Patents

Literature

966 results about "Chipped potatoes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potato chip. Potato chips (also called crisps in the United Kingdom and Ireland) are thinly cut potatoes that have been baked or fried and lightly salted or seasoned. Some popular flavours of potato chips are: salt and vinegar, ketchup, sour cream and onion.

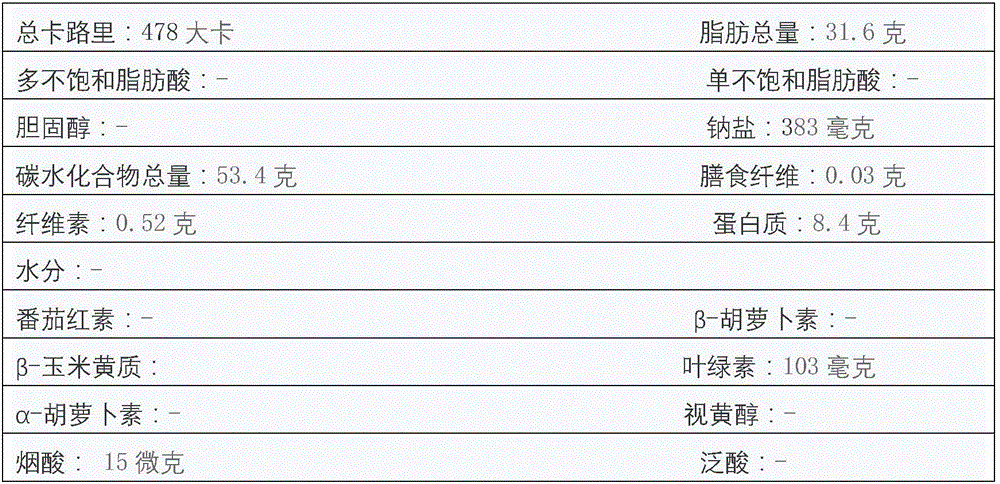

Nutritional potato chips and preparation method thereof

InactiveCN103535664AAdd flavorFull of nutritionFood ingredient functionsFood preparationBiotechnologyAdditive ingredient

The invention discloses nutritional potato chips and a preparation method thereof. The nutritional potato chips are characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of potatoes, 25-30 parts of rye flour, 3-4 parts of salt, 4-5 parts of oligosaccharide, 1-2 parts of zinc citrate, 8-10 parts of lily mayonnaise, 10-11 parts of almond, 11-12 parts of peanut, 12-13 parts of sesame, 1-2 parts of burdock, 1.5-1.8 parts of lophatherum gracile, 0.8-1.5 parts of tangerine peel, 1.5-2 parts of cassia seed, 1-1.5 parts of angelica, 2-2.5 parts of broadbean flower, 2-3 parts of apple blossom, 2-3 parts of stellaria media and 3-5 parts of rapeseed oil. The nutritional potato chips have superior flavor, are crisp, refreshing, scientific in proportion of all the ingredients and rich in nutrition, and have the effects of dispelling wind and heat, regulating qi, strengthening spleen, drying dampness, eliminating phlegm, replenishing blood, improving eyesight, cooling blood, detoxifying, maintaining beauty and keeping young.

Owner:ANHUI HUAIYUAN XINTAI CEREAL & OIL

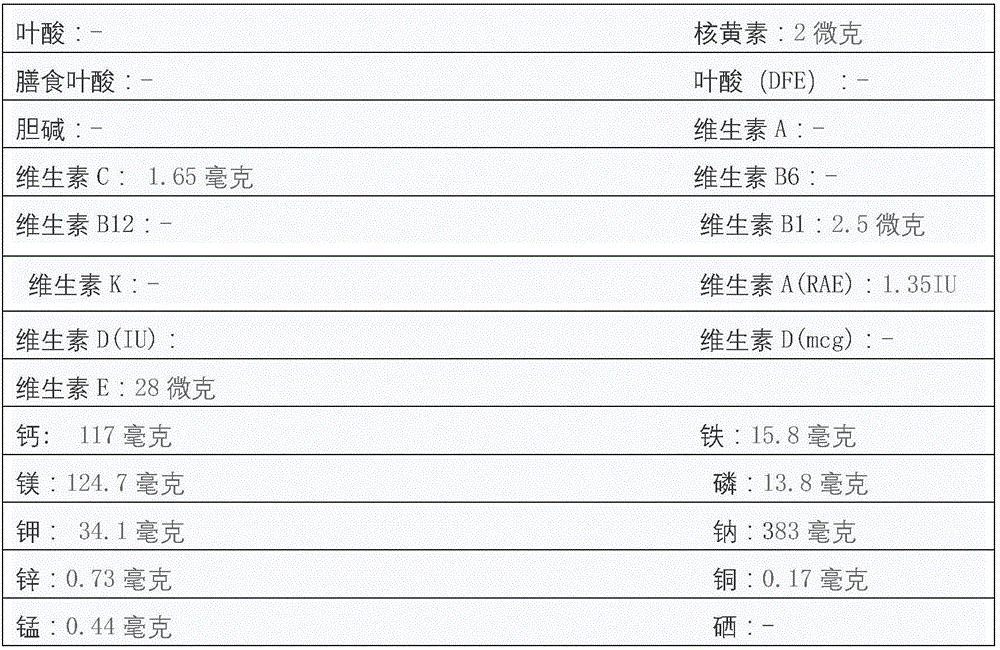

Enteromorpha potato chips and processing method thereof

InactiveCN105795395AGuaranteed qualityReduce moisture contentFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentMonosodium glutamateHazardous substance

The invention relates to the field of food, in particular to enteromorpha potato chips and a processing method thereof.The potato chips are full of seafood flavor, tasty in sour and sweet taste and slightly salty.The potato chips are golden matched with emerald green, and the color is very attractive and promotes appetite.The potato chips are unique in flavor, and have rich enteromorpha fresh flavor, and with the aromatic odor of orange juice, the potato chips can enable people to be full of energy and enhance appetite.Crisping of the potato chips is matched with flexibility of syrup, softness and hardness of the crisping sense are combined, and innovation and interest are added.The potato chips are safe and healthy, aginomoto and other hazardous substances are not added, and all indexes of enteromorpha powder conform to national safety standards.The potato chips are abundant in nutrition, and malnutrition, obesity and hazardous substance intake and other negative health problems caused when people eat a large number of potato chips are relieved.The potato chips have the healthcare function.

Owner:SHANGHAI OCEAN UNIV

Method for fabricating mango potato chips

InactiveCN103976312ANovel tasteNutrition and healthFood preparationMonosodium glutamateBiotechnology

The invention discloses a method for fabricating mango potato chips. The mango potato chips are prepared by the following steps: raw material selection, raw material pre-treatment, slicing, color-protecting, seasoning, frying, packaging and the like. A seasoner is prepared from the following raw materials by weight percent: 15-20% of mango powder, 2-4% of salt, 6-10% of white sugar, 1-2% of aginomoto, 1-3% of yeast extract, 3-5% of mint powder and 2-4% of yam flour. The potato chips prepared by the method are novel in taste, nutrient and healthy, and convenient to eat. The flavor contains Chinese herbal medicinal ingredients, can help digestion, and is good for health. The method is simple in process, the technique is easy to master, therefore, popularization is easy, and industrialized production is also easy.

Owner:ANHUI QUANLI ELECTRONICS TECH

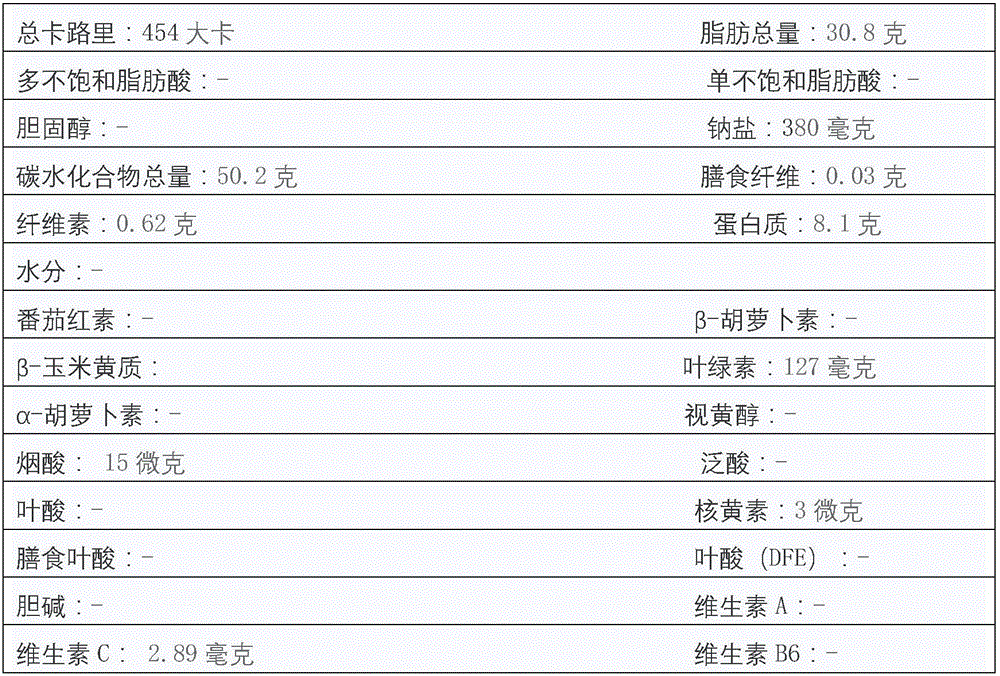

Process to produce a reduced fat potato chip

InactiveUS20060088633A1Reduce decreaseReduce oilFood preparationMeat/fish preservation by dryingChipped potatoesUnit operation

A novel improved process and apparatus is disclosed for producing low oil potato chip products having less than 30 percent by weight oil based on the total weight of an unseasoned chip. The process requires contacting the chip with a brine solution, frying the chip, and concurrently dehydrating and de-oiling the chip with superheated steam in a single unit operation.

Owner:FRITO LAY NORTH AMERICA INC

Potato chips and processing method thereof

The invention relates to potato chips and a processing method thereof. The potato chips are made from the raw material of fresh potatoes and ingredients by the processing steps of: pretreating, stirring, rolling, forming by roller cutting, baking, cooling and packaging, wherein the ingredients include the following components in parts by weight: 10-20 parts of potato starch, 10-14 parts of white granulated sugar, 6-8 parts of plant oil, 2-3 parts of table salt, 1.5-2.5 parts of aginomoto, 0.6-1 part of sodium bicarbonate, 0.6-1 part of ammonium bicarbonate and a proper amount of water. In theinvention, fresh potatoes are used as the raw material, and equipment of automatic impurity removing, washing, peeling, stirring, rolling, forming by roller cutting, baking, cooling and packaging is adopted, a proper amount of sodium bicarbonate and ammonium bicarbonate is added to be used as leavening agents in the processing so that processed non-fried healthy potato chips have excellent crispness and good taste. The invention not only has reasonable and practical processing method, but also is simple to operate, has good effect and is beneficial to the wide generalization.

