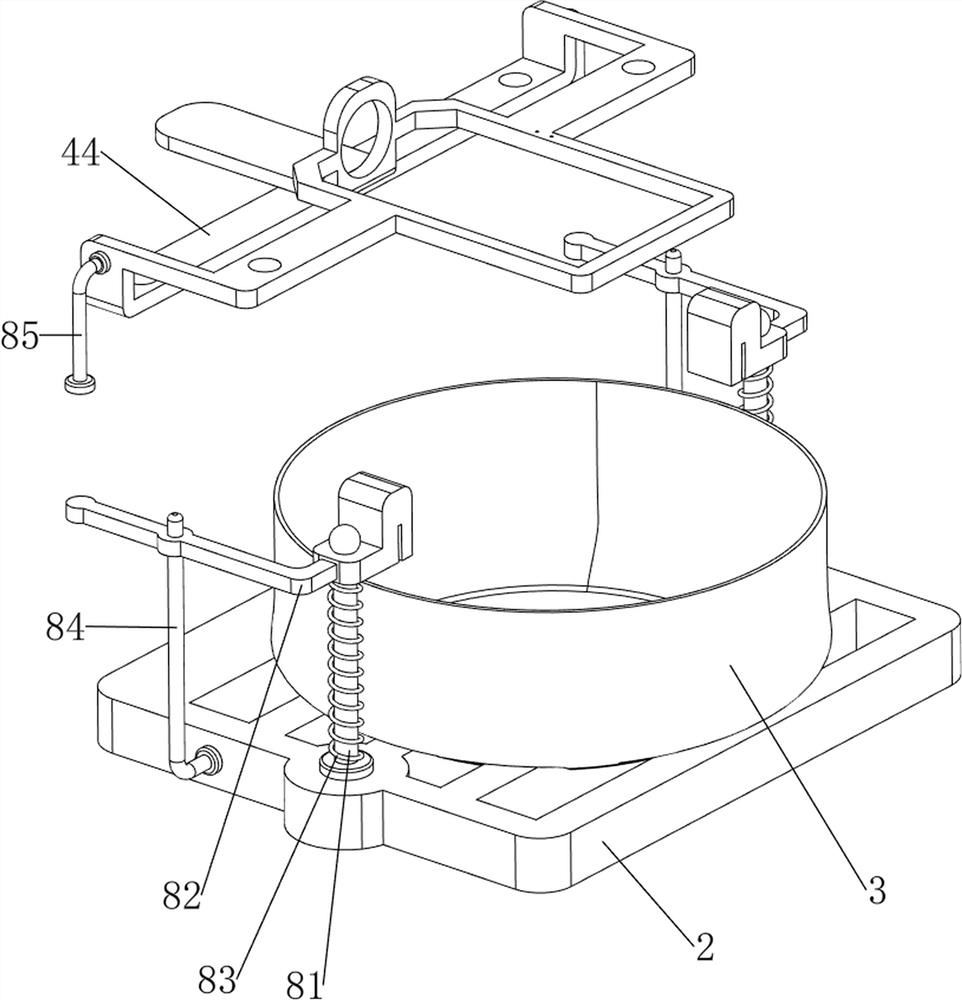

Egg paste mixing and stirring device for flour processing

InactiveCN113057188AAchieving stirringEvenly distributedMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsBiotechnologyEngineering

The invention relates to a flour stirring device, in particular to an egg paste mixing and stirring device for flour processing. The invention provides the egg paste mixing and stirring device for flour processing, which realizes automatic stirring of egg white and flour, uniform distribution of flour particles and automatic ripping of egg shells. The egg paste mixing and stirring device for flour processing comprises a base, wherein a workbench is arranged on the base; a mixing box which is placed at the top of the workbench; a lifting mechanism which is arranged at the top of the workbench; and a stirring mechanism which is arranged on the lifting mechanism. The spur gear drives the stirrer to rotate, the stirrer stirs flour and egg white in the mixing box to form egg paste, and the effect that the stirrer stirs the flour and the egg white to form the egg paste is achieved.

