Patents

Literature

75results about How to "Strengthen the degree of disturbance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

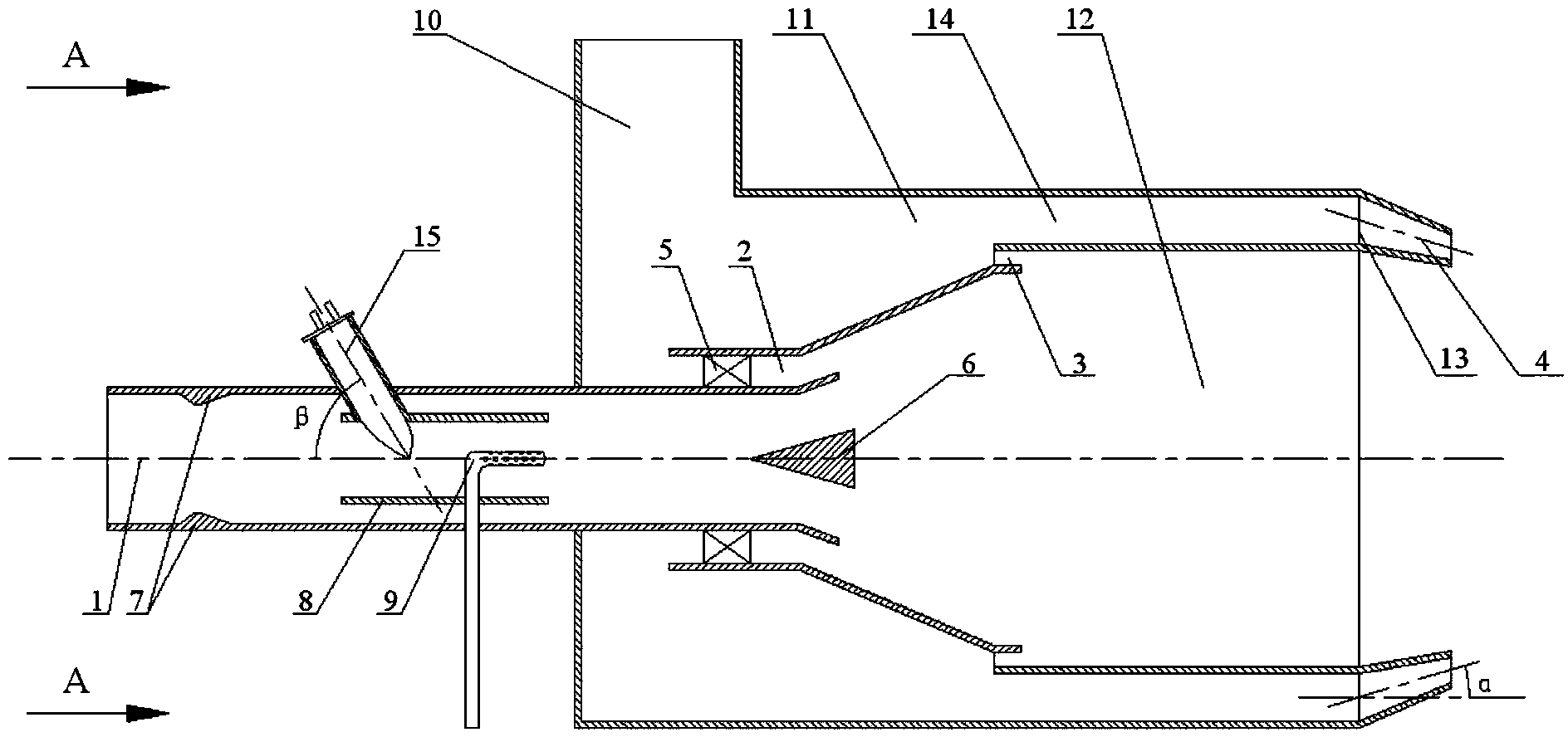

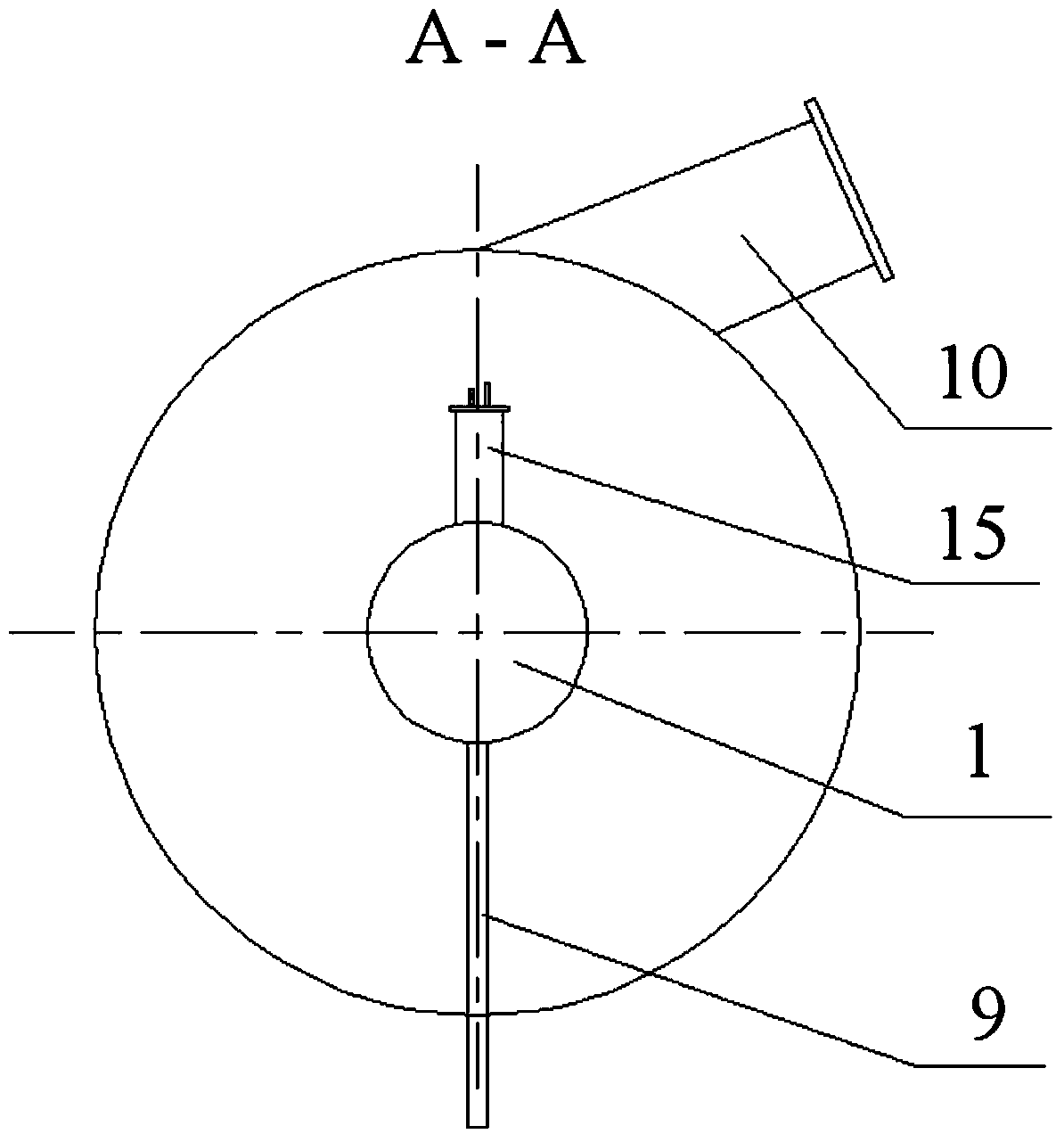

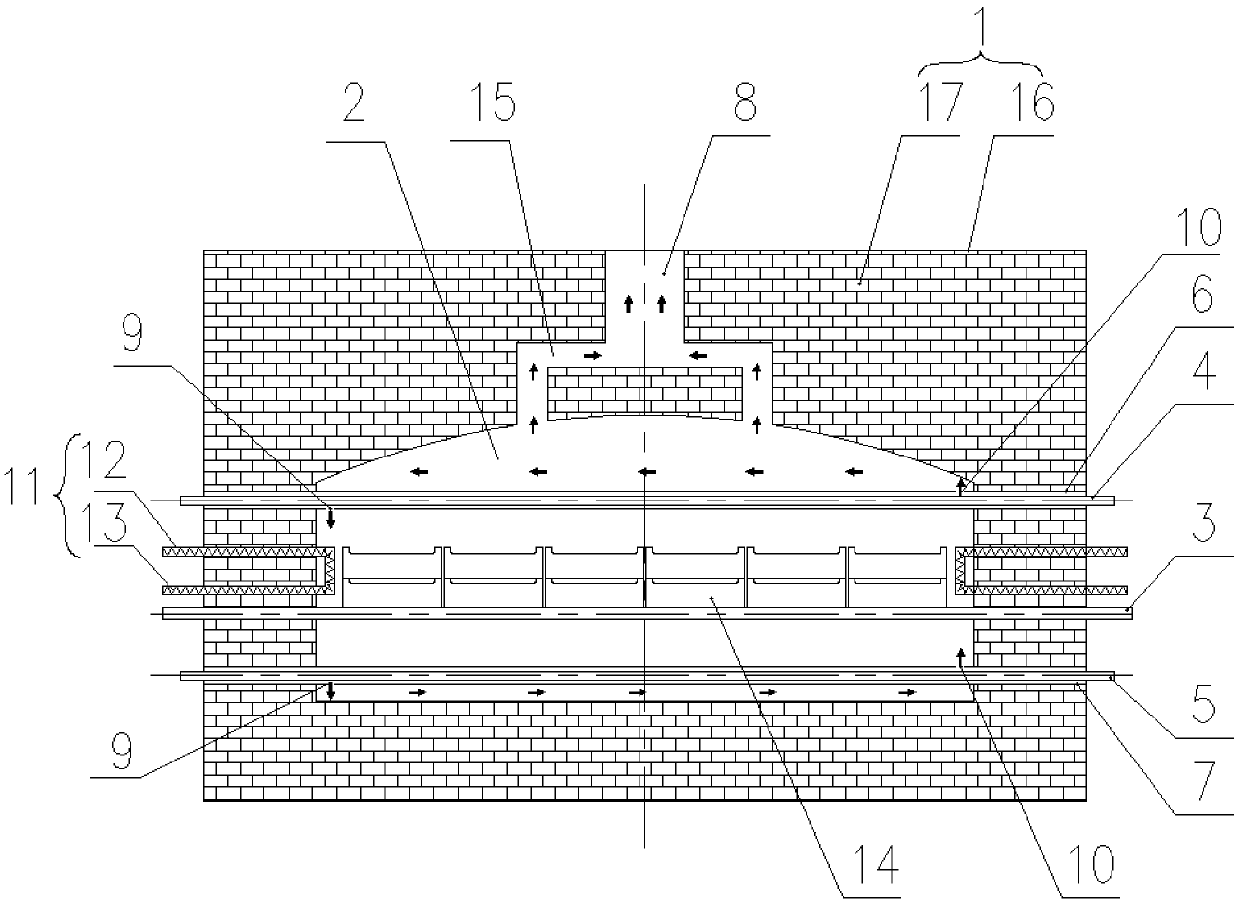

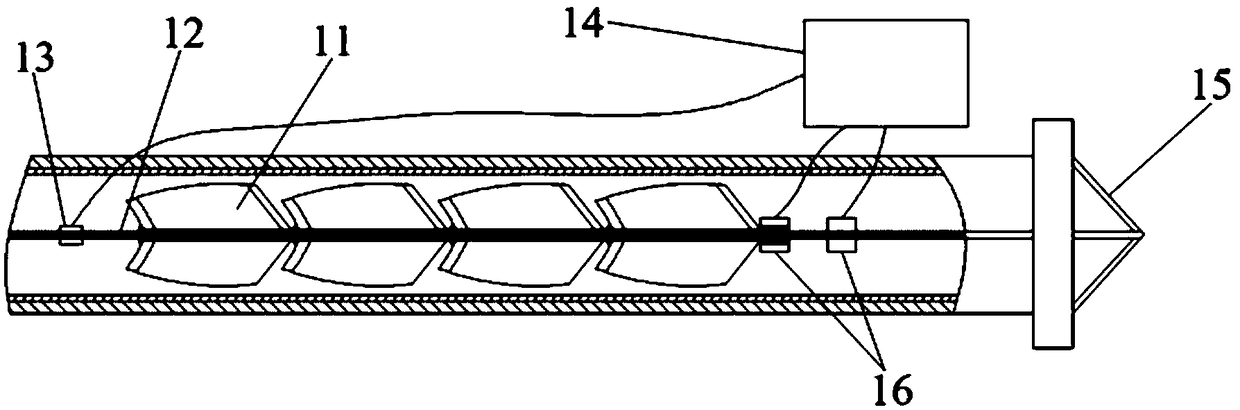

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

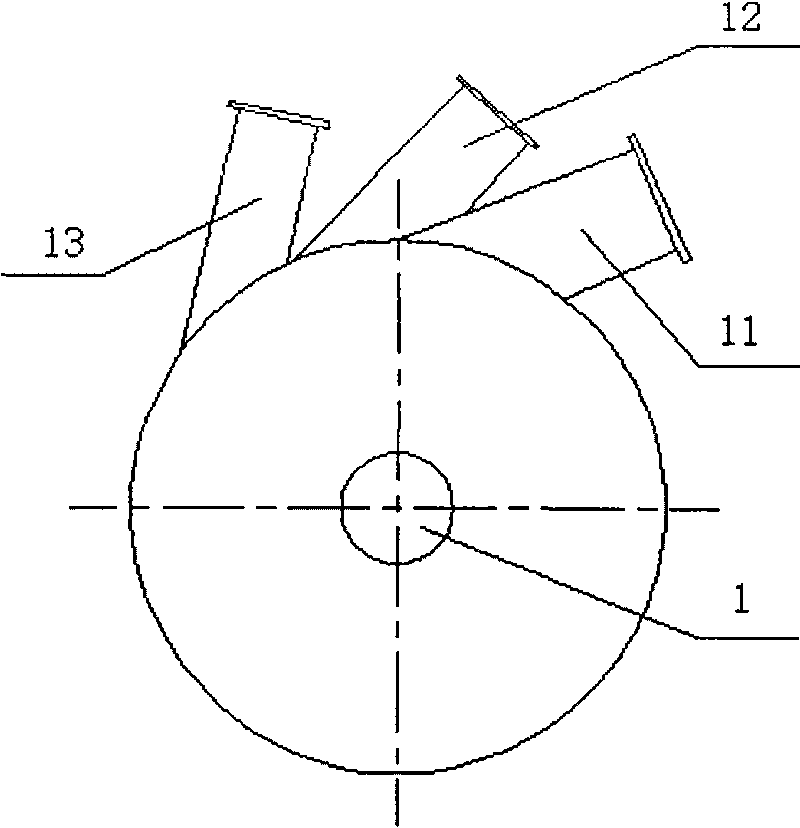

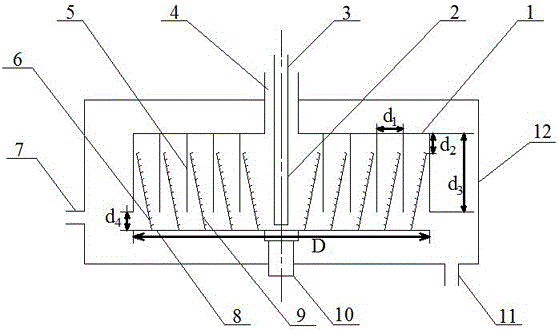

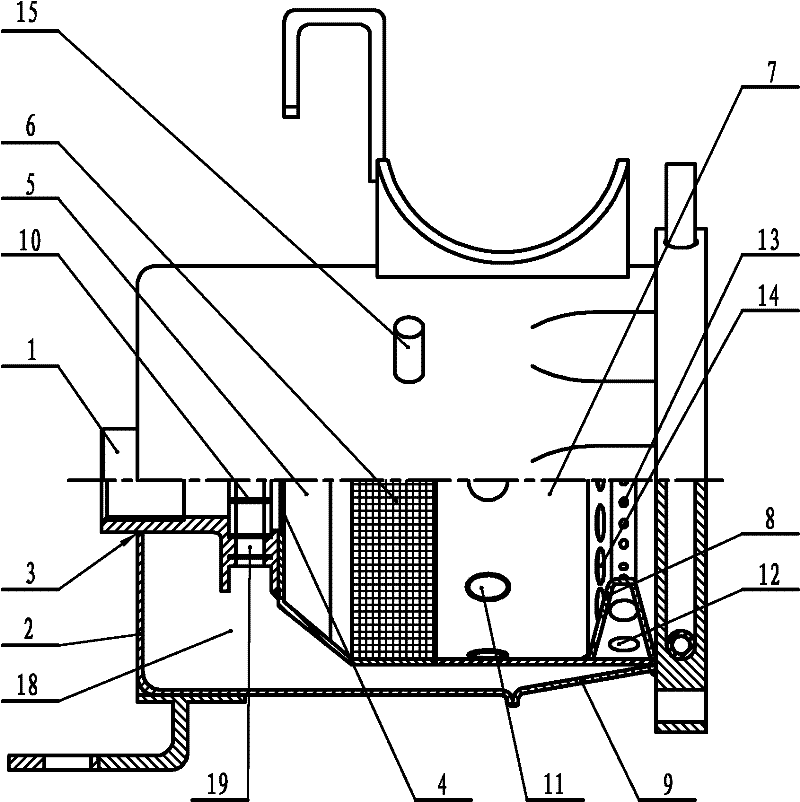

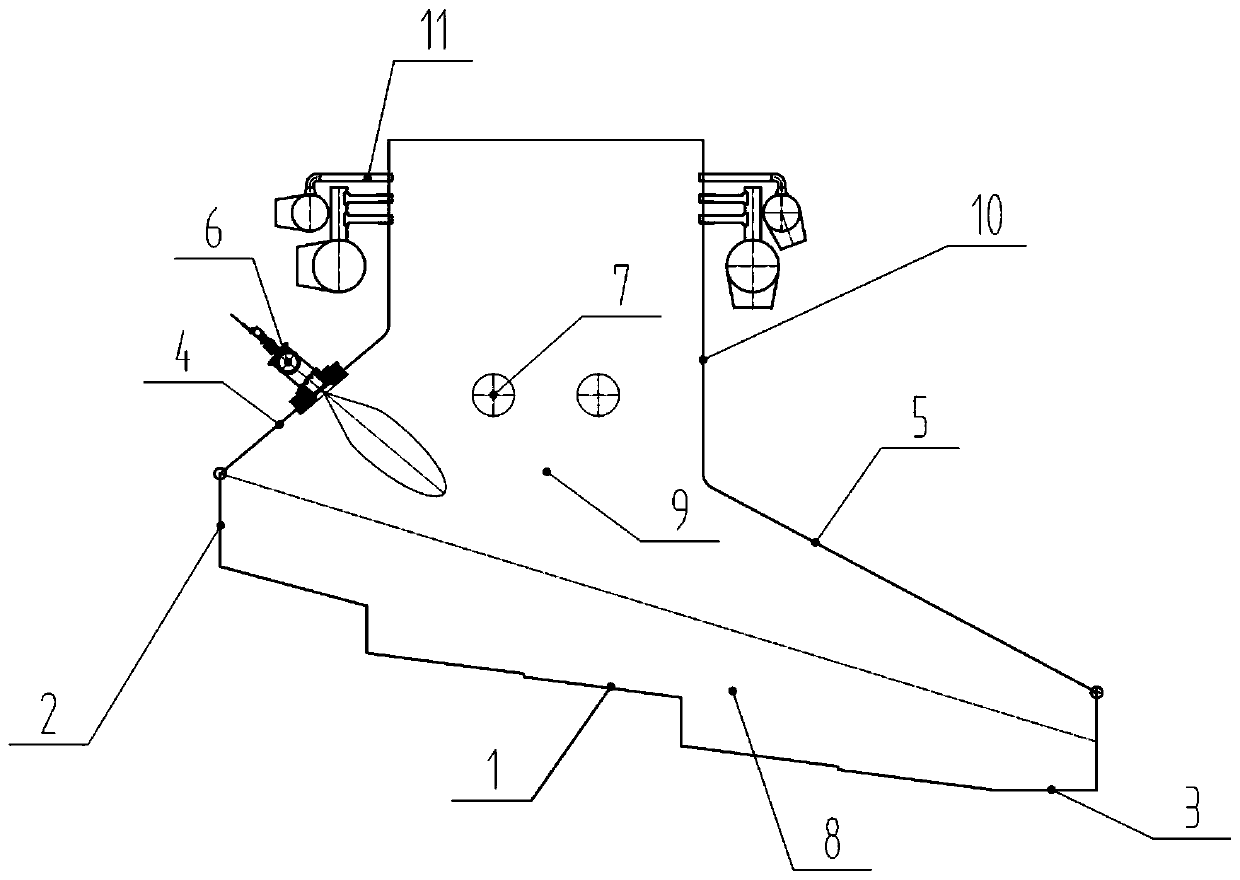

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

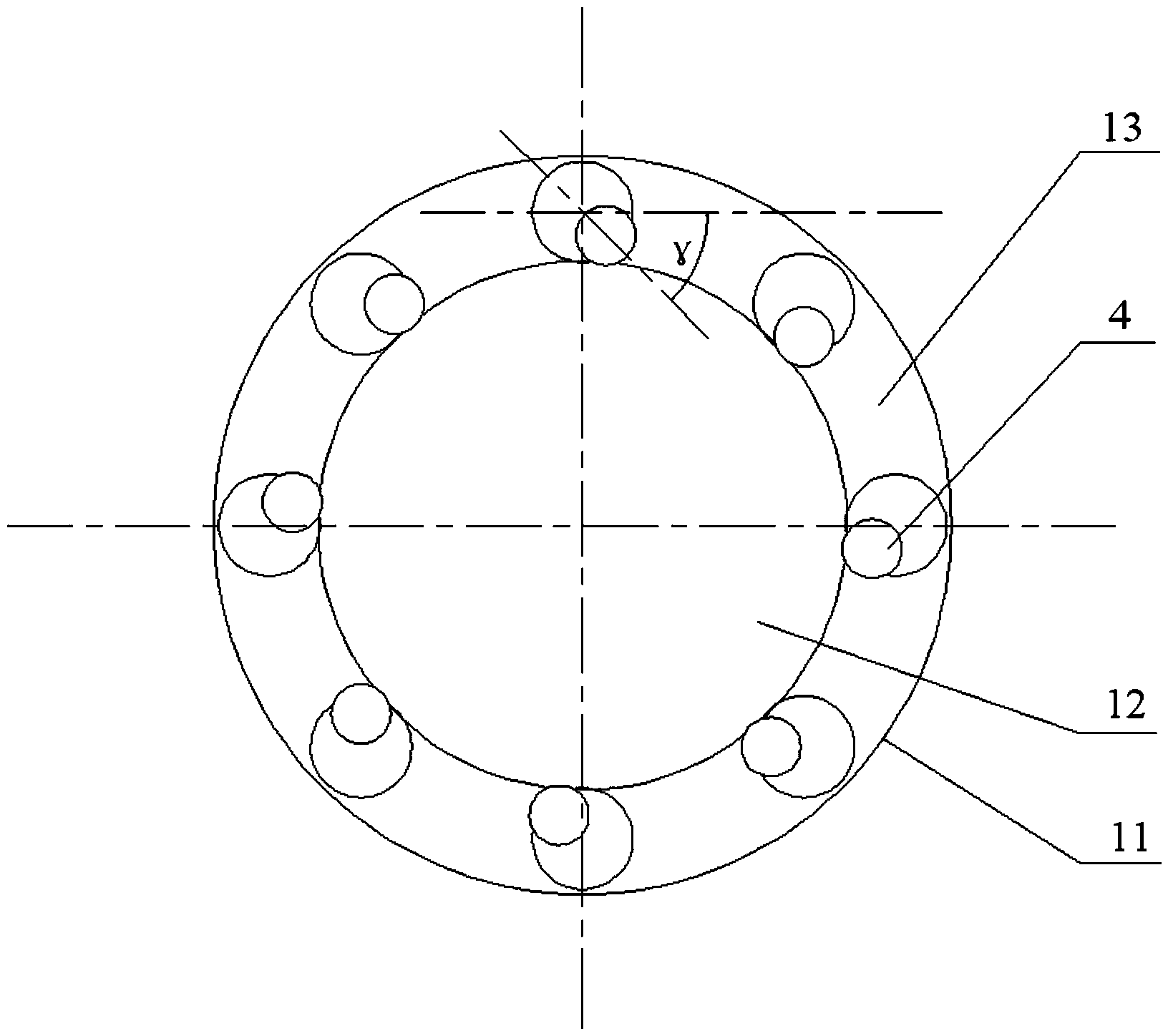

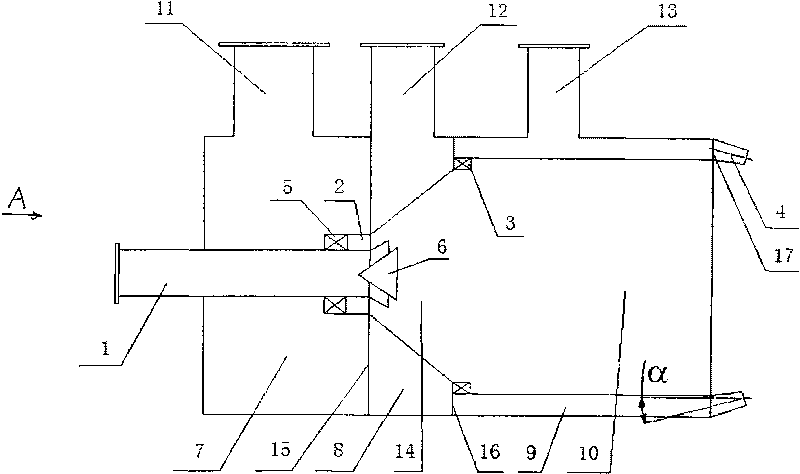

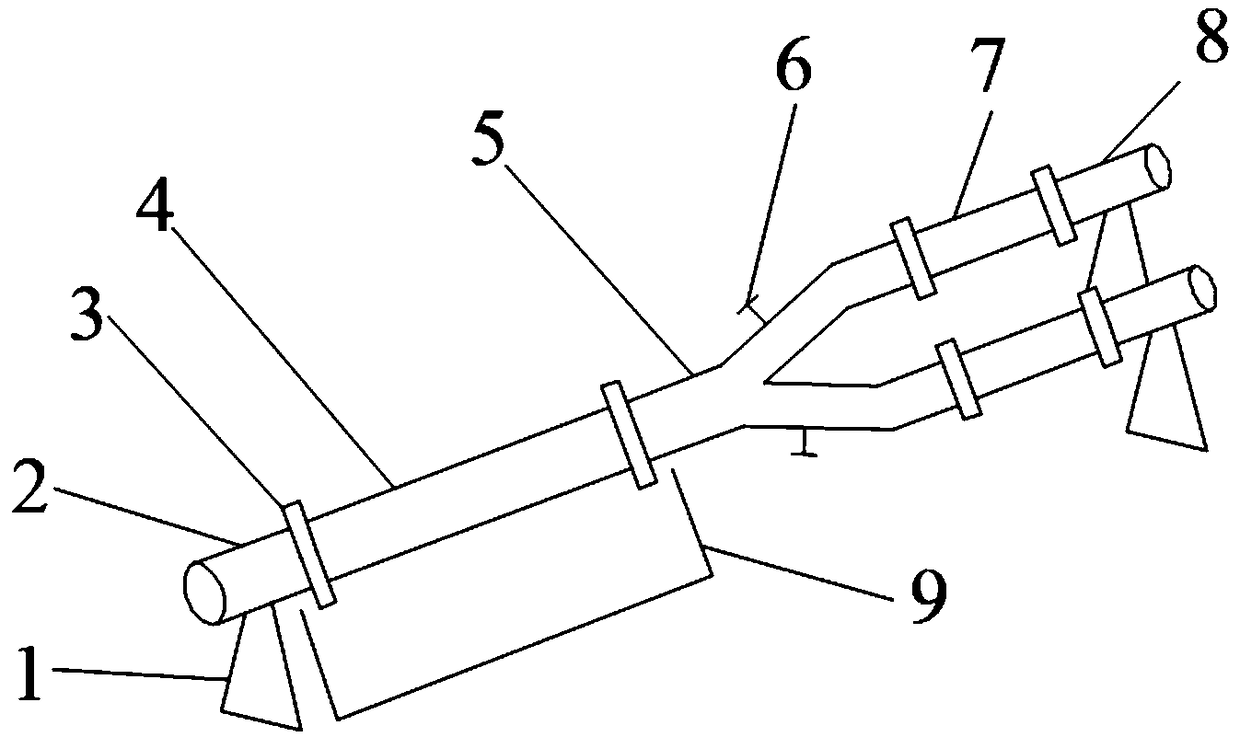

Low-NOx pulverized coal burner

The invention discloses a low-NOx pulverized coal burner, which comprises an inner secondary air box, a hierarchical air box and a disturbed air box. The inner secondary air box, the hierarchical air box and the disturbed air box are separated by a first clapboard and a second clapboard sequentially; the centers of the first clapboard and the second clapboard are provided with circular holes; each pipe wall of each of the three air boxes is correspondingly provided with an air inlet which inclines towards the circumferential direction; a primary air pipe axially passes through the inner secondary air box; an inner secondary air pipe with a swirl vane is coaxially sleeved outside the primary air pipe; the inner secondary air pipe is hermetically connected with the first clapboard; the inner secondary air pipe