Patents

Literature

43 results about "Rebaudioside C" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for extracting rebaudioside C in stevioside

The invention relates to a process for extracting rebaudioside C in stevioside, comprising the following steps: (1) taking 1-3 kg of 60-70 percent of total glucoside containing 19-25 percent of rebaudioside C and 8-10 percent of rebaudioside A, dissolving with 20-60 L purified water to prepare 5 percent of sugar liquor, desalting and decolouring by ion resin, absorbing by absorbent resins, desorbing 70 percent of alcohol water solution, desalting and decolouring by ion resins, finally adding 0.2 percent of active carbon by liquid weight, stirring, decolouring, condensing and drying into powder to obtain 0.75-2.22 kg of 85 percent of total glucoside containing 25 percent of rebaudioside C and 10-12 percent of rebaudioside A; (2) adding 6-18.6 L of mixed alcohol into a substance crystallizing tank, wherein the methanol accounts for 30 percent and the ethanol accounts for 70 percent, then placing 0.75-2.22 kg of products in the step (1), stirring and rising the temperature to 40 DEG C, preserving the temperature for 10 hours, filtering mother liquor, drying and grinding the filter cake to obtain 0.19-0.56 kg of products, placing the products in the crystallizing tank, adding 0.57-1.7 L of methanol, stirring and reflowing, and then separating crystal from mother liquor to obtain the product containing above 95-97 percent of rebaudioside C after drying. The invention has simple process and remarkable effect.

Owner:天津美伦医药集团有限公司

Methods for Using Rebaudioside C as a Flavor Enhancer

InactiveUS20120157553A1Increase sweetnessDecreasing the amount of a flavoring in a consumableMilk preparationBiocideThaumatinKiwi fruit

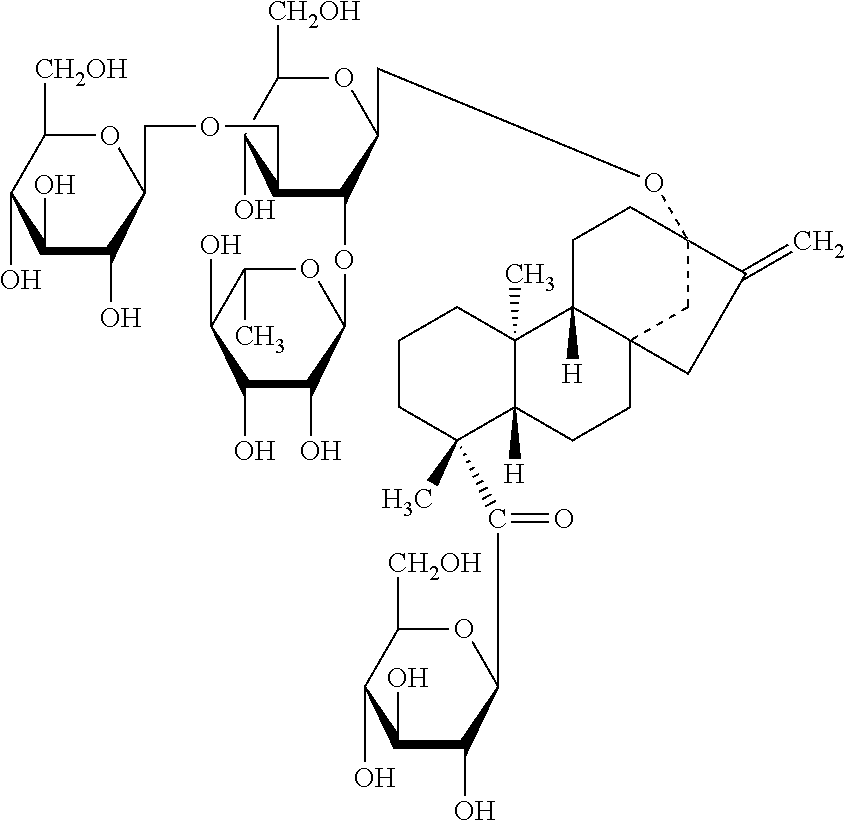

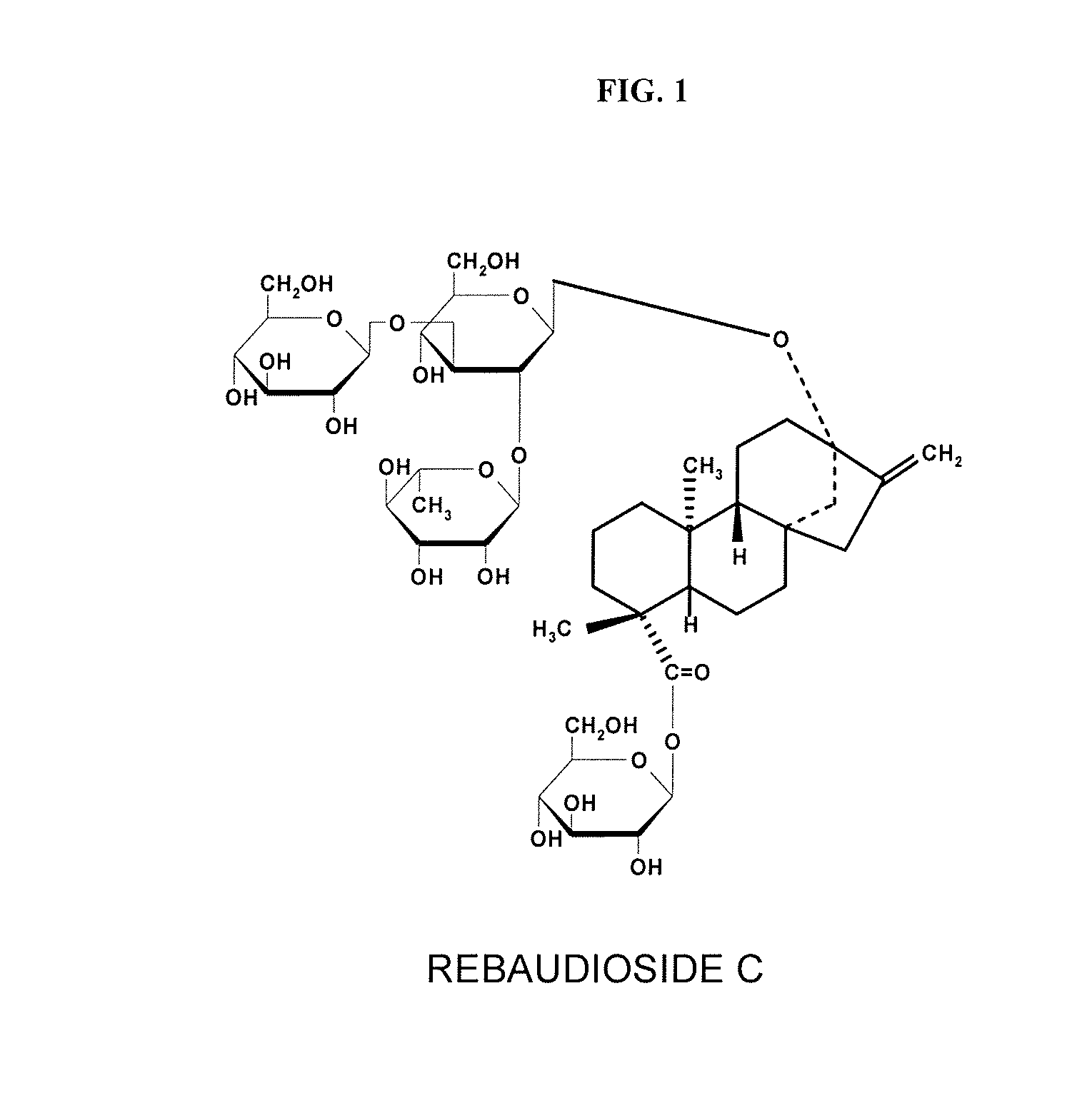

The present invention is directed to the use of one or more rebaudioside C polymorphs, or stereoisomers thereof, to enhance the sweet taste of a flavoring, such as glucosylated steviol glycoside, rebaudioside A, ammoniated glycyrrhizin, neohespherdin dihydrochalcone or thaumatin.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

