Patents

Literature

90 results about "French fries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

French fries, or simply fries (North American English), chips (British and Commonwealth English, Hiberno-English), finger chips (Indian English), or french-fried potatoes, are batonnet or allumette-cut deep-fried potatoes.. French fries are served hot, either soft or crispy, and are generally eaten as part of lunch or dinner or by themselves as a snack, and they commonly appear on the menus of ...

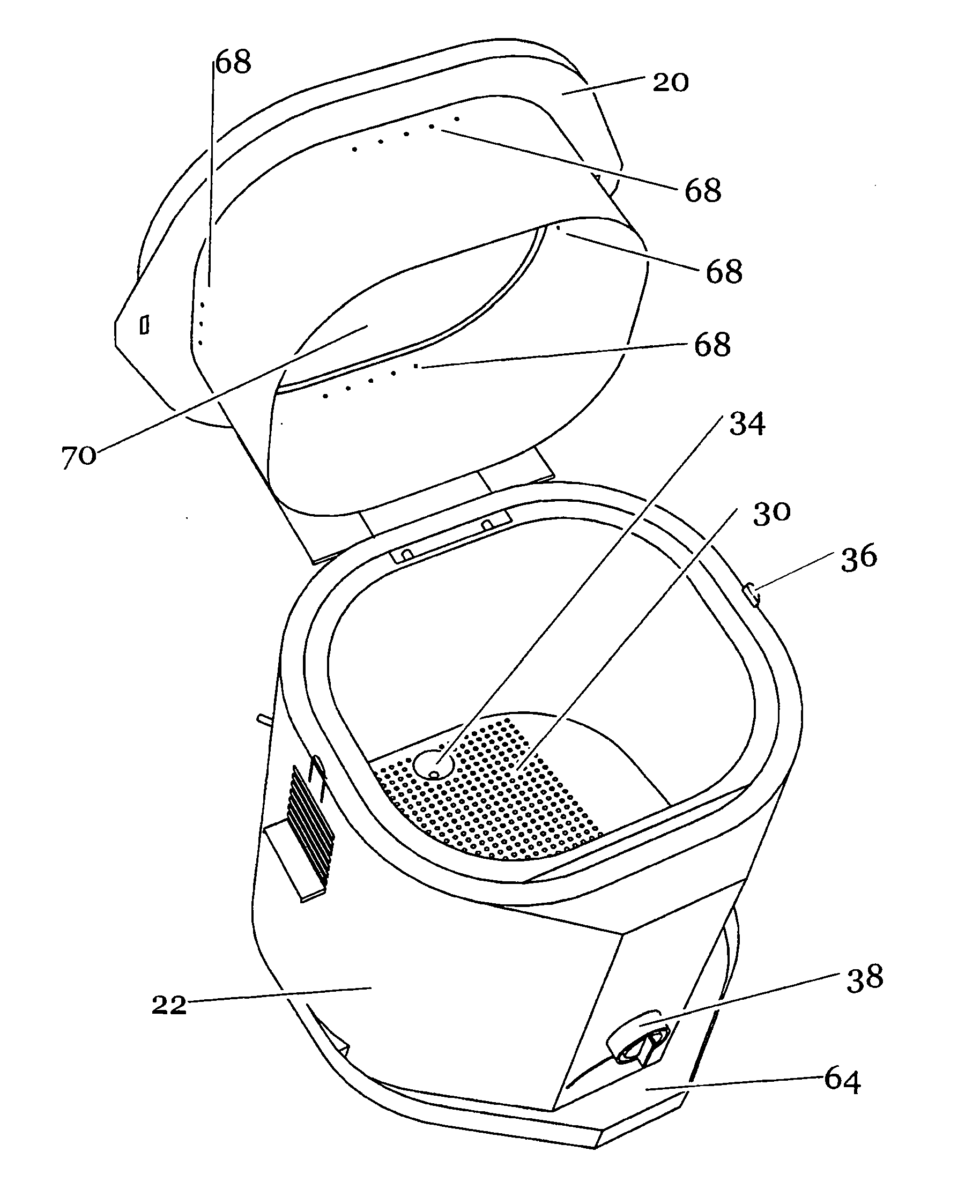

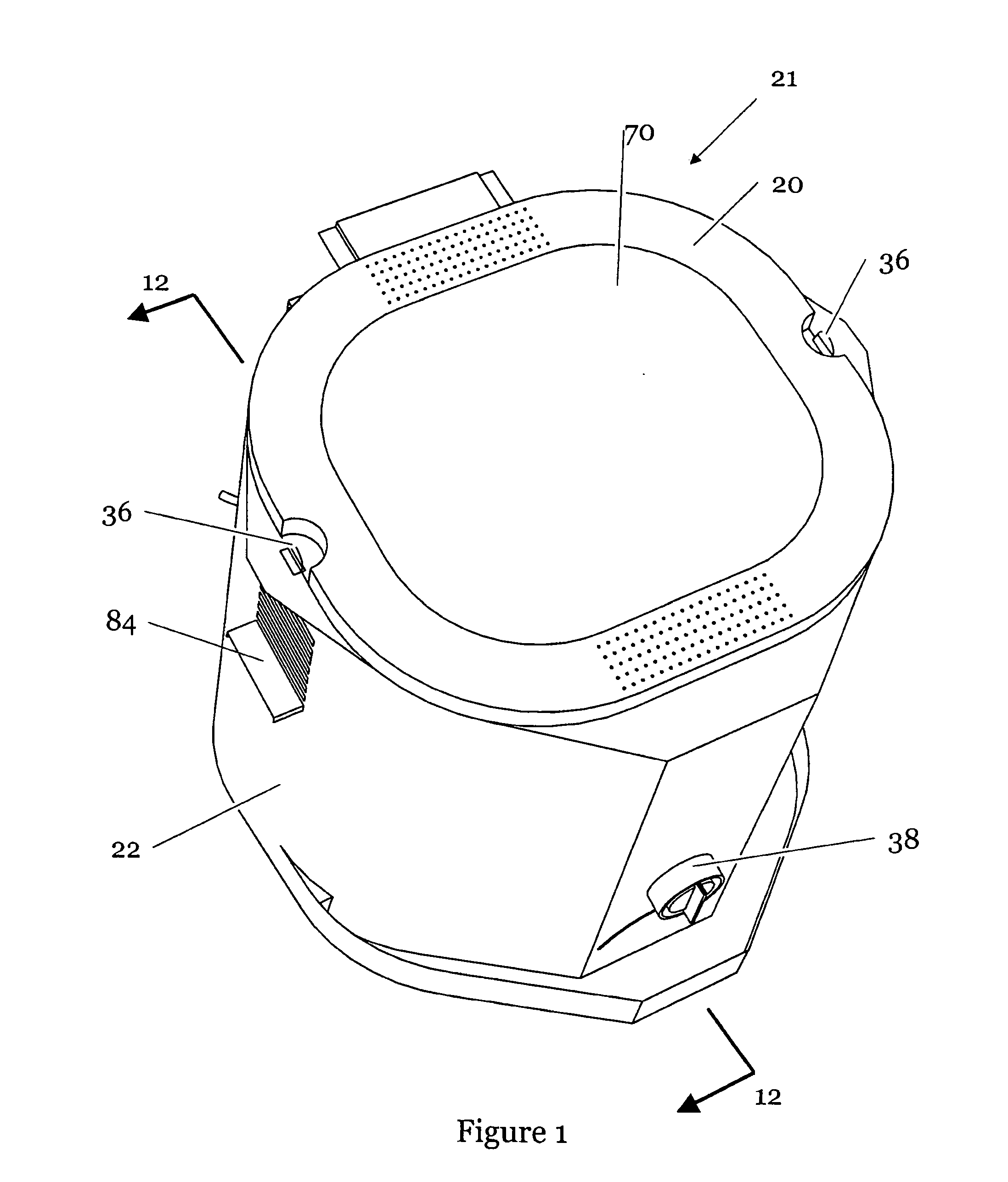

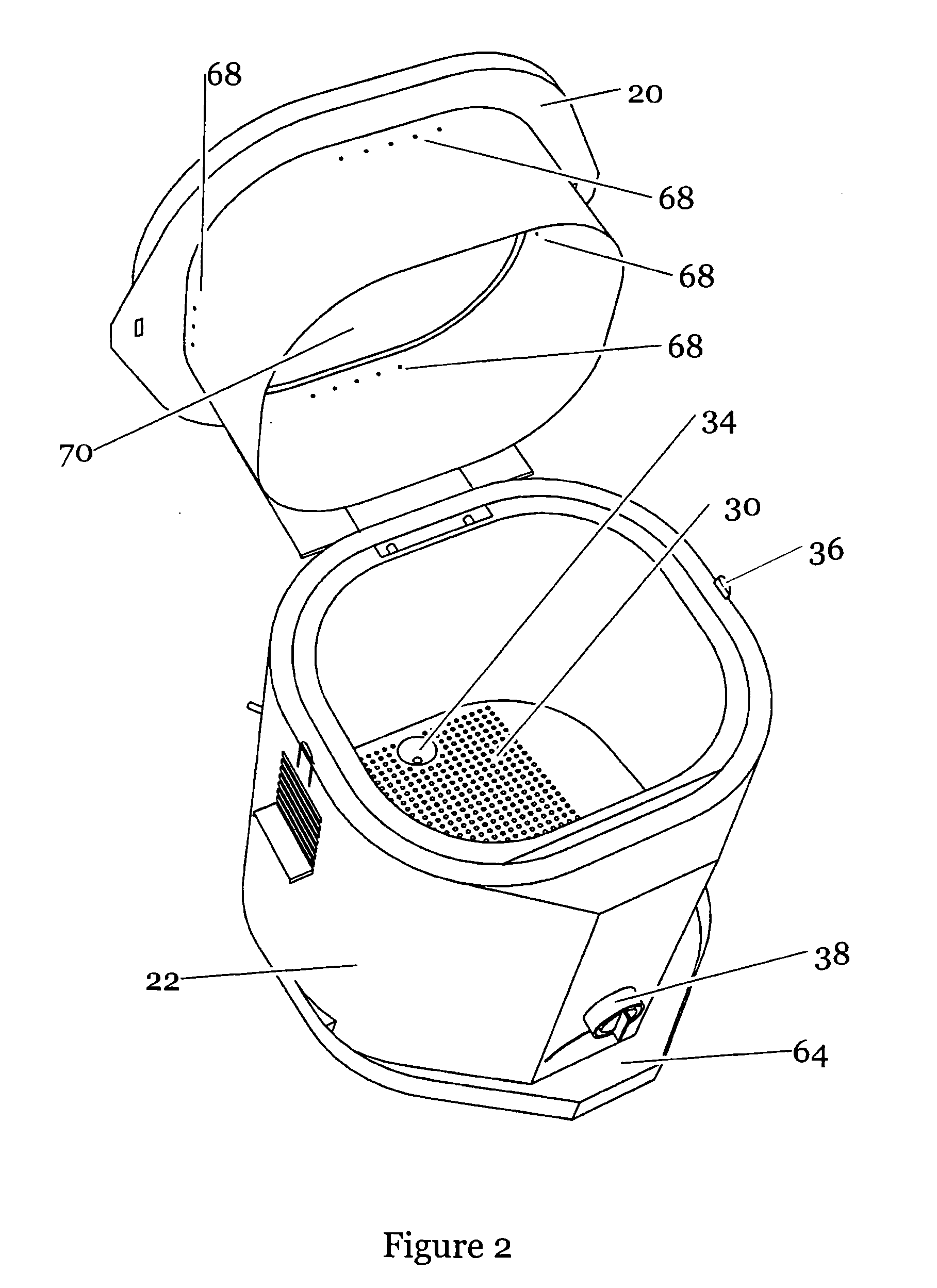

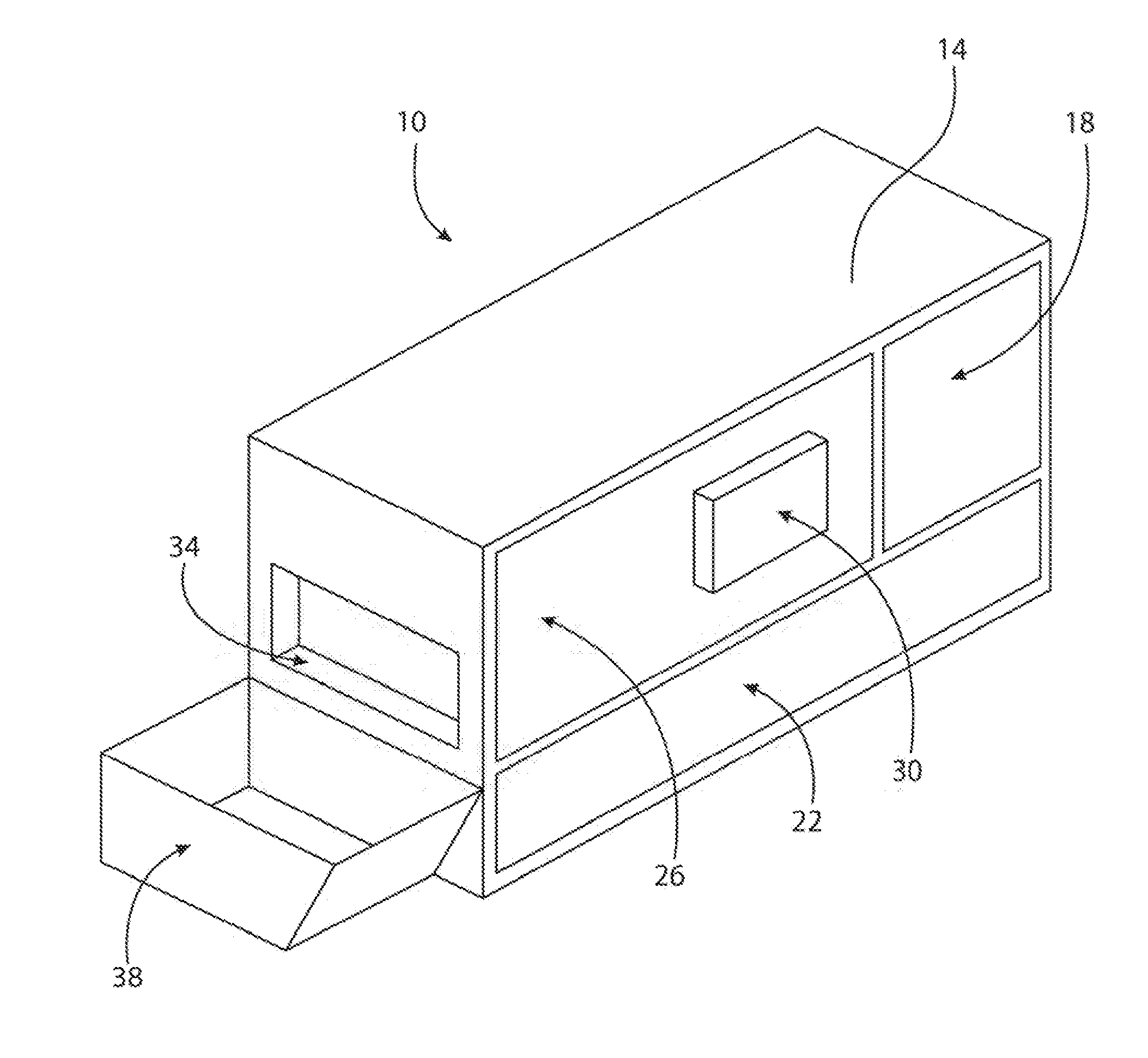

Device to efficiently cook food

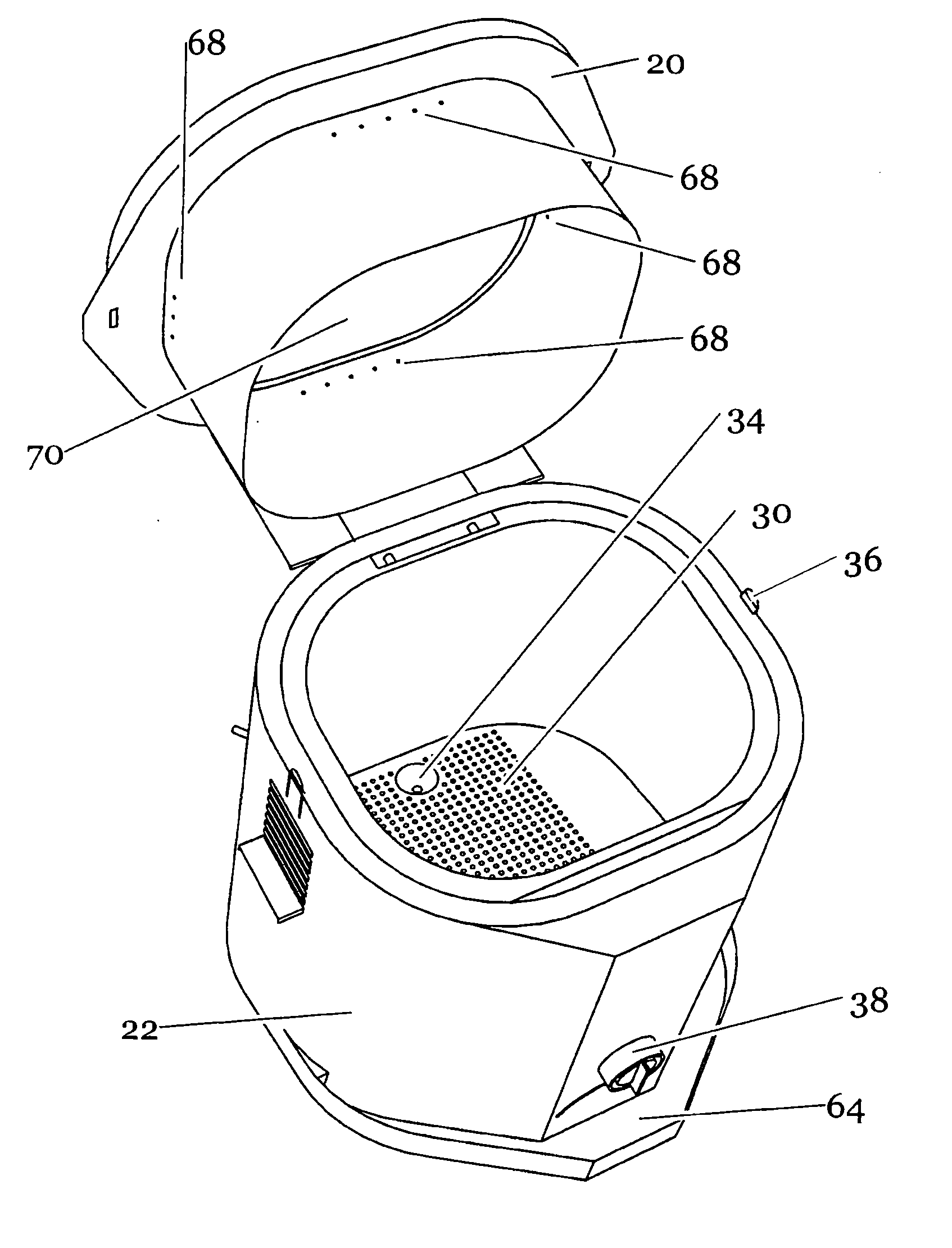

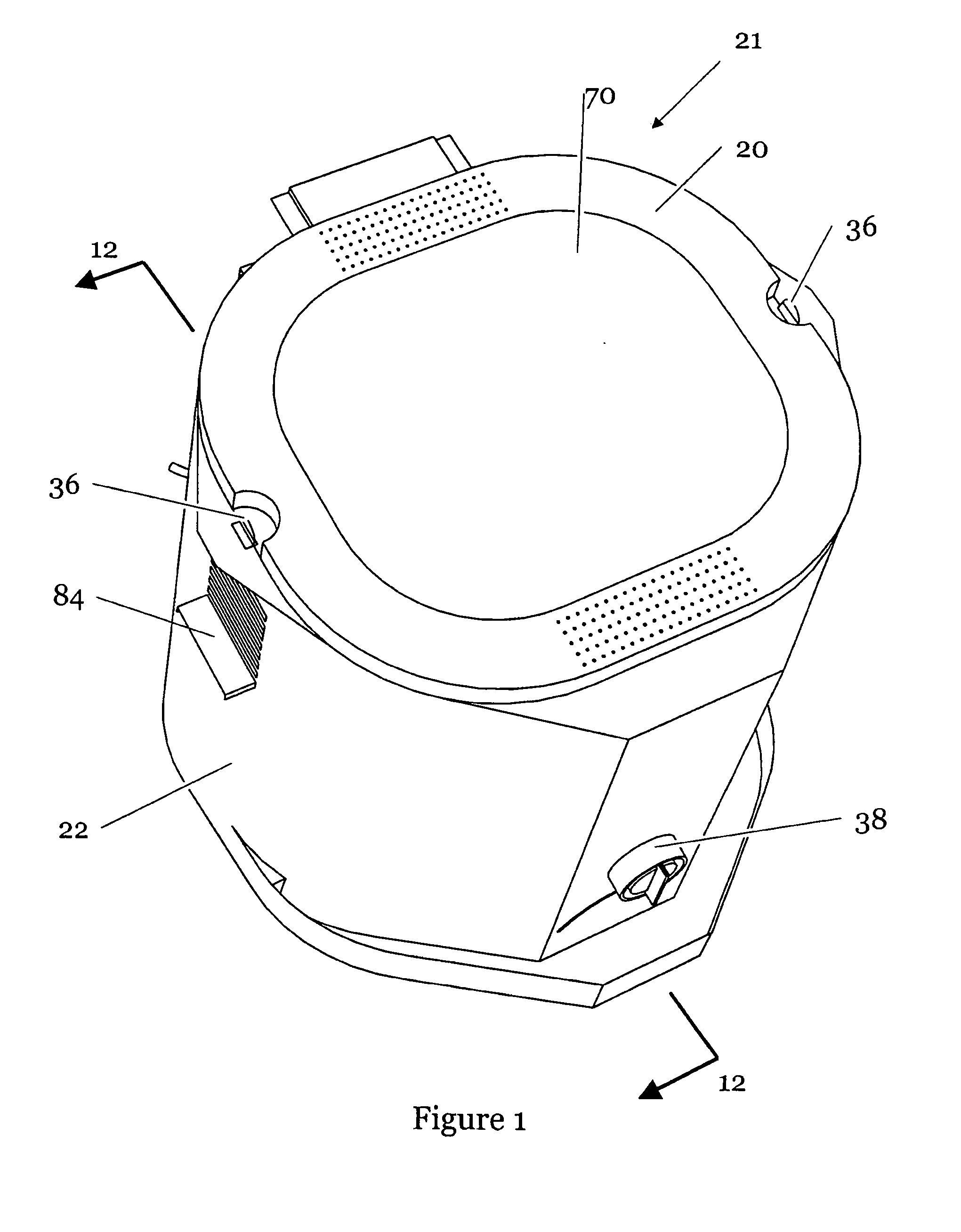

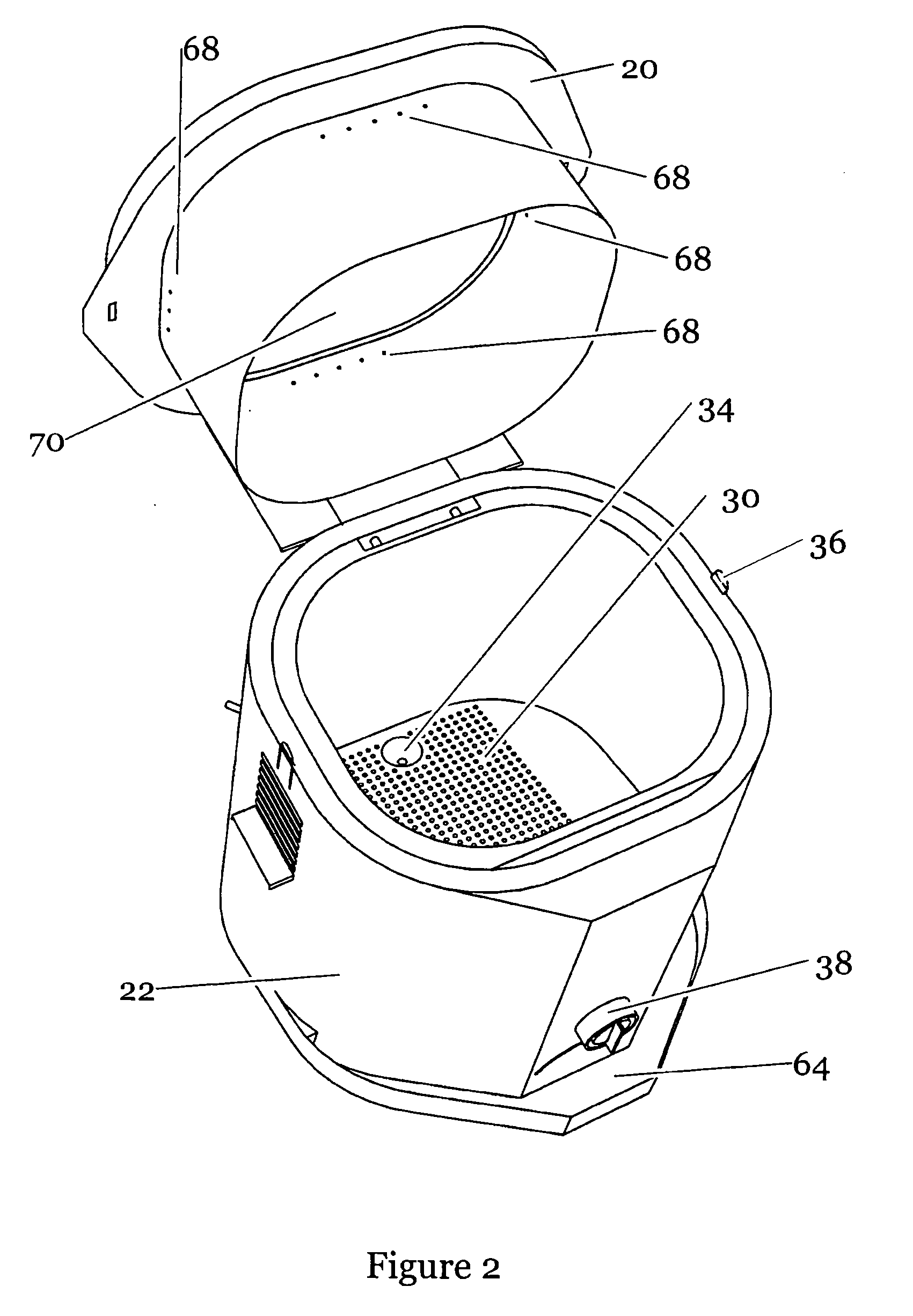

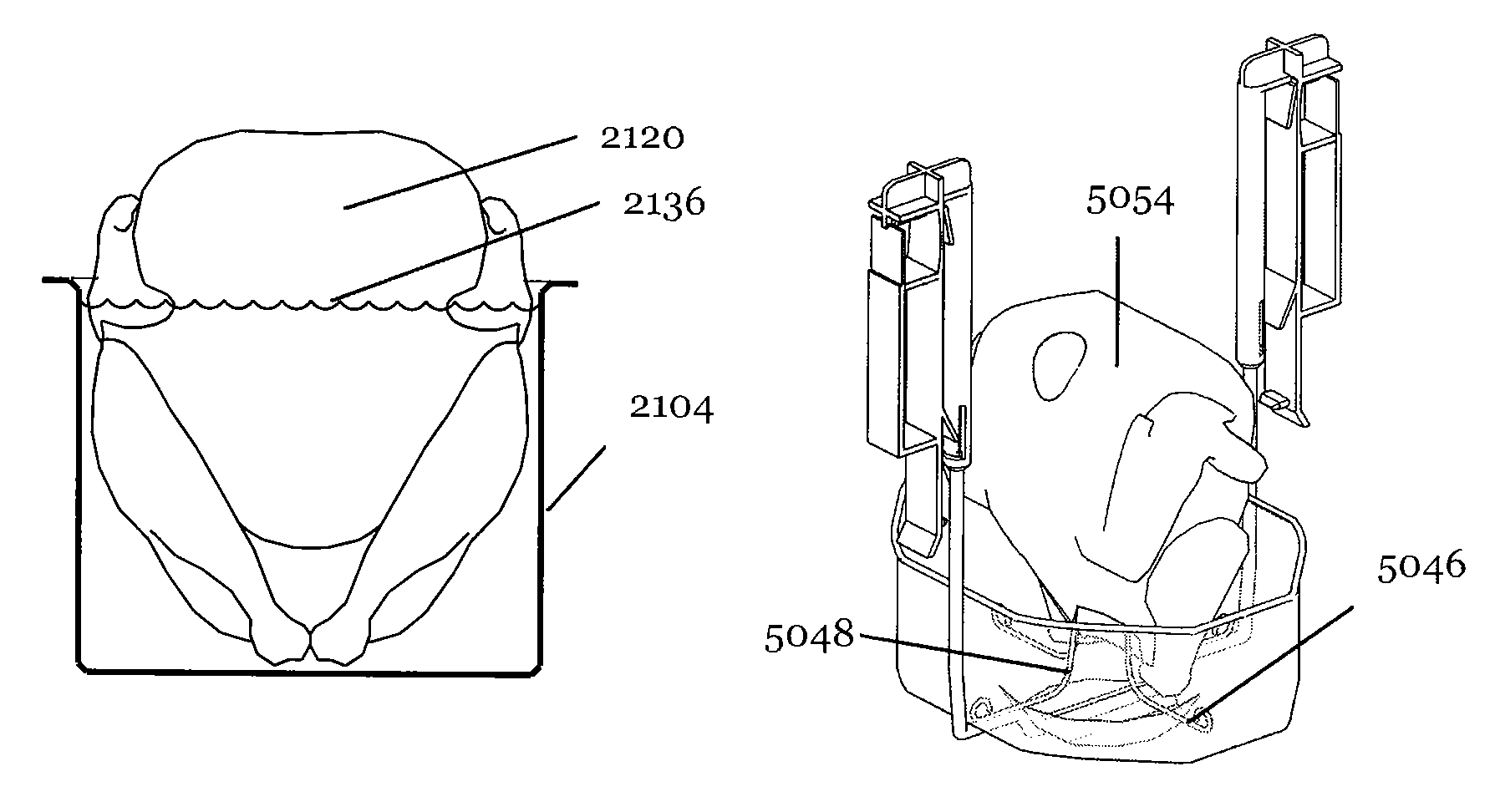

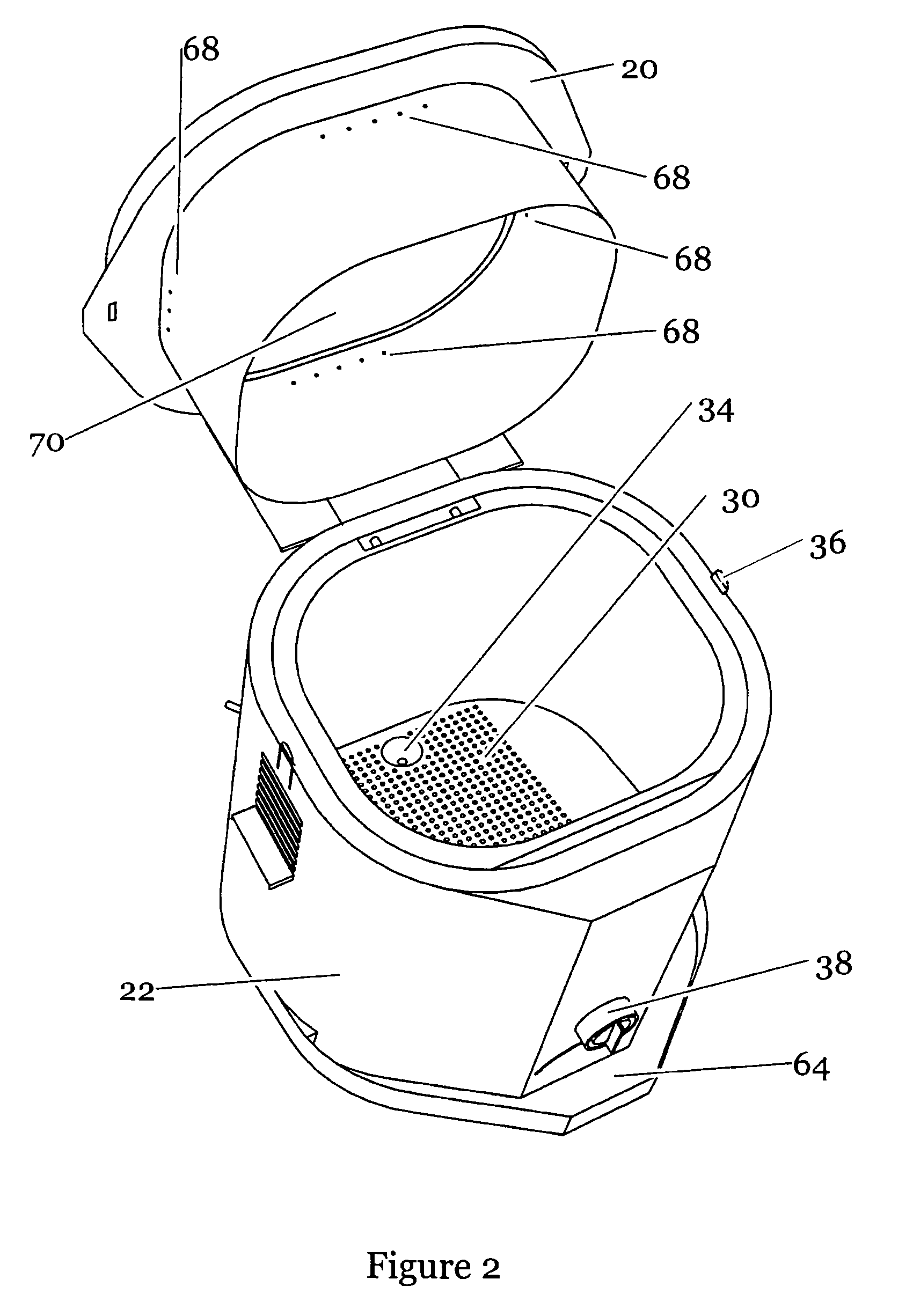

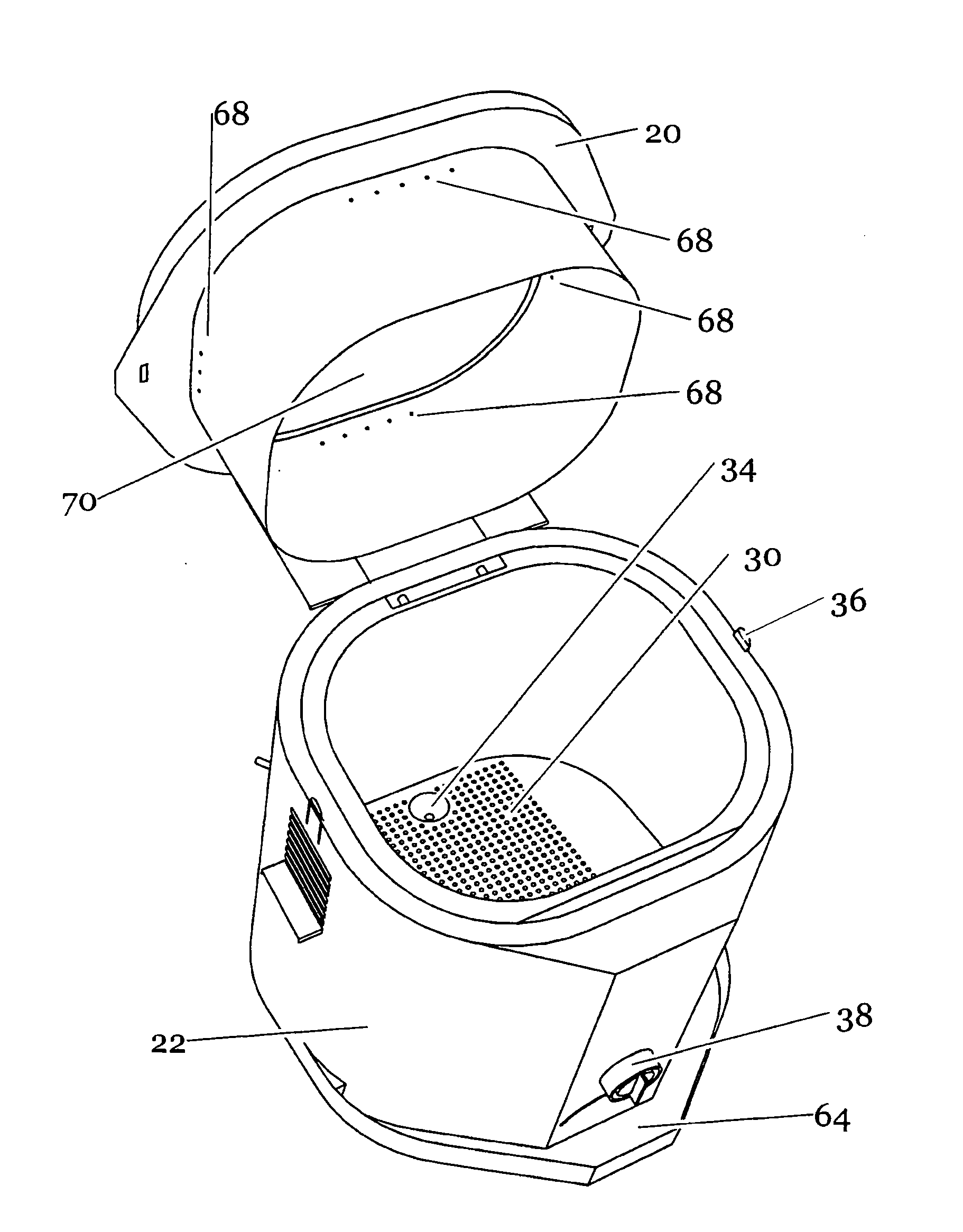

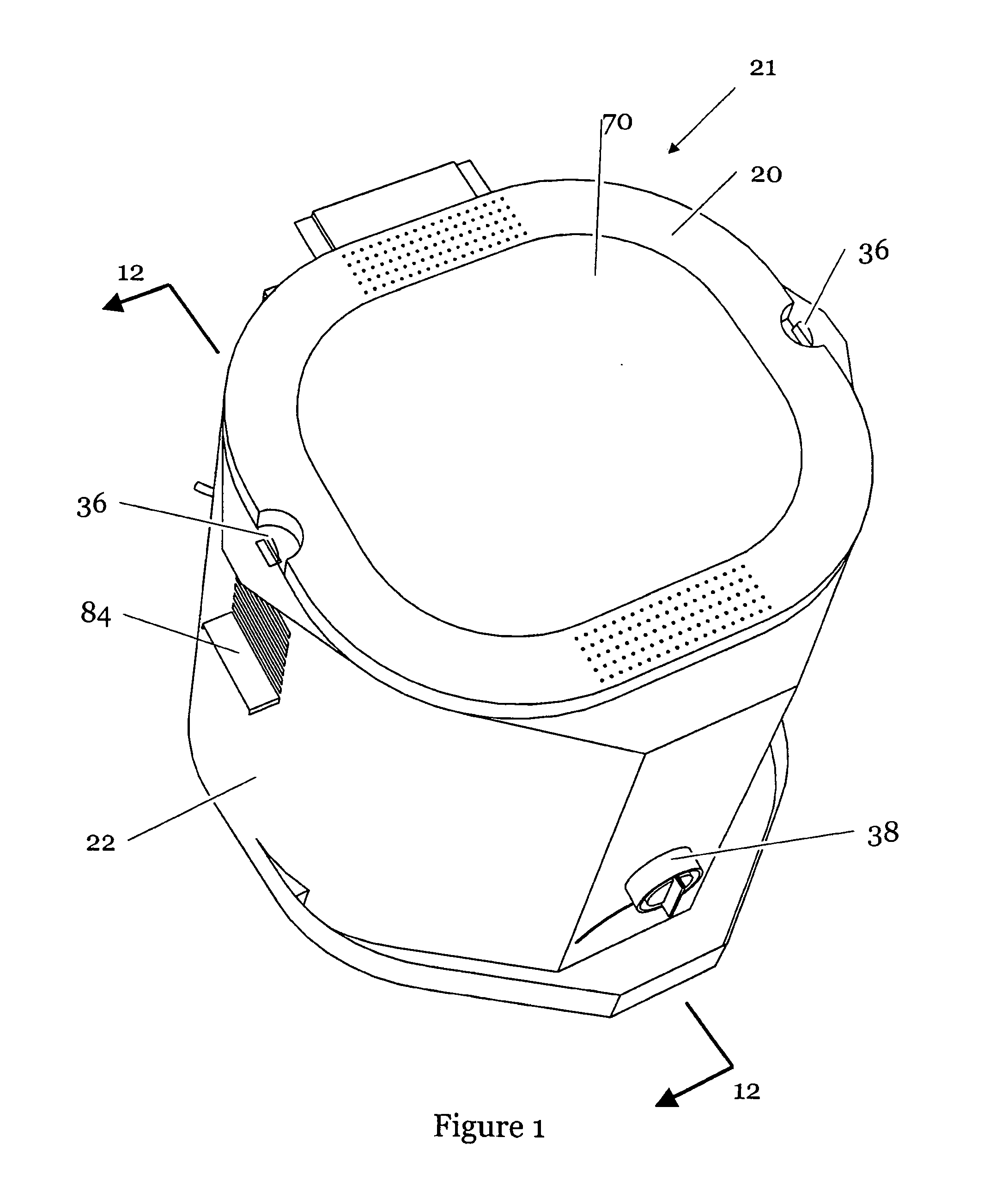

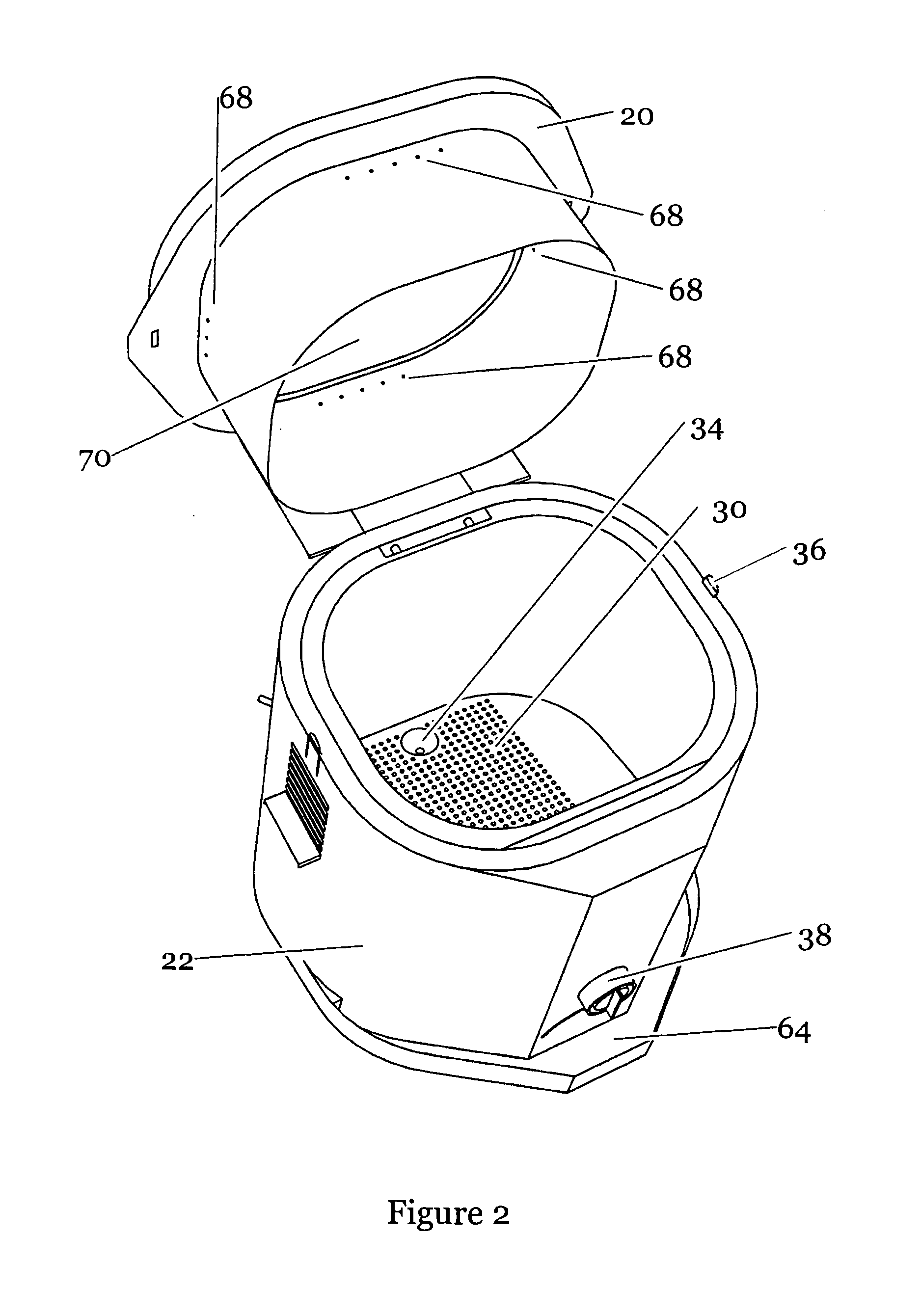

Deep fryers and associated accessories providing increased efficiency and convenience in the production of deep-fried foods. Preferred embodiments herein also may be versatile enough to, besides deep frying foods, be able to steam and boil foods. Preferred embodiments may employ multiple cooking cycles and versatile food support means to fully cook foods. These may provide special advantages for larger unitary foods, such as by way of nonlimiting example, a Thanksgiving turkey. Preferred embodiments may provide advantages including, but not limited to: minimizing countertop usage; reduction in the use of frying oil; compact storage; reduced shipping costs; lowering of warehousing costs; reduced manufacturing costs; and being lighter and more easy to