expands conicity and extends outwards to form a conical cylinder at the circular hole of the first clapboard; the conical cylinder is arranged in the hierarchical air box; the disturbed air box is coaxially provided with a precombustion chamber with two open ends; an annular channel is formed between the wall of the disturbed air box and the wall of the precombustion chamber; an annular end face is arranged at an outlet of the annular channel; a disturbed air nozzle is fixed at an opening of the annular end face; the inlet end of the precombustion chamber is hermetically connected with the second clapboard; an annular hierarchical air channel is formed at the root of the inlet of the precombustion chamber; and the conical cylinder is hermetically fixed with the inner wall of the hierarchical air channel.

Owner:ZHEJIANG JINGUO BOILER

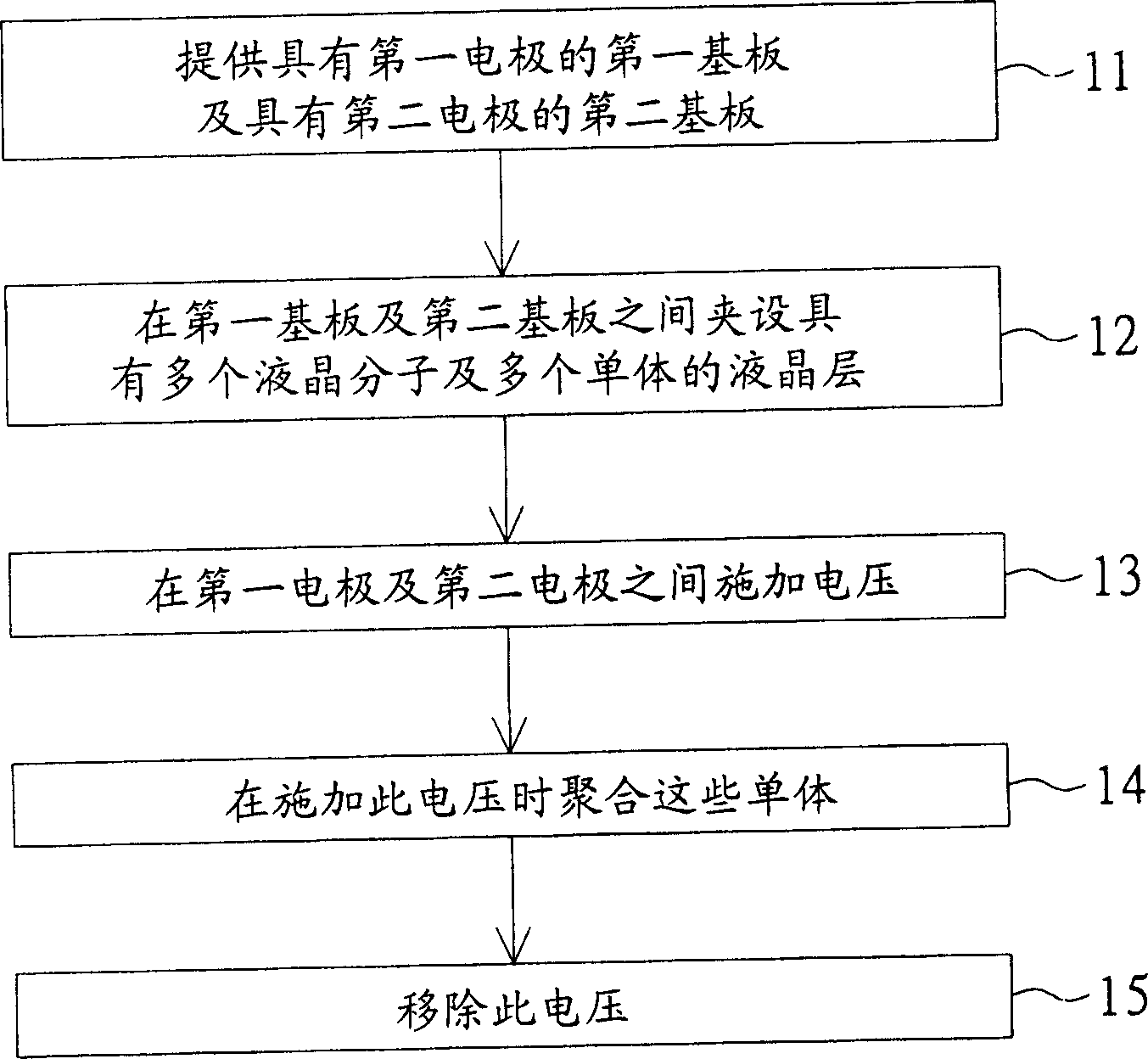

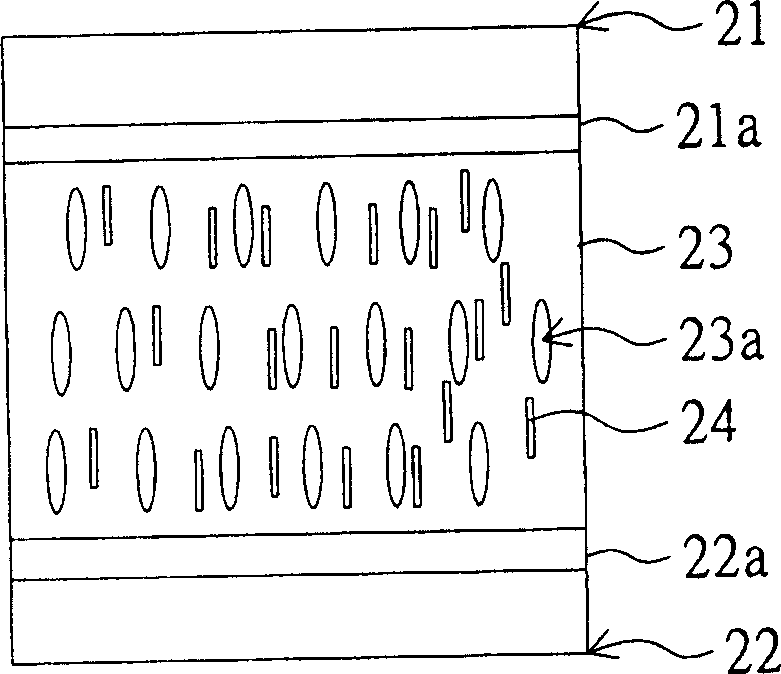

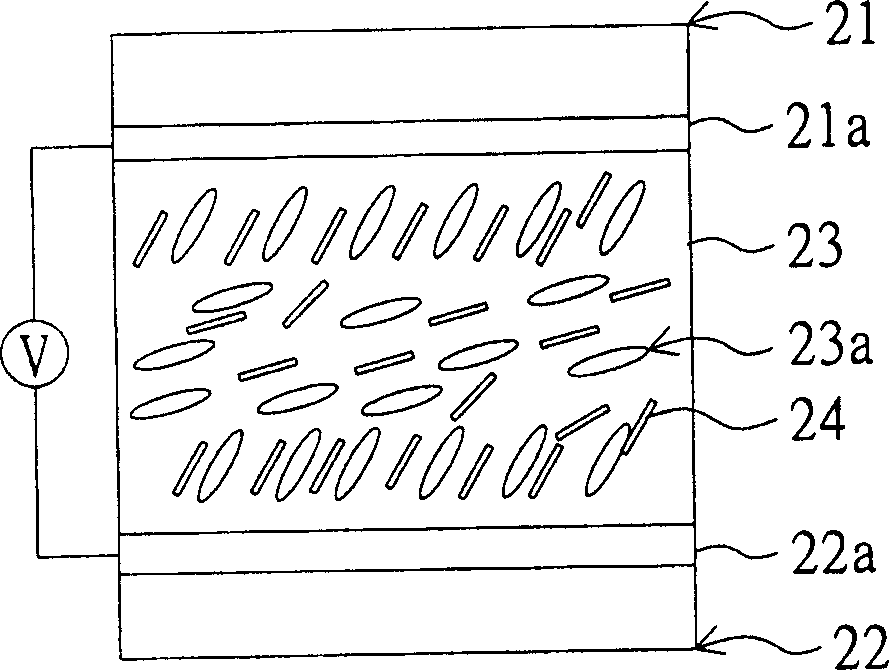

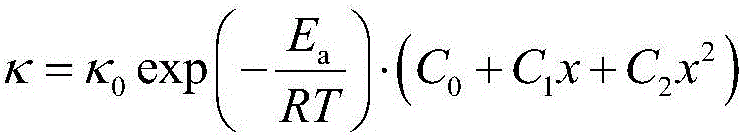

Monomer, and method for using it to fabricate LCD faceplate

InactiveCN1915951AAvoid the stack phenomenonAvoid lattice defect problemsLiquid crystal compositionsOrganic chemistryHalogenMonomer

This invention discloses a monomer shown in formula 1, wherein A is selected from formulae 2-4 or their combination; at least one of B and R is selected from alkyl, alkoxyl, ester group, formulae 5-8 or their combination; T is selected from O, N or their combination; X is selected from H, alkyl, halogen, cyano or their combination; n s a positive integer.

