Patents

Literature

470results about "Sugar products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

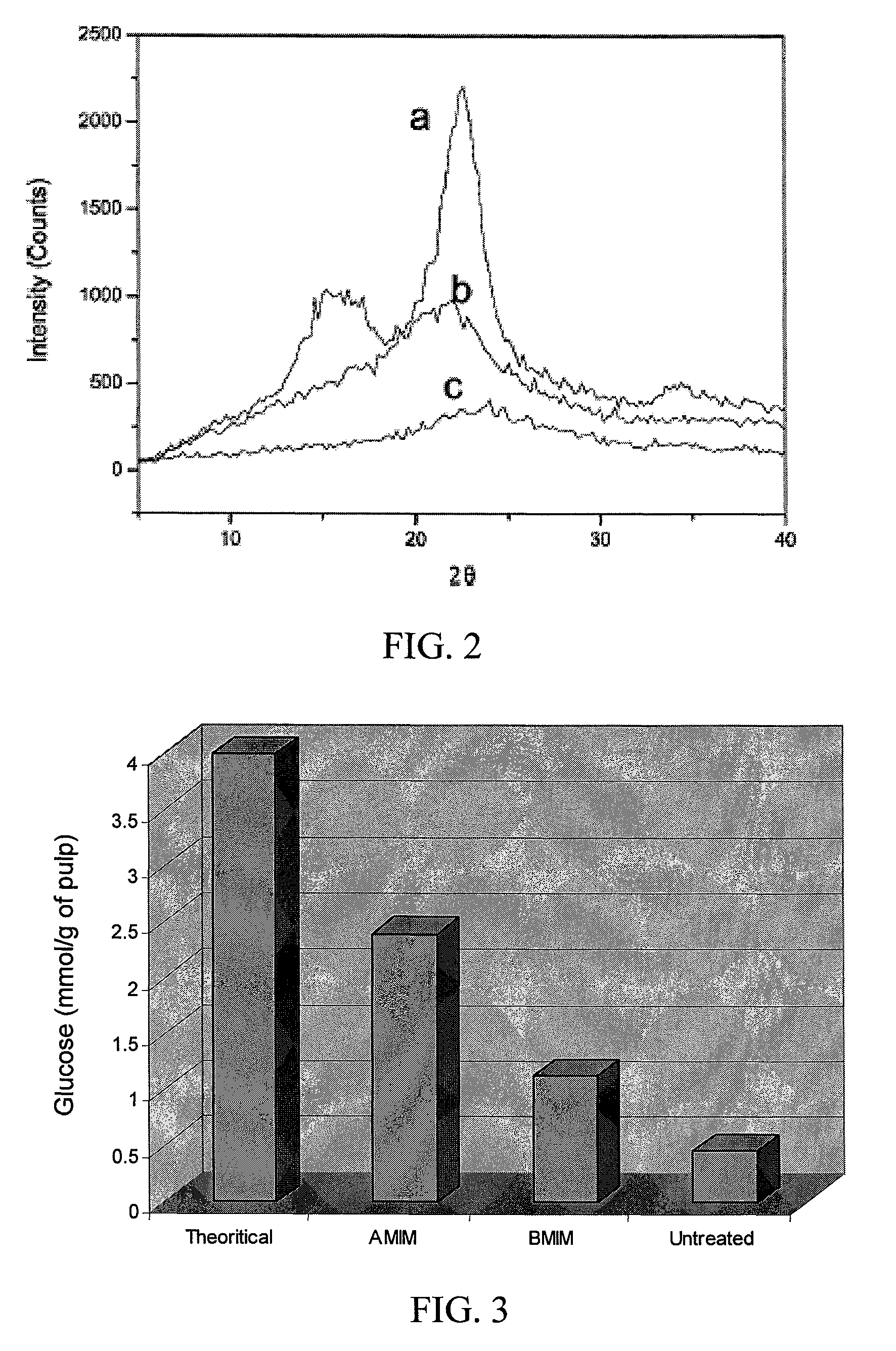

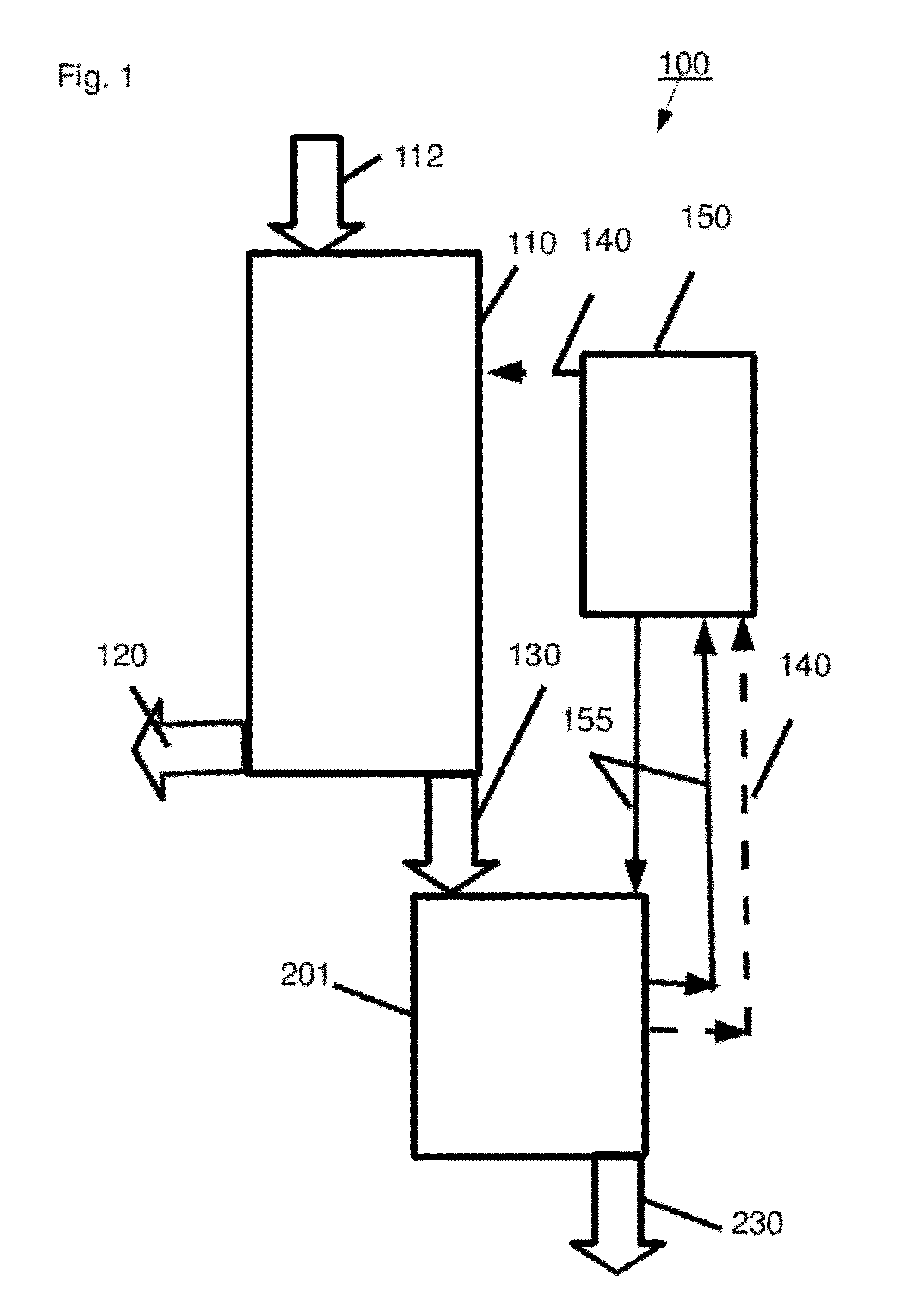

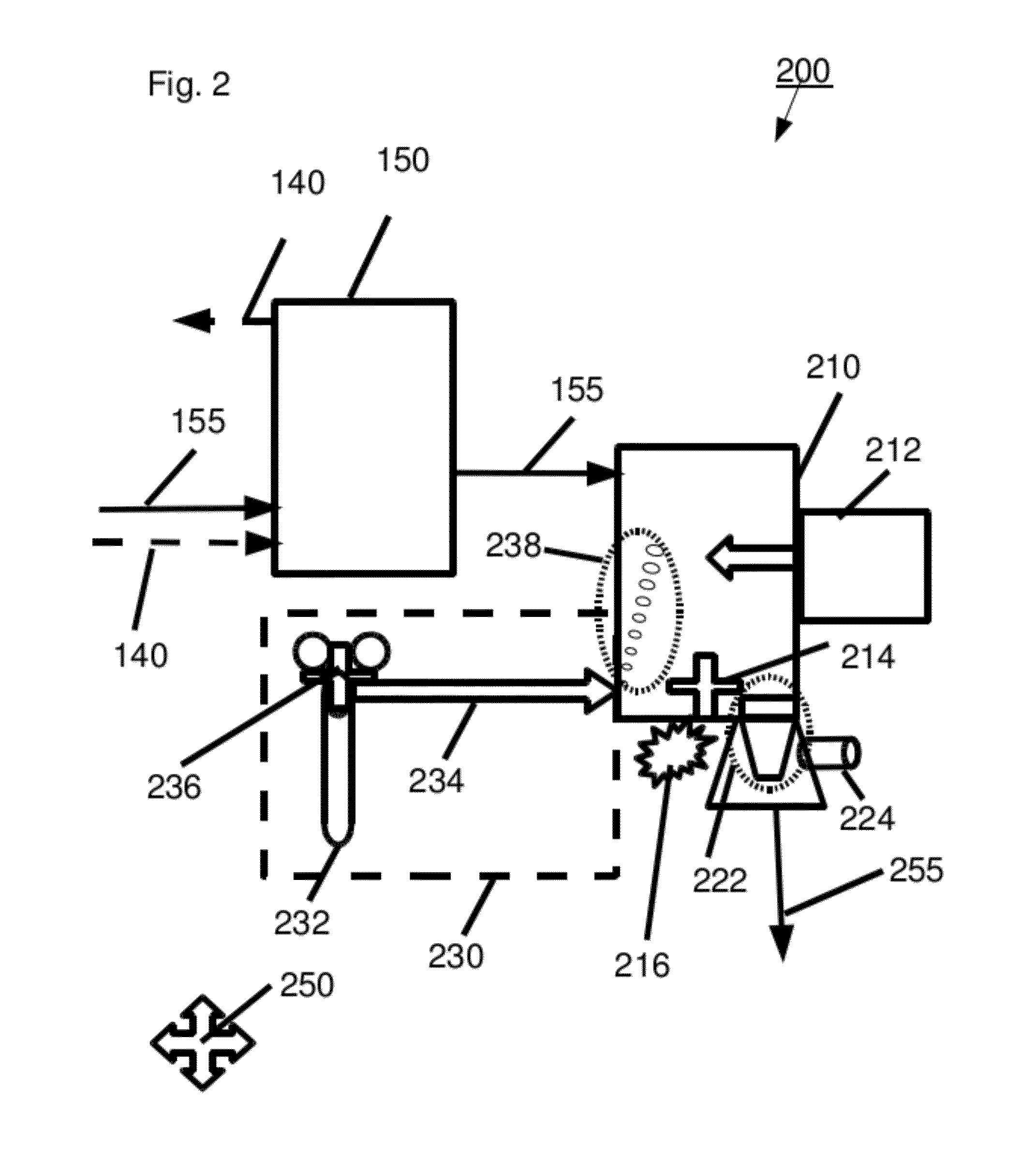

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

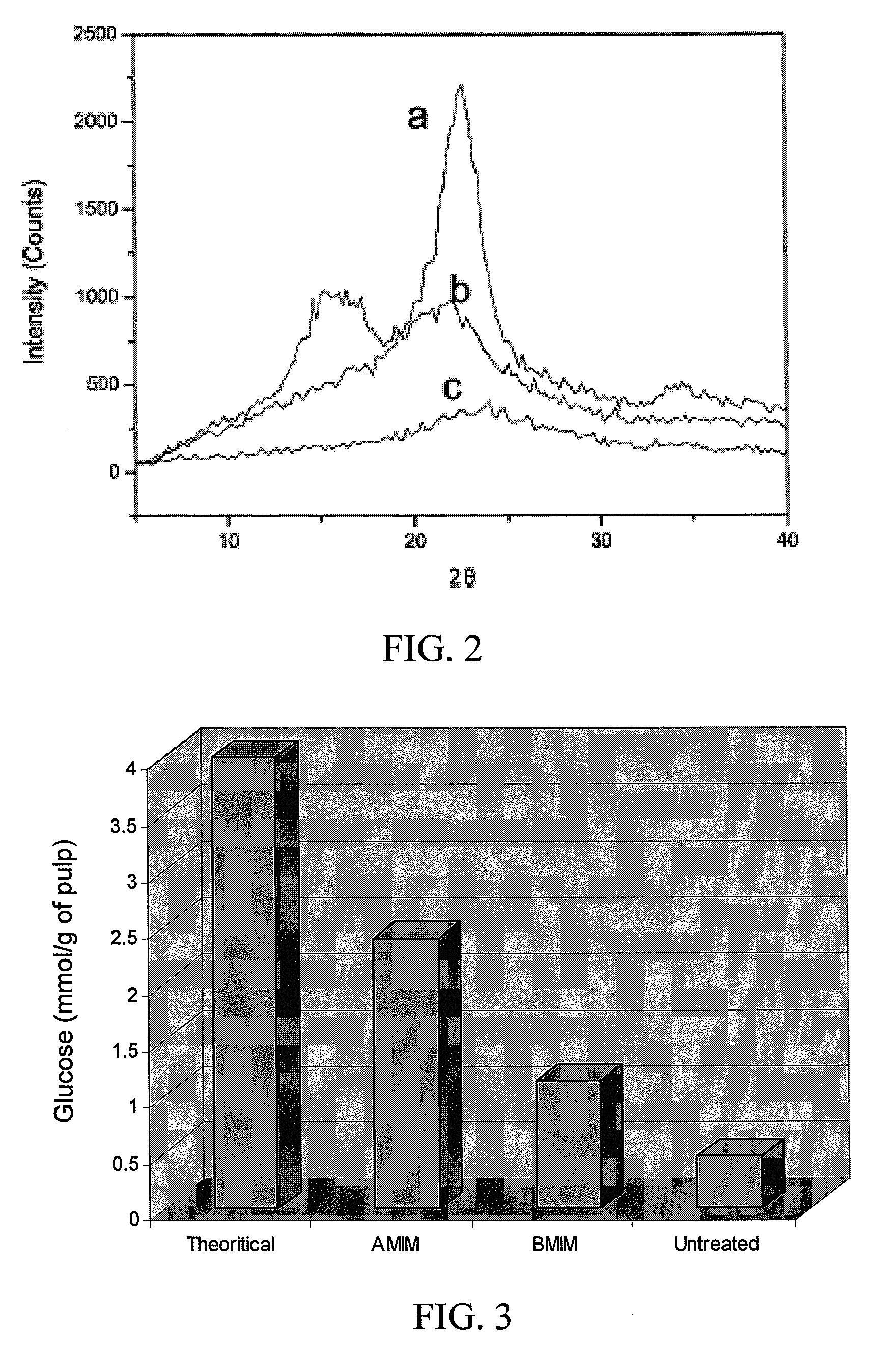

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

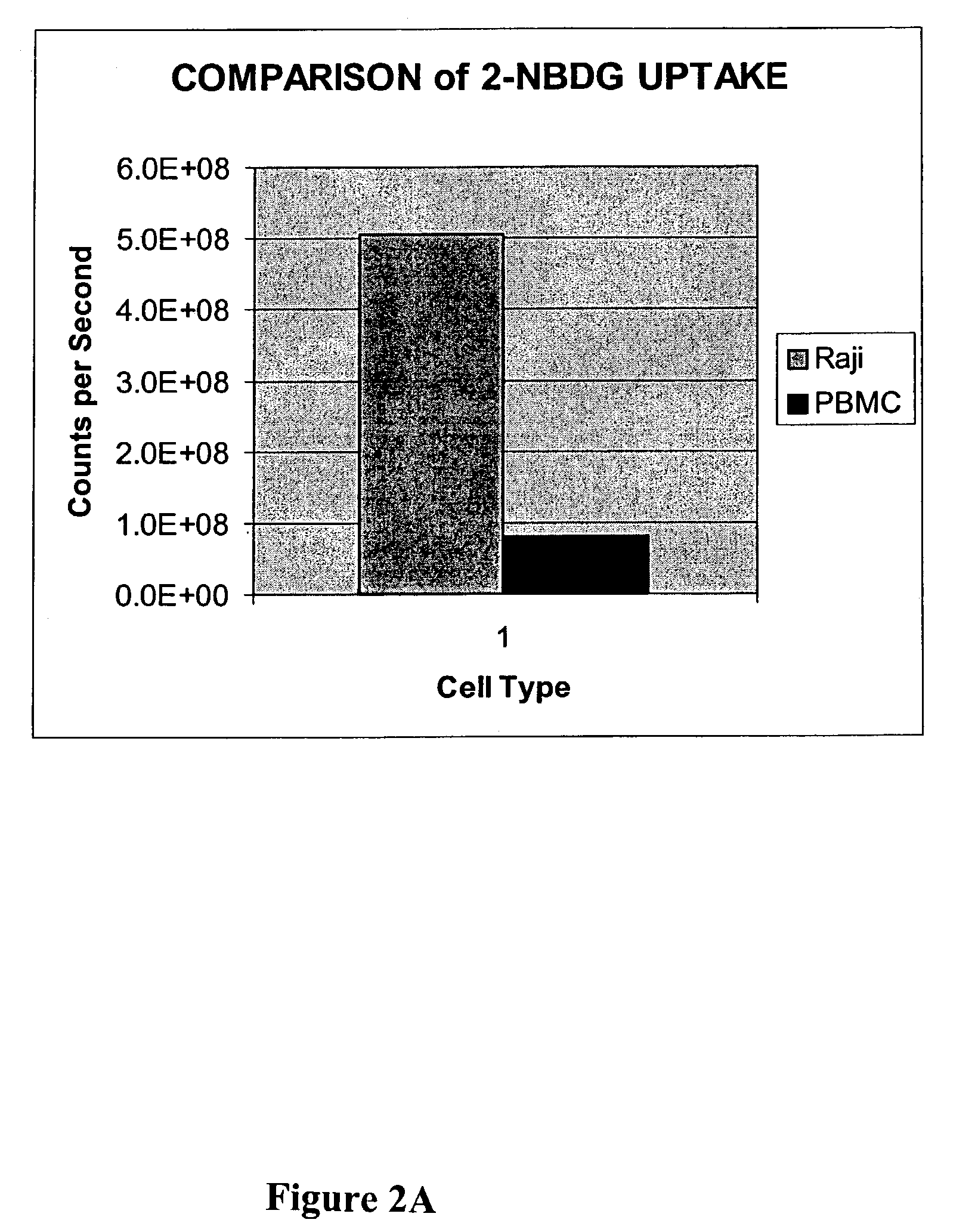

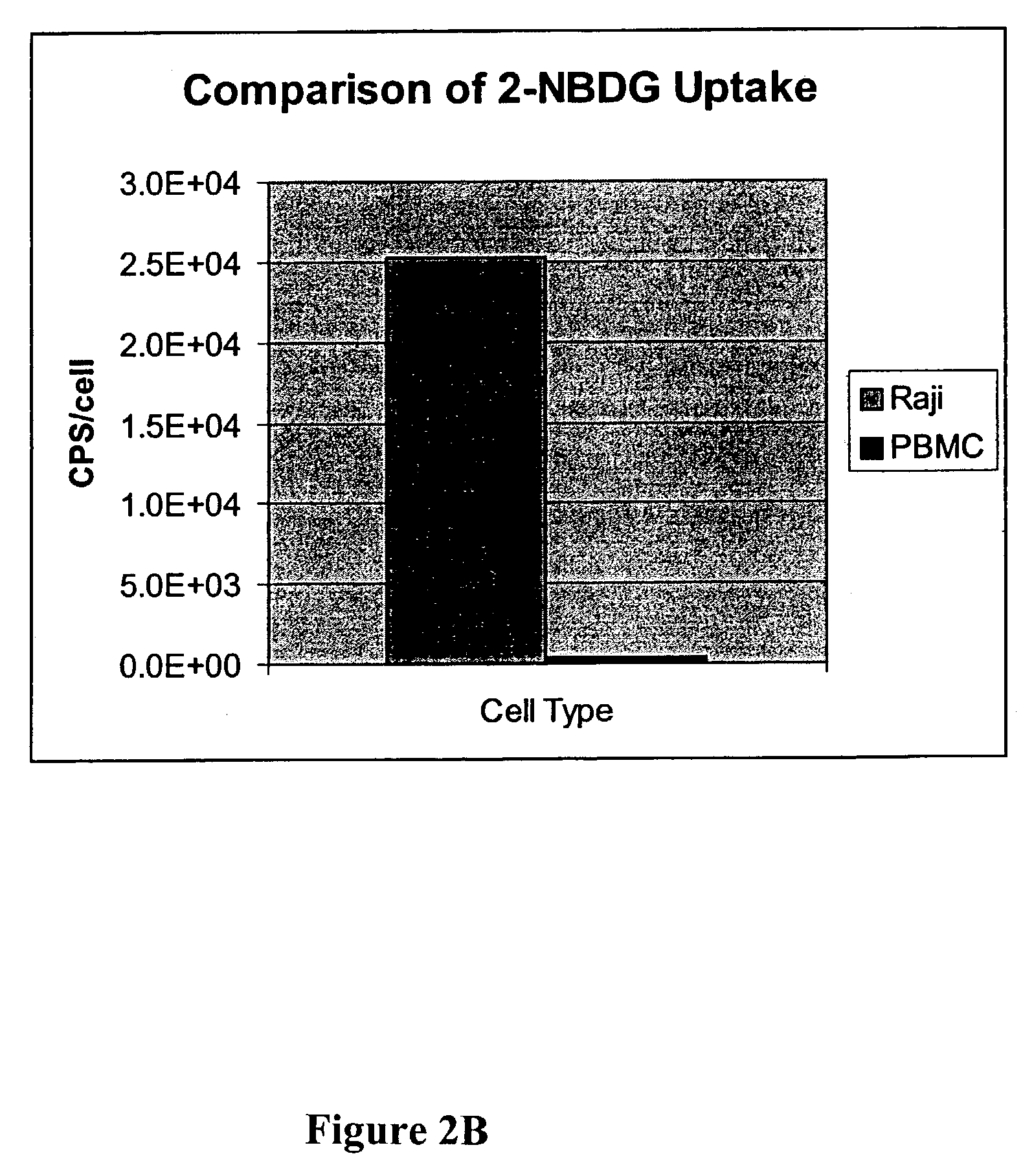

Methods for cancer imaging

InactiveUS6989140B2Ultrasonic/sonic/infrasonic diagnosticsIn-vivo radioactive preparationsCancer cellFluorescence

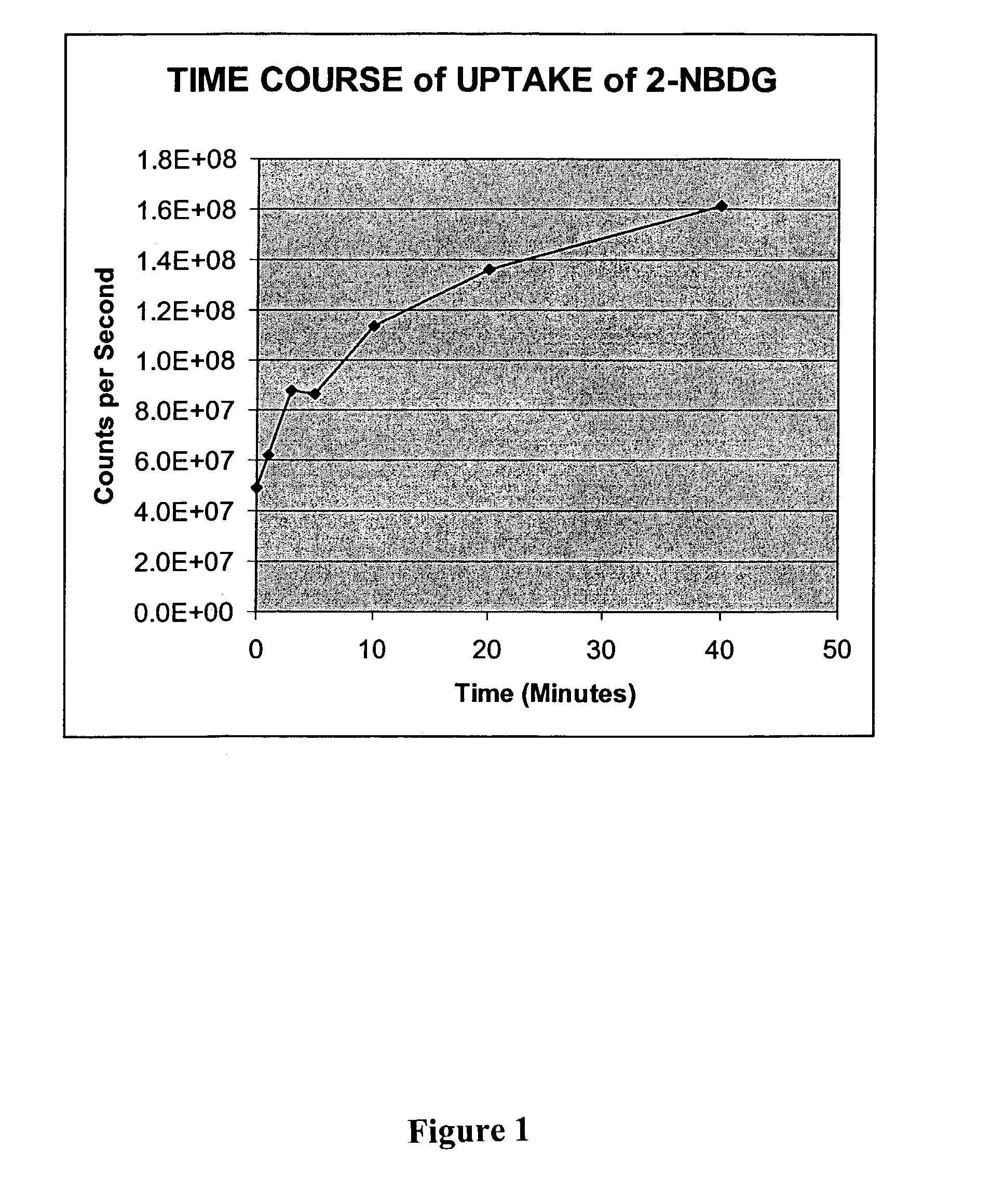

Methods are provided for cancer and pre-cancer detection by increased uptake of fluorophore glucose or deoxyglucose conjugates in cancerous and pre-cancerous cells relative to normal cells.