handle in the kitchen. Preferred embodiments of accessory items may simplify and facilitate production of deep fried foods, including cutting foods into shapes appropriate to produce French fries and blooming onions. Other accessories may facilitate the transference and maintenance of frying oil including: returning frying oil to original containers for storage and disposal; and filtering frying oil to prolong its useful life. Methods are disclosed which help purify oil for extended life without use of filtration.

Owner:RONS ENTERPRISES

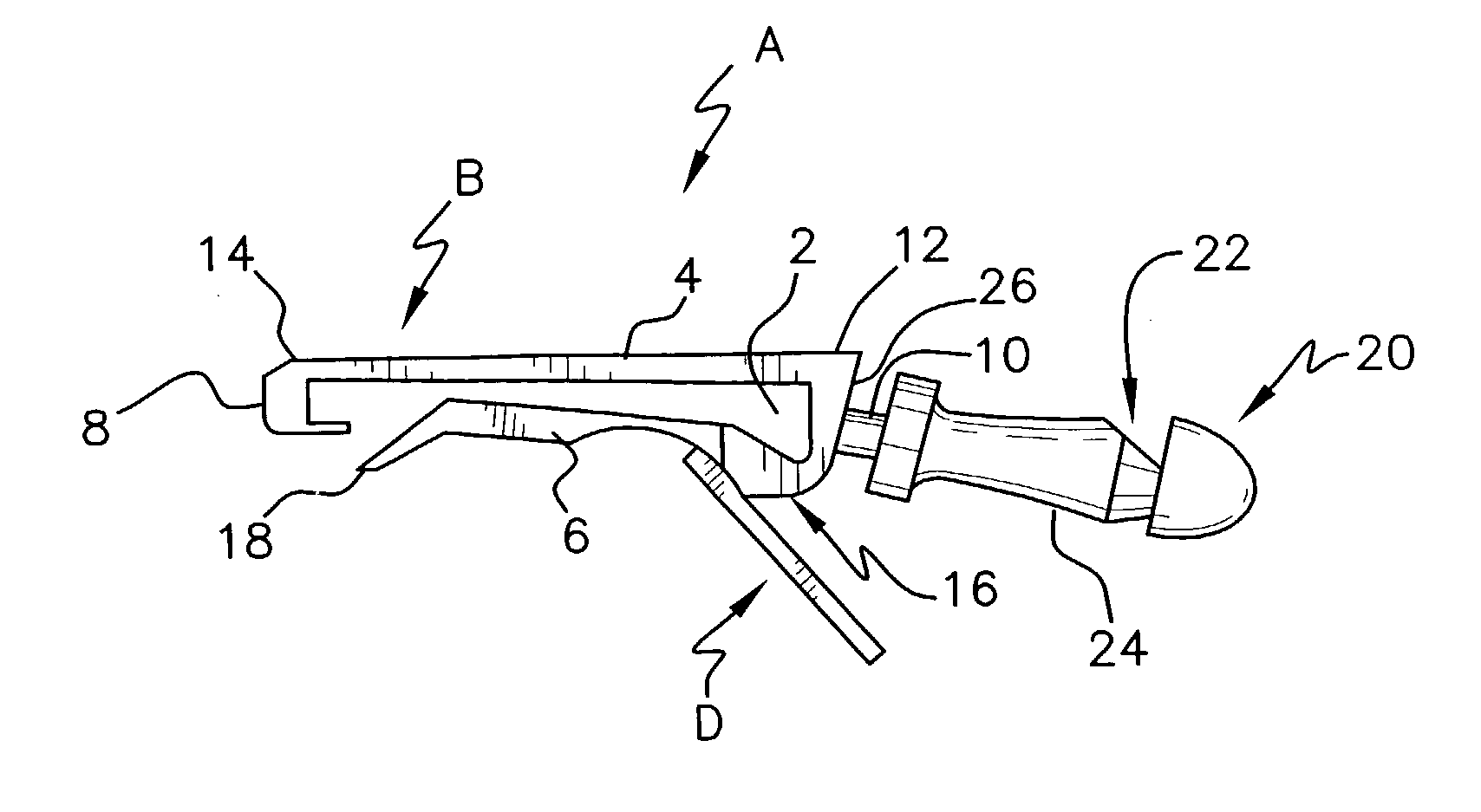

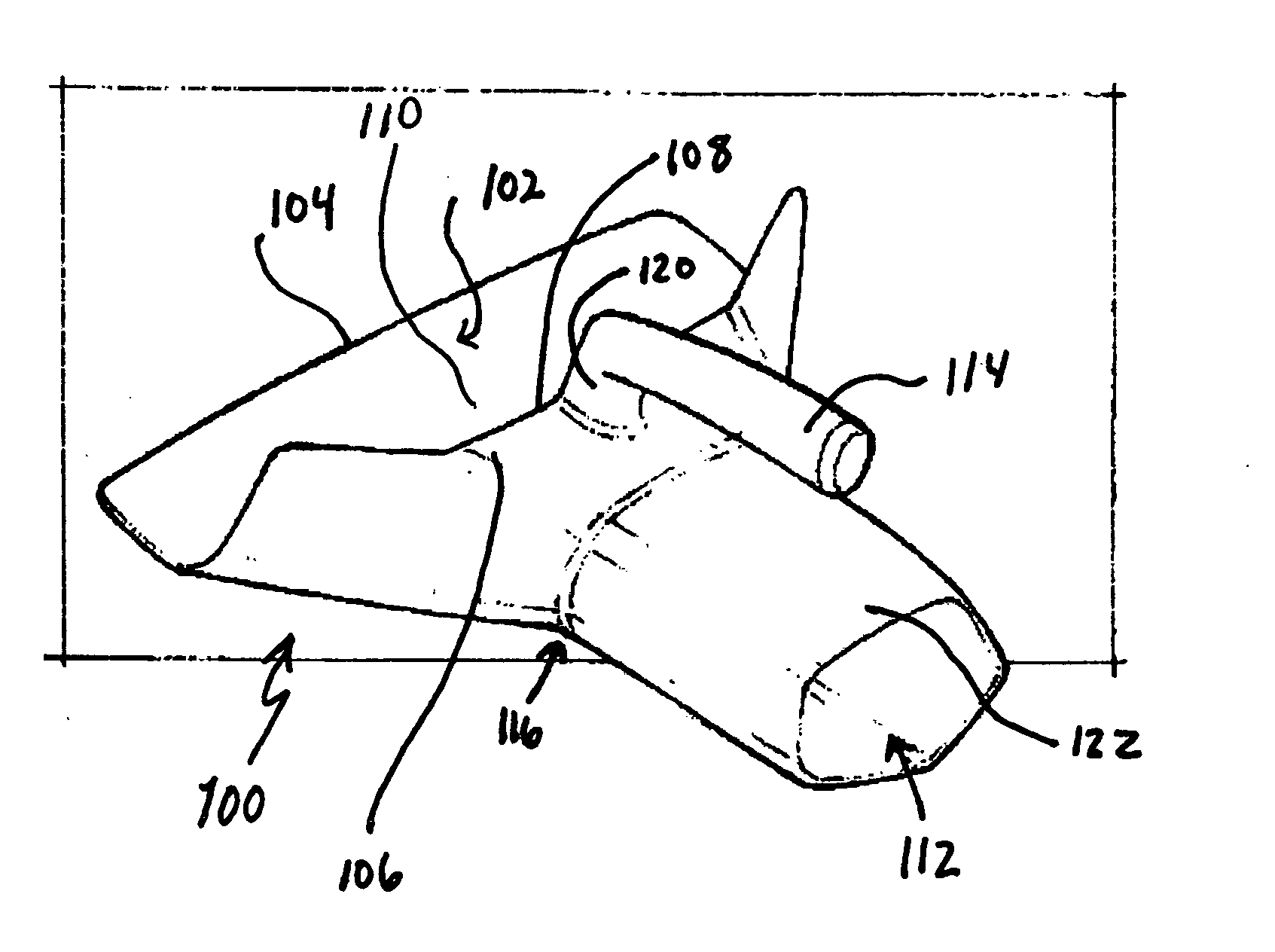

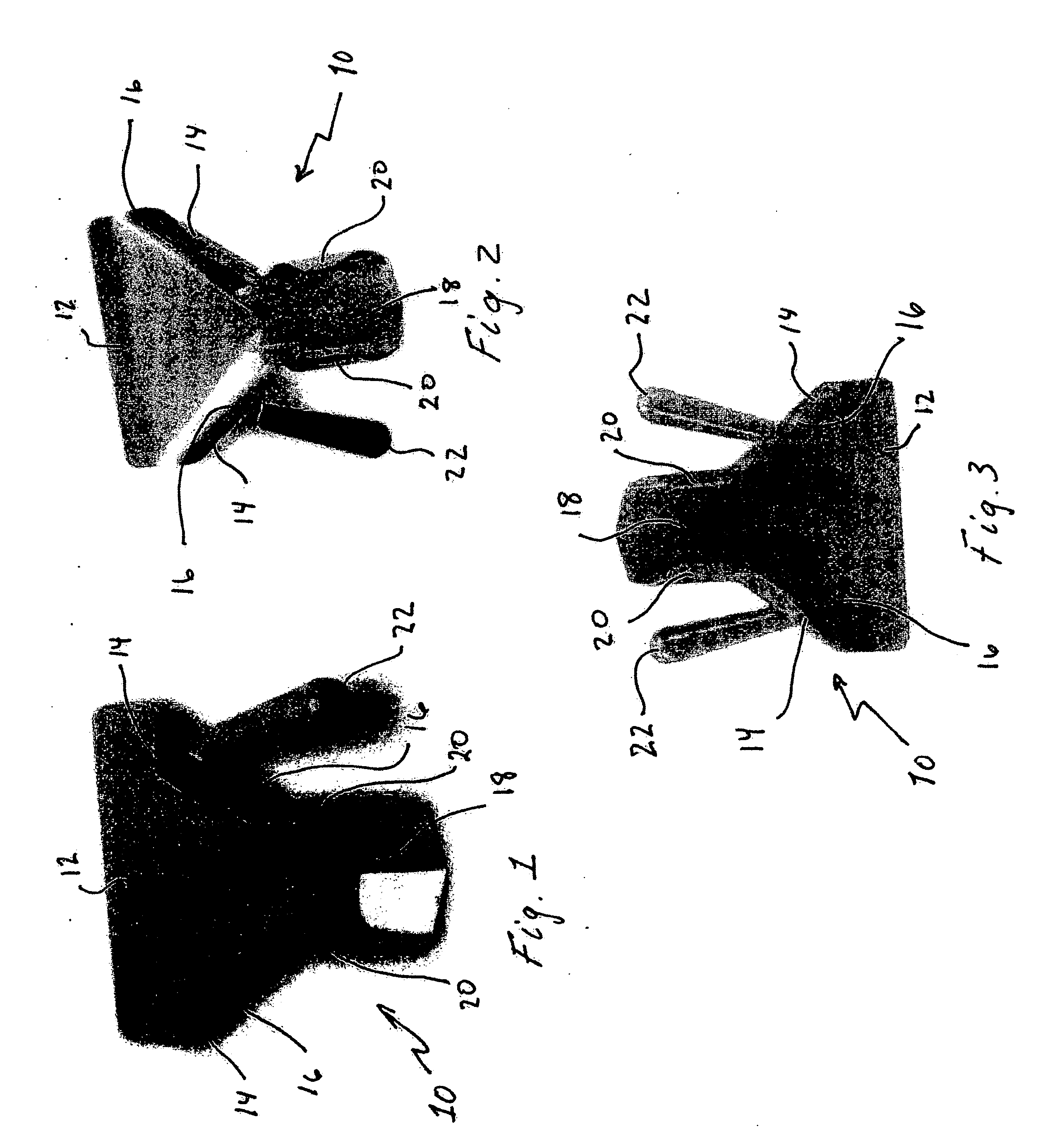

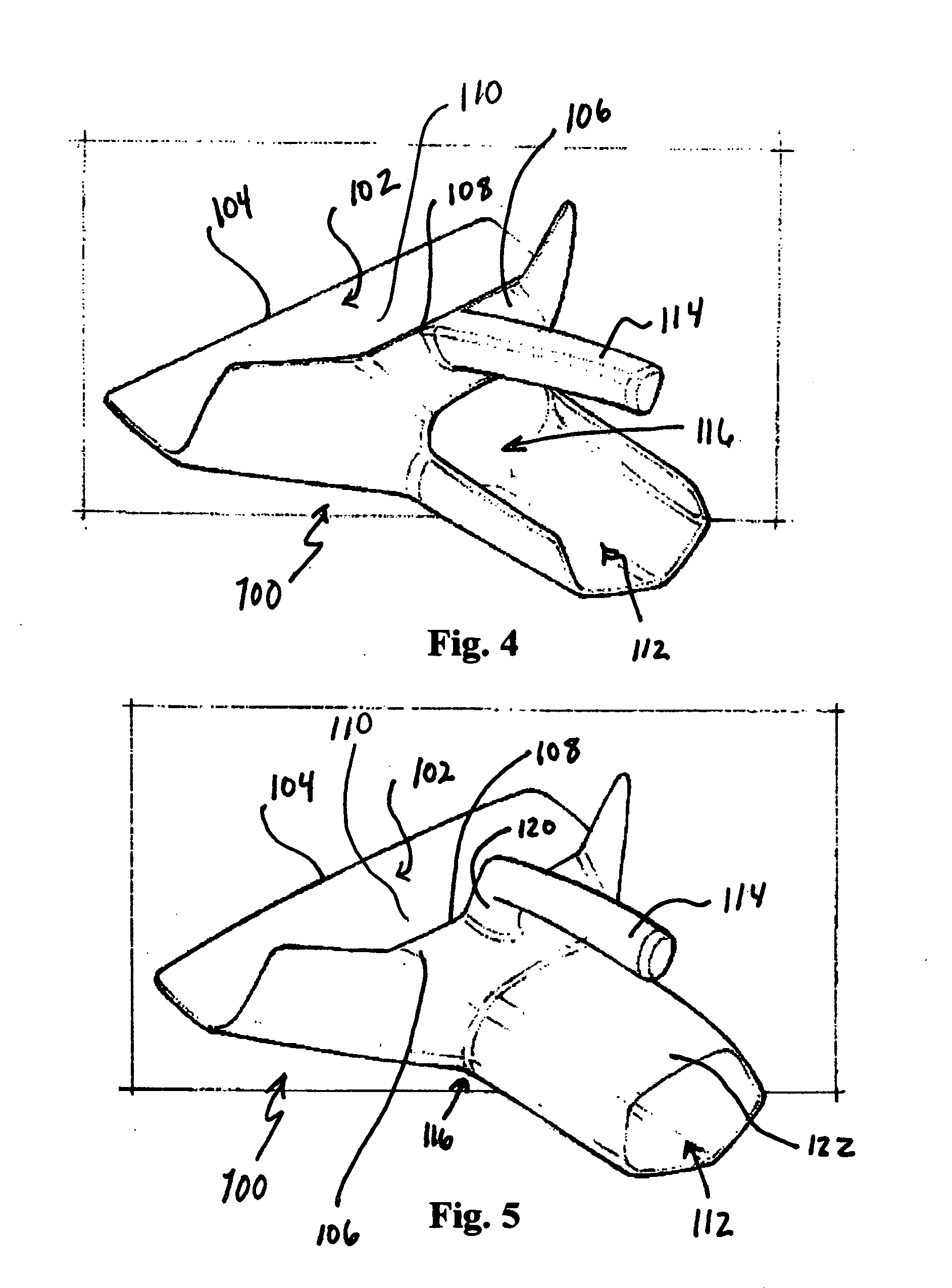

Hands free article support for supporting various articles in a vehicle and articles supported thereby

A hands free article support for supporting various articles in a vehicle and articles supported thereby. Preferably, the article support includes a body having an opening for receiving a predetermined portion of a vent of a vehicle. The body has an upper portion, a lower portion, a rear portion and a front portion. An attachment member extends forwardly from the front portion. The article support preferably includes a release member for permitting the body to be removed from the predetermined portion of the vent of a vehicle. Preferably, the article or articles supported by the hands free article support include a removable portion permitting the article to be readily and easily hung from the hands free article support. The removable portion may but need not include indicia corresponding to a game being played by a fast food provider with its customers. In its most preferred form, the article supported by the hands free article support is a french fry container or package.

