Patents

Literature

418 results about "Pre combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

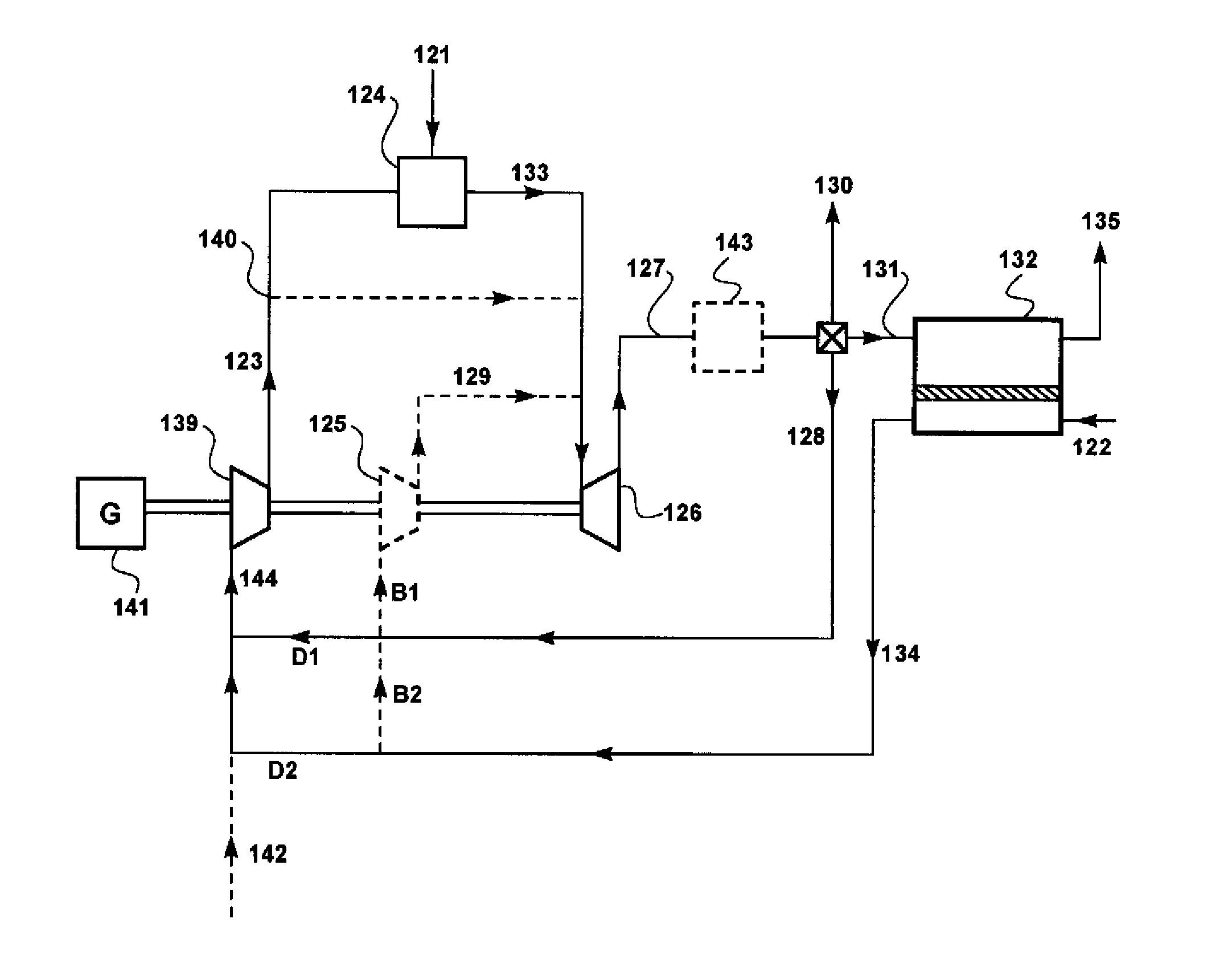

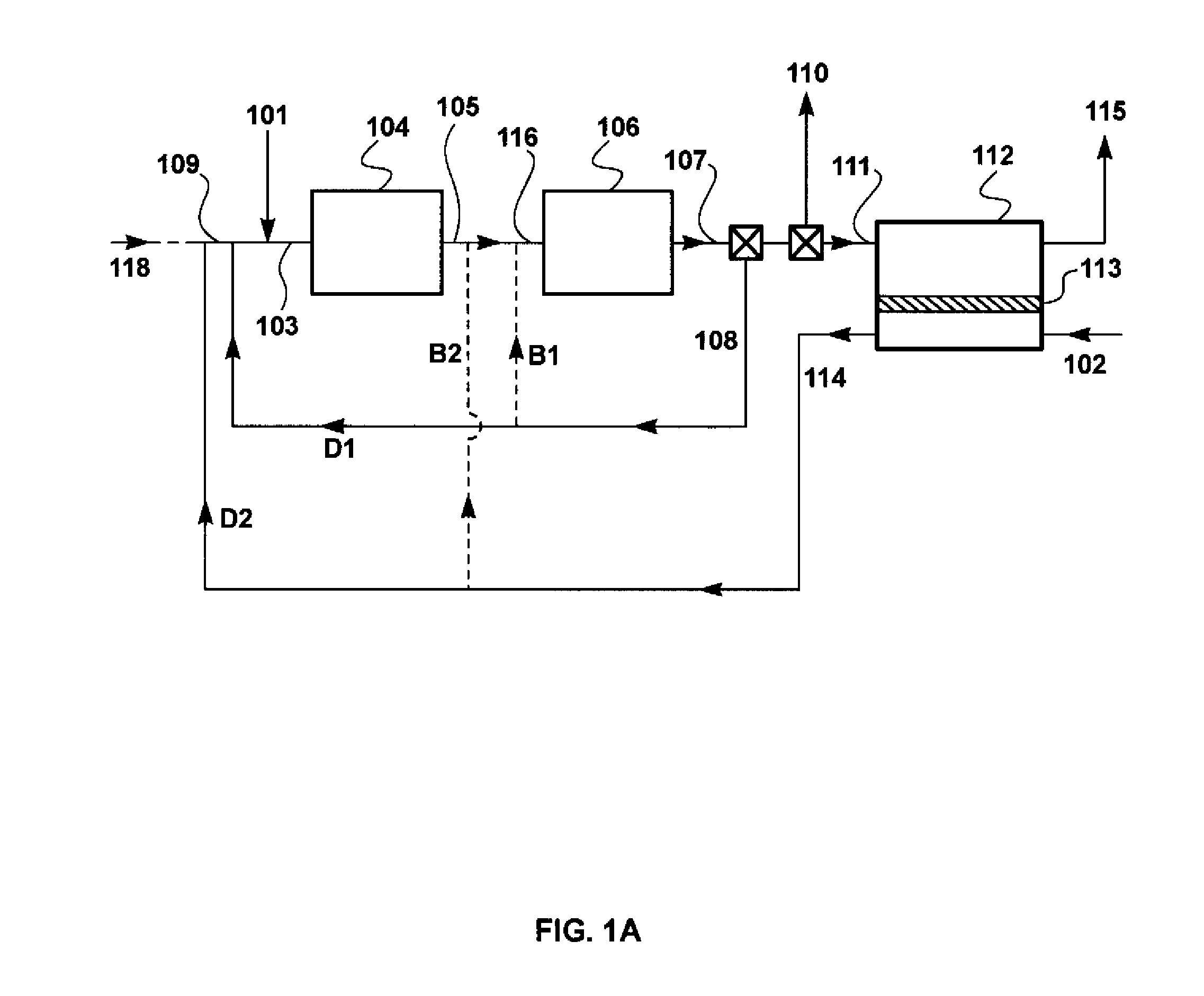

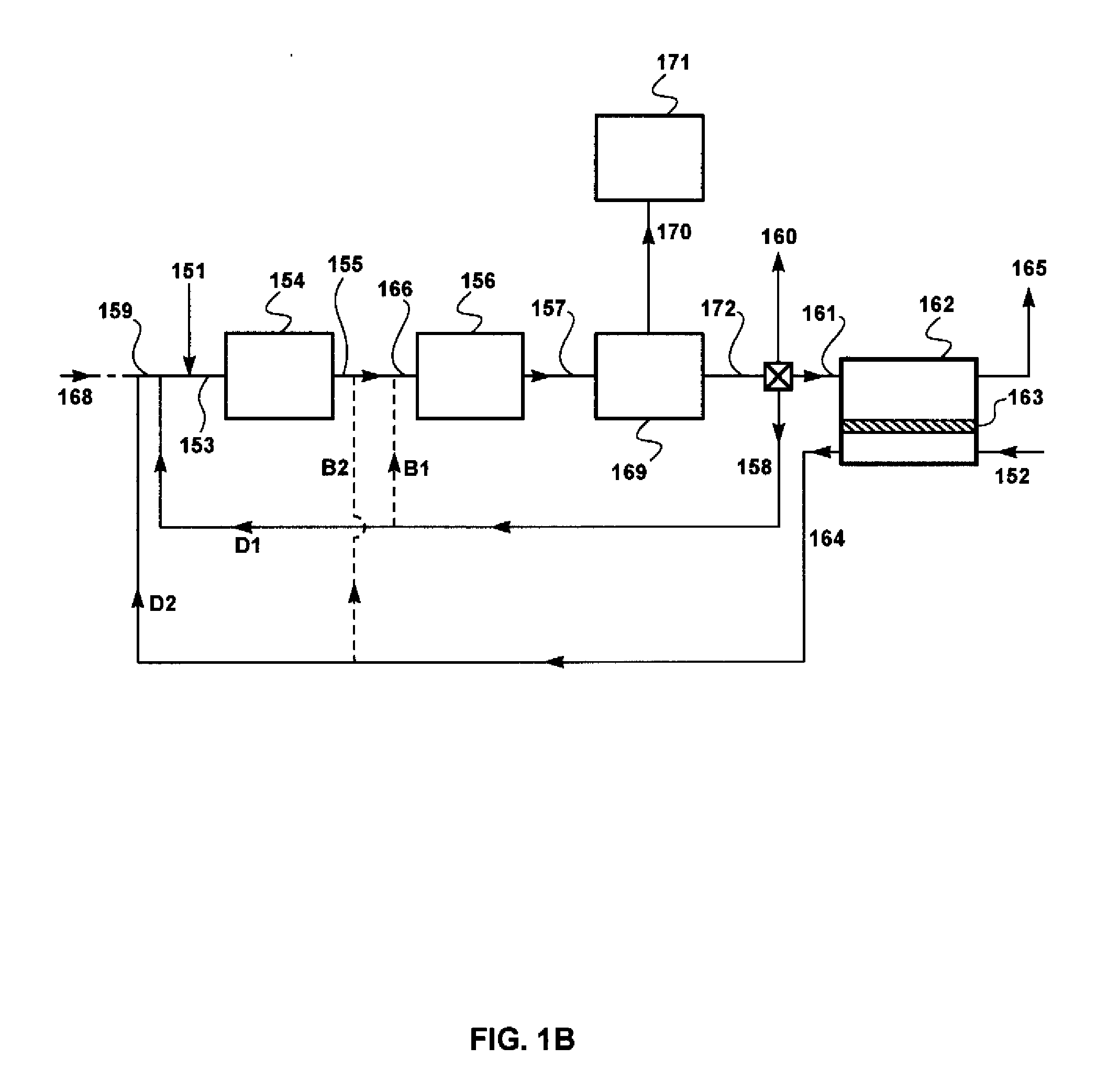

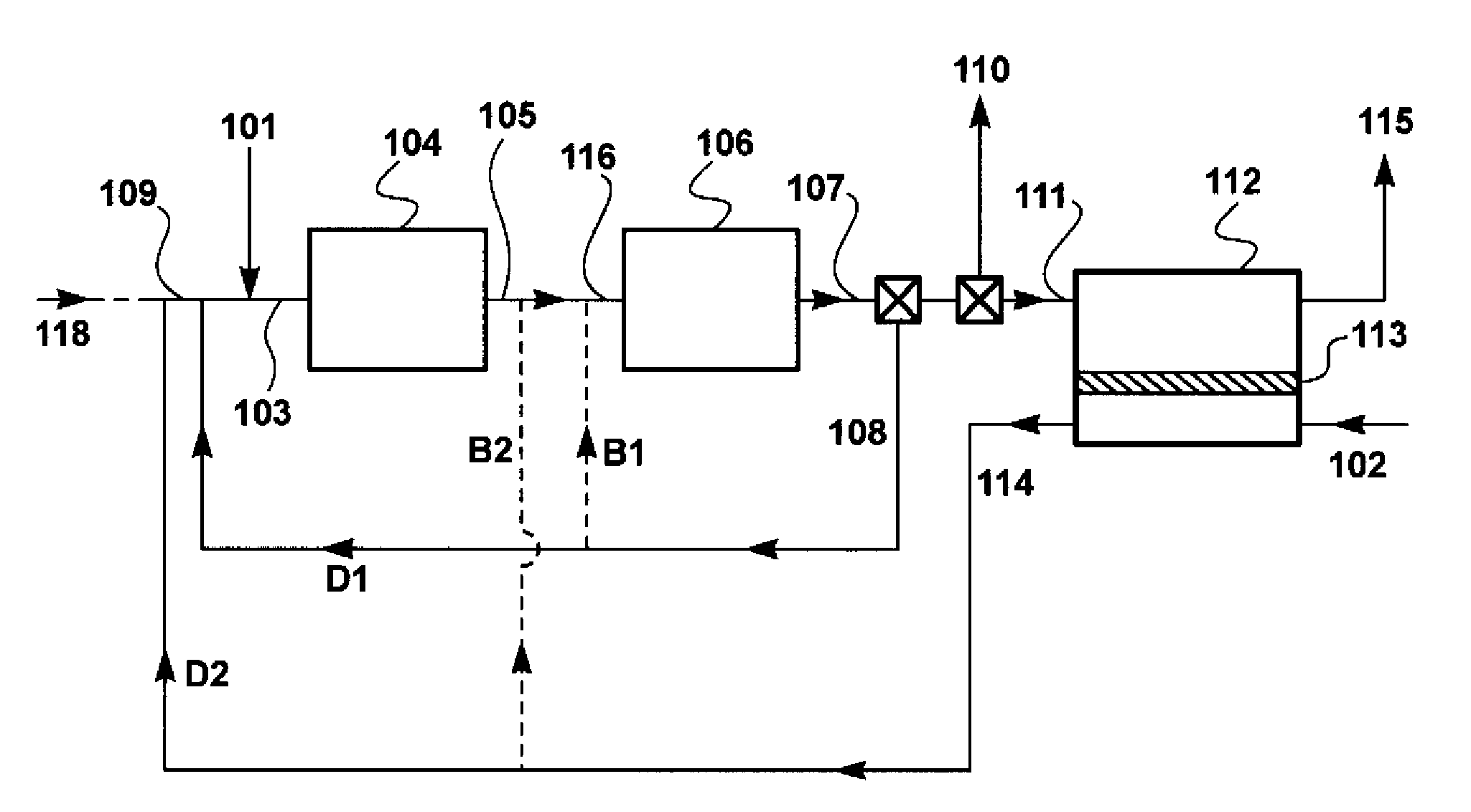

Power generation process with partial recycle of carbon dioxide

ActiveUS8220248B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationElectricityGeneration process

