Patents

Literature

81 results about "MacPherson strut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

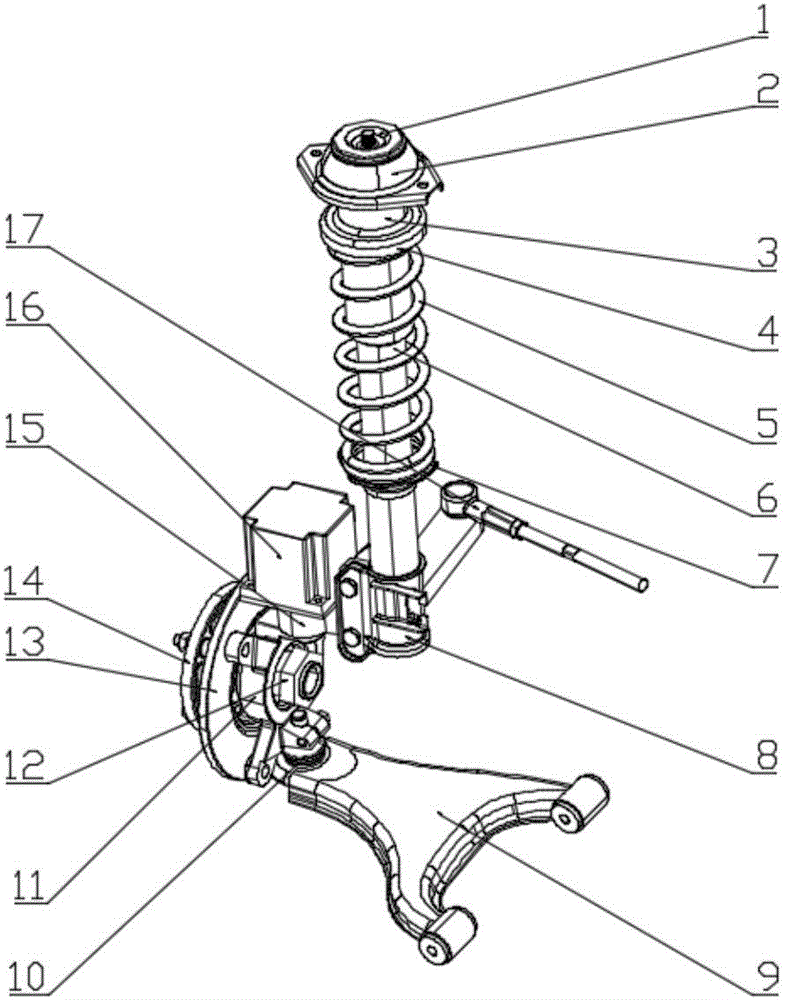

The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles and is named for American automotive engineer Earle S. MacPherson, who invented and developed the design.

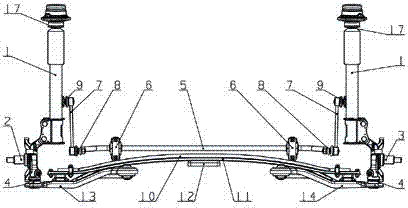

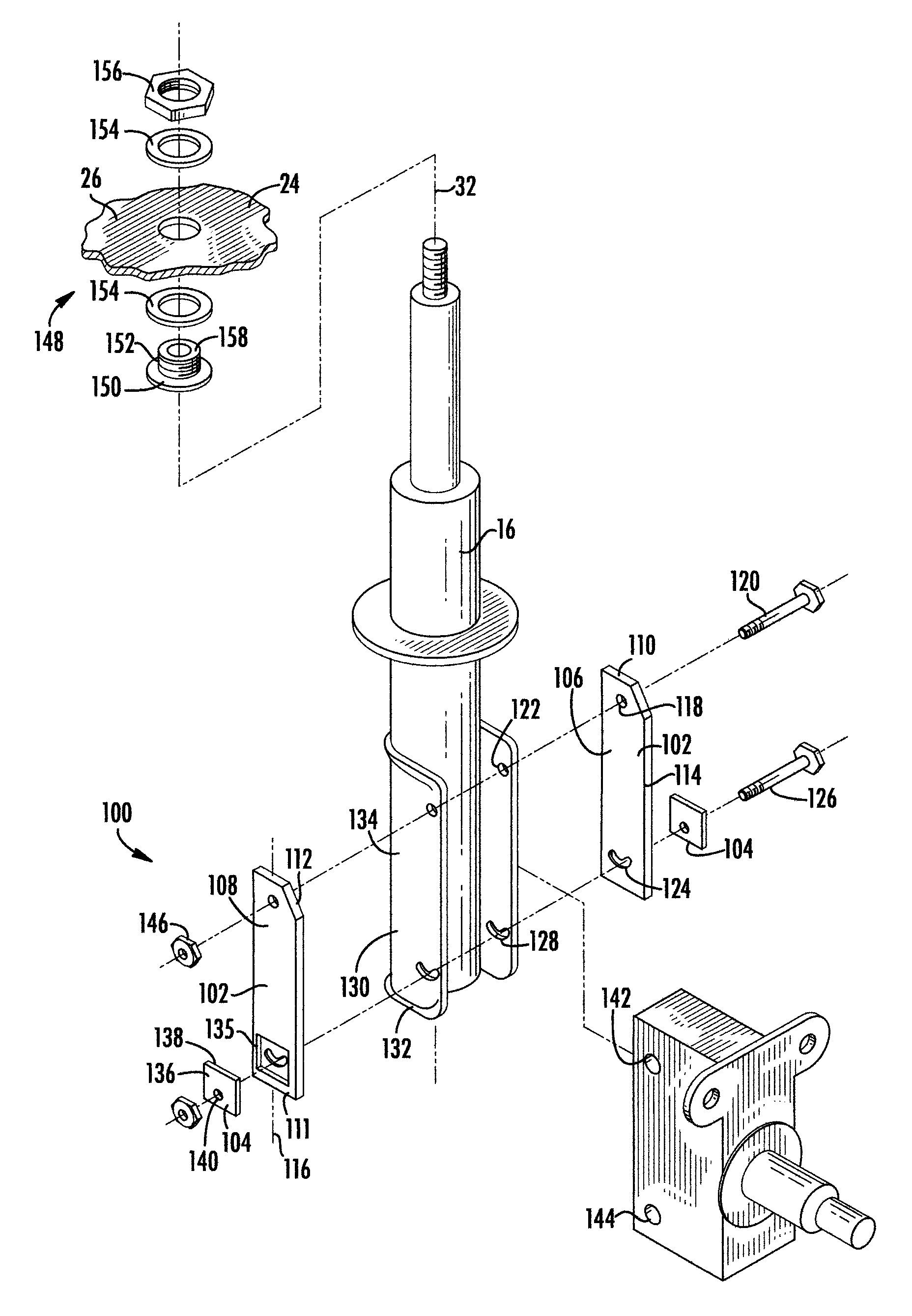

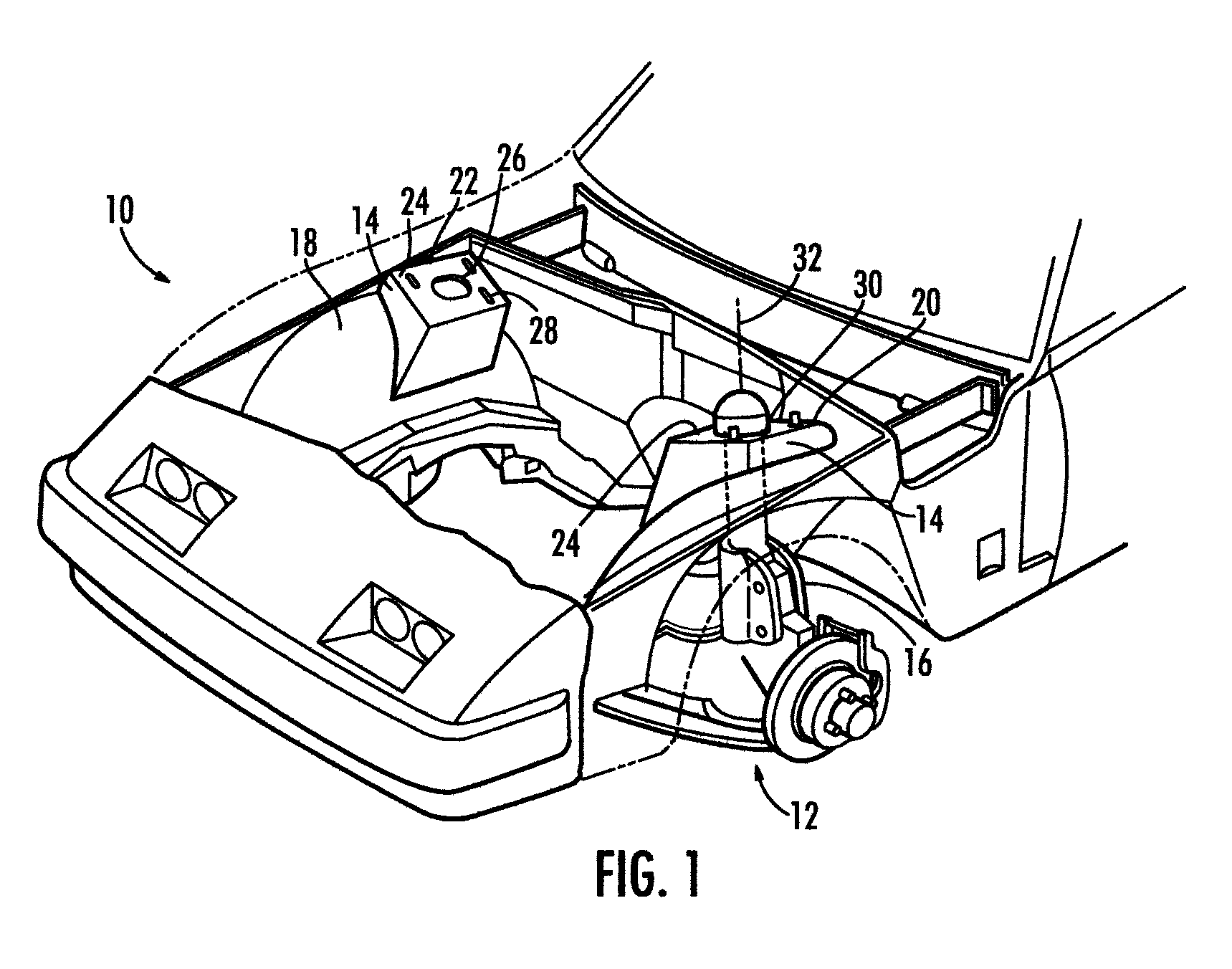

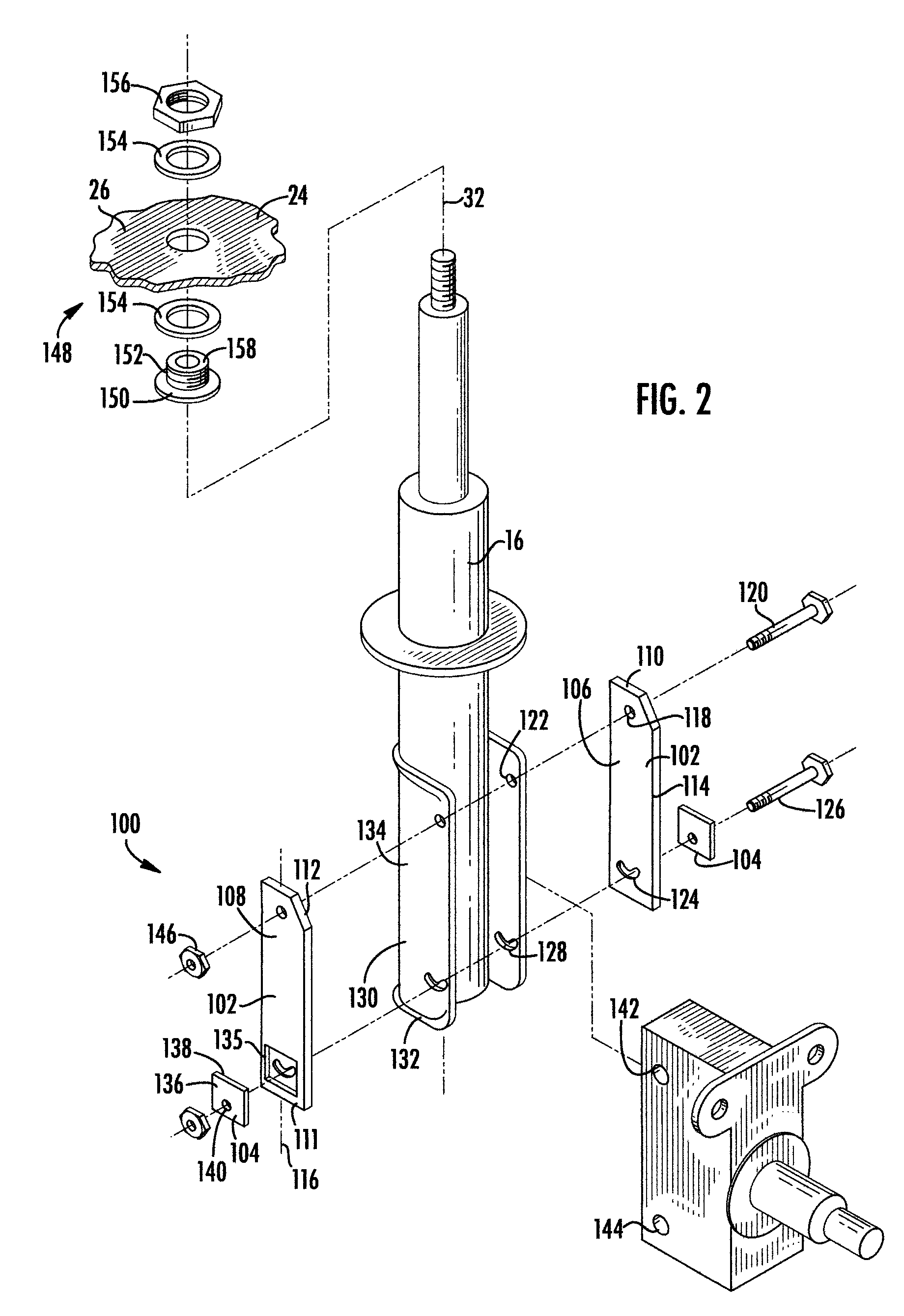

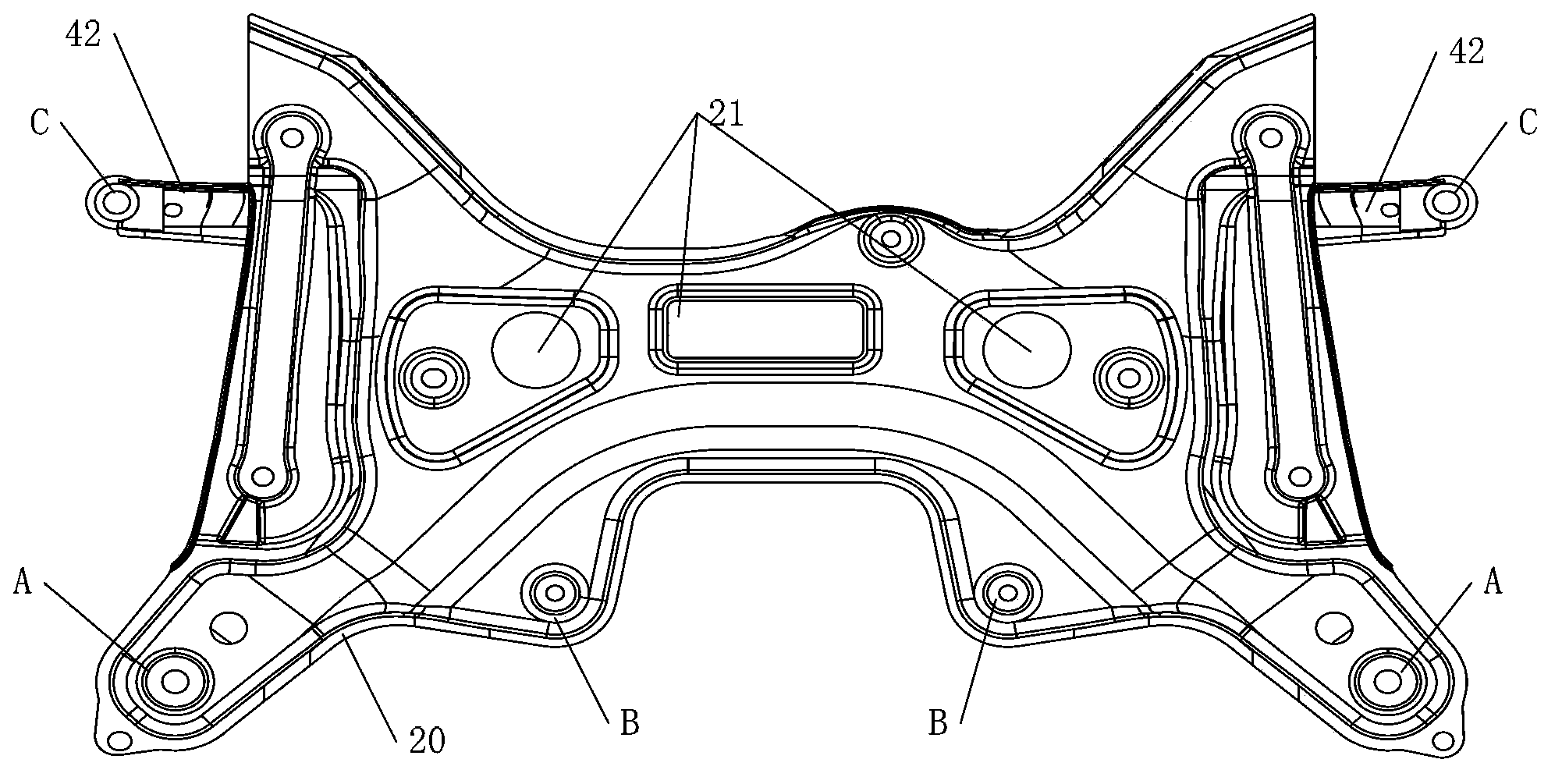

Isolated support for a rear suspension component 1

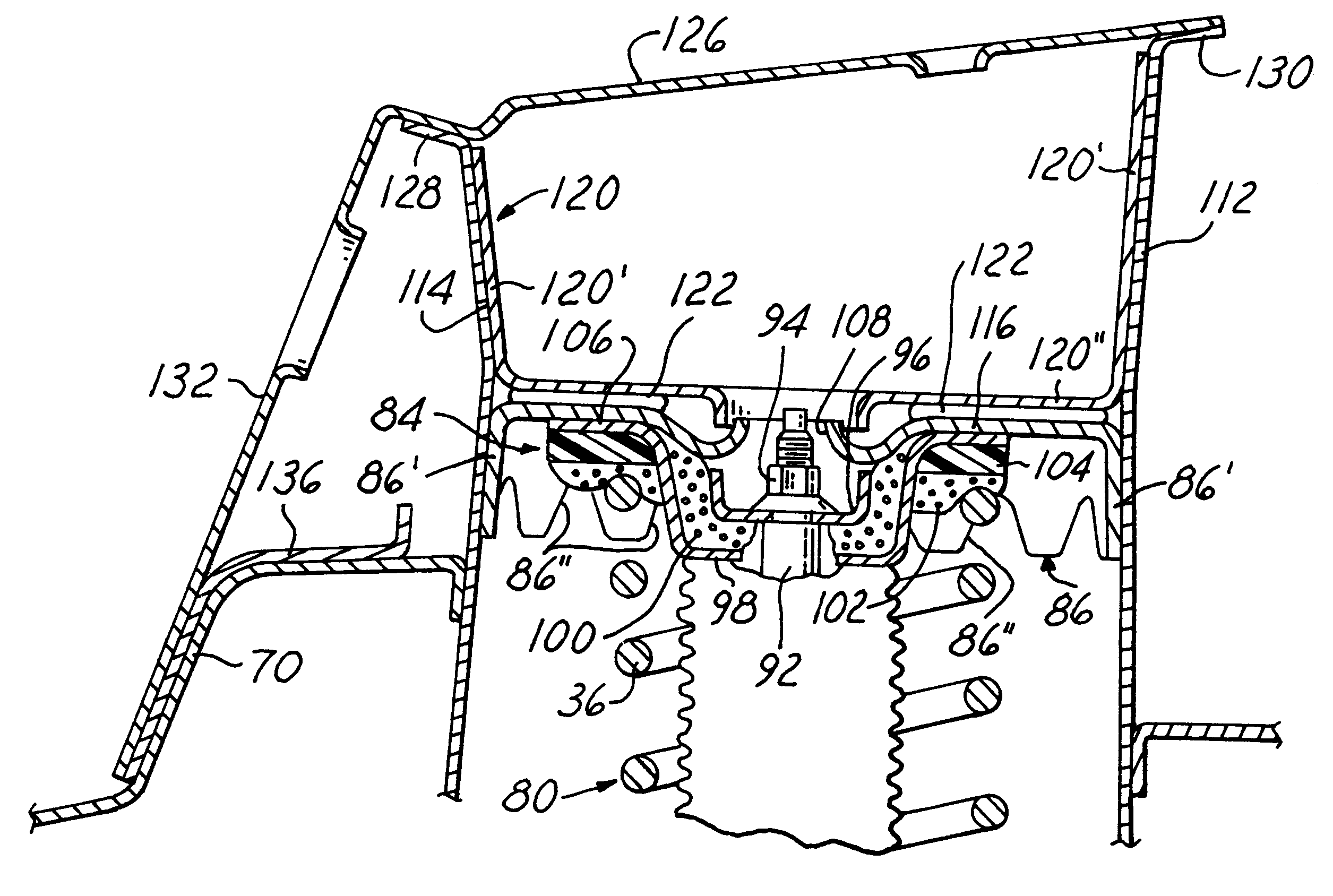

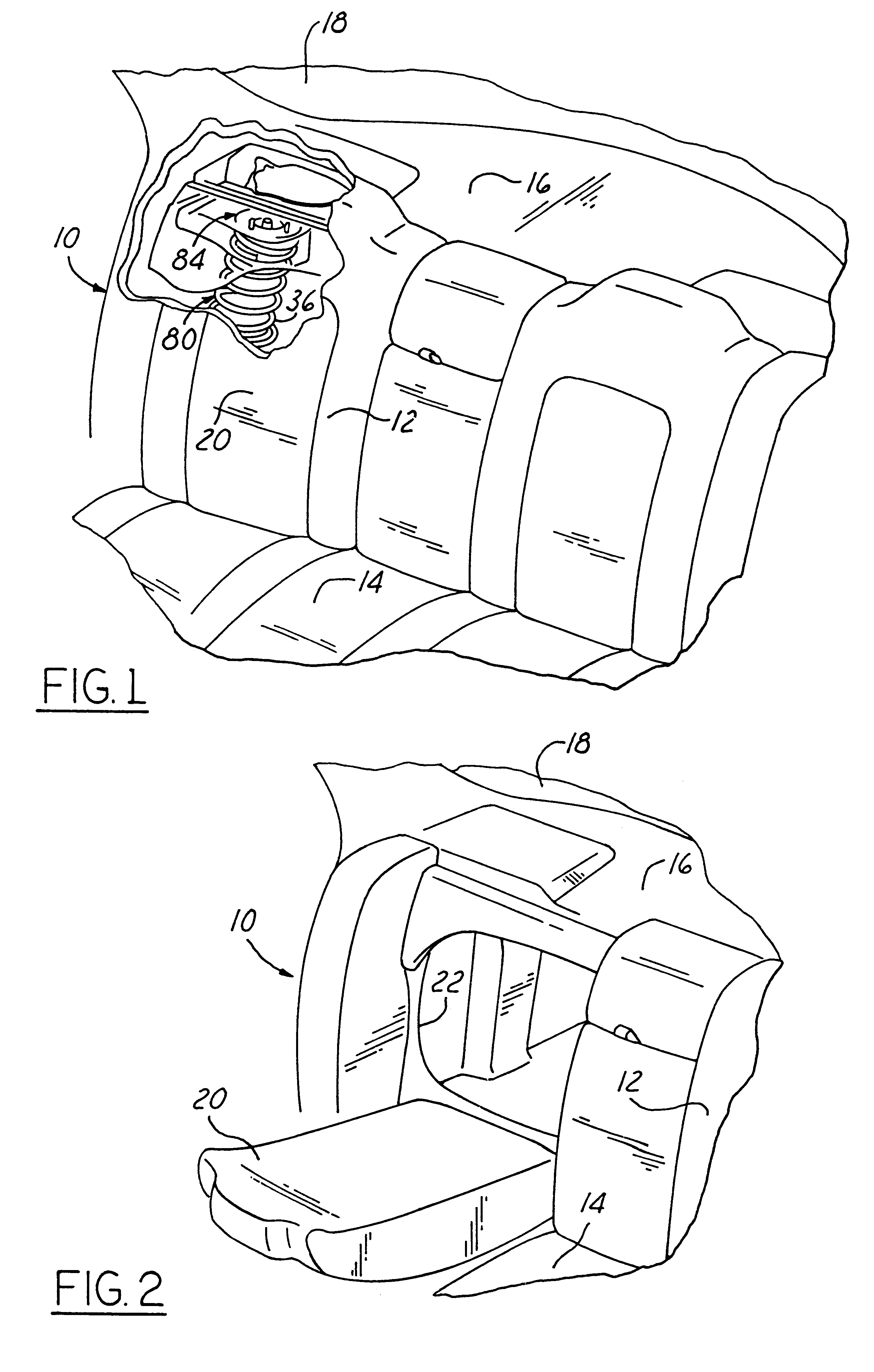

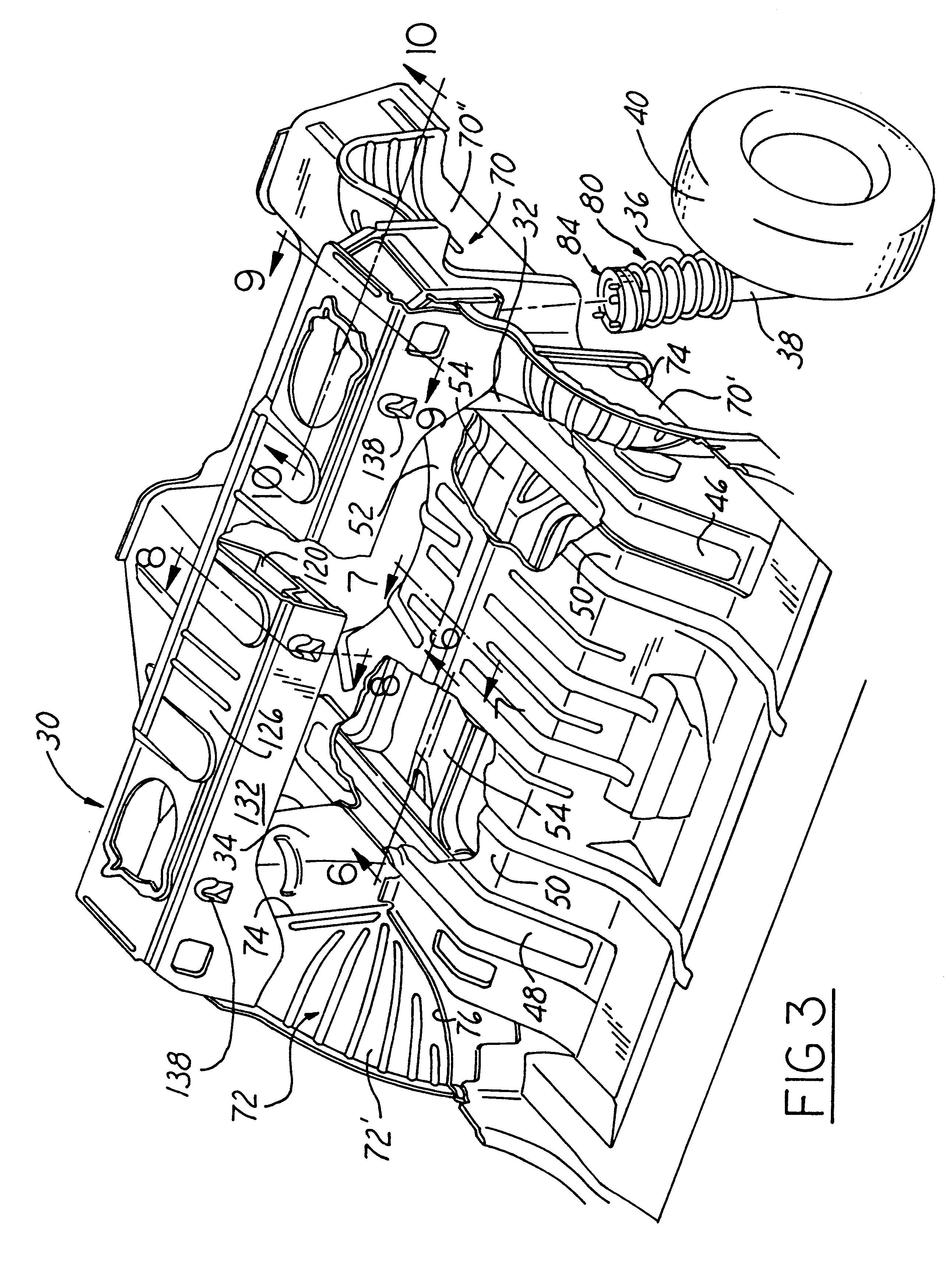

A framing structure for support of the rear suspension components of an automotive which includes a pair of generally vertically oriented suspension strut towers spaced laterally with respect to the vehicle and with each strut tower fixedly attached at lower end portions to a lower cross beam and fixedly attached at upper end portions to an upper cross beam and having an isolating structure at the upper end portion of each strut tower to which the upper end portion of a rear suspension component such as a shock absorber or a MacPherson suspension strut is attached in a manner isolating the suspension component from the strut tower and upper cross beam.