Owner:PARCELLES JUSTIN TROY

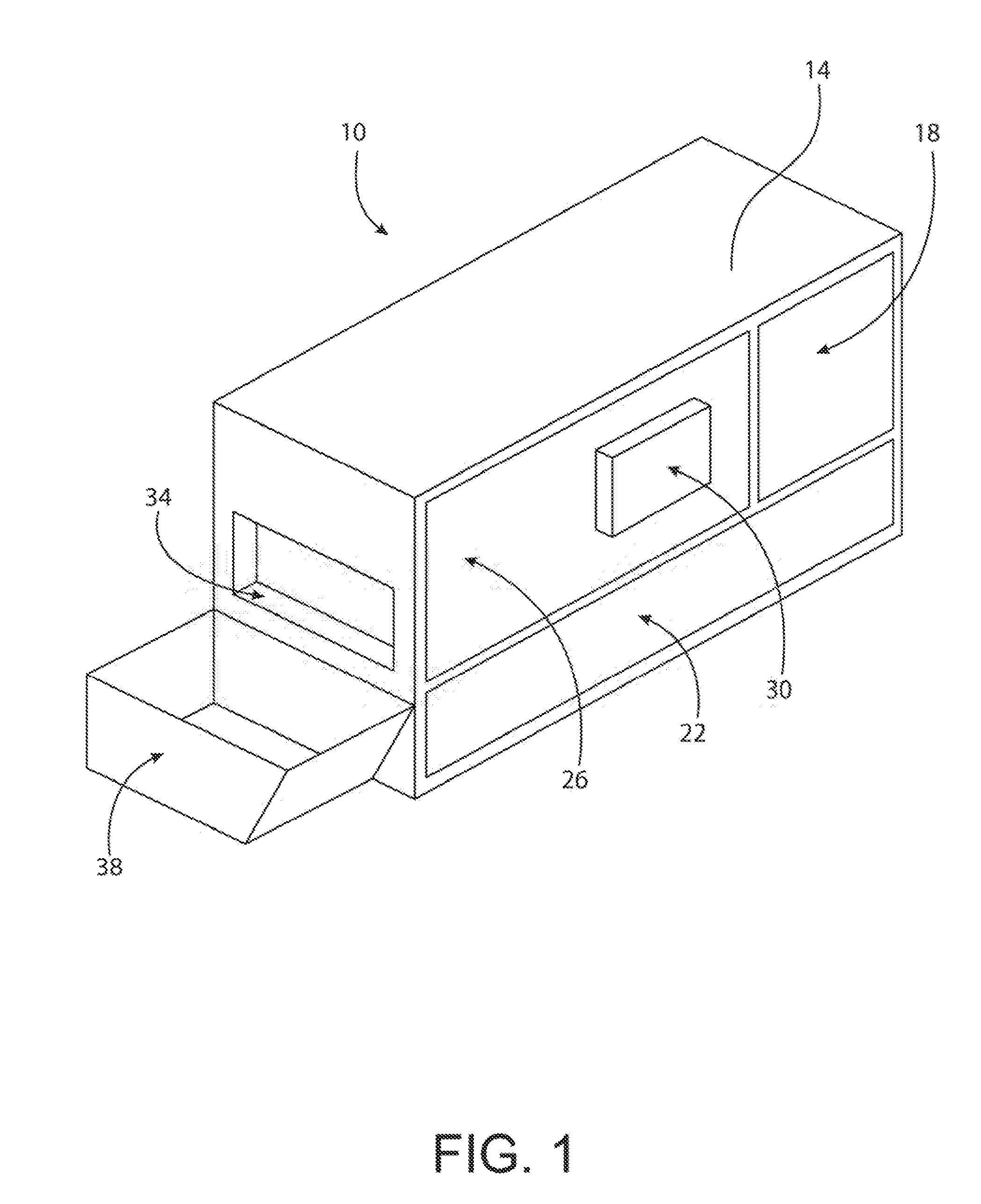

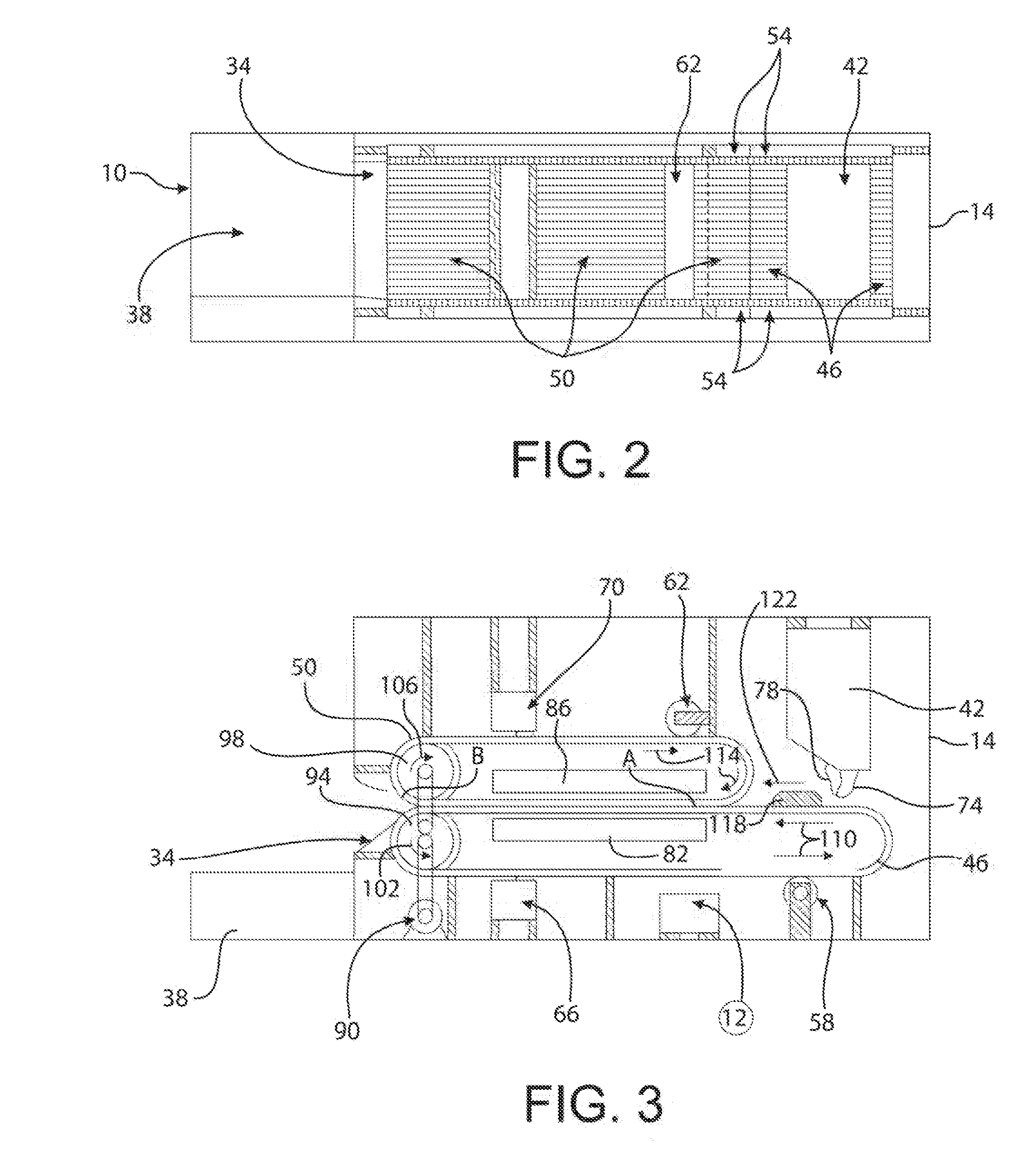

Device to efficiently cook food

ActiveUS8850965B2Low costReduce needMilk preservationMeat processingManufacturing cost reductionDeep frying

Deep fryers and associated accessories providing increased efficiency and convenience in the production of deep-fried foods. Preferred embodiments herein also may be versatile enough to, besides deep frying foods, be able to steam and boil foods. Preferred embodiments may employ multiple cooking cycles and versatile food support means to fully cook foods. These may provide special advantages for larger unitary foods, such as by way of nonlimiting example, a Thanksgiving turkey. Preferred embodiments may provide advantages including, but not limited to: minimizing countertop usage; reduction in the use of frying oil; compact storage; reduced shipping costs; lowering of warehousing costs; reduced manufacturing costs; and being lighter and more easy to handle in the kitchen. Preferred embodiments of accessory items may simplify and facilitate production of deep fried foods, including cutting foods into shapes appropriate to produce French fries and blooming onions. Other accessories may facilitate the transference and maintenance of frying oil including: returning frying oil to original containers for storage and disposal; and filtering frying oil to prolong its useful life. Methods are disclosed which help purify oil for extended life without use of filtration.

Owner:RONS ENTERPRISES

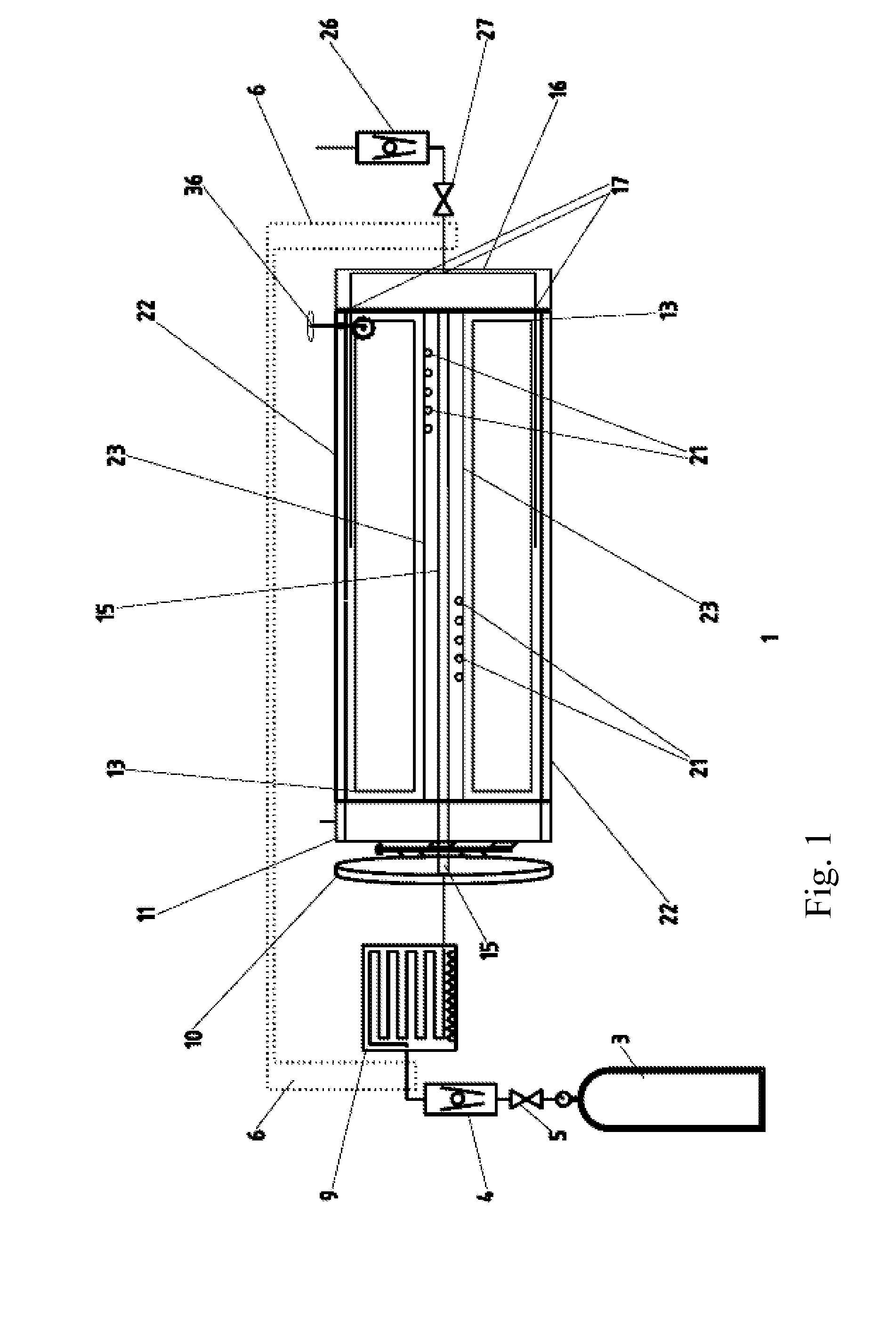

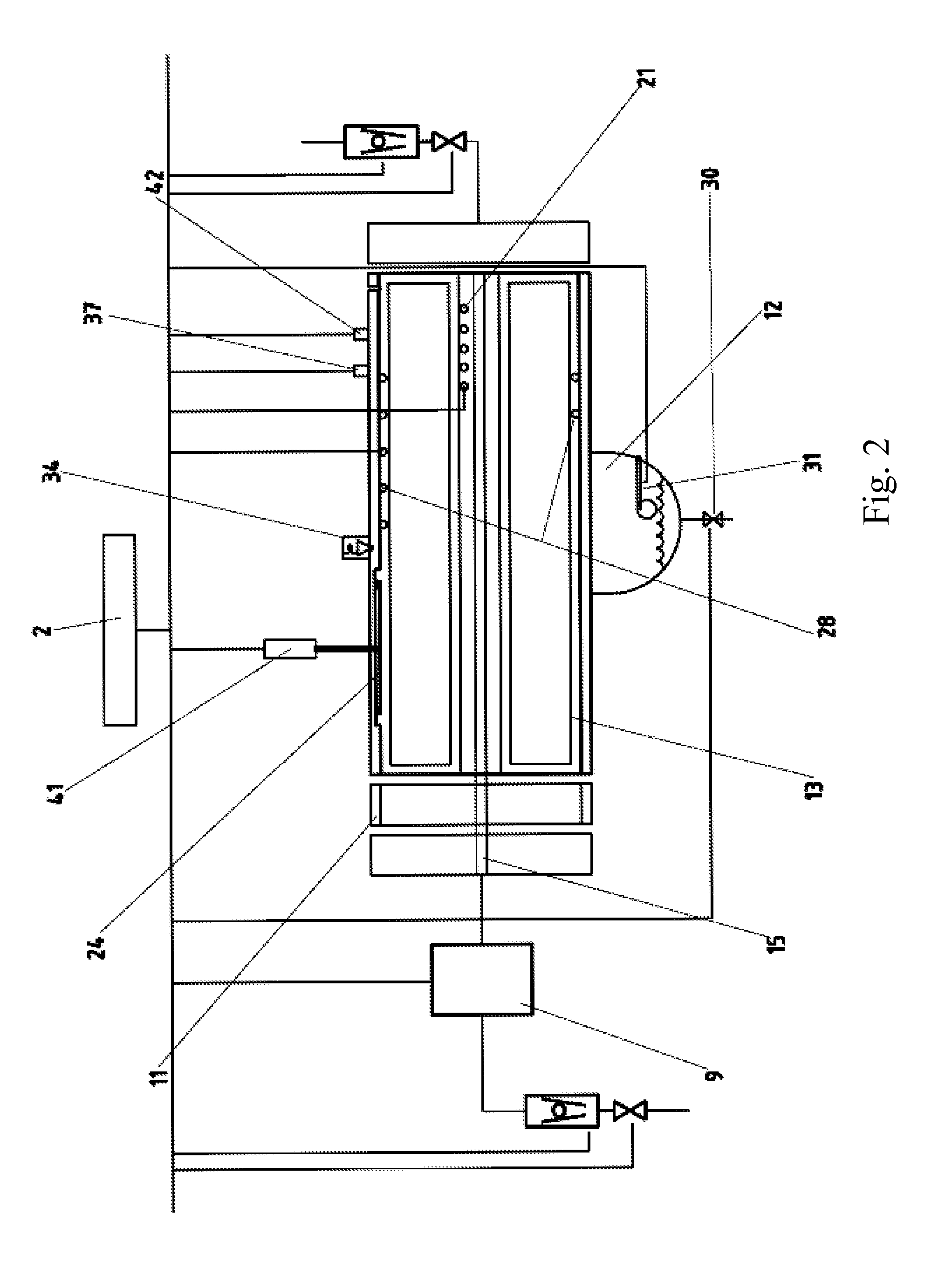

Device to efficiently cook food

Deep fryers and associated accessories providing increased efficiency and convenience in the production of deep-fried, steamed and boiled foods. Multiple cooking cycles and versatile food support means to fully cook foods are provided. Special advantages for larger unitary foods, such as for example, a large turkey, are provided. Advantages include without limitation minimizing countertop usage; reduction in the use of frying oil; compact storage; reduced shipping costs; reduced warehousing and manufacturing costs; and being lighter and more easy to handle in the kitchen. Accessory items simplify and facilitate production of deep fried foods, including cutting foods into shapes appropriate to produce French fries and blooming onions. Other accessories facilitate the transference and maintenance of frying oil including: returning frying oil to original containers for storage and disposal; and filtering frying oil to prolong its useful life. Methods are disclosed which help purify oil for extended life without use of filtration.

Owner:RONS ENTERPRISES

High protein, low carbohydrate meal replacements and food

InactiveUS20130022731A1Low carbohydrateLarge levelFood ingredient functionsFood preparationFood proteinMeal replacement

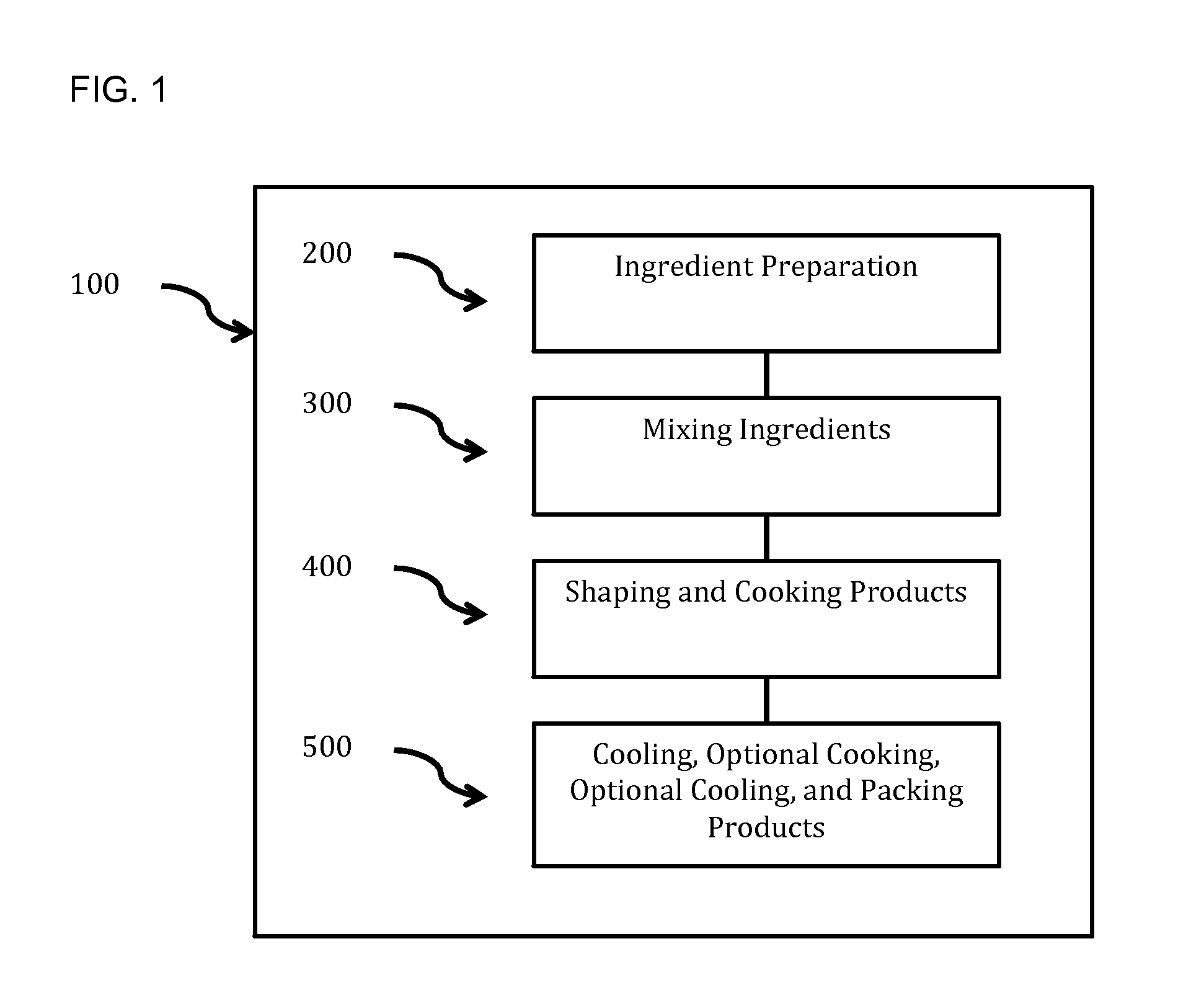

Protein-based meal replacements and foods, methods of manufacturing the protein-based meal replacements and foods, and different forms of the protein-based meal replacements and foods are disclosed. Implementations of the invention include combinations of egg based materials and value-added ingredients processed to form desired end products. Examples of end products include, but are not limited to, snack chips, crisps, croutons, French fries, cookies, donuts, breads, taco shells, tortillas, cereal, coatings, and other types of fried, baked, puffed, and / or otherwise cooked products.