Owner:AU OPTRONICS CORP

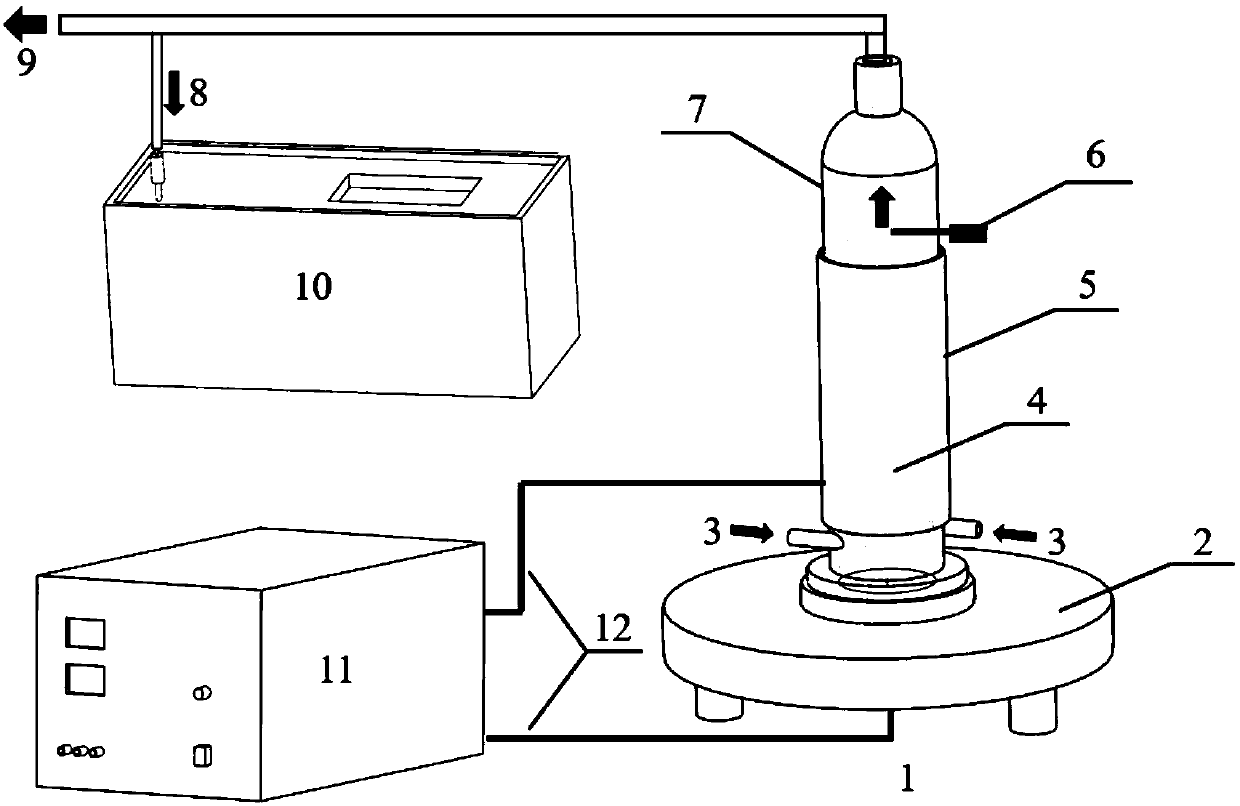

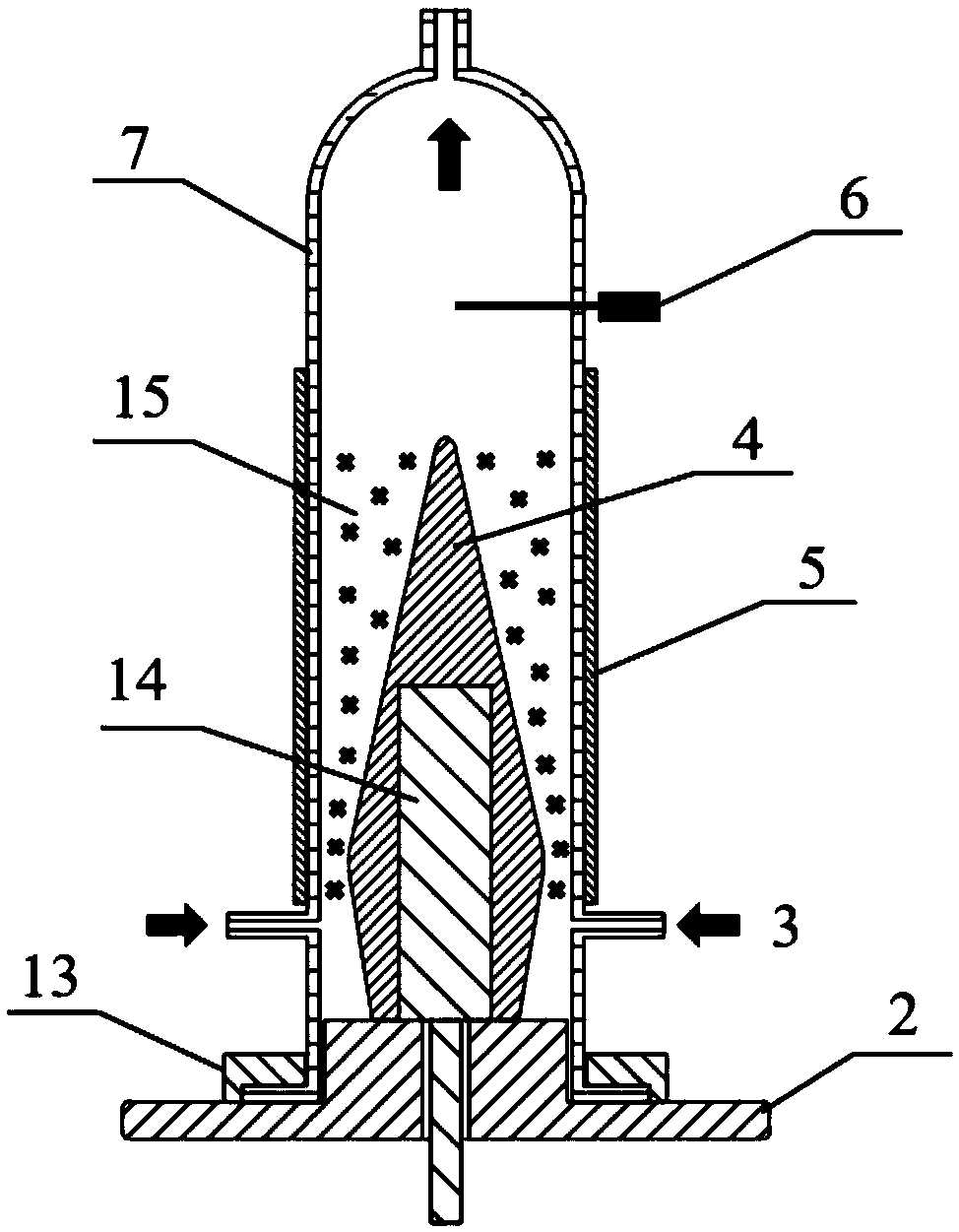

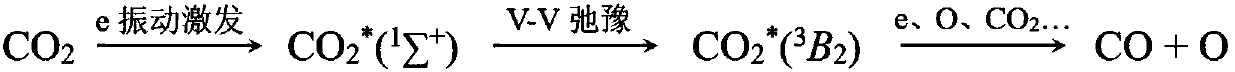

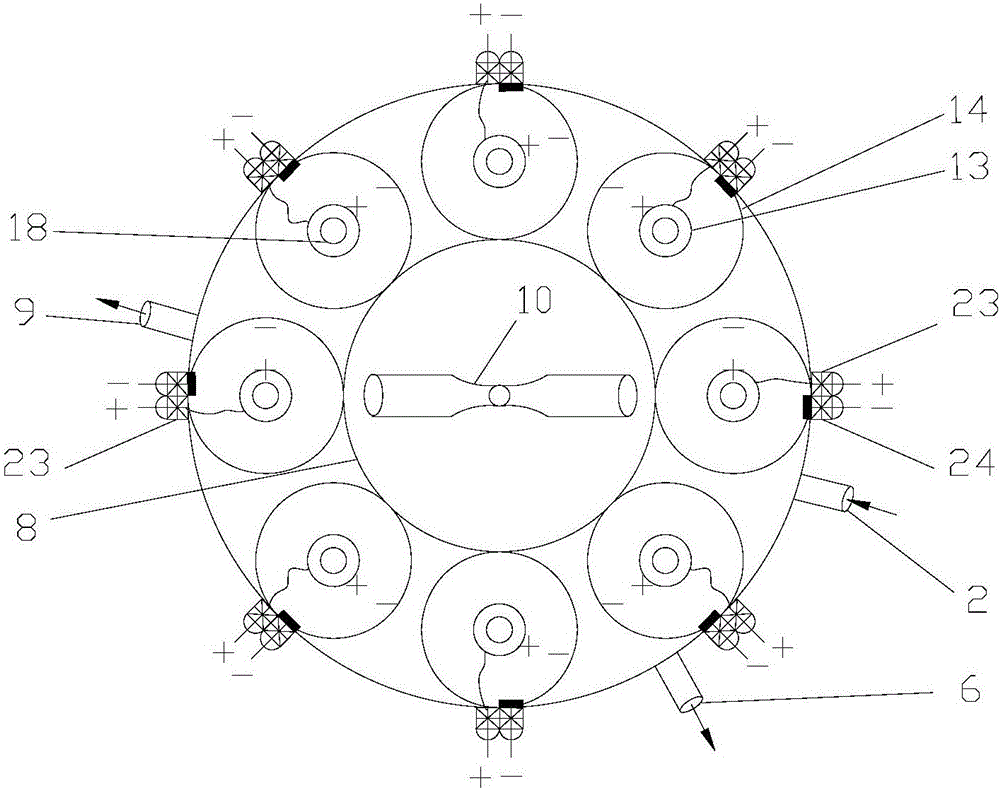

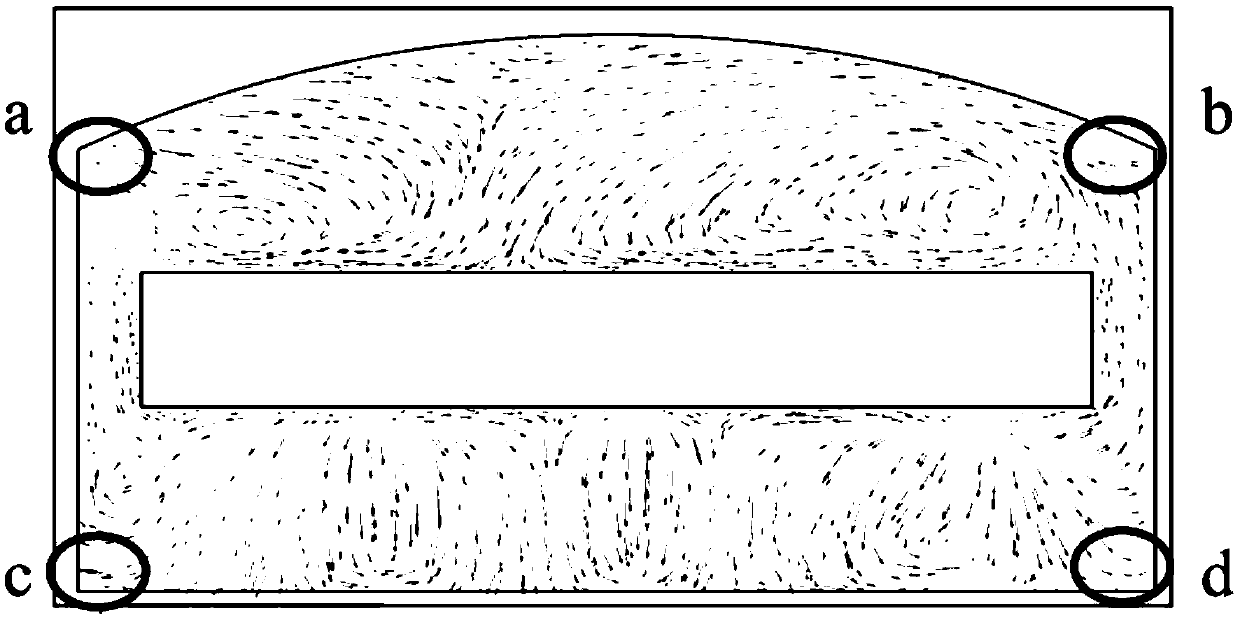

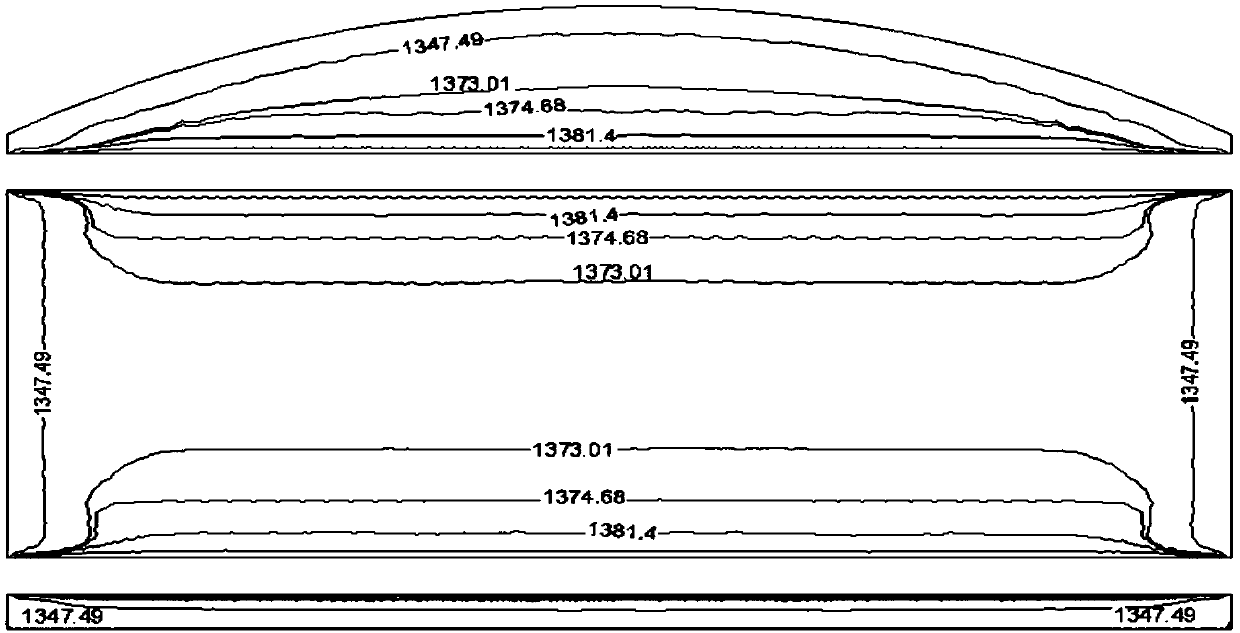

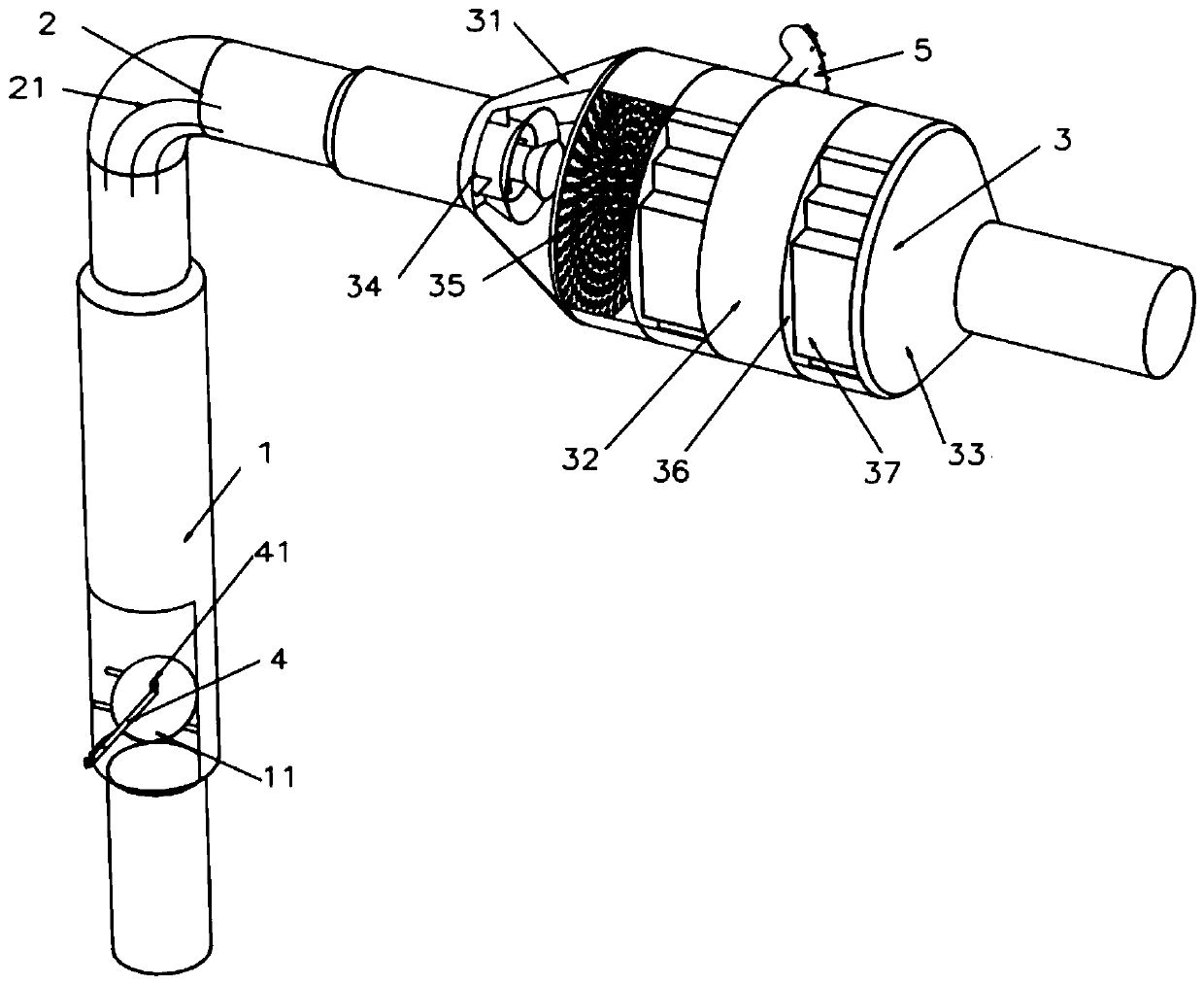

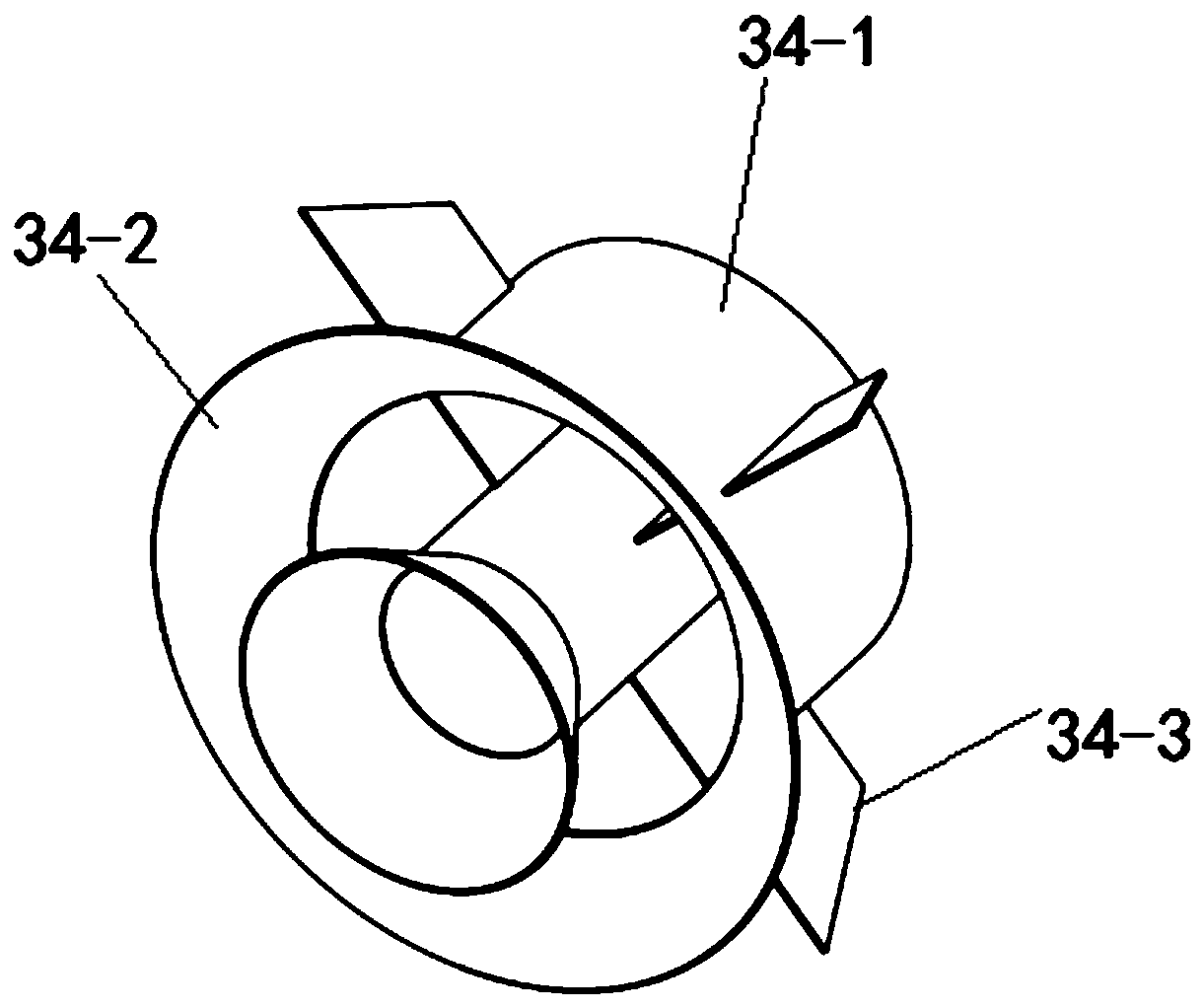

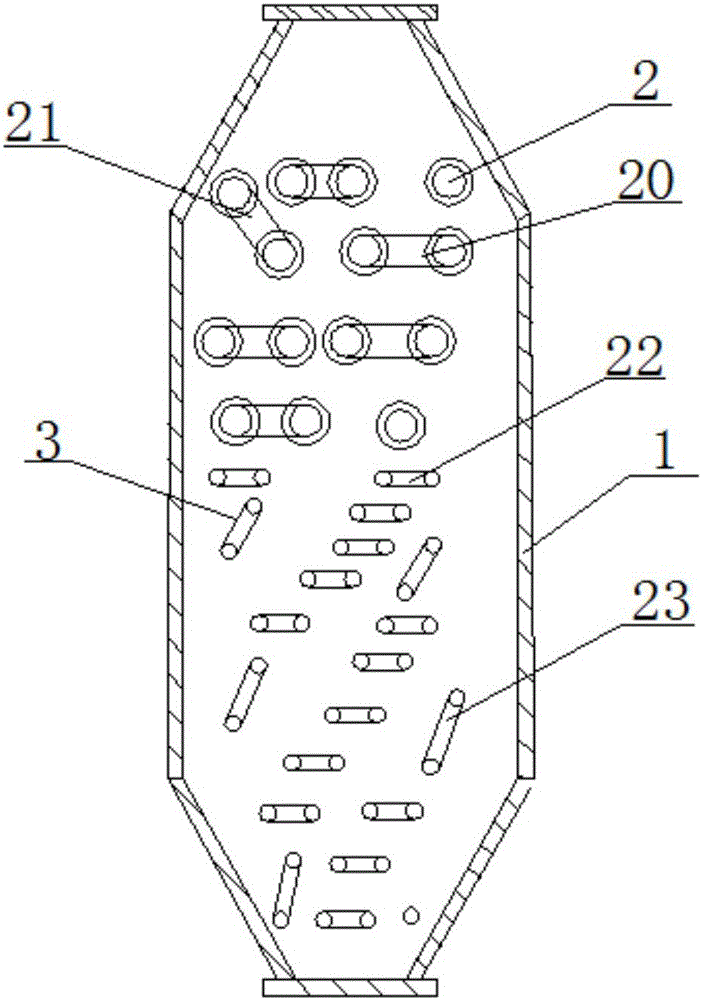

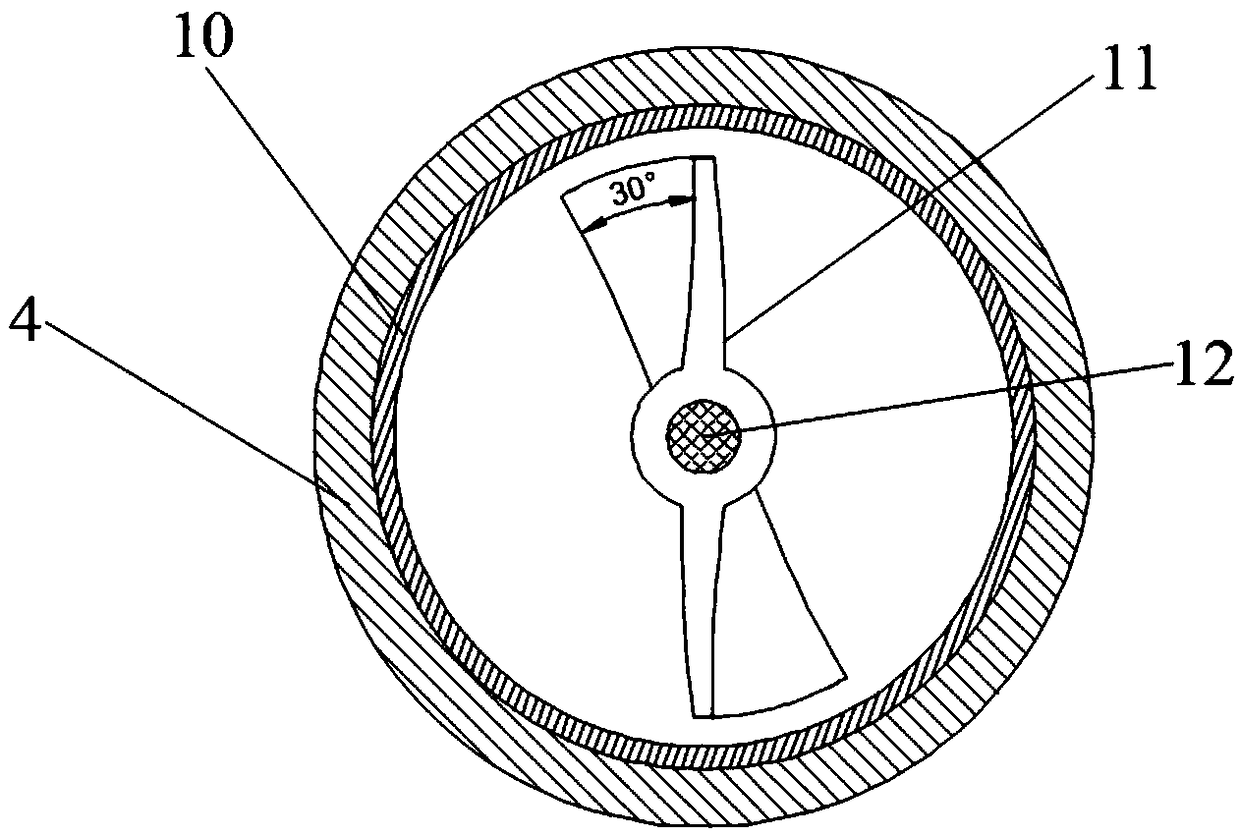

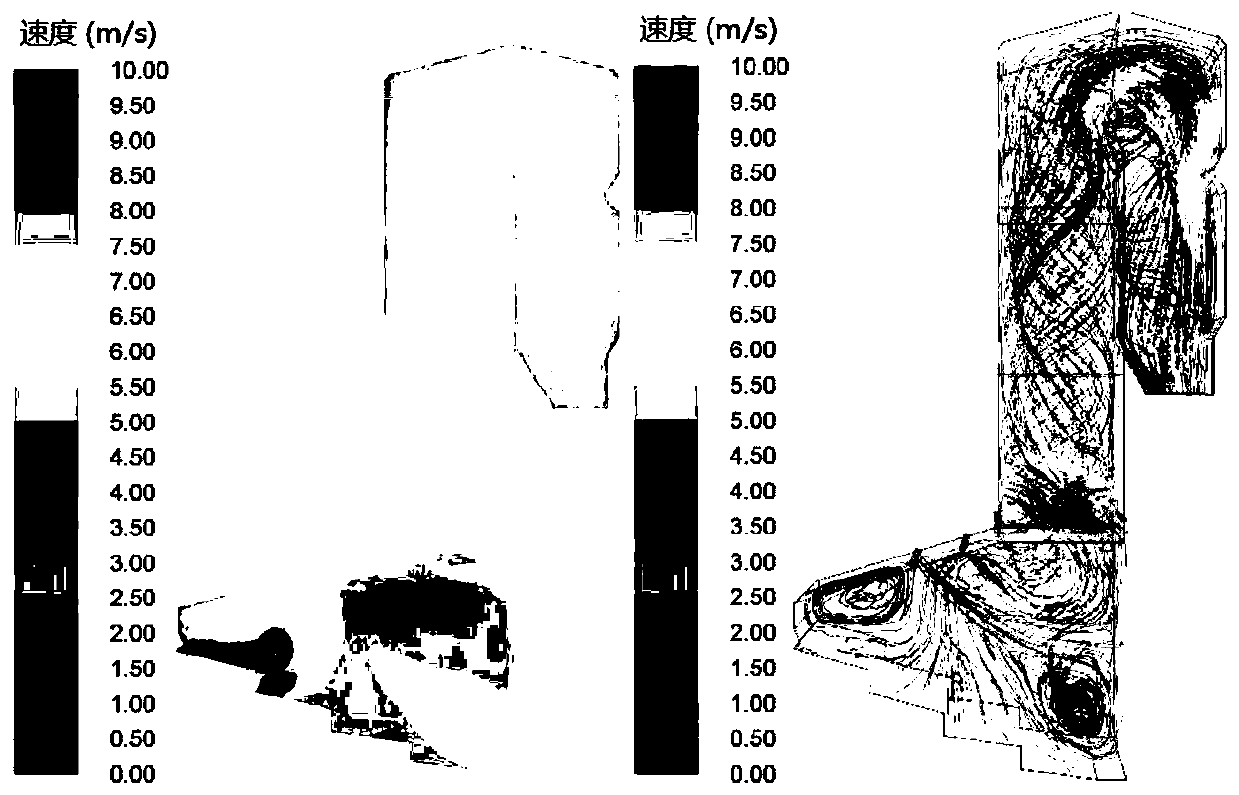

Reaction device and method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge

ActiveCN109663556AStrengthen the degree of disturbanceExtended stayGas treatmentDispersed particle separationFully developedHigh energy

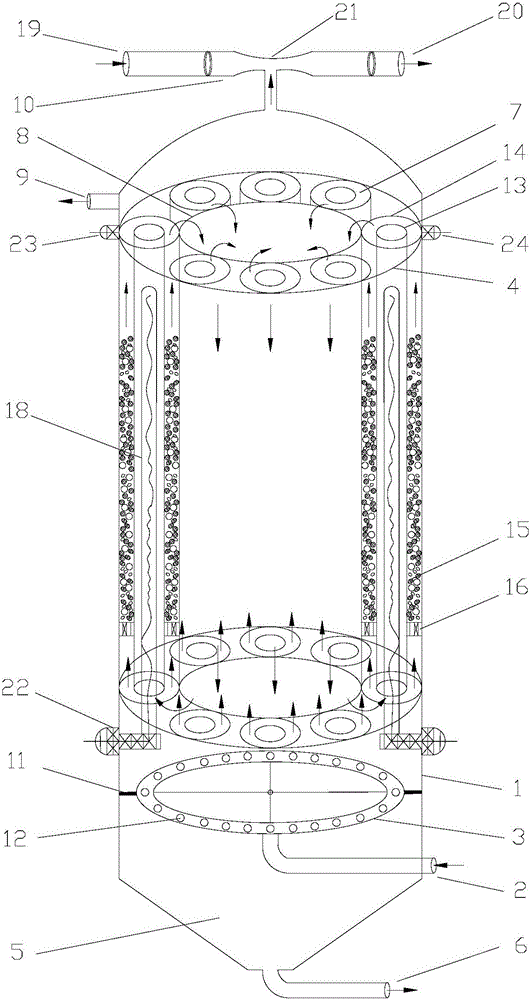

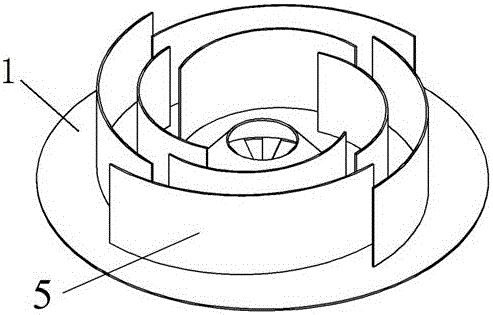

The invention discloses a reaction device and a method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge, wherein the device comprises a dielectric barrier discharge reactor, a high-voltage pulse power source and an online infrared analyzer. The dielectric barrier discharge reactor mainly comprises a tangential inlet, an inner electrode, an outer electrode, a quartz tube and the like. The inner electrode is an integral shape of the lower round table and the upper cone. The outer electrode is arranged around the outer wall of the quartz tube. The carbon dioxide forms a spiraling airflow through the two-way tangential flow. A filament discharge formed between the inner and outer electrodes is violently disturbed under the impetus of the spiral airflow, fully develops toward the increase direction of the pole gap, and forms a large-area, disturbance-enhancing discharge region. The carbon dioxide is efficiently activated and decomposed by high energy electrons and active particles. The reaction device and the method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge have the advantages that the gas residence time ofis long, the reaction zone is highly disturbed, the high-efficiency vibration excitation decomposition is fully developed, and the carbon dioxide activation effect is optimized.

