Patents

Literature

1613 results about "Dry matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The dry matter or dry weight is a measurement of the mass of something when completely dried. The dry matter of plant and animal material consists of all its constituents excluding water. The dry matter of food includes carbohydrates, fats, proteins, vitamins, minerals, and antioxidants (e.g., thiocyanate, anthocyanin, and quercetin). Carbohydrates, fats, and proteins, which provide the energy in foods (measured in kilocalories or kilojoules), make up ninety percent of the dry weight of a diet. Water content in foods varies widely. A large number of foods are more than half water by weight, including boiled oatmeal (84.5%), cooked macaroni (78.4%), boiled eggs (73.2%), boiled rice (72.5%), white meat chicken (70.3%) and sirloin steak (61.9%). Fruits and vegetables are 70 to 95% water. Most meats are on average about 70% water. Breads are approximately 36% water. Some foods have a water content of less than 5%, e.g., peanut butter, crackers, and chocolate cake. Water content of dairy products is quite variable. Butter is 15% water. Cow's milk ranges between 88-86% water. Swiss cheese is 37% percent water. The water content of milk and dairy products varies with the percentage of butterfat so that whole milk has the lowest percentage of water and skimmed milk has the highest.

Whey protein product and a method for its preparation

InactiveUS20110097442A1Improve sensory propertiesImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO OY

Granulated powder containing vegetable proteins and maltodextrins, process for producing same, and uses thereof

The present invention concerns a granulated powder comprising at least one vegetable protein and at least one starch hydrolyzate, characterized in that it has a laser volume average diameter D4,3 of between 10 μm and 500 μm, preferably between 50 μm and 350 μm, and even more preferably between 70 μm and 250 μm, and a dry matter content, determined after stoving at 130° C. for 2 hours, of greater than 80%, preferably greater than 85%, and even more preferably greater than 90%.The present invention also concerns process for manufacturing this granulated powder its use in various industrial field, and more particularly in the food-processing field, where it is used as a functional agent such as an emulsifying, overrun, stabilizing, thickening and / or gelling agent, in particular for totally or partially replacing certain animal proteins in the preparation of food products.

Owner:ROQUETTE FRERES SA

Efficient full-day cubed feed for barn feeding cattle and production method thereof

InactiveCN101385514AAvoid investmentAvoid production performance anomaliesFood processingAnimal feeding stuffDiseaseSodium Bentonite

The present invention relates to a yard feeding cattle efficient total ration blocky feed and a production method thereof. The yard feeding cattle efficient total ration blocky feed consists of 37 percent to 60 percent of crushed or cut forage grass, 38 percent to 60 percent of yard feeding cattle concentrate complemental feed and 2 percent to 3 percent of bentonite which are mixed in a mixer, the water content of a product is controlled within 14 percent, and finally, the prepared raw material is pressed and molded in a ring die waferer. The present invention leads total mixed ration (TMR) to be blocks, compared with the TMR in bulk, the present invention has the advantages that the present invention has stable feed quality, reduces the forage grass waste in the process of feeding and the labor intensity, improves the labor ration and can be fit for large scale industrialized production; the present invention improves the grain ration palatability obviously, effectively prevents the flocks and herds from being fussy, improves the dry matter feed intake and the weight grain of the ruminant and reduces the feed cost to save the feed grains; the present invention has balanced nutrition, thereby being good for improving the feed utilization rate and reducing the occurrence of various kinds of stress diseases of animals; the present invention is convenient for being stored and transported, etc.

Owner:李爱华

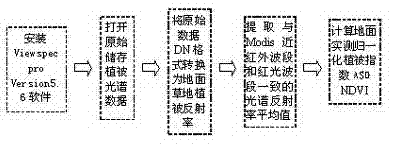

Grassland dry matter mass remote sensing estimating method

ActiveCN102393238APromote healthy and sustainable developmentMaintain ecological balanceWeighing apparatusData acquisitionRemote sensing application

The invention discloses a grassland dry matter mass remote sensing estimating method, which belongs to the field of remote sensing application. The method comprises the following steps of: collecting and processing field test data; downloading and processing Modis (Moderate Resolution Imaging Spectroradiometer) satellite data; analyzing and modeling the data and detecting the accuracy and the like. The method for establishing a ground spectrum model for predicating ground dry matter mass and correcting a Modis spectrum model through ground hyperspectral experiments is different from the method for directly predicating biomass liveweight by using NDVI (Normalized Difference Vegetation Index) data of the Modis remote sensing satellite in other like researches so that the grassland dry matter mass remote sensing estimating method is helpful for improving the predicating accuracy, is beneficial for scientific management and reasonable utilization of the grassland resources and has important practical significance in correct evaluation of the real productivity of the grassland and the sustainable use of the grass resources.

Owner:高吉喜

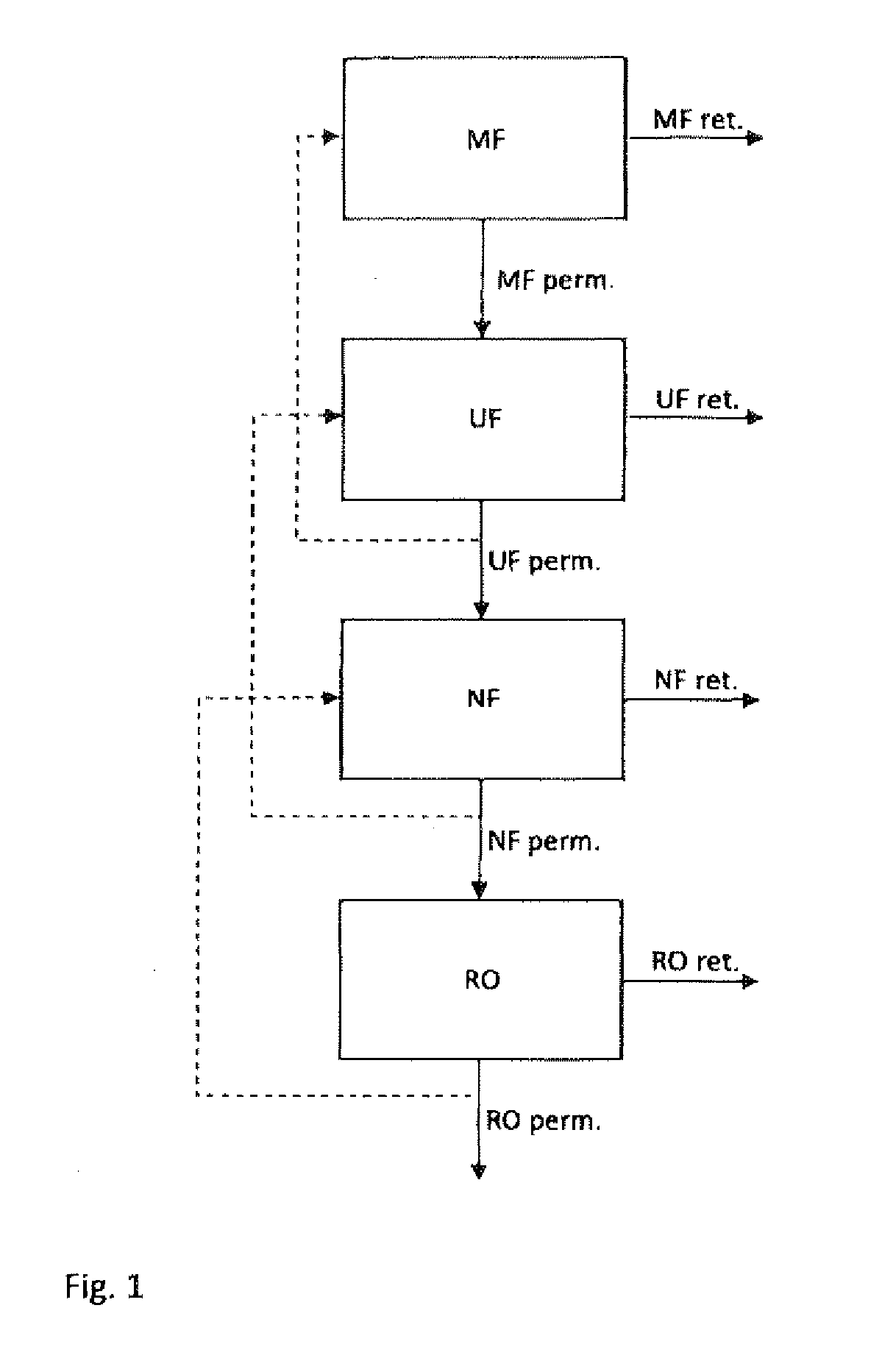

Method for treating biomass and organic waste with the purpose of generating desired biologically based products

The present invention provides a method for treatment of lignocellulosic organic waste or biomass, by which the carbohydrates are rendered more available for subsequent hydrolysis, e.g. by means of addition of enzymes or direct fermentation to one or more desired products. The invention more specifically relates to a method comprising a combination of the following process steps: thermal hydrolysis, wet oxidation and wet explosion. The method according to the present invention can operate with undivided or only poorly divided substrate having a high dry matter concentration.

Owner:CAMBI BIOETHANOL APS

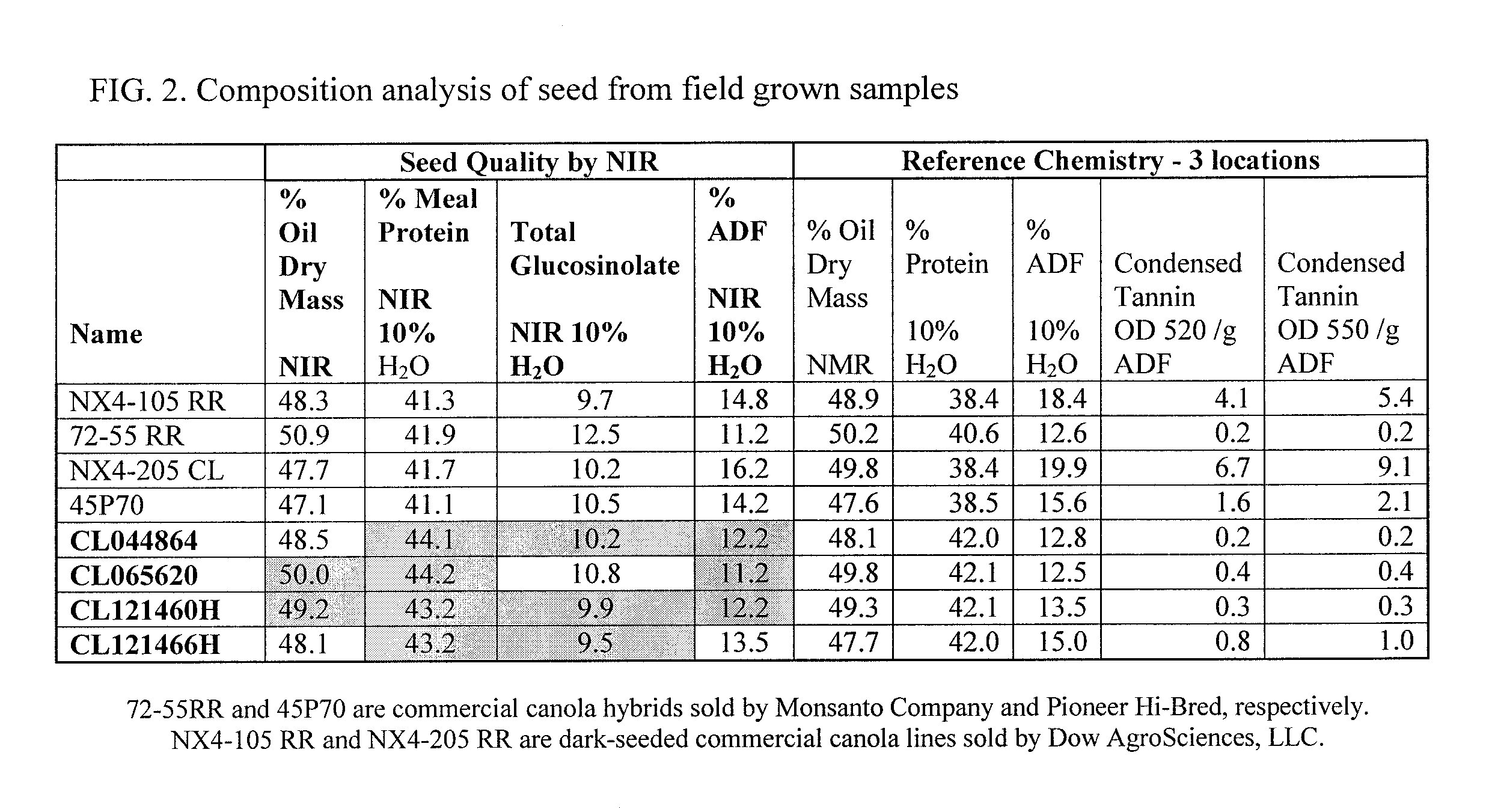

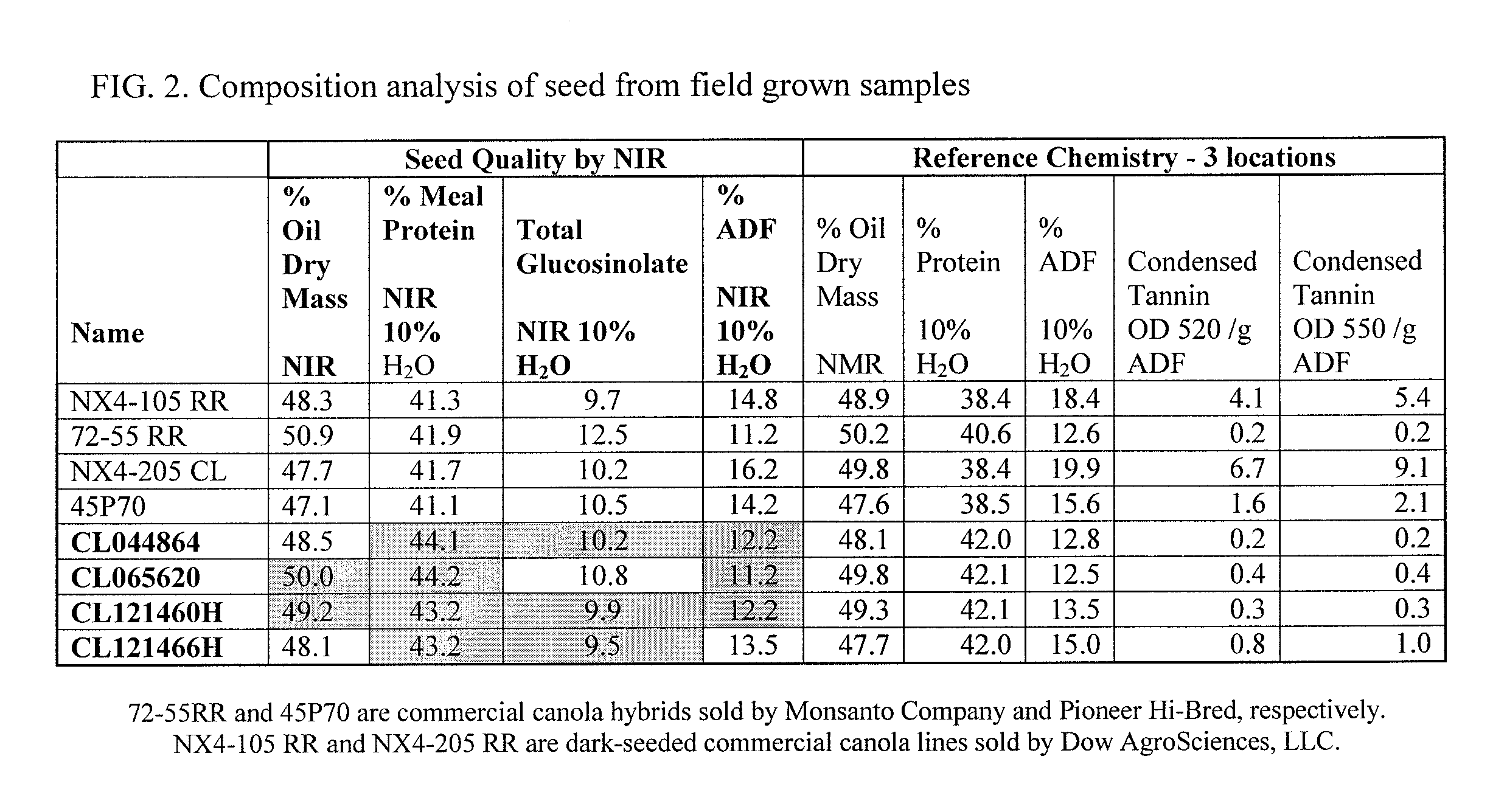

Canola Germplasm Exhibiting Seed Compositional Attributes That Deliver Enhanced Canola Meal Nutritional Value

ActiveUS20120216307A1High nutritional valueIncrease heightFood processingAnimal feeding stuffGermplasmPolyphenol

The present invention concerns a canola germplasm comprising at least 45% crude protein and not more than 18% acid detergent fiber content on an oil-free, dry matter basis. Certain embodiments further comprise one or more traits selected from the group consisting of reduced polyphenolic content and increased phosphorous content. In particular embodiments, the invention concerns canola plants comprising such germplasm and plant commodity products (e.g., seeds) produced therefrom. Canola plants comprising a germplasm of the invention may exhibit favorable seed composition characteristics that make them particularly valuable as a source for canola meal, and for methods of introducing at least one trait selected from the group consisting of high protein content, low fiber content, reduced polyphenolic content and increased phosphorous contentinto a canola variety in a seed coat color-independent manner.

Owner:AGRI GENETICS

Anti stress immunity enhancing agent for pig

InactiveCN101053370AIncrease feed intakeImprove immunityAnimal feeding stuffAccessory food factorsAnti stressWeaning

An anti stress immunity enhancing agent for pig, the weight ratio range of its component and dry matter is: citric acid 13 to 21 percent; oligomerization Fructose 15 to 25 percent; vitamin C 2 to 3percent; vitamin E 0.5 to 1 percent, vitamin B1 0.4 to 1.0 percent; vitamin B12 0.1to 0.6 percent; garlicin 1 to 4 percent; astragalus polyase 1 to 6 percent; bacitracin zinc 3 to 5 percent; the rest is carrier. The said anti stress immunity enhancing agent has reasonable compound, stable material resource, lower cost, simple producing technology, its merit is: increasing feed intake for pig, promoting growth; enhancing immunity of pig, preventing and curing diarrhea, tail-biting, anorexia etc stress symptom during the weaning, transforming, and transfer to group.

Owner:刘定发 +1

Canola Germplasm Exhibiting Seed Compositional Attributes That Deliver Enhanced Canola Meal Nutritional Value Having Omega-9 Traits

ActiveUS20120213909A1High nutritional valueIncrease heightFruit and vegetables preservationFood processingFiberGermplasm

A canola germplasm confers on a canola seed the traits of high protein content and low fiber content, wherein the canola plant produces a seed having, on average, at least 68% oleic acid (C18:1) and less than 3% linolenic acid (C18:3). The canola seed traits may also include at least 45% crude protein and not more than 18% acid detergent fiber content on an oil-free, dry matter basis. Certain embodiments further comprise one or more traits selected from the group consisting of reduced polyphenolic content and increased phosphorous content. In particular embodiments, the invention concerns canola plants comprising such germplasm and plant commodity products (e.g., seeds) produced therefrom. Canola plants comprising a germplasm of the invention may exhibit favorable seed composition characteristics that make them particularly valuable as a source for canola meal.