Owner:THRESHOLD PHARM INC

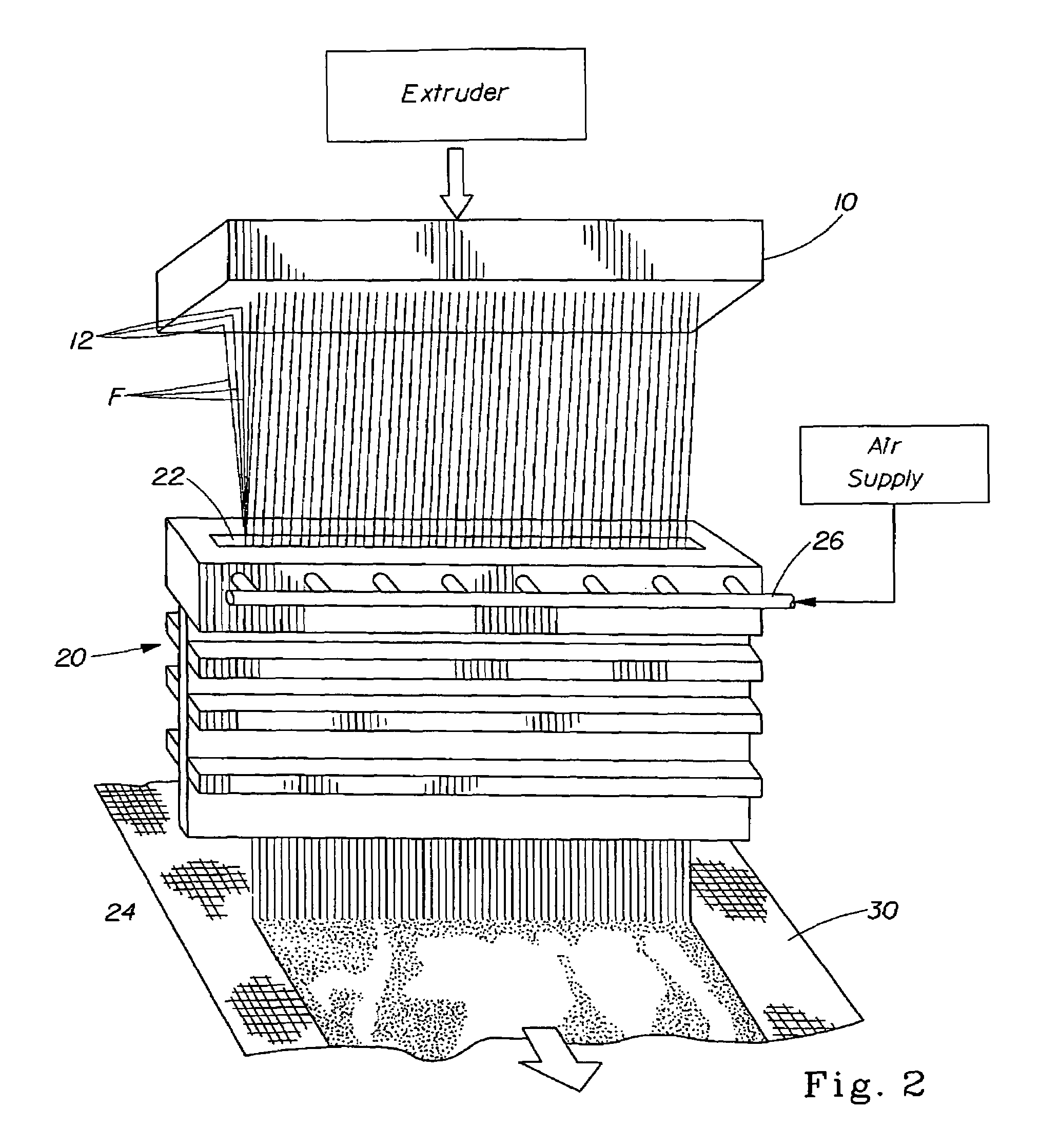

Melt processable starch composition

The present invention relates to starch compositions which contain starch and additives. The starch has a weight average molecular weight ranging from about 1,000 to about 2,000,000. The additives can be plasticizers or diluents. The composition containing the starch and the additive is formed by means of passing the composition through a die to produce fibers, foams or films. These compositions have an extensional viscosity in the range from about 50 to about 20,000 pascal seconds. The starch compositions preferably contain a polymer that is substantially compatible with starch and has a weight-average molecular weight of at least 500,000.

Owner:THE PROCTER & GAMBLE COMPANY

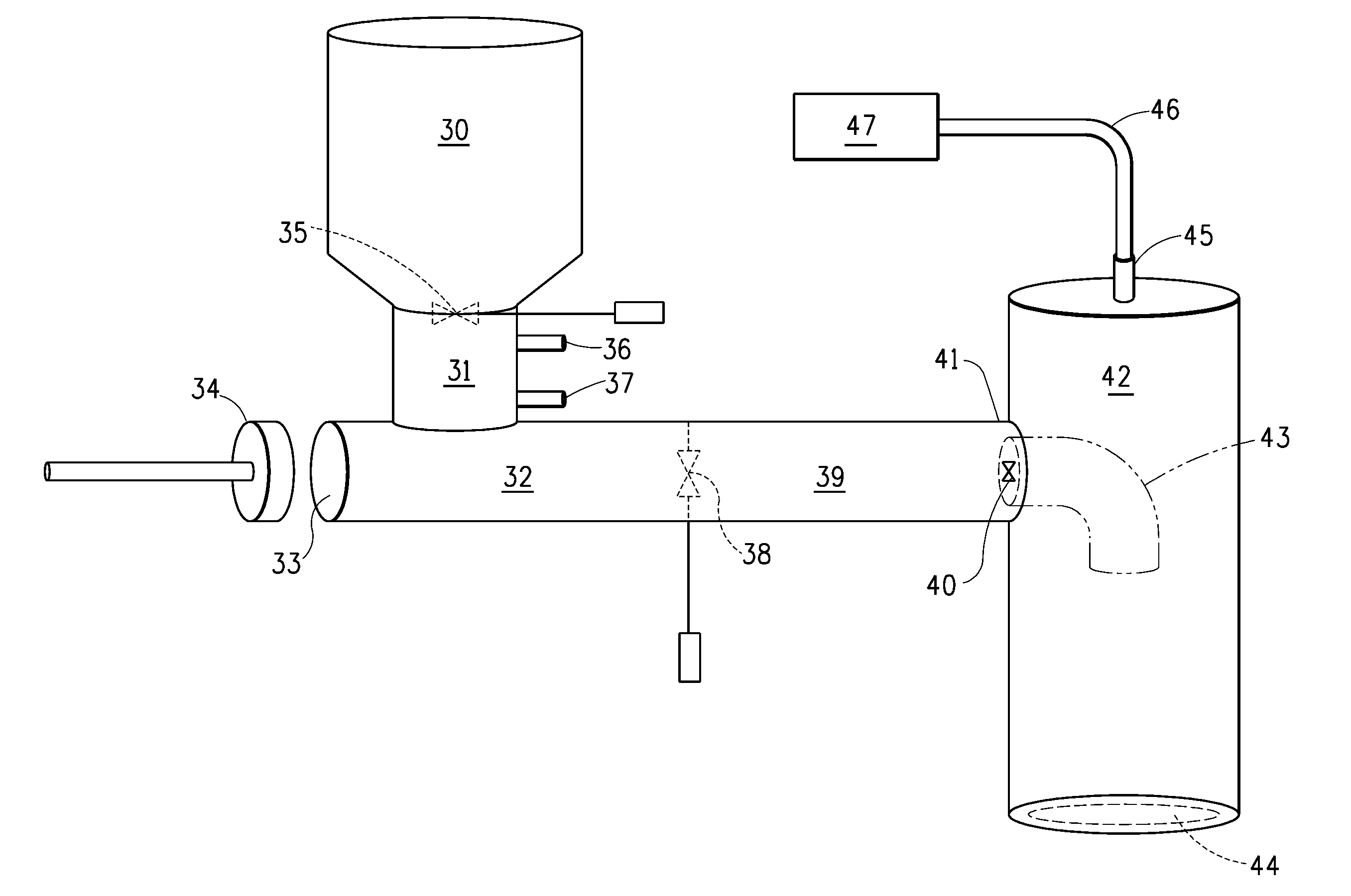

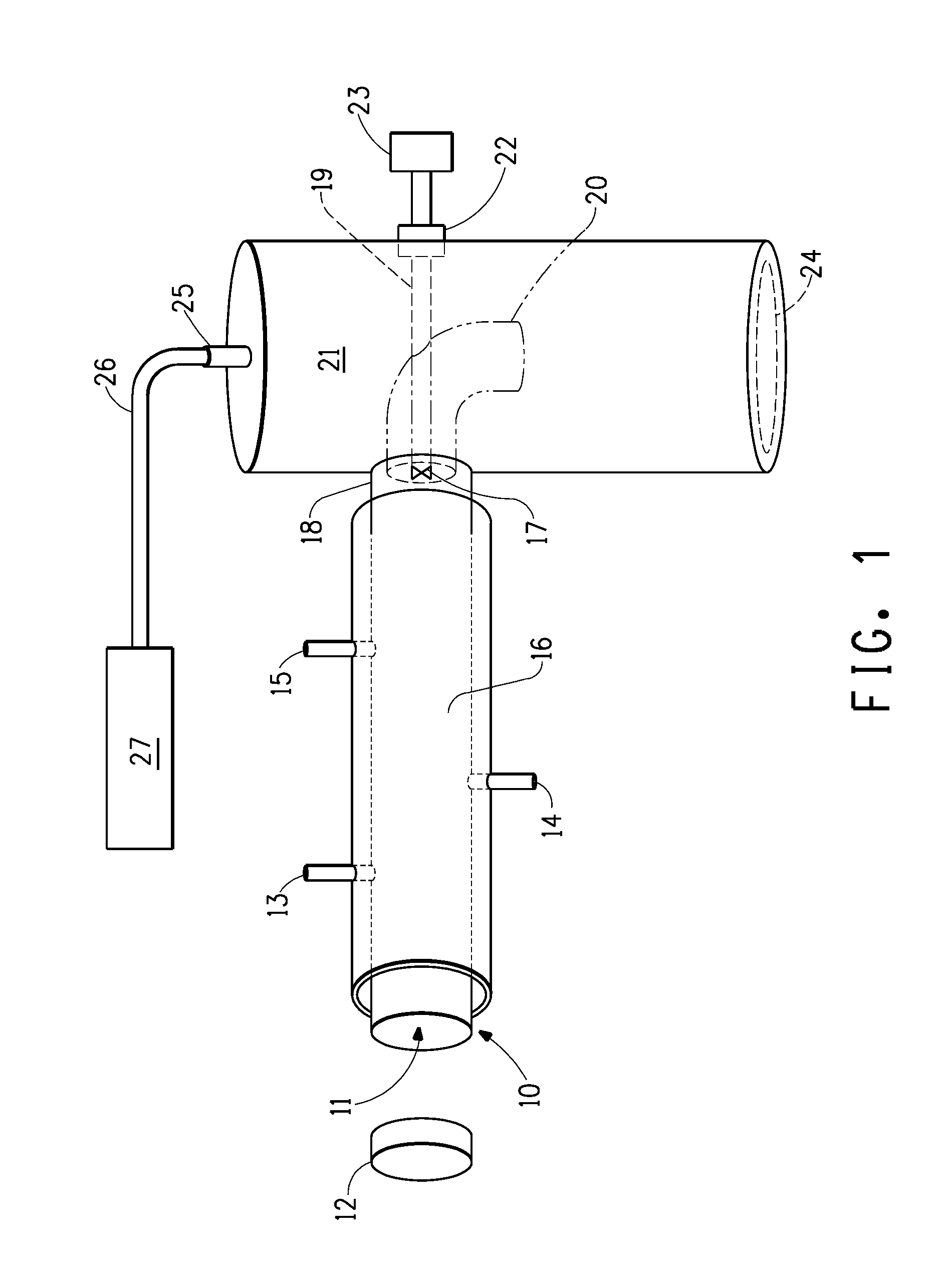

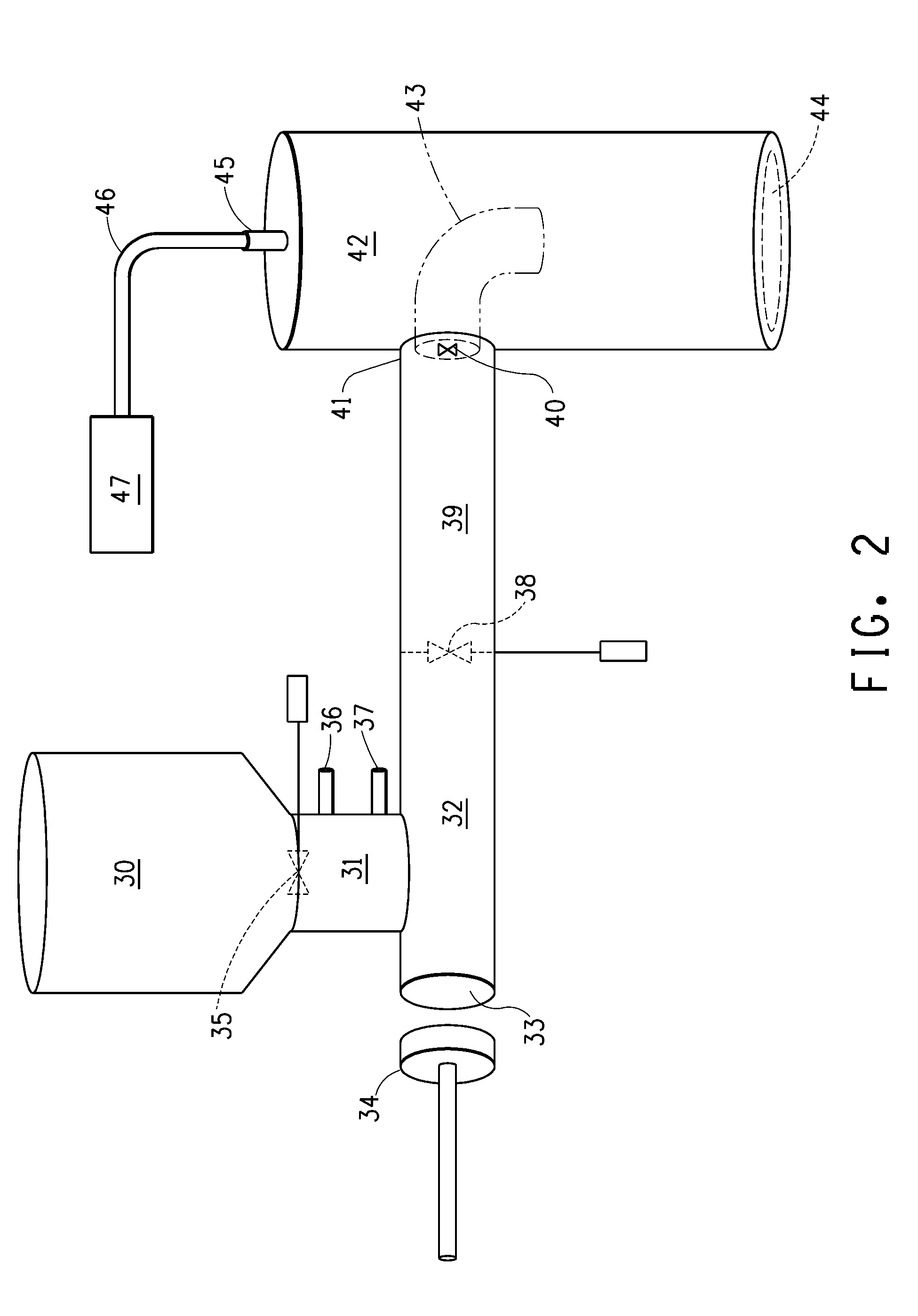

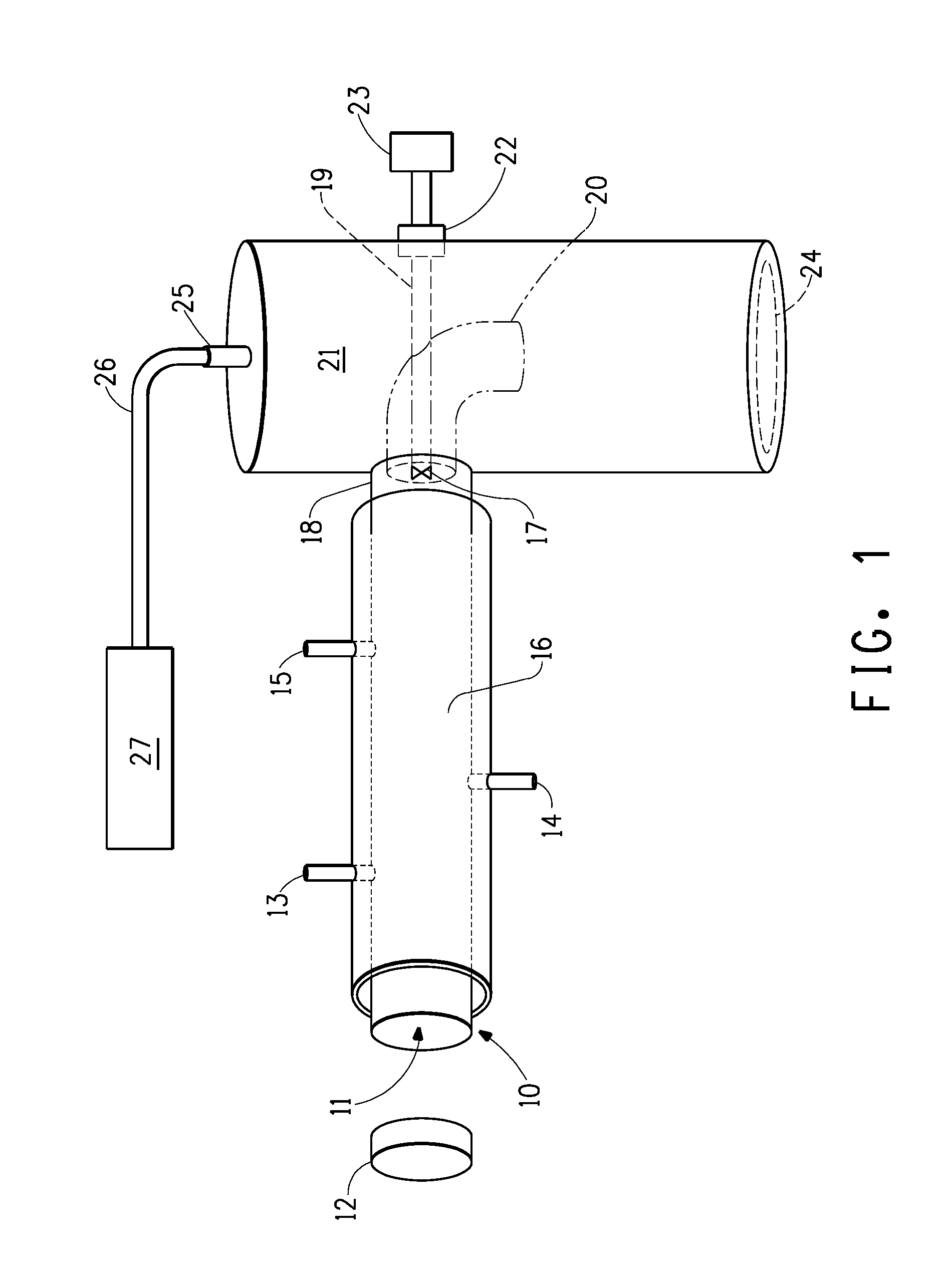

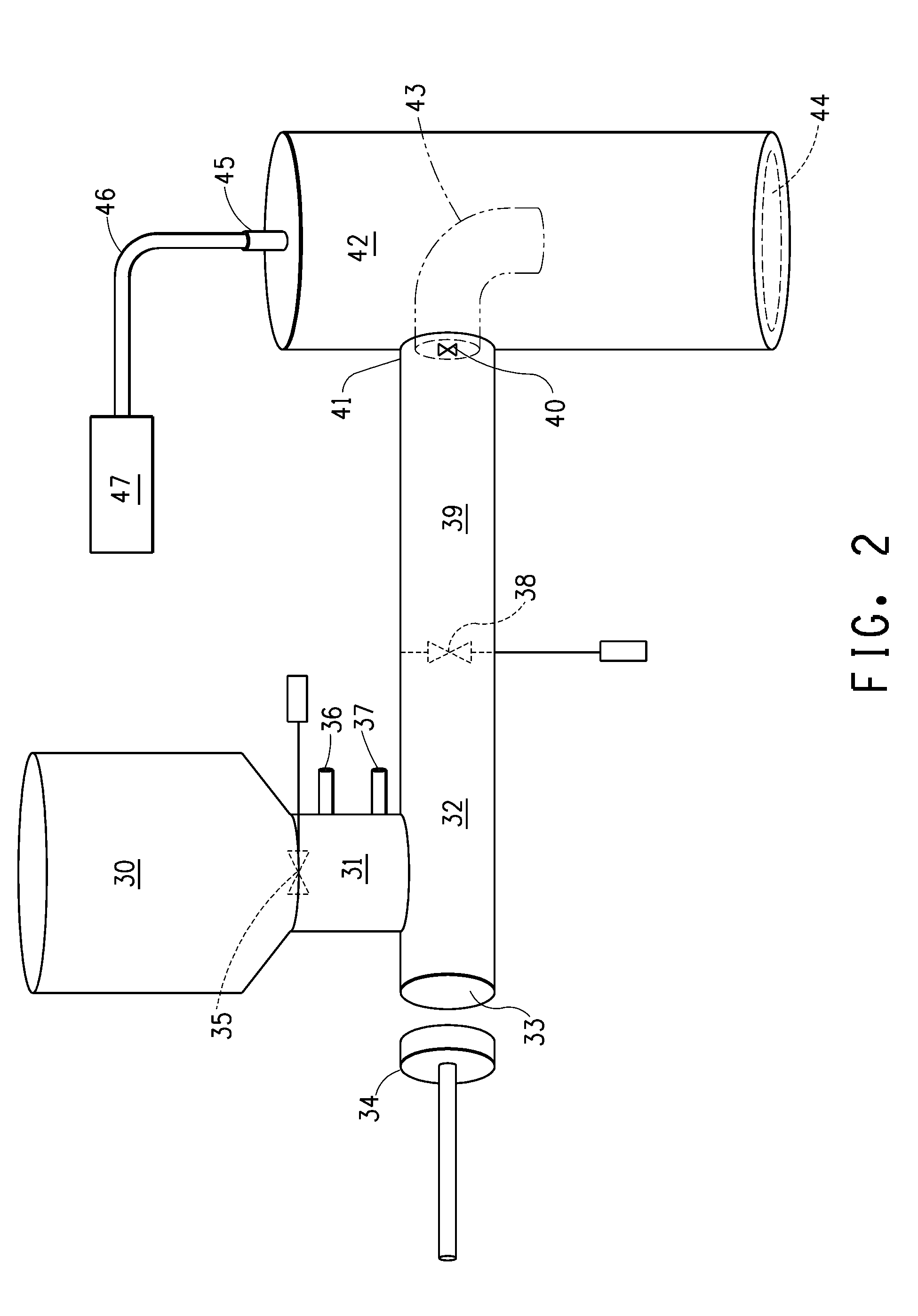

Biomass Treatment Method

InactiveUS20090050134A1Small sizeIncrease surface areaPressurized chemical processSugar productsFermentable sugarAmmonia

A method for treating biomass was developed that uses an apparatus which moves a biomass and dilute aqueous ammonia mixture through reaction chambers without compaction. The apparatus moves the biomass using a non-compressing piston. The resulting treated biomass is saccharified to produce fermentable sugars.