Owner:CHACHA FOOD CO LTD

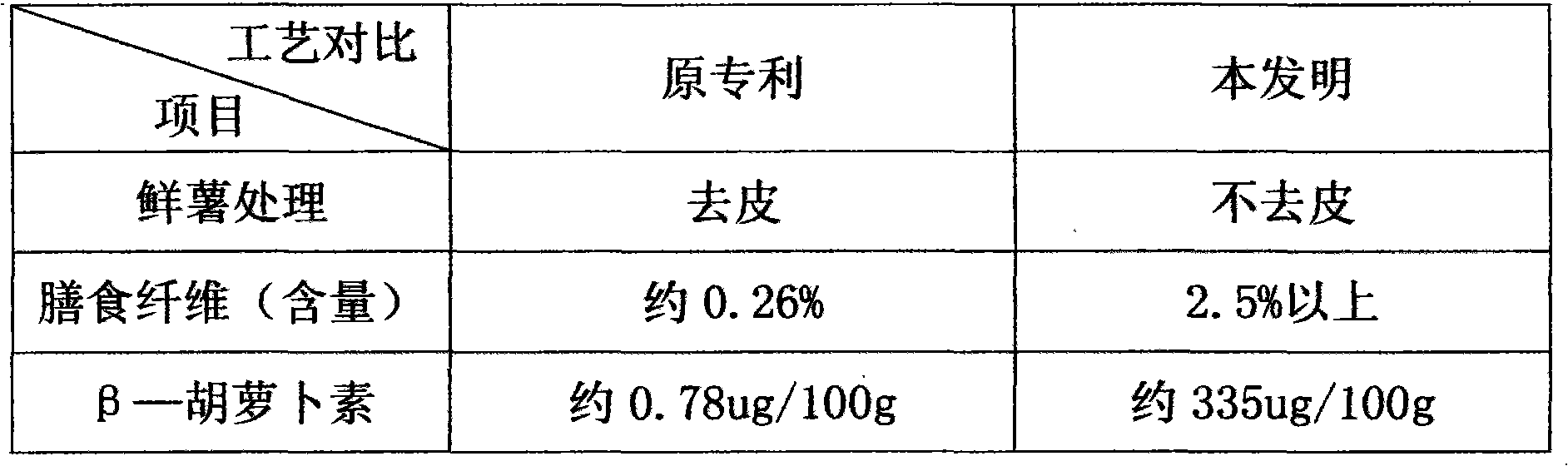

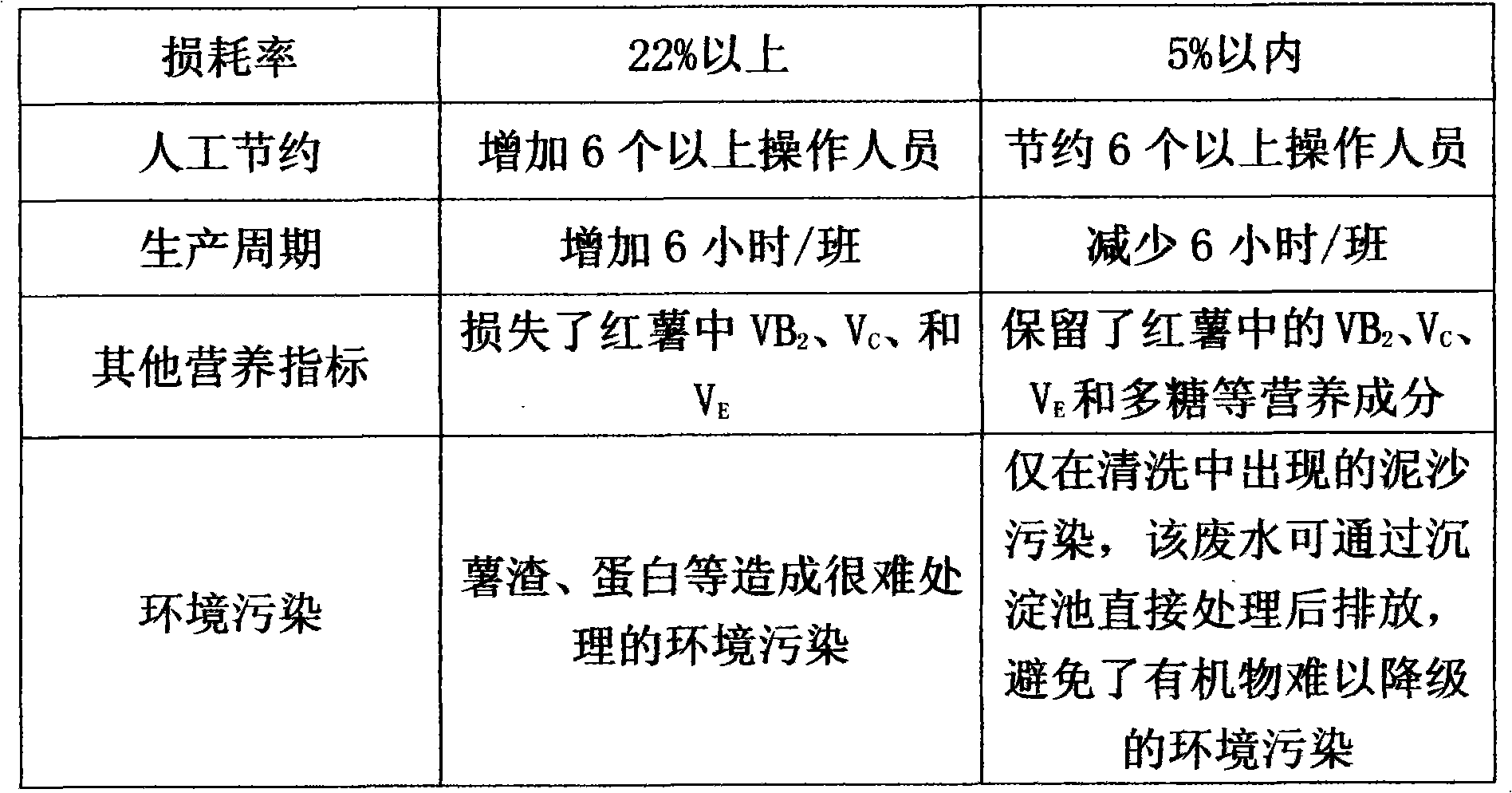

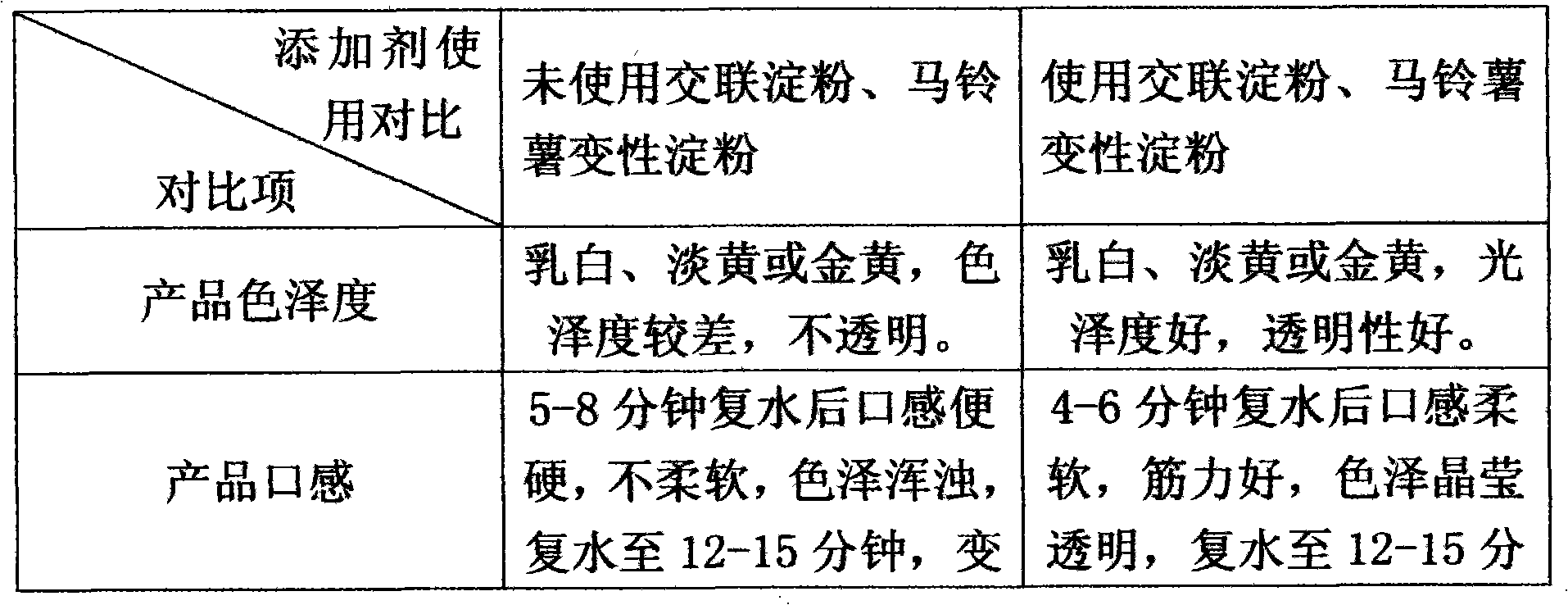

Process for producing vermicelli from sweet potato

A processing method for a full-potato vermicelli includes: washing fresh potatoes or manufacturing the fresh potatoes the impurities of which are removed into peeled or not-peeled potato chips. The processing method is characterized by including the steps of: preparing the slurry of potatoes, preparing the materials with a weight mixture ratio of 100 portions of the slurry of potatoes, 20 to 200 portions of dry potato amylum, 0.1 to 10 portions of modified amylu and 0 to 20 portions of complemented water, feeding the materials into a powder combining machine for uniformly mixing and stirring,curing and shaping, cooling, opening the powder, arranging into a shaping box or a bow for drying and shaping after being measured. The method of the invention is adopted to directly process fresh ordry potato compounds into the vermicelli or powder sheets; more of the nutrition components in the materials are preserved; the technique is simple; the mechanical degree of the production is high; the production cost is low; the additive value of a commodity is high; the quality of a product is good; the product has the characteristics of a natural green food.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

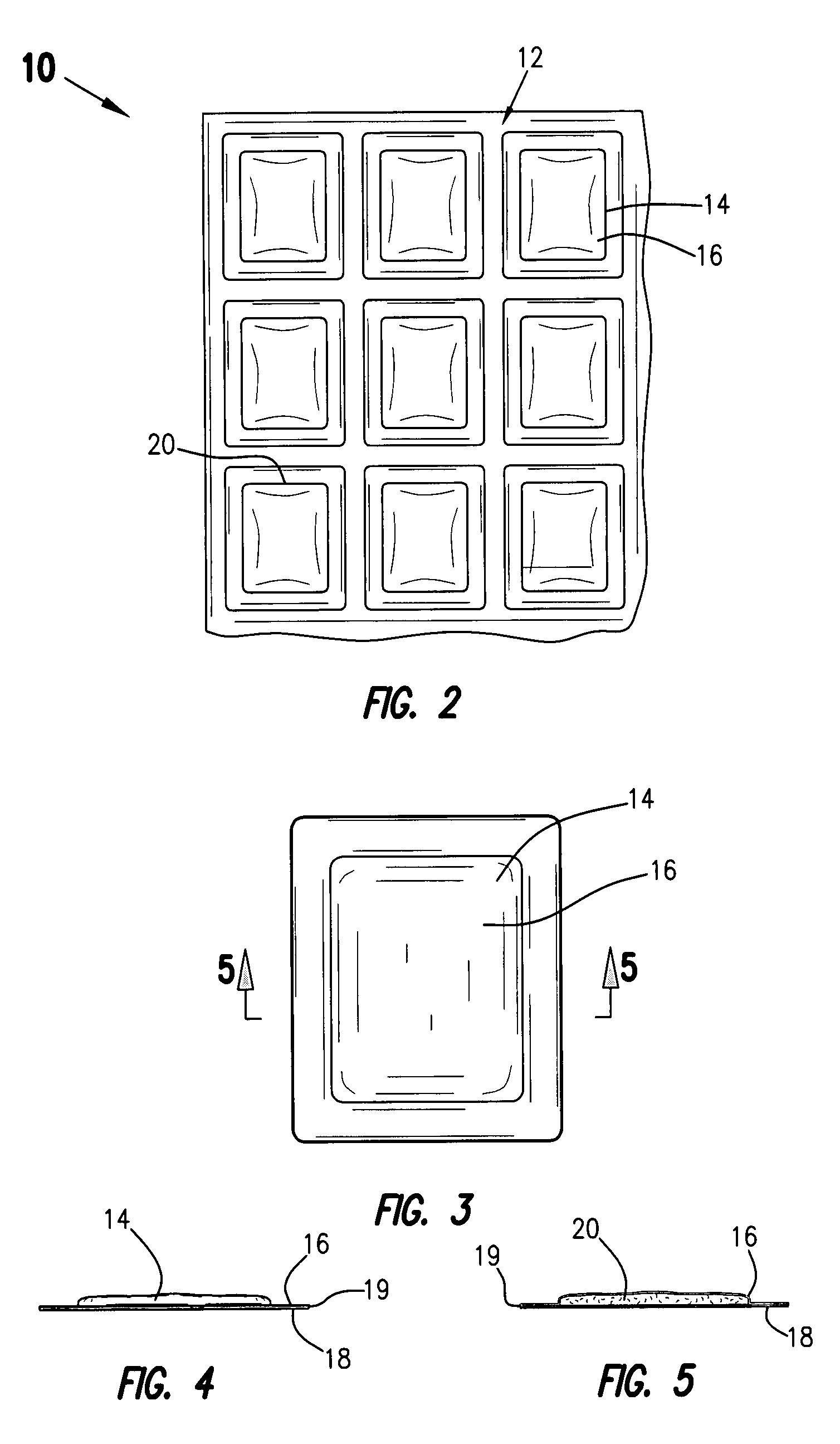

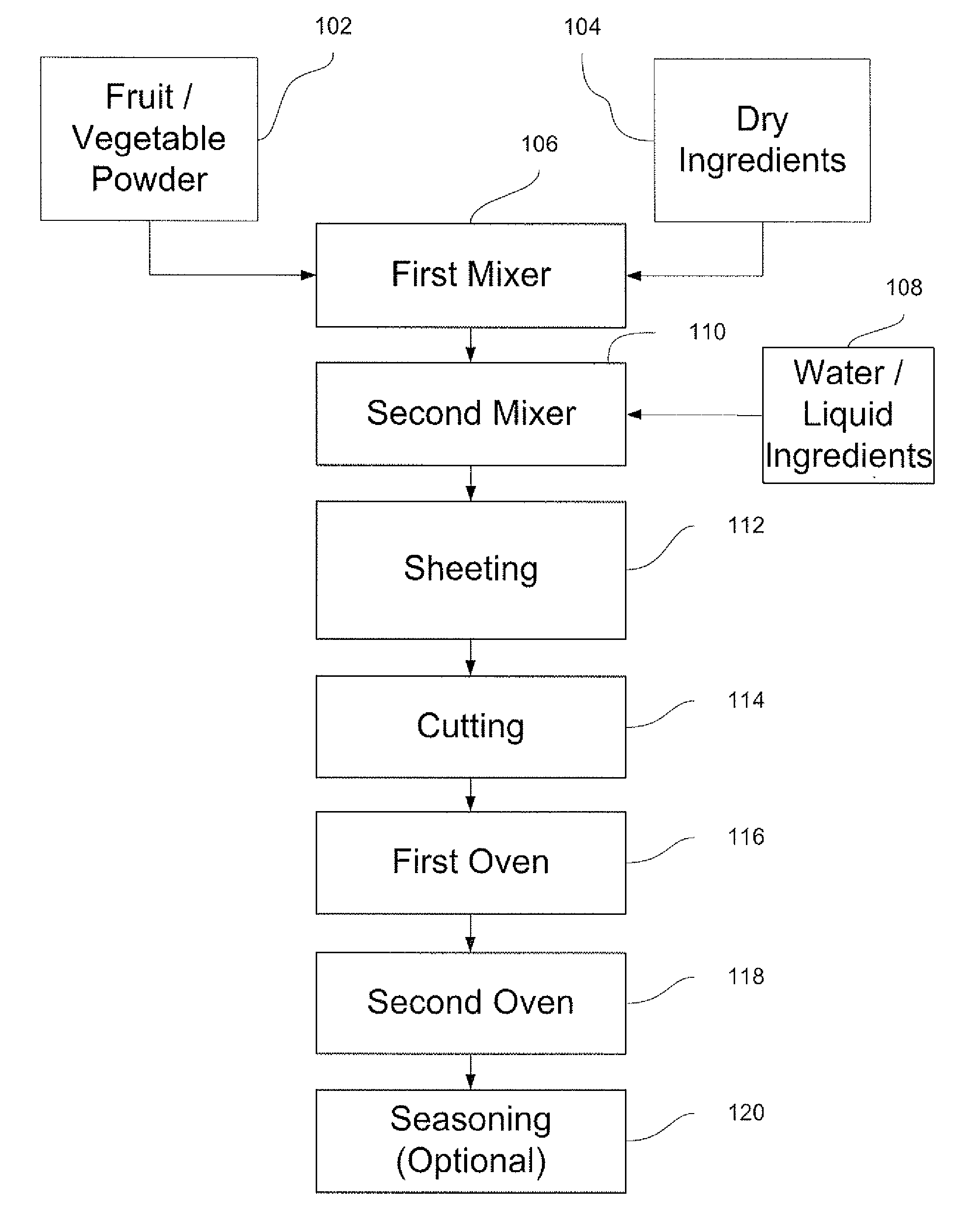

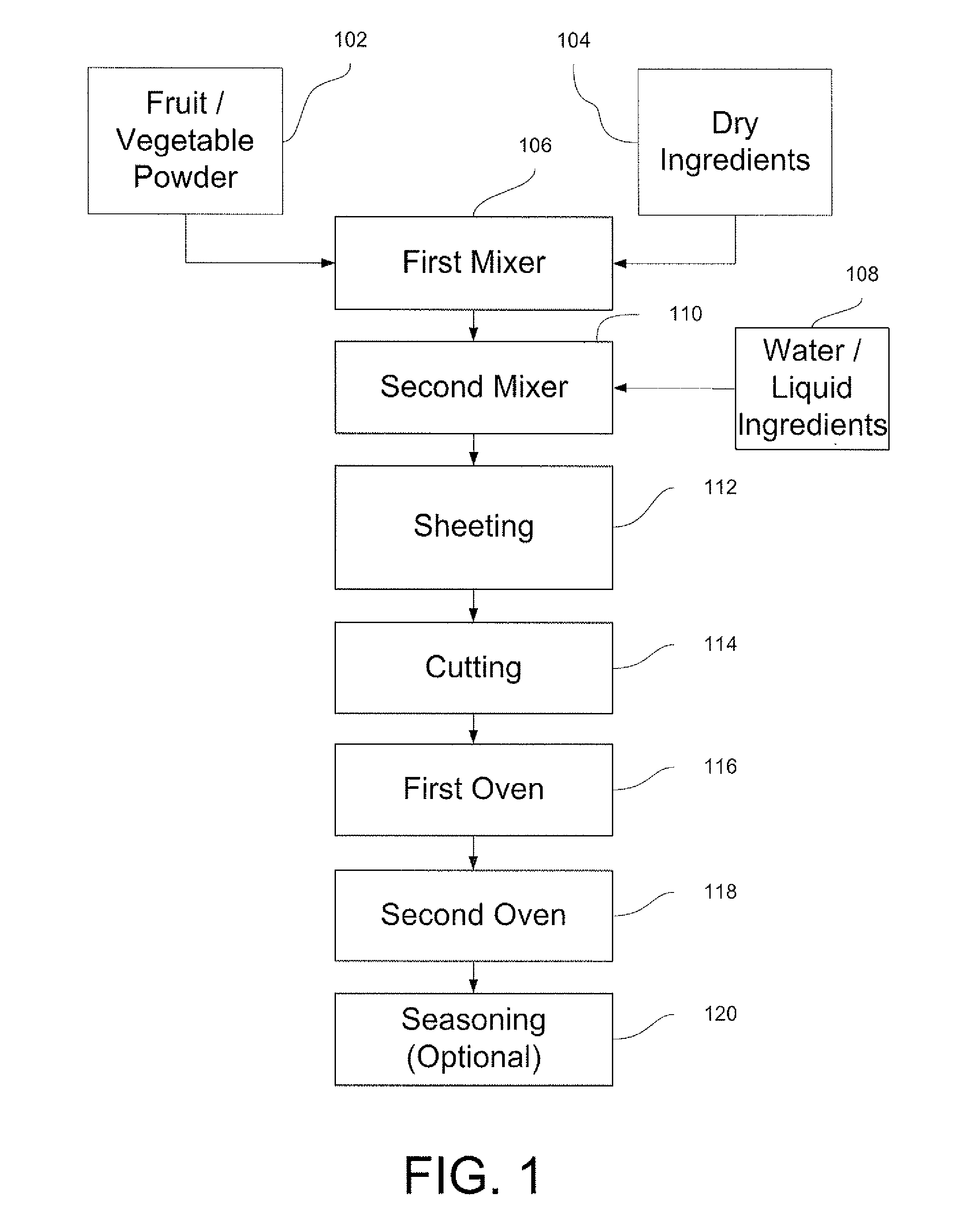

Snack Cracker and Method for Making Same

InactiveUS20100215826A1Reduced level of saturated fatLower Level RequirementsDough treatmentLeguminous plant bakery productsChipped potatoesAdditive ingredient

The present invention discloses formulations for sheeted, baked fruit and vegetable crackers that have a light, crispy texture similar to a potato chip or cracker. Undehydrated ingredients are combined with dry ingredients and oil to make a dough, which is then sheeted and cut into pieces. The pieces are baked to produce vegetable and fruit snack crackers.

Owner:FRITO LAY TRADING CO GMBH

Red date potato chips and preparation method thereof

The invention discloses red date potato chips. The red date potato chips are characterized by being prepared from the following raw materials in parts by weight: 100 parts of smashed potato, 20 parts of wheat germ powder, 5 parts of xylitol, 5 parts of red date meat paste, 5 parts of red bean paste, 5 parts of pumpkin, 1 part of cushaw flower, 2 parts of eggplant, 2 parts of Chinese broccoli, 0.2 part of lotus leaf powder, 2 parts of boletus edulis, 2 parts of green red pepper, 0.2 part of semen cassiae powder, 2 parts of ginger, 1.0 part of baking soda, 2 parts of salt, 10 parts of white sugar, 0.5 part of monosodium glutamate and a proper amount of water. The red date potato chips are prepared from the wheat germ powder, the red date meat paste, the red bean paste, the pumpkins, the cushaw flowers, the eggplants, the Chinese broccoli, the boletus edulis and the green red peppers, so that the red date potato chips contain rich vitamins, and are anti-oxidative and good to health, and the immune function of a human body can be improved; the lotus leaf powder and the ginger have the effects of invigorating the stomach and reducing blood pressure, so that the potato chips have a health care function; and the formula is in line with the needs of the human body, so that the physical health is maintained when a person enjoys the potato chips, and the potato chips belong to delicious food.