Owner:ZHEJIANG UNIV

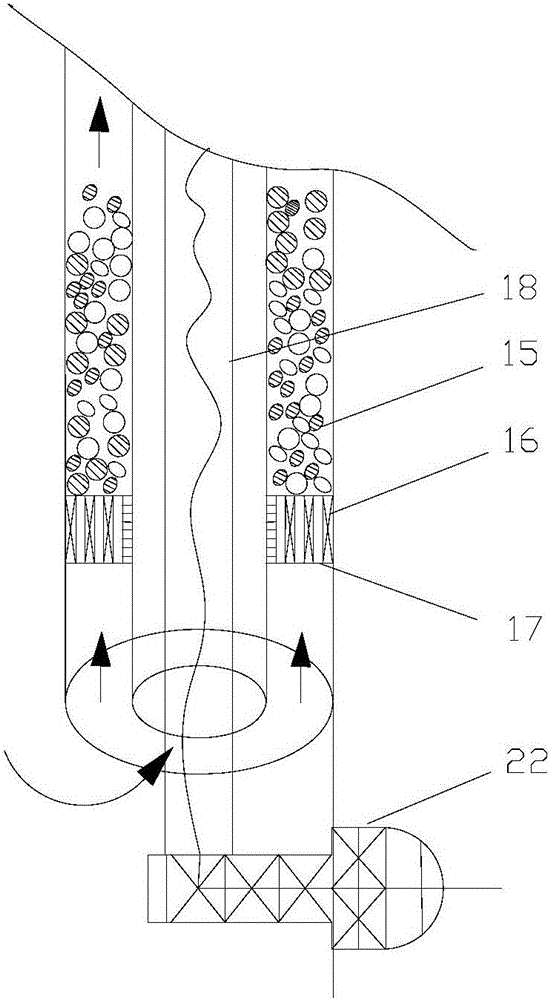

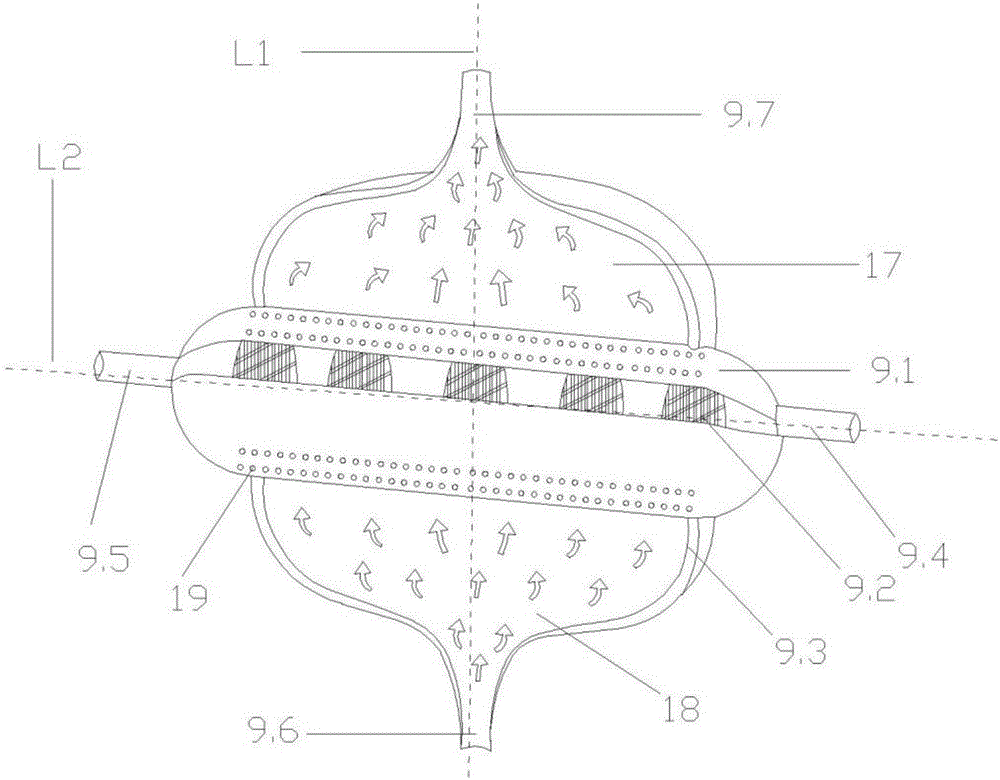

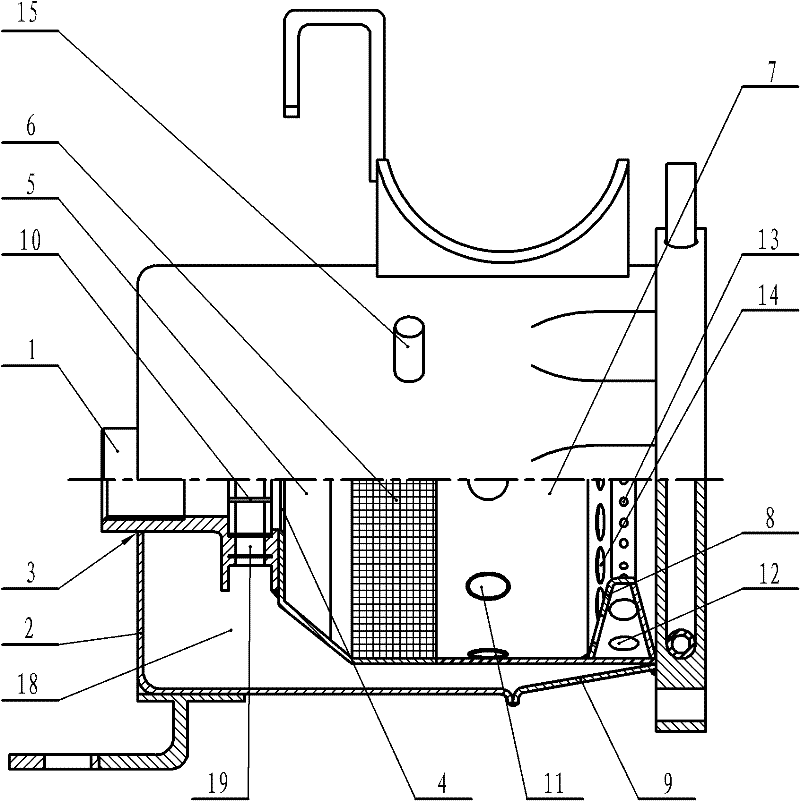

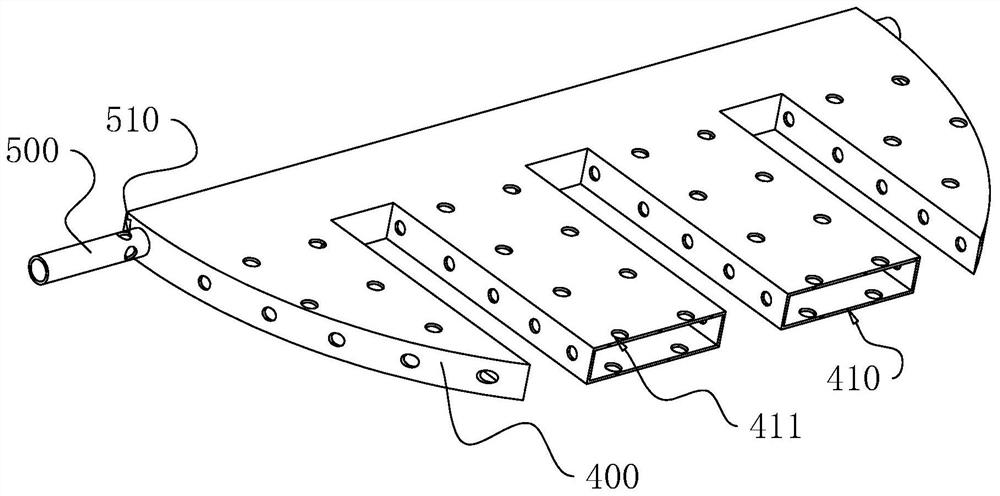

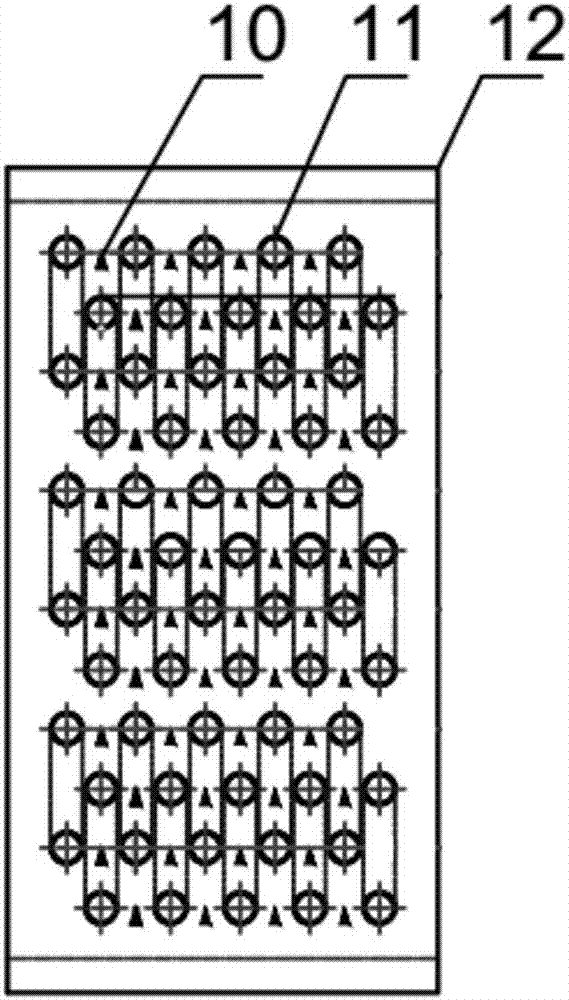

Composite baffling revolving bed mass transfer and reaction device

ActiveCN106622093AImprove uneven distributionIncrease contact timeDispersed particle separationLiquid-gas reaction processesContact timeGas phase

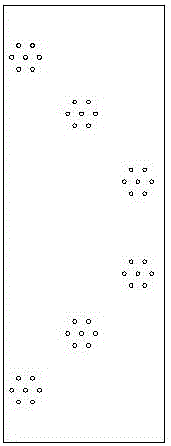

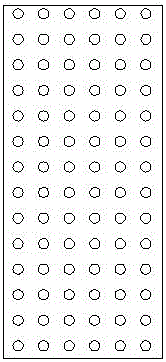

The invention particularly relates to a composite baffling revolving bed mass transfer and reaction device. The device comprises a static disk, a fluid distributor, a fluid inlet pipe, a gas outlet pipe, an upper guide flow plate, a lower guide flow plate, a gas inlet pipe, a moving disk, a rotating shaft, a fluid outlet pipe and a shell body; the static disk and the moving disk are placed in the shell body, and several concentric ring shaped guide flow plates with different diameters are arranged on the static disk; evenly distributed circular small holes are arranged on the upper guide flow plate, and several concentric circular cone shaped lower guide flow plates are arranged on the moving disk; evenly distributed puncture holes are arranged on the lower guide flow plate; the upper guide flow plate and the lower guide flow plate are aligned in a staggering manner; the static disk is fixedly connected with a gas outlet pipe, the moving disk is fixedly connected with the rotating shaft; one end of the rotating shaft crosses through the shell body and seals with the shell body. Through changing the flow path of the gas fluid flow body, the uniform gas fluid distribution is improved by fully using the inside diameter direction of a rotor and an axial space, the gas and fluid contact time is effectively prolonged; through adding the gas disturbance degree, the gas phase mass transfer efficiency is improved.

Owner:ZHONGBEI UNIV

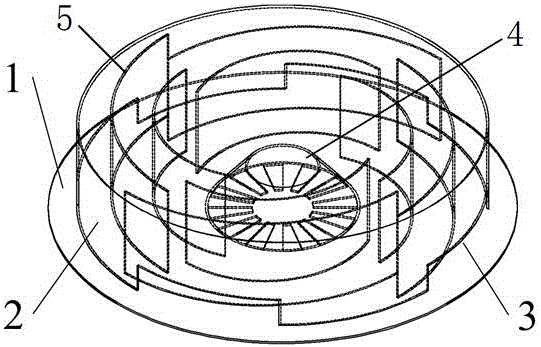

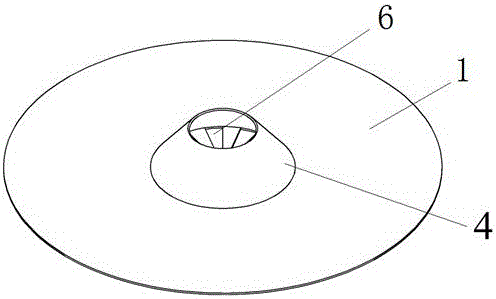

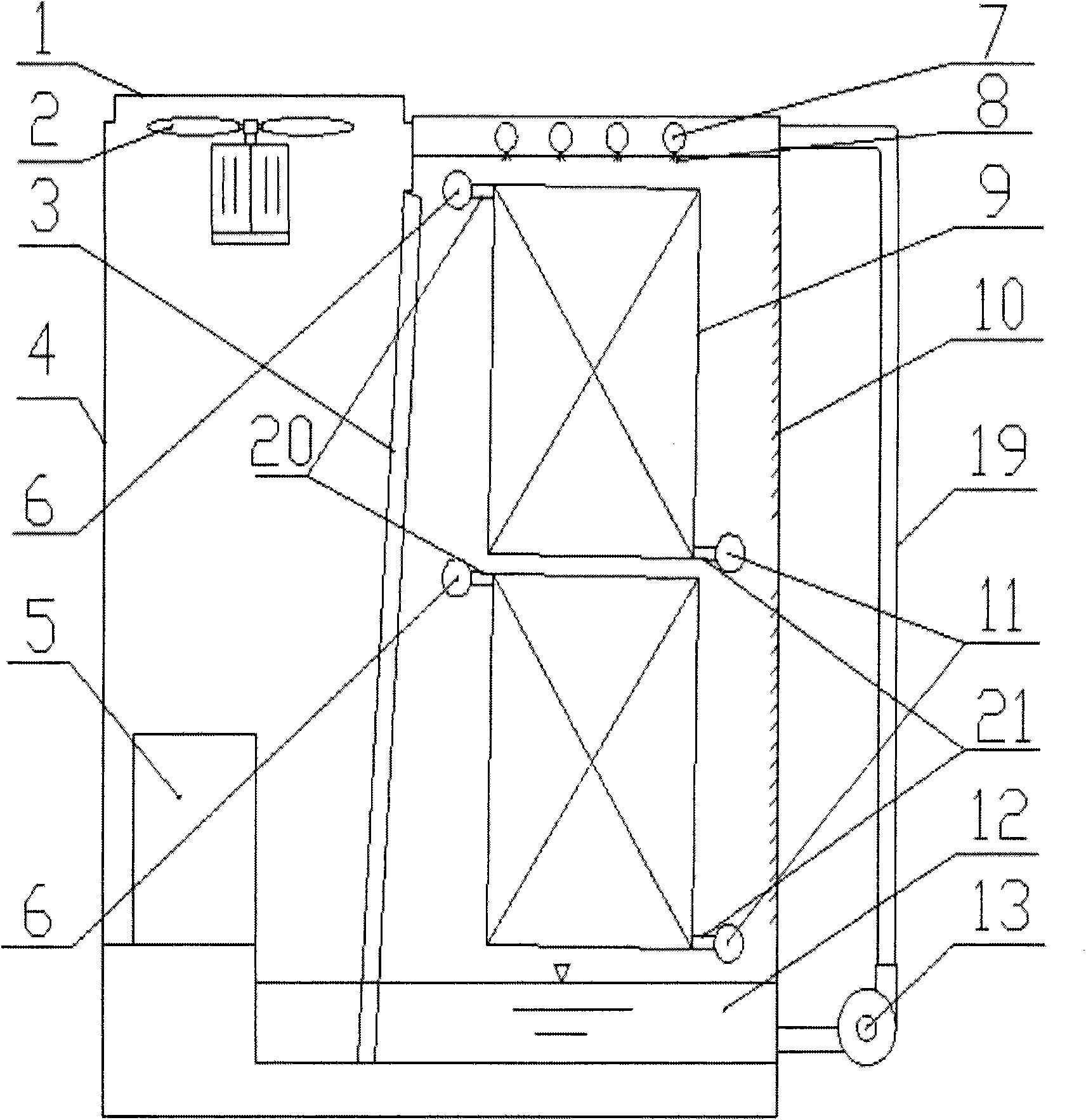

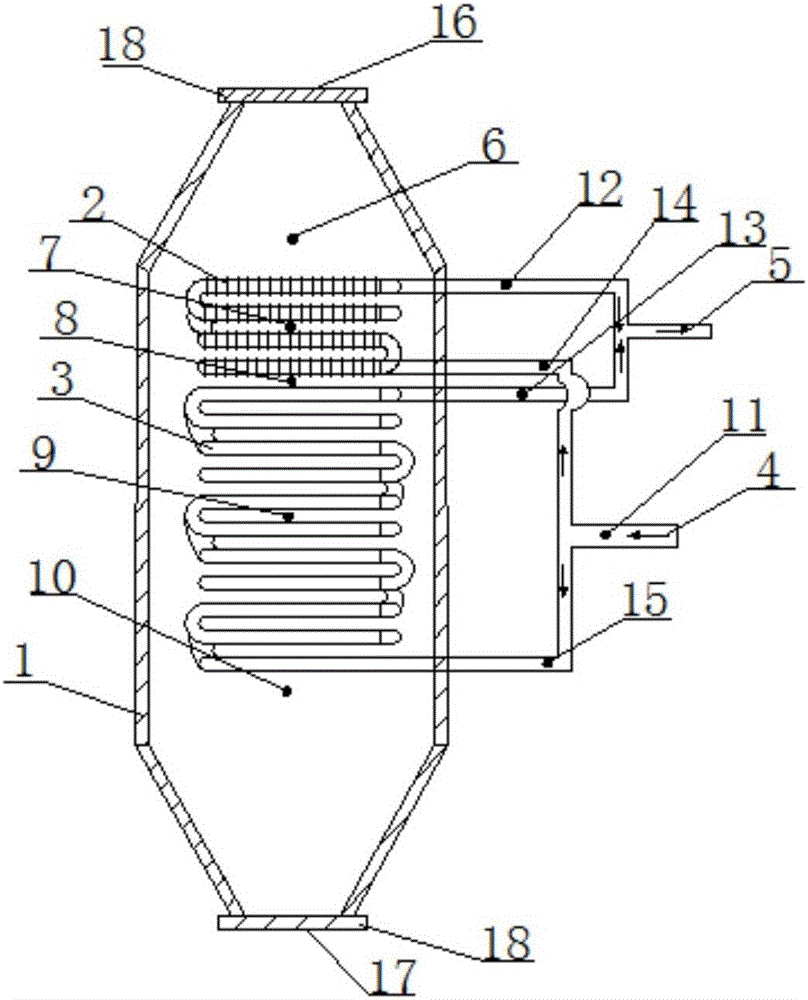

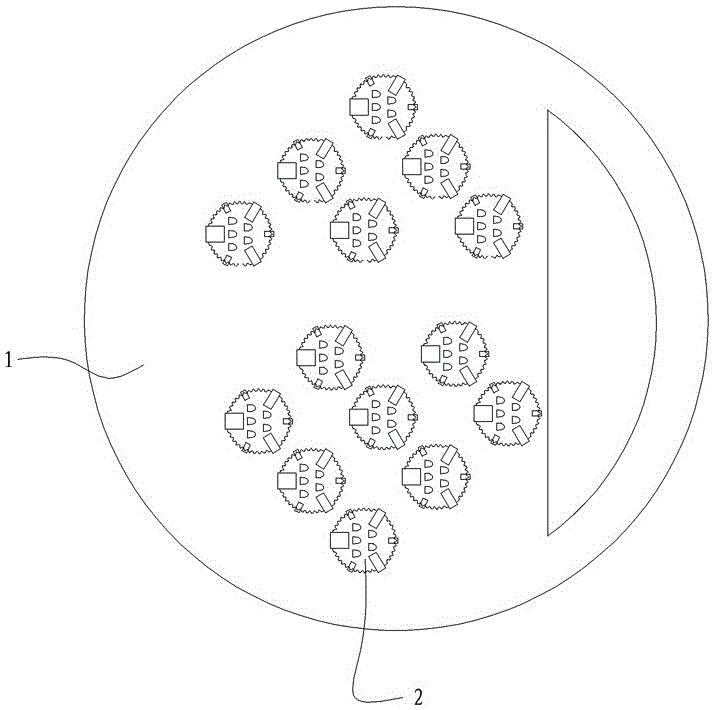

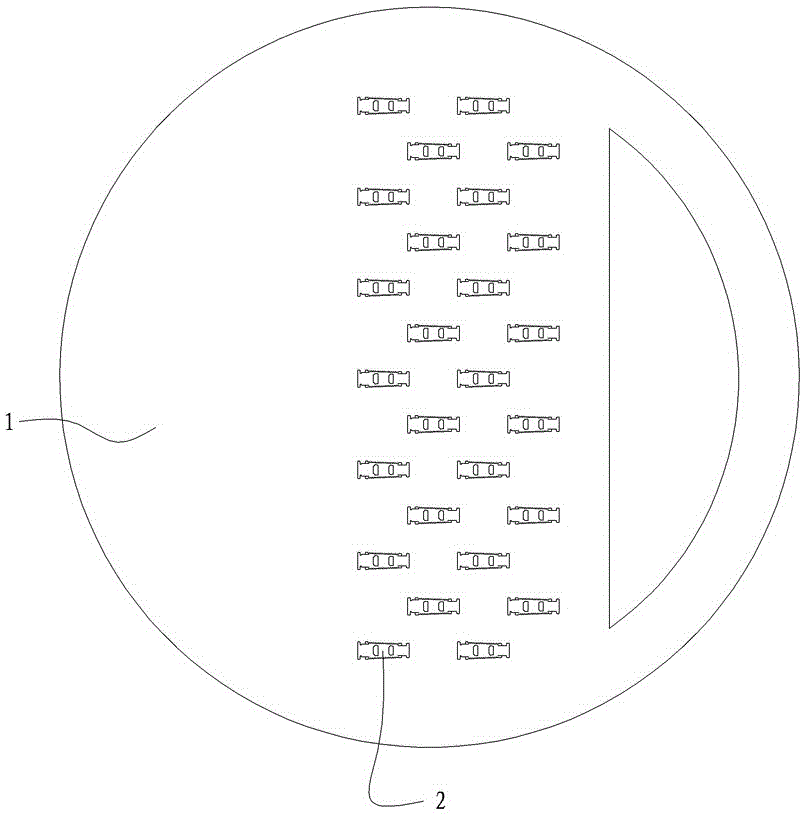

Internal recycle photoelectron-catalytic oxidation combined treatment device

ActiveCN105967313AAcid resistantCorrosiveWater/sewage treatment by irradiationWater treatment compoundsCatalytic oxidationWastewater

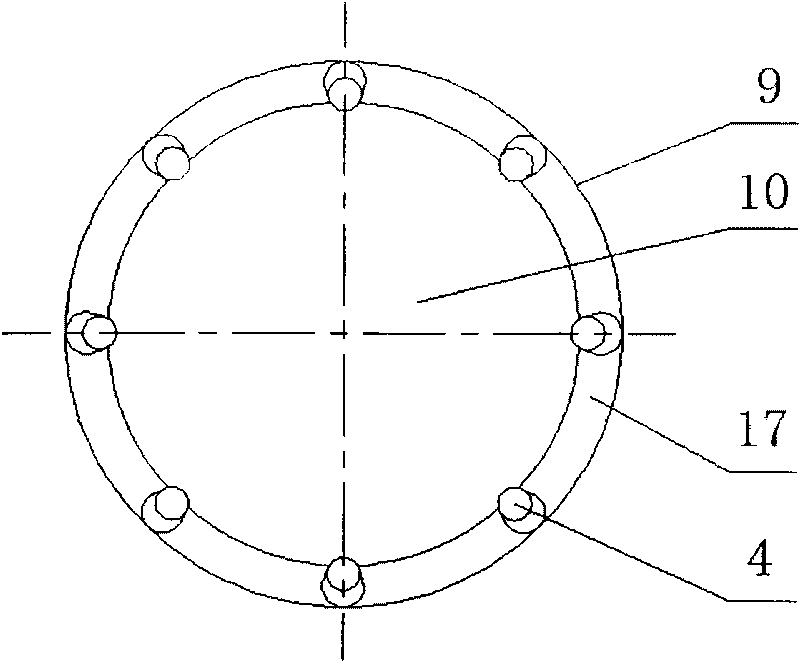

The invention discloses an internal recycle photoelectron-catalytic oxidation combined treatment device. According to the treatment device, a water inlet (2) is formed in the bottom of a treatment device cylinder (1) and is communicated with a circular water distributor (3); wastewater is uniformly distributed to the bottom of the device through the circular water distributor (3); a photoelectron-catalytic oxidation combined treatment system (4) is arranged above the circular water distributor (3); a sediment mud bucket (5) is arranged under the circular water distributor (3) and is communicated with a mud discharge hole (6); under the condition that a direct-current power supply is loaded to the photoelectron-catalytic oxidation combined treatment system (4), the wastewater is lifted to the top of the device from the bottom of a photoelectron-catalytic oxidation unit (7); part of the wastewater is discharged out from a water outlet (9) in the upper part of the device; another part of the wastewater is further circulated to the bottom of the photoelectron-catalytic oxidation unit (7) through a central partitioning cylinder (8) and is mixed with water, then circulation of the wastewater inside the photoelectron-catalytic oxidation combined treatment system (4) is achieved, mud dregs generated from reaction can be discharged out from the mud discharge hole (6) at regular time, and generated tail gases can be discharged out from a top tail gas treater (10).

Owner:CHINA NAT OFFSHORE OIL CORP +2

Vortex broken flow type hydrogen cold box

InactiveCN105921078AIncrease contact areaImprove heat transfer effectChemical/physical processesHydrocarbon oils treatmentEngineeringResidence time

The invention discloses a vortex broken flow type hydrogen cold box. The vortex broken flow type hydrogen cold box comprises an intercepting plate and a mixing box which are coaxially connected, wherein an annular gap is formed between the mixing box and a reactor cylinder body, a plurality of feeding inlets are uniformly formed in the bottom of the outer wall of the mixing box, an overflow cylinder is mounted on a gas-liquid mixture outlet in the center of the mixing box, the center height of the overflow cylinder is more than the height of the upper edge of each feeding inlet, the area of a gas-liquid inlet in the top end of the overflow cylinder is less than the sum of the areas of all feeding inlets, a plurality of broken flow holes are formed in the gas-liquid mixture outlet, and a plurality of guide plates of which the heads and the tails are connected in a staggered state and which are arranged in the shapes of circles are arranged around the overflow cylinder. According to the vortex broken flow type hydrogen cold box disclosed by the invention, the structure is simple, and the spiral guide plates, the overflow cylinder and the broken flow holes are arranged, so that a flat mixed structure is formed, under the condition of lowering the height of the hydrogen cold box, the gas-liquid two-phase mixed heat transfer effect is strengthened, and the problems of the existing hydrogen cold box such as short material residence time, insufficient mixing, nonuniform cooling, complex structure and big pressure drop can be effectively improved.

