Patents

Literature

158 results about "Rebaudioside D" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

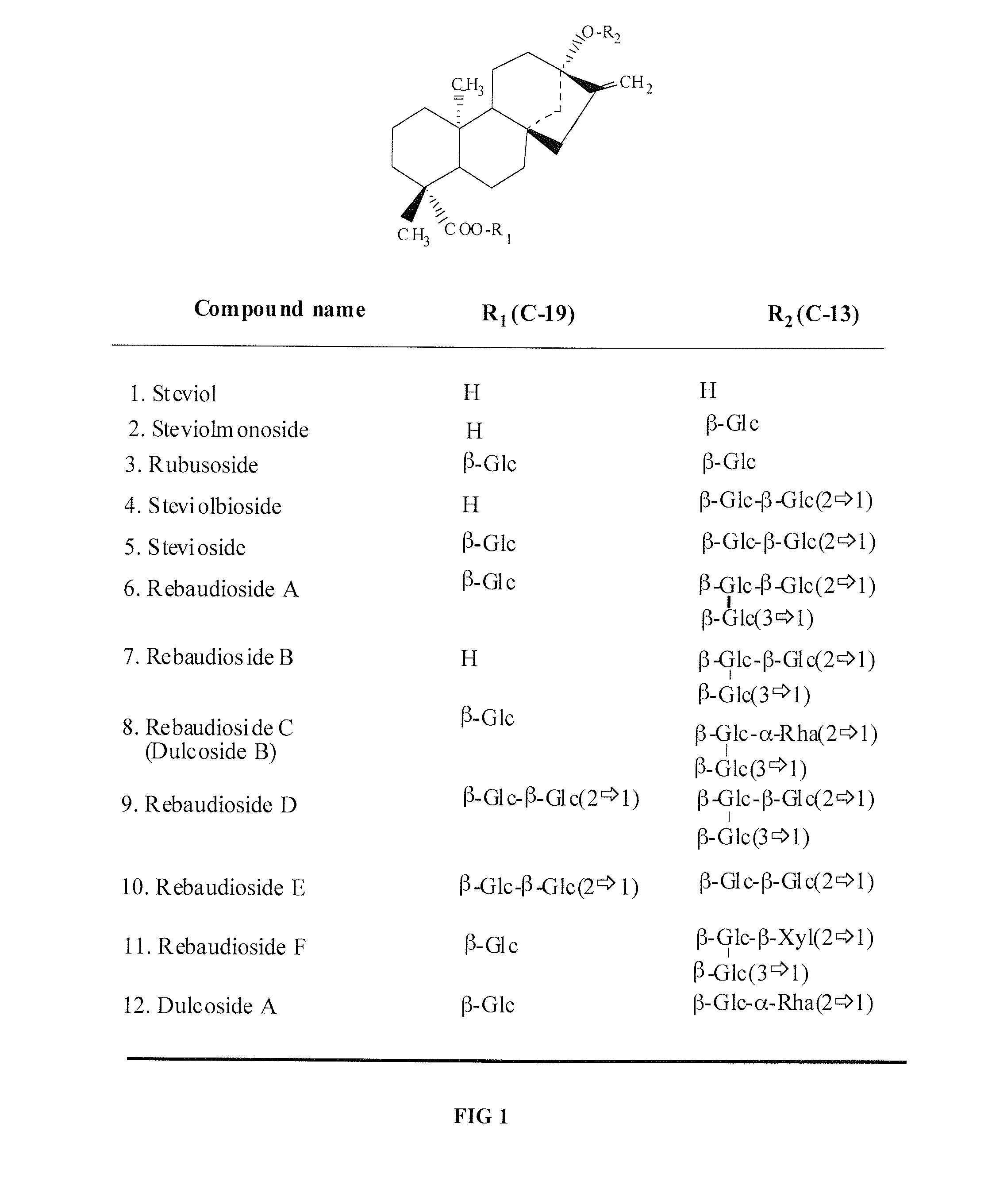

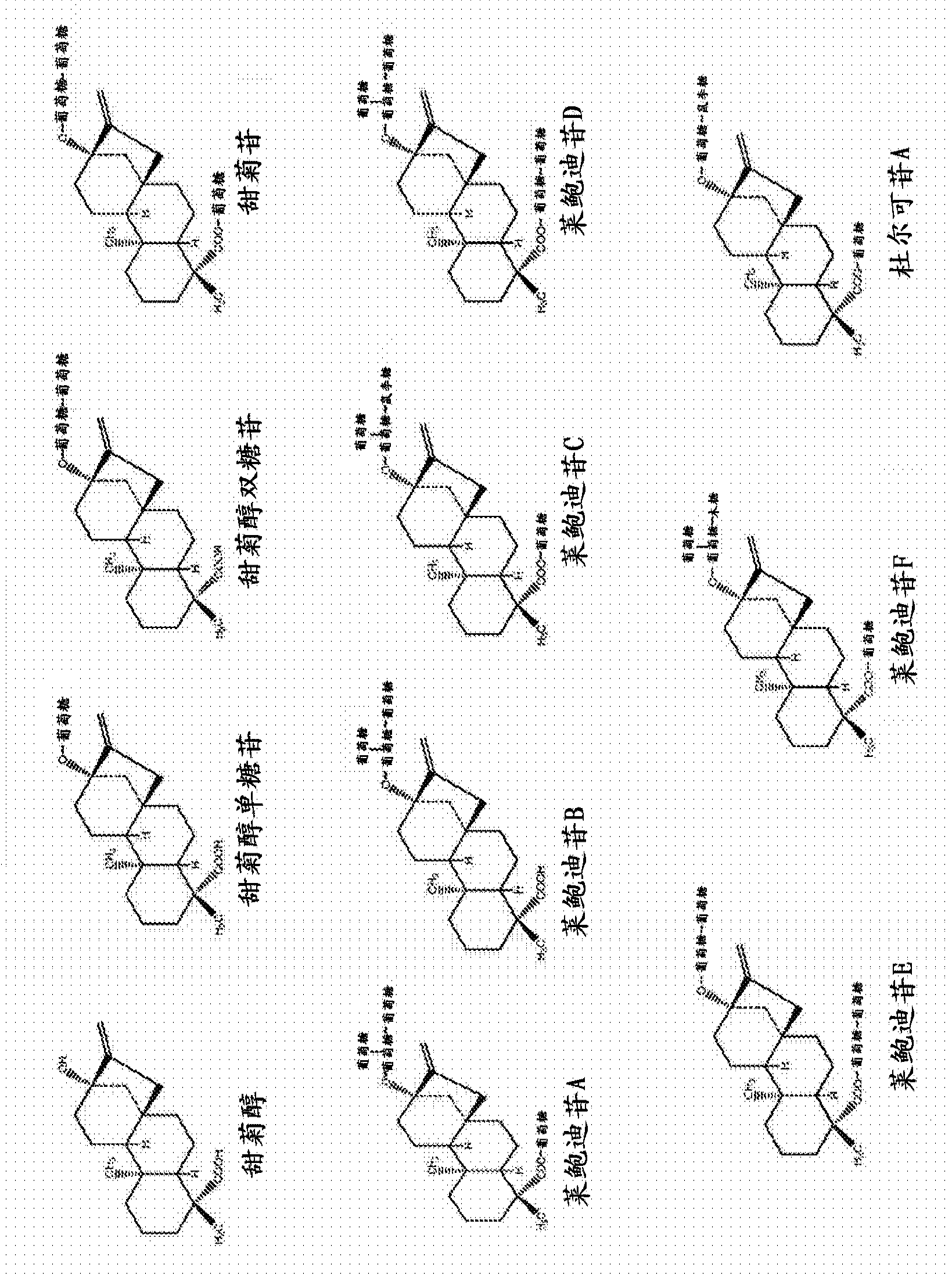

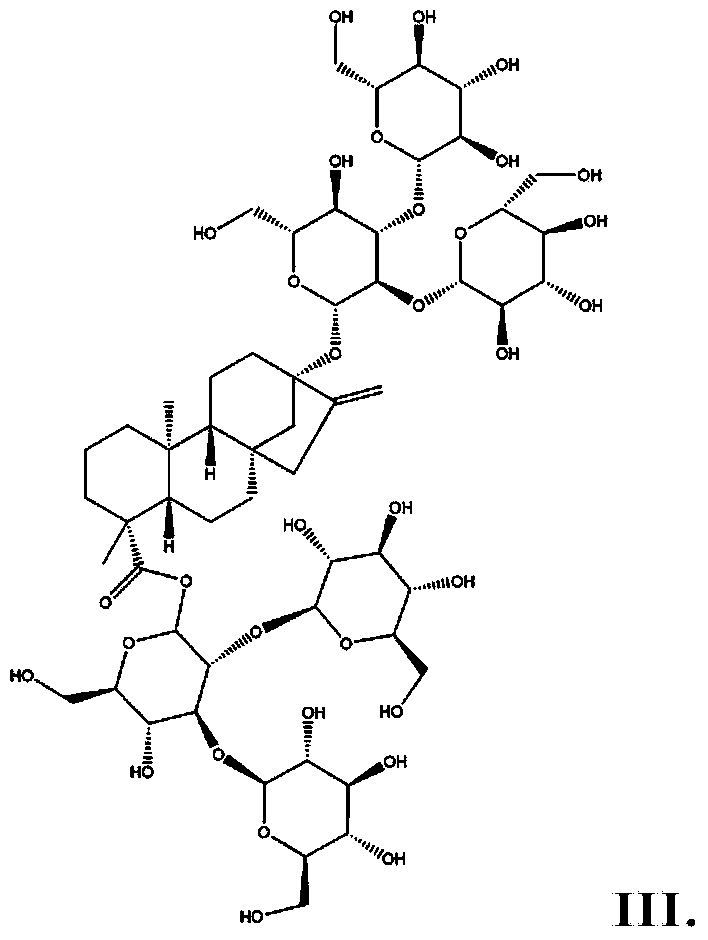

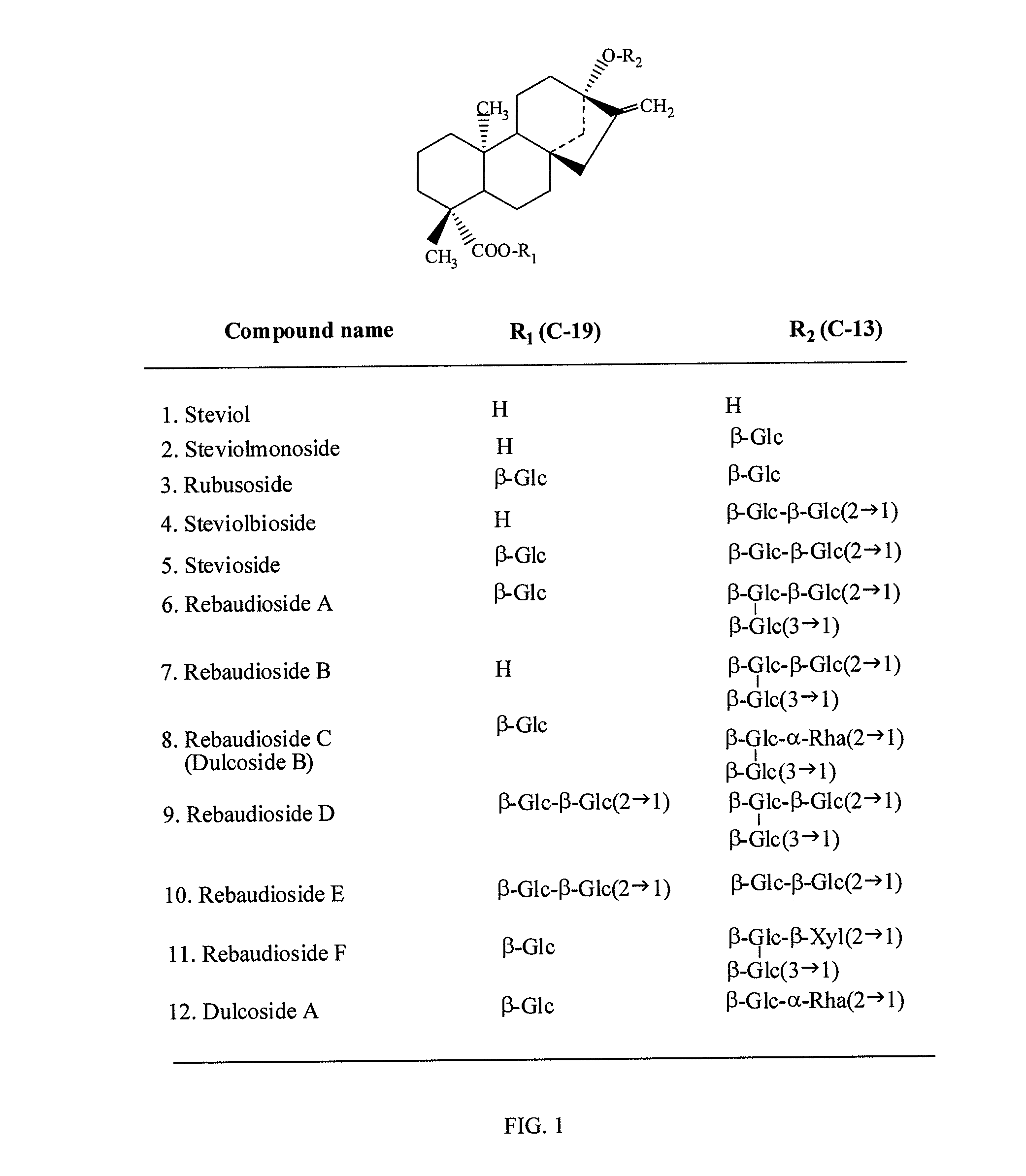

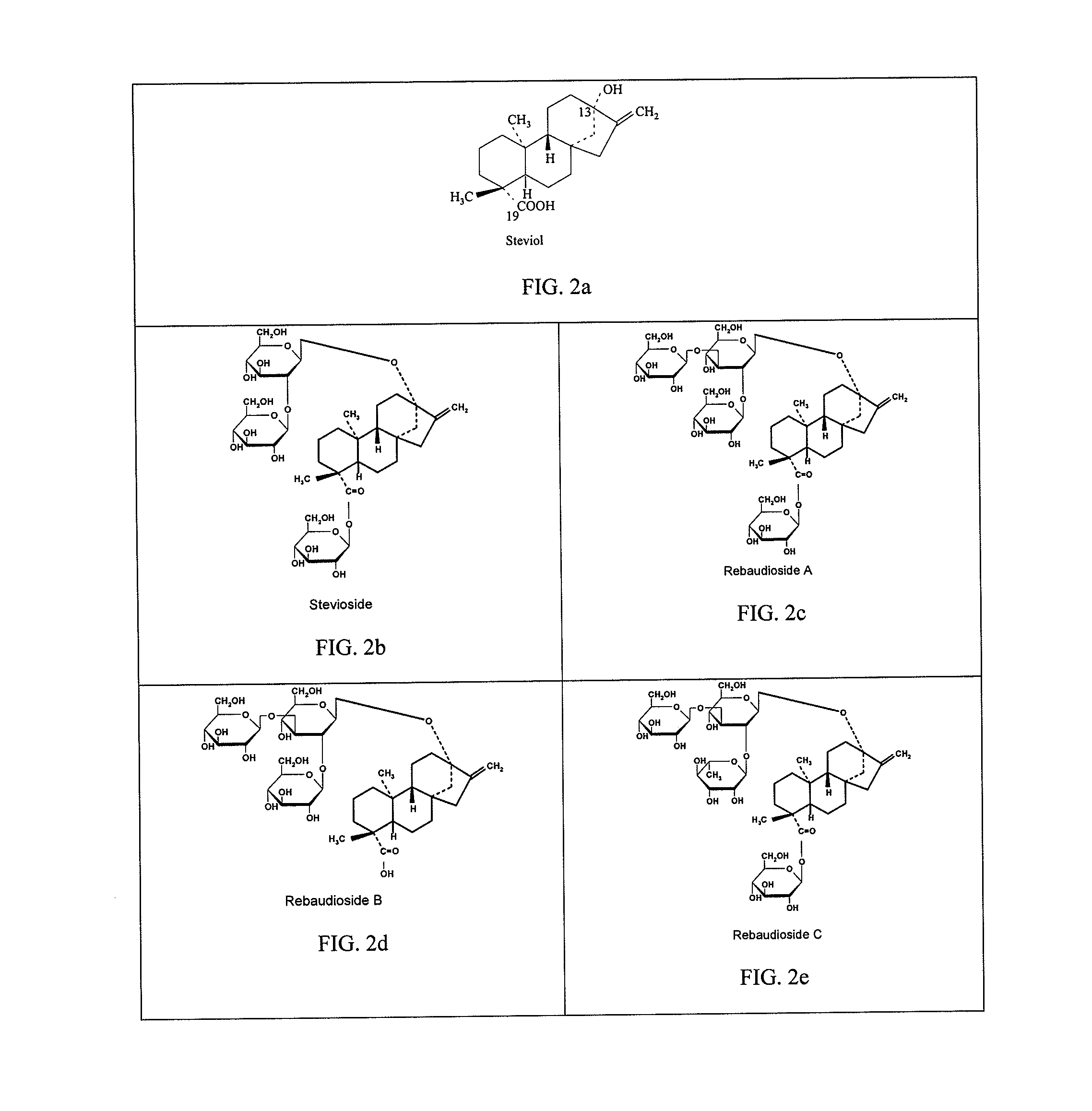

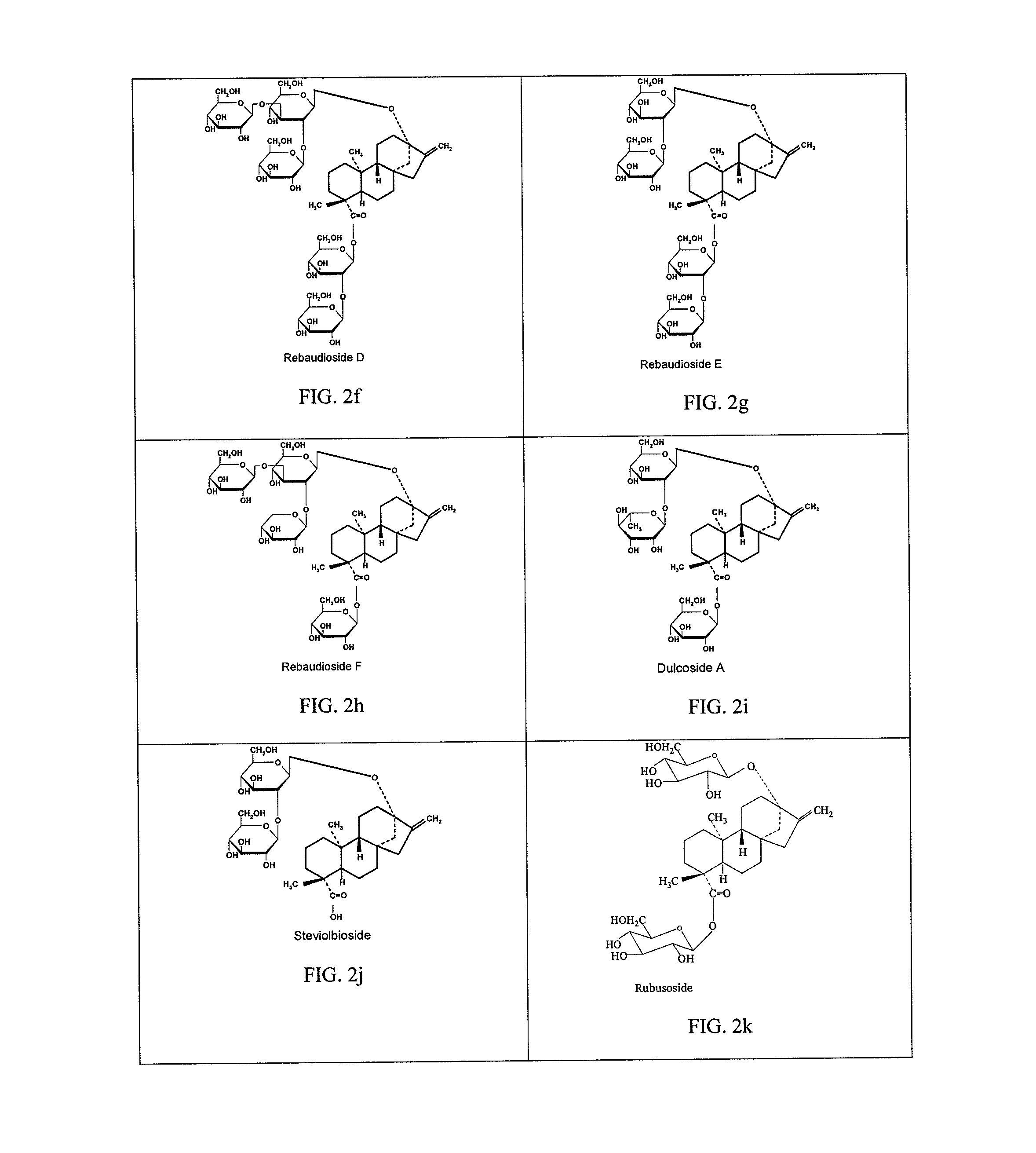

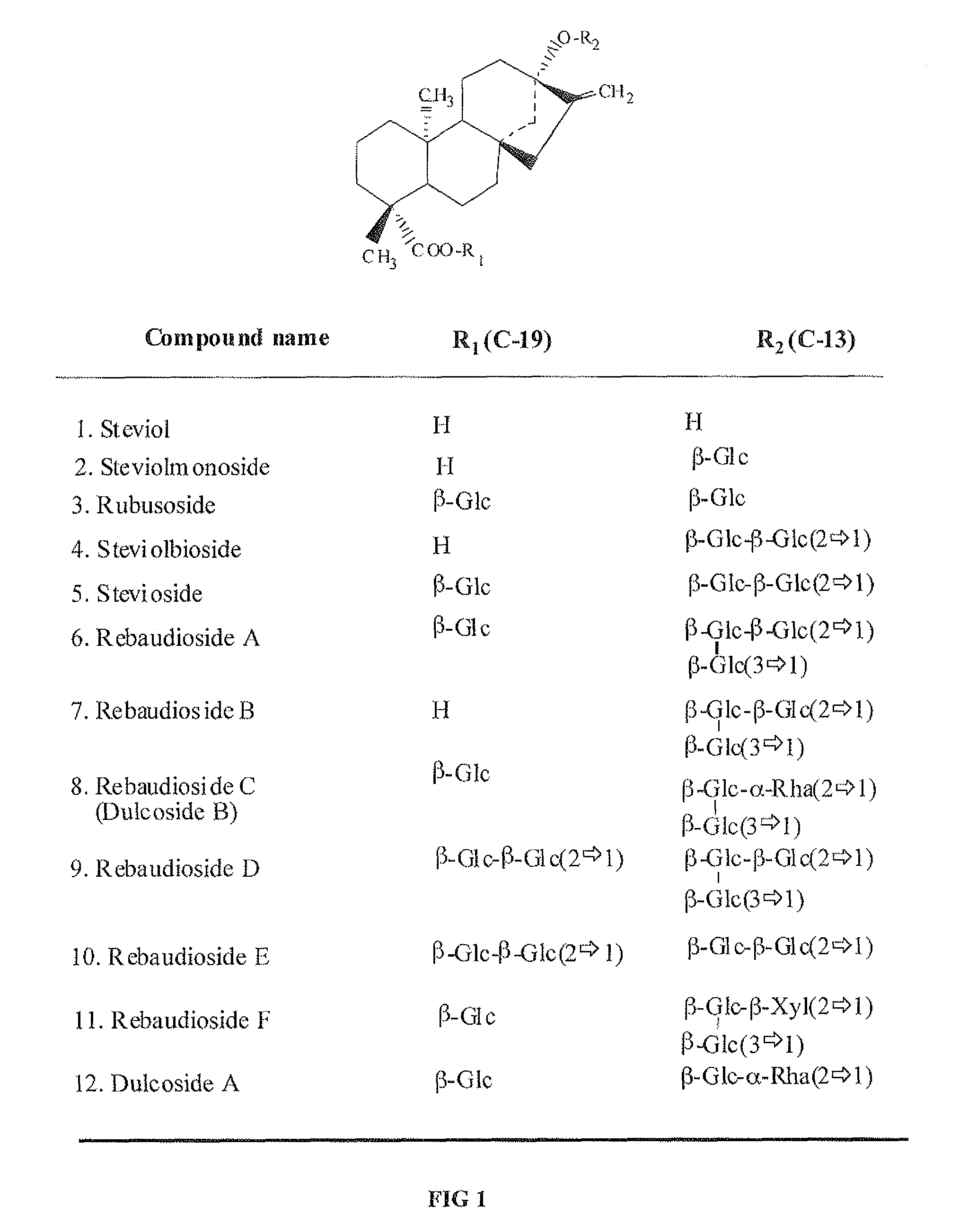

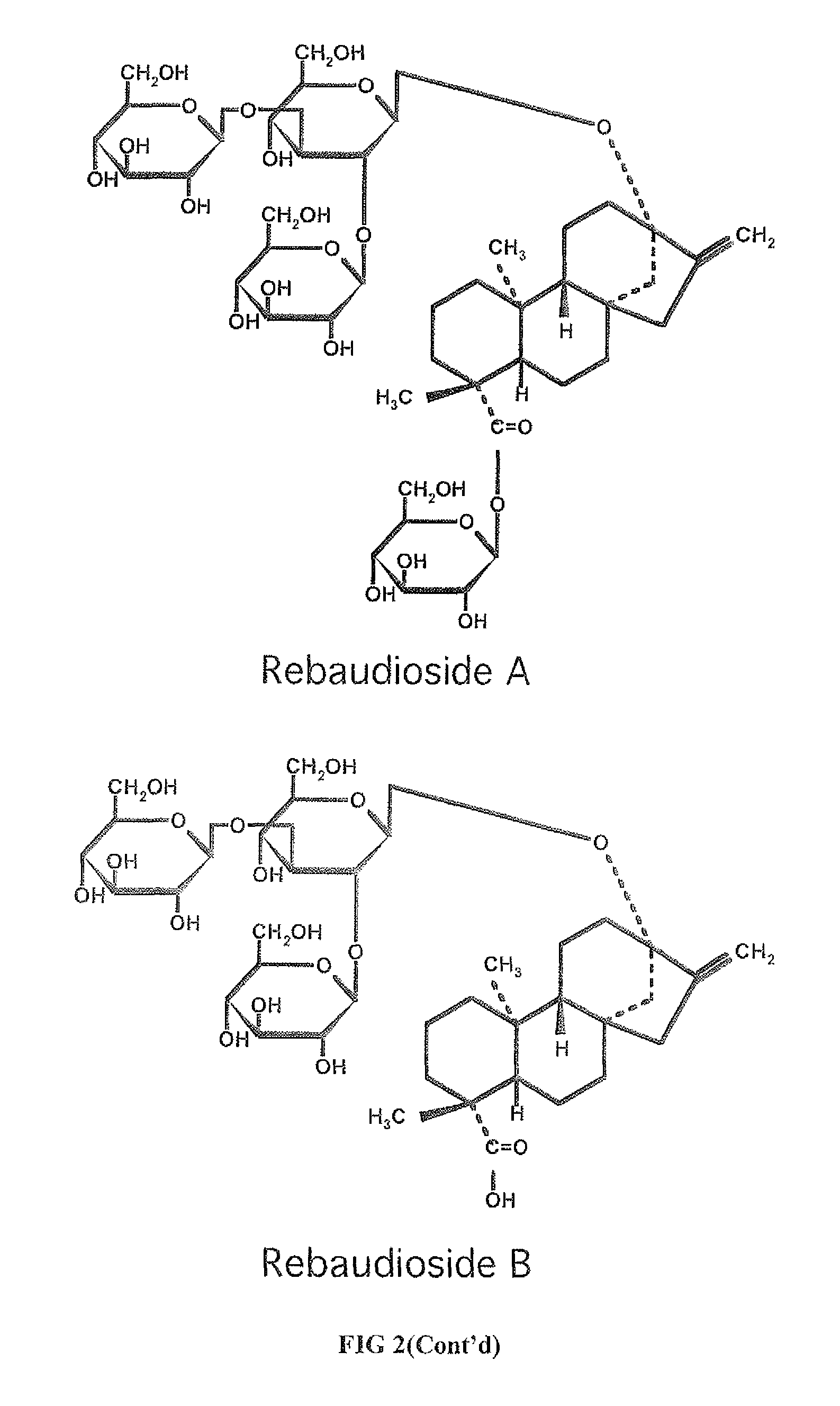

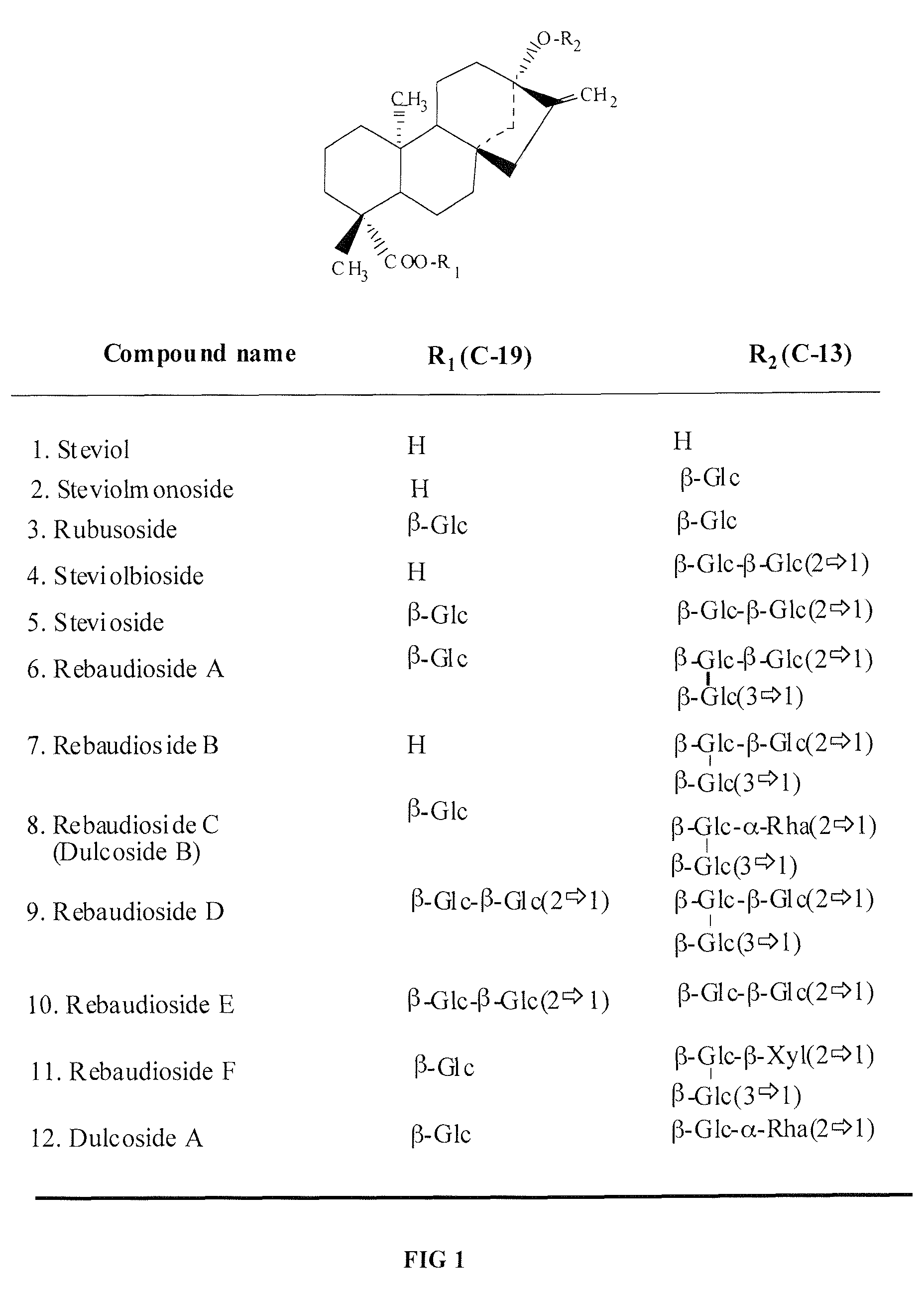

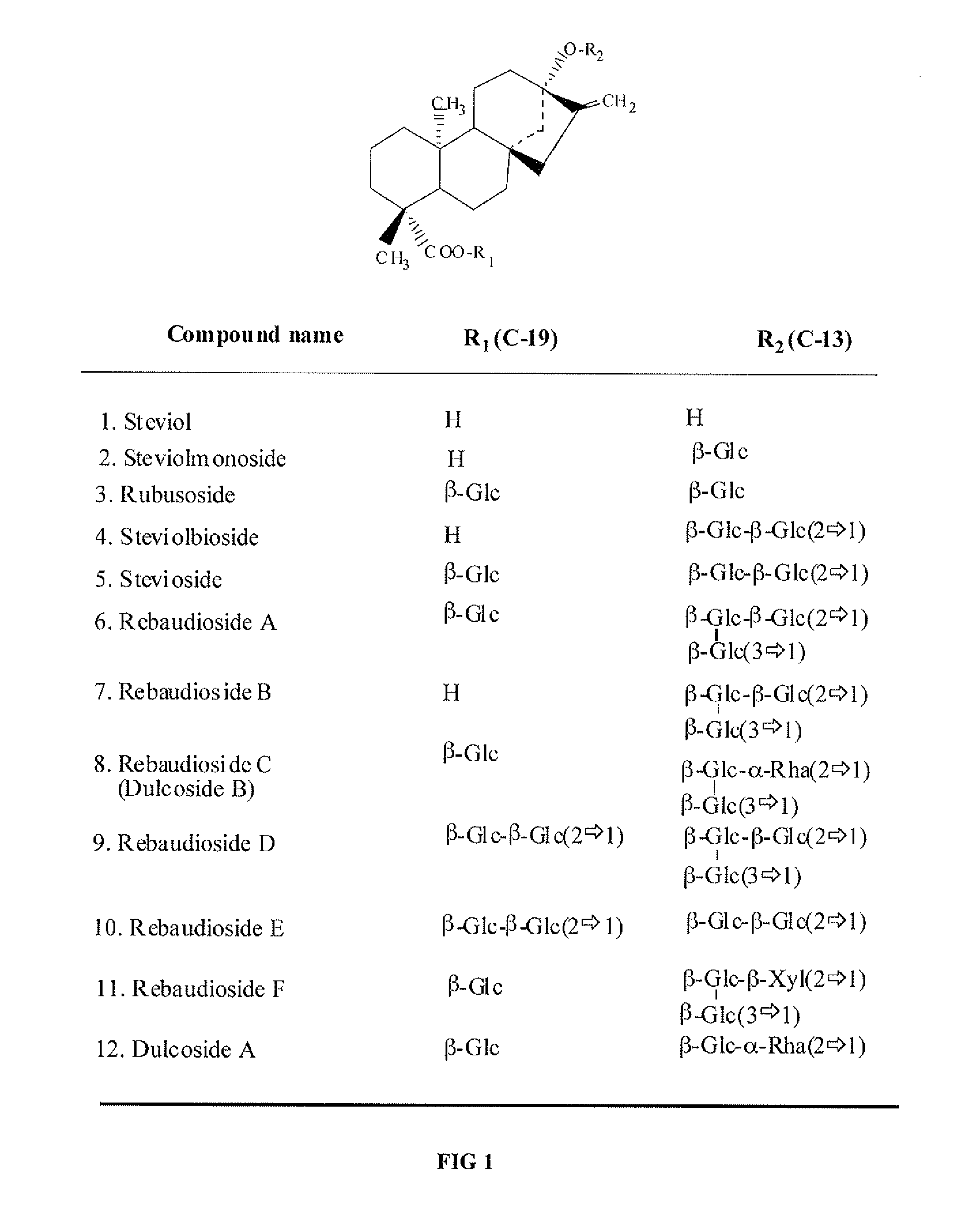

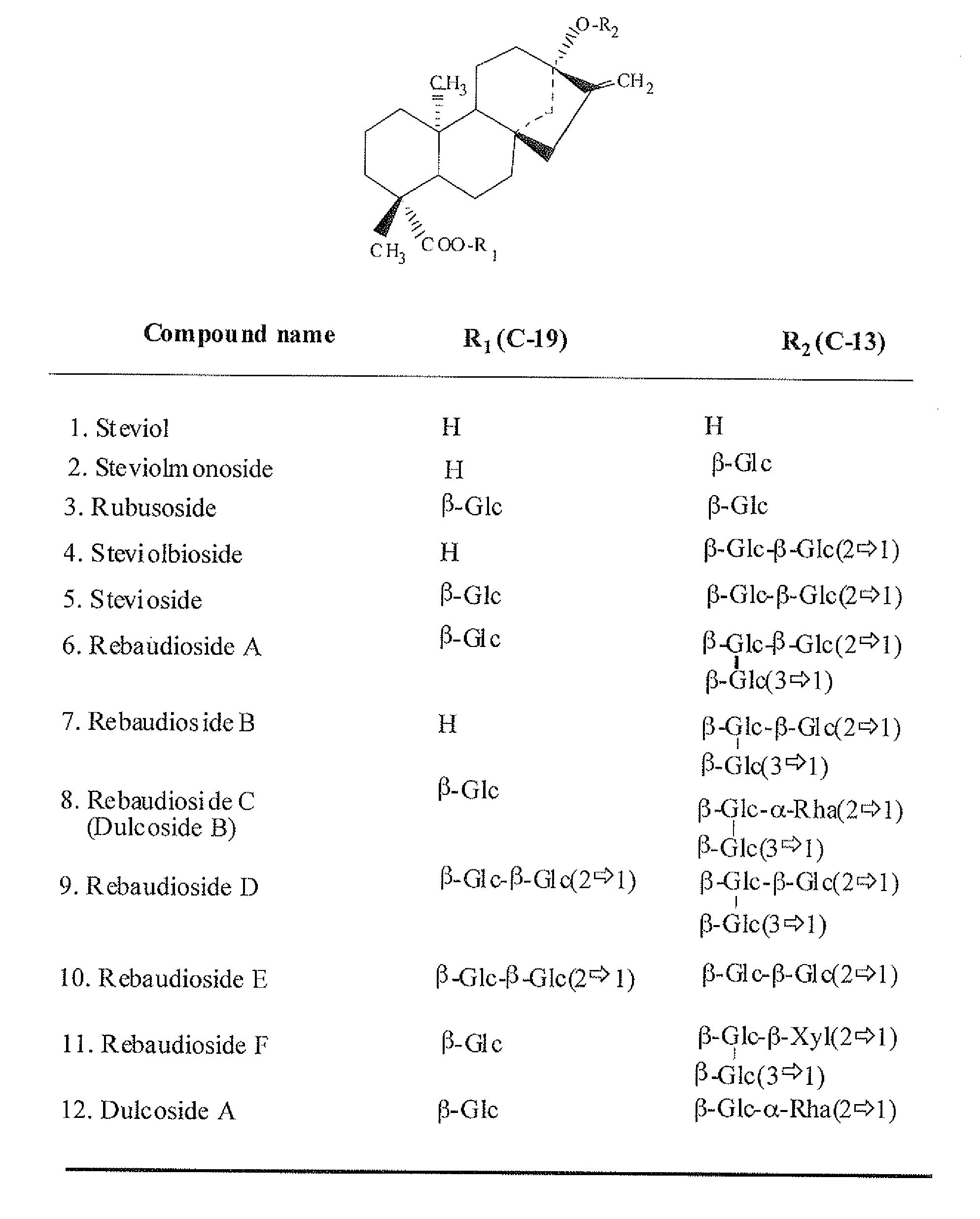

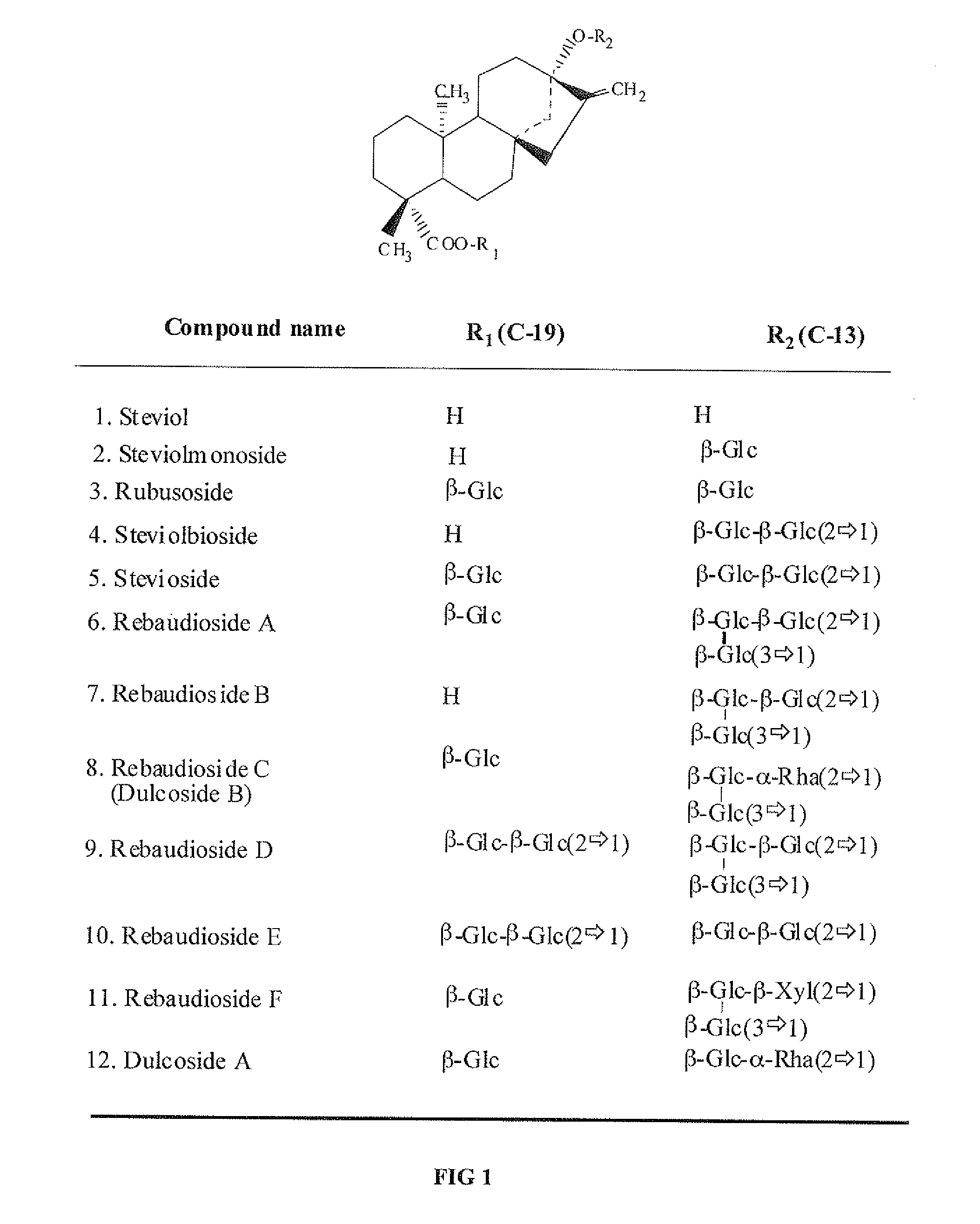

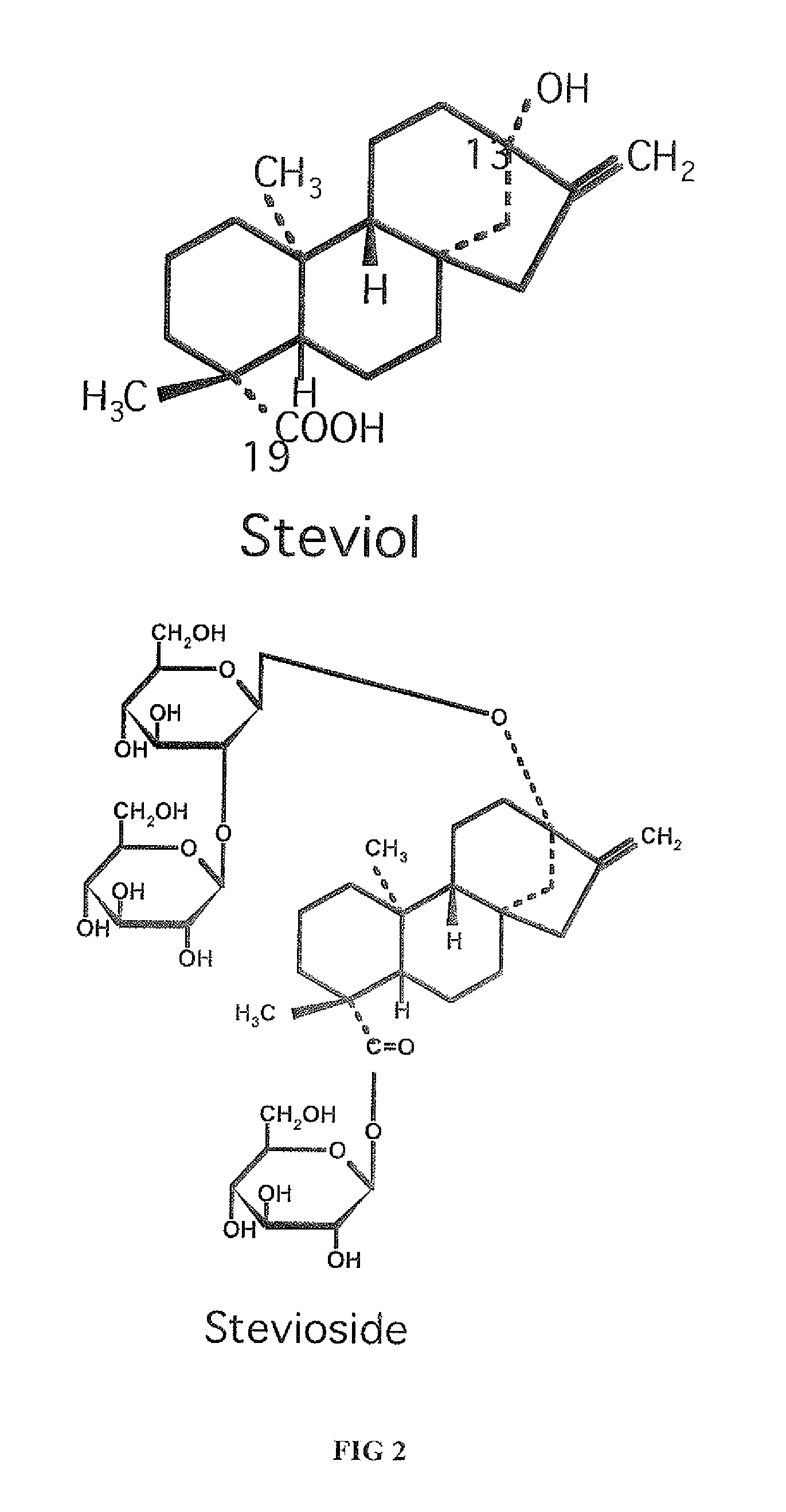

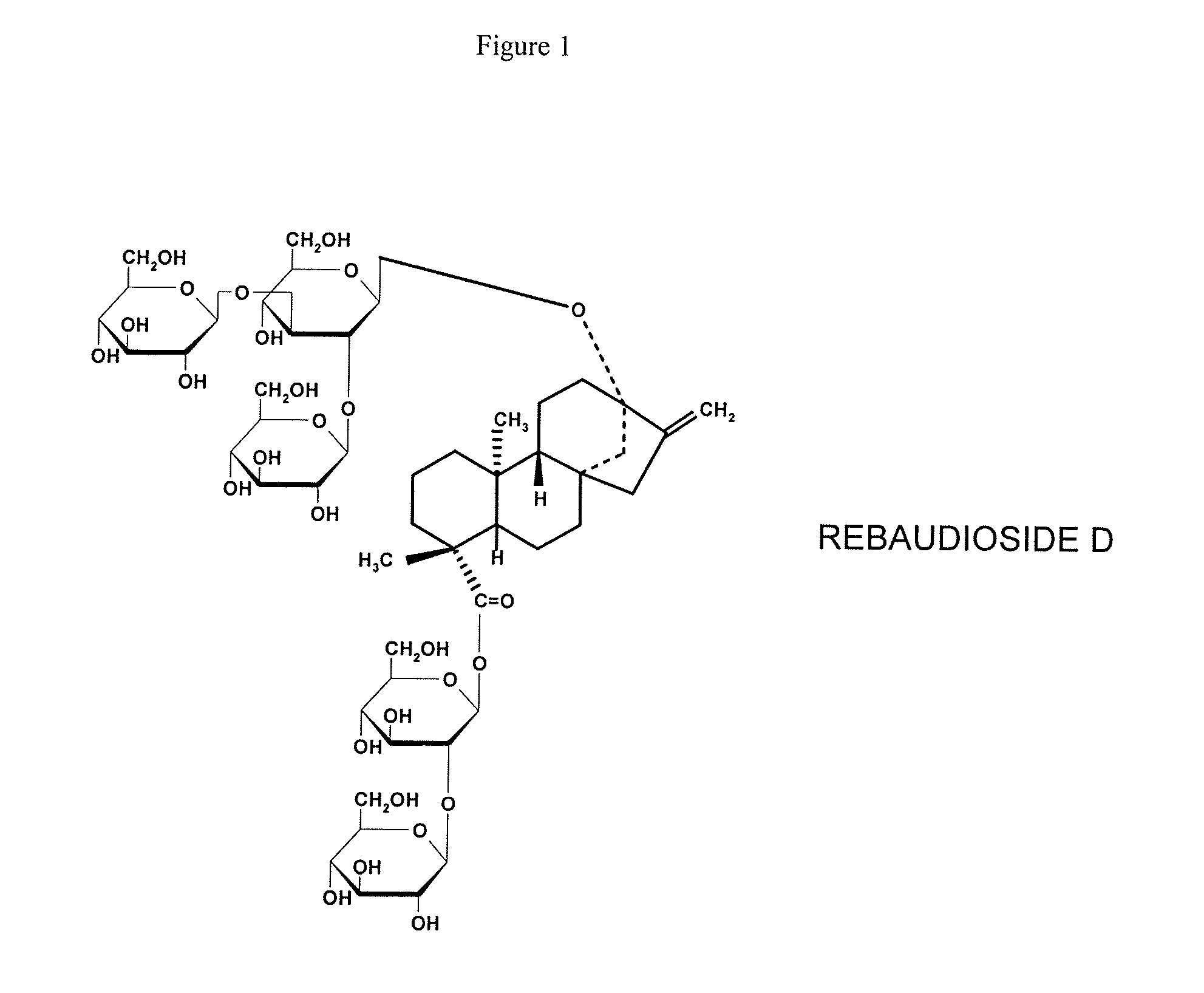

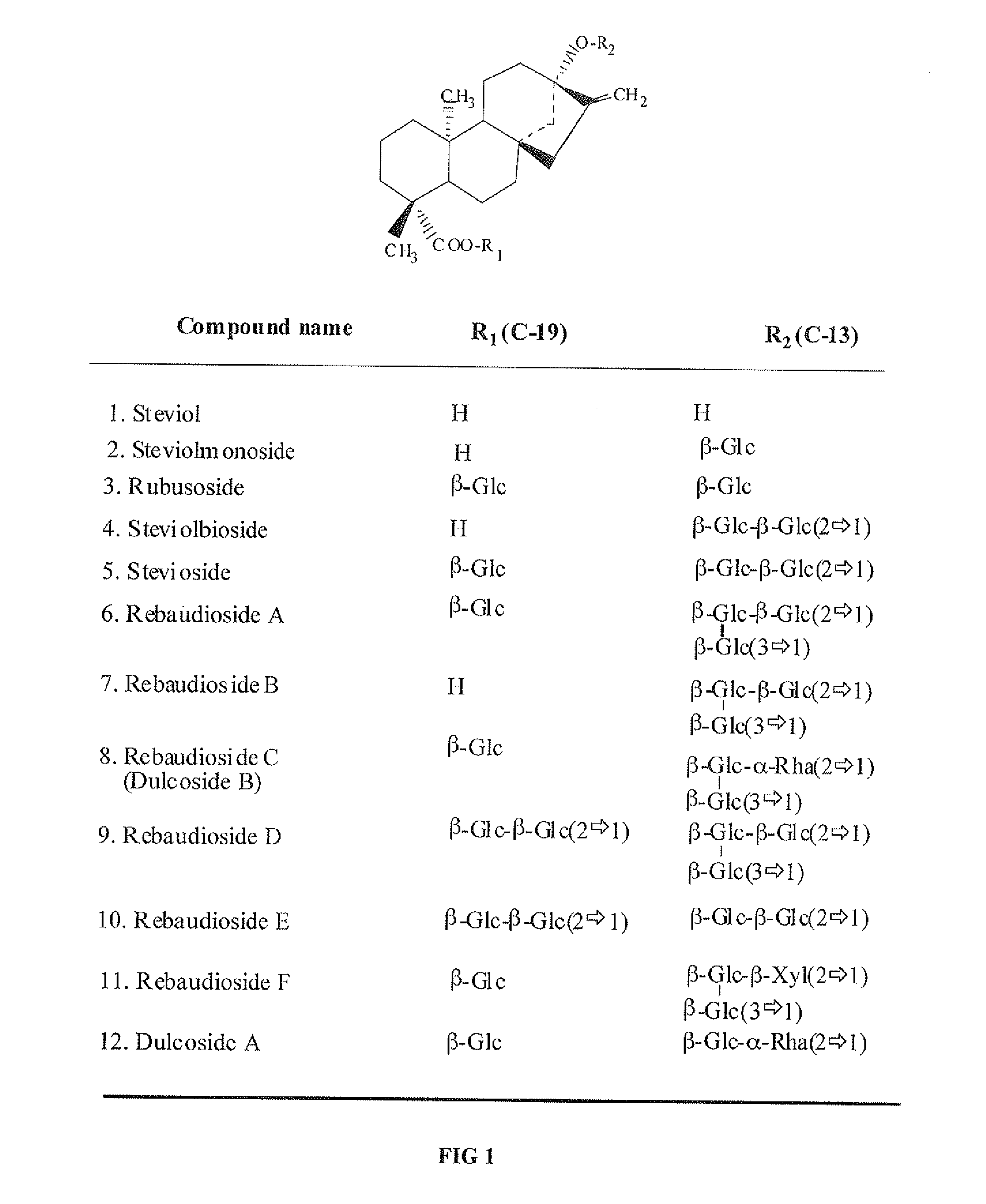