Owner:SUSTAINABLE TECH CORP +1

Drilling fluid additive with low freezing point

ActiveUS8673825B2Reduce coefficient of frictionImprove the lubrication effectSugar productsFlushingLiquid mediumSugar

A drilling fluid additive, is provided, and the additive comprises: syrup solids and a liquid medium; and the sugar content of the additive is directly proportionate to the freezing point of the additive.

Owner:MUD MASTERS ACQUISITION CORP

Crystallization of sugars

InactiveUS6579375B2Reduce in quantityPromote growthDough treatmentMilk preservationCrystallinitySolvent

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

Air drilling misting fluid contains syrups

ActiveUS7964537B2Reduce coefficient of frictionImprove the lubrication effectSugar productsFlushingLiquid mediumGolden syrup

Owner:MUD MASTERS ACQUISITION CORP

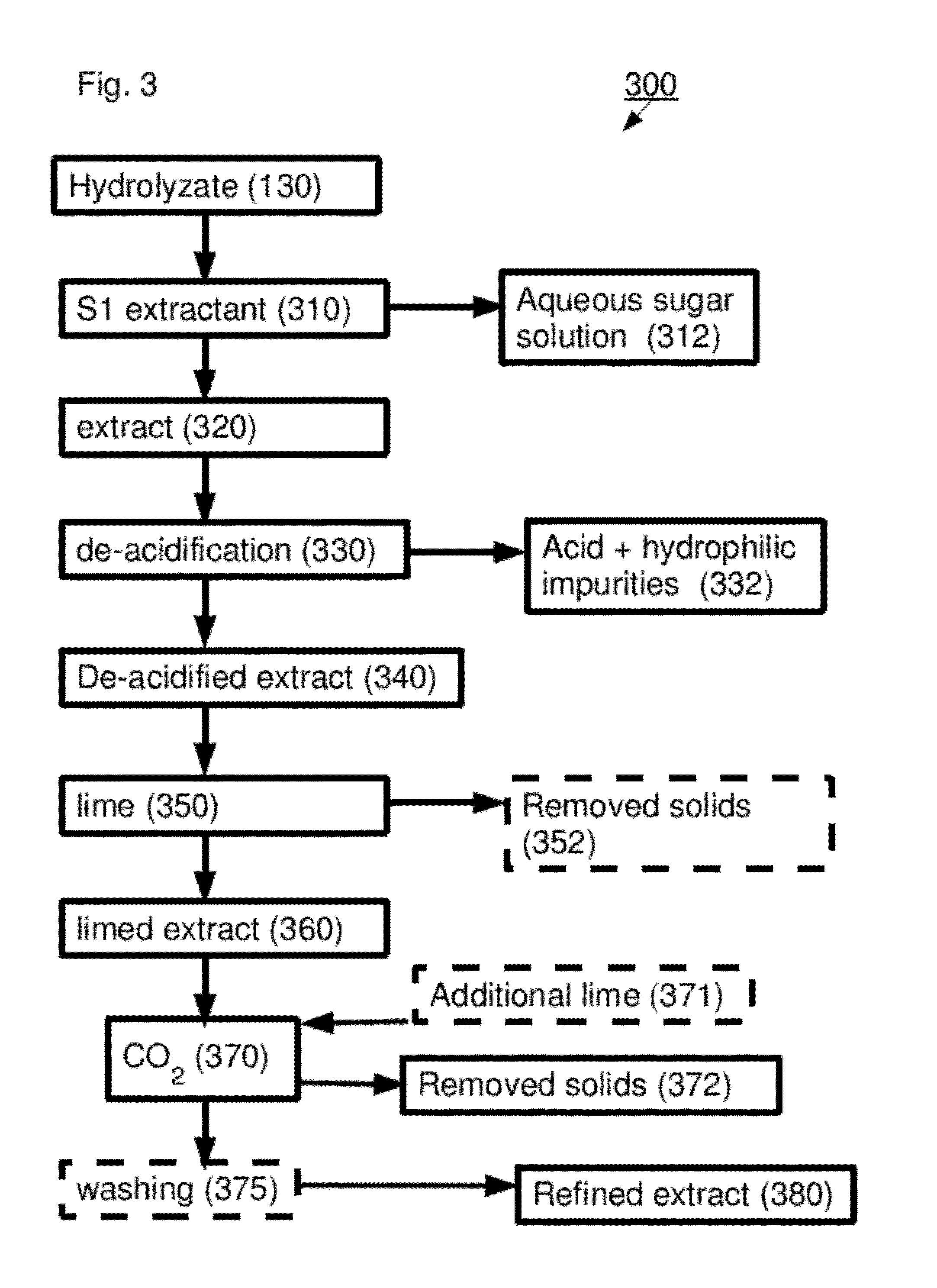

Method for extracting soluble sugar molecules from biomass material

InactiveUS20110318796A1Amount of removedDegree of eliminationSugar productsBiofuelsMicroorganismHydrolysate

Methods are provided for preparing a hydrolysate containing soluble sugar molecules from biomass that contains cellulose and hemicellulose. Hemicellulose sugars are extracted in the process, and the resulting hydrolysate may be used to support microbial fermentation to produce products of interest.

Owner:TALFRYN

Oligosaccharide-supplying compositions

InactiveUS6750331B1Easy to useEvenly dispersedSugar productsAntibiotics chemistryOligosaccharideNuclear chemistry

The present invention provides an oligosaccharide-supplying composition which contains 10 to 80% by weight of oligosaccharide, 0.3 to 10% by weight of a foaming component and 0.9 to 30% by weight of a neutralizing component and is in the form of foaming chewable tablets. The composition is highly useful in practice, has a uniform composition, excellent texture and high stability and can be easily taken.