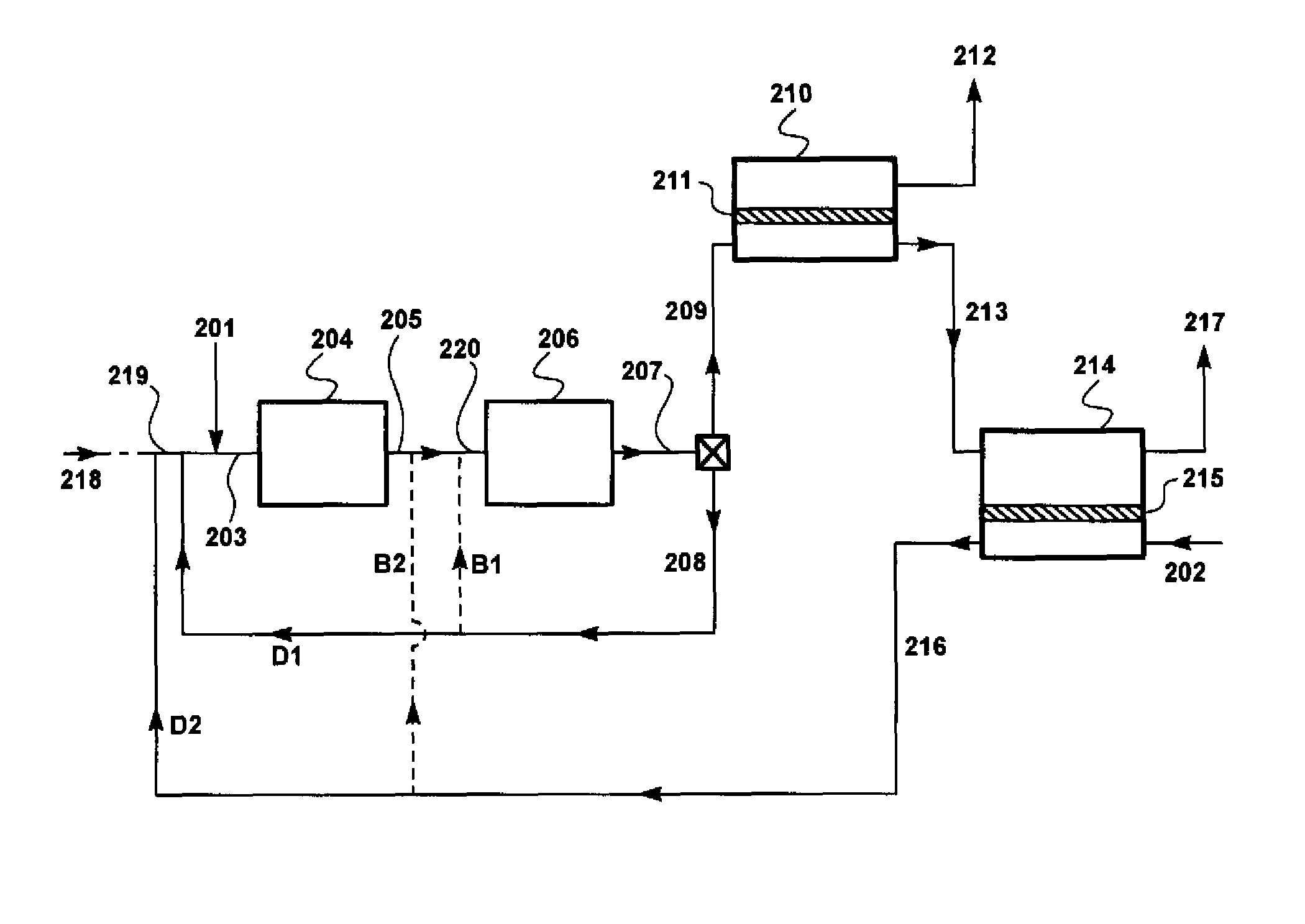

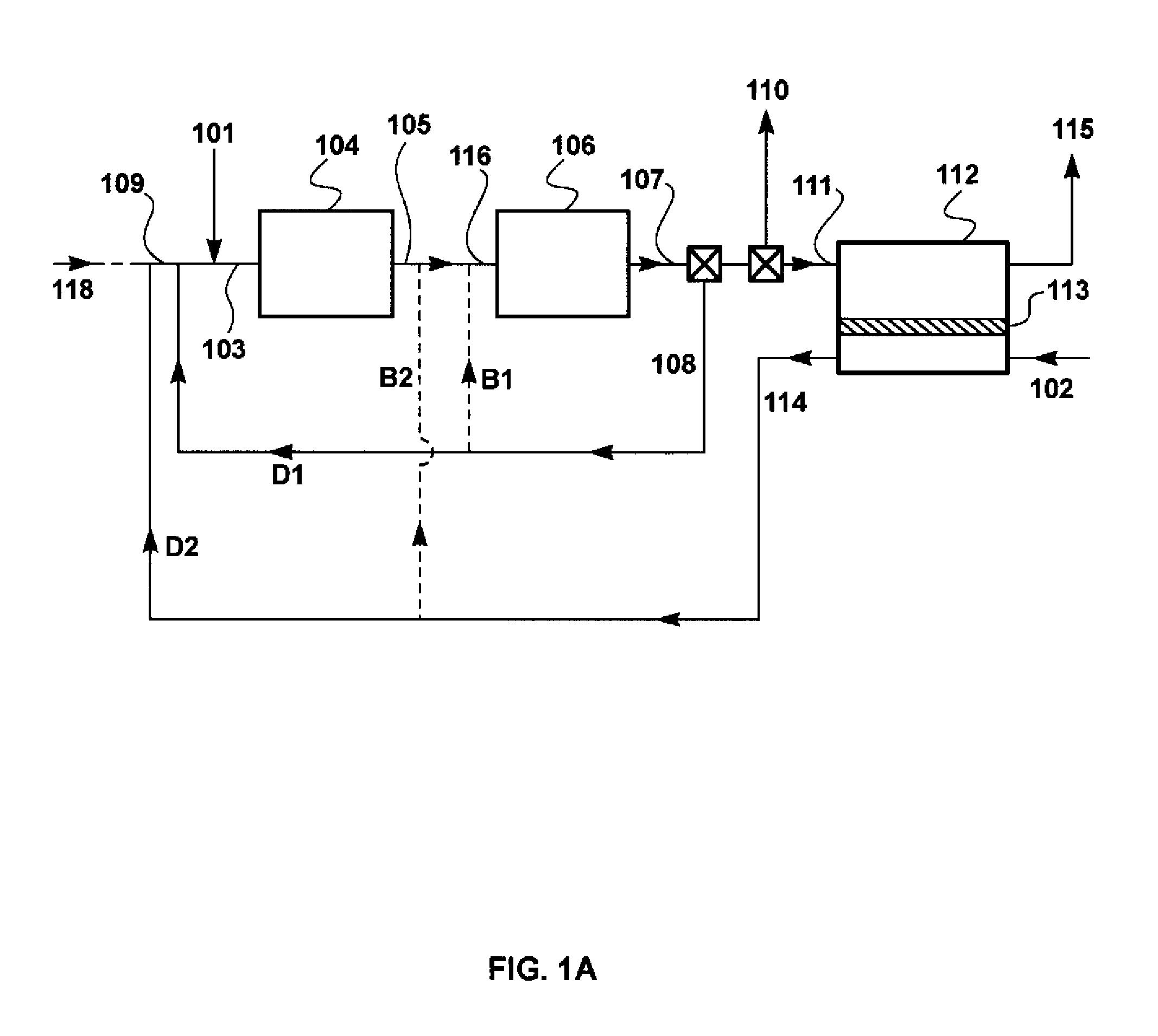

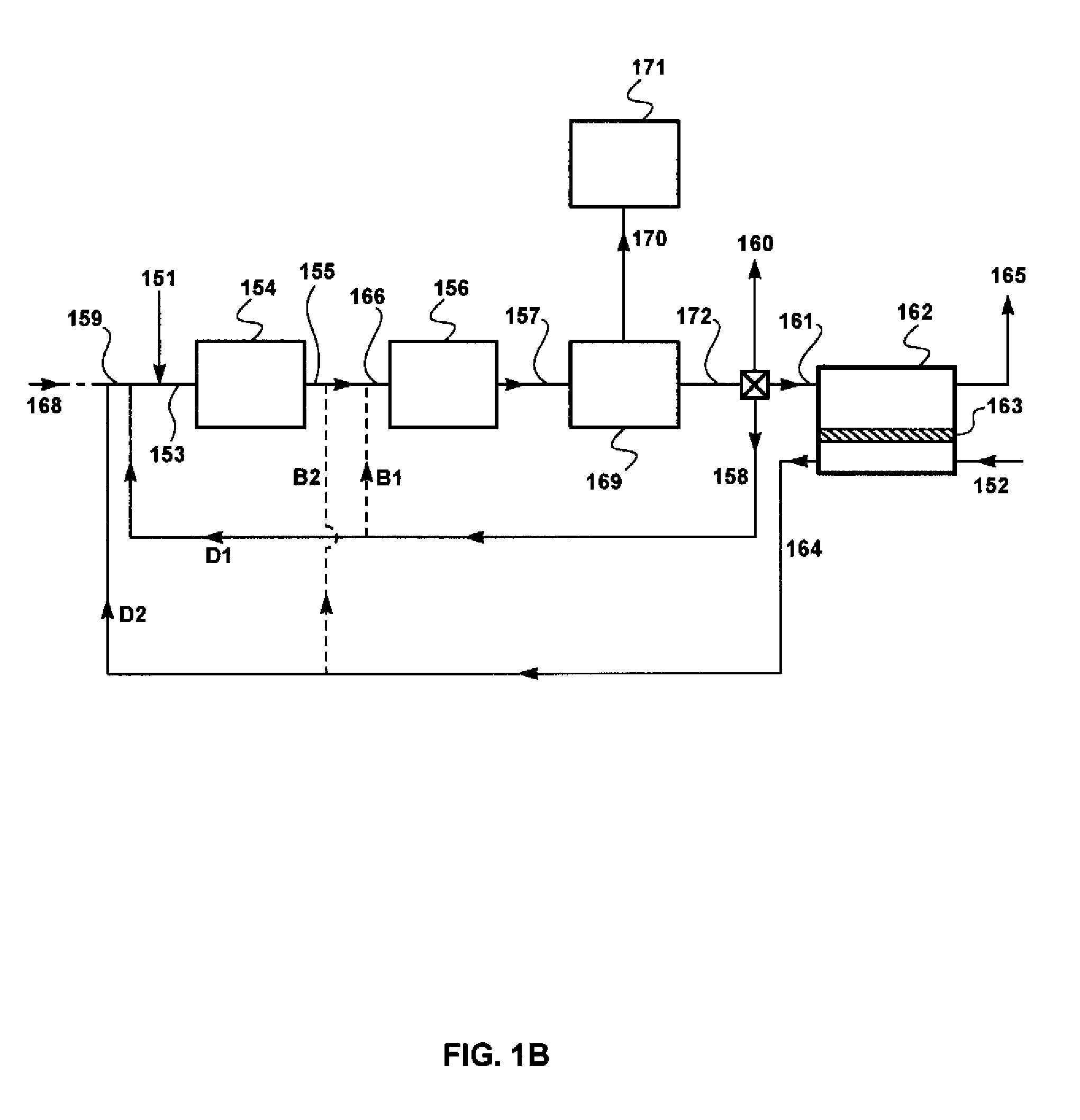

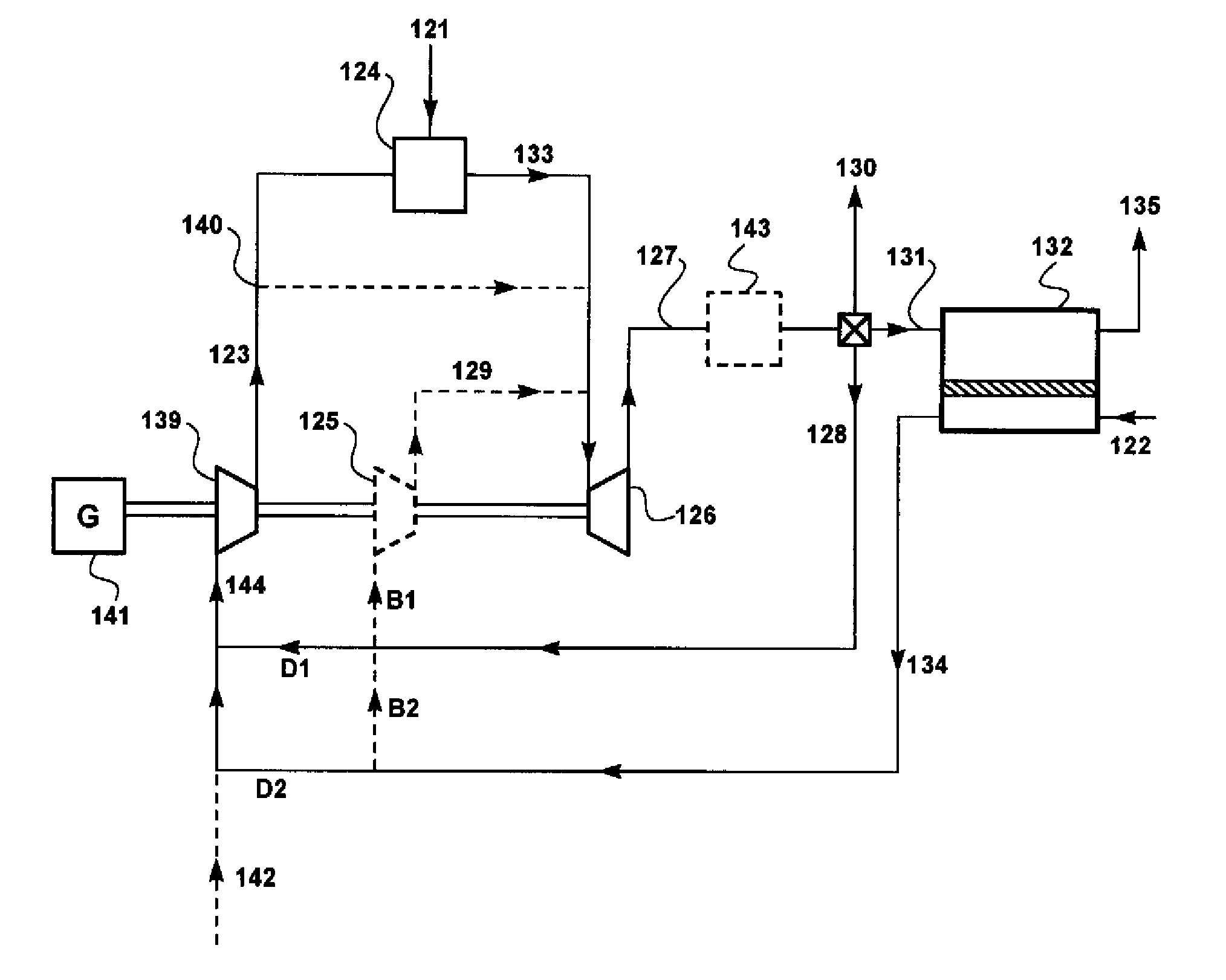

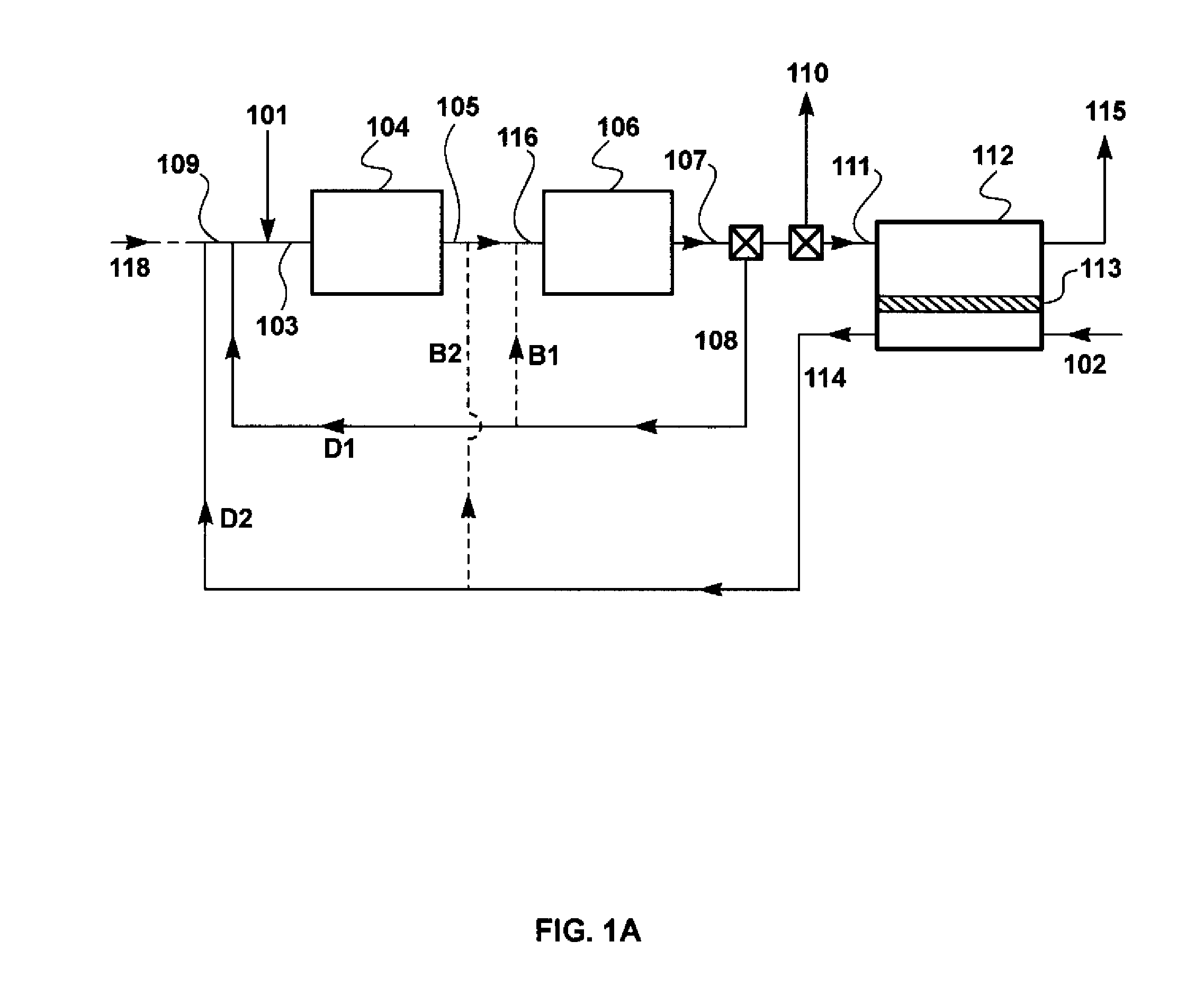

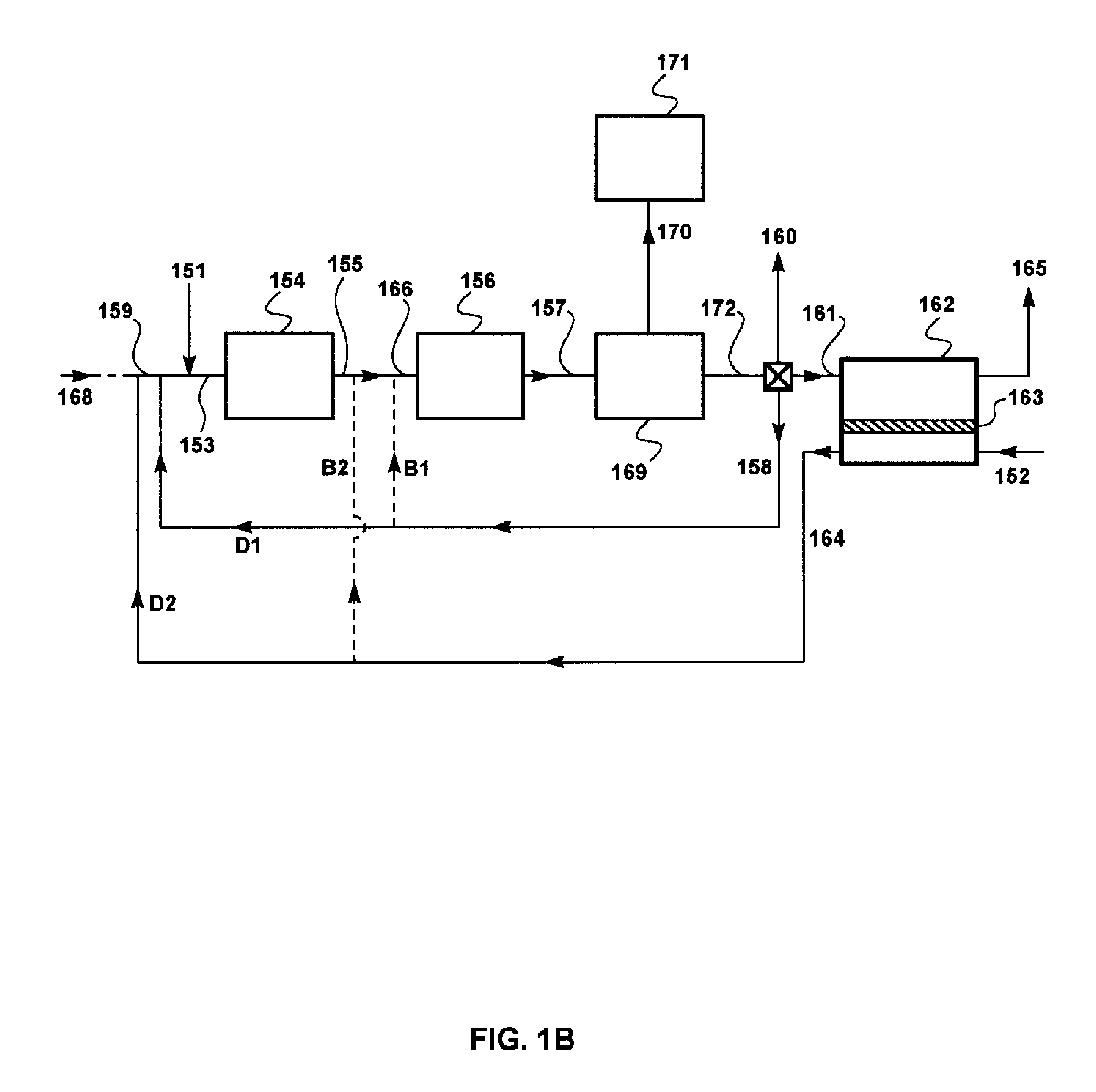

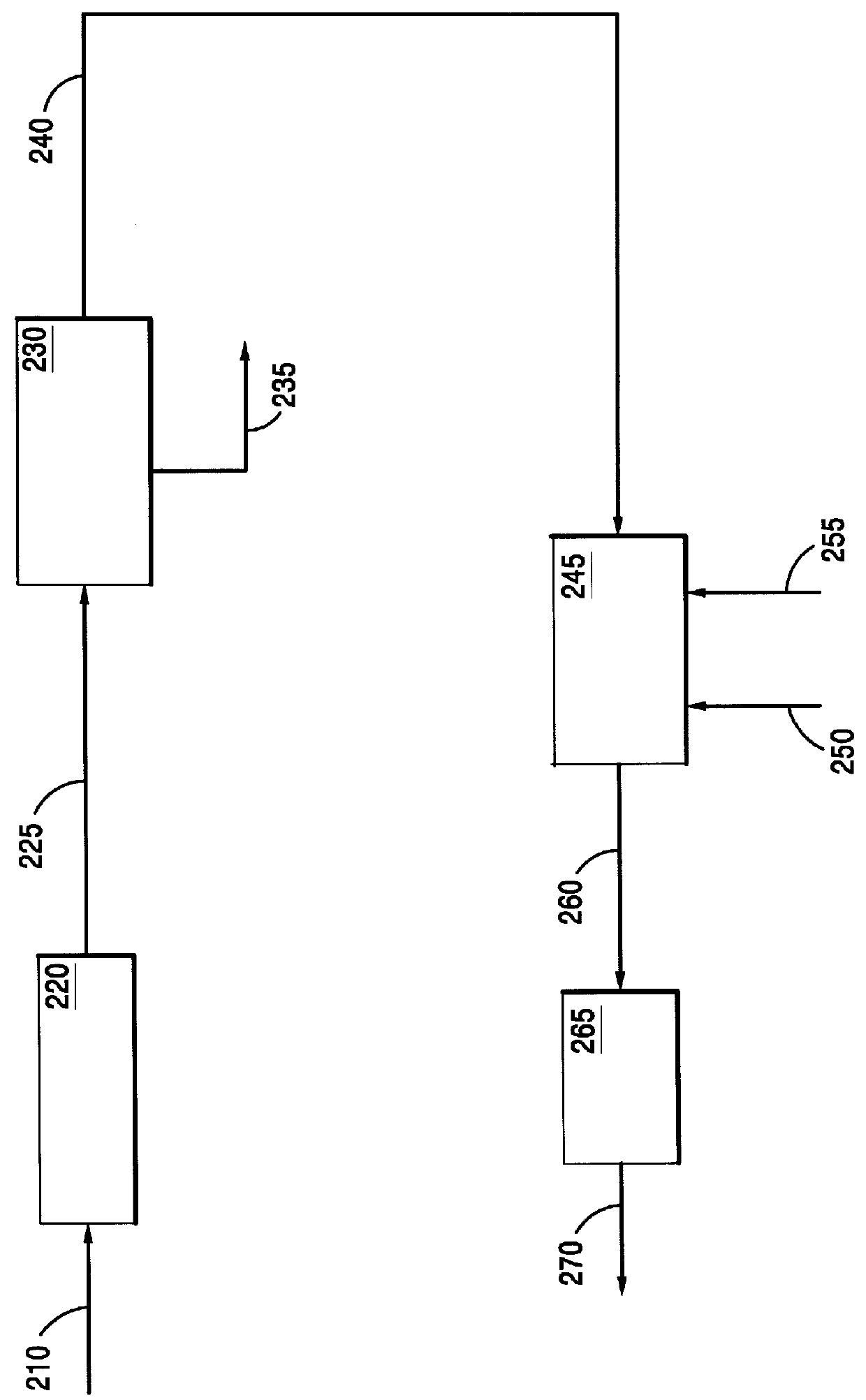

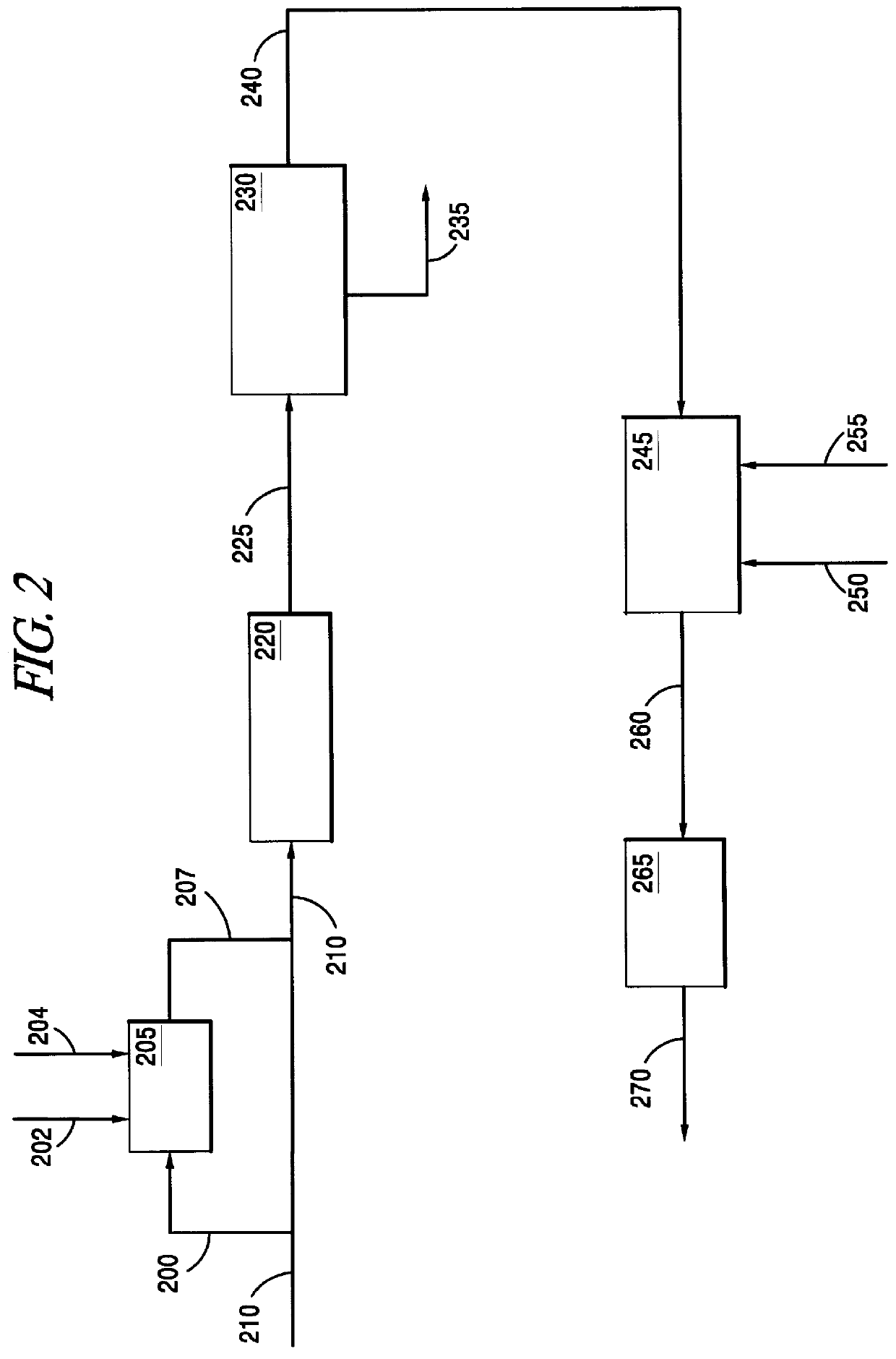

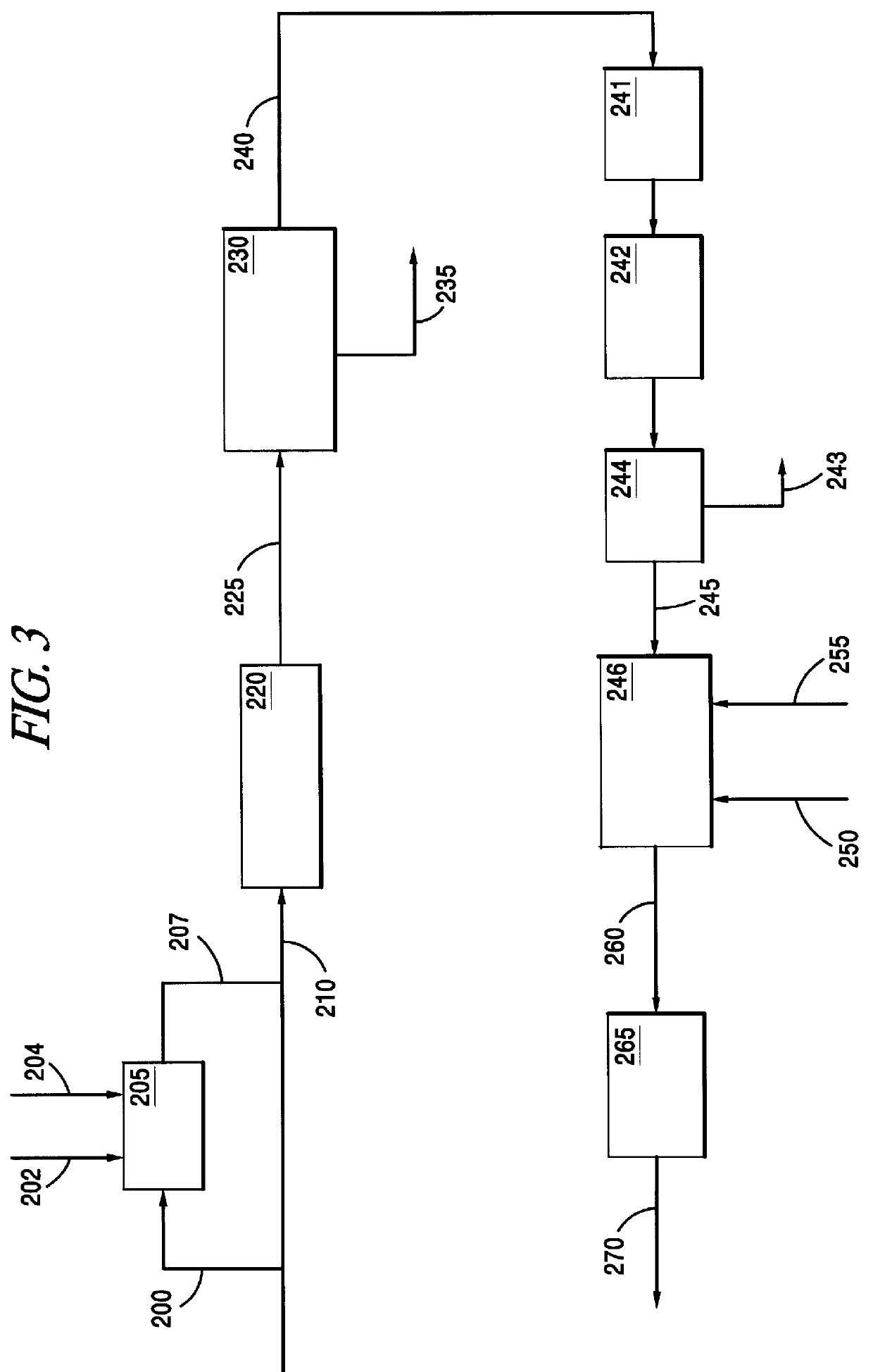

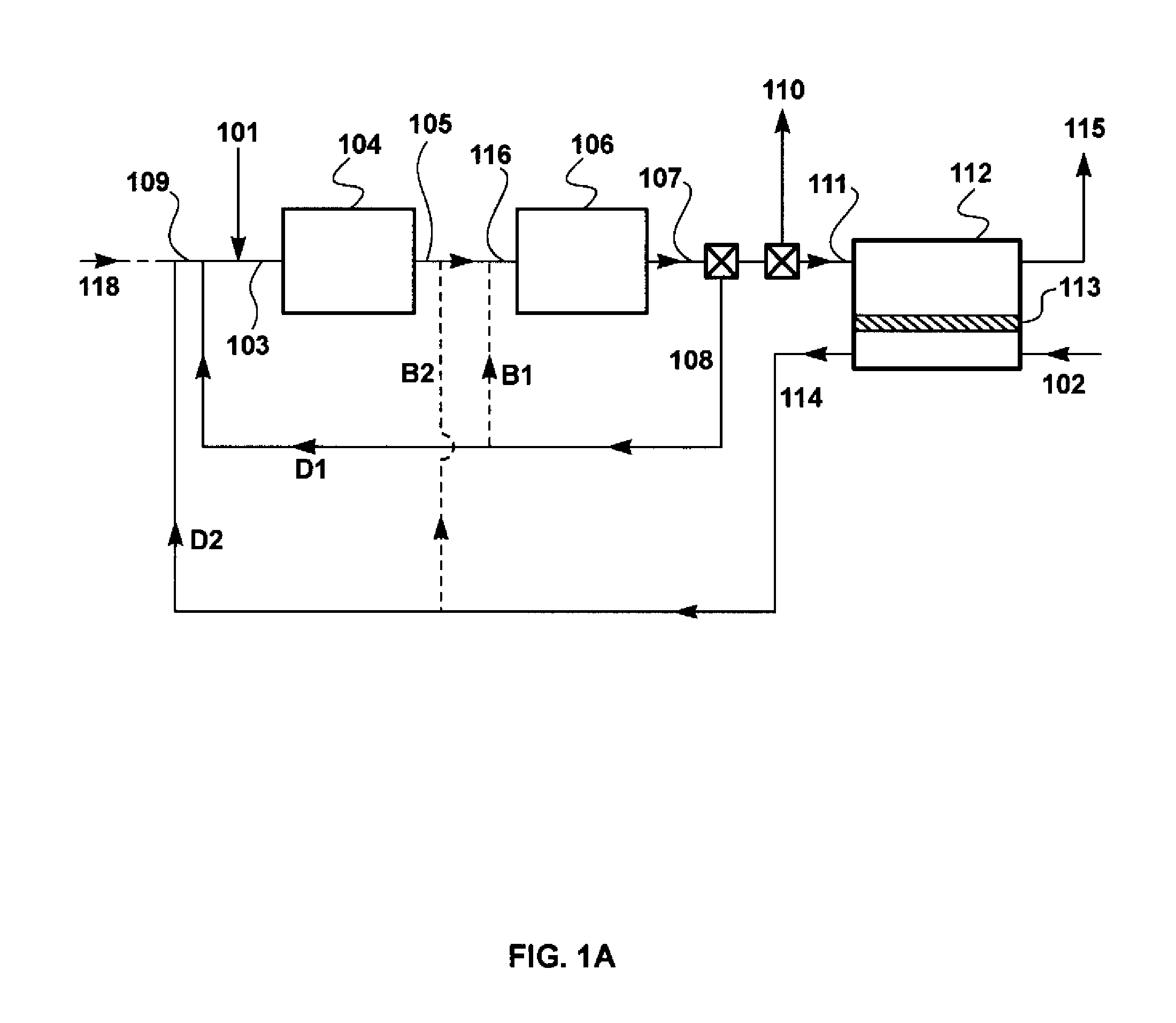

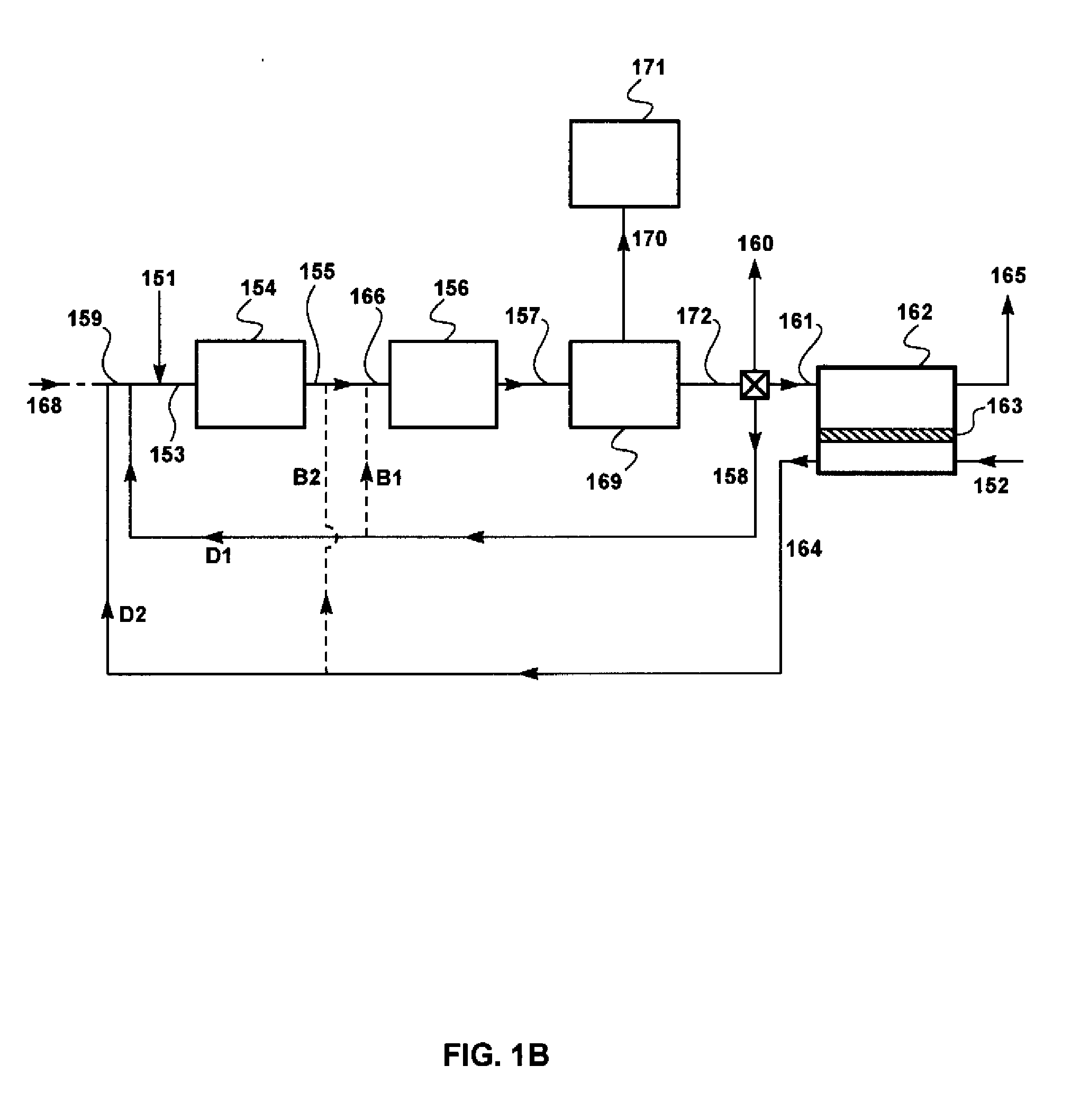

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

Power generation process with partial recycle of carbon dioxide

ActiveUS8220247B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

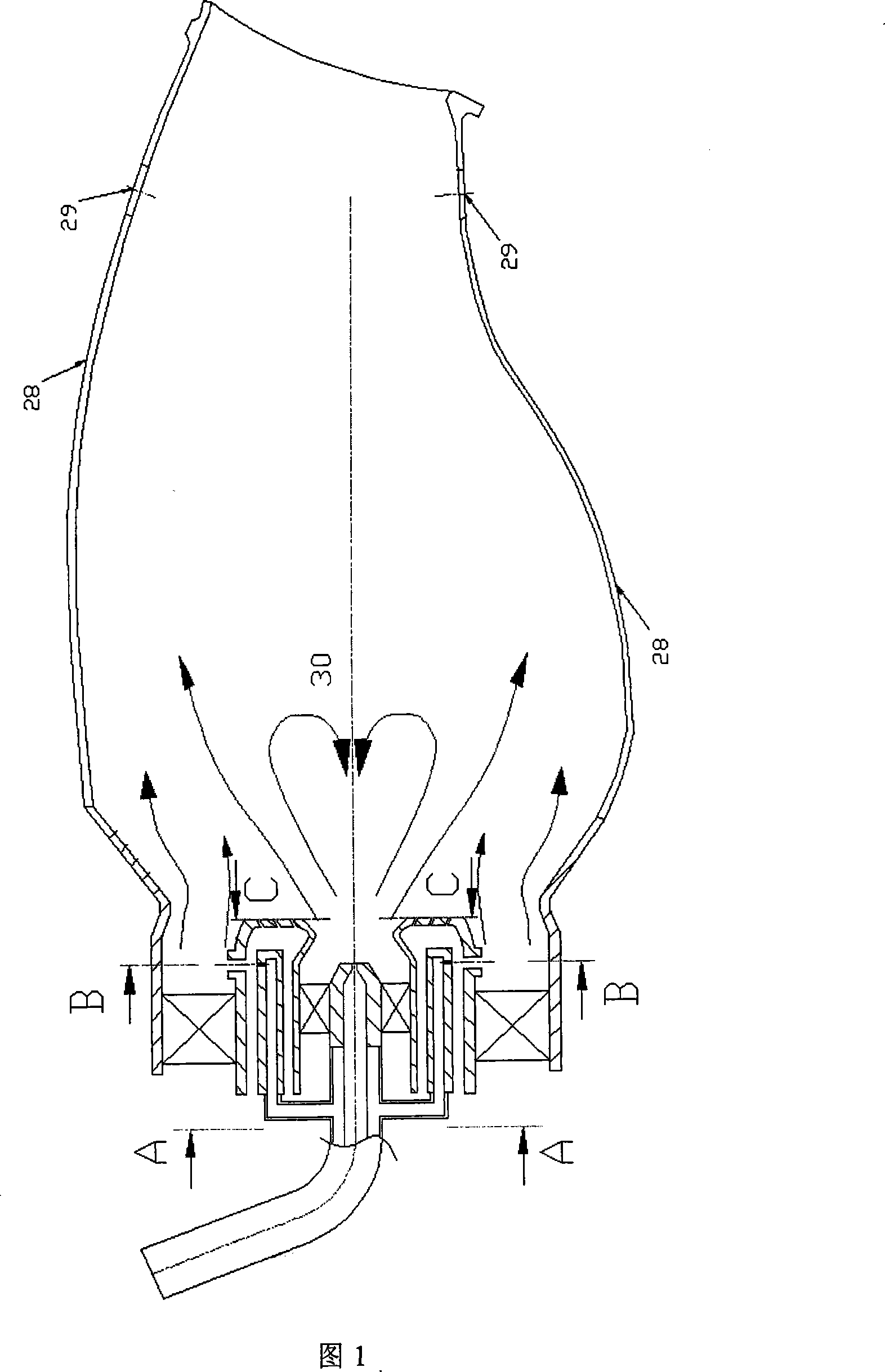

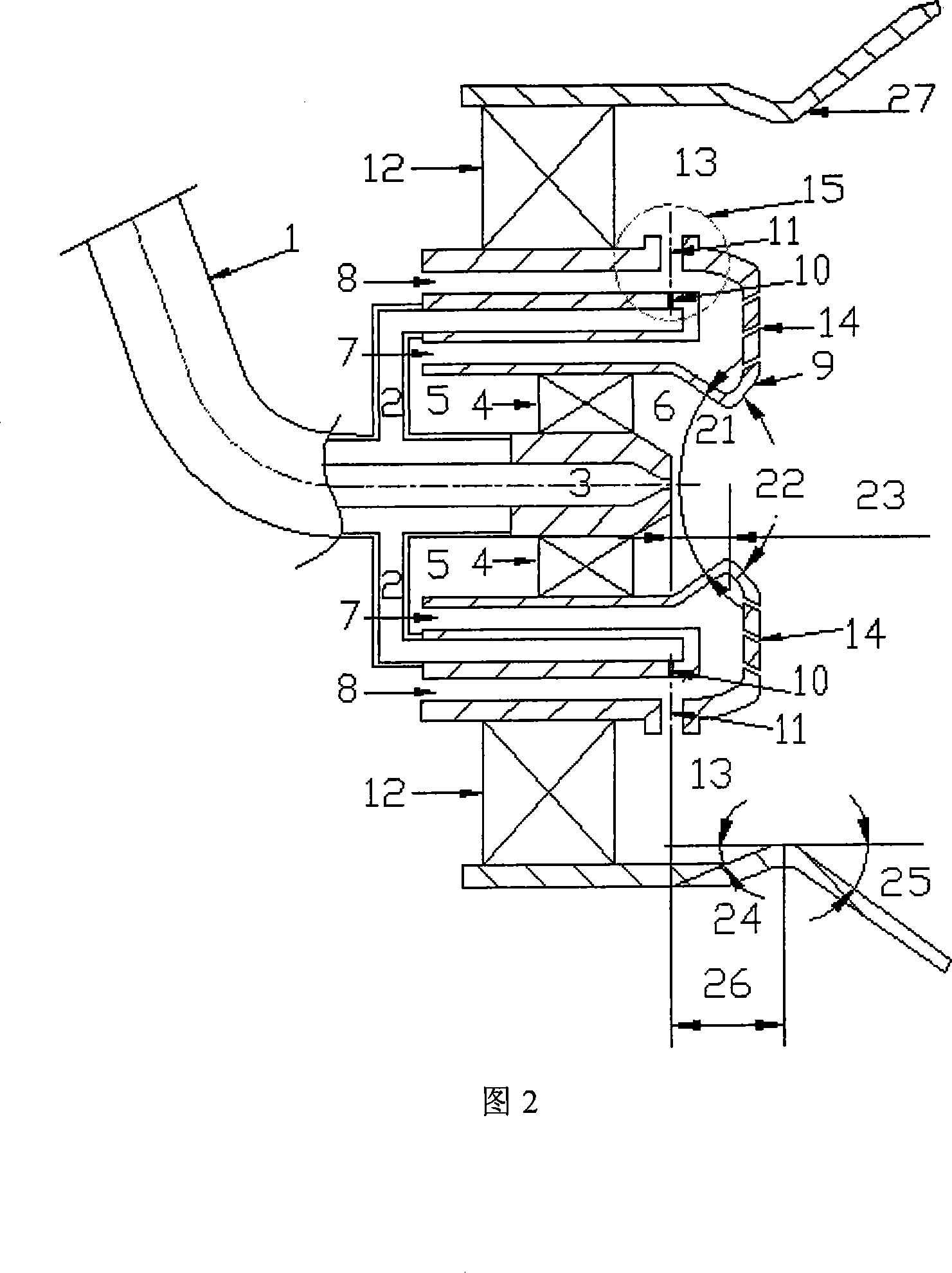

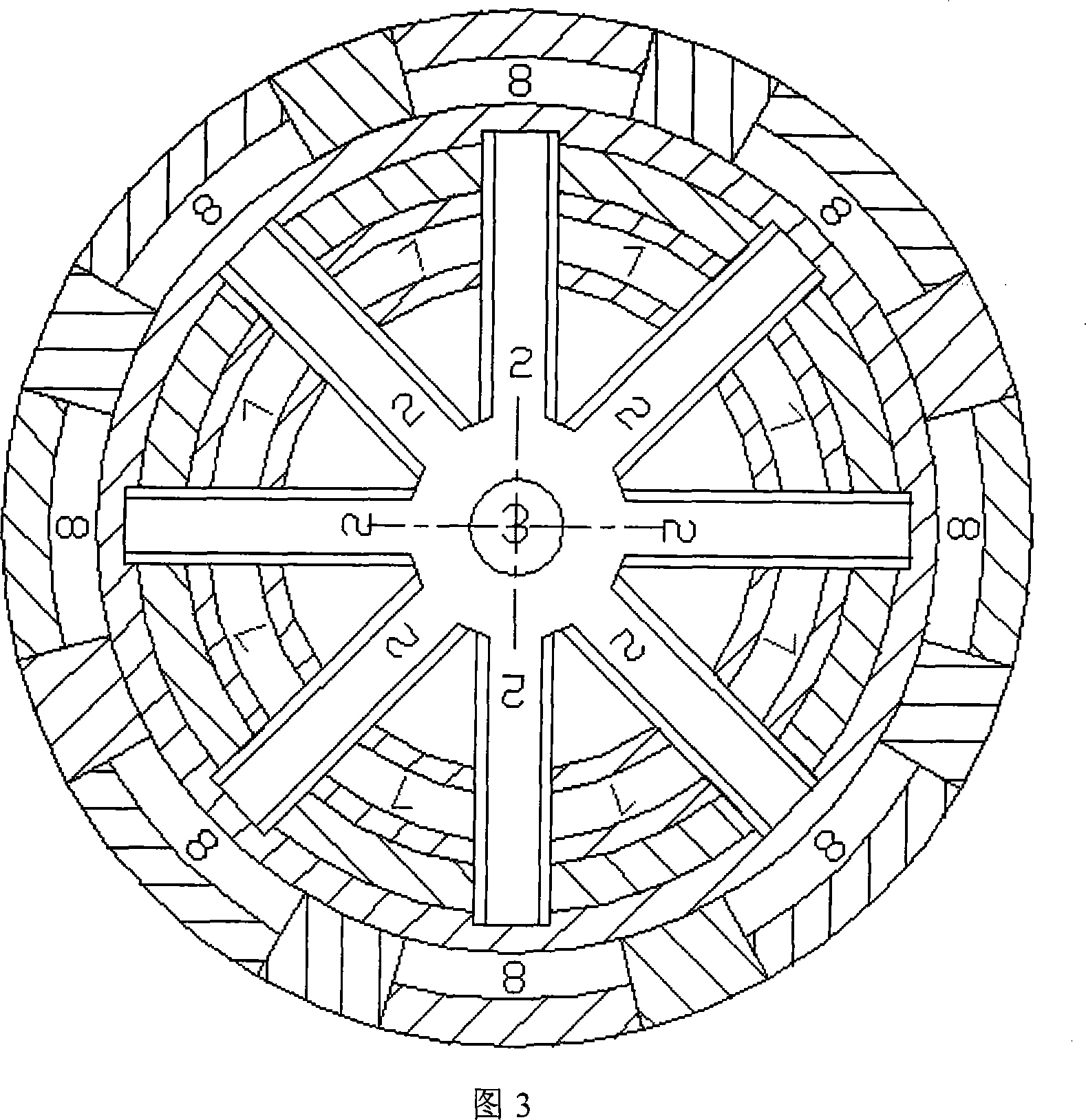

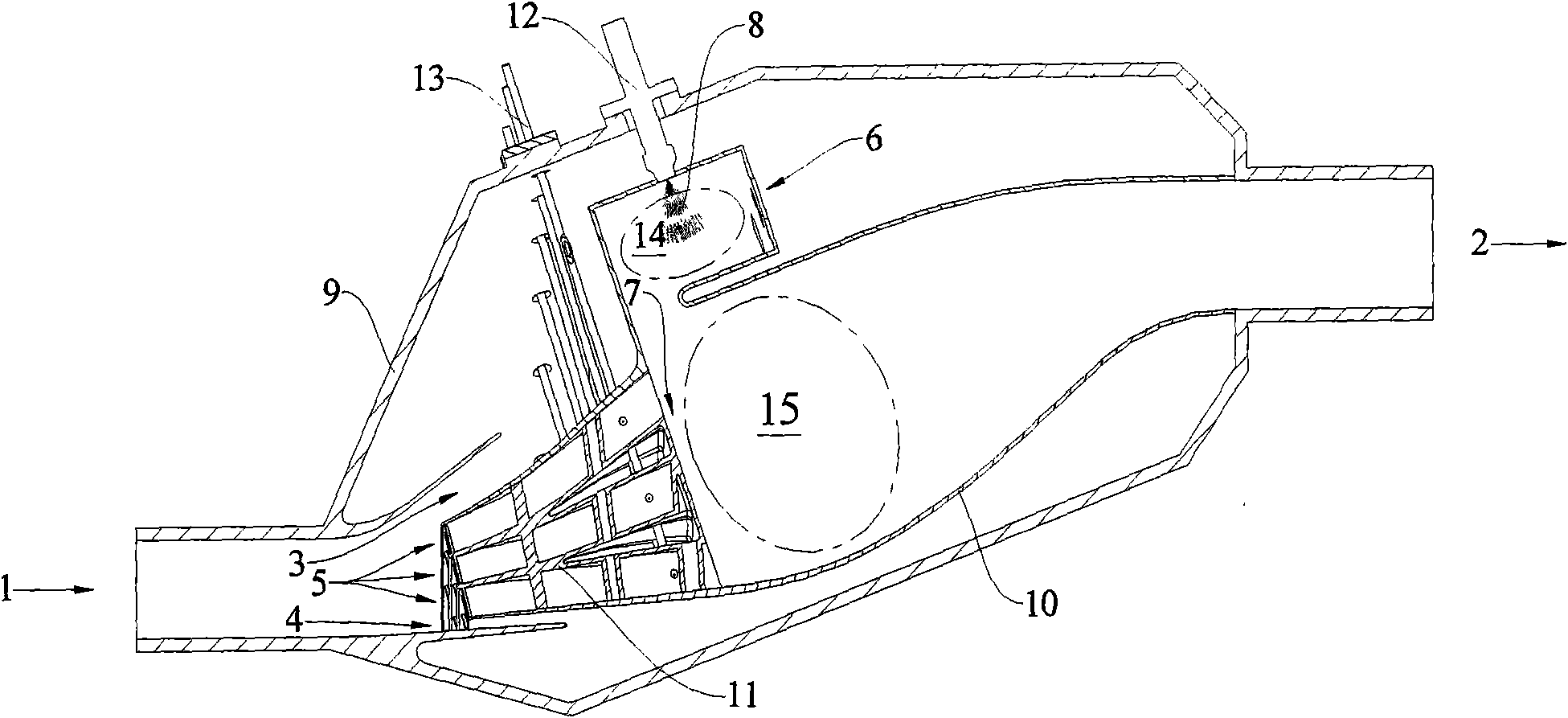

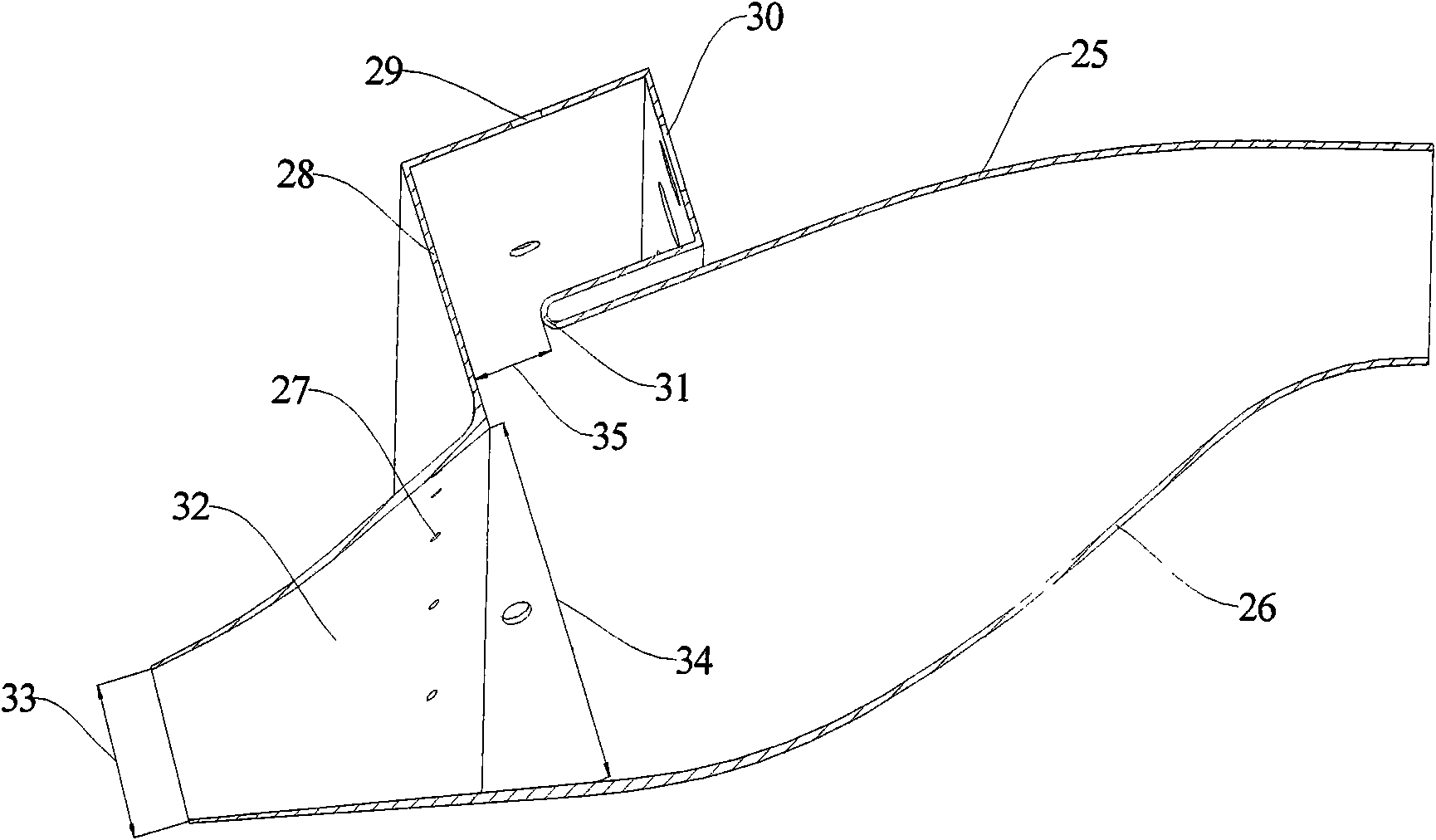

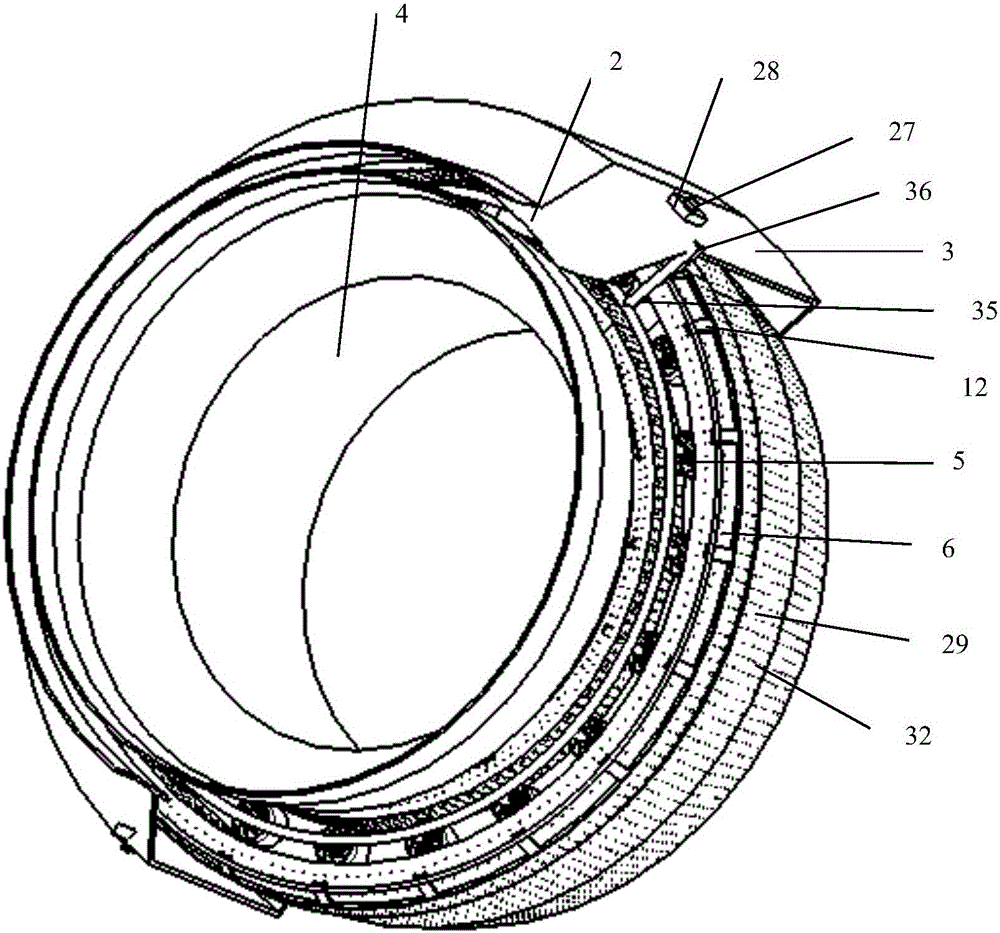

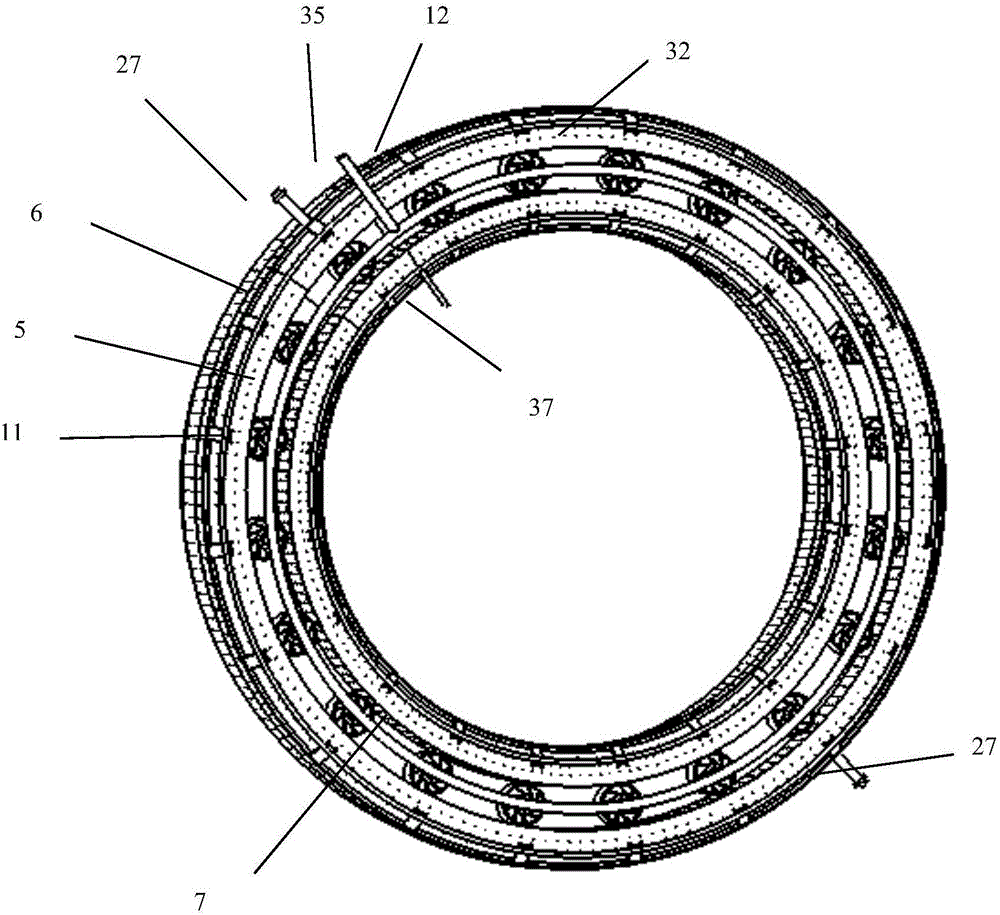

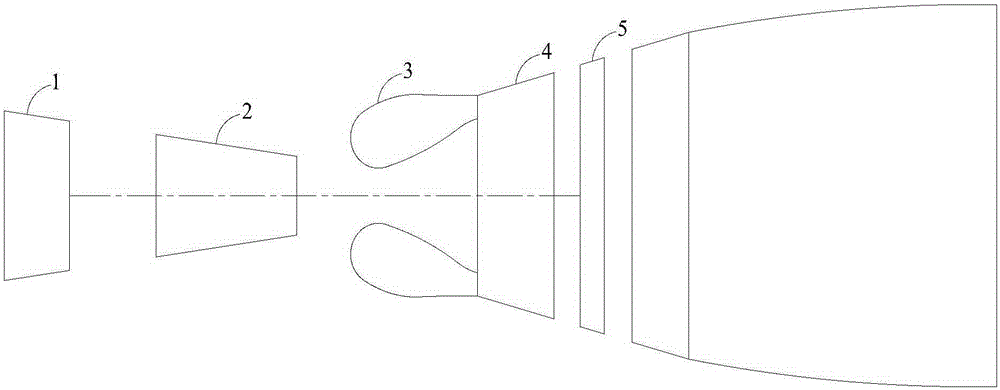

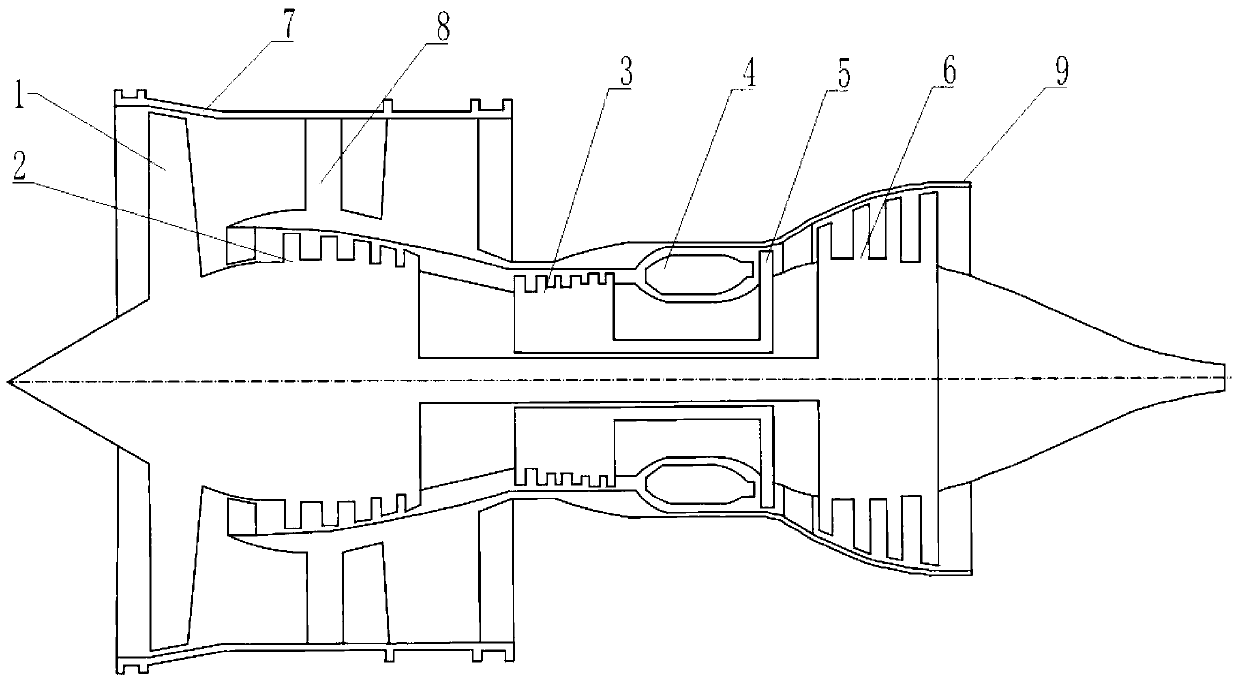

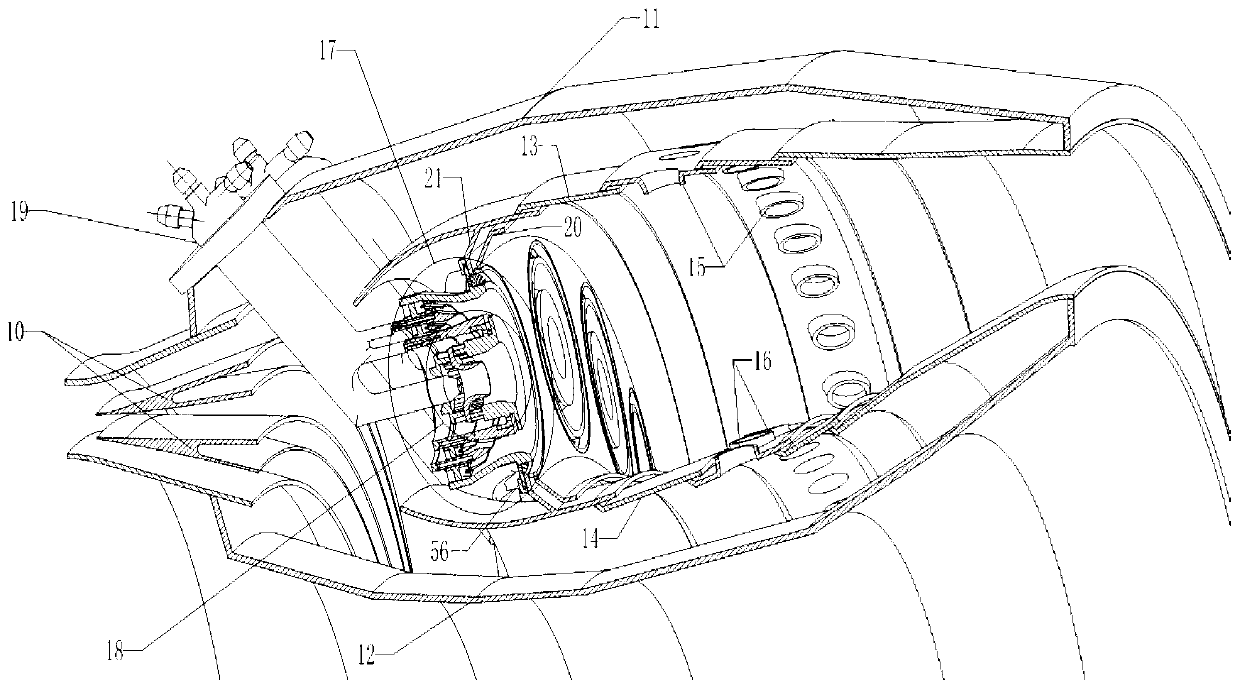

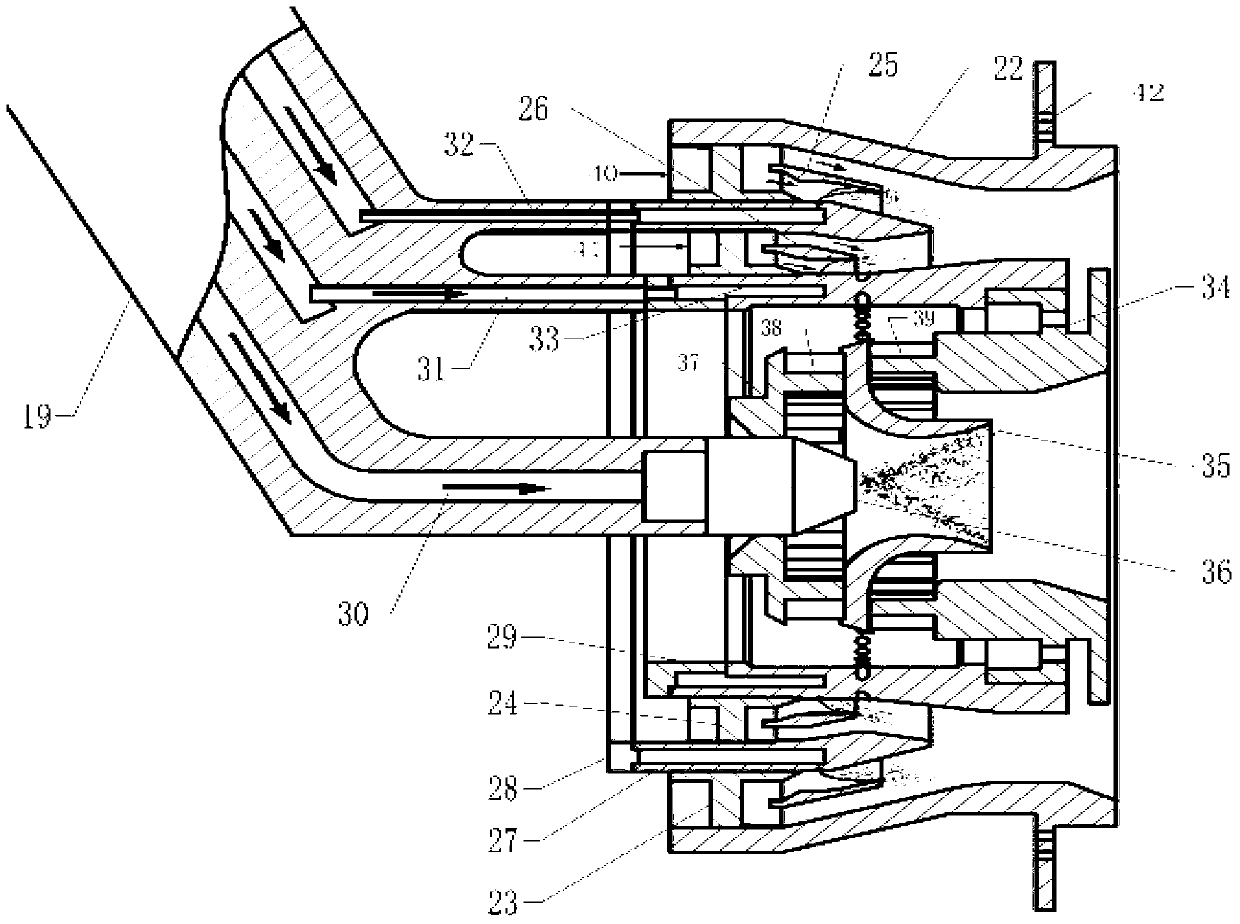

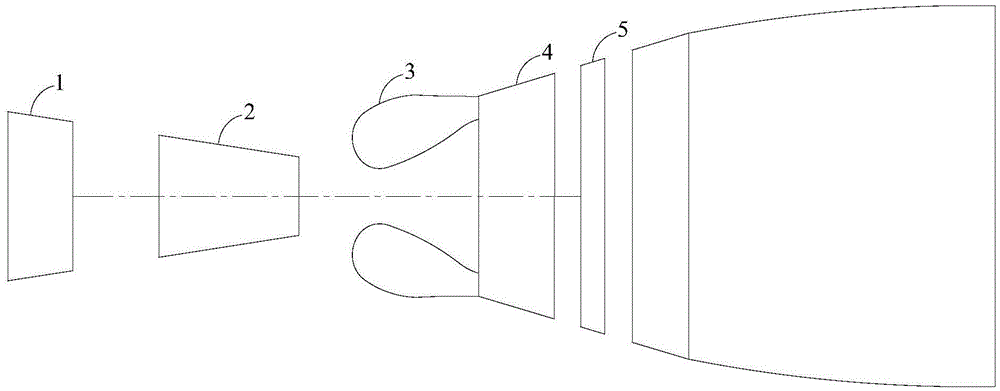

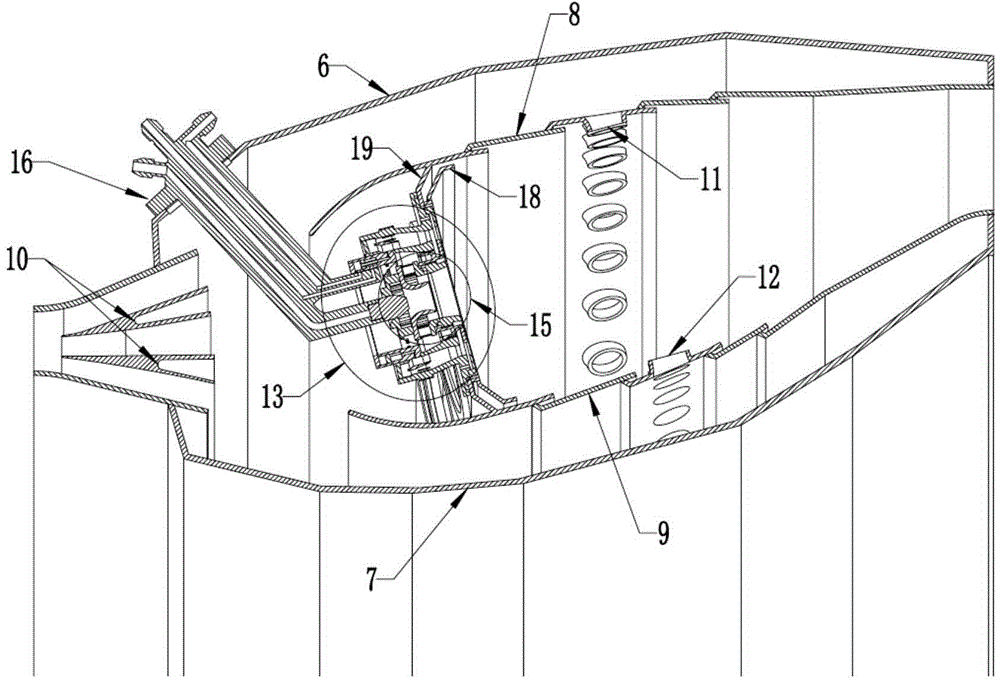

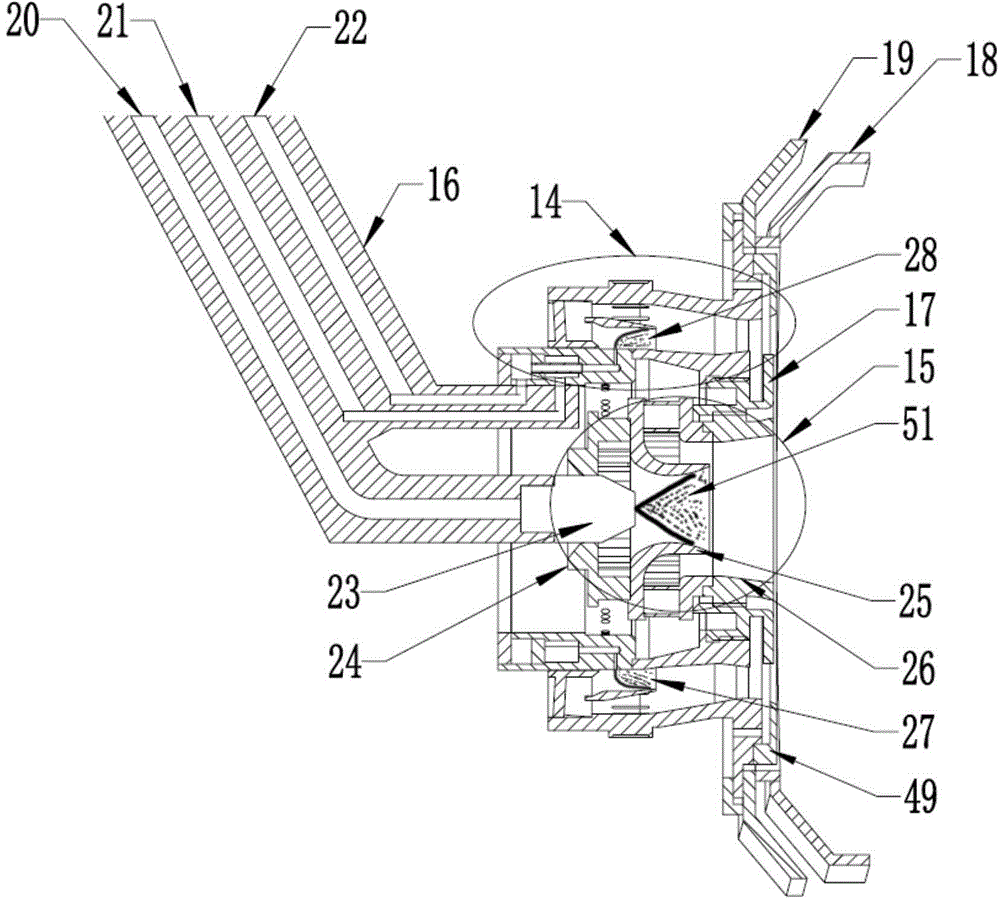

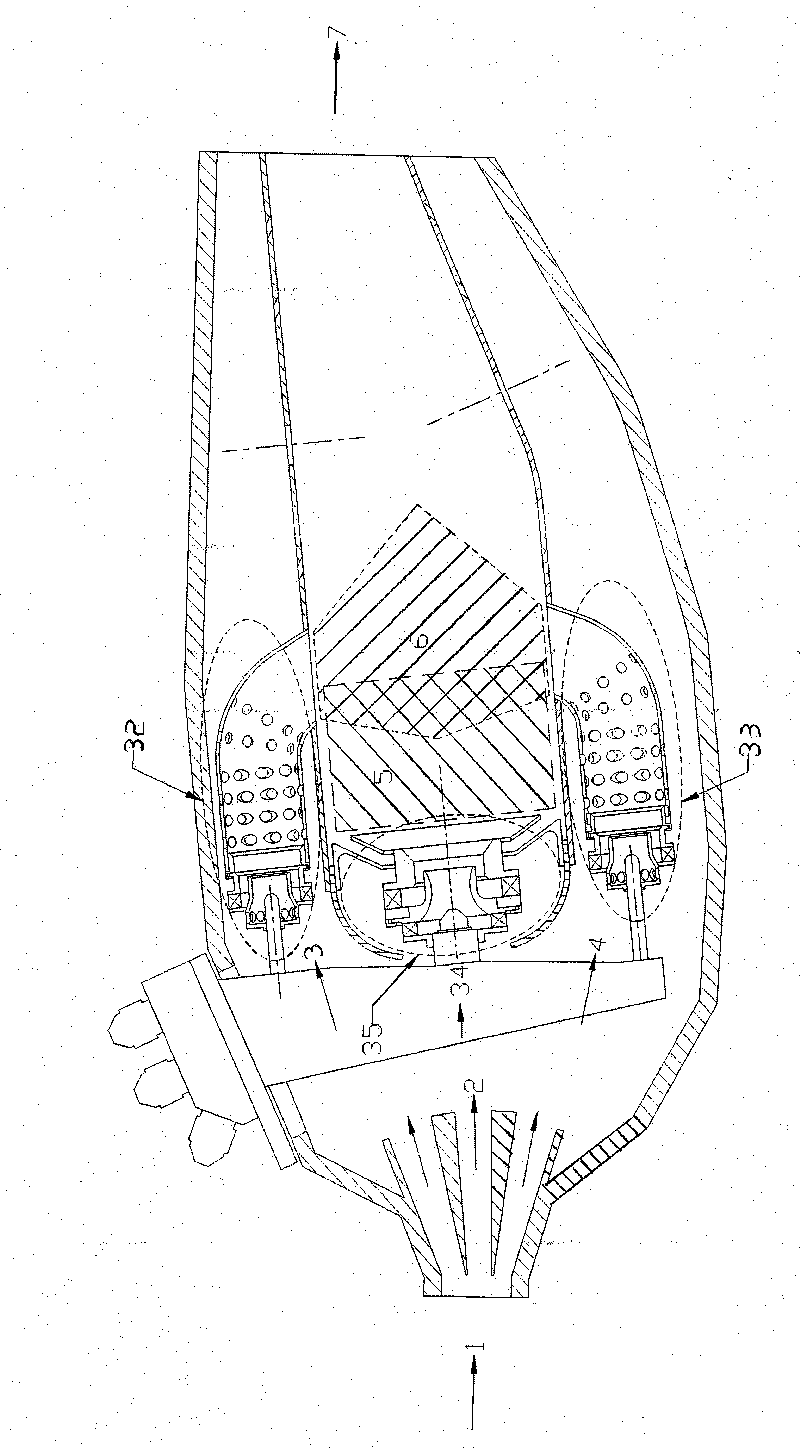

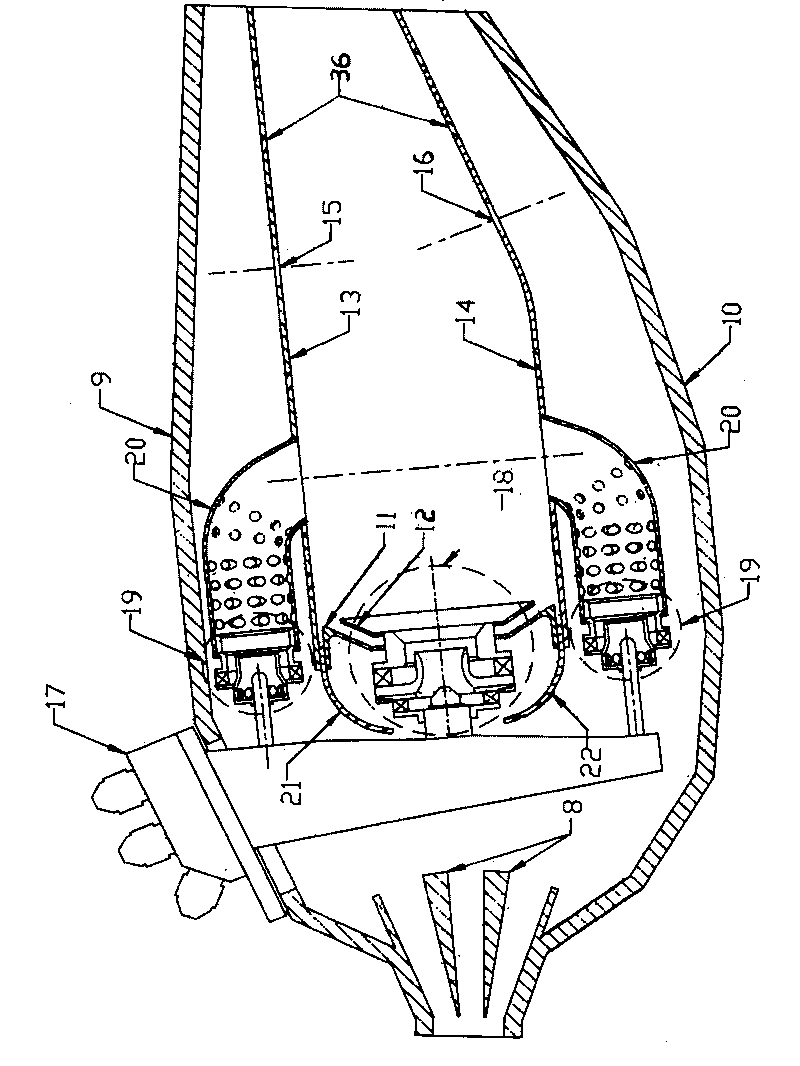

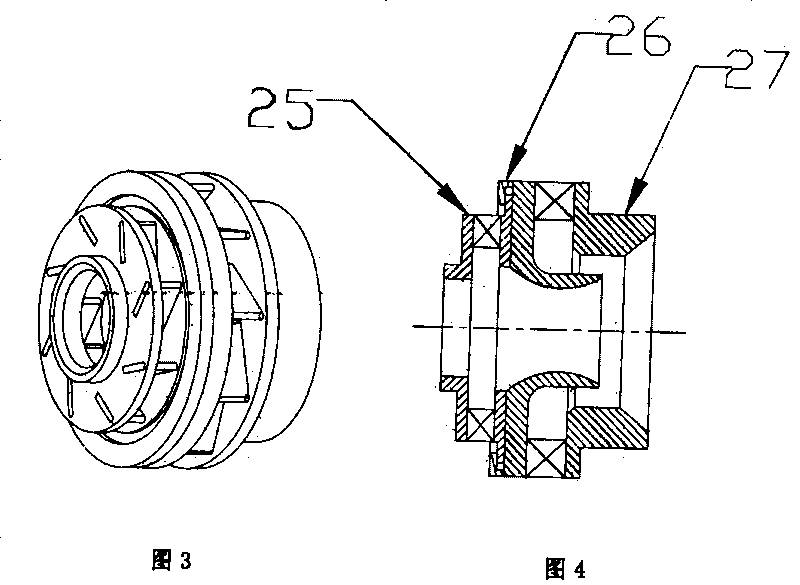

Aerial engine lean premixed preevaporated low contamination combustion chamber