Owner:AGRI GENETICS

Methods for improving the nutritional quality of residues of the fuel, beverage alcohol, food and feed industries

InactiveUS20060233864A1Improve nutritional qualityIncreased rate of weight gainBy-product recoveryFood processingBeet pulpIngested food

A method is provided for improving the nutritional quality of a fibrous by-product or residue of a food manufacturing process, wherein the fibrous by-product or residue is inoculated with at least one filamentous fungus, and the fibrous by-product or residue is fermented thereby to decrease dry matter content, increase protein content, and decrease fat content of the by-product or residue. Suitable byproducts or residues include spent brewer's grains, dried distiller's grains, dried distiller's solubles, distiller's dried grains with solubles, residues of the cereal processing industry, wheat bran, soybean hulls, citrus pulp, beet pulp, rice husks or hulls, bagasse, apple pommace, and combinations thereof. Enzymes produced during the fermentation may also be used as valuable coproducts such as animal feed supplements, or may be used in primary fermentations for the brewing and distilling industry.

Owner:ALLTECH CO LTD

Infant formula milk powder with the fatty acid structure adjusted

InactiveCN101061819AAvoid exposureDelayed Post OxidationMilk preparationWhey manufactureDocosahexaenoic acidVegetable oil

The invention provides an infant milk powder with adjusted structure of aliphatic acid, which comprises the following raw materials (by weight portion in tons): dry matter of fresh milk 276, desalinized whey powder 450, structured fatty oil 105, lactose 50, fructooligosaccharide 20, alpha-lactalbumin 10, docosahexaenoic acid 5, arachidonic acid 6, nucleic acid 0. 42, taurine 0. 45, choline 0. 42, L-carnitine 0. 06, beta-carotene 0. 012, composite vitamin 2. 5, composite microelement 3. 5 and balancing refined vegetable oil.

Owner:SANLU GROUP

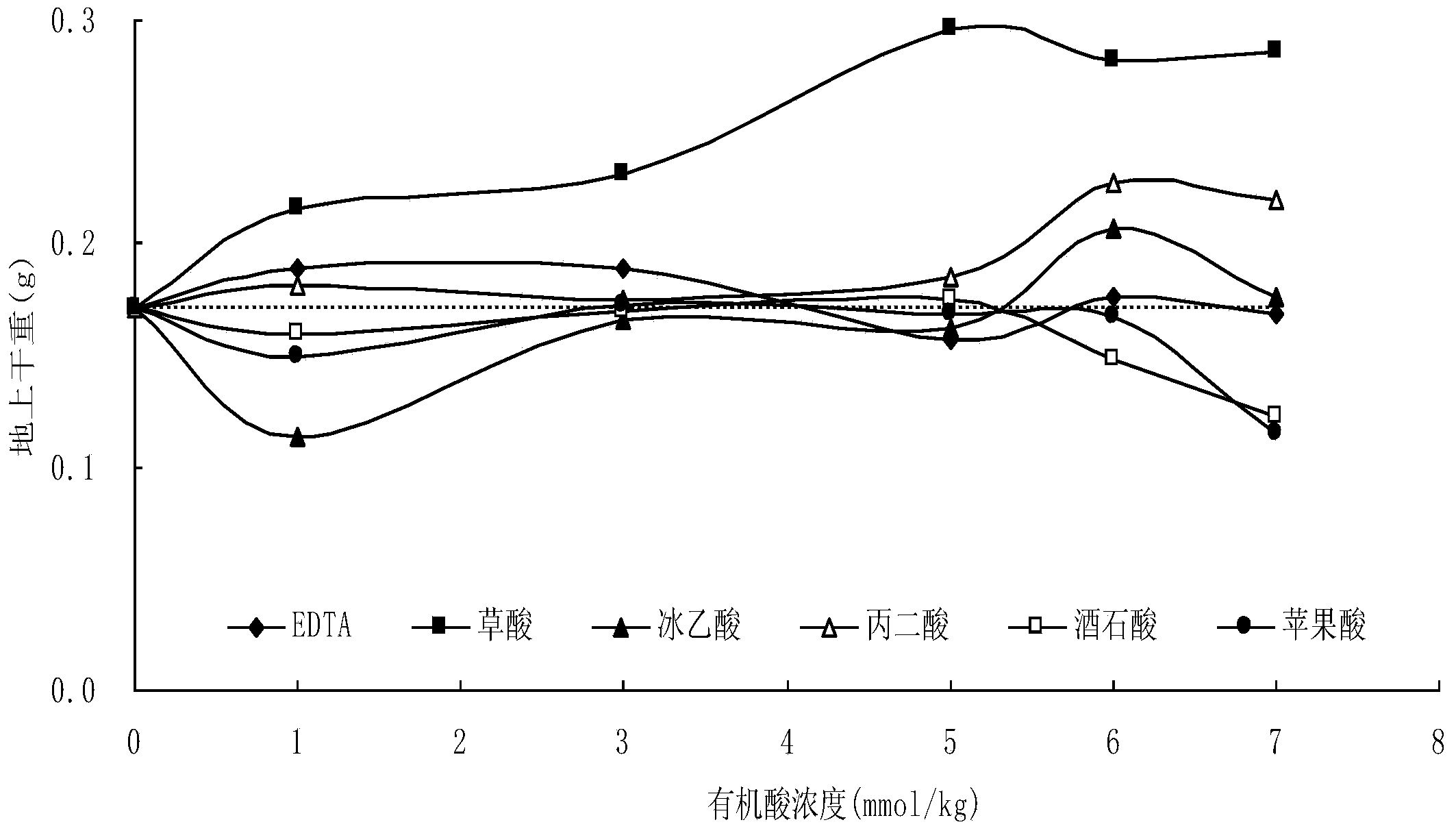

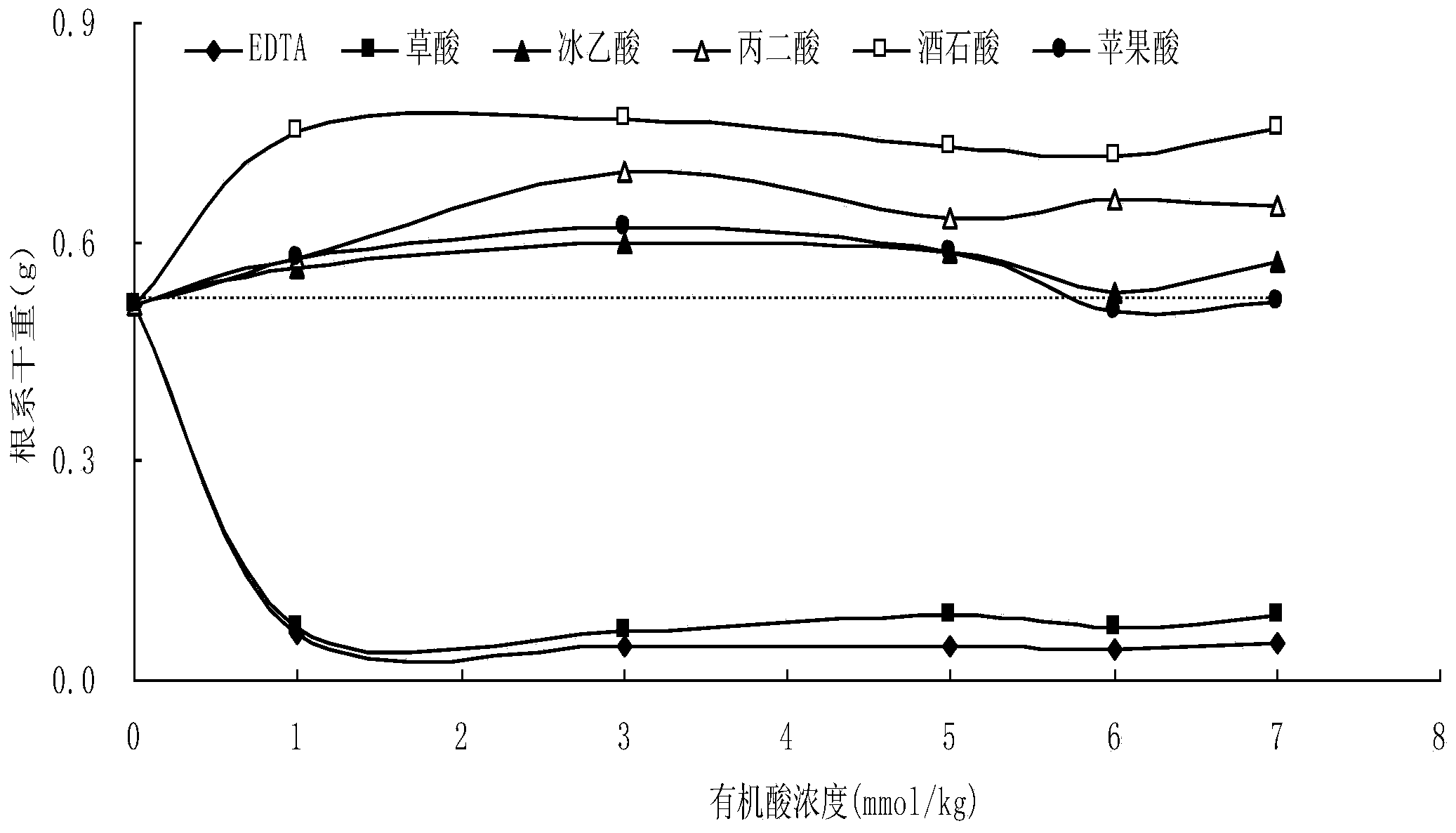

Phytoremediation method for soil with cadmium pollution

ActiveCN103521508APromote absorption and enrichmentImprove repair rateContaminated soil reclamationBiological activationPhytoremediation

The invention discloses a phytoremediation method for soil with cadmium pollution. The method comprises the following steps: ryegrass is planted in soil with cadmium pollution; organic acid is added before harvest, and the organic acid is one selected from ethylene diamine tetraacetic acid, oxalic acid, glacial acetic acid, propane diacid, tartaric acid or malic acid. In the method, based on ryegrass as a biomass raw material, when the ryegrass is used to restore the soil with cadmium pollution, through activation and induction actions of the organic acid, the bio-availability of heavy metal cadmium is raised, absorption and enrichment of cadmium of plants are promoted, and therefore the phytoremediation speed of soil with heavy metal pollution is raised. In addition, the organic acid can promote increase of amount of dry matter of overground parts and root systems of ryegrass to some extent, and finally, long-term goals of harmony of soil productivity restoration and local landscapes, ecological balance and sustainable development are achieved.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

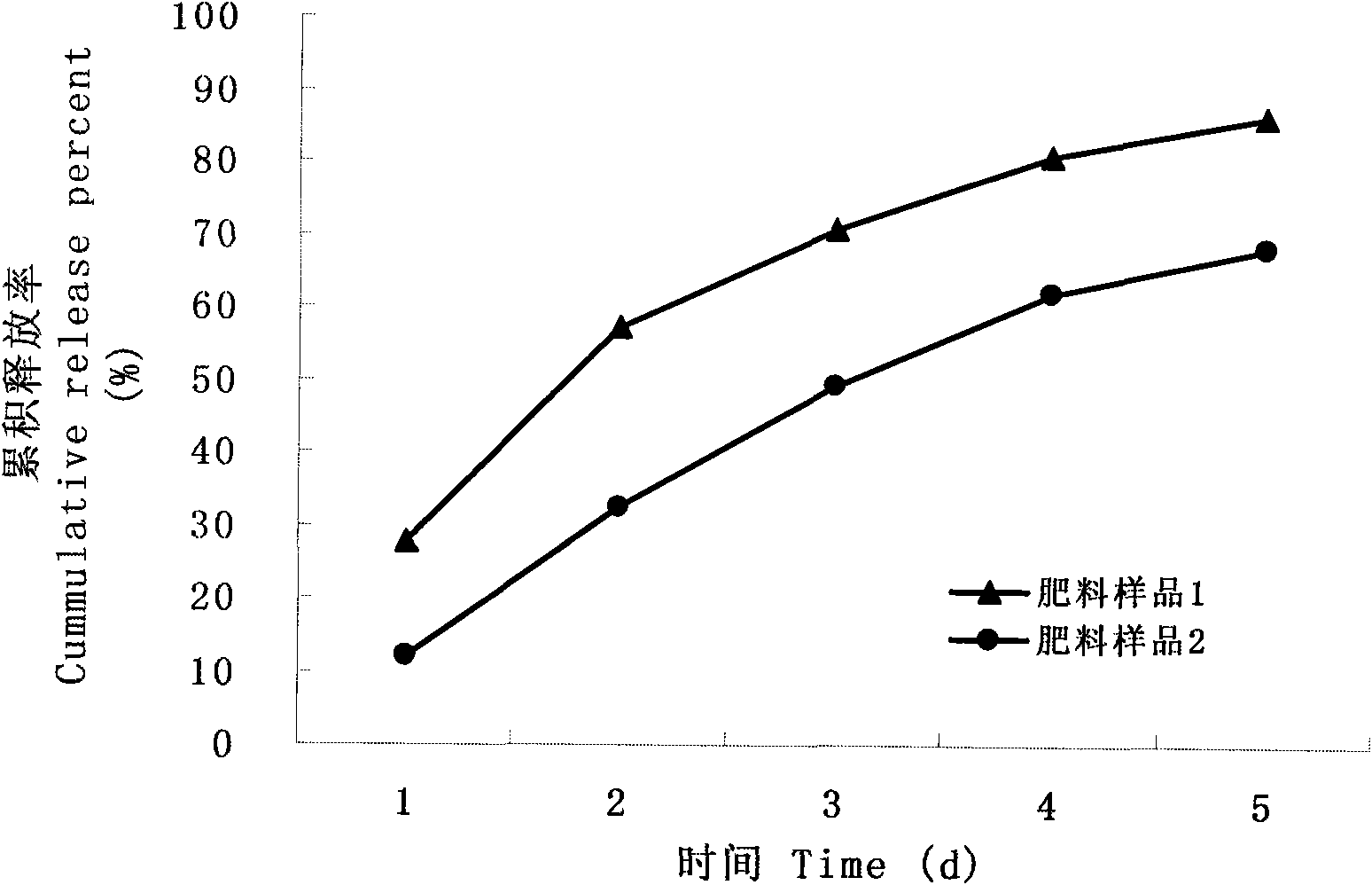

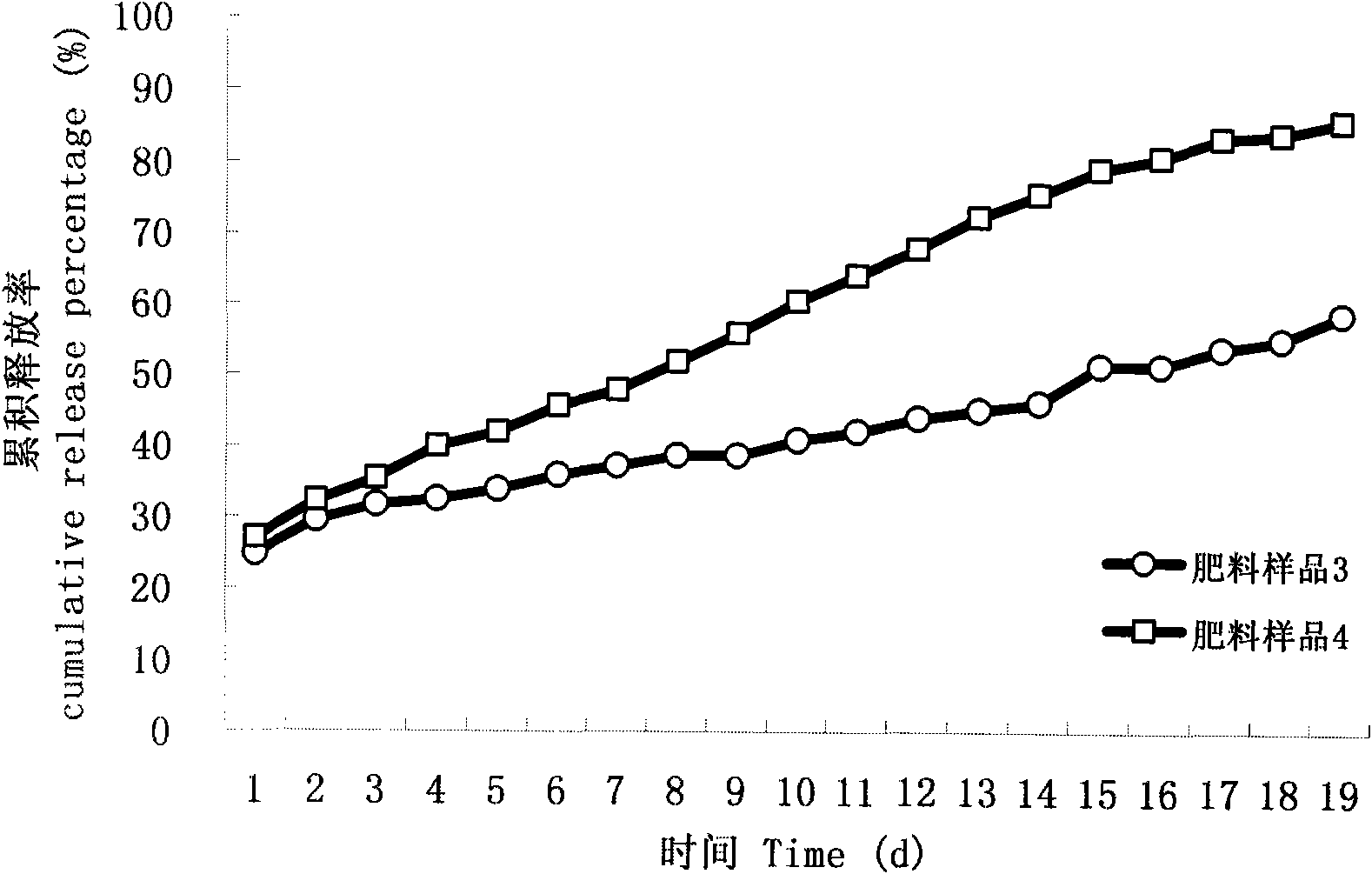

Water-based polymer coated controlled release fertilizer and method for preparing same

The invention relates to water-based polymer coated controlled release fertilizer and a method for preparing the same. The water-based polymer coated controlled release fertilizer comprises core fertilizer granules and high polymer films. The raw materials of the high polymer films comprise 150-250 parts by weight of hard monomer (methyl methacrylate), 150-250 parts by weight of soft monomer (butyl acrylate), 15-30 parts by weight of functional monomers (methacrylic acid, acrylic acid and acrylamide), 10-15 parts by weight of unsaturated organic silicon monomer, 1-3 parts by weight of emulsifier, 0.1-0.3 part by weight of cross-linking agent and 0.3-0.5 part by weight of catalyst, wherein the hard monomer, the soft monomer and functional monomers form the acrylic acid monomer. The weight ratio of the core fertilizer granules to the dry matter of high polymer emulsification is 8-12:1. The method for preparing the water-based polymer coated controlled release fertilizer comprises the steps of preparing coating mother solution, preparing coating solution, granulating the fertilizer and coating the fertilizer granules with a fluidized bed. The water-based polymer coated controlled release fertilizer has good controlled release effect and low cost and is environmental friendly. The release of the nutrients in the water-based polymer coated controlled release fertilizer can be controlled effectively and as slow as possible according to the grow need of the crop.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Organic-inorganic composite water-retaining agent and its preparing method

InactiveCN1438256ALow costSimple preparation processOrganic fertilisersSoil conditioning compositionsSaline waterDistilled water

The invention is an organic-inorganic compound water-keeping agent and the making method, making graft copolymerization, cross-linking, washing, dryness and crushing on crylic acid partly neutralized and concave-convex stick earth by evocating agent. The quality multiple of absorbing distilled water of its dry matter is 500-1500, that of absorbing 0.9 % NaCl solution, 80-150.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Quick biological drying method for household garbage

InactiveCN101899348AImprove environmental conditionsImprove degradation conditionsWaste processingSolid waste disposalEnergy recoveryOxygen

The invention relates to a quick biological drying method for household garbage. The method comprises the following steps of: uniformly mixing the household garbage from which large impurities are screened out, a biological drying product of the garbage and broken straw, and stacking the mixture in a groove-type compost reactor; covering bundled straw cushions on the garbage surface; supplying enough oxygen to aerobic microorganisms by a timed ventilation method; and after the temperature of the stack reaches a high-temperature section (more than 55 DEG C), adopting a stack temperature feedback ventilation method to evaporate moisture by fully using heat generated by metabolism of the aerobic microorganisms, and bringing out steam by using sufficient ventilation flow to realize quick drying of the garbage. The dried garbage is separated and recycled or transported to an incineration plant for energy recovery. The method improves a lower heat value of the dried garbage by 100 percent and a separation rate by 140 percent, obviously improves household garbage incineration and separation recycling values, and can be widely applied to drying treatment of household garbage which contains 65 to 50 percent of moisture and in which biodegradable organisms account for 50 to 35 weight percent of dry matters.

