Method for extracting rebaudioside D from stevioside crystalline mother liquor sugar

A technology for crystallizing mother liquor and stevioside, applied in the field of extracting rebaudioside D, can solve problems such as separation, and achieve the effects of simple process, low energy consumption and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] Specific embodiments: The method for extracting rebaudioside D in stevioside in the present invention will be described below through specific embodiments. In addition, the embodiments should be considered as illustrative rather than limiting the scope of the invention, the spirit and scope of which is defined only by the claims. For those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various changes or modifications to the crystallization conditions in these embodiments also belong to the protection scope of the present invention.

[0025] The assay method of total steviosides in the present invention is as follows:

[0026] HPLC quantitative determination method (JECFA2010 meeting standard)

[0027] Detection steps: detect the content of each glycoside according to the following liquid chromatography conditions.

[0028] Reagent: acetonitrile, transmittance >95% at 210nm.

[0029] Standard specifications:

...

Embodiment 1

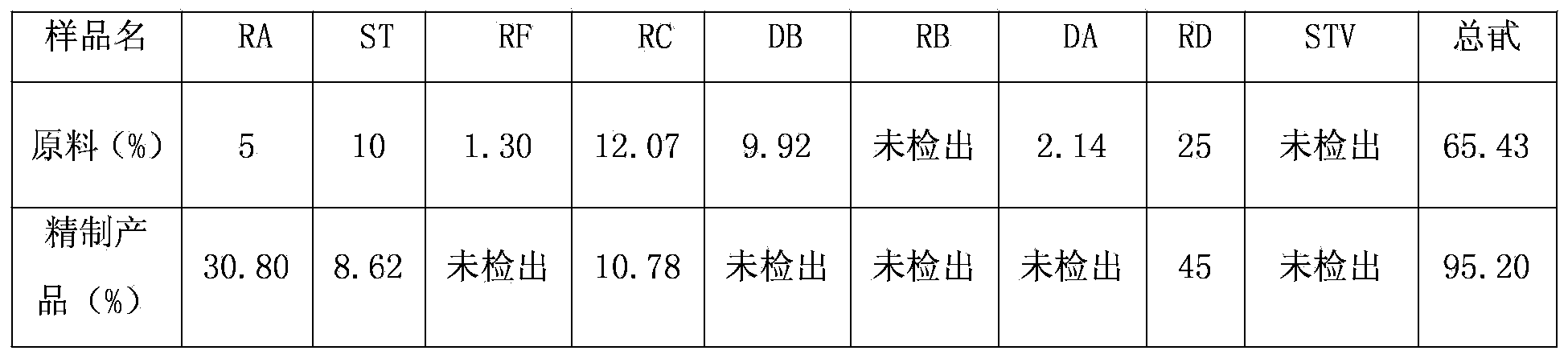

[0061] Take 100g of stevioside crystallization mother liquid sugar, add 300ml of solvent, water:methanol=1:7, the purity of methanol is 99.9%, put it in a three-necked flask after fully mixing, the temperature of the water bath is controlled at 50 degrees Celsius, the stirring speed is 20rpm / min, the time For 1 hour, the crystallization mixture was suction-filtered with a Buchner funnel, the obtained crystals were washed with a solvent, the solid-to-liquid ratio was 1:4, and dried overnight at 60°C to obtain 43 g of a dry sample. The liquid phase measurement result is:

[0062]

[0063] The RD content in the product can be raised to more than 40% by adopting the method of Example 1.

Embodiment 2

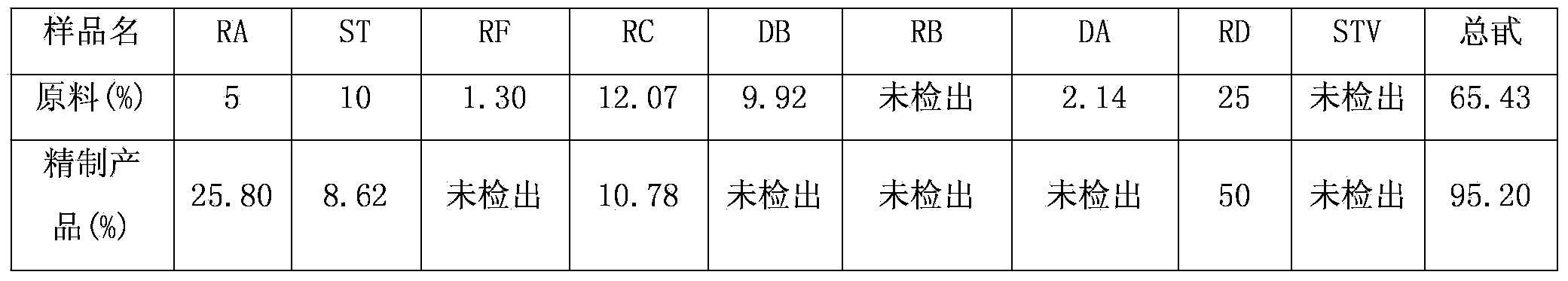

[0065] Take 200g of stevioside crystallization mother liquid sugar, add 400ml of solvent, water:methanol=1:9, the purity of methanol is 99.9%, put it in a three-necked flask after fully mixing, the temperature of the water bath is controlled at 65 degrees Celsius, and the stirring speed is 60rpm / min. After 4 hours, the crystallization mixture was suction-filtered with a Buchner funnel, and the obtained crystals were washed with a solvent at a solid-to-liquid ratio of 1:2, and dried overnight at 60°C to obtain 101 g of a dry sample. The liquid phase measurement result is:

[0066]

[0067] The RD content in the product can be raised to 50% by adopting the method of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com