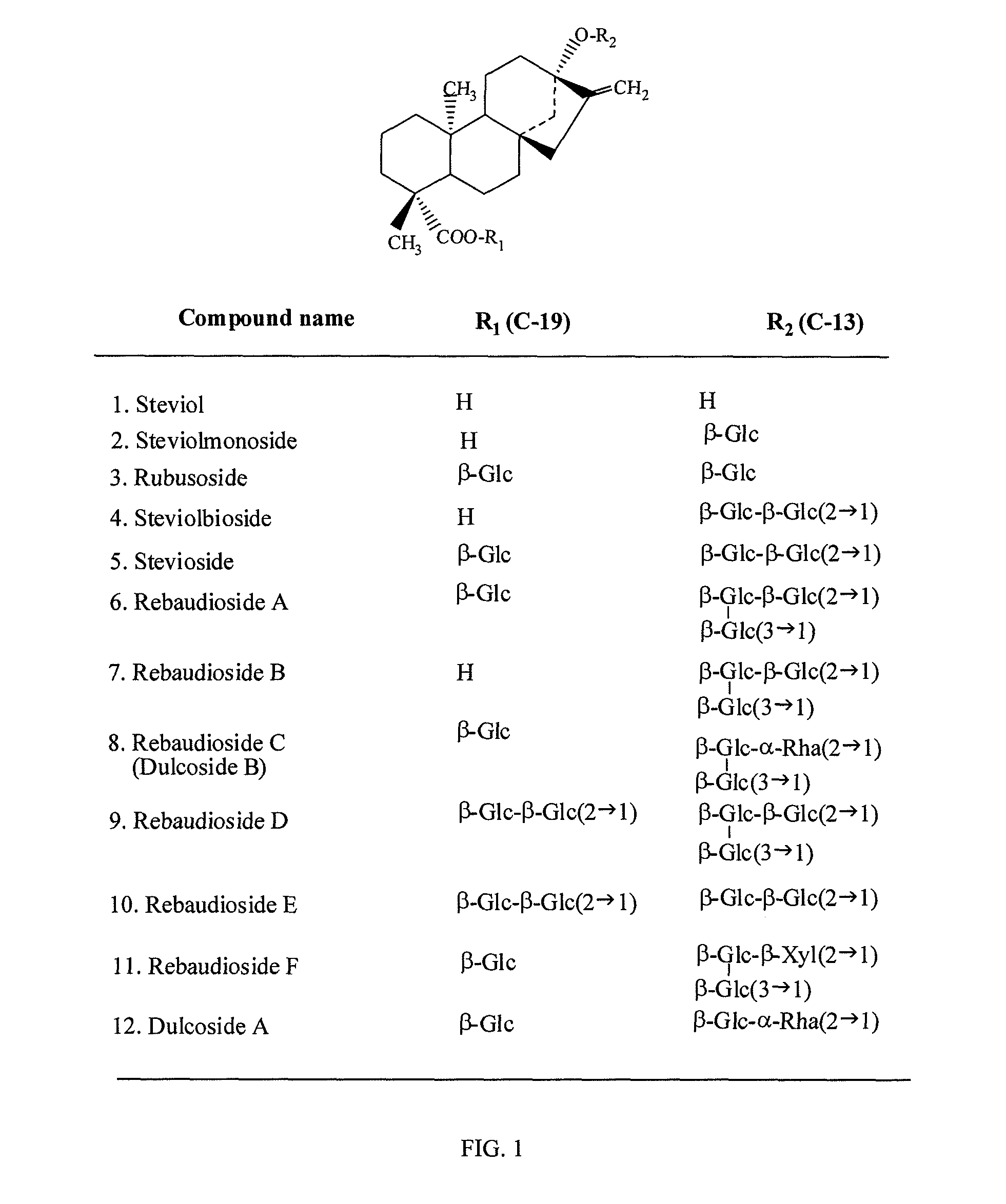

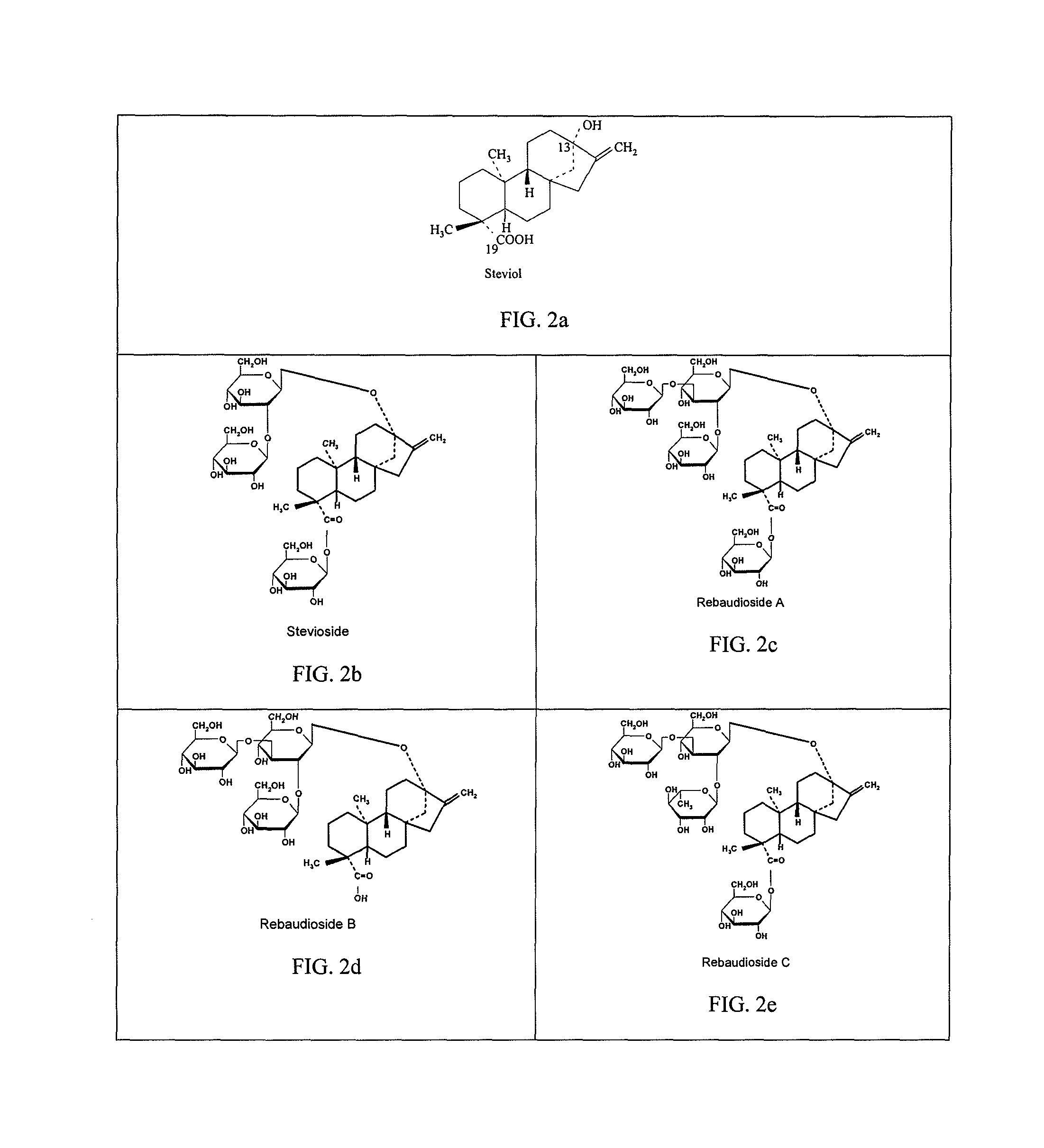

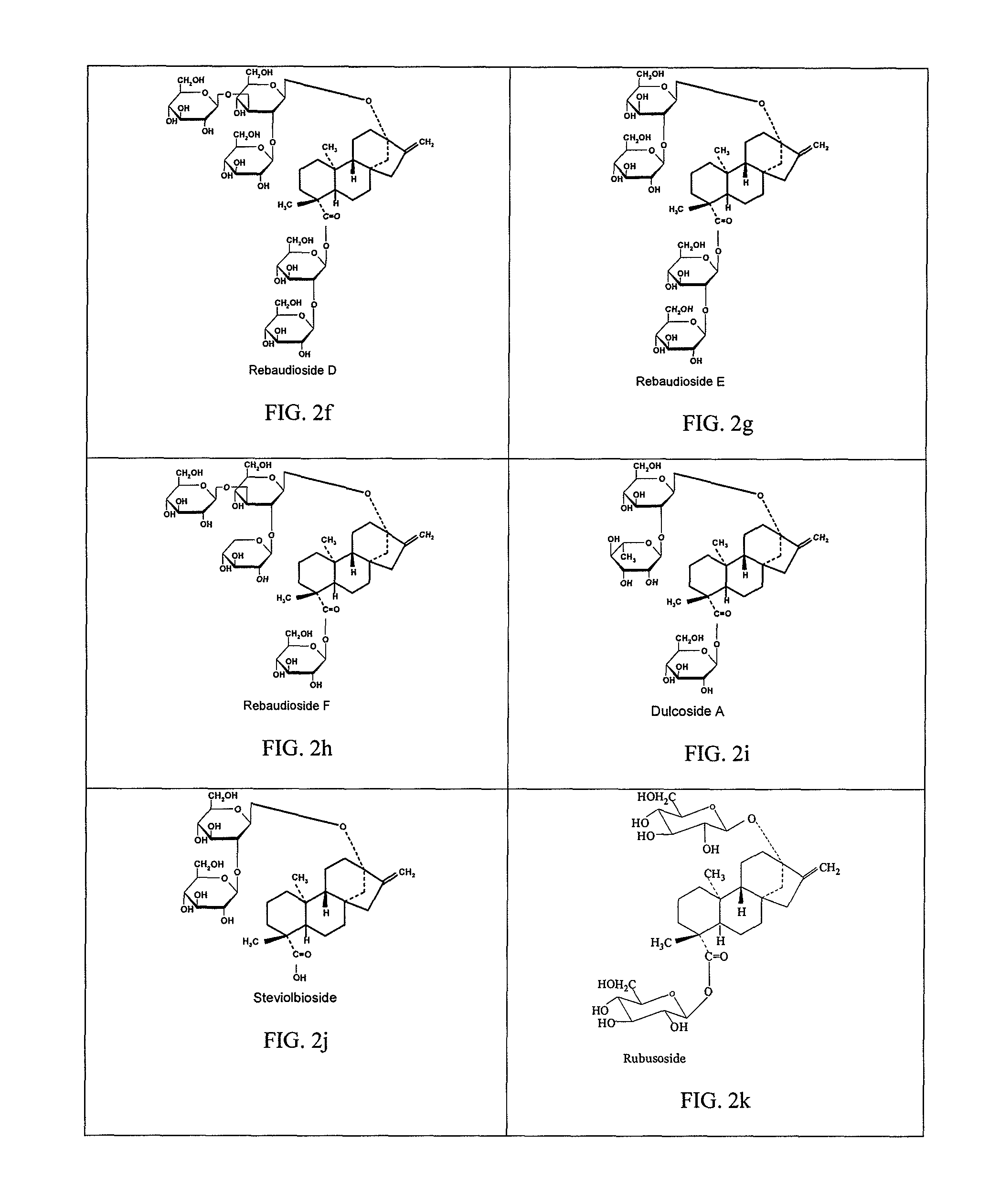

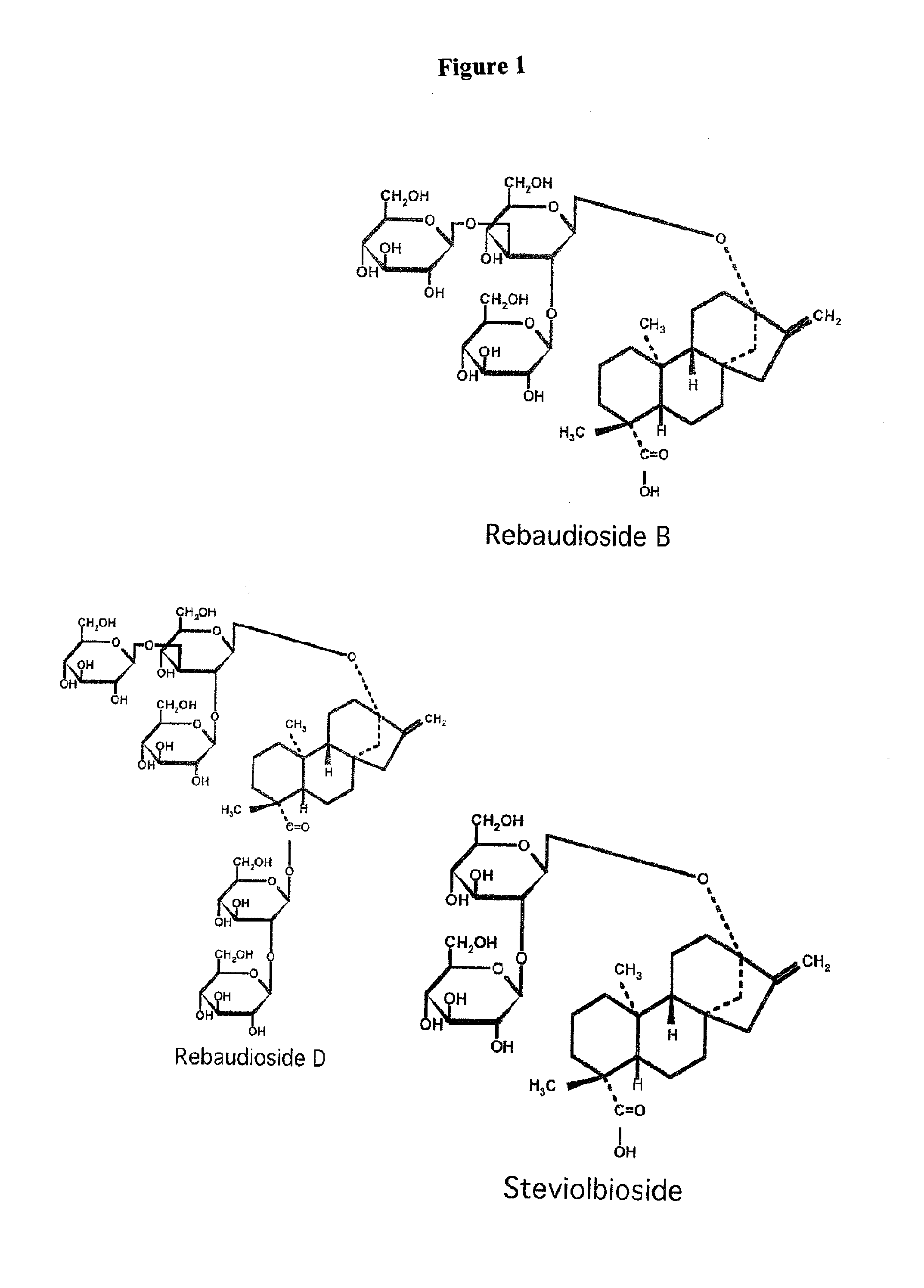

Rebaudioside B; Rebaudioside D; Rebaudioside E; The last three are present only in minute quantities, and rebaudioside B has been claimed to be a byproduct of the isolation technique. A commercial steviol glycoside mixture extracted from the plant was found to have about 80% stevioside, 8% rebaudioside A, and 0.6% rebaudioside C.

High-Purity Rebaudioside D

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The high purity Rebaudiosides are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectionaries, bakeries, cookies, chewing gums, and alike.

