Patents

Literature

91results about How to "Increased loading space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

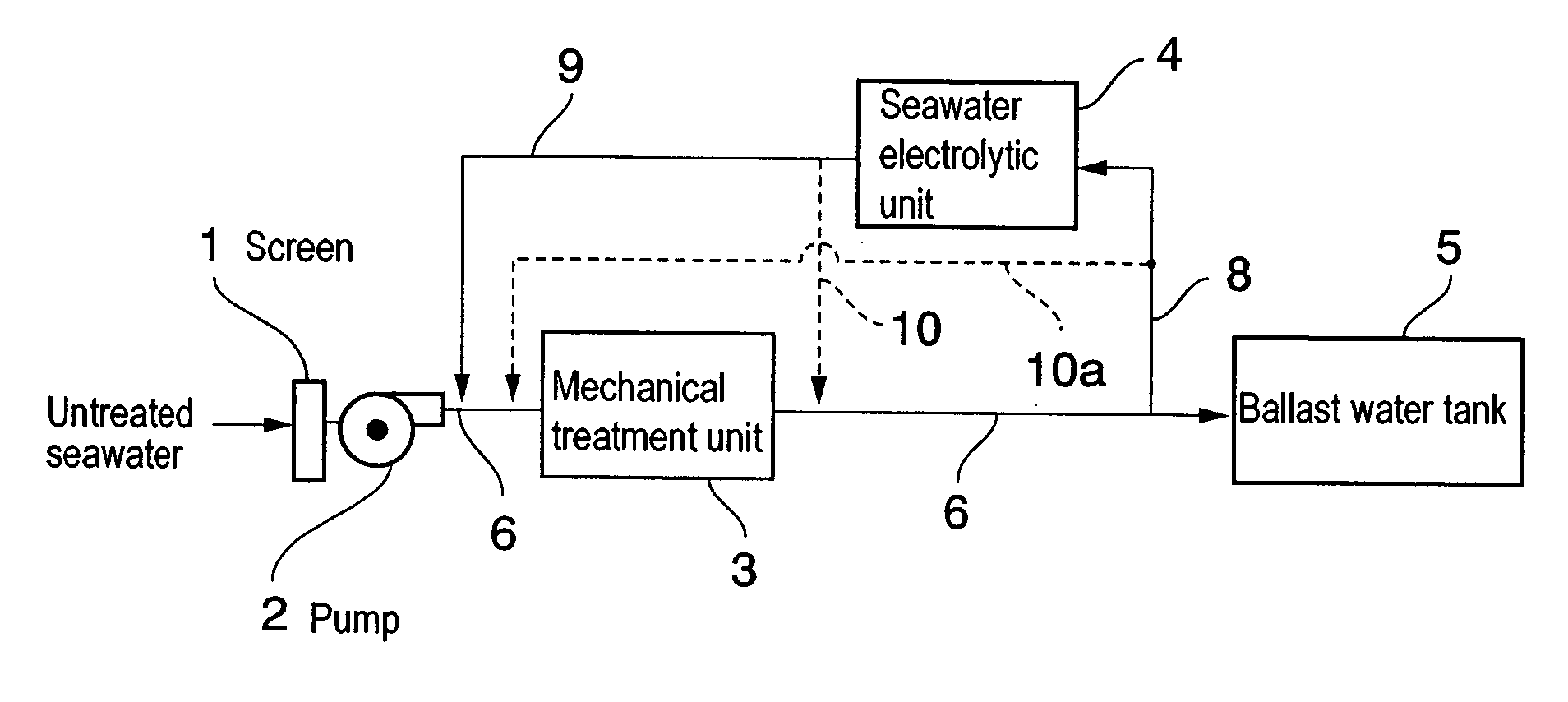

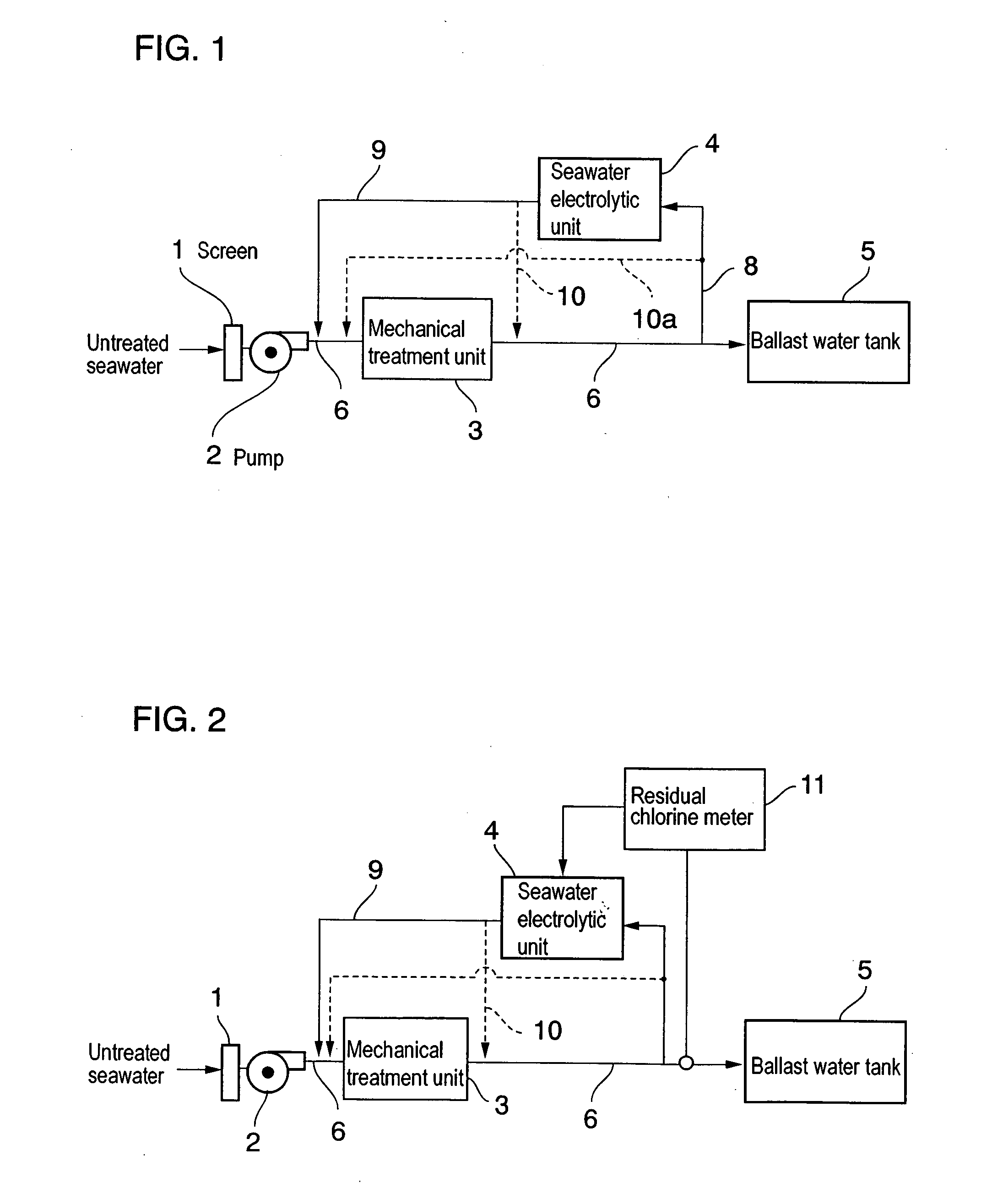

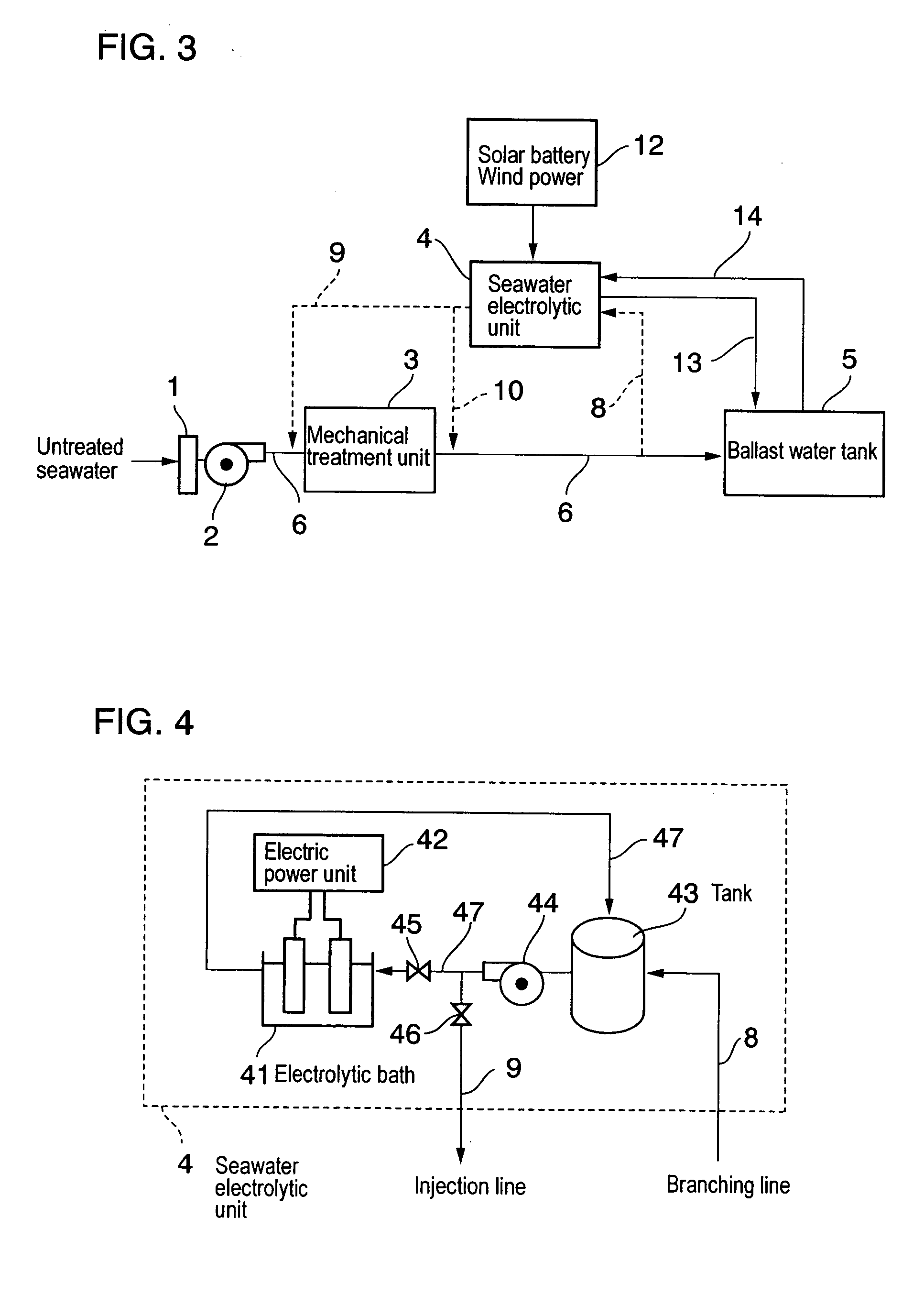

Method of Liquid Detoxification and Apparatus Therefor

InactiveUS20080164217A1Low power operationLength minimizationAuxillariesEnergy based wastewater treatmentOperational costsExtinction

Conversion of an untreated liquid to a clean harmless treated liquid through microbe removal, characterized in that a mechanical treatment for damaging microbes present in a liquid to thereby effect extinction thereof and sterilization, combined with a chlorination in which a chlorine-containing substance is formed from a liquid and injected into a liquid to thereby effect microbe extinction and sterilization, is applied to a liquid. There is further provided an electrolytic circulation system comprising applying a detoxification treatment for extinction of microbes in seawater and sterilization by means of detoxification facilities on land or on the sea to seawater introduced through a seawater introduction channel and accommodating the seawater having been thus treated in a ballast water tank. As a result, facility and operating costs can be reduced. Extinction of microbes of unlimited size and sterilization can be securely achieved without any strength drop on the side of treated liquid accommodation body. Further, the space for installation of detoxification apparatus for ballast water in ships can be reduced to thereby enable increasing of loading space for cargo, etc. Still further, on existing ships, the hull rework cost for installation of detoxification apparatus can be minimized.

Owner:MITSUBISHI HEAVY IND LTD

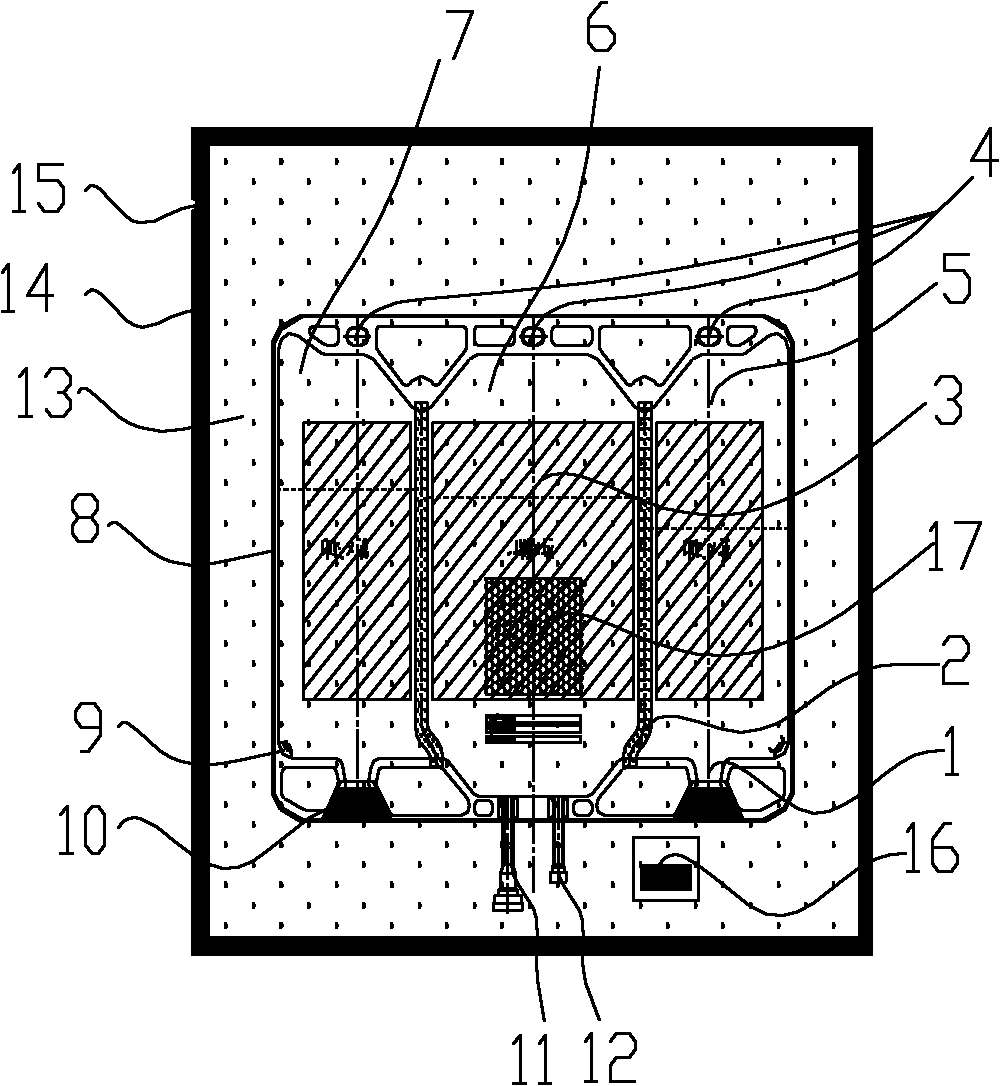

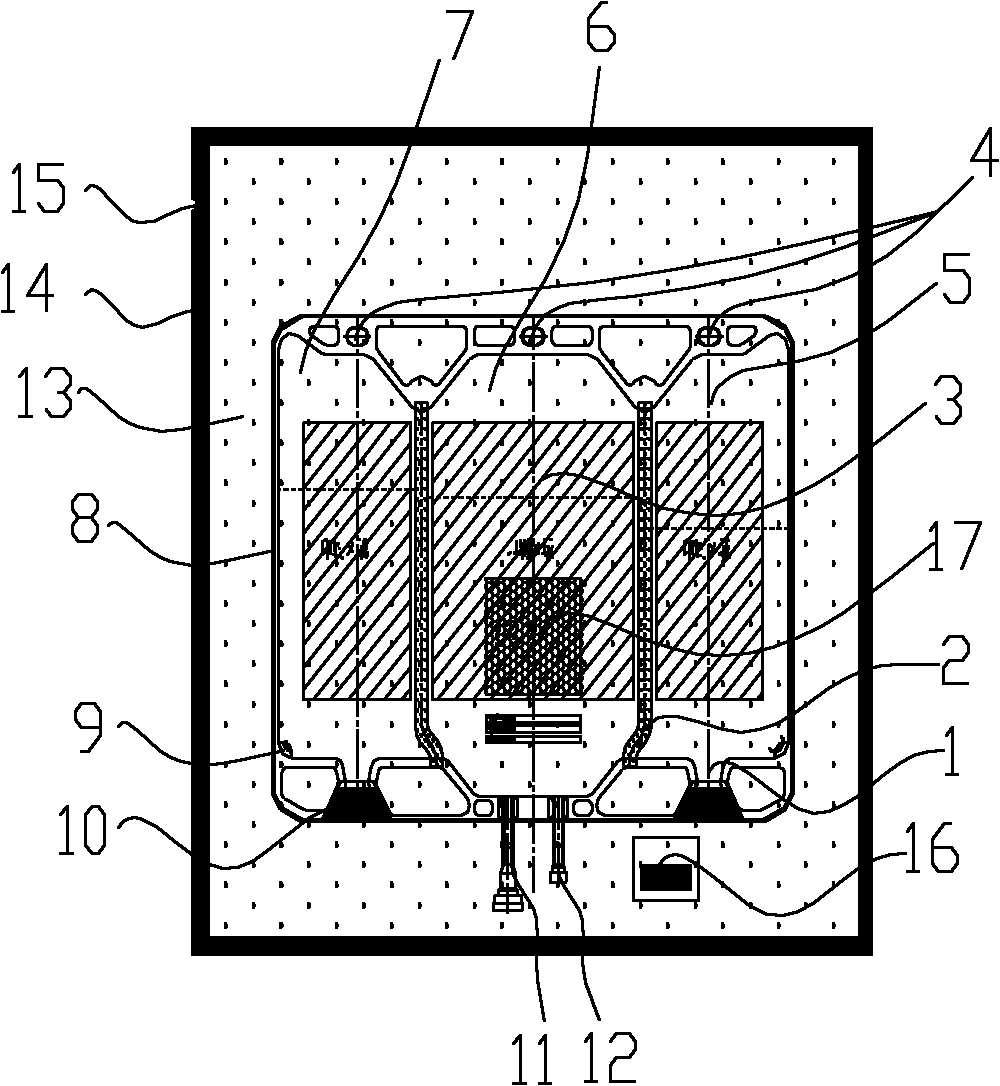

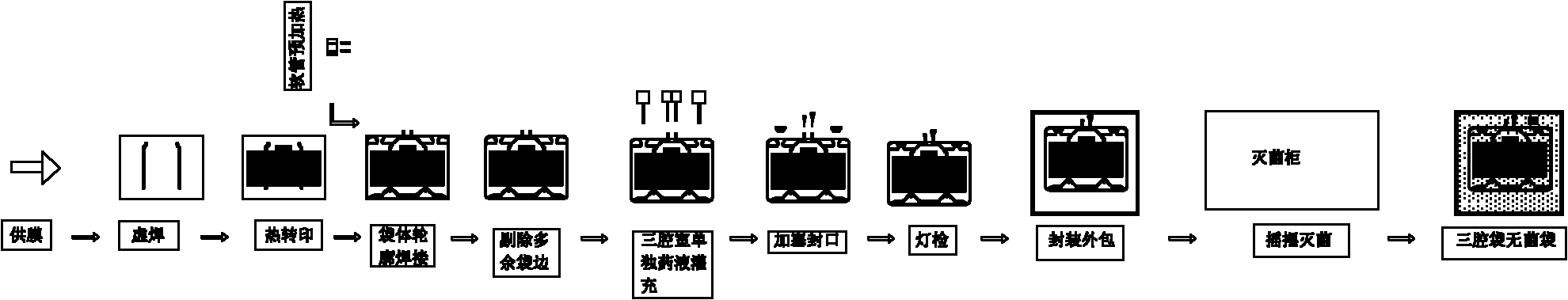

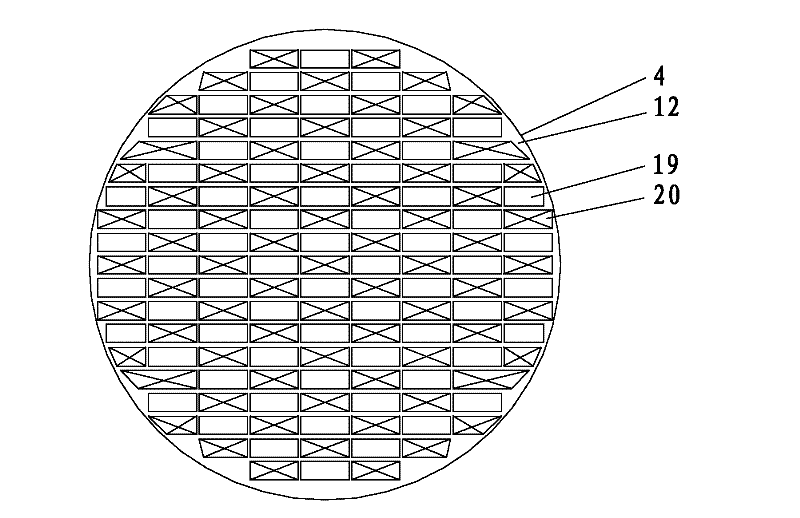

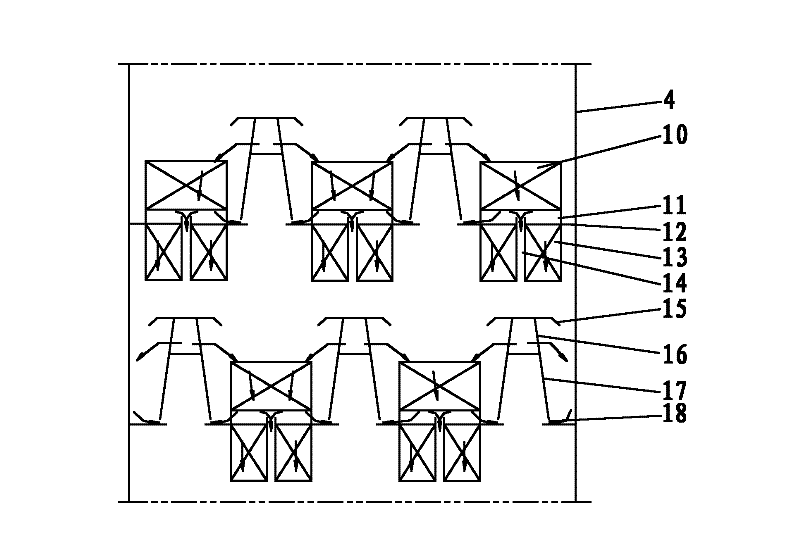

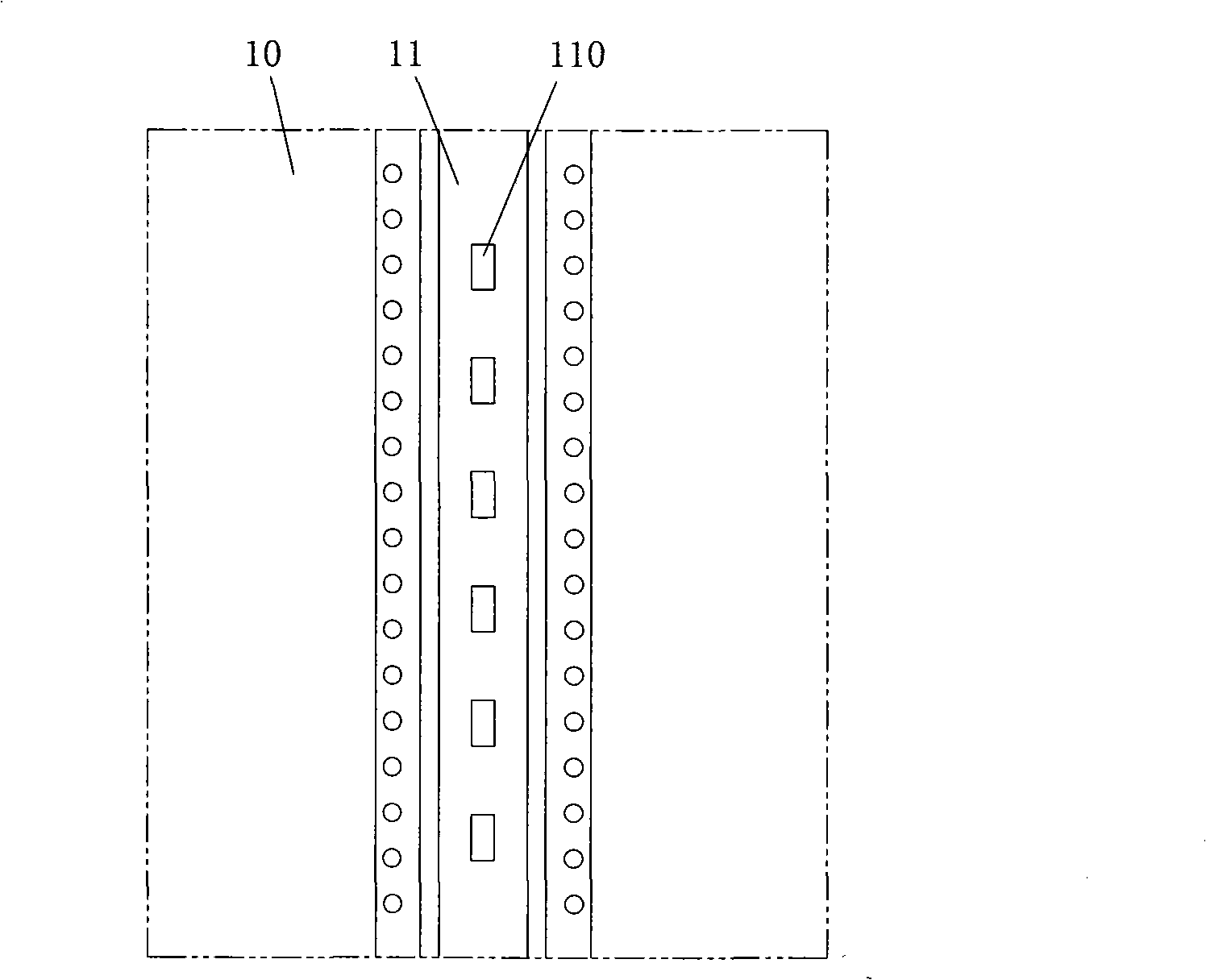

Three-cavity sterile bag and preparation method thereof

ActiveCN102090976AQuality assuranceGuaranteed stabilityPharmaceutical containersMedical packagingSolderingBiomedical engineering

The invention discloses a three-cavity sterile bag and a preparation method thereof. The square sterile bag consists of a double-cavity inner bag and an outer packaging bag, wherein the double-cavity inner bag is formed by welding horn-shaped liquid filling ports, arc-shaped insufficient soldering strips with opening points, thermal transfer with independent cavities, hanging holes, an A liquid medicament cavity, an intermediate liquid medicament cavity, a C liquid medicament cavity, three-cavity bag sides, three-cavity bag corners, straight-strip sealing grids, a medicament delivery plug and a medicament feeding plug into a whole through heat seal; and one side of the outer packaging bag is provided with an outer packaging bag welding edge and an outer packaging bag opening mouth. The preparation method of the sterile bag comprises the steps of bag molding, preparation of filling junctions of the bag, filling, lamp inspection, packaging and sterilization. The three-cavity sterile bag is simple in structure and easy to operate; and for the insufficient soldering of the bag, scientific external force opening points are designed, so that the insufficient soldering of the bag is more operable.