An aero-engine lean-oil premixed pre-evaporation low-pollution combustor consists of a head and a flame tube, the combustion gas is all supplied from the head of the combustor, and the cooling gas and mixed gas enter from the flame tube; the head is The double-ring cavity structure is divided into two stages, the pre-combustion stage and the main combustion stage. The pre-combustion stage is included, and the main combustion stage surrounds the pre-combustion stage. The pre-combustion stage includes a centrifugal nozzle and a swirler surrounding the centrifugal nozzle. After being sprayed out from the centrifugal nozzle, the fuel is sheared and broken by the air swirl from the swirler, mixed in the mixing chamber area of the pre-combustion stage and then enters the combustion area Diffusion combustion is formed inside; the main combustion stage includes a direct air atomizing nozzle, a main swirler and a premixing ring chamber, the main swirler is located upstream of the nozzle, and the premixing ring chamber is located downstream of the nozzle, and the fuel goes first in the nozzle It is mixed and atomized with air, and then tangentially injected into the premixed ring cavity for premixed pre-evaporation, and enters the combustion area to form premixed combustion; in the downstream of the pre-combustion stage combustion and main combustion stage fuel outlets, contraction and expansion ports are used to prevent backflow fire and carbon buildup. The invention has a simple structure and can effectively reduce the pollution discharge of the aero-engine under the condition of ensuring the working state.