Owner:WUHU XIANGRONG FOOD

Healthcare potato chip and processing method thereof

The invention discloses a healthcare potato chip and a processing method of the healthcare potato chip. The healthcare potato chip is composed of the following raw materials in percentage by weight: 72-85% of potato, 5-10% of glutinous rice flour, 2-5% of palm oil, 1-3% of Chinese herbal medicine, 0.5-2% of a condiment and the balance of water, wherein the Chinese herbal medicine is composed of 8-15 parts of liquorice, 5-11 parts of peppermint, 1-3 parts of corktree and 3-8 parts of chrysanthemum, and the Chinese herbal medicine is processed by steps of treating the raw materials, hot ironing and freezing, preparing additives, dipping, coating lining, microwave roasting and cooling, packaging, and the like. The healthcare potato chip has the characteristics of good taste, low heat and green health, the microwave roasting procedure is used for saving oil consumption and reducing the production cost, and the oil content of the chip is low, thereby capable of being stored for a long time.

Owner:王惠莹

Mung bean potato chips and preparation method thereof

InactiveCN103330172AGood for healthHeat-clearing and detoxifying hasFood preparationChipped potatoesBiotechnology

The invention discloses mung bean potato chips which is prepared by the following raw materials by weight: 800-1,000 parts of sweet potatoes, 100-150 parts of mung beans, 1-2 parts of sesame oil, 0.5-1 part of chilli sauce, 2-3 parts of herba houttuyniae, 1-2 parts of pomegranate leaves, 1-2 parts of broadleaf holly leaves, 1-2 parts of lily, 1-2 parts of chrysanthemum, 1-2 parts of lotus leaves, 1-2 parts of stellaria yunnanensis, 1-2 parts of lotus, 1-2 parts of wood greenstar roots and a proper amount of water. The sweet potatoes are used as a raw material for the chips provided by the invention. The sweet potatoes contain a plurality of nutritional ingredients and are beneficial to the health of human body especially for intestinal health; at the same time, the mung beans can clear heat and remove toxicity; herba houttuyniae, the broadleaf holly leaves, chrysanthemum, the lotus leaves and the like has the function of clearing heat and removing toxicity, so that the mung bean potato chips are suitable for being taken for relieving summer-heat.

Owner:WUHU XIANGRONG FOOD

Corn-flavored potato chips and producing method thereof

InactiveCN103494144AUnique tasteHigh nutritional valueFood homogenisationNatural extract food ingredientsCooking & bakingChipped potatoes

The invention discloses corn-flavored potato chips and a production method thereof. The corn-flavored potato chips are made of raw materials including, by weight, 100 parts of mashed potatoes, 20-35 parts of corn flour, 8-15 parts of glutinous rice flour, 25-40 parts of corn stigma decoction fluid, 5-10 parts of mint powder, 7-12 parts of licorice powder, 1-5 parts of fruit puree, 5-12 parts of traditional Chinese medicine decoction, 0.5-3 parts of orange peel powder, 0.5-2 parts of baking soda powder, 2-5 parts of salt, 5-10 parts of sugar, 0.5-1 part of gourmet powder and a moderate amount of water. By adopting the mashed potatoes, the corn flour, the glutinous rice flour, the mint powder, the mint powder, the licorice powder, the corn stigma decoction fluid and the traditional Chinese medicine decoction and by matching with moderate seasonings, the chips are processed via the steps of producing the meshed potatoes, producing the traditional Chinese medicine juice, producing paste, blending, producing wrappers, slicing, baking and the like. The corn-flavored potato chips having faint scent of corn, unique taste and high nutritional value do not undergo a frying process, are green and environmentally friendly and good for health, and are of the highest grade of leisure home food.

Owner:吴柠君

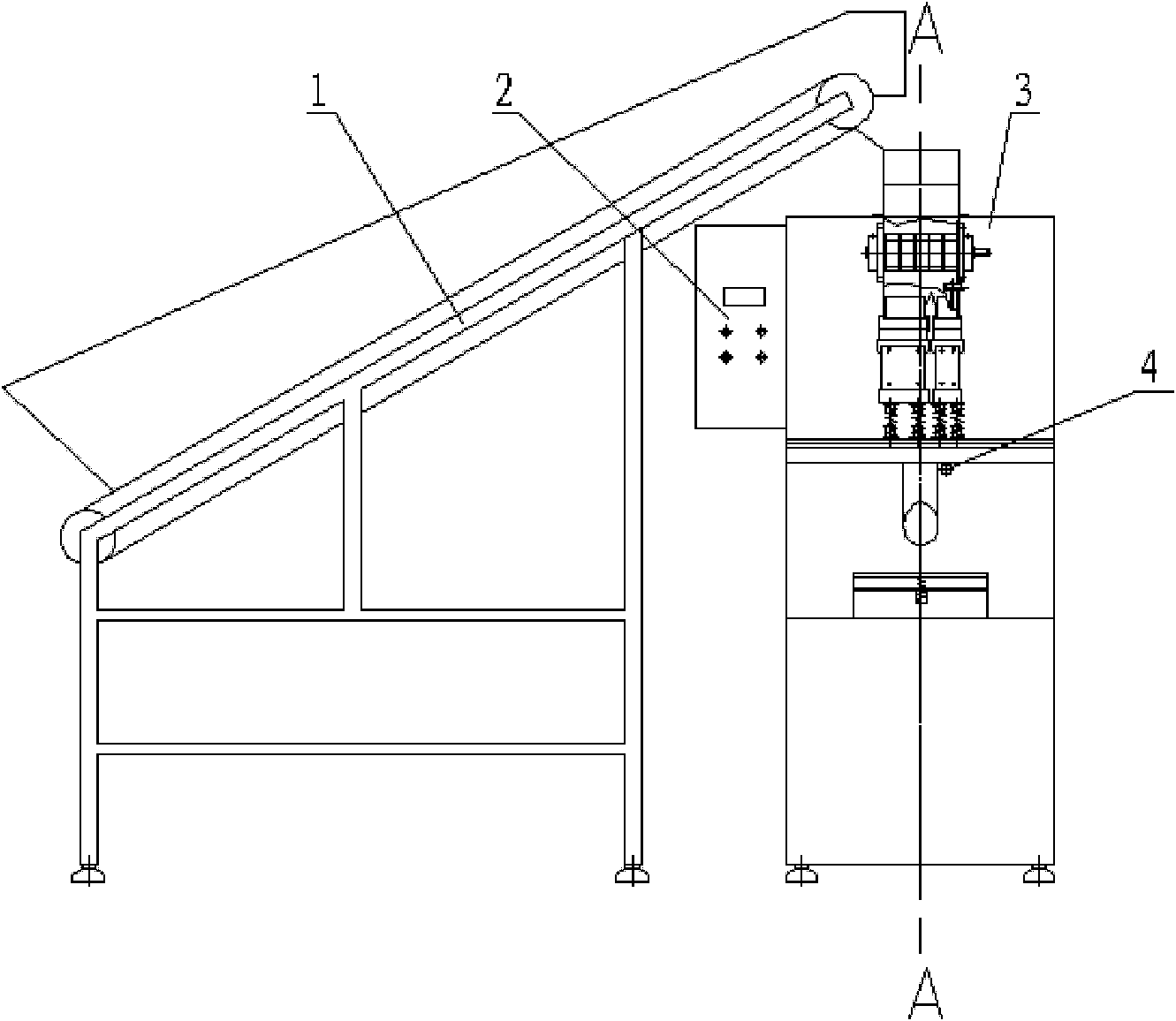

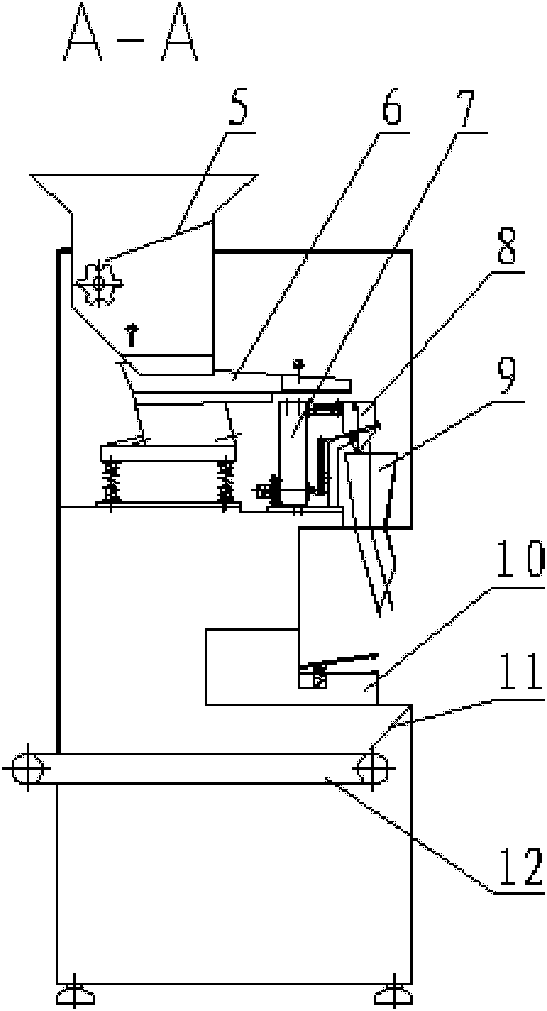

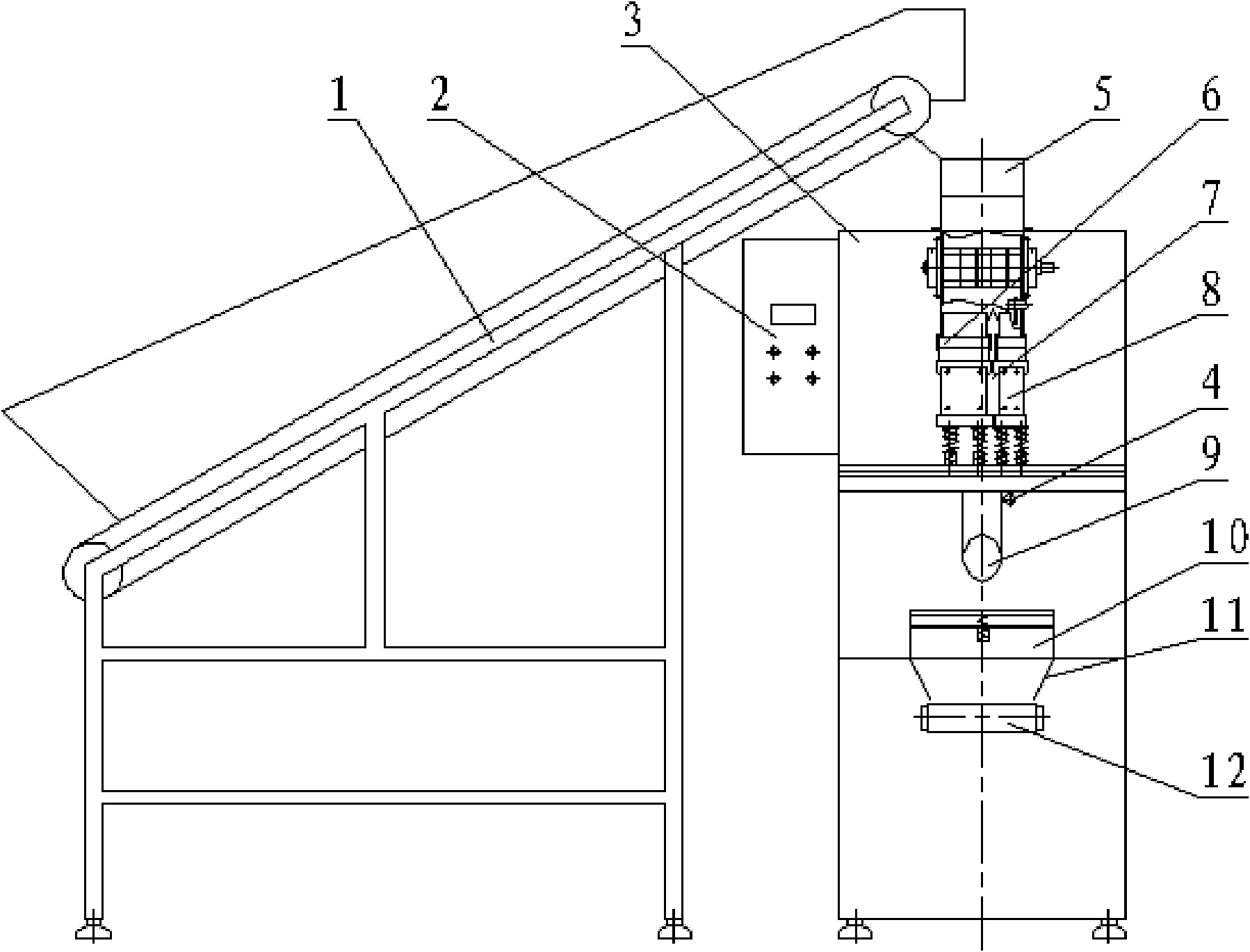

Semi-automatic packaging machine for irregular bulk foods

InactiveCN102180273ASmoothly fall intoIn line with the principles of ergonomicsPackaging automatic controlSolid materialTransport systemSemi automatic

The invention relates to a semi-automatic packaging machine which is suitable for irregular bulk foods such as short chips, spicy hot fishes, potato chips, short fried strips and the like which are cooked foods with a certain hardness and brittleness and are made from flour puffing and also suitable for solid bodies with very small particle diameters or powdery materials. The food packaging machine comprises a material storing and transporting system, a control system, a machine case, a photoelectric sensor, a top hopper feeding mechanism, a vibrating feeding system, a door opener, an electronic weighing device, a nozzle module, a clamping-type sealing machine, a sliding plate, a belt conveyer and the like and is characterized in that forms of a big / small vibrating feeder, a duplex twisting feeder, a twisting shaft and an elastic steel sheet are adopted to guarantee rapid and accurate feeding to the weighing device, wherein the period of weighing, packaging and sealing at a time is generally within 2-4s; a weighing hopper is divided into a fixed side and a movable side, wherein the movable side is hinged on the fixed side, the load of a transmission mechanism for realizing execution actions of the movable side is not applied on the weighing hopper and the sensitivity is high; the door opener is of a structure that an execution part does planar motions without a fixed pivot; and installation positions of the lower body of the nozzle, the photoelectric sensor, the clamping-type sealing machine and a seat accord with ergonomics principles. The machine provided by the invention also has the advantages of simple structure, light weight, high efficiency and the like.

Owner:朱桂华

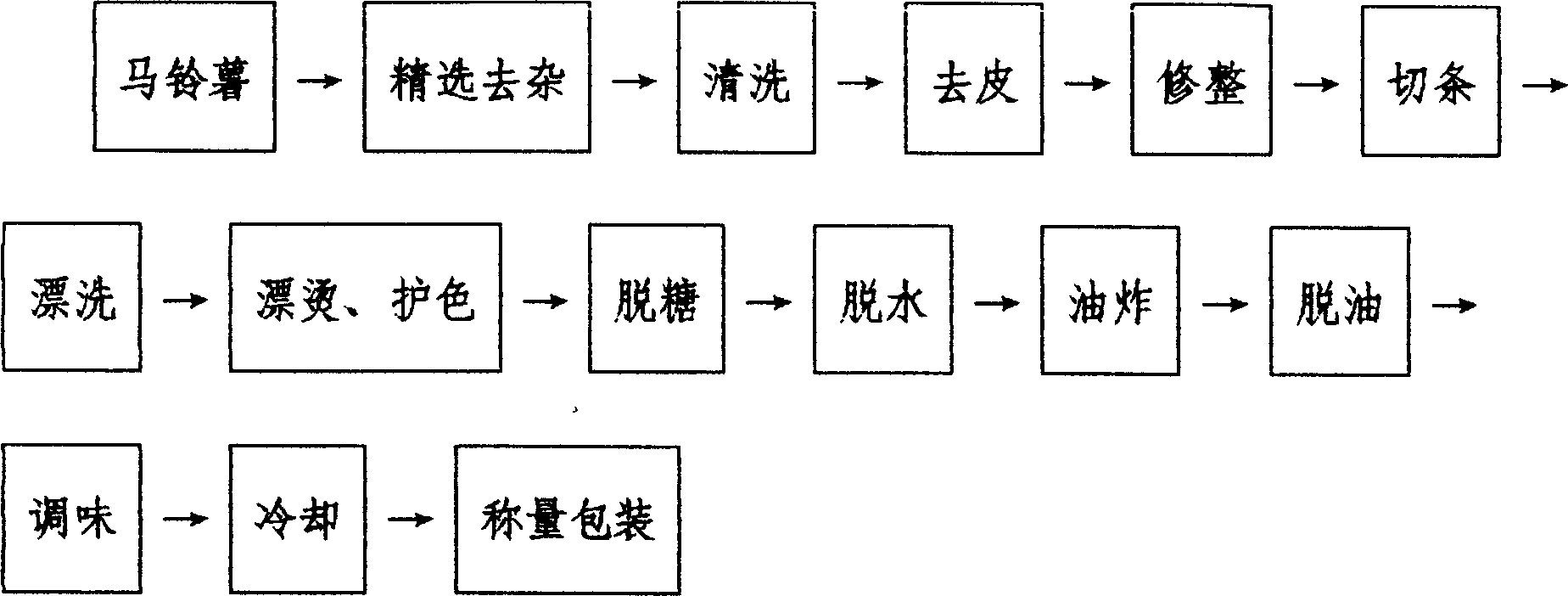

Natural potato chips and producing process thereof

The invention relates to the process for making natural French fries which integrates the steps of purification, peeling, desugarizing, de-watering, de-oiling, flavoring, cooling, and packaging. The invention can overcome the deficits of non-desugarizing, non-dewatering, non-deoiling and short keeping time in the current French fries processing technology.

