Patents

Literature

3089results about "Modified nutritive products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduced digestible carbohydrate food having reduced blood glucose response

ActiveUS20050118326A1Hypoglycemic responseReduced digestibleDough treatmentLeguminous plant bakery productsAdditive ingredientFood material

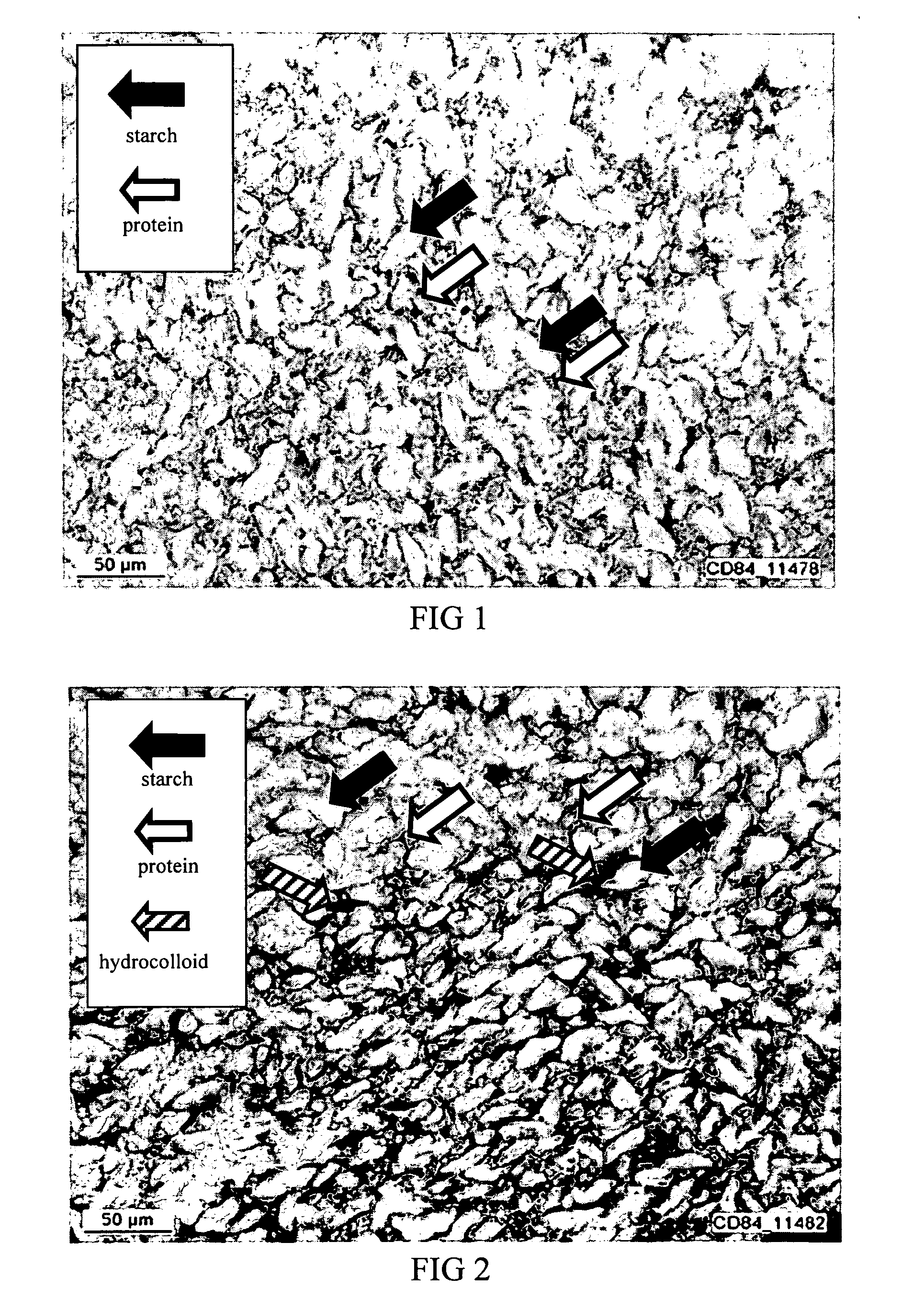

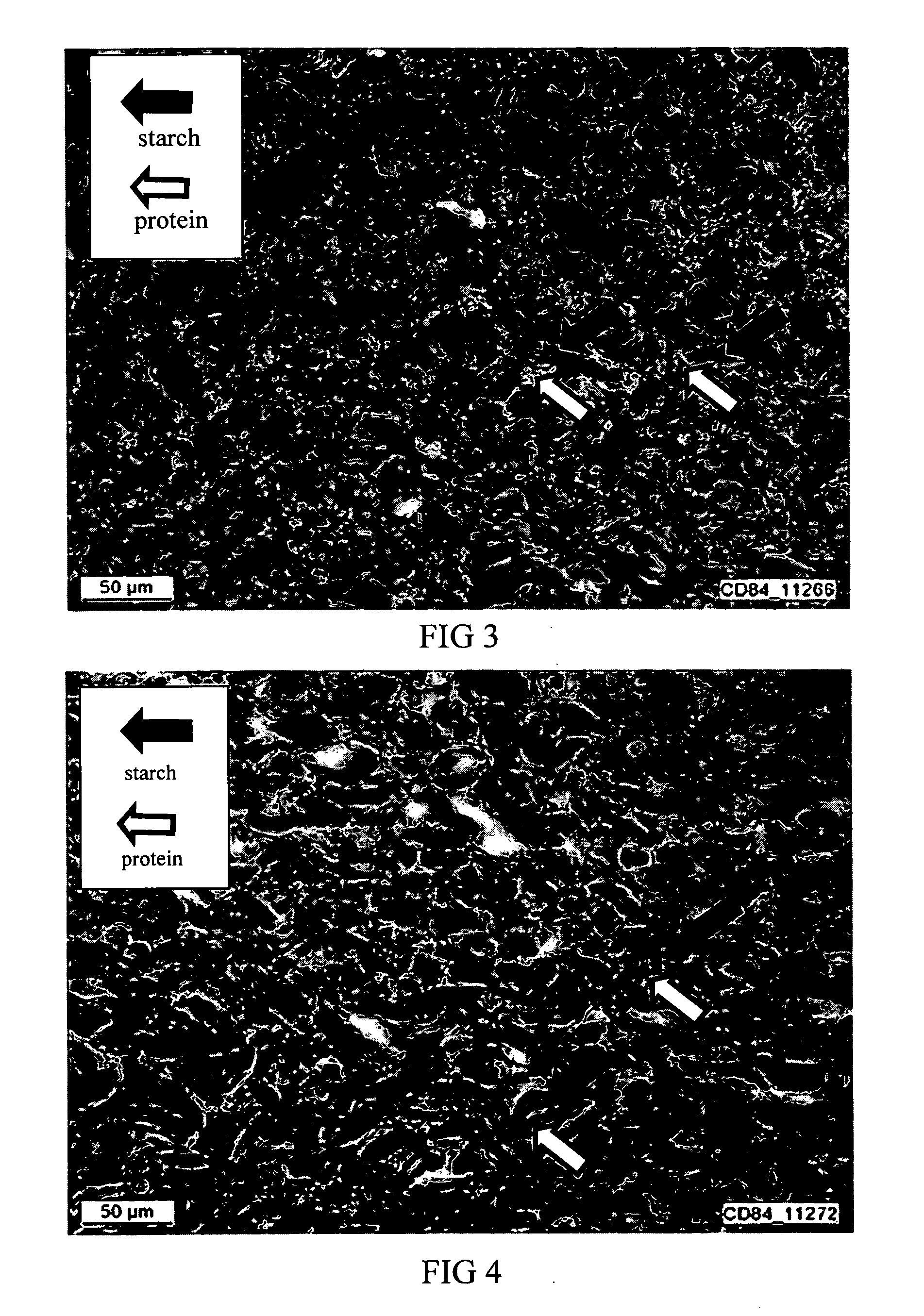

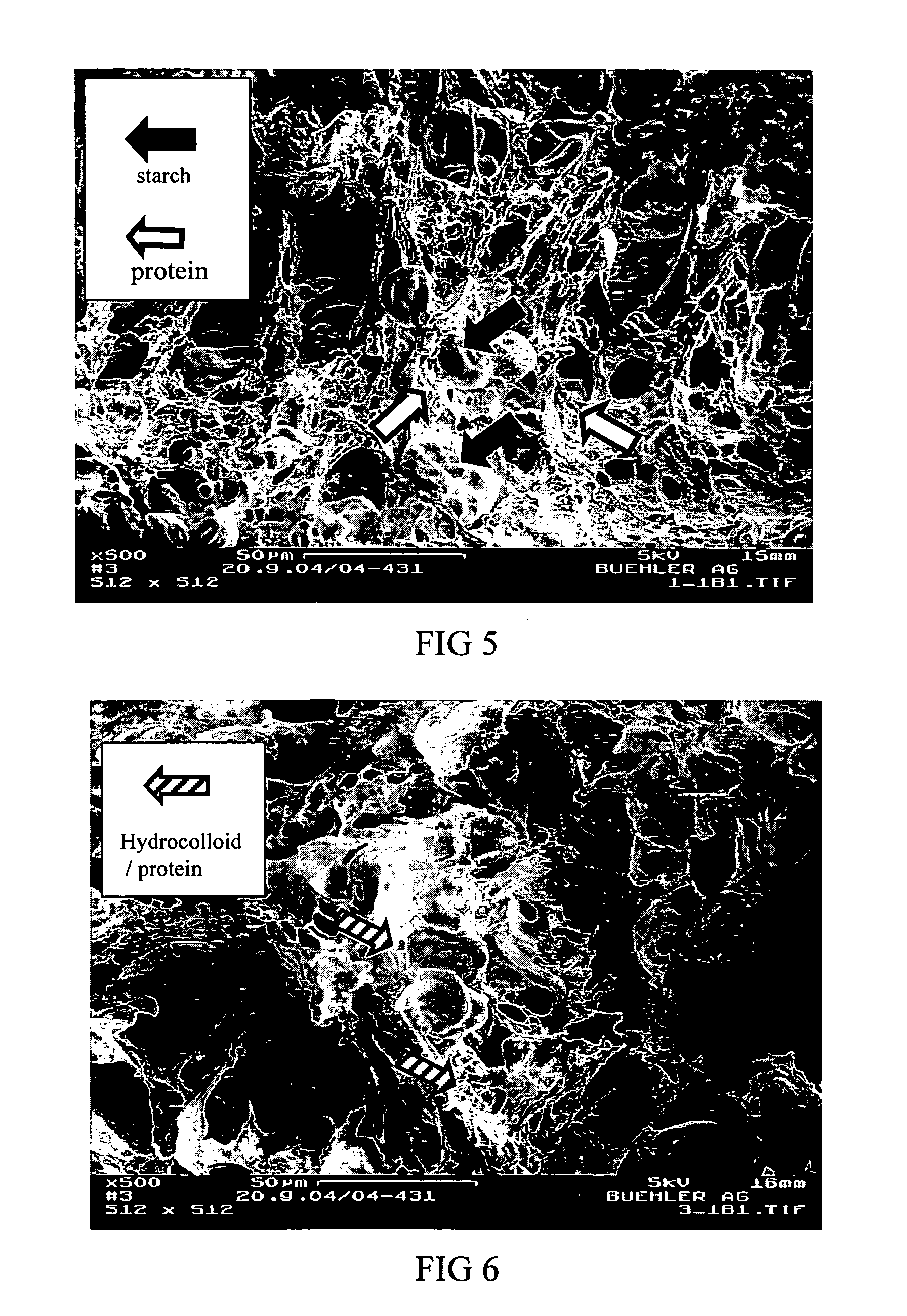

Reducing the digestion of digestible carbohydrates in a digestible carbohydrate-based material, and reducing the absorption of the digestion product(s) of digestible carbohydrates (that is, simple sugars) within the small intestine. The undigested digestible carbohydrate and the unabsorbed digestion products pass through the small intestines and into the colon, where they are fermented. In effect, the food materials made by practicing the present invention cause a controlled amount of digestible carbohydrate to by-pass the small intestine, resulting in the fermentation of digestible carbohydrates in the colon. The invention also provides for processing of a digestible carbohydrate-based ingredient with a non-digestible food film material, to form a reduced digestible carbohydrate food having a protective food film network, which can inhibit or prevent digestion of the digestible carbohydrate. The present invention also provides for processing of a digestible carbohydrate-based ingredient with a non-digestible food film material, to provide a resulting reduced digestible carbohydrate food containing a viscosity-building component that contributes to the formation of a viscous intestinal chyme that can inhibit or prevent digestion of the digestible carbohydrate and can inhibit adsorption of digestion products of digestible carbohydrates in the small intestine.

