Patents

Literature

631results about How to "Meet emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

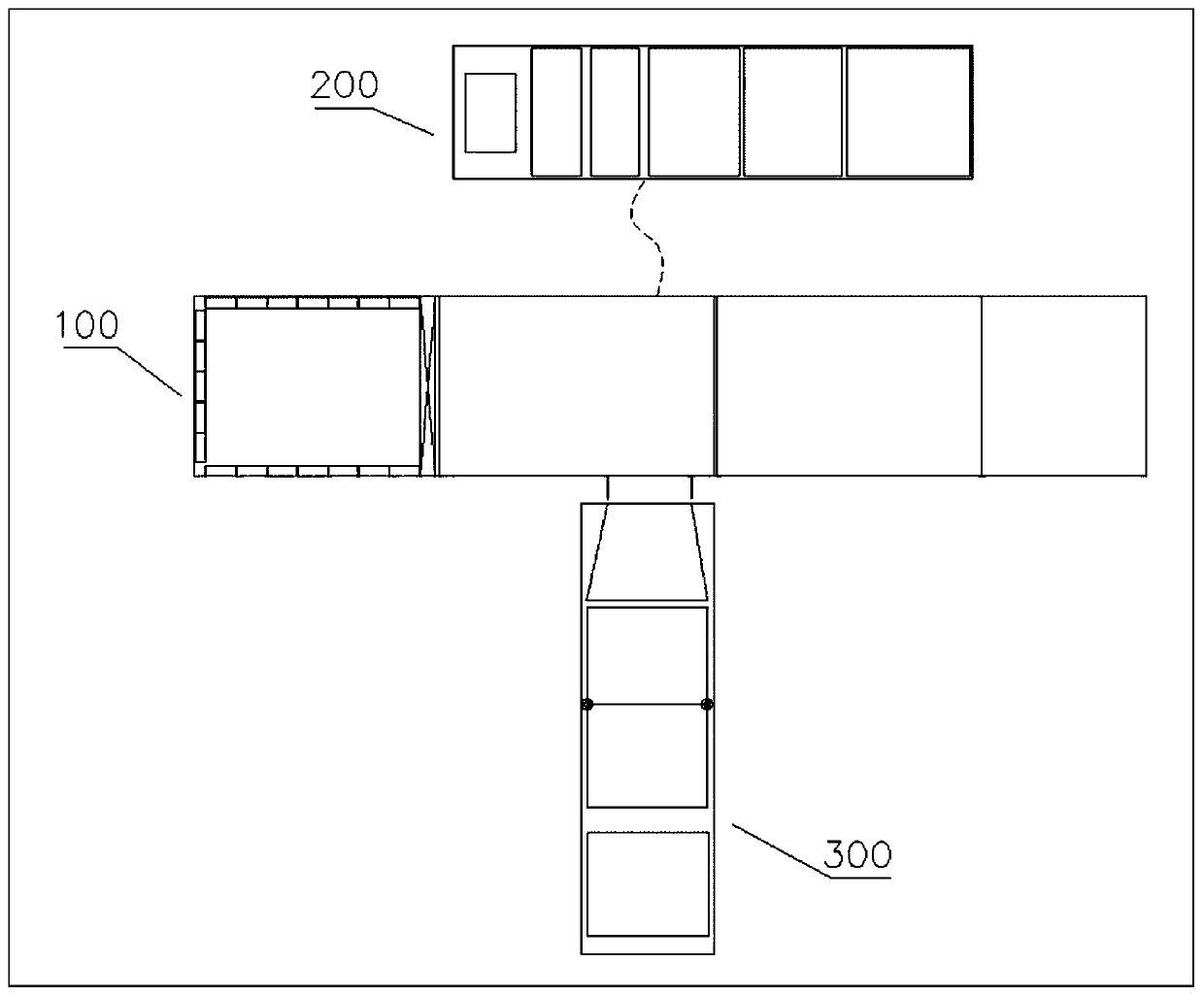

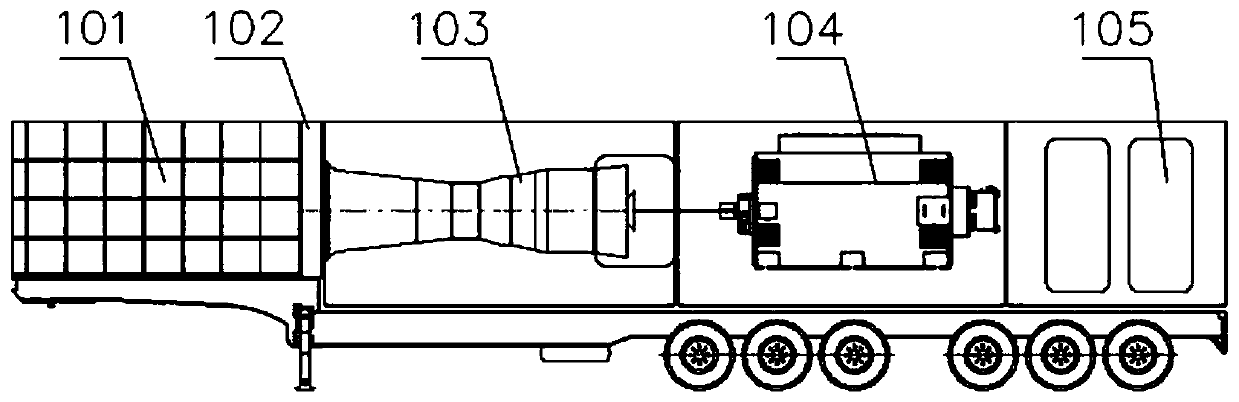

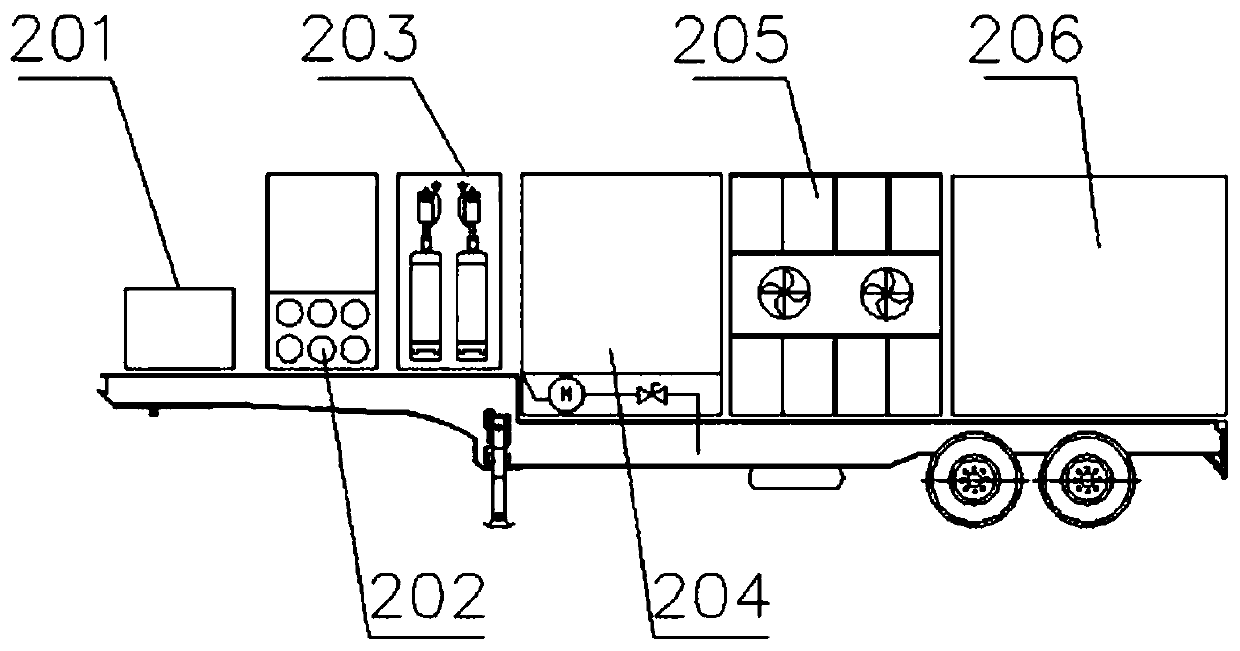

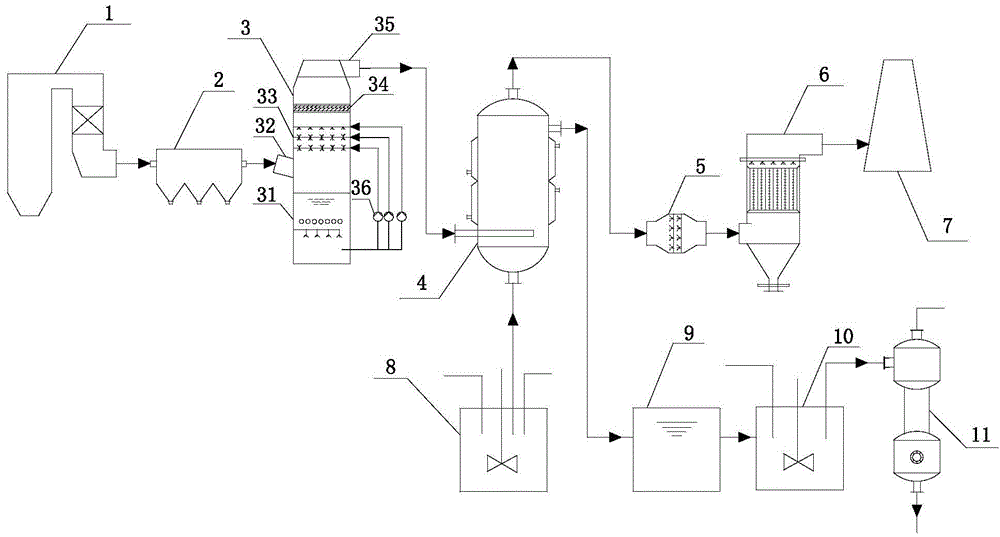

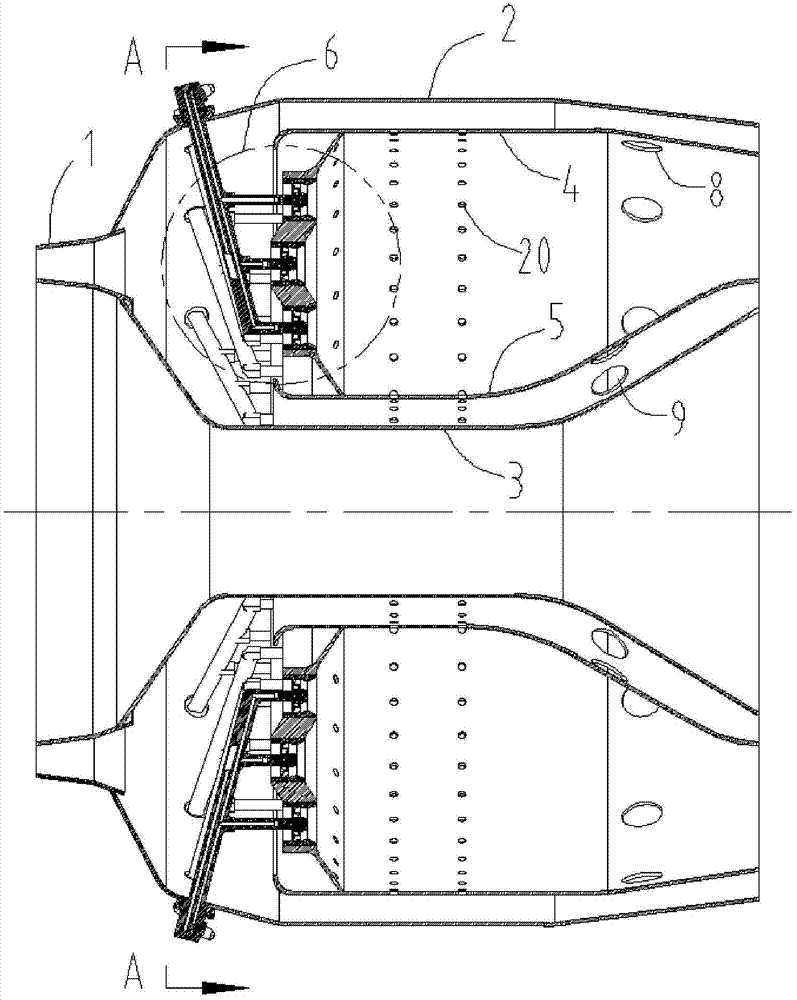

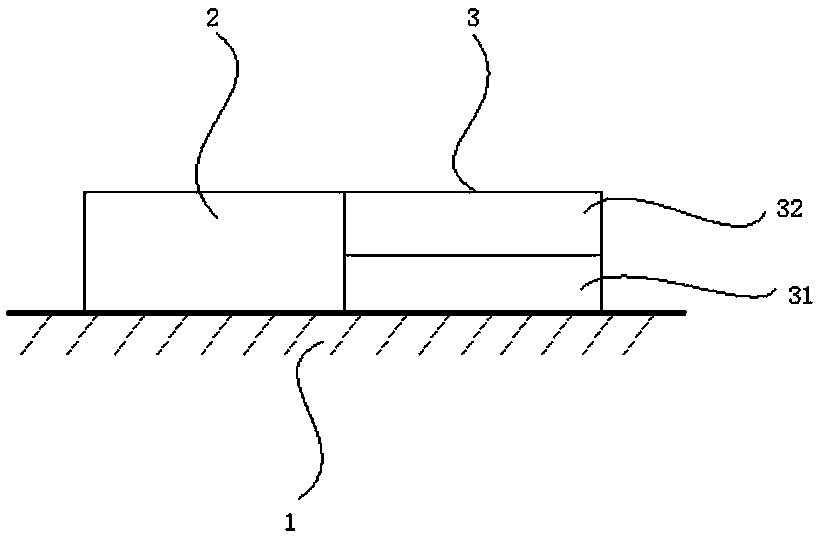

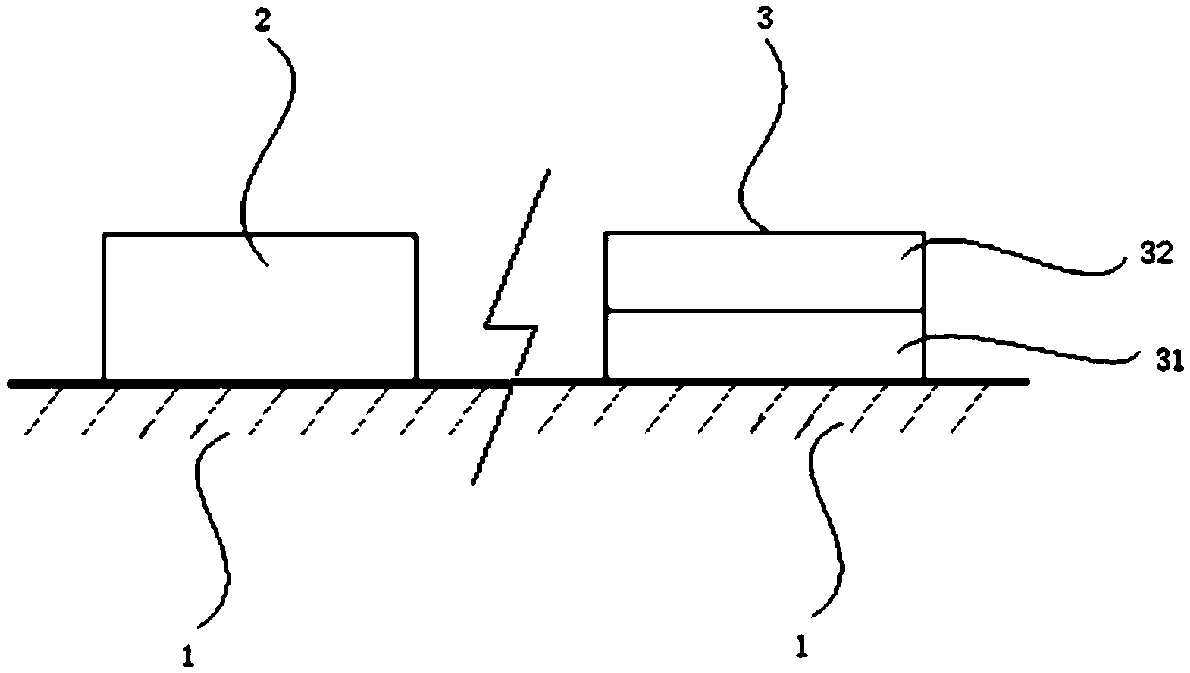

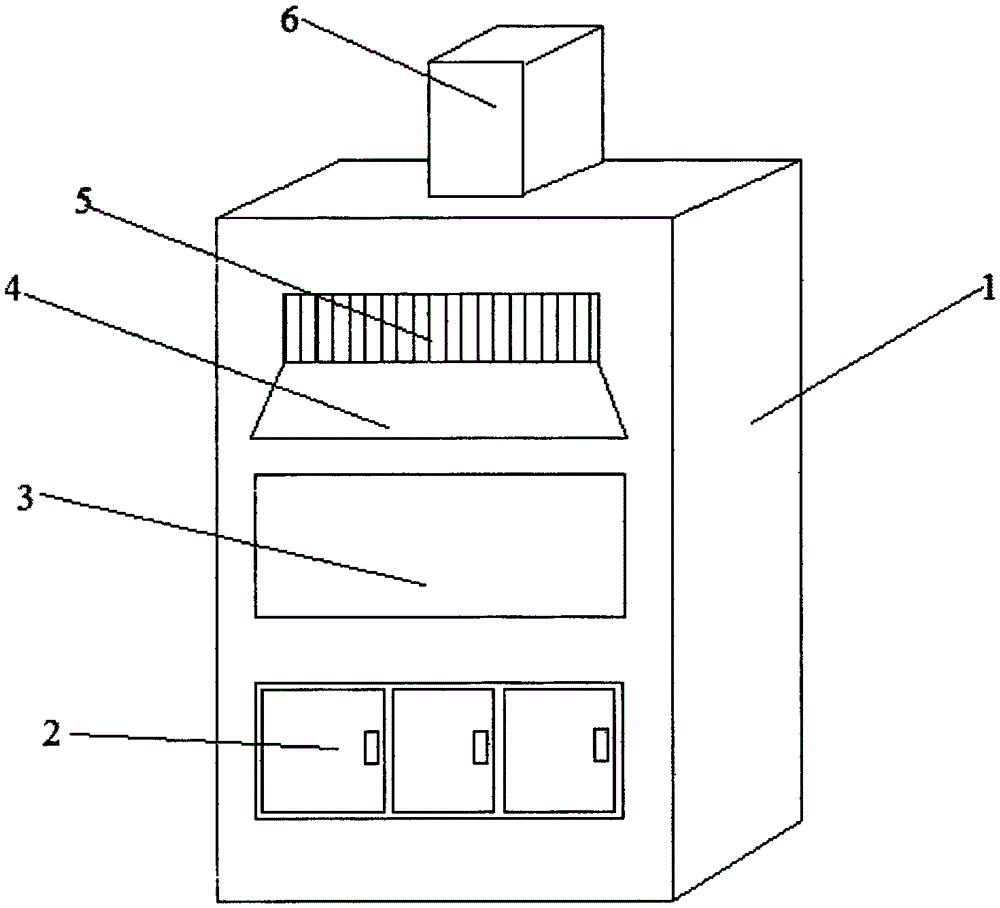

System used for providing mobile power

PendingCN110159432ASave installation timeEasy to transportEngine fuctionsGas turbine plantsAutomotive engineeringRoad transport

The invention discloses a system used for providing mobile power. Through reasonable integrating of a device needed by a fracture site power supply system, a connection cable and a connection hose, the system is divided into three transport carriers for moving and effective connection, on the first transport tool, an air inlet assembly and a turbine power generation system are combined together, mounted and directly transported to the customer site, and the mounting time of the air inlet assembly and the turbine power generation system on the user site is saved. An exhaust chimney and an exhaust silencer are designed on two different positions, and the waste gas exhaust need during work can be met while the road transport need is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

Method for treating radioactive wastewater

ActiveCN103177784AImprove processing precisionReduce competitionGeneral water supply conservationRadioactive contaminantsStrong acidsIon exchange

The invention discloses a method for treating radioactive wastewater. The method for treating the radioactive wastewater comprises the steps of firstly carrying out reverse osmosis treatment on the radioactive wastewater, then enabling the radioactive wastewater to enter a continuous electrodeionization unit to be treated, and further removing radionuclide so as to enable treated wastewater to reach discharge requirements; and respectively filling different mixed ion exchange resin in a plain water chamber and a thick water chamber in a continuous electrodeionization membrane stack of the continuous electrodeionization unit, wherein mixed ion exchange resin filled in the plain water chamber comprises, by volume ratio, 30%-60% of strong-acid cation exchange resin, 40%-60% of strong-base anion exchange resin, and 0%-30% of weak-base anion exchange resin, mixed ion exchange resin filled in the thick water chamber comprises, by volume ratio, 20%-50% of strong-acid cation exchange resin, and the balance strong-base anion exchange resin. A weak dissociation polymer portion is used for improving selectivity of continuous electrodeionization membrane stack to trace amount radionuclide, radionuclide with extremely concentration can be effectively removed, and the method for treating the radioactive wastewater ensures that the final discharged water satisfies the discharge requirements.

