Patents

Literature

151 results about "Rail freight transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rail freight transport is the use of railroads and trains to transport cargo as opposed to human passengers. A freight train, cargo train, or goods train is a group of freight cars (US) or goods wagons (International Union of Railways) hauled by one or more locomotives on a railway, transporting cargo all or some of the way between the shipper and the intended destination as part of the logistics chain. Trains may haul bulk material, intermodal containers, general freight or specialized freight in purpose-designed cars. Rail freight practices and economics vary by country and region.

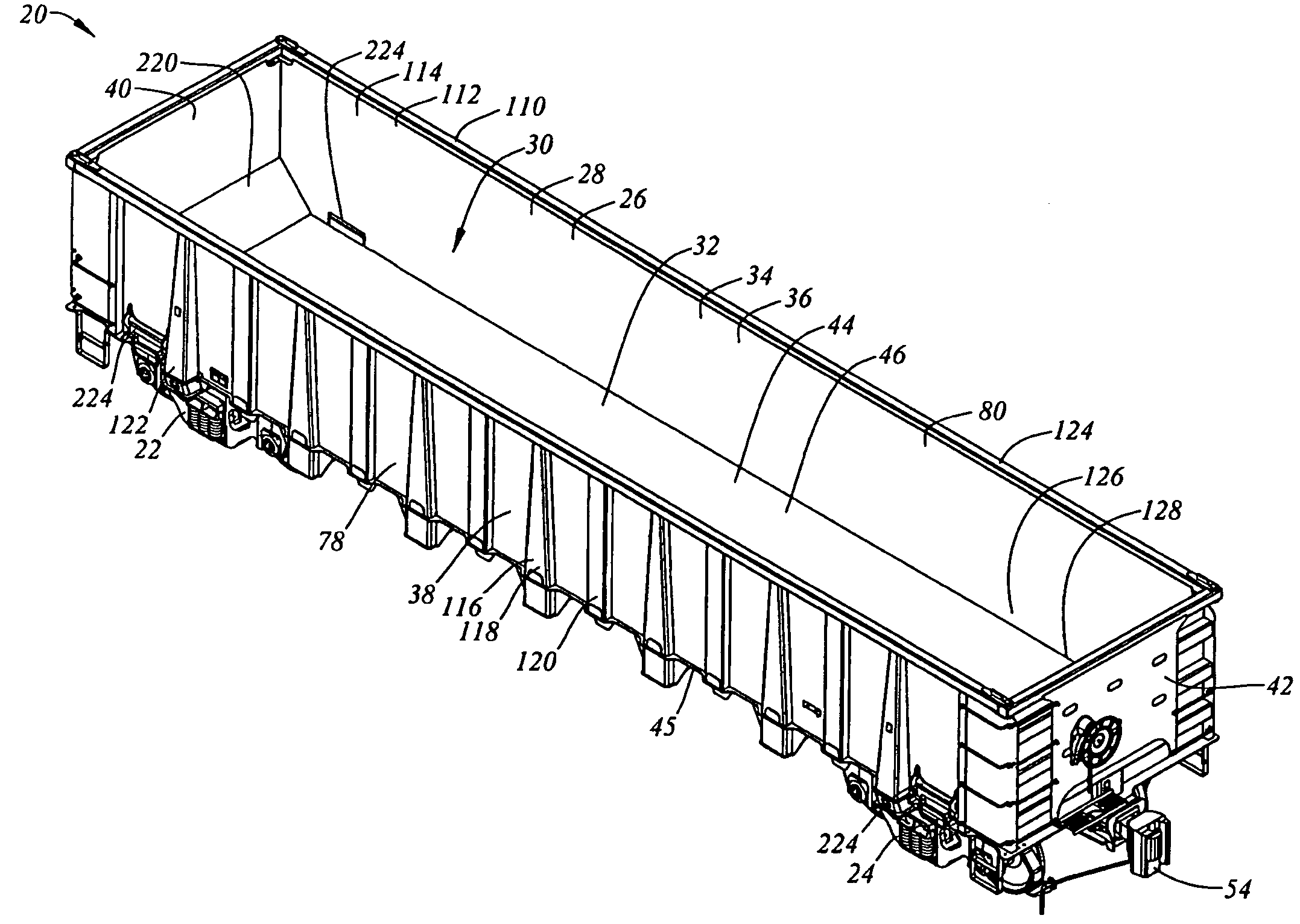

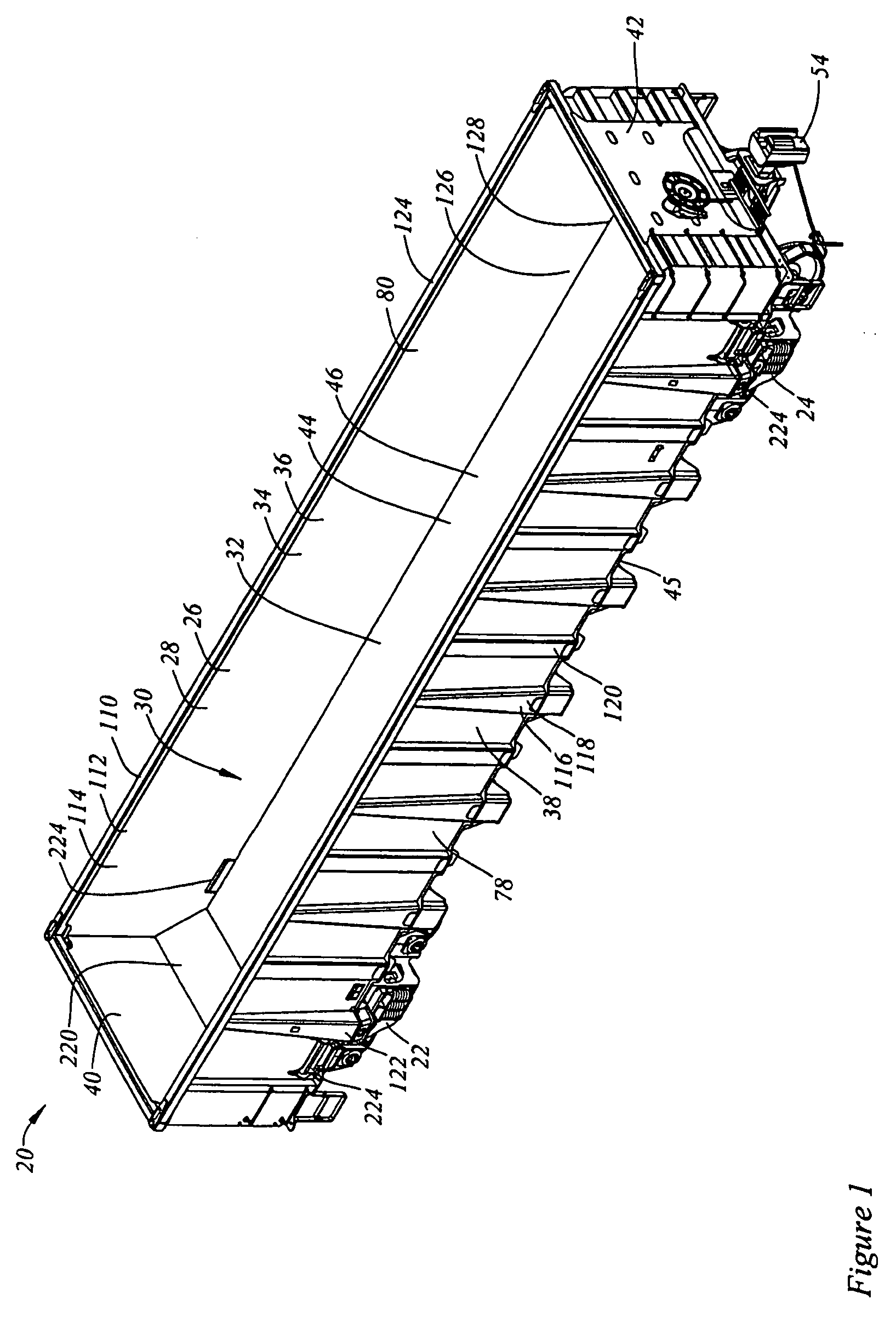

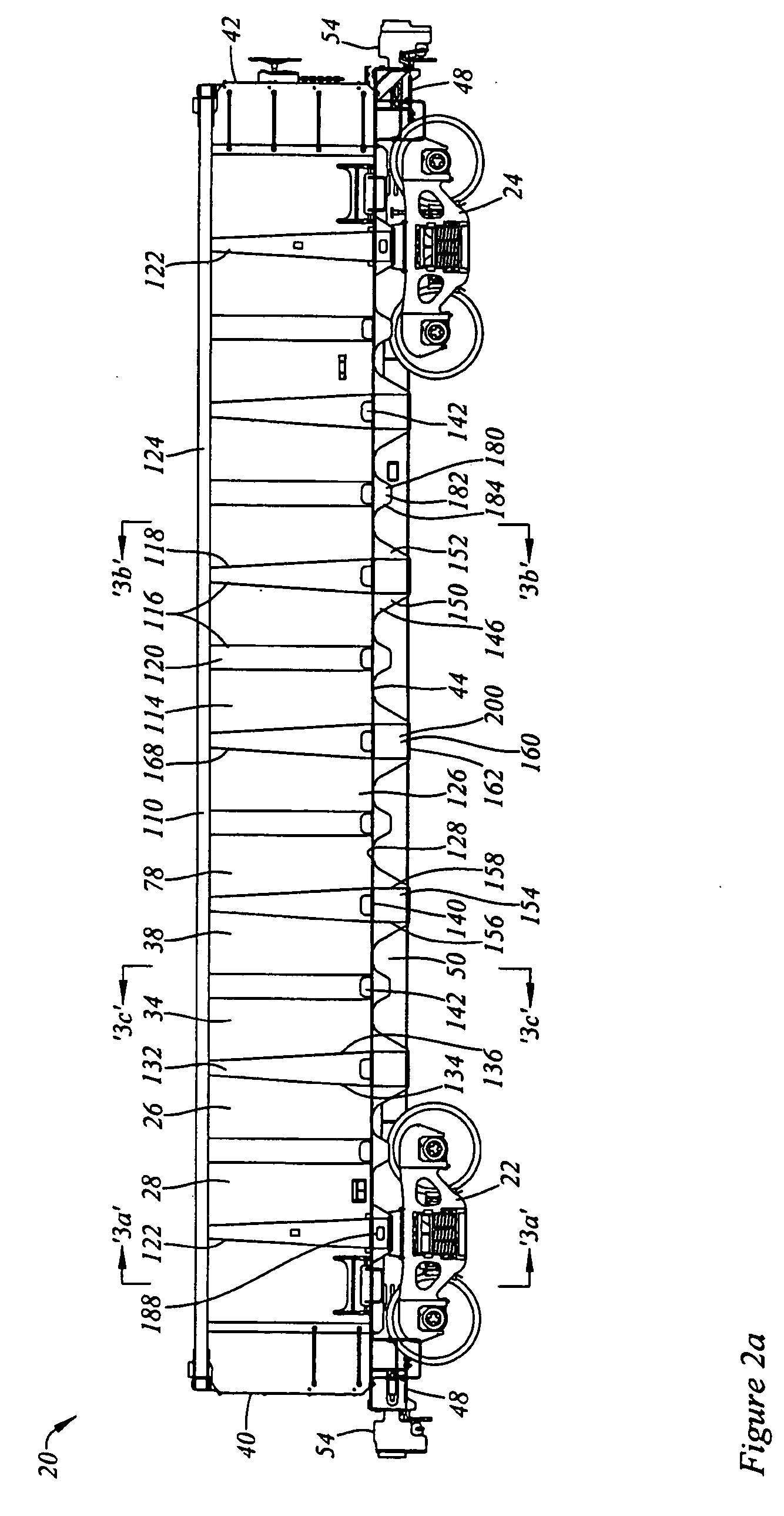

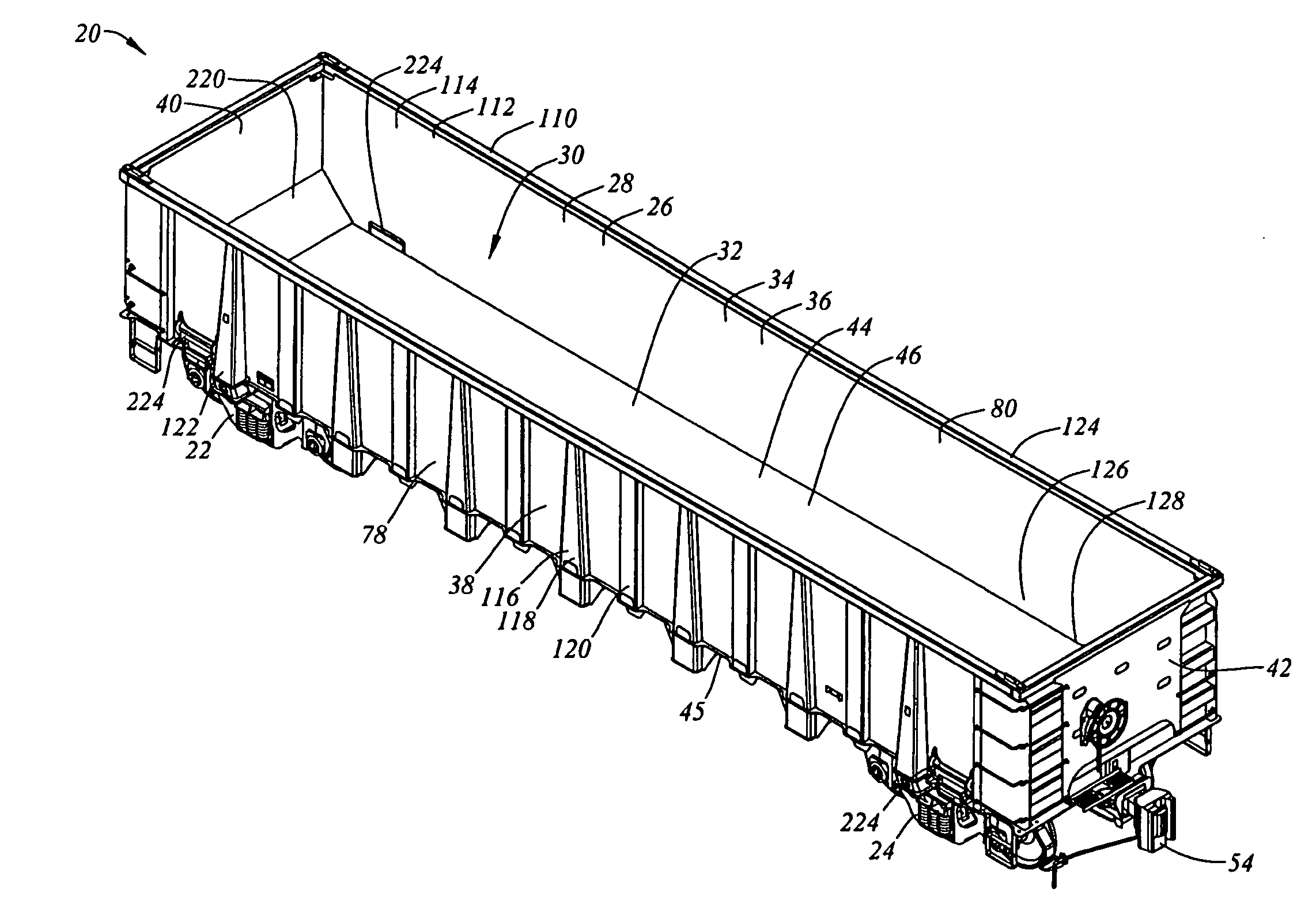

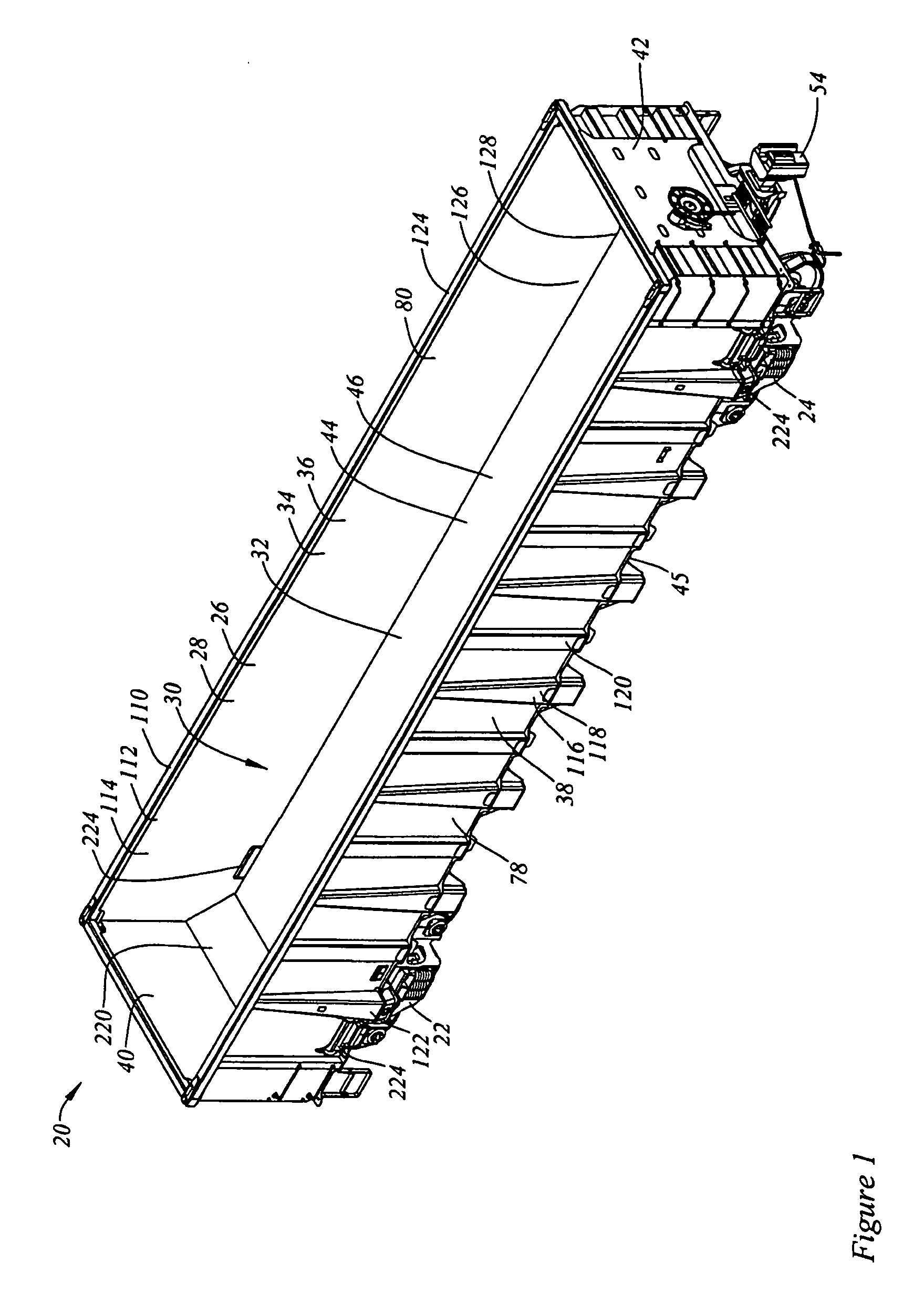

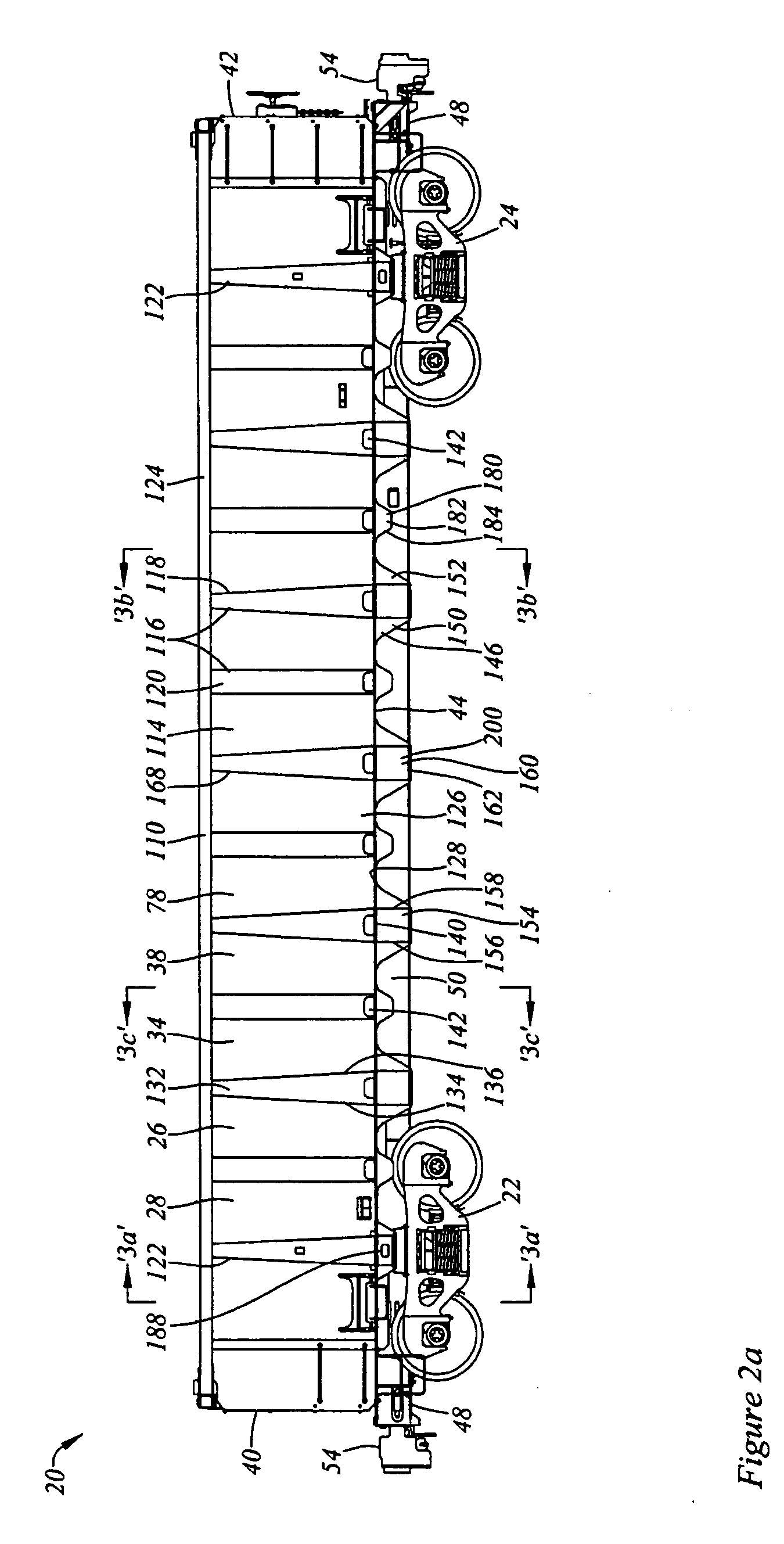

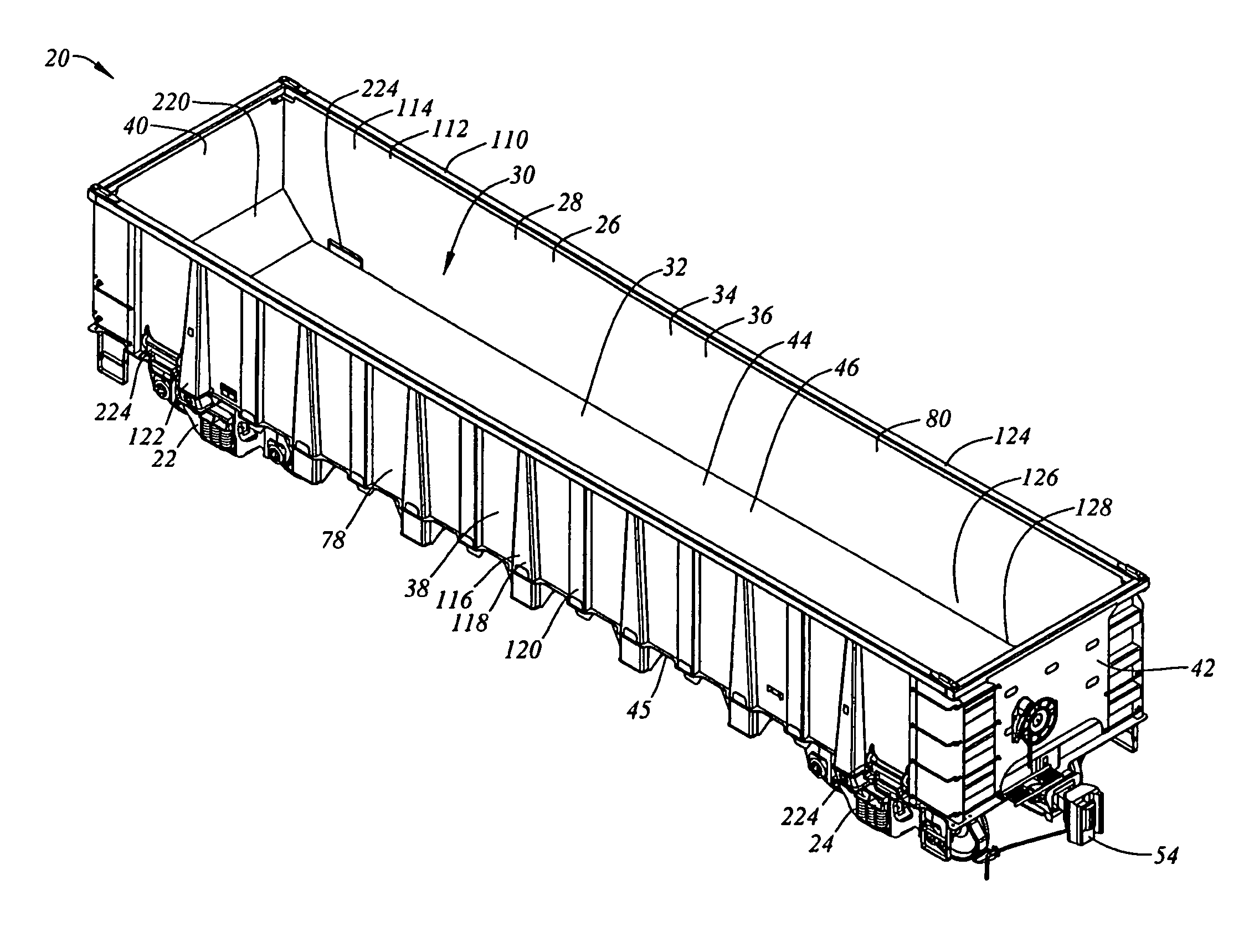

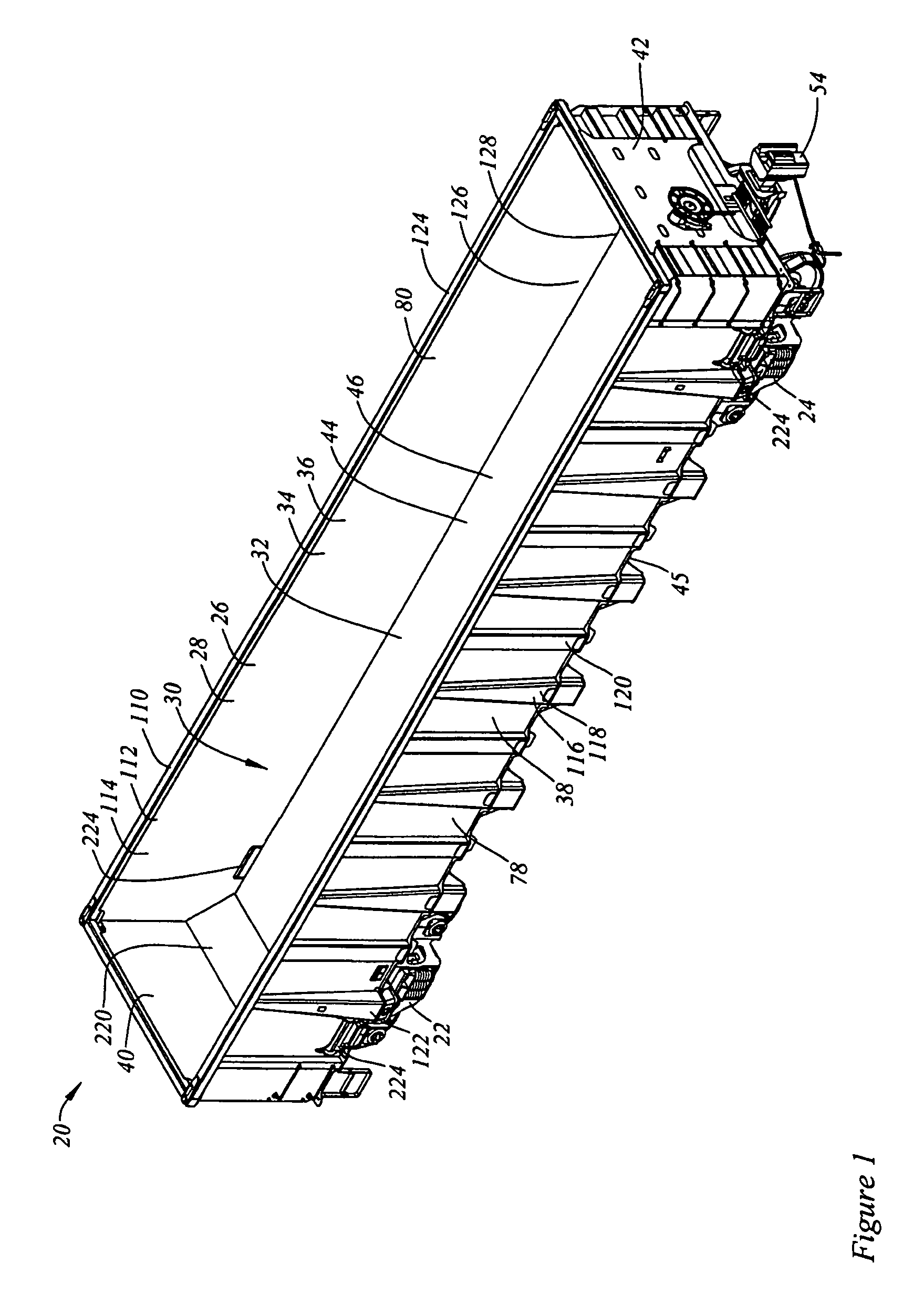

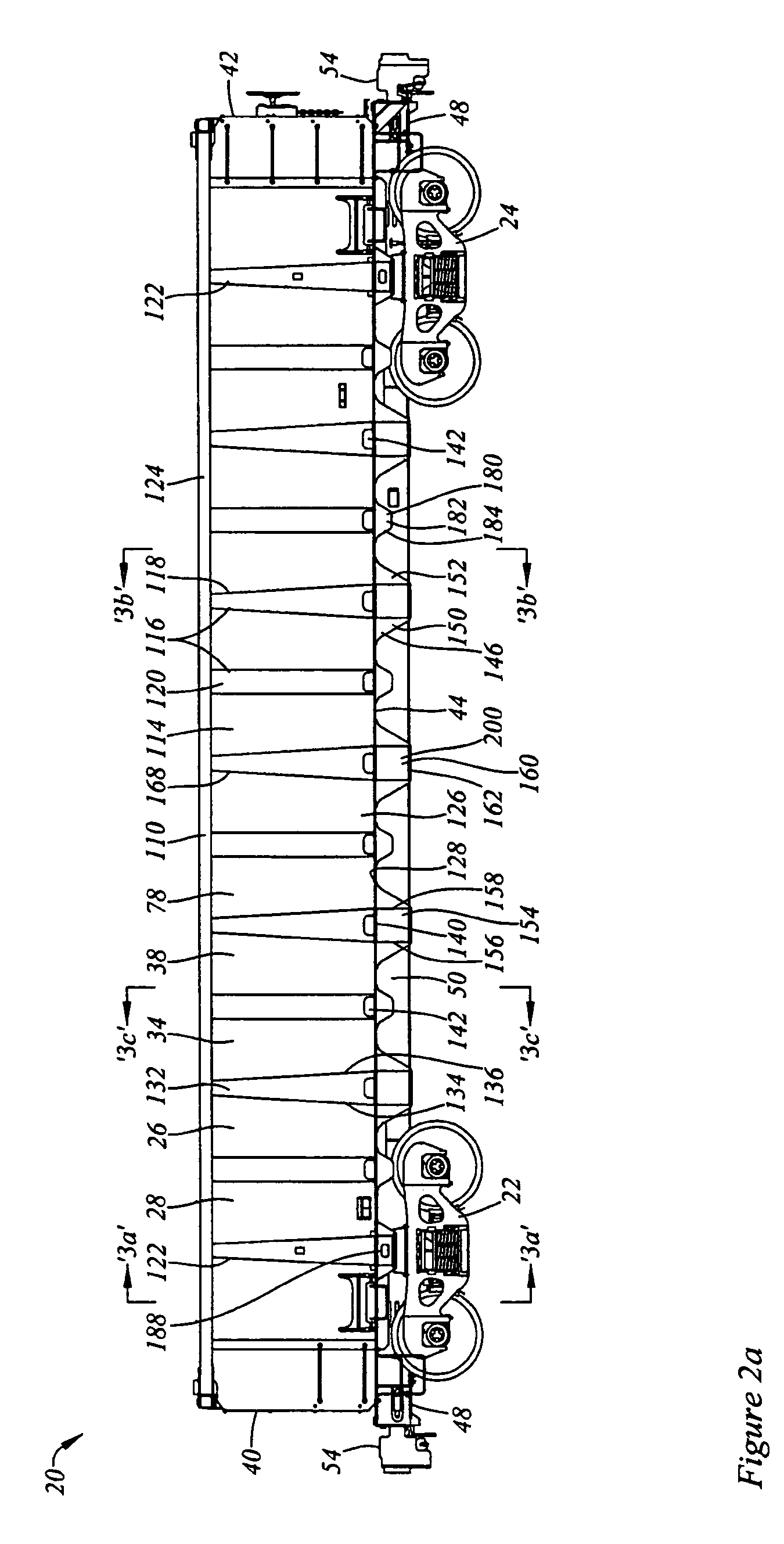

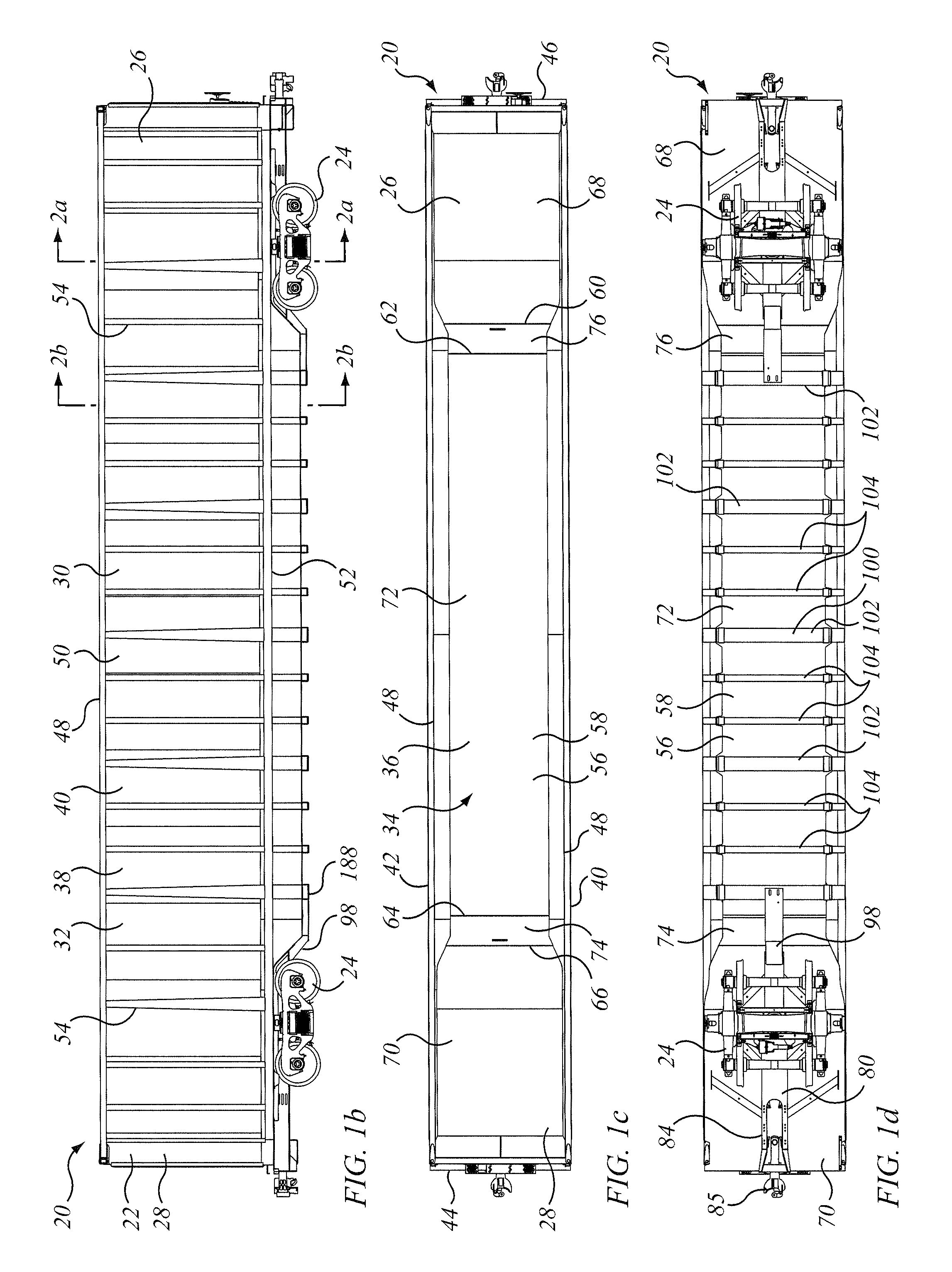

Rail road freight car

Owner:NATIONAL STEEL CAR

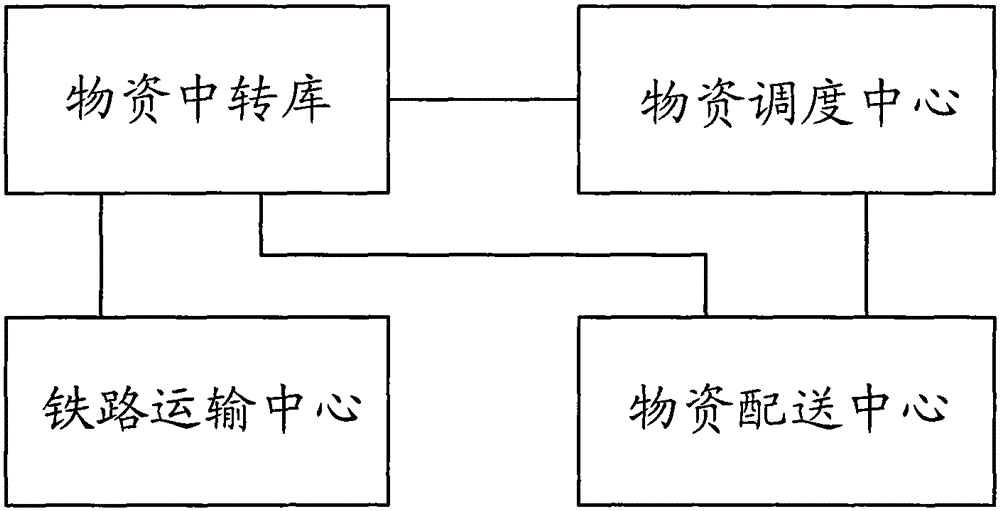

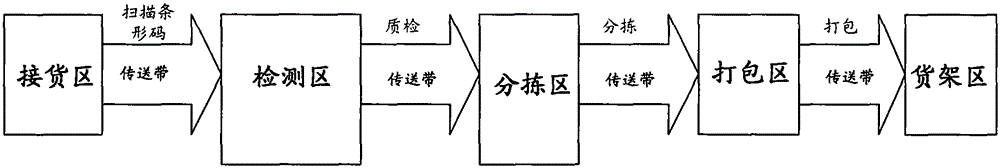

Green logistics service system

InactiveCN105184525AReduce pollutionImprove logistics service efficiencyLogisticsRail freight transportNew energy

The embodiment of the invention discloses a green logistics service system, which comprises a material transfer storehouse, a material dispatching center, a material distribution center and a railway transportation center, and is characterized in that the material transfer storehouse is used for storing transfer materials transported from the material distribution center; the material dispatching center determines a material transfer storehouse and dispatches an electric vehicle; the material distribution center sends the electric vehicle to a railway freight yard to load the materials and transport the materials to the material transfer storehouse; the railway transportation center sets transfer material information for the materials to be transferred and transmits the