Owner:TECHCOM GRP LLC

Healthier Baked Goods Containing Microalgae

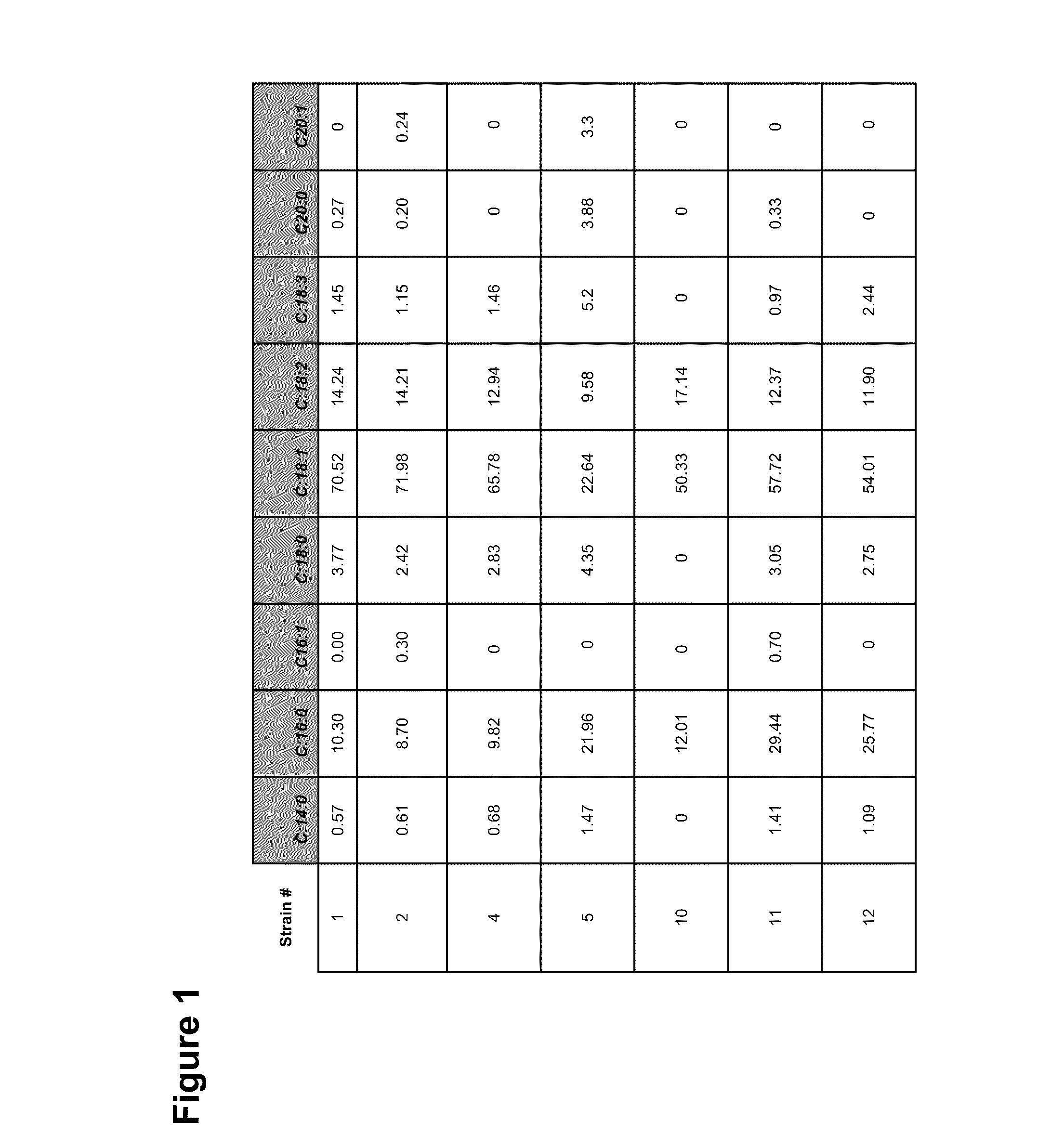

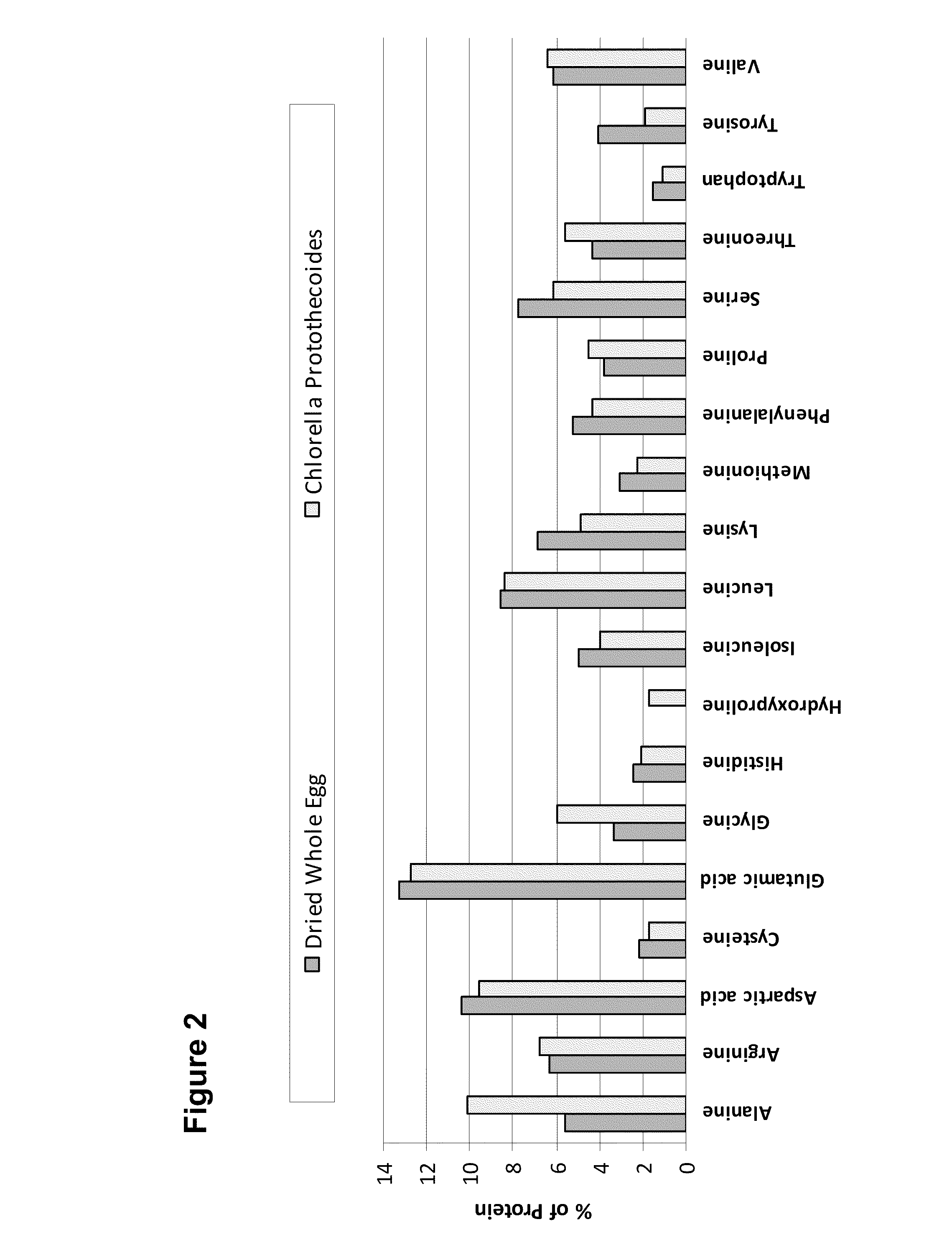

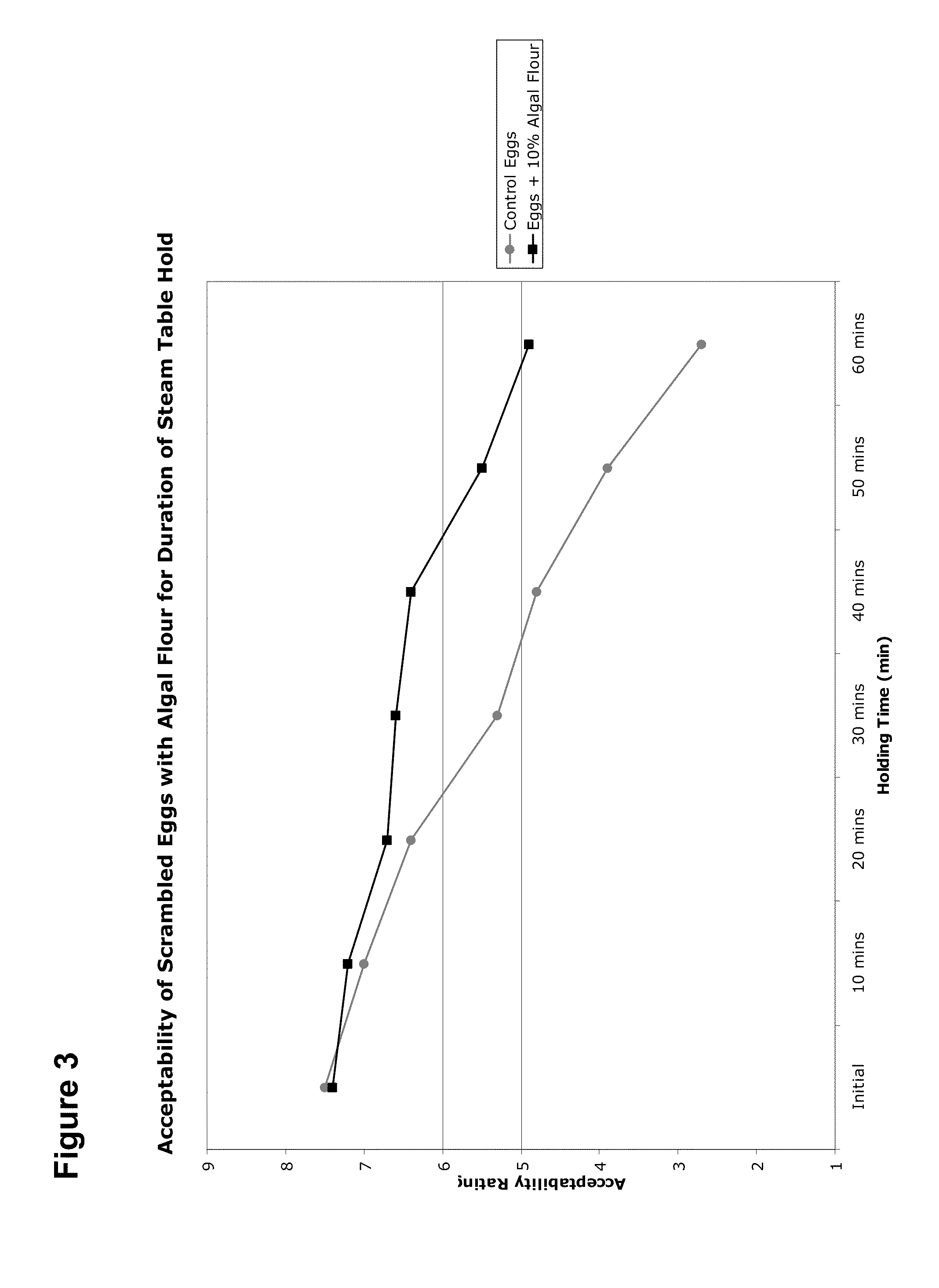

Provided herein are microalgae-containing baked goods with novel properties compared to preexisting products of the same type. Methods of formulating and manufacturing these foods to deliver reduced fat, reduced cholesterol, and increased fiber content are disclosed herein. Various embodiments include elimination or reduction of eggs, butter, animal fat, and saturated oils in favor of healthy oil-containing microalgae biomass and oils, including the manufacture of foods with lower calories than preexisting products of the same type. Methods of producing raw materials for the manufacture of novel processed baked foods and intermediates such as cake and bead mixes are also provided.

Owner:TERRAVIA HLDG INC

High protein puffed food product and method of preparation

Disclosed are ready-to-eat puffed dried food products that are high both in protein and in fiber. The cereals contain sufficient amounts of at least one protein ingredient to provide a total protein content about 50% to 75% (dry weight) of the cooked food product; sufficient amounts of at least one dietary fiber ingredient to provide a total fiber content of about 1-45% (dry weight); and sufficient amounts of a starch containing ingredient to provide a starch content of about 5-45%. The food products have a crush strength raging from about 0.25 to 3.5 kg / cm3.

Owner:GENERAL MILLS INC

High protein puffed food product and method of preparation

Disclosed are ready-to-eat puffed dried food products that are high both in protein and in fiber. The cereals contain sufficient amounts of at least one protein ingredient to provide a total protein content about 50% to 75% (dry weight) of the cooked food product; sufficient amounts of at least one dietary fiber ingredient to provide a total fiber content of about 1-45% (dry weight); and sufficient amounts of a starch containing ingredient to provide a starch content of about 5-45%. The food products have a crush strength raging from about 0.25 to 3.5 kg / cm3.

Owner:GENERAL MILLS INC

High protein edible composition and method of preparing the same

A dough composition for producing a baked, edible, high protein product having a protein concentration, based on calories, of at least 25%, comprising:(a) a mixture of high protein components,(b) flour,(c) leavening agent,(d) sweetener, and(e) water.

Owner:FOCUSED FOODS

Method and Formulations For Gluten-Free Bakery Products

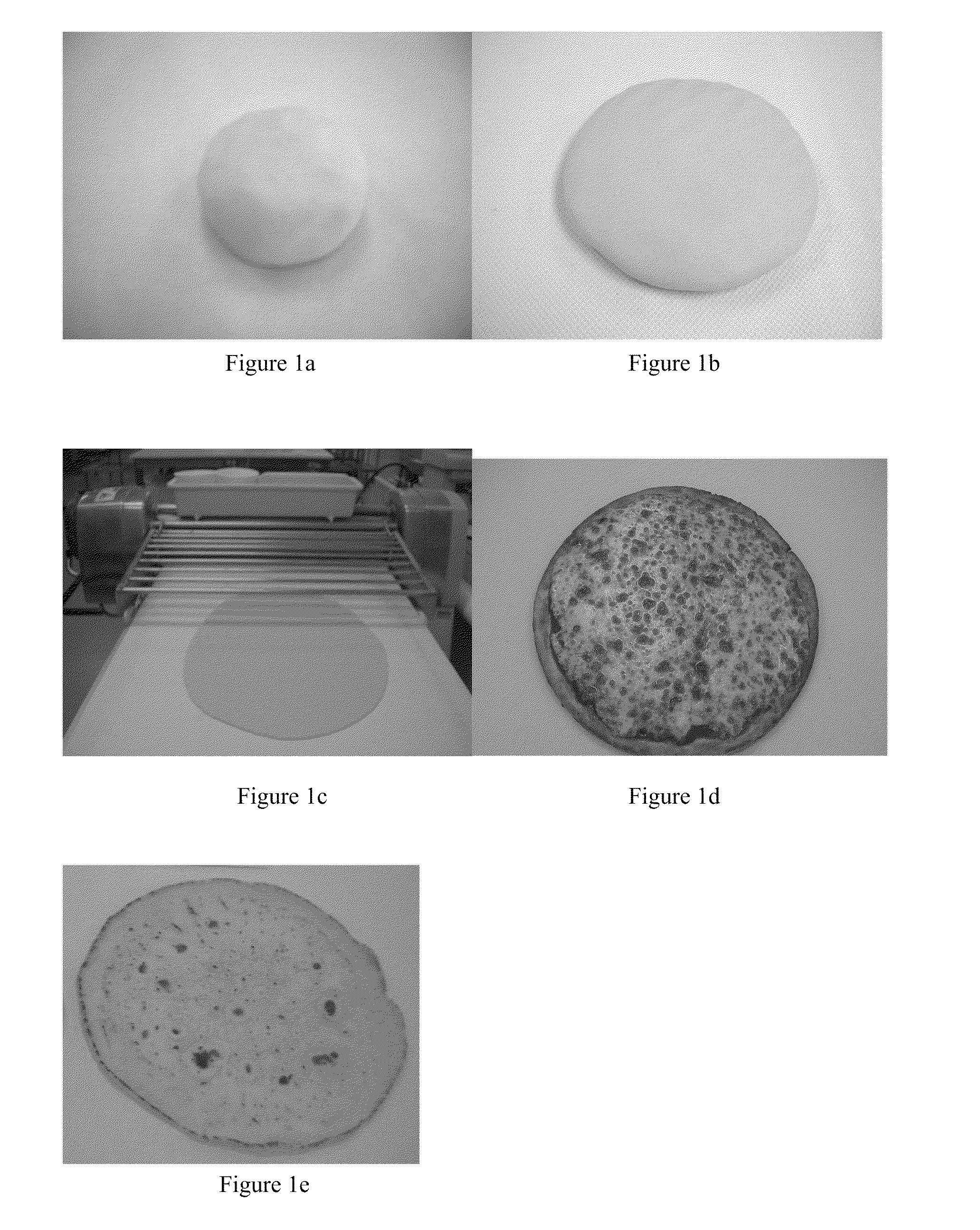

Provided herein are gluten-free compositions which can be made into a dough. The gluten-free dough can be subjected to a sheeting or pressing process and therefore can be prepared easily in commercial settings. The dough comprises gluten-free flour, modified starch, protein, leavening agents; oil and water.

