Patents

Literature

637results about "Hopper cars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

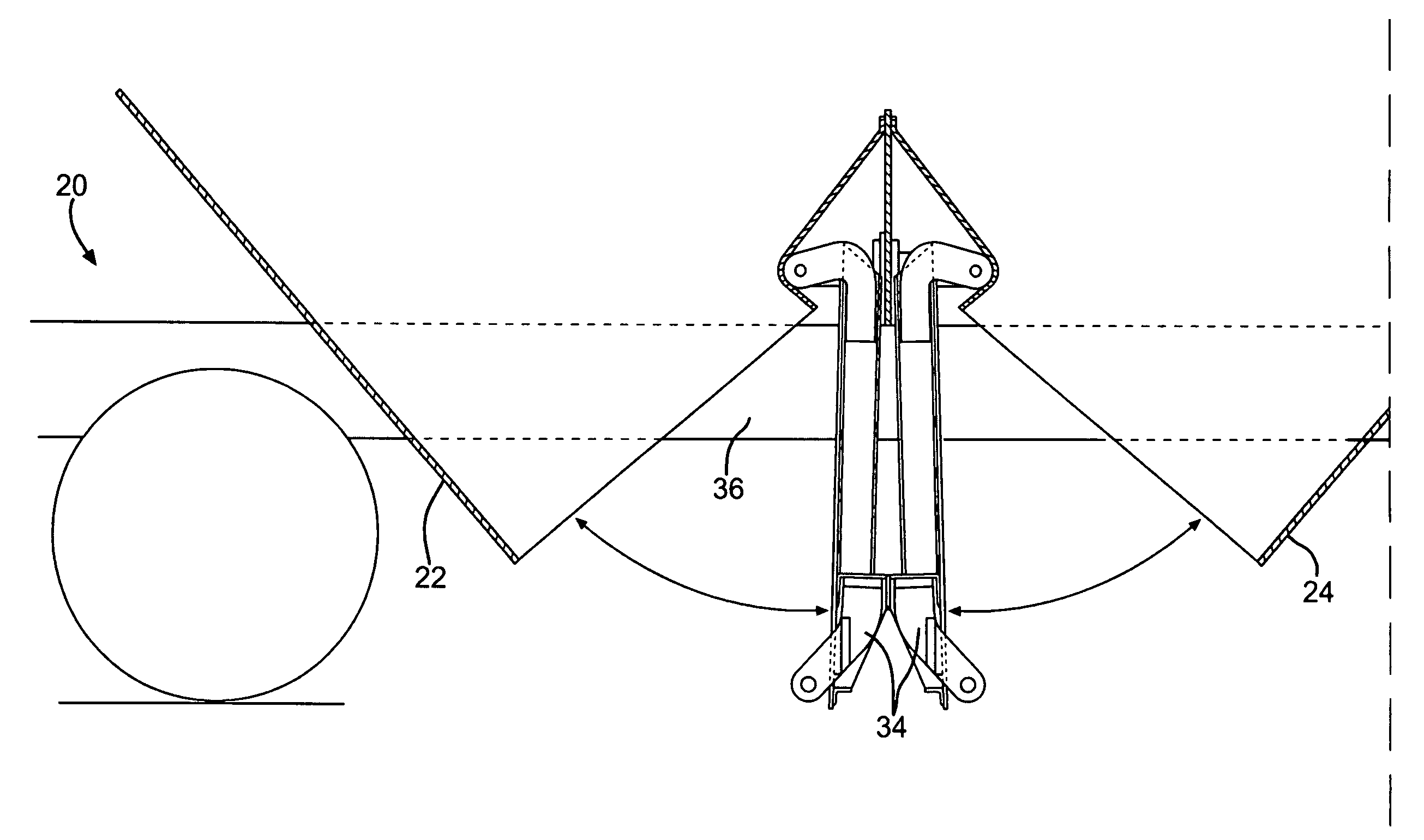

Containerised handling of bulk materials and apparatus therefor

InactiveUS7252309B2Advantageously producedFlow mixersLarge containersParticulate pollutionEngineering

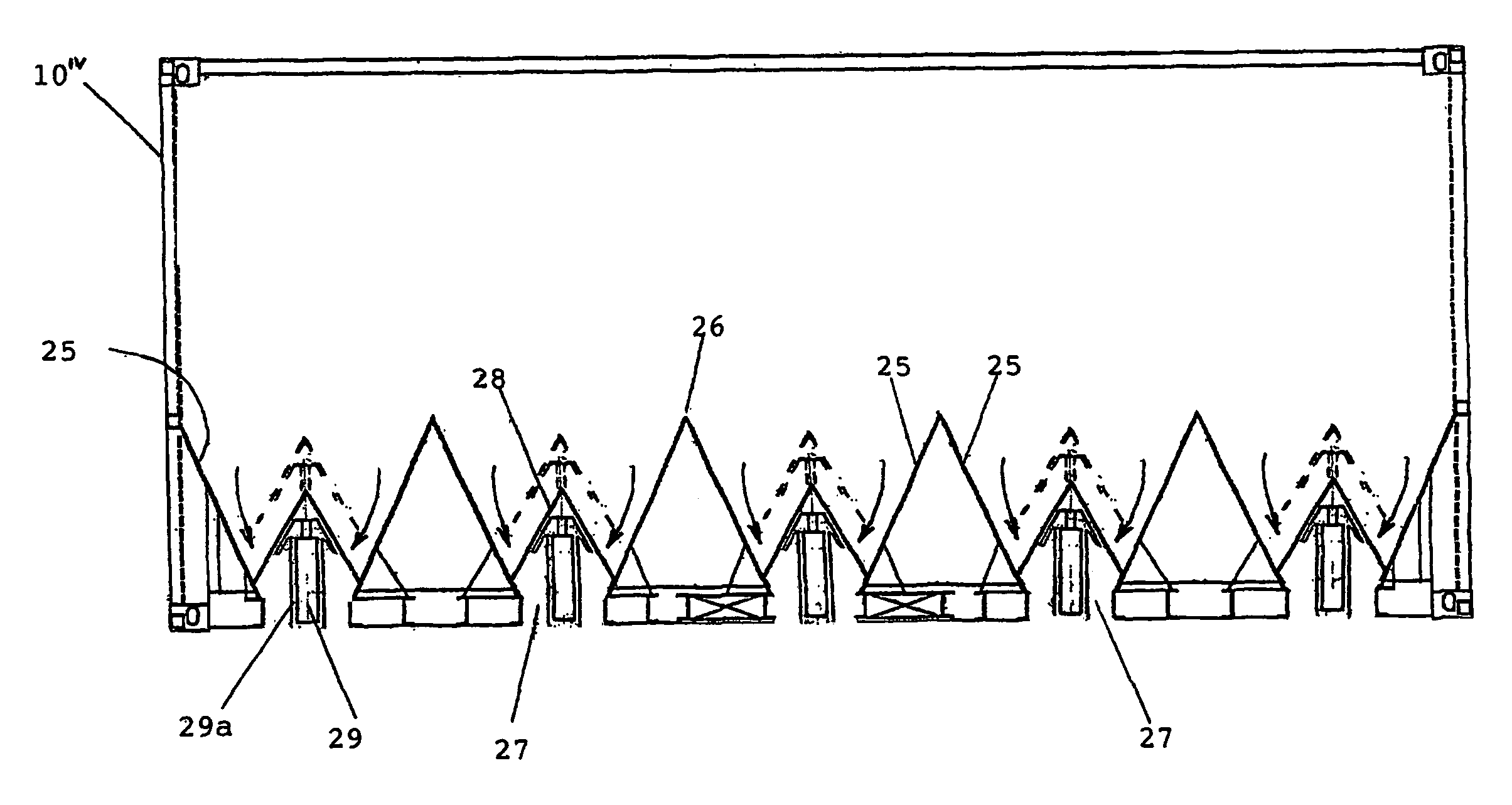

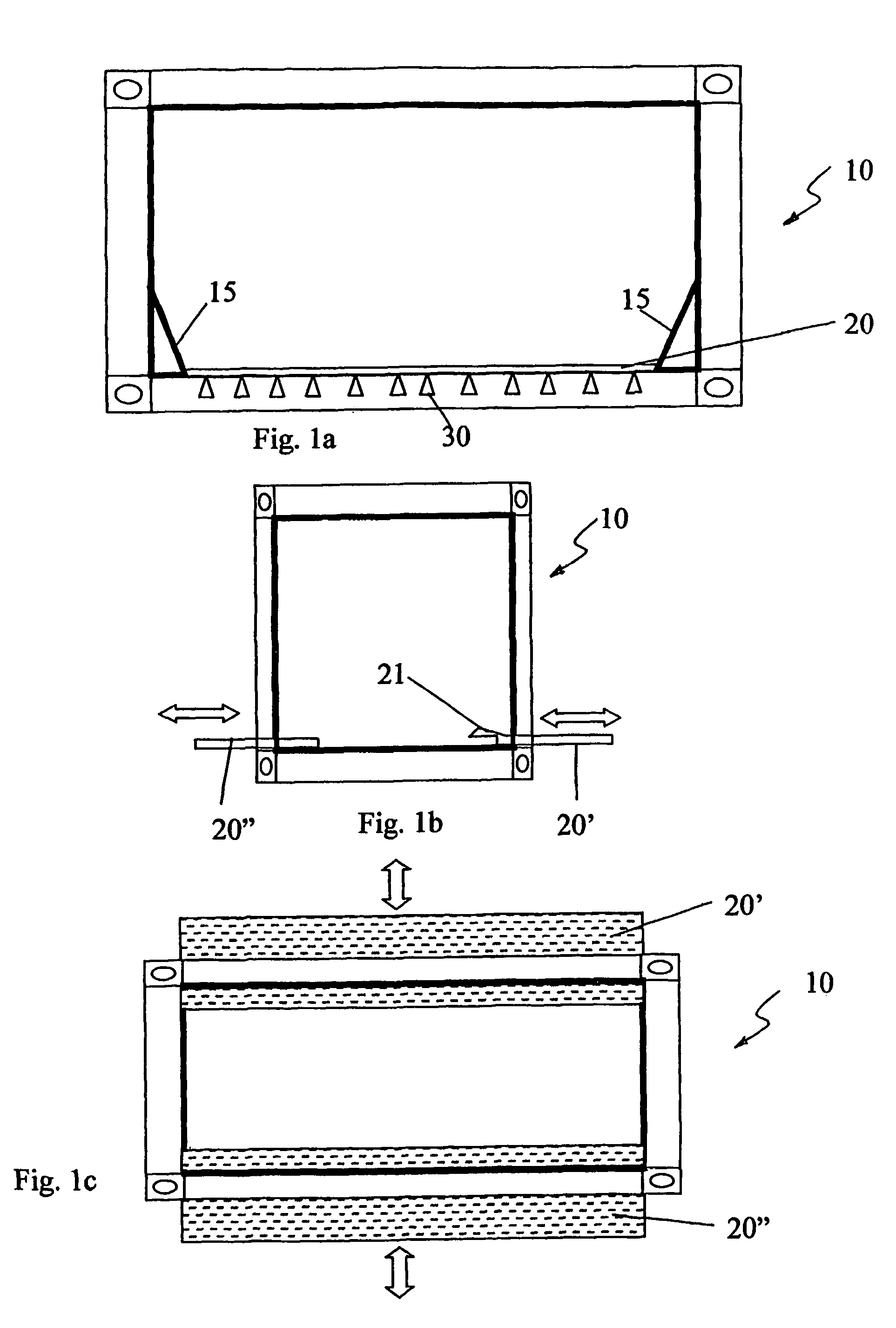

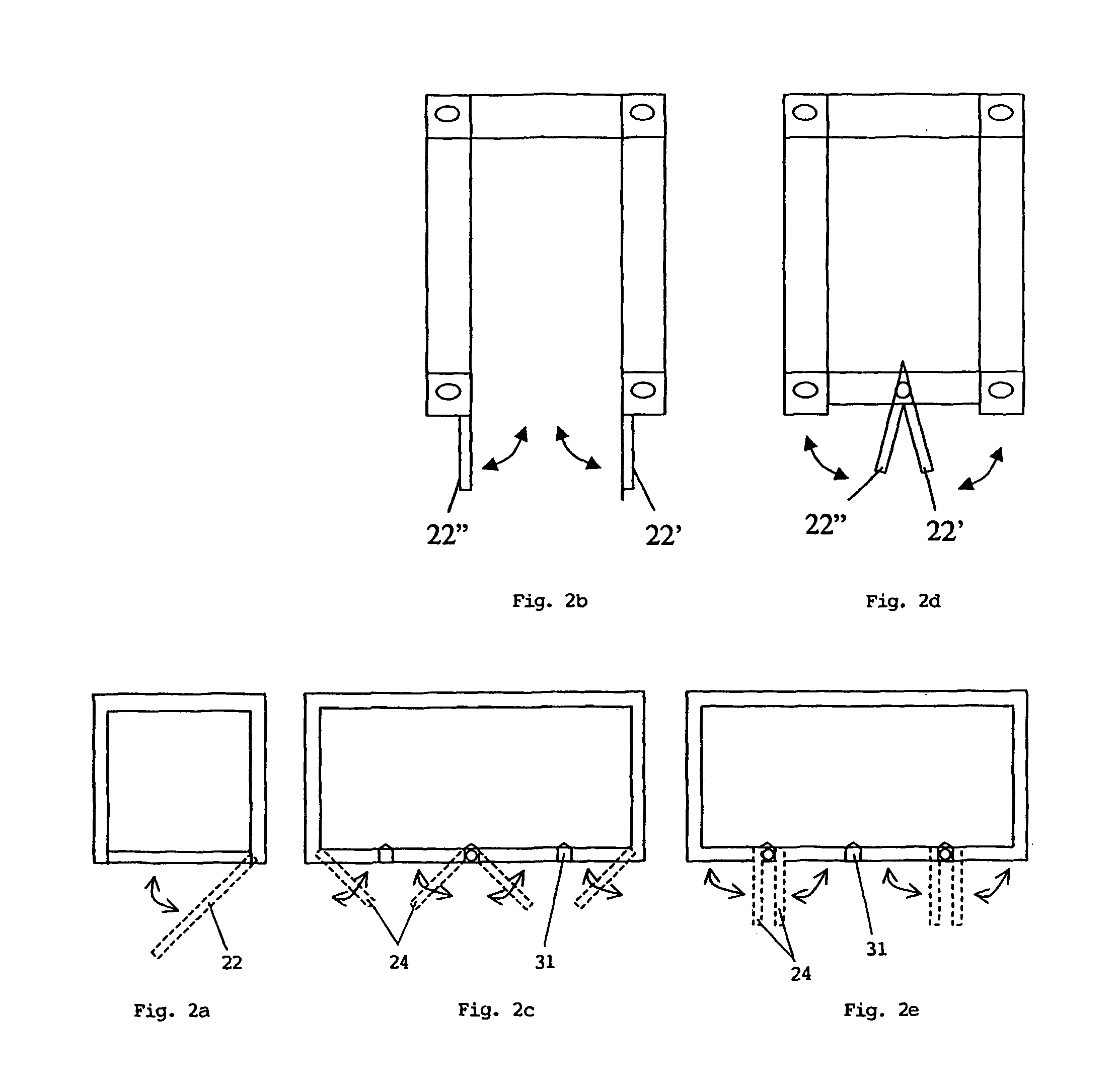

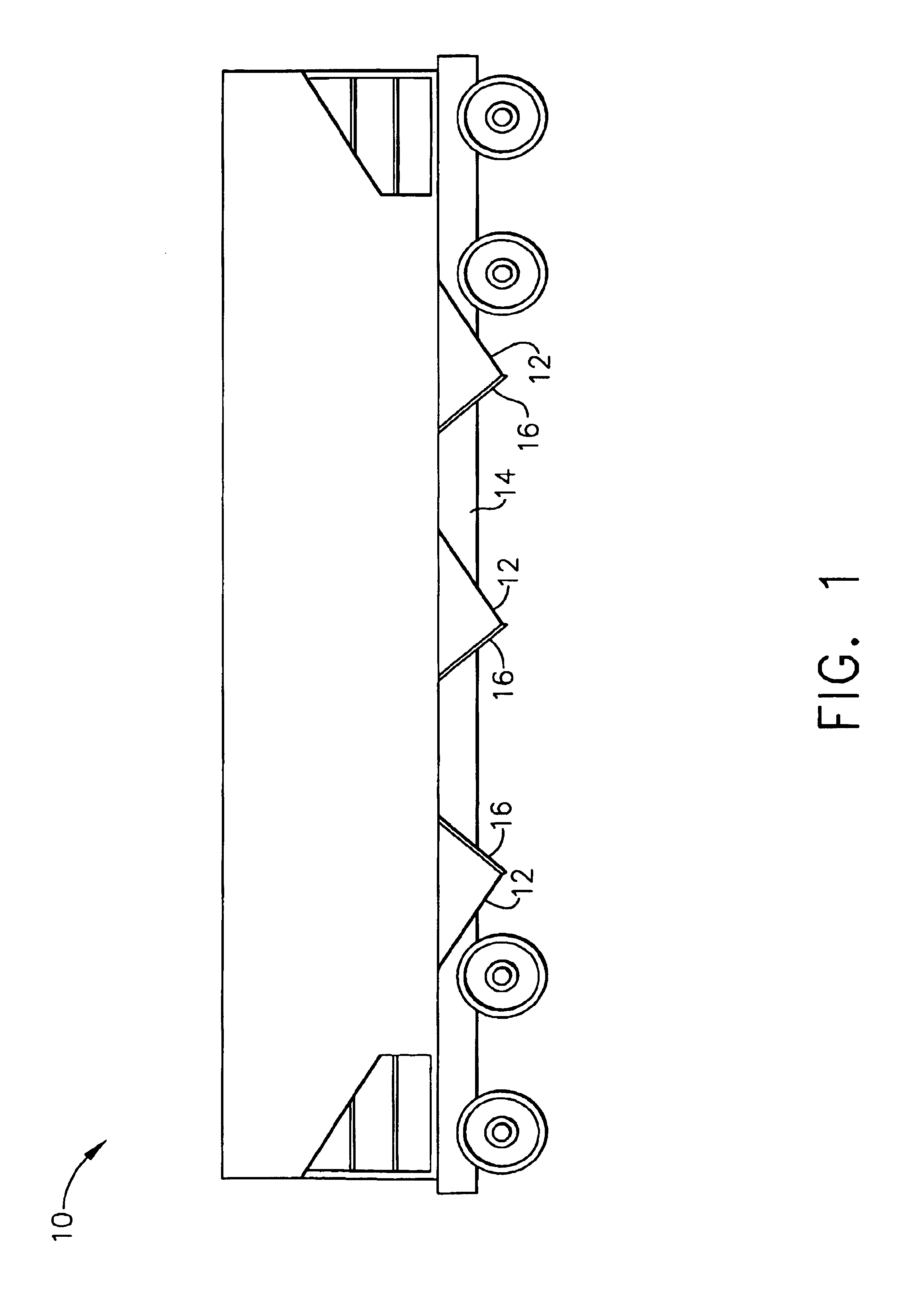

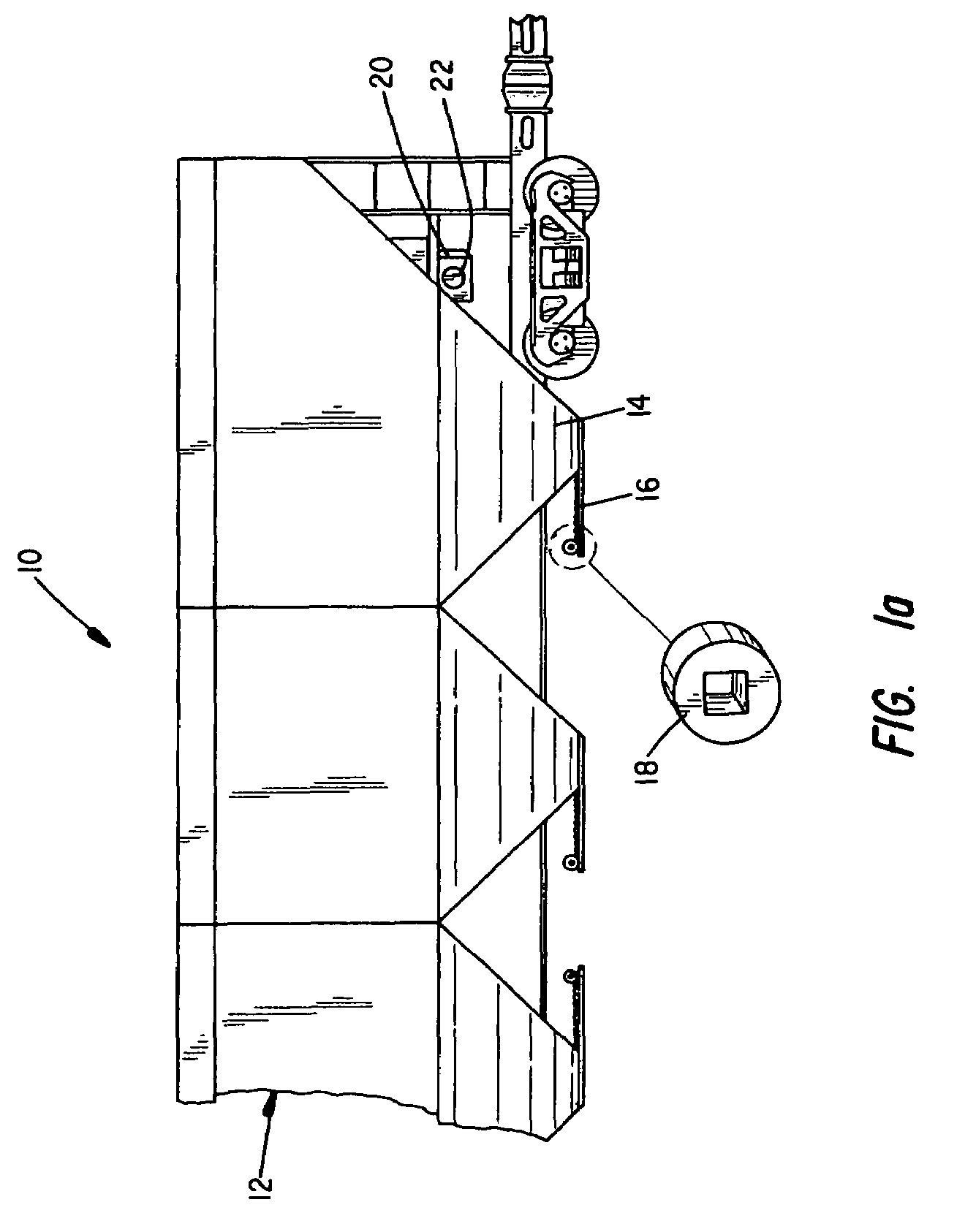

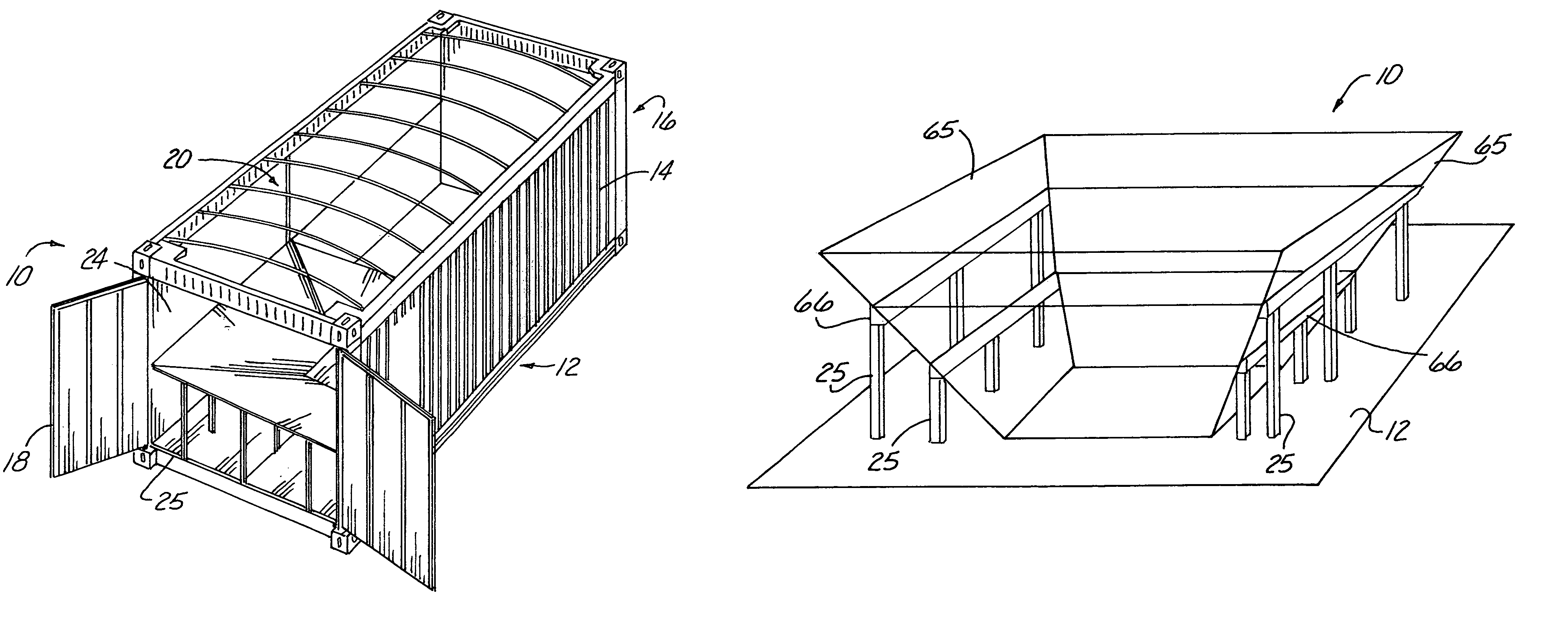

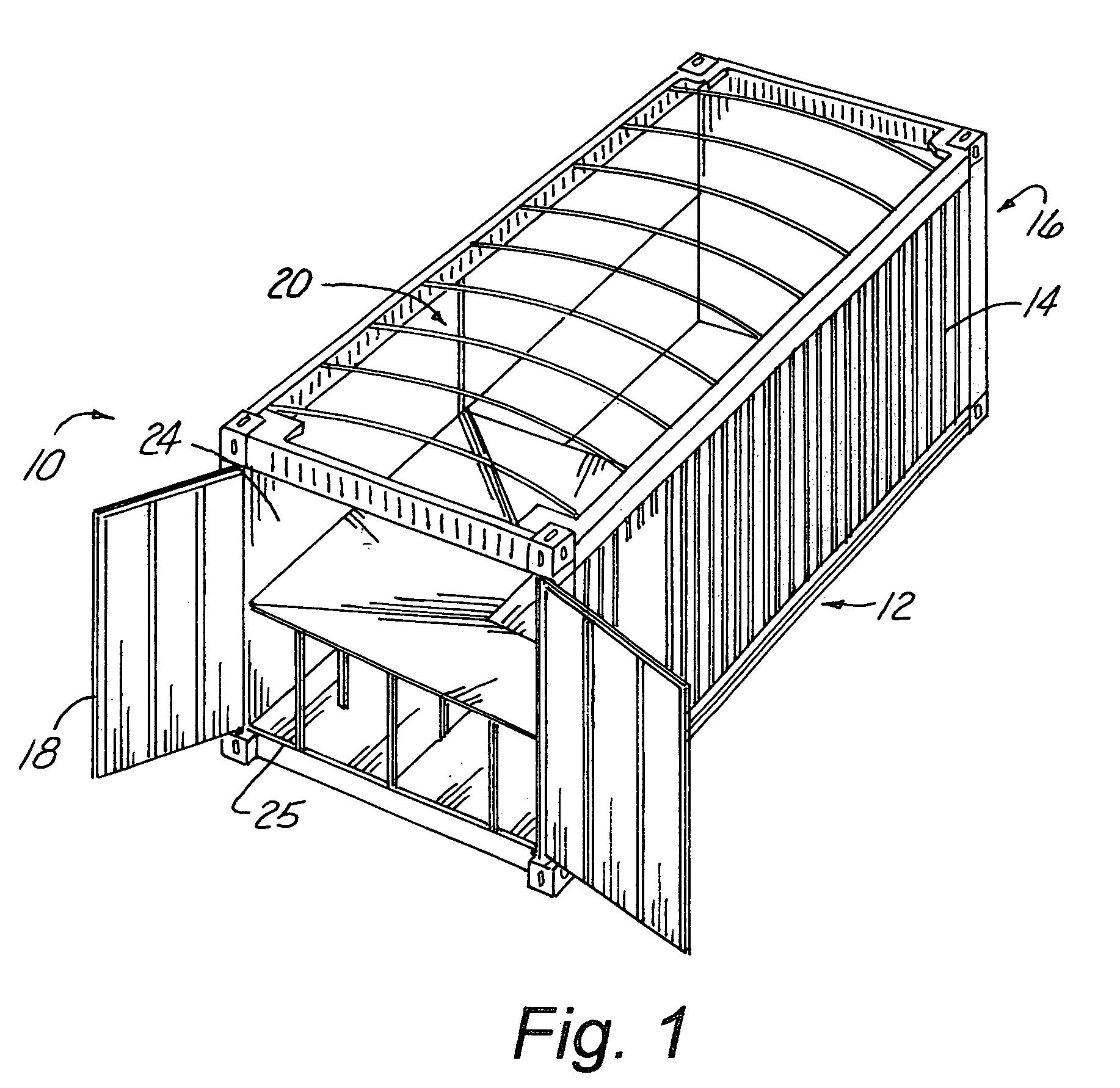

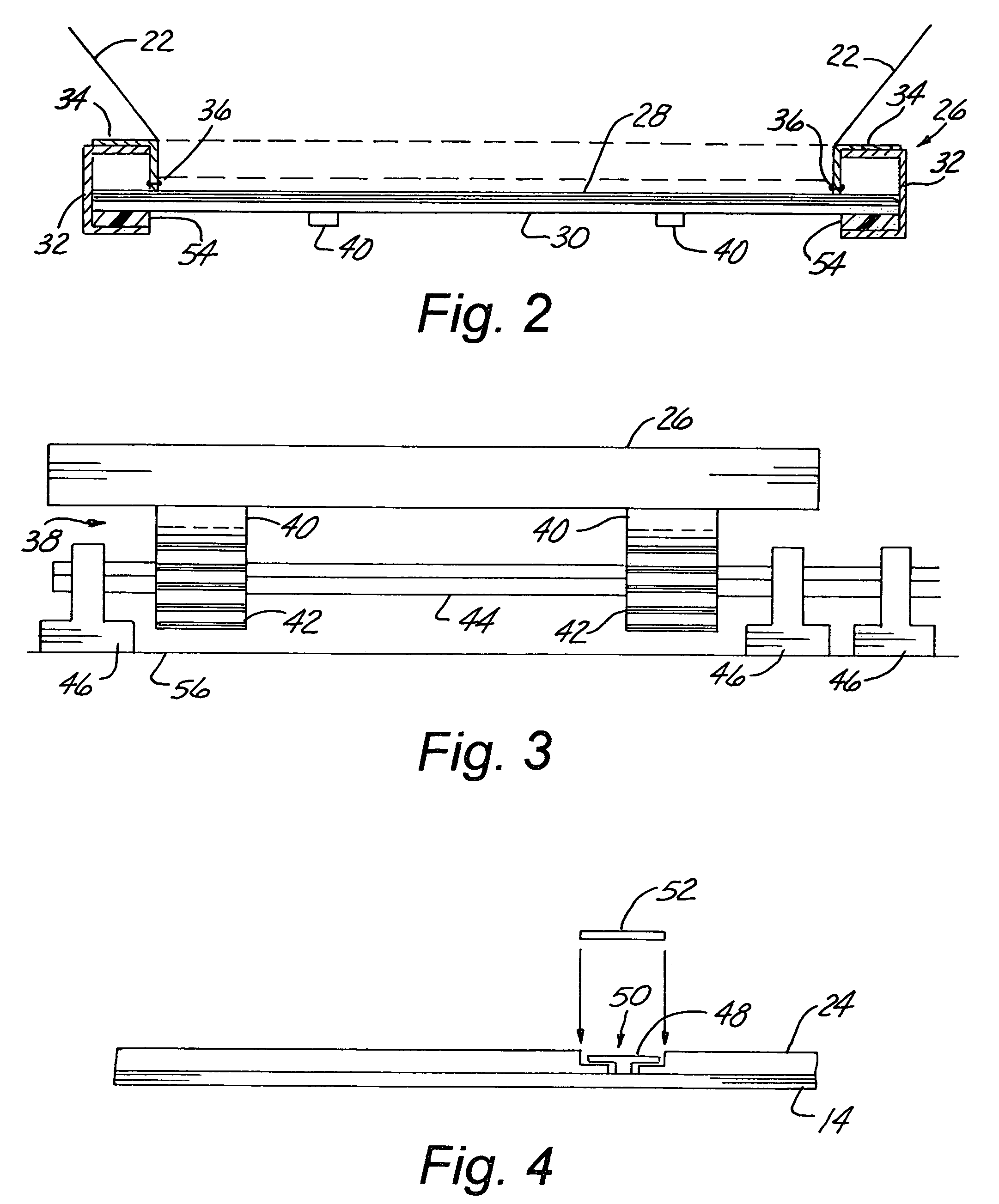

A freight container (10) has a base (20) or a portion thereof that can be opened to discharge its contents. This container (10) has a top which can be opened in similar manner as the base. Another container having at least one compartment, each compartment having a lower section with a reducing cross-sectional area and a pivotably operable closure assembly, with several such closure assemblies being linked together by means of bars. Such a container is used to contain raw building materials for stockpiling of these materials at a container port. It is also used to supply materials to a concrete production plant whee pollution control containers are provided below the supply container and above the scaling and mixing stations to reduce particulate pollution. A pair of slewing apparatuses is also provided to engage both ends of a container and turn the container over about its longitudinal axis, thereby emptying its contents.