transfer material information to the material dispatching center, by using a transportation mode of combining a city distribution electric logistic vehicle and a railway electric locomotive, and the materials to be transferred are transported and carried by relaying on a railway freight electric locomotive; and positioning information of the running railway electric locomotive is acquired, and the acquired positioning information is sent to the material distribution center. By applying the green logistics service system, truck exhaust gas emission pollutions are solved from the source, and an innovative new energy circulation industry which is capable of saving energy, reducing emission, relieving the traffic and reducing fog and haze, safe and efficient is constructed, thereby building a modern smart city big traffic livelihood green logistics sustainable development system.

Owner:北京永绅好运发达信息技术有限公司 +3

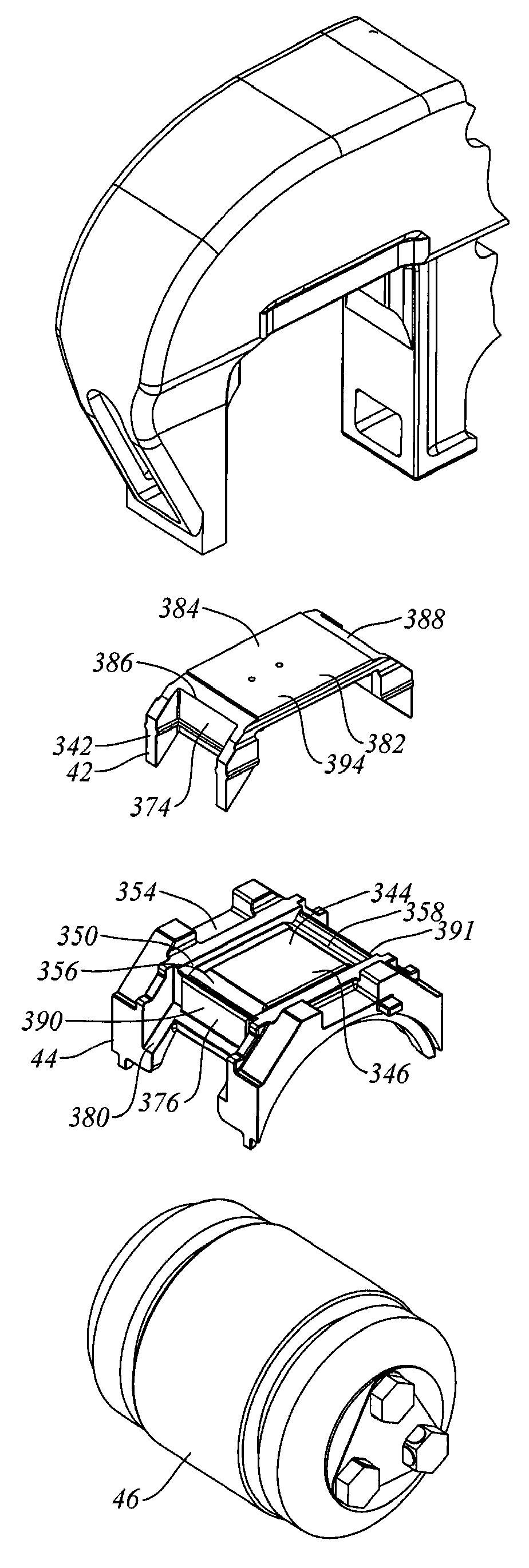

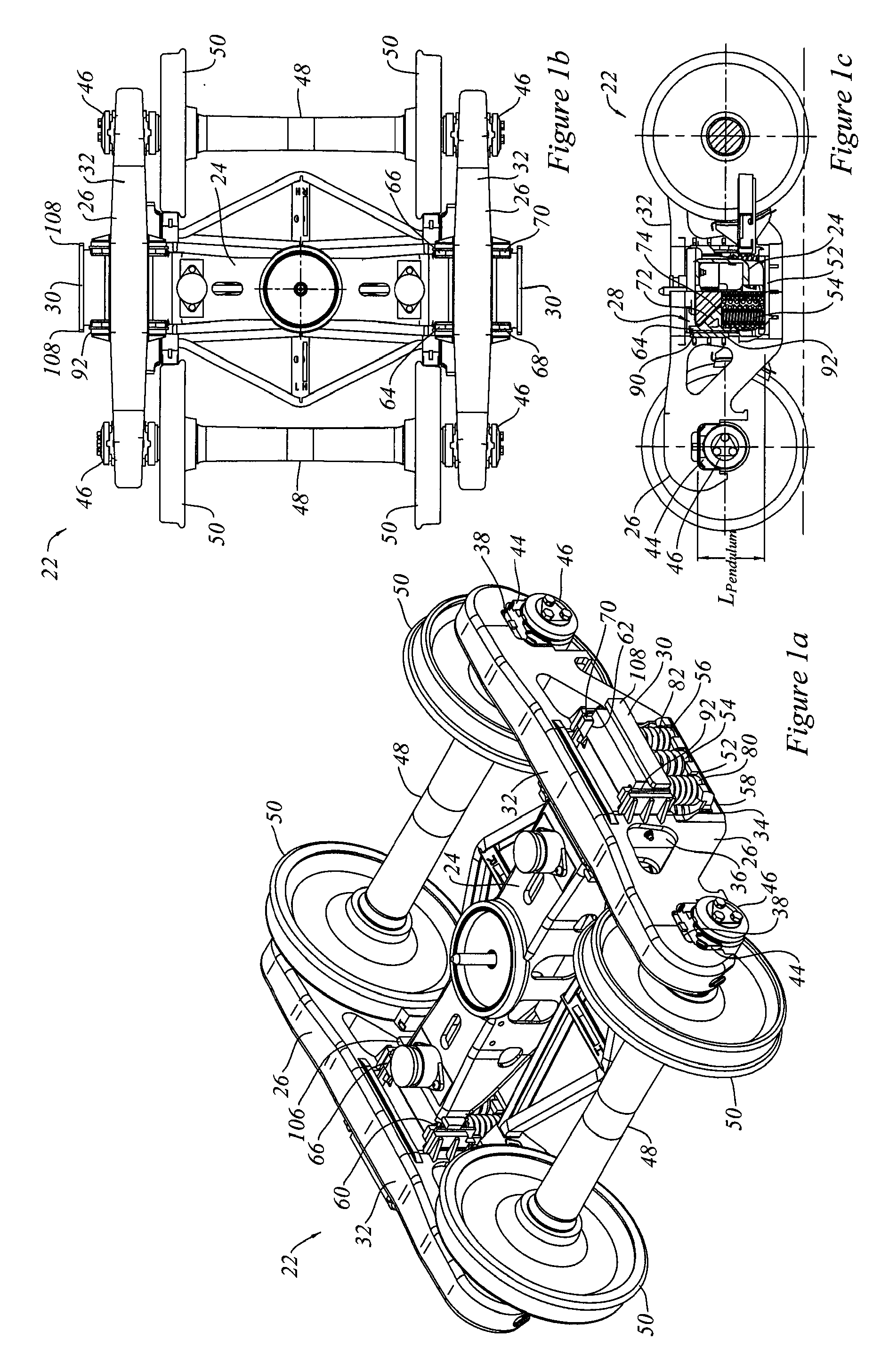

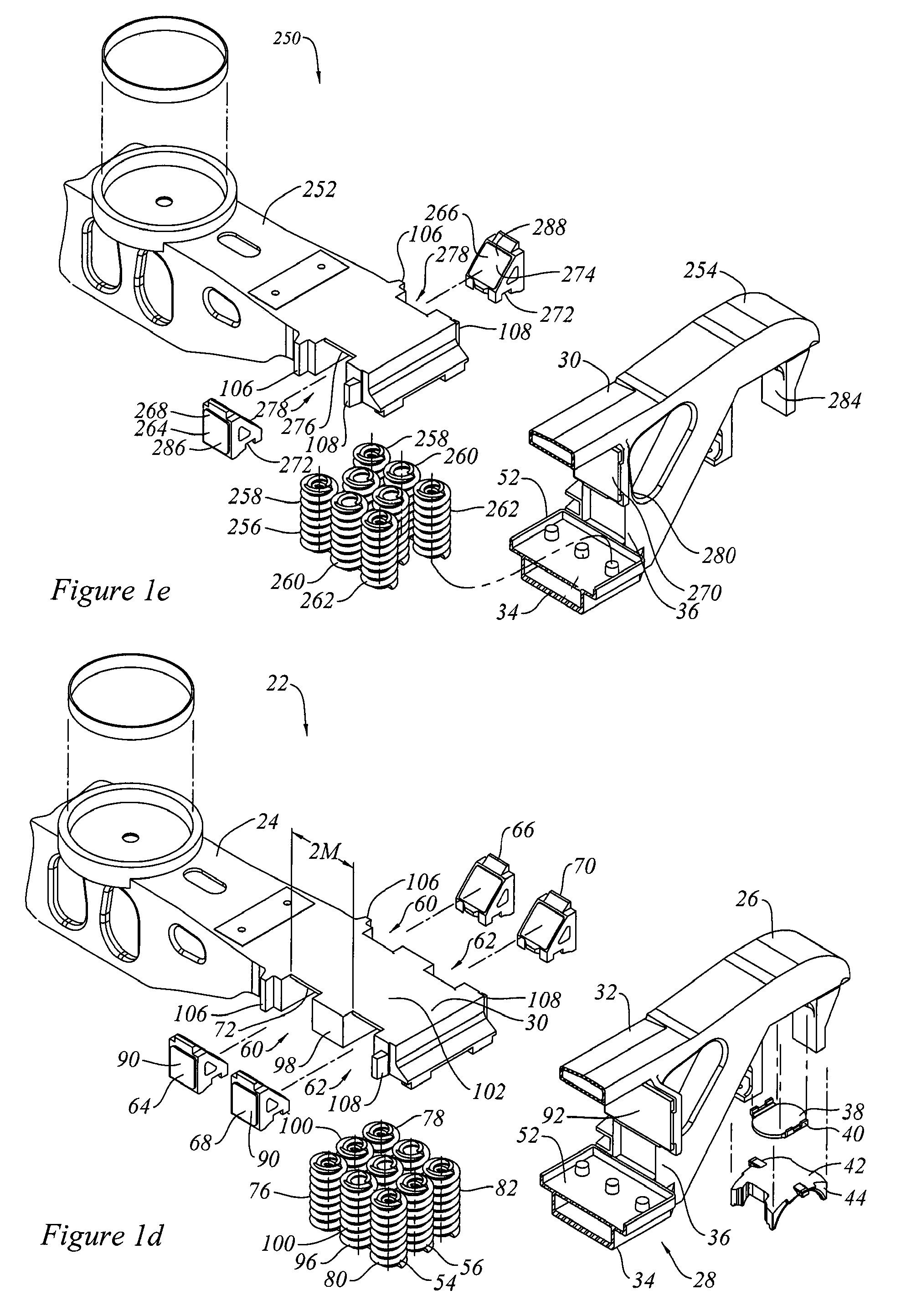

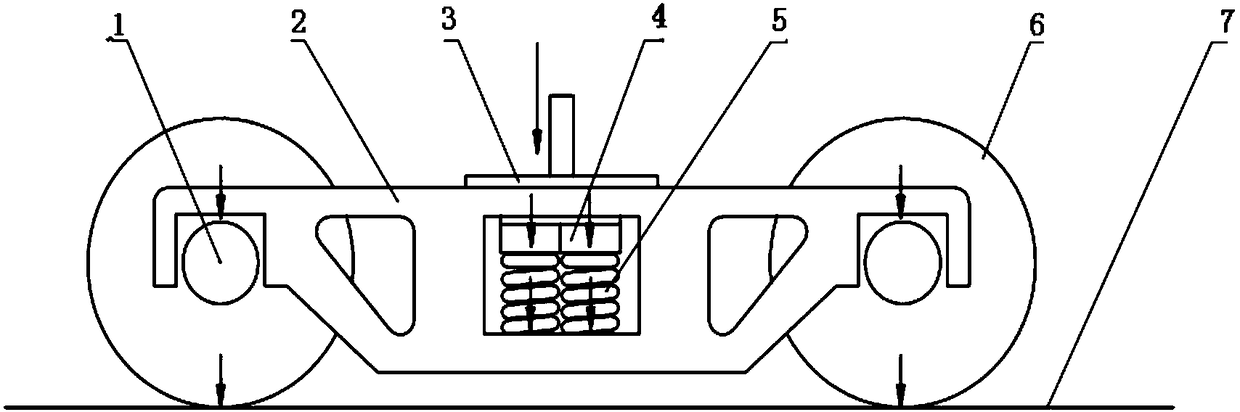

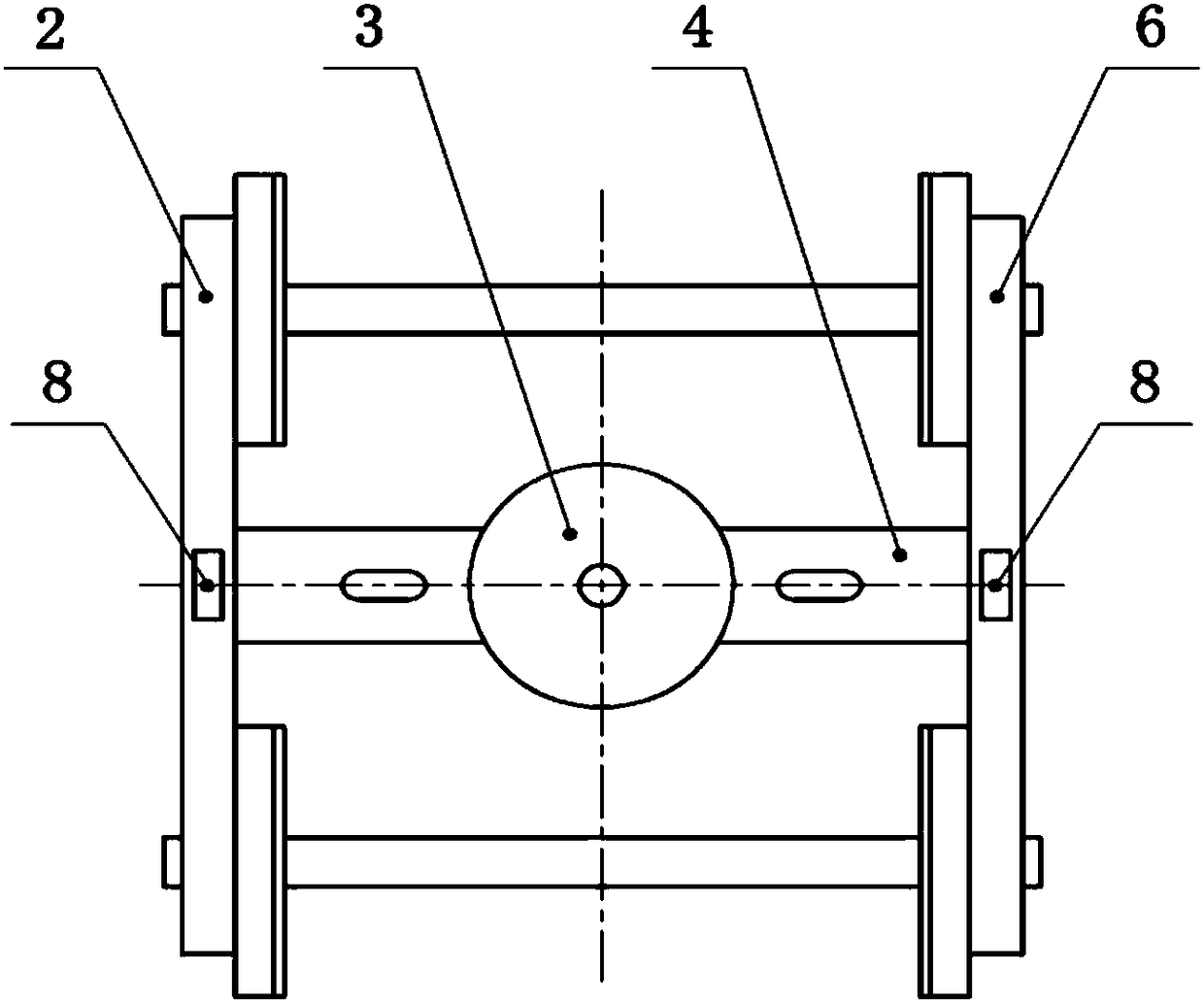

Rail road car and bearing adapter fittings therefor

A rail road freight car truck, which may be a Barber S2HD truck or other kind of truck, has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The sideframes are mounted on a pair of wheelsets. The bolster may be resiliently sprung and may have friction dampers. Either the friction dampers or the sideframe column wear plates may have a non-metallic wear plate, or wear surface, which may be replaceable, and which may tend to exhibit non-stick slip, or reduced stick slip behaviour in use. Bearing adapters may be mounted on the bearings of the wheelsets, and resilient pad members may be mounted on the bearing adapters. The pedestal seats may sit over the resilient pads. There may be a discontinuity in the vertical load path between the pedestal roof and the bearing. The discontinuity in the vertical load path may tend to shed a portion of the vertical load to either side of the top rollers of the bearing races to a greater extent than if the vertical load path discontinuity were not present.