Owner:RICH PRODUCTS

System for gluten replacement in food products

InactiveUS20080038434A1Process safetyQuality improvementDough treatmentBaking mixturesAdditive ingredientGluten intolerance

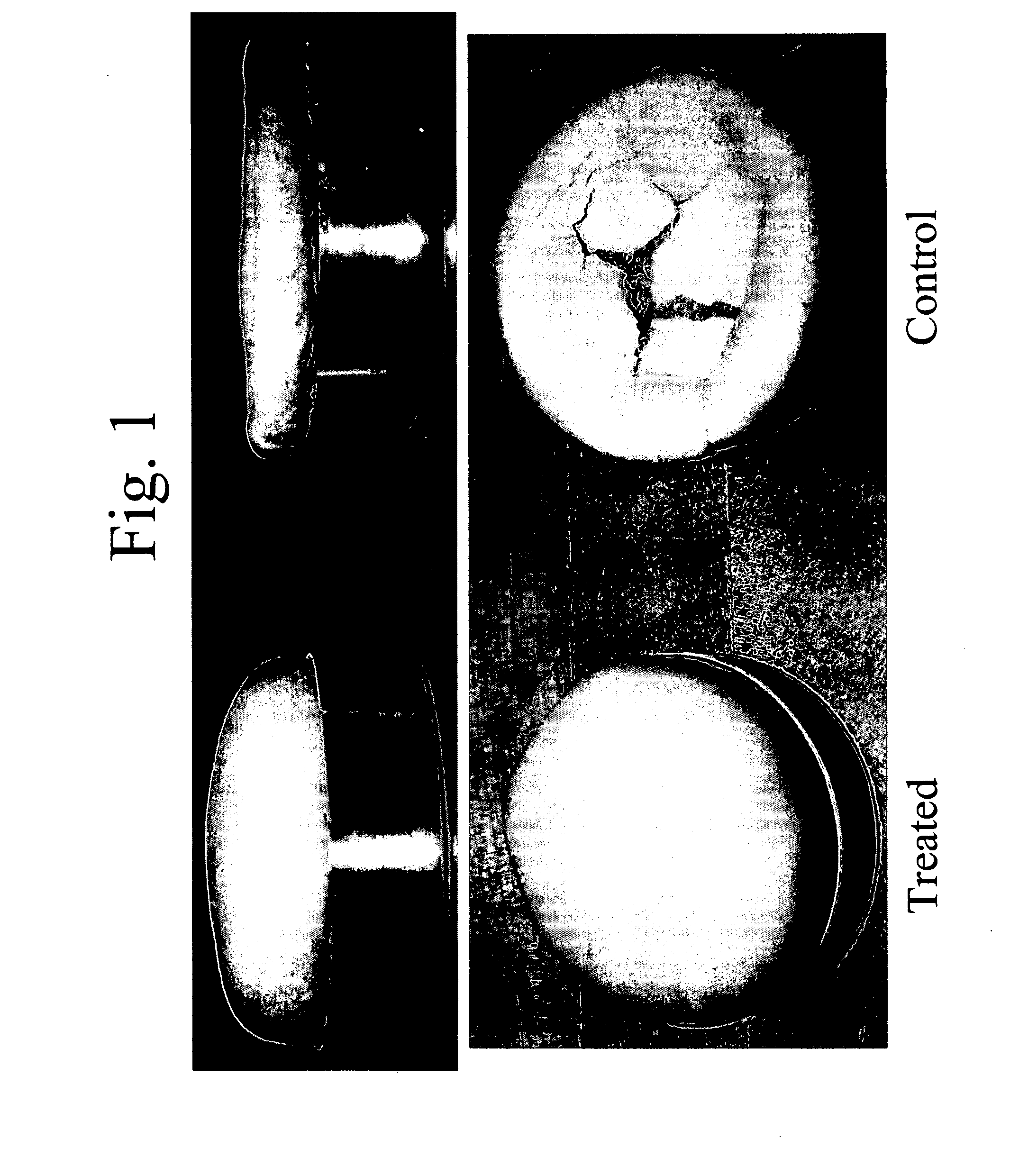

The present invention is a system for replacing gluten in food products. Preferably, the gluten replacement system of the present invention utilizes gluten-free ingredients that mimic the functions of gluten in a dough and in a final product made from the dough. The gluten replacement system can be used to formulate food products that are safe for consumption by those who have a gluten intolerance, allergy or sensitivity, or by those who follow a gluten-free diet. The present invention is also directed to a composition for making a gluten-free product. The composition preferably mimics the functions of gluten in a food product. This composition may include a gluten-free gas-retaining polymer and a gluten-free setting polymer, and it may also include a hydrocolloid or a starch, or both.

Owner:CARGILL INC

Food composition and method of making same

Owner:SLILATY GEORGE E

High-protein, low-carbohydrate bakery products

InactiveUS20050013900A1Good source of nutritionLow glycemic indexMilk preparationDough treatmentResistant starchProtein isolate

A high-protein, low-carbohydrate bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

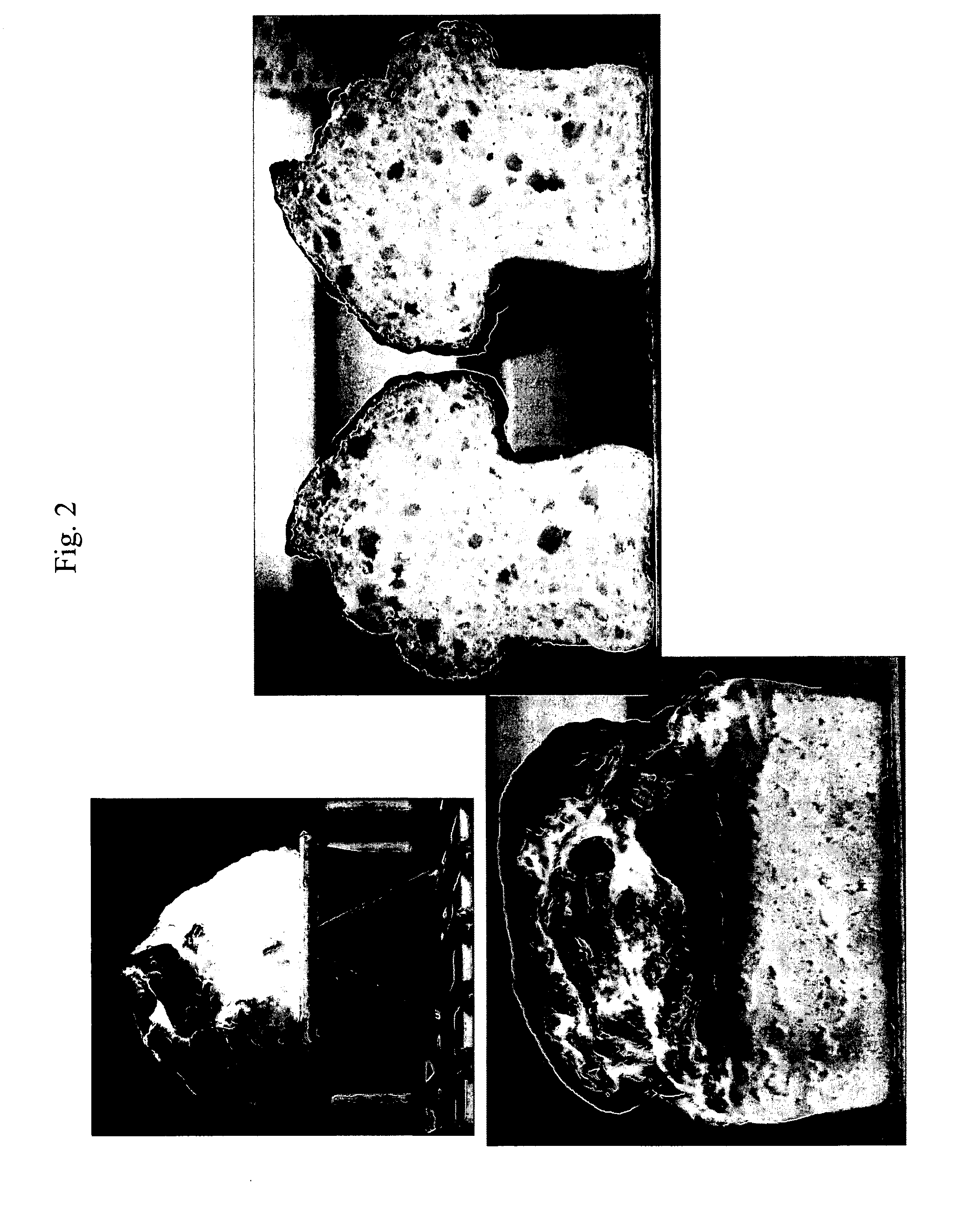

Pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and preparation method thereof

ActiveCN101971868AElasticity adjustableIncrease elasticityDough treatmentModified nutritive productsAlcohol sugarsFermentation

The invention discloses pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and a preparation method thereof. The pre-mixed flour of mochi bread comprises the following components: 30 to 50% of modified starch, 5 to 10% of water-milled glutinous rice flour, 7 to 13% of non reducing sugar, 6 to 10% of sugar alcohol, 1.8 to 3.8% of edible colloid, 2 to 3% of edible emulsifier, 1 to 3% of salt, 1 to 3% of full-cream milk powder and 20 to 30% of self-raising flour. To produce the mochi bread from the pre-mixed flour of the mochi bread, the pre-mixed flour of the mochi bread is uniformly mixed with whole eggs, water, syrup and soybean oil to obtain the required properties, and then the mixture is baked to obtain the mochi bread without fermentation. The preparation method of the mochi bread is simple, and the prepared mochi bread has honeycomb internal phase and is softer than the common bread and not sticky; moreover, the shelf life of the mochi bread is obviously prolonged that the mochi bread can be stored for a month at normal temperature.

Owner:广州合诚实业有限公司

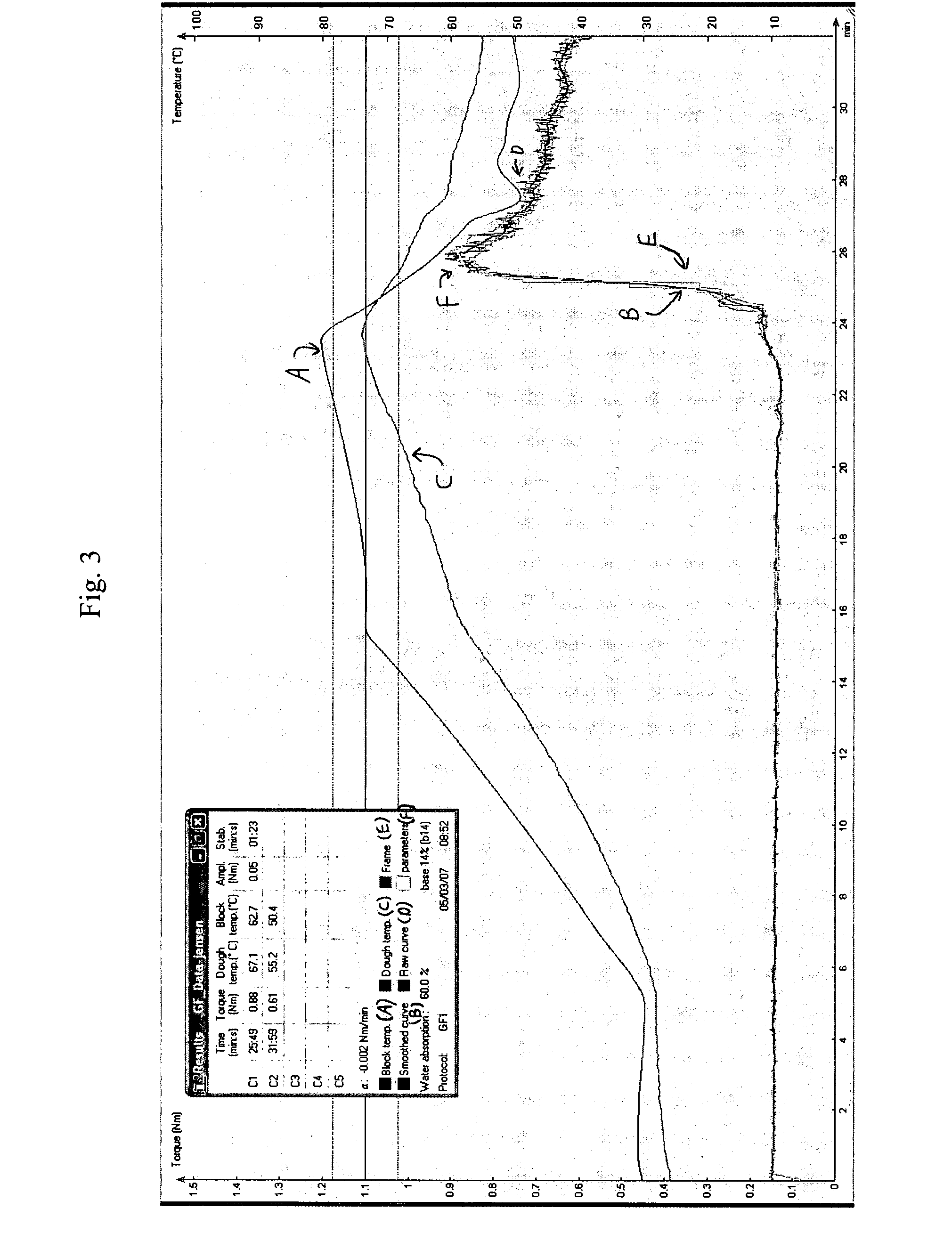

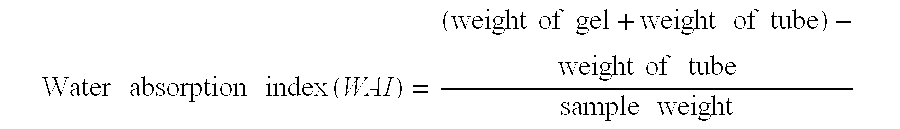

Rice flour compositions

ActiveUS20060286271A1Less expensiveAbsorbs less fatDough treatmentLeguminous plant bakery productsCross-linkSnack food

A rice flour composition having: from about 20% to about 95%, by weight, of a rice flour that has a WAI of from about 2.6 to about 9; and a Peak Viscosity from about 4 RVU to about 130 RVU; and from about 5% to about 80%, by weight, of rice starch materials that have a WAI of below about 2.2; a Peak Viscosity from about 100 RVU to about 900 RVU, and a soluble amylose content of less than 10%, by weight. The rice starch materials can be selected from the group consisting of waxy rice starch, acetylated rice starch, cross linked rice starch and mixtures thereof. The compositions can be used to produce food products such as fabricated sheeted snacks, extruded products, sauces, coatings for fried foods, dog foods, dog biscuits, baby foods and breads. The preferred dough formed from the inventive rice flour composition is sheetable and forms a cohesive dough. Fabricated snacks made from this dough has the desired taste and texture characteristics. A dry blend for a preferred fabricated snack comprises from about 2% to about 100%, preferably from about 20% to about 85%, most preferably from about 40% to about 75%, of the rice flour composition.

Owner:KELLOGG NORTH AMERICA

Snack Cracker and Method for Making Same

InactiveUS20100215826A1Reduced level of saturated fatLower Level RequirementsDough treatmentLeguminous plant bakery productsChipped potatoesAdditive ingredient

The present invention discloses formulations for sheeted, baked fruit and vegetable crackers that have a light, crispy texture similar to a potato chip or cracker. Undehydrated ingredients are combined with dry ingredients and oil to make a dough, which is then sheeted and cut into pieces. The pieces are baked to produce vegetable and fruit snack crackers.

Owner:FRITO LAY TRADING CO GMBH

Freezer to retarder to oven dough

A frozen dough comprising flour, a high yeast level comprising one or more yeast with activity covering temperature range of 33-140° F., emulsifiers, dough conditioners, stabilizers, sugar, lipid source and optionally supplemental gluten such that the frozen dough does not require a conventional proofing (proofer) step prior to freezing or prior to baking. When the frozen dough is thawed in a retarder at 33-42° F. for at least 12 hours, or at an elevated temperature of between 43-85° F. for at least 1 hour, and then baked, the baked products have good appearance, taste and texture, and a specific volume of at least 4 cc / gram.