Owner:FCA US

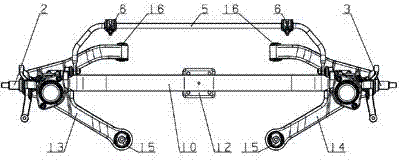

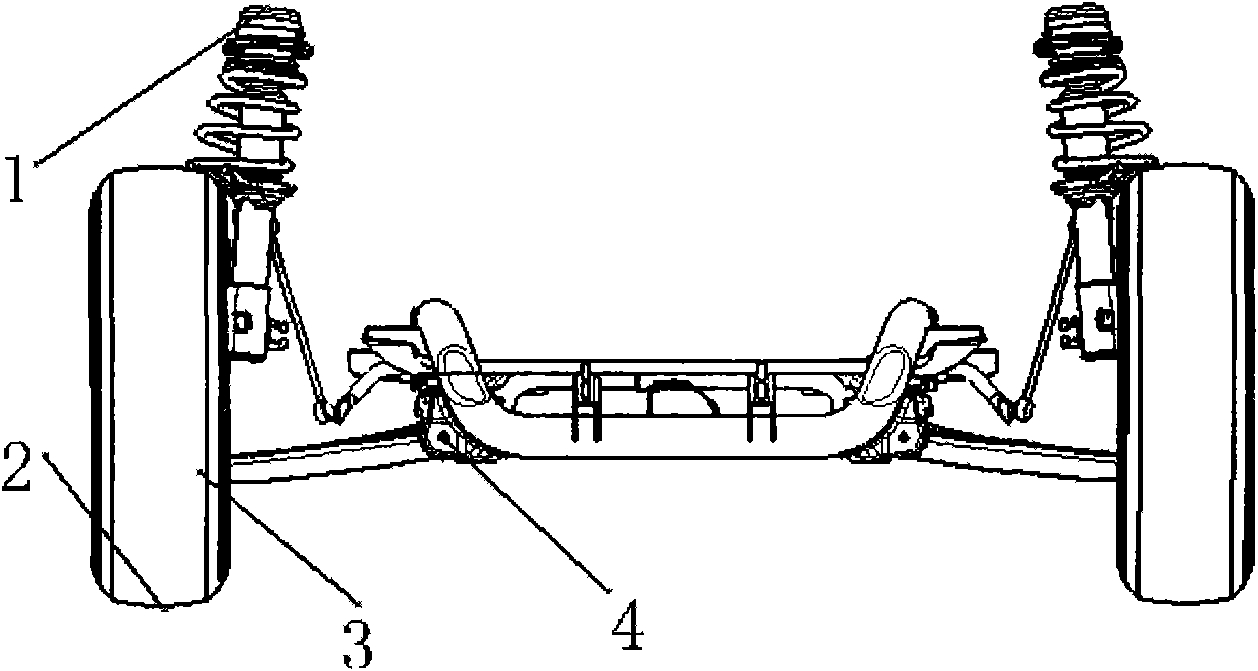

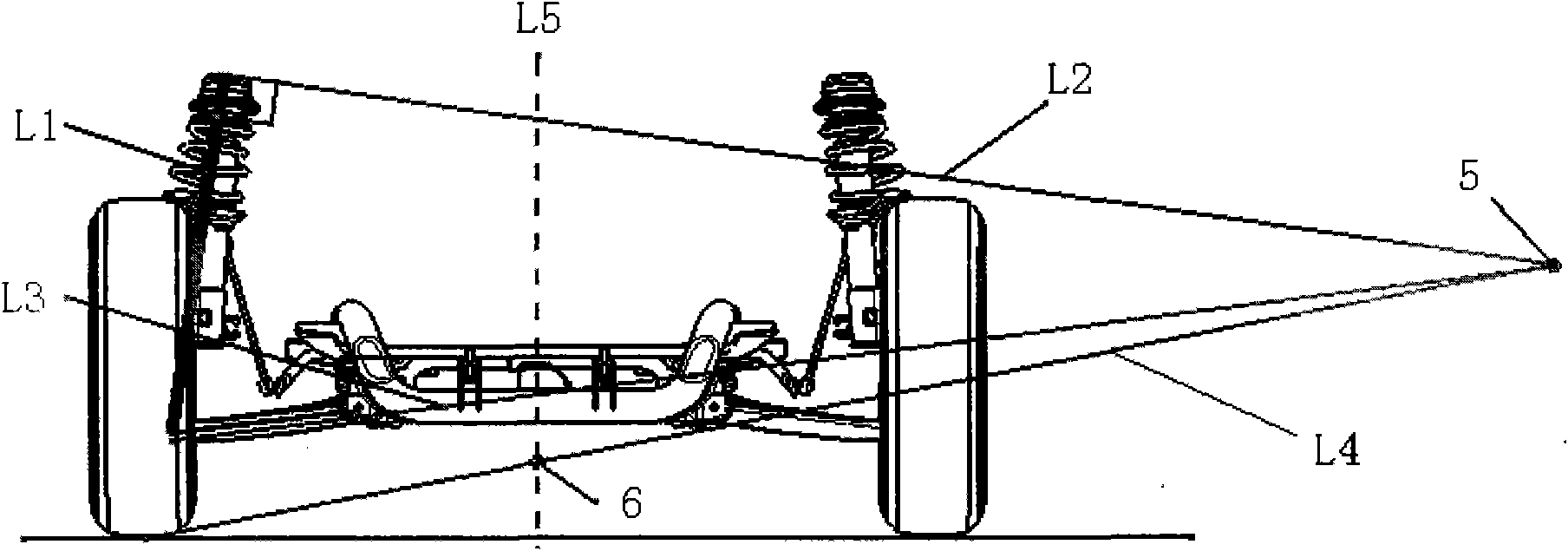

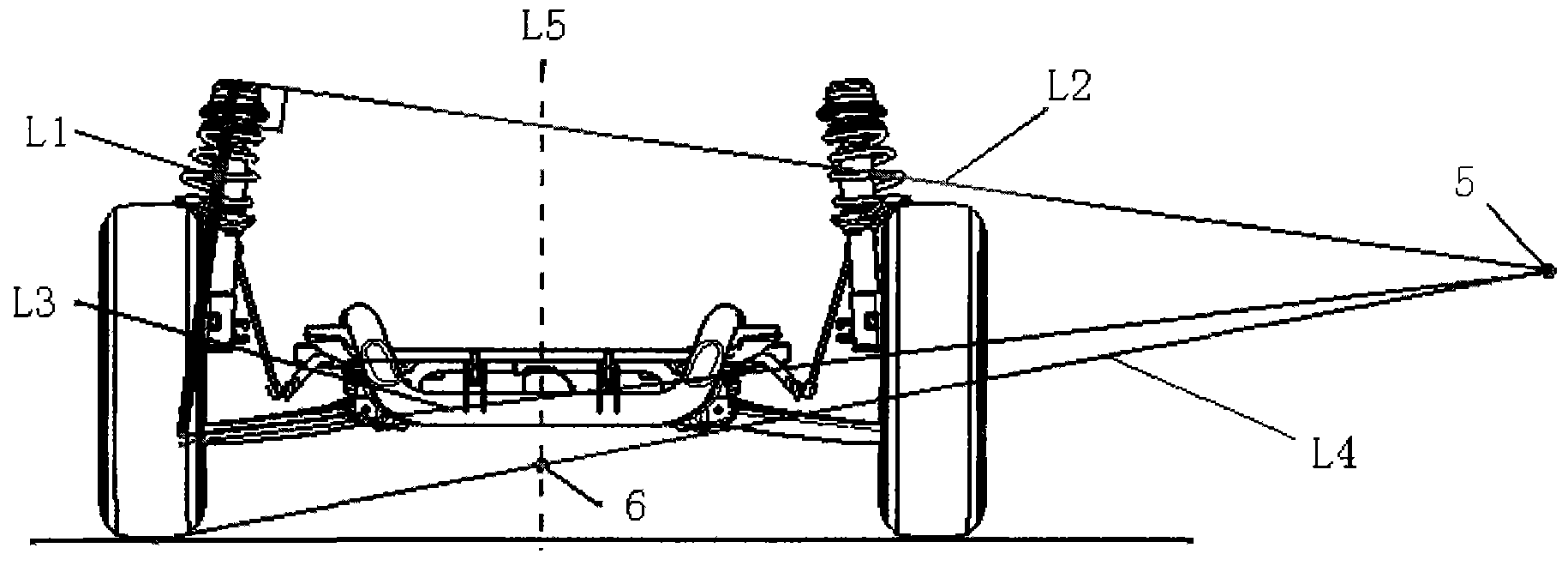

Independent front suspension with transversely arranged steel plate spring

InactiveCN102887042AImprove carrying capacityEasy to controlResilient suspensionsEngineeringOperational stability

The invention discloses an independent front suspension with a transversely arranged steel plate spring. The independent front suspension with the transversely arranged steel plate spring comprises a left front shock absorber and a right front shock absorber both provided with a limiting block, left and right steering knuckles, a steel plate spring, and a steady rod component, wherein left and right lower swing arms are respectively connected with the left and right steering knuckles through lower swing arm ball pins; the transversely arranged steel plate spring is composed of two transversely arranged upper and lower steel plate springs with variable cross-sections; the middle part of the steel plate spring is connected with a car body; the central line of the steel plate spring is consistent with an X-direction of a wheel center of a wheel; two ends of the steel plate spring are connected with the left and right lower swing arms through a vulcanized rubber component; the shock absorbers are arranged vertically in a front view of a car, inclined backwards in a side view thereof and have an included angle alpha of 2-4 degrees with the axial line. The independent front suspension, disclosed by the invention, has the advantages of compact arrangement, rational structure, relatively low manufacturing and processing cost; the transversely arranged steel plate spring is mutually matched with a single-angle shock absorber, so that the car can achieve relatively ideal comfort level in any load state, good operational stability of a McPherson suspension is continued, and internal space of the car is further maximized; and obvious improvements in the aspects of overall performances, cost and the like are achieved.

Owner:柳州孔辉汽车科技有限公司

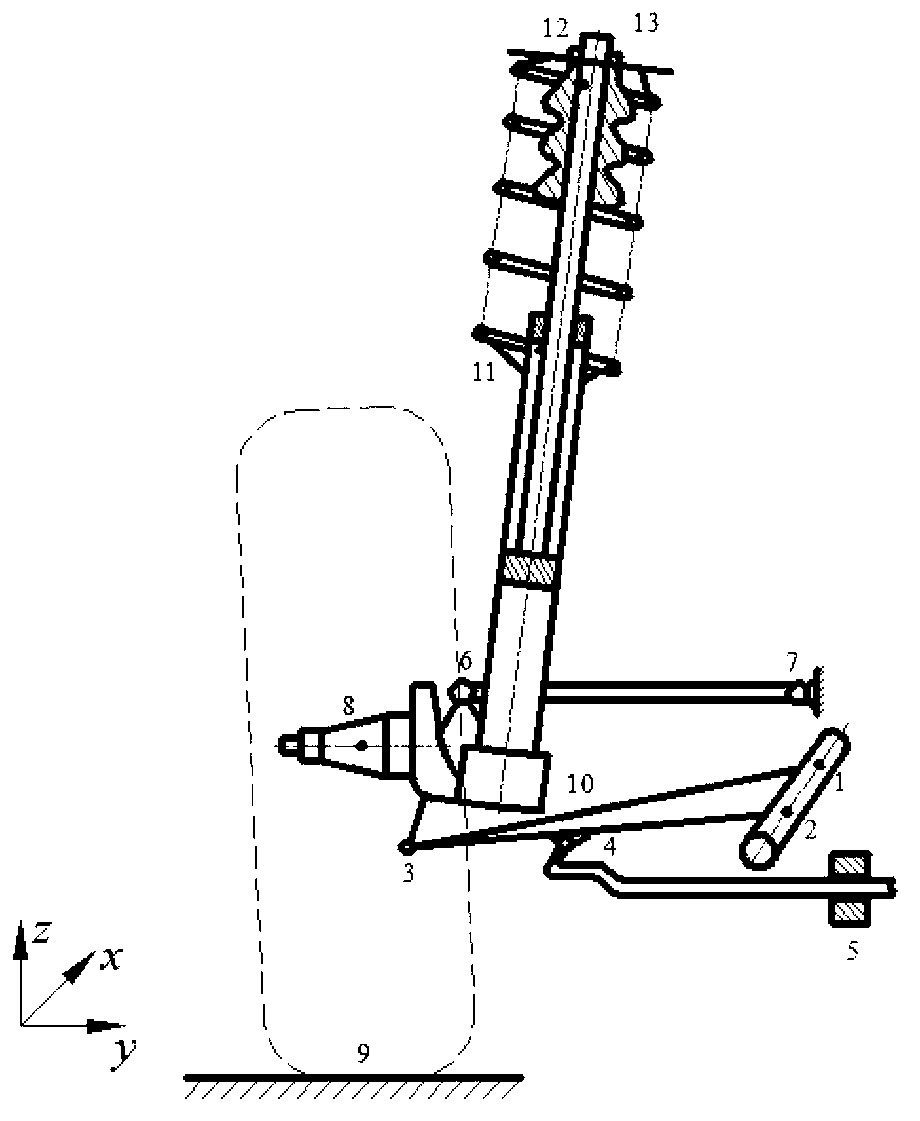

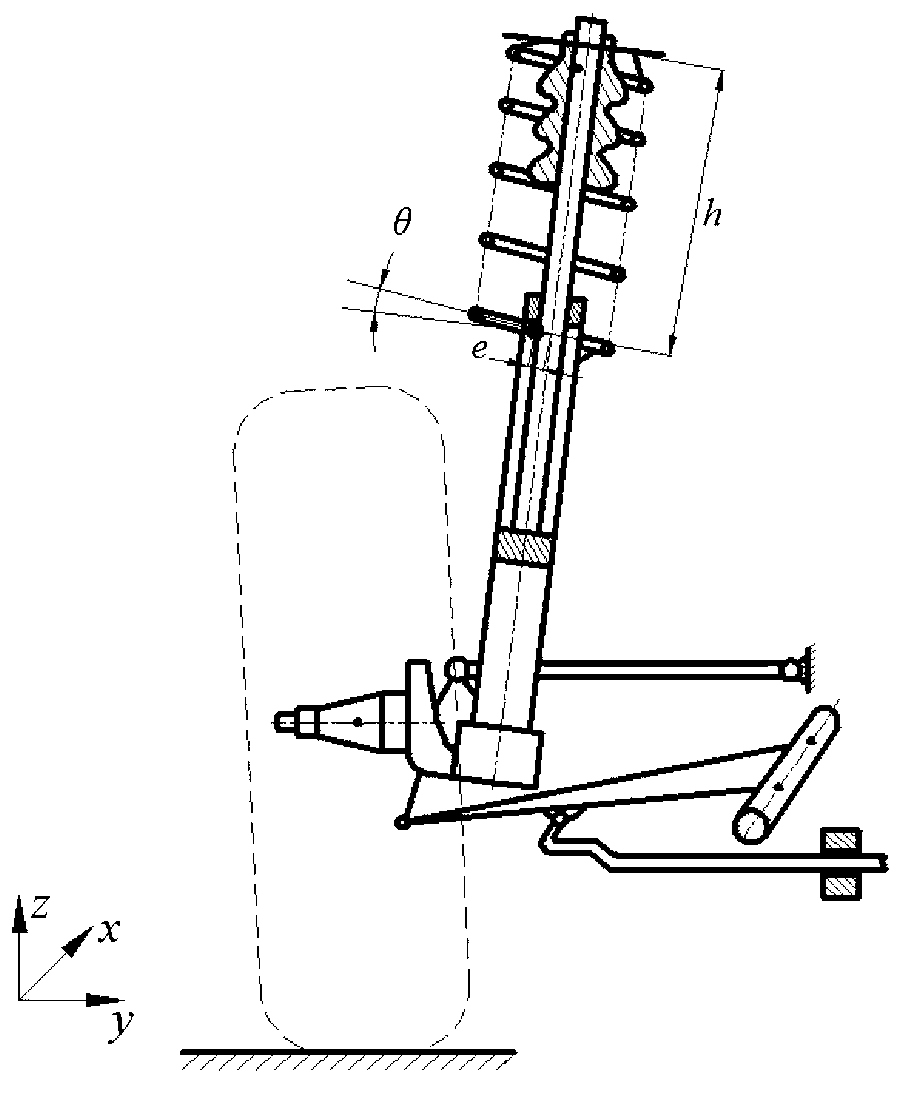

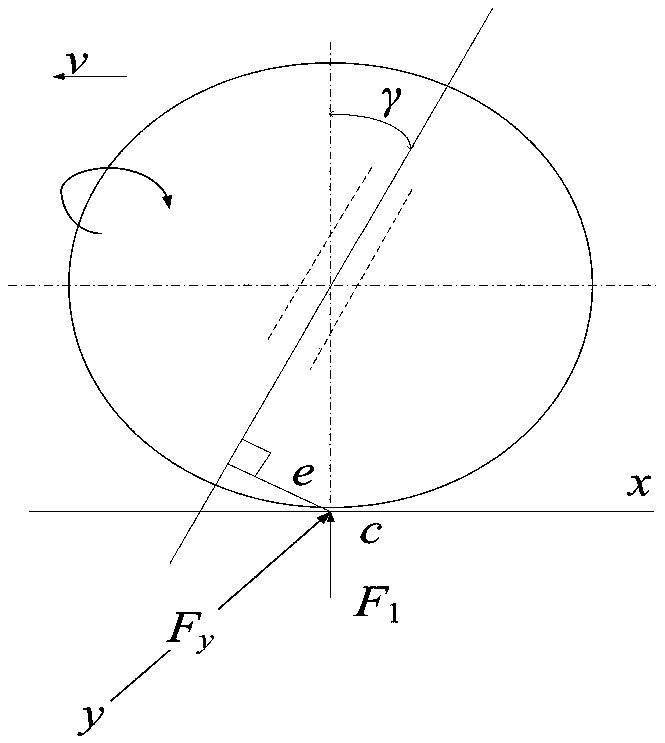

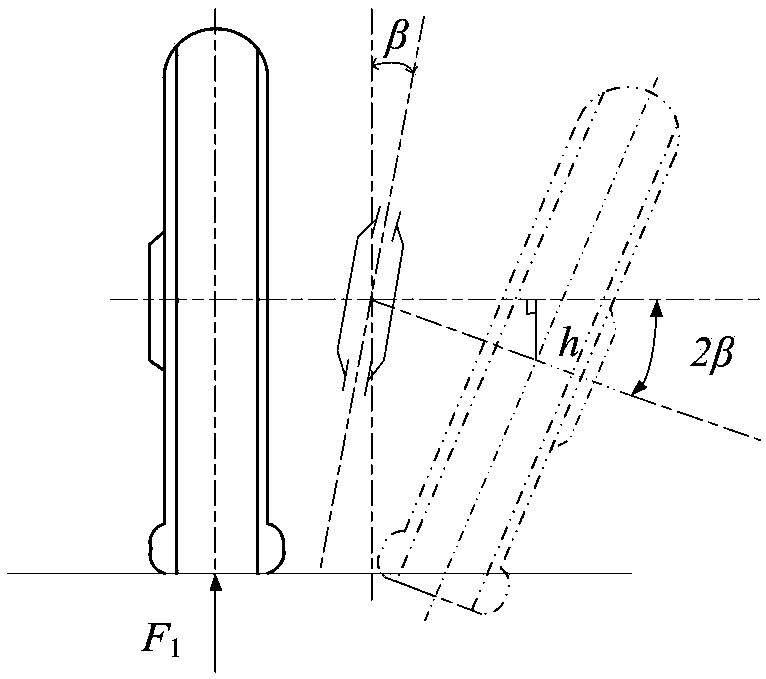

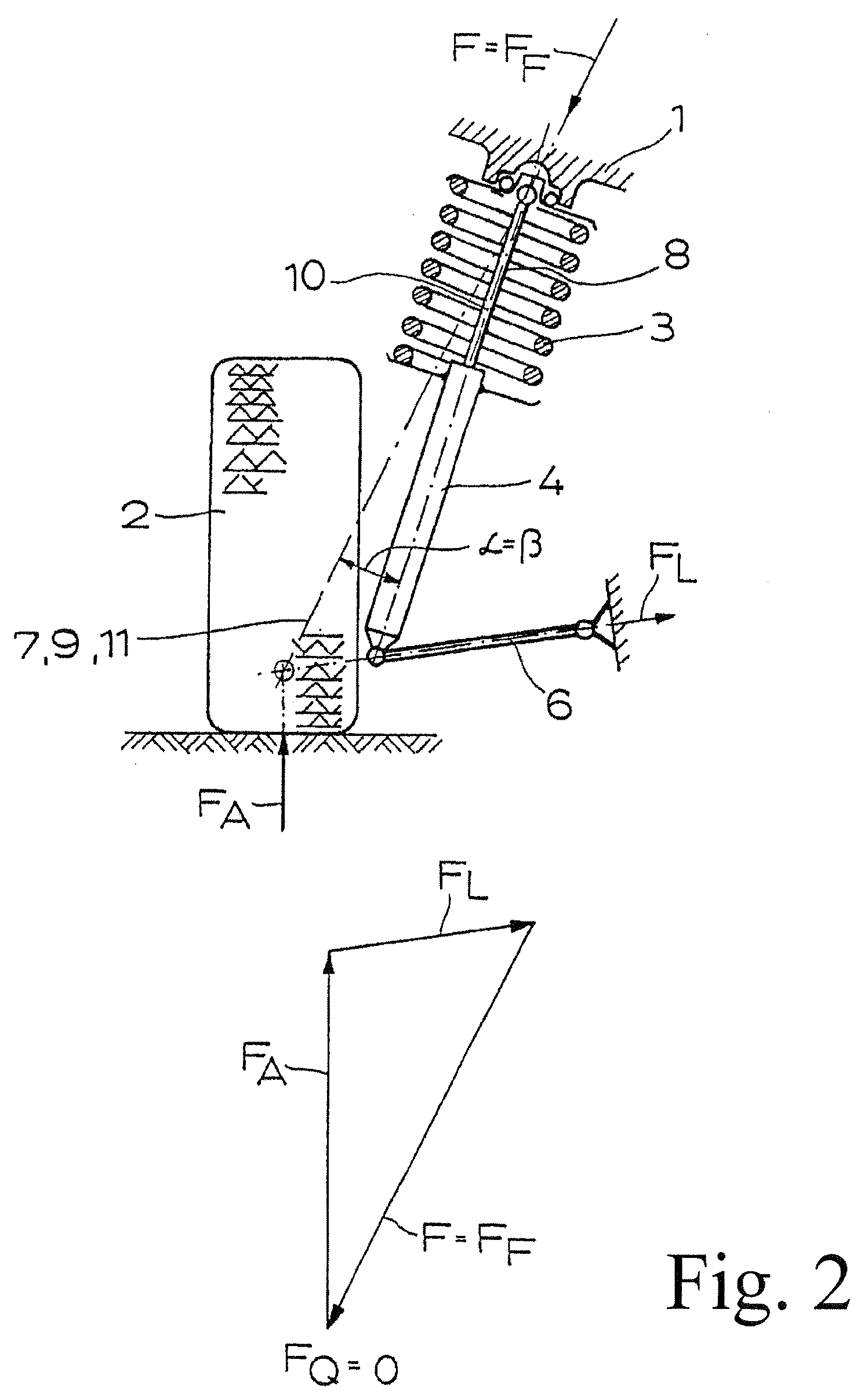

Optimization method facing lateral force of Macpherson suspension shock absorber

ActiveCN103310047AExtended service lifeImprove work performanceSpecial data processing applicationsForce linesCoil spring

The invention relates to an optimization method facing a lateral force of a Macpherson suspension shock absorber, which comprises the following steps: firstly, measuring hard point coordinates of a Macpherson suspension to be optimized and establishing a multi-rigid-body simulation model on the basis of the multi-body dynamics theory; then using the K&C characteristic of the actually measured Macpherson suspension as the datum and regulating hard point coordinates of the simulation model until an error of a simulation result is controlled in an acceptable range; and finally, respectively using a geometrical parameter of a spring seat and an actual acting force line of a coil spring as optimization design variables, using the lateral force at the positions of a guide seat and a piston of the shock absorber as an optimization target and selecting a response surface method to carry out optimization in multi-body dynamics software, so that the optimal geometrical parameter of the spring seat and the optimal spring actual acting force line which enable the lateral force of the shock absorber to be minimized can be obtained. Compared with the prior art, the optimization method respectively starts with the geometrical parameter of the spring seat of the shock absorber and the force line of the coil spring of the shock absorber, optimizes the lateral force at the positions of the guide seat and the piston of the shock absorber, improves the working performance of the suspension and prolongs the service life of the shock absorber.