Owner:BEIJING QINGHE CHAOHUA TECH CO LTD

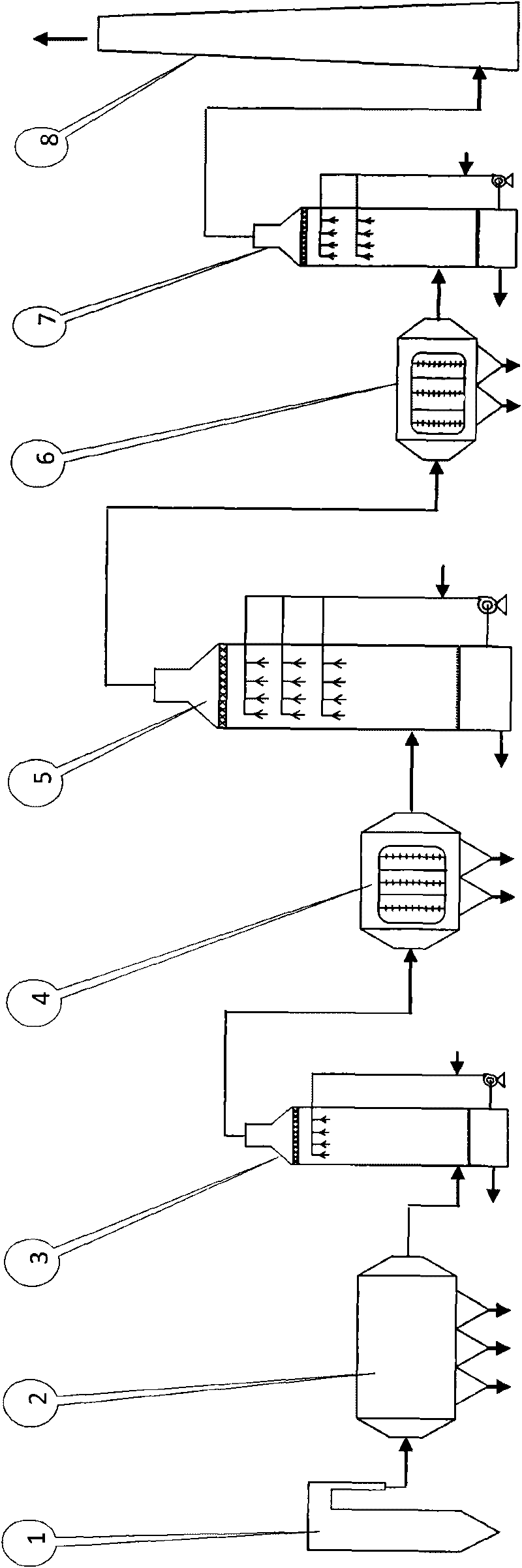

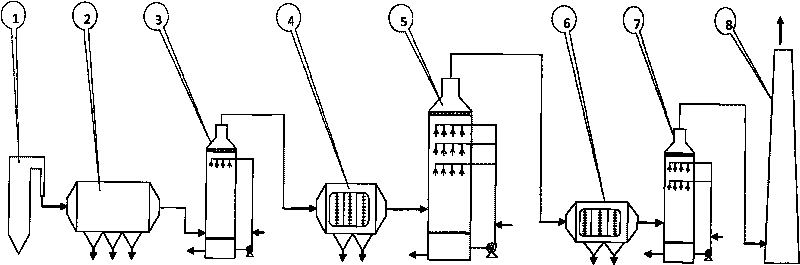

Method for removing various pollutants in fume by combining discharge plasmas and absorption

ActiveCN101716451ACombined removalLow investment costDispersed particle separationAir quality improvementElectricityMulti pollutant

The invention discloses a method for removing various pollutants in fume by combining discharge plasmas and absorption. The method comprises the following steps: electrically dedusting or dedusting fire coal or burning fume by a cloth bag; and sequentially pumping the fume through a pre-washing tower, a primary discharge plasma reactor, a primary absorption tower, a secondary discharge plasma reactor and a secondary absorption tower, wherein the pre-washing tower is used for pre-cleaning the fume, lowering the temperature and condensing the absorption liquid; the primary discharge plasma reactor is used for oxidizing NO, charging thin particulate matter, trapping and removing; the primary absorption tower is used for washing and removing SO2, NOx and charged thin particulate matter; the secondary discharge plasma reactor is used for oxidizing an element Hg, charging acid mist and ammonium mist, trapping and removing; and the secondary absorption tower is used for washing and removing oxidized Hg and other pollutants. By the treatment, the removal rates of the SO2, the NOx, the Hg and the thin particulate matter respectively reach above 95%, 75%, 75% and 80%; and the leakage amountof ammonia is below 5mg / m<3>.

Owner:BEIHANG UNIV

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

ActiveCN102059047AAchieve purificationMeet emission requirementsDispersed particle separationAtmospheric airHigh energy

The invention discloses a method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms. After being collected, organic waste gas is sequentially treated through a low-temperature plasma reactor and a biological treatment reactor and finally exhausted to the atmosphere through a chimney. In the low-temperature plasma reactor, polycyclic aromatichydrocarbon, halogenated hydrocarbon, heterocycle compounds and an organic nitrile compound which are insoluble in water and nonbiodegradable are oxidized into low-carbon organic acid, alcohol, esterand other organic compounds which are soluble in water and biodegradable by utilizing substances with strong oxidizing property, such as O3, OH., H2O2, O. and high-energy electrons generated by high voltage discharge. In the biological treatment reactor, the organic acid, the alcohol, the ester and other organic compounds are further converted into CO2, H2O and other inorganic compounds under theaction of microorganisms. Through the treatment, the total purification efficiency of nondegradable organic compounds containing benzene, methylbenzene, dimethylbenzene, phenol and the like in waste gas can be up to over 90 percent.

Owner:山东航源环境科技有限公司

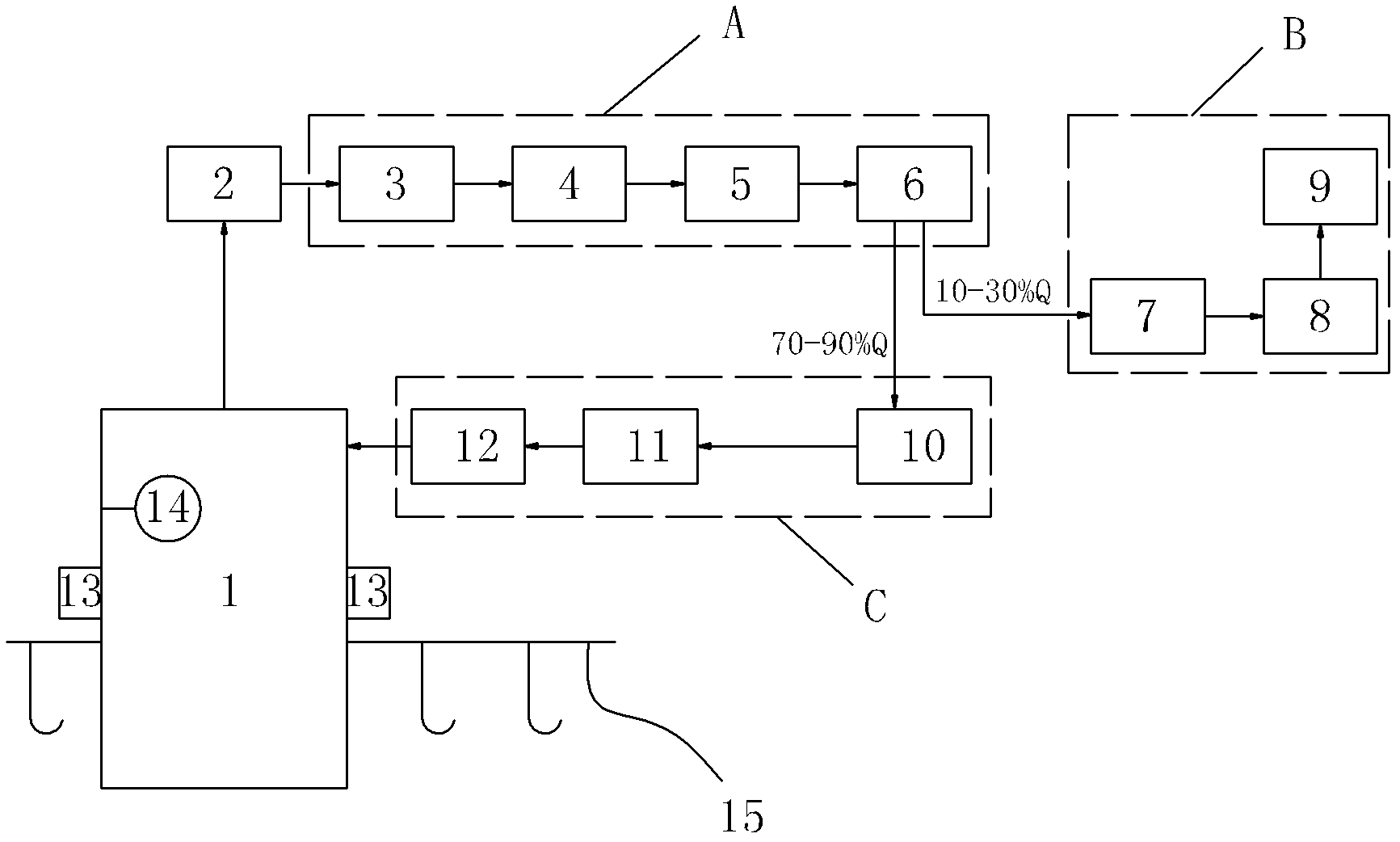

Treatment method for paint spraying waste gas

ActiveCN102580451AEmission reductionNo pollutionDispersed particle separationEnvironmental resistanceEnvironmental engineering

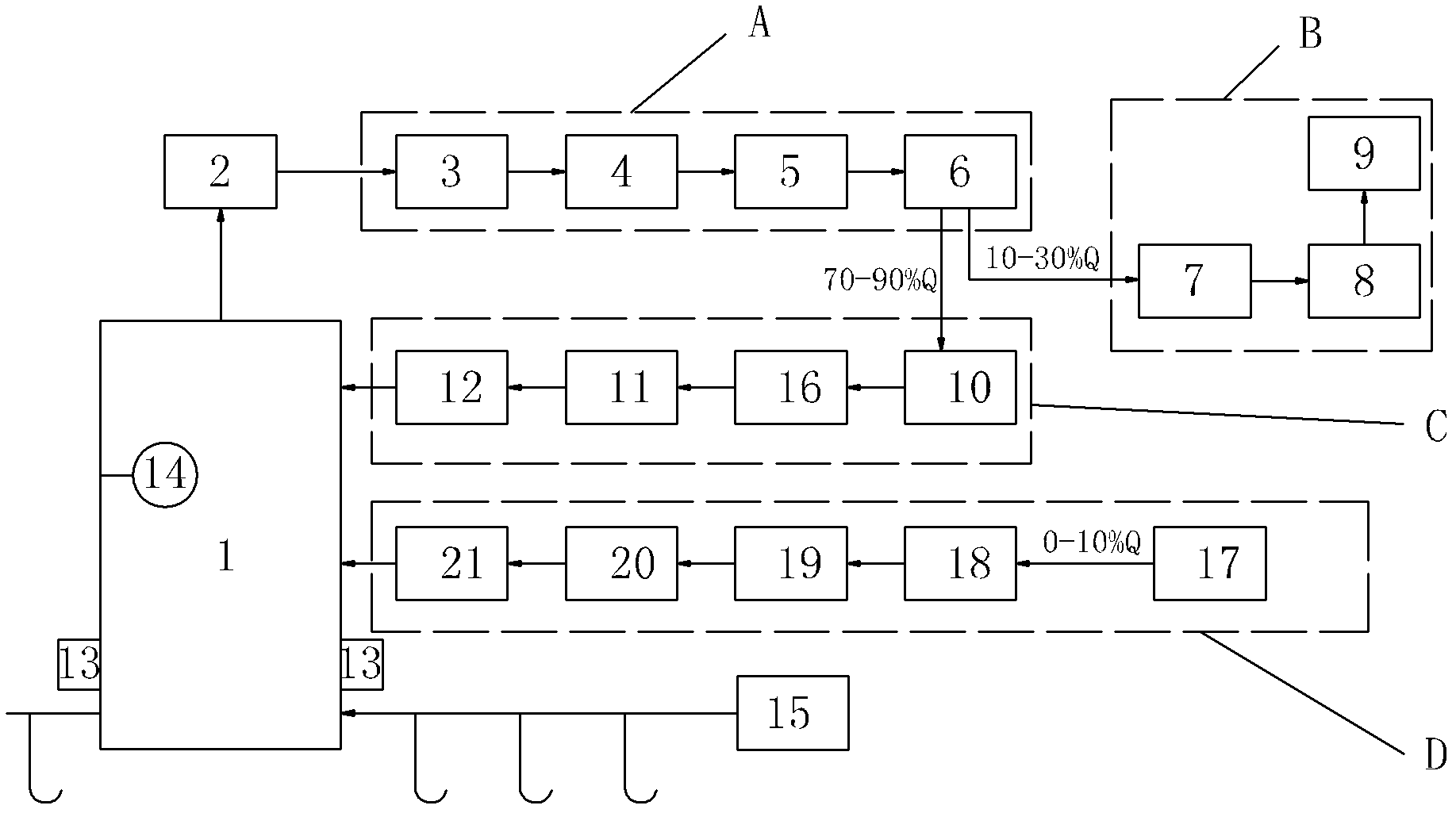

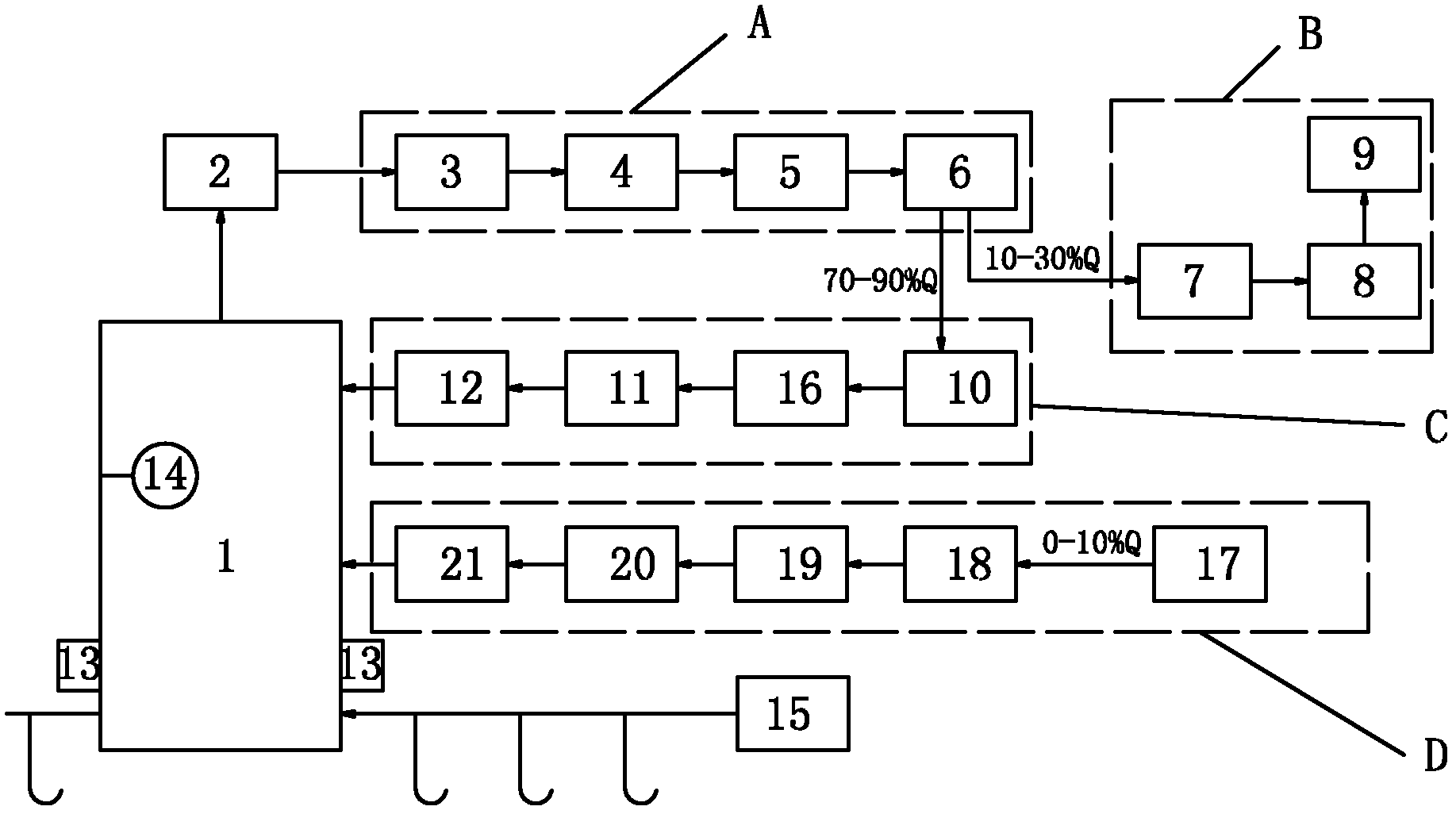

The invention belongs to the technical field of environmental protection and discloses a treatment method for paint spraying waste gas. The method is characterized in that paint spraying waste gas is treated through a circulating concentration manner, namely after large-flow and low-concentration gas discharged from a spraying chamber is treated by paint mist, most of the gas is circulated to the spraying chamber, and a small amount of the gas is discharged after being purified; and as paint spraying is performed, the concentration of gas in the spraying chamber increases gradually, and then large-flow gas is concentrated into small-flow gas to be purified, so that the purification efficiency, the stability and the security of waste gas can be improved advantageously, and the investment and running cost of treatment equipment can be reduced at the same time. The method has the advantages that the discharge flow rate of waste gas can be reduced, and paint spraying waste gas can be treated effectively to meet the national requirements of discharge of 'three wastes'.

Owner:ZHEJIANG HUANTAI ENVIRONMENTAL PROTECTION EQUIP

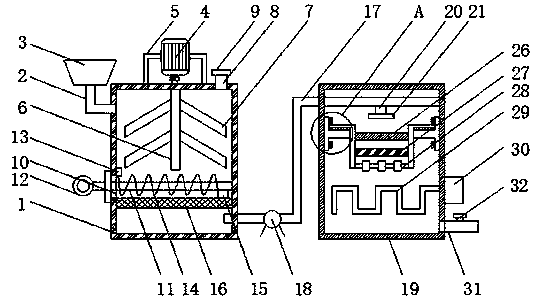

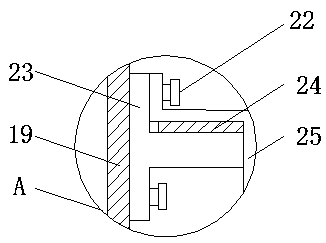

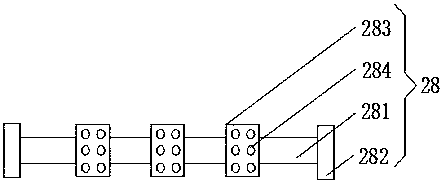

Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

InactiveCN101265004AKill eggs quicklyImprove sterilizationMaintainance for emmission reductionSludge treatmentHuman bodyDecomposition

The invention relates to a device for rapid decomposition, sterilization, drying and sanitary treatment of solid / liquid feces, aiming to solve the problems of human feces including environmental pollution, disease transmission and body health damage. The device comprises a solid-liquid separator, a semi-solid finishing machine, a secondary solid-liquid separation spiral pump, a urine treatment tank, a microwave sterilization drying chamber, a dry matter storage tank, and a deodorizing aeration tower. The feces can be rapidly sterilized, deodorized and dried after leaving human body, so as to become sterile and odorless dried particles in a short time, which can be used as fertilizer. The inventive device prevents transmission of pathogenic bacteria from source and solves fecal pollution problem. The inventive device has the advantages of low volume, light weight, and low energy consumption; and can be used in any places. Except fixed places, the device is more suitable for being installed and used in personal vehicles such as passenger train, passenger long-distance bus and passenger ship.

