Patents

Literature

228results about How to "Increase mixing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

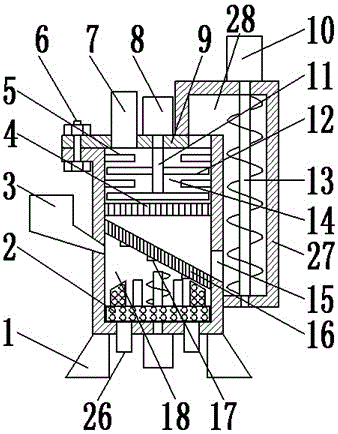

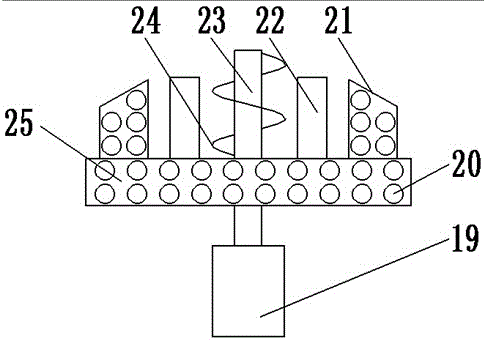

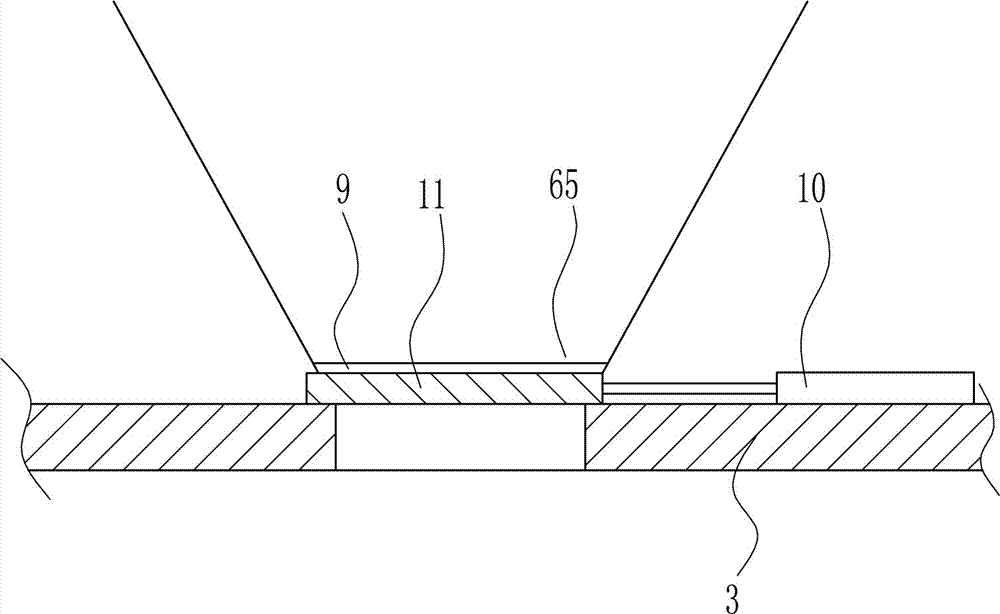

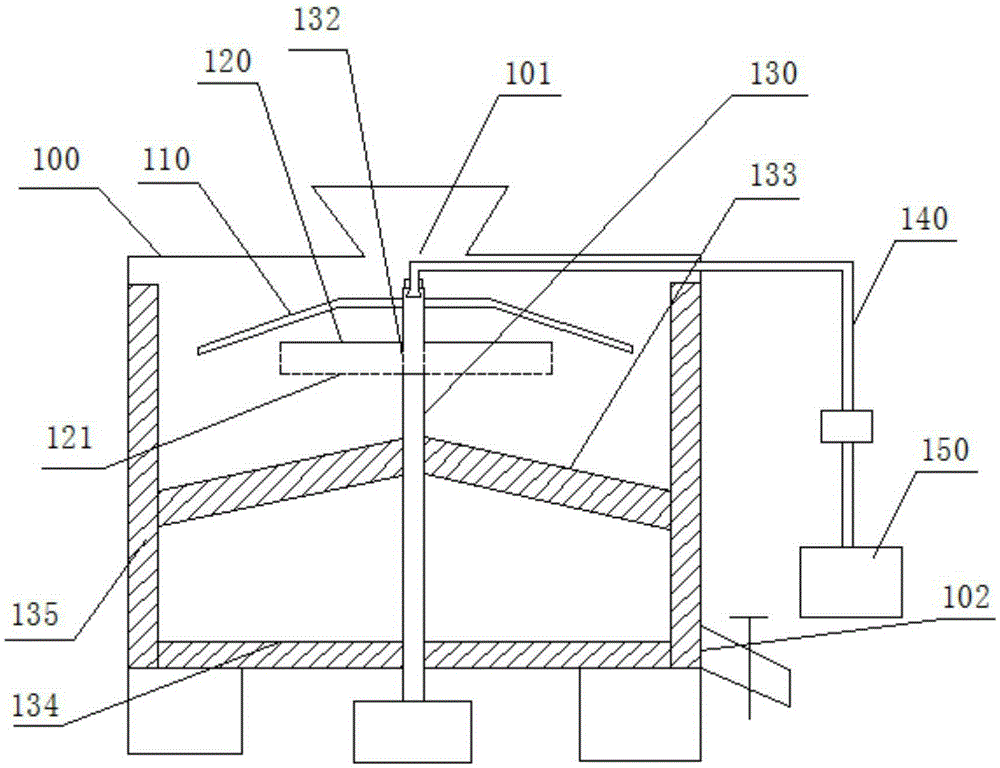

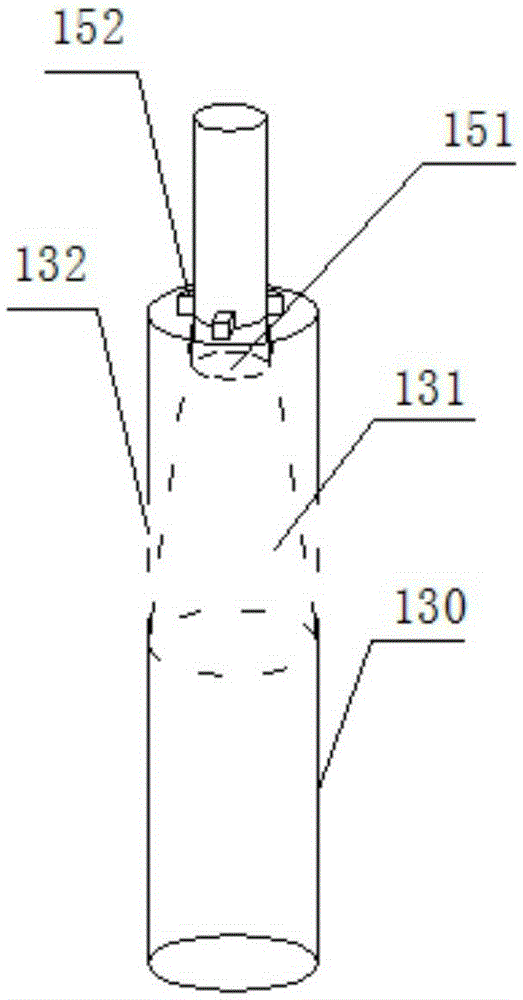

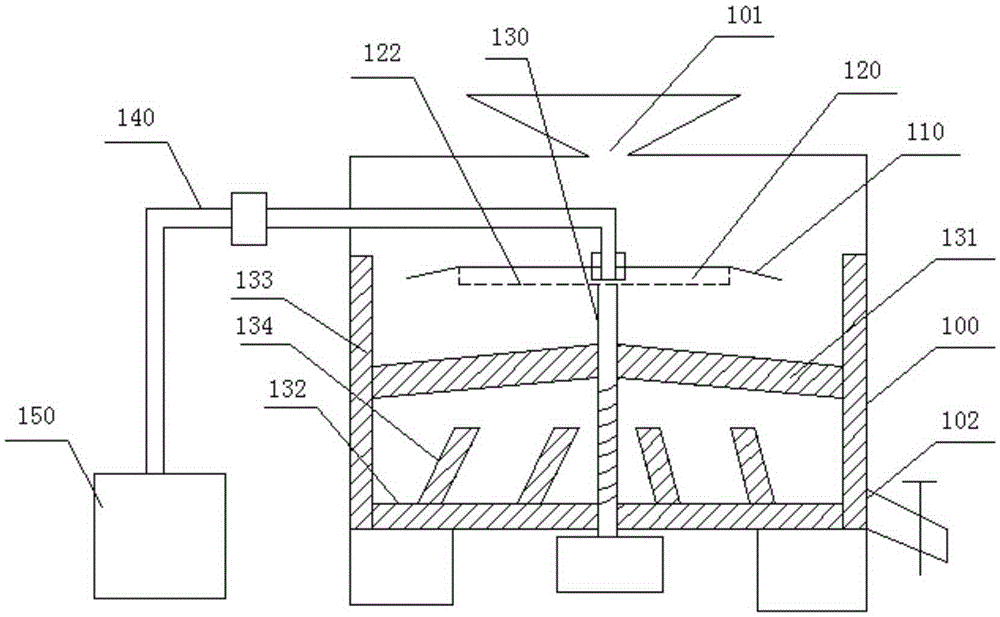

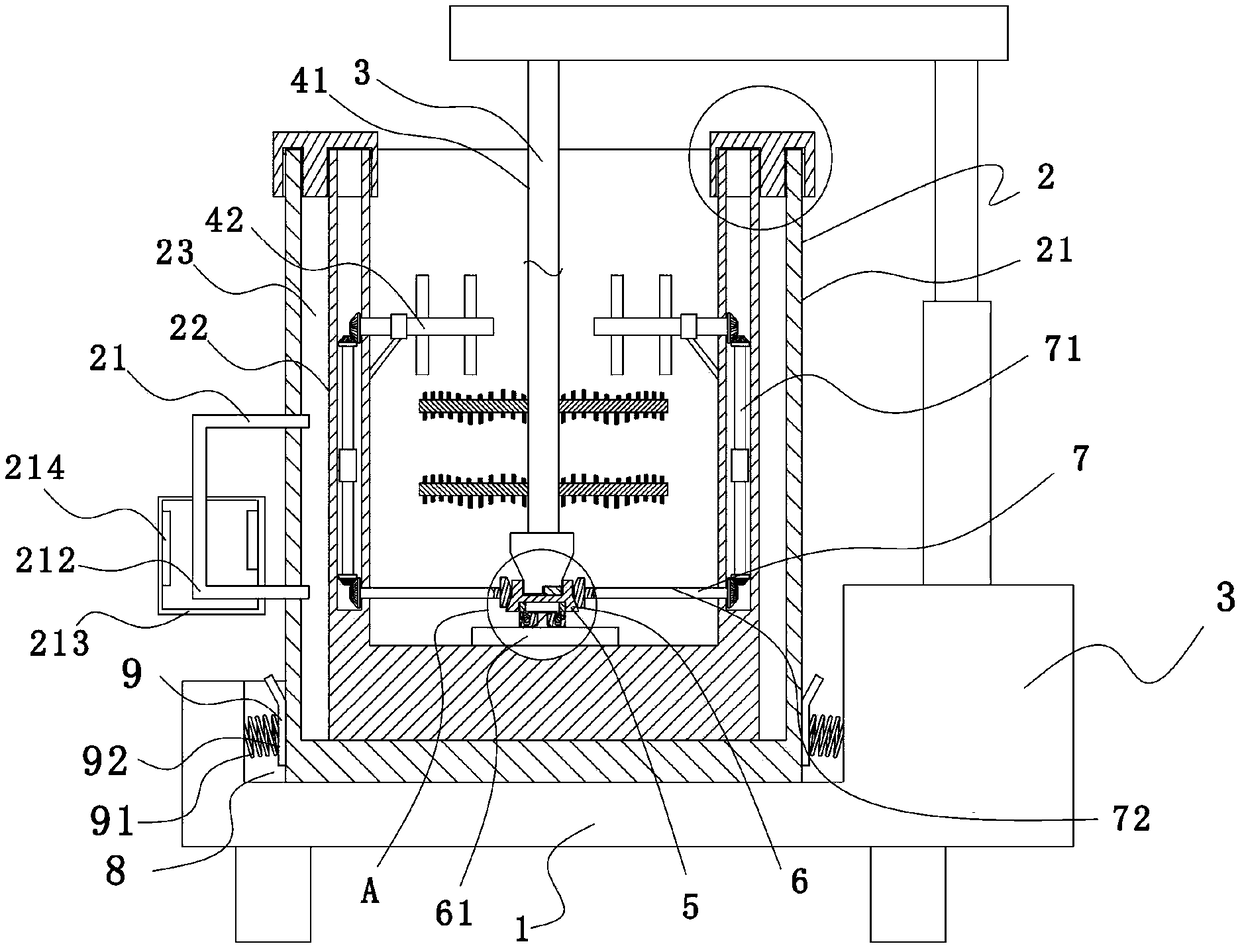

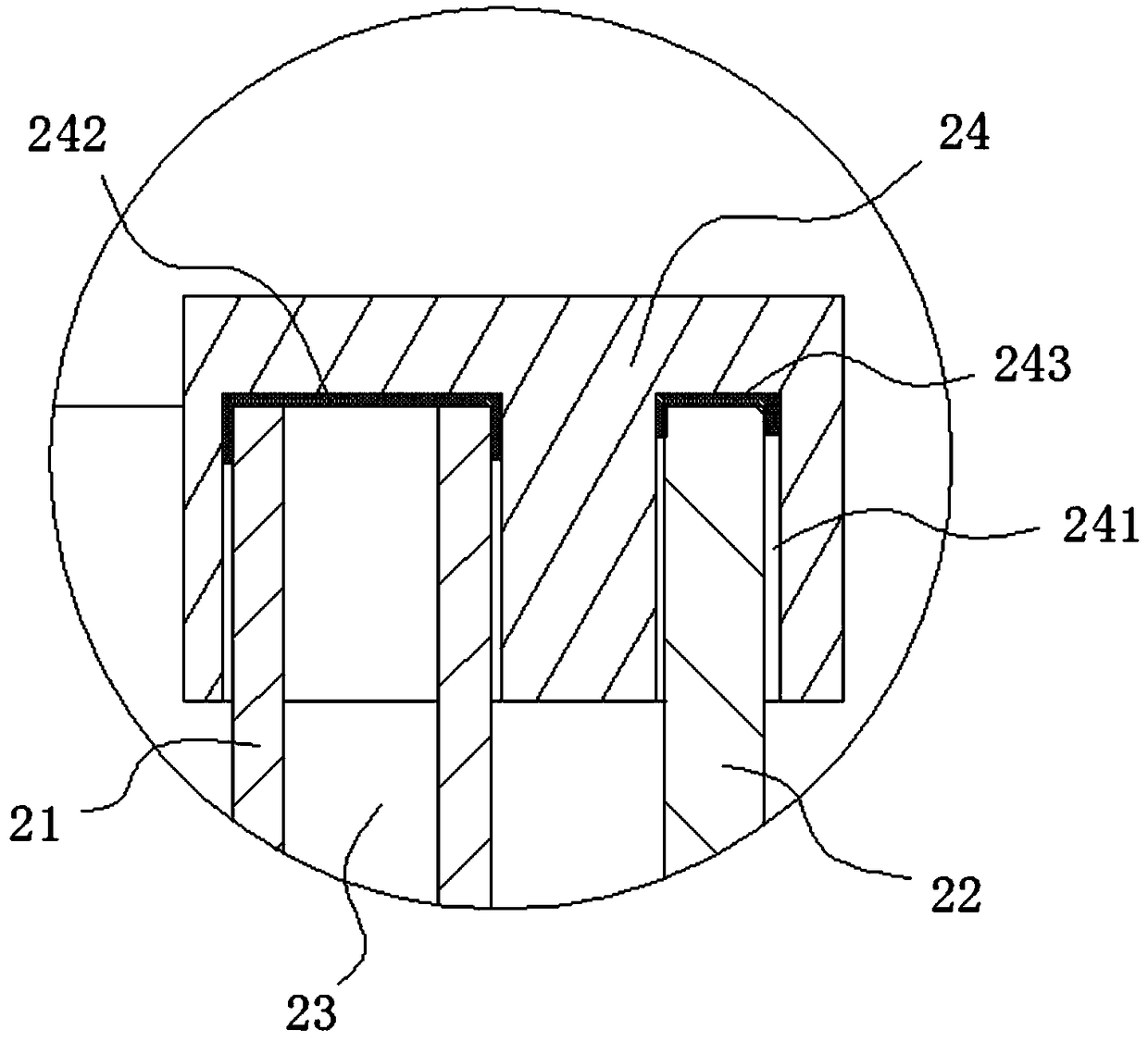

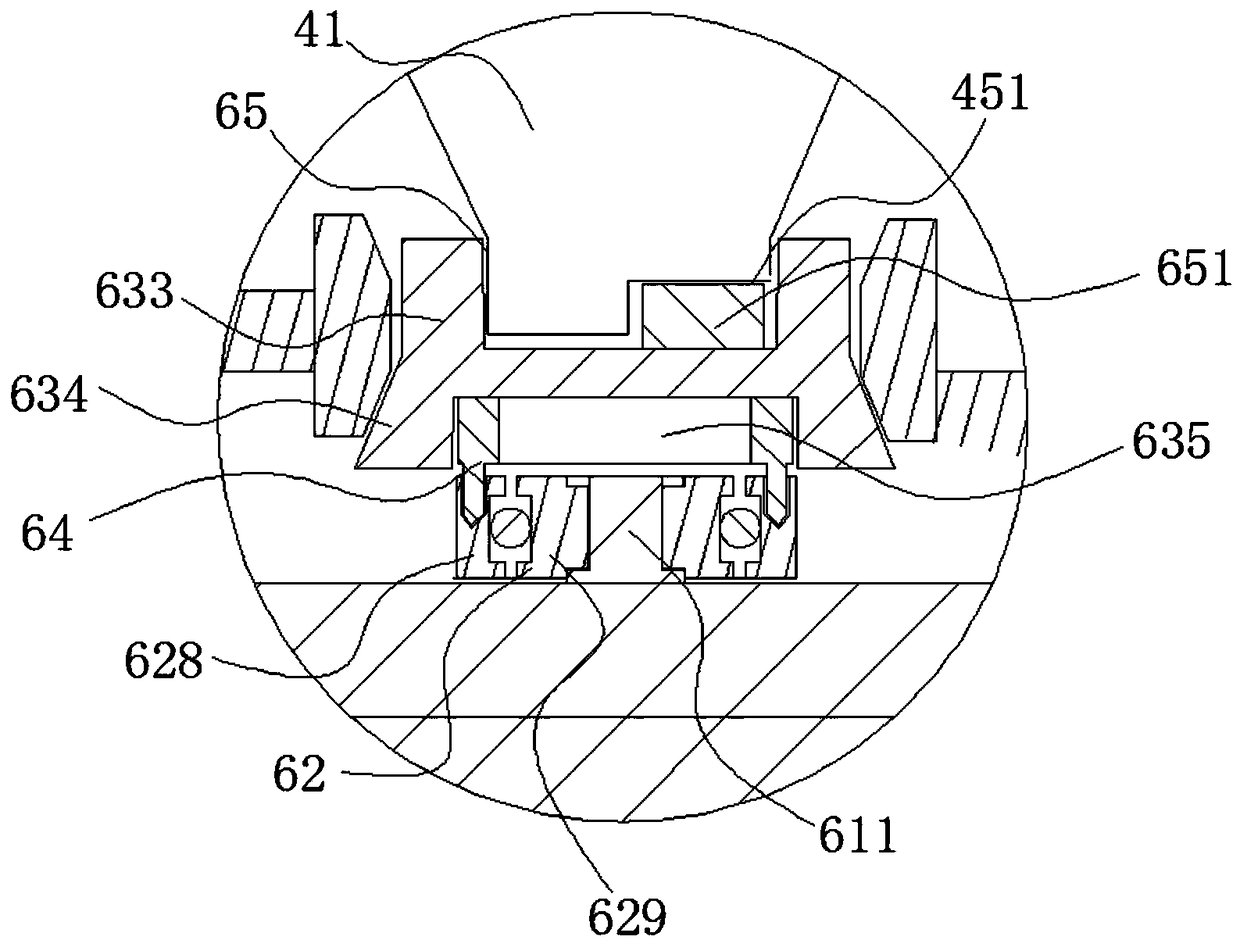

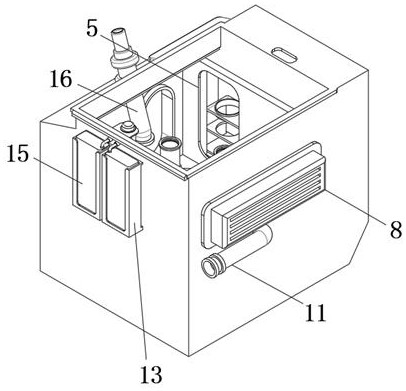

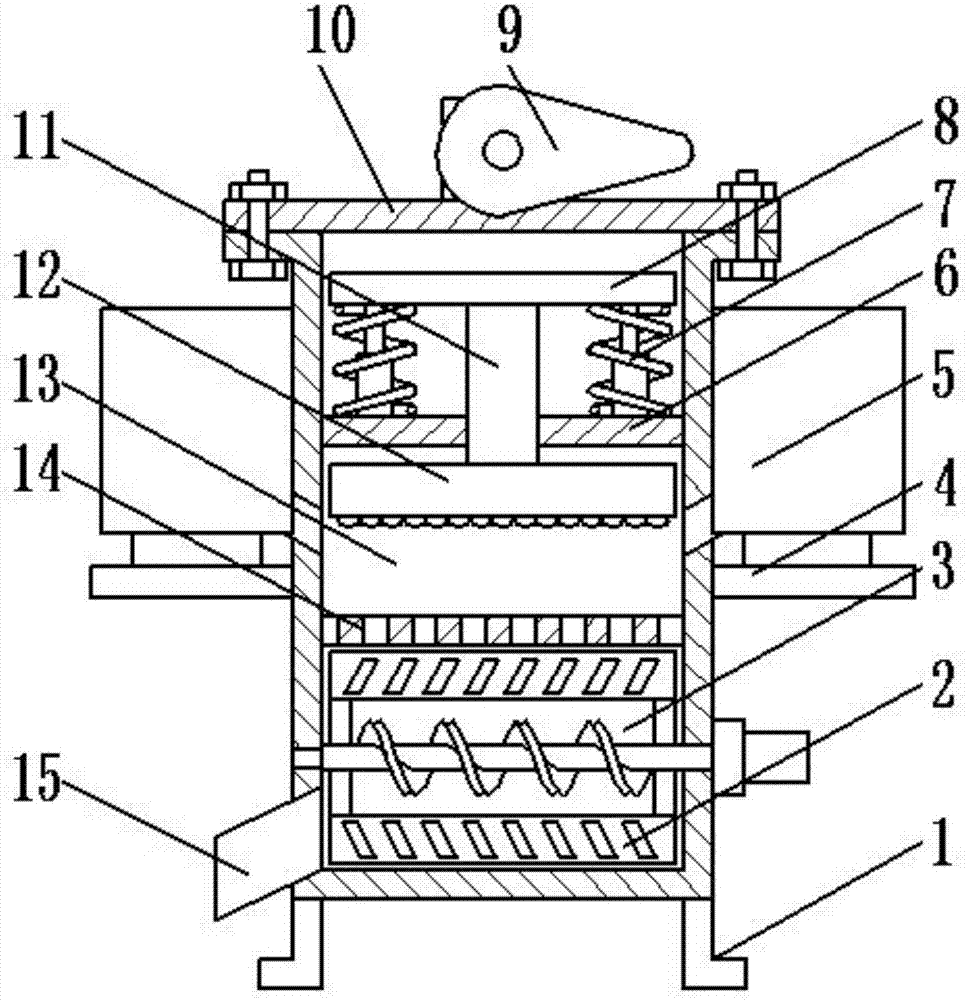

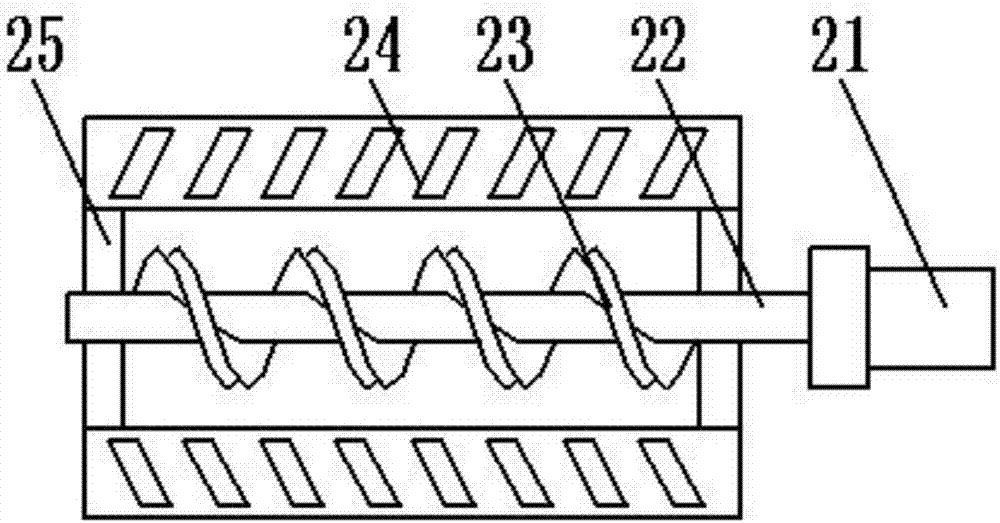

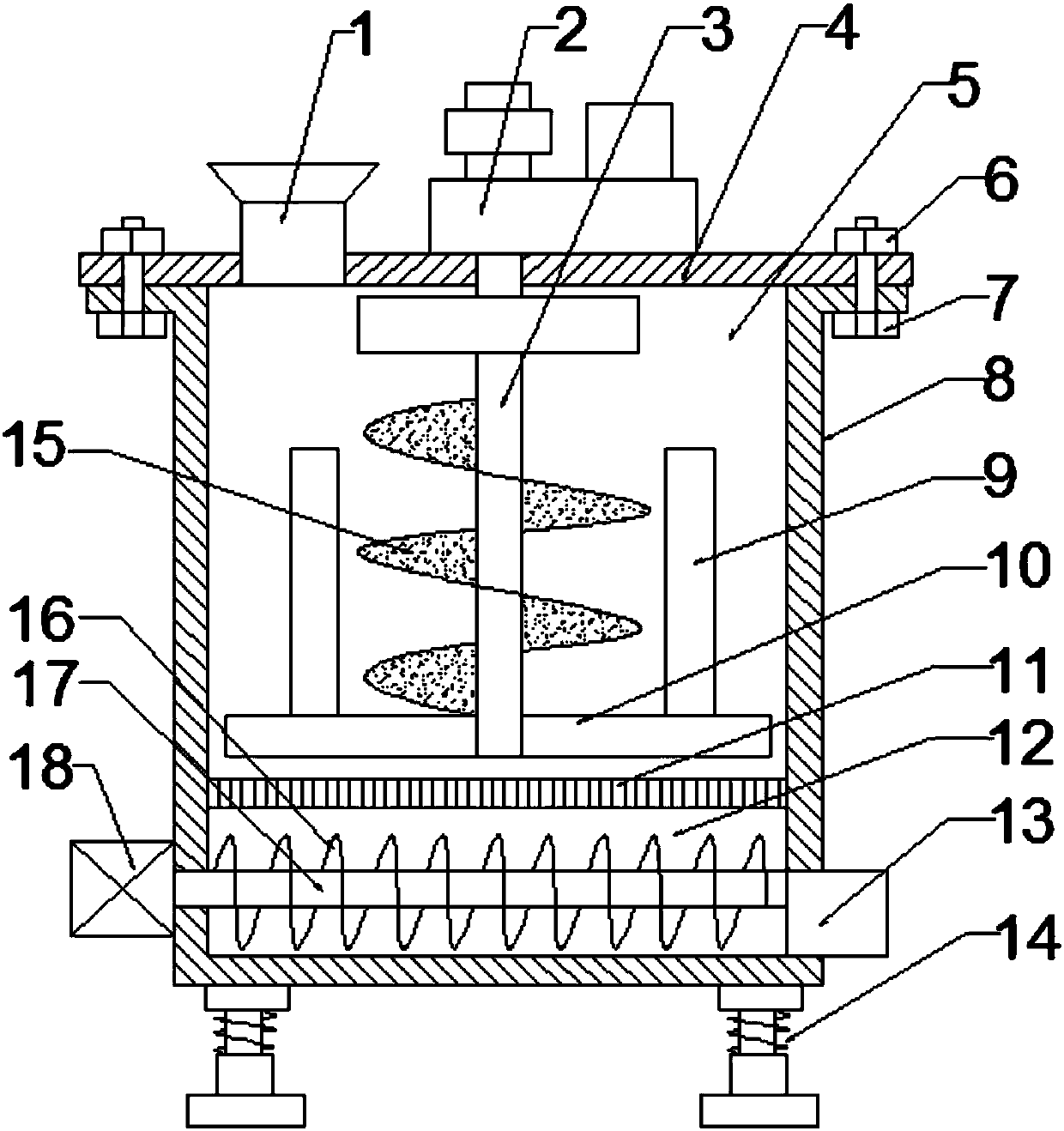

Battery negative electrode material mixing device with cyclic grinding equipment

The invention discloses a battery negative electrode material mixing device with cyclic grinding equipment. The battery negative electrode material mixing device comprises a mixing chamber; a discharge pipe is arranged at the bottom of the mixing chamber; a stirring mixing device is arranged inside the mixing chamber; the stirring mixing device is composed of a bottom scraper blade, a through hole, a first vertical rod, a second vertical rod, a stirring shaft, a spiral stirring blade and a stirring motor. The battery negative electrode material mixing device is simple in structure, reasonable in design and convenient to use; due to arrangement of a grinding chamber, materials can be ground, a filter plate at the bottom of the grinding chamber can filter out qualified materials obtained after grinding, then, small and large materials are separated out through an inclined plate, large-particle materials can be input into the grinding chamber again through a cyclic feeding device, secondary grinding treatment is performed, small-particle materials are separated out through the inclined plate to be input into the mixing chamber, and the materials and additives are mixed; the stirring mixing device can greatly increase the material mixing speed, the material production time can be shortened, and the production rate can be increased.

Owner:SHENZHEN JUOCAN TECH CO LTD

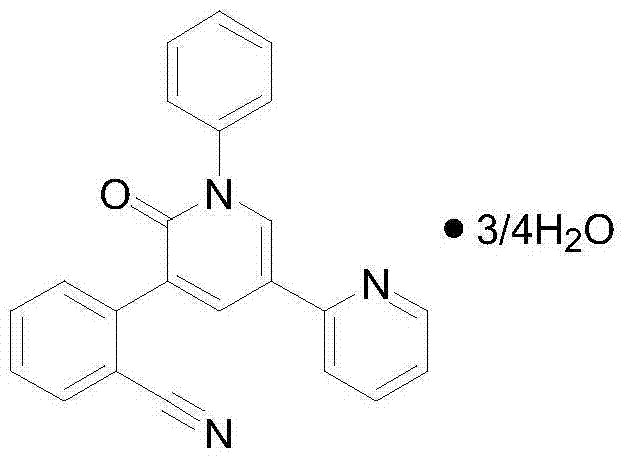

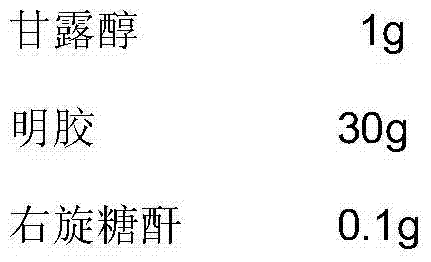

Perampanel freeze-dried oral disintegrating tablet and preparation method thereof

InactiveCN104706604AReduce dosageIncrease mixing rateOrganic active ingredientsNervous disorderFreeze-dryingAdhesive

The invention relates to a perampanel freeze-dried oral disintegrating tablet and a preparation method thereof. The perampanel freeze-dried oral disintegrating tablet comprises, by weight, 1-20 parts of a framework propping agent, 1-50 parts of an adhesive, 0.1-8 parts of a freeze drying protection agent and 2-12 parts of perampanel. The perampanel freeze-dried oral disintegrating tablet is convenient for patients to take and improves the medicine taking compliance of epilepsy patients, and the preparation method has the advantages of simplicity and short time.

Owner:BEIJING SUNHO PHARMA

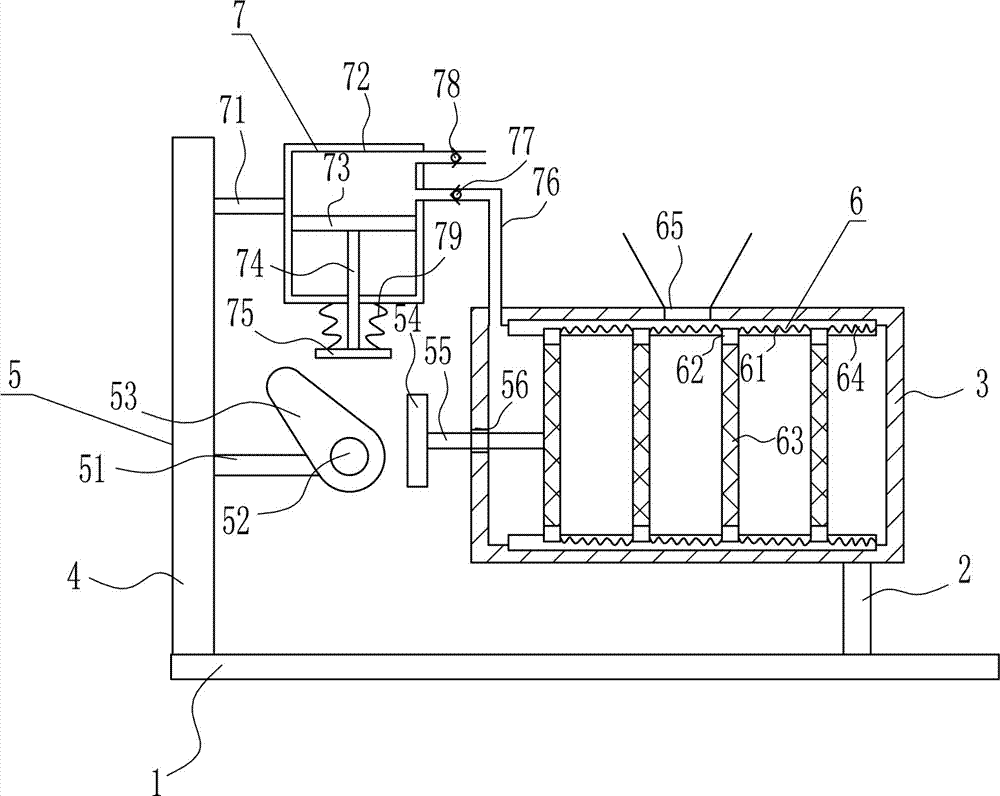

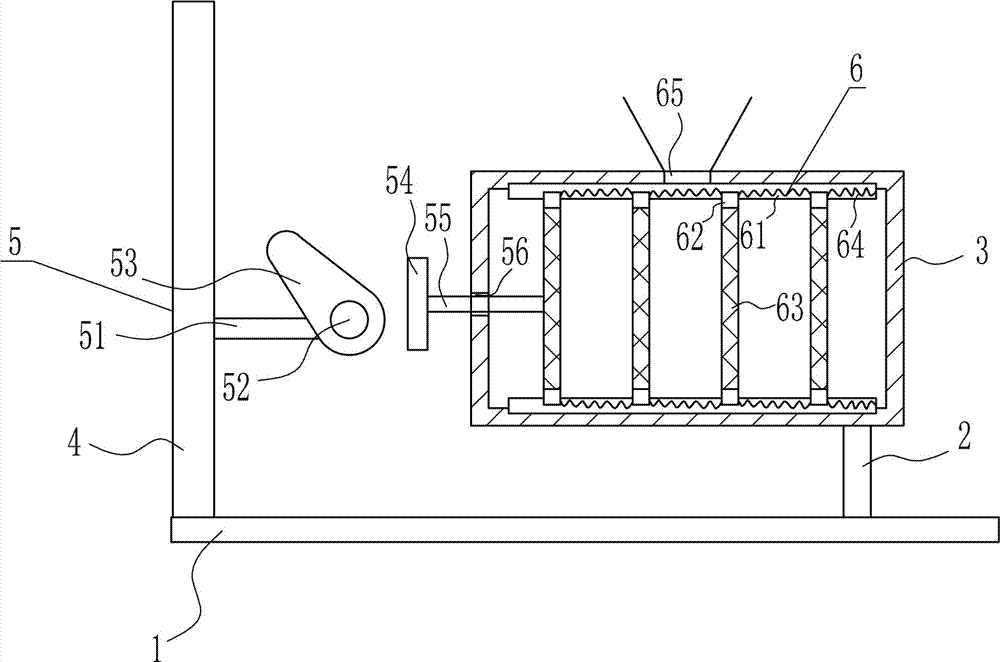

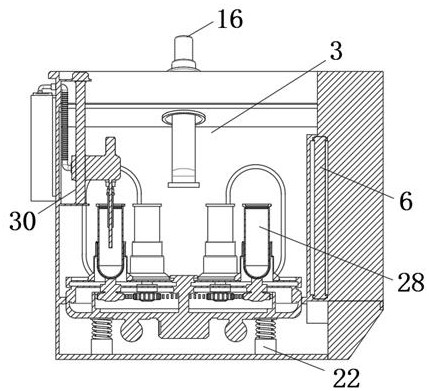

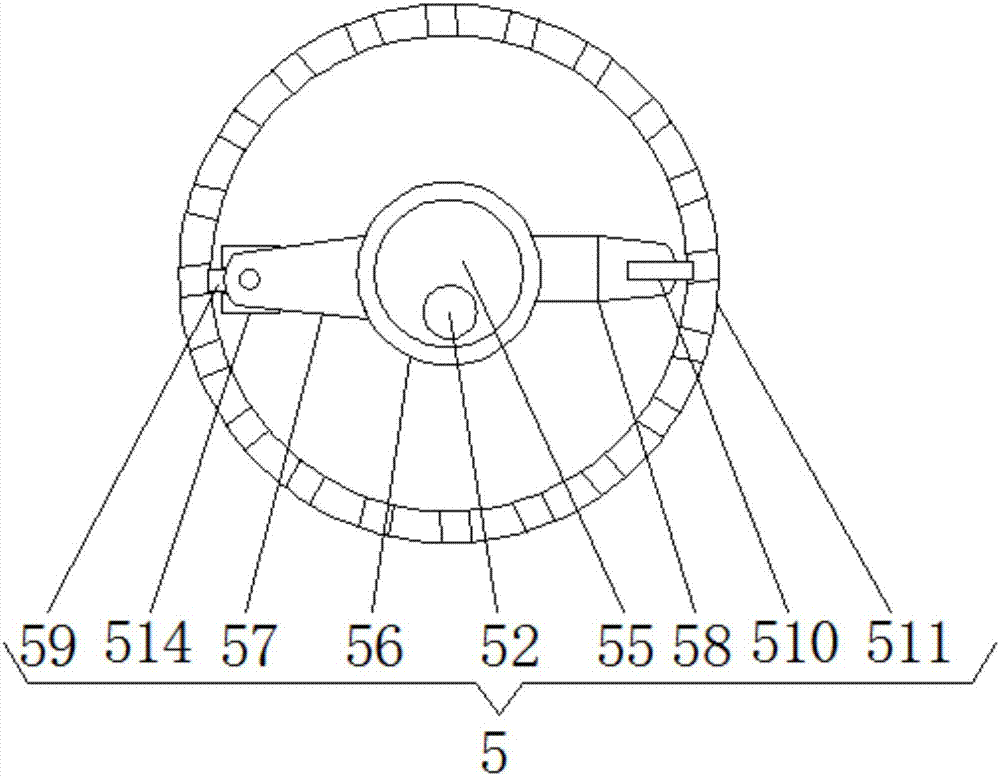