Owner:SICHUAN KELUN PHARMA CO LTD

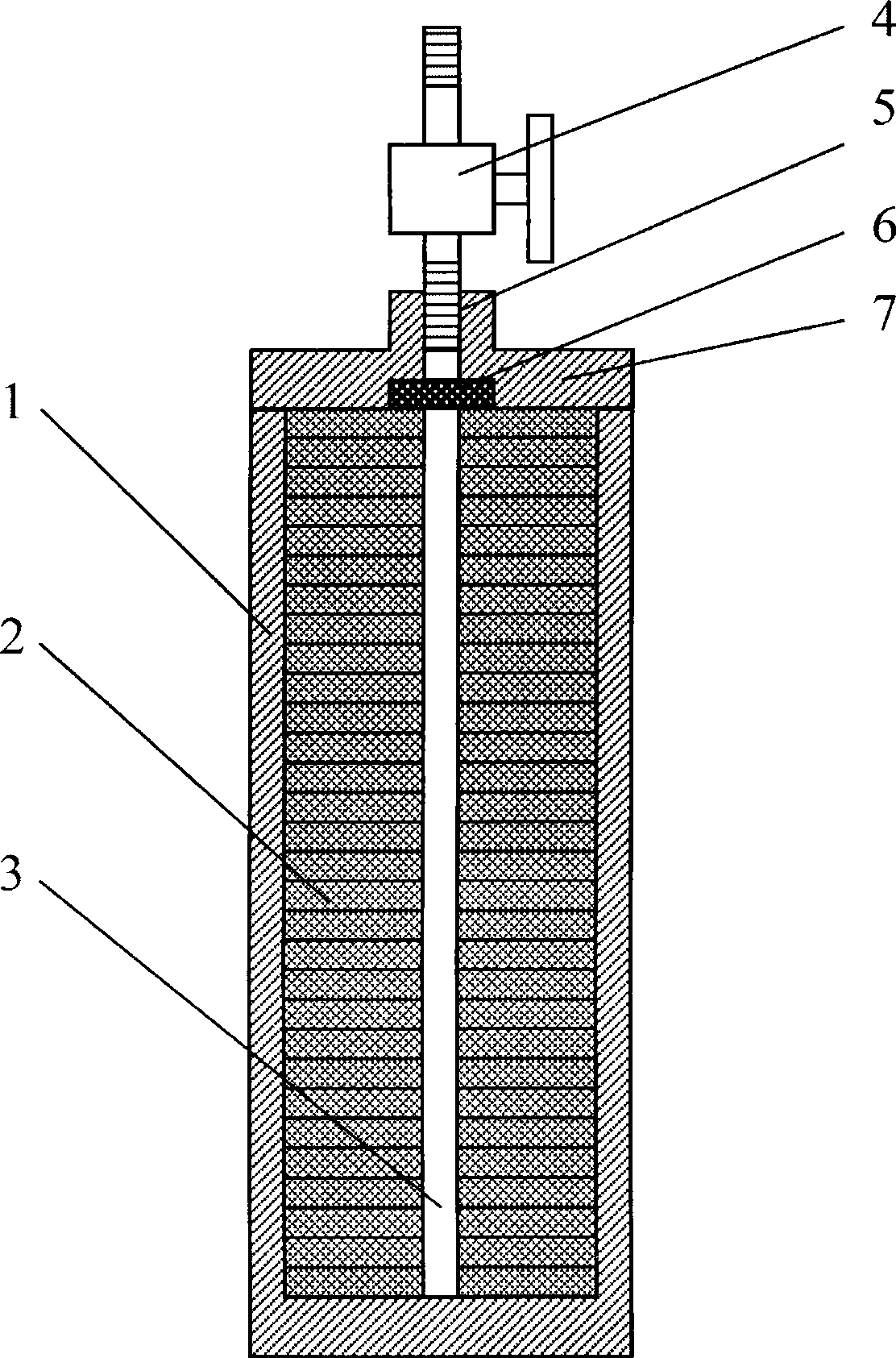

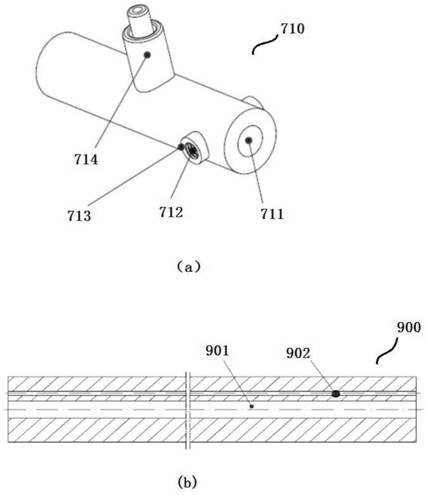

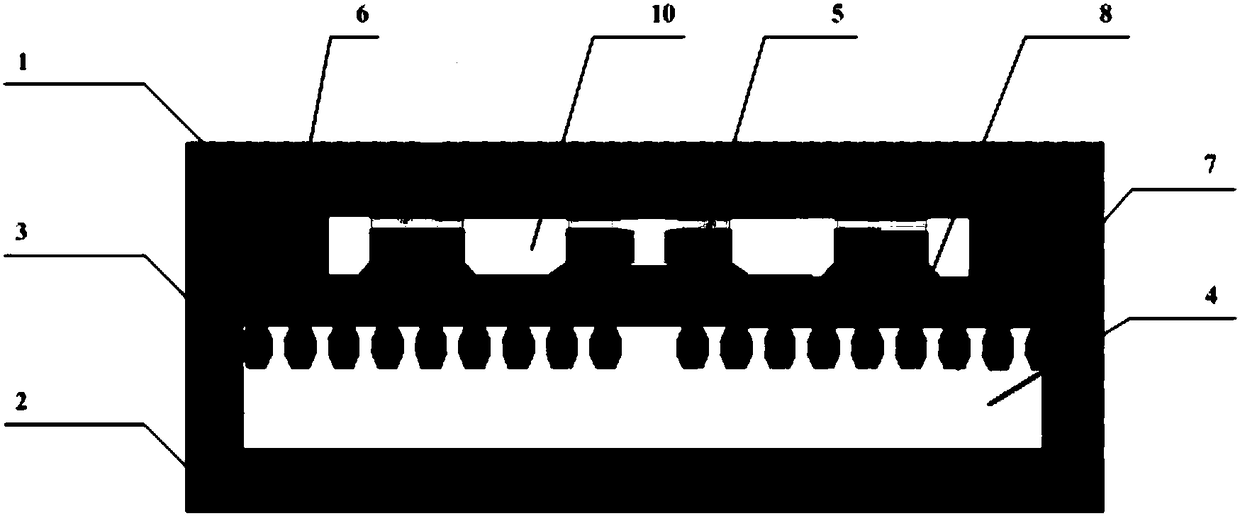

Hydrogen storing apparatus of metal hydrides and manufacturing method thereof

ActiveCN101413624AAvoid deformationAvoid destructionFixed capacity gas holdersHeat transmissionAdhesive

The invention relates to a metal hydride hydrogen storage device and a preparation method thereof; wherein, the device comprises a shell which is filled in superposed hydrogen-storage material sheet which consists of a spumescent metal substrate which absorbs no hydrogen and mixture of hydrogen-storage alloy powder and adhesive which are filled in the gap of the spumescent metal substrate; the hydrogen-storage material sheet is provided with a central hole which is coincident to the central hole of the shell head and is connected with the central hole of the head by a filter sheet which is embedded in the head; the central hole of the head is fixed with a joint pipe which is provided with a valve. The hydrogen storage device can effectively improve the heat transmission performance of the hydrogen storage alloy and hydride powder, effectively prevents the flowing and accumulating of the hydrogen-storage alloy and the hydride, solves the hydrogen absorption expansion problem of the hydrogen storage alloy powder, thus having the advantages of high-efficiency running, safety and reliability and being suitable for the production of meta hydride hydrogen-storage devices applied to various sites.

Owner:ZHEJIANG UNIV

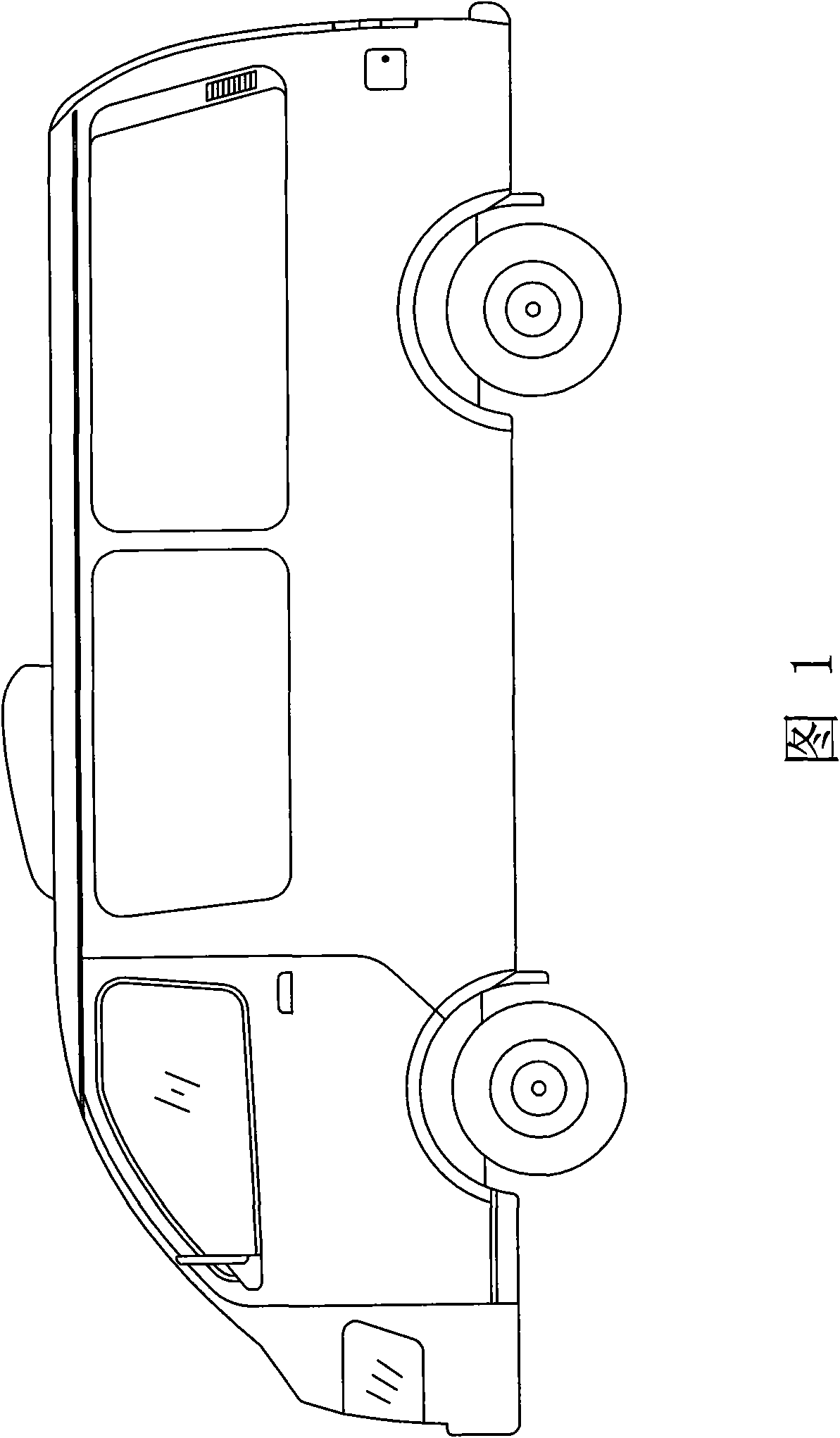

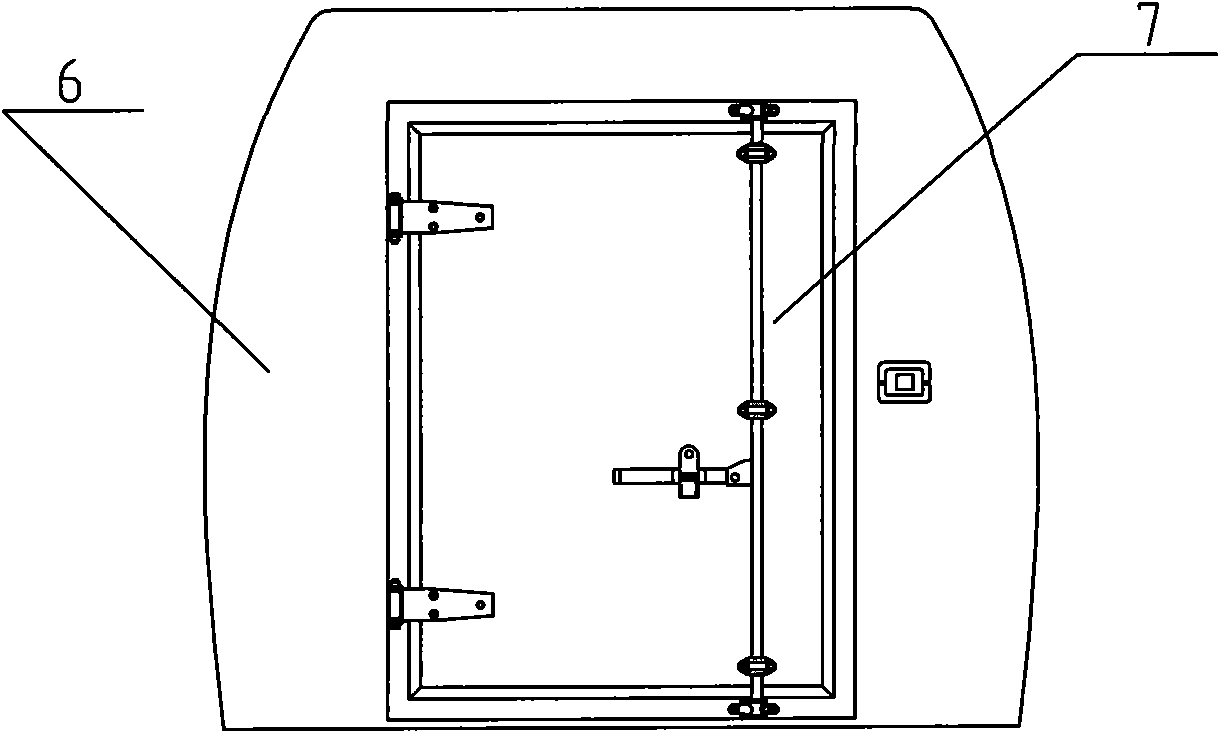

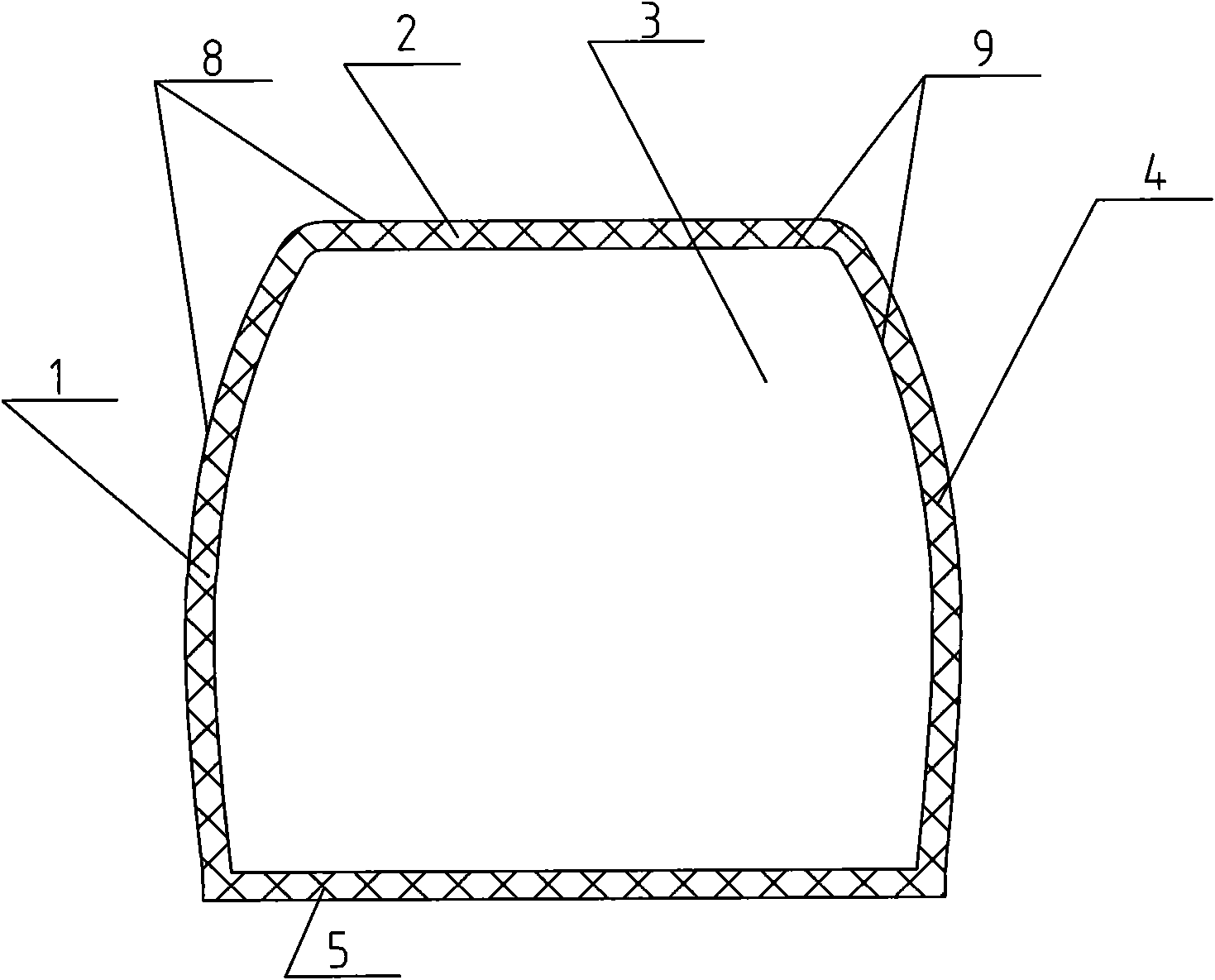

Integrated refrigerator car carriage structure and operating method thereof

ActiveCN101513851AIncreased loading spaceSimple structureRefrigerated goods vehicleLayered productsRefrigerator carWhole body

The invention discloses an integrated refrigerator car carriage structure. The carriage comprises a protective layer and an insulating layer. The insulating layer consists of six surfaces, that is, a left side plate, a right side plate, a top plate, a bottom plate, a front closing plate and a rear closing plate which are formed by pouring polyurethane material; the insulating layer and the protective layer are mutually bound to form a whole body, and the insulating layers of carriage plates of various surfaces are in gapless connection and are of the integrated structure. The operating method of the integrated refrigerator car carriage comprises the following steps: A) the front closing plate and the bottom plate are arranged; B) the bottom plate is taken as a base, the two sides and the top face of the carriage are provided with inner covering, and filling space is left between the inner covering and the protective layer; C) the carriage is internally equipped with a foaming formwork which is jointed with the inner covering; D) a filling groove is filled with a polyurethane foaming material; and E) the rear closing plate and a rear door are mounted. The refrigerator car carriage is characterized by simple structure, convenient manufacture, high space utilization rate and good insulating property; and the refrigerator car carriage can effectively reduce cold energy loss of the carriage.

Owner:GUANGZHOU BAIER COLD CHAIN POLYURETHANE TECH

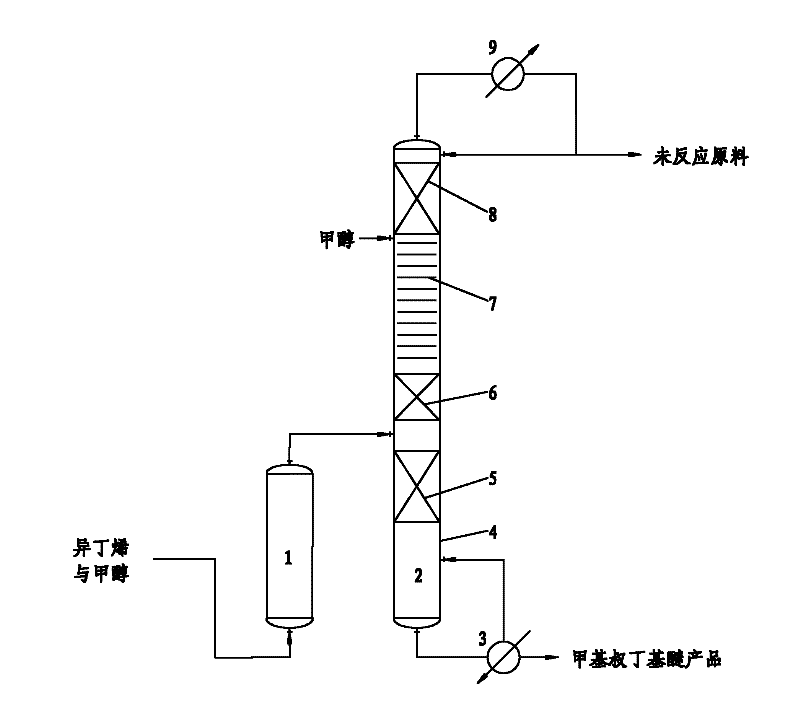

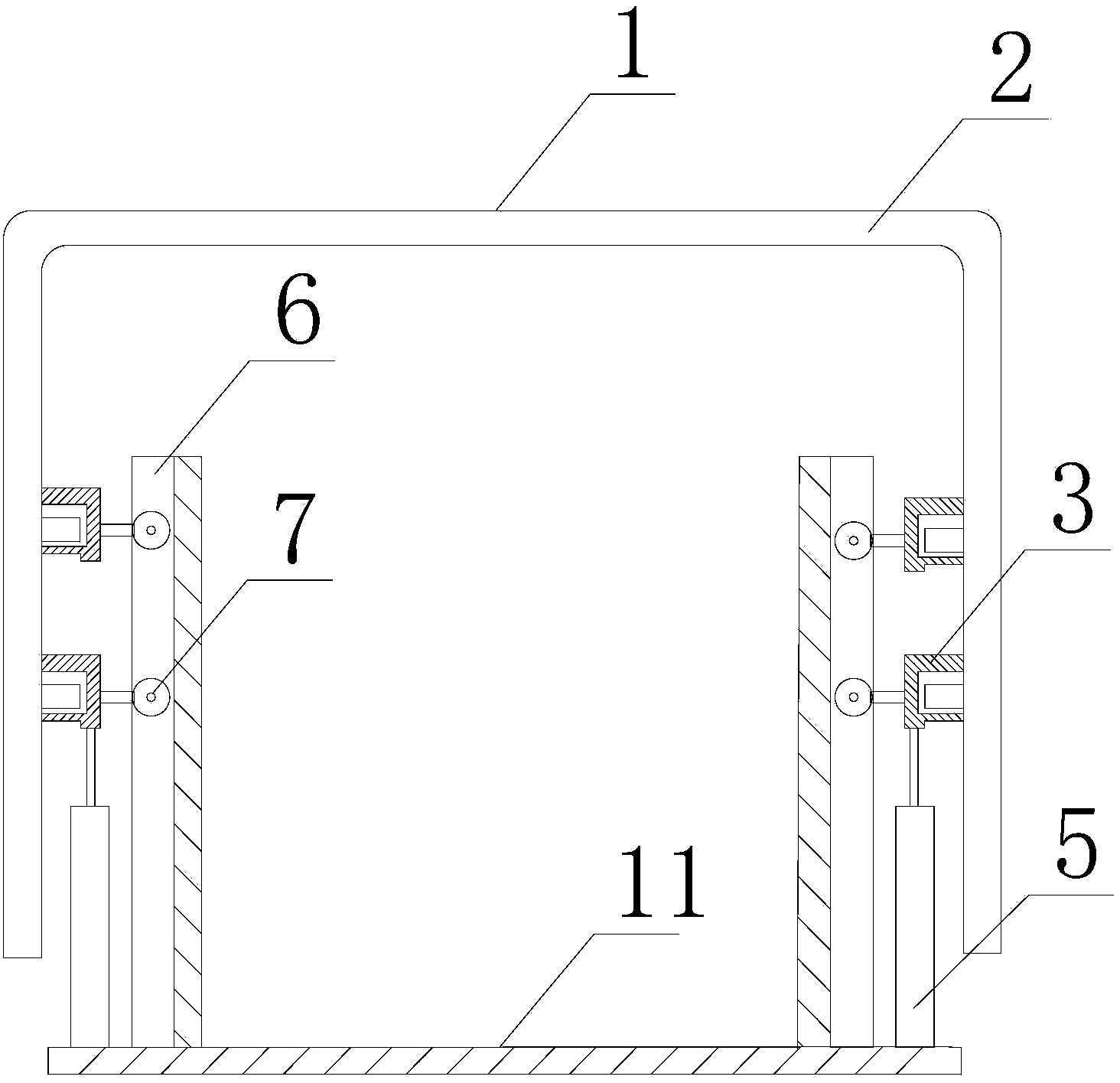

Process method for preparing methyl tert-butyl ether by differential reaction rectification and equipment for same

InactiveCN102516036AAvoid poisoningAvoid staggeredEther preparation by compound additionFixed bedTower

The invention relates to a process method for preparing methyl tert-butyl ether by differential reaction rectification and equipment for the same, wherein isobutene and methanol are used raw materials for preparing methyl tert-butyl ether. The process method comprises the following steps of: feeding isobutene and methanol in a fixed-bed reactor (1) in a certain mixing ratio to perform pre-reaction; feeding the raw materials after the pre-reaction in a catalytic reaction rectification tower (2); primarily separating the methyl tert-butyl ether generated in the pre-reaction from the unreacted raw materials under the action of a tower internal part (6) at a lower rectification section; further concentrating the generated methyl tert-butyl ether under the action of a tower internal part (5) at a stripping section; and finally obtaining a methyl tert-butyl ether qualified product at the bottom of the tower, and feeding the unreacted raw materials primarily separated by the tower internal part (6) at a lower rectification section in a differential catalytic reaction rectification tower plate (7) to continue to react.

Owner:HEBEI UNIV OF TECH

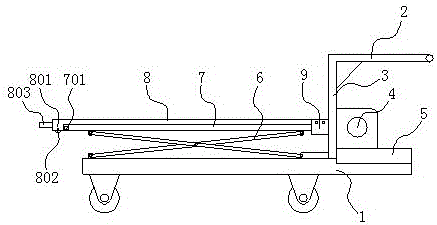

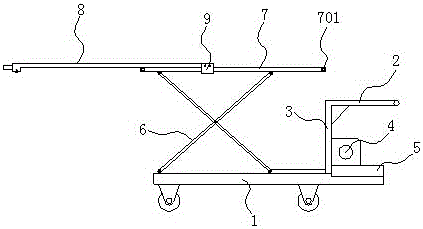

Lifting logistical trolley

The invention relates to a trolley, in particular to a lifting logistical trolley. The trolley comprises a trolley bottom plate, a carrying plate, a lifting mechanism and a handle; rollers are arranged at the bottom of the trolley bottom plate; the carrying plate and the lifting mechanism for pushing the carrying plate to rise and fall are arranged at the upper part of the trolley bottom plate; a sliding plate capable of realizing horizontal directional sliding limiting is arranged on the supporting surface of the carrying plate; in the initial state, the surface of the sliding plate at least covers the supporting surface of the carrying plate; and when the sliding plate slides in place in the sliding direction, at least half of the surface of the sliding plate extends out of one side of the carrying plate. Compared with the prior art, the trolley has the main advantages as follows: the sliding plate can extend outwards horizontally relative to the carrying plate after being lifted by the lifting mechanism, so that carried materials are extended out together to the designated carrying position, the materials are convenient to carry, and the carrying safety is improved. Besides, during conveying, the sliding plate can also be extended out, so that both the sliding plate and the carrying plate can carry the materials, and the carrying capacity of the lifting logistical trolley is improved.

