Low-floor chassis platform integrating hub motor

An in-wheel motor, low-floor technology, which is applied in electric vehicles, power management, electric power devices, etc., can solve the problems of limited load capacity and loading space, high chassis ground clearance, and heavy vehicle mass, and achieve the realization of the complete vehicle. Lightweight, improve vehicle-to-weight ratio, and improve the effect of vehicle-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

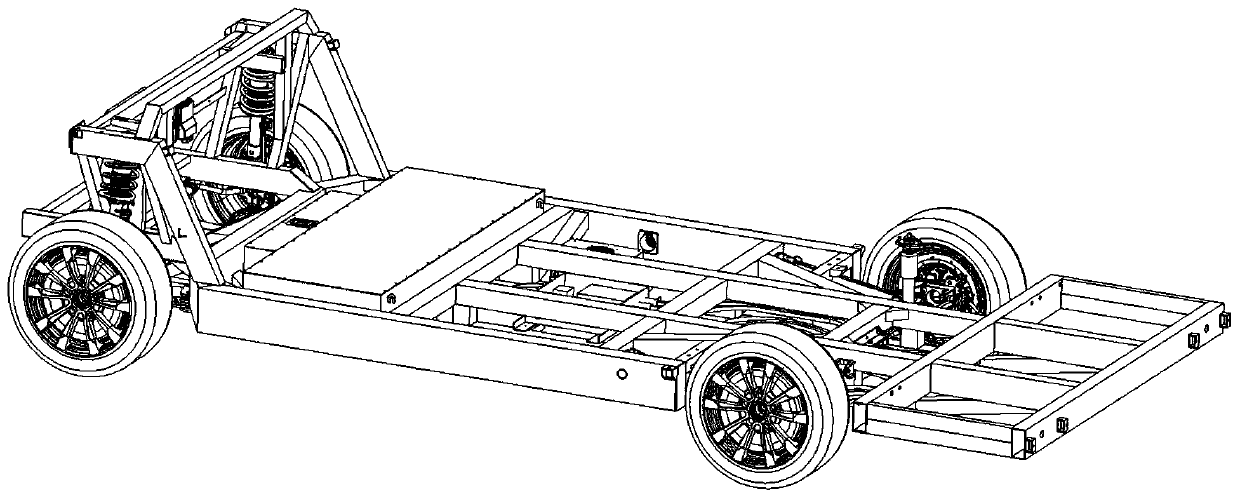

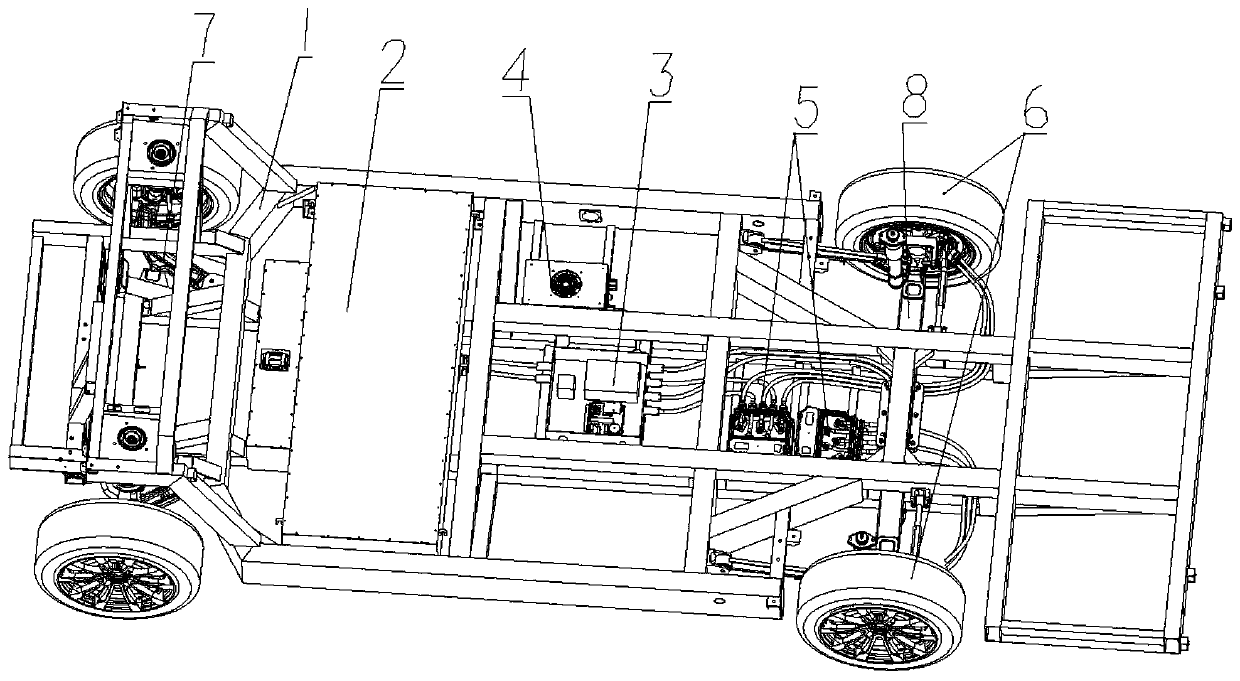

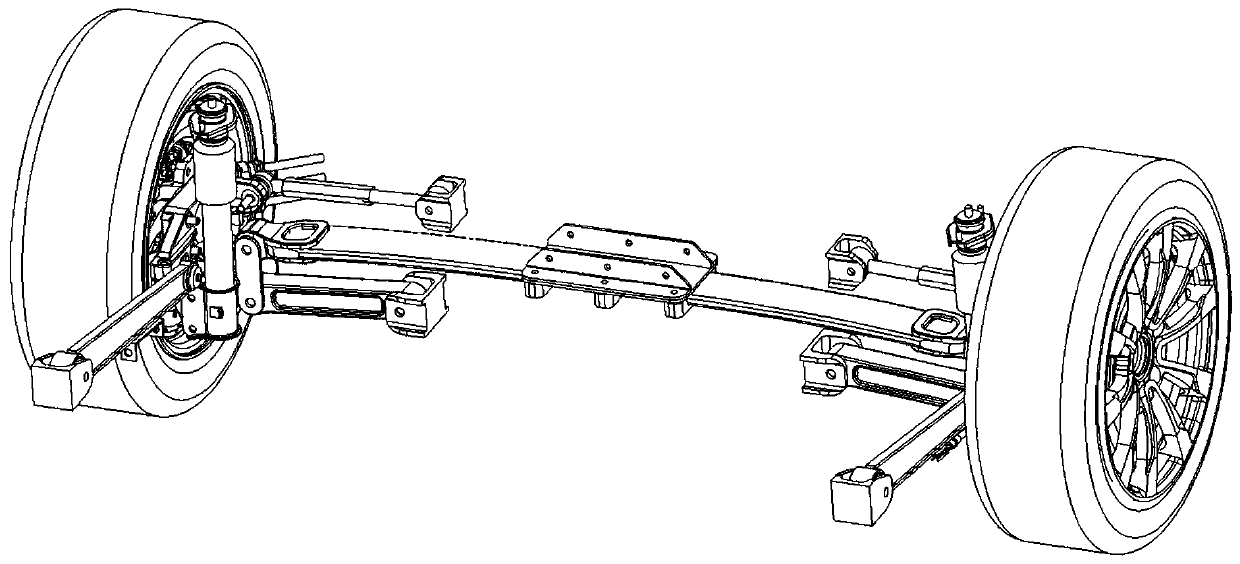

[0031] Such as figure 1 with figure 2 As shown, the specific implementation includes the lower vehicle body 1, the battery pack 2, the high voltage box 3, the charger 4, the inverter 5, the wheel assembly 6, the MacPherson suspension 7 and the multi-link and transverse leaf spring independent suspension Frame 8; Lower car body 1 adopts non-load-bearing body frame type lower car body, distributed rear wheel drive. The front suspension and the rear suspension of the lower body 1 are independently controlled separately, and the wheels of the front suspension and the rear suspension are separately controlled separately, and no transmission shaft and differential are installed between the front suspension and the rear suspension , neither the front suspension nor the rear suspension is equipped with a gearbox, the front suspension of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com