Owner:TONGJI UNIV

Wholewheat feed for medium and large pigs

ActiveCN102669476ANo effect on growthNutritional value impactFood processingAnimal feeding stuffBiotechnologyRapeseed

The invention relates to a feed, in particular to a wholewheat feed suitable for medium and big pigs of 50 kg before slaughter stage. The feed comprises the following components by mass percent of air dry matters: 0-2 percent of fish meal, 0-25 percent of bean pulp, 1-10 percent of rapeseed meal, 0-10 percent of bran coat, 0-30 percent of corn DDGS (distillers dried grains with soluble), 0-15 percent of whole milk rice bran, 0-60 percent of wheat, 0.3-1.5 percent of calcium carbonate, 0.5-1 percent of secondary calcium phosphate, 0-2 percent of soybean oil, 2 percent of premix and additive and 0 / 01-0.02 percent of wheat complex enzyme. The wholewheat feed has the benefits that firstly, corn is completely replaced by wheat through optimizing the feed formula, the growth of medium and big pigs is not influenced and the meat quality is remarkably improved; secondly, the feed active ingredients all conform to the feed hygienic standard and national standard, so that adverse effects can not be caused on the nutritional value of pork pigs; and thirdly, the pork pig raising cost is effectively lowered.

Owner:JIANGMEN HAID FEED

Granulated powder containing vegetable proteins and fibers, process for producing same, and use thereof

InactiveUS20110311599A1Inorganic/elemental detergent compounding agentsCosmetic preparationsBiotechnologyVegetable fibers

The present invention concerns a granulated powder containing at least one vegetable protein and at least one vegetable fiber, characterized in that it has a laser volume mean diameter D4,3 of between 10 μm and 500 μm, preferably between 50 μm and 350 μm, and even more preferably between 70 μm and 250 μm, and a dry matter content, determined after stoving at 130° C. for 2 hours, of greater than 80%, preferably greater than 85%, and even more preferably greater than 90%. The present invention also concerns a process for manufacturing this granulated powder as well as its use in various industrial field, and more particularly in the food-processing field, where it is used as a functional agent such as an emulsifying, overrun, stabilizing, thickening and / or gelling agent, in particular for totally or partially replacing certain animal proteins in the preparation of food products.

Owner:ROQUETTE FRERES SA

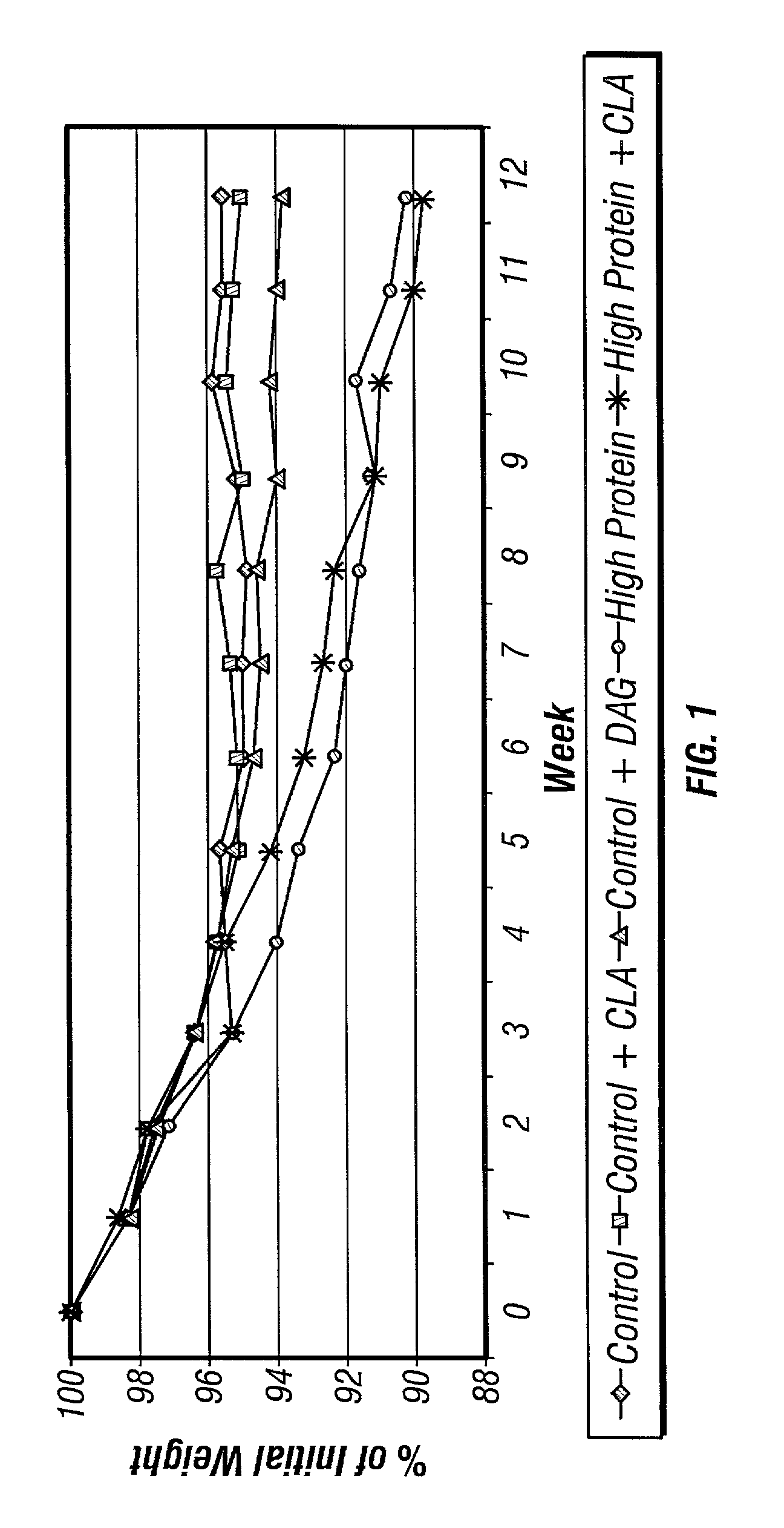

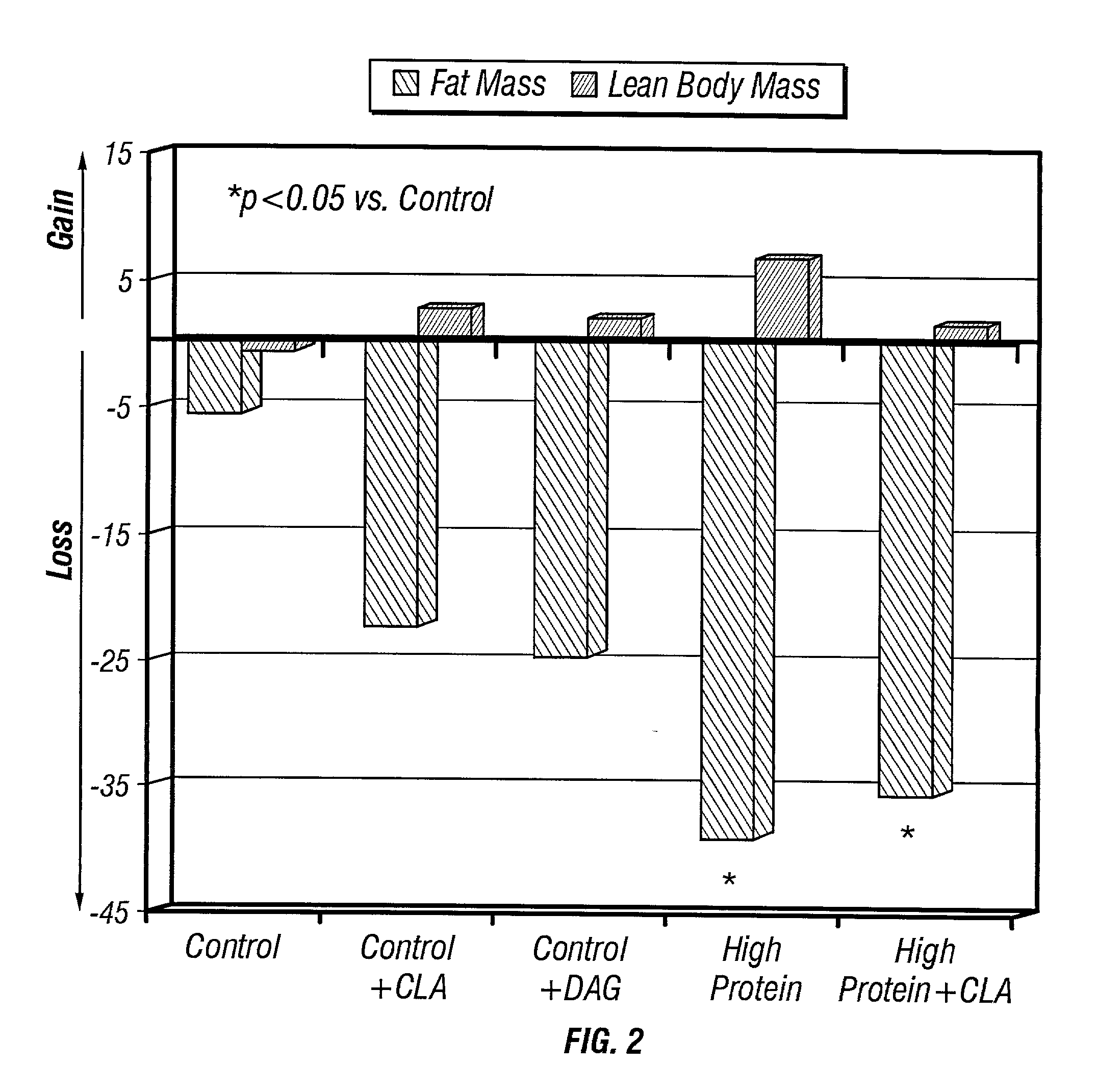

Weight management system for animals

InactiveUS20030138547A1Organic active ingredientsInorganic non-active ingredientsBiotechnologyAdditive ingredient

A pet food product for promoting comprehensive weight management in companion animals. The pet food includes, on a dry matter basis, about 35 to about 70% by weight of a protein, about 4 to about 10% by weight of a fat, about 5 to about 25% by weight of a fiber, about 10 to about 35% by weight of a digestible carbohydrate, and about 0.1 to about 1% by weight of a functional ingredient. In a preferred embodiment a diacylglyceride is the functional ingredient.

Owner:MARS INC

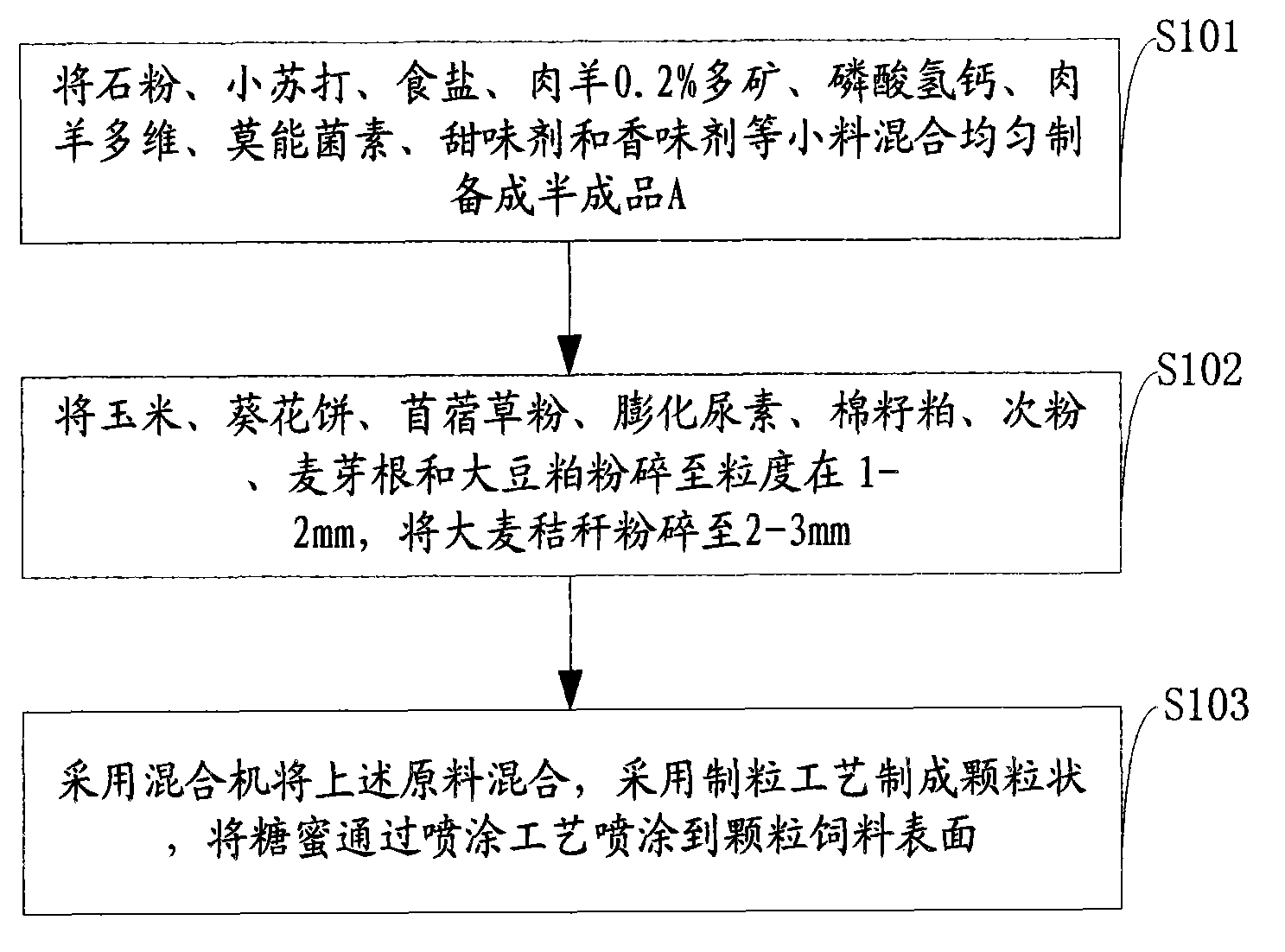

Formula of special completely mixed pellet feed for fattening sheep and preparation method

InactiveCN103238750AExcellent semen qualityPromote decompositionFood processingAnimal feeding stuffMonensinTreacle

The invention discloses a formula of a special completely mixed pellet feed for fattening sheep and a preparation method. The formula comprises corns, barley straws, sunflower cakes, alfalfa meal, cottonseed meal, wheat middling, malt roots, soybean meal, stone powders, molasses, puffing urea, baking soda, salt, 0.2% of polymineral for mutton sheep, calcium hydrogen phosphate, multivitamins for mutton sheep, monensin, a sweetener and a flavouring agent, wherein nutrients comprise dry matters, crude protein, calcium, total phosphorus, the salt, digestible energy for sheep and coarse fiber. The preparation method comprises the steps of: mixing the stone powder, the baking soda, the salt, the 0.2% of polymineral for mutton sheep, the calcium hydrogen phosphate, the multivitamins for mutton sheep, the monensin, the sweetener and the flavouring agent to prepare a semi-finished product A; grinding the corns, the sunflower cakes, the alfalfa meal, the puffing urea, the cottonseed meal, the wheat middling, the malt root, the soybean meal and the barley straws; and evenly mixing the materials by adopting a mixing machine, preparing the materials to be granular through a granulating process, and spraying the molasses on the surface of the pellet feed through a spraying process. The special completely mixed pellet feed for fattening sheep accords with the national green food concept, and has a good development prospect.