Owner:TONGJI UNIV

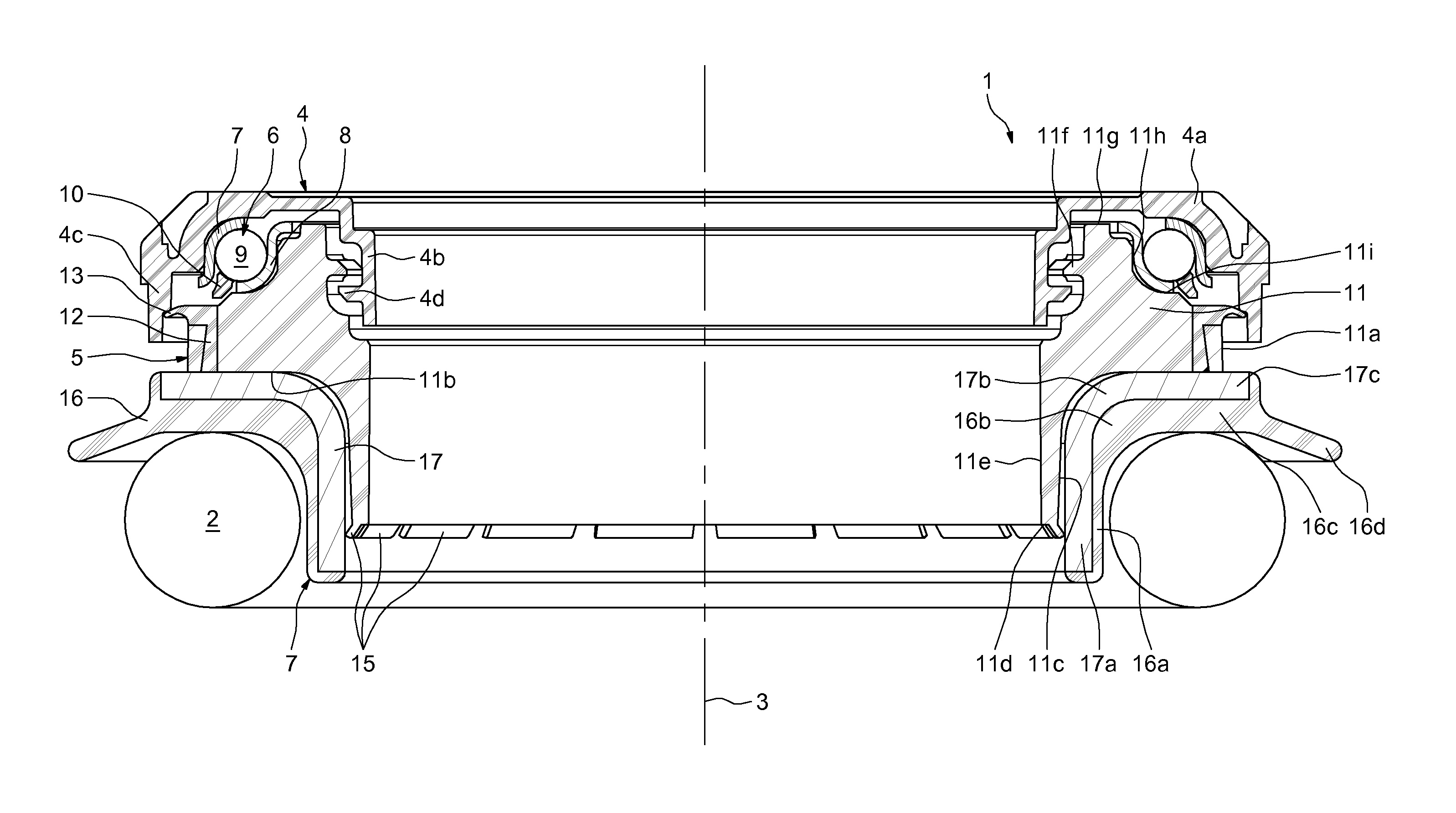

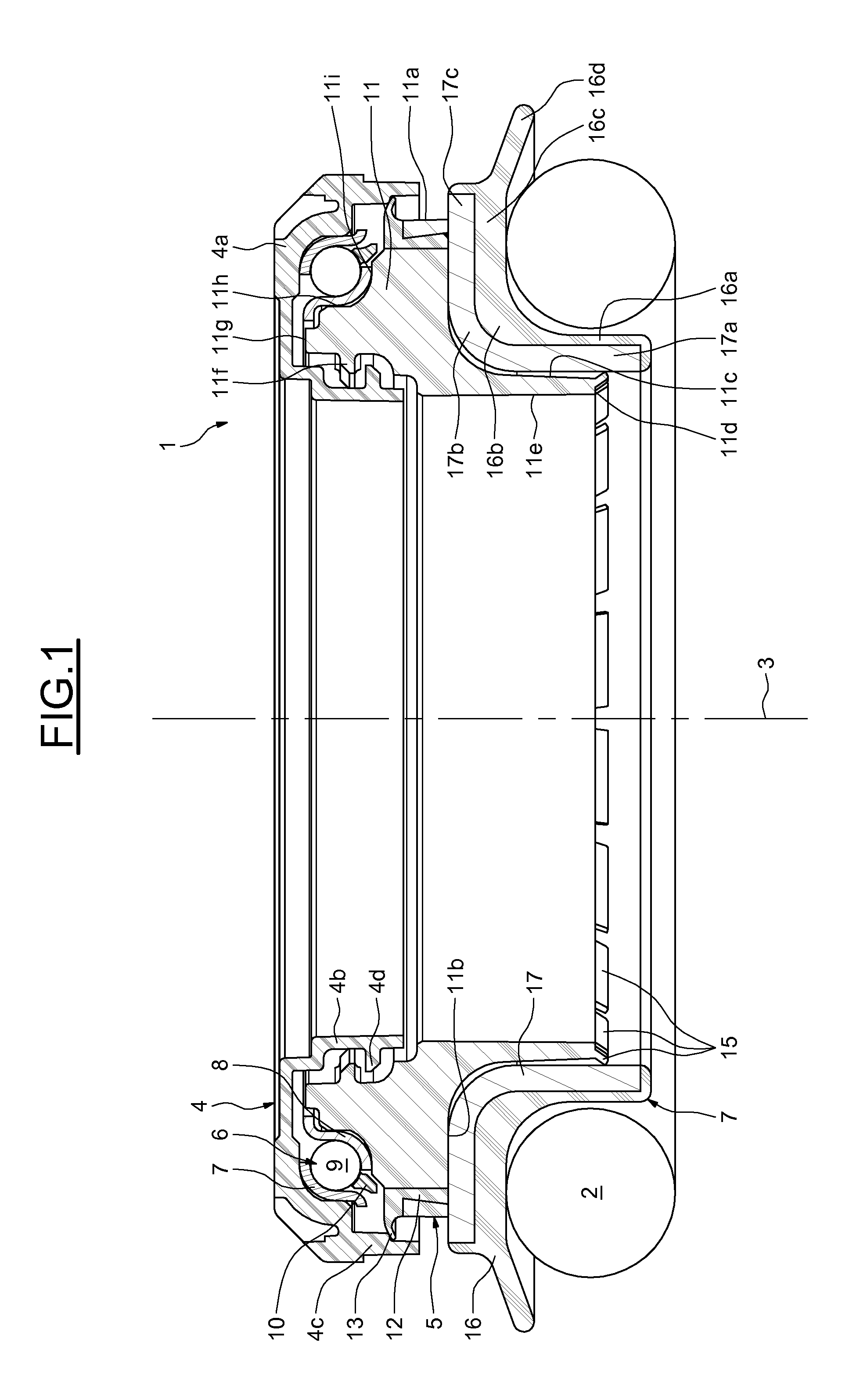

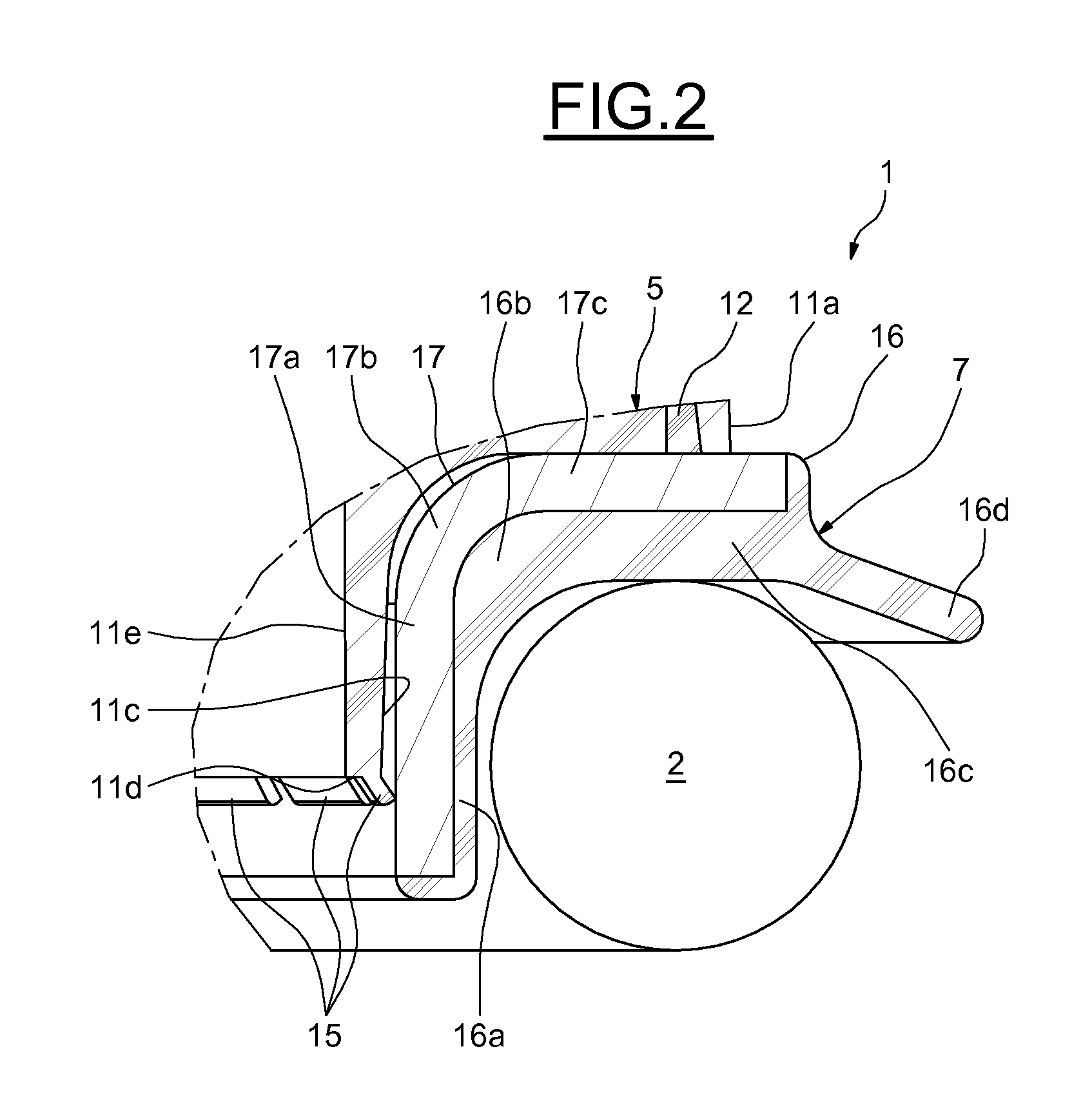

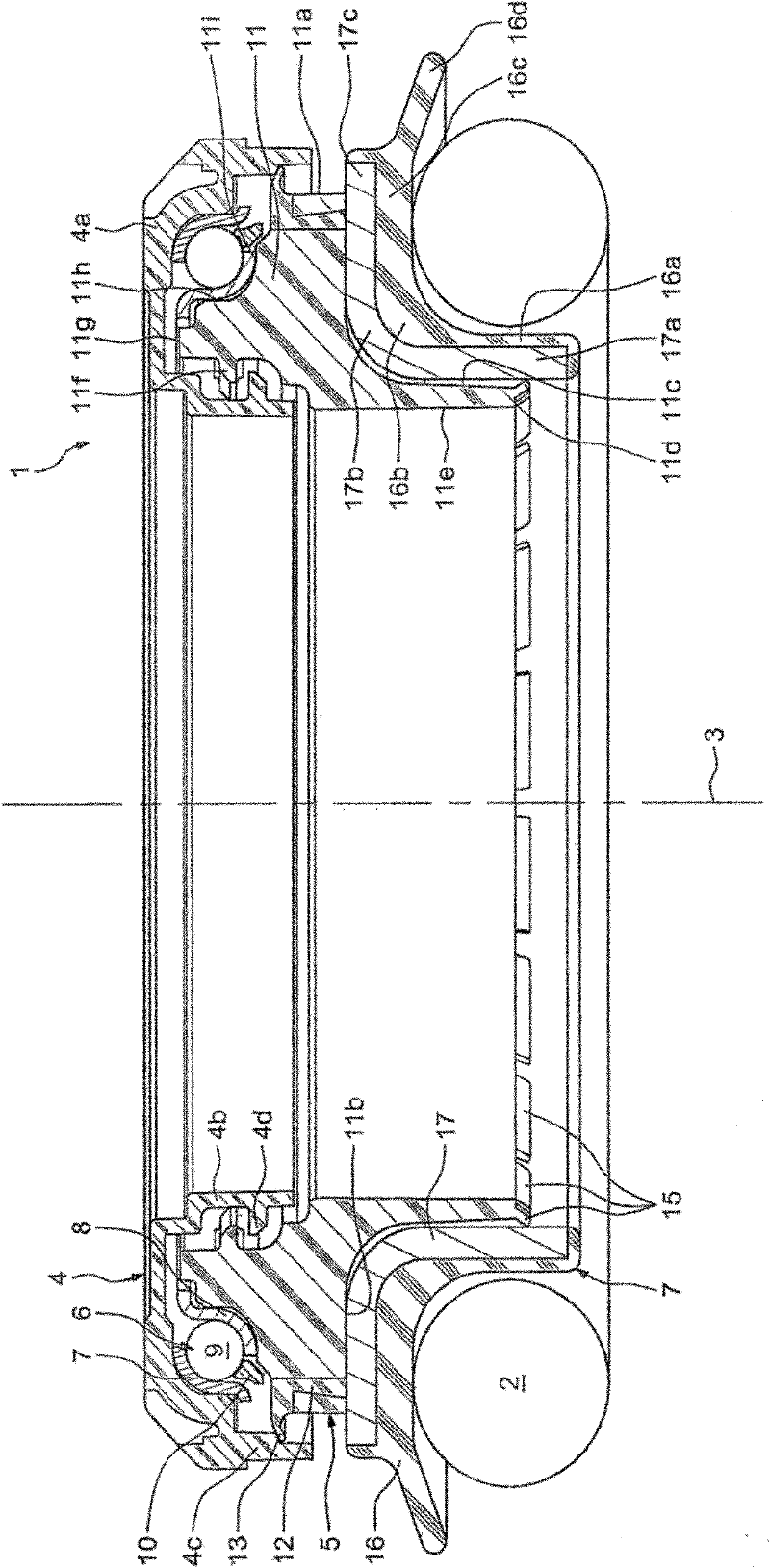

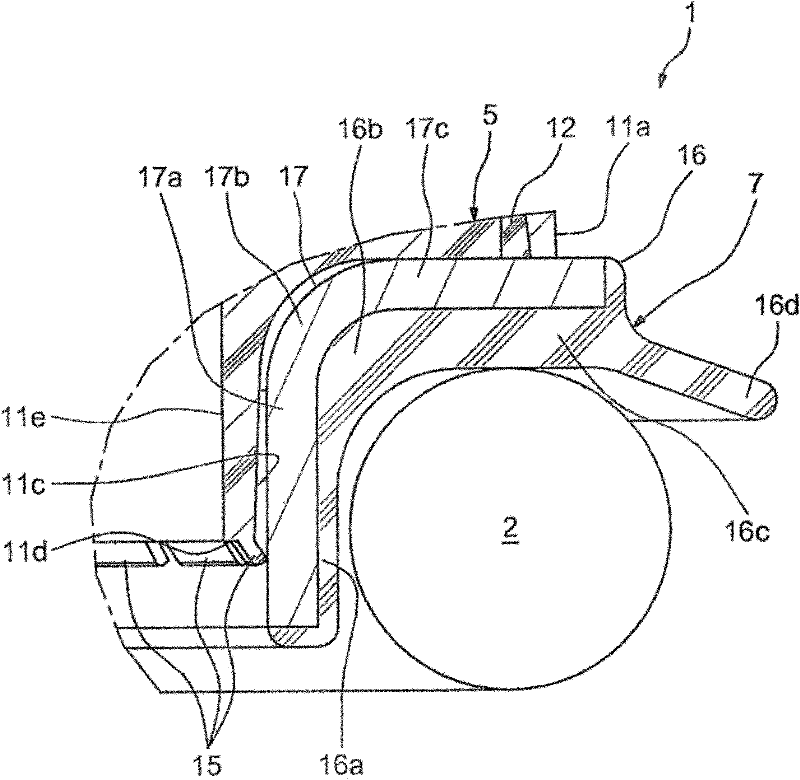

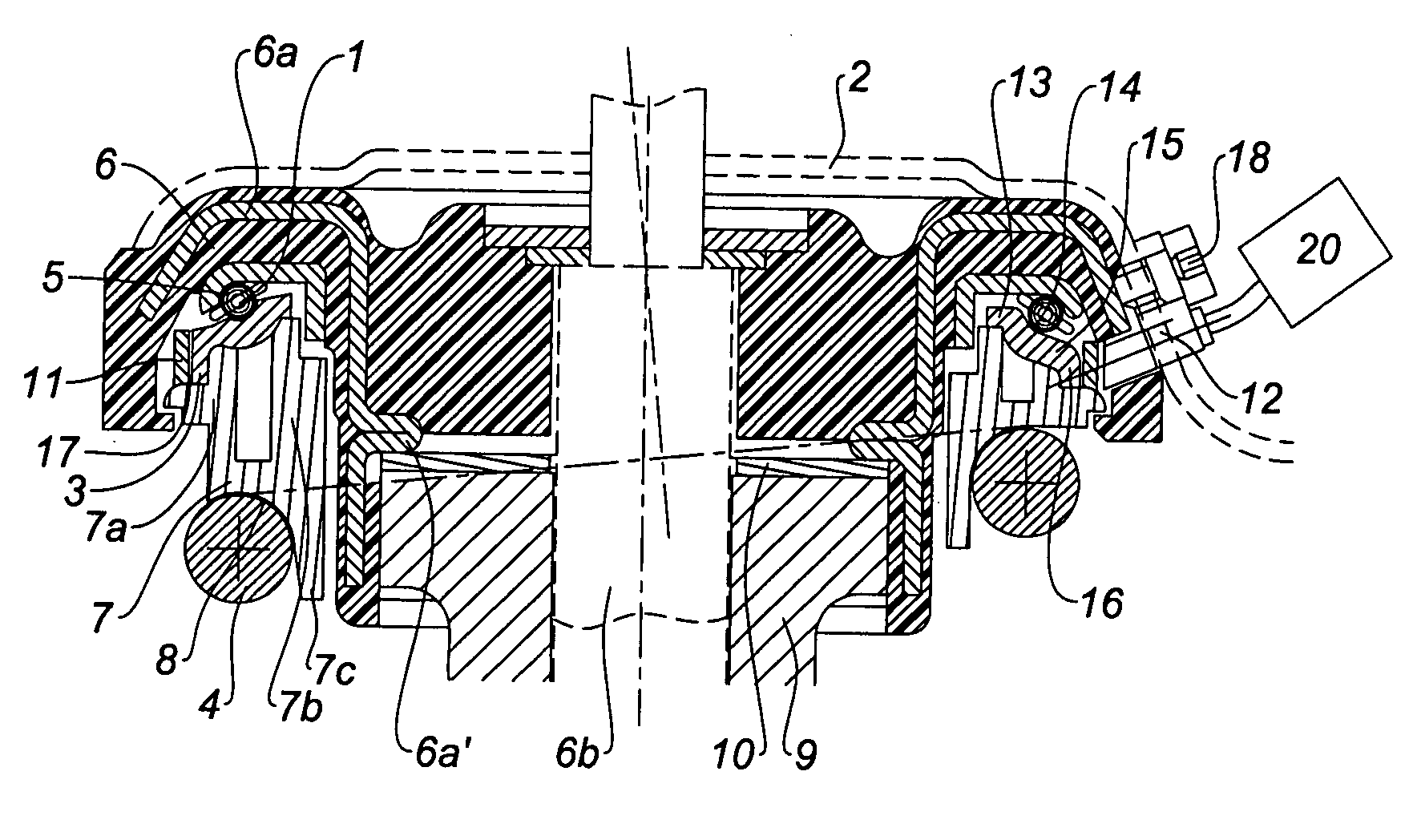

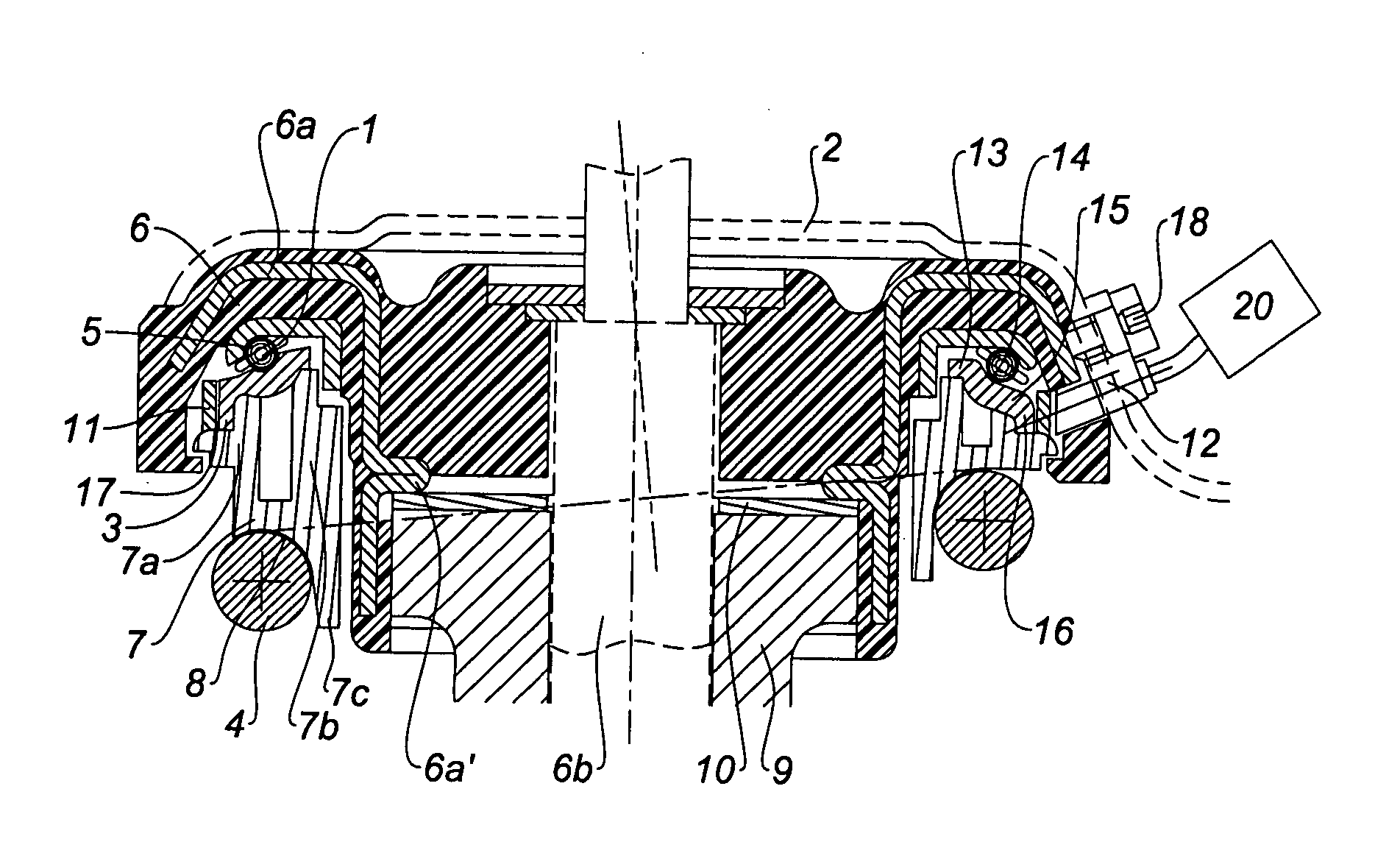

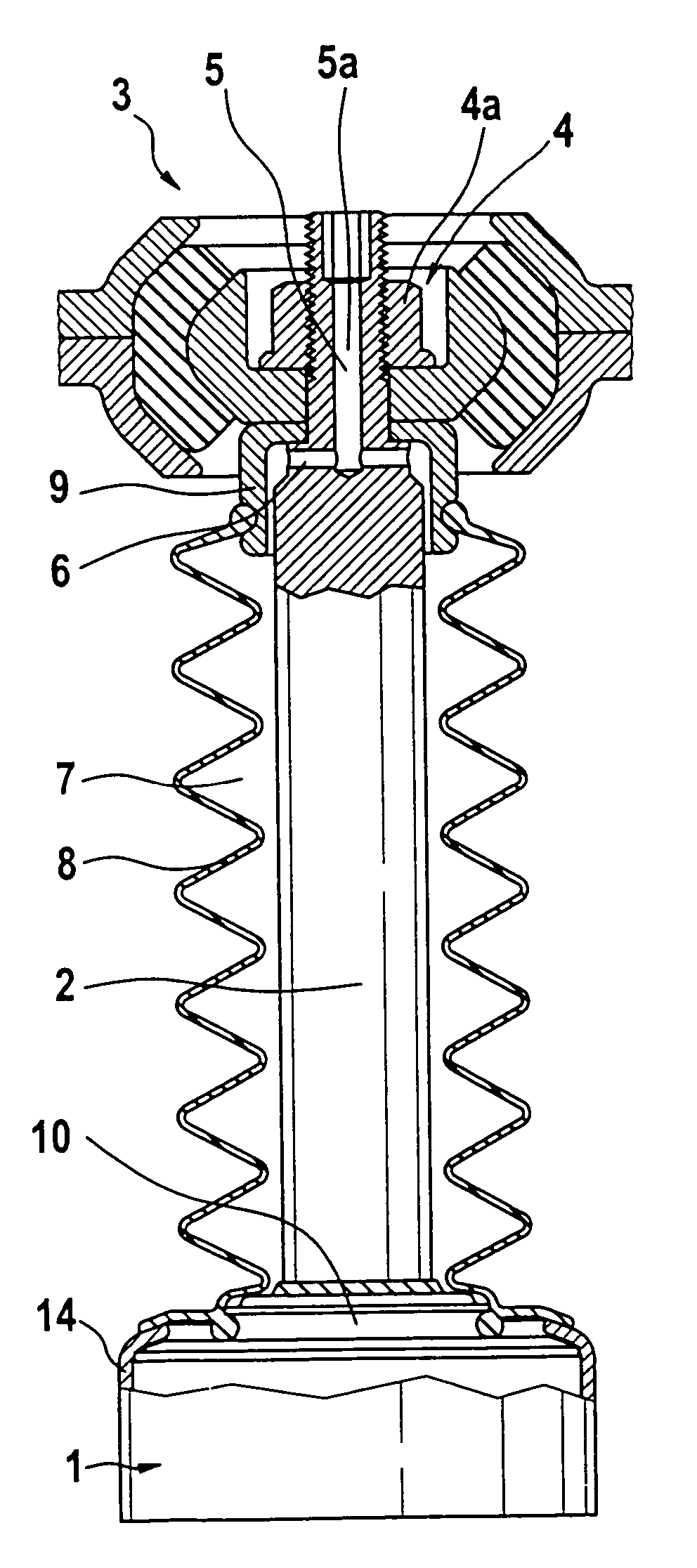

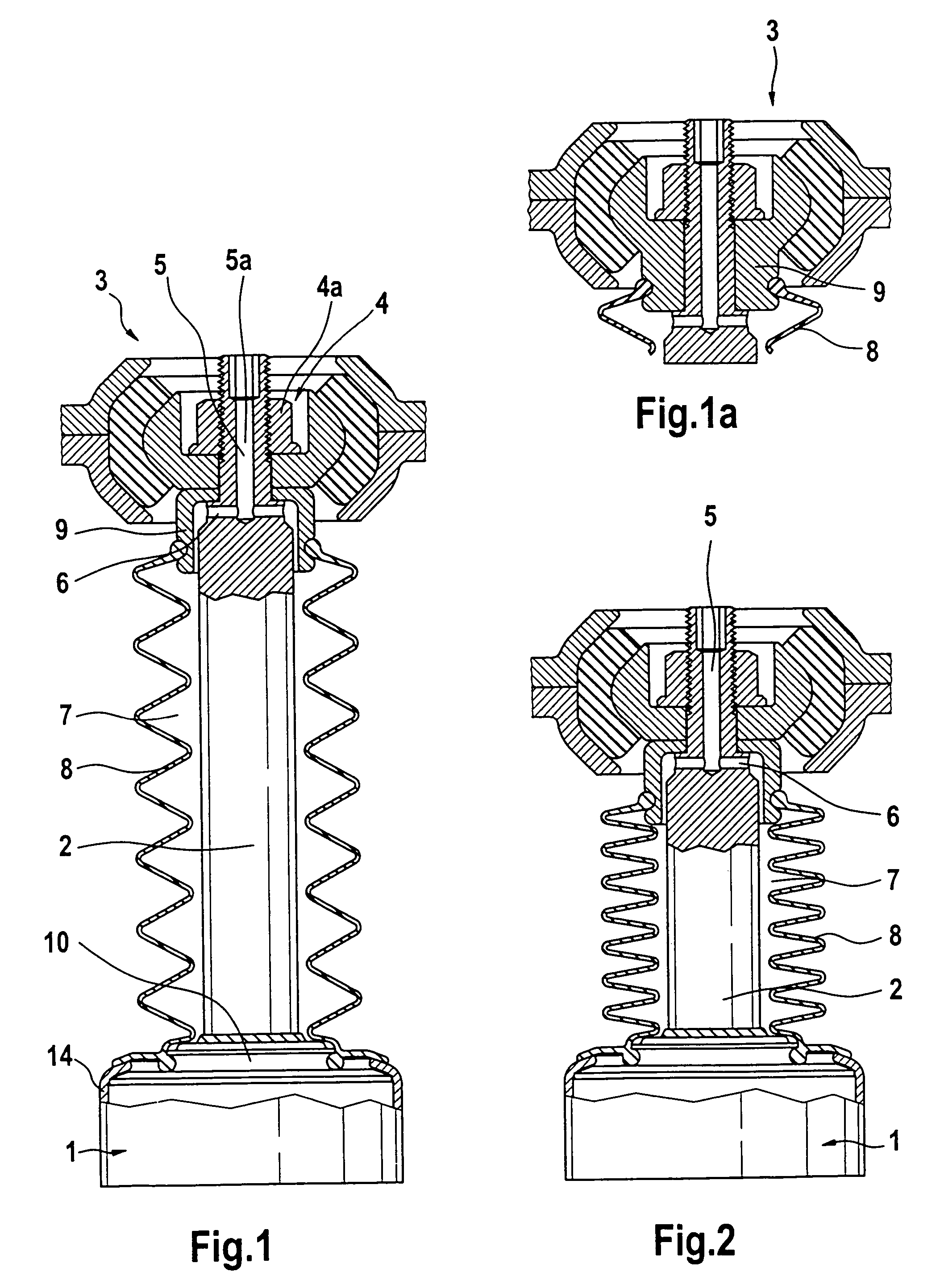

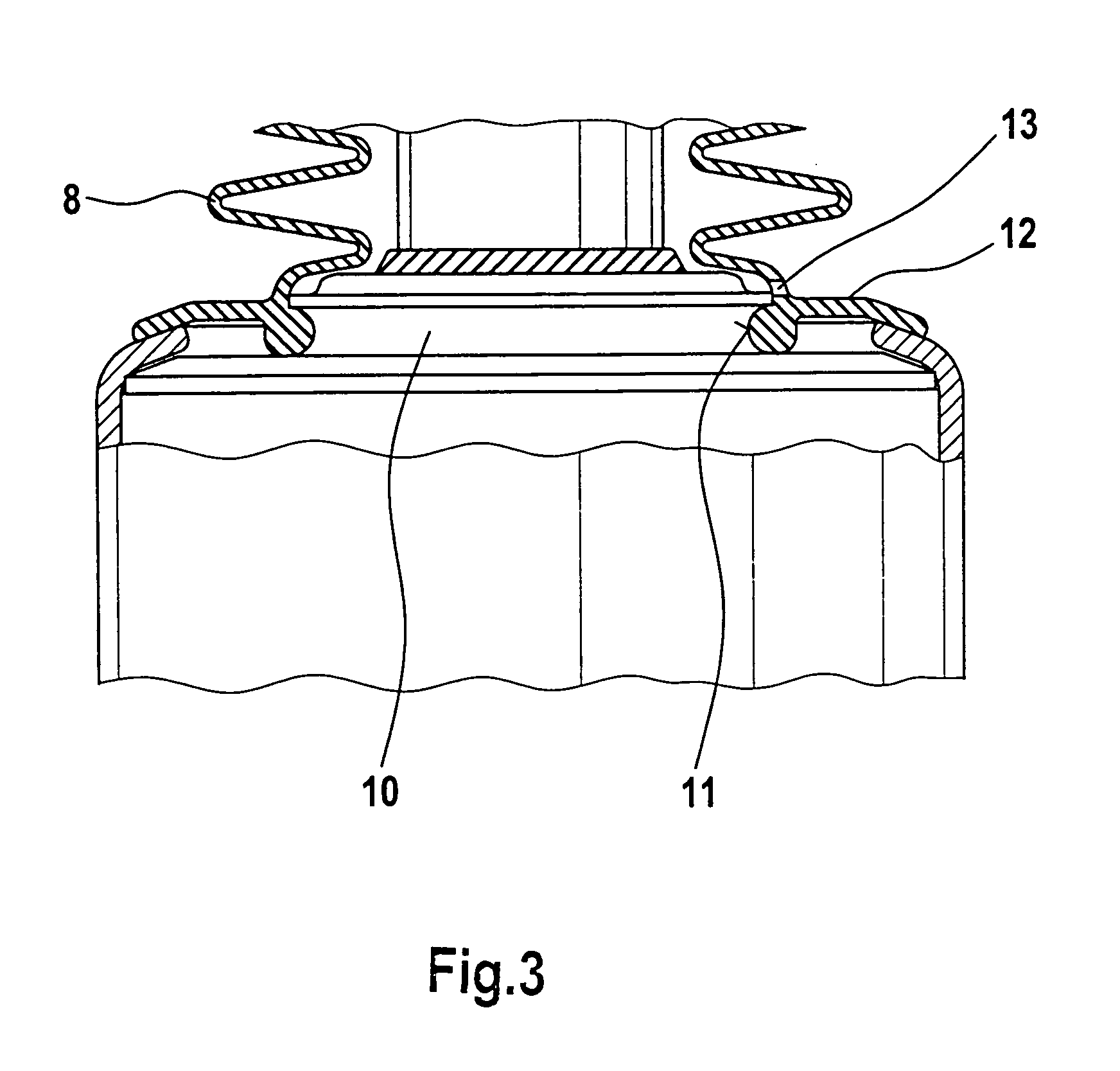

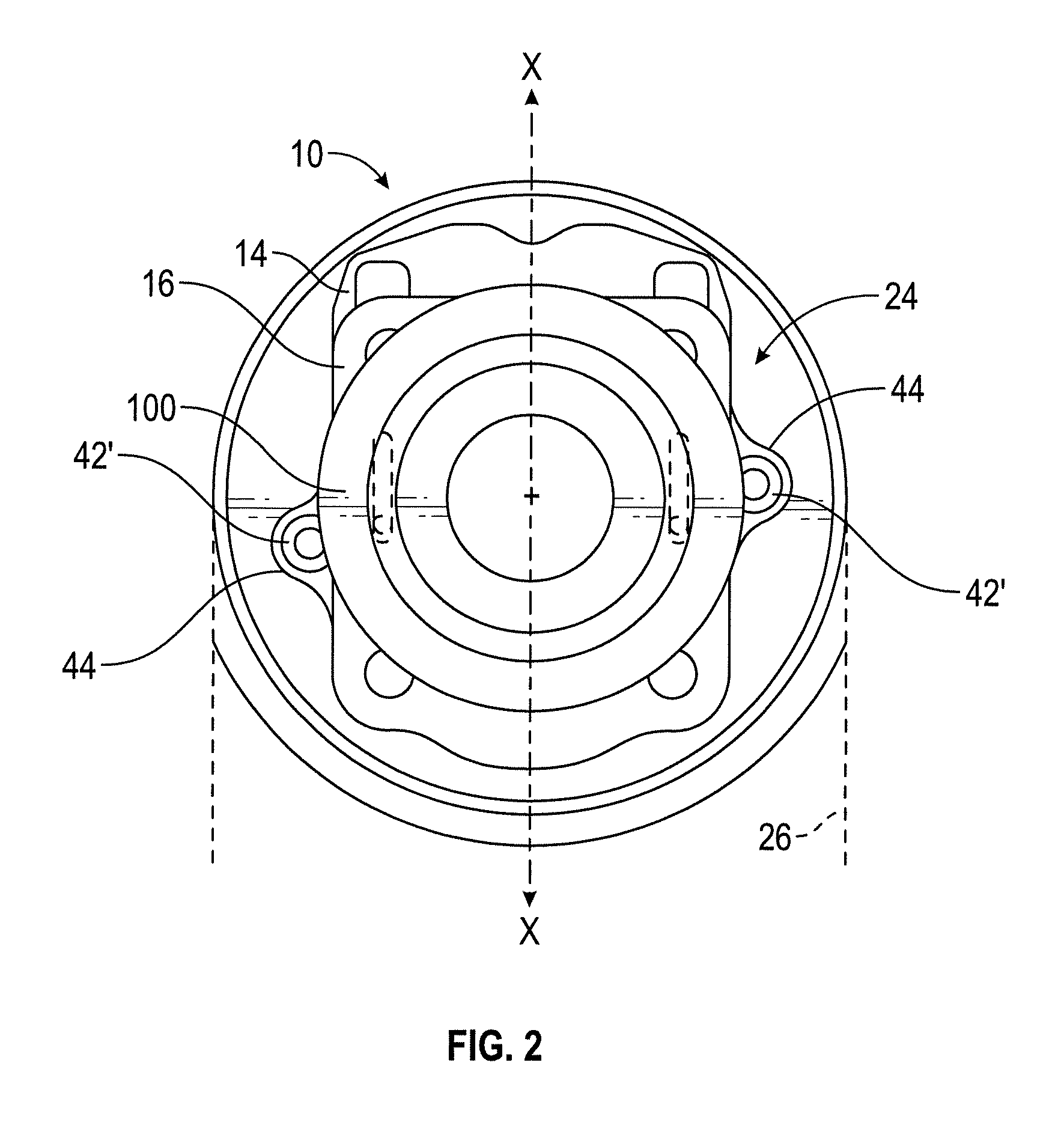

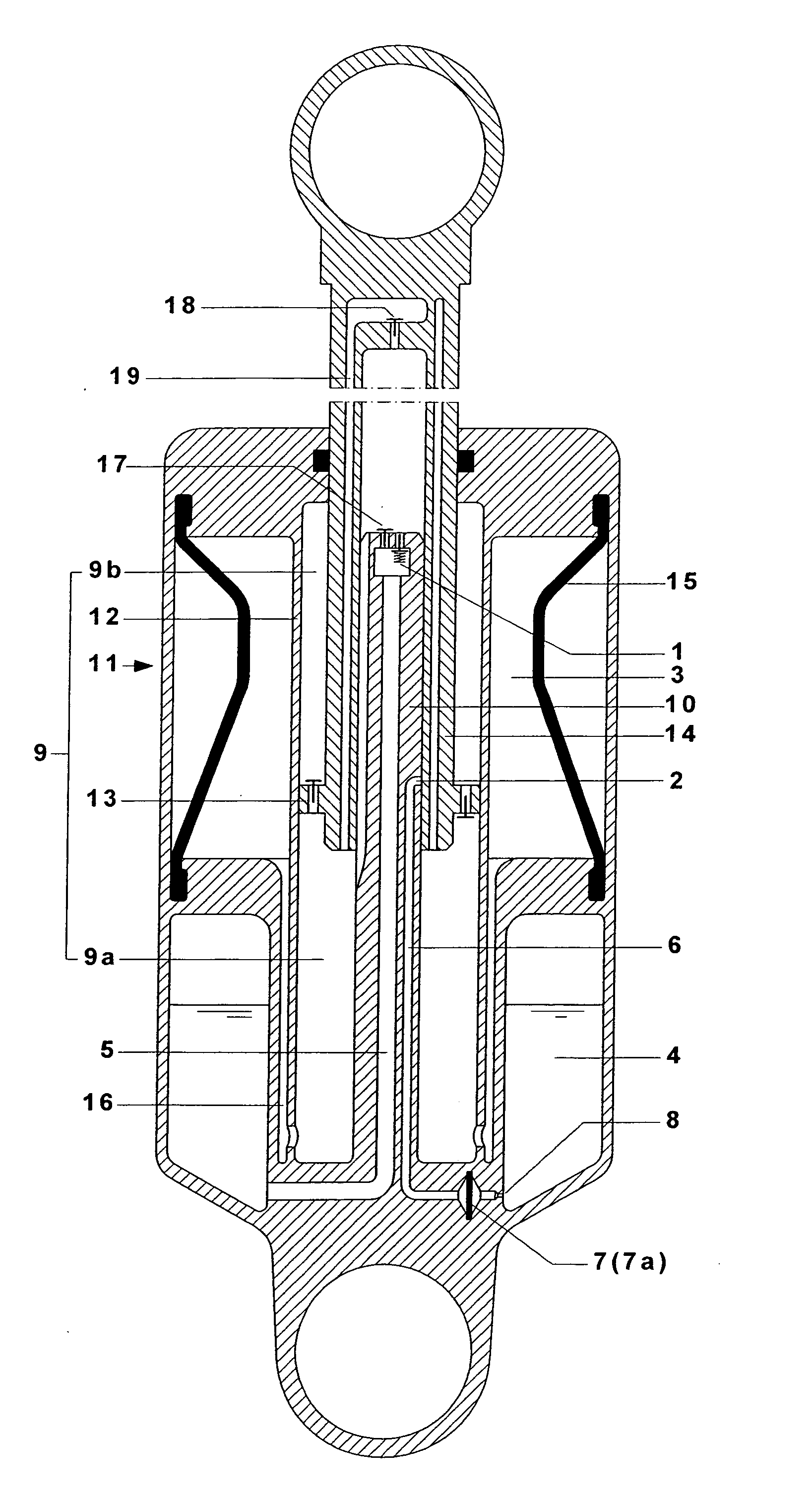

Bump stop and associated MacPherson strut

InactiveUS8496383B2Easy to installImprove operational safetyRoller bearingsSpringsEngineeringStops device

The bump stop device, particularly for a motor vehicle, comprises a bearing 6 forming an axial stop, a bottom support cover 5 of the bearing and a bottom retainer 7 for a spring comprising at least one stiffening strut. The support cover 5 and / or the retainer 7 comprises at least one axial securing means 15 of the bottom retainer and of the bottom support cover, the said means being situated axially set back from a bottom end of the retainer.