Owner:LANZHOU LS GRP

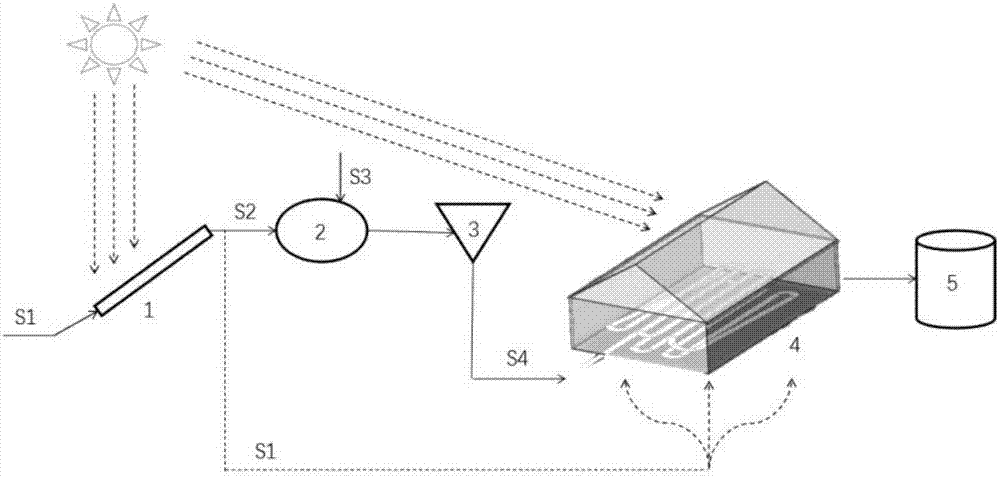

Novel solar energy photovoltaic photo-thermal integrated device

InactiveCN104935239AImprove absorption rateLower working temperaturePV power plantsPhotovoltaic energy generationEngineeringSolar cell

The invention provides a novel solar energy photovoltaic photo-thermal integrated device comprising a frame heat insulation layer, a pedestal heat insulation layer, a glass cover plate, and solar cell sheets, water cooling channels, air channels and a heat collection plate arranged in a sealed spaced formed by the frame heat insulation layer, the pedestal heat insulation layer and the glass cover plate; the heat collection plate is fixed on the frame heat insulation layer; the solar cell sheets are fixed on the heat collection plate; the water cooling channel is arranged between two adjacent solar cell sheets and on the heat collection plate; the air channels are arranged below the heat collection plate; the water cooling channel has a triangle section; two side wall of the water cooling channel are coated with a light selective absorption coating. The novel solar energy photovoltaic photo-thermal integrated device uses cooling water and air for simultaneous heat exchange, and obtained hot water and hot air can be applied to life water, home heating and greenhouse; work temperature of the solar cell sheets can be better ensured, heat can be fully absorbed, thus maximizing energy benefit.

Owner:JIANGSU UNIV

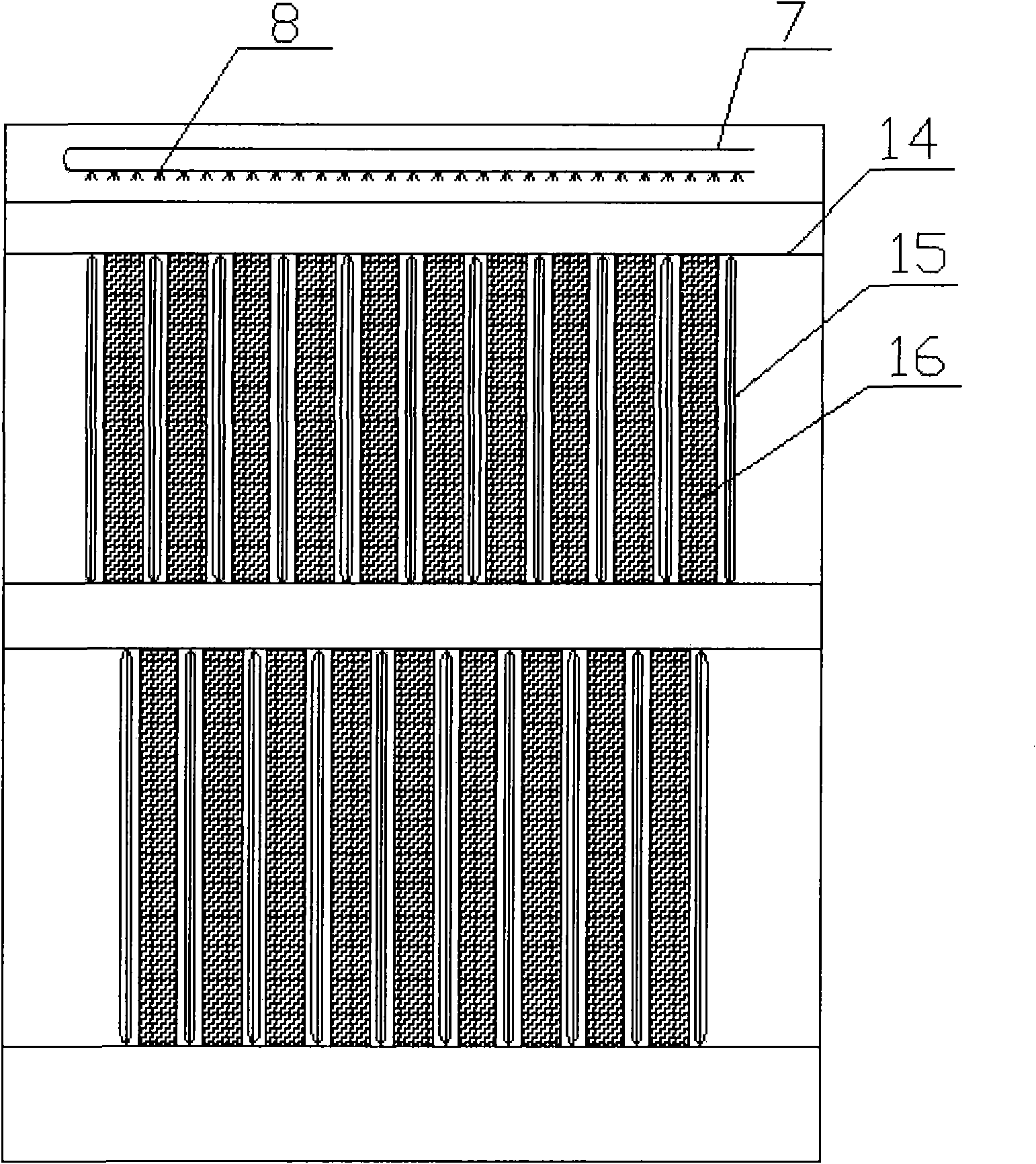

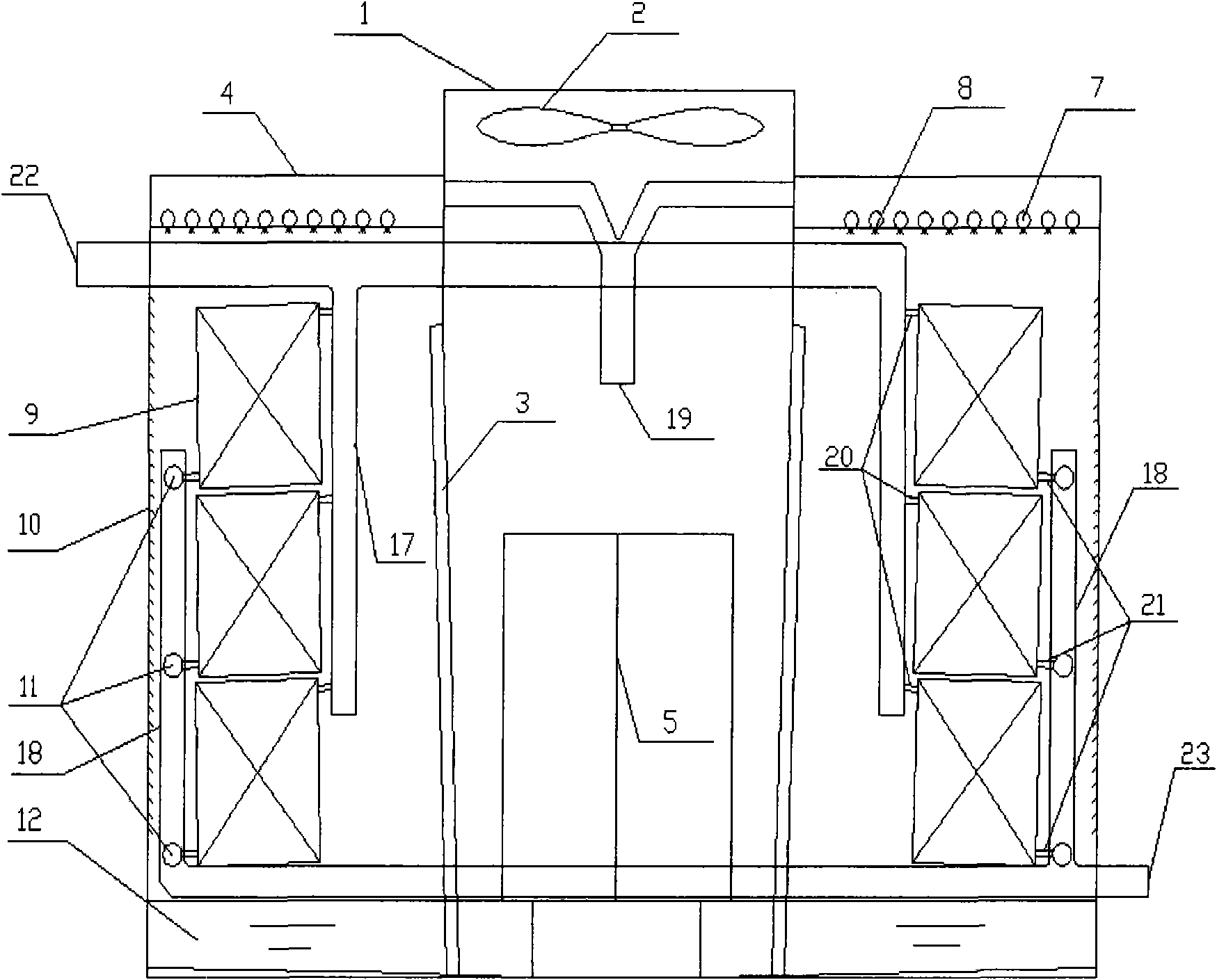

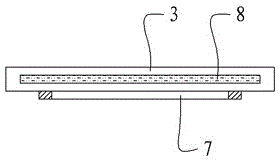

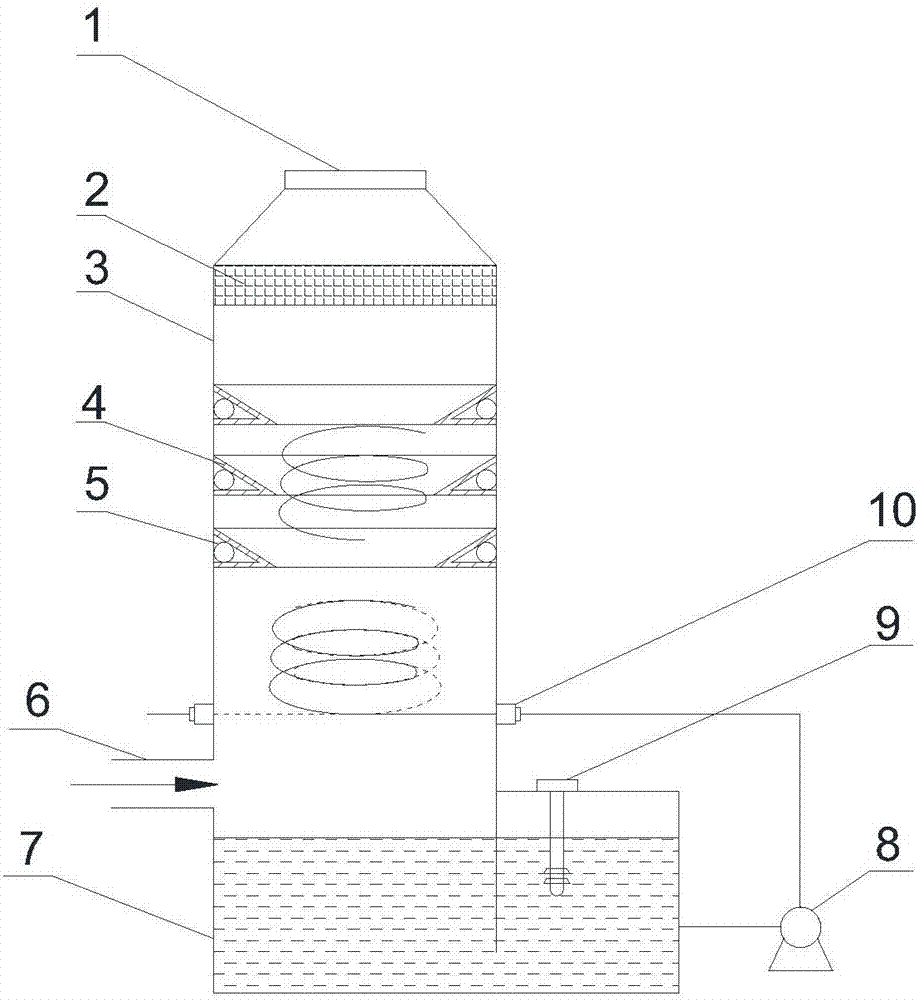

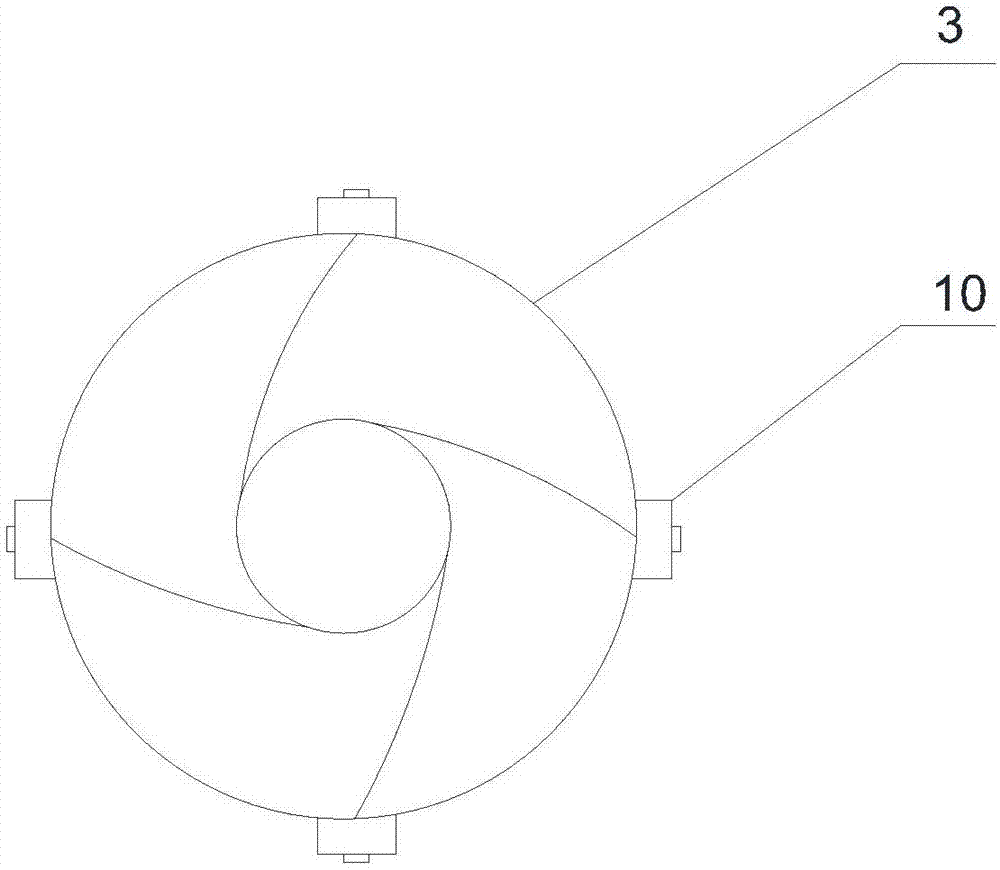

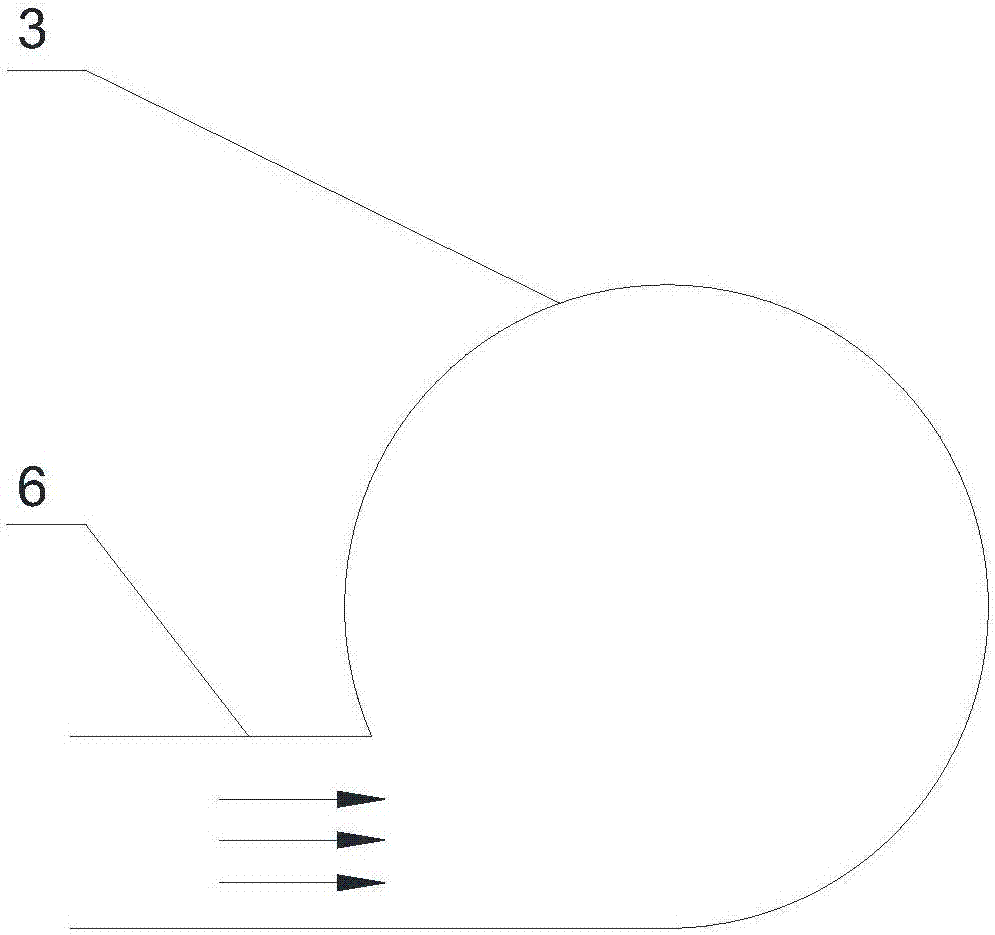

Packing material combination plate element unsaturated evaporative radiator

InactiveCN101629789AReduce the temperatureImprove heat transfer efficiencyDirect contact heat exchangersWater savingEvaporation

The invention provides a packing material combination plate element unsaturated evaporative radiator, which comprises a shell case, a fan, heat exchange elements, a spraying system and the like, wherein the lateral face of the case is provided with an air inlet and the top is provided with an air outlet, the air inlet of the case is provided with the heat exchange element, the spraying device is arranged above the heat exchange elements, the air outlet is provide with a draught fan, and a water baffle is arranged between the draught fan and the heat exchange elements. The heat exchange elements are formed by overlapping at least two groups of combination plate elements up and down, a polycarbonate asia ethyl ester packing material is filled between heat exchange plate pipes, the heat exchange plate pipes of two groups of up and down adjacent heat exchange elements are arranged in a staggering mode, the upper end of each heat exchange plate pipe is passed into a medium inlet pipe and is connected with a medium inlet header pipe, and the lower end of each heat exchange plate pipe is passed into a medium outlet pipe and is connected with a medium outlet header pipe; and water films are formed on the surfaces of the heat exchange elements under the action of the gravity of spray water, and the heat transfer is strengthened through water film evaporation. The packing material combination plate element unsaturated evaporative radiator achieves the crossed cross-flow type heat exchange between the water films and the air, and has high heat transfer efficiency, small wind resistance and perfect energy-saving and water-saving effect.

Owner:EAST CHINA UNIV OF SCI & TECH

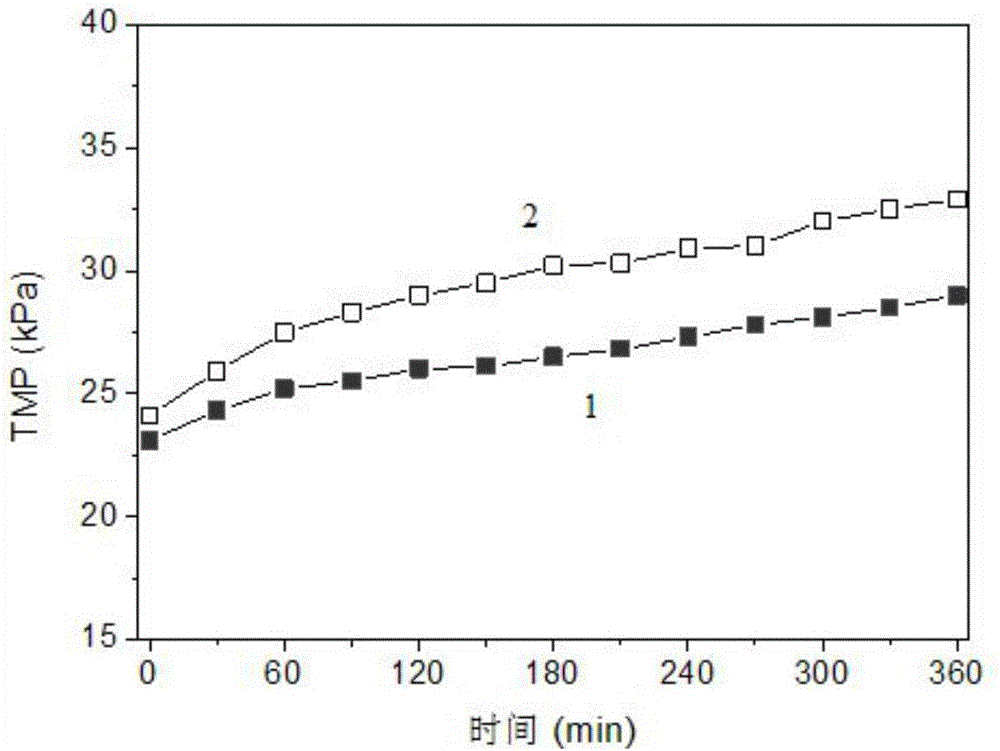

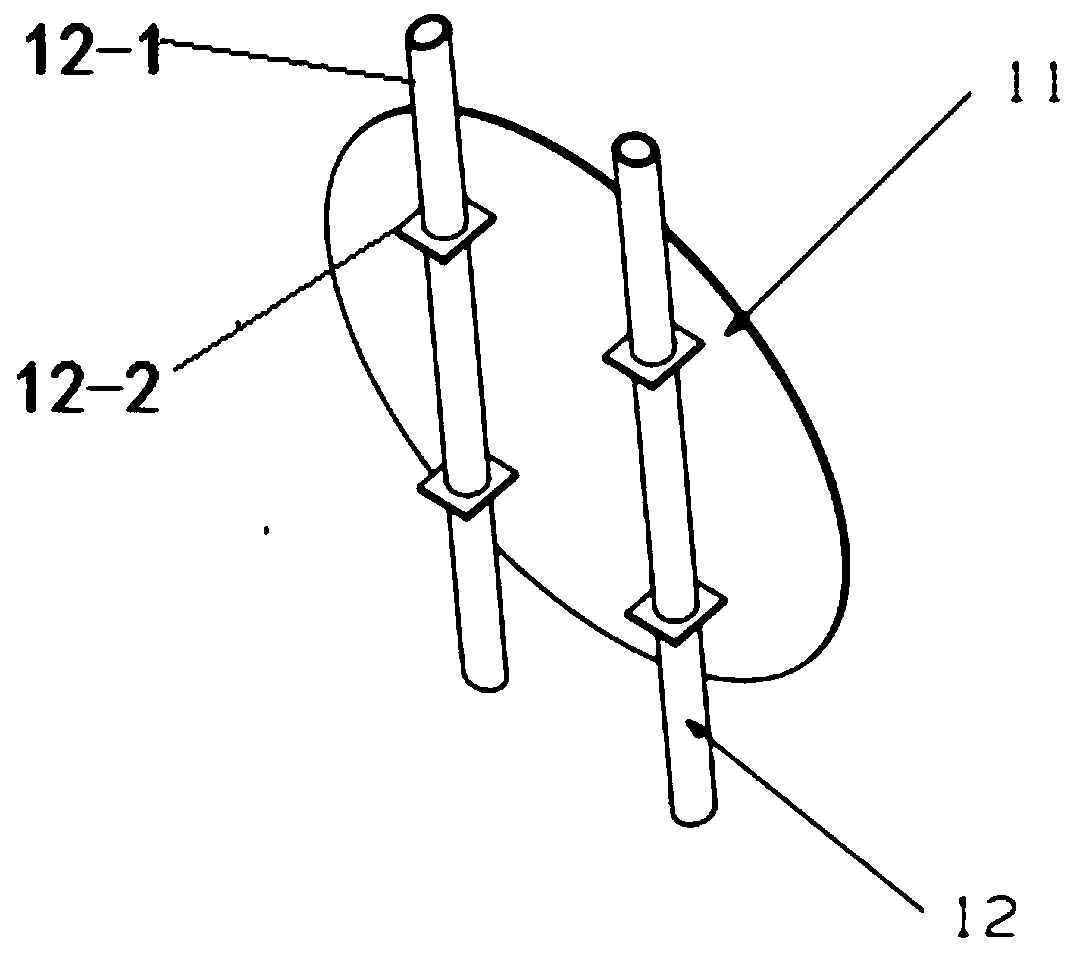

Membrane pollution vibration control device used in process of treating algae containing water through low-pressure spiral membrane and method for controlling membrane pollution through device

