Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

A treatment device and solid-liquid separator technology, applied in water treatment devices, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as long construction period, difficulty in equipment technical management, complex system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

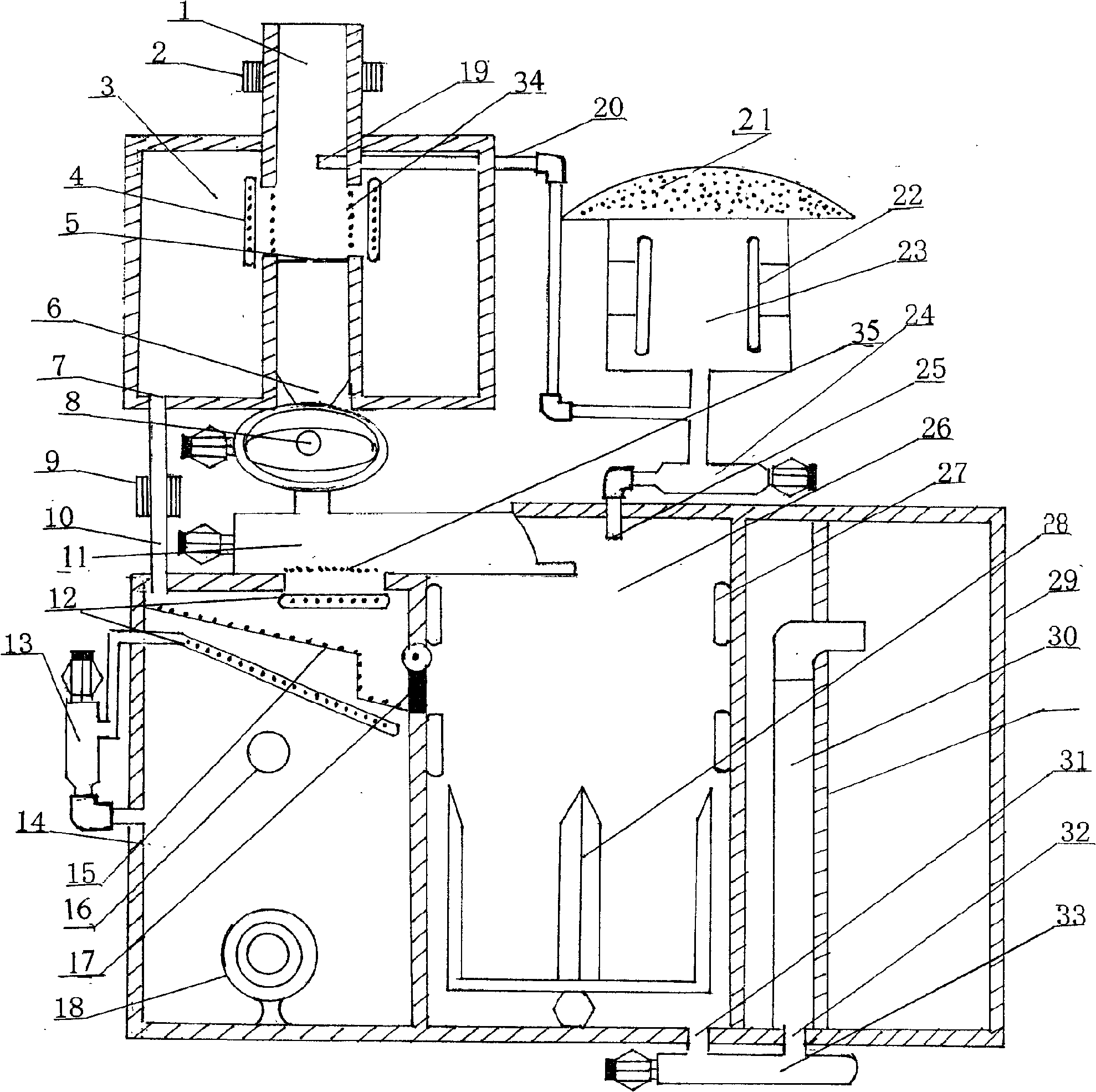

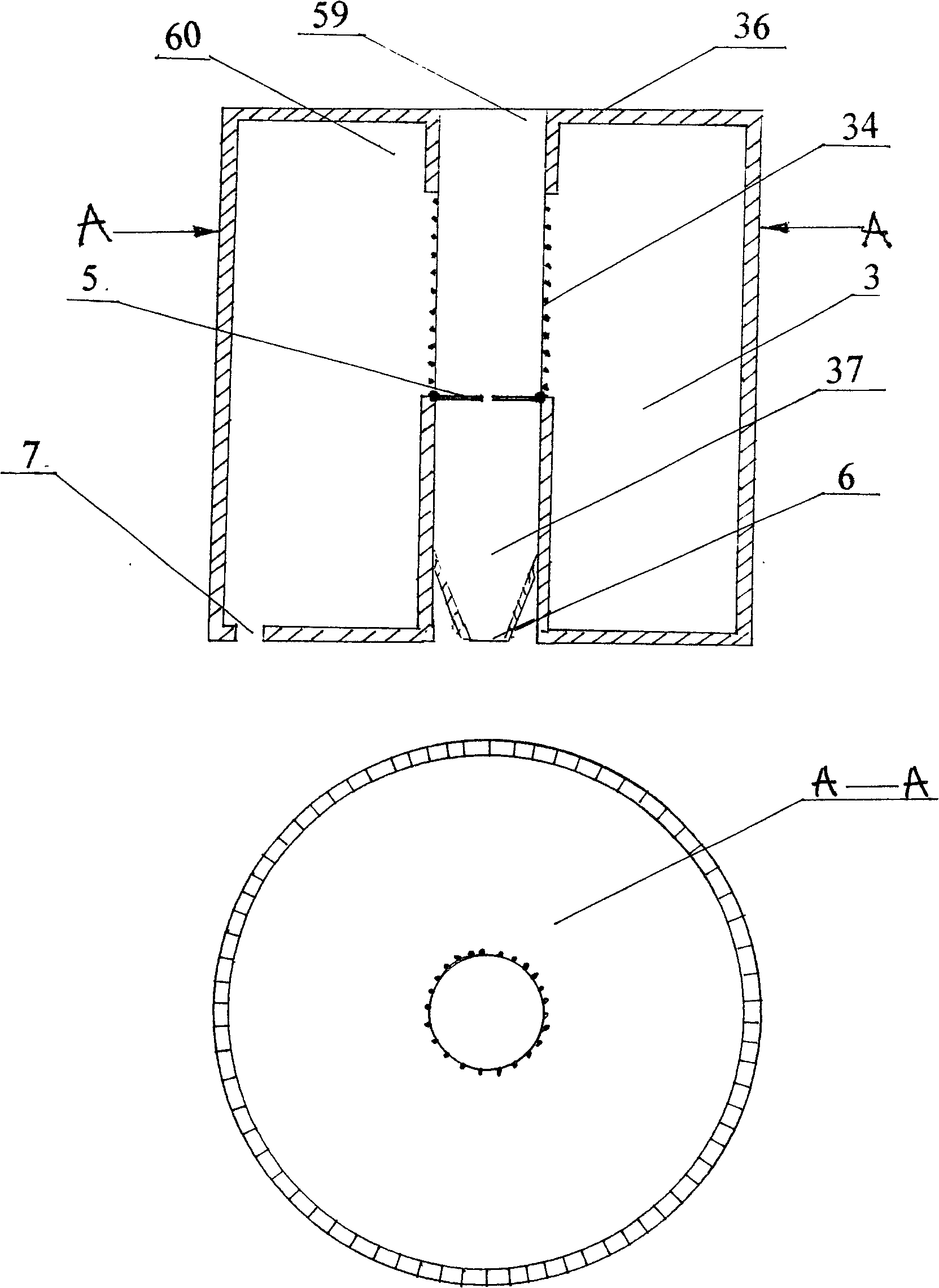

[0033] Such as figure 1 , figure 2 As shown: the upper unipolar magnetic descaling device (2) is set on the outside of the toilet excrement drop opening (1), and the inner cavity (59) of the solid-liquid separator (3) communicates with the toilet excrement drop opening (1), Gravity valve (5) is equipped with in the middle part of inner chamber body (59), and the top of gravity valve (5) has filter hole ring (34), and ring backwasher (4) is installed outside filter hole ring (34), gravity valve (5) ) is the solid object chamber (37) below, the solid object outlet (6) is arranged below the solid object chamber (37), and the bottom of the outer cavity (60) of the outer casing (36) has a liquid outlet (7).

Embodiment 2

[0035] On the basis of Example 1, as figure 1 , Figure 6 Shown, the dirt inlet (49) of the semi-solid finishing device (8) is connected with the solid matter outlet (6) of the solid-liquid separator (3), and the semi-solid finishing device (8) is formed by the finishing device shell (48) Dirt inlet (49), dirt outlet (50), axis bearing (51), finishing tooth (52), finishing ball (53), bracing frame (54), axis (55) form.