Owner:王丽丽

Soya bean milk egg noodle and producing method thereof

InactiveCN104366264AFull of nutritionAbundant raw materialsFood ingredient functionsFood preparationBiotechnologyAdditive ingredient

The invention discloses soya bean milk egg noodle and a producing method thereof, in order to develop new noodle food, the invention provides the noodle prepared by adding raw soya bean milk and eggs into flour, the soya bean milk egg noodle nutrition is increased, and the soya bean milk egg noodle is convenient to eat, and adapts to the needs of people's life. The technical scheme adopted to solve the technical problem is as follows: wheat flour as a main material is added with the soya bean milk, the eggs and table salt for rolling into the soya bean milk egg noodle; or the wheat flour is added with the soya bean milk, the eggs and the table salt for preparation of the soya bean milk egg noodle by the process of proportioning, kneading a dough, rolling into pieces, testing, packing and the like. By use of the design of the technical scheme, the noodle contains soya bean and egg ingredients, so that the soya bean milk egg noodle is rich in trace elements and the like, has the advantages of being rich in nutrition, natural, colored, capable of increasing appetite, smooth, delicious, non-stick, non-turbid when in slip-cooking, rich in raw materials, scientific and feasible in production process, convenient to eat and the like, and is a kind of new food noodle.

Owner:颜笑天

Almond petal cake and processing method for same

InactiveCN102894047ALoose structureReduce volumeDough treatmentBakery productsBiotechnologyAlmond Flavor

The invention provides an almond petal cake and a processing method for the same. The almond petal cake provided by the invention comprises the following ingredients: 2.5 parts of almond paste, 10 parts of flour, 10 parts of eggs, 5 parts of white granulated sugar, and an appropriate amount of a chemical leavening agent. The almond petal cake provided by the invention is produced by taking the almond paste, the eggs and the flour as raw materials, and performing a plurality of working procedures such as wiping, mixing into a slurry and baking; and the finished product is loose in structure, small in volume, almond-petal-shaped, crisp in taste, and with a strong flavour of almond; and the almond petal cake is a nut meat cake which is extremely rich in nutrition.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Noodles containing poria cocos powder and eggs and preparation method of noodles

InactiveCN108077750AGreat tasteRetain nutrientsLipidic food ingredientsFood ingredient functionsYeastDry weight

The invention discloses noodles containing poria cocos powder and eggs and a preparation method of the noodles in the technical field of processing of agricultural products and non-staple foods. The noodles are prepared from the following raw materials in parts by dry weight: 50-60 parts of high gluten flour, 15-25 parts of poria cocos powder, 15-25 parts of lily root powder, 20-25 parts of cassava powder, 30-40 parts of eggs, 4-6 parts of table salt, 8 parts of tea seed oil, 4 parts of flaxseed oil, 2 parts of maize germ oil and 70-80 parts of fresh milk. The noodles containing poria cocos powder and eggs are fully prepared from natural materials, the poria cocos is pulped to form poria cocos pulp so as to keep nutritional components in the poria cocos to the maximum limit, and lily rootsand cassava are directly pulverized so as to adjust the taste and structure of the noodles, so that the produced noodles have better taste than general noodles, are resistant to boiling and chewing,are not turbid, do not stick together, have the fragrance of powder and red yeast, can promote appetite, and are sweet in taste.

Owner:HUNAN LONGFENG PORIA COCOS SCI & TECH

Pizza and preparing method thereof

InactiveCN101642150AFull of nutritionGreat tasteDough treatmentPreservation by coatingSugarAdenophora

The invention relates to a pizza and a preparing method thereof, belonging to the technical field of food preparation. The pizza is characterized by comprising main material and accessory material, wherein the main material comprises the following components in parts by mass: 5-40 parts of adenophora, 50-100 parts of Chinese yam, 5-40 parts of pumpkin, 50-150 parts of potato, 10-80 parts of lettuce, 50-150 parts of egg and 10-40 parts of flour, and the accessory material comprises the following components in parts by mass: 0-5 parts of white sugar, 0-5 parts of table salt and 0-5 parts of aginomoto. The invention provides the pizza and the preparing method thereof. The prepared pizza has rich nutrition, good taste, reasonable matching and wide material acquirement, is quite fit for the taste of Chinese people and uses the materials familiar to people; and by the preparation method, people can make satisfied pizza according to different personal favors.

Owner:曲建波

Selenium-rich egg noodles and preparation method thereof

InactiveCN106901169AImprove immunityIncrease selenium contentFood scienceCoronary heart diseaseEgg noodles

The invention relates to food and a preparation method thereof, in particular to selenium-rich egg noodles and a preparation method thereof. The selenium-rich egg noodles are prepared from raw materials, in parts by weight, 100 parts of selenium-rich stone milled flour, 8-10 parts of selenium-rich eggs, 10-16 parts of selenium-rich water and 0.2-0.6 parts of table salt through flour milling, egg beating, dough kneading and other processes. The quality of the selenium-rich egg noodles is strictly controlled from the wheat breeding process, the selenium-rich egg noodles have high selenium content, can be eaten by different people, particularly, people with low immunity, athletes as well as patients suffering from diabetes, heart disease, coronary heart diseases and hypertention and can enhance human immunity after being eaten for a long term; the preparation method of the selenium-rich egg noodles is simple and suitable for industrial production.