Owner:BAOTOU DEER POTATO

Sea sedge and purple sweet potato chips and preparation method thereof

ActiveCN103445121AUnique flavorHigh nutritional valueFood preparationNutritive valuesSodium bicarbonate

The invention discloses sea sedge and purple sweet potato chips, which are prepared from the following raw materials in parts by weight: 80-90 parts of purple sweet potato, 8-10 parts of mung bean flour, 4-5 parts of sea sedge powder, 12-14 parts of apple, 2-3 parts of clausena lansium, 2-3 parts of Chinese yam, 2-3 parts of red dates, 2-3 parts of hawthorn, 1-2 parts of folium cortex eucommiae, 1-2 parts of sweet potato leaves, 1-2 parts of lophatherum gracile, 1-2 parts of astragalus membranaceus, 2-3 parts of indian kalimeris herb, 1-2 parts of pseudostellaria heterophylla, 6-7 parts of white granulated sugar, and 1-2 parts of sodium bicarbonate. According to the sea sedge and purple sweet potato chips, a plurality of condiments are added to adjust the taste of the chips; the mung bean flour and the sea sedge powder are added, so that the chips are more crispy and delicious; the chips are more unique in flavor after fermented by the sodium bicarbonate; a plurality of Chinese herbal medicinal ingredients are added to improve the nutritive value of the chips; the prepared chips have the effects of reducing blood pressure, stimulating appetite and digestion, tonifying spleen and stomach, tonifying liver and kidney, enhancing the body immunity, detoxifying and nourishing the skin, preventing cancers, protecting liver, and relaxing bowel.

Owner:安徽汇盛农业科技有限公司

Freezing-inhibiting and sweet potato enzyme-regulating browning promoting method

InactiveCN1672561APrevent browningNo security risksFood preservationFood preparationChipped potatoesEnzyme

The present invention belongs to the field of fruit and vegetable processing technology, and aims at solving the browning problem during producing freeze stored sweet potato chip. The freeze stored sweet potato chip producing process includes the following main steps: 1) sorting sweet potato material, washing and slicing into 4 mm thick chips; 2) scalding the chip at 100 deg.c for 15 sec; and freezing; 3) soaking the frozen chip at 25 deg.c for 30 mm to protect color; 4) amending the chip through vacuum penetration at vacuum of 0.08-0.10 MPa for 30 min, freezing to -18 deg.c fast and packing; and 5) cold storing at low temperature from -28 deg.c to -18 deg.c. Thus produced sweet potato chip has good color, no browning, long storing period and other features.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

Chips processing method reducing generation of acrylamide

InactiveCN102860479AShort duration of actionSuppress generationFood preparationChipped potatoesFood safety

Owner:HENAN UNIVERSITY OF TECHNOLOGY

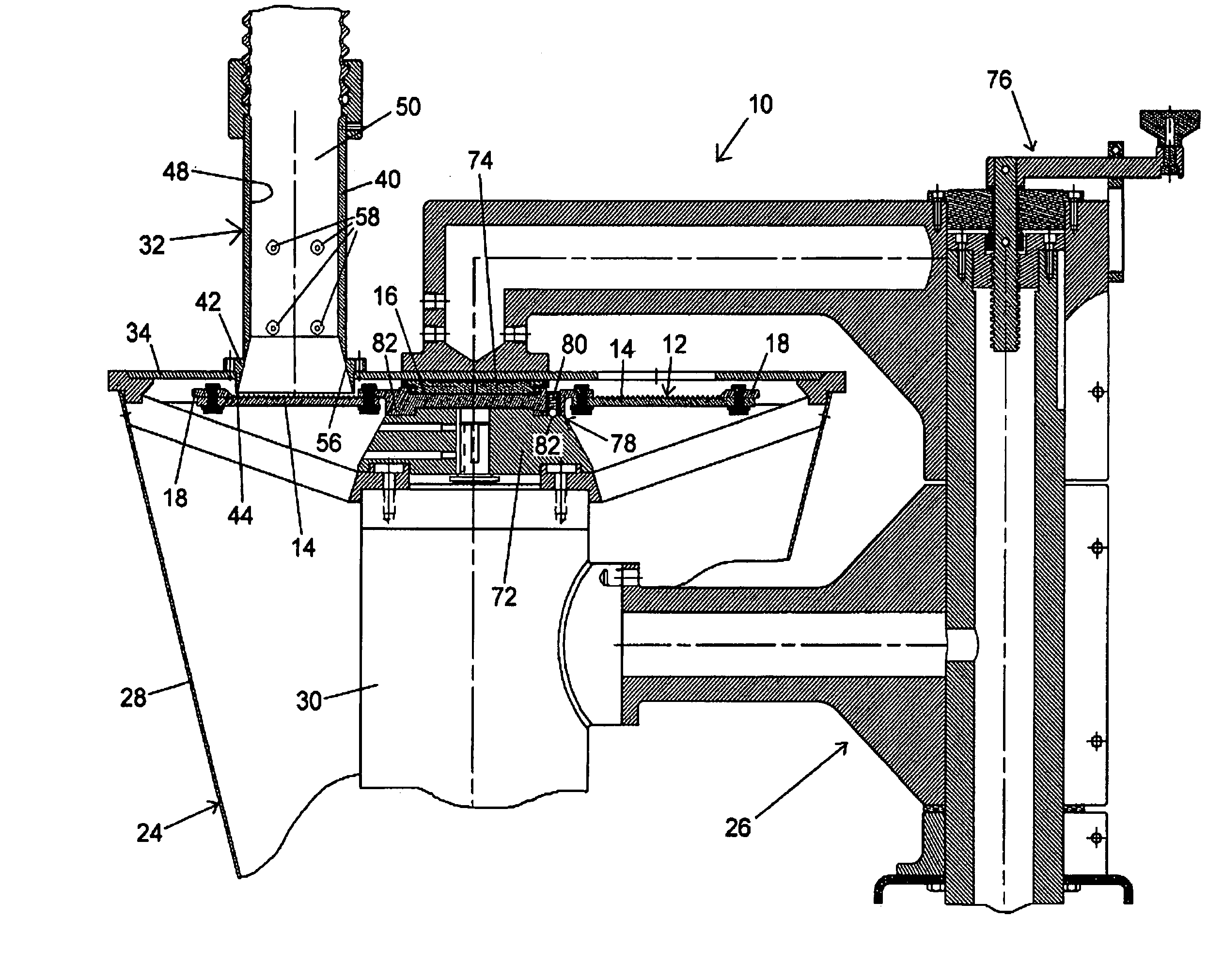

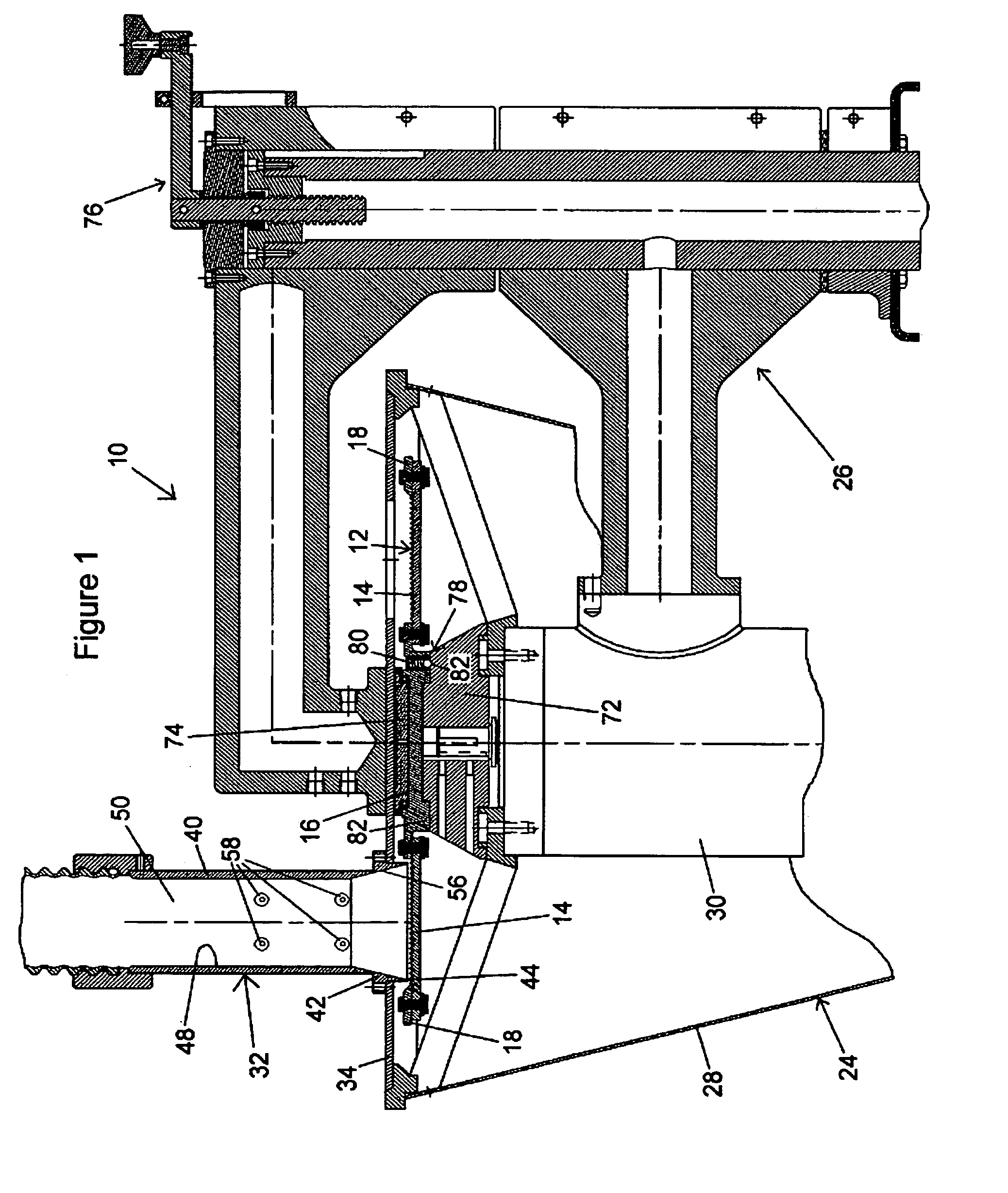

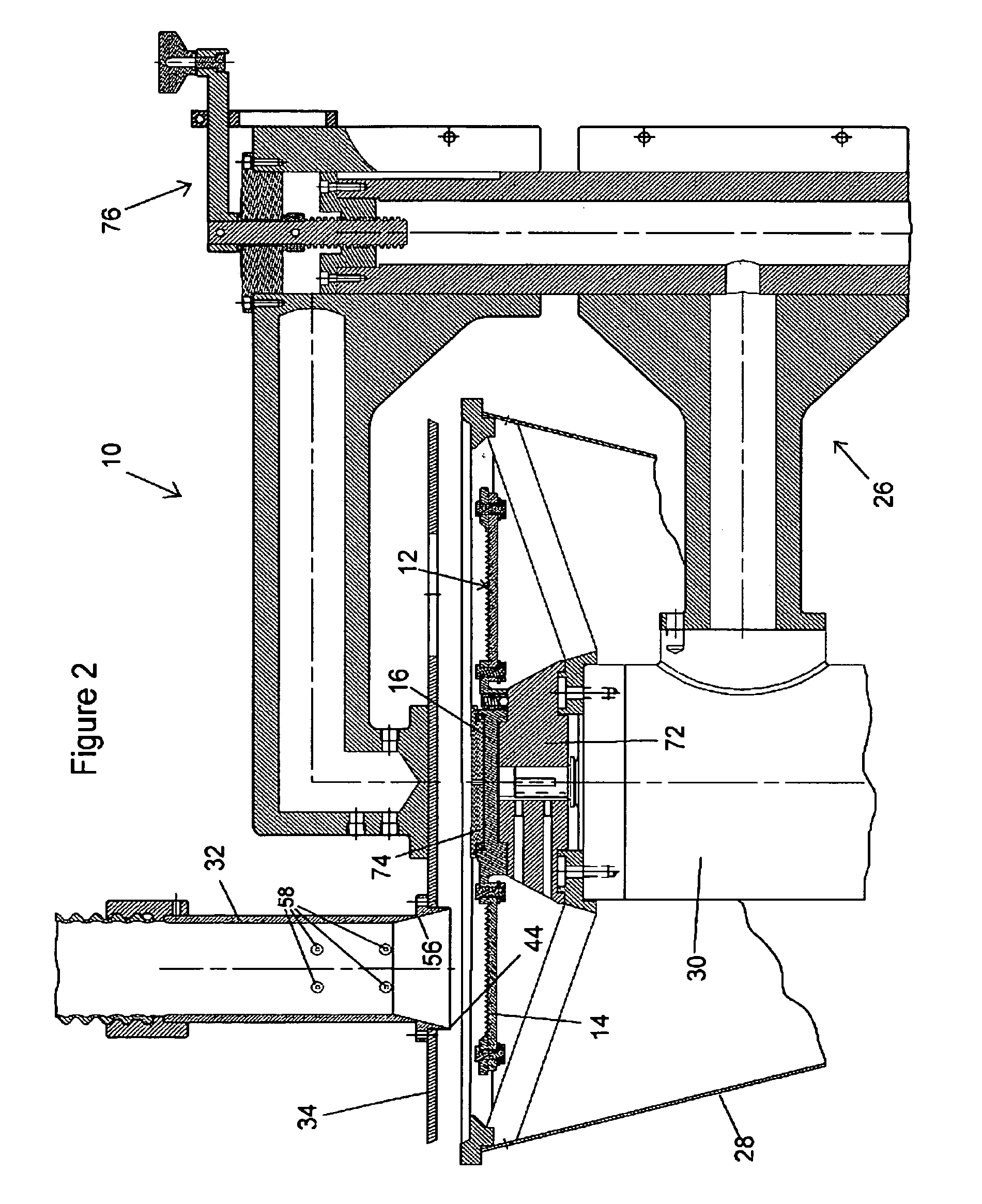

Apparatus for cutting food product

InactiveUS7000518B2Improve consistencyUniform thicknessFeeding devicesTurning equipmentChipped potatoesMechanical engineering

An apparatus for cutting food product so that the product is properly oriented and stabilized before and throughout the cutting operation to produce a sliced product of uniform thickness, even if the delivered food product varies in shape and size, such as when both round and elongate potatoes are used to produce potato chips. The apparatus includes a cutting device and housing thereabove that defines a passage with an opening in proximity to the cutting device, such that food product is delivered to the cutting device in a substantially vertical direction. To improve the stability of round product during the cutting operation, the housing has an upper portion and a flared lower portion immediately below the upper portion so that at least a portion of the opening of the passage is defined by the flared region and has a larger radius of curvature than the upper portion.