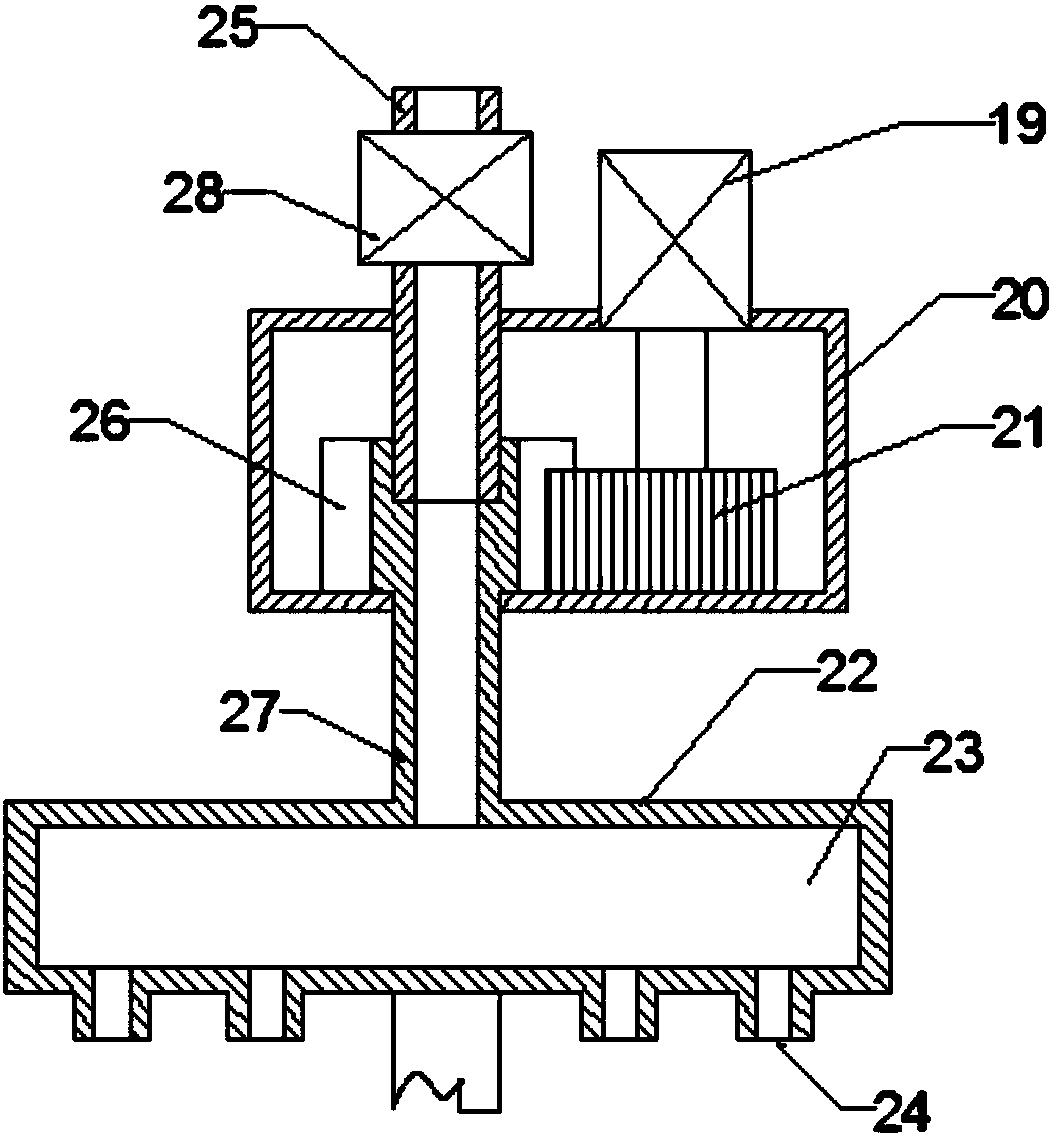

Liquid medicament mixing device for ophthalmology

InactiveCN107537378AWell mixedEvenly mixedShaking/oscillating/vibrating mixersMixer accessoriesResource savingEngineering

The invention relates to a medicament mixing device, in particular to a liquid medicament mixing device for ophthalmology. The liquid medicament mixing device for ophthalmology achieves the technicalpurposes of resource saving, convenient operation and high working efficiency. In order to achieve the technical purposes, the liquid medicament mixing device for ophthalmology includes a cross rod and the like; the right end of the top of the cross rod is provided with a first support rod, and the top of the first support rod is provided with a material mixing box; the left side of the top of thecross rod is provided with a left bracket, and the middle of the right side of the left bracket is provided with a driving device; the material mixing box is internally provided with a material mixing device. The liquid medicament mixing device has the advantages of resource saving, convenient operation and high working efficiency. The device works by using the driving device, and drives the material mixing device to mix medicament, and meanwhile, a feeding device adds medicament continuously; the device is shaken to shake the material mixing box, the speed of mixing materials is accelerated,and materials are mixed more evenly.

Owner:谢阳萍

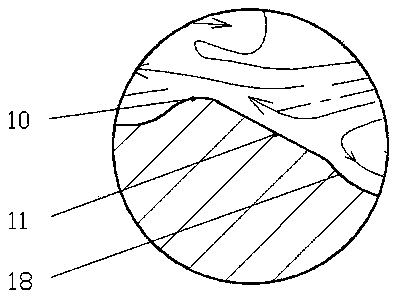

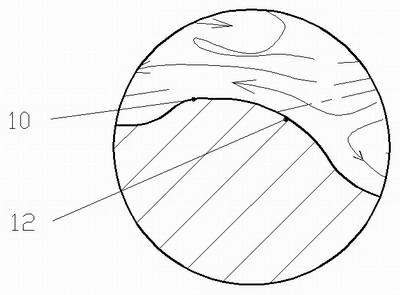

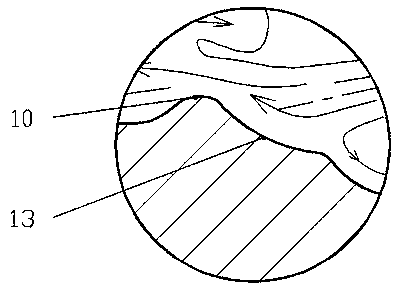

Collision shunt combustion chamber of diesel engine

ActiveCN103835803APromote combustionWell mixedInternal combustion piston enginesMachining systemDiesel engine

The invention discloses a collision shunt combustion chamber of a diesel engine, and belongs to the field of formation and combustion of gas mixtures of an engine. The combustion chamber is provided with a collision belt which divides the combustion chamber into an inner part and an outer part. A combustion chamber bottom clearance part is arranged outside the collision belt, and a combustion chamber center part is arranged inside the collision belt. Atomized fuel spray sprayed by a fuel sprayer is sprayed to the collision belt, part of the fuel spray is rebounded for secondary atomization, part of the fuel spray flows to the combustion chamber bottom clearance part and the combustion chamber center part along the atomization collision belt, and fuel and air can be better mixed. By the adoption of the combustion chamber, the mixing rate and space regions of fuel and air are greatly increased, thin diffusive combustion is formed in the combustion chamber, emission of carbon smoke and emission of NOx are reduced at the same time, combustion of the diesel engine is effectively improved, and economical efficiency is improved. Under the declared working condition, compared with an original machine system, the collision shunt combustion chamber has the advantages that economical efficiency is improved by 4%, emission of carbon is reduced by 50%, and emission of NOx is reduced by 8%.