Owner:PURECIRCLE SDN BHD

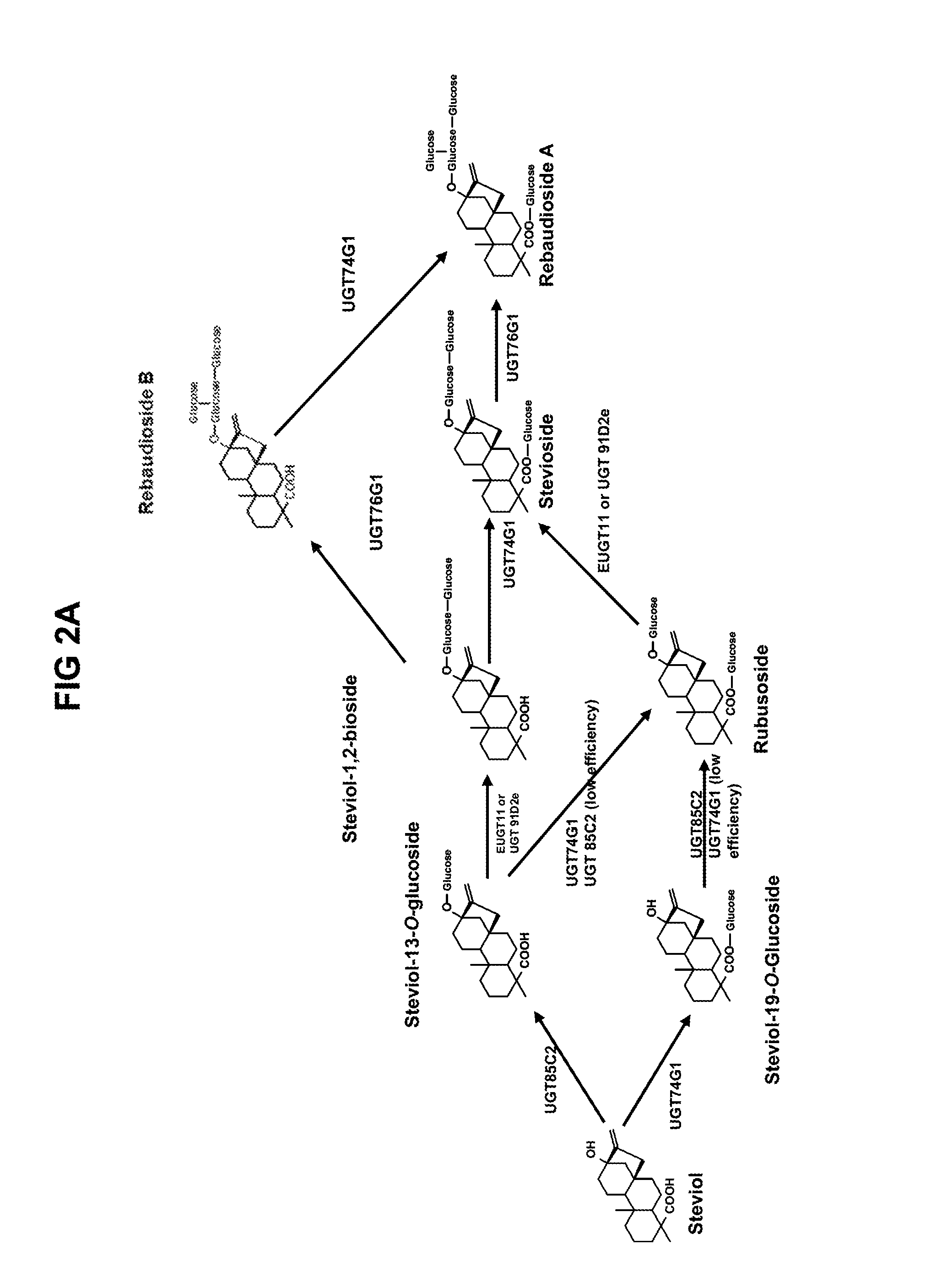

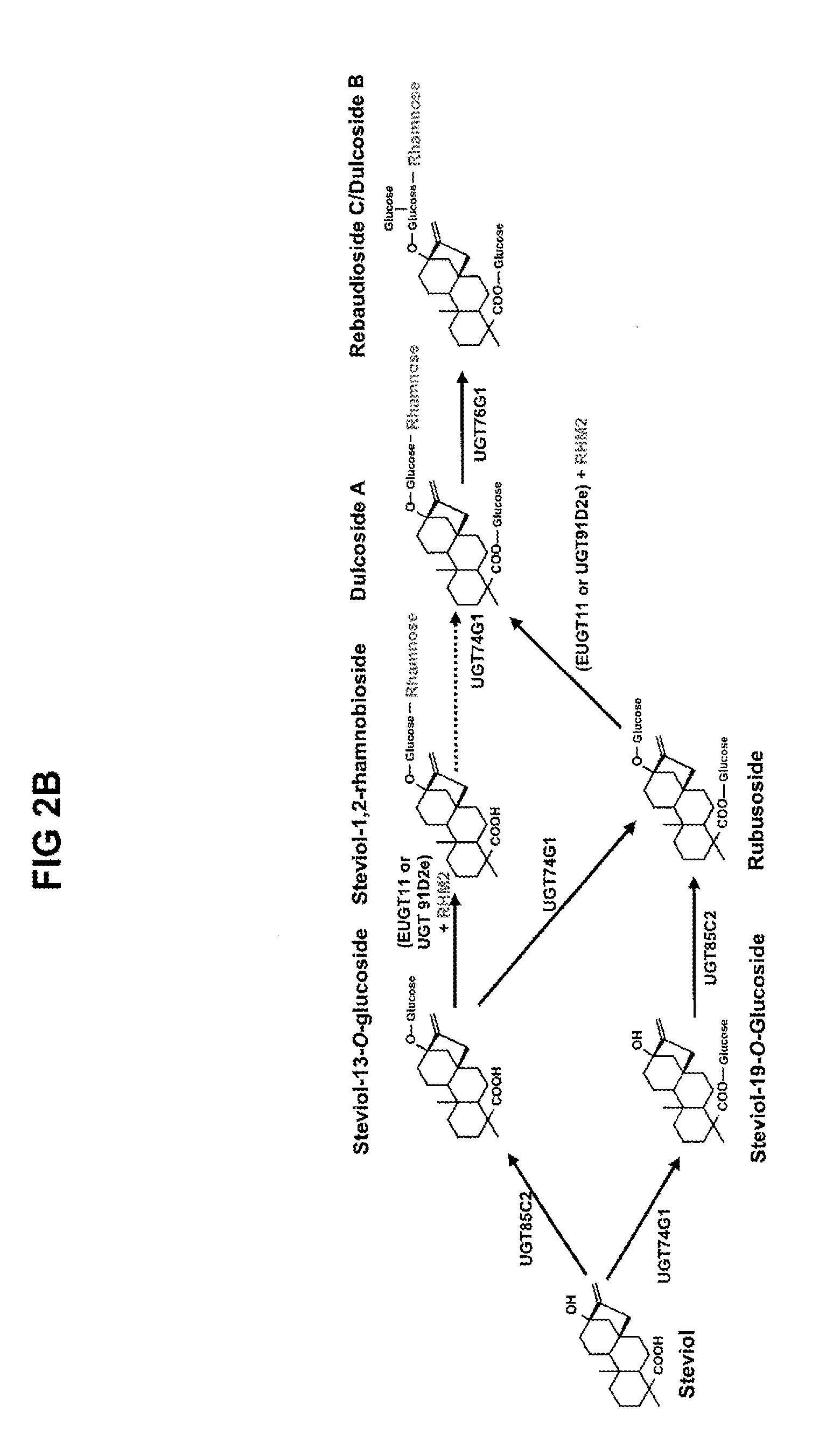

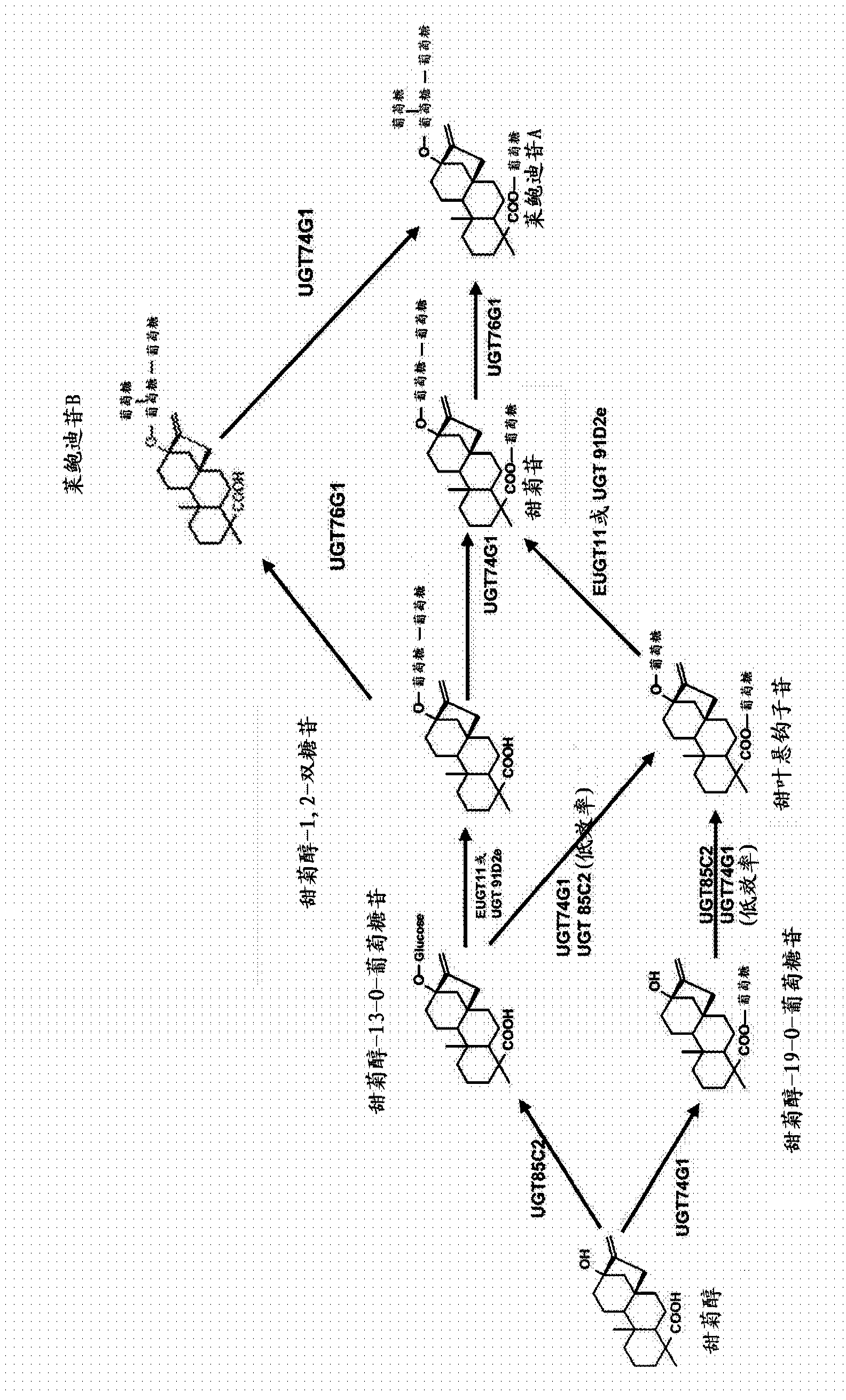

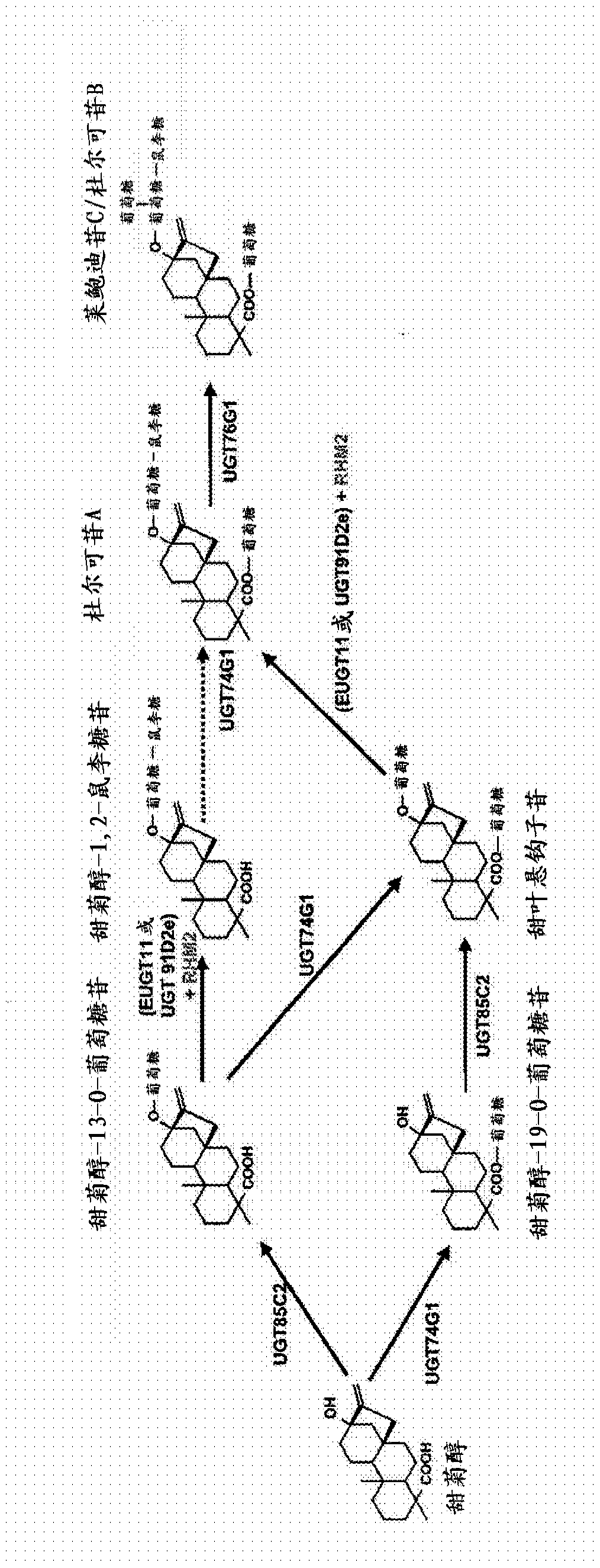

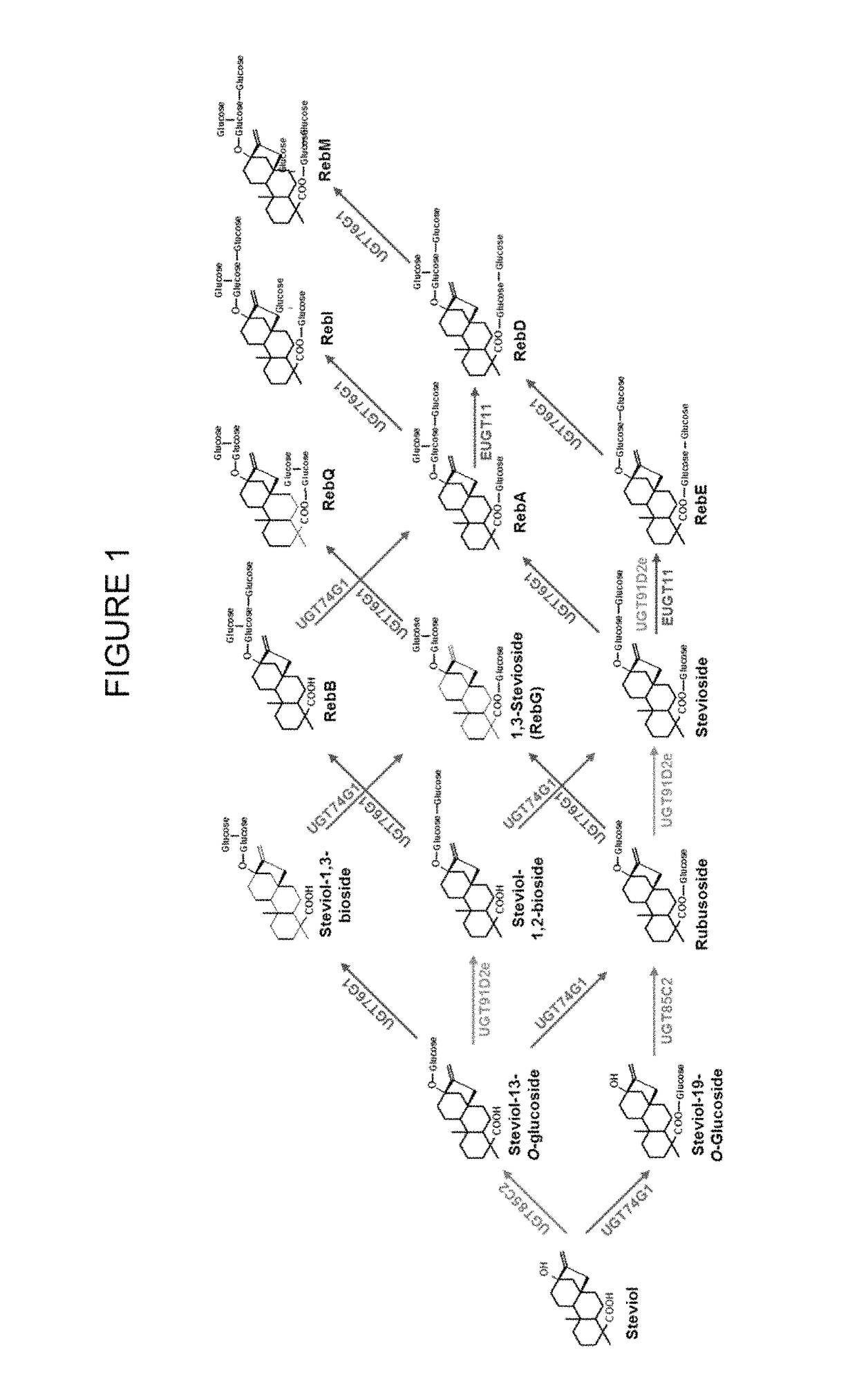

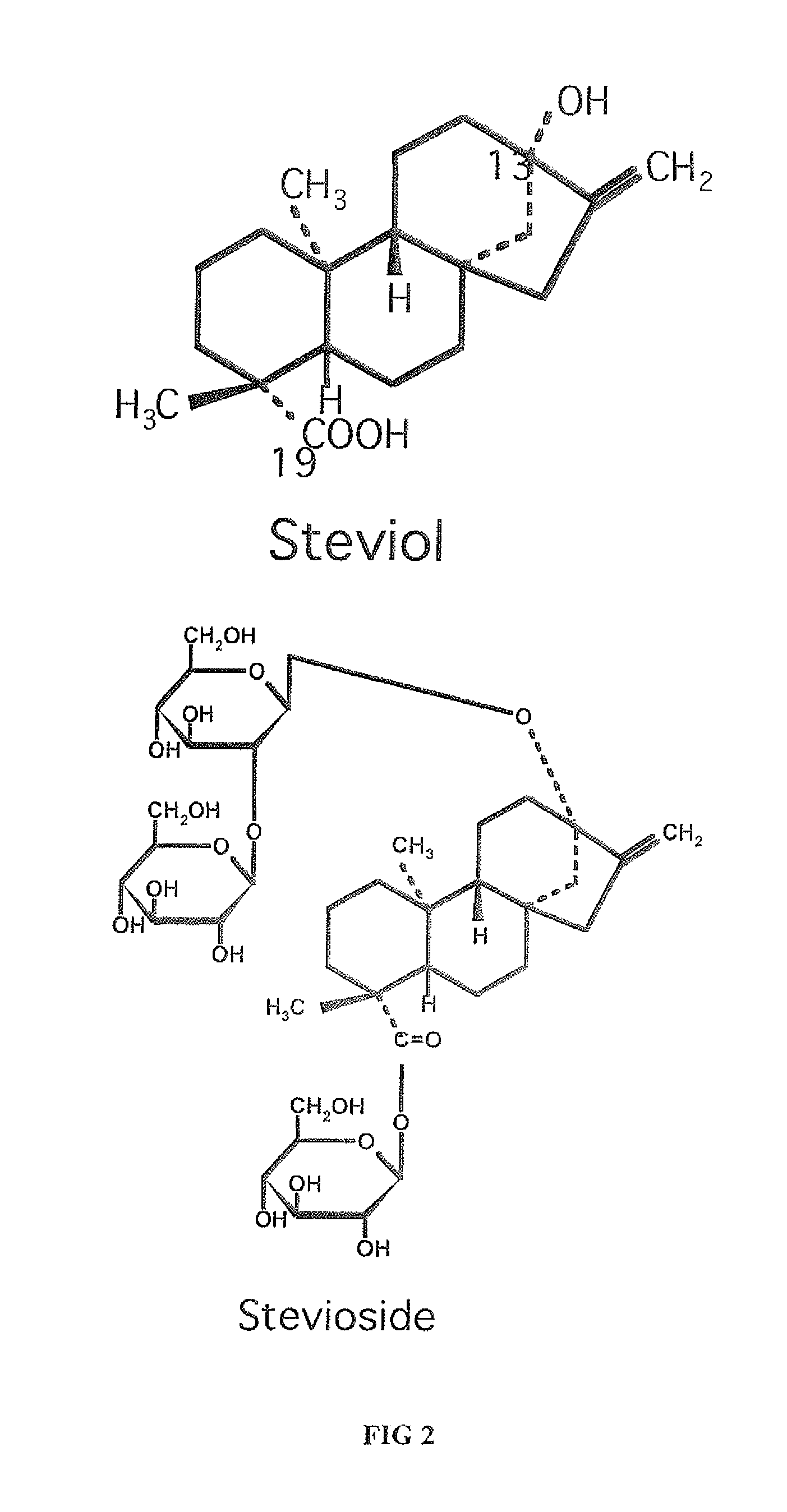

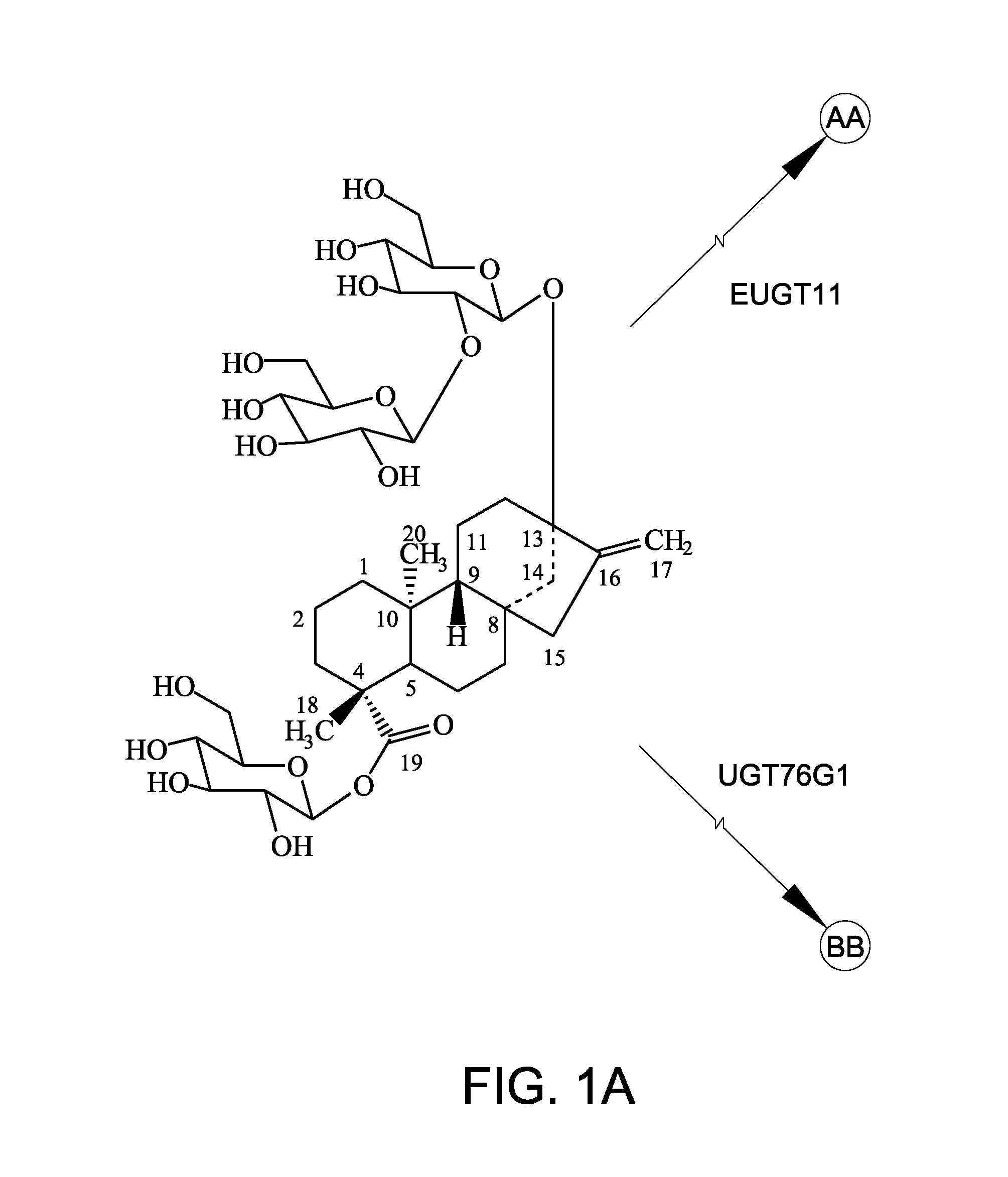

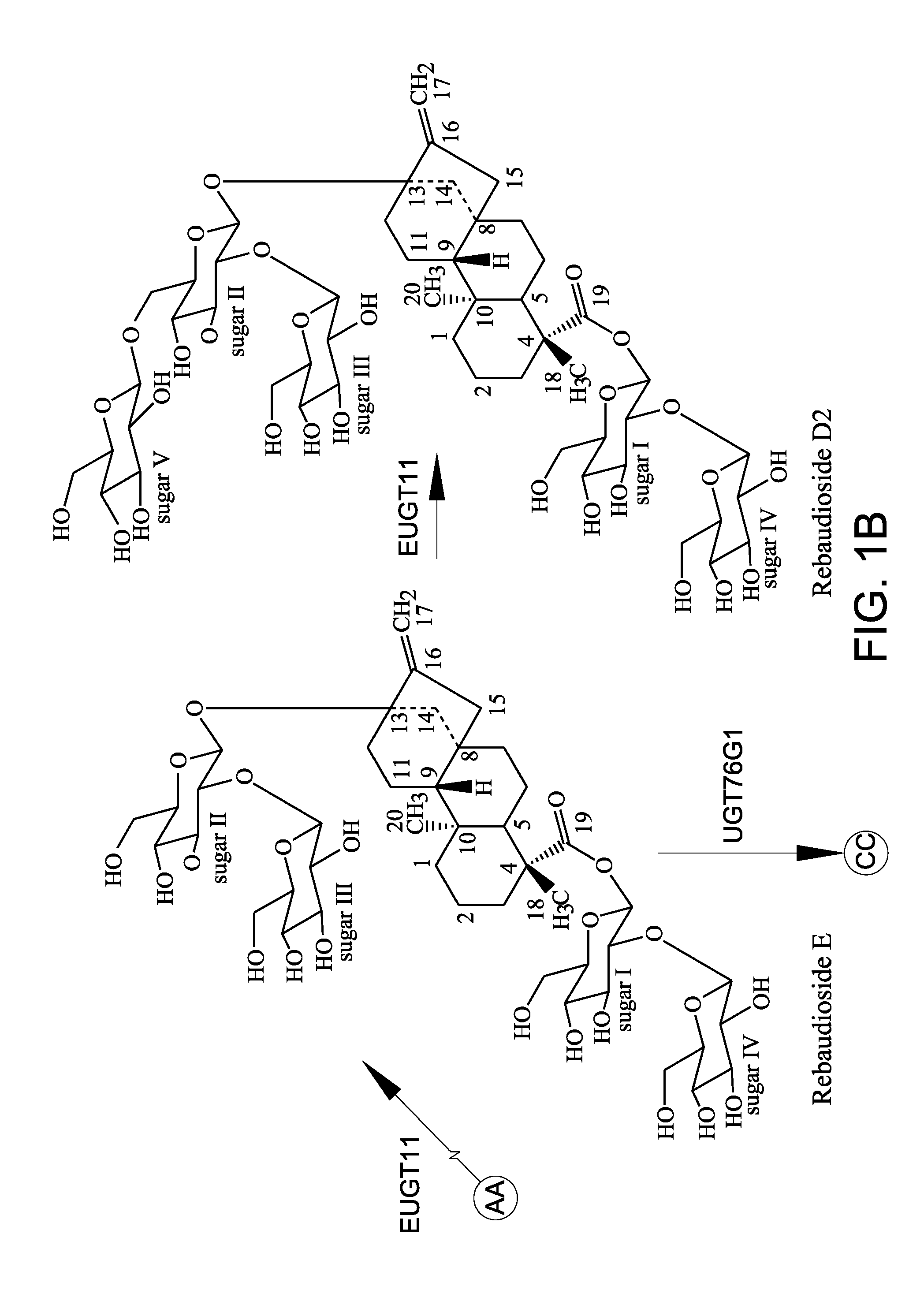

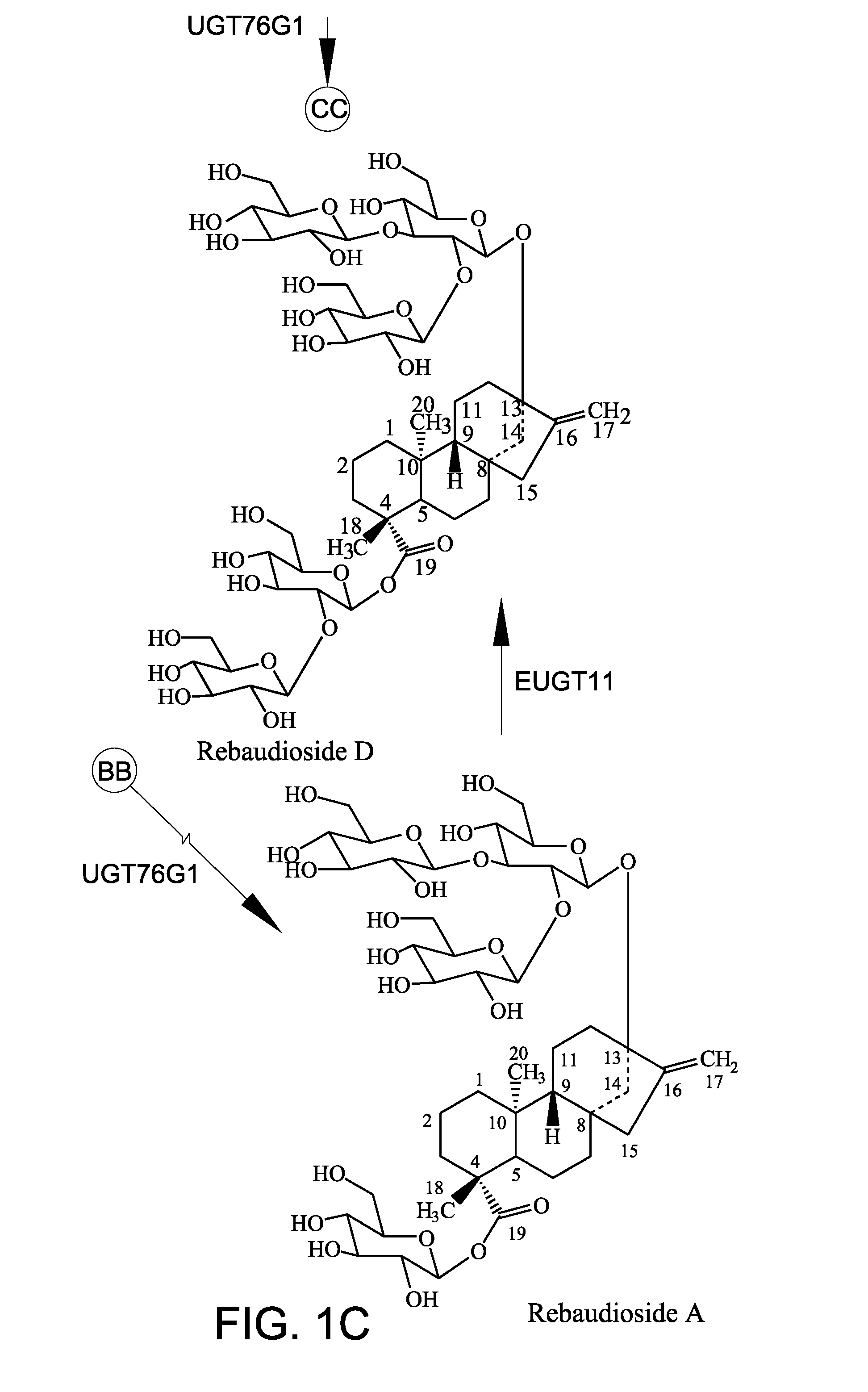

Recombinant Production of Steviol Glycosides

ActiveUS20140329281A1Lower Level RequirementsImprove the level ofBacteriaIsomerasesMicroorganismBiotechnology

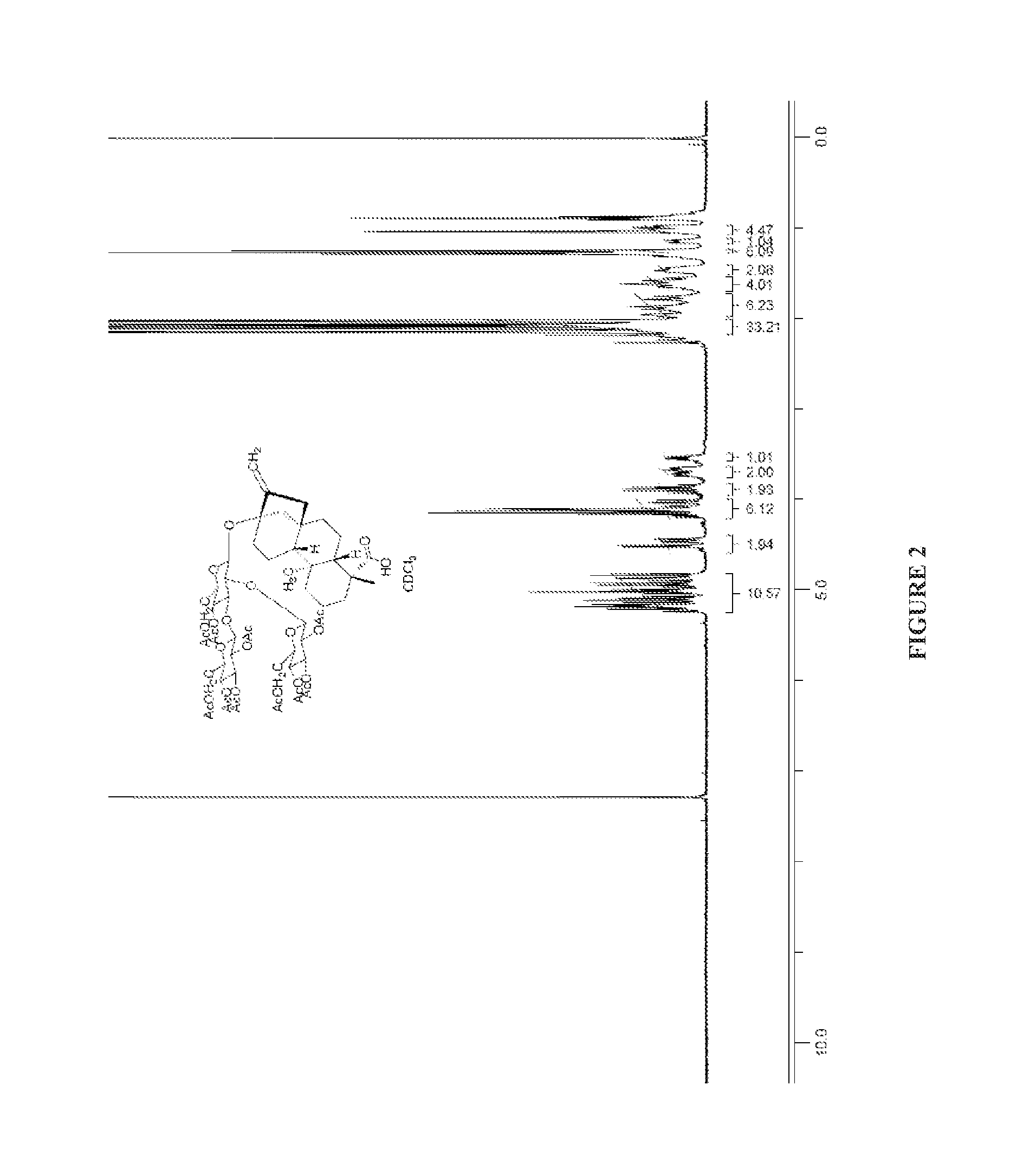

Recombinant microorganisms, plants, and plant cells are disclosed that have been engineered to express recombinant genes encoding UDP-glycosyltransferases (UGTs). Such microorganisms, plants, or plant cells can produce steviol glycosides, e.g., Rebaudioside A and / or Rebaudioside D, which can be used as natural sweeteners in food products and dietary supplements.

Owner:EVOLVA SA

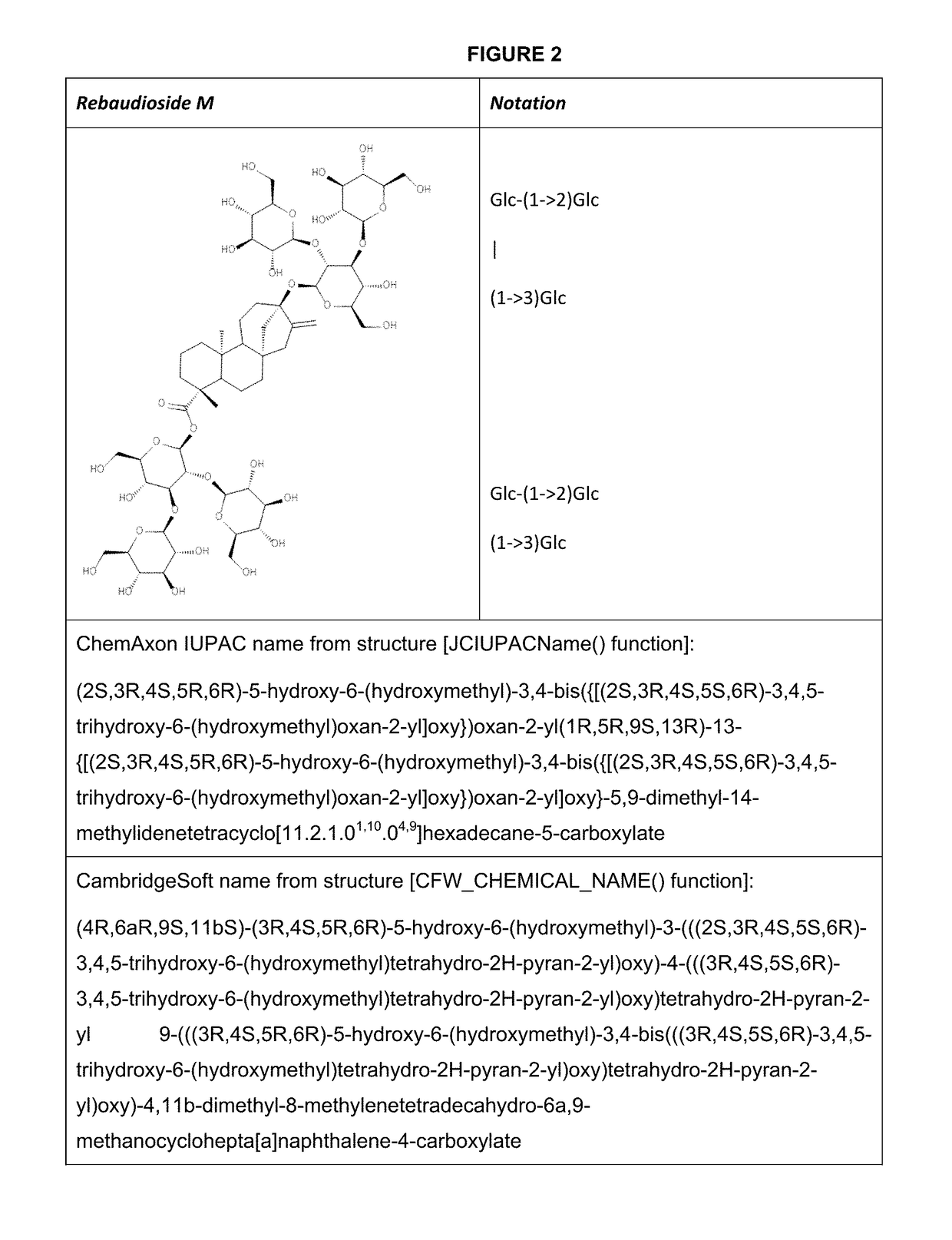