Owner:ONG BEE KIM

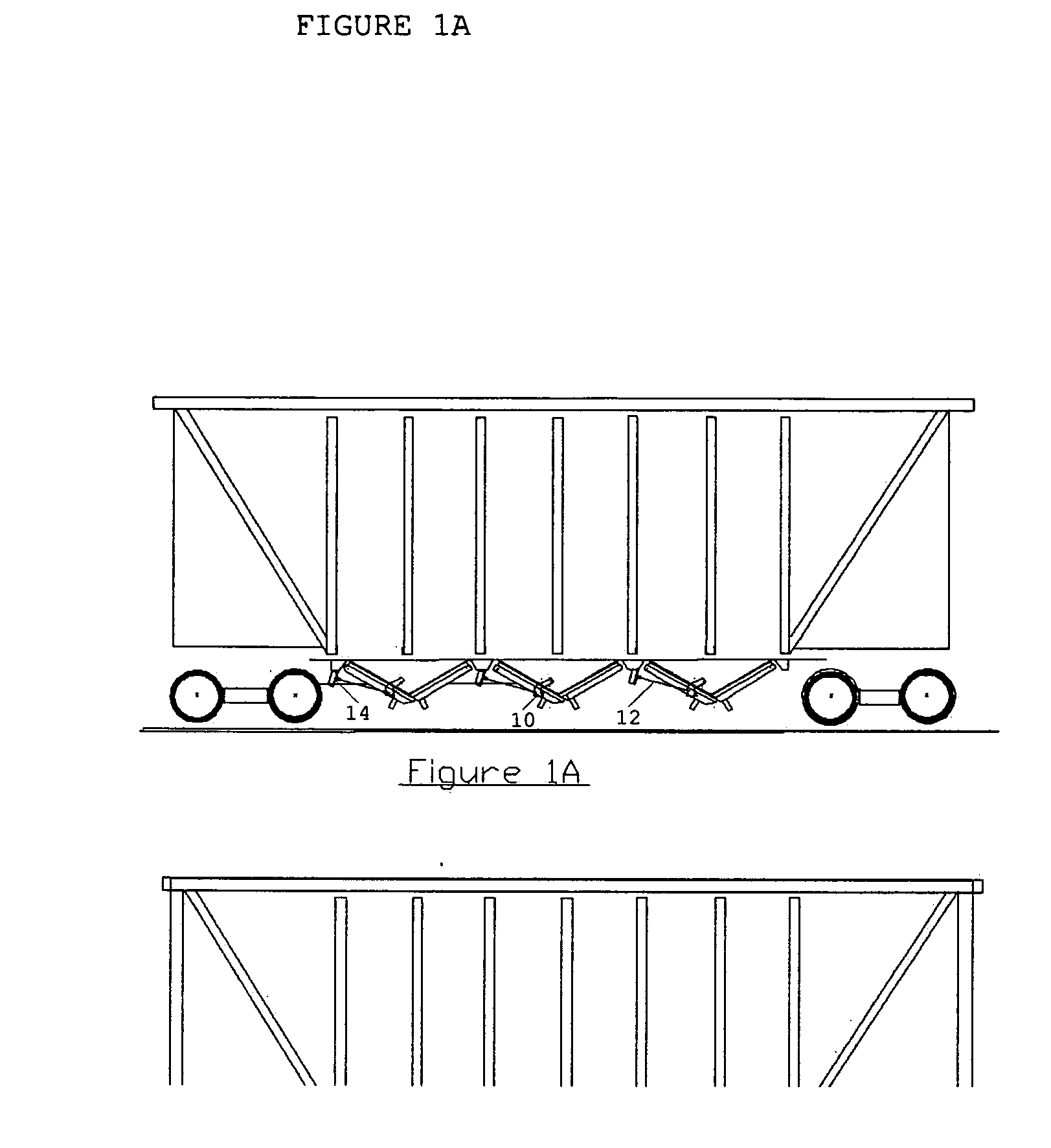

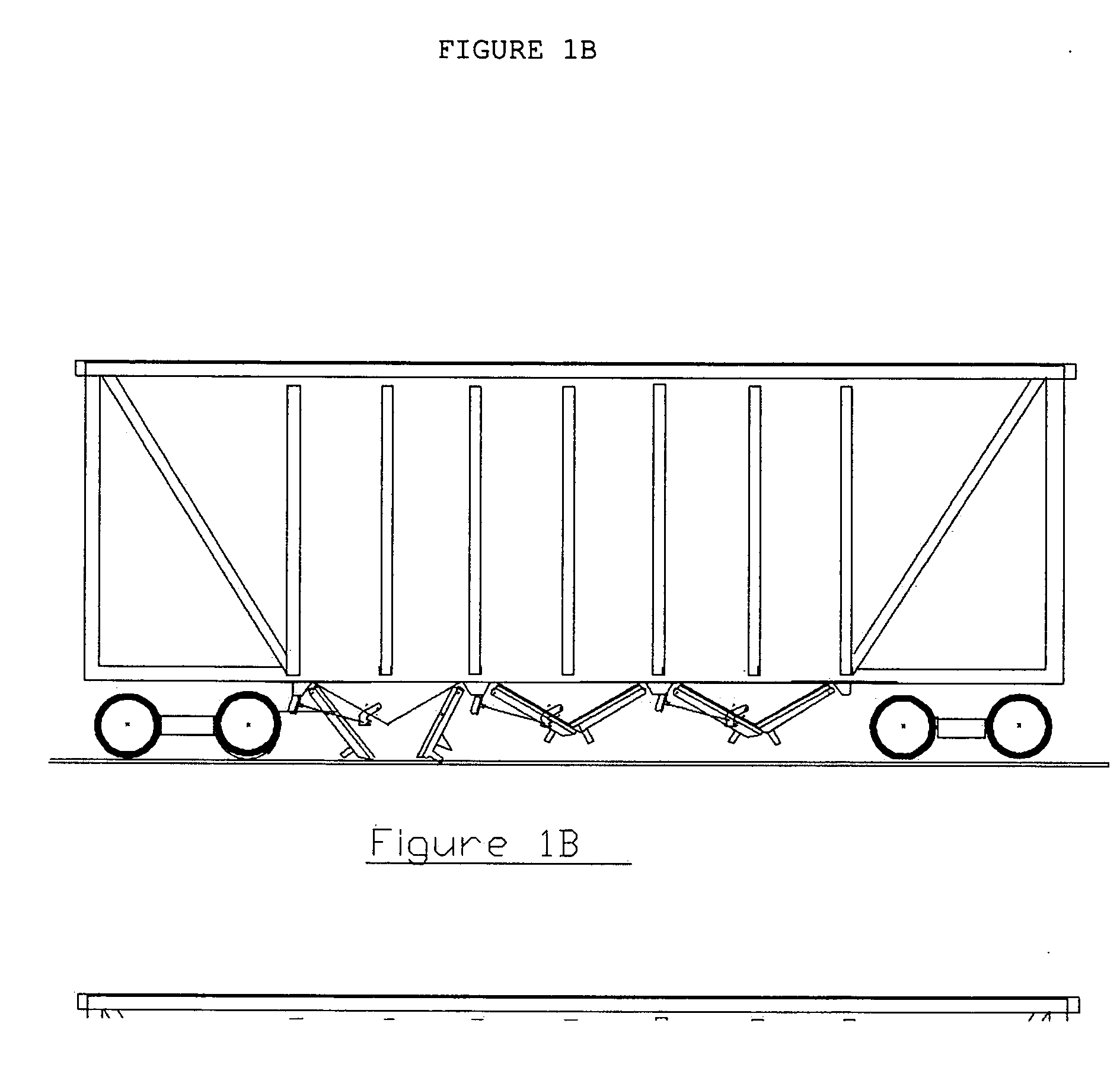

Manual railroad hopper car door actuating mechanism

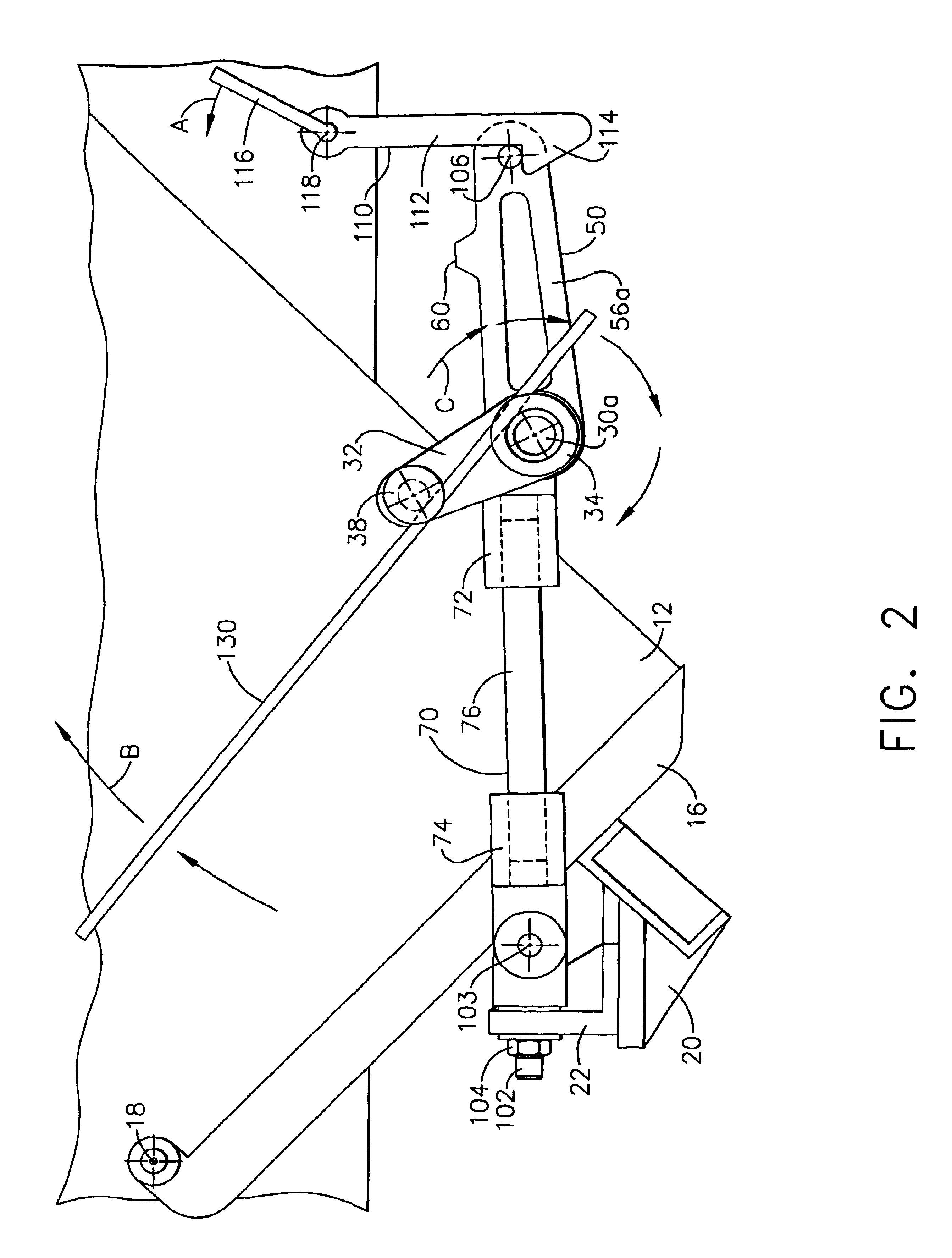

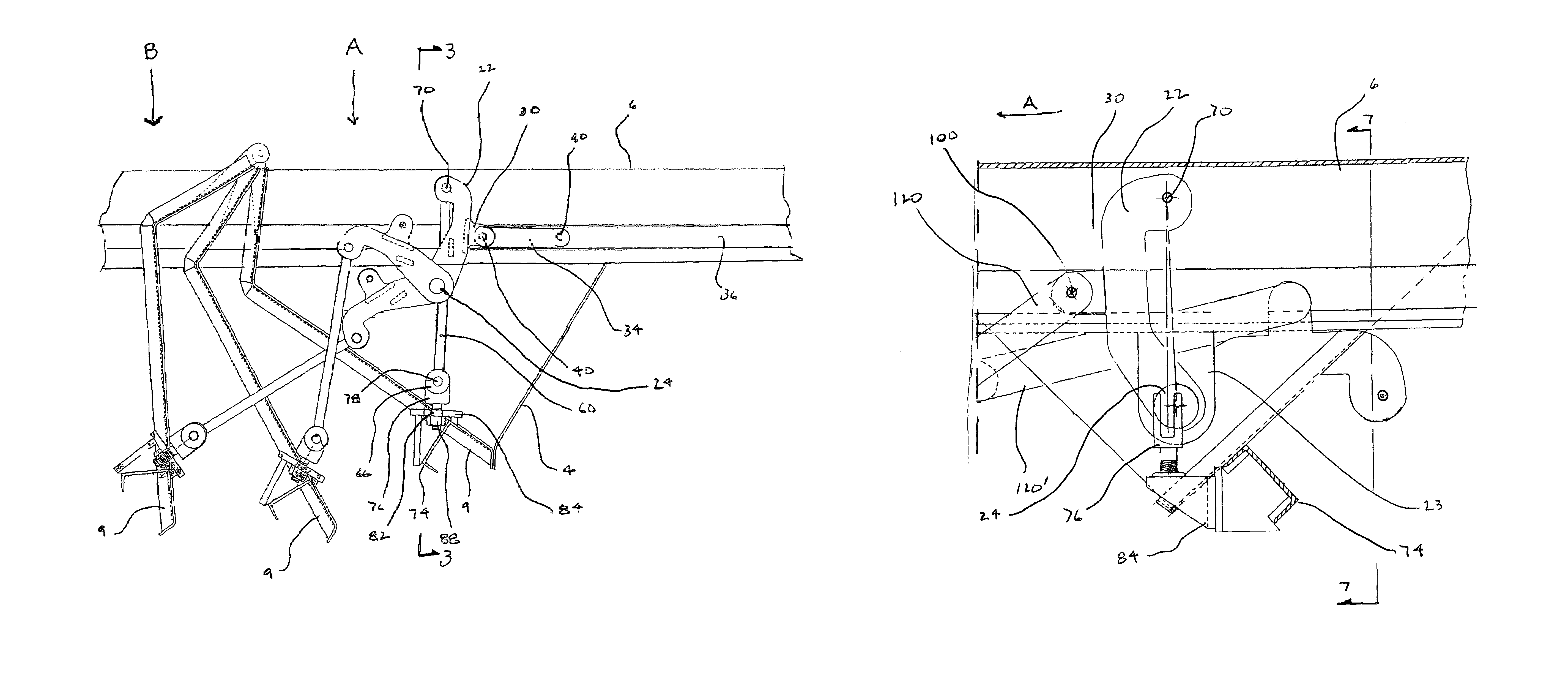

An actuating system for manually operating the doors of a railroad hopper car. An operating shaft having a handle is rigidly coupled to an actuating lever. A door opening lever, which is rotatably coupled to the actuating lever, is rotatably coupled to the door for a hopper chute. To operate the system, an operator rotates the handle of the operating shaft, rotating the actuating lever and the door opening lever, shifting the door from the closed to the open position.

Owner:VERTEX RAILCAR CORP

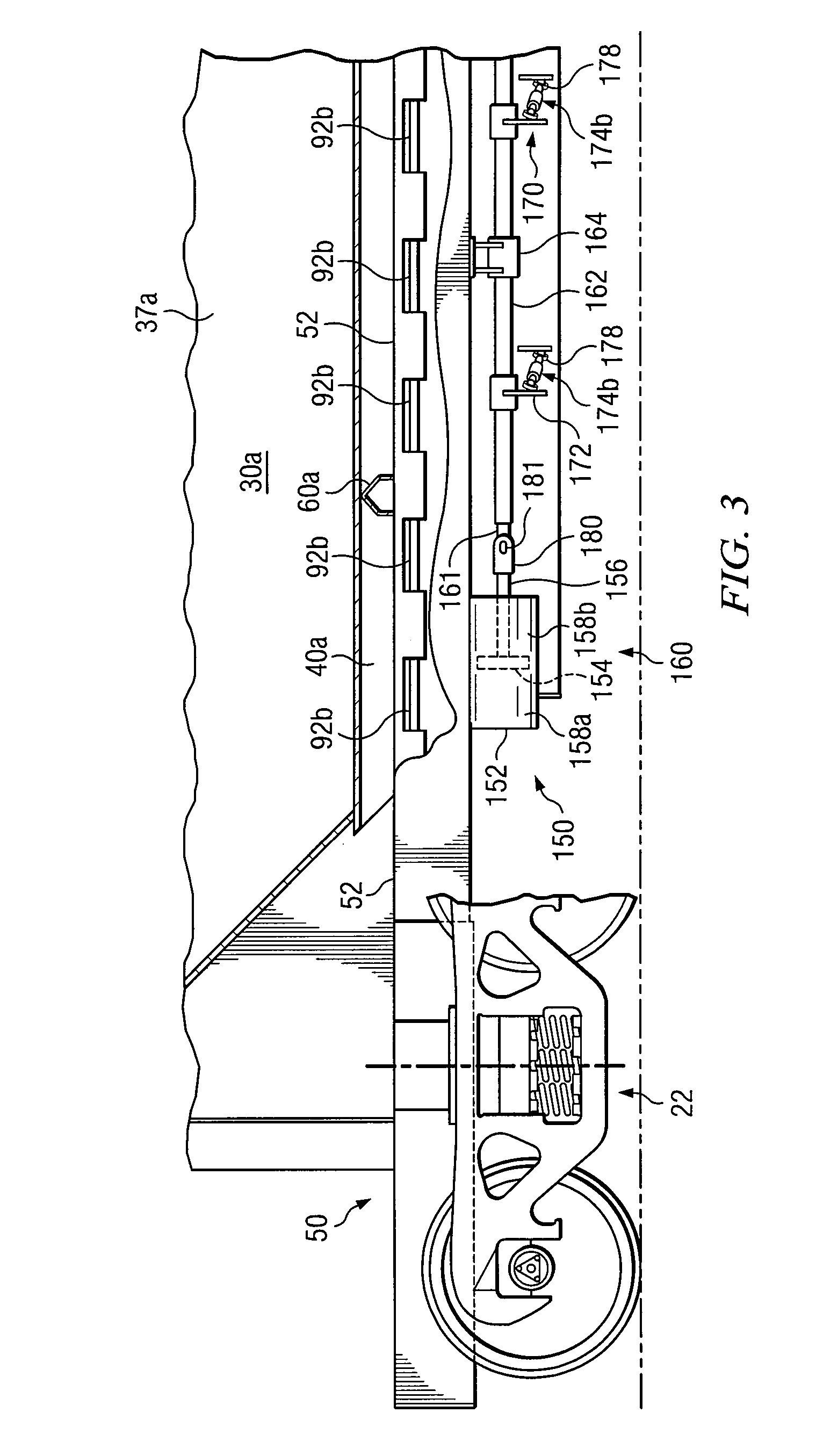

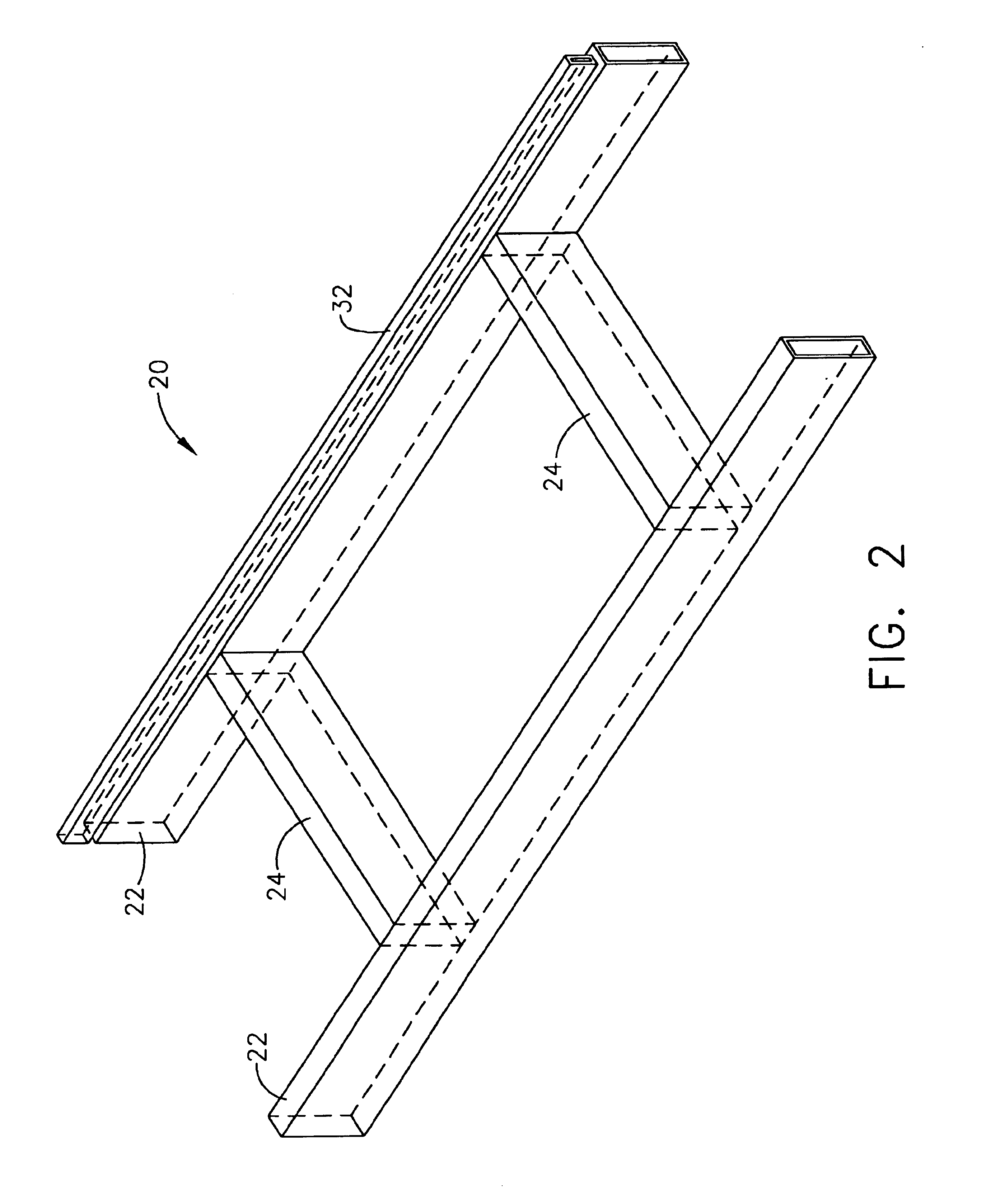

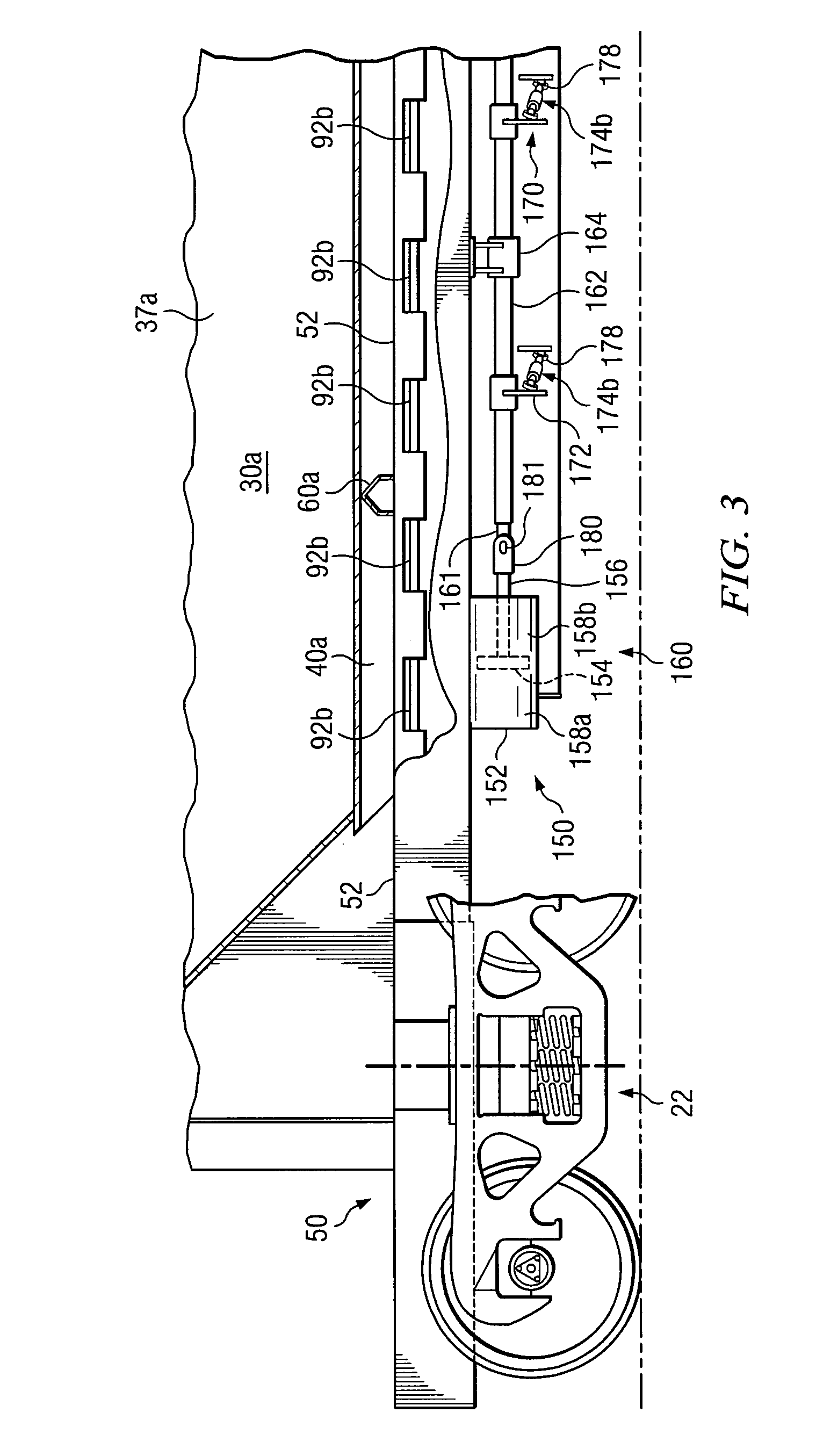

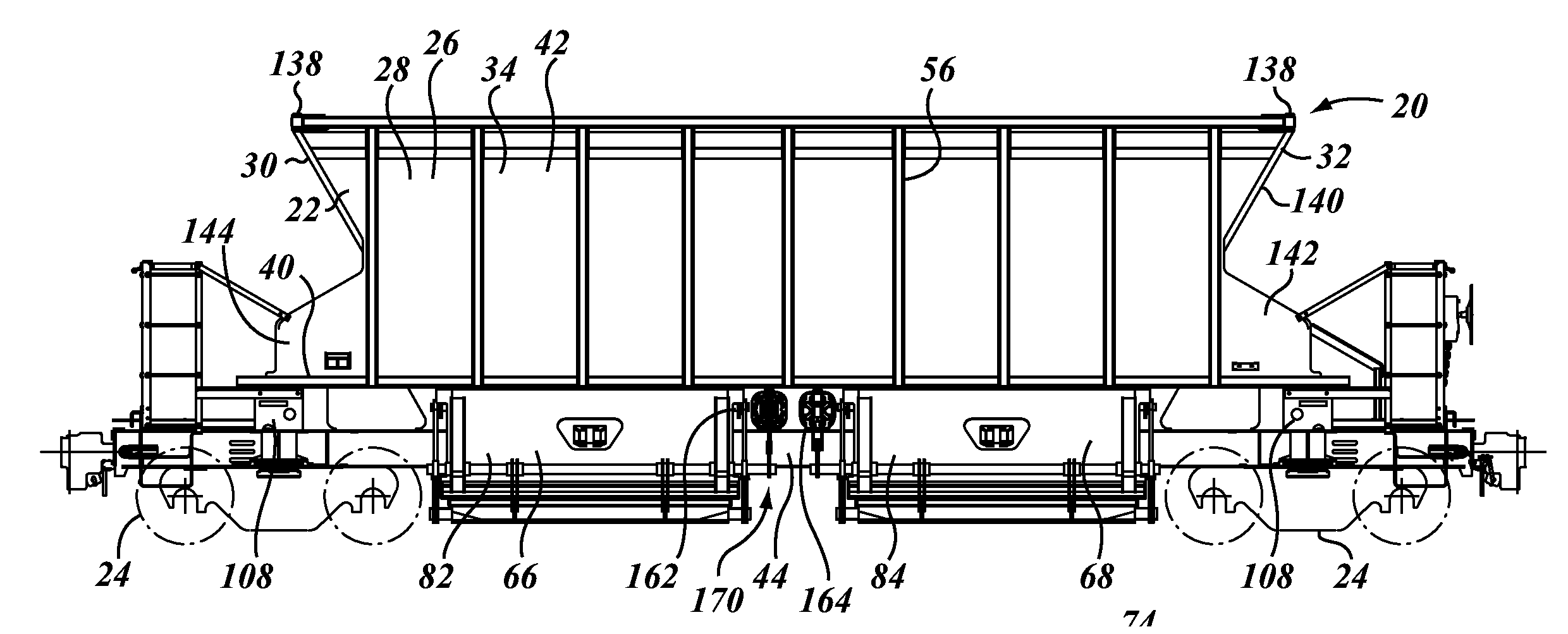

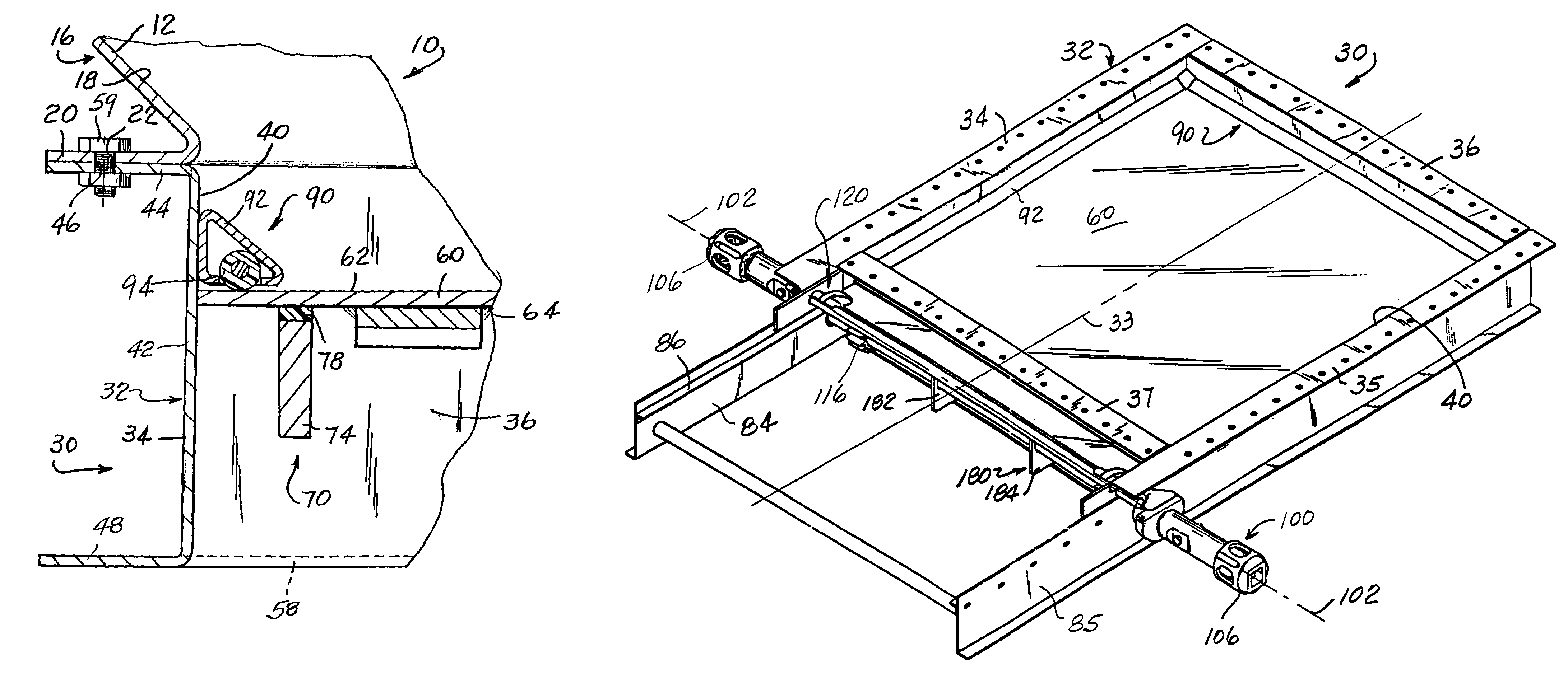

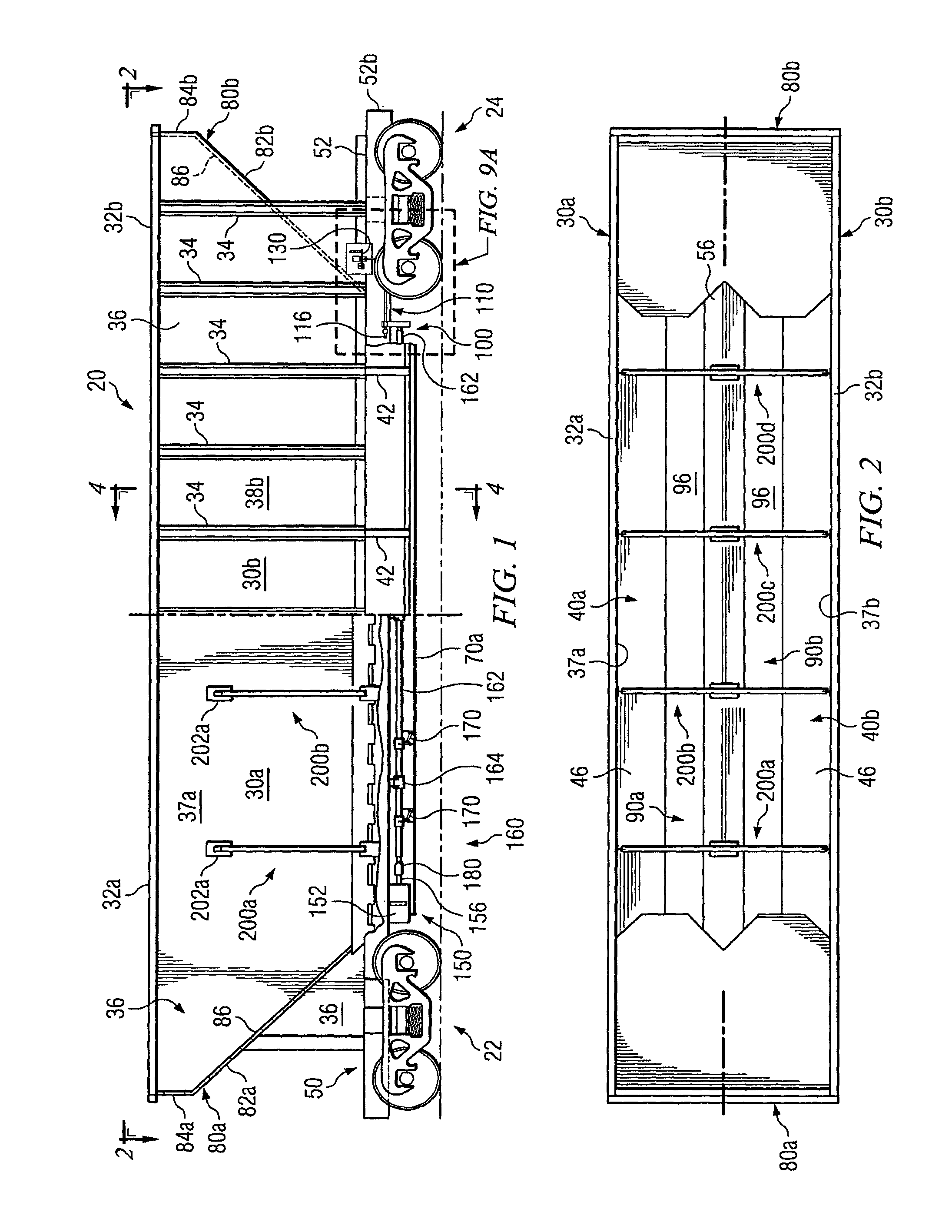

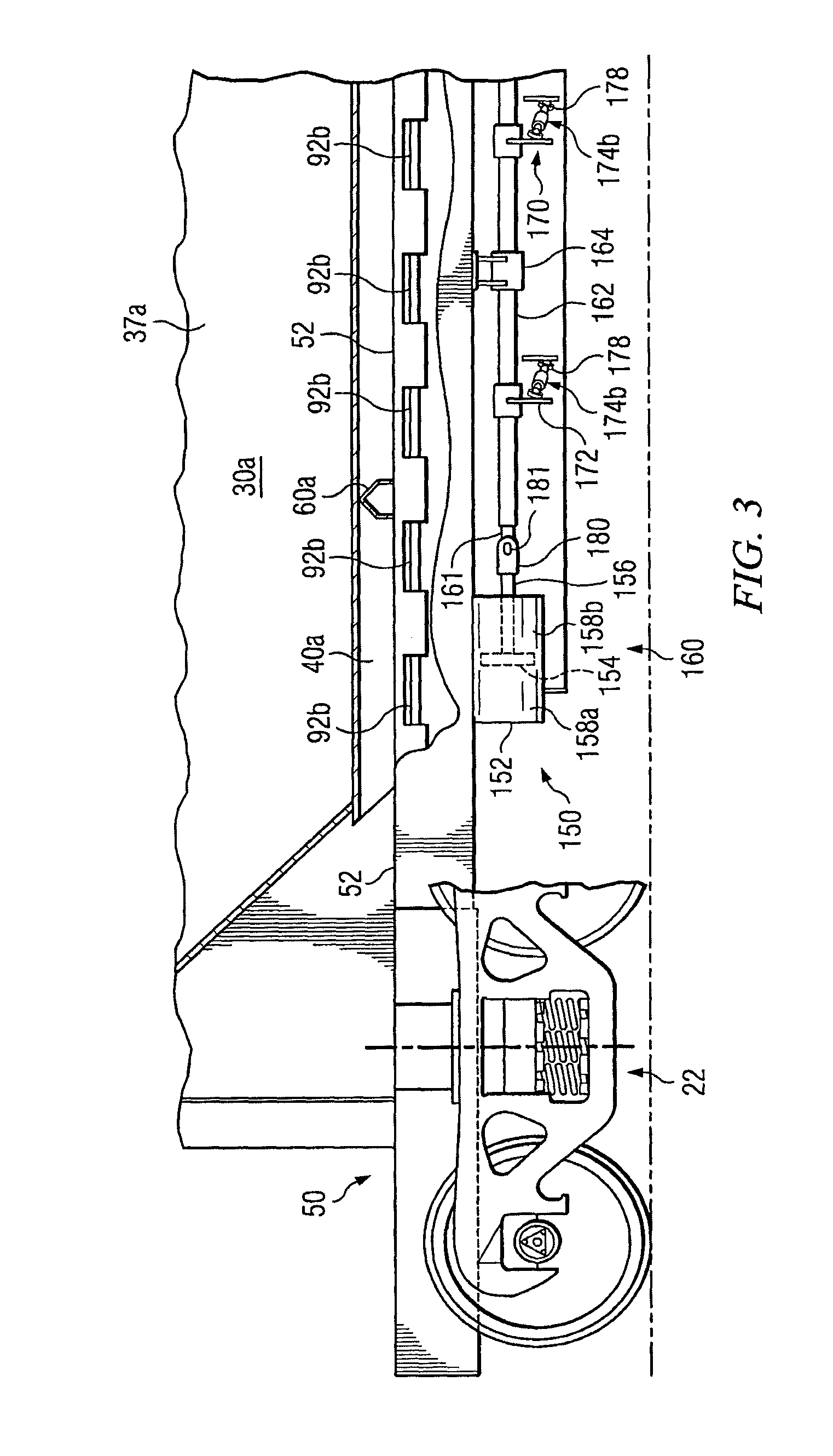

Railcar with discharge control system

ActiveUS7051661B2Improve carrying capacityReduce weightHopper carsWagons/vansControl systemOpen form

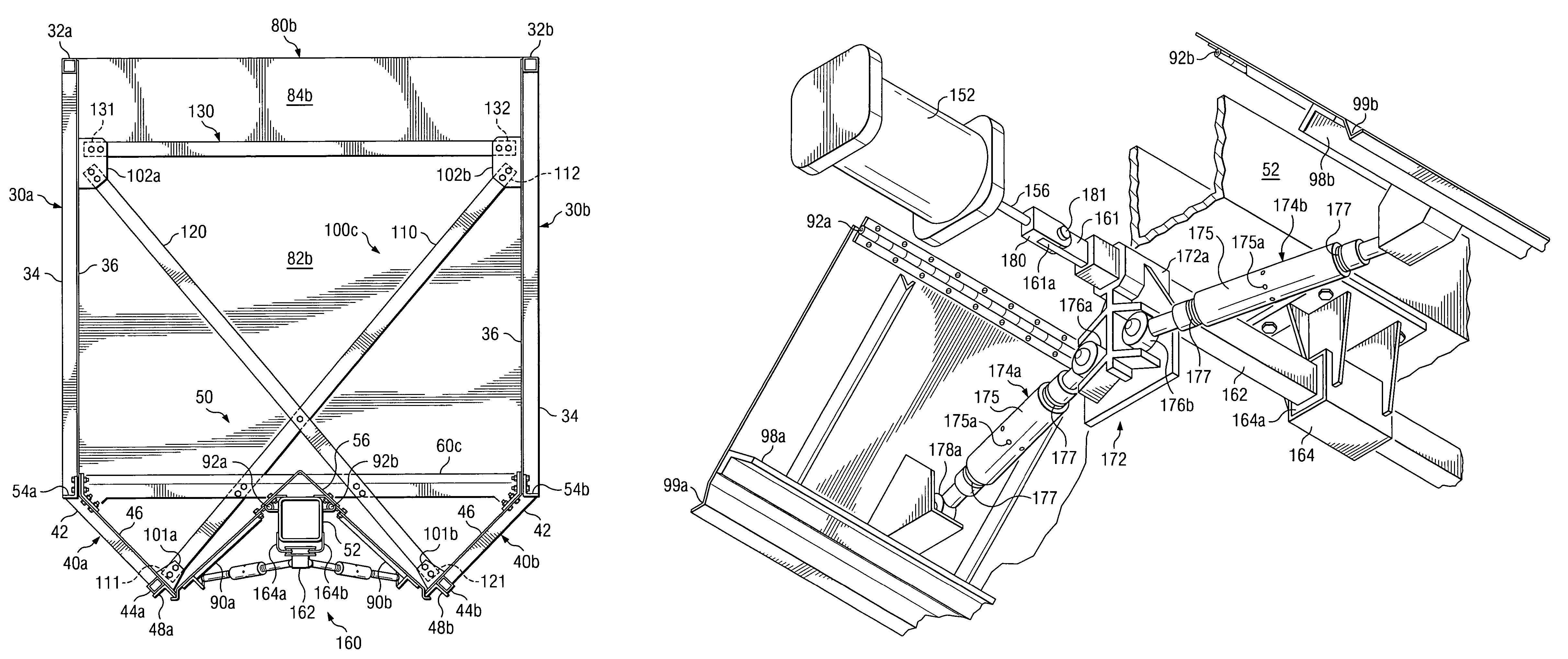

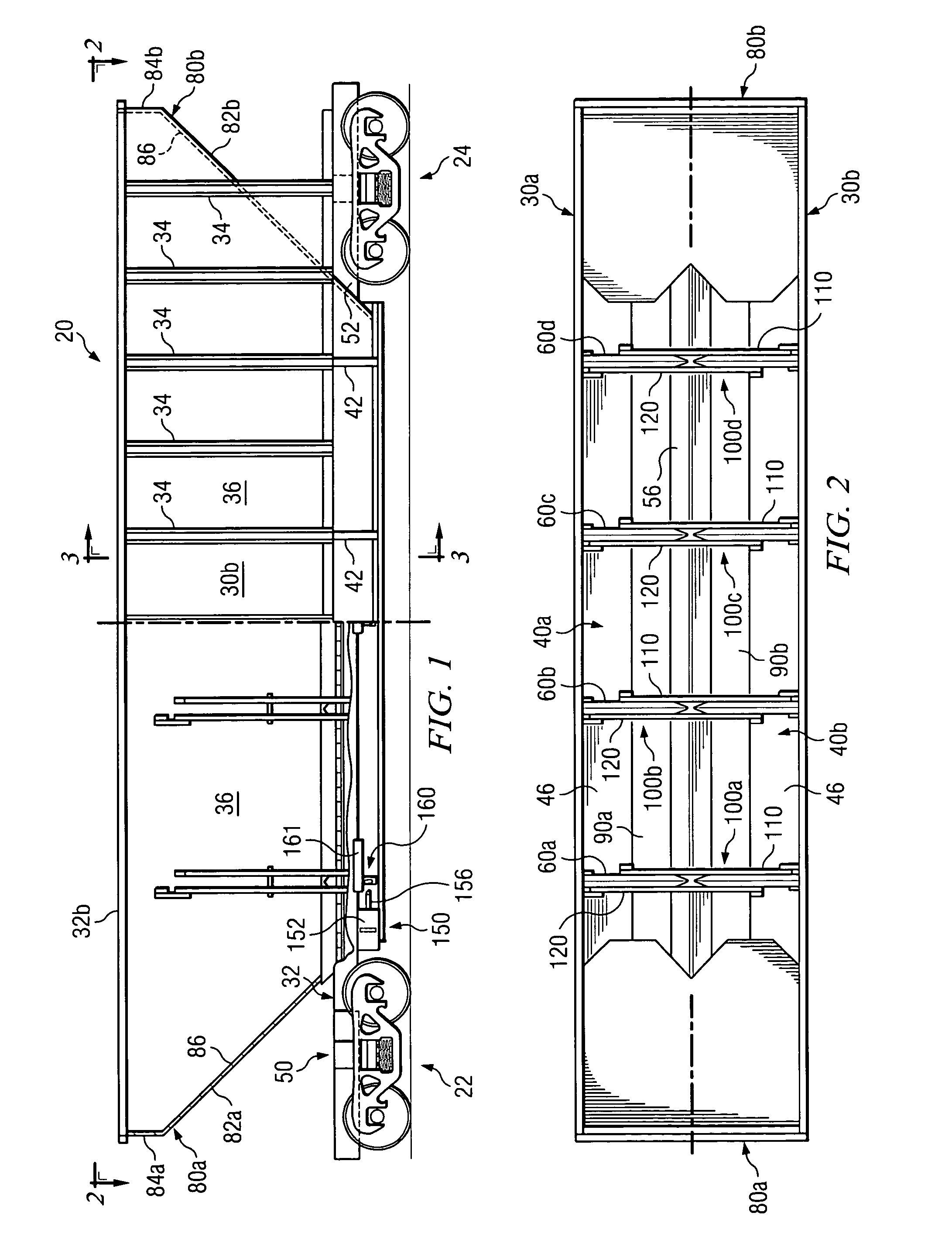

A railcar with discharge control system is disclosed. In one embodiment, a railway car includes an underframe and at least one hopper for transporting lading. The railway car further including the underframe including a center sill which defines in part a longitudinal axis of the railway car. A discharge opening formed proximate to a lower portion of the hopper. A respective door assembly pivotally mounted adjacent to the discharge opening to control the flow of lading from the hopper. The door assembly operable for movement between a first, closed position and a second, open position relative to the discharge opening. A discharge control system operable to move the door assembly between the first position and the second position. The discharge control system operably moves generally longitudinally along the axis of the railway car to move the door assemblies between the first, closed position and the second, open position.

Owner:TRINITY IND INC

Hopper car with lading dislodgement fittings and method of operation

A hopper car discharge section may be wide at the top and narrow at the bottom. Outflow is controlled by closure members, at least one of which is movable. The closure members come together to a closed condition or position for retaining lading. When apart, in an open position or condition, lading may be discharged. A seal member or seal member assembly is mounted to one or both of the closure members. The closure member may have a lading discharge encouragement feature, which may be in the nature of a tine, or blade, or knife that extends upwardly through the throat of the discharge section. Movement of the door may tend to move the blade, thereby tending to dislodge lading that may be otherwise reluctant to move.

Owner:NATIONAL STEEL CAR

Railway hopper car discharge gate

A railroad hopper car discharge gate is assembled from unitary stacked frames that provide unimpeded flow of lading during discharge. A low-wear glide system minimizes friction between the gate panels and other components of the apparatus, and an improved sealing system protects lading from contaminants such as rain, dust and insect infestation and provides enhanced vacuum sealing for greater efficiency during vacuum discharge.