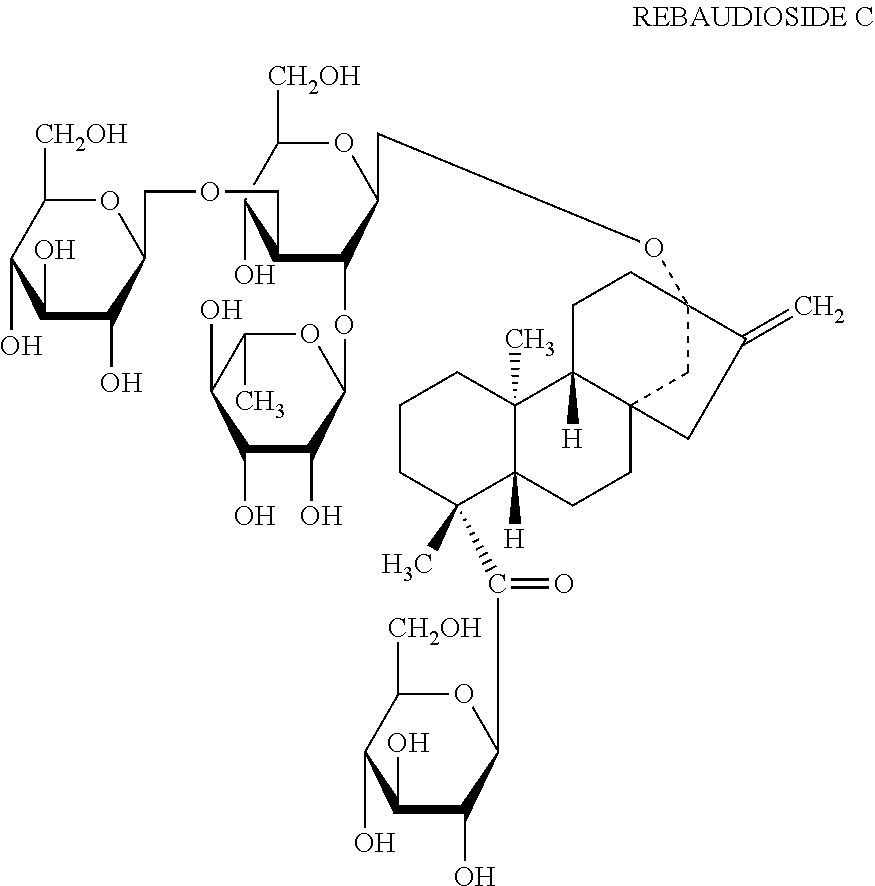

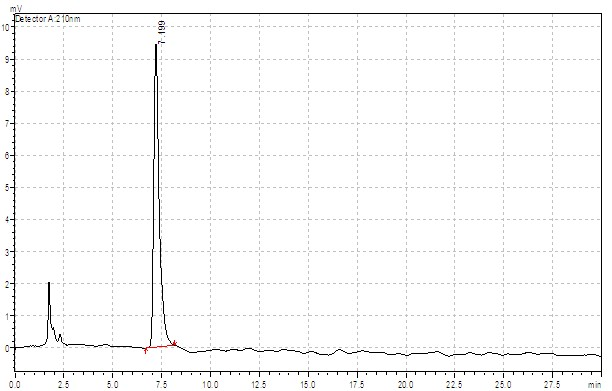

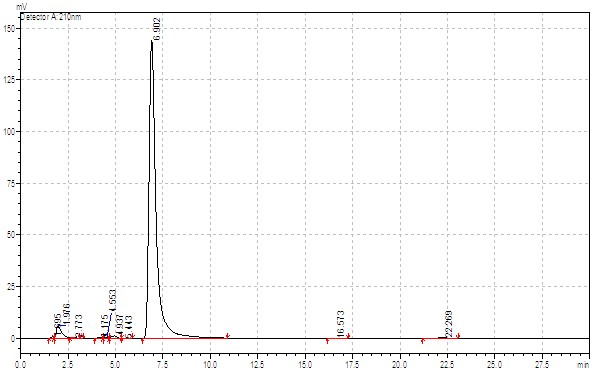

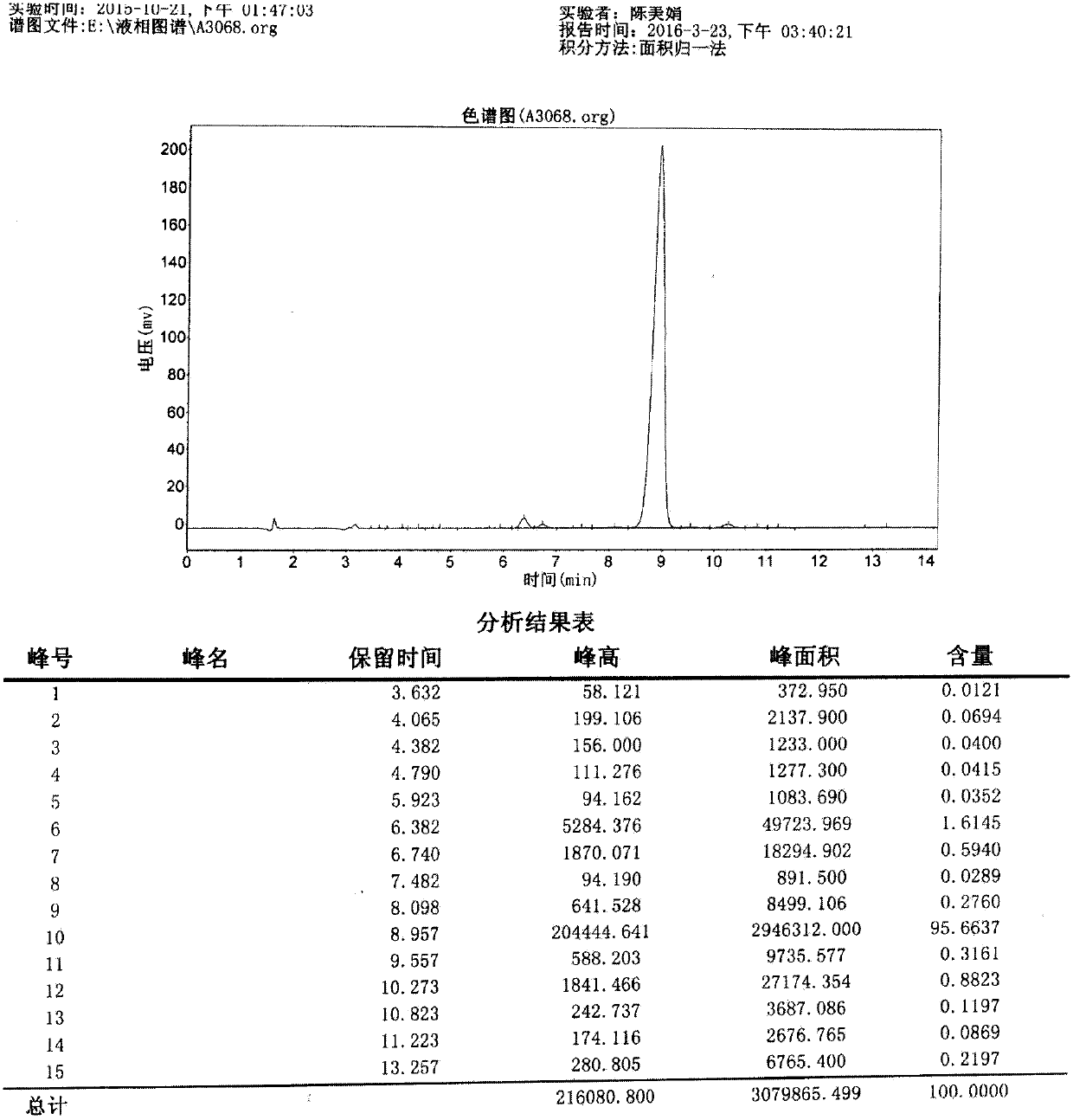

High-Purity Rebaudioside C And Process For Purification Of The Same

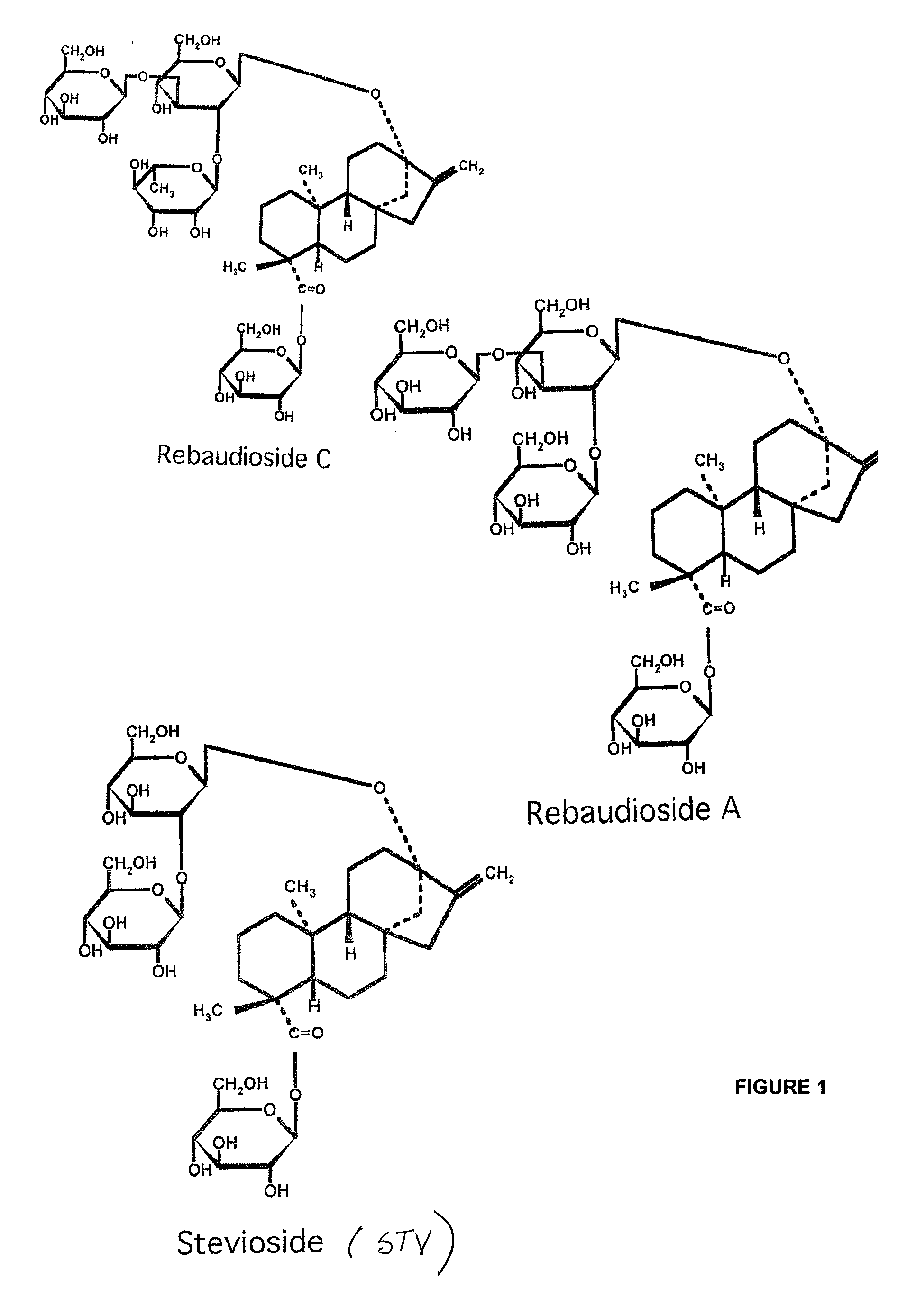

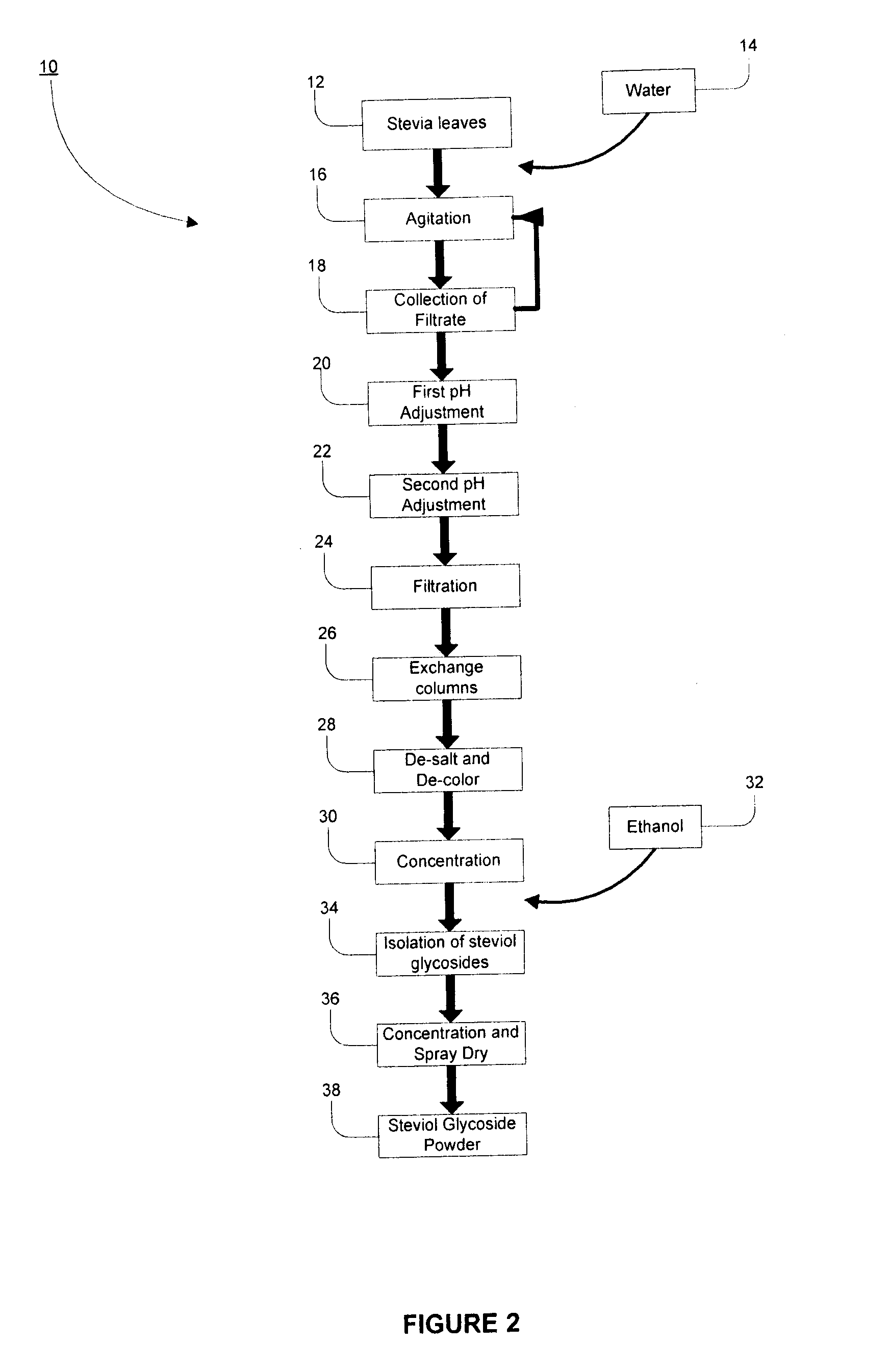

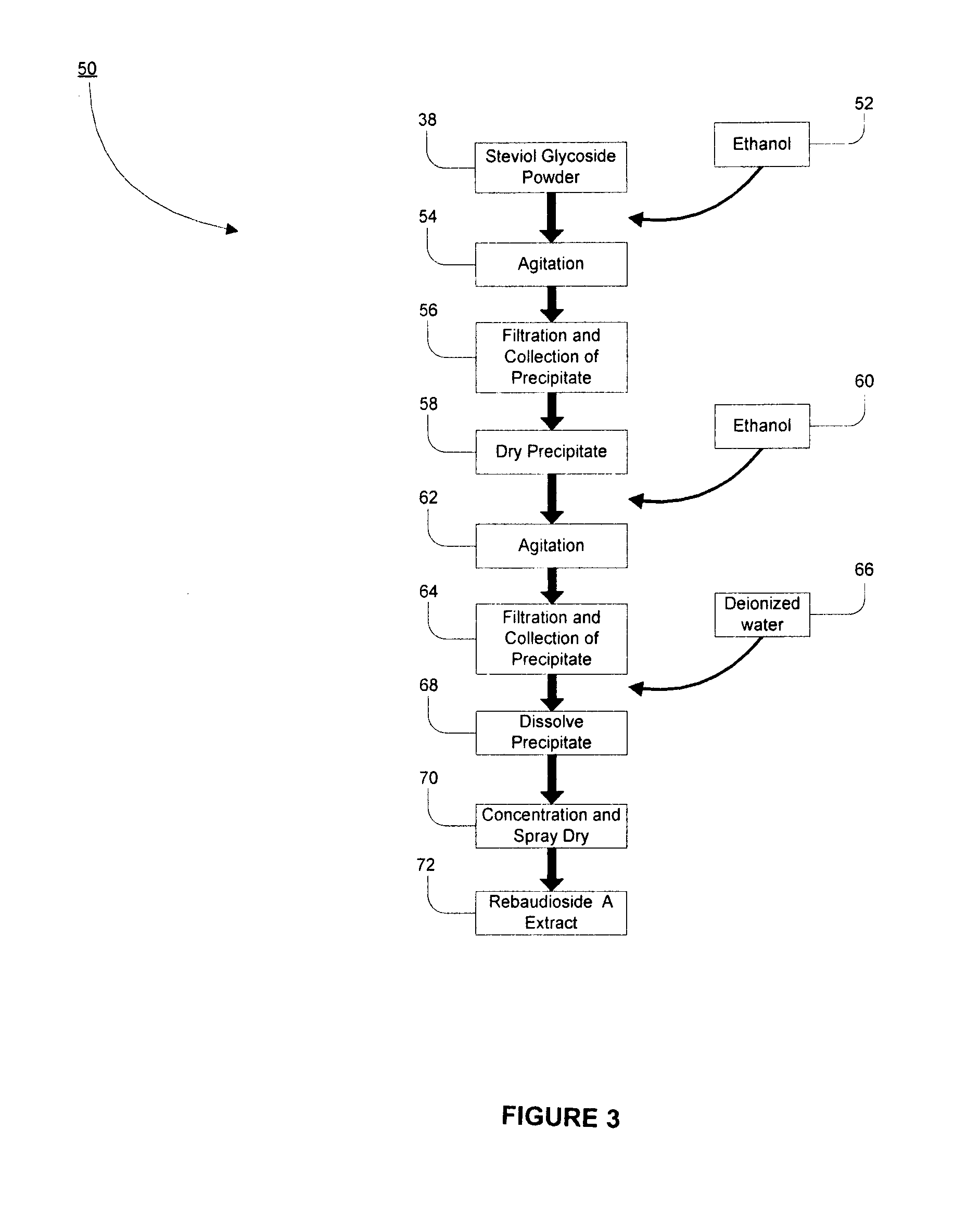

The invention provides a process of purifying Rebaudioside C from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A and Stevioside. The process is useful for producing high purity Rebaudioside C, Stevioside and Rebaudioside A. High purity rebaudioside C is useful as in combination with other caloric and non-caloric sweeteners as well as non caloric sweetener in various food and beverage compositions. The high purity Rebaudioside A and Stevioside are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectioneries, bakeries, cookies, chewing gums, and alike.

Owner:PURECIRCLE SDN BHD

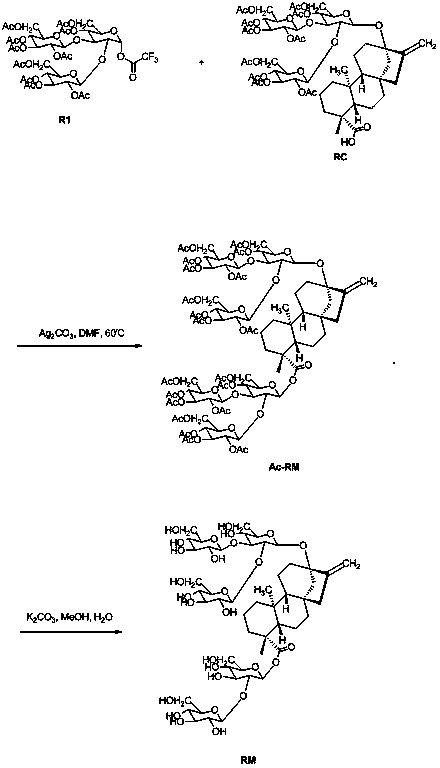

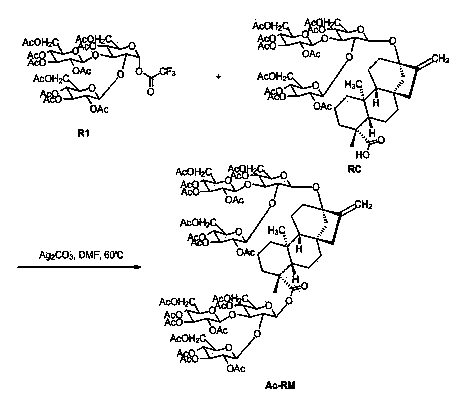

Process for preparing rebaudioside M

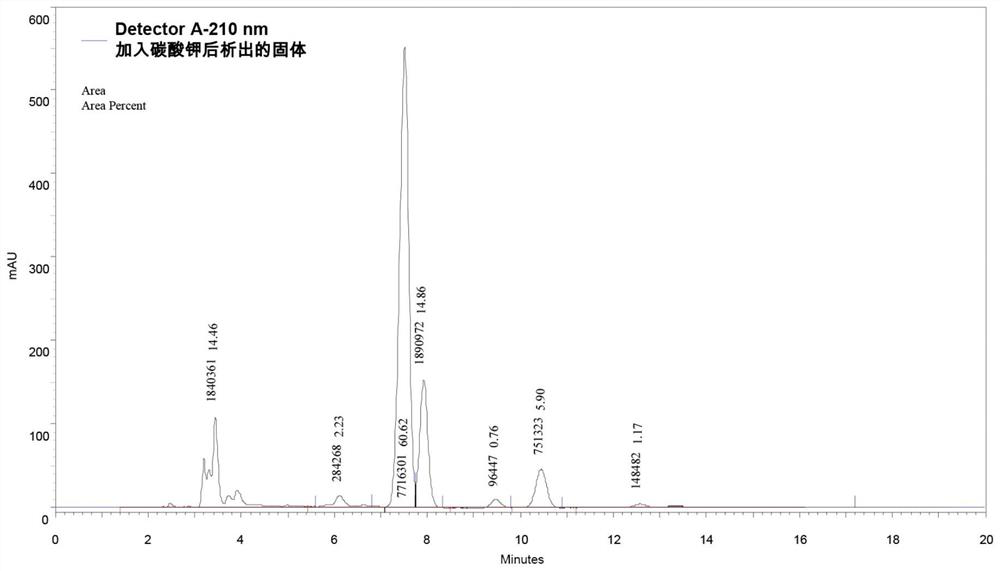

InactiveCN104163839ALow costMild reaction conditionsSugar derivativesSugar derivatives preparationChemical compoundHazardous substance

A process for preparing rebaudioside M is disclosed. The process includes: a step of subjecting rebaudioside C (RC) that is adopted as a substrate and a chemical compound R1 to a substitution reaction under the action of silver carbonate to obtain an intermediate Ac-RM; and a step of performing hydrolysis to obtain the product rebaudioside M (RM). By the manner, the process has characteristics of low raw material cost, mild reaction conditions, convenient purification, simple operation, good product quality, high yield, no generation of toxic harmful compounds in the whole process, and good environment protection effects, and is suitable for industrial production.

Owner:苏州景泓生物技术有限公司

Method for preparing rebaudioside C

ActiveCN102030788AHigh puritySimple methodSugar derivativesSugar derivatives preparationFood additiveSilica gel

The invention relates to a method for preparing high-purity stevioside rebaudioside RC, and belongs to the technical field of food additives. In the method, stevioside is used as a raw material, rebaudioside RC content in the raw material is about between 3 and 15 percent, and recrystallization technology and column chromatography technology are combined. The method comprises the following steps of: performing recrystallization by dissolving the stevioside which serves as the raw material in methanol; stirring and crystallizing at the temperature of 4 DEG C for 24 to 48 hours; recovering a solvent from crystallization mother liquor under reduced pressure to obtain a concentrate; performing silica gel column chromatography on the concentrate under the conditions that a stationary phase is silica gel with particle size of between 200 and 300 meshes, the weight of the silica gel mixed with a sample is 2.5 times that of the concentrate and the mass of pure silica gel is 20 to 50 times that of the concentrate; performing elution by using a mixed solvent system of trichloromethane and ethanol in the ratio of 2 to 1 or dichloromethane and ethanol in the ratio of 2 to 1, wherein water content in the ethanol is 2 to 10 percent; and collecting rebaudioside RC-containing main section eluent, mixing, concentrating, drying, detecting and packaging. By the method, a rebaudioside C product with purity of more than 95 percent can be obtained; and the method has a simple process and is suitable for large-scale industrial production.

Owner:SHENYANG TIANFENG BIOLOGICAL PHARMA

High-purity Rebaudioside C and process for purification of the same

The invention provides a process of purifying Rebaudioside C from the Stevia rebaudiana Bertoni plant extract along with Rebaudioside A and Stevioside. The process is useful for producing high purity Rebaudioside C, Stevioside and Rebaudioside A. High purity rebaudioside C is useful as in combination with other caloric and non-caloric sweeteners as well as non caloric sweetener in various food and beverage compositions. The high purity Rebaudioside A and Stevioside are useful as non-caloric sweeteners in edible and chewable compositions such as any beverages, confectioneries, bakeries, cookies, chewing gums, and alike.

Owner:PURECIRCLE SDN BHD

Glucosyl rebaudioside c

The invention provides a process of preparing glucosyl Rebaudioside C composition. The glucosyl rebaudioside C composition is useful as in combination with other caloric and non-caloric sweeteners as well as non caloric sweetener in edible and chewable consumables such as various foods and beverages, confectionaries, bakery products, cookies, chewing gums, and the like.

Owner:PURECIRCLE USA

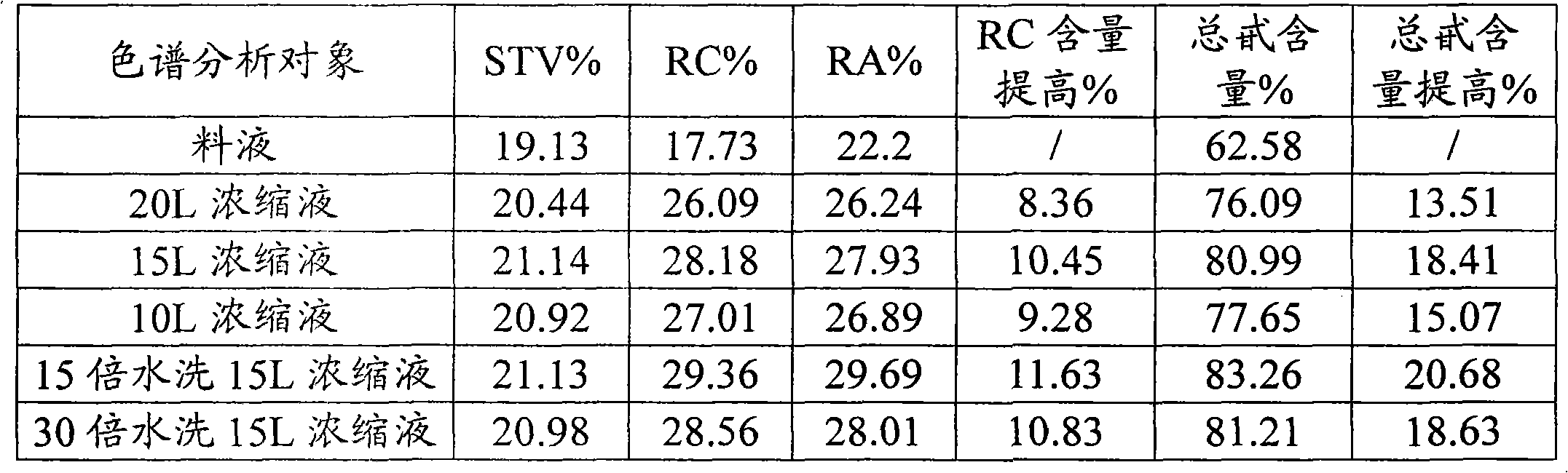

Purification method of stevioside RC (rebaudioside C)

InactiveCN102127130AMeet different needsSugar derivativesSugar productsPurification methodsUltrafiltration

The invention discloses a purification method of stevioside RC (rebaudioside C), comprising the following steps of: preparing feed liquid with the mass concentration of 0.5-1% from mother liquid sugar, enabling the feed liquid to flow through an ultrafiltration membrane device at the flow rate of 25-35L / m<2>h, and controlling the pH at 6.5-7.5, wherein the ultrafiltration membrane is preferred to be polyvinylidene fluoride (PVDF) spiral membrane of which the pore diameter is 0.01-0.2mu m, the surface layer thickness is 0.05mu m, the bottom layer thickness is 300mu m, and the cutting molecular weight is 5500-6500DA; concentrating the concentrated solution at the temperature of 55-65 DEG C; and respectively drying the obtained solid and liquid to obtain crude stevioside. The purity of the stevioside prepared by the method is higher, the total glycoside content can be improved by 13-20%, the RC content can achieve above 30%, and the RC content in the stevioside can also achieve above 85% by a refining step.

Owner:安徽润海生物科技股份有限公司

Sweetener Compositions and Methods of Making Same

InactiveUS20130344217A1Low production costParticular rounded and refreshing tasteSugar derivativesConfectioneryFunctional foodSteviol glycoside

Natural steviol glycosides sweetener compositions comprise a blend of Rebaudioside C extract and at least one of Rebaudioside A extract and STV extract including methods for producing the same and uses thereof in foods, beverages, functional foods and nutraceuticals.