Owner:DALIAN UNIV OF TECH

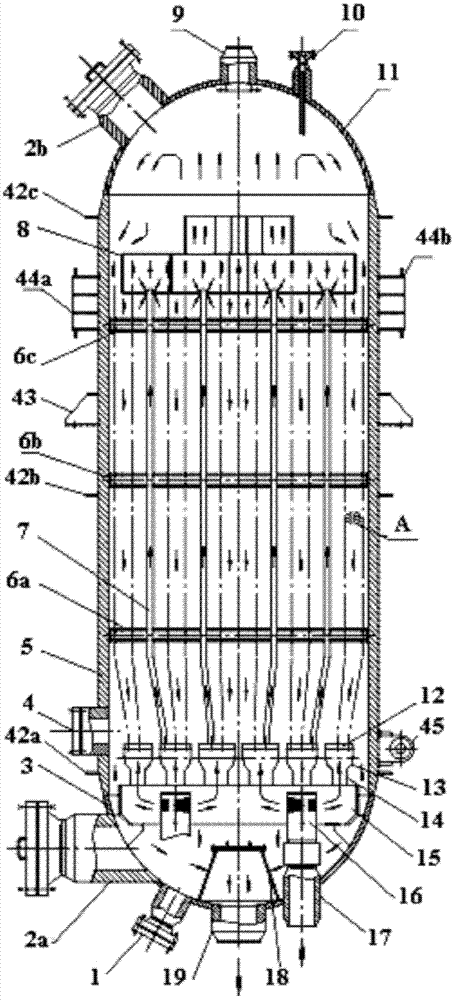

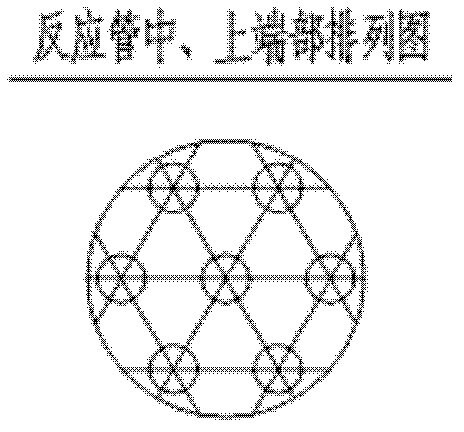

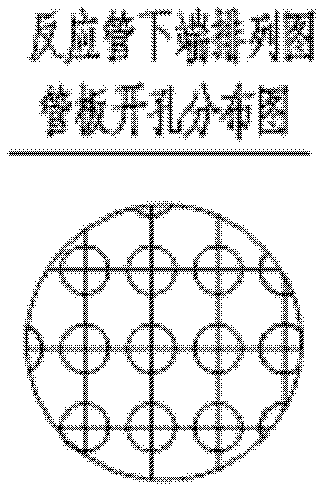

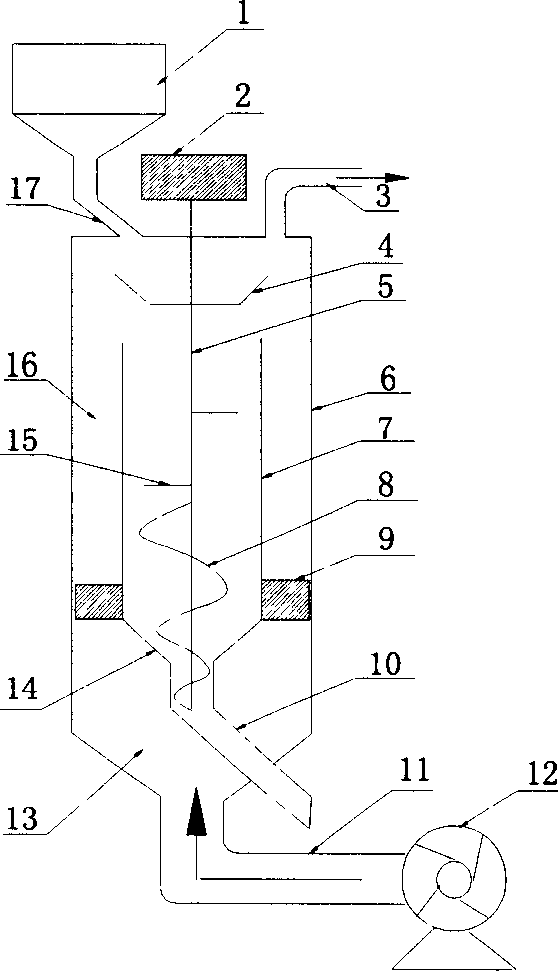

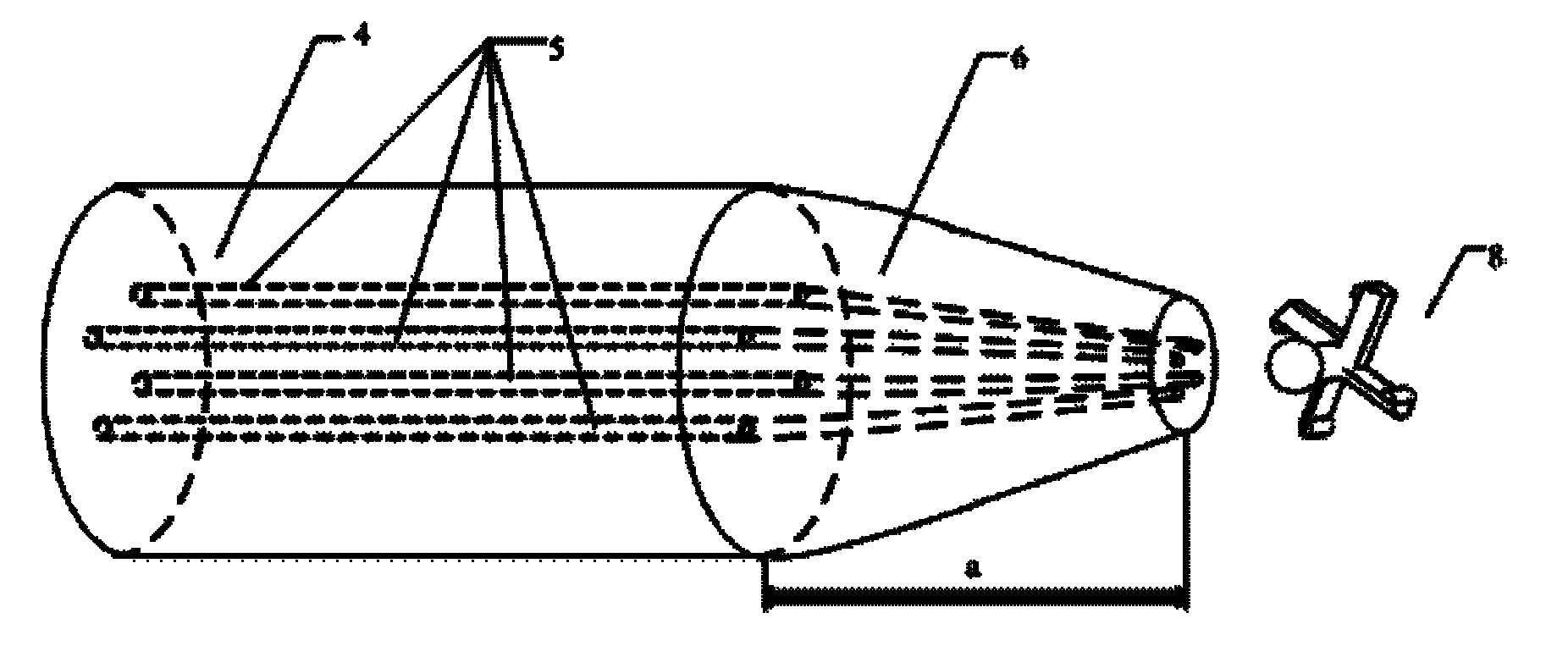

Gas-cooled methanol reactor

ActiveCN103111239AImprove production efficiencyImprove energy efficiencyOrganic compound preparationHydroxy compound preparationArchitectural engineeringMixed gas

The invention belongs to the coal-to-methanol field, and concretely discloses a gas-cooled methanol reactor. The reactor comprises a cylinder, an upper seal head packaged at the top of the cylinder and a lower seal head packaged at the bottom of the cylinder, the cylinder, the upper seal head and the lower seal head form a closed cavity, reaction tubes are arranged in the cavity, the top of each of the reaction tubes is inserted to a mixed gas tank, the middle of each of the reaction tubes is inserted to a tube support, and the bottom of each of the reaction tubes is inserted to a tube plate; tube supports are fixed on the reaction tubes, the bottom of the tube plate is fixed at the top of a U-shaped cylinder, the bottom of the U-shaped cylinder is fixed on a branch tube, the bottom of the branch tube is inserted to a manifold trunk, the top of a distribution tube is inserted to the manifold trunk, the bottom of the distribution is positioned outside the manifold trunk, and the bottom of an adaptor penetrates through the lower seal head; the top of the upper seal head is provided with a work starting gas inlet; and the bottom of the lower seal head is provided with an outlet collector, and the bottom of the outlet collector is provided with a generated gas outlet. The reactor has the advantages of methanol output improvement, cost reduction, energy saving and energy consumption reduction.

Owner:西安核设备有限公司

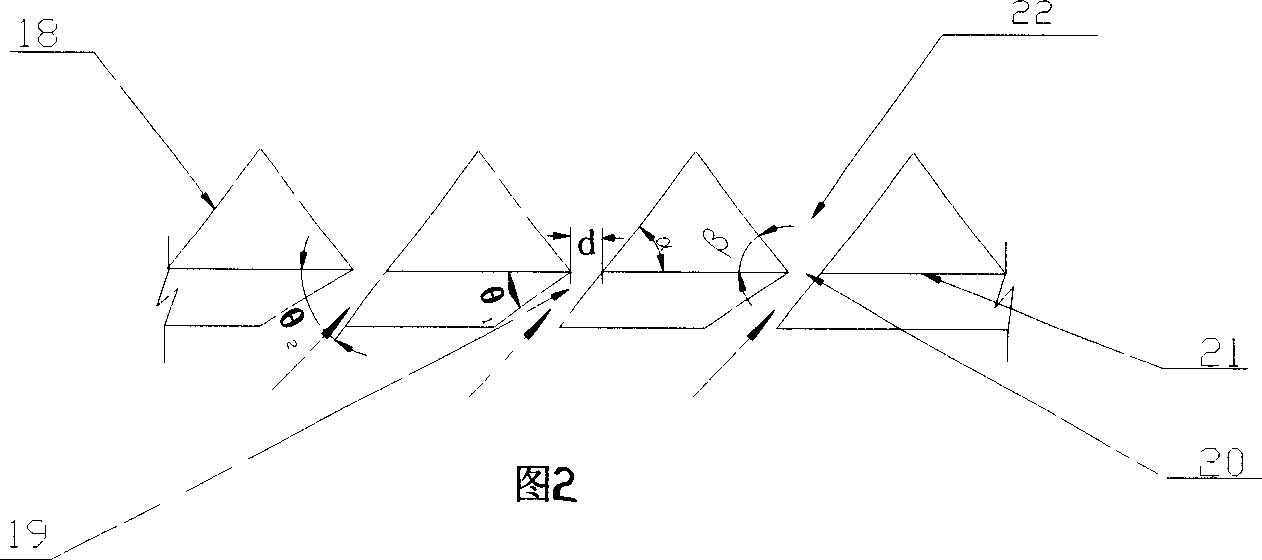

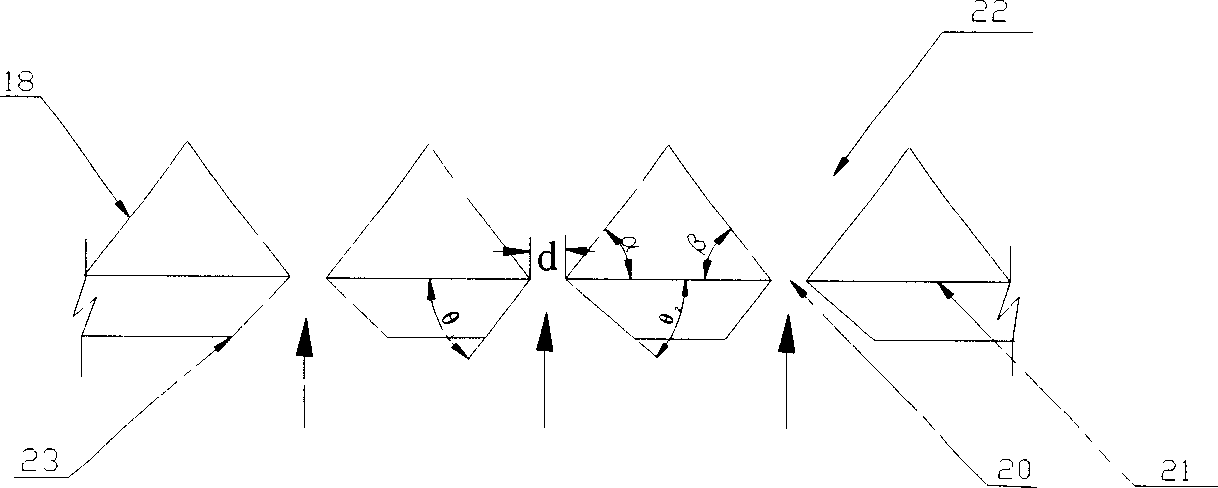

Circular spout bed equipped with circular multi-nozzle ventilation mechanism

InactiveCN1762569ACompact structureHigh partition heat transfer effectChemical/physical processesEngineeringNozzle

The ring spouted bed with ring-direction multiple spouts and V-shaped reduced flow chamber comprises: forming ring space by two concentric stand cylinders with shaft as center, arranging wind-distribution mechanism with pressure-stabilization wind chamber on ring space bottom, arranging transient cone connected to outlet pipe and rotation taper distributor connected to top motor by center shaft respective on lower and top of inner cylinder; arranging spiral dumper on bottom of inner cylinder and stirring blade on shaft; wherein, material passes the distributor by feeding pipe, added-pressure liquid enters wind-distribution mechanism through wind chamber to spay into ring space. This invention has compact structure, high heat-transfer effect, boosts gas-solid heat exchange rate, and reduces pressure loss.

Owner:SHANGHAI JIAO TONG UNIV

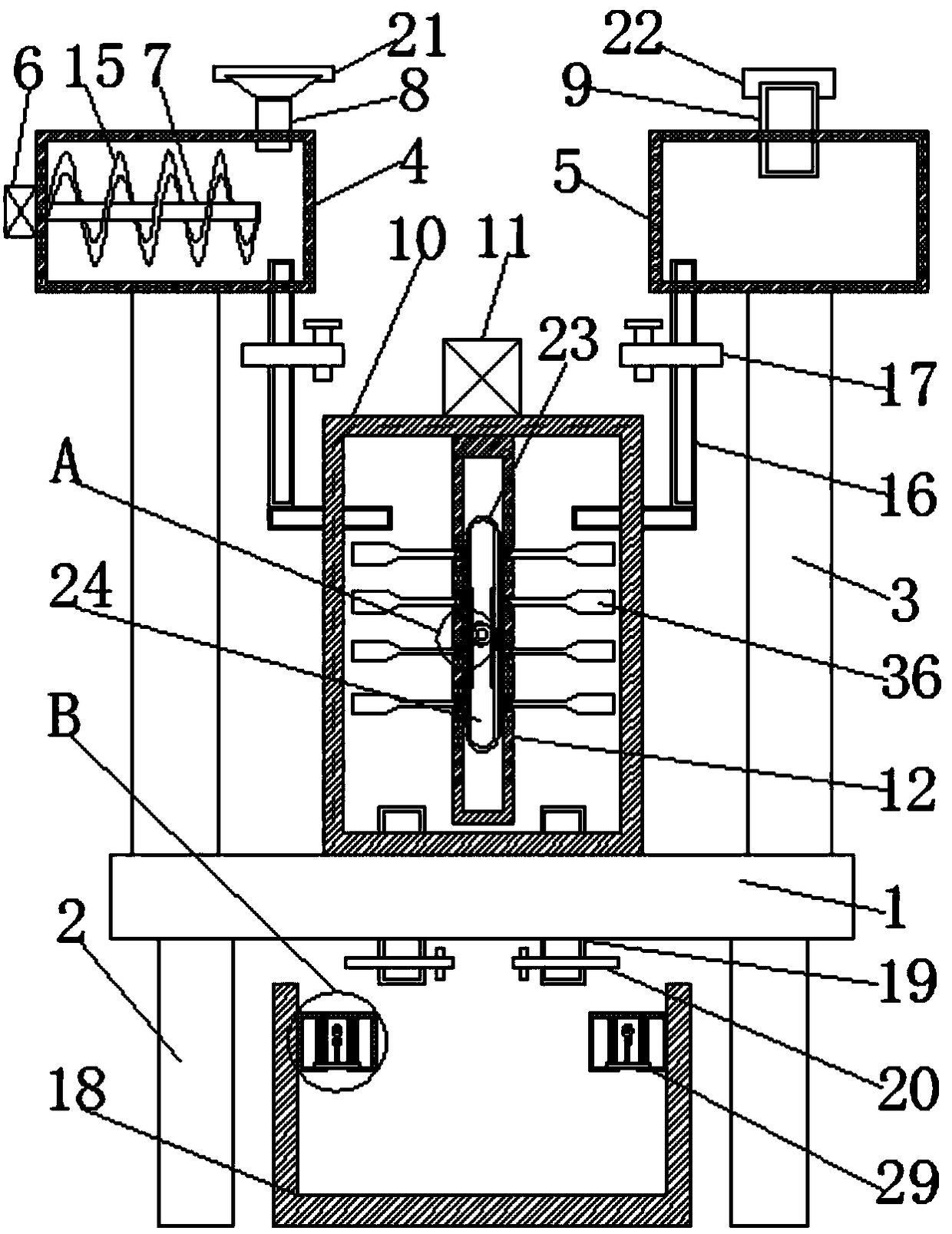

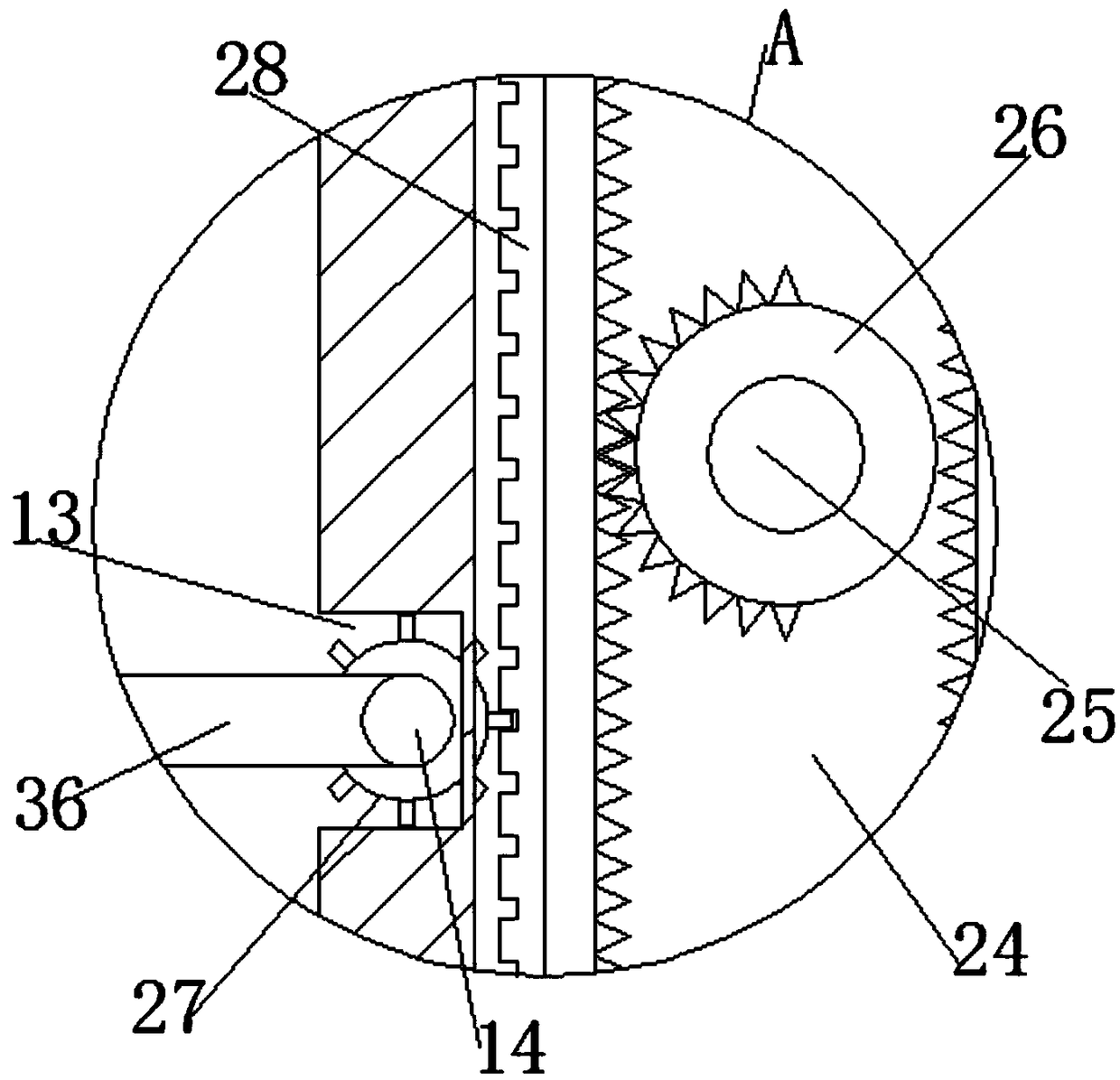

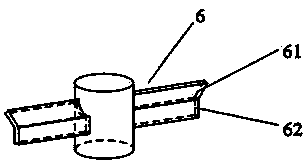

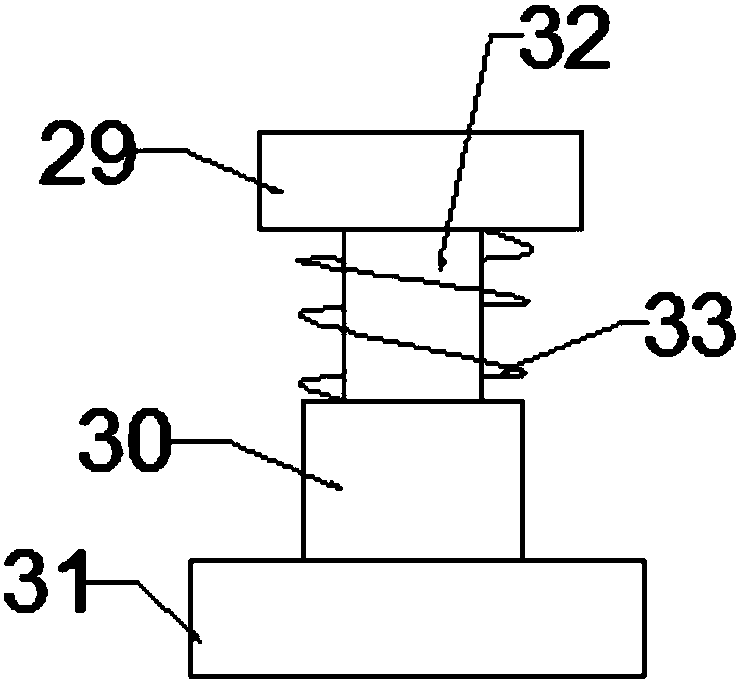

Material stirring machine

ActiveCN105251393AEvenly dispersedImprove qualityRotary stirring mixersMixing methodsEngineeringWater pipe

The invention discloses a material stirring machine. The material stirring machine comprises a shell, a baffle plate, a liquid throwing box, a stirring rod and a water pipe, wherein the shell is provided with a feeding port and a discharging port; the top part of the baffle plate is opposite to the feeding port; the side wall and the bottom part of the liquid throwing box are respectively provided with a plurality of first through holes arranged at intervals; the liquid throwing box is arranged under the bottom part of the baffle plate; the top part of the stirring rod penetrates through the liquid throwing box and the baffle in sequence and is fixedly connected with the liquid throwing box and the baffle plate; a groove is downwards formed in the top part of the stirring rod; the part, which is positioned between the top part and the bottom part of the liquid throwing box, on the stirring rod is provided with a plurality of second through holes at intervals along the circumferential direction of the stirring rod; the stirring rod is provided with at least two first stirring blades; one end of the water pipe is connected with a liquid storage box, the other end of the water pipe is provided with a round-platform-shaped first bulge inserted into the groove, and the outer wall of the other end of the water pipe is provided with a plurality of second bulges at intervals along the circumferential direction. The material stirring machine disclosed by the invention has the advantages that the dispersion of liquid materials and solid materials is uniform, and the stirring efficiency and the quality of the mixture are improved.