Owner:AB SKF

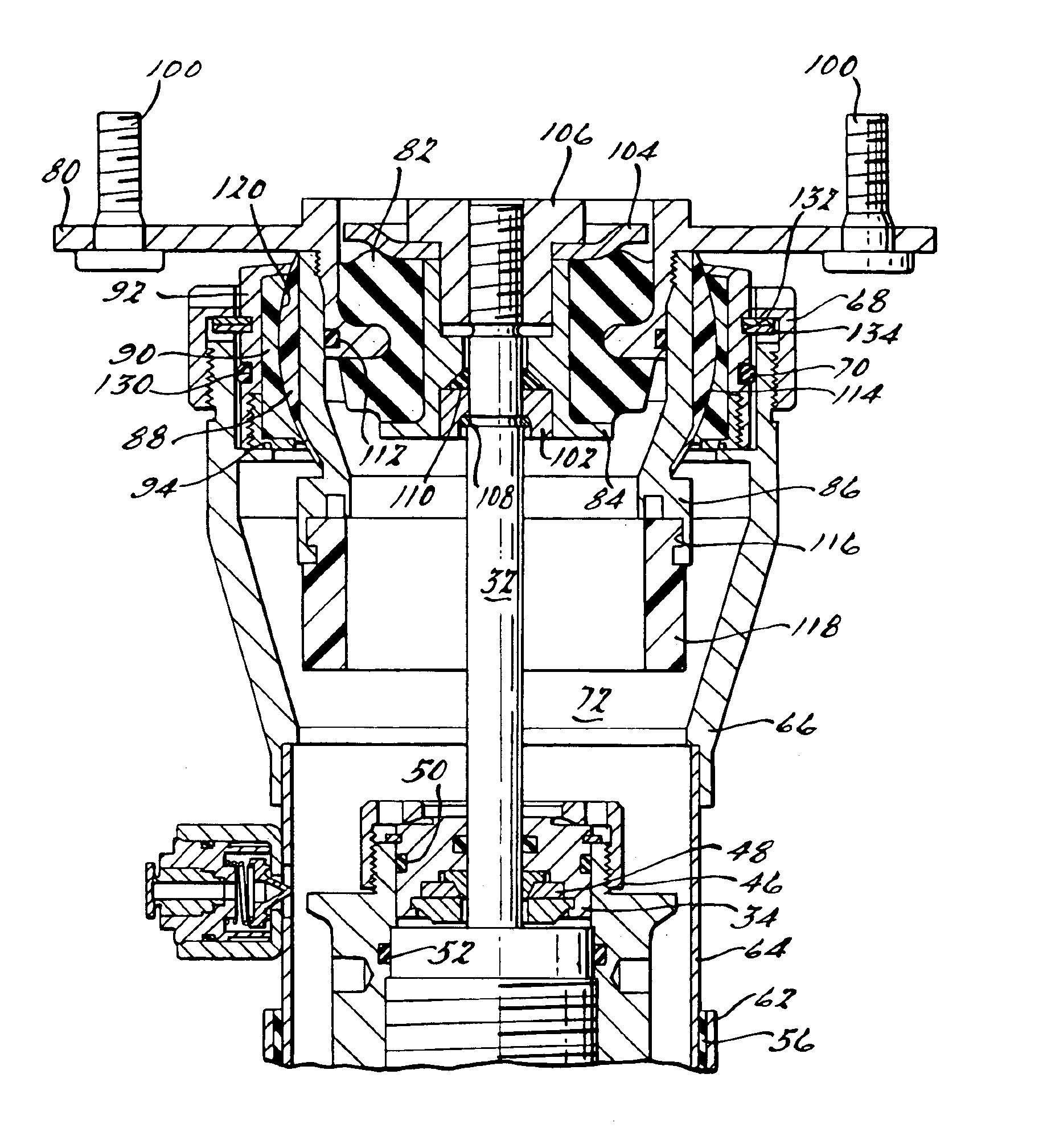

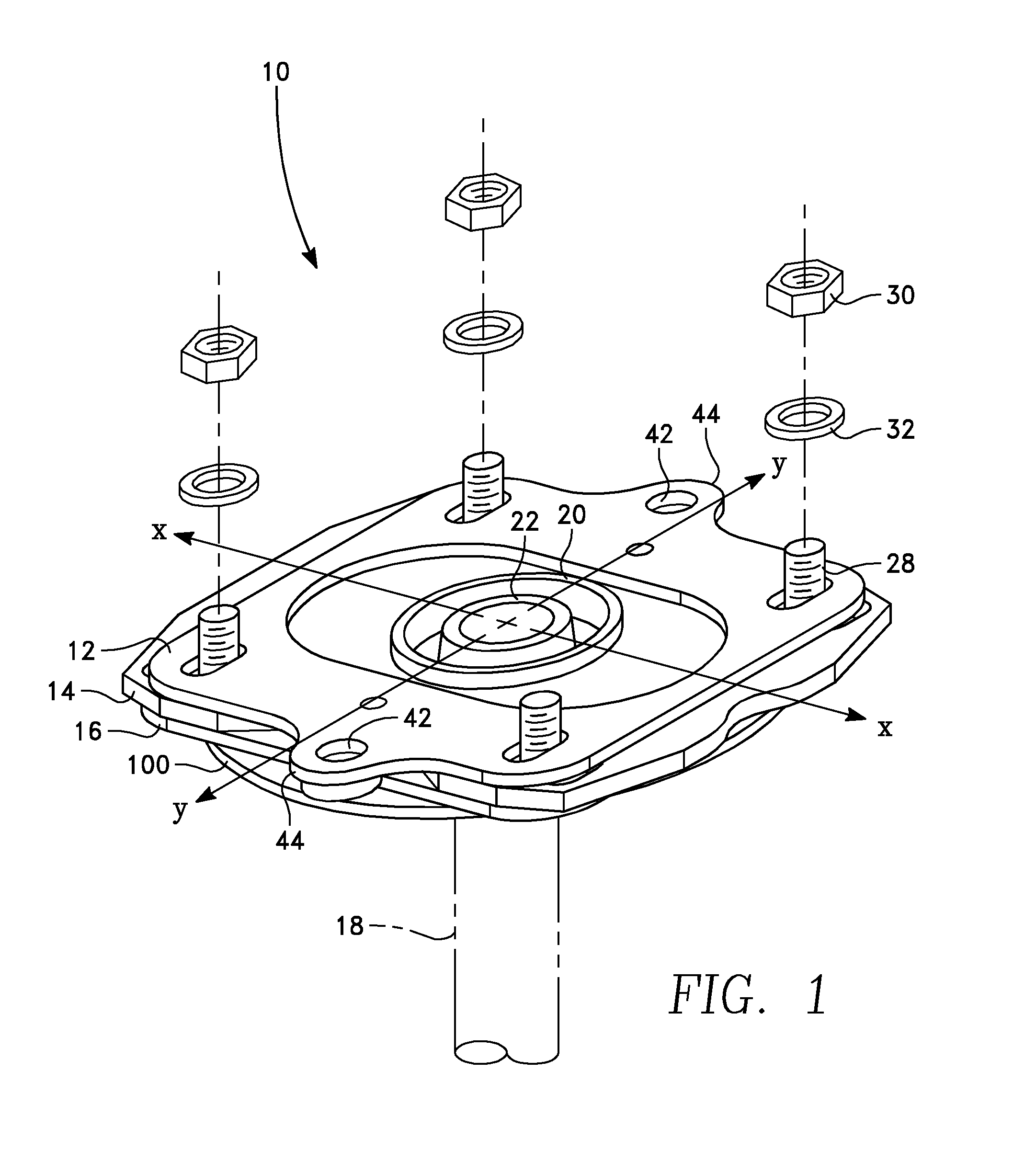

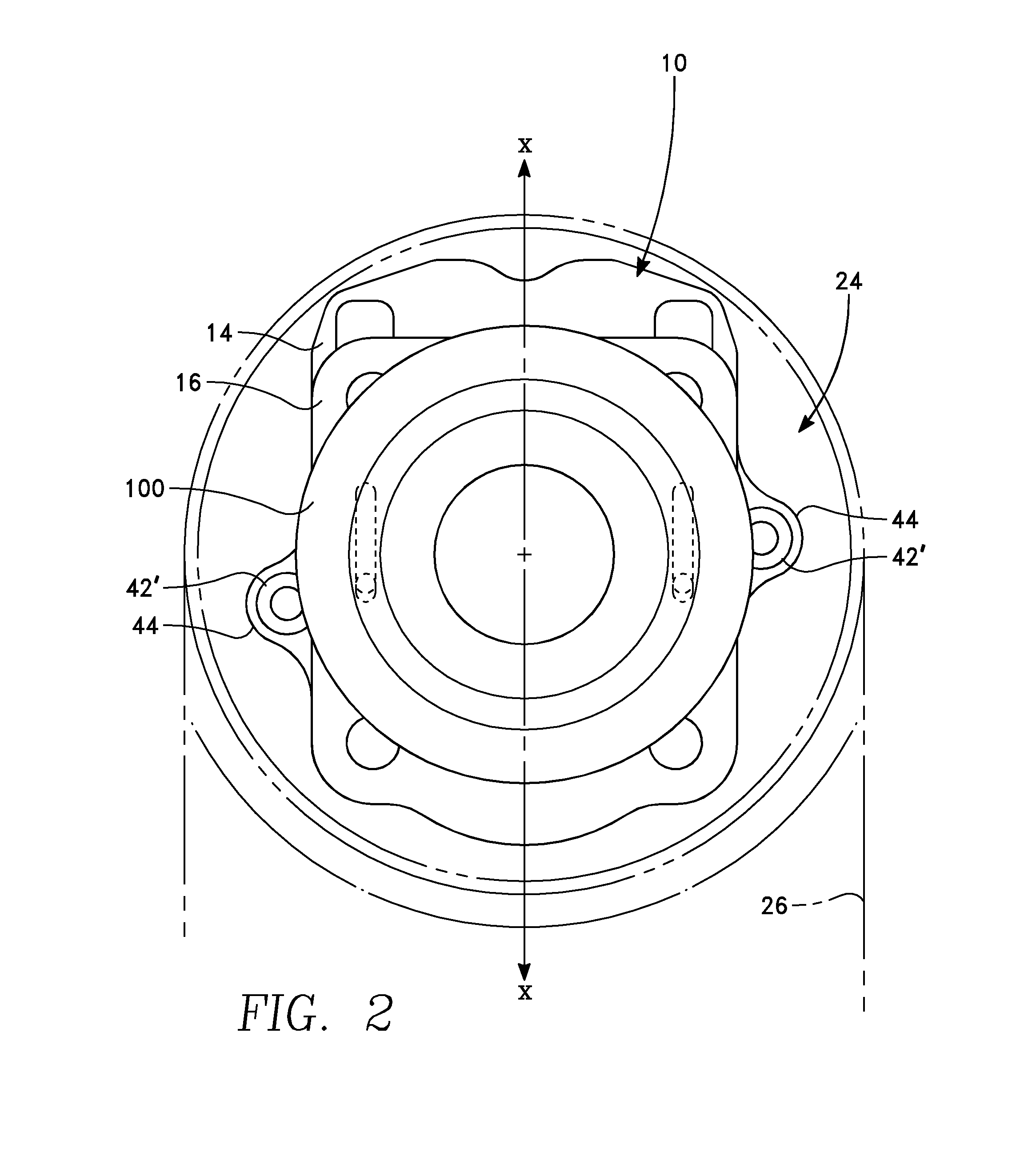

Upper shock mount isolator with integral air spring housing pivot bearing

An upper mounting system for a MacPherson strut includes a shock absorber mount and an air spring mount. The air spring mount is disposed coaxially around the shock absorber mount. A curved spherical interface of the air spring mount permits pivotal movement of the air spring such that it maintains a coaxial relationship with the shock absorber. The curved spherical interface also provides a seal for sealing the gas chamber of the air spring.

Owner:THE PULLMAN CO

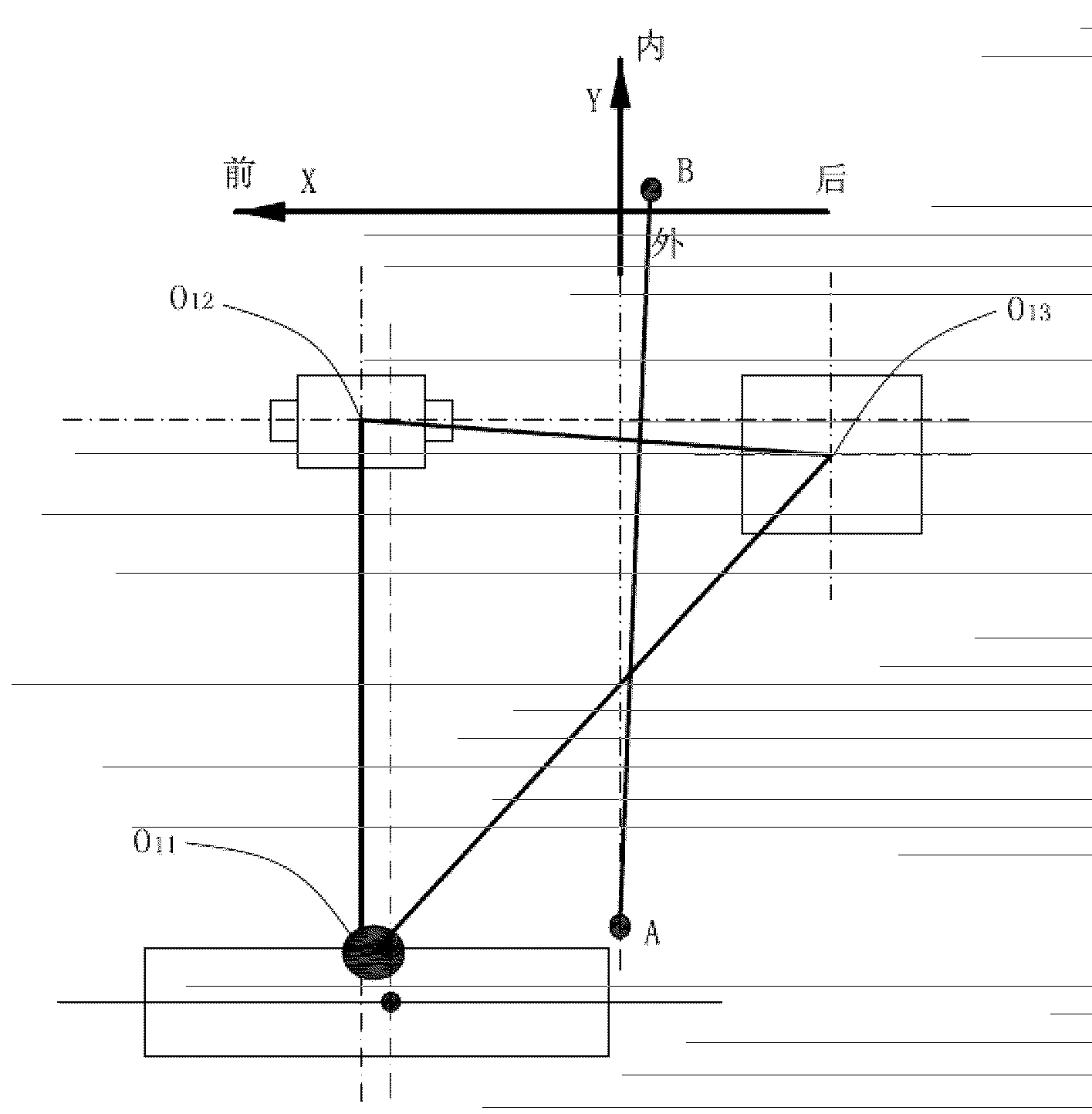

Method for designing McPherson suspension

ActiveCN101826125ALower the thresholdSpeed up research and developmentSpecial data processing applicationsControl armEngineering

The invention aims at providing a method for simply designing a McPherson suspension. The method comprises the following steps: firstly, establishing a coordinate system; then, obtaining hard point position parameters of connecting positions of each component in the McPherson suspension such as the shock absorber upper point, the tire grounding point, the control arm outer point and the control arm front point or back point and the like through measurement or calculation; carrying out calculation according to the parameters to obtain an equation of a main pin axial line and a control arm axial line; calculating the coordinates of an instantaneous rotation center through setting a first auxiliary line on the basis; and then, calculating the side inclination center height through setting a second auxiliary line. Thereby, the hard point positions of the connecting positions of each component in the McPherson suspension can be regulated according to the design requirements, and the side inclination center height of the McPherson suspension can be regulated. The method for designing the McPherson suspension of the invention has the characteristics of low threshold, convenience, accuracy and the like, is suitable for being used in the development work of the McPherson suspension, and can improve the developing speed.

Owner:CHERY COMML VEHICLE ANHUI

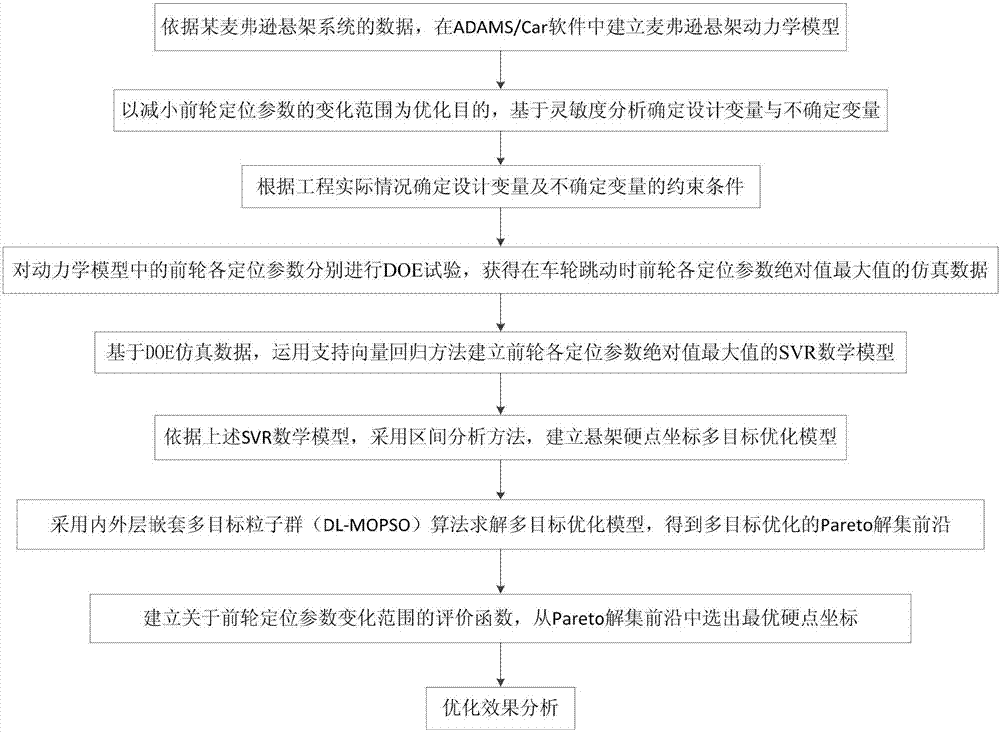

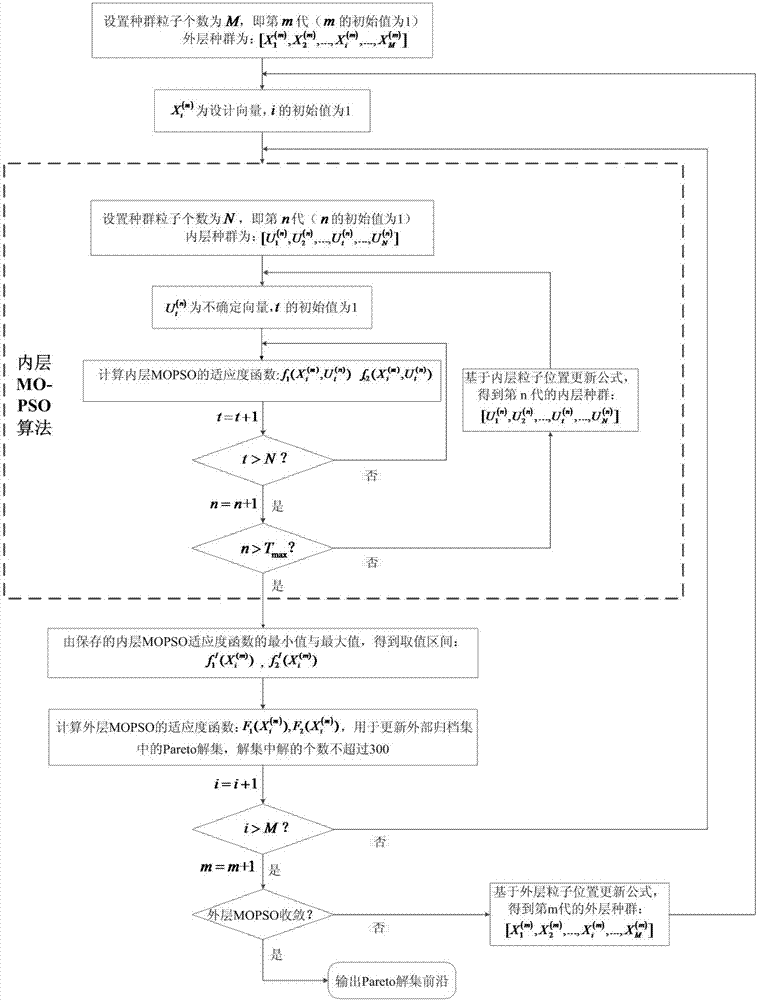

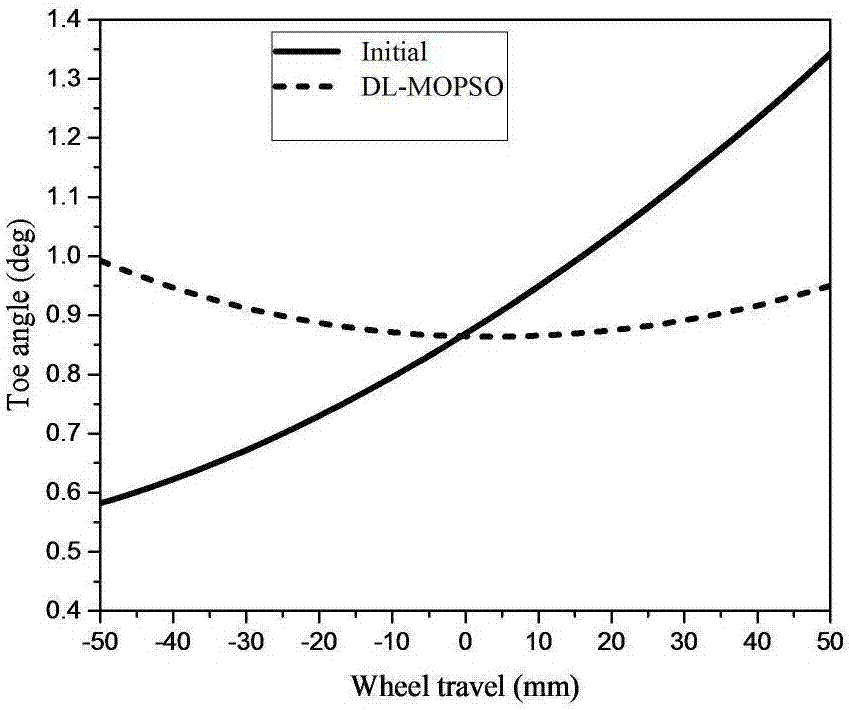

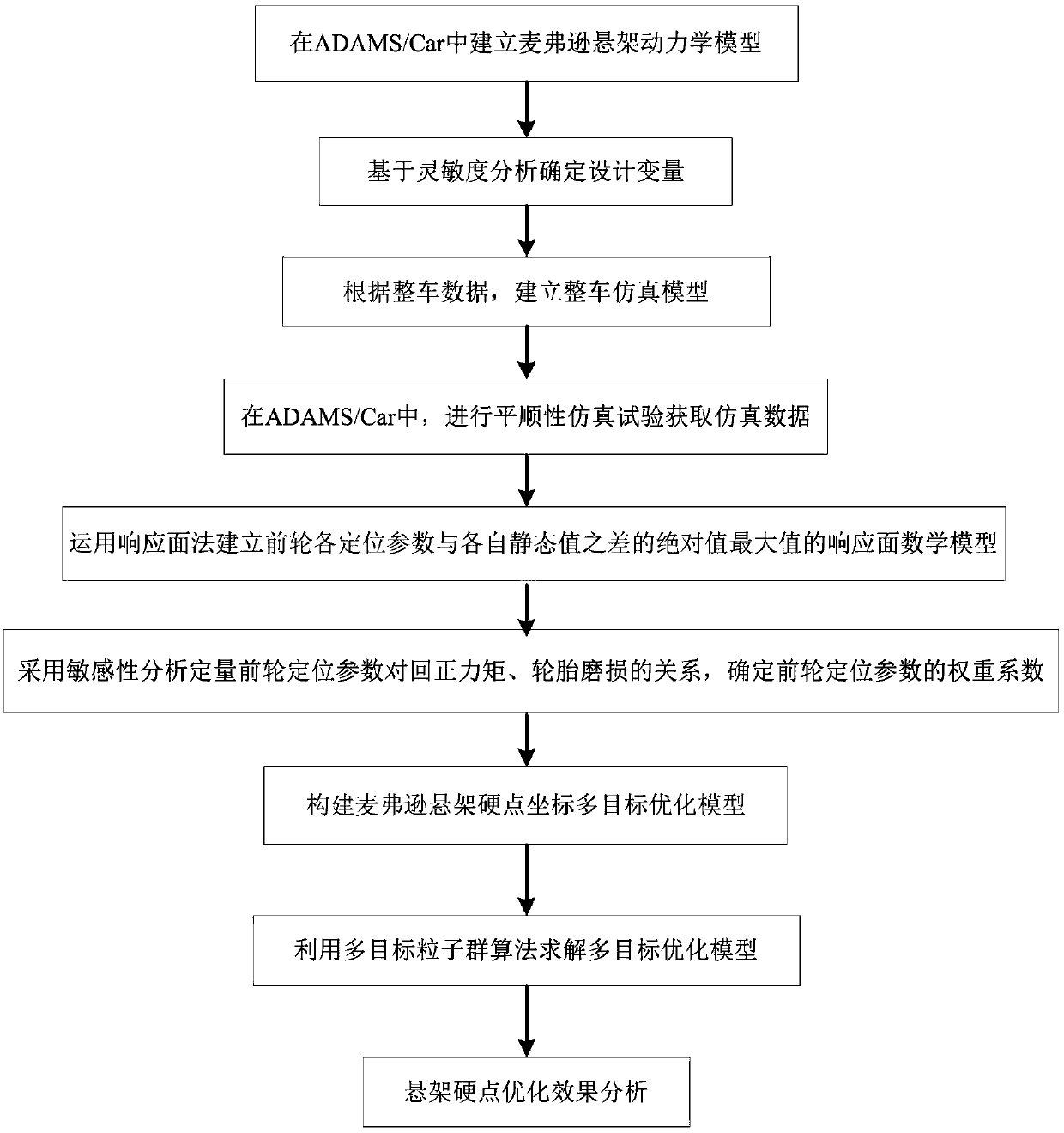

Macpherson suspension hard point coordinate optimization method based on inner layer and outer layer nested multi-objective particle swarm algorithm

ActiveCN106909743AStrong generalizationSolve disaster problemsGeometric CADSpecial data processing applicationsAlgorithmFront edge

The invention discloses a Macpherson suspension hard point coordinate optimization method based on an inner layer and outer layer nested multi-objective particle swarm algorithm. The method comprises the following steps: 1, building a multi-objective optimization model for Macpherson suspension hard point coordinates; 2, solving the multi-objective optimization model through the inner layer and outer layer nested multi-objective particle swarm algorithm, thus obtaining a multi-objective optimized Pareto solution set front edge; 3, carrying out weighting treatment on a change range of each locating parameter of a front wheel, and building an evaluation function on the change ranges of the locating parameters of the front wheel, thus selecting the optimal hard point coordinates from the Pareto solution set front edge according to the evaluation function. According to the Macpherson suspension hard point coordinate optimization method based on the inner layer and outer layer nested multi-objective particle swarm algorithm, the change ranges of the locating parameters of the front wheel can be effectively reduced when mechanical parameters of a suspension are not changed, thus substantially improving the operation stability of an automobile; meanwhile, the automobile still can obtain good operation stability when the mechanical parameters of the suspension are changed, thus effectively guaranteeing the robustness of the optimal design of the suspension hard point coordinates.

