Patents

Literature

410results about How to "Improve sensory properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

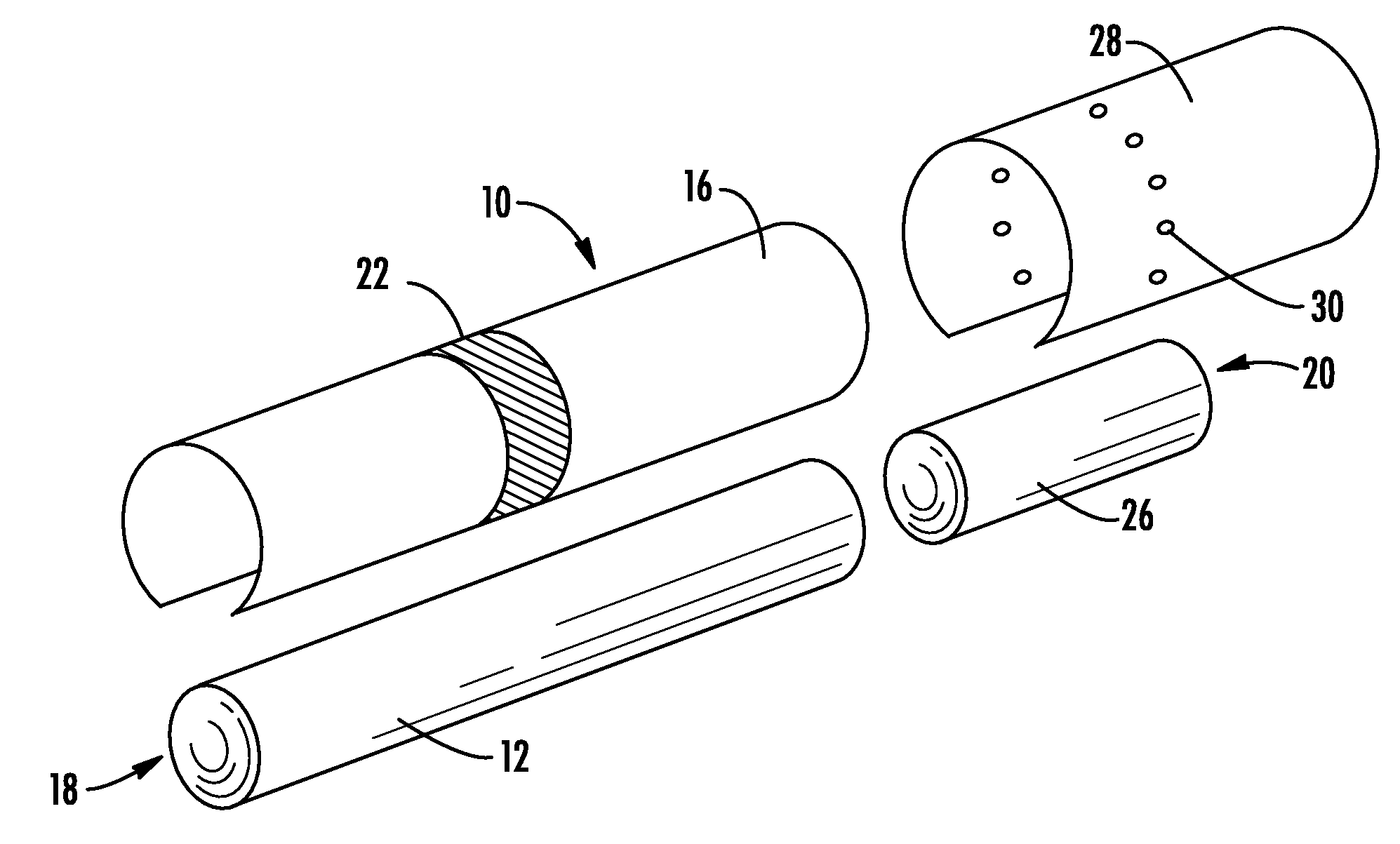

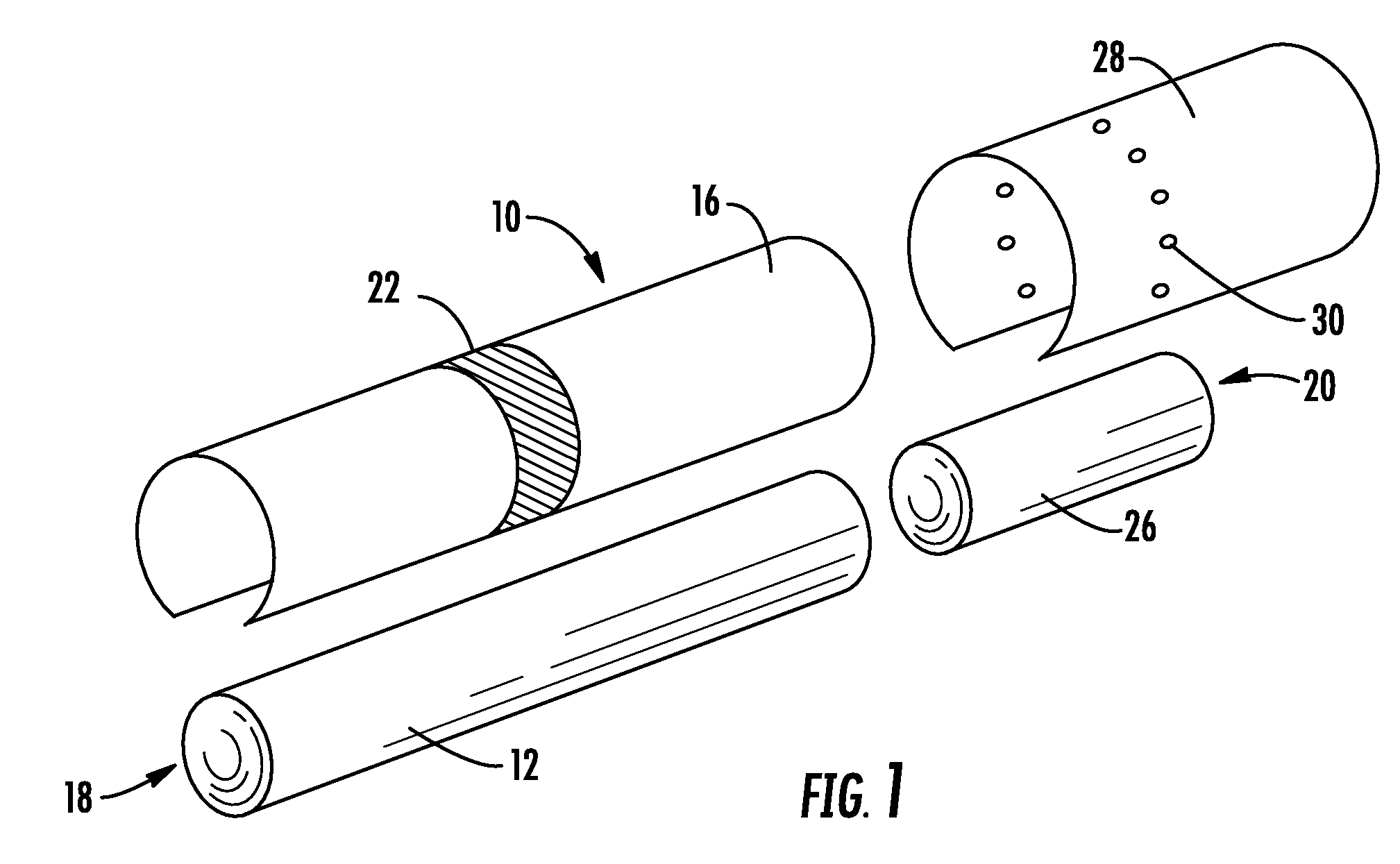

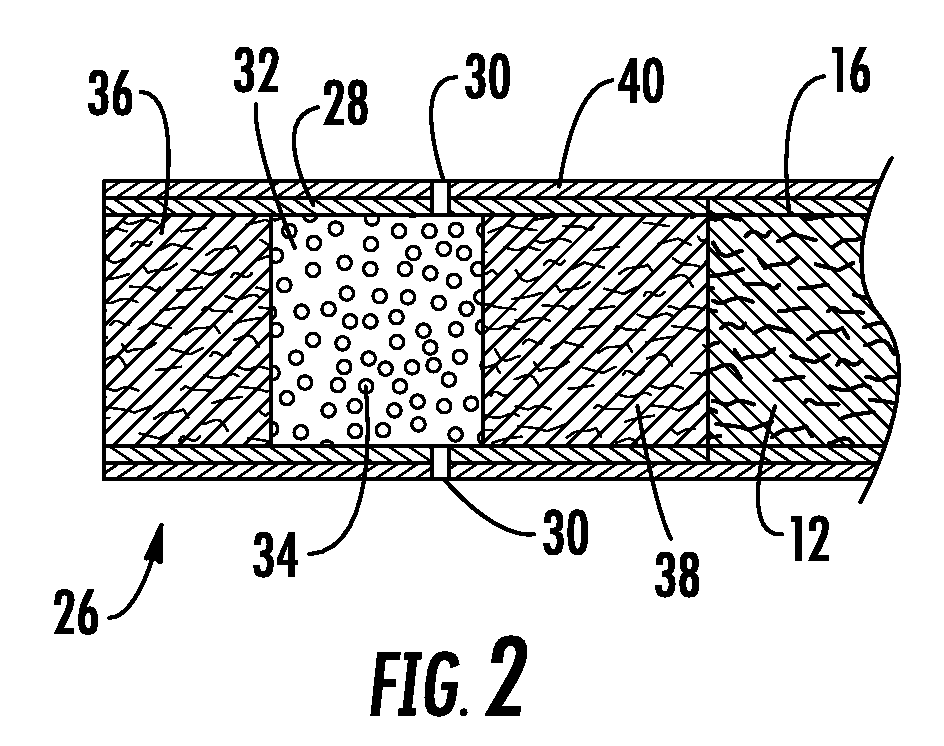

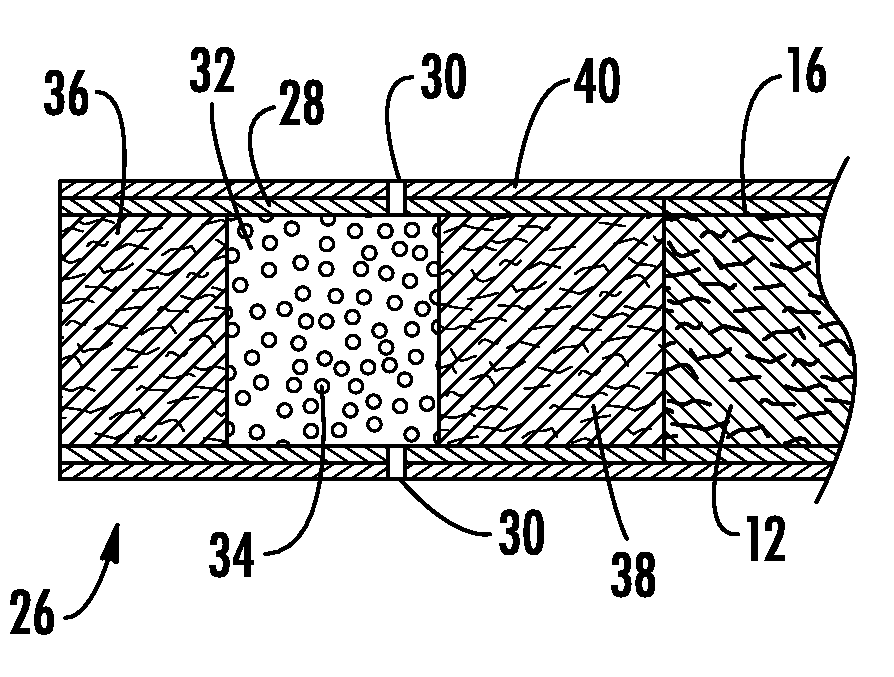

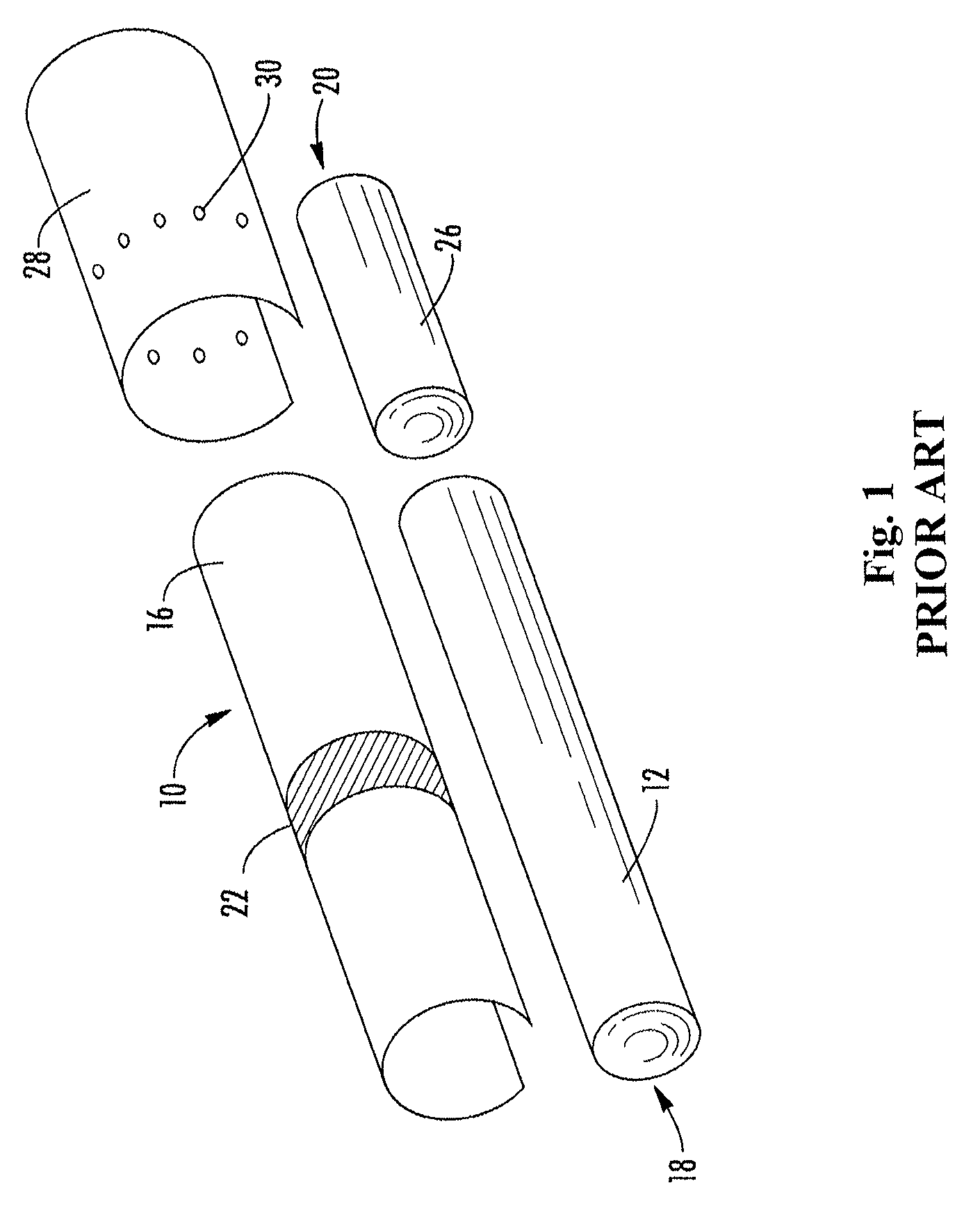

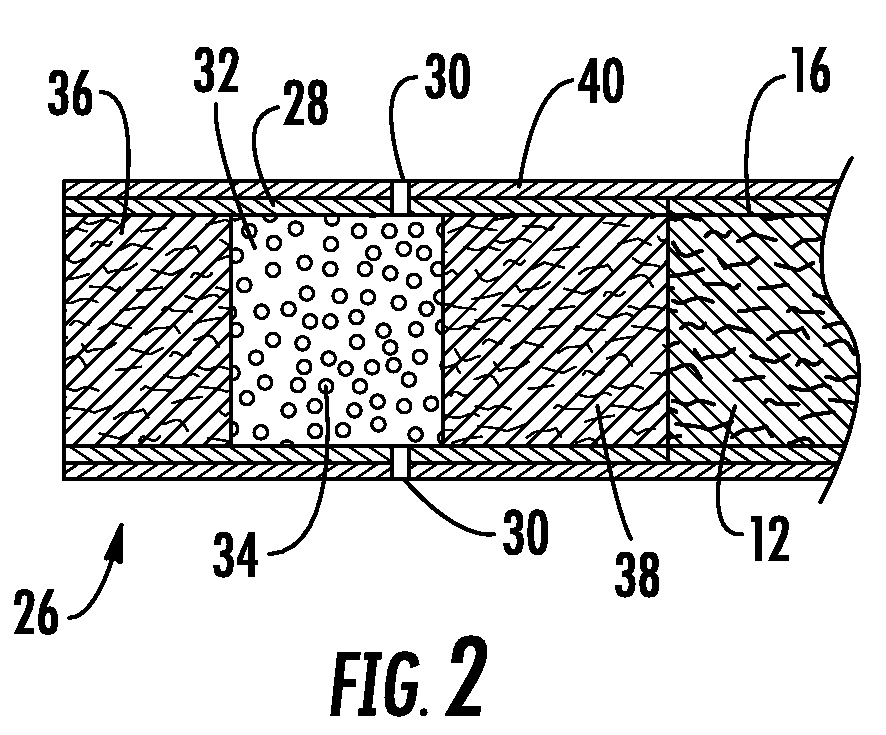

Cigarette comprising dark-cured tobacco

ActiveUS20080245377A1Less-costly to produceImprove sensory propertiesTobacco treatmentCigar manufactureActivated carbonEngineering

A cigarette is provided that includes a rod of smokable material circumscribed by an outer wrapping material and a filter element, which may include an adsorbent material such as activated carbon, attached to one end of the rod of smokable material. The smokable material includes at least about 5 percent by weight of a dark air-cured tobacco, based on the dry weight of the smokable material, blended with additional tobacco materials such as flue-cured tobacco, burley tobacco, Oriental tobacco, Maryland tobacco, and mixtures thereof.