Owner:菏泽市牡丹区铁领富硒产品研究所

Egg noodles

The invention discloses an egg noodle, which is composed of the following components: 5%-8% of eggs, 92%-95% of flour, 30%-35% of water, 0.5%-1.5% of table salt and 0.5%-0.8% of alkali . The egg noodles are made of eggs and flour as the main ingredients, and the eggs are put into the flour and seasonings are added and processed evenly. Eggs have the effects of promoting body fluid and quenching thirst, enriching blood and nourishing qi, calming the nerves and eliminating troubles, invigorating the spleen, suppressing cancer and fighting tumors, and nourishing yin and tonifying deficiency.

Owner:蒋坤

Chinese chive egg noodles

InactiveCN103461826AThe formula is scientific and reasonableUnique tasteFood preparationChinese ChiveFerrous Gluconate

The invention provides Chinese chive egg noodles. The Chinese chive egg noodles are characterized by being prepared from the following ingredients in parts by weight: 1-10 parts of Chinese chives powder, 0.15-0.2 part of egg white powder, 0.048-0.06 part of ferrous gluconate, 0.02-0.05 part of zinc gluconate, 90-100 parts of plain powder, 0.0003-0.0009 part of vitamin A, 0.03-0.05 part of taurine and 0.1-0.2 part of L-lysine hydrochloride. The Chinese chive egg noodles have scientific and reasonable formula and peculiar taste, and are rich in nutrition.

Owner:宜垦(天津)农业制品有限公司

Fruit and vegetable cake auxiliary material, preparation thereof and fruit and vegetable cake prepared from fruit and vegetable cake auxiliary material

InactiveCN107006574AReduce manufacturing difficultyLow costDough treatmentBakery productsHorticultureFruits and vegetables

The invention relates to a fruit and vegetable cake auxiliary material and a preparation method. The method is simple in operation and comprises the steps that all raw materials are treated, then fresh fruits and vegetables are steamed and crushed into puree, the fruit and vegetable puree is subjected to stir-frying with other raw materials together, and finally the stir-fried puree-shaped fruit and vegetable cake auxiliary material is obtained. The fruit and vegetable cake auxiliary material prepared from the raw materials by using the preparation method can be directly added when a cake is made; on the one hand, the problem that the fresh fruits and vegetables are inconvenient to store is solved; on the other hand, when the fruit and vegetable cake is made, it is only required that the fruit and vegetable cake auxiliary material, eggs, flour and a cake emulsifier are stirred together, and the fruit and vegetable cake can be easily obtained after the mixture is baked. The auxiliary material is convenient to use, the difficulty is low, the yield is high, the product quality is stable, and the production efficiency is high.

Owner:刘建刚

Egg noodle with kudzu root powder and preparation method thereof

The invention discloses an egg noodle with kudzu root powder and a preparation method thereof. The egg noodle is composed of the kudzu root powder, whole egg powder, buckwheat flour, flour, clausena lansium, sweet potato powder, smallanthus sonchifolius, hizikia fusifarme, trivhosantnes kirilouii seeds, royal jelly, ginger juice, linseeds, pyracantha fortuneana, gynura cusimbua, lichens, barberry juice, japanese tripterospermum herb, arundina graminifolia, platycladus orientalis and the like. The egg noodle is prepared from the kudzu root powder , the whole egg powder and the buckwheat flour as main raw material, is unique in flavor, is fine and smooth, is rich in nutrition, is balanced in nutrition and reasonable in formula, and is a food suitable for all people.

Owner:张曦曦

Juicy vegetable noodles and making method thereof

InactiveCN109303257AFull of nutritionAbundant raw materialsFood scienceTriticum turgidumVegetable Juices

The invention discloses juicy vegetable noodles and a making method thereof. The juicy vegetable noodles are made from the followings: wheat flour, table salt and eggs and are characterized in that the juicy vegetable noodles further comprise soybean milk, and 100 kg of the wheat flour, 2.2-2.8 kg of the eggs and 1-1.5 kg of the table salt, or 0.12-0.2 kg of edible alkali are mixed and rolled intoegg noodles. The noodles are made by adding the eggs or / and various normal vegetable juices into the flour, so that nutrient compositions of the noodles are increased, the noodles are convenient to eat, and the living needs of people are met.

Owner:徐小芹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com