Owner:OTSUKA PHARM CO LTD

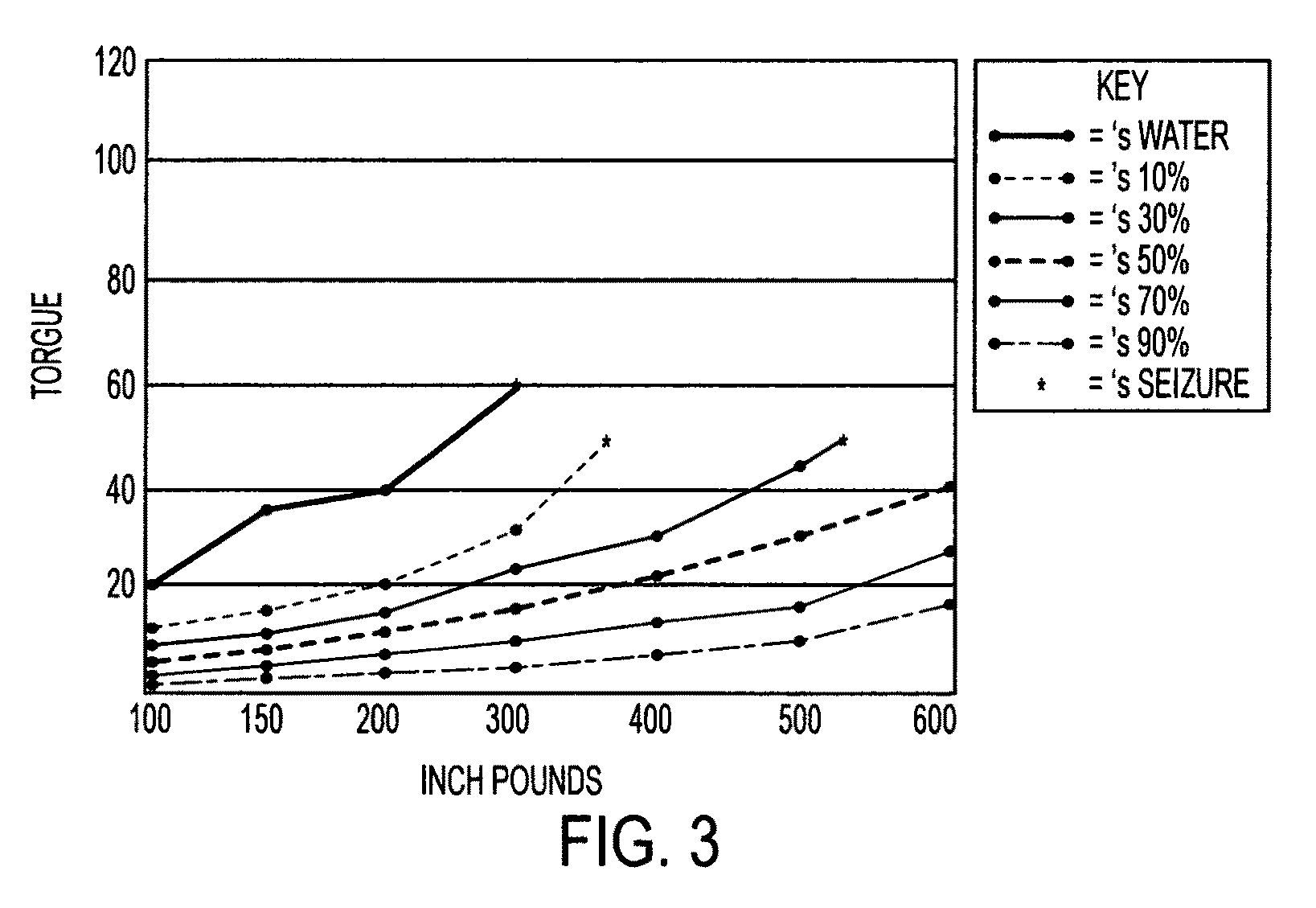

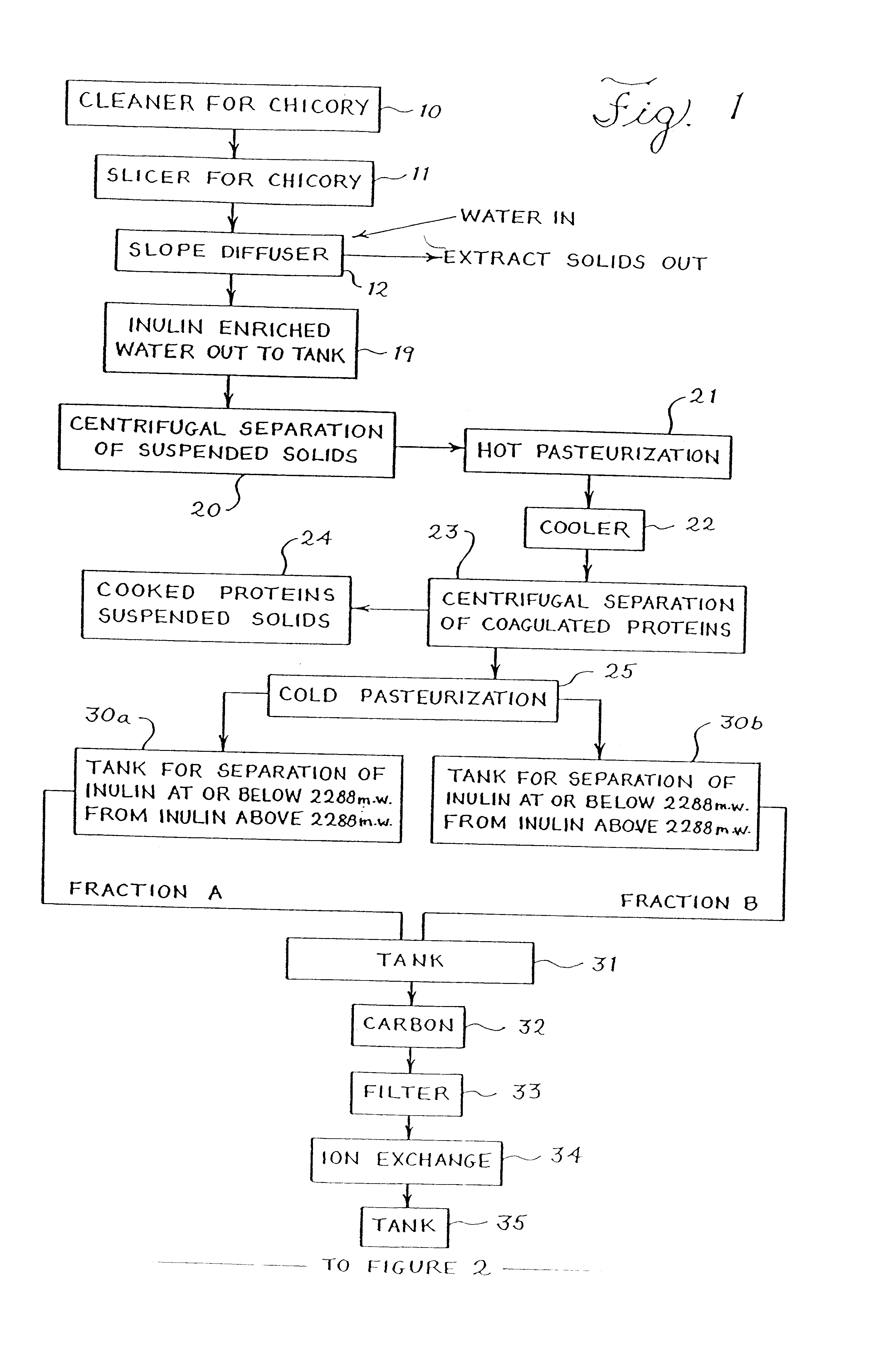

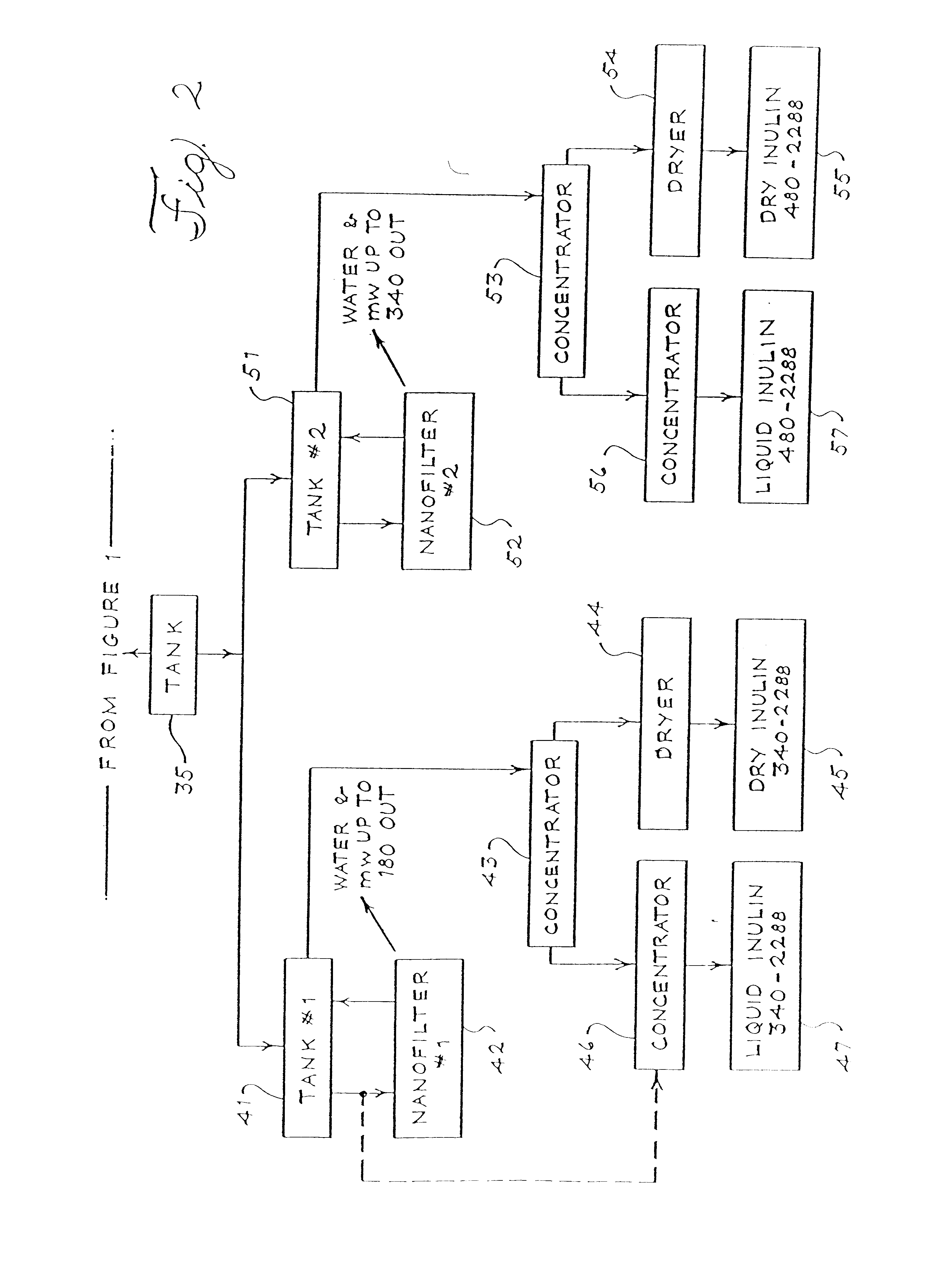

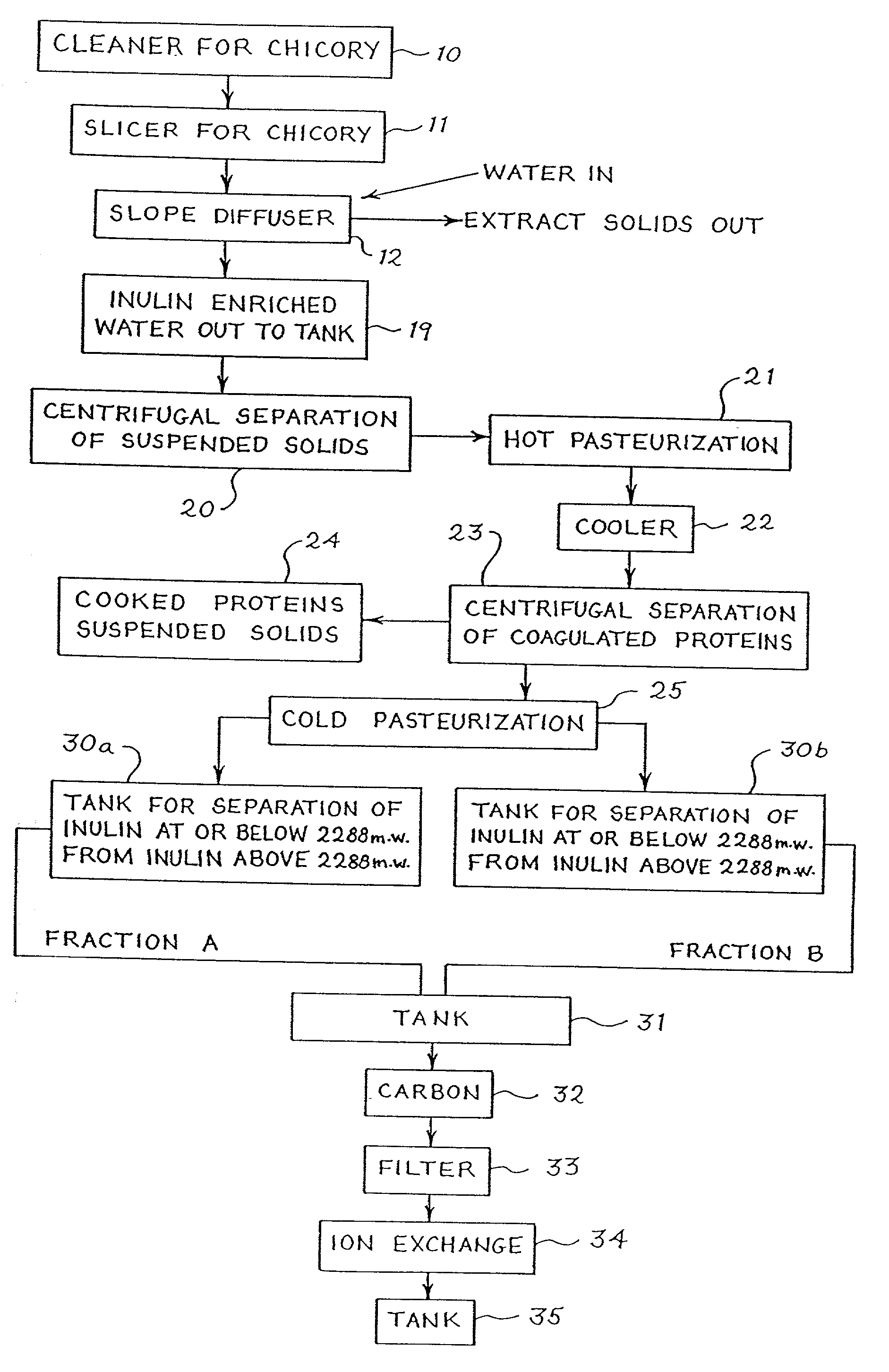

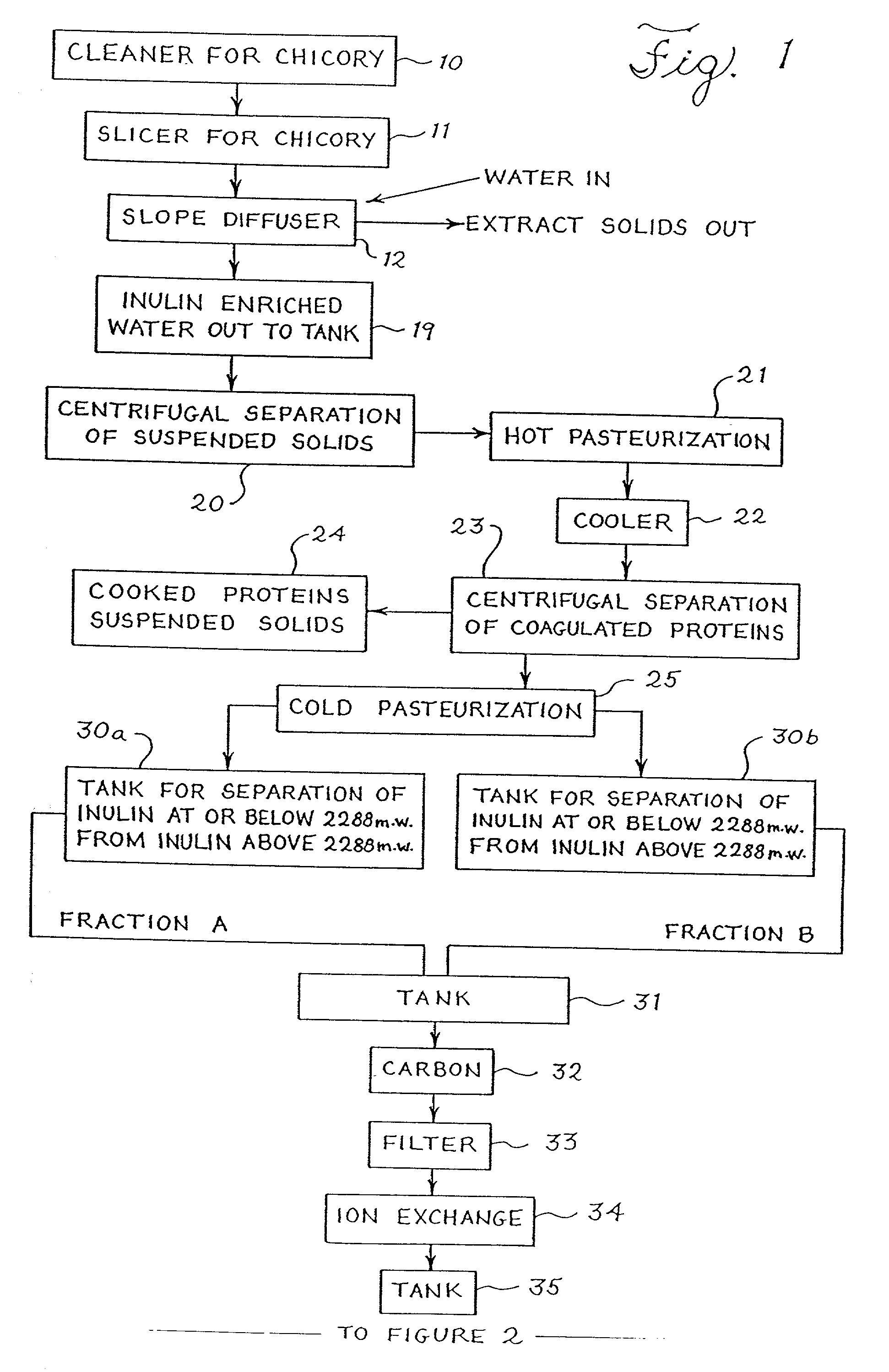

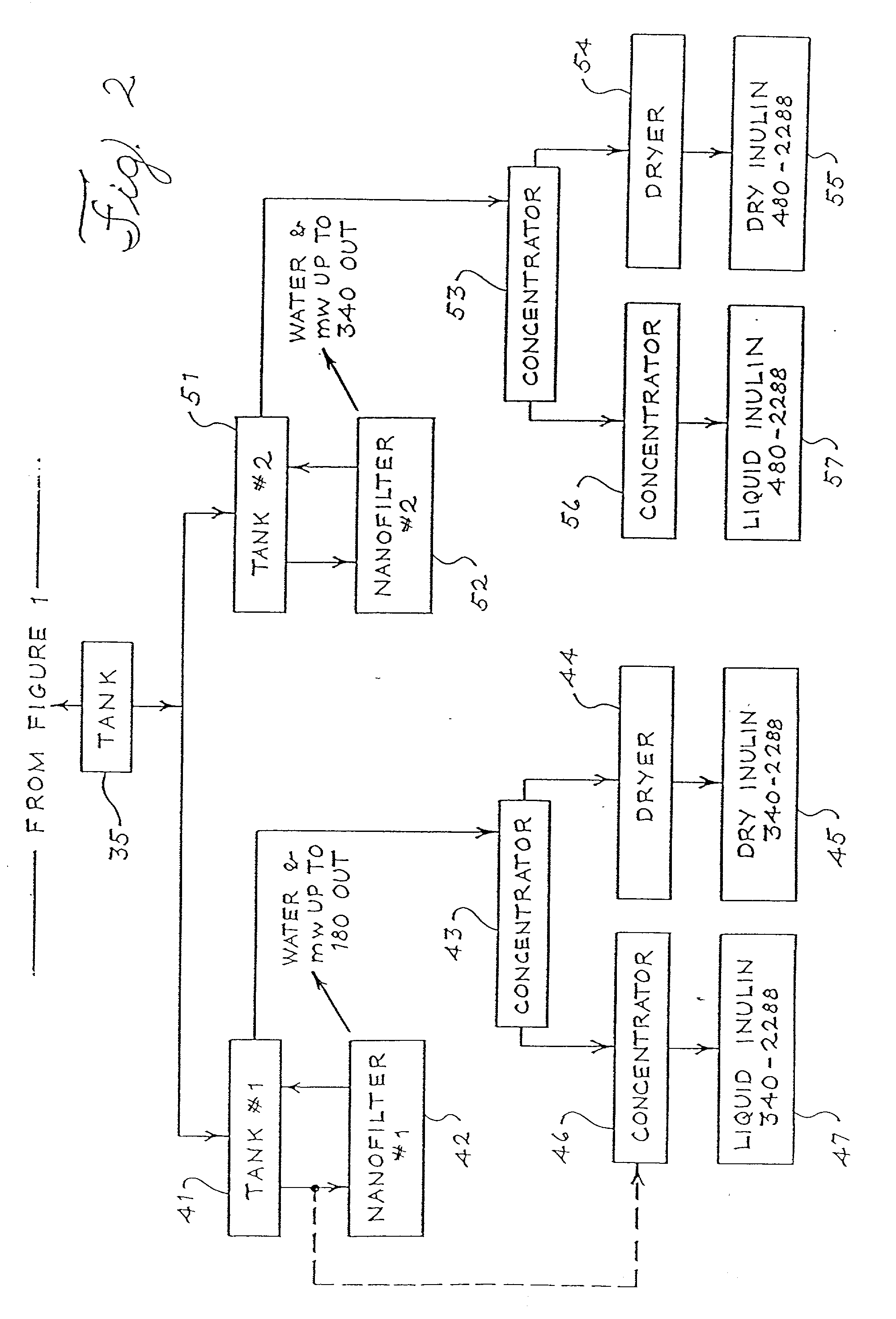

Processes for making novel inulin products

InactiveUS6569488B2Improve propertiesImprove solubilityMilk preparationSugar food ingredientsInulinWater soluble

The process for preparing the novel inulin products includes extracting inulin with water from subdivided plant materials, holding the inulin rich extraction water in a settling tank while maintaining the temperature from about 0° C. to 7° C. which causes higher molecular weight polysaccharides to separate from water soluble lower molecular weight polysaccharides, and separating the higher molecular weight inulin fructose fractions from the more water soluble lower molecular weight inulin fractions.

Owner:SILVER BARNARD STEWART

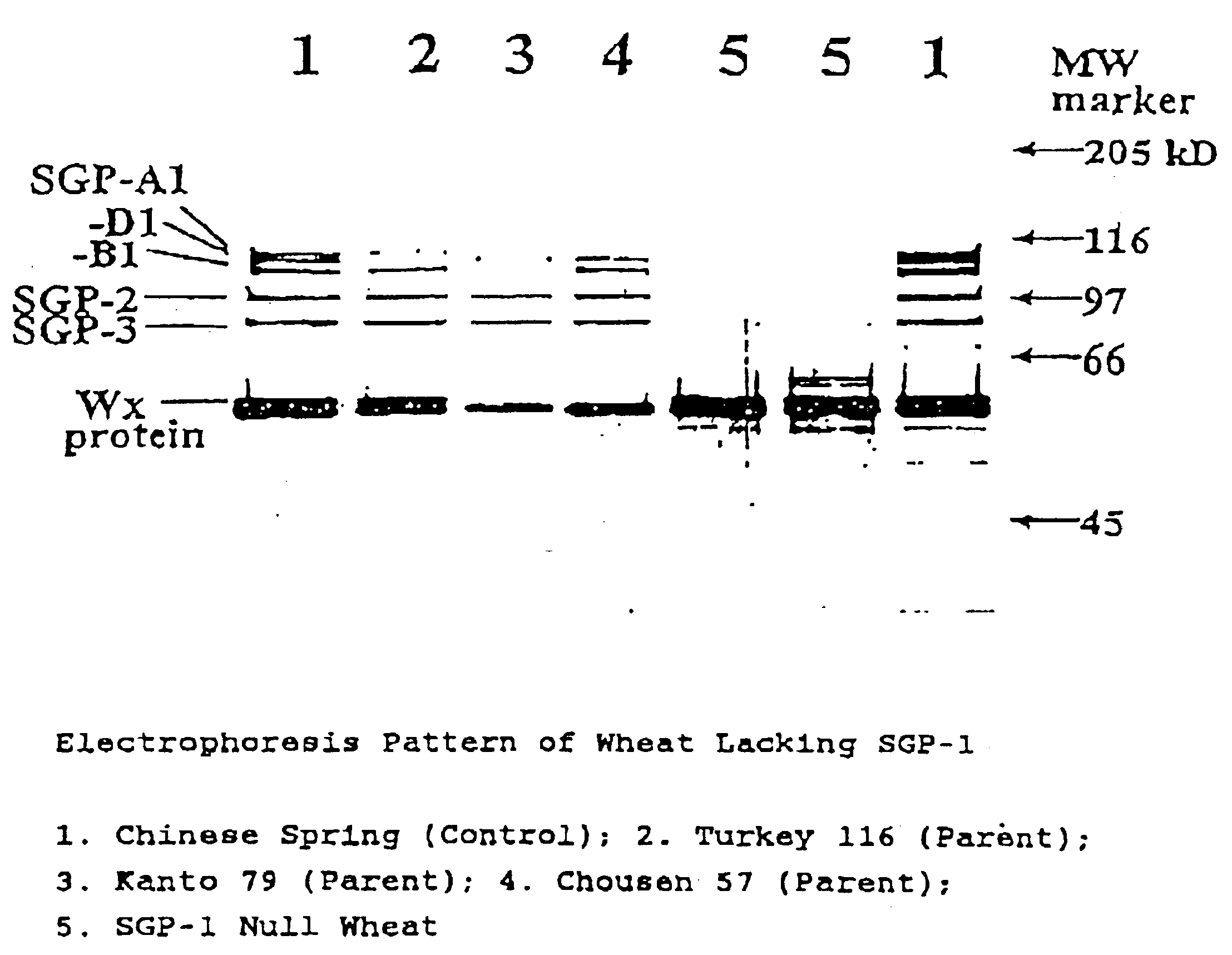

High amylose wheat starch and wheat containing the same

Wheat starch of the present invention is obtained from endosperm of a seed of wheat which is modified to lack starch granule protein-1 (SGP-1). The wheat starch has an apparent amylose content of about 35% or more. Wheat flour of the present invention is obtained from endosperm of a seed of wheat which is modified to lack SGP-1. Wheat of the present invention is modified to lack SGP-1. The wheat flour and the wheat comprise wheat starch which has an apparent amylose content of about 35% or more.

Owner:NAT INST OF AGROBIOLOGICAL SCI

Crystallization of sugars

InactiveUS20030084898A1Attractive bright and shiny appearanceProduced conveniently and consistentlyMilk preservationDough treatmentNucleationCrystallinity

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

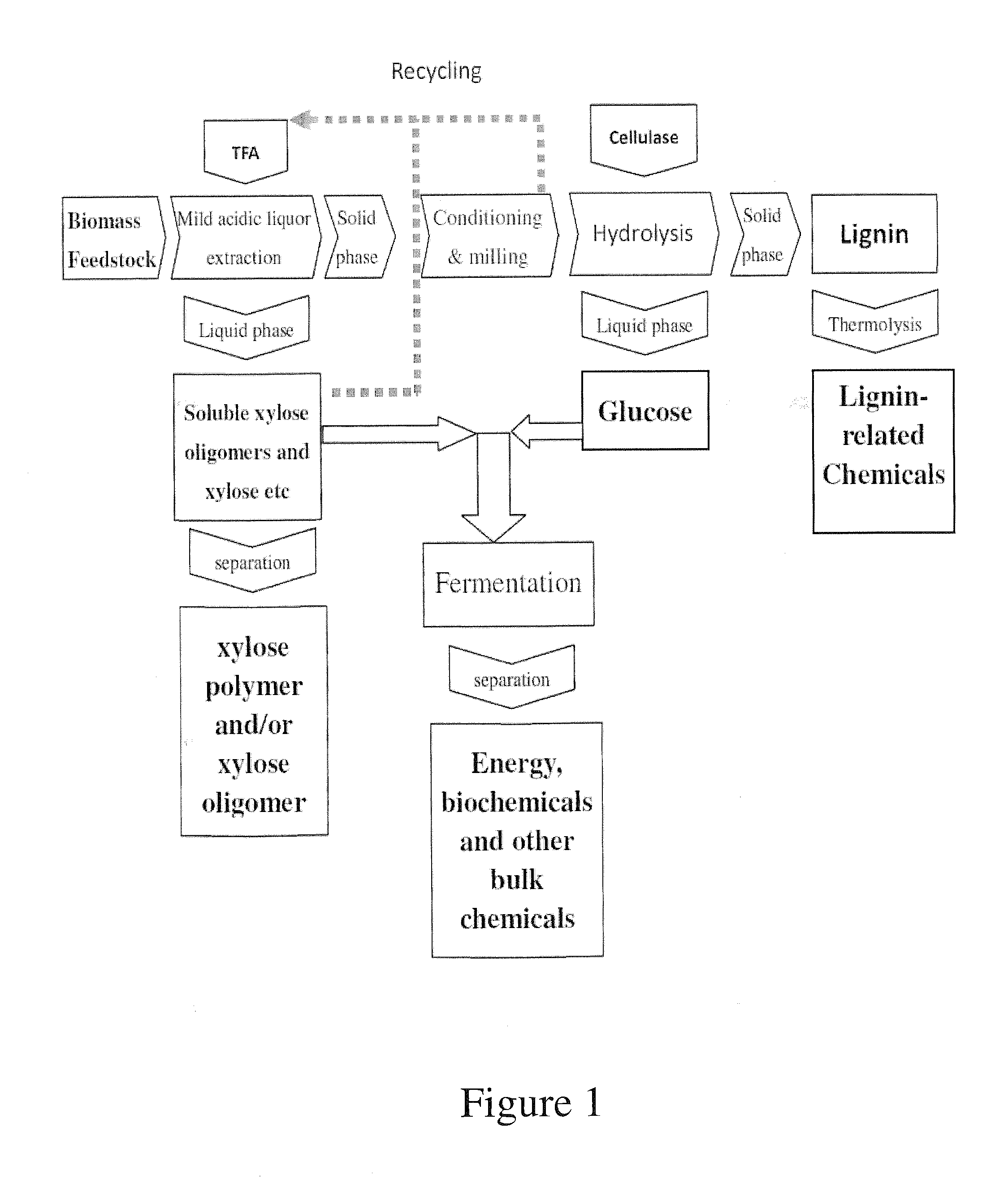

Process for biomass conversion

InactiveUS20100297704A1Easy to GrindIncrease ratingsSugar productsPretreatment with acid reacting compoundsPolymer scienceEnergy products

The present invention relates to a clean process of preparing high grade biomass products, and their use in the production of health care products, bio-energy products, biochemicals, bio-originated chemicals and biodegradable plastics.

Owner:LI RONGXIU

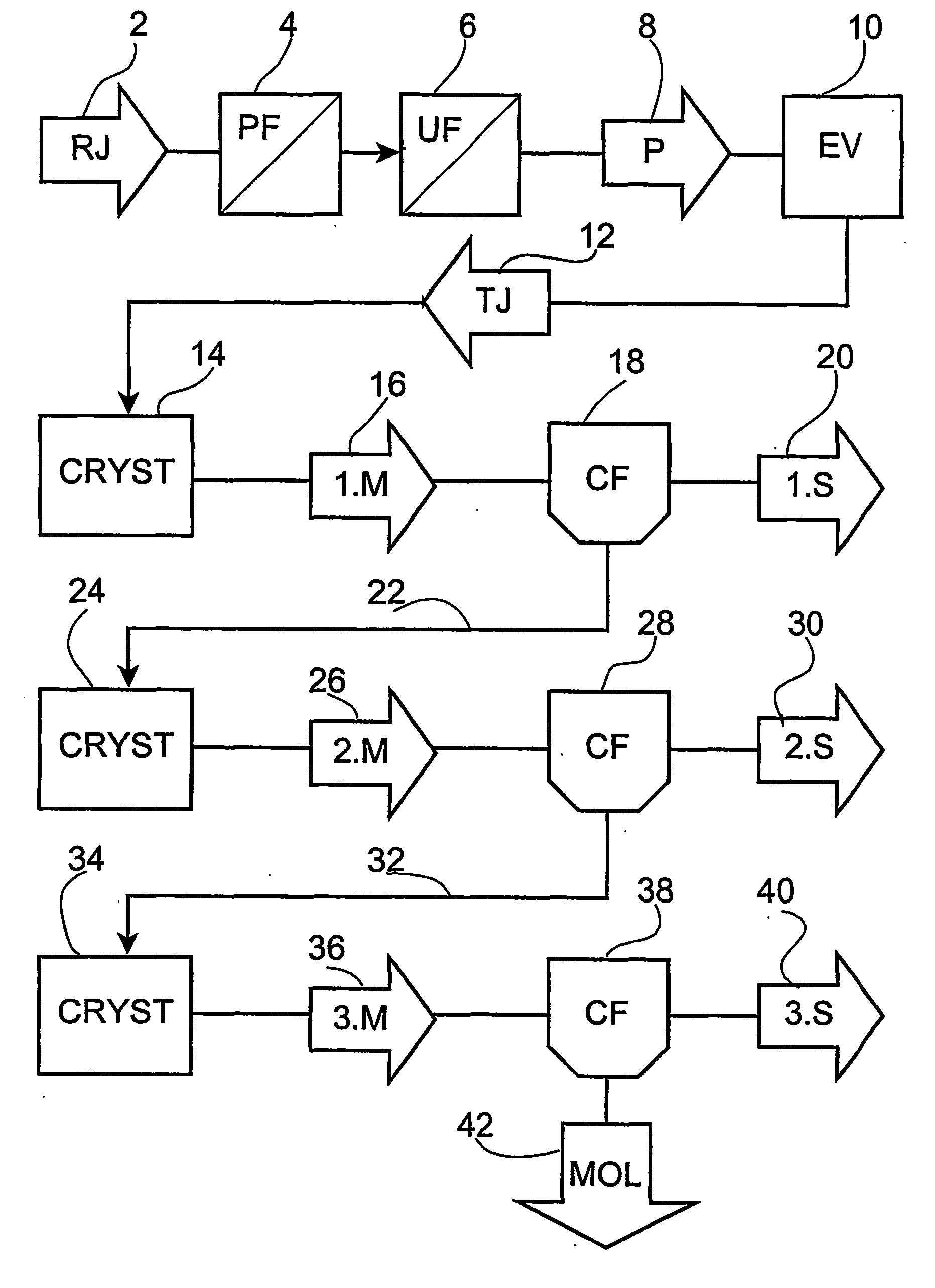

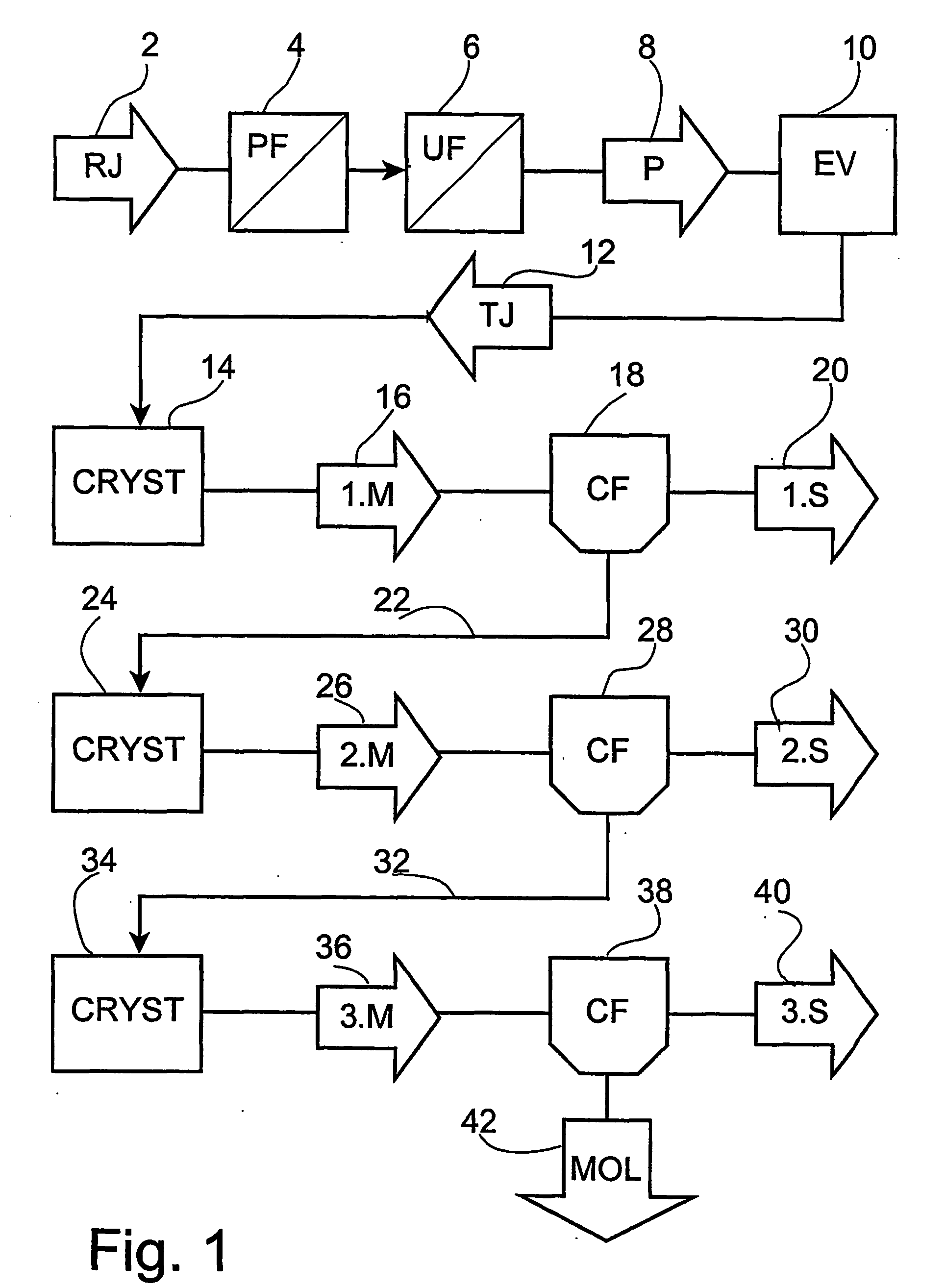

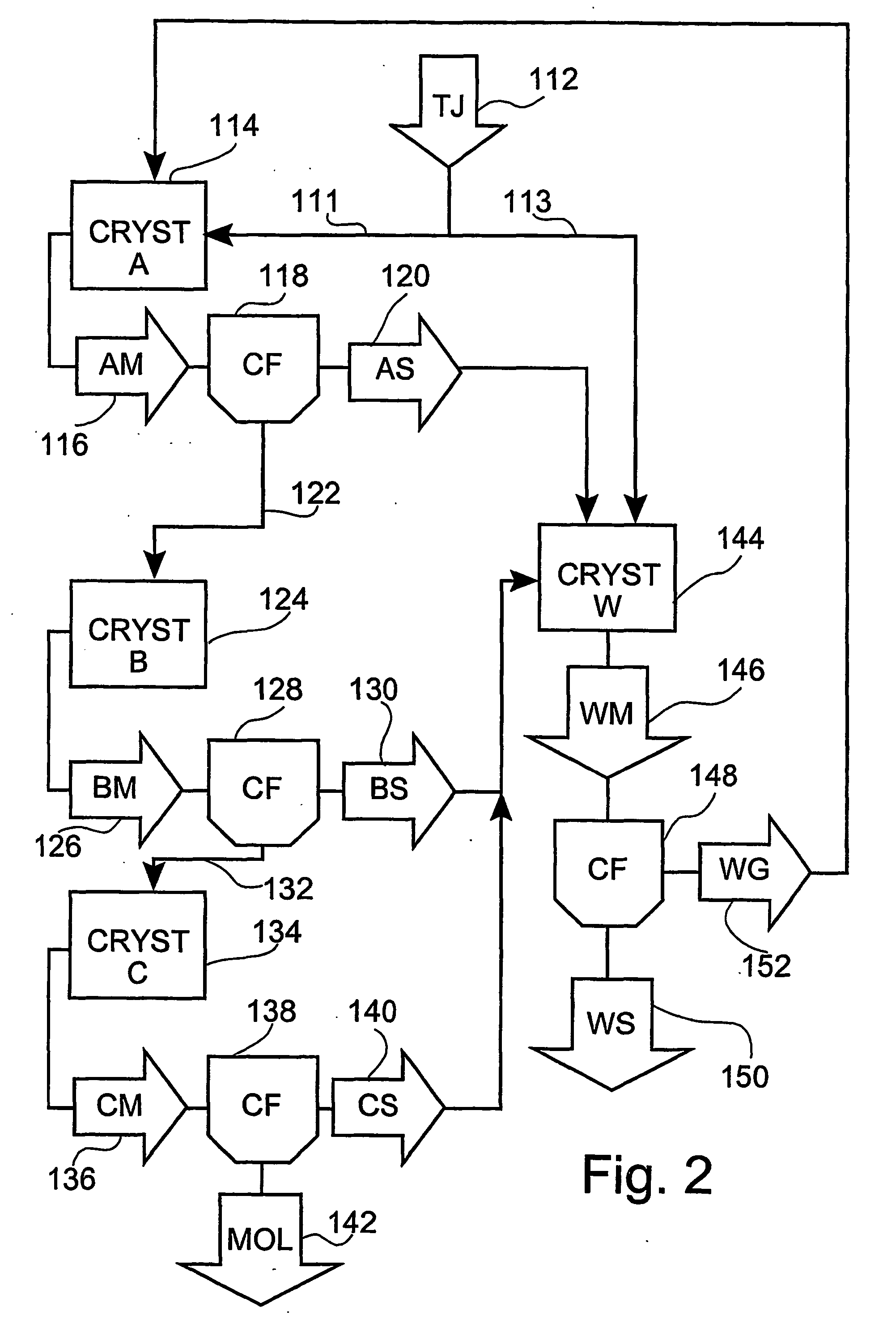

Process for the preparation of white and brown sugar from sugar beets

InactiveUS20040231663A1Avoid the needEasy to mergeSugar productsSugar crystal separationBiotechnologySugar

A process for the preparation of white and brown sugar from raw diffuser beet juice. The juice is purified by membrane filtration at 70-95° C. on a filter having a molecular weight cut-off between 2,000 and 500,000 Dalton and evaporated to a dry matter content of between 60 and 80% by weight under vacuum to a thick juice. A conventional multi-step evaporative crystallisation of the thick juice gives crops of white and brown sugar crystals. The brown sugar obtained have valuable organoleptic properties.

