Independent front suspension with transversely arranged steel plate spring

A leaf spring and front suspension technology is applied in the field of the independent suspension mechanism of the front axle of commercial vehicles, which can solve the difficulty of increasing the space angle of the shock absorber, the complicated working condition of the shock absorber, and the wear of the slider and the leaf spring, etc. problems, to achieve good motion characteristics, ensure handling stability, and avoid friction and heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

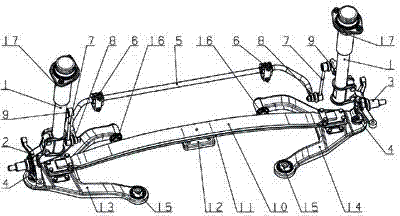

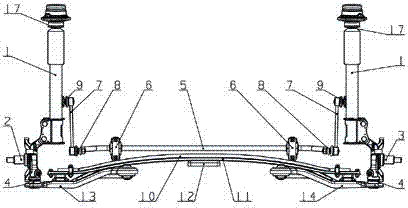

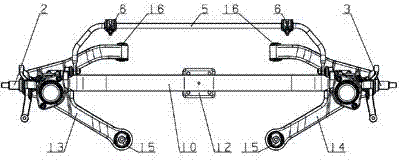

[0028] A leaf spring transverse independent front suspension, such as figure 1 As shown, it includes left and right front shock absorbers 1 with limit blocks 17, left and right steering knuckles 2 and 3, leaf springs, stabilizer bars 5, stabilizer bar fixing brackets 6 with rubber bushings, and stabilizer bar push rods. 7. The stabilizer bar assembly composed of the push rod lower ball pin 8 and the push rod upper ball pin 9, the left and right lower swing arms 13, 14, the left and right front shock absorbers 1 are connected with the left and right steering knuckles through bolts, the left 1. The right lower swing arm 13, 14 is respectively connected to the left and right steering knuckles through the lower swing arm ball pin 4, the stabilizer bar and the steering gear are arranged at the front and rear positions, (the steering gear is not shown in the figure), and the leaf spring is composed of 2 pieces The upper and lower leaf springs 10, 11 are composed of horizontal variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com