Purification method of stevioside RC (rebaudioside C)

A technology of stevioside and purification method, which is applied in the field of purification of stevioside RC, and can solve problems such as no purification method of RC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

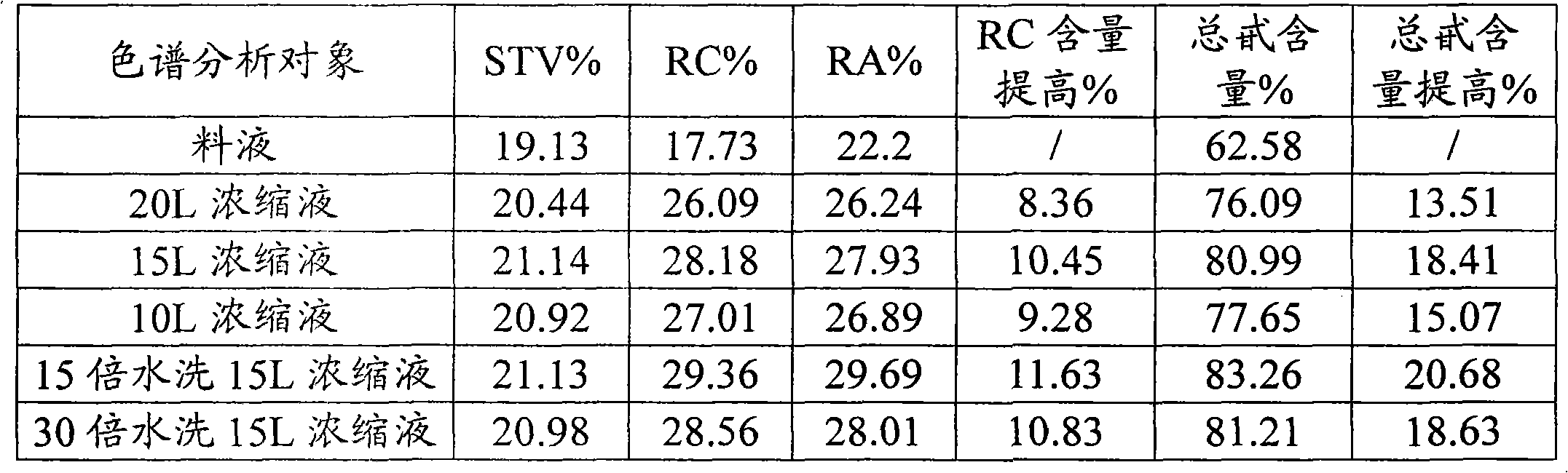

Embodiment 1

[0026] Embodiment 1: get mother liquor sugar, the content of RC recorded through liquid chromatography analysis is 17.73%, and total glucoside content is 62.58%. This mother liquor sugar is made into the feed liquid that mass concentration is 0.5%, takes feed liquid 300L, is 25-35L / m with flow velocity 2 The speed of h flows through the ultrafiltration membrane device produced by GE Company in the United States. During the process of the feed liquid flowing through the ultrafiltration membrane, interception is carried out according to the molecular weight of each component. The ultrafiltration pH is 7.2. The concentrated solution was intercepted in sections of 5 L, and the content of RC was detected by liquid chromatography analysis. The 8000 molecular weight membrane has a 1% interception of the mother liquor glycoside. When using the 5500-6500 membrane to treat the mother liquor sugar, it is found that the 6000 membrane can enrich 85%-90% of the sugar in the concentrated sol...

Embodiment 2

[0031] Embodiment 2: get 10 kilograms and 25 kilograms of 87% ethanol of 33.16% crude stevioside with RC content obtained in embodiment 1, 68% methyl alcohol, 87% acetone with 3: 2: 1 The mixed solvent made by fully mixing the proportions will rapidly drop to room temperature within 10 minutes after the dissolution is completed at 50°C. Stir the mixture for 4 minutes every 8 hours. After standing for 40 hours, separate the dissolved mixture from solid and liquid, and filter out The solid is added with no salt water to adjust the concentration to 22%, concentrated to 38%, and the solution is dried to obtain 3.0 kg of refined stevioside, the content of stevioside RC in this refined stevioside is 85.43%; the liquid obtained by solid-liquid separation Methanol, ethanol, acetone and excess water were distilled off, the concentration of stevioside aqueous solution was adjusted to 40%, and after drying, 5.8 kg of refined stevioside was obtained, and the total recovery rate of steviosi...

Embodiment 3

[0032]Embodiment 3: get the crude stevioside 10 kilograms and 30 kilograms of 83% ethanol, 72% methyl alcohol, 85% acetone with the ratio of 3:2:1 obtained in embodiment 1 with RC content of 33.16% Mix well to form a mixed solvent. After the dissolution is completed at 60°C, quickly drop to room temperature within 13 minutes. Stir the mixture for 6 minutes every 10 hours. After standing for 45 hours, separate the dissolved mixture through a plate and frame filter press for solid-liquid separation. , the filtered solid was added with anhydrous salt water to adjust the concentration to 20%, concentrated to 42%, and the solution was dried to obtain 2.6 kg of refined stevioside, the content of stevioside RC in the refined stevioside was 85.96%; solid-liquid Ethanol and excess water were evaporated from the separated liquid, and the concentration of the stevioside aqueous solution was adjusted to 42%. After drying, 5.9 kg of refined stevioside was obtained, and the total recovery ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com