Owner:NORTHWEST A & F UNIV

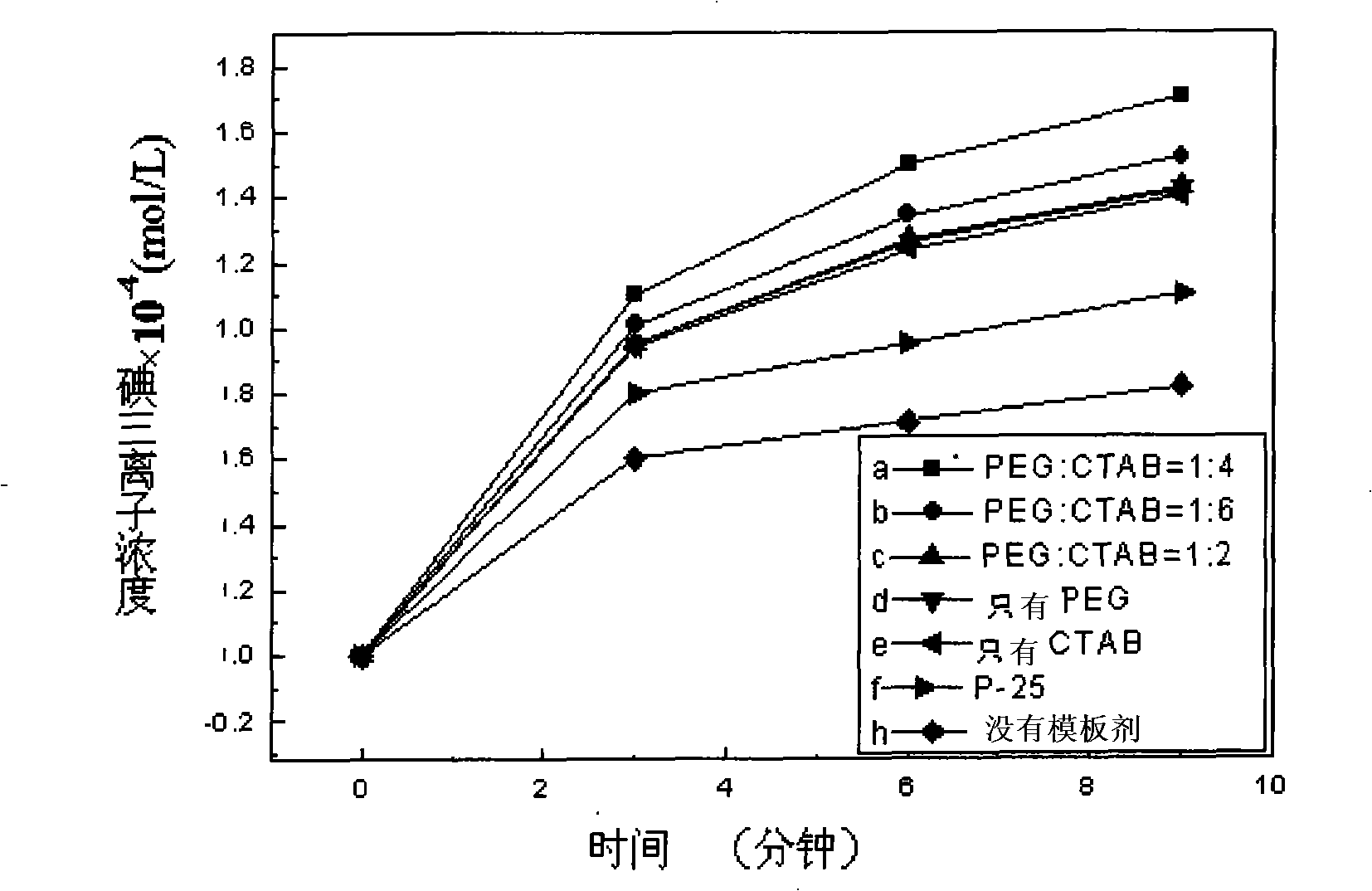

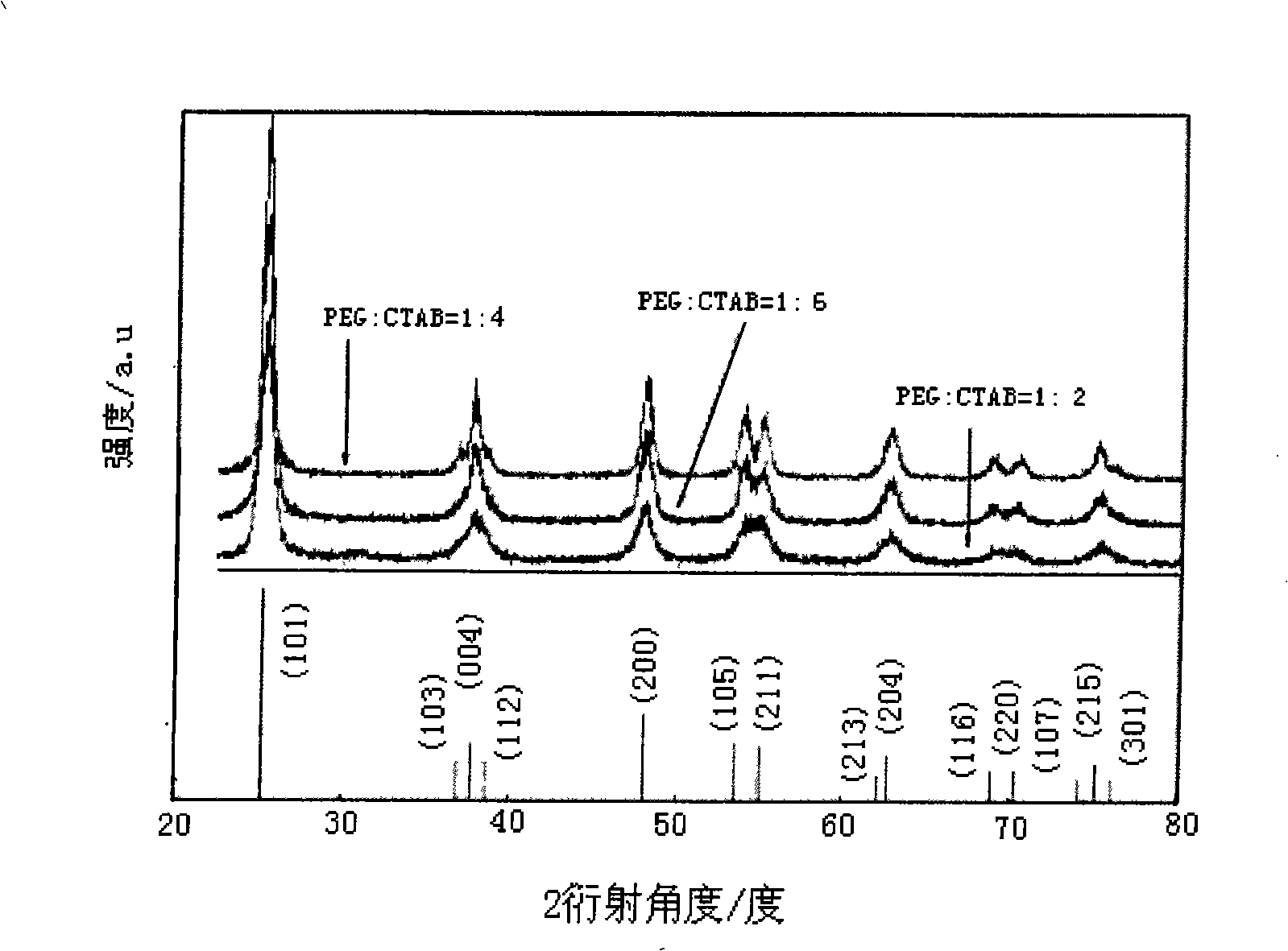

Method of preparing anatase structured highlight catalytic active nano-TiO2

InactiveCN101318128AImprove photocatalytic activityPhysical/chemical process catalystsTitanium dioxideAcetic acidInorganic salts

The invention discloses a preparation method for a high photo-catalytic activity nano-TiO2 with anatase structure, which comprises the following steps: (1) weighing organic titanium compounds or titanium inorganic salt which is dissolved in glacial acetic acid to prepare the mixed solution and dissolving the mixed solution in anhydrous alcohol to obtain solution 1; (2) selecting two or three templates, dissolving the templates in the anhydrous alcohol to obtain solution 2; (3) mixing the solution 1 and solution 2, adding distilled water, stirring, obtaining settled solution, standing for 2-5 days, forming gel and drying; (4) calcining the dried matter to remove the templates and obtaining the high photo-catalytic activity nano-TiO2 with anatase structure. The high photo-catalytic activity nano-TiO2 with anatase structure prepared by the method of the invention has smaller grain diameter smaller, larger specific surface and higher photo-catalytic activity than P-25, which can be widely used in the fields such as photocatalysis and sensitized solar batteries.

Owner:TIANJIN UNIV

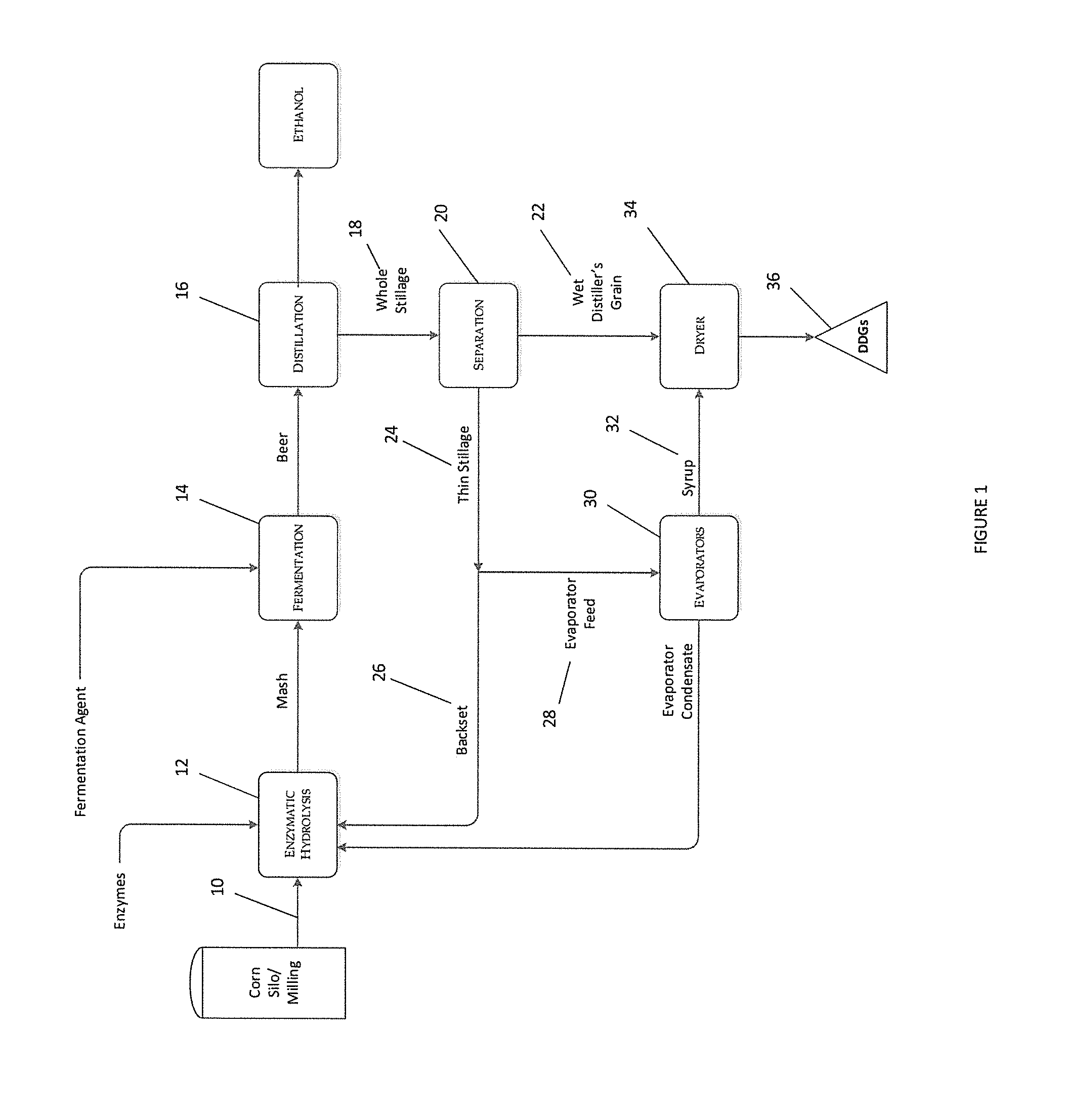

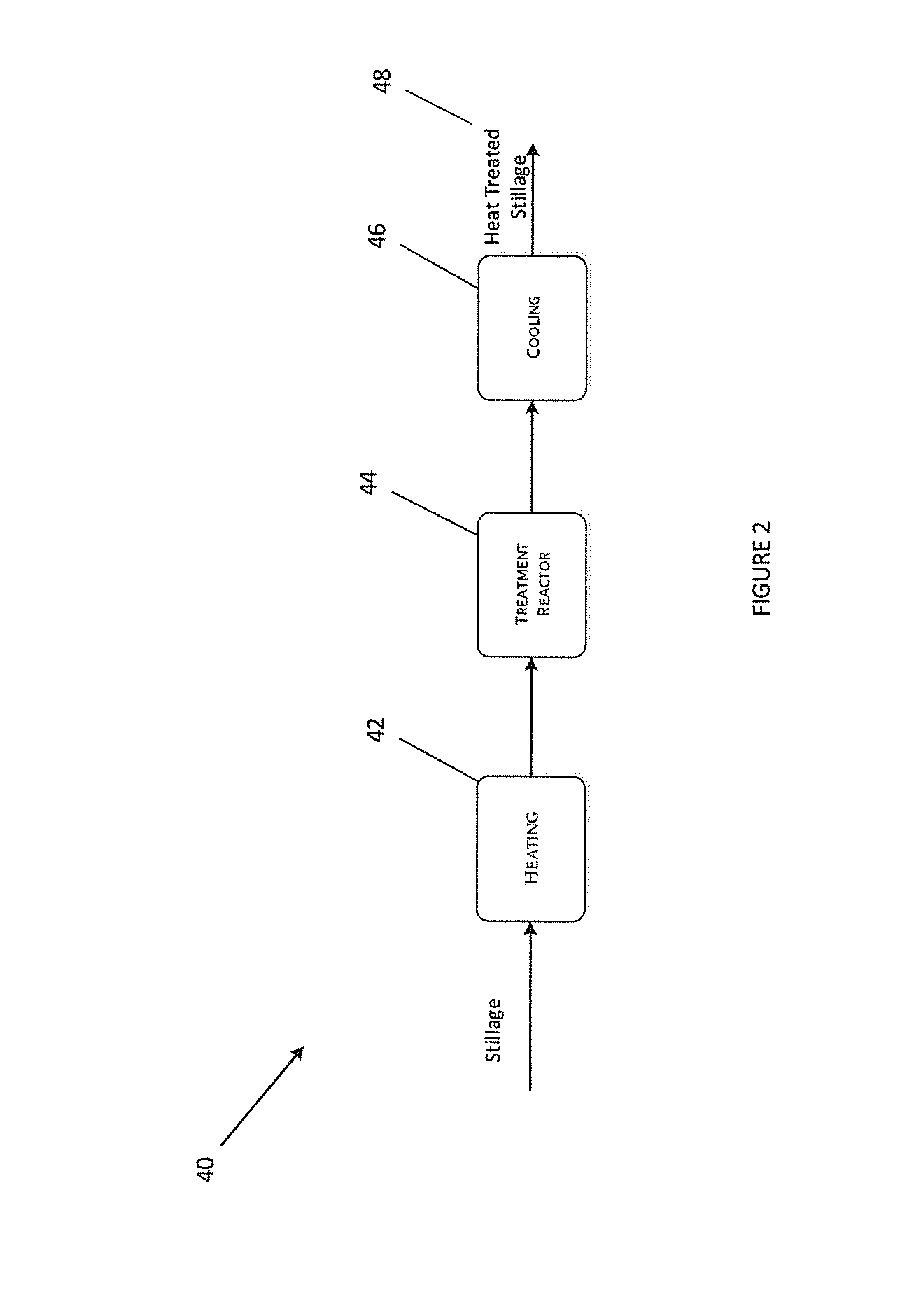

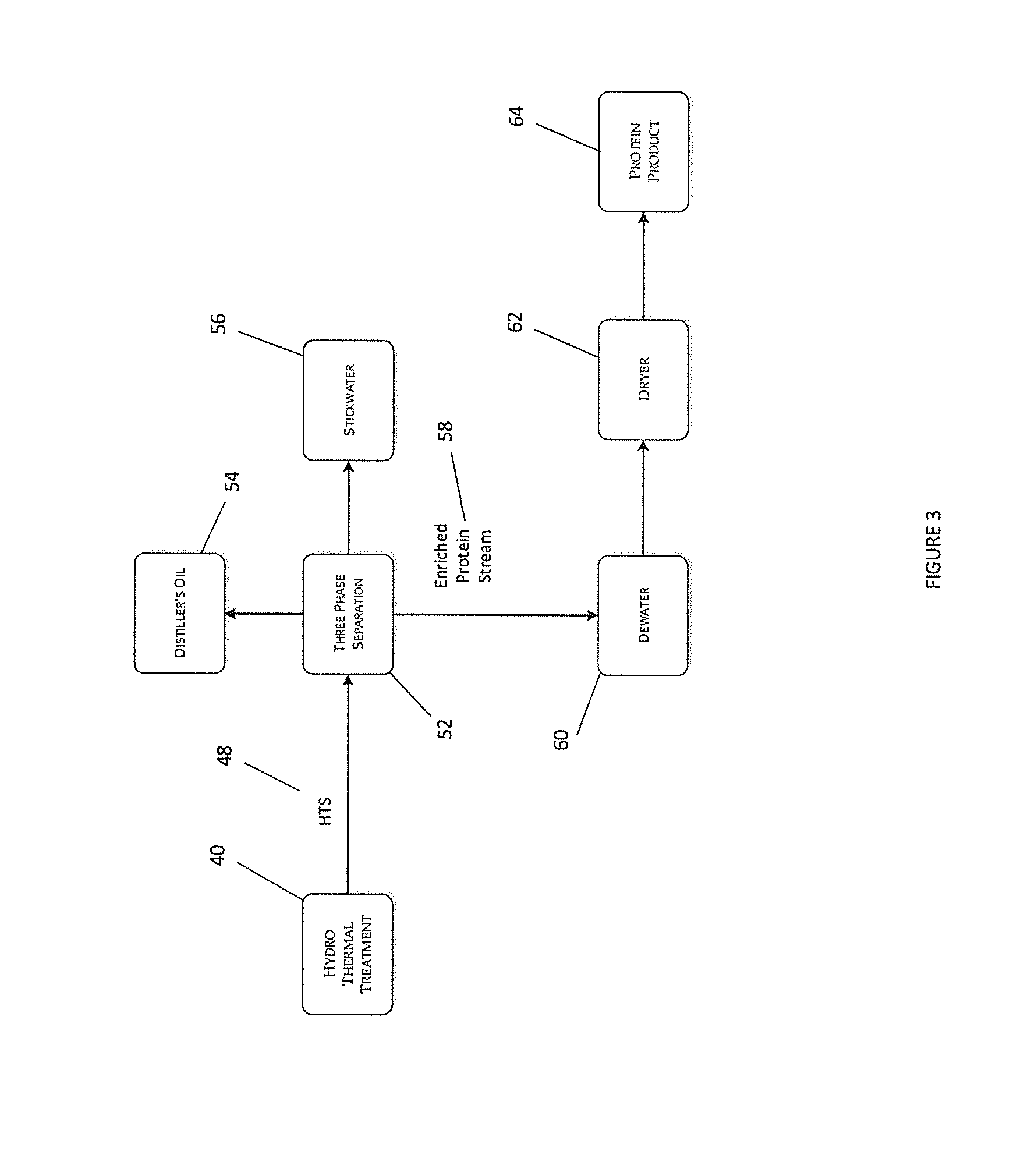

Protein product

InactiveUS20140343259A1Promote recoveryEasy to separateFermented solutions distillation/rectificationBiofuelsGlycerolChemistry

A protein product recovered from a fermentation process including a protein content of 45.0% or more calculated by weight of dry matter, a glycerol content of 1.0% or less calculated by weight of dry matter, and a mineral nutrient content of 6.0% or less calculated by weight of dry matter. A method for recovering a protein product by heating fermentation stillage to 200 degrees F.-350 degrees F., altering the physicochemical properties of the stillage to enable facile separation of the stillage, and separating a phase enriched in protein. Protein products, protein paste, high protein meal, and proteinaceous agglomerates recovered and formed.

Owner:VALICOR

Total mixed fermented feed for mutton sheep fattening and preparation method thereof

InactiveCN102318757AAdd flavorImprove qualityFood processingAnimal feeding stuffSodium bicarbonateWeight gaining

The invention discloses a total mixed fermented feed for mutton sheep fattening; the early-stage total mixed fermented feed comprises the following components by weight: 26-35 parts of mixed forage, 17-24 parts of straw, 7-13 parts of alfalfa, 15-24 parts of corn, 3-7 parts of cottonseed meal, 5-10 parts of sunflower cakes, 3-9 parts of flax cakes, 0.3-0.7 parts of calcium hydrophosphate, 0.5-1.0parts of sodium bicarbonate, 0.5-1.1 parts of table salt, and 0.7-1.2 parts of composite premix of vitamins and trace elements; the later-stage total mixed fermented feed comprises the following components by weight: 25-35 parts of sunflower disc powder, 7-12 parts of straw, 7-13 parts of alfalfa, 25-35 parts of corn, 5-10 parts of dry vinasse, 2-5 parts of cottonseed meal, 5-9 parts of sunflowercakes, 0.3-0.7 parts of calcium hydrophosphate, 0.5-1.0 parts of sodium bicarbonate, 0.5-1.1 parts of salt, and 0.7-1.2 parts of composite premix of vitamins and trace elements. By lactic acid fermentation, the preparation method of the invention can increase the digestibility for dry matter of the feed, and facilitates long-term storage; the protein content and quality of the fermented feed are increased and improved; the utilization rate and conversion efficiency of the feed are increased; the feed intake and weight gain efficiency of mutton sheep are significantly increased; the mutton quality is improved.

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Powder comprising ceramic granules

ActiveUS20120282469A1Raise the level of performanceReduce contentSynthetic resin layered productsCellulosic plastic layered productsCeramic sinteringVitrification

The invention relates to a granulated powder intended, in particular, for the production of ceramic sintered parts, said powder having the following chemical weight composition, based on dry matter, namely: at least 1% of a first binder having a glass transition temperature less than or equal to 25° C.; 0-4% of an additional binder having a glass transition temperature greater than 25° C.; 0-4% of a temporary additive different from the first binder and the additional binder, the total content of the first binder, the additional binder and the temporary additive being less than 9%; 0-15% of an additive for sintering the ceramic material; at least 2% impurities; and the remainder comprising a ceramic material, and optionally an agent for stabilising said ceramic material, to make up 100%. According to the invention, the median diameter D50 of the powder is between 80 and 130 μm, the percentile D99.5 is less than 500 gm and the relative density of the granules is between 30% and 60%.