Owner:BEIHANG UNIV

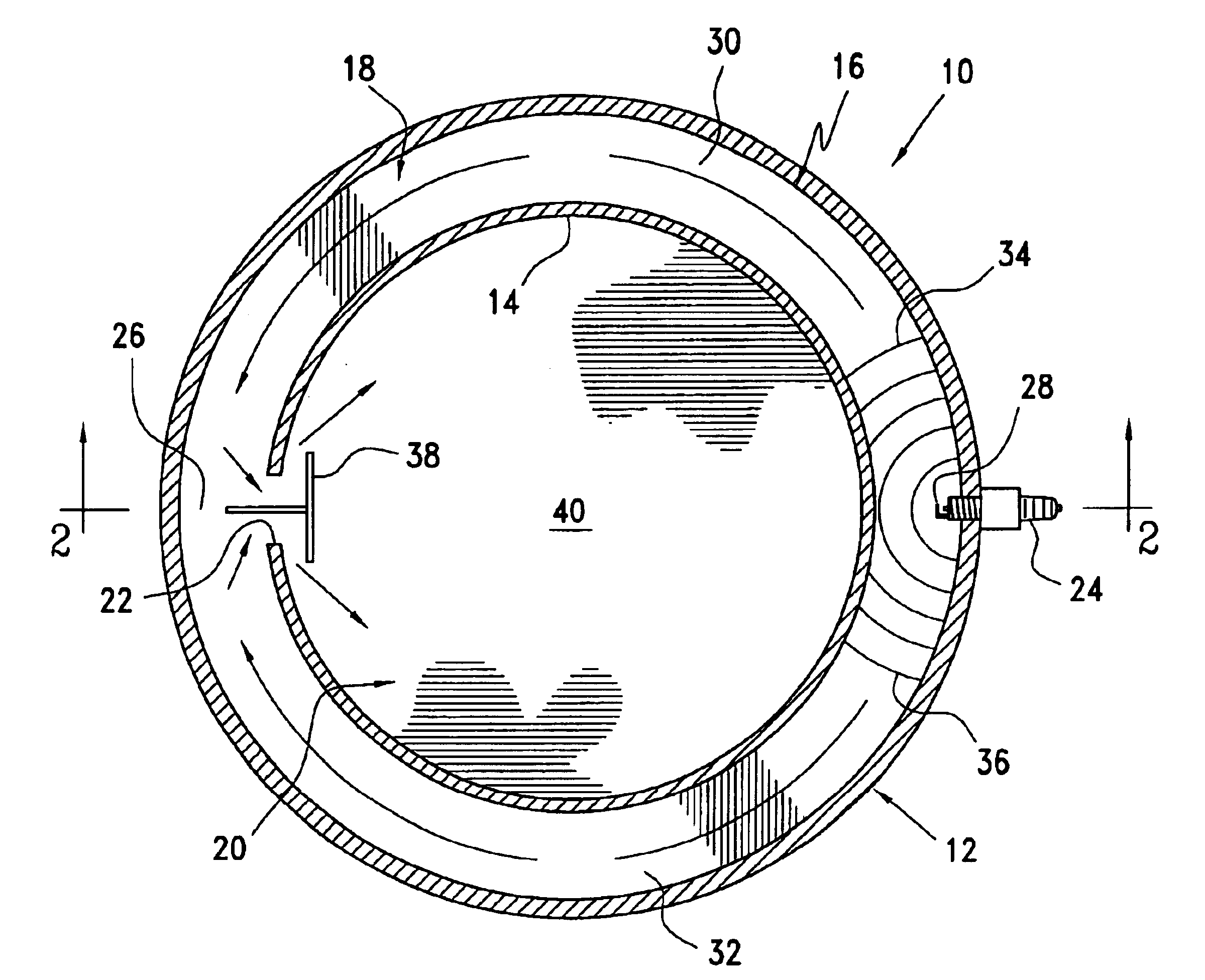

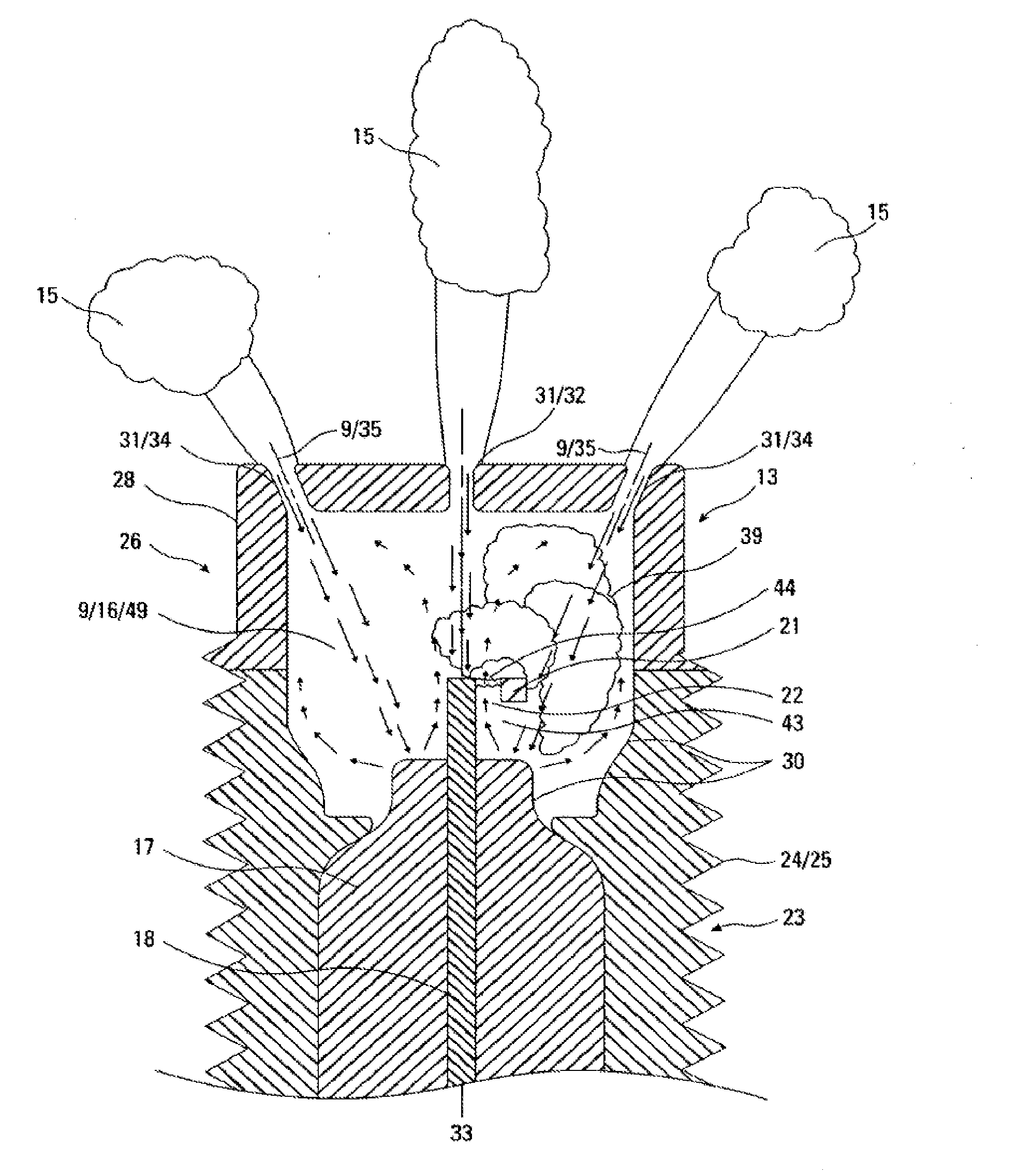

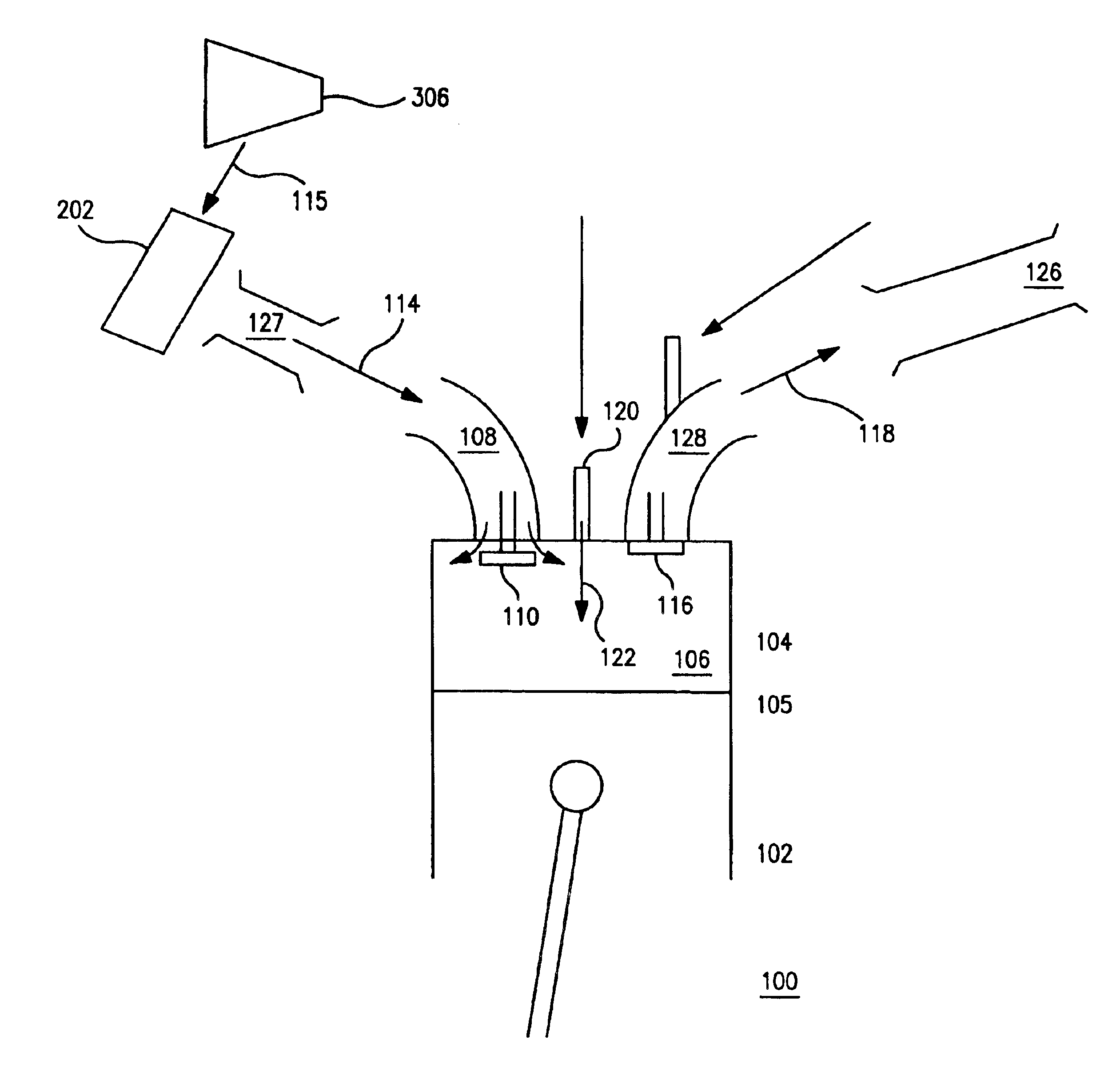

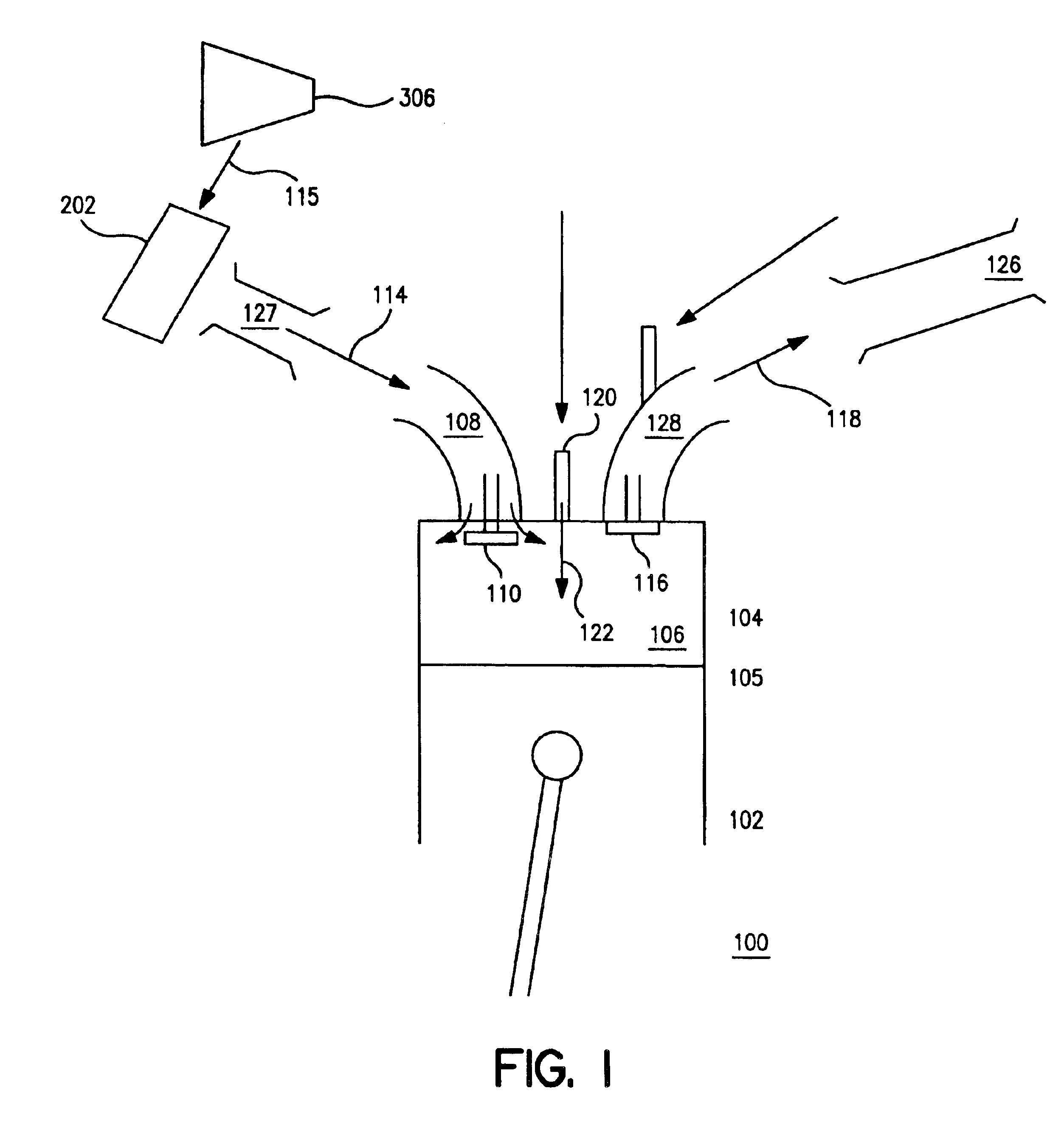

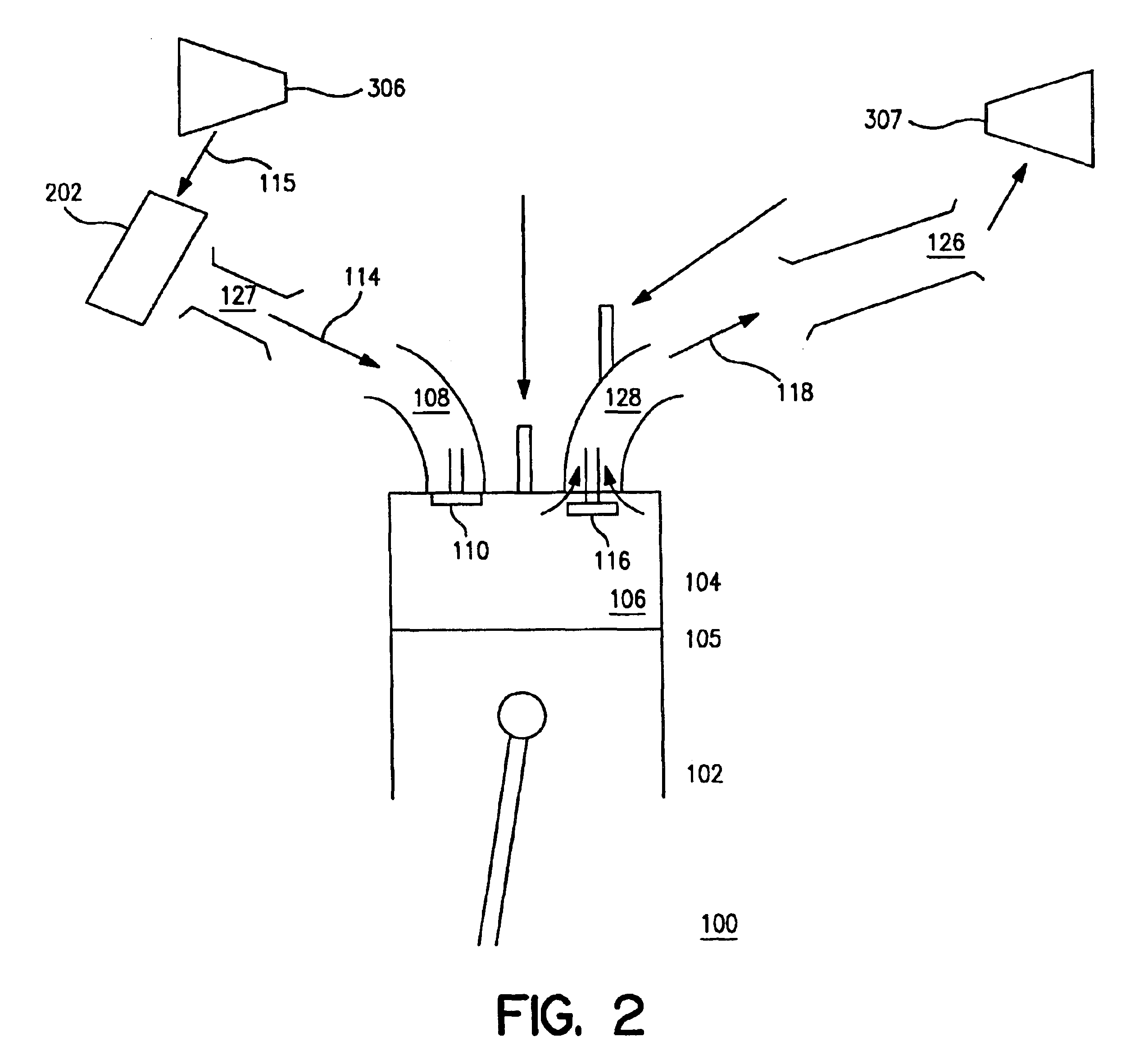

Multiple-front combustion chamber system with a fuel/air management system

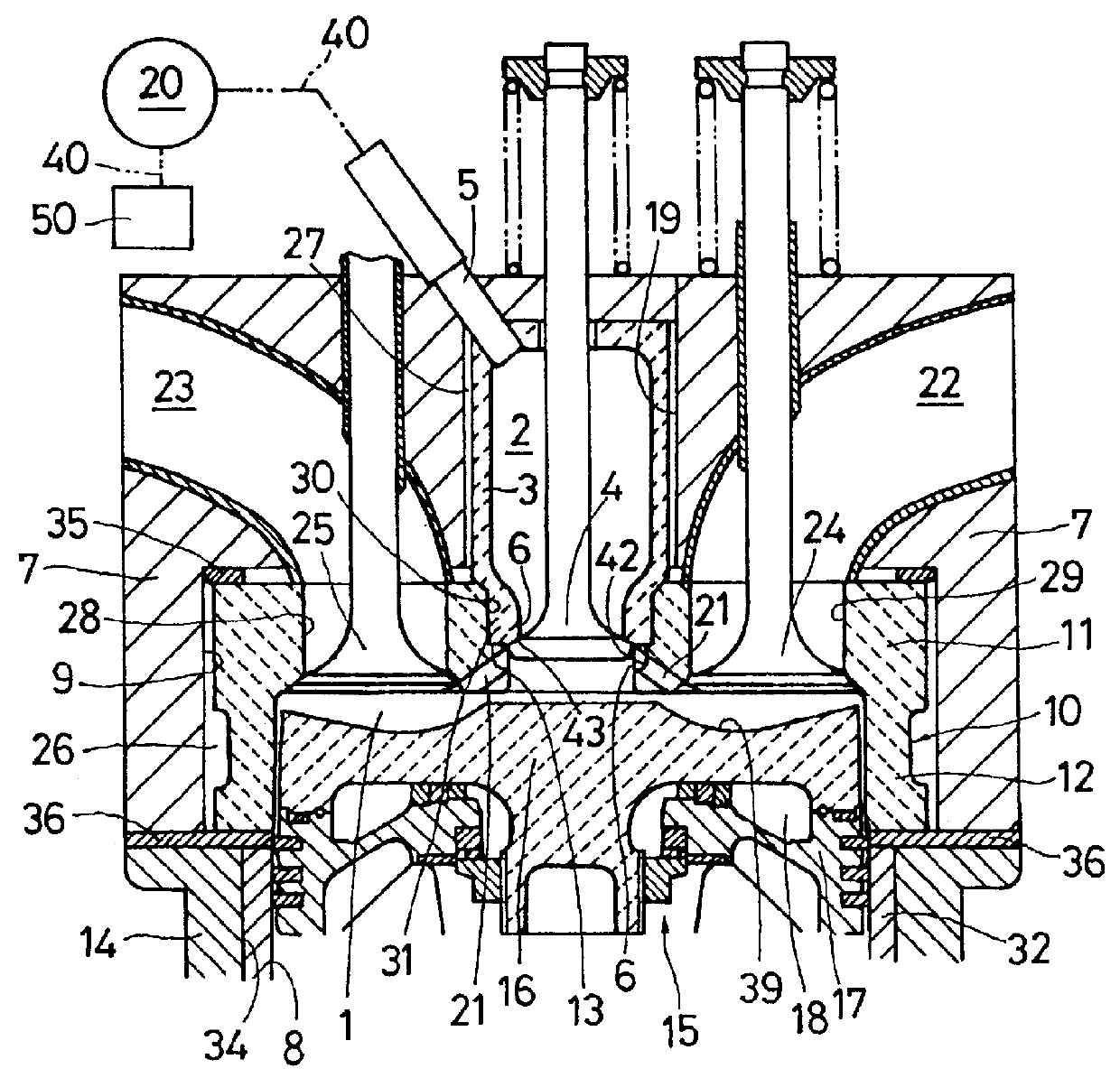

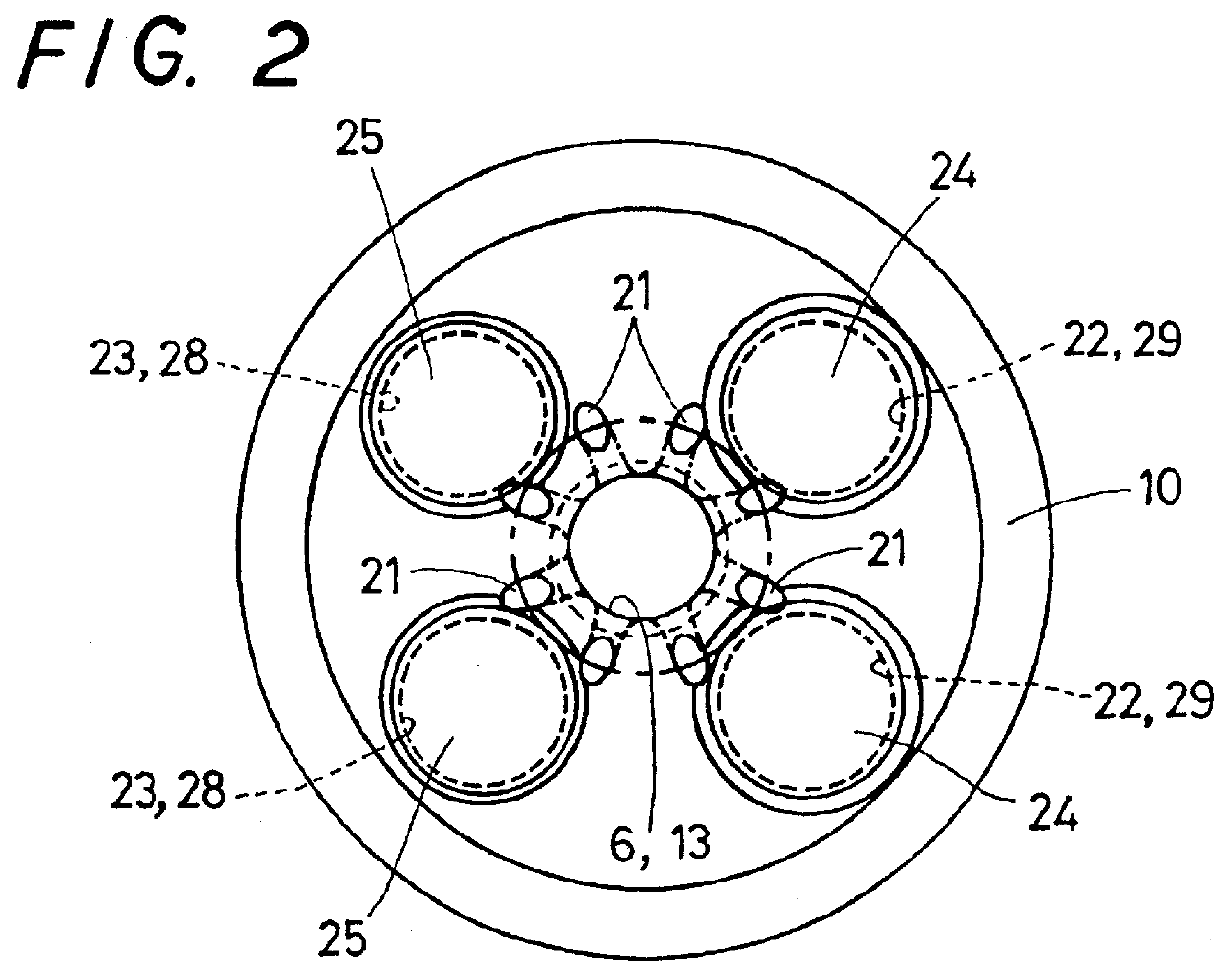

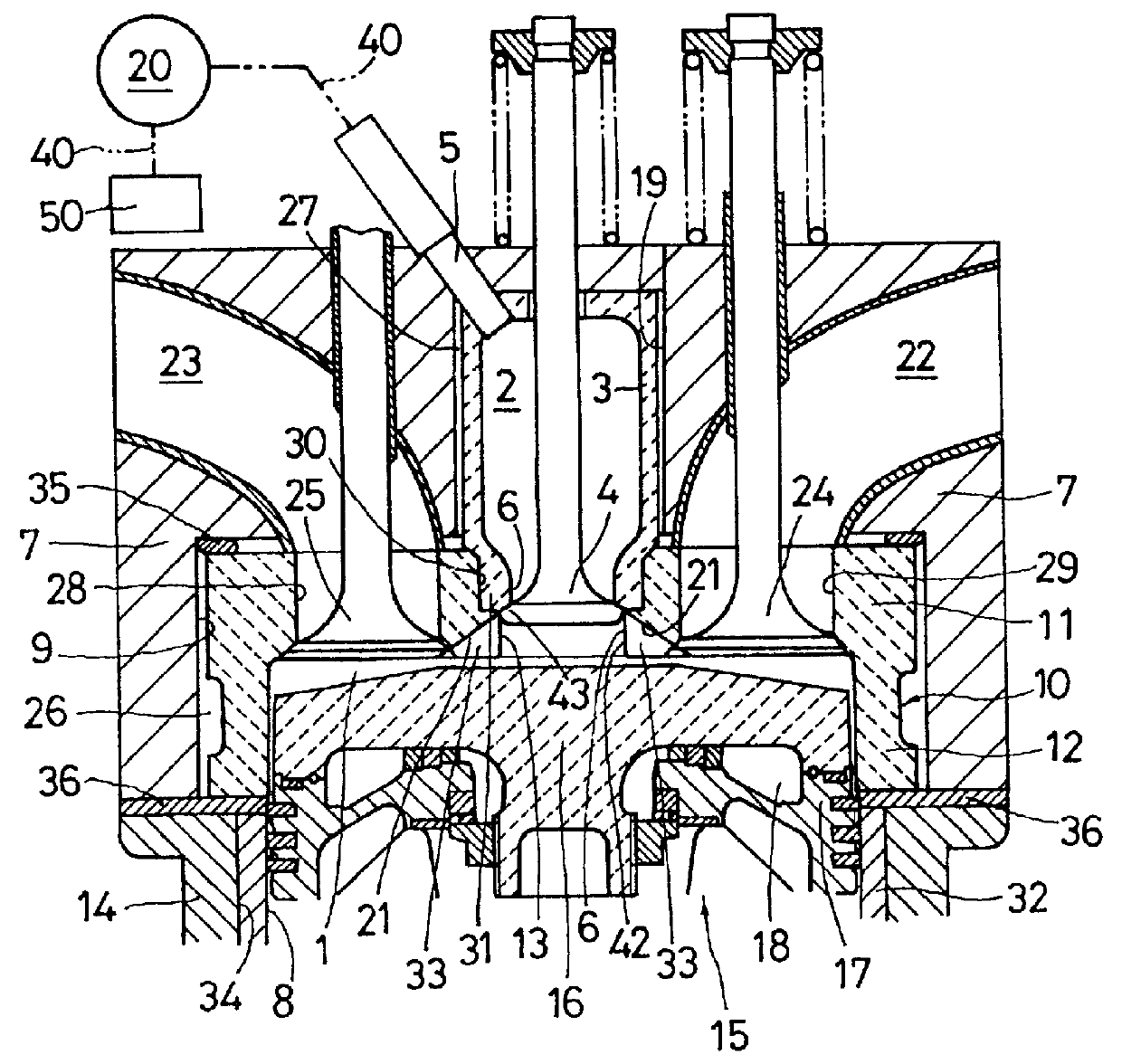

InactiveUS6912988B2Shorten the timeBoosting peak combustion pressureInternal combustion piston enginesNailing toolsCombustion chamberAir management

A combustion chamber of a positive-displacement spark-ignited internal combustion engine is divided into a main combustion chamber and a pre-combustion chamber having proximal and distal ends. The proximal end is connected to the main combustion chamber and a spark-ignition device is located at the distal end. Within the pre-combustion chamber, a plurality of passageways extend between its proximal and distal ends so that a flame front ignited by the ignition device at the distal end of the pre-combustion chamber propagates along the plurality of passageways as separate flame fronts toward the proximal end of the pre-combustion chamber. A displacer separates a premixing chamber from the pre-combustion and main combustion chambers. The displacer is relatively moveable for transferring the charge of fuel and air from the premixing chamber into the pre-combustion main combustion chambers.

Owner:ADAMS JOSEPH S

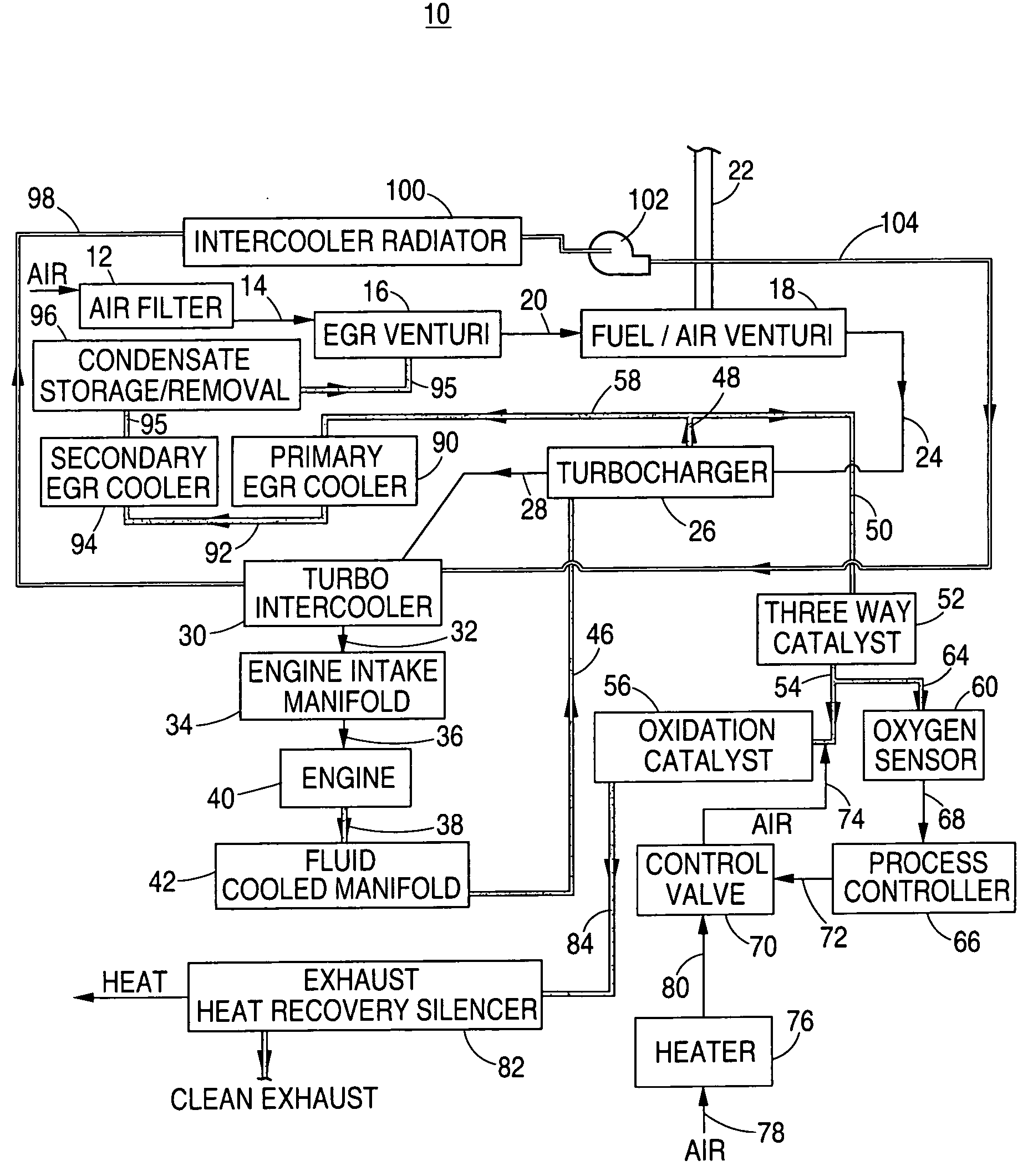

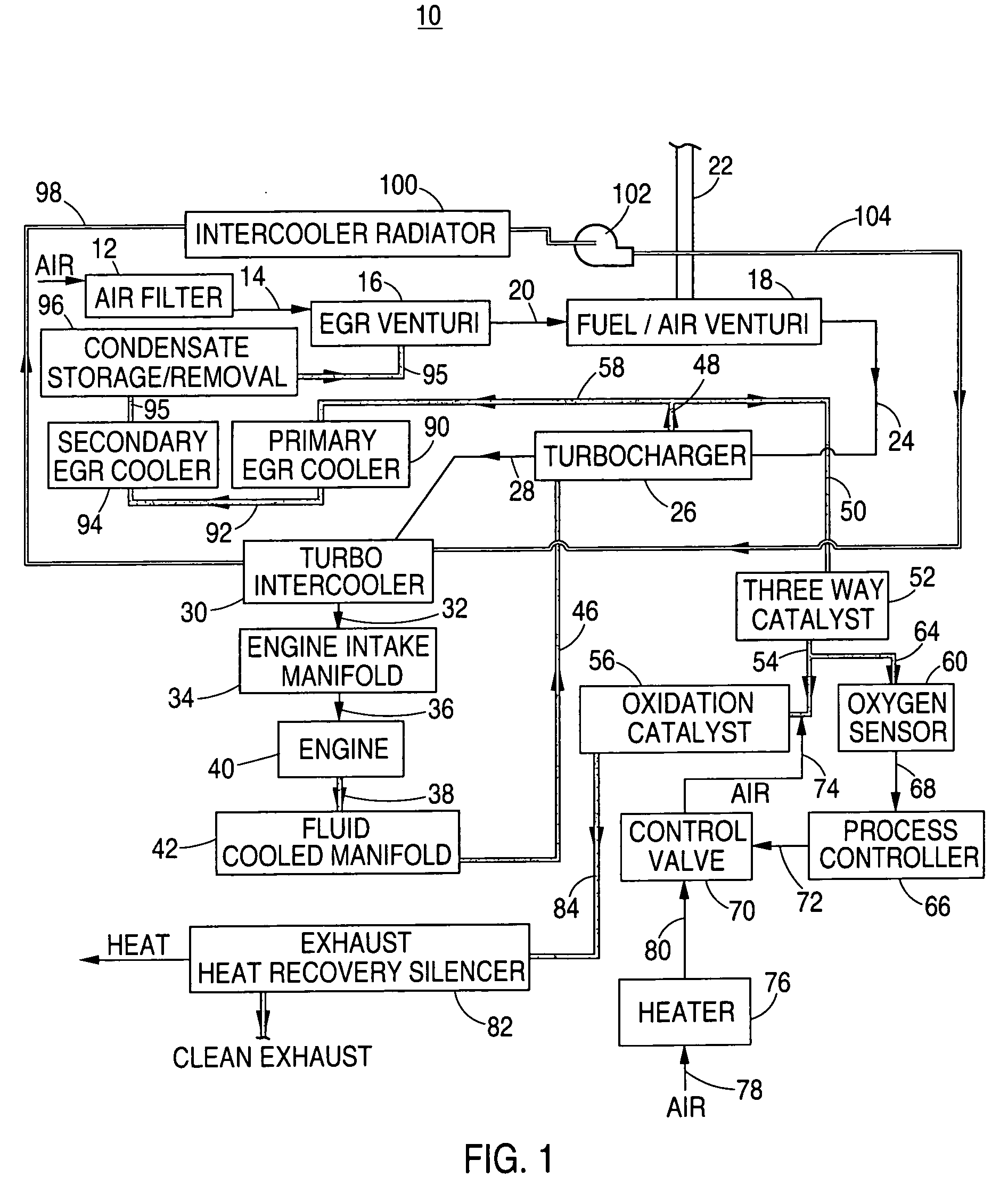

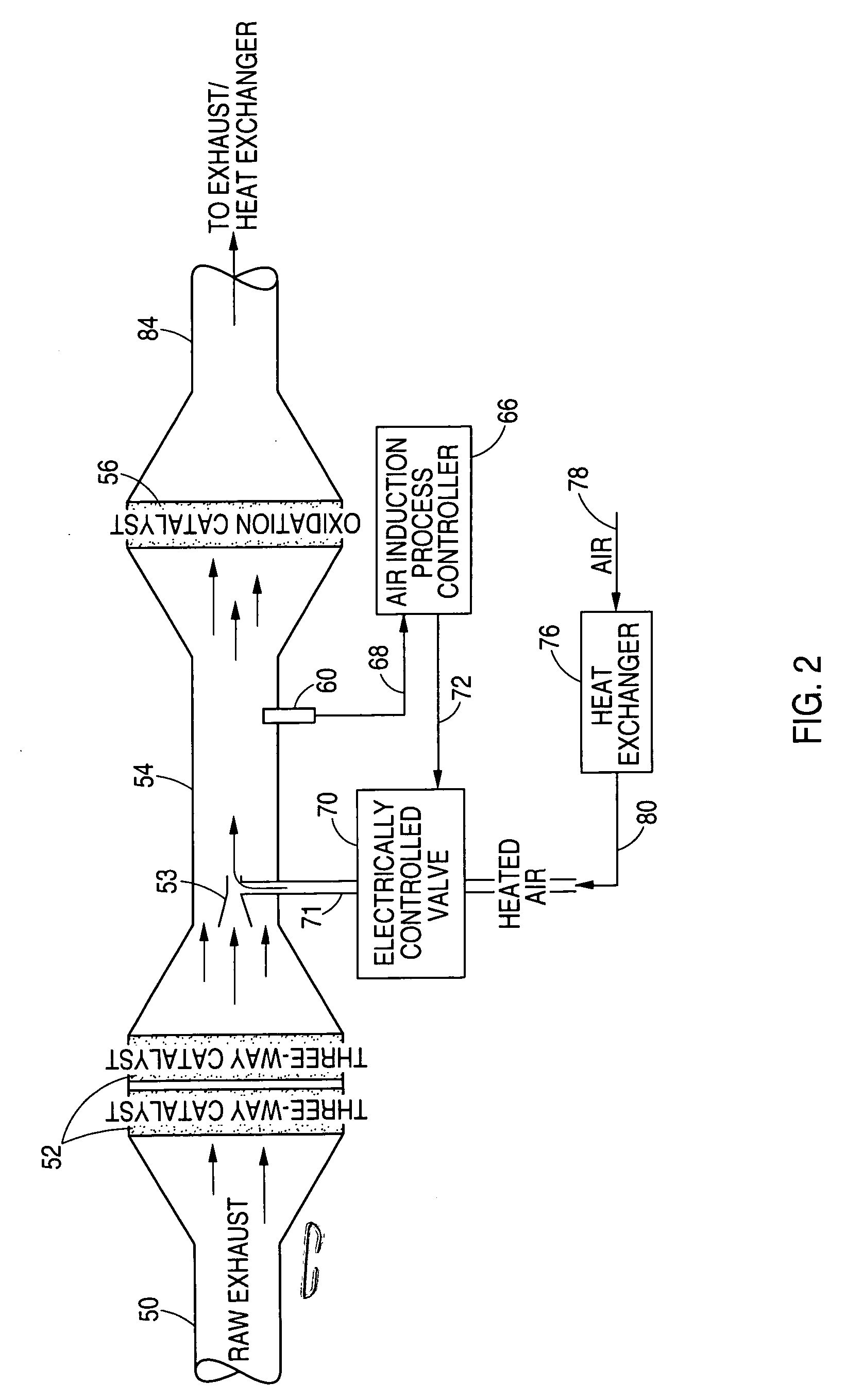

Air flow regulation system for exhaust stream oxidation catalyst

InactiveUS20060179824A1Improve oxidation capacityMinimize degradationNon-fuel substance addition to fuelInternal combustion piston enginesStream flowCogeneration

An air flow regulation system for enhancing the performance of oxidation catalyst in the exhaust stream of an internal combustion engine is provided wherein air flow into the exhaust upstream of an oxidation catalyst is dynamically controlled via a controlled feedback loop to ensure sufficient oxygen availability to induce enhanced oxidation catalyst performance while simultaneously limiting the exhaust cooling effect of the incoming air stream and the associated loss of catalytic conversion performance. The modulation of air temperature and flow into the exhaust gas stream of a reciprocating internal combustion natural gas fuel engine upstream of an oxidation catalyst is regulated such that oxidation of carbon monoxide, hydrocarbons, and ammonia is achieved to a level beyond the levels attainable and maintainable with a catalyst strategy that relies only upon pre-combustion air / fuel ratio management. In one aspect, the modulation of air flow into the exhaust is via an electronically controlled feedback loop. In another aspect, the induced air is heated to assure catalyst performance and retard the loss of recoverable heat from the exhaust stream for combined heat and power applications.

Owner:CHAPEAU

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

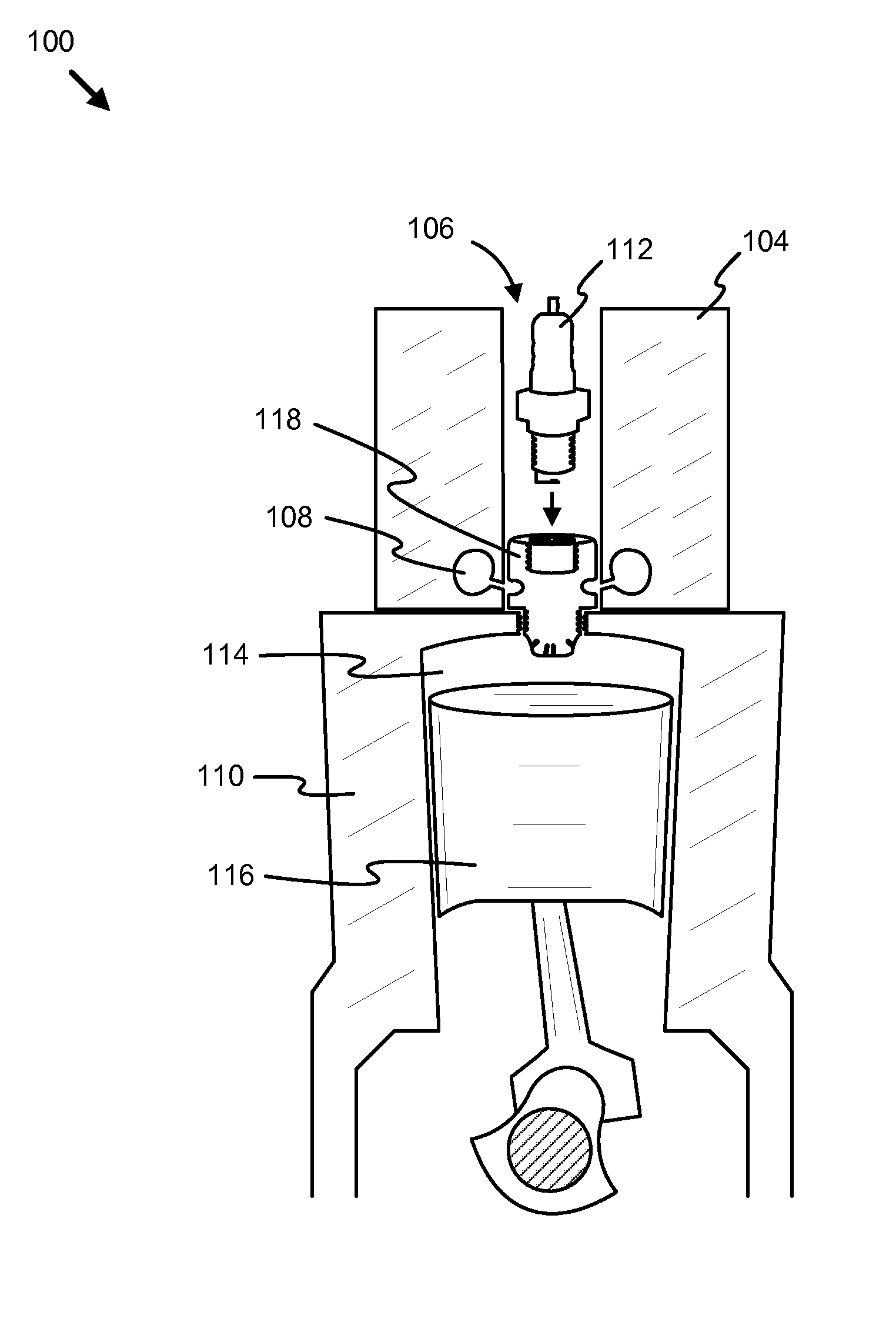

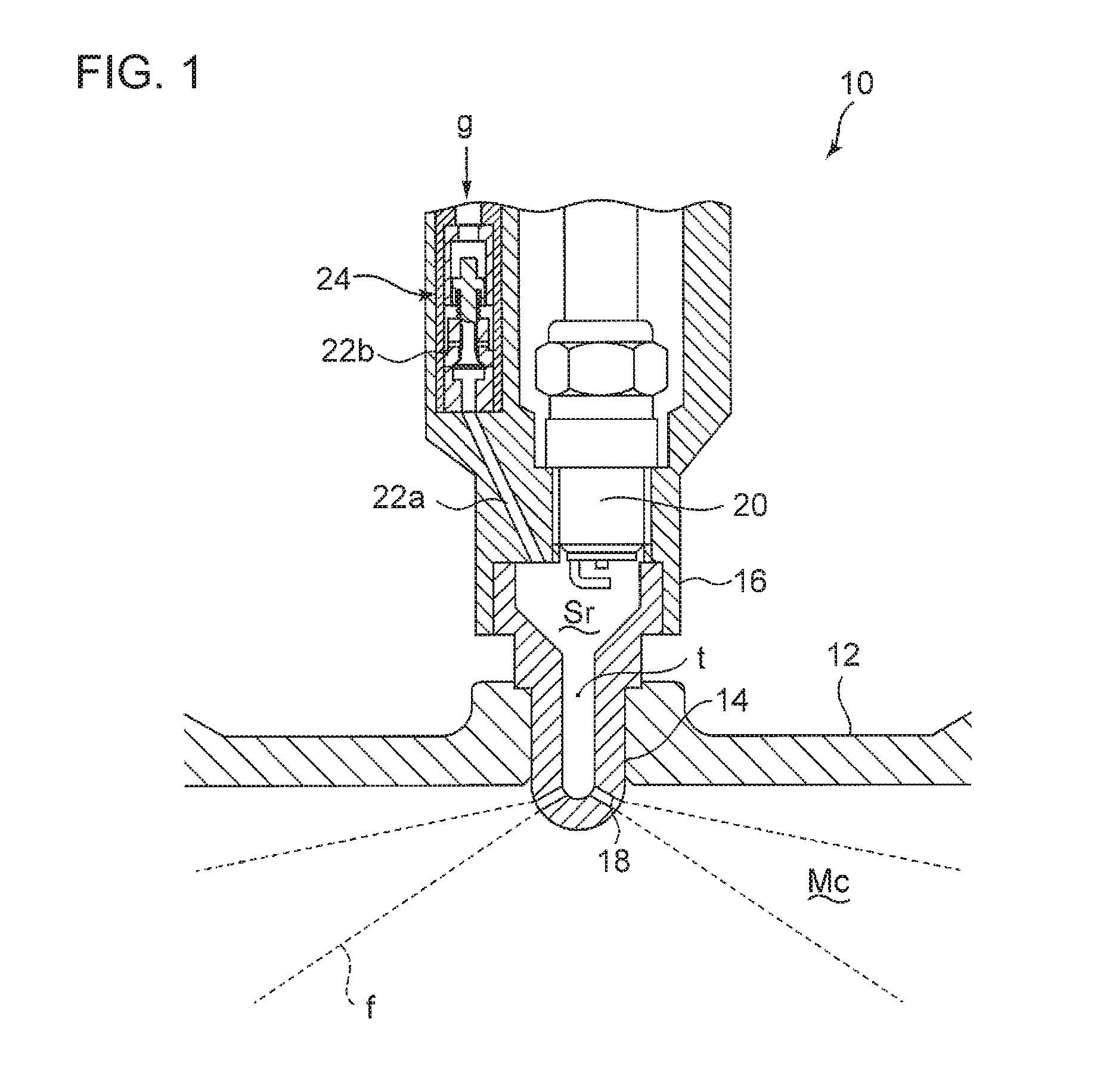

Prechamber Ignition System

ActiveUS20140102404A1Increase burn rateRaise the ratioInternal combustion piston enginesIgnition sparking plugsCombustion chamberEngineering

Generally, embodiments of a pre-chamber unit having a pre-combustion chamber including one or more induction ports in a configuration which achieves flow fields and flow field forces inside the pre-combustion chamber which act to direct flame growth away quenching surface of the pre-combustion chamber.

