Processing method of sweet potato whole powder

A technology of whole sweet potato flour and processing method, applied in the application, food preparation, food science and other directions, can solve the problems of low production efficiency, different degrees of ripening of sweet potato flour, large loss of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

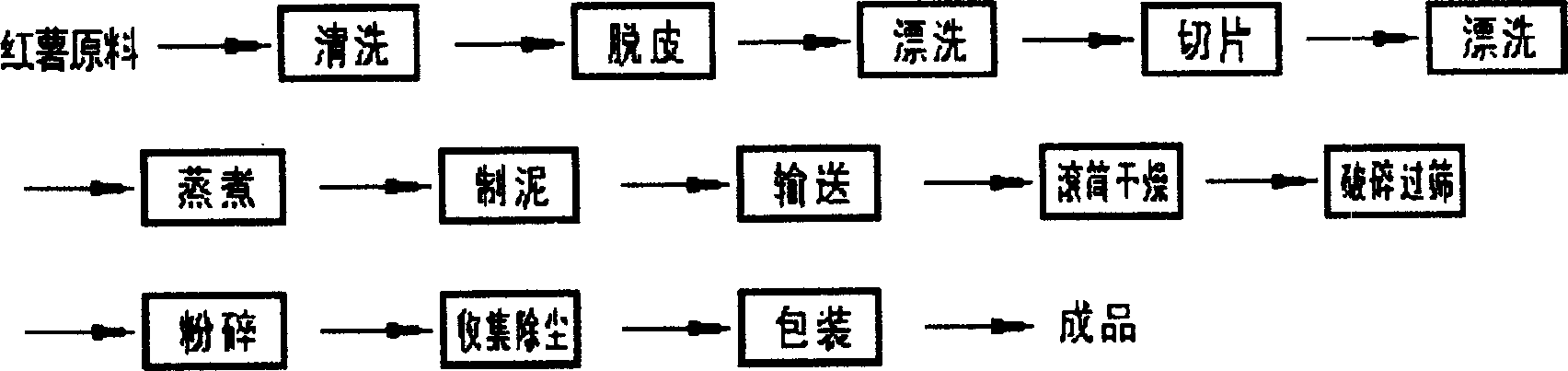

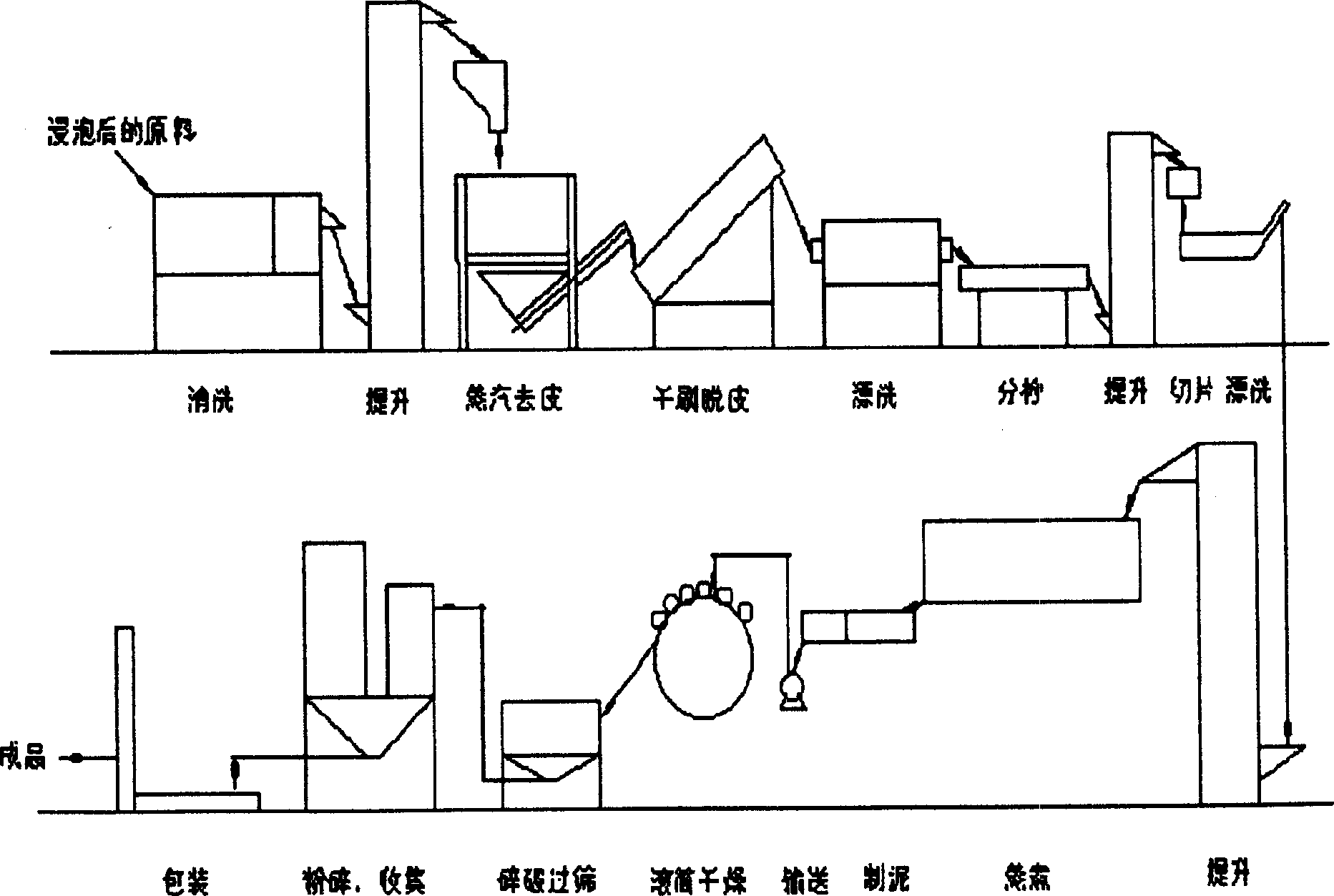

[0027] Such as figure 1 , figure 2 Shown, the present invention mainly comprises the following steps:

[0028] After the sweet potatoes are sent to the belt conveyor, a preliminary inspection is carried out on the sweet potatoes during the conveying process, and germinated, green sweet potatoes, rotten and diseased potato pieces are removed to ensure that the content of solanine in sweet potato products is controlled below 0.02%. After the initial inspection, the sweet potatoes are sent to the drum washing machine by the conveyor belt to complete the cleaning and removal of impurities.

[0029] Peeling: After the washed potato pieces are lifted by the hoist, they fall into the cooking tank through the feeding port, close the loaded cooking tank and quickly fill it with 1.5Mpa saturated water vapor, stir and mix properly, and then Instantaneously pressure-cook the cortex for a few seconds (depending on the structure of the cortex of the sweet potato), and open the cooking po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com