Owner:GREYPOINT CAPITAL INC

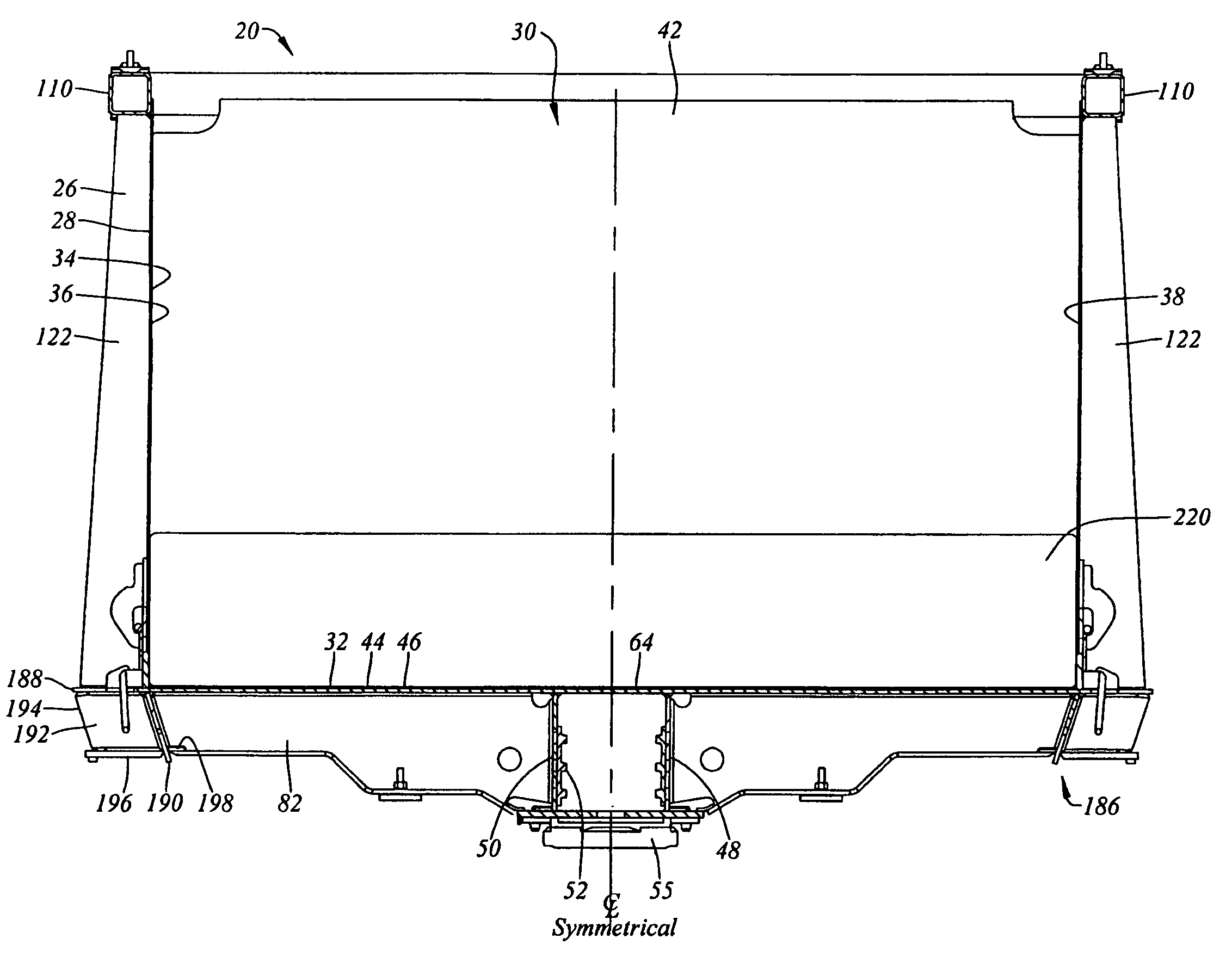

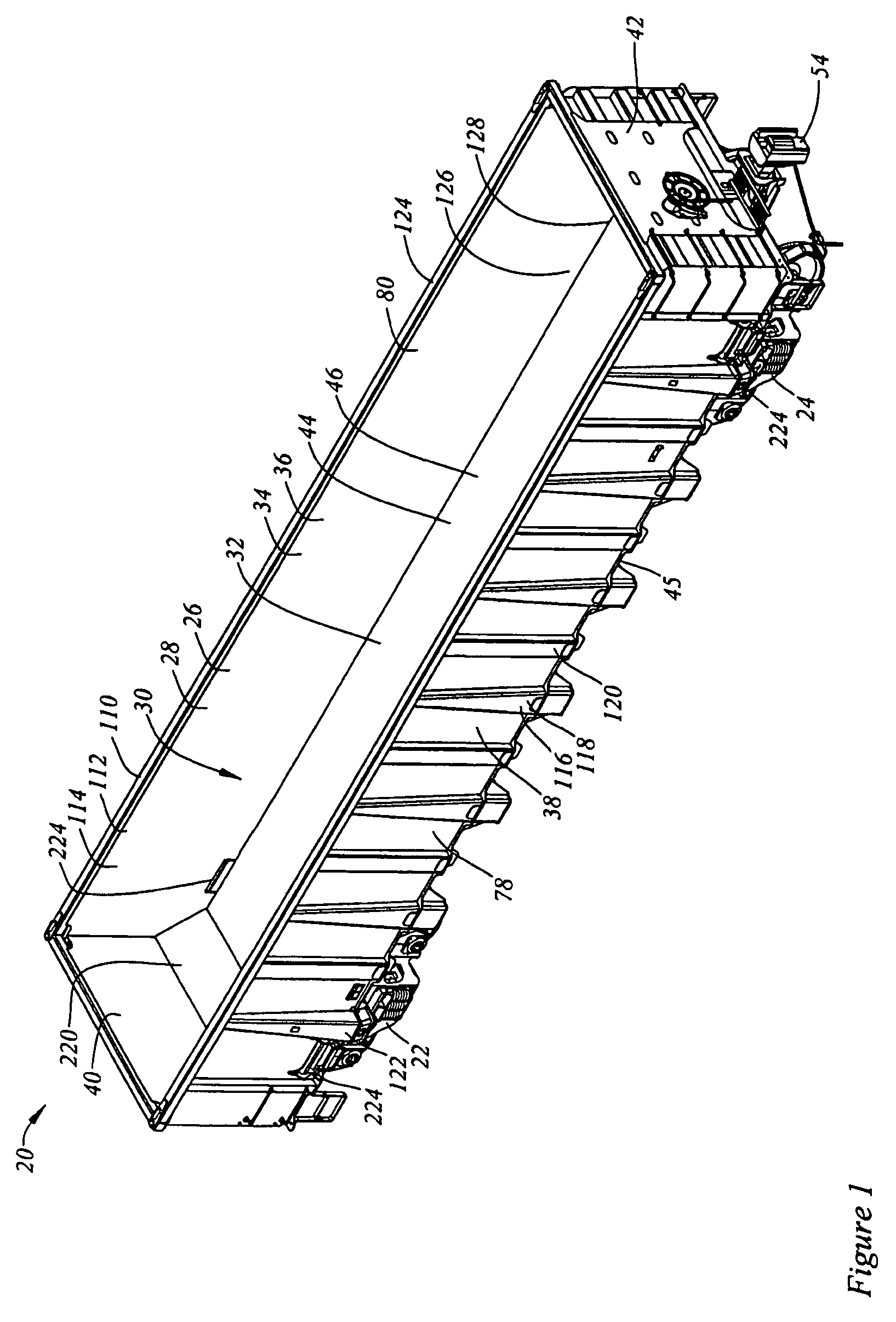

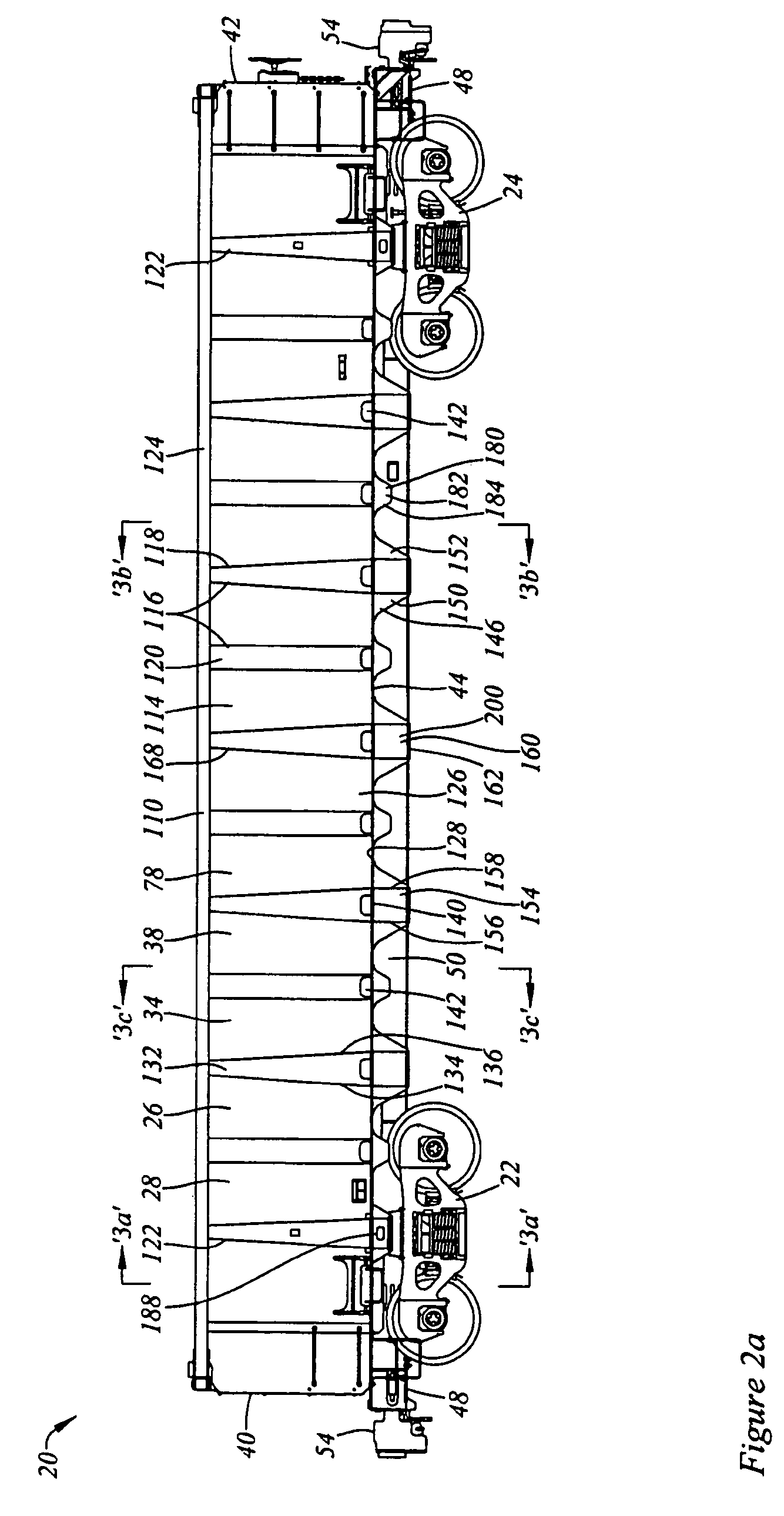

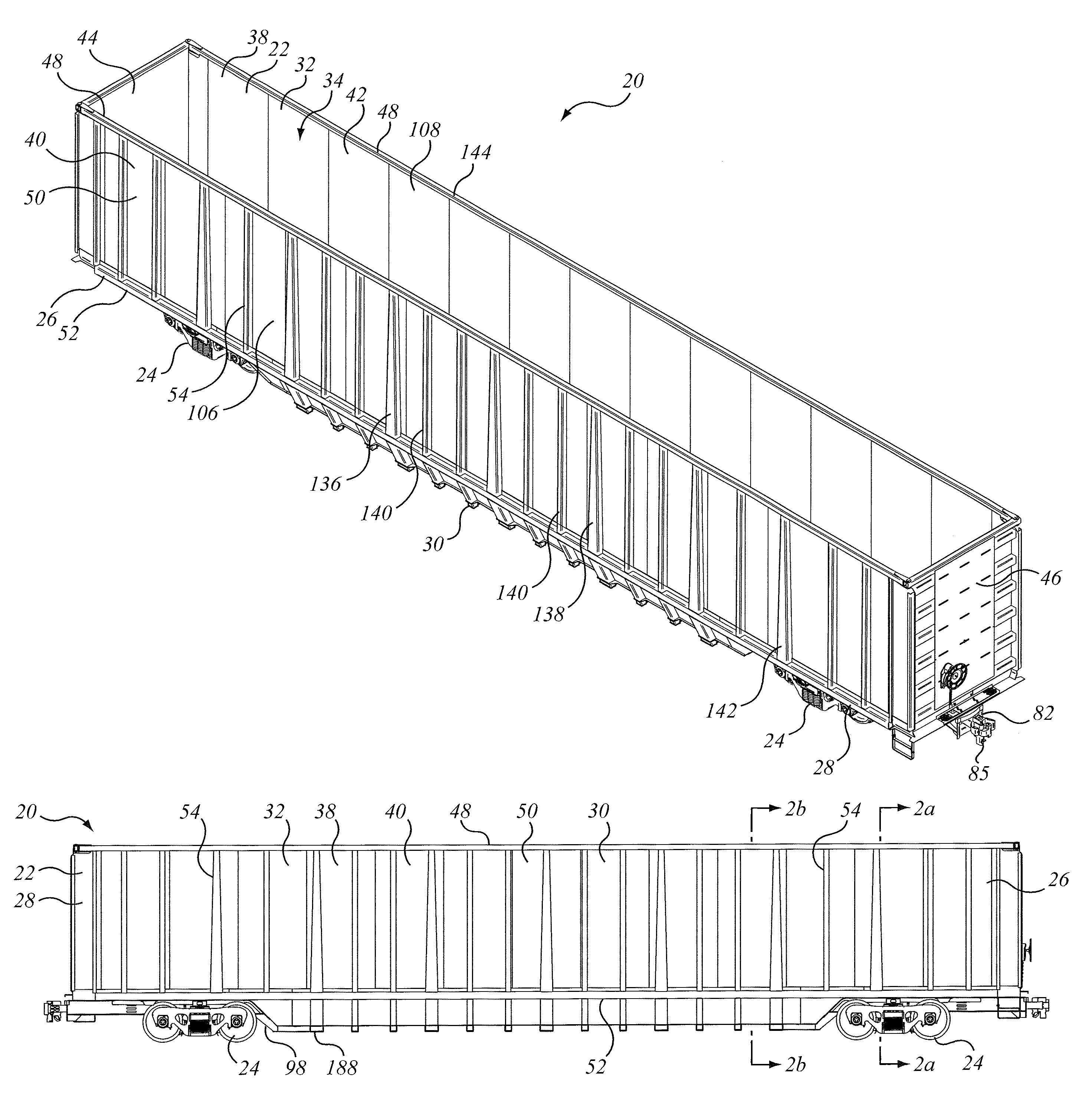

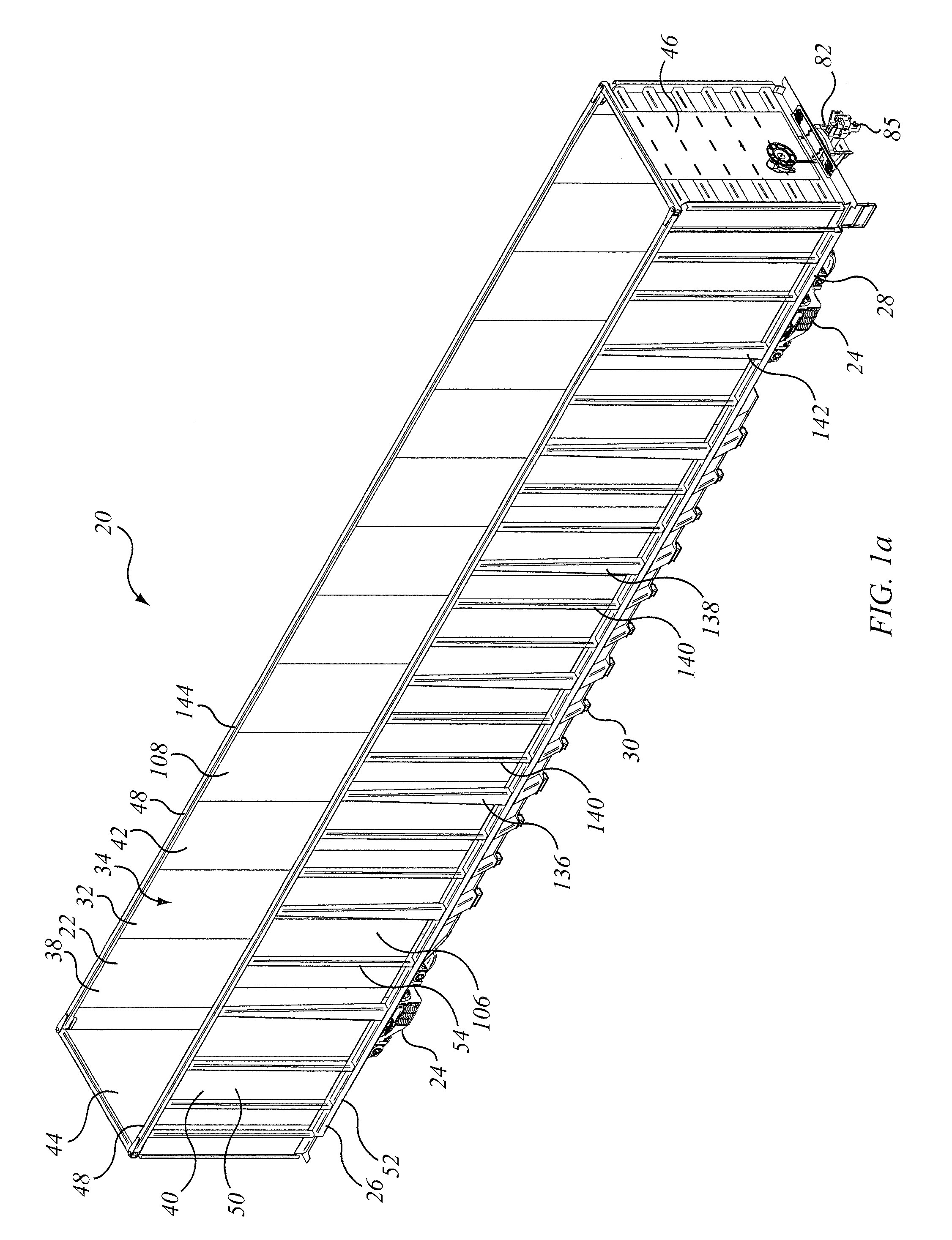

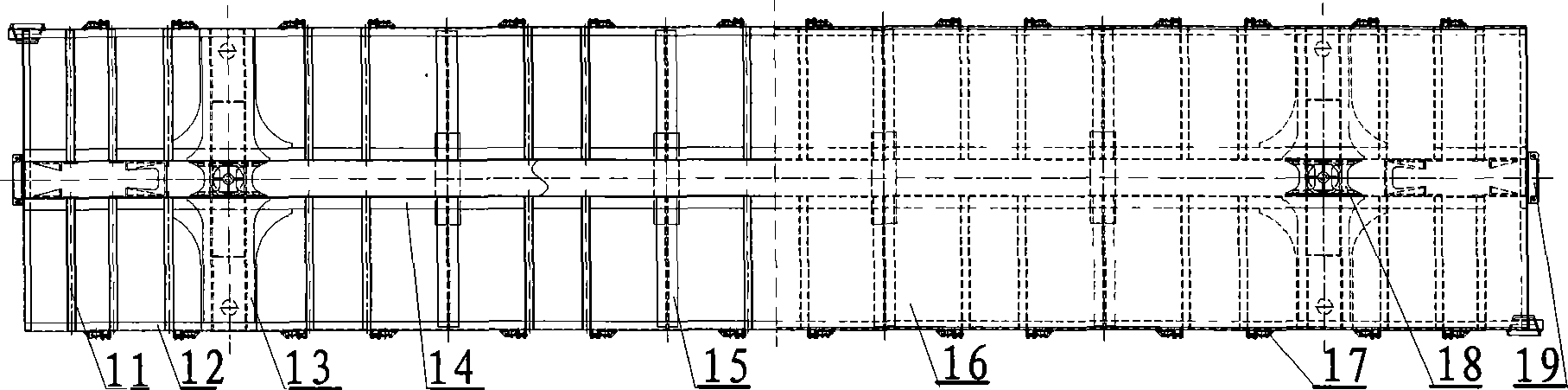

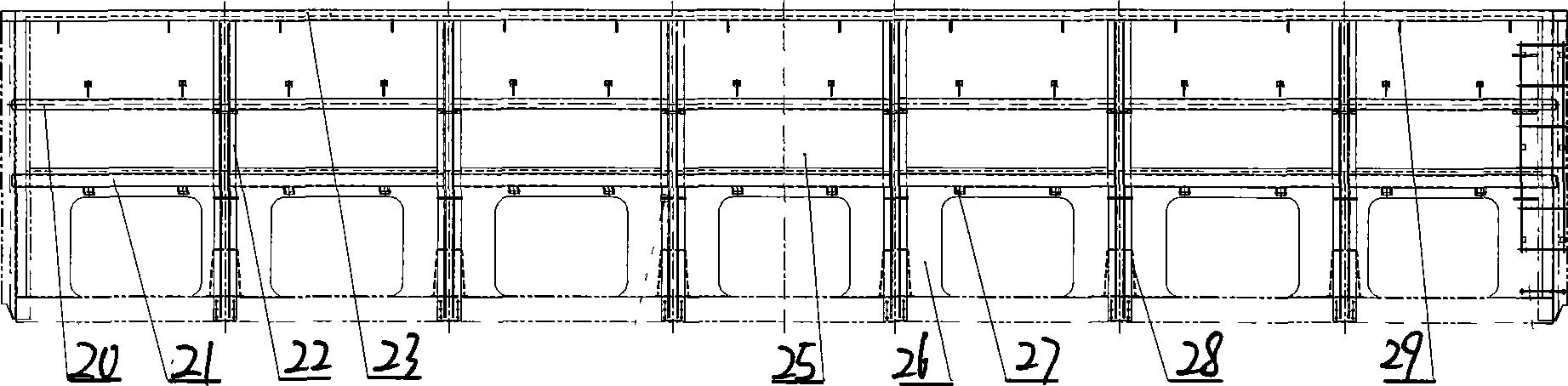

Rail road freight car

Owner:NATIONAL STEEL CAR

Rail road freight car structure

Owner:NATIONAL STEEL CAR

Rail road freight car structure

Owner:NATIONAL STEEL CAR

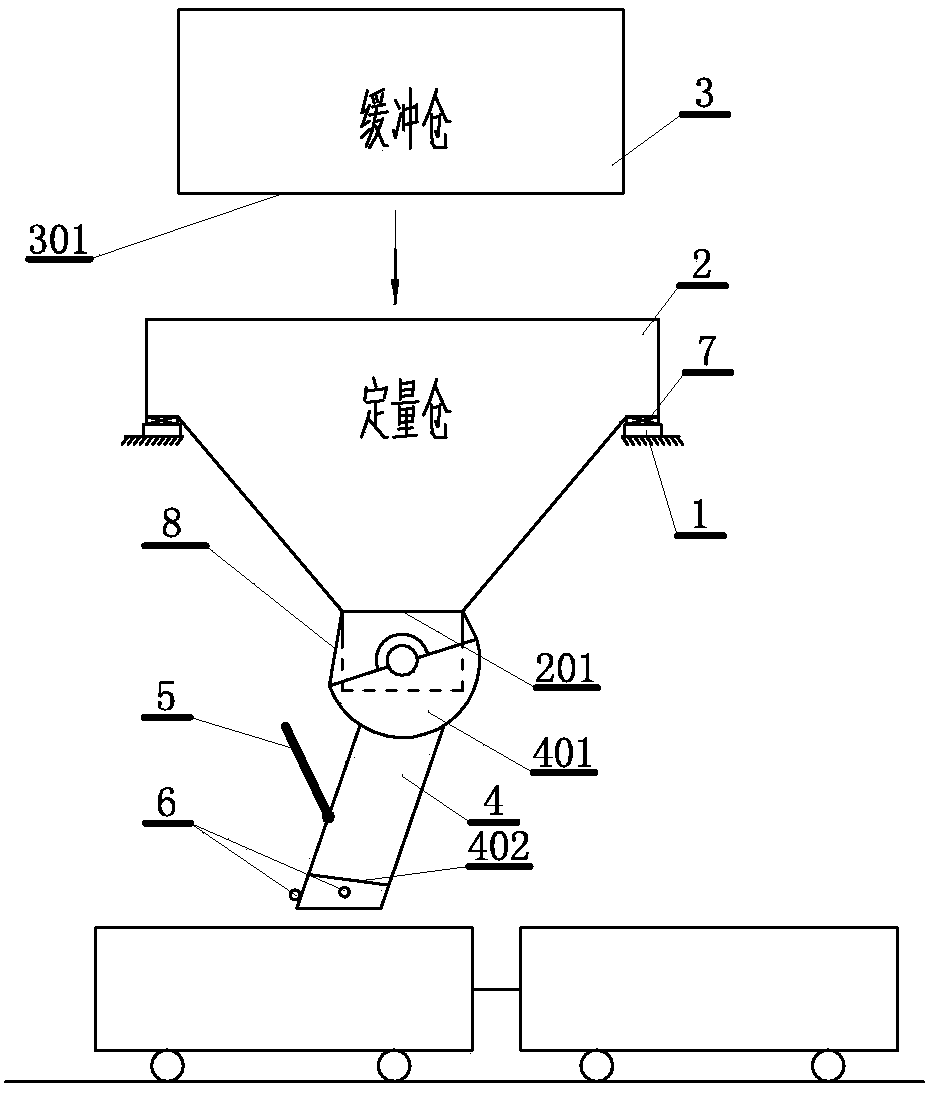

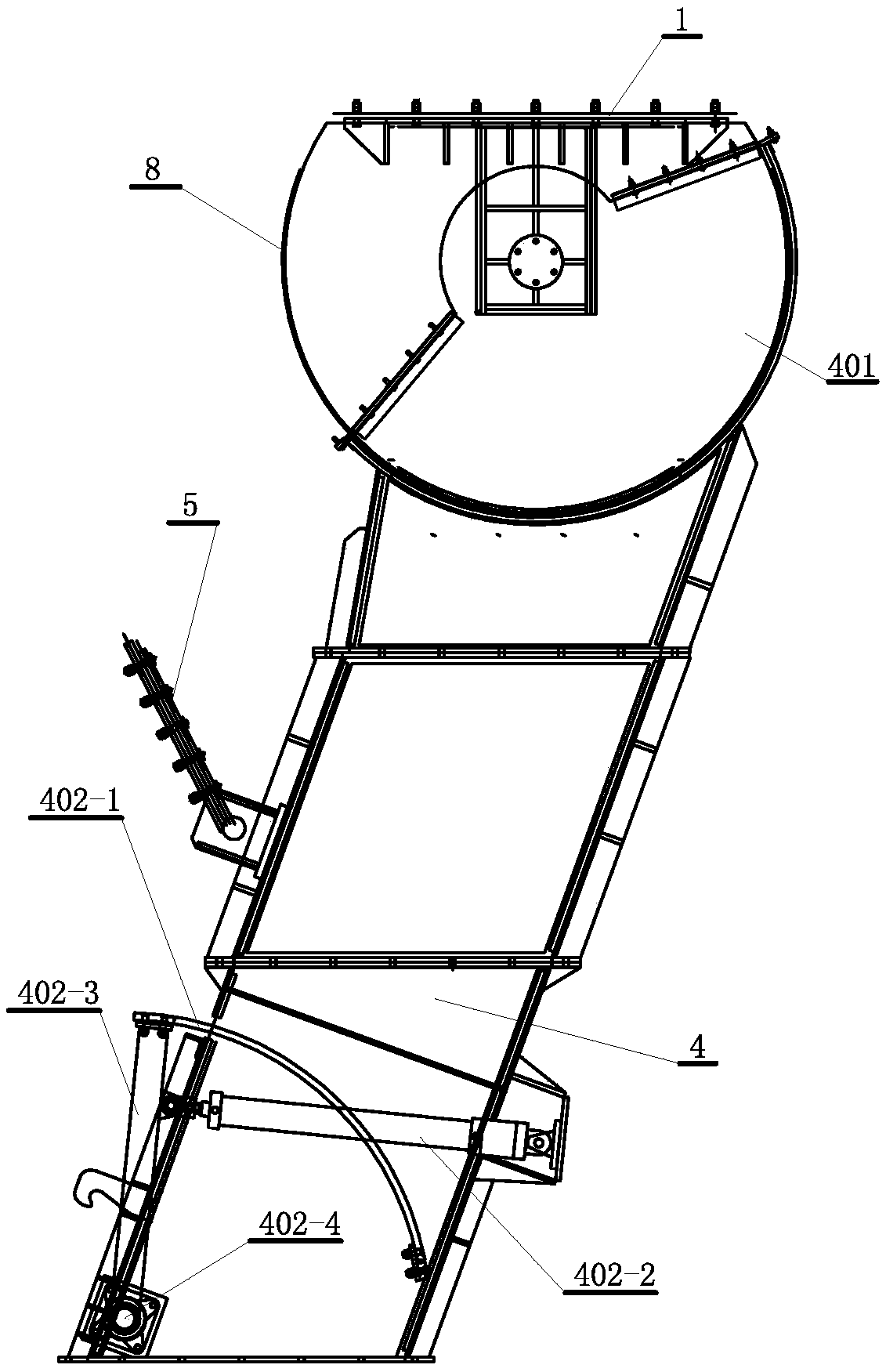

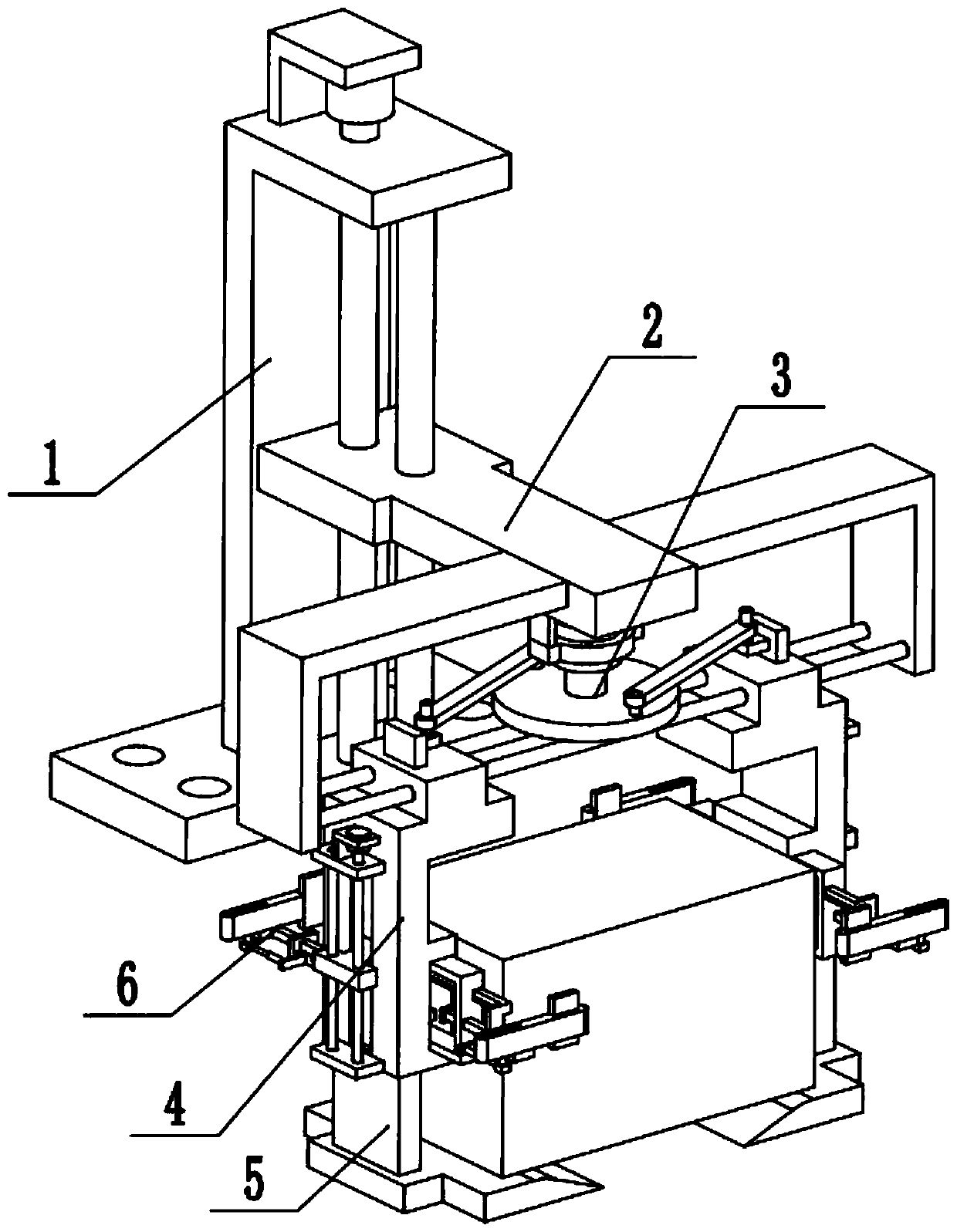

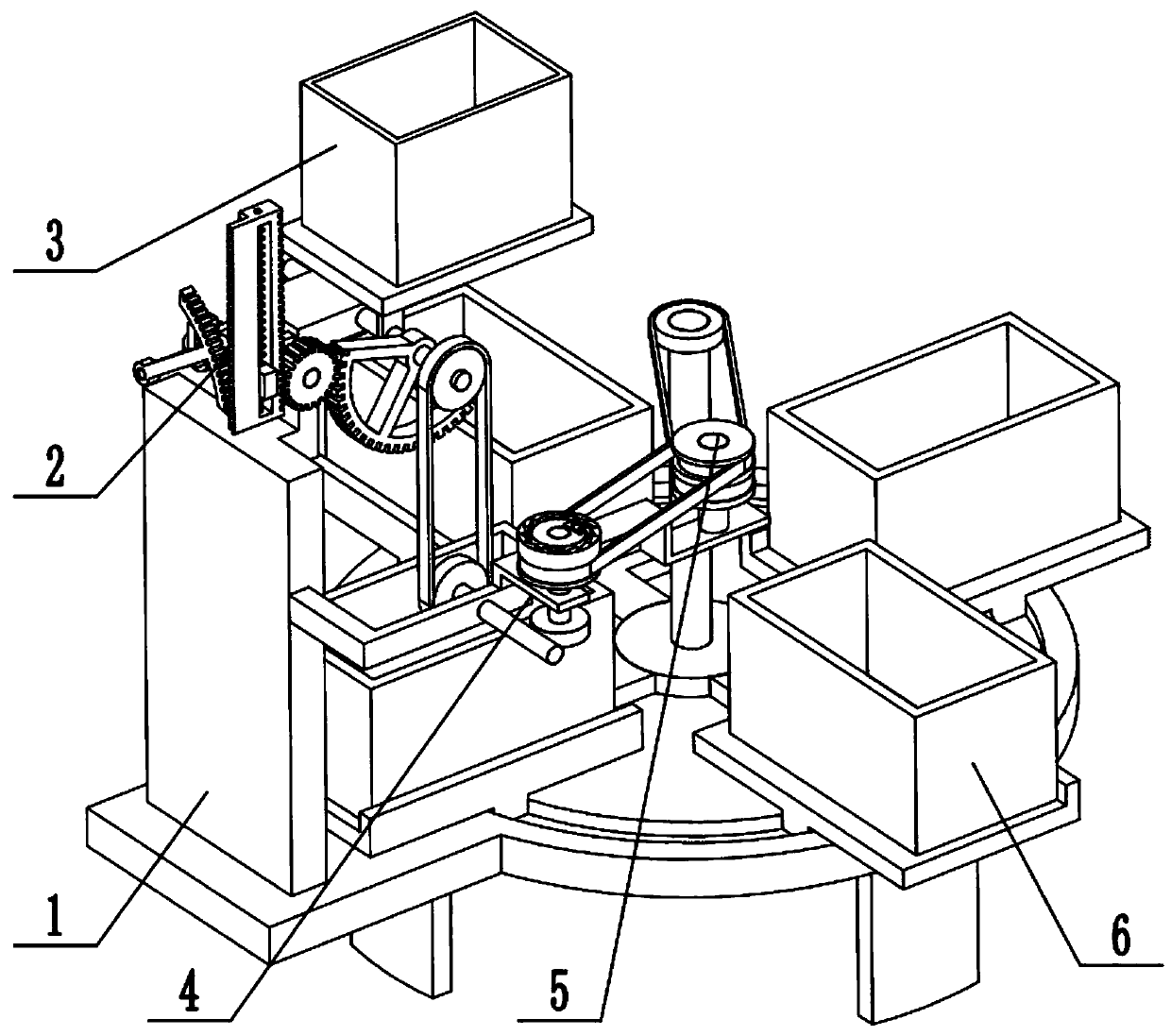

System and method of full-automatic continuous quantitative loading of railway freight train

PendingCN108792662ASolve fit problemsSolve coordination problemsConveyorsControl devices for conveyorsFreight trainsControl system

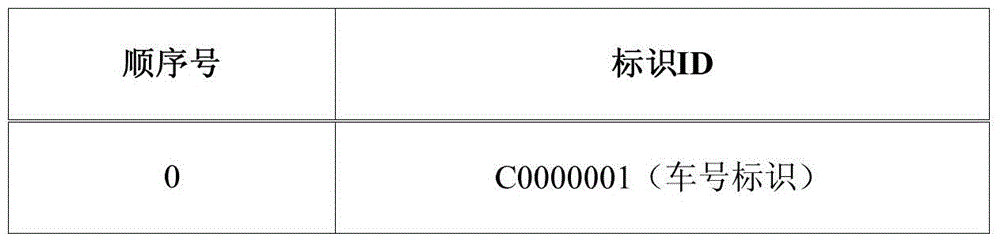

The invention discloses a system and a method of full-automatic continuous quantitative loading of a railway freight train. The system comprises a quantitative bin which is arranged in a train carriage loading region across a train track through a support, a material buffering bin is arranged on the upper side of the quantitative bin, a feeding gate is arranged at the lower end of the buffering bin in an alignment mode, and a material discharging gate is arranged at the lower end of the quantitative bin; the lower end of the quantitative bin is connected with a loading sliding groove, a vehicle loading control system is used for control the buffer bin and the quantitative bin to carry out continuous and quantitative loading of a freight train by judging the identification and the speed ofa vehicle identification. According to the system and the method, the problem of synchronization in cooperation and coordination of equipment and the train carriage is solved, the equipment feeding issynchronous with the train, manual intervention is not needed in a cooperating problem of the sliding groove and the carriage during material discharging, so that the labor intensity is reduced; andautomatic adjustment of the loading sliding groove can be realized, weighing, loading and leveling are realized, and the transportation efficiency is improved.

Owner:TIANDI SCI & TECH CO LTD

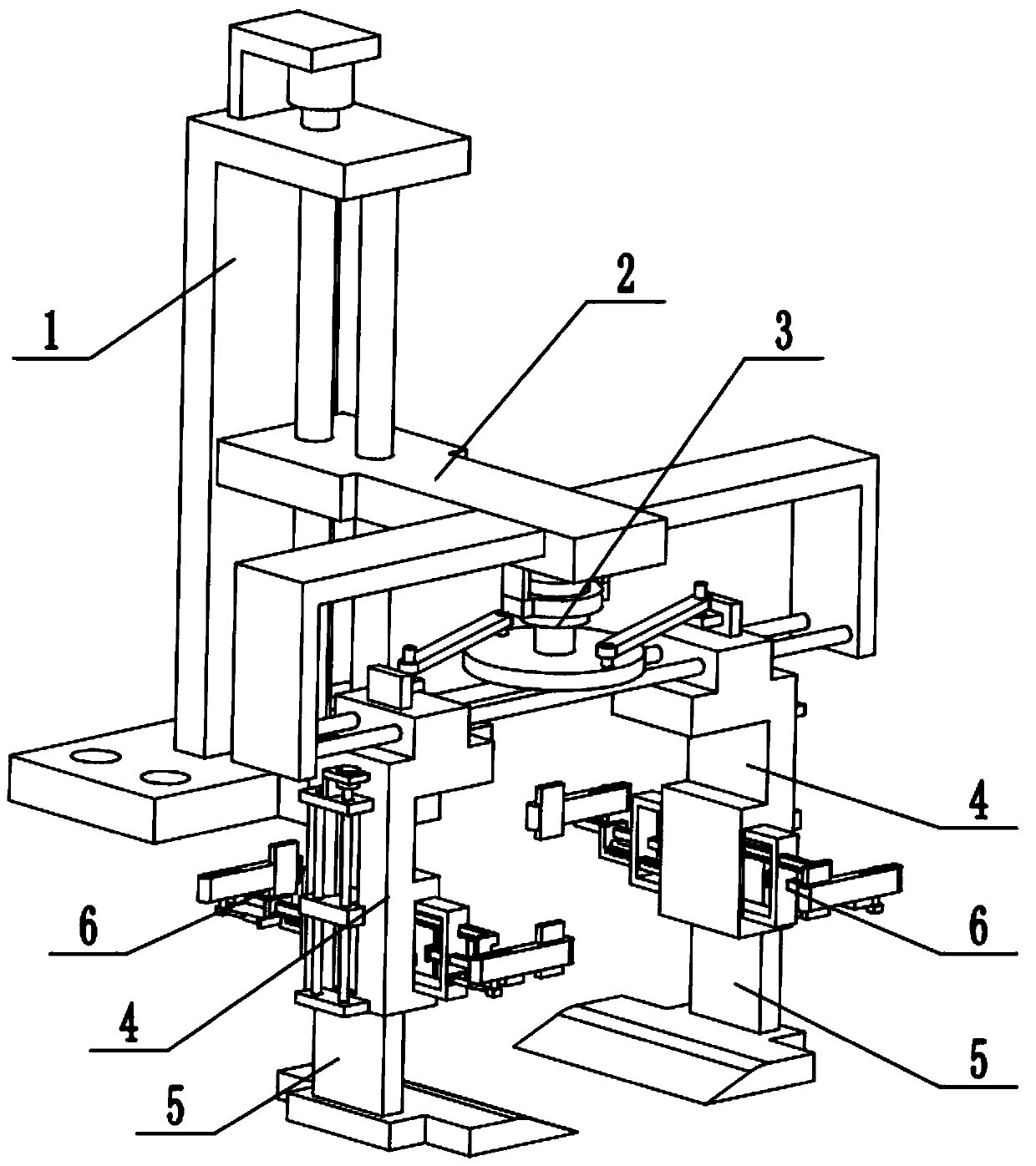

Rail freight hoisting equipment

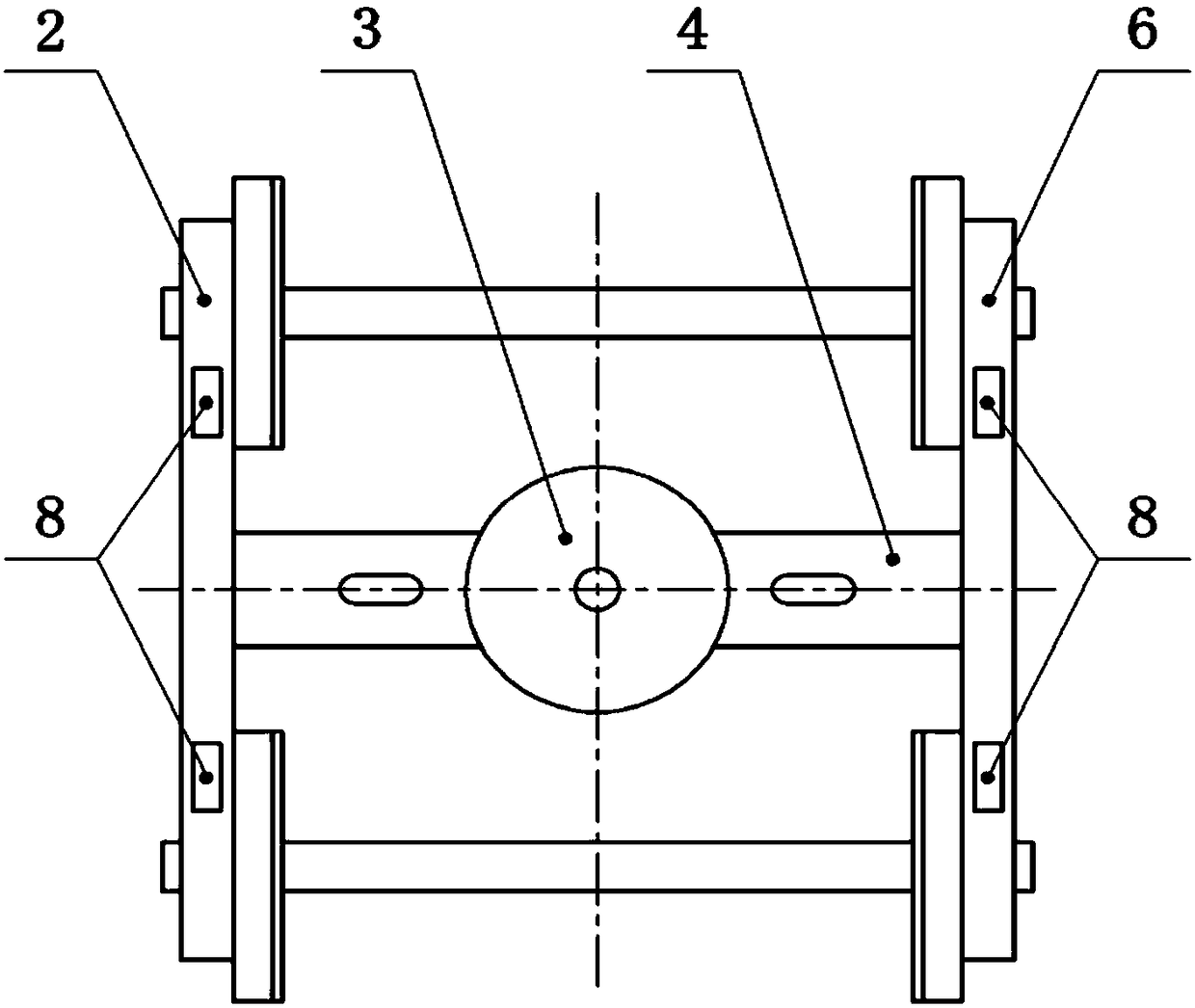

ActiveCN110316652AAvoid unbalanced weightAvoid damageLoad-engaging elementsRail freight transportEngineering

The invention relates to the technical field of lifting appliance application, in particular to rail freight hoisting equipment. The rail freight hoisting equipment comprises a rack, a height adjusting frame, a width adjusting frame, side frame plate assemblies, telescopic supporting plate assemblies and an auxiliary clamping assembly. The rail freight hoisting equipment has the advantages that when a container is hoisted, offset is avoided, and the rail freight hoisting equipment is suitable for long-distance transportation; and the upper face, the lower face, the left face, the right face, the front face and the back face of the container can be clamped, shaking is avoided, loading and unloading are stable, and the safety coefficient is high. The height adjusting frame is connected to the rack, and the middle end of the height adjusting frame is fixedly connected to the front end of the height adjusting frame. The left end and the right end of the width adjusting frame are in slidingfit connection with the two ends of the height adjusting frame correspondingly. Two side frame plate assemblies are arranged and symmetrically and fixedly connected to the left end and the right endof the width adjusting frame. Two telescopic supporting plate assemblies are arranged and are symmetrically arranged on the outers sides of the lower ends of the two side frame plate assemblies.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Rail road freight car

A drop-center rail road freight car may have a gondola body for carrying lading, which may have end sections and a deep central section therebetween. The body may include a decking or floor structure, and longitudinally extending side beams bordering the floor structure. The car may have U-shaped bending-moment transmitting cross-bearers. The cross-bearers and side beam stiffeners may have inner and outer flange continuity such as to transmit a bending moment. The car may have stub sills. The stub sills may each have an inboard gooseneck that extends downward and inboard. The gooseneck may have a longitudinally extending portion that connects to the endmost cross-bearer of the central portion of the car. The main shear plate may lap the side sills, and may be bent downwardly to mate with the end margins of the side sheet lower portion to form a converging box-like truncated pyramidal structure.

