Food wrapper with rip line

a food wrapper and line technology, applied in the field of food wrappers with rip, can solve the problems of no convenient means to access the fast food, and no existing design form both a sealed container and a convenient holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

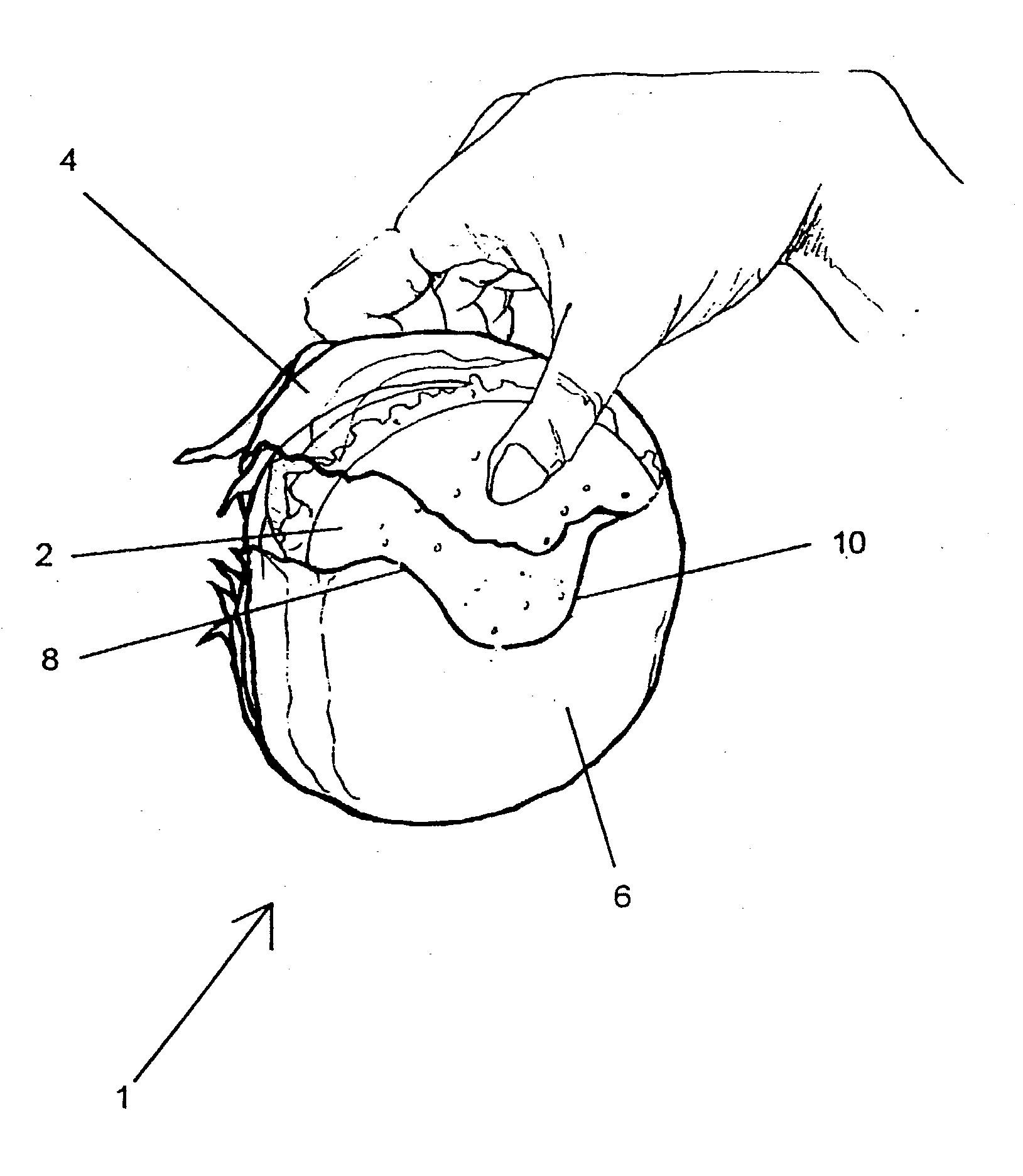

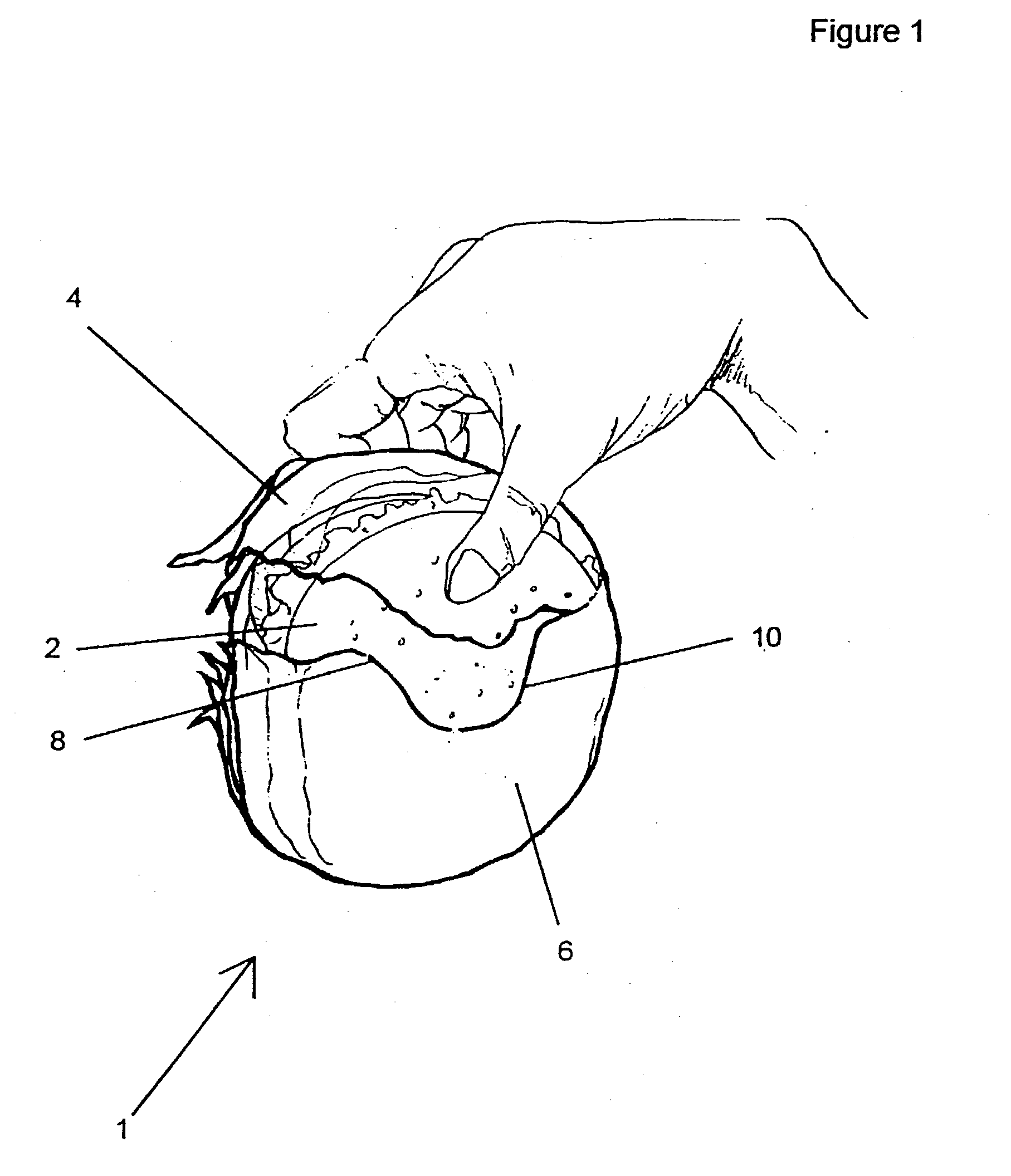

[0030] FIG. 1 illustrates fast food wrapper with rip line 1 in use with fast food 2. Fast food 2 may be a hamburger, chicken burger, sandwich, bagel, or any other type of fast food.

[0031] It can be seen from the illustration that wrapper top portion 4 may be easily pulled away from wrapper bottom portion 6 along rip line 8 to expose fast food 2. The user may continue to separate wrapper top portion 4 from wrapper bottom portion 6 until the two are no longer attached. Then, the user may hold fast food 2 by gripping wrapper bottom portion 6. This is more convenient, more sanitary, and much less messy than holding the fast food directly.