Owner:PROMETHEUS APPLIED TECH

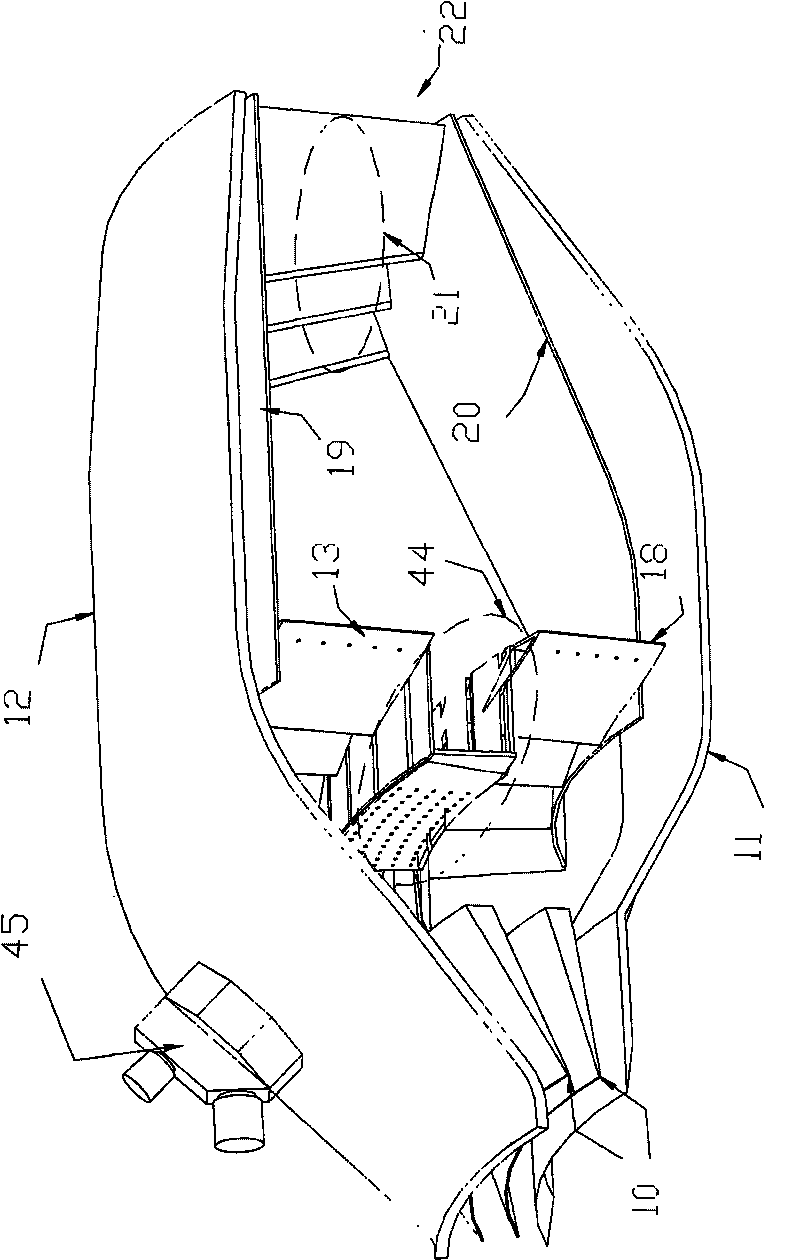

Integrated diffusion oriented combustion chamber

InactiveCN101650038AGuaranteed temperature distributionSimplified matching structureContinuous combustion chamberLow speedCombustion chamber

The invention relates to an integrated diffusion oriented combustion chamber which adopts a full ring combustion chamber structure. The integrated diffusion oriented combustion chamber mainly comprises a crankcase, a combustion liner and an oriented diffuser. The oriented diffuser realizes pneumatic and structural coupling, controls the tangential flow direction and carries out diffusion and speedreduction, and a local return low-speed zone is formed, thereby being good for flame linkage and tangential stable combustion; grading combustion is adopted, and a pre-combustion grade can be selected to work alone and work together with a main pre-combustion grade according to work conditions; the pre-combustion grade utilizes the trapped vortex combustion technology for stable work, goes into amain combustion zone to inflame a main combustion grade through a contraction outlet, and provides a stable ignition source for the main combustion grade; fuel of the main combustion grade is injected to a main combustion grade airflow in the oriented diffuser, atomization evaporation mixing with short distance is realized, and combustible mixture gas with uniform mixing is provided for the maincombustion zone. The invention allows tangential rotational flow of a gas compressor to directly go into the combustion chamber so as to realize tangential highly efficient and stable combustion; in addition, the discharge of pollutants is low, pre-rotation is provided for a turbine, the structure can be simplified, the weight is lightened, and the densification of a gas turbine is realized.

Owner:BEIHANG UNIV

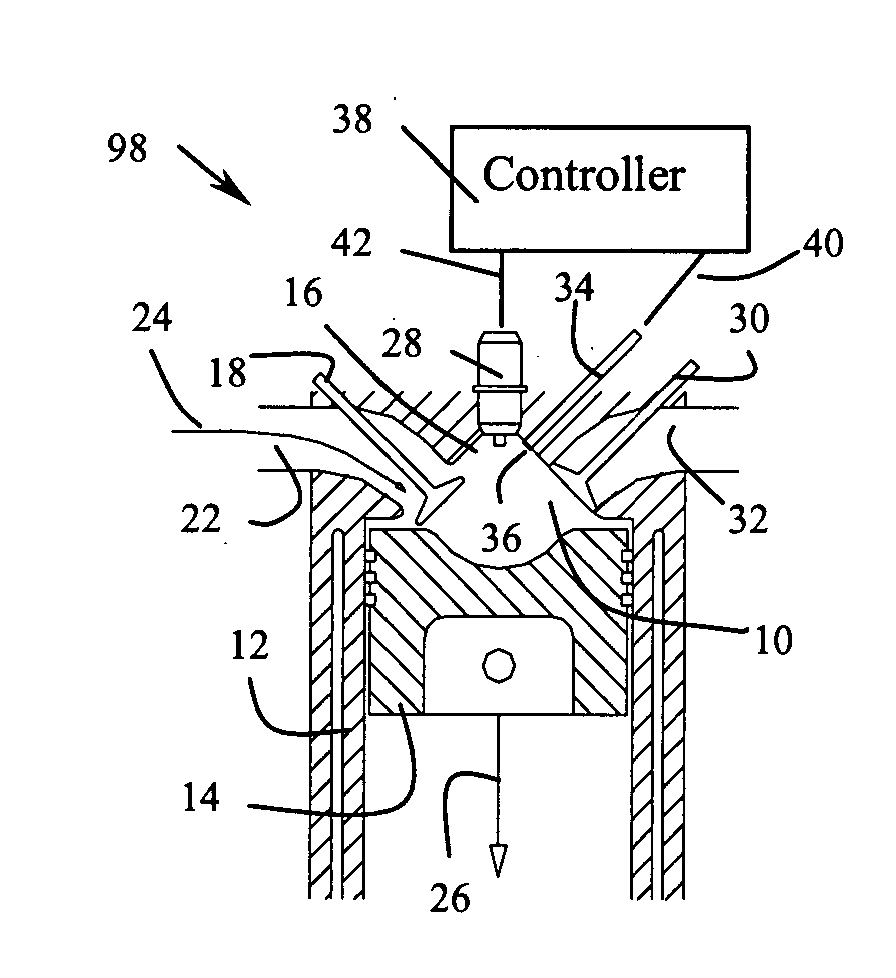

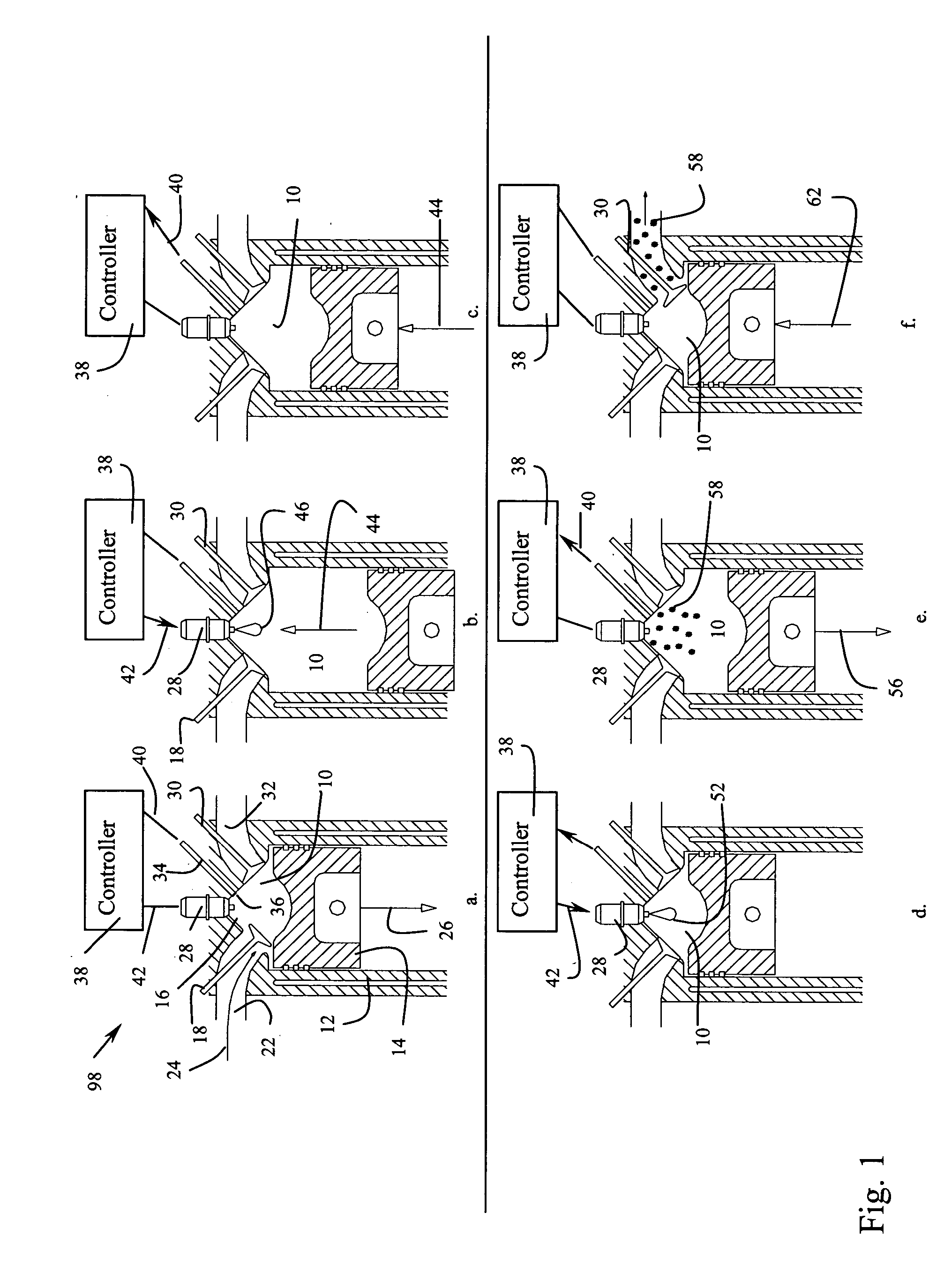

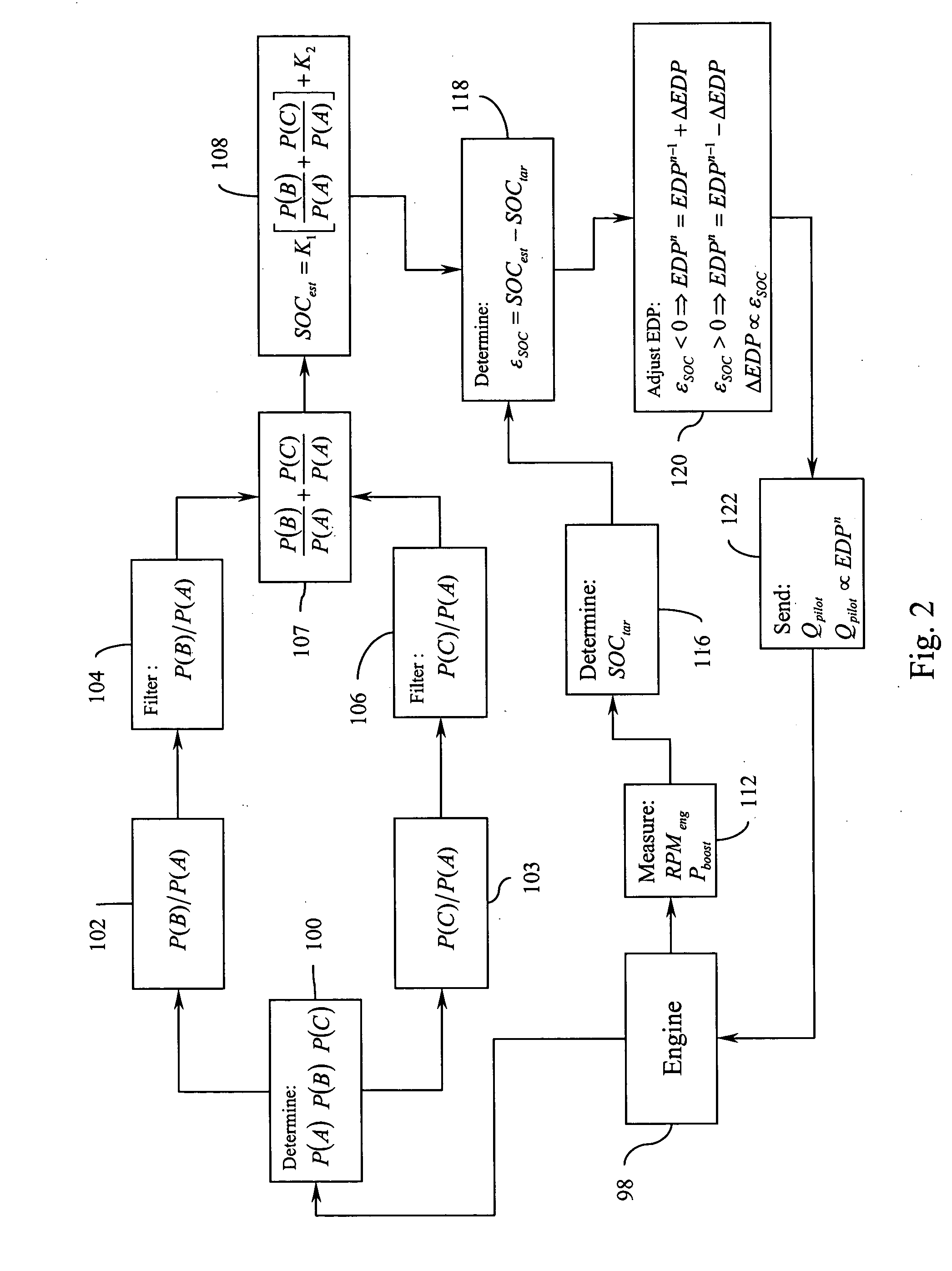

Method and apparatus for controlling an internal combustion engine using combustion chamber pressure sensing

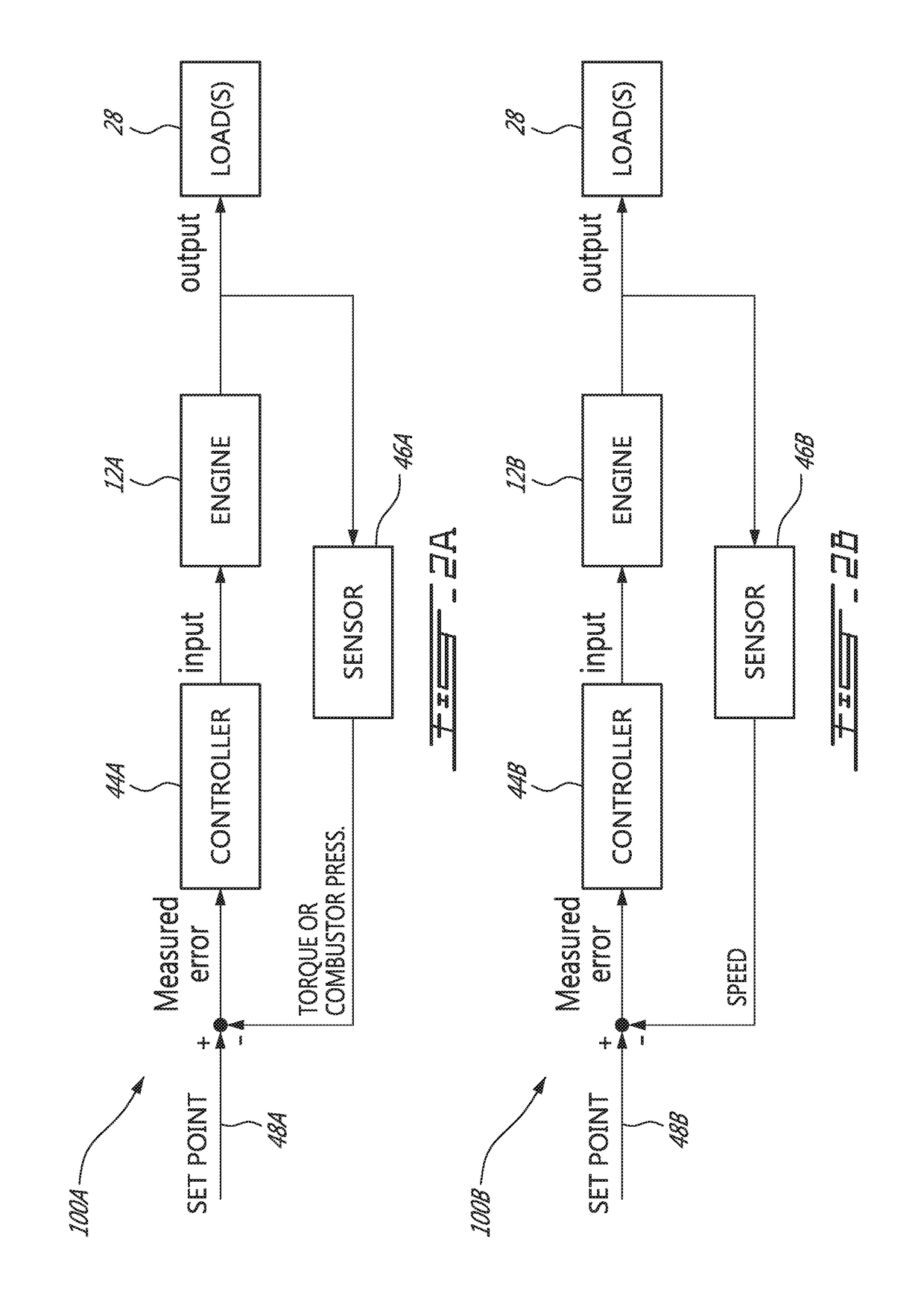

InactiveUS20050072402A1Quick changeElectrical controlInternal combustion piston enginesCombustion chamberPresent method

The present method and apparatus employ a signal indicative of cylinder pressure within the combustion chamber of an internal combustion engine to control combustion phasing or start of combustion (SOC) in subsequent cycles of the engine where the engine is driven by combustion of both a fuel / air premixed charge and a directly injected quantity of fuel. A ratio of signals indicative of pre-combustion pressure and post-combustion pressure within a cycle are employed to estimate SOC and then, based on a predetermined target SOC, an ignition lever is employed to adjust subsequent SOC. A preferred ignition lever is, in a pilot fuel ignited engine, pilot fuel quantity.

Owner:WESTPORT POWER

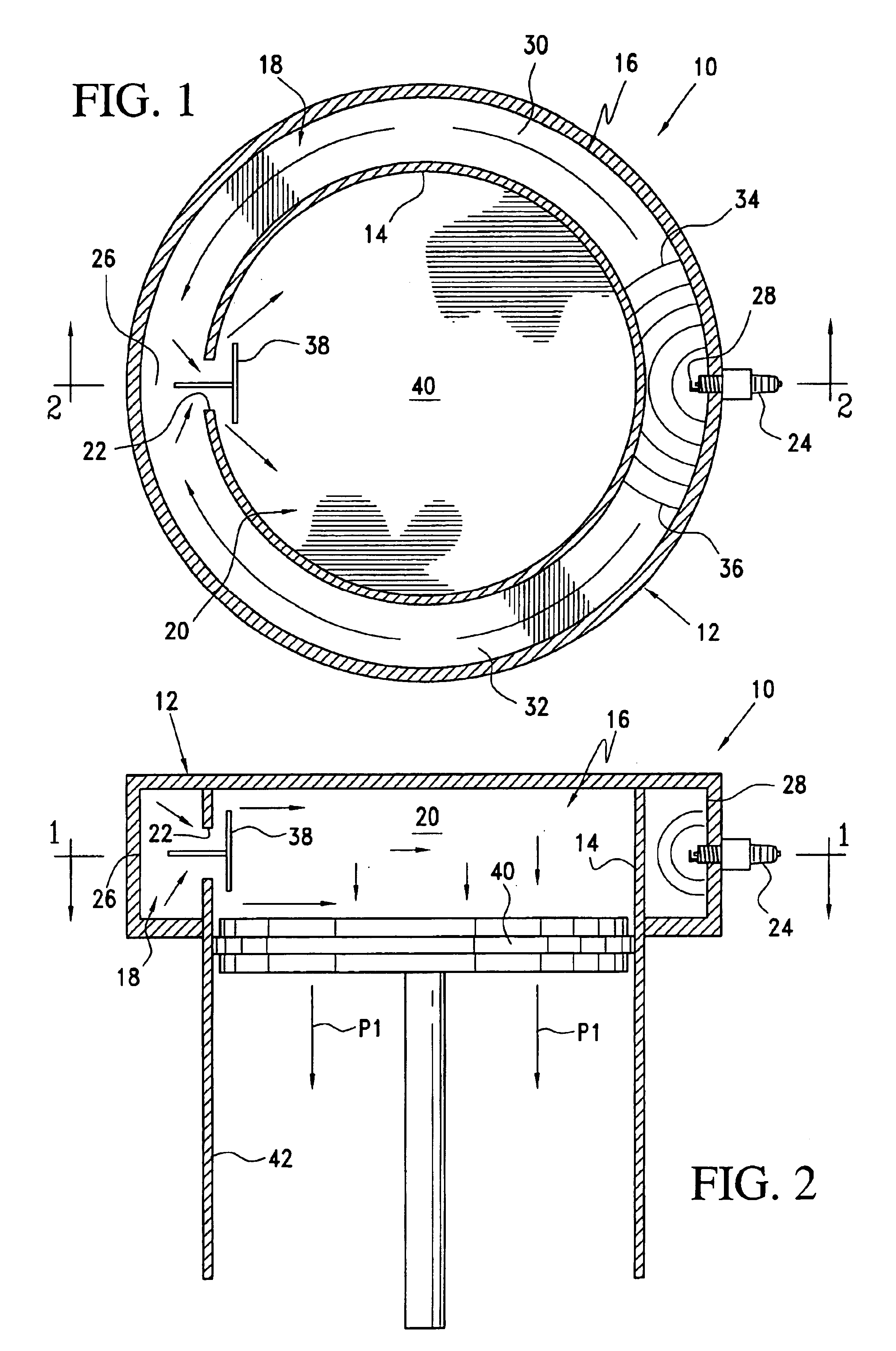

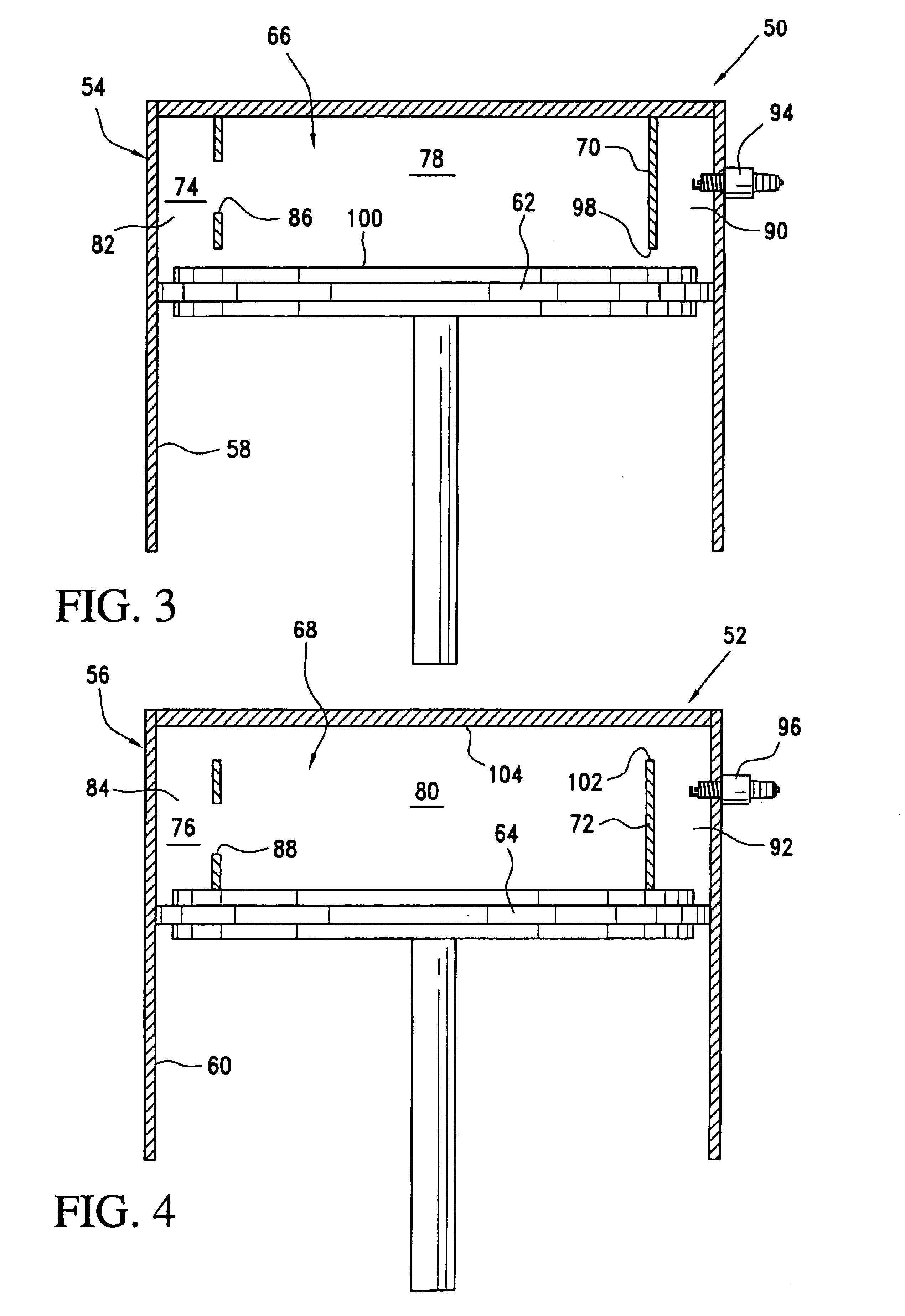

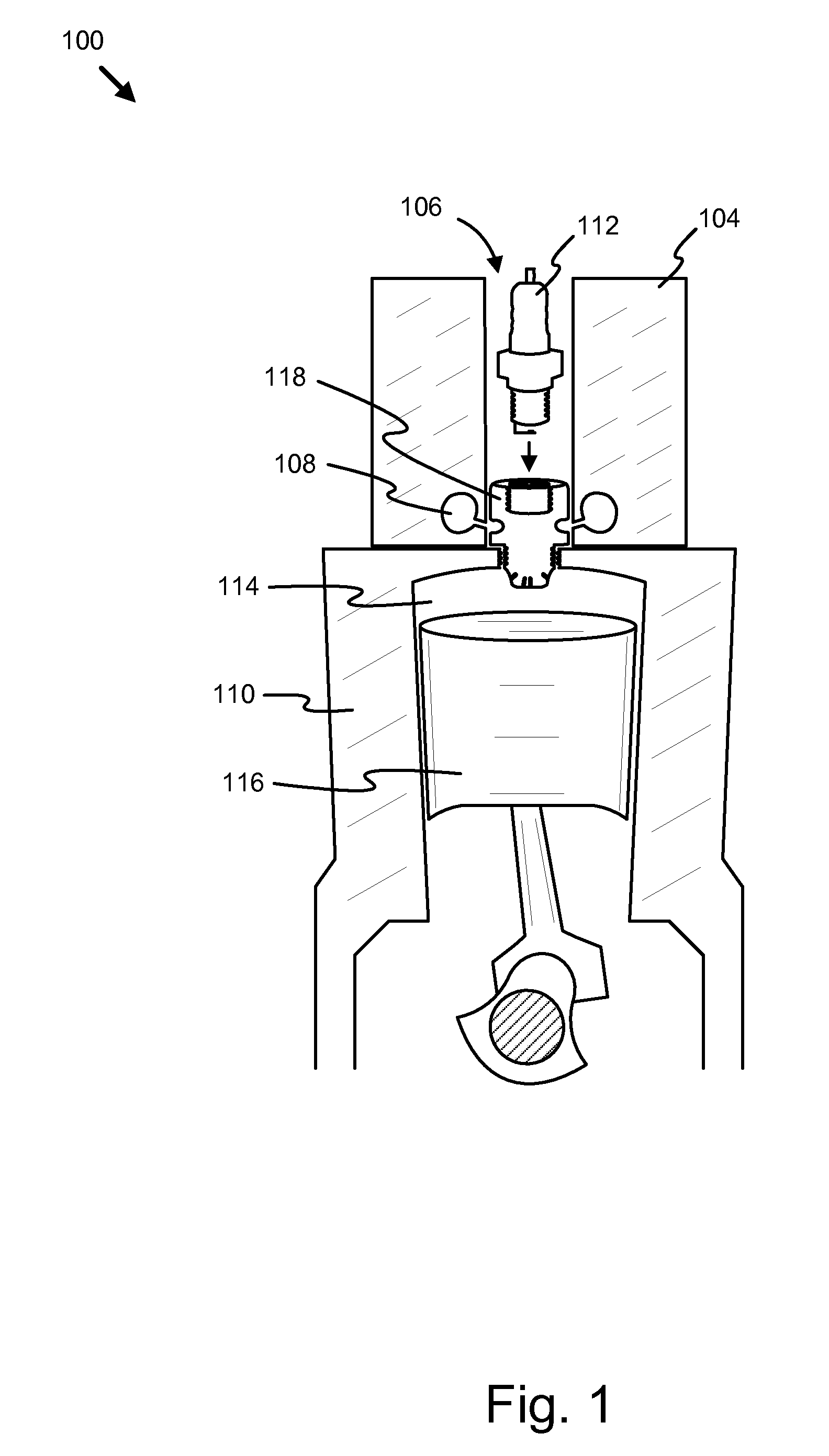

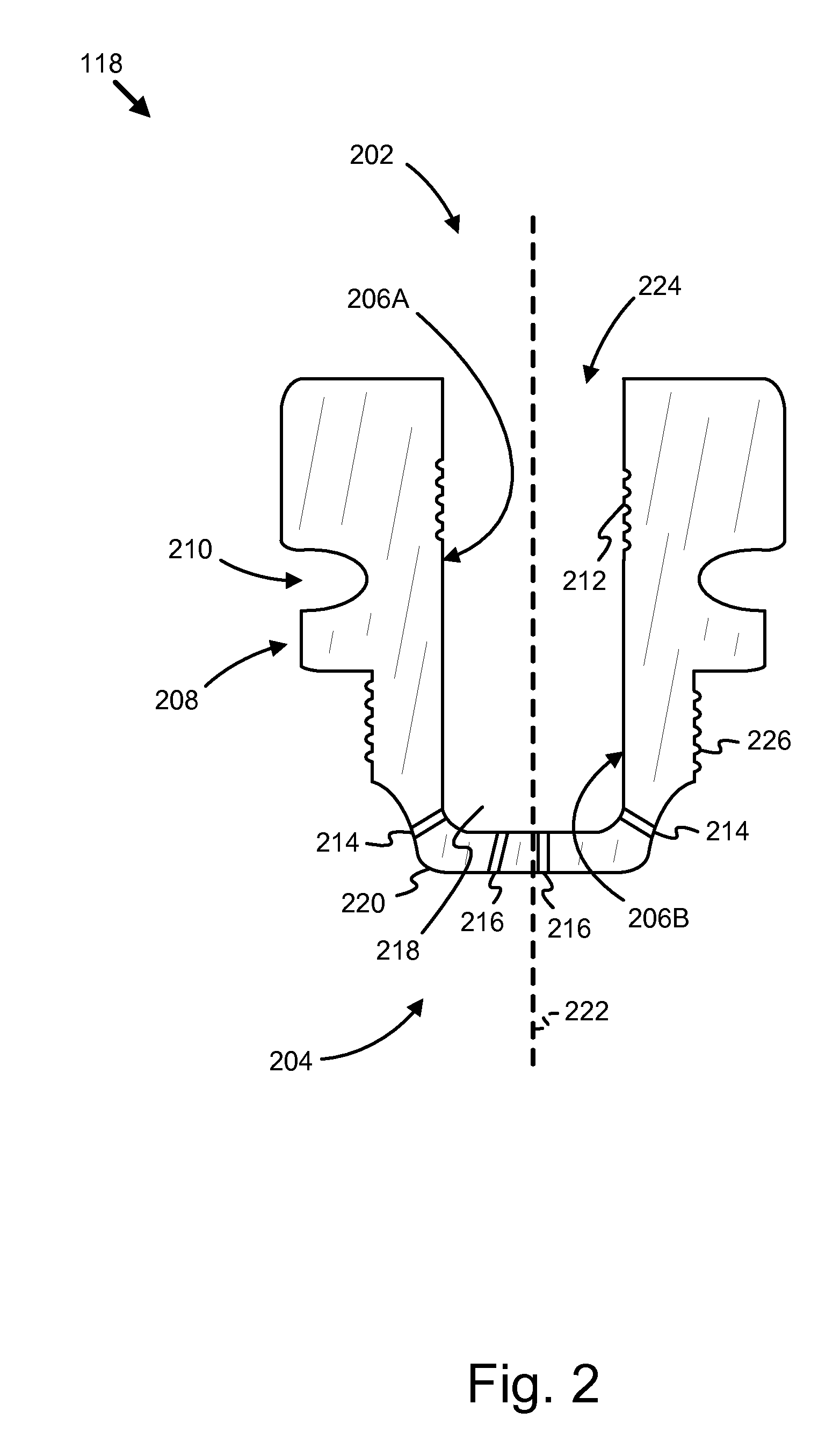

Pre-combustion device for an internal combustion engine

ActiveUS20110146618A1Liquid coolingInternal combustion piston enginesCylinder headExternal combustion engine

An apparatus is disclosed including a first end defining an inner passage along a first inner surface of the first end, where the inner passage has threads structured to receive a spark plug. The apparatus further includes a second end opposite the first end and extending into a combustion chamber of a cylinder, the second end defining a pre-combustion chamber along a second inner surface and threads on an outer surface structured to thread into a spark plug hole in a cylinder head, which may be an enlarged spark plug hole. The second end includes holes that fluidly couple the pre-combustion chamber of the second end with the combustion chamber of the cylinder.

Owner:CUMMINS INC

Combination combustion chamber

ActiveCN105953265AEnhanced blendingImprove flame stabilityContinuous combustion chamberCycloneCombustion instability

The invention relates to a combination combustion chamber. A combustion chamber head part consists of a main combustion stage and a pre-combustion stage; the main combustion stage consists of a single-grade axial cyclone, a main combustion stage nozzle and a venturi pipe; and the pre-combustion stage consists of double concave cavities and a pre-combustion stage nozzle. The main combustion stage adopts a single-oil-way centrifugal nozzle, and enables fuel to reach needed concentration and particle size distribution through pressure atomization. The pre-combustion stage adopts an evaporation pipe type nozzle; and the fuel is sprayed to an evaporation pipe for primary atomization through a straight spraying nozzle, and performs secondary atomization and evaporation mixing in the evaporation pipe under an air shearing effect. The combination combustion chamber not only can achieve the purpose of reducing the pollutant discharge in a low-pollution combustion chamber, but also can solve the problems of small-state combustion instability and large-stage visible smoke in a high-temperature-rise combustion chamber so as to widen stable working range of the high-temperature-rise combustion chamber through classified combustion, in particular special structural design and arrangement mode of the pre-combustion stage and the main combustion stage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

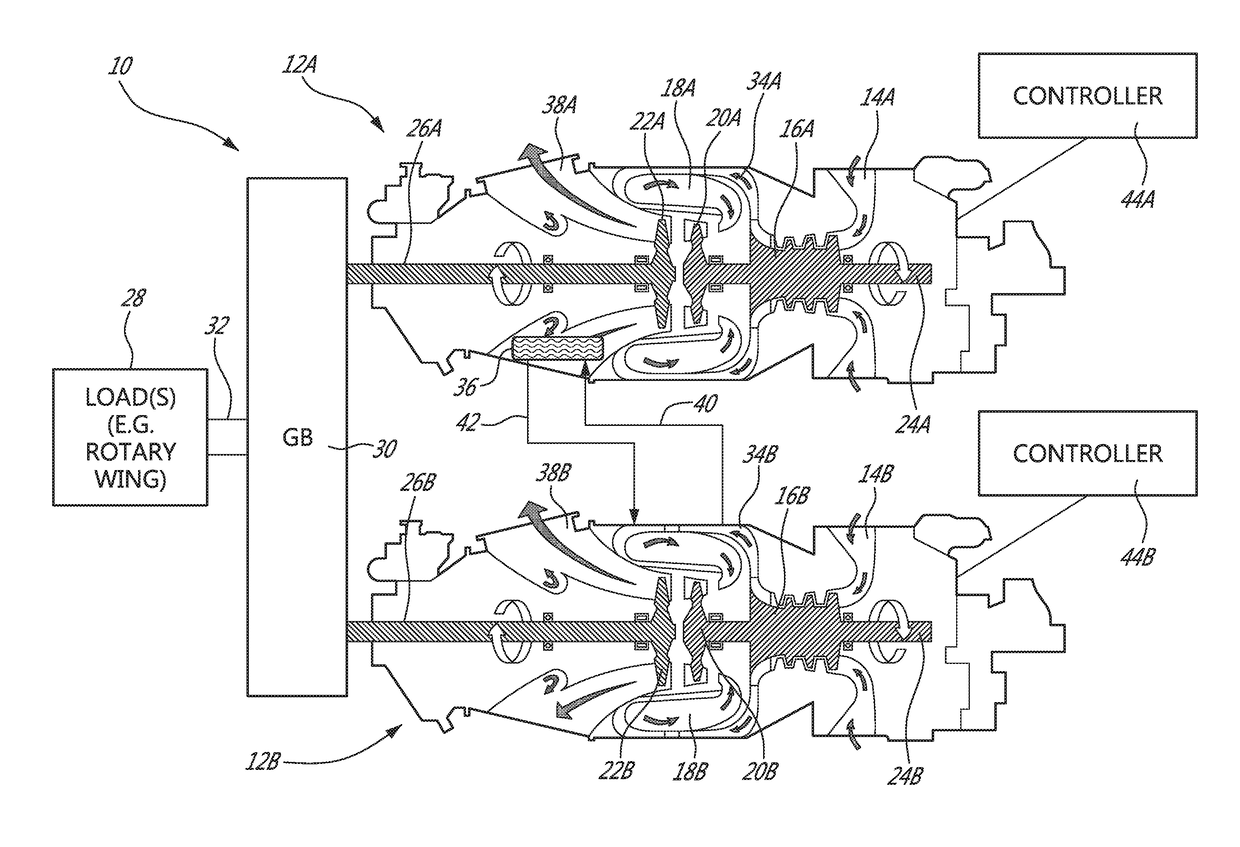

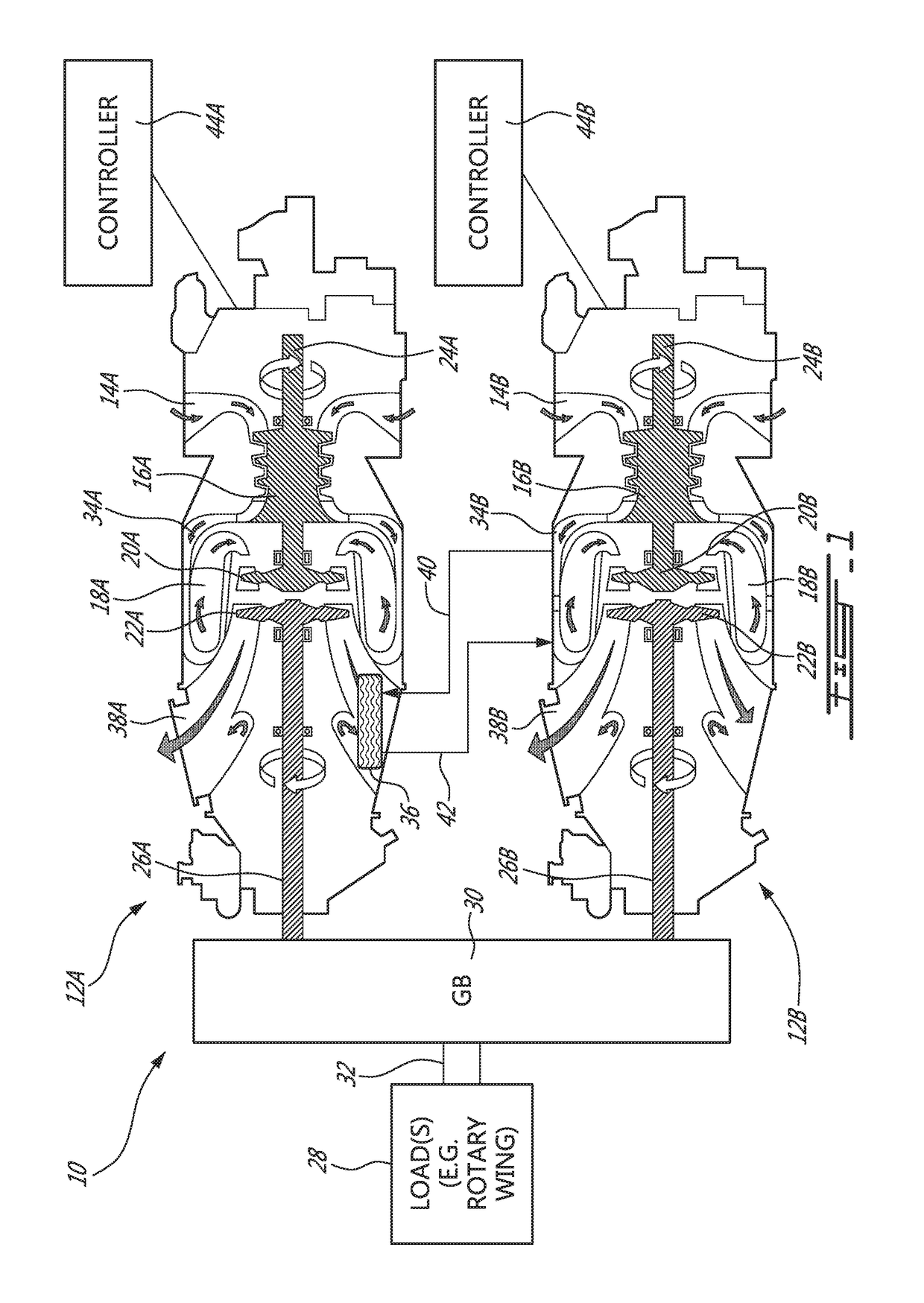

Multi-engine aircraft power plant with heat recuperation

ActiveUS20180080378A1Increase output power levelGas turbine plantsTurbine/propulsion fuel controlPower stationExhaust fumes

Multi-engine aircraft power plants and associated operating methods are disclosed. An exemplary multi-engine power plant comprises a first turboshaft engine and a second turboshaft engine configured to drive a common load such as a rotary wing of an aircraft; and a heat exchanger in thermal communication with an exhaust gas of the first turboshaft engine and in thermal communication with pre-combustion air of the second turboshaft engine. The heat exchanger is configured to permit heat transfer from the exhaust gas of the first turboshaft engine to the pre-combustion air of the second turboshaft engine.