Owner:常州市常航干燥设备有限公司

Drug mixing device for internal medicine

PendingCN108816137APrecise ratioIncrease the degree of mixingTransportation and packagingMixer accessoriesHigh densityMedicine

The invention discloses a drug mixing device for the internal medicine. The drug mixing device comprises a horizontal main plate, wherein two vertical support rods are arranged on one side wall of themain plate; two vertical struts are arranged on the other side wall of the main plate; the ends, away from the main plate, of the two struts are fixedly connected with a first drug adding box and a second drug adding box respectively; a first drive motor is arranged on the outer wall of one side of the first drug adding box; an output shaft of the first drive motor penetrates one side wall of thefirst drug adding box and is connected with a first stirring shaft; first blades are arranged on the first stirring shaft; a vertical first drug adding pipe is arranged in the first drug adding box and penetrates one side wall of the first drug adding box. Solid drugs can be smashed, working angles of the blades can be changed, solid drugs with higher density and solid drugs with lower density can be driven to move, and the drug mixing degree is increased.

Owner:张红霞

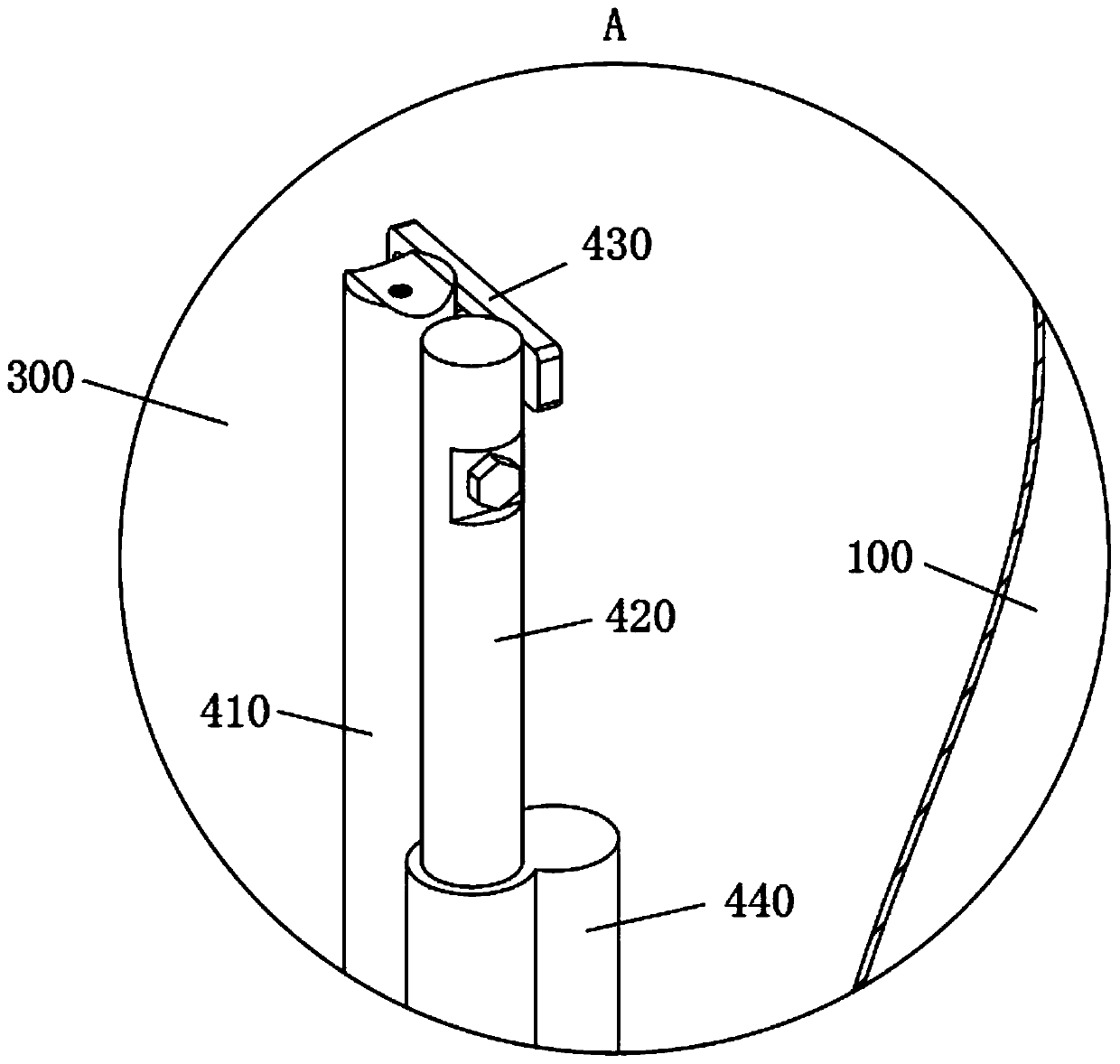

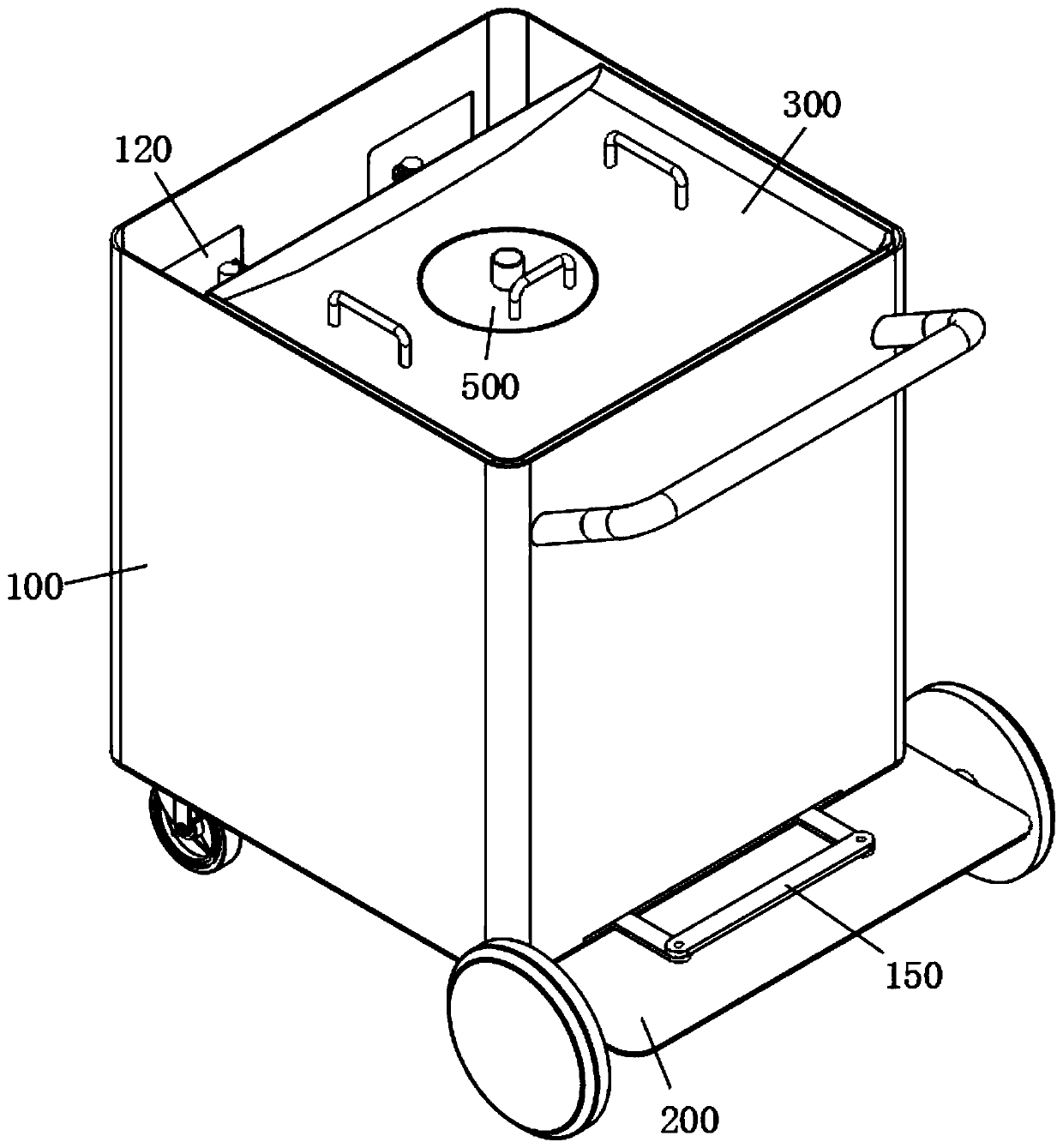

Manufacturing device for producing weather-resistant environment-friendly anticorrosive coating

ActiveCN111569760AScientific and reasonable structureEasy to useTransportation and packagingMixer accessoriesWeather resistanceElectric machine

The invention discloses a manufacturing device for producing a weather-resistant environment-friendly anticorrosive coating. The manufacturing device comprises a mounting support, wherein a dispersingbarrel is fixedly connected to one end of the top of the mounting support; a fixed mounting rack is fixedly connected to the middle part of the top end of the dispersing barrel; a dispersing motor isfixedly connected to the middle part of the top end of the fixed mounting rack; the input end of the dispersing motor is electrically connected with the output end of a mains supply; and an efficientdispersing and discharging mechanism is arranged on the inner side of the dispersing barrel. According to the invention, powdery raw materials are added into the dispersing barrel through a materialadding port; under the action of a driving gear and a rotating gear ring, the rotating gear ring, a connecting inclined rod, a mounting ring and a dispersing rotating shaft are driven to rotate in opposite directions, and therefore, stirring vertical plates, stirring arc plates and a mounting ring on the dispersing rotating shaft rotate in opposite directions in the dispersing barrel at the same time; and thus, efficient stirring in the dispersing barrel is achieved, the mixing rate of raw materials in the dispersing barrel is increased, the mixing time of anticorrosive paint is shortened, andthe processing efficiency of the anticorrosive paint is improved.

Owner:丹阳市美尔鑫化工有限公司

Concrete mixer

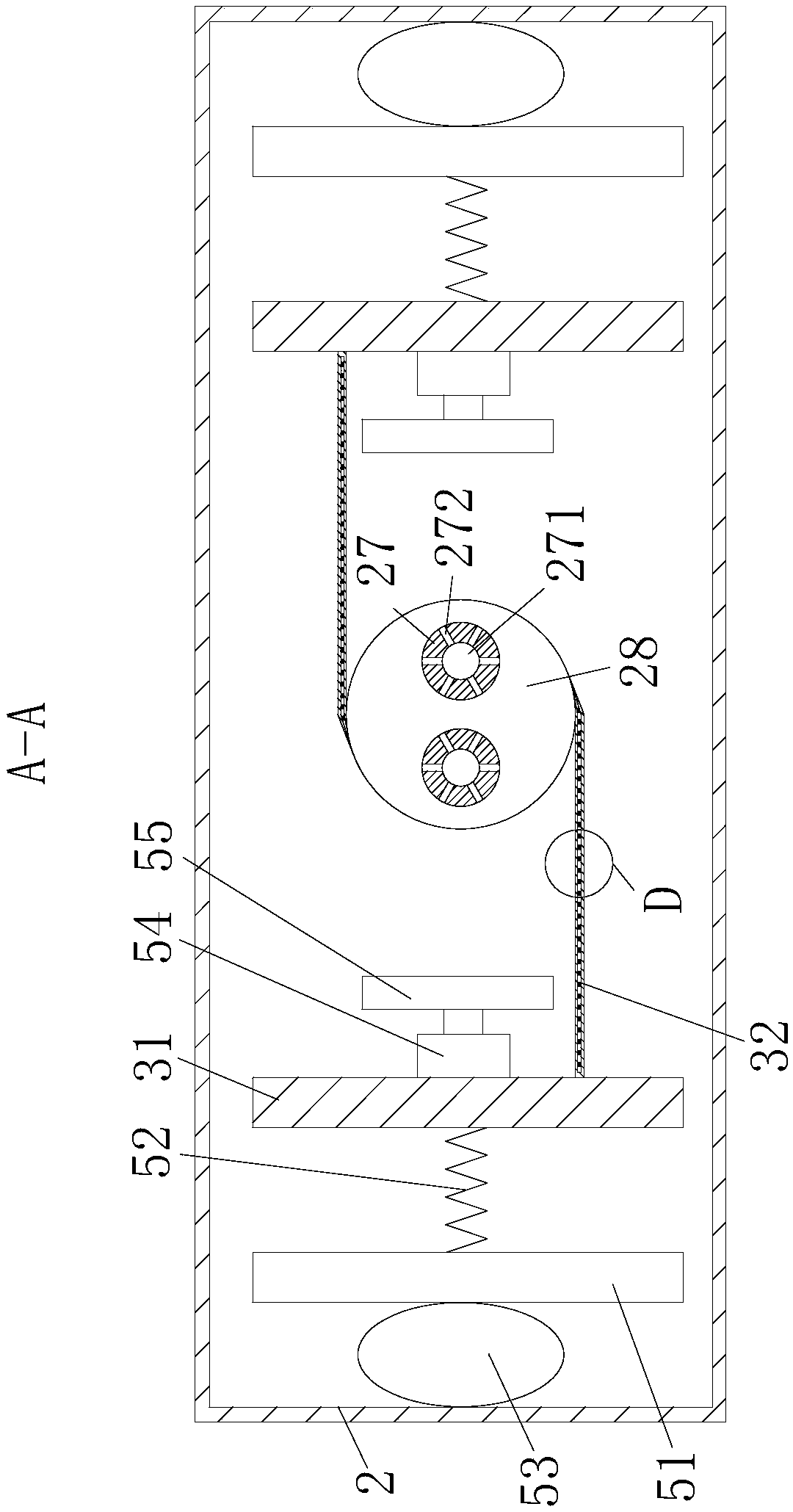

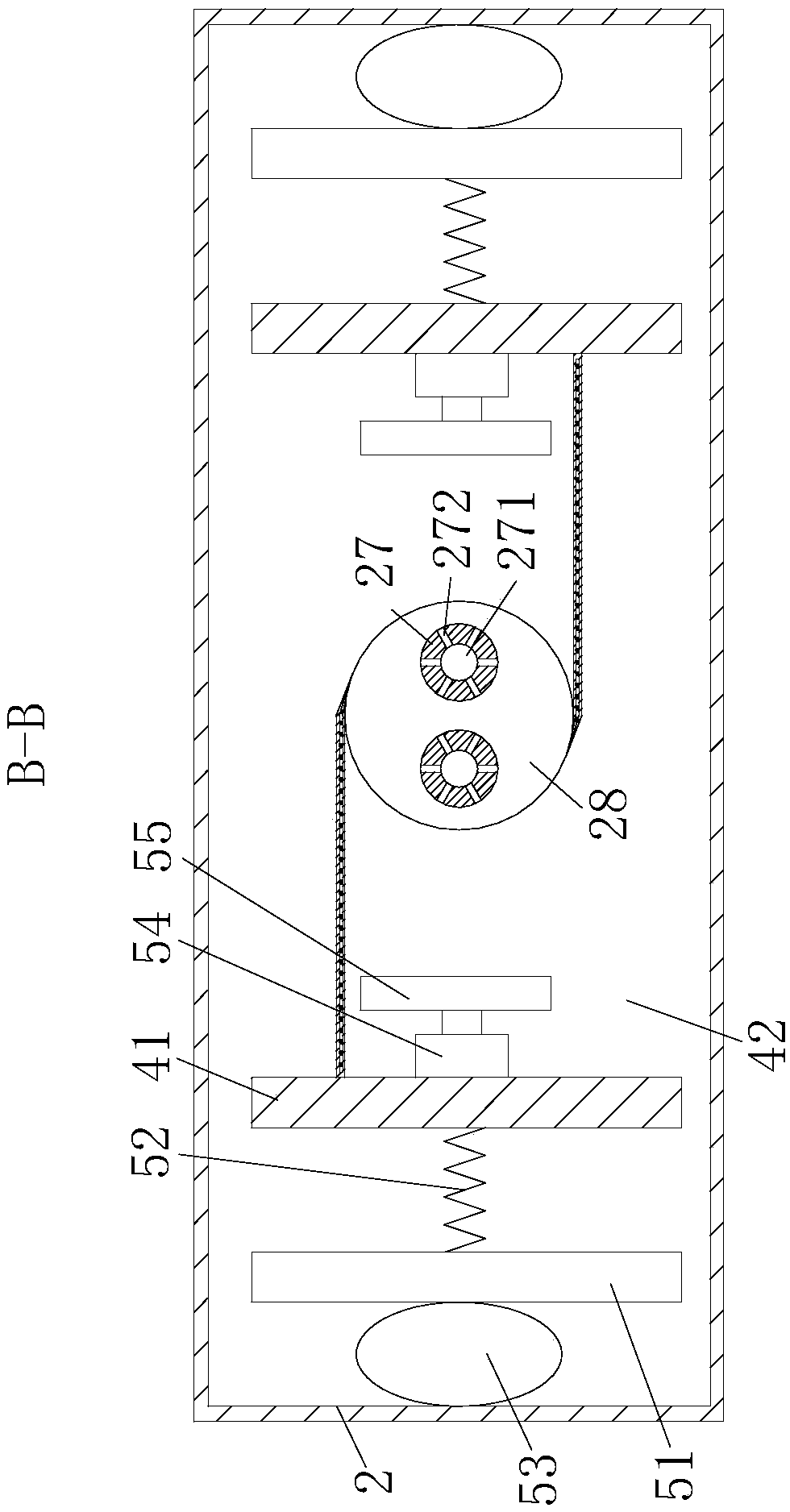

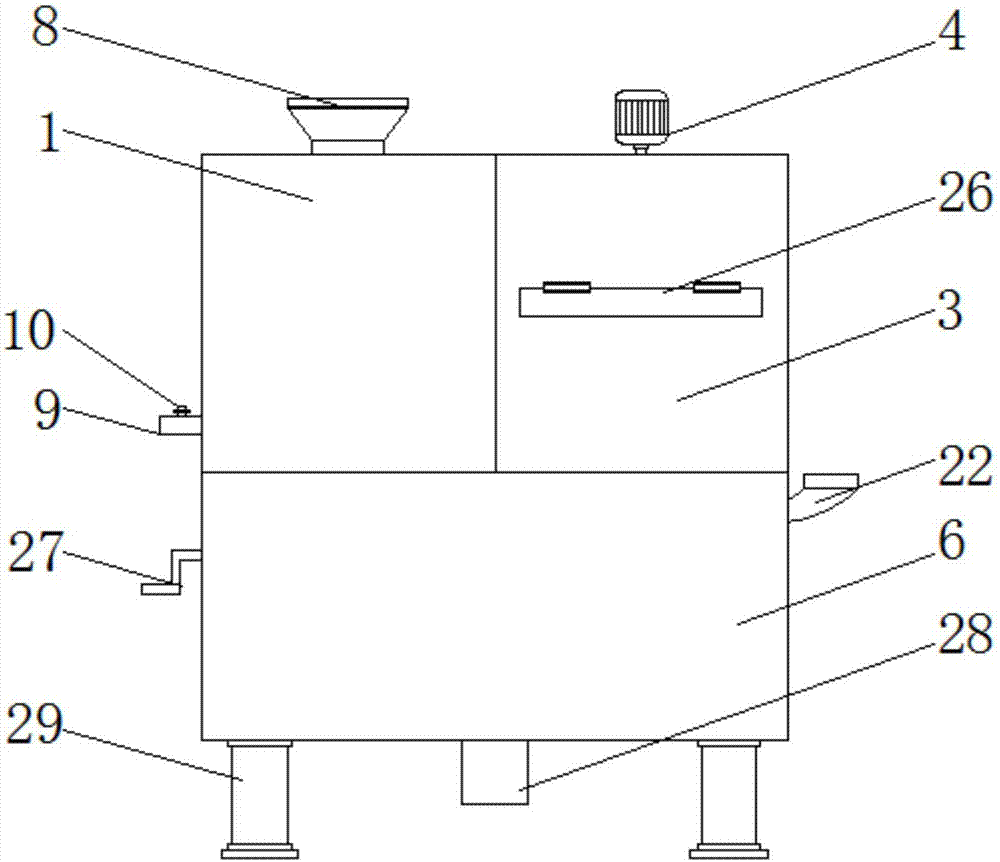

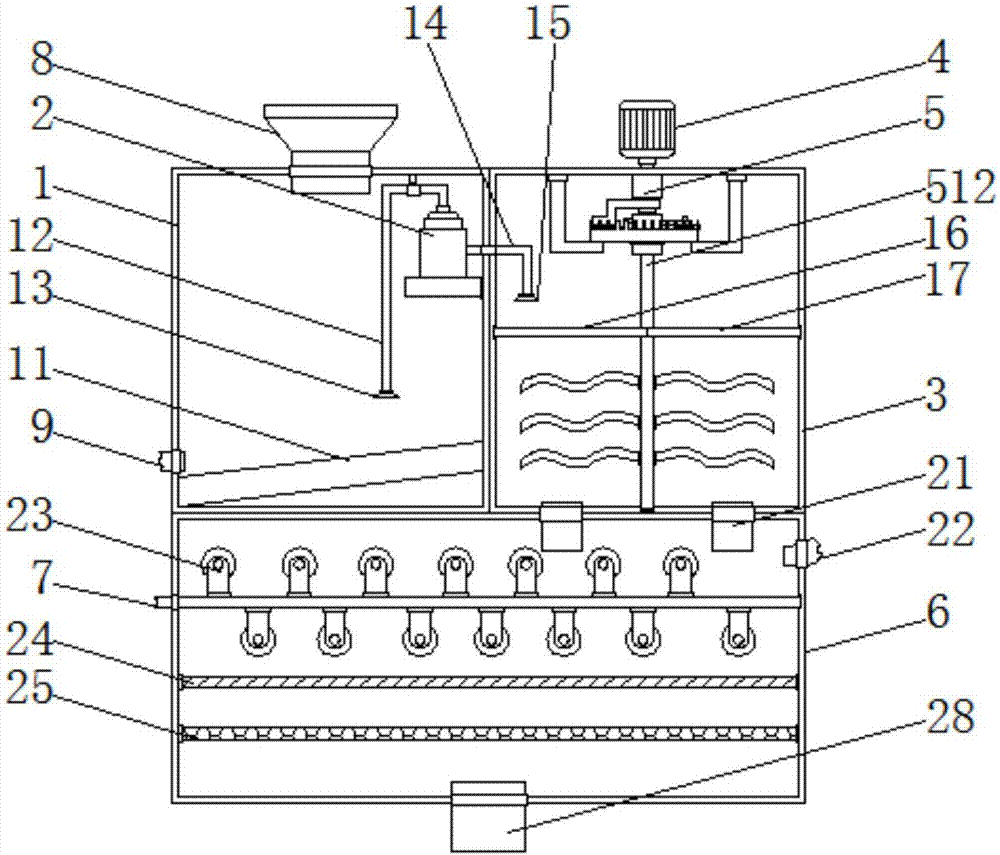

ActiveCN105397918AImprove qualityIncrease mixing rateCement mixing apparatusSold ingredients supply apparatusWater pipeEngineering

The invention discloses a concrete mixer which comprises a shell, a baffle, a liquid throwing box, a stirring rod and a water pipe. A feeding inlet is formed in the center of the top of the shell, and a discharging outlet is formed in the lower portion of the shell. A first round opening is formed in the top of the baffle. A second round opening is formed in the top of the liquid throwing box; multiple first through holes are formed in the lateral wall and the bottom of the liquid throwing box at intervals; the liquid throwing box is inserted into the first opening; the top of the liquid throwing box is flush with the top of the baffle. The top of the stirring rod is fixedly connected with the bottom of the liquid throwing box. At least two first stirring blades are arranged in the middle of the stirring rod. One end of the water pipe is connected with a liquid storage box, the outer wall of the other end of the water pipe is provided with two protrusions in the axial direction of the other end of the water pipe in a spaced mode, the inner walls of the two protrusions are fixedly connected with the outer wall of the other end of the water pipe, the other end of the water pipe penetrates through the second opening to extend into the liquid throwing box, and the two protrusions are located inside and outside the liquid throwing box respectively. Liquid raw materials and solid raw materials can be dispersed evenly, and the stirring efficiency and quality of a mixture are improved.