Owner:VIA SANA

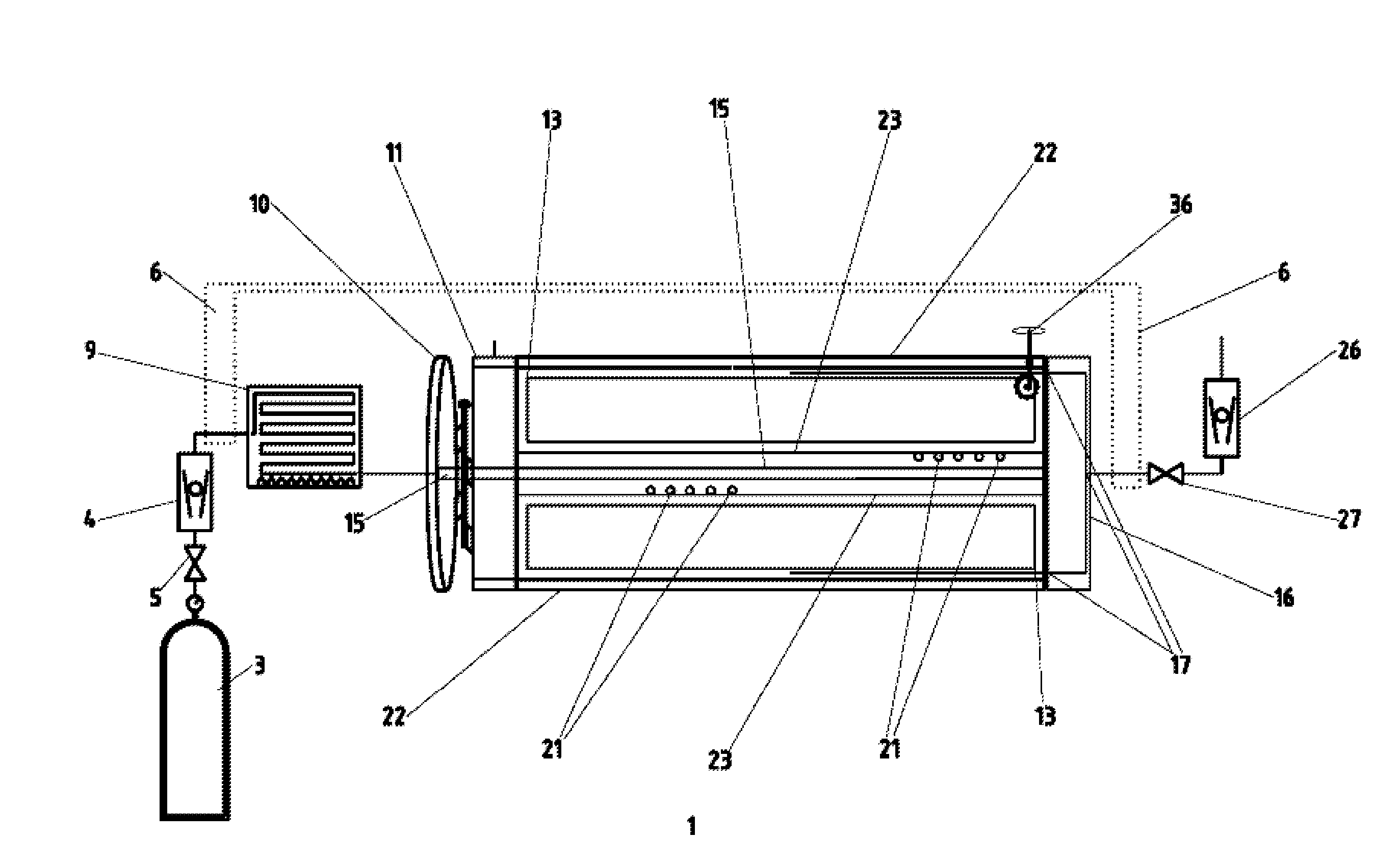

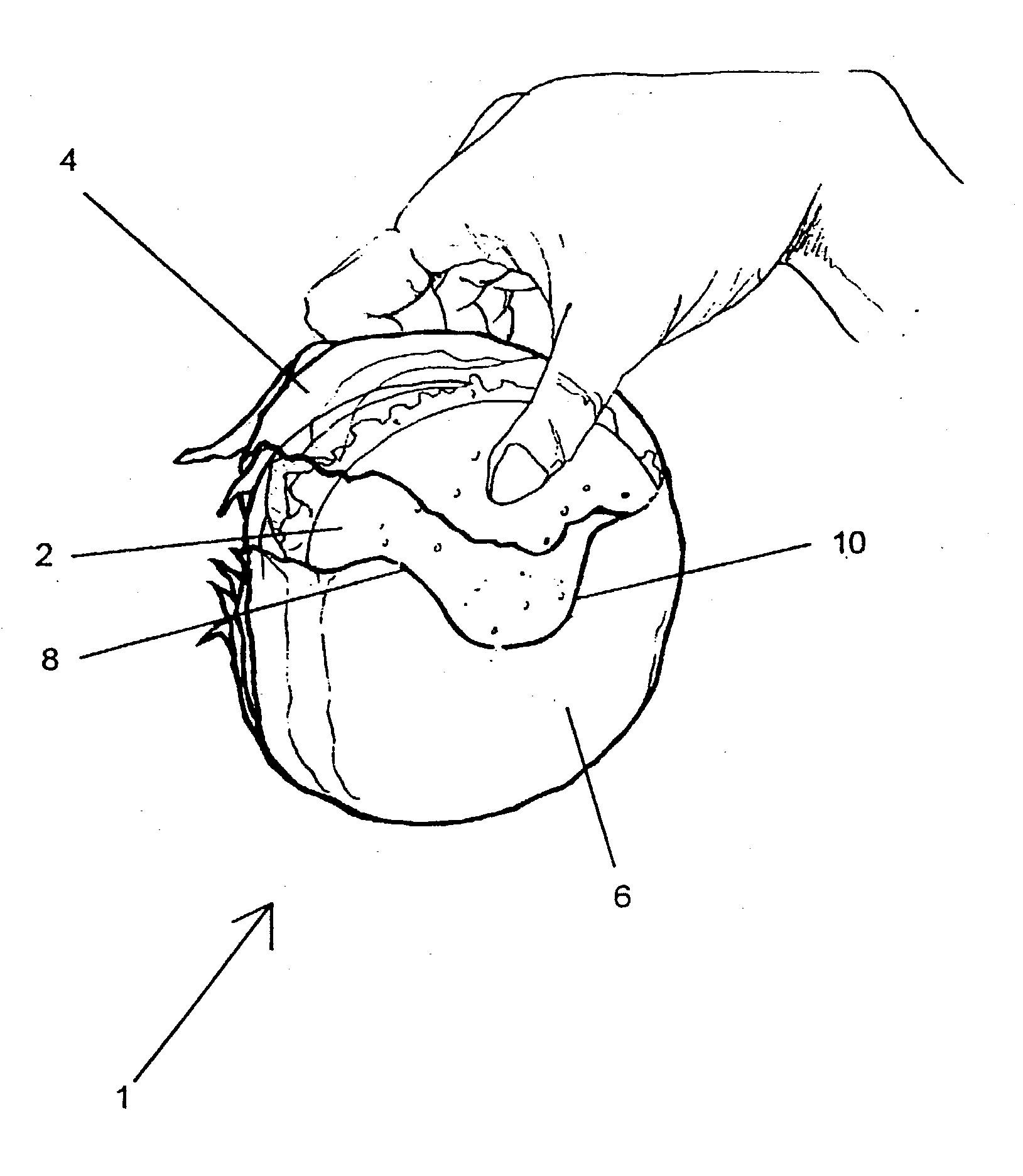

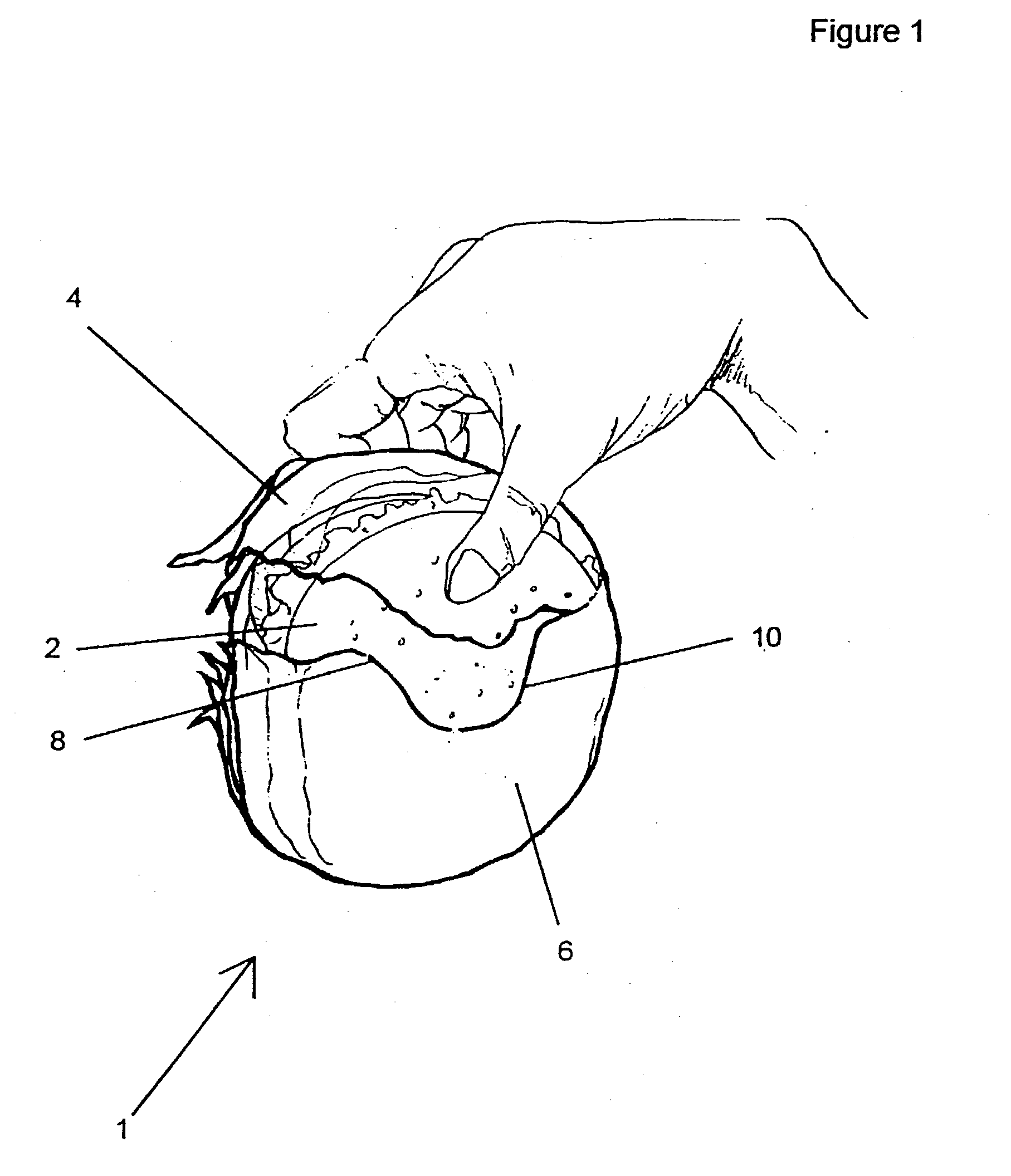

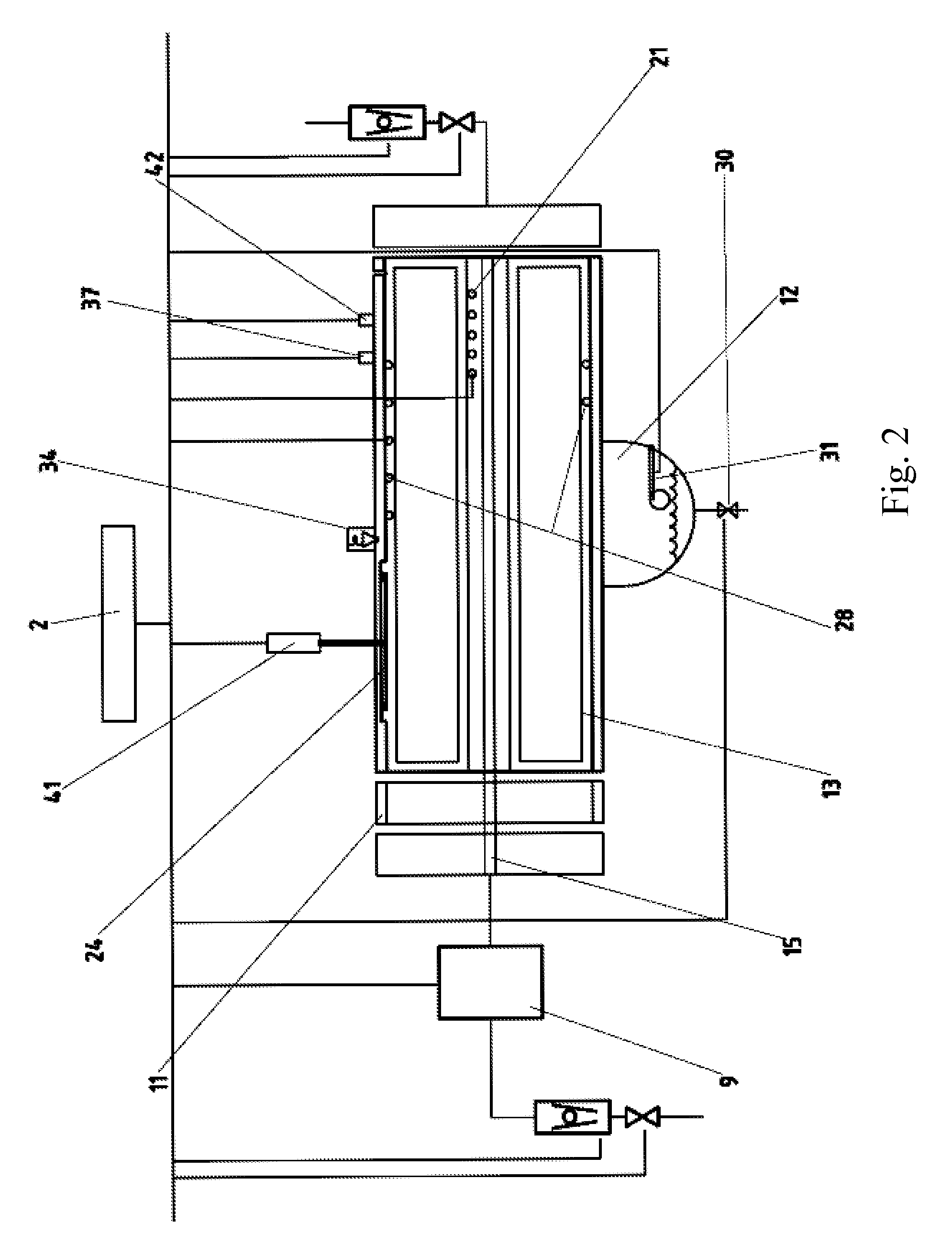

Method and apparatus for cooking low fat french fries

InactiveUS20080063773A1Avoid charringPrevent oxidationMilk preservationSteam cooking vesselsProcess engineeringHigh pressure

The present invention provides an apparatus and method for cooking French fries without cooking oil. The apparatus relies on high pressure inert gas at high temperature as the cooking medium. The inert gas acts both as a heat transfer medium to cook the potatoes, and as a protective atmosphere to prevent charring and oxidation of the potatoes.

Owner:MAGUIRE JAMES EDWARD

Food wrapper with rip line

A food wrapper with rip line capable of being sealed for food prior to consumption and being a holder for food during consumption, the rip line being perforated or partly perforated. Also taught is a condiment or premium pocket. Also taught is a food bag with rip line having an external complementary product pocket for holding french fries and the like.

Owner:PERENYI GABOR +1

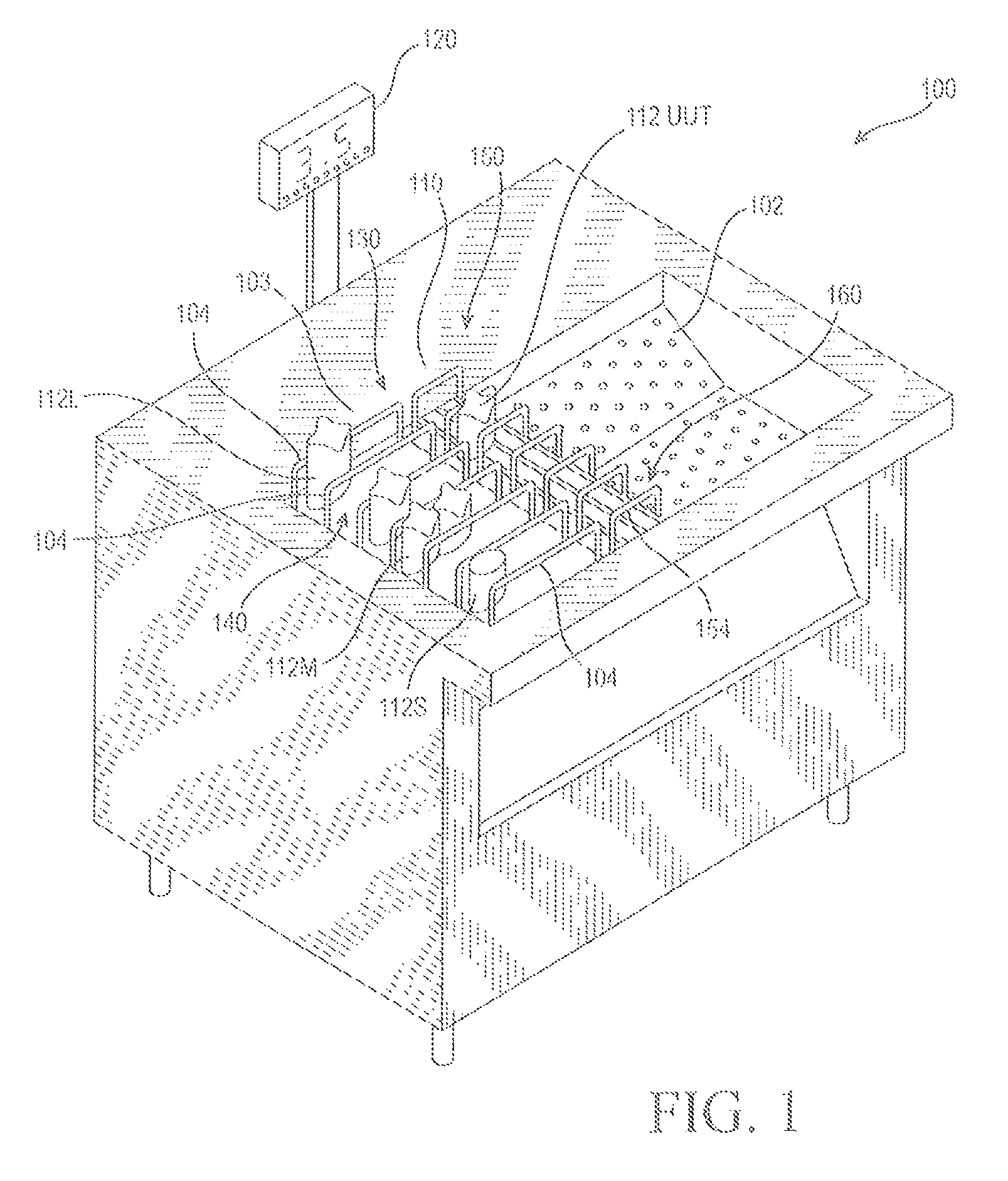

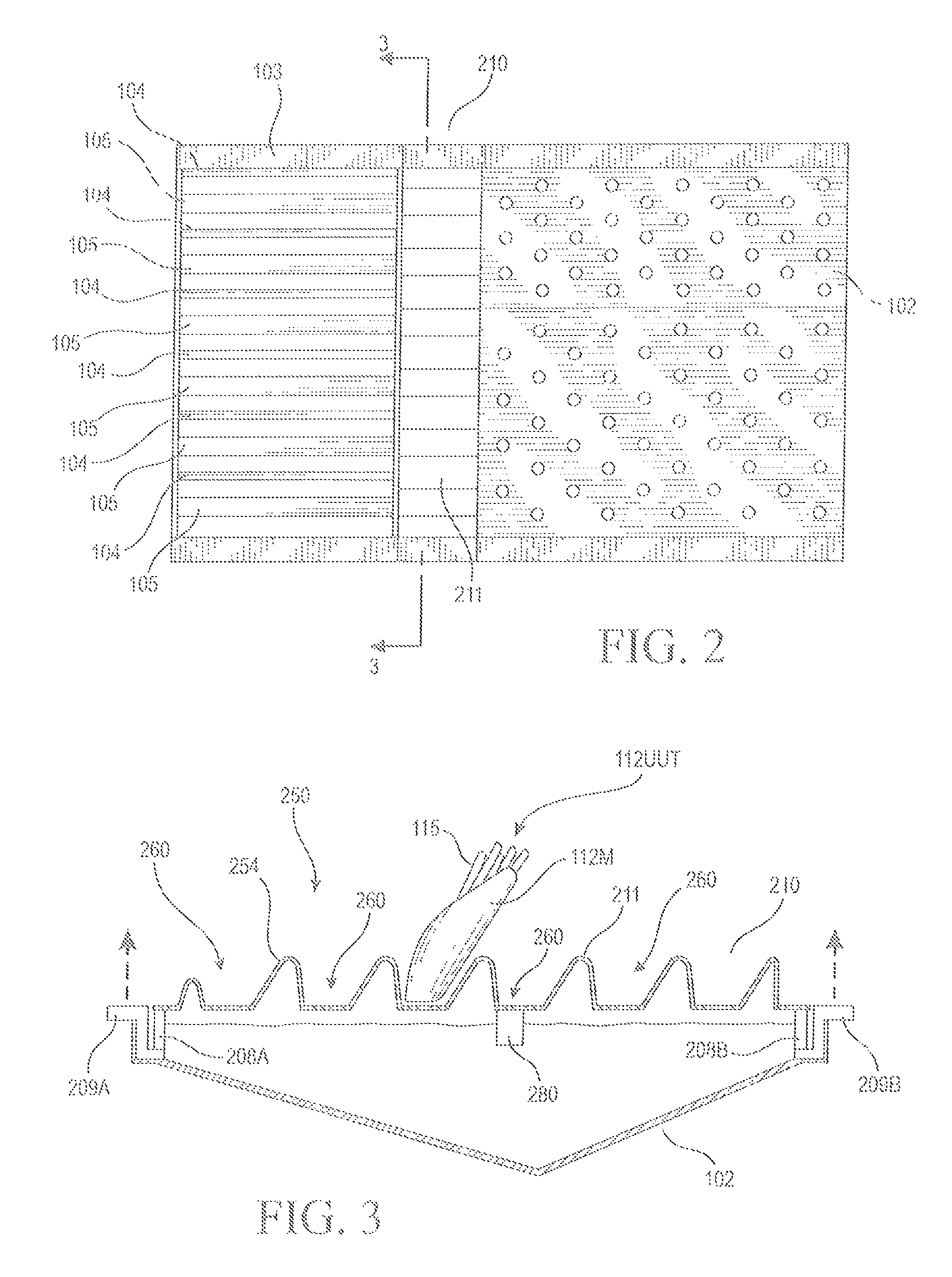

Automated method of packaging food items

An automated method of packaging cooked French fries in an individual portion-sized French fry container is provided, wherein the cooked French fries are mechanically delivered to a holding bin, an empty French fry container is mechanically scooped into the cooked French fries to fill the container, and the filled French fry container is mechanically deposited at a drop-off location. The cooked French fries may be received on an inlet chute, the inlet chute optionally vibrated to assist gravity in causing the French fries to travel into the holding bin. Seasoning may be applied to the French fries while the French fries are on the inlet chute, optionally restrained by one or more gates. After filling, the filled container may be mechanically shaken. Additionally, the empty French fry containers may be mechanically selected from a plurality of different-sized collapsed containers, mechanically obtained, and mechanically erected prior to scooping.

Owner:RESTAURANT TECH

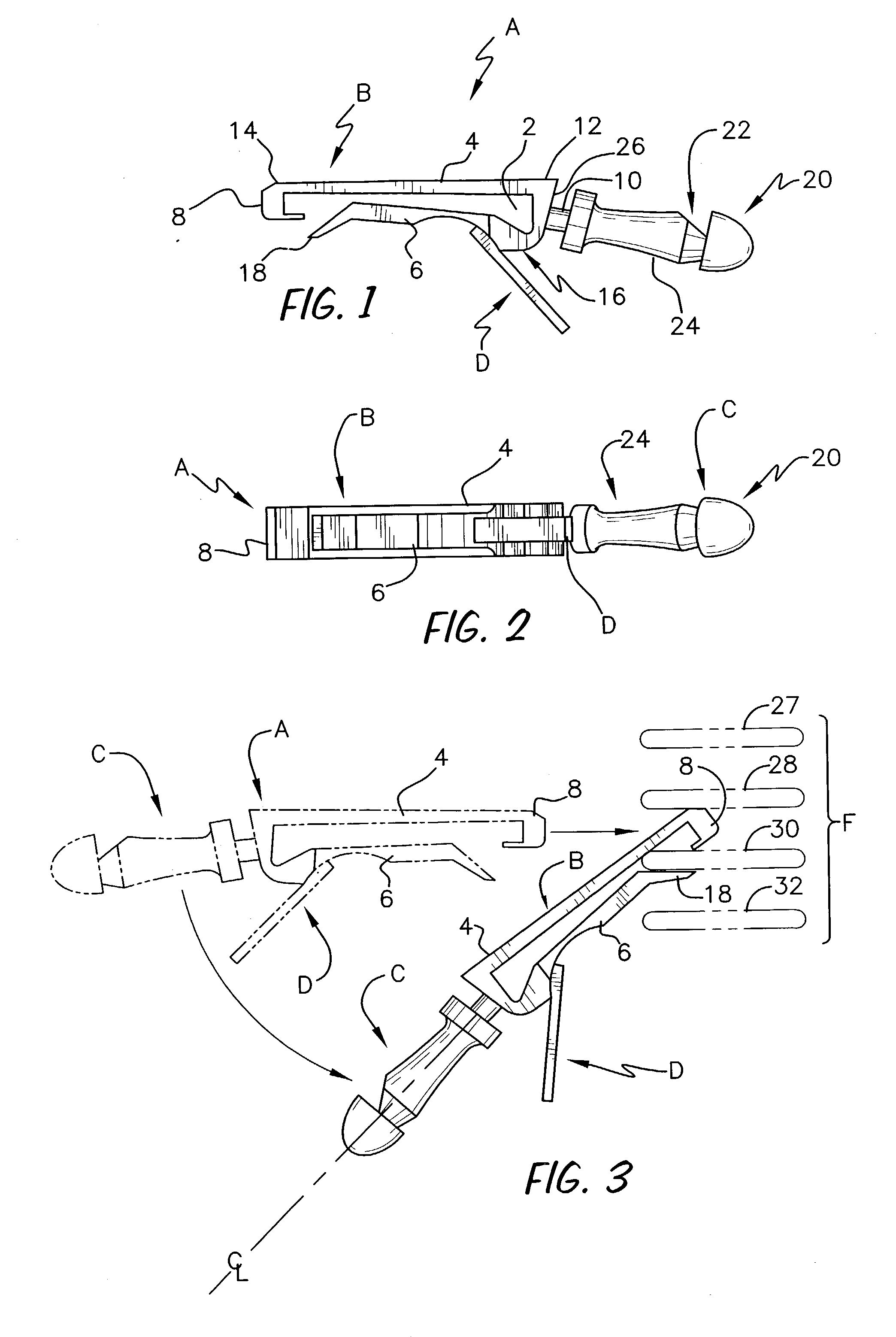

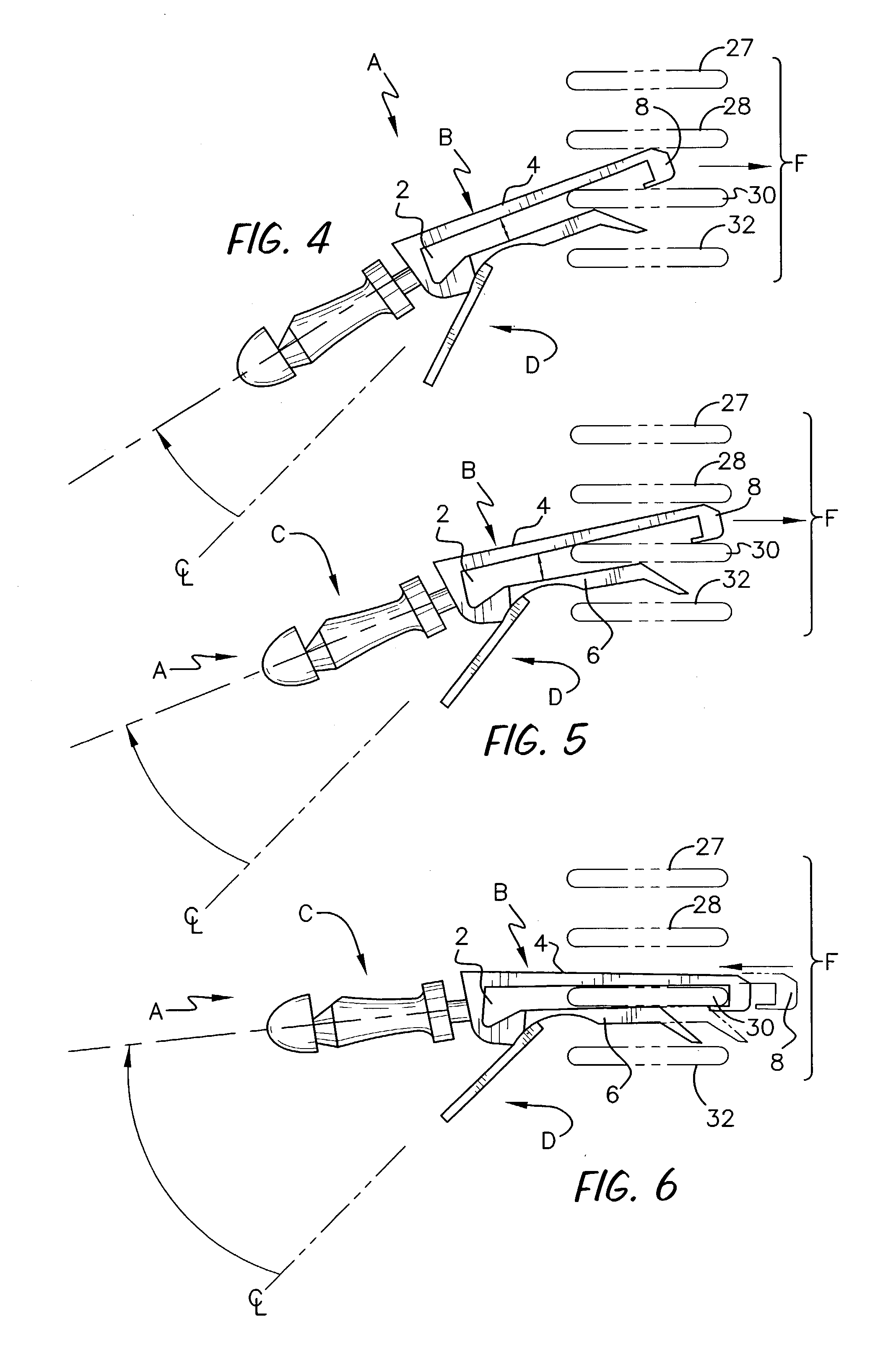

French fry scoop

The present invention is directed to a scoop for French fries comprising a mouth for scooping French fries from a bin, a funnel extending from the mouth at a first end and sized to accept an empty French fry package at a second end, wherein the mouth and the funnel share a central longitudinal axis. A handle is mounted substantially along the central longitudinal axis of the funnel and the mouth. The scoop may also include a hood at least partially covering the mouth. The funnel can either be substantially open or closed. The handle can be mounted to the funnel or the hood, if present. A shield may be connected to the hood to provide additional safety and sanitary enhancements.

Owner:THE COLMAN GRP INC

Parfried frozen french fry having high solids content

InactiveUS20050266144A1High solid contentReduce moisture contentFood coatingFood preparationAlternative methodsSolid content

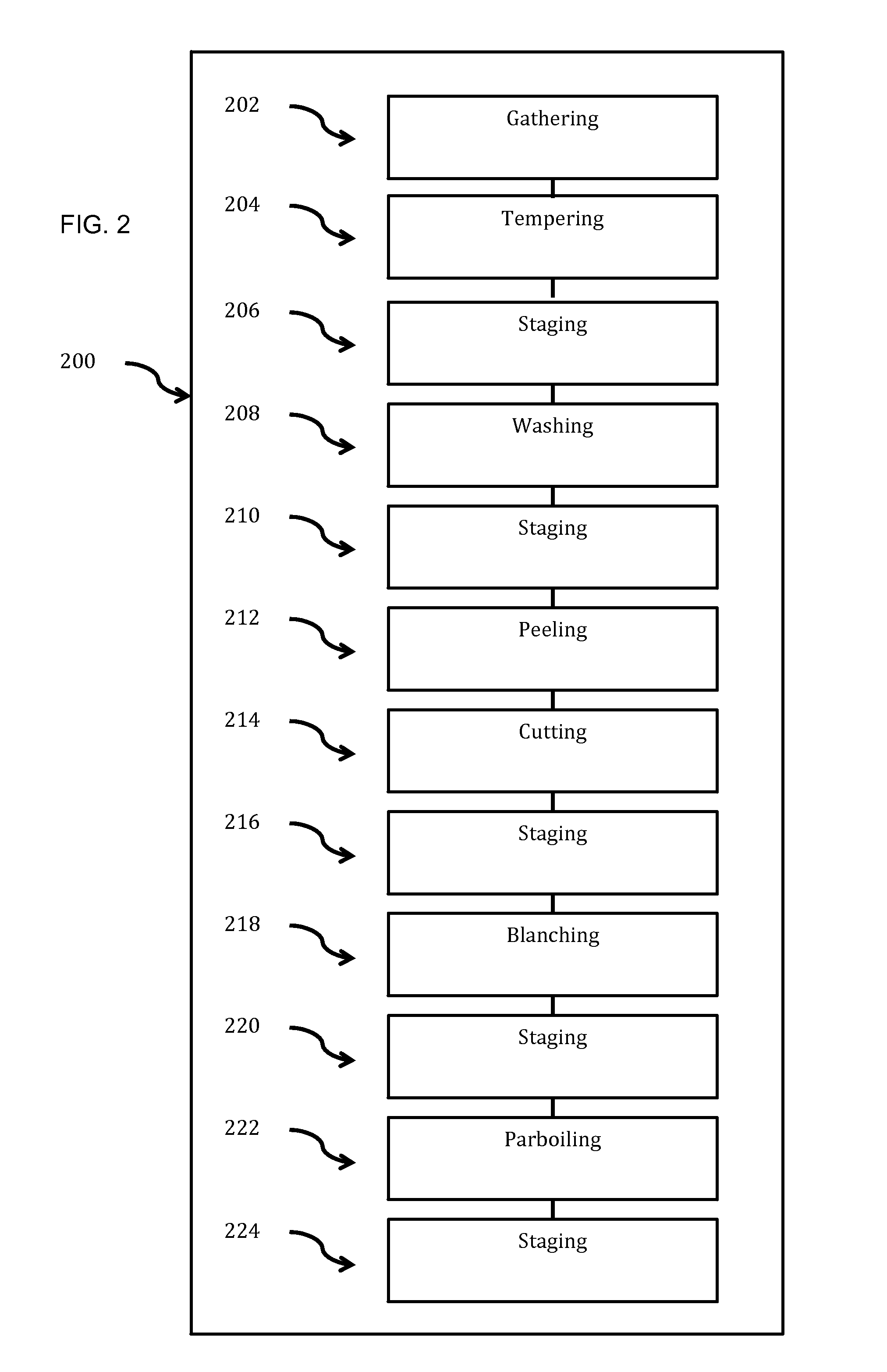

Improved parfried and frozen French fry potato strips and a related production process are provided, wherein the French fry strips exhibit a relatively high solids content and a correspondingly low moisture content in the parfried frozen state. Elongated cut French fry strips are initially blanched and then subjected to an extended dry step for removing moisture therefrom. Following the dry step, the potato strips are partially rehydrated by contacting the external surfaces thereof with a moisture-laden agent such as a batter coating, followed by a single parfry step and prompt freezing. The parfried frozen potato strips exhibit a high solids content on the order of about 33-42%. These high solids strips can be finish prepared by finish frying, or by alternative methods such as heating in a convection oven, with the finish prepared potato strips exhibiting a desirable set of taste, texture and color attributes.

Owner:J R SIMPLOT

Device to efficiently cook food

Deep fryers and associated accessories providing increased efficiency and convenience in the production of deep-fried, steamed and boiled foods. Multiple cooking cycles and versatile food support means to fully cook foods are provided. Special advantages for larger unitary foods, such as for example, a large turkey, are provided. Advantages include without limitation minimizing countertop usage; reduction in the use of frying oil; compact storage; reduced shipping costs; reduced warehousing and manufacturing costs; and being lighter and more easy to handle in the kitchen. Accessory items simplify and facilitate production of deep fried foods, including cutting foods into shapes appropriate to produce French fries and blooming onions. Other accessories facilitate the transference and maintenance of frying oil including: returning frying oil to original containers for storage and disposal; and filtering frying oil to prolong its useful life. Methods are disclosed which help purify oil for extended life without use of filtration.