Owner:GLG LIFE TECH CORP

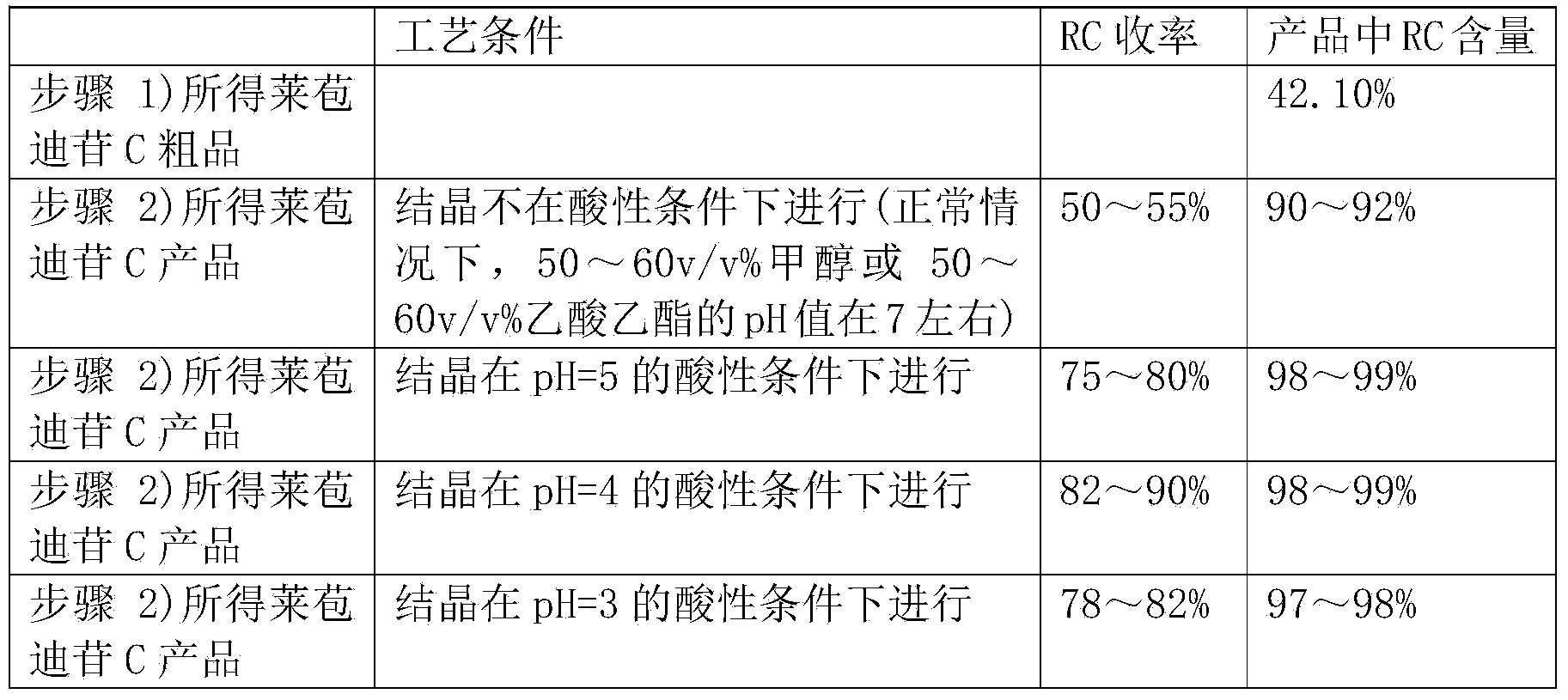

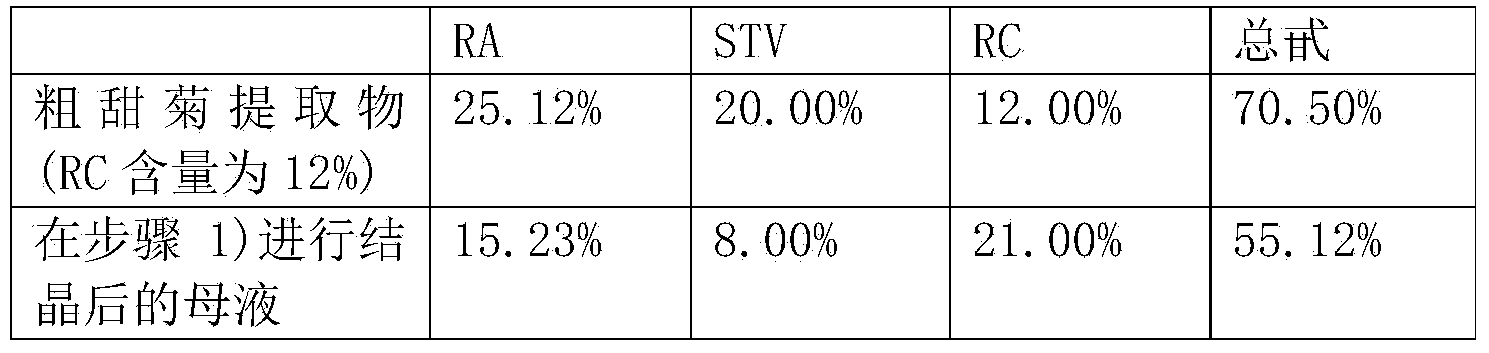

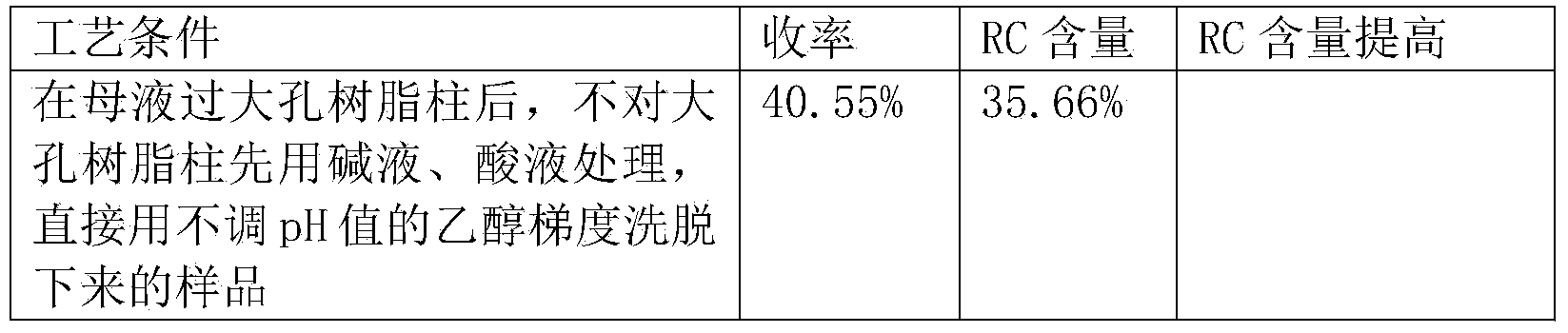

Technology for purifying rebaudioside C

ActiveCN103804440AEasy to separateWon't breakSugar derivativesSugar derivatives preparationSolventMacroporous resin

The invention discloses a technology for purifying rebaudioside C. The technology comprises the following steps: 1) crystallizing a coarse stevia extract with a solvent A, loading a mother liquor on a macroporous resin column, washing the column by using an alkali liquor and an acid liquor firstly, and then washing the column by using water until an effluent is neutral, eluting by using 10-30v / v% ethanol of which the pH is 3-5; finally, eluting by using 60-85v / v% ethanol of which the pH is 7-8, collecting 60-85v / v% ethanol eluant, concentrating and drying to obtain a crude product of the rebaudioside C; 2) dissolving the crude product of the rebaudioside C with a solvent B, and adjusting the pH to 3-5 by using an acid, devitrifying under the condition of 2-10 DEG C, collecting crystals, washing to neutral and drying, so as obtain the rebaudioside C. By adopting the technology disclosed by the invention, the product of which the RC content is higher than 97% can be obtained just by primary crystallization, the RC overall recovery rate can be higher than 75%, and the technology is simple and easy to operate, and beneficial to industrial production.

Owner:GUILIN NATURAL INGREDIENTS CORP

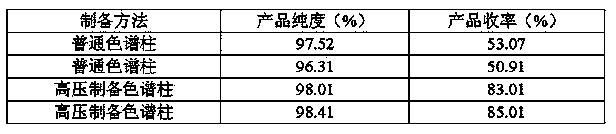

Method for preparing rebaudioside C from stevia sugar

InactiveCN103965271AImprove efficiencyEfficient methodSugar derivativesSugar derivatives preparationFood technologySilica gel

The invention belongs to the technical field of medicine food, and relates to a preparation method for separating rebaudioside C from stevia sugar, specifically to a method for preparing rebaudioside C by applying an axial direction high pressure preparation chromatography technology. The method specifically comprises: taking stevia sugar, adding methanol to dissolve, adding silica gel and stirring, drying, loading the silica gel mixed with a sample and a blank silica gel into a chromatographic column to carry out chromatography, loading the silica gel mixed with the sample in a high pressure chromatographic column, axially compressing the chromatographic column bed, rinsing the column to balance the column bed, adding a trichloromethane or dichloromethane and water-containing alcohol mixed solvent to elute after completing the balance, collecting the elution solution, adopting thin-layer monitoring, mixing the rebaudioside C main section, and carrying out reduced pressure concentration, drying and detection to obtain the high purity rebaudioside. Compared with the open type chromatographic column, the method of the present invention is efficient, fast, simple and easy-performing and is suitable for industrial production, wherein the prepared product has high purity.

Owner:SHENYANG TIANFENG BIOLOGICAL PHARMA

Methods for using rebaudioside C as a flavor enhancer

InactiveUS8524785B2Increase sweetnessDecreasing the amount of a flavoring in a consumableMilk preparationBiocideThaumatinKiwi fruit

The present invention is directed to the use of one or more rebaudioside C polymorphs, or stereoisomers thereof, to enhance the sweet taste of a flavoring, such as glucosylated steviol glycoside, rebaudioside A, ammoniated glycyrrhizin, neohespherdin dihydrochalcone or thaumatin.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Method for purifying rebaudioside c

The present invention is a method for purifying Rebaudioside C by subjecting 'waste material', generated during the Rebaudioside A manufacturing process, to liquid-liquid extraction and recrystallizing the Rebaudioside C.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