Owner:AERO TRANSPORTATION PRODS

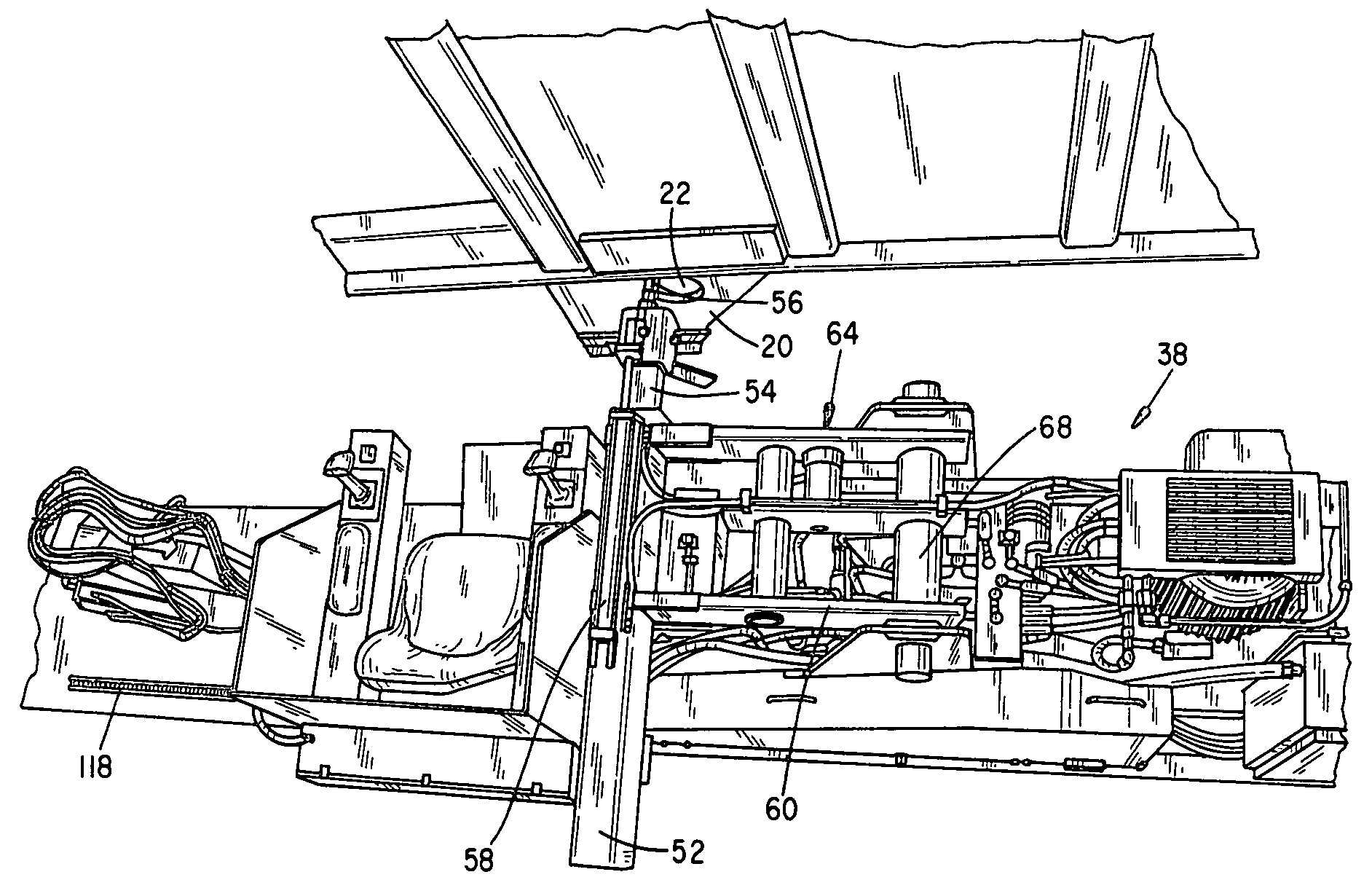

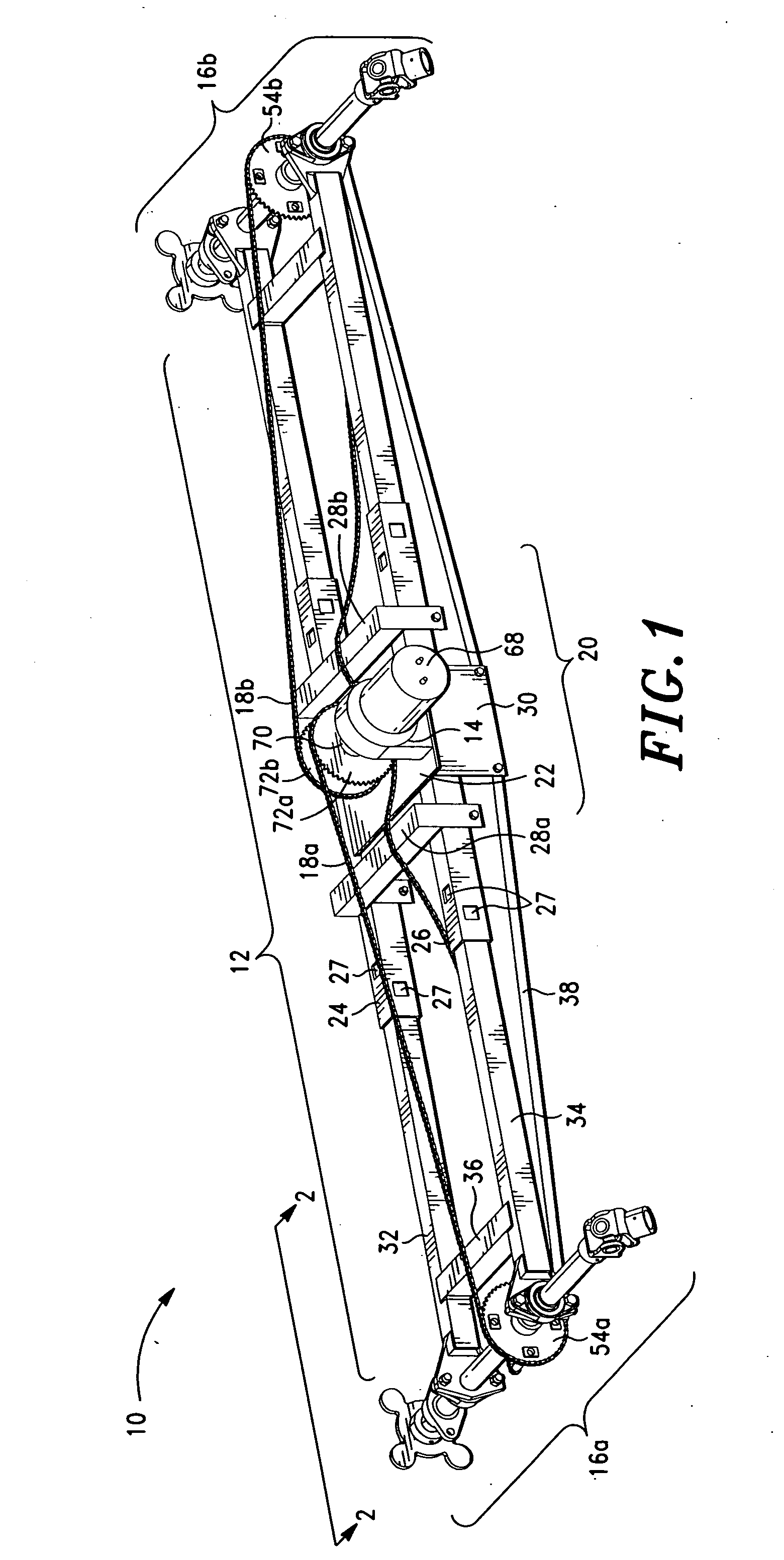

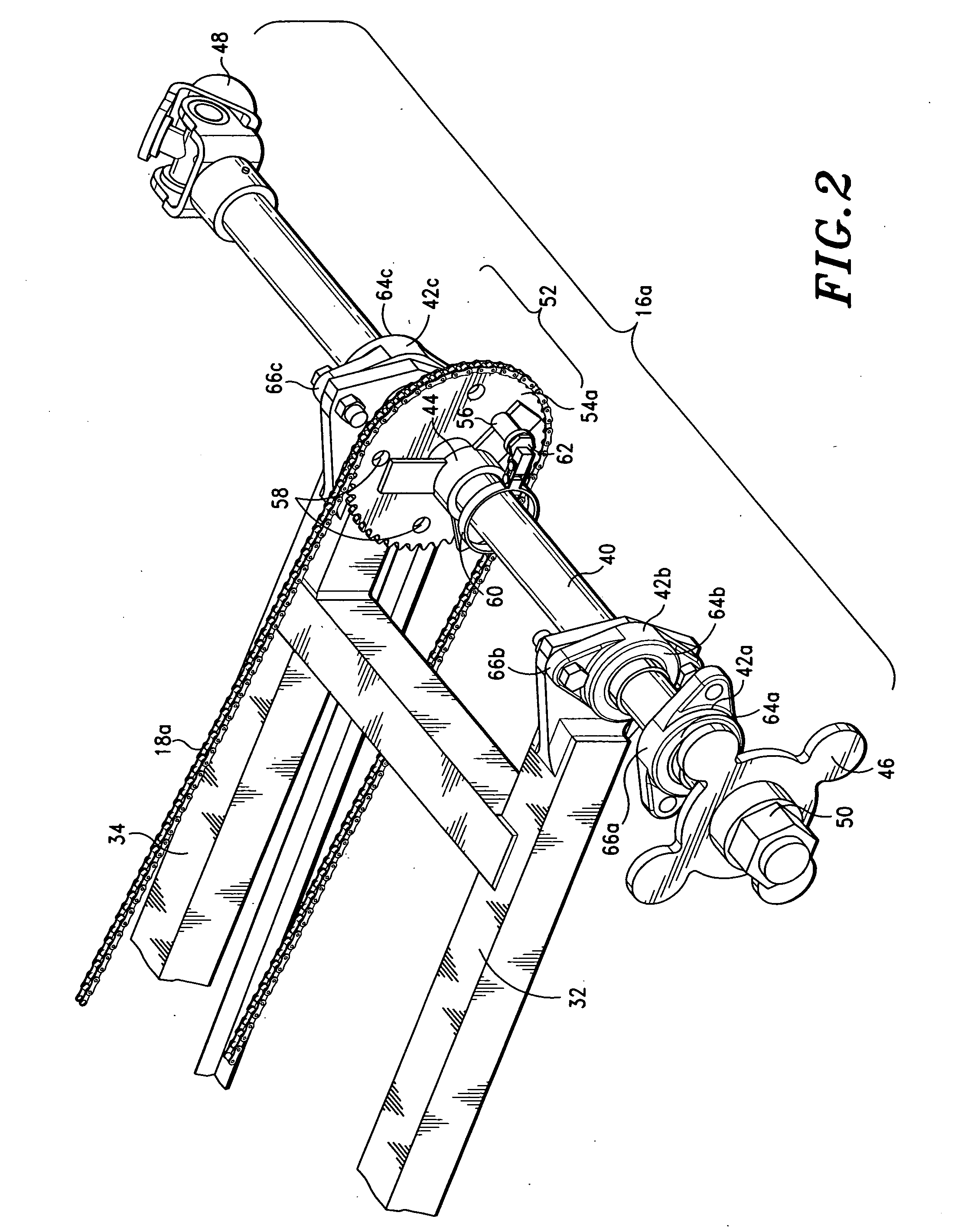

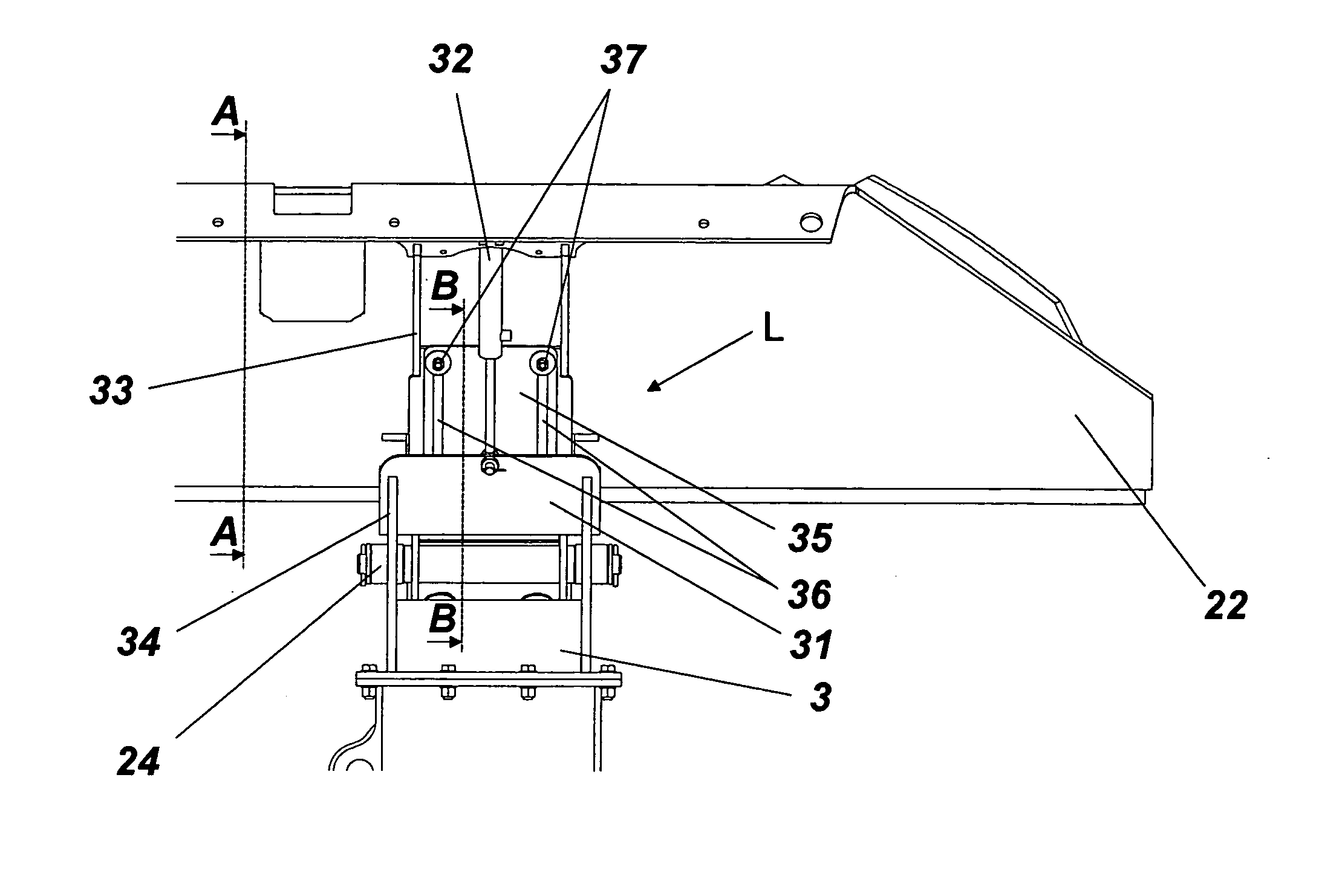

Spike-type railcar mover with optional gate opener

InactiveUS7377219B2Easy to removeReduce tensionRefuge islandsTrain hauling devicesOn boardDrive motor

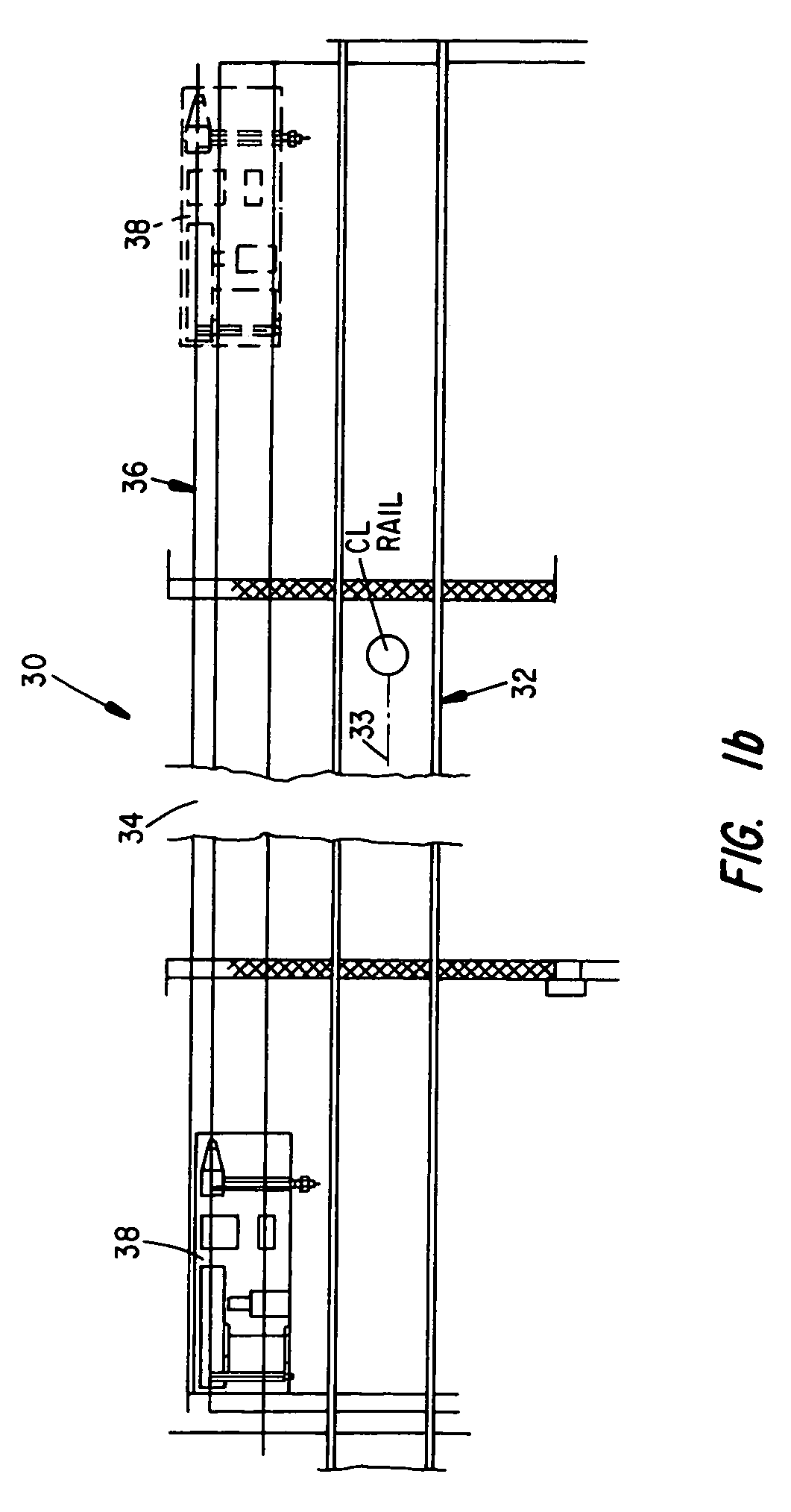

A single-carriage reversing train positioning system which includes an extending spike-type car engaging member for engaging and moving one or more railcars. An extending chuck assembly may be provided with the ability to operate gates in bottom-discharging railcars. The system uses a single self-propelled carriage with an on-board carriage drive system that includes a drive motor which operates the car along a fixed chain situated along a guideway. A generally horizontally disposed, laterally extendable pin car-engaging assembly is mounted on the car-moving carriage for aligning with and engaging a hook loop on a railcar for moving the car. A gate-operating assembly which includes a laterally extendable chuck system which aligns with, engages and rotates gate-operating capstans on bottom discharging railcars may also be provided.

Owner:CALBRANDT

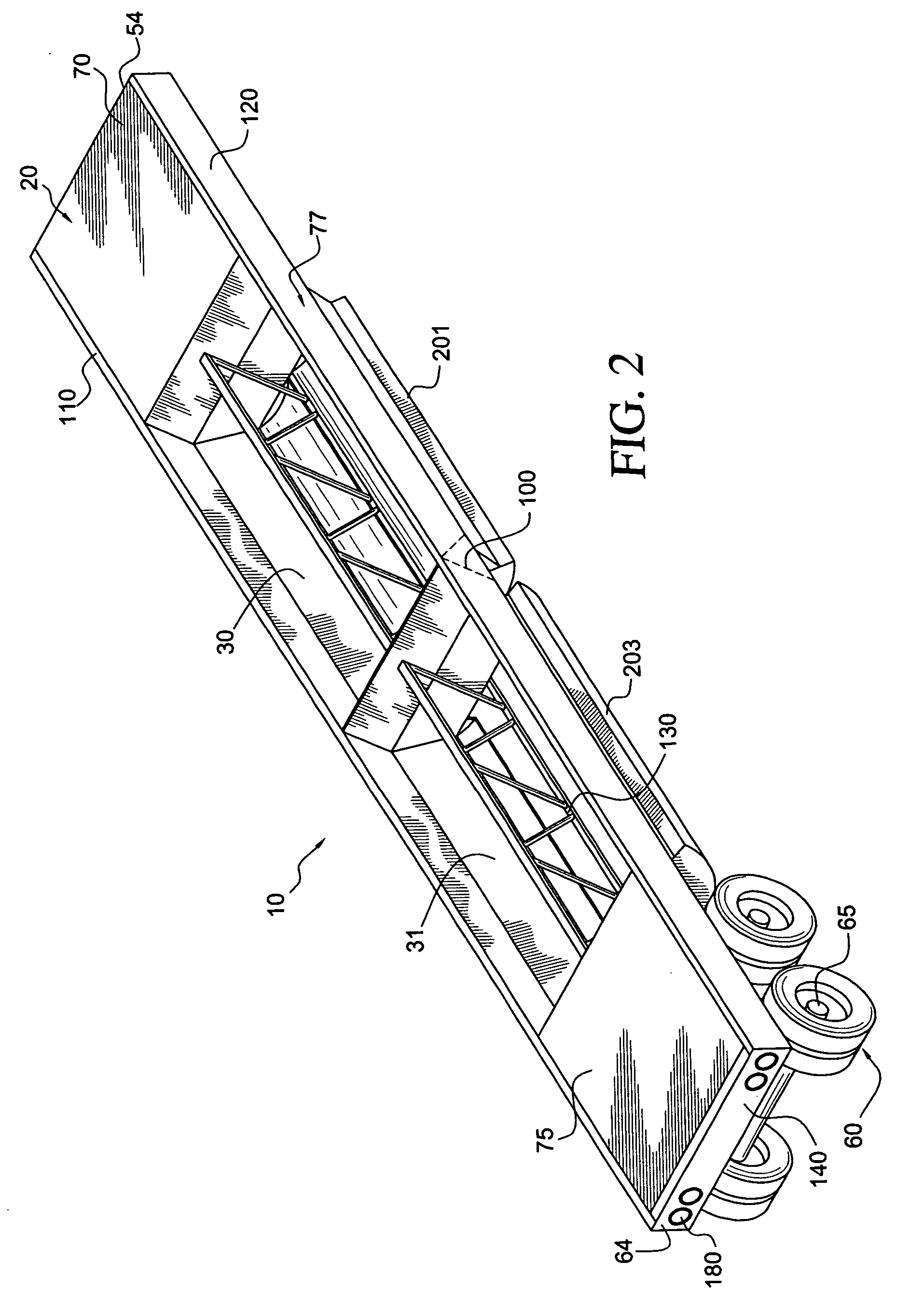

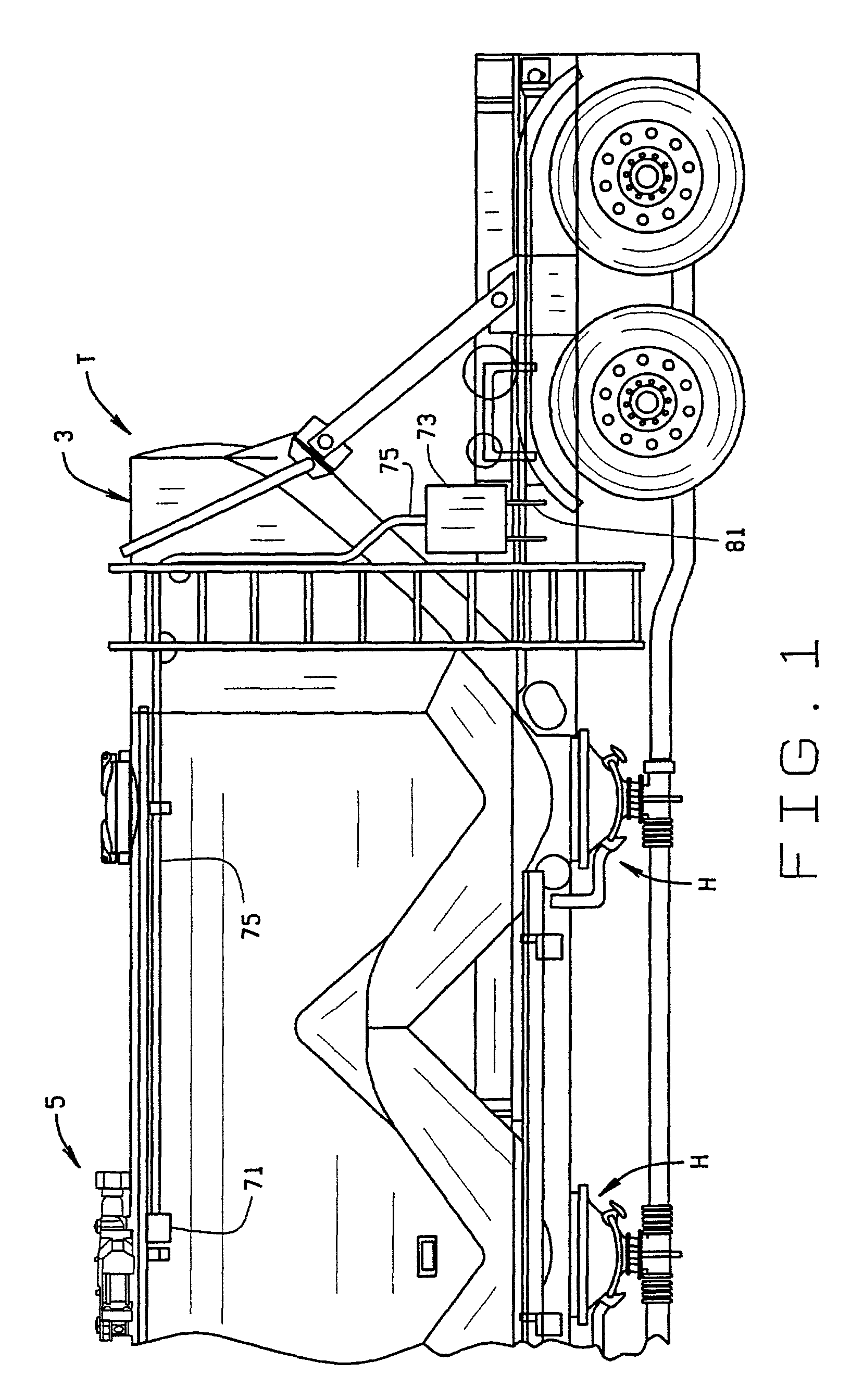

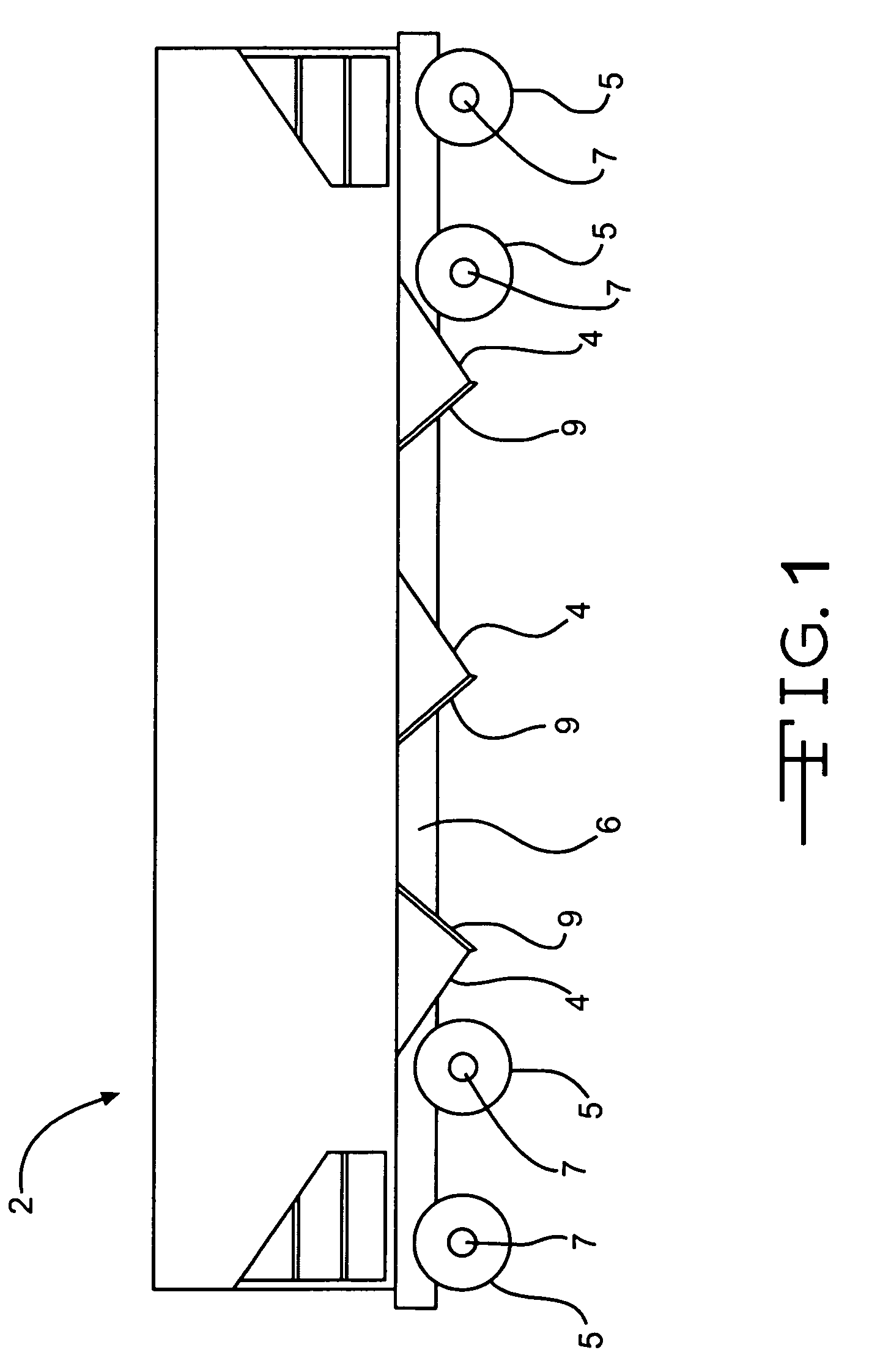

Monolithic dual-purpose trailer

ActiveUS20070096537A1Readily apparentHopper carsVehicle with tipping movementVehicle frameDual purpose

A monolithic dual-purpose trailer for transporting cargo includes a frame including two longitudinally extending side rails and a central reinforcing member in the form of an engineered truss is located between the two side rails. Wheels are mounted to the frame. A deck including a load bearing surface with a grate is formed on the frame. Hoppers are positioned below the grate. The frame is formed as one solid welded unit. The deck has a portion formed of flat aluminum. A perimeter frame rail is located around the deck. The trailer can transport multiple types of loads and does not have to be converted from one mode to another and additionally has reduced longitudinal flexing.

Owner:HICKS RANDALL

Rail car door opener

A servo that is attachabley secured to the rail car frame at each door lock that is connected to the latch via a draw bar with sufficient modulus to withstand the repeated force required to move the latch thus opening the door. The servo provides a pulling action with the motive force being pneumatic pressure but not limited to pneumatic whereas hydraulic or electric energy can be supplied to the servo providing the motive force to pull the draw bar attached to the latch, that when said servo provides a pulling force sufficient to over come the friction ot the latch to the striker plate the latch moves in a upward direction thus releasing the door to open. A second element of the servo is to provide a pushing action via the draw bar to the door latch to drive it all the way into the closed position.

Owner:MARCHIORI DAVID +1

Identity preserved container

An identity preserved container for storage, transportation, and segregation of a flowable cargo is provided. The container comprises a frame supporting an enclosure with a top, bottom, side walls, front wall, and a back wall. A liner is provided and secured to an interior of the enclosure, comprising side panels and funnels panels forming a bin terminating in a centrally located opening in said bottom of the enclosure. The container also includes a belly door located in the opening in the bottom of the enclosure wherein the belly door moves between a closed and an open position.

Owner:MORTON WILLIAM R +1

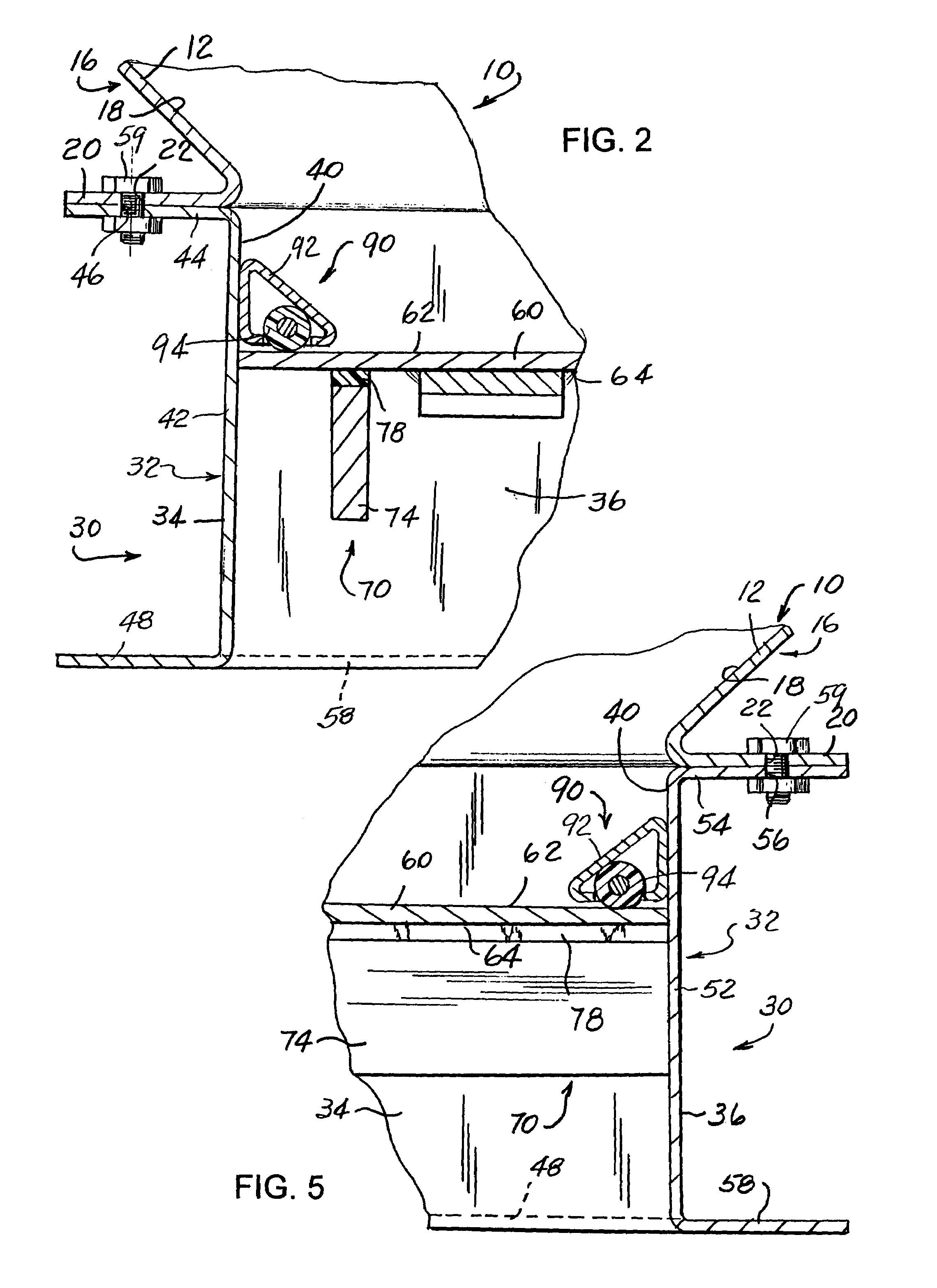

Railroad hopper car transverse door actuating mechanism

An actuating system for operating transverse doors of a railroad hopper car. The mechanism includes an operating member which is coupled to a door or doors of the car by a shaft and a linkage which couples a power source to the operating member, where the operating member rotates to move the door away from the hopper. The mechanism can operate doors which open in opposed direction with a single power source. The mechanism can be used in new car construction, and can be retrofitted onto existing hopper cars.