Owner:齐梓凡

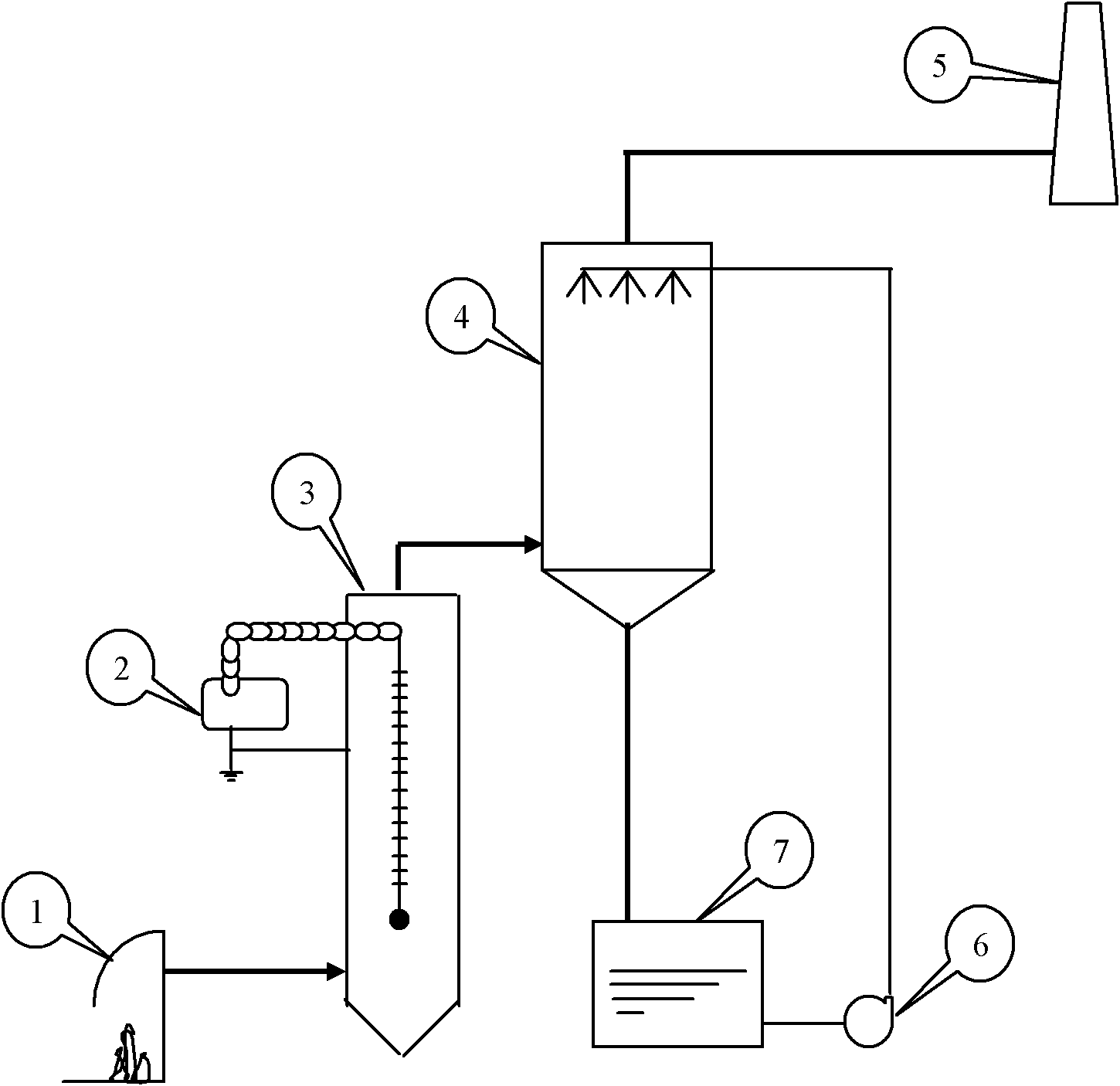

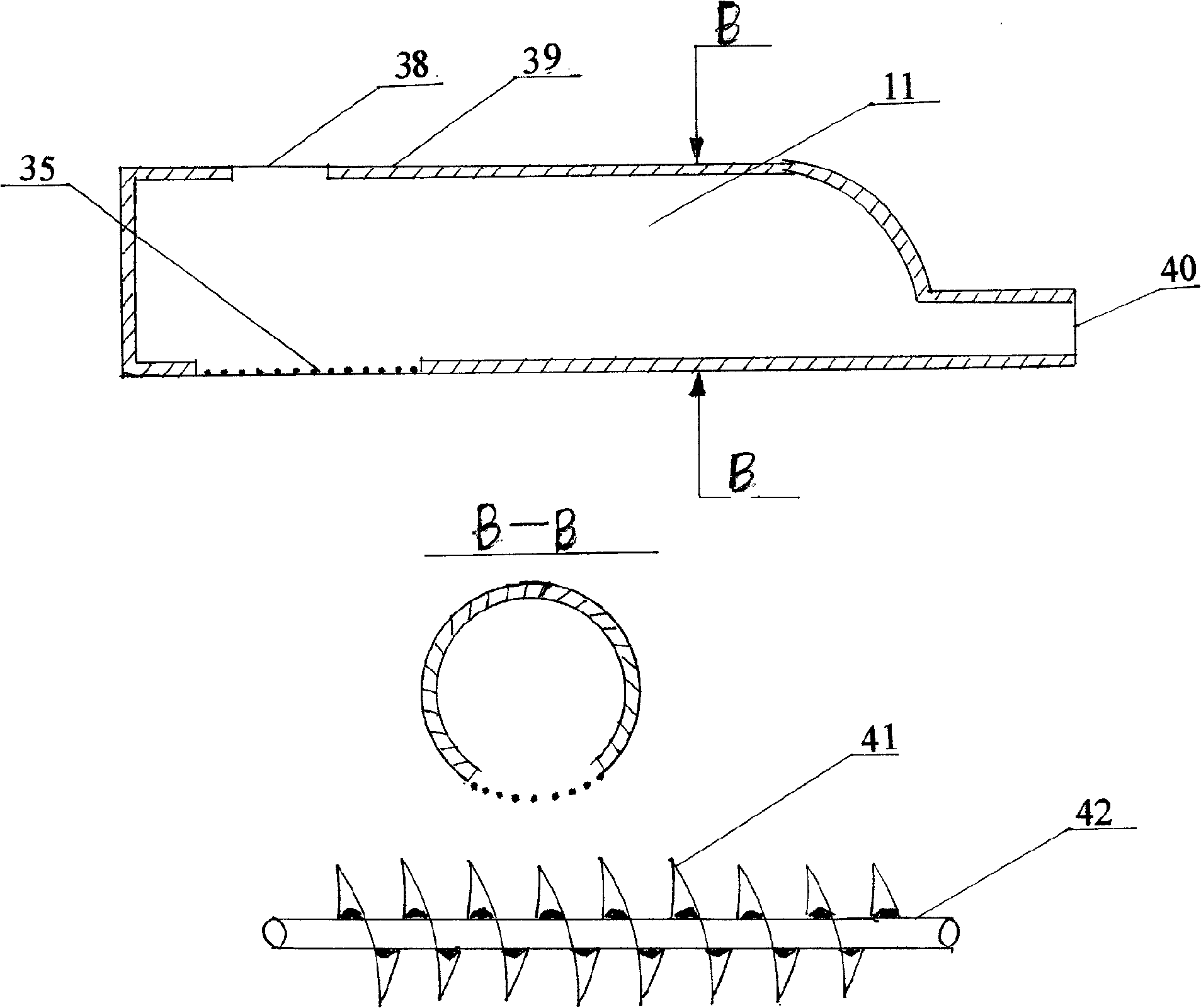

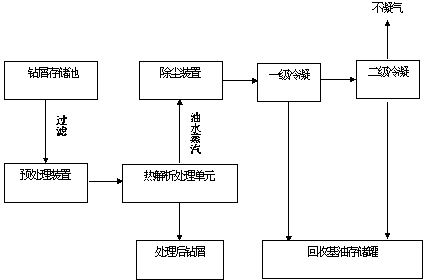

Oil-base drilling cuttings thermal analytical treatment method

ActiveCN104178200AReduce oil contentMeet emission requirementsLiquid hydrocarbon mixture productionAfter treatmentReaction temperature

The invention belongs to the technical field of environment protection of oil and gas fields and particularly provides an oil-base drilling cuttings thermal analytical treatment method. The method comprises the following main steps: conveying the oil-base drilling cuttings after pre-treatment to a processing unit; heating to raise the reaction temperature to the volatilization temperature of hydrocarbon in the components in the drilling cuttings; then, maintaining for a certain standing time till oil gas is completely volatilized; after treatment, storing the drilling cuttings by virtue of a discharge device for discharging; feeding the oil gas into a recovering and separating unit by virtue of an exhaust device; recovering components with different condensation points in different condensation recovery units; and maintaining the recovered oil unchanged for further preparing an oil-base drilling fluid. The method solves the defects and shortcomings of other methods well. By adopting the oil-base drilling cuttings thermal analytical treatment technology, the oil content of the drilling cuttings is low (less than 1%), so that the discharge requirement is satisfied. The method provided by the invention further achieves the purposes of treating the oil-base drilling cuttings and recycling resources while the problem of environmental pollution is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

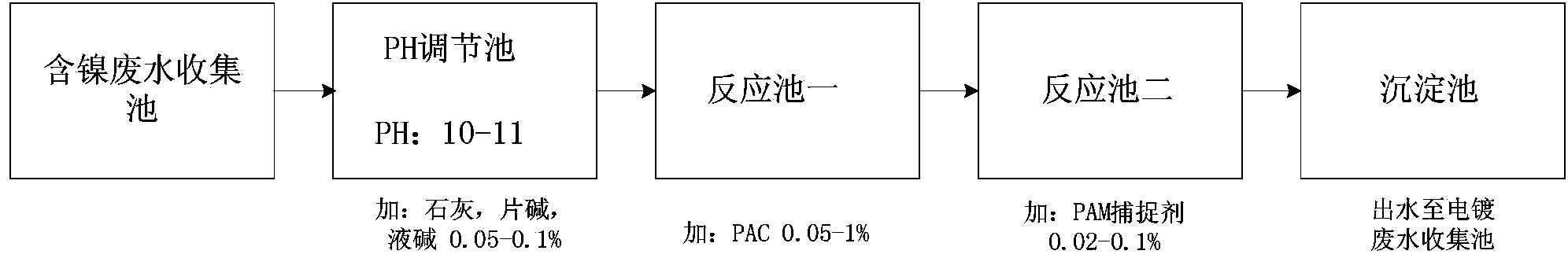

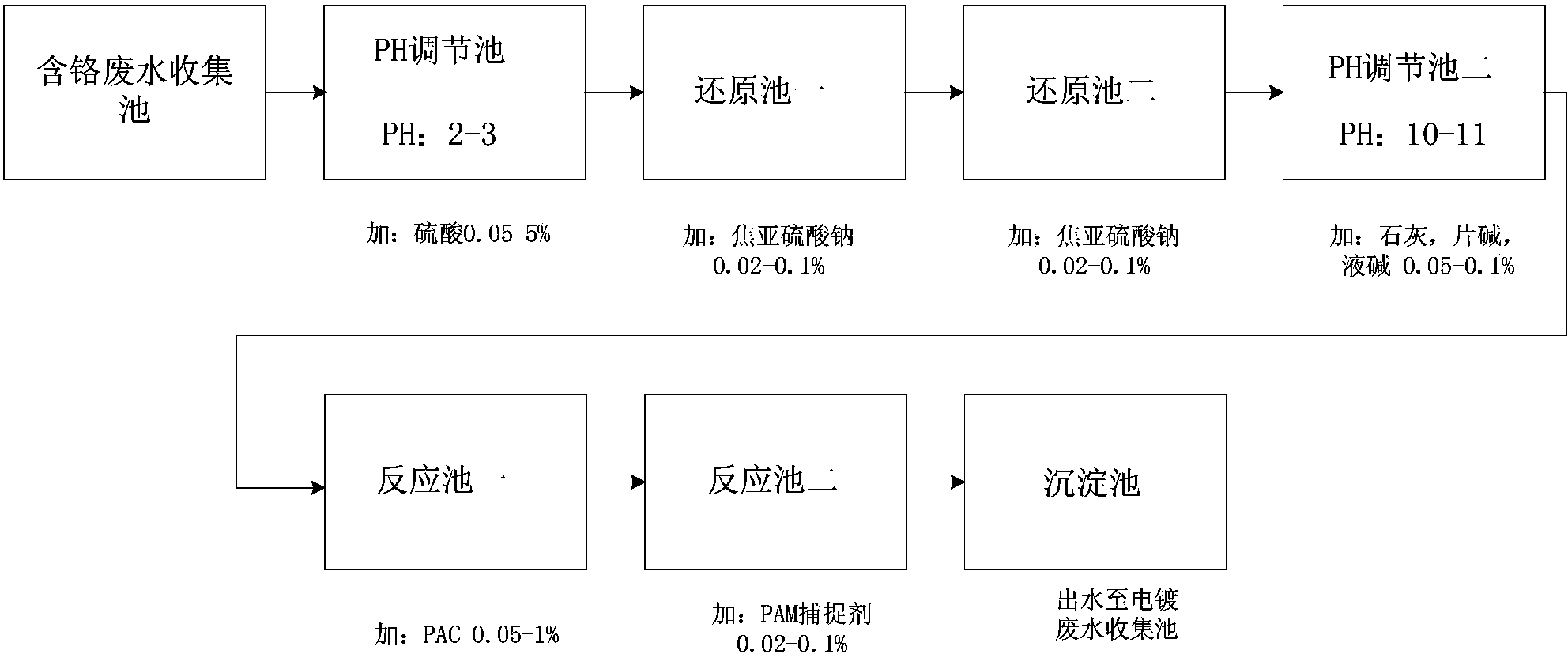

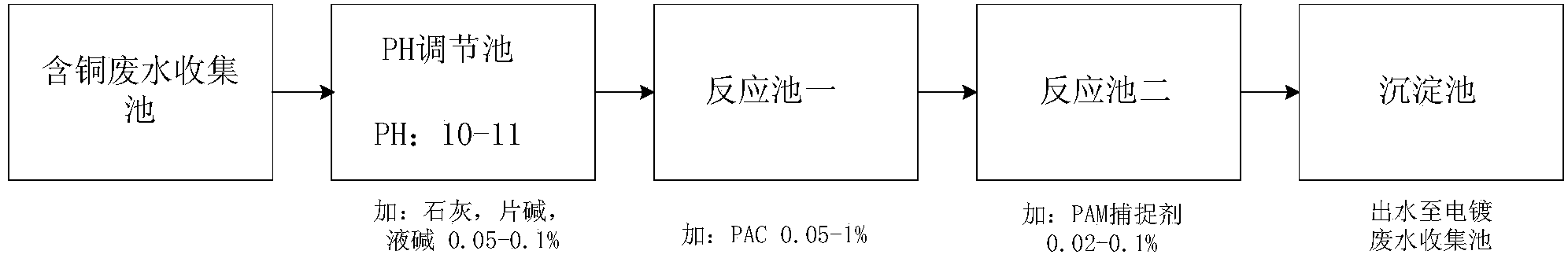

Treatment method for electroplating industrial wastewater

ActiveCN104045182AMeet emission requirementsReduce complexityMultistage water/sewage treatmentChemical reactionCyanide

The embodiment of the invention discloses a treatment method for electroplating industrial wastewater, which comprises the following steps: pretreating nickel-containing wastewater; pretreating chromium-containing wastewater; pretreating copper-containing wastewater in a manner the same with the nickel-containing wastewater pretreatment manner; pretreating cyanide-containing wastewater; treating electroplating mixed wastewater, wherein the electroplating mixed wastewater comprises pretreatment wastewater, cleaning wastewater, electroplating wastewater and the like generated in a workshop production process and also comprises the pretreated nickel-containing wastewater, chromium-containing wastewater, copper-containing wastewater and cyanide-containing wastewater; discharging these pretreated four wastewater to a comprehensive wastewater collection tank together with other pretreatment wastewater, cleaning wastewater and the like, wherein a stirring system is arranged in the comprehensive collection tank; and finally, performing comprehensive electroplating wastewater treatment. According to the invention, non-toxic and harmless chemical reaction treatment is performed on the heavy metals and virulent cyanide, thus realizing one-stop circular electroplating wastewater treatment, improving the treatment efficiency of the electroplating industrial wastewater and reducing the water pollution.