Owner:FIVEN NORGE AS

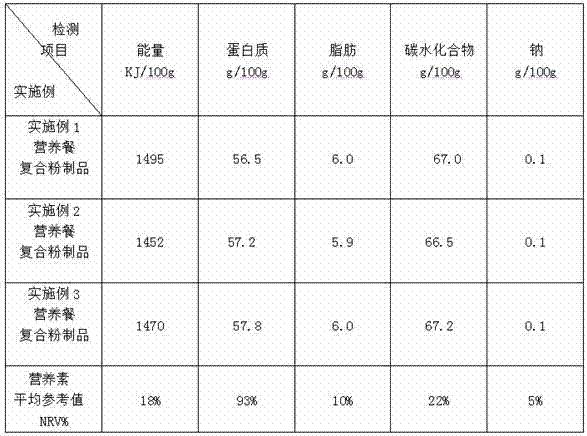

Compound powder product for nutritious meal and preparation method thereof

PendingCN106962761AIncrease vitalityEasy to eatNatural extract food ingredientsFood dryingTremellaFiltration

The invention discloses a compound powder product for nutritious meal and a preparation method thereof. The compound powder product for the nutritious meal is prepared by taking brown rice, quinoa, oats, corns, other cereals, hericium blazei tremella, other edible fungus, pumpkins, papayas, apples, other fruits and vegetables, roots and stems of Chinese yams, kudzu roots, konjak and other plants, semen cassiae, lotus leaves, medicinal and edible Chinese herbal medicines and the like as raw materials, respectively crushing, puffing, hydrolyzing, high-pressure homogenizing, filtering, concentrating and spray-drying to obtain dry matter fine powder, then blending and mixing with collagen protein powder, whey protein powder, soyabean protein powder and inulin and other series processes. The compound powder product for the nutritious meal, disclosed by the invention, is rich in dietary fibers and natural active substances, compound, multi-component, more nutritious, simple and convenient to eat, favorable for improvement in body vitality and normal digestive system, and the like; the preparation method integrates puffing, enzymolysis, filtration, concentration, spray-drying and blending, is higher in extraction rate compared with a traditional production method and is more comprehensive in component compared with a single production method.

Owner:FUJIAN TIANSIDUN BIOTECH

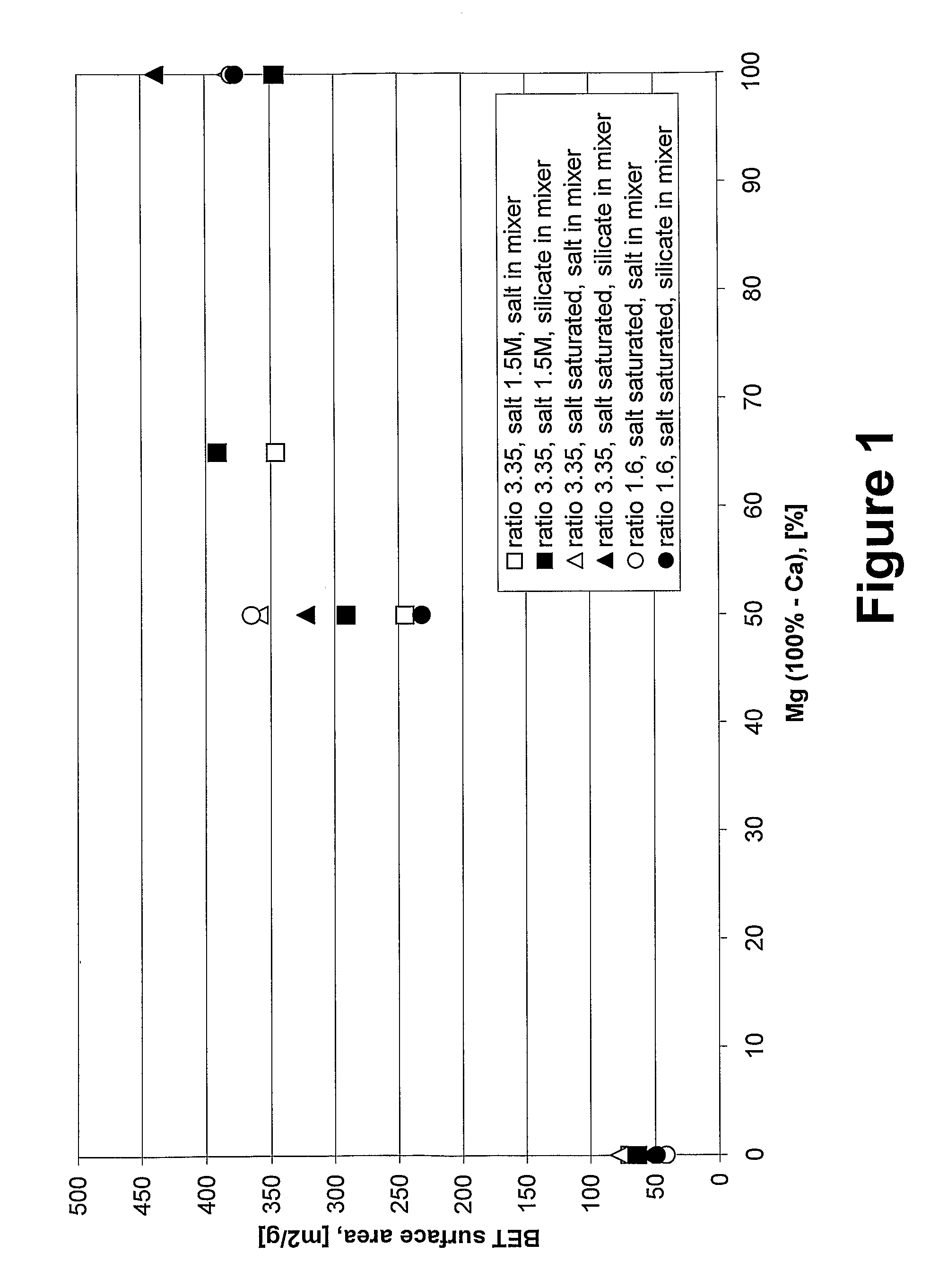

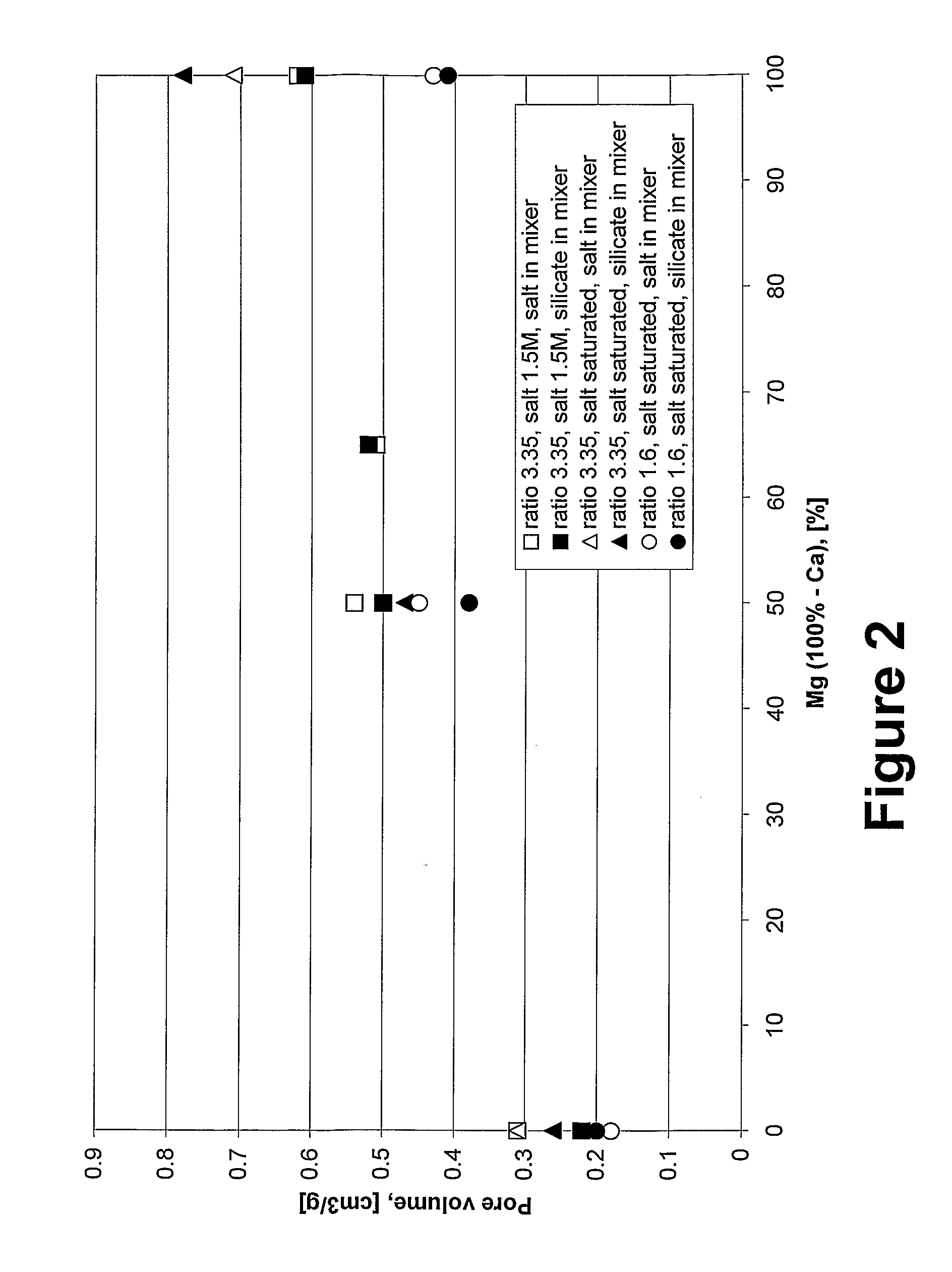

Agglomerates of Precipitated Silica, Method for Their Preparation and Their Use as Filter Medium for Gas Filtration

ActiveUS20080034968A1Improve performanceSimpler and cheapOther chemical processesAluminium silicatesFilter mediaSilicon dioxide

A method of producing a material including agglomerated particles of precipitated silica, including preparing a solution of at least two metal salts (Me), wherein the metal ions are divalent or polyvalent. A solution of alkali metal (M) silicate having a molar ratio SiO2 / M2O of 1-4 is prepared. The solutions are mixed and the mixture stirred, allowing a coagulum to immediately form. The coagulum is rinsed, collected, dewatered, impregnated and processed to provide a material having a dry matter content of >75%, preferably >97%. A material obtainable by the process is also provided.