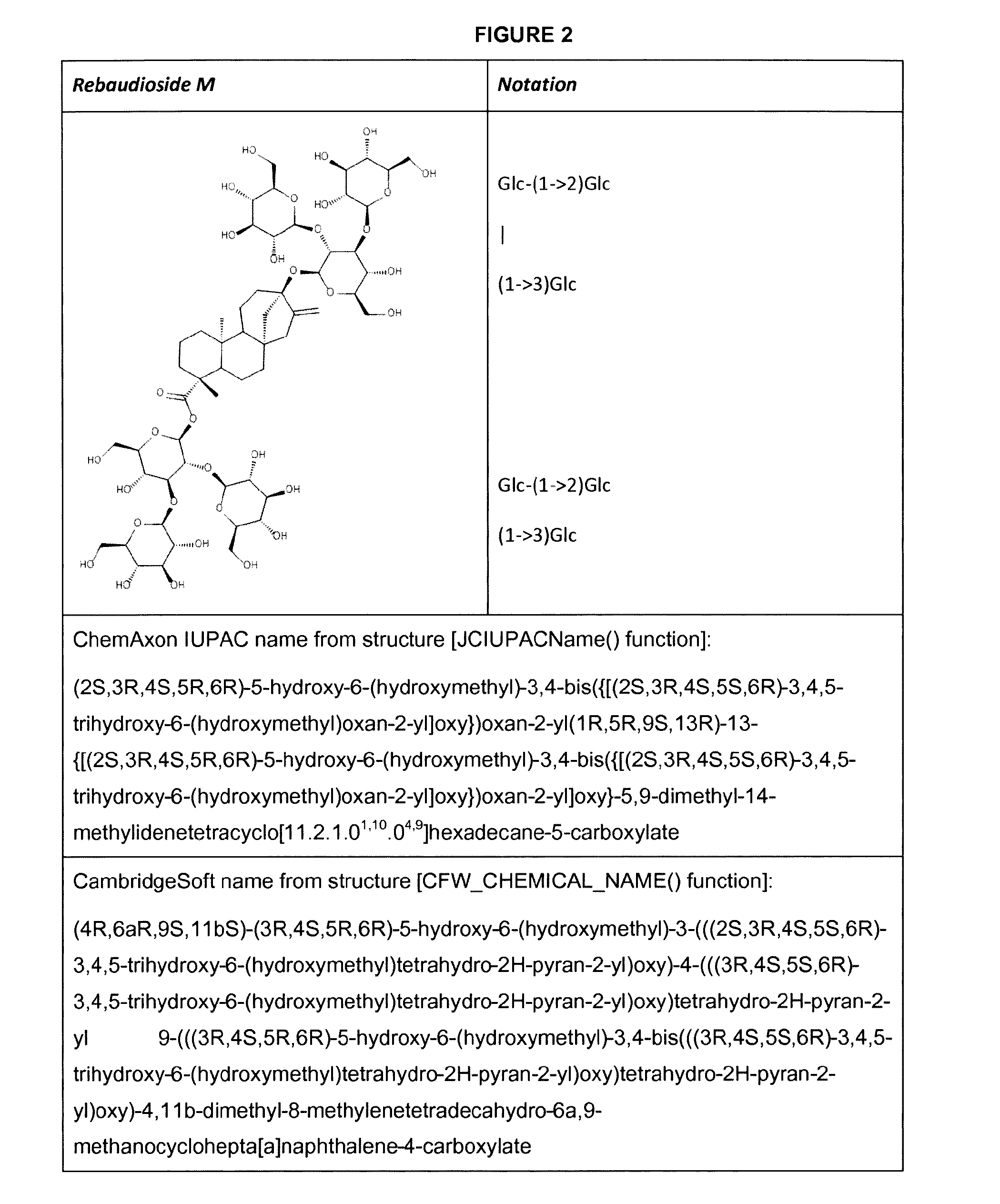

Compositions and Methods for Improving Rebaudioside M Solubility

ActiveUS20150017284A1Good water solubilityReduce precipitationMilk preparationDough treatmentSolubilityRebaudioside D

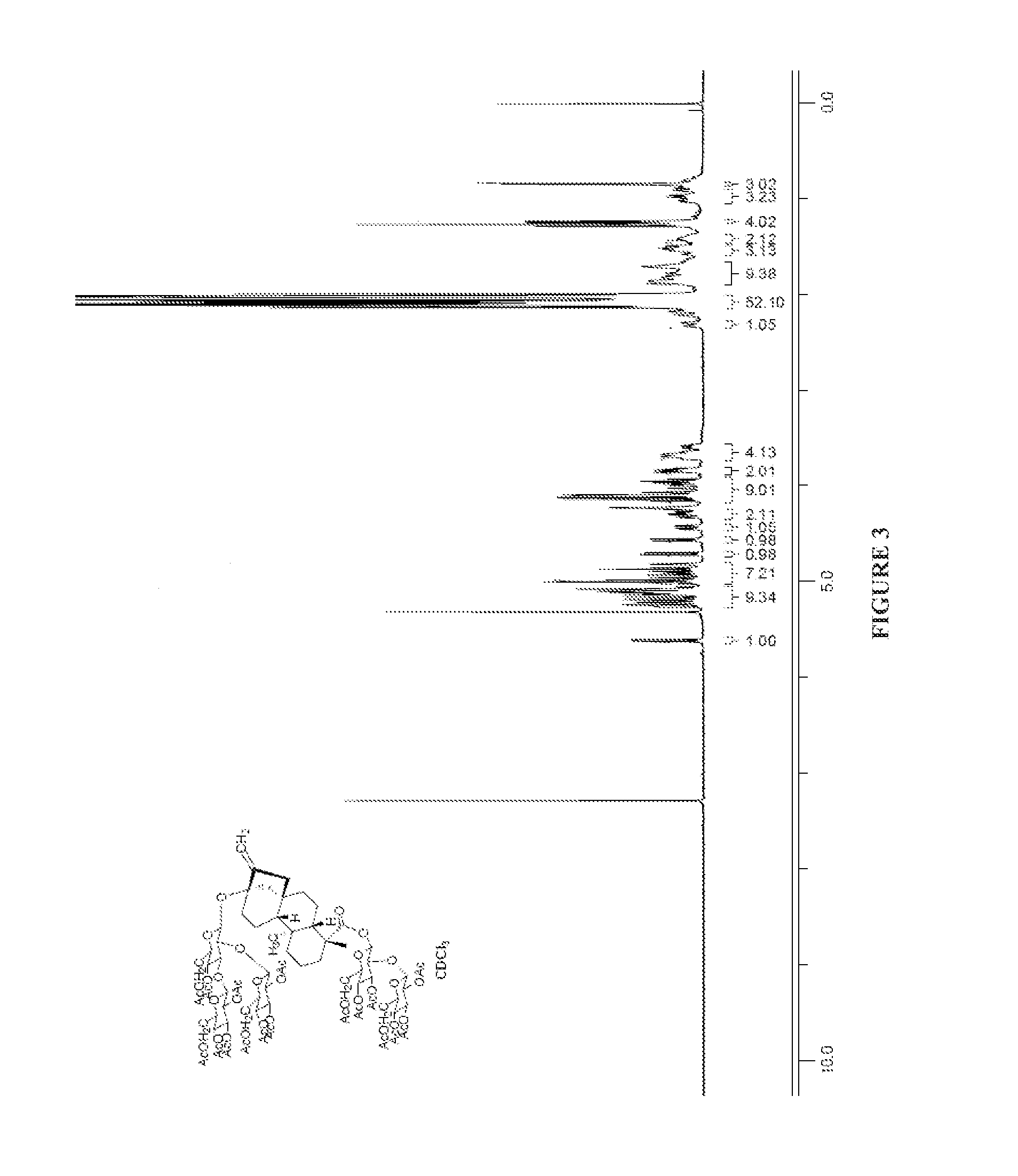

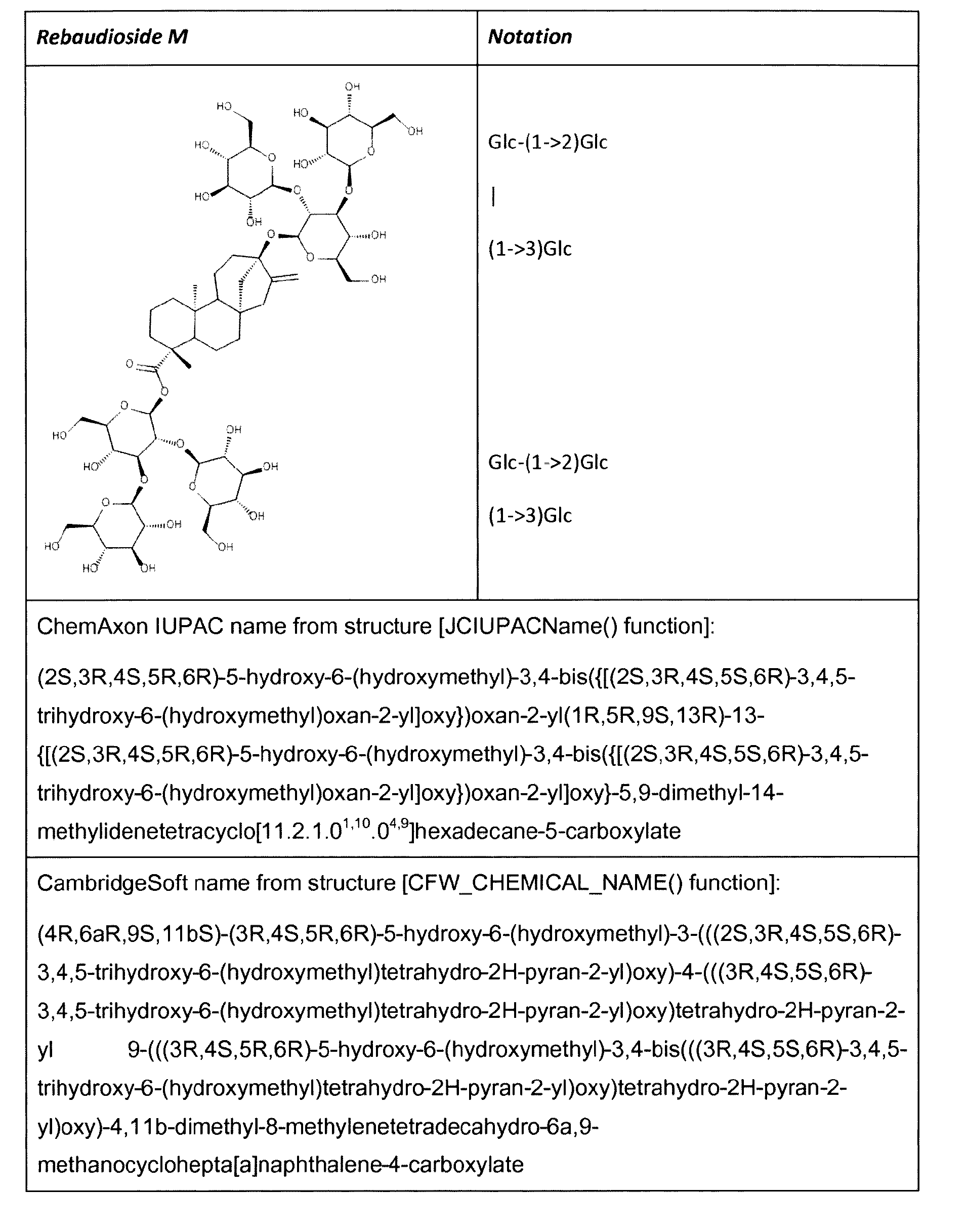

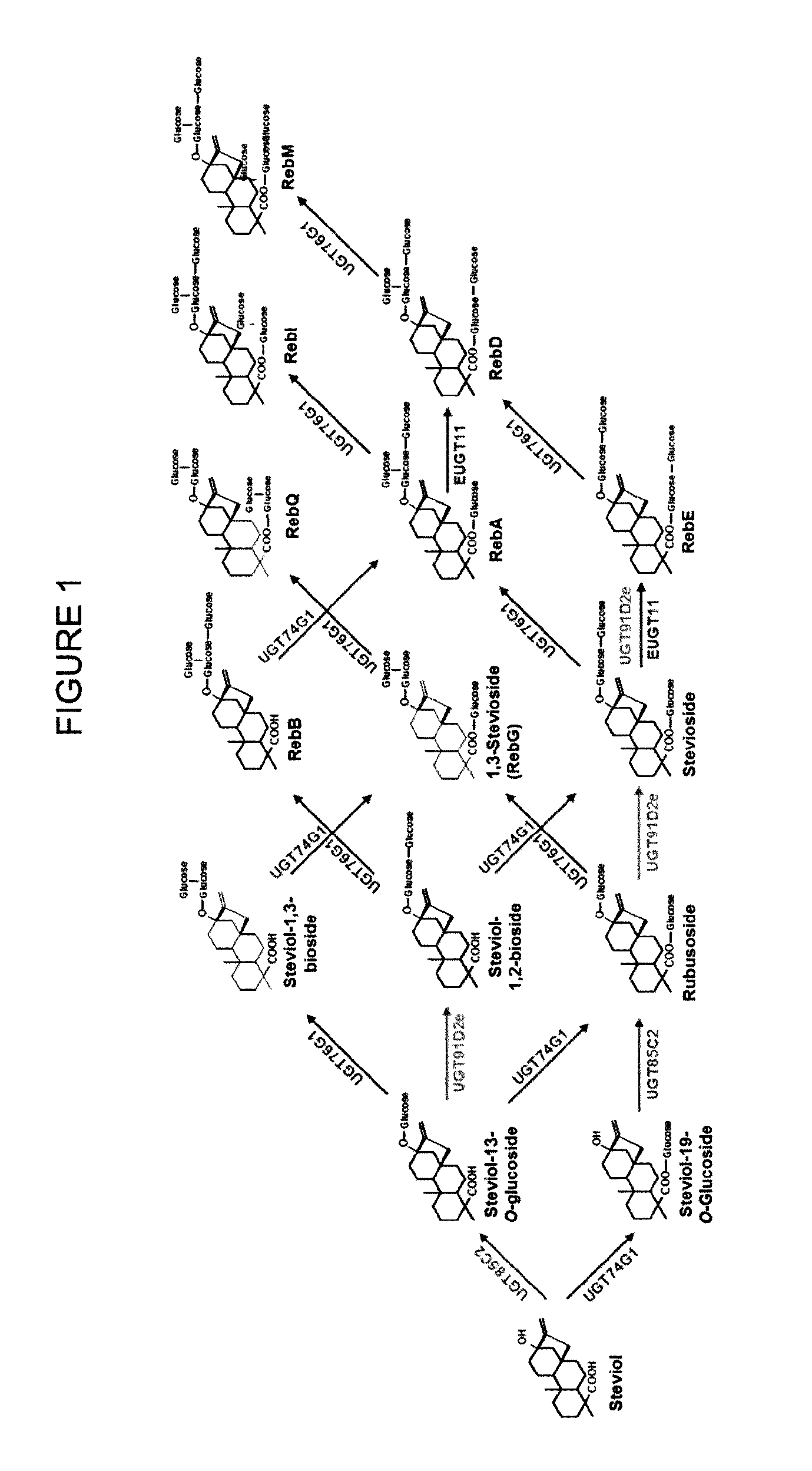

Rebaudioside M compositions with improved aqueous solubility and methods for preparing the same are provided herein. The rebaudioside M compositions include (i) disordered crystalline compositions comprising rebaudioside M and rebaudioside D, (ii) spray-dried compositions comprising rebaudioside M, rebaudioside D and steviol glycoside mixtures and / or rebaudioside B and / or NSF-02, (iii) spray-dried compositions comprising rebaudioside M, rebaudioside D and at least one surfactant, polymer, saponin, carbohydrate, polyol, preservative or a combination thereof. Sweetened compositions, such a beverages, containing the rebaudioside M compositions with improved water solubility are also provided herein.