Owner:邳州市蓝天节能建材有限公司

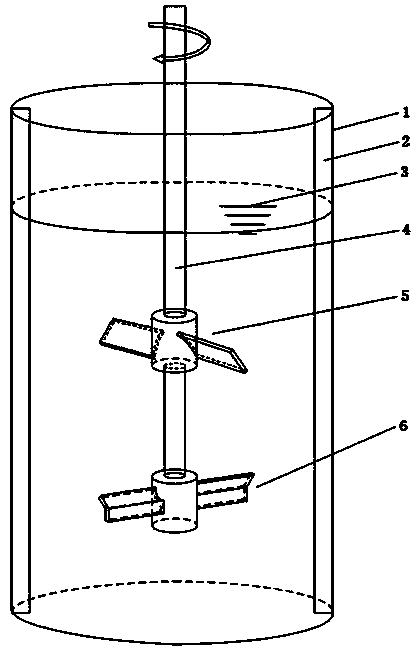

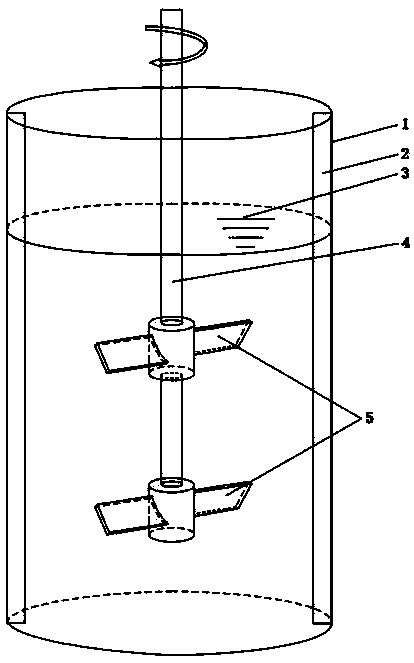

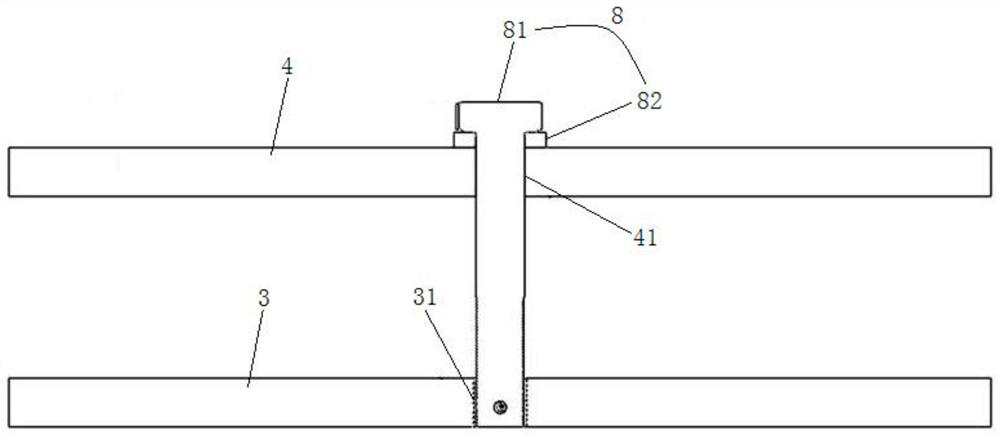

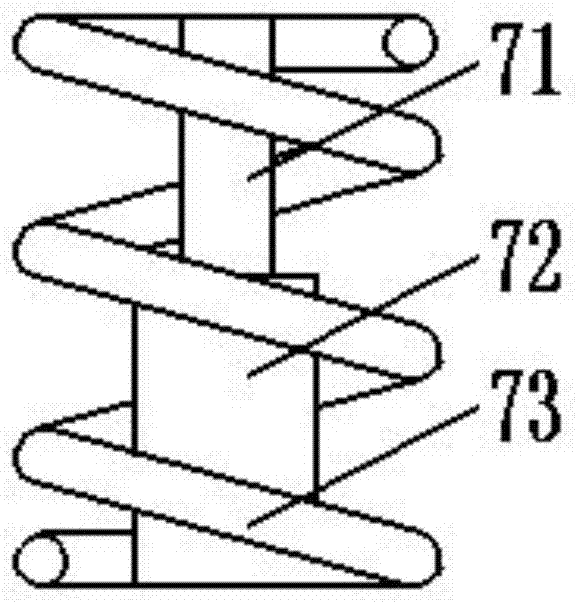

Combined paddle stirring device

ActiveCN108339445AIncrease axial displacementAvoid depositionTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

The invention belongs to the technical field of stirring equipment, and discloses a combined paddle stirring device. The combined paddle stirring device comprises a stirring tank and a stirring shaft,wherein the stirring shaft is vertically disposed inside the stirring tank, the stirring shaft is provided with an inclined blade paddle and at least one folded blade paddle, and the inclined blade paddle is arranged above the folded blade paddles; each folded blade paddle includes an inclined folded blade paddle body and a vertical folded blade paddle which is connected with the corresponding inclined folded blade paddle. The inclined blade paddle is combined with the folded blade paddles, radial and axial driving forces on fluid are generated by using the inclined blade paddle, and interaction between the inclined part and vertical part of each folded blade paddle is combined, so that the axial discharge capacity of the stirring paddles is increased, suspension of particles off the bottom is driven effectively, the mixing rate of materials in the stirring device is improved, the mixing time is shortened, surface aeration and power consumption are reduced, and the problem of poor mixing ability in axial and radial directions of an existing combined paddle stirring device is solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

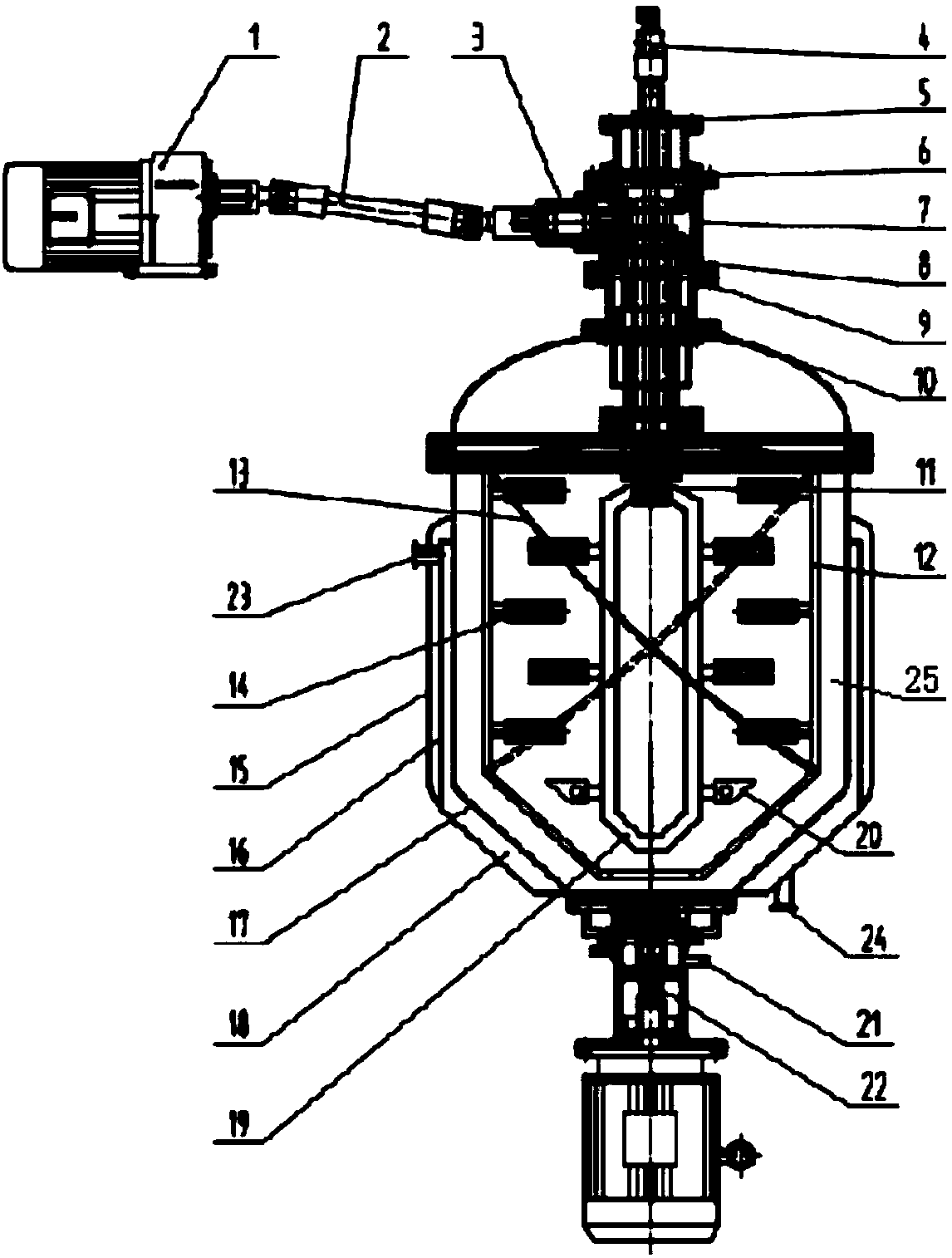

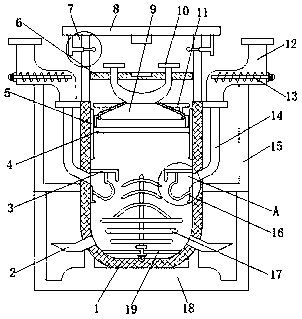

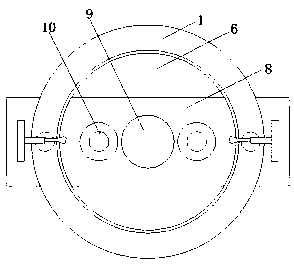

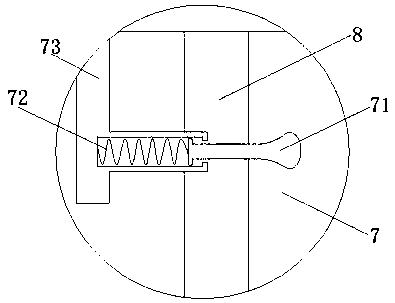

Bidirectional helical ribbon stirring type inner and outer heating water-cooling emulsifying machine

InactiveCN108380069AWell mixedHigh speedRotary stirring mixersTransportation and packagingMotor driveCoupling

The invention discloses a bidirectional helical ribbon stirring type inner and outer heating water-cooling emulsifying machine and belongs to the technical field of emulsifying machines. The bidirectional helical ribbon stirring type inner and outer heating water-cooling emulsifying machine comprises upper and lower stirring motors, wherein a universal shaft coupler is mounted at an output end ofthe stirring motor at the upper side; a first stirring paddle is inserted into an inner cavity of a pot body; the pot body is sequentially provided with a heat-insulation shell, a heating middle layerand an inner layer from outside to inside; a bidirectional helical ribbon is arranged on an inner wall of the pot body through first stirring paddle blades; a main pot steam inlet is formed in the top of an outer wall at the left side of the pot body. The device is convenient to operate; the stirring motors drive a transmission mechanism and bidirectional stirring is realized through a gear mechanism; multi-phase materials in the pot body can be more uniformly mixed through bidirectional helical ribbon stirring and the speed is more rapid; each first stirring paddle blade is of a pore structure, so that the mixing speed of the materials in a stirring process is easy to improve; the heating speed is more rapid through simultaneous inner and outer heating and the heating is more uniform; the consistency of the temperature of the materials in the whole pot body is ensured.

Owner:扬州市钰翔轻工机械设备厂

Pesticide spraying device for banana seedling planting

InactiveCN111406729AIncrease mixing rateImprove mixing efficiencyInsect catchers and killersBiologyHorticulture

The invention belongs to the technical field of banana planting, and particularly relates to a pesticide spraying device for banana seedling planting. The pesticide spraying device comprises an outerbox body and a mixing box, wherein the bottom of the outer box body is fixedly connected with a bottom plate; and the interior of the outer box body is in sliding embedded connection with the mixing box. According to the device, the inner side of the outer box body is provided with the mixing box, the interior of the outer box body is provided with a push rod, and the push rod is used for adjusting the position of a rotating block, so that two spraying modules are moved to the outer side of the outer box body, banana seedlings on the two sides of the outer box body can be sprayed with pesticides, and the working efficiency of the pesticide spraying device for banana seedling planting is effectively improved; and by rotating the bottom plate, the relative positions of the spraying modules and a bearing plate can be adjusted, so that the application range, corresponding to different terrains and different planting forms, of the pesticide spraying device for banana seedling planting is expanded.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

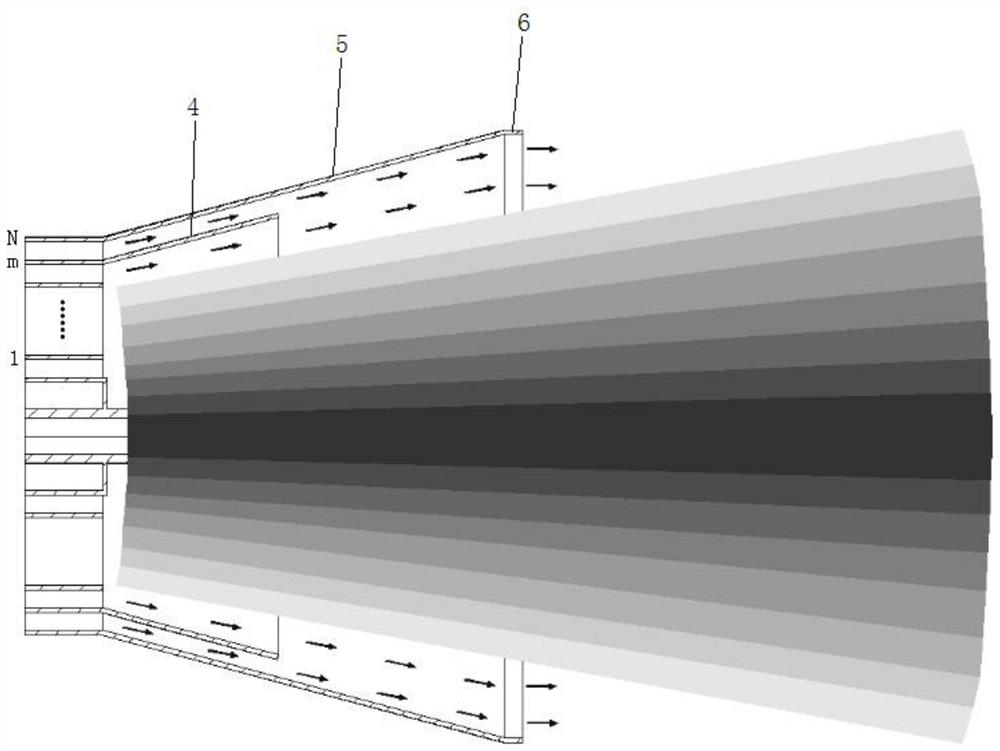

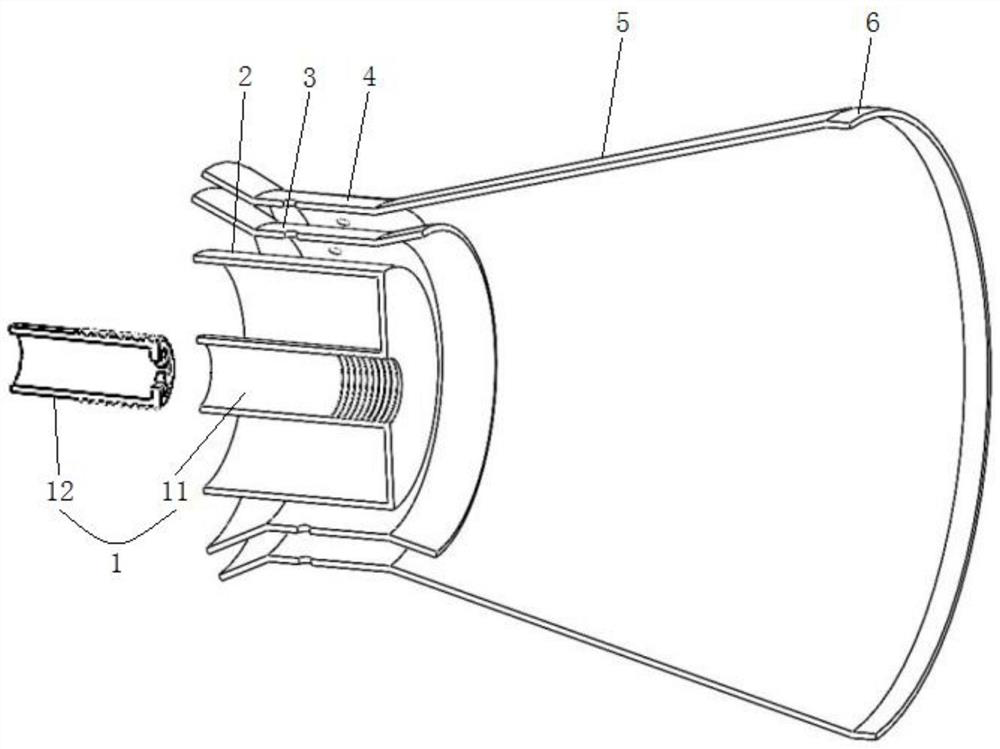

Multi-channel reverse injection type swirl single cone combustor and use method thereof

PendingCN111895400AIncrease mixing rateFire stablePulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a multi-channel reverse injection type swirl single cone combustor and a use method thereof. The combustor comprises a pulverized coal supply mechanism, a transition channel,a multi-stage air distribution assembly, diversion plates, a stable combustion cavity and a rectifying cavity; the multi-stage air distribution assembly comprises N air ducts, the N air duct is connected with the stable combustion cavity and the rectifying cavity in sequence to form a combustor body, the pulverized coal supply mechanism penetrates through the inner part of the combustor body,and the transition channel sleeves the pulverized coal supply mechanism; except for the N air duct, the other air ducts are of double-layer hollow structures, and one end of at least one diversionplate is inserted into the corresponding air duct; at least one direct current channel is formed between each diversion plate and the stable combustion cavity, flaring is formed in the other end of each diversion plate, and the angle of the flaring is the same as the angle of the stable combustion cavity. The combustor adopts the design of the multi-stage air distribution assembly, air is dividedinto N strands to enter the combustor body, and the turbulence intensity at the airflow boundary is strong, so that the air and powder mixing rate is strengthened, pulverized coal ignites stably, andhigh-efficiency and low-nitrogen combustion of the pulverized coal can also be guaranteed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Manufacturing method for ultraviolet-proof flower-in-water fabric

InactiveCN107385956AHigh squeeze rateGood effectBiochemical fibre treatmentLight resistant fibresDesign patternDyeing

The invention relates to a manufacturing method for an ultraviolet-proof flower-in-water fabric. The manufacturing method comprises the following steps: S1, dyeing of a raw fabric; S2, surface dyeing removal; S3, fabric printing: printing designed patterns on a basic fabric by using a printer, and printing floating printing paste on the designed patterns to form designed floating printing patterns; S4, fabric treatment; and S5, padding treatment: impregnating the flower-in-water fabric obtained in the S4 step in padding liquid used in ultraviolet-proof treatment, carrying out single-dipping and single-nipping procedure, and drying at the temperature of 142-148 DEG C to obtain the ultraviolet-proof flower-in-water fabric, wherein the mangle expression is greater than or equal to 82%. The manufacturing method for the ultraviolet-proof flower-in-water fabric has the advantages of environmental protection, uniform color, washing resistance and good ultraviolet isolation property.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

Printing ink hot-stirring device

ActiveCN108607386AReduce displacementWell mixedTransportation and packagingRotary stirring mixersPrinting inkGraphite

The invention discloses a printing ink hot-stirring device which includes a pedestal, a barrel body, a driving unit, and a stirring unit, wherein the barrel body includes an external barrel and an internal barrel disposed therein. The stirring unit includes a first stirring member arranged vertically and a plurality of second stirring members arranged transversally, wherein the second stirring members are disposed in the internal barrel. The internal barrel is provided with a transmission mechanism, which drives the second stirring members to rotate during rotation of the first stirring member. A heating channel is formed between the internal barrel and the external barrel and is filled with hot water. By filling the heating channel with hot water, the printing ink can be heated well during a mixing and stirring process, thus greatly improving the mixing effect of raw materials, and further improving the quality of the printing ink. Due to the hot water heating mode, temperature of a barrel arm of the internal barrel is not excessively high, so that coking of graphite sticking on the wall of the internal barrel can be prevented, thus further improving the quality of the printing ink.

Owner:江西超洋科技有限公司

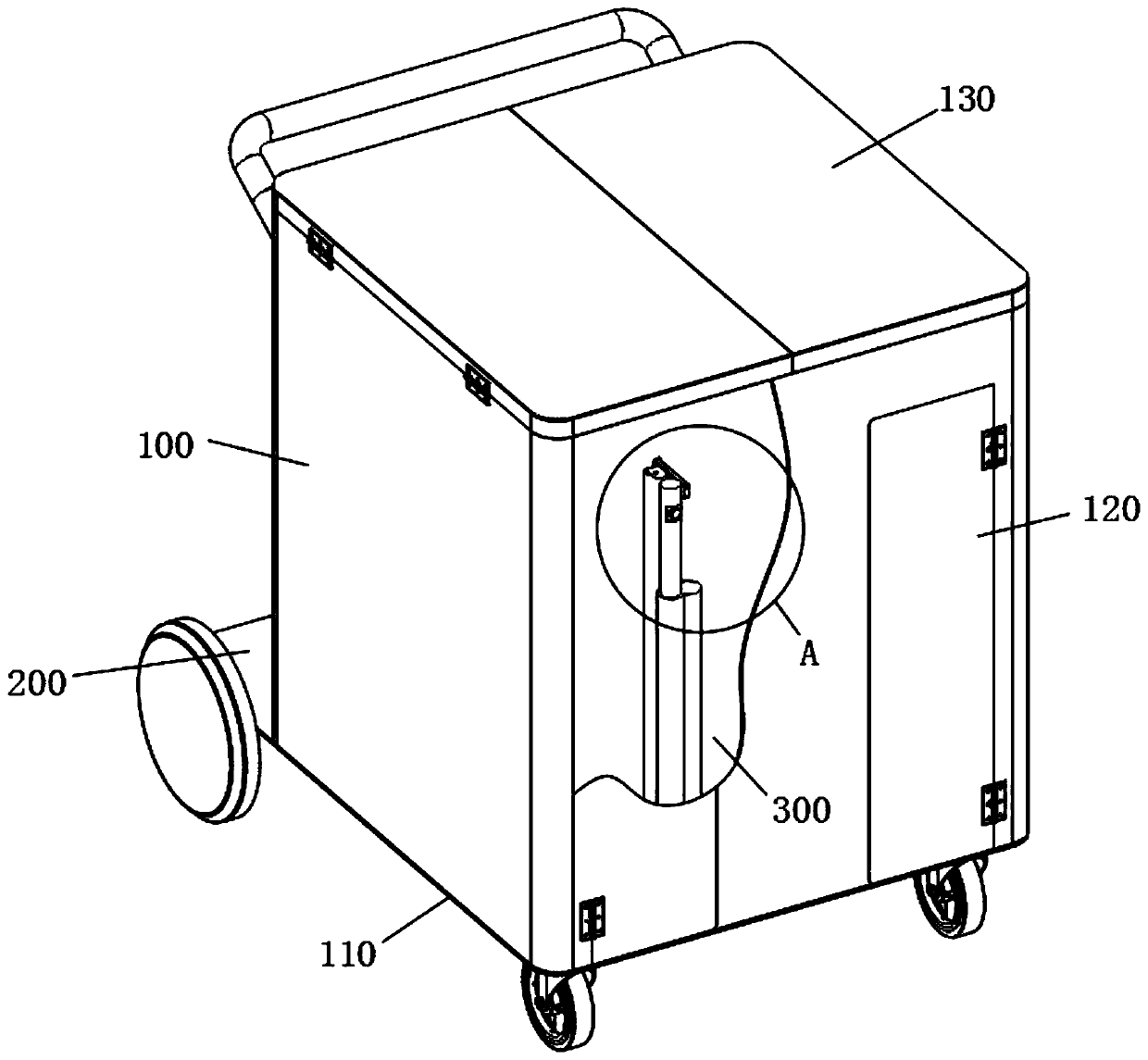

Medical cell culture equipment and cell culture method

ActiveCN111748473AIncrease mixing rateEnsure and maintain cell culture temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringBiotechnology

The invention discloses medical cell culture equipment and a cell culture method, which relate to the technical field of cell culture. The equipment comprises an incubator, a sealing cover is hinged to the top surface of the incubator; two operation holes are fixedly formed in the end surface of the incubator; rubber operation gloves are mounted on the surfaces of the two operation holes; the interior of the incubator is divided into a culture cavity and a transfer cavity through a partition plate; a transfer hole is formed in a communication part of the culture cavity and the transfer cavity;a sealing door mechanism is fixedly mounted on the inner wall of the culture cavity; one surface of the sealing door mechanism is slidably sealed with the transfer hole. Through the design of the transfer cavity, the sealing door mechanism and a positive-pressure air blowing assembly in the incubator, the probability that external impurity-containing and bacterium-containing air enters a culturedish can be effectively reduced in a cavity separation and positive-pressure air blowing mode during sampling of the equipment, and the normal environment during cell culture can be effectively guaranteed through reduction of the pollution probability.