Owner:SVENSKA AEROGEL

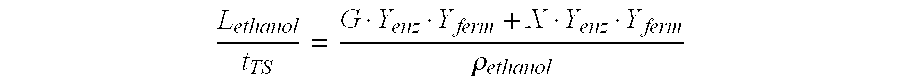

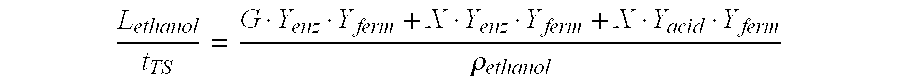

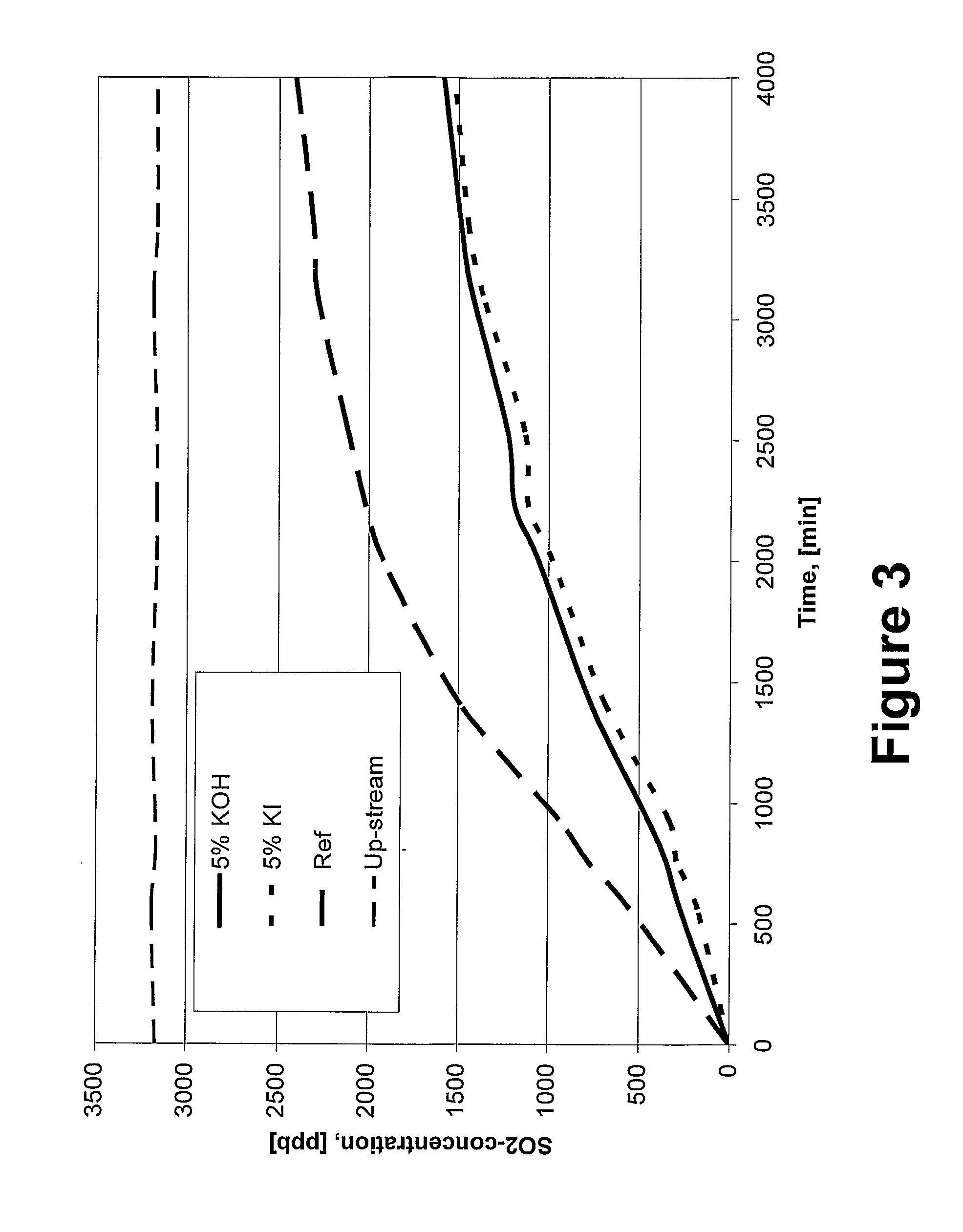

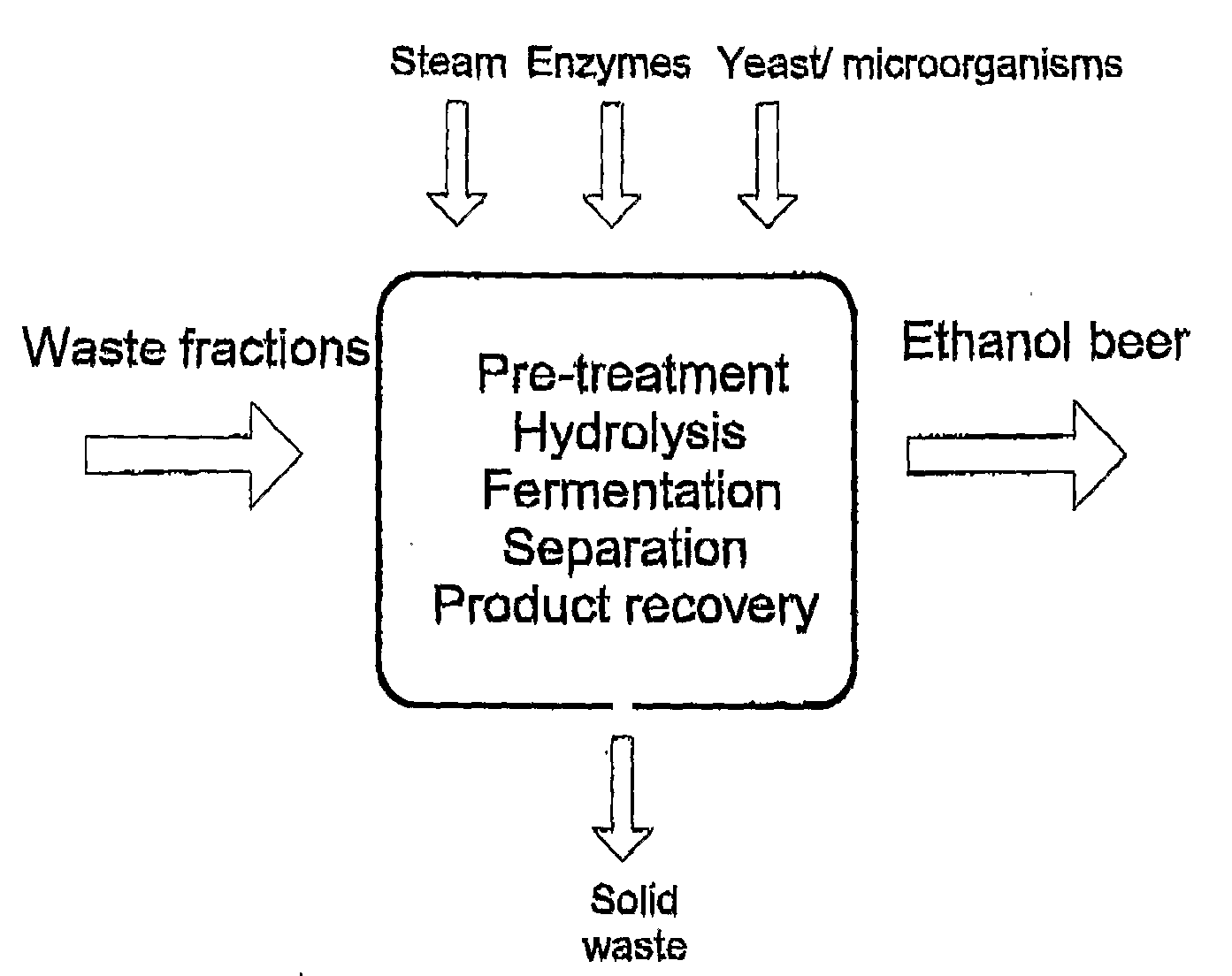

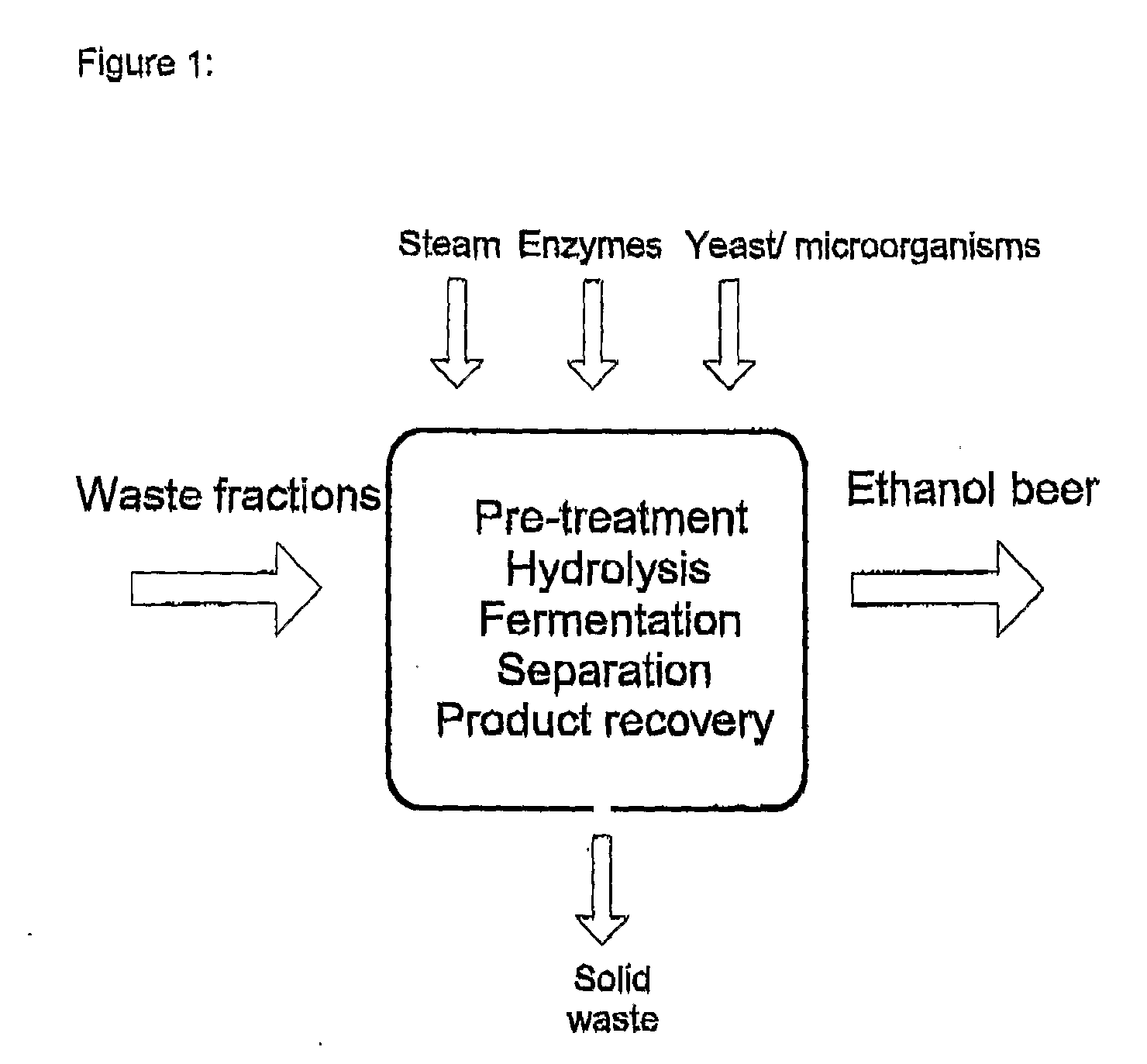

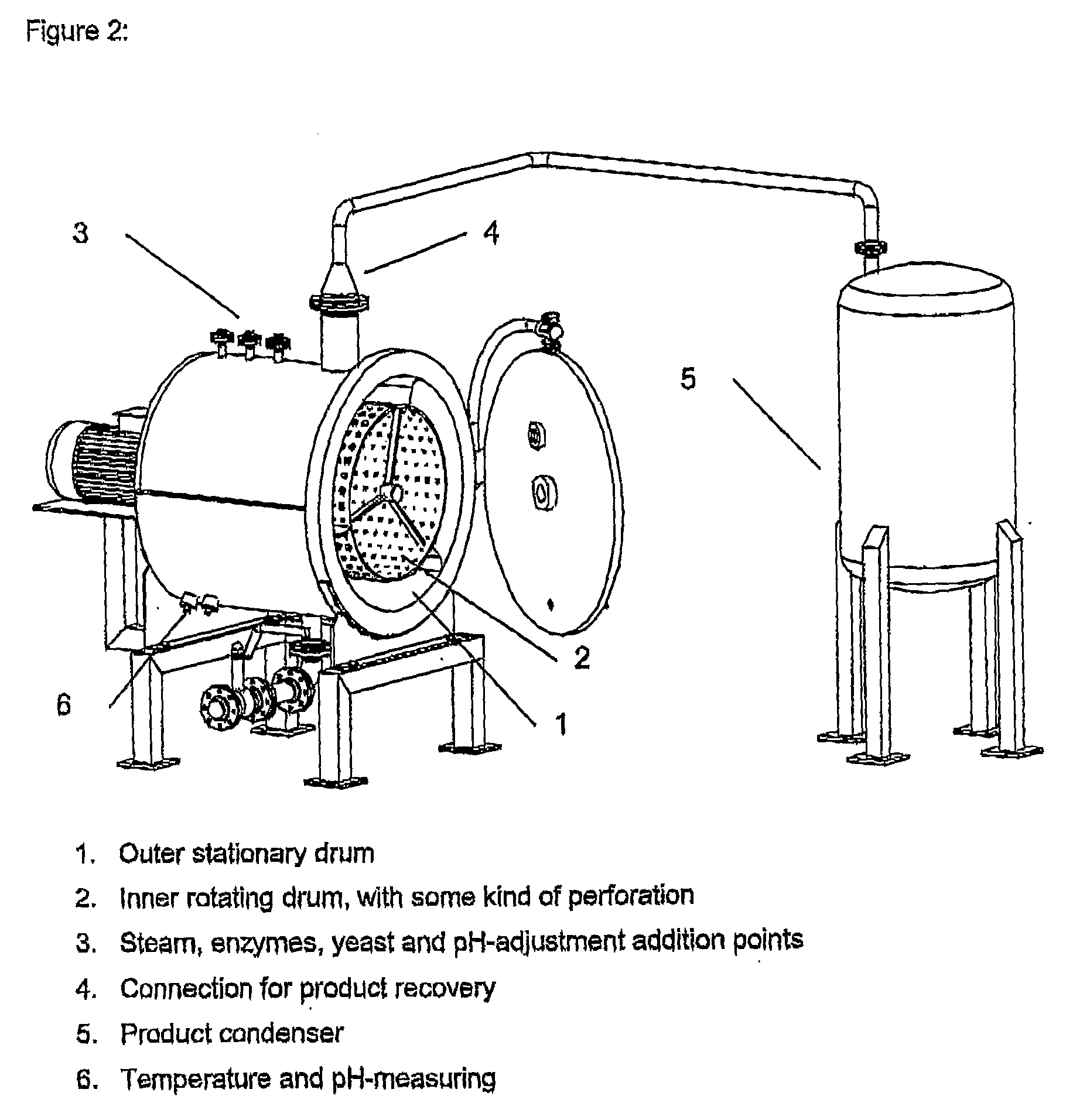

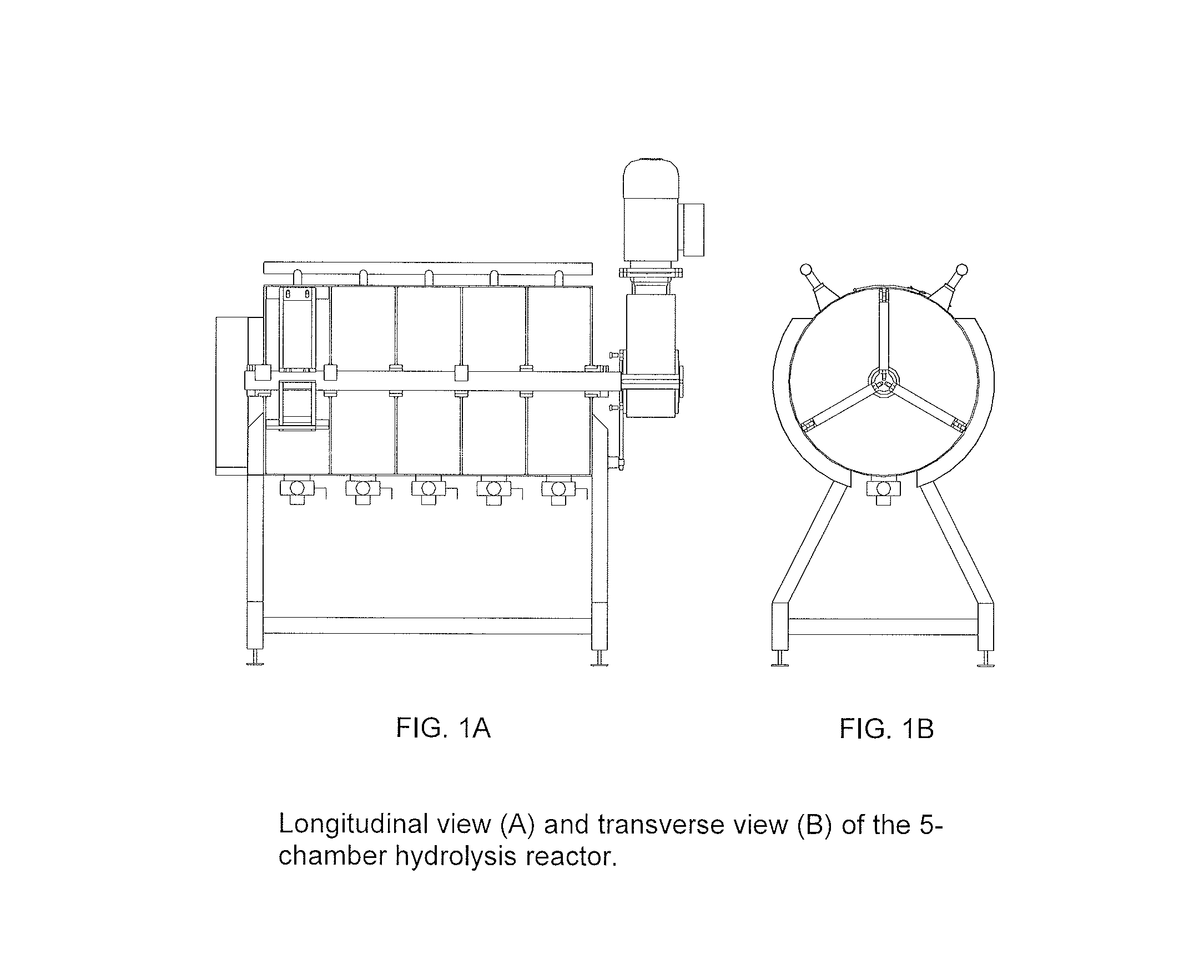

Non-Pressurised Pre-Treatment, Enzymatic Hydrolysis and Frementation of Waste Fractions

ActiveUS20090004714A1Effective treatmentBiological substance pretreatmentsHydrolasesSingle vesselFree falling

The present invention relates to a process for production of fermentation products, including bioethanol by non-pressurised pre-treatment, enzymatic hydrolysis and fermentation of waste fractions containing mono- and / or polysaccharides, having a relatively high dry matter content. The process in its entirety, i.e. from non-pressurised pre-treatment over enzymatic hydrolysis and fermentation to sorting of fermentable and non-fermentable solids can be processed at a relatively high dry matter content in a single vessel or similar device using free fall mixing for the mechanical processing of the waste fraction.

Owner:DONG ENERGY POWER AS +1

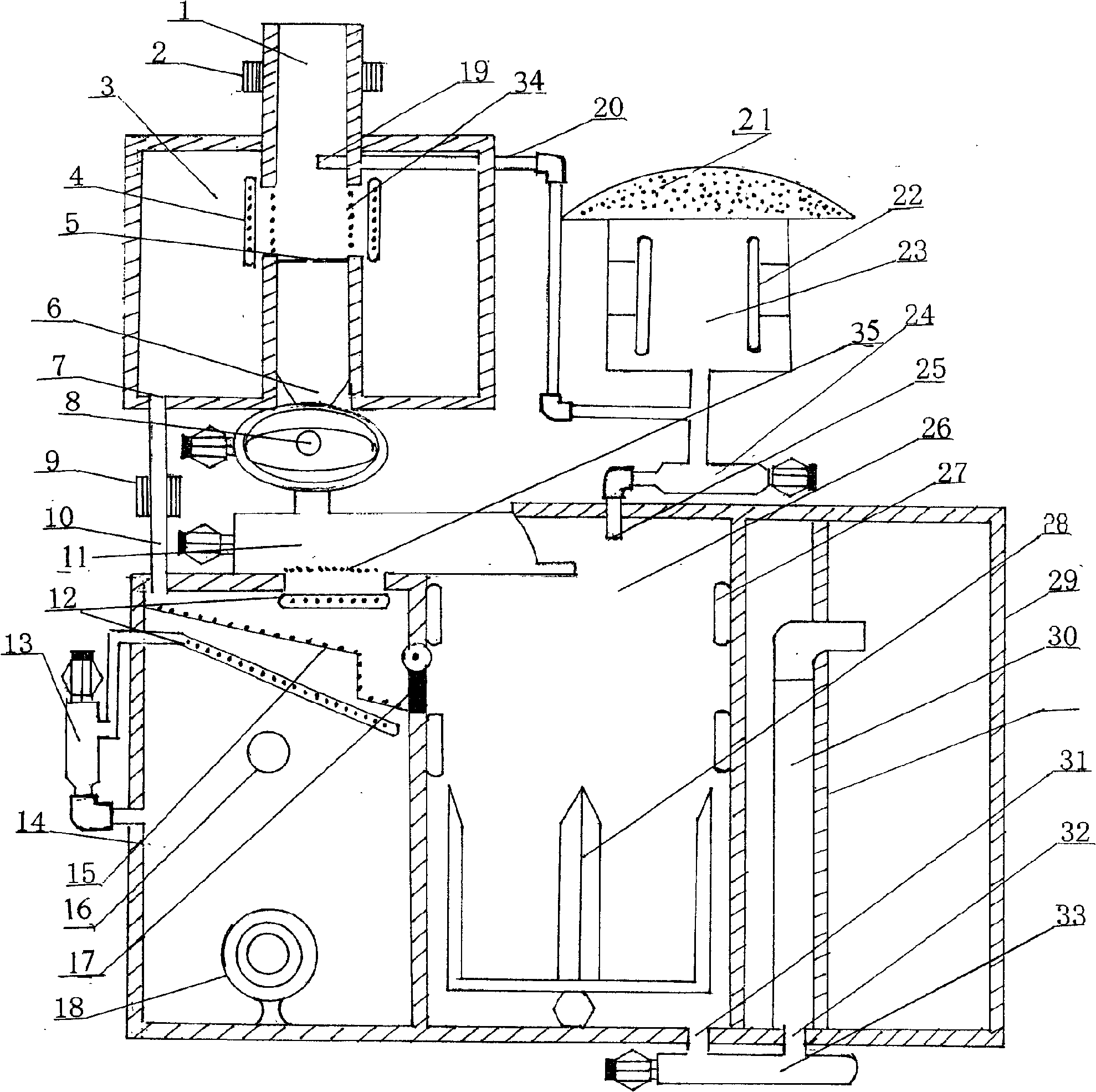

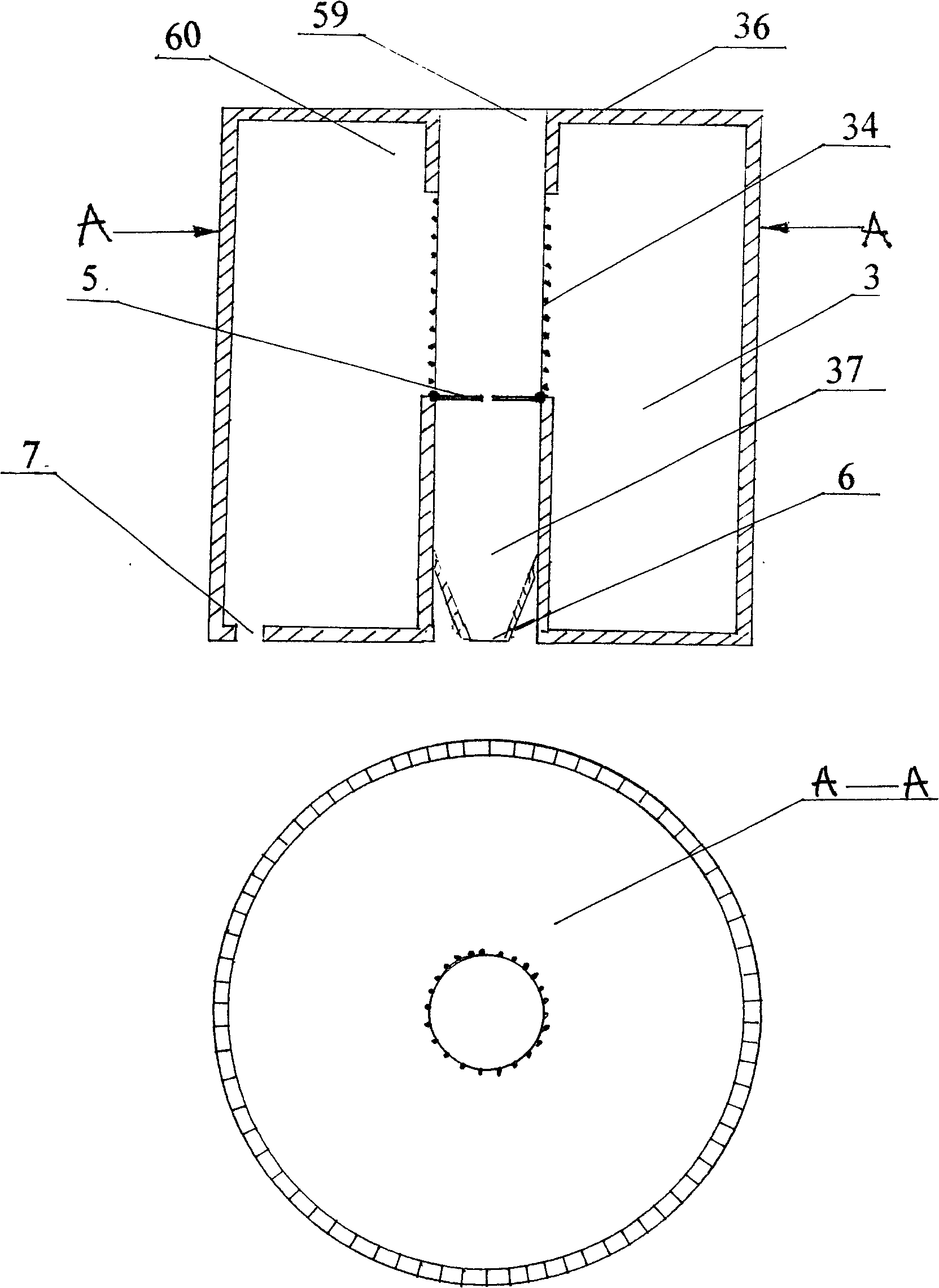

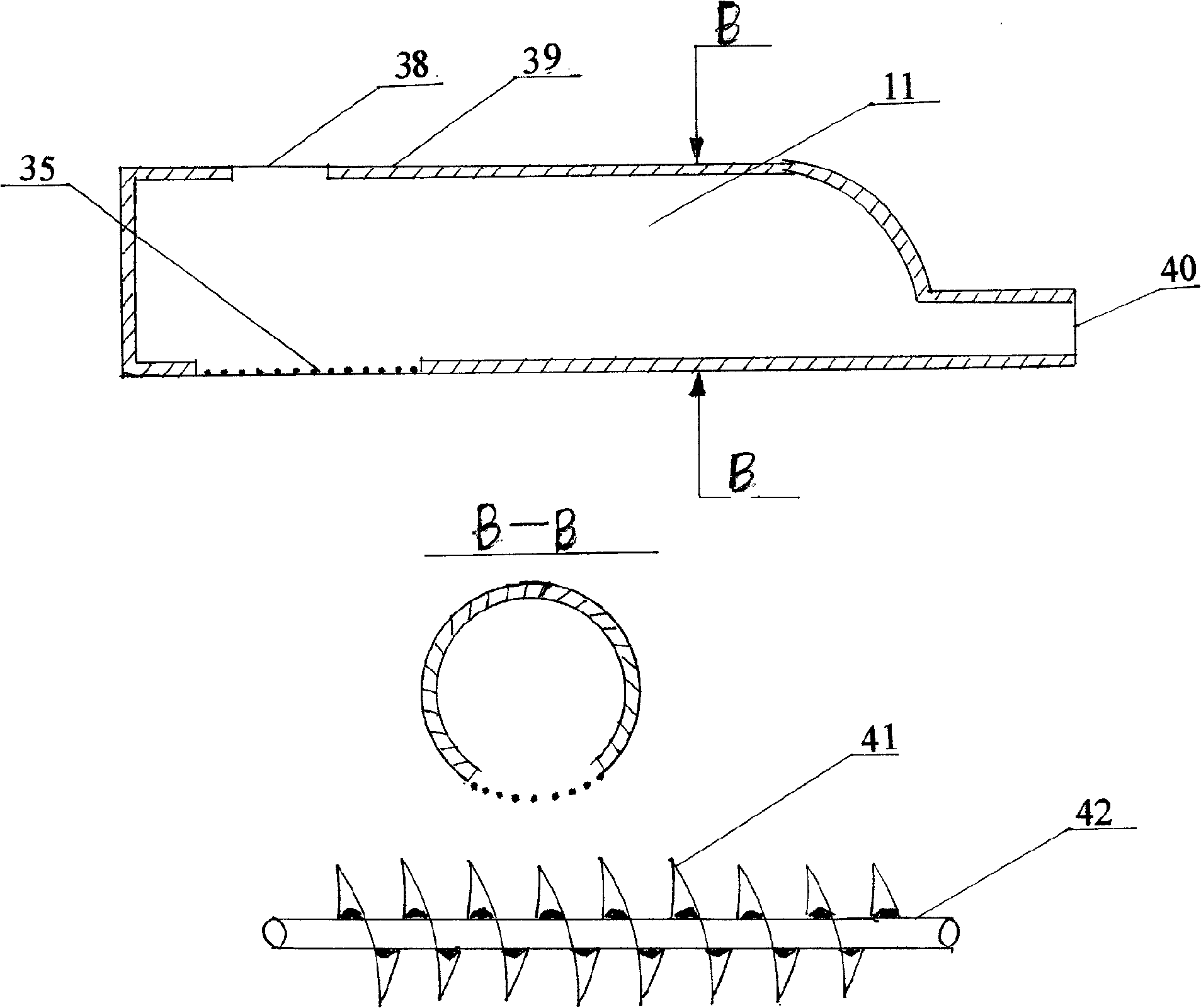

Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

InactiveCN101265004AKill eggs quicklyImprove sterilizationMaintainance for emmission reductionSludge treatmentHuman bodyDecomposition

