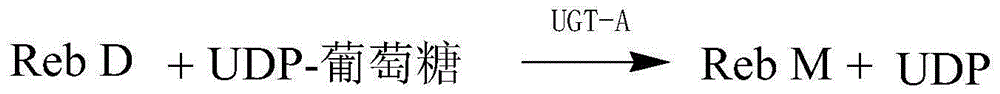

Method for preparing rebaudioside M according to saccharomyces cerevisiae enzymatic method

A technology of Saccharomyces cerevisiae and recombinant Saccharomyces cerevisiae, which is applied in the field of preparing rebaudioside M by using Saccharomyces cerevisiae enzymatic method, which can solve the safety problems of rebaudioside M, save fermentation time and steps, reduce costs, and have good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

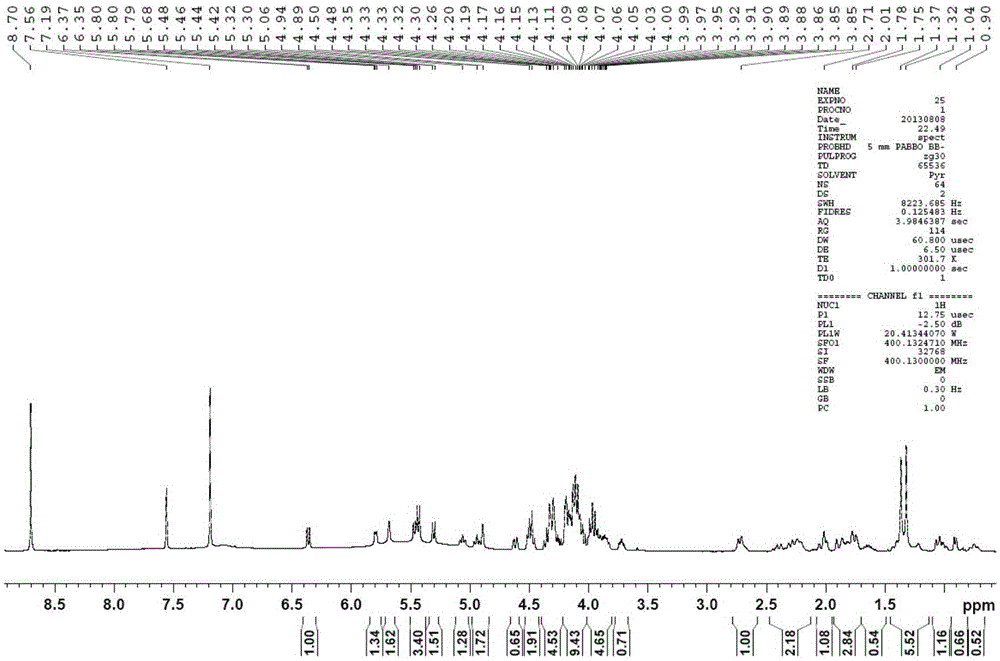

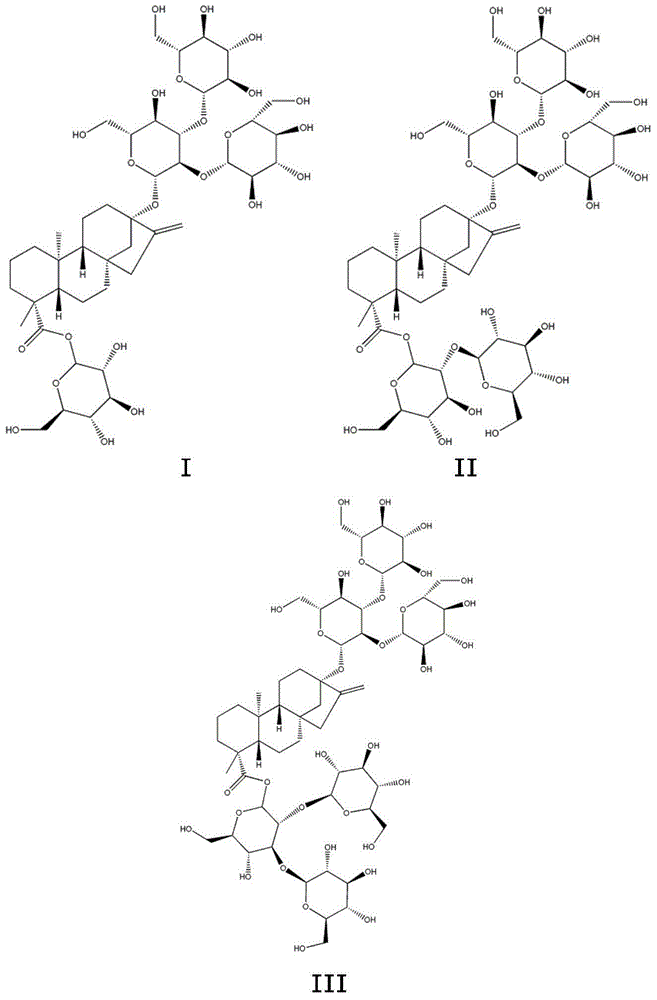

Image

Examples

Embodiment 1

[0046] Example 1 Preparation of recombinant S. cerevisiae cells containing UGT-A

[0047]According to the pYES2 plasmid sequence, primers pYES2-AgeI-F (GATGATCCACTAGTAACCGGTAGAAGCCGCCG) and pYES2-AgeI-R (CGGCGGCTTCTACCGGTTACTAGTGGATCATC) were designed, and the AgeI cutting site was introduced into the pYES2 plasmid by circular expansion PCR to obtain the plasmid pYES2-AgeI.

[0048] Using the INVSc2 genome as a template, primers ADH2-F (CACTAGTAACCGGTGCAAAACGTAGGGGC) and ADH2-R (GTCCAGCCCAAGCTTGTATTACGATATAG) were designed, the ADH2 promoter gene fragment was amplified by PCR, and the gel was cut and recovered. The obtained gene fragment was digested with AgeI / HindIII, the purified fragment was recovered, and T4 ligase was added to connect the fragment into the corresponding restriction site of pYES2-AgeI to obtain the pEZADH2 plasmid.