ActiveCN105692875AReduced Integrity ImpactAvoid damageSemi-permeable membranesTreatment using aerobic processesVibration controlHigh flux

The invention relates to a membrane pollution vibration control device used in the process of treating algae containing water through a low-pressure spiral membrane and a method for controlling membrane pollution through the device. The device and the method aim at solving the problem that at present, no vibration control technology provided for the low-pressure spiral membrane pollution phenomenon is available. A vibration driver is arranged in the device, a spiral membrane reactor is driven by a drive motor to rotate along the axis, rotate back to the original position, reverse and rotate back to the original position, and therefore the vibration effect of a membrane assembly is achieved. According to the vibration method, the time when the spiral membrane maintains high-flux operation is prolonged, and the quality of effluent is guaranteed.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

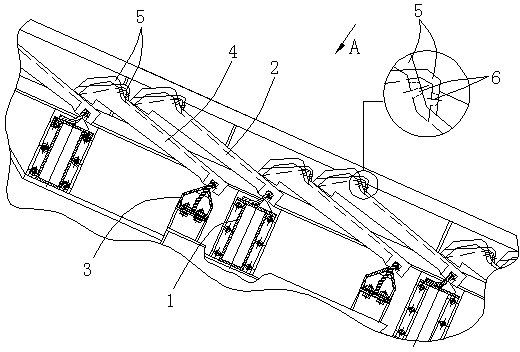

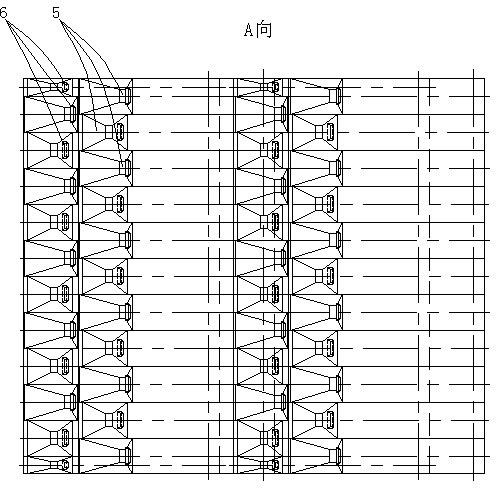

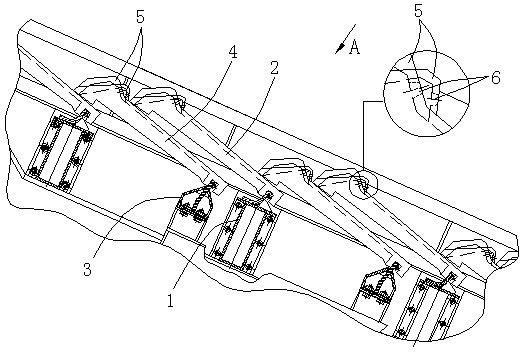

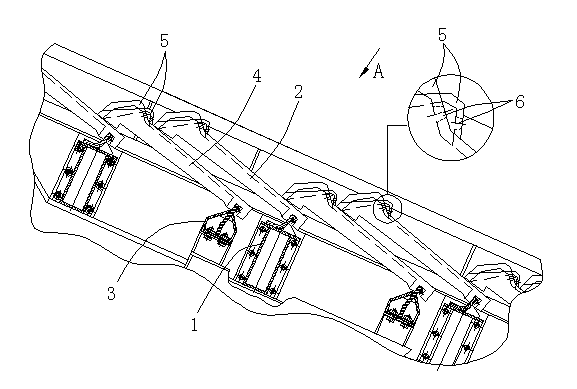

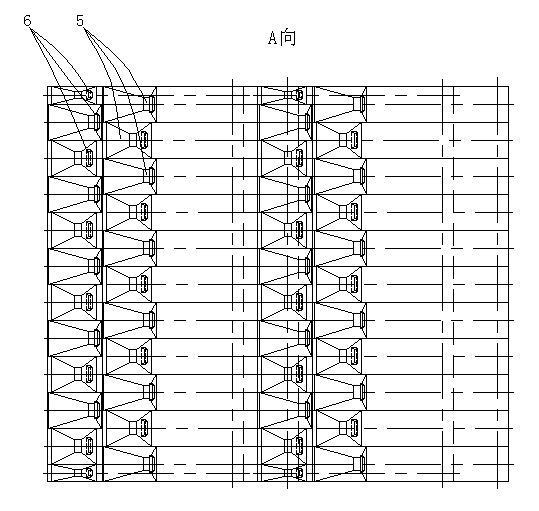

Incinerator grate with transversely and longitudinally staggered head bosses

ActiveCN101929679AFast dryingImprove the effect of incineration treatmentIncinerator apparatusInstabilityEngineering

The invention discloses an incinerator grate with transversely and longitudinally staggered head bosses. A fixed beam passes through clamping grooves on the tail parts of the same row of fixed grate sheets so as to form fixed grate plates; a movable beam passes through clamping grooves on the tail parts of the same row of movable grate sheets so as to form movable grate plates; the movable grate plates and the fixed grate plates are longitudinally superposed and alternately arranged and gathered to form the grate; a head boss is arranged on the front end of the upper surface of each grate sheet; a primary air hole is formed on the head boss of each grate sheet; the head bosses of two adjacent grate sheets on the same row of grate plates are transversely and longitudinally staggered; and the front ends of each row of grate sheet are flush with one another. Through the incinerator grate with the transversely and longitudinally staggered head bosses, a garbage material layer can be effectively scattered so as to change the garbage height at each position of the incinerator material layer, increase the instability of the garbage material layer and facilitate garbage scattering and loosening; moreover, the incinerator grate realizes all-round scattering, loosening and stirring of the garbage material layer in an incinerator, improves the drying and burning efficiency of garbage, shortens the drying time and contributes to the fast burning of the garbage.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Roller way sintering furnace with uniform hearth temperature

The invention discloses a roller way sintering furnace with uniform hearth temperature. The roller way sintering furnace comprises a furnace body and a hearth, wherein a transmission roller way, an upper heating element and a lower heating element are arranged in the hearth, the upper heating element and the lower heating element are arranged above and below the transmission roller way correspondingly, the upper heating element is correspondingly provided with an upper protective sleeve, the lower heating element is correspondingly provided with a lower protective sleeve, and the top of the furnace body is provided with an exhaust port. One end of the upper protective sleeve is provided with at least one first air inlet hole, the other end of the upper protective sleeve is provided with atleast one second air inlet hole, one end of the lower protective sleeve is provided with at least one first air inlet hole, the other end of the lower protective sleeve is provided with at least onesecond air inlet hole, the first air inlet holes are the same in size and orientation, the second air inlets are the same in size and orientation, the orientations of the first air inlet holes are opposite to the orientations of the second air inlet holes, and the orientations are all located in the vertical face of the hearth. Uniformity of the flow field and the temperature inside the hearth canbe improved, and the comprehensive performance of sintered products is ensured.

Owner:湖南烁科热工智能装备有限公司

High-pressure SCR system with high efficiency and emission reduction for ships

PendingCN110295981AIncrease the degree of disturbanceWell mixedInternal combustion piston enginesExhaust apparatusNitrogen oxidesUrea

The invention discloses a high-pressure SCR (selective catalytic reduction) system with high efficiency and emission reduction for ships. Through arranging a spoiler at the inlet of a mixer, and sequentially arranging a rectifier and a flow equalizing plate at the inlet of a reactor, mixing degree of reducing agents such as urea solution and waste gas to be treated is improved; mixed waste gas isuniformly distributed on the cross section of a flow passage and vertically enters a catalyst hole; abrasion of a catalyst is reduced; ash deposited on the surface of the catalyst is timely and regularly cleaned; blocking of the catalyst is avoided; denitration efficiency of the whole system is improved; ammonia escape rate is reduced; and nitrogen oxide emission is reduced.

Owner:中国船舶重工集团柴油机有限公司

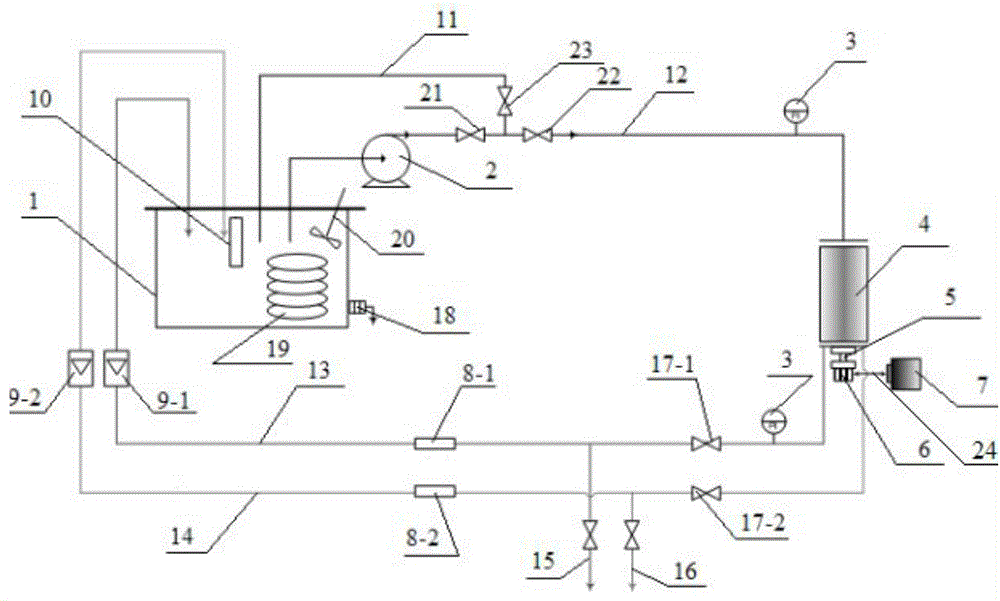

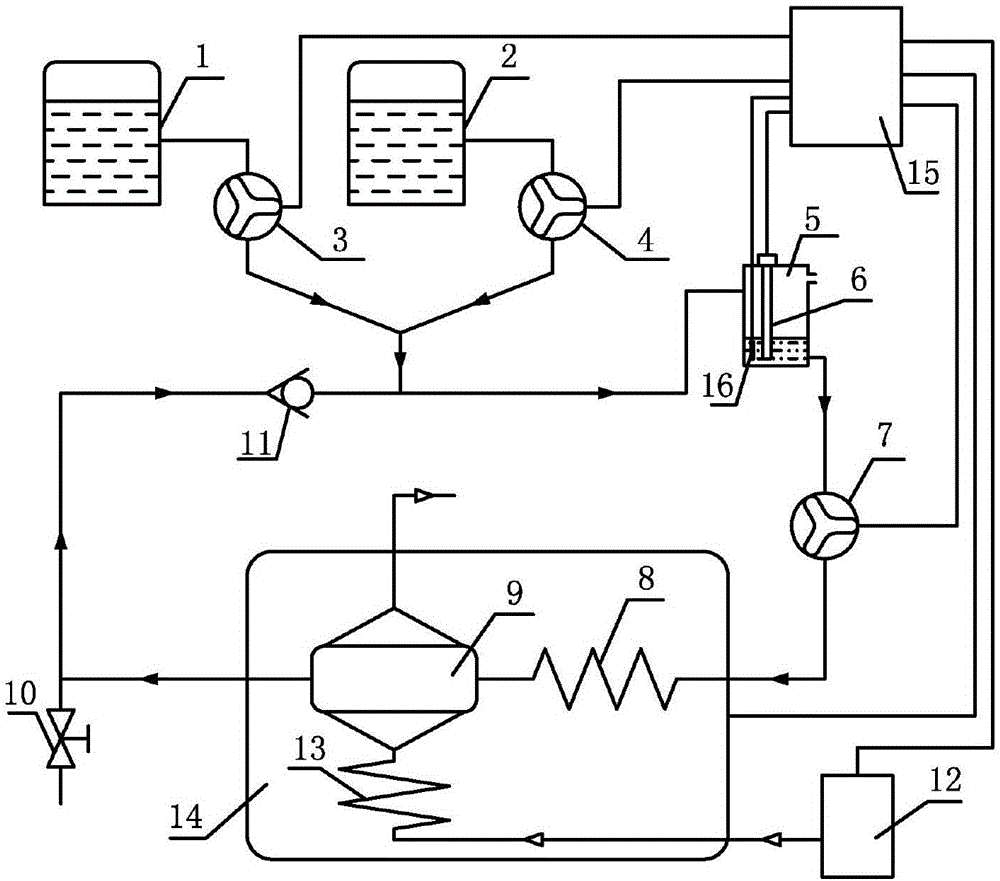

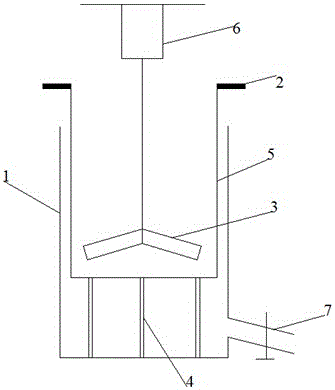

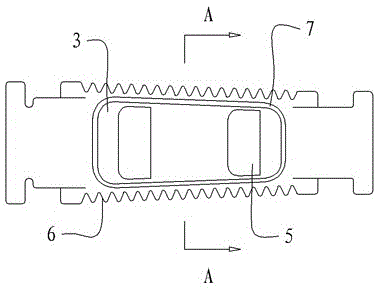

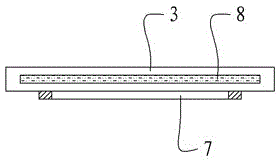

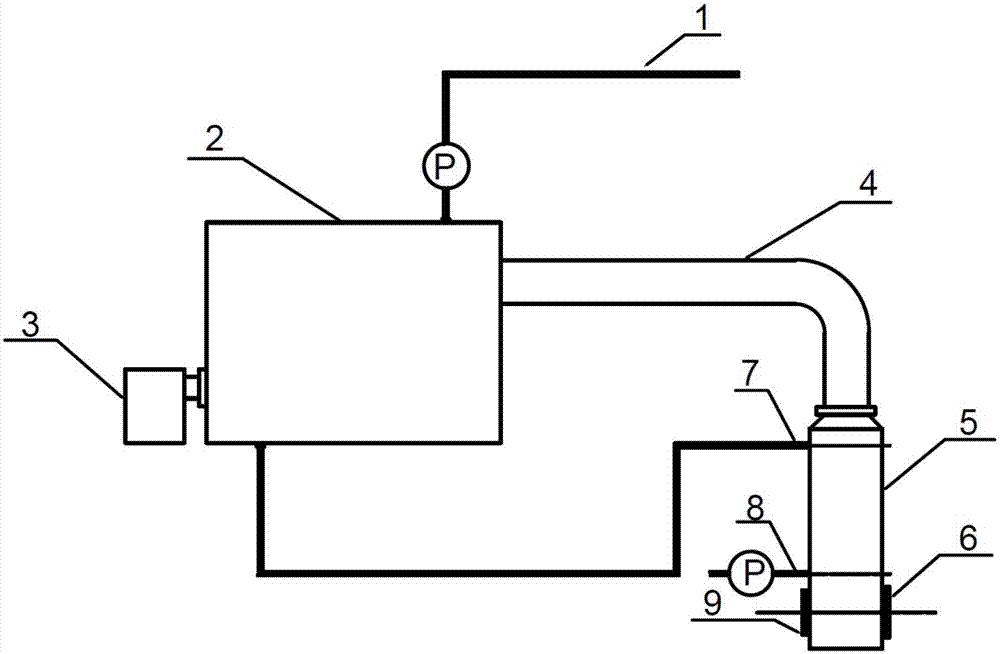

Device for fluidization loading or taking out low-temperature protection agent for biological tissue

ActiveCN106234351AAccelerate the rate of penetration into biological tissueEasy loadingDead animal preservationElectricityTemperature control

The invention relates to a device for fluidization loading or taking out a low-temperature protection agent for a biological tissue. The device is characterized by comprising a solution circulating module, a solution supplying module, a sample container, a temperature control box and a controller. The sample container is arranged in the temperature control box; the sample container is provided with a liquid inlet and a liquid outlet; the solution circulating module communicates with the liquid inlet and the liquid outlet of the sample container, so that a solution flows through the sample container in a circulating way; the solution supply module communicates with the solution circulating module so as to supply the solution to the solution circulating module; the controller is respectively and electrically connected with the solution supplying module, the solution circulating module and the temperature control box. According to the automation device, the threshold treatment temperature can be reduced, and meanwhile, the speed rate for loading and taking the low-temperature protection agent in and out of the biological tissue is accelerated.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

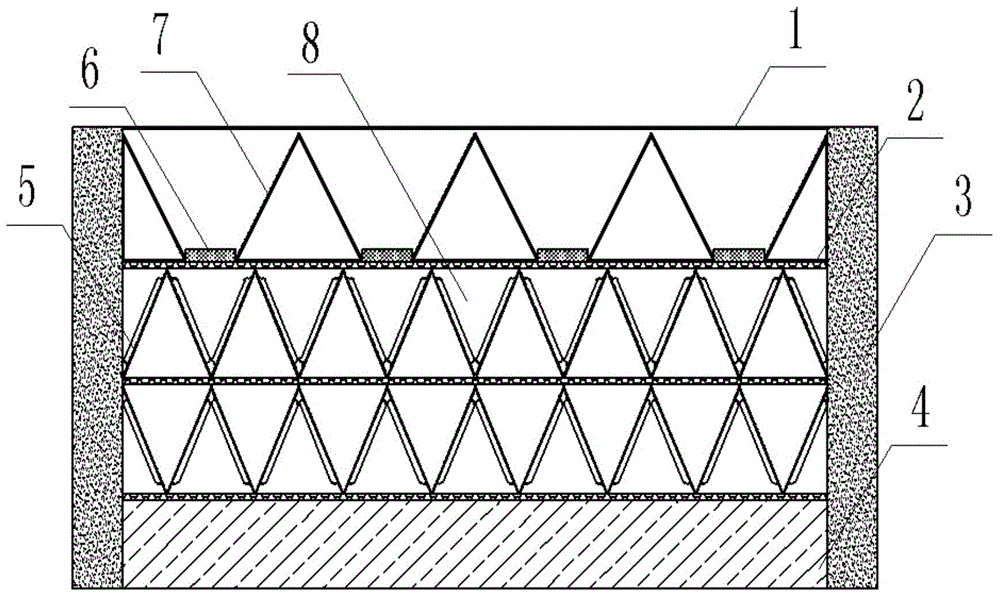

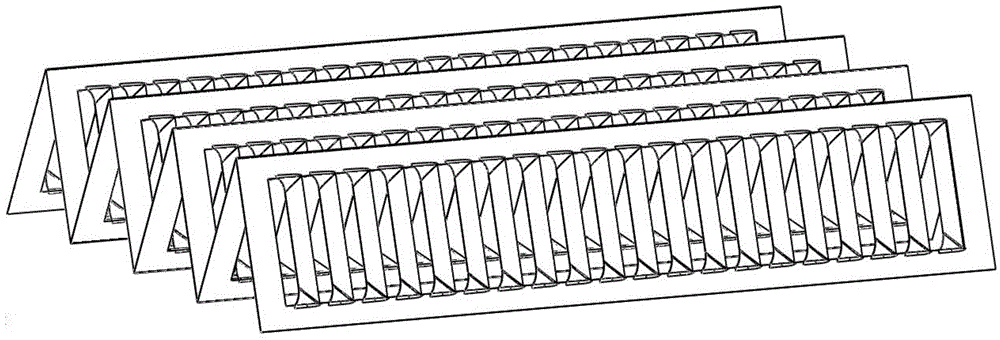

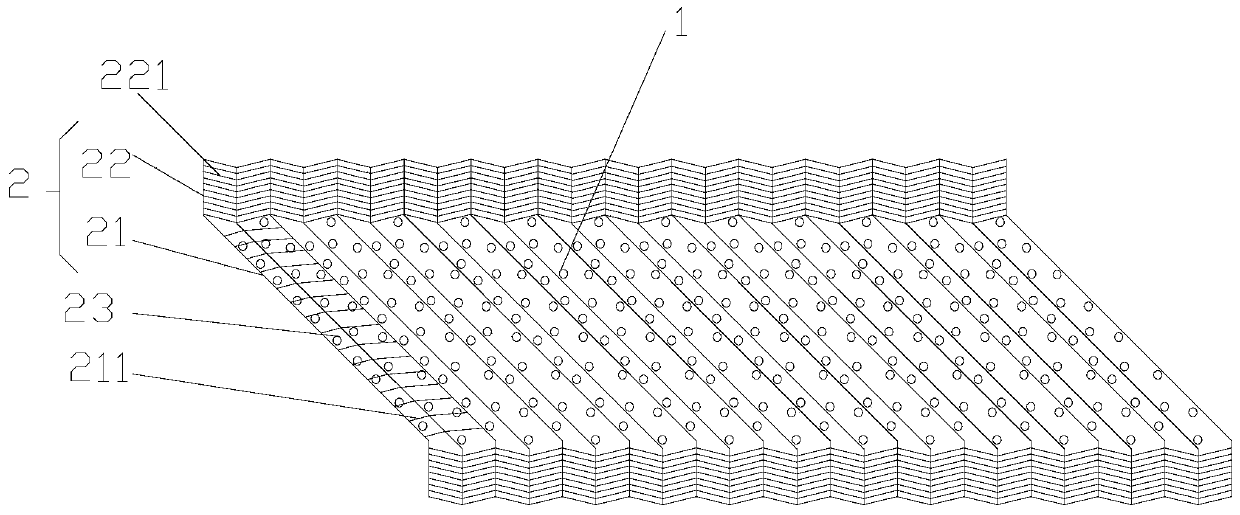

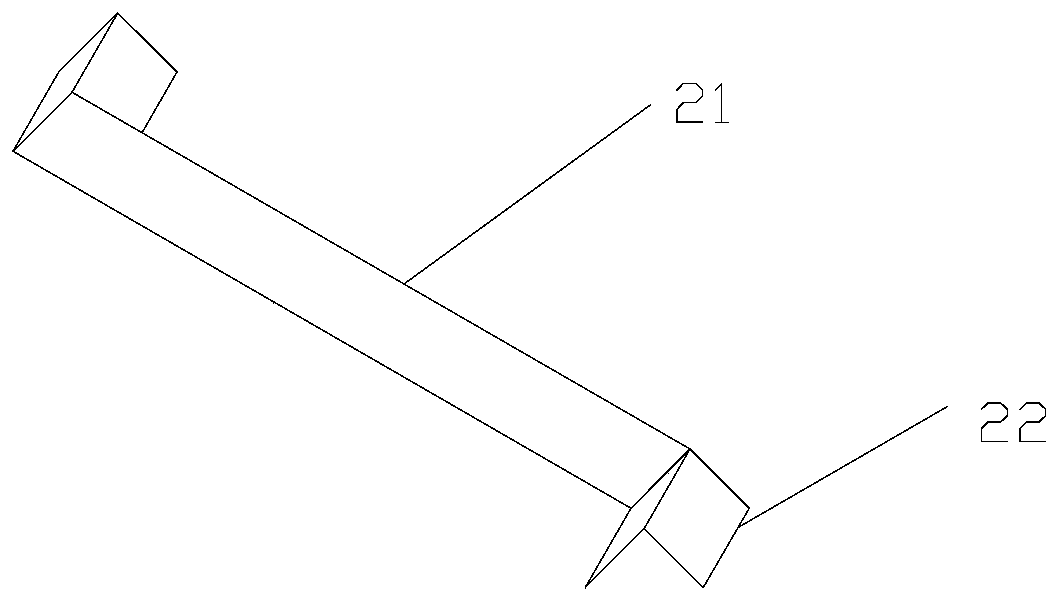

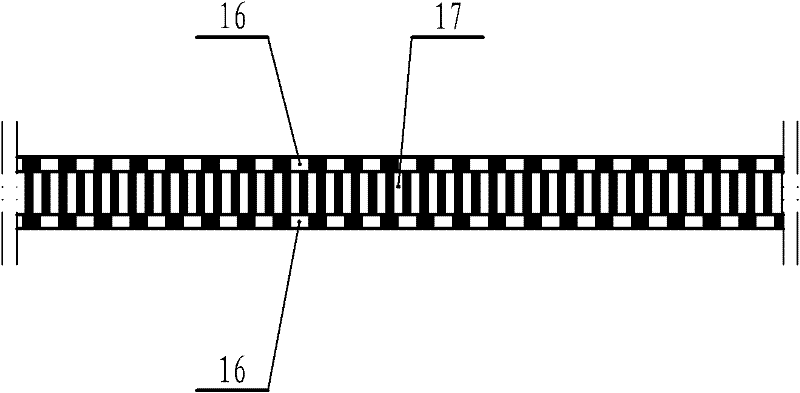

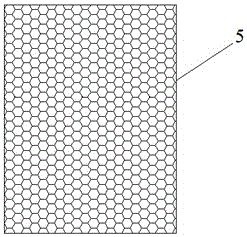

High efficiency structured packing

PendingCN110449113AFull contact exchangeStrengthen the degree of disturbanceChemical/physical/physico-chemical processesVapor liquidEngineering

The invention provides a high efficiency structured packing, which includes a packing layer main body and packing sections. The high efficiency structured packing is characterized in that: the packingcomprises bevel edge packing, straight edge packing and openings, the packing layer main body consists of several packing sections, each packing section consists of bevel edge packing and straight edge packing, the top and bottom of the bevel edge packing are respectively provided with a section of straight edge packing, and the bevel edge packing is equipped with a plurality of openings. Compared with the prior art, the high efficiency structured packing provided by the invention is reasonable in structure, the straight edge packing makes the vapor-liquid phase flow channel between two adjacent packing layers smoother, and reduces the circulation resistance drop of vapor-liquid two phases; the opening rate is appropriately increased, thus making the two side areas wet and vapor-liquid contact exchange fuller, and effectively improving the utilization rate of the specific surface area of the packing; the alternate combination structure of straight edge ripples and inclined ripples enhances the disturbance degree of vapor-liquid phases, improves the driving force of mass transfer, and reduces the resistance of mass transfer, thereby further improving the treatment capacity and masstransfer efficiency.

