Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

An oxygen-enriched micro-oil and burner technology, which is applied to burners, burners, combustion ignition and other directions of burning powder fuel, can solve the problem of incomplete combustion of pulverized coal, reduced burnout rate of pulverized coal at the burner outlet, and nitrogen oxides. The problem of high emissions, to achieve the effect of reducing emissions, promoting combustion, and improving burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

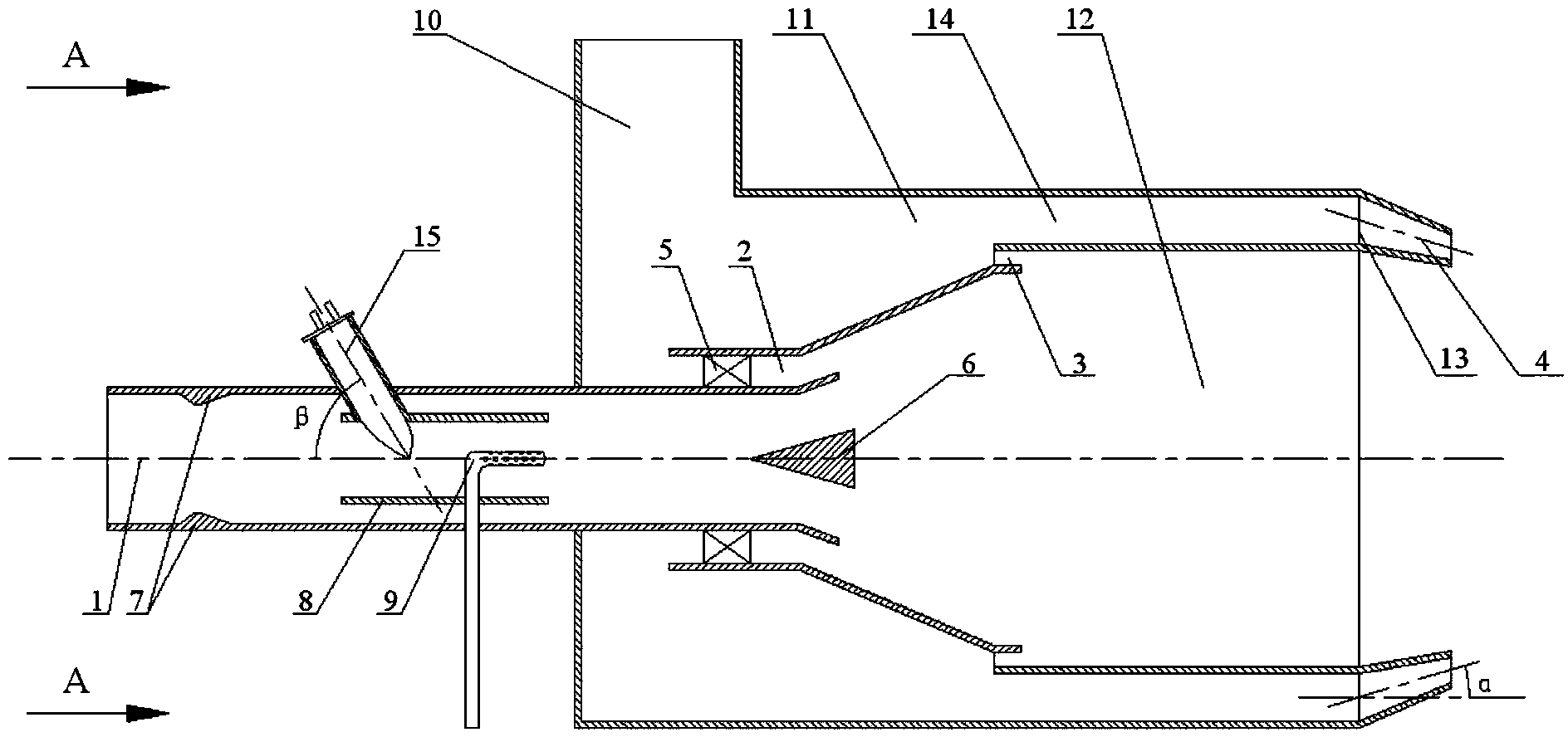

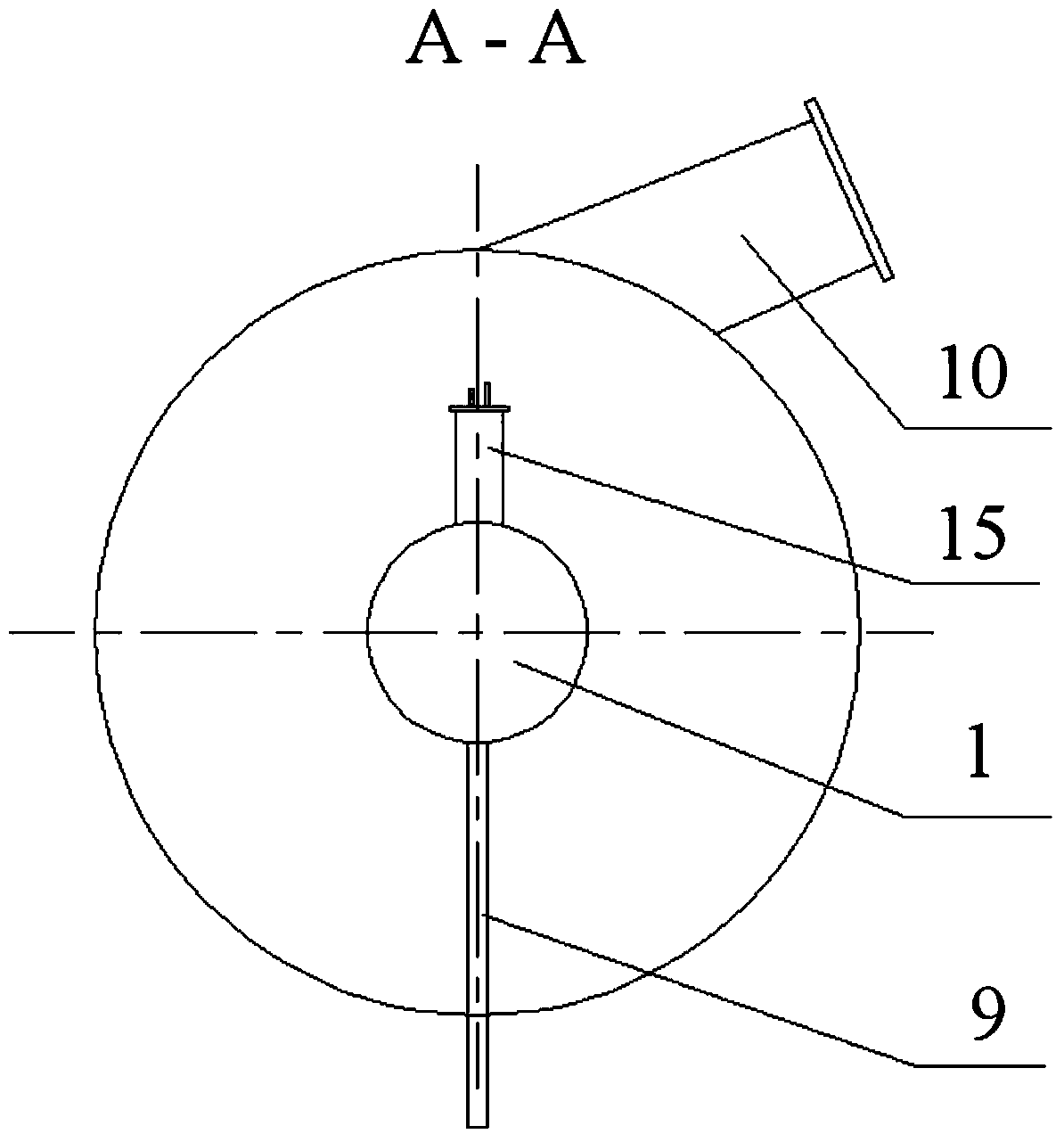

[0028] Such as figure 1 As shown, the present invention includes a primary air duct 1, an oil-coal mixed combustion chamber 8, an oxygen-enriched conduit 9, a secondary air duct 2, a secondary air box 11 and a pre-combustion chamber 12, a primary air duct 1, a cylindrical oil-coal mixed The central axes of the combustion chamber 8, the secondary air duct 2, the secondary air box 11 and the pre-combustion chamber 12 coincide.

