Optimization method facing lateral force of Macpherson suspension shock absorber

An optimization method and shock absorber technology, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of high cost and time-consuming, and achieve the effect of simple operation, reliable results and improved work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] An optimization method for the lateral force of the McPherson suspension shock absorber, its specific implementation process includes the following steps:

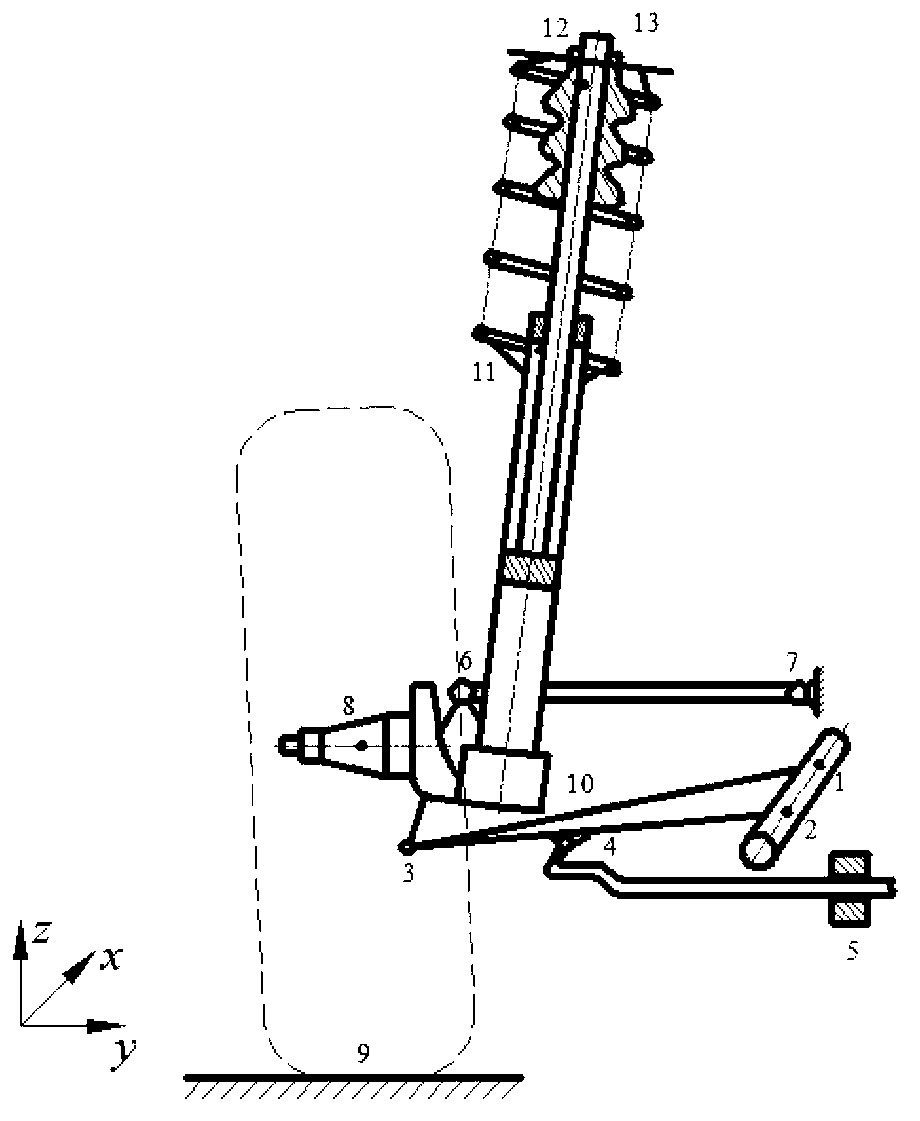

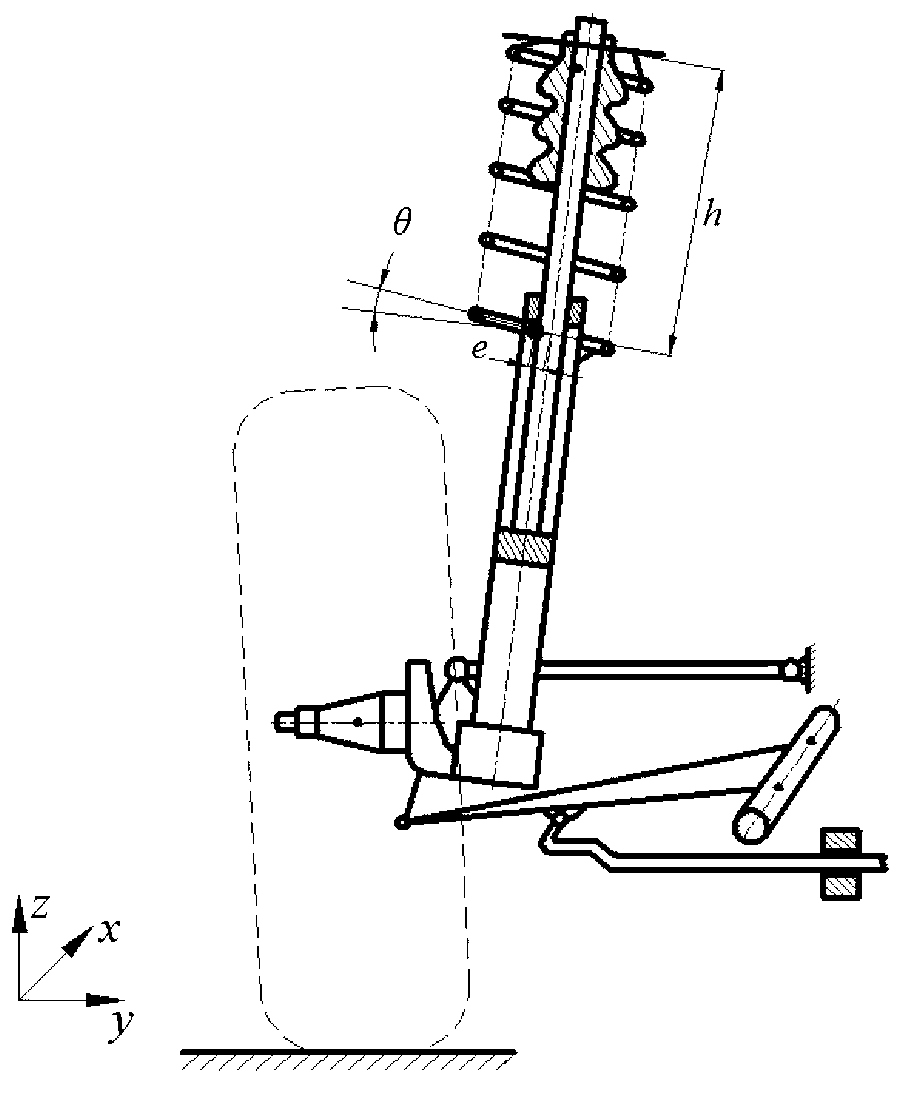

[0022] A: Establish a three-dimensional coordinate system representing the left, right, front and rear, and height of the vehicle, and obtain the hard point coordinates of the McPherson suspension in this coordinate system through measurement and calculation, such as figure 1 shown. The hard point indicates the connection position of each component, including control arm front point 1, control arm rear point 2, control arm outer point 3, stabilizer bar and control arm connection point 4, and stabilizer bar rubber bushing installation point 5 , tie rod outer point 6, steering tie rod inner point 7, wheel mid point 8, wheel ground point 9, shock absorber lower point 10, spring lower center point 11, spring upper center point 12, shock absorber upper point 13 ;

[0023] B: In the multi-body dynamics analysis software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com