Gas-cooled methanol reactor

A reactor, methanol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high catalyst cost, high manufacturing cost, inability to reach production capacity, etc., and achieve high methanol yield , less consumables, uniform in and out of the air box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

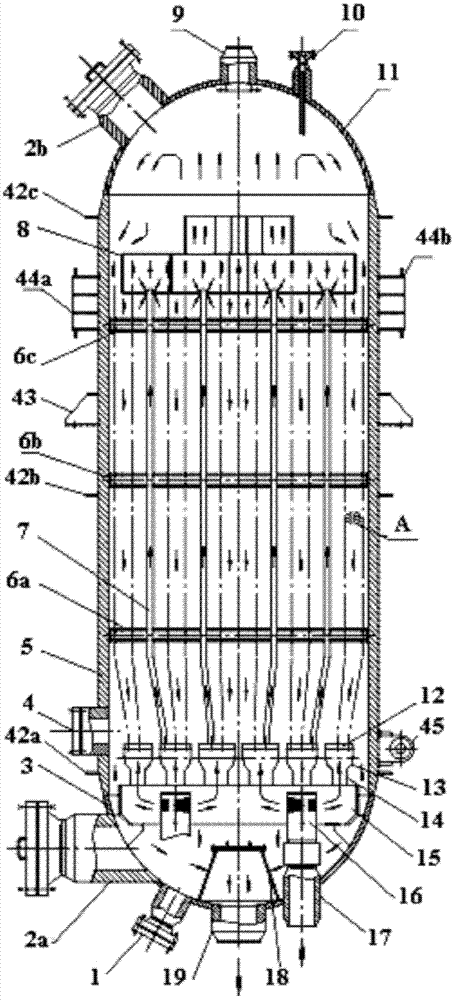

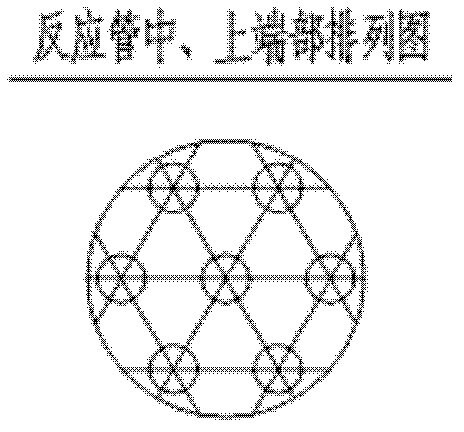

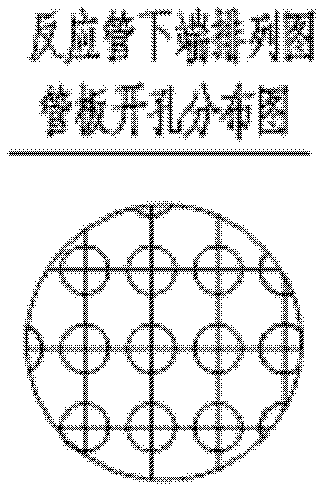

[0035] like figure 1 As shown, a kind of air-cooled methanol reactor provided by the present invention comprises a catalyst discharge port 1, a lower manhole 2a, an upper manhole 2b, a lower head 3, a hand hole 4, a cylinder body 5, a pipe support 6, a reaction Tube 7, reaction tube block 7a, mixed gas box 8, start-up gas inlet 9, temperature measuring port 10, upper head 11, tube plate 12, U-shaped cylinder 13, branch pipe 14, collecting pipe 15, distribution pipe 16, Connecting pipe 17, outlet collector 18, generated gas outlet 19, insulation ring 42, rigid ring support 43, shaft lifting lug 44, and tail lifting lug 45.

[0036] like figure 1As shown, the top of the cylindrical cylinder 5 is welded with the upper head 11 , the bottom of the cylindrical cylinder 5 is welded with the lower head 3 , and the cylindrical cylinder 5 , the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com