[0049] According to the nucleotide sequence shown in SEQIDNO.2 in the sequence listing, the UGT-A gene fragment was gene-synthesized and conn...

Embodiment 2

[0051] Embodiment 2 prepares UGT-A freeze-dried powder

[0052] The recombinant cells of UGT-A prepared in Example 1 were ultrasonically disrupted in an ice bath, the disrupted solution was centrifuged (8,000 rpm, 10 min), and the supernatant was collected and freeze-dried for 24 hours to obtain a freeze-dried powder of UGT-A.

Embodiment 3

[0053] Example 3 Preparation of recombinant Saccharomyces cerevisiae permeable cells containing UGT-A

[0054] Method 1: Weigh 1g of wet thallus of the recombinant cells of UGT-A prepared in Example 1, resuspend to 20ml75mmol imidazole-0.1mol / LKCl-10mmol / LMgCl2+1ml toluene: dehydrated alcohol (v / v)= 1:4, 25°C, shaken at 160rpm for 15min, centrifuged to collect cells (4,000rpm, 10min), concentrated 10 times and resuspended in 0.1mol / L phosphate buffer (pH7.0) to obtain UGT-A recombinant Saccharomyces cerevisiae Sex cells are used for catalysis.

[0055] Method 2: Pick a single colony from the plate and place it in SC-Ura+2% glucose medium, culture at 30°C with 200rpm shaking for 48h, inoculate EZ-A bacteria into 50ml YPD+1%glucose medium at 30°C, at a ratio of 2%. After shaking at 200rpm for 48h, add 500ul of 20% TritonX-100 (V / V), continue shaking for 2h, collect cells by centrifugation (4,000rpm, 10min), and resuspend with 5ml of 0.1mol / L phosphate buffer (pH7.0) cells, rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com