Owner:NATIONAL STEEL CAR +1

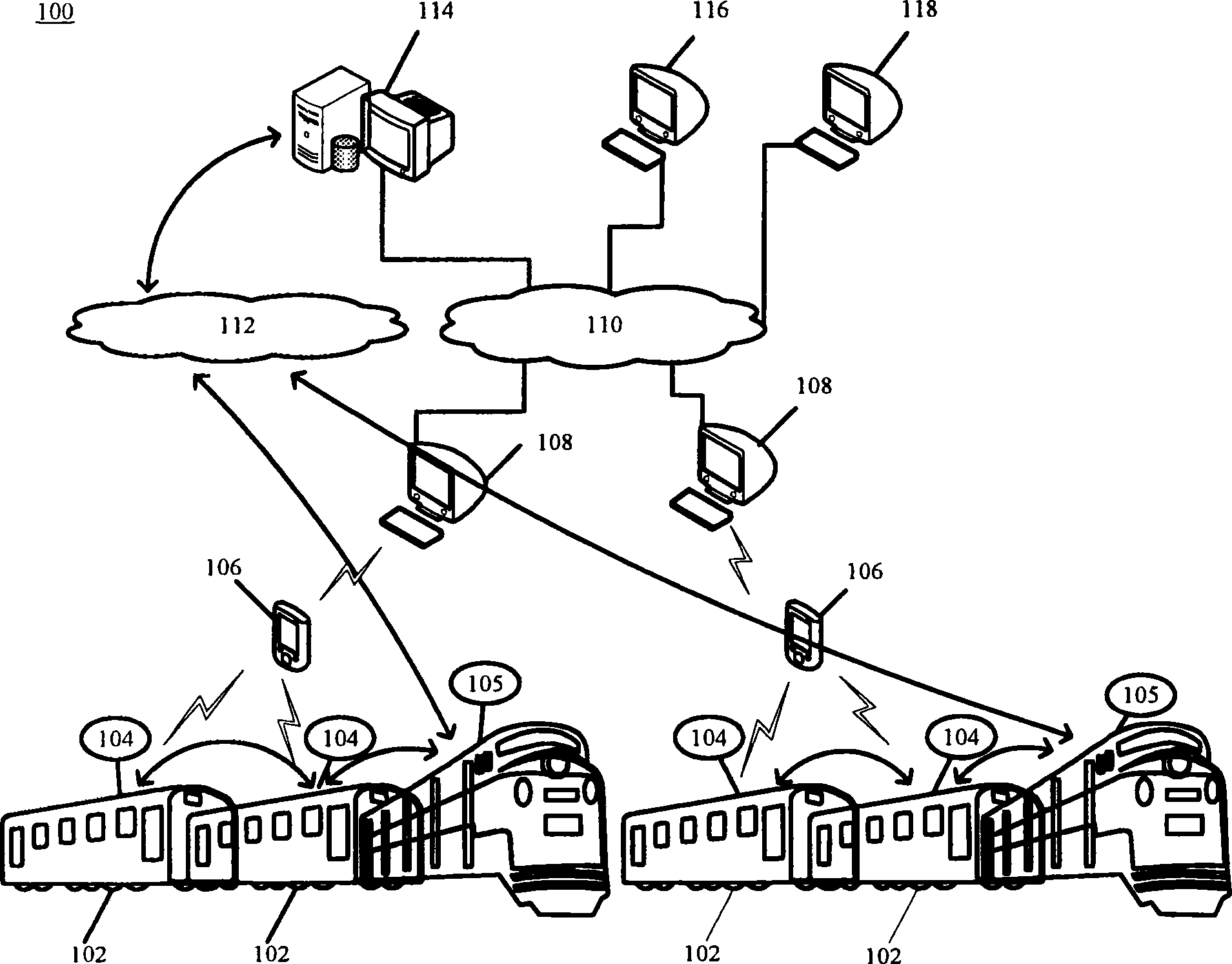

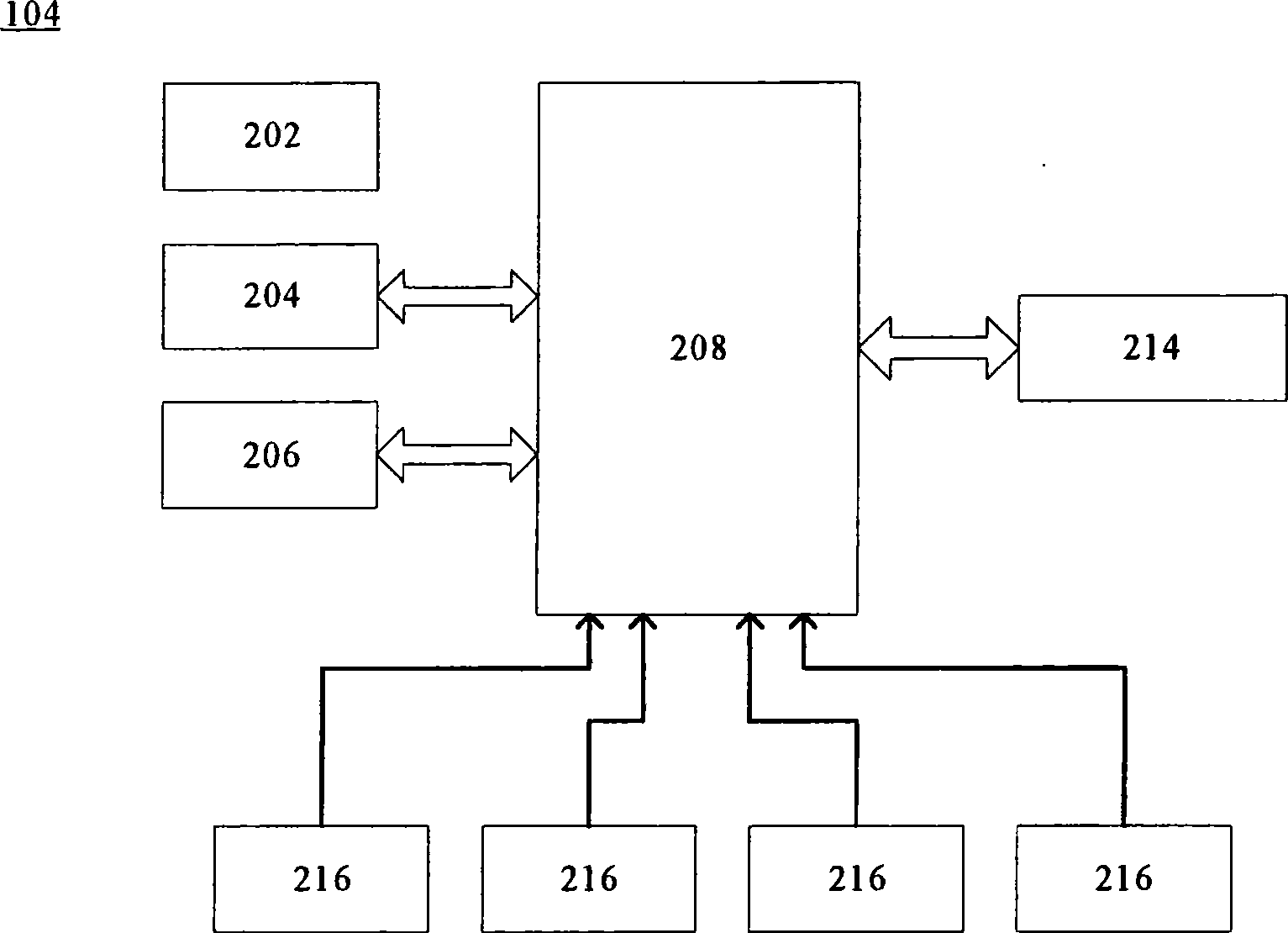

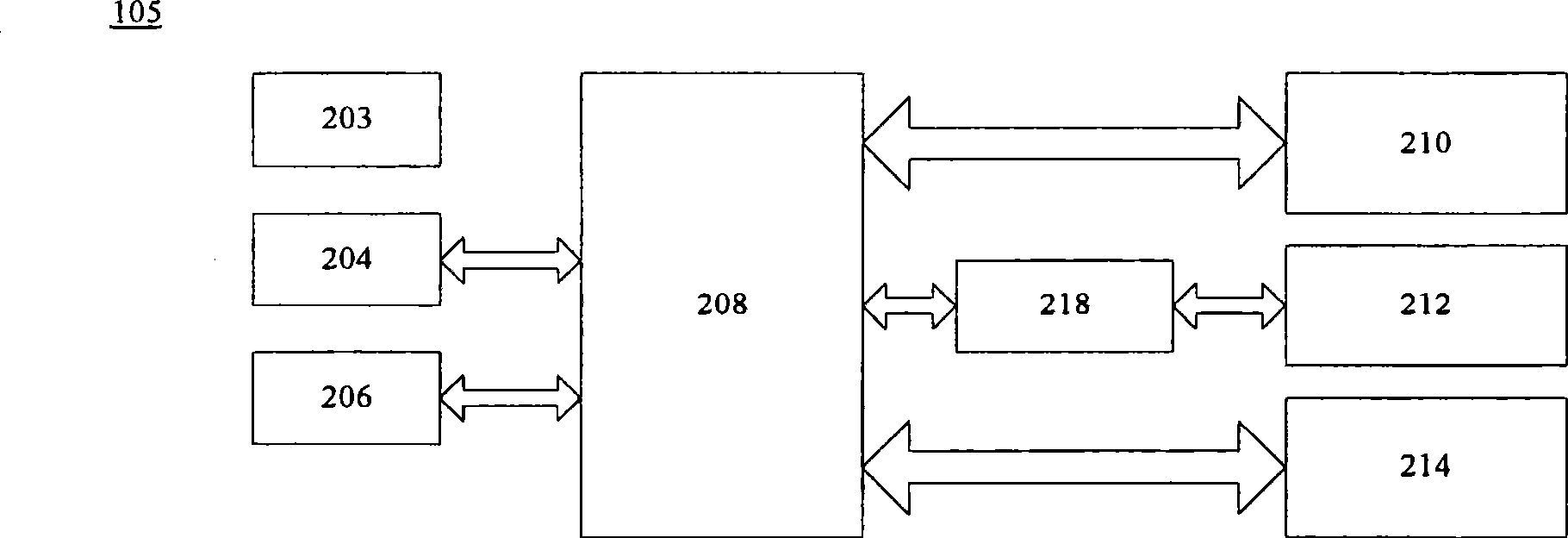

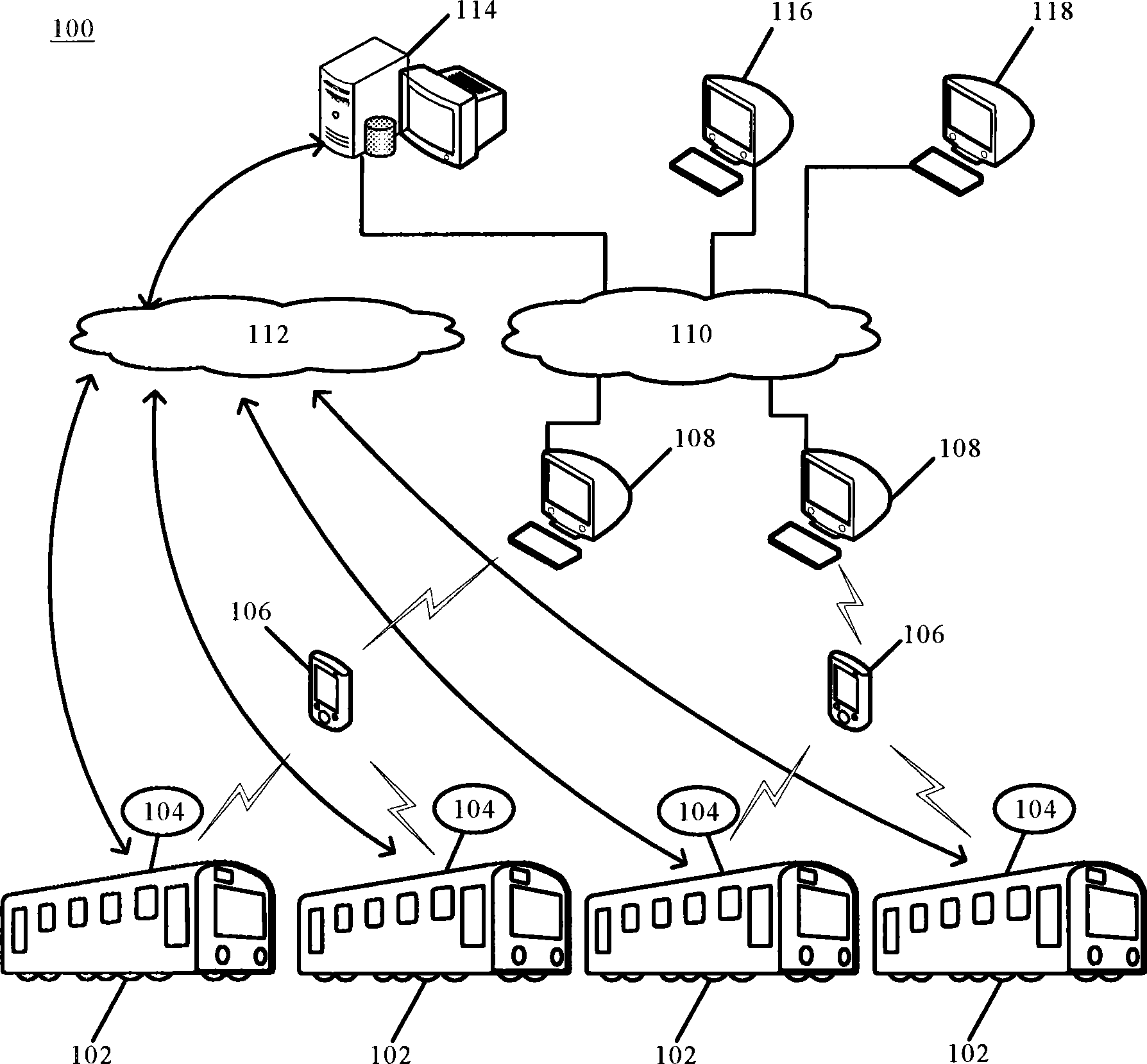

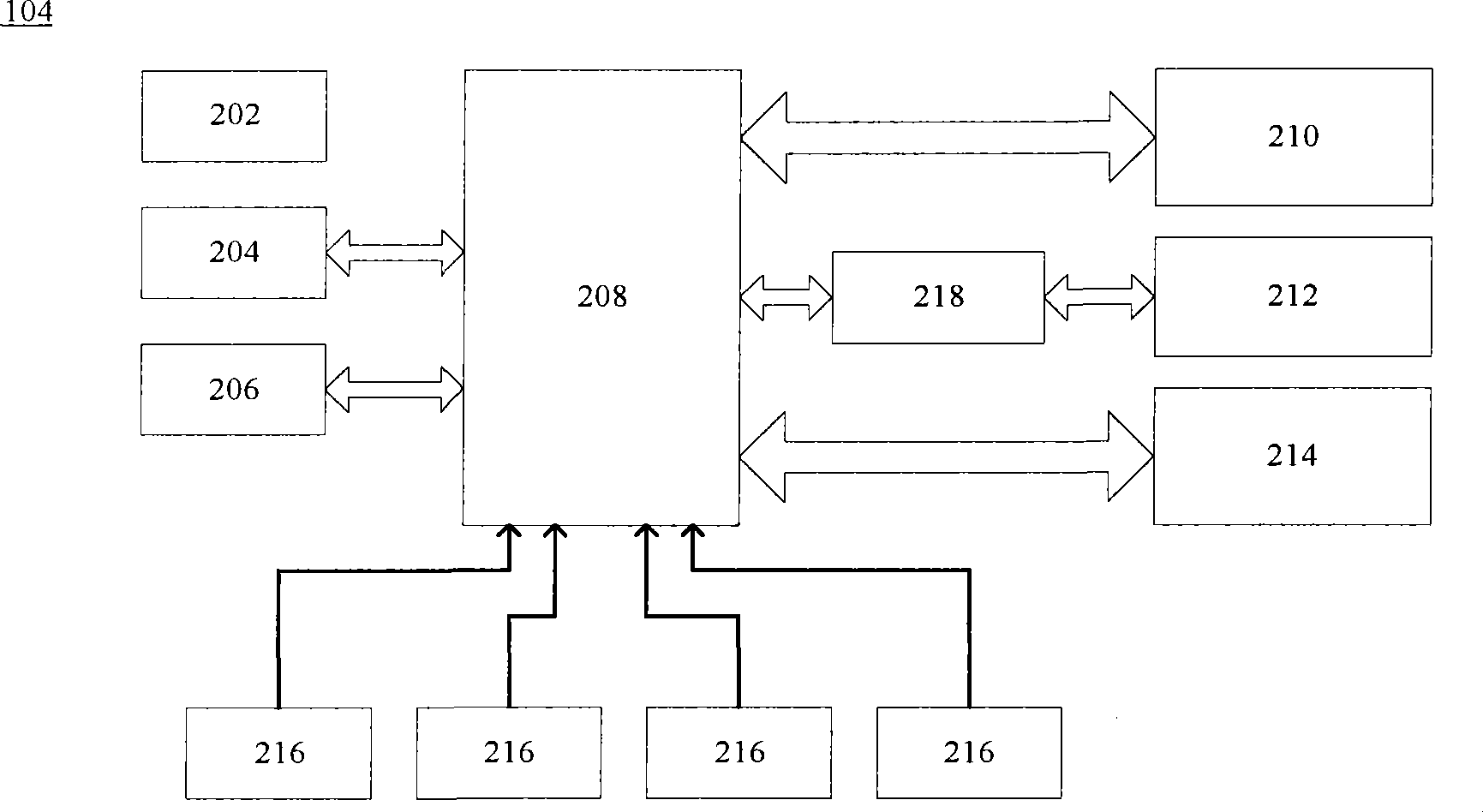

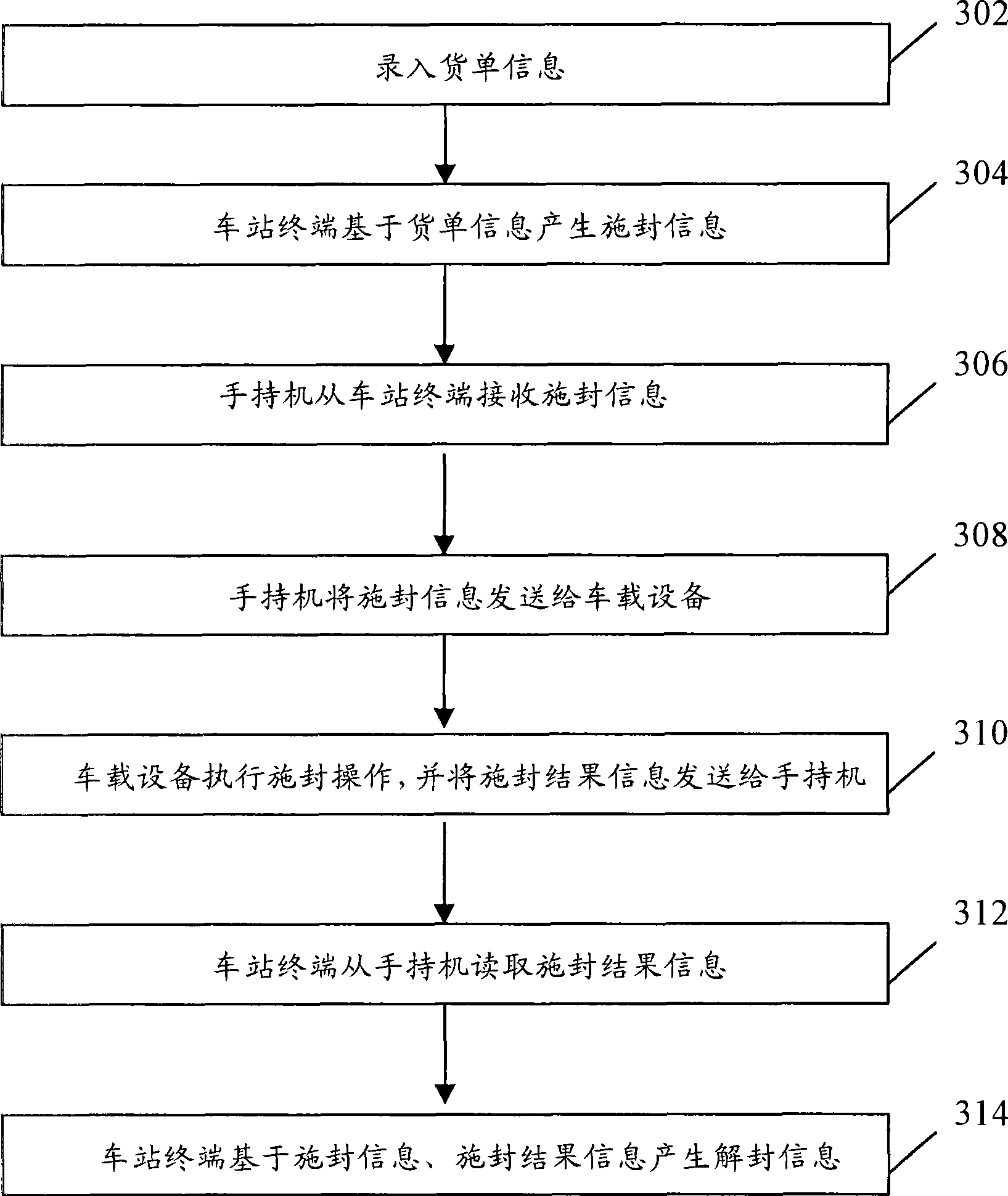

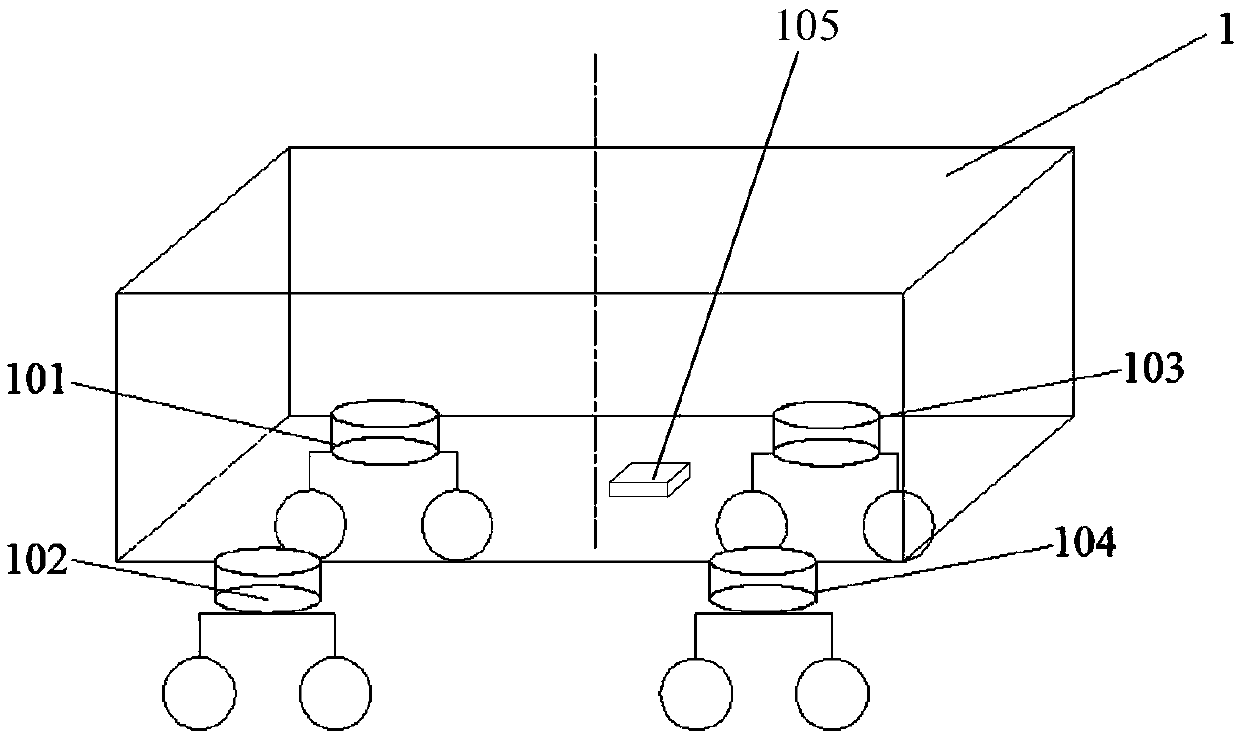

Anti-theft alarming method, system and apparatus for railway freight box wagon / container

InactiveCN101468652AEffective monitoring statusReduce the rate of cargo theftAlarmsRailway signalling and safetyTemporal informationRail freight transport

The invention discloses a method, a system and a device for railway freight box car / container antitheft warning. The method comprises: S1), a vehicle-mounted monitoring device (104) is started to monitor if a closed door of the box car / container is opened illegally; S2), if the door of the box car / container is opened illegally during a period from the time when the S1) is carried out to the time when the train arrives a freight transportation terminal, the vehicle-mounted device (104) allows the information on the time when the door is opened to be collected in a vehicle-mounted collecting device (105) arranged on the head of the train vehicle-mounted monitoring devices on other car boxes / containers by using Zigbee technology; and S3), the vehicle-mounted collecting device (105) transmits warning information to a central monitoring device (114) in real time. The method, the system and the device can effectively monitor the state of the box car / container, tell accident liability, improve working efficiency and reduce the steal rate during railway freight transportation.

Owner:NUCTECH CO LTD +1

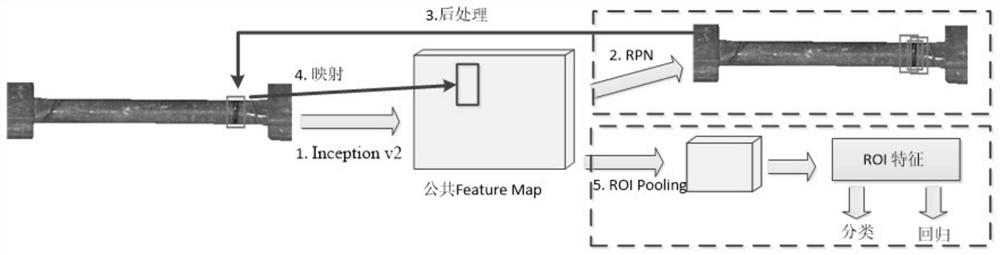

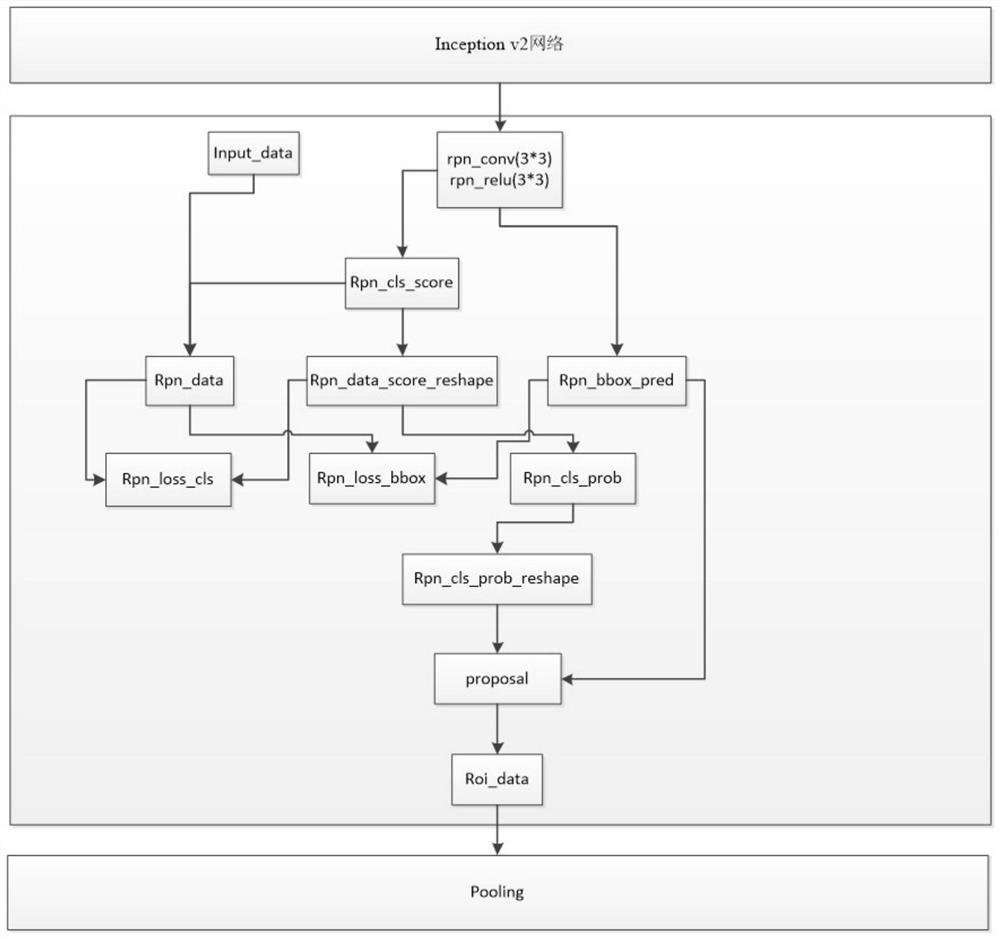

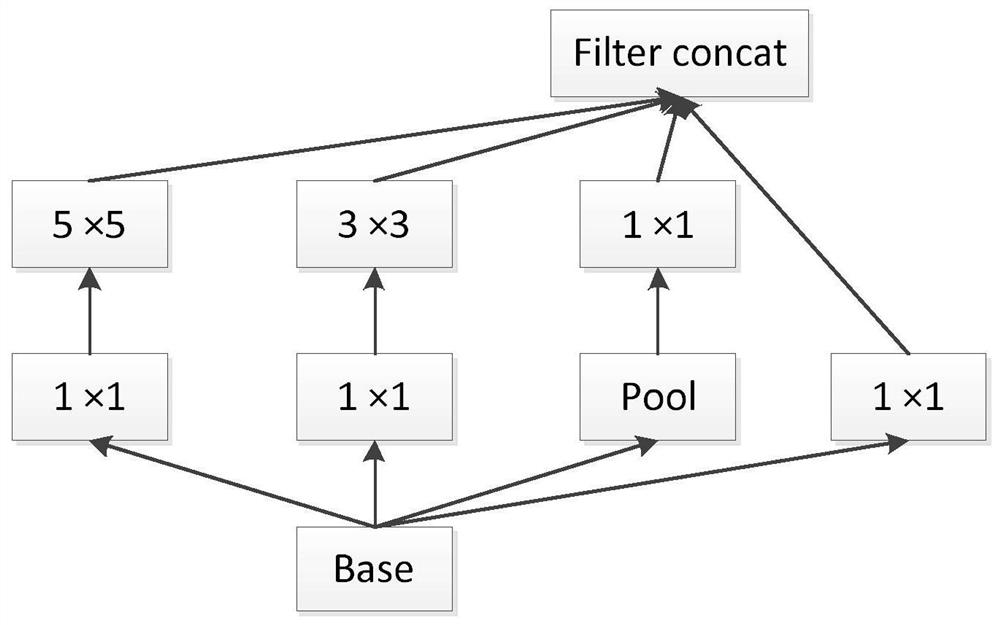

Railway wagon lower pull rod breaking fault detection method based on deep learning

InactiveCN111652296AGuaranteed safe operationGuaranteed detection accuracyImage analysisCharacter and pattern recognitionRail freight transportTruck

The invention discloses a railway wagon lower pull rod breaking fault detection method based on deep learning, and belongs to the technical field of image recognition. According to the invention, theproblems of low detection precision and low detection efficiency existing in the detection of the pull-down rod breaking fault by adopting a manual detection mode are solved. According to the invention, a deep learning model is built on the basis of a convolutional neural network, automatic identification and detection are carried out on a pull-down rod breaking fault occurring in an image, if thepull-down rod breaking fault is detected in the image, position information of the breaking fault is generated and uploaded to a train inspection operation platform, and after manual rechecking, a faulted train is correspondingly disposed in time, so that safe and efficient operation of railway freight transportation is guaranteed. An automatic image recognition mode is used for replacing a puremanual vehicle inspection mode, and the detection efficiency can be effectively improved while the detection precision is guaranteed. The method can be applied to fracture fault detection of the lowerpull rod of the wagon.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Integrated data system for railroad freight traffic

Owner:GREENBRIER MANAGEMENT SERVICES

Method for constructing vehicular wireless network of railway freight train

InactiveCN104590321AGuaranteed safety and reliabilityRealize intelligent informatizationPV power plantsNetwork topologiesFreight trainsRail freight transport

The invention discloses a method for constructing a vehicular network of a railway freight train. The method can comprise embodiments of all parts of the network and is used for providing an intelligent infrastructure for the freight train. One embodiment can comprise control devices, multiple information collecting devices and a power supplying device, wherein the control devices are arranged on a locomotive / vehicle, the multiple information collecting devices are arranged on the locomotive / vehicle, and the power supplying device is mounted on the vehicle; the control devices are used for enabling node interconnection and vehicle external communication and providing network service, data transmission, data processing and data storage; the information collecting devices are used for acquiring and monitoring data of vehicle components; the vehicular control devices are equipped with wireless supplying devices which are used for supplying power to the information collecting devices. One embodiment can comprise a light energy recovered power supplying device, and a light source can be natural light or laser or the like. Vehicular network support nodes are dynamically adjusted, and control nodes in the same train marshalling can construct a logic-independent network.