Owner:RICH PRODUCTS

High fat biscuit mix and products resulting therefrom

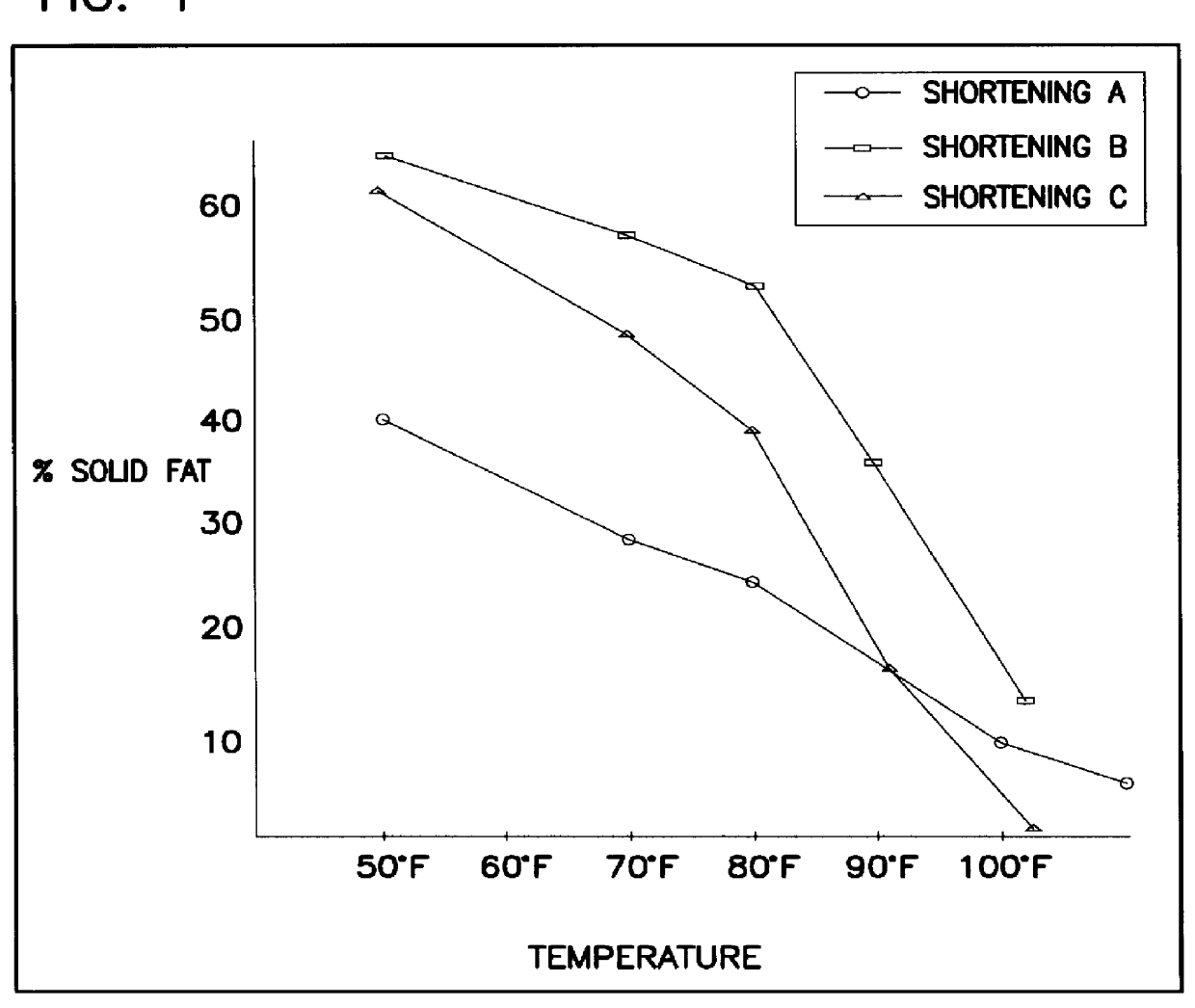

The invention is a high fat biscuit mix as well as dough and biscuit products resulting therefrom. The mix comprises flour, a leavening agent, and emulsifier along with a protein supplement and shortening. The shortening has a high initial solids content at low temperatures (50 DEG F.) and a melting point of 104 DEG F. or less resulting in a biscuit product having an improved moistness, flakiness and uniform height. The protein supplement and emulsifier generally provide a product having an improved outer crust layer, improved height and shape, and an interior which is tender without being doughy. The mix and resulting dough comprise a high concentration of fat and further a high concentration of fat contributed by shortening chips within the dough.

Owner:U S BANK NAT ASSOC +1

Formulation providing a low carbohydrate cereal based system including a novel dough and a pizza crust or bread product having open cell structure

InactiveUS20050276896A1Enhance manufacturing characteristicReduce the amount requiredDough treatmentBaking mixturesFiberCompound (substance)

A novel dough composition for improved dough can be used to produce a baked, high protein, low carbohydrate bread product. The formulation and process can be used to make low carbohydrate dough that can be used to manufacture bread and other bread-like products of high quality and consumer acceptance. The bread is characterized by low nutritive carbohydrate content, bread-like open cell structure and a high quality nutrition, texture and flavor. The dough comprises an aqueous leavened dispersion that comprises an effective but low amount of wheat flour for texture and flavor, an effective amount of gluten, in excess of the flour content, and an effective amount of a protein source along with an effective amount of an edible fiber to provide high protein content, low carbohydrate content and bread-like texture.

Owner:SCHWANS GLOBAL SUPPLY CHAIN

High-protein, reduced-carbohydrated flat bakery and other food products

InactiveUS20050031754A1Effectively reducing the “net” carbohydrate totalIncrease nutritionDough treatmentBaking mixturesAdditive ingredientProtein isolate

A high-protein, low-carbohydrate flat bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydrolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

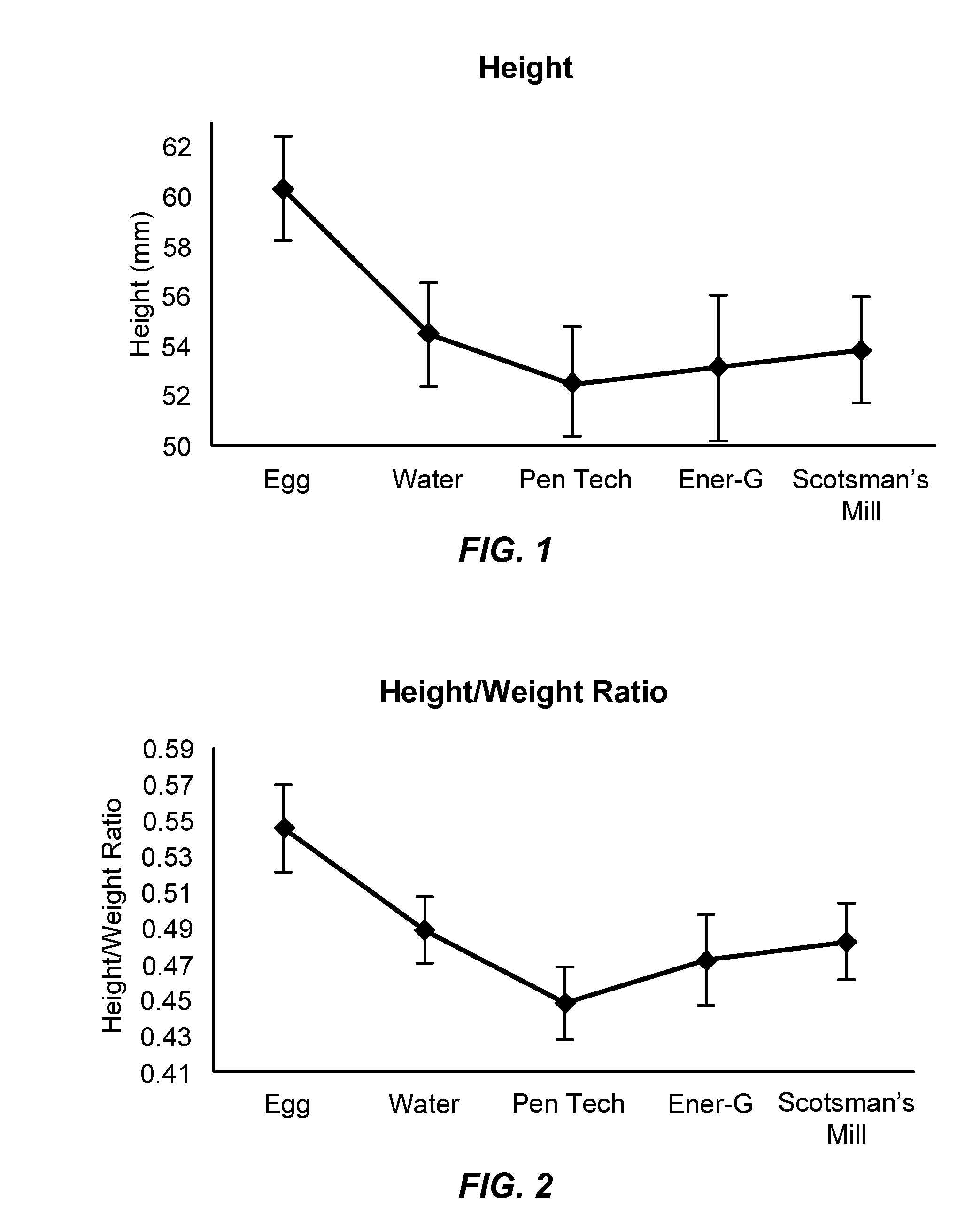

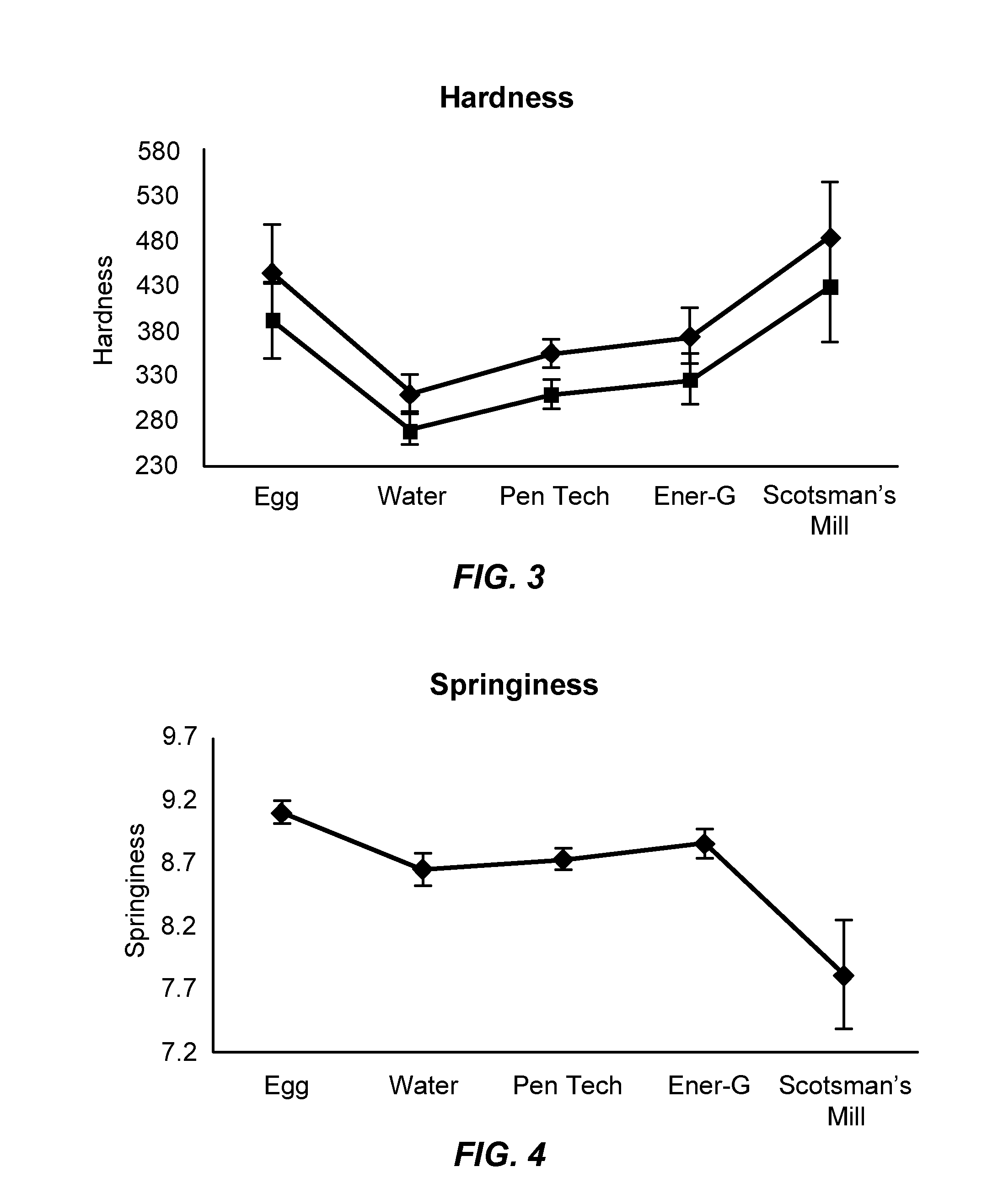

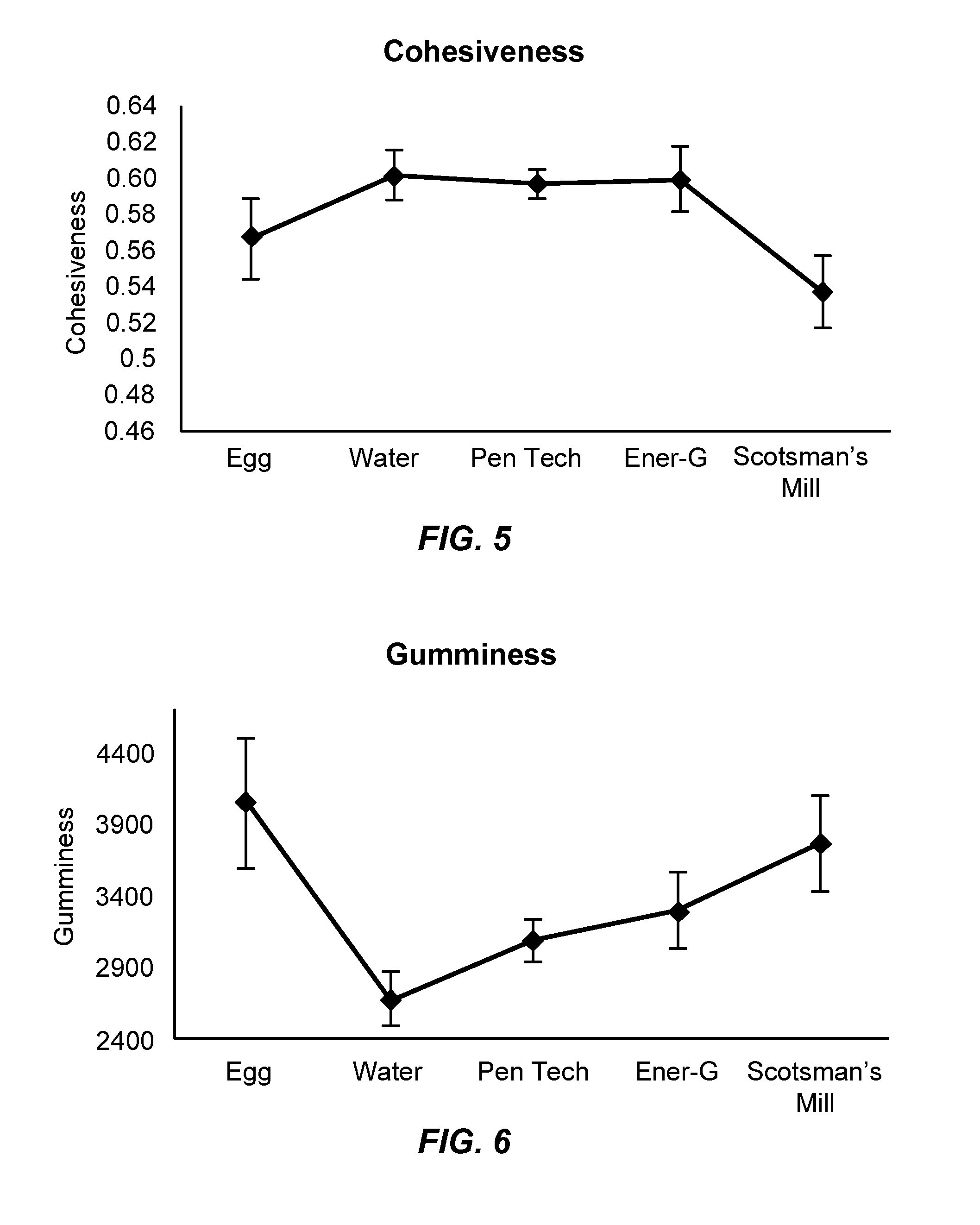

Plant-based egg substitute and method of manufacture

Disclosed herein are non-egg compositions that can be used as egg substitutes. The disclosure is directed to egg substitutes and methods of manufacturing the same, and compositions comprising the egg substitutes, including edible compositions such as baked goods and edible emulsions.

