Method for determining a rolling condition via frequency analysis of the rotation of the suspension stop

a frequency analysis and suspension stop technology, applied in the direction of cycle equipment, instruments, transportation and packaging, etc., can solve the problems of limitations inherent and prove difficult to decorrelate the various rolling parameters affecting the rotation speed signal of the wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

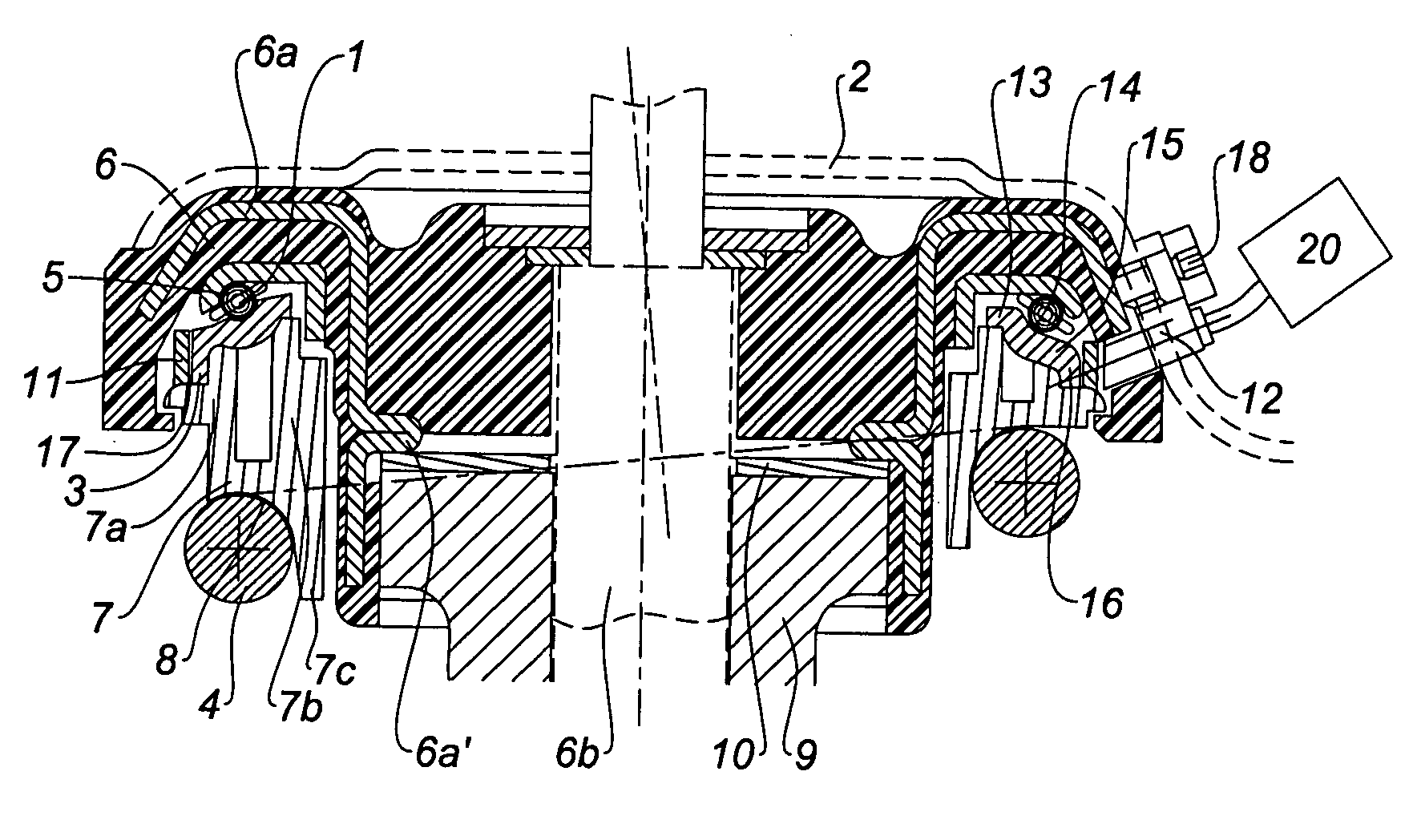

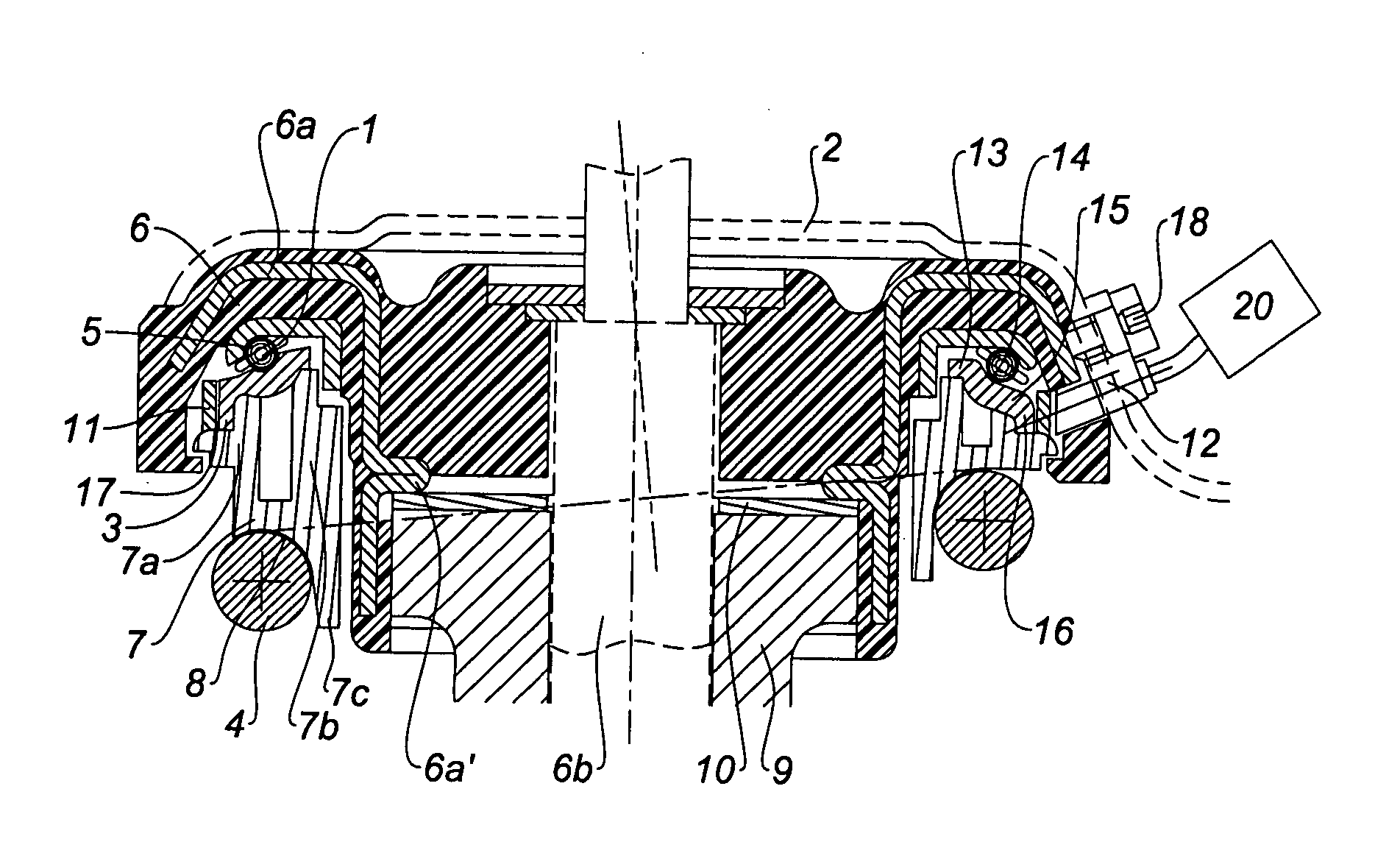

Image

Examples

first embodiment

[0031] the rolling condition is then determined by comparing the datum measured with a calibration value corresponding to the rolling parameter. In particular, the calibration value may be extracted from an evolution law of the datum according to the rolling parameter, said law being able to be established via experimentation or via simulation.

[0032] In said embodiment, the method allows a rolling condition to be determined in the form of a rolling parameter, for example the pressure of the tyre. Furthermore, the periodic implementation of the method allows the rolling parameter to be continuously monitored and therefore makes it available in real time for, for example, a control computer of the dynamics of the vehicle.

[0033] In an alternative embodiment, the rolling parameter may be recorded periodically, the calibration value being adjusted according to the history of values recorded. Said embodiment allows possible deviations to be taken into account in the time of the evolutio...

second embodiment

[0034] the rolling condition is determined by comparing the variation of a rolling parameter with a threshold corresponding to said condition. In said embodiment, it is, for example, possible to determine a “flat tyre” rolling condition if the pressure in the tyre varies by more than a given percentage in a predetermined time range.

[0035] In particular, when the rolling parameter is recorded periodically, said parameter may be compared with at least one value recorded such as to determine the rolling condition.

[0036] When the method according to the invention is implemented to determine a plurality of rolling conditions, it may be envisaged that some of said conditions correspond to the rolling parameters and that others correspond to rolling parameter evolutions. In particular, for the pressure of the tyre, a joint determination of the value of said, pressure and that of a “flat tyre” condition may be envisaged, said two conditions thus being able to be treated in a differentiate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com