Owner:浙江圣远供应链管理集团股份有限公司

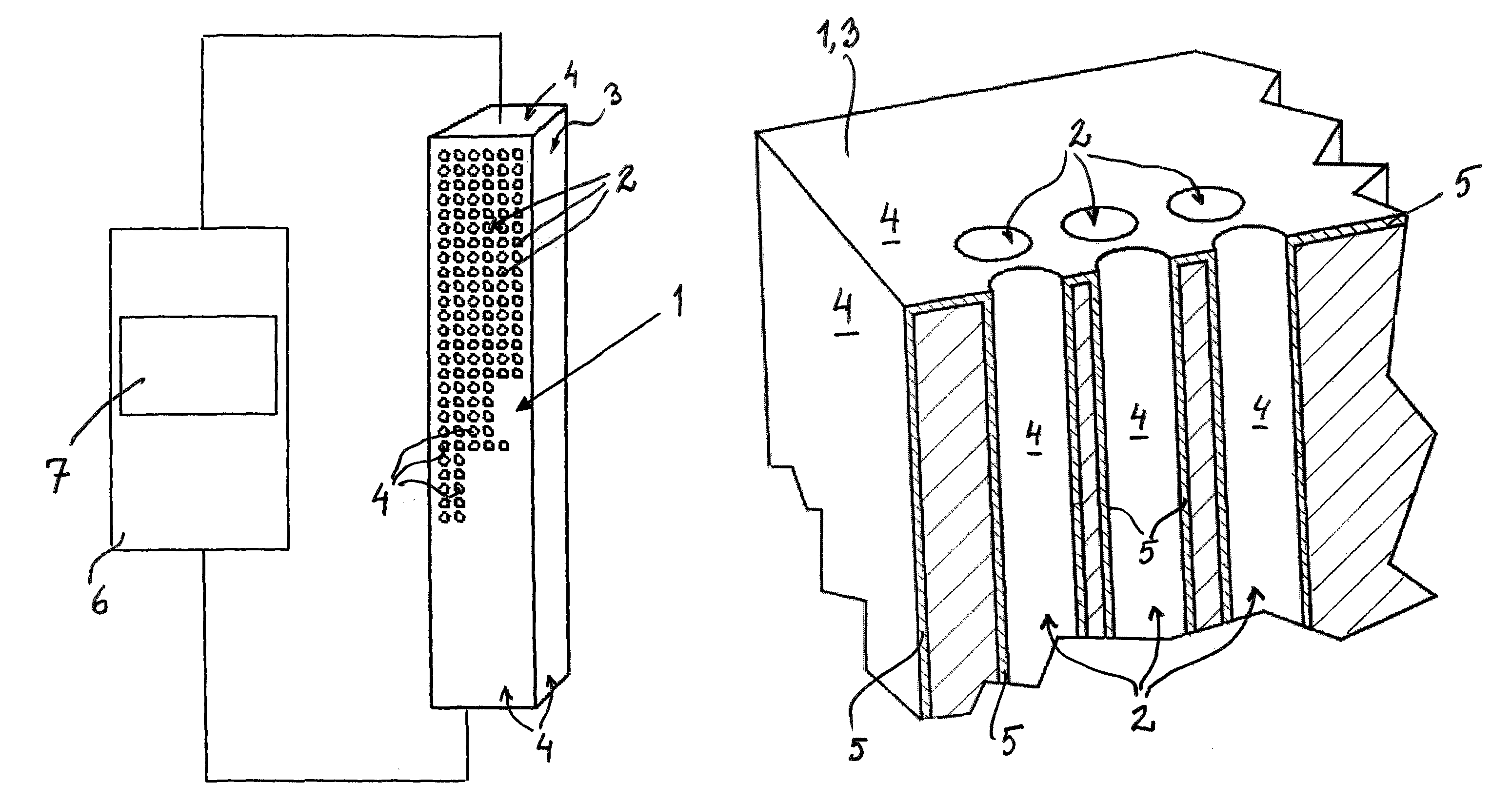

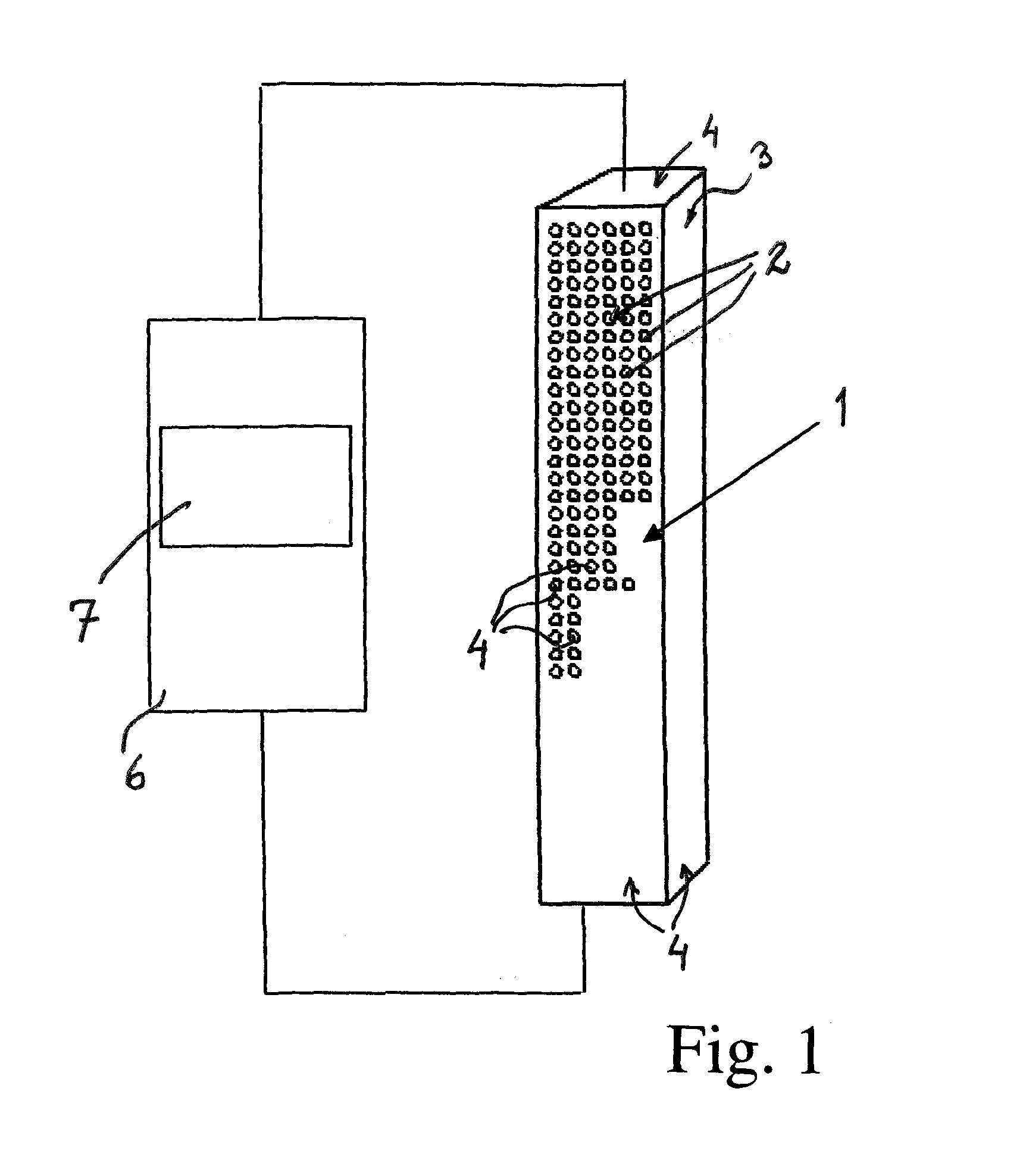

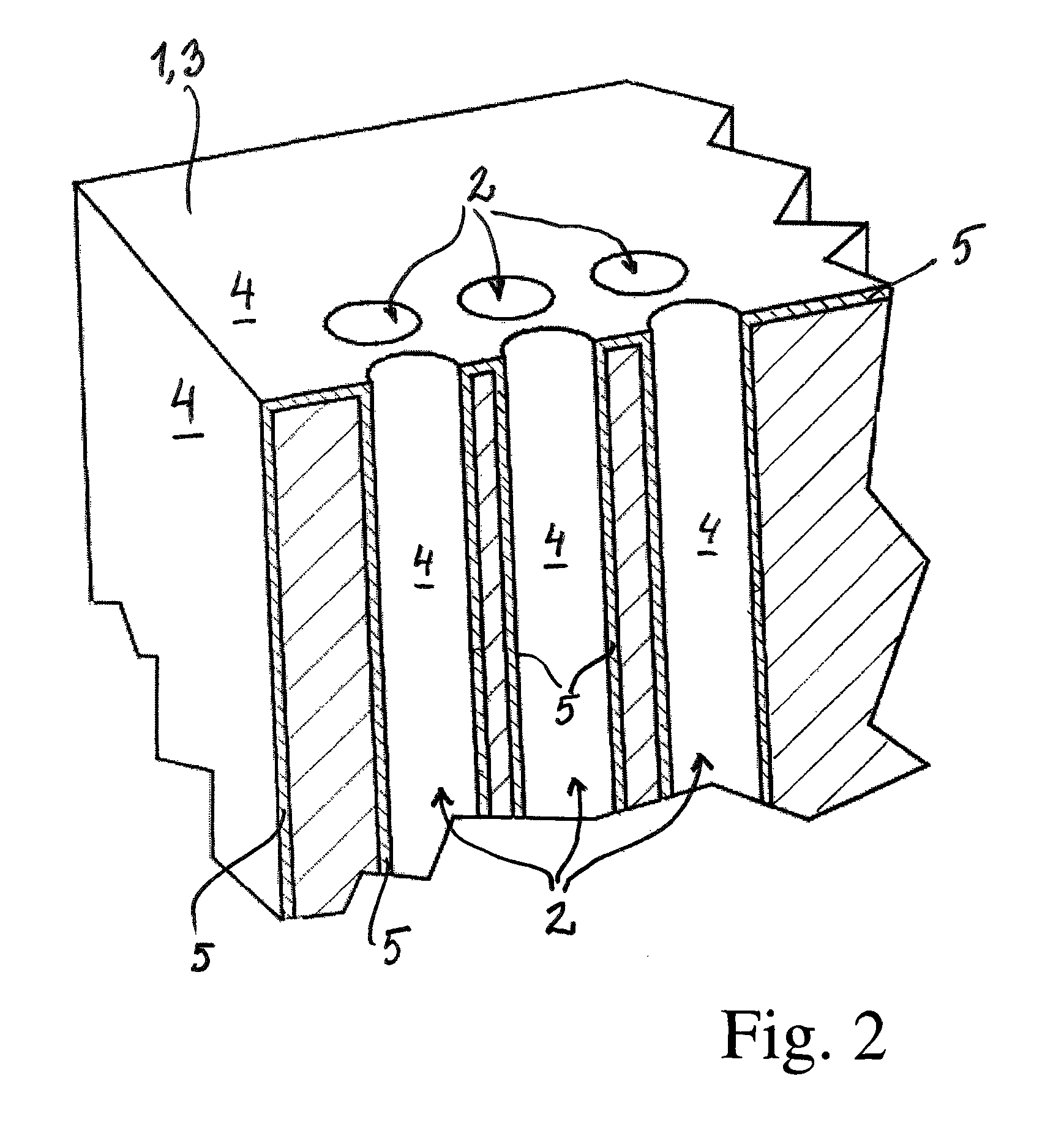

Method for electrical flashover ignition and combustion of propellent charge, as well as propellent charge and ammunition shot in accordance therewith

InactiveUS8607704B2Increase load weightIncreased loading spaceAmmunition projectilesIncandescent ignitionElectricityCombustion

The invention relates to a method of, in the electrical ignition of a propellent charge (1) provided with an electrically conductive surface coating (5) and comprising one or more propellant components (3), ensuring that ignition and progressive combustion of the propellent charge take place. The method is characterized in that said electrically conductive surface coating, when ignition of the propellent charge is desired, is connected to an electrical high-voltage source (6), in that said high-voltage source is made to generate at least one high electrical pulse to said connected electrically conductive surface coating, and in that said at least one high electrical pulse produces an instantaneous flashover ignition of the electrically conductive surface coating of the propellent charge and of all its propellant components, simultaneously. The invention also relates to a propellent charge and to an ammunition shot comprising the propellent charge.

Owner:BAE SYST BOFORS

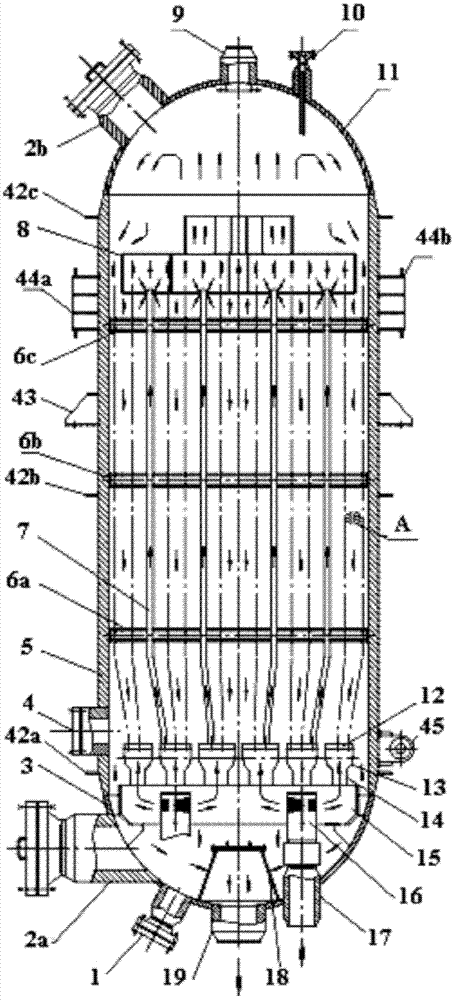

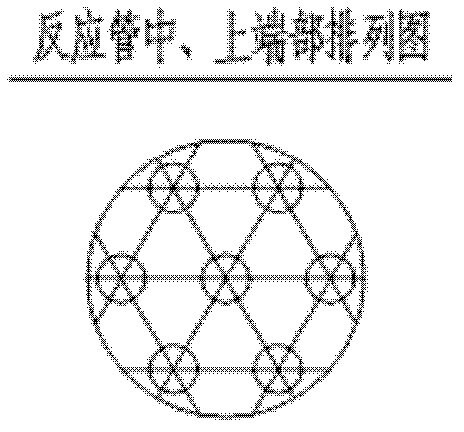

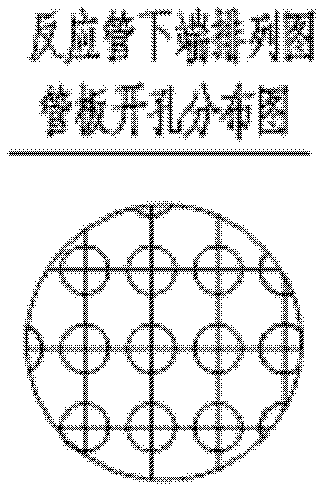

Gas-cooled methanol reactor

ActiveCN103111239AImprove production efficiencyImprove energy efficiencyOrganic compound preparationHydroxy compound preparationArchitectural engineeringMixed gas

The invention belongs to the coal-to-methanol field, and concretely discloses a gas-cooled methanol reactor. The reactor comprises a cylinder, an upper seal head packaged at the top of the cylinder and a lower seal head packaged at the bottom of the cylinder, the cylinder, the upper seal head and the lower seal head form a closed cavity, reaction tubes are arranged in the cavity, the top of each of the reaction tubes is inserted to a mixed gas tank, the middle of each of the reaction tubes is inserted to a tube support, and the bottom of each of the reaction tubes is inserted to a tube plate; tube supports are fixed on the reaction tubes, the bottom of the tube plate is fixed at the top of a U-shaped cylinder, the bottom of the U-shaped cylinder is fixed on a branch tube, the bottom of the branch tube is inserted to a manifold trunk, the top of a distribution tube is inserted to the manifold trunk, the bottom of the distribution is positioned outside the manifold trunk, and the bottom of an adaptor penetrates through the lower seal head; the top of the upper seal head is provided with a work starting gas inlet; and the bottom of the lower seal head is provided with an outlet collector, and the bottom of the outlet collector is provided with a generated gas outlet. The reactor has the advantages of methanol output improvement, cost reduction, energy saving and energy consumption reduction.

Owner:西安核设备有限公司

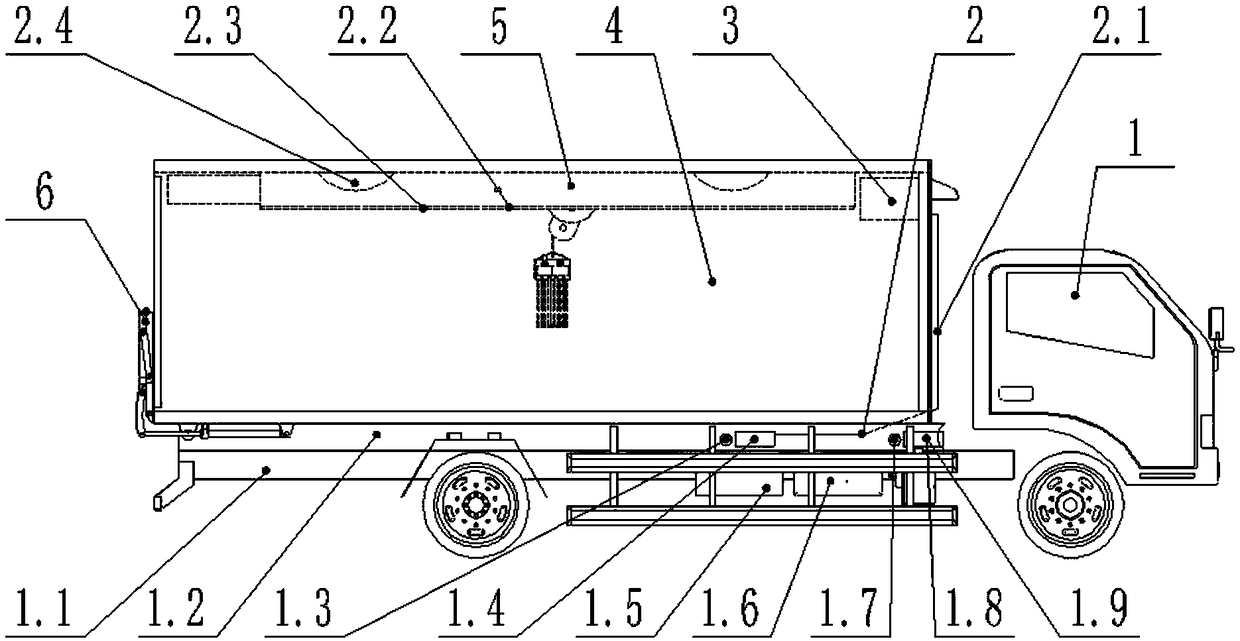

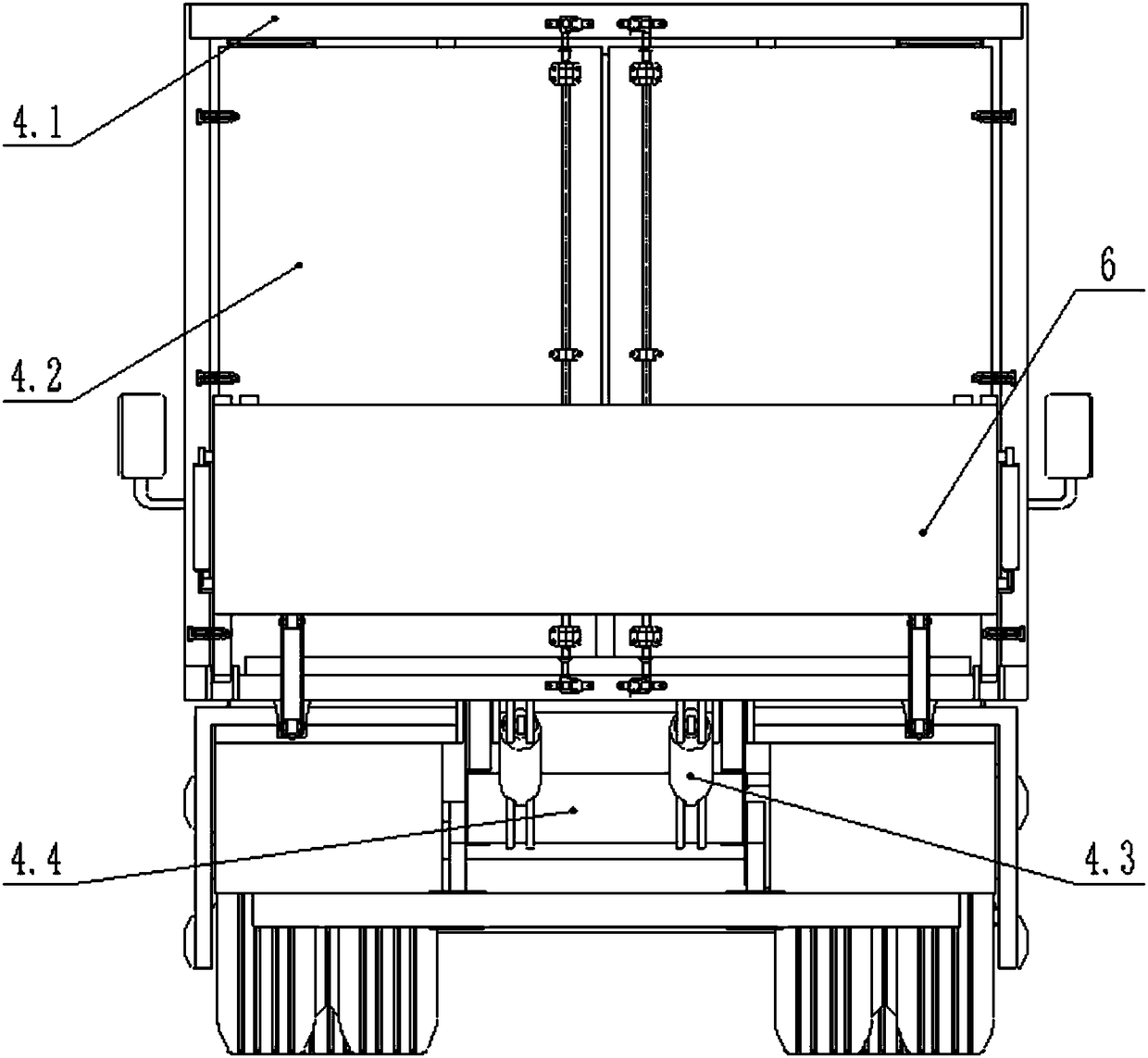

Dead livestock conveying vehicle

PendingCN108407703ACause secondary pollutionSimple structureVehicles with cranesRefrigerated goods vehicleDead bodyHealth safety

The invention discloses a dead livestock conveying vehicle. The dead livestock conveying vehicle comprises a chassis, a disinfecting system, a refrigerator, a goods box, a loading mechanism and a pedal mechanism, the goods box is mounted on the chassis, and the refrigerator and the loading mechanism are mounted in the goods box. The disinfecting system is located in the goods box, and the pedal mechanism is mounted on the goods box. The loading space of the conveying vehicle is large, and dead bodies can be automatically loaded and unloaded, when the livestock dead bodies are located, the deadbodies can be easily placed on any position in the goods box, the dead bodies are prevented from being stacked, and the work efficiency and the personnel health safety are greatly improved. The conveying vehicle is provided with the pedal mechanism, the goods box can be automatically connected with a pedal on the ground, conveying of the dead bodies and walking of personnel into and out of the goods box are facilitated greatly, and the pedal mechanism cannot interfere unloading of the dead bodies. The conveying vehicle is provided with the disinfecting system, double disinfecting and sterilizing of the goods box can be achieved through disinfecting liquid and ultraviolet lamp light rays, and breeding and reproduction of bacteria and viruses of the livestock dead bodies in the conveying process are limited.

Owner:HEBEI UNIV OF TECH

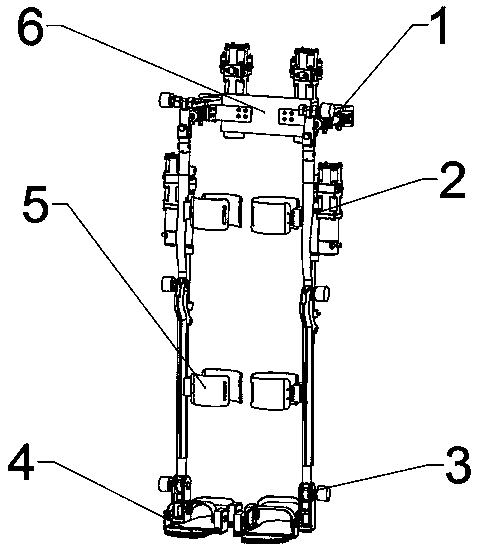

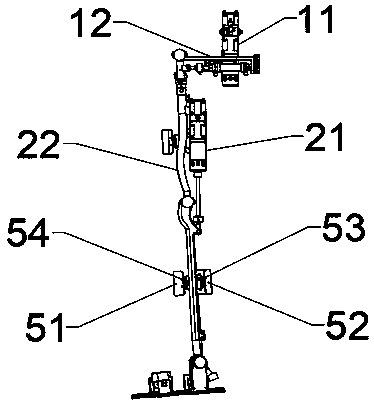

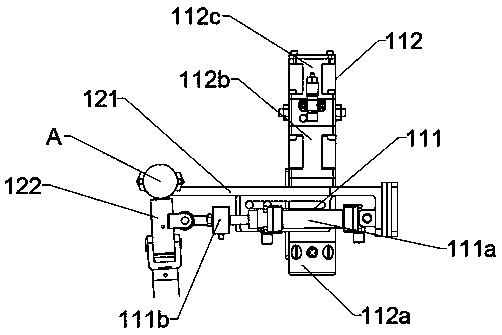

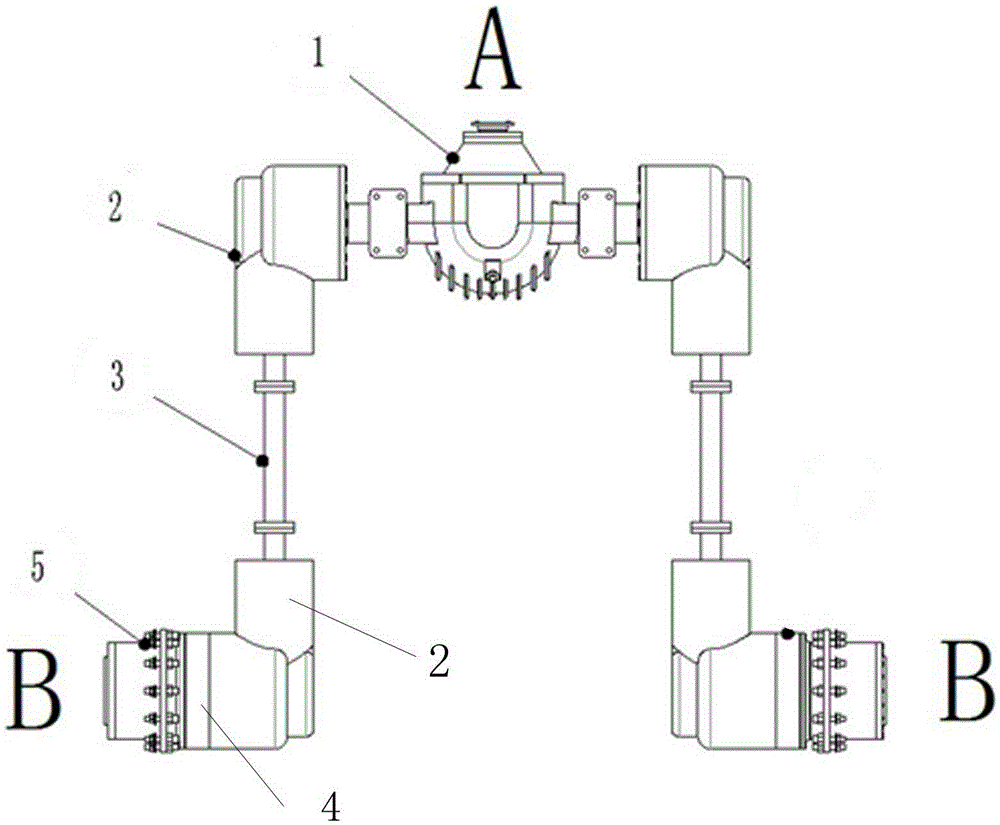

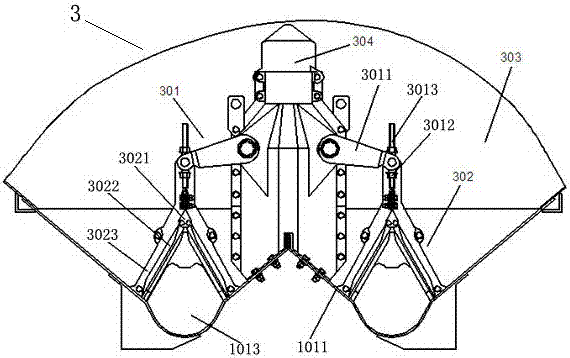

Distributed type hydraulic power source lower extremity exoskeleton robot

ActiveCN109648542AReduce weightReduce usageProgramme-controlled manipulatorJointsJoint componentExoskeleton robot

The invention discloses a distributed type hydraulic power source lower extremity exoskeleton robot. The distributed type hydraulic power source lower extremity exoskeleton robot is formed by connecting a left lower extremity body and a right lower extremity body which are of the same structure and comprises hip joint components, knee joint components, ankle joint components, foot portion wear devices and wear binding devices, wherein the hip joint components are connected with the knee joint components through hip joint swing rods, the knee joint components are connected with the ankle jointcomponents through knee joint shank rods, the ankle joint components are connected with the foot portion wear devices through ankle joint support seats, and the hip joint swing rods and the knee jointshank rods are all provided with the wear binding devices. According to the distributed type hydraulic power source lower extremity exoskeleton robot, a power source is distributed to hip and knee joints, the robot back space is released, and the load space is increased; compared with an existing centralized type power source, valve block and pipeline structures are removed, and the robot weightis reduced; valve block and pipeline elements are reduced, power source interception loss is reduced, and the power source efficiency is improved; the distributed type hydraulic power source lower extremity exoskeleton robot is convenient to maintain, and partial problems are repaired partially; and by means of use of single-action moving cylinders, the control difficulty of the robot in the swinging phase is reduced.