Owner:AS DE DANSKE SUKKERFABRIKKER

Chitosan-containing polysaccharide, method for preparing the same and use thereof

InactiveUS7195675B2Efficient productionNovel physiological activityBiocideSugar productsSolid componentDisease

The present invention herein provides a chitosan-containing polysaccharide and a method for the preparation thereof as well as a medicine and a food containing the polysaccharide.The chitosan-containing polysaccharide is prepared by a method comprising the steps of heat-treating a fungus in a concentrated aqueous caustic alkali solution; subjecting the resulting solution to a solid-liquid separation treatment; dissolving the resulting solid contents in an aqueous organic acid solution; adding, to the resulting solution, an alcohol or a caustic alkali to thus form precipitates; washing the resulting precipitates; and then drying them. This chitosan-containing polysaccharide is a compound in which homopolymers of glucosamine are linked with glucan through covalent bonds; it has a molar ratio of glucosamine and glucose constituting the polysaccharide ranging from 1:5 to 5:1; it has a molecular weight of about 150,000; and it does not contain any β(1→3) bonds, but comprises β(1→4) bonds and β(1→6) bonds. The polysaccharide is free of any protein and reducing polysaccharide. The chitosan-containing polysaccharide is effective for the treatment or prevention of any diseases originated from living habits or customs such as hypertension and diabetes.

Owner:TONE BORING

Processes for making novel inulin fractions

InactiveUS20020098272A1Improve propertiesImprove solubilitySugar food ingredientsSugar productsInulinWater soluble

The process for preparing the novel inulin products includes extracting inulin with water from subdivided plant materials, holding the inulin rich extraction water in a settling tank while maintaining the temperature from about 0° C. to 7° C. which causes higher molecular weight polysaccharides to separate from water soluble lower molecular weight polysaccharides, and separating the higher molecular weight inulin fructose fractions from the more water soluble lower molecular weight inulin fractions.

Owner:SILVER BARNARD STEWART

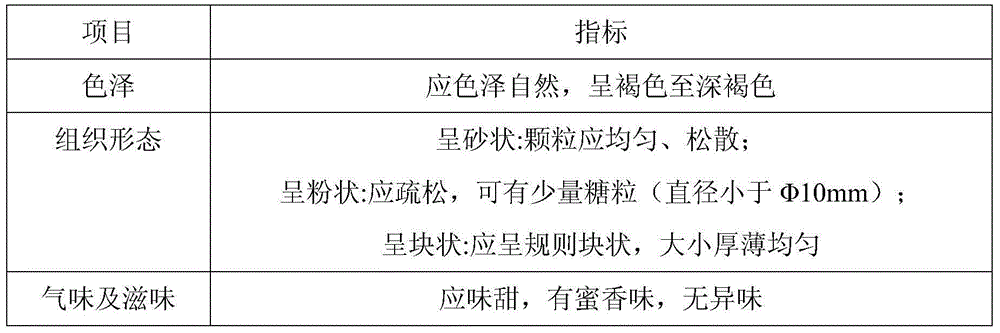

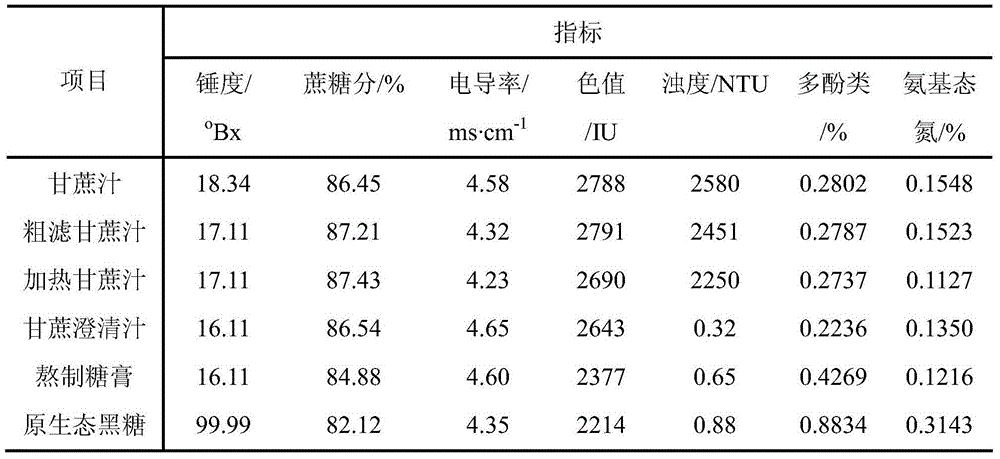

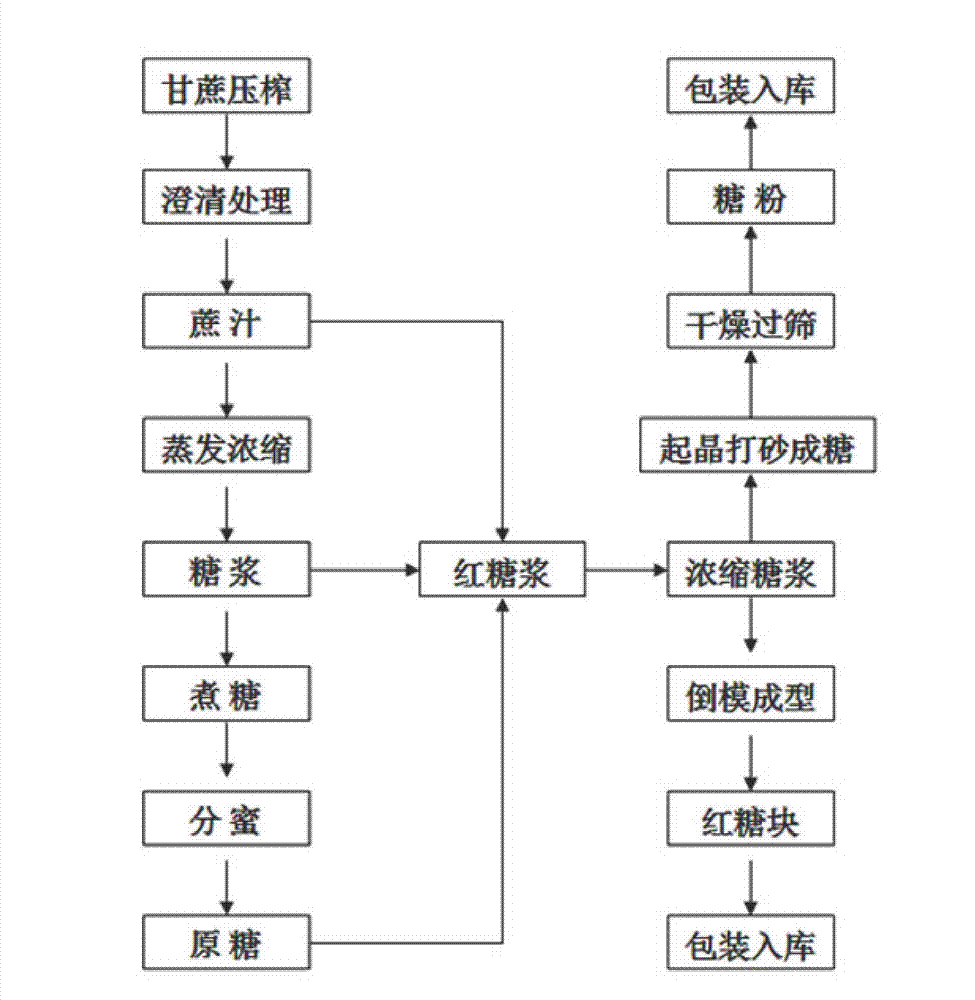

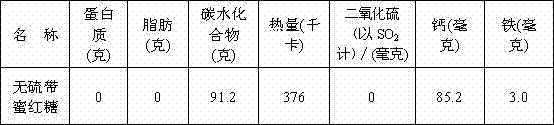

Method for producing raw juice brown sugar

The invention relates to a method for producing raw juice brown sugar and belongs to the technical field of food processing. The invention aims at solving the technical problem of providing a method for producing raw juice brown sugar with higher quality. The method for producing the raw juice brown sugar comprises the following steps: a, juicing sugarcane, and sieving, so as to obtain raw juice after sieving and screening residue; b, heating the raw juice after sieving, eliminating formed floating condensation products, so as to obtain clear juice, and filtering, so as to obtain filtrate I; c, standing the filtrate I for 2-3 hours, and removing fine silt impurities at the bottom layer, so as to obtain sugar juice clear liquid; d, evaporating and concentrating the sugar juice clear liquid obtained in the step c into syrup with the brix of 85-90 degree Bx, then carrying out sugar boiling to obtain massecuite, sanding, and moulding, so as to obtain lump sugar; or evaporating and concentrating the sugar juice clear liquid obtained in the step c into clear syrup with the brix of 55-60 degree Bx, and then carrying out sugar boiling at normal pressure, so that liquid brown sugar with the concentration of 68-78 degree Bx is obtained.

Owner:MIYI HUASENTY CO LTD

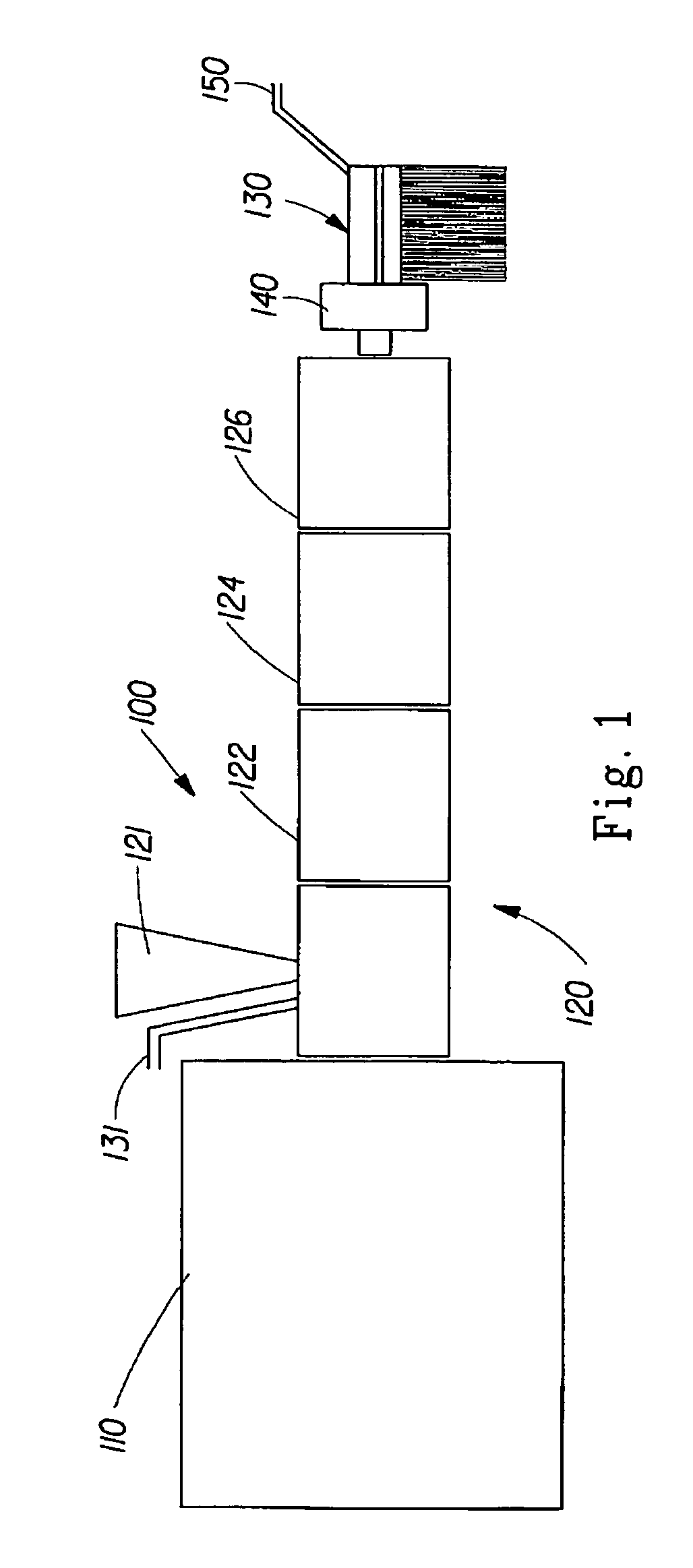

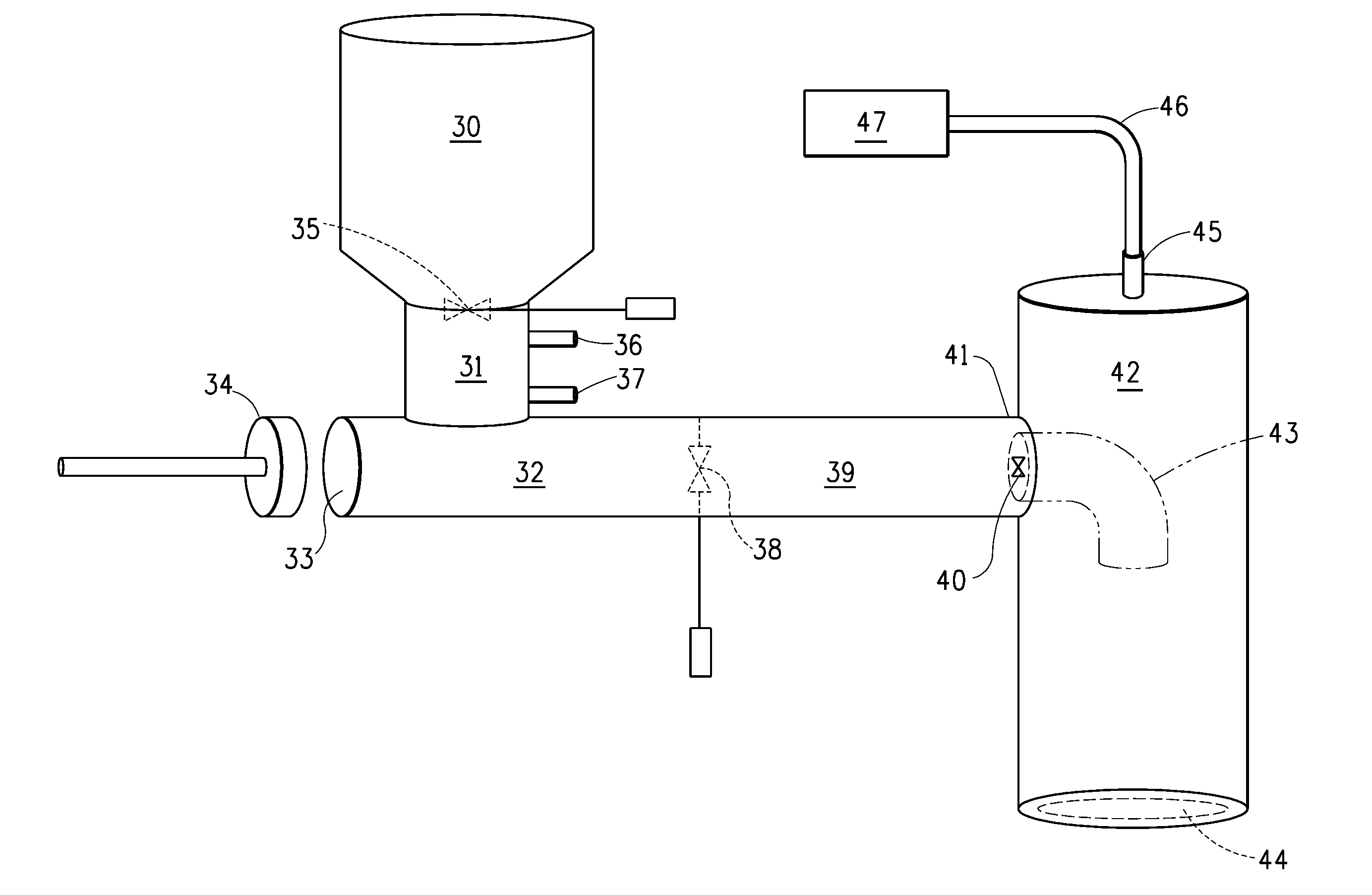

Biomass treatment method

InactiveUS7819976B2Small sizeIncrease surface areaPressurized chemical processSugar productsFermentable sugarAmmonia

A method for treating biomass was developed that uses an apparatus which moves a biomass and dilute aqueous ammonia mixture through reaction chambers without compaction. The apparatus moves the biomass using a non-compressing piston. The resulting treated biomass is saccharified to produce fermentable sugars.