Owner:R J REYNOLDS TOBACCO COMPANY

Cigarette comprising dark air-cured tobacco

ActiveUS8186360B2Less-costly to produceImprove sensory propertiesTobacco treatmentCigar manufactureActivated carbonEngineering

Owner:R J REYNOLDS TOBACCO COMPANY

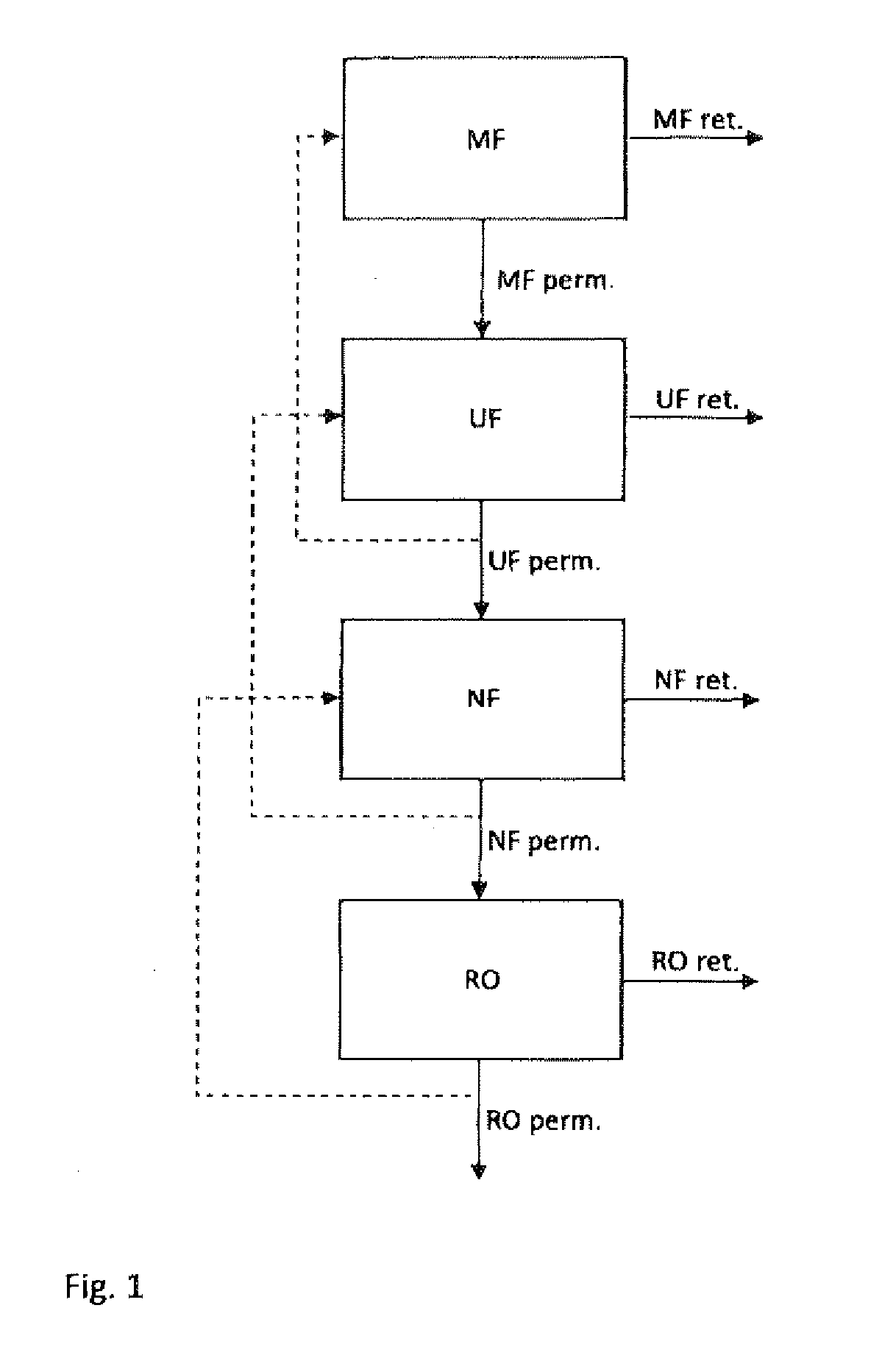

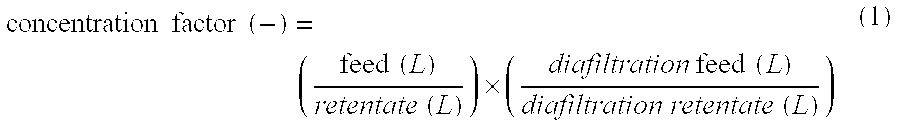

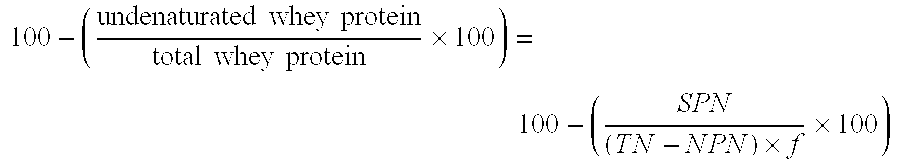

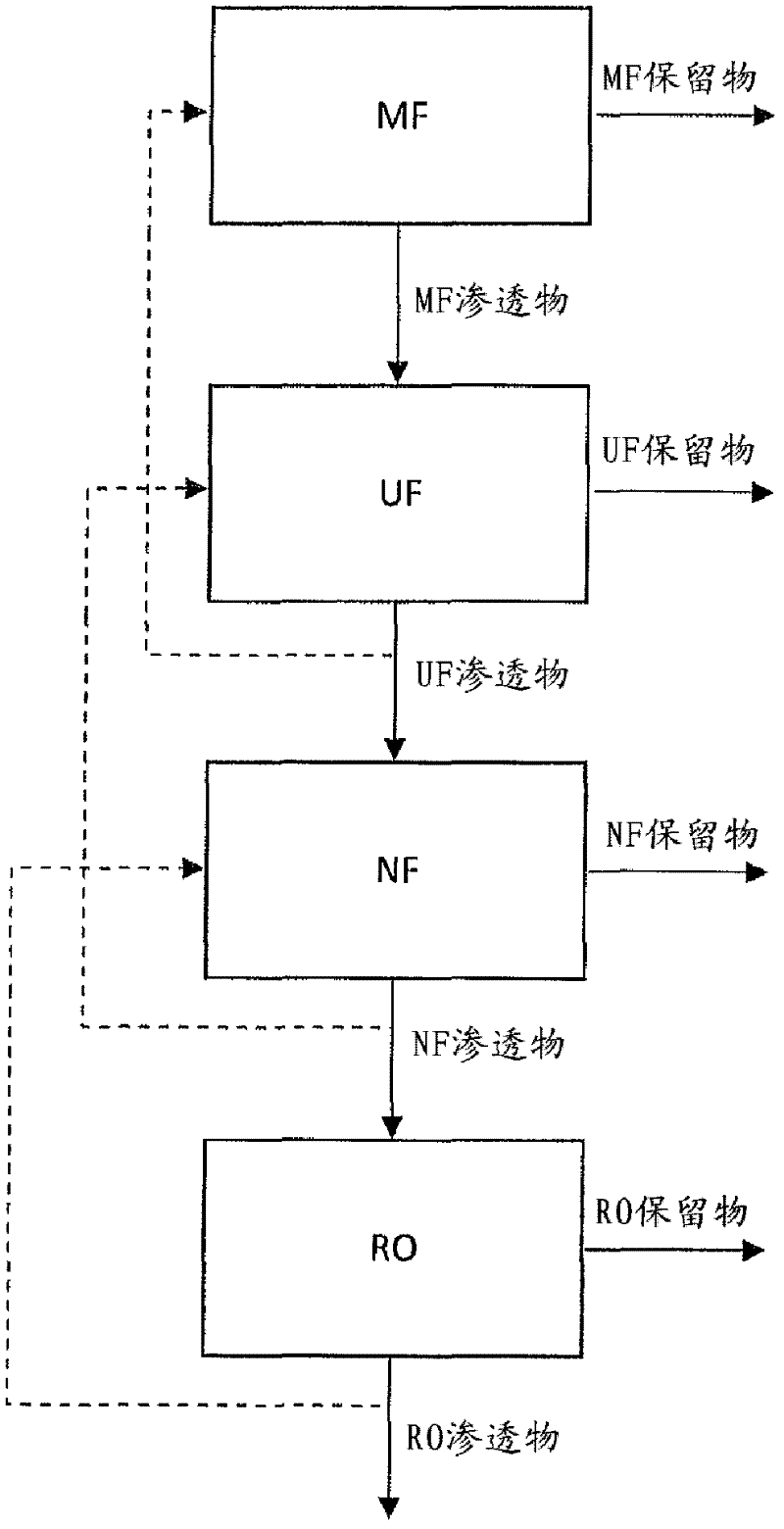

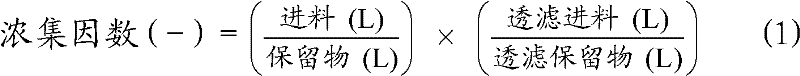

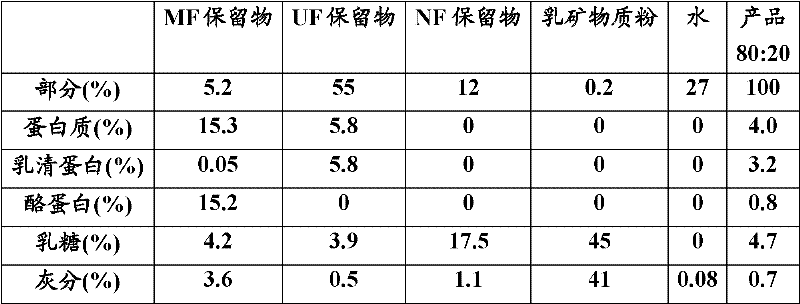

Whey protein product and a method for its preparation

InactiveUS20110097442A1Improve sensory propertiesImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO OY