Owner:HAMPTON CREEK INC

Flour formulations for making gluten-free food products

The invention provides a gluten-free flour formulation containing a plurality of ingredients. Each ingredient in the formulation is substantially or completely free of gluten protein. In one embodiment, the formulation meets the requirements for kosher certification. The gluten-free flour formulation includes at least two ingredients of the following: ground or partially ground particles of dried roots of a root-tuber crop, dried kernels or nuts of a nut-tree and dried fruits of a species in the Musaceae family. In some embodiments, the gluten-free flour formulation includes ground or partially ground particles of dried cassava root, almond nuts and dried plantain fruits, wherein the proportions of the ground cassava root, almond nuts and dried plantain fruits range from about 15% to about 85%, from about 20% to about 60%, and from about 5% to about 30%, respectively.

Owner:SINGH MENEGHINI AQUAH MOIRA

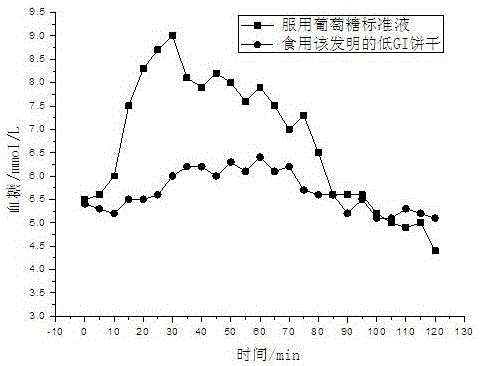

Low-glycemic-index biscuits and making method thereof

InactiveCN106614916AEnhanced GI valueLow GI valueDough treatmentModified nutritive productsFiberSodium bicarbonate

The invention relates to low- glycemic-index biscuits and a making method thereof. The making method comprises the following steps: taking raw materials in parts by weight, mixing table salt with konjaku flour and inulin, and adding water for stirring so as to obtain a mixture A; heating anhydrous butter until the anhydrous butter is melted, performing rapid stirring to get foam, adding eggs, and continuing to quickly get foam so as to obtain a mixture B; adding water to ammonium bicarbonate and sodium bicarbonate for stirring and dissolving so as to obtain a mixture C; uniformly mixing flour with maltitol, xylitol, defatted soy flour, tartarian buckwheat powder, wheat dietary fibers, green bean powder, scindapsus aureus, resistant dextrin, buckwheat, nonfat dry milk powder and celery powder, enabling the prepared mixture A, the mixture B and the mixture C to be concocted into dough by a dough mixer, and performing refrigeration standing; pressing the dough into sheets with a noodle press, so as to obtain shaped biscuit blanks; and putting the biscuit blanks in an oven, performing baking under 180 DEG C for 10min, then performing cooling, and performing packaging so as to obtain the low- glycemic-index biscuits. The GI value of the made biscuits made by the method disclosed by the invention is 41.8 or below, so that the made biscuits are really suitable for diabetics to eat.

Owner:上海融朋电子商务有限公司

Food product

InactiveUS20060222740A1Easy to operateIncrease humidityConfectionerySweetmeatsWheat flourFood products

This invention pertains to a baked product comprising rice flour, pregelatinised rice starch, and optionally modified rice starch. Such products have good acceptability in internal and external properties and appearance, similar to that of wheat flour containing baked products.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Modified starches for use in gluten-free baked products

InactiveUS20050008761A1Maintaining and improving tasteMaintaining and improving and textureDough treatmentConfectioneryGluten freeChemistry

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

High-protein, reduced-carbohydrate bakery and other food products

InactiveUS20050037125A1Effectively reducing the “net” carbohydrate totalIncrease nutritionDough treatmentBaking mixturesProtein isolateAdditive ingredient

A high-protein, low-carbohydrate bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydrolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

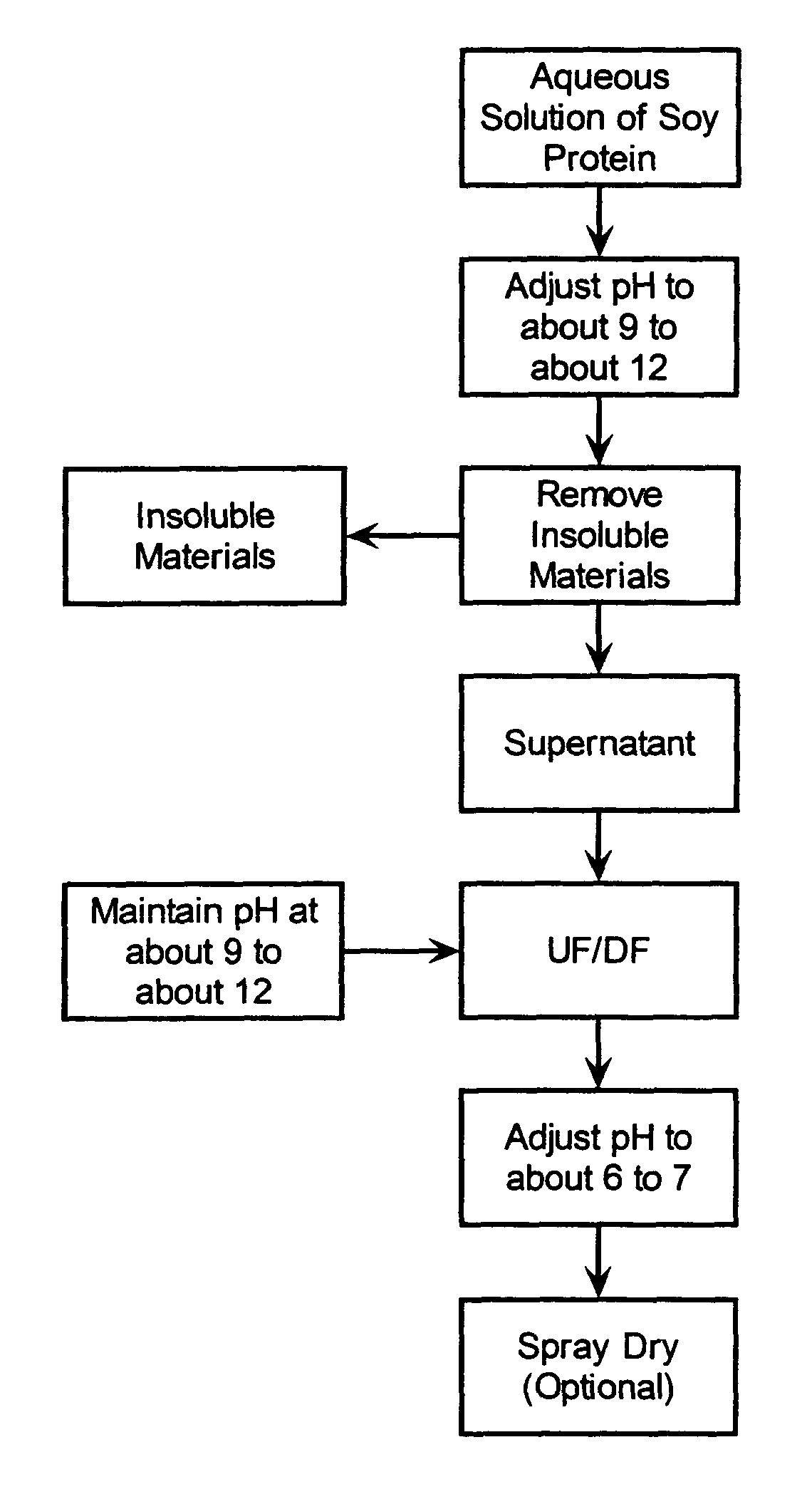

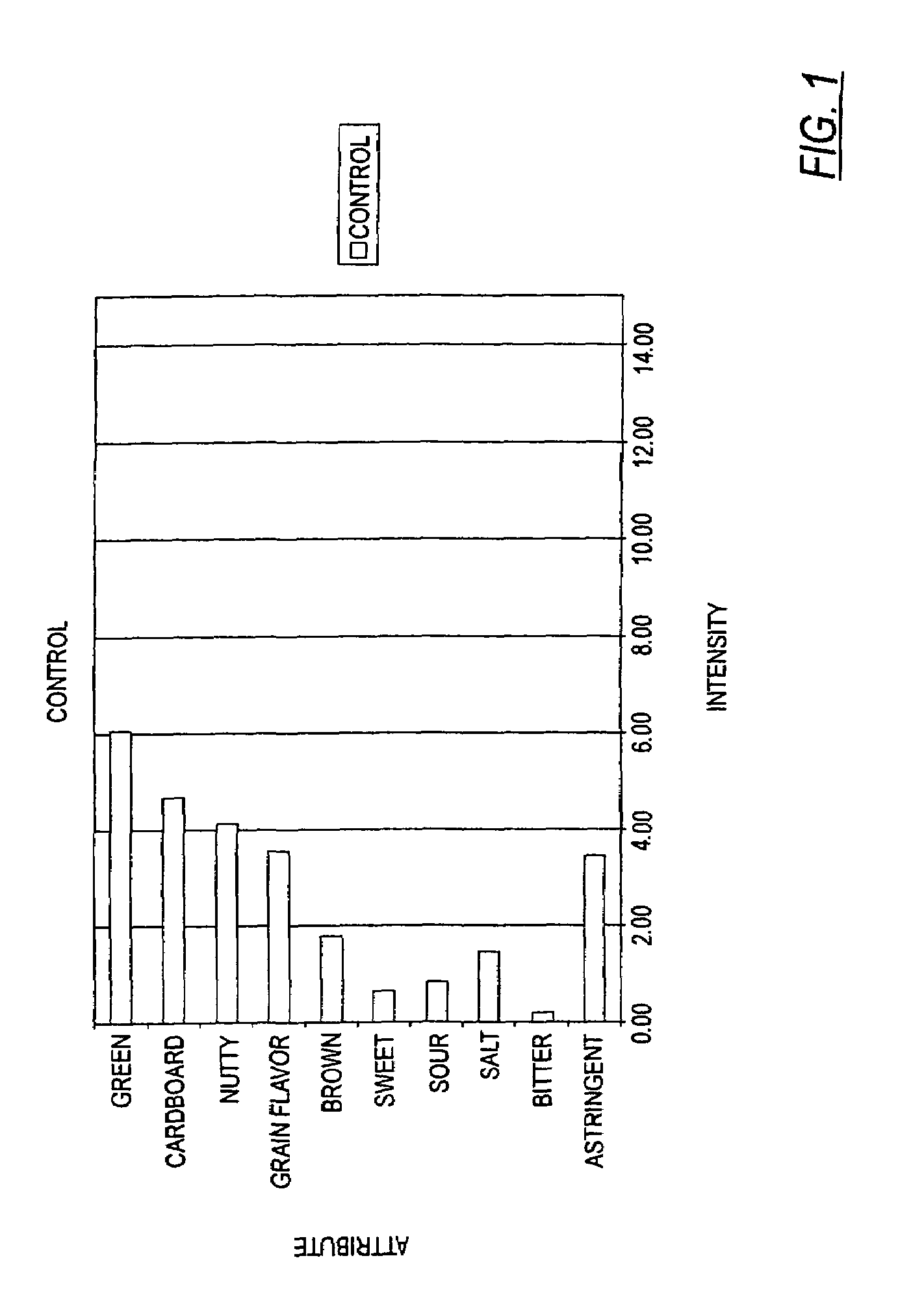

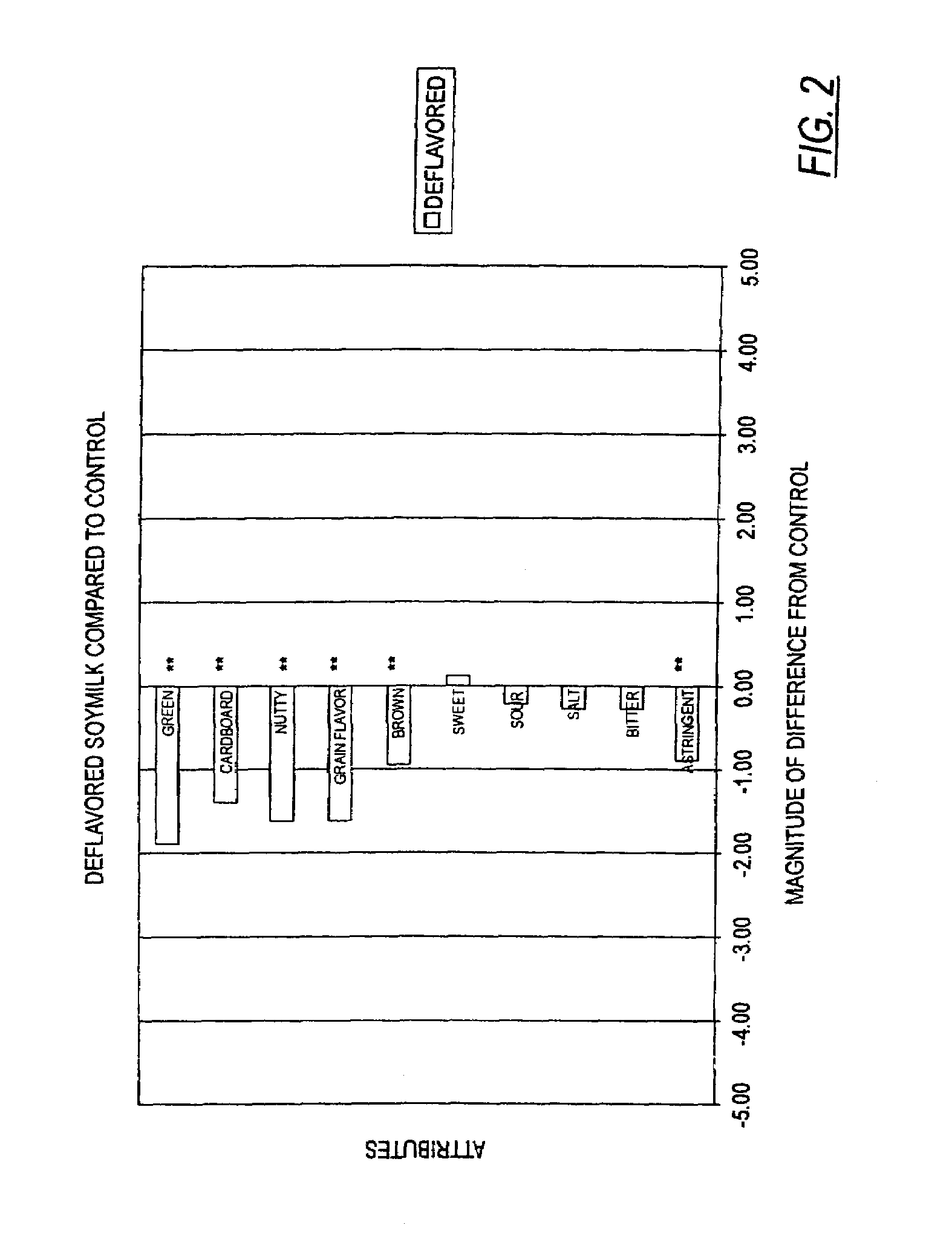

Method of deflavoring soy-derived materials for use in beverages

Soy-containing beverage comprising an aqueous liquid containing deflavored soy protein material are provided. Especially preferred beverage include flavored soymilk beverage and soymilk smoothies.