Owner:HEFEI UNIV OF TECH

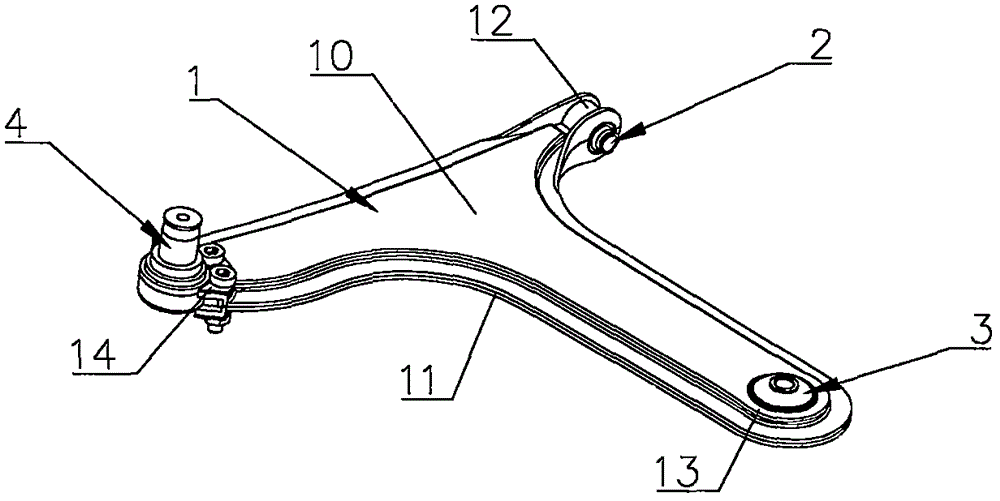

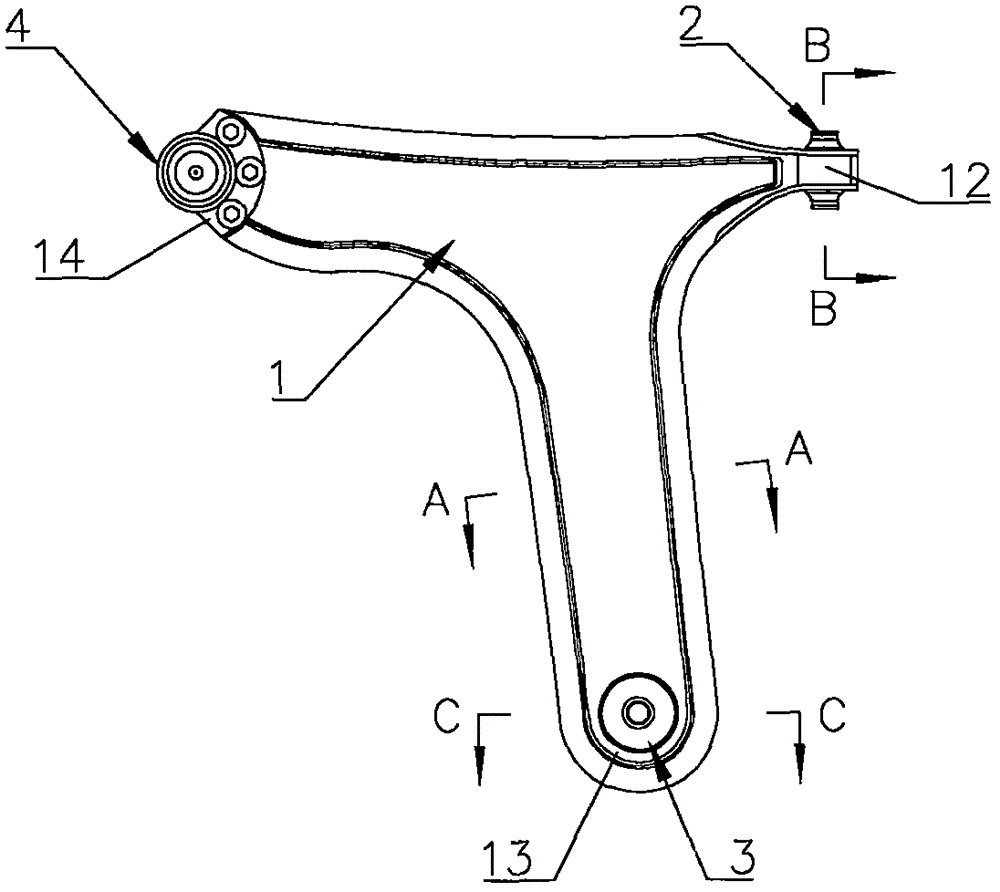

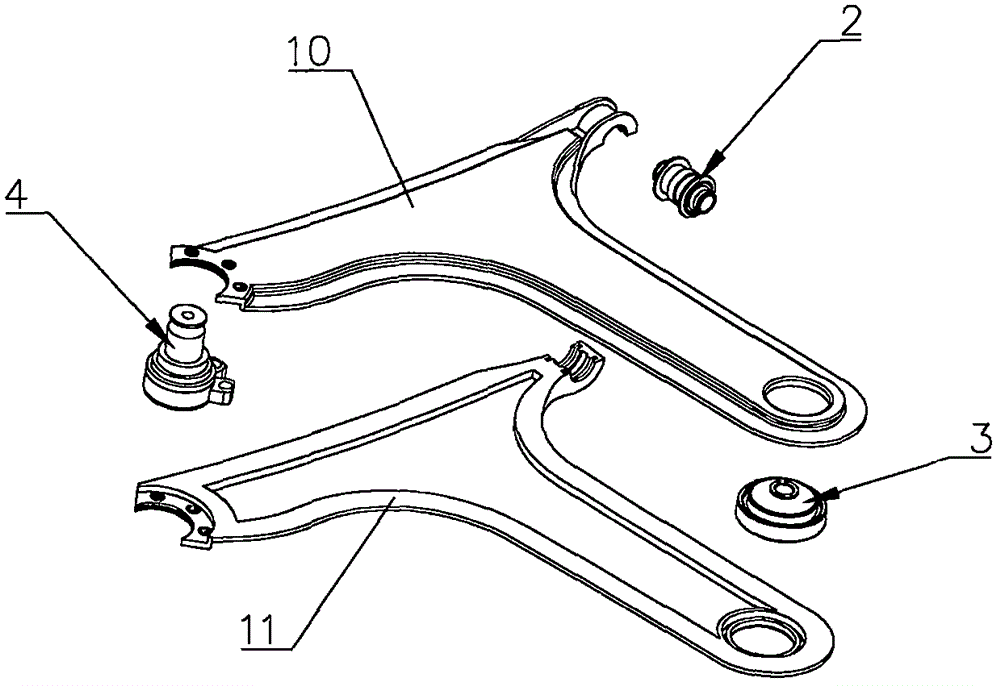

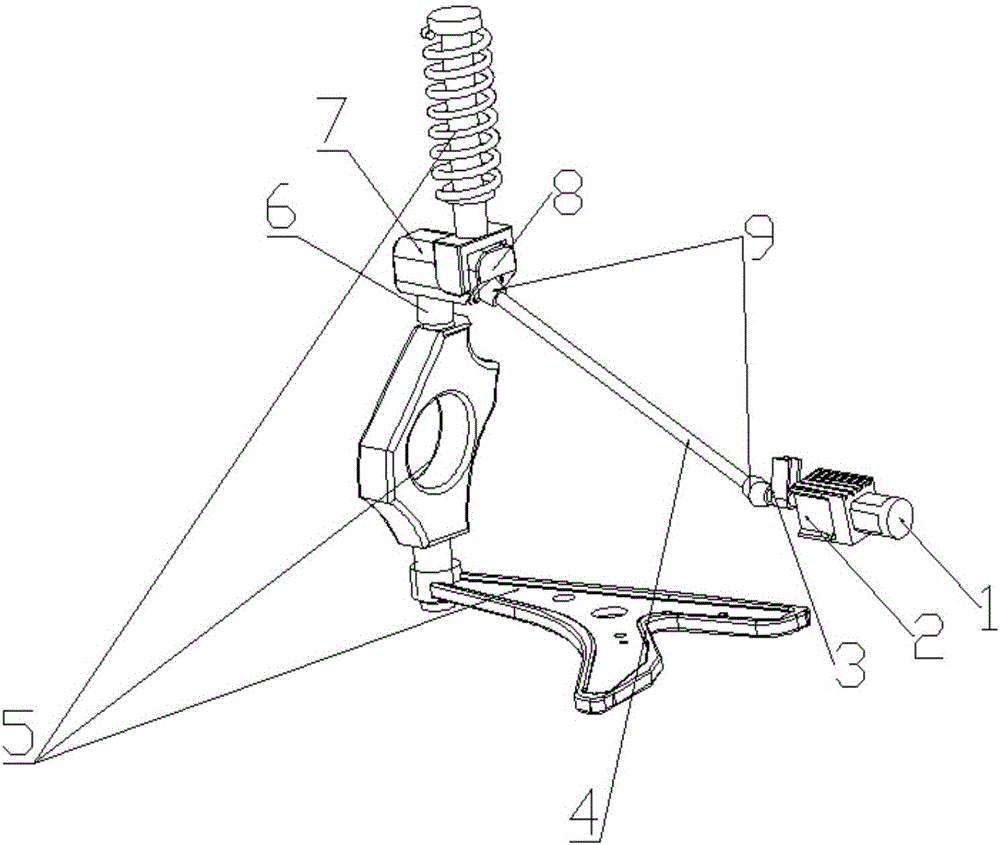

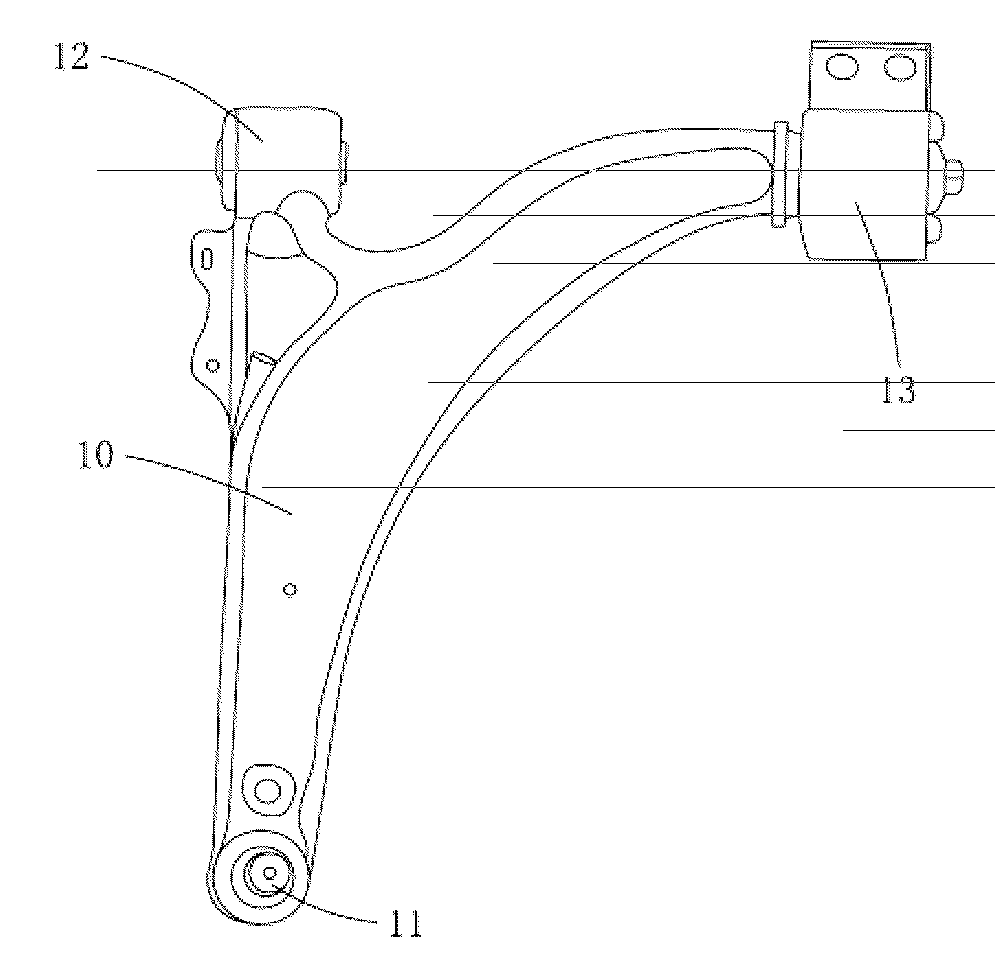

Carbon fiber composite McPherson suspension control arm and preparation method thereof

ActiveCN105730174ALow costGuaranteed structural strengthPivoted suspension armsControl armEngineering

The invention relates to a light-weight suspension system of an automobile, in particular to a carbon fiber composite McPherson suspension control arm. The carbon fiber composite McPherson suspension control arm comprises a control arm body, a first bushing connected with an automobile body, a second bushing connected with a steering knuckle and a ball pin, wherein the control arm body is made of a carbon fiber composite and is hollow in the middle part; a first bushing end on which the first bushing is mounted, a second bushing end on which the second bushing is mounted, and a ball pin end to which the ball pin is connected are respectively arranged on the control arm body. The control arm disclosed by the invention has the advantages of being light in mass, high in intensity, high in impact resistance and the like, and the thickness can be designed, realization of the light weight of automobile parts is facilitated, and the development requirements of a conventional automotive technology for the respects of being energy-saving, environmentally-friendly, safe and the like are met; in addition, the invention further provides a preparation method of the control arm.