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

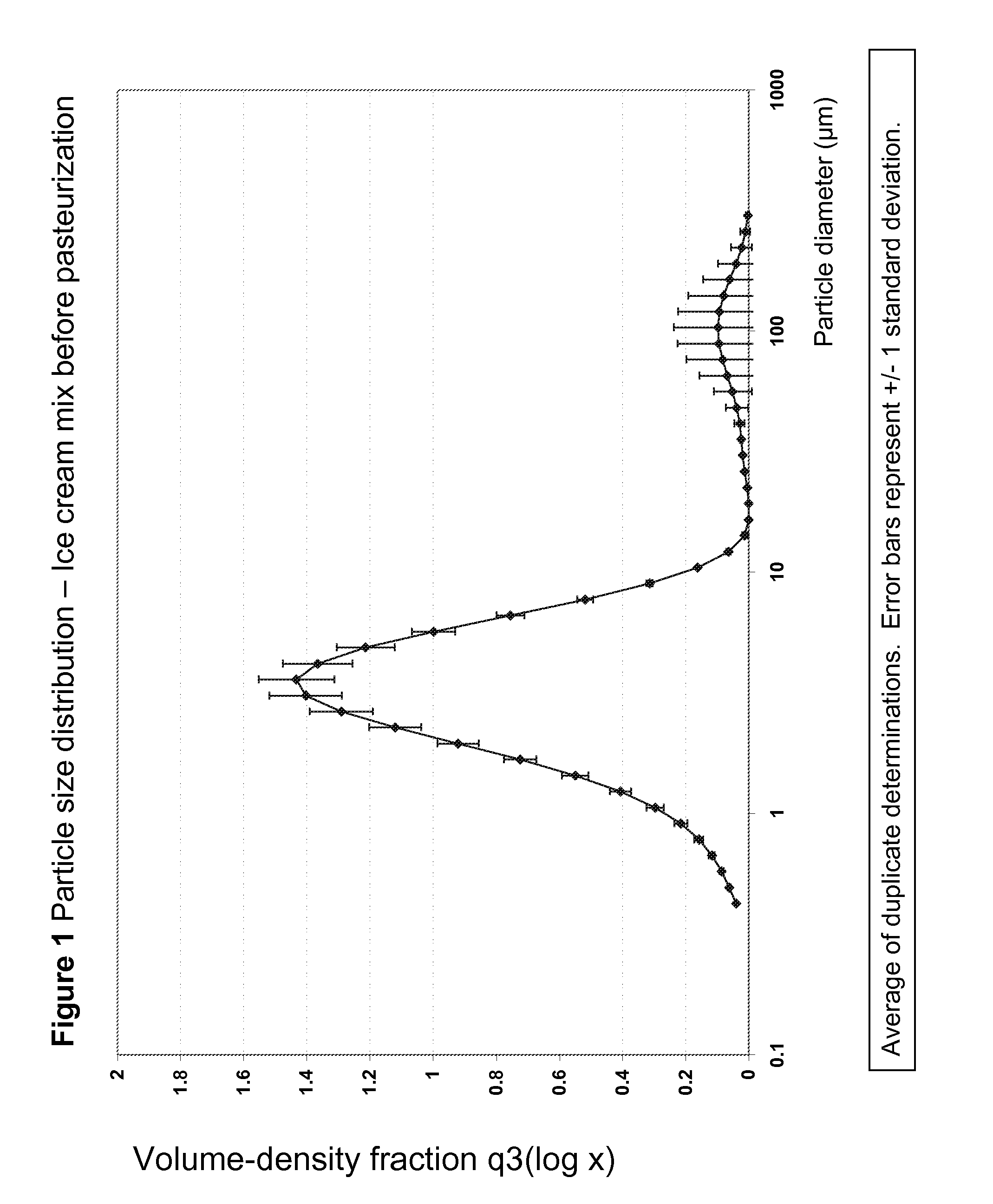

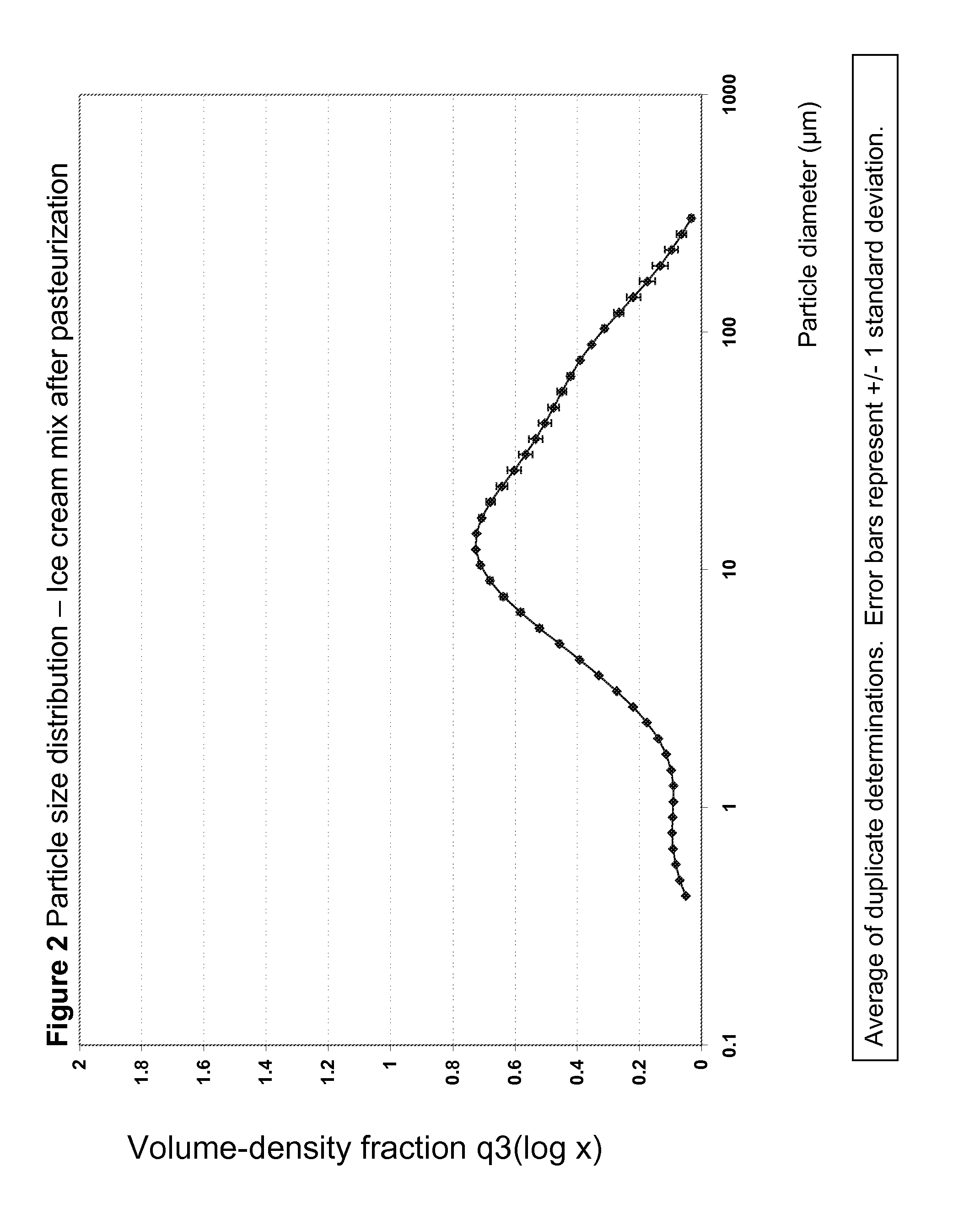

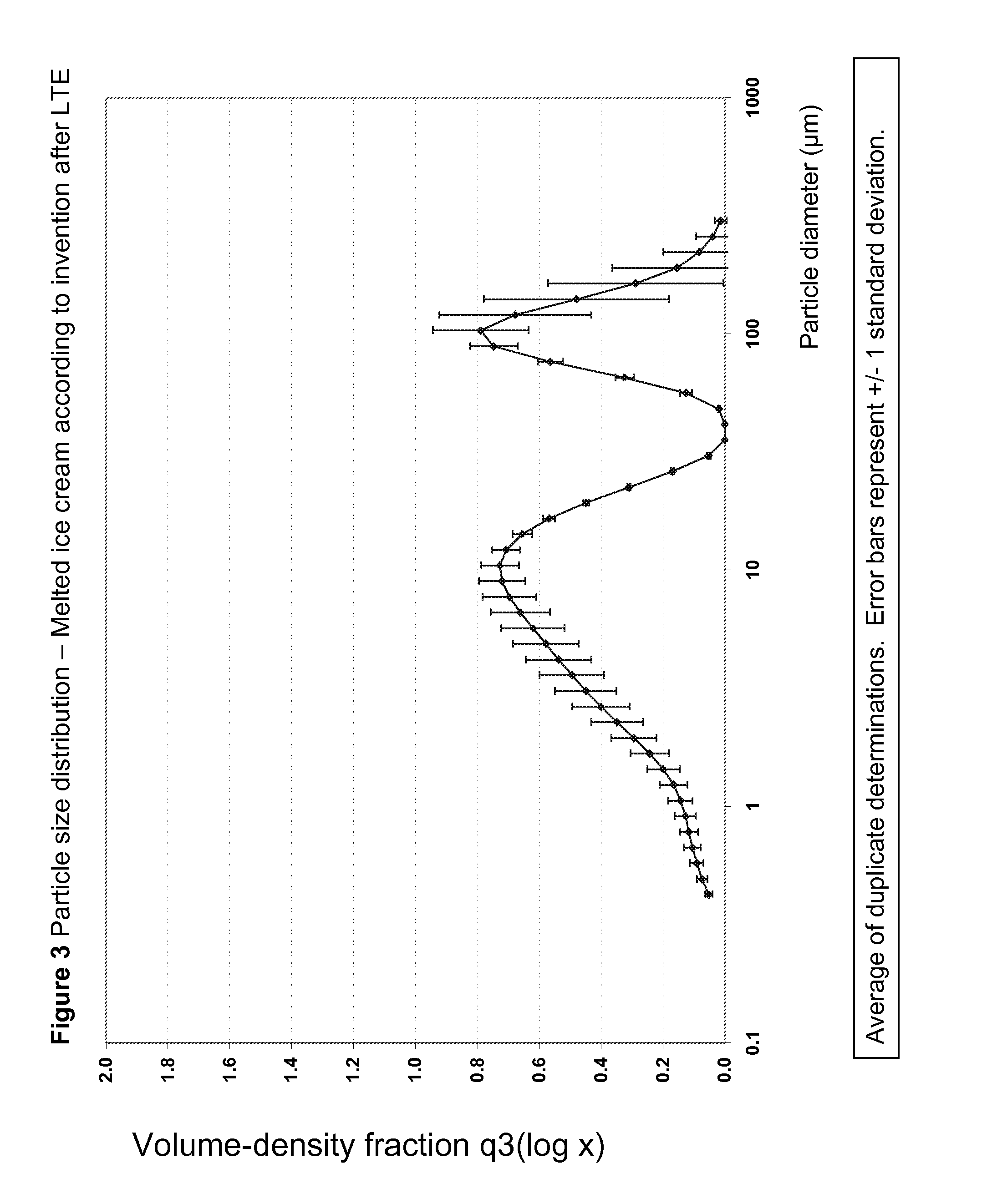

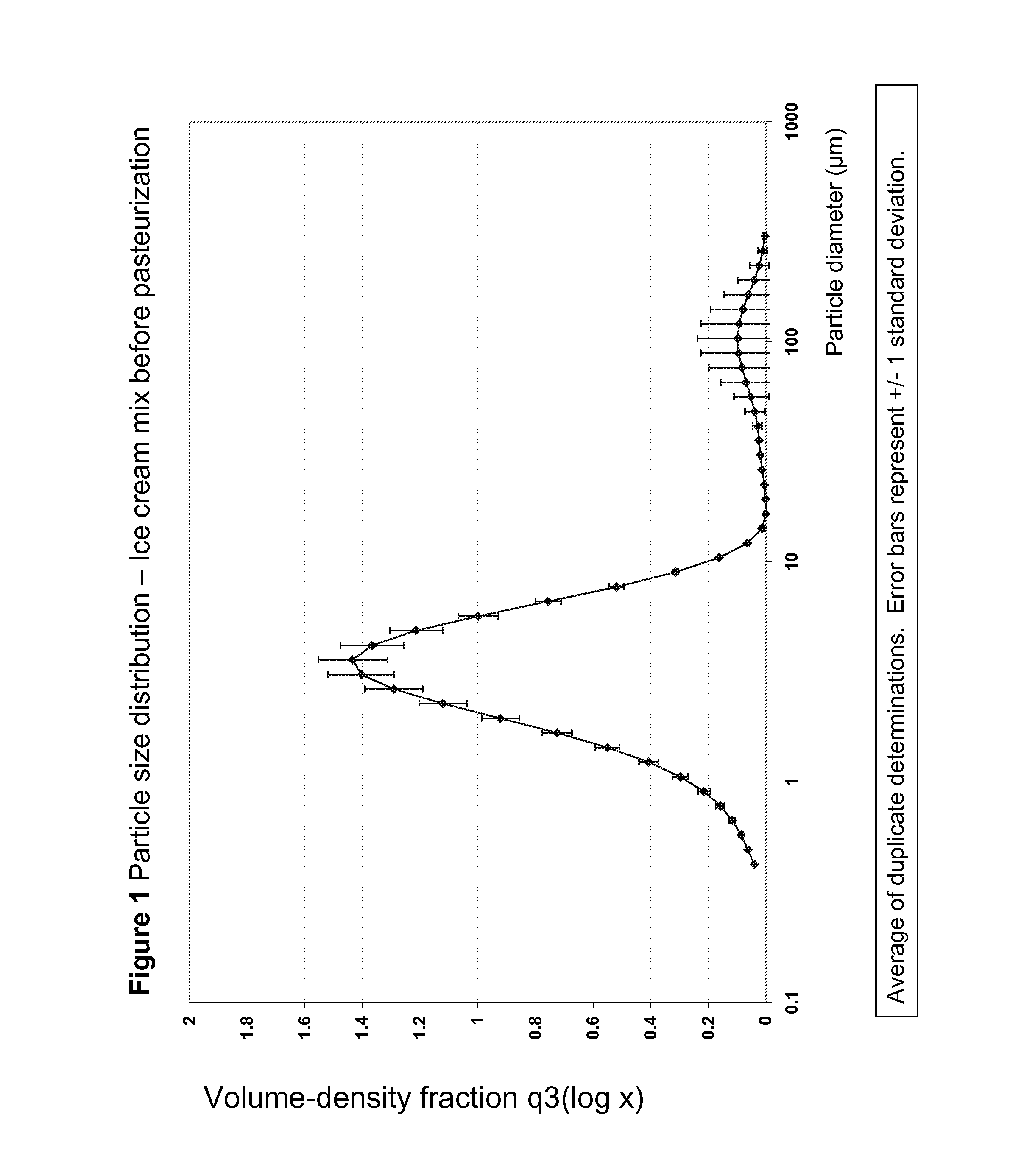

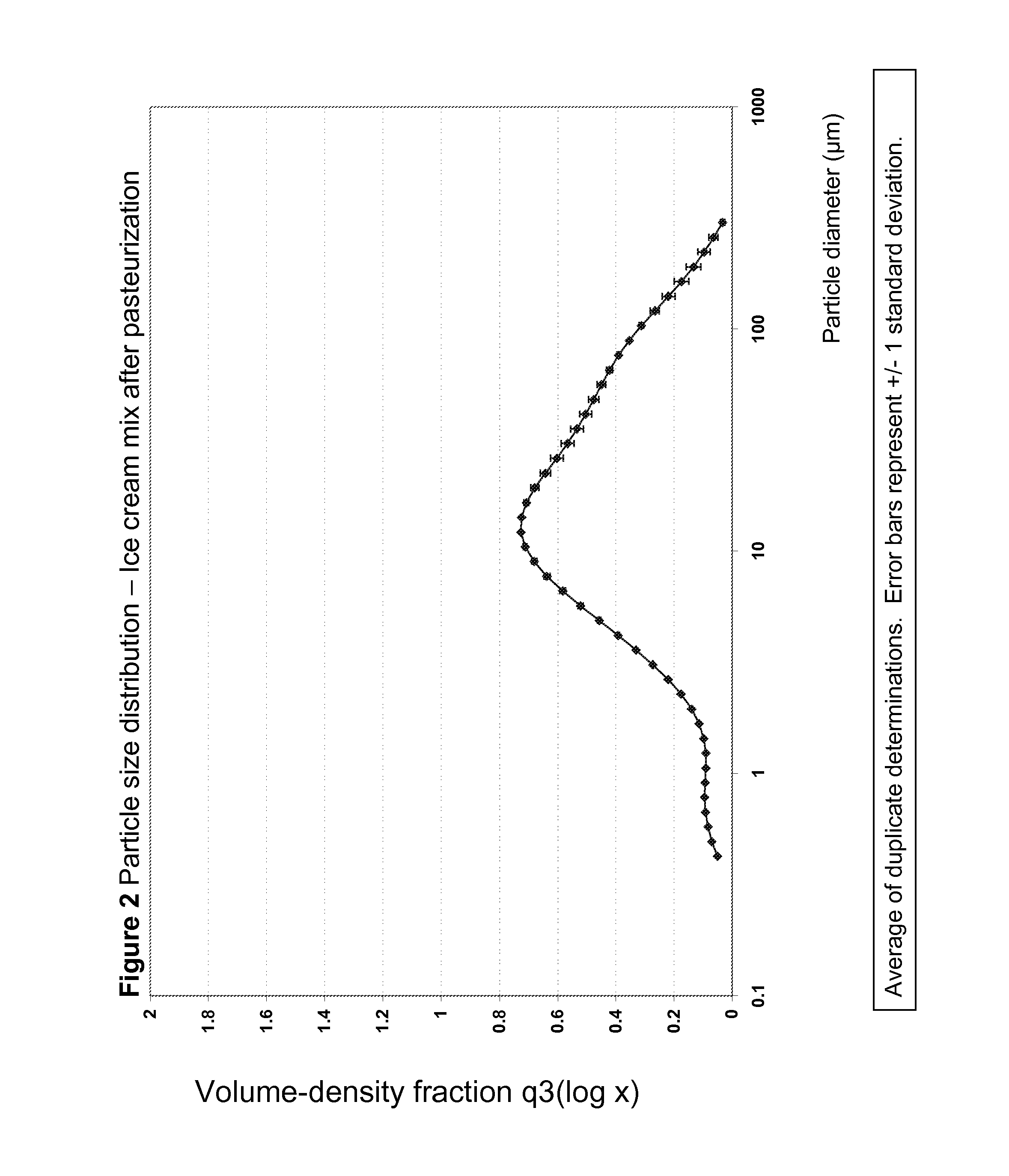

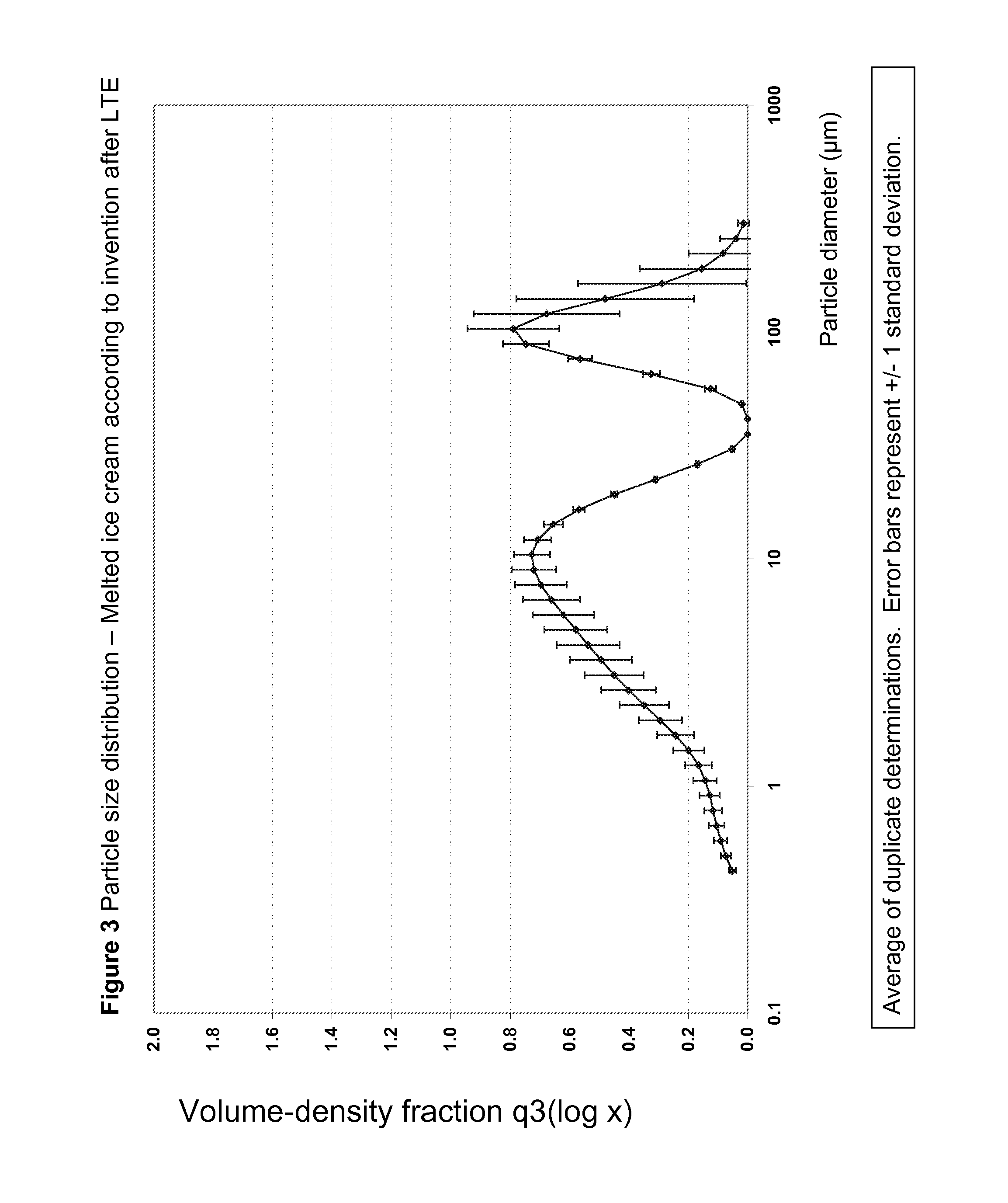

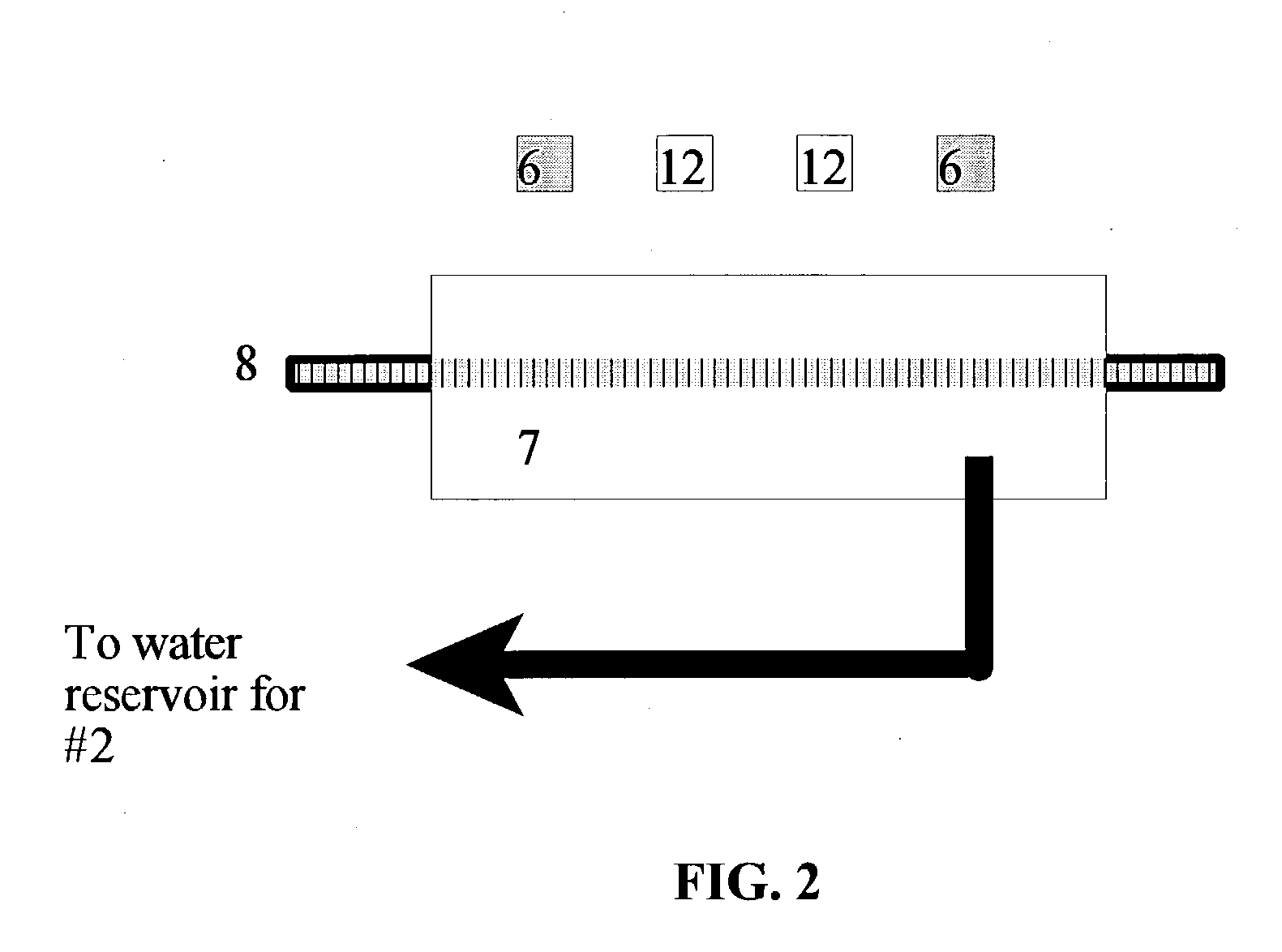

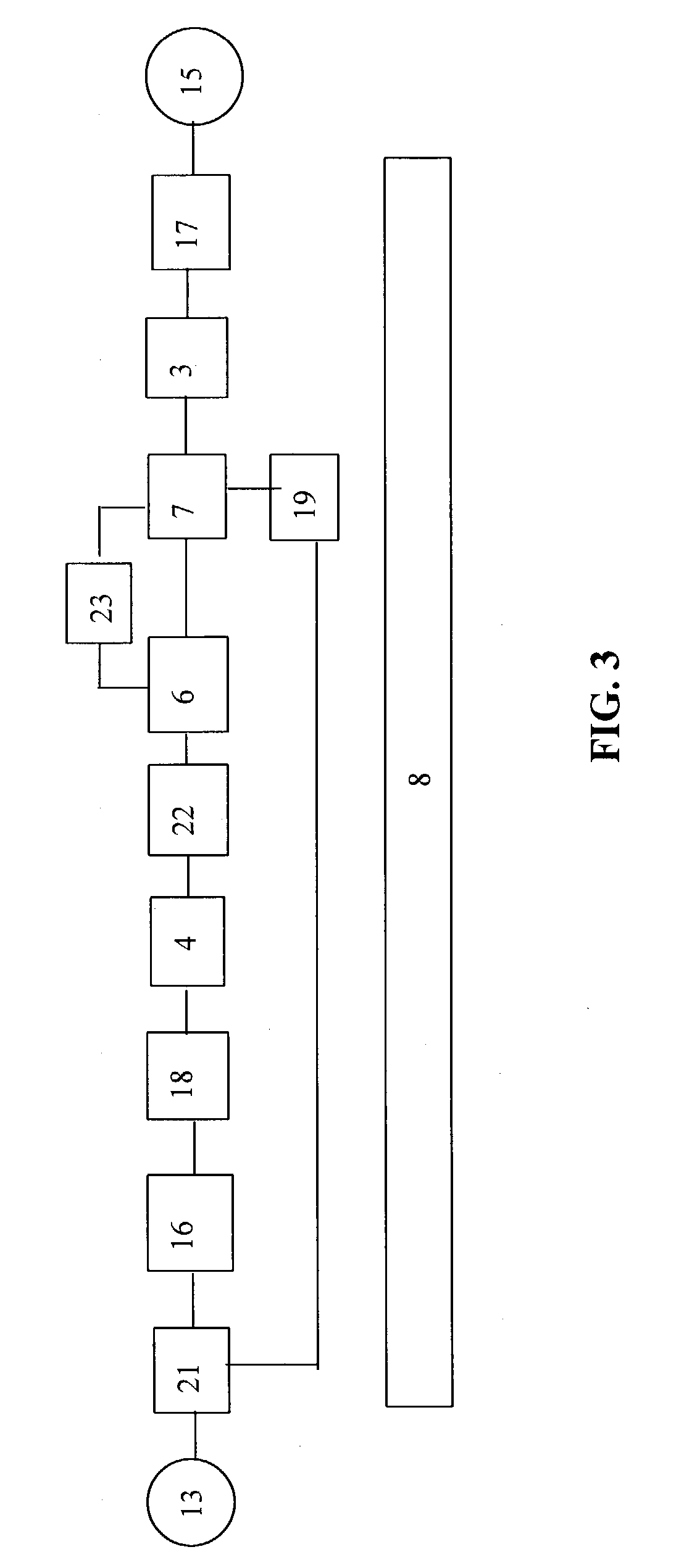

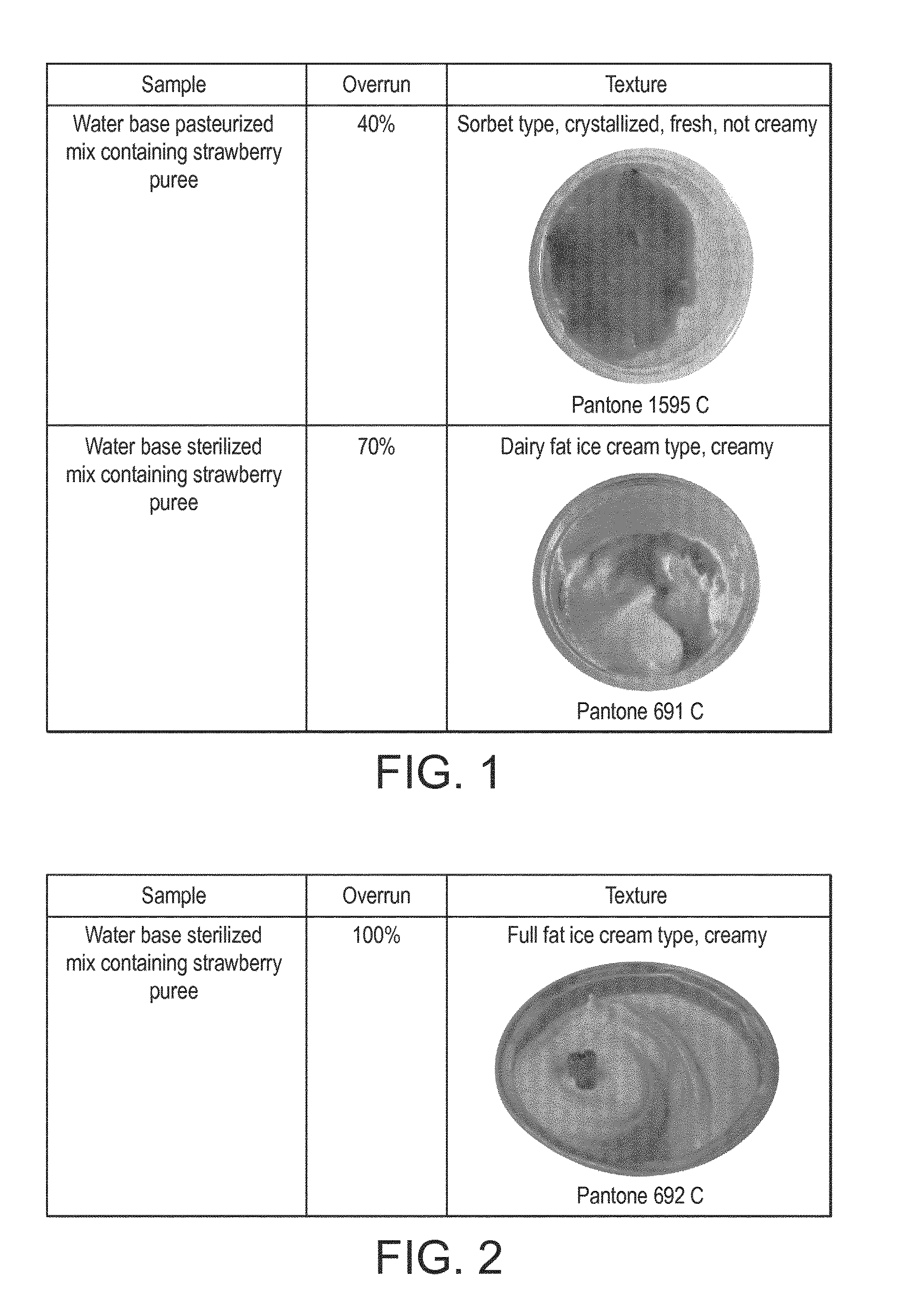

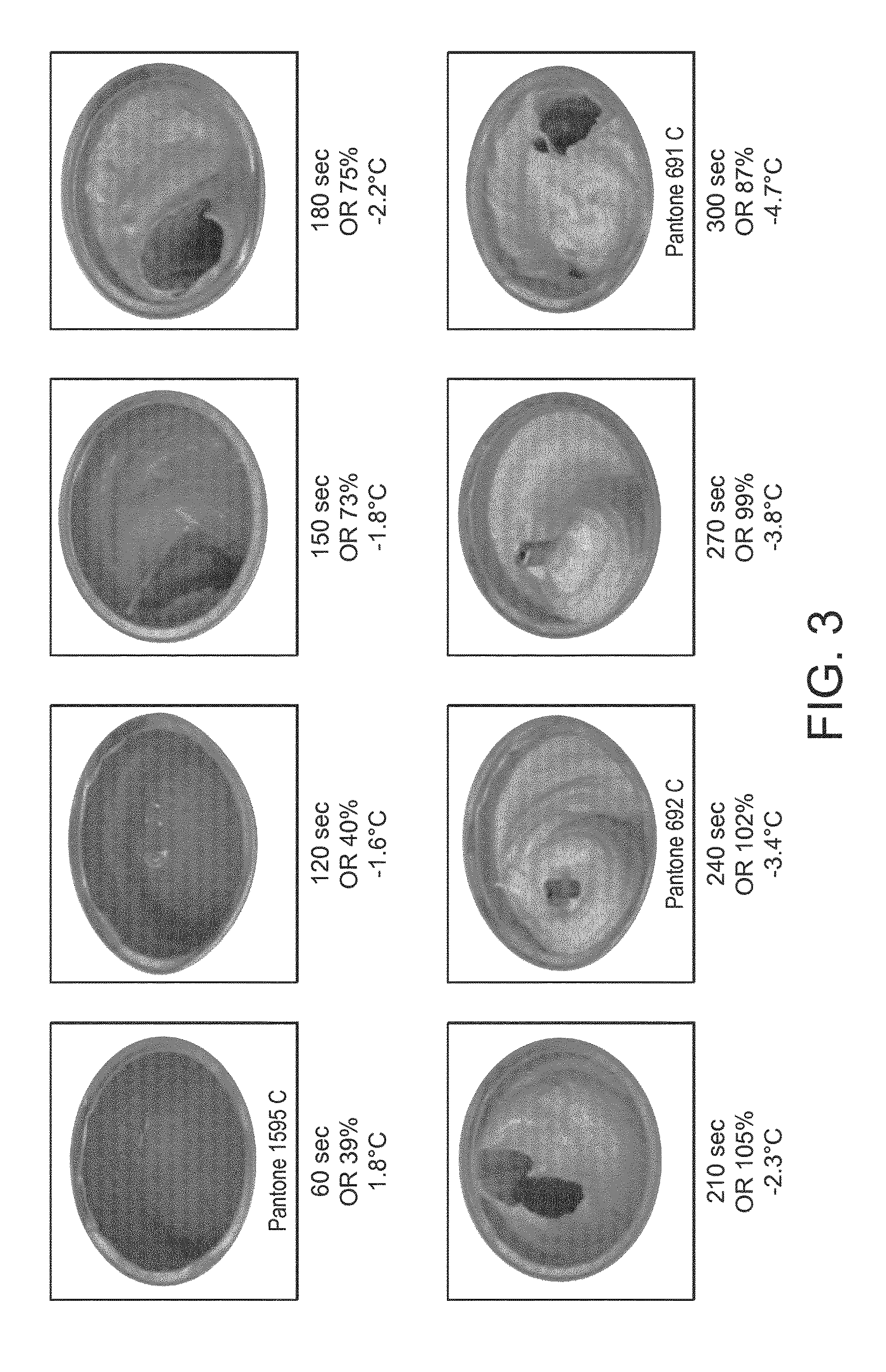

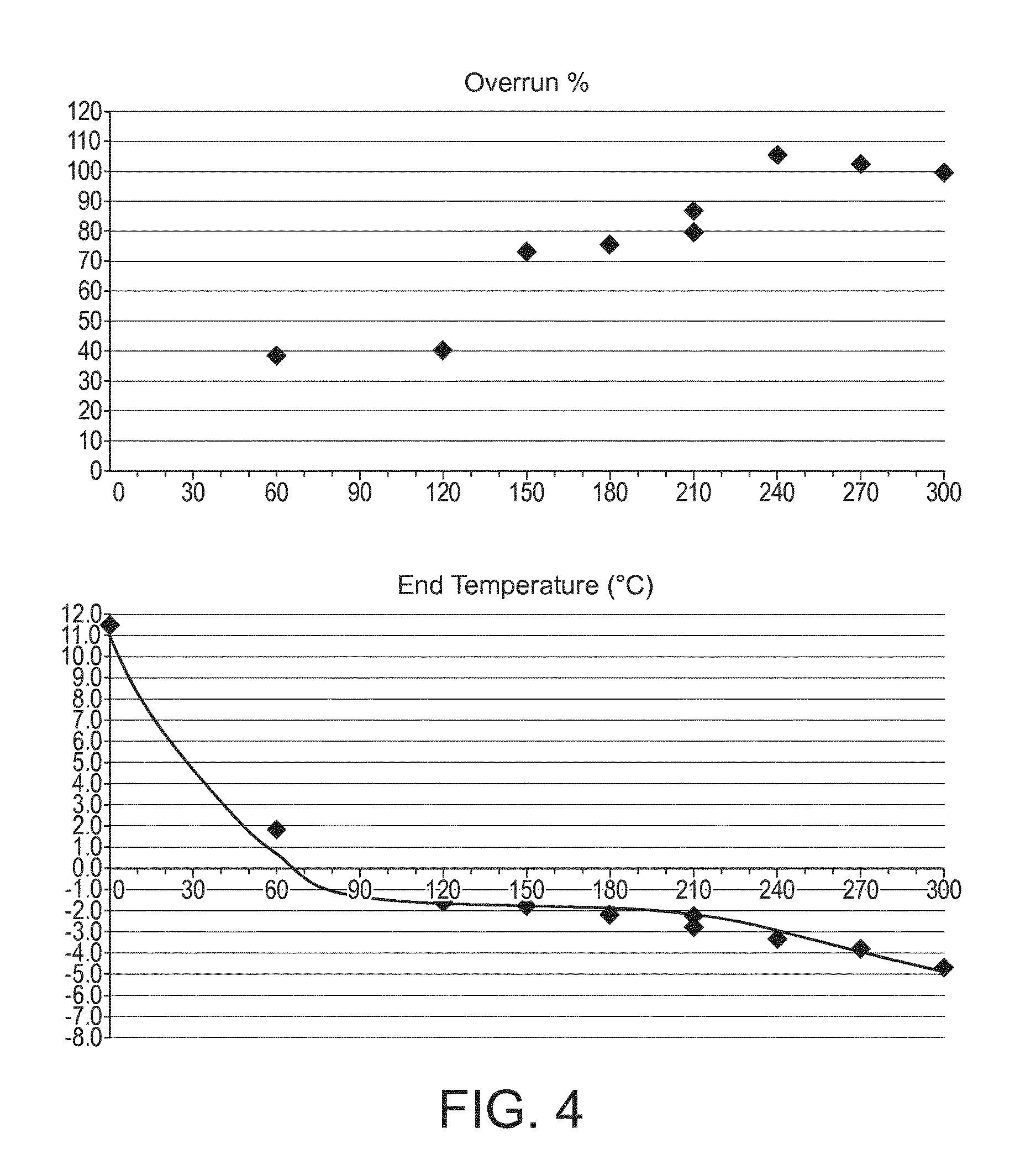

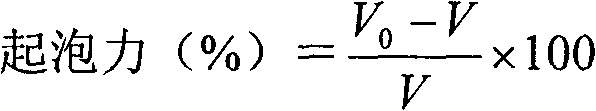

Frozen aerated products

ActiveUS20110311703A1Enhanced and improved organoleptic propertyImprove sensory propertiesFrozen sweetsFood preparationMilk proteinOrganoleptic

The present invention relates to frozen aerated products including products manufactured by low-temperature extrusion with superior creaminess. In particular, the invention is concerned with a partially coagulated protein system induced by controlled coagulation of milk protein which imparts outstanding sensory attributes on frozen confectionery including low-temperature extruded frozen products, in particular when containing low fat. A method of producing such frozen aerated confectionery product and the products obtainable from the method are also part of the present invention.

Owner:SOC DES PROD NESTLE SA

Frozen aerated products

ActiveUS8936821B2Enhanced and improved organoleptic propertyImprove sensory propertiesFrozen sweetsFood preparationProcess engineeringSugar food

The present invention relates to frozen aerated products including products manufactured by low-temperature extrusion with superior creaminess. In particular, the invention is concerned with a partially coagulated protein system induced by controlled coagulation of milk protein which imparts outstanding sensory attributes on frozen confectionery including low-temperature extruded frozen products, in particular when containing low fat. A method of producing such frozen aerated confectionery product and the products obtainable from the method are also part of the present invention.

Owner:SOC DES PROD NESTLE SA

Frozen confectionery products with improved texture

ActiveUS20130129896A1Enhanced and improved organoleptic propertyImprove sensory propertiesFrozen sweetsCheese manufactureWhey proteinProduct base

The present invention relates to a method for producing frozen confectionery products. In particular, the invention is concerned with a method which contributes to the improvement of textural and sensorial attributes of the confections obtained thereof, in particular of products based on lower fat formulations. The method includes the use of controlled heat (between 90° C. and 140° C. for 5 seconds to 30 minutes) on an acidified ice confection mix (pH between 5.6 and 6.5) to at least partially form a coagulated protein system including casein whey protein. Such a protein system is used according to the invention in frozen confection prepared by conventional freezing alone or combined with low temperature freezing wherein it improves the microstructure and stability on frozen products.