Owner:沈玲玲

System for monitoring loading and strengthening status of goods in transit in real time

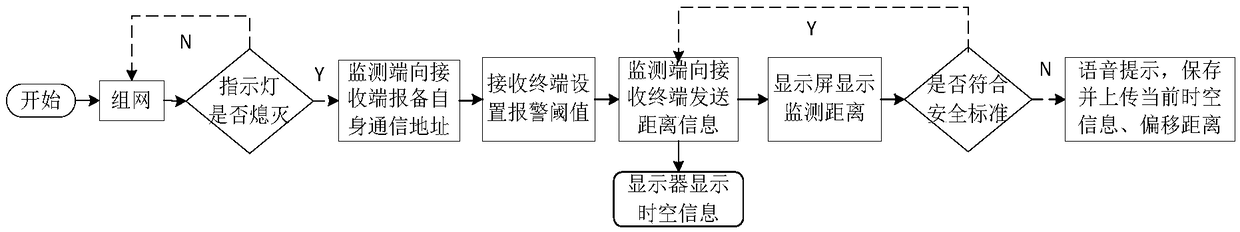

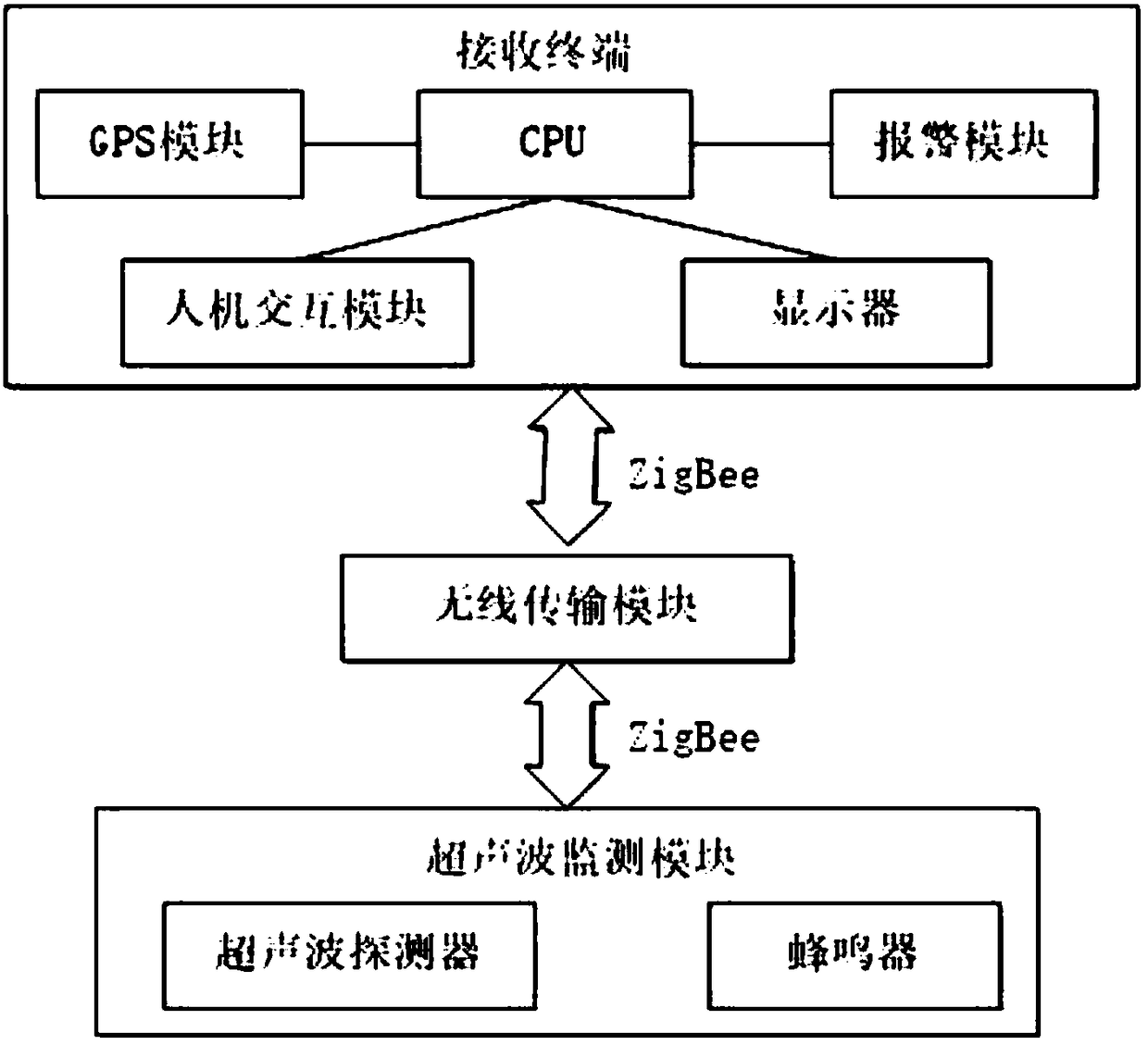

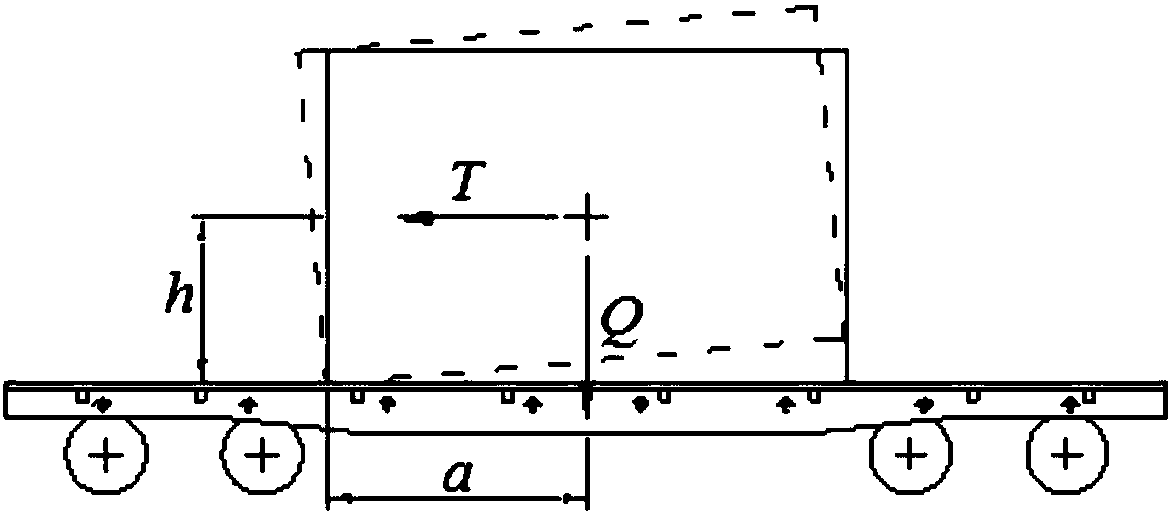

PendingCN108267742AEnsure transportation safetyFind and eliminate potential safety hazards in timeTransmission systemsSatellite radio beaconingWireless transmissionRail freight transport

The invention provides a system for monitoring loading and strengthening status of goods in transit in real time. The system comprises an ultrasonic monitoring unit, a wireless transmission unit and areceiving terminal, wherein the ultrasonic monitoring unit is connected with the wireless transmission unit by means of a circuit; the wireless transmission unit is connected with the receiving terminal by means of a wireless network. The ultrasonic monitoring unit detects the distance information between the monitoring unit and goods carried by a vehicle by transmitting ultrasonic waves, and transmits the distance information to the wireless transmission unit; the wireless transmission unit transmits the distance information to the receiving terminal by means of the wireless network; the receiving terminal is arranged in a cab; the distance information is displayed in real time by means of a display screen of the terminal, and the offset state of the goods is determined according to a preset alarm distance threshold. The device provided by the invention can be used for performing real-time monitoring and alarm on the displacement of the goods in freight transportation on a road and arailway, and can help a driver to find the movement, eccentric load and eccentric weight of the goods in time, thus reducing the occurrence of related accidents, and guaranteeing the safe transportation of the goods.

Owner:BEIJING JIAOTONG UNIV

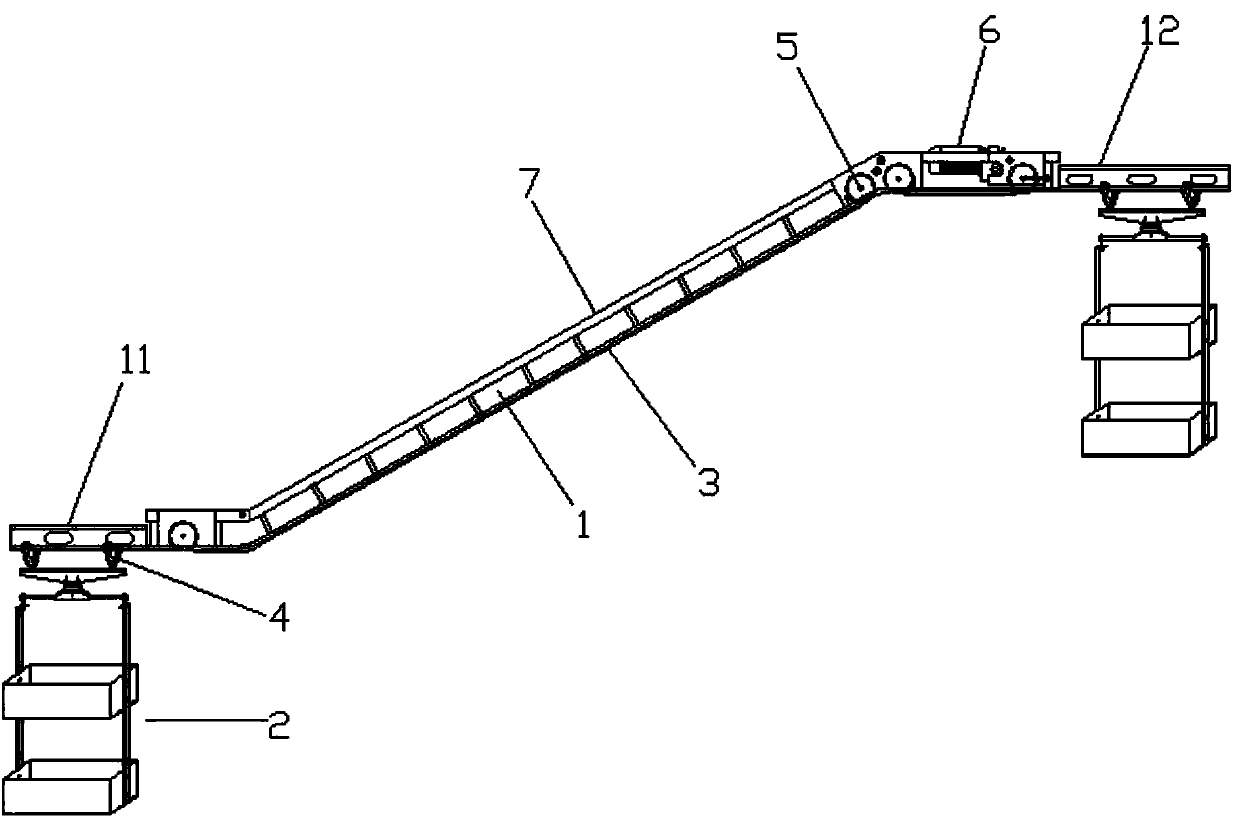

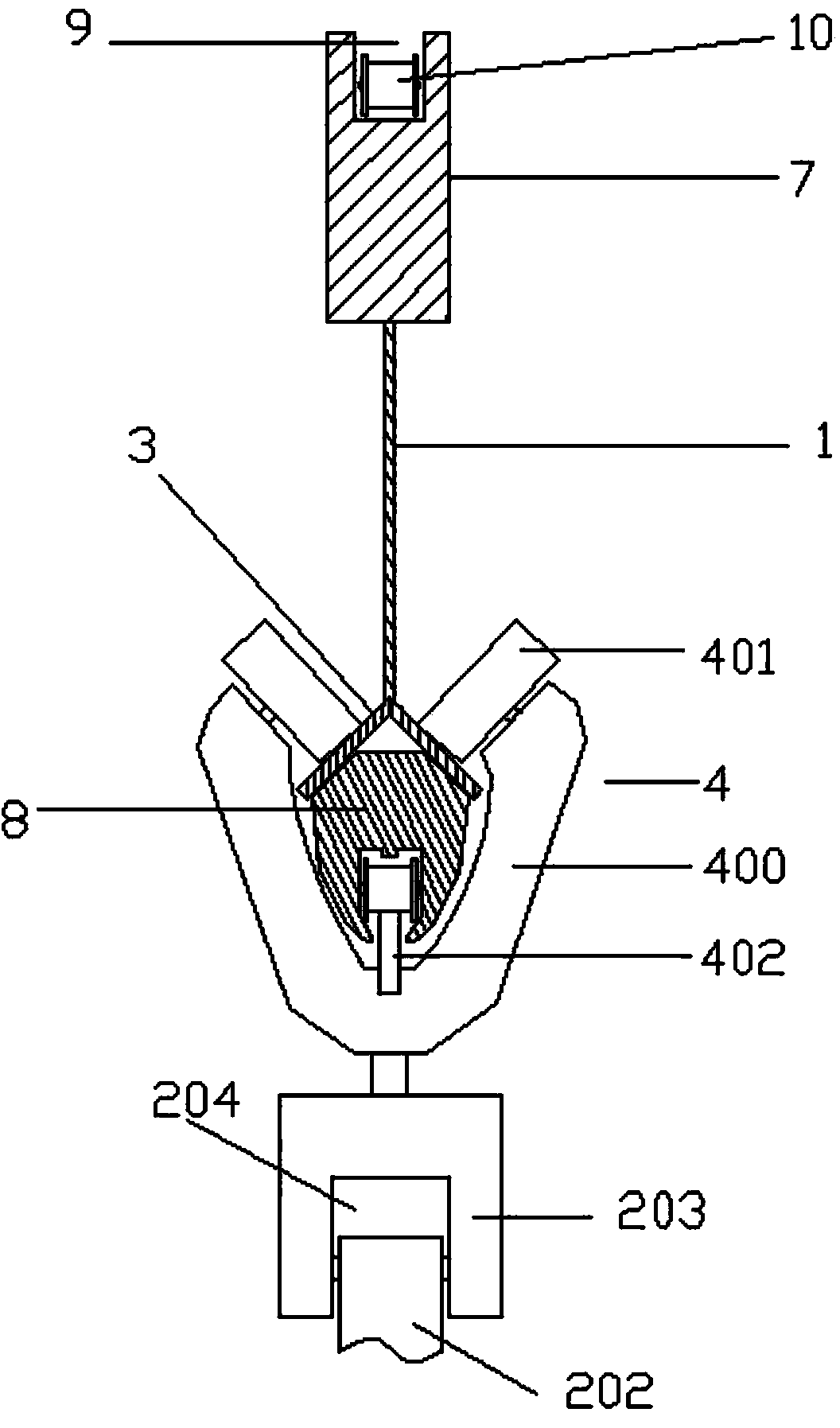

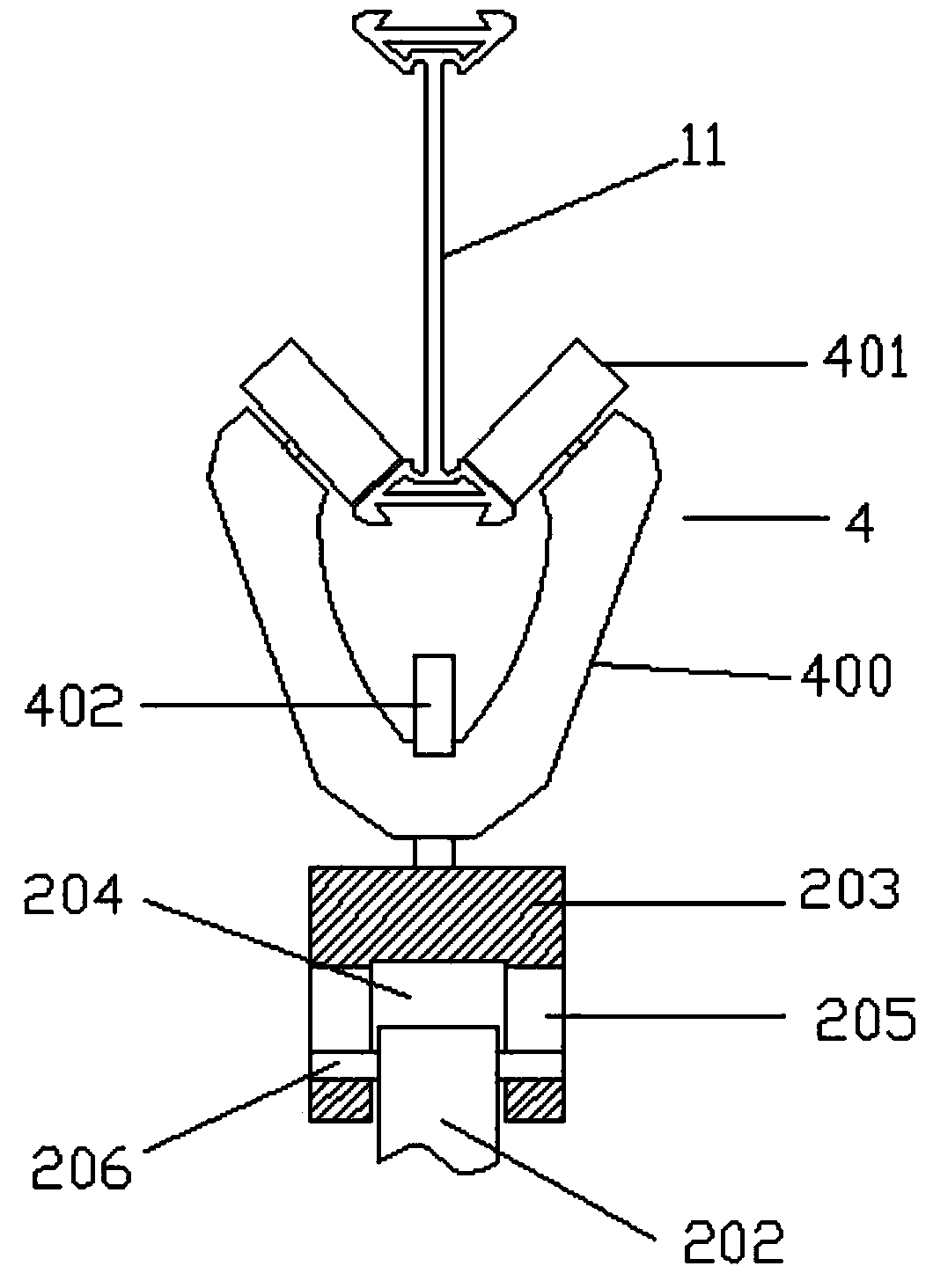

Rail crane climbing mechanism

ActiveCN103991788AAvoid collisionConvenient logistics and freightTrolleysRail freight transportEngineering

The invention relates to the technical field of rail freight transport and particularly discloses a rail crane climbing mechanism. The mechanism comprises an oblique rail and a crane, wherein the lower edge of the oblique rail extends to form a hanged barrier strip; a hanging seat is arranged on the upper end of the crane and comprises a V-shaped connecting body and a bearing; the lower end of the V-shaped connecting body is fixedly connected with the crane through a connecting rod; the bearing is obliquely arranged inside the opening of the V-shaped connecting body; chain wheels are respectively arranged at two ends of the oblique rail; one of the chain wheels is driven through a motor; a chain upper guiding seat is arranged above the oblique rail; a chain lower guiding seat is fixed at the lower side of the hanged barrier strip; chain guiding grooves distributed along the oblique rail are arranged in both the chain upper guiding seat and the chain lower guiding seat; the two chain wheels are connected through chains; the chains are respectively clamped in the chain guiding grooves; a metal tooth piece is fixed inside the bottom of the V-shaped connecting body. Therefore, the mechanism disclosed by the invention has the beneficial effects that uphill and downhill motions of the crane are rapidly, conveniently and stably realized and the logistics transportation among different layers of a workshop is realized.

