Separation and purification method for rebaudioside C

A technology for separation and purification and stevioside, which is applied in the field of separation and purification of rebaudioside C, can solve the problems of little attention to rebaudioside C, and achieve the effects of low cost, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

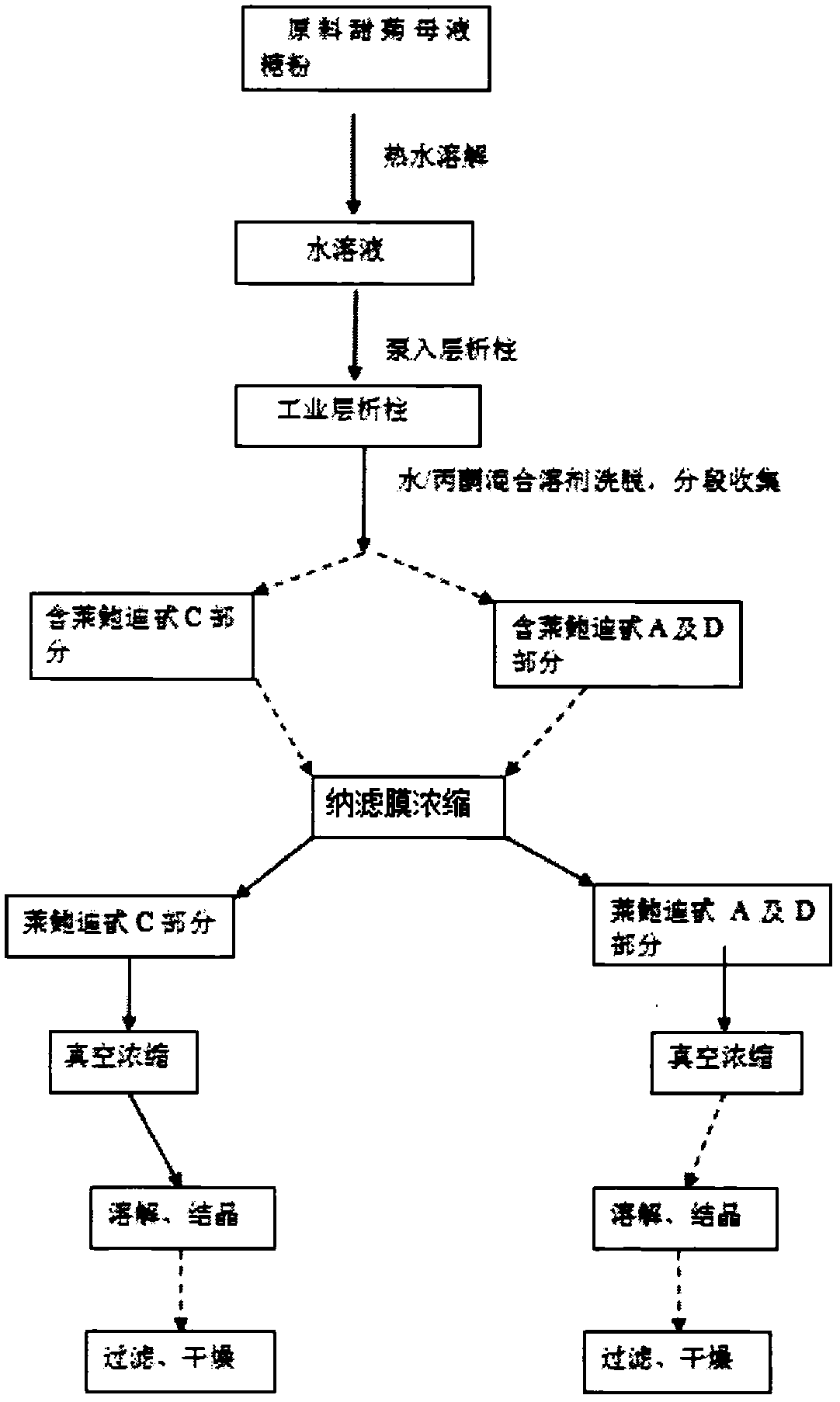

[0022] (1) Add 50kg of stevioside, a raw material containing 15.2% rebaudioside C, into a 500L reactor, then add 150L of deionized water and stir to raise the temperature to 70°C. After the solids are completely dissolved, remove the solution from the reactor and pumped into a single-effect concentrator to concentrate to about 50% of the original volume to obtain a sample.