Owner:浙江菲尔特过滤科技股份有限公司

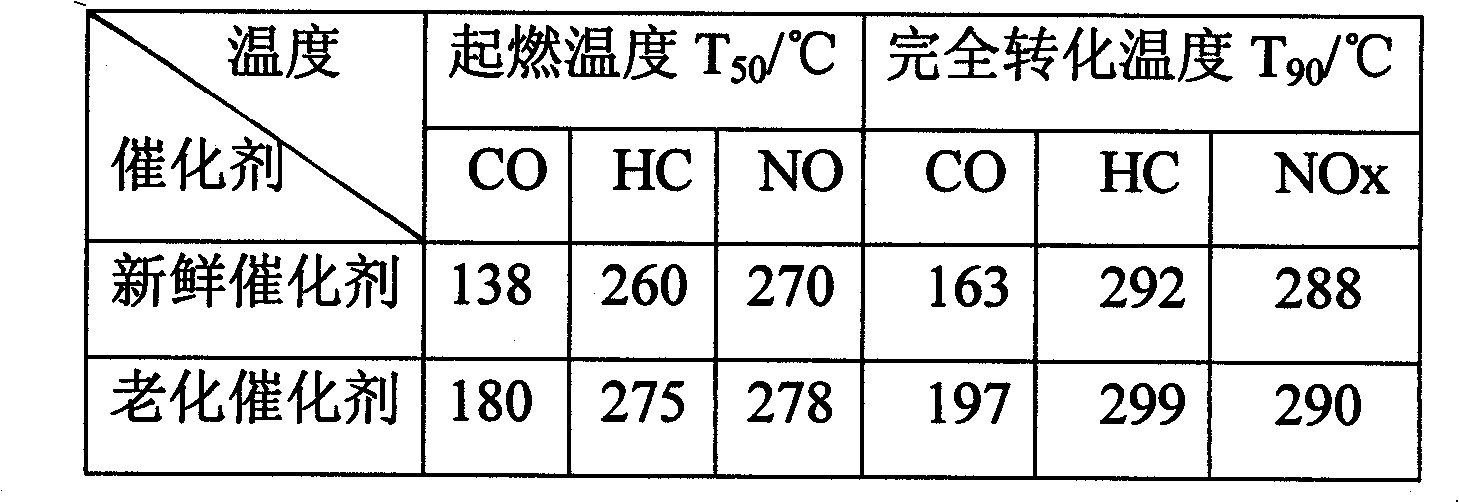

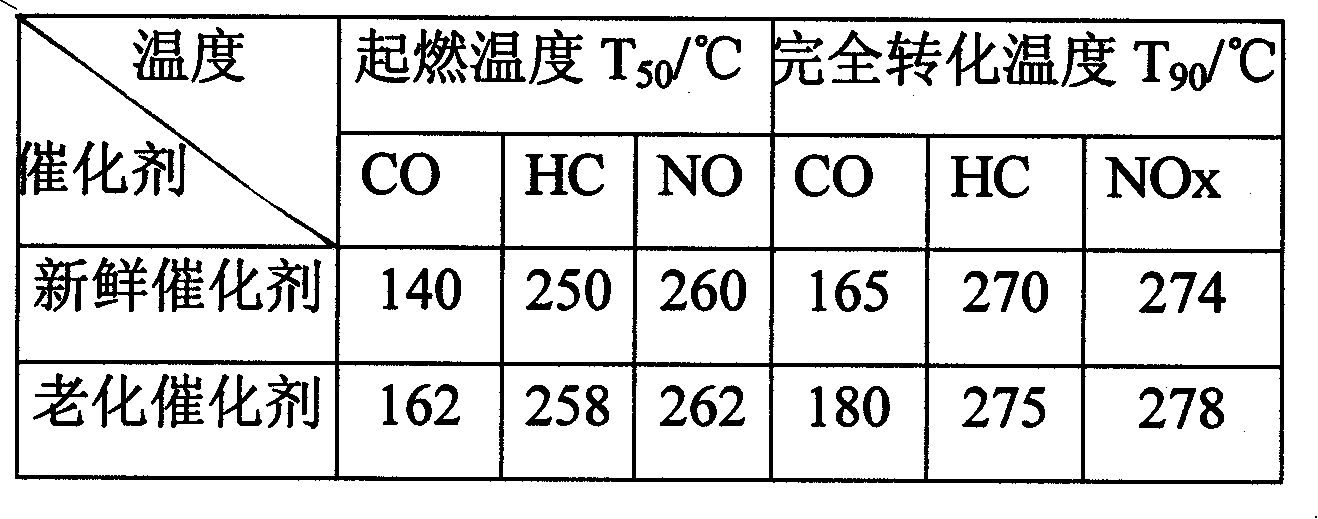

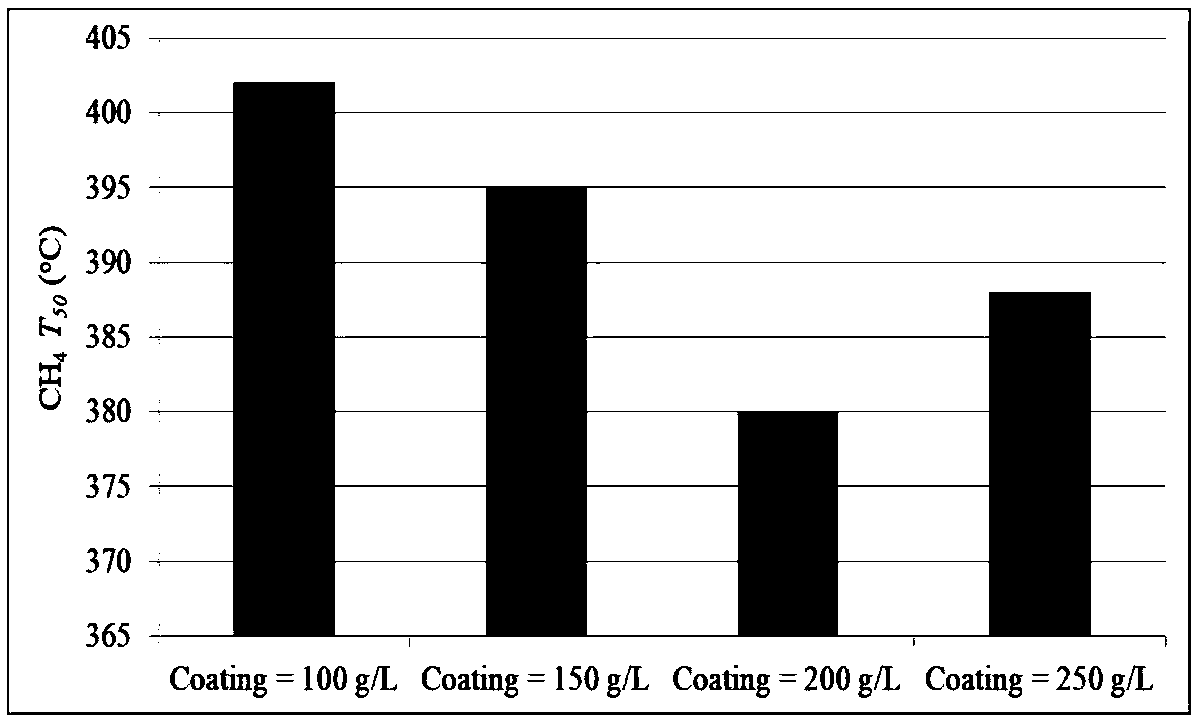

High-temperature stability catalyst used for three-effect catalysis

ActiveCN101773830AProcess stabilityMeet emission requirementsDispersed particle separationCatalyst activation/preparationSolid solutionComposite oxide

The invention discloses a high-temperature stability catalyst used for the catalytic purification of the tail gas of an automobile, which belongs to the technical field of pollution control and relates to a high-temperature stability catalyst capable of keeping three-effect catalysis performance under the condition of high temperature. The high-temperature stability catalyst is characterized in that the prepared high-temperature stability material is a composite oxide solid solution comprising noble metal, cerium oxide, zirconia and an assistant. Compared with a three-effect catalysis material obtained by a traditional immersion method, the catalyst prepared by the invention can ensure the stable existence of noble metal oxide under the condition of high temperature, has favorable catalysis effect and can reach the requirement of the discharge of the tail gas.

Owner:EAST CHINA UNIV OF SCI & TECH

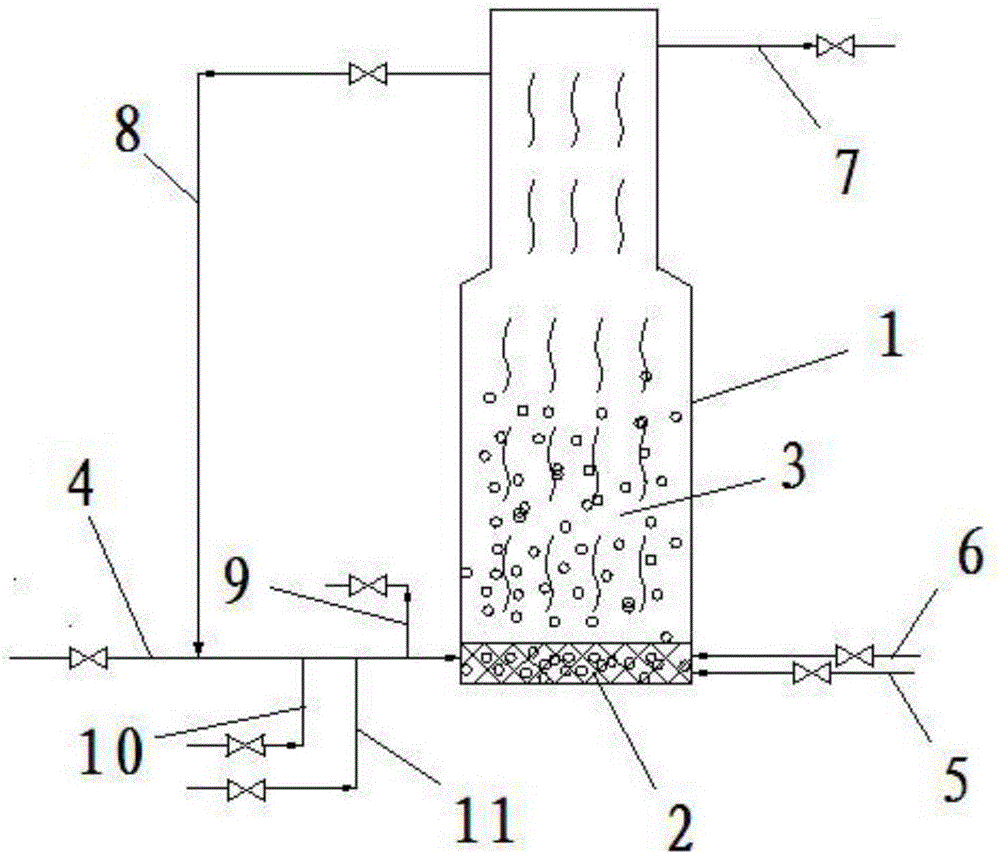

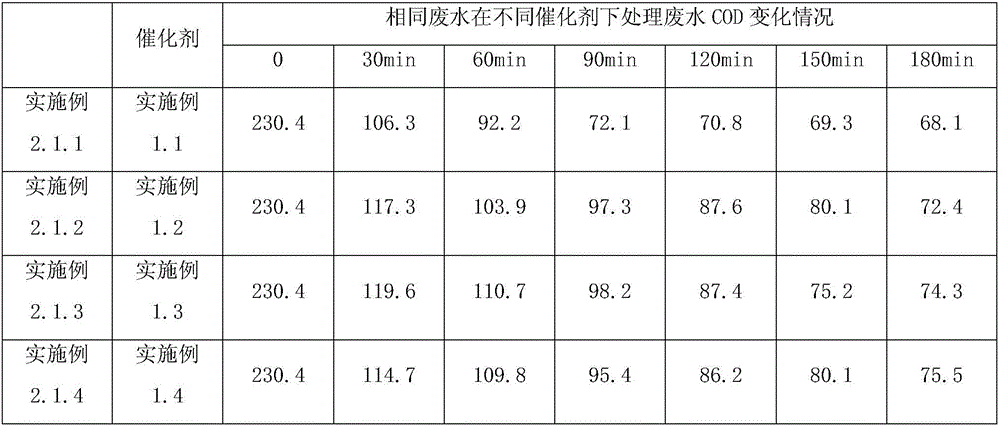

Method for preparing Fenton-like reaction catalyst and application thereof

ActiveCN105879872AHigh catalytic efficiencyAvoid side effectsMolecular sieve catalystsWater treatment compoundsBrown iron oxideMolecular sieve

The invention provides a method for preparing Fenton-like reaction catalyst. Inert oxide or a molecular sieve is used as a carrier, and the carrier is loaded with nano-scale iron oxide. The method includes mixing the iron oxide and the carrier with each other and then molding the iron oxide and the carrier to obtain particles; calcining the particles at the temperature of 200-500 DEG C to obtain the Fenton-like reaction catalyst with the particle size of 10-40 mesh. A weight proportion of the iron oxide to the carrier is 1:(0.4-1). The method has the advantages that the Fenton-like reaction catalyst prepared by the aid of the method is high in catalytic activity, selectivity and stability and can be used as Fenton-like oxidation reaction catalyst for advanced treatment of wastewater after the wastewater is subjected to biochemical treatment, accordingly, the catalytic efficiency can be improved in reaction procedures, float mud can be prevented, the COD (chemical oxygen demand) removal rate of the treated wastewater can be obviously increased as compared with existing Fenton treatment, and wastewater treatment discharge requirements can be met; the pH of treated outflow ranges from 7.0 to 8.0, and the treated outflow can be directly discharged without pH regulation; waste mud generated in treatment procedures can be utilized and can be used for producing coatings.

Owner:河北协同水处理技术有限公司 +1

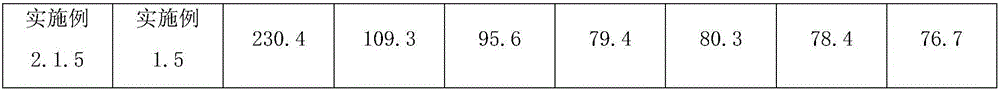

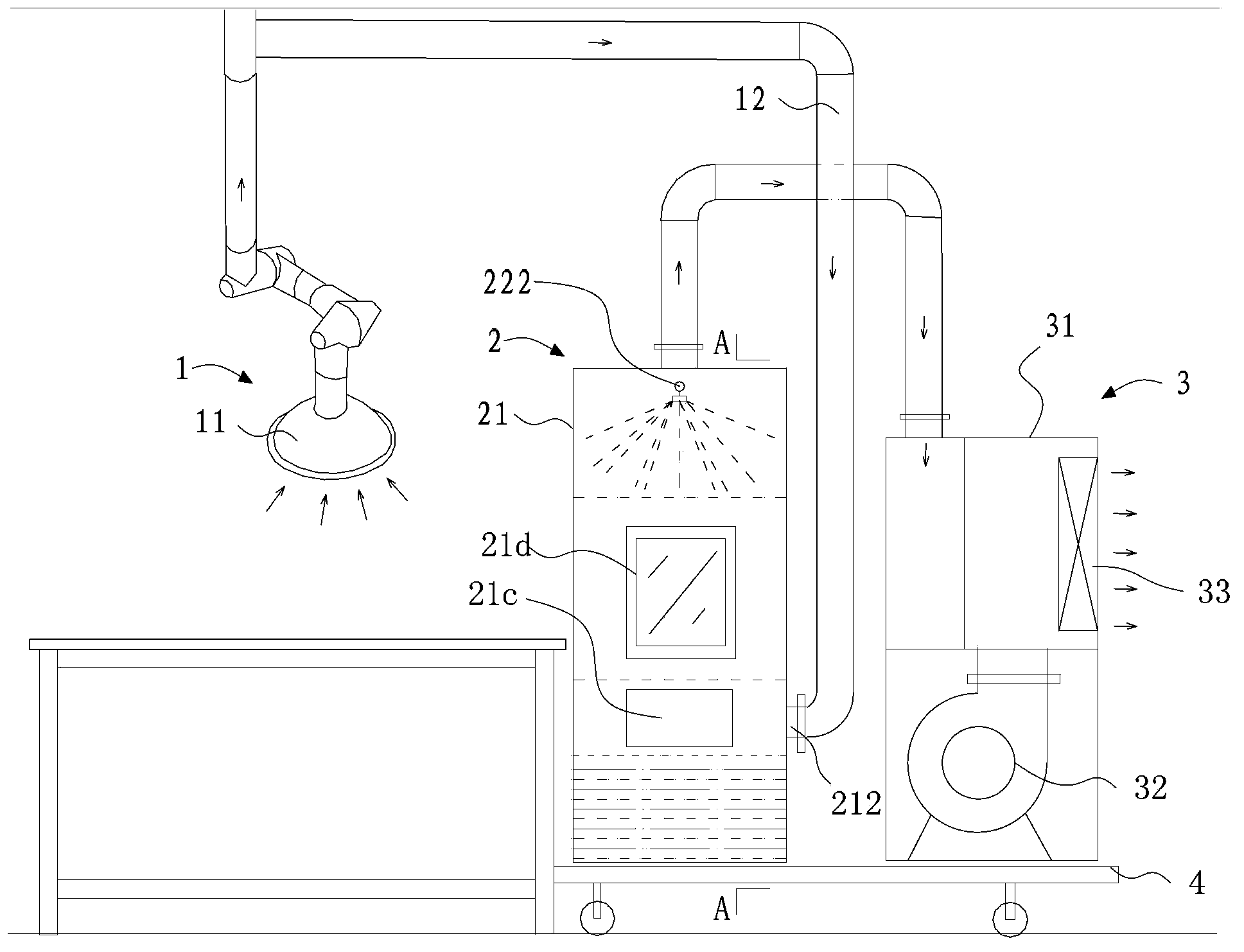

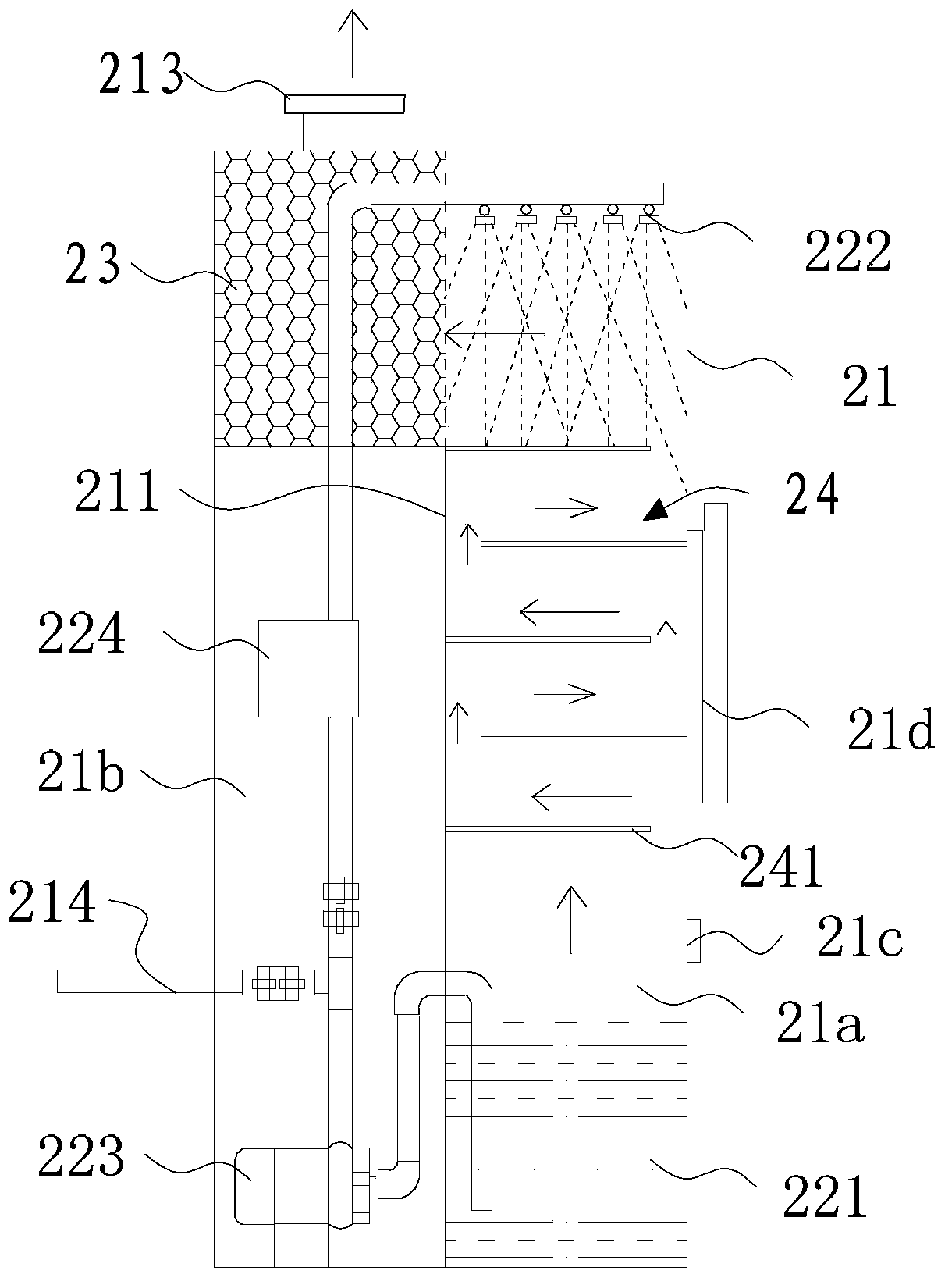

Waste gas and dust treating device

InactiveCN103505969ASimple structureMeet cleanliness requirementsUsing liquid separation agentAfter treatmentEmission standard

The invention provides a waste gas and dust treating device. The waste gas and dust treating device comprises a gas collecting device, a purification treatment device and a discharging device, wherein the gas collecting device is used for collecting waste gas and dust; the purification treatment device for purifying waste gas and dust collected by the gas collecting device is communicated with the gas collecting device and comprises a spraying device for spraying a washing liquid for washing the waste gas and the dust collected by a dust collecting device and a defogging device for dewatering and defogging gas which is obtained after the washing liquid sprayed by the spraying device is treated; the discharging device is used for discharging the gas treated by the purification treatment device and is communicated with the purification treatment device. The waste gas and dust treating device is simple in structure, and capable of effectively treating waste gas and dust and enabling the waste gas and the dust to achieve emission standards, thereby reducing pollution to workshop environment as well as harms to human bodies; the gas discharged after treatment of the waste gas and dust treating device can meet the cleaness requirement of the workshop environment and can be directly discharged into the workshop environment, so that both the cleaness requirement and the sealing requirement of the workshop environment are met.