Owner:SOC DES PROD NESTLE SA

Frozen confectionery products

ActiveUS9253993B2Enhanced and improved organoleptic propertyImprove sensory propertiesMilk preservationFrozen sweetsProduct baseOrganoleptic

The present invention relates to a method for producing frozen confectionery products comprising a coagulated protein system which contributes to the improvement of textural and sensorial attributes of the confections, in particular of products based on lower fat formulations. Such a protein system is used according to the invention in frozen confection prepared by conventional freezing alone or combined with low temperature freezing wherein it improves the microstructure and stability on frozen products.

Owner:SOC DES PROD NESTLE SA

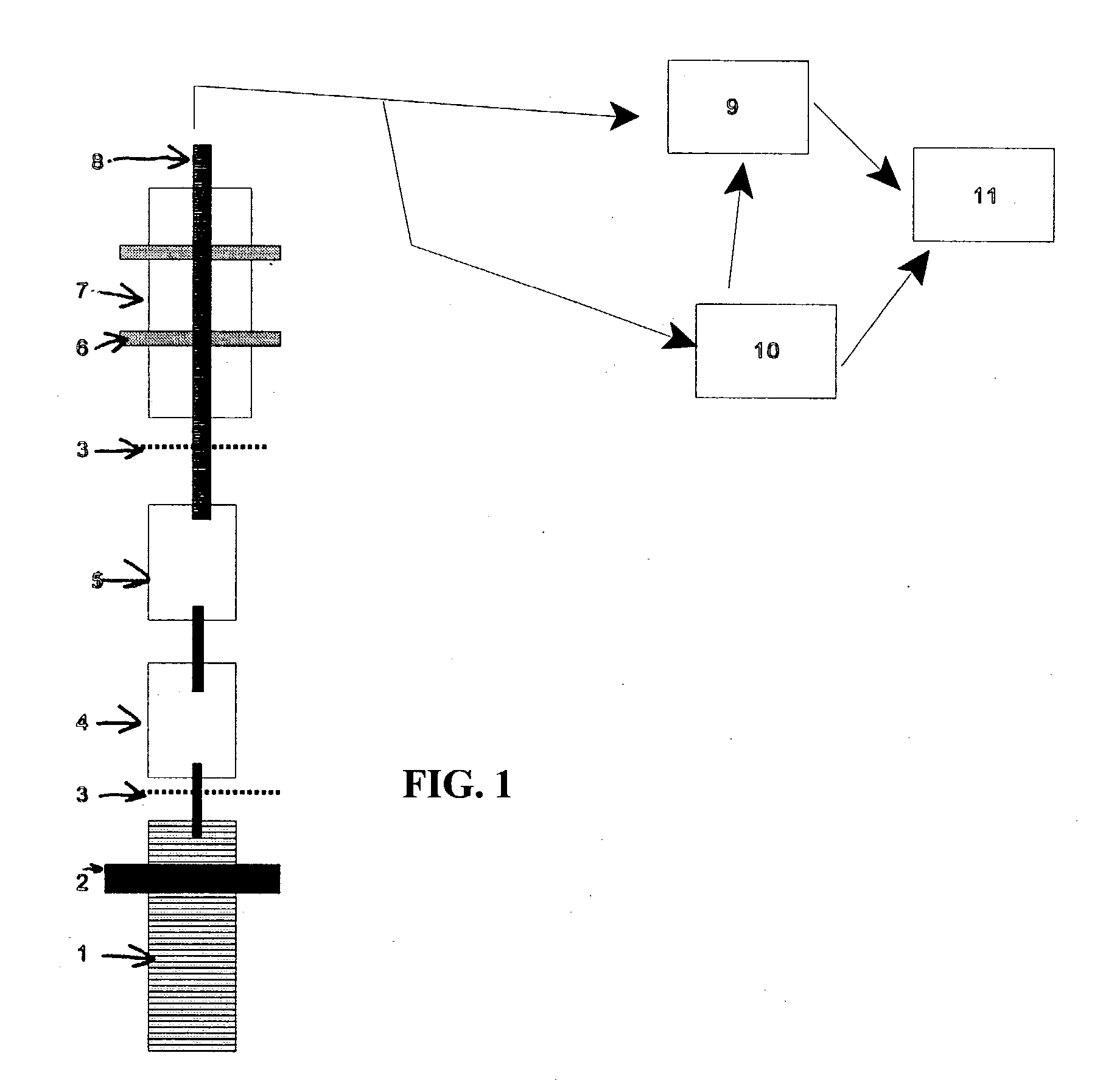

System for maintaining fresh quality and safe food attributes of minimally processed produce

InactiveUS20030198716A1Improve sensory propertiesReduce riskMilk preparationDough treatmentPreservativeUltraviolet lights

A system and method of maintaining the integrity of freshly harvested, or freshly cut fruits and vegetables. Specifically, the invention focuses on a distinct series of processes which confer a lower total microbial count, delay browning, improve general organoleptic properties, and decrease the amount of chemical contaminants on the exposed surfaces without the use of preservatives. Examples of such process may be applying a first produce integrity maintenance process, a second produce integrity maintenance process, application of an antibrowning agent to the produce by a produce antibrown agent applicator, exposing the produce to ultraviolet light by an ultraviolet light system, and applying an ozone treatment by an ozone treatment system.

Owner:HANKINSON THOMAS R

Liquid composition for frozen confection, method of production and process of preparation

InactiveUS20170042182A1Improve sensory propertiesConvenient coatingFrozen sweetsFood preservationWhey proteinSolid content

The present invention relates a liquid composition for frozen confection, in particular to a shelf stable composition which is suitable for making freshly prepared frozen confection. The liquid composition for frozen confection comprising 0.01 to 2% whey protein by weight based on the total composition (wt.); 0.01 to 3% wt of stabilizers, below 4.5% wt of fat, below 15% wt of sweetener, at least 25 % wt fruit, and having pH in the range from 3.5 to 4.2, preferably in the range of from 3.6 to 3.8 and solid content above 10% wt. The invention also relates to a method of production of the liquid composition and to a method of preparation of the frozen composition.