Owner:ZHEJIANG UNIV

Novel telescopic vehicle shed

The invention discloses a novel telescopic vehicle shed. The novel telescopic vehicle shed is arranged on a vehicle compartment and comprises a plurality of supports, horizontal guide tracks, a tarpaulin, support devices, vertical sliding slots, a horizontal driving device and pulleys, wherein the vertical sliding slots are fixed on two side plates of the vehicle compartment along the vertical direction; the pulleys are matched with the vertical sliding slots and are arranged on the horizontal guide tracks; the support devices are arranged outside the vehicle compartment; the horizontal guide tracks are fixed on the support devices along the horizontal direction; the horizontal driving devices are used for drawing the plurality of supports to move along the horizontal guide tracks; the part, which is positioned at the head part of the vehicle compartment, of each horizontal guide track has an angle of inclination downwards; the plurality of supports are arranged on the horizontal guide tracks, and each support is movably connected with the corresponding horizontal guide track; the tarpaulin covers the top of the plurality of supports. The novel telescopic vehicle shed provided by the invention can realize expansion or contraction along the horizontal direction and expansion and contraction in the vertical direction, so that the novel telescopic vehicle shed is easy to open or close and can keep out rain; the expansion and contraction degree of the telescopic vehicle shed can be changed according to needs and further the loading capacity of the vehicle compartment is changed.

Owner:石超

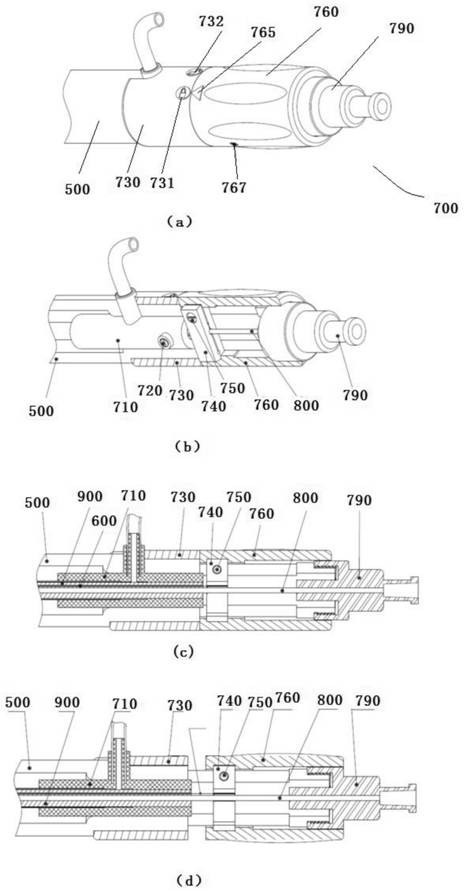

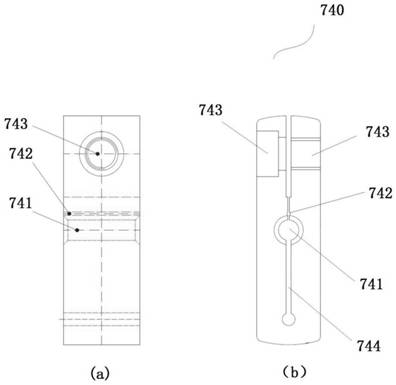

Front-end rear release mechanism of interventional stent conveyor, conveyor and using method

PendingCN113599040ARelease function after implementing the front endAvoid early releaseStentsEngineeringMechanical engineering

The invention provides a front-end rear release mechanism of an interventional stent conveyor, a conveyor and a using method. The front-end rear release function of an interventional stent is achieved by arranging a moving claw capable of moving on a first limiting piece in the axial direction on a front-end assembly and connecting the moving claw with a metal block of a rear-end assembly of the conveyor through a drawing wire. The rear end assembly realizes positioning locking and axial movement of a release sleeve and a screw rod through a guide locking mechanism arranged on the release sleeve and the screw rod, so that positioning locking and axial movement of the moving claw on the first limiting piece are realized, and the problem that the interventional stent is released in advance due to the fact that the moving claw is unlocked in advance can be solved; and meanwhile, the problem that the interventional stent cannot be released due to the fact that the moving claw cannot be unlocked can be solved. The guide locking mechanism is designed to be a guide column and an L-shaped guide groove formed in the outer surface of the screw rod, it is guaranteed that the front-end rear release mechanism is safe in self-locking and rapid in unlocking, and the safety, reliability and positioning accuracy of the conveyor are further improved.

Owner:北京有卓正联医疗科技有限公司

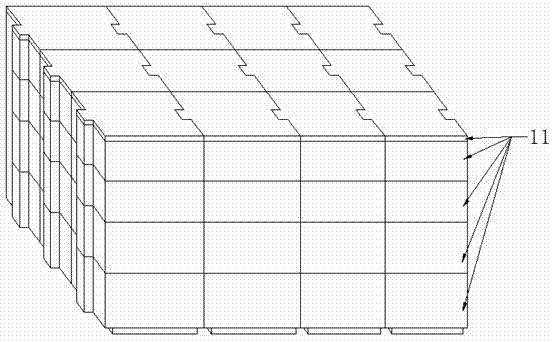

Fruits and vegetables temperature control storage and transportation dedicated plastic pass box unit with hold-over plate for insulating truck

InactiveCN103171828AImprove the cooling effectReasonable and flexible structureShock-sensitive articlesRigid containersAir cycleChilling injury

The invention discloses a fruits and vegetables temperature control storage and transportation dedicated plastic pass box unit with hold-over plates for an insulating truck. The fruits and vegetables temperature control storage and transportation dedicated plastic pass box unit with the hold-over plates for the insulating truck includes multiple same box bodies and a box lid. Vertical concave slots or convex slots are formed in the box lid and the center positions of both sides of each box body. The box bodies are connected into a stacking in a front-and-back direction. The box lid and each box body are of plastic hollow grid structures. A layer of cold storage frame capable of containing the hold-over plates is arranged on the bottom surface of the box body, and the box lid is the hollow cold storage box which the hold-over plates can be put in. The cold storage box on the bottom surface of the last box body is embedded into the next box body, and the box body is fixed in an up-and-down direction. The box lid covers on the topside box body, the box lid and the box bodies are piled and sent into the insulating truck. The whole insulating truck is taken as an insulating unit, the hold-over plates are uniformly distributed inside the unit, due to the fact that the pass box has no insulating layer, air circulation is fluent inside the stacking so as to be beneficial to the uniform temperature distribution in the stacking, fruits and vegetables chilling injury caused by partial supercooling is prevented, and fruits and vegetables loading space is large; car utilization rate is high, the stacking is solid, and the temperature control effect is good.

Owner:ZHEJIANG UNIV

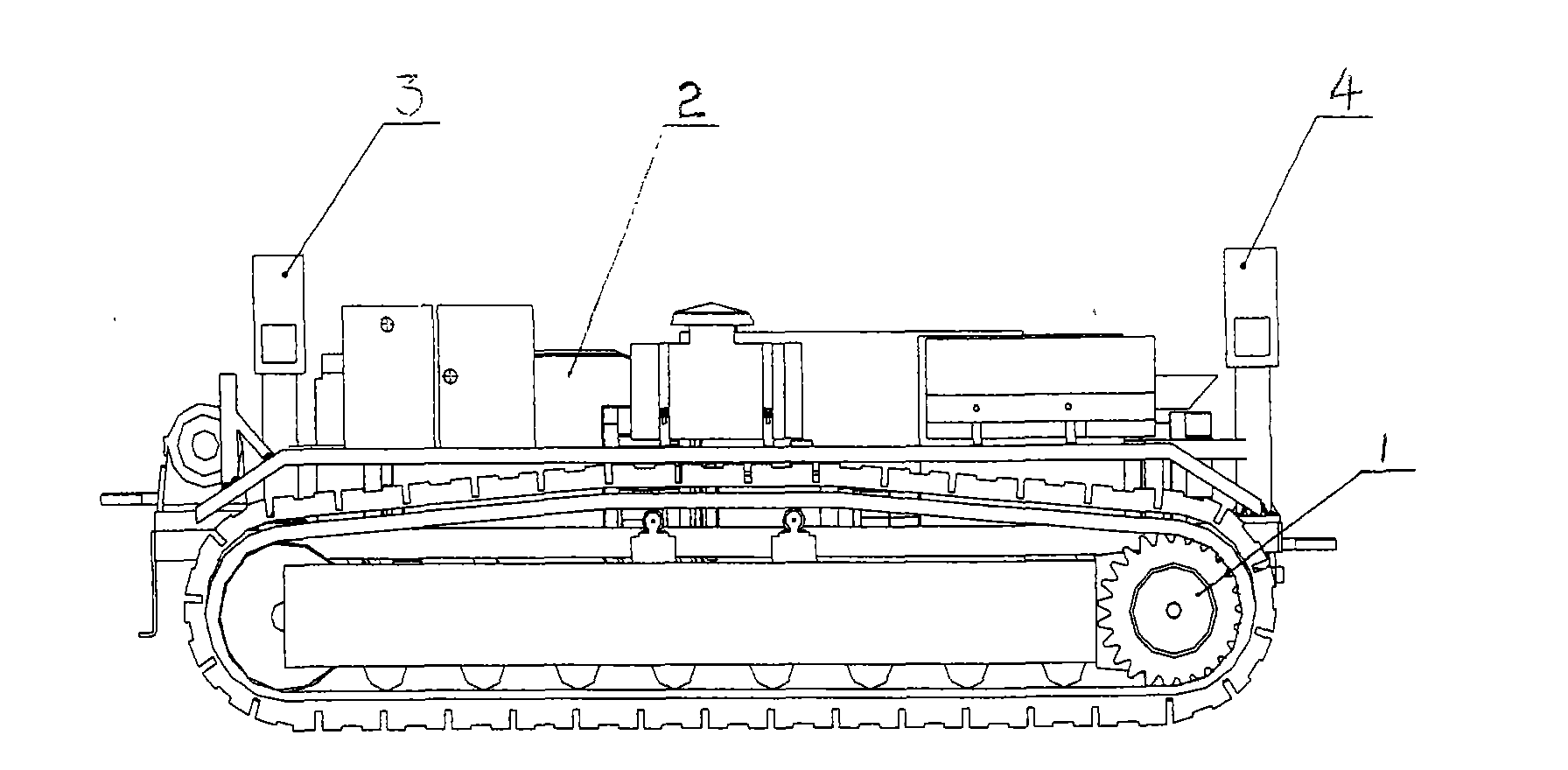

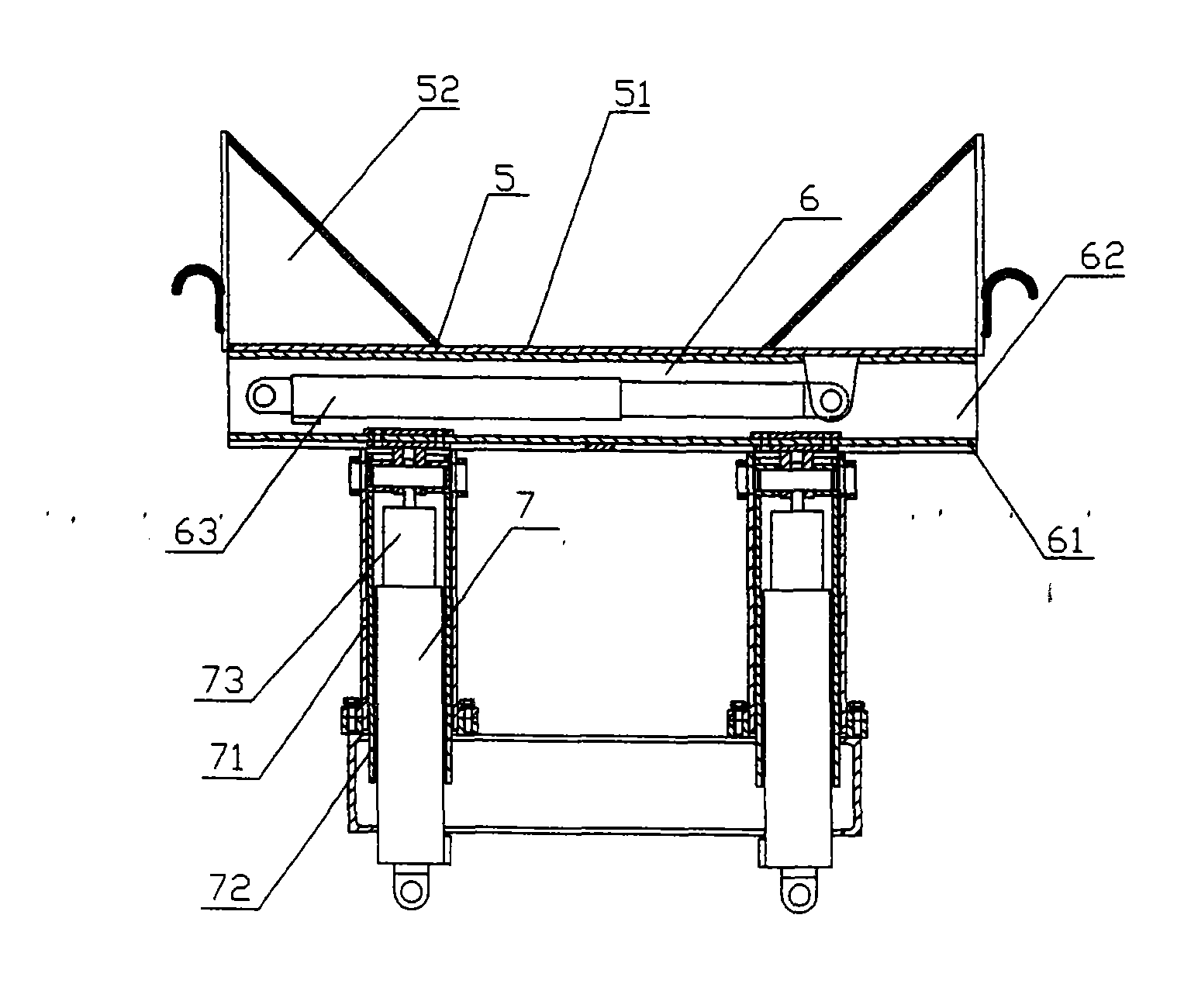

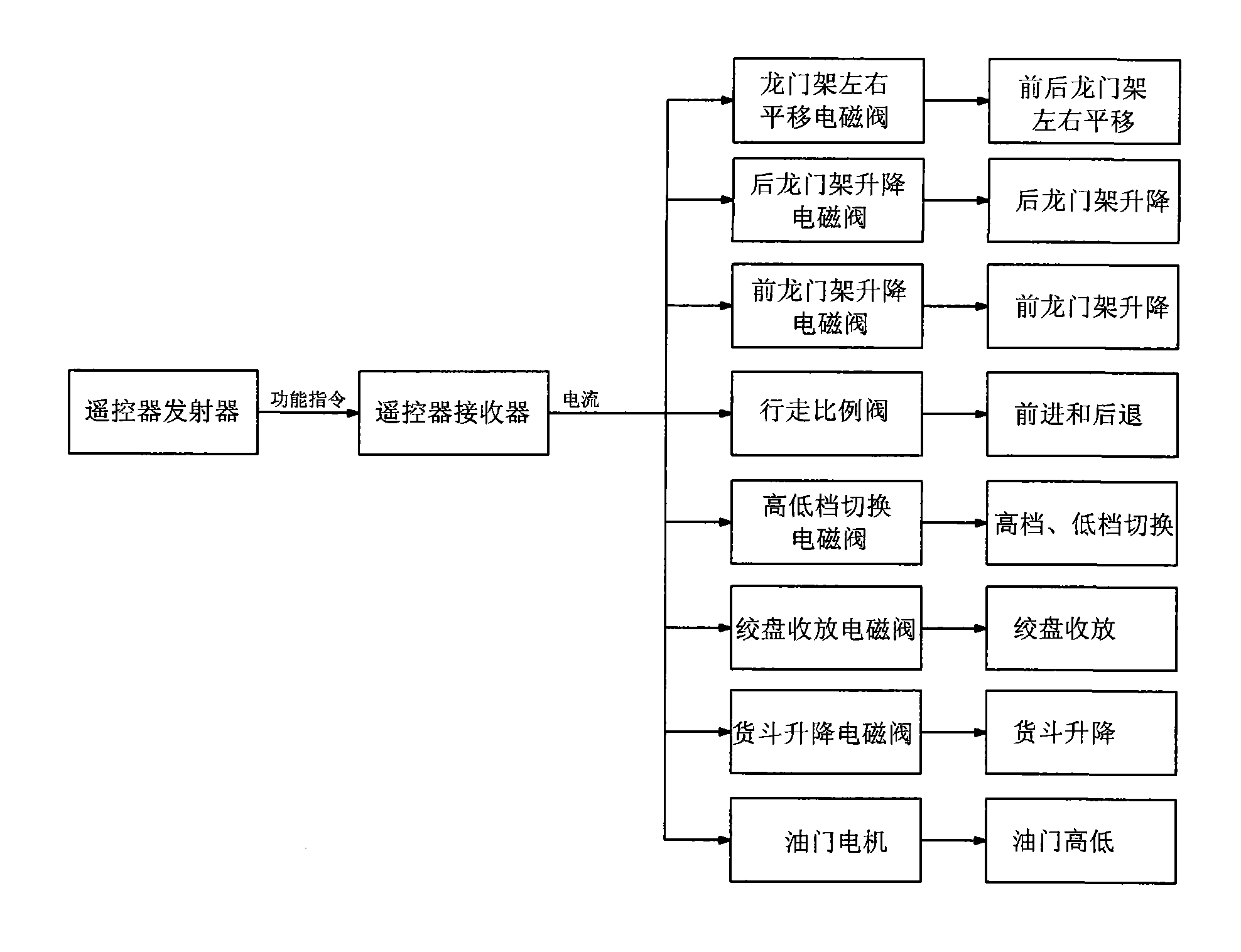

Remotely controlled tracked carrier

ActiveCN101659210AReduce lossesImprove securityTransmission systemsEndless track vehiclesRemote controlGravity center

The invention relates to a traffic and transport means, in particular to a remotely controlled tracked carrier, wherein existing remote control technology is combined with the tracked carrier and the remote control technology is adopted to realize manless drive of the carrier, thus reducing the lose of highly dangerous production activities thereof to the lowest, and playing very important role in personnel safety. In addition, the manless driven remotely controlled tracked carrier also brings more technical effects, as the driving space is reduced, the height of the carrier is directly lowered, and small height size reduces the center of gravity of the whole carrier and requirement of the road condition; in addition, more loading and unloading space can be released, thus reducing the width of the carrier, lowering various cost for repairing the roads in mountainous areas, and further showing the application value of the remotely controlled tracked carrier, and having high safety and low cost.

Owner:STATE GRID CORP OF CHINA +2

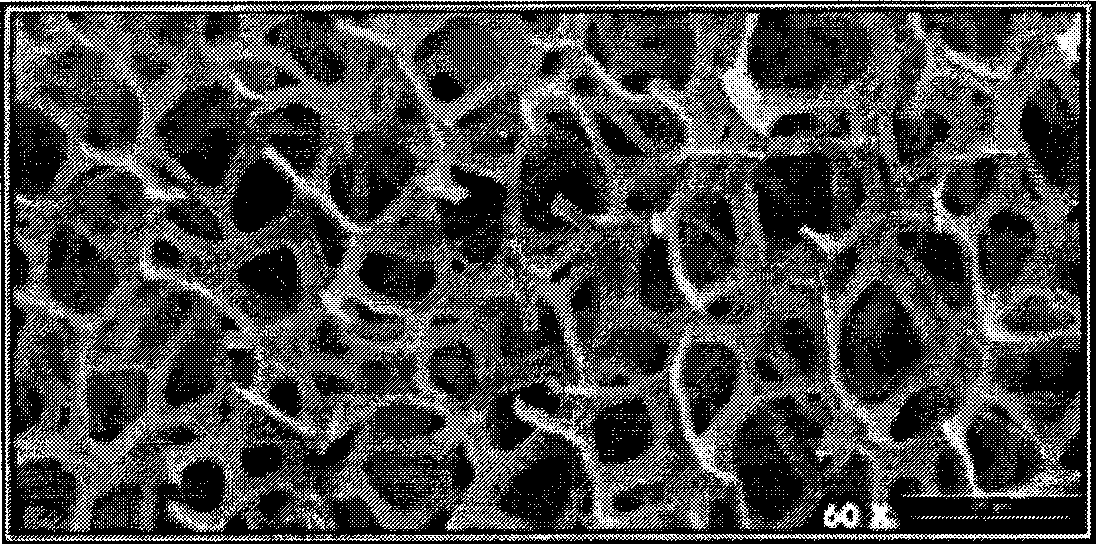

Lithium-sulfur battery flexible electrode material and preparation method and application thereof

ActiveCN108269984AGood self-supporting performanceImprove conductivityCell electrodesLi-accumulatorsEngineeringCharge discharge

The invention relates to a lithium-sulfur battery flexible electrode material and preparation method and application thereof. The lithium-sulfur battery flexible electrode material comprises a VOx nanometer hollow sphere wound with a single-walled carbon nanotube, wherein elemental sulfur is coated in the VOx nanometer hollow sphere, and x is equal to 1.5 to 2.5. By means of an absorption effect of VOx on lithium polysulfide and a wrapping effect of a hollow sphere structure on the polysulfide, the VOx nanometer hollow sphere is combined with the single-walled carbon nanotube, the binding capability of the lithium-sulfur battery flexible electrode material on the elemental sulfur and the polysulfide is synergically improved, and the lithium-sulfur battery flexible electrode material has excellent cycle stability and high battery capacity during the charge-discharge process. The initial discharging capacity of a VOx flexible film with a diameter about 200 nanometer under 1C rate currentcan reach 1,069mAh / g or above and still can reach 614mAh / g or above under 20C rate current; the lithium-sulfur battery flexible electrode material is excellent in cycle efficiency, and the capacity still can be maintained at 69% or above after charging and discharging for 300 circles; and after the lithium-sulfur battery flexible electrode material is used as a lithium-sulfur battery positive electrode assembled to form a flexible soft package battery, the voltage stability is high under different bending angles, the cycle property is excellent under different bending angles, and the capacityreduction rate is average less than 0.32% after 20-100 circles.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