Owner:KRAFT FOODS INC

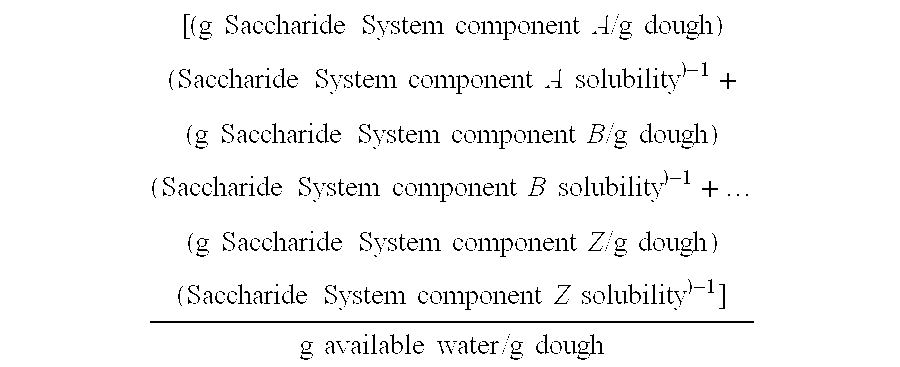

Reduced sucrose cookie dough

A reduced sucrose cookie dough is provided comprising a Saccharide System. The Saccharide System comprises a crystalline sugar alcohol comprising at least one member selected from the group consisting of crystalline maltitol, -crystalline lactitol, and crystalline isomalt and at least one member selected from the group consisting of a liquid sugar alcohol and a long chain sugar complex. The Saccharide System has a Collective Solubility that is within about 20% of the solubility of sucrose in the dough. The cookie dough has a sucrose content of less than 0.5 grams per serving size. Methods of making the cookie dough are also provided.