Owner:VERTEX RAILCAR CORP

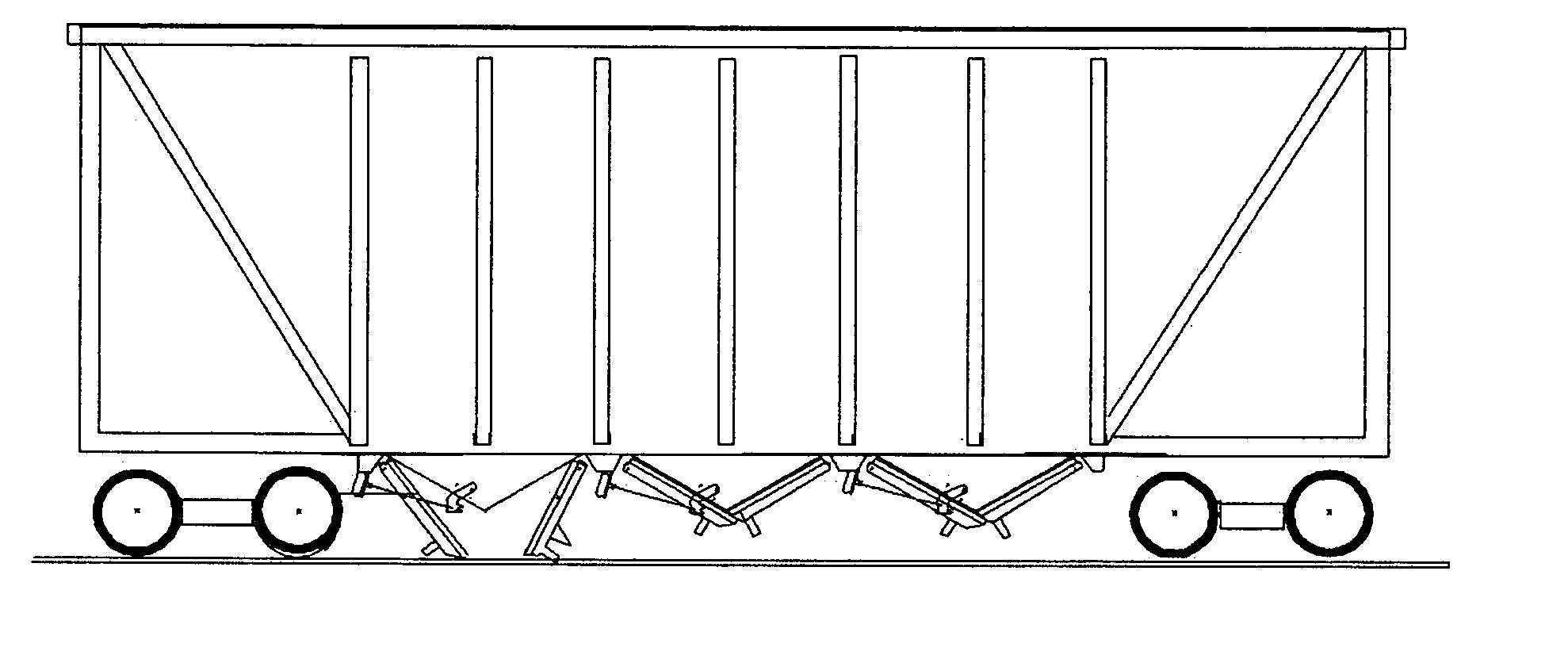

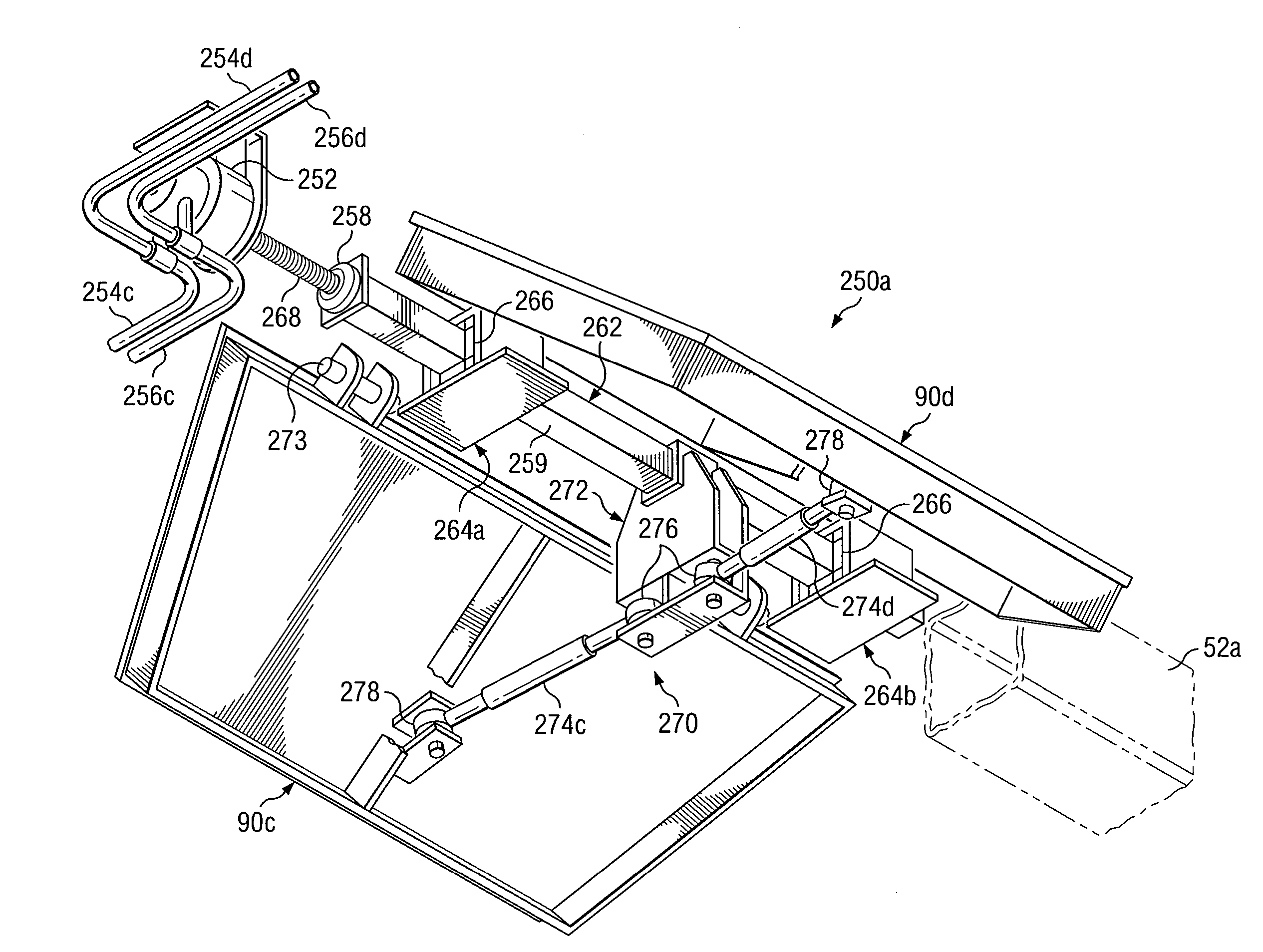

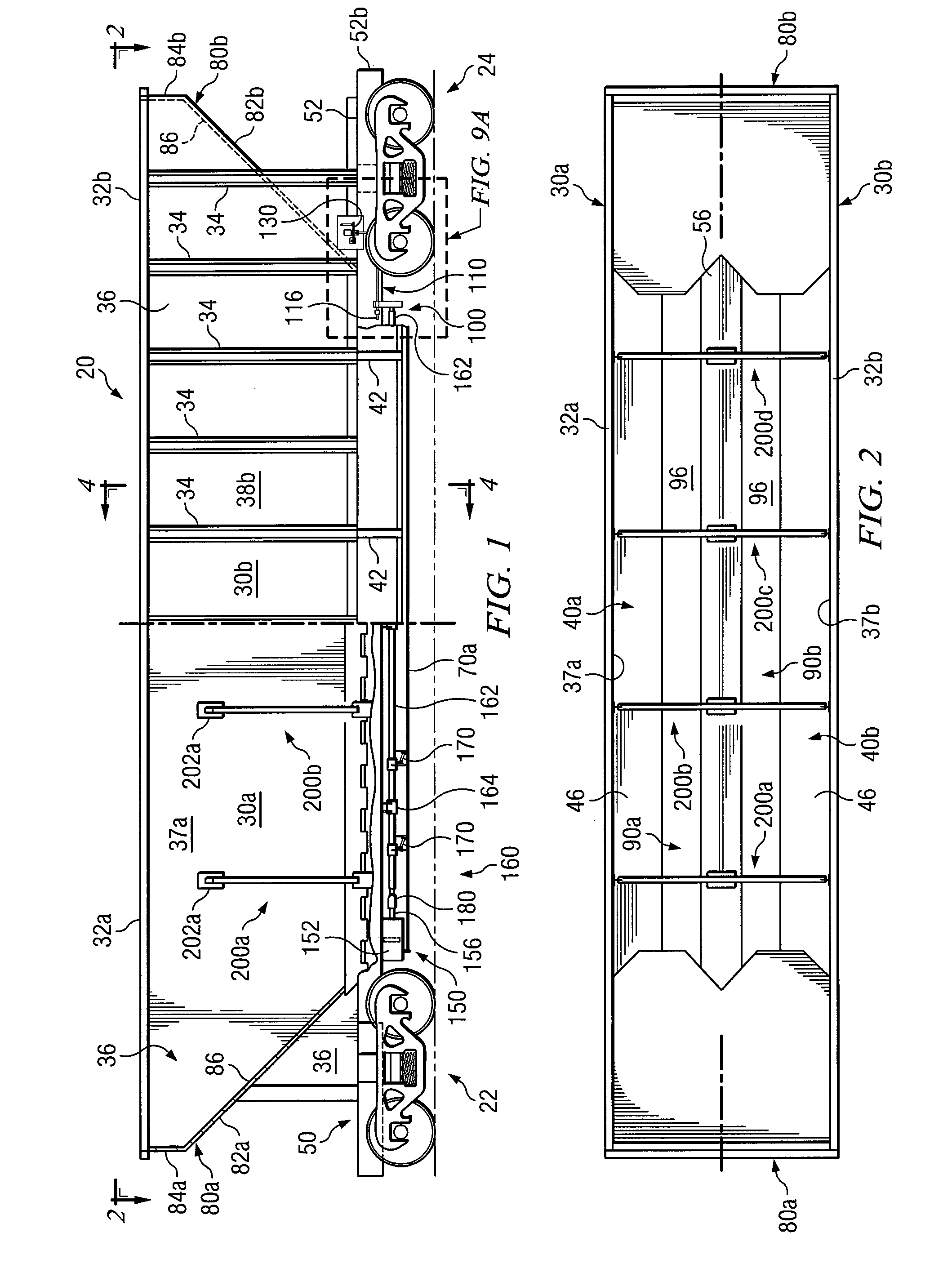

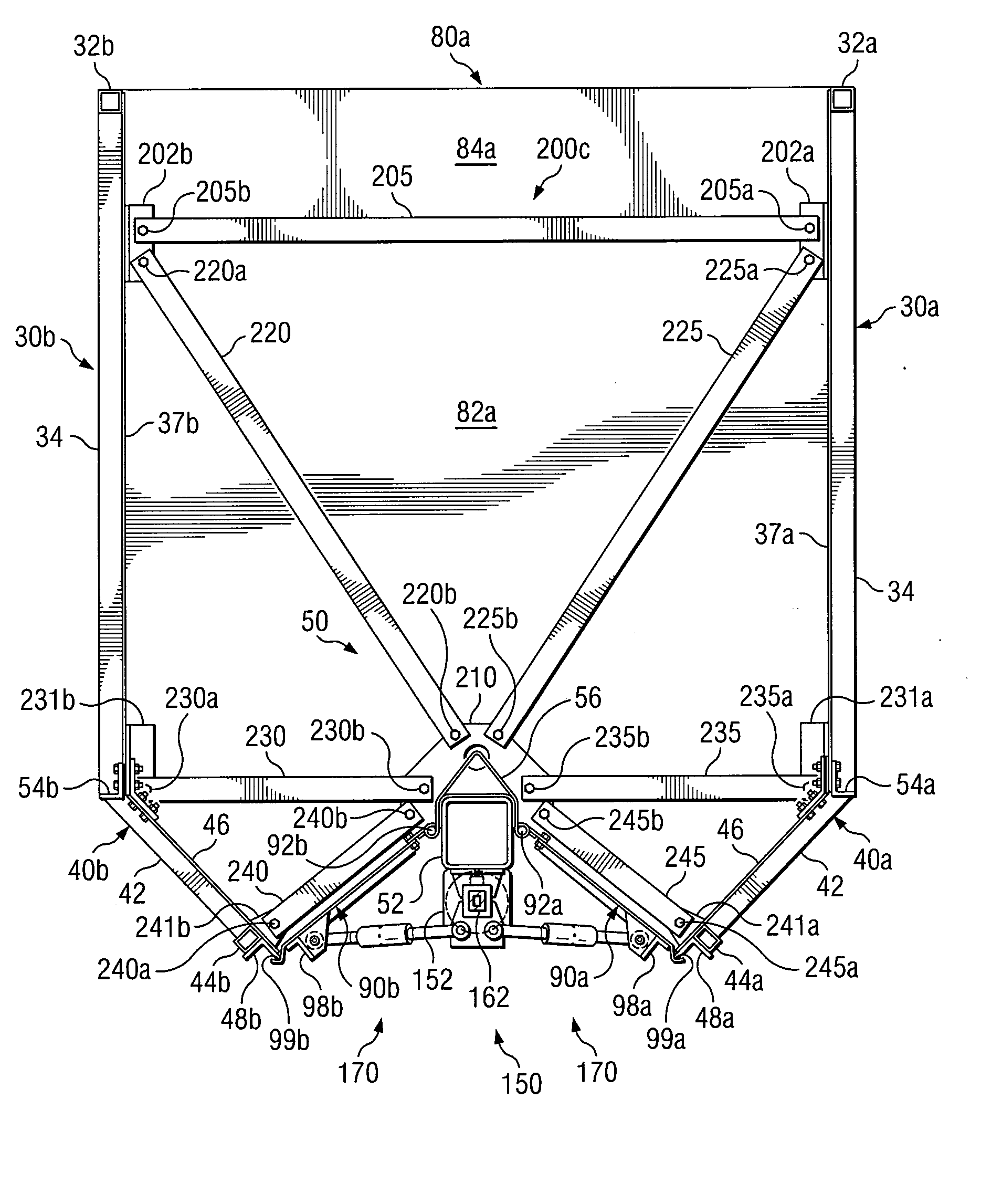

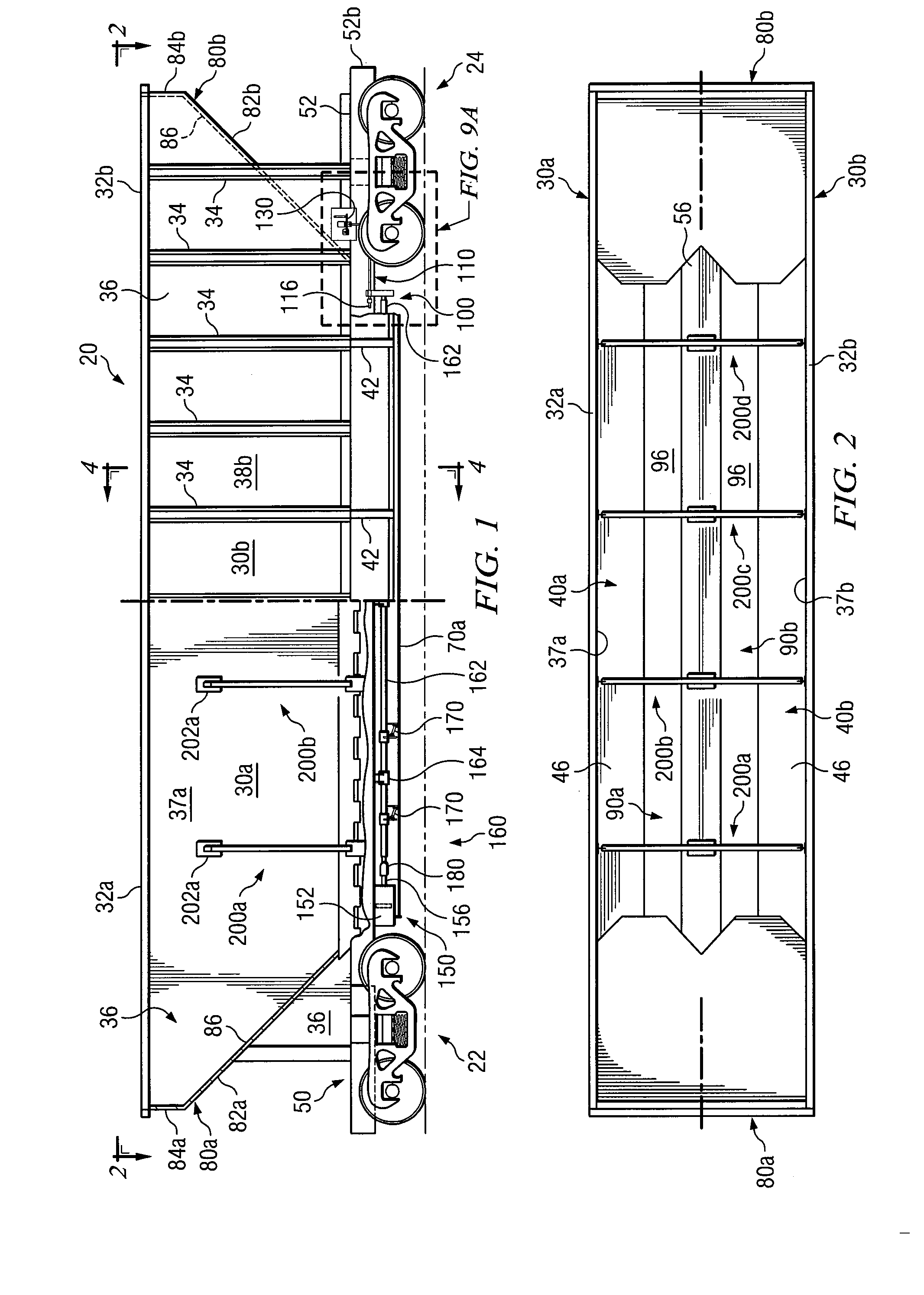

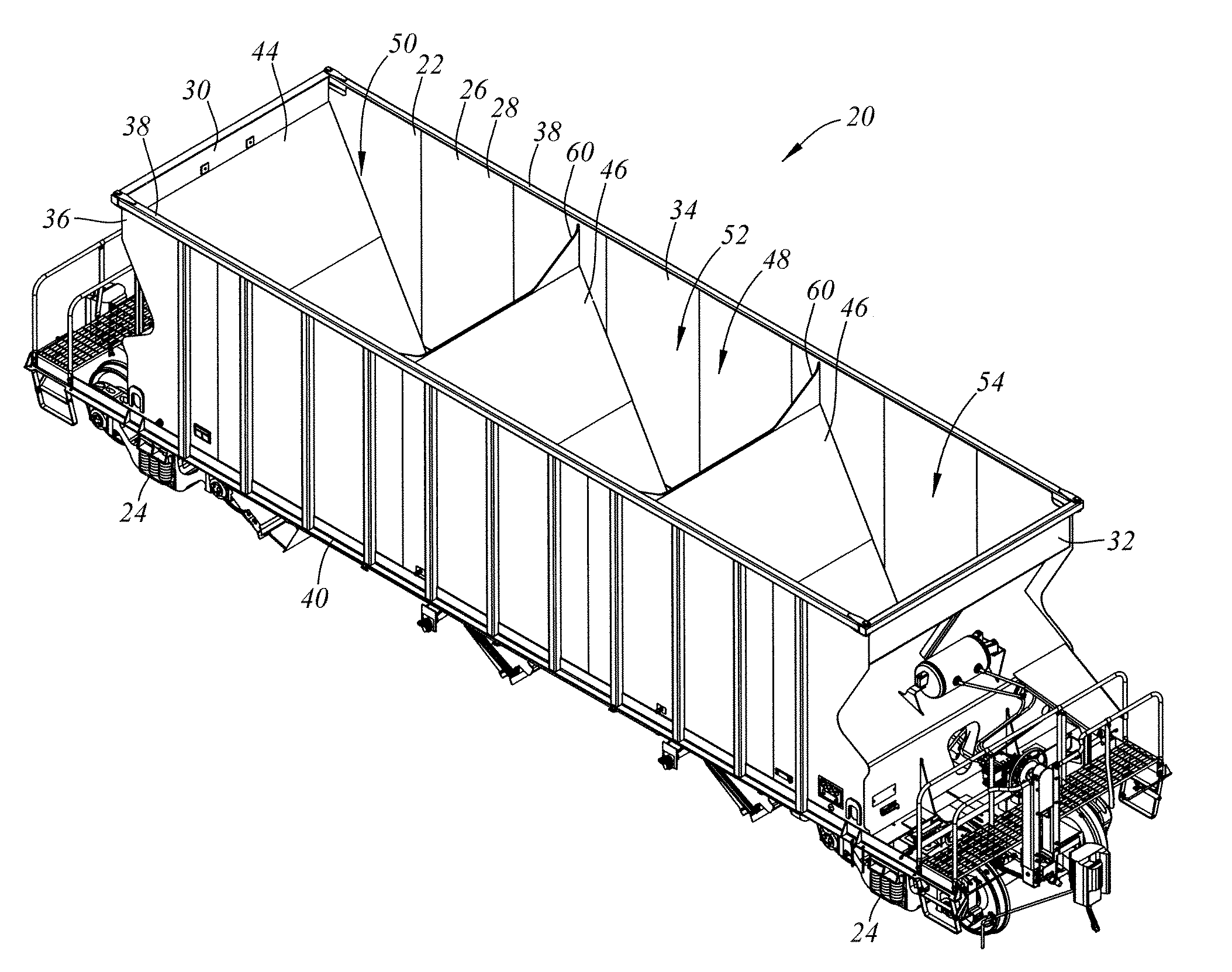

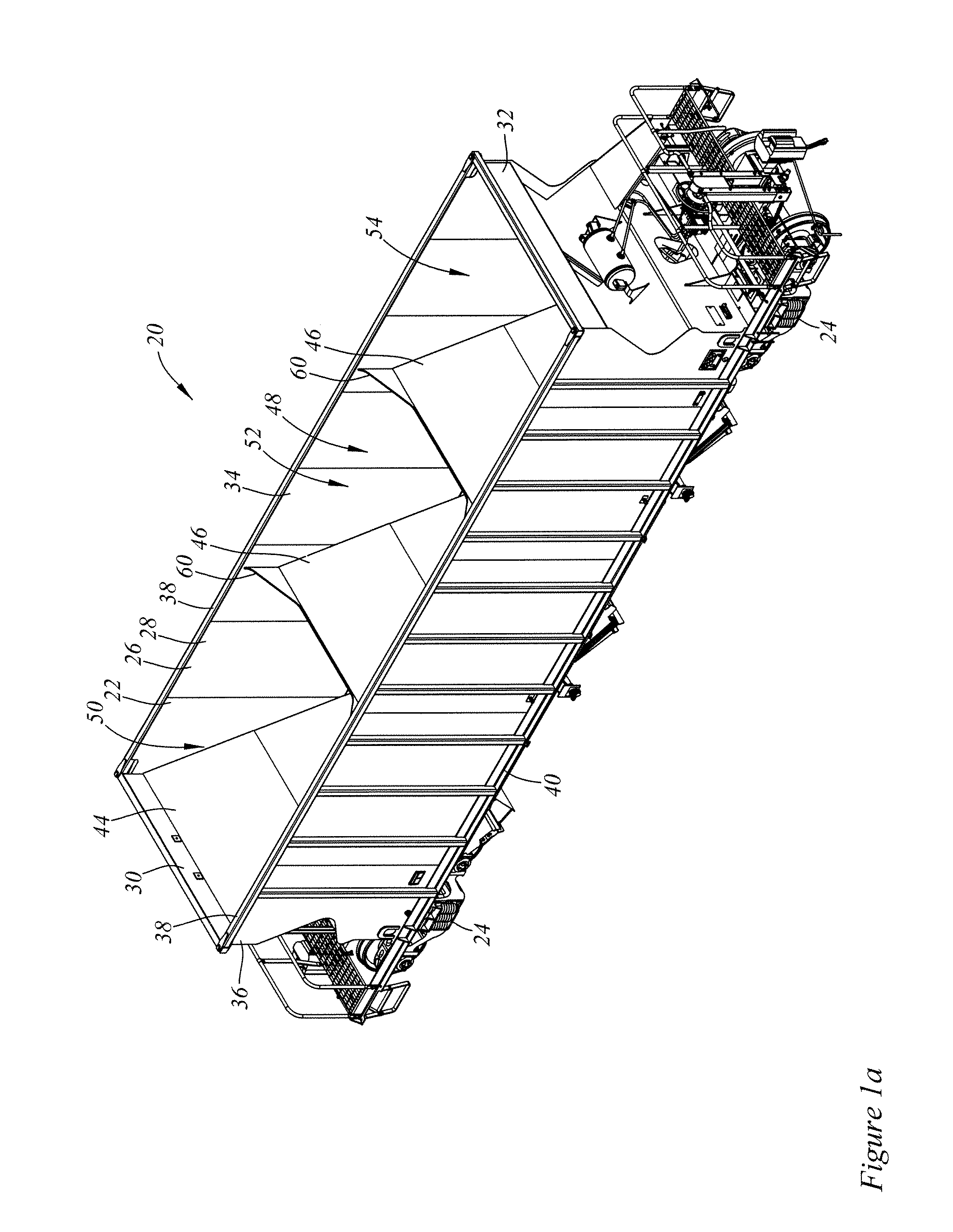

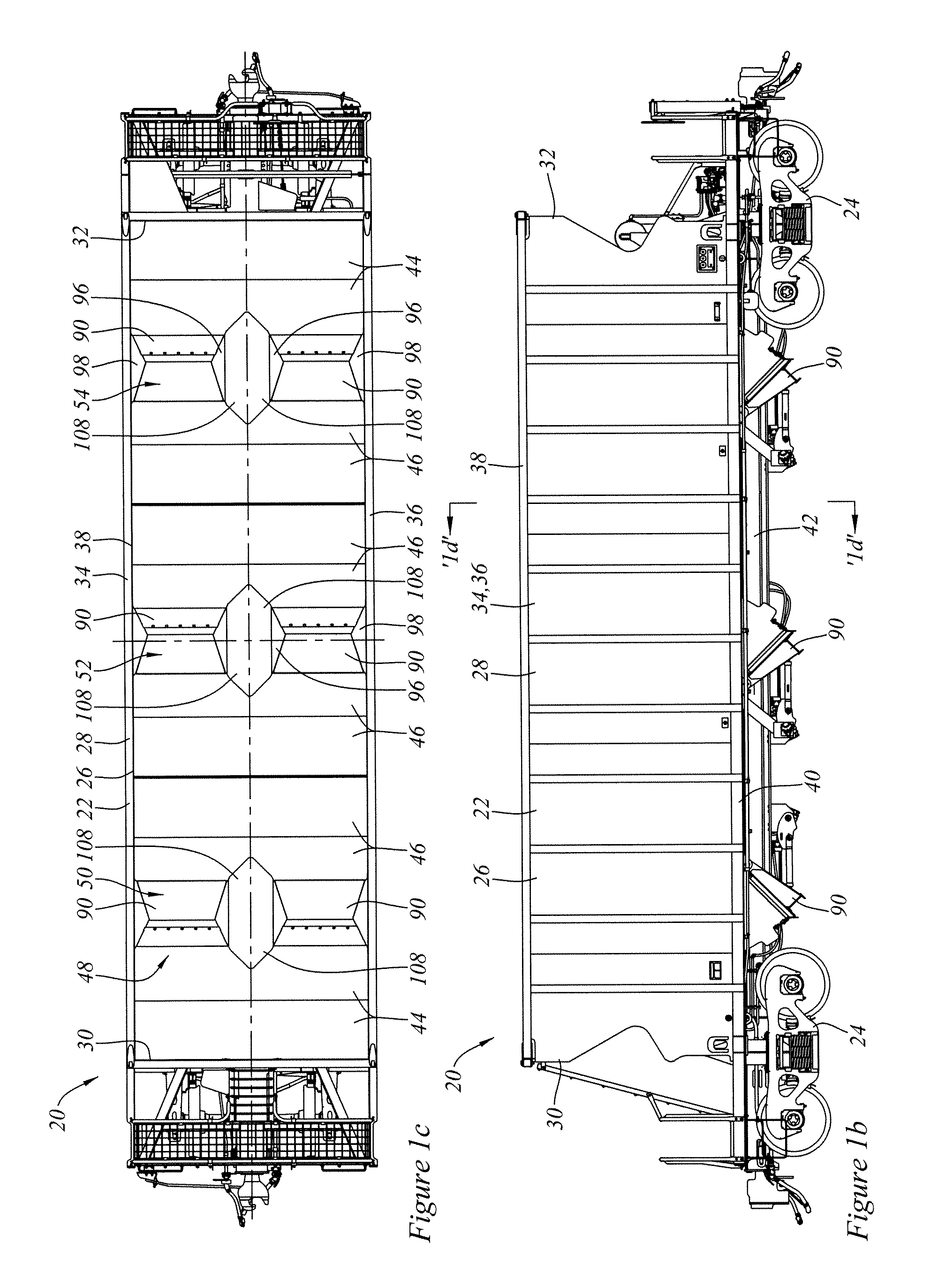

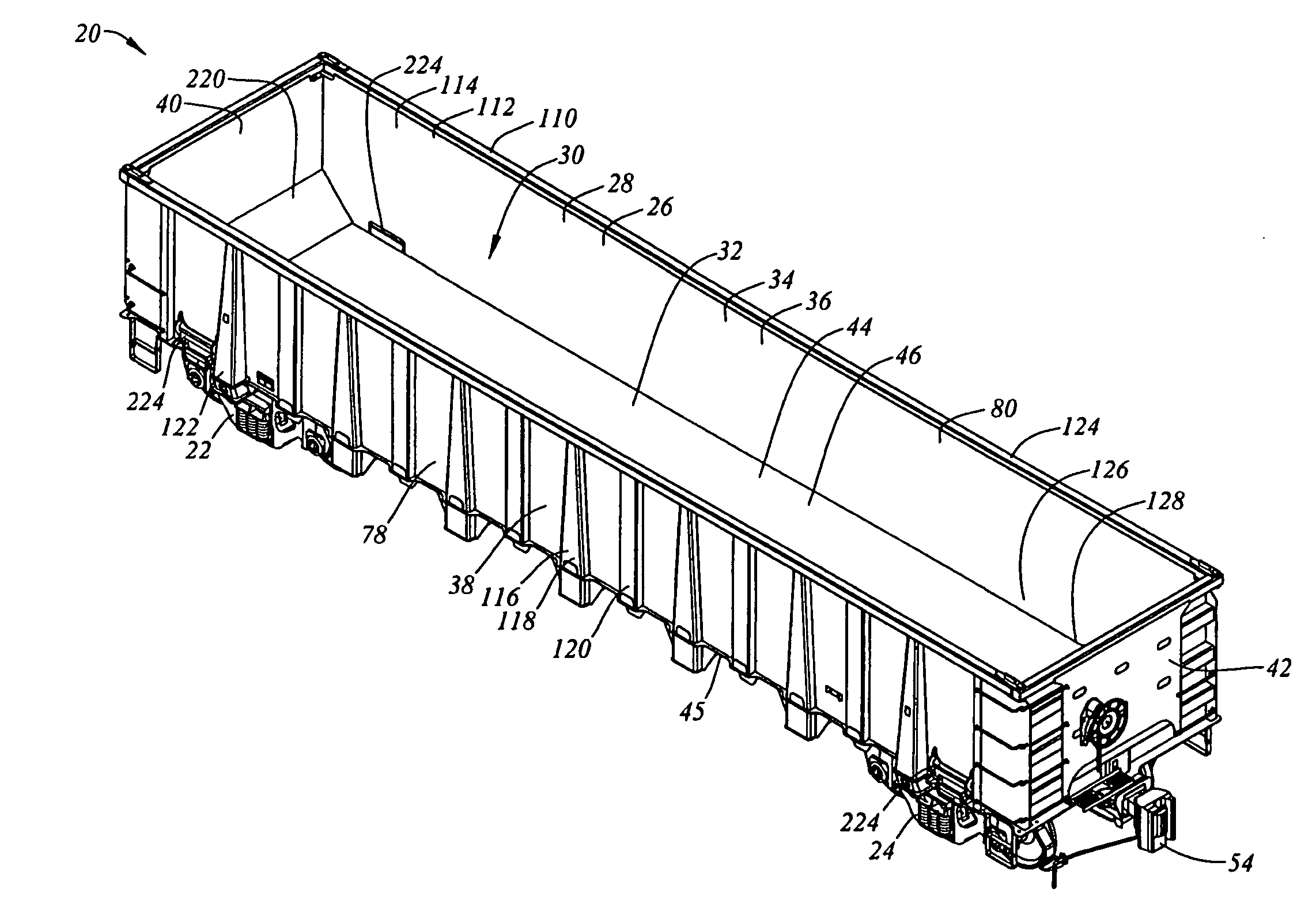

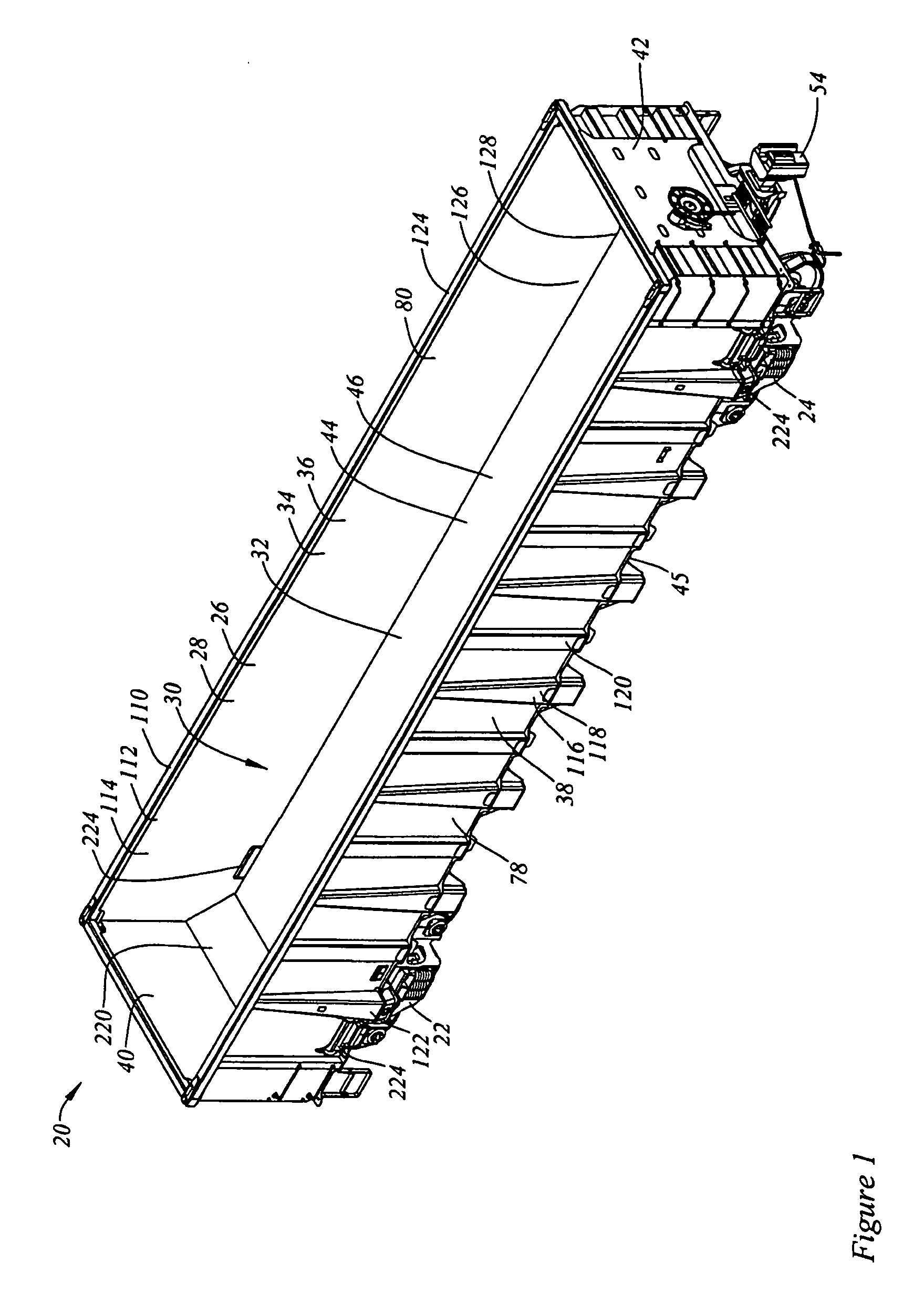

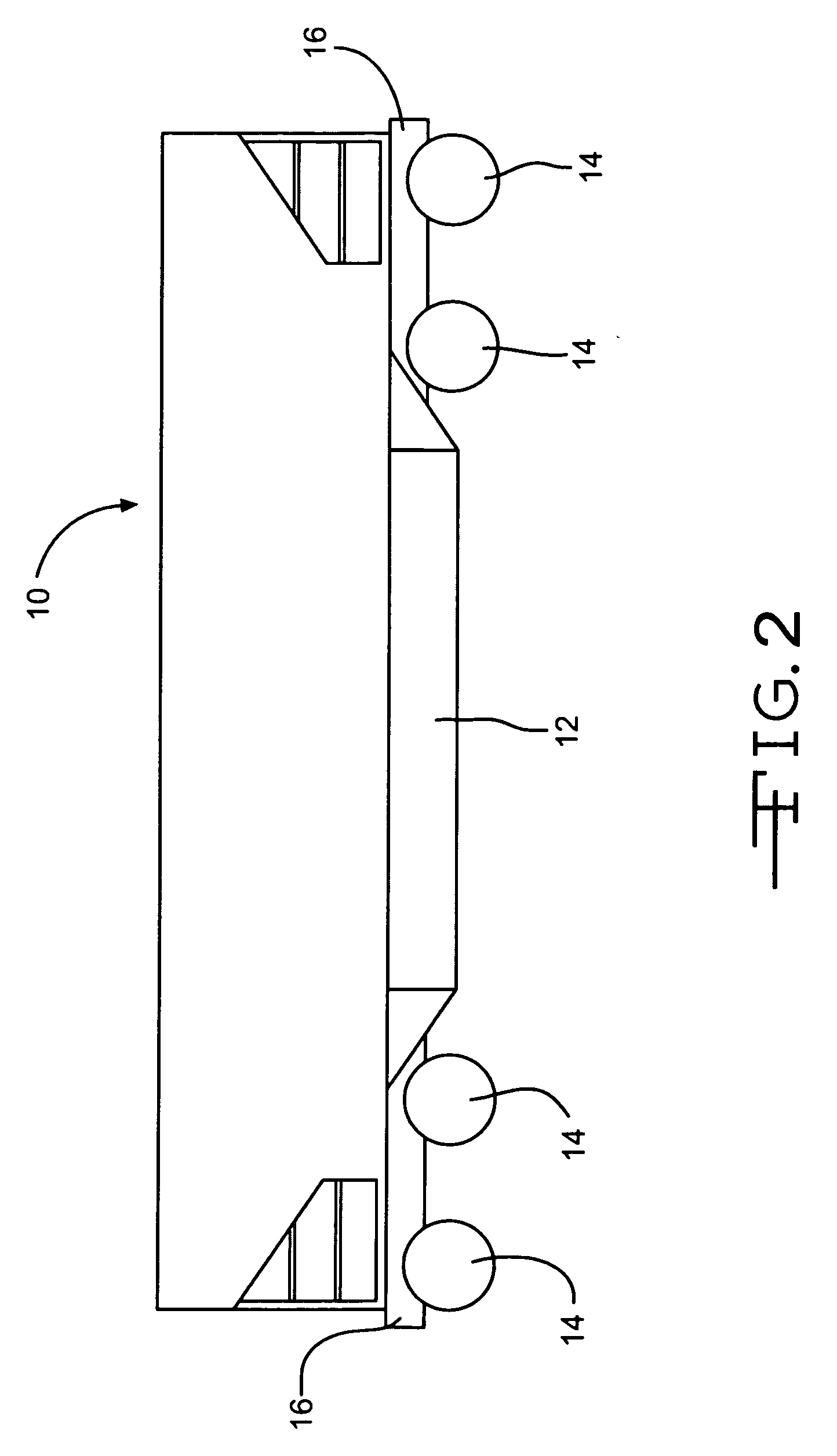

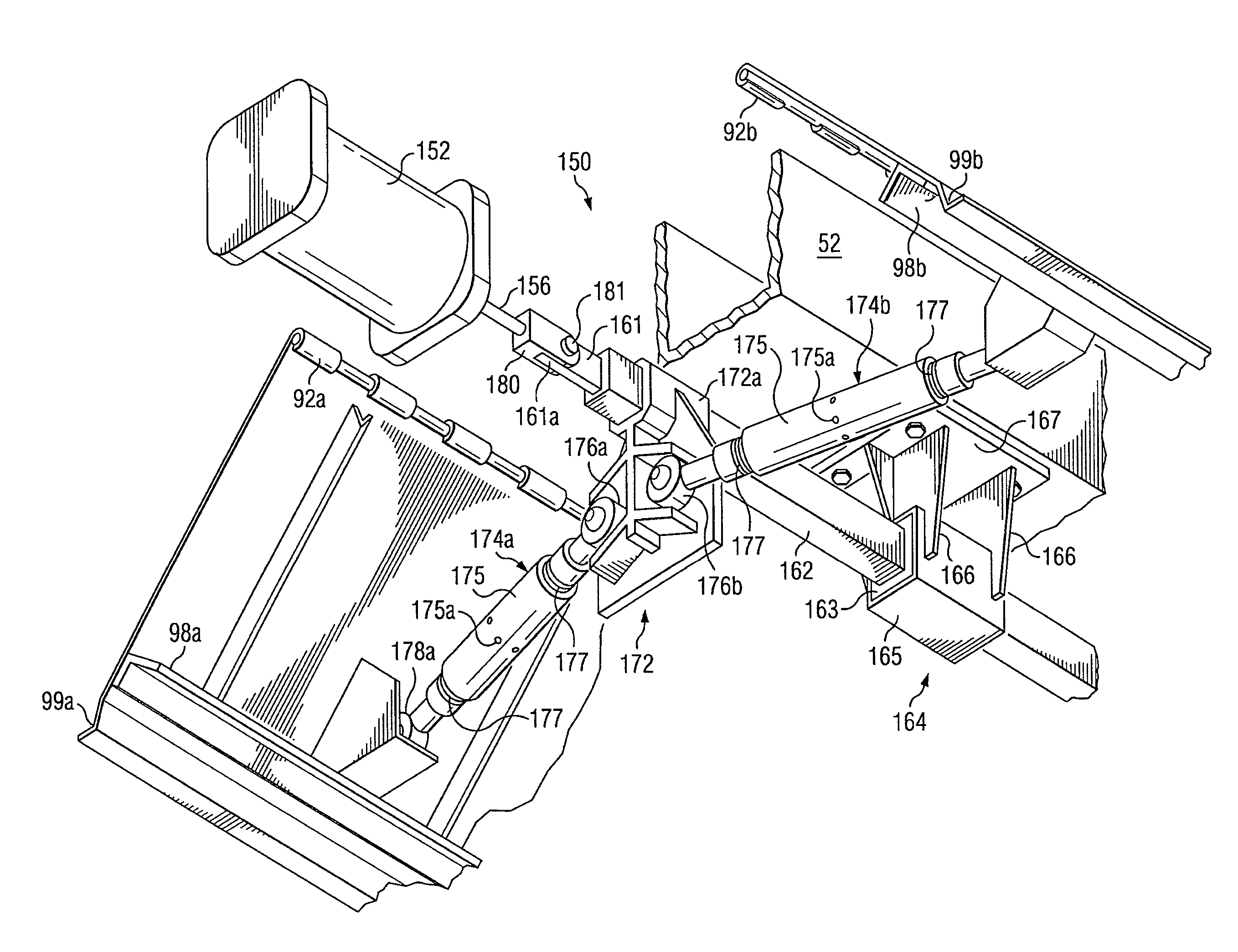

Hopper cars with one or more discharge control systems

ActiveUS7735426B2Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

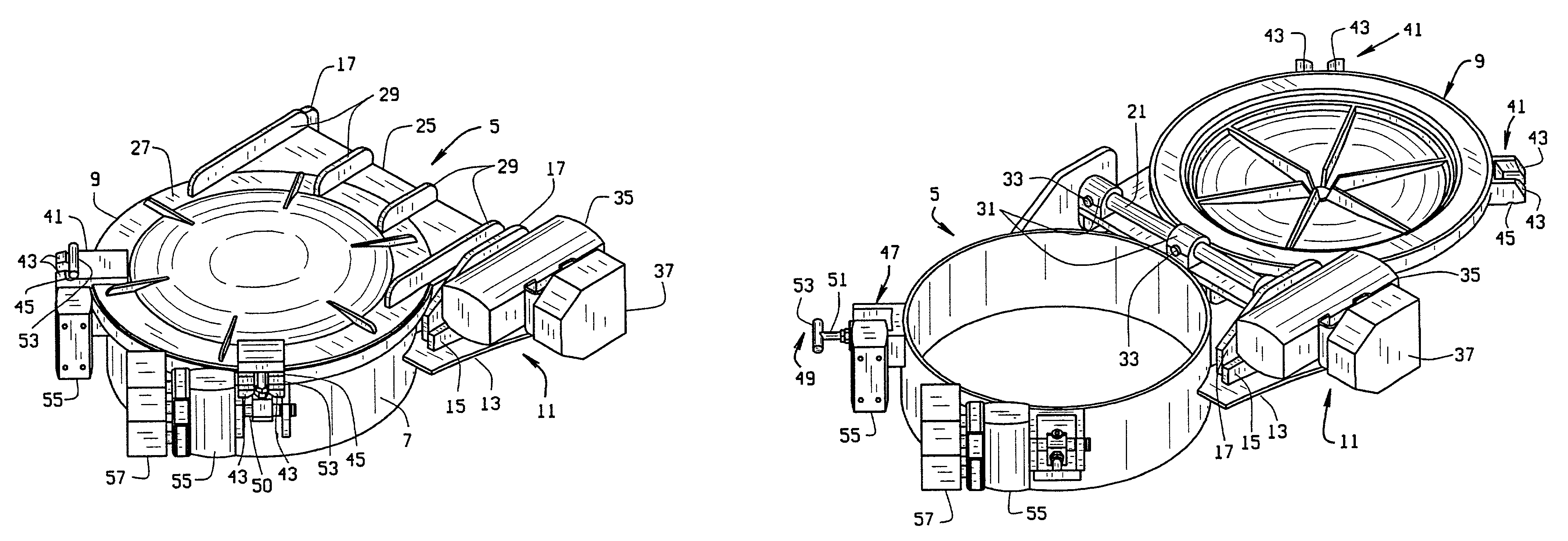

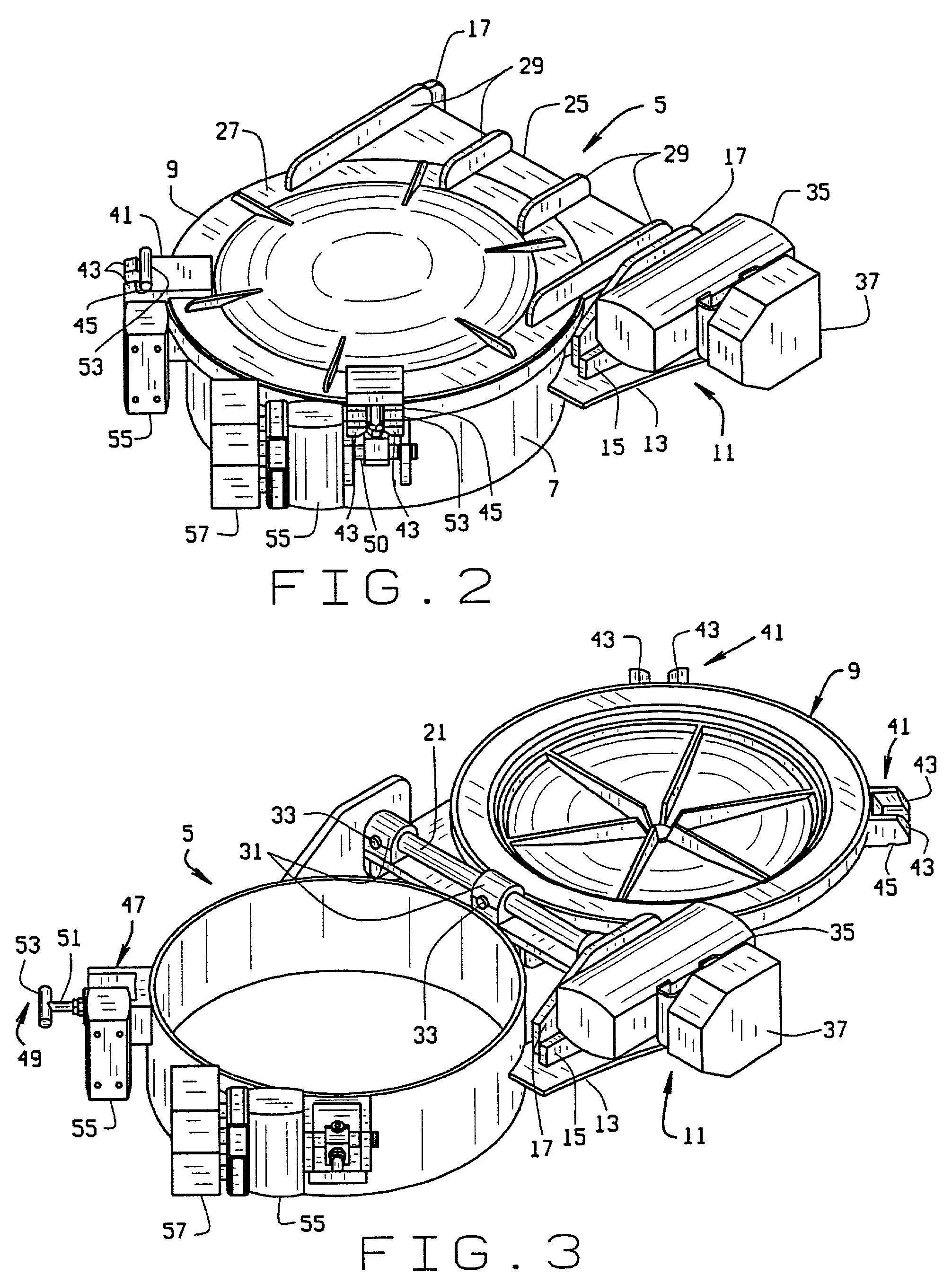

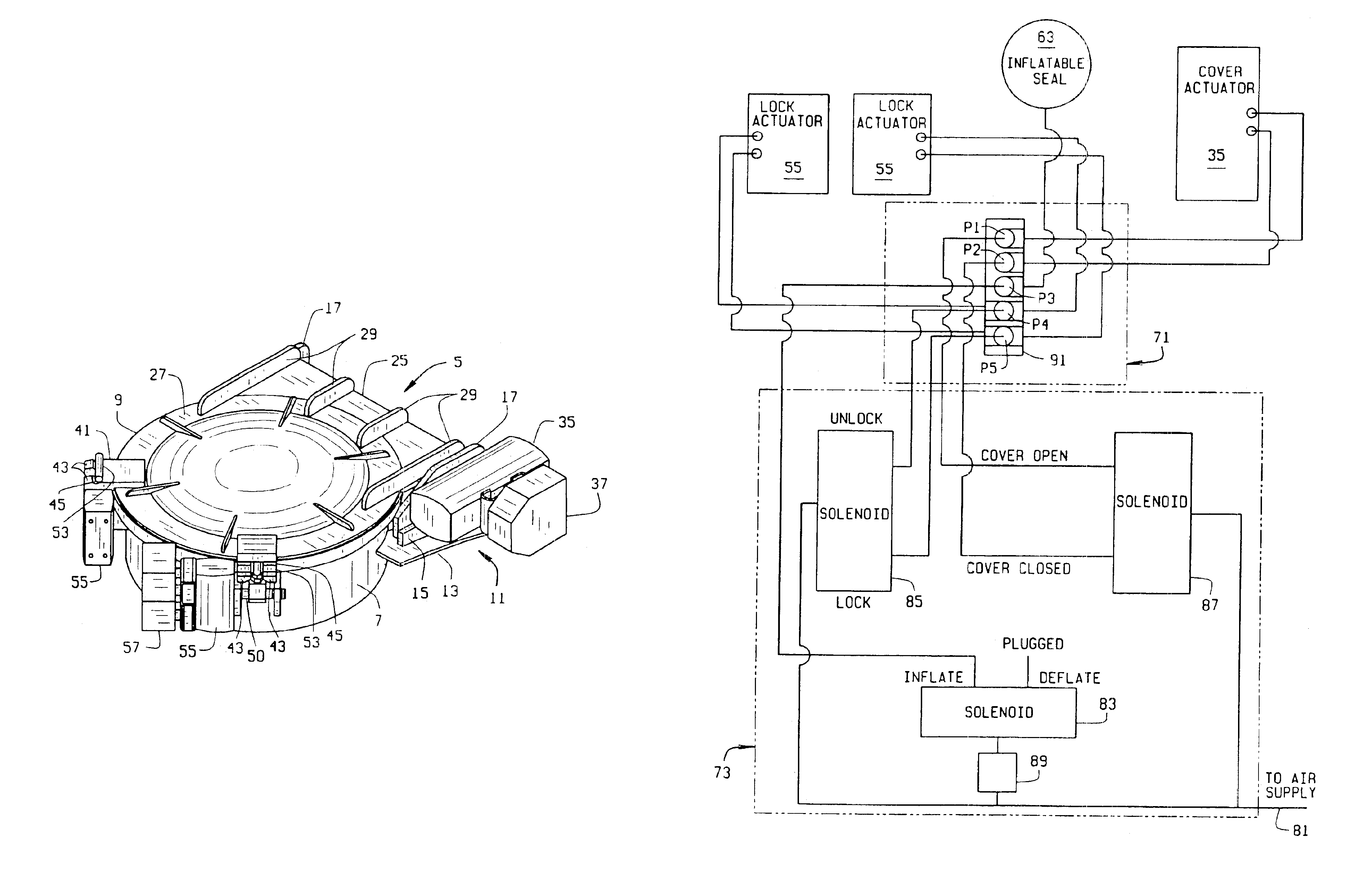

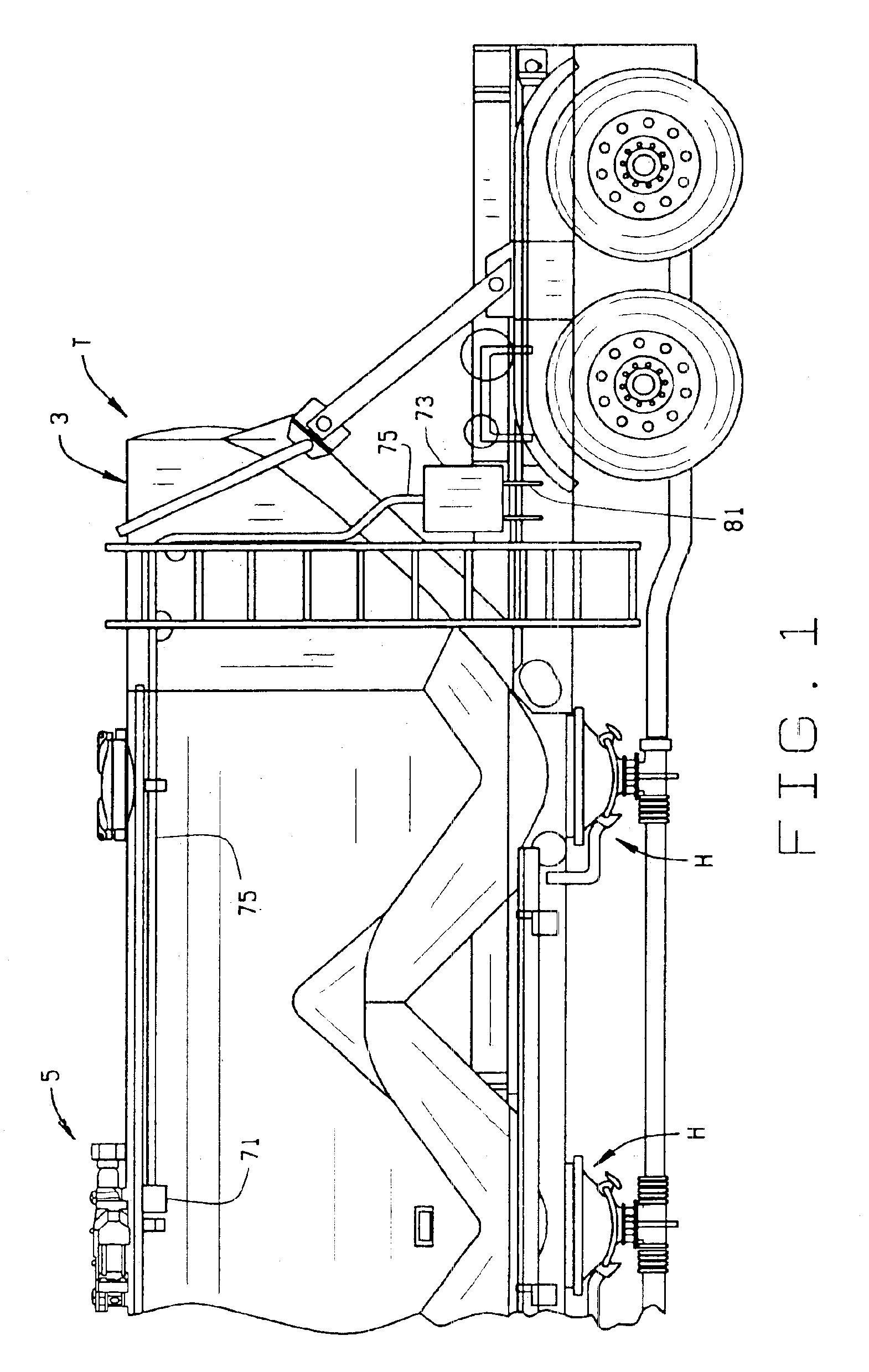

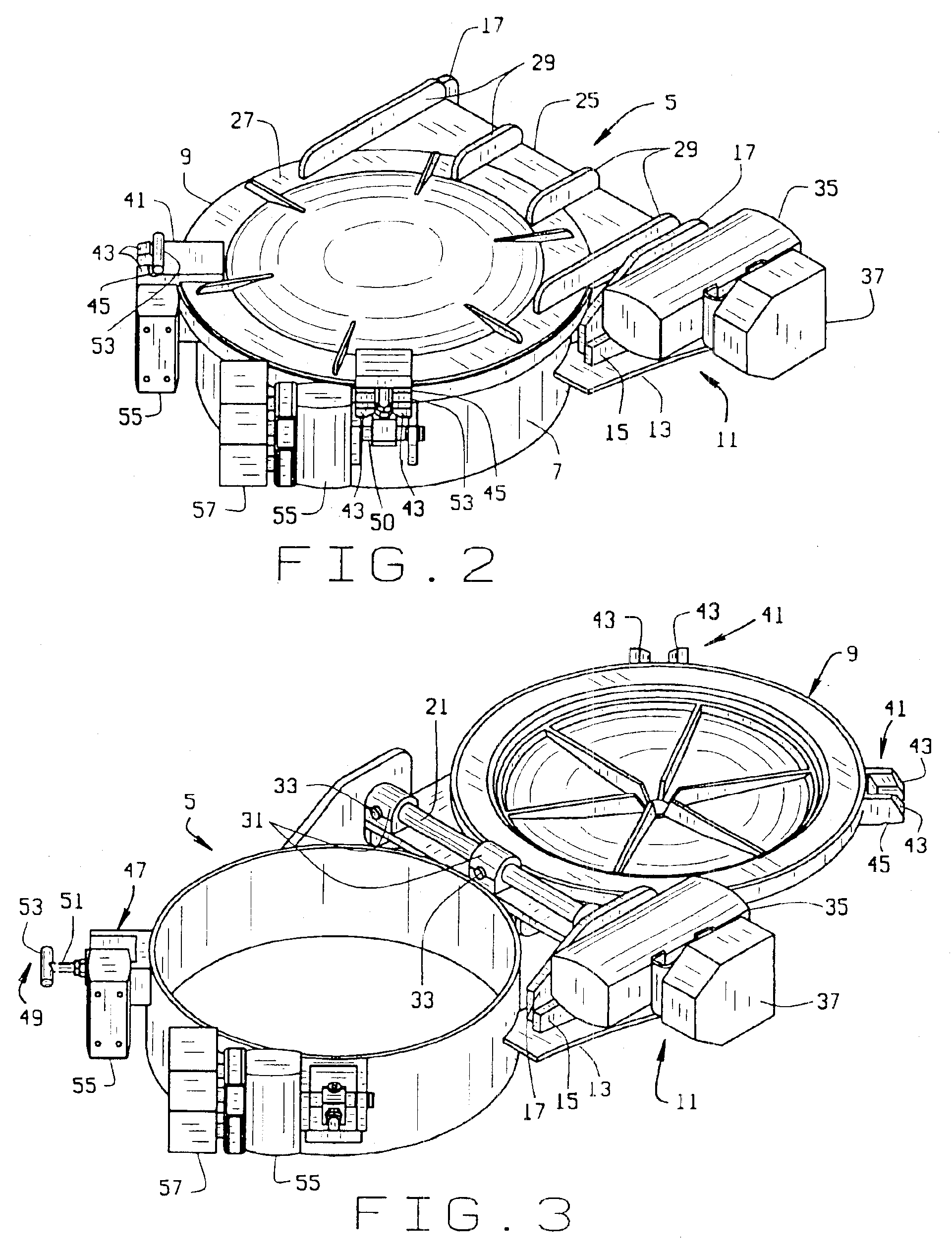

Remotely operated manhole cover for a tanker

A remotely operated manhole cover for a tanker or trailer is provided. The manhole cover includes a hollow neck which is welded in place in the shell of the tanker or trailer. The neck defines an opening which allows access to the interior of the tanker or trailer for filling or cleaning of the tanker. A lid is pivotable about an axis between a closed position in which the manhole cover is closed, and an open position in which the lid is clear of the neck opening to allow access to the interior of the tanker. The lid is provided with an inflatable seal and locking flanges which extend from a rim of the lid. Pivotal locking members