Treatment method for paint spraying waste gas

A technology for waste gas and paint spraying room, which is applied to the spraying waste gas generated in the painting process of the spraying room, and the control field of spraying waste gas, which can solve the problems such as the failure to effectively control the spraying waste gas, the low concentration of organic substances, and the large air volume of the spraying waste gas. To achieve the effect of reducing operating costs, stable purification efficiency, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

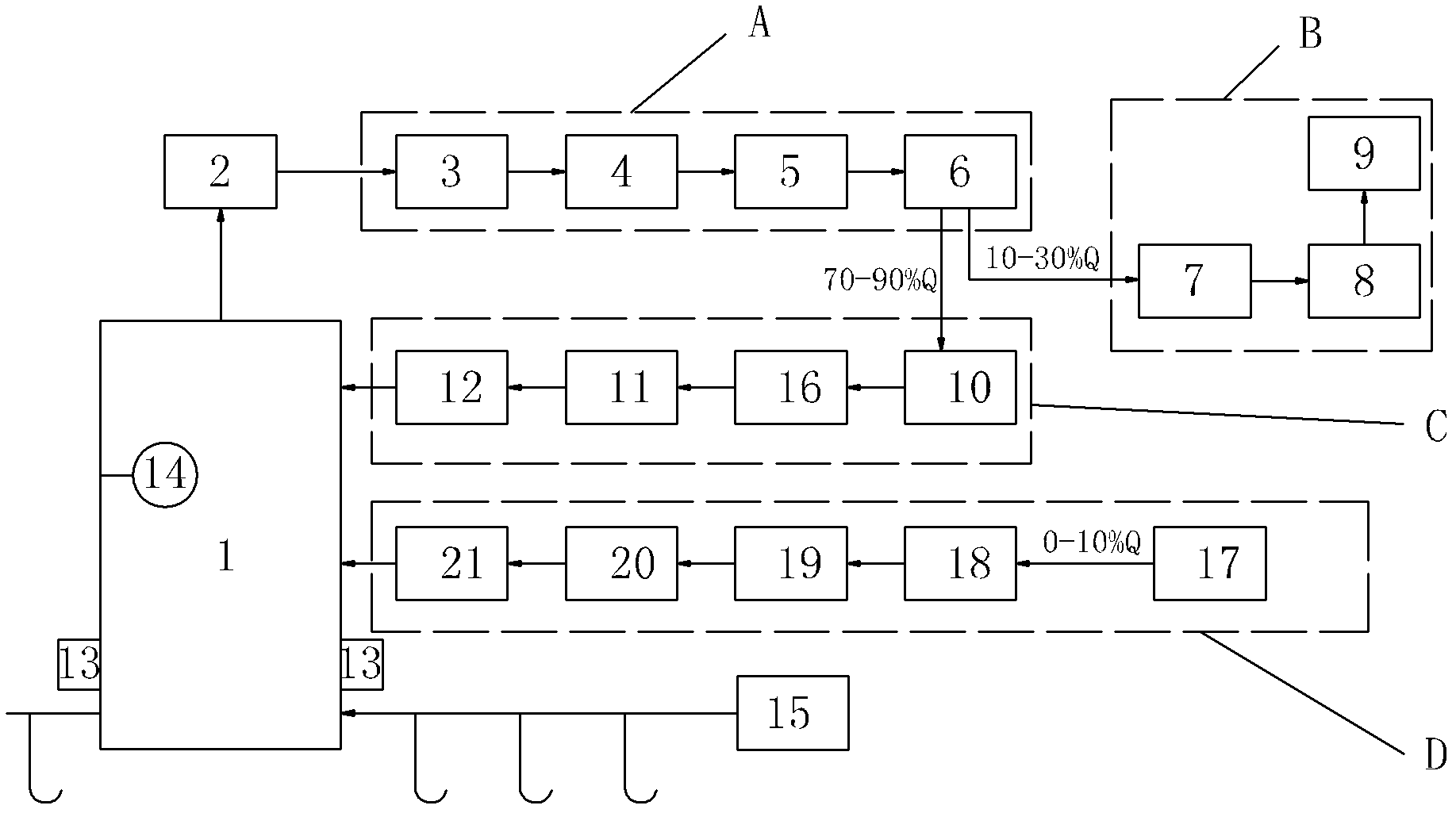

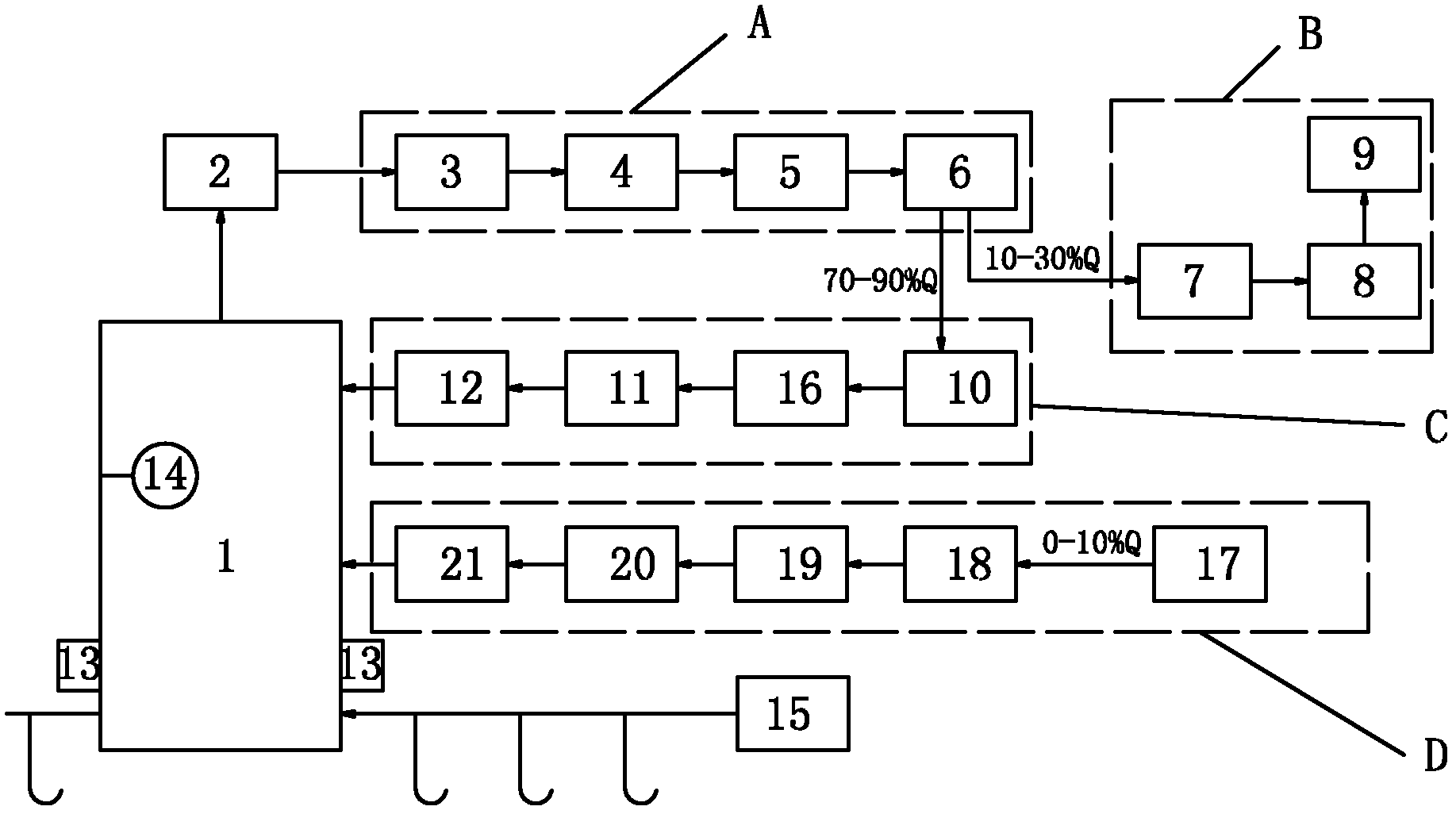

[0072] The structure and method of this scheme are basically the same as those of Scheme 1, the difference lies in:

[0073] One is that in the circulation unit C, an air-conditioning unit can be added to adjust the temperature and humidity according to the requirements of the painting room temperature and humidity;

[0074] The second is to increase the special fresh air supply unit C: draw part of the fresh air 17 from the external environment, the air volume is about 0-10% of the total exhaust air volume Q of the spray booth 1, and pass through the primary filter 18 and the intermediate filter 19 to achieve high efficiency. After the filter 20 is filtered, it is sent into the spray booth 1 by the fan 21 (fresh air 17 of the fresh air unit C-primary filter 18-medium efficiency filter 19-high efficiency filter 20-fan 21-connection channel of the spray booth 1 They are all connected in series by pipelines), and this part of the gas needs to be supplemented in the worker's oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com