Owner:RONS ENTERPRISES

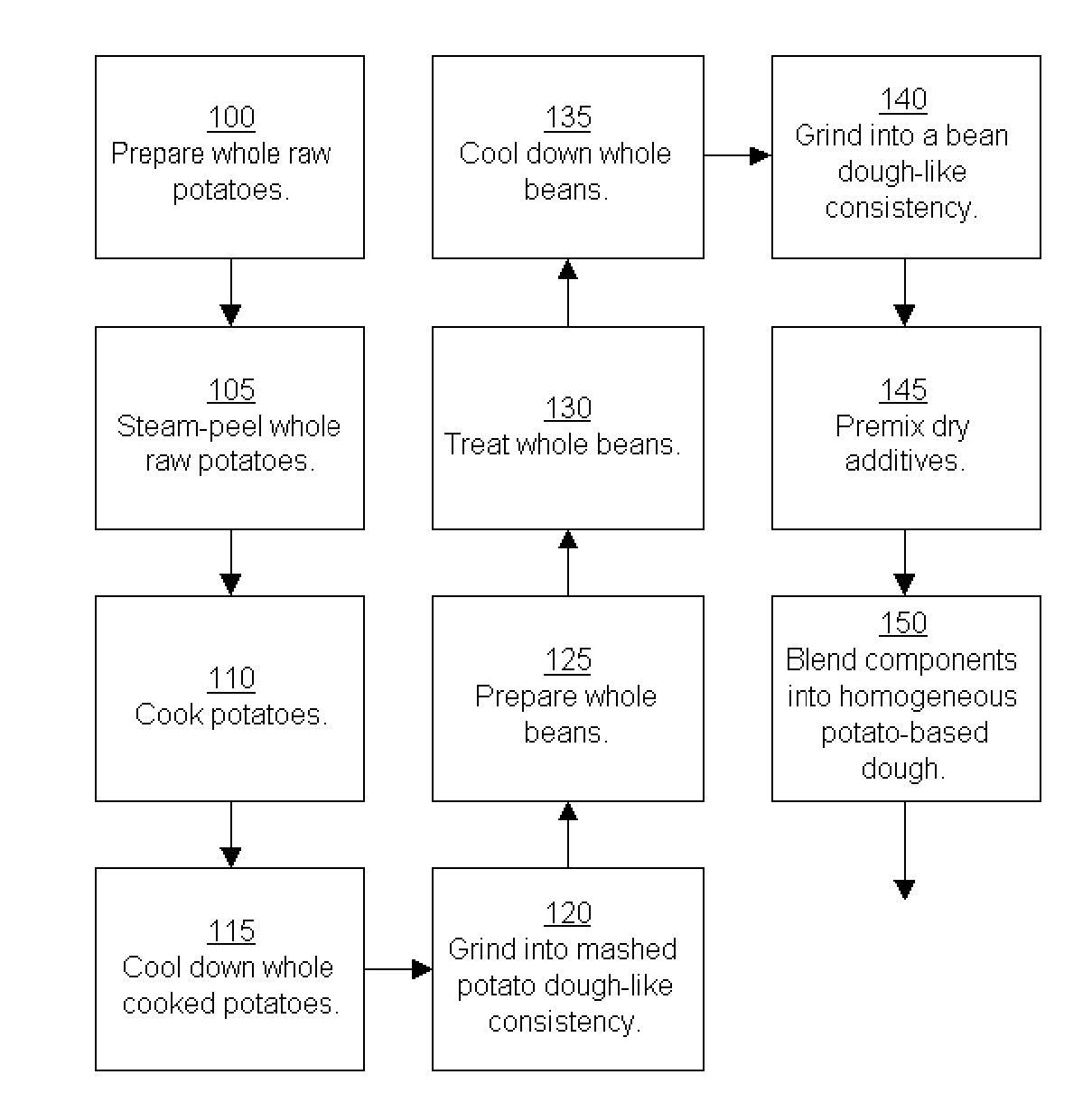

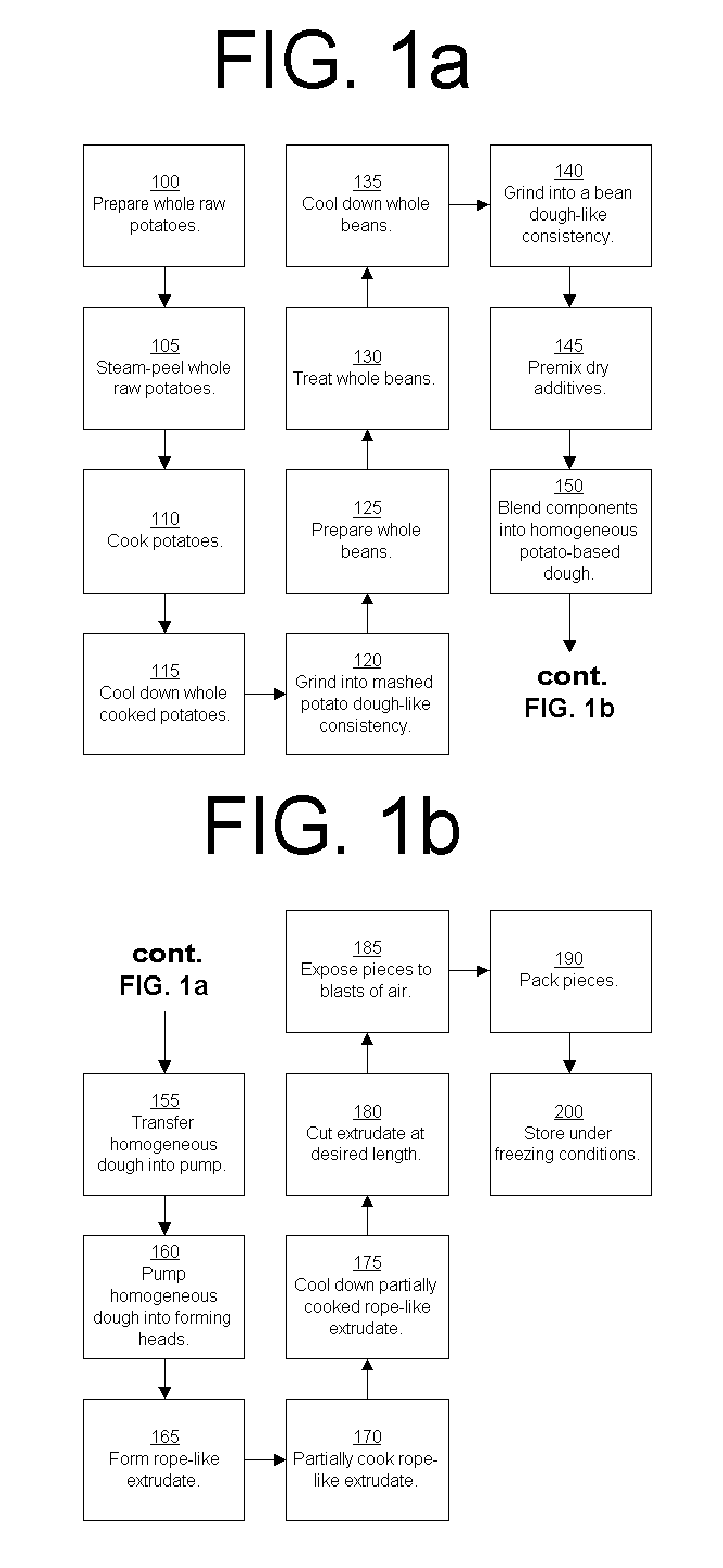

Method of making French fry-style products and composition thereof.

InactiveUS20060233937A1Reduce health hazardsLow in fatFood shapingFood ingredient functionsVegetable oilCooling down

A method is described for making a frozen French fry-style food product, having from about 50.0% to about 70.0% moisture, from about 4.0% to about 8.0% protein, from about 2.5% to about 5.0% fat, and from about 0.25% to about 0.50% fibers, in addition to calcium and phosphorous sources. This frozen potato-based product is made from a composition comprising of steam peeled and cooked whole raw potatoes, soaked or cooked whole beans processed and mixed with the peeled cooked potatoes to create a dough-like consistency to which proteinatious flours, starchy flours, vegetable oil, and other additives are added and blended into a homogeneous potato-based dough. The homogeneous potato-based dough is extruded into a rope-like extrudate which is partially steam-cooked at a desired temperature, then immediately cooled down to a desired temperature. The cold rope-like extrudate is cut into uniform small rods, 2.5 inches long, which are packaged and stored under blast freezing conditions.

Owner:NASSAR ABDALLA +2

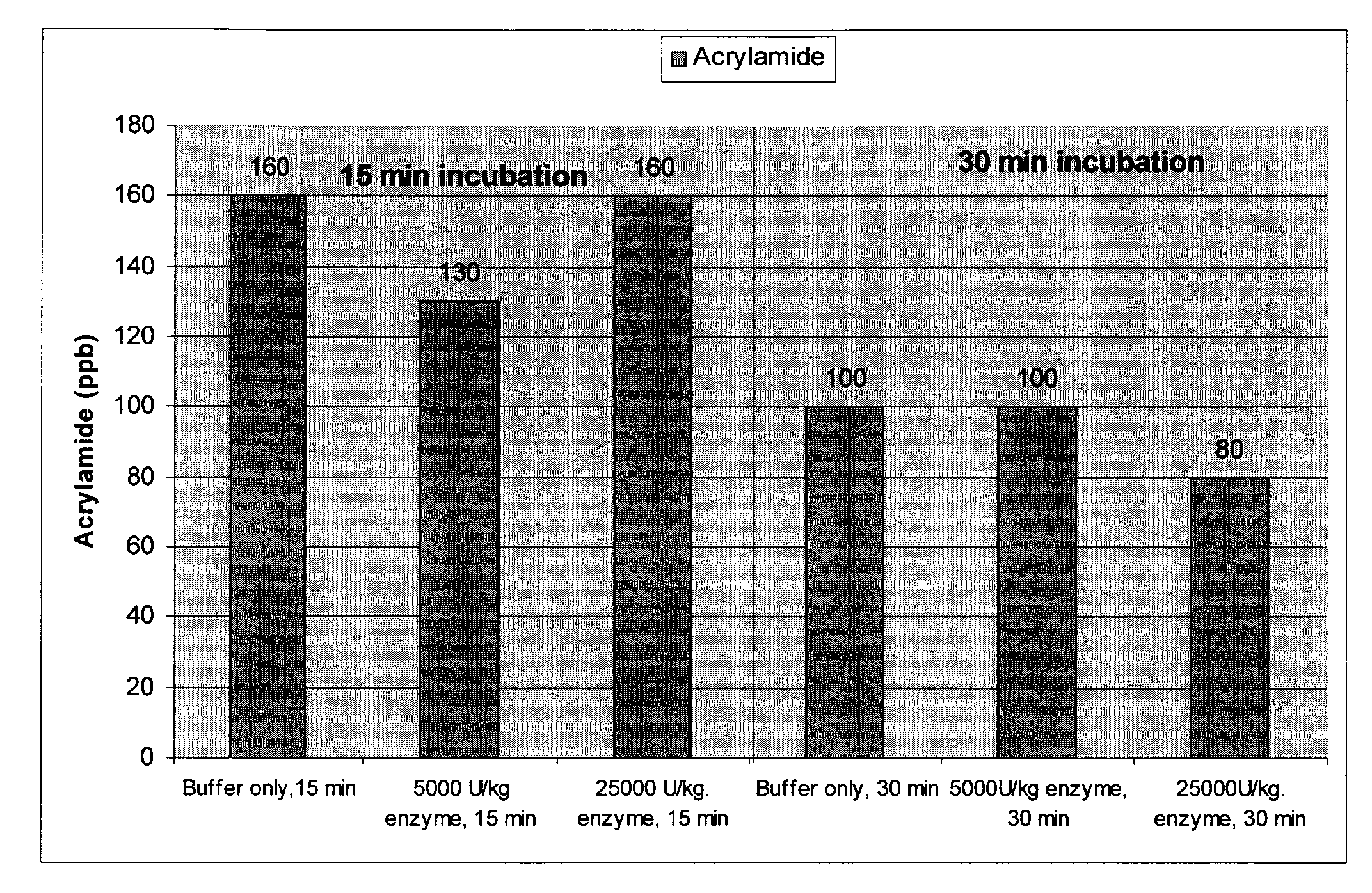

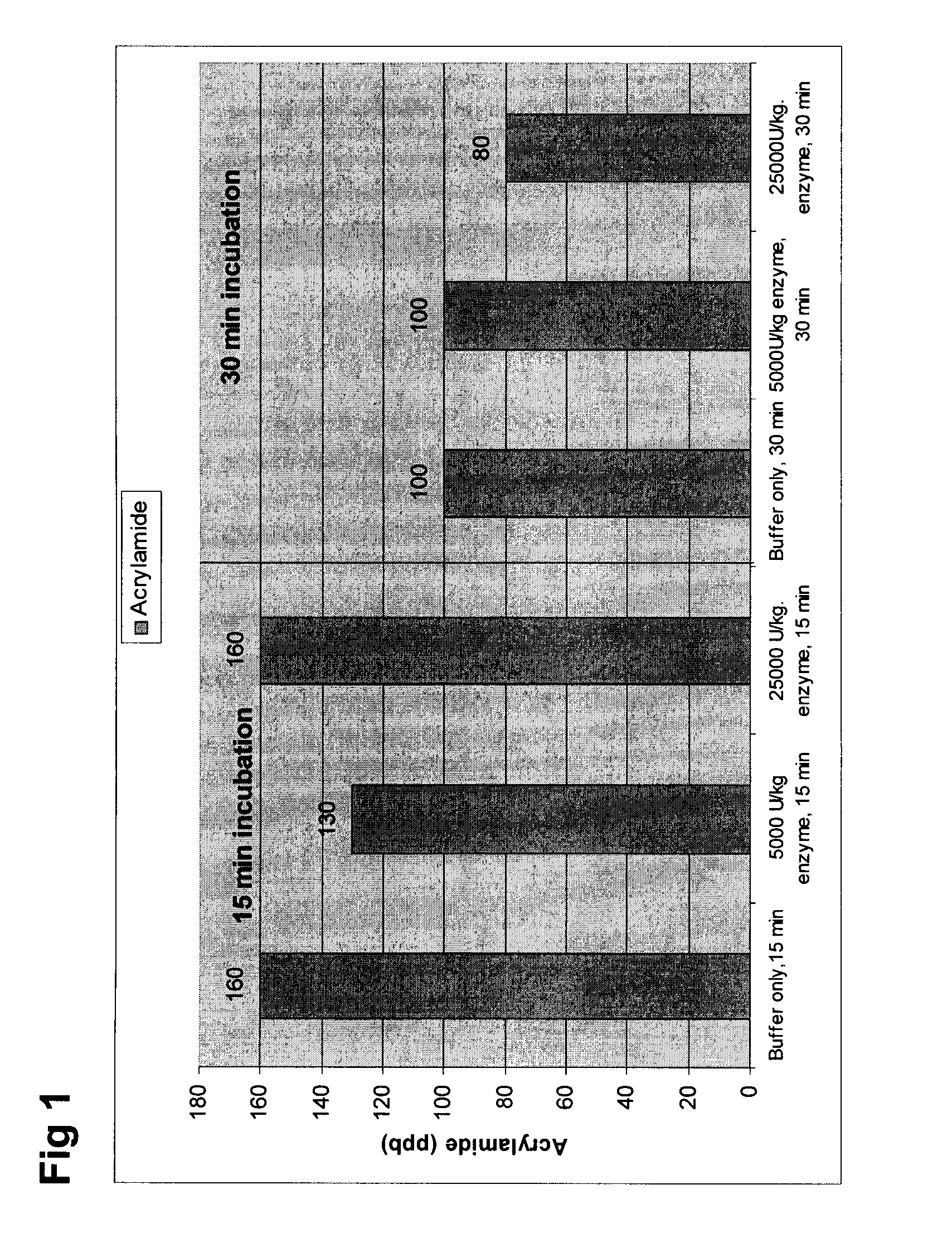

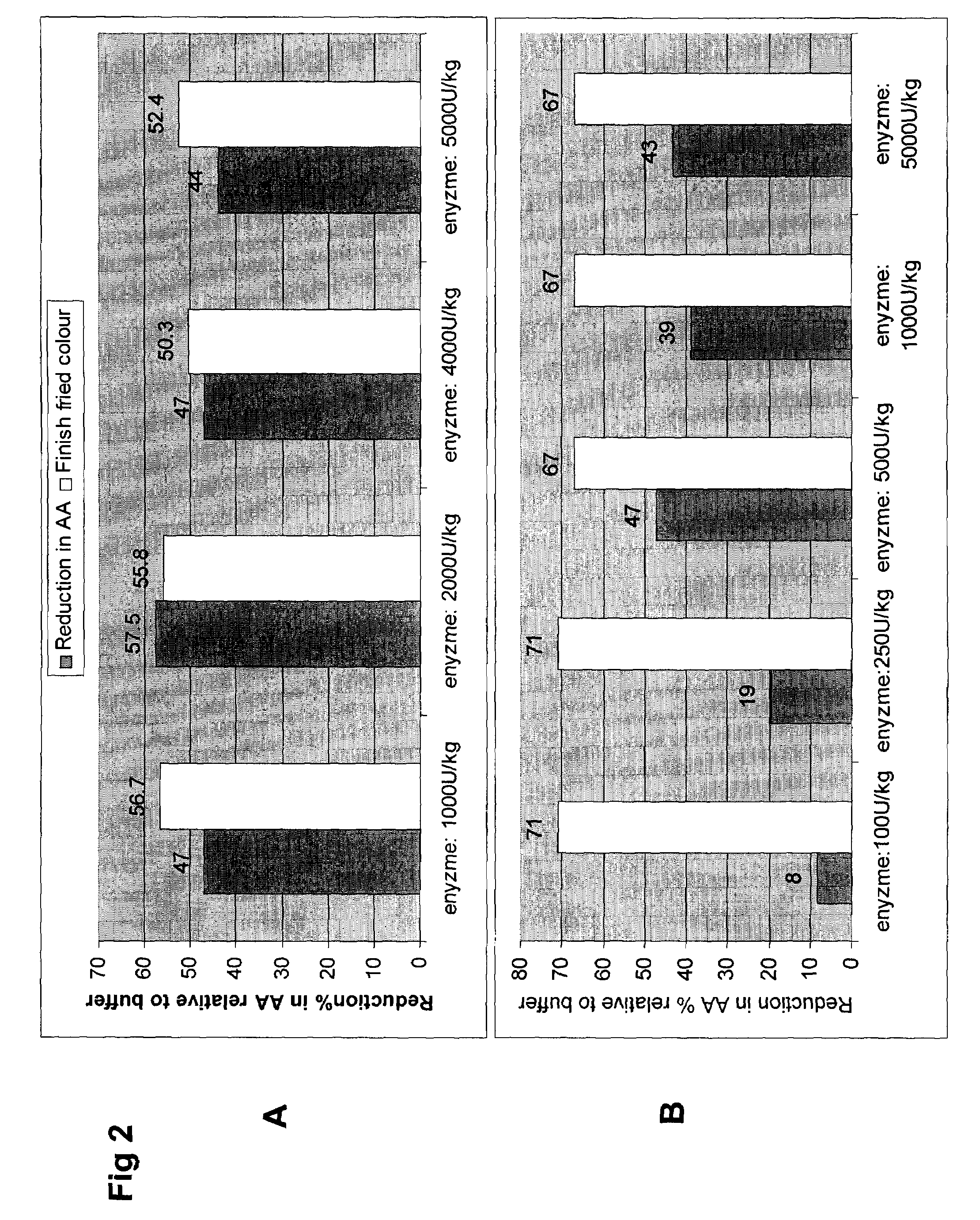

Compositions and methods for surface modification of root vegetable products

InactiveUS20100040729A1Reduce acrylamide contentReduce formationDough treatmentHydrolasesEnzymeVegetable Product

The invention relates to methods and compositions for enzymatic surface modification of root vegetable products by contacting the products with enzyme during a drying process. One embodiment of the invention relates to methods and compositions reducing acrylamide produced by cooking, heating or processing in root vegetable products, such as French fries.

Owner:MCCAIN FOODS

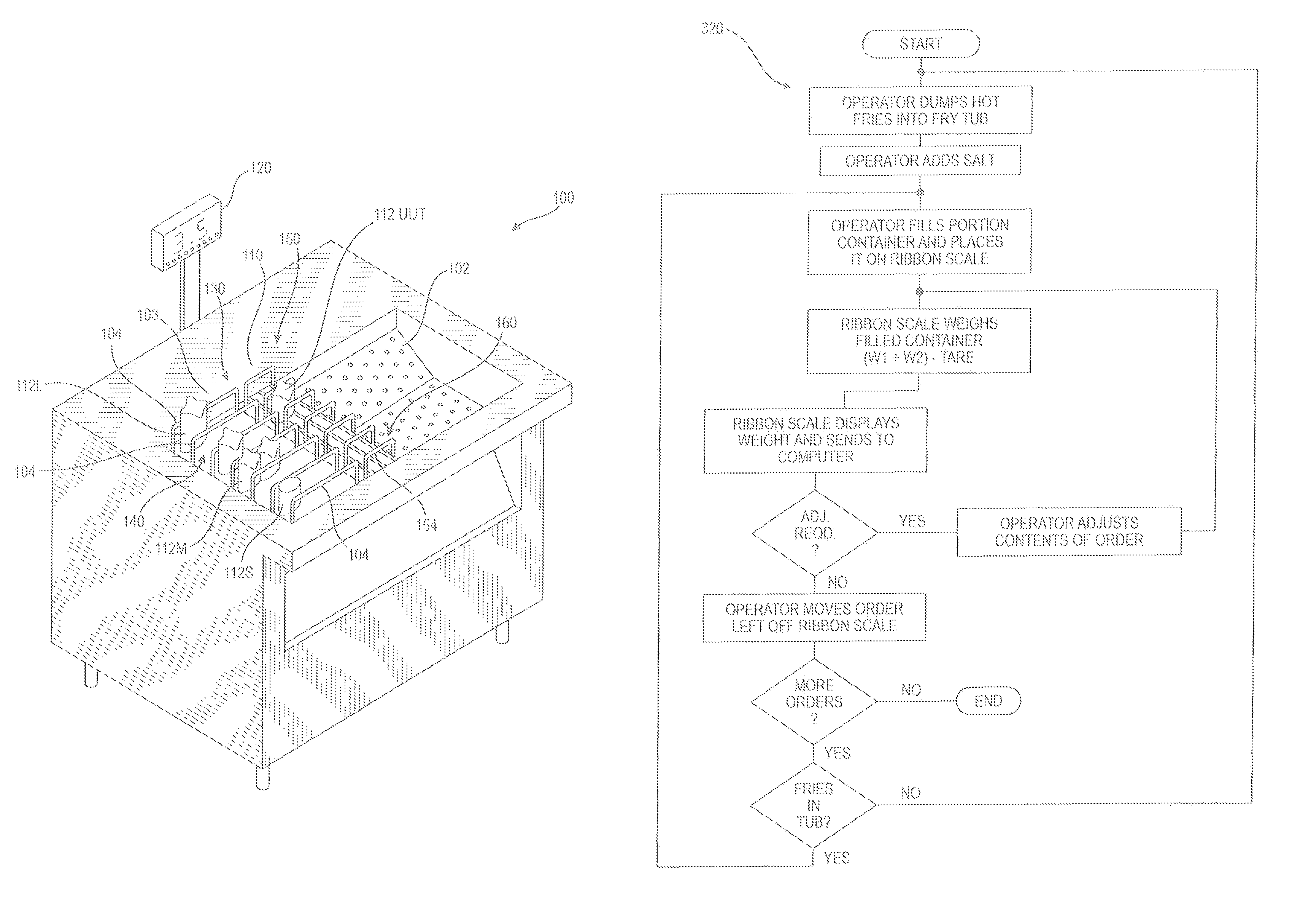

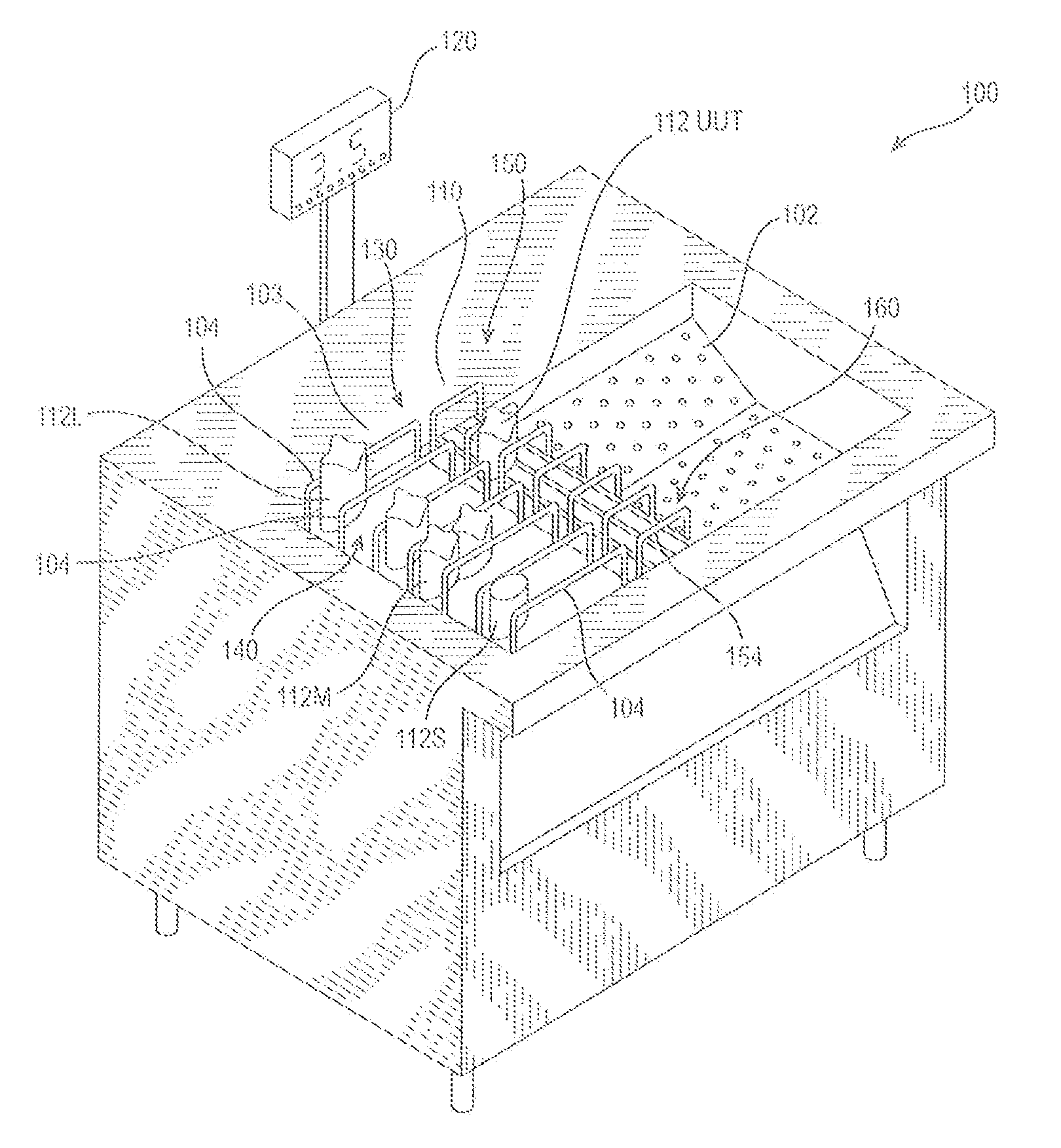

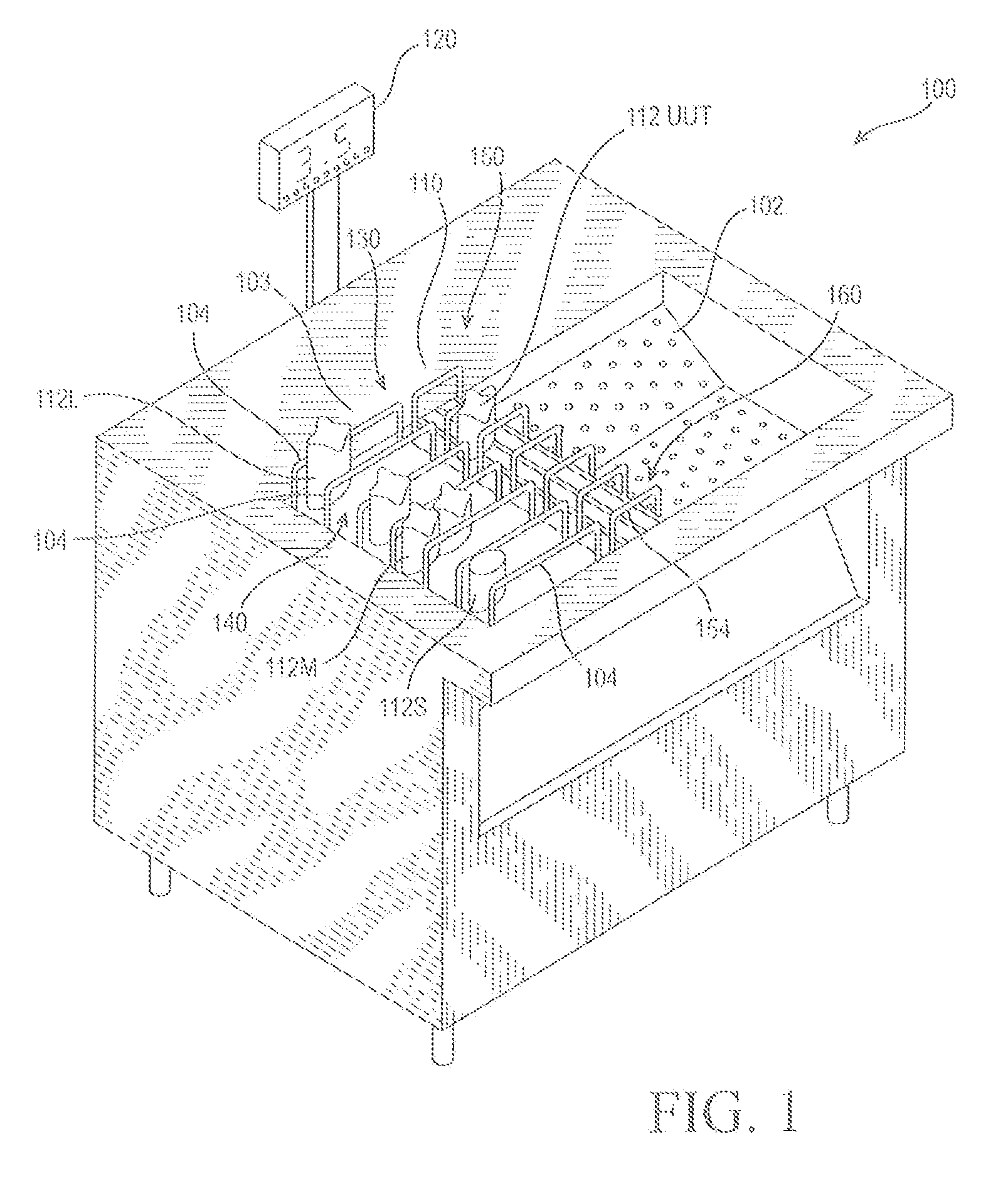

Fry station with integral portion weight sensing system and method

InactiveUS8816223B2Avoiding excessive portionLower Level RequirementsMaterial check-weighingFeeding apparatusPortion sizeOrder form

Owner:RESTAURANT ACCURACY SYST

Method and apparatus for cooking low fat french fries

InactiveUS7794765B2Prevent charring and oxidationMilk preservationSteam cooking vesselsProcess engineeringProduct gas

Owner:MAGUIRE JAMES EDWARD

Oven-baked french fries having extended hold time

Coated French fried potatoes which maintain crispness for at least about 10 minutes. The French fries have at least a 0.1 mm starch-based surface coating and Texture Value of at least about 170 after an extended holding time. The holding time is a measurement based on (1) 4 minutes holding under a heat lamp, (2) 3 minutes holding under a heat lamp in Foodservice serving bags and (3) at least 3 minutes holding in a closed carry-out bag. The par-fries have specific properties which, upon oven-finishing, deliver a unique texture. The coated oven-finished French fries have about 28% to about 50% bulk moisture and from about 8% to about 25% total fat. The par-fried potato strips used to prepare the oven-finished French fried potatoes are coated with a starch suspension. The coating has a low water solubility starch fraction as one of its ingredients. The low water solubility starch fraction has a water solubility index of less than about 30%. The par-fries can be finished in a conventional oven in less than about 10 minutes. The time required to finish the par-fries in a forced air convection oven is less than about 5 minutes. The coated par-fried potato strips have a bulk moisture of about 30% to about 55%, and a total fat of about 6% to about 25%.

Owner:THE PROCTER & GAMBLE COMPANY +1

Method of producing a baked egg based foodstuff and the products thereof

A method of making an egg based product includes providing a selected amount of a liquid egg base that is poured onto a cooking surface such that the egg base has a selected thickness. The egg base is heated to a selected temperature such that the liquid egg base coagulates into a solid mass. The solid mass is formed into French fry shaped pieces and transferred to an oven where the French fry shaped pieces are subsequently baked for a selected amount of time. The French fry shaped pieces are removed from the oven for consumption or refrigerated or placed in frozen storage for reheating by an end user or consumer.

Owner:REMBRANDT ENTERPRISES

Food material technology with controllable functional characteristics and industrial process applications, and the resulting fabricated foods

ActiveUS7691430B2Increase and decrease levelReduce frictionDough treatmentBaking mixturesCooking & bakingProcess equipment

A novel high-protein, reduced carbohydrate food material technology, and high-protein, reduced carbohydrate food products made therefrom, in which the food products meet high organoleptic, stability, and taste / texture standards. This novel material technology possesses numerous controllable functional characteristics, including high to low adhesion, high to low volume expansion, high to low tensile strength, and high to low break elongation, all of which are critical to both processing needs as well as final food product specifications. The material technology allows for the processing of proteinaceous foods on common process equipment, the foods including but not limited to chips, snacks, crackers, wafers, bars, flat breads, cookies, biscuits, breads, bagels, cakes, waffles, pancakes, french fries, pasta, pizza dough, breakfast cereals, muffins, doughnuts, pastries, and meat analogs. The material is an edible dough that possesses the material characteristics necessary for numerous industrial food processes, including direct reduction sheeting, lamination sheeting, extrusion, die cutting, and rotary molding, followed by on or more of baking, drying, microwaving, boiling, steaming, frying, seasoning, and enrobing.