Owner:NESTEC SA

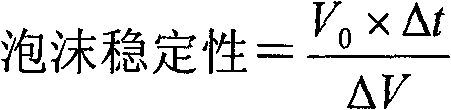

Egg white powder with high foamability and preparation method thereof

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

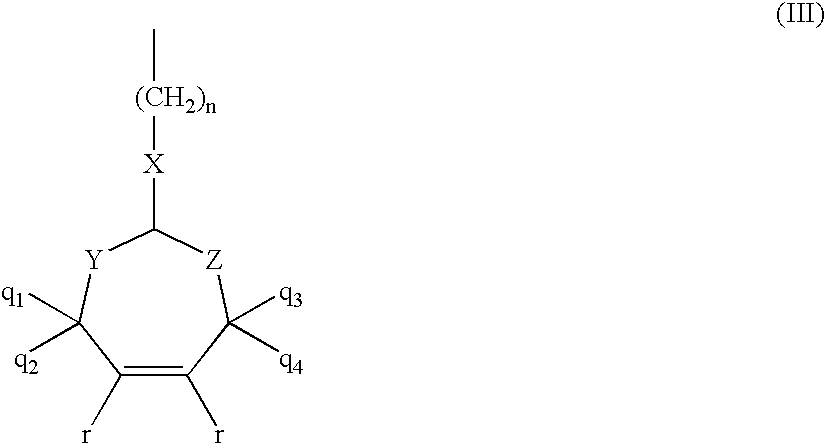

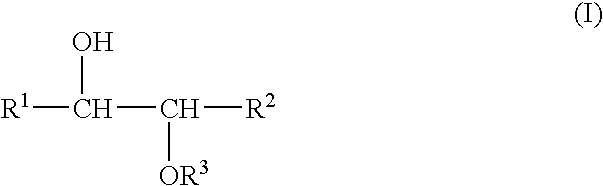

Sun protection compositions

InactiveUS20050112156A1Improve water resistanceImprove sensory propertiesCosmetic preparationsToilet preparationsDiolSun protection

The invention relates to new sun protection compositions with improved water resistance which are distinguished by the fact that they have an effective content of diol dimer fatty acid esters and, more particularly, dimer diol dimer fatty acid esters.

Owner:COGNIS DEUT GMBH & CO KG

Transition metal carboxylates as catalysts for oxygen scavenging

InactiveUS20050104033A1Improve sensory propertiesReduce taste and odor problemHydrogenOther chemical processesPtru catalystCarboxylic acid

Disclosed herein are oxygen scavenging compositions and packaging articles that comprise (a) a metal catalyzed oxidizable compound and (b) at least one of a transition metal carboxylate, wherein the transition metal carboxylate comprises at least one carboxylate group and wherein each carboxylate group comprises between 20 and 30 carbon atoms, inclusive, such as cobalt behenate or cobalt arachidate.

Owner:CRYOVAC ILLC

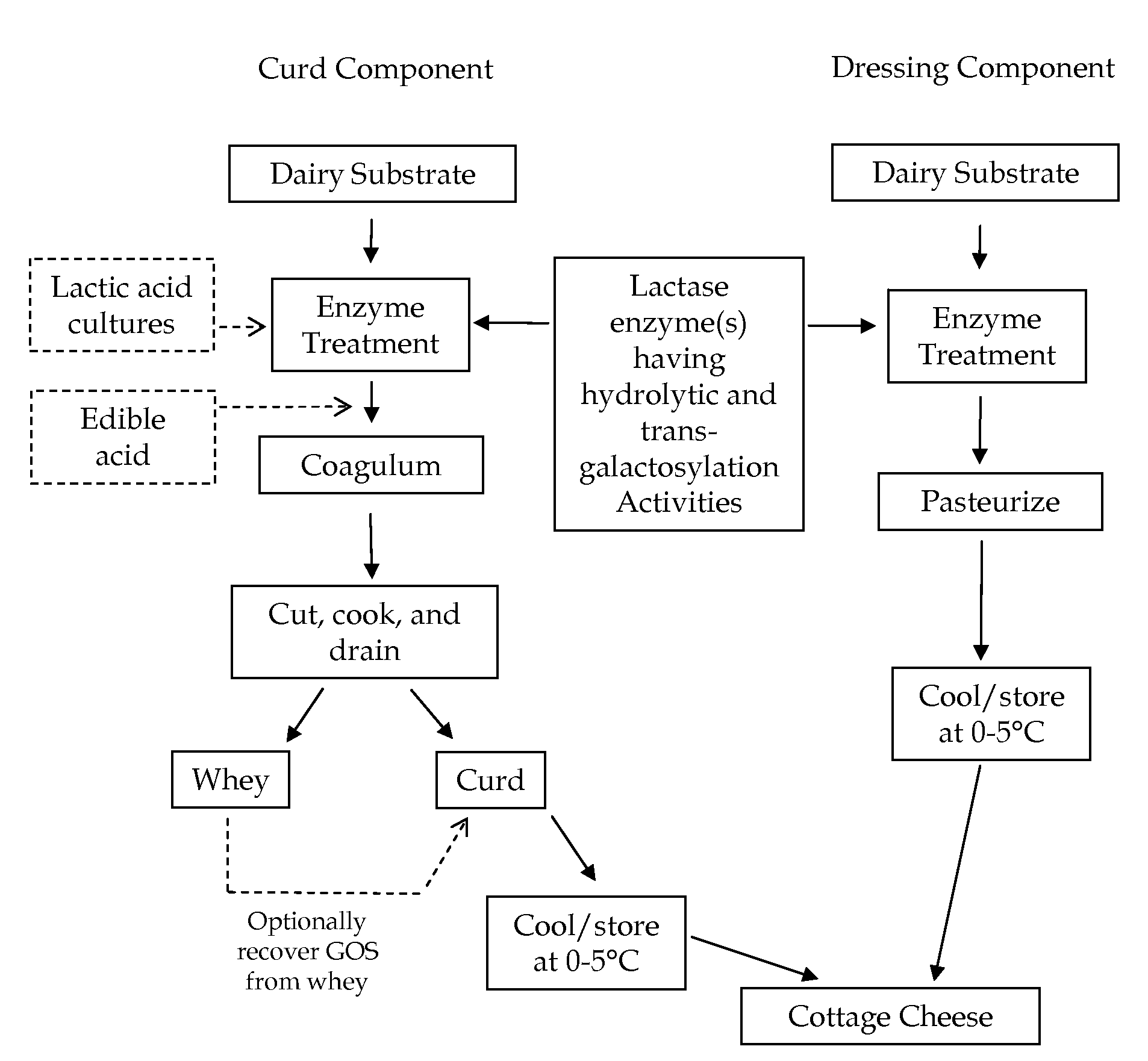

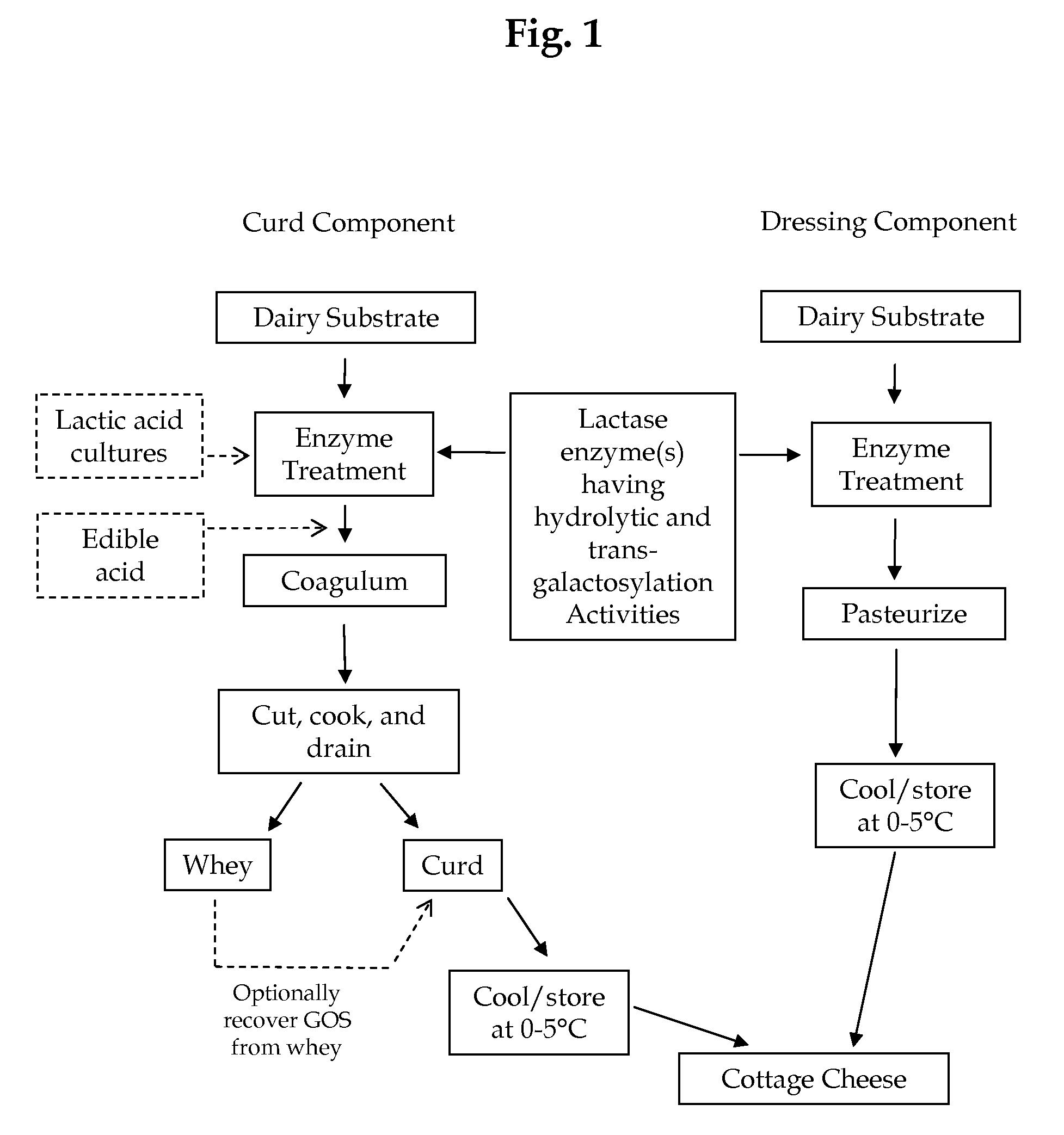

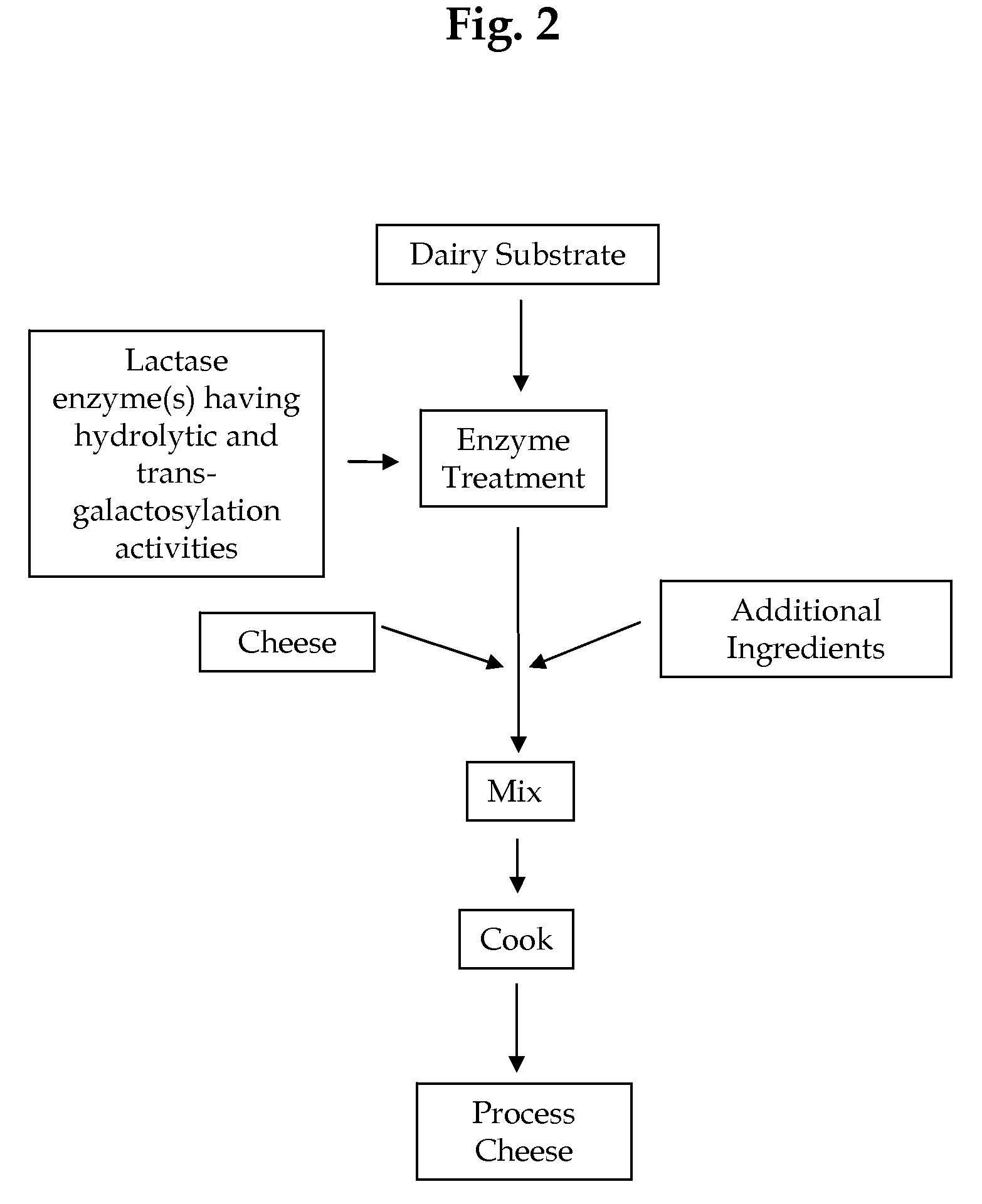

Cheese Products Containing Galacto-Oligosaccharides And Having Reduced Lactose Levels

InactiveUS20090297660A1Lower Level RequirementsReduce lactose levelMilk preparationWhey manufactureLactaseGalactooligosaccharide

The processes described herein are directed to cream cheese products containing galacto-oligosaccharides and having significantly reduced lactose levels. More specifically, lactose-containing dairy substrates are contacted with lactase enzyme(s) having hydrolytic and trans-galactosylation activities effective for converting at least 20 percent of the lactose in the dairy substrate to galacto-oligosaccharides. The enzyme-treated dairy substrate is then processed into galacto-oligosaccharide containing cream cheese products having reduced lactose levels. The cream cheese products provided herein have excellent nutritional and organoleptic properties.

Owner:KRAFT FOODS INC

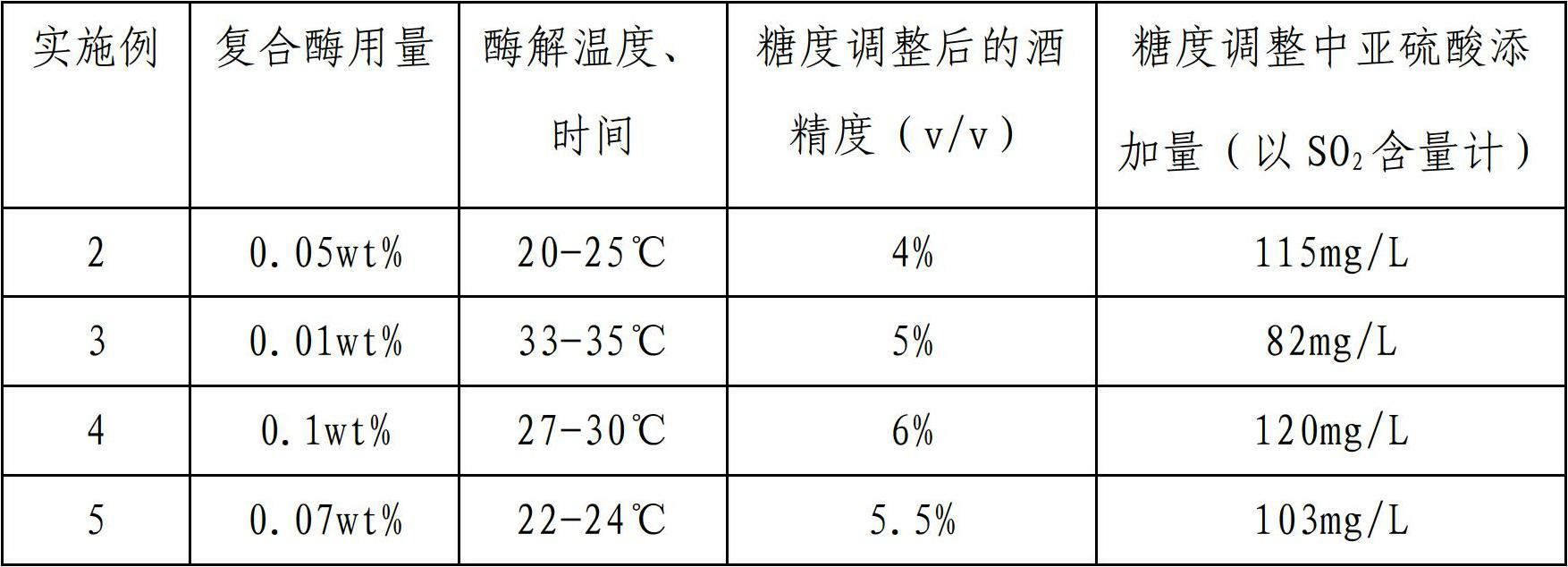

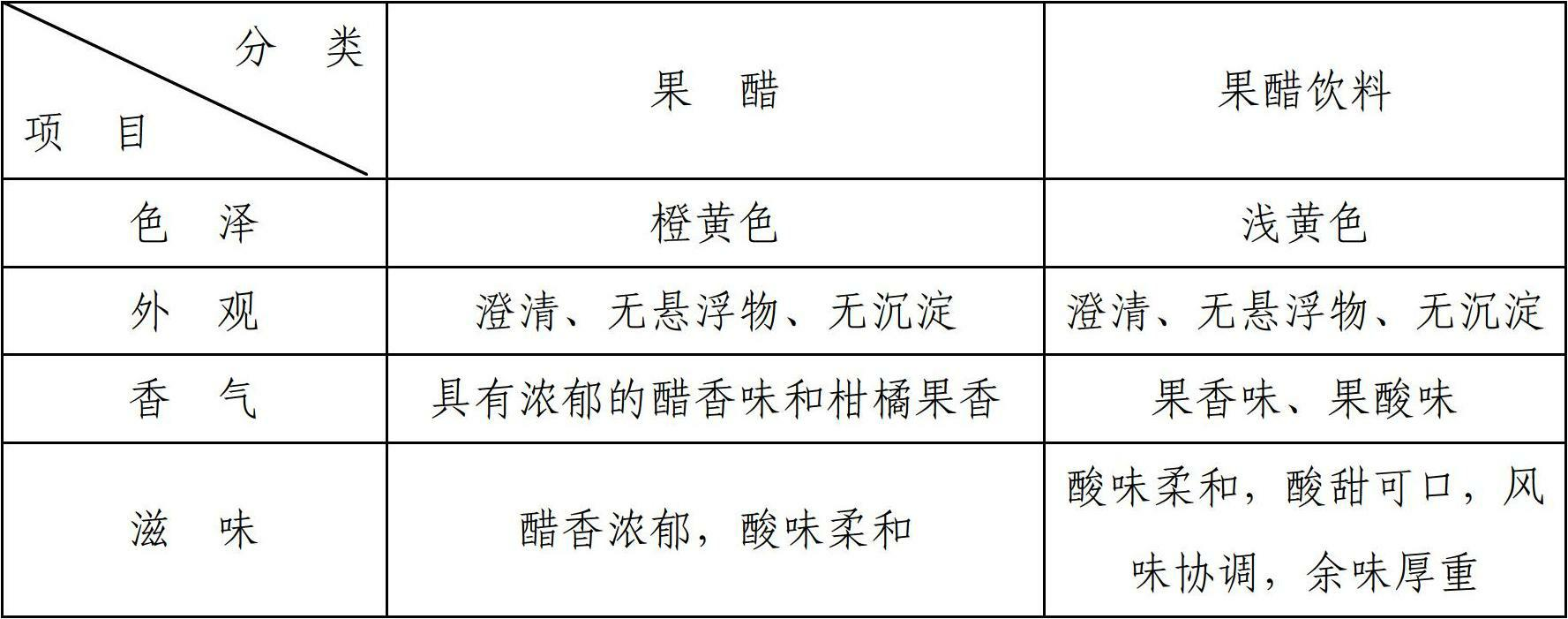

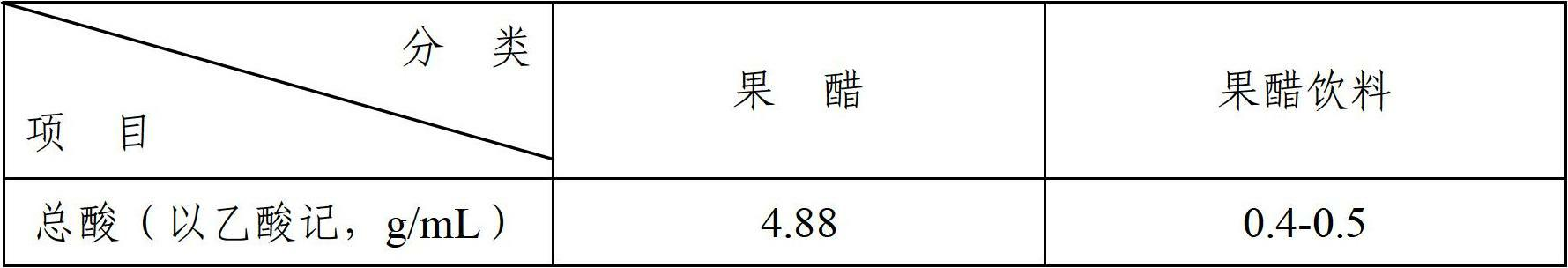

Technique for fermentation production of fruit vinegar beverage by utilizing orange peel residue