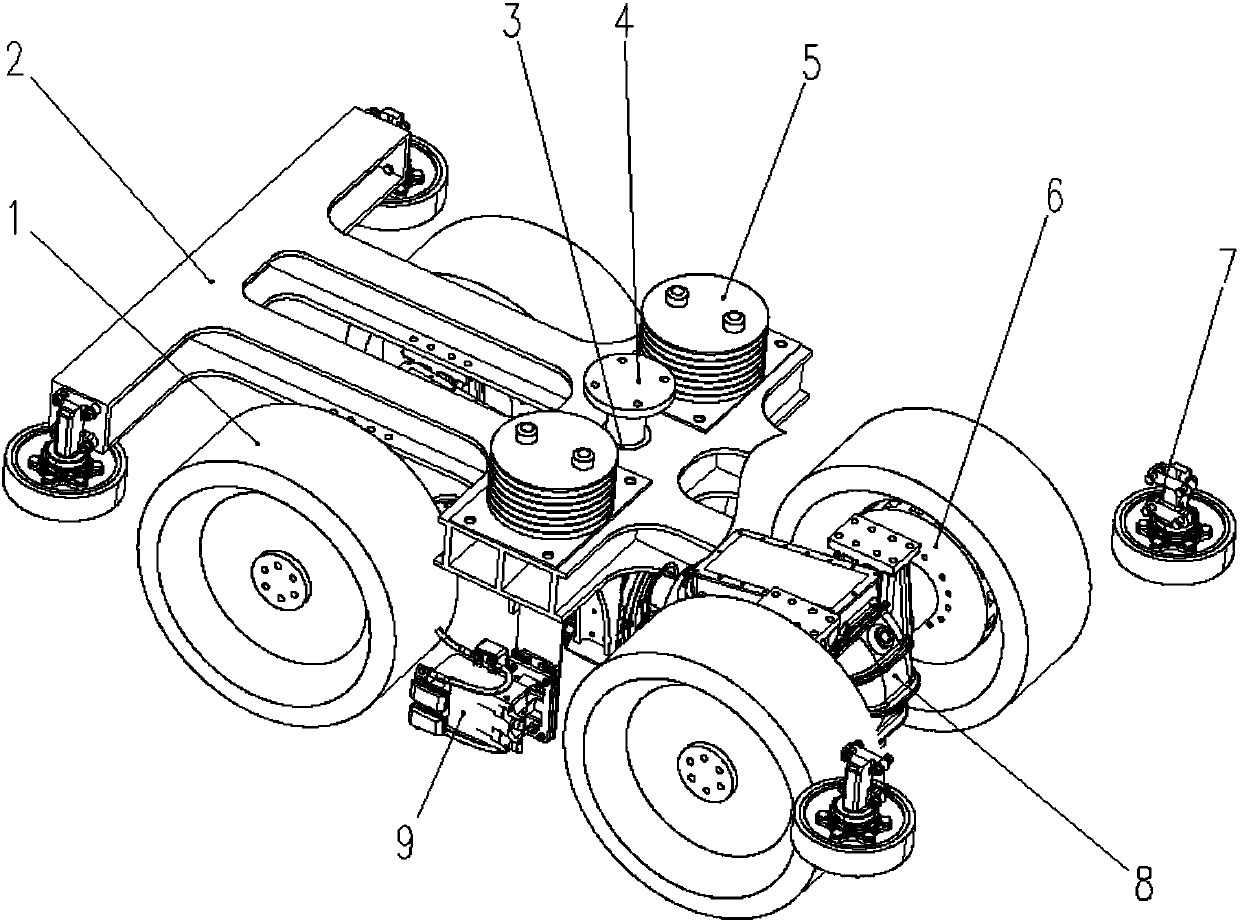

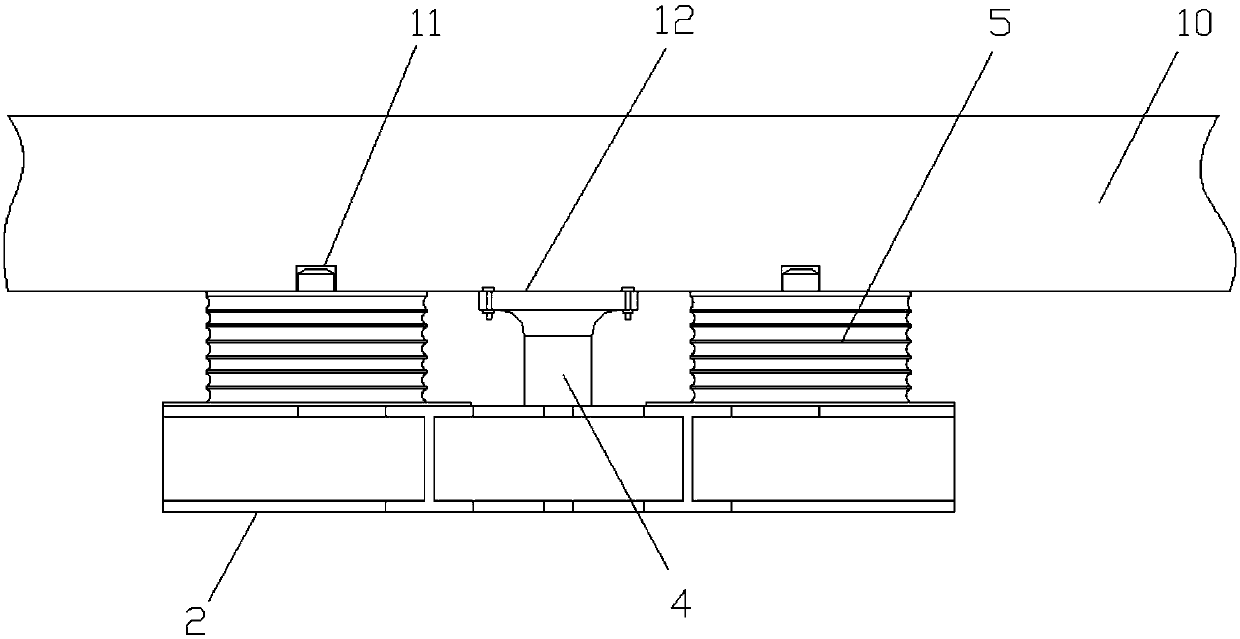

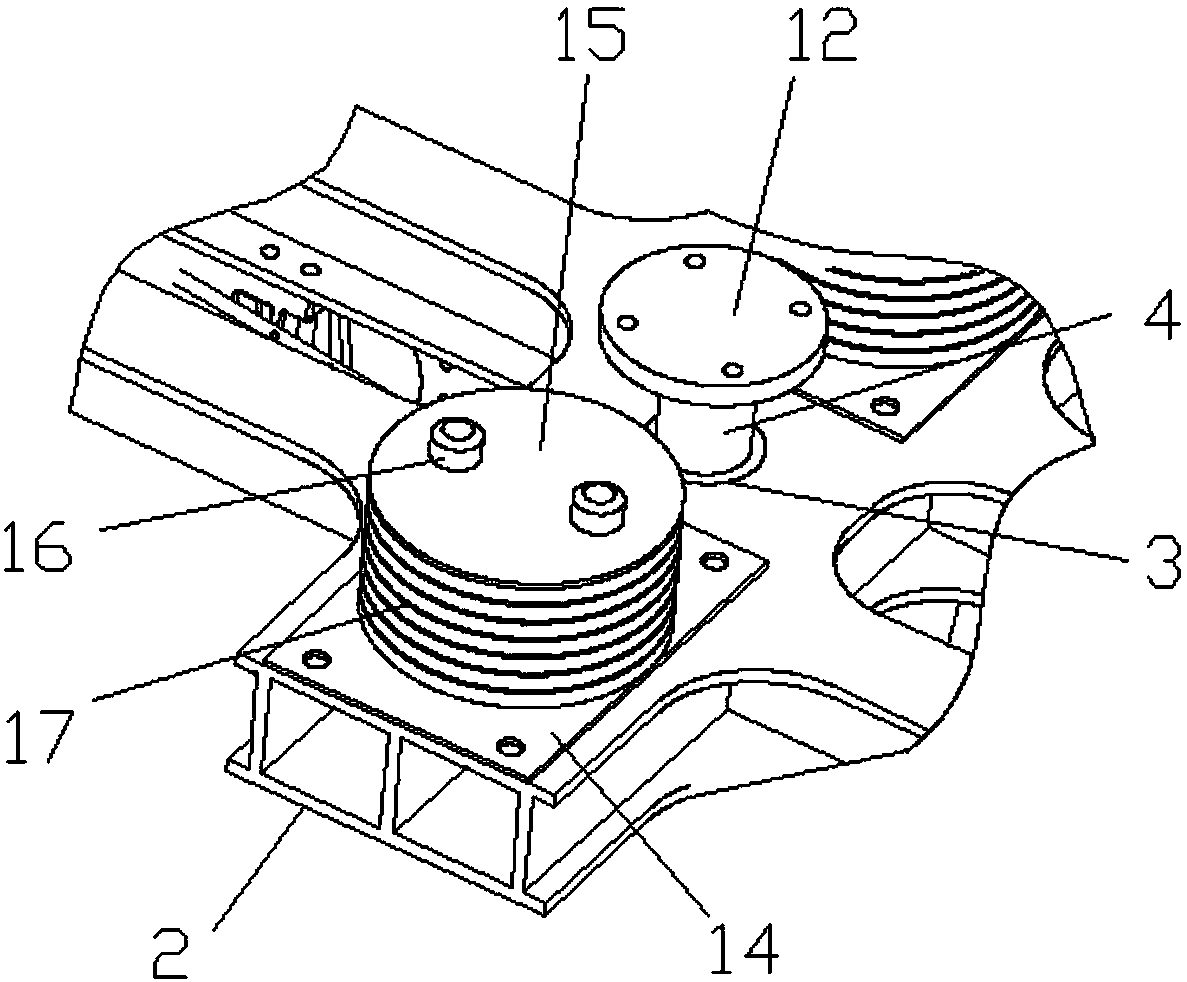

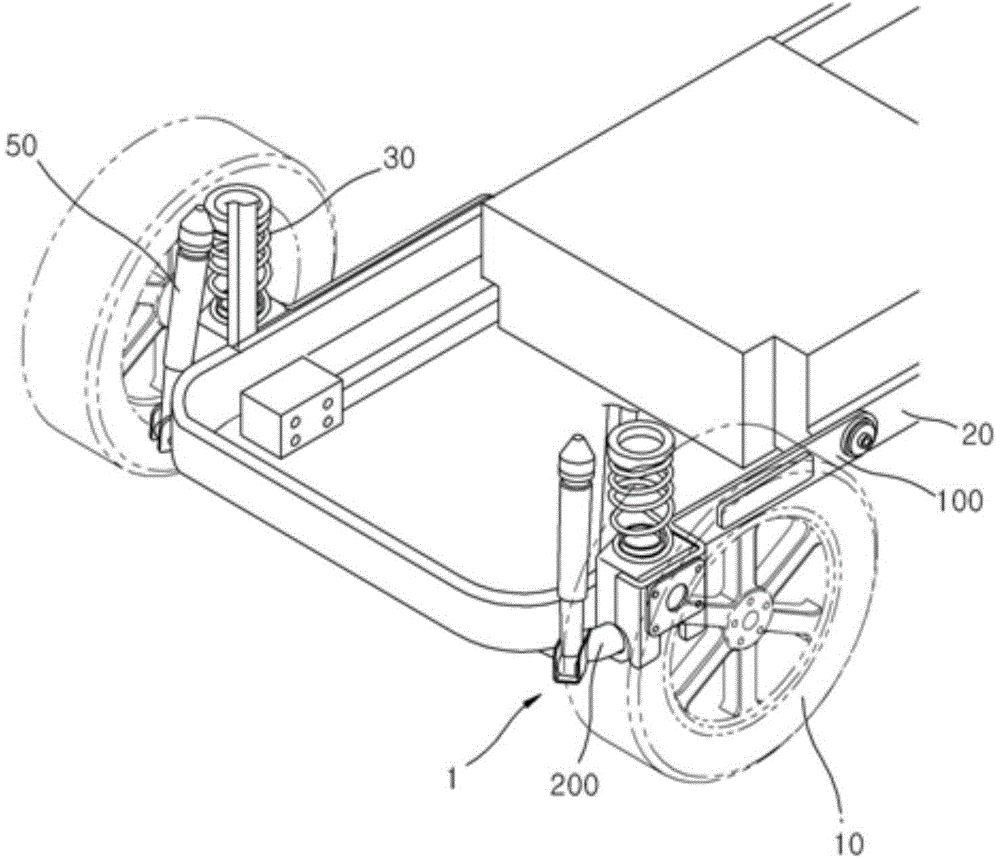

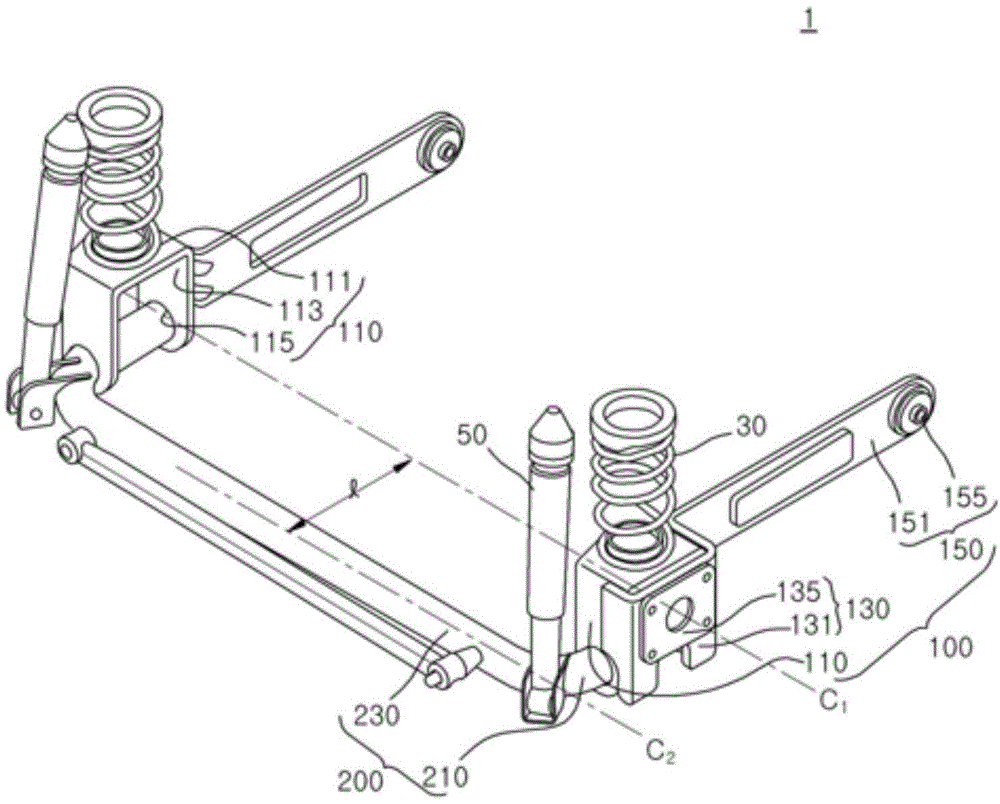

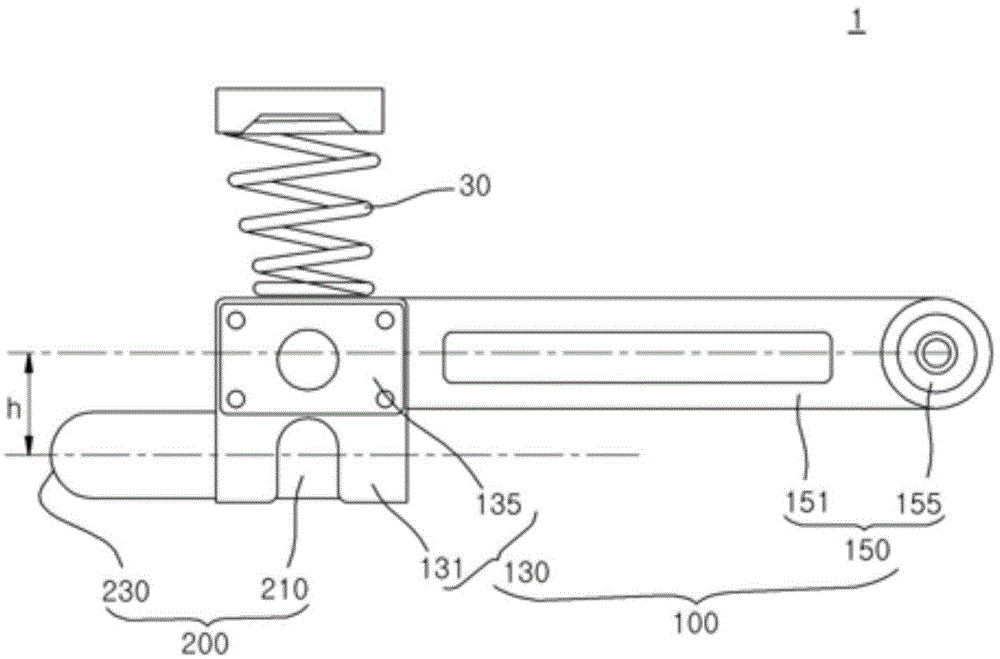

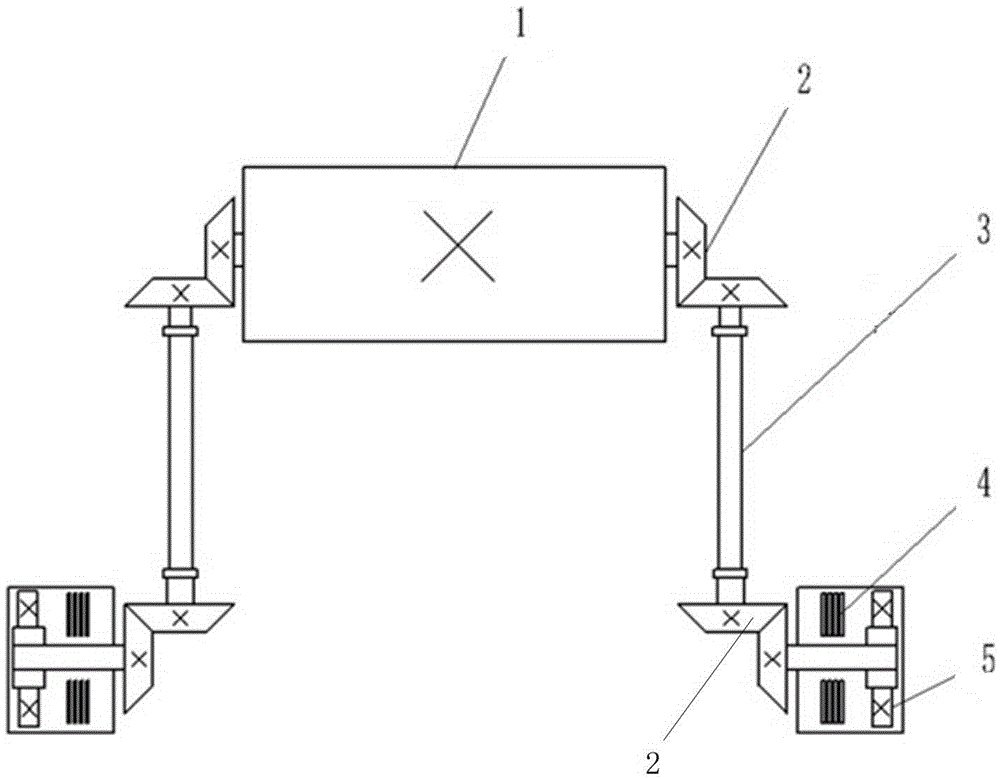

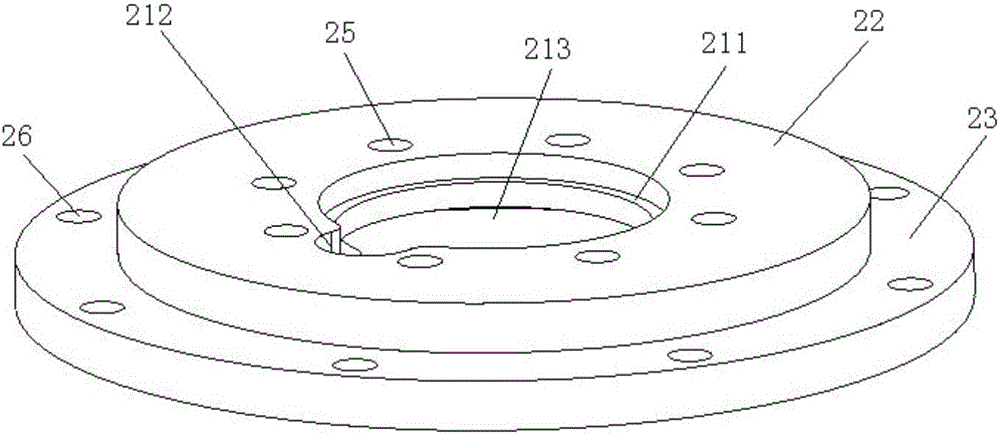

Bogie and logistics transport vehicle

PendingCN107697087AIncreased loading spaceSimple structureRail derailment preventionBogiesBogieLogistics management

The invention relates to a bogie and a logistics transport vehicle. The bogie comprises a framework, a traction center pin, a traction ball hinge and a bearing spring, wherein a pin hole is formed inthe middle of the framework; the traction center pin is arranged in the pin hole in a penetrating mode, and the top of the traction center pin is fixedly connected with a vehicle body bottom frame ofthe logistics transport vehicle; the traction ball is arranged on the traction center pin in a sleeving mode and located in the pin hole; the bearing spring is fixed to the framework; the vehicle bodybottom frame is arranged on the bearing spring in a pressing mode. The logistics transport vehicle comprises the bogie and the vehicle body arranged on the bogie. According to the logistics transportvehicle, the structure of the bogie is simplified, the occupied space of a device is reduced, and the logistics transport vehicle can be suitable for underground pipeline transportation with limitedspace.

Owner:CRRC YANGTZE CO LTD

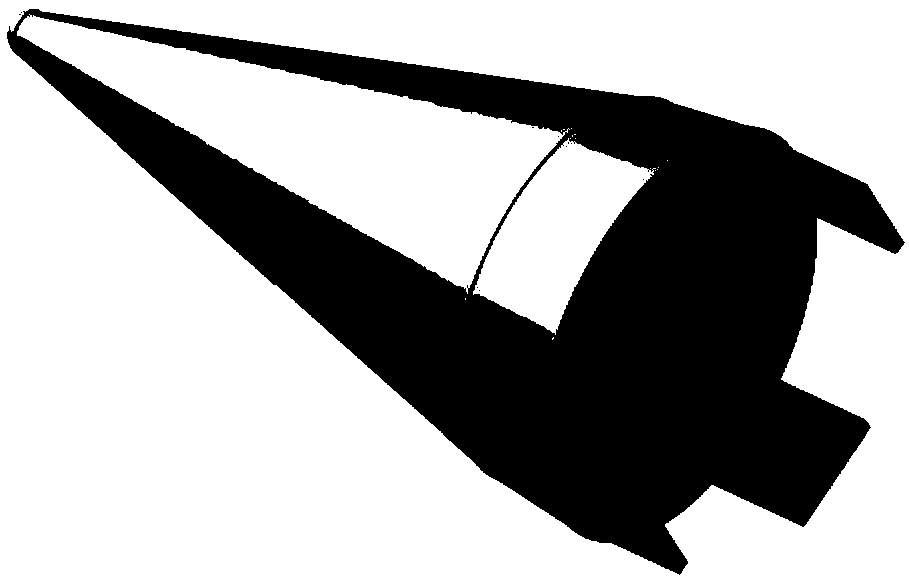

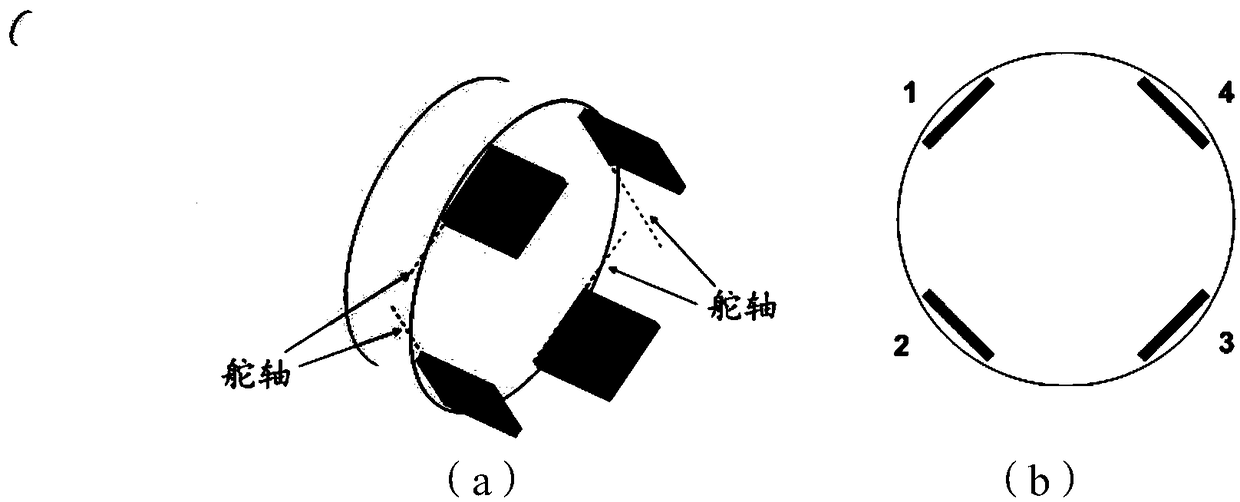

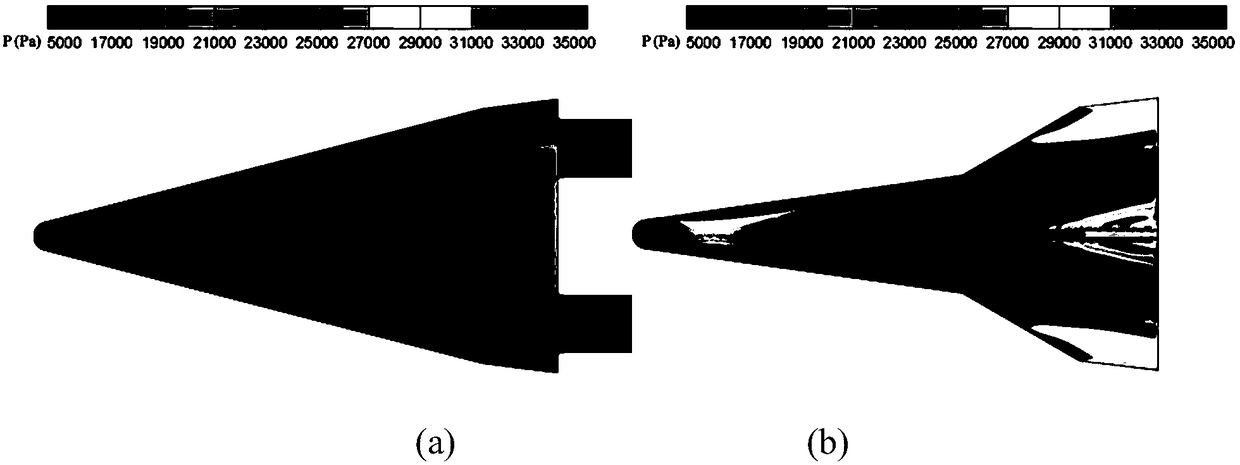

A rotary aircraft based on a new type of flap rudder surface

PendingCN109131950AFlow does not affectSmall aerodynamic interferenceCosmonautic vehiclesSystems for re-entry to earthFlight vehicleBody of revolution

A rotary aircraft based on a new type of flap rudder is based on a sphere-conical configuration of a rotary aircraft. This aircraft has a new type of flap control rudder surface. By designing four x-shaped distributed flaps on the tail of the body of rotary aircraft, and using the flaps as the full-motion rudder surface of the aircraft, the maneuverability of the aircraft at hypersonic speed can be obtained by flap deflection. The new type of flap rudder surface, replacing a common tail layout scheme, is helpful to reduce or eliminate the aerodynamic interference and heating problems in the conventional tail-fin configuration scheme, and effectively increase the loading space inside the aircraft instead of conventional tail-fin configuration scheme. The novel flap type control rudder is arranged at the bottom of the body of revolution fuselage, the flow of the flap rudder surface under the hypersonic environment will not affect the flow of the upstream body of revolution fuselage, theaerodynamic interference between the flap rudder and the body of the aircraft fuselage is small, and the problem of mutual interference between the tail fins of the conventional body of revolution fuselage is effectively avoided.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