Owner:THE COCA-COLA CO +1

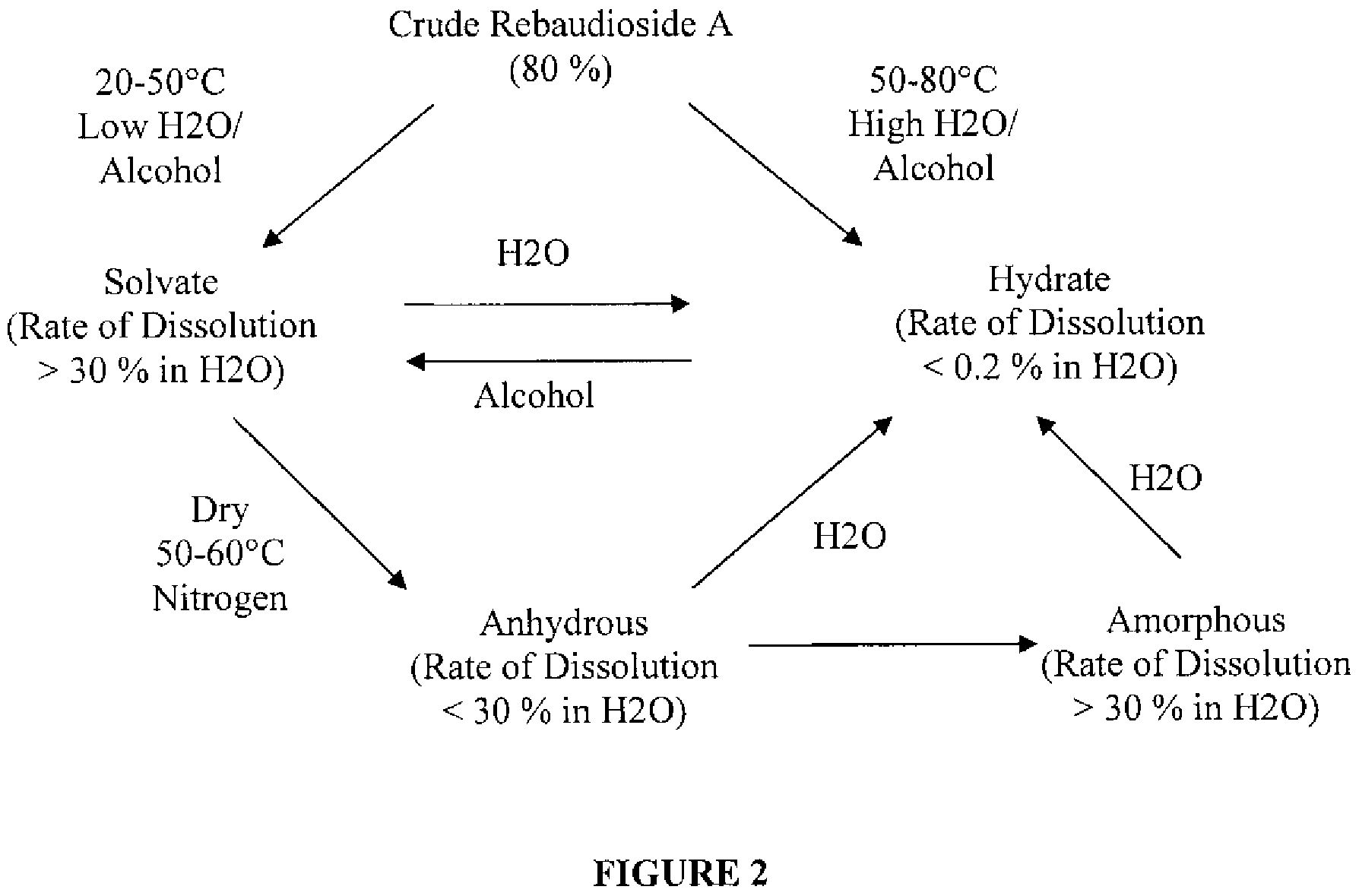

Method to improve water solubility of rebaudioside d

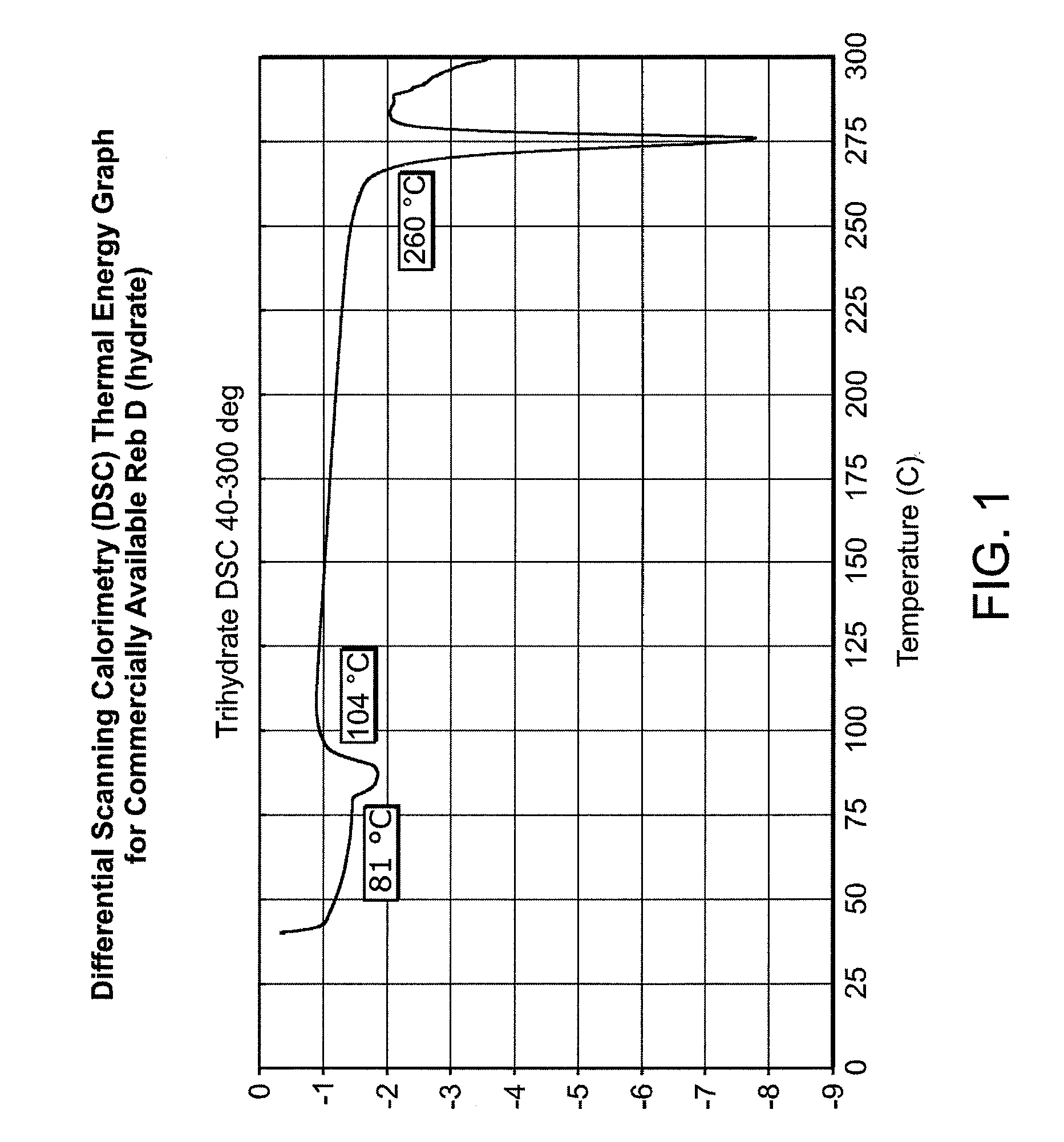

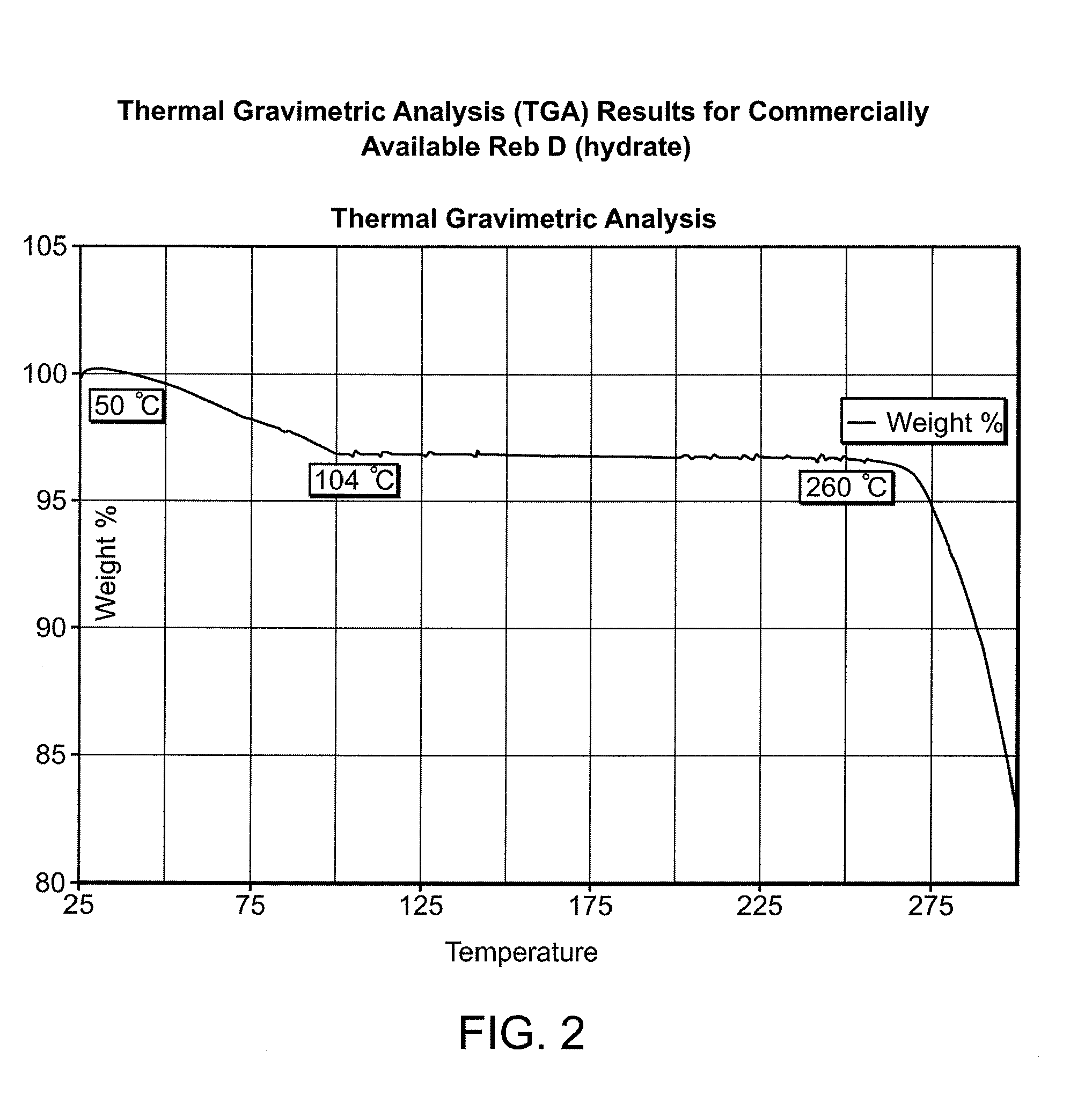

Thermally stable anhydrous Rebaudioside D can be provided by methods disclosed here and has been found to be more soluble in aqueous solutions than the previously known non-anhydrous Rebaudioside D. This physical property makes the anhydrous Reb D amenable to food and beverage manufacturing applications for which the non-anhydrous form is not suitable. Anhydrous Rebaudioside D is useful in sweeteners, and can be included in food and beverage products, which are also disclosed

Owner:PEPSICO INC

Non-caloric sweetener

ActiveUS20150315623A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsUdp glycosyltransferaseRebaudioside D