The invention relates to a device for rapid decomposition, sterilization, drying and sanitary treatment of solid / liquid feces, aiming to solve the problems of human feces including environmental pollution, disease transmission and body health damage. The device comprises a solid-liquid separator, a semi-solid finishing machine, a secondary solid-liquid separation spiral pump, a urine treatment tank, a microwave sterilization drying chamber, a dry matter storage tank, and a deodorizing aeration tower. The feces can be rapidly sterilized, deodorized and dried after leaving human body, so as to become sterile and odorless dried particles in a short time, which can be used as fertilizer. The inventive device prevents transmission of pathogenic bacteria from source and solves fecal pollution problem. The inventive device has the advantages of low volume, light weight, and low energy consumption; and can be used in any places. Except fixed places, the device is more suitable for being installed and used in personal vehicles such as passenger train, passenger long-distance bus and passenger ship.

Owner:齐梓凡

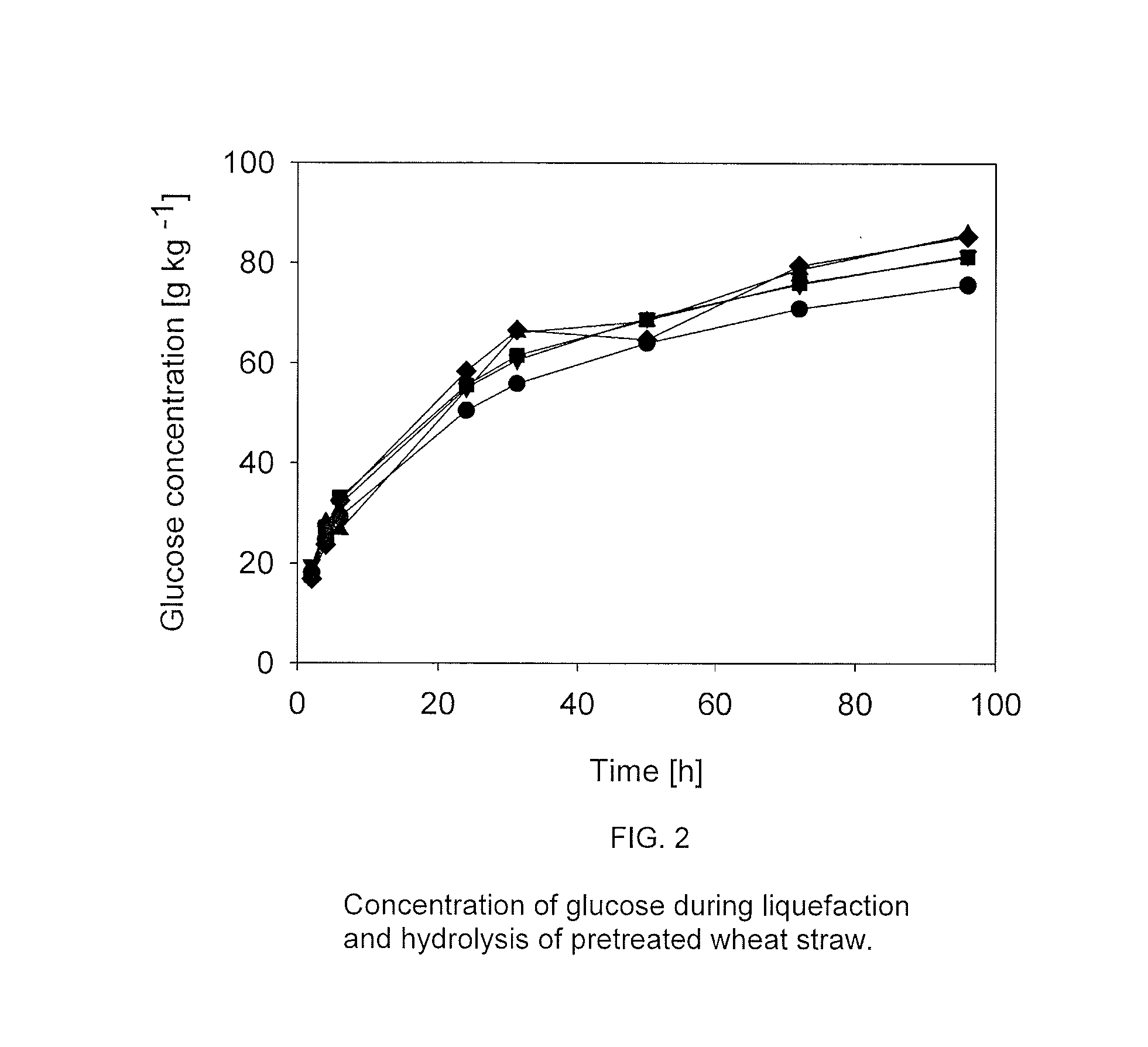

Enzymatic hydrolysis of biomasses having a high dry matter (DM) content

ActiveUS20080182323A1Secures accessibilityHigh dry matter contentBiofuelsAnimal feeding stuffFree fallingEnzymatic hydrolysis

Disclosed are processes for liquefaction and saccharification of polysacharide containing biomasses having high dry matter content (>20%) and preferably possessing large average particle size. The polysaccharide containing biomasses are subject to enzymatic hydrolysis in a mixer that utilizes “free fall” mixing. “Free fall” mixing provides mechanical degradation of the biomass during hydrolysis and, in the case of lignocellulosic biomass, promotes movement of cellulase enzymes along cellulose chains, which improves enzymatic hydrolysis at high dry matter.

Owner:INBICON AS

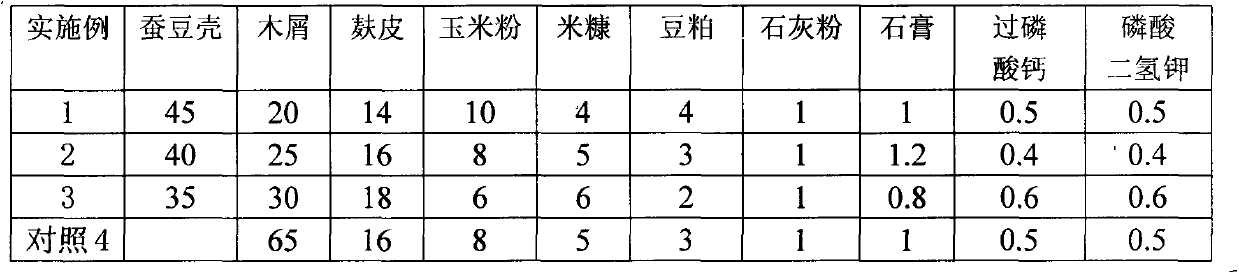

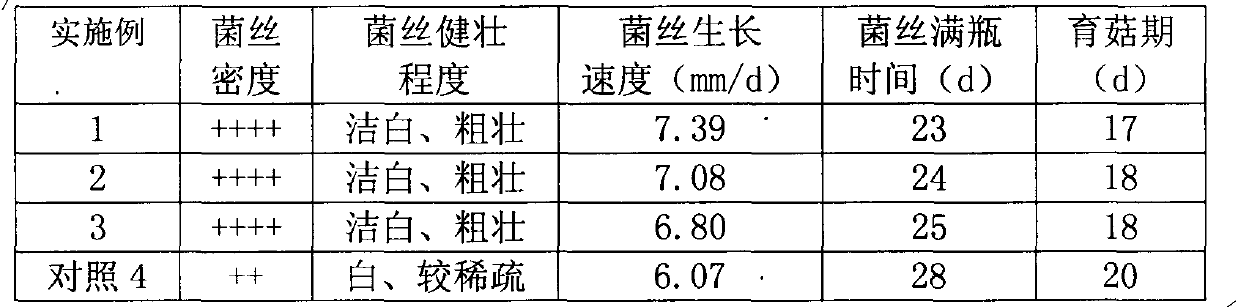

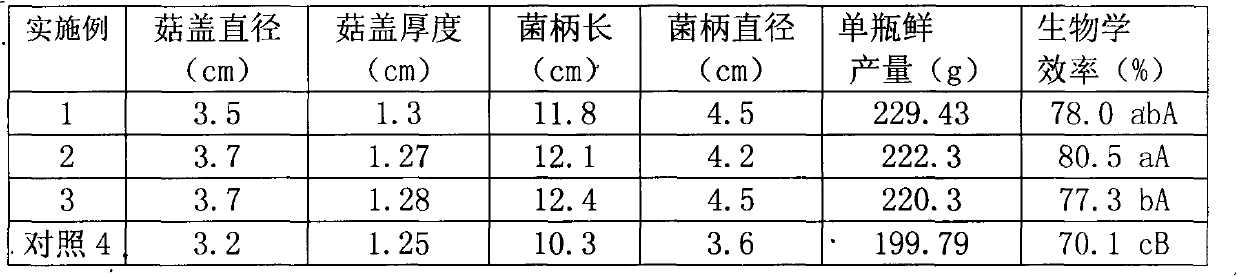

Pleurotus eryngii culture medium as well as preparation method and application thereof

InactiveCN103102203ASufficient nutritionImprove the growing environmentFertilizer mixturesBiotechnologyNutrition

The invention provides a pleurotus eryngii culture medium which is characterized in that the culture medium adopts broad been skins as base materials and comprises water and a dry substance mixed with the water. The water content of the culture medium is 63-66%. The dry substance comprises the following components including the broad been skins, wood dust, wheat bran, corn powder, rice bran, bean pulp, lime powder, gypsum, calcium superphosphate and monopotassium phosphate. The invention further discloses a preparation method and application of the pleurotus eryngii culture medium. Compared with the prior art, the pleurotus eryngii culture medium has the advantages that the broad been skins and other components are organically combined together by adopting a reasonable ratio so as to provide sufficient nutrition and a good growing environment for pleurotus eryngii and guarantee the high yield and the high quality of the pleurotus eryngii; and meanwhile, the broad been skins are used for replacing the wood dust so that wastes can be recycled and the wastes are changed into valuable things, so as to be good for environmental friendliness.