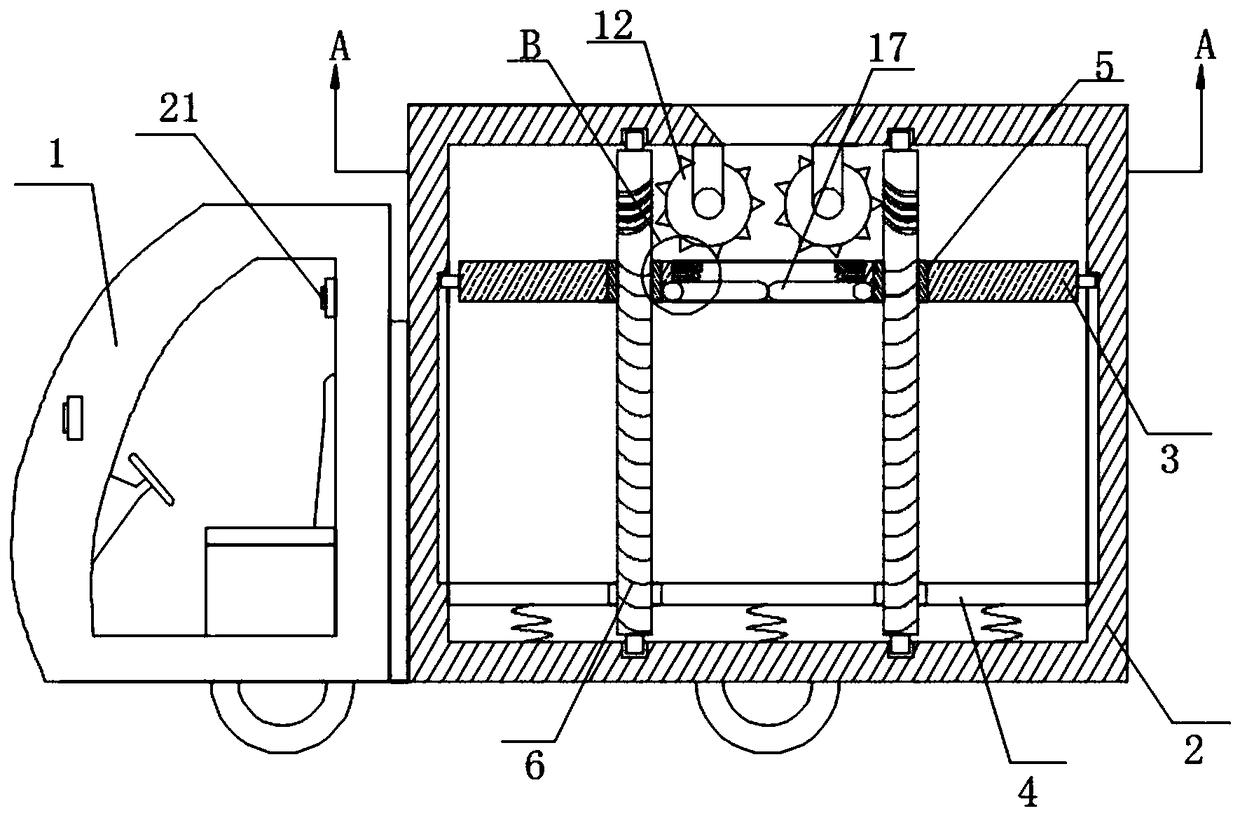

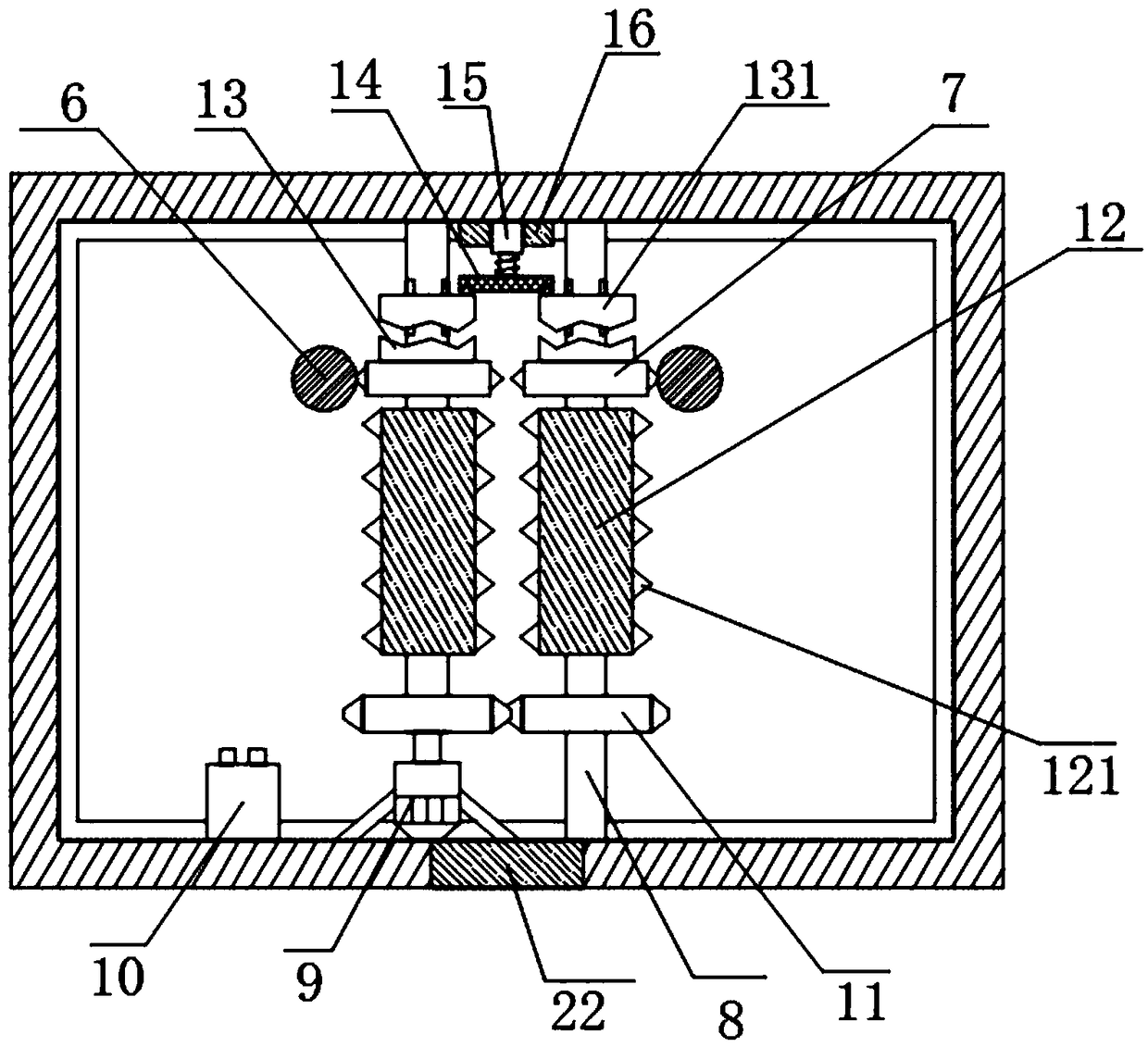

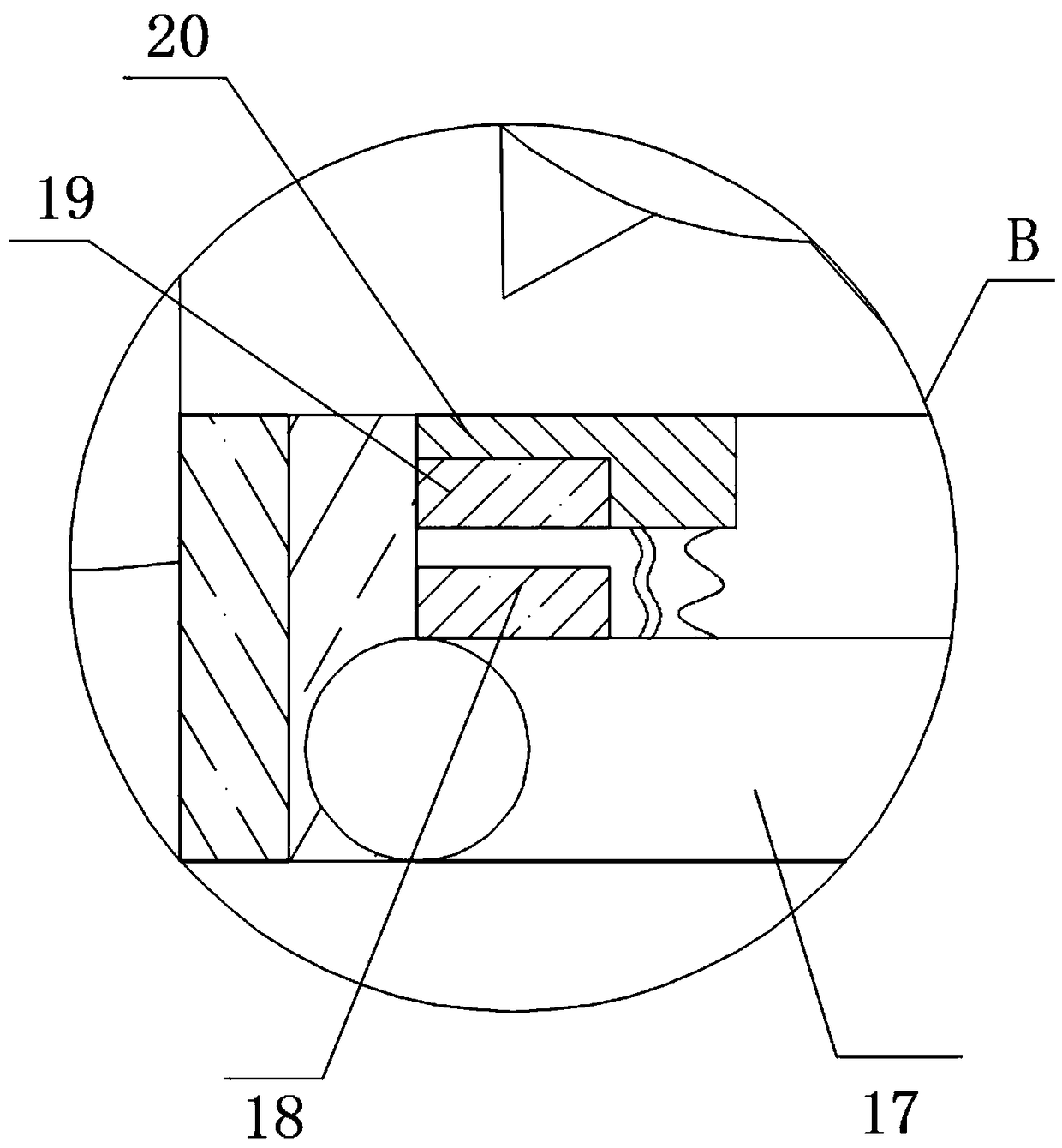

Sanitation garbage truck with loading space increasing function

The invention provides a sanitation garbage truck with a loading space increasing function. The sanitation garbage truck comprises a truck head, a carriage, a forward-reverse switch, wheels, a compression plate and a fixing plate. The carriage is connected to the side wall of the truck head, the forward-reverse switch is connected to the inner side wall of the truck head, the wheels are arranged at lower ends of the truck head and the carriage, the compression plate is slidably connected to the inner side wall of the carriage, and the fixing plate is fixedly connected to the inner side wall ofthe carriage. The sanitation garbage truck has advantages that defects of the prior art are overcome, reasonable design and compact structure are achieved, garbage can be smashed by rotating drums and sawteeth, and accordingly the garbage size can be reduced; in addition, the garbage can be compressed by the compression plate in vertical movement, and accordingly the garbage space is further reduced, and the loading capacity of the sanitation garbage truck is increased.

Owner:ANHUI XINYU ENVIRONMENTAL SANITATION MACHINERY

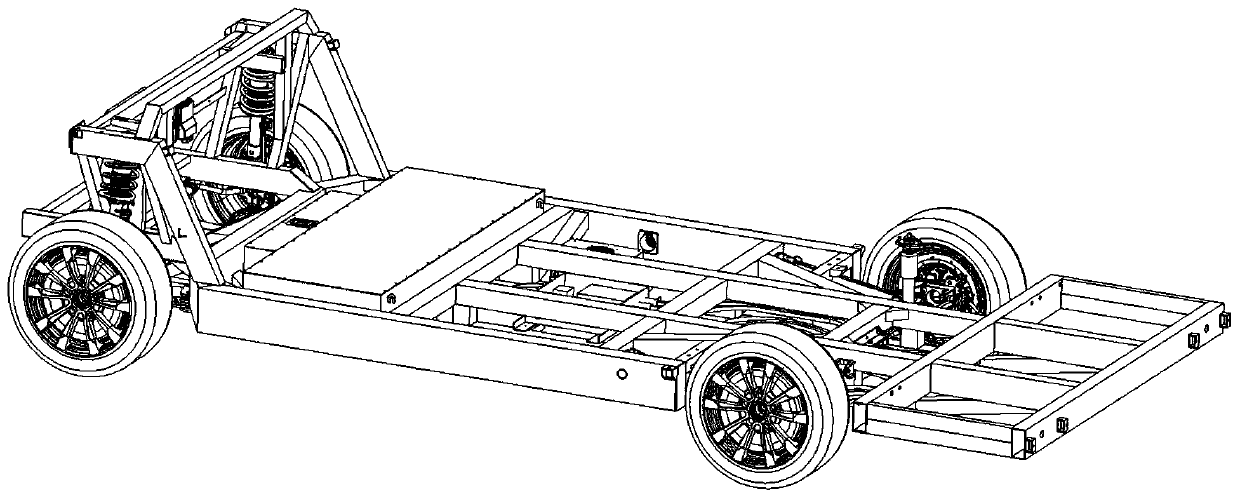

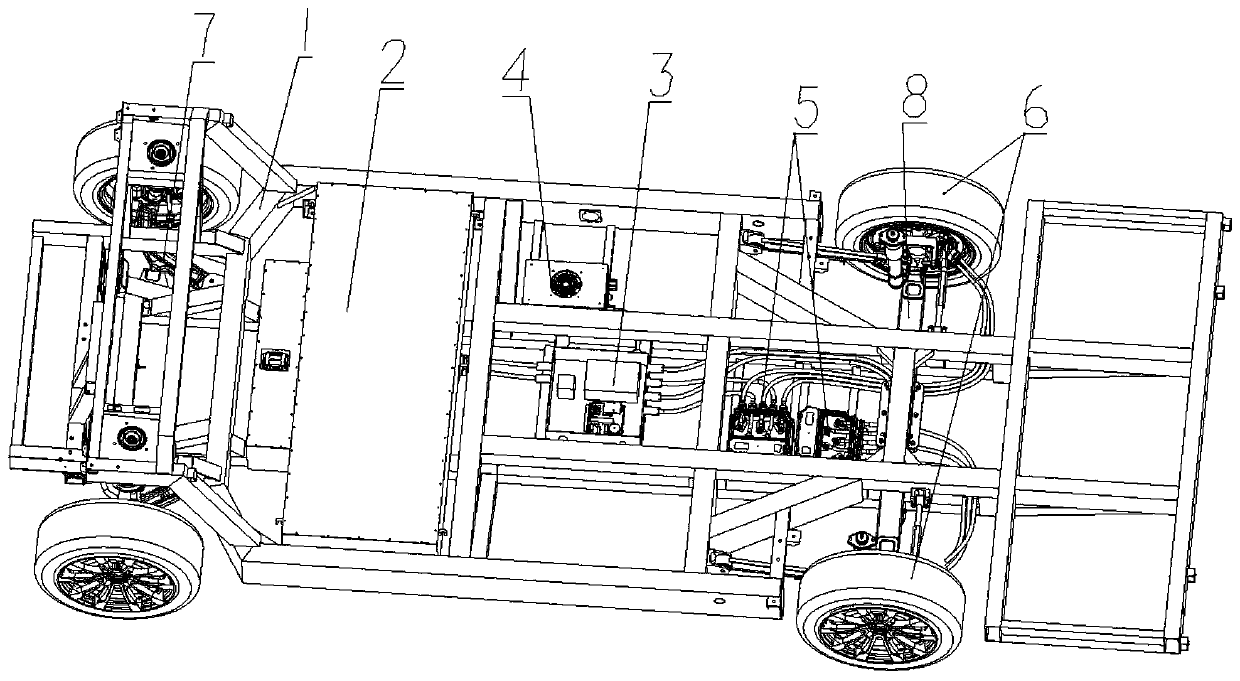

Low-floor chassis platform integrating hub motor

PendingCN110435381AIncrease the load-to-weight ratioHigh strengthSpeed controllerElectrodynamic brake systemsLow voltageDrive shaft

The invention discloses a low-floor chassis platform integrating a hub motor. The low-floor chassis platform comprises a lower vehicle body, a low-voltage control element, a wheel assembly, Macphersonsuspensions, a multi-connecting rod and a transverse leaf spring independent suspension, wherein a front suspension and a rear suspension of the lower vehicle body are independently controlled, and atransmission shaft and a differential mechanism are not arranged between the front suspension and the rear suspension; the Macpherson suspensions are arranged on the front suspension of the lower vehicle body, and a transverse stabilizer rod is installed to be matched with the Macpherson suspensions; the transverse stabilizer rod spans between the Macpherson suspensions on wheels on the two sidesof the front suspension; the wheel edges of the front suspension integrate a traditional caliper and a disc brake; the front part of the lower vehicle body is a chassis platform front cabin space forintegrating and installing the low-voltage control element; and the middle rear part comprises a high-voltage control element. According to the low-floor chassis platform, the weight of the whole platform is effectively reduced, the height of a chassis is reduced, the weight of a whole vehicle is effectively reduced, the system efficiency is improved, the loading volume is increased, the loadingratio of the whole vehicle is improved, meanwhile, better bearing capacity can be obtained, and the expansion performance is high.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Side frame for large-scale box

InactiveCN101318587AIncreased loading spaceAvoid touching each otherLarge containersLoading-carrying vehicle superstructuresShear stressWave shape

The invention relates to a side wall used in a large-scale case, comprising a plurality of unframed lateral plates which are mutually spliced and a splice structure for connecting the splice ends of two adjacent unframed lateral plates; the splice structure consists of an inner connecting piece which is clamped at both sides of the splice ends of two adjacent unframed lateral plates and positioned in the case, an outer connecting piece which is positioned at the outside of the case and a rivet used for connecting the inner connecting piece, the outer connecting piece and the splice ends of the unframed lateral plates, and the cross section of the overlap section of the inner connecting piece and the splice end of the unframed lateral plate is corrugated. The side wall used in a large-scale case in the invention adopts a corrugated inner connecting piece to replace the original inner connecting piece with a convex wave shape, thus the strength and rigidity of the connecting structure both meet the requirements of the case, steps projected from the inner side of the side wall can be eliminated, mutual collision and damage between cargoes and the steps at the side wall can be avoided, and the loading space of the case can be enlarged; moreover, as the overlap section of the inner and outer connecting pieces and the splice ends of two adjacent unframed lateral plates adopts inosculated corrugation for matching, the shearing stress of the rivet is reduced and the transverse connecting strength and connecting reliability of the side wall can be improved.

Owner:CIMC VEHICLES (GROUP) CO LTD

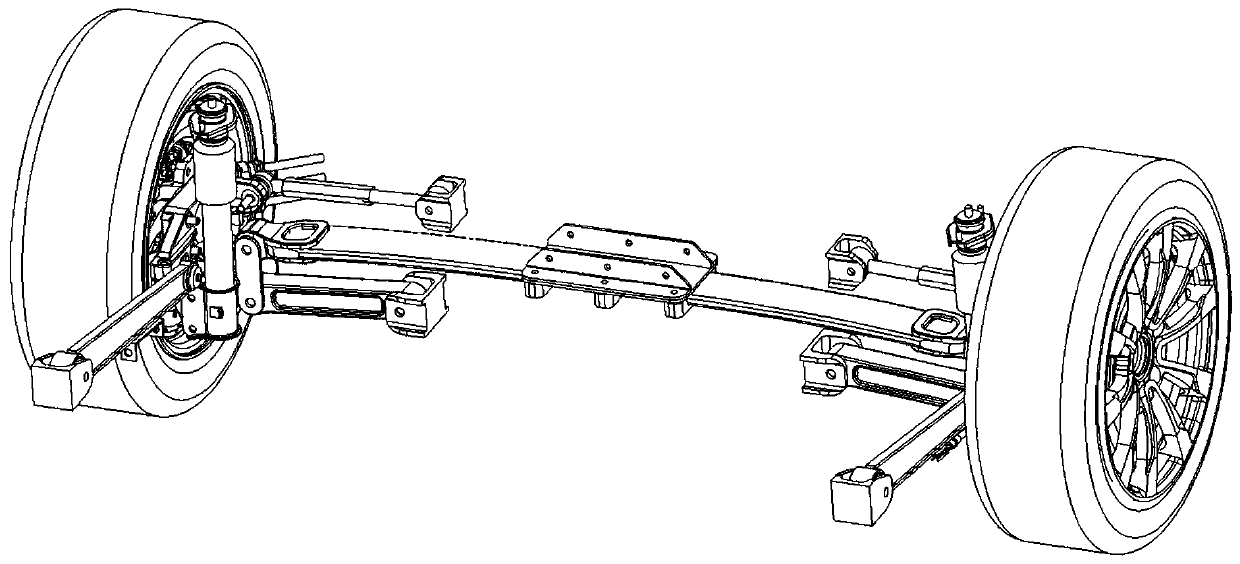

Torsion beam axle device for vehicle

ActiveCN104908551AIncreased loading spaceIncrease lateral stiffnessInterconnection systemsBeam axleAutomotive engineering

A torsion beam axle device for a vehicle may include: a pair of trailing arm members having wheels coupled thereto and rotatably coupled to a vehicle body; and a torsion beam member having both ends coupled to the trailing arm member, and bent in a shape protruding toward a rear side of the vehicle body.

Owner:HYUNDAI MOBIS CO LTD

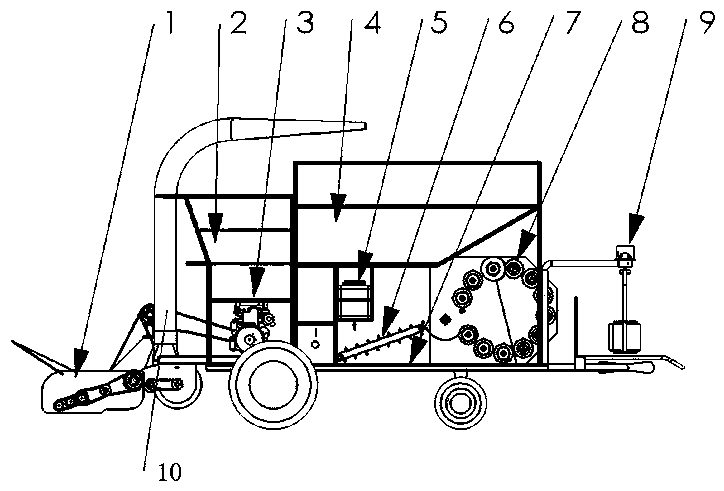

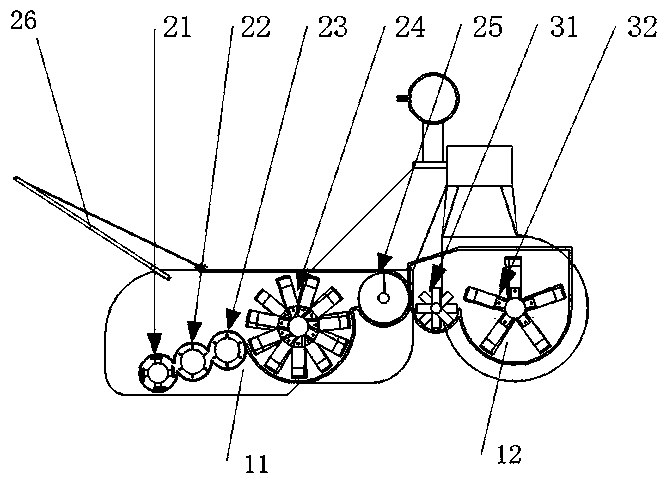

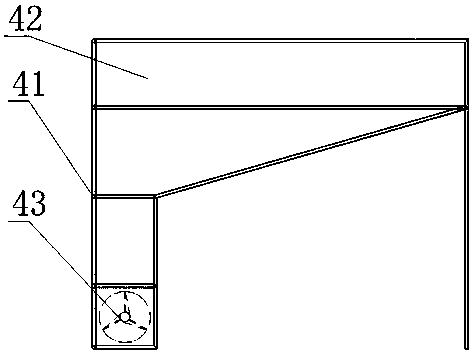

Silage corn harvesting and bundling film wrapping machine

PendingCN109699289AEasy to crushSuitable for makingMowersIndependant bindersAgricultural engineeringConveyor belt

The invention relates to the technical field of agricultural machinery, in particular to a silage corn harvesting and bundling film wrapping machine used for corn harvesting. The silage corn harvesting and bundling film wrapping machine comprises a walking machine body provided with a cab, and further comprises a harvesting device located at the front end of the cab of the machine body, a storagebin located in rear of the cab, a feed bundling machine located in rear of the storage bin, a conveyor belt connecting the storage silo and a compression bundling device, a sprinkler device located above the conveyor belt and a film wrapping machine body located at the most tail end of the machine body. The silage corn harvesting and bundling film wrapping machine has the advantages that harvesting, smashing, sprinkling, bundling and film wrapping are integrated, so that all parts are compact, the overall size is small, harvesting is convenient and fast, the effect is good, and the applicationrange is wide.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

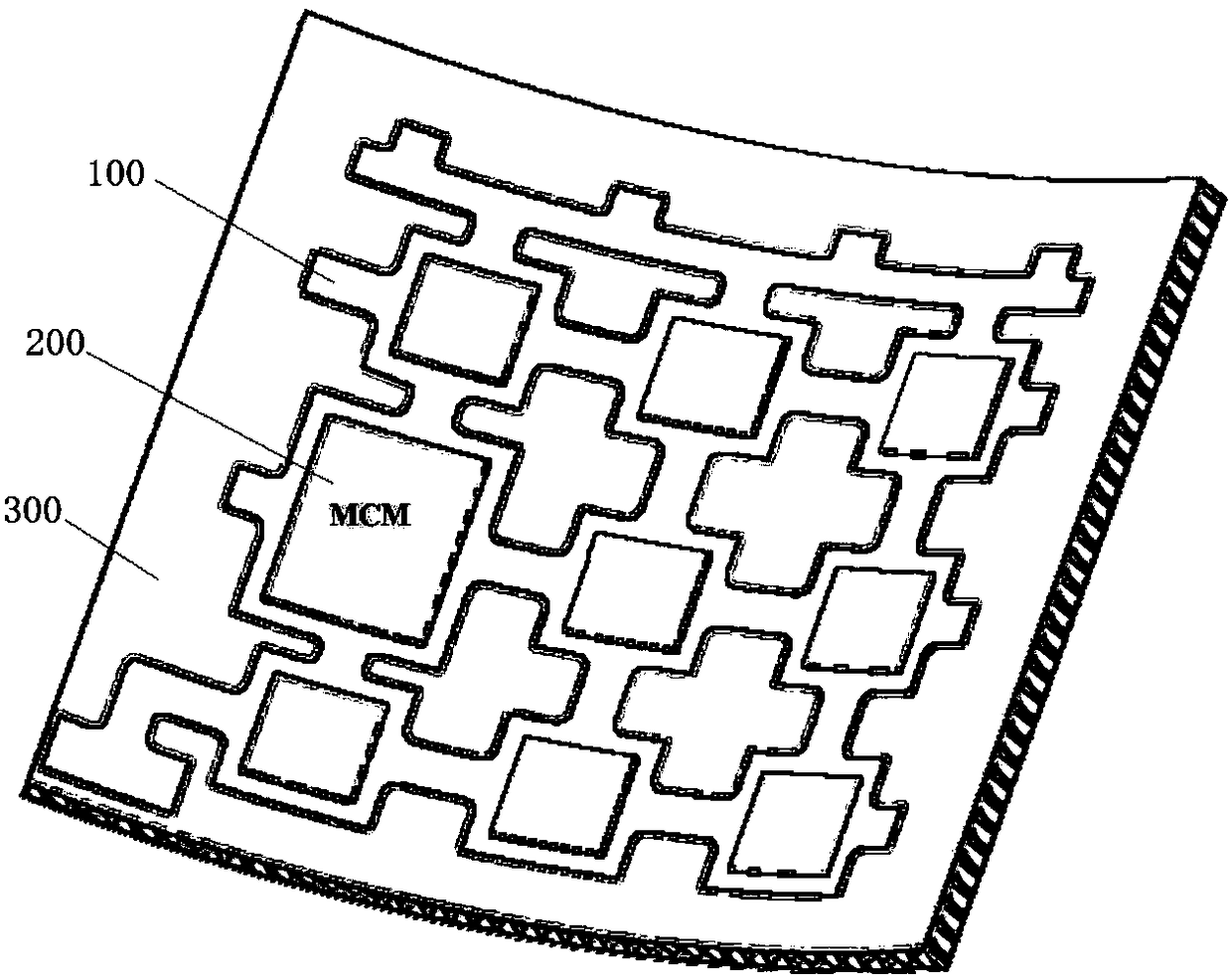

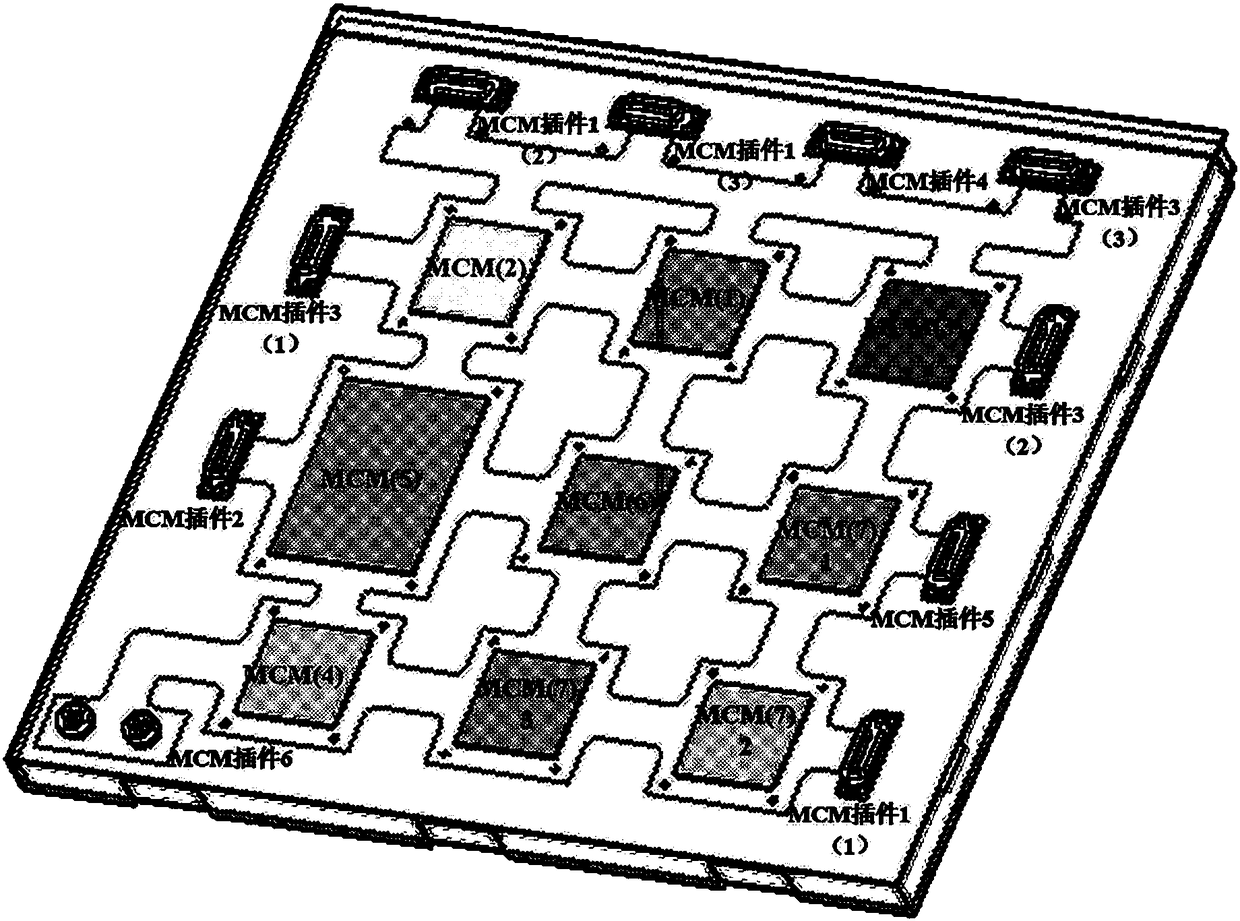

Curved Surface Flexible Aerospace Multifunctional Structure Computer

ActiveCN106970689BReduce volumeReduce weightDigital processing power distributionEngineeringSpaceflight

The invention provides a curved surface type flexible astronautic multifunctional structure computer. Functional circuits of a power supply, a CPU, data storage, man-machine interaction, a field bus and the like are reconstructed into multiple multi-chip modules (MCM) and MCM plug-ins; topological configuration of the structure computer is determined by a curved surface structure of a spacecraft; flexible connection cables are designed based on the topological configuration to realize flexible connection among the MCMs; and finally a system is combined with the curved surface structure of the spacecraft to form the novel integrated flexible multifunctional structure computer fusing active electronic circuits and mechanical configuration of an astronautic structure. According to the computer, integrated design of electronic control, thermal control and a structure body is realized, so that the problem of large volume in an existing spaceborne computer device is effectively solved, the parasitic mass of the system can be greatly reduced, the function density is increased, and the internal loading space of the spacecraft is expanded; and the computer is especially suitable for a type of spacecrafts with lightweight structure and large loading space requirements.