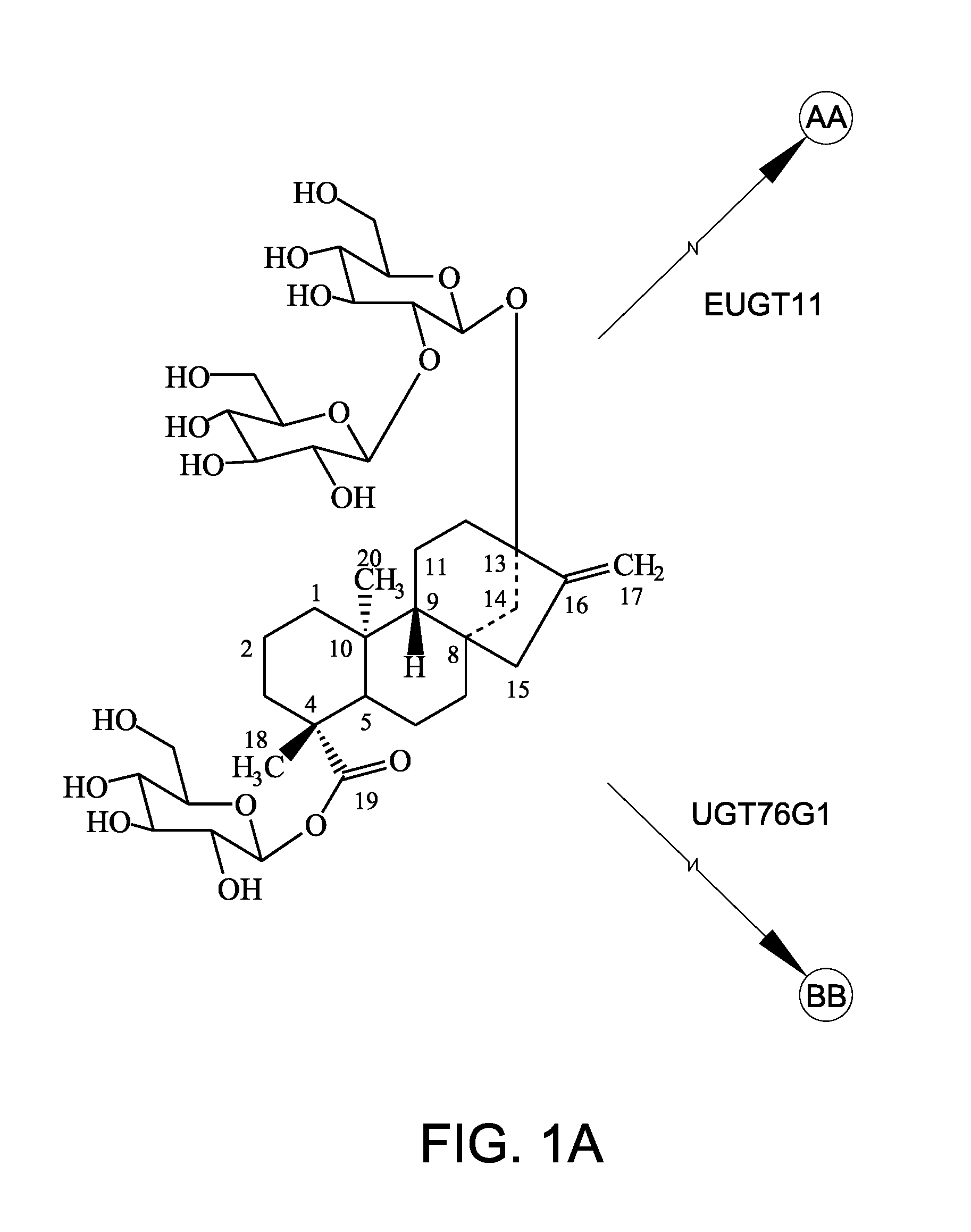

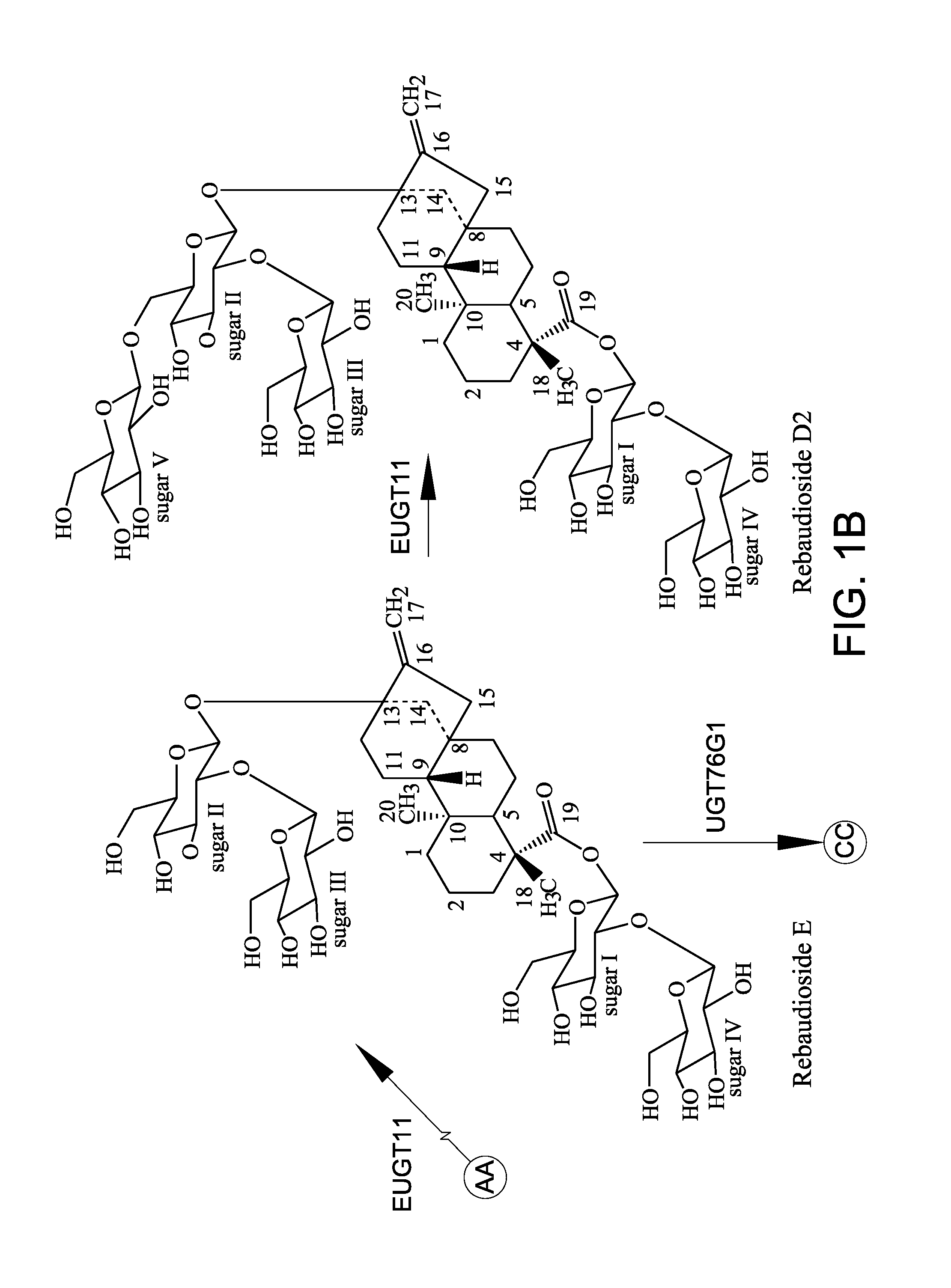

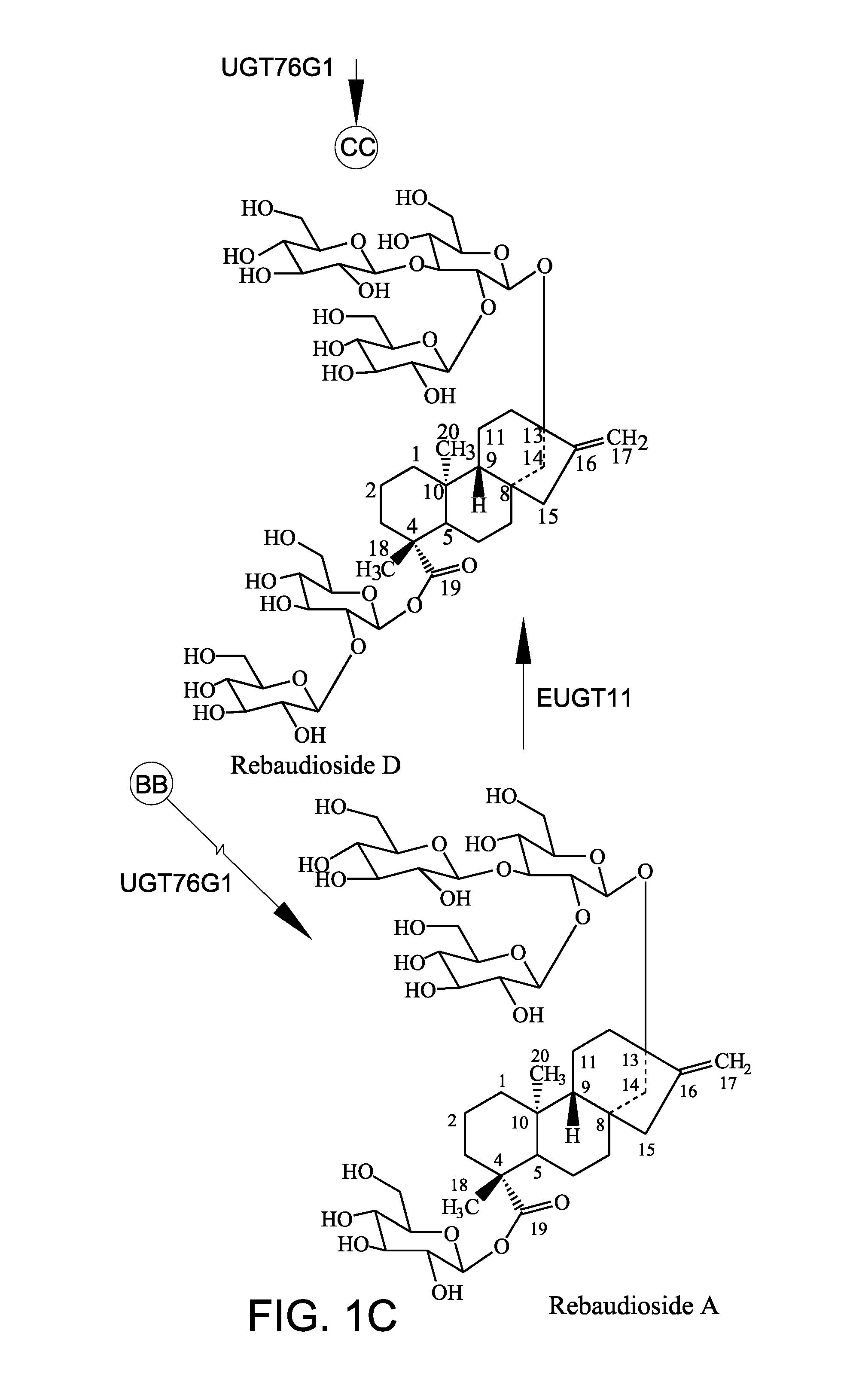

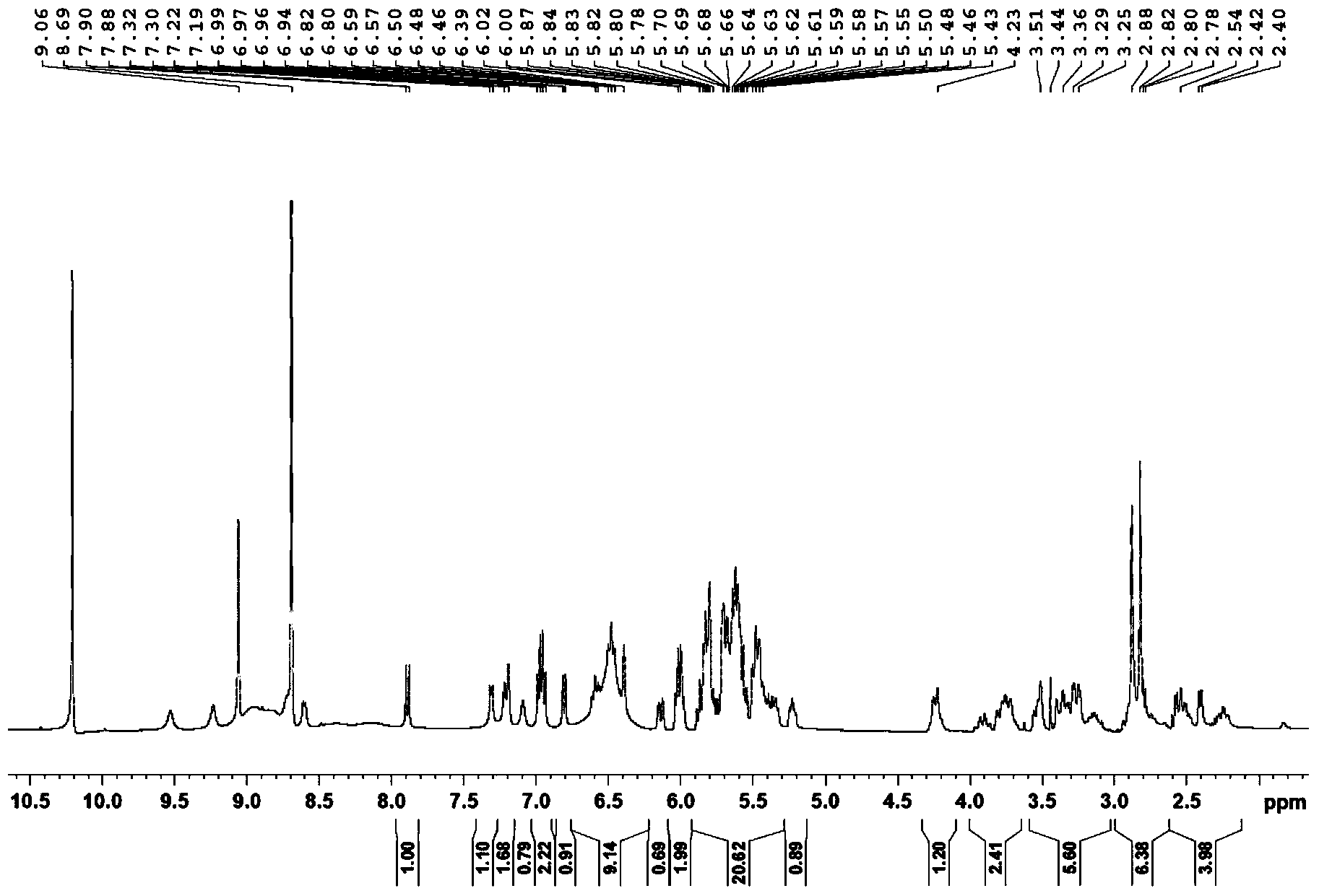

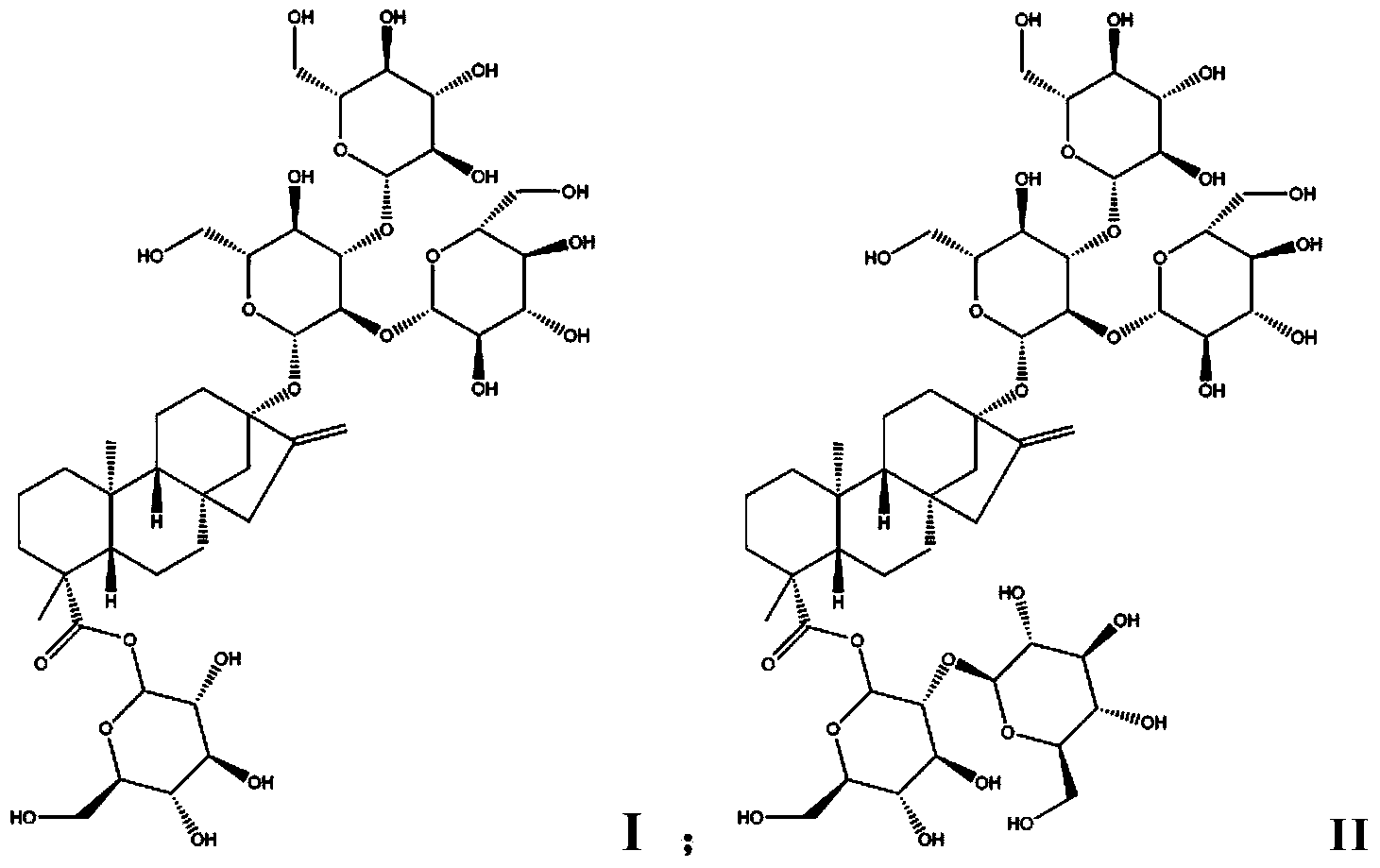

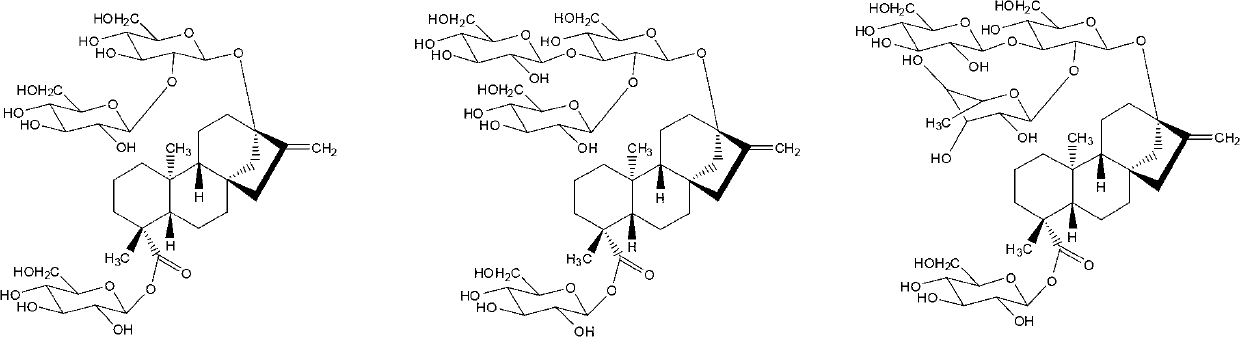

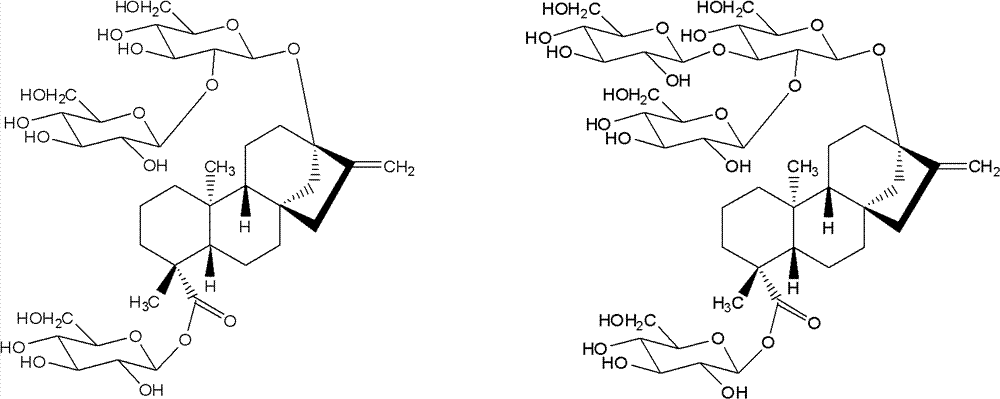

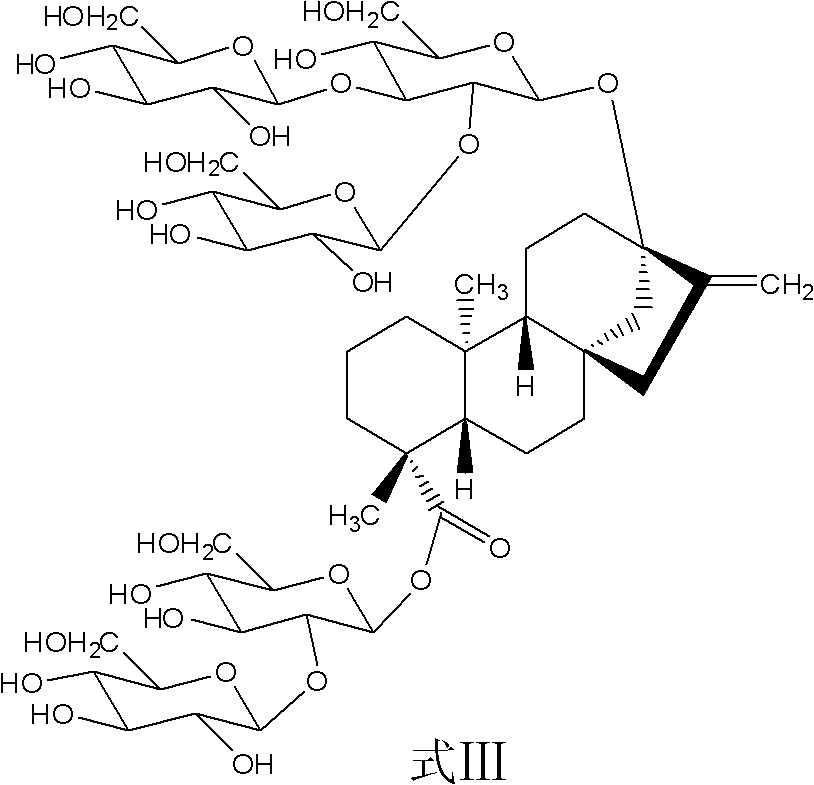

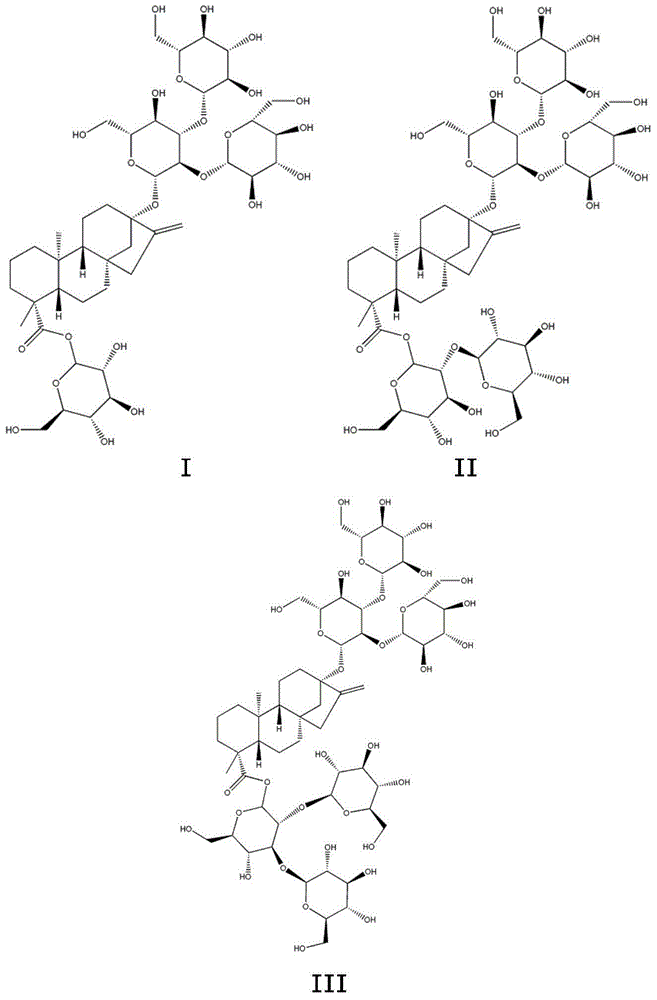

Disclosed is a steviol glycoside referred to as rebaudioside D2. Rebaudioside D2 has five β-D-glucosyl units connected to the aglycone steviol. Also disclosed are methods for producing rebaudioside D2, a UDP-glycosyltransferase fusion enzyme, and methods for producing rebaudioside D and rebaudioside E.

Owner:CONAGEN INC

Recombinant production of steviol glycosides

Recombinant microorganisms, plants, and plant cells are disclosed that have been engineered to express recombinant genes encoding UDP-glycosyltransferases (UGTs). Such microorganisms, plants, or plant cells can produce steviol glycosides, e.g., Rebaudioside A and / or Rebaudioside D, which can be used as natural sweeteners in food products and dietary supplements.

Owner:EVOLVA SA

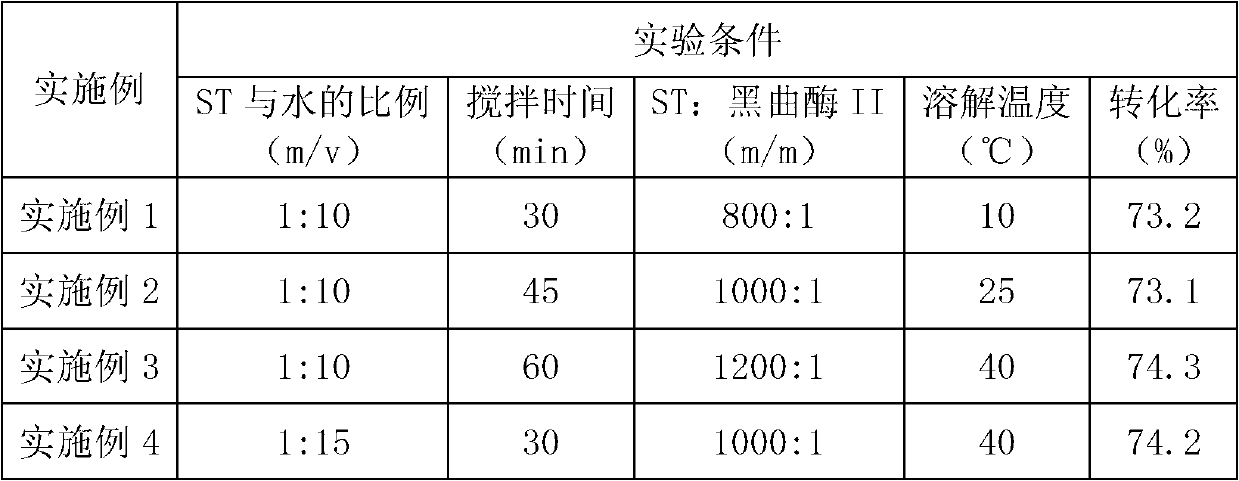

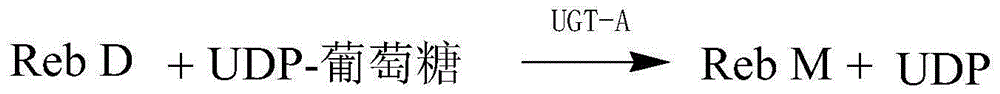

Method for preparing rebaudioside M through enzyme method

ActiveCN103757074AImprove conversion rateHigh purityFermentationSucrose synthetaseUdp glucosyltransferase

The invention relates to a method for preparing rebaudioside M through an enzyme method. According to the method, rebaudioside A or rebaudioside D is used as a substrate, and the substrate reacts to generate the rebaudioside M in the presence of sucrose and UDP under the catalytic action of a mixture of UDP-glucosyltransferase and sucrose synthetase or recombinant cells containing the UDP-glucosyltransferase and the sucrose synthetase, wherein the reaction is performed in a water-phase system having a pH value of 5.0-9.0 at 20-60 DEG C. The method for preparing rebaudioside M through an enzyme method has important application value; and compared with the existing technology of extracting rebaudioside M from stevia rebaudian leaves, the method provided by the invention obviously shortens the production cycle, improves the productivity and lowers the cost, and can provide products having higher purity. Thus, the method can be used in the food and beverage industry in a more economical manner.

Owner:PEPSICO INC

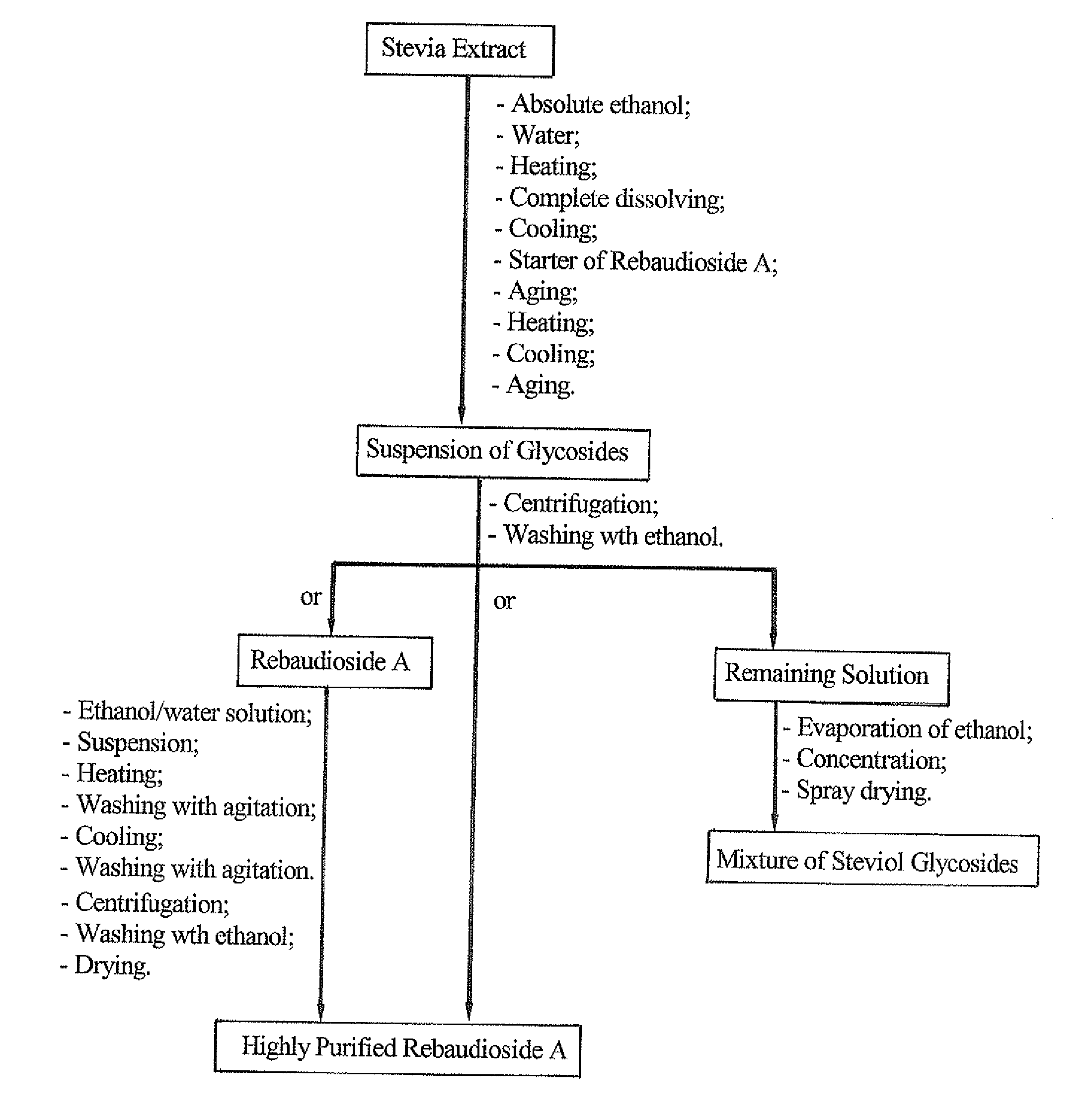

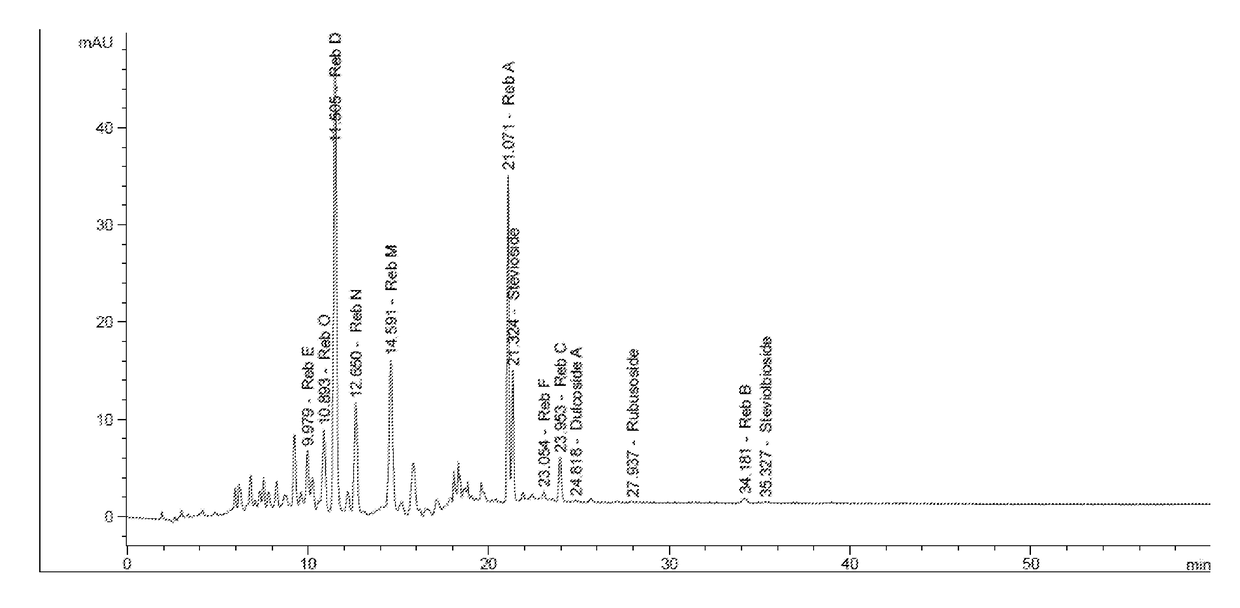

High-purity steviol glycosides

Methods of preparing highly purified steviol glycosides, particularly Rebaudioside D, are described. The methods include purification from the extraction stage of the Stevia rebaudiana Bertoni plant, purification of steviol glycoside mixtures, Rebaudioside D and Rebaudioside A from a commercial Stevia extract, and purification of Rebaudioside D from remaining solutions obtained after isolation and purification of Rebaudioside A and a high purity mixture of steviol glycosides. The methods are useful for producing high purity Rebaudioside D, Rebaudioside A, and steviol glycoside mixtures. The high purity steviol glycosides are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectioneries, bakery products, cookies, and chewing gums.

Owner:PURECIRCLE USA

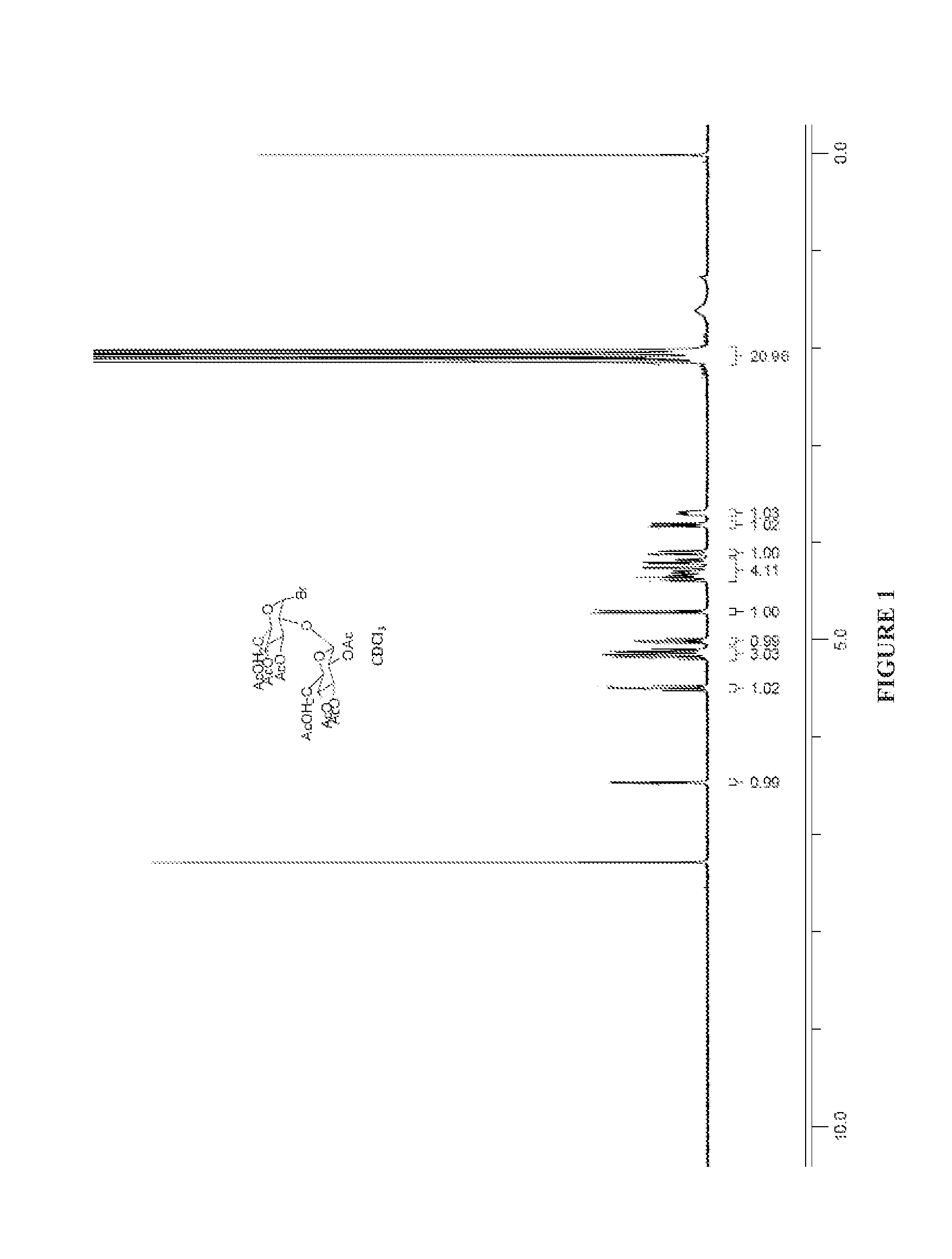

Novel Process for the Preparation of Rebaudioside D and Other Related Naturally Occurring Sweetners

A novel process for preparation of Rebaudioside D (RD), and other related naturally occurring sweeteners is provided. RD is a natural sweetening agent which can decrease the bitter aftertaste of steviol glycosides. The said process is suitable for commercial manufacturing by using readily available natural products and nontoxic reagents.

Owner:PHARMA SHANGHAI

Methods for improved production of rebaudioside d and rebaudioside m

ActiveUS20160186225A1Increased specificity/activityIncrease ratingsBacteriaConfectioneryRebaudioside DBiochemistry

Owner:EVOLVA SA

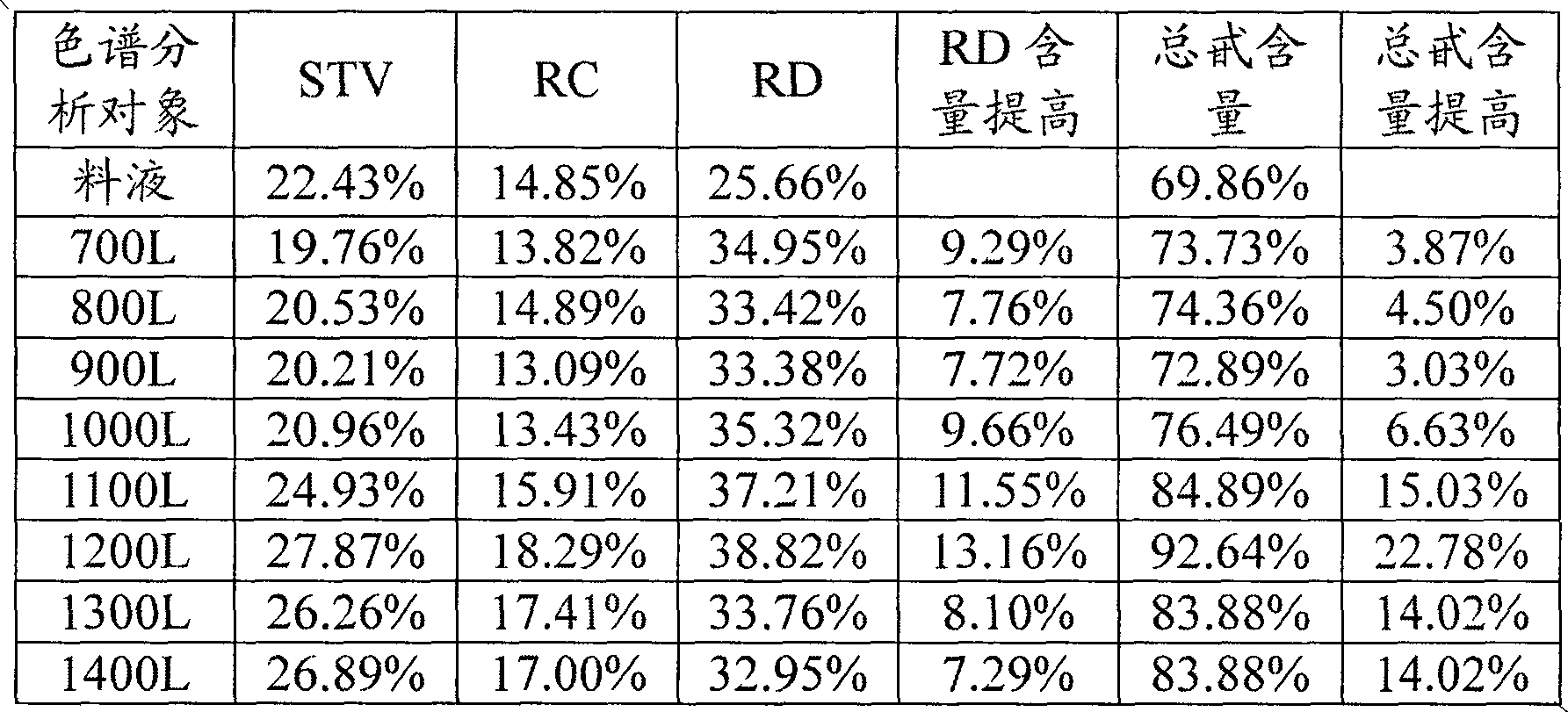

Method for purifying stevioside RD (Rebaudioside D)

The invention discloses a method for purifying stevioside RD (Rebaudioside D), which comprises the steps of: preparing mother liquor stevioside into 25-40mg / ml of feed liquid, enabling the feed liquid to flow through a macroporous adsorption resin column at a speed of 2.5-4.0L / min, wherein the resin column is a styrene polar copolymer, the average pore size of the resin column is 40-50A, the pore capacity is 0.9-1.0ml / g, the pH value during the adsorption is 4.5-5.5; and after the complete absorption, eluting and adsorbing on the stevioside absorbed on the resin column with alcohol with mass concentration of 75-80 percent, collecting eluent by sections, determining a critical point, collecting eluent at the critical point, concentrating the eluent at a temperature of 60-80 DEG C, and respectively drying obtained solid and liquid to obtain coarse stevioside. The stevioside obtained by using the method has higher purity, and the content of the RD can reach above 40 percent; and the content of the RD in the stevioside can reach above 95 percent through a refining step.

Owner:安徽润海生物科技股份有限公司

High-purity rebaudioside D and low-calorie yogurt containing the same

ActiveUS8414949B2Total calories lowExcellent taste profile and texture and mouthfeelCosmetic preparationsMilk preparationAcetic acidRebaudioside D

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The invention further provides a low-calorie yogurt containing the purified Rebaudioside D and a process for making the low-calorie yogurt containing the purified Rebaudioside D.