Owner:上海汽飞吊挂设备有限公司

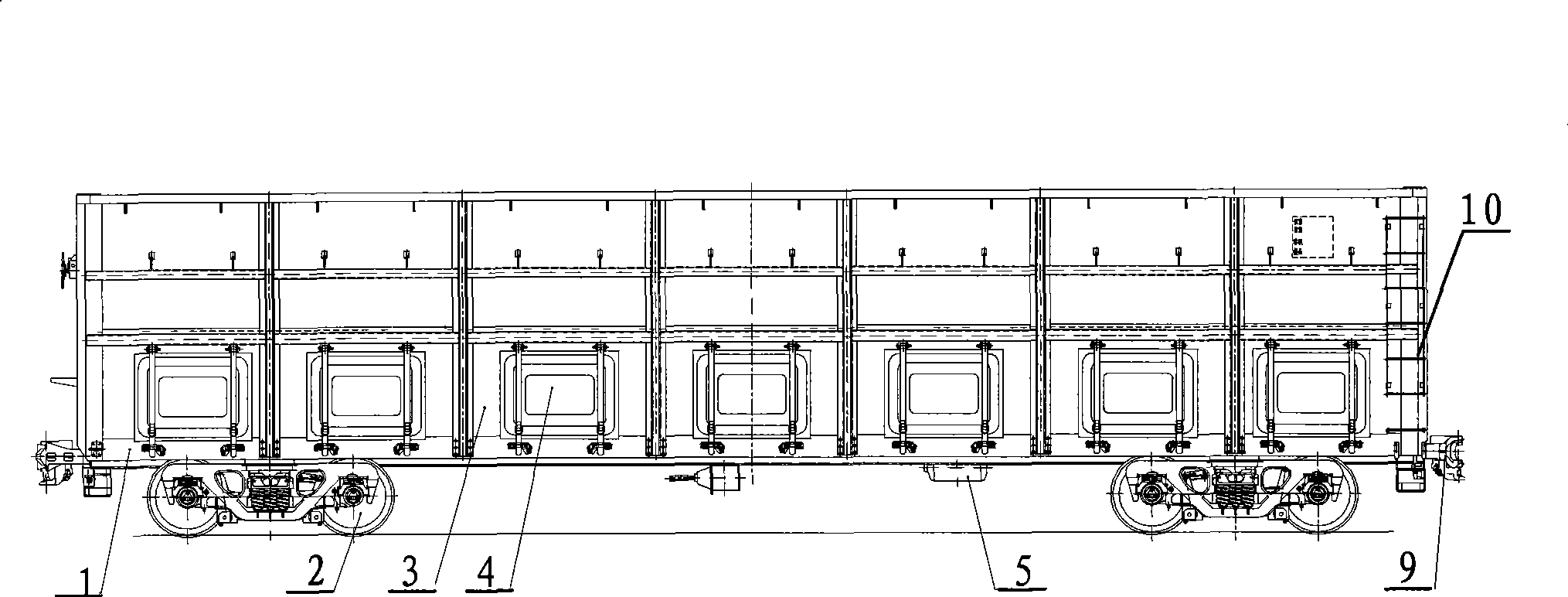

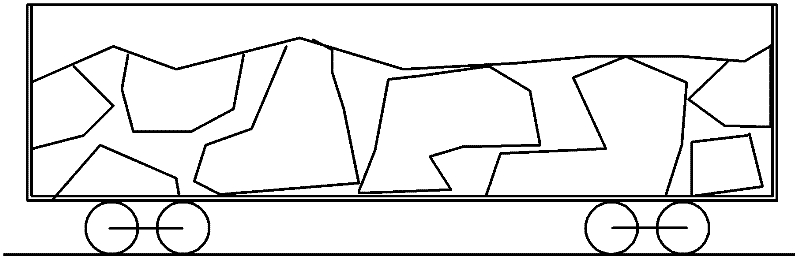

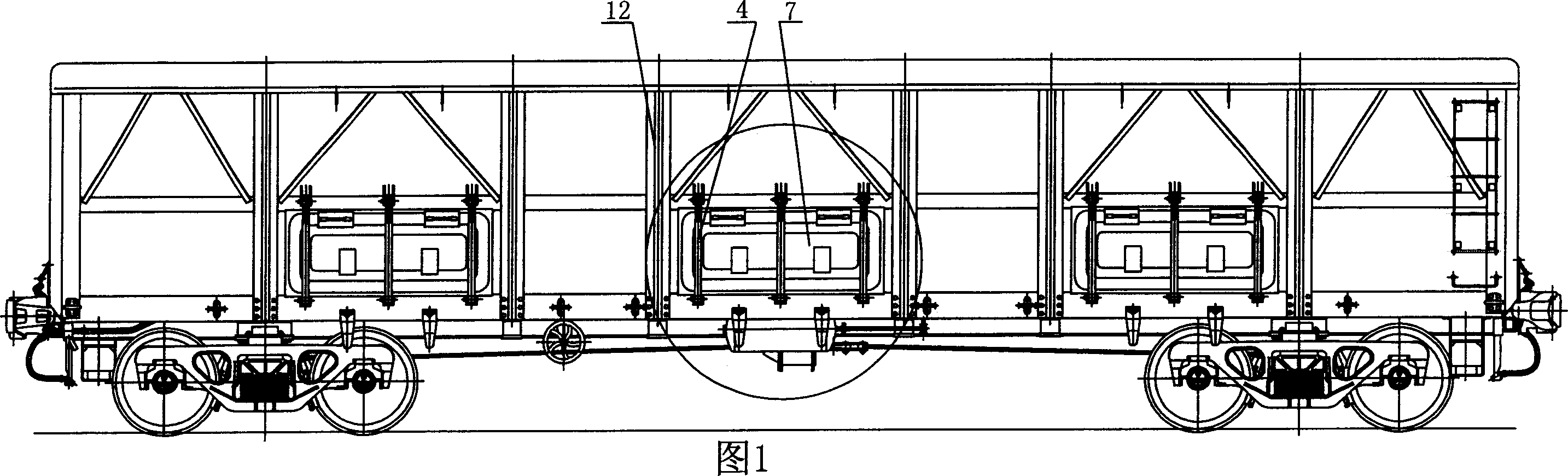

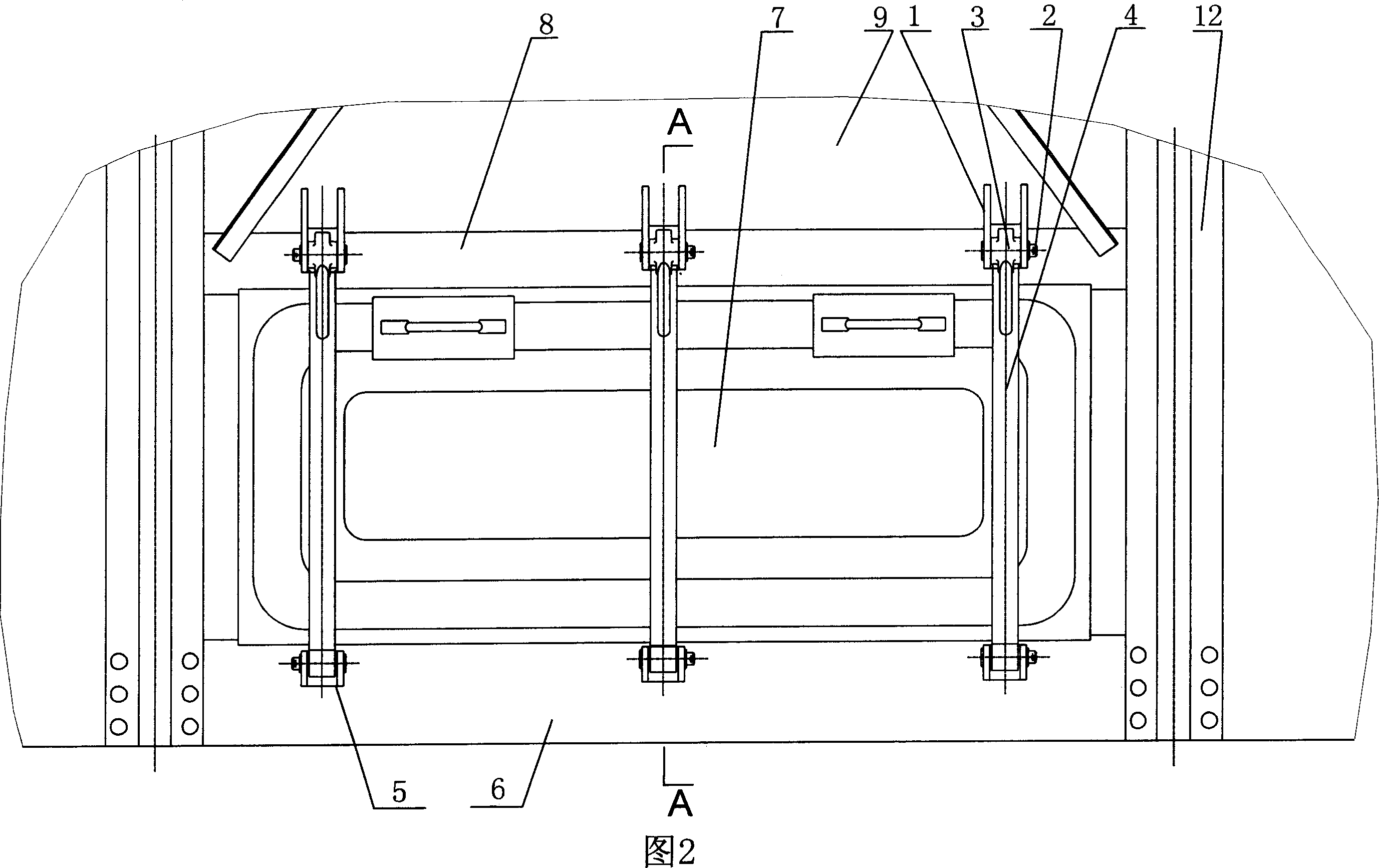

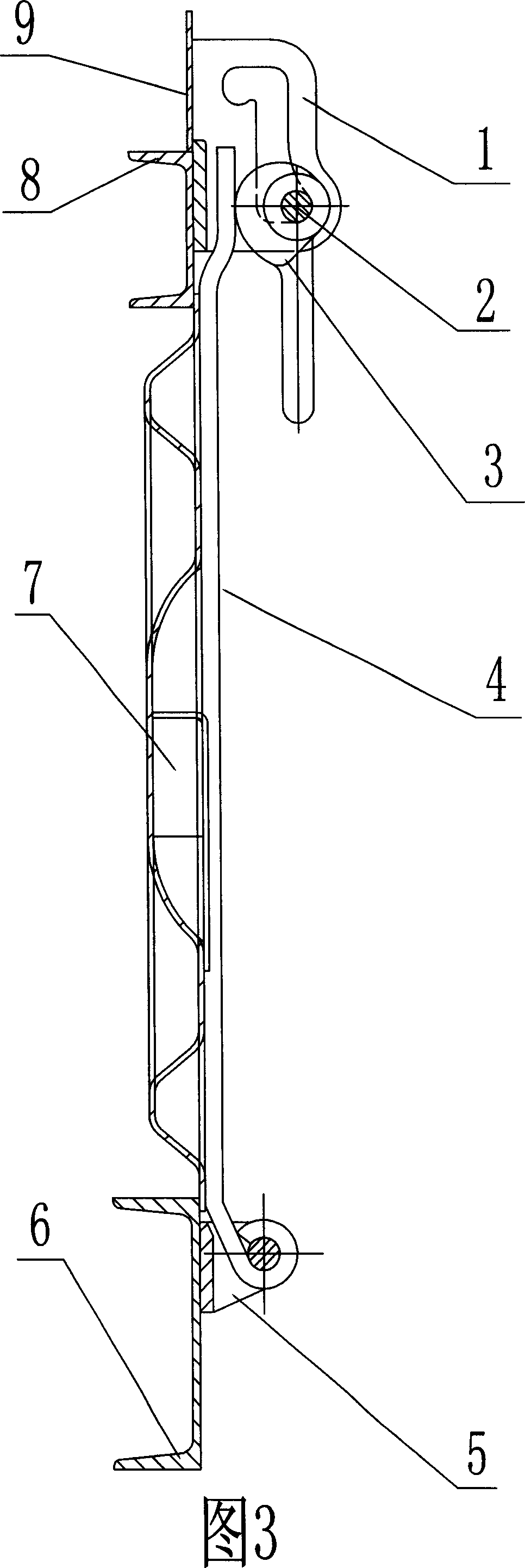

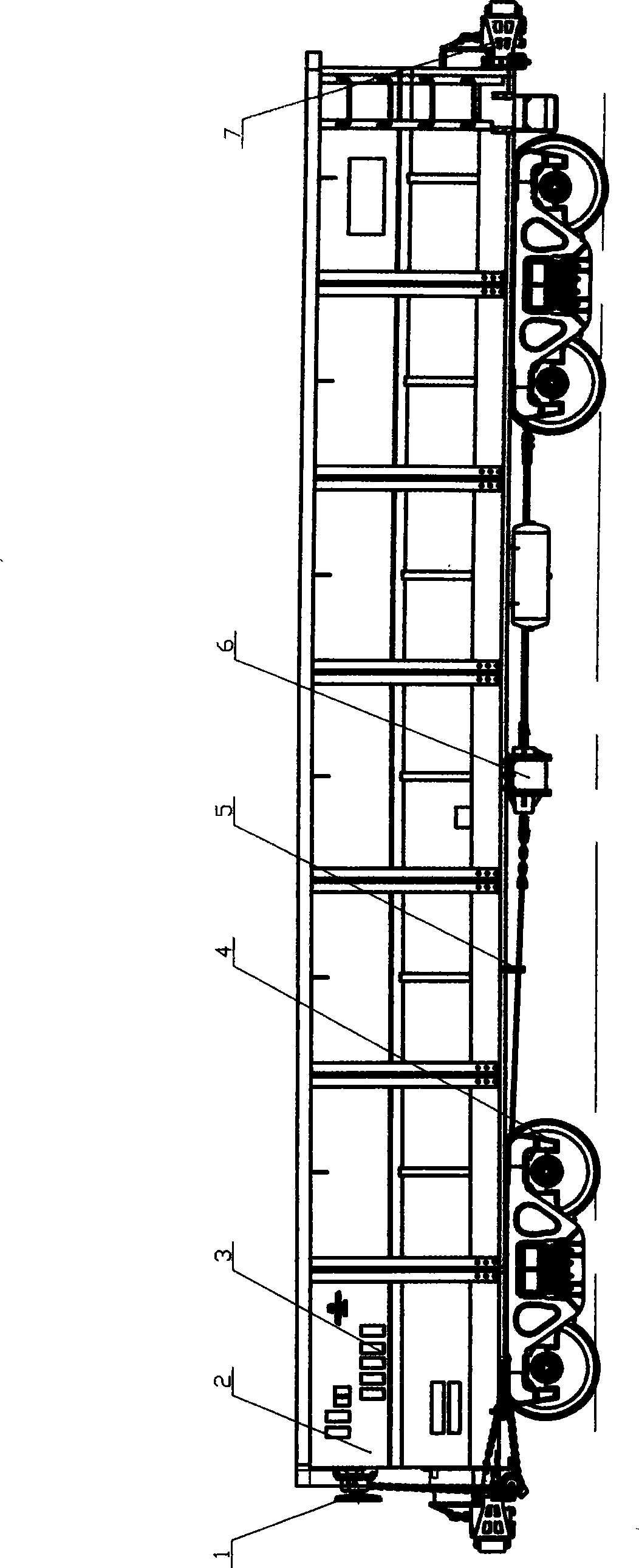

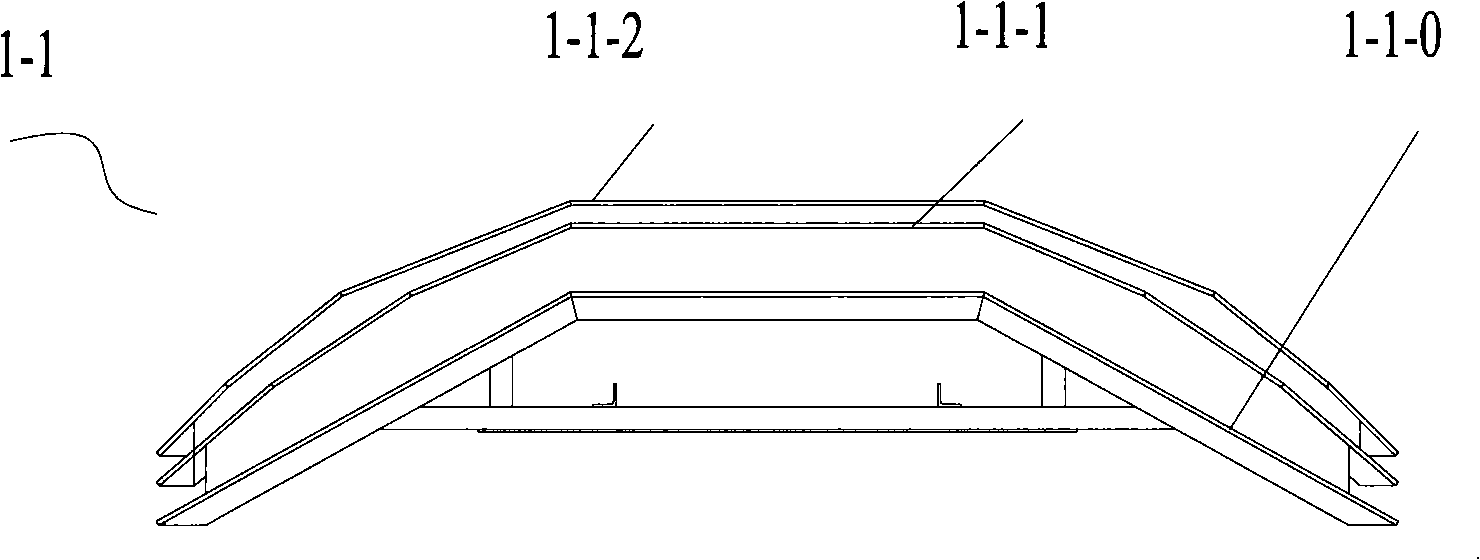

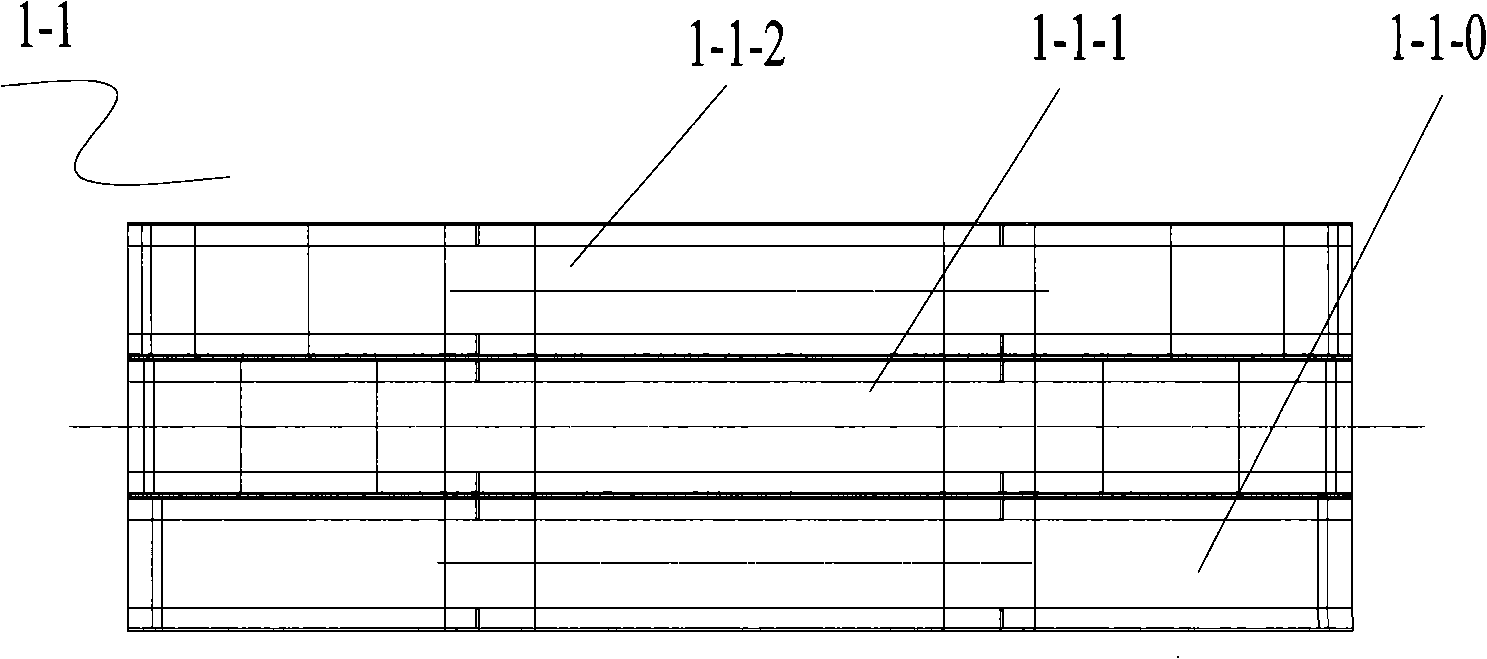

A railway freight open wagon

A railway freight open wagon belongs to the transportation traffic tool, especially the railway transportation vehicle. It comprises a wagon body, a steering frame and so on. The wagon body comprises a bottom frame, a side wall and an end wall. The side wall and the end wall are welded on the bottom frame. The side wall is provided with a lower side door. The key technology is that the side wall is the external slab-column structure; the outer wall of the side plate is provided with a side transverse belt along the transverse direction and provided with a side column along the vertical direction; the upper end edge of the upper side plate is the upper side beam. The end wall is the external slab-column structure; the outer wall of the end plate is provided with mutually parallel end transverse belts along the transverse direction and provided with an angle column along the vertical direction; the upper end edge of the end plate is the upper beam. This invention with strong transportation function, larger volume is suitable for transporting each light goods.

Owner:CRRC MEISHAN

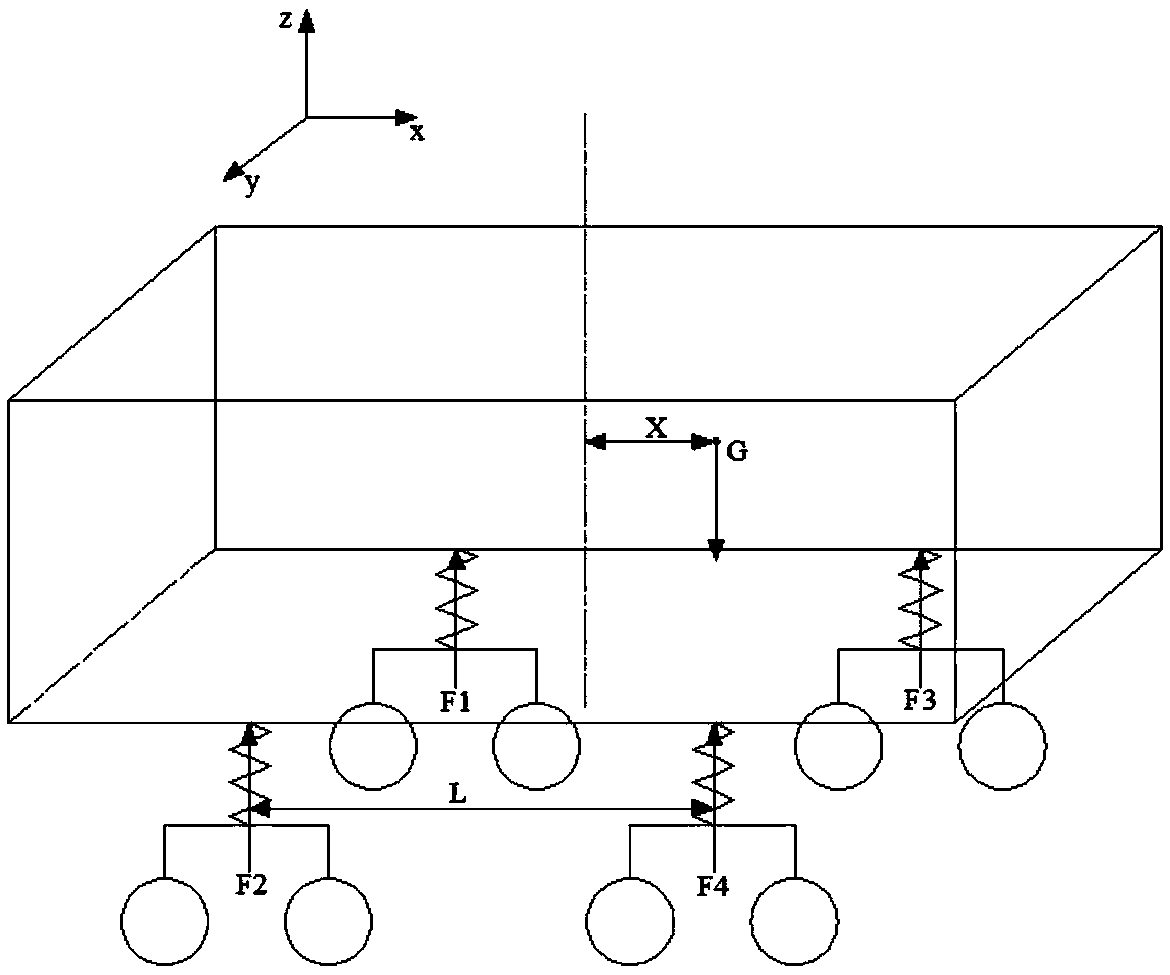

Vehicle-mounted weighing system of freight train as well as weighing method

InactiveCN108225513AAchieve full dynamic weighingWeighing at any timeTransmission systemsSatellite radio beaconingBogieFreight trains

The invention discloses a vehicle-mounted weighing system of a freight train as well as a weighing method. The weighing system comprises a weighing sensor, a connecting cable and a vehicle-mounted intelligent terminal, wherein the vehicle-mounted intelligent terminal consists of an ARM embedded controller unit, a power supply unit, a positioning unit, a wireless data transmission unit, a digital I / O interface unit, a weighing signal amplifying and conditioning circuit, an analog-digital conversion circuit and a data storage unit. A bogie strain-based indirect type weighing method is adopted bycombining the own structure of a rail wagon. For the safe working characteristic of railway freight, the weight of the wagon is monitored in real time in the loading, transportation and unloading processes of the freight train, and whole-course dynamic weighing of the whole wagon and the whole route is realized. The vehicle-mounted weighing system has remote monitoring and failure diagnosis functions, is high in measuring result precision and stability, has the characteristics of reliable performance, low cost of monitoring equipment and low requirements on mounting and use conditions, and iseasy to popularize and use.

Owner:西安航天三沃机电设备有限责任公司

Anti-theft alarm method, system and vehicle-mounted equipment for railway freight boxcar/container

InactiveCN101470934AEffective monitoring statusReduce the rate of cargo theftBurglar alarm by openingAnti-theft devicesRail freight transportEngineering

The invention discloses a theftproof and alarm method of a railway freight box car or a container, a system and a vehicle-mounted device thereof. The method comprises the following steps: firstly, enabling the vehicle-mounted device (104) which is installed on the box car or the container to start monitoring whether a closed car door of the box car or the container is opened illegally or not, secondly, recording state information which comprises the geographic coordinates, the speed and the time of the box car or the container by the vehicle-mounted device if the car door of the box car or the container is illegally opened in the period from the end of the first step to the freight end point of the box car or the container, and sending the state information and alarming information that the car door is illegally opened to a central monitoring device (114) through a mobile communication network (112) in real time. The accident responsibility can be effectively distinguished through applying the method, the system and the vehicle-mounted device, the working efficiency is improved, the stealing rate of railway freight can be lowered, and the state of the box car or the container can be effectively monitored.

Owner:NUCTECH CO LTD +1

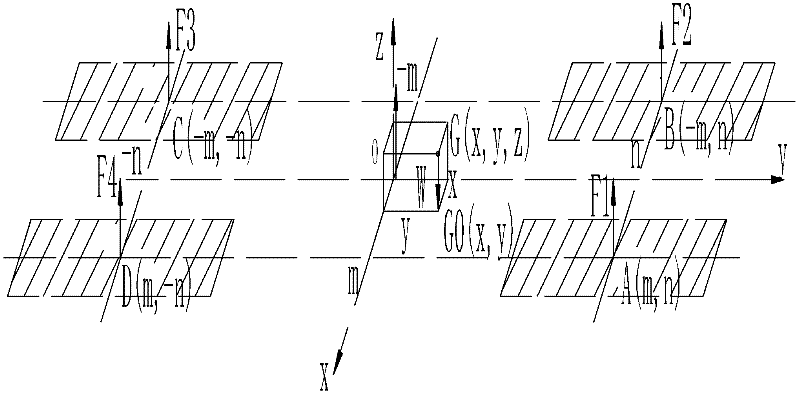

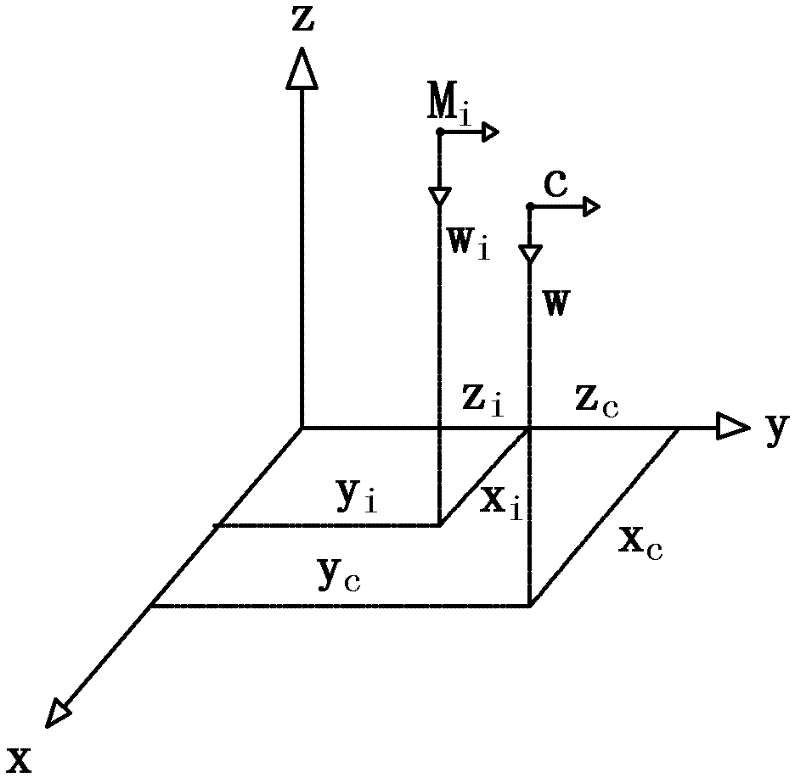

Real-time monitoring method of railway freight car overload and unbalanced load

InactiveCN102288364AEasy to adjust in real timeGuaranteed safe stateStatic/dynamic balance measurementFreight trainsRail freight transport

Provides a real-time monitoring method for overweight and unbalanced loads of railway wagons. Aiming at the characteristics of railway freight safety work, during the loading process of railway wagons, the weight value of the cargo, the total weight value of the cargo and the relevant projection of the center of gravity of each corner of the four corners of the wagon are displayed visually and in real time. Point data to facilitate the loader to make timely judgments. The invention is more convenient for the truck loader to adjust the reasonable and safe loading weight and loading position of the goods loaded on the truck in real time, and can ensure that the goods are in a safe state during the process of loading and transporting the goods.

Owner:杨中权

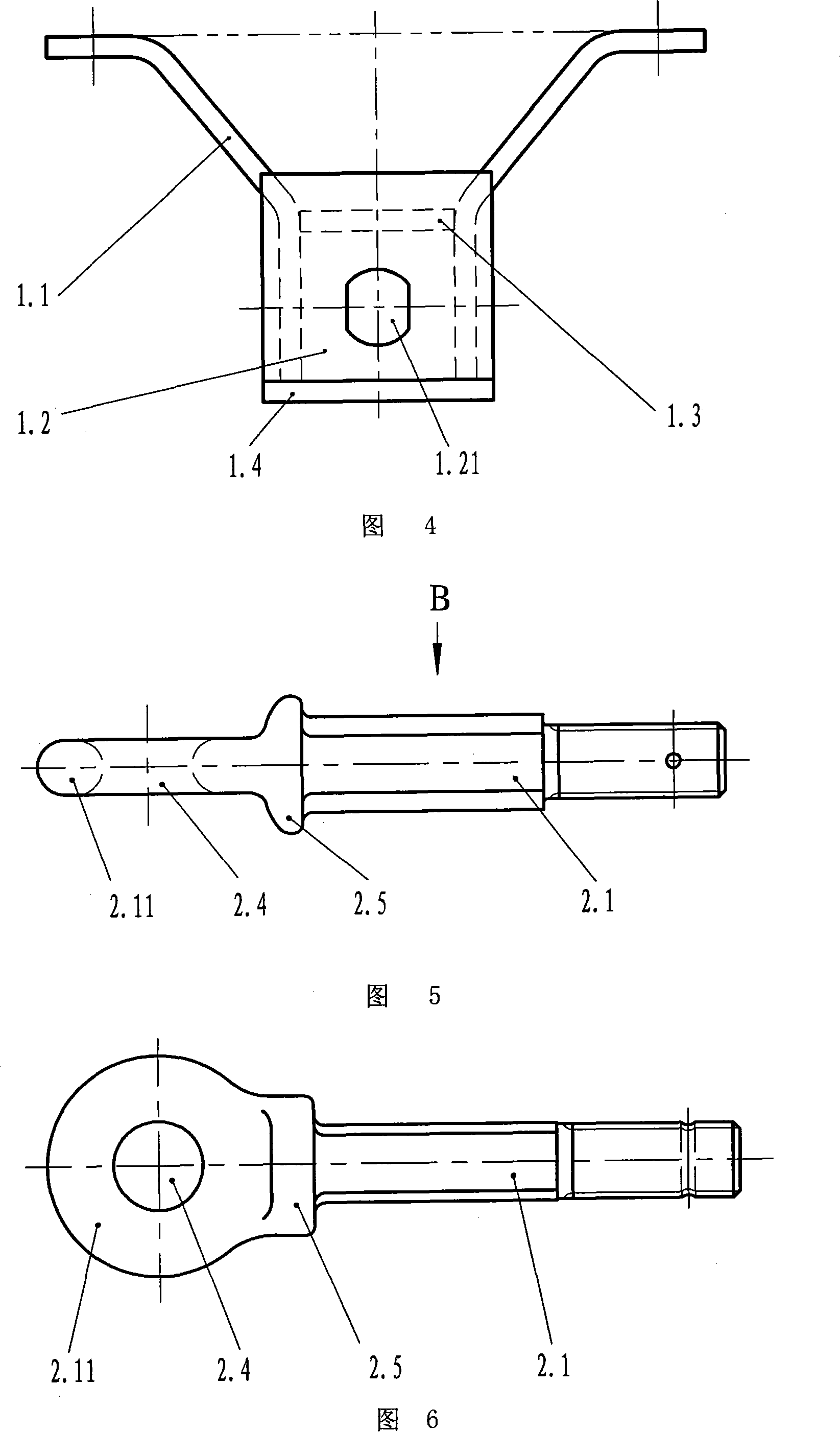

Door lock at underside of open freight car of railroad freingt activity

InactiveCN1959047APrevent jumpingEliminate potential safety hazardsVehicle locksWing fastenersRail freight transportEngineering

The present invention discloses a kind of railroad transportation open wagon lower side door lock, it is formed from hinge which is hinged on the hinge seat of lower door beam and fixedly connected together with lower door and lock body which is fixed on side wall plate and upper door beam. It is characterized by that the described lock body mainly includes integrated H-type lock seat, lock iron matched with said lock seat and pin shaft for limiting said lock iron in the hinge groove of said lock seat. Besides, said invention also provides the working principle of said open wagon lower side door lock and its operation method.

Owner:CRRC MEISHAN

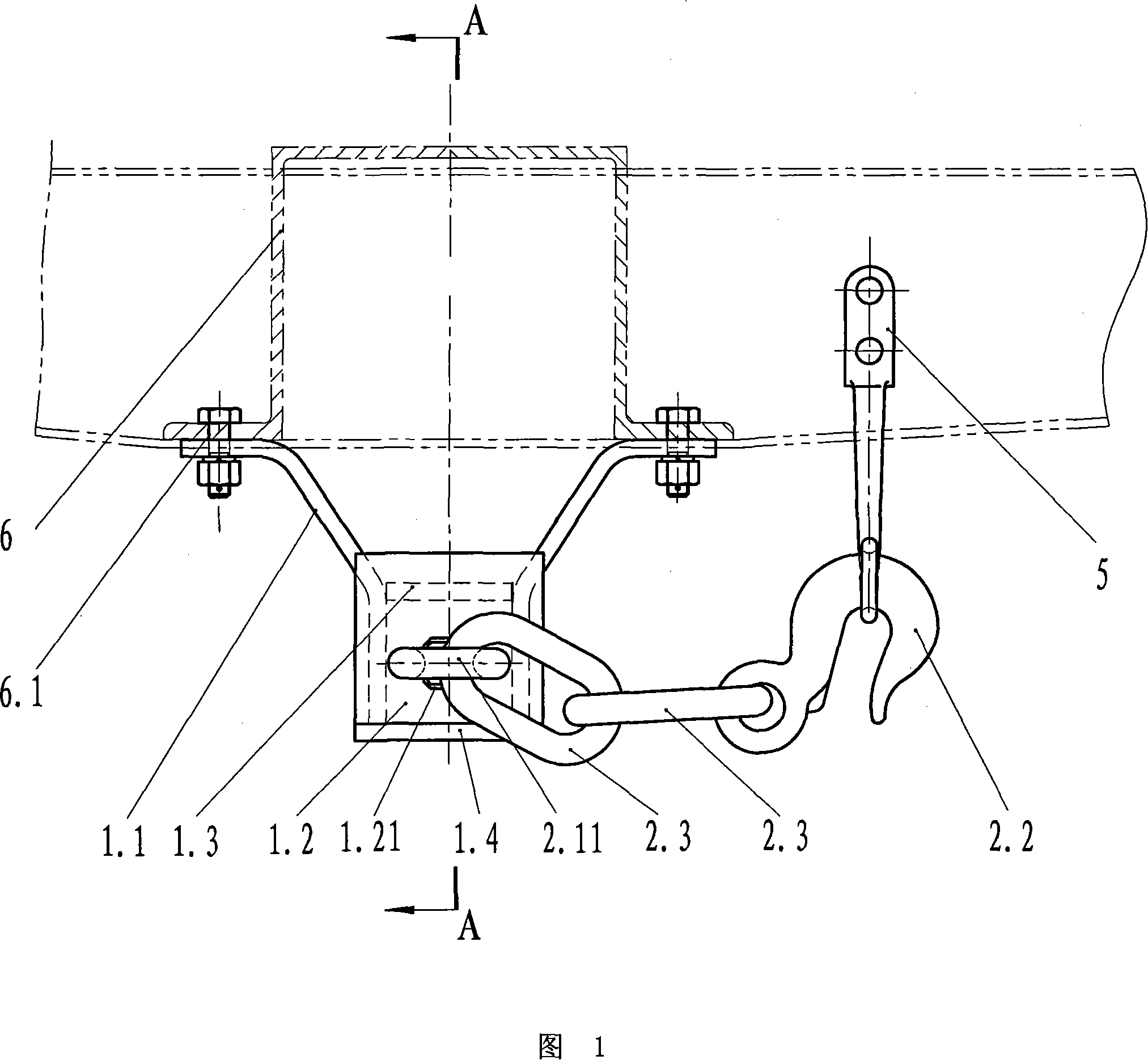

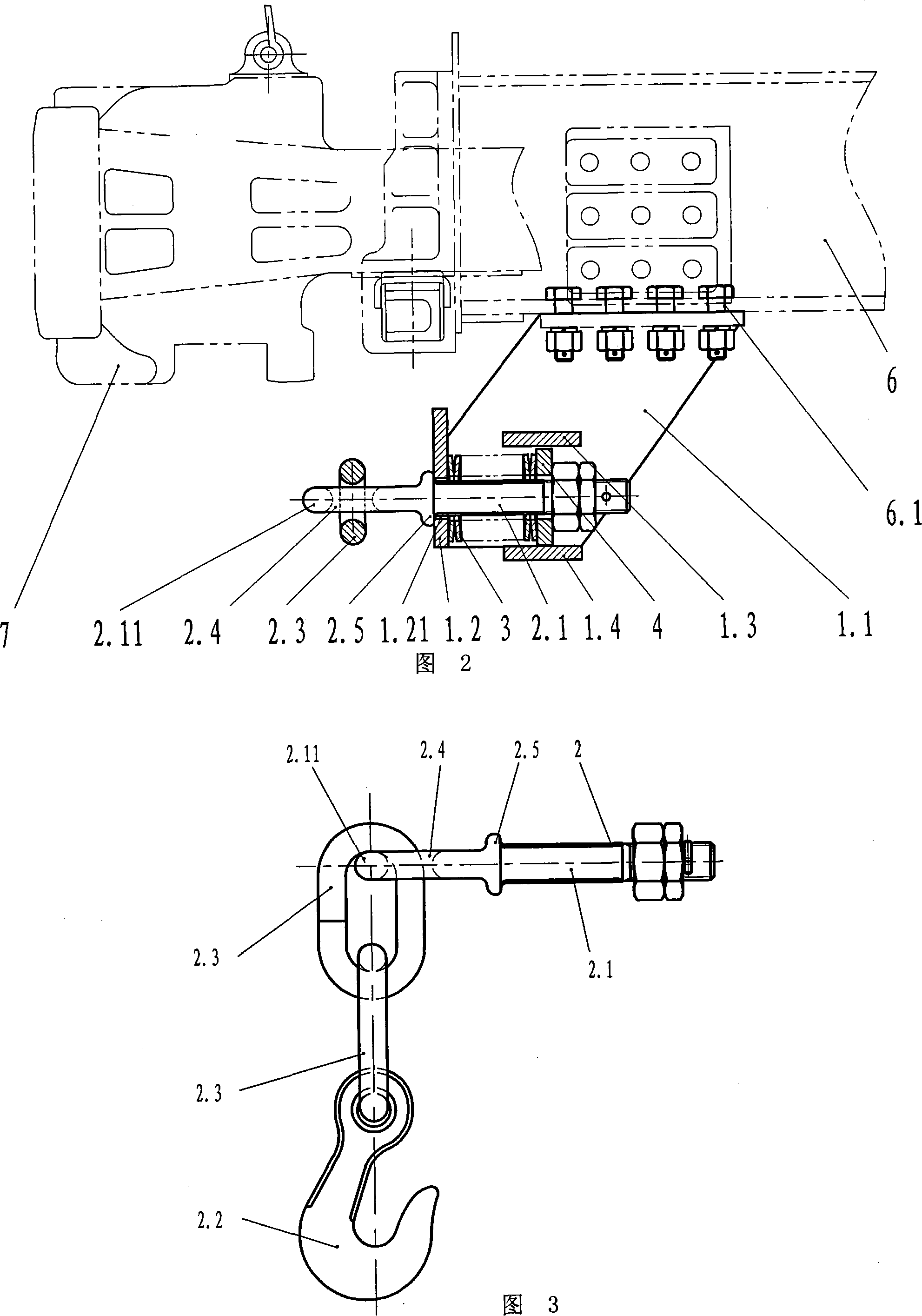

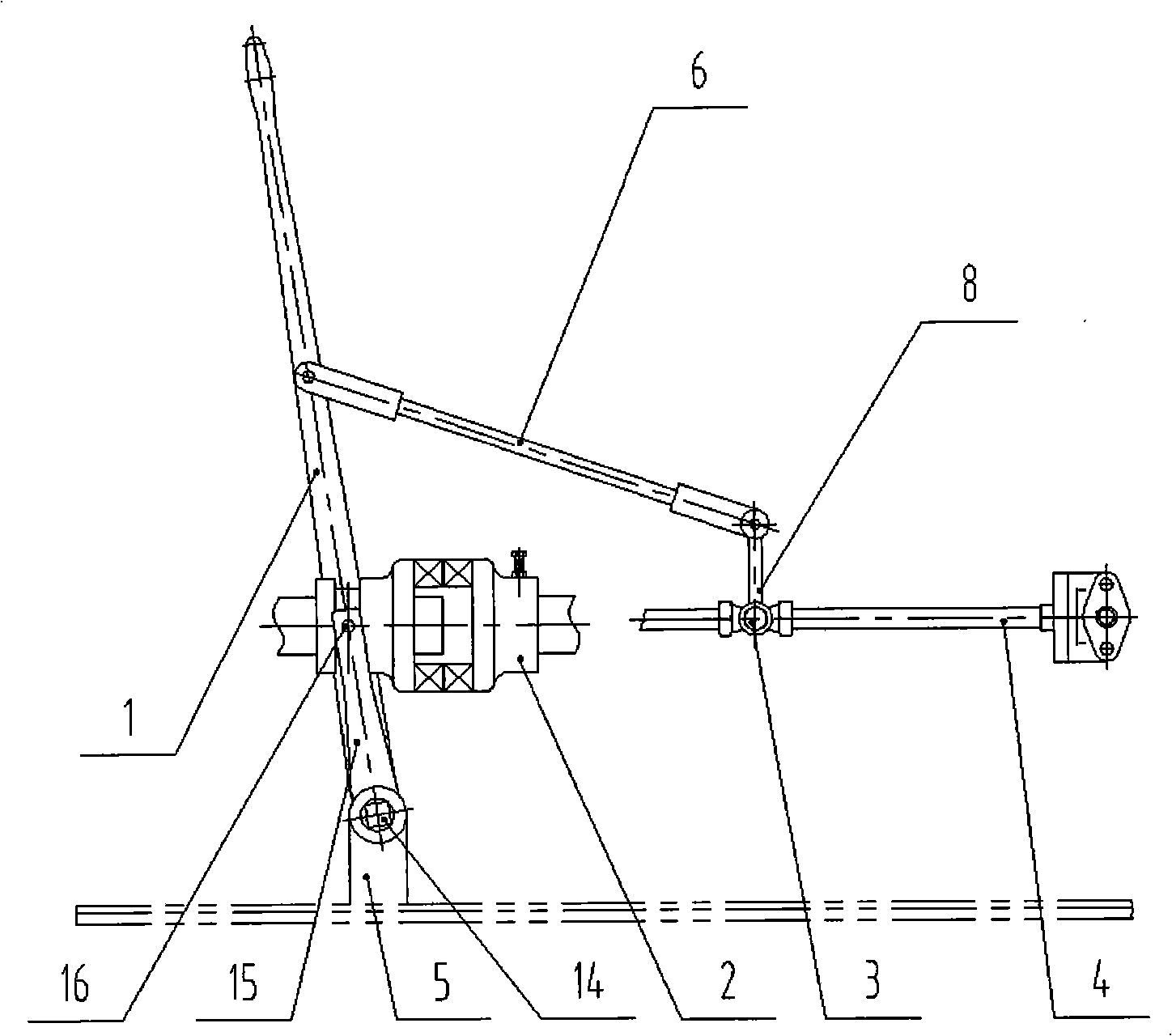

Railway goods train hook safety hook-chain mechanism

ActiveCN101121412AEnsure driving safetyEasy maintenanceRailway couplingsFreight trainsRail freight transport

The present invention relates to a tractive connection mechanism of a lorry, in particular to a safety protection device for a draw gear of a freight train. A seat board is fixed under the end of a tractive beam of the lorry and an upper baffle and a lower baffle are welded on the seat board. A front baffle constituting a safety chain seat is welded before the upper baffle and the lower baffle. The front baffle is opened with a support hole, through which a buffer rod drills. The noumenon of the buffer rod is located in the safety chain seat and a buffer spring and an active stop dog are sleeved on the noumenon of the buffer rod. The other end of the buffer rod noumenon is a buffer rod head and the end of the buffer rod head is opened with a connecting hole. The buffer rod head is connected with a connecting link via a connecting hole. The link is connected with the head of the draw gear. The advantage is that the present invention can provide the emergency protective measures for the draw gear of the tractive train and ensure the safety of the train furthest.