Owner:URSCHEL LAB

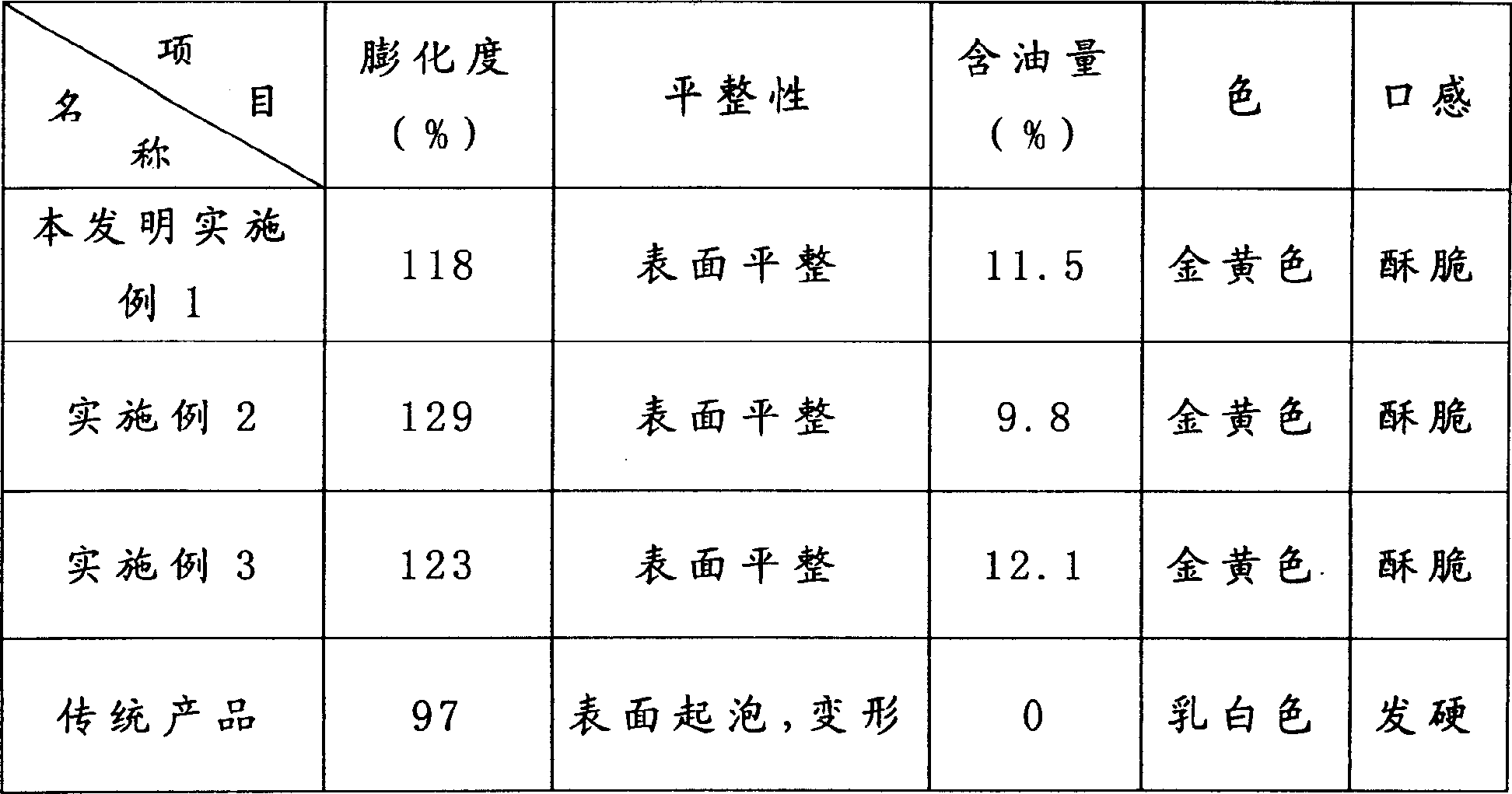

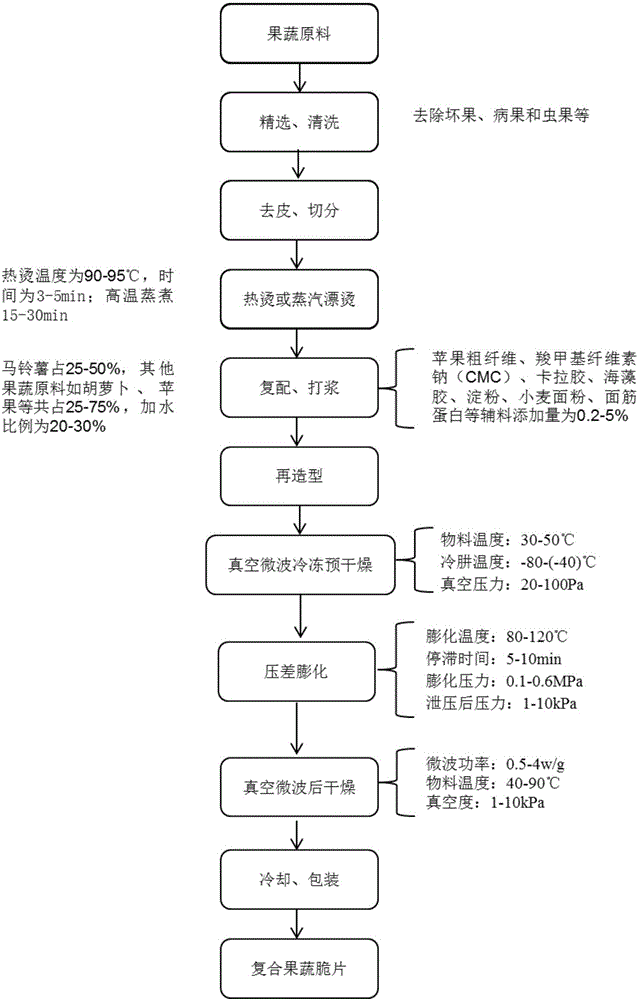

Preparation method of reshaped compound fruit and vegetable crisp chips

ActiveCN106262080AHigh nutritional valueImprove diet balanceFood dryingChipped potatoesPressure difference

The invention discloses a preparation method of reshaped compound fruit and vegetable crisp chips, comprising the following steps: pretreating multiple fruit and vegetable raw materials, mixing with auxiliary materials and pulping to obtain compound fruit and vegetable pulp; reshaping the compound fruit and vegetable pulp to form compound fruit and vegetable chips; carrying out vacuum microwave freeze predrying on the compound fruit and vegetable chips to a semidry state, and carrying out pressure differential bulking treatment on the semidry compound fruit and vegetable chips; and carrying out vacuum microwave drying on the compound fruit and vegetable chips after pressure differential bulking to obtain compound fruit and vegetable crisp chips. The method disclosed by the invention adopts a vacuum microwave freeze predrying, pressure differential bulking and vacuum microwave combined technology and a raw material compounding technology, improves the bulking degree, crispness and other qualities by adding auxiliary materials, develops non-fried reshaped compound fruit and vegetable crisp chips which are green, safe, nutrition balanced and convenient, solves the problems of unbalanced nutrition and high calories of traditional potato chips, apple flakes and other fruit and vegetable crisp chips with single raw materials, and simultaneously solves the problems of low bulking degree, relatively low crispness and the like of the traditional pressure differential bulked fruit and vegetable crisp chips.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

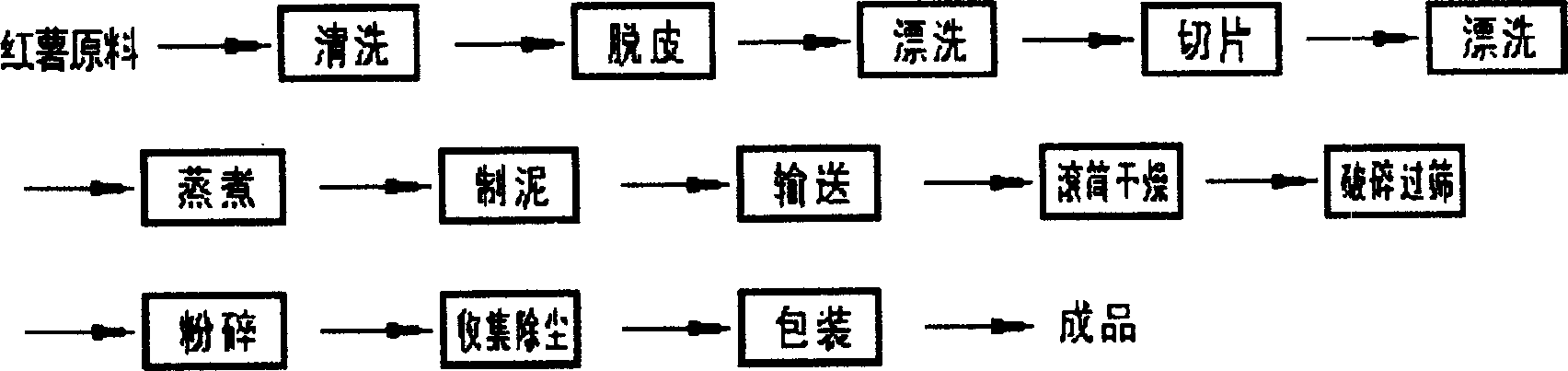

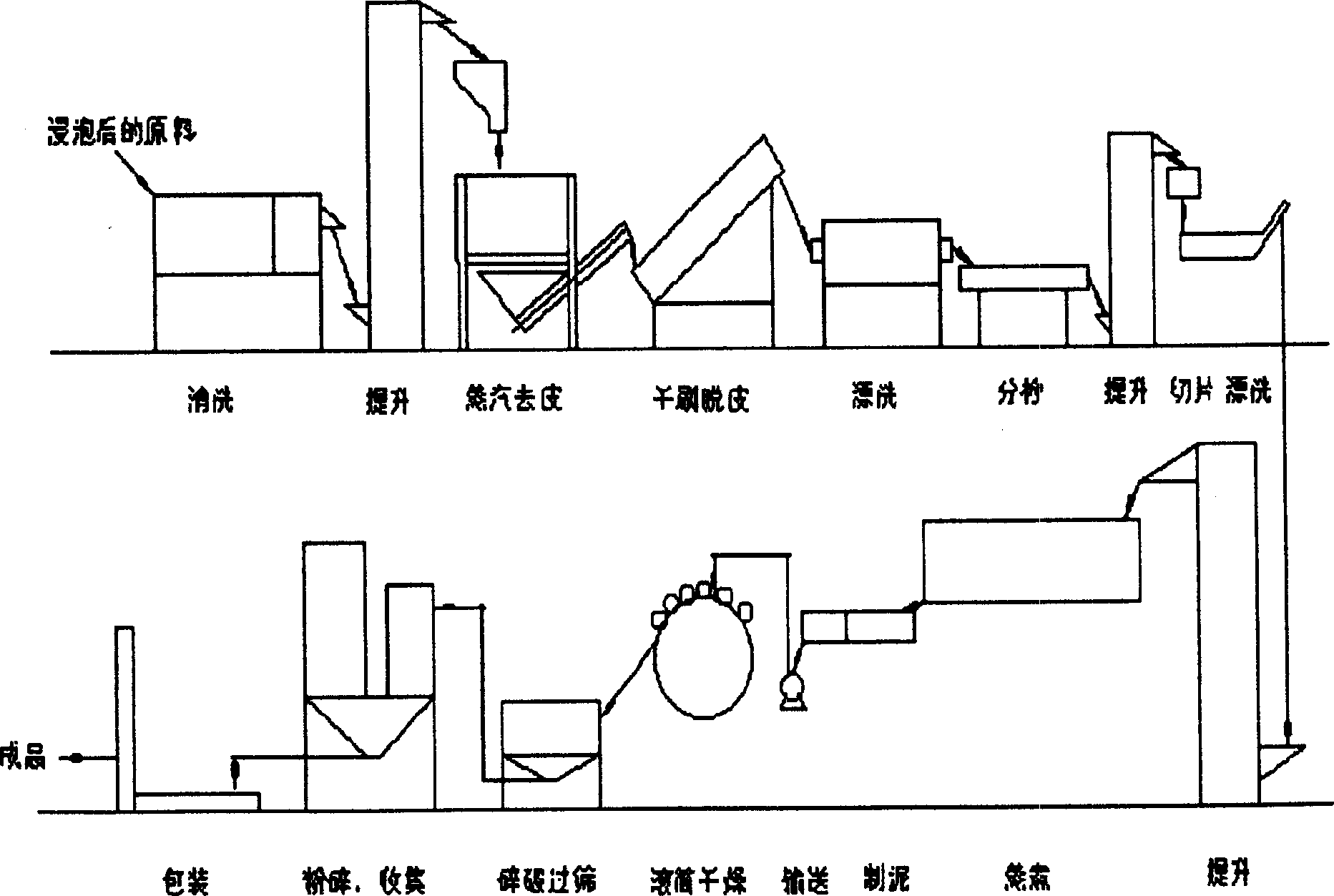

Processing method of sweet potato whole powder

InactiveCN1669470AAvoid breakingRealize continuous productionFood preparationChipped potatoesChemistry

The invention discloses the processing method of sweet potato whole powder comprising the steps of, (1) cleaning and removing impurities, selecting potato blocks and cleaning, (2) peeling, removing cuticular layer of the potato blocks, (3) slicing the potato into chips or French fries, (4) boiling and cooking, (5) squeezing the potato chips into pasty state, (6) drying the pasty potato in cylinder-shaped drier, finally disintegrating into 40-100 mesh and sacking.

Owner:何贤用

Processing method of oil-free fresh potato flakes

The invention relates to a method for processing oil-free fresh-cut potato chips; the method is as follows; the potato chips treated with cold bleaching are subject to continuous high temperature steaming to dehydrate and fully cook the surface, the well cooked oil-free potato chips are sent into a seasoning machine and blended with seasoning dry powder, the potato chips with even seasoning are processed with crisp savory baking on a continuous crisp savory baking device and no edible oil is used in the whole processing procedure; the shape of the fresh-cut potato chip is a thick or thin corrugated sheet shape with the thickness from 1.2mm to 1.8mm, the potato chip is steamed in a continuous high temperature steaming machine with the temperature from 30 DEG C to 100 DEG C for 5-8 minutes; the produced oil-free potato chip not only has the flavor of fried or baked potato chips, but also protects the original fragrance of potatoes to the utmost extent; the potato chip well preserves nutritive ingredients, has crisp and savory taste, does not use any additive, and is safe for eating and suitable for industrial production by adopting flow operation and high automation degree.