Owner:湖南南华爱世普林生物技术有限公司

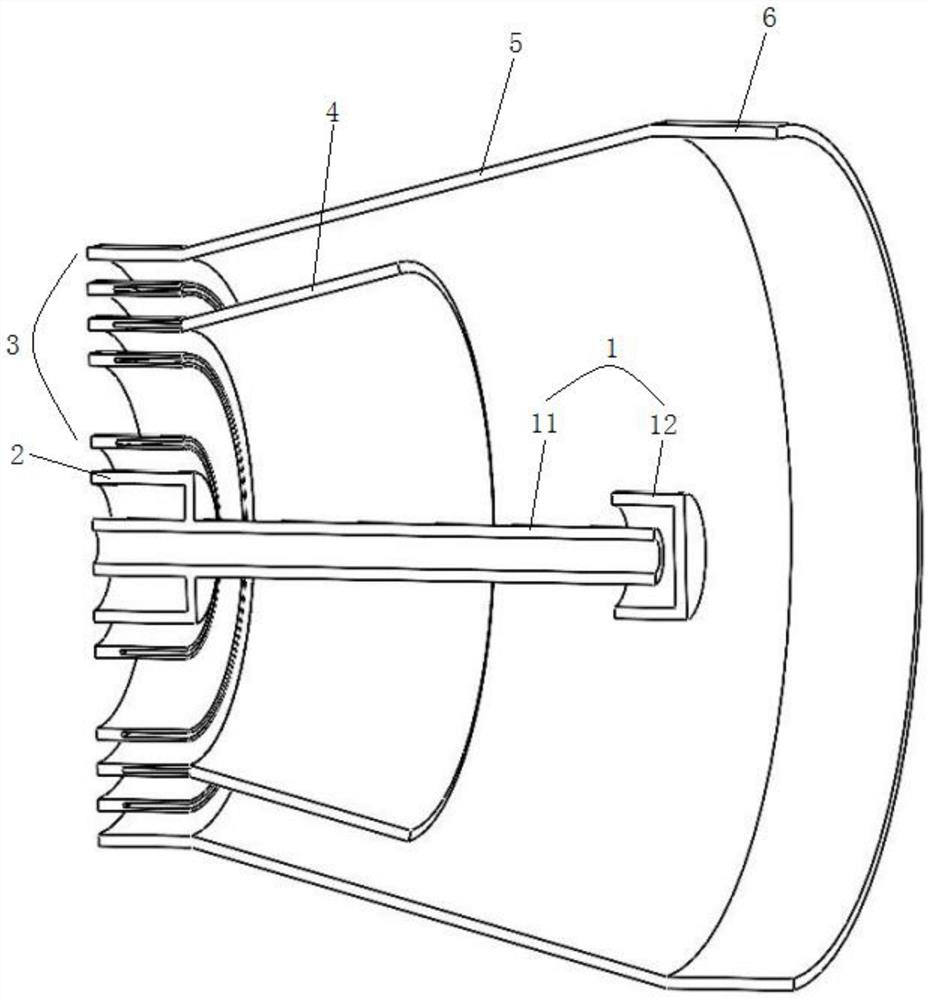

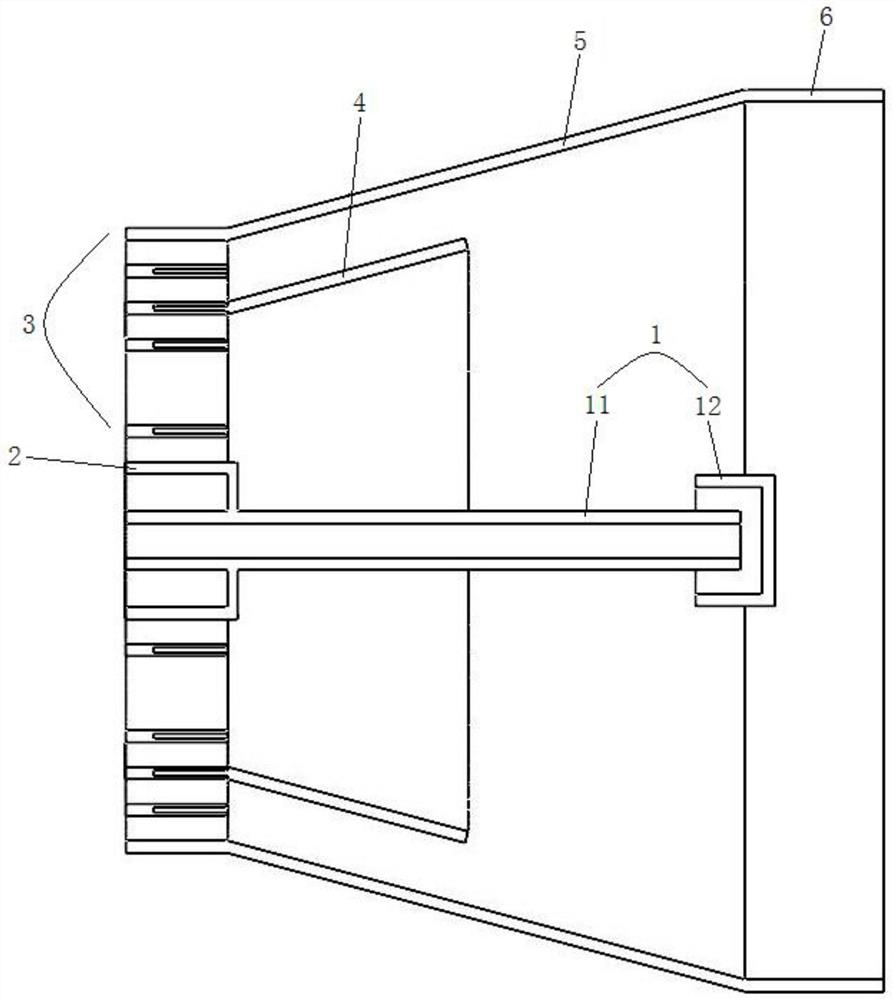

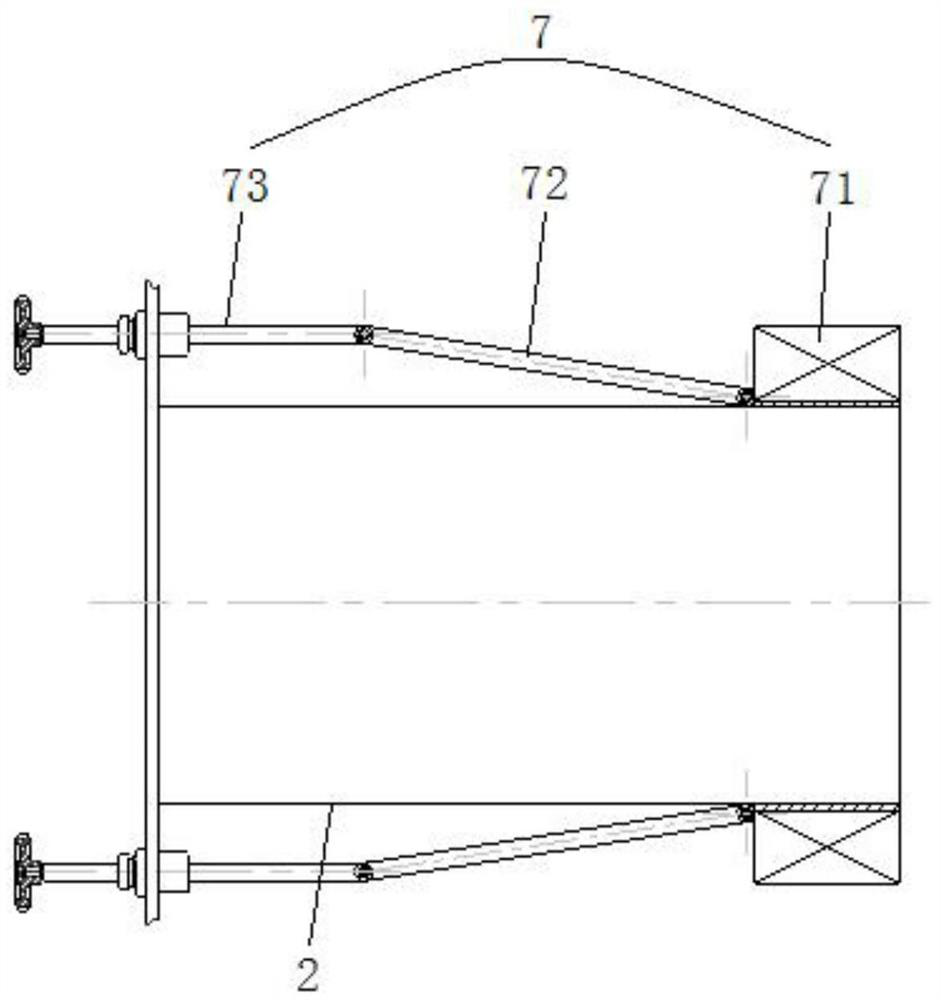

Double-channel combustor with thick pulverized coal and thin pulverized coal being separated and use method thereof

PendingCN111895397AReduce maintenance frequencyExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention relates to a double-channel combustor with thick pulverized coal and thin pulverized coal being separated and a use method thereof. The double-channel combustor with the thick pulverizedcoal and the thin pulverized coal being separated comprises a pulverized coal supplying mechanism, a transition channel, an internal secondary air guide duct, an external secondary air guide duct, acombustion stabilizing cavity and a rectifying cavity. The external secondary air guide duct, the combustion stabilizing cavity and the rectifying cavity are sequentially connected. The pulverized coal supplying mechanism comprises an air-pulverized coal pipe and a thick and thin pulverized coal separating device. The air-pulverized coal pipe communicates with the combustion stabilizing cavity. The thick and thin pulverized coal separating device is detachably connected to the air-pulverized coal pipe. The internal secondary air guide duct is coaxially arranged in the outer secondary air guideduct in a spaced manner. The transition channel is coaxially arranged in the internal secondary air guide duct in a spaced manner. The outlet end of the internal secondary air guide duct forms an expanded opening. The angle of the expanded opening is identical with the angle of the combustion stabilizing cavity. By the adoption of the double-channel combustor with the thick pulverized coal and the thin pulverized coal being separated, air can be divided into internal secondary air and external secondary air to respectively enter the combustor, the internal secondary air is combined with the transition channel to sufficiently mix pulverized coal and air, the external secondary air can form a cooling air layer flowing along the wall face of the combustion stabilizing cavity in the combustion stabilizing cavity, and the wall face of the combustion stabilizing cavity is protected against ash accumulation and coking.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

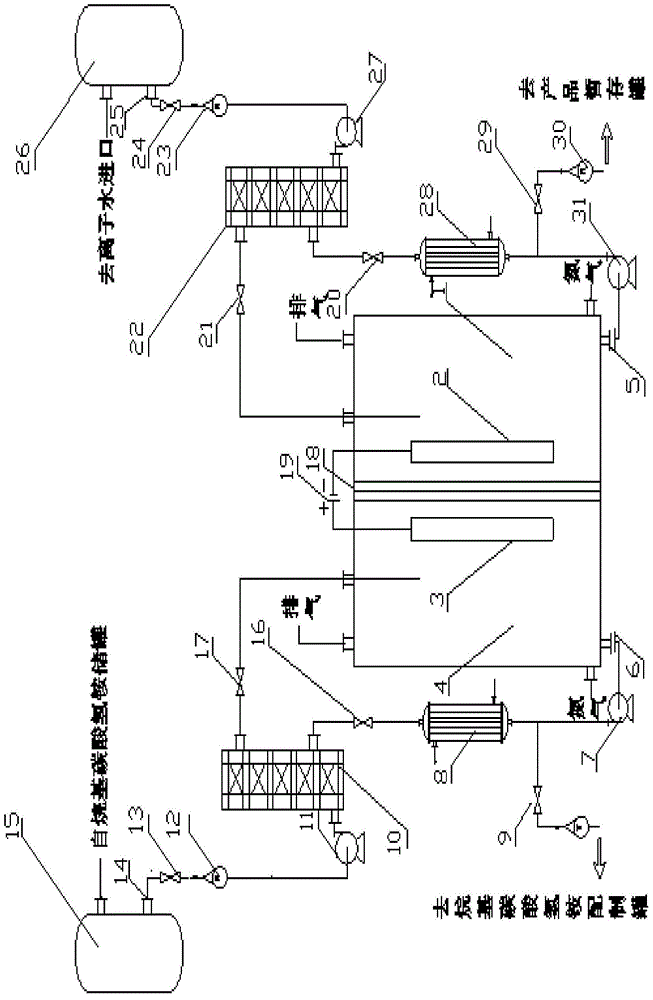

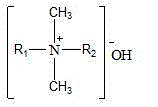

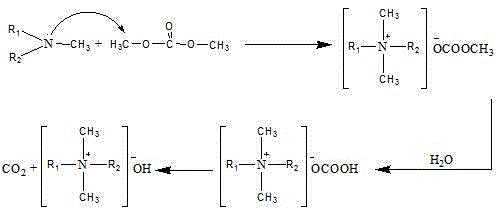

Method for preparing long-chain alkyl ammonium hydroxide by continuous electrolysis

ActiveCN104313634AInhibit side effectsHigh purityElectrolysis componentsElectrolytic organic productionHigh concentrationElectrolysis

The invention relates to a method for preparing long-chain alkyl ammonium hydroxide by continuous electrolysis. The method comprises the following steps: forming a circulation loop by virtue of an anode compartment, an anode static mixer, a heat exchanger and an anode circulating pump; forming a circulation loop by virtue of a cathode compartment, a cathode static mixer, a heat exchanger and a cathode circulating pump; carrying out electrolysis under a certain electrolytic condition; opening an anode charging pump while the electrolytic rate is gradually reduced; mixing a high concentration alkyl ammonium hydrogen carbonate aqueous solution and a low concentration anode liquid in an anode storage tank by virtue of the static mixer and feeding into the anode compartment to maintain the concentration of the anode compartment so as to ensure a relatively high electrolytic rate; and when the cathode liquid reaches a certain concentration, conveying the alkyl ammonium hydrogen carbonate aqueous solution to a product temporary storage tank by virtue of the cathode circulating pump. The method provided by the invention has the advantages of being free of pollution in the preparation process, low in cost and high in product impurity and can be continuously and industrially produced.

Owner:CHINA RES INST OF DAILY CHEM IND

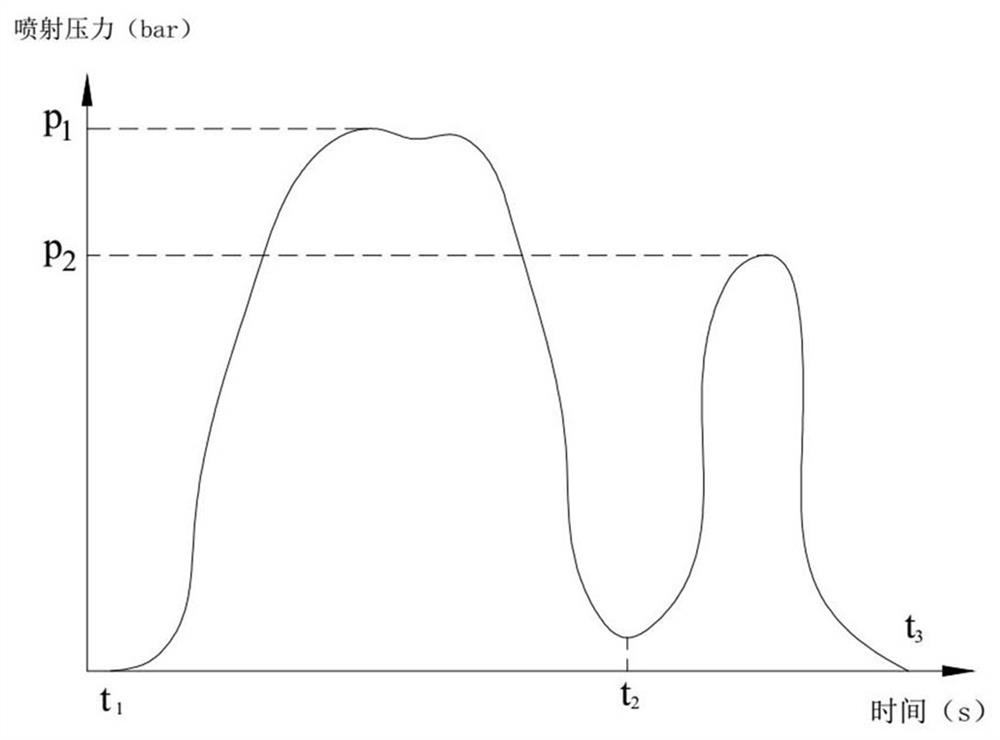

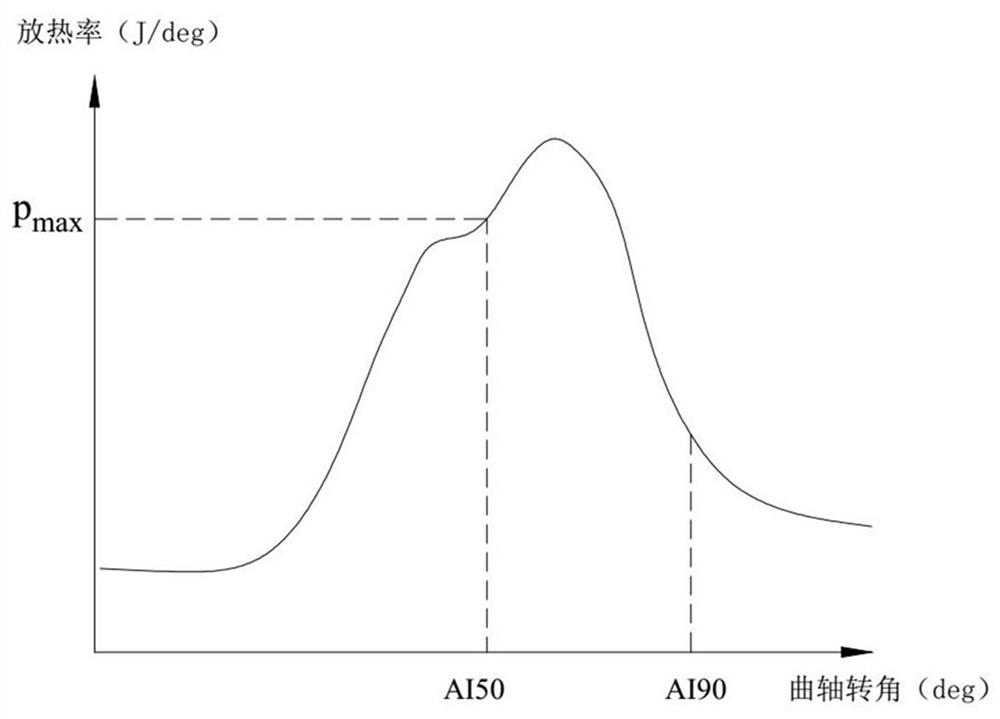

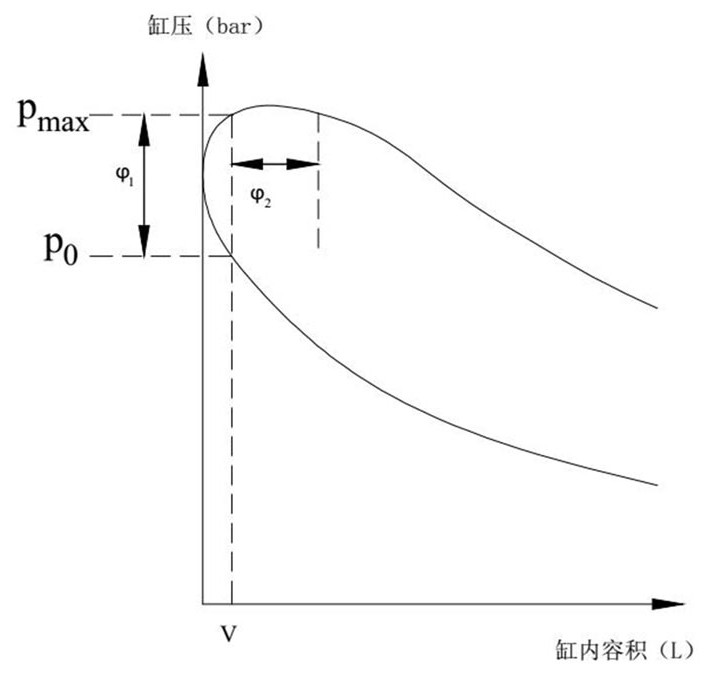

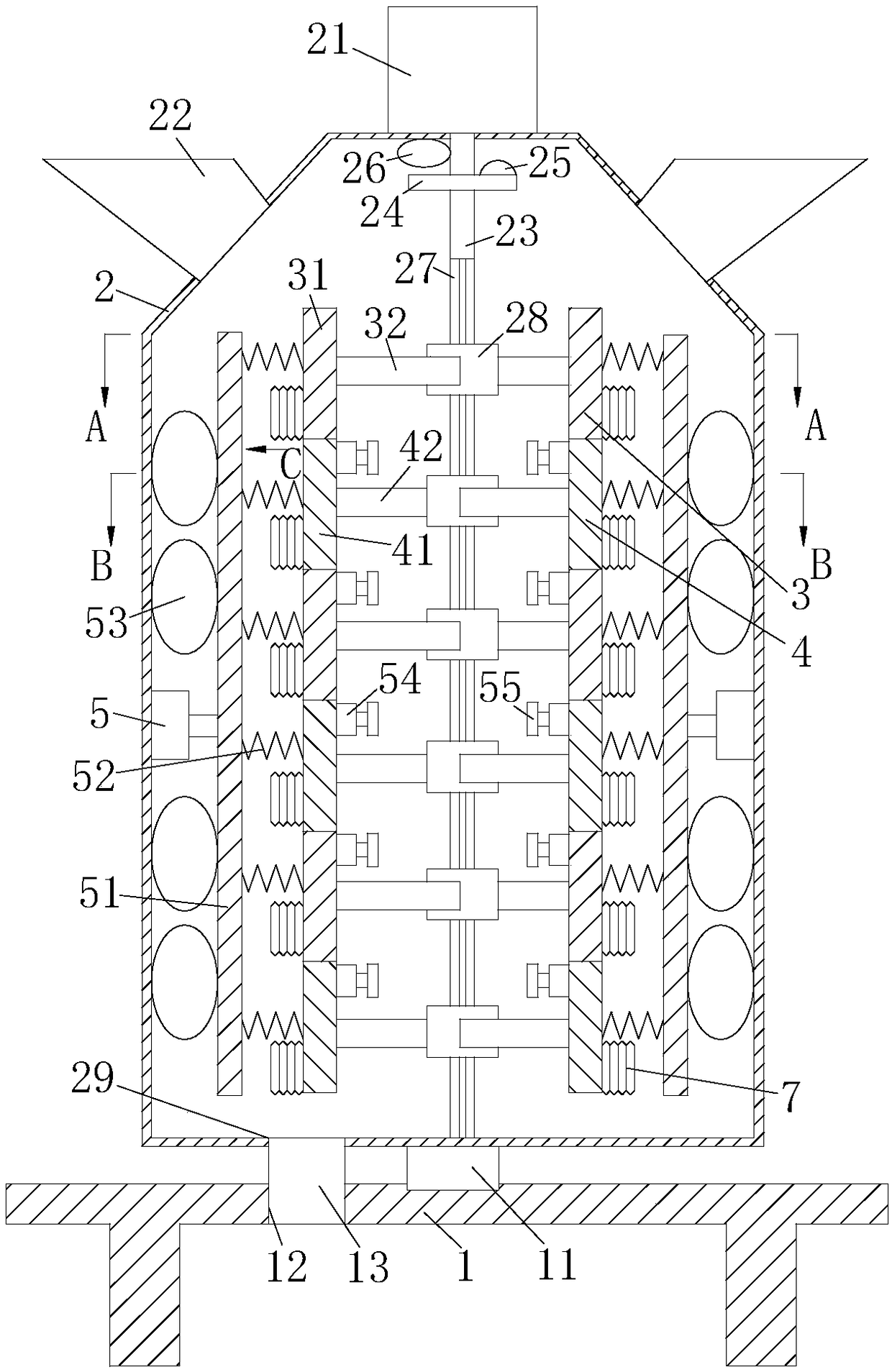

Control method of combustion system, combustion system and diesel engine

ActiveCN113250843AExcellent power outputIncrease mixing rateElectrical controlMachines/enginesCombustion systemThermodynamics

The invention relates to the technical field of diesel engines, and particularly discloses a control method of a combustion system, the combustion system and the diesel engine. According to the control method of the combustion system, through two times of main fuel injection, the space intensity of the entrainment effect of oil beams injected twice in a cylinder can be superposed, two times of organization of the oil beams onto a flow field in the cylinder is achieved, and turbulent flow in the cylinder is strengthened. The oil-gas mixing rate in the cylinder is increased, and the combustion speed and the air utilization rate in the cylinder in the middle and later periods of combustion are also effectively increased. By determining the duration of primary main fuel injection and first injection pressure, it is ensured that the cylinder pressure at least can reach the cylinder pressure upper limit threshold value, and during second main fuel injection, the cylinder pressure is reduced from the cylinder pressure upper limit threshold value to the set cylinder pressure within the period of time. The change rate of the curve slope of a cylinder pressure change curve at each time point is within the set slope change rate range, and the rotating angle of a crankshaft is not smaller than a first preset rotating angle, so that the optimal space entrainment superimposed effect is ensured, and the optimal power output of the diesel engine can be guaranteed.