InactiveCN102669780APromote recyclingIncrease added valueVinegar preparationFood preparationHealth protectionPectinase

The invention relates to a technique for fermentation production of fruit vinegar basic solution and fruit vinegar beverage thereof by utilizing orange peel residue. The technique comprises the following steps of crushing raw materials, carrying out enzymolysis, regulating sugar degree, and carrying out alcohol fermentation and acetic fermentation, wherein the enzymolysis step is specifically as follows: adding composite enzyme with mass percentage of 0.01-0.1% to the crushed orange peel residue, and carrying out enzymolysis at 20-35 DEG C for 2-4h, and the composite enzyme consists of French raman pectinase and Hesibi cellulose based on the mass ratio of 5:1. Through the orange fruit vinegar basic solution and production technique of fruit vinegar beverage, disclosed by the invention, the production cost is low, the production efficiency is high, the transformation rate of the orange peel residue is high, about 6 tons of orange fruit vinegar basic solution can be produced by taking 1 ton of crushed orange peel residue as a raw material, and the content of acetic acid is as high as 4.88%; and simultaneously, the produced fruit vinegar beverage is a novel beverage integrating functions of nutrition, health protection, food therapy and the like, and the shelf life of the fruit vinegar beverage is as long as 12 months at normal temperature.

Owner:CHONGQING ACAD OF AGRI SCI

Products comprising an applicator and a wax dispersion

InactiveUS20060233866A1Improve sensory propertiesGood caring propertyCosmetic preparationsToilet preparationsWaxEngineering

This invention concerns products for cleansing and other applications, which products comprise an applicator such as a puff (pouf), pad, sponge, foam, mitt, glove, swab, cotton ball or bar, to which a wax dispersion has been applied. The invention further concerns the manufacture and use of such products.

Owner:JOHNSON & JOHNSON GMBH

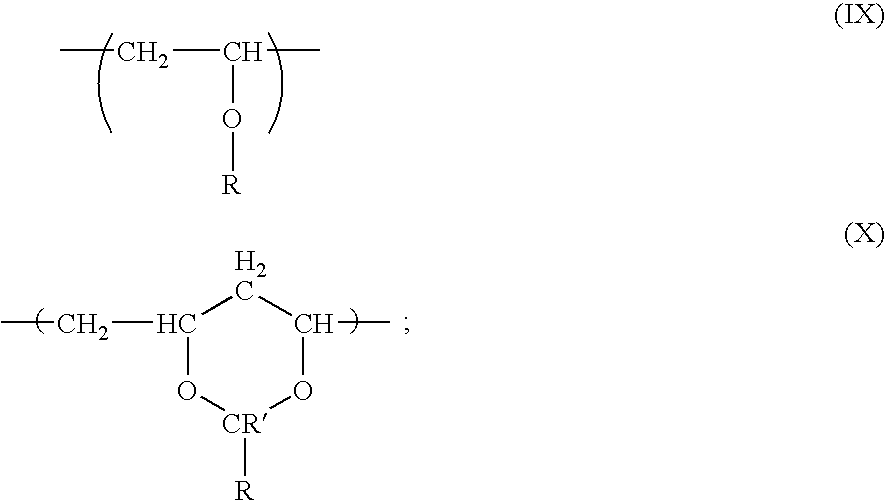

Cosmetic composition containing hydroxyethers

InactiveUS7083780B2Improve sensory propertiesImprove solubilityCosmetic preparationsOrganic chemistryAlcoholPolyol

Owner:COGNIS DEUT GMBH & CO KG

Enhancing the nutritional value of food products

InactiveUS20130011529A1Improve sensory propertiesAlcoholic beverage preparationBakery productsNutritive valuesNutritional status

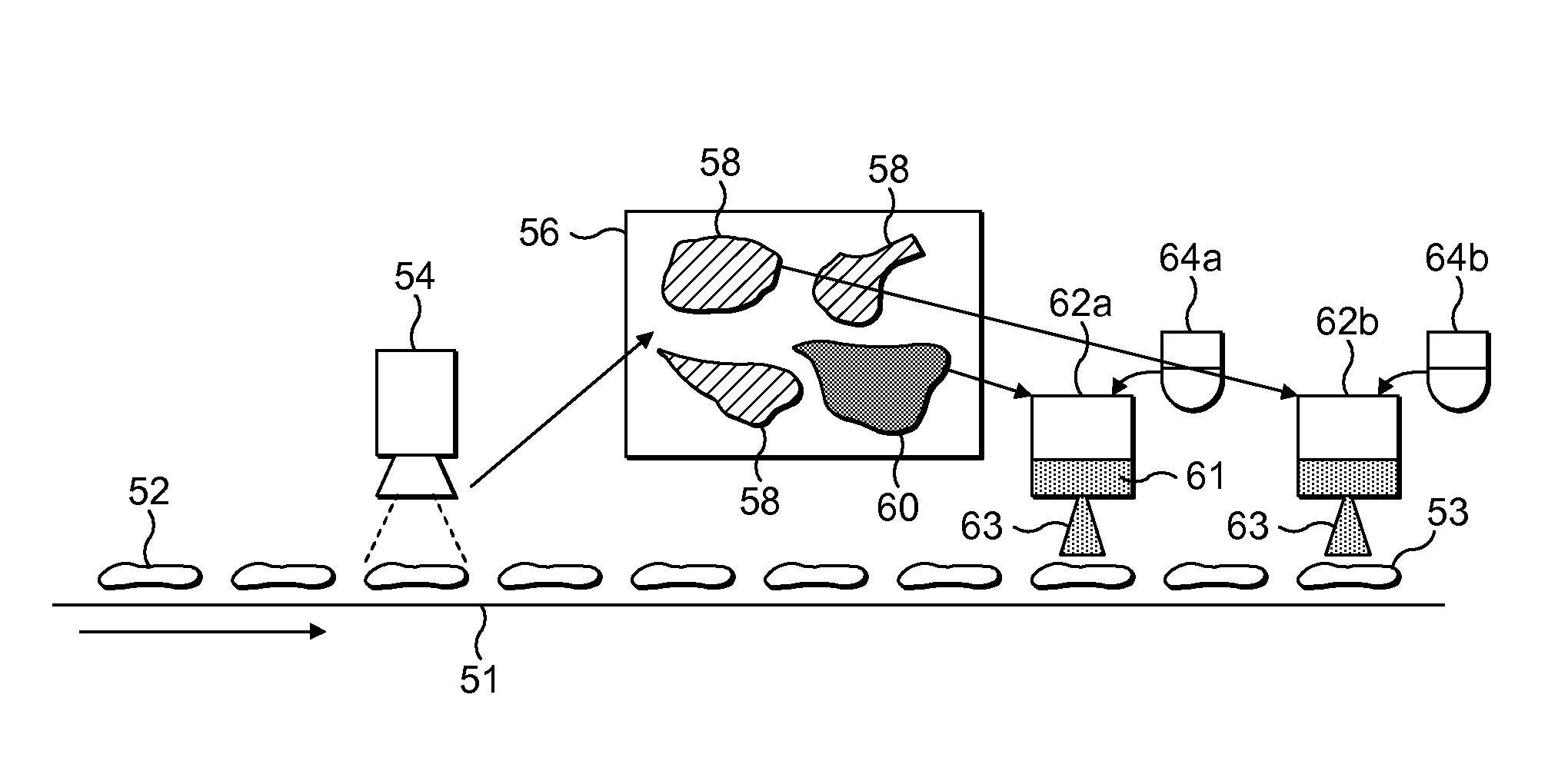

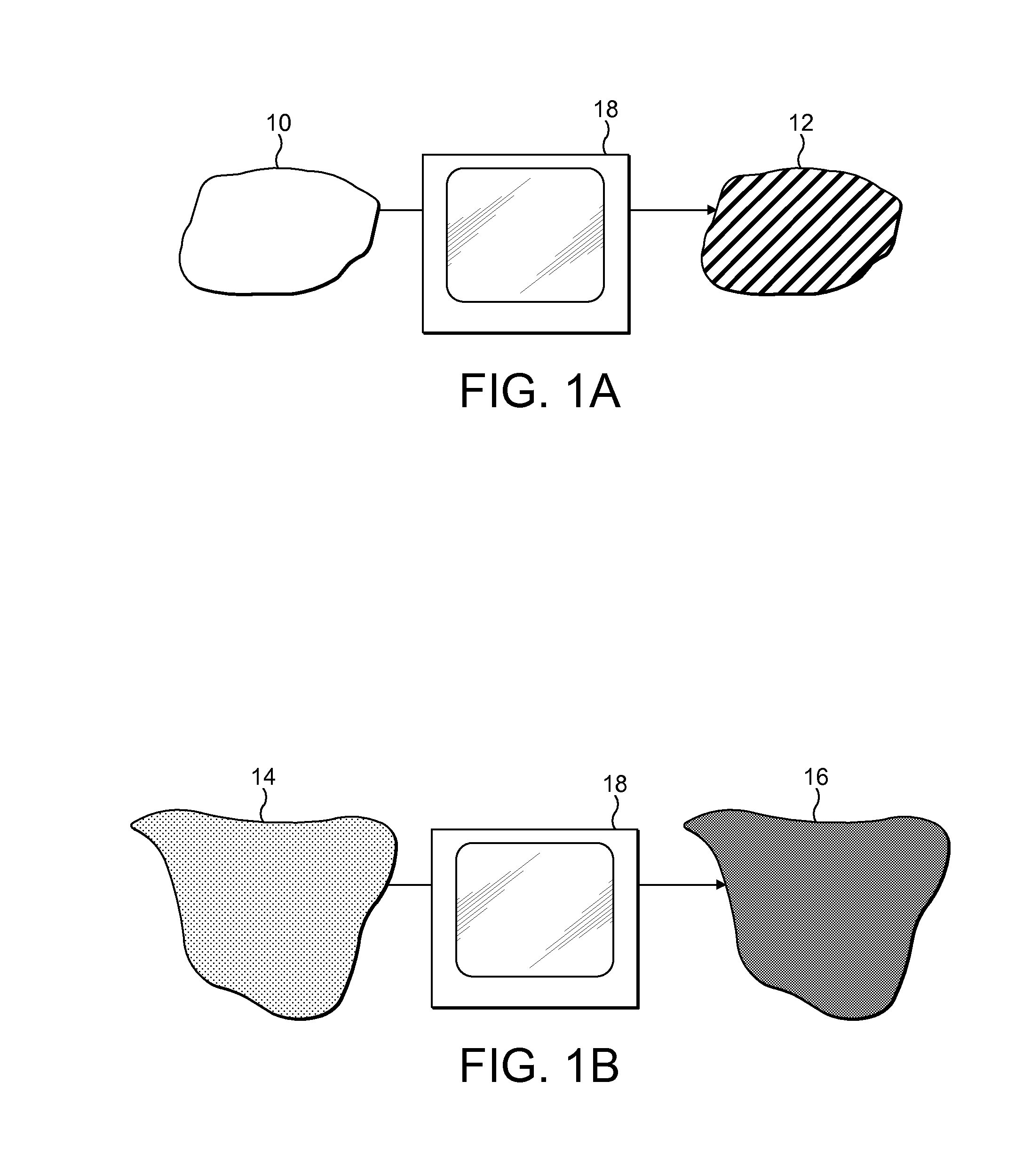

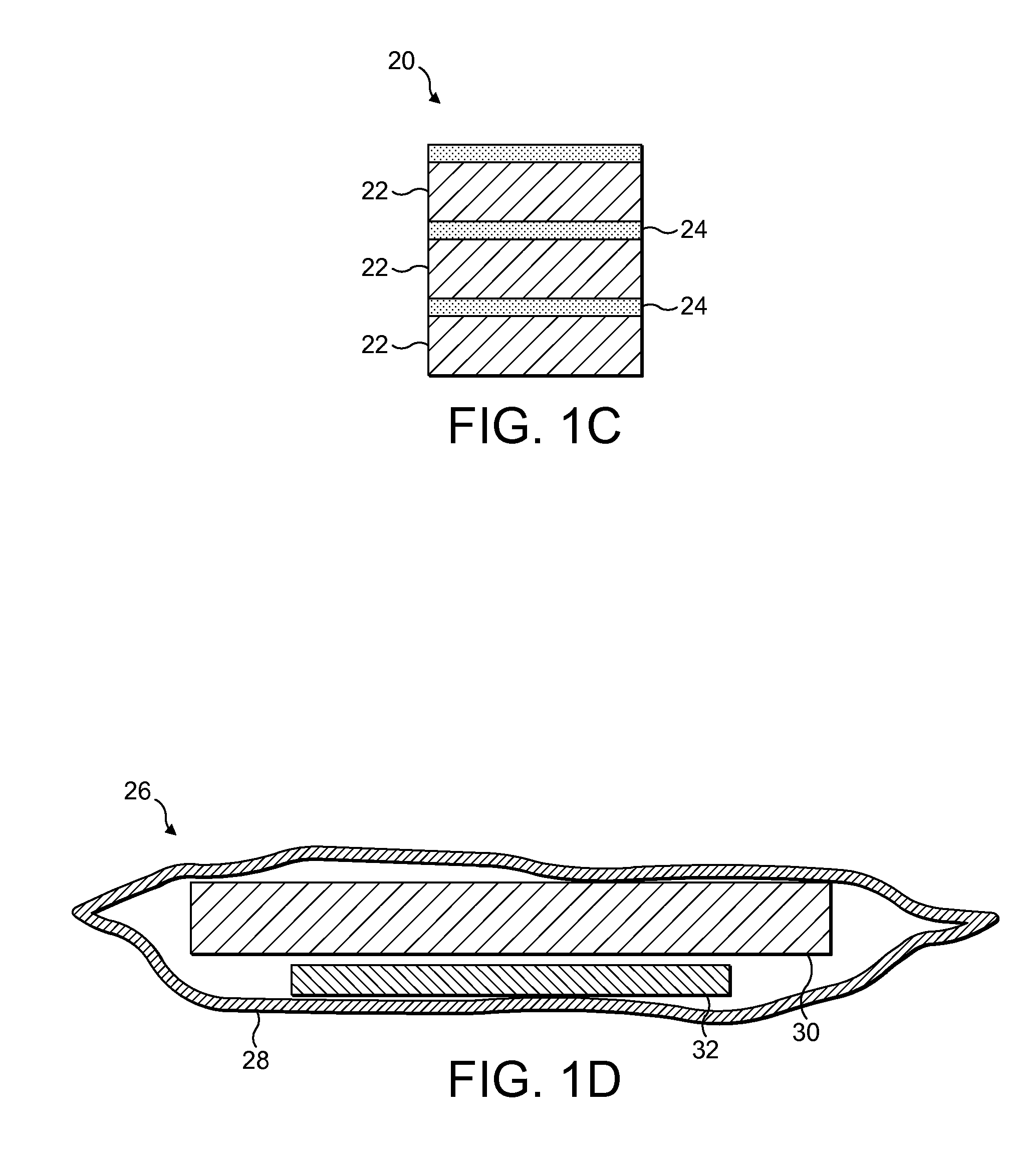

This invention provides processes and apparatus for enhancing the nutritional value of food products. Nutrition-enhancing agents are applied or dispensed onto or into food products during their manufacture by food-grade controlled-droplet dispensing heads (or head). In preferred embodiments, the dispensing heads are controlled by a controller, such as a programmed PC-type computer, in dependence on sensor data, such as electromechanical, optical, or image sensor data. The controller and sensors operate so that different food items can have selected nutrition-enhancing agents properly applied or dispensed without waste or overspray. The invention also provides food products which have been enhanced according to the provided processes and apparatus with nutrition-enhancing agents.

Owner:NESTEC SA

Whey protein product and a method for its preparation

InactiveCN102595915ASimple structureImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO LTD

Shortening system

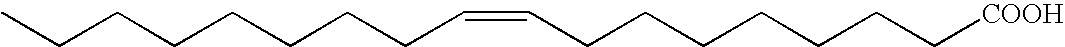

InactiveUS20090220653A1Improve sensory propertiesGreat tasteFatty acid hydrogenationEdible oils/fats ingredientsGeometric isomerVegetable oil

A shortening system, such as a spray shortening system; for instance, a shortening system containing unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil or canola oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of conserved trans monoglyceride and / or diglyceride, advantageously a monoglyceride or a mono- and diglyceride that is mostly monoglyceride, based on a highly unsaturated ‘oil, such as a highly unsaturated vegetable oil, e.g., canola or soybean oil,’ which has been selectively and partially hydrogenated so as to result in conservation of the geometric isomer of the C18:1 ester, namely the C18:1t or elaidic ester, as well as to methods for making and using such a shortening system, products from the use of such a shortening system, and the monoglyceride and / or diglyceride constituent of the shortening system, and methods for making and uses thereof.