Owner:浙江桐朕石化设备有限公司

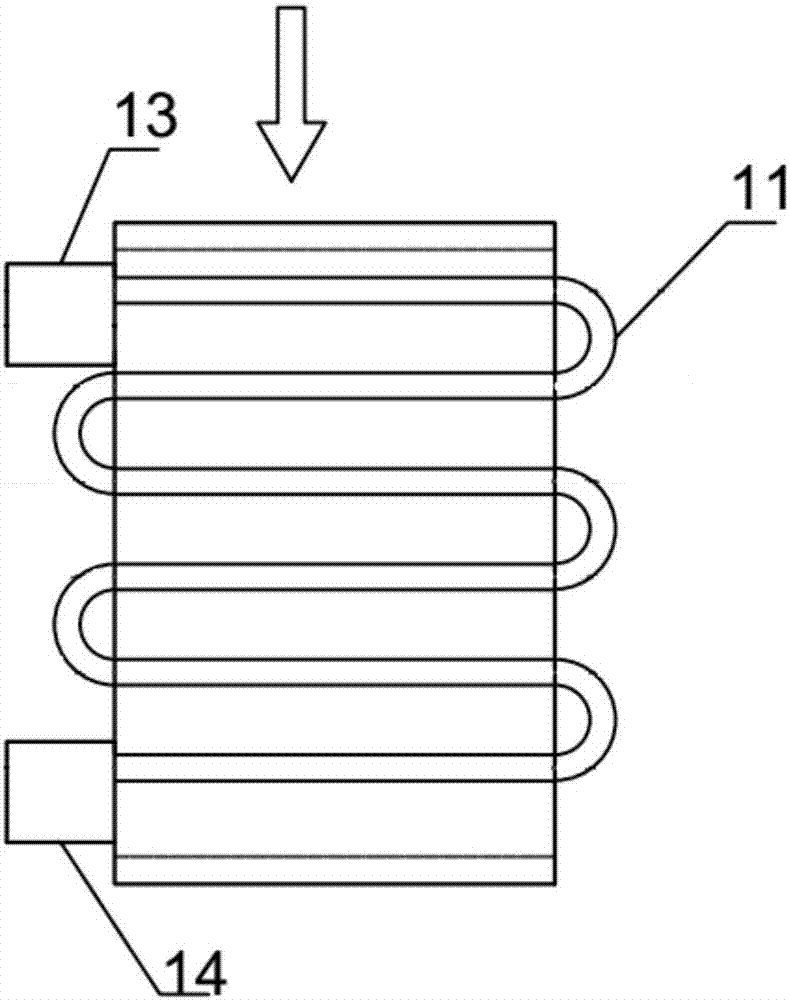

Heat exchanger for waste heat recovery of coal-fired boiler

ActiveCN106016238AStrengthen the degree of disturbanceReduce resistanceFeed-water heatersCounter flowEngineering

The invention discloses a heat exchanger for waste heat recovery of a coal-fired boiler. The design concept combining a section-separated heat transfer enhancement principle and a technology for flexibly adjusting the tube wall temperature through graded water supply is adopted, the heat exchanger is divided into a high-temperature section adopting carbon steel and a low-temperature section adopting ND steel, tube bundles are staggered, media inside and outside tubes are in a counter-flow type, the tube wall temperature of the high-temperature section and the low-temperature section is adjusted precisely in a graded water supply manner, so that the tube wall temperature is higher than the acid dew point temperature of flue gas throughout, and a low-temperature corrosion relieving effect is realized. The technical problems of low heat transfer temperature pressure and serious low-temperature acid-dew-point corrosion in low-temperature flue gas waste heat recovery of the coal-fired boiler are solved very well, by means of combination of section-separated heat transfer enhancement and flexible adjustment of the tube wall temperature through graded water supply, the heat exchange performance and the anti-corrosion effect of the low-temperature heat exchanger are improved obviously, the efficiency and the economical efficiency of the low-temperature flue gas waste heat recovery of the coal-fired boiler are improved substantially, and the heat exchanger has good social and economic benefit and great industrial application and popularization potential.

Owner:苏华建设集团有限公司

new combustion chamber

A novel combustion chamber comprises an oil jet nozzle seat, a combustion chamber housing, a front air barrel, a rear air barrel and a butterfly-like air plate, wherein an air channel is arranged between the combustion chamber housing and the front air barrel and the rear air barrel; the oil jet nozzle seat is fixedly connected to the combustion chamber housing and the front air barrel, respectively; an oil jet nozzle is provided with an air inlet on which a plurality of vortex plates are evenly distributed; the rear air barrel is provided with a plurality of rear air barrel front-section airinlets and a plurality of rear air barrel rear-section air inlets, respectively; a plurality of air curtain holes are formed on the bottom of the butterfly-like air plate; a plurality of reflecting holes are formed on a side wall, facing the direction of the front air barrel, of the butterfly-like air plate; and a heat-resistant alloy fibre evaporation mesh is jointed on the internal surface of the front air barrel. The novel combustion chamber of the invention allows the air to enter the combustion chamber via the reflecting holes in a direction opposite to the direction of a combustion gas flow in the combustion chamber, so that the turbulence condition of a fuel-oil mixed gas is evener and more rational. Moreover, the heat-resistant alloy fibre evaporation mesh improves the atomizationdegree of the fuel oil and promotes the secondary evaporation of the wall-attached fuel oil, so that the combustion efficiency can stably reach 95% or higher; therefore, the energy-saving effect is very obvious.

Owner:北京北机机电工业有限责任公司

Incinerator grate with transversely and longitudinally staggered head bosses

ActiveCN101929679BFast dryingImprove the effect of incineration treatmentIncinerator apparatusEngineeringDrying time

The invention discloses an incinerator grate with transversely and longitudinally staggered head bosses. A fixed beam passes through clamping grooves on the tail parts of the same row of fixed grate sheets so as to form fixed grate plates; a movable beam passes through clamping grooves on the tail parts of the same row of movable grate sheets so as to form movable grate plates; the movable grate plates and the fixed grate plates are longitudinally superposed and alternately arranged and gathered to form the grate; a head boss is arranged on the front end of the upper surface of each grate sheet; a primary air hole is formed on the head boss of each grate sheet; the head bosses of two adjacent grate sheets on the same row of grate plates are transversely and longitudinally staggered; and the front ends of each row of grate sheet are flush with one another. Through the incinerator grate with the transversely and longitudinally staggered head bosses, a garbage material layer can be effectively scattered so as to change the garbage height at each position of the incinerator material layer, increase the instability of the garbage material layer and facilitate garbage scattering and loosening; moreover, the incinerator grate realizes all-round scattering, loosening and stirring of the garbage material layer in an incinerator, improves the drying and burning efficiency of garbage, shortens the drying time and contributes to the fast burning of the garbage.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

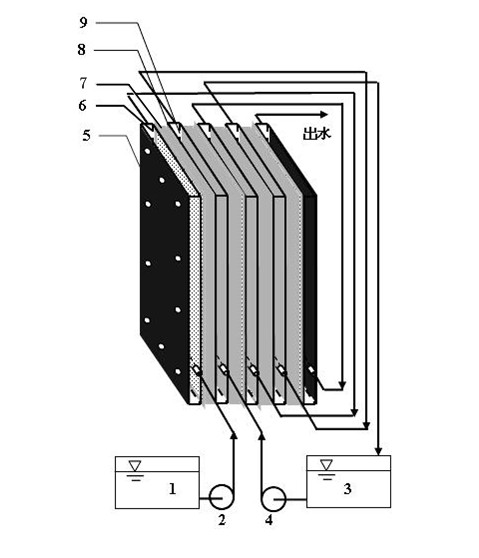

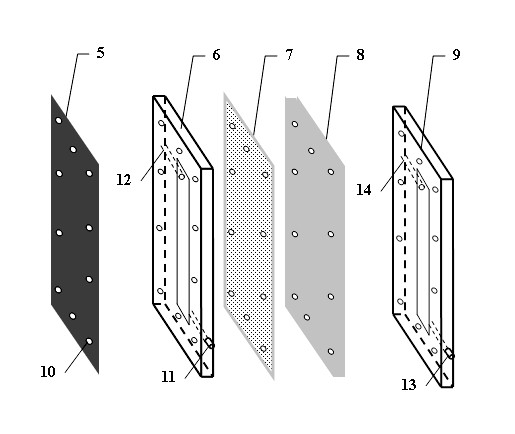

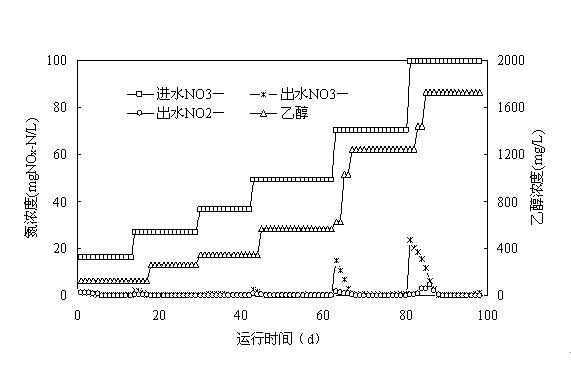

Plate-frame immobilized cell membrane bioreactor and application thereof

InactiveCN102173509AEliminate the effects ofStrengthen the degree of disturbanceTreatment with anaerobic digestion processesMembrane bioreactorAdverse effect

The invention discloses a plate-frame immobilized cell membrane bioreactor. The bioreactor is characterized in that cover plates are arranged on the outmost layers; the middle part is formed by successively arranging and assembling frames and flat-shaped immobilized cells; the frames include W frames and a C frame; the W frames represent the frames for the underground water to flow; the C frame represents the frame for the ethanol water to flow; the arrangement sequence of the cover plates, the frames and the flat-shaped immobilized cells is as follows: one cover plate, one W frame, one flat-shaped immobilized cell, the C frame, the other flat-shaped immobilized cell, the other W frame and the other cover plate; the lower and upper ends of the W frames and the C frame are respectively provided with inlets and outlets; and bolt holes are arranged around the cover plates and the frames. The bioreactor has the following advantages: the oxygen in the air is avoided from being dissolved in the underground water and ethanol water in the reactor, thus reducing the adverse effects of the dissolved oxygen on denitrification; at the same time, the effective reaction area of the immobilized cell in unit volume and the treatment capability in unit volume are obviously improved; and besides, recycling of the carbon source of denitrification is also realized, thus reducing waste of the carbon source of denitrification.

Owner:EAST CHINA UNIV OF SCI & TECH

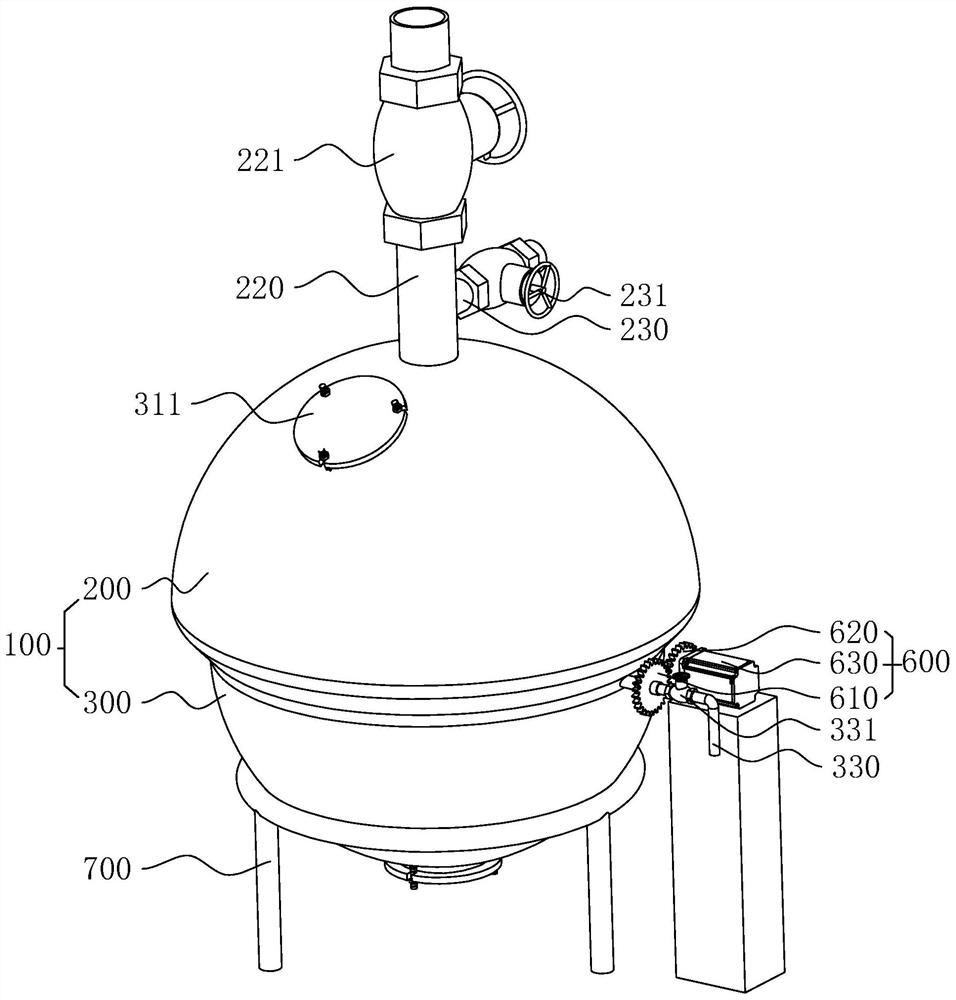

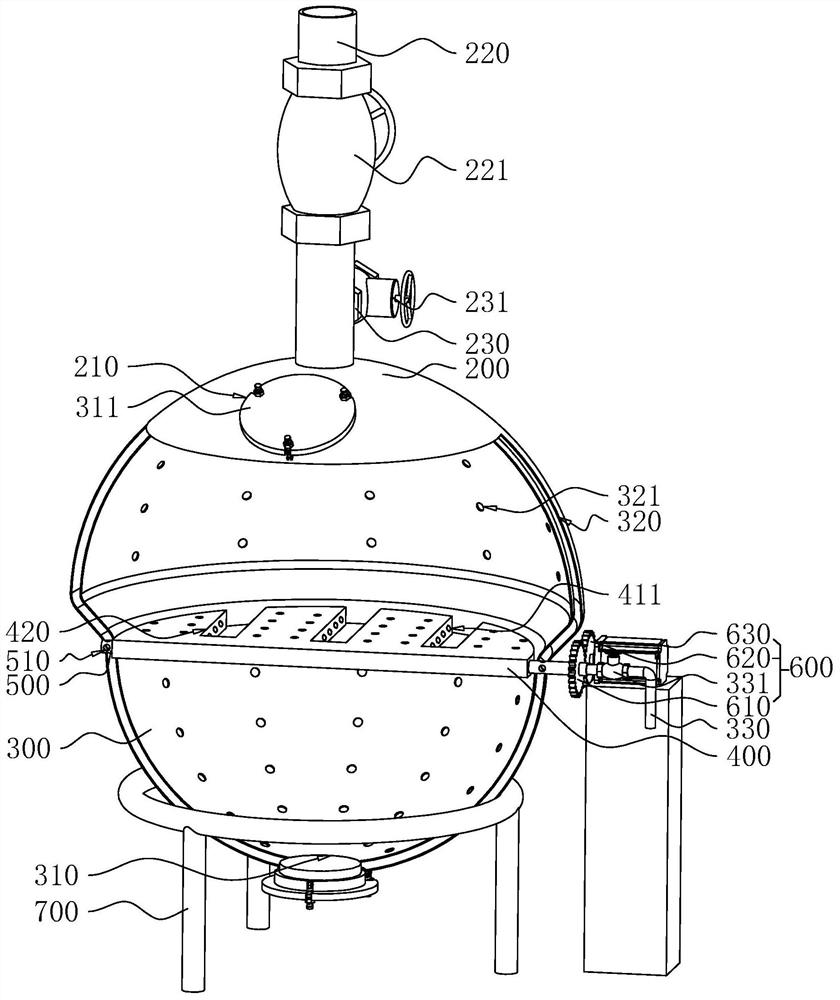

Production method of Luzhou-flavor liquor and steaming kettle applied to method

PendingCN111996090AReduce the amount of furfuralReduce quality impactAlcoholic beverage preparationProcess engineeringFurfural

The invention discloses a production method of Luzhou-flavor liquor and a steaming kettle applied to the method, relates to the field of liquor production. The production method of the Luzhou-flavor liquor comprises the following steps: S1, preparing a prefabricated material; S2, preparing auxiliary materials; S3, performing auxiliary material treatment; S4, blending the ingredients; S5, performing steaming in a steamer; S6, steaming grains; S7, discharging from the steamer; S8, performing ventilation and grain stillage cooling; S9, preparing powder of yeast for making hard liquor; S10, performing yeast mixing; S11, performing fermenting in a tank; and S12, distilling the prefabricated fermented grains, namely adding the prefabricated fermented grains into a steamer pot for distilling, distilling off raw wine to obtain fermented grains, discarding a part of the fermented grains, and adding the rest of the fermented grains into the step S4 for recycling. Due to the fact that the steaming kettle is adopted for steaming the rice hulls, the amount of furfural generated in the rice hulls is reduced, and the influence of furfural in the rice hulls on the quality of white spirit is reduced; and the invention further provides the steaming kettle which has the effect of improving the material heating uniformity.

Owner:济南今朝酒业有限公司

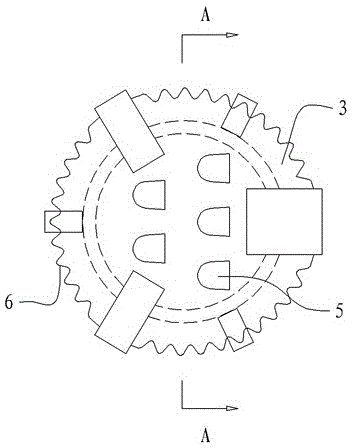

Round valve tray

ActiveCN104984720BDisperse finely and evenlyFully contactedChemical/physical/physico-chemical processesPolystyreneEngineering

The invention relates to a circular float valve tray, and belongs to the technical field of general physical separation devices. The circular float valve tray comprises a tower plate and float valves capable of moving up and down, wherein mounting holes used for the mounting of the float valves are formed in the tower plate; each float valve comprises a circular valve cap arranged above the tower plate and valve legs extending downwards from the periphery of the valve cap to the lower part of the tower plate; the valve legs are distributed on the periphery of the corresponding valve cap at intervals; at least two upwards arched tongue holes are formed in each valve cap; downwards bent sawtooth-shaped edges are arranged on the periphery of each valve cap, and are used for being propped against the upper surface of the tower plate when the corresponding float valve falls down; a lap of bumps are fixed on the bottom surface of each valve cap; the tongue holes are positioned within the lap of bumps of the corresponding valve cap; an interlayer cavity is formed in each valve cap and is filled with a polystyrene foam layer. The circular float valve tray has the advantages that the dispersion of airflow is fine and uniform, and the full contact of gas and liquid is realized.

Owner:SUZHOU RUNHONG TRADING

Method and device for separate oxidation and cyclone purification of organic waste gas

ActiveCN107051195AIncrease contact areaHigh catalytic efficiencyDispersed particle separationCycloneReaction rate

The invention discloses a method and a device for separate oxidation and cyclone purification of organic waste gas. The device comprises a cyclone purifying tower and a catalytic absorbent recycling system arranged at the bottom of the cyclone purifying tower, wherein a catalytic absorbent cyclone atomizing layer, an ultraviolet separate oxidation layer and an absorbed waste gas demisting layer are sequentially arranged in the cyclone purifying tower from bottom to top; the catalytic absorbent recycling system is used for providing a nano-titania atomization liquid required for atomization for the catalytic absorbent cyclone atomizing layer and recycling the nano-titania slurry falling to the catalytic absorbent recycling system under the action of gravity. Cyclone atomizers are adopted for atomizing the nano-titania slurry, the contact area of the nano-titania slurry and organic waste gas is increased, and the catalytic efficiency is improved; the cyclone atomizers are arranged in a tangent circle manner, so that the nano-titania slurry spirally rises along the tangent circle, the disturbing degree of the organic waste gas and a catalyst is improved, and the reaction rate is increased.