Owner:李盛泉

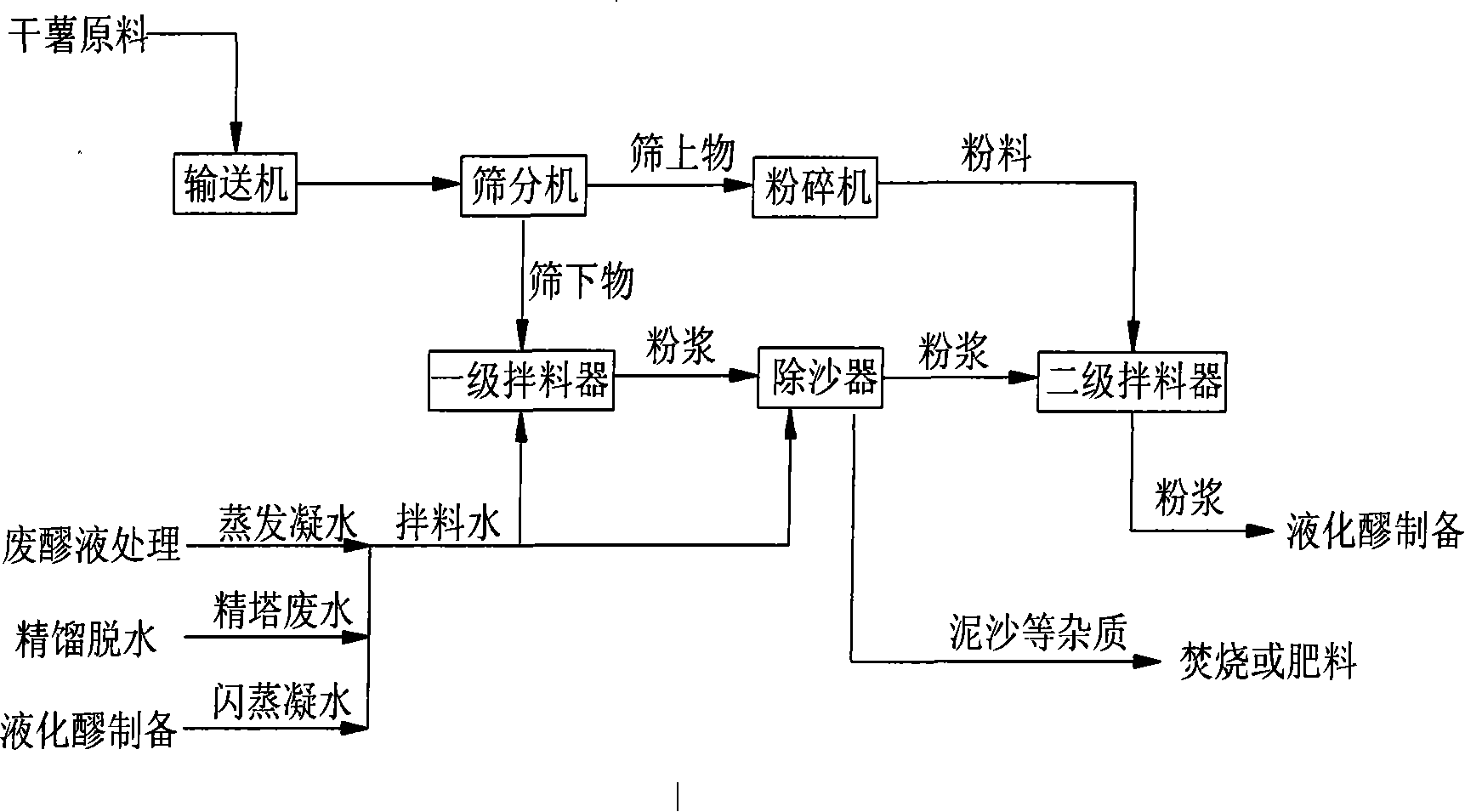

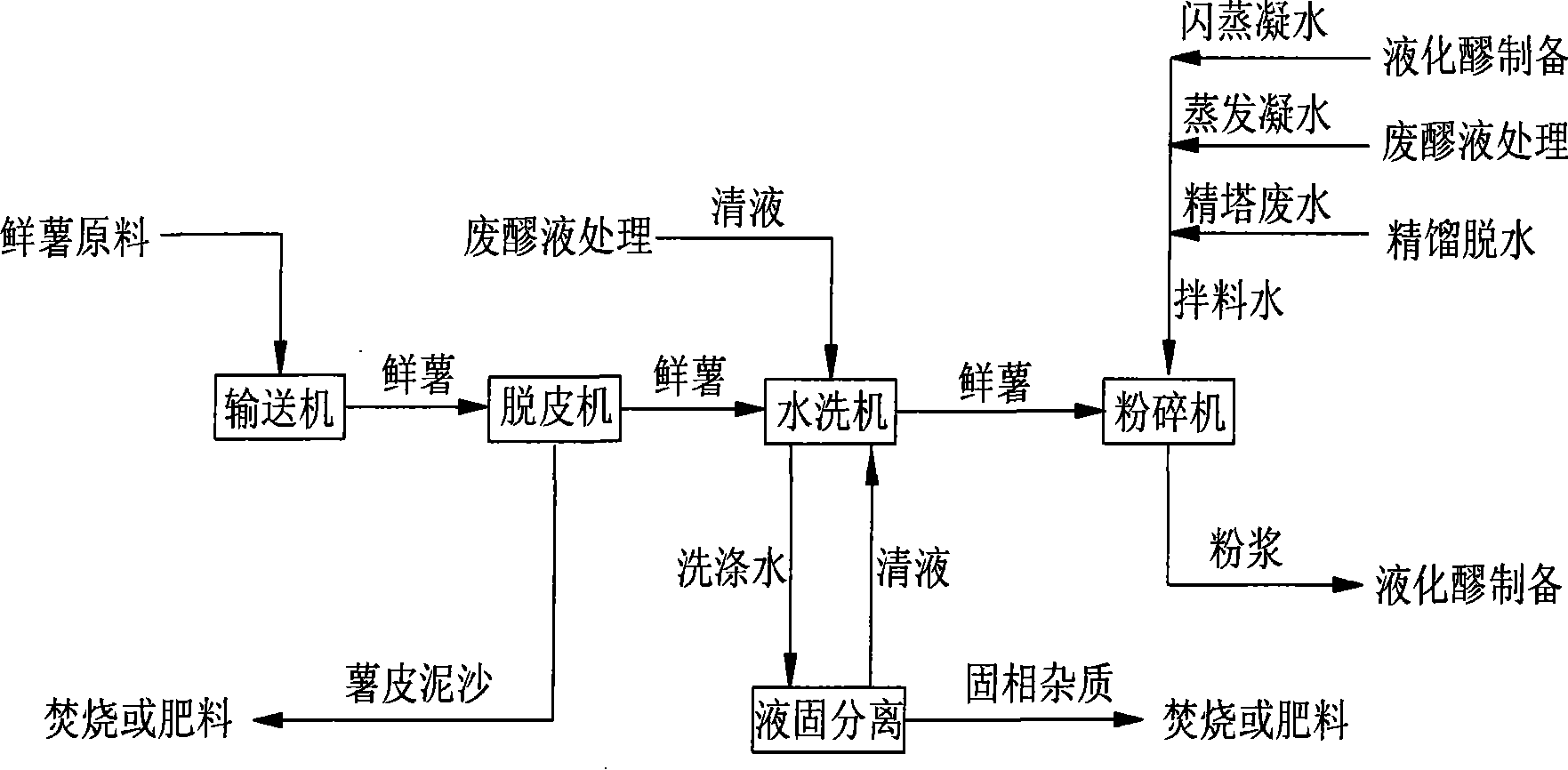

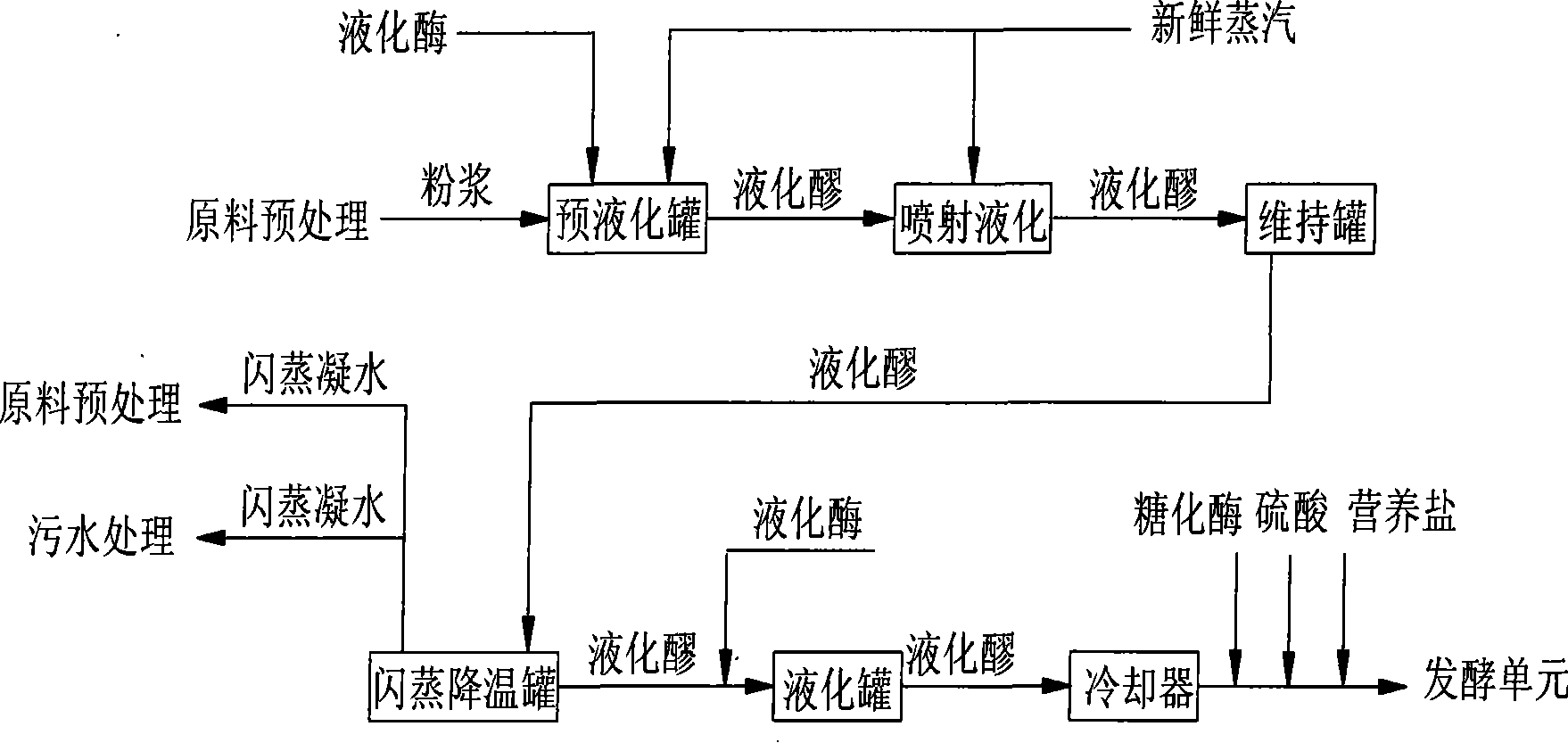

Novel method for producing ethanol with potato raw material

InactiveCN101245354AEfficient removalAchieve fermentationBiofuelsFermentationAlcohol productionEvaporation

The invention relates to a new method for producing alcohol by using potato raw material, which is mainly characterized in that: the pretreatment process of the raw materials of the dry potato chips adopts the two-level pulp-making production technique, thin pulp with a relatively low viscosity obtained by the level one material stirring and pulp making undergoes sand removing operation process, the thin pulp is subject to the secondary material stirring and pulp making to obtain a thicker powder pulp; a washing water mixture containing potato skins and sands which is drained from a fresh potato raw material water washing machine is separated by a liquid-solid separation device, the obtained clean liquid is returned to the water washing machine for continuous circulating usage; the washing water with the alcohol degree of 5 to 12 percent which is drained from a tower kettle of a CO2 washing tower is arranged to a rectification dehydration unit together with fermented mash after adding base solution, so as to ensure the acid value and the oxidation time of the produced alcohol to be qualified; a part of the clean liquid which is drained when the waste mash of the crude tower passes through the solid-liquid separation device is directly sent to a fresh potato pretreatment unit as the supplementary water of the washing water of the water washing machine for washing the cassava, thus reducing the production load of the evaporation and the concentration of the clean liquid, and the supplementary water of the cleaning water of the water washing machine does not consume other water.