Owner:WEICHAI POWER CO LTD

Mixing process production device for construction

PendingCN109395635AMix thoroughlyAvoid damageShaking/oscillating/vibrating mixersTransportation and packagingCircular discEngineering

The invention belongs to the technical field of construction material processing, and particularly relates to a mixing process production device for construction. The mixing process production devicecomprises a framework and a base, wherein at least three first mixing units and second mixing units are arranged in the framework; the first mixing units and the second mixing units are alternately arranged and located on a same vertical line; each first mixing unit comprises a first pushing plate and a first elastic belt; the first pushing plate and a second pushing plate are respectively fixedlyconnected onto corresponding discs by virtue of the first elastic belt and a second elastic belt; the junctions between the first elastic belt and the second elastic belt and the corresponding discsare opposite to each other, so that when the first elastic belt is loosened, the second elastic belt is in a straining state; a first air cylinder is communicated with a first airbag; and the first air cylinder is horizontally arranged, and an extension end of the first air cylinder is fixedly connected with a third pushing plate. By adopting the mixing process production device, the constructionmaterials can be sufficiently stirred and mixed, and the mixing process production device is difficult to damage in the mixing process and is simple and convenient in operation.

Owner:金彬

Wastewater treatment device used in ceramic diaphragm production

InactiveCN107487884AEasy to handleWill not affect the useMultistage water/sewage treatmentWastewaterPulp and paper industry

The invention discloses a wastewater treatment device used in ceramic diaphragm production. The wastewater treatment device comprises a sedimentation tank, wherein a water pump is fixedly connected at the top on one side of an inner wall of the sedimentation tank, a screening tank is fixedly connected at one side of the sedimentation tank, two sides of the top of an inner wall of the screening tank are fixedly connected with an L-shaped plate respectively, the top of the L-shaped plate is movably connected with a toothed disk, and a movable rod penetrates through a middle part of the toothed disk. The invention relates to the technical field of wastewater treatment. For the wastewater treatment device used in ceramic diaphragm production, by providing the sedimentation tank and fixedly connecting the water pump at the top on one side of the inner wall of the sedimentation tank, different from a single way, the diversified ways for treatment can greatly enhance the treatment effect. A clamping groove is formed in a surface of the movable rod, and two sides inside the clamping groove are movably connected with a first screening plate and a second screening plate respectively, so that the use of the device cannot be affected, the normal use of the device can be ensured to a large extent, and the service life is prolonged.

Owner:张建宏

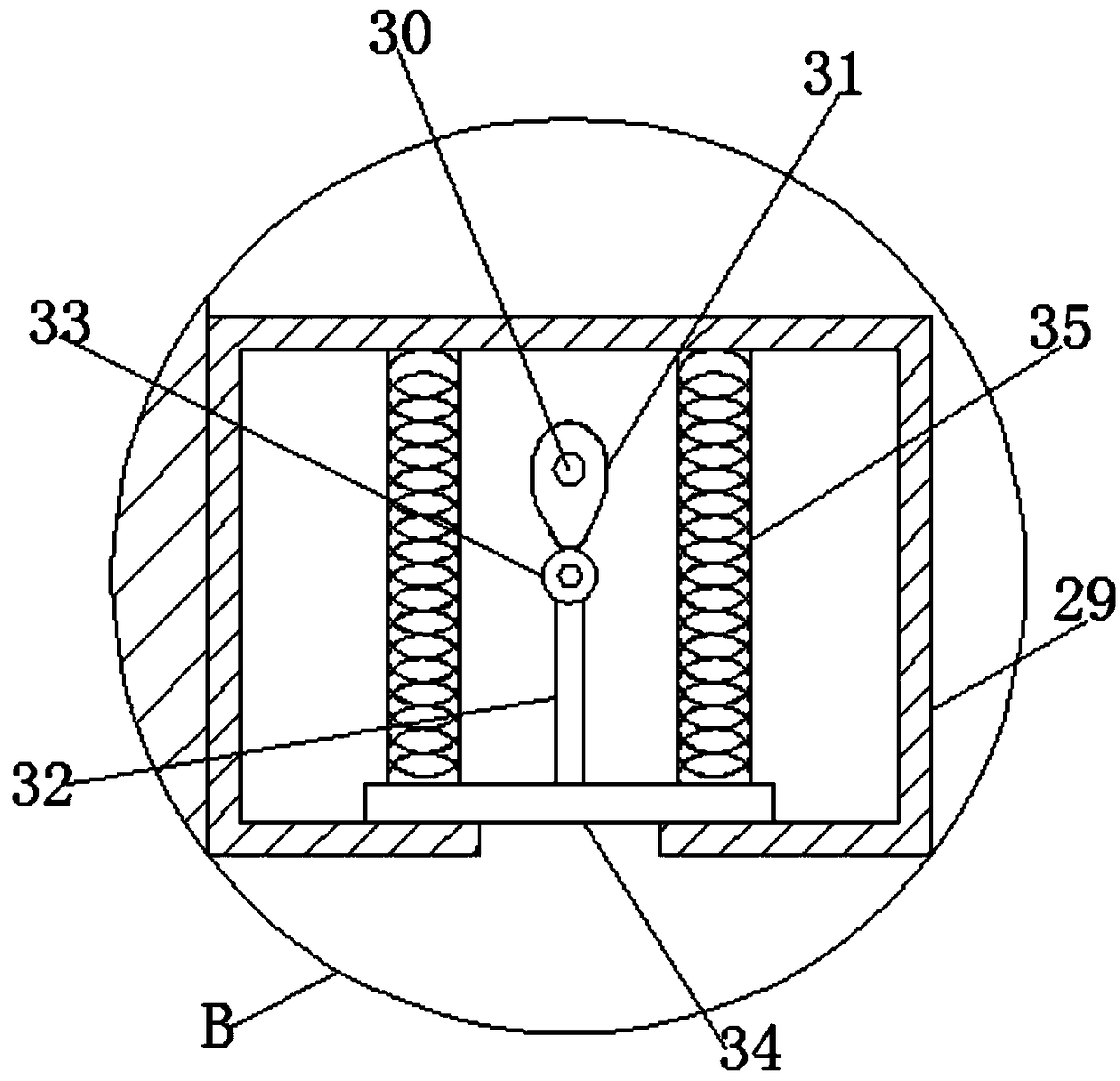

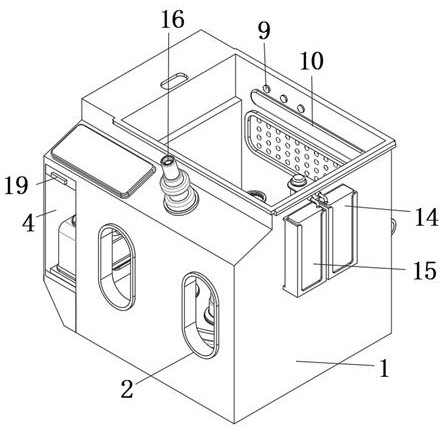

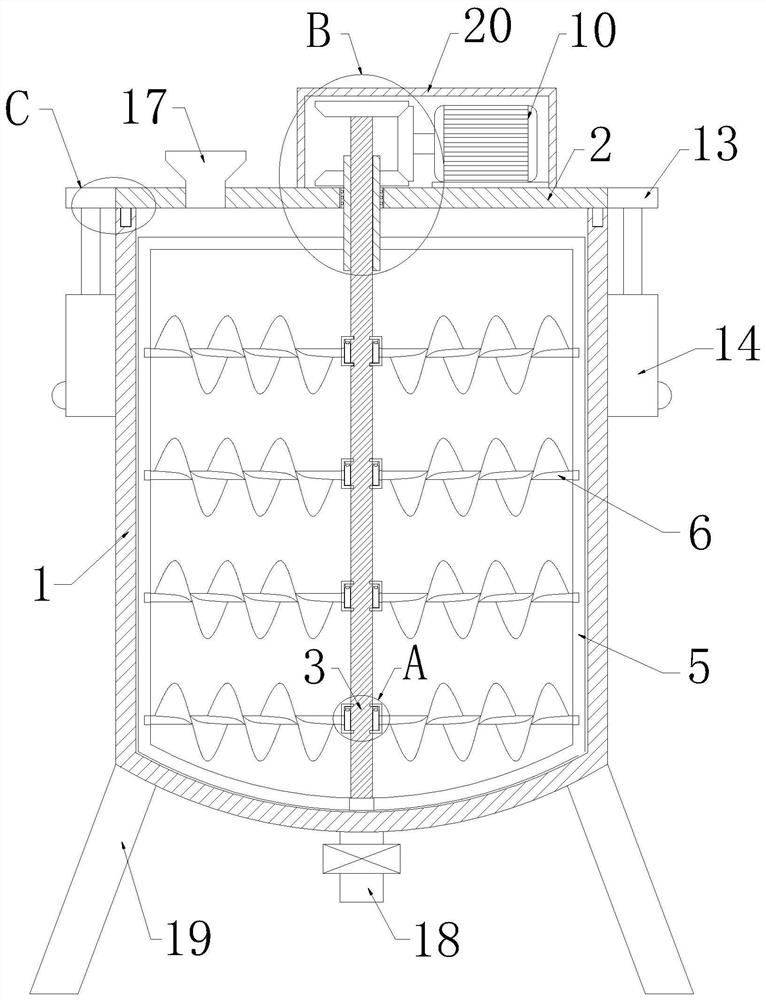

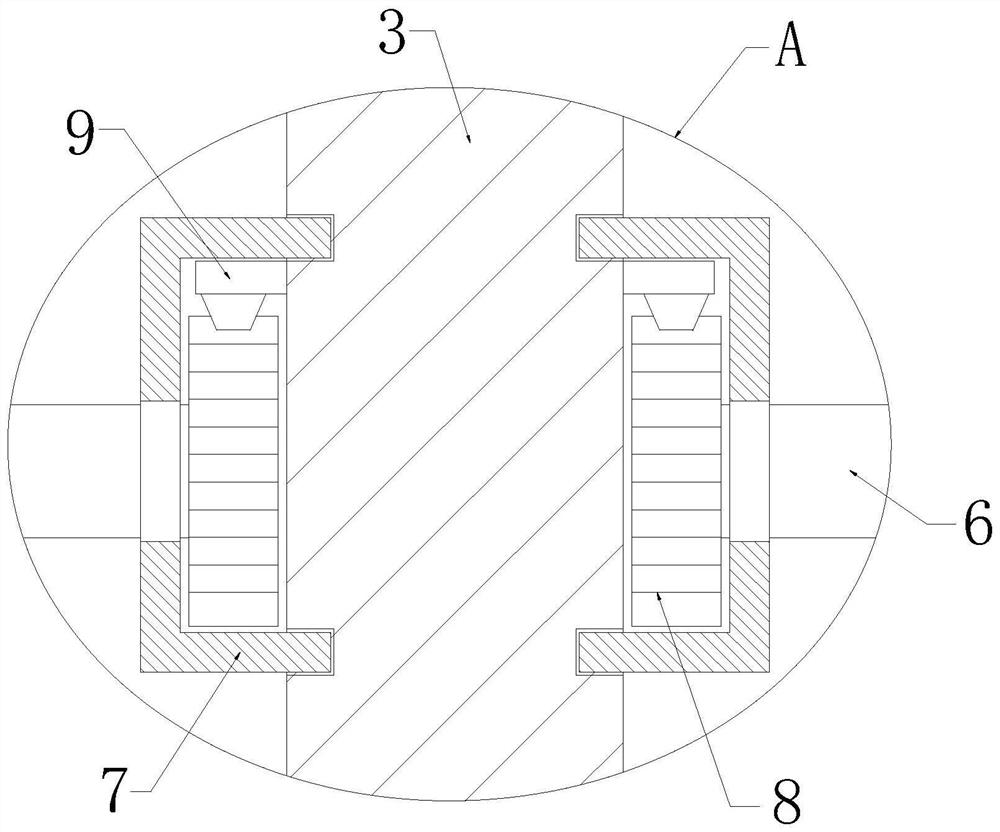

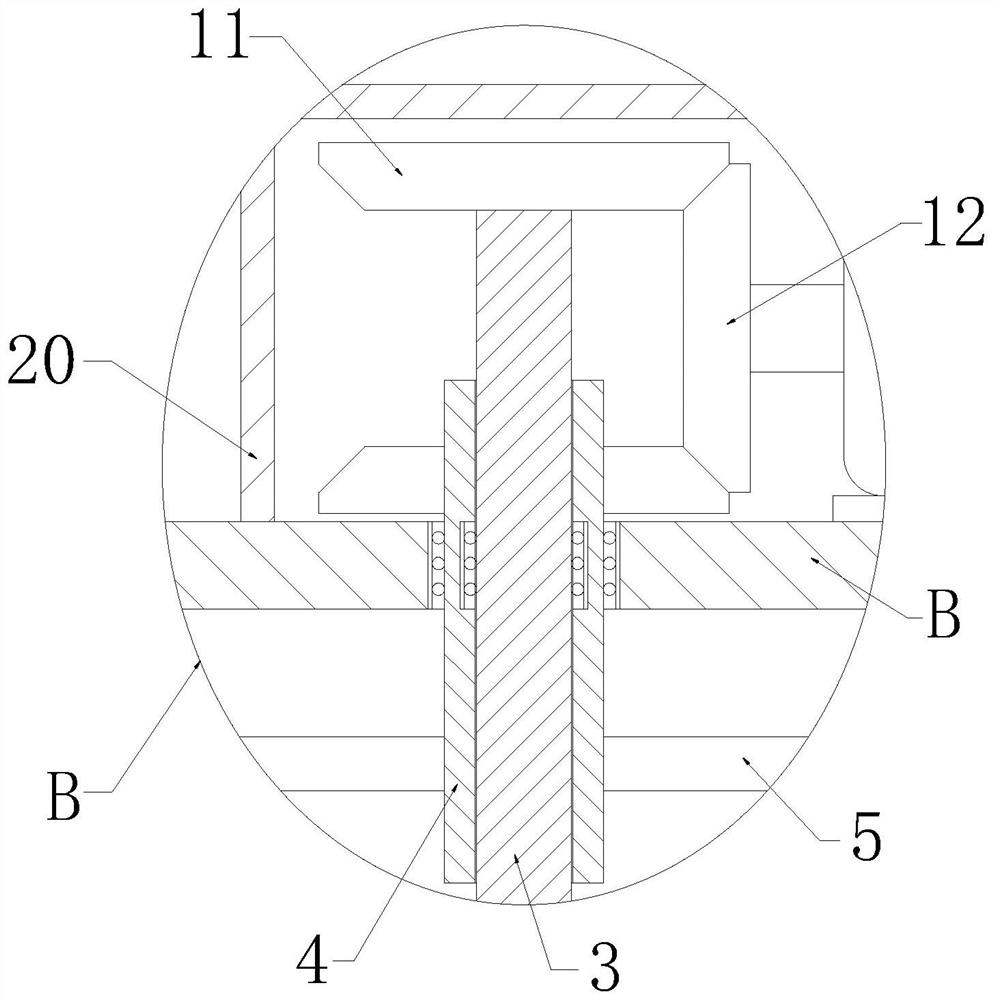

Plastic production stirring and mixing device with smashing function

The invention provides a plastic production stirring and mixing device with a smashing function, and belongs to the technical field of chemical engineering. The device comprises supporting legs, and astirring and mixing chamber is arranged on the tops of the supporting legs; the supporting legs are welded to the bottom of the stirring and mixing chamber; a stirring device is arranged in the stirring and mixing chamber; a material discharging pipe is arranged on the left side of the stirring and mixing chamber; the material discharging pipe is welded to the left side of the stirring and mixingchamber; a filter plate is arranged on the top of the stirring and mixing chamber; a smashing cavity is formed in the top of the filter plate; the smashing cavity is internally provided with a smashing block, a vertical connection rod, a transverse supporting rod, reset devices and a baffle. The device is simple in structure and reasonable in design; due to the arrangement of a material inlet box, materials are easily gathered and input into the smashing cavity; under the action of a smashing block, the materials are smashed, the smashed materials are uniformly input into the stirring and mixing chamber through the filter plate and then stirred and mixed, and the material stirring and mixing speed is greatly increased.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