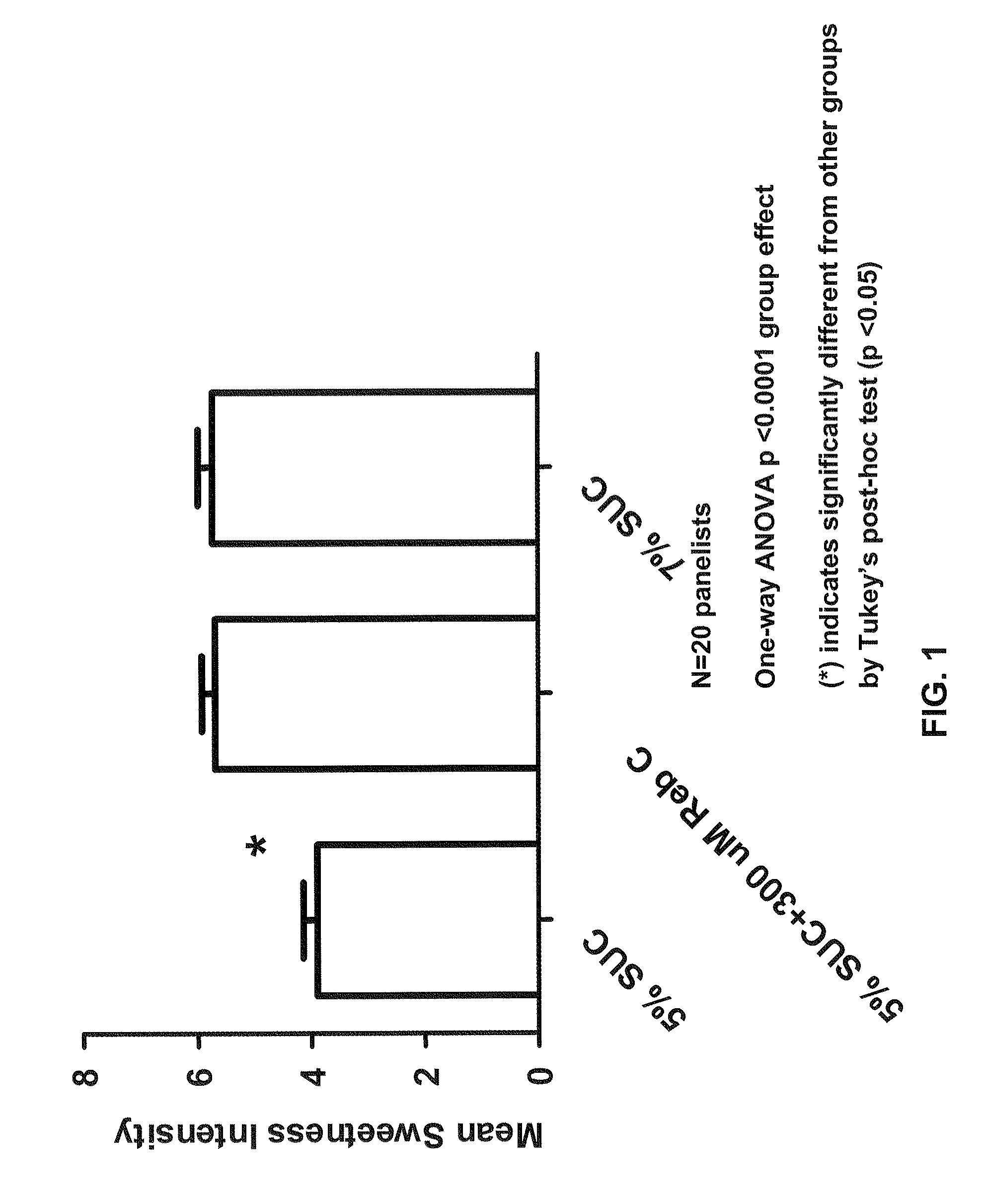

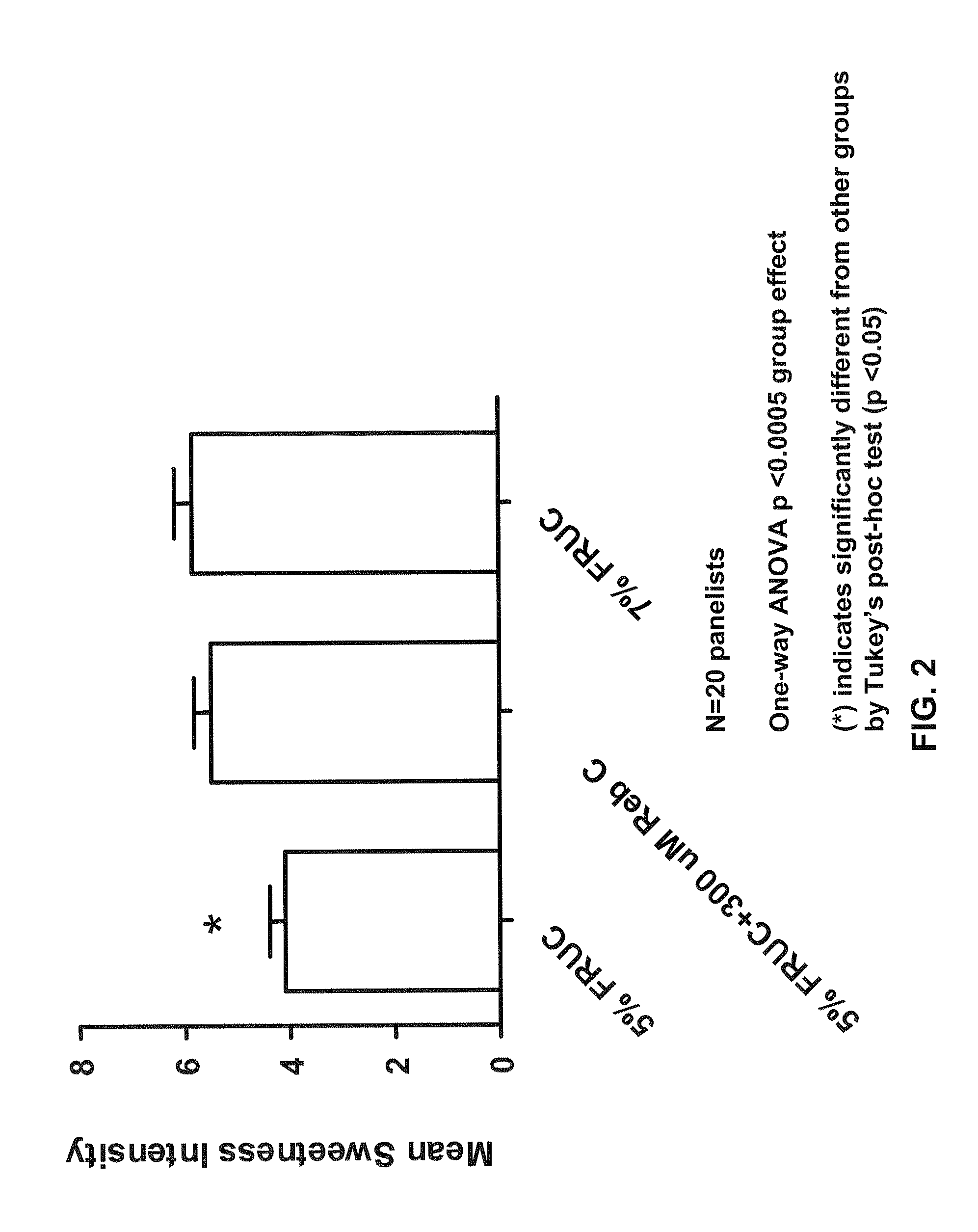

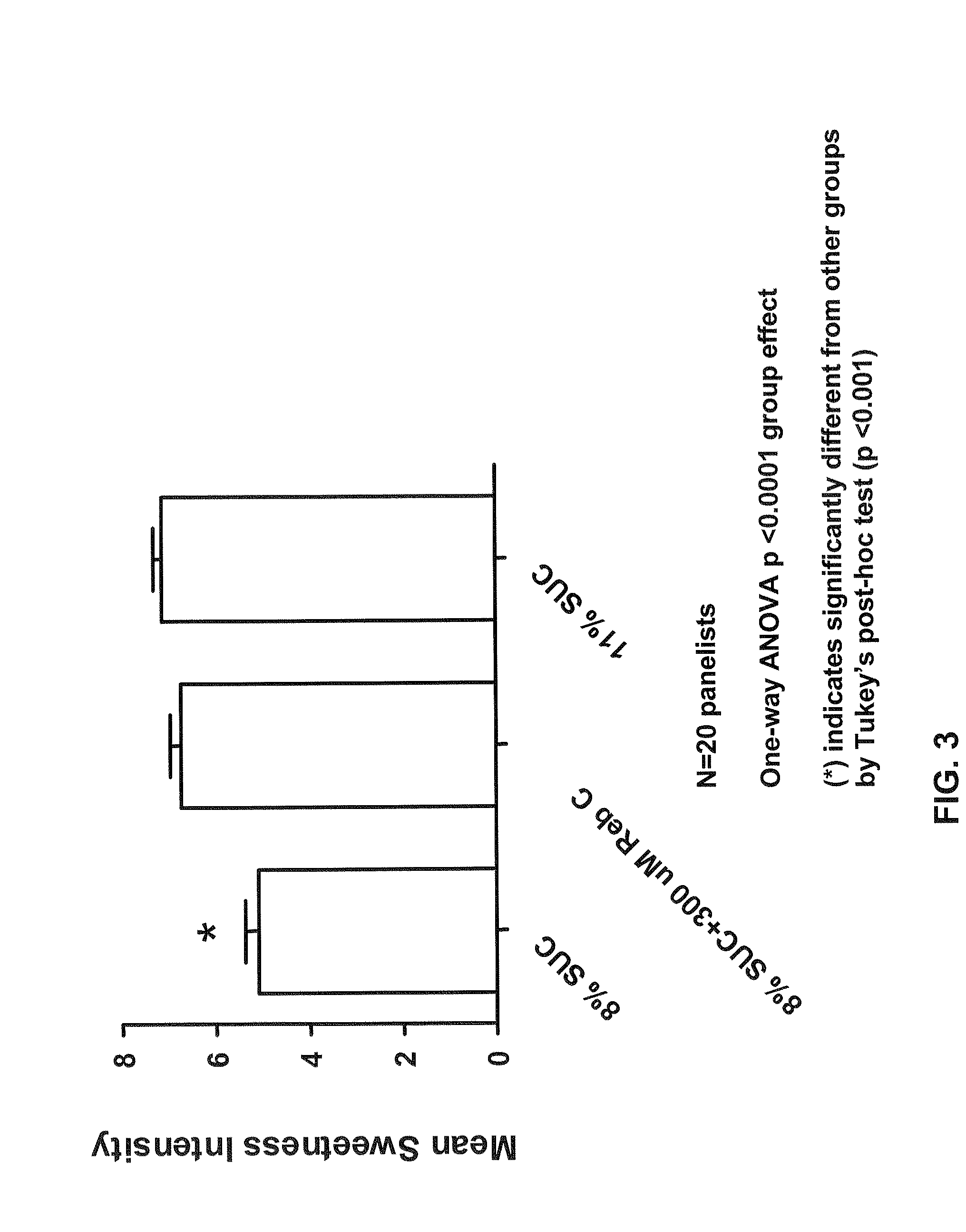

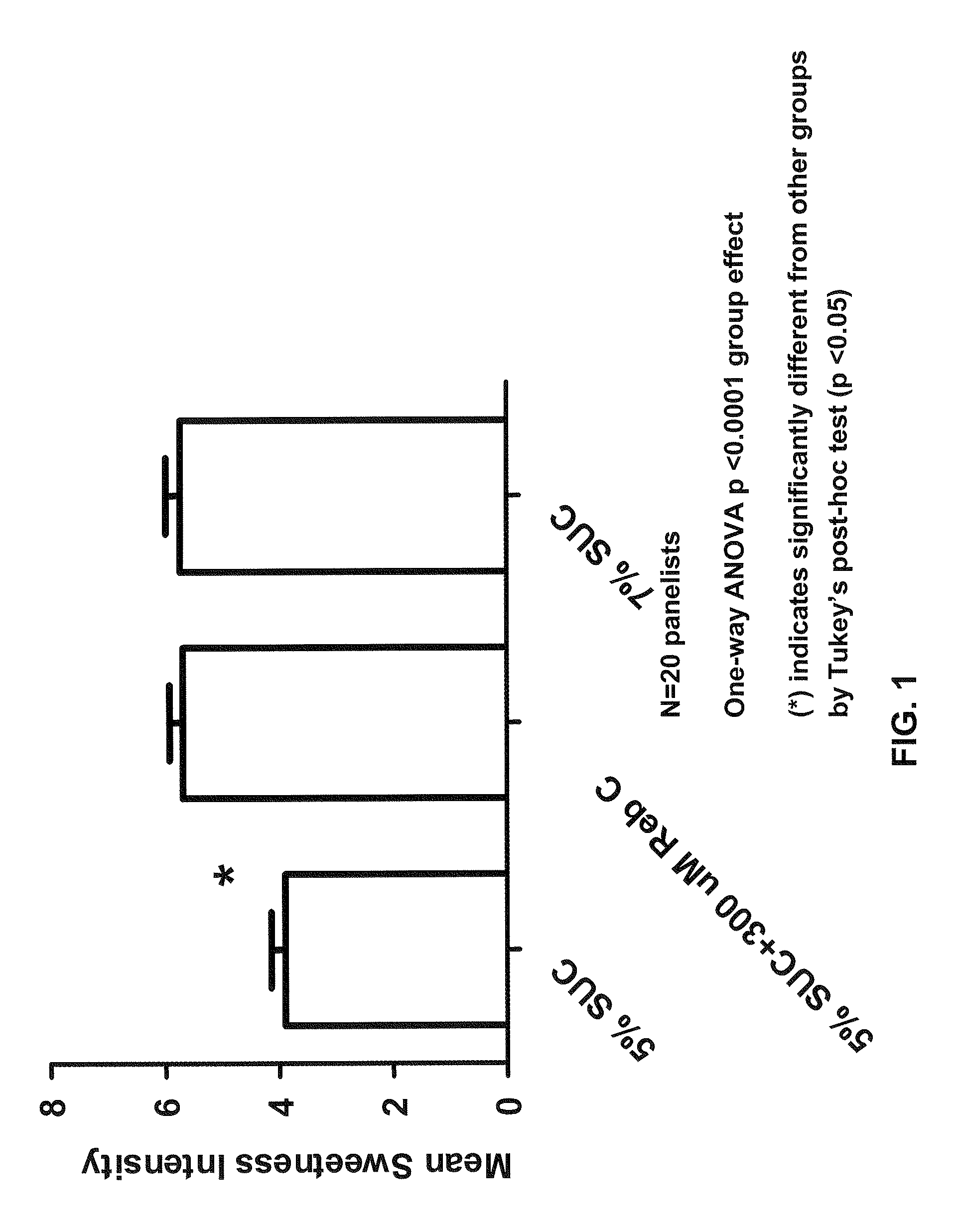

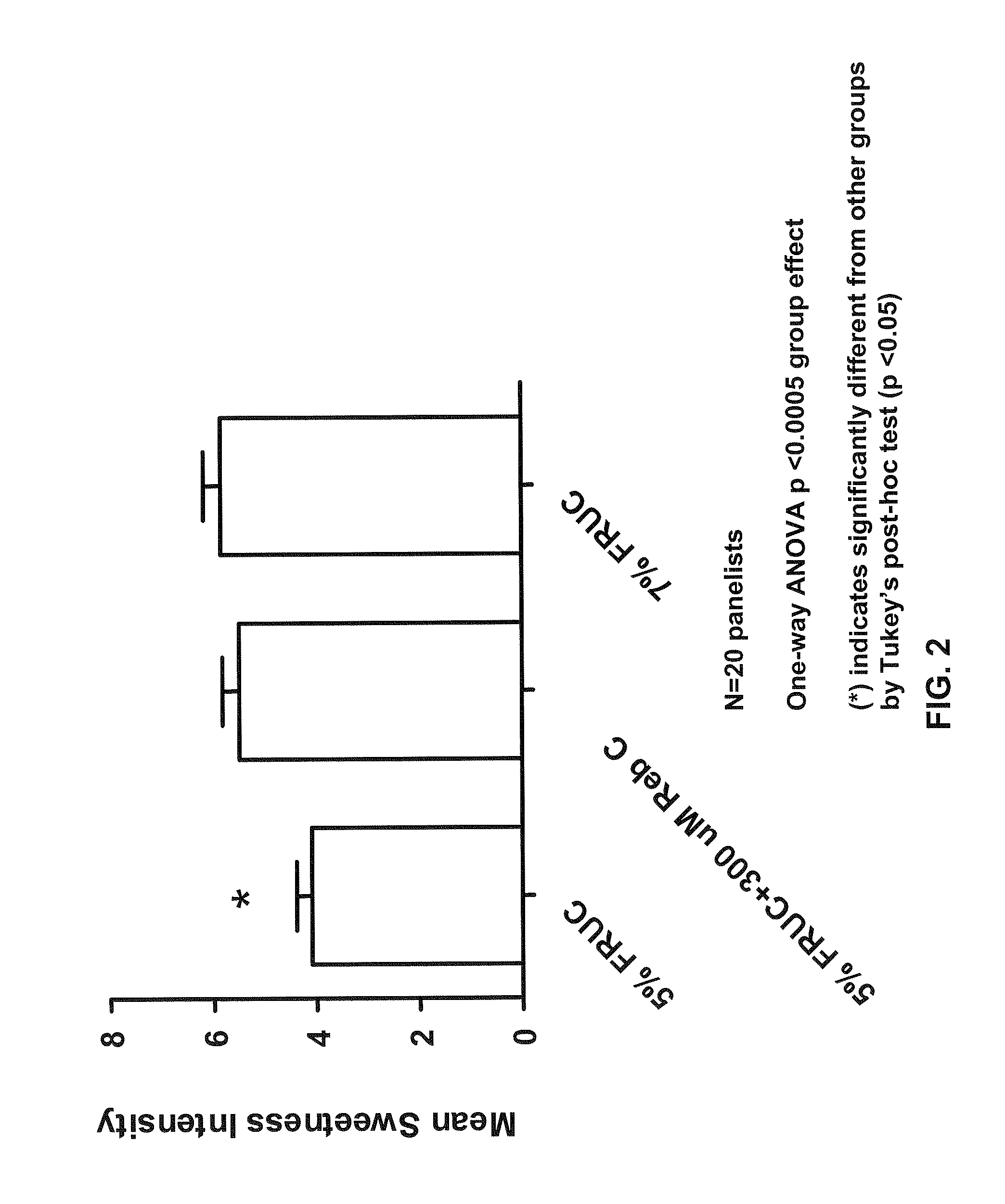

Rebaudioside C and Its Stereoisomers as Natural Product Sweetness Enhancers

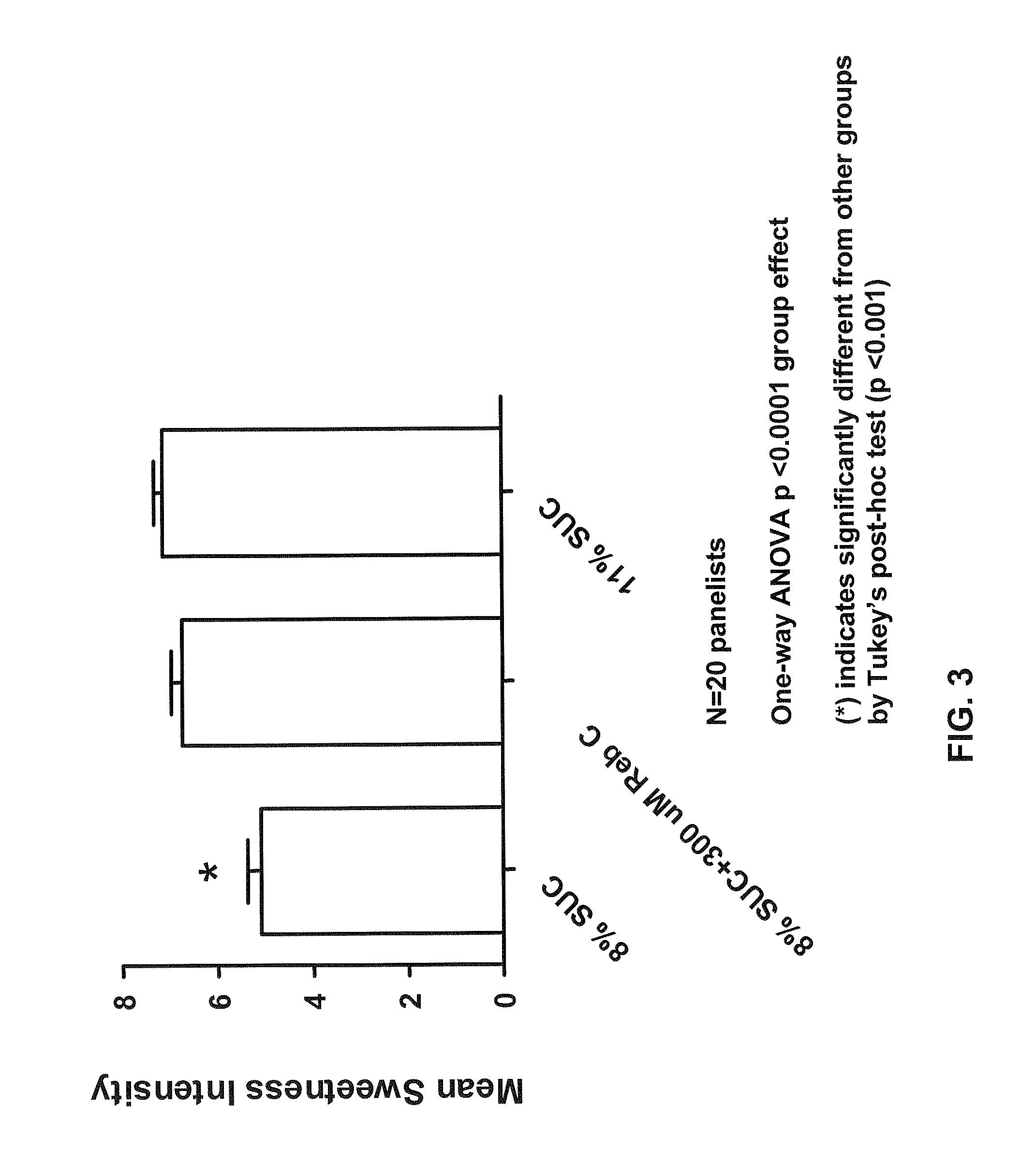

ActiveUS20110070172A1Increase sweetnessDecreasing the amount of a carbohydrate sweetenerCosmetic preparationsBiocideFructoseSucrose

The present invention is directed to the use of rebaudioside C, or a stereoisomer thereof, for enhancing the sweet taste of carbohydrate sweeteners, such as sucrose and fructose. The present invention is also directed to consumables comprising a combination of a carbohydrate sweetener and rebaudioside C, or a stereoisomer thereof.

Owner:REDPOINT BIO CORP

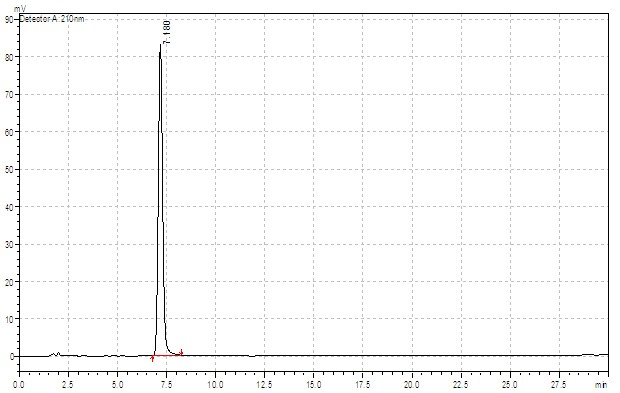

Separation and purification method for rebaudioside C

InactiveCN107778338ALow costHigh puritySugar derivativesSugar derivatives preparationPurification methodsChromatographic column

The invention discloses a separation and purification method for rebaudioside C. A proper industrial chromatographic column and solution are adopted, a process step is optimized, and high performanceliquid chromatography detection is adopted and combines with column chromatography separation and recrystallization to obtain rebaudioside C from a stevioside raw material. The method is low in cost and high in purity and yield, is economic, and has the purity higher than 95% and yield higher than 60%.

Owner:苏州迪科传动机械有限公司

Method for reaction separation purification of rebaudioside A

ActiveCN104725443AHigh purityIncrease added valueSugar derivativesFermentationOrganic synthesisWater insoluble

The present invention discloses a method for reaction separation purification of rebaudioside A, and belongs to the technical field of organic chemistry. In the prior art, the stevia sugar crude product mainly contains stevioside, high-quality sweeteners such as rebaudioside A and rebaudioside C, and small amounts of other steviol derivatives, the rebaudioside A and the stevioside have the similar structure, and the dissolubility of the two substances can be increased when the two substances co-exist in a polar solution, such that the multi-stage sectional organic solvent re-crystallization is required to obtain the high-purity rebaudioside A. According to the present invention, the beta-galactosidase having lipase activity and galactosidase activity and derived from sulfolobus solfataricus is utilized to carry out highly specific catalytic hydrolysis on the stevioside, such that the poor-quality stevioside can be subjected to complete catalysis conversion into the water-insoluble steviol, the rebaudioside A and other steviols can not be hydrolyzed so as to remain in the solution and the high-purity rebaudioside A can be obtained through the simple aqueous phase re-crystallization, and the by-produced steviol is the organic synthesis intermediate having the wide use and the added value of higher than the stevioside.

Owner:JIANGNAN UNIV

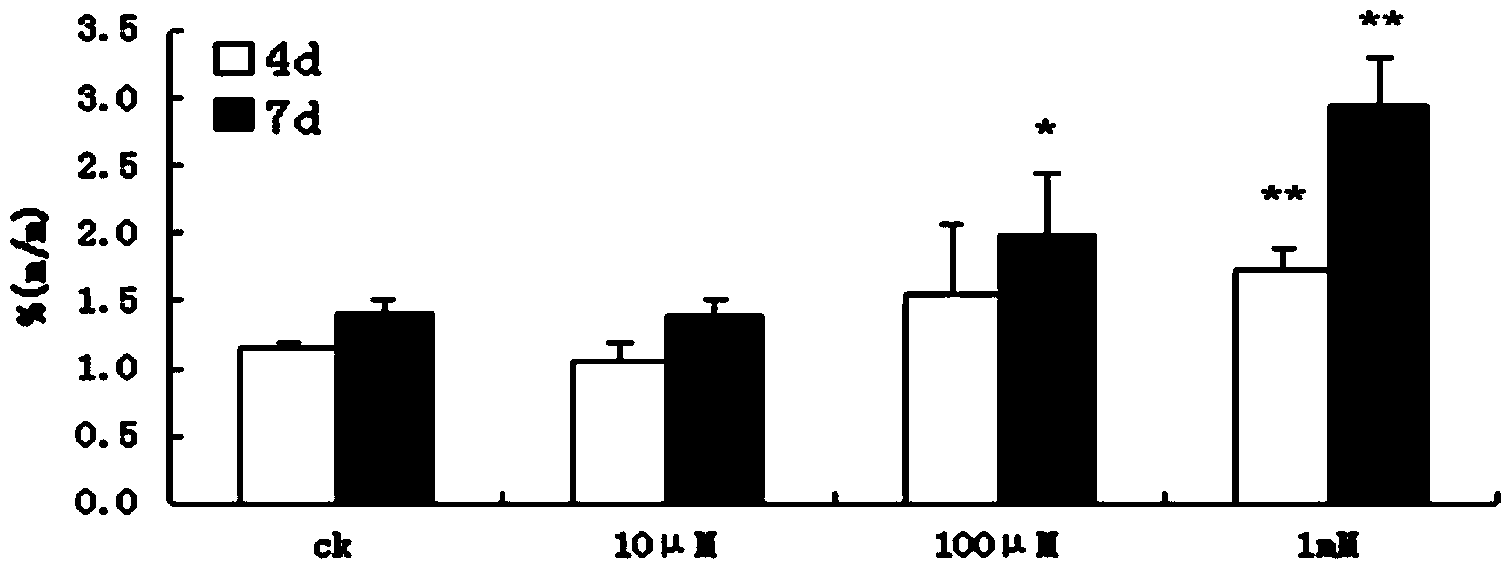

Method for improving content of rebaudioside-A (RA), stevioside (ST), rebaudioside-C (RC) and/or total glucoside in stevia rebaudiana bertoni

The invention discloses a method for improving the content of rebaudioside-A (RA), stevioside (ST), rebaudioside-C (RC) and / or total glucoside in stevia rebaudiana bertoni. The method comprises the step of spraying a mixed solution of jasmonic acid and jasmonic acid acetone on stevia rebaudiana bertoni plants before the step of harvesting the stevia rebaudiana leaves. According to the method, the content of the RA, the ST, the RC and / or the total glucoside in stevia rebaudiana bertoni leaves in the harvest period can be obviously improved.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Stevia sugar consisting of Reb C (Rebaudioside-C) and STV (Stevioside)

The invention provides a stevia sugar consisting of Reb C (Rebaudioside-C) and STV (Stevioside). The stevia sugar is prepared by mixing and compounding the Reb C and the STV as the main sweet component of the stevia sugar. The weight ratio between the Reb C to the STV is (1-50): (50-99). In the invention, after the Reb C as a sweet taste reinforcing agent, which is purely natural and calorie-free and tastes mellow and refreshing, is compounded with calorific sweeteners the mouthfeel can be improved, and the calorie can be reduced by 25-50%, therefore, the defect of lingering bitterness of the STV on the mouthfeel is overcome, so that the stevia sugar has the advantages of better taste, fresher taste quality, better security and convenience for use, and meets demands of people on health at the same time.