Owner:BEIJING SKYWING TECH CO LTD

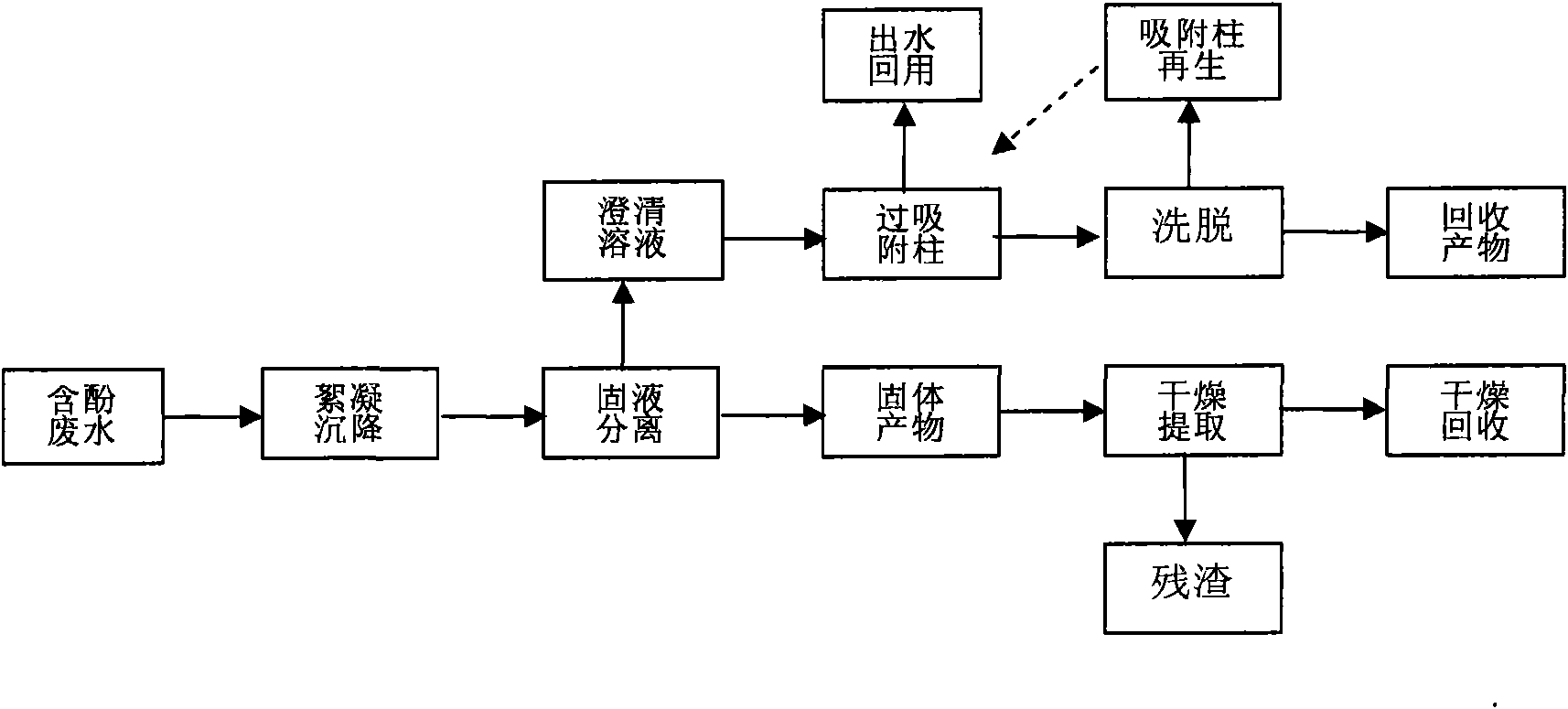

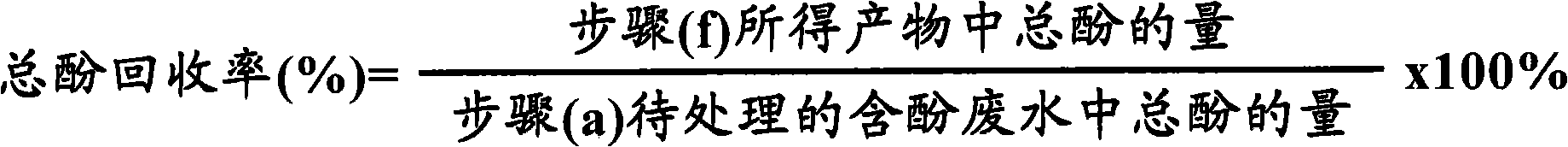

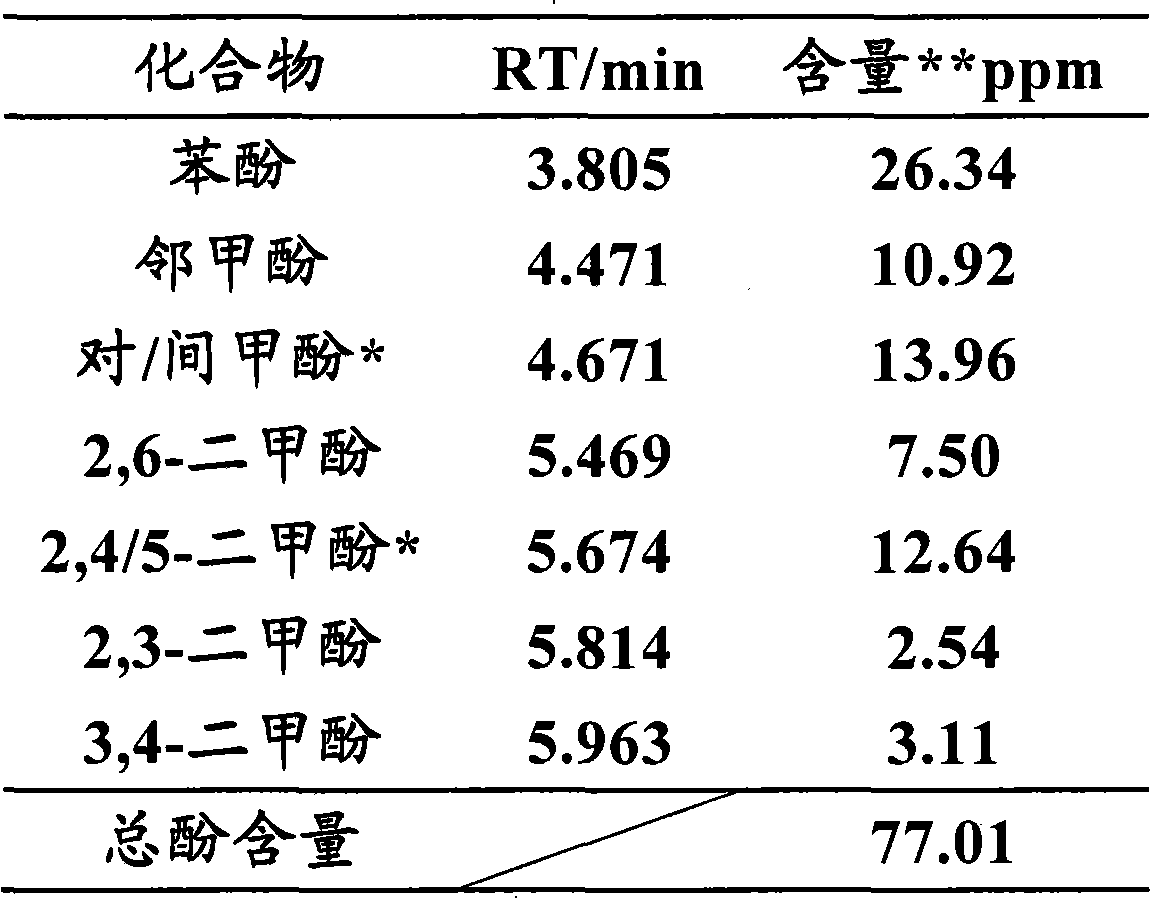

Method for processing and recycling waste water containing phenolic compounds

InactiveCN102417248AEasy to purifyRealize automatic continuous productionOrganic chemistryOrganic compound preparationFlocculationAlcohol

The invention relates to a method for processing and recycling waste water containing phenolic compounds, in particular to a method for recycling phenolic compounds from the phenolic waste water, comprising the following steps: (a) adding a flocculating agent in the phenolic waste water to be processed for flocculation; (b) carrying out solid-liquid separation on the material of the step (a); (c) determining the pH value of the liquid material obtained by the step (b), and adjusting the pH value to acidity; (d) letting the material obtained by the step (c) pass through a resin column, and measuring the total phenol content in water; (e) eluting the resin column which absorbs the phenolic compounds with a small molecular alcohol and / or ketone solvent; and (f) recovering the solvent from the eluate, and drying to obtain a product which is rich in phenolic compounds. Correspondingly, the invention further provides a method for processing the waste water containing phenolic compounds and the obtained phenolic product. According to the invention, the method disclosed herein is suitable for processing the waste water with low phenol content, and is environmental friendly; by using the raw materials which has the advantages of low pollution, or low price, or easy processing, and or recycling property, the method has the advantages of low cost and low energy consumption.

Owner:ENN SCI & TECH DEV

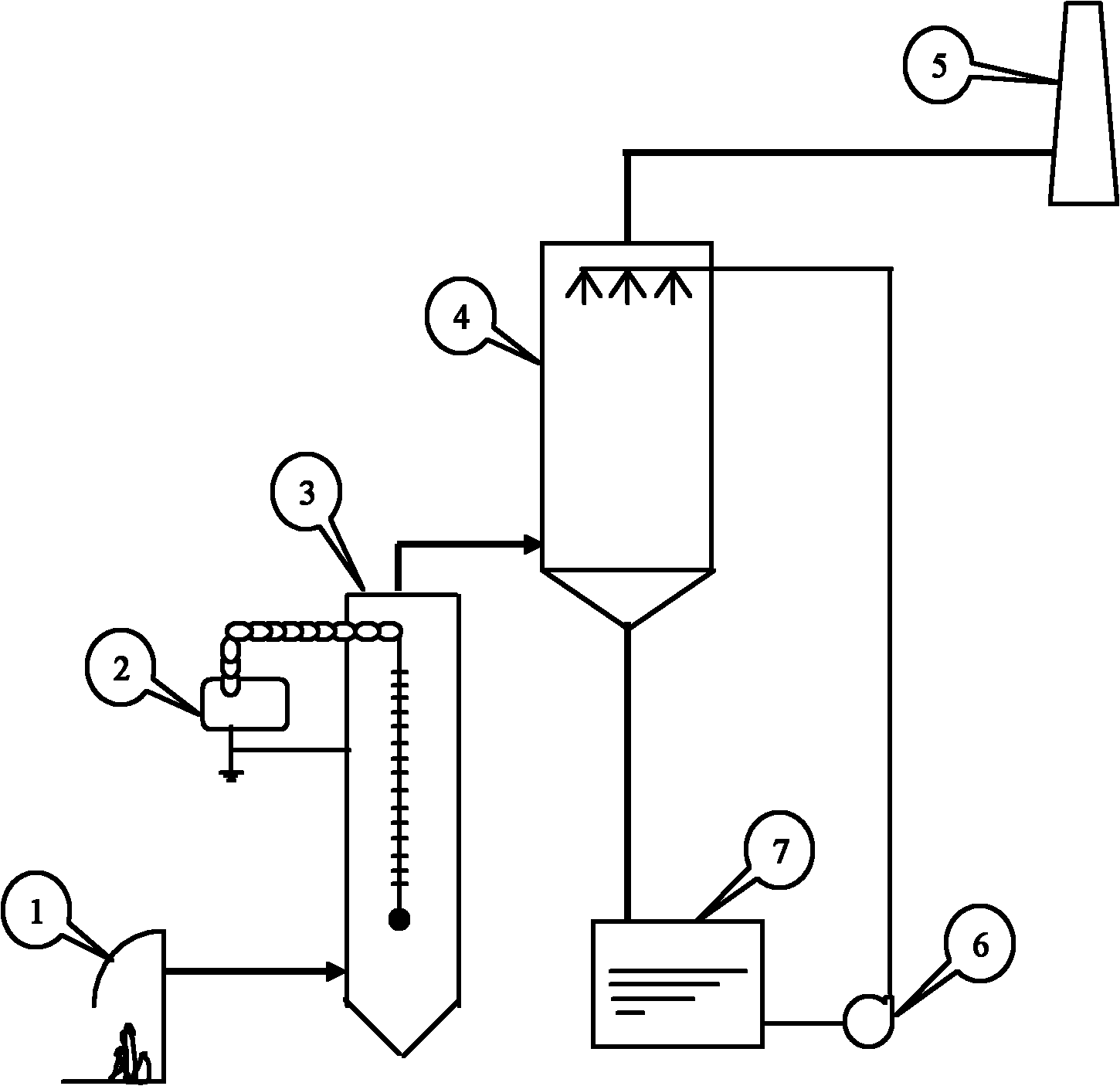

System and process for removing PM2.5 through wet flue gas demercuration and cooperative desulfurization

ActiveCN104014217AMeet low emission requirementsMeet emission requirementsCombination devicesLiquid wasteFlue gas

The invention discloses a system and process for removing PM2.5 through wet flue gas demercuration and cooperative desulfurization. The system comprises a bag type dust collector, a wet desulfurization absorption tower, an oxidation tower, a wet electric precipitator, an oxidizing agent preparation device and an integrated oxidation and demercuration byproduct preparation structure comprising a waste reservoir, a settling pond and a solid-liquid separator. The process comprises the following steps: dissolving and absorbing particulate mercury and Hg<2+> in flue gas on a slurry spraying layer during wet desulfurization, thus realizing first-stage demercuration; further oxidizing elemental Hg0 in the flue gas into Hg<2+> by adopting an oxidizing agent, and dissolving and removing the Hg<2+>; removing residual Hg<2+>, particulate mercury, PM2.5 and acid mist in the flue gas by adopting the wet electric precipitator; and preparing byproducts from oxidation and demercuration liquid wastes by adopting a precipitation separation method. According to the system and process, effective demercuration and cooperative desulfurization and fine particle removal are realized, the byproducts are effectively recycled, secondary pollution is avoided, and a comprehensive flue gas treatment effect is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

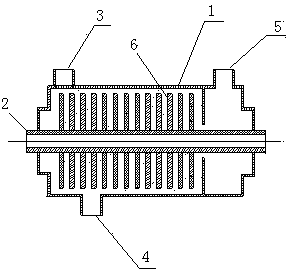

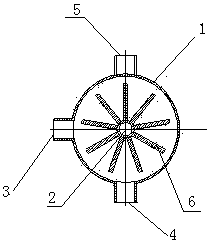

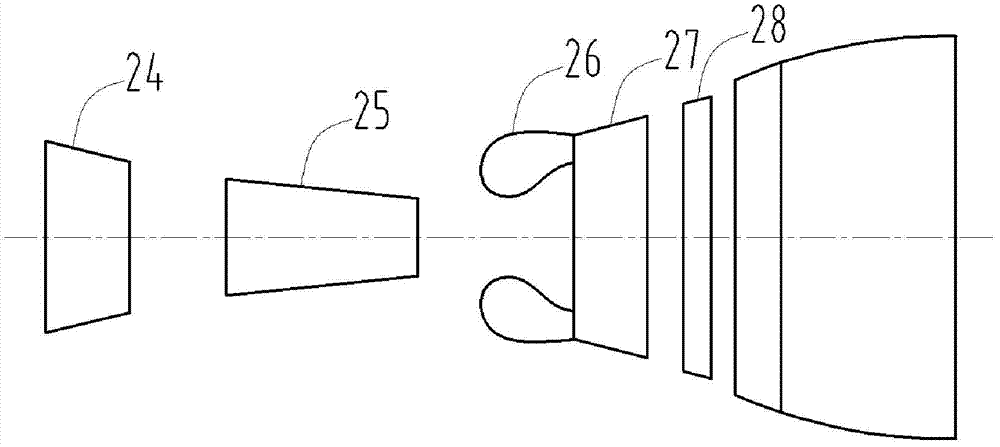

Annular combustion chamber based on Venturi pre-mixing bispin nozzle

ActiveCN102889618AEmission reductionFacilitate oil and gas mixingContinuous combustion chamberSpray nozzleAerospace engineering

The invention discloses an annular combustion chamber based on a Venturi pre-mixing bispin nozzle. The combustion chamber has a single-ring-cavity structure; a plurality of sets of combustion heads are arranged at the head of the annular combustion chamber; each set of combustion head is provided with a pre-combustion grade nozzle and a plurality of main-combustion grade nozzles; the main-combustion grade nozzles are symmetrically arranged along a radial direction of the annular combustion chamber by taking the pre-combustion grade nozzle as a center; each main-combustion grade nozzle is of a structural form that an outer ring sprays two grades of spinning flow around a Venturi pre-mixing center and comprises a main oil nozzle, an axial air spinner and a Venturi pre-mixing section which are coaxial; each axial air spinner has a two-grade spinning structure and is connected with the Venturi pre-mixing section; each main oil nozzle is arranged in the center of the axial air spinner; the outlet end face of each main oil nozzle is arranged at the throat of the Venturi pre-mixing section; and fuel is supplied to the pre-mixing grade nozzles and the main-combustion grade nozzles through two-channel fuel connection nozzles.

Owner:江苏中国科学院能源动力研究中心 +1

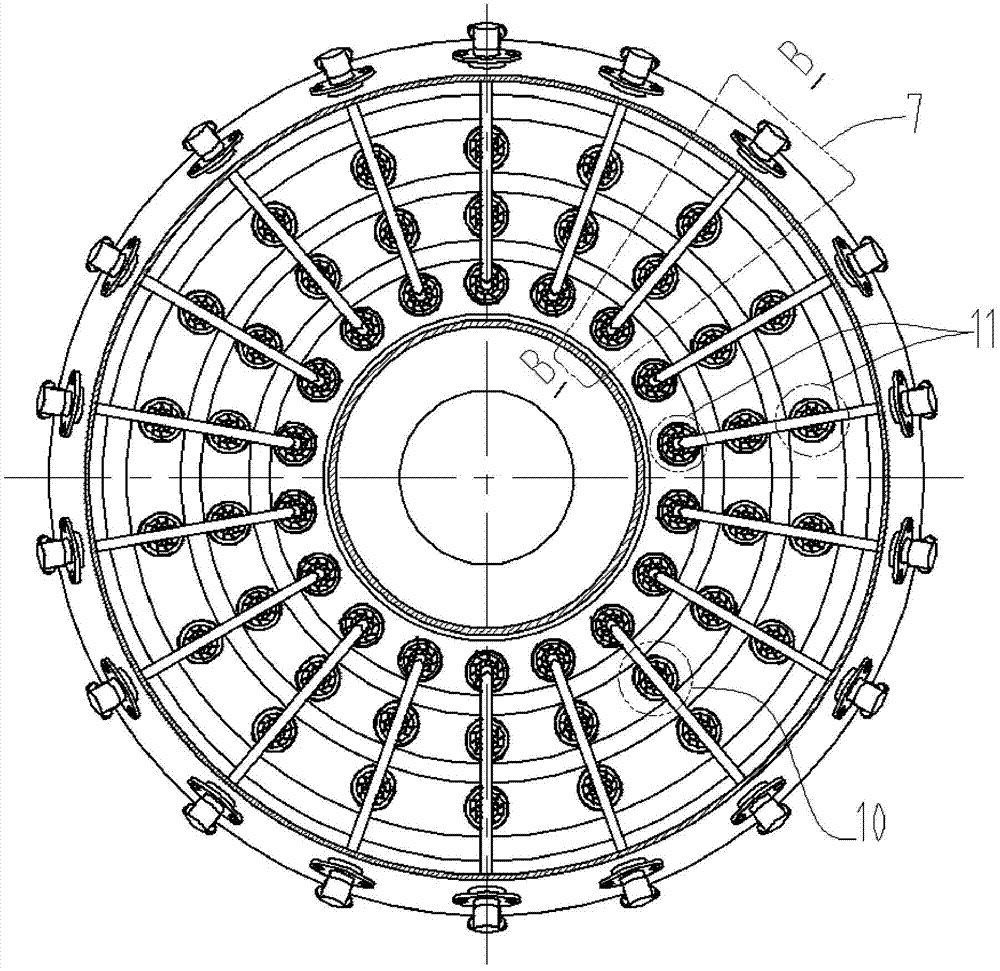

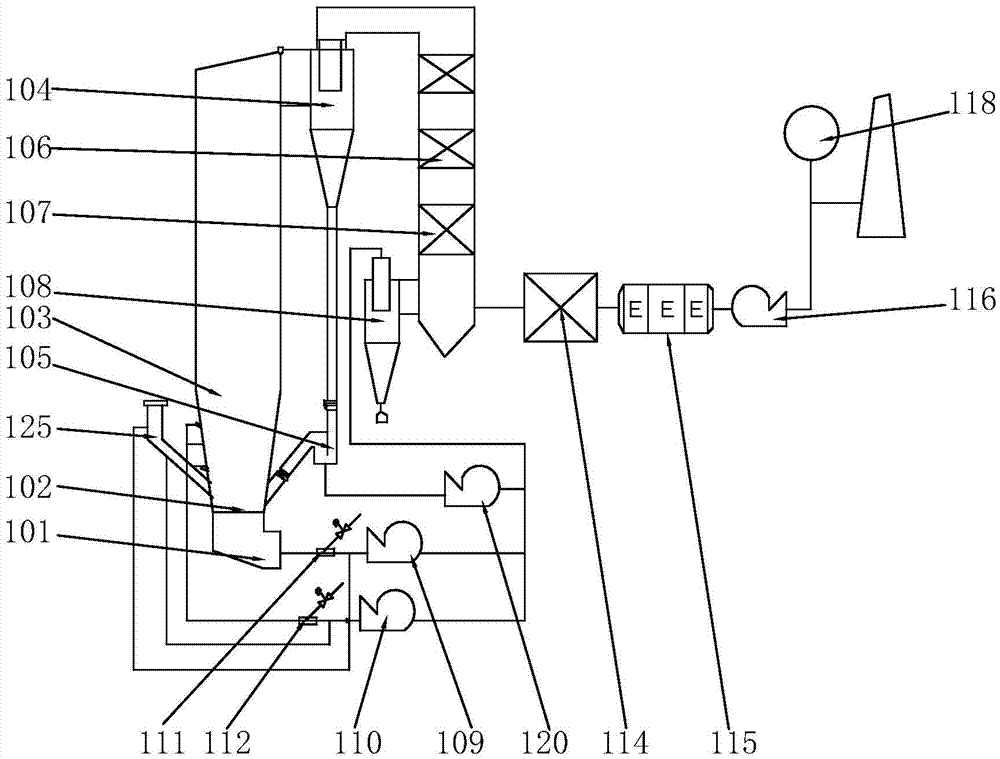

Recirculating fluidized bed oxygen-enriched combustion apparatus and operation method thereof

ActiveCN104848213AUniform fluidizationAvoid depositionFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion

The invention discloses a recirculating fluidized bed oxygen-enriched combustion apparatus, which comprises an air compartment, an air distribution device arranged above the air compartment and a hearth arranged above the air distribution device; the upper part of the hearth is connected with a high-temperature cyclone separator; the upper part of the high-temperature cyclone separator is connected with a heating surface; the lower part of the heating surface is connected with an economizer. The invention further discloses an operation method of the recirculating fluidized bed oxygen-enriched combustion apparatus. The recirculating fluidized bed oxygen-enriched combustion apparatus and the operation method thereof, disclosed by the invention, overcome the defects in the prior art, and intermediate temperature flue gas is used as primary air and secondary air which respectively enter the hearth to serve as recirculating air, in addition, oxygen is injected into the primary air and the secondary air, and the oxygen injection amount can be adjusted, meanwhile, an oxidizing agent is provided for combustion in the hearth, the concentration of CO2 discharged from a boiler of a recirculating fluidized bed can be enriched to more than 80%, and the capture of the CO2 in the flue gas after combustion of coal is facilitated.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Biological treatment method for wastewater of containing acrylics and esters

InactiveCN1600706AReduce processing costsLow costTreatment with aerobic and anaerobic processesHigh densityWastewater

The characteristics are following steps: 1. proceeding acidate hydrolyzation to waste water; 2. proceeding anaerobic biologic treatment to acidate hydrolyzed waste water by utilizing anaerobic biologic treater; 3. proceeding aerobic biologic treaterment to waste water by utilizing aerobic biologic treater. By the invention, high-density organic waste water is treated by modern biologic treating technology to achieve discharging requirement.