Owner:GENERAL MILLS INC

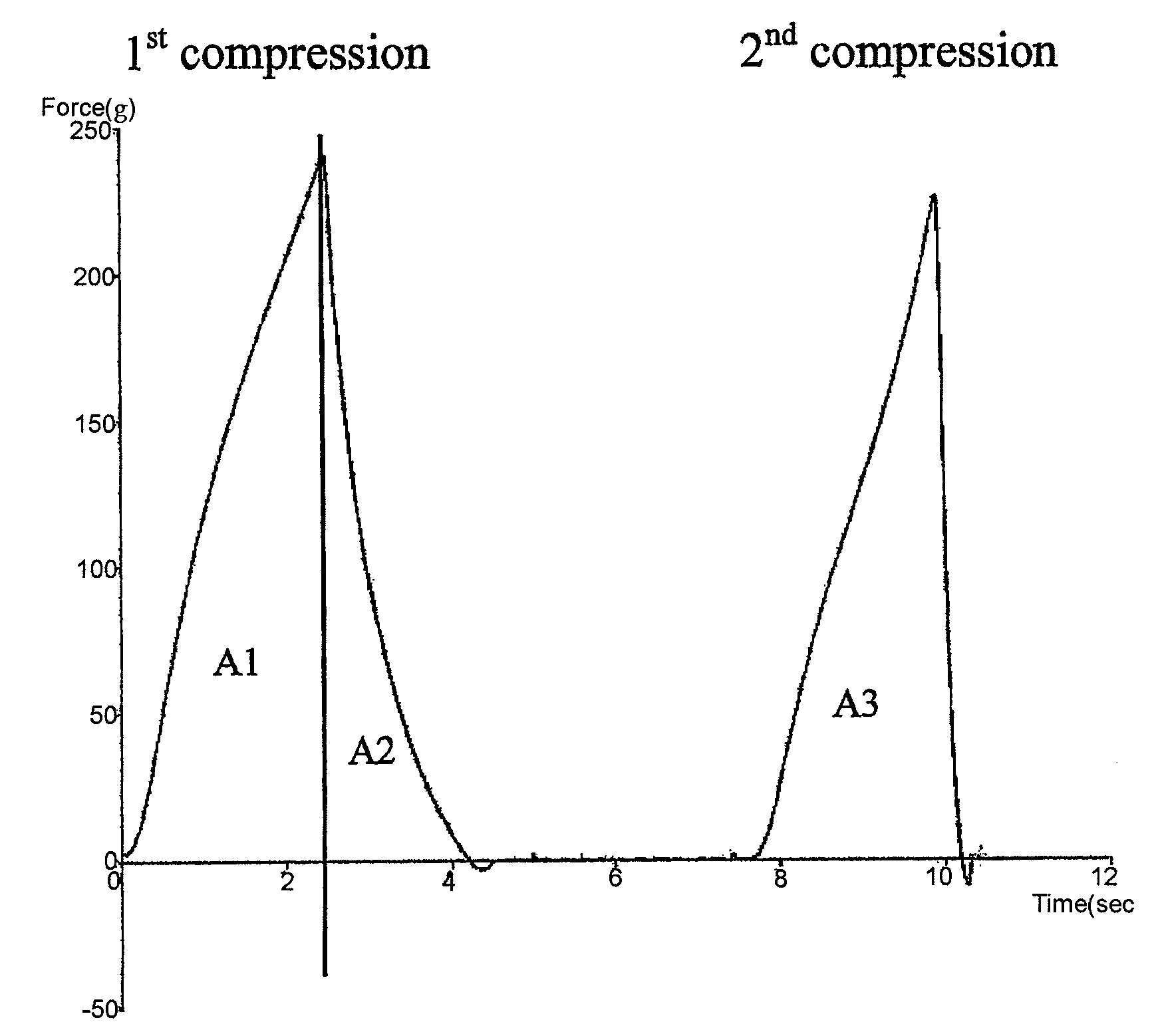

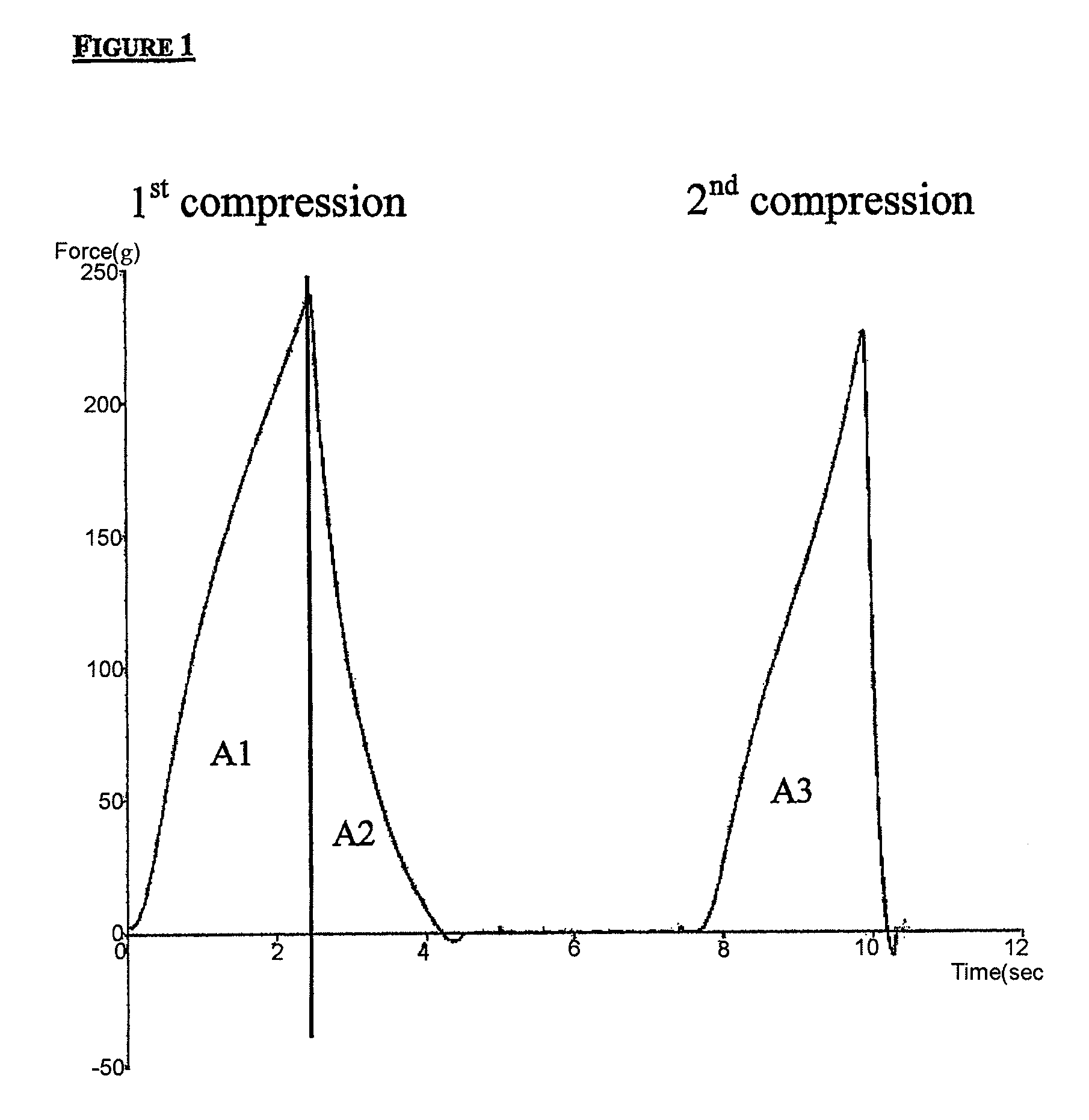

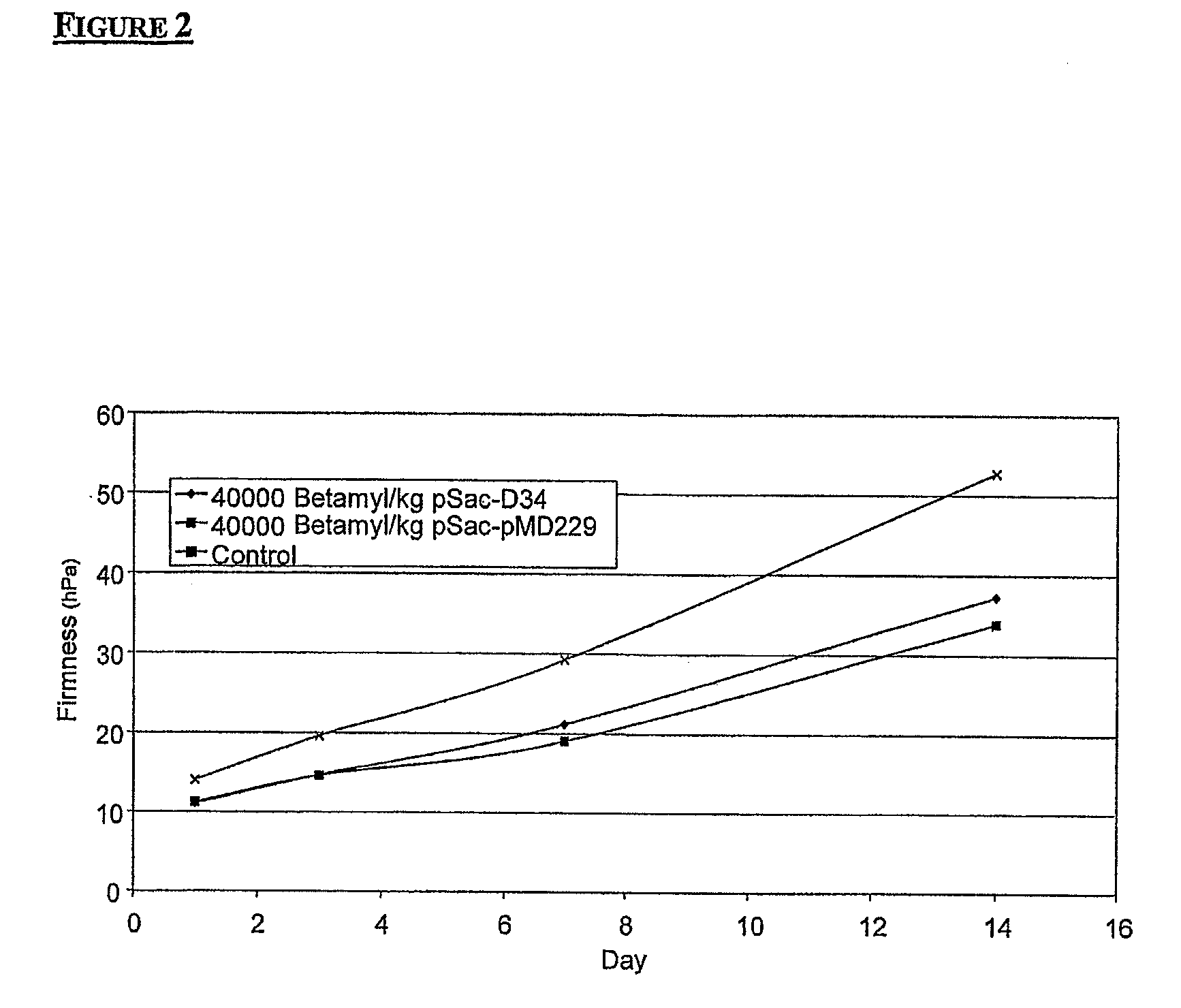

Modified amylase from pseudomonas saccharophilia

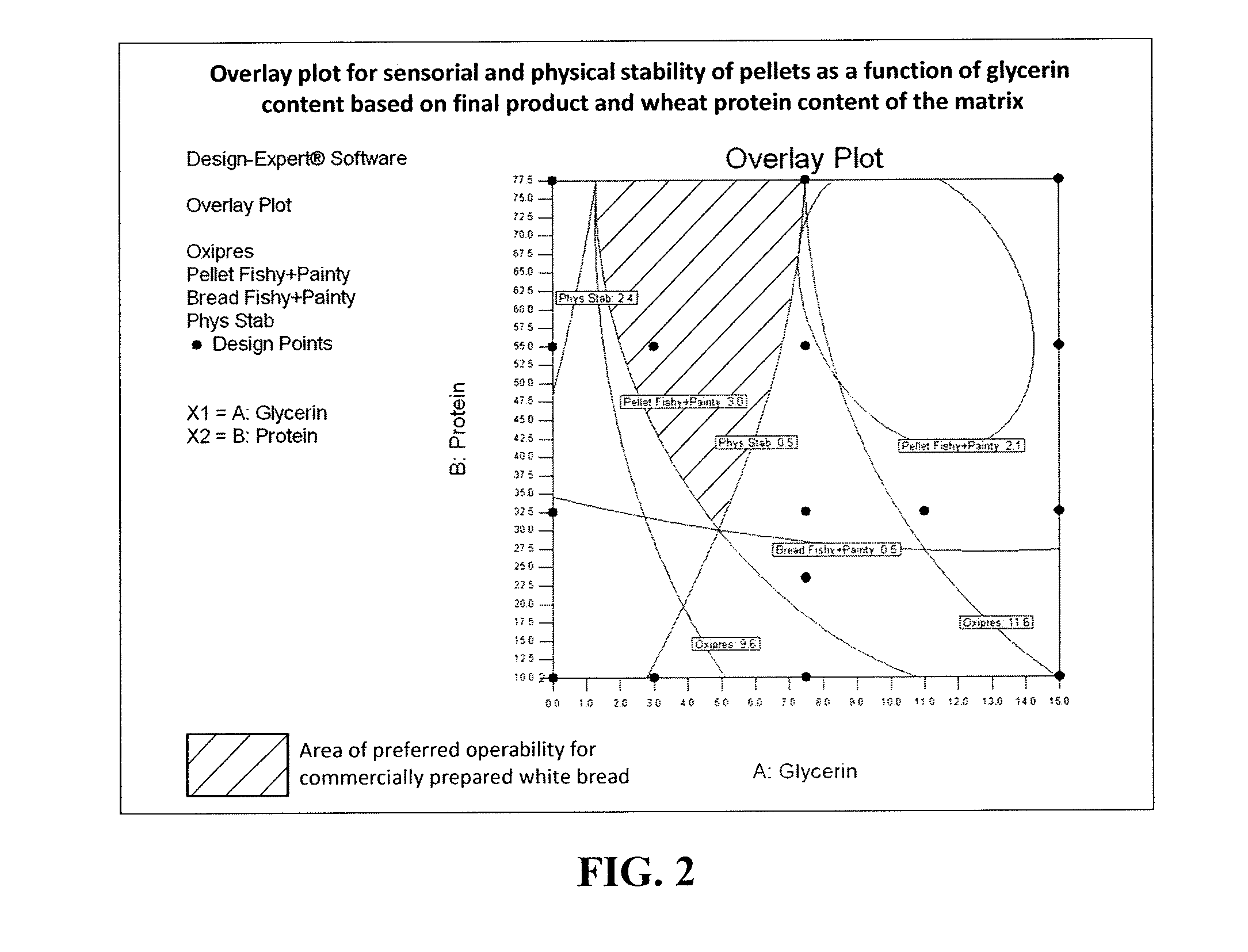

Described is a PS4 variant polypeptide derivable from a polypeptide having amylase activity selected from: (a) a polypeptide comprising an amino acid mutation at each of positions 33, 34, 121, 134, 141, 146, 157, 161, 178, 179, 223, 229, 272, 303, 307, 309 and 334; (b) a polypeptide comprising an amino acid mutation at each of positions 33, 34, 121, 134, 141, 145, 146, 157, 178, 179, 223, 229, 272, 303, 307 and 334; (c) a polypeptide comprising an amino acid mutation at each of positions 33, 34, 121, 134, 141, 146, 157, 178, 179, 223, 229, 272, 303, 307, 309 and 334; and (d) a polypeptide comprising an amino acid mutation at each of positions 3, 33, 34, 70, 121, 134, 141, 146, 157, 178, 179, 223, 229, 272, 303, 307, 309 and 334; referring to the numbering of a Pseudomonas saccharophilia exoamylase shown as SEQ ID NO: 1.

Owner:AS DE DANSKE SUKKERFABRIKKER

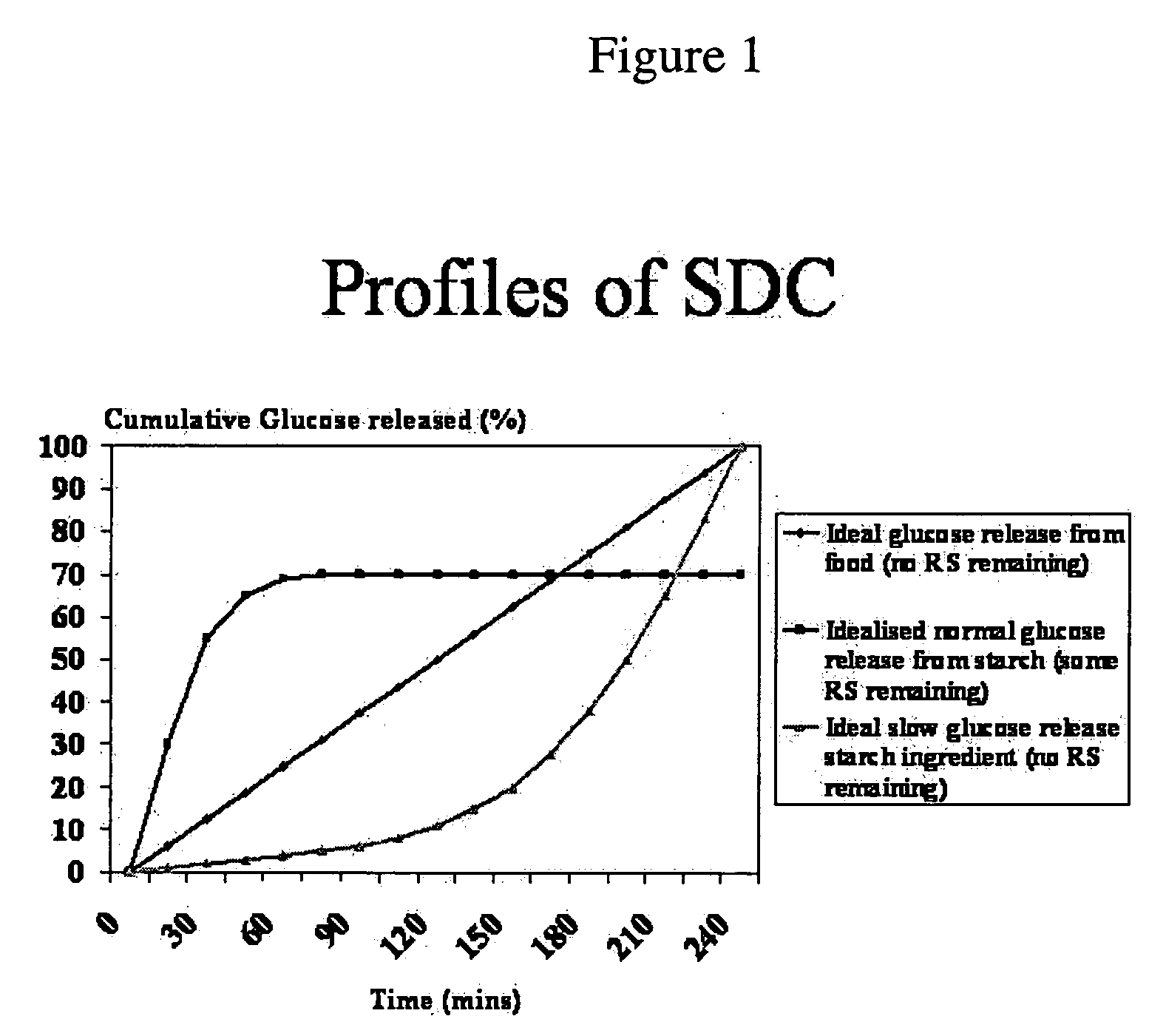

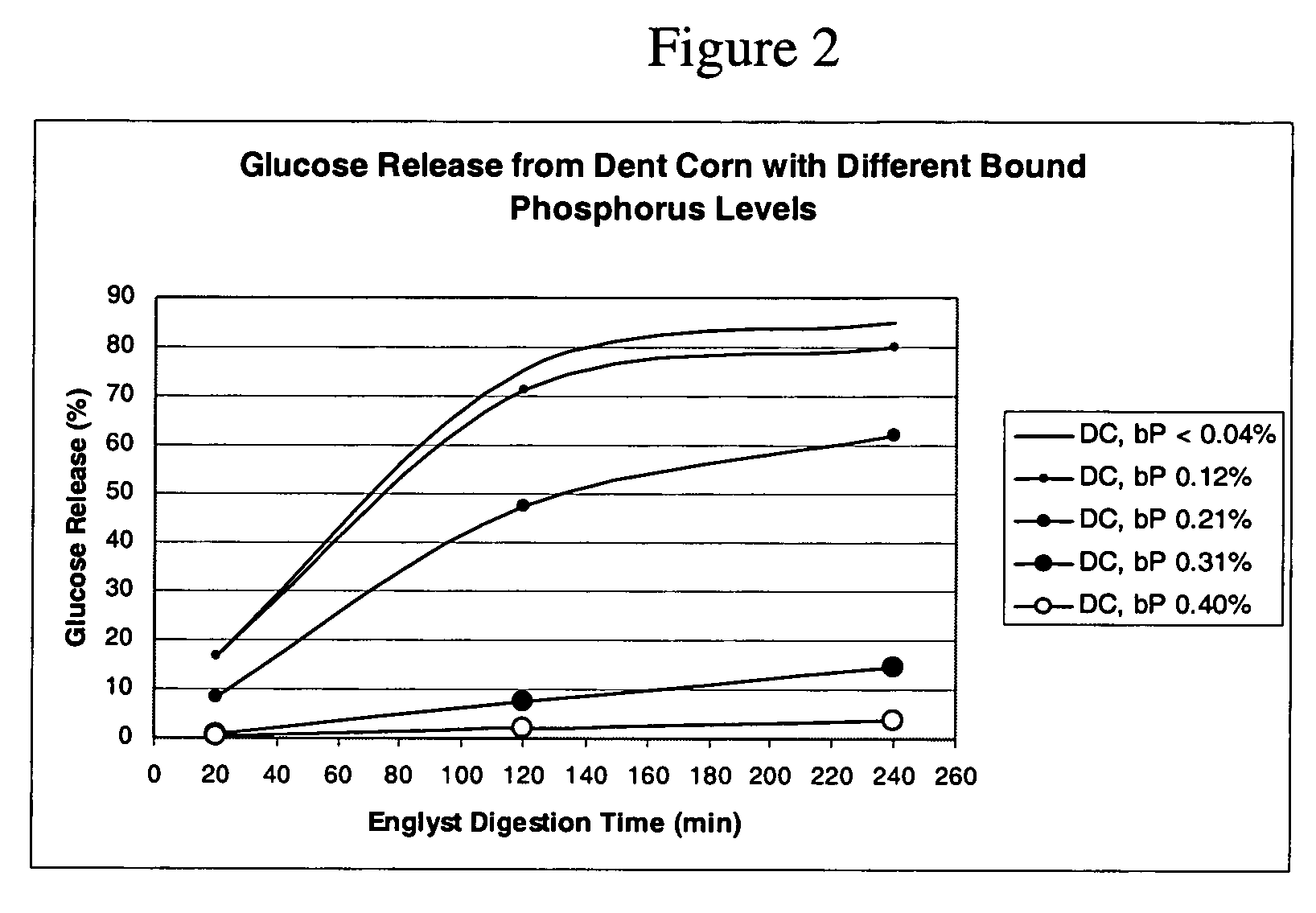

Use of a chemically modified starch product

InactiveUS20060025381A1Reducing initial acute elevationBiocideOrganic active ingredientsGlucose polymersD-Glucose

The present invention relates to the use of a chemically modified starch to control and / or regulate the blood glucose level of mammals and post-prandial absorption. Such chemically modified starches, when properly formulated into foods, may be used to provide the consumer with glucose over an extended time period and more constant glucose levels.

Owner:BRUNOB II BV

Weight loss composition and method for losing weight

InactiveUS6210702B1Sufficient quantityPreventing and treating atherosclerosis, high cholesterol and heart diseasePharmaceutical non-active ingredientsModified nutritive productsControlled dietsUnsaturated fatty acid

This invention relates to a dieting method and novel line of food products. These novel food products replace similar food products and are utilized by the dieting method to induce a slowed carbohydrate absorption rate thereby achieving weight loss. Furthermore, the dieting method will induce a high satiating effect to control eating habits and provide the dieter with additional doses of mono and poly unsaturated fatty acids to prevent any decrease in energy consumption.