are provided on the neck and are movable between a locked position in which locking member engages the lid locking flange and an unlocked position in which the locking members are disengaged from the lid locking flange. Separate actuators are provide for the cover and the locking members. A controller is provided to energize the cover and locking member actuators and to inflate and deflate the seal. The controller activates the locking member and lid actuators and inflates or deflates the seal in sequence to unlock and open the lid or to close and lock the lid. The controller includes a manually operable switch assembly which activates the manhole cover to open and close the lid. The switch assembly is located remote from the manhole cover, and preferably near the bottom of the tanker.

Owner:KNAPPCO CORP

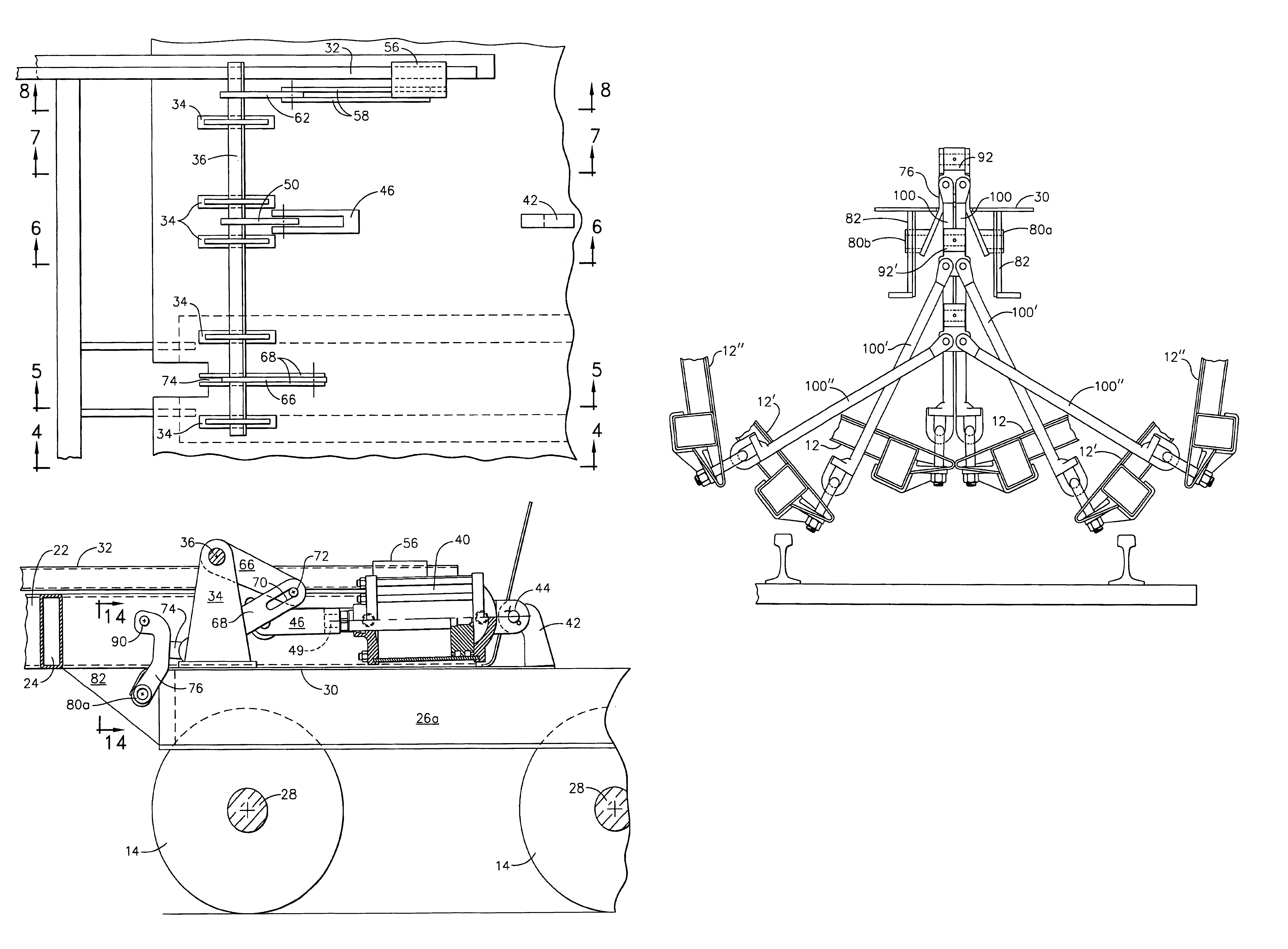

Railroad hopper car longitudinal door actuating mechanism

ActiveUS6955126B2Fast emptyingHopper carsWagons/vansElectrical and Electronics engineeringBuilding construction

An actuating system for operating longitudinal doors of a railroad hopper car. The mechanism includes an operating member which is coupled to each end of the door set of the car by a shaft and a linkage which couples a power source to the operating member, where the operating members rotate to move the doors away from the hopper. Reversing the rotation of the operating members closes the door set of the hopper. The mechanism can be used in new car construction, and can also be retrofitted onto existing hopper cars.