Owner:北京东方石油化工有限公司

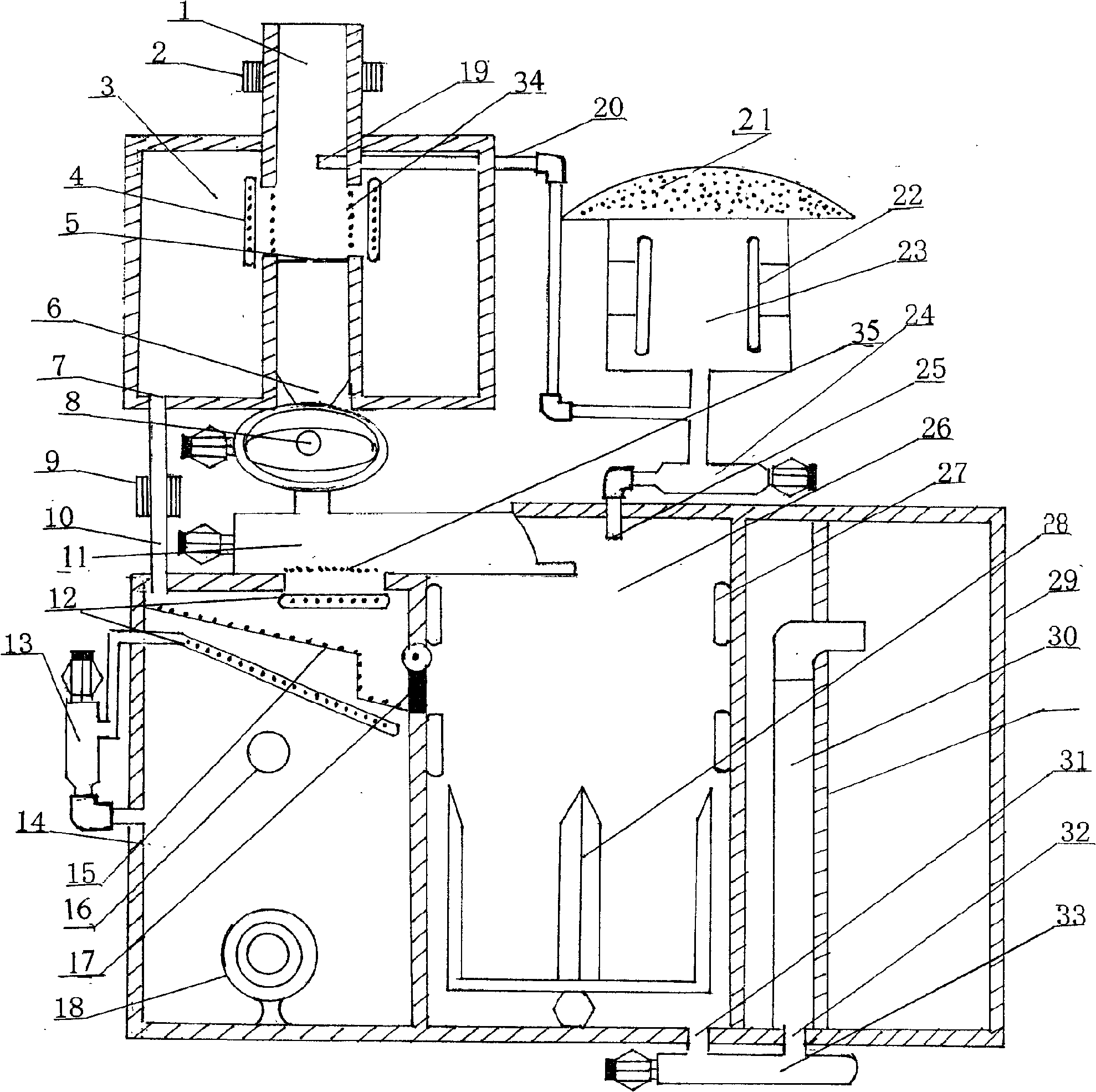

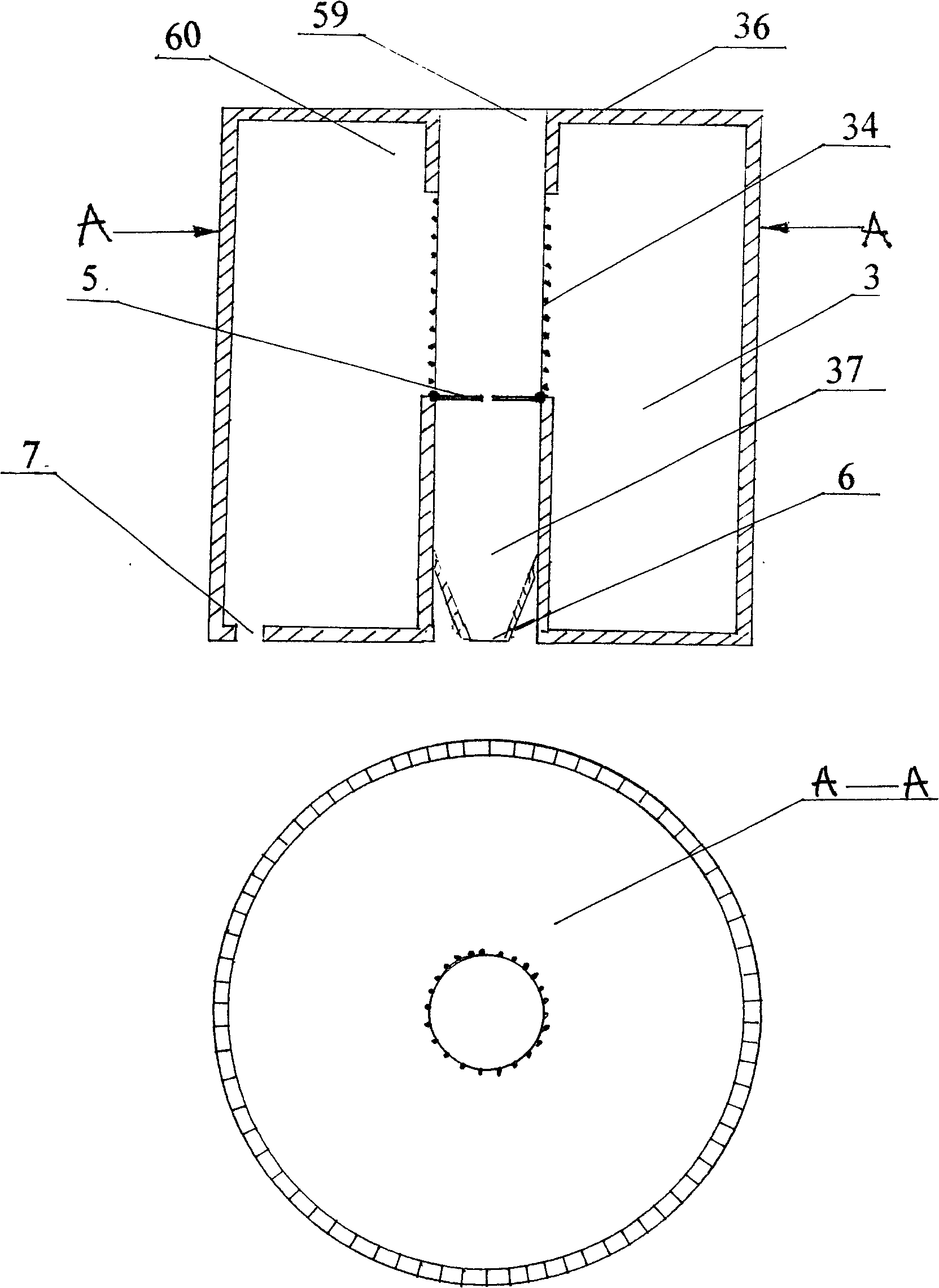

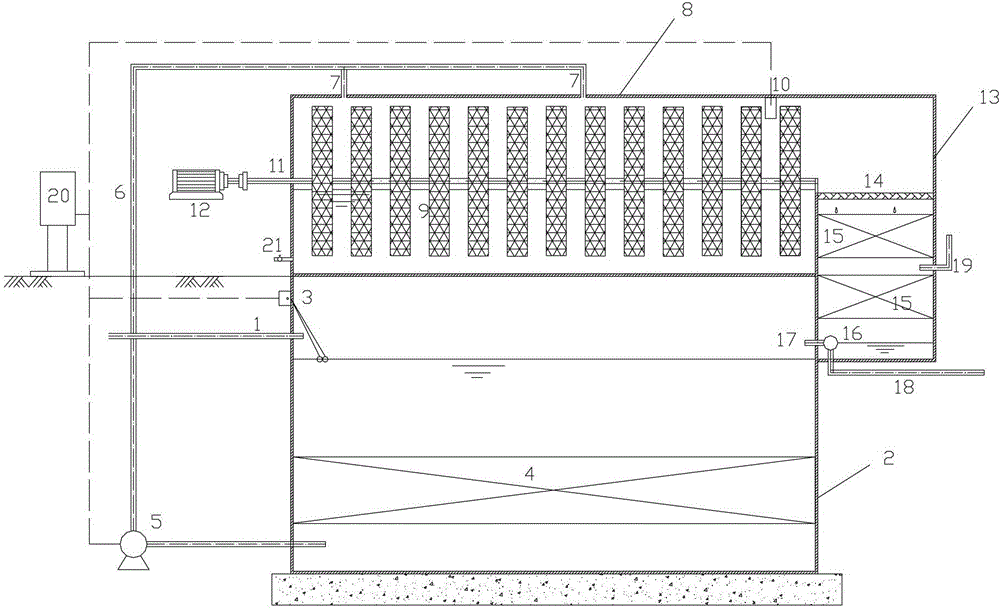

Combined type biological rotating disk treatment device and method using same to treat sewage

The invention discloses a combined type biological rotating disk treatment device which is composed of a water inlet tank, a biological rotating disk reactor, a biological drop filter tank and the like. The invention further discloses a method using the combined type biological rotating disk treatment device to treat sewage. Sewage firstly enters the water inlet tank, is pumped by a jet pump and enters all section of a biological rotating disk through a plurality of pipelines. After the sewage is nitrified and denitrified by the biological rotating disk, the sewage falls into the biological drip filter tank through a water distribution plate. After being filtered, one part of the sewage is drained, and one part of the sewage flows back to the water inlet tank. A casing is covered on the biological rotating disk reactor, the jet pump can supply oxygen fro the biological rotating disk reactor, and air in the tank is filtered by the biological drop filter tank to be drained. A dissolved oxygen and liquid level control device are arranged in the tank. The jet pump is controlled to be opened according to dissolved oxygen and water inlet liquid level. Thus, low-energy-consumption running is achieved.

Owner:南京元凯生物能源环保工程有限公司

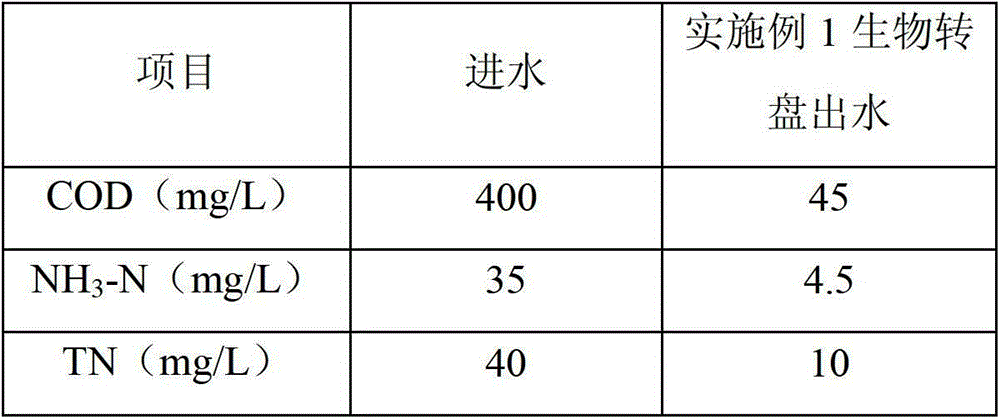

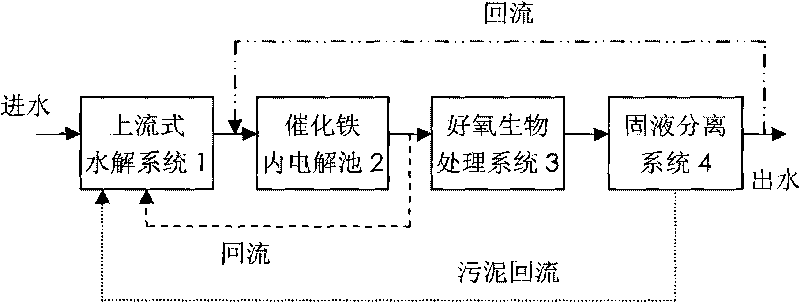

Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

InactiveCN101693581AGuaranteed reaction efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentWater qualityTherapeutic effect

The invention pertains to the technical field of treatment of waste water, and particularly relates to a method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water, which comprises the following steps: waste water after primary treatment directly enters an up flow type hydrolysis system 1 and stays for 4.0-10.0 hours; the effluent enters an electrolytic cell in the catalytic iron; the mass ratio of iron scraps and copper scraps in the electrolytic cell of the catalytic iron is 1:1 to 20:1, the bulk specific weight thereof is 0.1 to 0.3, the contact time thereof in a filling area is 0.5 to 2.0 hours, and the reflux ratio of the effluent refluxing to the up flow type hydrolysis system is 20 to 100 percent; the effluent enters an aerobic biological treatment system and stays for 6.0 to 12.0 hours; then the effluent enters a solid-liquid separation system with a reflux ratio of sludge being 10 to 50 percent; and the effluent of the solid-liquid separation system refluxes to the electrolytic cell of the catalytic iron with the reflux ratio being 20 to 200 percent. Under the premise of fully playing the function of different treatment units and maintaining the treatment effect and respective advantages, the treatment method of waste water realizes the coupling synergetic action of the three units, strengthens the impact of the system to water quality and water quantity load, reduces a plurality of steps of pretreatment, effectively improves the removal rate of ammonia nitrogen, and can be flexibly adjusted.

Owner:TONGJI UNIV +1

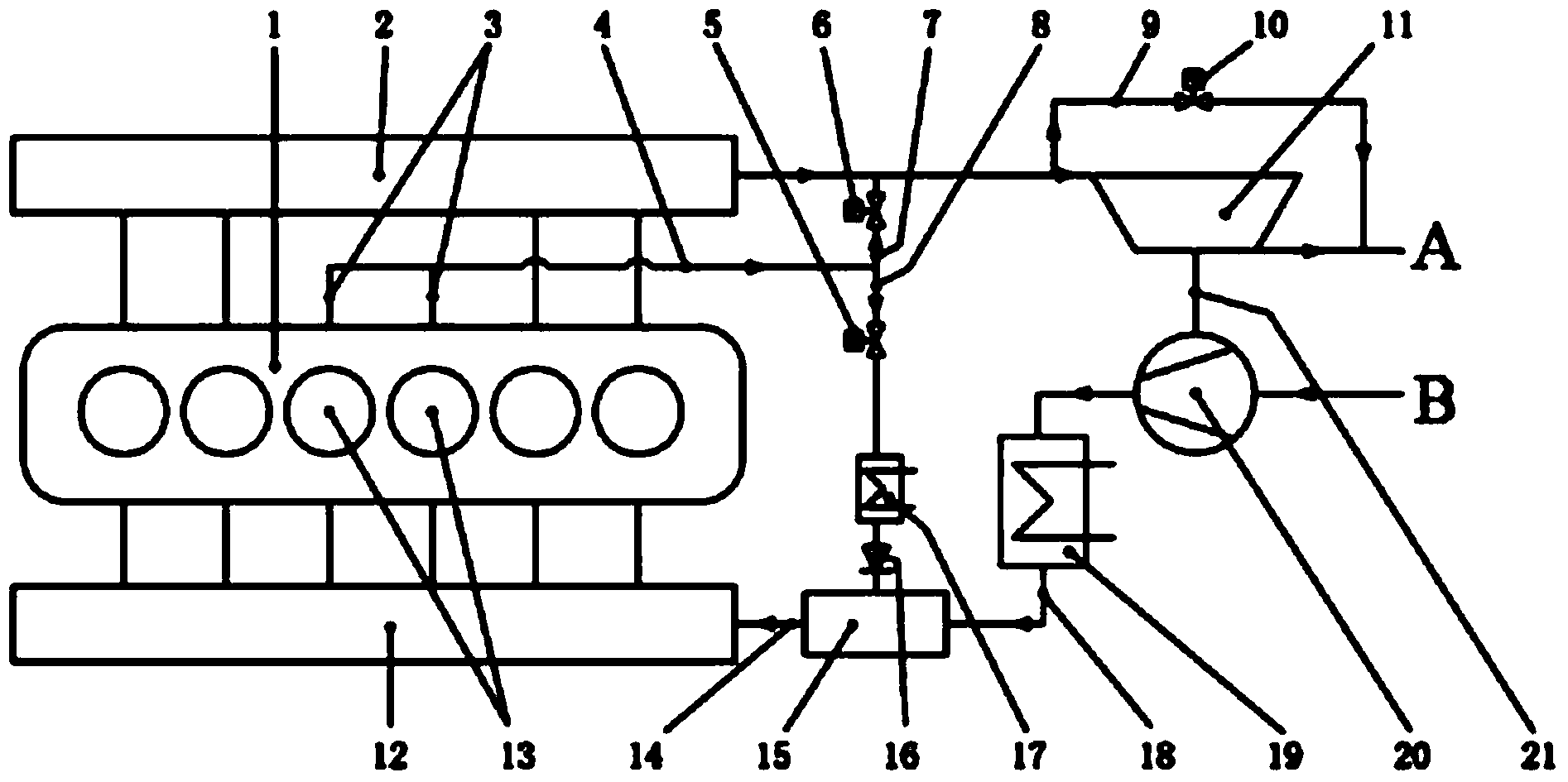

EGR (Exhaust Gas Recirculation) system used for marine medium-speed diesel engine

InactiveCN103470408AOvercome the intake and exhaust pressure deficitPrevent inflowInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerEngineering

The invention discloses an EGR (Exhaust Gas Recirculation) system used for a marine medium-speed diesel engine. The EGR system comprises an exhaust pipeline, an EGR pipeline, an EGR by-pass pipeline, an EGR mixer and an exhaust gas by-pass pipeline, wherein an EGR valve, an EGR one-way valve and an EGR cooler are mounted on the EGR pipeline; the EGR valve is used for opening and closing the EGR pipeline; the EGR one-way valve is used for stopping air from flowing into the EGR pipeline; the EGR cooler is used for reducing the temperature of gas mixed with exhaust gas and air; an EGR by-pass valve is mounted on the EGR by-pass pipeline and is used for controlling the flow of exhaust gas which flows to the EGR by-pass pipeline and the EGR pipeline; an exhaust gas by-pass valve is mounted on the exhaust gas by-pass pipeline and is used for controlling the flow of exhaust gas which passes through a turbocharger. Through adjusting the opening and closing of the EGR by-pass valve, exhausted gas enters a cylinder again, larger intake and discharge reverse pressure difference of the marine medium-speed diesel engine is overcome, and the NOx discharge is reduced.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