Owner:SUN YAT SEN UNIV

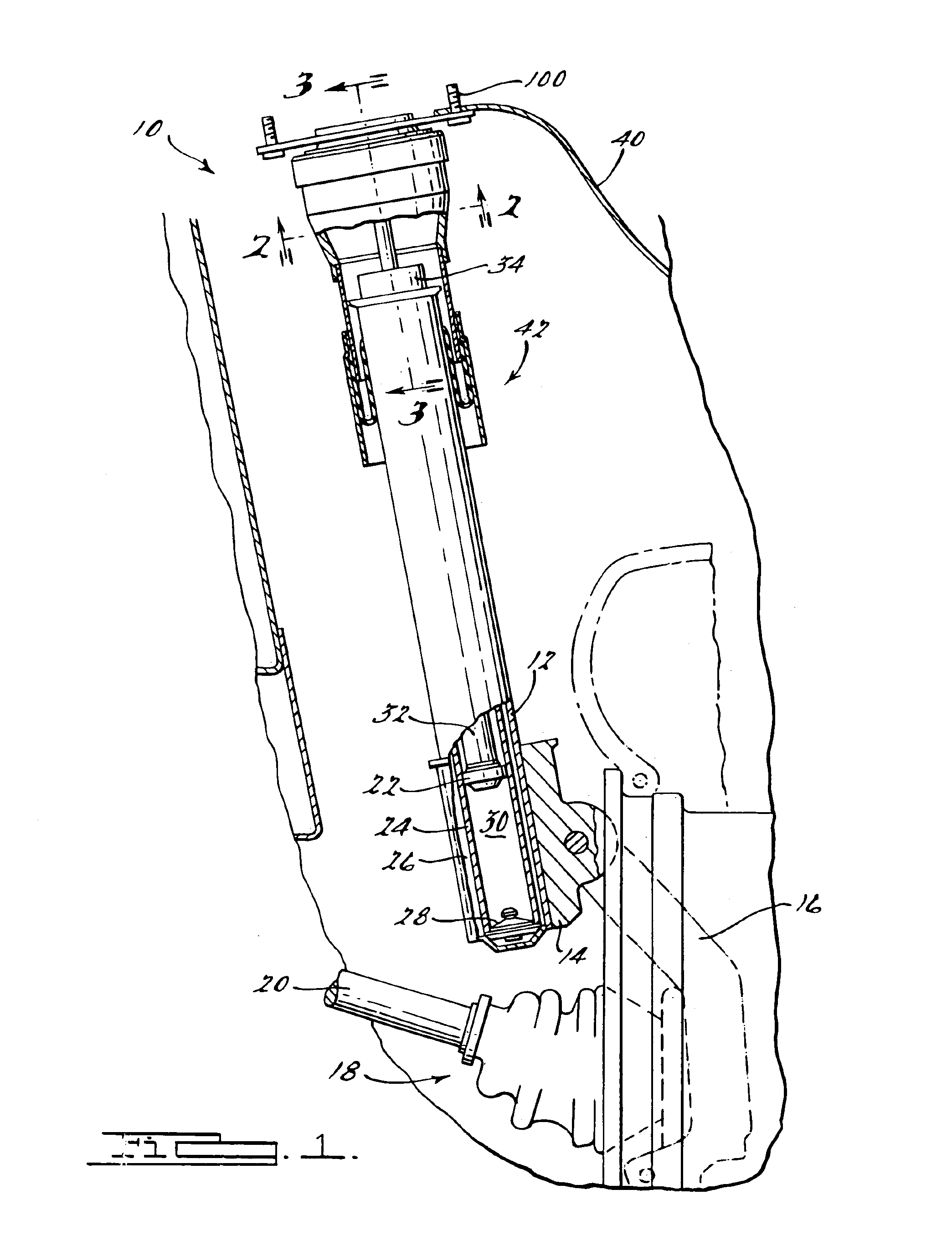

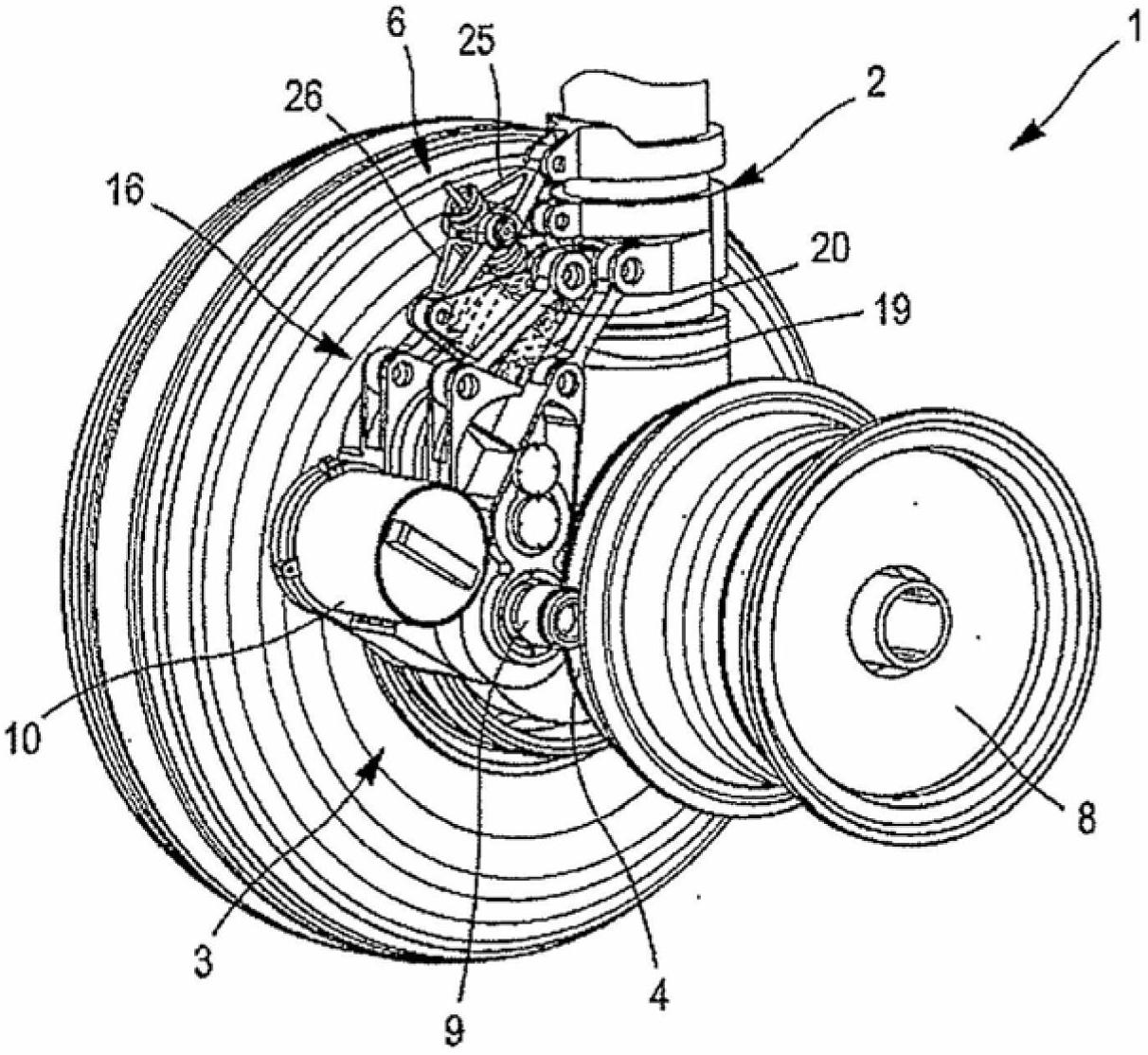

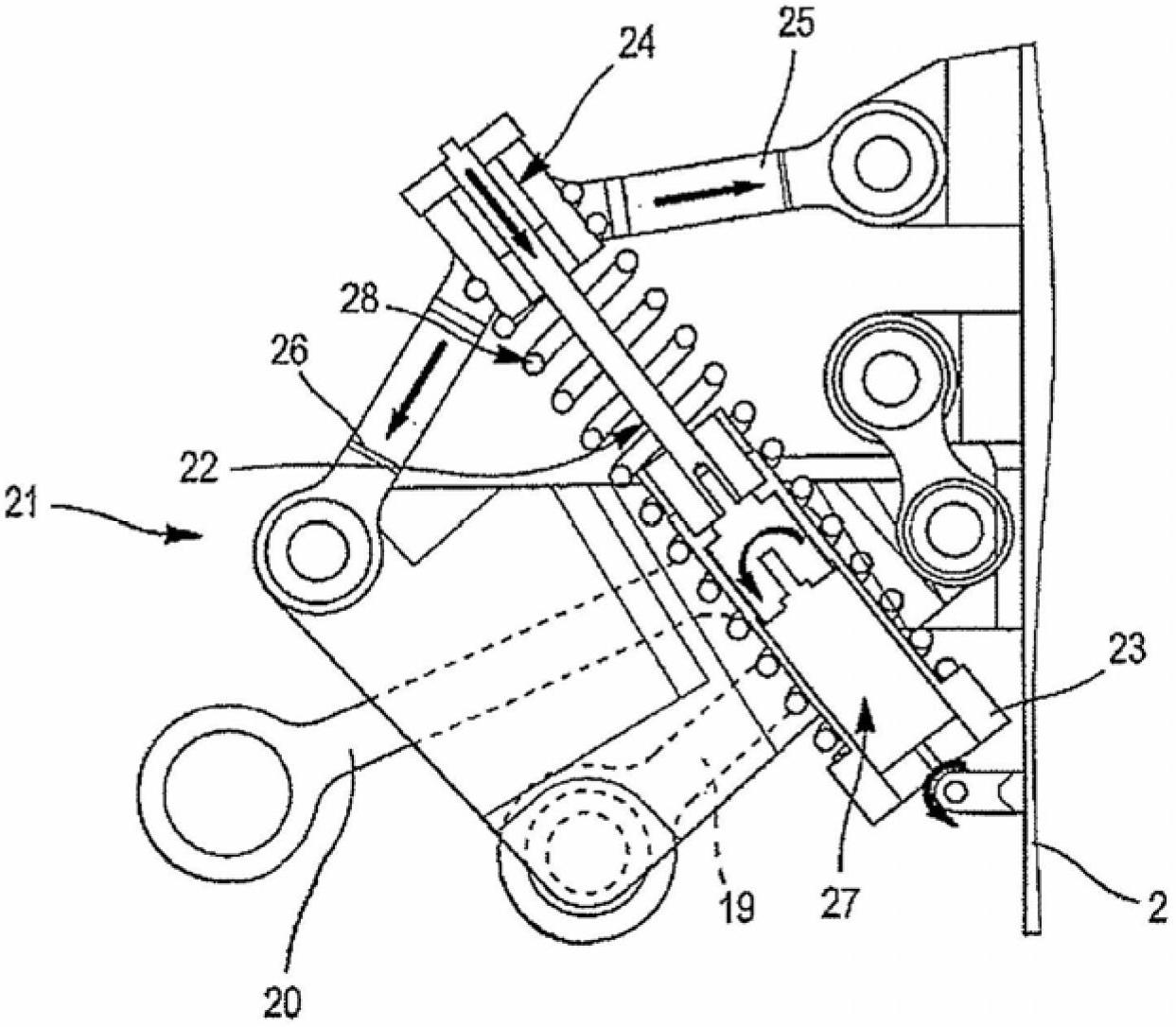

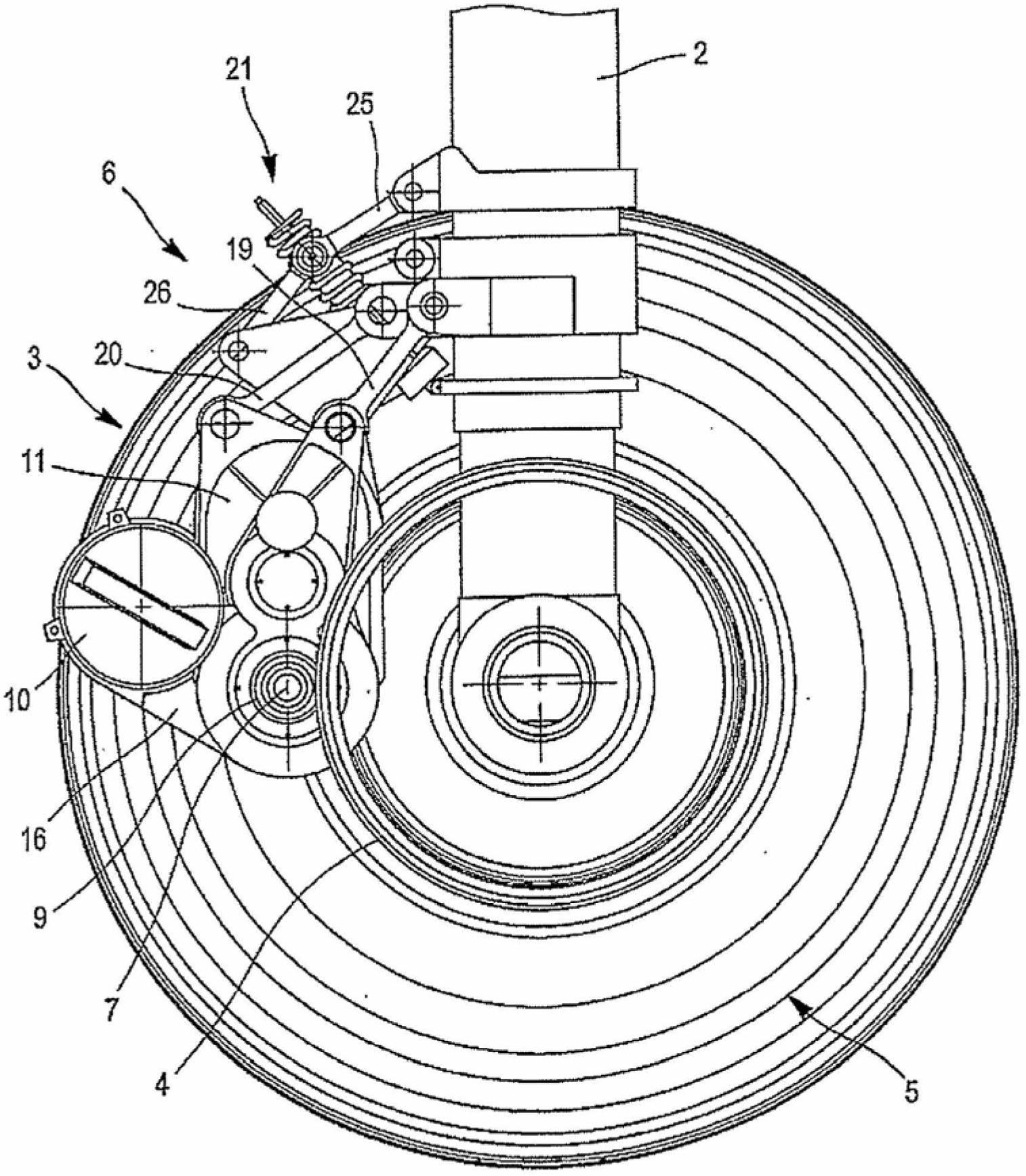

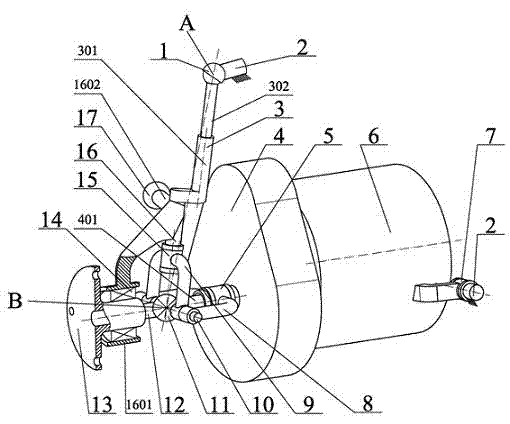

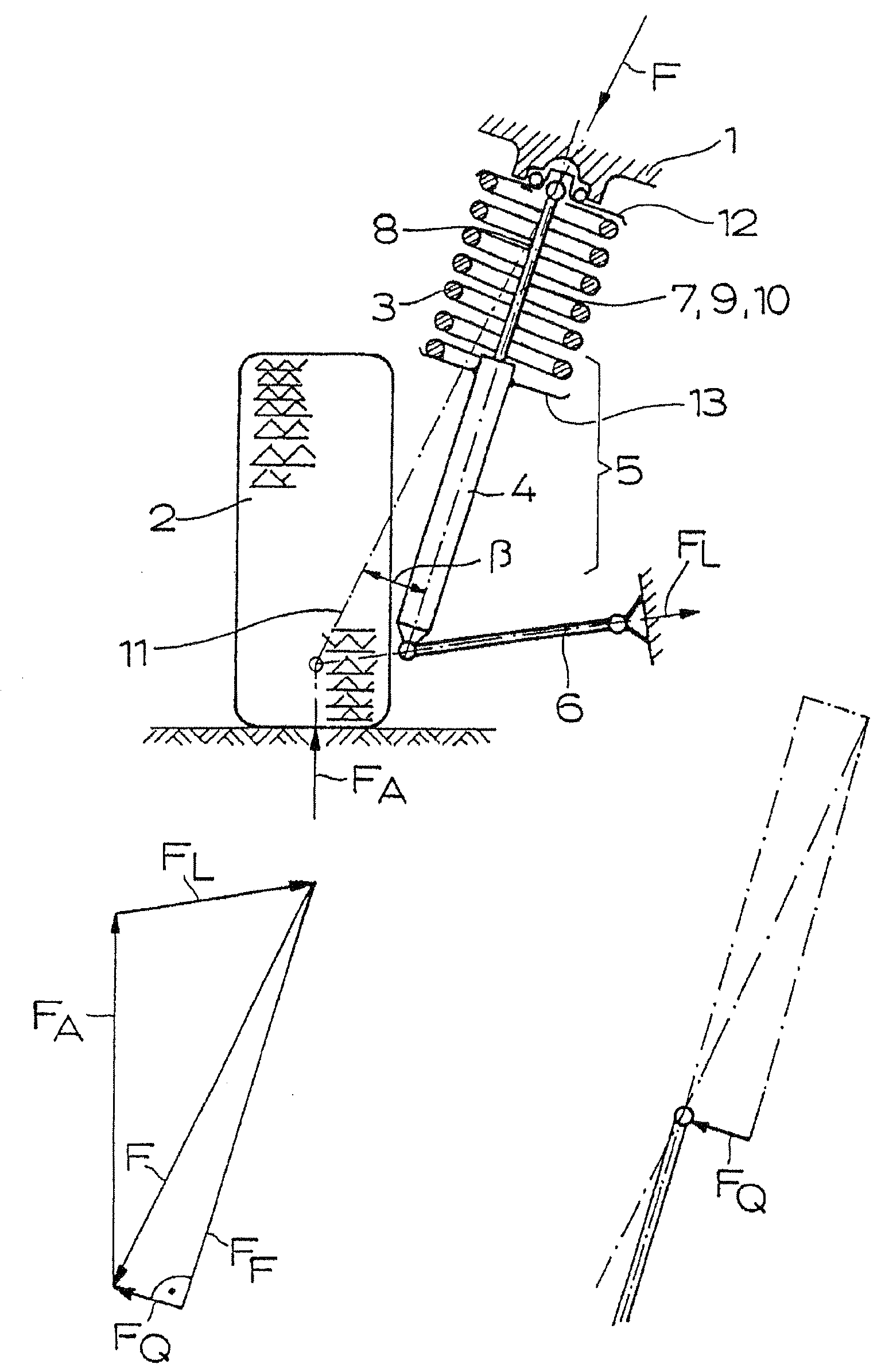

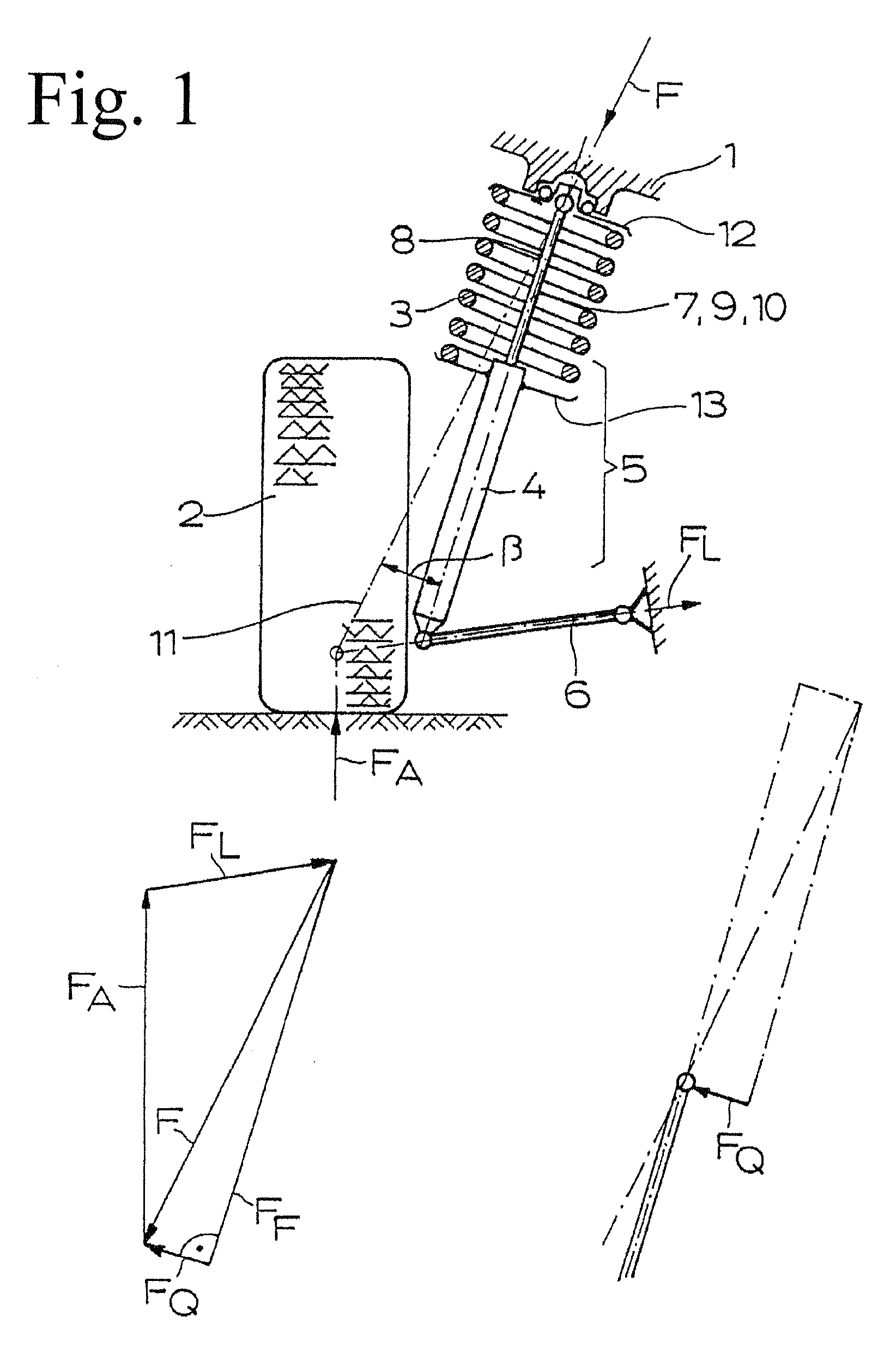

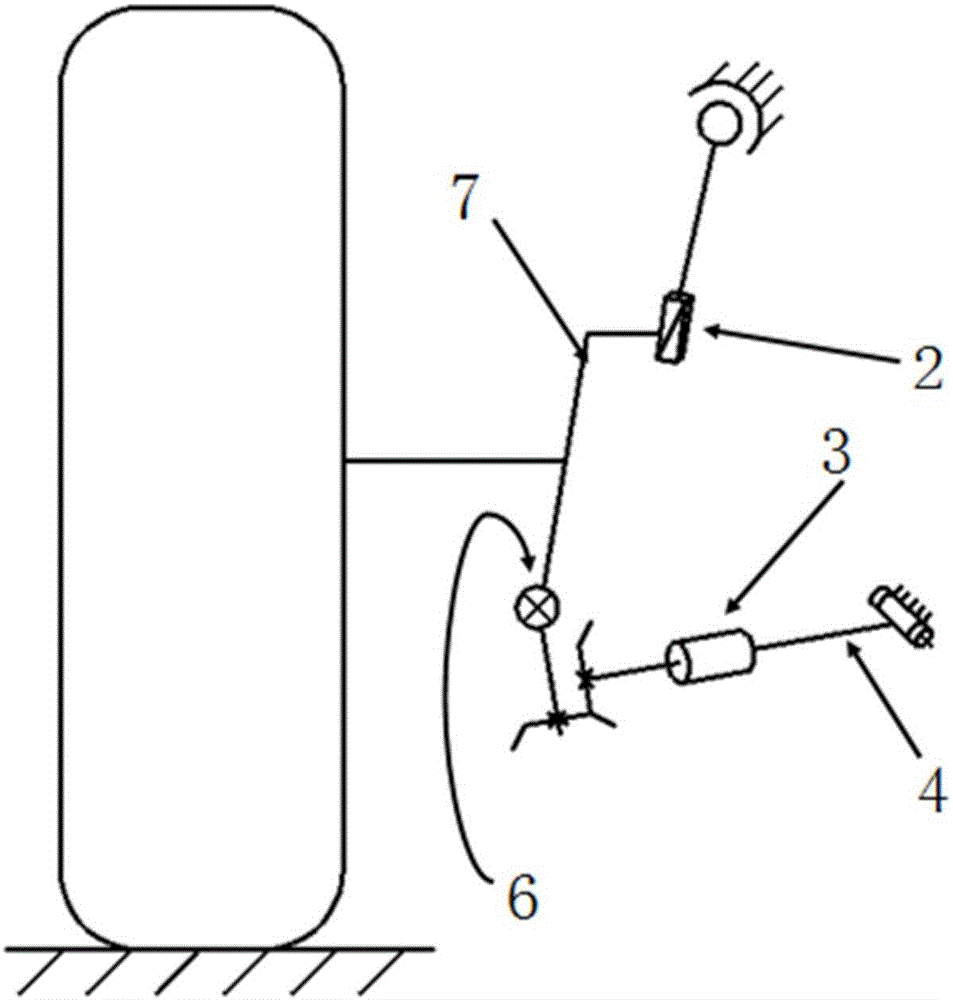

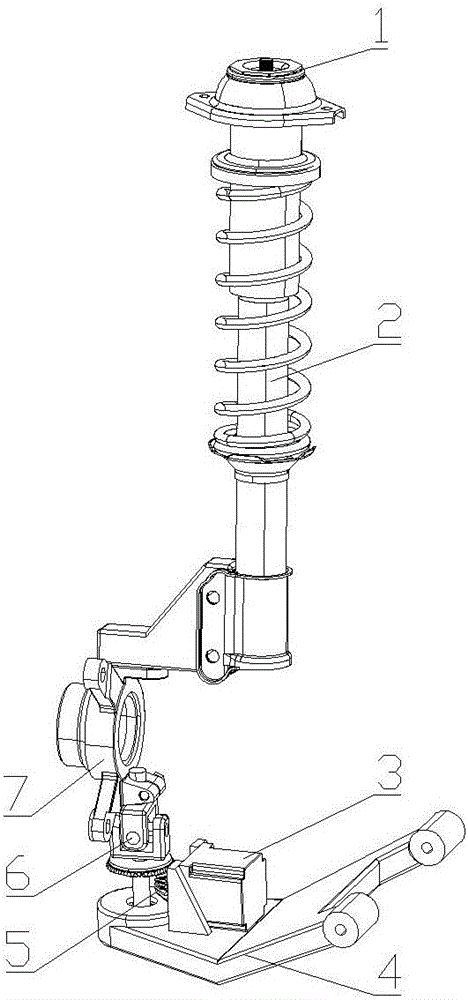

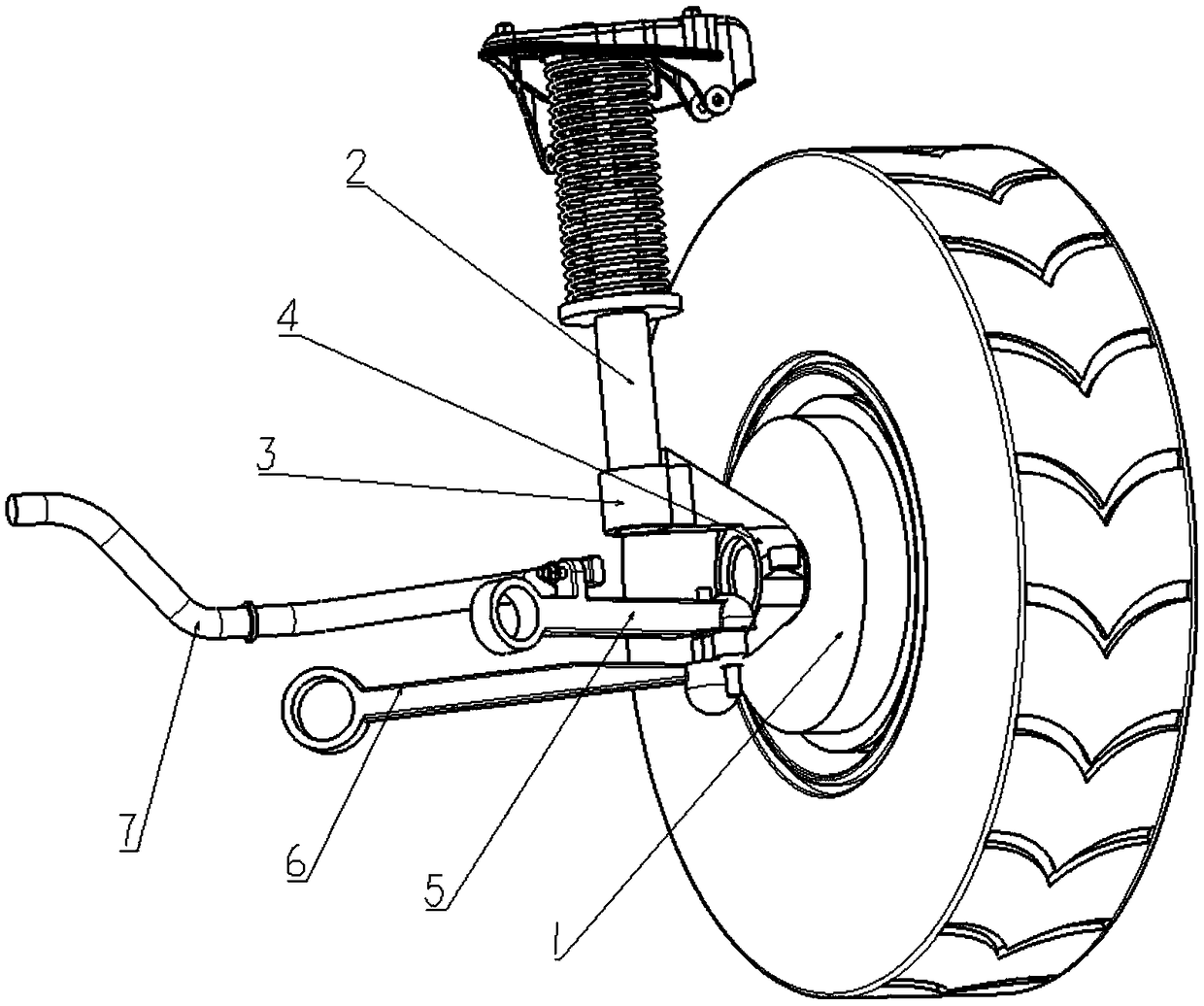

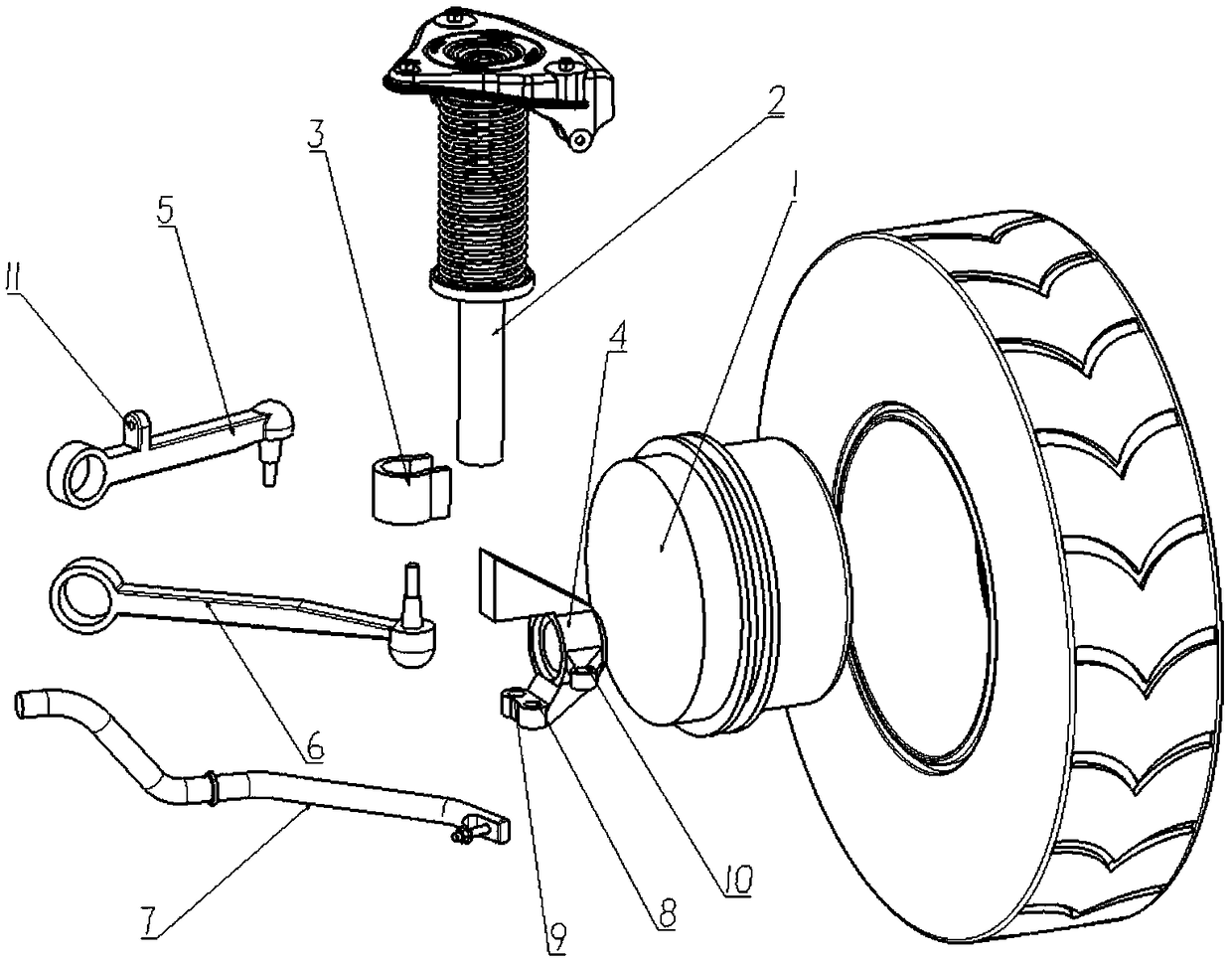

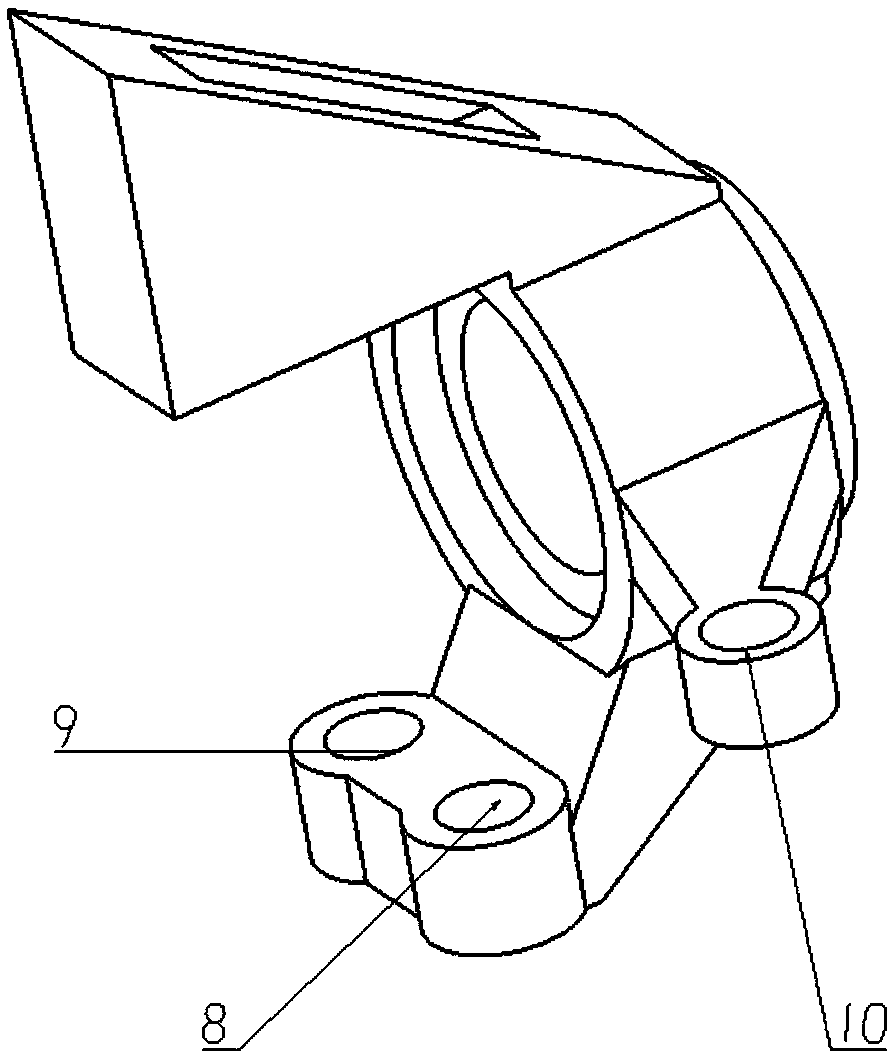

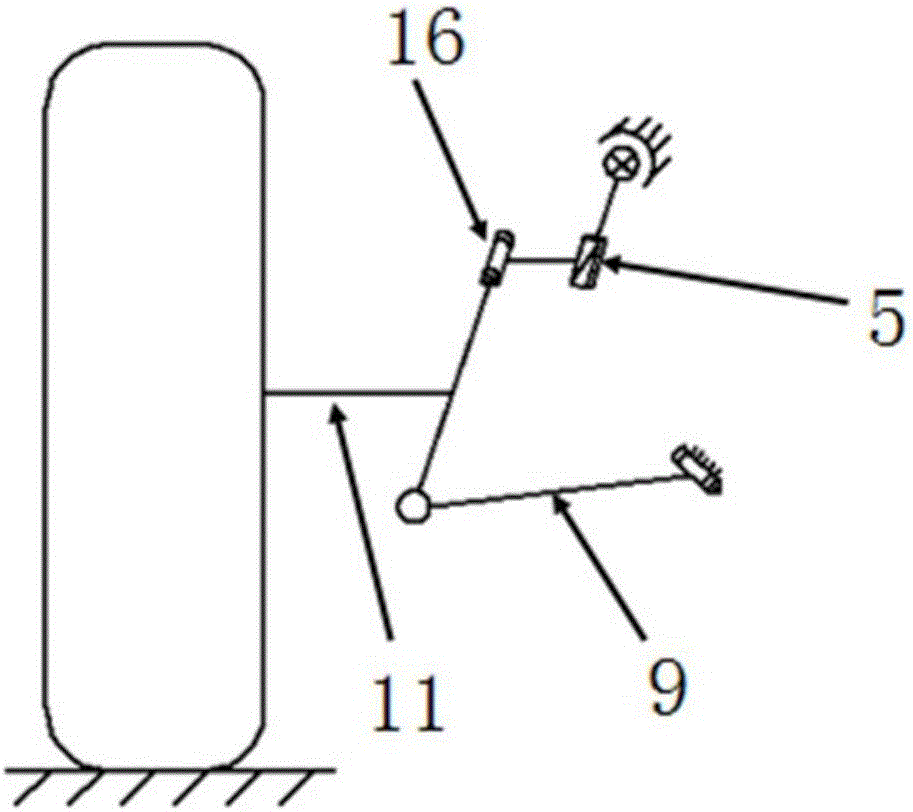

System for motorising a wheel connected to a suspension

The invention relates to a system for motorising a wheel (5) connected to a suspension, the system including an engine block (3) and a driving member (4) secured to the wheel (5). According to the invention, the engine block is secured to the suspended portion of the MacPherson strut (2) and a clutch device (6) connects the output shaft (7) of the engine block (3) to the driving member (4).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +2

Bump stop and associated macpherson strut

The bump stop device, particularly for a motor vehicle, comprises a bearing 6 forming an axial stop, a bottom support cover 5 of the bearing and a bottom retainer 7 for a spring comprising at least one stiffening strut. The support cover 5 and / or the retainer 7 comprises at least one axial securing means 15 of the bottom retainer and of the bottom support cover, the said means being situated axially set back from a bottom end of the retainer.

Owner:AB SKF

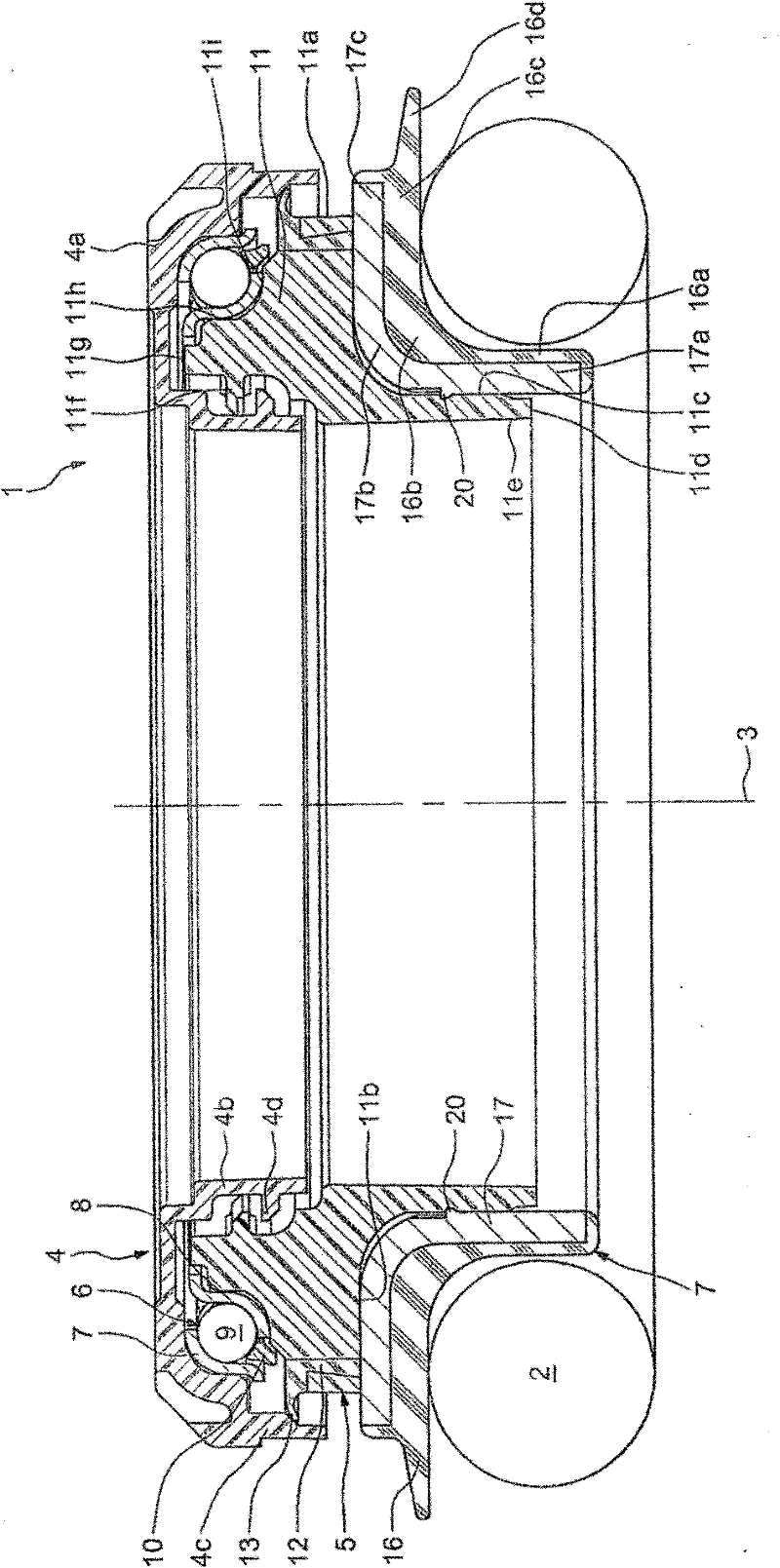

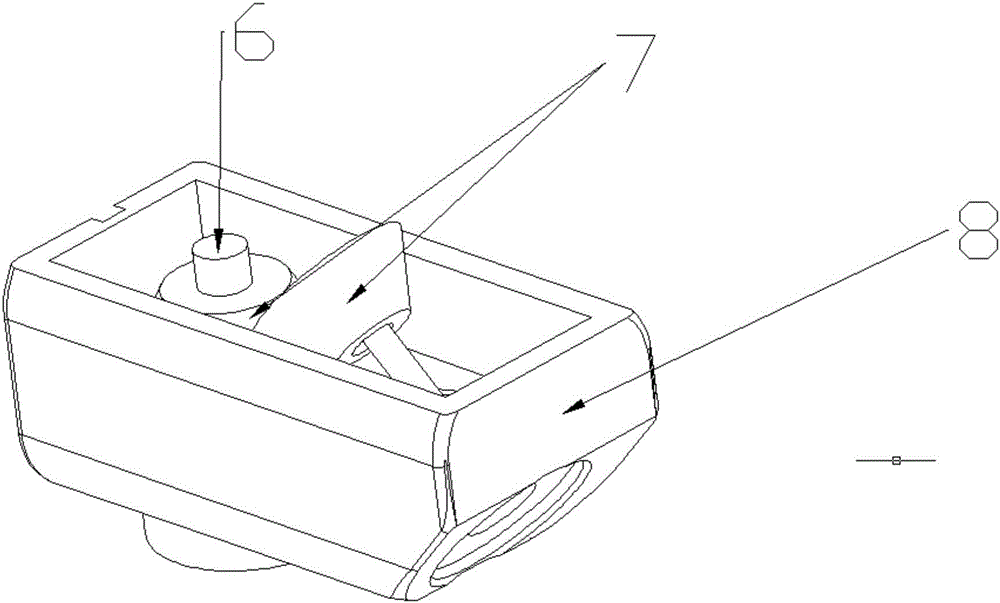

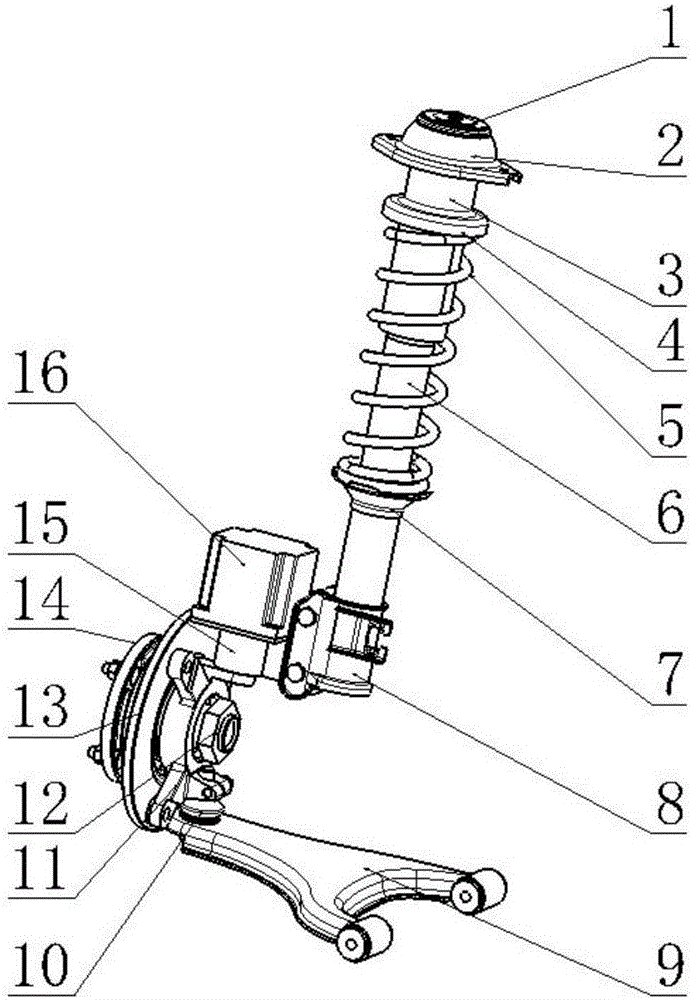

Speed reducing type electric drive system in integrated McPherson hanger bracket wheel

ActiveCN102887058AHighly integratedReduce the amplitudeSteering linkagesMotor depositionElectricityVehicle frame

The invention discloses a speed reducing type electric drive system in an integrated McPherson hanger bracket wheel, wherein an electric motor housing is integrated with an McPherson hanger bracket lower swing arm, a speed reducing box housing is integrated with a steering knuckle, and a distribution mode that an electric motor deviates from the center of a wheel and is close to an elastic hinge of a lower swing arm is adopted. The speed reducing type electric drive system has the advantage that the vibration of the electric motor relative to a frame can be reduced when the wheel jumps, and has the characteristics of high integration degree and light weight due to adoption of an equivalent spring.

Owner:TONGJI UNIV

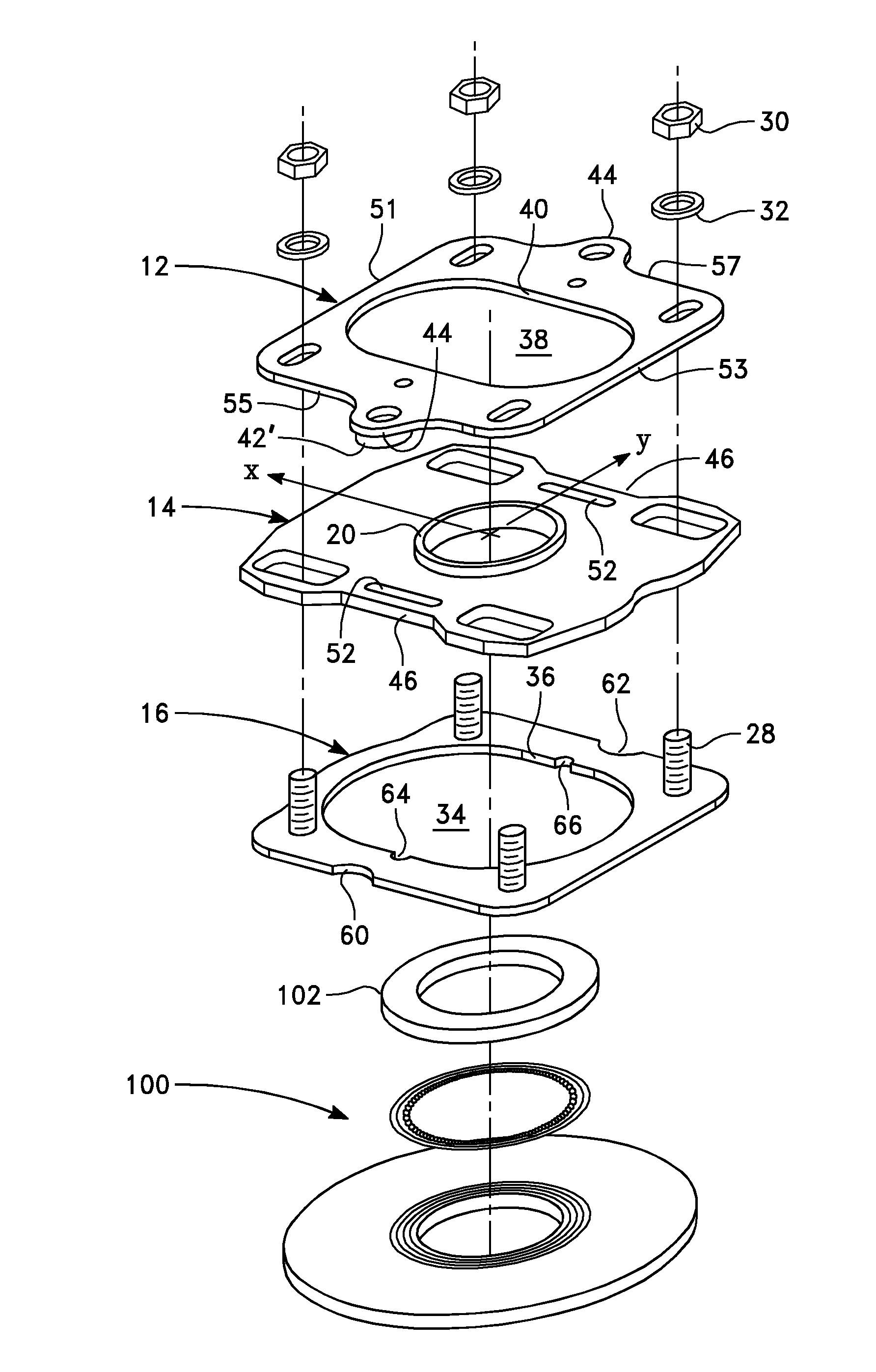

Plates allowing adjustment of caster and camber

An apparatus allows for the independent adjustment of caster and camber for vehicles utilizing MacPherson strut front suspensions. The apparatus has, in stacked arrangement, a fastener plate, a lower plate, and an upper plate. Camber adjustments are generally made by manipulation of the lower plate and caster adjustments are generally made by manipulation of the upper plate. The upper plate may be mounted in two different positions to allow for different camber adjustments, such as for competitive situations and non-competitive situations. The device utilizes a thrust bearing having a race in the upper face of the spring perch and an opposing race which mounts around the base of the bearing cup.