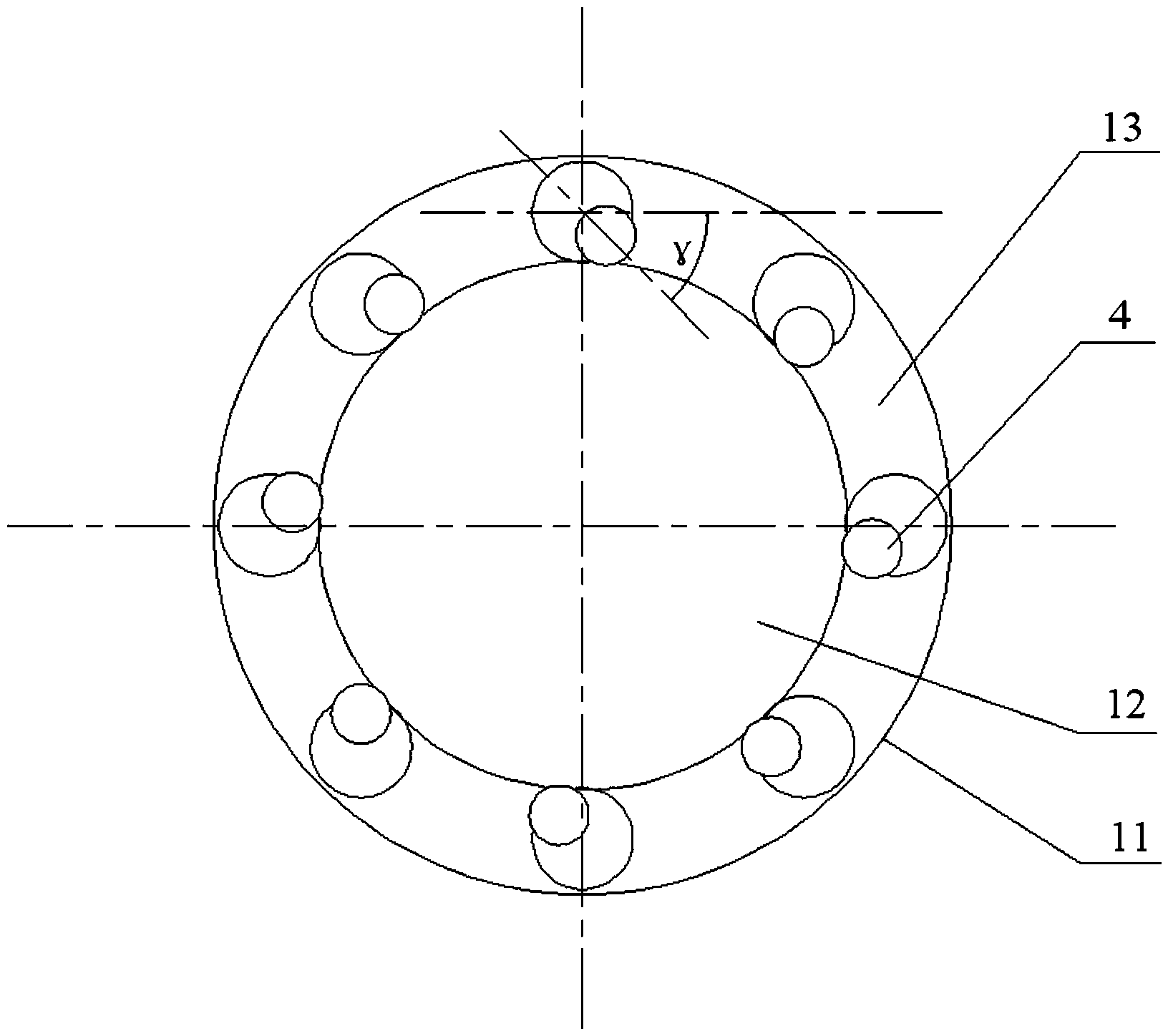

[0029] The secondary air box 11 is provided with a circumferentially inclined secondary air inlet 10 on the pipe wall (such as figure 2 shown). According to the principle of fluid mechanics, the airflow enters the windbox in this way, which makes the airflow in the windbox more uniform, thereby improving the uniformity of the airflow at the outlet interface of the burner. The inlet end of the primary air duct 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com