Owner:PURECIRCLE SDN BHD

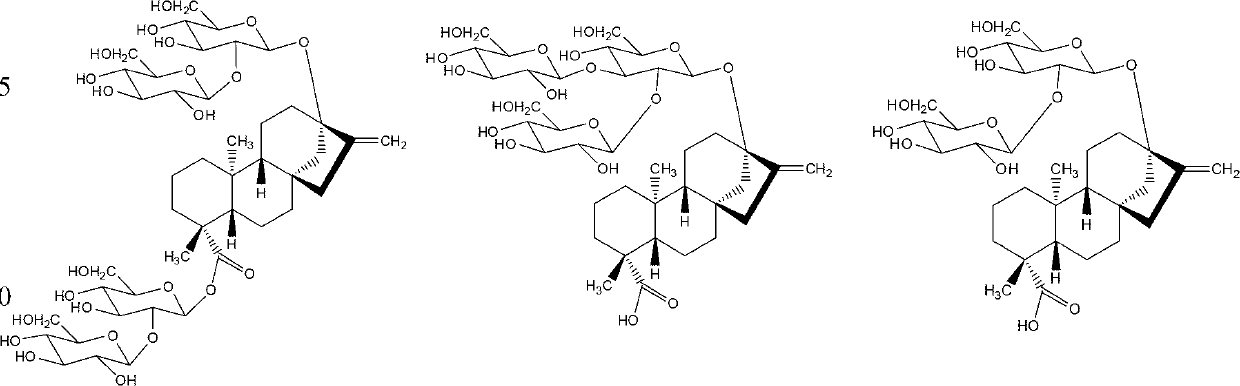

Method for transforming stevioside into rebaudioside E

InactiveCN102766667ALow costEasy to zoom inMicroorganism based processesFermentationSucroseSaccharum

The invention discloses a method for transforming stevioside into rebaudioside E. The stevioside is transformed into the rebaudioside E by using aspergillns niger II which is added with a sugar source. According to the method, the stevioside is used as a raw material to obtain a transformation rate of the rebaudioside E, the transformation rate of the rebaudioside E is larger than and identical to 70%, the rebaudioside E content in solid matters can at least reach to 60%, after a further separation and purification, the rebaudioside E content can reach to 80% and is even larger than 90%, the rebaudioside E is free from extraneous odour, similar to cane sugar and capable of being used as a sweetener independently, the rebaudioside E production cost is low, and the method is easy to magnify and suitable for industrial production.

Owner:成都南诺格生物科技有限责任公司

High-purity Rebaudioside D

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The high purity Rebaudiosides are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectionaries, bakeries, cookies, chewing gums, and alike.

Owner:PURECIRCLE SDN BHD

High-Purity Rebaudioside D And Low-Calorie Chocolate Containing The Same

ActiveUS20110091637A1Total calories lowExcellent taste profileFrozen sweetsCocoaRebaudioside DLow calorie

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The invention further provides a low-calorie chocolate containing the purified Rebaudioside D and a process for making the low-calorie chocolate containing the purified Rebaudioside D.

Owner:PURECIRCLE SDN BHD

Composite sweeting agent and preparation method thereof, and method for improving taste of stevia glycoside sweeting agents

The present invention relates to a composite sweeting agent and a preparation method thereof, and a method for improving taste flavor of stevia glycoside sweeting agents, and belongs to the field of food chemical industry. Based on deficiencies in the prior art, a purpose of the present invention is to provide a new method for improving the taste and the flavor of the natural stevia glycoside sweeting agents. Specifically the present invention relates to new uses of application of rebaudioside D as a taste-modifying agent and / or a flavoring agent, specifically application of rebaudioside D in improvement of the existing sweeteners, especially the taste and the flavor of the natural stevia glycoside sweeting agents. The present invention further provides a composite sweeting agent prepared by mixing rebaudioside D and at least one selected from stevioside and rebaudioside A. According to the present invention, the composite sweeting agent has a taste similar to sucrose, and does not has lingering bitterness and acerbity; no artificially synthesized component and no energy component are introduced; and characteristics o pure nature and no energy of the stevioside and the rebaudioside A are maintained.

Owner:成都华高瑞甜科技有限公司

High-Purity Rebaudioside D And Low-Calorie Carbonated Lemon-Flavored Beverage Containing The Same

ActiveUS20110091634A1Improved taste propertyImprove mouthfeelFood preparationRebaudioside DLow calorie

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The invention further provides a low-calorie carbonated lemon-flavored beverage containing the purified Rebaudioside D and a process for making the low-calorie carbonated lemon-flavored beverage containing the purified Rebaudioside D.

Owner:PURECIRCLE SDN BHD

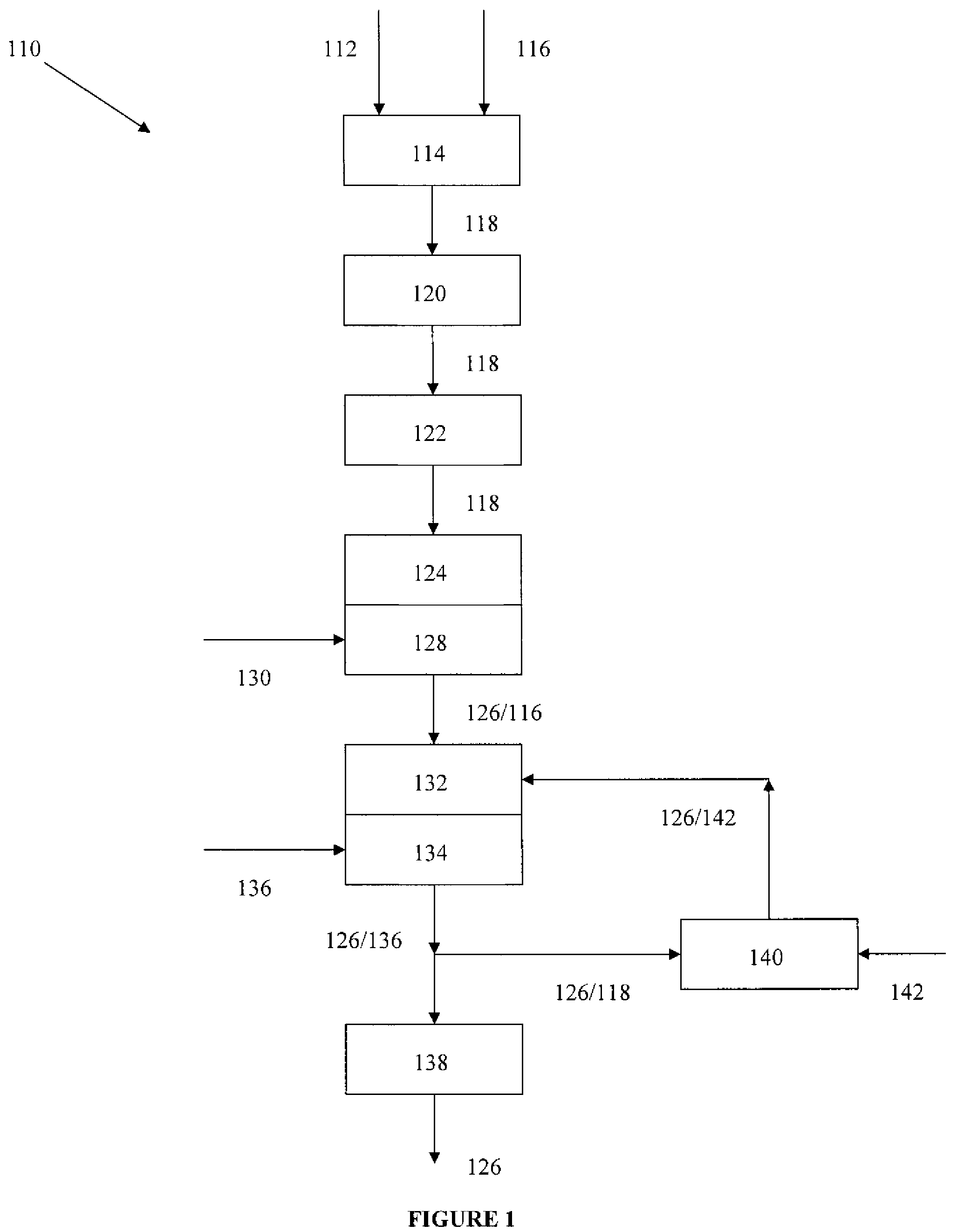

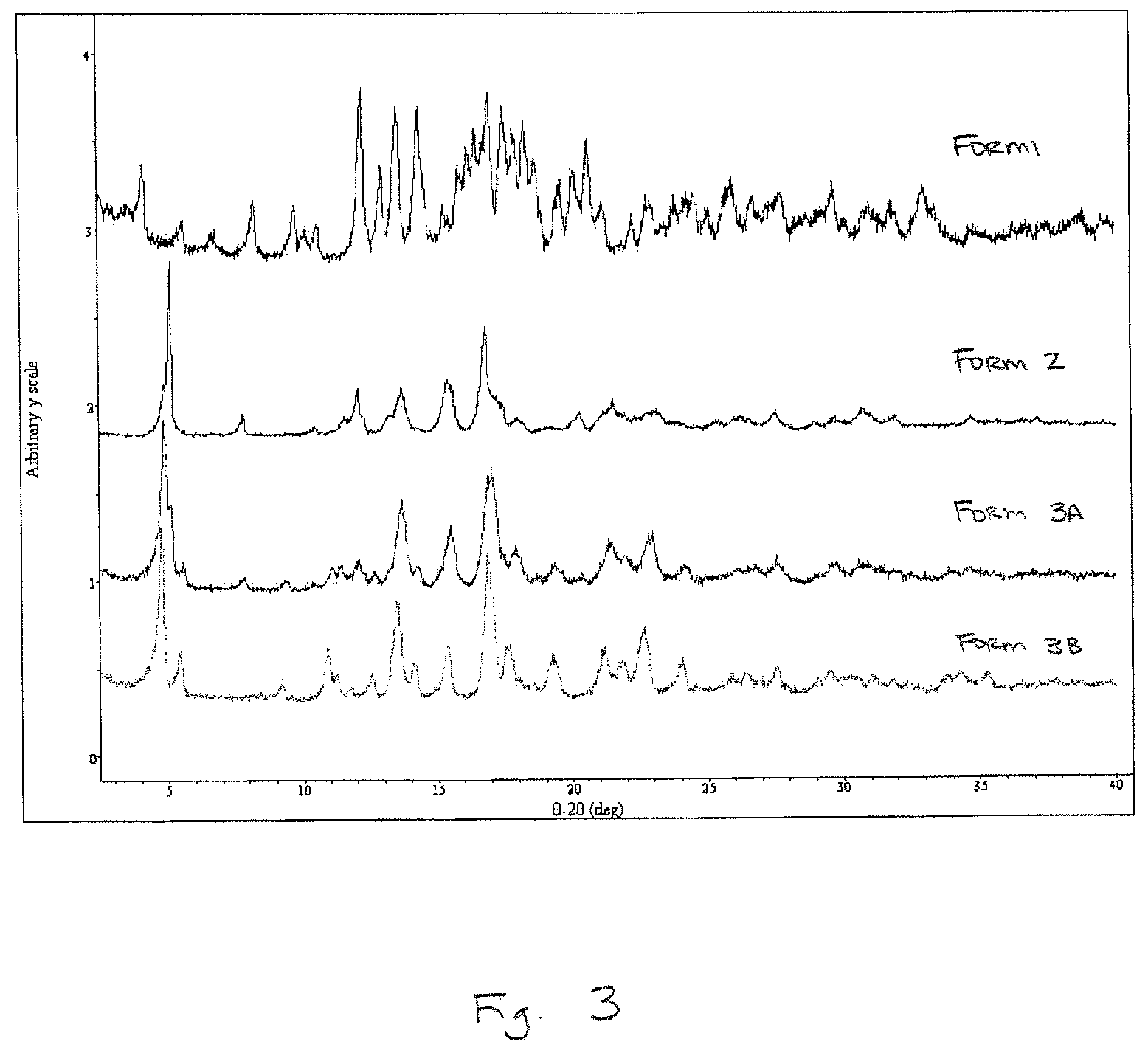

Rebaudioside A composition and method for purifying rebaudioside A

Exemplary embodiments of this invention encompass a method for purifying crude rebaudioside A. In particular, this invention relates to a method for purifying crude rebaudioside A compositions comprising purities from approximately 40% to approximately 95% rebaudioside A to obtain a substantially pure rebaudioside A product with a single crystallization step. Resulting polymorph and amorphous forms of rebaudioside A and methods for preparing polymorph and amorphous forms of rebaudioside A from crude rebaudioside A compositions and substantially pure rebaudioside A compositions also are disclosed.

Owner:THE COCA-COLA CO

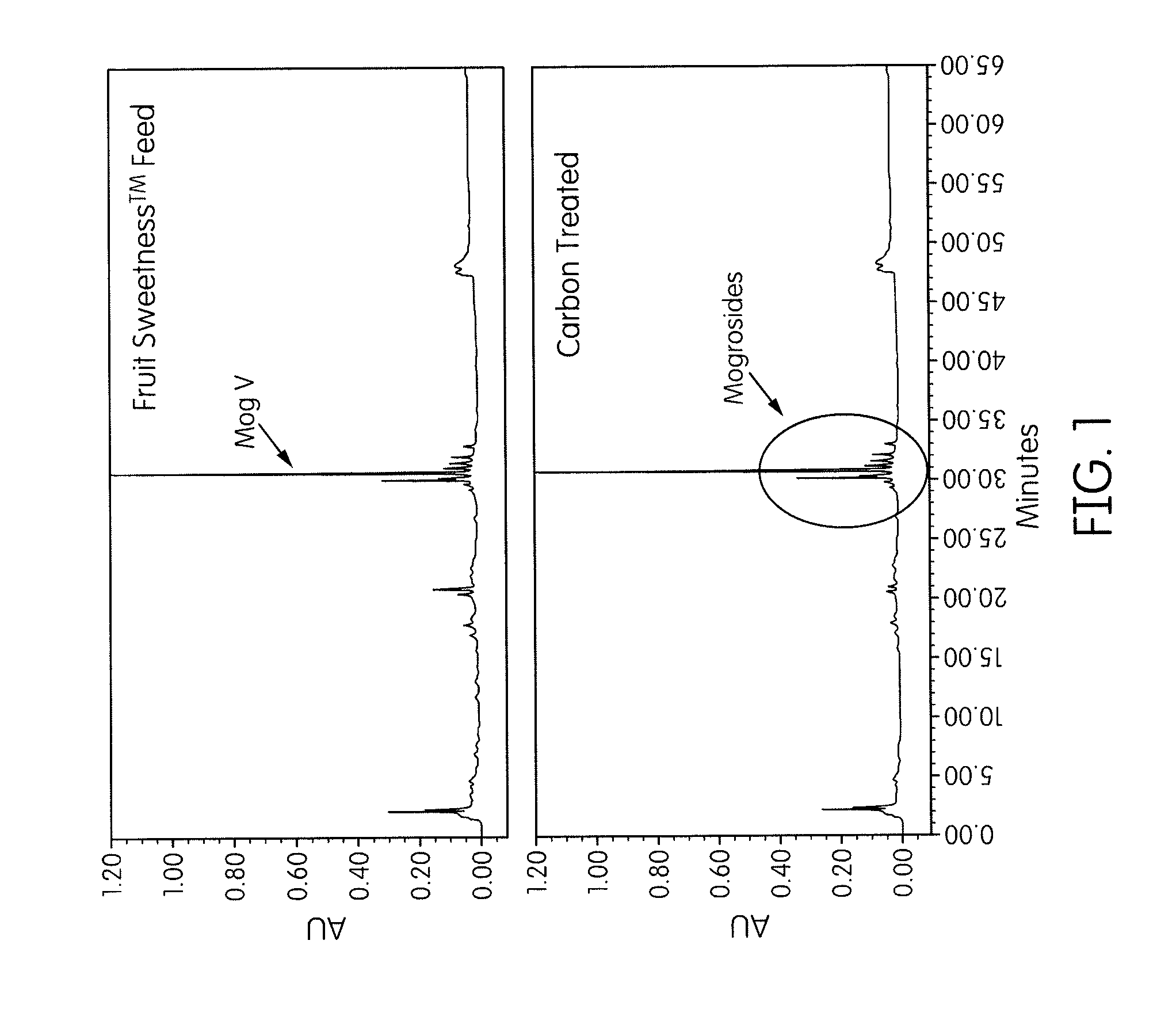

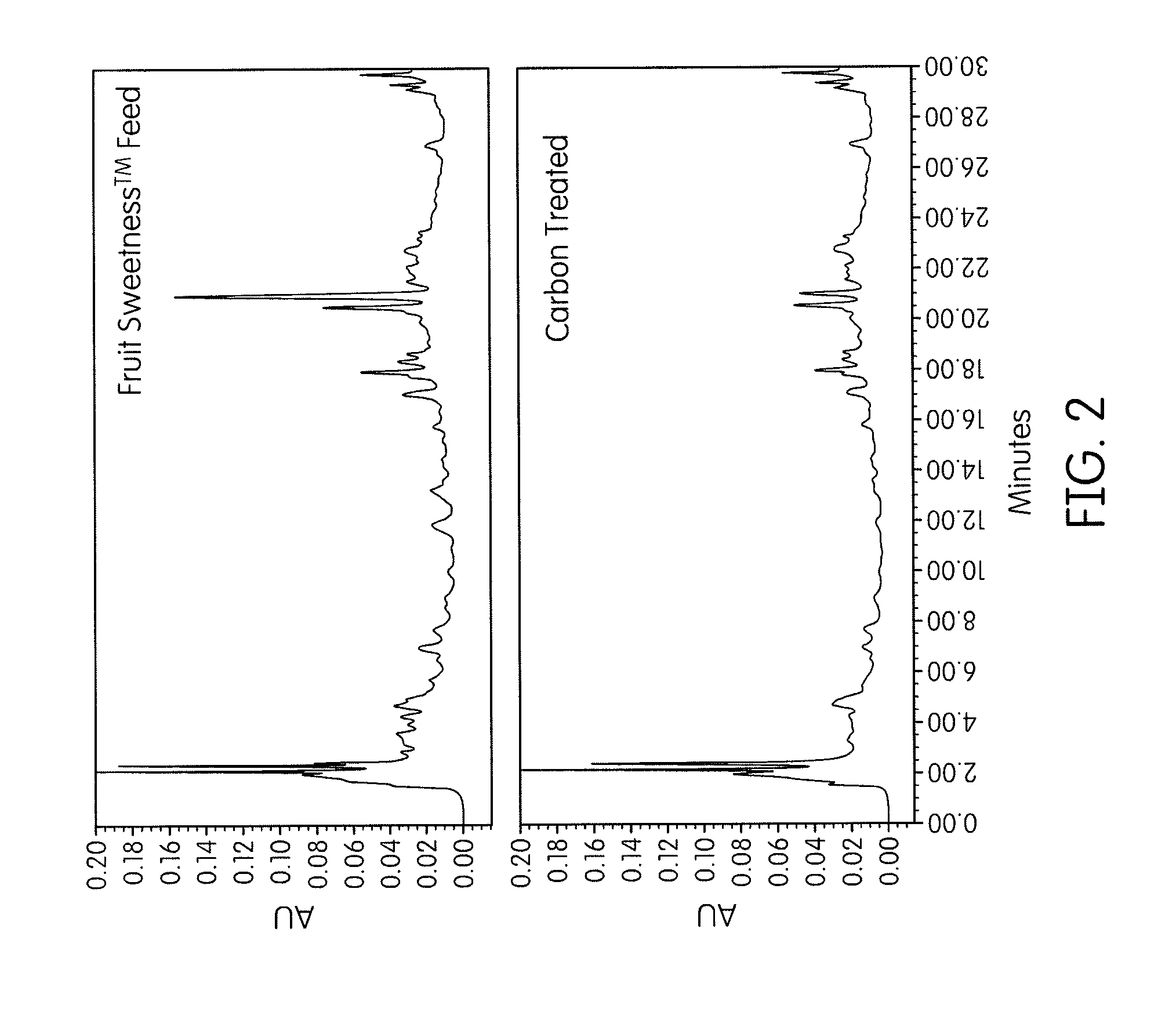

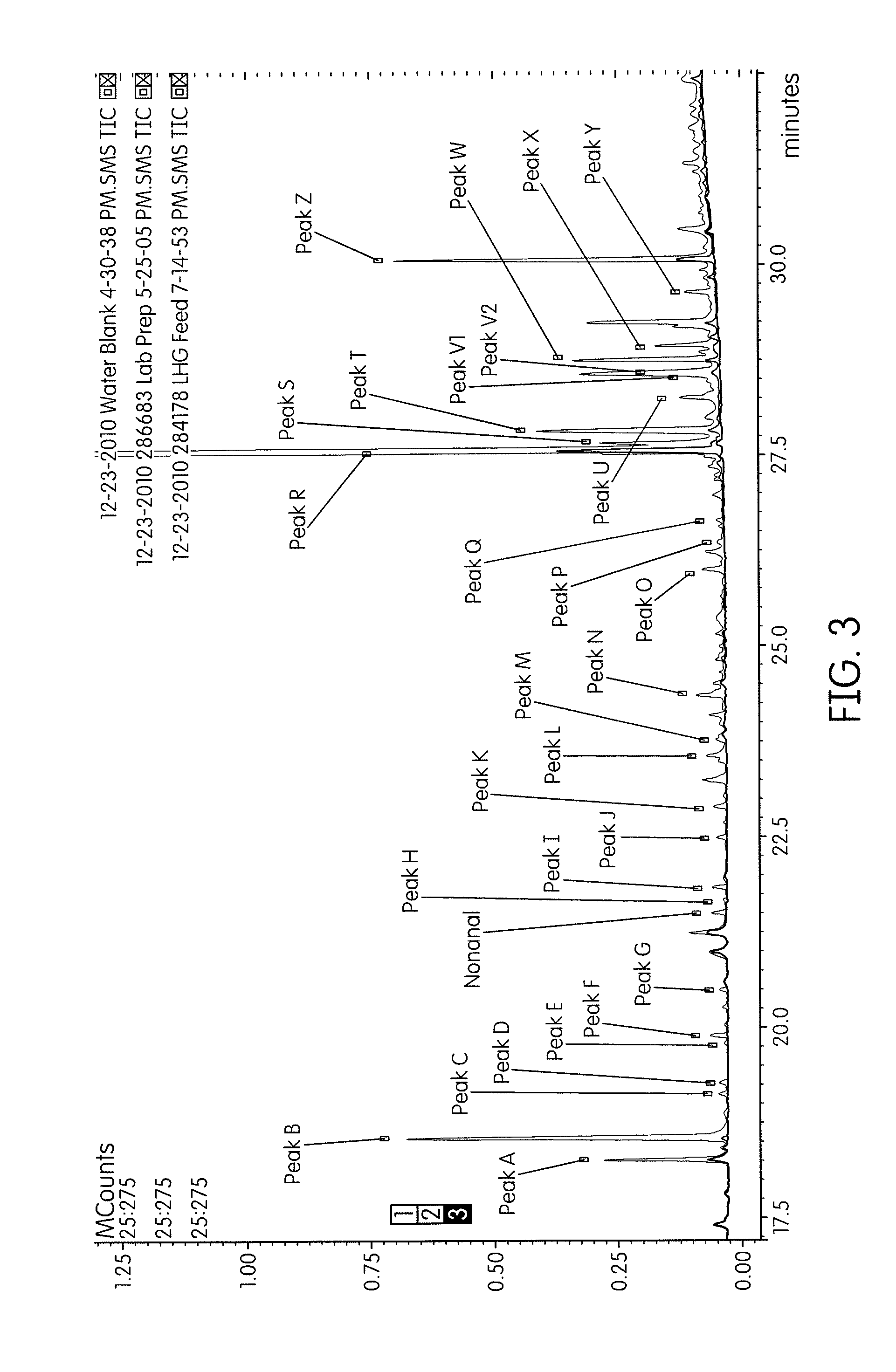

Rebaudioside-mogroside v blends

A composition includes Mogroside V and a Rebaudioside component in a weight ratio ≧1:1 and ≦6:1, wherein the Rebaudioside component consists of one or more compounds selected from the group consisting of Rebaudioside A, Rebaudioside B and Rebaudioside D. A method of purifying a Luo Han Guo extract includes contacting the Luo Han Guo extract with activated carbon and a macroporous polymeric adsorbent resin, an ion exchange resin, or both. A composition includes a Luo Han Guo extract, wherein Mogroside V constitutes from 50 wt % to 75 wt % of the Luo Han Guo extract and the composition includes from 0 to 13 wt % in total relative to the Mogroside V of aromatic glycosides, and from 0 to 15 ppm of semi-volatile organic compounds relative to the Mogroside V.

Owner:TATE & LYLE SOLUTIONS USA LLC

Highly soluble rebaudiside d

ActiveUS20130274351A1Improved RebD solubilityImproved Reb D solubilityBiocideCosmetic preparationsGlycosideRebaudioside D

The invention relates to a process for producing highly soluble compositions containing purified steviol glycosides from Stevia rebaudiana Bertoni plant extract, more particularly Rebaudioside D. Obtained highly soluble compositions are useful as non-caloric sweeteners or in combination with sugar or high intensity sweeteners in edible and chewable compositions such as beverages, confectionaries, bakery products, chewing gums and the like.