Owner:VERTEX RAILCAR CORP

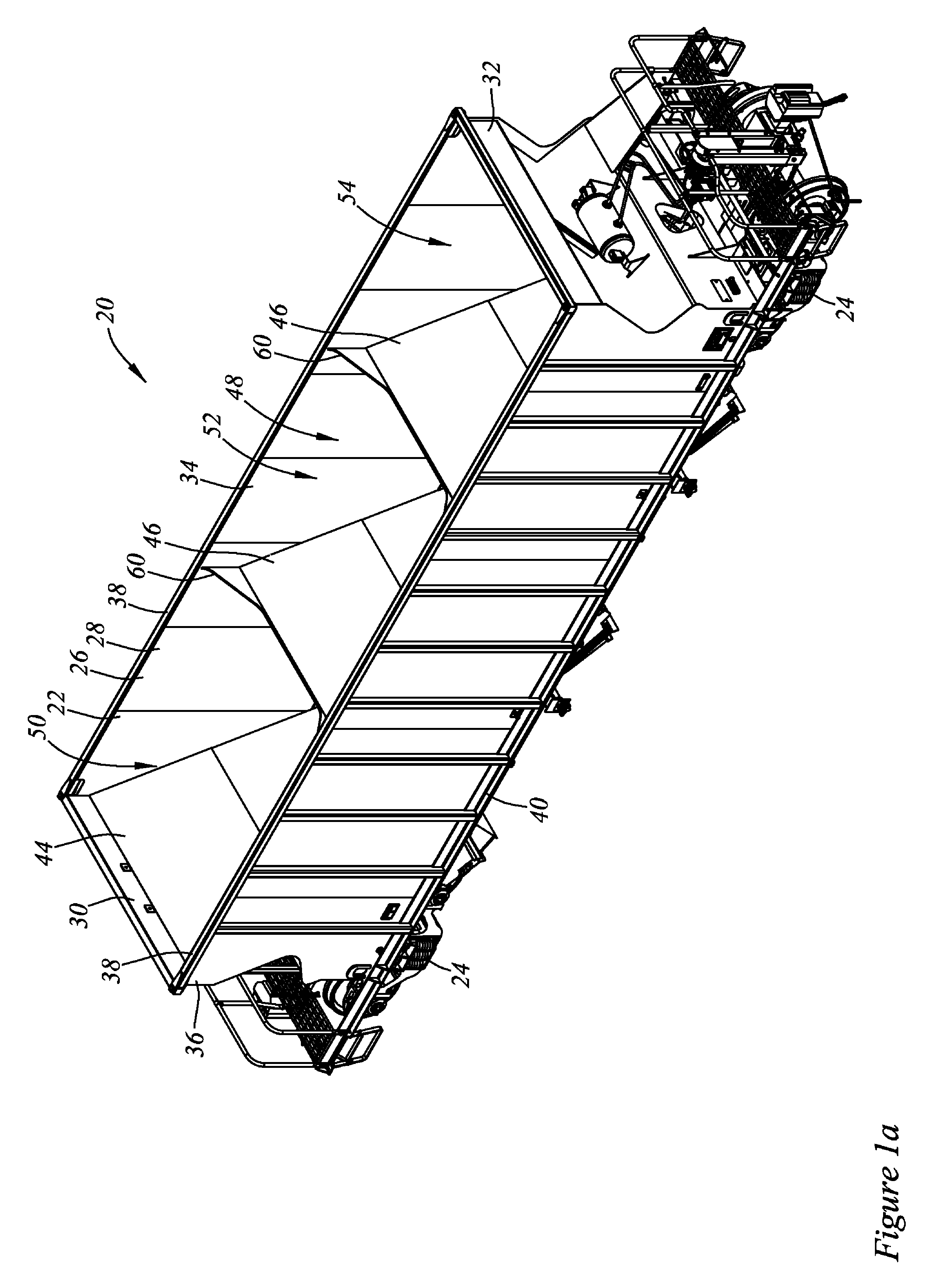

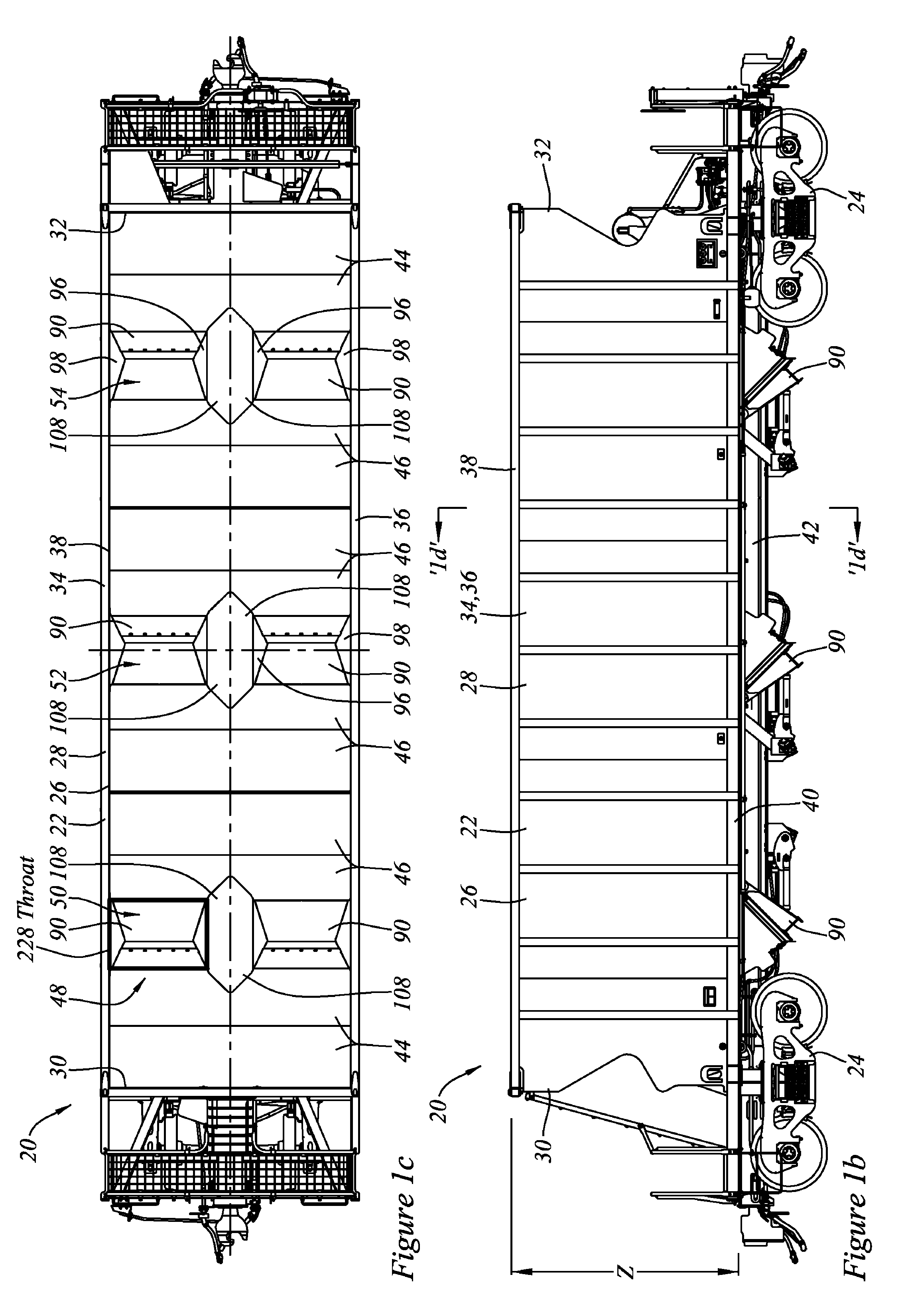

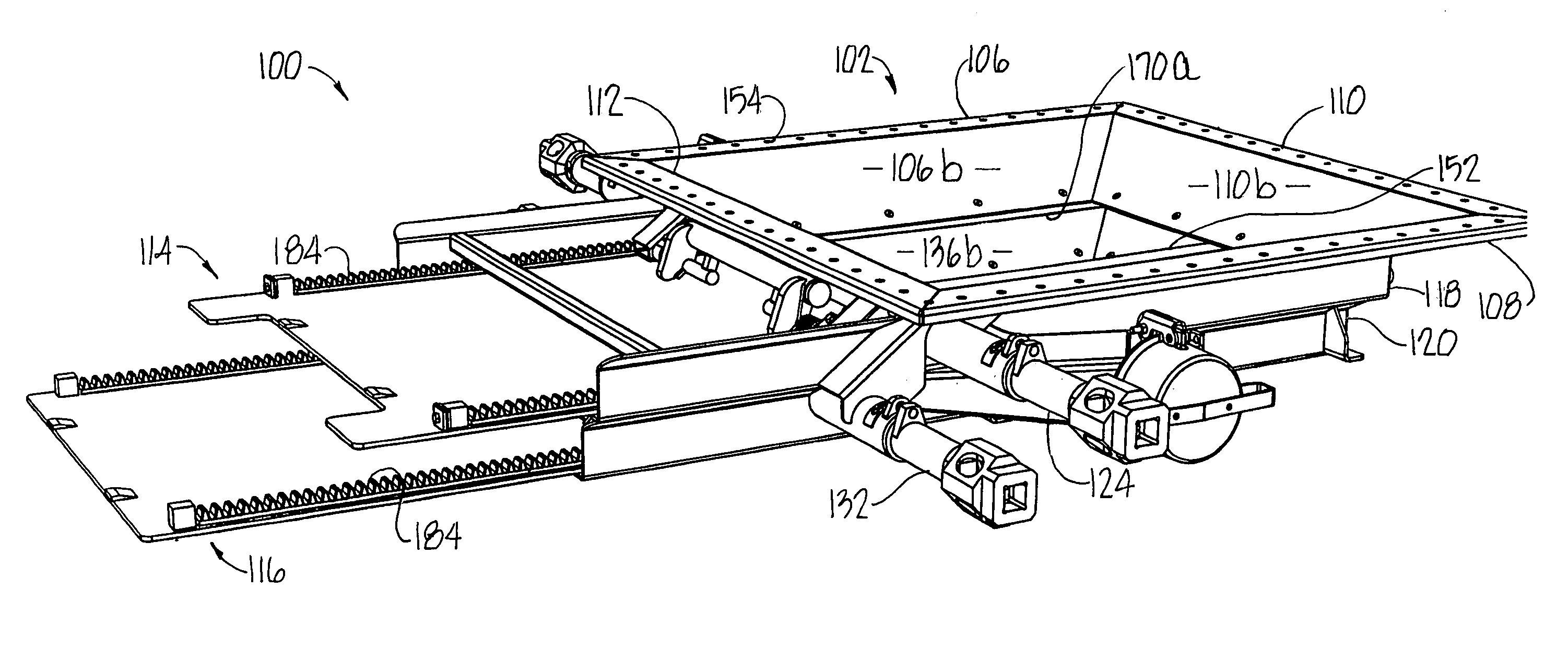

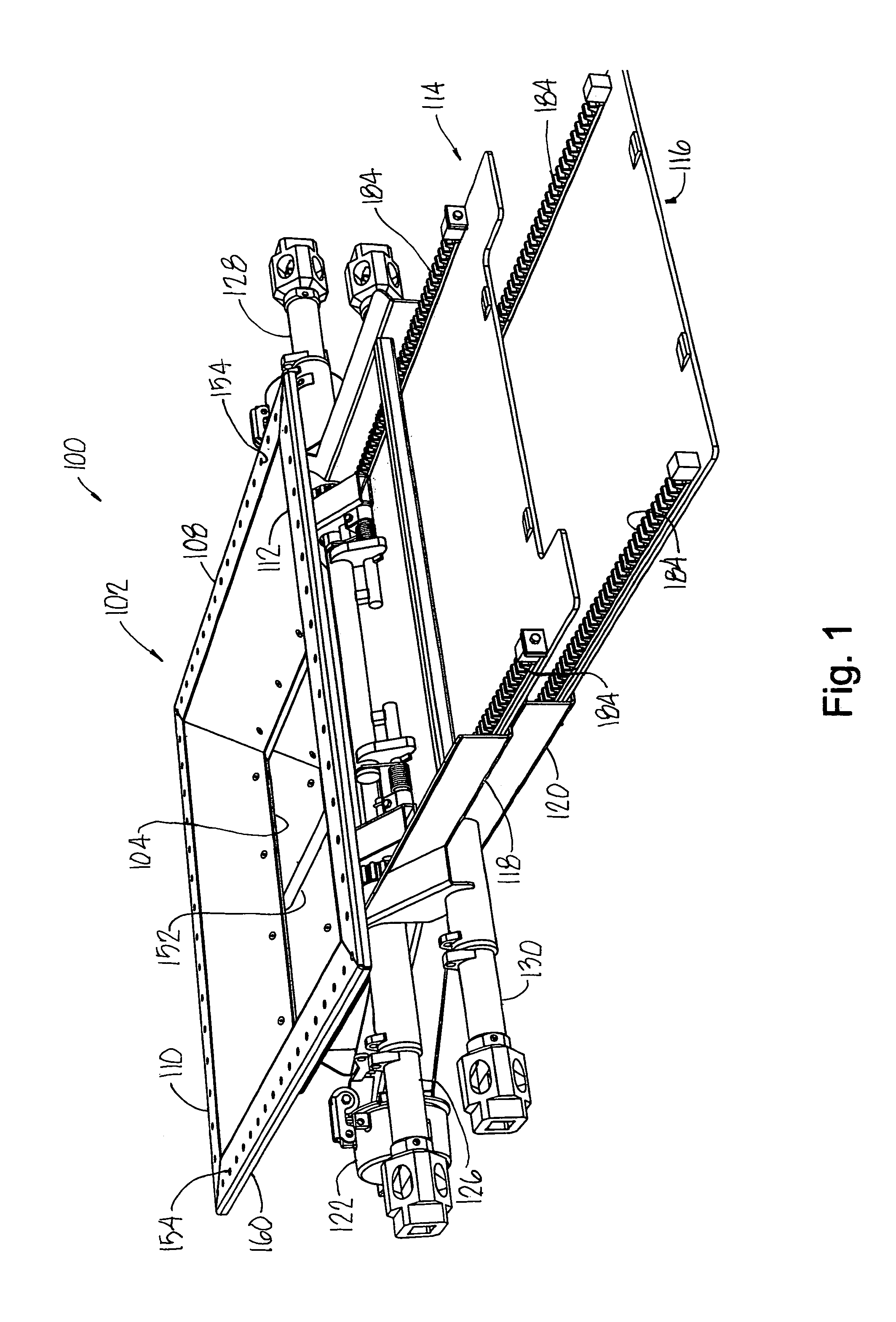

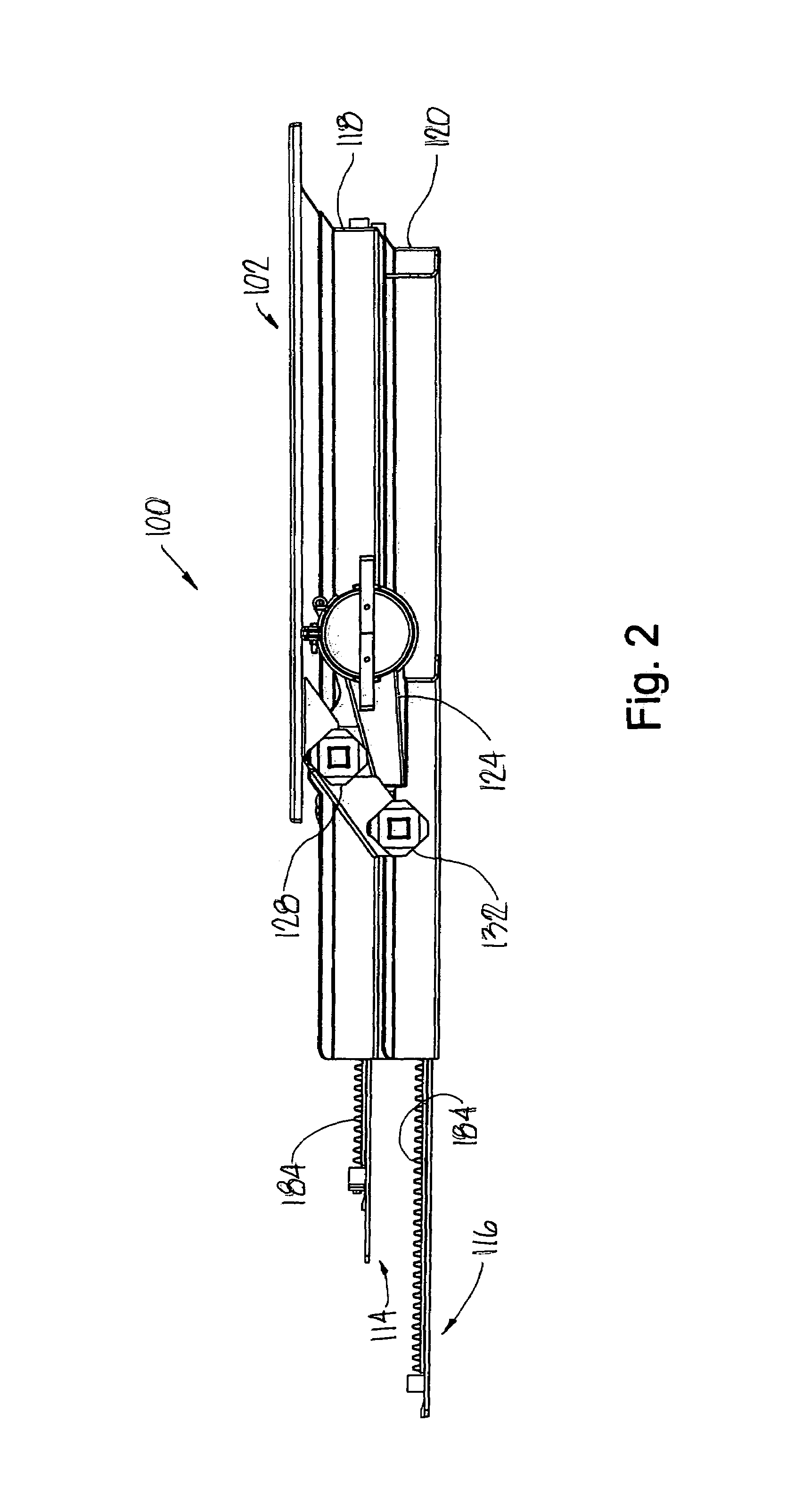

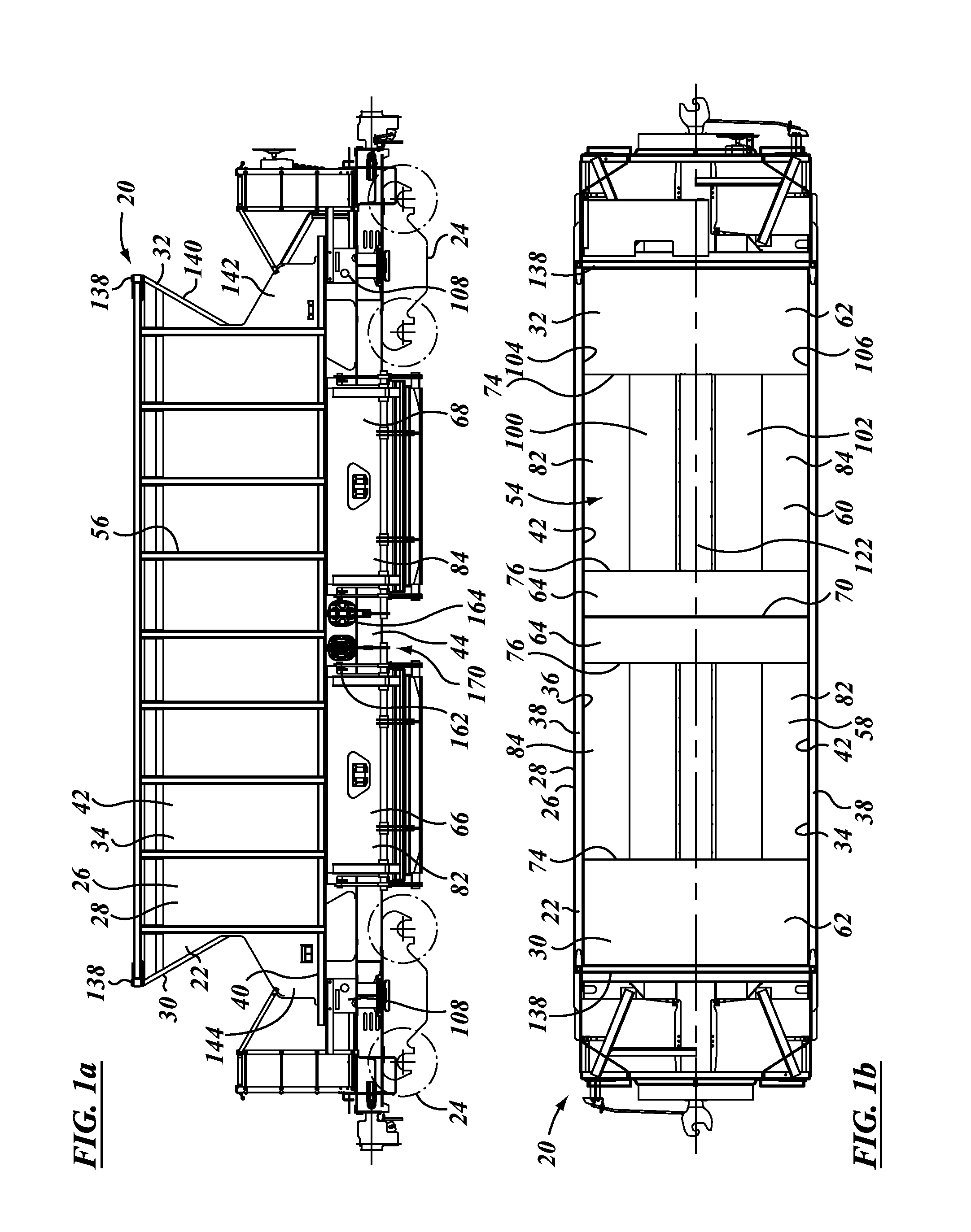

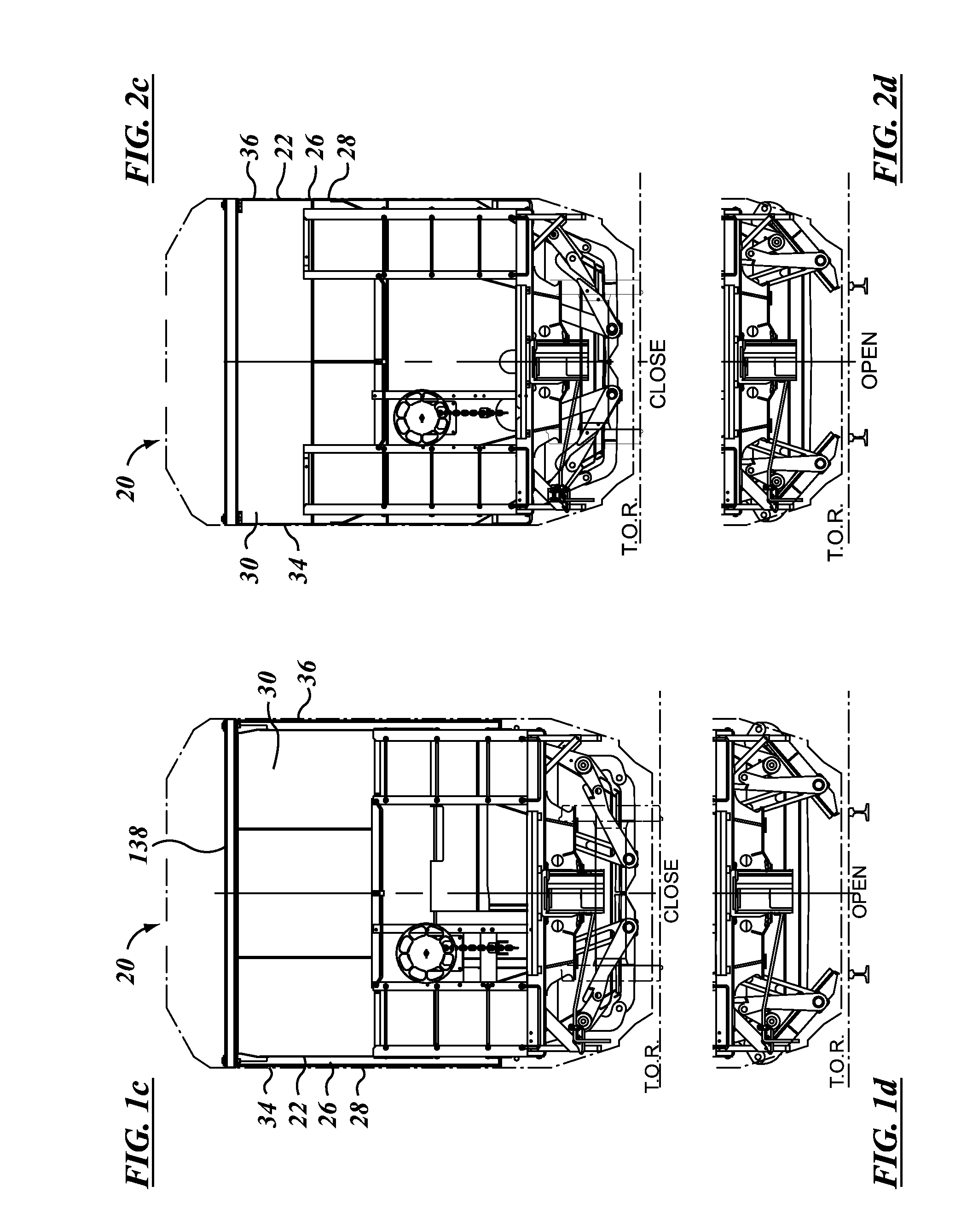

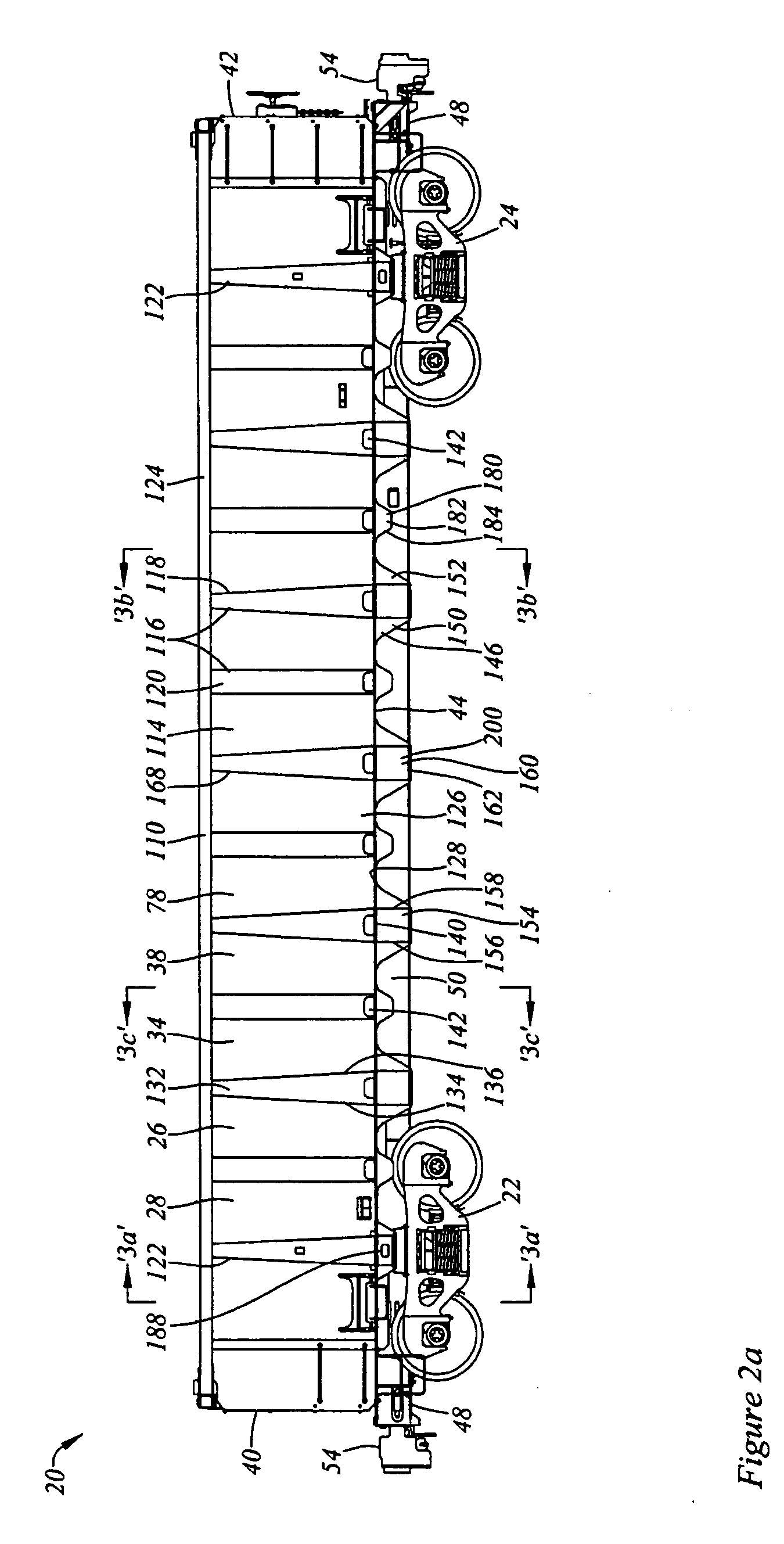

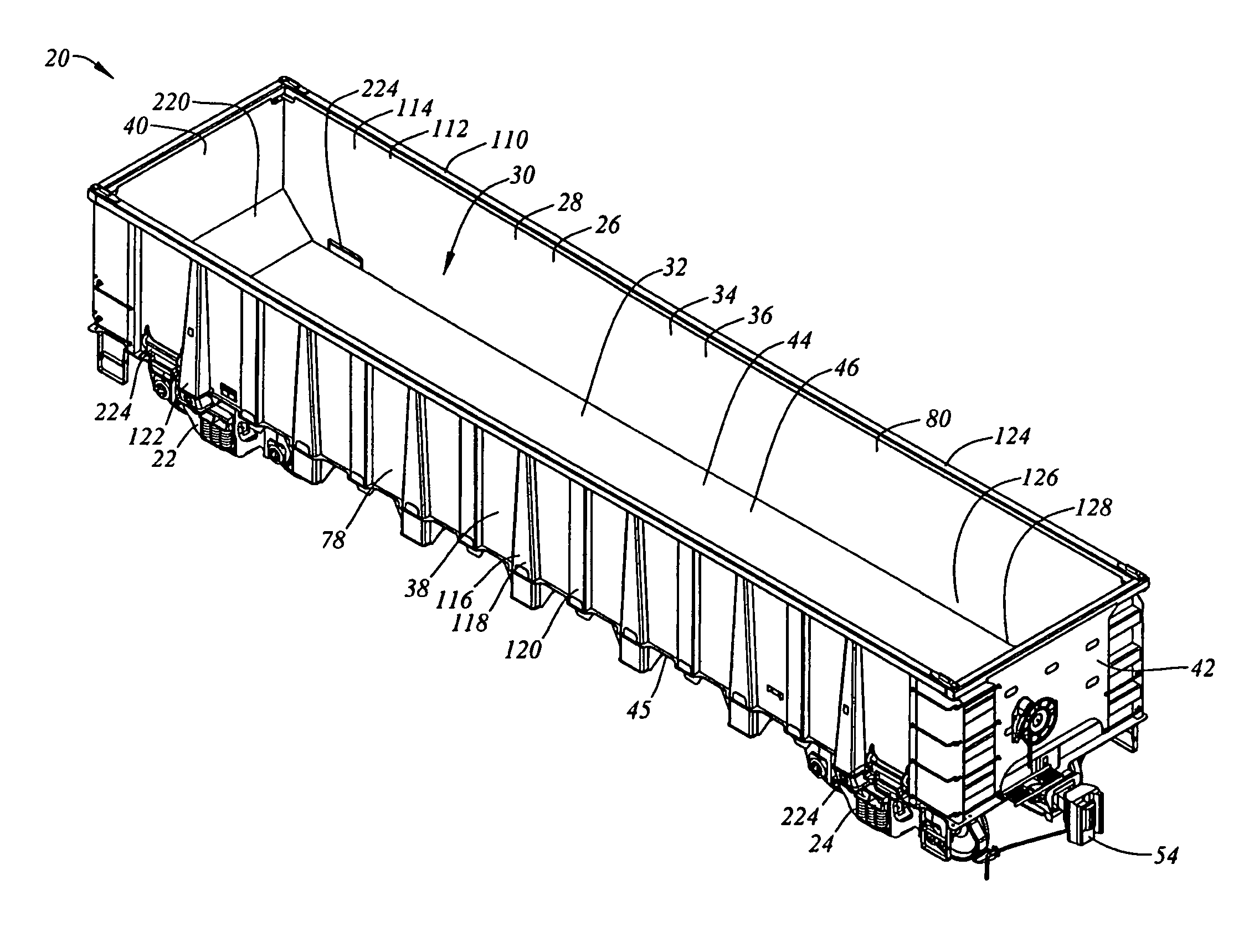

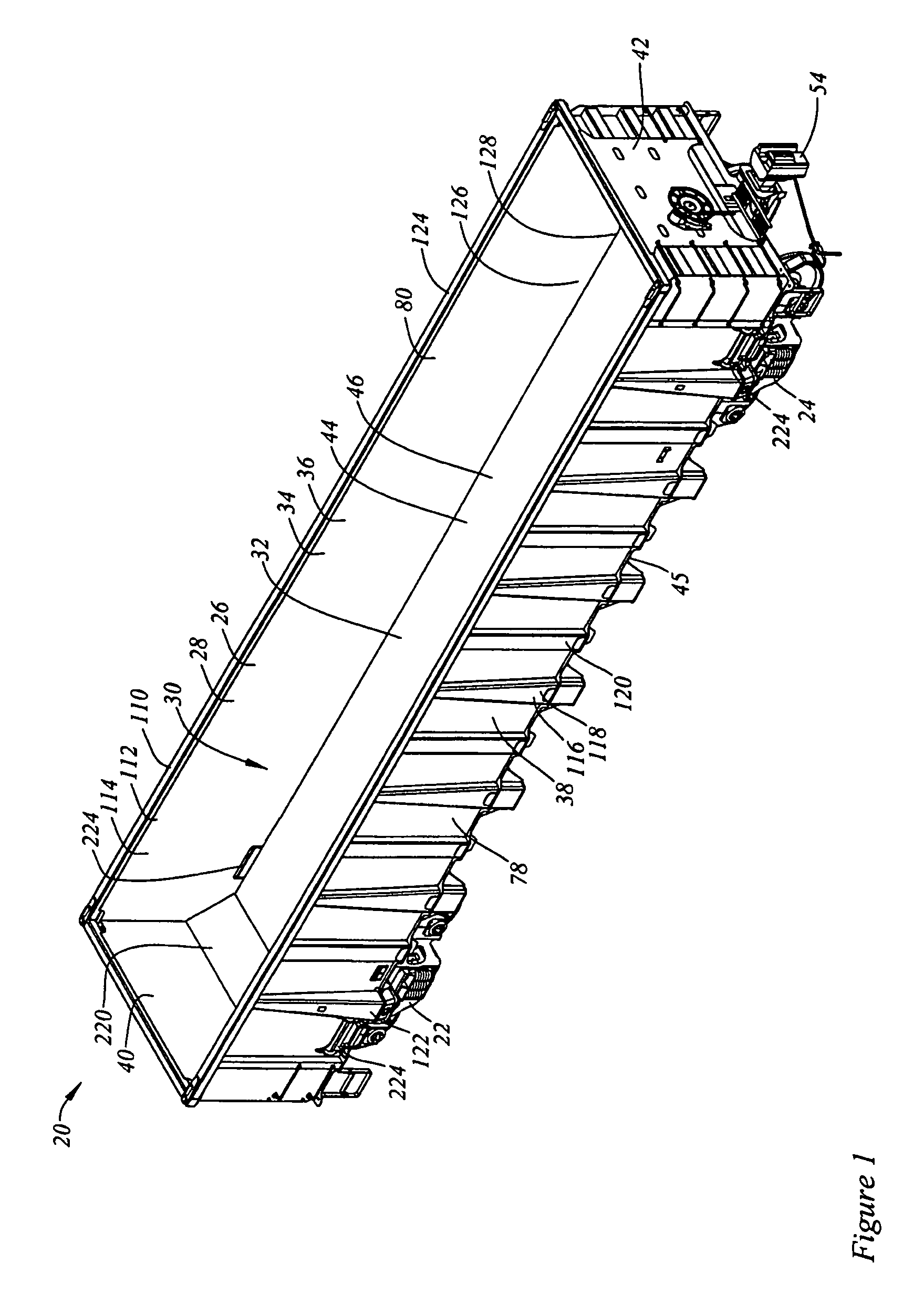

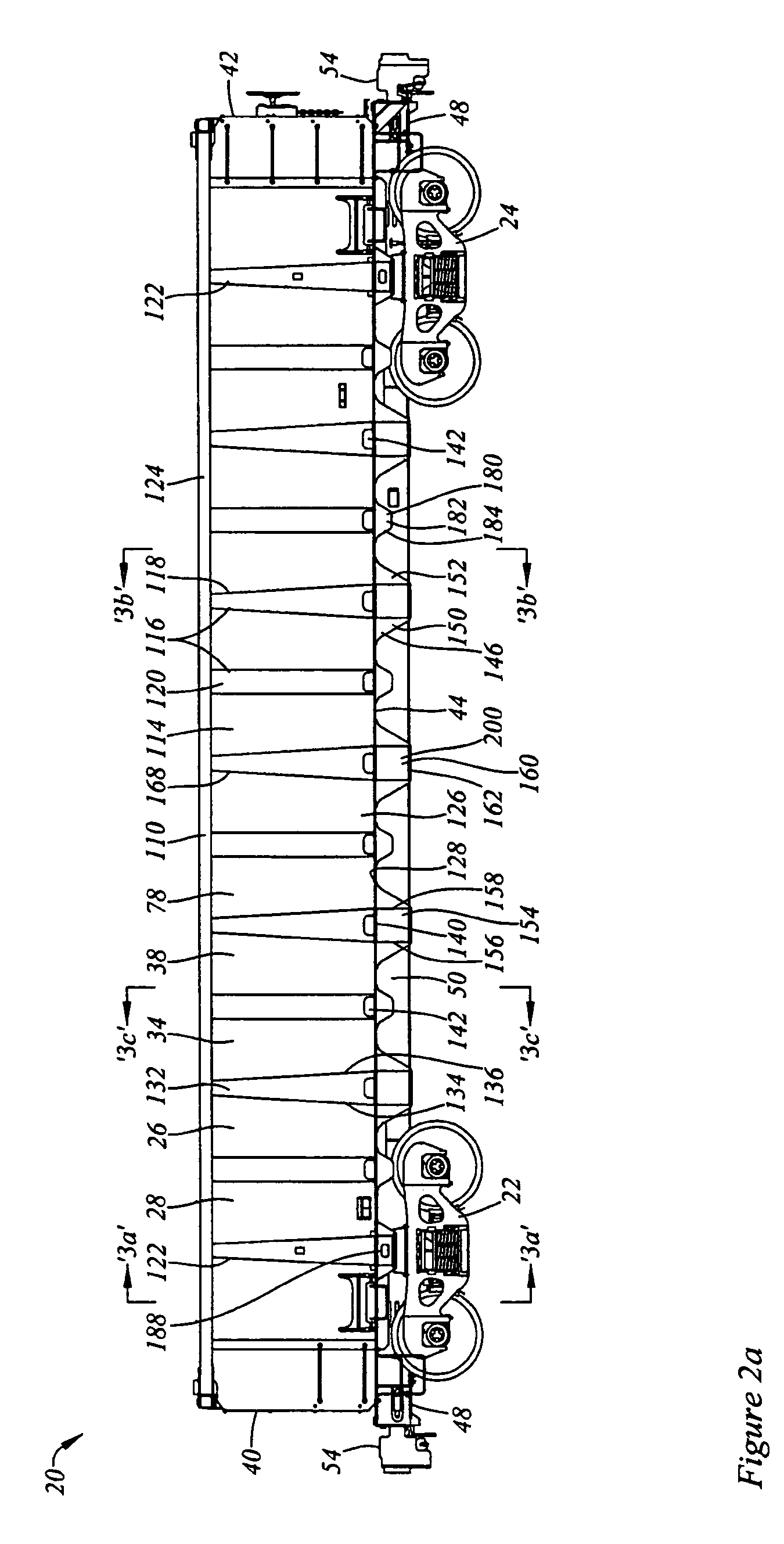

Hopper Cars With One Or More Discharge Control Systems

ActiveUS20070084378A1Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

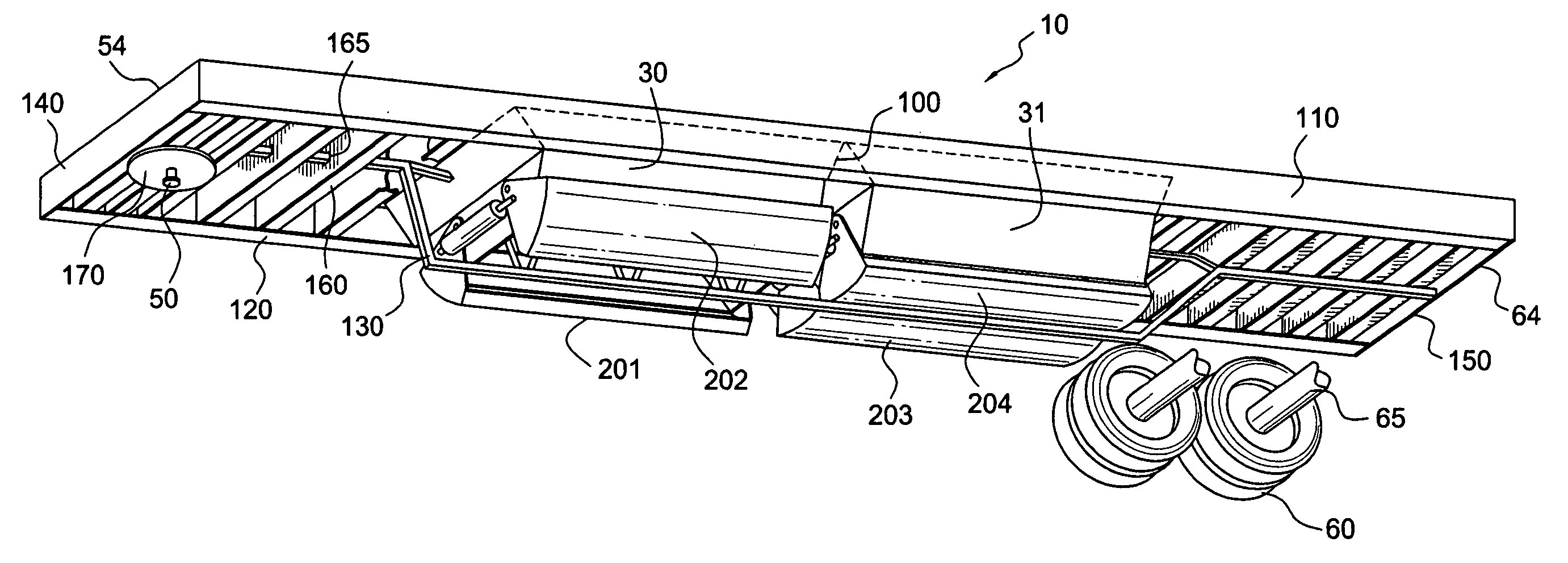

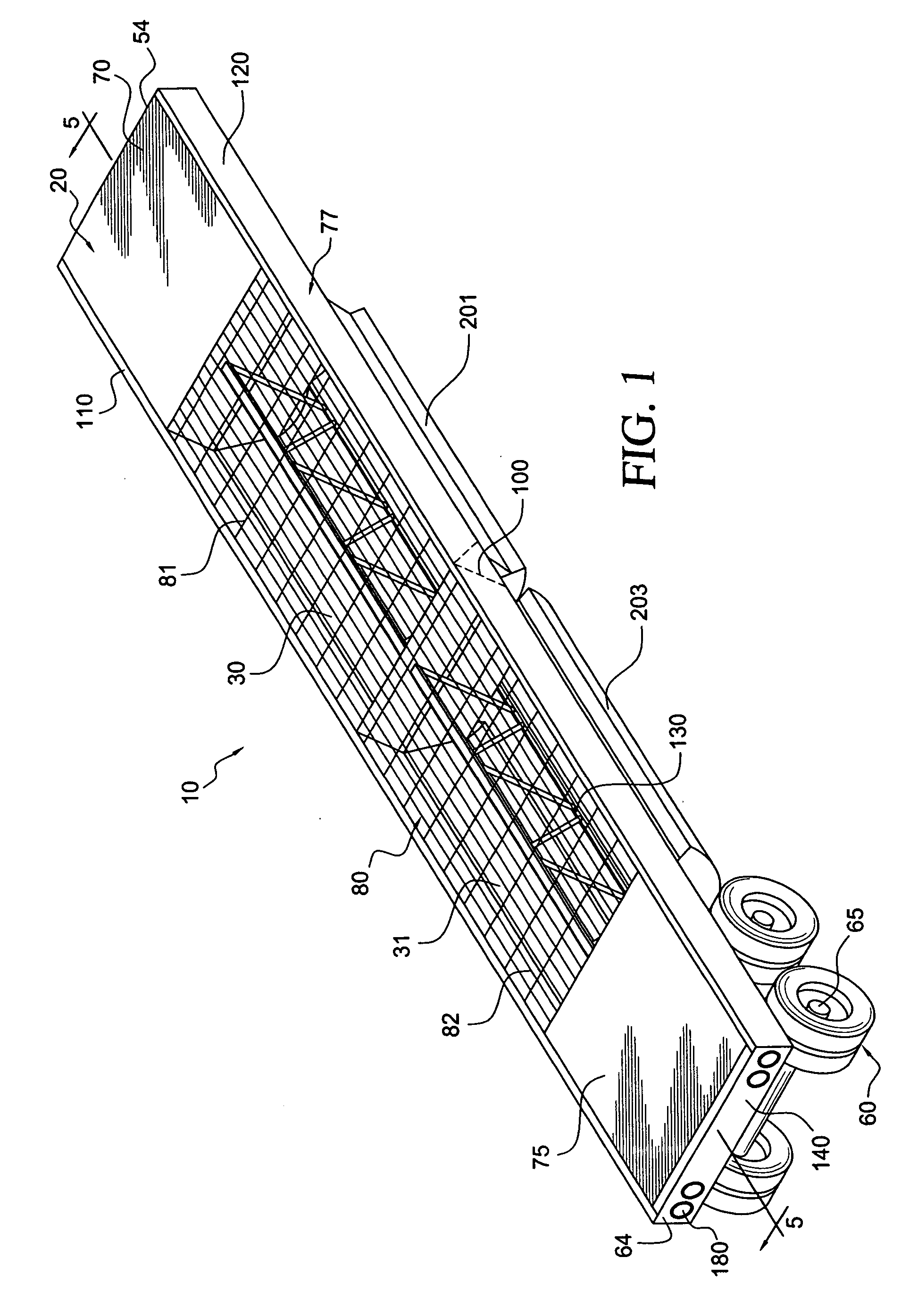

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

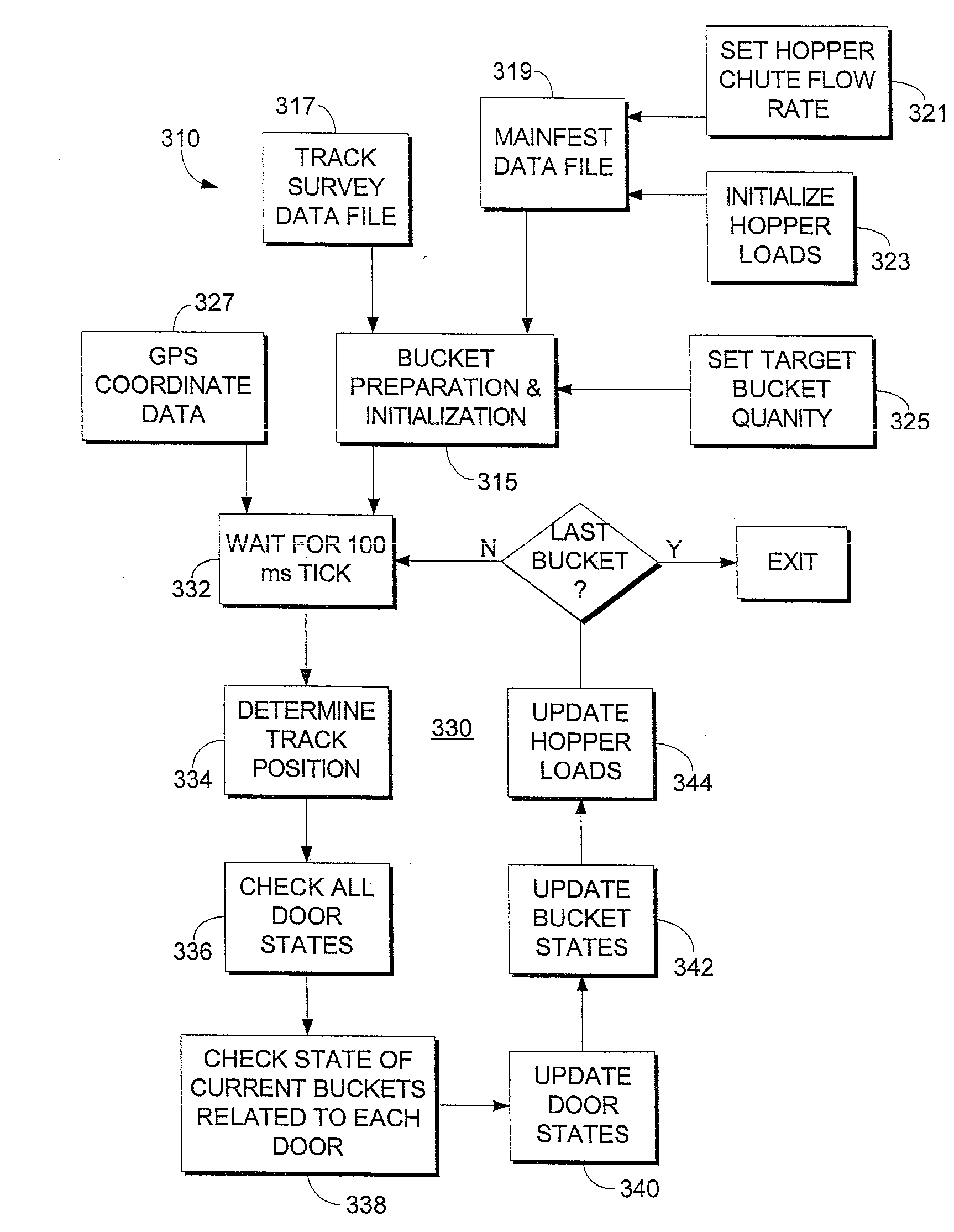

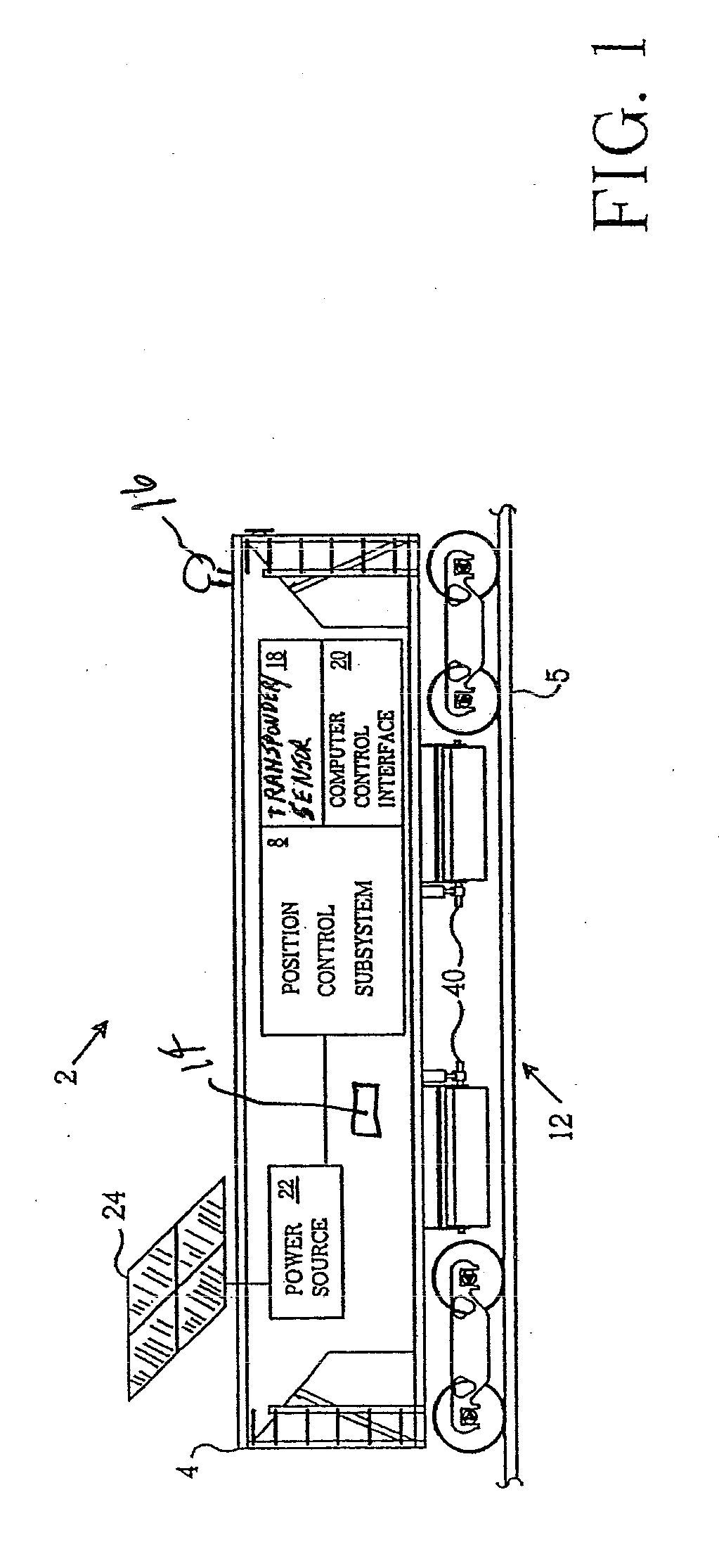

Method and apparatus for applying railway ballast

InactiveUS20070129858A1Control spreadImprove accuracyBallastwayDigital data processing detailsTerrainAviation

A method and apparatus for spreading ballast along railways makes use of an inertial measurement system to determine where to apply ballast from a hopper car. A variety of techniques can be used to determine the location and speed of the ballast spreading train, including manual or automated visual techniques, laser technology, radar technology, radio frequency transponders, magnetic sensor, thermal imaging and aerial photogrammetry. The invention also contemplates “on the fly” surveys and terrain profiling using lasers or radar.

Owner:HERZOG CONTRACTING

Rail road hopper car fittings and method of operation

A hopper car discharge section may be wide at the top and narrow at the bottom. Outflow is controlled by closure members, at least one of which is movable. The closure members come together to a closed condition or position for retaining lading. When apart, in an open position or condition, lading may be discharged. A seal member or seal member assembly is mounted to one or both of the closure members. When open, the seal member or seal member assembly lies substantially flush with, or shy of, the slope of the surface of the closure member. When closed, the seal member may be self-energizing, in the sense that as lading is added the seal may tend to seal more tightly. The seal assembly may include a cantilevered spring that presents a land to the opposed closure member, and a fulcrum, over, or across, which the spring is cantilevered, such that pushing down on one end of the spring may tend to cause the other end to flex upward. The fulcrum may also be cantilevered outward from the slope sheet of the closure member to which the seal assembly is attached. The discharge section may be robustly reinforced to discourage deformation.

Owner:NATIONAL STEEL CAR

Remotely operated manhole cover for a tanker

A remotely operated manhole cover for a tanker, trailer, or other storage unit is provided. The manhole cover includes a hollow neck which is welded in place in the shell of the tanker or trailer. The neck defines an opening which allows access to the interior of the tanker or trailer for filling or cleaning of the tanker. A lid is pivotable about an axis between a closed position in which the manhole cover is closed, and an open position in which the lid is clear of the neck opening to allow access to the interior of the tanker. The lid is provided with an inflatable seal and locking flanges which extend from a rim of the lid. Movable locking members are provided on the neck and are movable between a locked position in which locking member engages the lid locking flange and an unlocked position in which the locking members are disengaged from the lid locking flange. Separate actuators are provide for the cover and the locking members. A control unit is provided to energize the cover and locking member actuators and to inflate and deflate the seal. The control unit activates the locking member and lid actuators and inflates or deflates the seal in sequence to unlock and open the lid or to close and lock the lid. The control unit includes a manually operable switch assembly which activates the manhole cover to open and close the lid. The switch assembly is located remote from the manhole cover, and preferably near the bottom of the tanker.

Owner:DELAWARE CAPITAL FORMATION INC

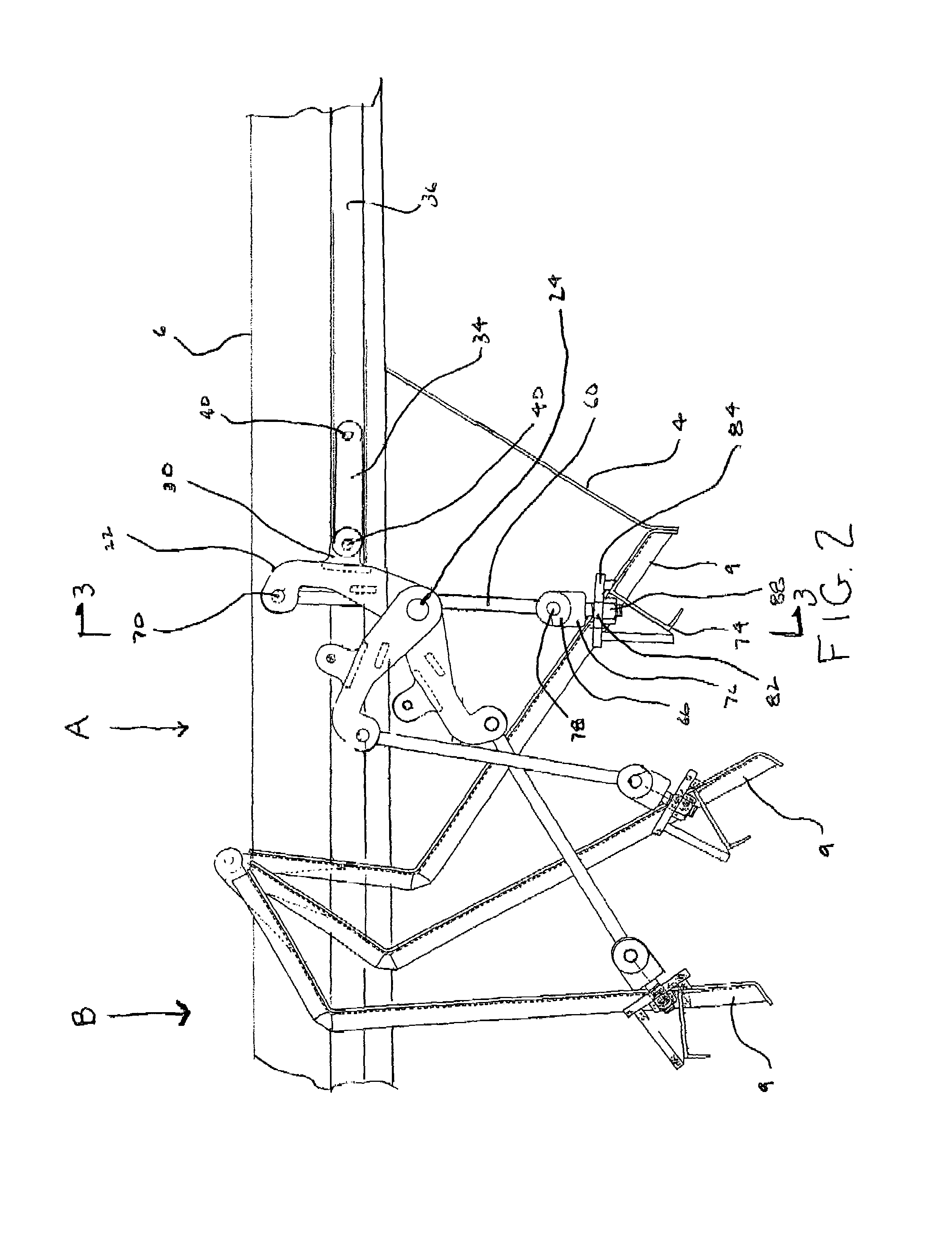

Railroad car and door mechanism therefor

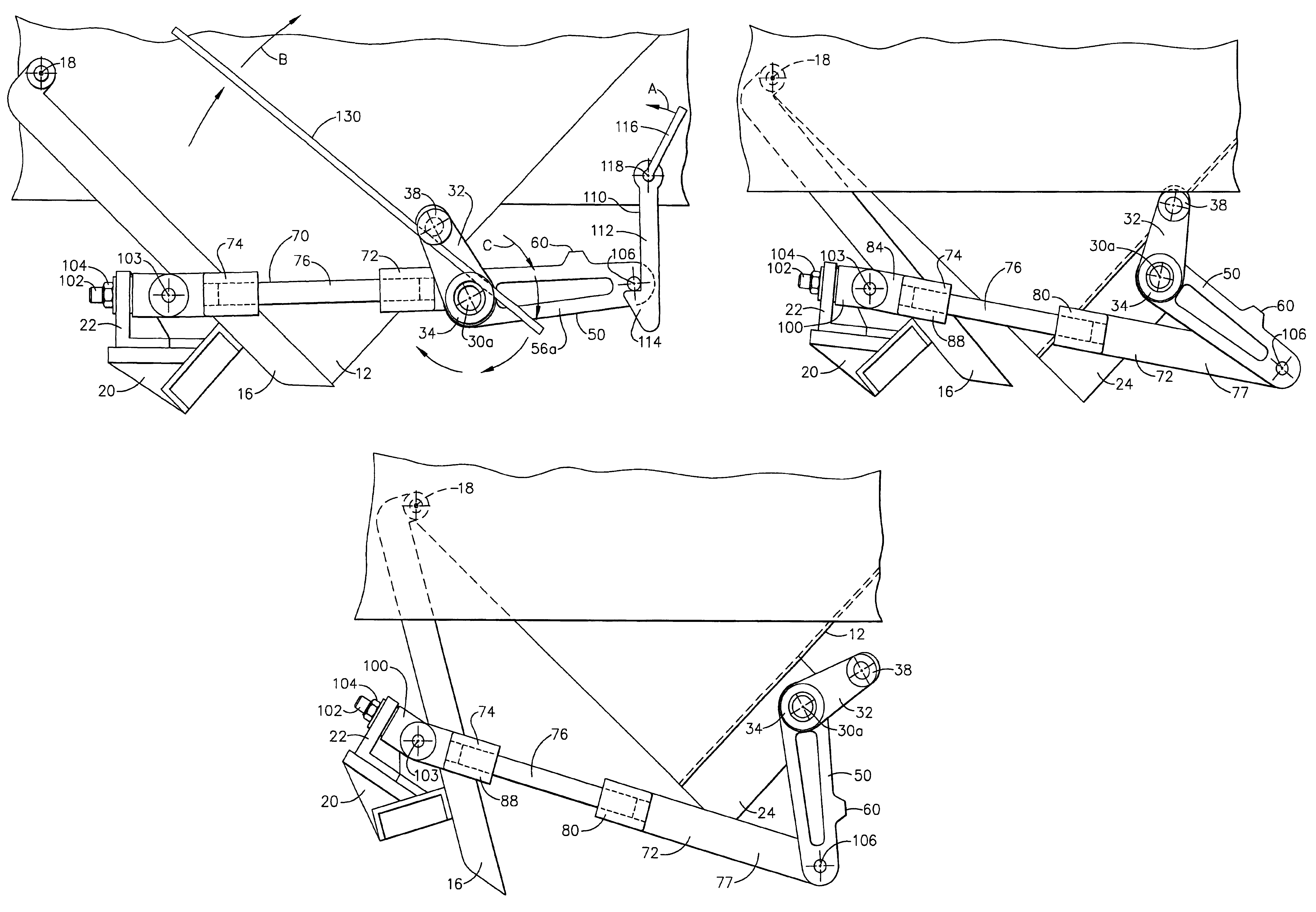

A hopper car discharge outflow is controlled by closure members, at least one of which is movable. The doors are hingeless, being mounted on four bar linkages, such that the distal edge of the doors sweeps predominantly horizontally while the proximal edge of the door moves predominantly upwardly. The doors move through noncircular arcs, such that the size of the vertically projected door opening is abnormally large compared to the clearance heights of the door. The doors are driven by a transverse drive linkage that is driven by a transversely mounted actuator. The actuator is mounted in an accommodation in the lee of slope sheets between adjacent hoppers in a mid-span portion of the car. Drive from the actuator is carried to a pair of symmetrically mounted doors through drive train linkages. The drive train includes longitudinally extending torque tubes that transmit drive to both fore and aft ends of the door assemblies. The car also has a lost motion secondary lock system, an alternate manual drive door opening and closing drive train, and abnormally high side sills and a center sill that passes clear through the discharge sections at a height clearly lower than the upper margin of the discharge sections.