Owner:PRATT & WHITNEY CANADA CORP

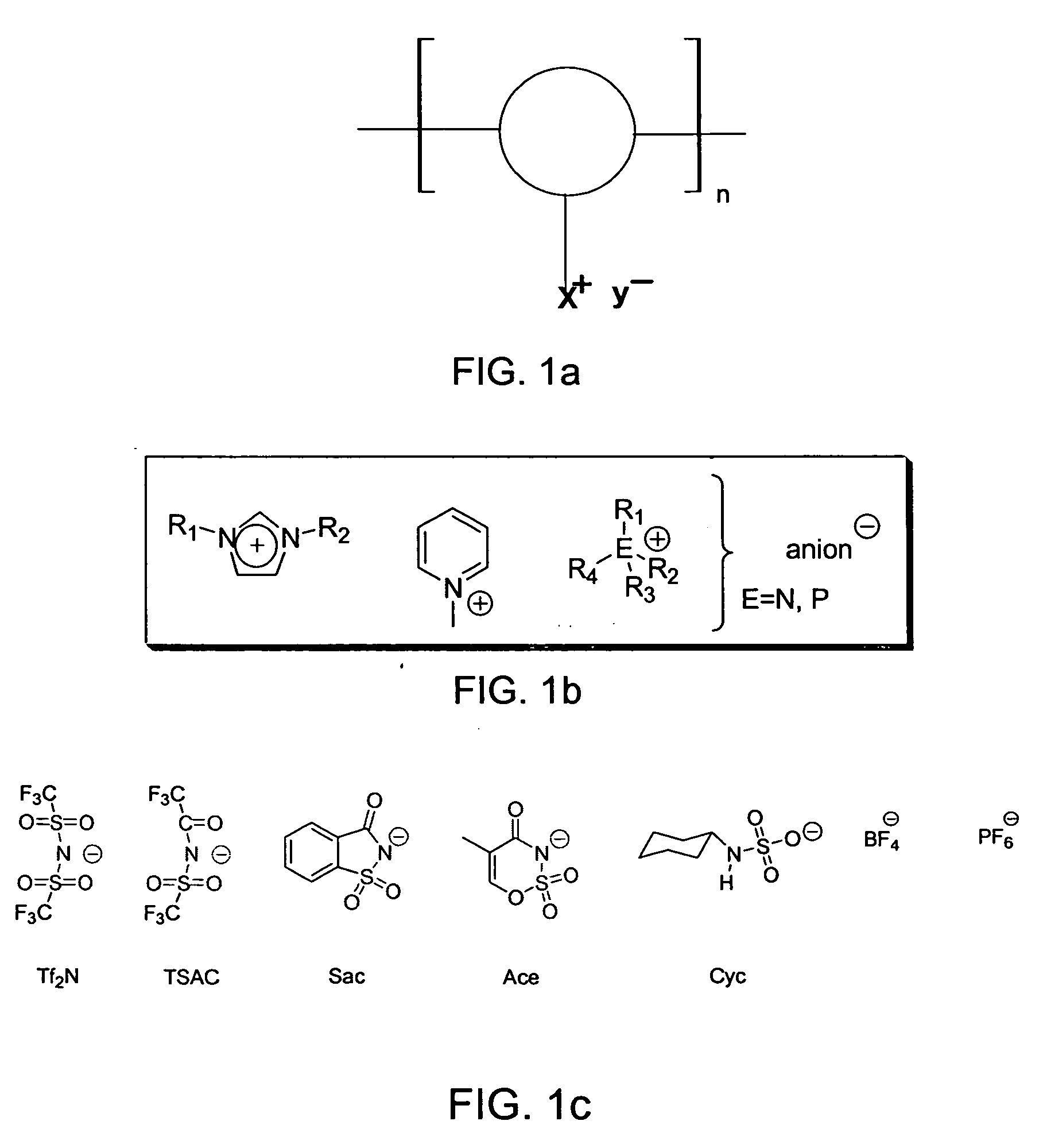

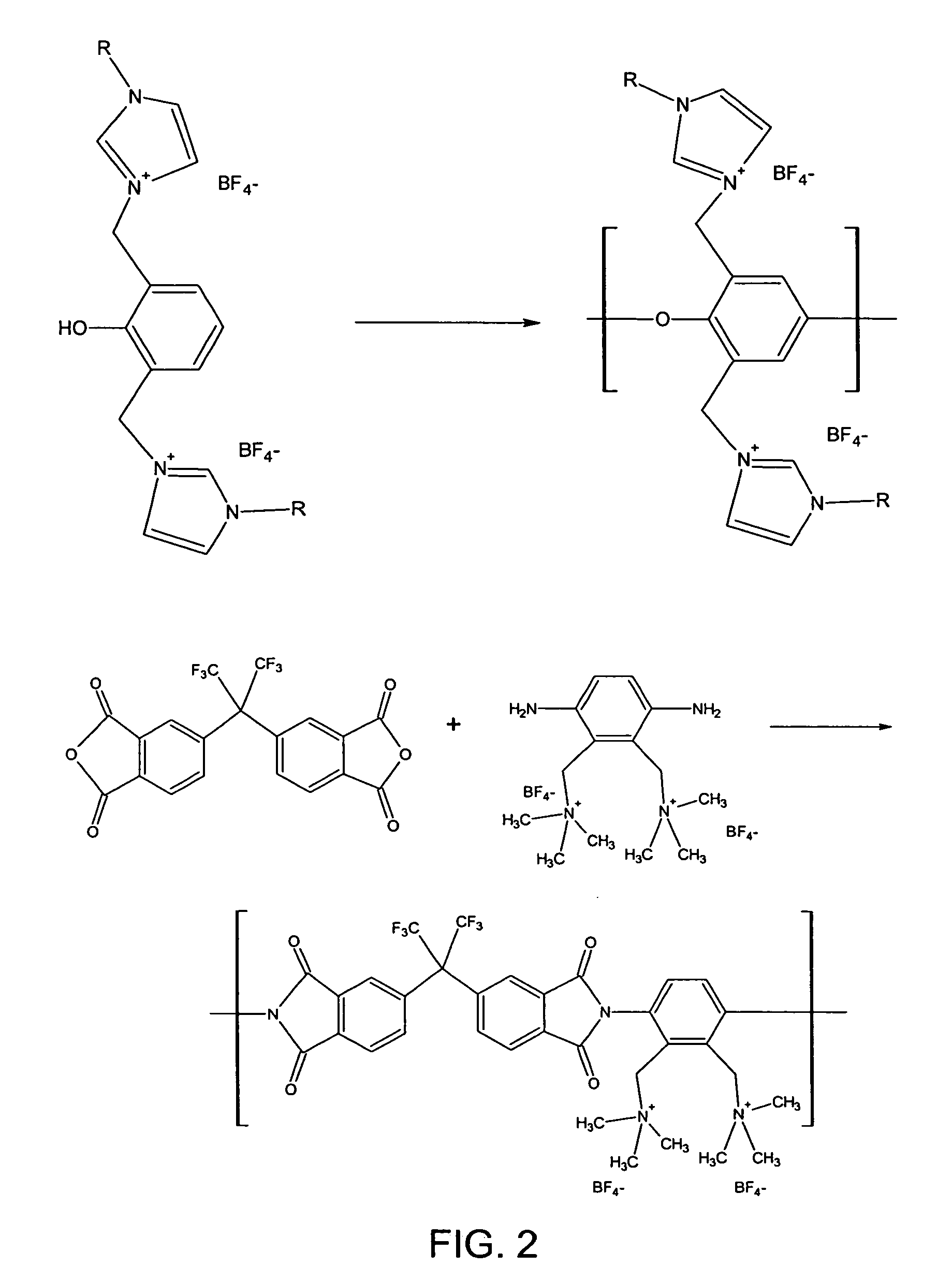

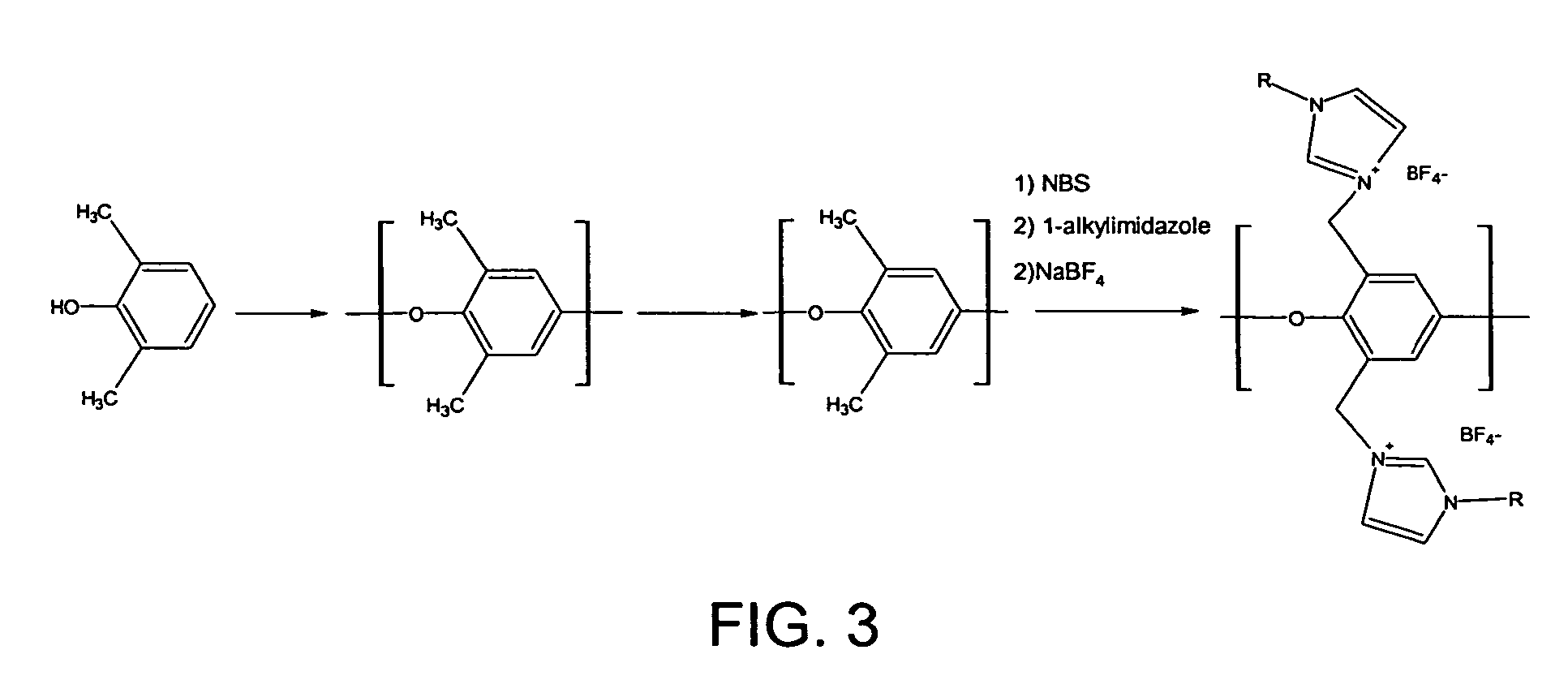

Polymers containing ionic groups for gas separation and storage

Polymeric materials containing ionic groups, which can be used as membranes and sorbents for separating gas components, for example, separating CO2 from flue gas streams and from natural gas streams, and sorbents for storing gas components. Such separation materials are used for pre-combustion separations, post-combustion separations, and natural gas separations, and are alternatives to the conventional amine absorption process.

Owner:UNIVERSITY OF WYOMING

Process for treating H.sub.2 S containing streams

InactiveUS6030597AIncrease temperatureIncrease airflowOther chemical processesDispersed particle separationSorbentSulfur

This invention is directed to an improved process for conversion of H2S to sulfur, using MOST(Mobil Offgas Sulfur Treatment) catalyst or sorbent. The sorbent is typically a magnesium-aluminate spinet, with oxidation promoters such as ceria and vanadia. H.sub.2 S from the feed gas is used to regenerate sulfated sorbent, simultaneously producing elemental sulfur which is then condensed out. The improvement involves combusting part of the feed, converting some of the feed H.sub.2 S to SO.sub.2 prior to contacting the sulfated sorbent. Thus much of the stoichiometric oxygen required for conversion of H.sub.2 S to S is supplied in the form of SO.sub.2 by this pre-combustion step, instead of coming totally from the oxidized / sulfated solid sorbent. This can decrease the amount of sorbent required, as well as the frequency of regenerations, thus reducing process cost. The hot combustion gas also helps to heat the feed stream. One or more Claus reactors may optionally be added, to further increase sulfur recovery efficiency.