Owner:邬金飞

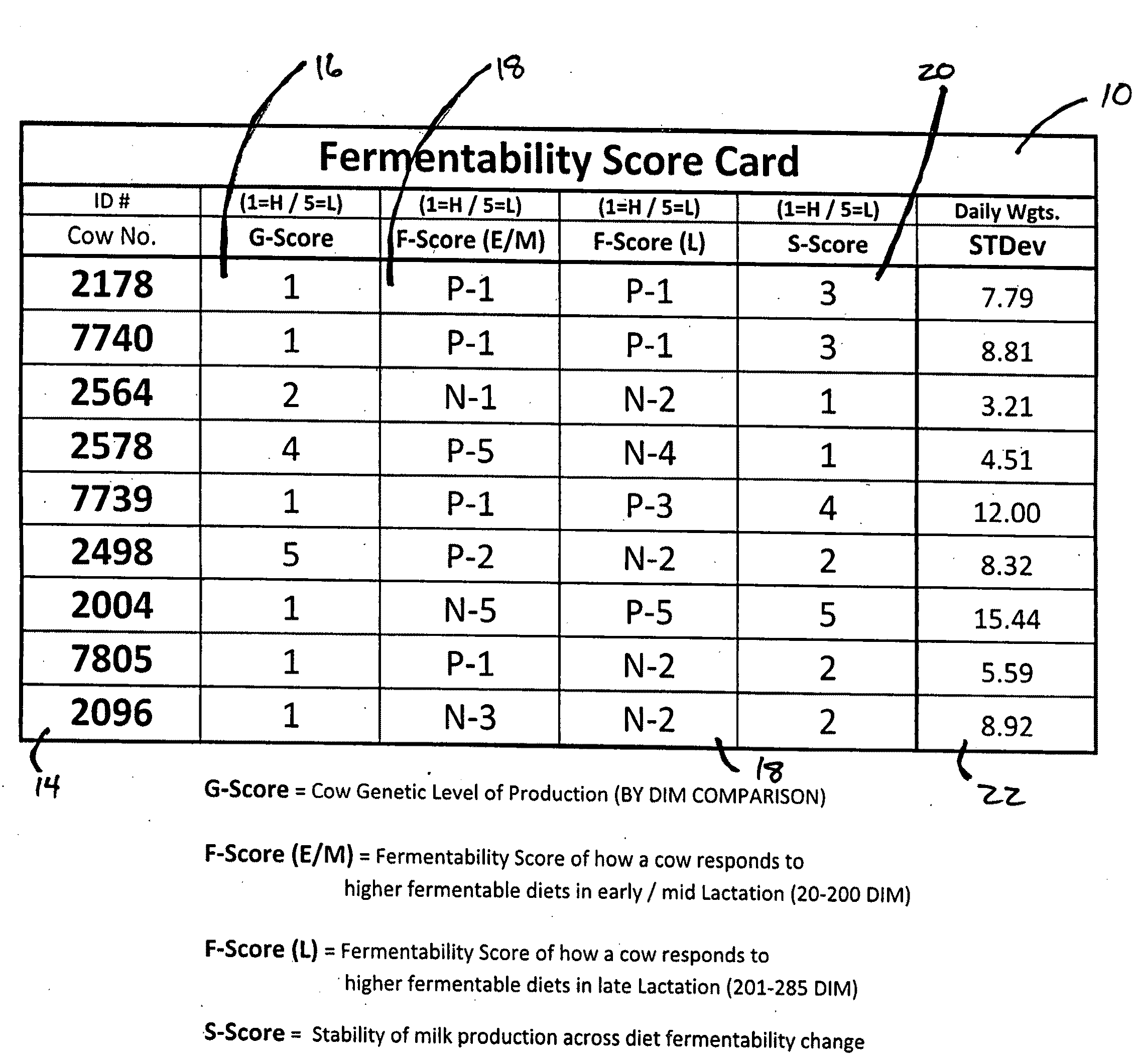

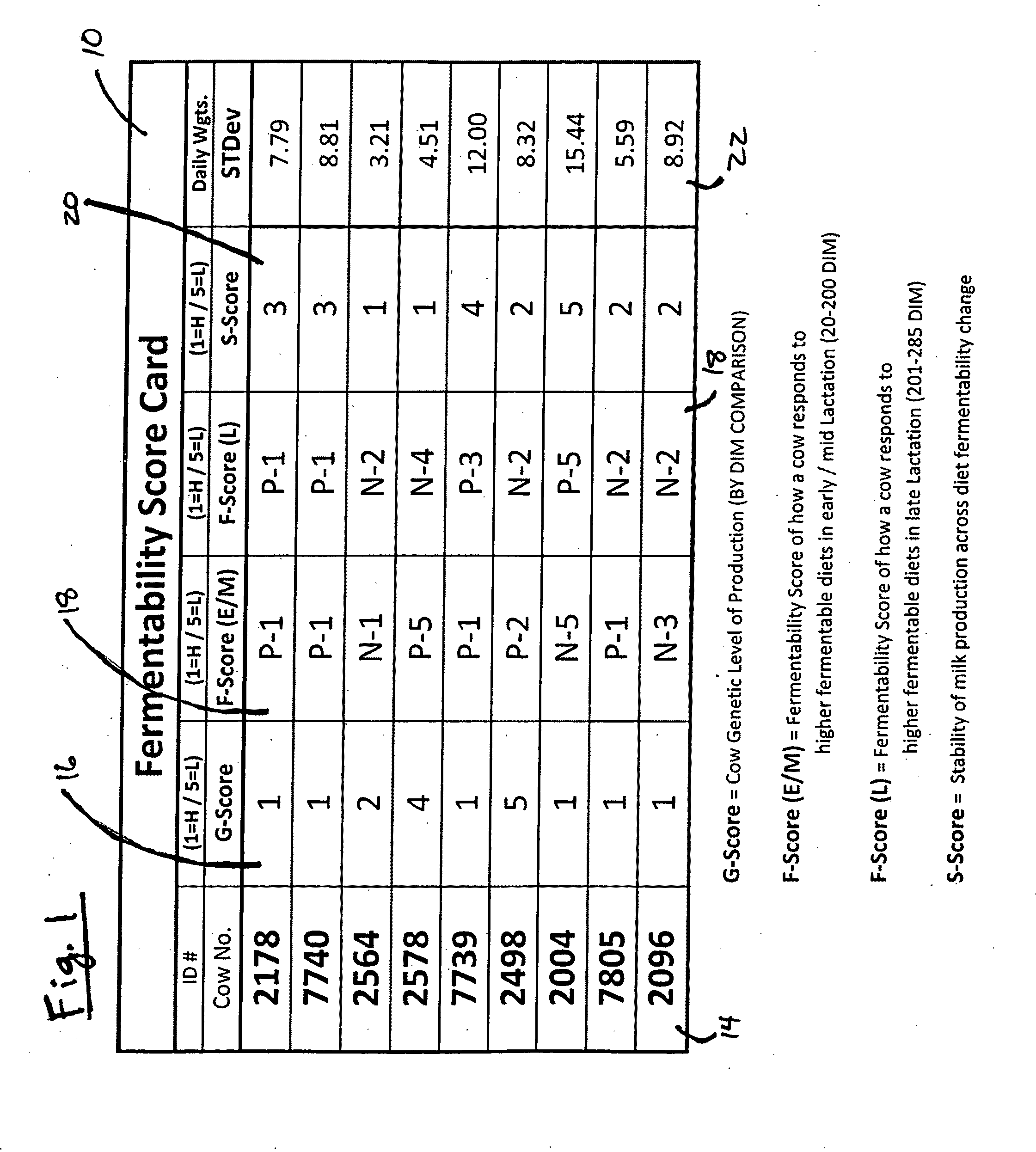

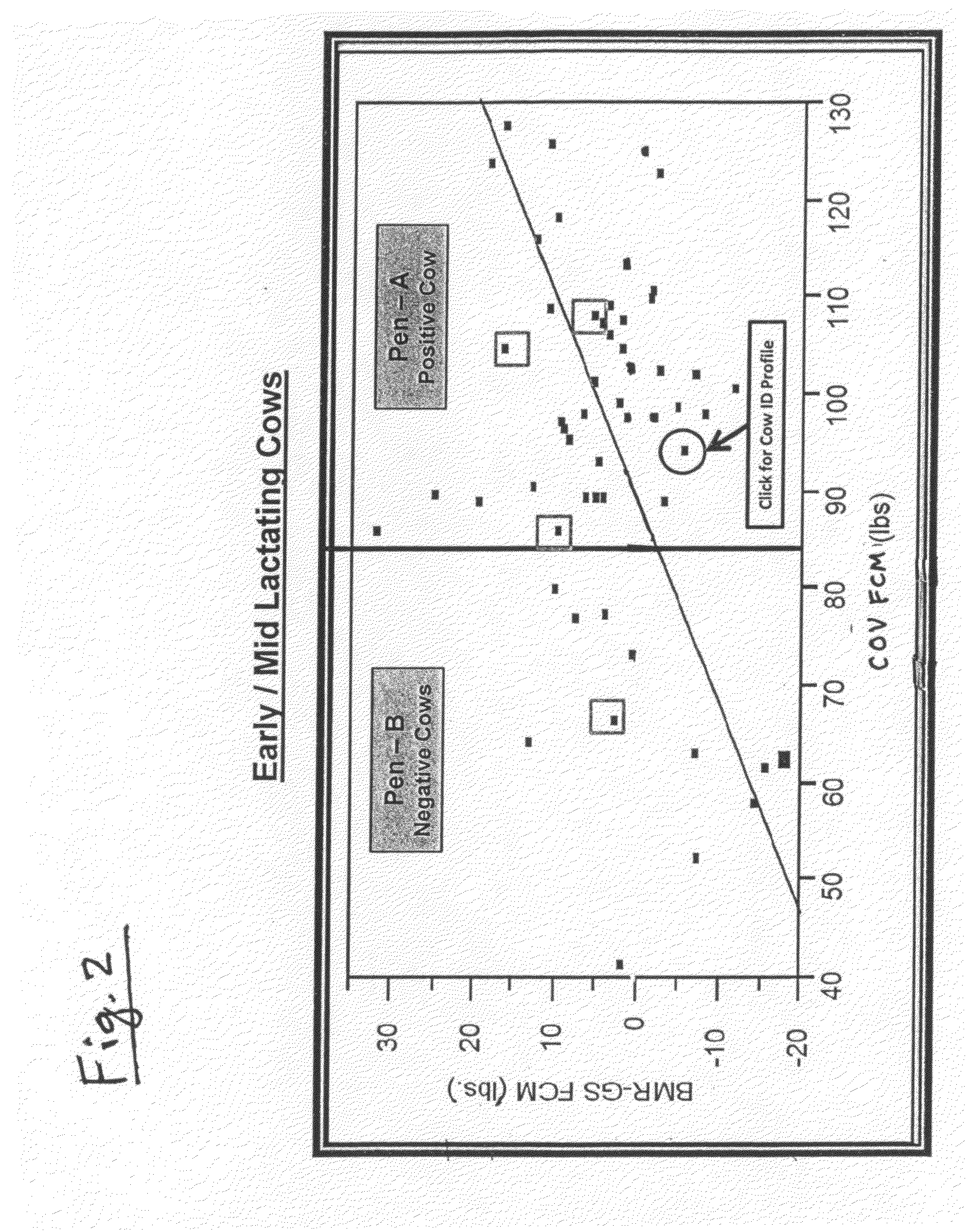

System for real-time characterization of ruminant feed rations

InactiveUS20090092715A1Improve energy efficiencyHealth be optimizedMaterial analysis by optical meansAnimal feeding stuffAgricultural scienceAdditive ingredient

Owner:NUTRI INNOVATIONS LLC

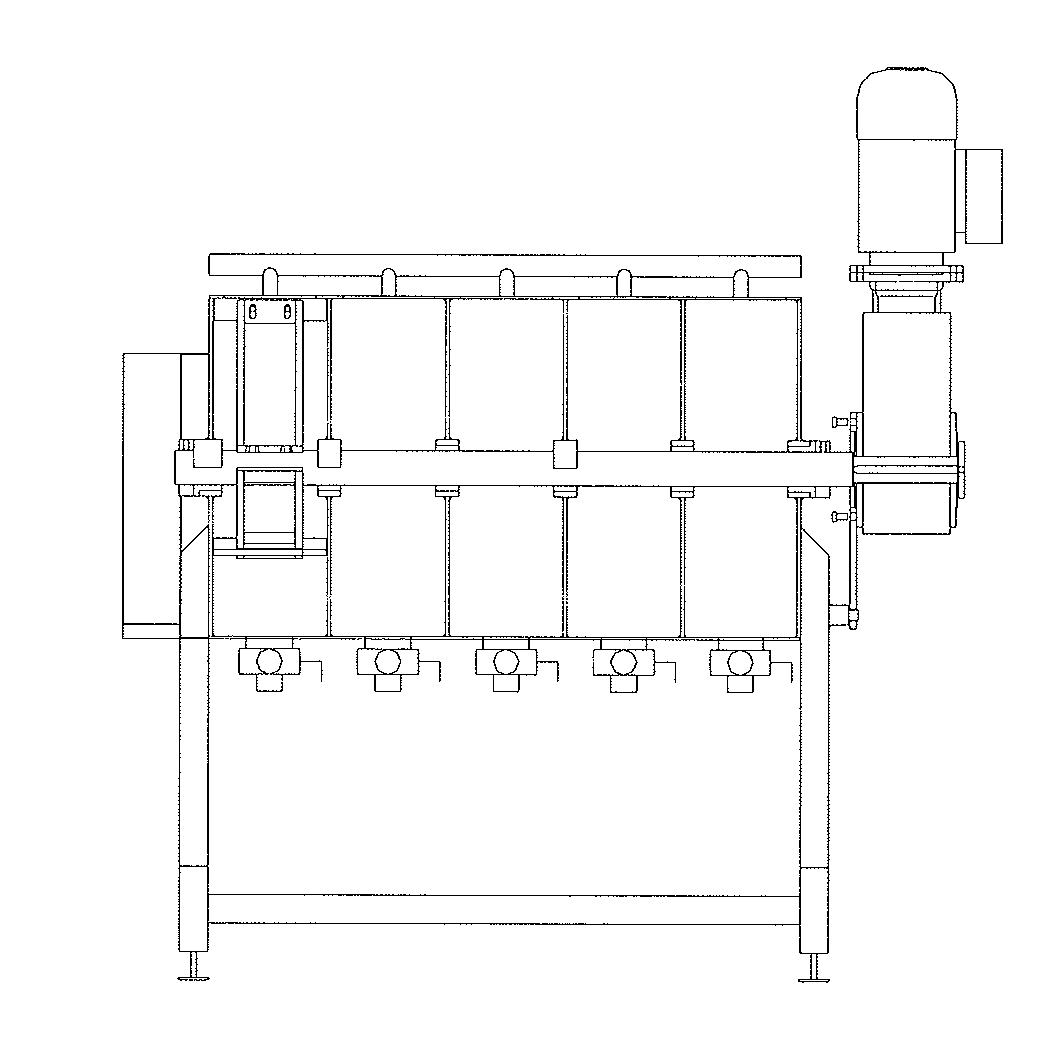

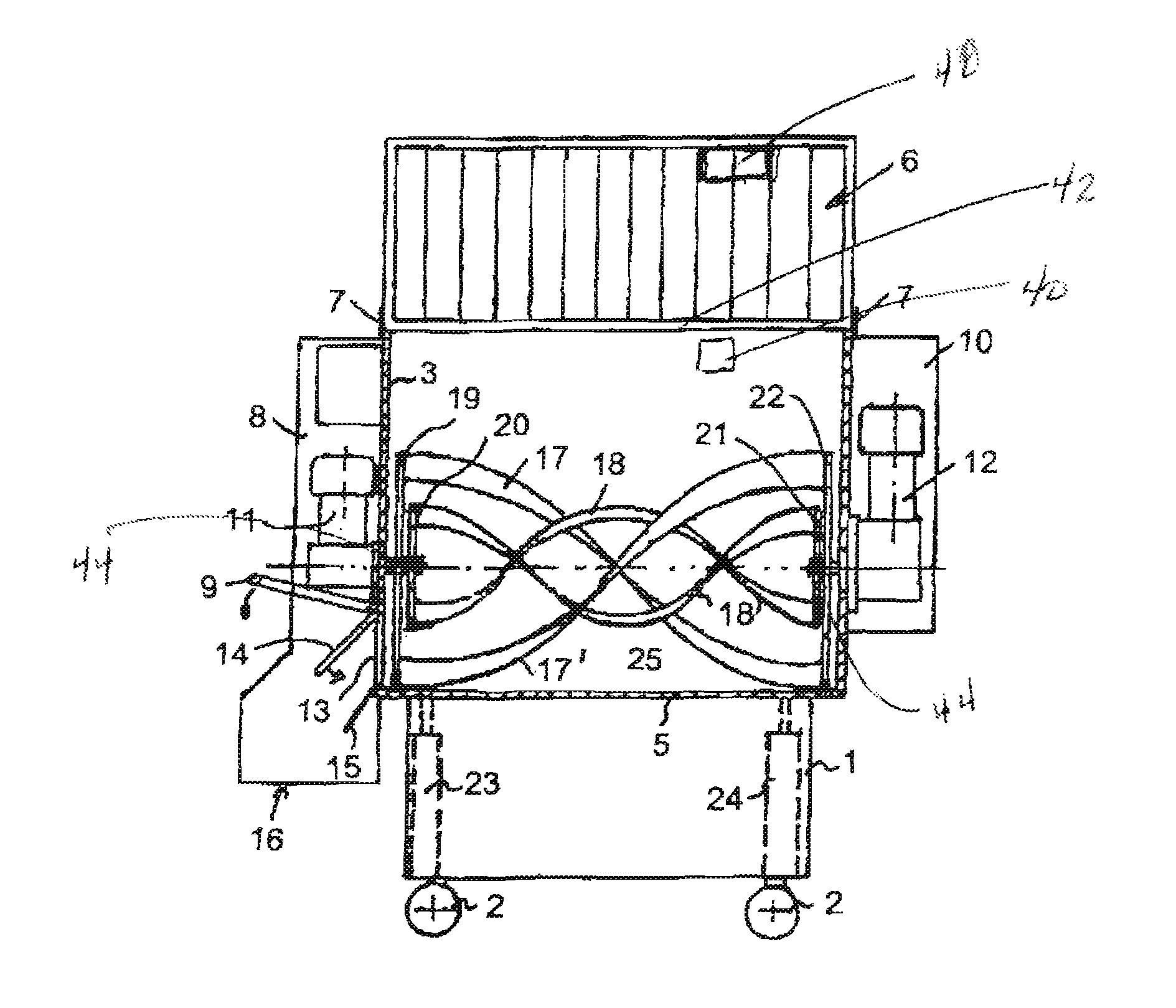

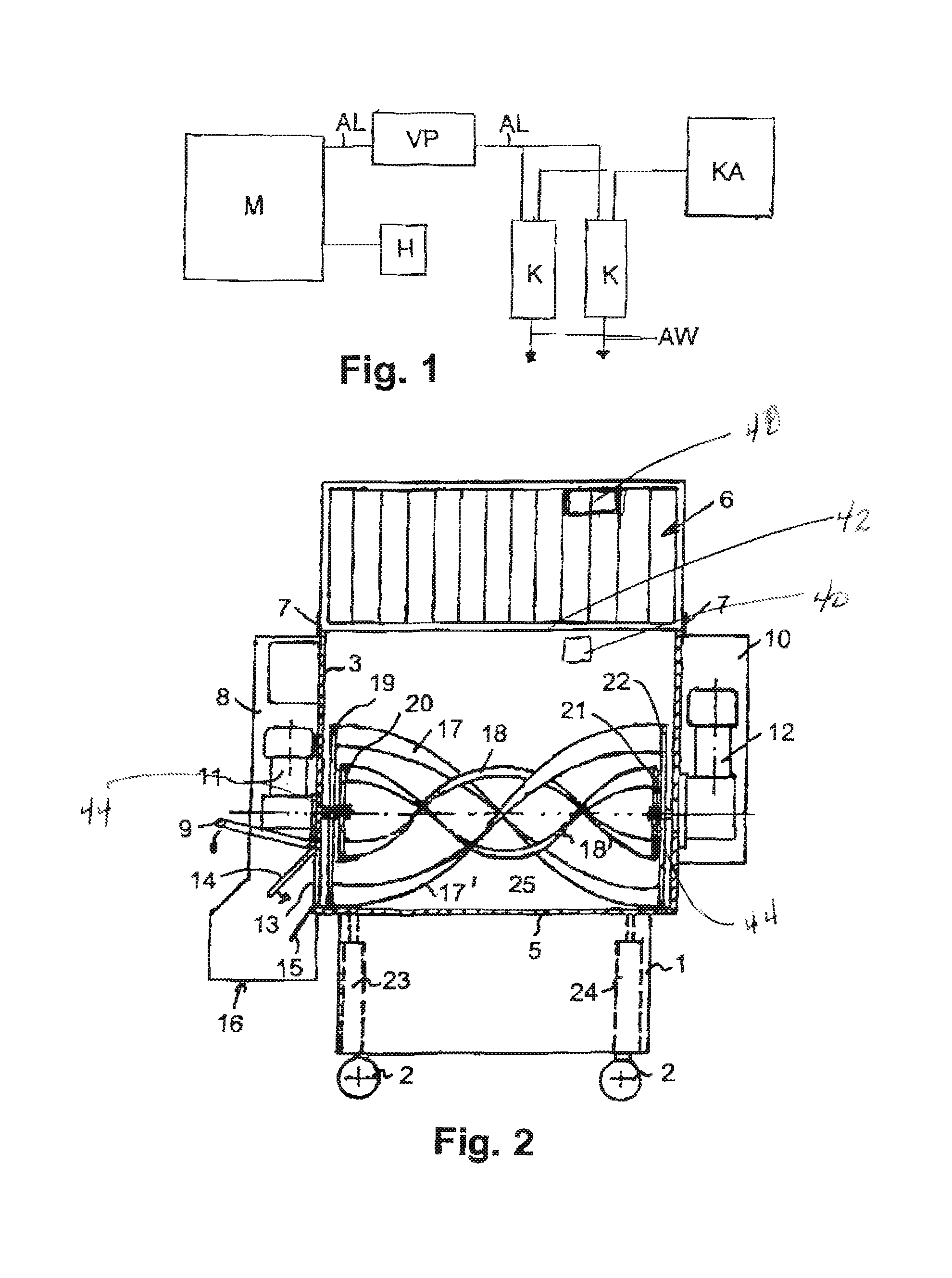

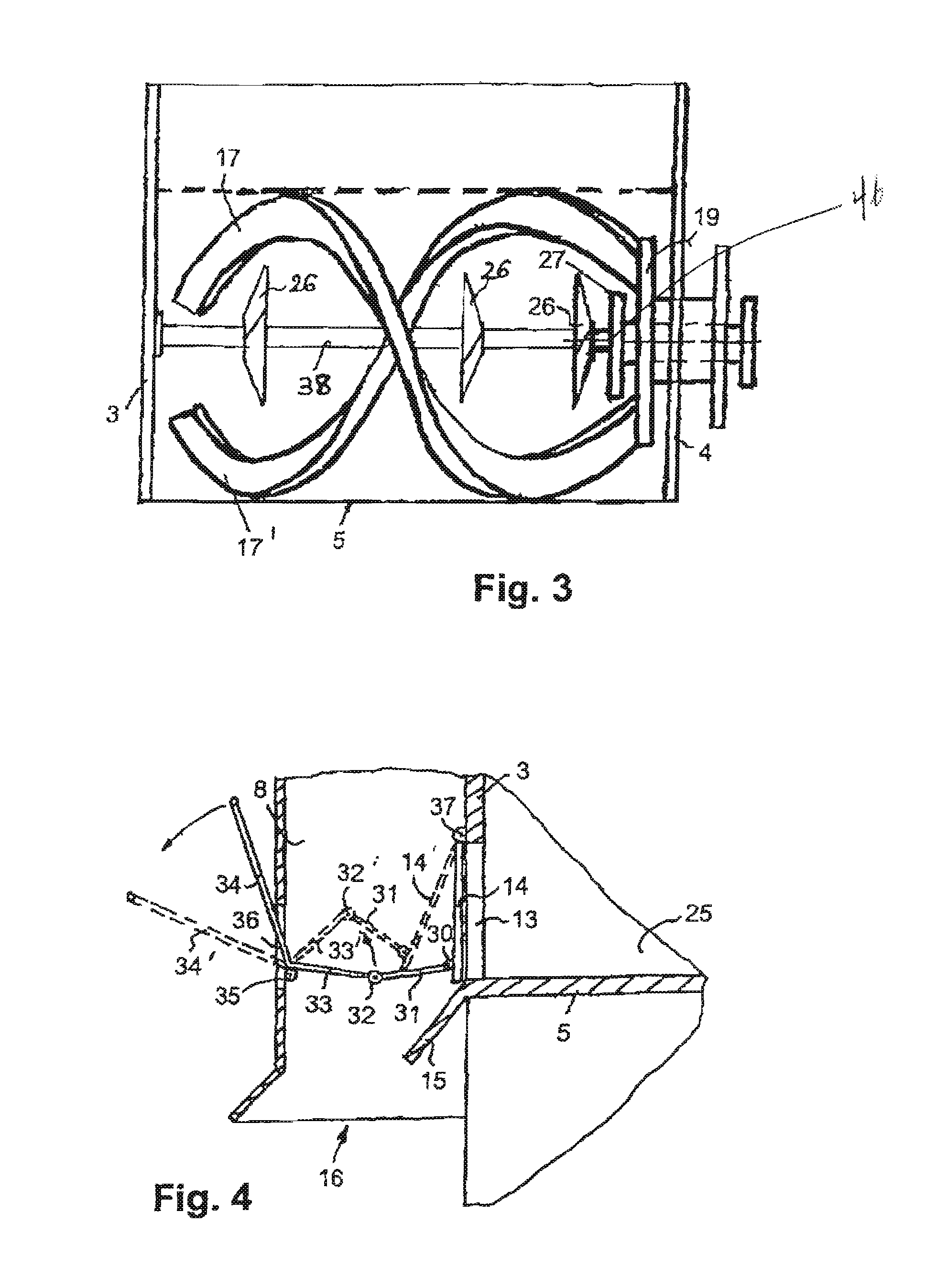

Installation for drying organic matter

ActiveUS8561314B2Efficient heatingFast heatingDrying solid materials with heatDrying solid materials without heatLitterEngineering

An installation for drying organic matter, especially kitchen and food wastes or other biological matter, including matter that contains packaging residues, napkins, straws or the like. The installation comprises the following components: (a) a vacuum mixer (M) having a closable charging opening for introducing the organic matter and a closable discharge opening, disposed at the bottom or laterally towards the bottom, for the dried matter, (b) at least one vacuum pump (VP) for evacuating the air in the mixer to generate the vacuum, the pump being connected to at least one evacuation tube mounted above the maximum filling level in the housing of the mixer (M), (c) a heater (H) for heating the organic matter, (d) at least one condenser (K), connected to the air evacuation duct (AL) of the vacuum pump (VP) and having a cooling unit (KA) connected thereto to condense the evacuated air, and (e) a discharge duct (AW) for the condensate obtained from the evacuated air by cooling in the condenser (K).

Owner:INOTEC MASCHENENTWICKLUNG & VERTRIEB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com