Owner:CRRC MEISHAN

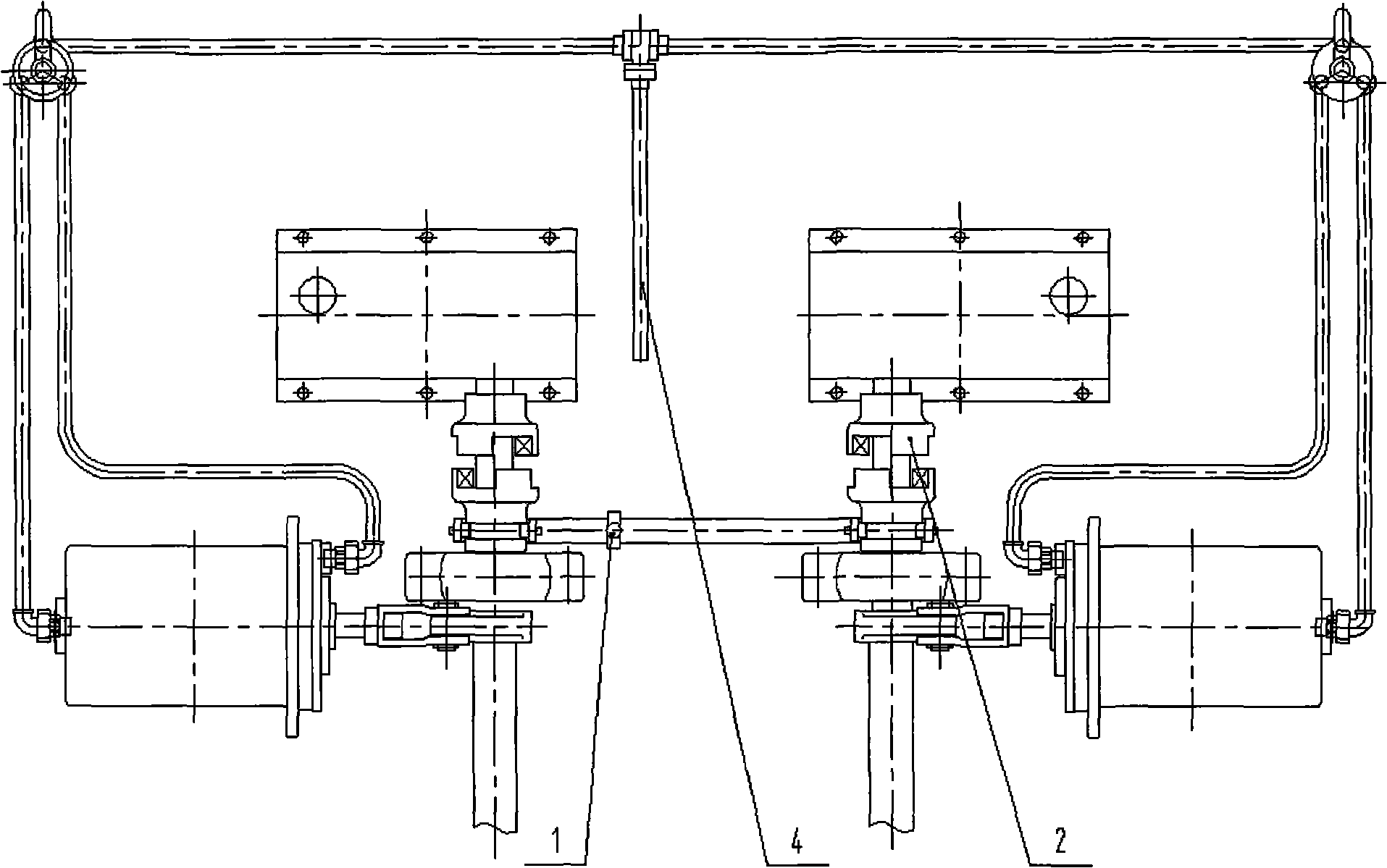

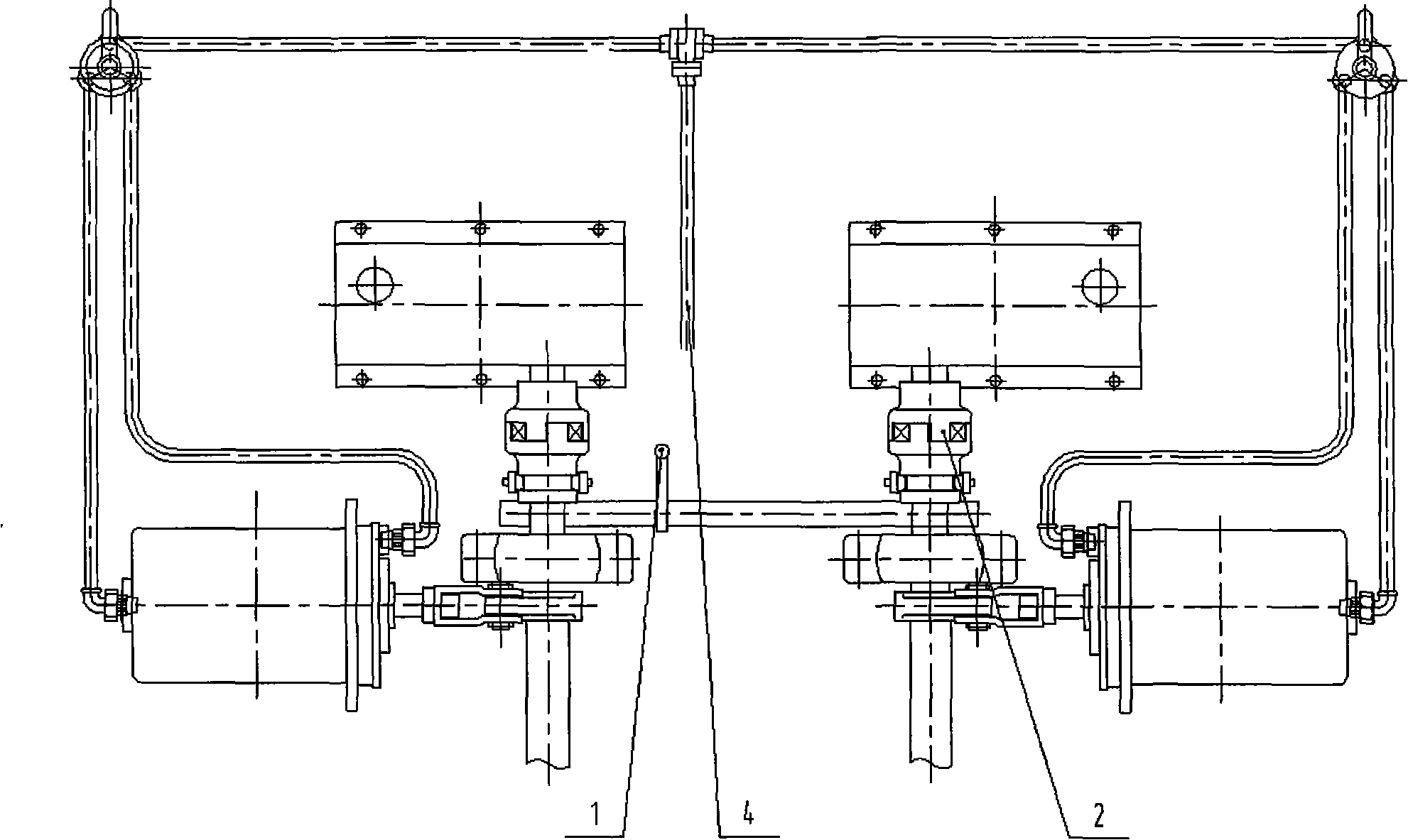

Wind power/manual linkage apparatus for discharge of railway freight transport hopper wagon

ActiveCN101314356AEliminate wind misoperation problemsEasy to operateHopper carsRail freight transportDrive shaft

The invention relates to an unloading device of a railway freight transportation hopper car. The unloading device is a link mechanism arranged between a pneumatic unloading device and a hand-operated unloading device of the railway freight transportation hopper car, belonging to the rail traffic field. The unloading device comprises a clutch and a main air pipe of a pneumatic system, wherein the clutch is arranged on a poking fork which has a poking pin; the poking fork is arranged on a main transmission shaft which is arranged on a support; and the main transmission shaft is provided with a handle. The key technology of the unloading device comprises the following steps that: the handle is connected with a connecting rod, and the other end of the connecting rod is connected with a changeover cock which is arranged on the main air pipe of the pneumatic system. The unloading device adopts a linkage mechanism, that is, the handle, the connecting rod, the changeover cock and the car body are formed into a four-linkage mechanism; therefore, by means of the transmission function of the four-linkage mechanism and the switching of the changeover cock, hand-operated action is realized when pneumatic function is shut down, thereby solving the problem of pneumatic misoperation during hand-operated unloading. In addition, the linkage mechanism can reach the goal of reliable operation through controlling the length and the position of the connecting rod so as to eliminate hidden danger.

Owner:CRRC MEISHAN

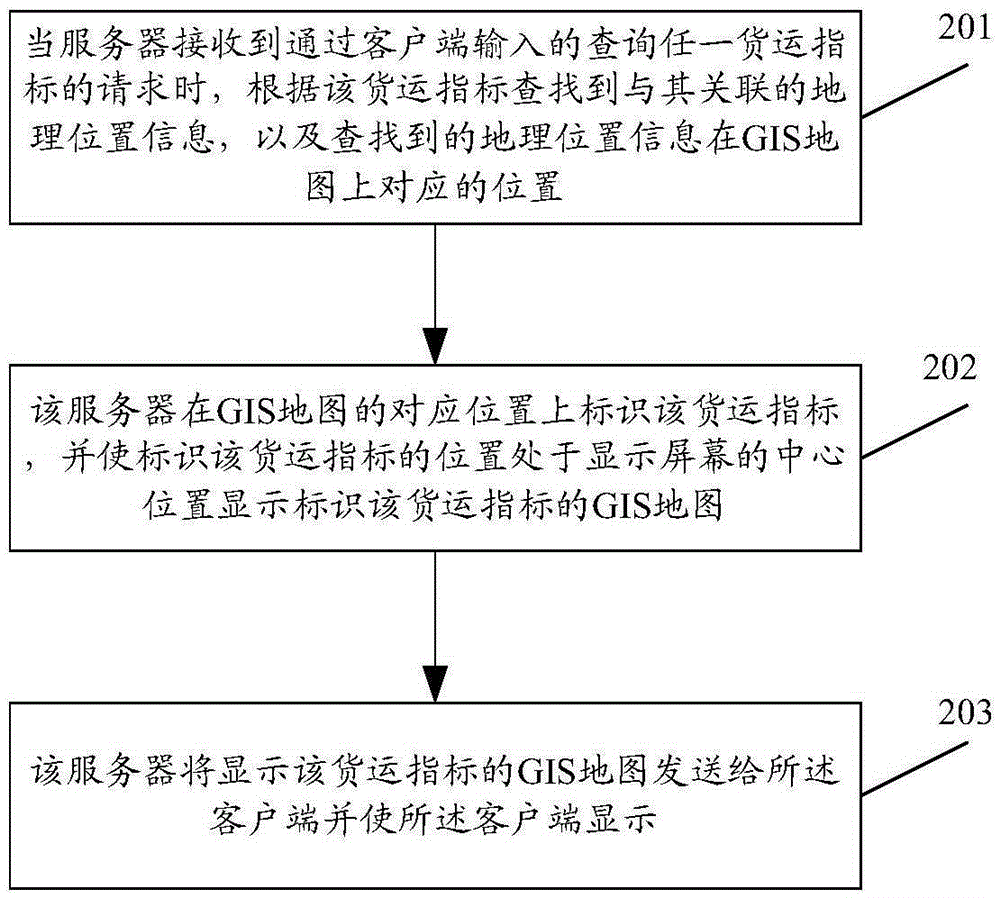

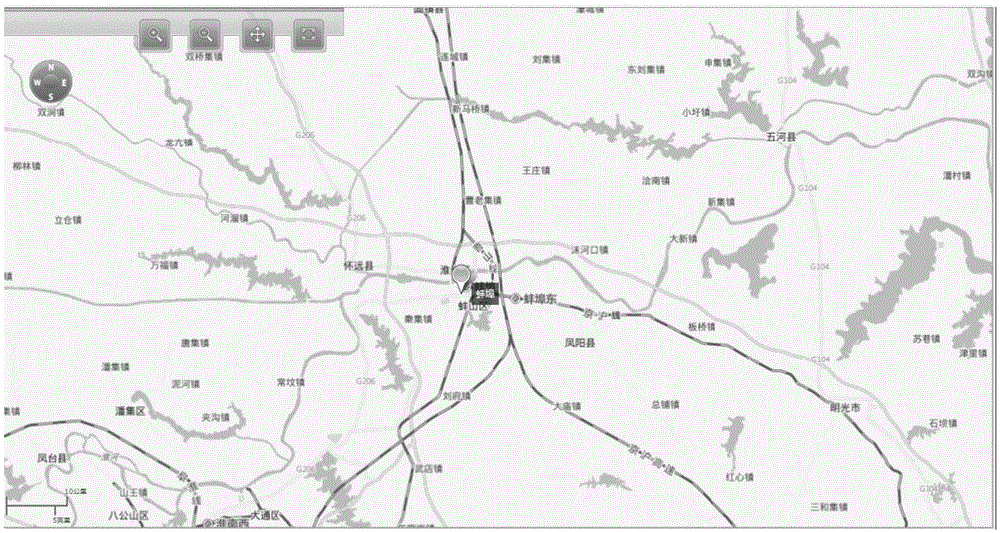

Railway freight business information query method and apparatus

PendingCN105302901AImprove experienceImprove query efficiencyGeographical information databasesSpecial data processing applicationsRail freight transportGeolocation

The application provides a railway freight business information query method. The method comprises: associating freight indexes with geographical location information of a GIS map; when receiving a request used for querying any freight index and input by a client, finding the geographical location information associated with the freight index according to the freight index and finding the position, corresponding to the geographical location information, on the GIS map; marking the freight index in the corresponding position of the GIS map, and enabling the position marking the freight index to be in the center of a display screen for displaying the GIS map marking the freight index; and sending the GIS map displaying the freight index to the client and enabling the client to perform display. Based on the same inventive concept, the application furthermore provides a railway freight business information query apparatus, so that the query efficiency and function of a railway freight system can be improved.

Owner:CHINA RAILWAY INFORMATION TECH CENT

Novel high speed transport vehicle for bulk cargo

InactiveCN101468649AImprove transportation efficiencyHigh-speed and large-scale marshallingRailway transportAxle-box lubricationBogieBulk cargo

The invention discloses a novel high-speed loose goods transporting vehicle to overcomes the drawbacks of the prior railway freight vehicle in operation of difficult residual goods cleansing, unsmooth water discharge, ineffective overall vehicle carrying and easily deformed or broken chassis. The vehicle uses a high-speed steering frame and an ABD series control valve wind brake. End walls of the body of the vehicle are vertically arranged at two ends of a chassis. An integral side wall is fixed on the chassis and a bedplate of the vehicle by side columns and rib plates. The side columns are arranged vertically at two ends of sleeper beams and cross bearers and are riveted with channel steel side beams by high-strength rivets. The angle alpha between the side wall and the vertical side columns is between 10 and 18 degrees. A side wall supporting plate is arranged on the side wall and the bedplate between each two side columns. Corner columns of the body of vehicle are provided with corner column reinforcing plates. The side wall in the middle of the body of the vehicle close to the bedplate is provided with a grid discharge port and a discharge port protective shade. The whole vehicle is made of weather-resistant steel. The vehicle has the characteristics of good water discharge effect and strong overall structural strength. The vehicle is suitable for transporting loose raw materials such as coal, concentrate fines, sintering ores and sinter balls.

Owner:鞍钢集团(鞍山)铁路运输设备制造有限公司

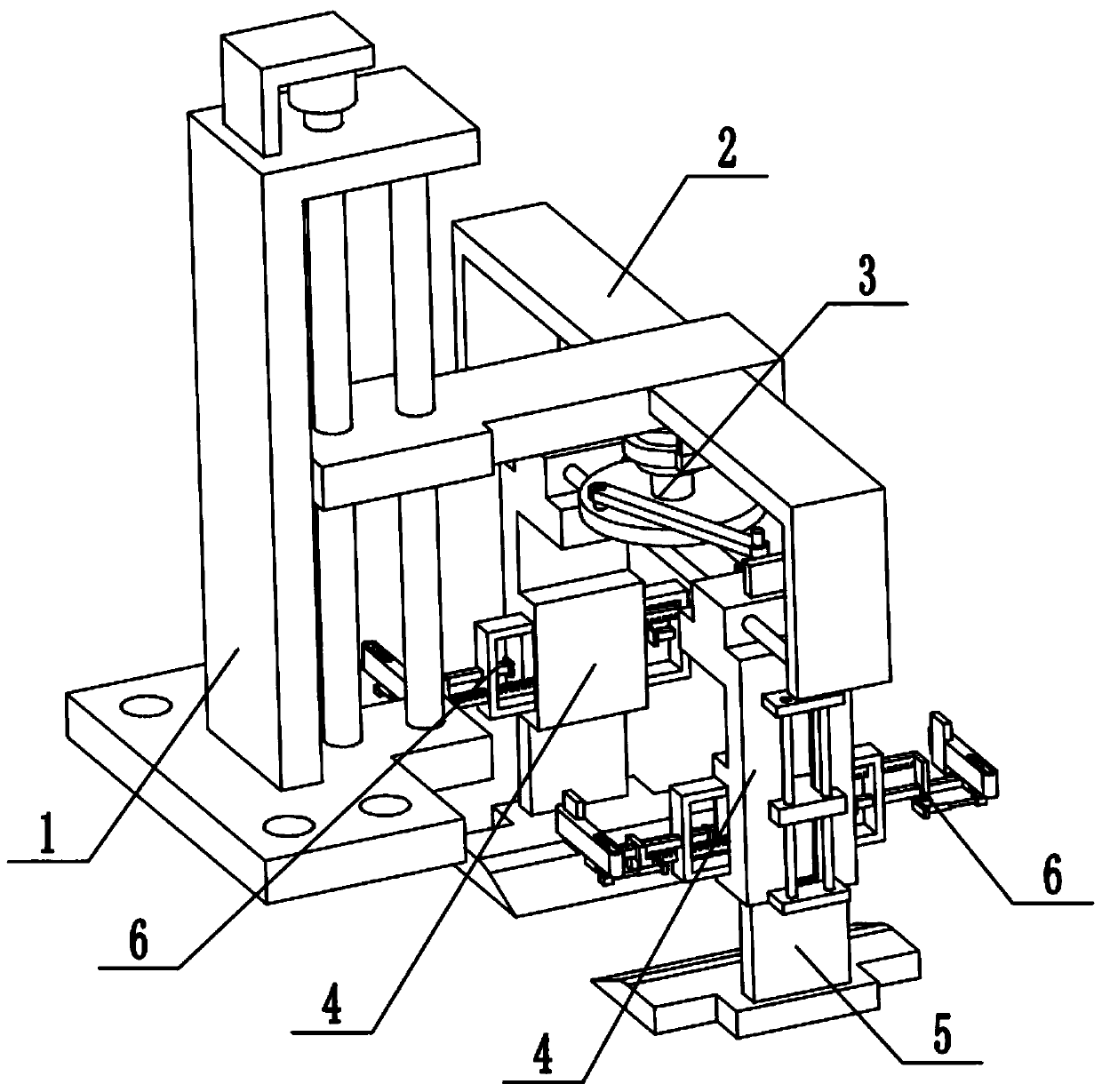

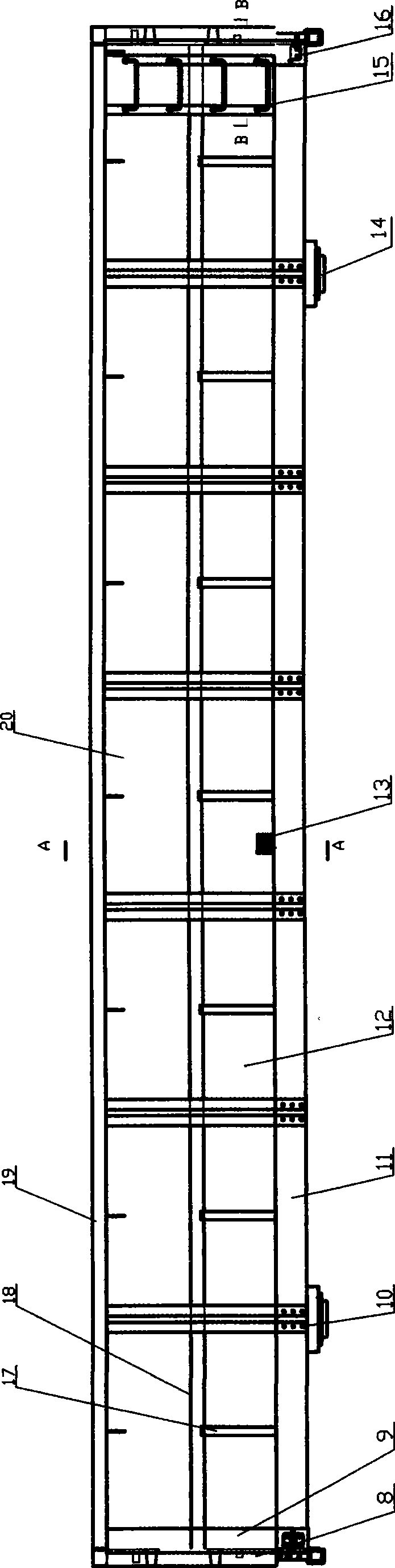

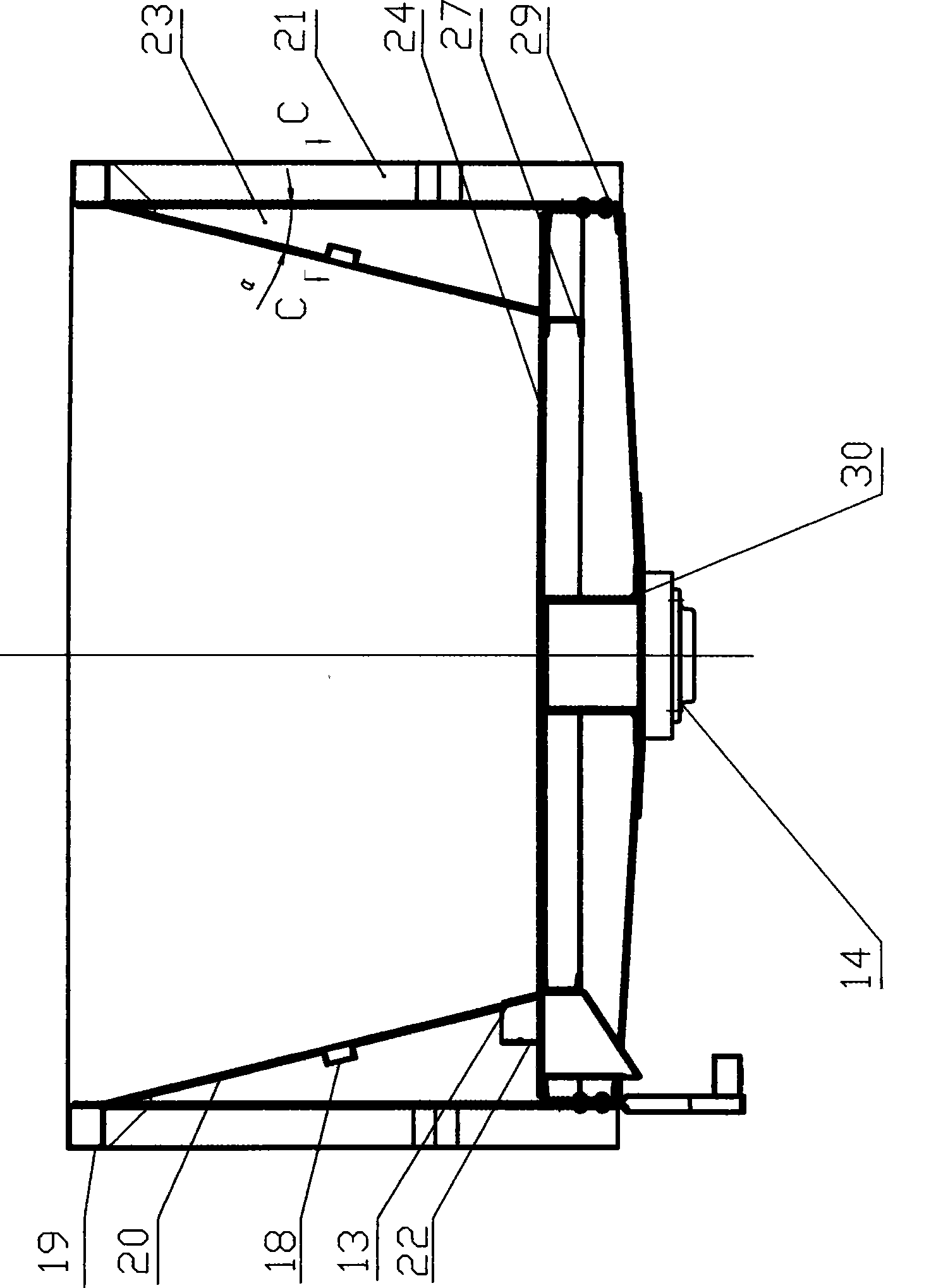

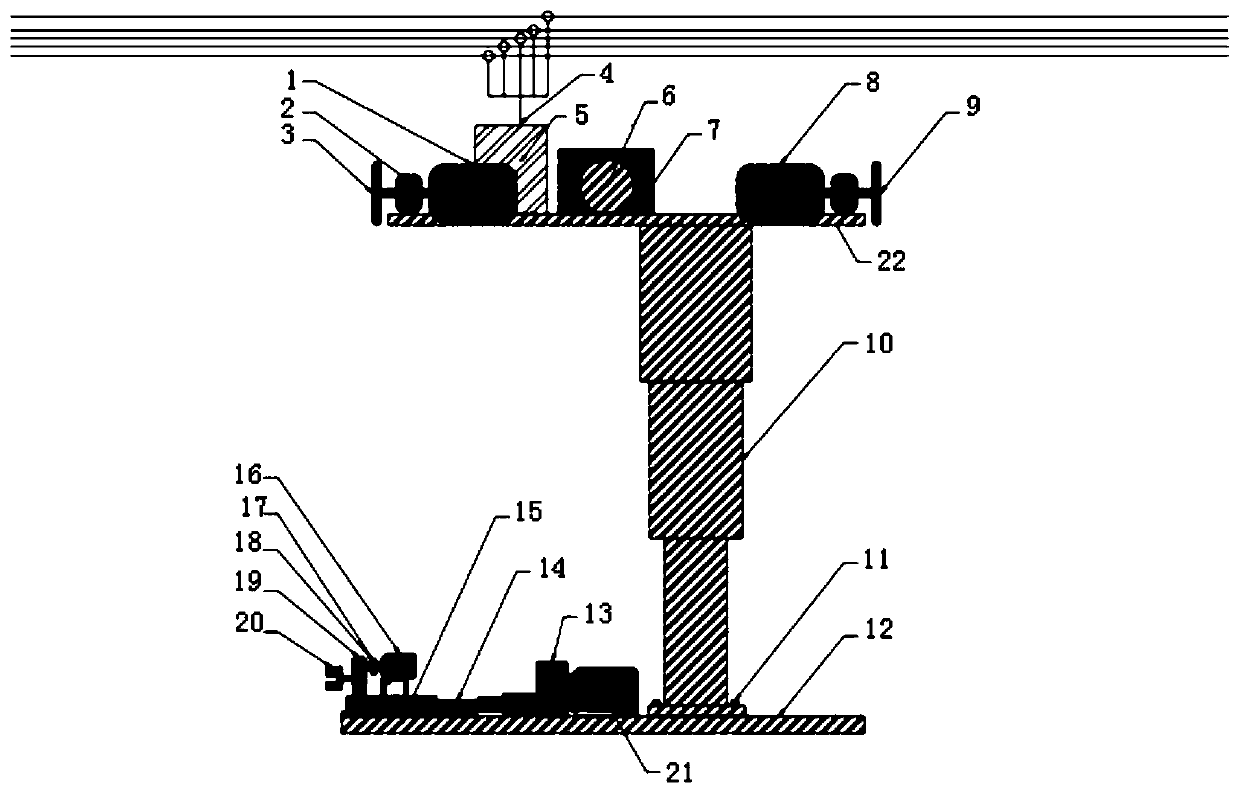

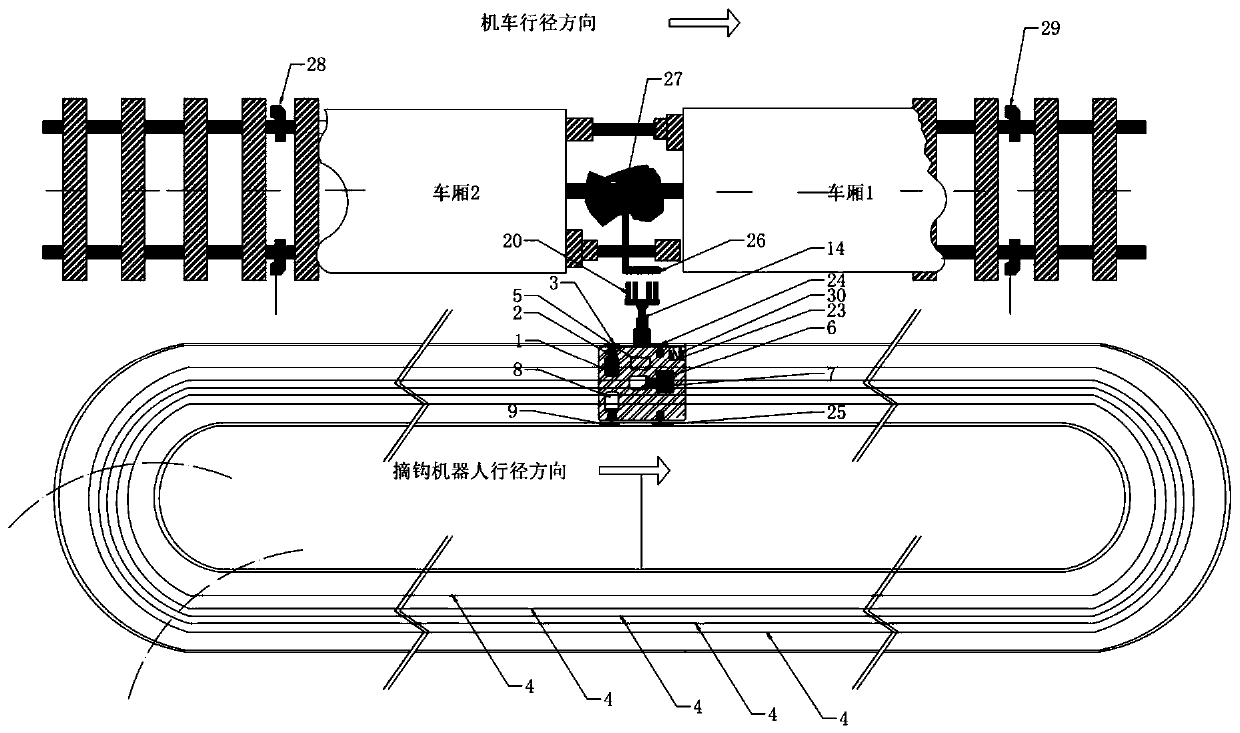

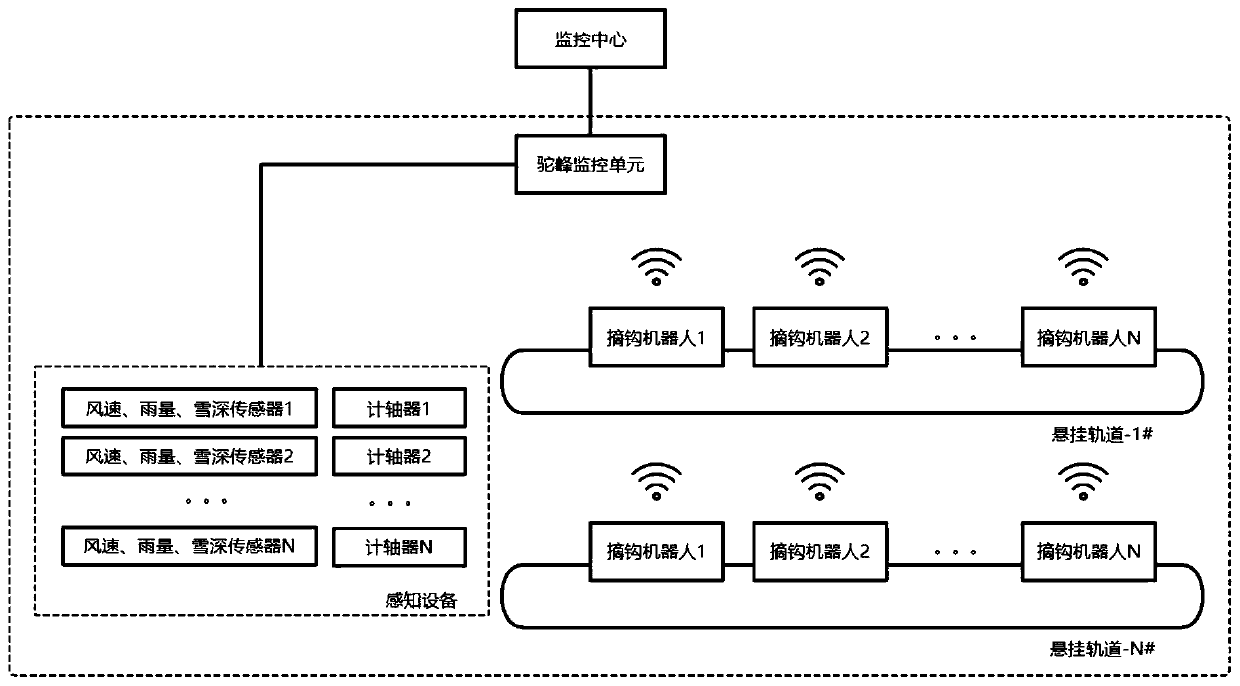

Suspended type railway freight automatic decoupling device, system and method

InactiveCN110281970AEliminate operational safety hazardsImprove marshalling work efficiencyRailway coupling accessoriesManipulatorRail freight transportEngineering

The invention provides a suspended type railway freight automatic decoupling device, system and method. The suspended type railway freight automatic decoupling device comprises a hump monitoring unit, sensing equipment and a decoupling robot. Through real-time communication between the hump monitoring unit and a monitoring center, information such as a break-up operation advice note and locomotive parameters is obtained; and meanwhile, information collected by the sensing equipment is analyzed; a decoupling instruction is given to the decoupling robot; and then each unit of the decoupling robot cooperates with each other to finish a decoupling task. The suspended type railway freight automatic decoupling device has the advantages that the idea is skillful, the structure is reasonable, the use is convenient, the adjusting is flexible, the university is high, the maintenance is easy, the working efficiency of a railway freight marshaling station is obviously enhanced, and the suspended type railway freight automatic decoupling device can be widely used for various electrical railway constructions.