Owner:AS DE DANSKE SUKKERFABRIKKER

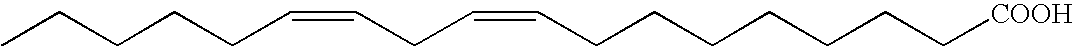

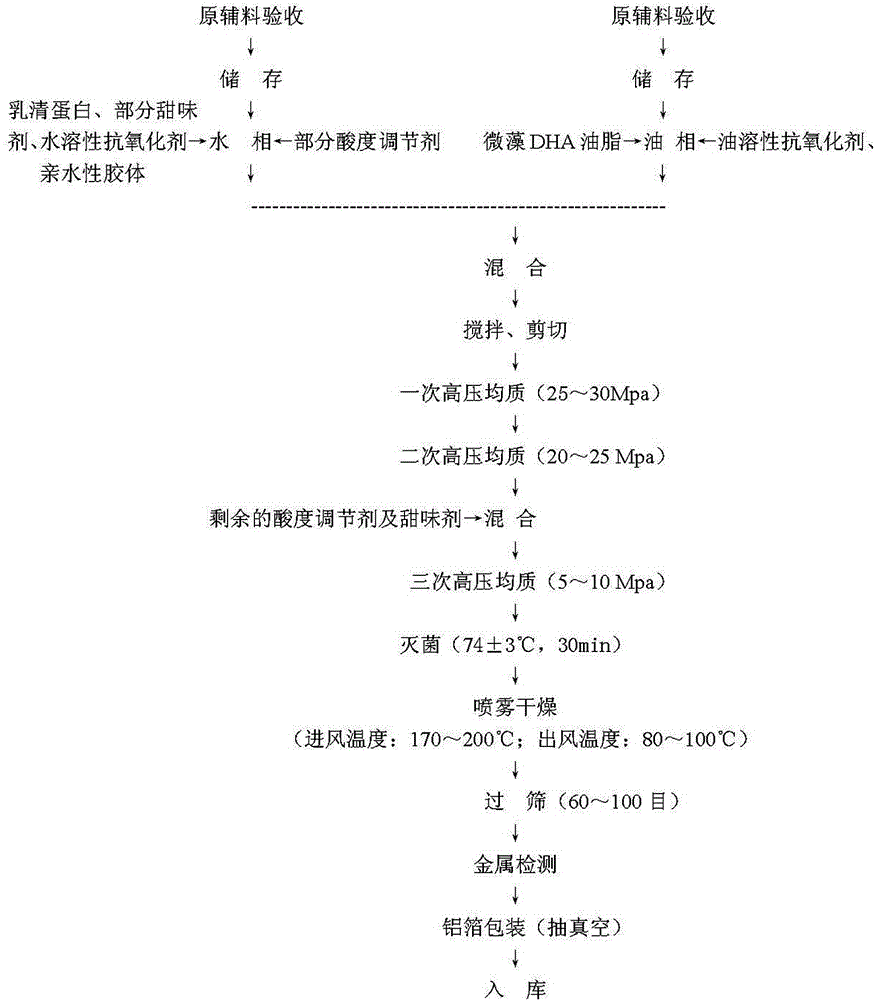

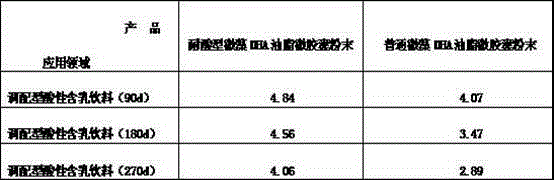

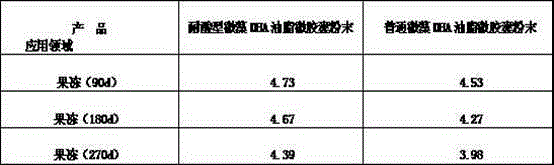

Acid-proof type microalgae DHA oil microcapsule powder and preparation method thereof

ActiveCN104432059AImprove stabilityNo flocculationSugar food ingredientsFood shapingBiotechnologyAcid water

The invention relates to an acid-proof type microalgae DHA oil microcapsule powder and a preparation method thereof. The acid-proof type microalgae DHA oil microcapsule powder is prepared from 12.6%-30.3% of core materials and 69.7%-87.4% of wall materials, concretely comprising the following active ingredients in percentage by weight: 12.5%-30.0% of microalgae DHA oil, 0.1%-0.3% of antioxidant, 25.0%-50.0% of whey protein, 3.0%-8.0% of food emulsifier, 20.0%-54.4% of sweetener, 4.40%-8.0% of hydrophilic colloid, and 0.60%-1.20% of acidity regulator. The prepared acid-proof type microalgae DHA oil microcapsule powder has good acid-proof property, and can be applied in a food system of an acid water system with pH of more than or equal to 3.5, the oxidization speed of microalgae DHA can be effectively reduced and delayed, the activity of the microalgae DHA can be maintained, the stability of microalgae DHA in acid water system food can be enhanced, and the shelf life of the acid water system food with microalgae DHA can be prolonged.

Owner:RUNKE BIOENG FUJIAN

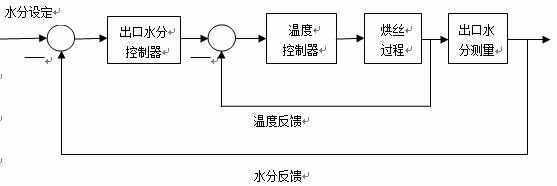

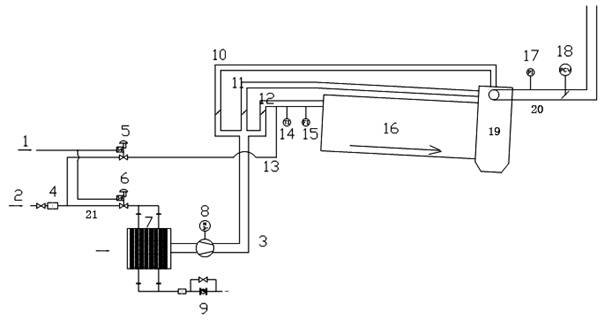

Cut-tobacco drier based on independent tobacco cutting characteristics of papermaking method reconstituted tobacco and cut-tobacco drying control method thereof

ActiveCN102631017AQuality improvementIncrease profitTobacco preparationControl systemPulp and paper industry

The invention relates to the related technical field of tobacco production, and in particular relates to a cut-tobacco drier based on the independent tobacco cutting characteristics of papermaking method reconstituted tobacco and a cut-tobacco drying control method thereof. The cut-tobacco drier comprises a barrel, a moisture discharge rotary net, a cut-tobacco drying heating air system, a humidifying air system and a control system. Through the control method provided by the invention, the traditional cut-tobacco drier is completely suitable for the papermaking method reconstituted tobacco after independent tobacco cutting, the control aim of 12-13% of moisture content at exit is achieved, and the independent tobacco cutting quality and the effective utilization rate of the papermaking method reconstituted tobacco can be effectively improved. The low-intensity processing mode can effectively maintain the physical characteristics and chemical characteristics of the papermaking method reconstituted tobacco after independent tobacco cutting, the sensory characteristic is effectively enhanced, and relatively high friability and relatively low doubling rate are realized; and thus the reconstituted tobacco can be blended with other natural tobacco, and a firm guarantee is provided for the grouping processing of tobacco primary process and flexible processing production new mode.

Owner:CHINA TOBACCO ZHEJIANG IND

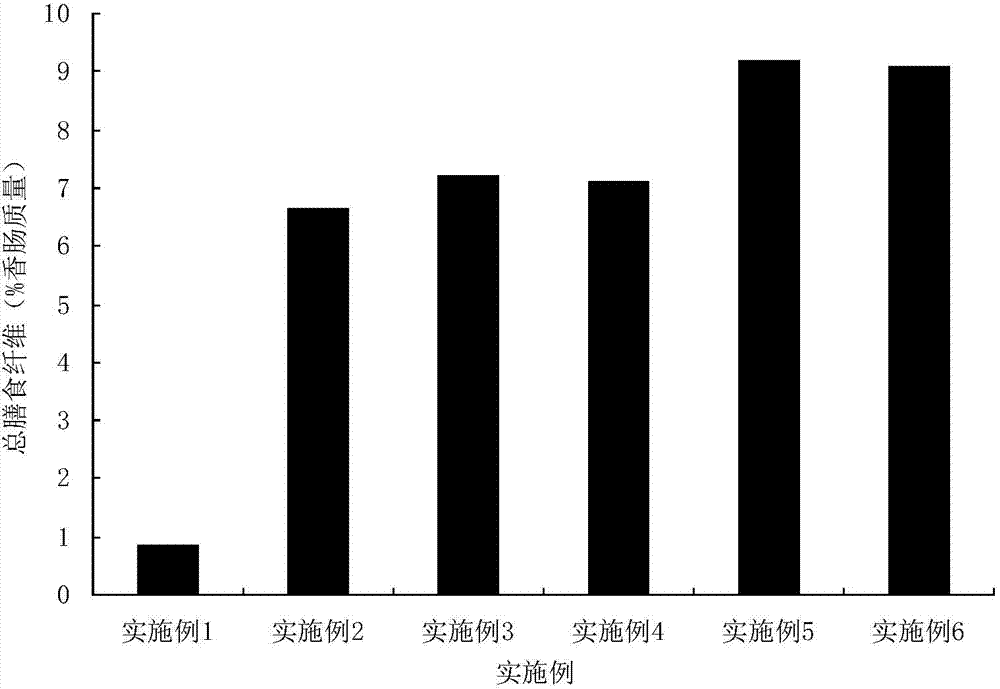

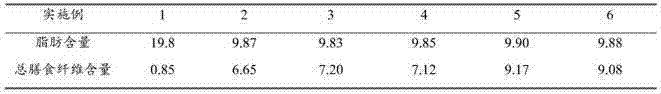

Preparation method of low-fat high-dietary-fiber grain sausage

ActiveCN104207180ALow in fatKeep the flavorFood ingredient functionsFood preparationFiberBARLEY BRAN

The invention discloses a preparation method of low-fat high-dietary-fiber grain sausage and belongs to the technical field of food processing. In the method, pork is employed as a main material with addition of modified oat dietary fiber, or modified barley dietary fiber, and inulin, wherein a total dietary fiber addition amount of the sausage accounts for 6-10% of the weight of the pork. The modified oat dietary fiber, or modified barley dietary fiber, is prepared with oat, or barley bran, as a raw material, and through following processes: a degreasing and drying process, a sieving process, a crushing process, an enzymatic hydrolysis process, a precipitating process, a drying process, a superfine grinding process and a high-pressure modifying process. By means of the method, the grain sausage is low in the content of fat and is high in the content of the dietary fiber, wherein the content of the fat is only 9.90% while the content of the dietary fiber is 9.17%. Meanwhile, the grain sausage has an excellent texture and sensory characteristics and is suitable for industrial popularization.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Nutritional frozen dessert and methods of manufacture

InactiveUS7169416B2Improve sensory propertiesMaintain good propertiesMilk preparationMilk preservationBiotechnologyFood science