Owner:NATIONAL STEEL CAR

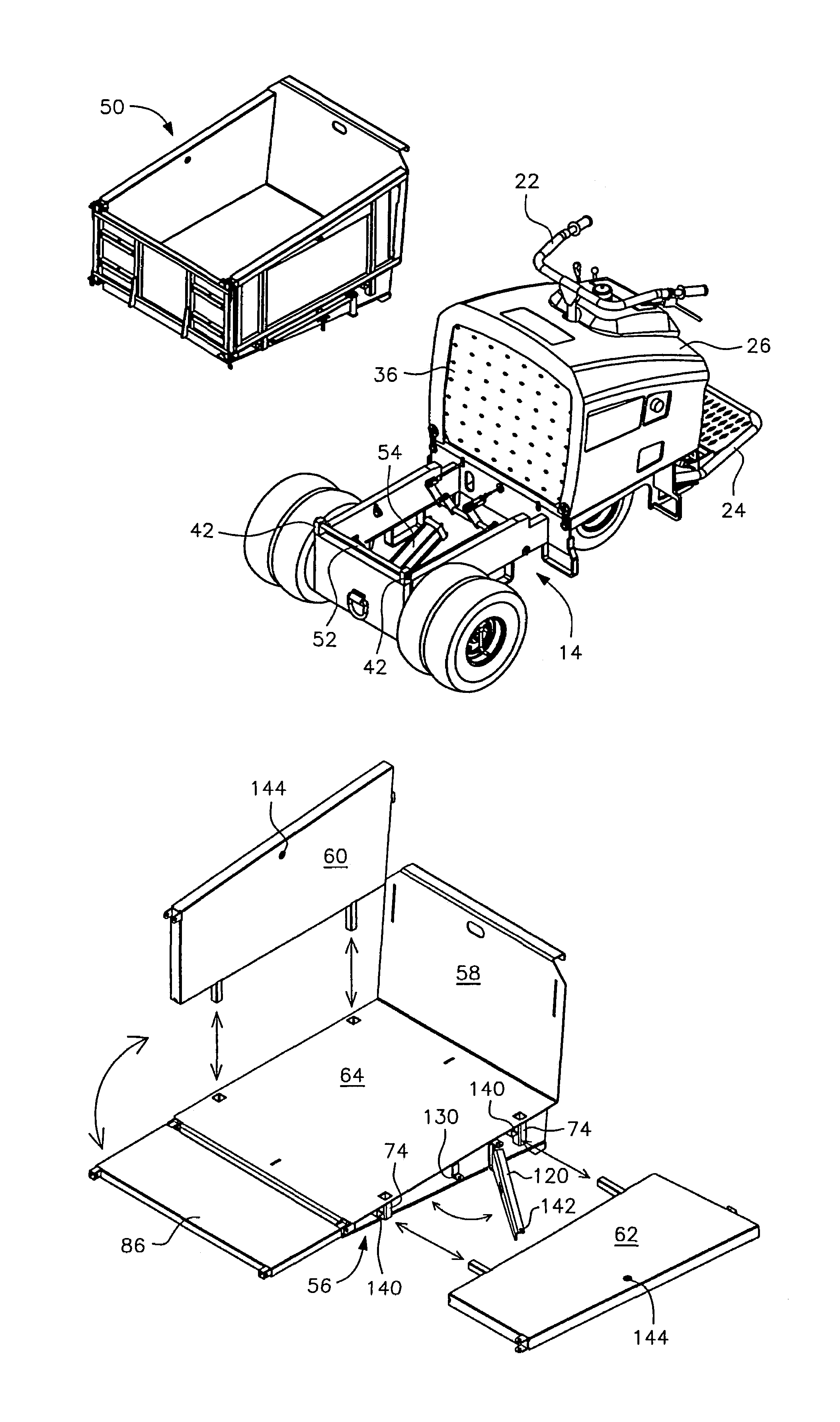

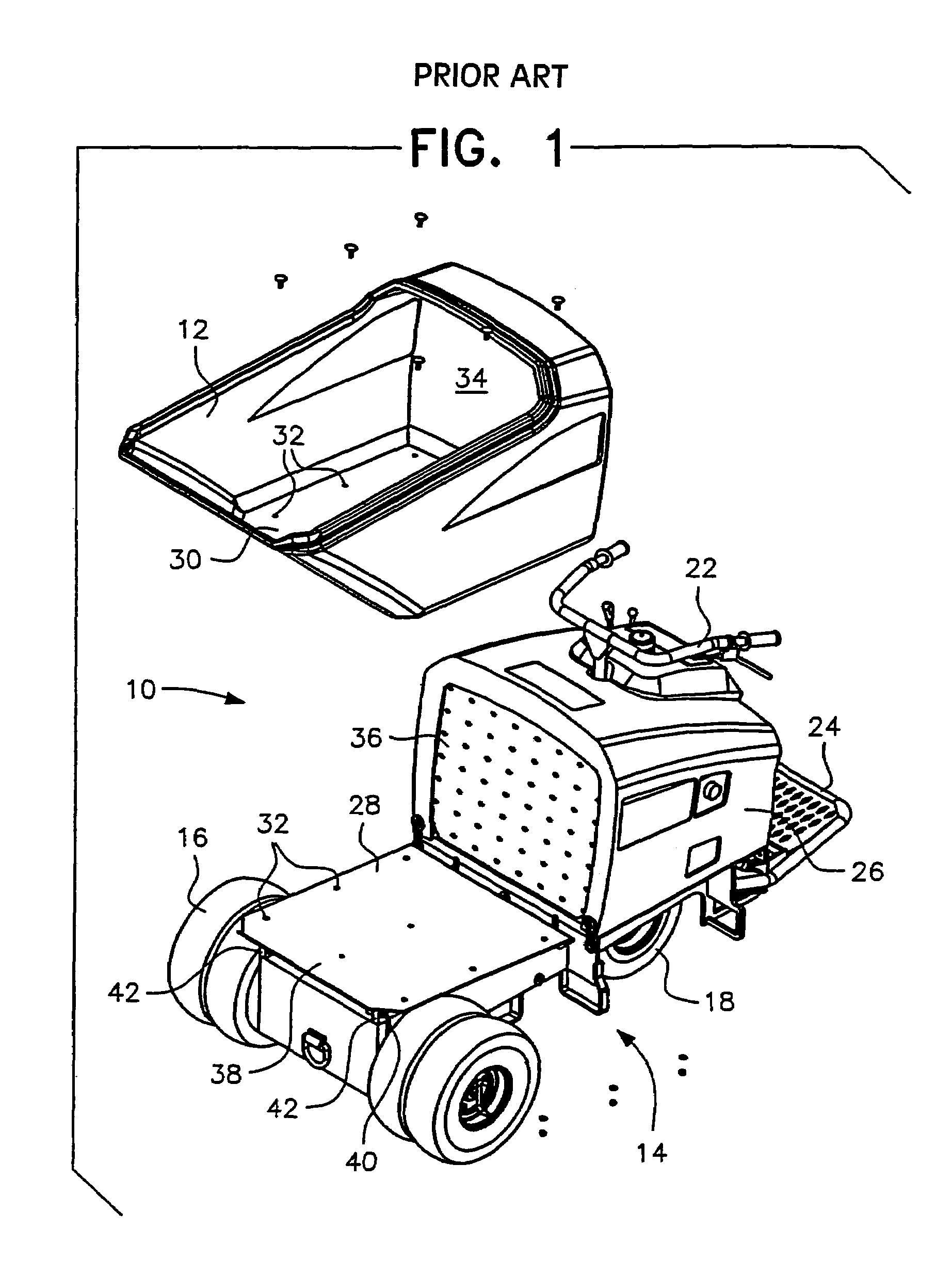

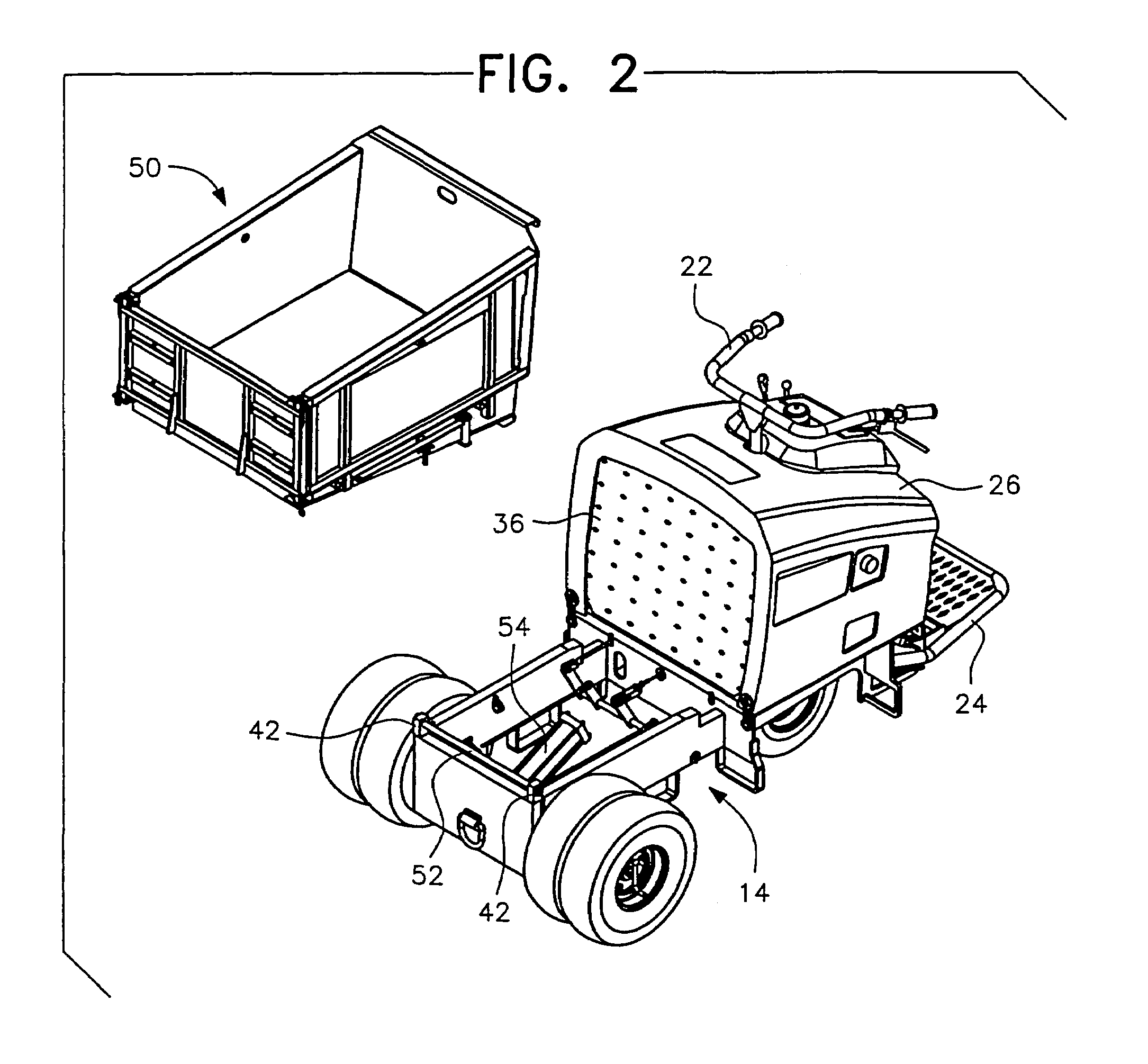

Mortar buggy with stake bed assembly

ActiveUS7201453B2Easy to pourReadily and easily convertedVehicle with living accommodationSuperstructure subunitsAlloyEngineering

Owner:TORO CO THE

Railroad hopper car discharge gate assembly

InactiveUS6899038B2Prevent inadvertent movementPromote sportsHopper carsWagons/vansEngineeringMechanical engineering

A discharge gate assembly adapted to be secured in material receiving relation relative to a standard opening toward a bottom of a railroad hopper car. The gate assembly of the present invention satisfies AAR requirements and specifications and includes a rigid frame defining a ledgeless and generally square discharge opening which is sized substantially equivalent to the standard opening defined toward the bottom of the railcar whereby allowing commodity discharged from the opening in the railroad hopper car to pass through the gate assembly with minimum interference or obstruction thereby promoting the discharge of commodity from the railroad car. A gate is slidably movable between open and closed positions relative to the discharge opening on the gate assembly and is suspended, in a closed position, by a series of supports extending therebeneath.

Owner:MINER ENTERPRISES INC

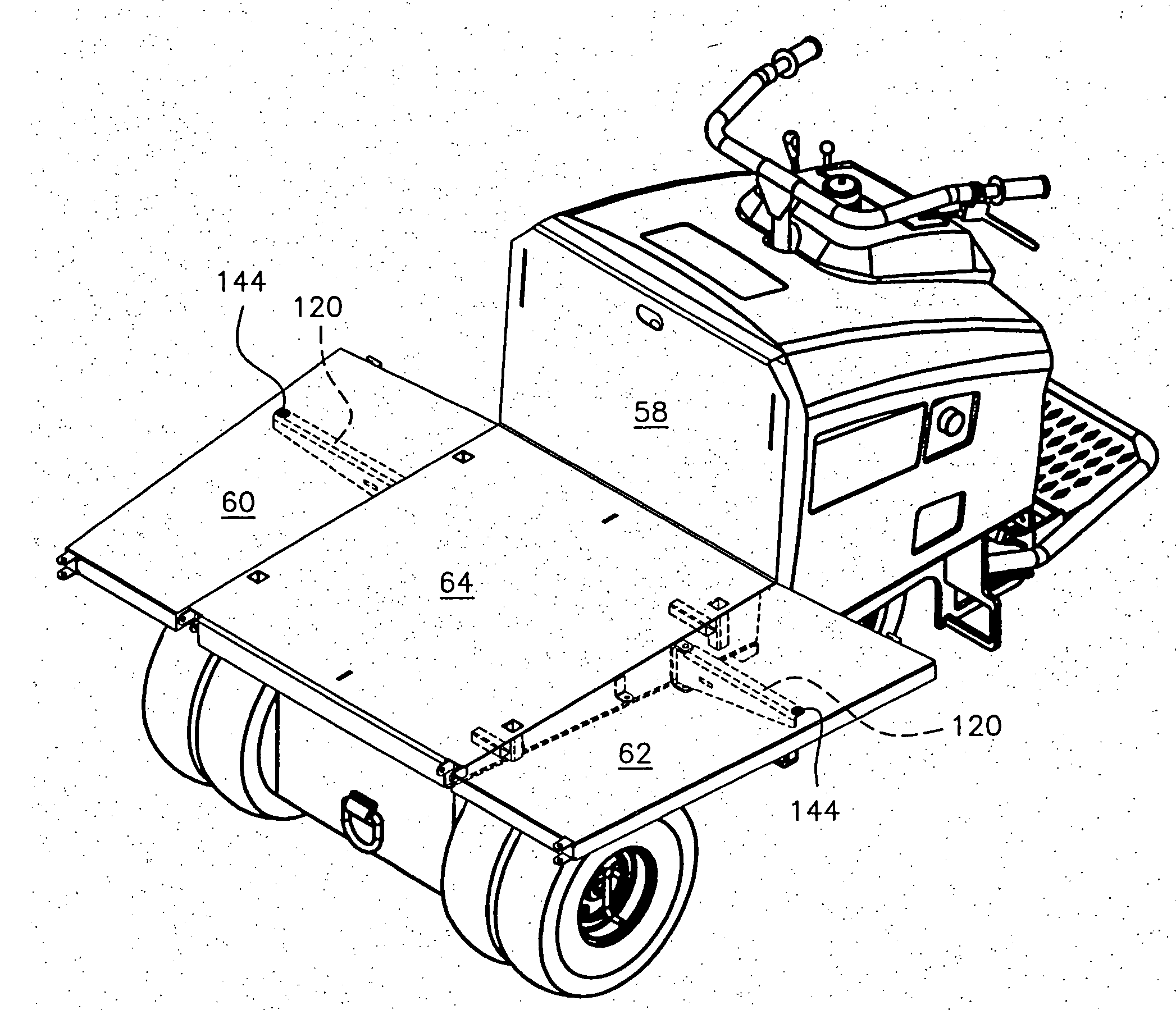

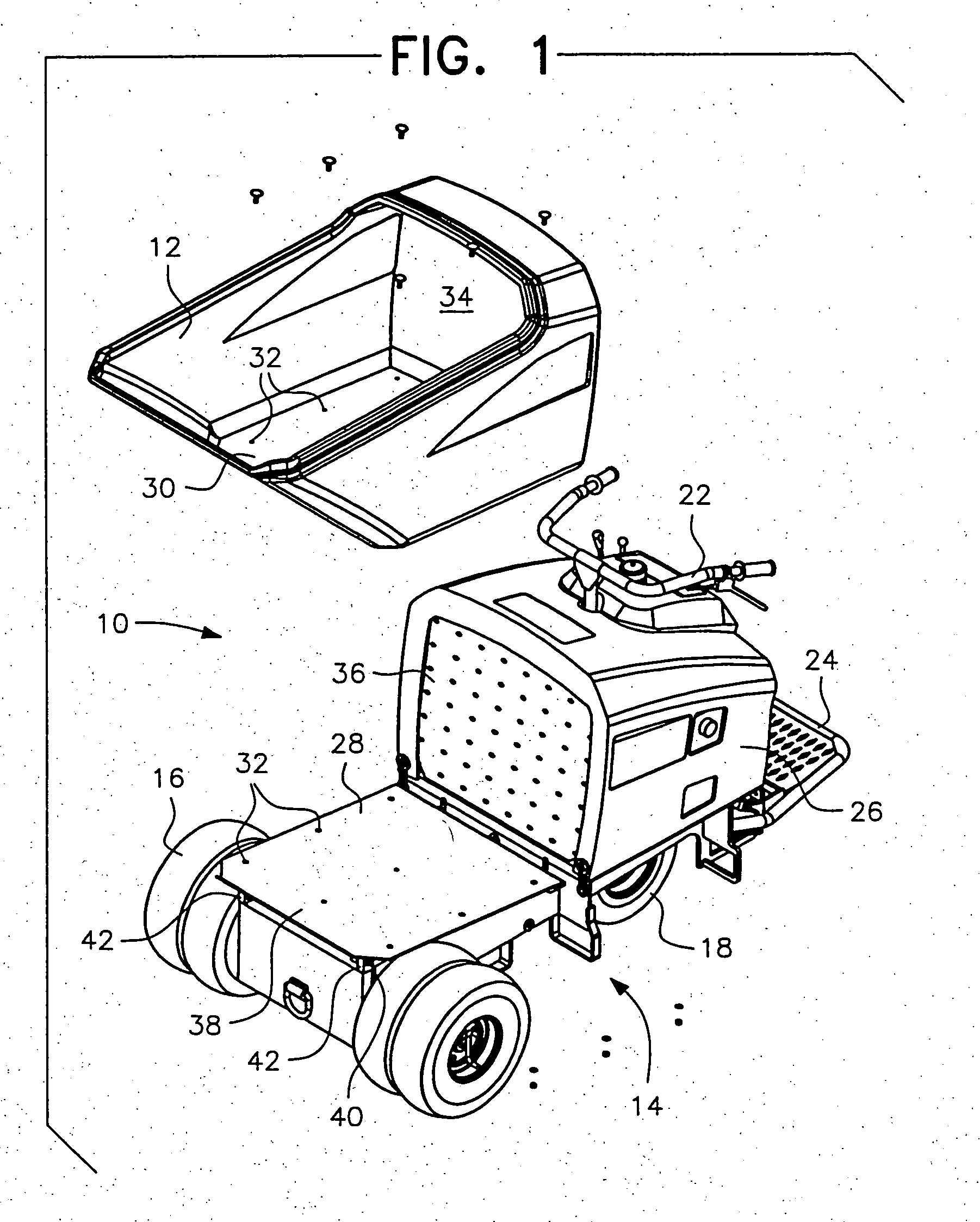

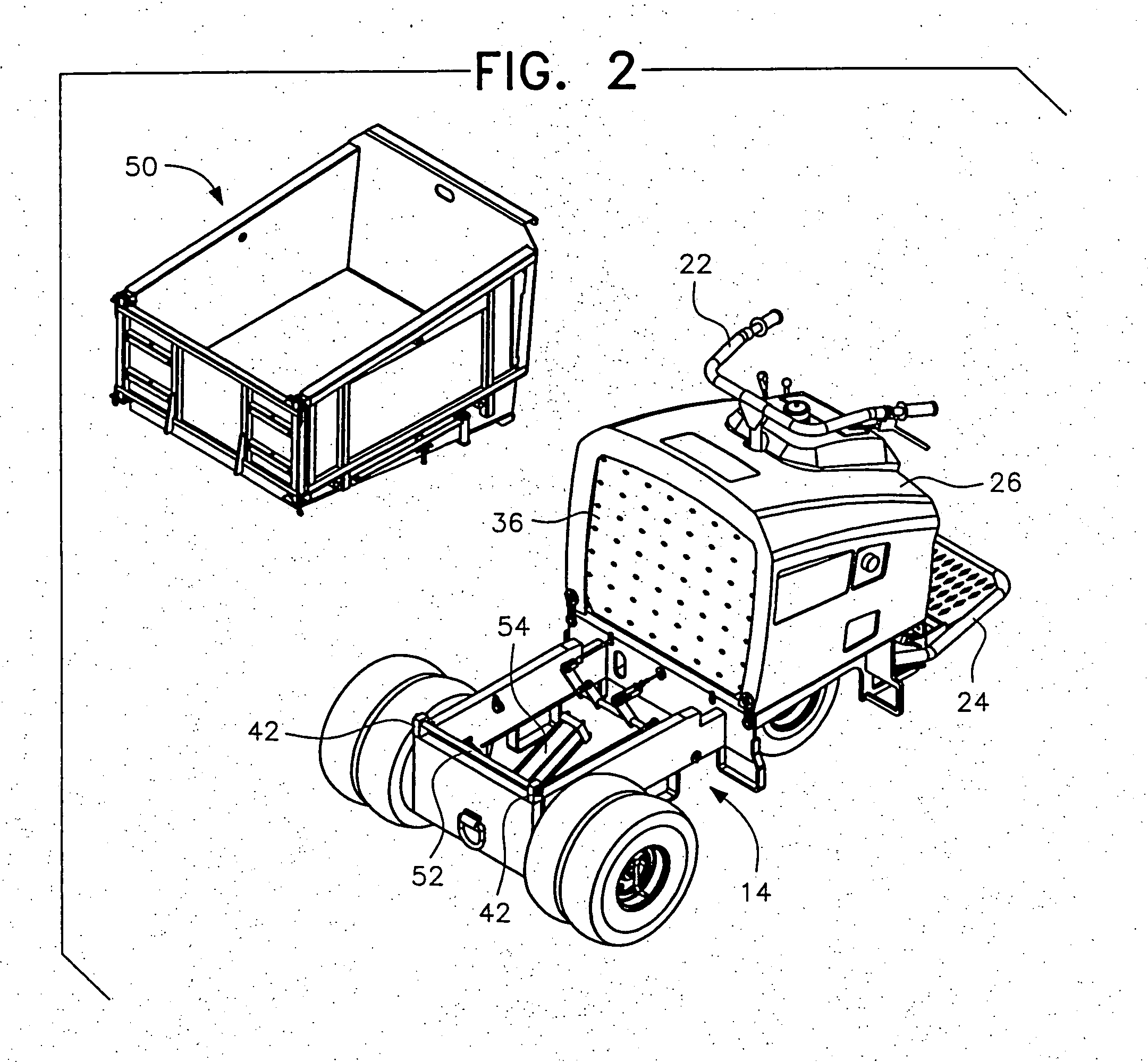

Mortar buggy with stake bed assembly

ActiveUS20050168004A1Easy to pourReadily and easily convertedLoading/unloading vehicle arrangmentVehicle with living accommodationAlloyEngineering

A mortar buggy with stake bed assembly provides a removable flat heavy duty base platform and a rear panel that can be fitted onto the chassis of an existing mortar buggy or similar conveyance in place of a hopper. The stake bed assembly provides removable front and side panels made of solid steel or similar alloy that can be configured to attach vertically in a hopper configuration or horizontally in an extended flat bed configuration, to provide additional loading surface for long or large items. The stake bed assembly also provides for a removable front tailgate with the ability to hinge at both its top and bottom so that the front tailgate can swing either up or down.

Owner:TORO CO THE

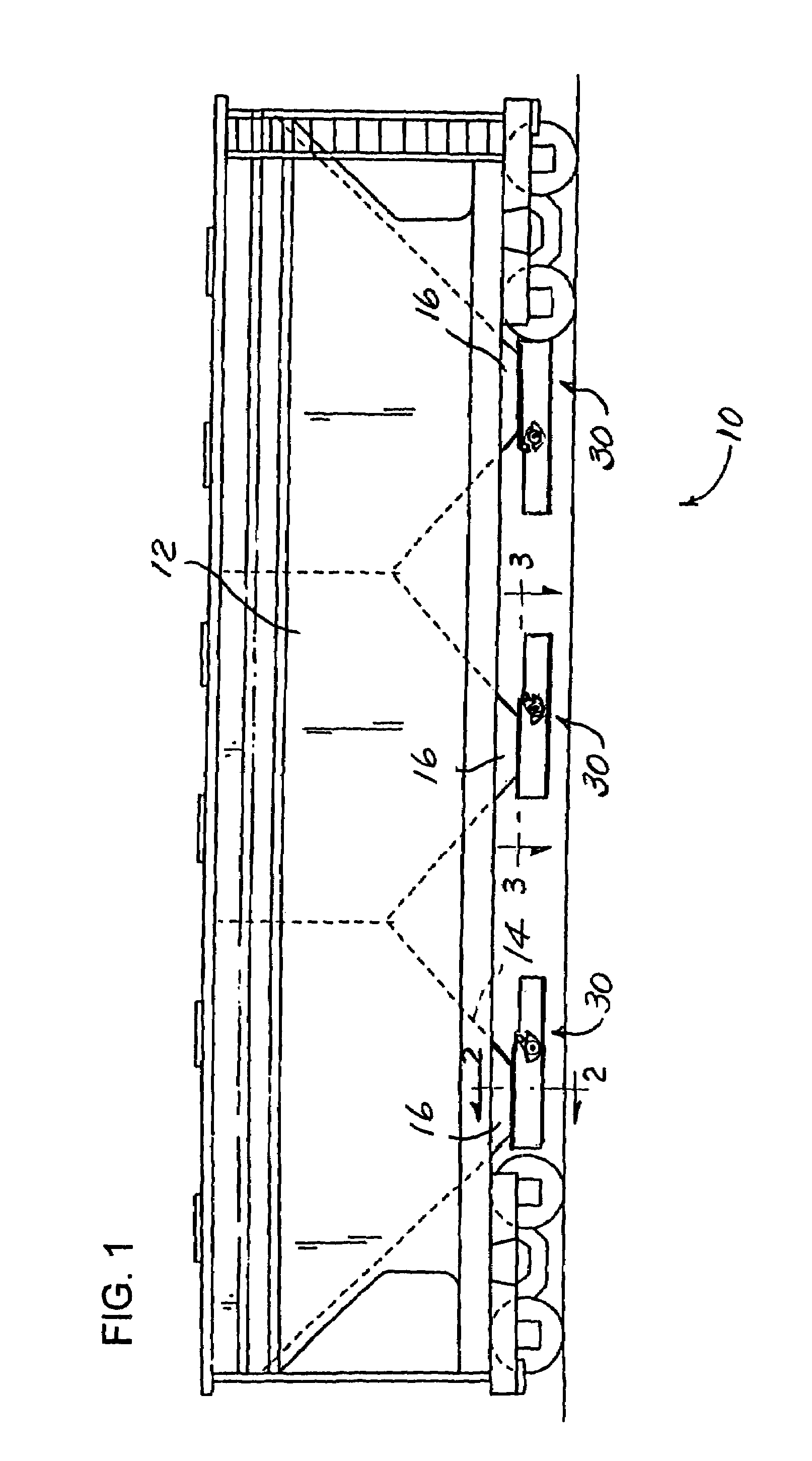

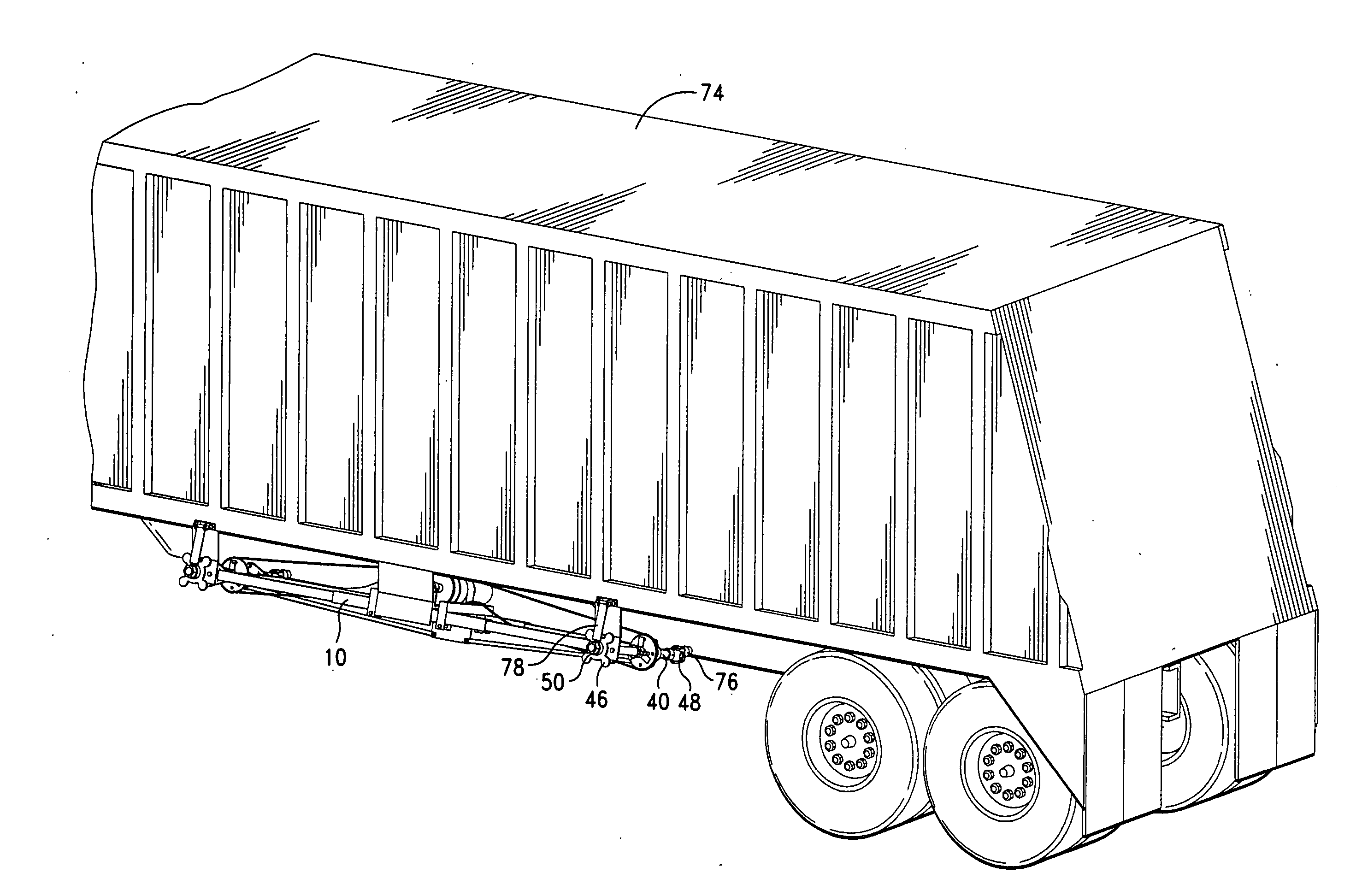

Apparatus for operating commodity trailer hopper trap doors

InactiveUS20050168047A1Simple and safe operationEliminate needHopper carsVehicle with endless chains/beltsElectric machineryEngineering

An apparatus for operating first and second commodity trailer hopper trap doors is provided that includes a support frame extending between first and second ends, first and second driveshaft assemblies attached at each end of the support frame, a motor assembly attached to the support frame, and first and second linking mechanisms coupled between the motor assembly and the first and second driveshaft assemblies such that the motor assembly is operable to move the first and second linking mechanisms and thereby rotate the first and second driveshaft assemblies, thus operating the commodity trailer hopper trap doors. Various embodiments of the apparatus are provided.

