Membrane pollution vibration control device used in process of treating algae containing water through low-pressure spiral membrane and method for controlling membrane pollution through device

A device control and membrane fouling technology, which is applied in aerobic process treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve problems such as low-pressure roll-type membrane fouling, and achieve avoiding excessive damage, simple operation, and enhanced vibration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

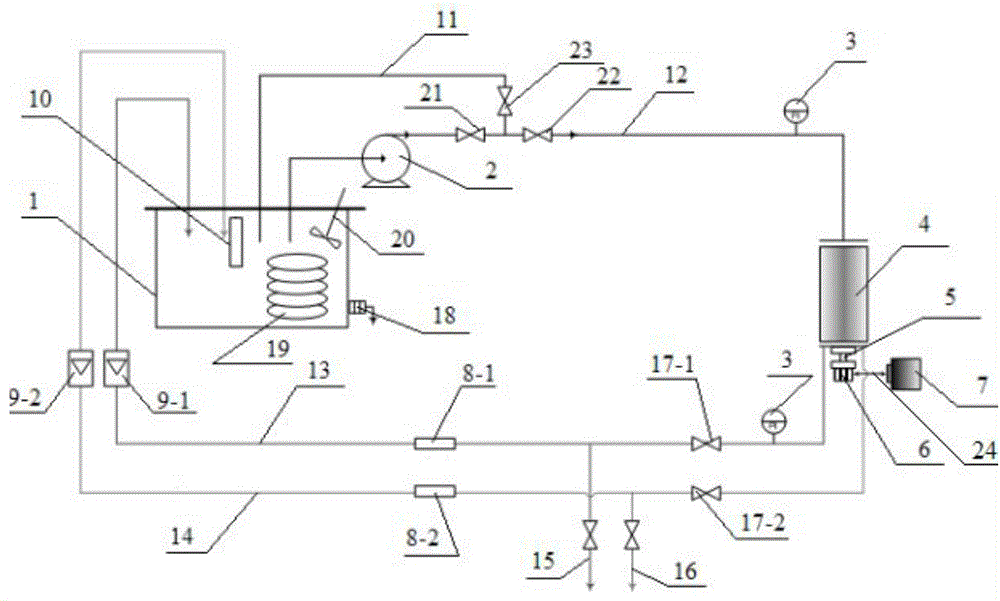

[0025] Embodiment 1: The membrane fouling vibration control device in the process of treating algae-containing water with a roll-type low-pressure membrane in this embodiment consists of a raw water tank 1, a peristaltic pump 2, a pressure sensor 3, a roll-type membrane module reactor 4, and a drive shaft 5. Gear 6, vibration driver 7, first conductivity sensor 8-1, second conductivity sensor 8-2, first rotameter 9-1, second rotameter 9-2, pH meter 10, backflow Pipe 11, water inlet pipe 12, concentrated liquid outlet pipe 13, filtered water outlet pipe 14, concentrated liquid sampling port 15, filtered water sampling port 16, first water outlet regulating valve 17-1, second water outlet regulating valve 17-2 , outlet 18, temperature controller 19, agitator 20, the first water inlet regulating valve 21, the second water inlet regulating valve 22, backflow water regulating valve 23 and transmission mechanism 24; one end of the transmission shaft 5 is connected to The coiled memb...

specific Embodiment approach 2

[0033] Specific implementation mode two: A method of controlling membrane pollution by using a roll-type low-pressure membrane to treat algae-containing water with a membrane pollution vibration control device in this embodiment is as follows:

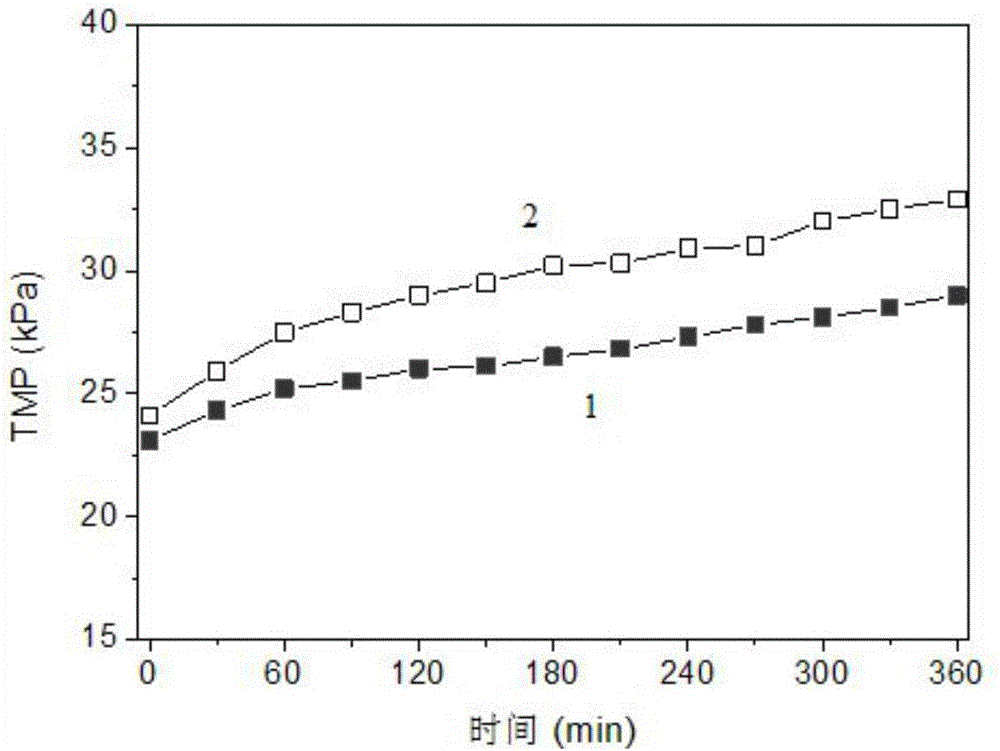

[0034] The raw water in the raw water tank 1 enters the coiled membrane module reactor 4 through the water inlet pipe 12 through the peristaltic pump 2, and the coiled membrane module reactor 4 is driven by the vibration driver 7 through the transmission mechanism 24, the gear 6 and the transmission shaft 5 to make the The coiled membrane module reactor 4 realizes the repeated movement of rotation along the axis, rotation and return, reverse rotation, and return to the return position. During operation, the concentrate in the concentrate outlet pipe 13 can be directly drained or Return to the raw water tank 1. During operation, the membrane permeate in the filtered water outlet pipe 14 can be directly drained or returned to the raw wate...

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the rotation angle of the coiled membrane module reactor 4 along the axis line is the same as the reverse rotation angle. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com