Owner:安徽润海生物科技股份有限公司

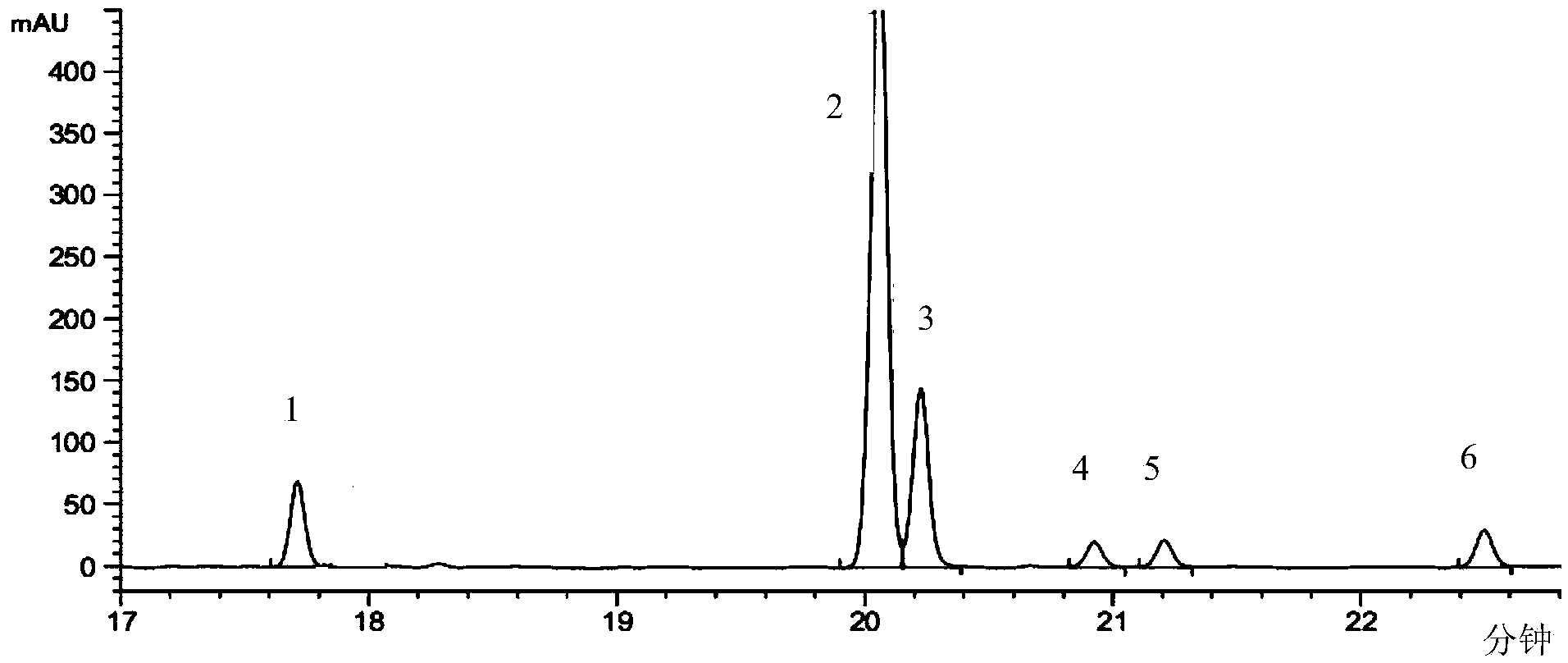

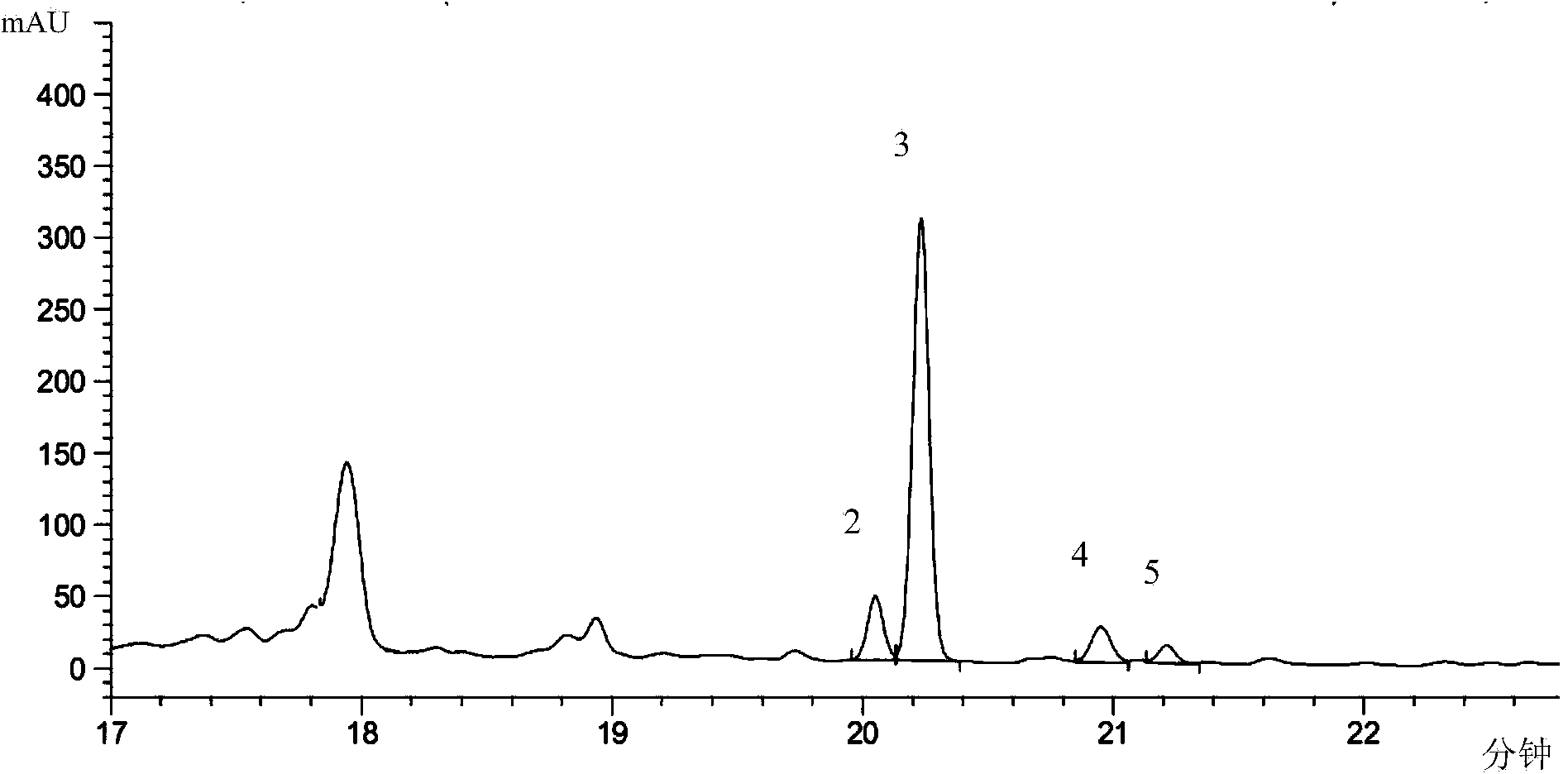

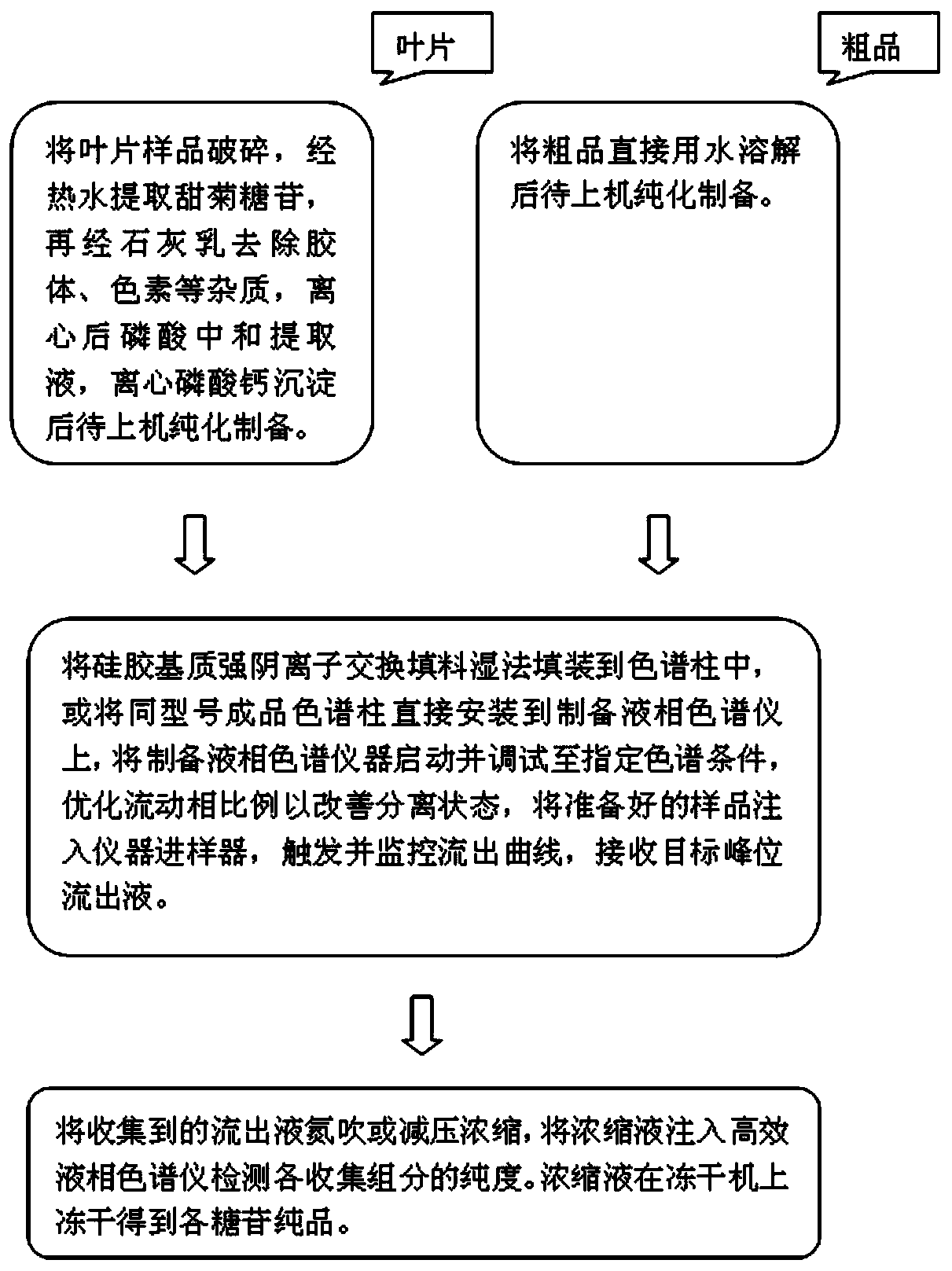

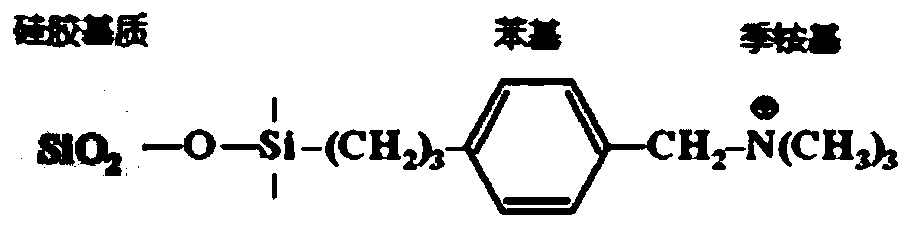

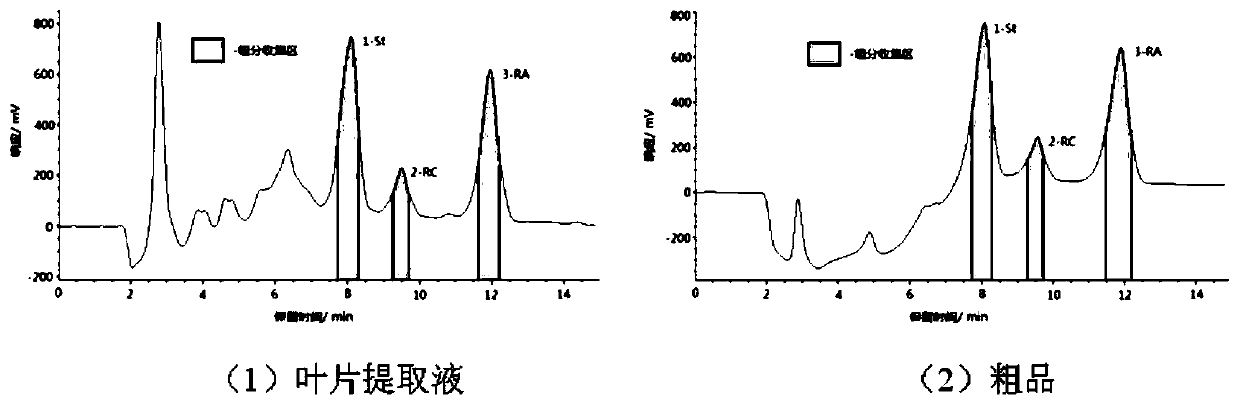

Method for separating and purifying stevioside by using silica gel substrate strong anion exchange chromatography

PendingCN109897074AExtended service lifeEasy to operateSugar derivativesSugar derivatives preparationChromatographic separationIon exchange

The invention relates to a method for separating and purifying stevioside by using silica gel substrate strong anion exchange chromatography. Stevia leaves or stevioside crude products are used as rawmaterials, HP-SAX silica gel substrate strong anion exchange chromatography filler or a homotype finished product chromatographic column is used as a separation medium, separation and purification are performed with liquid chromatography, and three steviosides including stevioside, rebaudioside C and rebaudioside A are obtained simultaneously. The invention also relates to an application of the method in preparation of the stevioside, the rebaudioside C and the rebaudioside A by separation and purification. The method is convenient and rapid, single separation can be completed within 15 min,the purity of purified products is higher than 99.0%, repeatability is good, operability is high, an organic solvent aqueous solution in any proportion and even 100% water can be used as a chromatographic separation medium to wash away impurities such as inorganic salt and pigment caused by samples on the head of the chromatographic column, the separation medium is not prone to hydrolysis or collapse in the washing process, and the separation medium has long service life and can be reused for a long time.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

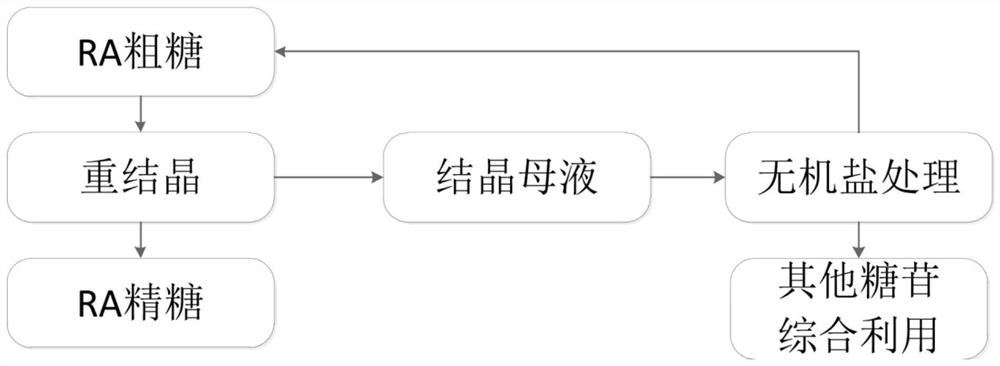

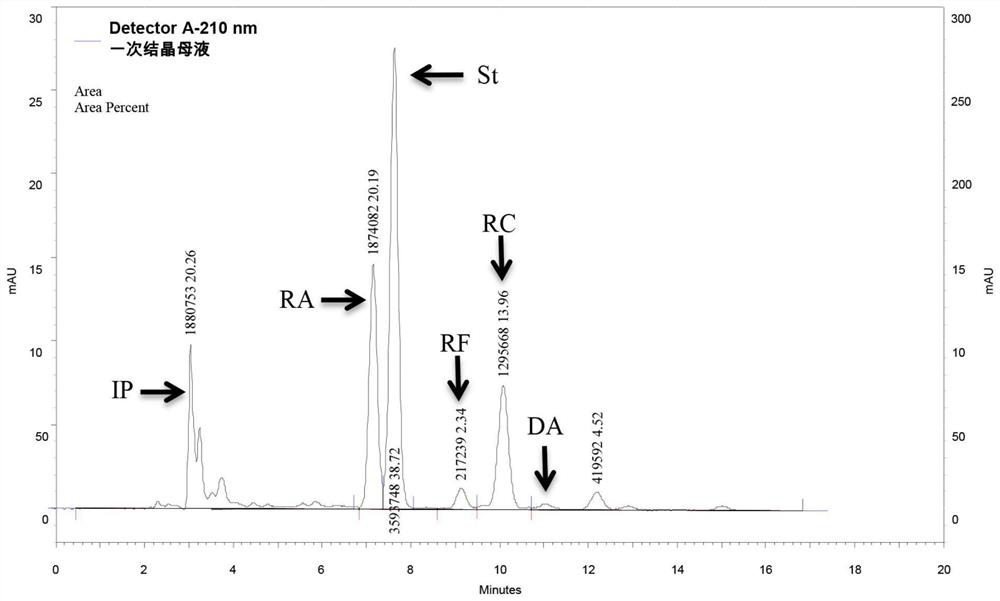

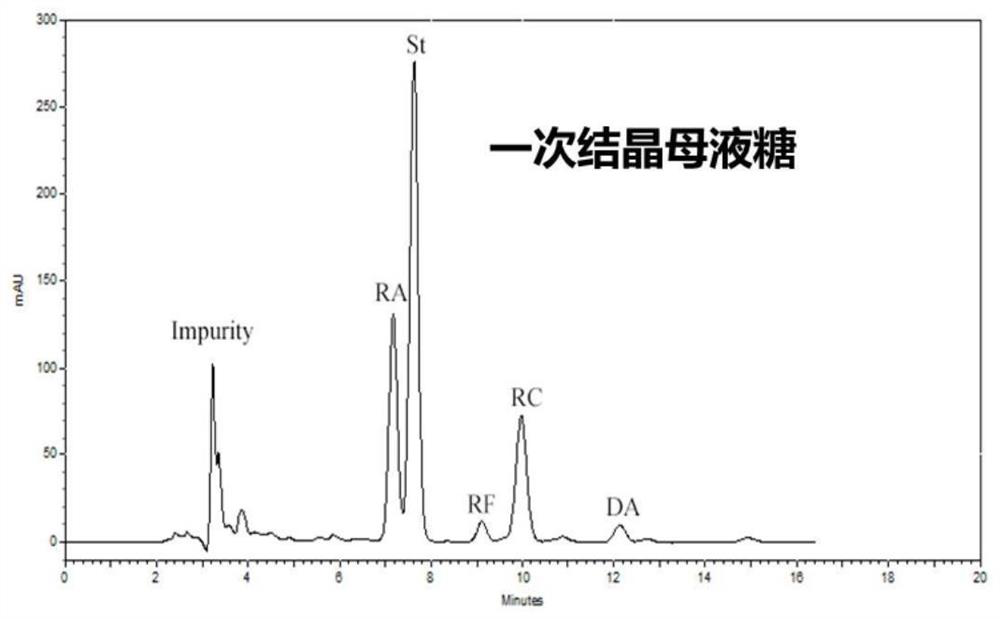

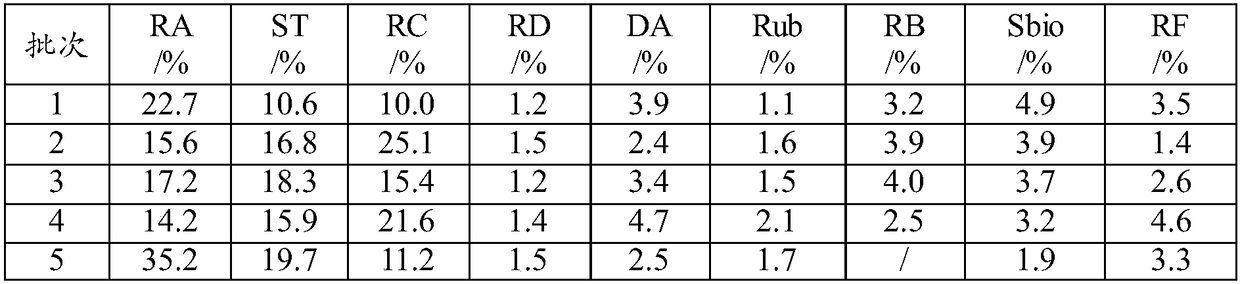

Method for recovering rebaudioside A from primary crystallization mother liquor of steviol glycosides (SGs)

ActiveCN111662344AEfficient recyclingEasy to recycleSugar derivativesSugar derivatives preparationInorganic saltsFluid phase

The invention relates to the field of separation of natural sweeteners. The solubility of each substance is changed by adding inorganic salt so as to selectively recover rebaudioside A (RA) in primarycrystallization mother liquor. The stevioside extracted from plants is a mixture and mainly contains rebaudioside A (RA), stevioside (ST), rebaudioside C (RC) and the like, wherein RA has the highestsweetness and is a primary crystallization product. The primary crystallization mother liquor mainly contains RA, ST, RC and some flavone and polyphenol impurities. According to the method, the crystallization characteristics and solubility of different components in the stevioside crystallization mother liquor are changed by utilizing the inorganic salt. An inorganic salt aqueous solution is directly added into the primary crystallization mother liquor and stirred, solids are separated out, filtered, washed and dried, and RA in the mother liquor can be recovered; and moreover, because part of impurities are removed, the taste is good. According to the technical method, equipment does not need to be increased, the operating steps are simple and short, and the energy consumption is low. RA, ST and RC are enriched in a liquid phase while most RA is recovered, and the substances are further separated and purified.