Owner:NAT UNIV OF DEFENSE TECH

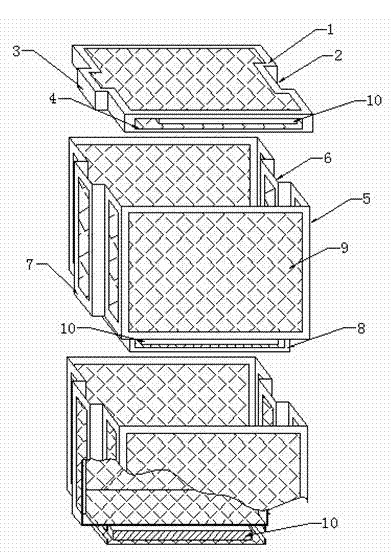

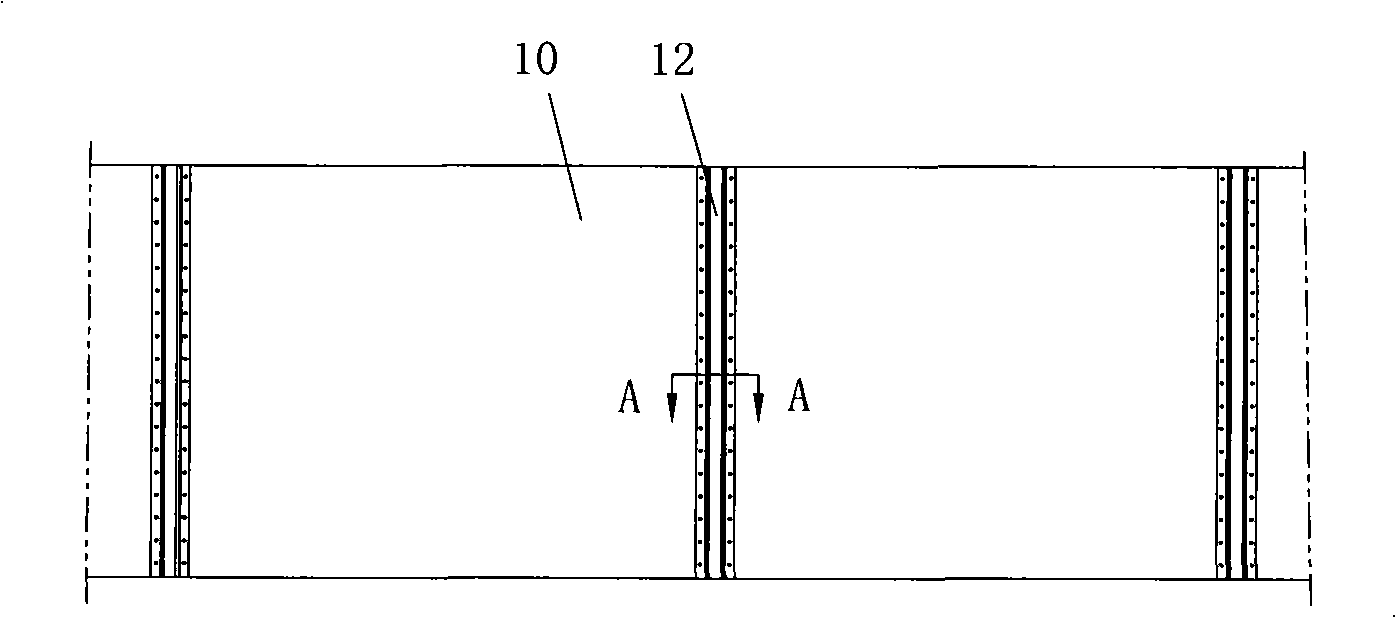

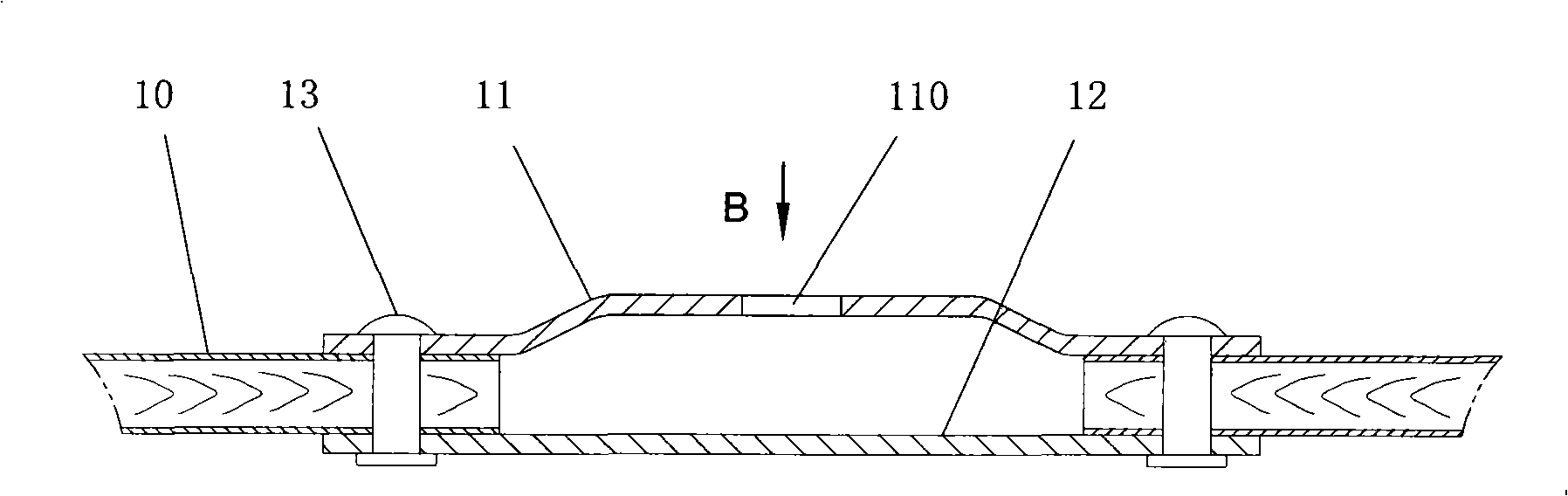

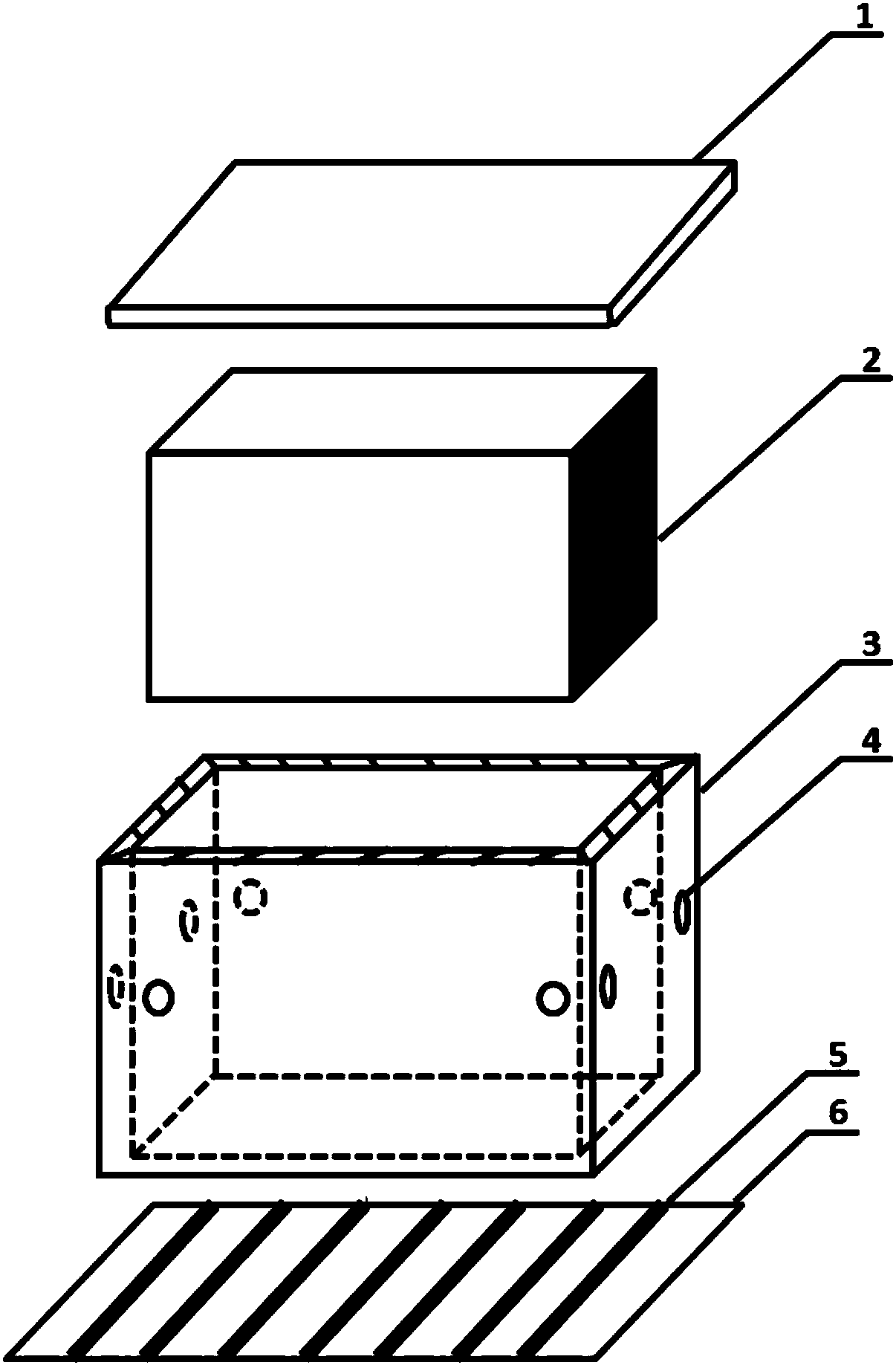

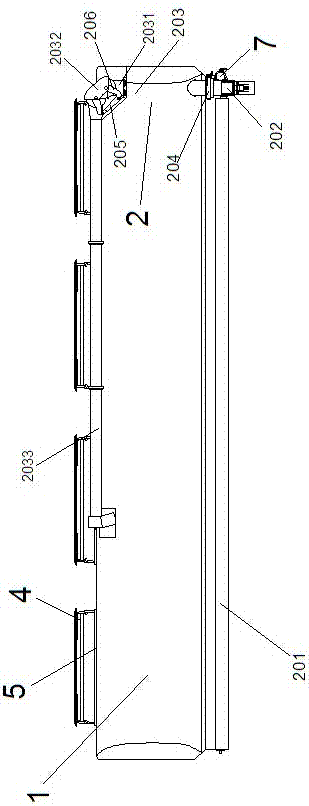

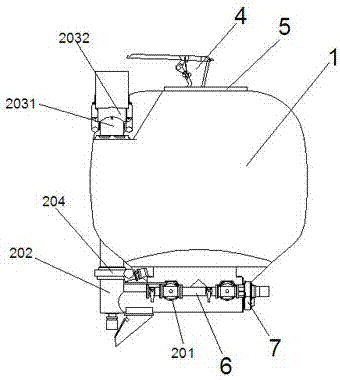

Film type heat insulation box for liquefied natural gas ship and construction method thereof

ActiveCN107792299AMeet strength requirementsLow costVessel designingFor bulk goodsThermal insulationEngineering

The invention discloses a film type heat insulation box for a liquefied natural gas ship and a construction method thereof. The film type heat insulation box is composed of plywood and a hard polyurethane foam plate. The heat insulation box adopts one layer, a compact metal film covers the upper surface of the heat insulation box, and the heat insulation box is directly connected with an inner bottom plate of a hull through viscous resin ropes. The construction method comprises the steps of plate cutting, drilling, forming of a T-shaped groove, assembling and bonding. Through optimal assembling of the low-density hard polyurethane foam plate and the plywood, the daily evaporation rate of a liquefied natural gas cabin of the liquefied natural gas ship is decreased, and the long-term servicestability of a heat insulation system is improved; and meanwhile a multiple-layer heat insulation box is simplified into a one-layer heat insulation box, so that the weight of the whole heat insulation box is reduced, the loading space is enlarged, the construction, mounting and transport costs are lowered, and the transport efficiency and safety are improved.

Owner:SHANGHAI JIAO TONG UNIV

Double-stage parallel-connection rigid power transmission system for auxiliary transport vehicle under low type coal mine

InactiveCN105416054AWork around limited usageSave installation spaceAxle unitsControl devicesDrive shaftThrough transmission

The invention belongs to the field of auxiliary transport vehicles for coal mines and provides a double-stage parallel-connection rigid power transmission system for an auxiliary transport vehicle under a low type coal mine in order to solve the problem of use limitation of the transport vehicle under the low coal mine. The system comprises a drive axle main body and two groups of wheel side brakes, wherein the two groups of wheel side brakes are connected in parallel to two sides of the rear of the drive axle main body respectively through transmission mechanisms in a transmission ratio being 1; each transmission mechanism comprises two transmission cases rigidly connected through a transmission shaft, one transmission case is connected with a middle half axle of the drive axle main body, and the other transmission case is connected with the corresponding wheel side brake. According to the system, a conventional wet type drive axle is effectively separated, so that the drive axle main body moves forwards and is closer to the hinged position of the vehicle while the tire installation positions are not changed, original drive axle installation space is saved for goods loading, more loading space is saved for a rear rack, and the problem of use limitation of the transport vehicle under the low type or ultra-low type coal mine is solved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A double horizontal auger conveying tank for transporting bulk feed or grain

ActiveCN104960799BIncrease loading capacityIncrease unloading speedLarge containersLoading/unloadingEngineeringUltimate tensile strength

The invention discloses a dual-horizontal-auger conveying tank for transporting bulk feed or grain and belongs to the field of carrier vehicles / semitrailers for bulk feed or grain. A dual-horizontal-auger loading system, a door opening and material discharging system and a four-bar linkage feeding door mechanism are arranged on a tank body of the conveying tank. Materials enter the tank body to be stored through the four-bar linkage feeding door mechanism, then enter the dual-horizontal-auger loading system through the door opening and material discharging system, and are discharged outside through the door opening and material discharging system. The dual-horizontal-auger loading system comprises a dual-horizontal-auger shaft assembly, a transverse auger assembly and a vertical lifting auger assembly, wherein the dual-horizontal-auger shaft assembly, the transverse auger assembly and the vertical lifting auger assembly are connected in sequence. According to the dual-horizontal-auger conveying tank for transporting bulk feed or grain, the structure intensity of the tank body is guaranteed, the structural design of the tank body is changed effectively, the dual-horizontal-auger greatly enlarges the loading volume of the tank body, and increases the unloading speed at the same time, auger conveying systems are fixedly connected on the tank body structure, a part of loading space occupied by the auger conveying systems mounted on the outer rear portion of the tank body is reduced, and the loading space of the tank body is enlarged.