Owner:CROUTCHER BRIAN

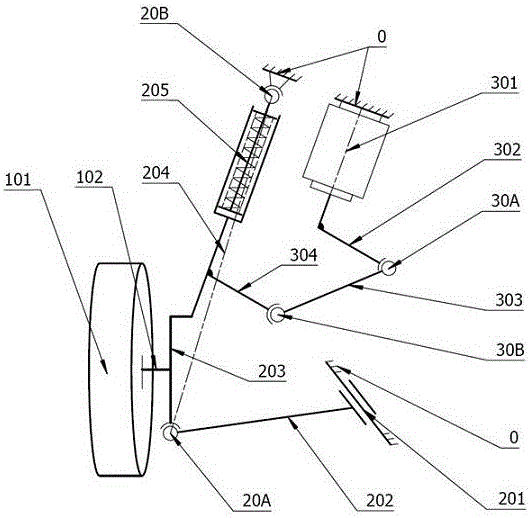

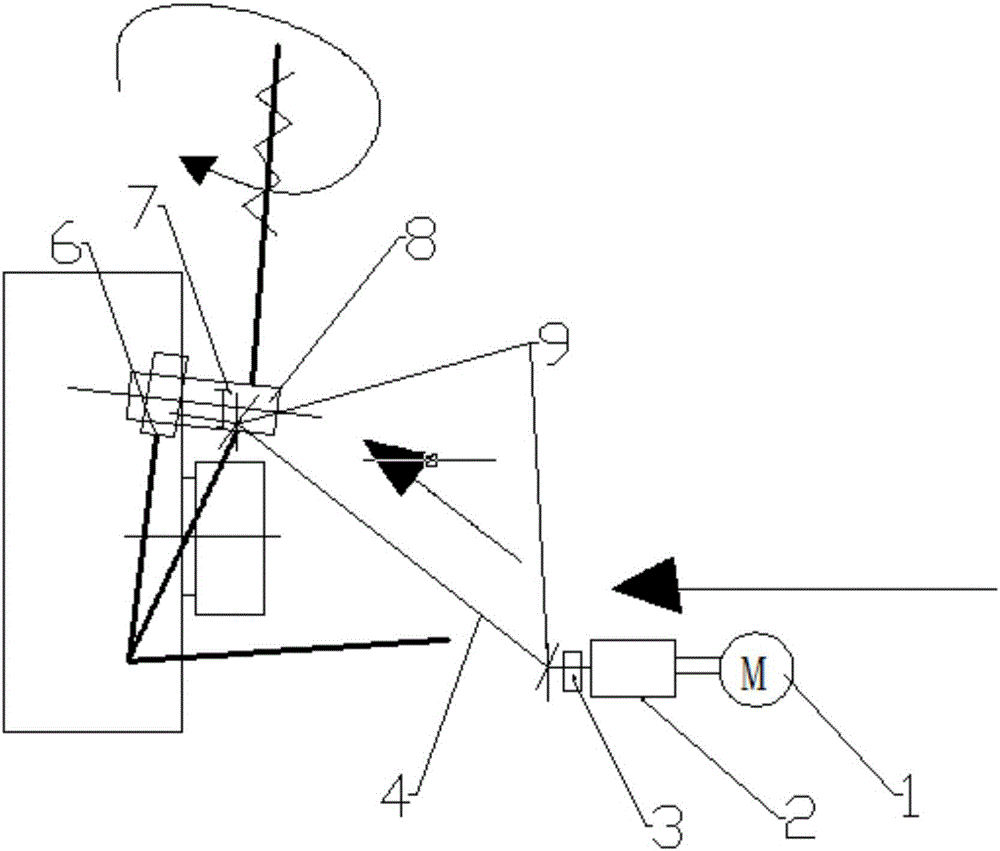

Double-crank transmission Macphersan wiring control independent steering system

ActiveCN106541986ALess impact on unsprung massLittle changeSteering linkagesElectrical steeringVehicle frameSteering angle

The invention provides a double-crank transmission Macphersan wiring control independent steering system which comprises a frame, wheels, an axle, a Macphersan suspension connecting rod guide mechanism, a steering motor and a space double-crank transmission mechanism. The system has the beneficial effects of being beneficial for manipulation stability of a vehicle and high in universality. The space double-crank mechanism is adopted, motor output power is transferred to a knuckle efficiently, and the knuckle can rotate around a main hinge pin line to achieve steering. By adjusting the length of a connecting rod, the wheel rotating amount caused by wheel hopping is reduced, kinds of key parts are reduced greatly, and the batch manufacturing cost is reduced. The system has the beneficial effects of being large in independent steering angle range of the wheels, simple in structure, reliable in work, convenient to assemble and low in cost.

Owner:TONGJI UNIV

Wire-control four-wheel independent steering system based on universal transmission structure

InactiveCN106240628AEasy to controlReduce mistakesSteering linkagesFluid steeringLinear relationshipEngineering

Owner:JILIN UNIV

Macpherson suspension wheel rim electric driving system for steering wheel

InactiveCN102785565AHighly integratedReduce the amplitudeSteering linkagesMotor depositionVehicle frameSteering wheel

The invention discloses a Macpherson suspension wheel rim electric driving system for a steering wheel. A motor casing is fixedly connected with a gearbox casing and is supported on a support through an elastic hinge; one end of a lower swing arm connecting rod is connected with the gearbox casing through a first rotating hinge; one end of a steering knuckle connecting rod is connected with a steering knuckle through a third rotating hinge; the lower swing arm connecting rod is connected with the steering knuckle connecting rod through a second rotating hinge; a damper piston rod slides along a central axis of a damper work cylinder barrel; the upper end of the damper piston rod is connected with a frame through a vibration isolating block assembly with a bearing; the damper work cylinder barrel is fixedly connected with the steering knuckle; an axle shaft sleeve is formed in the steering knuckle; a hub is supported on the axle shaft sleeve through a hub bearing; a steering knuckle arm on the steering knuckle is connected with a steering pull rod through a spherical hinge; one end of a universal joint is fixedly connected with a gearbox output shaft; the other end of the universal joint is fixedly connected with an axle shaft; the axle shaft is fixedly connected with the hub; and the hub is fixedly connected with a brake rotating piece and a rim. The Macpherson suspension wheel rim electric driving system disclosed by the invention has the advantages that a motor casing, the gearbox casing and a lower swing arm of a Macpherson suspension are integrated, the vibration of a motor relative to the frame is reduced and the equivalent unsprung weight is light.

Owner:TONGJI UNIV

Front suspension tuning apparatus

InactiveUS7163215B2Reduce manufacturing costEasy to operateSteering partsPivoted suspension armsFlangeMacPherson strut

The present invention provides a suspension tuning device for vehicles with struts. More specifically, the suspension tuning device generally comprises a pair of plates constructed to mount juxtaposed to the strut / spindle mounting flange of a standard MacPherson strut, each plate includes an inset sub-plate having an offset aperture which cooperates with one of the spindle attachment bolts to control wheel camber.

Owner:STEEDA AUTOSPORTS

Construction method of McPherson suspension multi-objective optimization function based on sensitivity analysis

ActiveCN108984888AEnsure objectivityGuaranteed reasonablenessGeometric CADDesign optimisation/simulationCamber angleWeight coefficient

The invention discloses a construction method of a McPherson suspension multi-objective optimization function based on sensitivity analysis, the method being characterized by including: establishing mathematical models of front wheel alignment parameters, alignment torque and tire wear, quantifying the influence degree of front wheel alignment parameters on alignment torque and tire wear by usingsensitivity analysis method, and determining weight coefficients of Kingpin back inclination angle, Kingpin inclination angle, camber angle and toe angle under a high-speed working condition and a low-speed working condition; establishing a vehicle simulation model, and obtaining the simulation data through ride comfort test, and thus establishing the multi-objective optimization model of McPherson suspension hard point coordinates. The invention can effectively guarantee the objectivity and rationality of the weight coefficient in the McPherson suspension hard point coordinate multi-objectiveoptimization model, thereby improving the handling stability of the automobile and reducing the tire wear.

Owner:HEFEI UNIV OF TECH

Method for determining a rolling condition via frequency analysis of the rotation of the suspension stop

InactiveUS20070255467A1Reliable determinationRolling contact bearingsBearing assemblyFrequency spectrumControl engineering

A method for determining at least one rolling condition of a motor vehicle wheel, which wheel being mounted on the chassis of the vehicle via a MacPherson strut integrating a suspension stop which includes a rotating component in relation to the chassis is described. The method envisages using a device for detecting the angular displacements of the rotating component, which device is suitable for generating an analogue signal which is representative of the angular displacements according to time. The method envisages carrying out a frequency analysis of the analogue displacement signal such as to obtain a spectrum including at least one frequency window wherein at least one datum of the spectrum is based on a rolling parameter; measuring at least one of the data; determining, from the measured datum or data, at least one rolling condition corresponding to the rolling parameter or to the development of the rolling parameter.

Owner:SNR ROULEMENTS SA

Automotive front Macpherson suspension and automobile comprising same

ActiveCN103465745AReduce vibrationMotor coordinationSteering linkagesPivoted suspension armsRubber materialVehicle frame

The invention relates to an automotive front Macpherson suspension and an automobile comprising the same. A control arm of the automotive front Macpherson suspension comprises a control arm body, a ball pin, a front frame bushing and a rear frame bushing, wherein the ball pin is positioned on the control arm body and is connected with a steering joint; the front frame bushing and the rear frame bushing are positioned on the control arm body and are connected with a frame; at least one of the front frame bushing and the rear frame bushing is made of a rubber material, and the radial rigidity is greater than the axial rigidity. Moreover, the invention also provides an arrangement relationship between key hard points of the control arm. According to the automotive front Macpherson suspension and the corresponding automobile, the rigidity characteristic of front and rear automobile reinforcing bushings on the control arm is perfectly designed, the relationship between the key hard points of the control arm is advantageously designed, the dynamic unbalance of a tire assembly when a vehicle runs at high speed and the vibration transferred to a driver by the frame are reduced, and the driving control and the driving comfort are improved.

Owner:SAIC GENERAL MOTORS +1

Wheel suspension

InactiveUS20080224371A1Less negative effectLess movementSpringsResilient suspensionsEngineeringMacPherson strut

A wheel suspension has a wheel-guiding McPherson strut unit which includes a helical compression spring and a shock absorber, and which is connected to a vehicle body, on the one hand, and to a wheel on the other, and with a suspension arm wherein the compression spring is provided between an upper spring plate connected to the body and a lower spring plate connected to the shock absorber. The undesired, but unavoidable relative movements between the lower spring end of the compression spring and the lower spring plate connected to the shock absorber have an effect that is less negative than usual due to a coating provided between the lower spring end of the helical compression spring and the lower spring plate connected to the shock absorber protecting the lower spring end of the helical compression spring and / or the lower spring plate connected to the shock absorber.

Owner:MUHR UND BENNDER KG

Bellows for hydraulic, hydropneumatic, or pneumatic piston-cylinder units

InactiveUS7823709B2Simple designFlexible wall reciprocating enginesLiquid springsInterior spaceMobile vehicle

A bellows for hydraulic, hydropneumatic, or pneumatic piston-cylinder units, especially for vibration dampers or MacPherson strut units for motor vehicles, is located between the end of a piston rod and a cylinder, and covers the part of the piston rod which projects out from the cylinder to provide protection against dirt and / or damage. An interior space of the bellows undergoes a change in volume as a result of the relative movement of the piston and cylinder. The end area of the piston rod distal from the cylinder includes at least one flow connection leading to the interior of the bellows. The flow connection allows an incoming and / or outgoing flow of air. The end area of the piston rod, i.e., the end which passes through a mounting bearing connecting the piston-cylinder unit to the body of the vehicle, is provided with a flow connection connecting the interior space of the bellows to the atmosphere.

Owner:ZF SACHS AG

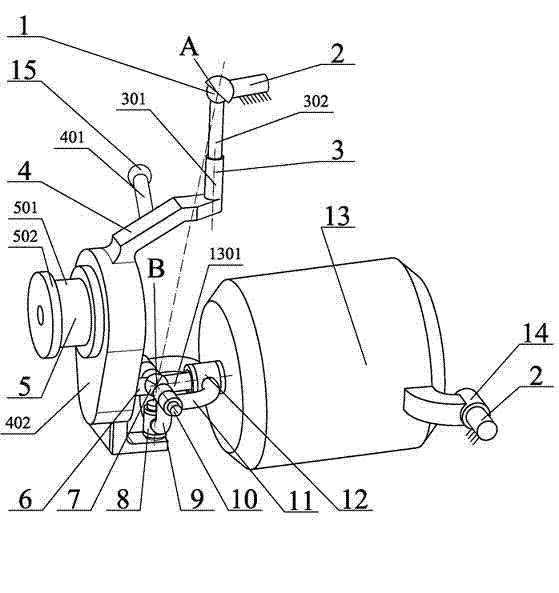

Drive-by-wire four-wheel independent steering system with steering motor mounted on Macpherson suspension lower swinging arm

ActiveCN106627745ARealize integrationSave spaceSteering linkagesElectrical steeringSystem integrationVehicle frame

The invention relates to a drive-by-wire four-wheel independent steering system with a steering motor mounted on a Macpherson suspension lower swinging arm. The drive-by-wire four-wheel independent steering system comprises a frame, wheels, a suspension rack and a steering motor assembly, wherein the suspension rack is respectively connected with the wheels and the frame; the suspension rack has a lower swinging arm, a knuckle and a Macpherson suspension rack of a spring damper; the lower swinging arm and the spring damper are both connected with the frame and the knuckle; the knuckle is connected with the wheels; the steering motor assembly is fixed on the lower swinging arm and connected with the knuckle via a universal transmission device to drive the knuckle to rotate along a main pin axis. Compared with the prior art, the drive-by-wire four-wheel independent steering system with the steering motor mounted on the Macpherson suspension lower swinging arm is advantaged by high system integration degree, great modularization and flexible steering as well as wide steering range.

Owner:TONGJI UNIV

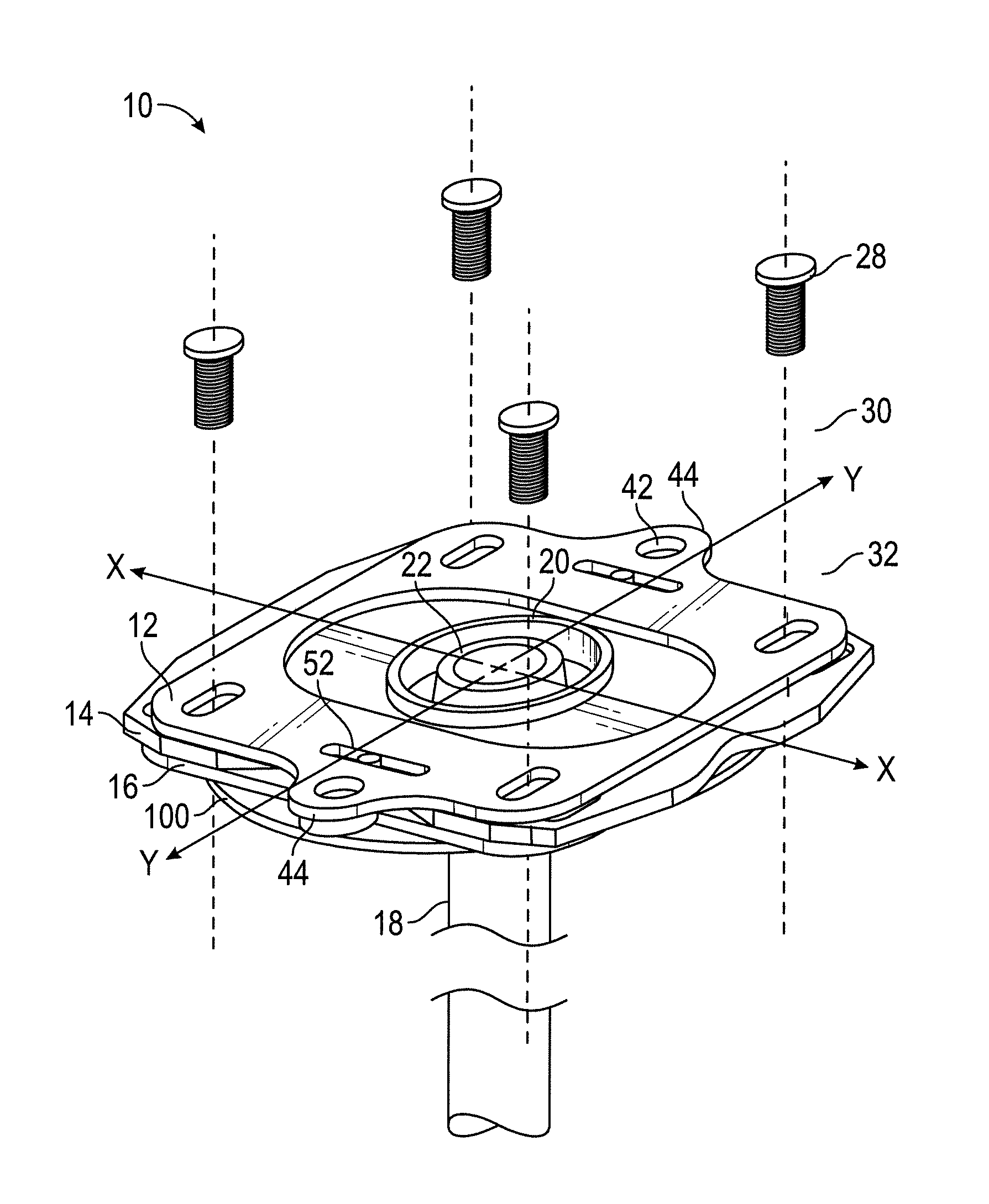

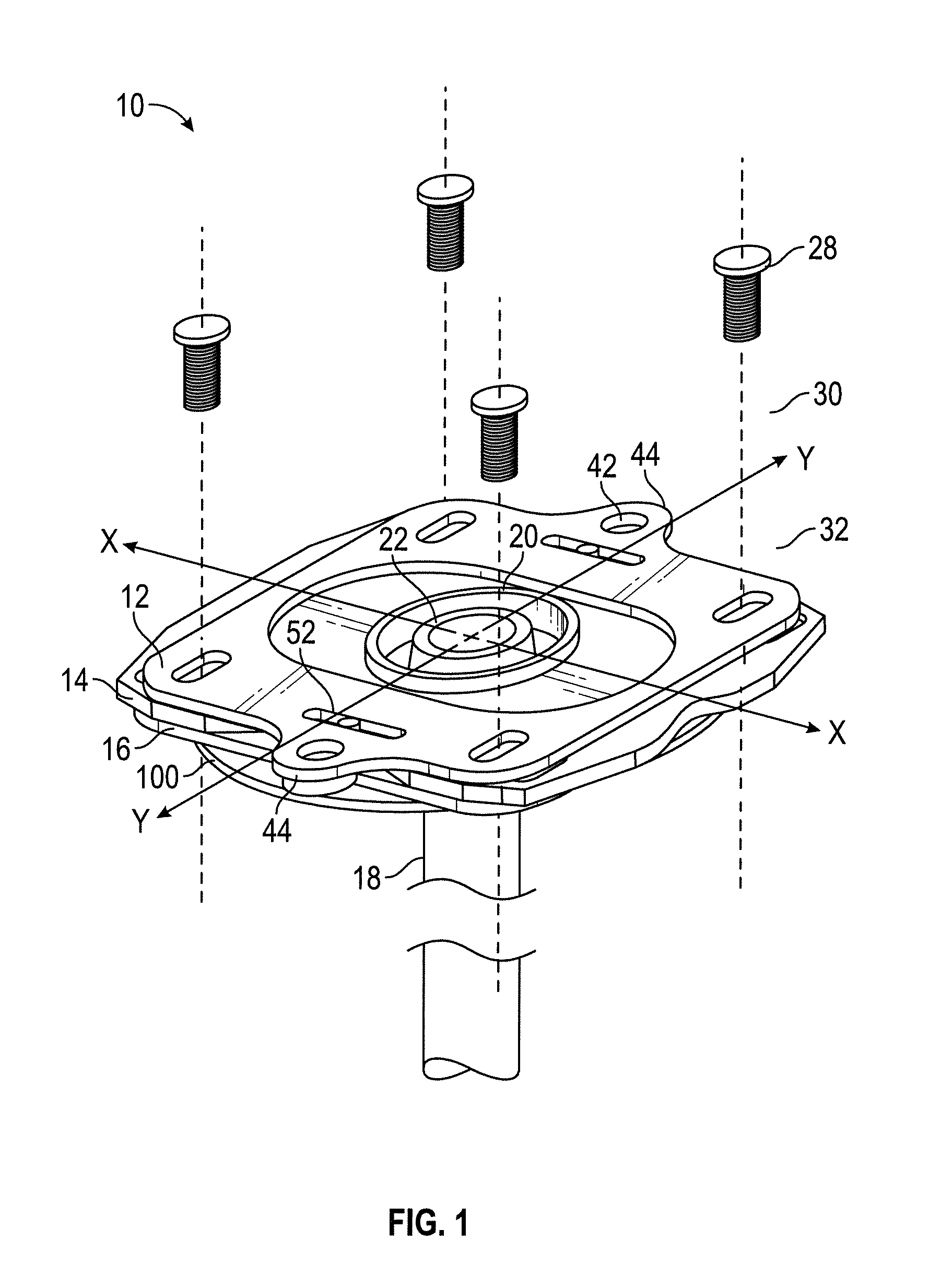

Plates Allowing Adjustment of Caster and Camber

An apparatus allows for the independent adjustment of caster and camber for vehicles utilizing MacPherson strut front suspensions. The apparatus has, in stacked arrangement, a fastener plate, a lower plate, and an upper plate. Camber adjustments are generally made by manipulation of the lower plate and caster adjustments are generally made by manipulation of the upper plate. The upper plate may be mounted in two different positions to allow for different camber adjustments, such as for competitive situations and non-competitive situations. The device utilizes a thrust bearing having a race in the upper face of the spring perch and an opposing race which mounts around the base of the bearing cup.

Owner:CROUTCHER BRIAN

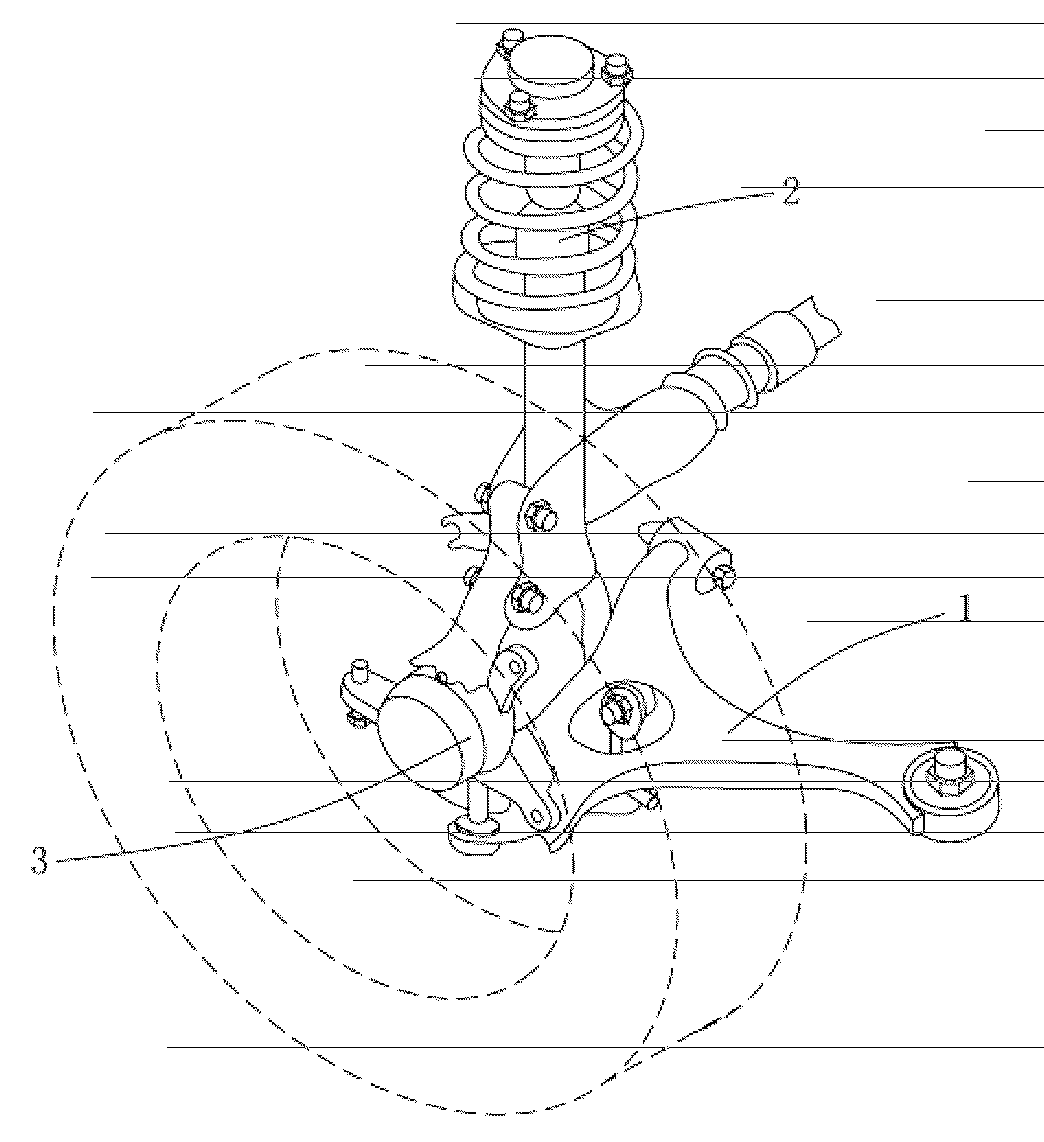

Suspension angle assembly of electric vehicle driven by hub motor

PendingCN108909388ALarge Kingpin CamberSave spaceInterconnection systemsMotor depositionVehicle frameUniversal joint

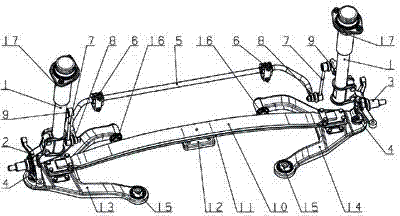

The invention relates to a suspension angle assembly of an electric vehicle driven by a hub motor. The suspension angle assembly comprises a front lower swing arm and a rear lower swing arm which areboth shaped like connecting rods, wherein two position-fixing holes are arranged at the lower end of a steering knuckle; one end of the front lower swing arm is fixedly connected to one of the position-fixing holes at the lower end of the steering knuckle by a ball pin and the other end of the front lower swing arm is fixed to a vehicle frame by a universal joint; one end of the rear lower swing arm is fixedly connected to the other one of the position-fixing holes at the lower end of the steering knuckle by another ball pin and the other end of the rear lower swing arm is fixed to the vehicleframe by another universal joint; a stabilizer bar assembly is fixedly connected to the front lower swing arm and the other end of the stabilizer bar assembly is mounted on the vehicle frame; and theintersection point of extension lines of straight lines on which the front lower swing arm and the rear lower swing arm are positioned and the pivot point of a ball hinge which fixes and connects theupper end of a shock absorber support assembly with the vehicle frame are the kingpin axis of the vehicle. The problems that the size of lower swing arms of a MacPherson strut suspension affects thesteering operability and that the increase of the unsprung weight affects the driving comfort can be solved.

Owner:JILIN UNIV

Four-wheel independent steering-by-wire system with steering motor positioned at steering knuckle of Macpherson suspension

InactiveCN106741143ARealize integrationGood suspension kinematicsSteering linkagesElectrical steeringResponse sensitivityVehicle frame

The invention relates to a four-wheel independent steering-by-wire system with a steering motor positioned at a steering knuckle of a Macpherson suspension. The four-wheel independent steering-by-wire system comprises a frame, wheels, a suspension and a steering motor assembly, wherein the suspension is connected with the wheels and the frame respectively; the suspension is the Macpherson suspension comprising a lower suspension arm, the steering knuckle and a spring absorber, the lower suspension arm and the spring absorber are connected with the frame and the steering knuckle respectively, and the steering knuckle is connected with the wheels; the steering motor assembly is connected with the steering knuckle; and the wheels are driven to steer by driving the steering knuckle. Compared with the prior art, the system has the advantages of high system integration level, high modularization degree, steering response sensitivity, wide steering range and the like.