Owner:SEARS IP LLC

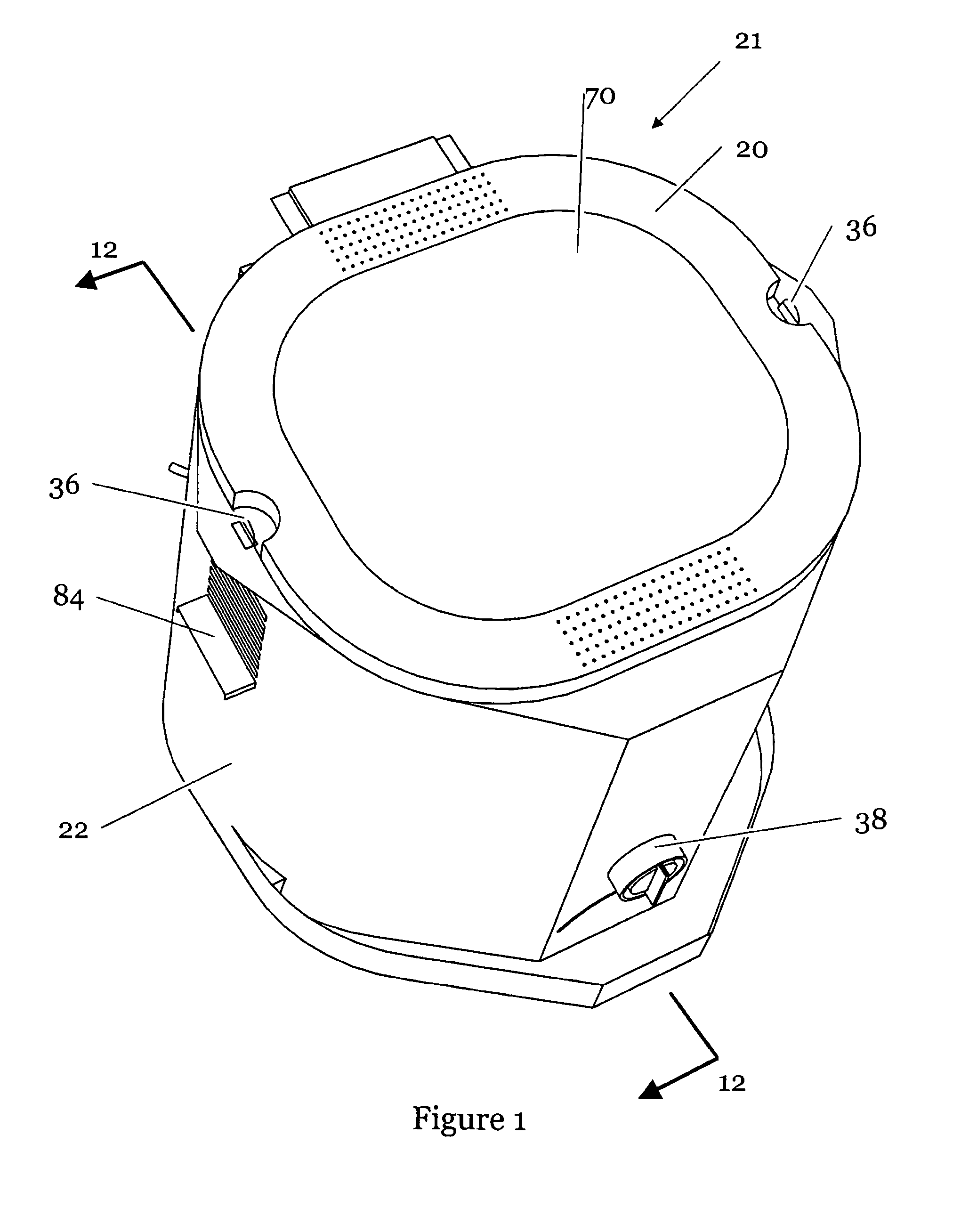

Fry station with integral portion weight sensing system and method

InactiveUS20130008725A1Avoiding excessive portionDiminish profit levelWeighing indication devicesMaterial check-weighingPortion sizeDisplay device

A food portion preparation station has an integral portion weight sensing system configured for portion control. A fry ribbon with integral portion weight sensing includes a weight sensor and software to weigh individual orders of comestibles such as french fries in selected portion sizes and as the operator is adding comestibles to the container, an instant indication is provided on a display showing the operator that a full order or portion is delivered while avoiding unnecessary loss in excessive portions, thereby preserving the restaurant owner's profit margin. Comestibles are taken from a holding area and placed into a container having a selected portion size corresponding to an assigned weight. The fry ribbon structure incorporates the weight sensor and each weighed portion is moved laterally along the queue defined by ribbon area for retrieval and service to a customer.

Owner:RESTAURANT ACCURACY SYST

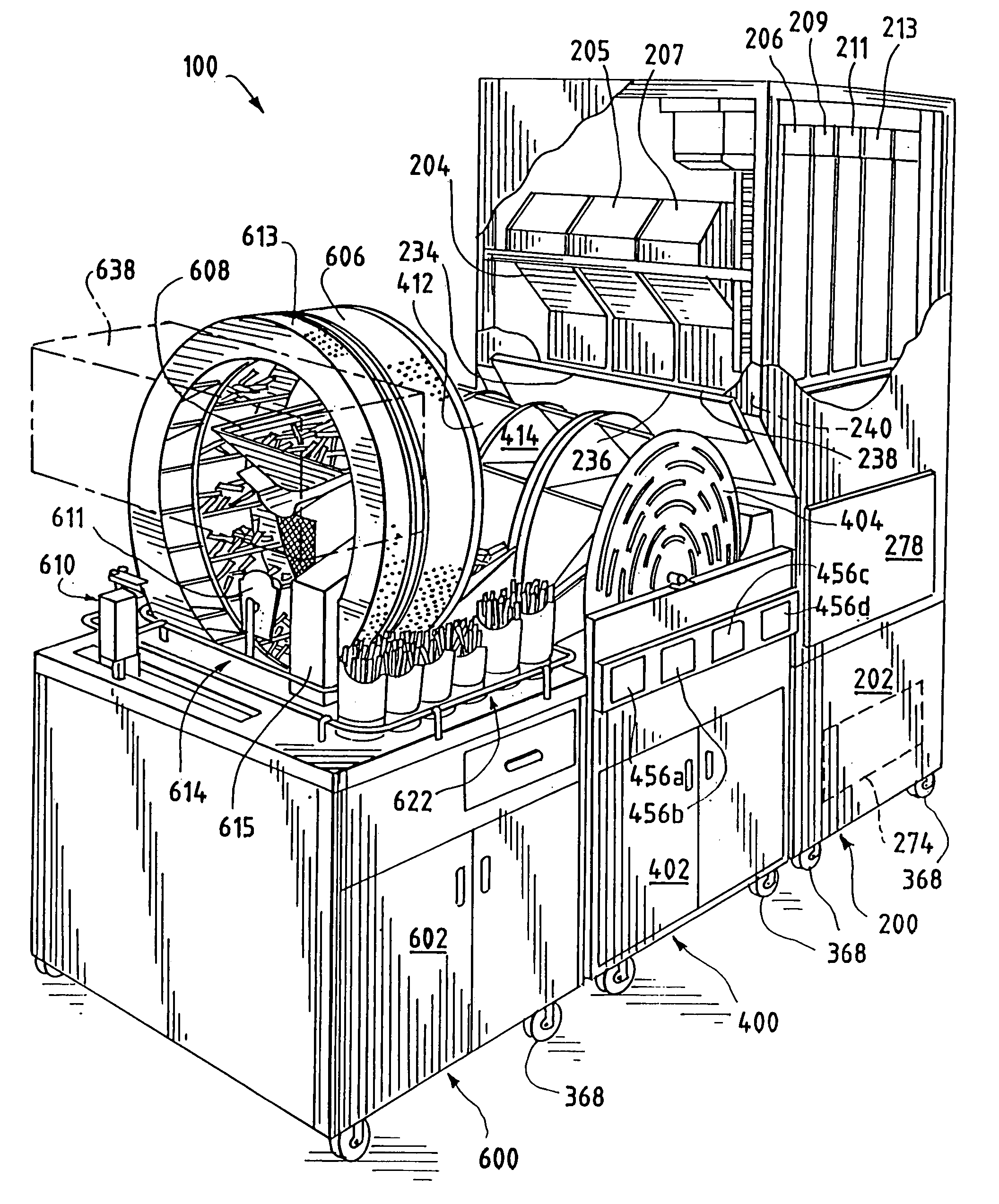

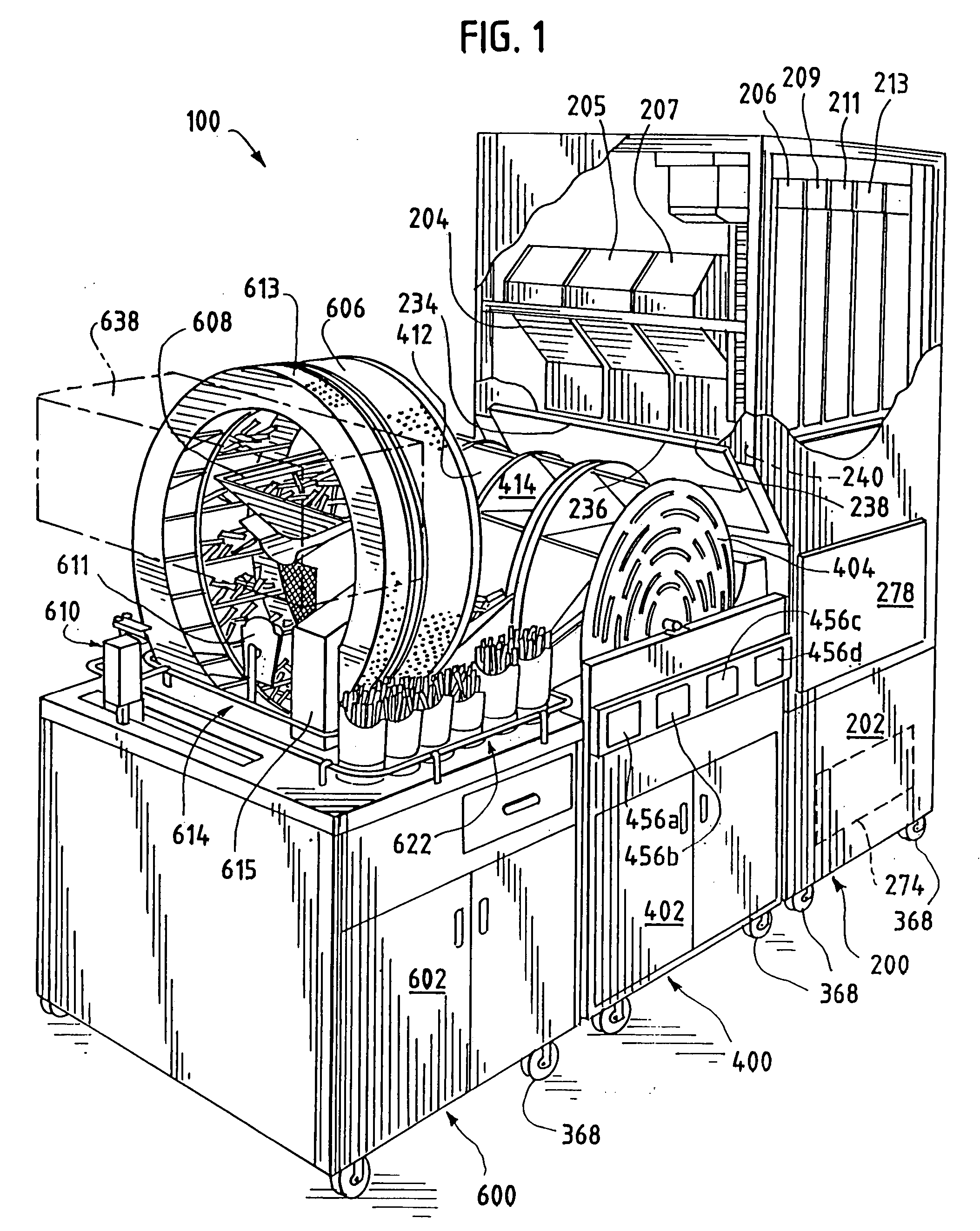

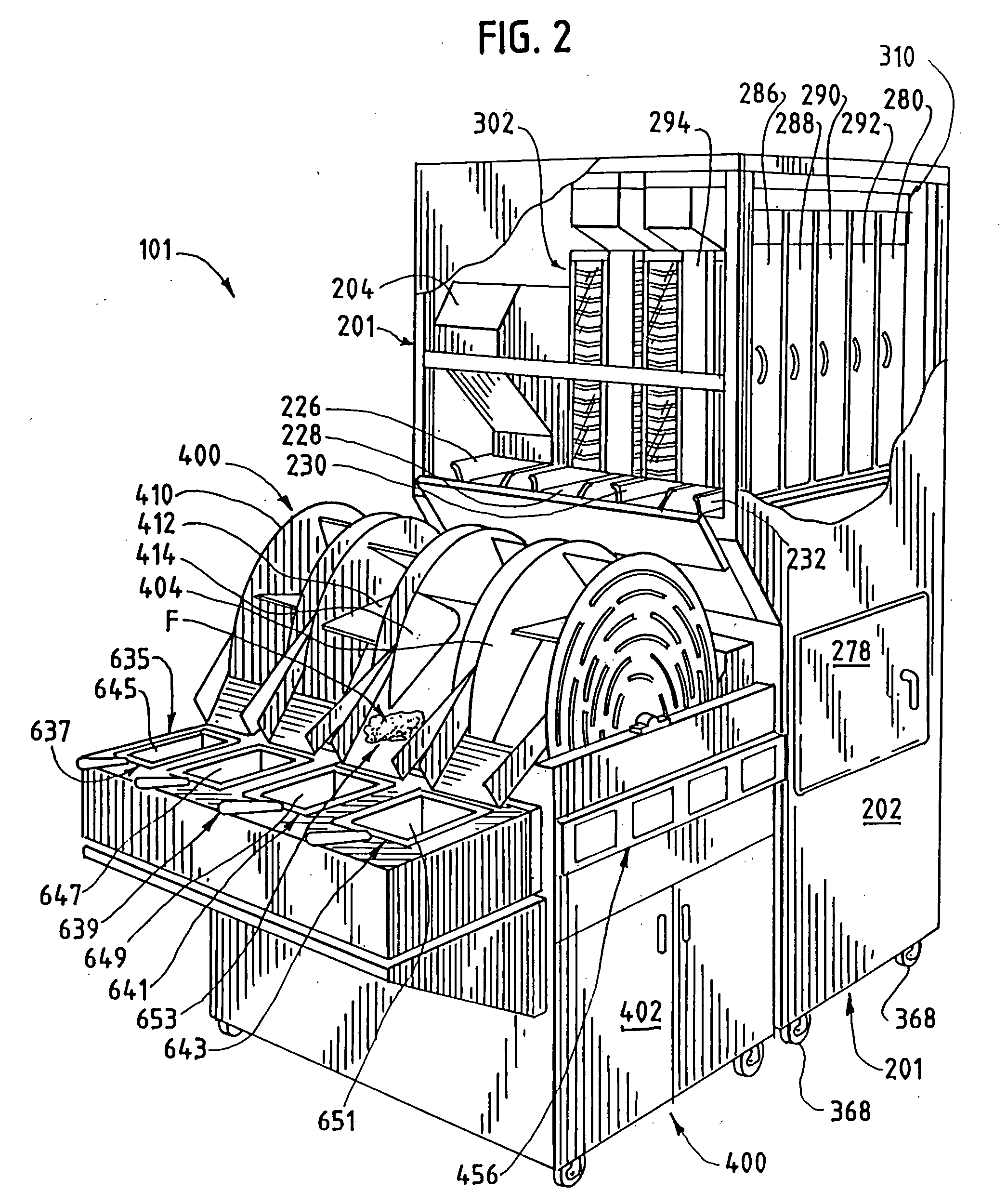

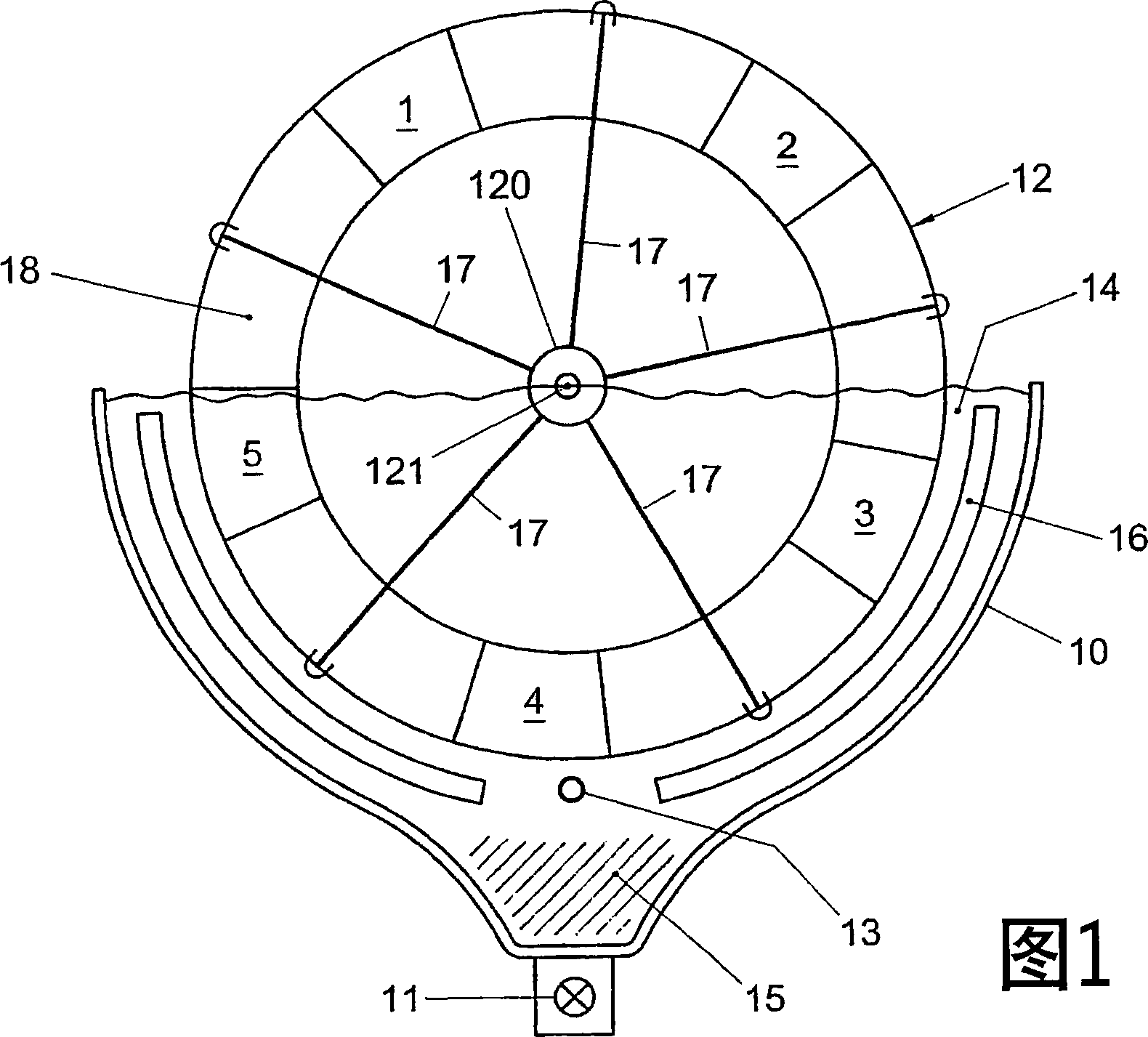

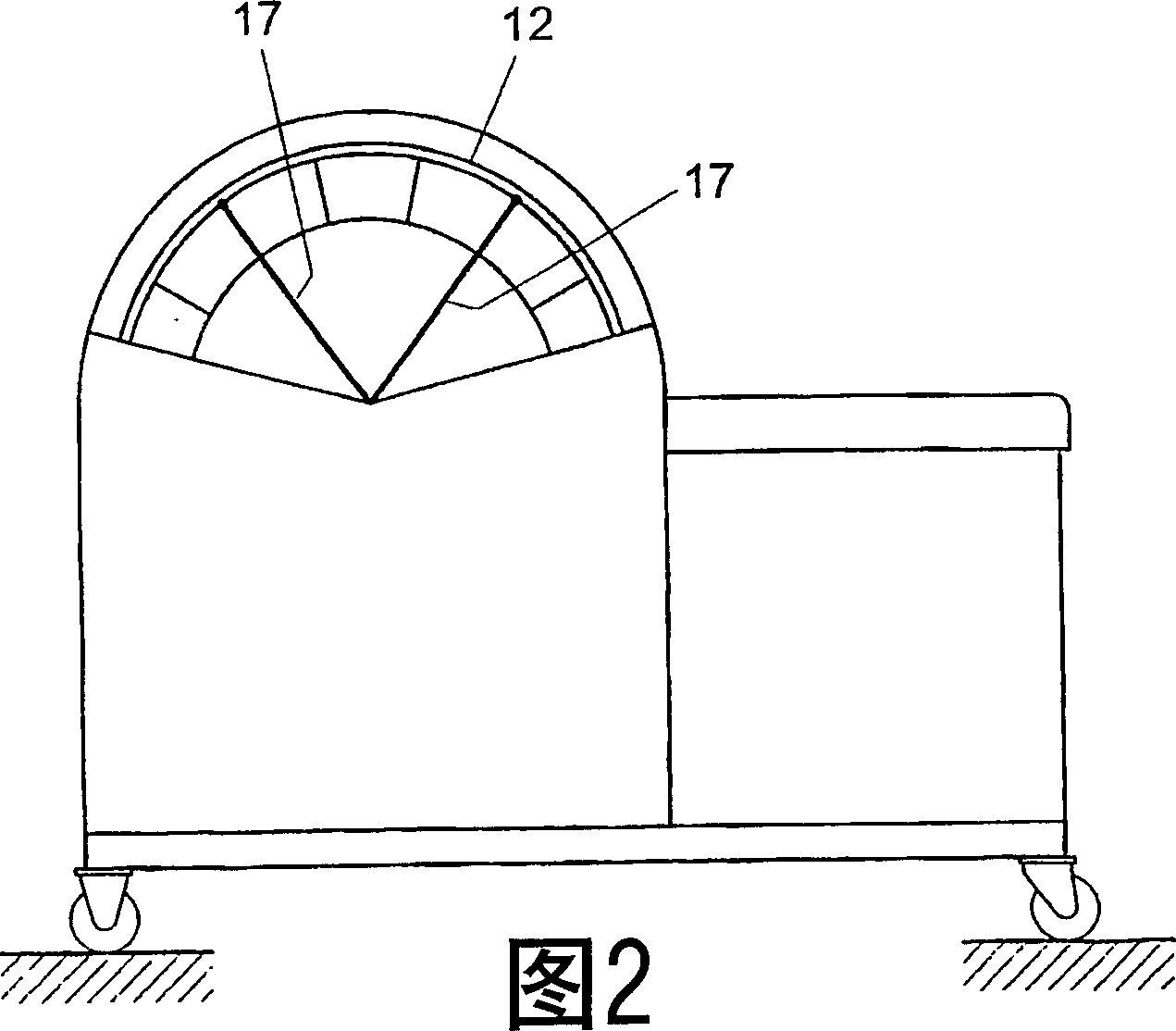

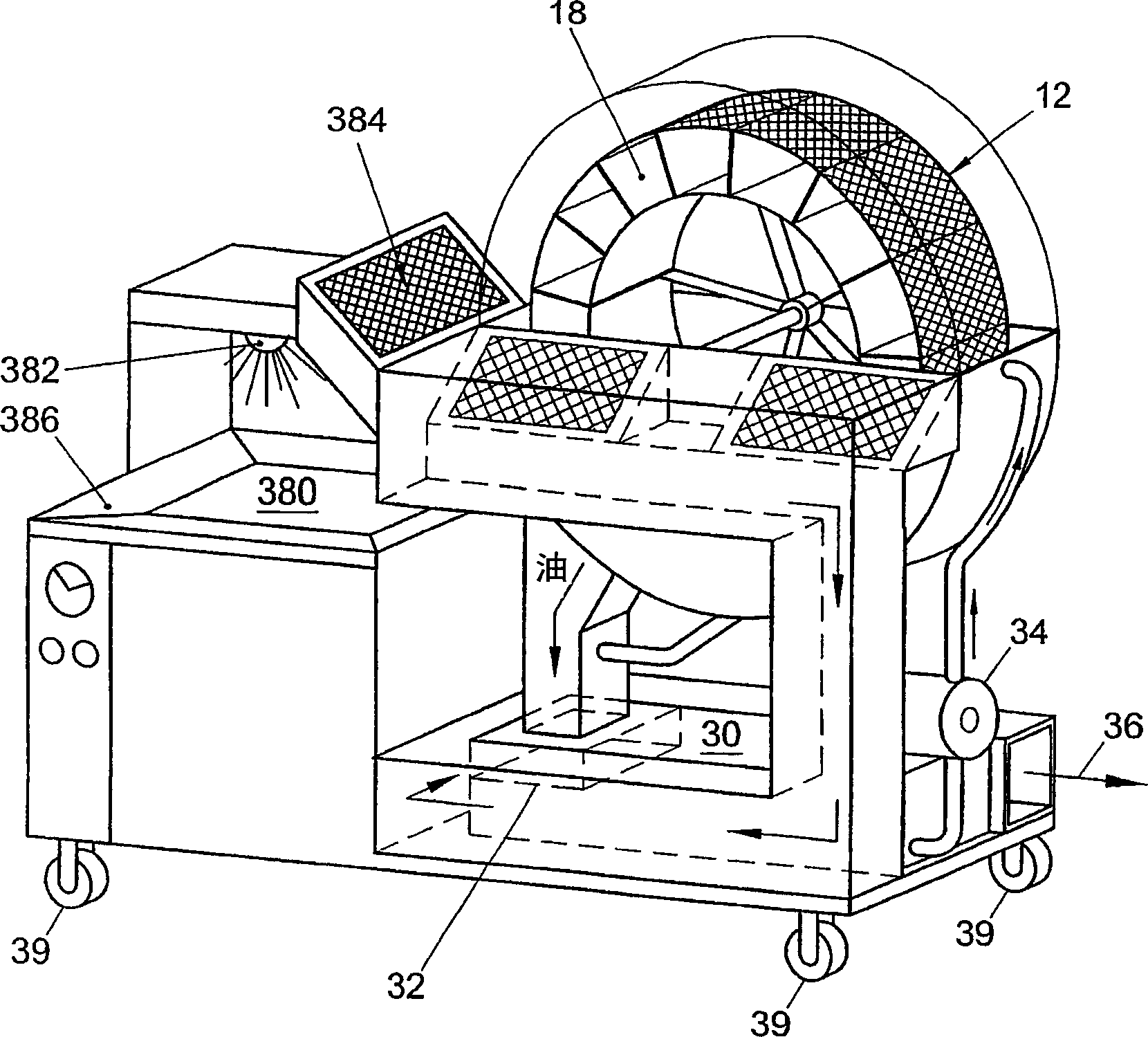

Food heating apparatus

A rotating wheel is suspended with its lower part in heated fluid such as oil. Batches of food such as French fries are inserted in respective baskets. The baskets are connected at respective positions to the wheel, so that each basket is kept oriented at a respective fixed angle relative to the wheel. The wheel is rotated at a constant speed. As a result the baskets are moved from a loading region outside a heated fluid into a heated fluid and again out of the fluid. The rotation speed is such that the food is done when a basket in which the food is contained leaves the fluid. The wheel makes the baskets turn over relative to an axis of gravity while the baskets move through the fluid, so that the food is evenly heated. Preferably, the wheel contains a lid surface around its perimeter, against which the baskets are placed to close off an opening of the baskets. The lid surface is preferably composed of individually detachable segments to facilitate cleaning.