Owner:大连谷瑞特科技有限公司

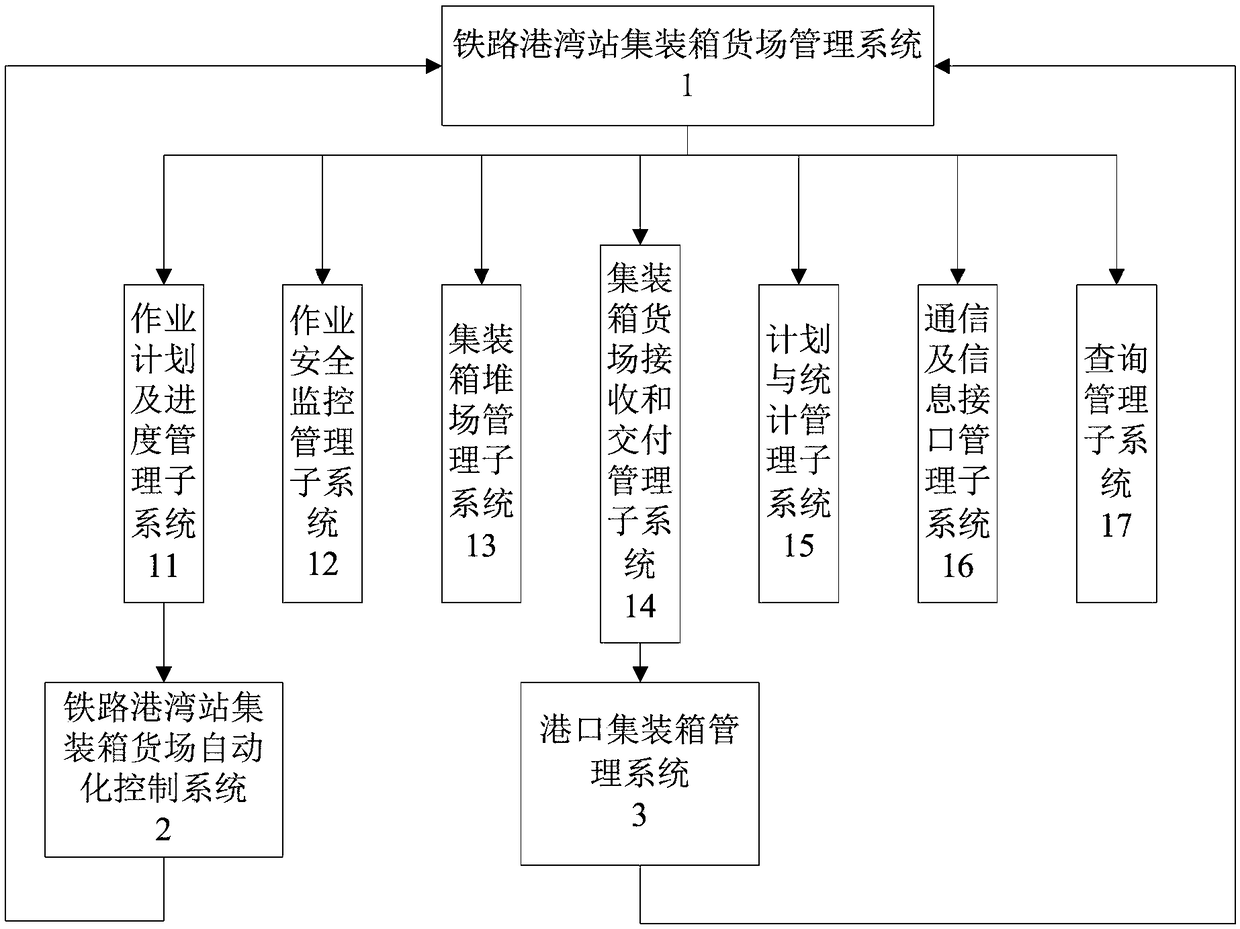

Container unloading and loading transport system and method for railway harbor station of iron-water combine transport

ActiveCN109242379AAutomate jobsRealize fully automated managementLogisticsTransport systemRail freight transport

The invention provides a container unloading and loading transport system and method for railway harbor station of iron-water combine transport. The unloading transportation system includes the container yard management system of railway harbor station, the container yard management system of railway harbor station includes the operation plan management subsystem, and the transportation system also includes the container yard automation control system of railway harbor station; the operation plan management subsystem is used for formulating a container unloading operation plan of the train from the train unloading to the container yard of the port area according to the vehicle information and container information of the arriving train provided by the railway freight safety monitoring andmanagement information system, and distributing the container unloading operation plan, the vehicle information and the container information of the arriving train to the container yard automation control system of the railway harbor station; the port bay station container yard automation control system is used to execute the container unloading operation plan. The invention realizes automation ofcontainer operation and automatic collection, tracking and exchange of container operation information.

Owner:中铁武汉勘察设计院有限公司

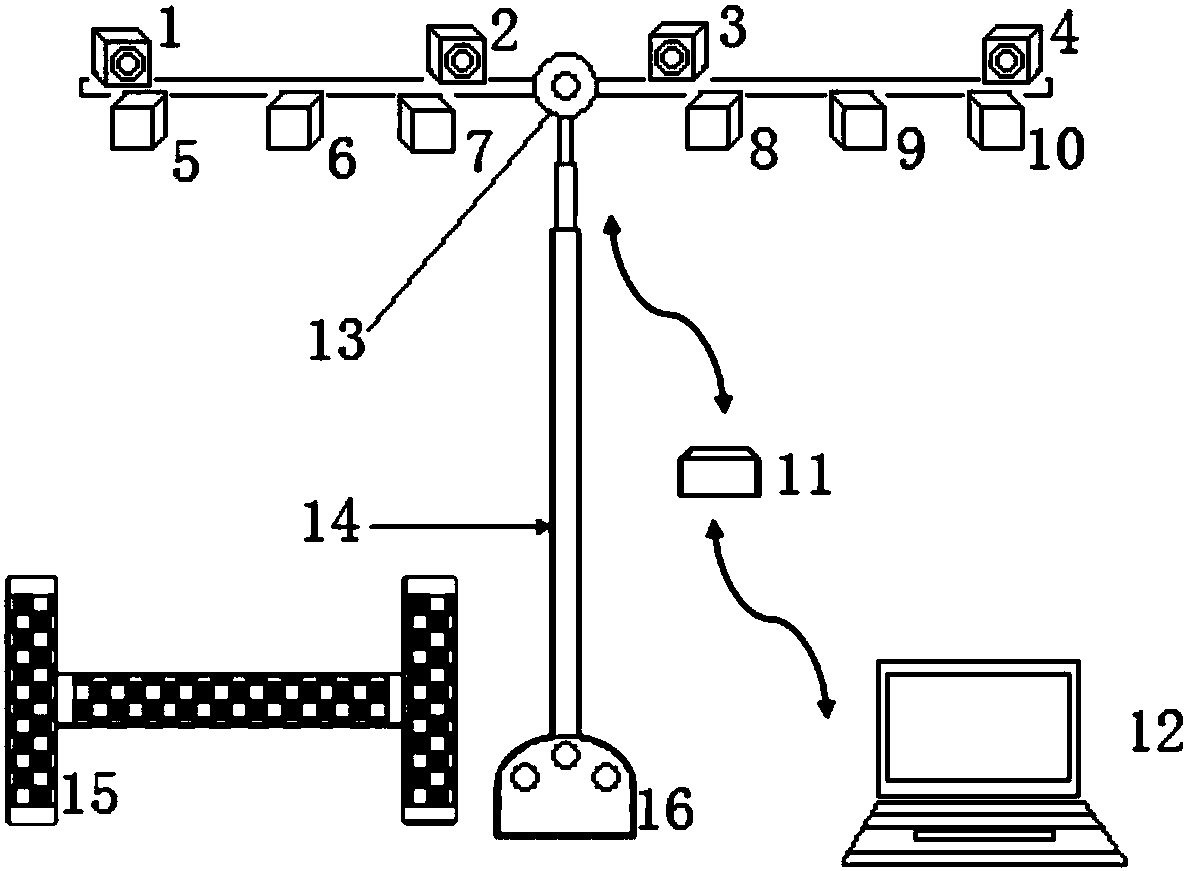

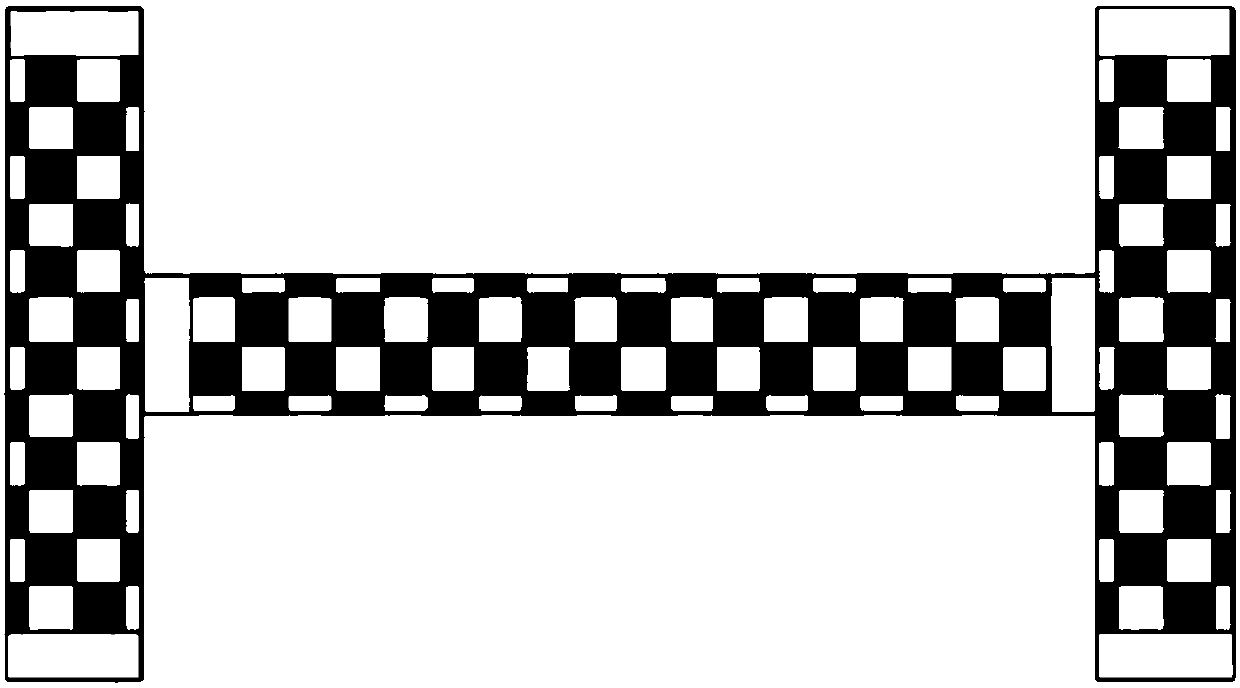

Automatic limit detection device for rail freight train

ActiveCN107685747AImprove work efficiencyReduce distractionsUsing optical meansRailway auxillary equipmentFreight trainsRail freight transport

The invention relates to an automatic limit detection device for a rail freight train to realize automatic limit measurement of the freight train. The device comprises a T-shaped supporting frame, animage data acquisition module, a data processing module and a rail coordinate datum target. The T-shaped supporting frame comprises a hook connector, a telescopic vertical rod and a transverse rod, wherein the hook connector is positioned at the bottom and matched with a connection hook between freight train carriages, one end of the telescopic vertical rod is connected with the hook connector, and the other end of the telescopic vertical rod is in rotational connection with the transverse rod through a rotatable connector. The image data acquisition module is arranged on the transverse rod and used for acquiring forward and downward surface images of the freight train. The data processing module comprises a data processing terminal which controls the image data acquisition module to shootsynchronously through a hard trigger synchronizer. The rail coordinate datum target is used for establishing a rail plane-coordinate system to fit a rail plane. Compared with the prior art, the automatic limit detection device has advantages of movability, one-man operation, high measurement accuracy and the like.

Owner:TONGJI UNIV

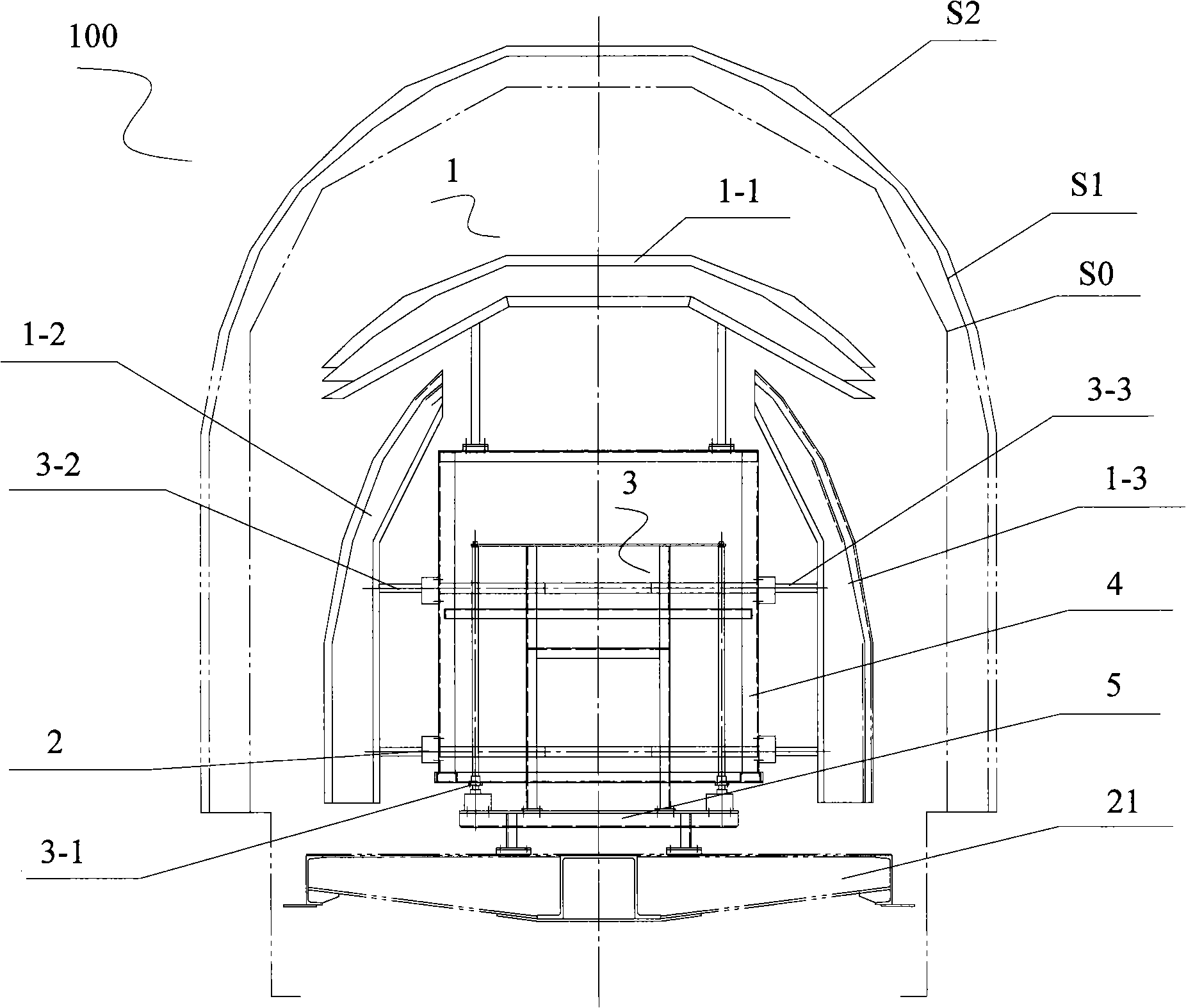

Railway freight safety door calibration device and railway freight safety door calibration vehicle

ActiveCN101285678AImprove calibration accuracyControl speedUsing optical meansRailway auxillary equipmentLinear motionRail freight transport

The invention discloses a calibration device for railway freight safety doors, comprising a telescopic demarcation door, a servo system and a transmission mechanism, wherein the outer surface of the telescopic demarcation door comprises a standard demarcation surface, a first-level demarcation surface and a second-level demarcation surface; the shapes and sizes of the standard demarcation surface, the first-level demarcation surface and the second-level demarcation surface under working condition are respectively identical to the shapes and sizes of standard demarcation, first-level demarcation and second-level demarcation; the servo system comprises a driving motor and is used to control the demarcation door to expand and contract; the transmission mechanism has an output end connected with the demarcation door, and has an input end connected with an output shaft of the driving motor, so as to convert the rotating motion output by the driving motor into the linear motion of the demarcation door. The calibration device for railway freight safety doors can simultaneously carry out the calibration of standard demarcation, first-level demarcation and second-level demarcation to safety doors, and has high calibration precision. On the basis of the calibration device, the invention also discloses a calibration vehicle for railway freight safety doors, which does not need field installation or debugging, and can save calibration time and improve calibration efficiency.

Owner:CRRC QIQIHAR ROLLING CO LTD

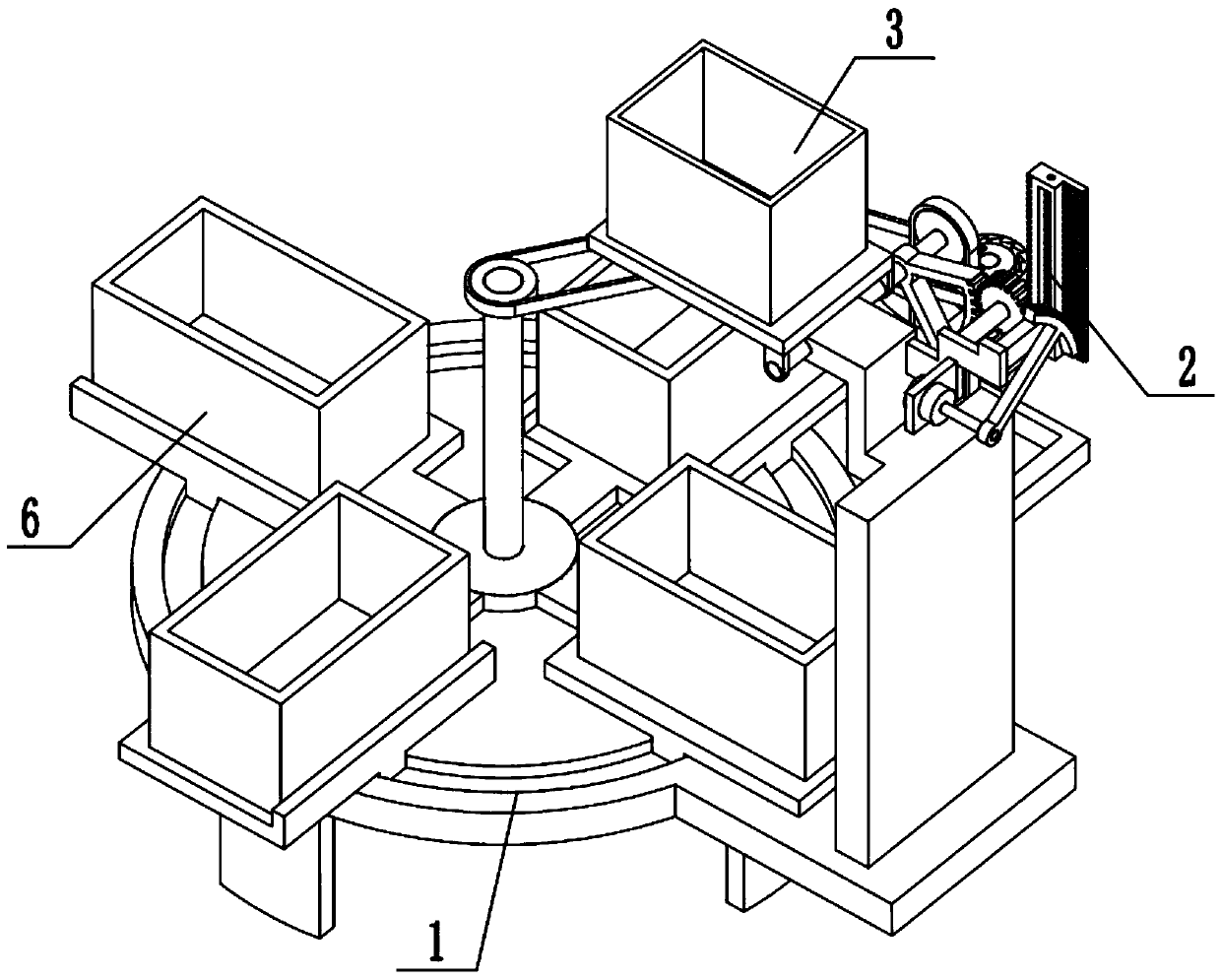

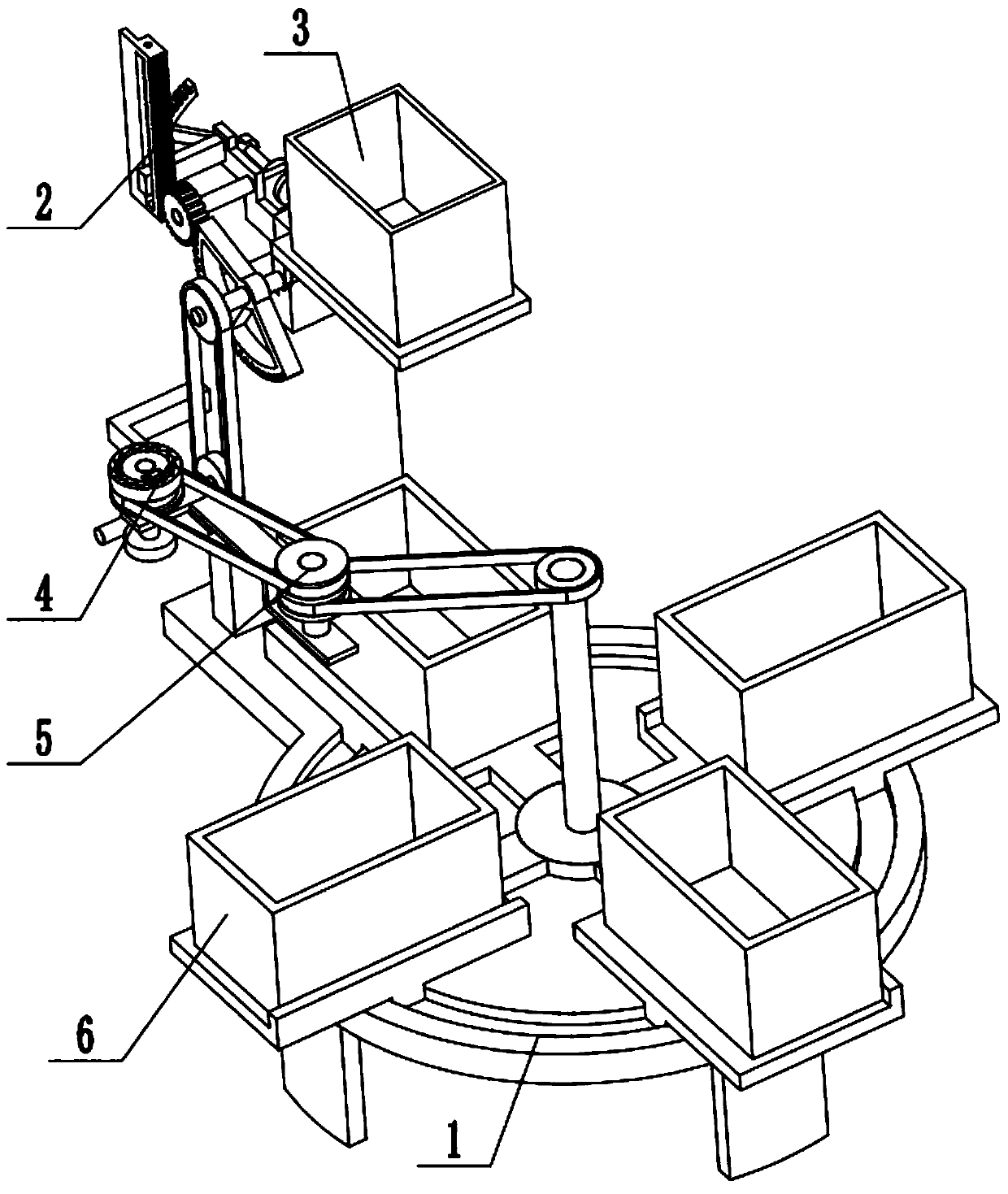

Auxiliary device for railway freight

ActiveCN110356864AAchieve equal distributionImprove work efficiencyLoading/unloadingRail freight transportEngineering

The invention provides an auxiliary device for railway freight, and relates to the field of railway freight. The auxiliary device comprises a rack, an overturning control mechanism, an overturning boxassembly, an intermittent rotation control mechanism, a power transmission mechanism and a transfer box assembly. The auxiliary device has the beneficial effects that cargoes are evenly distributed into each transfer box, the cargoes are equivalently distributed, it is guaranteed that the cargoes in each transfer box are equal, the operation that the cargoes are manually carried into the transferboxes one by one, and it cannot be conveniently guaranteed that the cargoes in each transfer box are equal through manual carrying is omitted, and the working efficiency is improved. The overturningcontrol mechanism is arranged at the upper end of the rack, the overturning box assembly is rotationally connected to the upper end of the rack, the overturning control mechanism and the overturning box assembly are in engaged transmission connection, the intermittent rotation control mechanism is fixedly connected to the middle of the rack, the intermittent rotation control mechanism and the overturning box assembly are in transmission connection through a belt, and the power transmission mechanism is fixedly connected to the intermittent rotation control mechanism.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

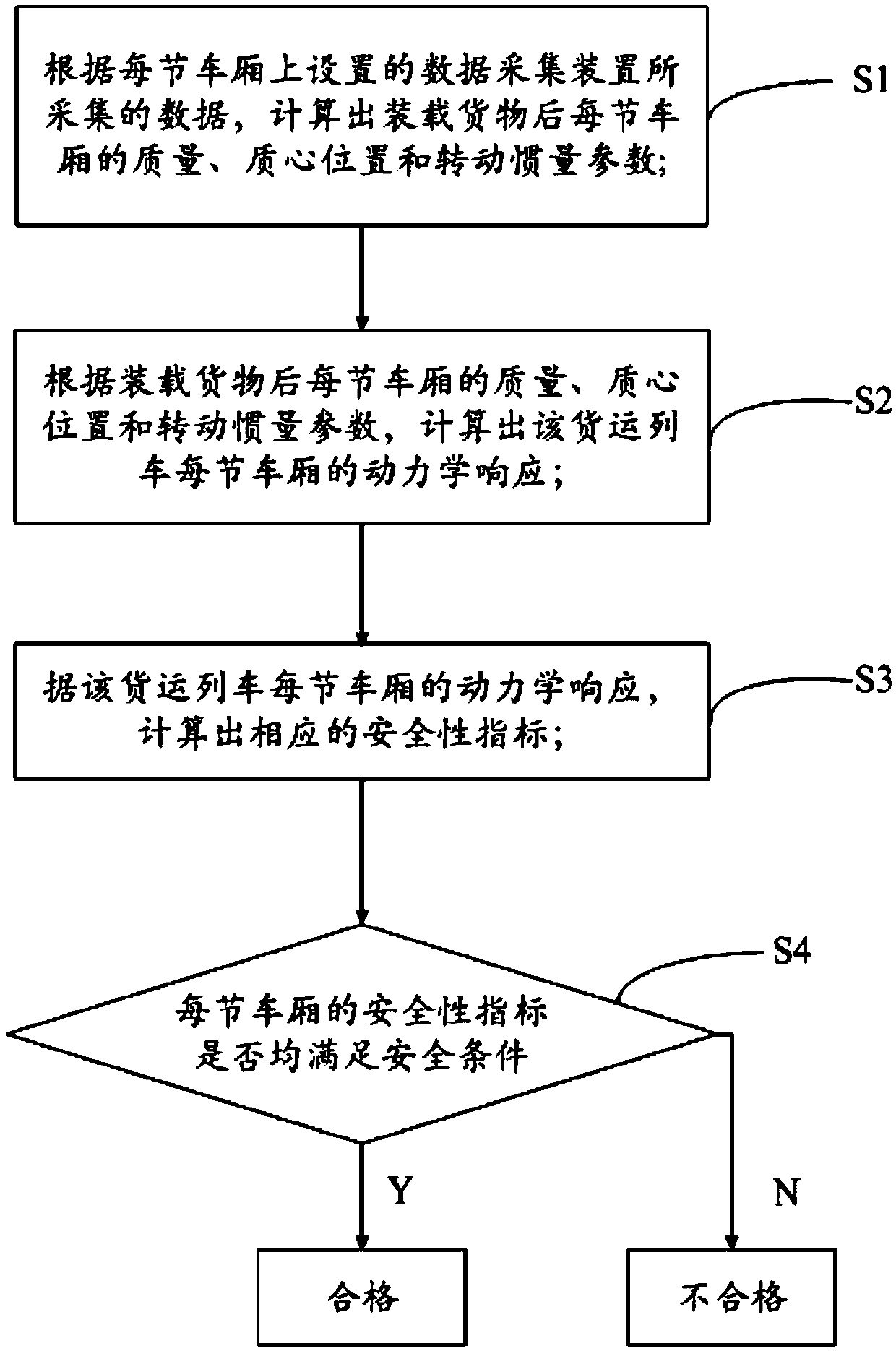

The invention discloses a rRailway freight train operation safety assessment method and system

ActiveCN109615269AAccurate and effective assessmentAvoid potentially serious accidents such as derailmentsSustainable transportationResourcesFreight trainsRail freight transport

The invention discloses a railway freight train operation safety assessment method and system, and the method comprises the steps: firstly, calculating the mass, t, the centroid position and the rotational inertia parameters of each carriage after loading goods according to the data collected by a data collection device arranged on each carriage; T; then, t, the mass of each carriage is adjusted after the cargos are loaded; i; inputting the centroid position and the rotational inertia parameters into the built dynamic model of the corresponding freight train; T; the method comprises the stepsthat firstly, t, the dynamic response of each carriage is calculated, corresponding safety indexes are calculated according to the dynamic response of each carriage, t, then whether the safety indexesof the carriages meet the safety operation condition or not is judged, and only if the safety indexes of the carriages do not meet the safety condition, it is considered that the safety indexes of the freight train are unqualified. Therefore, whether the safety index of the multi-section marshalling freight train loaded with the goods is qualified or not can be accurately and effectively evaluated, and therefore potential serious accidents such as derailment are avoided.

Owner:SOUTHWEST JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com