Owner:SUSTAINABLE TECH CORP +1

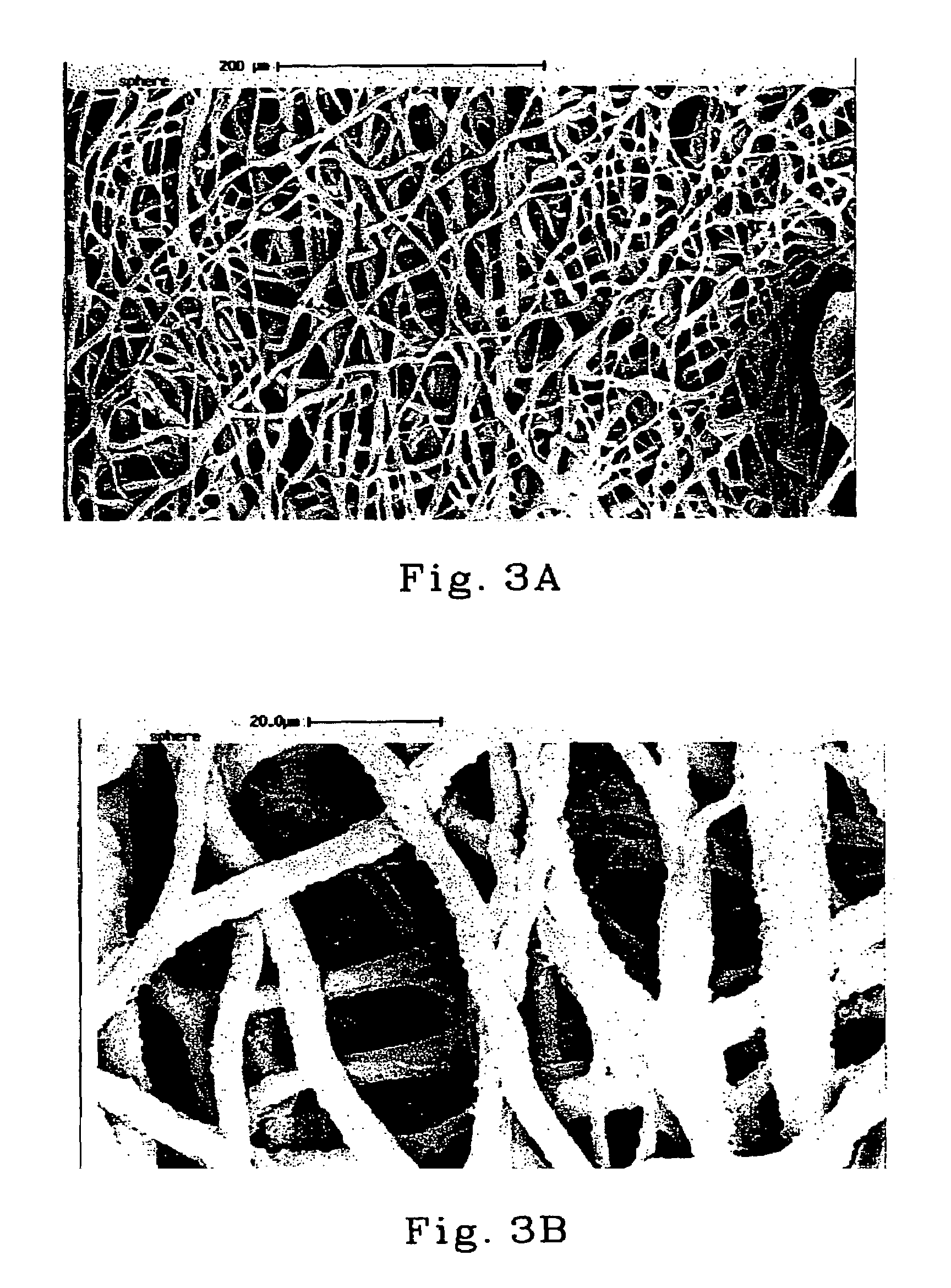

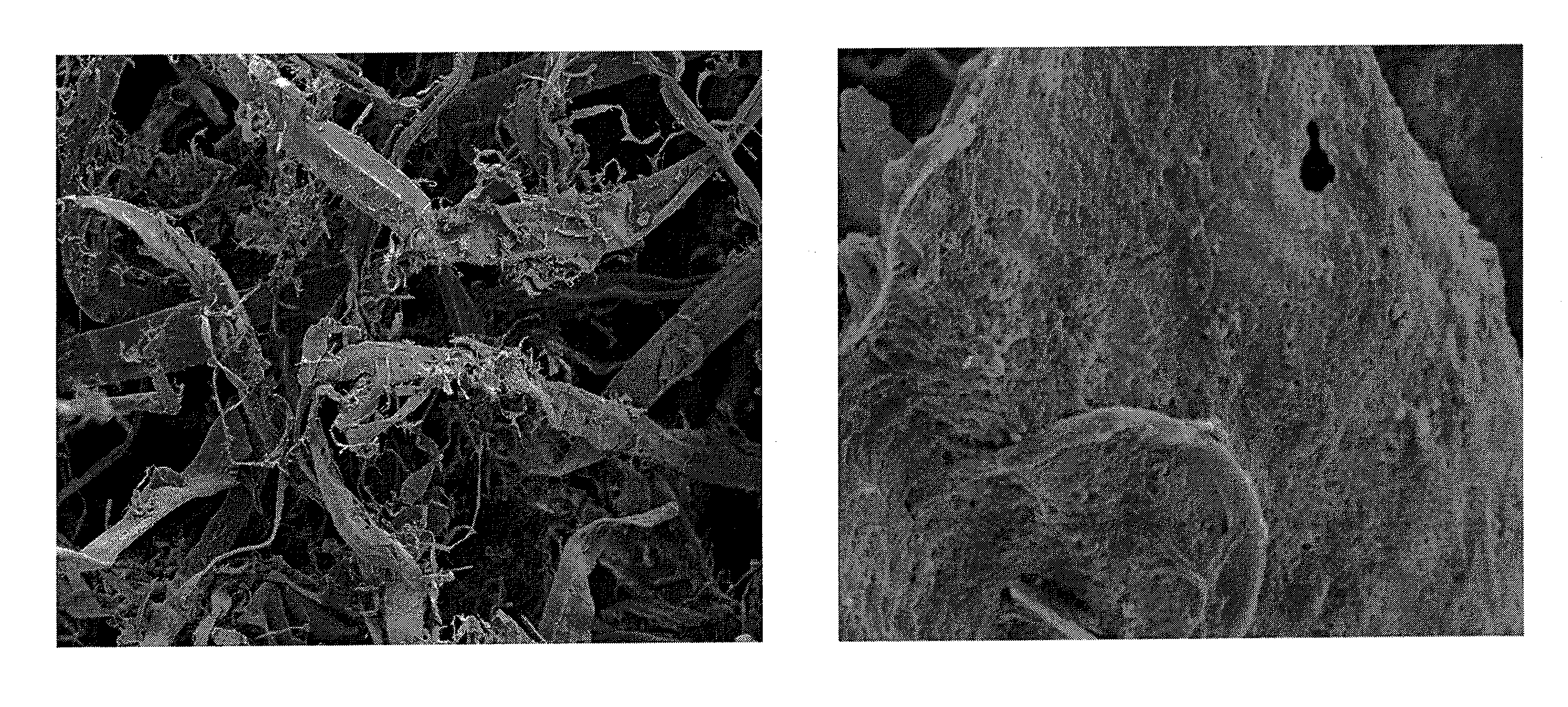

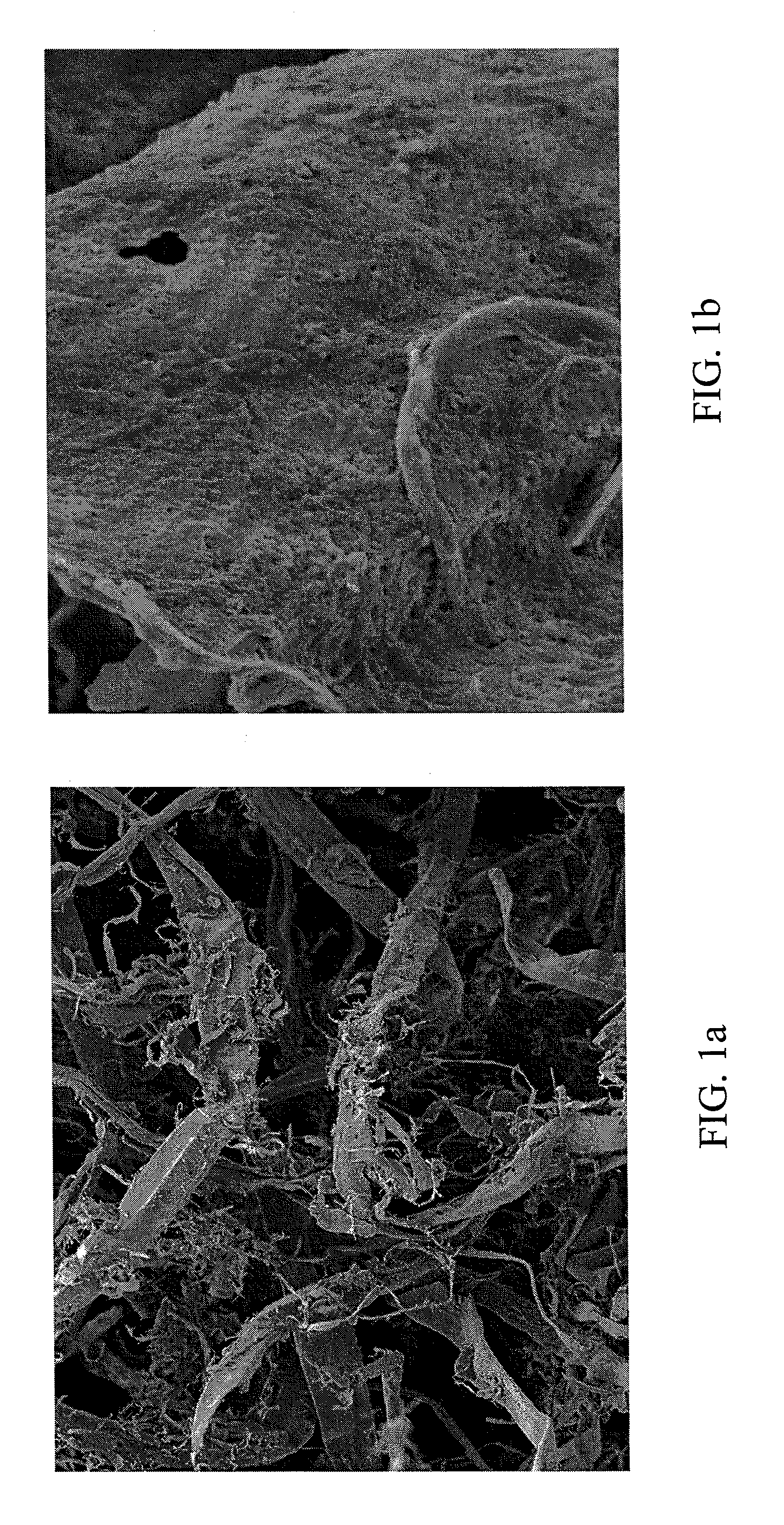

Nanocellulose compositions and processes to produce same

A composition comprising nanocellulose is disclosed, wherein the nanocellulose contains very low or essentially no sulfur content. The nanocellulose may be in the form of cellulose nanocrystals, cellulose nanofibrils, or both. The nanocellulose is characterized by a crystallinity of at least 80%, an onset of thermal decomposition of 300° F. or higher, and a low light transmittance over the range 400-700 nm. Other variations provide a composition comprising lignin-coated hydrophobic nanocellulose, wherein the nanocellulose contains very low or essentially no sulfur content. Some variations provide a composition comprising nanocellulose, wherein the nanocellulose contains about 0.1 wt % equivalent sulfur content, or less, as SO4 groups chemically or physically bound to the nanocellulose. In some embodiments, the nanocellulose contains essentially no hydrogen atoms (apart from hydrogen structurally contained in nanocellulose itself) bound to the nanocellulose. Various compositions, materials, and products may incorporate the nanocellulose compositions disclosed herein.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