Owner:GRIER RALPH ELLIS

Rail road freight car structure

Owner:NATIONAL STEEL CAR

Rail road freight car structure

Owner:NATIONAL STEEL CAR

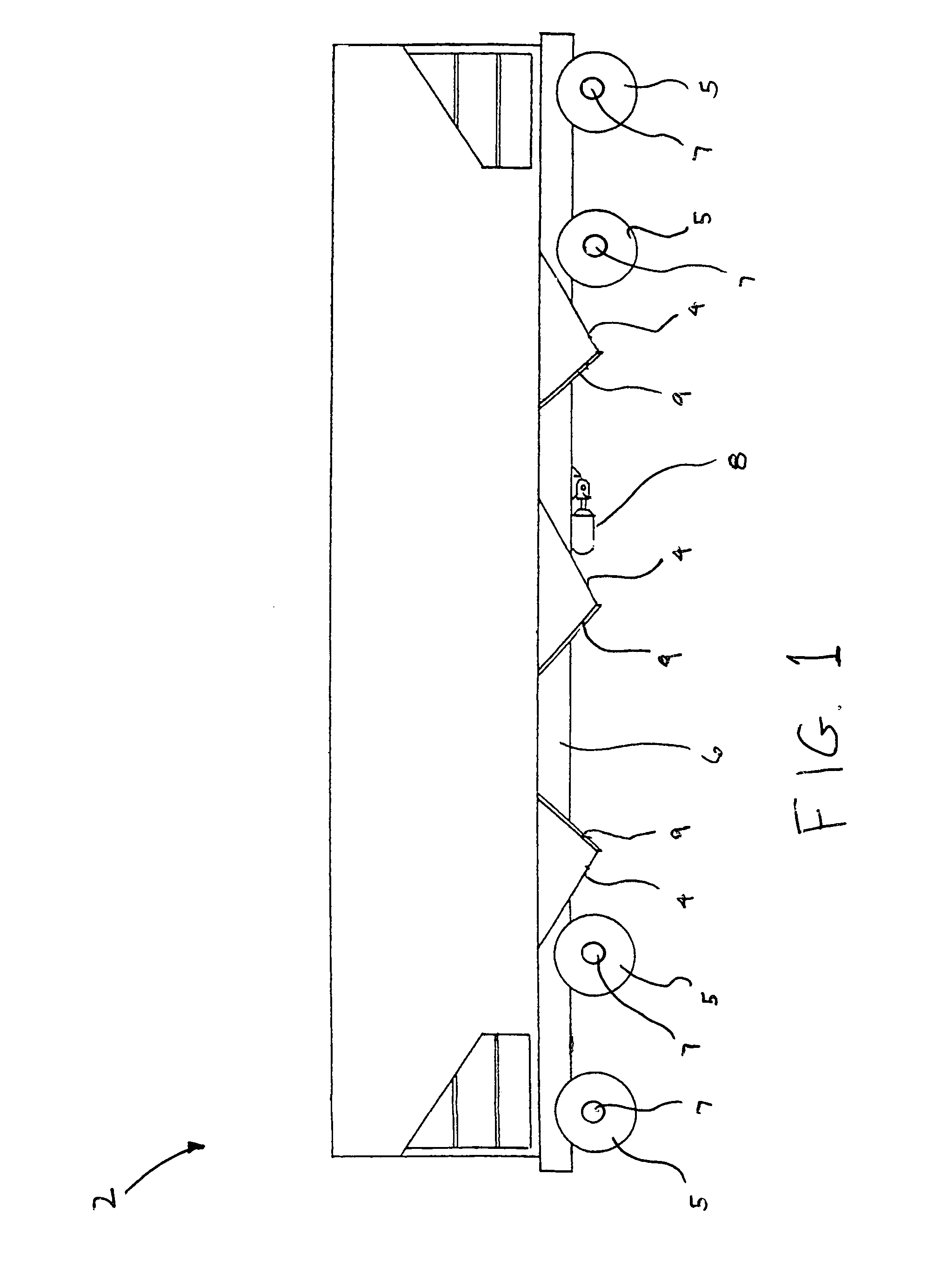

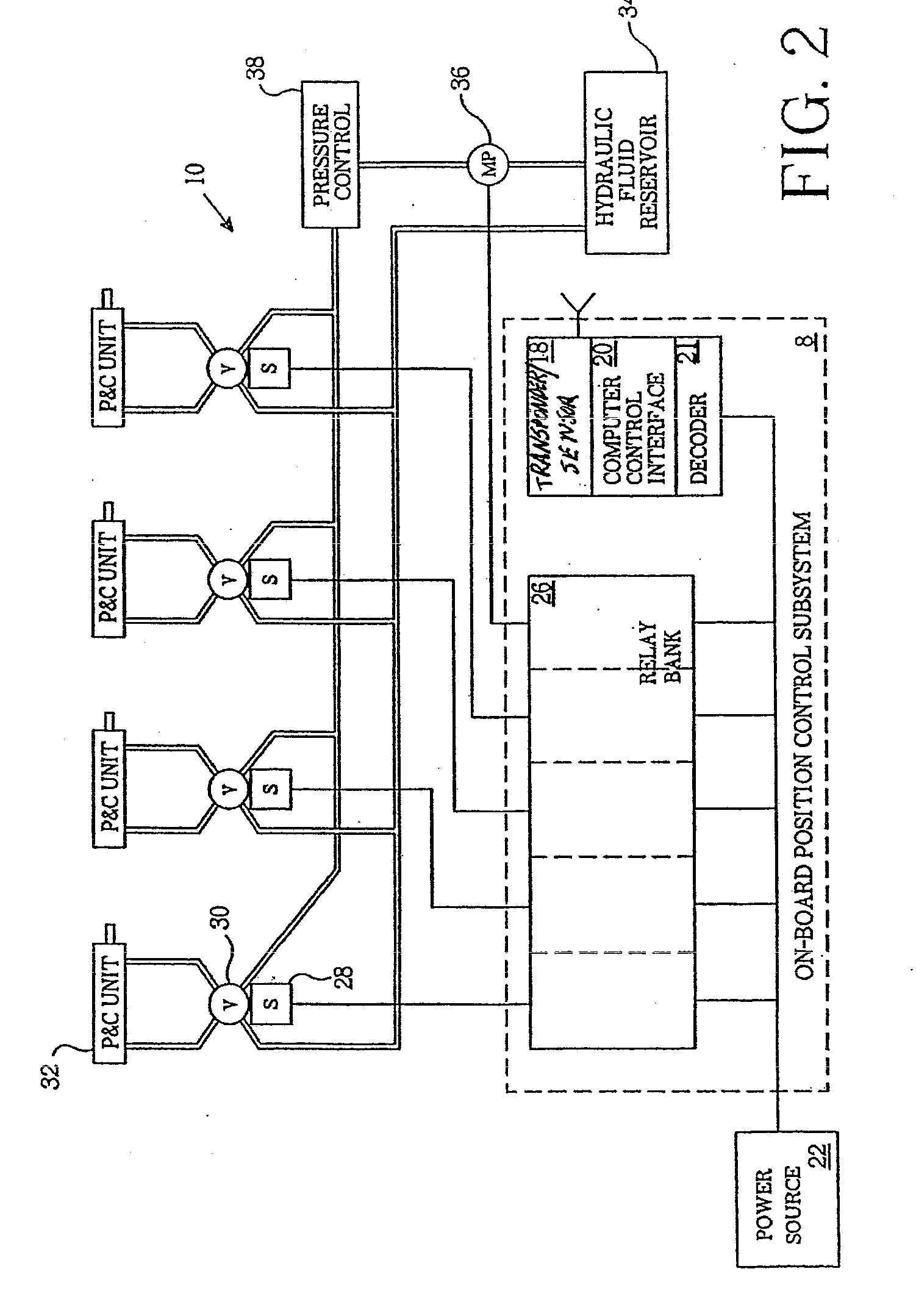

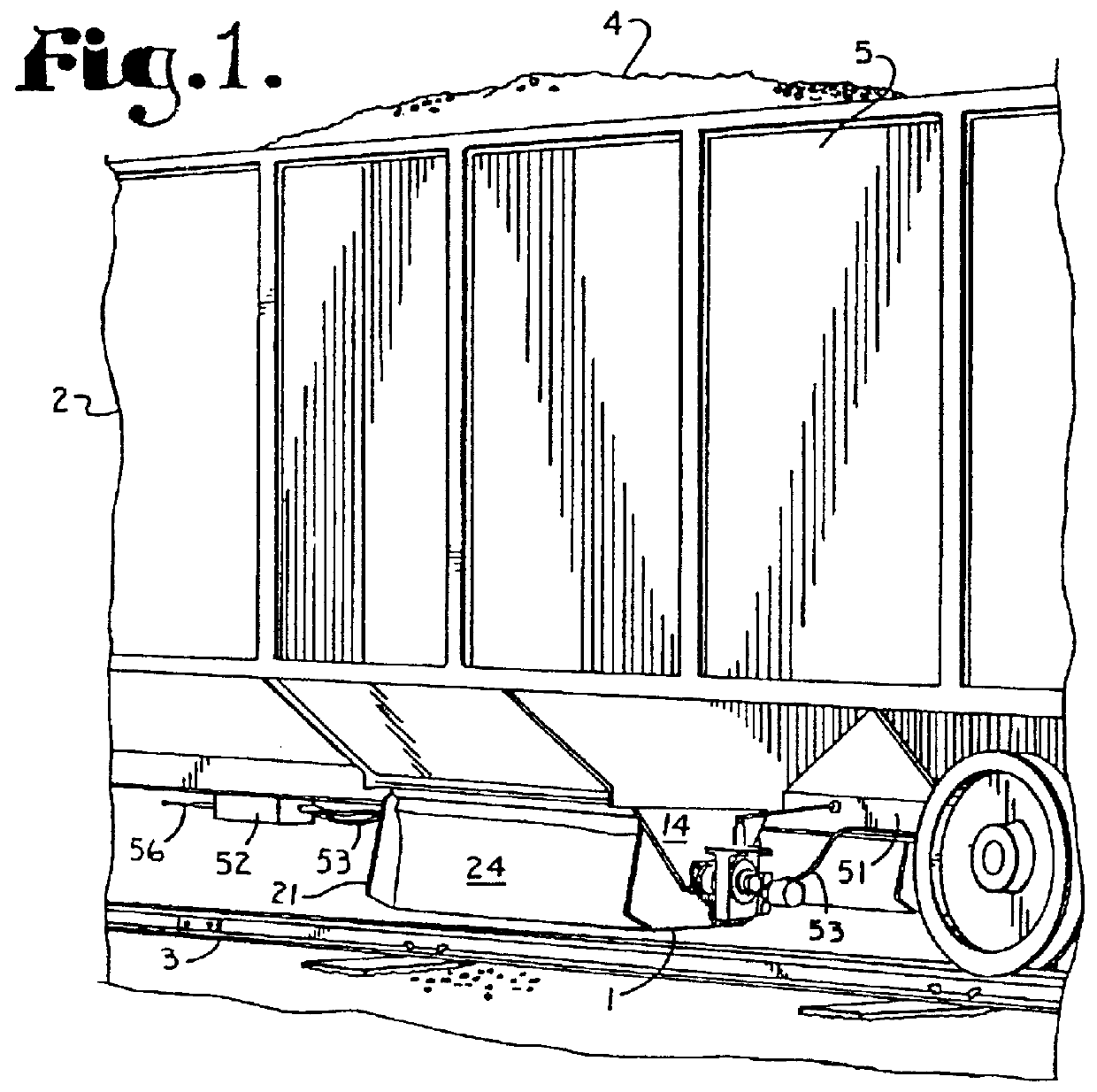

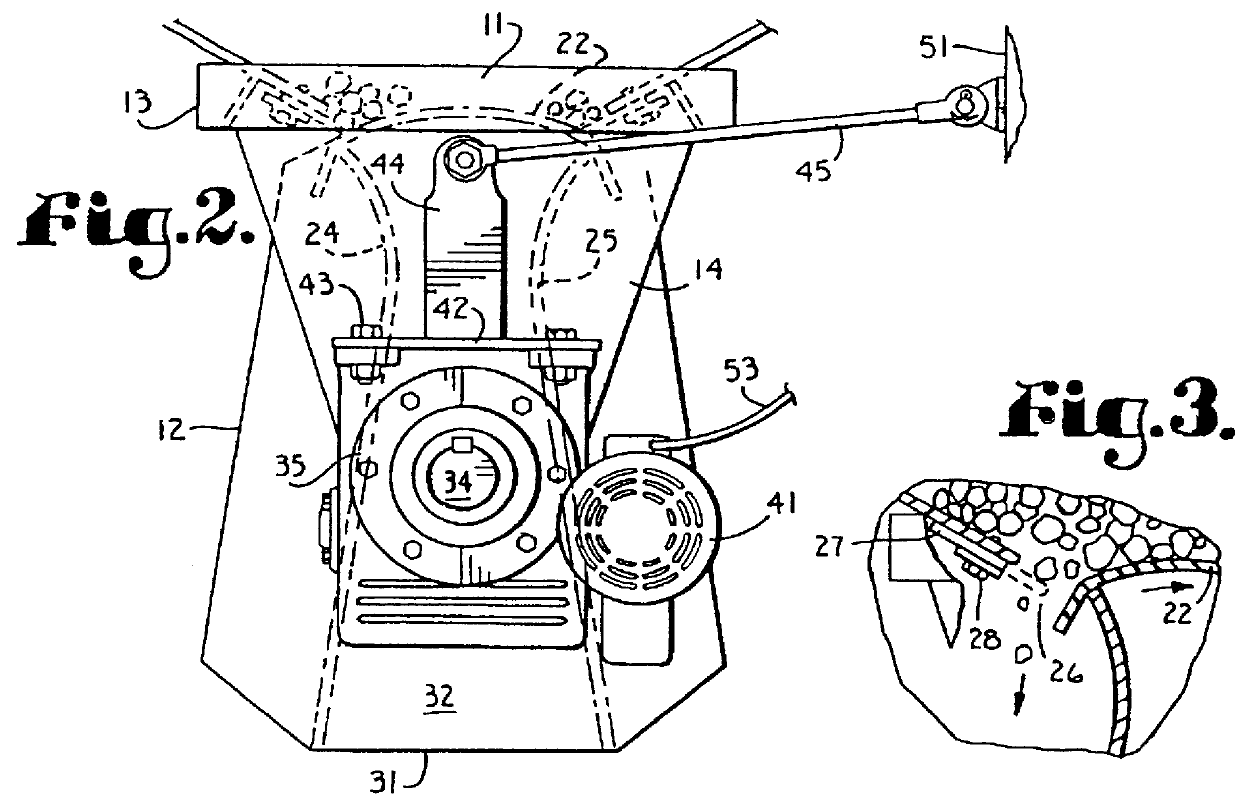

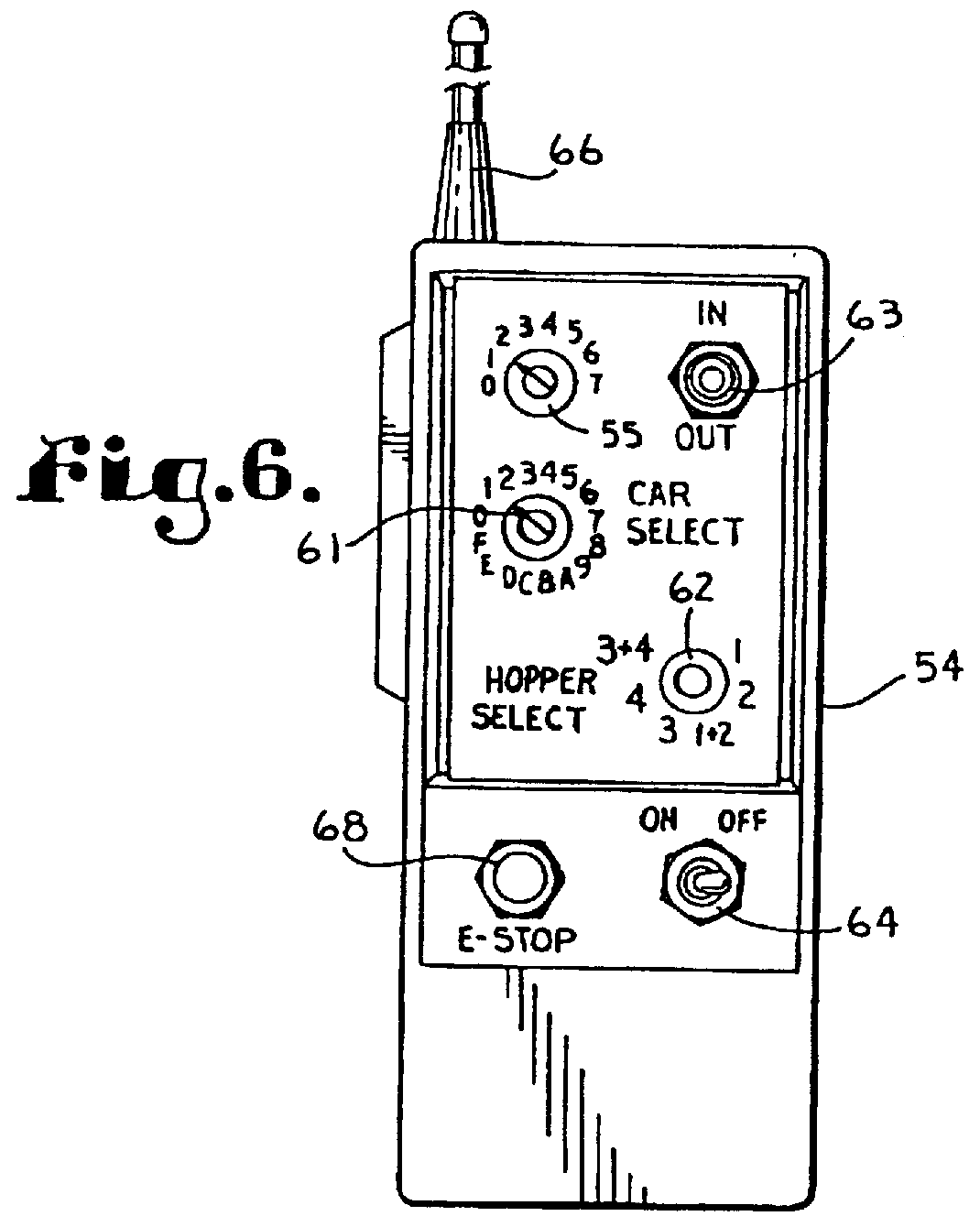

Railroad hopper car with ballast distributing blades and remote control system

A ballast distributing railroad car has a number of ballast hoppers, each with a selectively operable hopper discharge control member which is operable to selectively drop material from the respective hopper either inside of or outside of the rails of a railroad track. The railroad car also has a pair of ballast distributing blades pivotally attached beneath it, either between the hopper discharge control members or one at either end of the car, with the blades being mirror images of each other. Each blade and each hopper discharge control member can be selectively operated via an independent hydraulic actuator. A remote control radio transmitter and car mounted receiver provide for remote, individual and selective control of hopper discharge control members and blades on a car.

Owner:HERZOG CONTRACTING

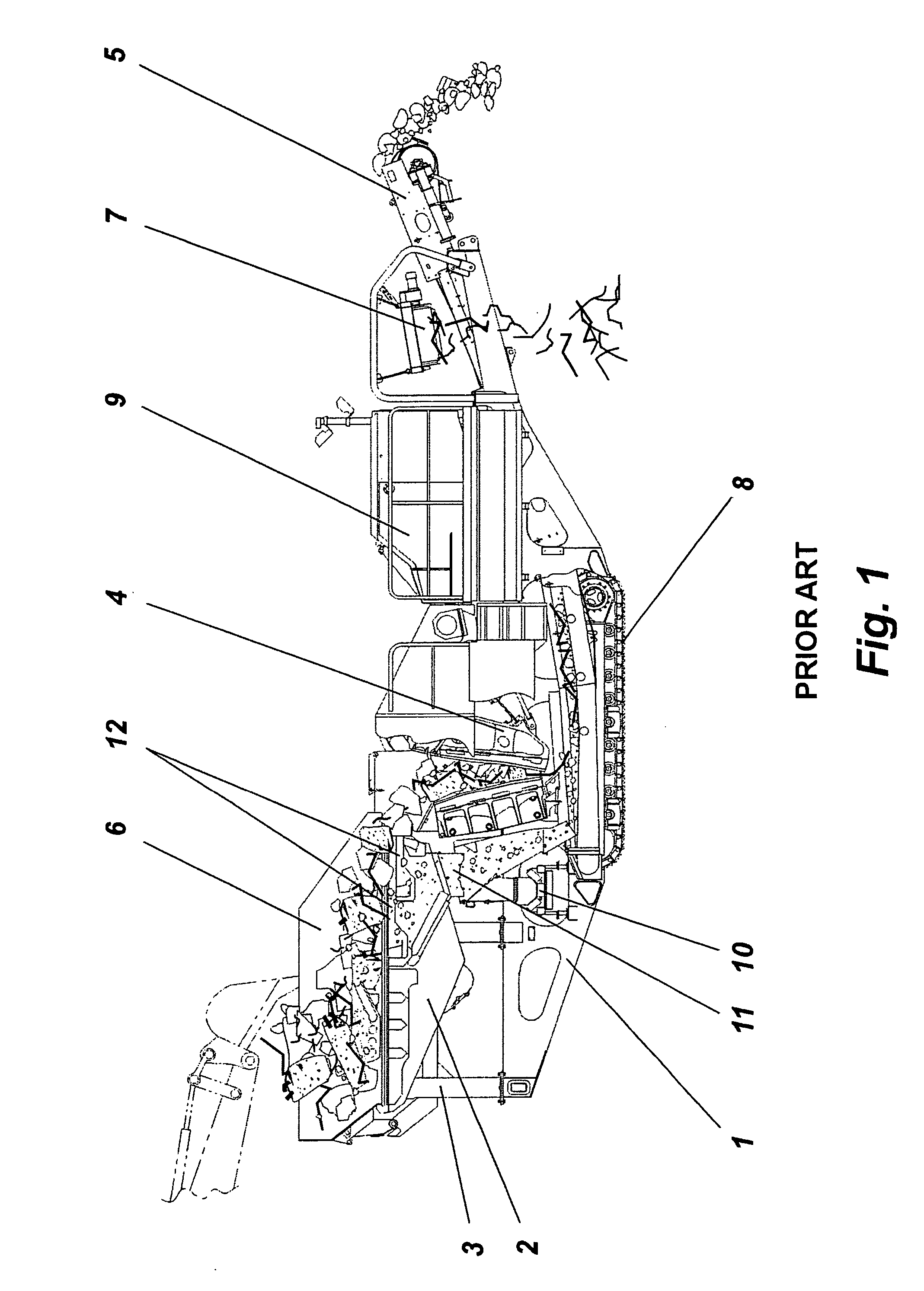

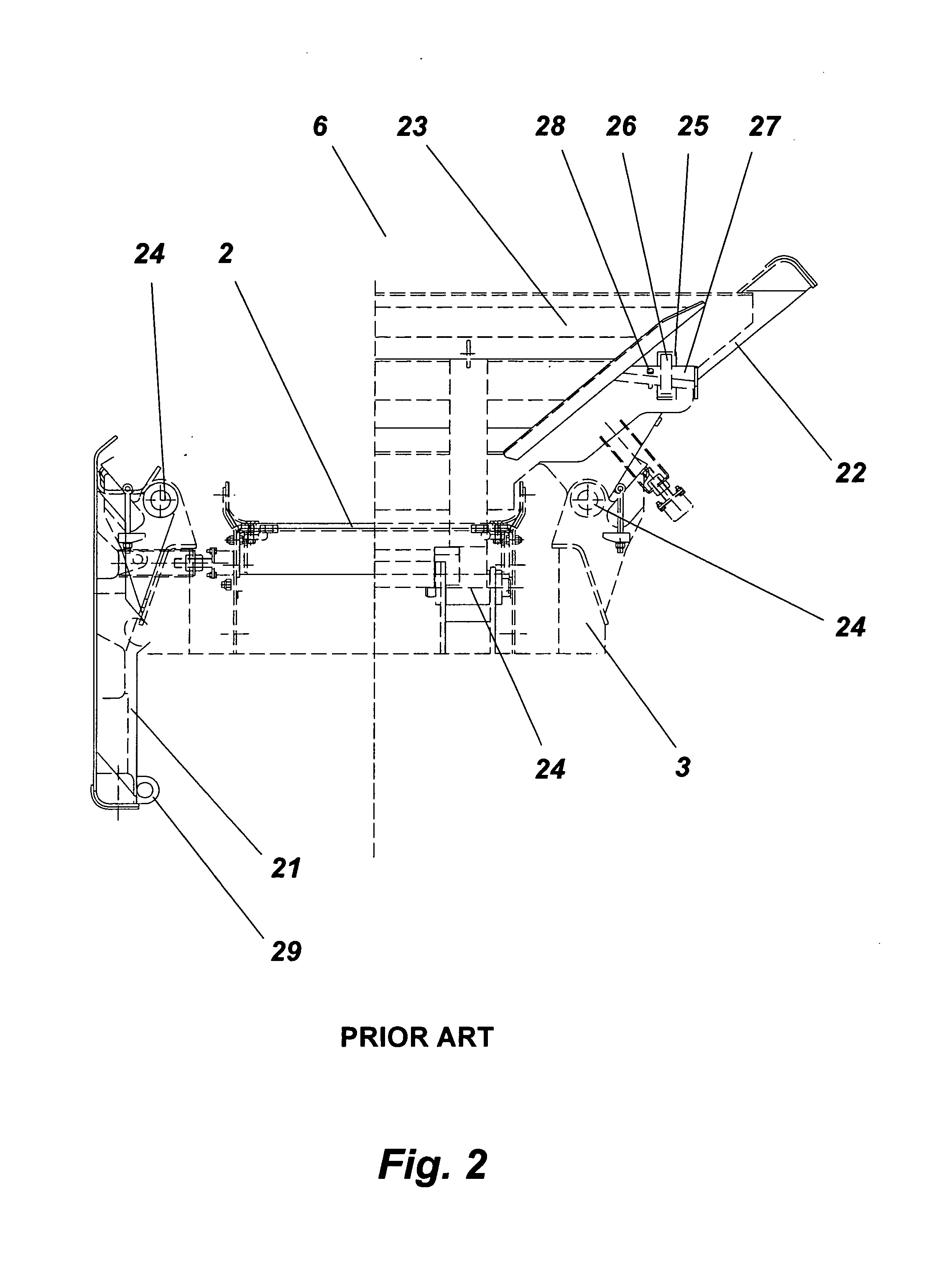

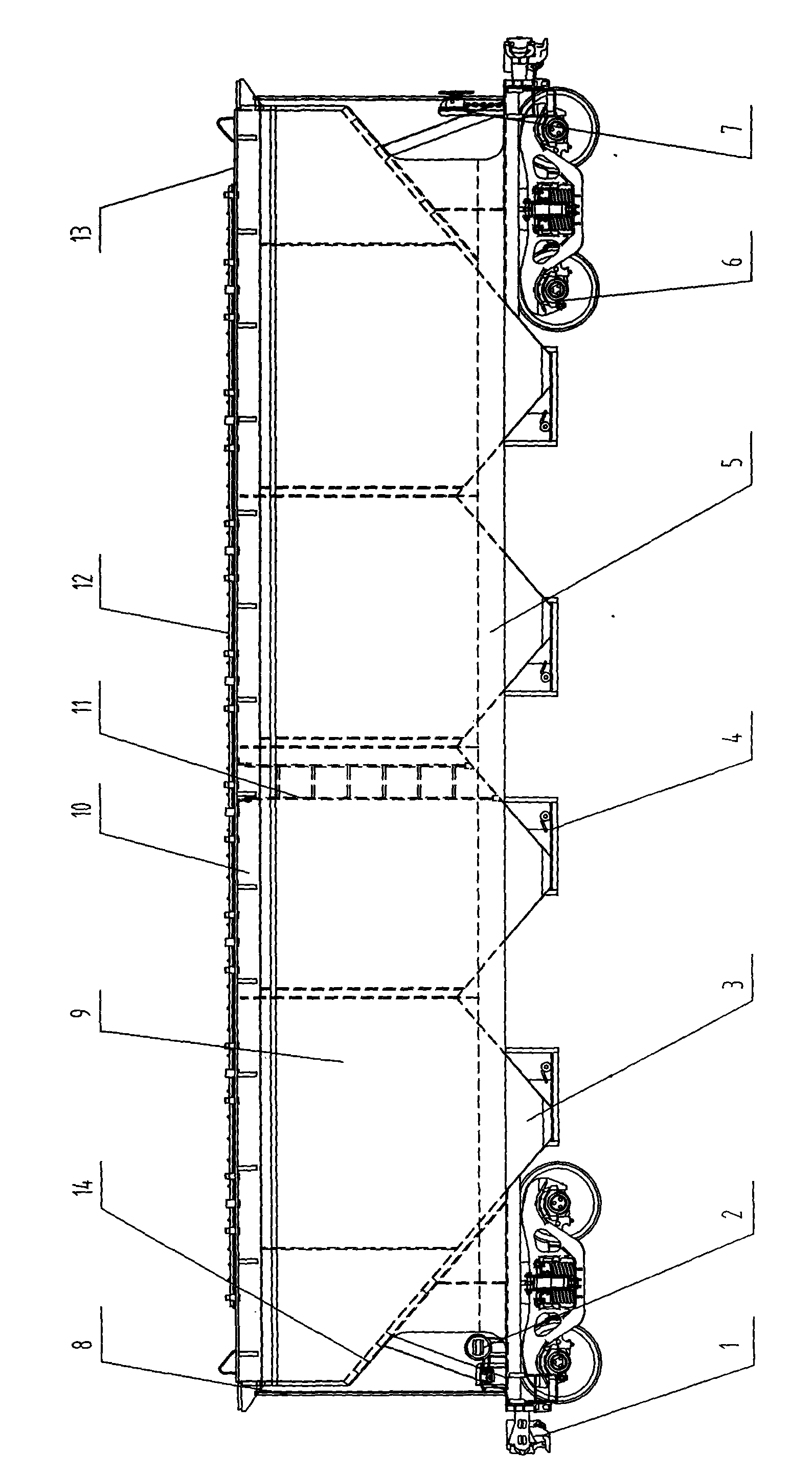

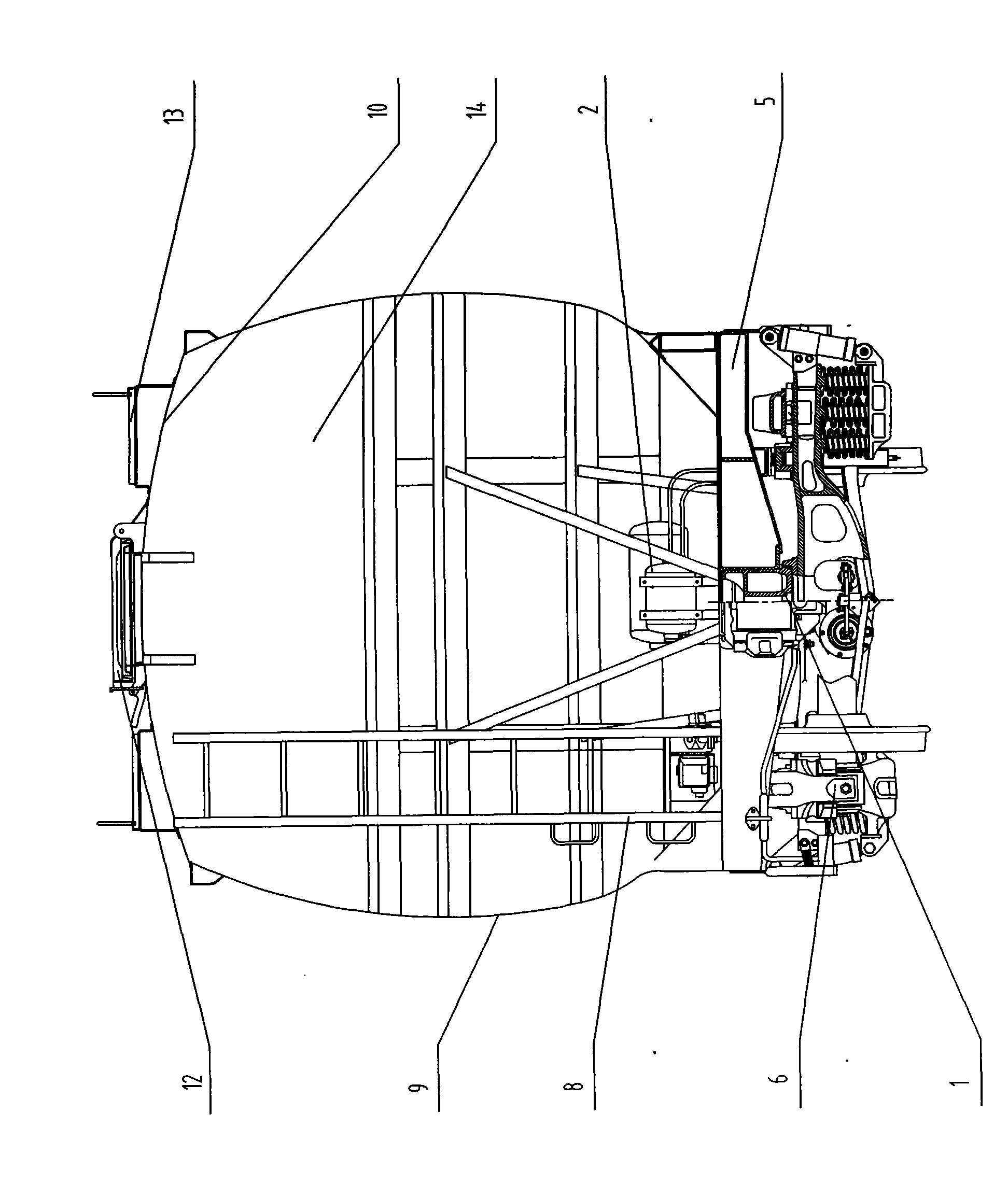

Feeder hopper, a method for locking the walls of a feeder hopper and a locking means

ActiveUS20060016104A1Machines/dredgers working methodsLoading/unloading vehicle arrangmentEngineeringMaterials processing

Feeder hopper for a movable mineral material processing device, whose walls are arranged to be turned upward to a working position, and which are locked into said working position. To lock the walls, there is at least one locking means in connection with them, said locking means containing at least a locking member and transfer means. According to the method the locking member is transferred to the locking position with the transfer means.

Owner:METSO OUTOTEC (FINLAND) OY

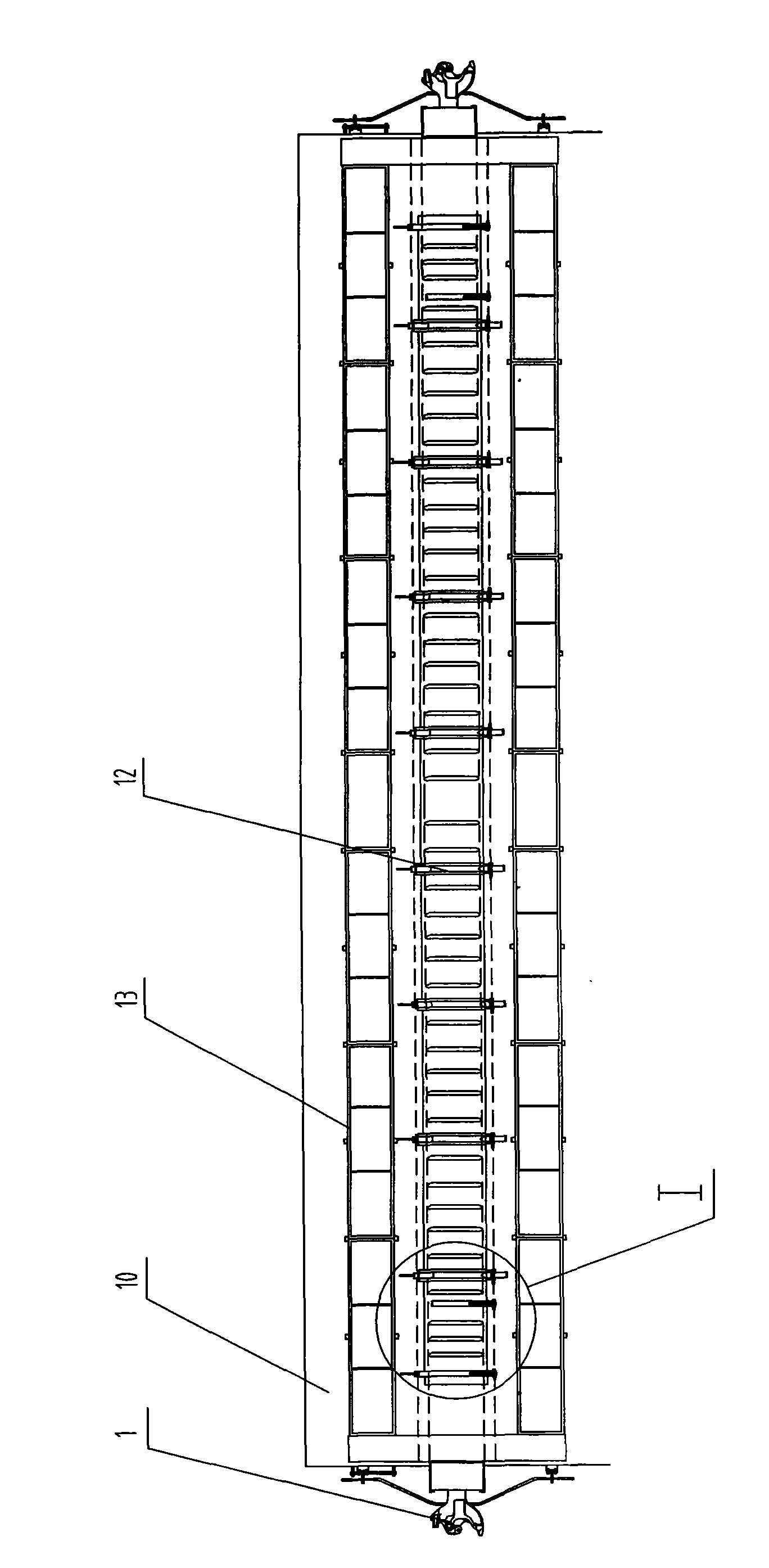

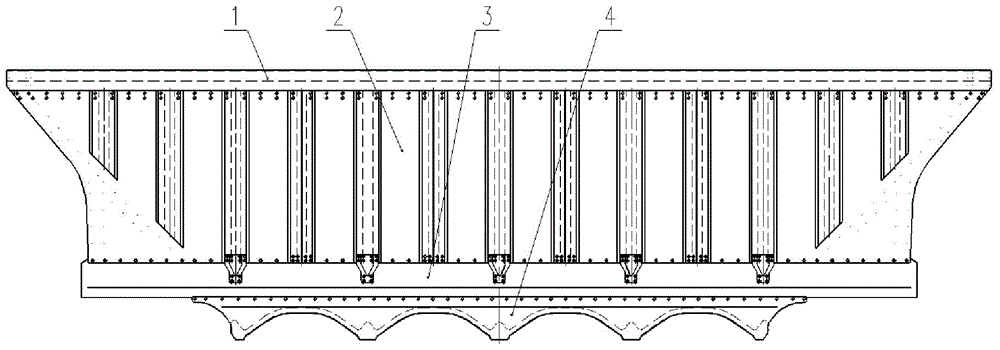

Center sill free stainless steel foodstuff hopper wagon

InactiveCN101590855AReduce the number of groupsImprove turnover rateUnderframesHopper carsBogieAgricultural engineering

The invention relates to a center sill free stainless steel foodstuff hopper wagon, which is a hopper wagon for transporting free-flowing foodstuffs. An underframe is arranged on a steering frame, a wagon body is arranged on the underframe, a coupler and draft gear, a hand braking device and an air braking device are arranged on the underframe, a hopper part and a bottom door assembly are arranged under the wagon body, a platform is arranged on the wagon body, the underframe is provided with two side walls and two end walls, a wagon roof is arranged on the walls, the underside of the underframe is provided with four hopper parts, and the side walls adopt four thin-wall arc structures; one end of the end wall is provided with an end ladder; the wagon roof consists of nine turnable loading port cover parts, and each loading port cover part consists of a port cover, a left blocking bar, a right blocking bar and a compacting fixing device; and the left blocking bar is arranged at the left end of the port cover, the right blocking bar is arranged at the right end of the port cover, and the compacting fixing device is arranged between the left blocking bar and the right blocking bar. The center sill free stainless steel foodstuff hopper wagon has the advantages that the two side walls of the entire wagon body adopt the four thin-wall arc structures so that the dead weight is light and the volume is large so as to use the vehicle gauge and the load carrying capacity to the utmost extent, thus the center sill free stainless steel foodstuff hopper wagon is suitable for the requirement on overloading transportation.

Owner:CRRC SHENYANG CO LTD

Railroad hopper car transverse door actuating mechanism

InactiveUS20060254456A1Optimization mechanismFast emptyingHopper carsWagons/vansEngineeringMechanical engineering

An actuating system for operating transverse doors of a railroad hopper car. The mechanism includes an operating member which is coupled to a door or doors of the car by a shaft and a linkage which couples a power source to the operating member, where the operating member rotates to move the door away from the hopper. The mechanism can operate doors which open in opposed direction with a single power source. The mechanism can be used in new car construction, and can be retrofitted onto existing hopper cars.

Owner:FT & JP ENTERPRISES

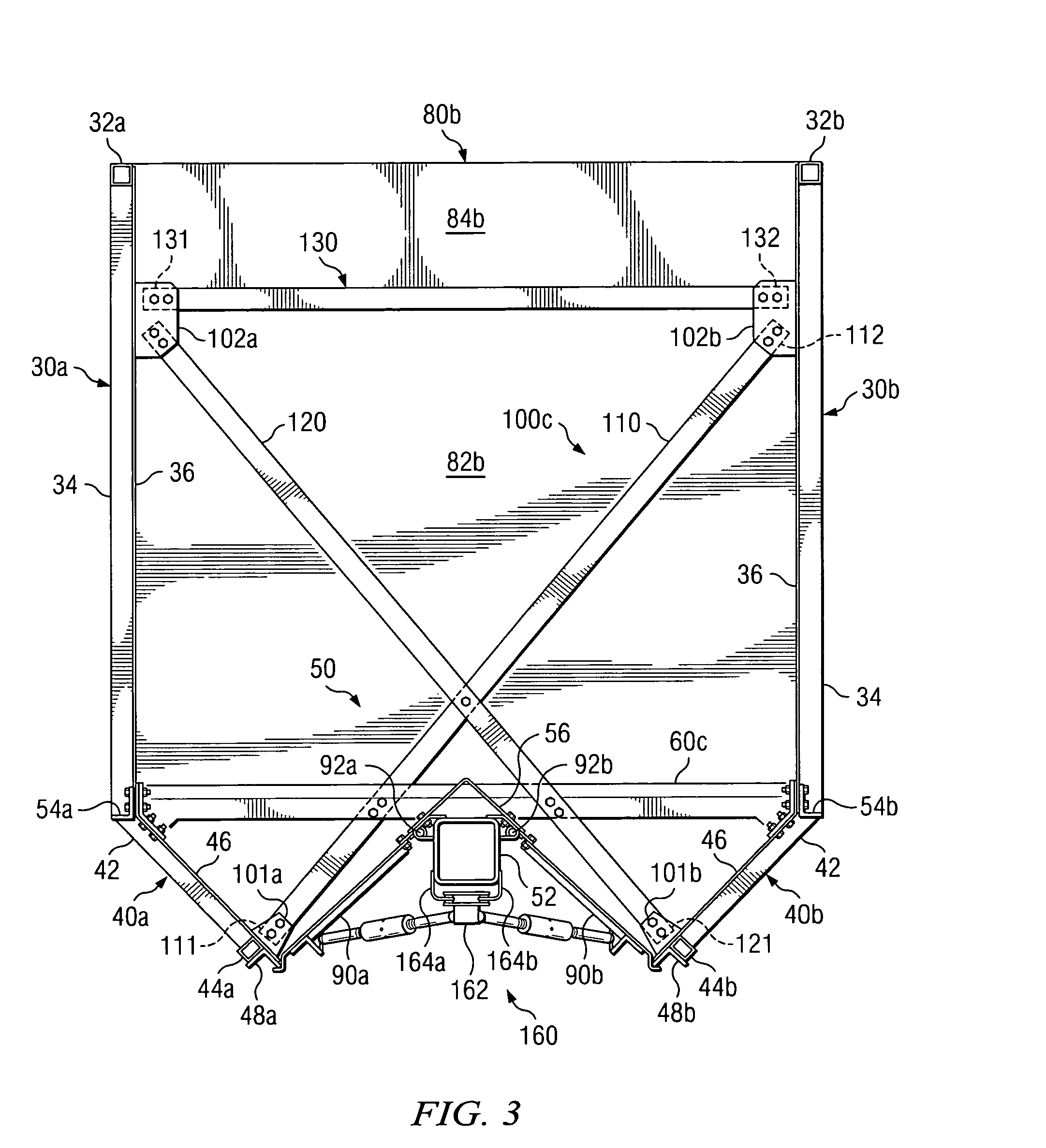

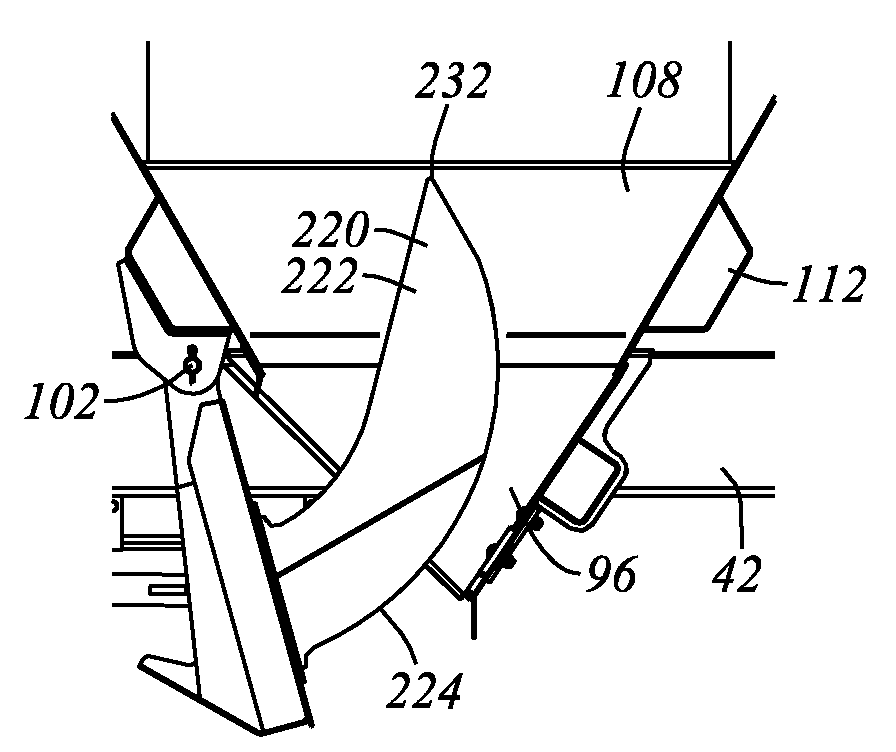

Hopper cars with one or more discharge control systems

ActiveUS8915194B2Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

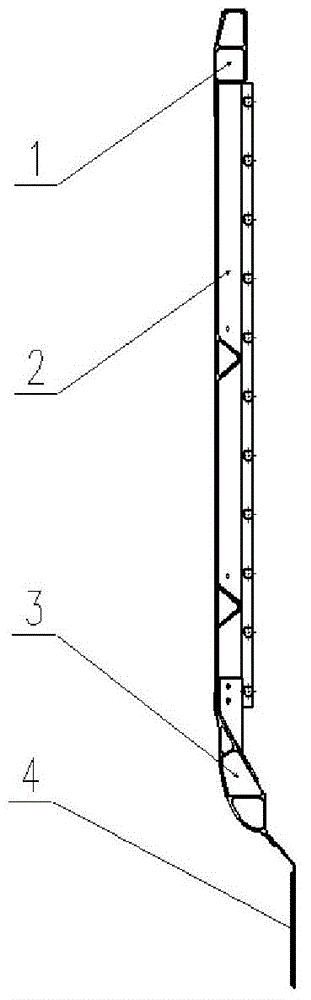

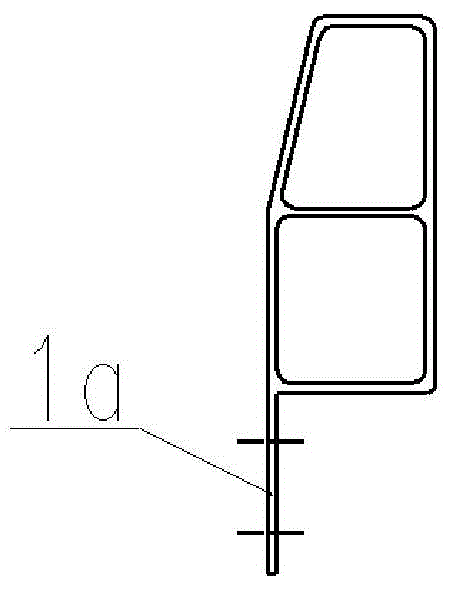

Side wall structure for hopper car

InactiveCN103909941AIncrease volumeSimple structureAxle-box lubricationHopper carsPlate columnUltimate tensile strength

The invention discloses a side wall structure for a hopper car. The side wall structure comprises an integrally formed upper side beam (1), an integrated side wall plate (2), an integrally formed lower side beam (3) and a lower side wall (4). The upper side beam (1) and the integrated side wall plate (2) below are riveted. The side wall plate (2) and the integrally formed lower side beam (3) below are riveted. The side wall plate is in a wall plate and side column integrated plate-column structure, and the side columns are arranged on the inner side of the car body. The lower side beam (3) and the lower side wall (4) below are riveted. According to the side wall structure, by means of the integrated side wall plate with the built-in side columns, both the strength reduction due to rivet holes and the increased weight and cost due to the usage of rivets are prevented, the side columns are arranged inside, so that space among the side columns is used, and the car body volume is increased.

Owner:CRRC YANGTZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com