Owner:SOUTH CHINA UNIV OF TECH +1

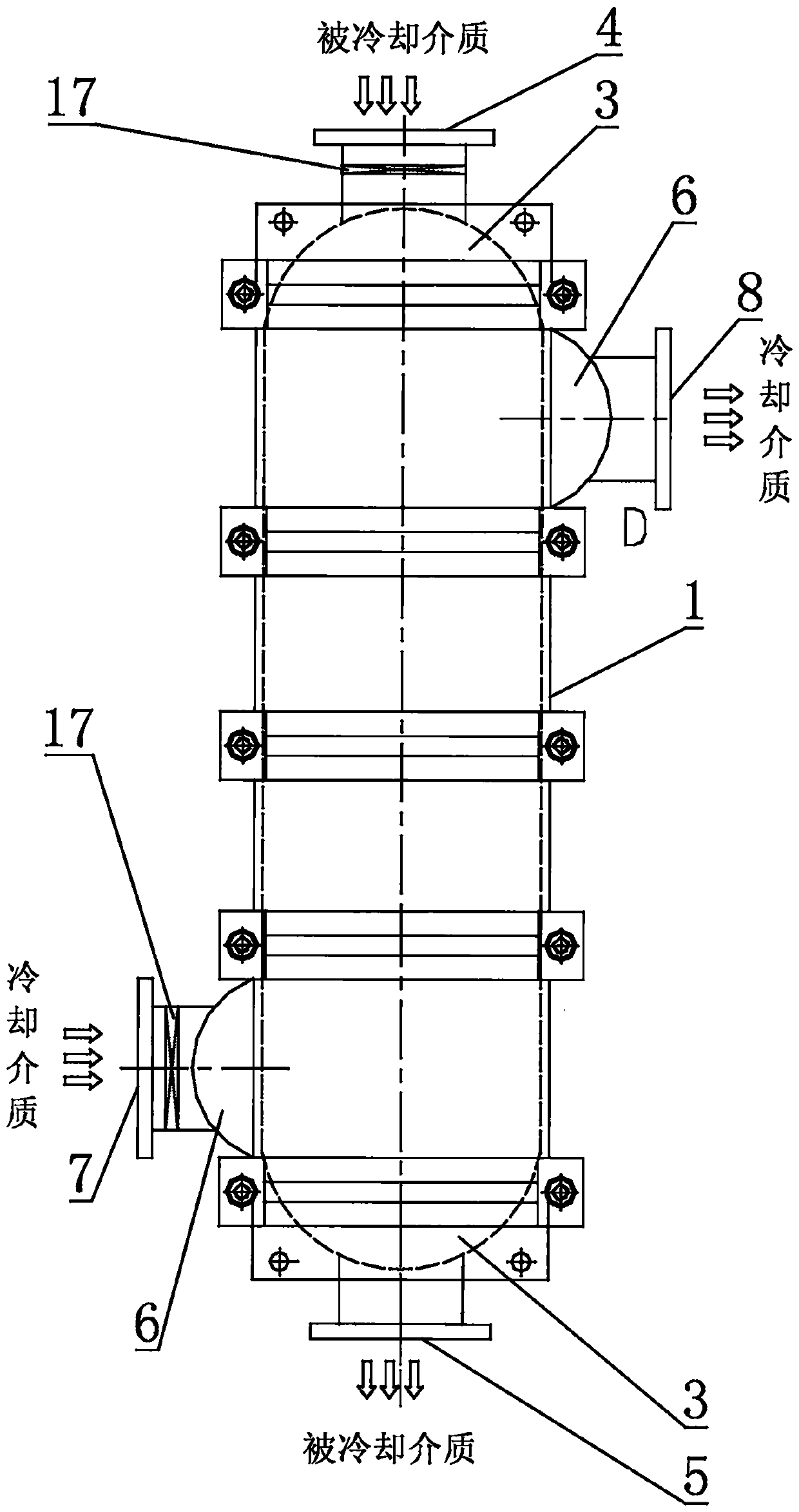

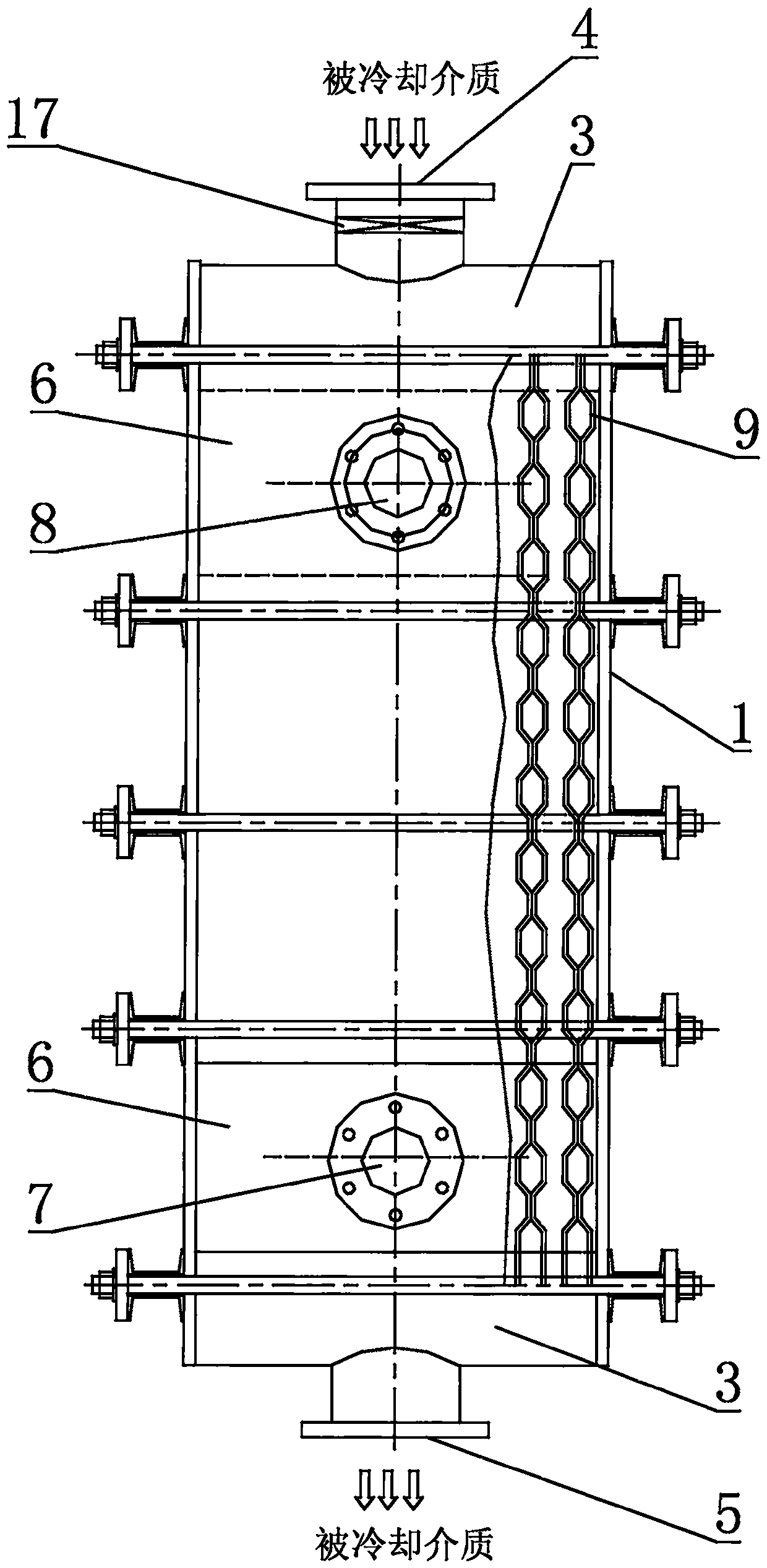

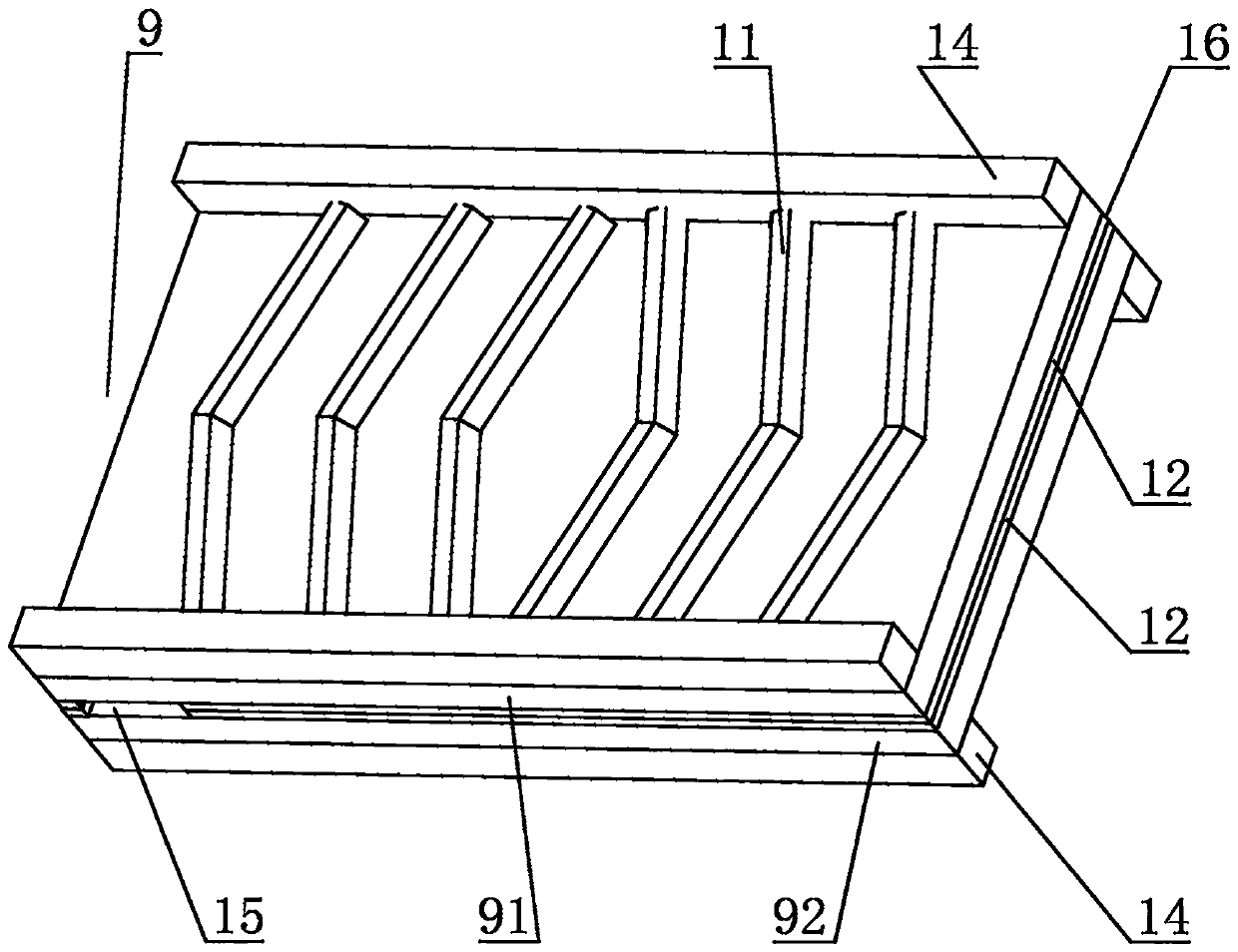

Welding plate heat exchanger

PendingCN109595958AStrengthen the degree of disturbanceExtended stayCorrosion preventionHeat exchanger fasteningEngineeringUltimate tensile strength

The invention discloses a welding plate heat exchanger. The welding plate heat exchanger comprises a shell and a heat exchange plate set inside the shell; the shell is rectangular and horizontally arranged; large half round channels are arranged at the two ends of the shell; the top of one of the large half round channels is provided with a cooled medium inlet; the top of the other large half round channel is provided with a cooled medium outlet; a small half round channel is arranged on the shell wall of the upper side, close to the cooled medium inlet, of the shell; the top of the small halfround channel is provided with a cooling medium outlet; a small half round channel is arranged on the shell wall of the lower side, close to the cooled medium outlet, of the shell; the top of the small half round channel is provided with a cooling medium inlet; the heat exchange plate set is formed by overlapping a plurality of heat exchange plate pair layer by layer; and each heat exchange platepair comprises an upper heat exchange plate and a lower heat exchange plate which are opposite. The effects that the welding plate heat exchanger can bear high temperature, is resistant to corrosion,high in intensity, not prone to deforming, not prone to being blocked and high in heat exchange efficiency can be achieved.

Owner:浙江干氏制冷设备有限公司

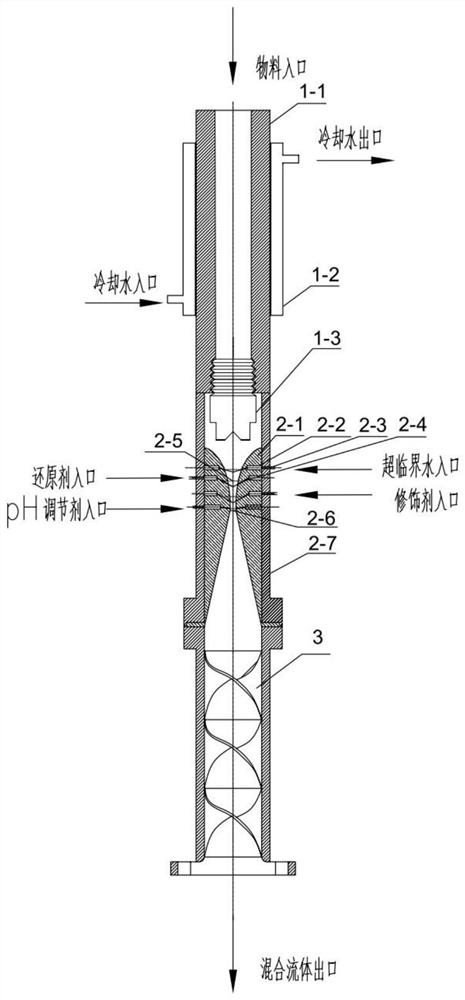

Multi-section jet flow efficient mixing device and method for supercritical hydrothermal synthesis of nano metal powder

ActiveCN111761072AIncrease the degree of mixingImprove natureTransportation and packagingMixer accessoriesHydrothermal synthesisStatic mixer

The invention discloses a multi-section jet flow efficient mixing device and method for supercritical hydrothermal synthesis of nano metal powder. The device comprises an atomizer, a Rafal annular feeder and a static mixer which are sequentially communicated from top to bottom, wherein the top of the atomizer is a precursor material inlet and the bottom is a precursor material outlet; the top of the static mixer is an inlet and the bottom is an outlet; the interior of the Rafal annular feeder is a vertical channel gradually narrows from two ends to the middle, and a middle region is communicated with four reaction fluid inlet pipes for feeding supercritical water, a modifying agent, a reducing agent and a pH regulator. The whole device disclosed by the invention realizes quick mixing and uniform mixing of the fluid through nozzle atomization, annular feeding acceleration and disturbance, the acid-base property of a mixed solution is regulated, and the quality of the nano metal particleis effectively guaranteed.

Owner:XI AN JIAOTONG UNIV

Filter device for laboratory

PendingCN106237679AIncrease filtration rateImprove experimental efficiencyStationary filtering element filtersVacuum pumpingSolid matter

The invention discloses a filter device for a laboratory and belongs to the field of laboratory filter devices. The filter device solves the problems that in the prior art, a filter device of a laboratory is low in filter speed or external equipment such as vacuum pumping equipment needs to be used in the filtering process, cost is high, and much land is occupied. The filter device comprises a filter tank with a top opening, filtering holes are evenly formed in the side faces and the bottom face of the filter tank, a motor with a vertically-downward rotating shaft is arranged above the opening of the filter tank, the rotating shaft is connected with a stirrer, and stirring paddles of the stirrer are arranged in the filter tank. According to the filter device, by arranging the stirrer to improve the disturbing degree of a solution to be filtered in the filtering process, solid matter is prevented from adhering to the wall of the filter tank, the filtering speed is increased, and experiment efficiency is improved.

Owner:成都铭利特生物科技有限公司

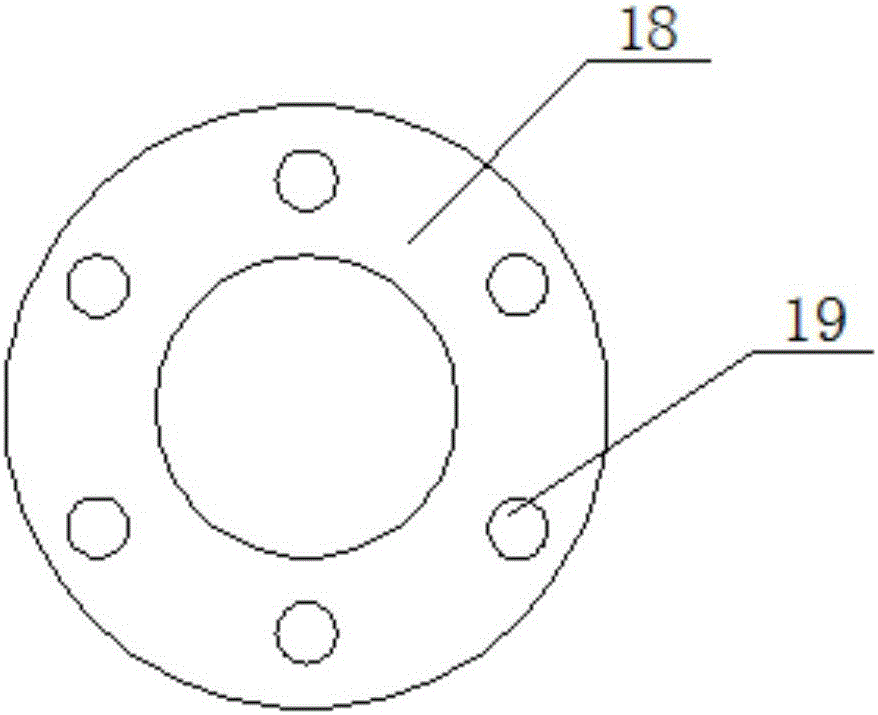

Continuous self-cleaning oil-water separation device

PendingCN108975455ASimplify design and manufacturing complexitySimple structural designWaste water treatment from quariesFatty/oily/floating substances removal devicesParticulatesBarrel Shaped

The invention discloses a continuous self-cleaning oil-water separation device. The device is mainly composed of a supporting frame, a liquid inlet pipe, flanges, a coating material, a flow dividing pipe, a valve, multi-stage structure absorption cotton, a liquid draining pipe, a separation liquid collecting box, a stainless steel net, a fluid driving rotor, a steel wire rope, a position sensor, acontroller, an electromagnetic limiting device and a fixing piece. The stainless steel net is produced to be barrel-shaped to be matched with the flanges, the two ends of the stainless steel net arewelded with the flanges and connected with the liquid inlet pipe and the flow dividing pipe respectively, the outside of the stainless steel net is coated with the coating material with the certain thickness and the certain strength, the separation liquid collecting box is placed on the lower face, and the fluid driving rotor is arranged in the stainless steel net. The device achieves self-cleaning by internally arranging the fluid driving rotor, the separation precision is improved through secondary separation conducted by the rear-arranged multi-stage structure absorption cotton, macroporesat the front end can further contain impurity particles in the oil-water separation liquid, the separation liquid is purified particularly, the post-treatment difficulty of the separation liquid is simplified, and the service life of the absorption cotton is prolonged.

Owner:BEIJING UNIV OF CHEM TECH

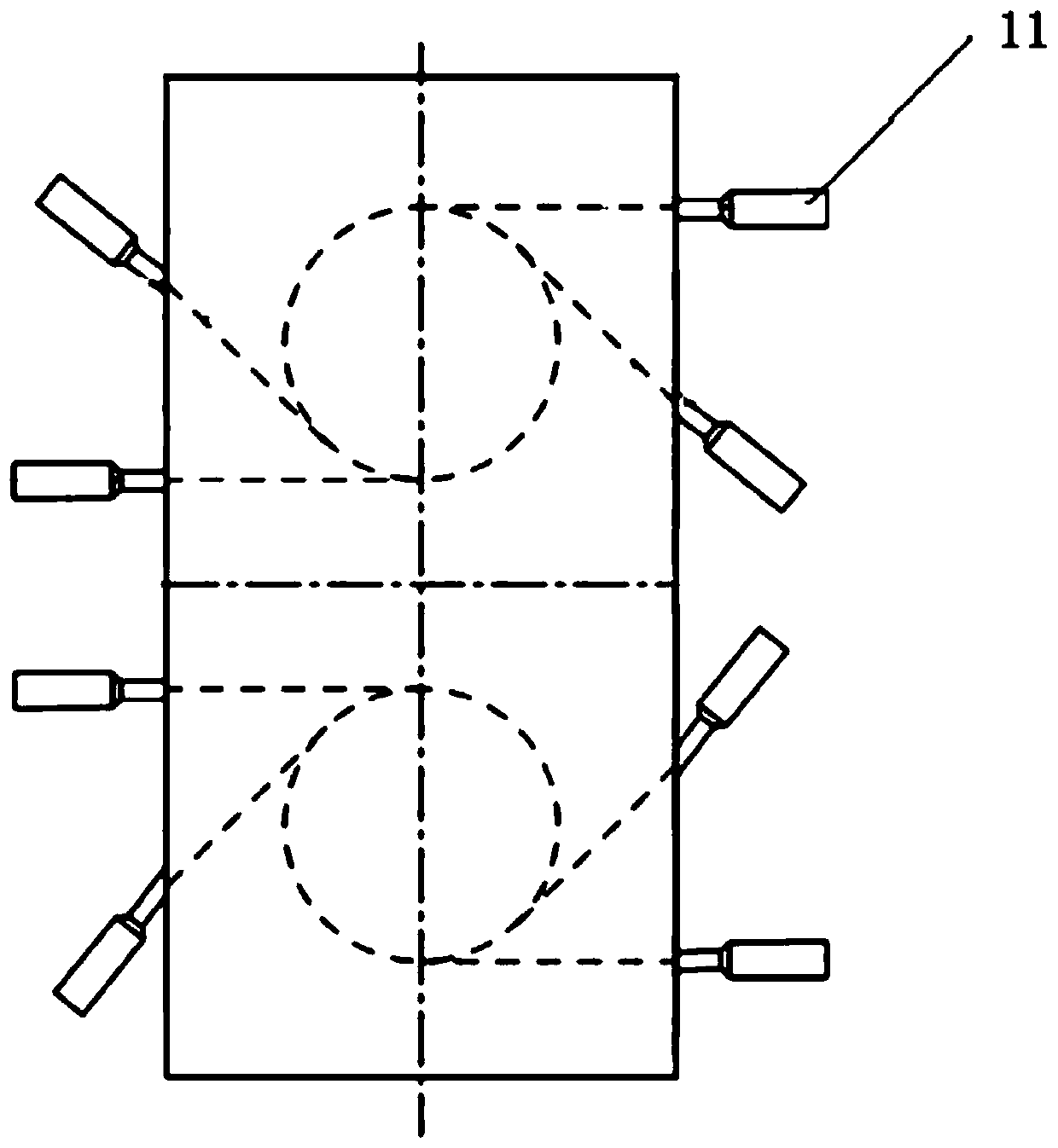

Novel 900-t/d high-heat-value domestic garbage incinerator

PendingCN110425544AIncrease widthIncrease throughputIncinerator apparatusNon-combustible gases/liquids supplyFailure rateCombustor

The invention relates to a novel 900-t / d high-heat-value domestic garbage incinerator. The incinerator is characterized in that a hearth is 4.5-8m in the width; the incinerator comprises a fire grate(1) at the bottom of the hearth, a feed inlet (2) at the front end, a slag outlet (3) at the tail end, fire-resistant furnace walls (8) at two sides of the fire grate, a hearth wall front arch (4) atthe upper part of the hearth, two ignition burners (6) at the upper part of the hearth; left and a right side walls (9), an auxiliary burner (7), a first flue inlet (10) at the front middle part of the hearth, a secondary air pipe (11) at the lower part of the first flue, and water-cooled walls arranged on the first flue (10), the front arch (4), a rear arch (5) and the side walls (9). The incinerator is suitable for the incineration treatment of high-heat value domestic garbage, and has the advantages of wide working condition adaptability, long service life of a boiler, low failure rate, high combustion efficiency, low pollutant discharge and the like.

Owner:GUANGZHOU HUANTOU DESIGN & RES INST CO LTD

System for preparing biomass pellet fuel by taking straws and black liquor of paper mills as raw materials

The invention relates to a system for preparing a biomass pellet fuel by taking straws and black liquor of paper mills as raw materials. The system comprises a flat plate type solar thermal collector, a straw and black liquor mixing dryer, a pulverizer, a greenhouse-heat-collecting type solar energy drying chamber and a biomass forming machine. Solar energy is adopted as the source of drying energy to play the roles of cleaning, drying and energy saving; the straws and the black liquor of the paper mills are adopted as the source of biomass forming raw materials to increase the characteristic of the biomass pellet fuel; moreover, the toughness of the straws is reduced after the straws are mixed with the black liquor and preliminarily dried and the biomass raw materials are pulverized on the basis, so that the biomass raw material pulverizing energy can be reduced and the energy loss is reduced. The system disclosed by the invention has the advantages of solving the problem of pulverizing the biomass straw raw materials, increasing the forming characteristic of the biomass forming pellet fuel and reducing the drying time and energy of the biomass raw materials.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Tongue valve tray

ActiveCN104941232BDisperse finely and evenlyFully contactedDispersed particle separationFractional distillationPolystyrenePhysical separation

The invention relates to a tongue type floating valve tower disc and belongs to the technical field of a common physical separation working device. The tongue type floating valve tower disc comprises a tower plate and a floating valve capable of moving up and down, wherein a mounting hole for mounting the floating valve is formed in the tower plate; the floating valve comprises a rectangular valve cover arranged above the tower plate and valve legs which extend downward from the two opposite edges of the valve cover to the lower side of the tower plate; at least two upward arched tongue holes are formed in the valve cover; the other two side edges of the valve cover are provided with downwards-folded saw tooth edges; the saw tooth edges of the valve cover are used for being abutted against the upper surface of the tower plate when the floating valve falls down; one circle of bulge is fixed on the bottom surface of the valve cover; the tongue holes are located in the circle of the bulge of the valve cover; a cavity with a clamping space is formed in the valve cover; and the cavity is internally filled with a polystyrene foam layer. The tongue type floating valve tower disc has the advantages of fine, dense and uniform airflow dispersion and sufficient gas-liquid contact.

Owner:SUZHOU KD PETROCHEM ENG

Low-temperature-corrosion-resistant smoke waste heat exchanger and heat exchange system based on same

ActiveCN107356136AChange the mainstreamMainstream flow favorsFluid heatersCorrosion preventionStraight tubeUltimate tensile strength

The invention discloses a low-temperature-corrosion-resistant smoke waste heat exchanger and belongs to the fields of smoke waste heat utilization and low-temperature-corrosion-resistant design. The low-temperature-corrosion-resistant smoke waste heat exchanger comprises a shell and finned tubes; the upper part of the shell is provided with a water outlet header, and the lower part of the shell is provided with a water inlet header; and straight tube sections of the finned tubes are arranged in the shell, bent tube sections of the finned tubes extend out of the shell, grooves are formed in the bottoms of the straight tube sections of the finned tubes, and a plurality of smoke flow guide blocks are densely distributed among the straight tube sections of every two adjacent finned tubes and along the axial directions of the finned tubes. The thermal stress and structural strength are calculated to meet the requirement of a project, in addition, the heat exchange efficiency can be increased to a certain extent, and the low-temperature-corrosion-resistant smoke waste heat exchanger has an obvious industrial application value.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com