Owner:MOBIL OIL CORP

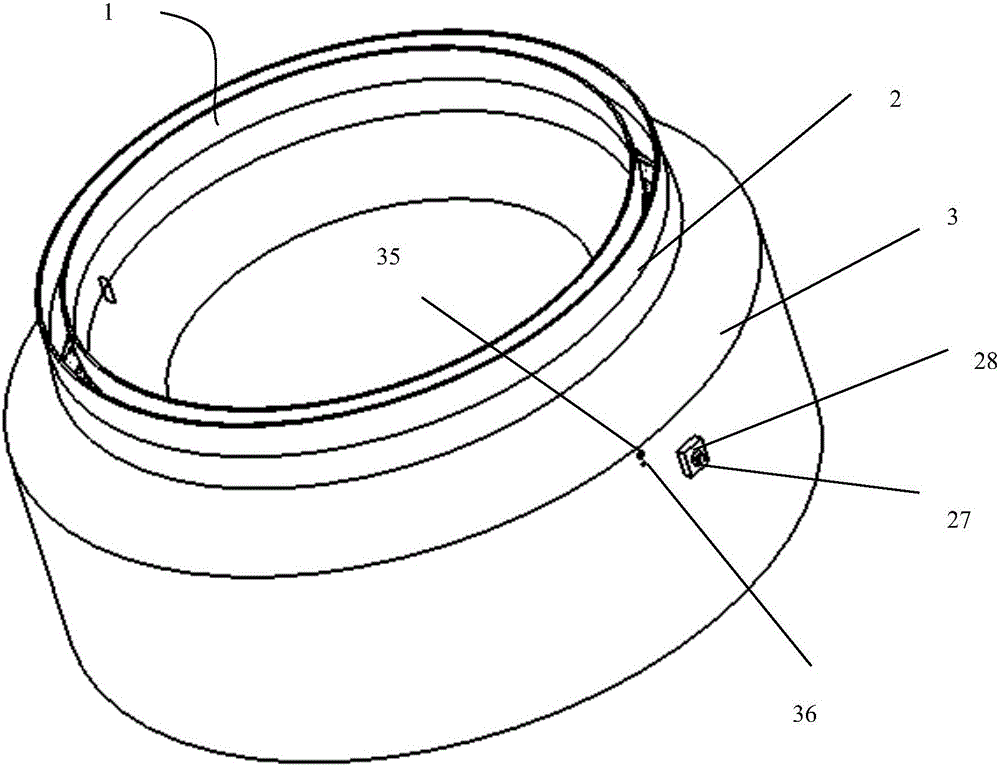

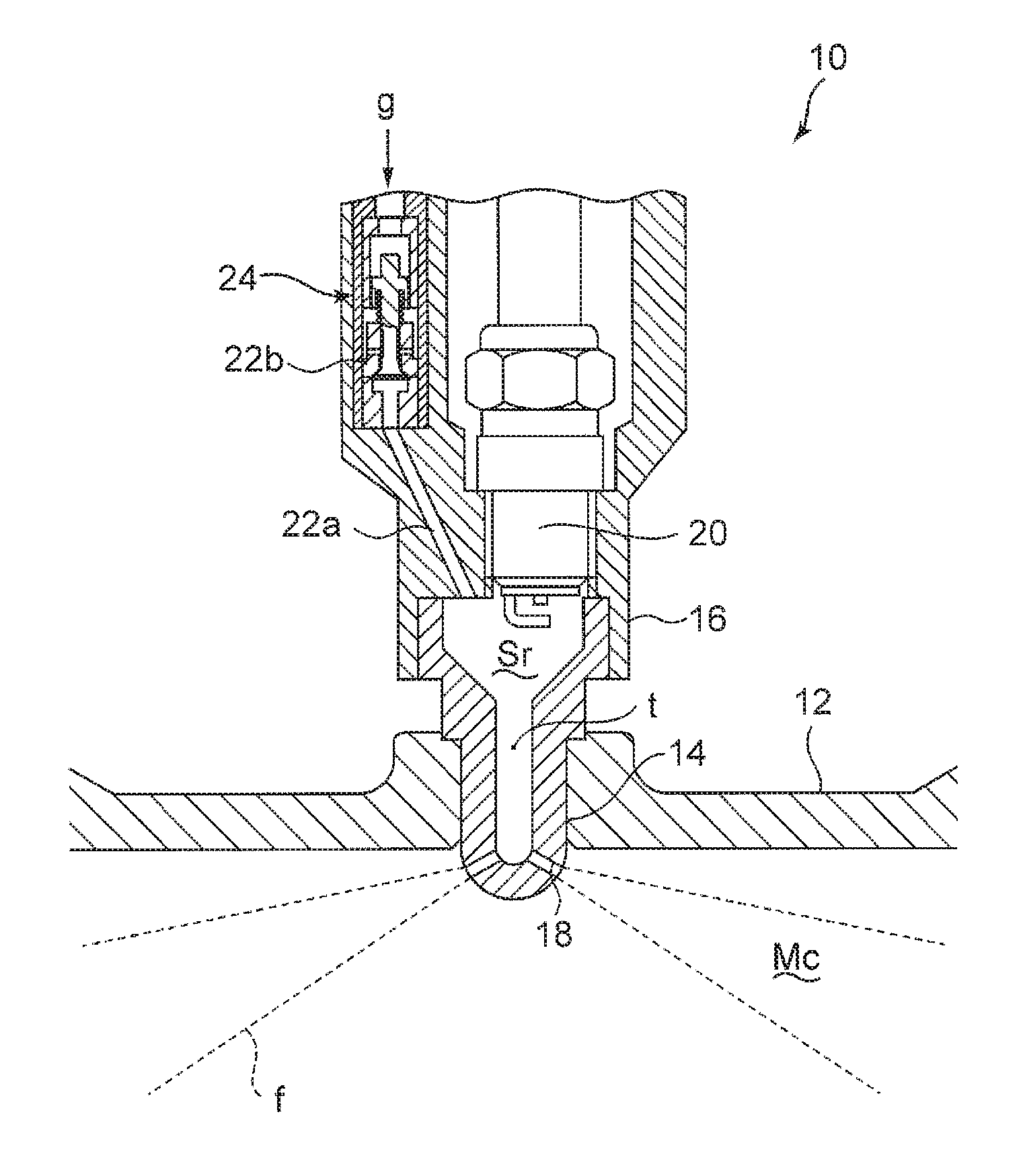

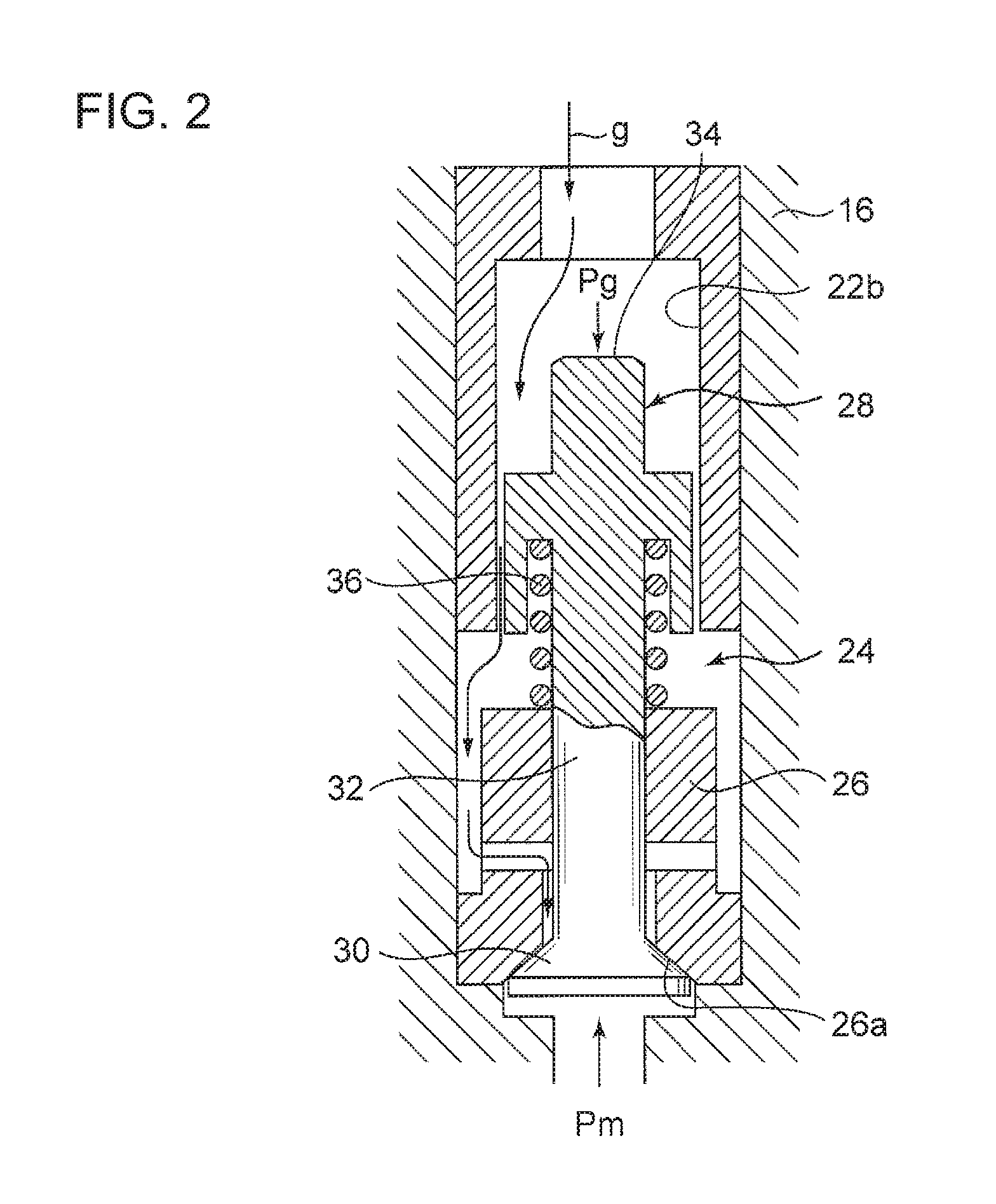

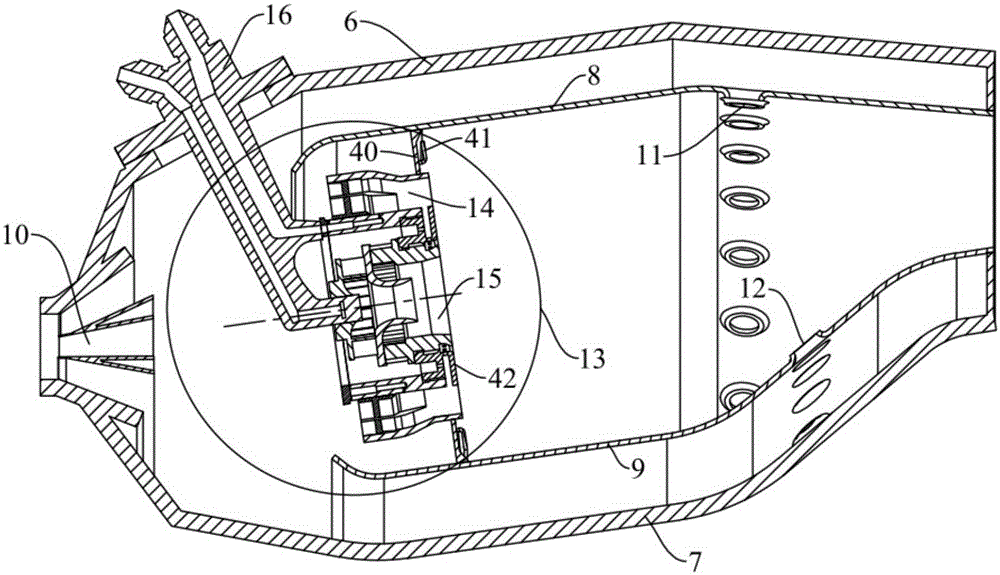

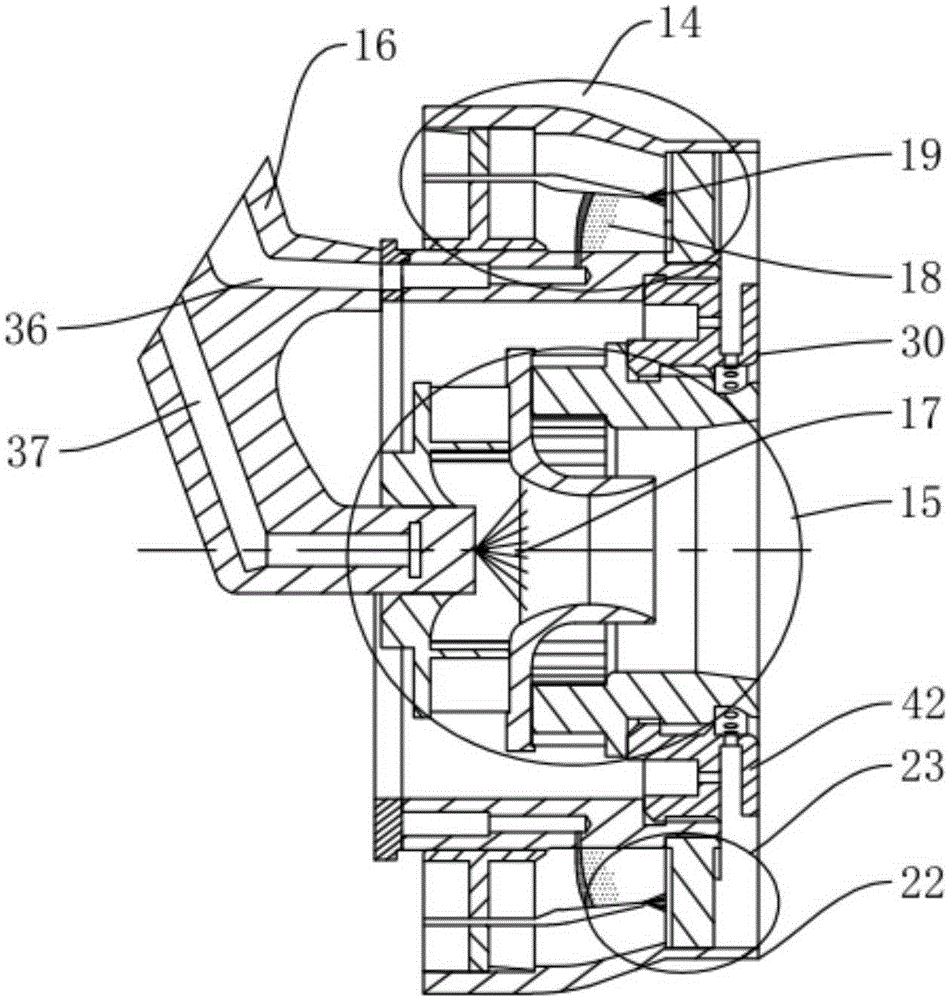

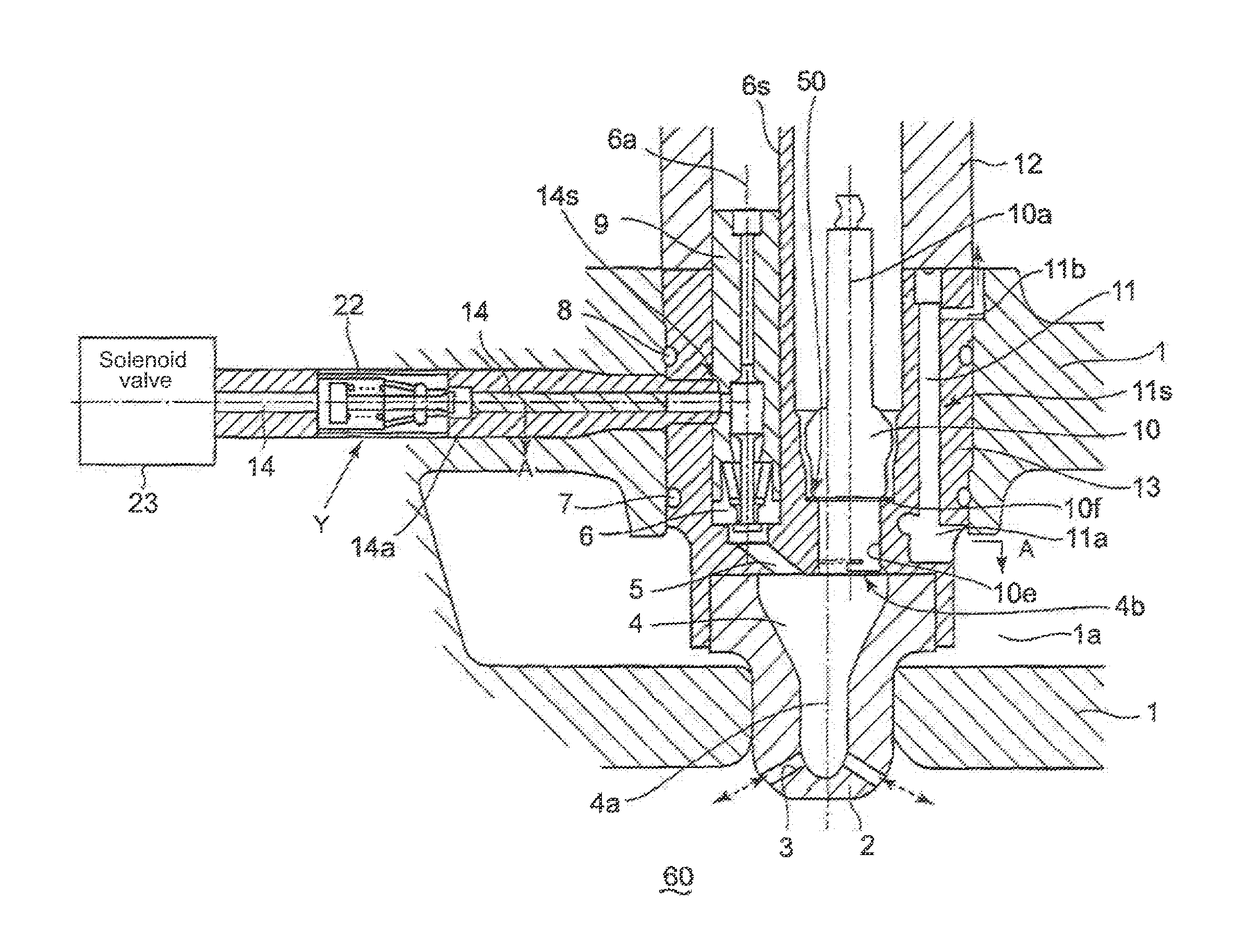

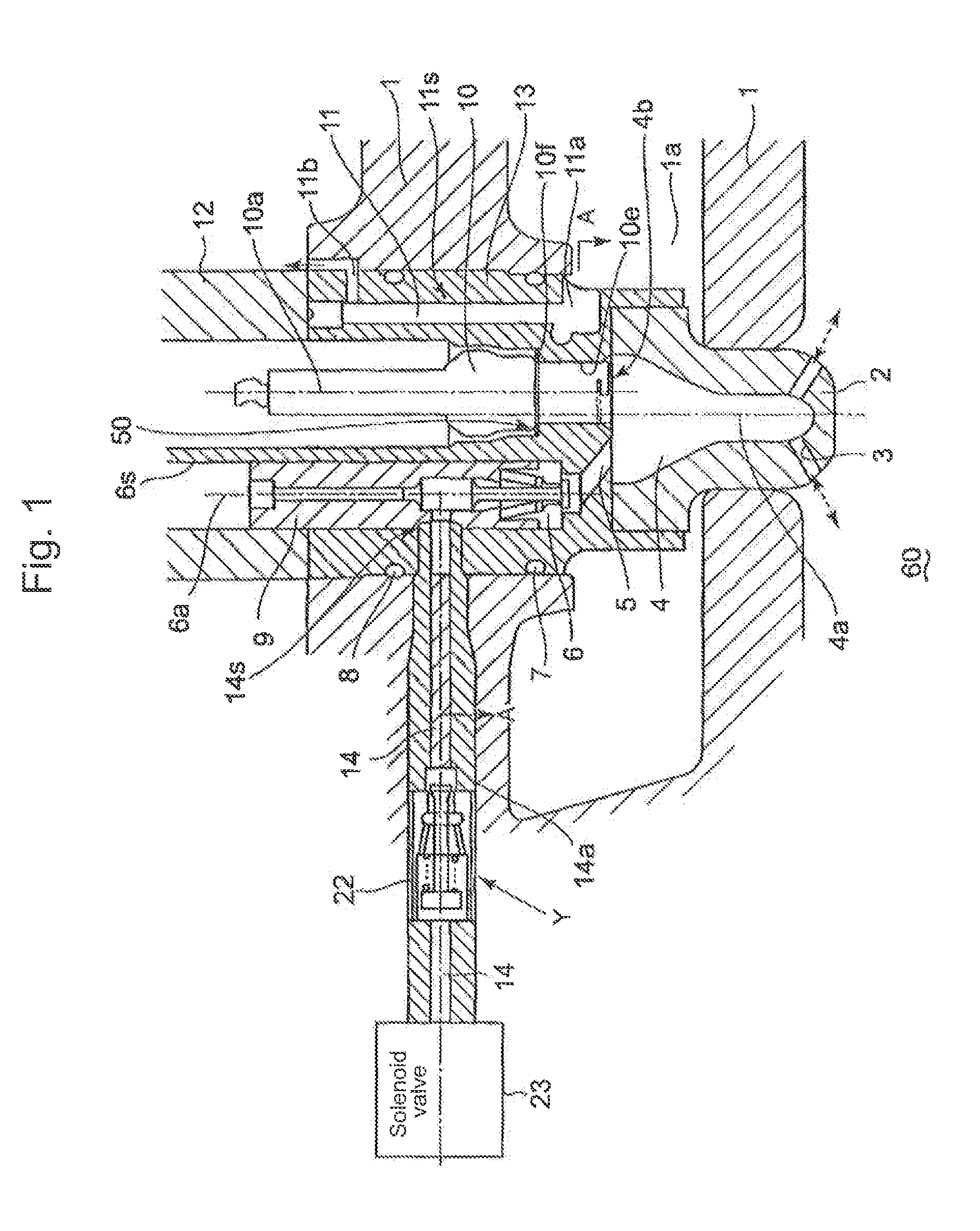

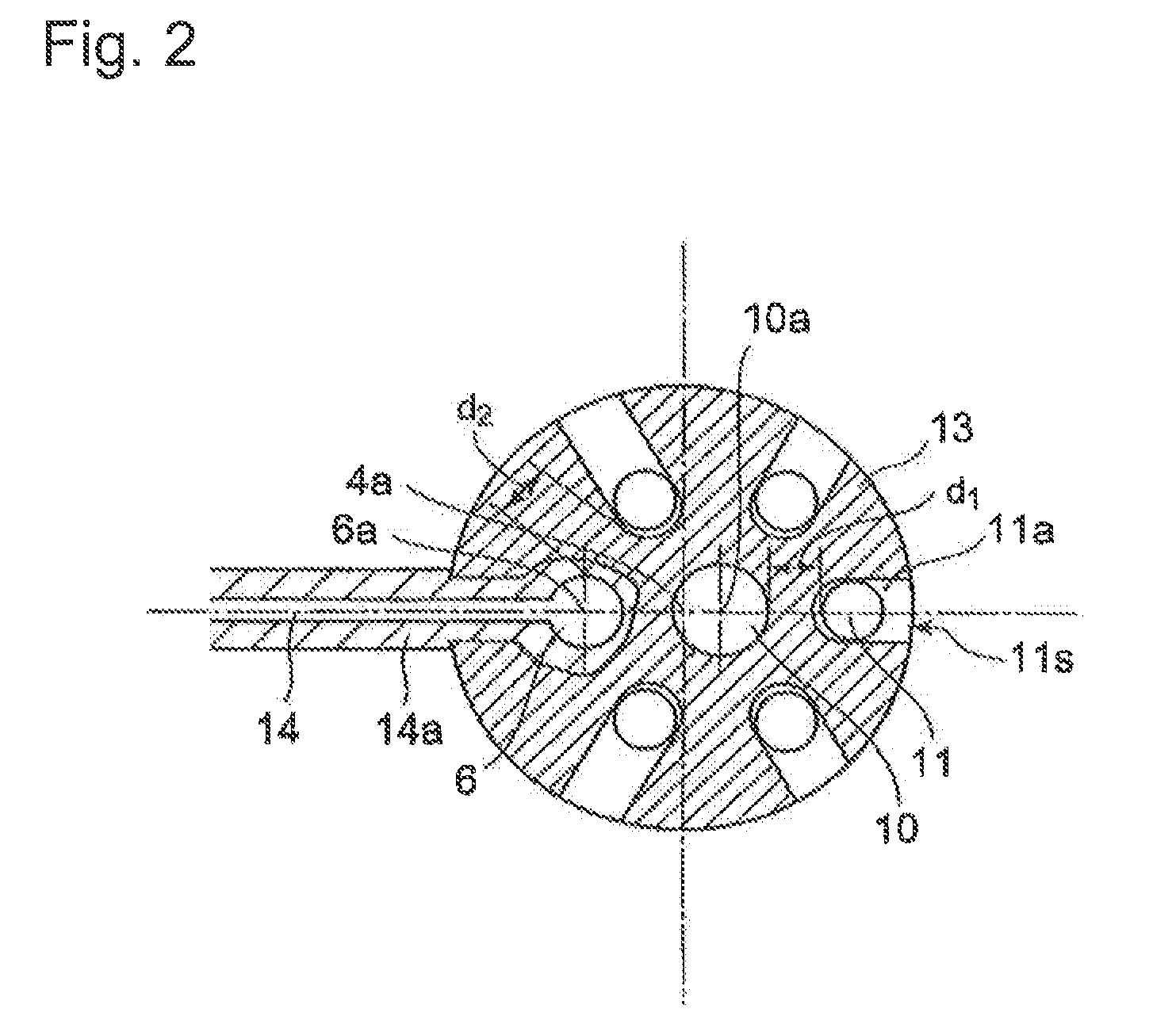

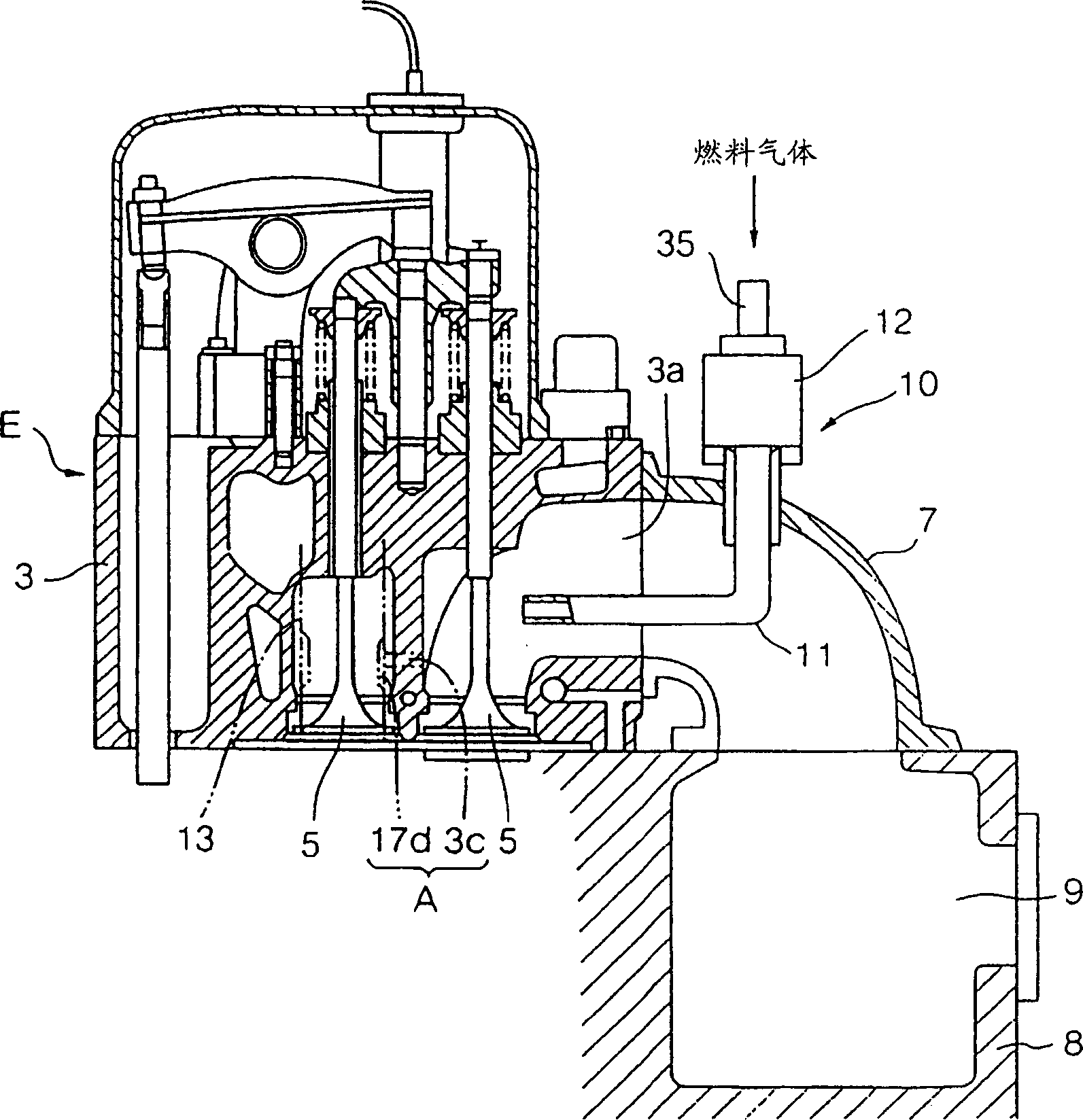

Pre-combustion-chamber type gas engine

ActiveUS20160245151A1Extension of timeImprove combustion efficiencyInternal combustion piston enginesFuel supply apparatusCombustion chamberCylinder head

An object is to improve a trap effect to trap ignition fuel gas supplied to a pre-combustion chamber and reduce an amount of non-combusted ignition fuel gas flowing out of the pre-combustion chamber to suppress a decrease in combustion efficiency. A pre-combustion-chamber type gas engine includes: a pre-combustion chamber Sr disposed on a cylinder head portion 10; a spark plug 20 disposed on an upper part of the pre-combustion chamber Sr; a pre-combustion-chamber gas supply mechanism configured to supply ignition fuel gas “g” to the pre-combustion chamber Sr via gas supply channels for the pre-combustion chamber 22a and 22b with an opening on an upper part of the pre-combustion chamber Sr; and a check valve 24 disposed in the gas supply channel 22b for the pre-combustion chamber. The opening of the gas supply channel 22a for the pre-combustion chamber is disposed on a lower surface of a cover member 16 forming the pre-combustion chamber Sr or on an upper section of a side wall of a pre-combustion-chamber member 14, the opening facing in a tangent direction of a side-wall inner peripheral surface 14a of the pre-combustion-chamber member 14. The ignition fuel gas “g” supplied to the pre-combustion chamber Sr forms a swirl flow s1 which swirls about a longitudinal axis x of the pre-combustion chamber Sr inside the pre-combustion chamber Sr.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

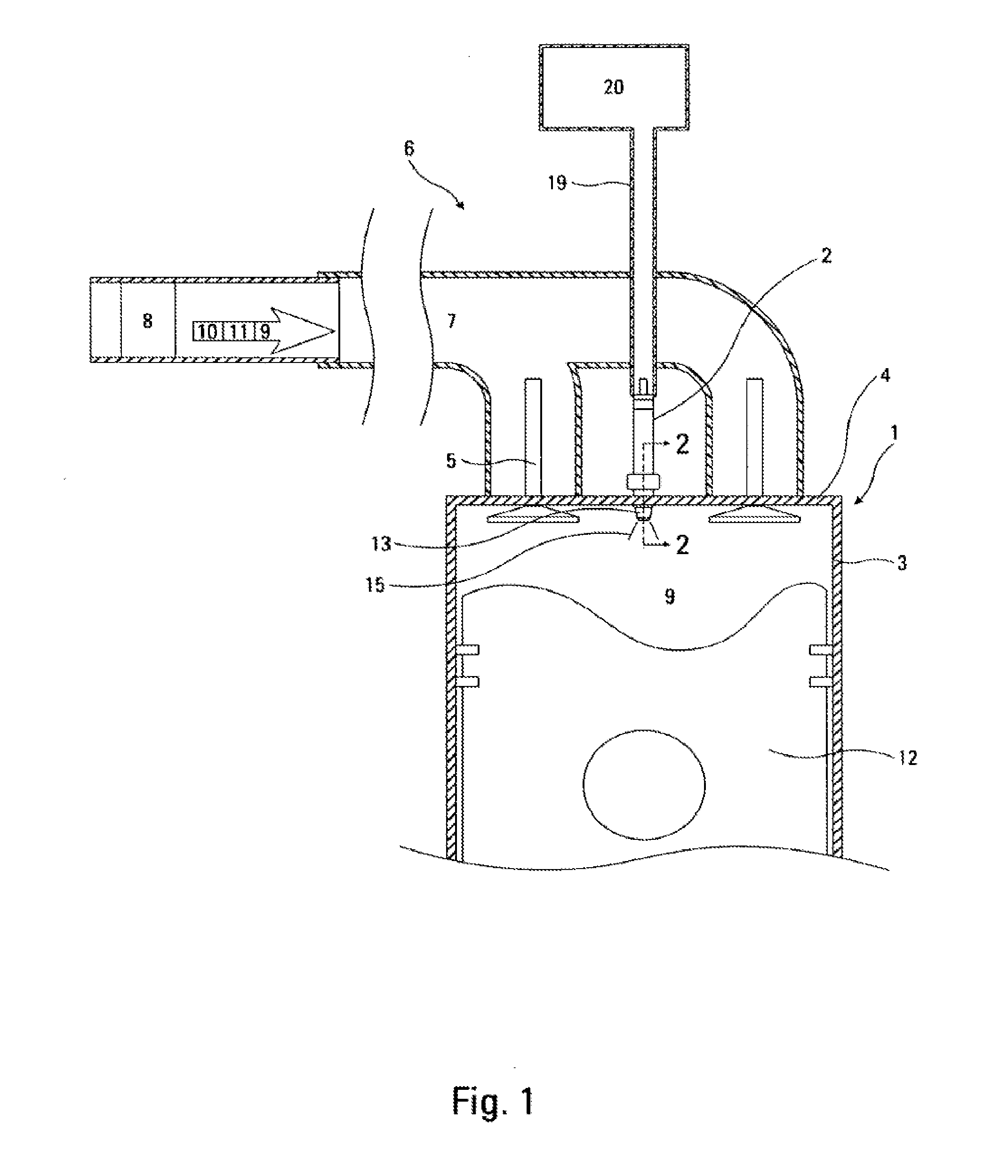

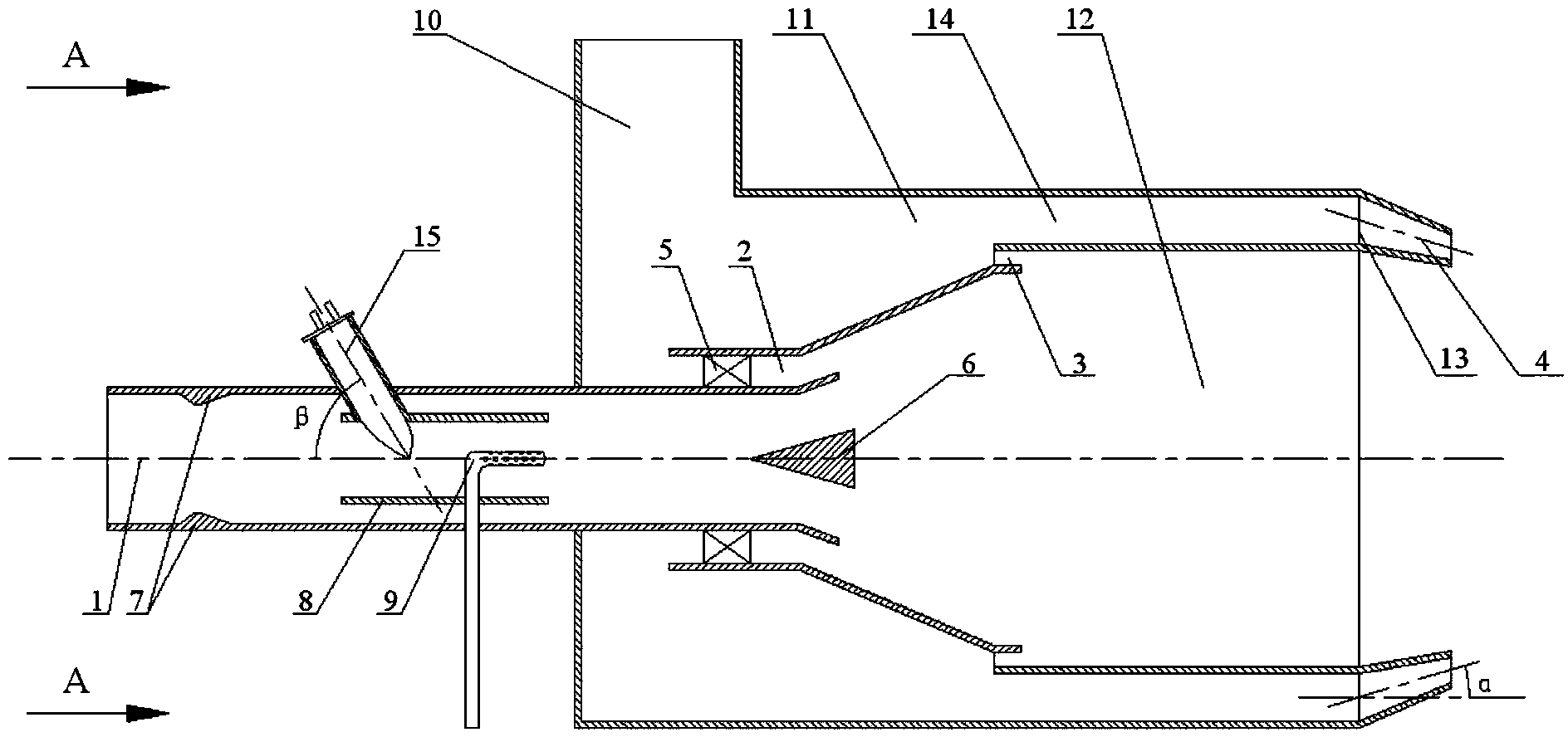

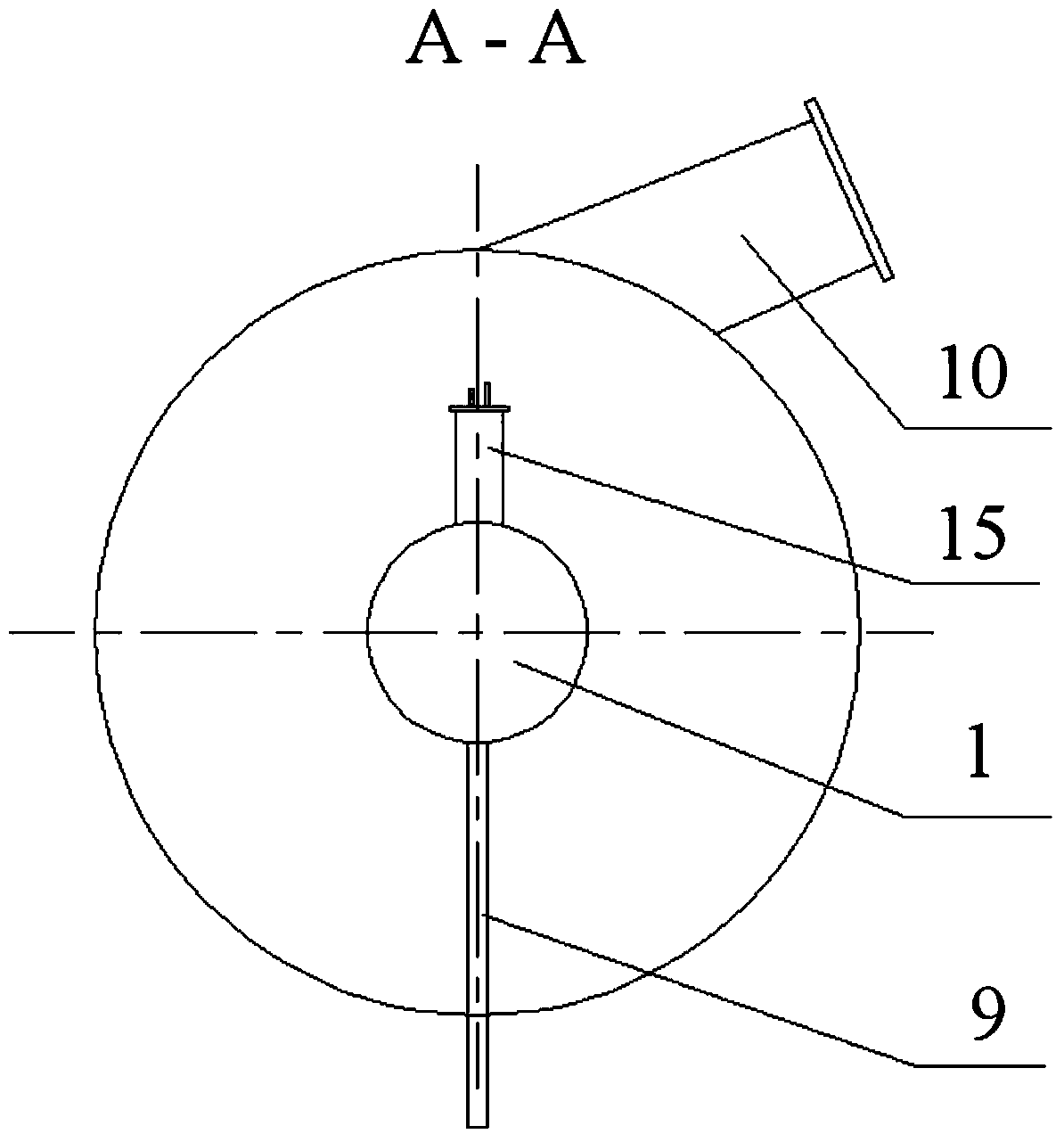

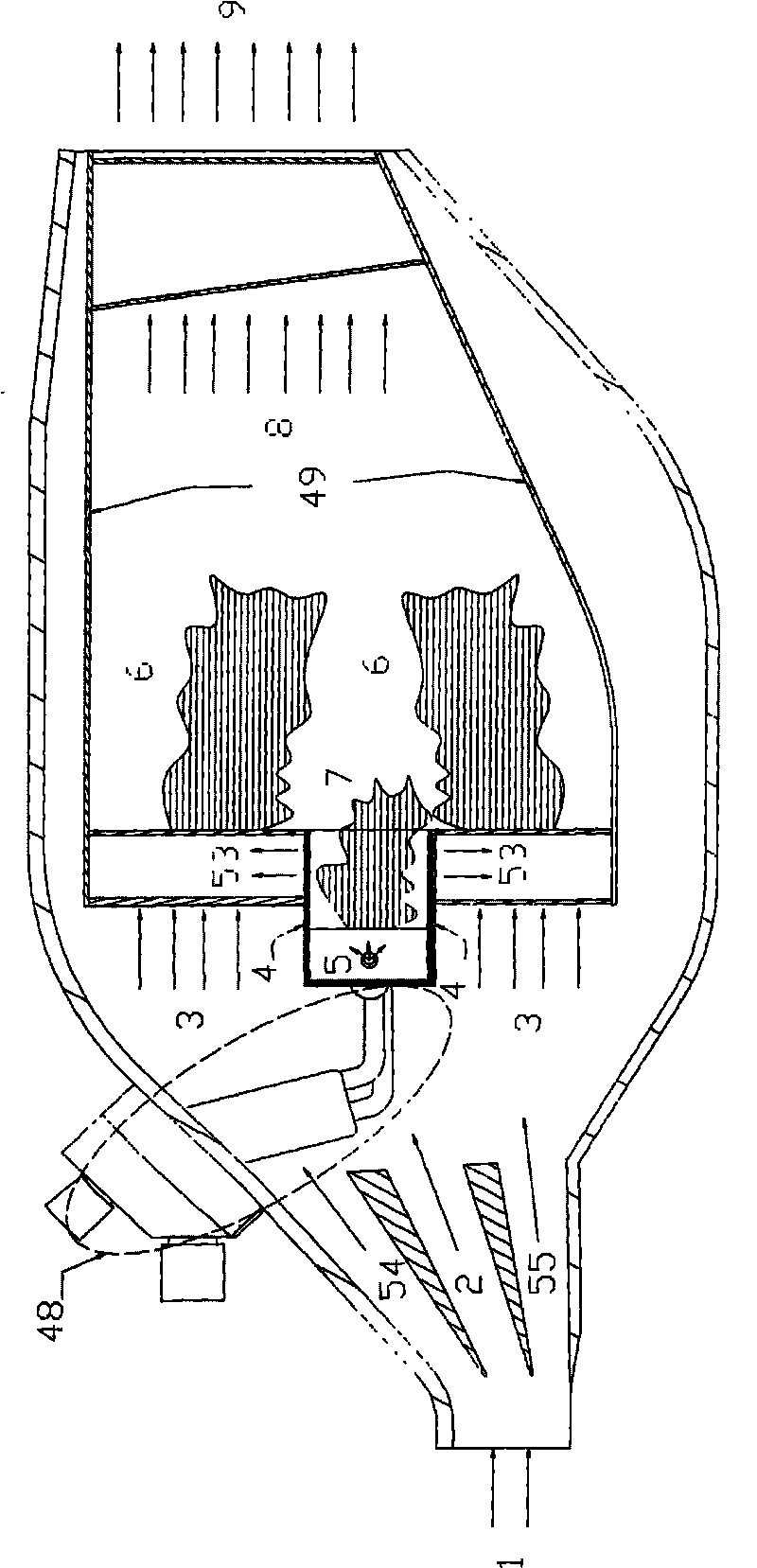

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

Methyl alcohol heater

PendingCN108049999ASimple structureCompact structureAir-treating devicesVehicle heating/cooling devicesCombustion chamberFuel oil

The invention discloses a methyl alcohol heater. The methyl alcohol heater comprises a machine body, wherein an air inlet is formed in one end of the machine body; a pre-combustion chamber is arrangedat the other end of the machine body; the pre-combustion chamber is arranged in a heat exchanger, and communicates with a main combustion chamber in the heat exchanger; an air exhaust hoe is formed in the heat exchanger; a heat exchange medium outlet of the heat exchanger is connected with a heating medium inlet of a radiator in a car; a heat exchange medium inlet of the heat exchanger is connected with one end of a circulating pump; the other end of the circulating pump is connected with a heating medium outlet of the radiator in the car; a fuel pump used for providing methyl alcohol is arranged between a position, at the air inlet, in the machine body and a pre-combustion chamber; a liquid outlet end of the fuel pump is connected with a spray nozzle; and an ignition electrode is arranged on a position, close to the spray nozzle, in the machine body. The methyl alcohol heater does not affect vehicle endurance mileage, is simple and compact in structure, and has the characteristics ofbeing sufficient in combustion and good in environment friendliness; and according to a test, content of emission pollutants of the methyl alcohol heater is only 1 / 3-1 / 2 that of the fuel oil heater,so that smoke is not generated during starting and stopping.

Owner:KAILONG HIGH TECH

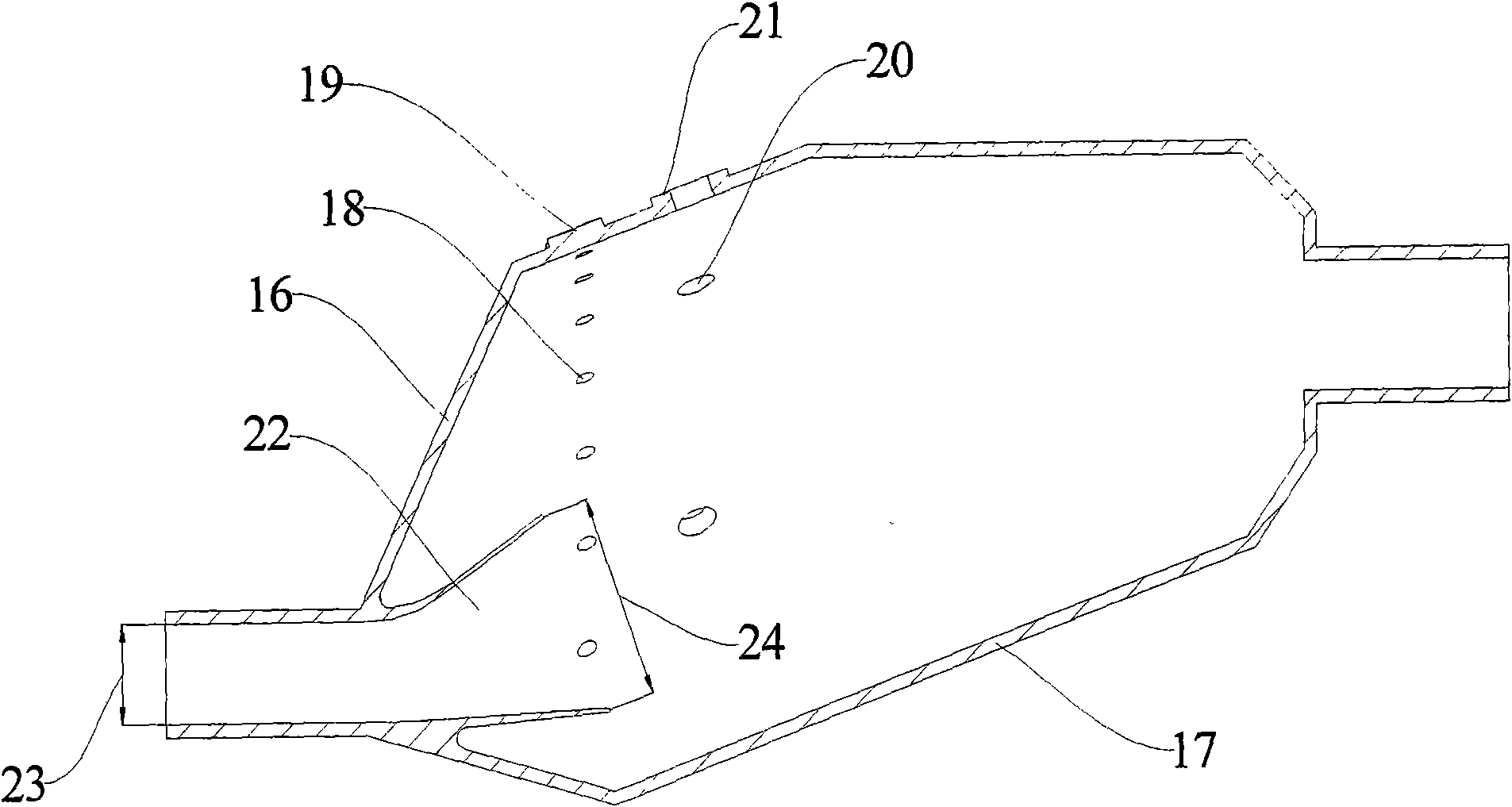

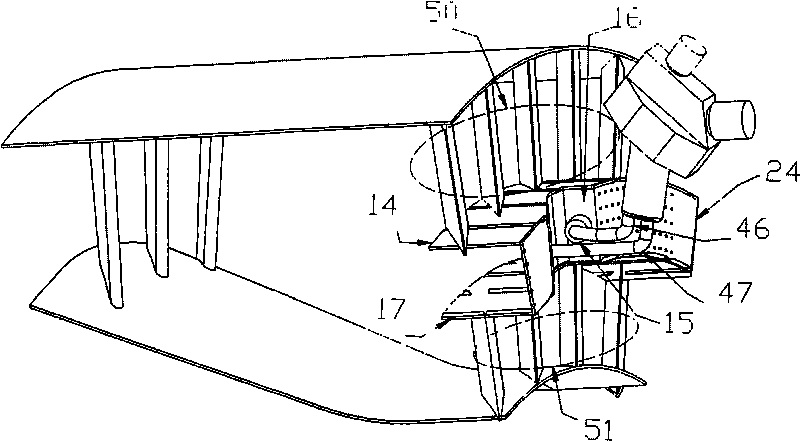

Low-pollution combustion chamber with main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow

InactiveCN105180215AImprove blending uniformityStrong shearContinuous combustion chamberAviationCyclone

The invention discloses a low-pollution combustion chamber with a main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow. The low-pollution combustion chamber adopts a single annular cavity structure, and comprises a diffuser, a combustion outdoor box, a combustion indoor box, a flame cylinder outer wall, a flame cylinder inner wall and a combustion chamber head part; the combustion chamber adopts a classification combustion scheme; the combustion head part is divided into a pre-combustion stage and the main combustion stage; the pre-combustion stage adopts a mode of combining rotational flow-stable diffusion combustion with rotational flow premixing combustion; the combustion mode reduces the pollutant discharge under small working conditions when not influencing stable combustion; and the main combustion stage adopts a premixing pre-evaporation combustion mode to be in favor of uniform combustion. The combustion chamber adopts a center classification structure; the pre-combustion stage is simple in structure; the main combustion grade adopts a two-grade reverse cyclone distributed in the radial direction; and two parts of reverse rotational flows shear an oil film, so that the atomization effect is greatly improved, the atomization of fuel of the main combustion stage and the mixing with air are enhanced, the premixing pre-evaporation of the fuel is reinforced, and the pollution discharge of whole landing and taking-off circulation of an aero-engine combustion chamber is further reduced.

Owner:BEIHANG UNIV

Power generation process with partial recycle of carbon dioxide

ActiveUS20110219777A1Reduce environmental impactDecrease in carbon dioxide contentGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