Owner:SICHUAN UNIV

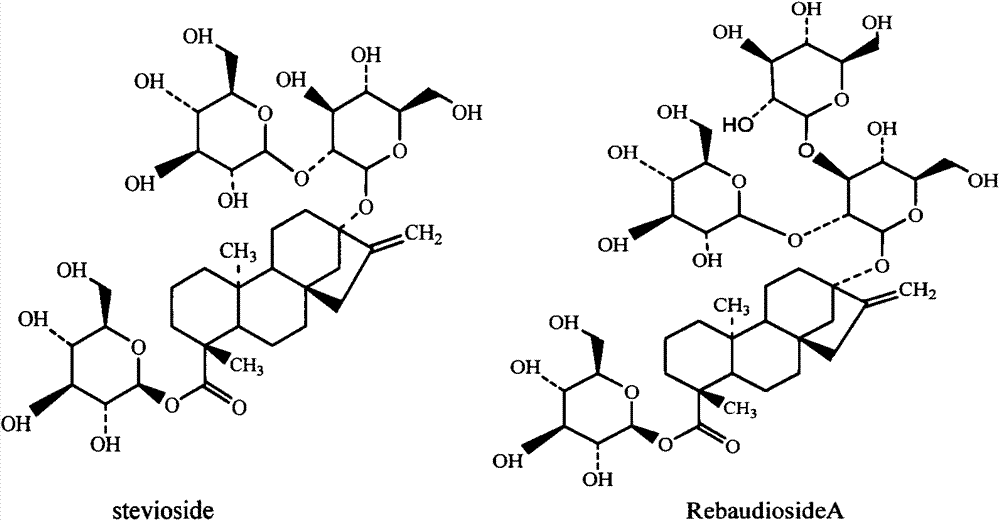

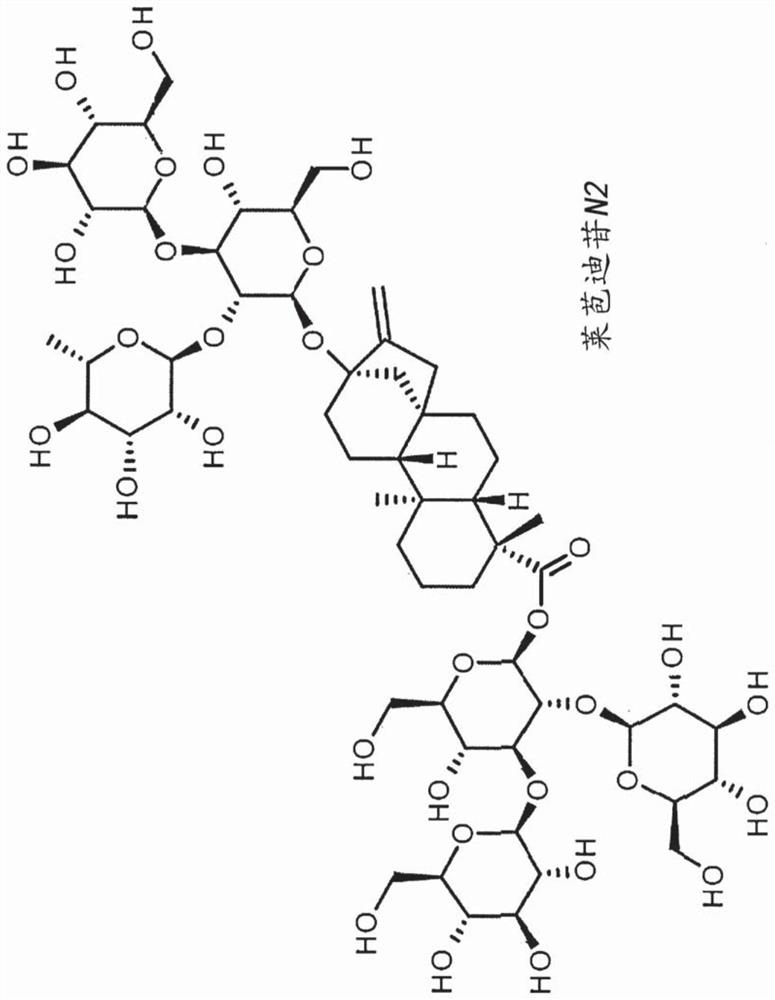

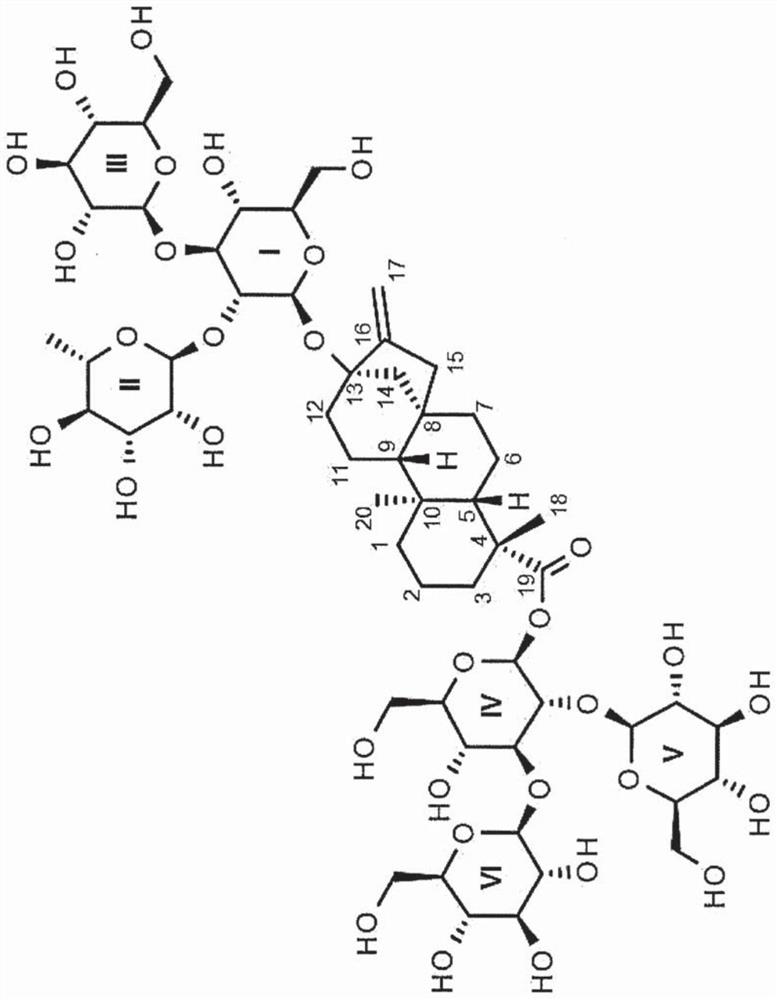

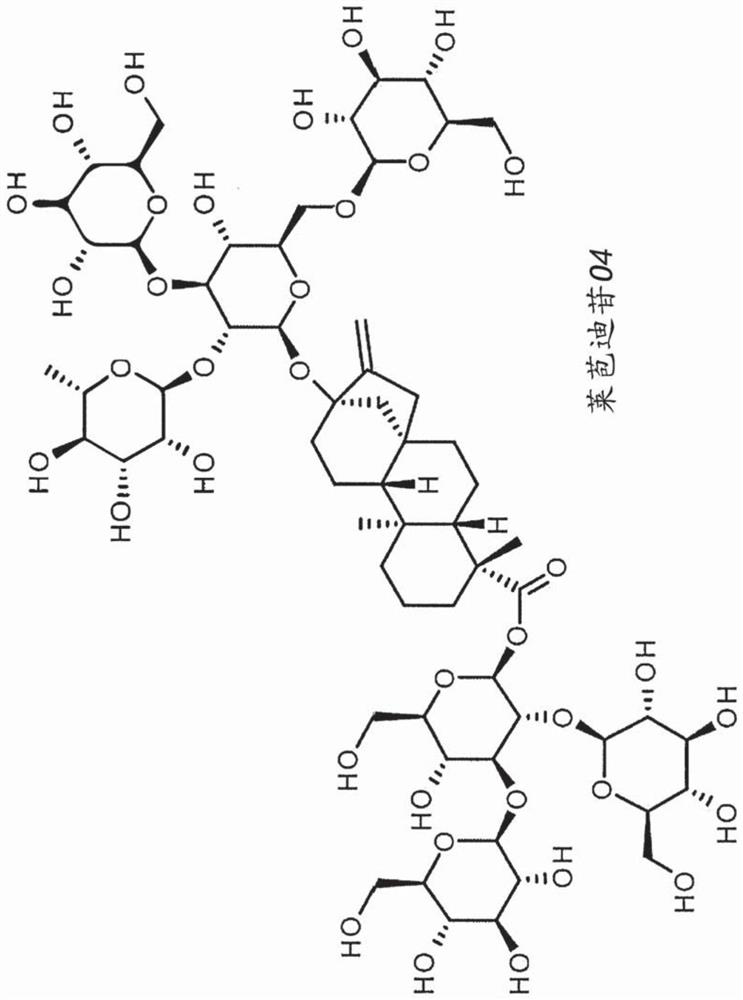

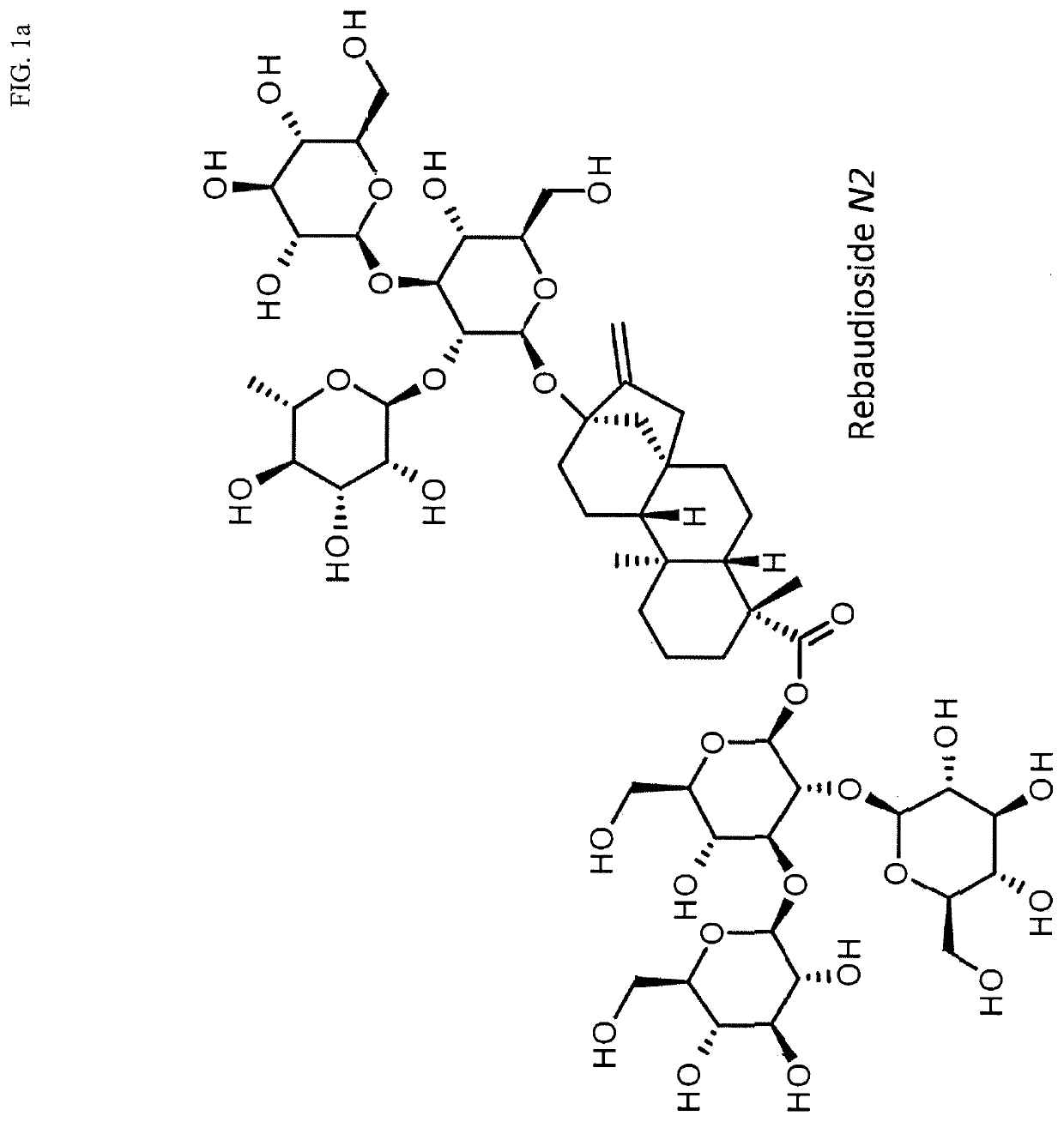

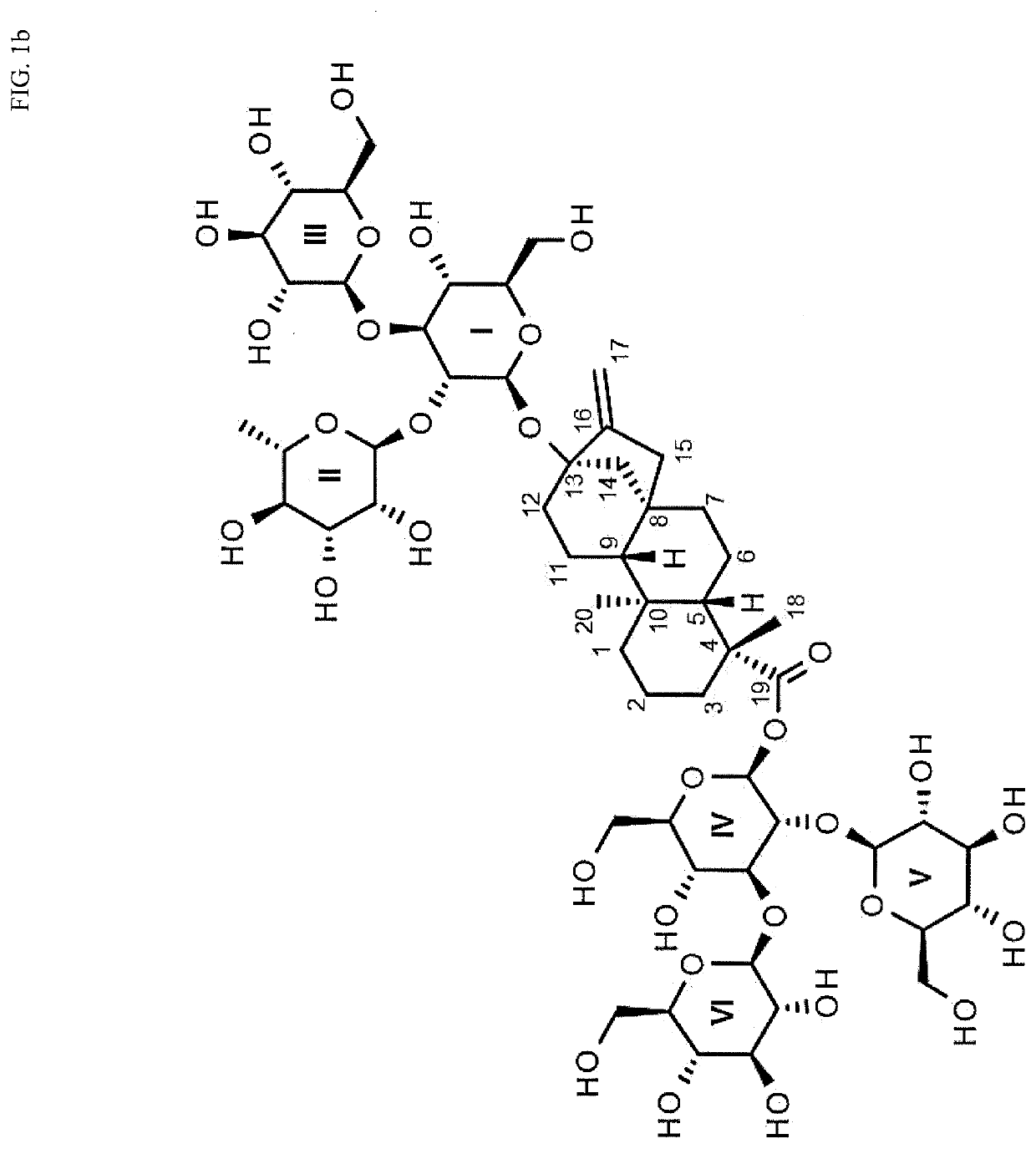

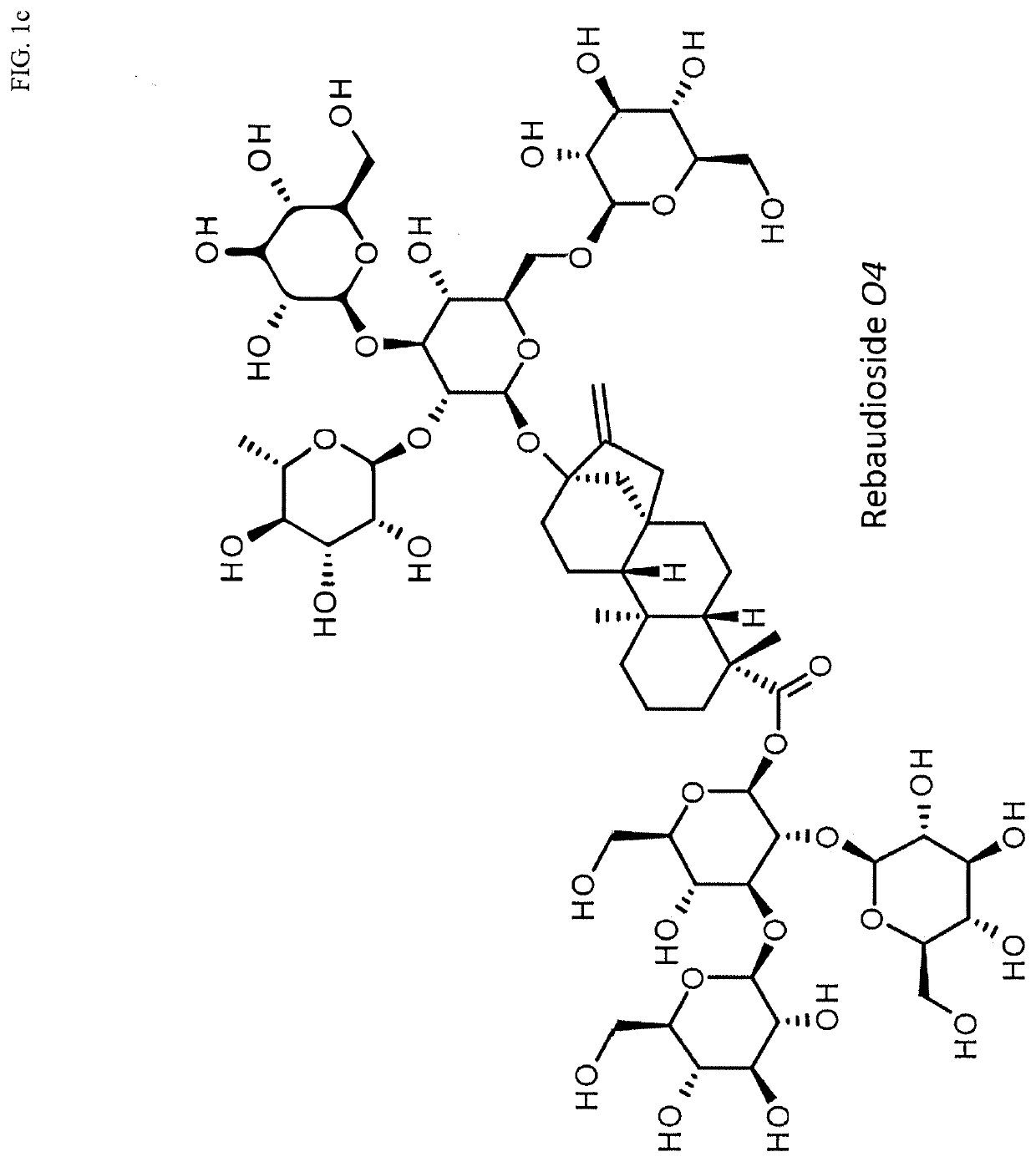

High-purity steviol glycosides

Methods of preparing highly purified steviol glycosides, particularly steviolmonoside, steviolmonoside A, steviolbioside A, steviolbioside B, steviolbioside C, steviolbioside D, steviolbioside E, rubusoside, dulcoside A, dulcoside C, dulcoside D, stevioside A, stevioside B, stevioside C, stevioside G, stevioside H rebaudioside B2, rebaudioside A4, rebaudioside C, rebaudioside C3, rebaudioside C4,rebaudioside C5, rebaudioside C6, rebaudioside E3, rebaudioside E4, rebaudioside E5, rebaudioside E6, rebaudioside E7, rebaudioside D5, rebaudioside D6, rebaudioside D7, rebaudioside D8, rebaudiosideH2, rebaudioside H3, rebaudioside H4, rebaudioside H5, rebaudioside H6, rebaudioside K, rebaudioside N2, rebaudioside N3, rebaudioside N4, rebaudioside N5, rebaudioside M3 and / or rebaudioside 04 are described. The methods include utilizing enzyme preparations and recombinant microorganisms for converting various staring compositions to target steviol glycosides. The highly purified steviol glycosides are useful as non-caloric sweetener, flavor enhancer, sweetness enhancer, and foaming suppressor in edible and chewable compositions such as any beverages, confectioneries, bakery products, cookies, and chewing gums.