Owner:TIANJIN UNIV

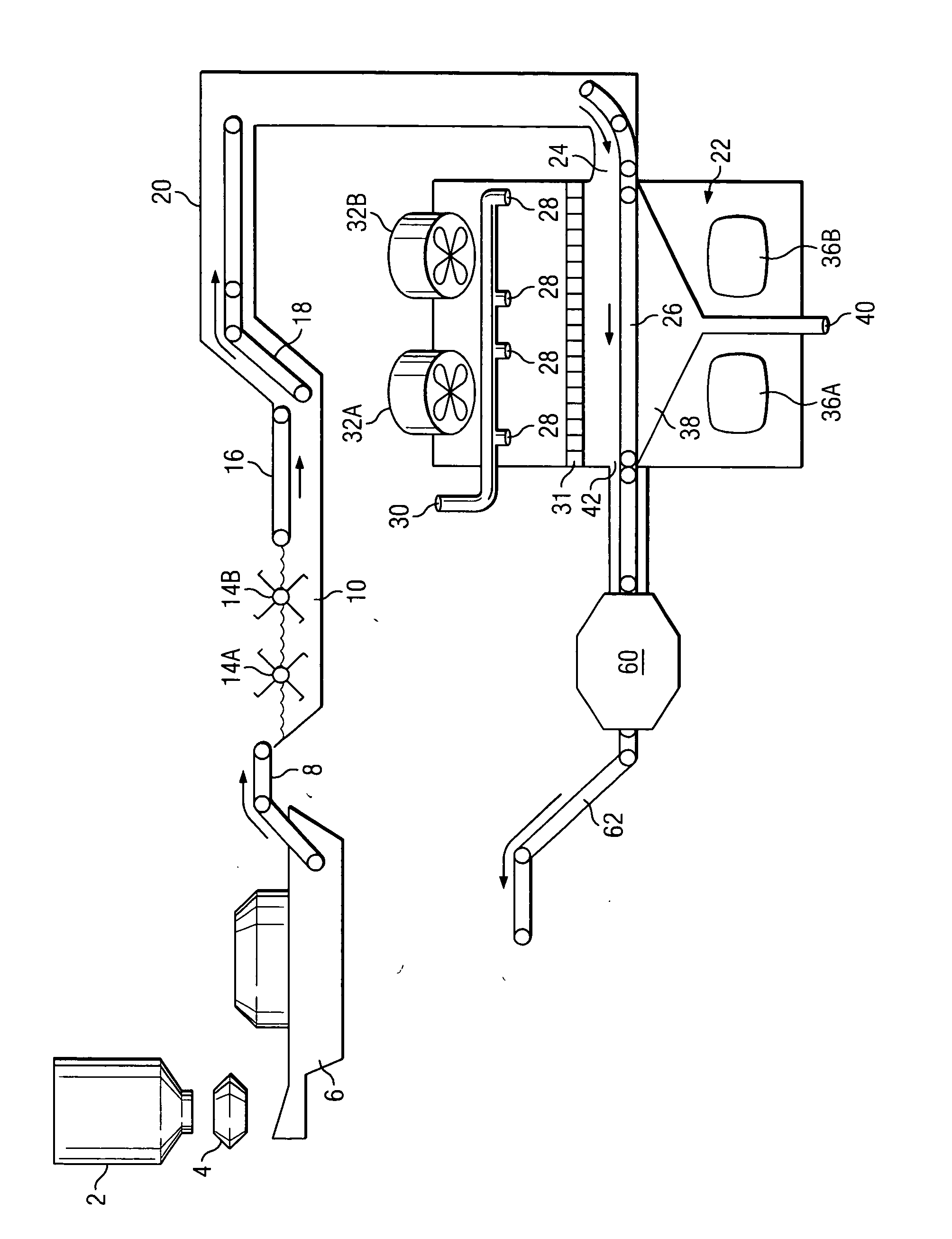

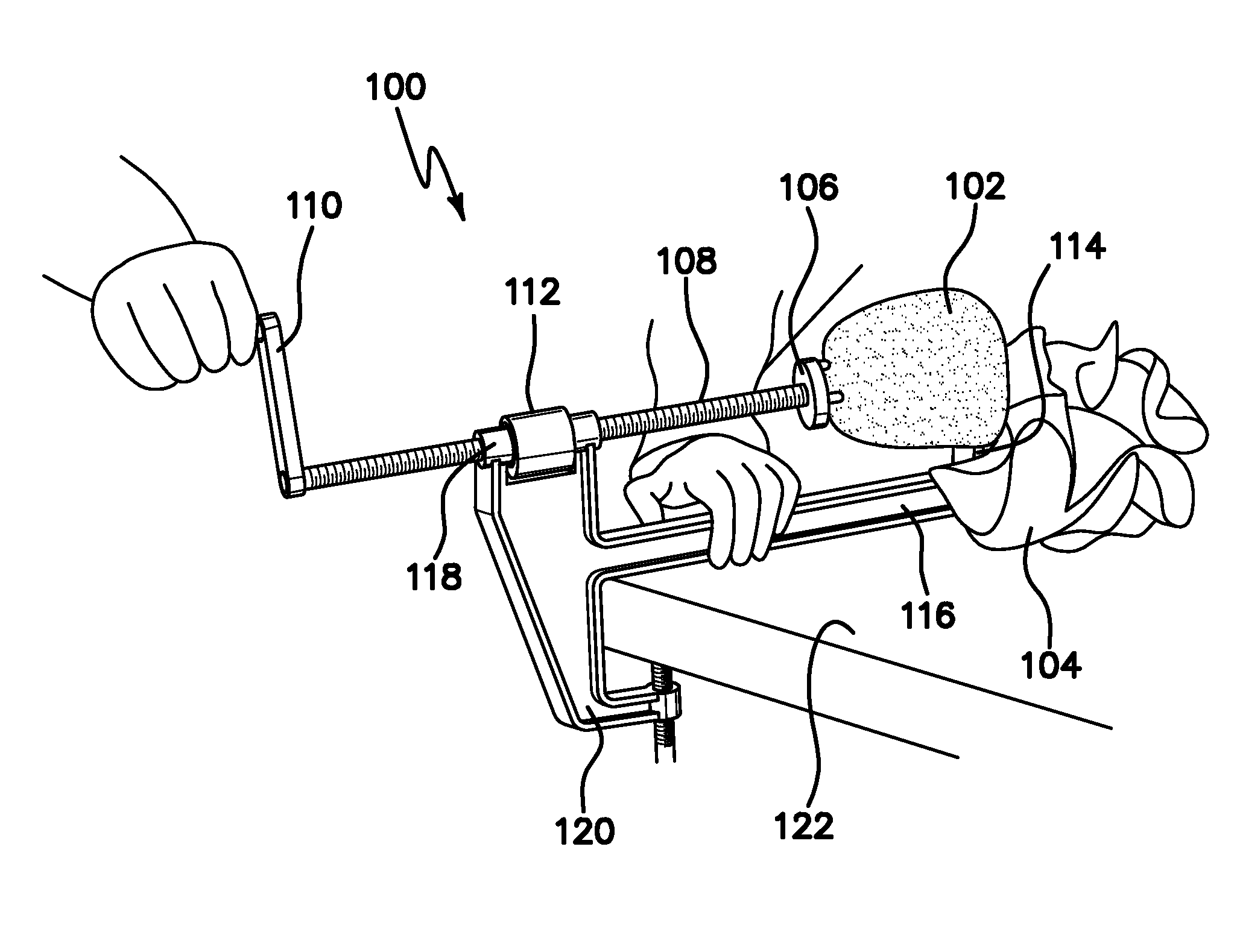

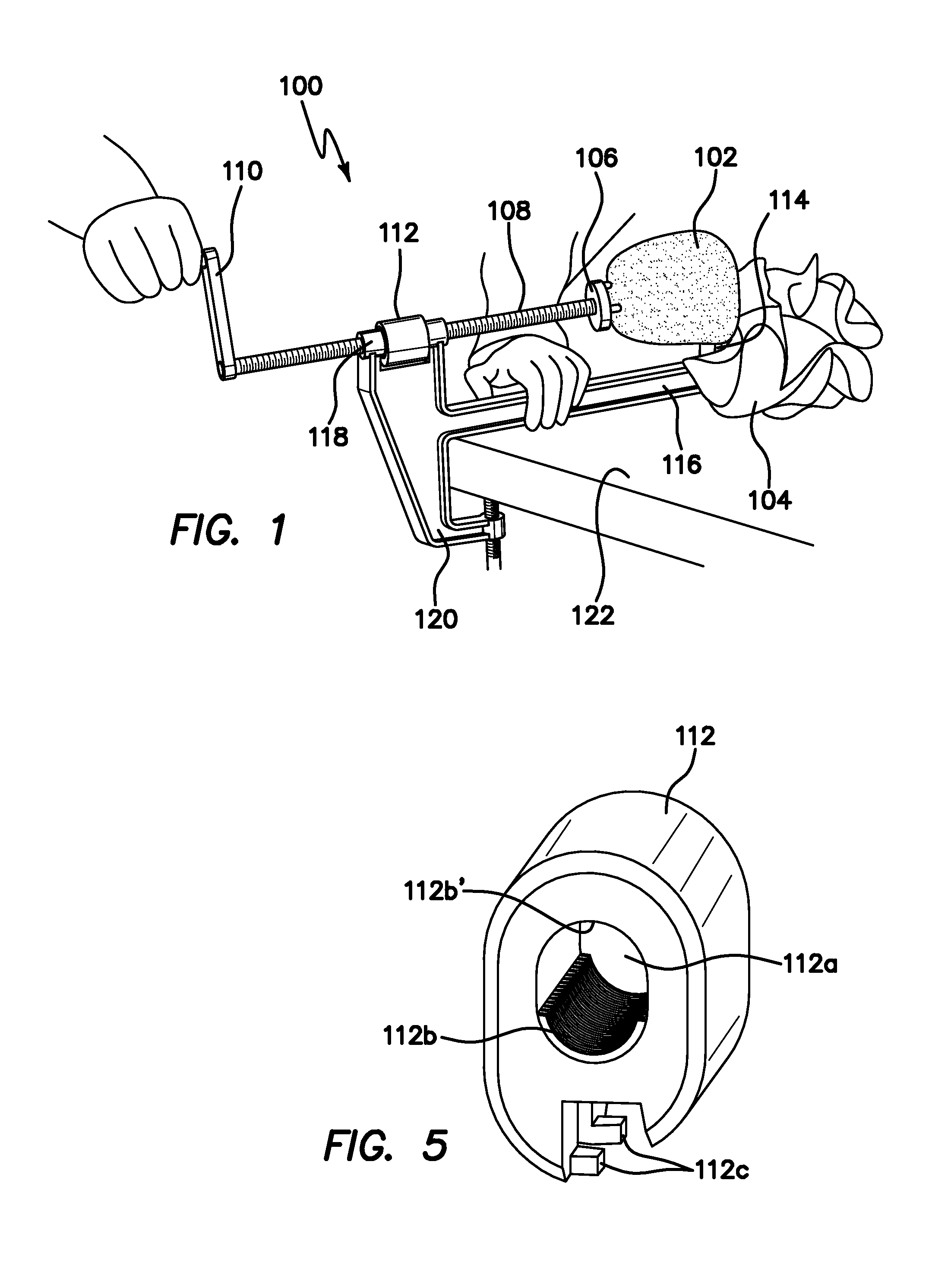

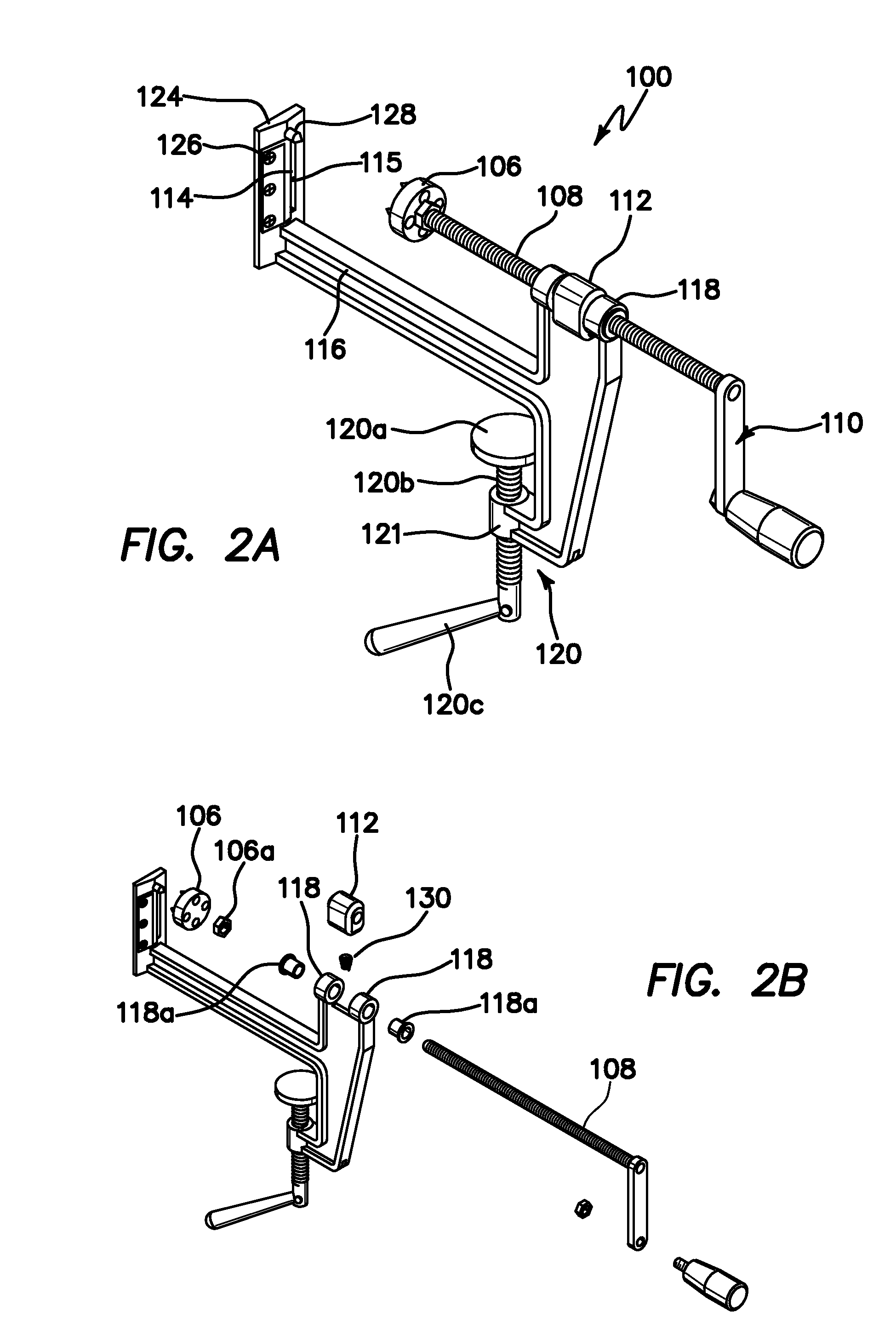

Apparatus and method for cutting produce in a continuous curl for the purpose of making a curly spiraled potato chip

InactiveUS20080314262A1Uniform thicknessSimpler to useFood shapingVegetable peelingChipped potatoesEngineering

An apparatus for manufacturing a curly sliced potato chip includes: a base frame; a cutting blade coupled to the base frame; and a rotatable threaded rod having a predetermined threaded pitch to which rod the potato is mounted. The rod is turned to rotate the potato while it is in a cutting position and to displace it toward or away from the cutting blade. A quick release engaging member has a threaded portion with a pitch compatible with the pitch of the rod. The member is fixed relative to the base frame and is selectively coupled with the threaded rod to selectively drive the potato mounted on the rod toward or away from the cutting blade as the rod is rotated. The potato is displaced toward or away the cutting blade at a linear displacement rate determined by the pitch of the threaded rod.

Owner:STARK STEVEN

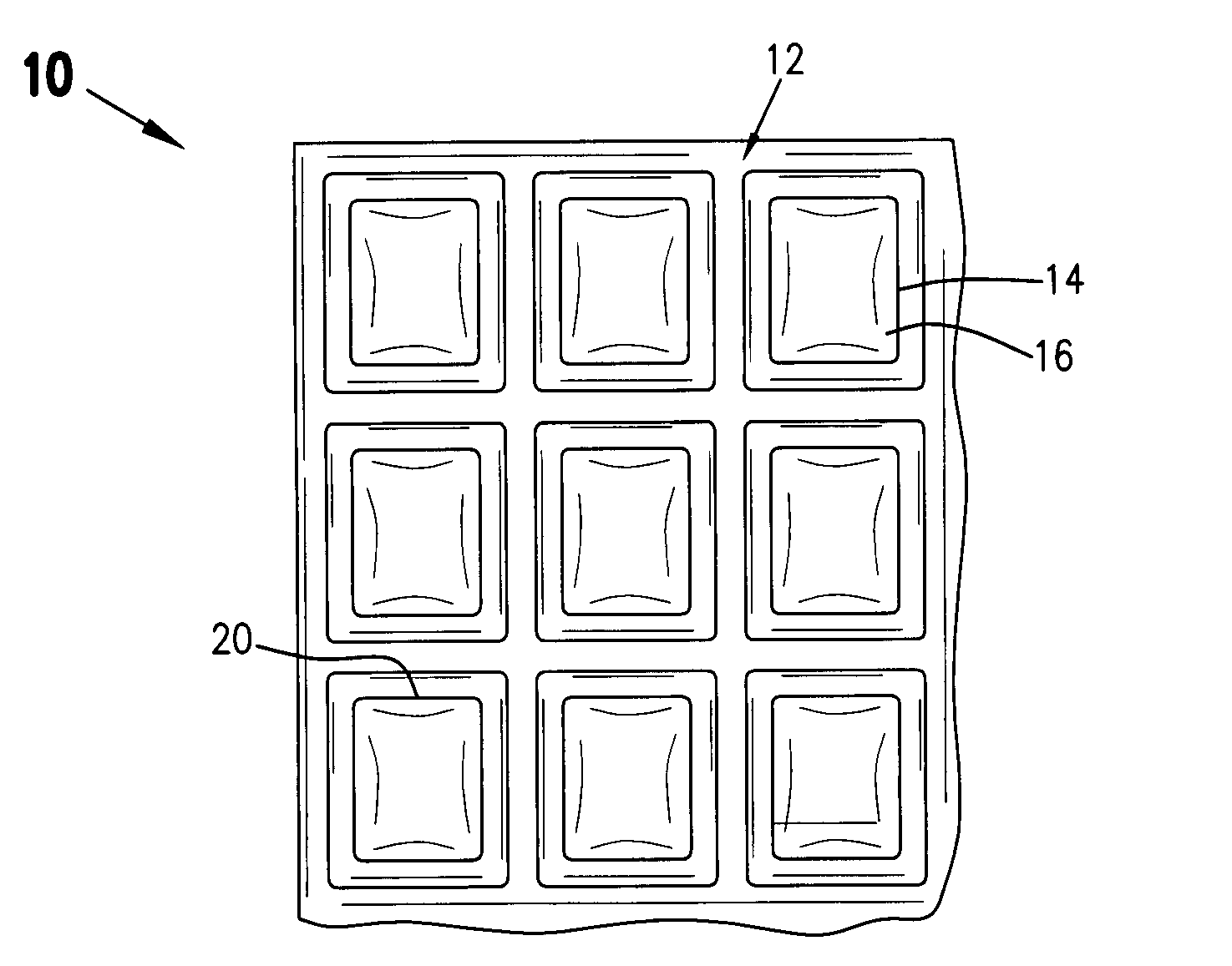

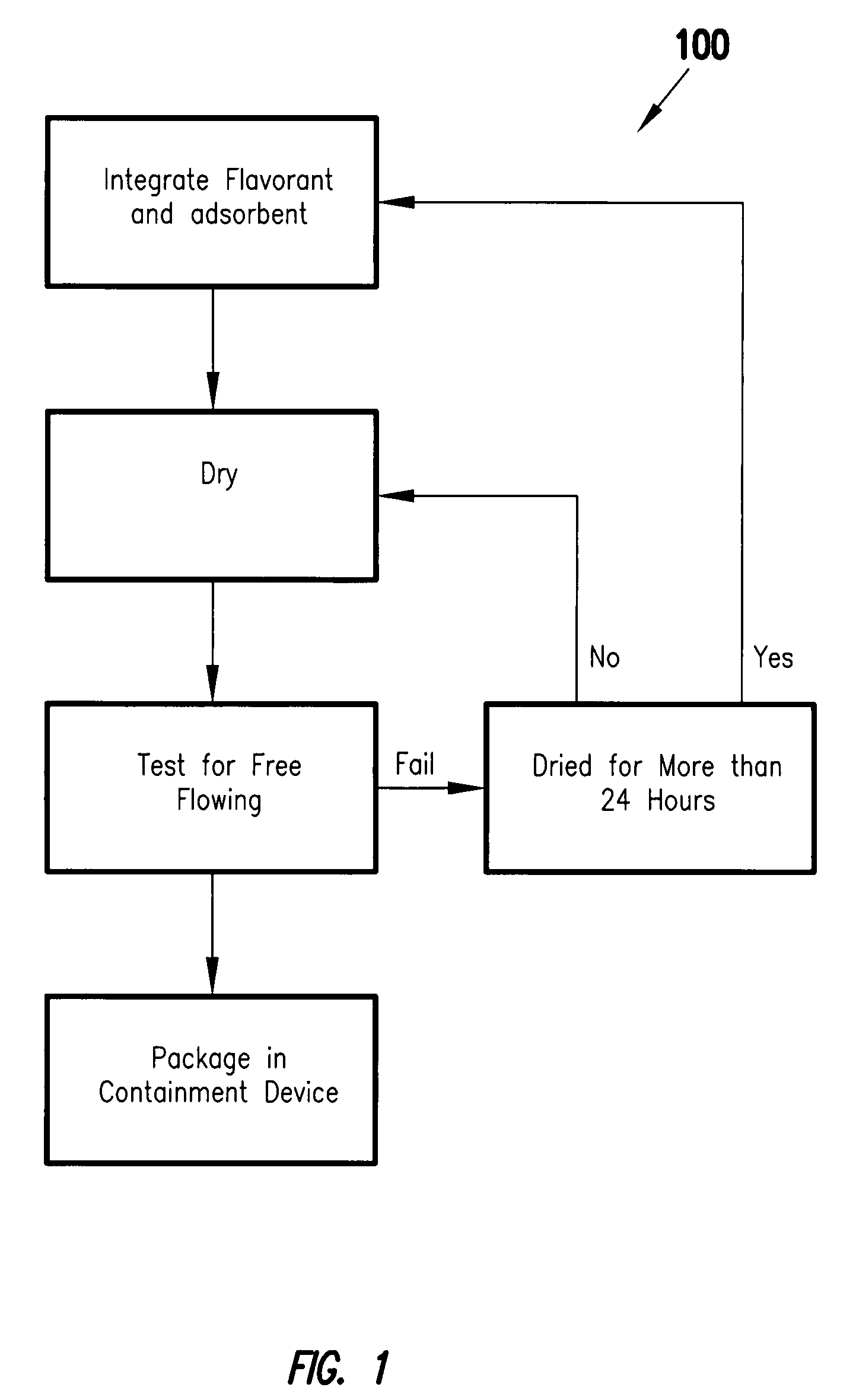

Flavor emitting compositions, devices and packaged food products therewith

Instead of direct introduction into recipes of food products, for example, flavorant emitting compositions including at least one flavorant are in combination with a stabilizer, e.g., adsorbent or absorbent, and indirectly added to the food product via a closed environment of a package by readily releasing the flavorant from the substrate. When a device, such as a porous sachet comprising the compositions is placed in a closed environment of a food package, for example, a constant fresh aroma and / or taste is delivered to the closed atmosphere of the packaged foodstuff and deposited onto the foodstuff per se for preserving and maintaining product freshness for enhanced consumer acceptance. Representative packaged products would include snack foods, such as barbecue chips, potato chips, bakery products, to name but a few.