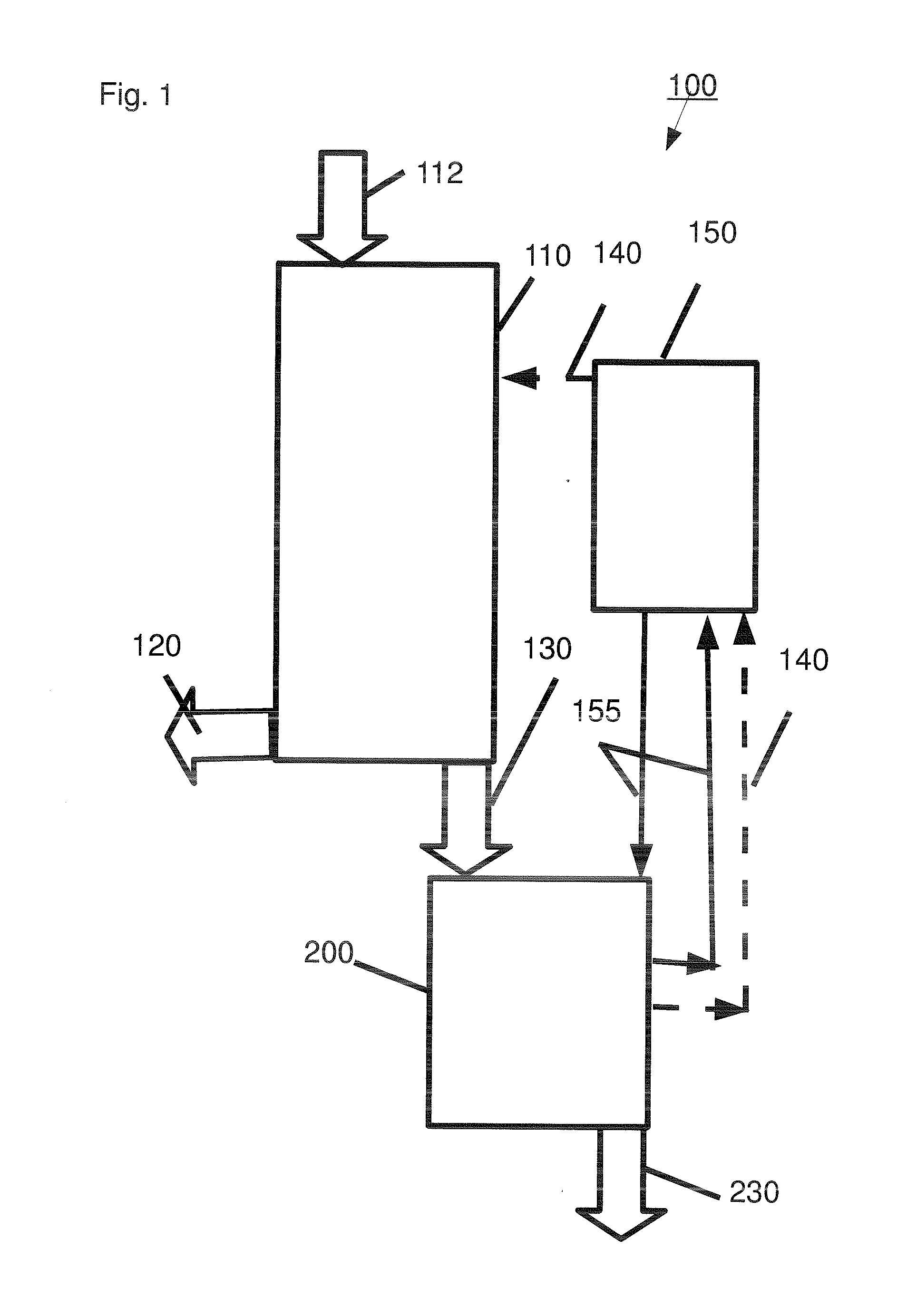

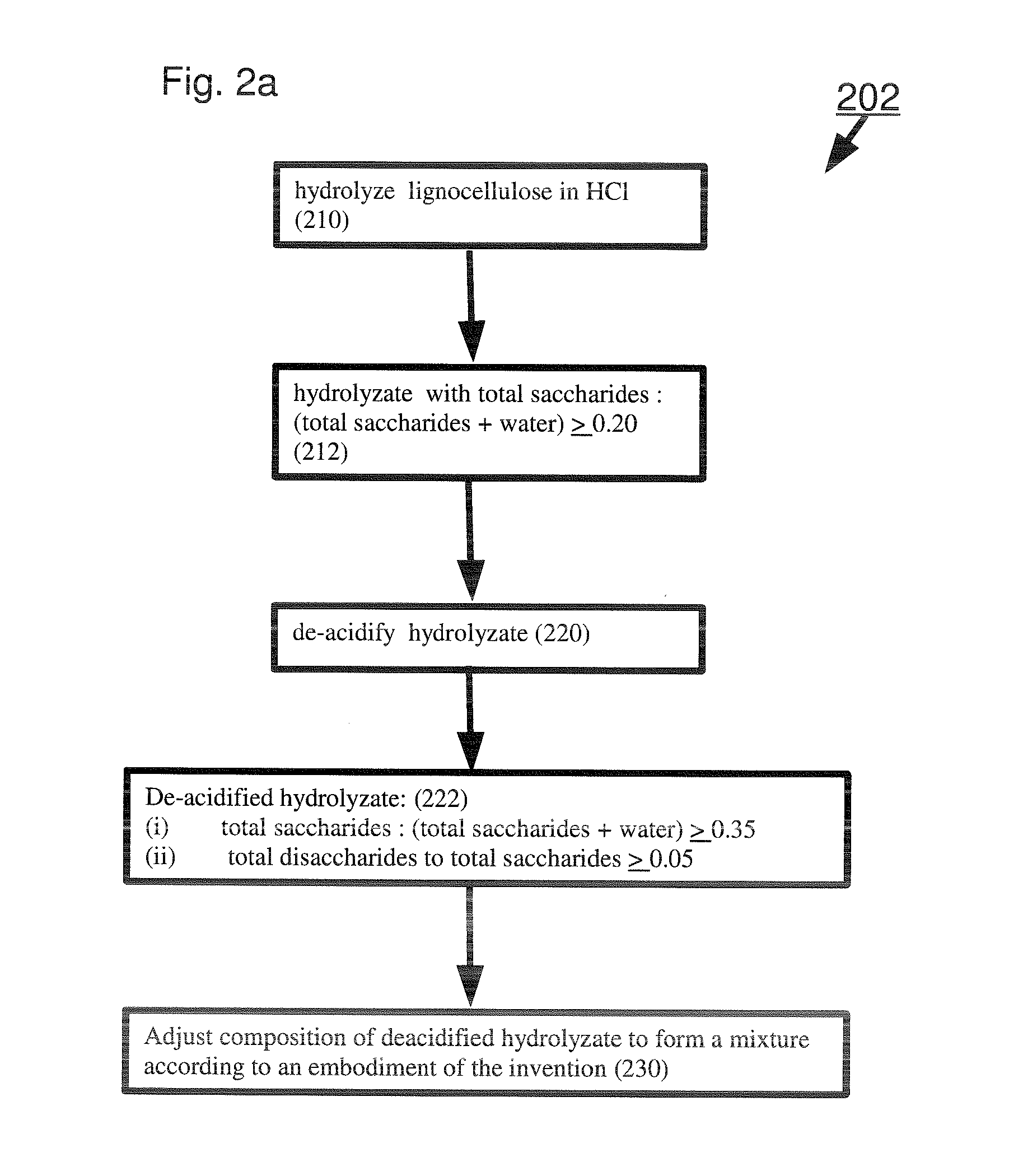

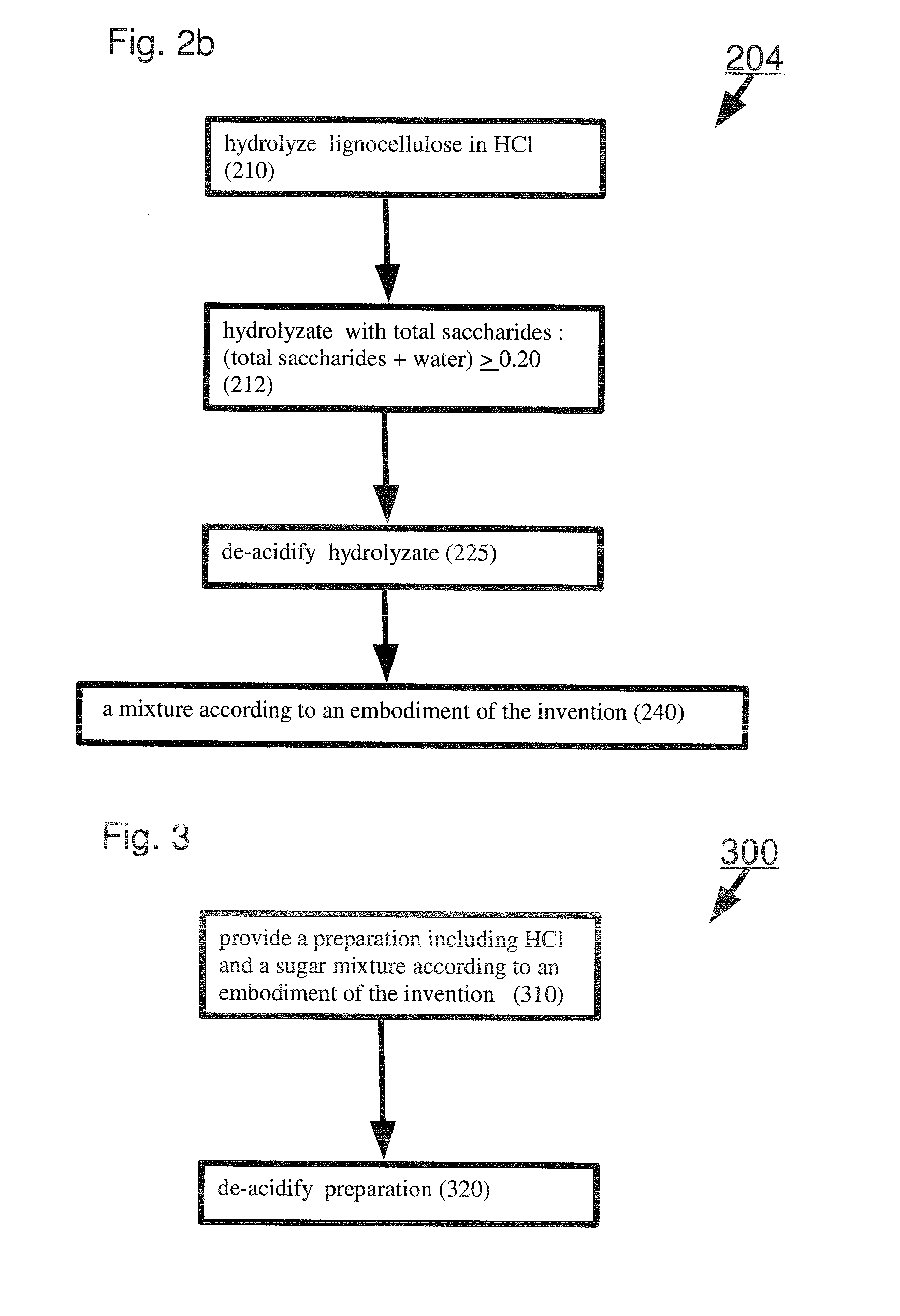

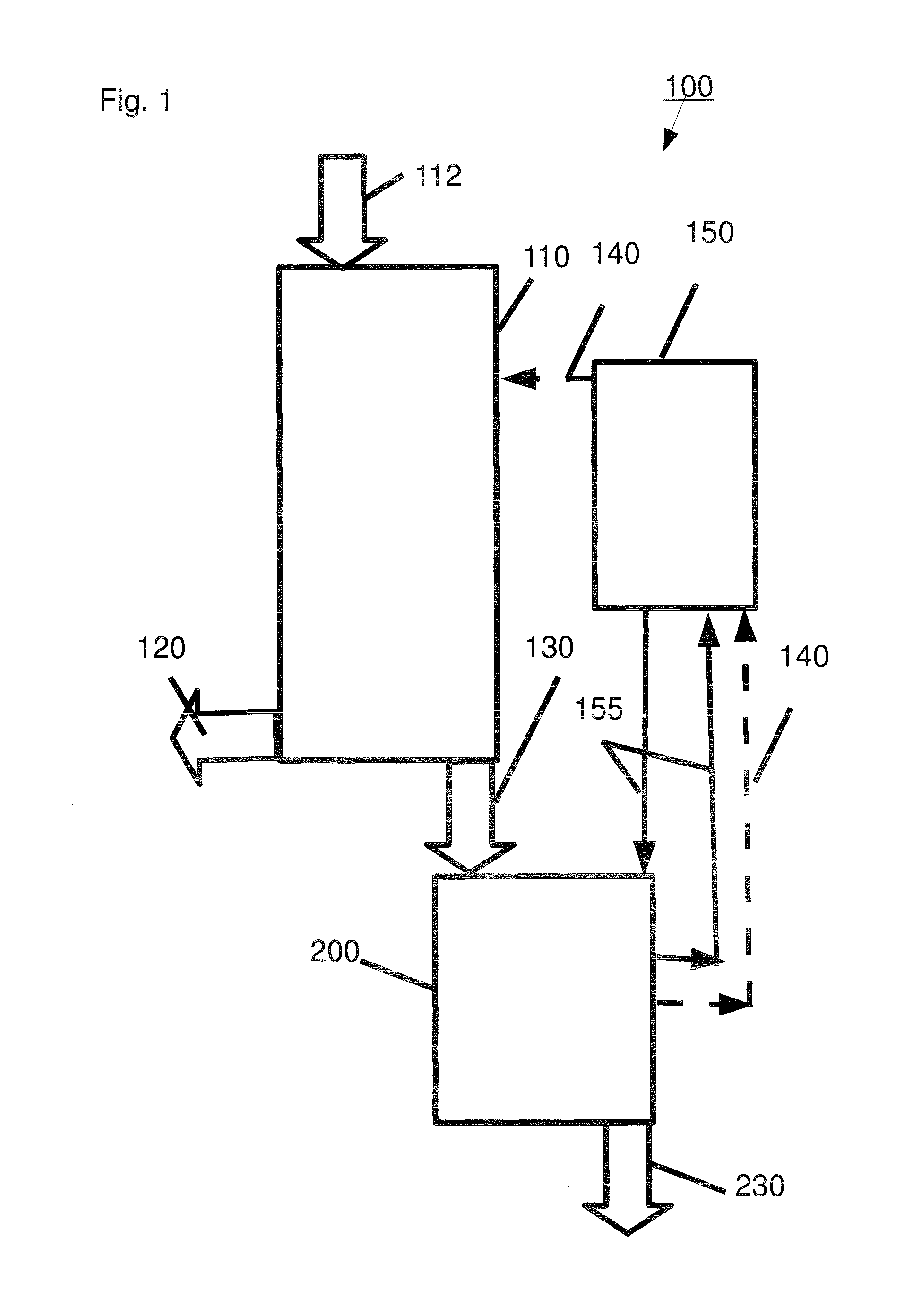

Sugar mixtures and methods for production and use thereof

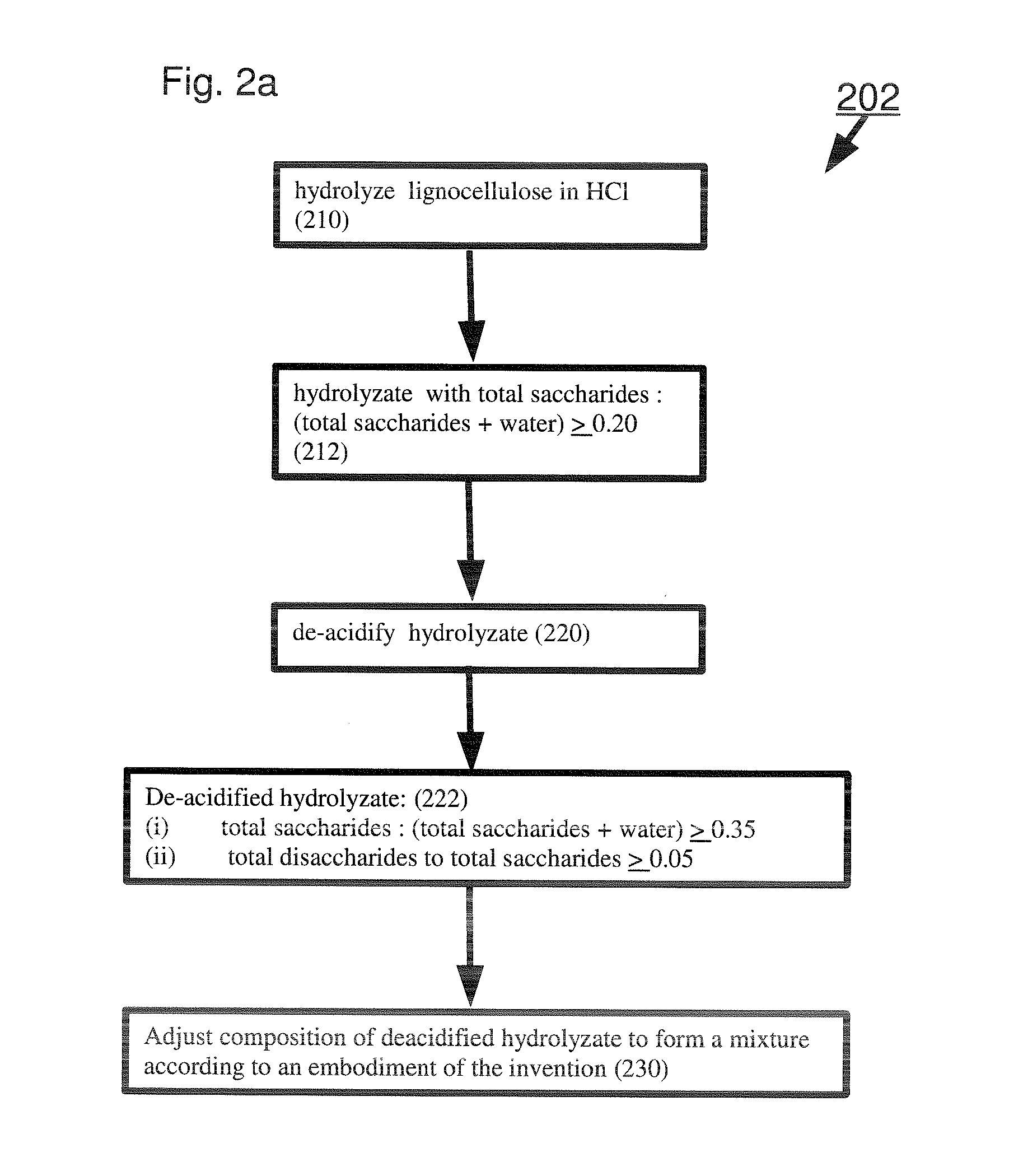

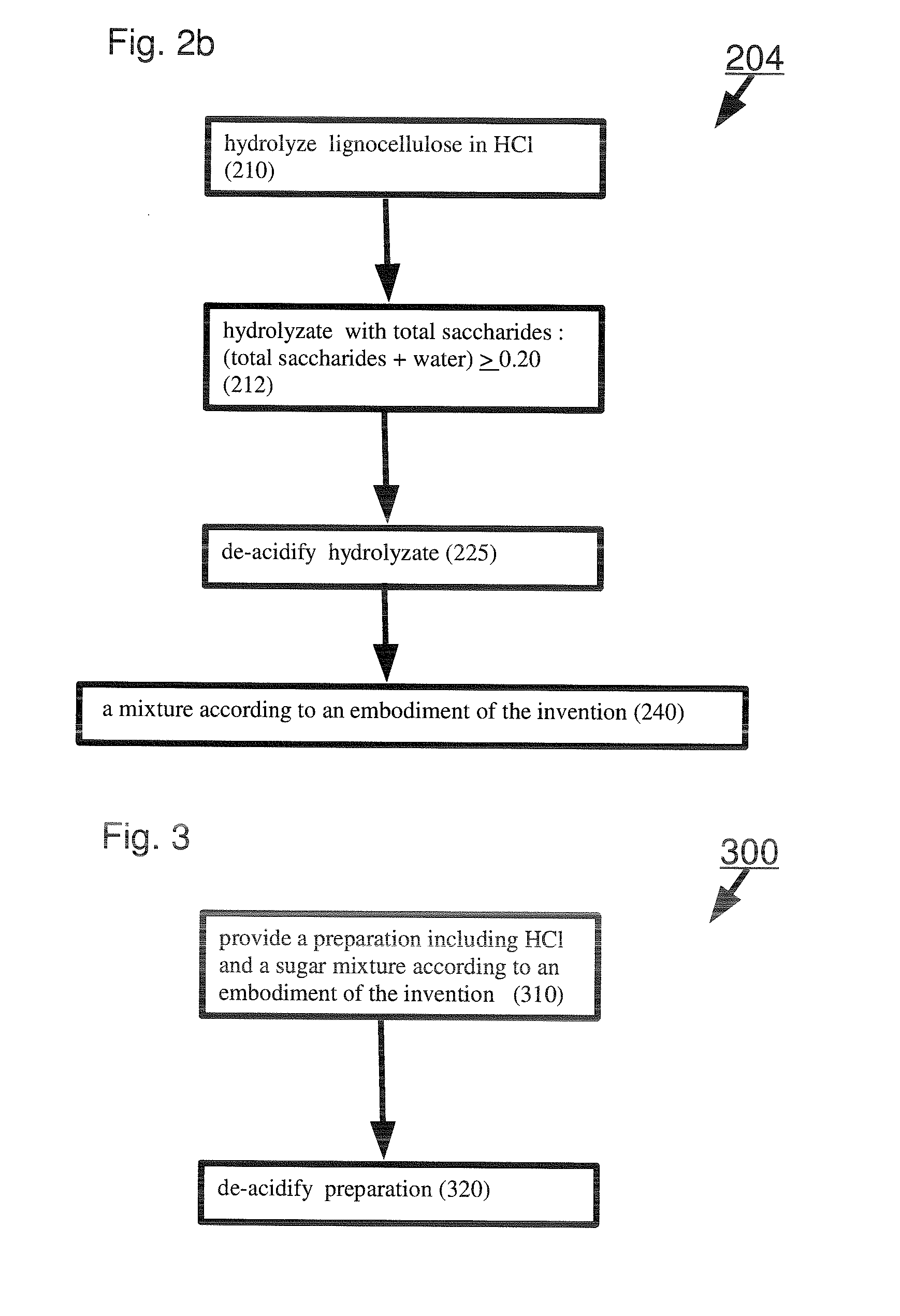

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

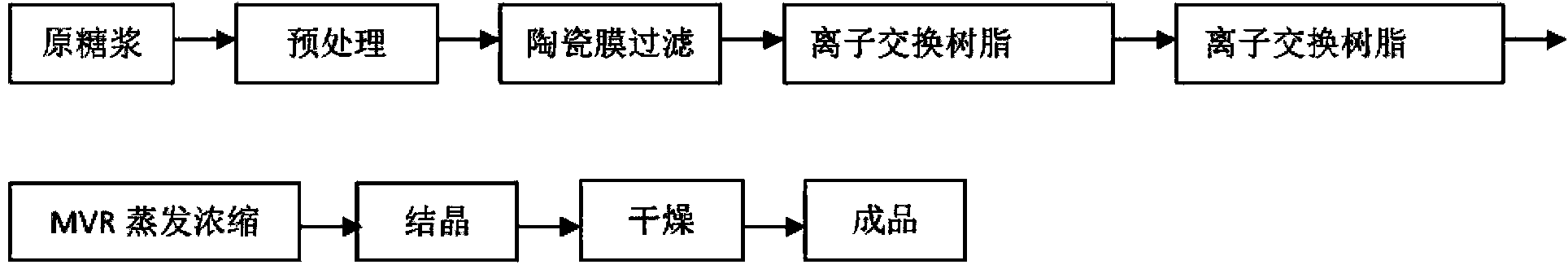

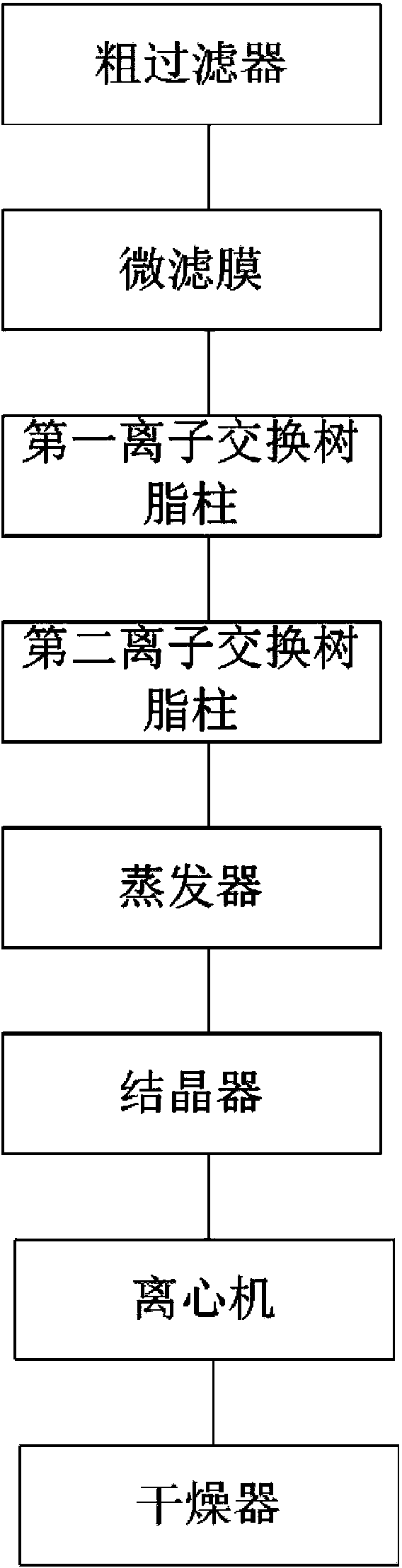

Process for preparing sugar by two-step method and device thereof

ActiveCN103710470ANo color reversionOptimal production process parametersSugar productsSucroseIon exchange

The invention discloses a process for preparing sugar by a two-step method and a device thereof. The process comprises the following steps: adding water into crude sugar for dissolving to obtain crude syrup; feeding the crude syrup into a primary filter and a micro-filtration membrane in sequence for filtering to obtain filtrate; feeding the filtrate into a first ion exchange resin tower to obtain a first penetrating fluid, wherein the first ion exchange resin refers to macroporous strong-basicity anion exchange resin; feeding the first penetrating fluid into a second ion exchange resin tower to obtain a second penetrating fluid, wherein the second ion exchange resin refers to strong-acidity cation exchange resin, weak-acidity cation exchange resin or a mixing bed of anion and cation exchange resin; feeding the second penetrating fluid into an evaporator for concentrating to obtain sucrose concentrated liquor; and crystallizing, centrifuging and drying to obtain a sucrose finished product. The process disclosed by the invention can be used for producing high-purity refined sucrose in batch, wherein a pigment removal rate reaches 99.9%, a salt removal rate reaches 98%, and sucrose component of the product reaches 99.9% which reaches the standard of national senior sugar.

Owner:JIANGSU JIUWU HITECH

Method for preparing dephenolization cottonseed protein and raffinose

ActiveCN101785527AHigh nutritional valueSimple processSugar productsFood processingFiltrationActive protein

The invention relates to a method for deep processing cottonseeds, in particular to a method for preparing dephenolization cottonseed protein and raffinose. Gross cottonseeds are firstly delinted by a delinting machine to obtain naked seeds; after being husked by a husking machine, the naked seeds are subjected to kernel husk separation by an angle sieve to obtain cottonseed kernels and cottonseed husks; the cottonseed kernels are subjected to softening conditioning, compacting and drying; the dried blanks are sent to an extractor by a scraper blade and a closed auger and then are sprayed in stages by the No.6 solvent oil to obtain mixed oil; the mixed oil is subjected to sedimentation and centrifugal separation and purification, then is processed by a first evaporator and a second evaporator and is processed by a stripping tower to remove the solvent to obtain crude oil; the crude oil is refined to obtain edible oil; wet cotton dregs are put in a dephenolizing extractor and are subjected to liquid separation and filtration and purification to recover the solvent and also extract the crude product of the raffinose; and after being extruded, the wet cotton dregs are subjected to drying, desolventizing and conditioning and then are sent to a grinding packing department. The process technology has the advantages of high oil yielding rate, complete dephenolization, high content of active protein, simple process and low production cost.

Owner:邯郸晨光植物蛋白有限公司

Sugar mixtures and methods for production and use thereof

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS8182557B2Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

Methods and Systems for Solvent Purification

ActiveUS20120167874A1Characteristic be alterReduce pollutant loadSugar productsSolvent extractionMedicineSolvent

Owner:VIRDIA

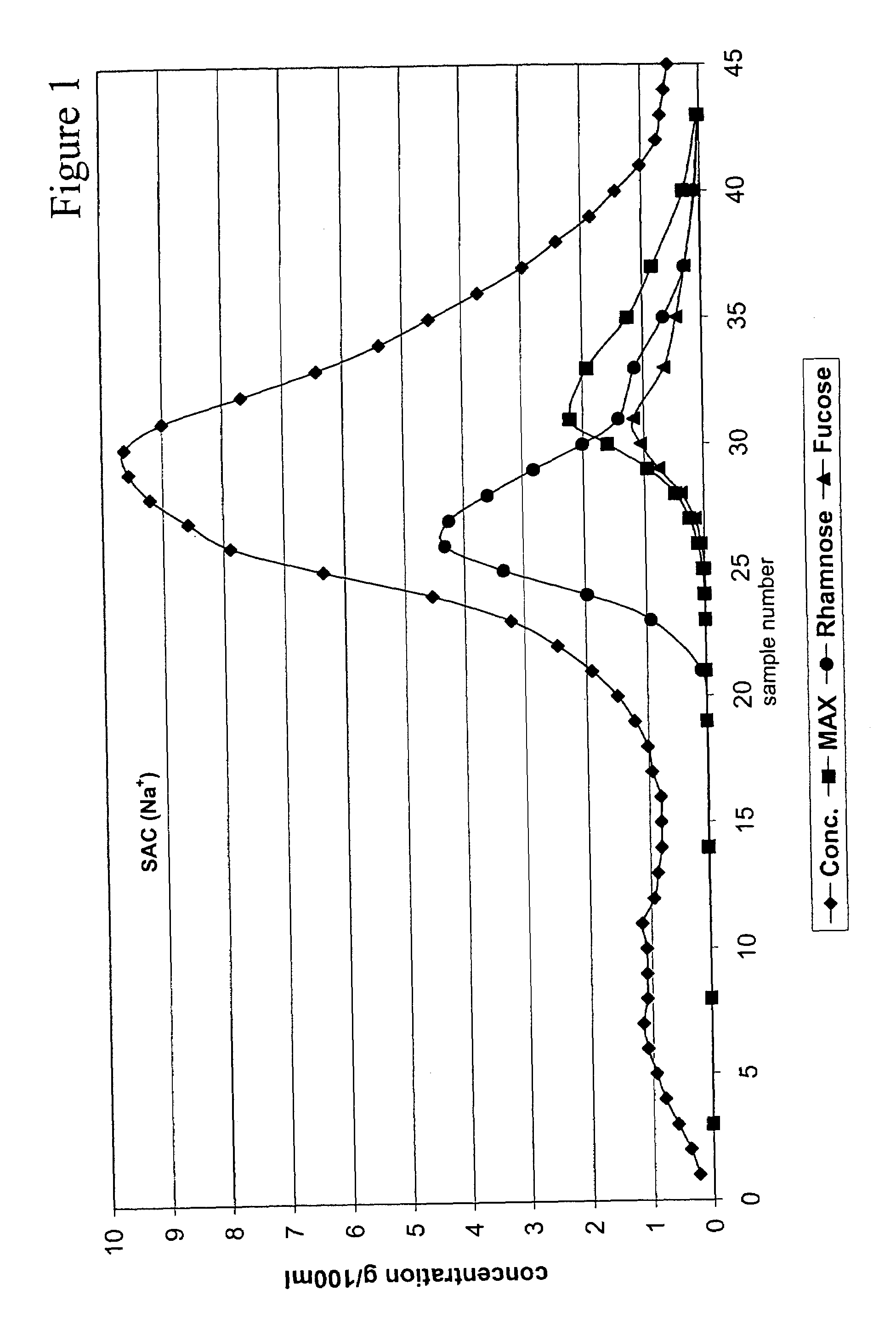

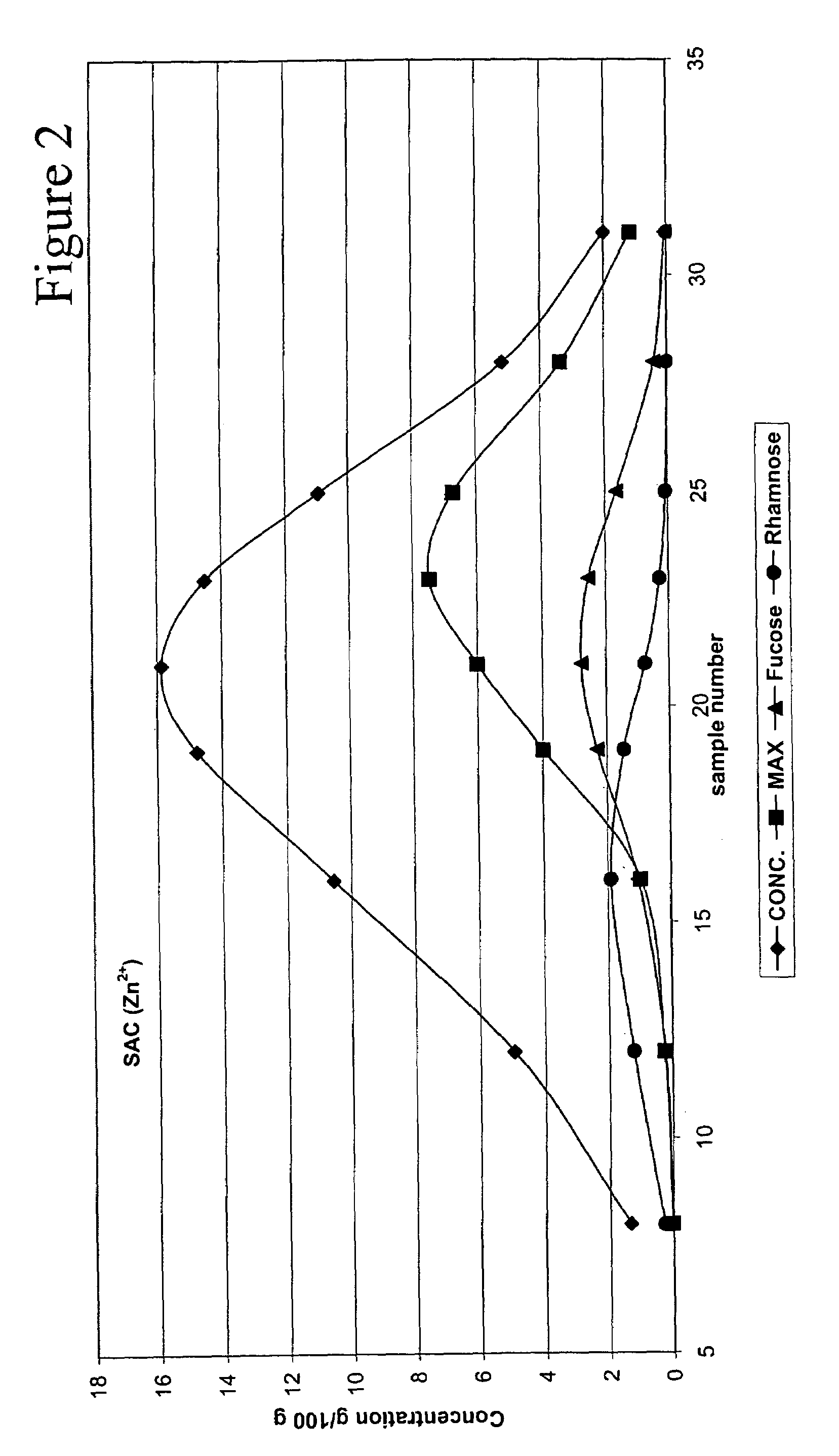

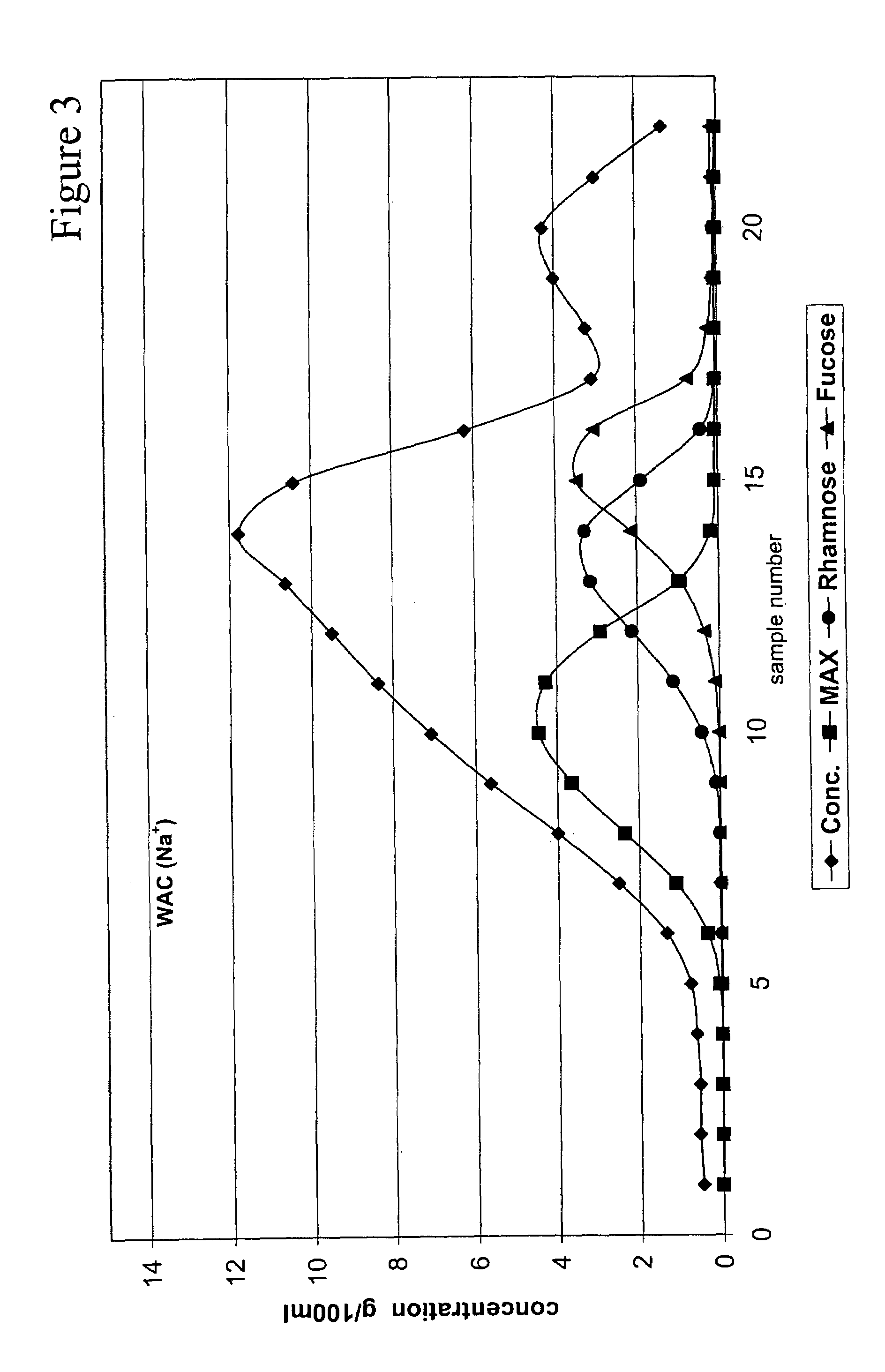

Separation of sugars

InactiveUS7037378B2Avoid insufficient puritySugar derivativesSugar productsChromatographic separationDeoxy sugar

Owner:DANISCO SWEETENERS

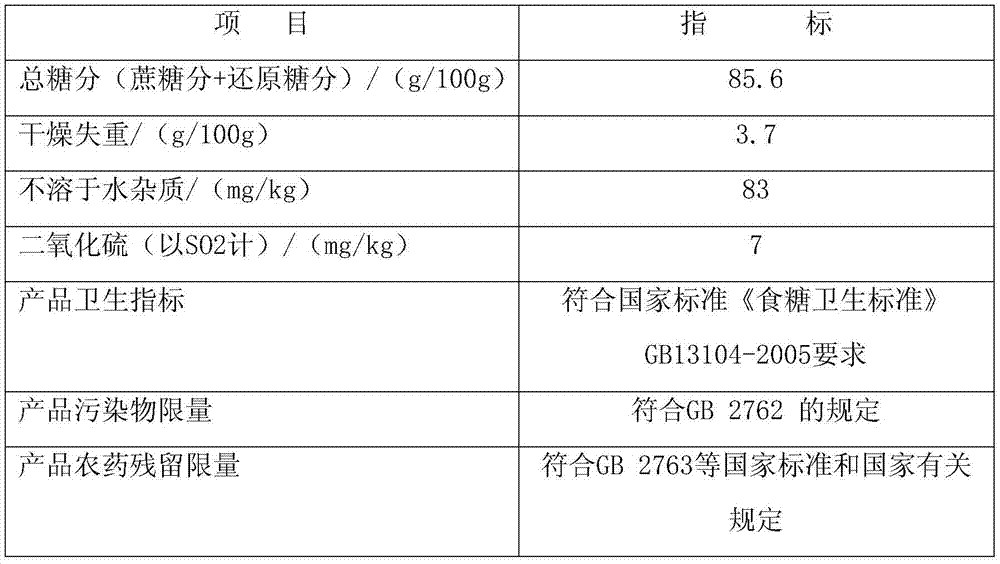

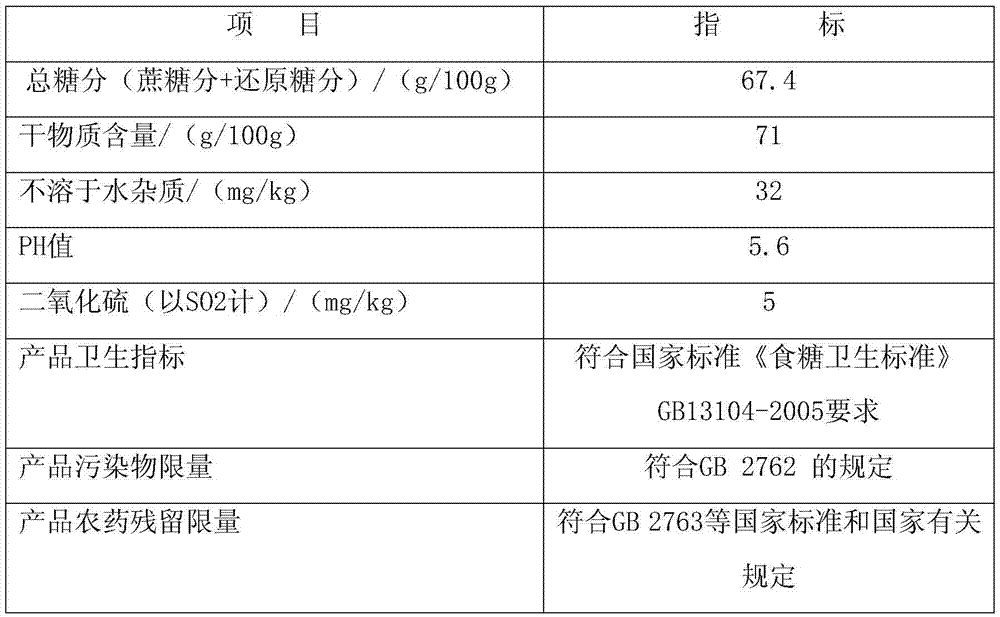

Method for producing sulfur-free honey-carrying brown sugar

The invention discloses a method for producing sulfur-free honey-carrying brown sugar. Cane juice, syrup and raw sugar are used as raw materials. The method comprises the following steps of: preparing brown syrup of which the cane sugar content is 85 to 95 percent according to a certain proportion, evaporating and concentrating into sugar paste of which the Brix is 92 to 98oBx, discharging, stirring, cooling, stimulating sugaring, drying, sieving, cooling to room temperature, finally obtaining the honey-carrying brown sugar of which the cane sugar content is 85 to 95 percent, metering and packing. By using the method for preparing the brown sugar, processing aids containing potential food safety hazard are not added in the production process, so the cane sugar content is high, the brown sugar has obvious advantages of original ecological and health-care food, crystallization and sugaring can be quickly realized, and the operation is convenient; and the finished sugar keeps the favor of original cane, is rich in nutritional components, and meets the requirement for original ecological sugar.