Owner:QUALIFRYER

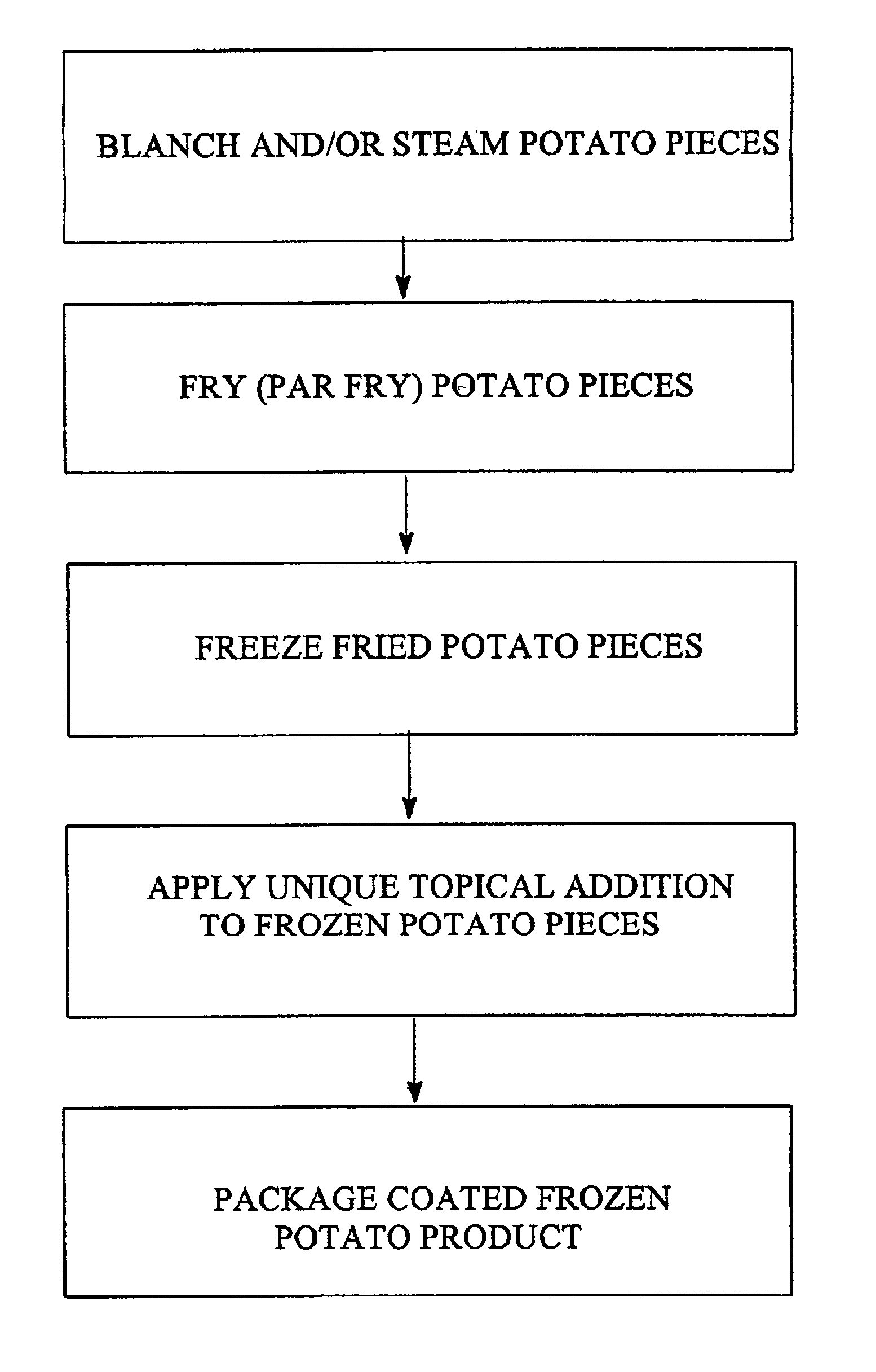

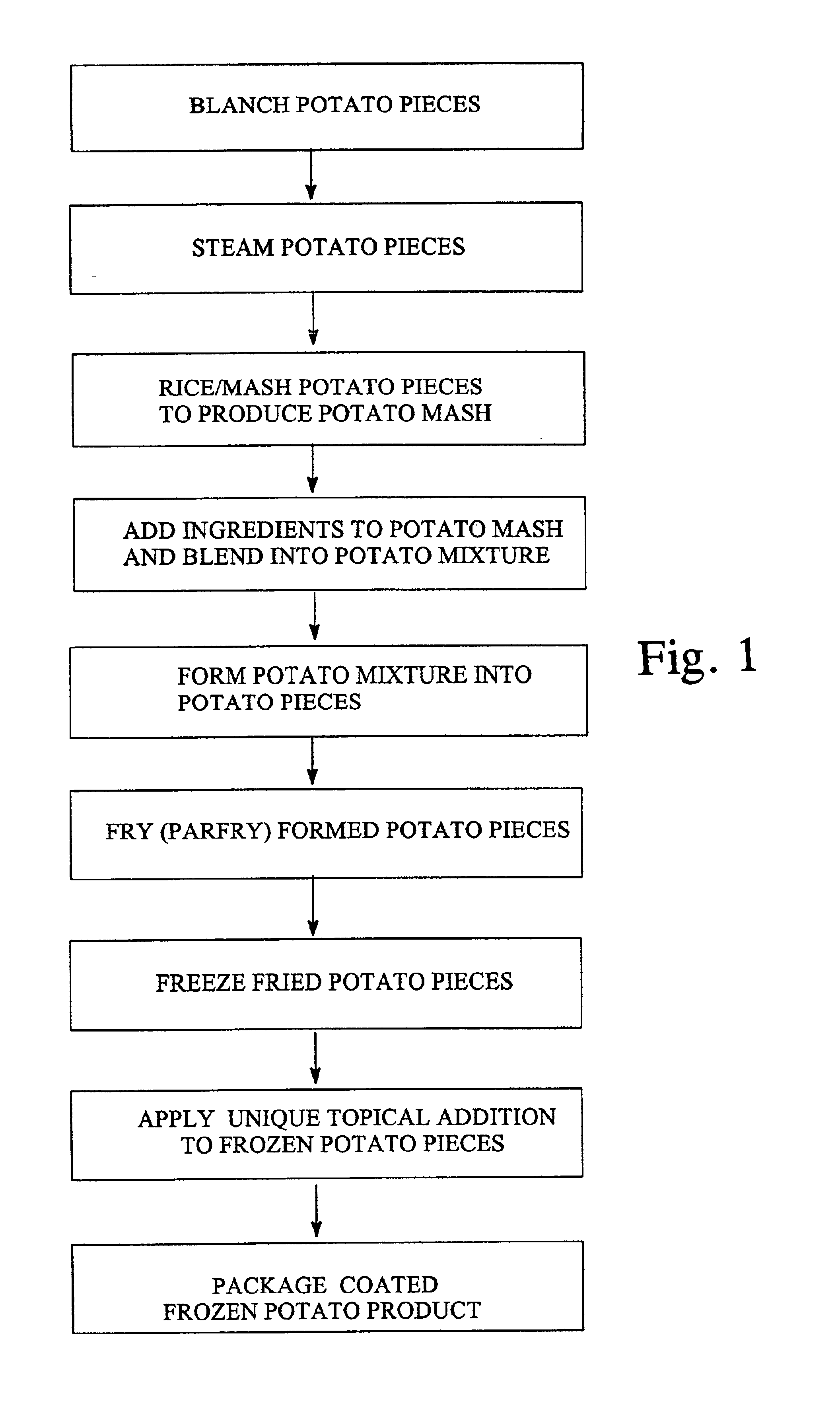

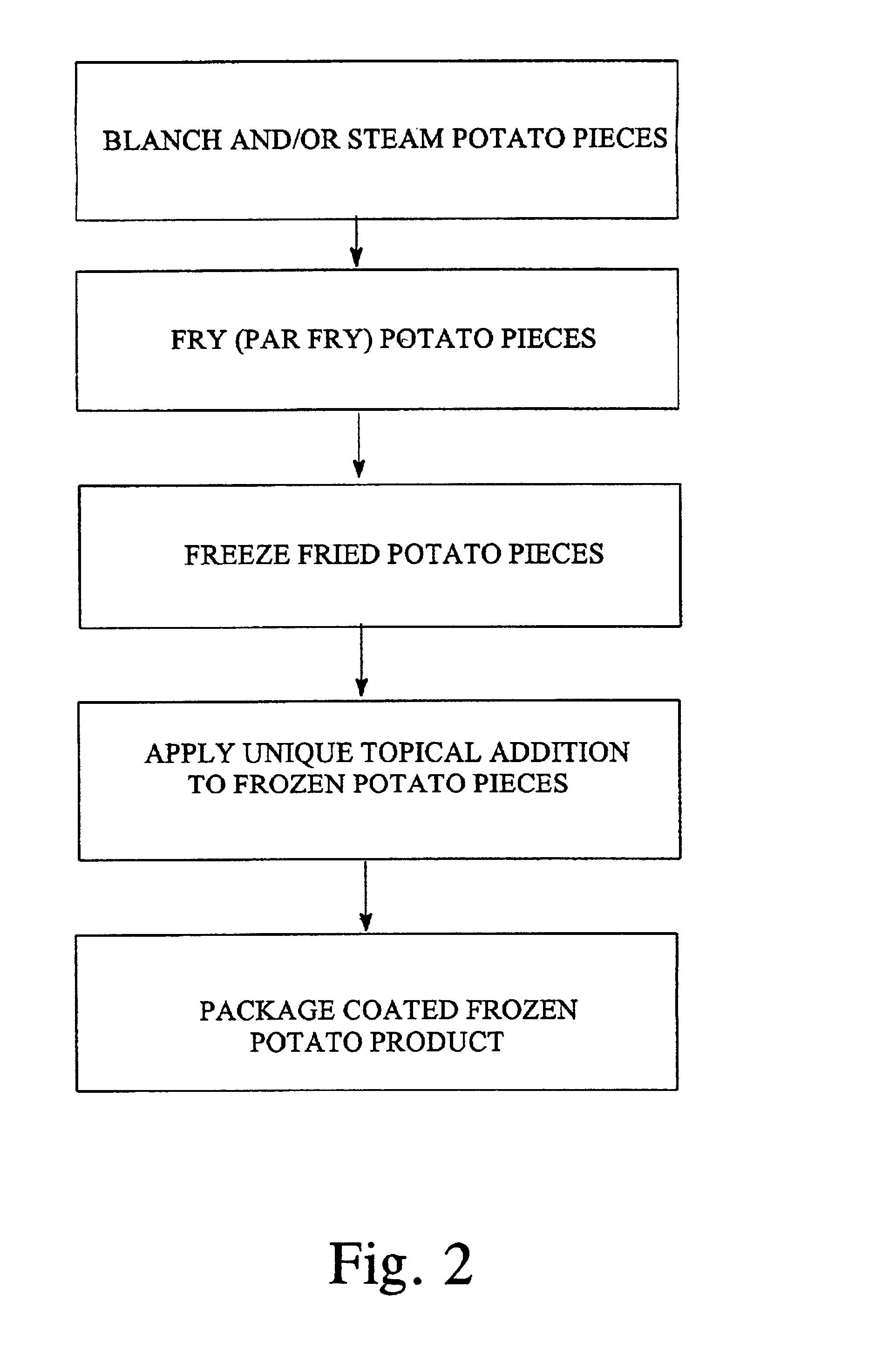

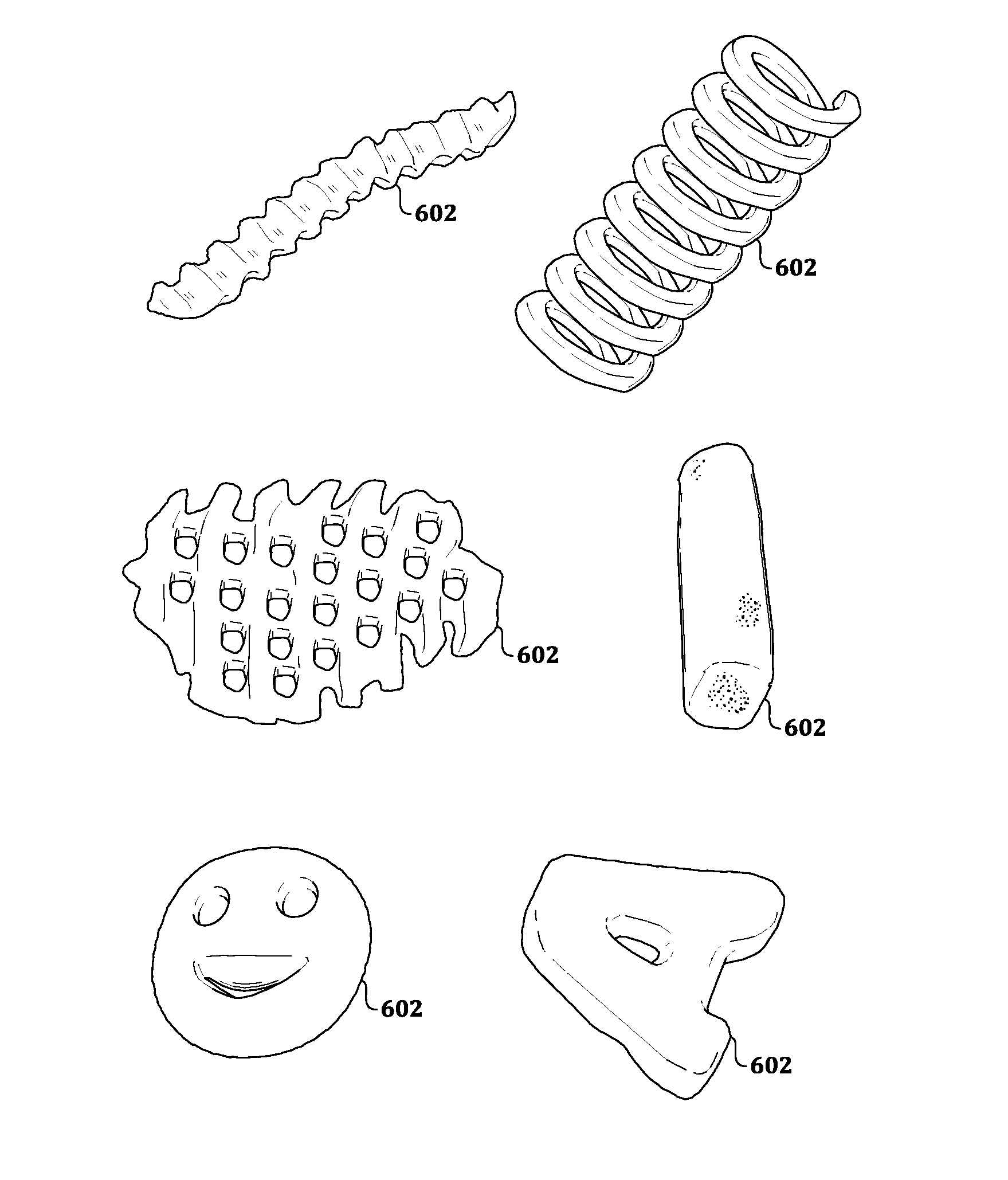

Process of preparing frozen french fried potato product

A frozen French fried potato product possessing unique taste characteristics is manufactured by producing potato pieces having a desired shape, frying the potato pieces, freezing the potato pieces, and applying a topical addition to the frozen potato pieces. The topical addition is preferably an encapsulated topical addition in which a water soluble ingredient other than salt is encapsulated in an encapsulation material. To impart sweet taste characteristics to the frozen French fried potato product, the topical addition is an encapsulated sugar. The resulting frozen French fried potato product is constituted by potato pieces that have been fried and frozen, with the topical addition such as encapsulated sugar applied to the outer surface of the frozen French fried potato pieces.

Owner:HEINZ +1

Methods and Compositions for Preparation of Formed Food Products Using Fresh or Prepared Vegetables and/or Legumes and Other Ingredients

InactiveUS20140363553A1Fast preparation timeLess timeMeat/fish preservationFood coatingAdditive ingredientFood flavor

Fresh potatoes, and / or other fresh vegetables or legumes, or any ingredients already frozen, processed, or otherwise prepared, are processed to make more healthful French fry products and other formed food items in any of a variety of shapes and flavor profiles while attaining the organoleptic qualities of traditional formed-food products.

Owner:B&G FOODS NORTH AMERICA INC

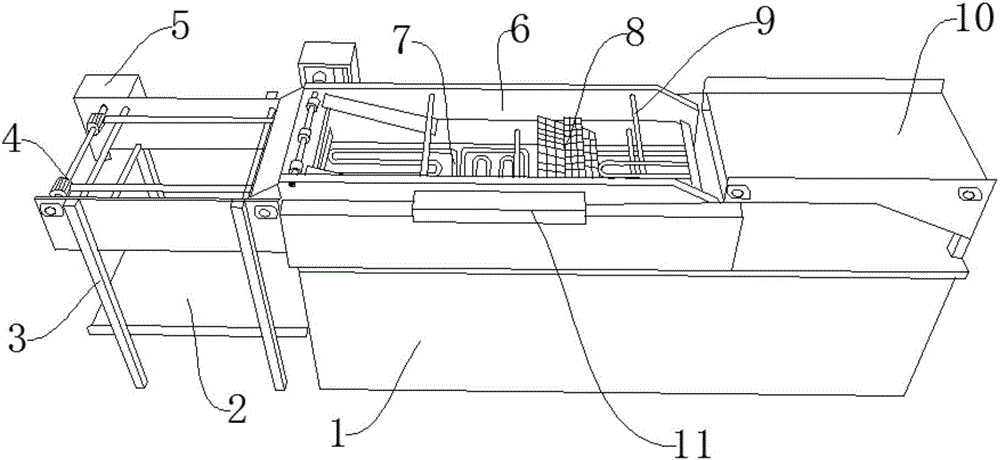

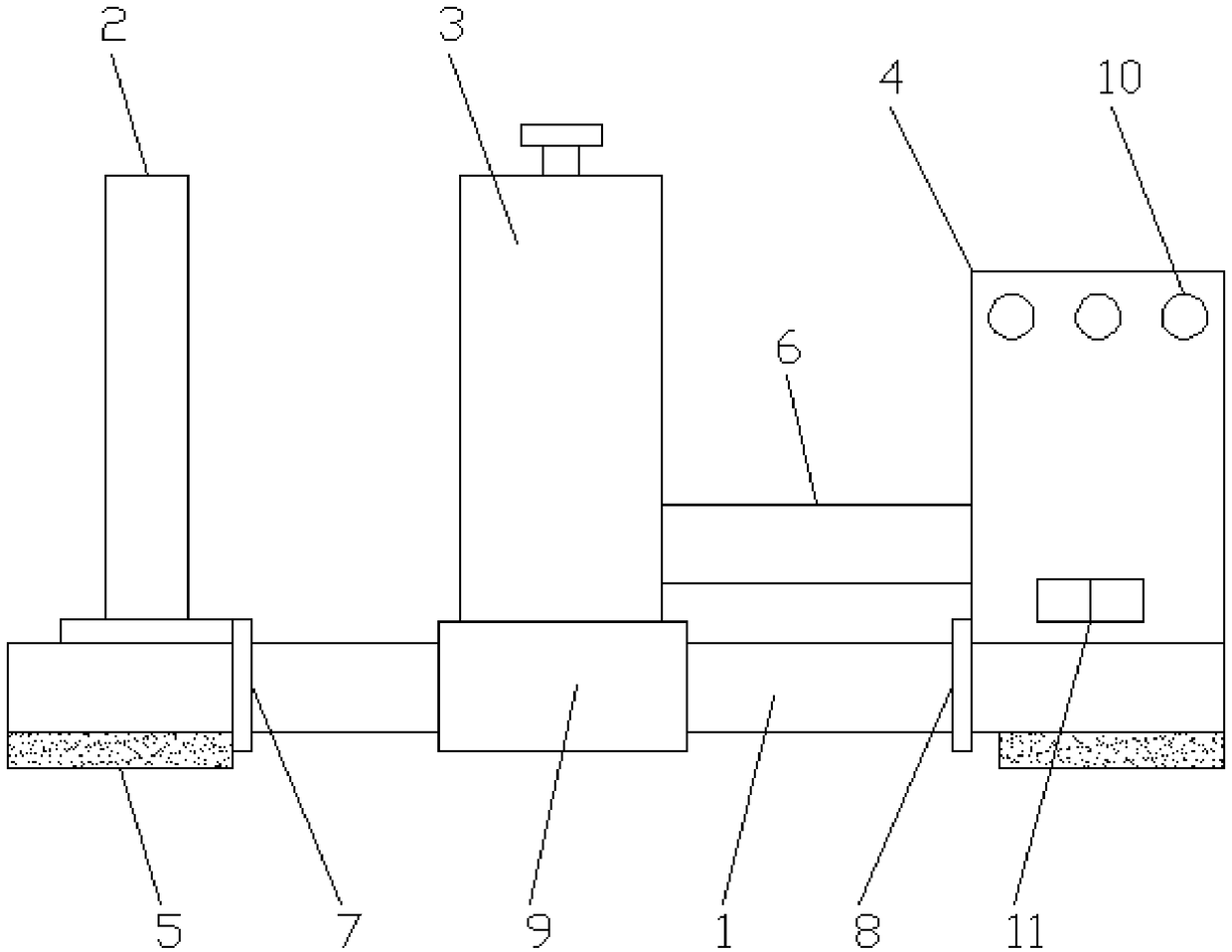

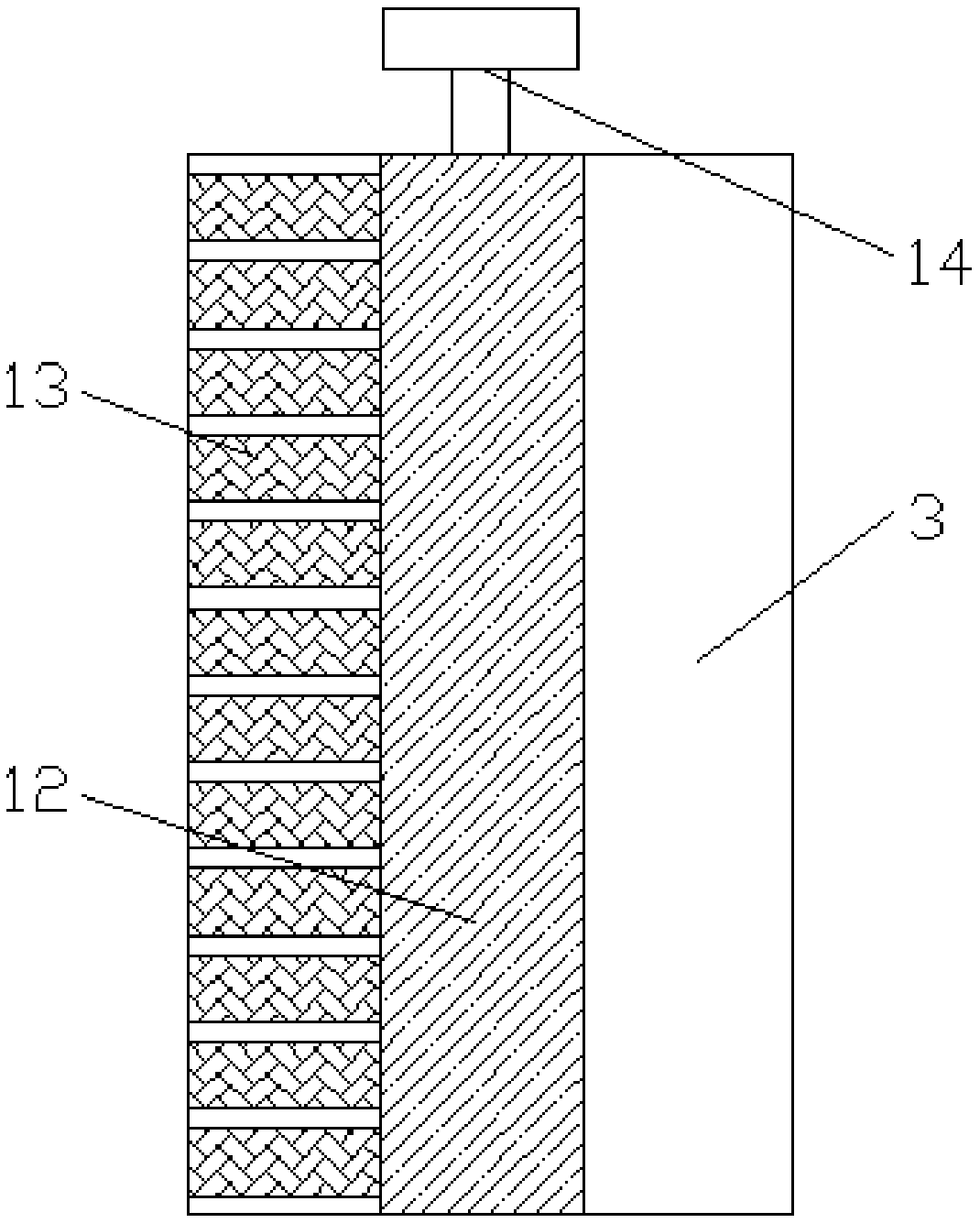

Novel French-fries processing factory deep-frying equipment

The invention discloses a novel frying equipment for a french fries processing plant, comprising a protective shell, a french fries placing plate, a support frame, a transmission wheel, and a controller. One side of the protective shell is provided with the french fries placing plate. One side of the french fries placing plate is provided with the support frame, the upper part of the support frame is provided with the transmission wheel, one side of the transmission wheel is provided with the controller, and one side of the controller is provided with There is a frying box, a heating pipe is arranged below the frying box, a tumbling fan is arranged above the side of the heating pipe, a connecting shaft is arranged on one side of the tumbling fan, and one side of the connecting shaft is arranged A French fries entry device is provided, and a reinforcing plate is arranged on one side of the French fries entry device. The beneficial effects are as follows: the structure is compact, the operation is convenient, the frying, discharging and feeding actions of the french fries are realized, the safety factor of the operator is improved, and the work efficiency is high.

Owner:XUZHOU BEIER ELECTRIC CO LTD

Method of producing a baked egg based foodstuff and the products thereof

A method of making an egg based product includes providing a selected amount of a liquid egg base that is poured onto a cooking surface such that the egg base has a selected thickness. The egg base is heated to a selected temperature such that the liquid egg base coagulates into a solid mass. The solid mass is formed into French fry shaped pieces and transferred to an oven where the French fry shaped pieces are subsequently baked for a selected amount of time. The French fry shaped pieces are removed from the oven for consumption or refrigerated or placed in frozen storage for reheating by an end user or consumer.

Owner:GOLDEN OVAL EGGS

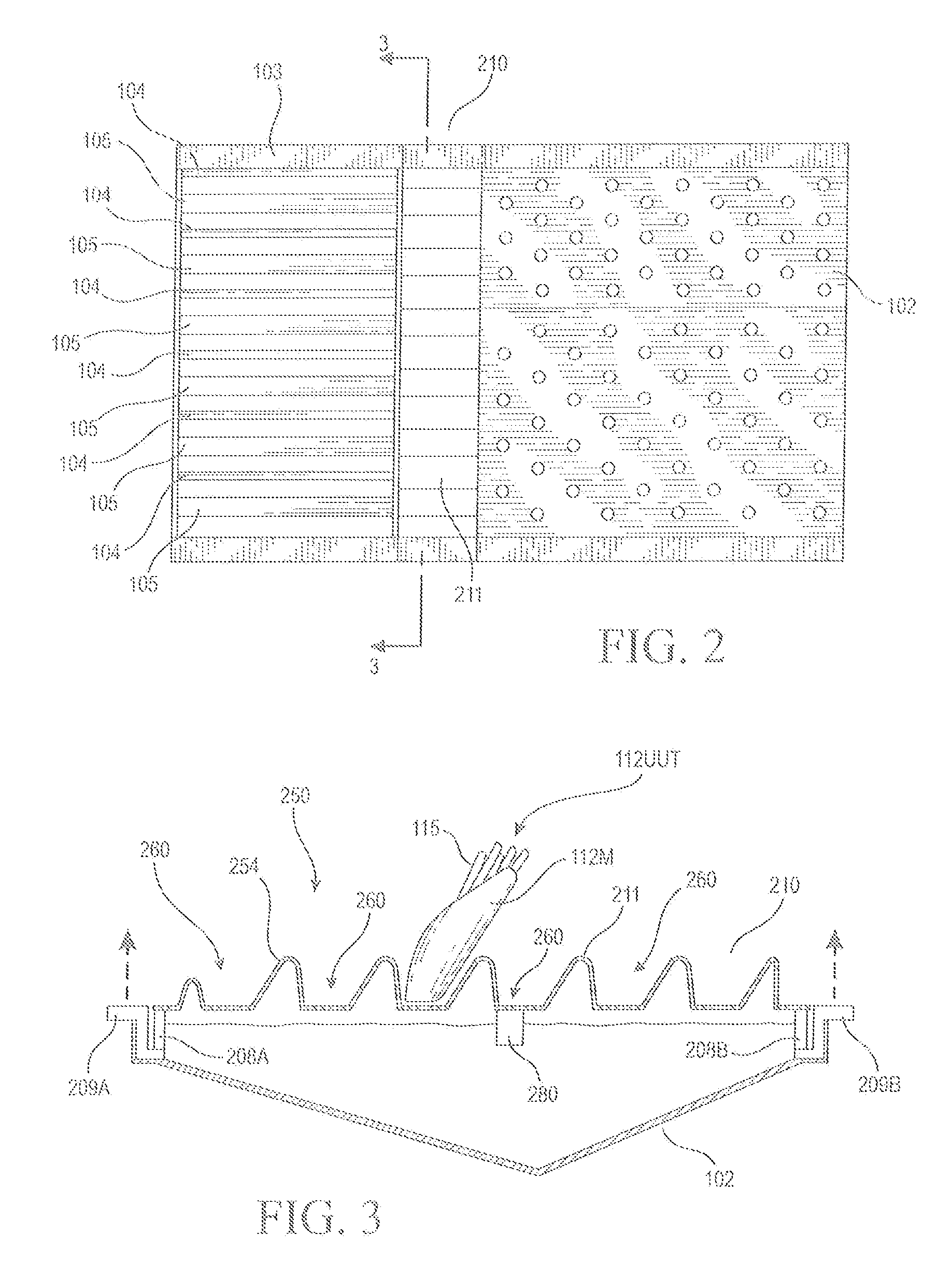

Food cooking apparatus and method

A food product comprising: a potato mixture that is cooked without frying; where the food product has the appearance, taste and texture similar to a French fry cooked in oil; and where the food product has less than 20 calories per cubic inch. A food cooking apparatus comprising: a bottom continuous belt comprising a plurality of bottom channels; a top continuous belt, that meshes with the bottom continuous belt; and where the food cooking apparatus is configured to rotate the top continuous belt and bottom continuous belt such that any food desposited onto the bottom channels is suitably cooked when it leaves the bottom continuous belt and enters the finished food holding container.

Owner:KOT LESZEK

French fry production method with reduced crumb generation

InactiveUS20080008797A1Reduce debris generationSpeed up the processFruits/vegetable preservation by coatingFood preparationGramOrganoleptic

An improved production process for preparing parfried and frozen French fry potato products with reduced crumb generation particularly upon finish preparation as by finish frying. Potato products such as French fry strips are cut, blanched and parfried, followed by a water treatment step as by applying a light spray or mist of water at ambient temperature and preferably at a rate selected to avoid any substantial overspray. The potato products are frozen for shipment and / or storage awaiting finish preparation. Upon finish preparation as by finish frying in hot oil, the potato products exhibit substantially reduced crumb generation. The improved process is particularly useful when parfrying and / or finish frying the potato products in a liquid or substantially non-hydrogenated oil, such as a zero grams Trans Fat (ZGTF) oil, with dramatically reduced crumb generation upon finish fry preparation while retaining a substantially optimized balance of sensory characteristics.

Owner:J R SIMPLOT

Methods and materials for high dextrin dry food coatings

InactiveUS20050003072A1Improve sensory propertiesSatisfied with the resultFood coatingFood preparationDried foodDextrin

The present invention provides a process for preparing a potato product with a film-like coating on the outer surface which coating according to the steps of: cutting the potatoes; blanching the potatoes; and coating the potatoes with a dry coating composition comprising at least 50% by weight dextrin and from 5% to 25% by weight of a hydrolyzed starch characterized by a DE of from 0.2 to 5. The method provides coated potato products (french fries) characterized by desirable textural properties at low coating weights.