Owner:LUOYANG CIMC LINYU AUTOMOBILE

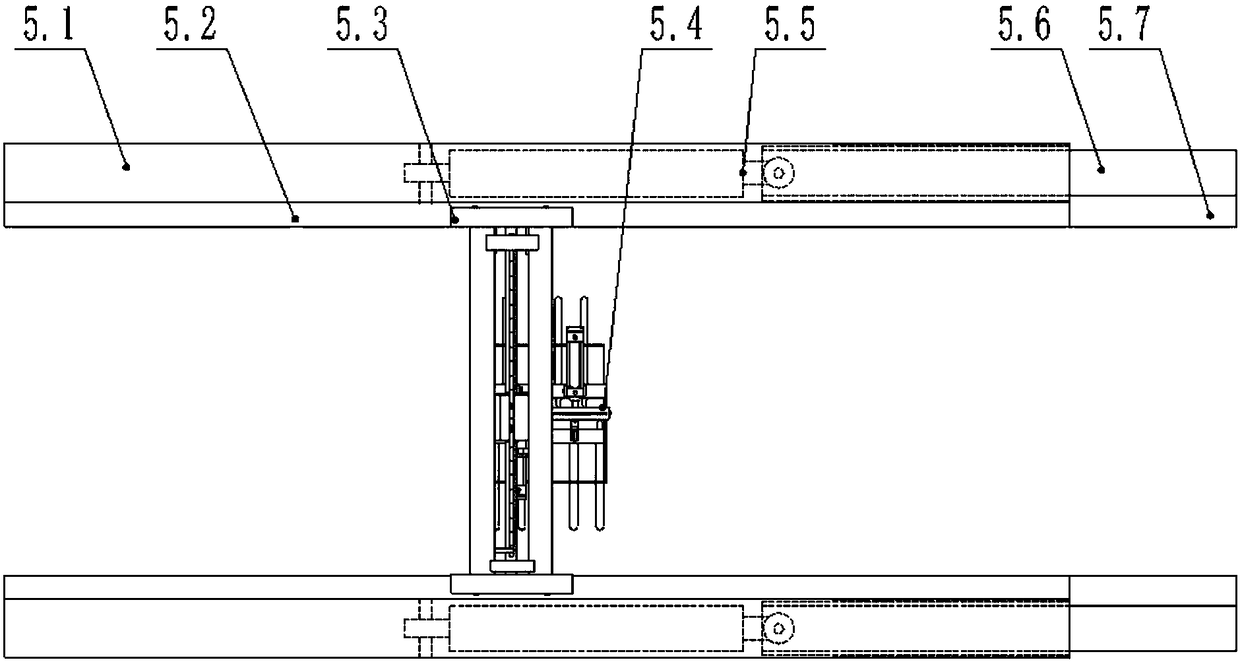

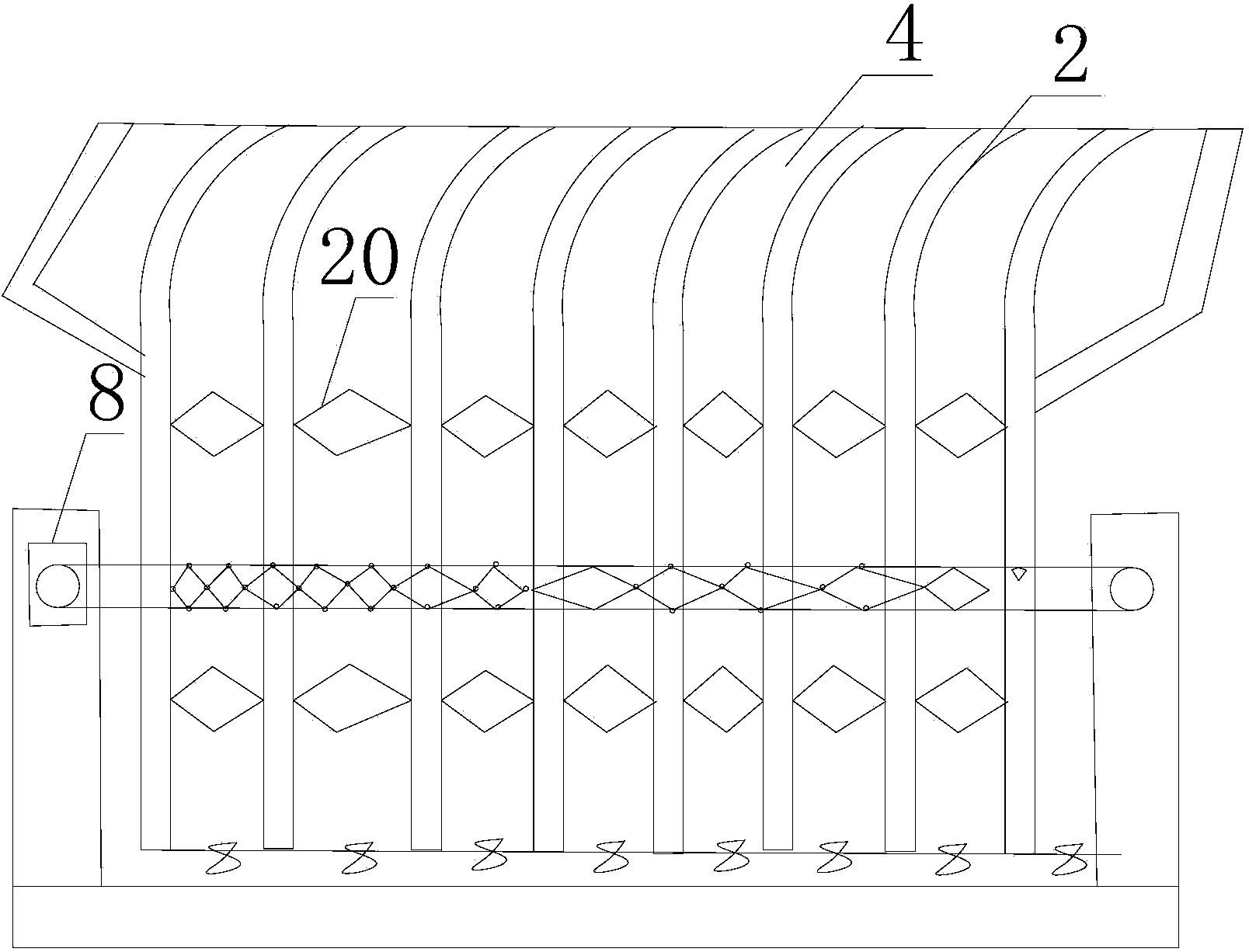

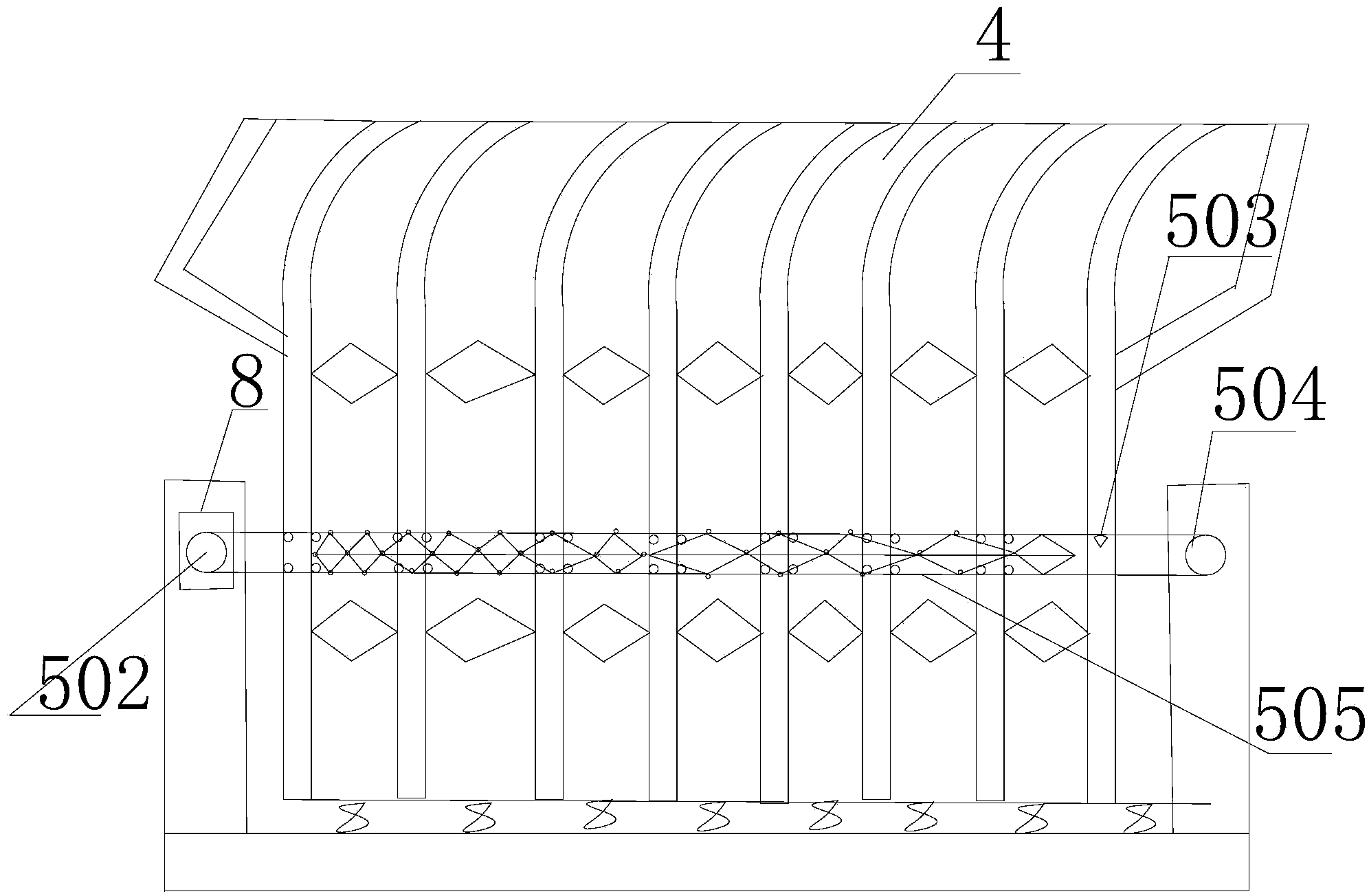

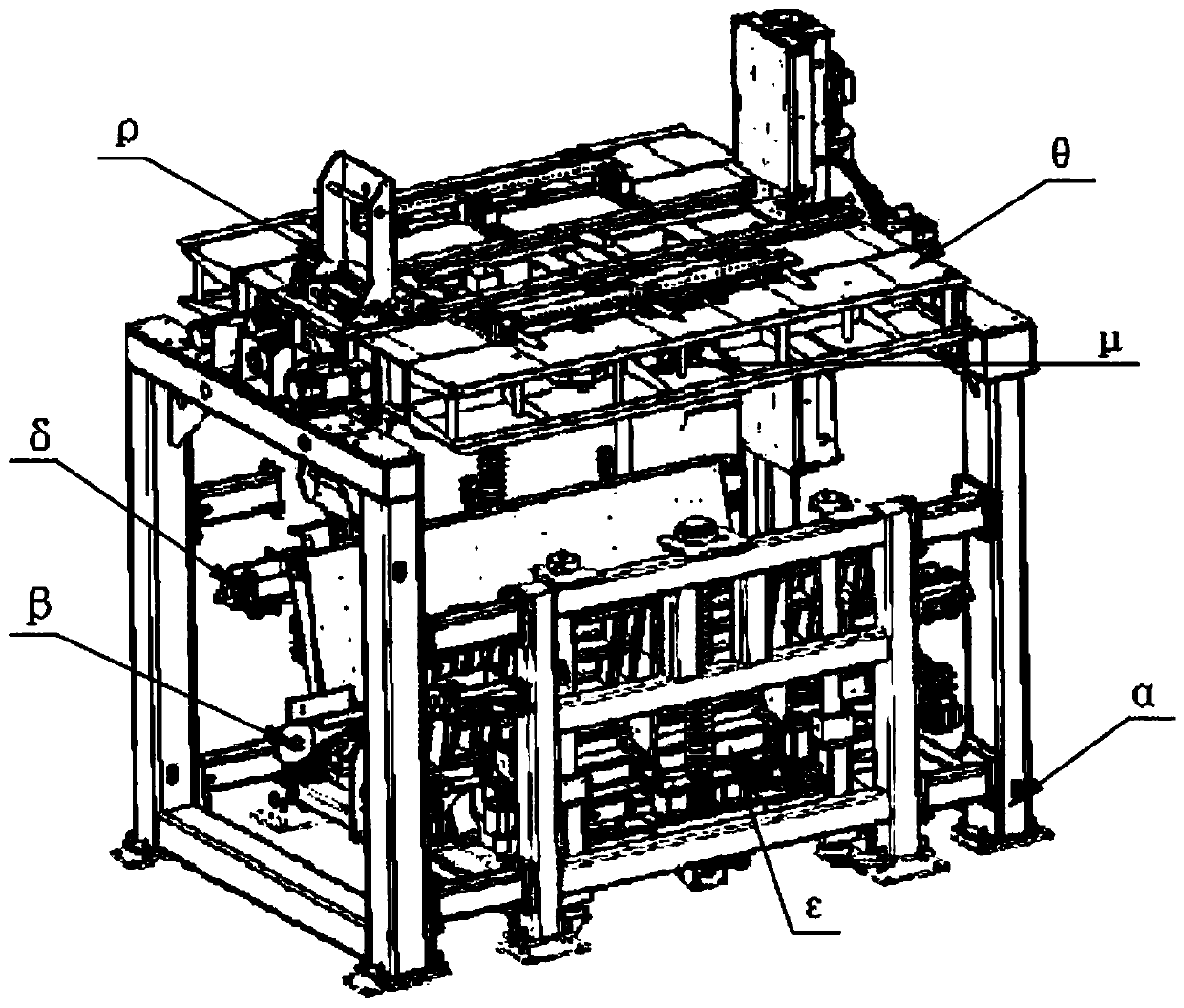

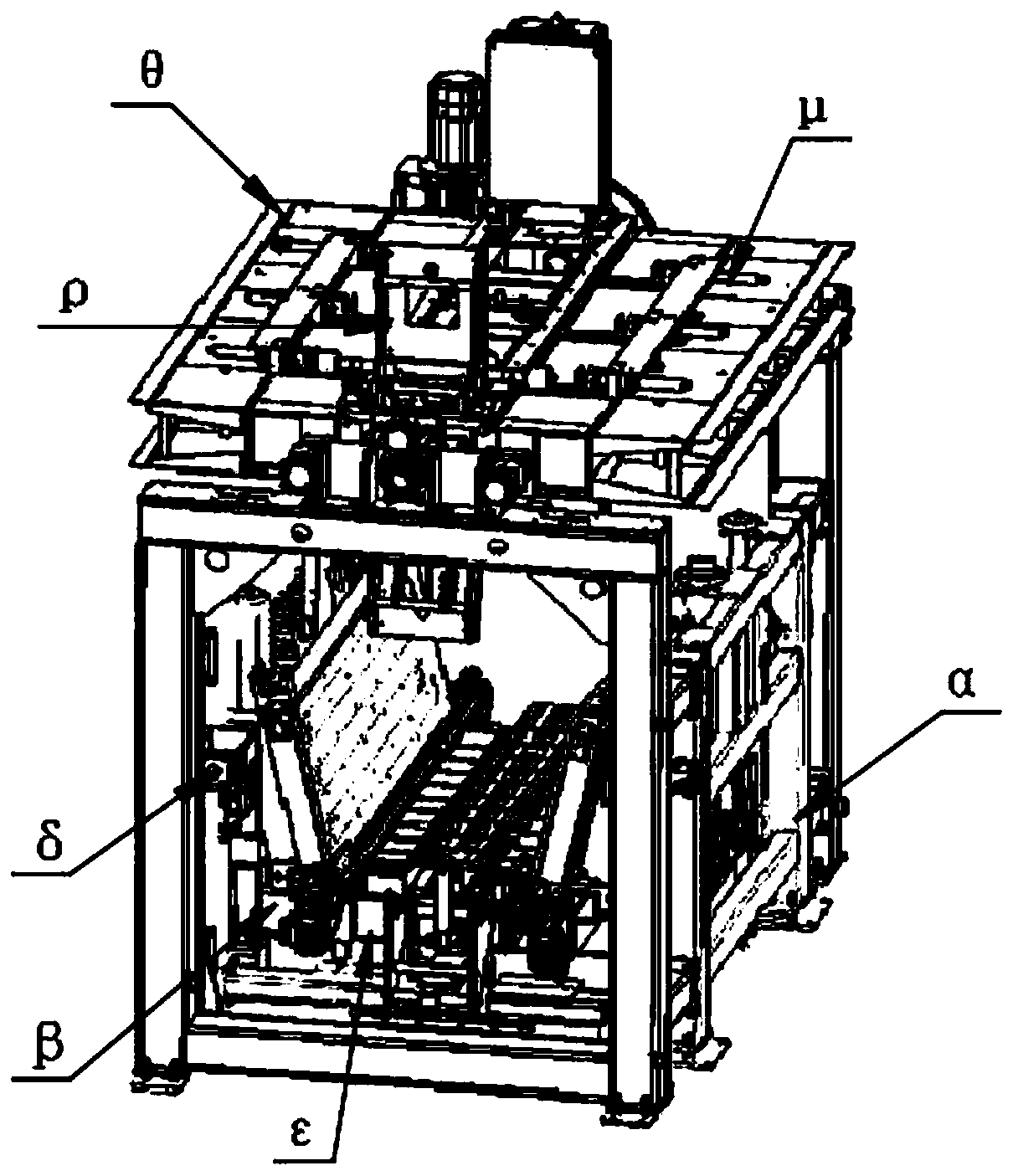

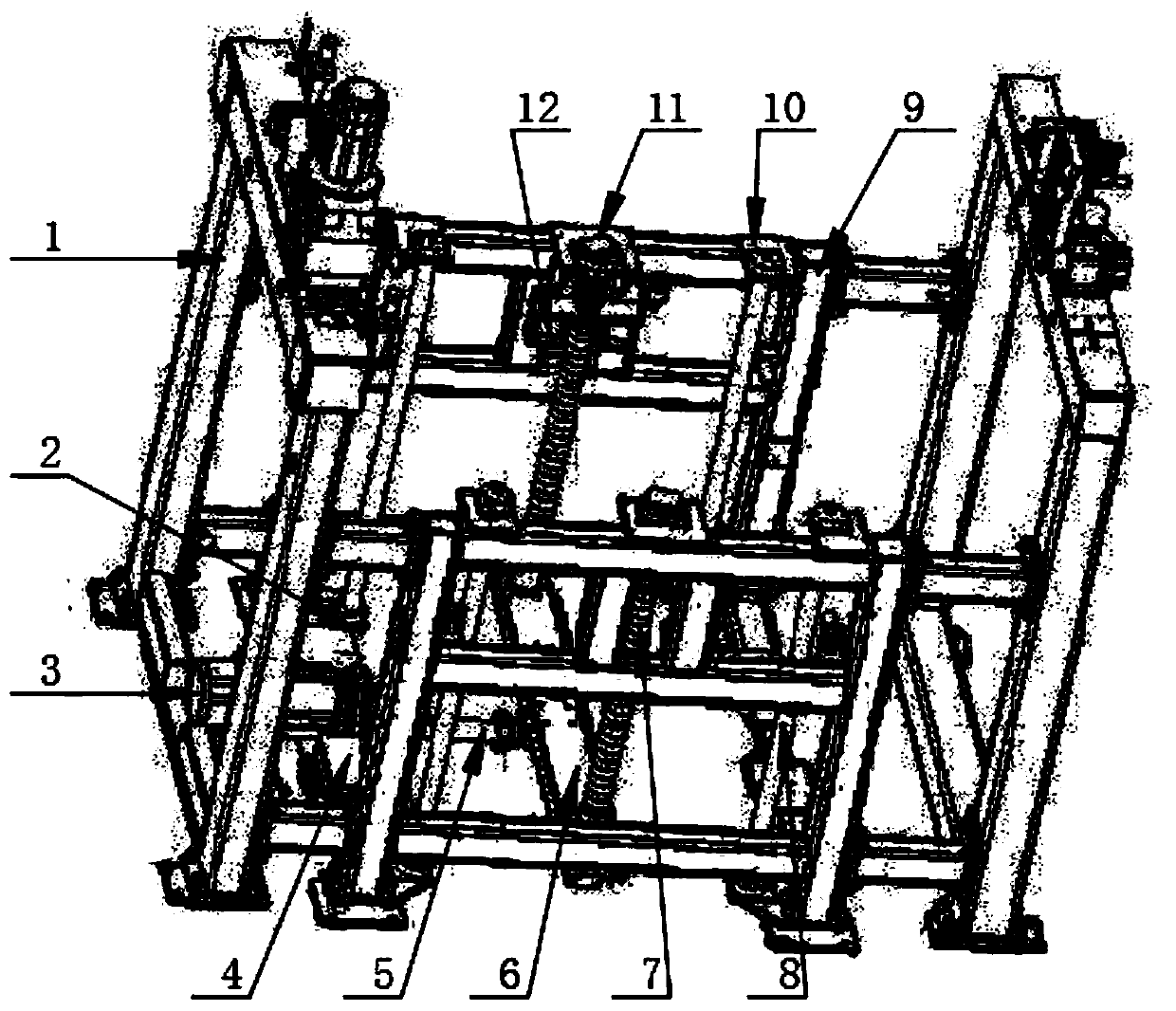

Fixture for foaming of refrigerator box body

The invention discloses a fixture for foaming of a refrigerator box body. The fixture includes a lifting transmission mechanism, a belt conveying mechanism, a supporting pipe mechanism, locking mechanisms, a turnover positioning mechanism, transmission limiting mechanisms and front baffle limiting mechanisms. The lifting transmission mechanism is internally provided with the belt conveying mechanism. The supporting pipe mechanism is arranged at the top of the belt conveying mechanism. The locking mechanisms are arranged on two sides of the lifting transmission mechanism correspondingly. The turnover positioning mechanism is arranged at the center of the top of the lifting transmission mechanism. The transmission limiting mechanisms are arranged on two sides of the turnover positioning mechanism, and the front baffle limiting mechanisms are arranged at the top and the bottom of the turnover positioning mechanism correspondingly. The lifting transmission mechanism, the belt conveying mechanism, the supporting pipe mechanism, the locking mechanisms, the turnover positioning mechanism, the transmission limiting mechanisms and the front baffle limiting mechanisms are combined to improvethe overall production efficiency and automation.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

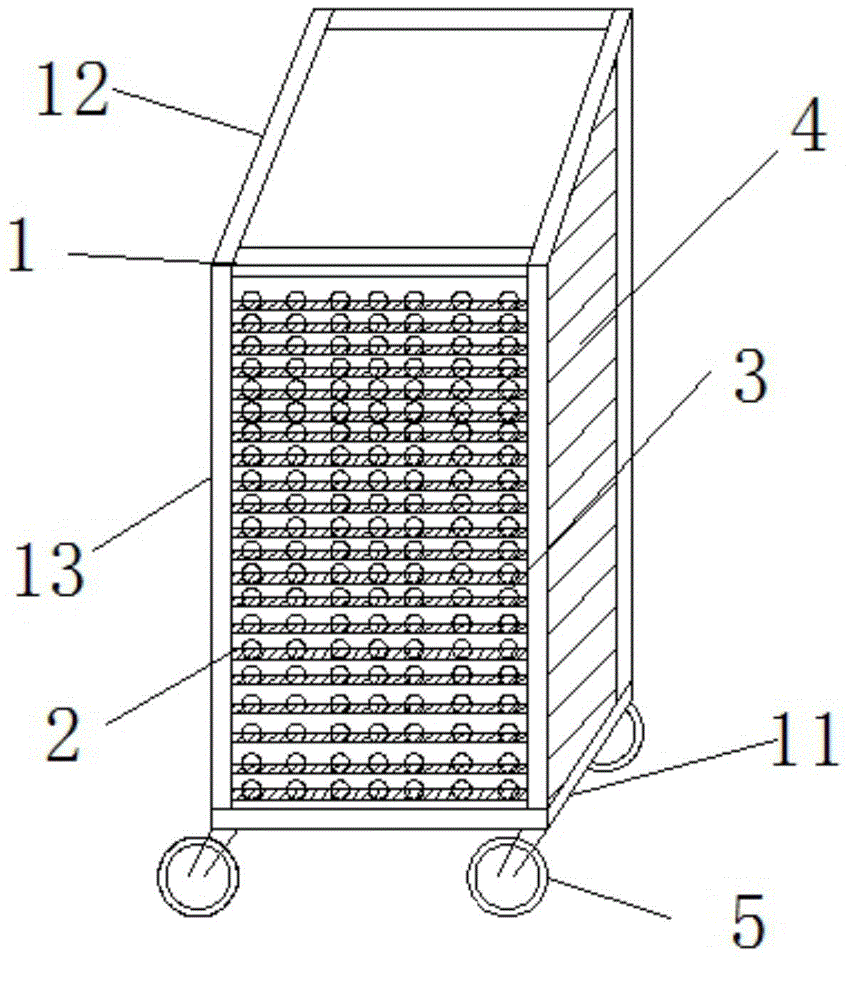

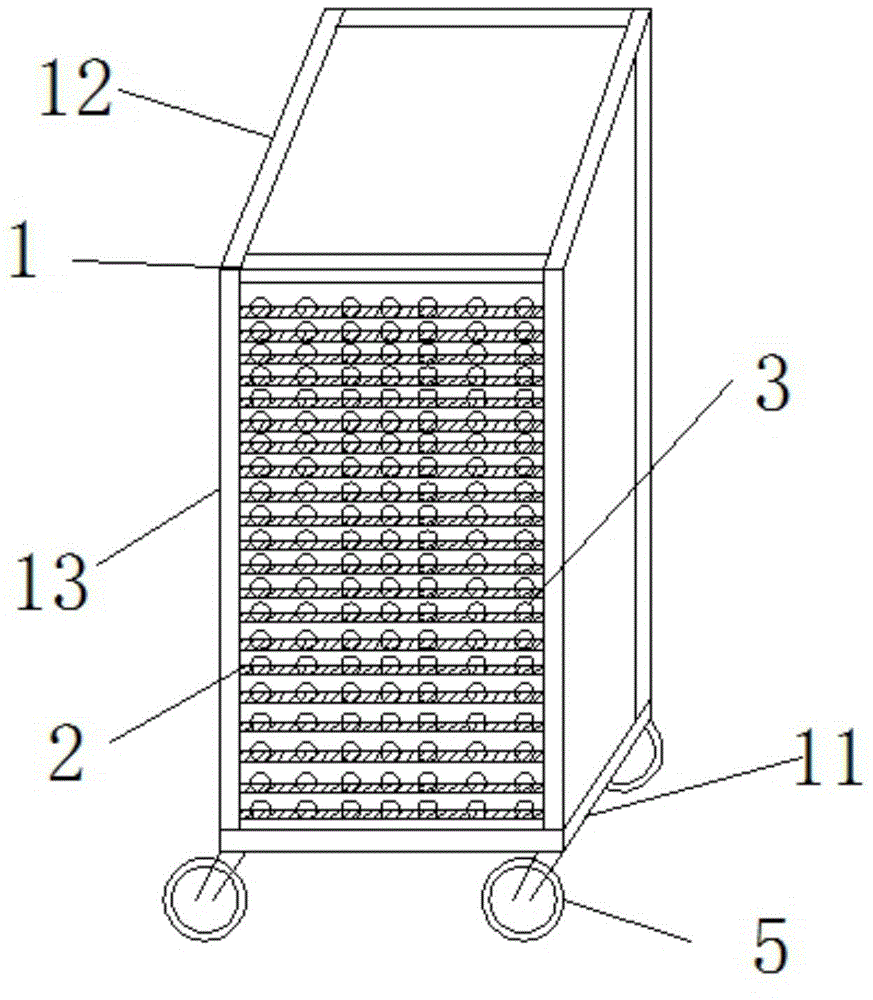

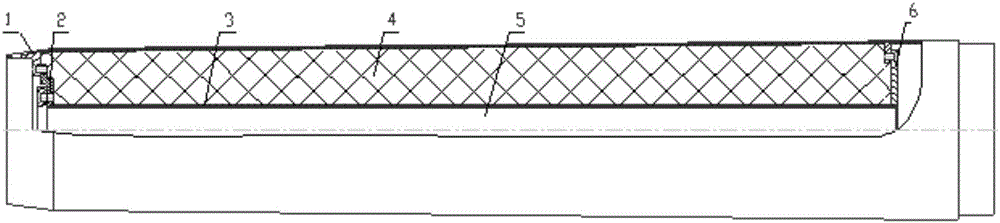

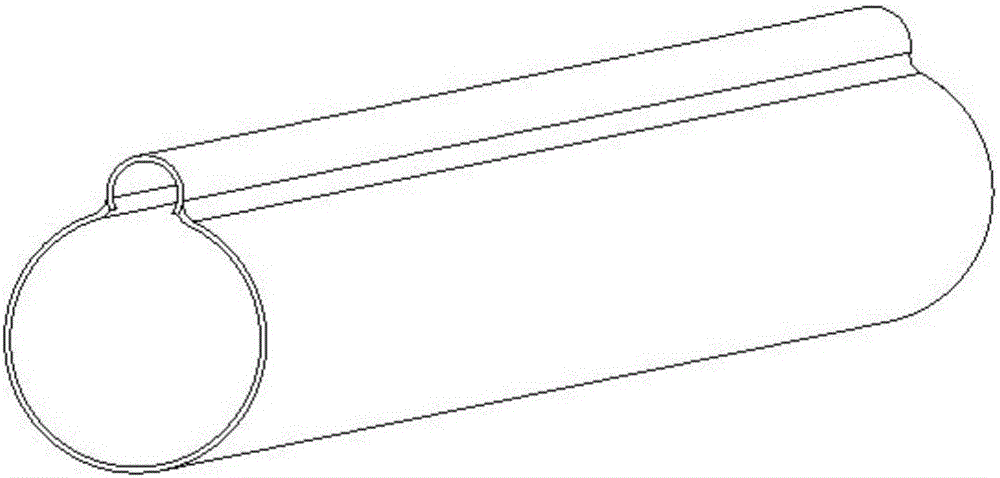

Drying plate frame

The invention relates to a drying plate frame. The drying plate frame comprises a bracket; the bracket comprises a lower frame, an upper frame and four vertical supporting columns, wherein the four vertical supporting columns are connected between four corners of the upper frame and the lower frame; a plurality of supporting beams which are uniformly distributed from top to bottom are connected to the inner sides of the horizontally opposite supporting columns; rolling bearings are uniformly mounted on the supporting beams; a baffle is arranged at one side of the bracket along the direction to which the rolling bearings rotate; universal wheels are arranged at four corners of the lower frame. The drying plate frame is simple in structure, convenient to operate, obvious in ventilating effect, large in loading space, and high in practicability.

Owner:JIANGSU TISUNBA ELECTRONICS TECH

Integrated type warhead

InactiveCN105043170AIncreased loading spaceSimple designAmmunition projectilesProjectilesDetonationDiameter ratio

The invention relates to an integrated type warhead. The integrated type warhead comprises a metal shell (1), a front baffle (2), a cable pipe (3), a main charge part (4), a detonation or detonation amplification charge box (5) and a rear baffle (6). A front boss and a rear boss are arranged inside the metal shell and provided with the two baffles respectively. The cable pipe is arranged at the axes of the two baffles. The shell, the two baffles and the cable pipe seal the main charge part into the shell together. The cable pipe (3) is formed by combining a round pipe and a U-shaped pipe and is in a flange shape in appearance. The U-shaped pipe is filled with a cable (8). The round pipe is filled with the detonation or detonation amplification charge box (5). The various requirements for penetrating of the cable through a cabin, fixing of the cable, isolating of the main charge part and filling of the detonation or detonation amplification charge box of the warhead are met through the integrally designed cable pipe structure at the axis, the charge space is greatly increased, and therefore the warhead small in size and large in length-diameter ratio achieves the high charge-weight ratio.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

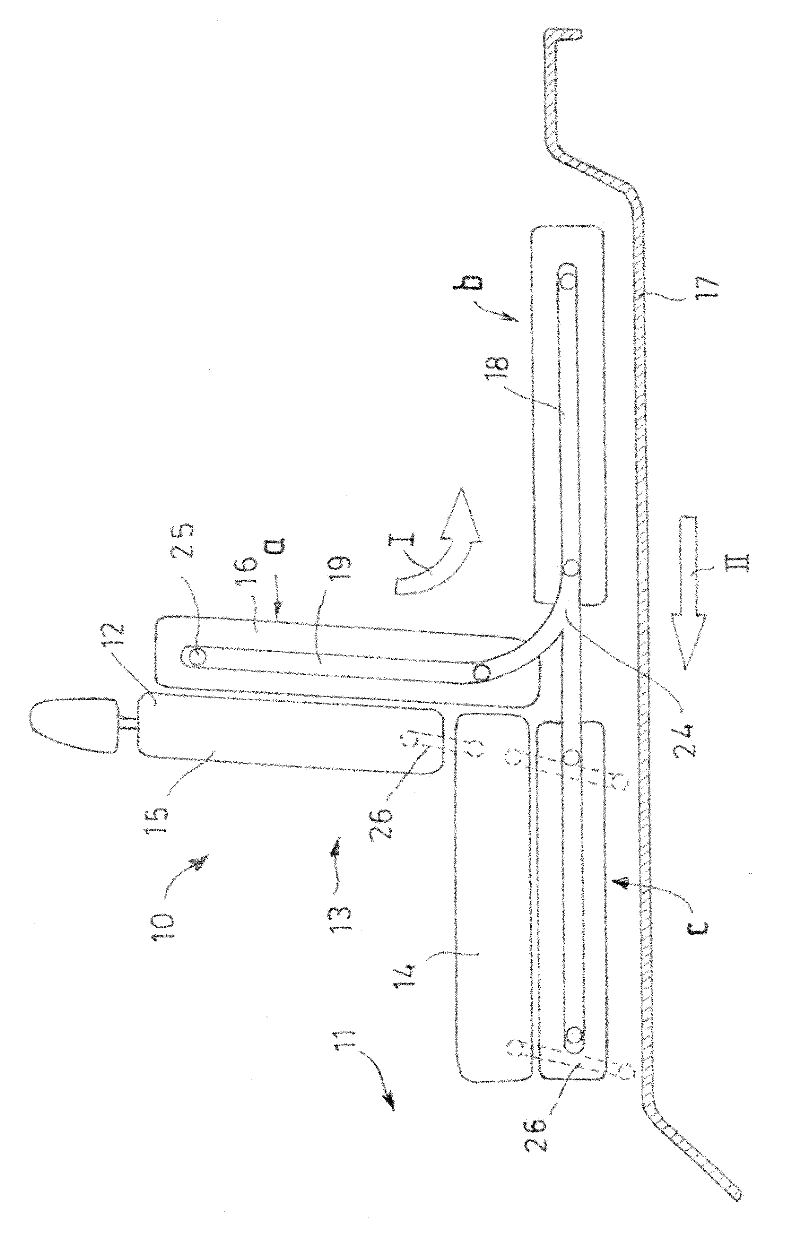

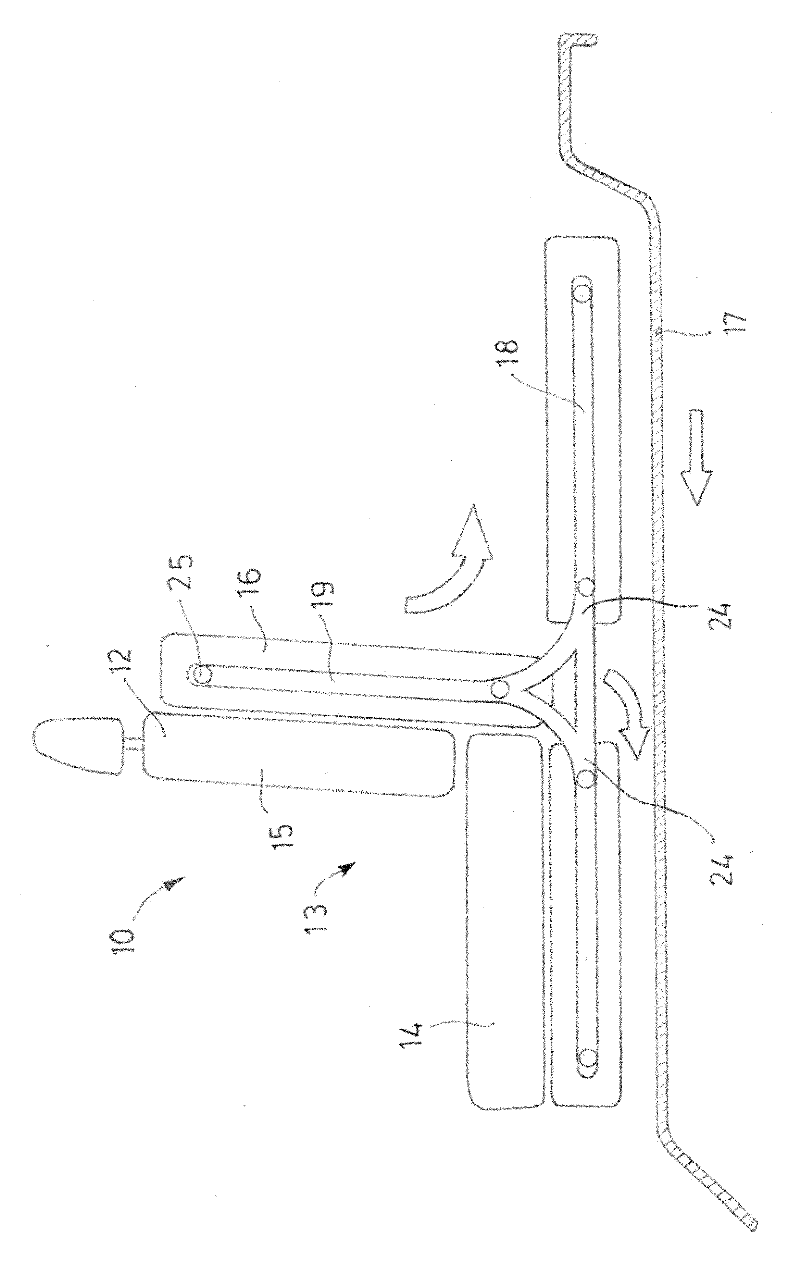

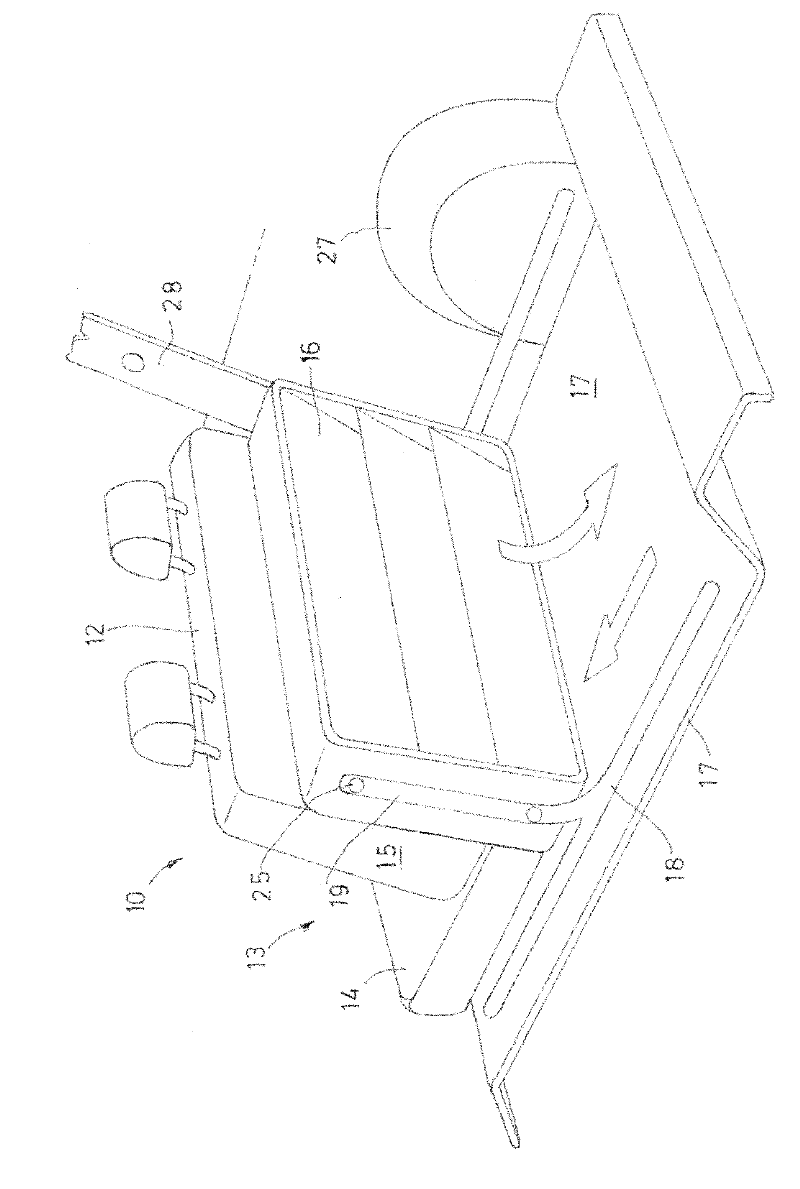

Seat system for vehicle, particularly motor vehicle

InactiveCN102126452AIncreased loading spaceSimple structureStowing appliancesDismountable/non-dismountable seatsMechanical engineering

The present invention relates to a seat system (10) for vehicle, particularly motor vehicle. The seat system is provided with at least two parallelly equipped seat units (13), particularly seats and / or elongated seats, wherein, each seat unit (13) is respectively provided with a seat part (14) and a backrest (15). Hereon for enlarging a loading space, one or a plurality of backrests (15) of a back seat row (12) are at least partially formed according to a mode that the positions can be changed. The invention suggests that one or the plurality of backrests (15) of the back seat row (12) are at least partially formed to position-changeable moving components (16).

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com