Annular combustion chamber based on Venturi pre-mixing bispin nozzle

An annular combustion chamber and Venturi technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of large emissions, high CO and UHC emissions, and low equivalence ratio in the combustion area, reducing emissions, enhancing The effect of mixing oil and gas and reducing the generation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

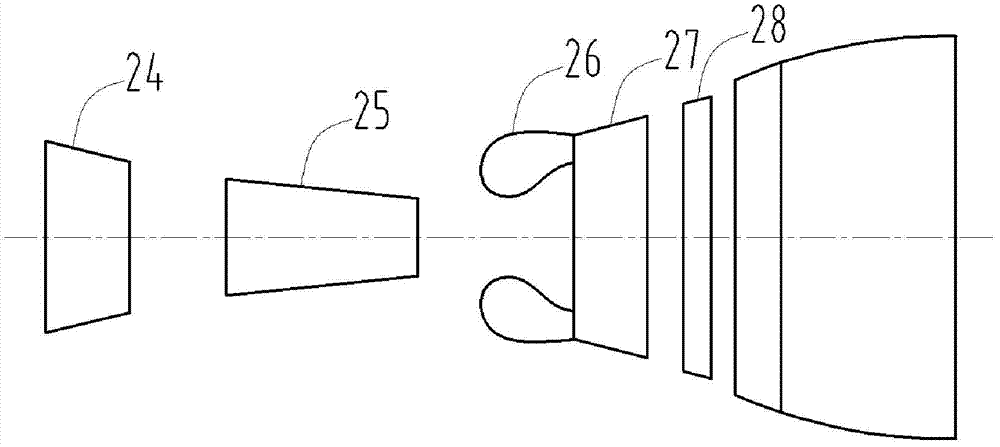

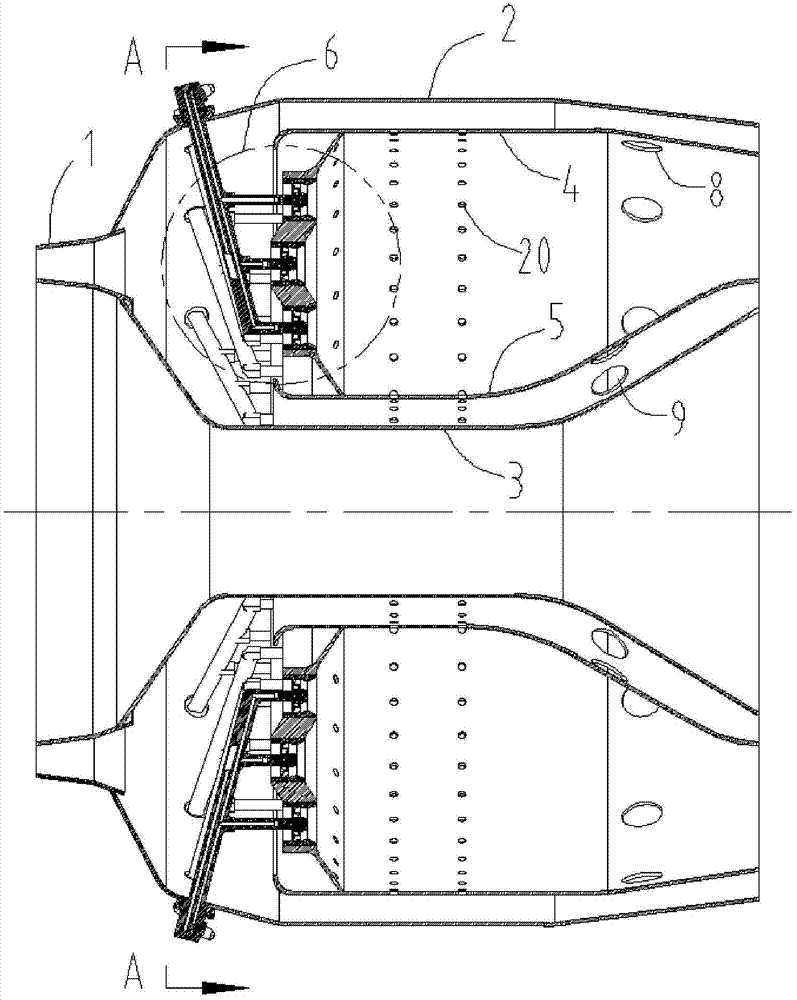

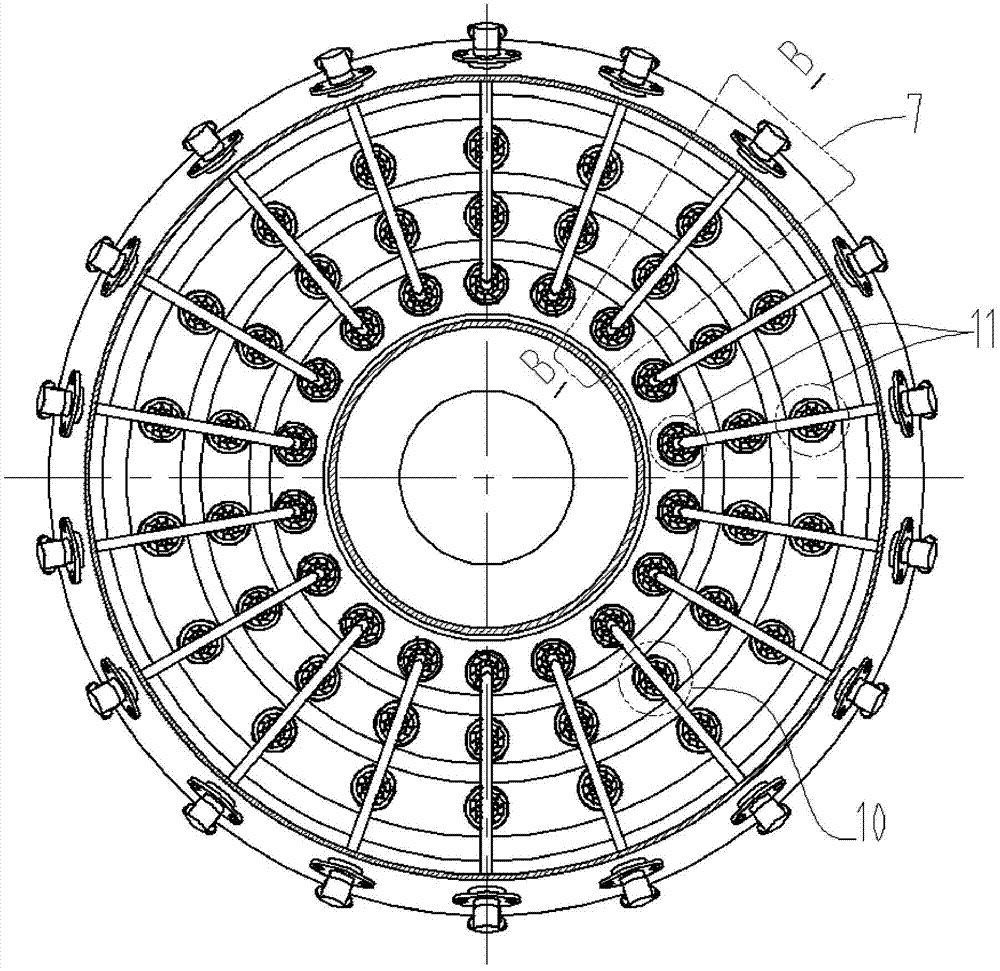

[0035] The present invention provides an annular combustion chamber based on a Venturi premixed double-rotation nozzle which can solve the shortcomings of the known technology. The main combustion stage nozzle on the combustion chamber adopts a multi-nozzle arrangement along the radial direction of the combustion chamber, which is beneficial to fuel oil. The air is evenly distributed on the cross section of the combustion zone to accelerate the mixing of oil and gas in the combustion zone, thereby effectively reducing the emission of pollutants in the combustion chamber; at the same time, the main combustion stage nozzle adopts a two-stage swirl structure based on Venturi premixing. It has the function of auxiliary atomizing liquid mist and enhancing the mixing of oil and gas, which is beneficial to reduce the generation of pollutants; in addition, the combustion chamber adopts the fuel grade control method to control the main fuel stage nozzle and the pre-combustion stage nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com