[0032] Wrapper bottom portion 6 conveniently holds all of the various components of fast food 2 together so that they do not spill out. Further, rip line 8 may be designed with a cut-away section 10 to provide easier access to fast food 2.

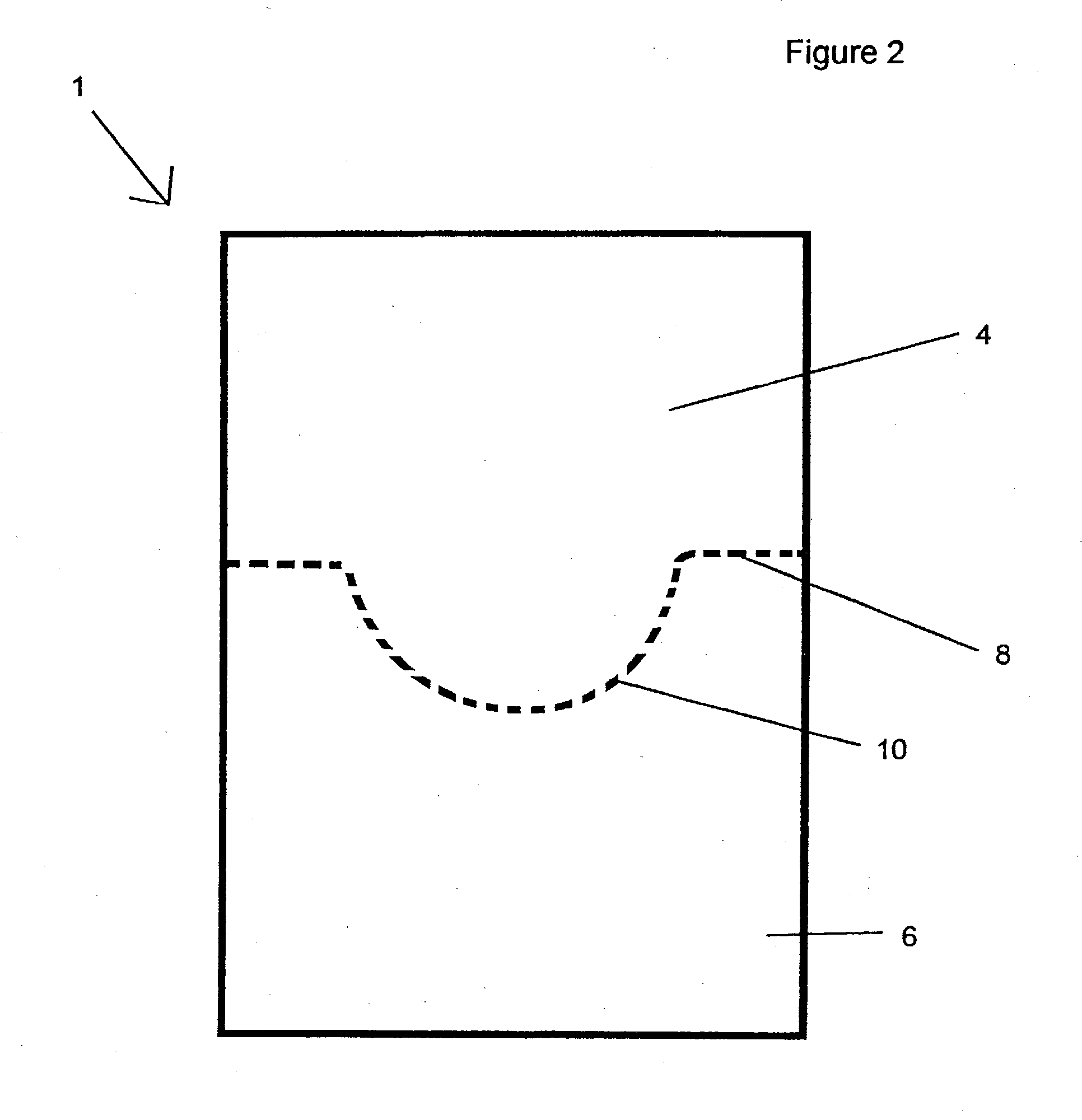

[0033] FIG. 2 illustrates fast food wrapper with rip line 1 before use. Fast food wrapper with rip line 1 may be rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com