Owner:BRIO FOOD CO LLC

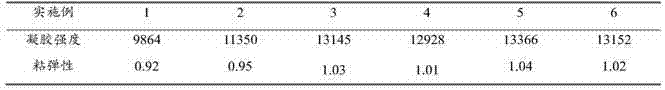

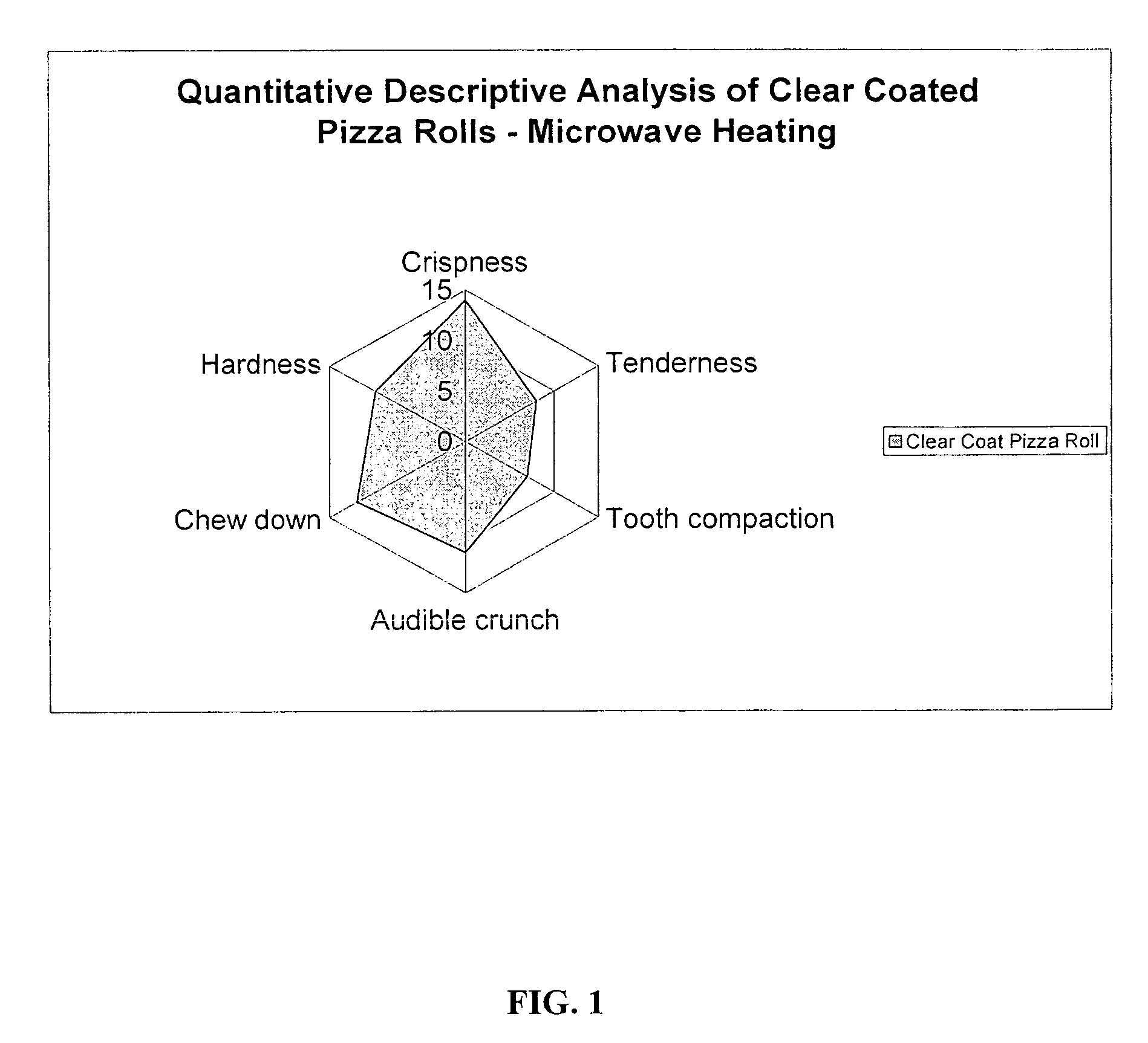

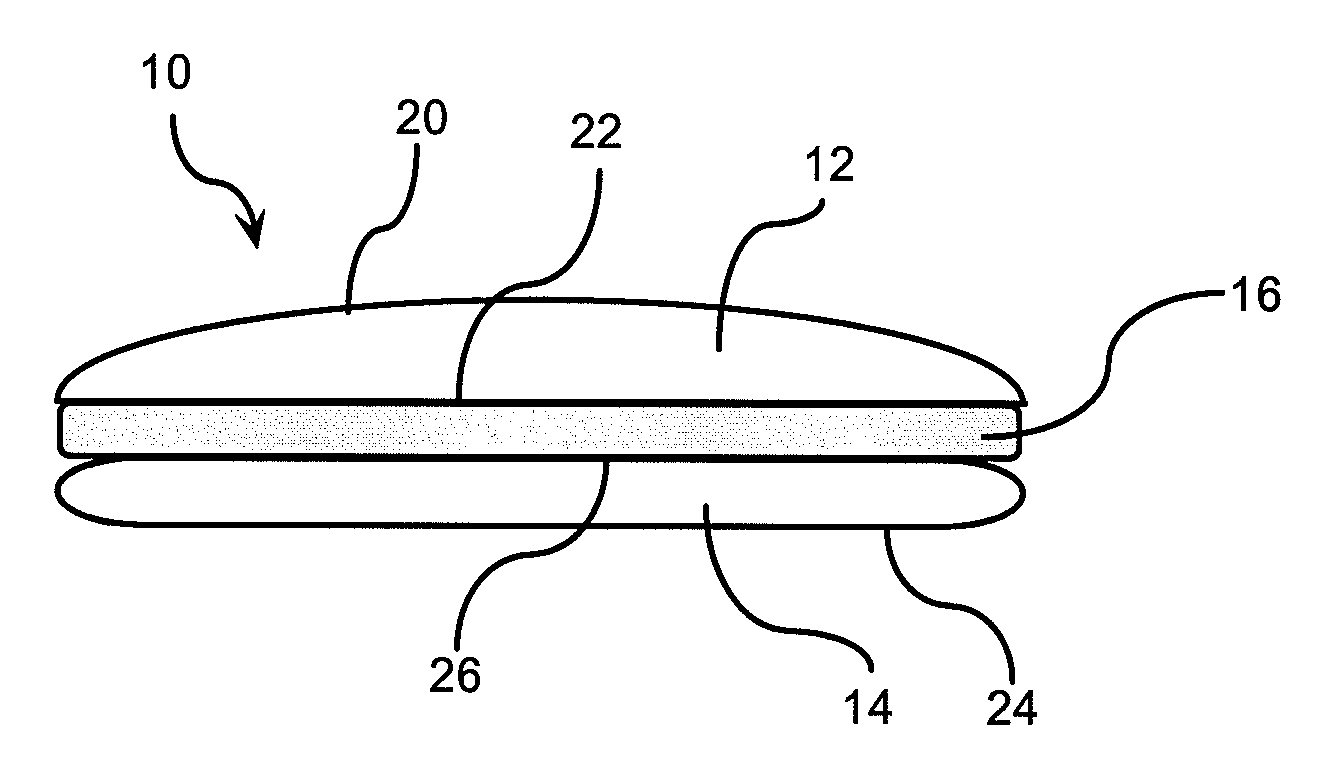

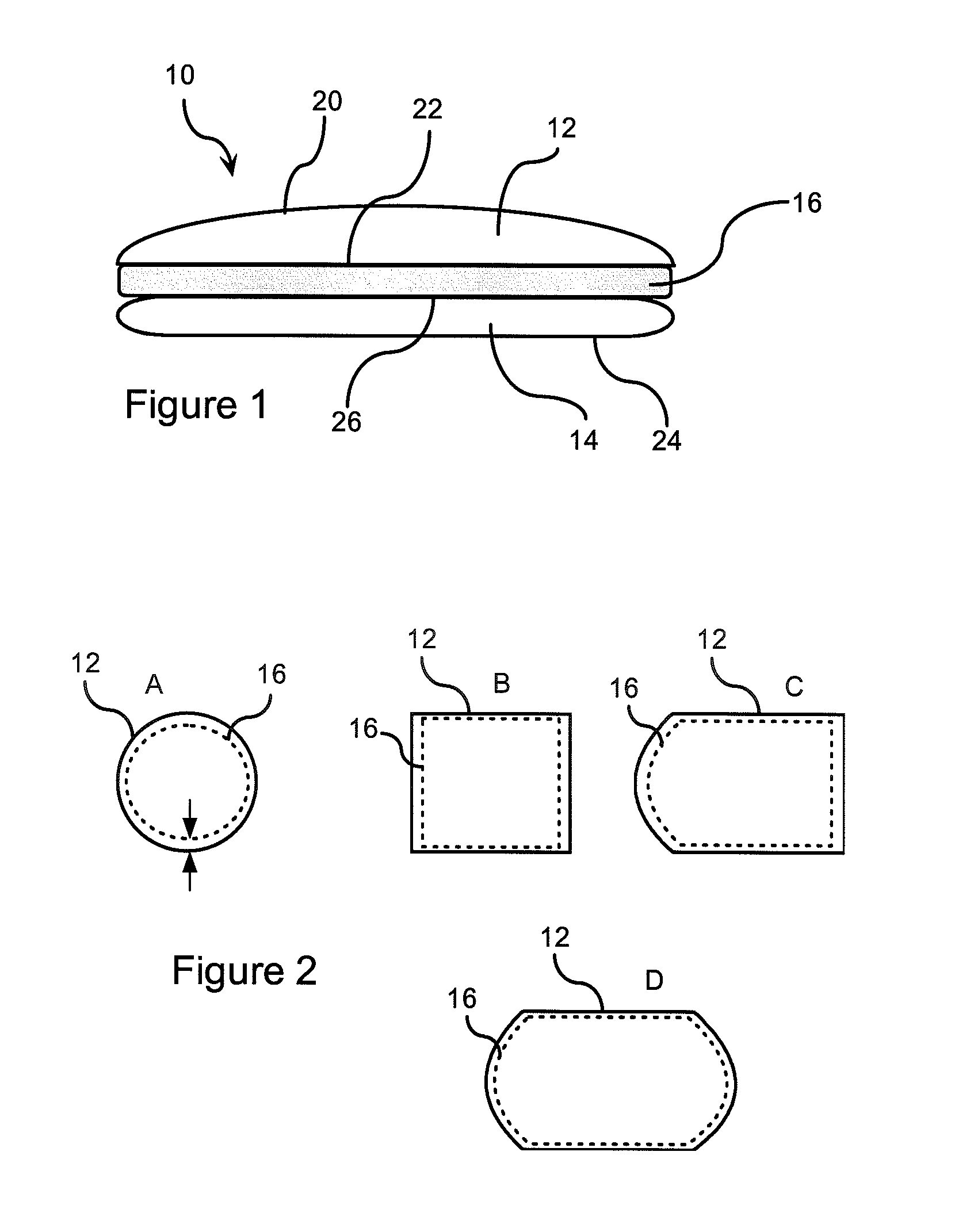

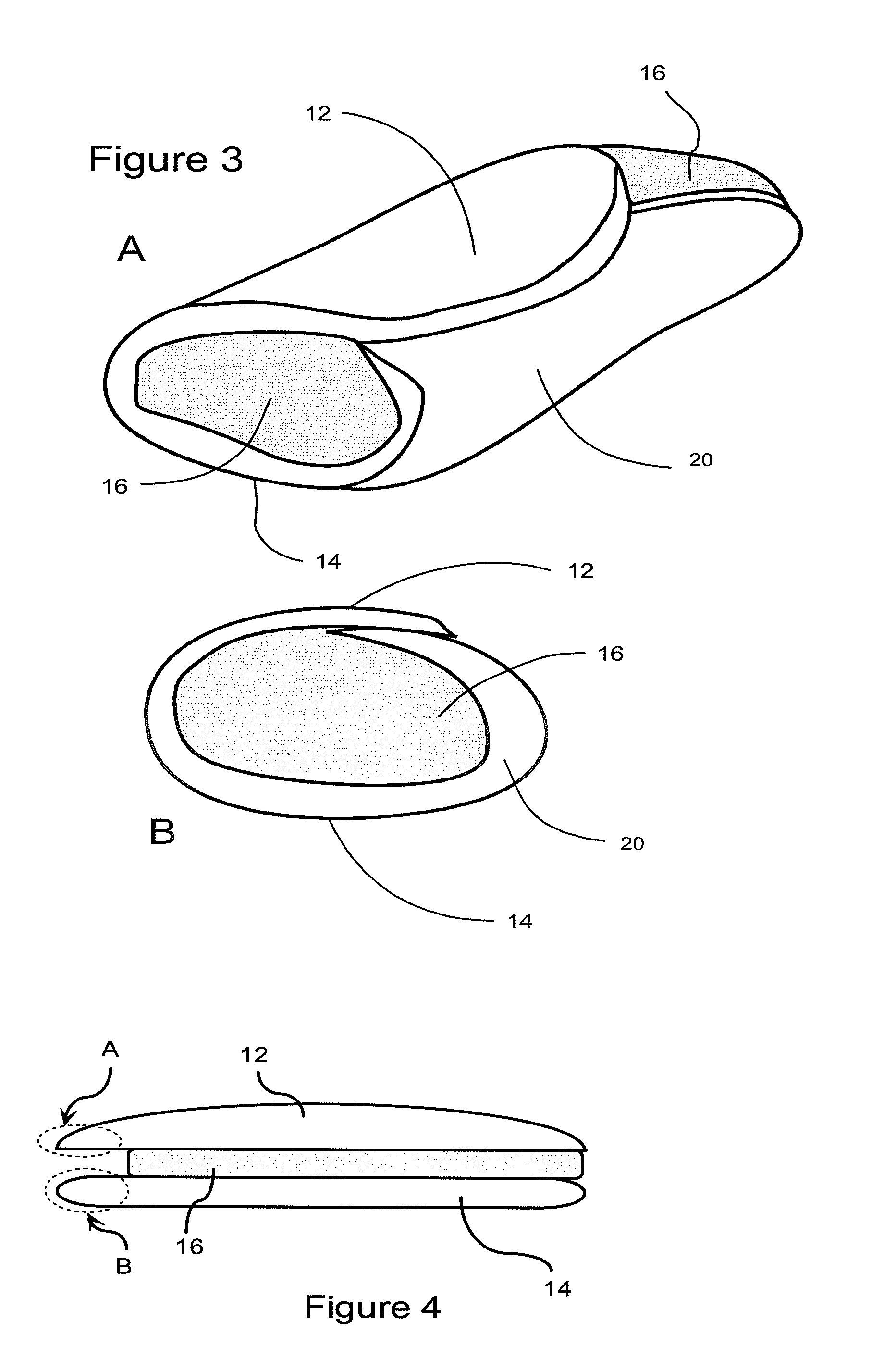

Dough-enrobed foodstuff

InactiveUS7998512B1Clear appearanceImprove crispnessConfectioneryPreservation by coolingFood itemFOOD STARCH

A dough-enrobed foodstuff is provided that contains a filling and is coated with a coating composition that includes a dextrin where less than 50% of the dextrin is soluble in about 25° C. (77° F.) water and modified food starch having an amylose content of less than 50% based on the weight of the modified food starch. The coated foodstuff is thermally processed such that the coating becomes substantially clear. The coated thermally processed foodstuff is then frozen. On reheating, the coated foodstuff is crispier than an uncoated, frozen foodstuff after reheating and substantially prevents the filling from breaking the dough-enrobed foodstuff upon reconstitution by subsequent thermal processing.

Owner:ADVANCED FOOD TECH

Baked Microwavable Frozen Bread and Bakery Products

InactiveUS20080063755A1Satisfactory textureSatisfactory chewability characteristicBakery product refreshing by heating/thawingDough treatmentMicrowave ovenFood products

A fully assembled frozen food product is provided which comprises a bread portion having a top portion and a bottom portion and having a filling between, and co-extensive with, the top and bottom portions, wherein the fully assembled frozen food product can be heated in a microwave oven to provide a heated food product which is then ready to be eaten, wherein the bread portion of the heated food product is not dried out and wherein the filling in the heated food product has an essentially uniform temperature.

Owner:KRAFT FOODS GRP BRANDS LLC

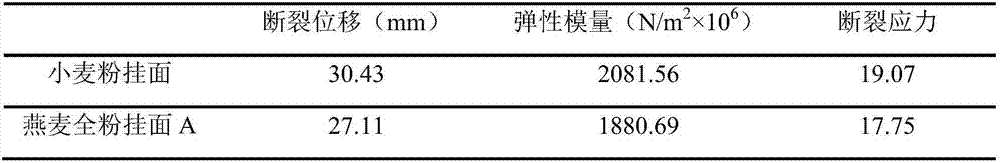

Whole-oat hypolipidemic functional fine dried noodle and production method thereof

InactiveCN106858316AIncrease the amount addedImprove digestion and absorption rateFood preservationInorganic compound food ingredientsSecondary hyperlipidemiaGluten

The invention provides a whole-oat hypolipidemic functional fine dried noodle and a production method thereof. According to the invention, the preprocessed whole oat flour is acquired according to the steps of preparing flour, stabilizing, pre-curing and finely smashing, and then the technologies, such as, formulation optimization, vacuum dough kneading and special rolling, are adopted for increasing the oat additive amount while guaranteeing the organoleptic quality of the fine dried noodle. The oat functional fine dried noodle is prepared from the following raw materials in parts by weight: 10-100 parts of preprocessed whole oat flour, 0-90 parts of wheat flour, 0-10 parts of high-activity gluten powder, 1-3 parts of salt, 0-3 parts of edible glue, 0-3 parts of soda and 0-3 parts of additional starch. According to the invention, under the condition of adding no any additives, 100% oat functional fine dried noodle product is produced, the quality is natural, the functional fine dried noodle belongs to dietary nutrition healthy food and has more obvious effects of reducing blood fat and restraining fat and an excellent staple food choice is supplied for the hyperlipidemia and obese patients.

Owner:KEMEN NOODLE MFG CO LTD

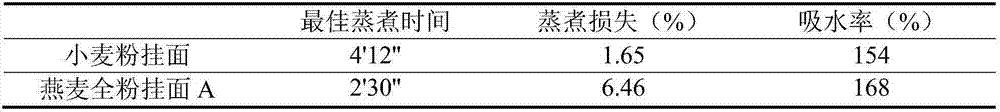

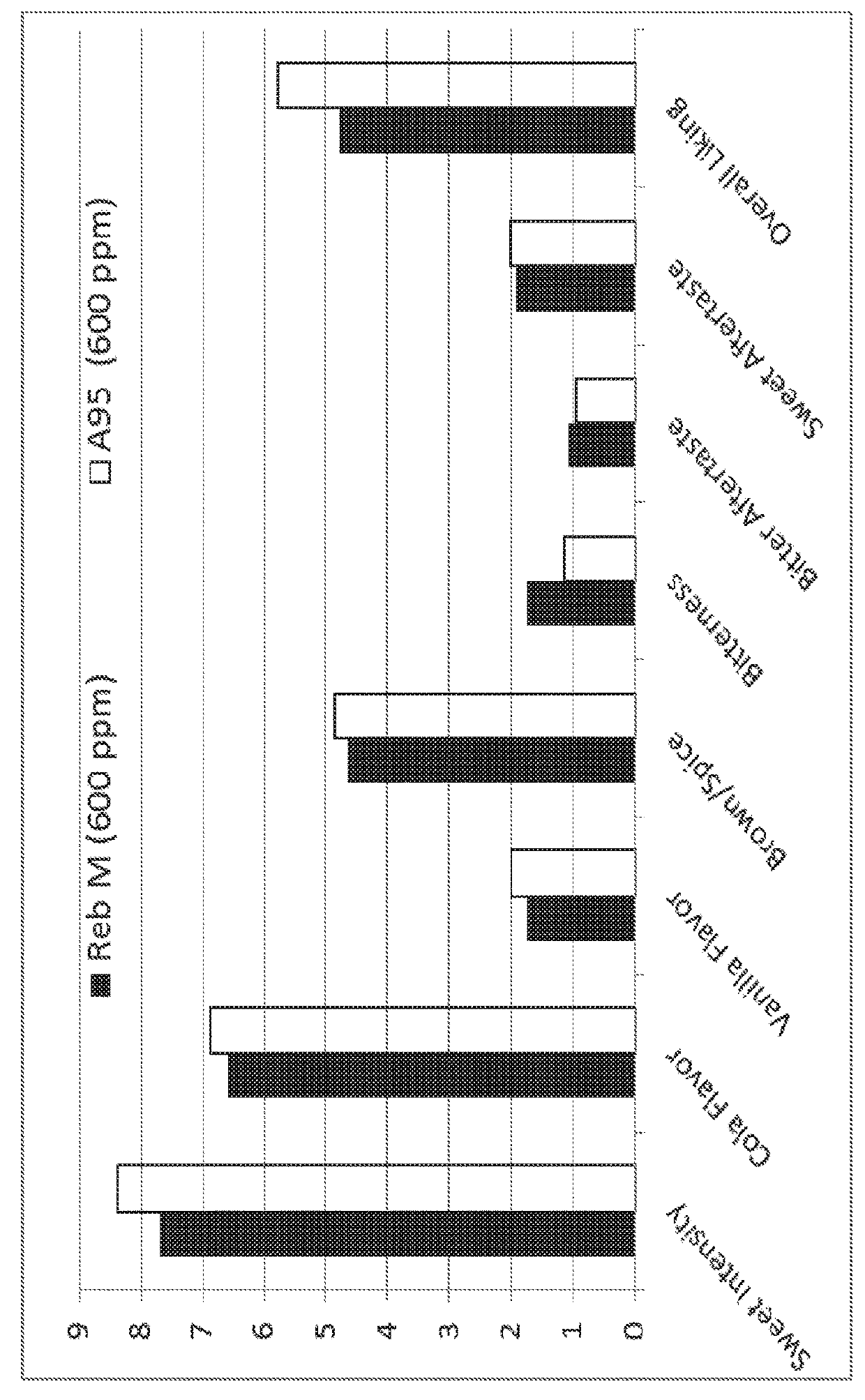

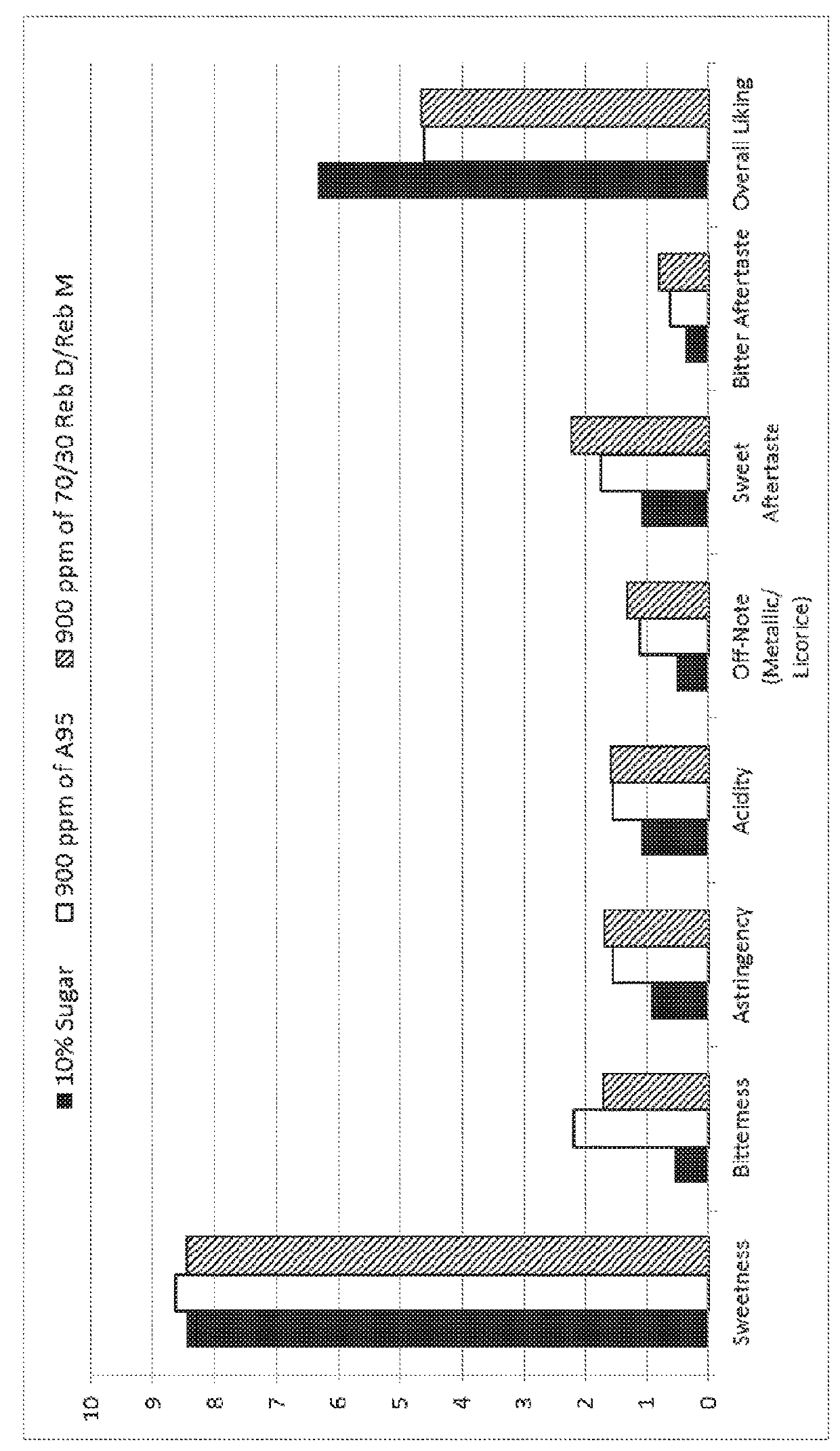

Steviol Glycoside Sweeteners with Improved Flavor Profiles

InactiveUS20180263269A1Improve sensory propertiesImprove the level ofDough treatmentSugar productsRebaudioside DFood flavor

Steviol glycoside compositions comprising certain proportions of rebaudioside D, rebaudioside M, rebaudioside A, rebaudioside N, rebaudioside O, and rebaudioside E are provided. Sweetener compositions comprising the steviol glycoside compositions and additional substances are also provided. Consumables, particularly beverages and beverage products containing said steviol glycoside compositions, and sweetener compositions comprising the same, are also provided. Methods of preparing the sweetener compositions and consumables are also detailed herein.

Owner:THE COCA-COLA CO +1

Milk chocolate containing water

InactiveUS7186435B2Improve sensory propertiesEasy to demouldFrozen sweetsConfectioneryButter cocoaMilk Chocolate

A process for manufacturing milk chocolate products containing a higher than normal water content by preparing a dark chocolate containing up to 30% by weight of water, adding a milk powder suspension optionally together with seed crystals of cocoa butter or cocoa butter equivalent, and mixing under low shear. The invention also relates to high water content milk chocolate products, methods of preparing a chocolate coated ice cream article with such products and to the resulting chocolate coated ice cream articles.

Owner:NESTEC SA

Process method for baking angilica keiskei koidzumi

ActiveCN103719305AGuaranteed nutrition and health careReduce lossesPre-extraction tea treatmentVitamin CTwo step

The invention relates to the field of tea preparation and particularly relates to a process method for baking angilica keiskei koidzumi. According to the process method, an angilica keiskei koidzumi baking technical method, comprising the steps of baking at low temperature, adding jasmine flowers and producing fragrance at high temperature, is established, the steps of a preparation process are simple, the loss of chalcone and vitamin C in angilica keiskei koidzumi during preparation is reduced, and the content of chalcone and vitamin C is obviously higher than that of tea products which are prepared by only frying leaves under conventional process conditions, so that the nutritional healthcare effects of angilica keiskei koidzumi are guaranteed; according to the prepared angilica keiskei koidzumi product, baking and frying processes are replaced with low-temperature baking, so that the tea is uniform in heated degree and good in sensory character, and the problem of charring due to excessive baking and frying is effectively solved; due to the two steps of adding jasmine flowers and producing fragrance at high temperature, the fragrance of angilica keiskei koidzumi is guaranteed.

Owner:青岛海隆达生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com