Owner:TONGJI UNIV

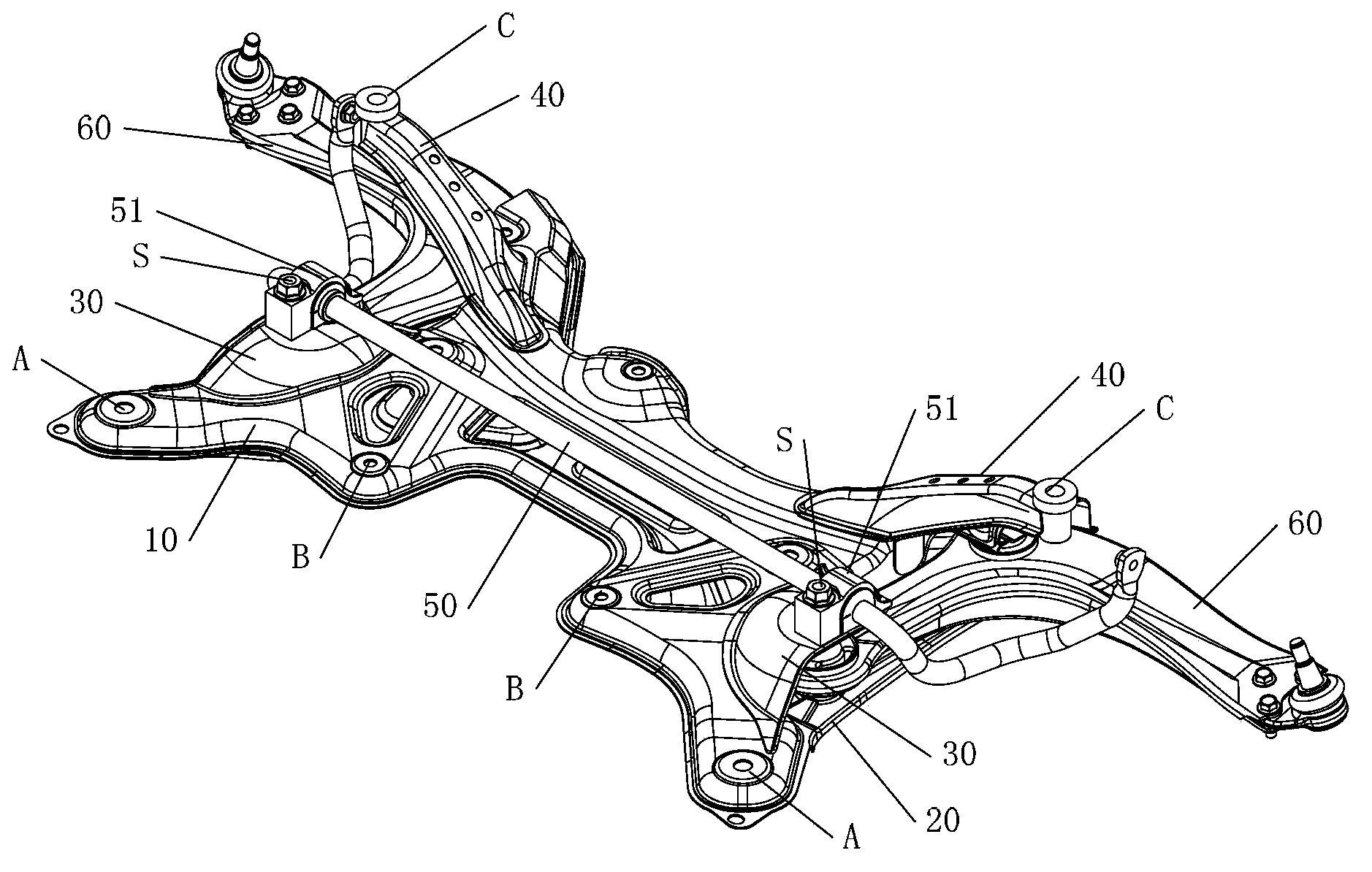

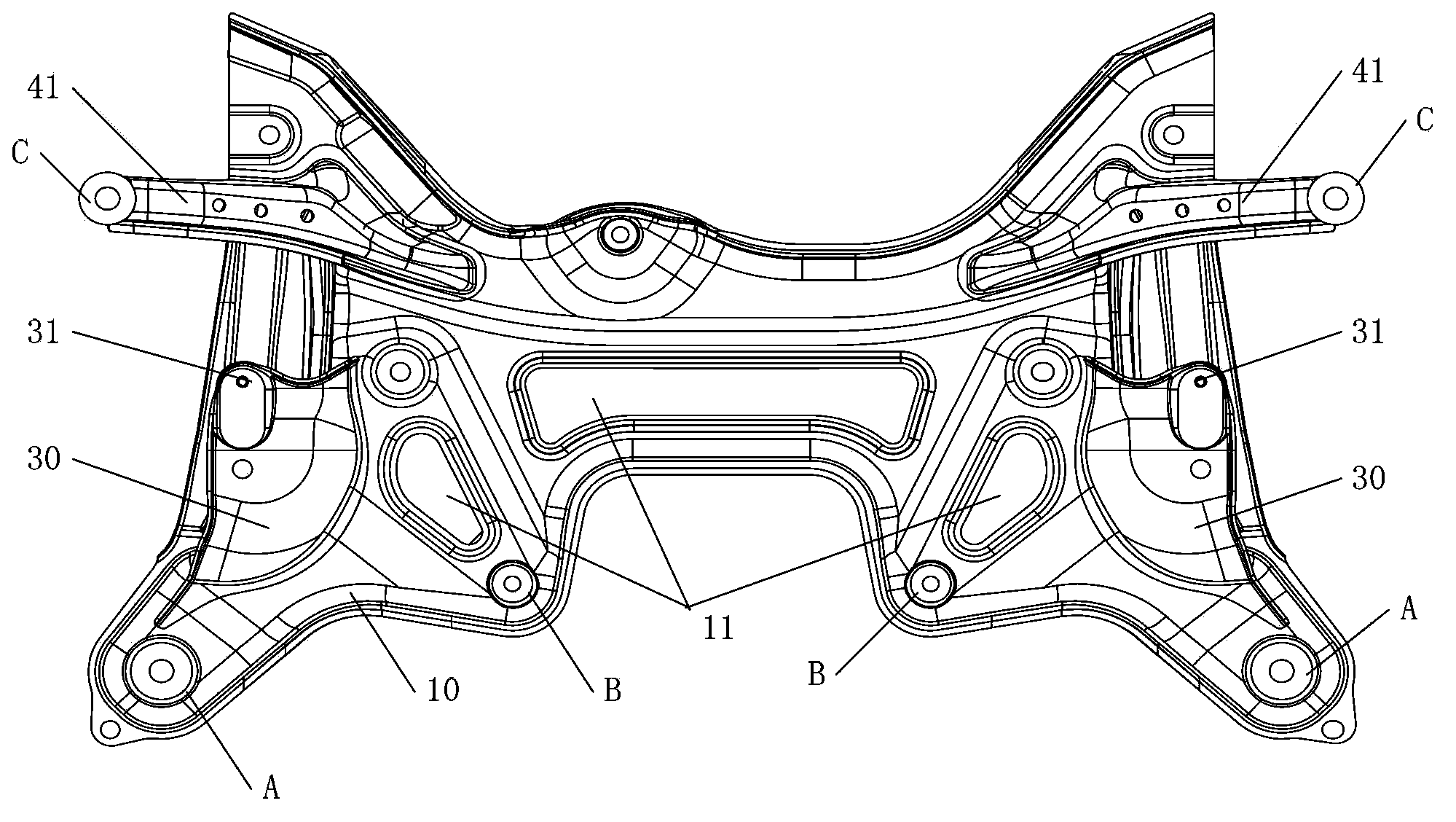

Automobile front auxiliary frame and corresponding automobile

ActiveCN103786788ARaise Constraint ModeGood for NVH characteristicsUnderstructuresVehicle frameMacPherson strut

The invention provides an automobile front auxiliary frame and a corresponding automobile. The automobile front auxiliary frame comprises a front auxiliary frame upper plate and a front auxiliary frame lower plate which are in matched connection with each other. Stabilizing rod mounting plates are arranged on two sides of the front auxiliary frame upper plate respectively, every stabilizing rod mounting plate is provided with a mounting hole for installing a stabilizing rod, a space between every stabilizing rod mounting plate and the front auxiliary frame lower plate is suitable for placing one end of a swing arm, and the end of the swing arm and the stabilizing rods are installed by utilizing a shared fastener to penetrate the mounting holes. The automobile front auxiliary frame is suitable for a Macpherson suspension; compared with other auxiliary frames, the number of installed and welded sheet metal parts is reduced, the stabilizing rods and the swing arm share assembling bolts, use of welding fasteners is reduced, assembling fasteners of a whole front suspension are reduced, the structure is lightened, and the cost is reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

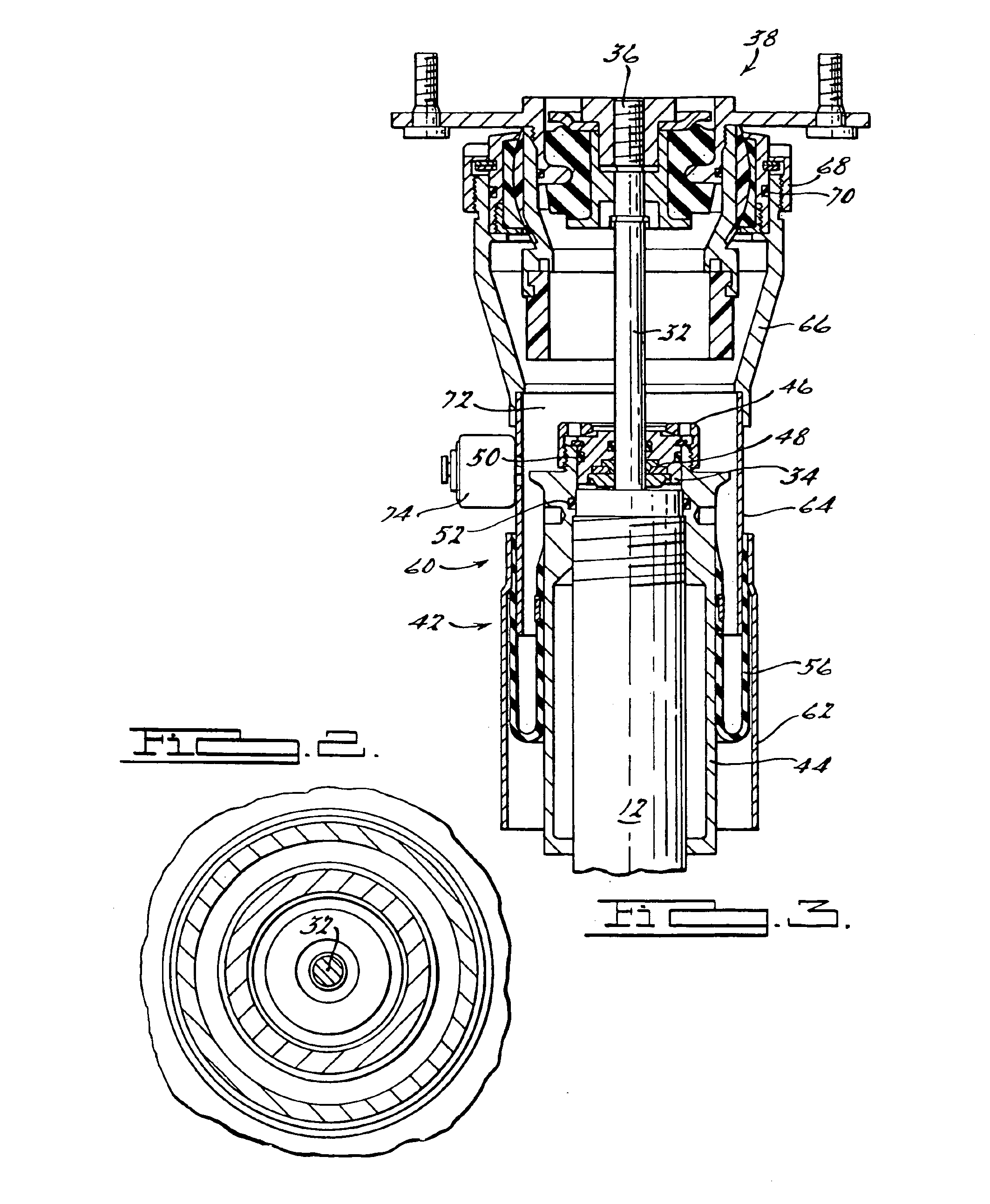

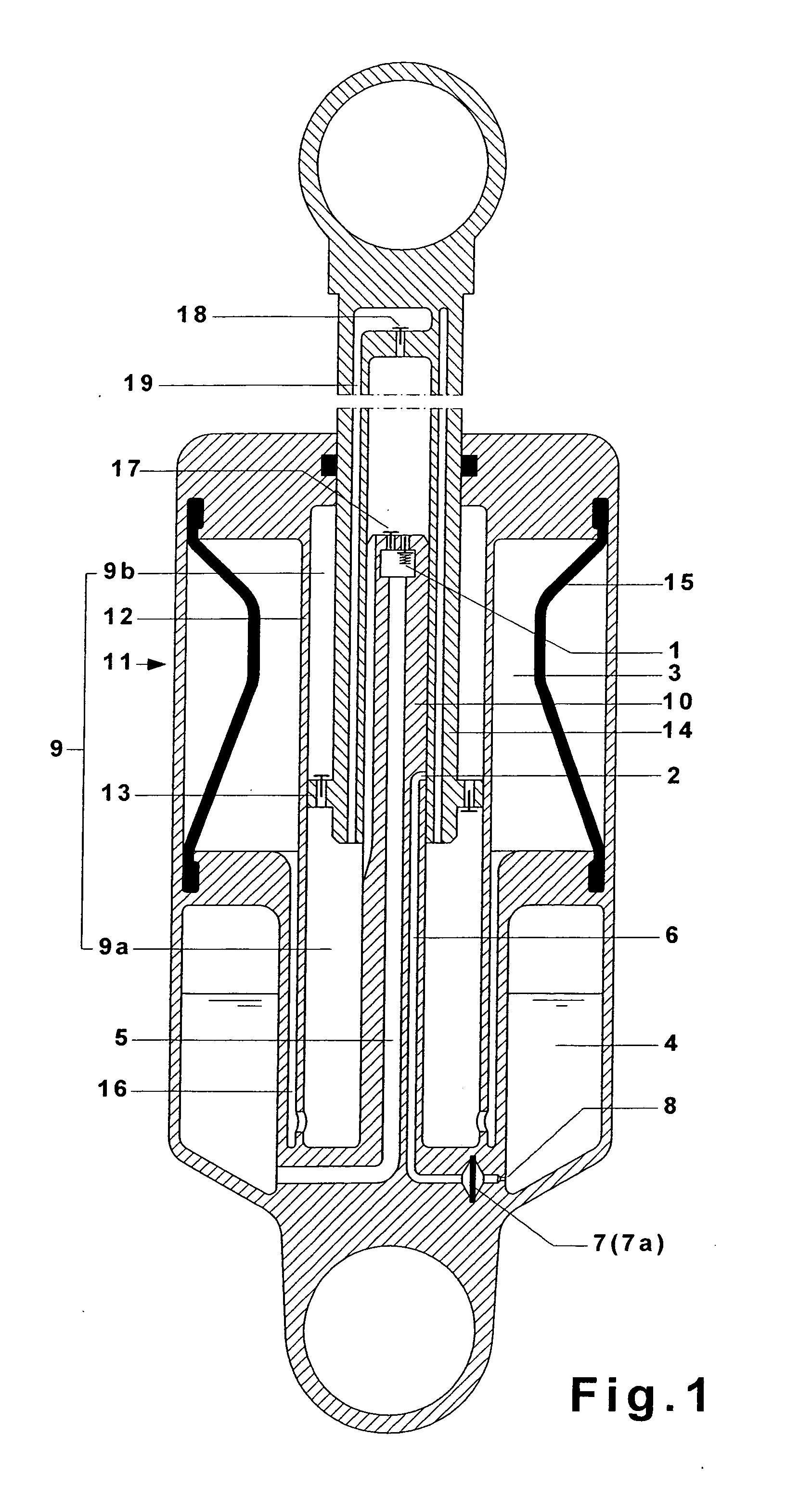

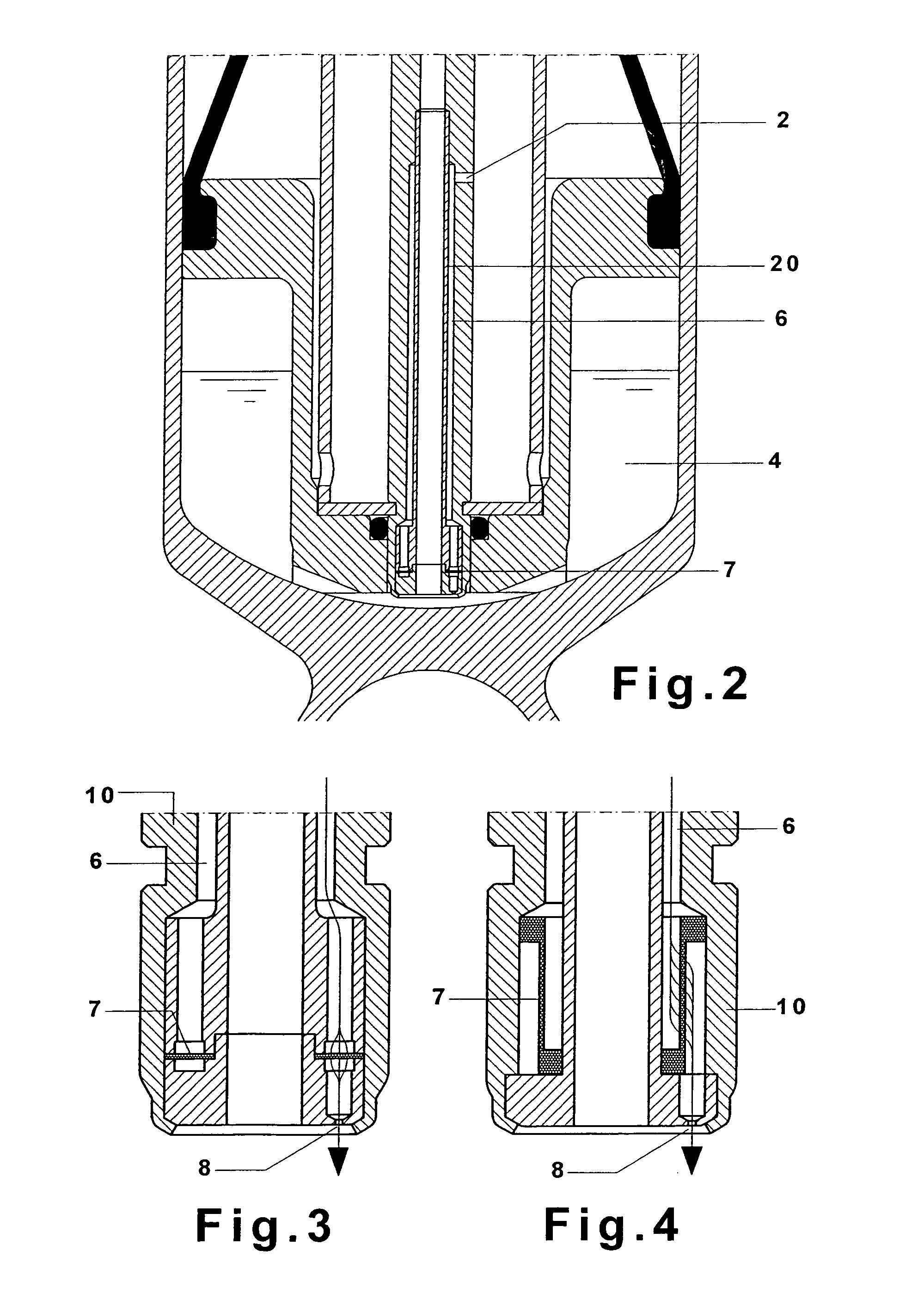

Self-pumping hydropneumatic MacPherson strut unit

InactiveUS20060071377A1Simple and reliable processLeveling is simple and reliableLiquid springsLiquid based dampersHigh pressureHigh pressure chamber

A self-pumping hydropneumatic MacPherson strut unit is provided with a working cylinder filled with oil under pressure and a piston and rod unit displaceable in the cylinder so as to define two working spaces in the cylinder, and high-pressure and low pressure chambers surrounding the cylinder. The strut unit further has a piston pump operable to transport a working medium from the low-pressure chamber into one of the working spaces of the working cylinder, wherein the one working space being in flow communication with the high-pressure chamber. The piston pump has a cylinder defined by the inner surface of the piston and rod unit, a hollow pump rod coupled to the working cylinder and having an inner bore in flow communication with the low-pressure chamber, a deregulating opening and a deregulating channel provided with a throttle in flow communication with the deregulating opening and the low pressure chamber. Installed in the deregulating channel is a filter device operable to prevent the throttle from impurities carried by the working medium during displacement thereof through the deregulating opening to the low pressure chamber.

Owner:ZF FRIEDRICHSHAFEN AG

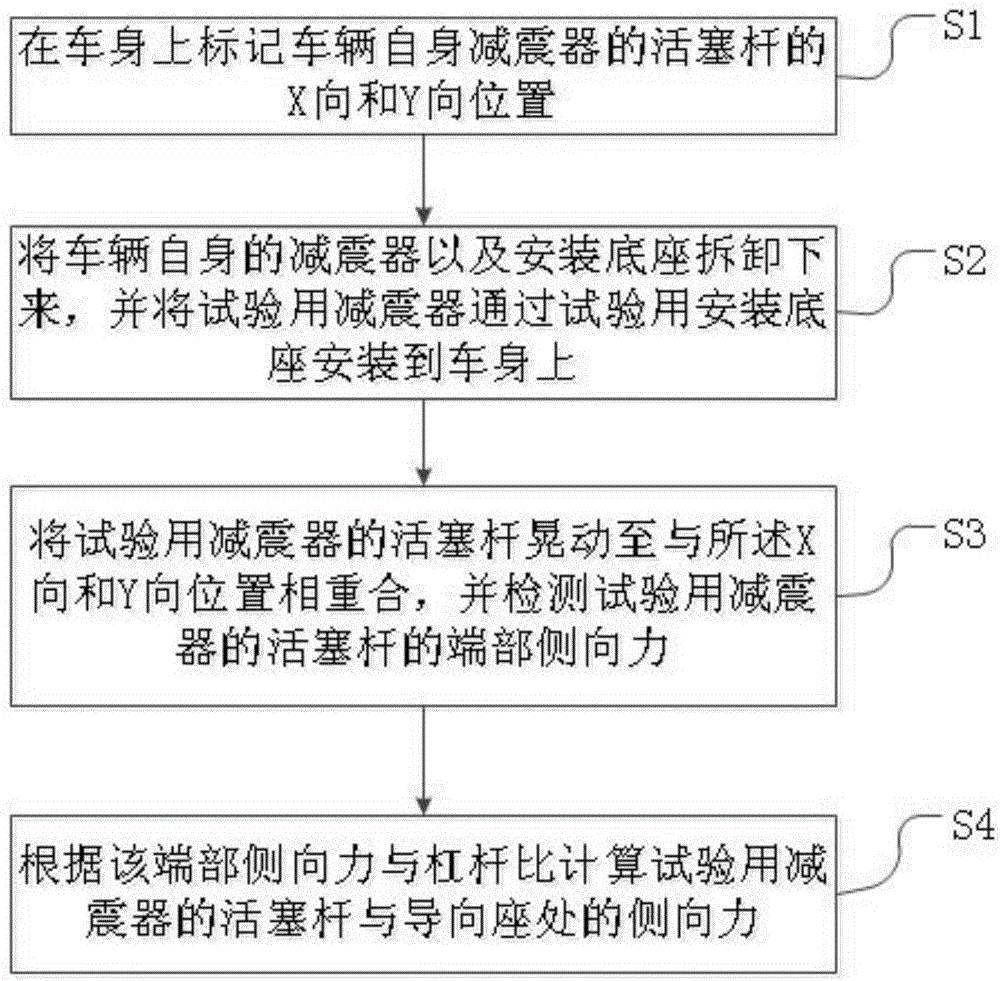

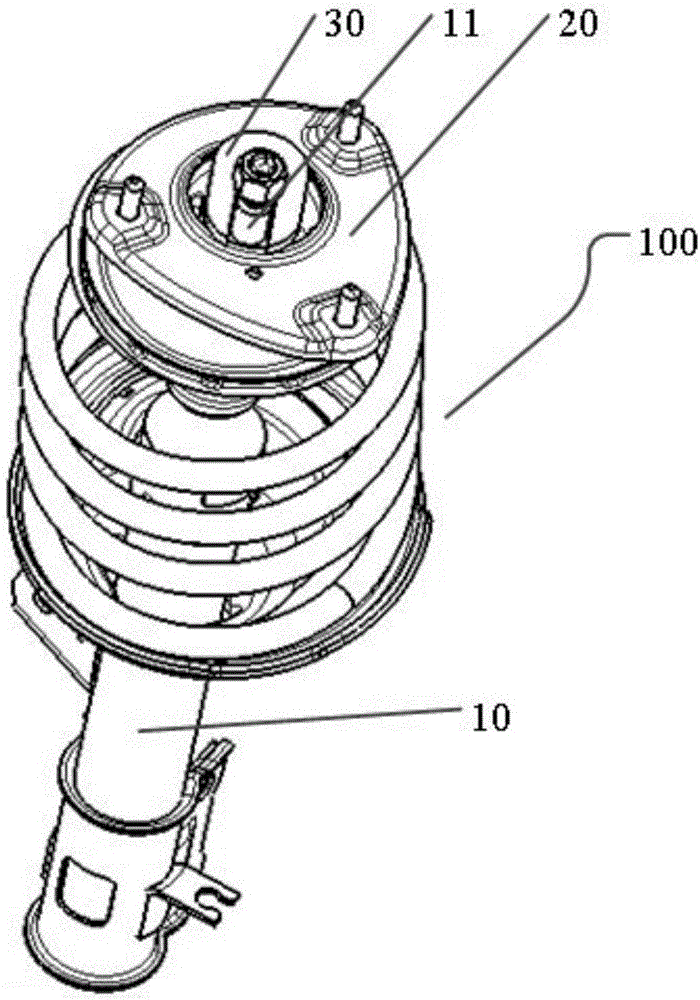

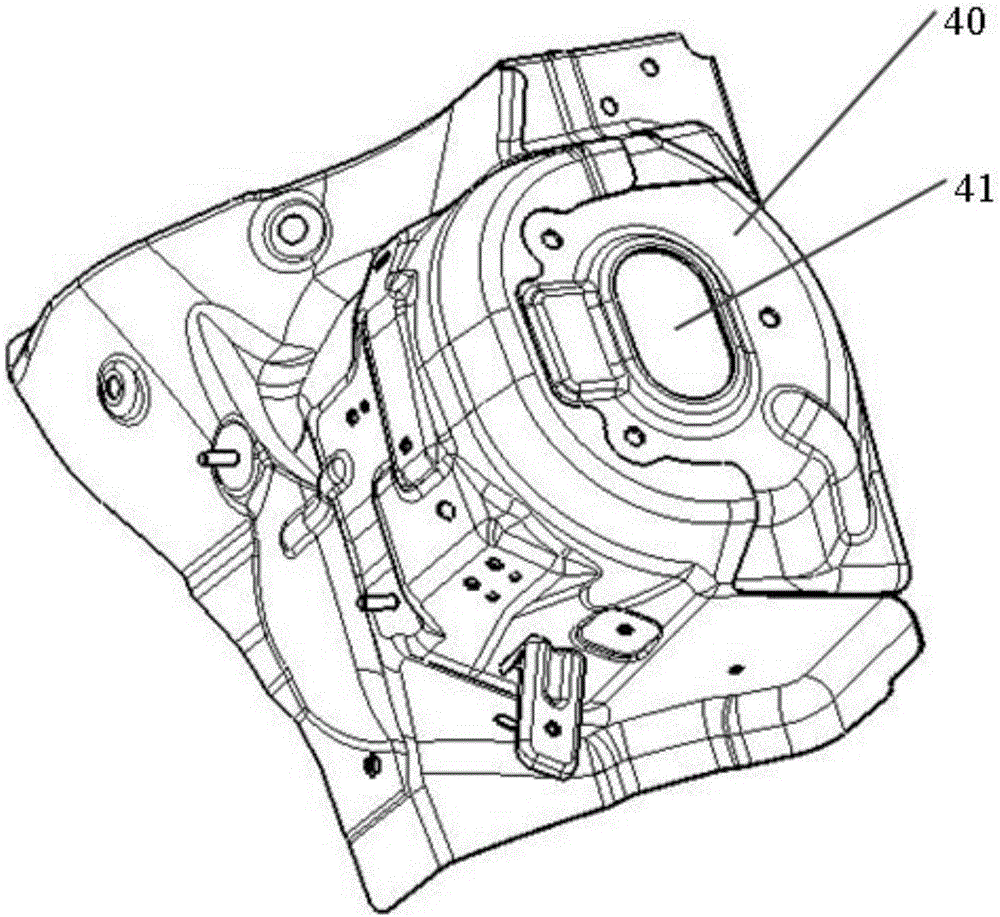

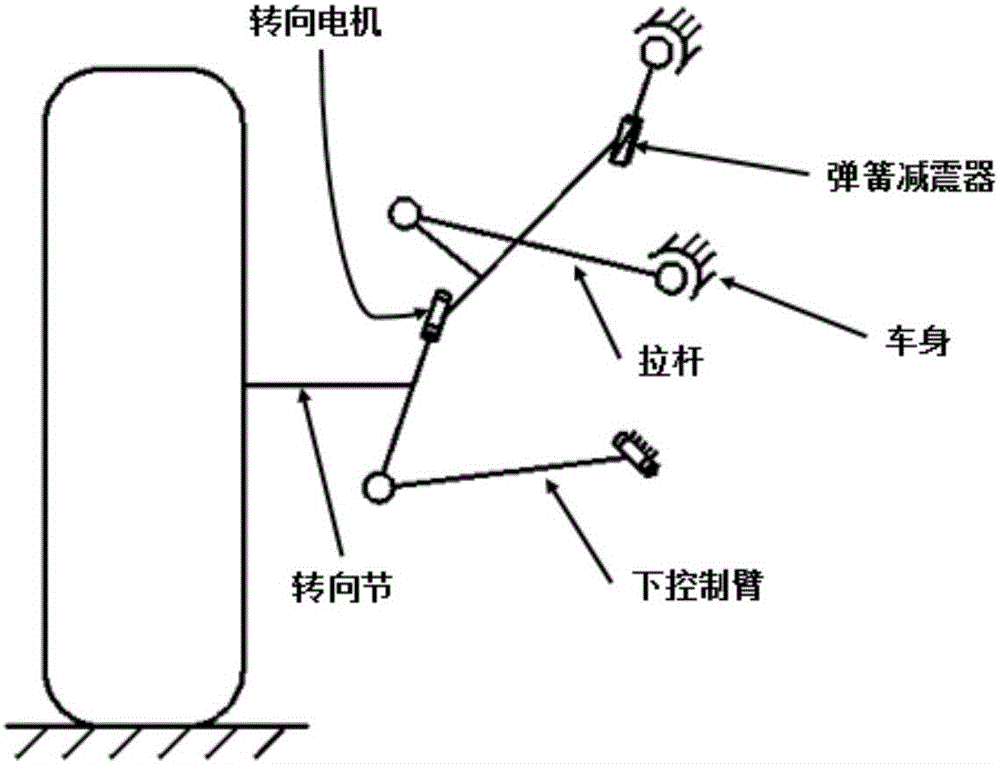

Macpherson suspension shock absorber lateral force measuring method and Macpherson suspension shock absorber lateral force auxiliary measuring tool

The invention provides a Macpherson suspension shock absorber lateral force measuring method and a Macpherson suspension shock absorber lateral force auxiliary measuring tool. A shock absorber penetrates a guiding seat on a vehicle body and is connected with a vehicle body tower bag. The above method includes the steps that firstly, the X-direction position and the Y-direction position of a piston rod of the shock absorber of the vehicle body is marked on the vehicle body; secondly, the shock absorber of a vehicle and an installation base are demounted, and a test shock absorber is installed on the vehicle body through a test installation base; thirdly, a piston rod of the test shock absorber is wobbled till the X-direction position coincides with the Y-direction position, and the lateral force at the end portion of the piston rod of the test shock absorber is detected; and fourthly, the lateral force at the position of the piston rod of the test shock absorber and the lateral force at the position of the guiding seat are calculated according to the lateral force at the end portion and the lever ratio. By means of the method, the supporting force at the position of the piston rod of the shock absorber of the vehicle and the supporting force at the position of the guiding seat can be actually measured, and compared with the prior art, the measurement value is more accurate, and the quality of a Macpherson suspension can be better ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Drive-by-wire four-wheel independent steering system with steering motor provided on knuckle of McPherson suspension

InactiveCN106741146ARealize integrationSave spaceSteering linkagesElectrical steeringSystem integrationSteering angle

The present invention relates to a drive-by-wire four-wheel independent steering system with a steering motor provided on a knuckle of a McPherson suspension. The system comprises a frame, wheels, a suspension and the steering motor. The suspension comprises the knuckle, the knuckle is connected with the output shaft of the steering motor through a key, the knuckle is controlled by the steering motor to rotate around the axis of the steering motor, and thus the wheels fixedly connected with the knuckle rotate correspondingly. The suspension is further provided with a lever, for guiding the movement of the suspension. Compared with the prior art, the drive-by-wire four-wheel independent steering system has the advantages of high system integration, short transmission chain of steering motion, an increase in the wheel limit steering angle, higher bearing capacity for aligning torque and the like.

Owner:TONGJI UNIV

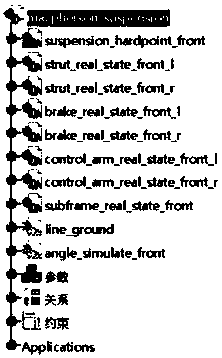

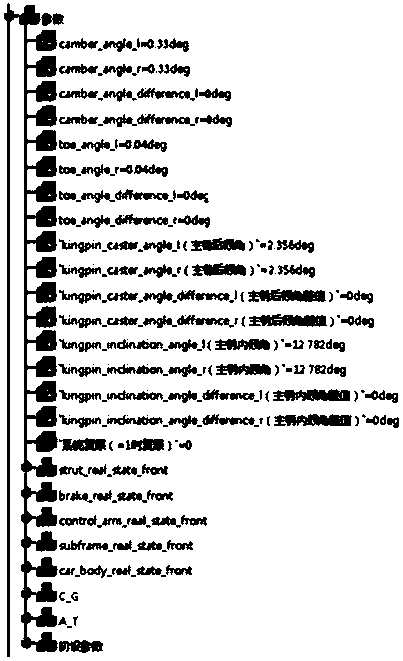

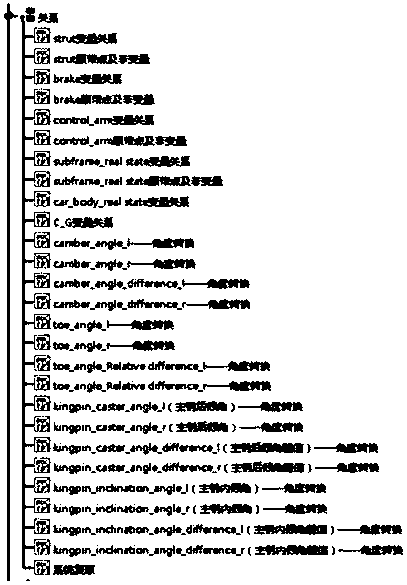

Macpherson suspension four-wheel parameter verification method based on CATIA parametric module

ActiveCN107832554AReduce development costsThe calculation result is accurateGeometric CADSpecial data processing applicationsComputer Aided DesignKey factors

The invention relates to the field of automobile computer aided design, in particular to a Macpherson suspension four-wheel parameter verification method based on a CATIA parametric module. Accordingto the method, a Macpherson suspension part architecture model is set up based on a CATIA platform, and parameter variables and relation variables are set; the parameter variables are modified according to actual conditions, and states needing to be stimulated are obtained through matching; and after setting of the parameter variables of each different state is completed, a system can simulate a four-wheel parameter result corresponding to the state timely through a relation formula, namely the relation variables, and a specific difference value between the result and a preset four-wheel parameter value is displayed. The method can adapt to different models just by modifying parameters according to the actual conditions; variable parameter settings cover all key factors influencing Macpherson structure suspension four-wheel parameters, so that the method has high universality; and the method can guide a design department, a production department or a supplier to correct some dimensionsto meet the preset four-wheel parameter value.

Owner:北汽蓝谷麦格纳汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com