Owner:PURECIRCLE USA

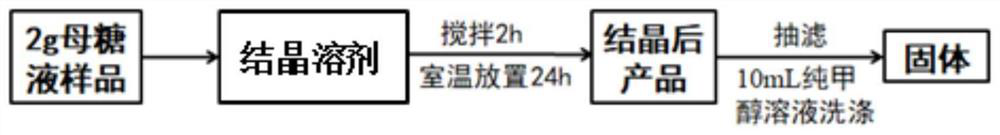

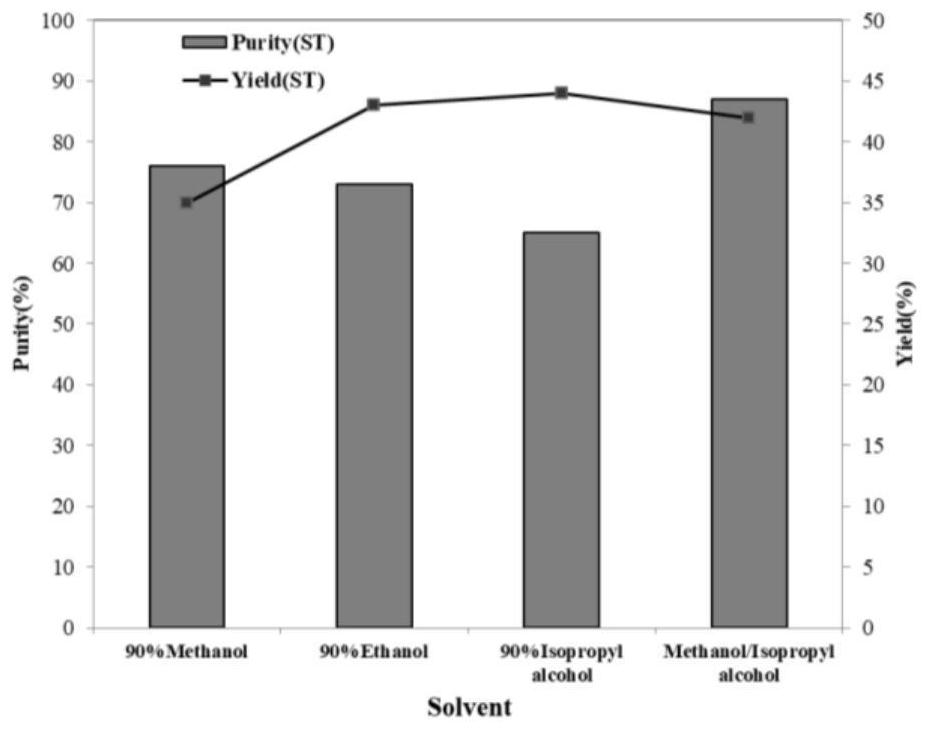

Method for obtaining high-purity stevioside and enriching rebaudioside C from primary crystallization mother liquor of stevioside through secondary crystallization

PendingCN113201034AThe secondary crystallization process is simple and efficientReduce energy consumptionSugar derivativesSugar derivatives preparationFluid phaseSugar

The invention relates to the field of separation of natural high-potency sweeteners. The solubility of each component in stevioside is changed by selecting a crystallization solvent so as to selectively recover stevioside in primary crystallization mother liquor. Stevioside extracted from plants is a mixture and mainly contains rebaudioside A (RA), stevioside (ST), rebaudioside C (RC) and the like, and high-purity RA can be obtained through one-time crystallization. The remaining primary crystallization mother liquor mainly contains ST, RA, RC and some bitter impurities such as flavones and polyphenols. The ST content is maximum. According to the method, the solubility difference of different components in the stevioside crystallization mother liquor in an improved crystallization solvent is utilized. When mother liquor sugar is subjected to secondary crystallization, solid is separated out and then filtered, washed and dried, and ST in the mother liquor can be recycled. According to the technical method, equipment does not need to be added, operation steps are simple, and energy consumption is low. And when most of ST is recycled, RC is enriched in a liquid phase, so that the substances are further separated and purified.

Owner:SICHUAN UNIV

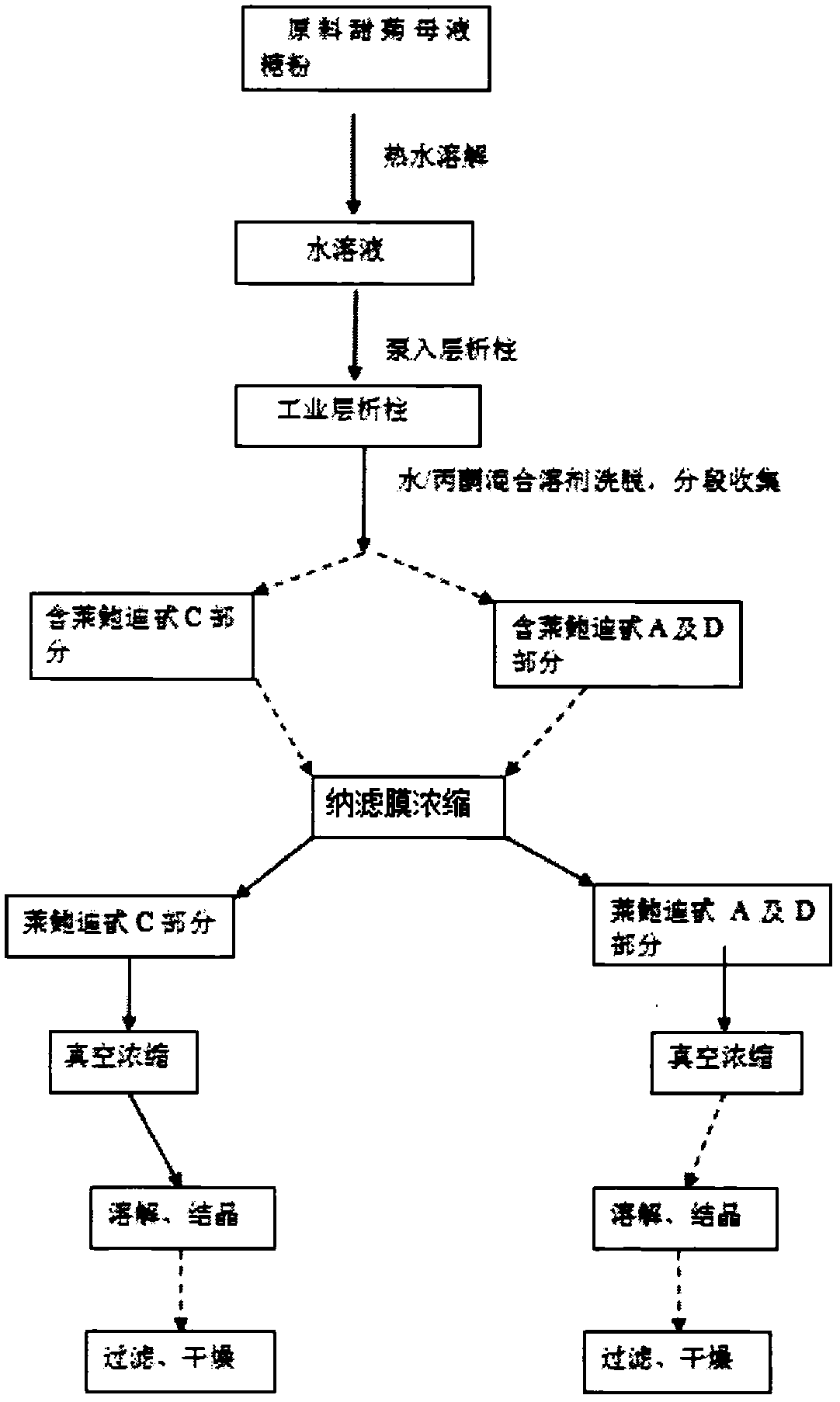

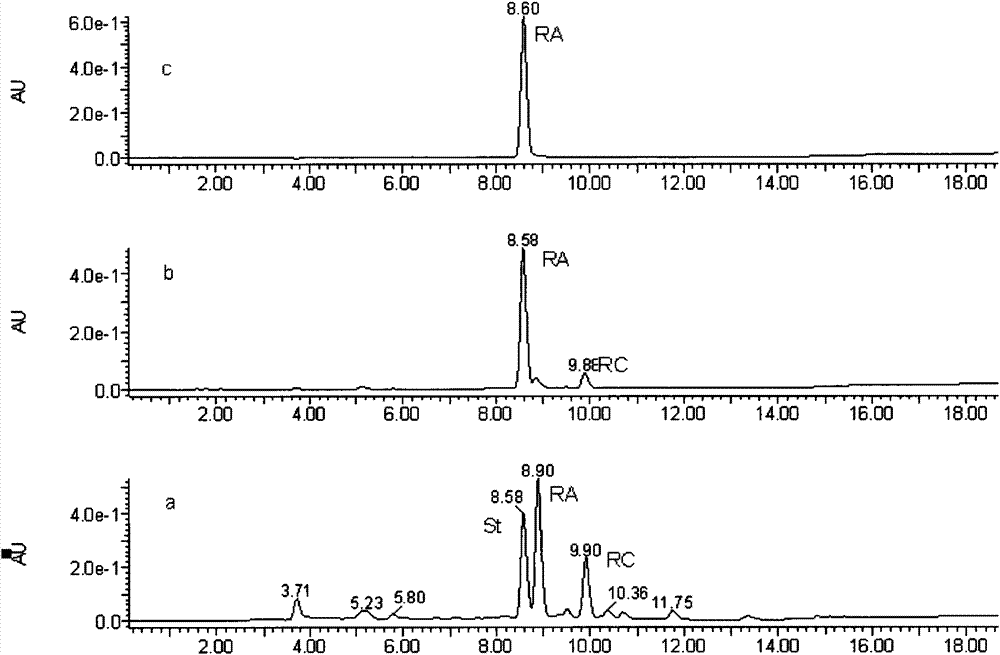

Method for separating and purifying rebaudioside C

ActiveCN108530503ASimple processEasy to operateSugar derivativesSugar derivatives preparationFiltrationSilanes

The invention provides a method for separating and purifying rebaudioside C. The method includes steps of a), mixing stevioside mother liquor sugar and water with each other, preparing mother liquor sugar solution, loading samples by the aid of pumps, allowing the samples to flow through chromatographic columns filled with fillers, carrying out elution by the aid of methanol aqueous solution, detecting and collecting rebaudioside C components by means of HPLC (high-performance liquid chromatography), concentrating the rebaudioside C components by the aid of nano-filtration membranes and dryingthe rebaudioside C components to obtain rebaudioside C component dried substances; b), dissolving the rebaudioside C component dried substances, which are obtained at the step a), by the aid of ethylalcohol-acetone-water, carrying out primary crystallization and further carrying out filtering and drying to obtain primarily crystallized crystals; c), dissolving the primarily crystallized crystals, which are obtained at the step b), by the aid of ethyl alcohol-methanol-water, carrying out secondary crystallization, and further carrying out still standing, filtering and drying to obtain rebaudioside C finished products. Silica gel is used as a matrix for the fillers, and octadecyl silane and divinyl benzene are bonded on the silica gel. The method has the advantages that the high-purity rebaudioside C can be prepared by the aid of the method, and the method is high in yield; rebaudioside A can be recycled, the fillers are long in service life, and solvents are easy to recycle.