Owner:SAMMAN RATIB AL

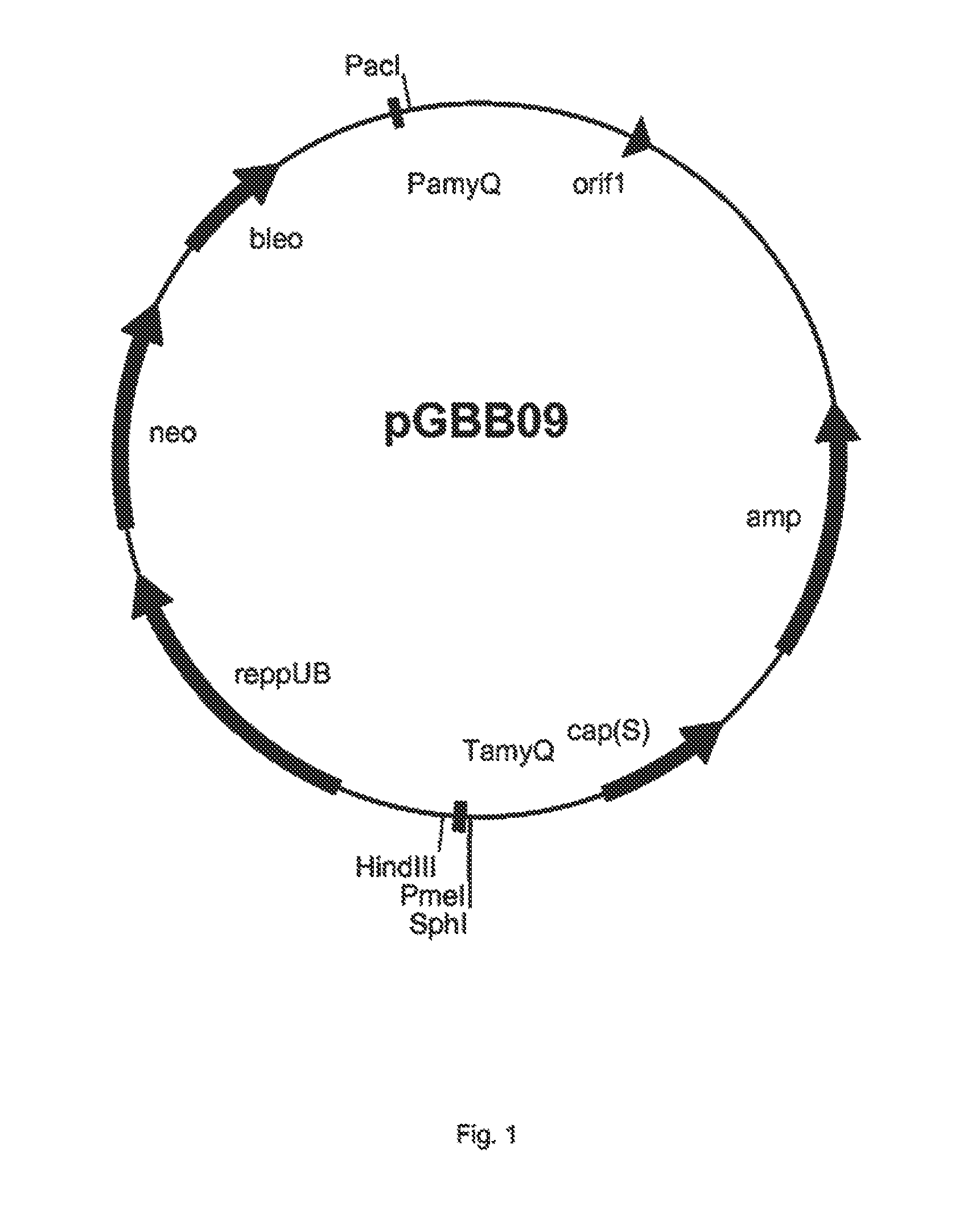

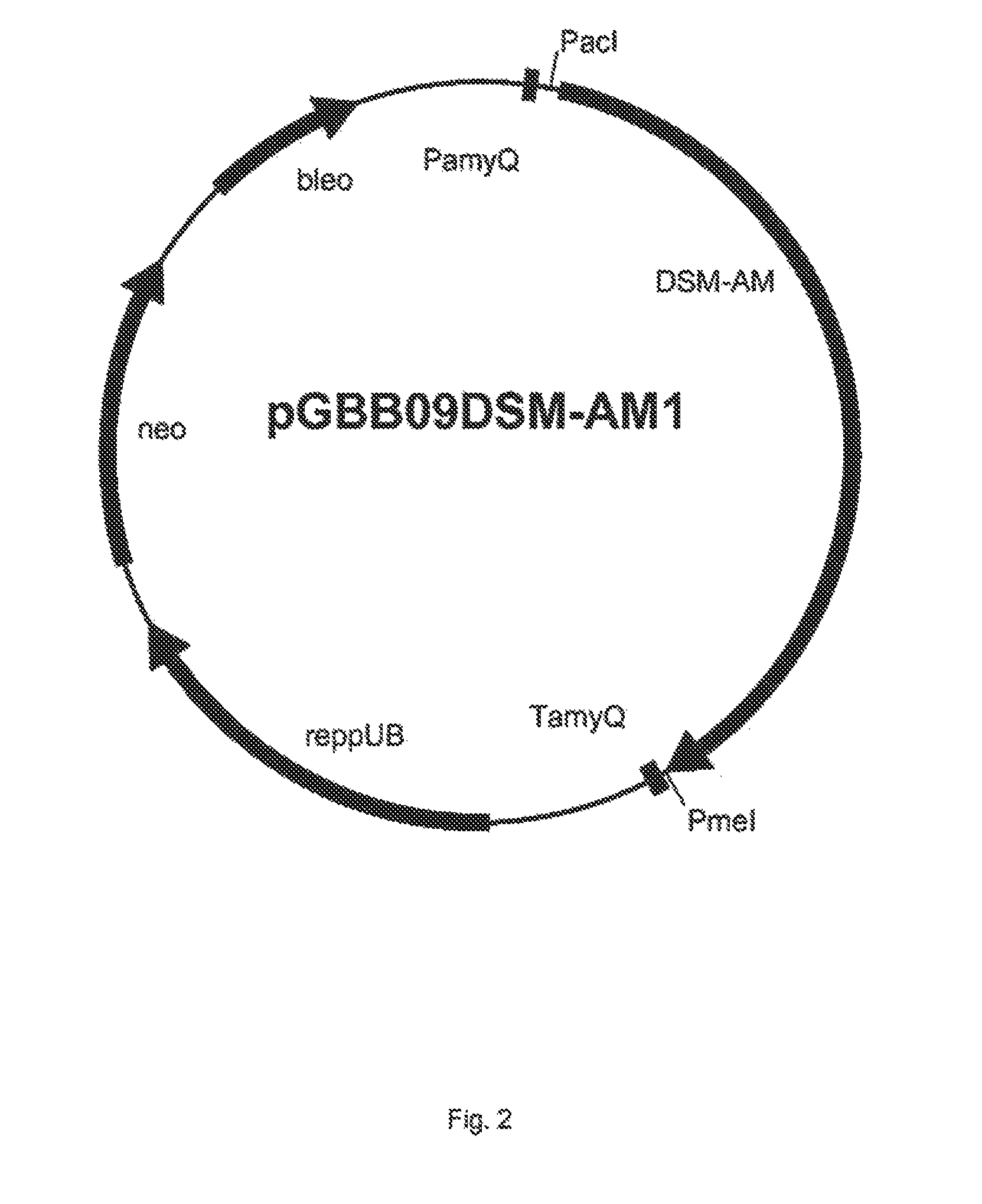

Alpha-amylase

This invention relates to an alpha-amylase, a process for its preparation and the use of the amylase. The invention relates to a newly identified polynucleotide sequence from Alicyclobacillus pohliae comprising a gene that encodes the alpha-amylase enzyme. The invention features the full-length coding sequence of the gene as well as the amino acid sequence of the full-length functional protein of the gene. The invention also relates to methods of using these proteins in industrial processes, for example in food industry, such as the baking industry. Also included in the invention are cells transformed with a polynucleotide according to the invention suitable for producing these proteins and cells.

Owner:DSM IP ASSETS BV

Hair blackening and caring healthy cake food

InactiveCN1736213AObviously not hungryImprove sleep qualityModified nutritive productsFood preparationSmoked PlumAdditive ingredient

The invention discloses a hair blackening and caring healthy cake food, which is prepared from the following ingredients: black soya bean, black rice, smoked plum, black sesame seeds, matrimony vine, cornus officinalis, haw, rhizoma dioscoreae, Siberian solomonseal rhizome, lotus seeds, walnut kernel, poria cocos, asparagus root, mulberry, tuber of multiflower knotweed, safflower, Chinese angelica root, dried rehmannia root and licorice root.

Owner:宋秀华

Encapsulated omega-3 fatty acids for baked goods production

InactiveUS20100310728A1Prevents substantial smearing and dissolutionHardens the encapsulated productReady-for-oven doughsDough treatmentCooking & bakingAntioxidant

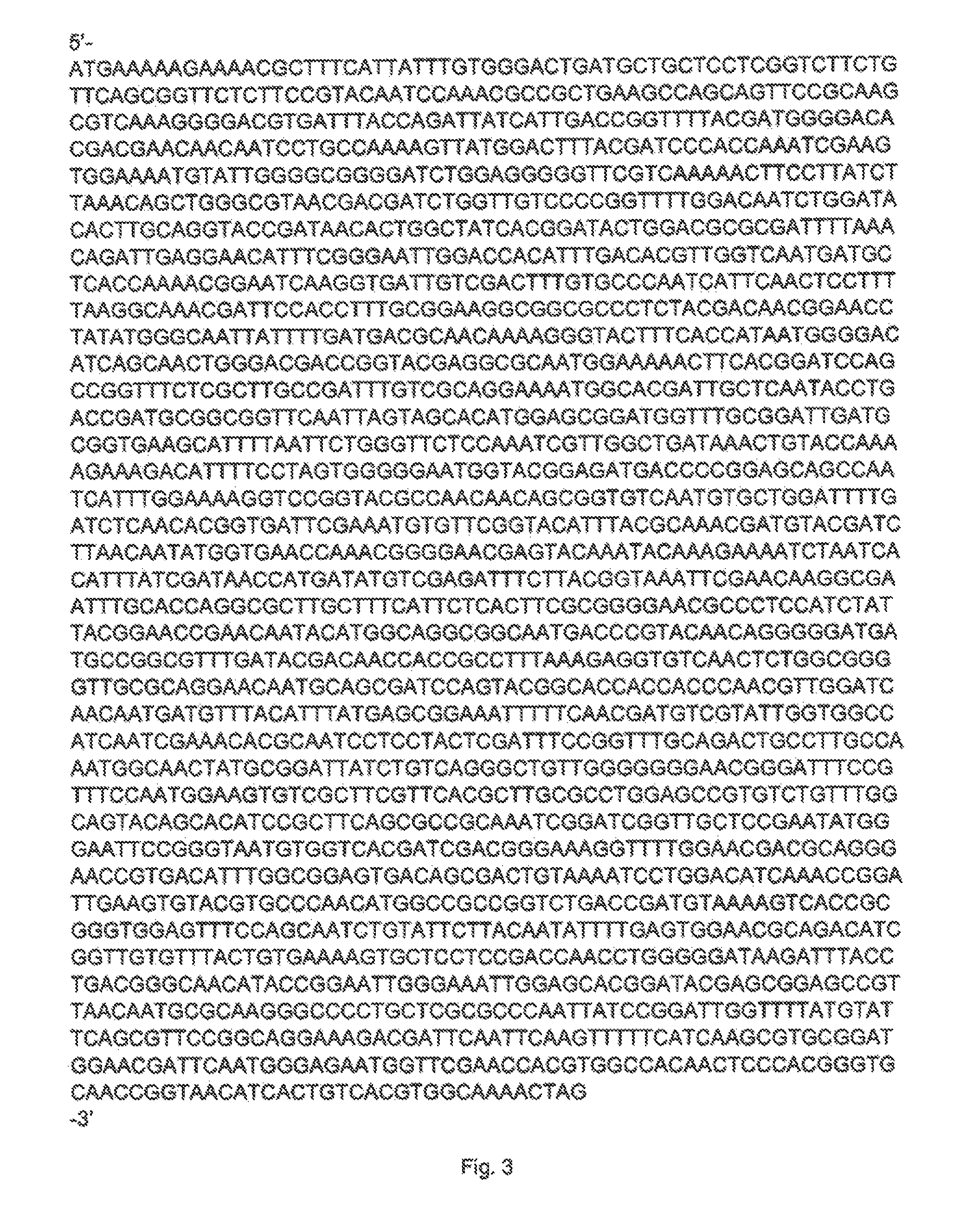

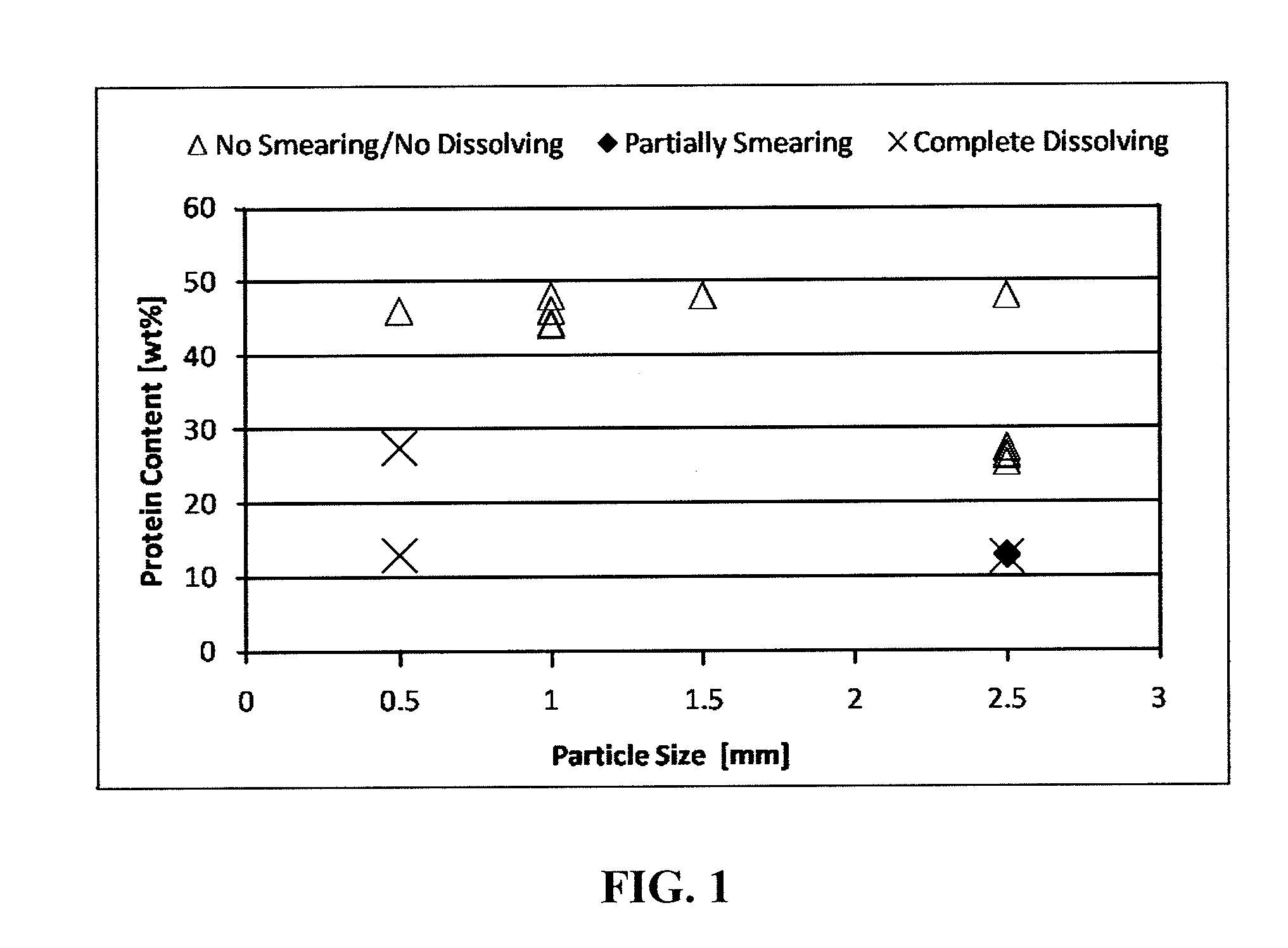

Encapsulated polyunsaturated fatty acids which can be incorporated into a baked good dough or batter without smearing or dissolution of the encapsulated product contains film-coated oil droplets encapsulated by a matrix material, a liquid plasticizer which plasticizes the matrix material, and an acidic antioxidant dispersed throughout the plasticized matrix material which helps to prevent oxidation of the polyunsaturated fatty acids; and the production of a fishy taint or malodors and mal-flavors. The matrix material includes a starch component which helps to avoid a rubbery consistency and texture and promotes extrudability, and a protein component, which hardens the encapsulated product and prevents substantial smearing and dissolution during dough or batter mixing and baking. The matrix material protein content is from about 25% to about 77.5% by weight of the matrix material. The protein content of the encapsulated product is from about 15% to about 65% by weight, of the encapsulated product.

Owner:GEN MILLS IP HLDG II

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com