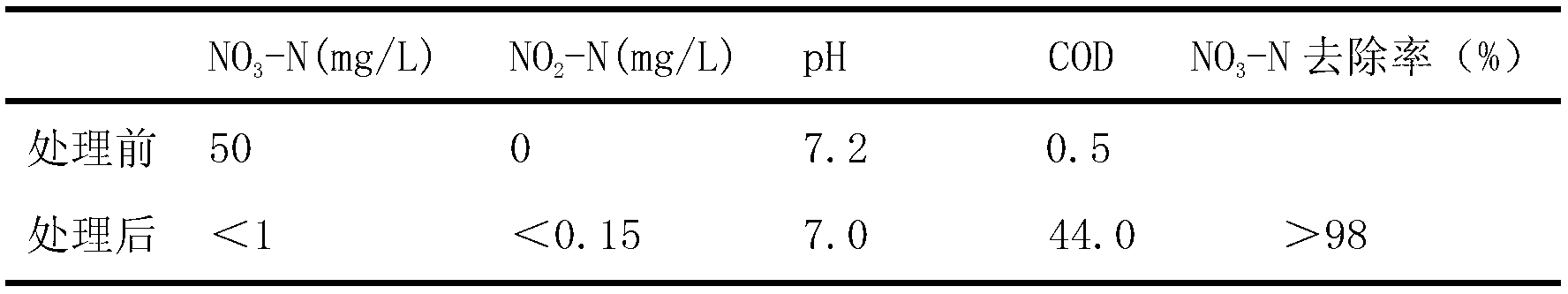

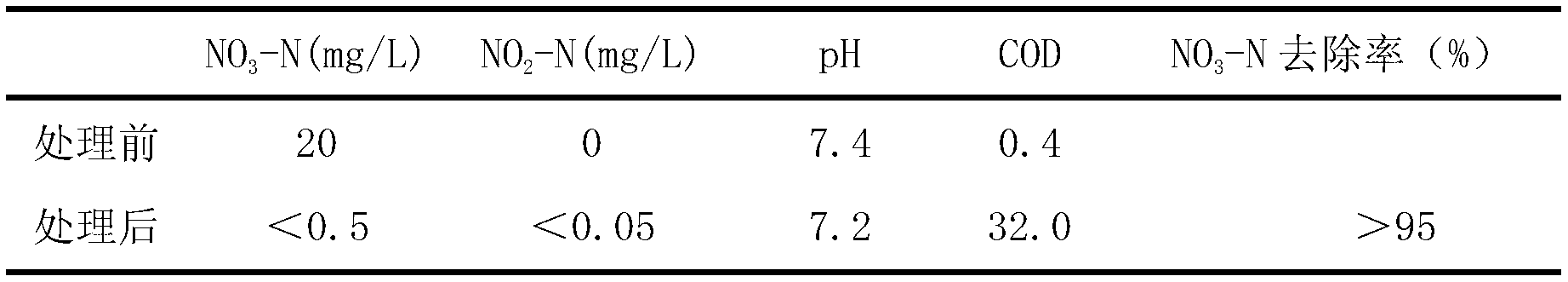

Preparation method of mixture of polyester and thermoplastic starch rich in starch and application thereof

ActiveCN103194050AImprove the mixing effectStrong mechanical propertiesWater contaminantsBiological water/sewage treatmentSolid carbonThermoplastic

The invention discloses a preparation method of a mixture of polyester and thermoplastic starch rich in starch and an application thereof, belonging to the technical field of environment protection. According to the method, the polyester and the thermoplastic starch rich in starch are taken as the raw materials, and addition agents such as aluminic acid ester coupling reagent and the like are added, thermoplastic starch / polyester blending material is prepared through banburying by a torque rheometer, and then a product is prepared through smashing, extrusion and pelleting. The thermoplastic starch base mixture rich in starch can be used as both a carbon source and a biofilm carrier for denitrification in the water treatment deep denitrification technology, so that the defect that the carbon source dosage is not easy to control in a conventional denitrification technology is overcome, the defects that the microorganism is difficult to form a membrane, the cost is high and the staring time is long when only biodegradable polymer is taken as a solid carbon source are overcome, and the thermoplastic starch base mixture rich in starch has strong adaptability to both water dissolved oxygen concentration and pH.

Owner:CHONGQING UNIV

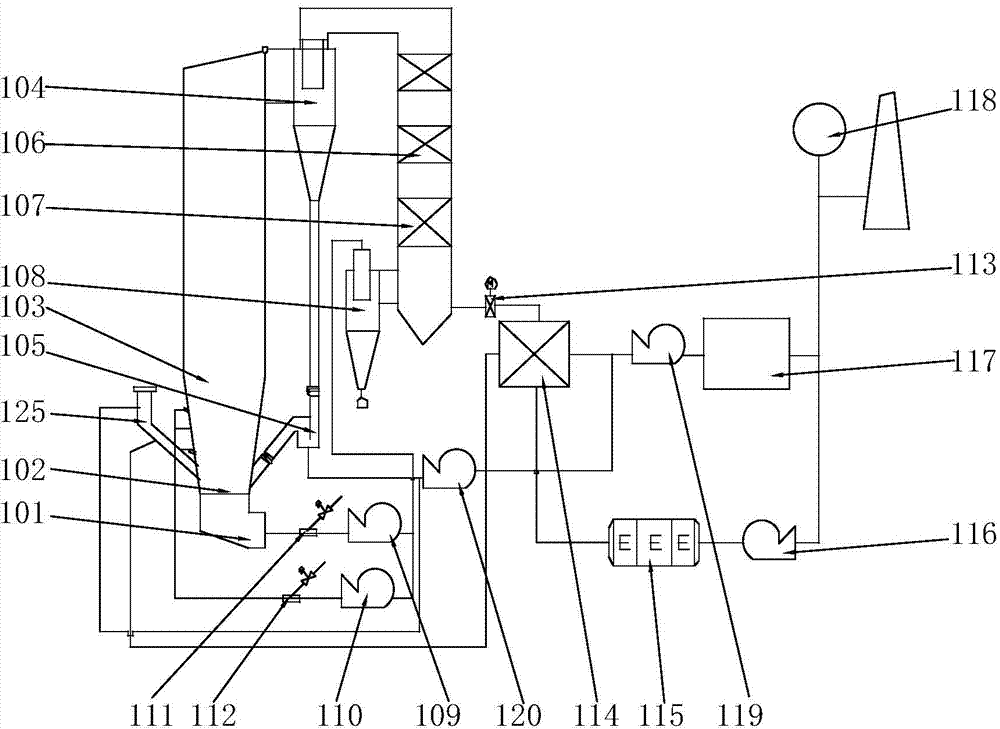

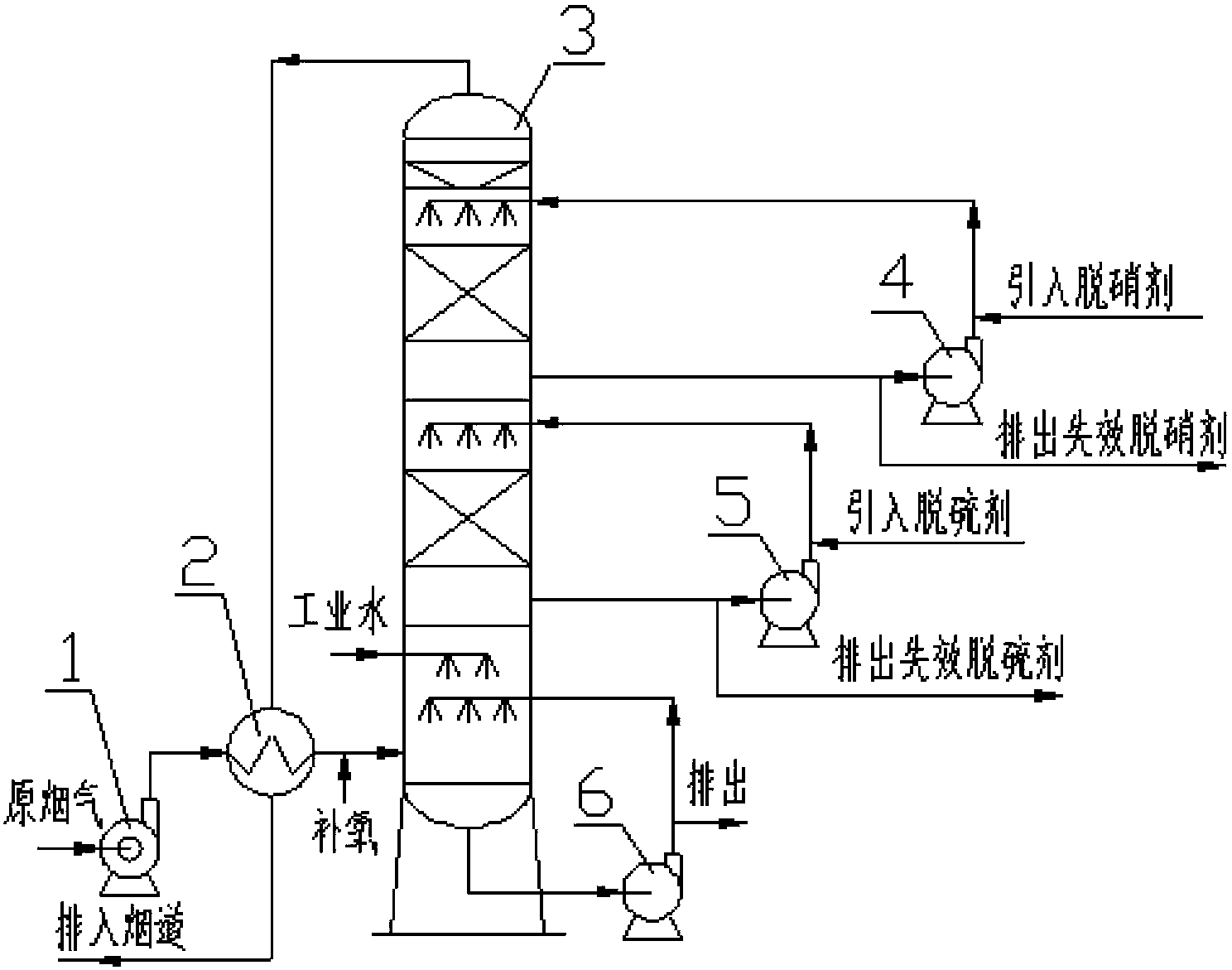

Wet-type smoke desulphurization and denitrification integrated system and method

InactiveCN103894051AThe desulfurization and denitrification process is simpleReduced footprintUsing liquid separation agentIntegrated systemsDenitrification

The invention relates to a wet-type smoke desulphurization and denitrification integrated system and method. The system comprises a draught fan and a desulphurization and denitrification tower, wherein the bottom of the desulphurization and denitrification tower is provided with a water washing section, the middle part of the desulphurization and denitrification tower is provided with a desulphurization section, and the upper part of the desulphurization and denitrification tower is provided with a denitrification section; a first spraying pipe of the water washing section is connected with a water circulating system; a second spraying pipe of the desulphurization section is connected with a desulphurization liquid circulating system; a third spraying pipe of the denitrification section is connected with a denitrification liquid circulating system; the top of the desulphurization and denitrification tower is provided with a mist catcher, and is connected with a heat exchanger through a pipeline. The method comprises the steps of sending smoke subjected to heat exchange into the water washing section through the draught fan, cooling the smoke by enabling the smoke to be in contact with washing water in a countercurrent manner, and then placing the smoke into the desulphurization section for desulphurization by enabling the smoke to be in contact with sprayed desulphurization liquid in a countercurrent direction; and placing the smoke into the denitrification section for denitrification by enabling the smoke to be in contact with sprayed denitrification liquid in a countercurrent manner, removing liquid drops of the denitrified smoke through the mist catcher, sending the smoke to the heat exchanger, and discharging the purified smoke into the atmosphere through a chimney via a flue.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

Medical waste liquid treatment device and use method

InactiveCN108191136ASpray evenlyMeet emission requirementsSpecific water treatment objectivesTreatment involving filtrationActivated carbonLiquid waste

The invention discloses a medical waste liquid treatment device and belongs to the technical field of medical waste liquid treatment. The device comprises an impurity removal box, wherein an impuritydischarging port is formed in the left side of the impurity removal box, a push rod is arranged in an inner cavity of the impurity removal box, the left end of the push rod extends to the left side ofthe impurity discharging port, a pull ring is mounted at the left end of the push rod, a filtering plate is mounted under a scraper plate, a liquid discharging pipe is mounted at the bottom of the right side of the impurity removal box, a water pump is mounted on the liquid discharging pipe, the other end of the liquid discharging pipe extends to the top of an inner cavity of a purification box,and a heating pipe is mounted at the bottom of the inner cavity of the purification box. The device effectively filters out impurities in a waste liquid, pollution to the environment is reduced, organic matter in the waste liquid can be effectively removed through an adsorbent resin layer in a filter vat, peculiar smell in the waste liquid is removed through an activated carbon adsorption layer, adisinfection device is used for disinfecting the waste liquid, besides, the heating pipe is arranged and used for high-temperature sterilization treatment on the waste liquid, so that the waste liquid meets the discharge requirements, and pollution to the environment is further reduced.

Owner:苏州比雷艾斯电子科技有限公司

Close coupled catalyst

InactiveCN1799689AImprove anti-aging propertiesMeet emission requirementsCatalyst carriersDispersed particle separationActive componentPhysical chemistry

The invention relates to a close-coupled catalyst with high activity and thermal stability to purify the tail gas of cold start of motor. Said close-coupled catalyst comprises at least three kinds of alumina in different physical phased as catalyst carrier; the Pd as active component; at least one of rare-earth oxides as Y2O3, La2O3, Nd2O3 and Sm2O3; at least one of alkaline earth oxides as SrO, BaO and CaO; and ZrO2.

Owner:SICHUAN UNIV

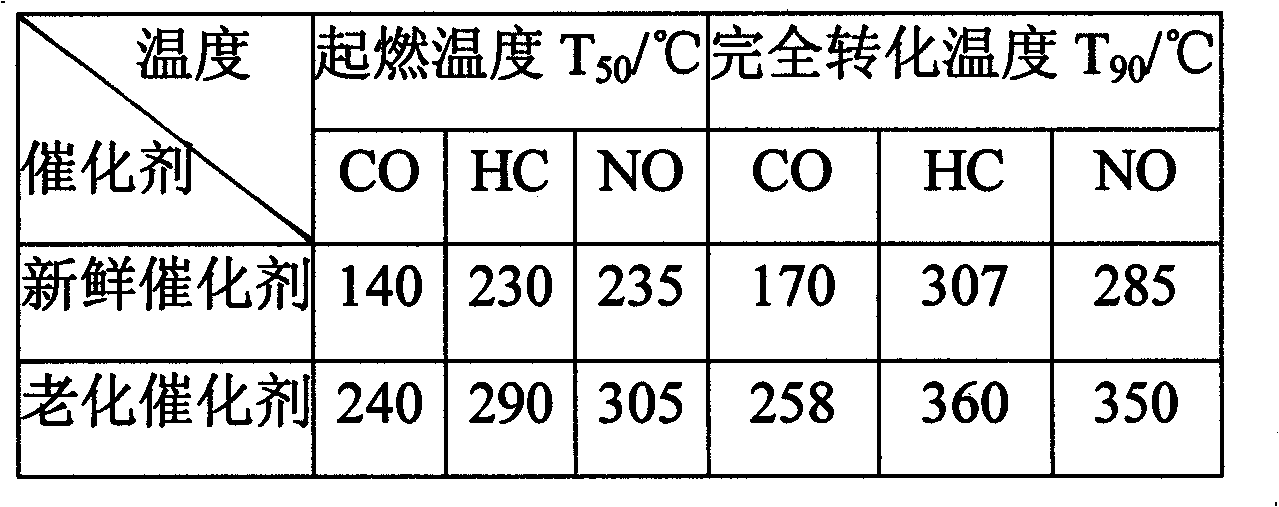

Tail gas treatment catalyst as well as preparation method and application thereof

ActiveCN109225316AMeet emission requirementsImprove purification efficiencyGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a tail gas treatment catalyst. The catalyst is prepared from a carrier, a first catalyst and a second catalyst, wherein the first catalyst and the second catalyst are arrangedat two ends of the carrier; the first catalyst can be used for purifying and treating pollutants in tail gas; the second catalyst can be used for carrying out purification treatment on a byproduct ammonia gas obtained by the purification treatment of the first catalyst, and part of pollutants which are not completely purified through the first catalyst; the second catalyst is of a double-layered structure and a lower layer is composed of an oxygen storage material, aluminum oxide and a second active component; the second active component is a composition of Pt and Pd or a composition of Ce, Fe, Ni and Cu; an upper layer is composed of a molecular sieve and a third active component; the third active component is Cu or a composition of Cu and Fe. The tail gas treatment catalyst provided by the invention is high in purification treatment efficiency; the emission of CH4, CO and NOx in the tail gas can be remarkably reduced; especially, the content of the byproduct NH3 is reduced and national grade-VI emission requirements can be met.

Owner:SINOCAT ENVIRONMENTAL TECH

Experimental ventilation cabinet filtering device

ActiveCN105311911AReasonable structureUniform controlCombination devicesDirt cleaningActivated carbonUltraviolet

The invention provides an experimental ventilation cabinet filtering device. A gas inlet is formed in one end of a filter tank, and an exhaust port is formed in the other end of the filter tank; an acid absorption device, an alkali absorption device, an activated carbon adsorption device, an ultraviolet sterilization device, a spray-washing device, a gas drying device and a gas detection device are arranged between the gas inlet and the exhaust port sequentially. According to the invention, waste gas is well controlled to be within a safe range through arranging a plurality of gas filtering devices, and gases can be uniformly and thoroughly filtered separately through arranging a plurality of seal plates; besides, the detection device is arranged, and the concentrations of solutions for acid and alkali absorption can be automatically fed back and adjusted according to data from the detection device, so that the gas meets requirements of safety and environmental protection; further, the spray-washing device is arranged to further effectively treat gas; the ventilation cabinet filtering device provided by the invention can optimally realize the effective treatment to waste gas, thereby meeting the emission requirements of environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