Owner:MULTISORB TECH INC

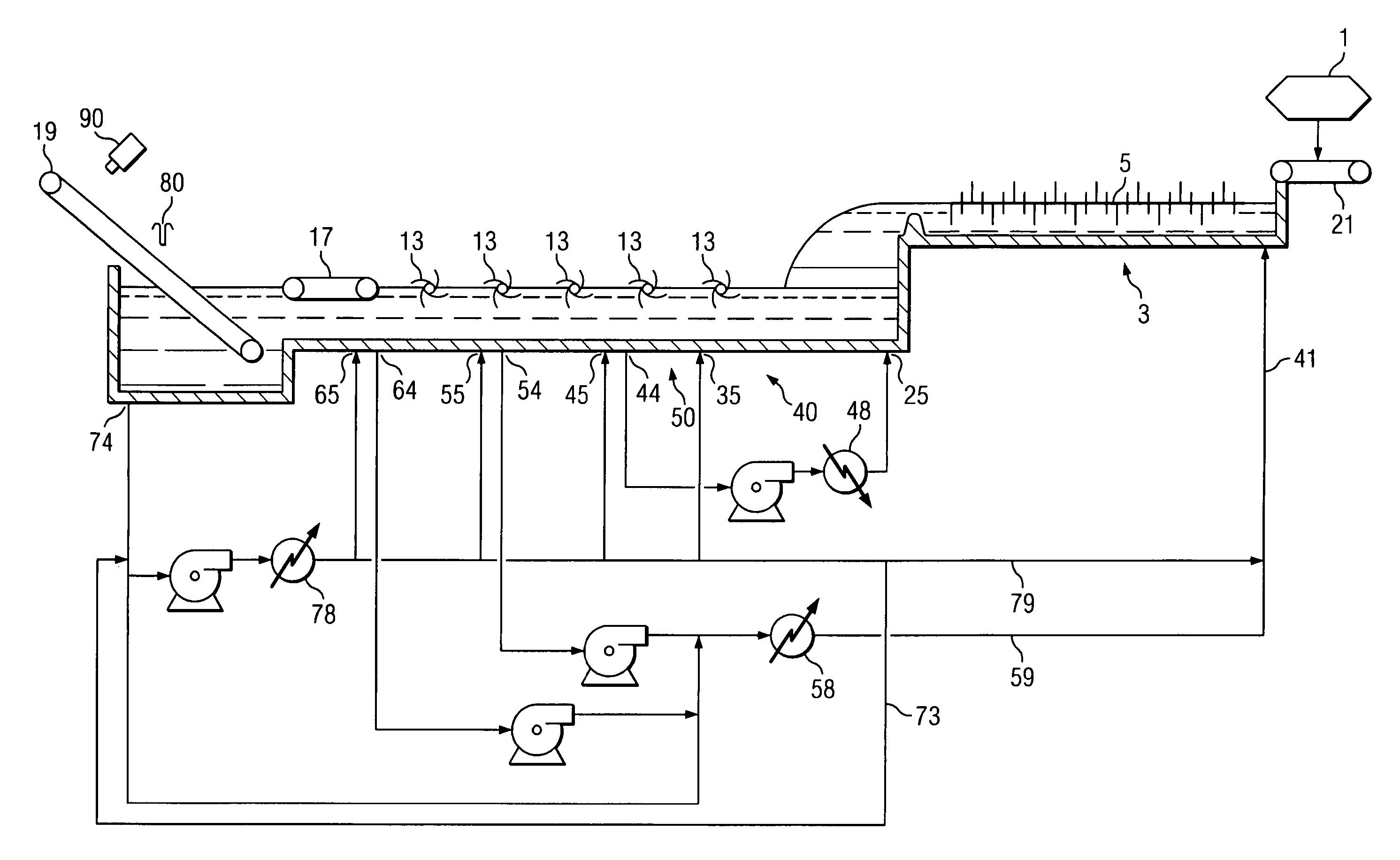

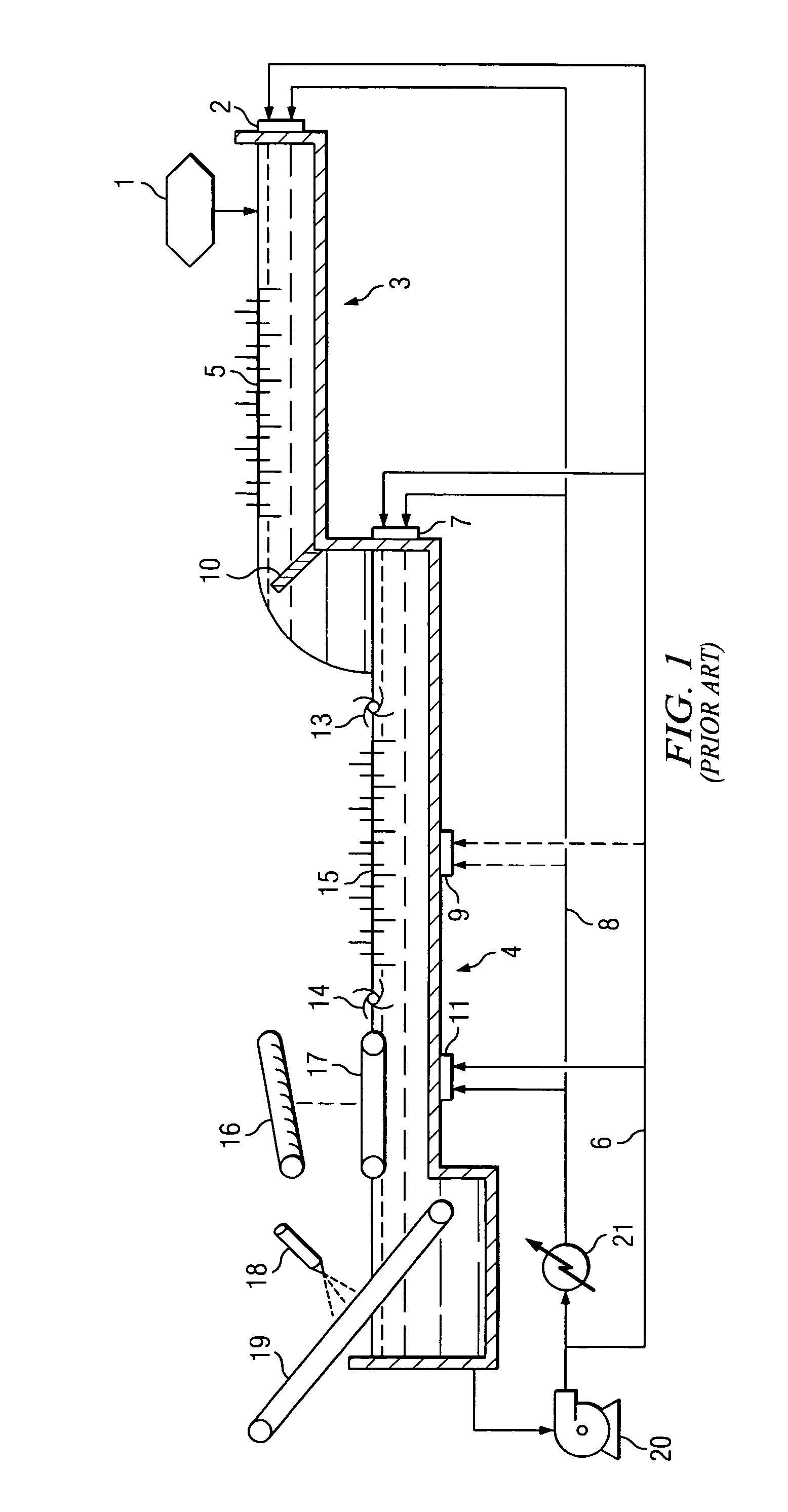

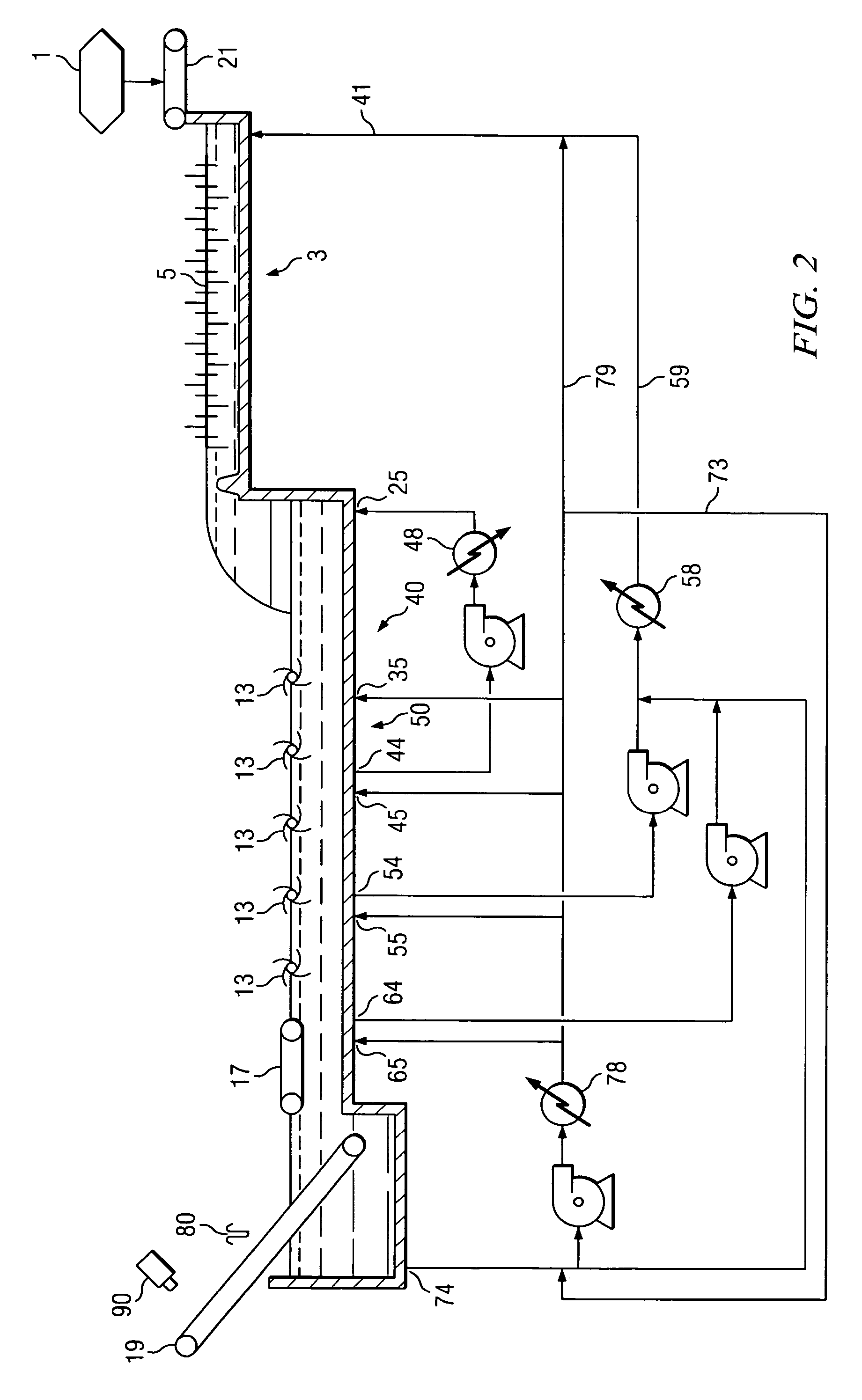

Method for continuously making kettle style potato chips

ActiveUS7303777B2Process economyDesirable tasteTea substituesTea alkaloid content reductionChipped potatoesTime profile

A continuous cooking process is disclosed that mimics the U-shaped temperature-time profile produced by a batch kettle fried potato chip operation. Potato slices are placed into hot oil in a flume portion of a continuous fryer. The potato slices exit the flume into an upstream portion of the fryer. Cooling oil is injected to the upstream portion of the continuous fryer to continuously achieve the trough portion of the U-shaped temperature-time profile. The potato slices are then further fried in the downstream portion of the fryer in a region having an increased hot oil temperature. The increased hot oil temperature occurs by injecting hot oil into the downstream portion. The temperature of injected hot oil can be controlled by the exit moisture content of the potato slices.

Owner:FRITO LAY NORTH AMERICA INC

Production of Sheeted Fruit and Vegetable Snacks

InactiveUS20080182004A1Increase contentGreat tasteDough treatmentFood preparationChipped potatoesAdditive ingredient

The present invention discloses formulations for sheeted, baked fruit and vegetable chips that have a light, crispy texture similar to a potato chip. The ingredients are combined with water and oil to make a dough, which is then sheeted and cut into pieces. The pieces are baked to produce vegetable and fruit snack chips.

Owner:FRITO LAY NORTH AMERICA INC

Purple sweet potato chips for relieving restlessness and nourishing kidney and preparation method thereof

InactiveCN104366369AFull of nutritionSimple processFood ingredient functionsFood preparationThirstBearded tooth

The invention discloses purple sweet potato chips for relieving restlessness and nourishing kidney. The purple sweet potato chips disclosed by the invention are prepared from the following raw materials in parts by weight: 250-260 parts of purple sweet potatoes, 17-18 parts of black sesame, 20-25 parts of caraway, 7-8 parts of nutrition additives, 6-7 parts of banana pulp, 7-9 parts of black chicken bones, 10-11 parts of passion flower, 4-5 parts of black soybean meal, 14-16 parts of peanut sauce, 5-6 parts of mint oil, 8-11 parts of hawthorn fruits, 8-9 parts of hericium erinaceus, 4-5 parts of pork skin, 1.6-2.2 parts of diospyros lotus, 1.9-2.3 parts of tuber fleeceflower stem, 1.5-2.1 parts of gynostemma pentaphylla, 1.5-2 parts of rehmannia flower, 1.3-2 parts of mint, and 1.6-2.1 parts of eupatorium. The purple sweet potato chips disclosed by the invention are simple in process and low in production cost, and is endowed with rich nutrition of the purple sweet potatoes; and furthermore, the added food and medicinal materials including black sesame, hericium erinaceus, rehmannia flower, diospyros lotus and the like are high in pharmacological effect, moderate in property and flavour and rich in nutrition, and therefore, the purple sweet potato chips disclosed by the invention can be used for improving immunity, have the effects of tonifying spleen and qi, nourishing kidney, quenching thirst, clearing heat, relieving restlessness and the like, and are the best health food suitable for people of all ages.

Owner:WUHE TONGSHIFU FOOD

Edible mushroom health food

An edible fungi health food, the finished dry matter contains 20-60% edible fungus dry powder, 20-40% flour, 20-40% bean or potato starch, and the fineness of the edible fungus dry powder is 150- 200 mesh, use 20-60% edible fungus dry powder, add 20-40% flour, 20-40% bean or potato starch, add appropriate amount of water and noodles, and make edible fungus noodles through the noodle production process; also Soda powder can be added to produce edible fungus biscuits with biscuit production process; edible mushroom potato chips can be produced with potato chip production process; by implementing the present invention, a kind of edible fungus health food that is convenient for long-term preservation is provided, so that consumers can conveniently Abundant and large intake of edible fungi can provide health benefits for the human body. At the same time, the unique taste of edible mushroom health food also enriches people's food varieties.

Owner:兴文县石海珍稀农产品开发有限责任公司

Processing technology of potato chips

InactiveCN105639537ARetain colorPreserve the flavorFood ingredient as taste affecting agentFood dryingNutritive valuesChipped potatoes

The invention discloses a processing technology of potato chips. The processing technology of the potato chips comprises the following steps of (1) preparing raw materials: cleaning potatoes; performing steam processing; performing steam peeling; mashing to form mashed potatoes;(2) taking the following raw materials in parts by weight: 80 to 100 parts of the mashed potatoes, 5 to 10 parts of carrot meal, and 1 to 3 parts of vegetable oil, adding water to mix uniformly, and preparing to form block masses; (3) cooking: cooking the prepared block masses through steam for 1 to 2 hours at the temperature of 90 to 100 DEG C, and cooling; (4) cutting into slices; (5)blanching;(6) performing heat pump drying; (7) putting the hot-air dried potato chips into a microwave oven for two-stage microwave, and reducing the water content of the potato chips to be 2 to 4 percent; (8) seasoning and packaging: conveying the microwaved potato chips into a roller seasoning machine to season the potato chips. According to theprocessing technology of the potato chips provided by the invention, the nutrient content loss is less, the nutritive value is high, the health-care effects of improving the human immunity and lowering the cholesterol are realized, and the prepared potato chips are good in crisp degree, good in taste, and long in quality guarantee period.

Owner:赵新友

Cream sweet potato chips and preparation method thereof

The invention relates to cream sweet potato chips capable of preserving sweet potato cream and having fragrant and crisp taste and a preparation method thereof. The cream sweet potato chips are prepared from the following components: 90-95% of sweet potato mud, 1-3% of cheese power, 3-5% of white granulated sugar, 0.3-0.8% of foreign wine, 0.2-0.6% of salt, 0.05-0.2% of black pepper and 0.3-0.8% of white sesame seeds. The invention can preserve the sweet potato cream and has fragrant and crisp taste; and the sweet potato, the white granulated sugar and the white sesame seeds mutually complement and promote, thereby greatly improving the condensation nutritive value of the cream sweet potato.

Owner:杭州秀山美地农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com