Owner:广西浦北县湘桂糖业有限责任公司

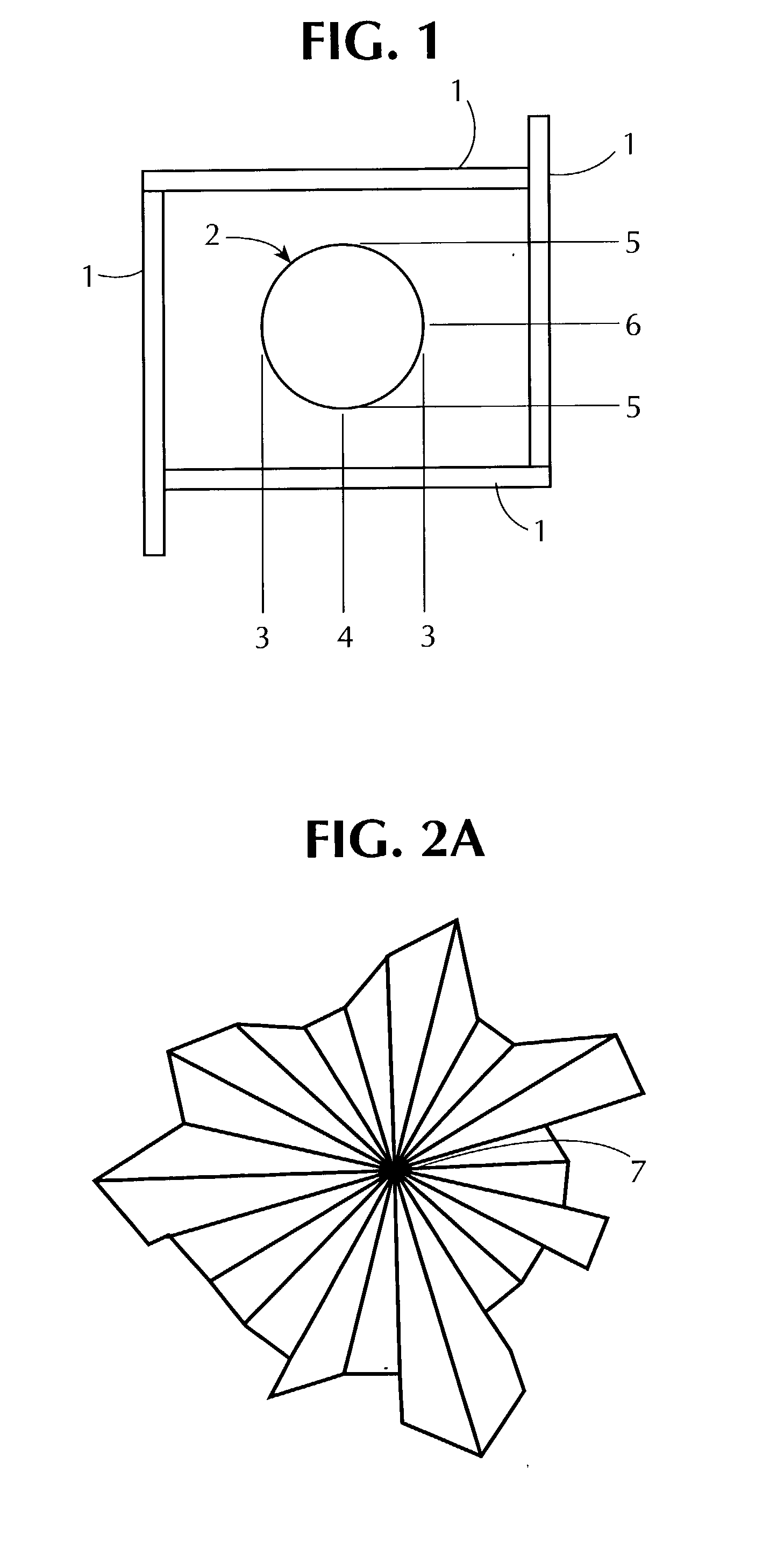

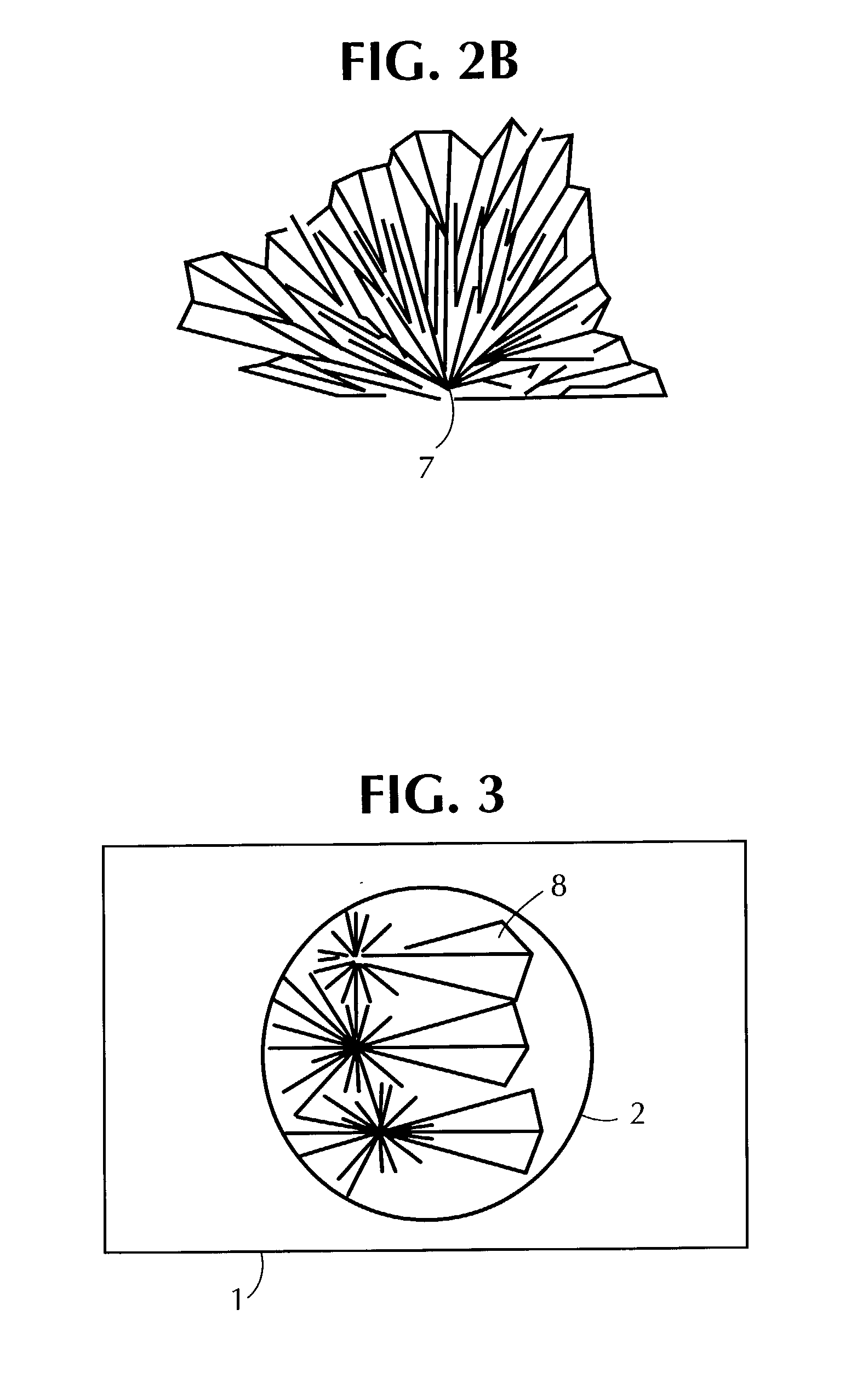

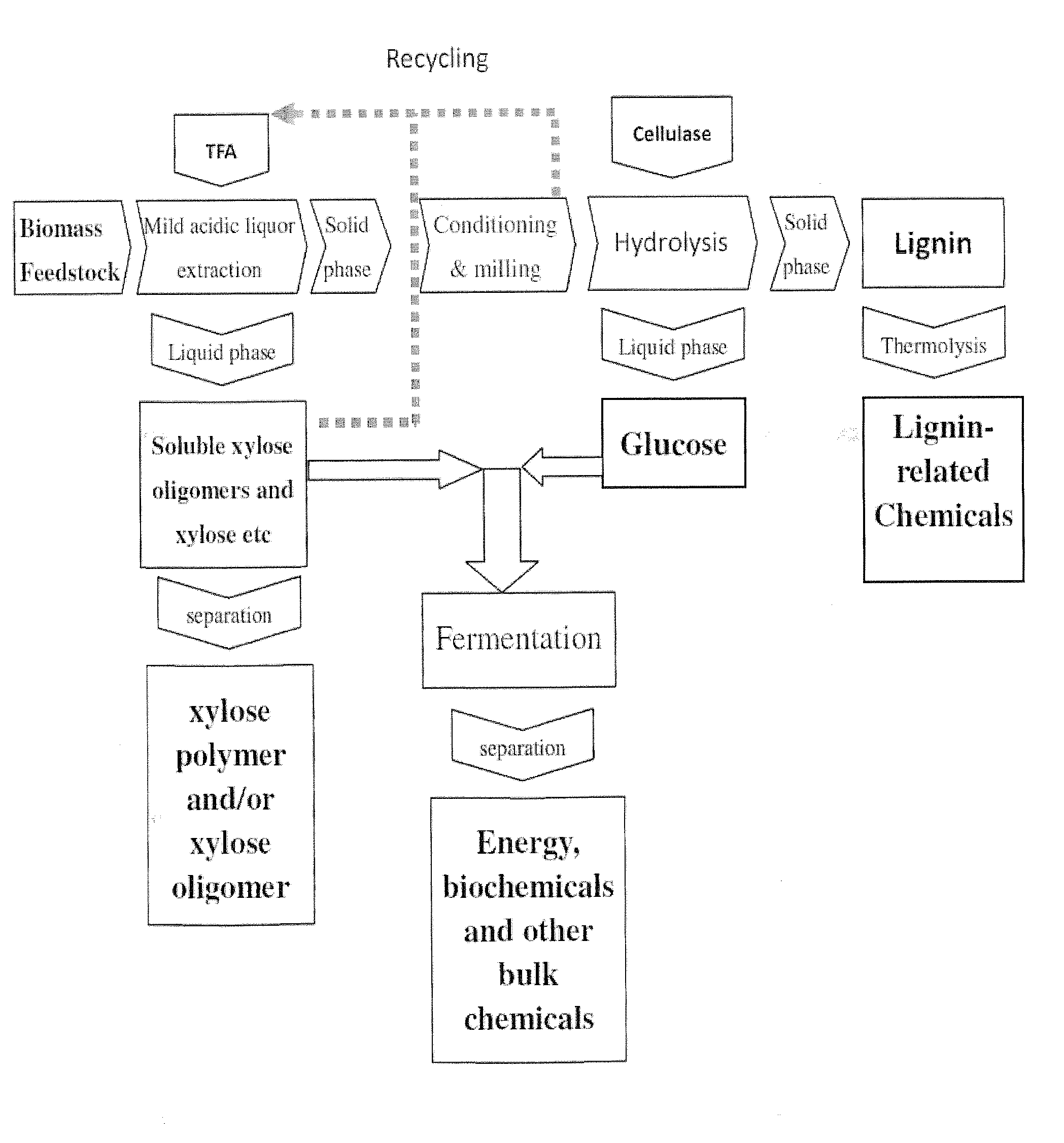

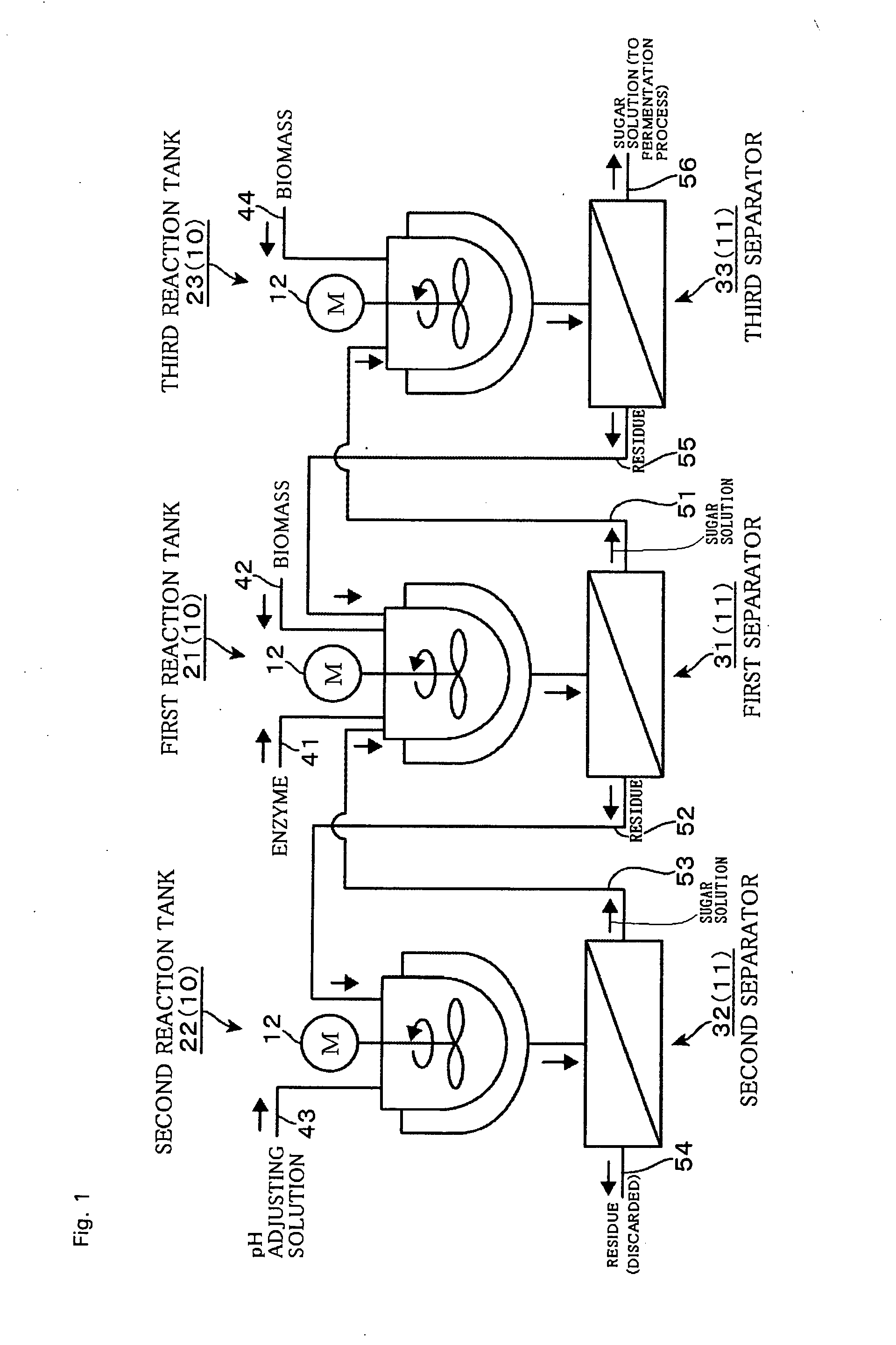

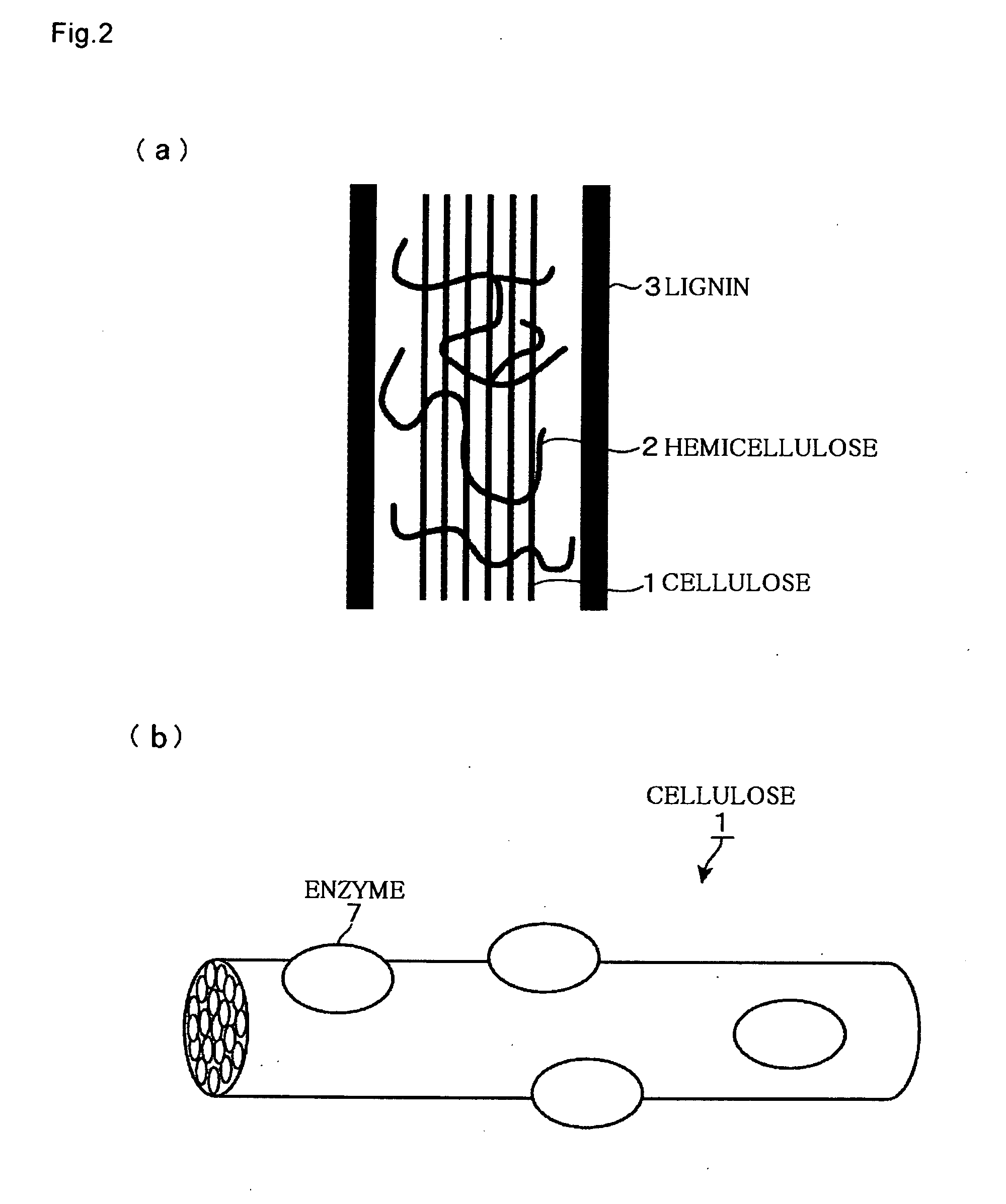

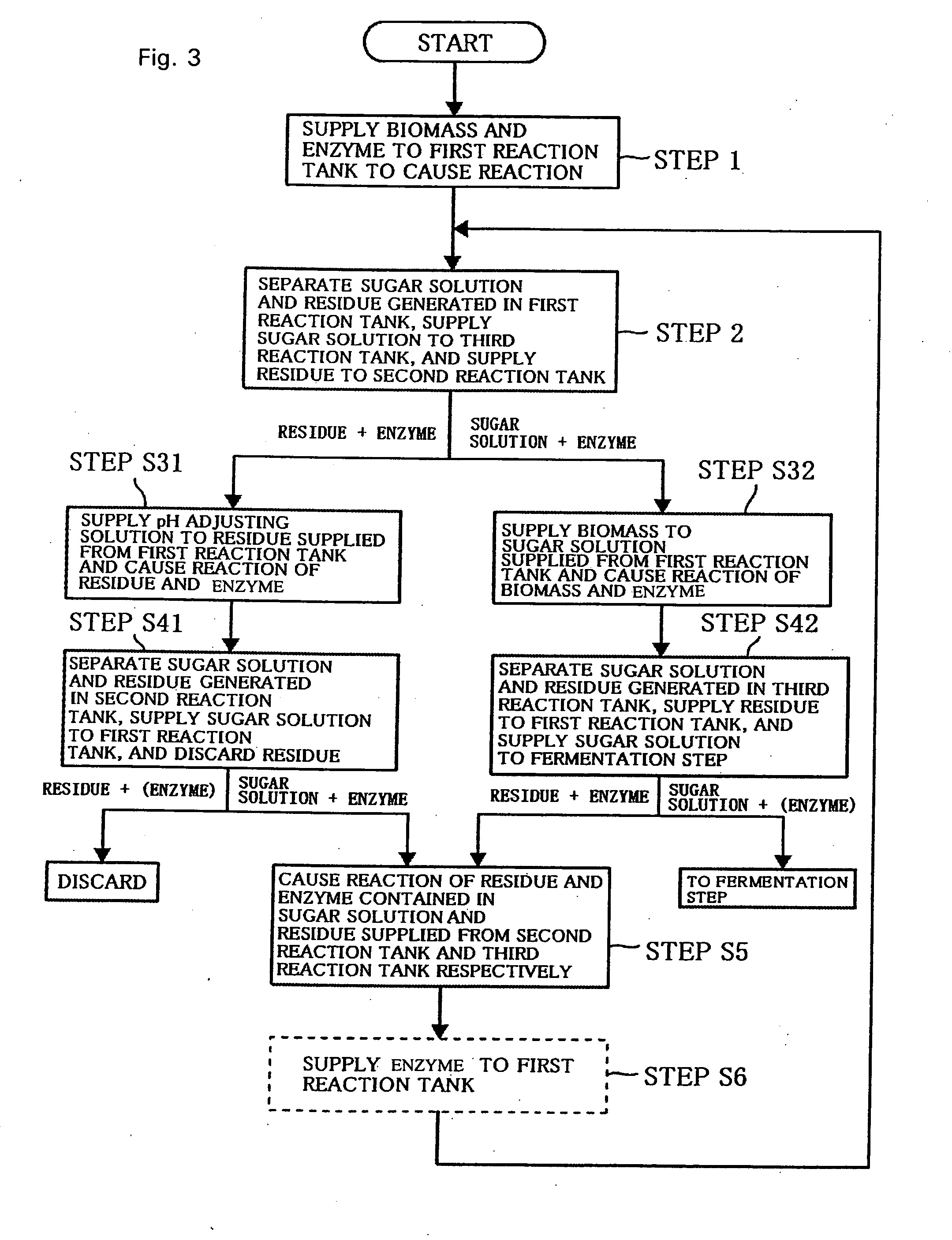

Method of producing sugar solution and saccharification device

InactiveUS20120107920A1Reduce the amount requiredLow costBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseFolch solution

To achieve efficient use of enzyme in obtaining a sugar solution through a reaction of the enzyme and biomass containing cellulose. In obtaining a sugar solution through a reaction of enzyme and biomass containing cellulose, the biomass and the enzyme are caused to react in a first reaction tank, whereby a sugar solution in which the enzyme is dispersed and a residue containing the unreached biomass adsorbing the enzyme are generated, these sugar solution and residue are next separated, a pH adjusting solution is supplied to the residue in a second reaction tank to prepare a dilute solution whose sugar concentration is lower than that of the sugar solution, and in this dilute solution, a sugar solution is generated through a reaction between the residue and the enzyme adsorbed to the residue.

Owner:JGC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com