Owner:PURECIRCLE SDN BHD

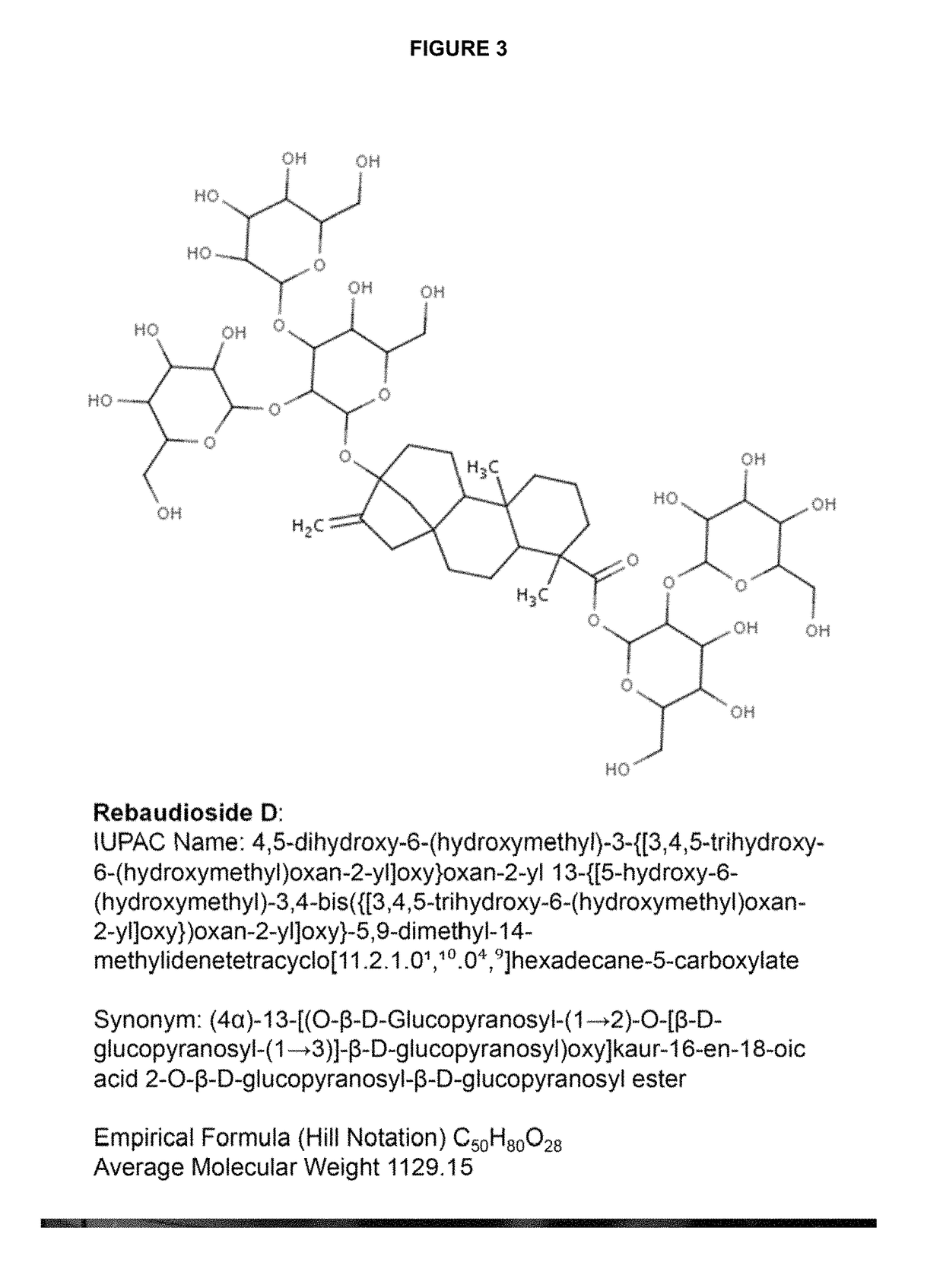

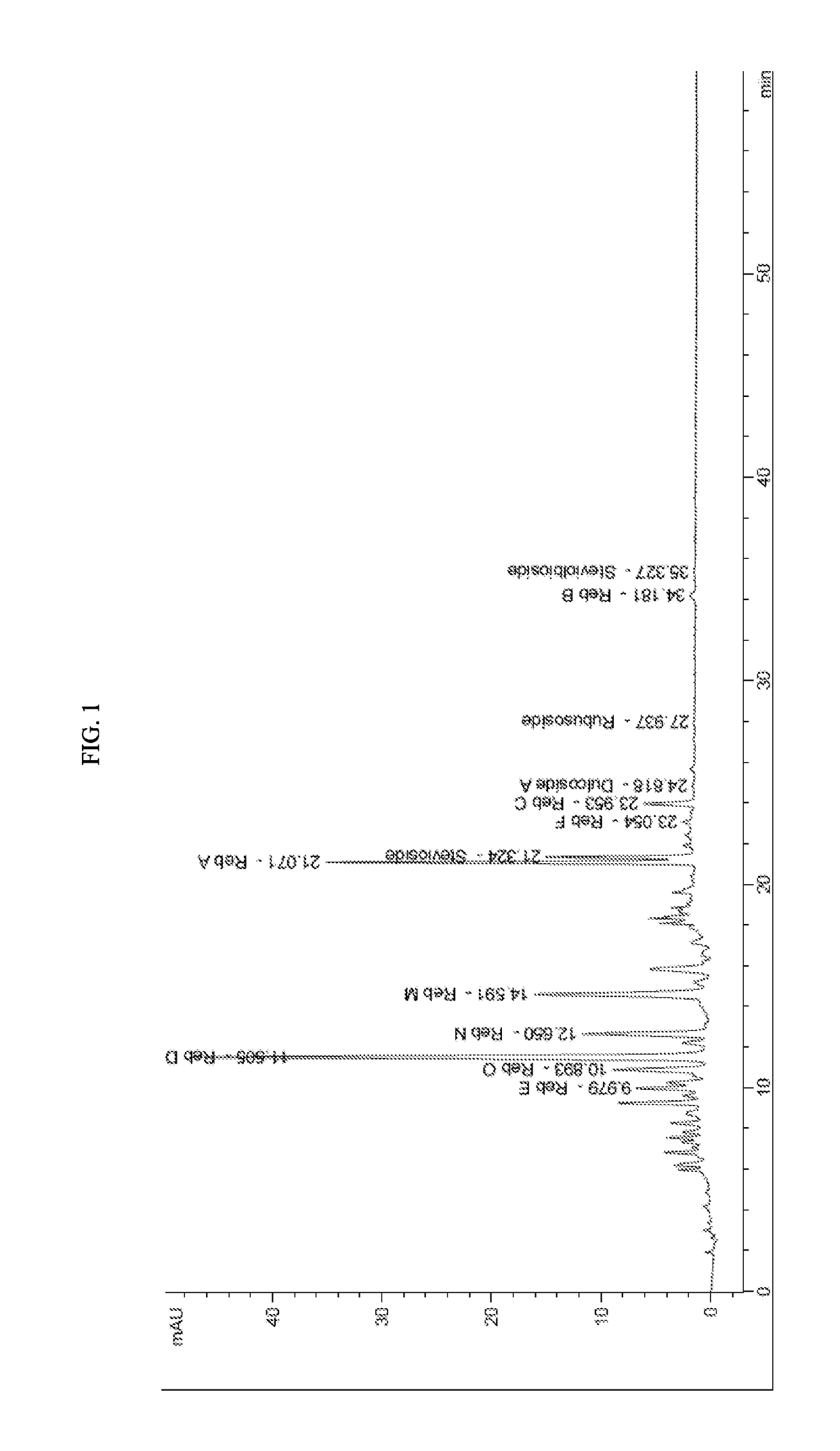

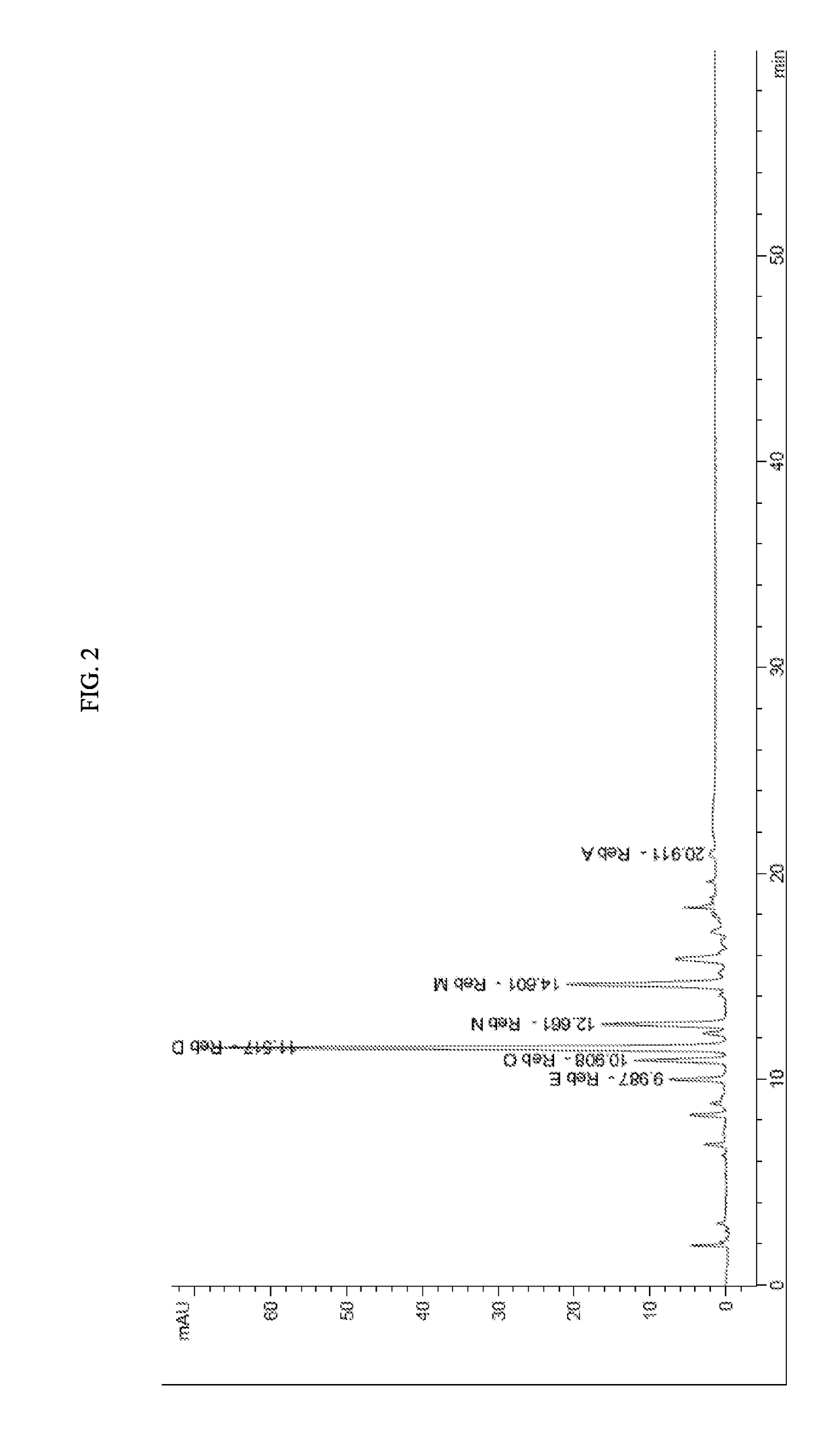

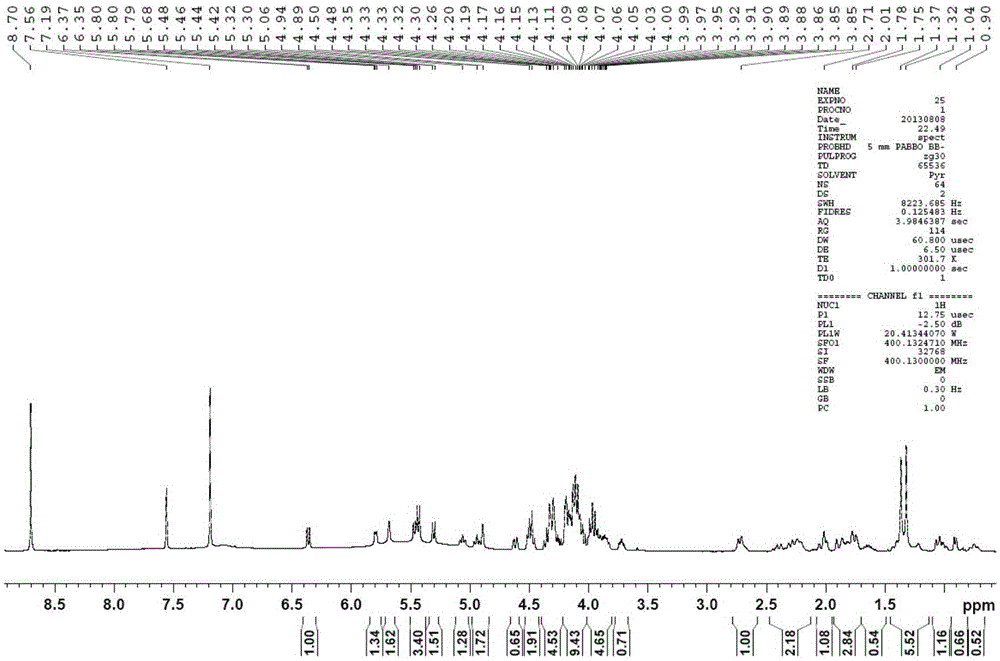

Methods of preparing steviol glycosides and uses of the same

Methods of preparing steviol glycosides, including Rebaudioside D, Rebaudioside E, Rebaudioside M, Rebaudioside N and Rebaudioside O are provided herein. Sweetener and sweetened consumables containing Rebaudioside D, Rebaudioside E, Rebaudioside M, Rebaudioside N and Rebaudioside O are also provided herein.

Owner:PURECIRCLE USA

Method for preparing rebaudioside M according to saccharomyces cerevisiae enzymatic method

InactiveCN105200098AImprove securitySave fermentation timeMicroorganismsMicroorganism based processesFood additiveUdp glucosyltransferase

The invention discloses a method for preparing rebaudioside M according to a saccharomyces cerevisiae enzymatic method. The method for preparing rebaudioside M comprises the following steps: utilizing recombinant saccharomyces cerevisiae containing UDP-glucosyltransferase or UDP-glucosyltransferase prepared from the recombinant saccharomyces cerevisiae to catalyze rebaudioside A or rebaudioside D in the presence of a glucosyl group donor, so as to generate rebaudioside M. The recombinant saccharomyces cerevisiae is obtained by introducing a strong promoter into a plasmid to obtain a vector plasmid, inserting a UDP-glucosyltransferase gene into the vector plasmid through a restriction site to obtain an expression vector under the control the strong promoter, and carrying out saccharomyces cerevisiae transformation. The method for preparing rebaudioside M has the advantages that the high-safety recombinant saccharomyces cerevisiae is utilized for catalytic production; the produced UDP-glucosyltransferase is higher in expression level and activity; the produced rebaudioside M can be directly utilized as a food additive, and is short in production period, higher in yield, and relatively low in cost.

Owner:PEPSICO INC

Method for extracting rebaudioside D from stevioside crystalline mother liquor sugar

ActiveCN103709215AHigh puritySimple processSugar derivativesSugar derivatives preparationRebaudioside DSolvent

The invention discloses a method for extracting rebaudioside D from stevioside crystalline mother liquor sugar, and belongs to the fields of bioengineering and novel sweetening agents. The method mainly comprises the following steps: dissolving primary crystal transformation mother liquid sugar after RA extraction into a mixed organic solvent of water and methanol with the ratio of 1:(7-10); keeping the stirring speed at 20-100rpm / min at 50-70 DEG C for 1-10 hours to crystallize; removing impurities in the mother liquor after washing a solid substance by solid-liquid separation; baking to obtain a high-purity rebaudioside D (RD) product. The ratio of the RD in the raw material sample can be improved to over 50% from 20-30% by primary crystallization, and the RD product with high purity can be obtained by repeating for a plurality of times on the basis, so that a foundation is established for production of the high-purity RD product. The method is simple in technology, low in energy consumption, and easy to produce, and is used for stirring and controlling temperature in production. The mother liquor can be recycled after being concentrated, and the solvent can be recycled after being distilled. Thus, good economic benefits and low environmental pollution are achieved.

Owner:天津北洋百川生物技术有限公司

High-Purity Rebaudioside D And Low-Calorie Tooth Paste Composition Containing The Same

ActiveUS20110091394A1Excellent taste profileGood mouthfeelCosmetic preparationsToilet preparationsRebaudioside DLow calorie

The invention provides methods of purifying Rebaudioside D from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A. The methods are useful for producing high purity Rebaudioside D and Rebaudioside A. The invention further provides a low-calorie tooth paste composition containing the purified Rebaudioside D and a process for making the low-calorie tooth paste composition containing the purified Rebaudioside D.

Owner:PURECIRCLE SDN BHD

High-purity steviol glycosides

Methods of preparing highly purified steviol glycosides, particularly Rebaudioside D, are described. The methods include purification from the extraction stage of the Stevia rebaudiana Bertoni plant, purification of steviol glycoside mixtures, Rebaudioside D and Rebaudioside A from a commercial Stevia extract, and purification of Rebaudioside D from remaining solutions obtained after isolation and purification of Rebaudioside A and a high purity mixture of steviol glycosides. The methods are useful for producing high purity Rebaudioside D, Rebaudioside A, and steviol glycoside mixtures. The high purity steviol glycosides are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectioneries, bakery products, cookies, and chewing gums.

Owner:PURECIRCLE USA

Preparation method for compound stevioside of RA (rebaudioside A) and RD (rebaudioside D)

ActiveCN102406113ALow costThe principle is simpleSugar derivativesSugar derivatives preparationFiltrationRebaudioside D

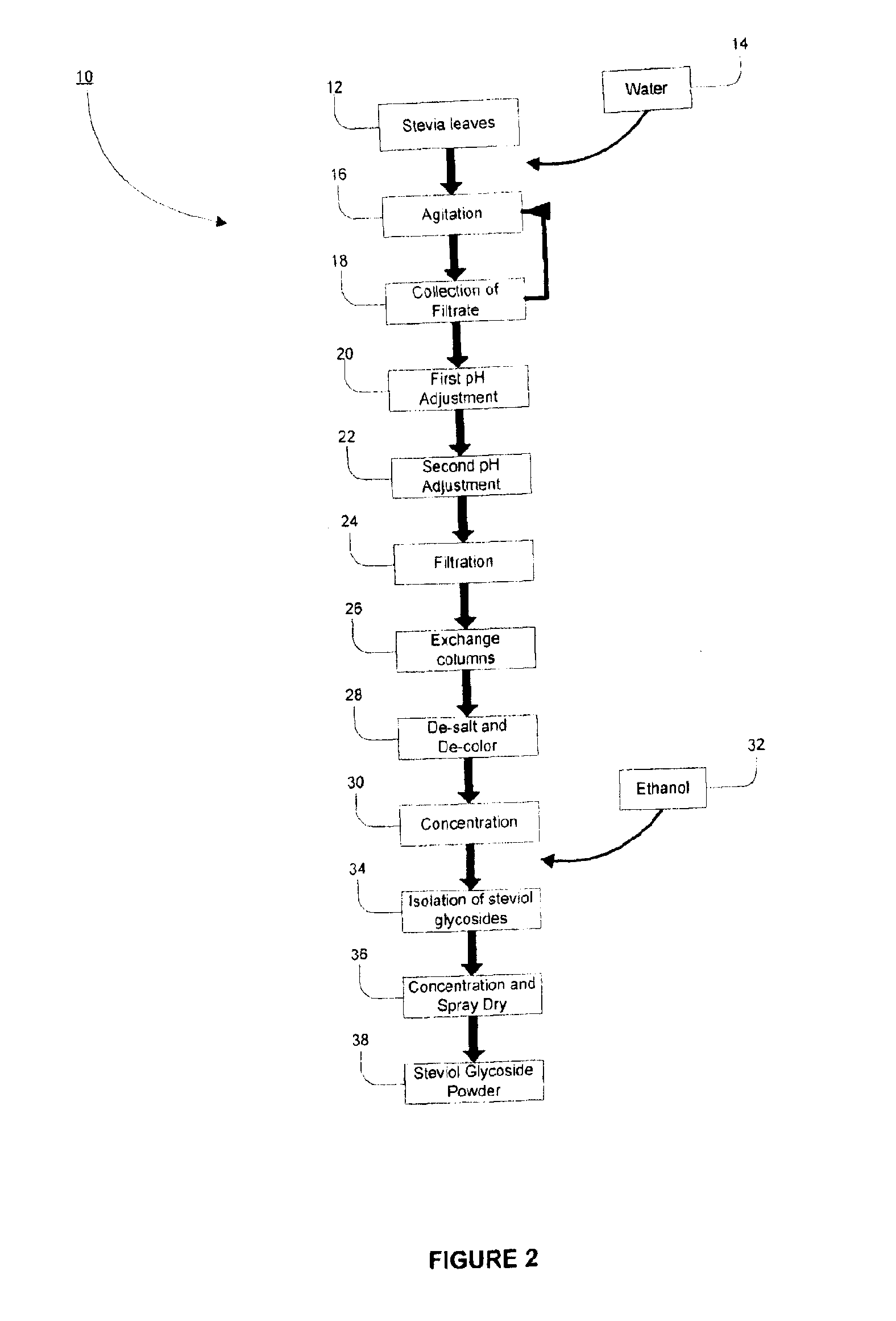

The invention discloses a preparation method for compound stevioside of RA and RD. The method is characterized by comprising the following steps in order: (1) extracting crushed stevia rebaudiana leaves with water and conducting filtration; (2) passing the filtrate through a macroporous resin column, carrying out eluting with an alcoholic solvent, passing the eluent through ion exchange resin, and taking the effluent liquid; (3) adding a decoloring agent into the effluent liquid, conducting filtering and drying, thus obtaining a stevioside crude product; (4) adding an alcoholic solvent for dissolving, performing reflux heating, and during the process, adding the same amount of water as the stevioside crude product so as to make the stevioside crude product dissolved in the system completely; then implementing standing and filtering so as to obtain a crystal; (5) carrying out dissolution with an alcoholic solvent as well as reflux heating again, and adding water for repeated crystallization; (6) conducting washing with an alcoholic solvent and drying, thus obtaining a finished product. The invention has the advantages of: low cost, easy crystallization component control; good mouthfeel of the prepared compound stevioside of RA and RD, no remaining taste, adaptation to market needs; and better product stability.

Owner:NINGBO GREEN HEALTH PHARMACEUTICAL CO LTD

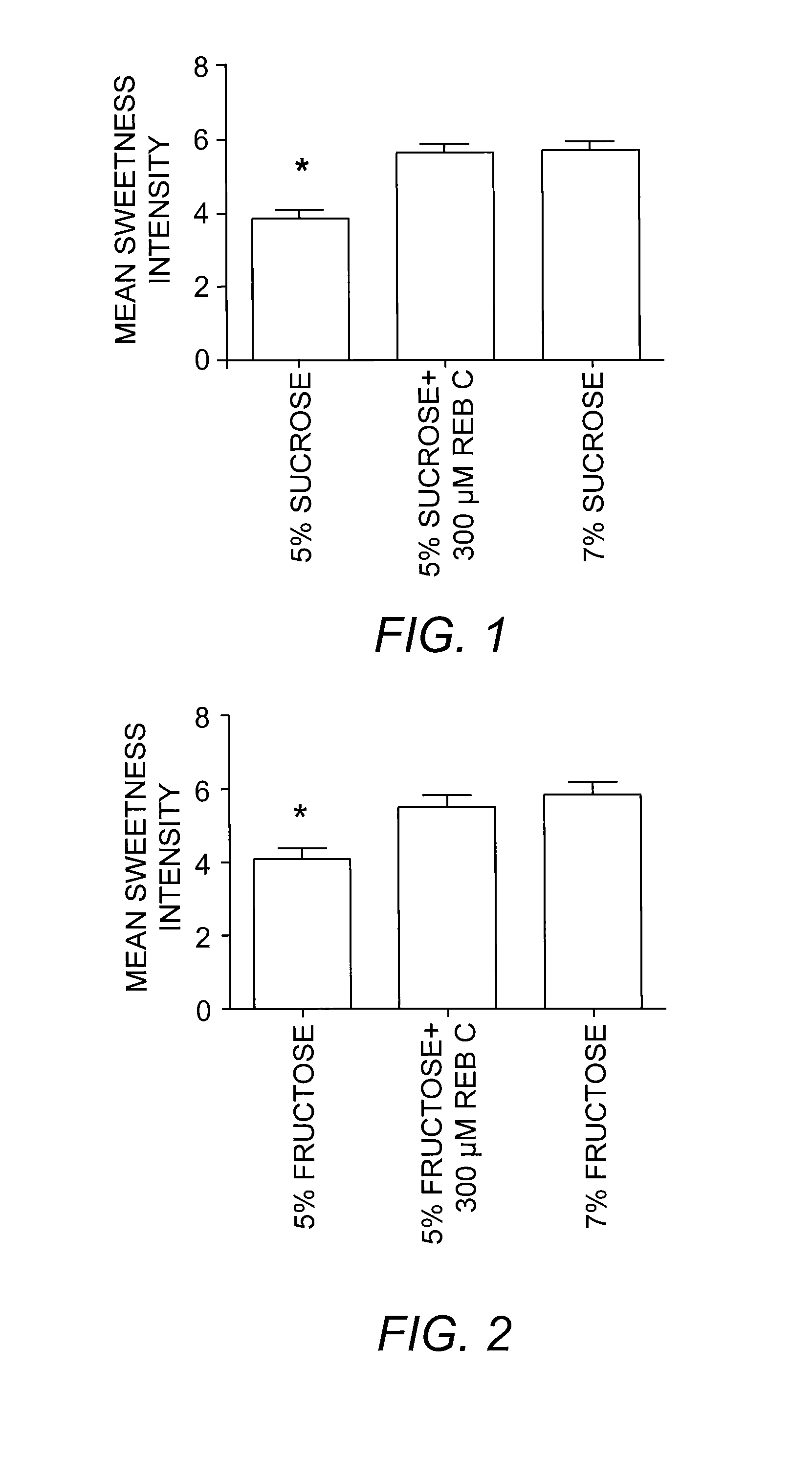

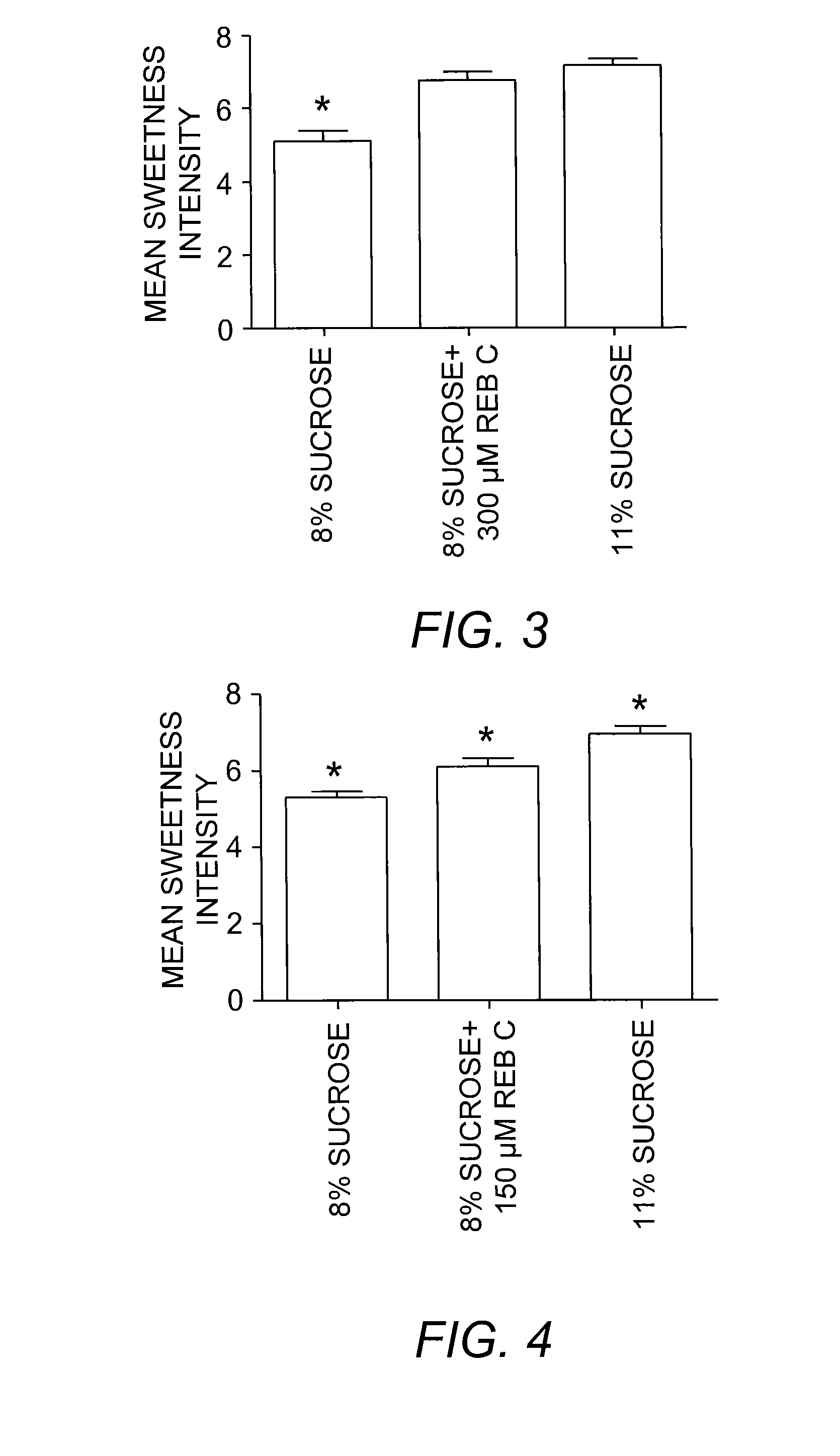

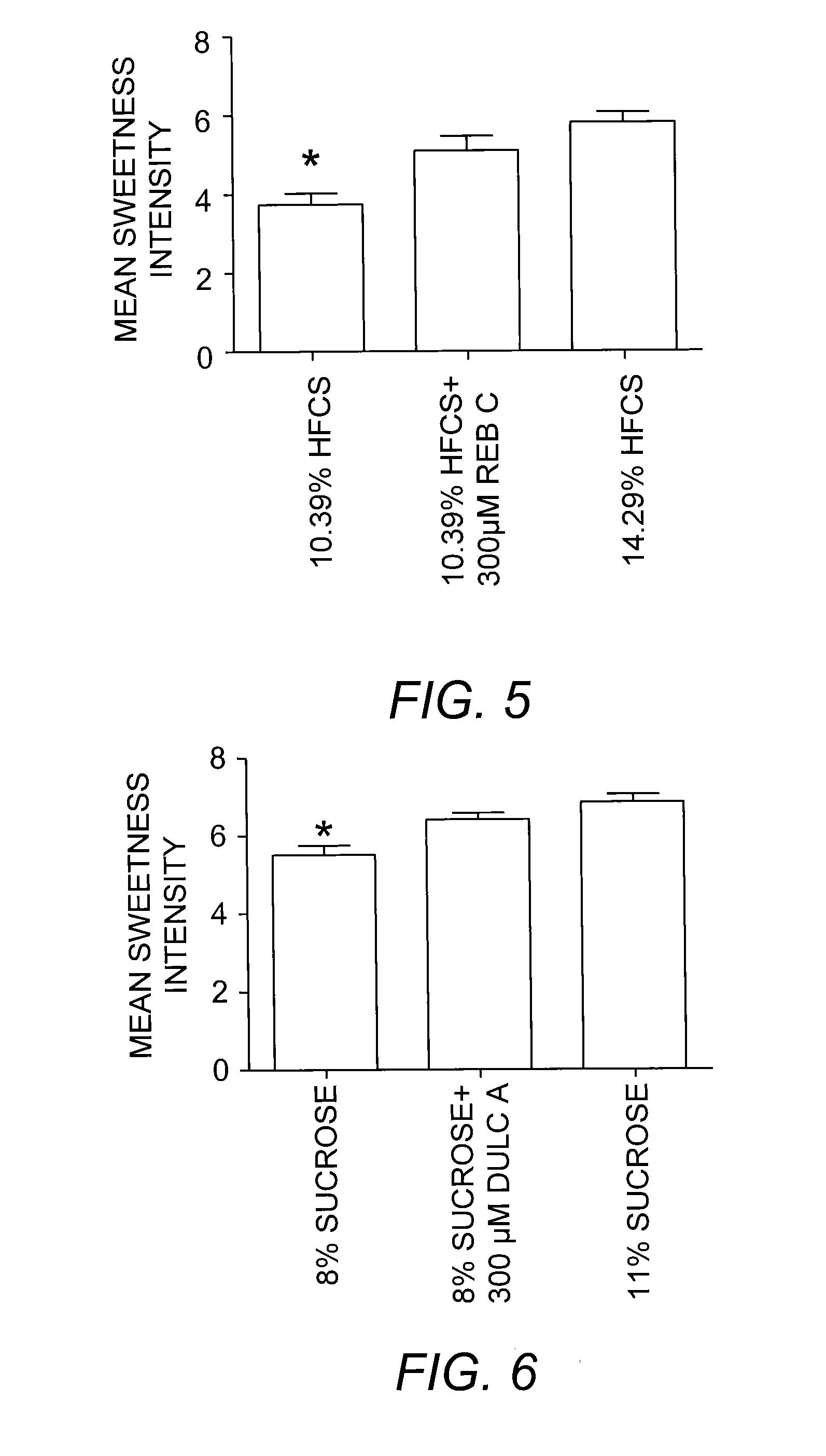

Sweetness Enhancers Including Rebaudioside A or D

The present invention is directed to the use of rebaudioside A or rebaudioside D in combination with one or more compounds of Formula (I), or a stereoisomer thereof, wherein R2 is rhamnose, and R and R1 are each independently selected from the group consisting of hydrogen, glucose, and beta-sophorose, for enhancing the sweet taste of carbohydrate sweeteners, such as sucrose and fructose. The present invention is also directed to consumables which include a combination of a carbohydrate sweetener, rebaudioside A or rebaudioside D, and one or more compounds of Formula (I), or a stereoisomer thereof.

Owner:REDPOINT BIO CORP

Non-caloric sweetener

ActiveUS20160208303A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsUdp glycosyltransferaseRebaudioside D

Disclosed is a steviol glycoside referred to as rebaudioside D2. Rebaudioside D2 has five β-D-glucosyl units connected to the aglycone steviol. Also disclosed are methods for producing rebaudioside D2, a UDP-glycosyltransferase fusion enzyme, and methods for producing rebaudioside D and rebaudioside E.

Owner:CONAGEN INC

Processes of Purifying Steviol Glycosides

InactiveUS20140004248A1Effect on adsorption capacityReduce adsorptionSugar derivativesConfectioneryAlcoholRebaudioside D

A process for producing the natural sweetener composition which comprises at least one of steviolbioside (STB) extract, Rebaudioside B extract and Rebaudioside D extract (“collectively, the “extracts”) comprises the steps of preparing a mother liquor comprising a mass content of at least 20% of at least one of the extracts; preparing feed liquid comprising at least 20 mg / mL of mother liquor; flowing feed liquid through a porous adsorption column, having a pore size of at least 40 Angstroms, a pore volume of a least 0.8 mL / g and at a flow rate of at least 1L / min and at a pH of between 4 to 5; eluting at least one steviolbioside (STB) extract, Rebaudioside B extract and Rebaudioside D extract with alcohol having a mass concentration of at least 65%; fractionally collecting one or more eluates based on chromatographic critical points for each of the steviolbioside STB extract, the Rebaudioside B extract and the Rebaudioside D extract; concentrating the extracts at a temperature of between 60-80° C.; and drying the extracts so formed.

Owner:GLG LIFE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com