Embodiment 3

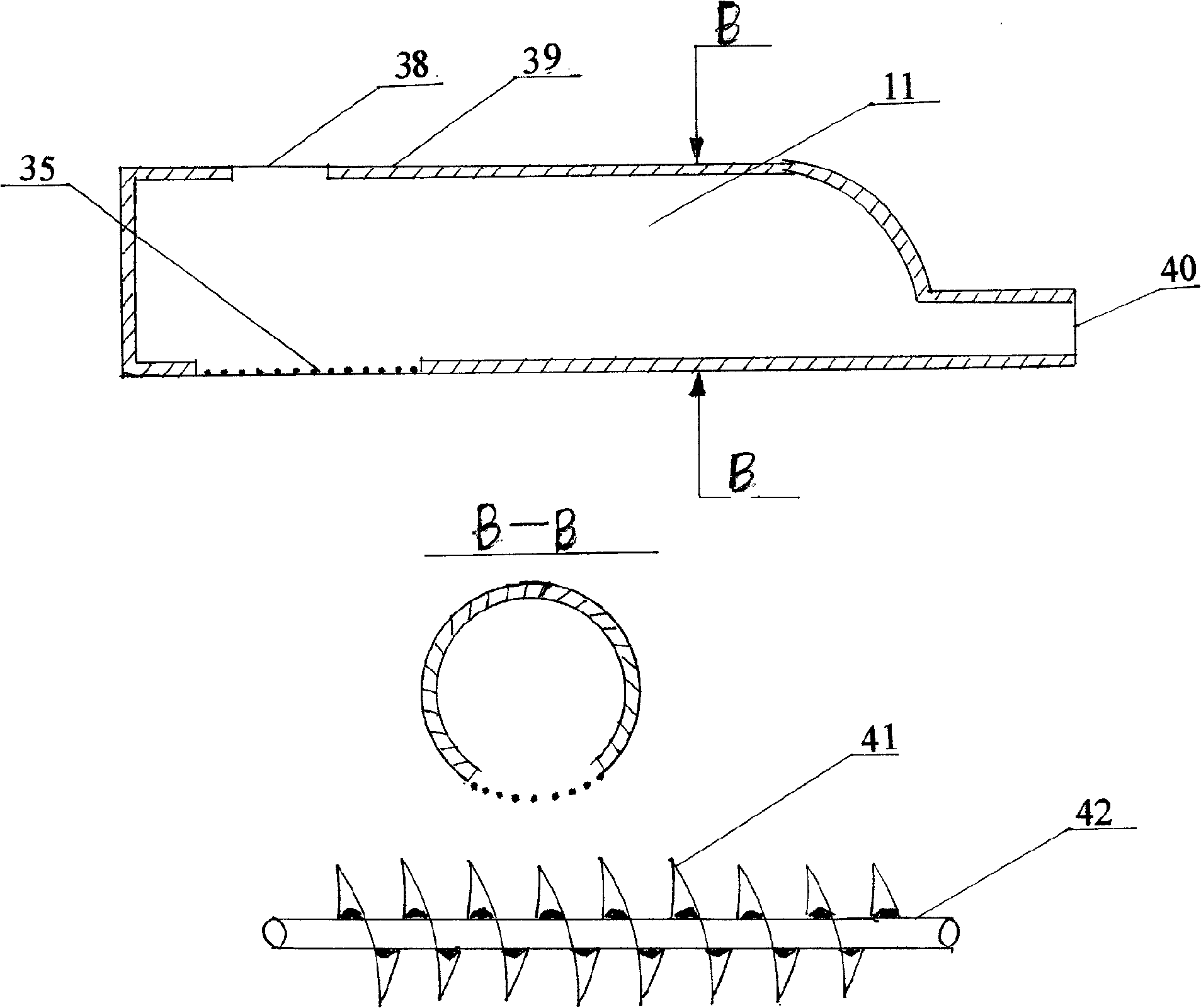

[0037] On the basis of embodiment one and example two, as figure 1 , image 3 As shown, the inlet (38) of the secondary solid-liquid separation screw pump (11) is connected with the dirt outlet (50) of the semi-solid finishing device (8), and the secondary solid-liquid separation screw pump (11) is connected by The liquid leakage plate (35) is composed of a screw pump housing (39), a solid object extrusion port (40), a spiral sheet (41), and a screw rod (42). The secondary solid-liquid separation screw pump (11) has a liquid leakage plate (35) on the top of the urine treatment box (14), and one end of the solid matter extrusion port (40) extends into the microwave sterilizing drying chamber (26) the upper part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com