[0023] (2) The above-mentioned sample is directly pumped into the top of the industrially prepared chromatographic column filled with a resinous polymer, and the weight of the resinous polymer is 10 times the weight of stevioside in step (1). Gradient elution with a mixed solution of water and acetone, the concentration gradient of the mixed solution of water and acetone is 10%-35% (volume ratio)

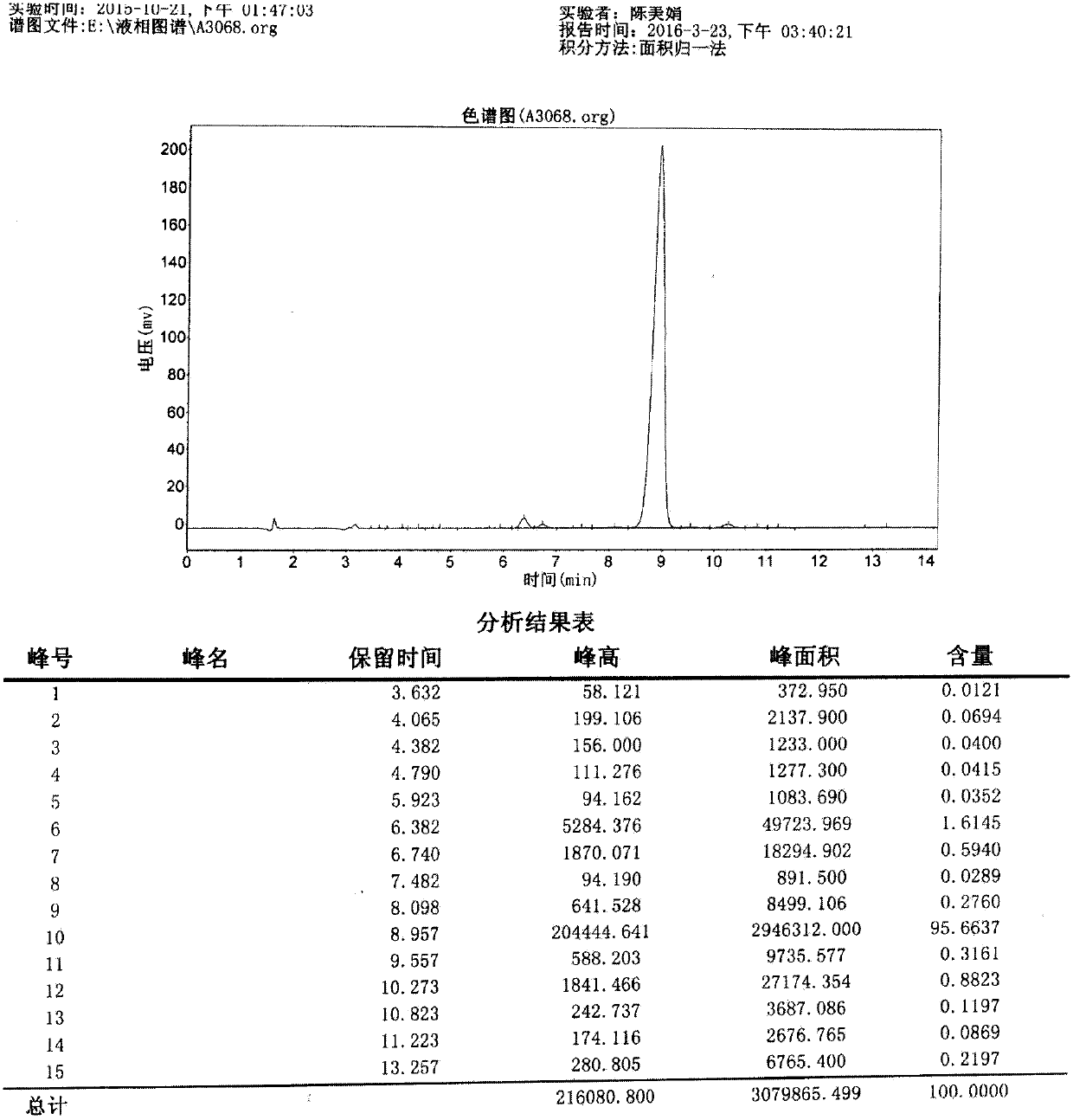

[0024] (3) Collect the elution solution eluted from the resin polymer chromatography column in sections, and then use high-performance liquid chromatography to analyze and detect it respectively. After the rebau...

Embodiment 2

[0030] Target raw material: 60kg of stevioside, purchased, including 24% stevioside, 27% rebaudioside A, 15.5% rebaudioside C, and the balance is impurities.

[0031] Chromatographic column: high-pressure industrial preparation column, column size 800*3000mm, filled with 1000L RohmHaasAmberlite1600.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com