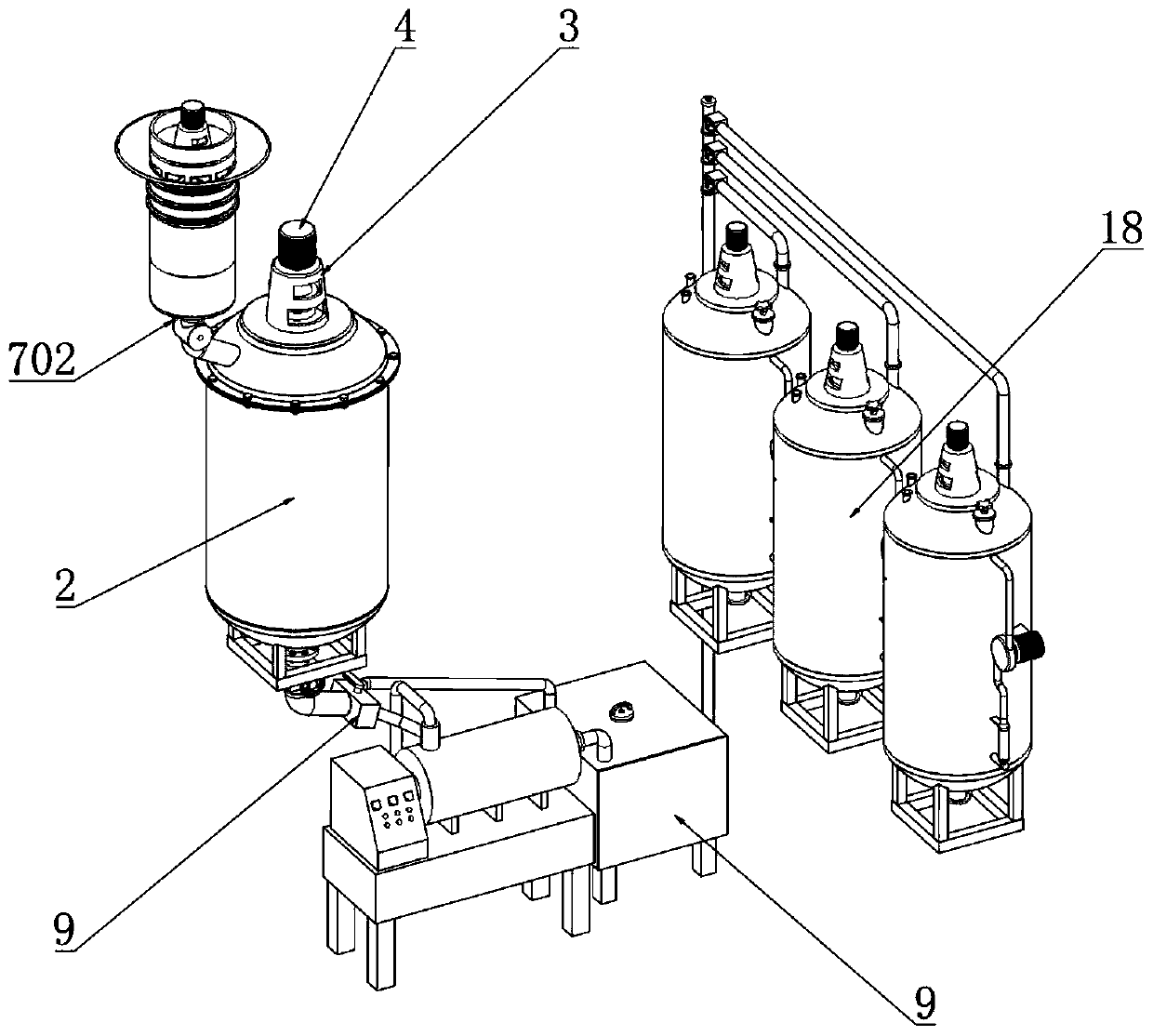

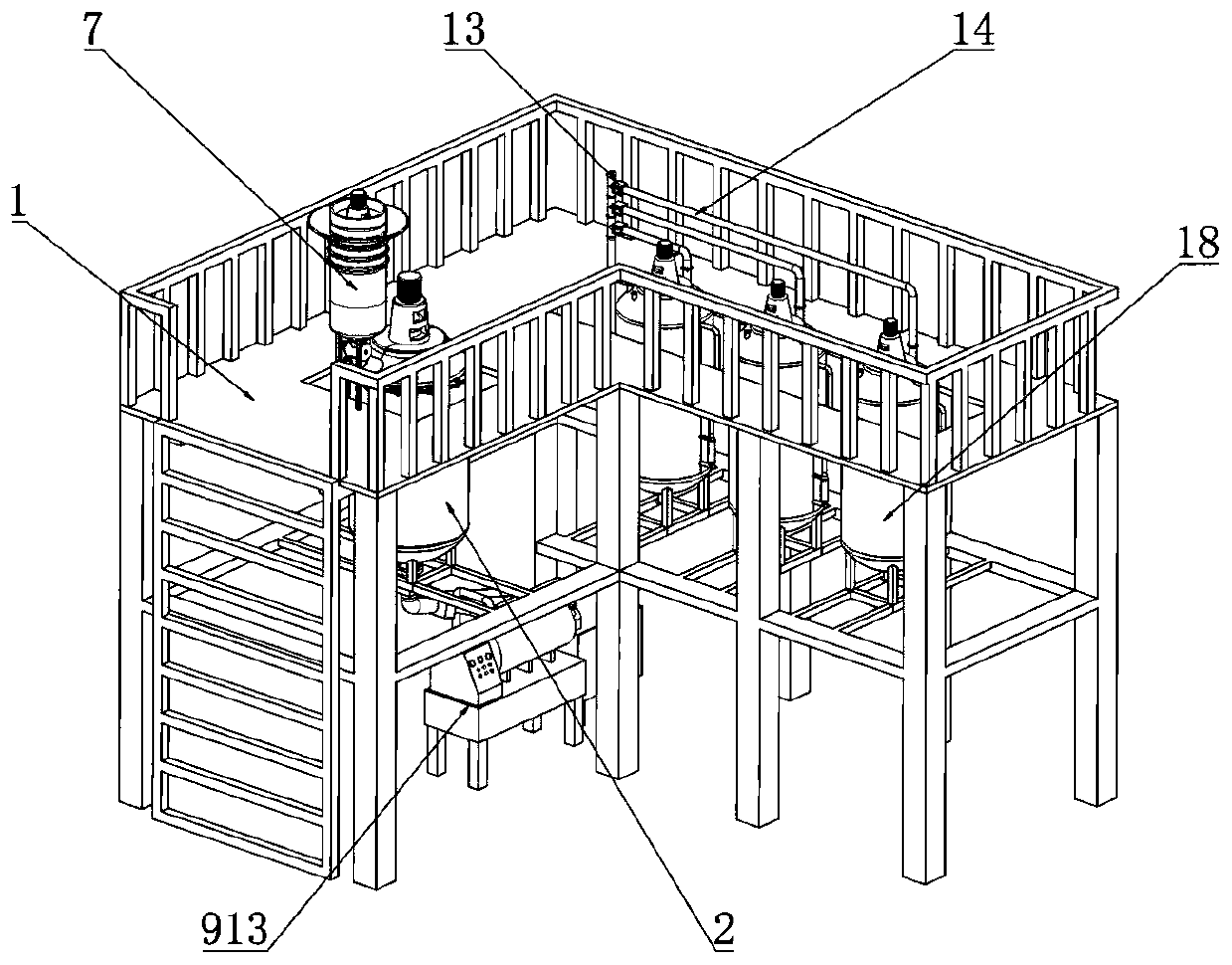

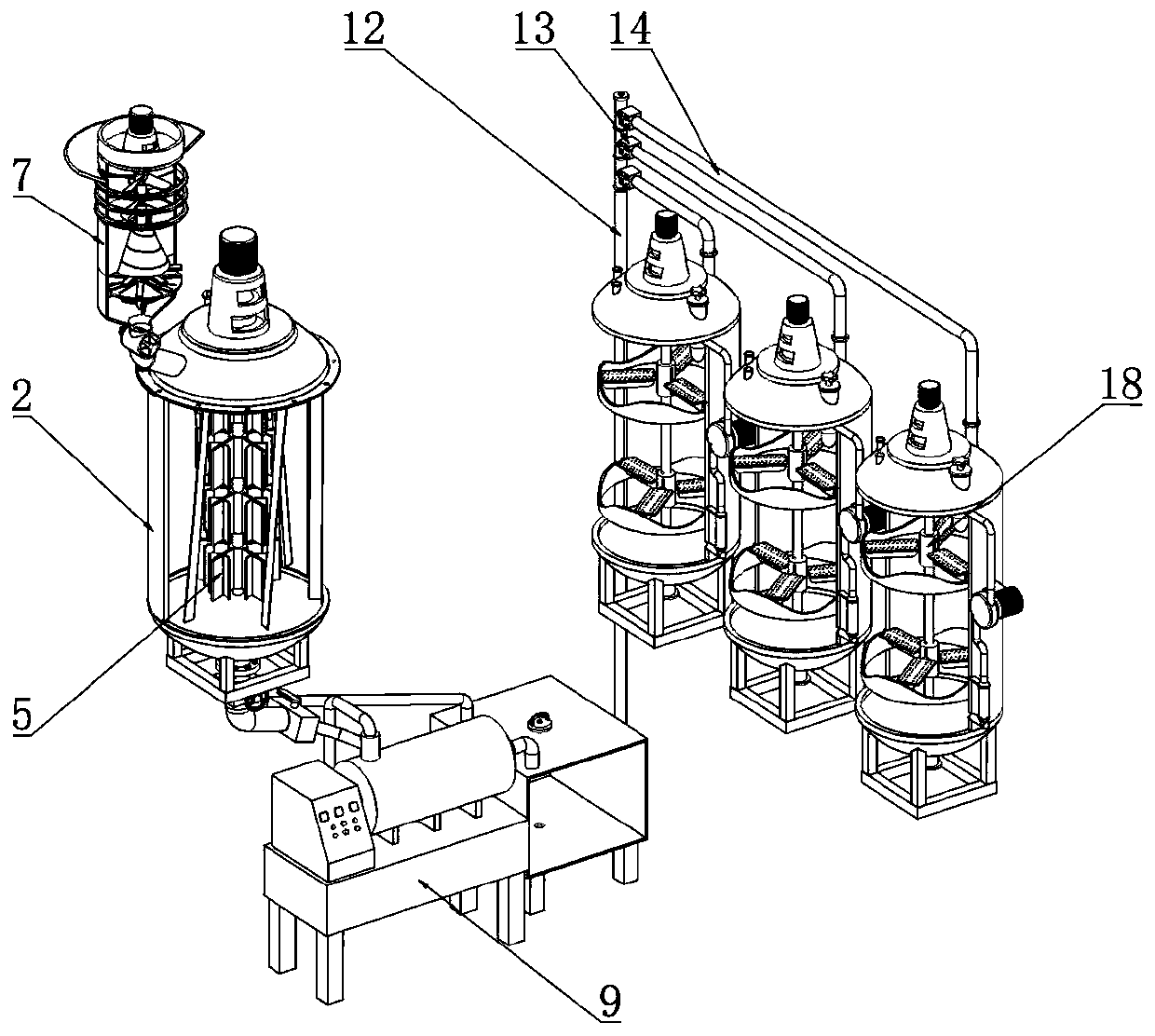

High-viscosity environment-friendly anticorrosive paint production line

PendingCN111773969AAvoid stickingImprove uniformityRotary stirring mixersTransportation and packagingManufacturing lineIndustrial engineering

The invention relates to the technical field of paint production, and discloses a high-viscosity environment-friendly anticorrosive paint production line. The production line includes a batching tank,the top of the batching tank is opened, a cover plate is arranged above the batching tank, the cover plate is connected with the batching tank through a connecting mechanism, a rotating shaft is arranged in the batching tank, a movable first bearing of the rotating shaft is rotationally connected with a sleeve, one end of the sleeve penetrates through the side wall of the cover plate and extendsoutwards, the sleeve is rotationally connected with the cover plate through a second bearing, a driving mechanism matched with the sleeve and the rotating shaft is arranged at the top of the cover plate, and two U-shaped scraping plates are symmetrically arranged in the batching tank and fixedly connected with the sleeve in a sleeving mode. The mixing speed and the mixing uniformity in the batching tank can be improved, and the paint can be prevented from being bonded on the inner wall of the batching tank, so that the use by people is facilitated.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

Accurate fertilizing device for soilless culture

InactiveCN107455062AOptimal Growth Nutrient RequirementsEasy to take out for cleaningPressurised distribution of liquid fertiliserAgriculture gas emission reductionHigh concentrationWater storage tank

The invention discloses an accurate fertilizing device for soilless culture. The device comprises a fertilizer storage drum and a water storage tank, wherein the fertilizer storage drum is used for storing high-concentration fertilizer stock solution; the water storage tank is used for storing clean water; a discharging port is embedded on the right side of the bottom of the fertilizer storage drum; a filtering mesh screen is embedded in the discharging port; a fertilizing tank is connected with the tail end of the discharging port through a rubber pipe; a water suction pump is fixed at the top on the left side of the water storage tank; a water outlet of the water suction pump is connected with a water inlet of the fertilizing tank through a rubber water pipe; a protecting cover is covered on the top of the fertilizing tank; circular guide pipes served as the water inlet and a fertilizer inlet are respectively embedded on left and right sides of the upper surface of the protecting cover; a stirrer is penetrated through the middle of the protecting cover; a pump flow rating pipe is arranged at the bottom on the front side of the fertilizing tank; a head valve is arranged at the water outlet of the pump flow rating pipe; a fertilizing pump is arranged at an output port of the head valve; an injection nozzle is connected with the output port of the fertilizing pump. The accurate fertilizing device for soilless culture is capable of realizing the quantitative accurate fertilizing operation and increasing the fertilizing uniformity and is simple and convenient in operation.

Owner:莘县谷升农业科技有限公司

Graphene production raw material mixing device

InactiveCN108671792AEven flow distributionImprove uniformityTransportation and packagingRotary stirring mixersEngineeringGraphene

The invention discloses a graphene production raw material mixing device comprising a mixing chamber, the upper end of the mixing chamber is provided with a cover plate, the upper wall of the cover plate is provided with a threaded hole, the side wall of the threaded hole is screwed with a liquid inlet tube, one end of the liquid inlet tube extends to the inside of the mixing chamber, a through hole is formed in the sidewall of the bottom end of the liquid inlet tube, the side wall of the through hole is fixedly provided with a liquid outlet passage through a screw, the side wall of the liquidoutlet passage is connected to a connecting frame through a stud, the side wall of the connecting frame is slidably connected with a guide rail, the side wall is fixed on the side wall of the mixingchamber by a rivet, and the side wall of the guiding rail is slidably connected with a filter net. A raw material can be continuously screened into the mixing chamber through a movable screen, the uniformity of the raw material injected into the mixing chamber is improved, the clogging during the raw material injection process is avoided, the mixing uniformity is improved during the mixing of thegraphene raw material, the mixing rate of the raw material is increased, and the raw material mixing efficiency is also improved..

Owner:江苏匠心信息科技有限公司

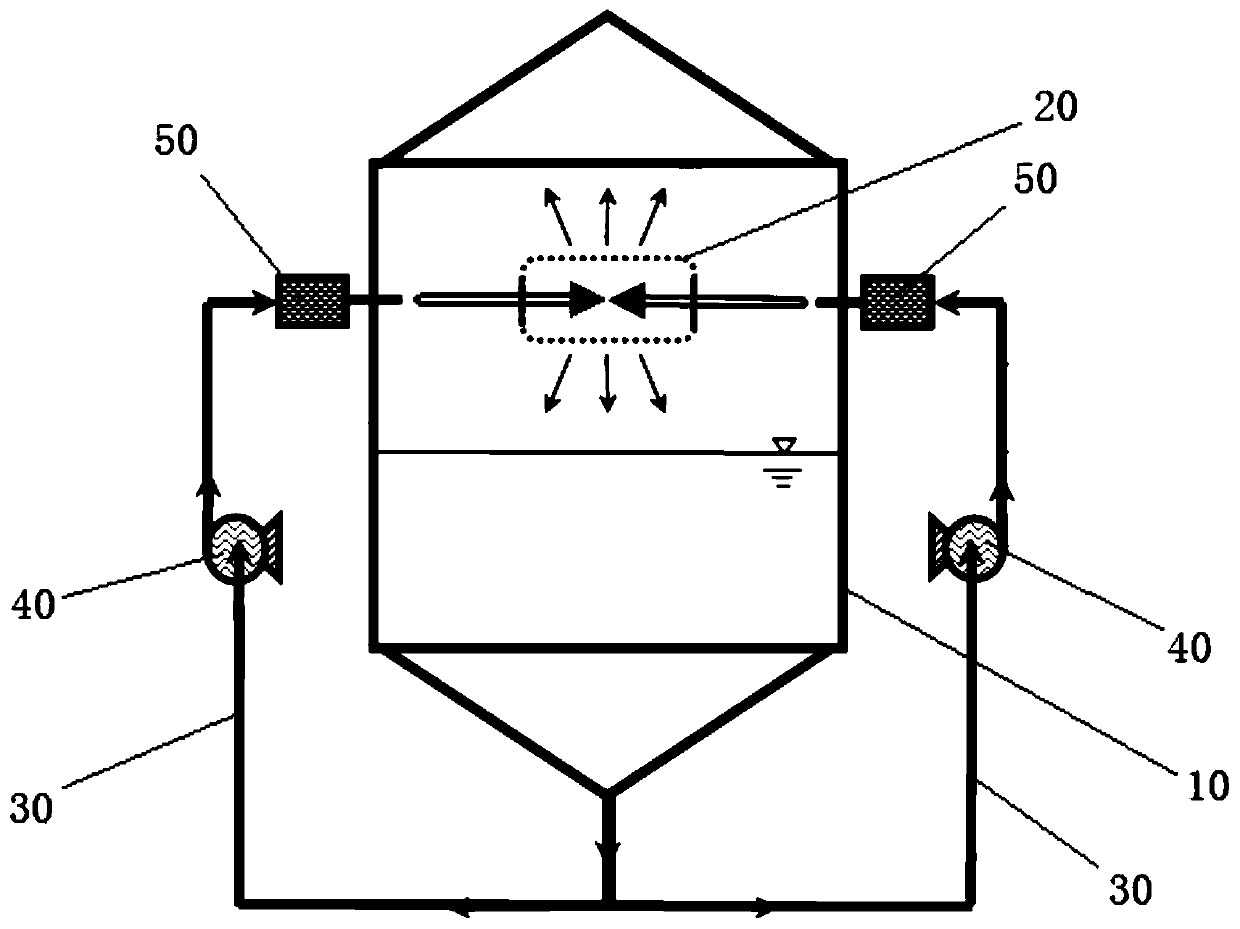

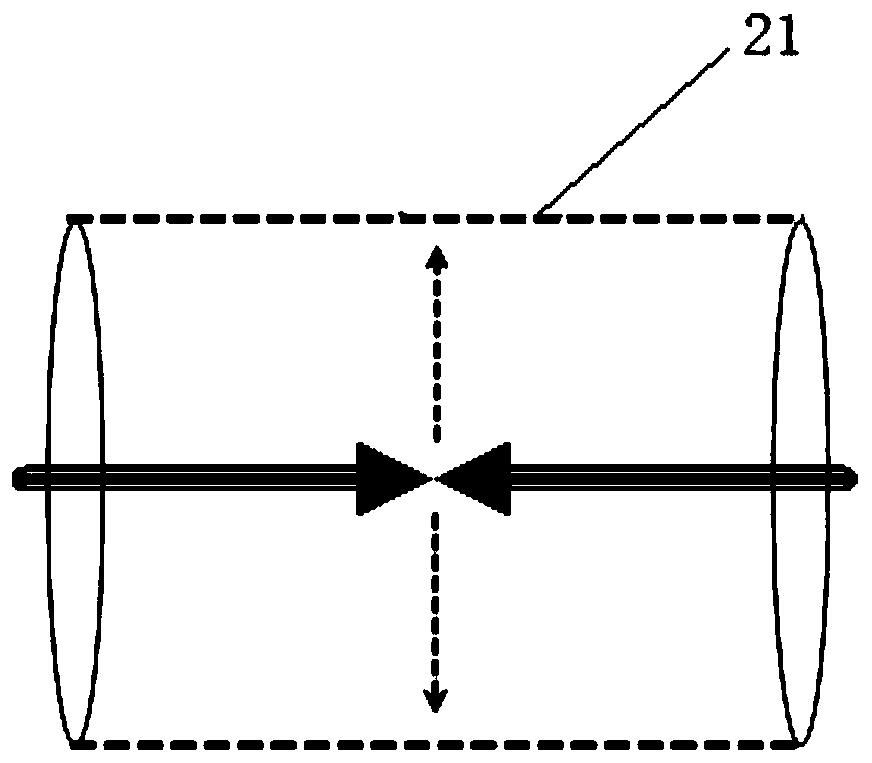

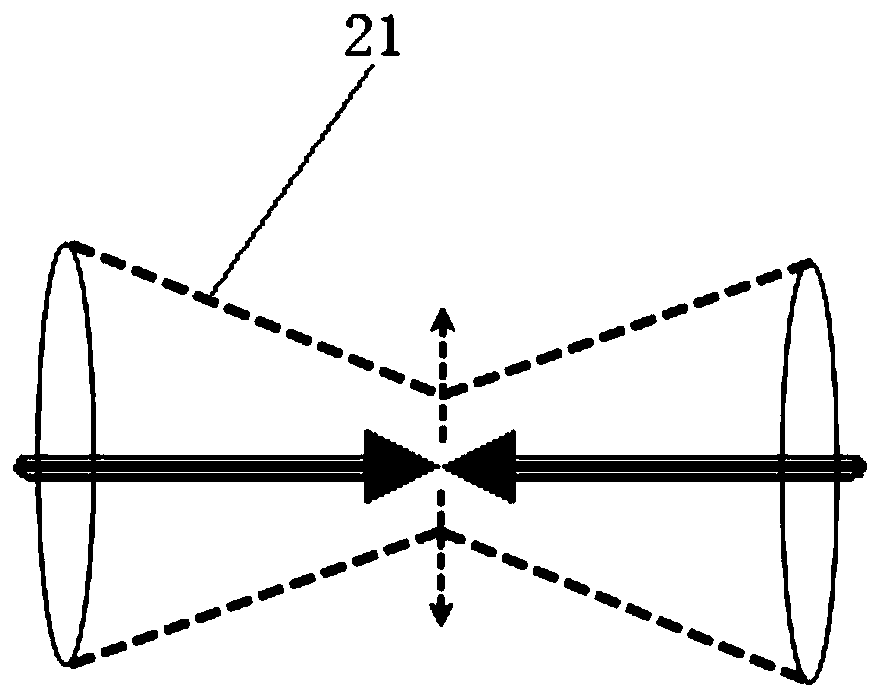

Liquid non-submerged impinging stream reaction device and reaction method

ActiveCN110152588AIncrease the rate of chemical reactionsImprove heat transfer performanceHydrocarbon oil crackingChemical/physical/physico-chemical nozzle-type rreactorsChemical reactionCavitation

The invention provides a liquid non-submerged impinging stream reaction device and reaction method. The device comprises a reaction shell and a non-submerged impinging stream reaction component, the reaction shell has a cavity, and the non-submerged impinging stream reaction component is arranged in the cavity for completing a reaction of a jet fluid of a liquid raw material under the action of non-submerged impinging, cavitation and shearing. The device and method provided by the invention utilize the non-submerged impinging stream reaction component to complete the chemical reaction of the liquid raw material in the non-submerged impinging, cavitation and shearing process, so that the reinforcing effect on the liquid raw material fluid can be significantly improved, and the fluid can react efficiently under milder reaction conditions.

Owner:捷创(东营)能源技术有限责任公司 +1

Micro stirrer driven by a multi-core fiber

InactiveCN102156326AHigh torqueEasy to modifyCladded optical fibreRadiation/particle handlingHigh densityLow density

The invention provides a micro stirrer driven by a multi-core fiber, comprising a pyramidal multi-core fiber made of a section of multi-core fibers via fused biconical taper and small particles made from composite materials, wherein the small particles are located at the pyramidal end of the pyramidal multi-core fiber; the non-pyramidal end of the pyramidal multi-core fiber is connected with a light source; a plurality of fiber core emergent lights of the pyramidal multi-core fiber simultaneously act on the small particles in a vertical suspension liquid; the upper body of each small particle is a sphere and a rotating shaft which are made from materials with lower density; and the bottom of the each small particle is of a windmill-shaped structure with a plurality of wings made from materials with higher density. The micro stirrer provided by the invention has the characteristics of small volume, light weight, simple structure, low price, easiness in operation, high mixing efficiency, benefit of the reduction of reagents, and the like and can be widely applied to the fields of biology and chemistry.

Owner:HARBIN ENG UNIV

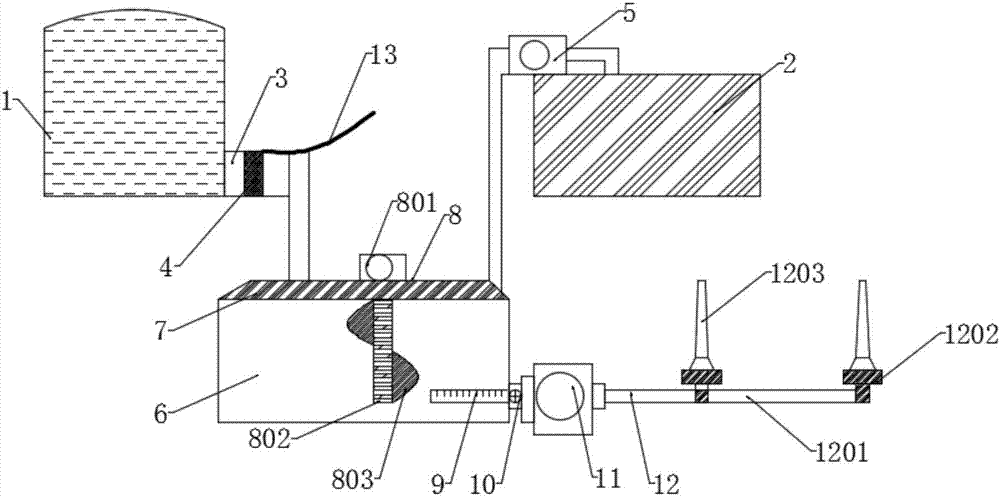

Fermented feed humidifying device convenient for discharging

The invention discloses a fermented feed humidifying device convenient for discharging, and belongs to the field of feed processing equipment. The fermented feed humidifying device comprises a shell body and shock-absorbing bases, wherein the shell body is arranged as a hollow cylinder; an upper end cover is arranged at the position of an opening in the top of the shell body; the upper end cover is fixedly connected with the shell body through the mutual screwing of bolts and nuts; a feed hopper and a driving and spraying device are arranged on the upper end cover; the feed hopper is arrangedon the left side of the upper end of the upper end cover; a humidifying chamber and a discharging chamber are arranged in the shell body; the humidifying chamber is located above the discharging chamber; a discharging rotation shaft is horizontally arranged in the discharging chamber; helical blades are arranged on the discharging rotation shaft; a discharging pipe is arranged on the right side ofthe shell body; and the discharging pipe communicates with the right side of the discharging chamber. The fermented feed humidifying device disclosed by the invention is reasonable in structure design; through the arrangement of the driving and spraying device and the stirring device, the humidifying effect of fermented feeds is more uniform and the production quality of the fermented feeds is improved; and through the arrangement of the discharging device, the fermented feeds can be automatically discharged, and time and labor are saved.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Preparation method of anti-wrinkle anti-aging cream

PendingCN112089657AImprove wrinkle and anti-aging abilityImprove marketing influenceCosmetic preparationsToilet preparationsGlycerolOil phase

The invention provides a preparation method of anti-wrinkle anti-aging cream. The anti-wrinkle anti-aging cream is prepared from the following raw materials, water, glycerin, butanediol, caprylic / capric triglyceride, cyclopentasiloxane, butyrospermum parkii butter, isopropyl myristate, hydrogenated polyisobutene, erythritol, palmitoyl tetrapeptide-7, acetyl hexapeptide-8, palmitoyl tripeptide-8, tripeptide-1, palmitoyl tripeptide-5, cetostearyl alcohol, cetostearyl glucoside and glyceryl stearate. By combining preparation of oil-phase component solution, preparation of water-phase component solution, homogeneous fusion of mixed solutions, sterilization and homogenization and stirring of finished product, the nutrition matrix of the anti-wrinkle anti-aging cream contains a large number of anti-wrinkle anti-aging nutritional factor components for effectively promoting the rejuvenation and growth of tender facial skin. The anti-wrinkle anti-aging cream can be used for fully removing authentic wrinkles and resisting aging for the face, and can also be used for obviously removing false wrinkles, so that the anti-wrinkle and anti-aging capabilities of the anti-wrinkle anti-aging cream are greatly improved.

Owner:文艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com