Owner:PENFORD FOOD INGREDIENTS

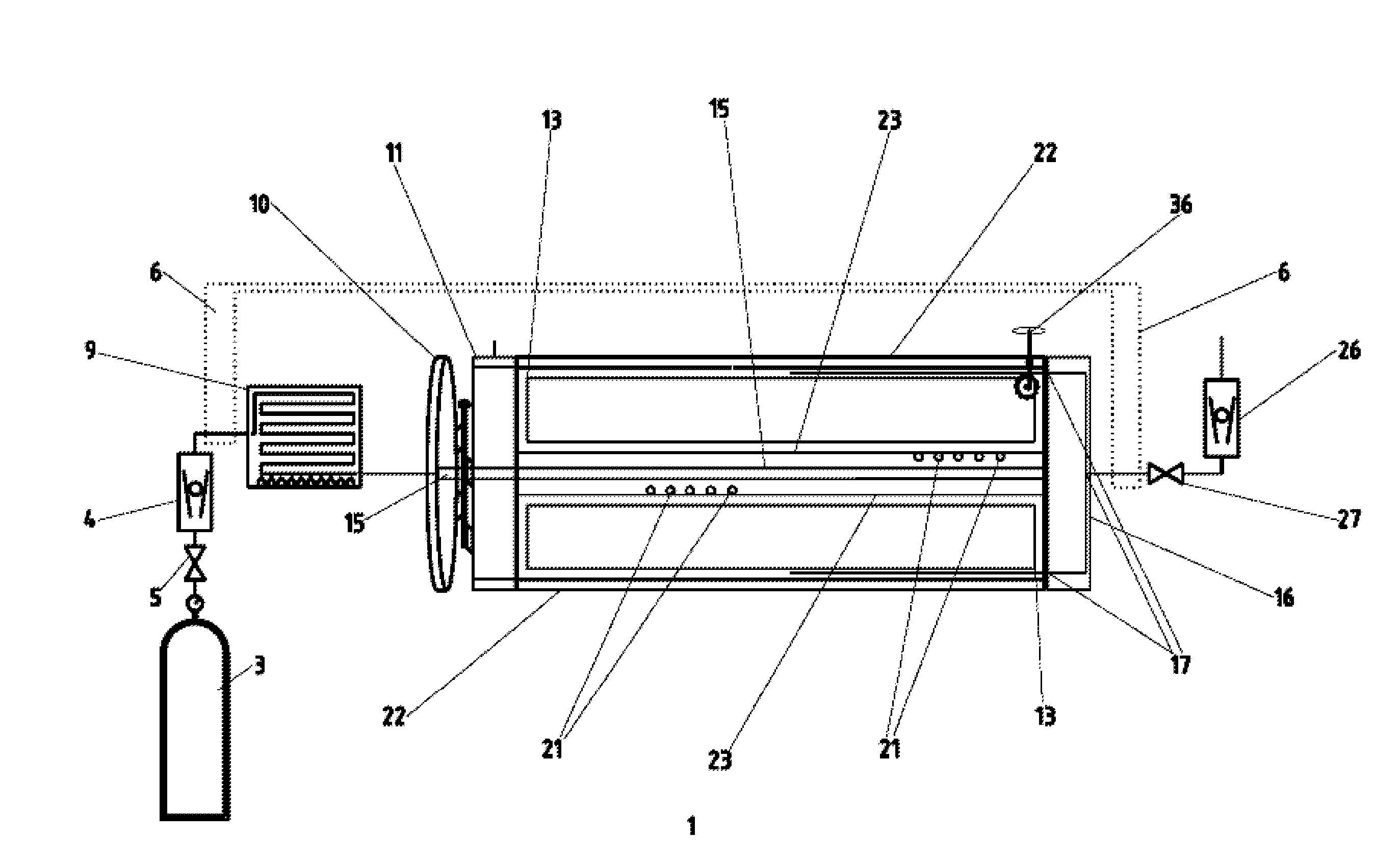

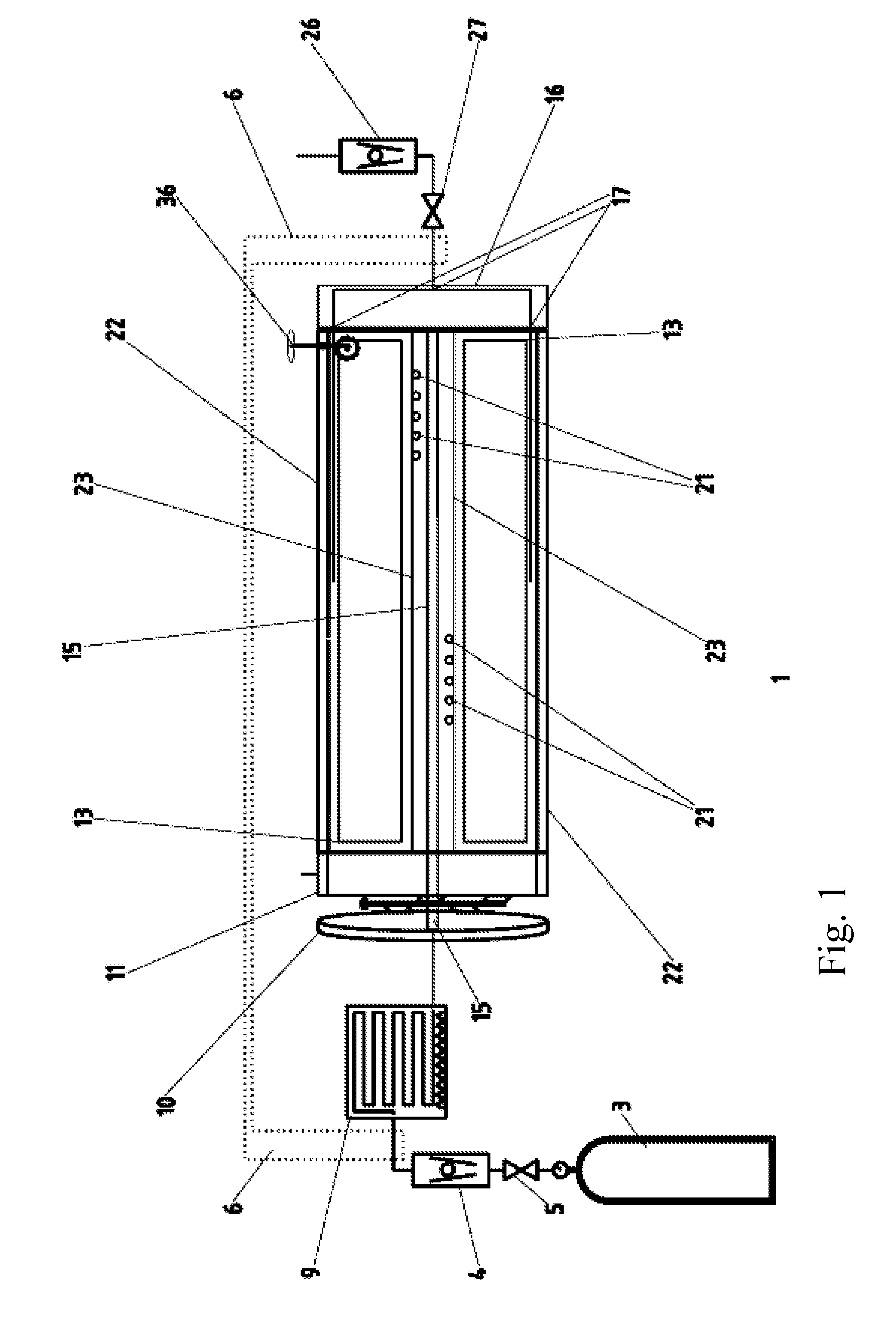

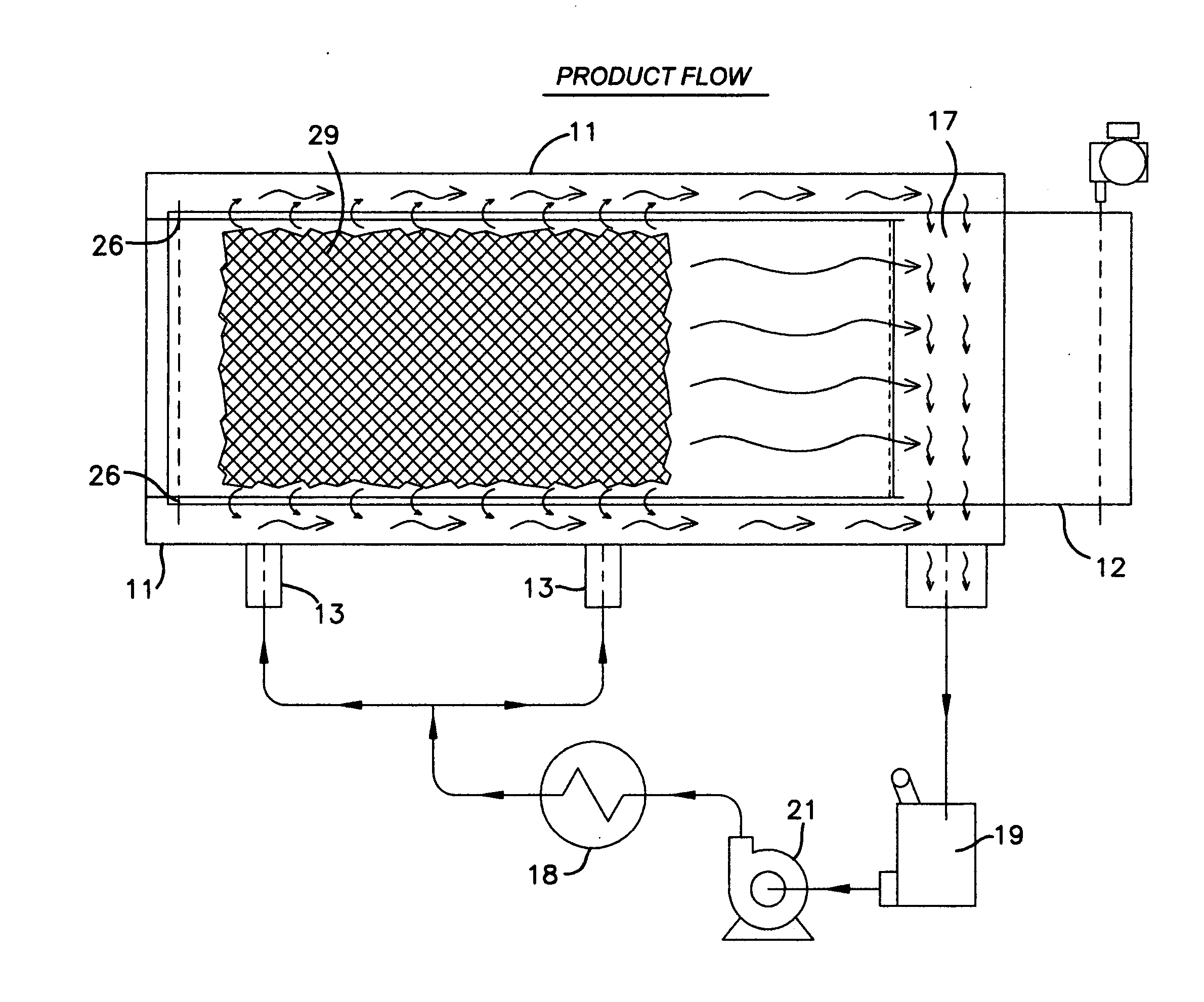

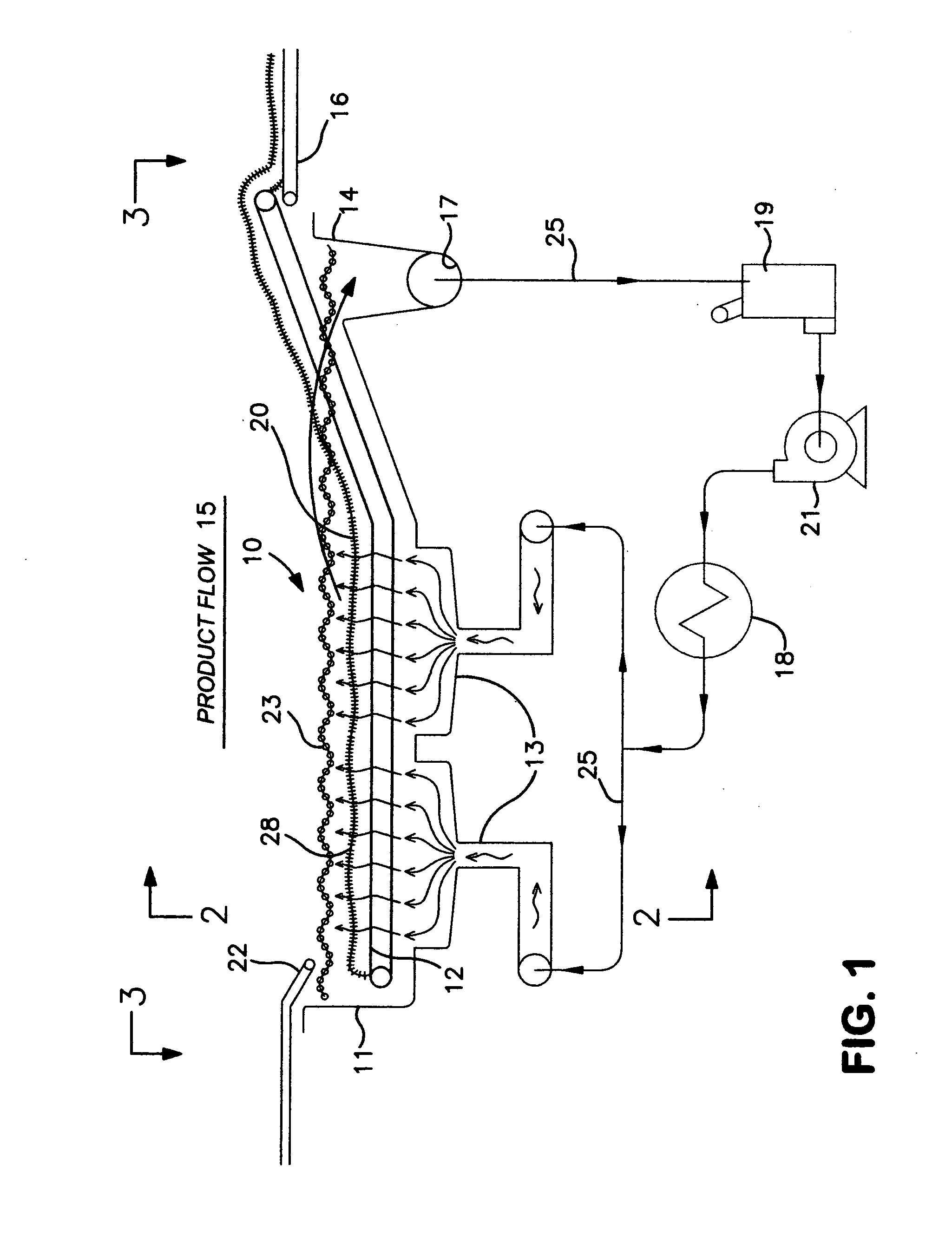

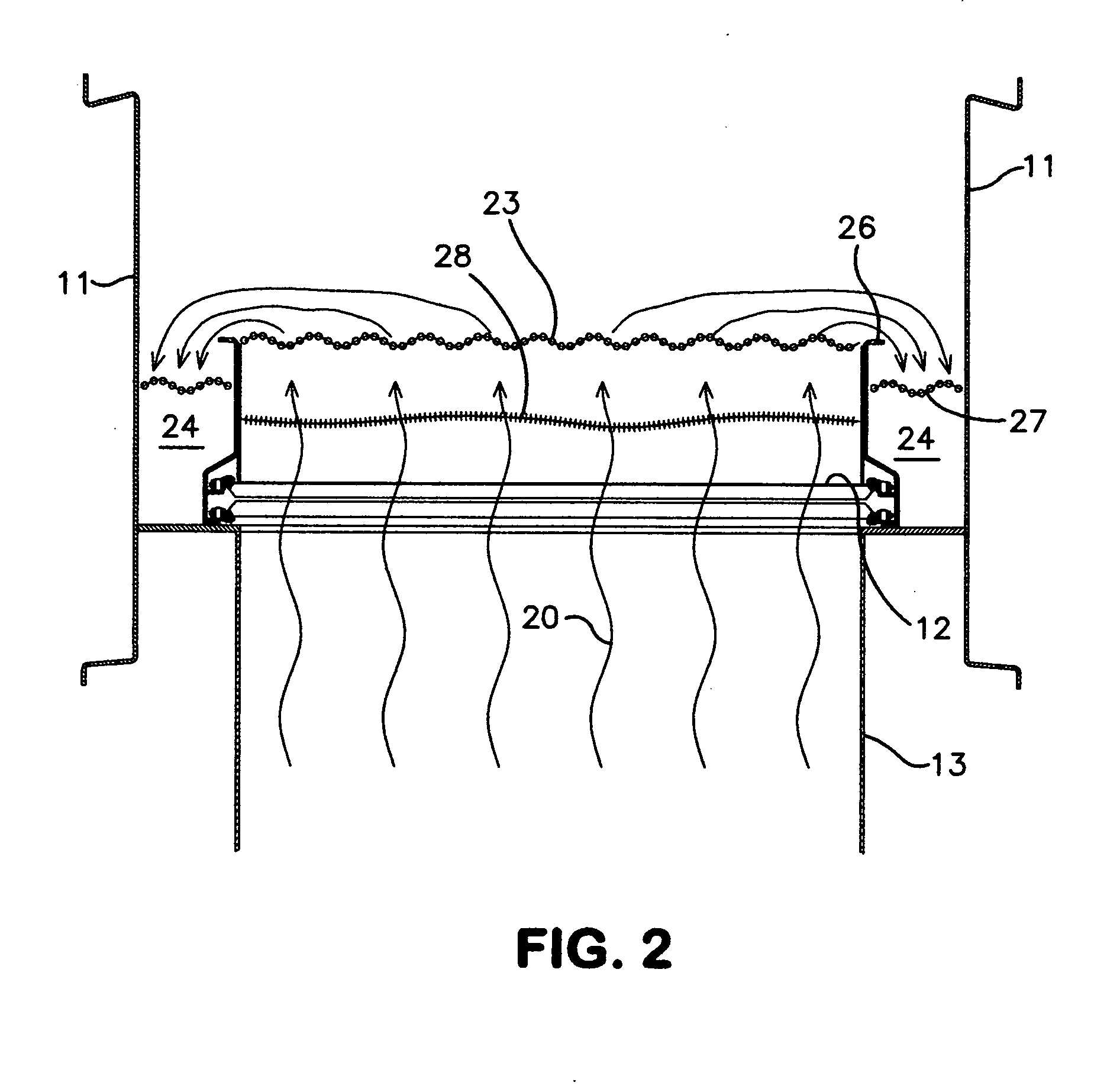

Vertical flow french fryer

ActiveUS20100227035A1Increase product yieldImprove uniformityFood preparationDeep fat fryersEngineeringConveyor belt

Cooking of French fried potatoes by facilitating a generally vertical arrangement of potato strips while in the frying operation is disclosed wherein the slices may be cooked within a very deep pack while oil is urged to flow upwardly through the pack and steam entrapment within the cooking slice pack is minimized. A conveyor belt carrying the slices through the cooker has a multiplicity of openings facilitating oil flow there through and the cooker is configured to permit oil discharge for reheating purposes both laterally and longitudinally of the processing path.

Owner:HEAT & CONTROL

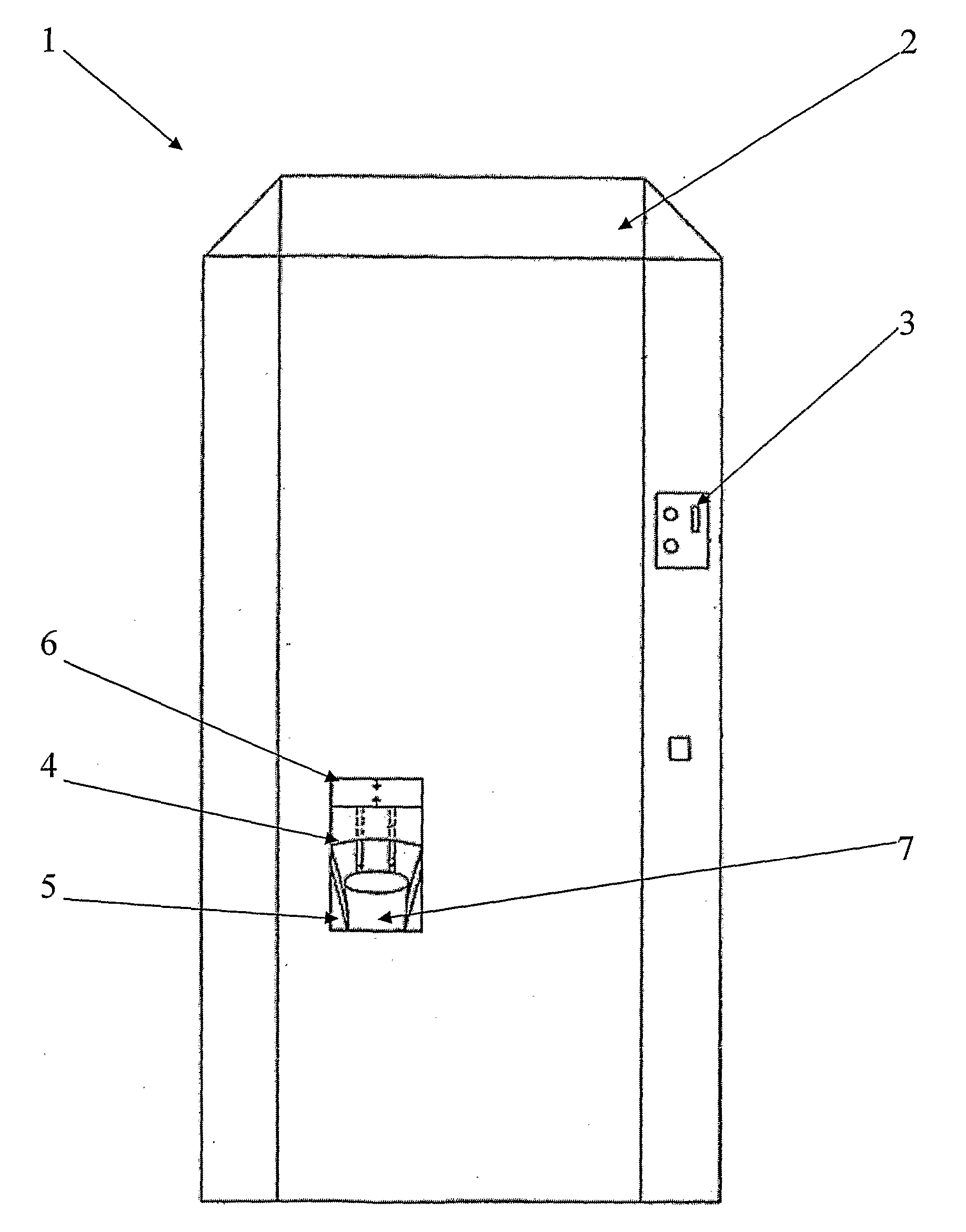

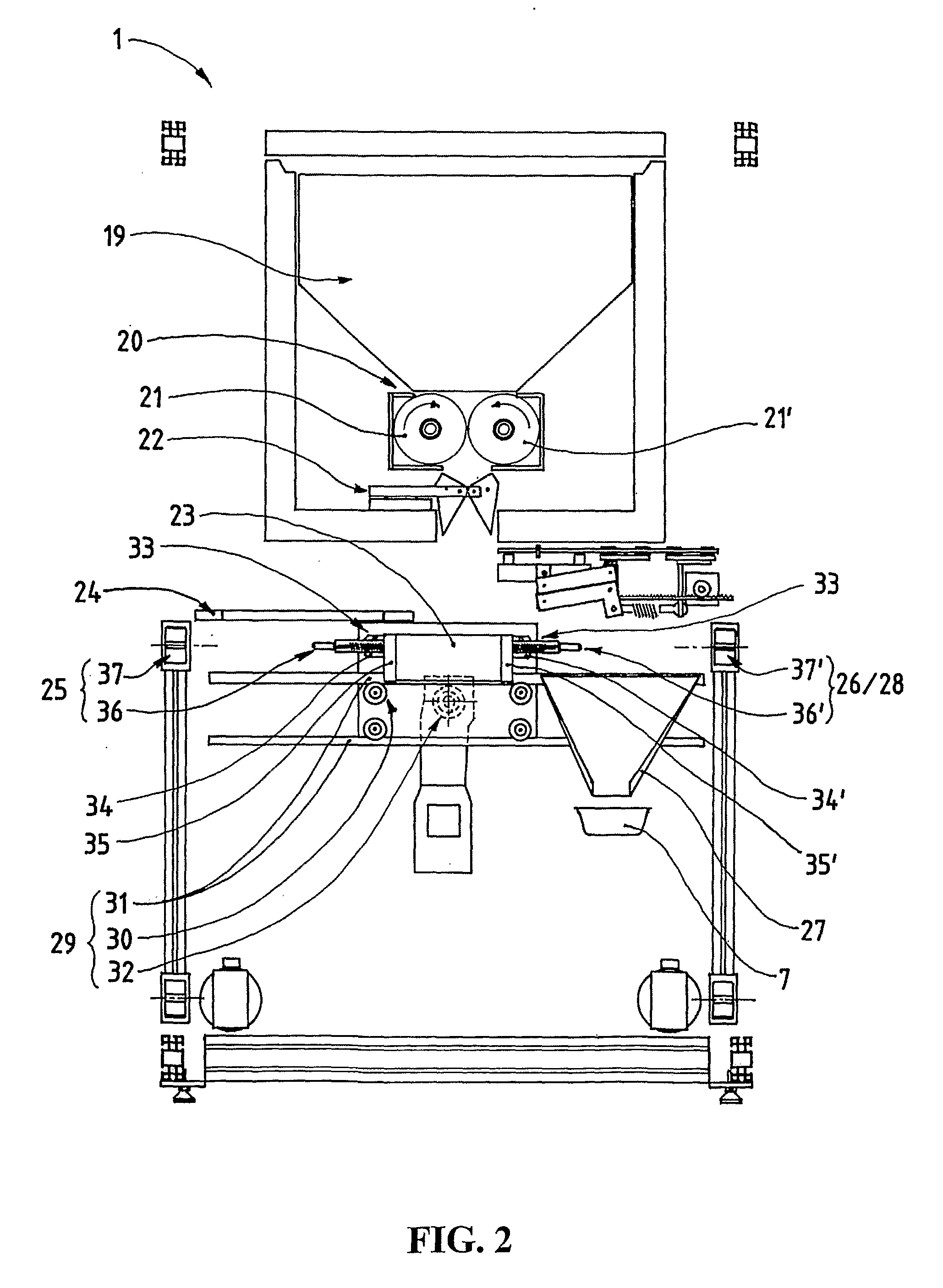

Prepayment Device for Delivery of French Fries

InactiveUS20080092752A1Coin-freed apparatus detailsApparatus for meter-controlled dispensingEngineeringMechanical engineering

The invention concerns a prepayment device for dispensing French fries. The pre-cooked and frozen French fries are discharged from storage, and a determined amount is weighed corresponding to one or more portions. The French fries are then received by a receiver which moves between the weighing zone, and the cooking zone, followed by conveyance of the discharged and transported cooked French fries to a container from storage. The device uses a swinging movement of the receiver, enabling the French fries to be mixed and turned ensuring that they are homogeneously cooked. An additional feature of the device is that the cooked French fries are discharged with a tilting movement about an axis towards the transport for the cooked French fries to the container.

Owner:BOUALAM MOHAMED +2

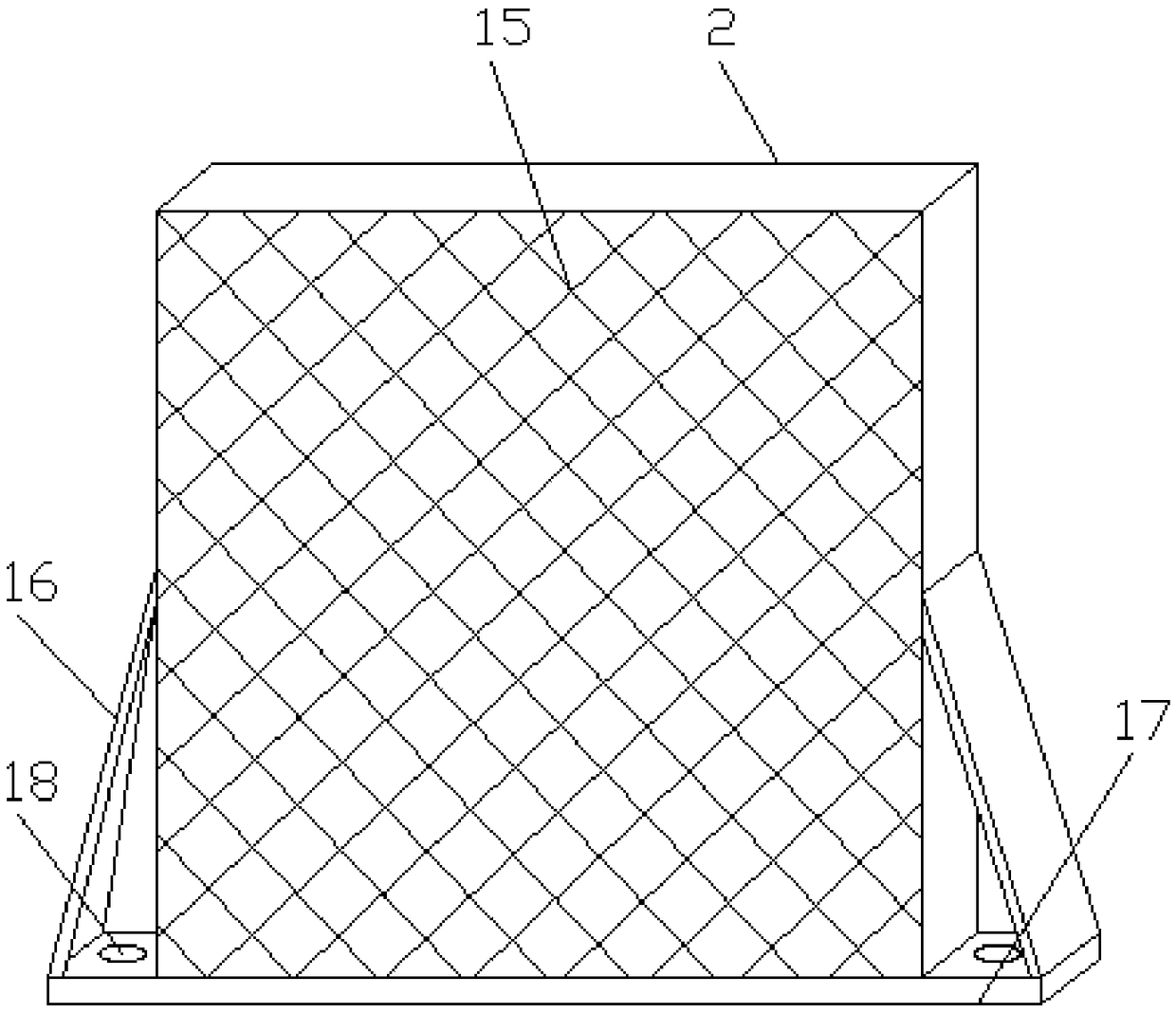

Cutting device for cutting potatoes into French fries and discharging French fries conveniently

InactiveCN109454693AAvoid getting stuckImprove shear efficiencyMetal working apparatusPulp and paper industryKnife blades

The invention discloses a cutting device for cutting potatoes into French fries and discharging French fries conveniently. The cutting device structurally comprises a French fry shredding and cuttingdevice, a strip cutting device, a pushing device, an air cylinder and EVA rubber damping pads. The strip cutting device is arranged on the left side of the top of the French fry shredding and cuttingdevice, cutter blade meshes are distributed inside the strip cutting device, a first limiting baffle plate is welded on the right side of the bottom of the strip cutting device, sliding sleeve blocksare arranged on the two sides of the middle of the French fry shredding and cutting device in a sleeve mode, and the pushing device is arranged at the tops of the sliding sleeve blocks. A reinforcingplate is arranged inside the pushing device, long convex columns are distributed on the left part of the reinforcing plate, the air cylinder is arranged on the right portion of an air pressure rod, asecond limiting baffle plate is welded on the left side of the bottom of the air cylinder, and EVA rubber damping pads are adhered to corners of the bottom of the French fry shredding and cutting device. The cutting device for cutting the potatoes into the French fries and discharging the French fries conveniently has the advantages that the cutting efficiency is improved, the overall stability isimproved, and the risk during cutting can be avoided, so that the cutting device is safe and reliable.

Owner:芜湖市传世信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com