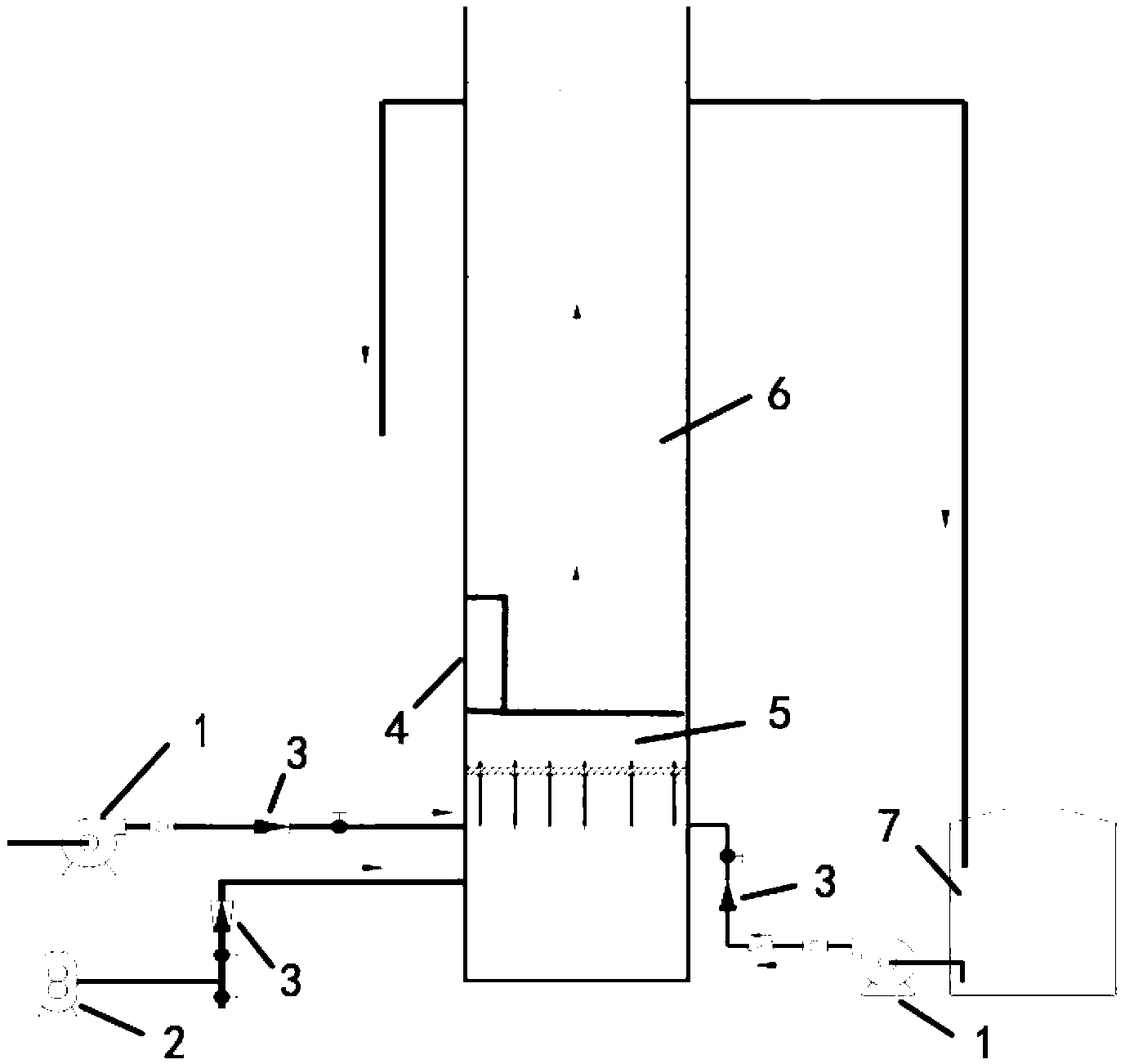

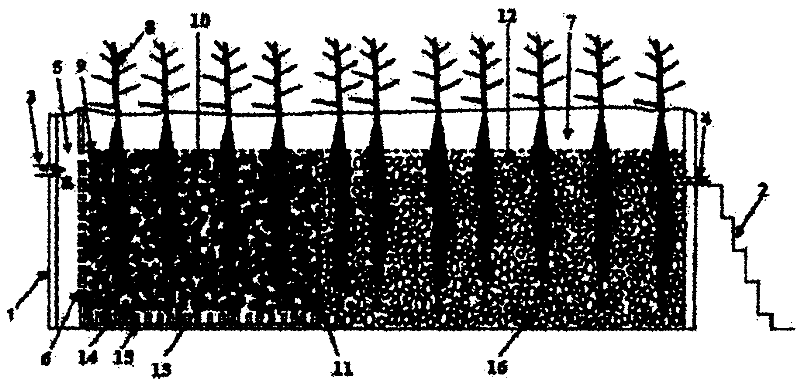

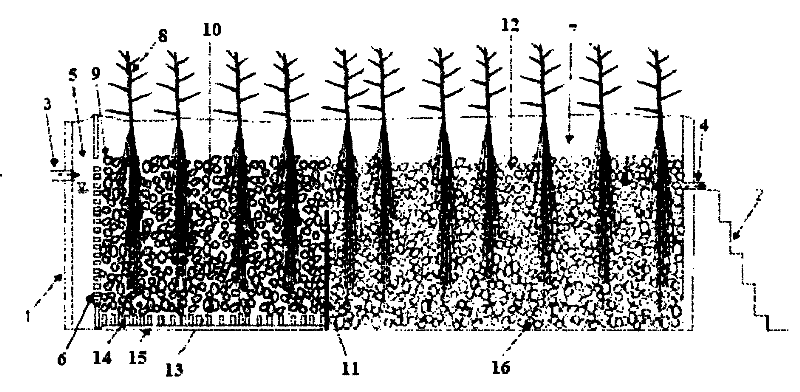

Active-matrix-reinforced underflow constructed wetland device

InactiveCN102173511AReduce dissolved oxygen contentIncrease dissolved oxygen contentTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandActive matrix

The invention provides an active-matrix-reinforced sub-surface flow constructed wetland device and belongs to the technical field of environmental protection. The device comprises a wetland groove and a water-drop aeration step, wherein an opening which is arranged at the front end of the wetland groove is used as a water inlet, an opening which is arranged at the rear end of the wetland groove is used as a water outlet, and the upper end of the water-drop aeration step is connected with the water outlet of the wetland groove. Different pollutant purification functional regions are arranged in the device by segments, and different segments are filled with different active matrixes and equipped with corresponding process conditions so as to comprehensively and greatly improve the efficiency of treating pollutants in slightly-polluted water.

Owner:SHANGHAI JIAO TONG UNIV

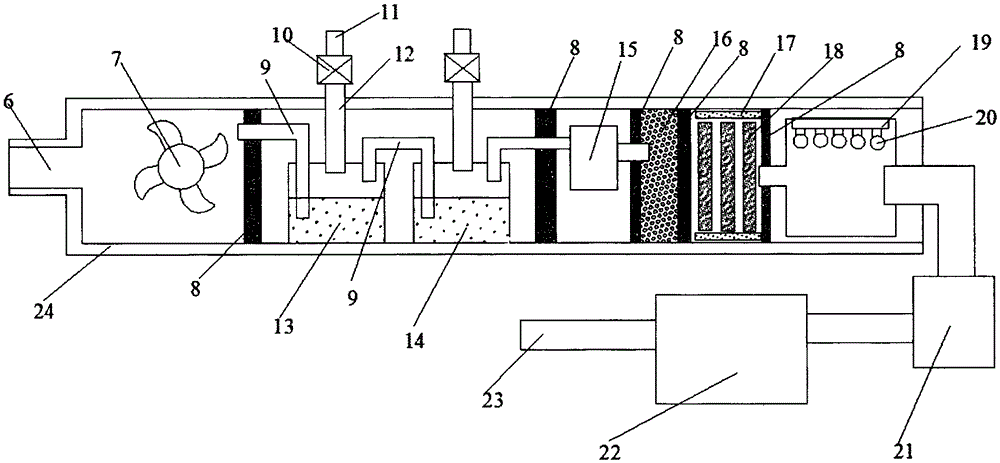

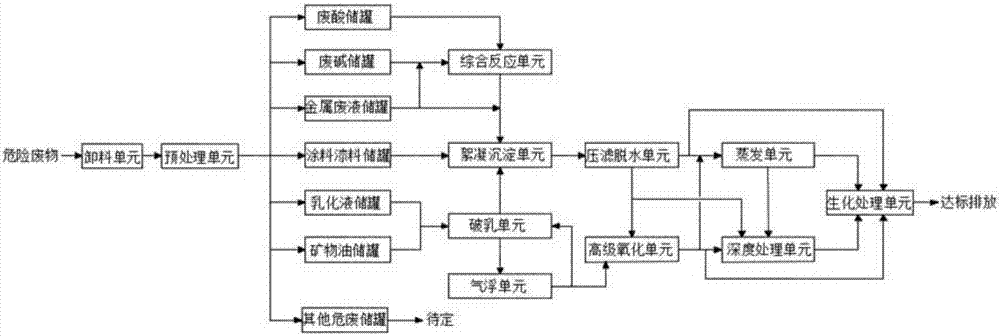

Physicochemical treatment system and physicochemical treatment method for hazardous wastes

PendingCN107572718AImprove adaptabilityReduce processing costsSludge treatment by de-watering/drying/thickeningWater contaminantsTreatment systemTreatment unit

The invention relates to the technical field of hazardous wastes, in particular to a physicochemical treatment system and a physicochemical treatment method for the hazardous wastes. The physicochemical treatment system for the hazardous wastes comprises a storage unit, a comprehensive reaction unit, a flocculent settling unit, a demulsification unit, an air flotation unit and a pressure filtration dehydration unit. The system also comprises an advanced oxidation unit, a deep treatment unit, an evaporation unit and a biochemical processing unit.

Owner:ENN ENVIROTECH CO LTD

Asymmetric split turbine of turbocharger

ActiveCN101634244AAddressing High Discharge Pressure RequirementsReduce control difficultyNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

The invention discloses an asymmetric split turbine of a turbocharger, comprising an engine. The engine is provided with an exhaust tube of the engine, a turbine casing and a turbine rotor, wherein, the turbine casing is provided with a casing high pressure flow channel and a casing low pressure flow channel, the exhaust tube of the engine is provided with a high pressure exhaust manifold and a low pressure exhaust manifold, the high pressure exhaust manifold is connected with the casing high pressure flow channel, the low pressure exhaust manifold is connected with the casing low pressure flow channel, and the A / R value of the casing high pressure flow channel is less than that of the casing low pressure flow channel. By adopting the asymmetric split structure, the two flow channels of the turbine casing have different A / R values and are respectively connected with different exhaust pipelines of the engine, thus effectively lowering the exhaust back pressure of part of engine cylinders and reducing the influence of EGR operation process on the pressurizing unit. The asymmetric split turbine has good succession, simple structure, easy upgrade and switch of products, low cost and easy and fast realization of engineering.

Owner:康跃科技(山东)有限公司

Method for monitoring distribution of pulverized coal in low-NOx tangential coal-fired boiler

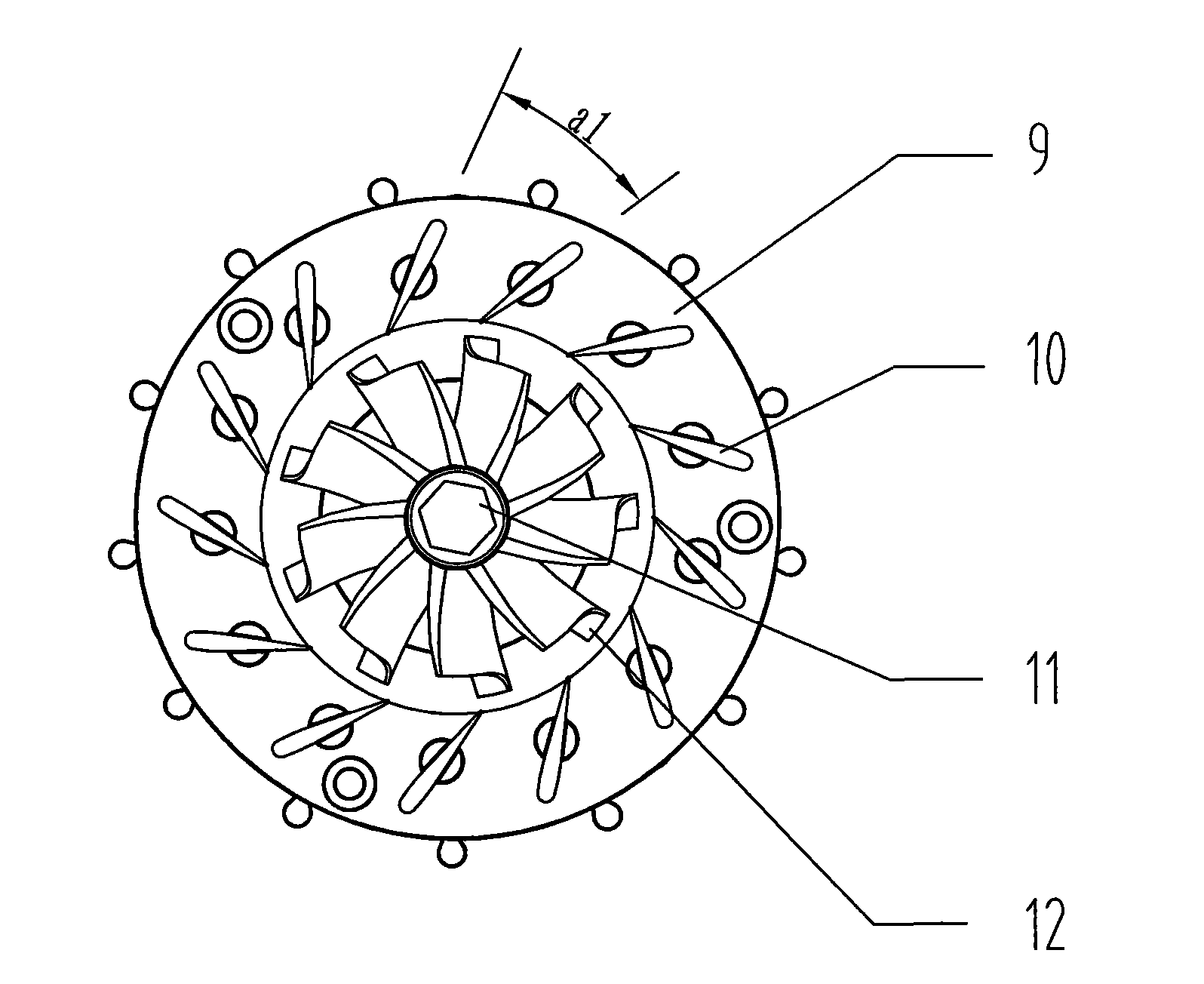

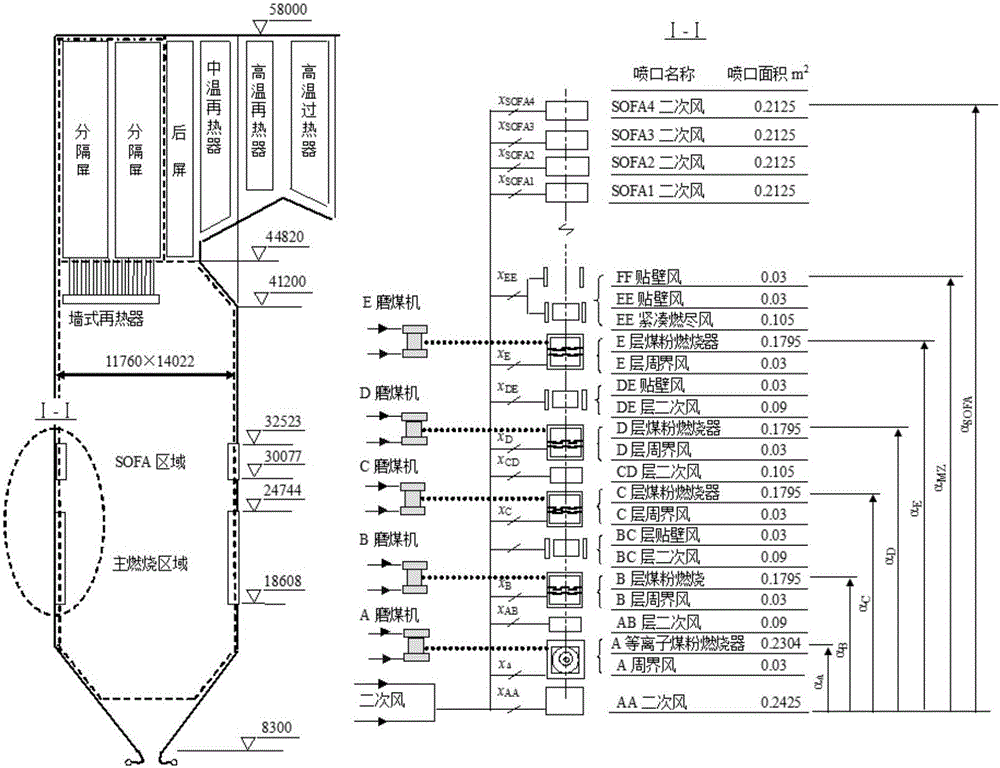

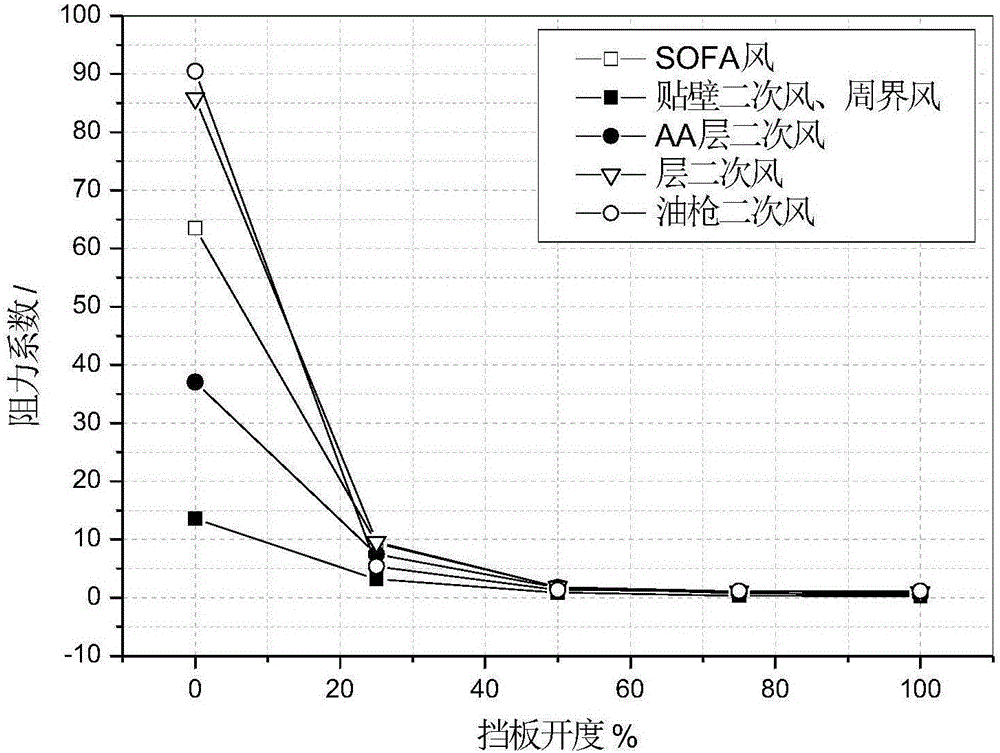

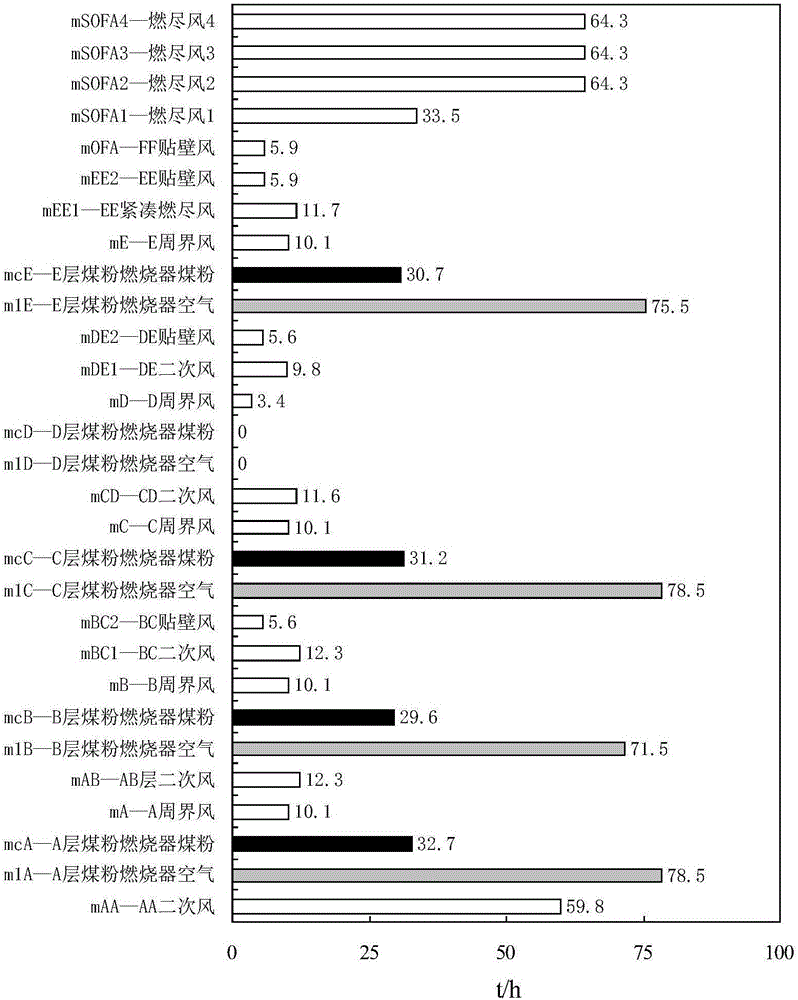

ActiveCN105783025AMeet emission requirementsPurpose of Proper Air ClassificationFuel supply regulationCombustionEngineering

The invention discloses a method for monitoring distribution of pulverized coal in a low-NOx tangential coal-fired boiler. The method includes the steps that under the cold state condition that the boiler is not ignited, a resistance characteristic test is conducted on secondary air baffles, and the resistance characteristic of the baffles and the resistance characteristic of a hearth are obtained; the air speed, generated during heat-state operation of the boiler, of secondary air nozzles is computed according to the resistance characteristics; and the excess air coefficients of different combustion segments in the boiler are computed, and the distribution state of pulverized coal in the boiler is obtained. The method has the beneficial effects that the information of the excess air coefficients of all the combustion segments in the boiler can be provided for operators, so that the operators can confirm the air classification intensity of the main combustion region, and the method is especially suitable for the low-NOx tangential coal-field boiler adopting a direct-blowing type pulverizing system.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com