Owner:SEPAX TECH

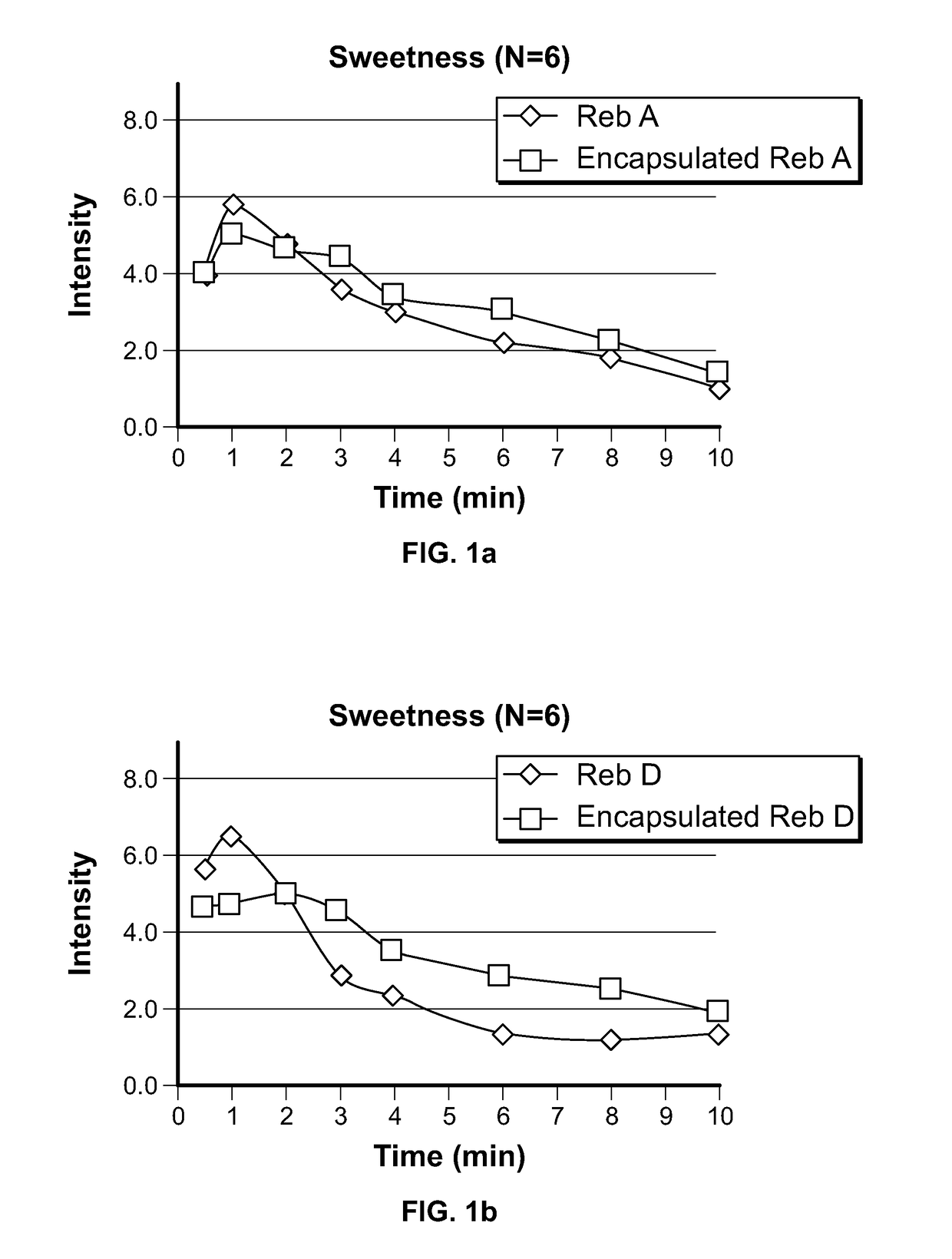

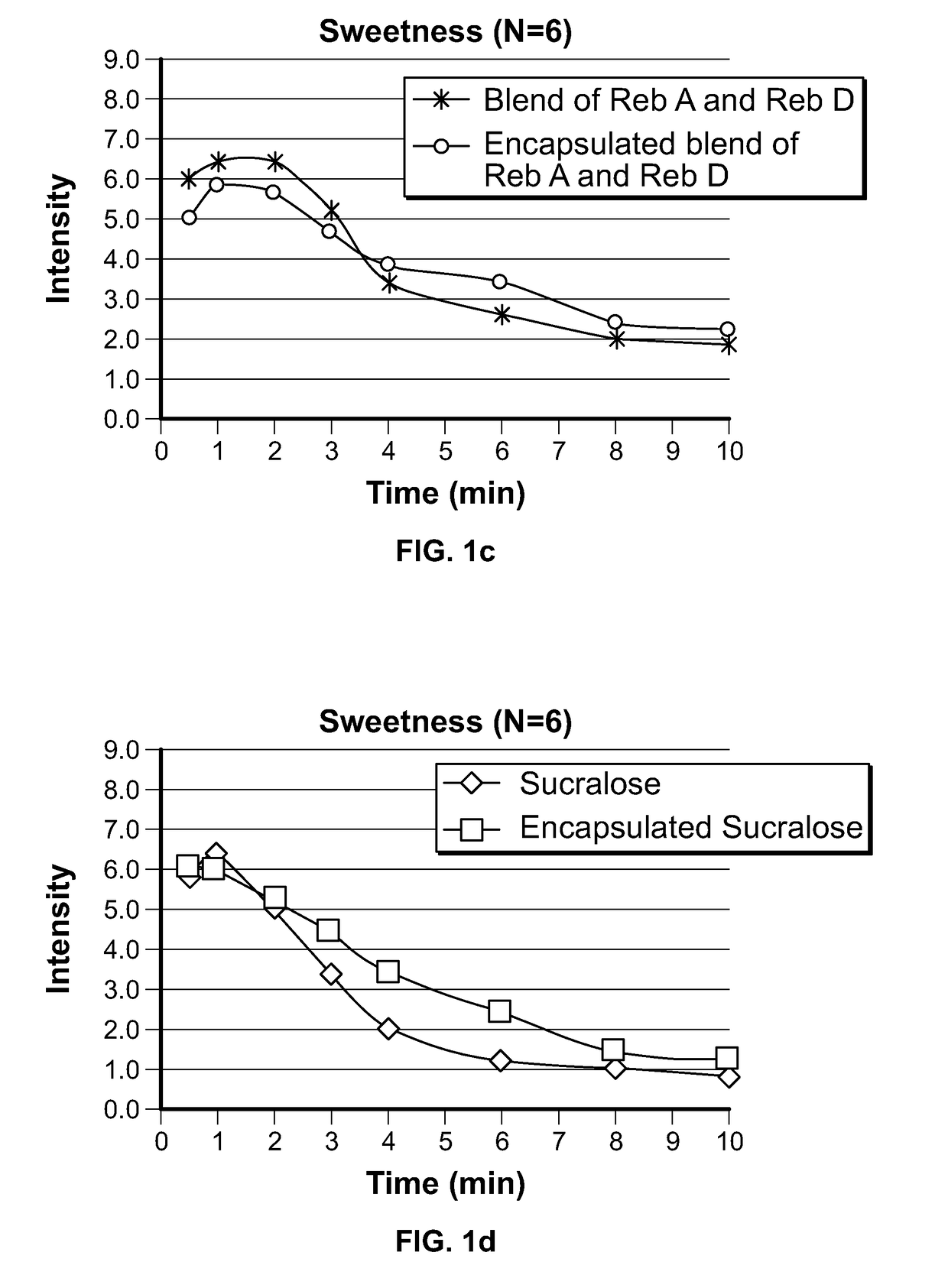

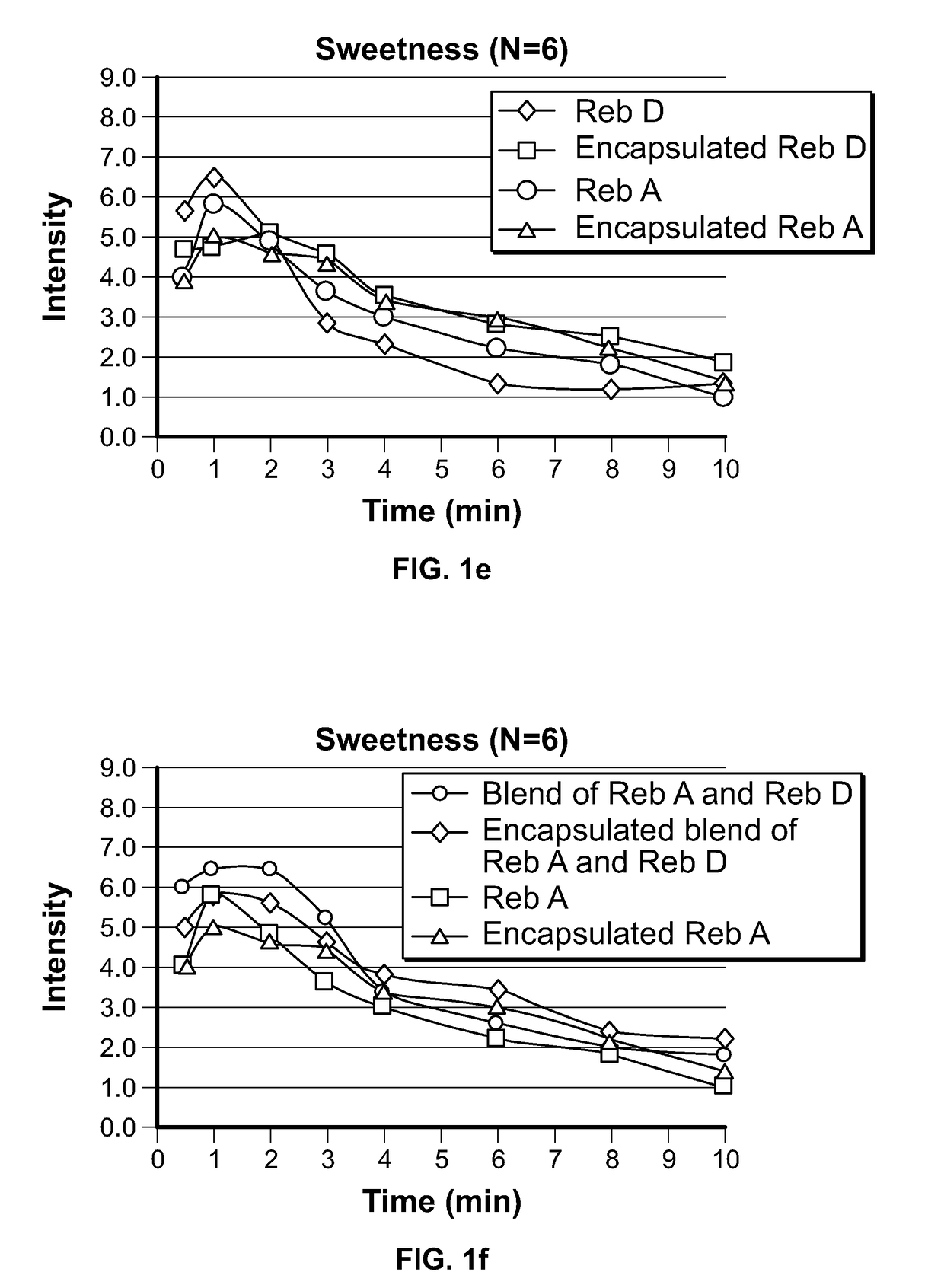

Long-lasting sweetener formulations

Long-lasting sweetener formulations which comprise at least one encapsulated sweetener compound and are suitable for use in confectionery products are disclosed. In certain, non-limiting embodiments of the disclosed formulations, the sweetener compound is stevioside, rebaudioside A, rebaudioside B, rebaudioside C, rebaudioside D, rebaudioside E, rebaudioside F, rebaudioside M, steviobioside, rubusoside and dulcoside A. In certain embodiments, the disclosed formulations provide enhanced sweetness duration for chewing gum.

Owner:WM WRIGLEY JR CO

Method for purifying rebaudioside c

InactiveUS20130144046A1Sugar derivativesSugar derivatives preparationBiochemical engineeringBiochemistry

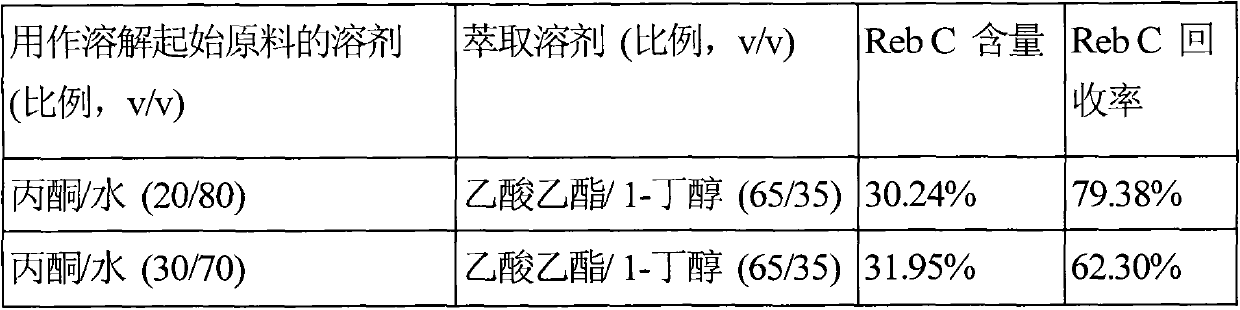

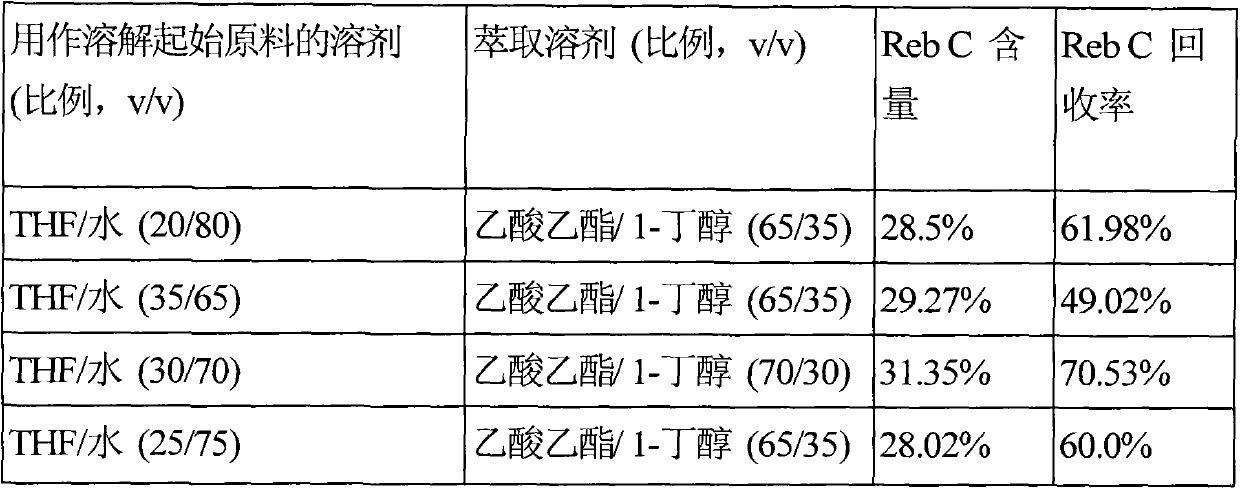

The present invention is a method for purifying Rebaudioside C by subjecting “waste material,” generated during the Rebaudioside A manufacturing process, to liquid-liquid extraction and recrystallizing the Rebaudioside C.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

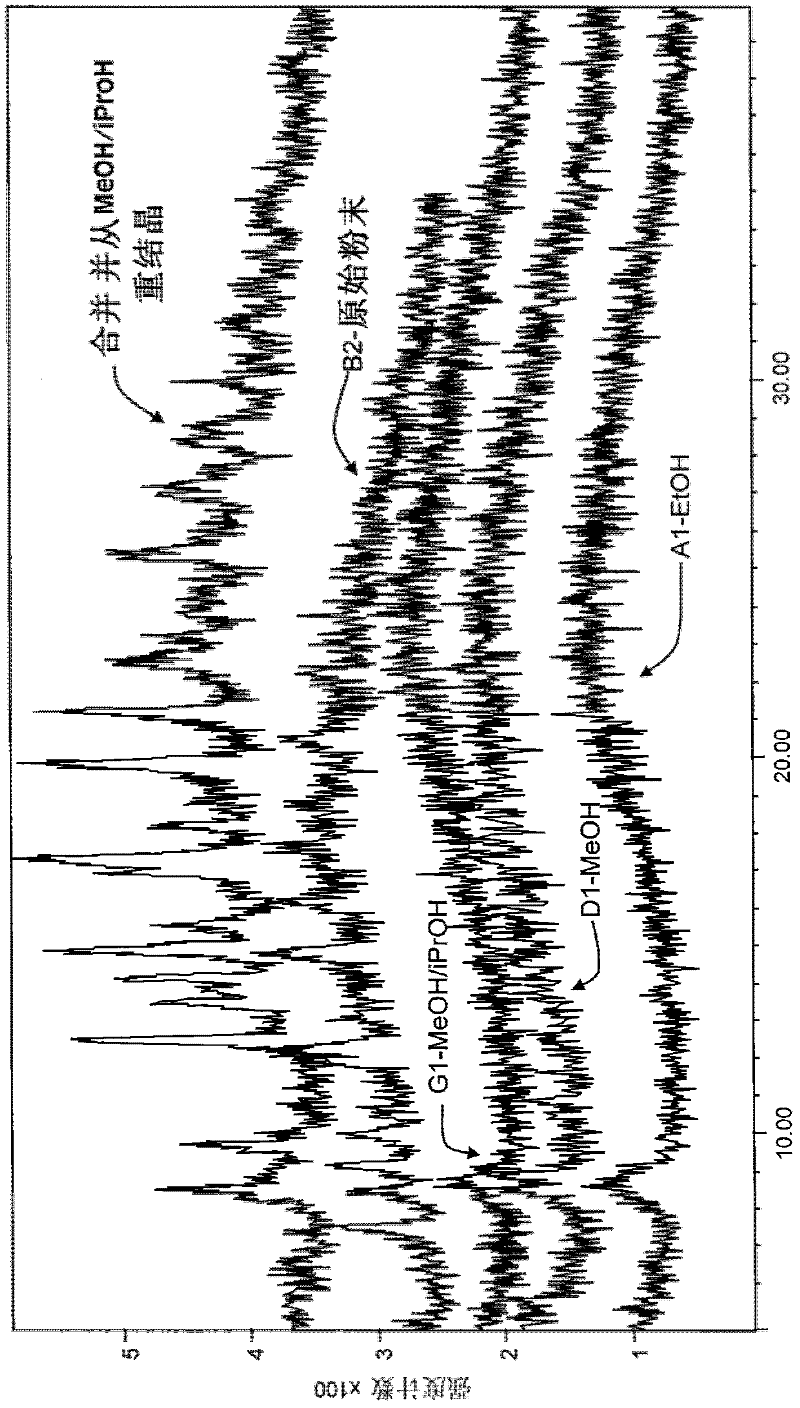

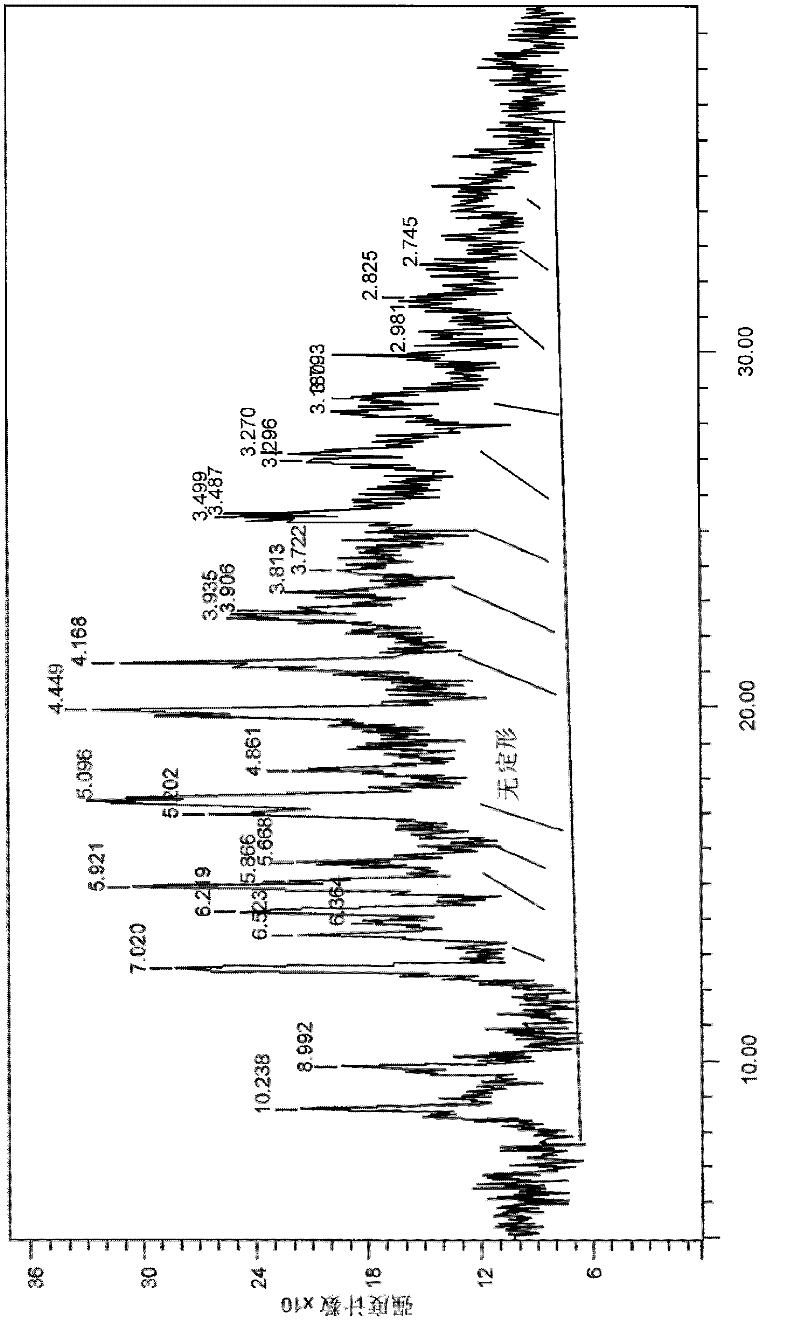

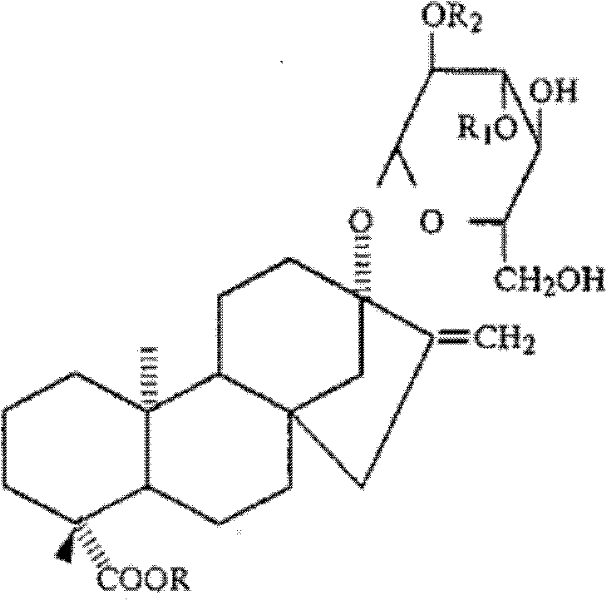

Novel polymorphs of rebaudioside C and methods for making and using the same

Embodiments of this invention encompass a method for producing and purifying rebaudioside C. In particular, this invention relates to a method for purifying rebaudioside C compositions to obtain a substantially pure rebaudioside C product using one or more crystallization steps. Resulting polymorphic forms of rebaudioside C, substantially pure rebaudioside C compositions and their uses are disclosed.

Owner:REDPOINT BIO CORP

Rebaudioside C and its stereoisomers as natural product sweetness enhancers

ActiveUS8609069B2Increase sweetnessDecreasing the amount of a carbohydrate sweetenerCosmetic preparationsBiocideSucroseNatural product

The present invention is directed to the use of rebaudioside C, or a stereoisomer thereof, for enhancing the sweet taste of carbohydrate sweeteners, such as sucrose and fructose. The present invention is also directed to consumables comprising a combination of a carbohydrate sweetener and rebaudioside C, or a stereoisomer thereof.

Owner:REDPOINT BIO CORP

High-purity steviol glycosides

Methods of preparing highly purified steviol glycosides, particularly steviolmonoside, steviolmonoside A, steviolbioside A, steviolbioside B, steviolbioside C, steviolbioside D, steviolbioside E, rubusoside, dulcoside A, dulcoside C, dulcoside D, stevioside A, stevioside B, stevioside C, stevioside G, stevioside H, rebaudioside B2, rebaudioside A4, rebaudioside C, rebaudioside C3, rebaudioside C4, rebaudioside C5, rebaudioside C6, rebaudioside E3, rebaudioside E4, rebaudioside E5, rebaudioside E6, rebaudioside E7, rebaudioside D5, rebaudioside D6, rebaudioside D7, rebaudioside D8, rebaudioside H2, rebaudioside H3, rebaudioside H4, rebaudioside H5, rebaudioside H6, rebaudioside K, rebaudioside N2, rebaudioside N3, rebaudioside N4, rebaudioside N5, rebaudioside M3 and / or rebaudioside O4 are described. The methods include utilizing enzyme preparations and recombinant microorganisms for converting various staring compositions to target steviol glycosides. The highly purified steviol glycosides are useful as non-caloric sweetener, flavor enhancer, sweetness enhancer, and foaming suppressor in edible and chewable compositions such as any beverages, confectioneries, bakery products, cookies, and chewing gums.

Owner:PURECIRCLE USA

Method for purifying rebaudioside C

The present invention is a method for purifying Rebaudioside C by subjecting “waste material,” generated during the Rebaudioside A manufacturing process, to liquid-liquid extraction and recrystallizing the Rebaudioside C.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

A method for separating and extracting phenolic glycosides from nigella sativa seeds

ActiveCN112300230BConducive to sustainable usePromote development and utilizationSugar derivativesSugar derivatives preparationBiotechnologyNIGELLA SATIVA SEED

The present invention relates to a Nigella sativa Method for separating and extracting phenolic glycosides from seeds: drying Nigella sativa After the seeds are crushed, degrease with petroleum ether, extract with 60-80% ethanol, recover the solvent under reduced pressure, and obtain the extract extract; Eluted to obtain 7 components Fr1-Fr7; 3) The fourth component Fr4 was separated by silica gel column chromatography to obtain 5 components 4-1~4-5; 4) Component 4-3 was separated by gel column Chromatography, silica gel column chromatography separation, obtain 3,5 dihydroxyphenethyl alcohol-3- O - β ‑Pyranoside; Component 4‑2 was separated by reverse phase column chromatography and Sephadex LH‑20 dextran gel column chromatography to obtain broadbactin C. The extraction process of the invention is simple, the product is easy to obtain, the solvent can be recycled, the extraction amount is large, and industrial production is possible.

Owner:HENAN UNIVERSITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com