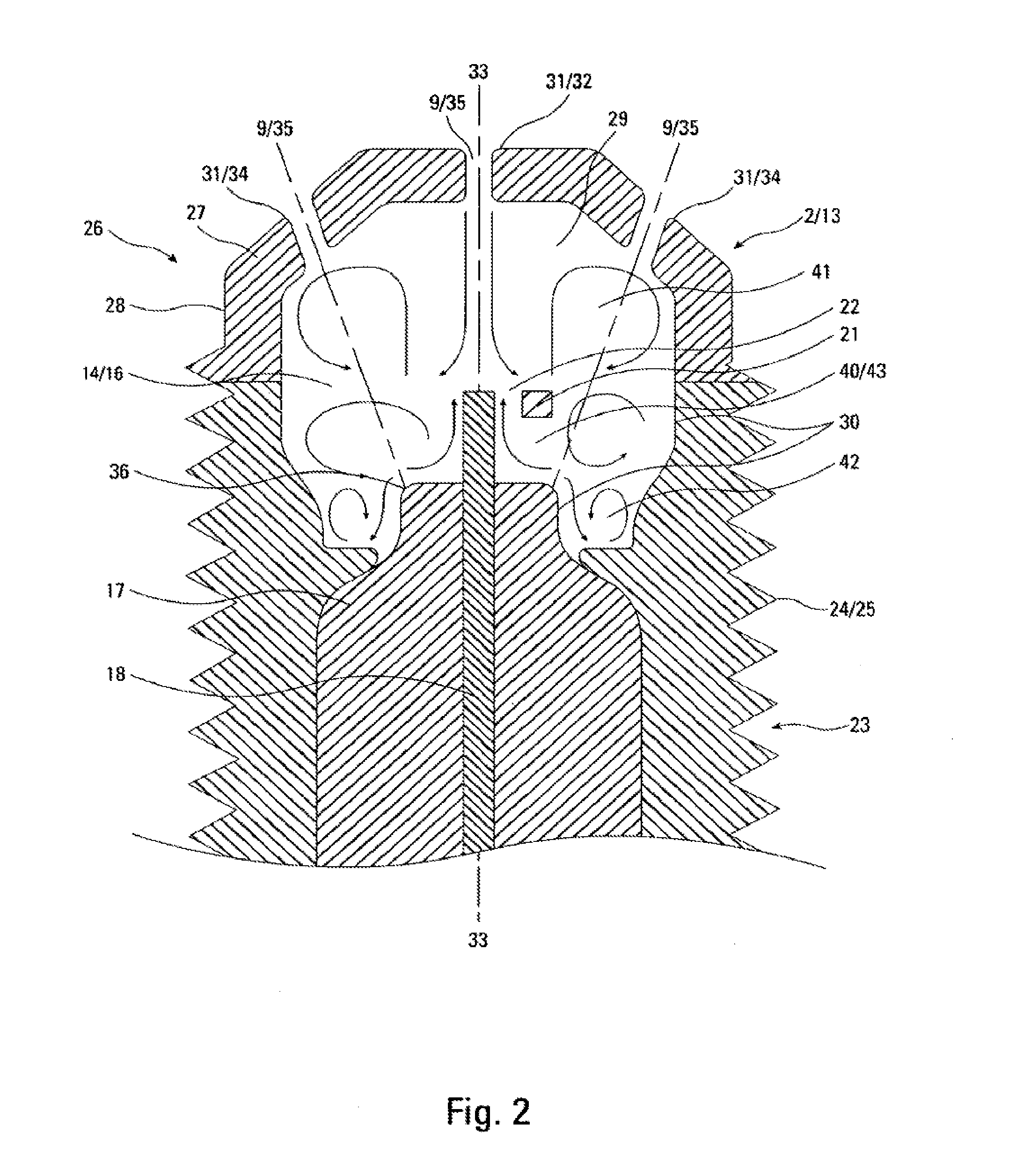

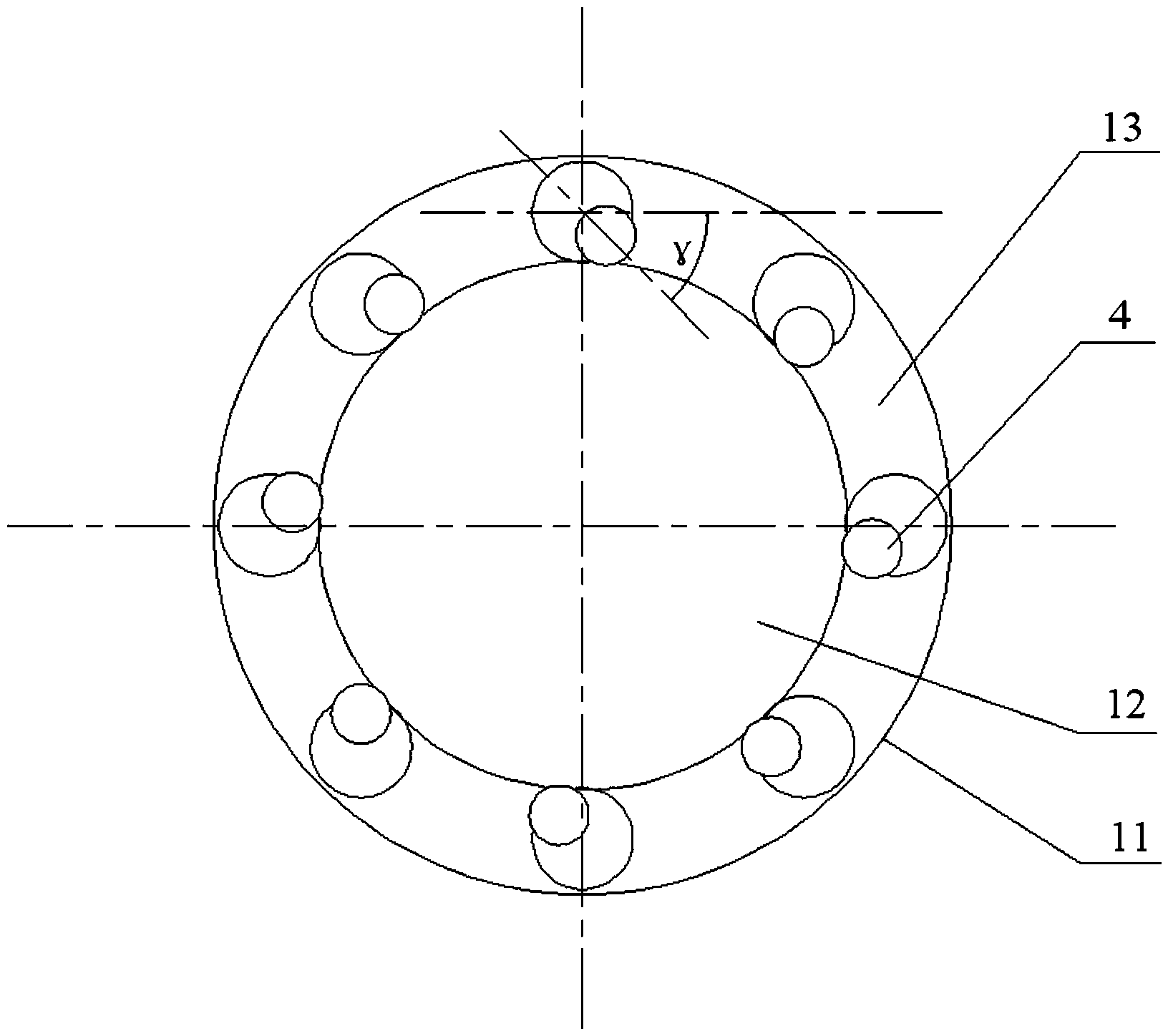

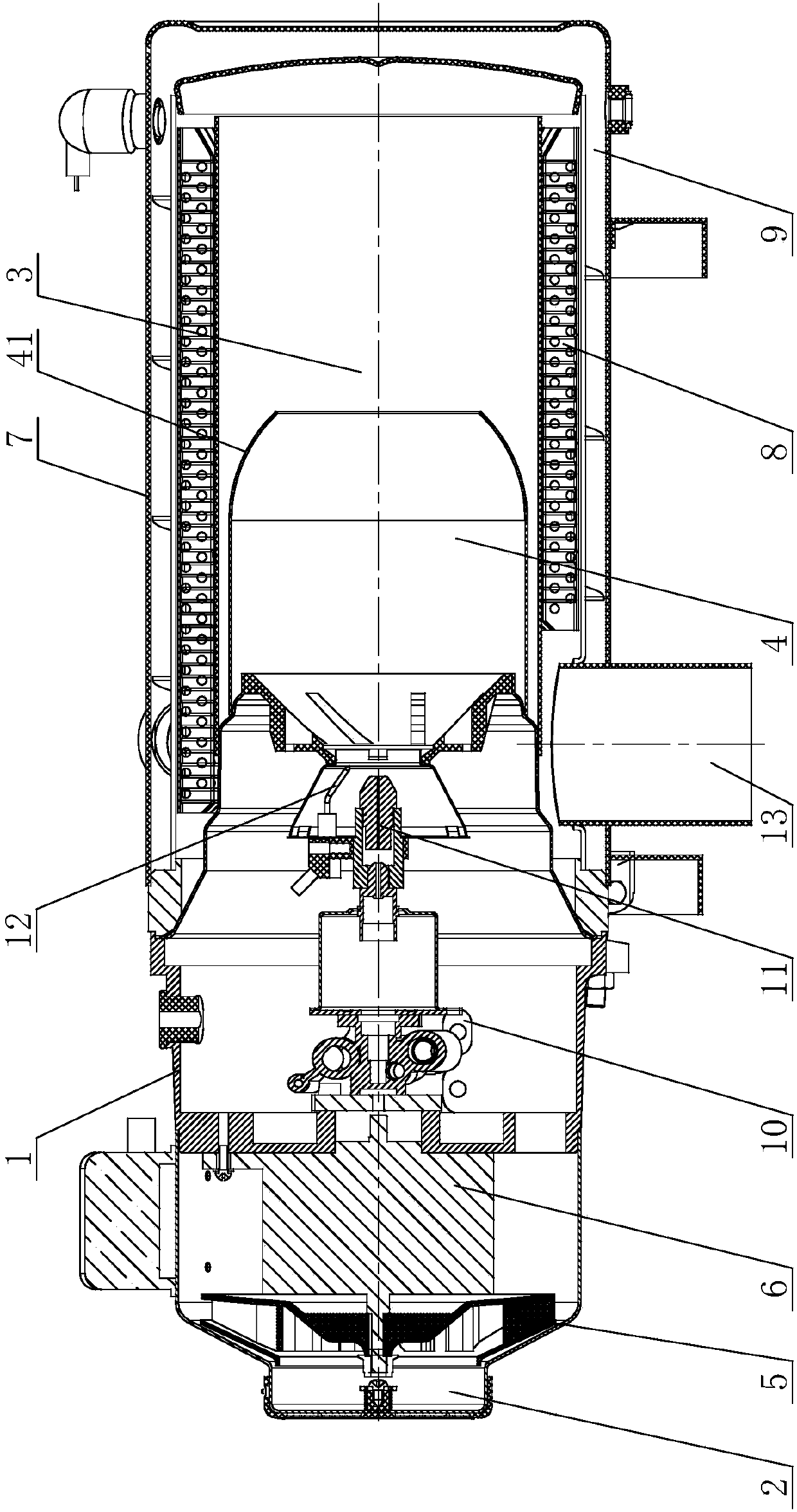

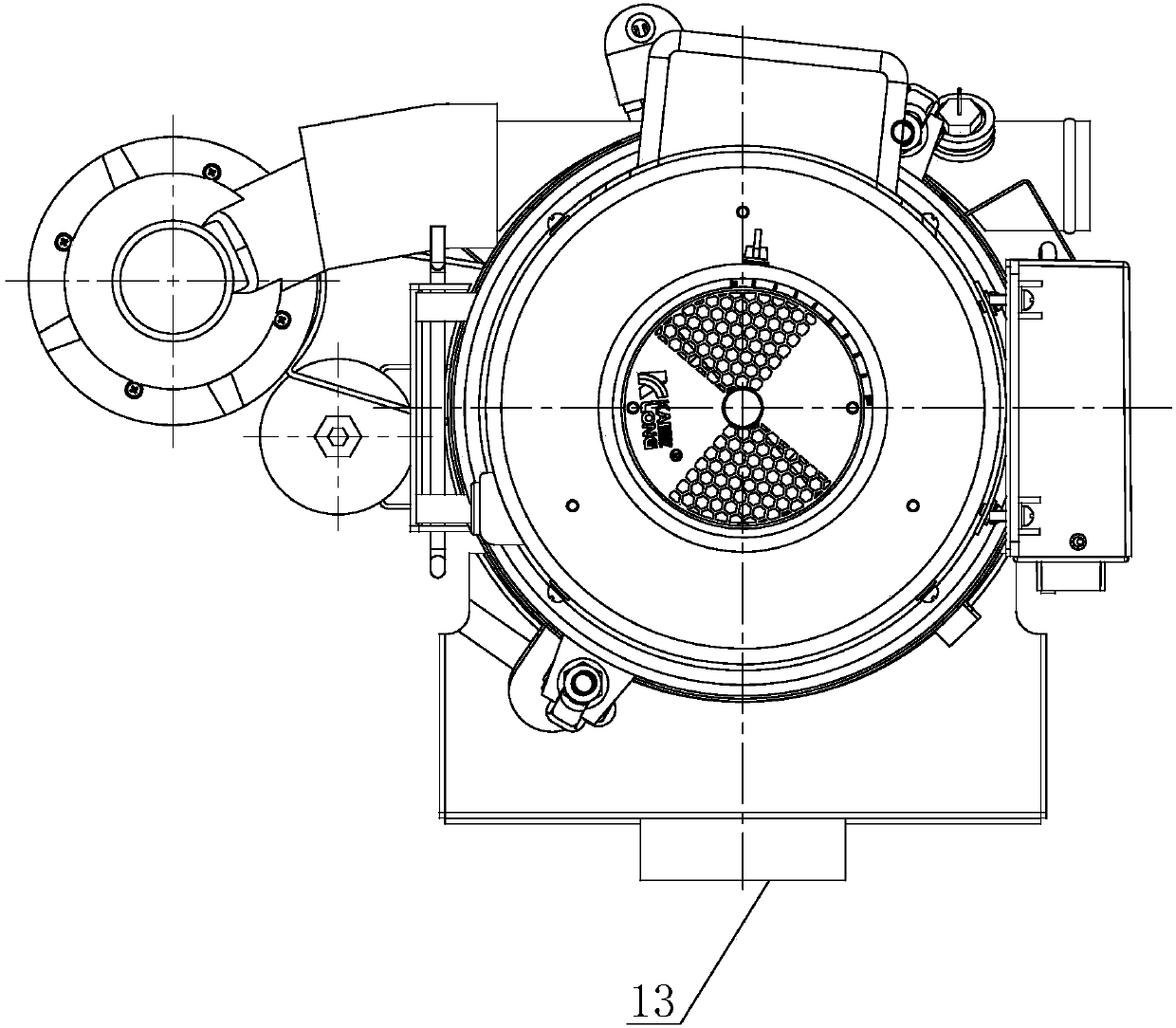

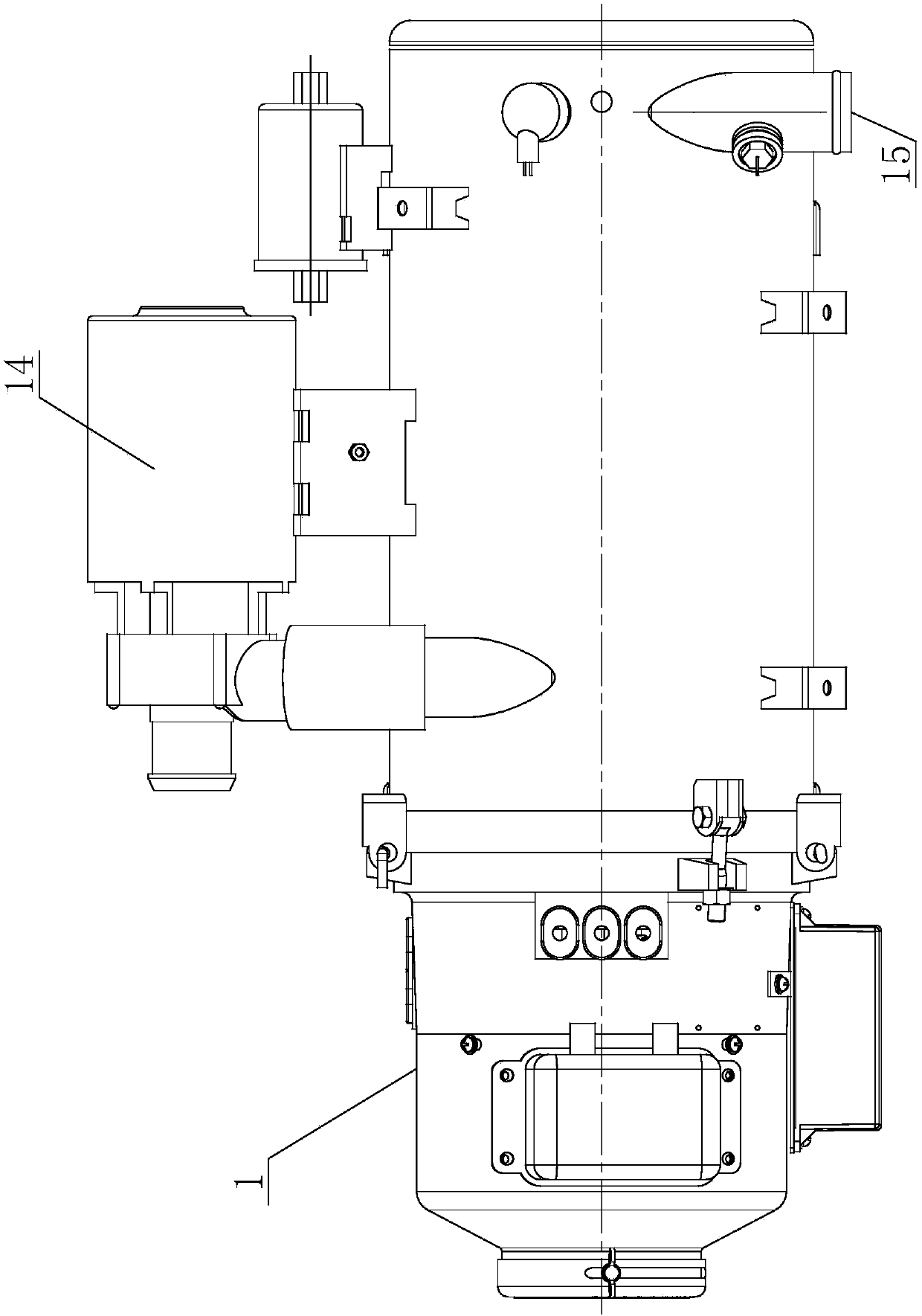

Double-pre-film pneumatic nebulization low pollution combustor head structure

The invention discloses a double-pre-film pneumatic nebulization low pollution combustor head structure. Combustion is organized in a combustor head in a center classification mode. The combustor head structure is divided into a main combustion level and a pre-combustion level. The pre-combustion level is of a double-level swirl cup structure, combustion is organized in a partially premixing mode, and the requirements for combustion stability and pollutant discharge of small working conditions are met. The main combustion level is of an axial swirler double-pre-film structure, combustion is conducted in a combustor in a premixing mode, and combustion pollutants can be effectively reduced through premixing combustion. The double-pre-film type main combustion level structure comprises two stages of independent oil collecting rings, two stages of axial swirlers and two stages of pre-film plate structures. Each stage of independent oil collecting ring is provided with a plurality of beveled fuel injection holes. Each stage of fuel is injected out through the fuel injection holes and then strikes the pre-film plates to be expanded into oil films. The structure is beneficial for fuel classification of the whole combustor under different working conditions, ensures reasonable oil-gas distribution, and further reduces the pollutant discharge level in the whole cycle of landing and taking off of the combustor of an aero-engine.

Owner:BEIHANG UNIV +1

Central cavity stable fire tangential combustion chamber

InactiveCN101737802AReduce dwell timeCompact structureContinuous combustion chamberLow speedCombustion chamber

The invention discloses a central cavity stable fire tangential combustion chamber, which consists of a shunting type diffuser, a combustion chamber external cartridge receiver, a central cavity rear step pre-combustion stage, an outer ring blunt body flame stabilizer main combustion stage, an inner ring blunt body flame stabilizer main combustion stage, a fuel supply system, an inner flame tube,an outer flame tube and an outlet supporting plate. An air flow with a deflection angle is diffused into the combustion chamber by the shunting type diffuser; the central cavity pre-combustion stage consists of a rear step, a top plate, a nozzle, a tangential slot inner ring and a tangential slot outer ring, and in the pre-combustion stage, the flame is stabilized by a low-speed recirculation zone generated by the rear step; the inner ring and the outer ring blunt body flame stabilizer main combustion stages consist of the inner ring, the outer ring and blunt body stabilizers with deflection angles, the high temperature and high pressure fuel jetted out of the inner ring and outer ring blunt body flame stabilizers is mixed with air, is ignited by the pre-combustion stage, and is burnt stably in a low-speed zone after a blunt body; and the outlet supporting plate is arranged between the inner flame tube and the outer flame tube and has an included angle with the axial line of the combustion chamber, and the outlet gas of the combustion chamber has an deflection angle. The central cavity stable fire tangential combustion chamber realizes tangential flow and tangential combustion while ensuring stable combustion for providing power; besides, the structure is simplified, and the weight of the combustion chamber is reduced.

Owner:BEIHANG UNIV

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

Power generation process with partial recycle of carbon dioxide

ActiveUS20110219778A1Reduce environmental impactDecrease in carbon dioxide contentGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

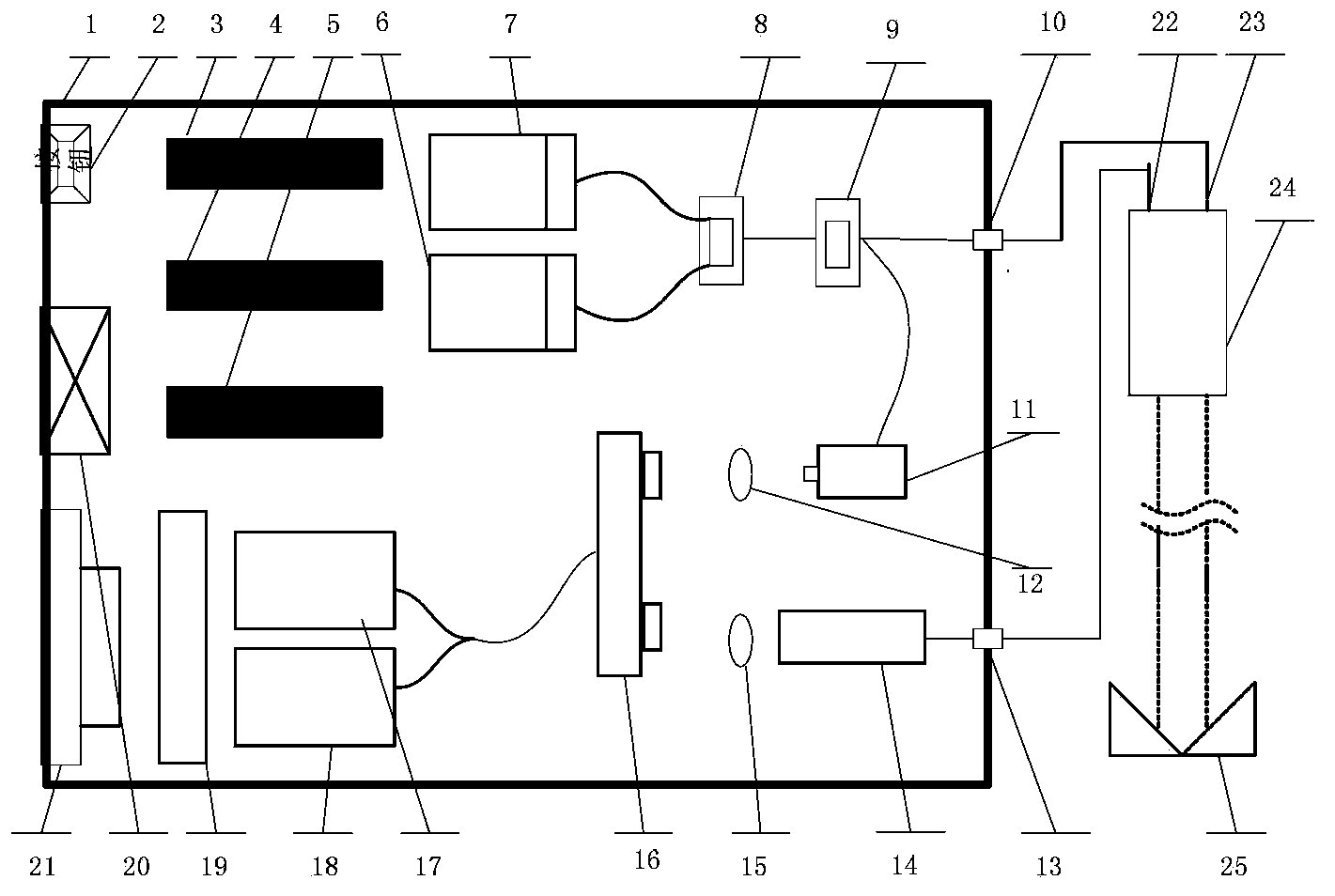

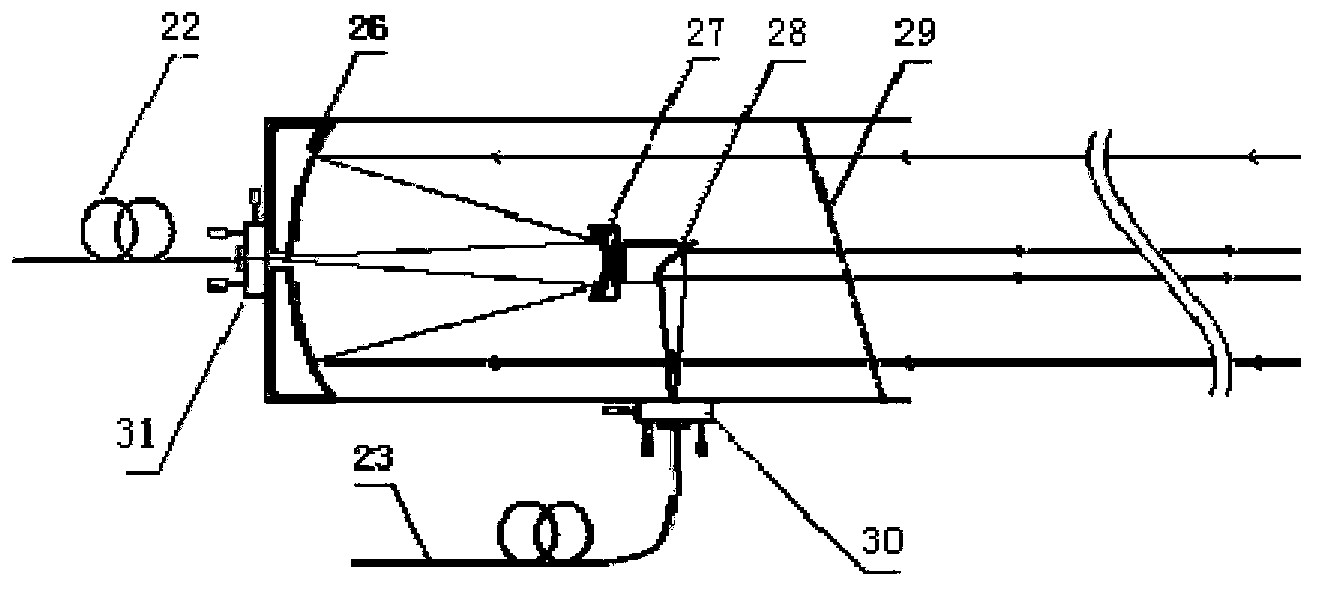

System and method for simultaneously monitoring multiple components of building fire early-stage characteristic gases

InactiveCN103411919AMeet the needs of early characteristic gas monitoringReal-time online monitoringColor/spectral properties measurementsMultiplexingFrequency-division multiplexing

The invention discloses a system and a method for simultaneously monitoring multiple components of building fire early-stage characteristic gases. Characteristic gases (CO, CO2, C2H2 and HCN) released in a fire early-stage pre-combustion stage are simultaneously detected by adopting a tunable semiconductor laser absorption spectrum-based modulation frequency multiplexing technique; the influence on a measuring result caused by light intensity fluctuation due to gas disturbance in a laser light source and a light path is eliminated by adopting a self-balancing detection technique, and high detection sensitivity is obtained by combining a wavelength modulation technique, and multiple components of the building fire early-stage characteristic gases are simultaneously detected by using a multi-wavelength, self-balancing detection and frequency division multiplexing-based signal detection technique.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

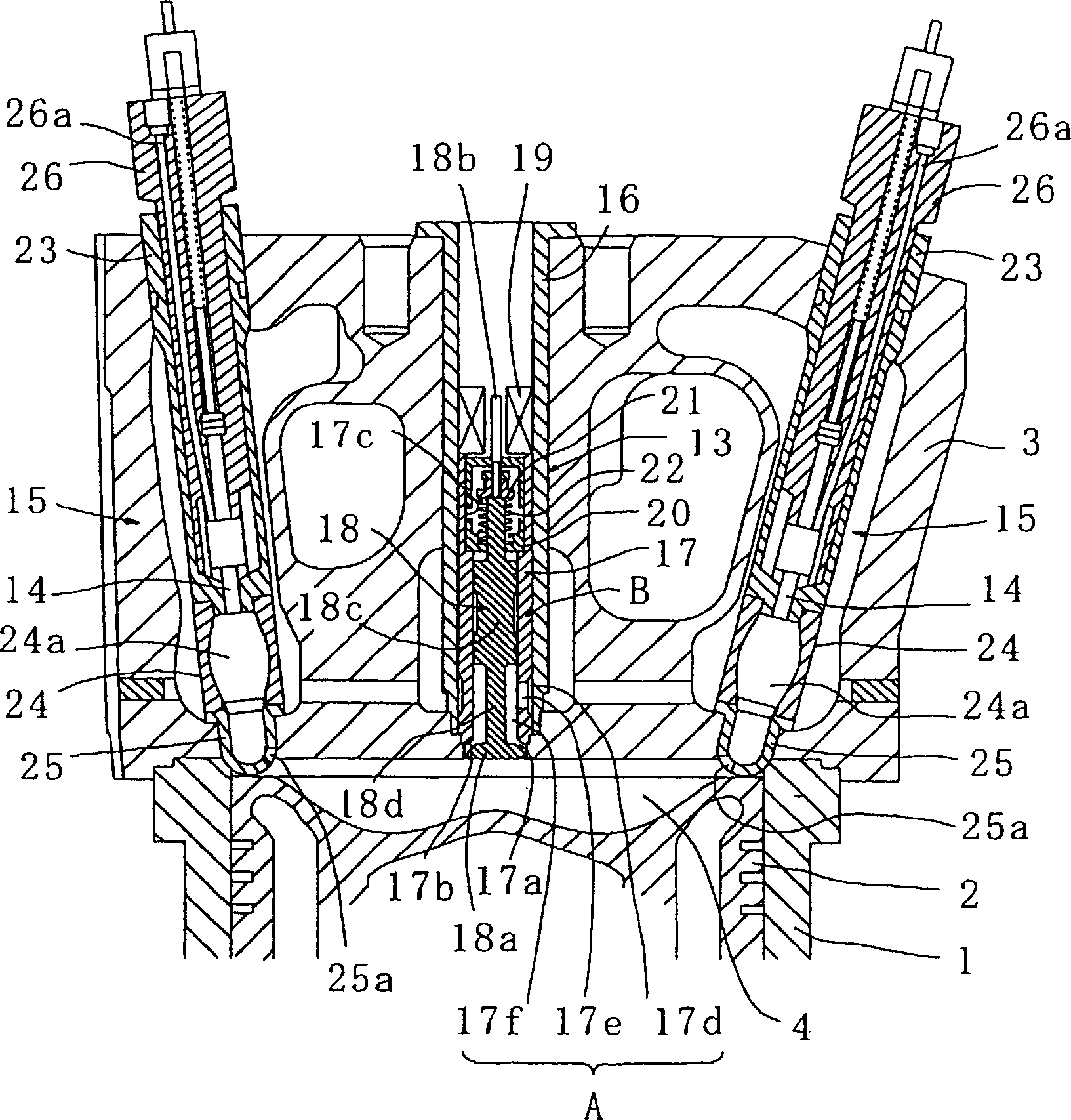

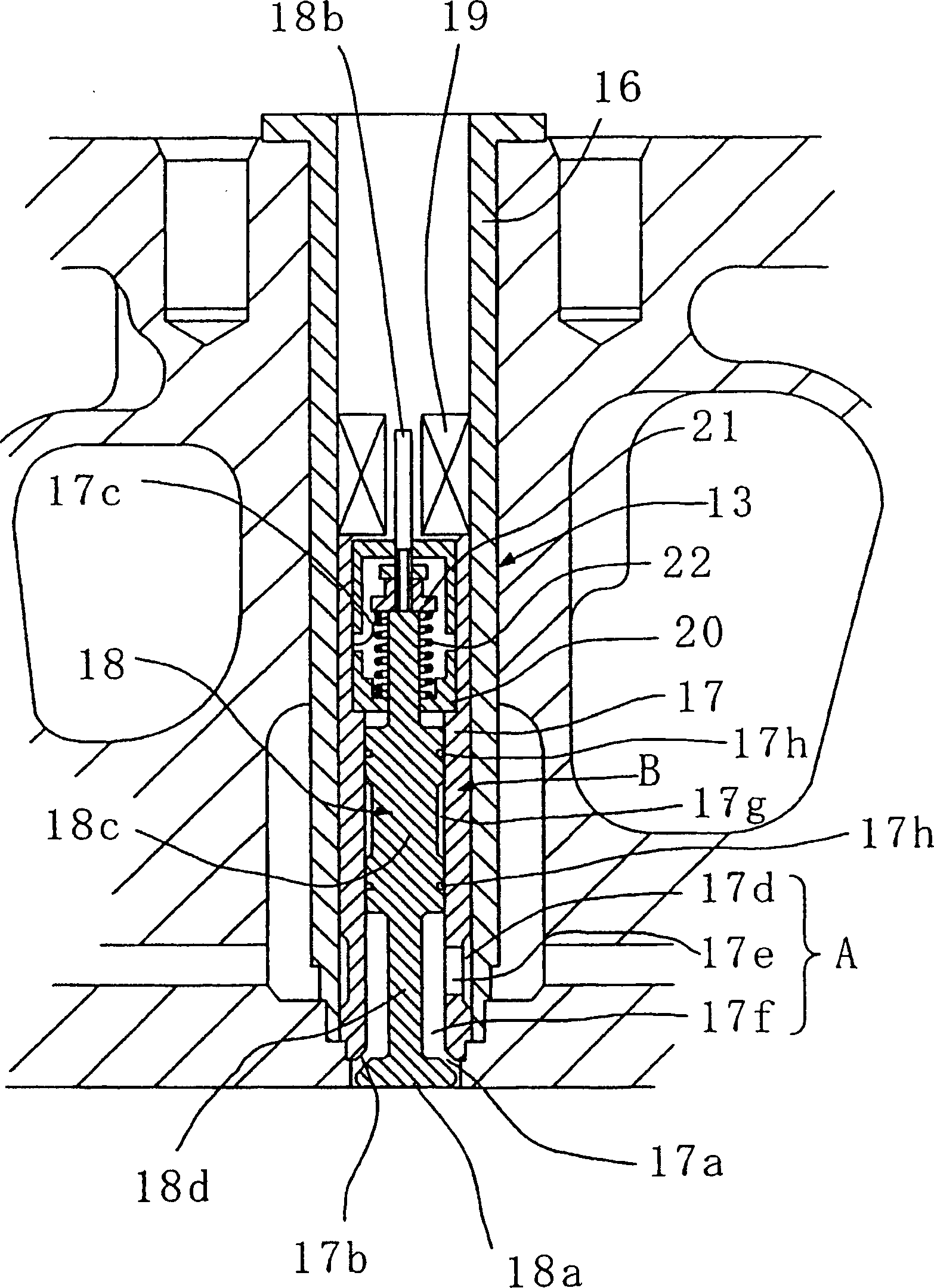

Gas engine with pre-combustion chamber

InactiveUS6073605AImprove performanceIncrease speedInternal combustion piston enginesFuel supply apparatusCombustion chamberCylinder head

This gas engine with pre-combustion chambers. effectively uses ejection energy of flames and air-fuel mixtures ejected from the pre-combustion chambers into the main combustion chambers to shorten the combustion duration and thereby enhance performance. Installed in the cylinder head at the central part of the cylinders are pre-combustion chamber structures. that form pre-combustion chambers; Combustion chamber structures are formed with communication port that communicate the pre-combustion chambers with the main combustion chambers. Control valves are provided to open and close the communication ports. The communication ports comprise main communication ports and sub-communication ports formed around the main communication ports. The sub-communication ports are formed in the combustion chamber structures so that they extend radially toward the cylinder periphery.

Owner:ISUZU MOTORS LTD

Turbo-charged internal combustion engine with in-cylinder EGR and injection rate shaping

InactiveUS6968831B2Improve efficiencyImprove transient responseInternal combustion piston enginesCylinder headsExhaust valveExternal combustion engine

A turbo-charged internal combustion cylinder assembly includes a combustion chamber which may be communicably connected to a compressor via an intake port through an intake manifold and aftercooler so the compressor may provide pre-combustion gases to the combustion chamber when the intake valve is open. An exhaust port communicably connects the combustion chamber to an exhaust manifold. An exhaust valve may open to exhaust post-combustion gases to the exhaust manifold while an intake valve is substantially closed, and the exhaust valve may open to admit post-combustion gases to the combustion chamber while the intake valve is substantially open and an exhaust port pressure in the exhaust port is higher than a combustion chamber pressure in the combustion chamber. A fuel injector may admit fuel to the combustion chamber. A spill valve may control a rate of fuel injection to the combustion chamber, the spill valve having a first position providing a maximum fuel injection rate, a second position providing a substantially zero fuel injection rate, and at least one intermediate position providing an intermediate fuel injection rate between the maximum fuel injection rate and the zero fuel injection rate.

Owner:VOLVO LASTVAGNAR AB

Gas engine

ActiveUS20110214639A1Avoid stickingAvoid flowLiquid coolingInternal combustion piston enginesCombustion chamberDead volume

Provided is a gas engine having a spark plug provided with a pre-combustion chamber and a check valve, the gas engine, in which the check valve is arranged in the neighborhood of the pre-combustion chamber, being capable of preventing adhesion of a solenoid controlled valve provided at an upstream side of the check valve due to soot accumulation, and dead volume in a fuel inlet passage. In a gas engine in which fuel gas is supplied to the pre-combustion chamber through the fuel gas inlet passage and the fuel gas supplied in the pre-combustion chamber is ignited by spark discharge at the spark plug that is fitted to a mounting hardware piece via a seat surface, a solenoid valve for performing open-close control of the fuel gas is provided, and a first check valve is also provided posterior to a discharge side of the solenoid valve so as to prevent back flow of the combustion gas from the pre-combustion chamber to the solenoid controlled valve.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Dual fuel engine

InactiveCN1500179AImprove transient responseEasy dischargeInternal combustion piston enginesOutput powerCombustion chamberFuel efficiency

A dual fuel engine, which is designed to allow choosing between gas operation and diesel operation, with low emission of NOx ensured even during diesel operation, and which is capable of adjusting the compression ratio during the gas operation according to the operating state, so as to provide a quick start and an operation with high combustion efficiency, throughout the load region, comprising a cylinder head that is provided with a compression ratio control valve, and a pre-combustion chamber unit having a pre-combustion chamber and an electromagnetic type fuel injection valve liquid fuel injection valve. The compression ratio control valve opens / closes a communication port connecting a main combustion chamber and an inlet port. In the gas operation, the valve opening period of the compression ratio control valve is adjusted according to the rotary state.

Owner:NIIGATA POWER SYST CO LTD

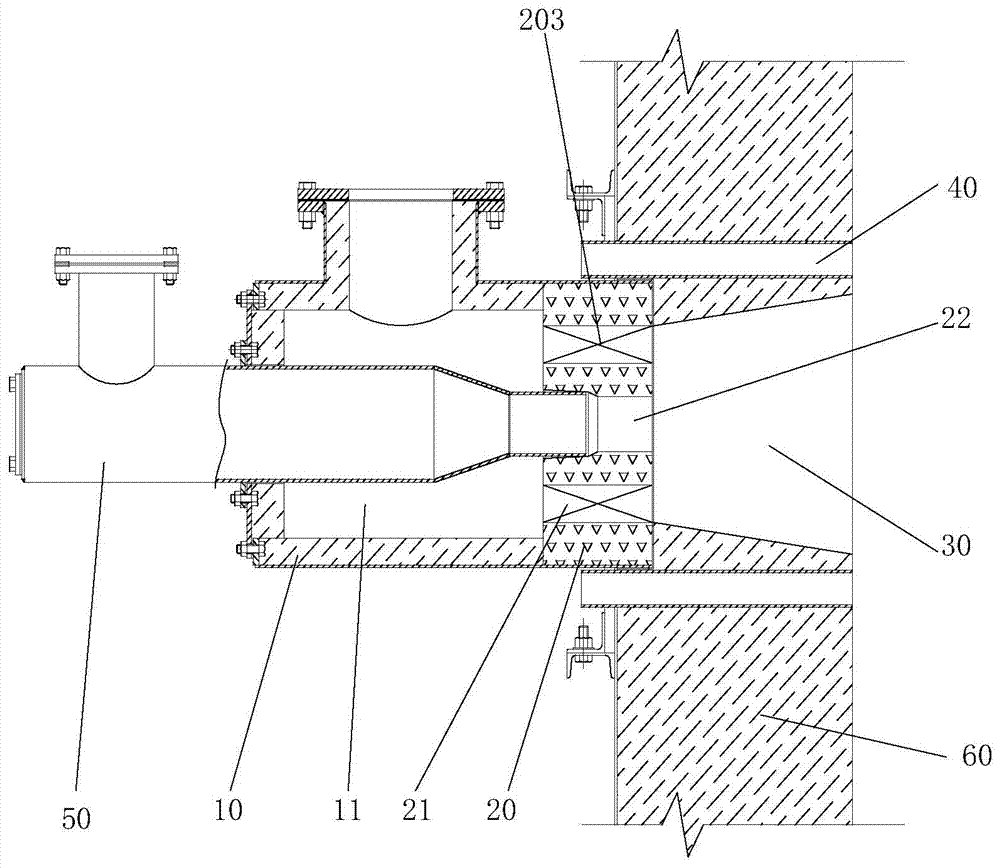

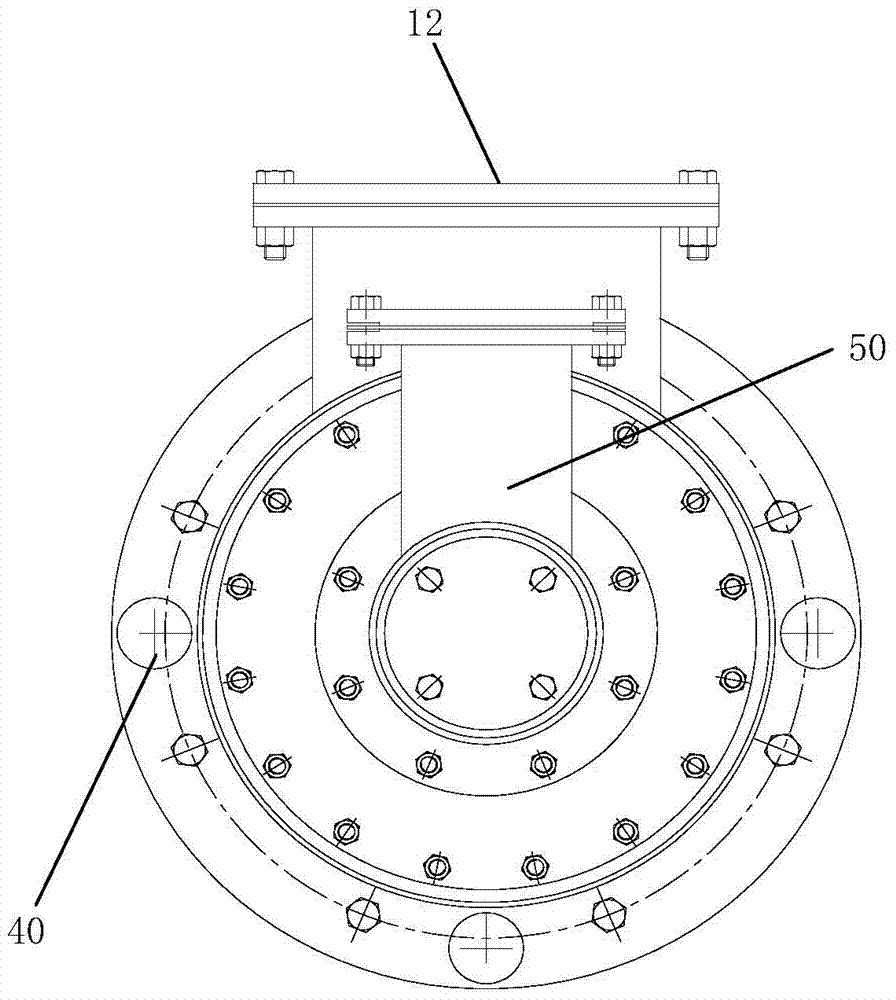

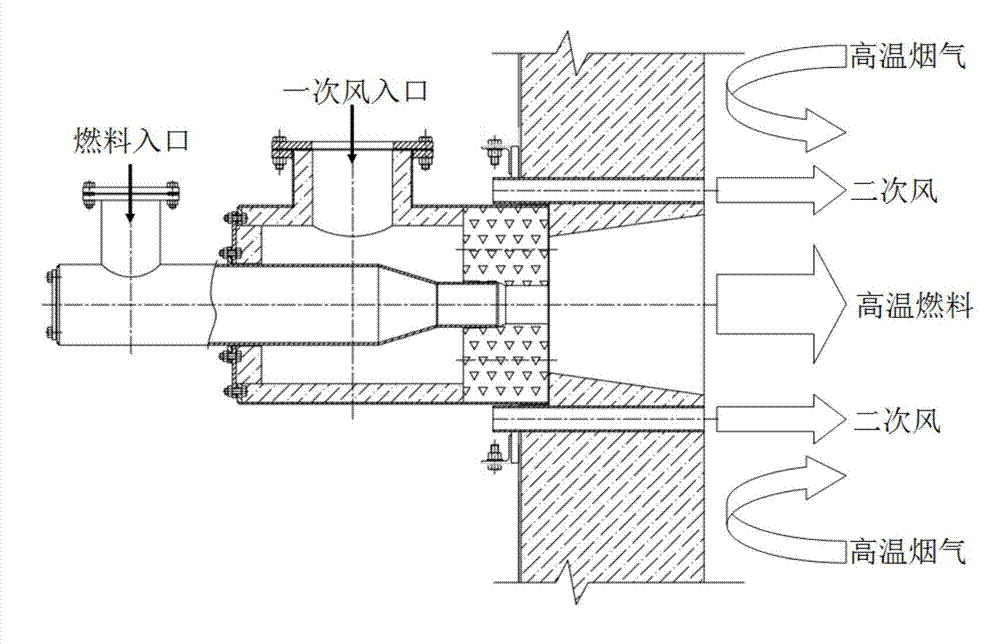

Grading oxygen-enriched flameless combustion gas burner and control method thereof

ActiveCN104235849AUnlimited calorific valueEfficient use ofIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHeating furnace

The invention discloses a grading oxygen-enriched flameless combustion gas burner which comprises a burner shell, an air distribution plate, a pre-combustion chamber, secondary air spray pipes and a fuel spray pipe. The wall of a heating furnace is provided with a channel penetrating through the wall, the burner shell is arranged on one side of the channel, the pre-combustion chamber is formed in space in the channel, the burner shell is provided with a combustion-supporting air channel, the fuel spray pipe is provided with a fuel channel, the air distribution plate is provided with a primary air inlet and a fuel inlet, the secondary air spray pipes are arranged and provided with secondary air channels used for introducing oxygen-enriched air or air into a hearth of the heating furnace, the secondary air spray pipes penetrate through the wall of the heating furnace, and the secondary air channels are communicated with the hearth of the heating furnace. The grading oxygen-enriched flameless combustion gas burner optimizes temperature distribution in the furnace and meanwhile reduces emission of NOx.

Owner:WISDRI WUHAN WIS IND FURNACE

Counter-flow flame combustion chamber

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com